Latent heat recoverable multi-phase change sludge drying method and device

A technology of sludge drying and multiphase transformation, which is applied in the latent heat recovery type multiphase transformation sludge drying and reduction treatment, and the harmless treatment of excess sludge in urban sewage treatment plants. Utilization, untreated drying tail gas, high energy consumption and other problems, to achieve the effect of reducing drying cost, good energy saving effect and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

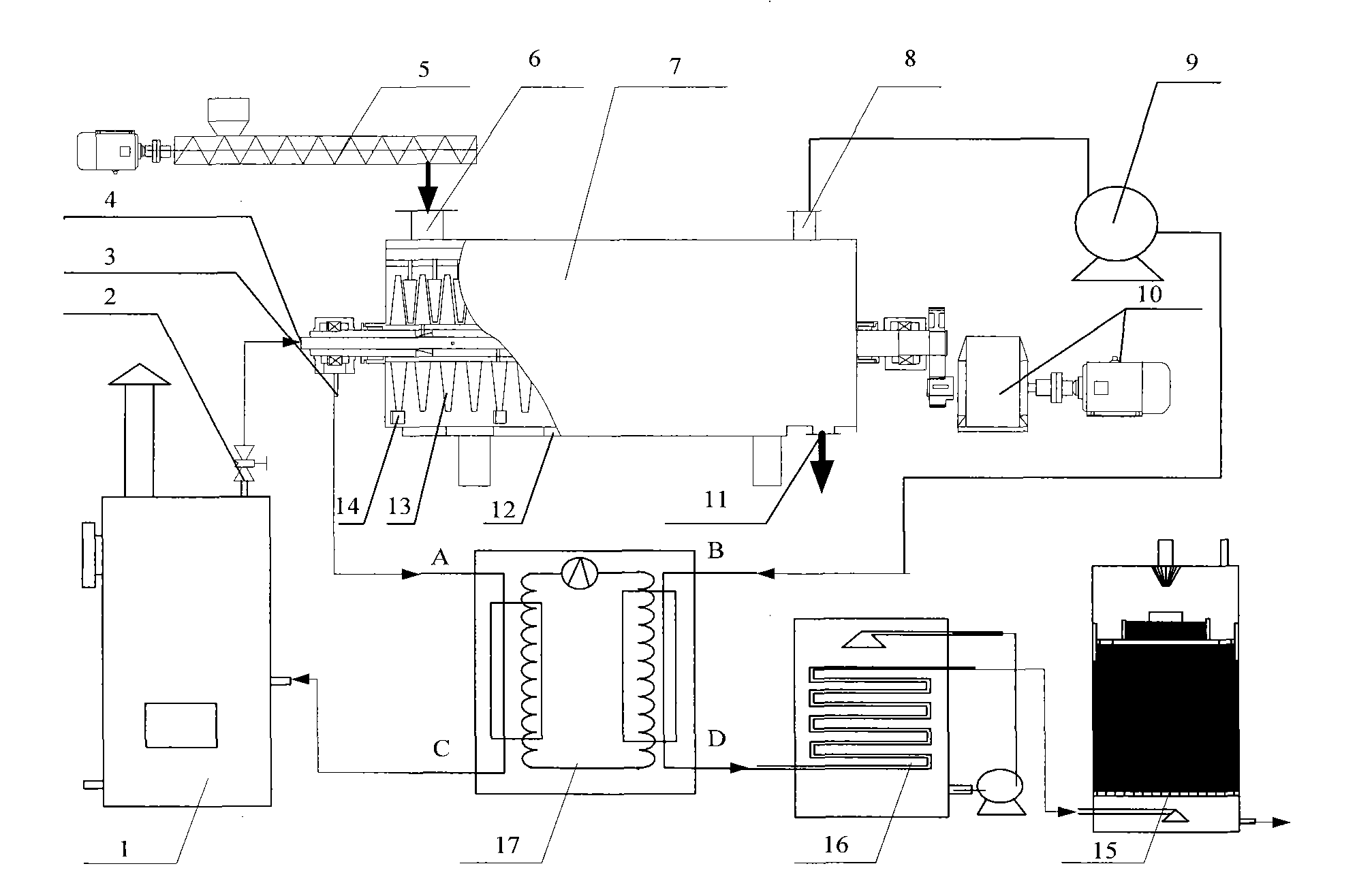

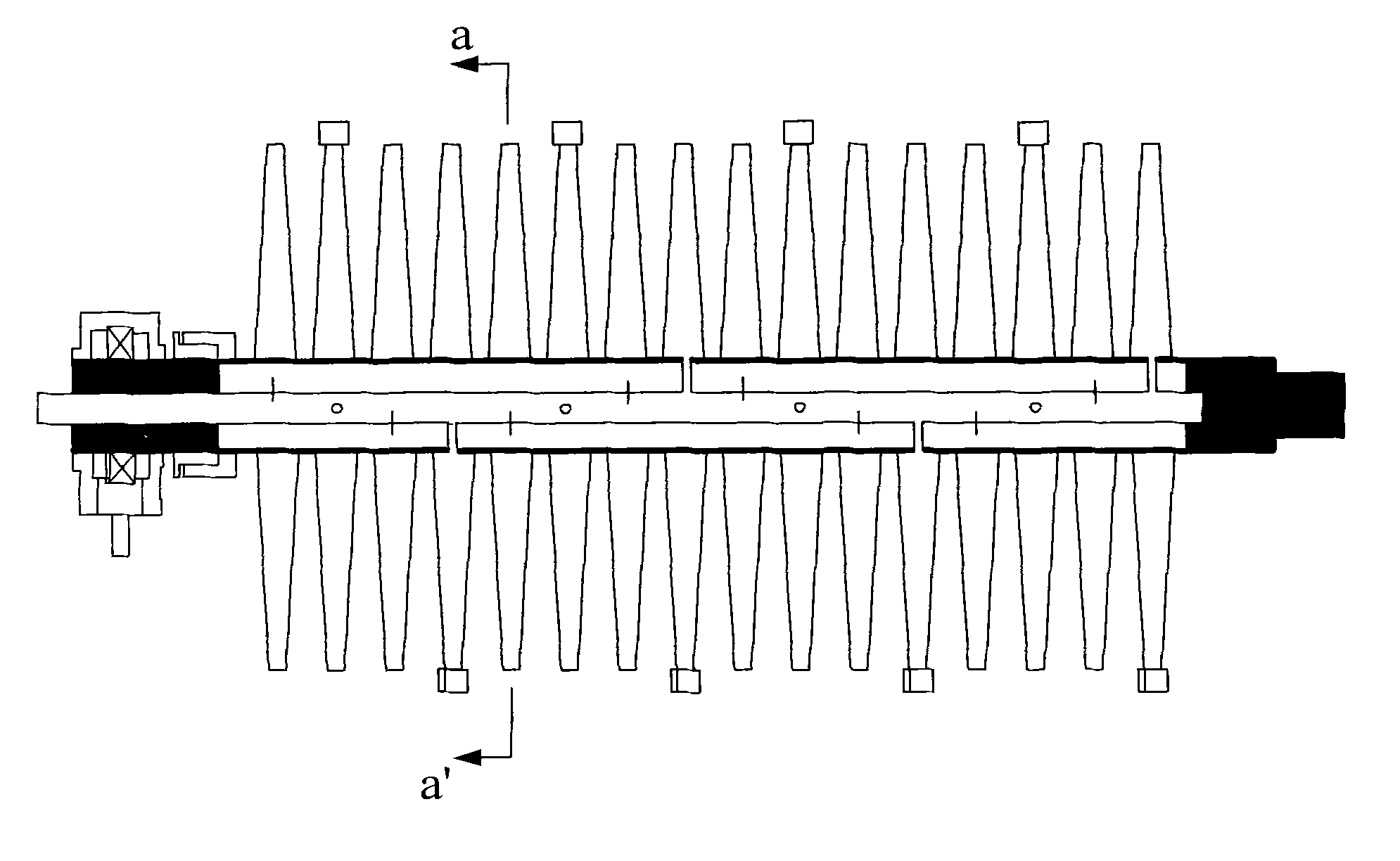

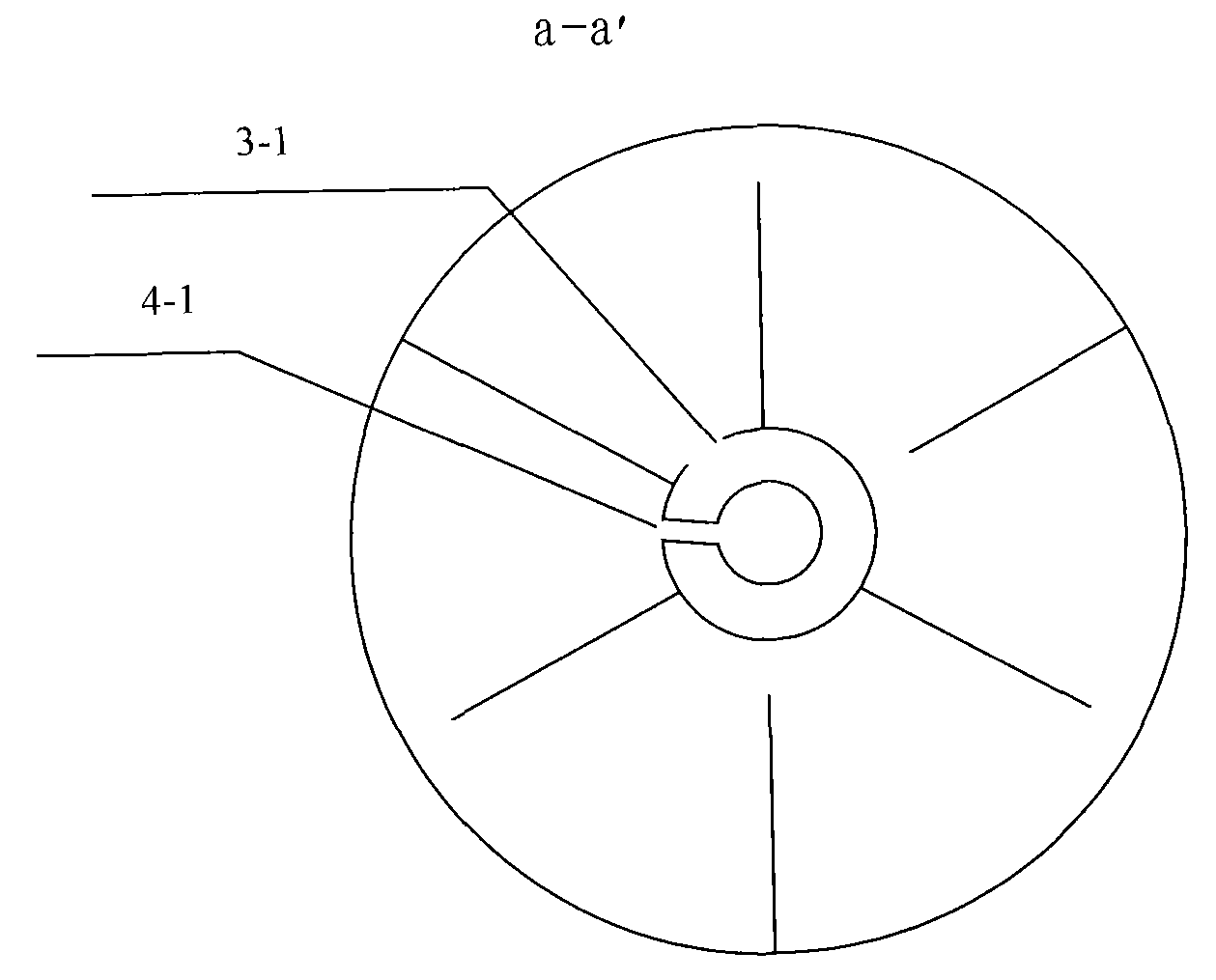

[0035]The mechanically dewatered sludge (with a moisture content of about 80%) stored in the sludge hopper is sent into the rotary sludge dryer 7 through the screw feeder, and the sludge is dried by the rotation of the deflector 14 on the hollow disc 13 Turn over, stir, constantly update the heating interface, contact the inner wall of the cylinder and the hollow disk 13, and be fully heated to evaporate the surface water contained in the sludge (sludge waste steam), and discharge it from the exhaust outlet 8 of the dryer. The dried sludge moves forward under the forward force of the deflector 14 and is discharged at the sludge outlet 11 of the drying machine. The heat required for sludge drying comes from the water vapor generated by the steam generator 1. The water vapor enters the disk cavity from the steam inlet 4-1 of the steam pipe 4 of the dryer, and undergoes sufficient phase conversion heat in the cavity, and The sludge is dried by heat conduction, and the steam after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com