Device and method for preparing pulverized coal with low energy consumption

A technology of pulverized coal and coking coal, applied in the steam generation method using heat carrier, coke cooling, petroleum industry, etc., can solve the problems of energy recovery, environmental pollution, etc., to save drying costs, reduce input, and solve dust pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

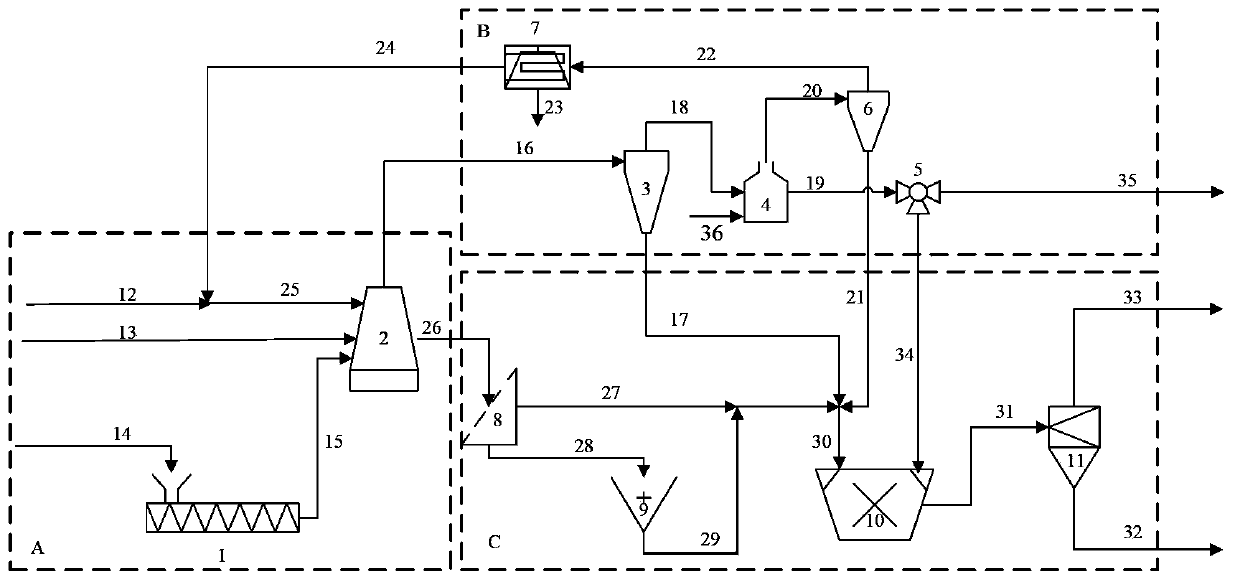

Method used

Image

Examples

Embodiment 1

[0031] After the lignite is fed and measured by the meter, it is mixed with the high-temperature semi-coke from the pulverized coal pyrolysis (raw coal particle size<6mm) device in the CDQ oven. The water content of the lignite is 34.5%, and the semi-coke temperature is 450- Between 550°C, the mass ratio of lignite to semi-coke is 1:9. At the same time, a mixed inert gas is introduced into the CDQ. Part of the sensible heat of the high-temperature semi-coke is absorbed by the lignite, and the rest is exchanged with the inert gas. This process Not only the lignite is dried, but also the semi-coke is cooled.

[0032] The high-temperature coke quenching gas from the top outlet of the CDQ enters the first-stage dust collector, and after the dust carried by the first-stage dust collector is removed, the first-stage dust removal gas is sent to the waste heat boiler, and the heat carried by the waste heat boiler gas heats the water The superheated steam is converted into superheated ...

Embodiment 2

[0035] After the low-rank coal is fed and measured by the meter, it is mixed with the high-temperature semi-coke from the lump coal pyrolysis (raw coal particle size>20mm) device in the CDQ oven. The water content of the low-rank coal is 16.8%, and the semi-coke The temperature is between 650-780°C, the mass ratio of bituminous coal to semi-coke is 5:5, and a mixed inert gas is introduced into the CDQ at the same time, part of the sensible heat of high-temperature semi-coke is absorbed by bituminous coal, and the rest is exchanged with inert gas heat, this process not only dries the raw coal but also cools the semi-coke.

[0036] The high-temperature coke quenching gas from the top outlet of the CDQ enters the first-stage dust collector, and after the dust carried by the first-stage dust collector is removed, the first-stage dust removal gas is sent to the waste heat boiler, and the heat carried by the waste heat boiler gas heats the water The superheated steam is converted in...

Embodiment 3

[0039] After the bituminous coal is fed and measured by the meter, it is mixed with the high-temperature semi-coke from the granular coal pyrolysis (raw coal particle size is 6-20mm) device in the CDQ oven. The water content of the bituminous coal is 11.3%, and the semi-coke temperature is Between 550-650°C, the mass ratio of bituminous coal to semi-coke is 4:6. At the same time, mixed inert gas is introduced into CDQ, part of the sensible heat of high-temperature semi-coke is absorbed by bituminous coal, and the rest is exchanged with inert gas. This process not only dries the raw coal but also cools the coke.

[0040] The high-temperature coke quenching gas from the top outlet of the CDQ enters the first-stage dust collector, and after the dust carried by the first-stage dust collector is removed, the first-stage dust removal gas is sent to the waste heat boiler, and the heat carried by the waste heat boiler gas heats the water The superheated steam is converted into superhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com