Patents

Literature

5173results about How to "Improve drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

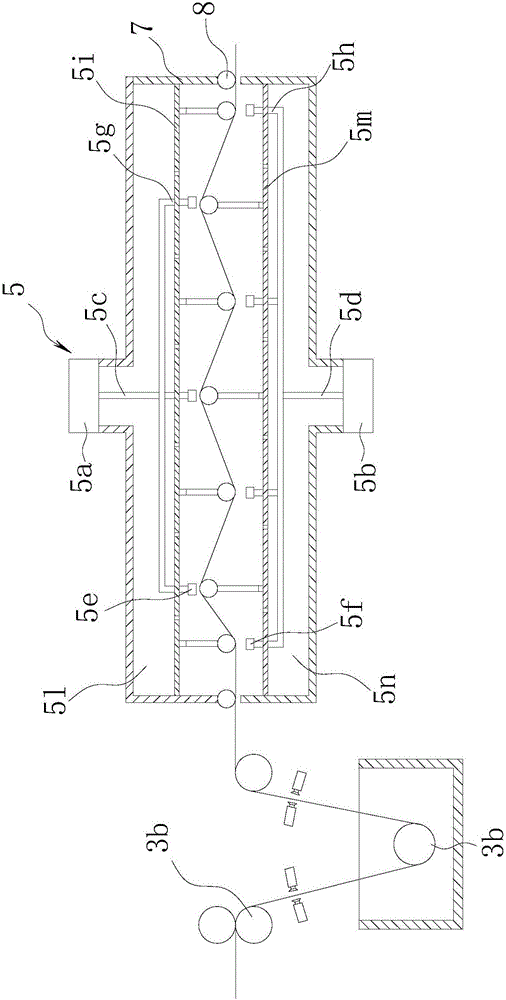

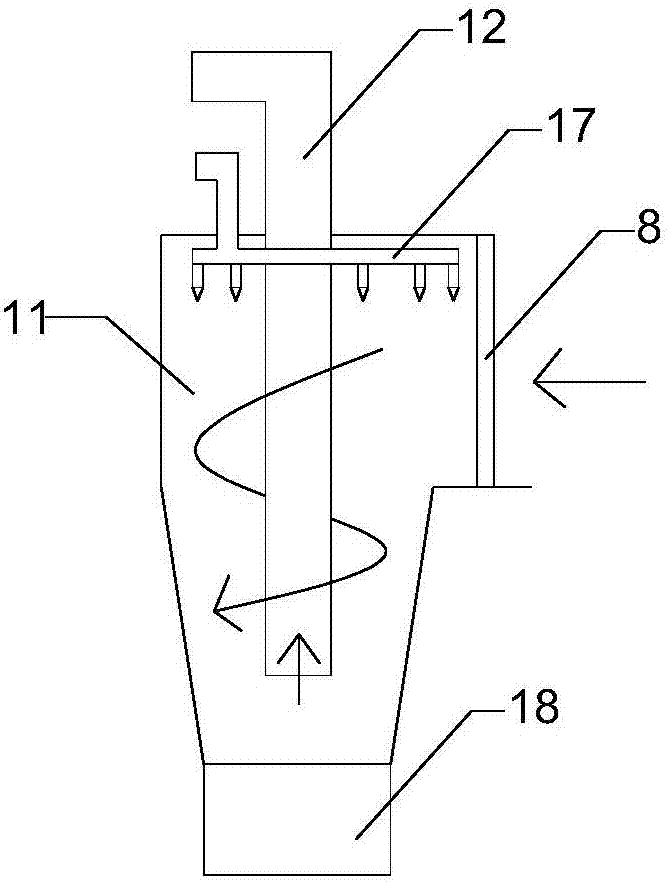

Circulating sludge biological fermentation tank, processing system and processing method

ActiveCN102153388AReduce wind pressureReduce air volumeBio-organic fraction processingSludge treatment by de-watering/drying/thickeningSludgeControl room

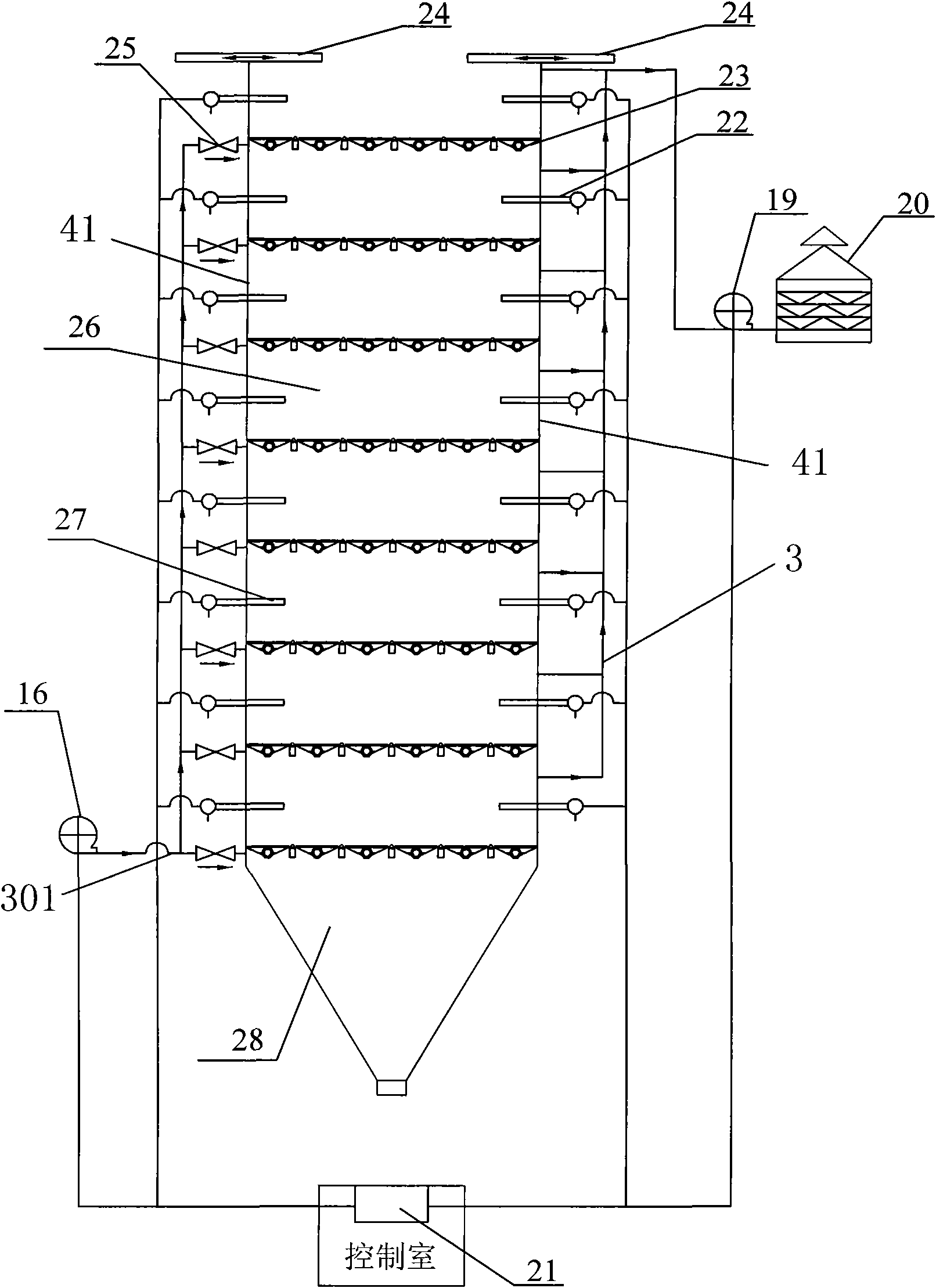

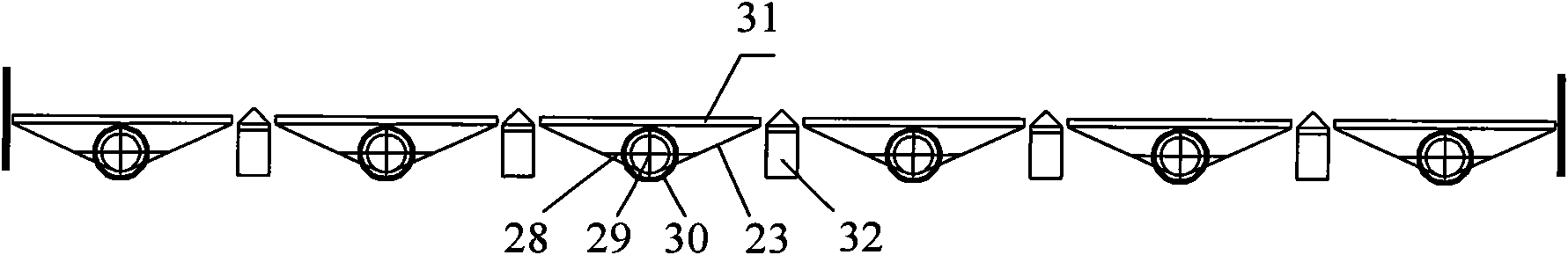

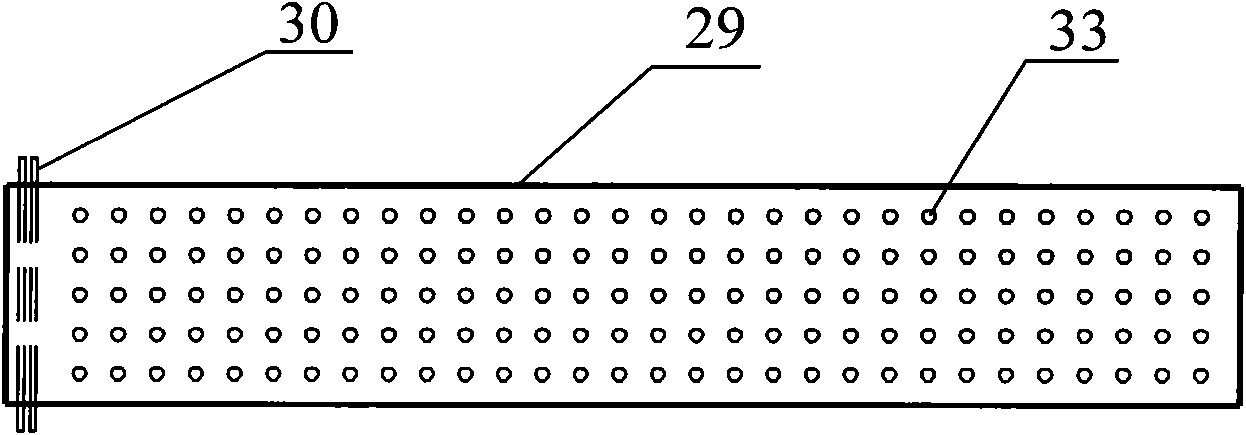

The invention discloses a circulating sludge biological fermentation tower which comprises a tower body, an openable tower cover, a storage tank and a plurality of rotatable fermentation devices, wherein the openable tower cover is arranged on the top of the tower body; the storage tank is arranged at the bottom of the tower body; the rotatable fermentation devices are arranged in the tower body in parallel; the fermentation devices divide an inner cavity of the tower body into a plurality of layers of fermentation bins along the axial direction; the lower part of each layer of fermentation device is provided with a ventilating oxygen supply pipeline communicated with a blower; the upper part of each layer of fermentation device is provided with an air outlet pipeline communicated with aninduced draft fan and a monitoring device; the monitoring device is controlled by a control room; and a mechanism for driving the fermentation devices and the tower cover to move, the blower and the induced draft fan are all controlled by the control room. The invention also discloses a circulating sludge biological processing system and a processing method. By the circulating sludge biological fermentation tower, the circulating sludge biological processing system and the processing method, industrial biological fermentation desiccation treatment can be continuously and stably carried out onsludge under the conditions of high efficiency and low energy consumption.

Owner:深圳市如茵生态环境建设有限公司

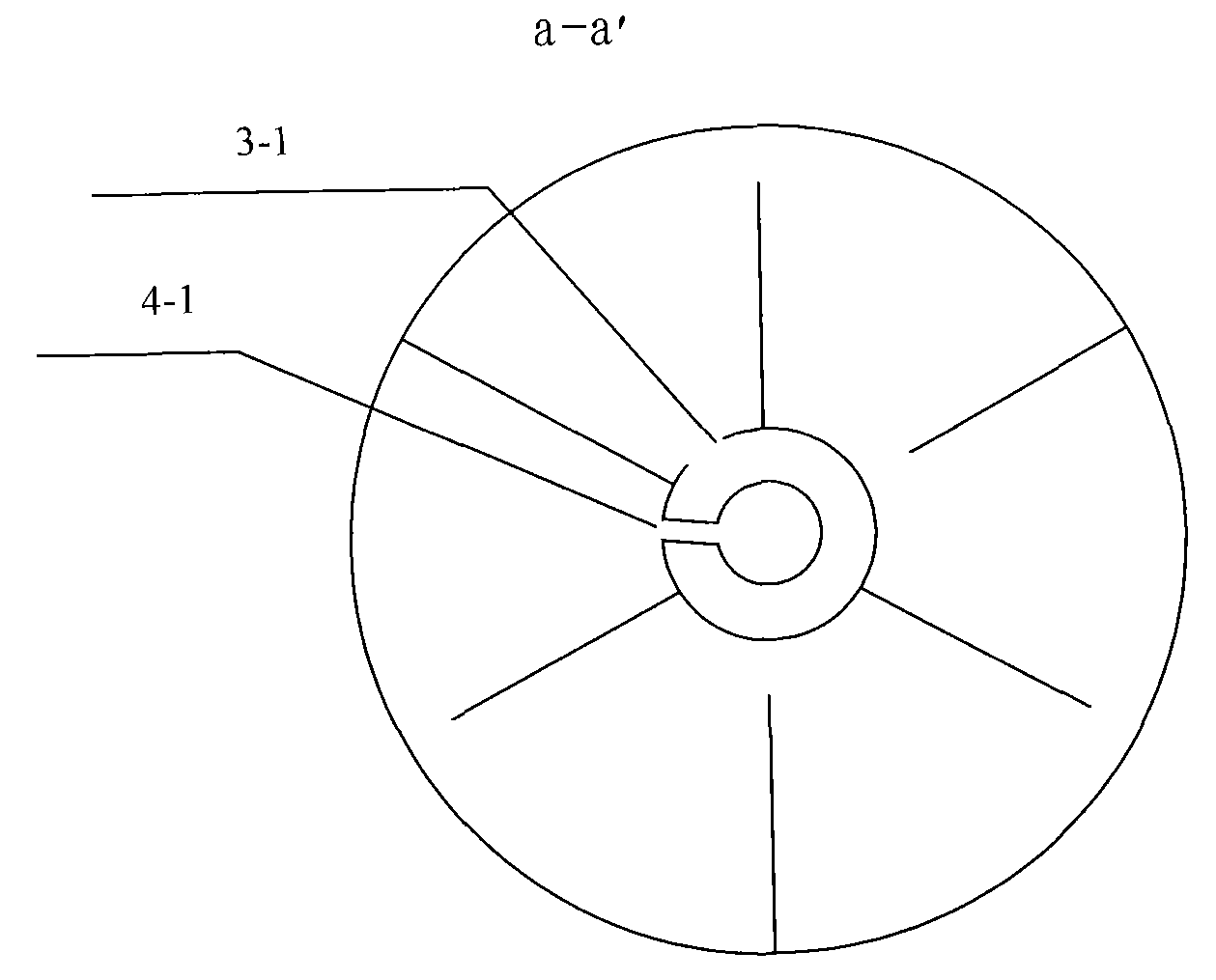

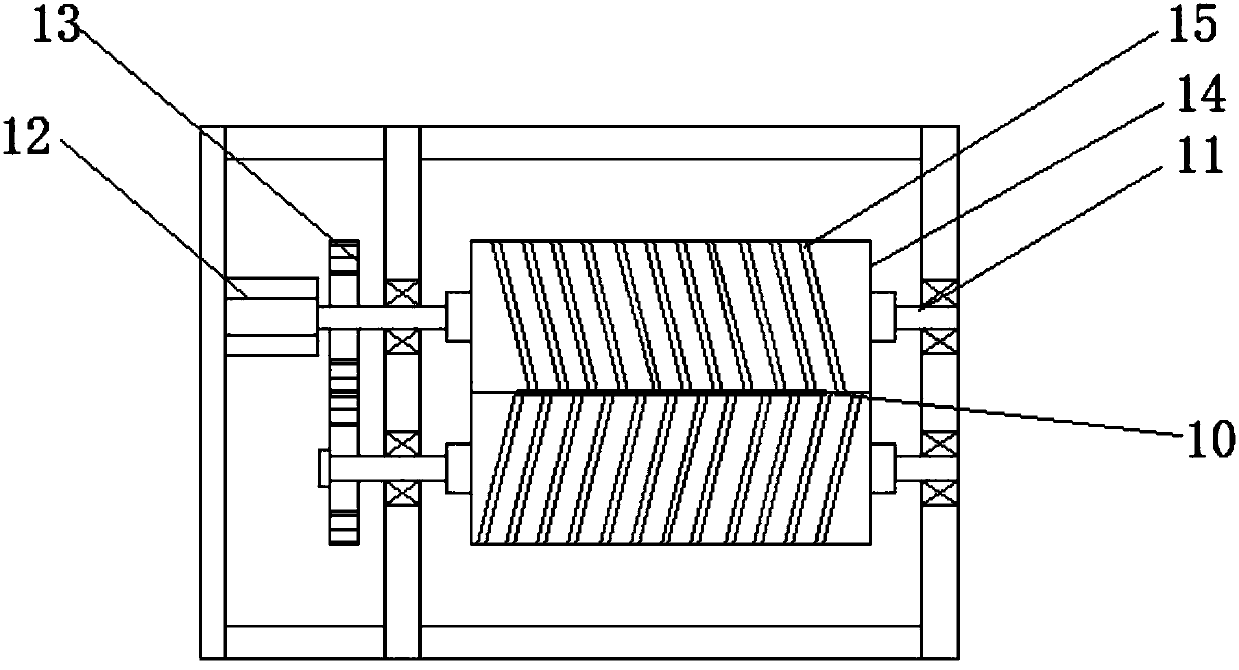

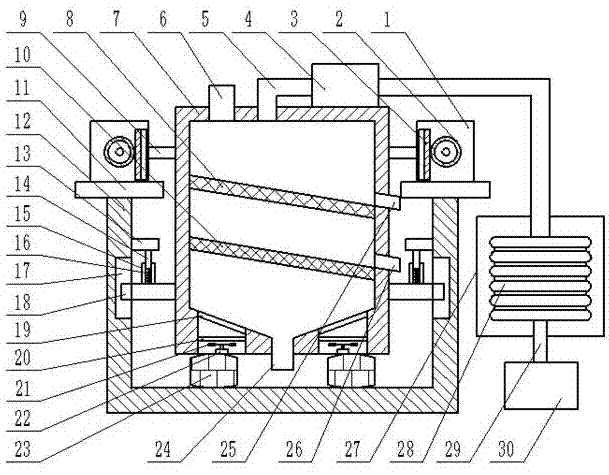

Latent heat recoverable multi-phase change sludge drying method and device

ActiveCN101774743AReduce drying costsEnergy balanceSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermal energyBrick

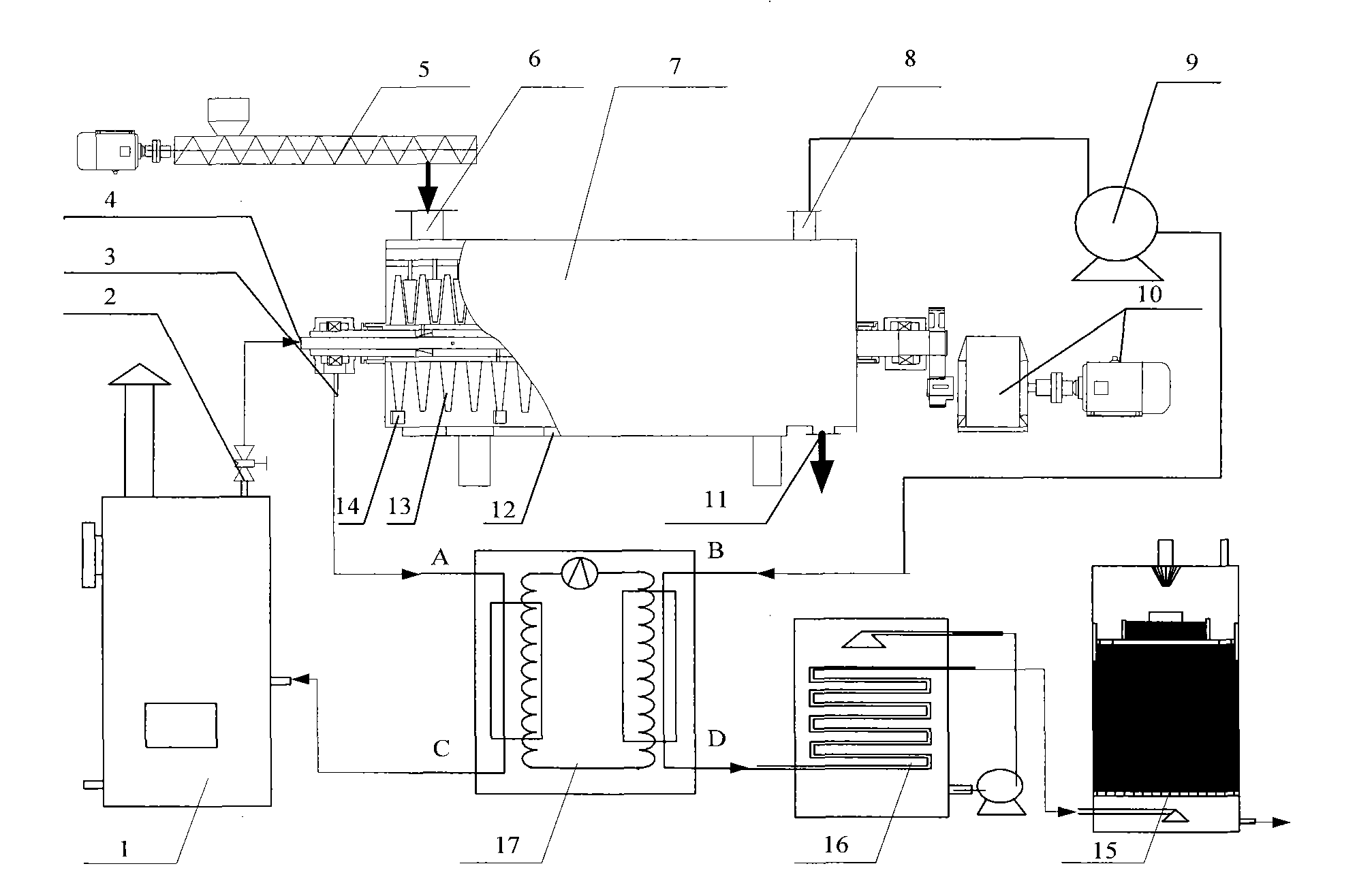

The invention discloses a latent heat recoverable multi-phase change sludge drying method and a latent heat recoverable multi-phase change sludge drying device, which are designed for solving the technical problems that the energy consumption is high, the latent heat of the sludge vapor cannot be recovered and reused, the dried tail gas pollutes the environment, the operating cost is high and the like in the conventional sludge drying technology. Due to the combination of a low-temperature vapor turntable dryer, a sludge waste vapor latent heat recover heat pump and a tail gas purification device, and the use of indirect phase change heat exchange for low-temperature vapor, the heat exchange is improved, and the loss of organic components of the sludge is low. The latent heat of the sludge drying tail gas is recovered by using the latent heat recover heat pump, and the recovered heat energy is reused for sludge drying. Therefore, the heat efficiency is improved, the operating cost is reduced, and the problems that the heat utilization ratio is low, the operating cost is high and the like in the sludge drying process are better solved. The dried products meet the requirement of baking light and energy-saving bricks and producing cement laminated products, and over 90 percent of heat value of the original sludge is maintained. Therefore, the resource utilization value of the sludge is maximized.

Owner:SHENYANG INST OF AERONAUTICAL ENG

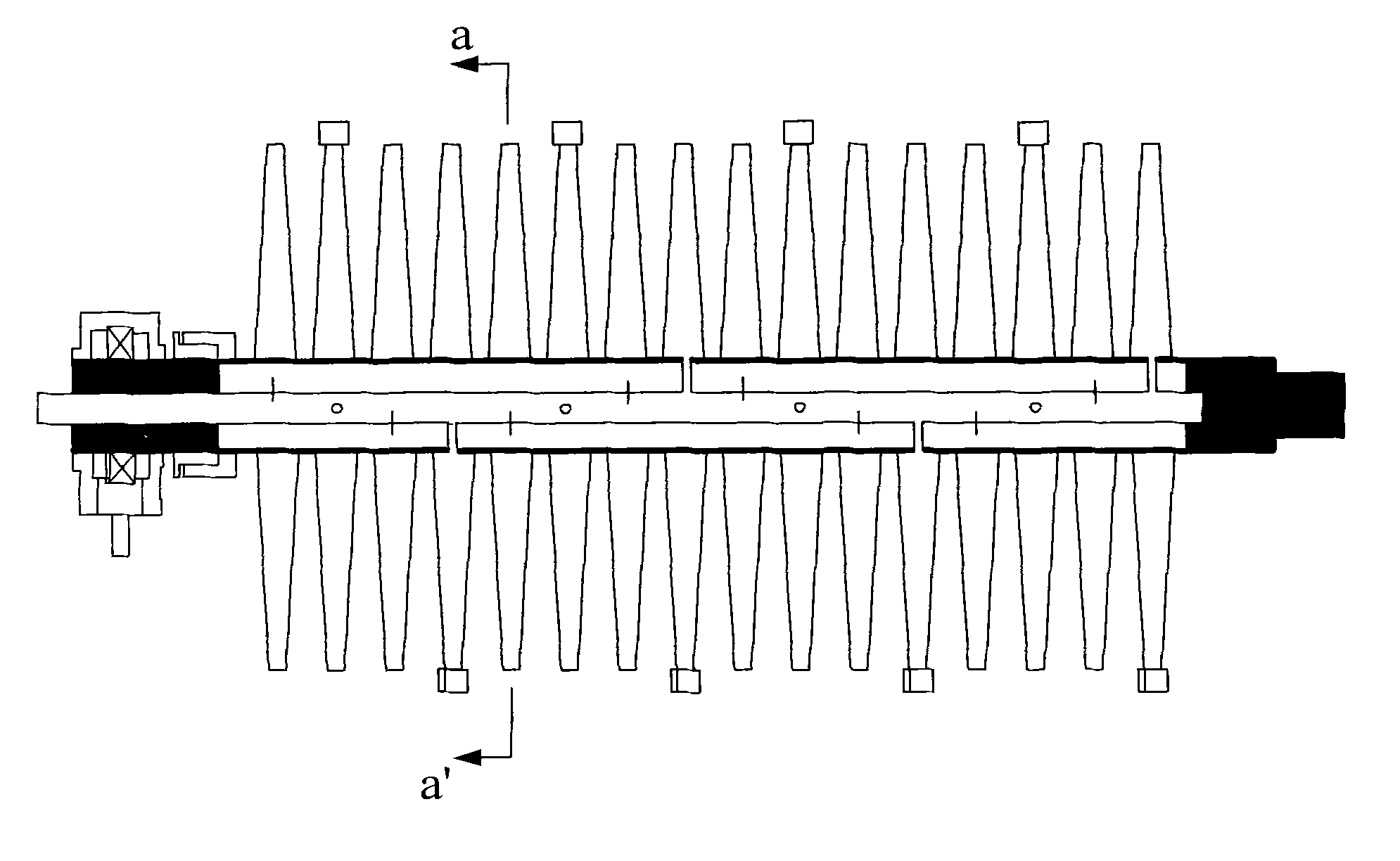

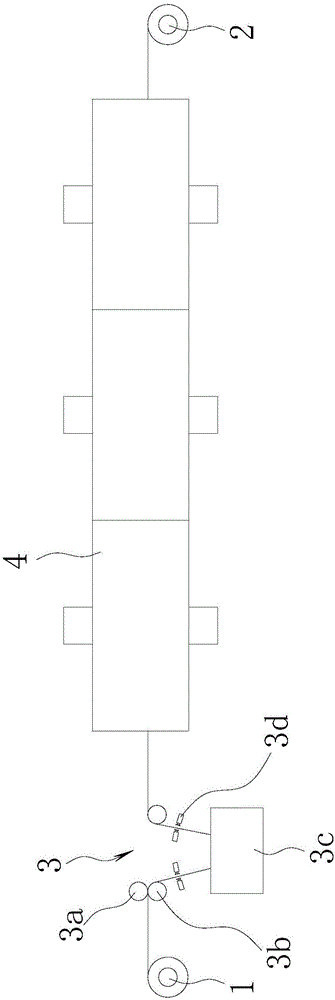

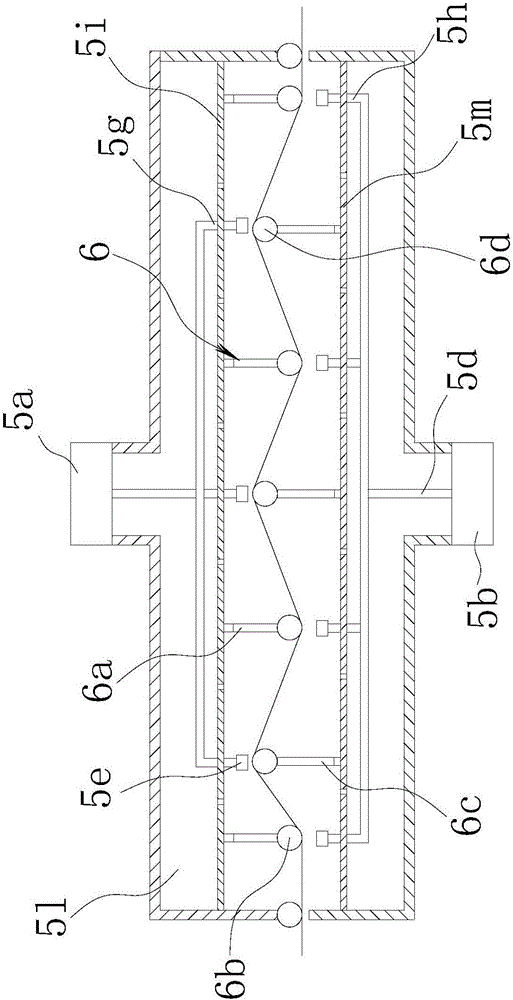

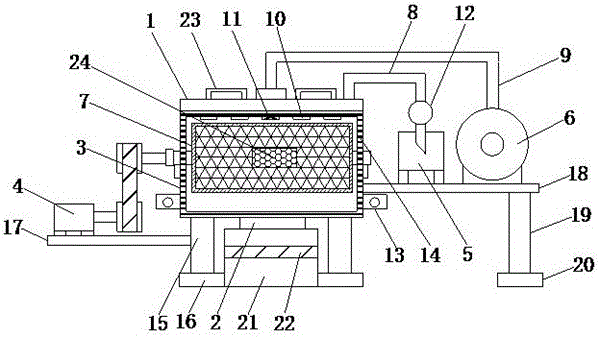

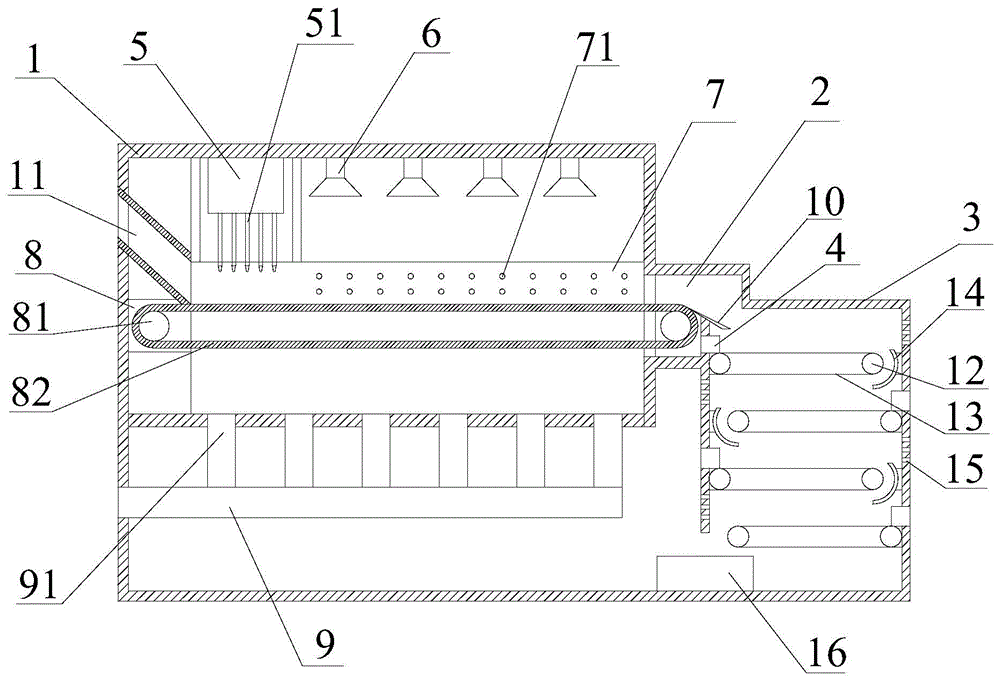

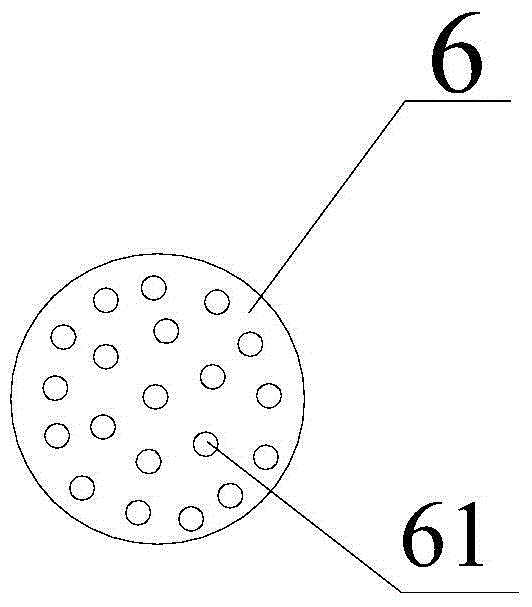

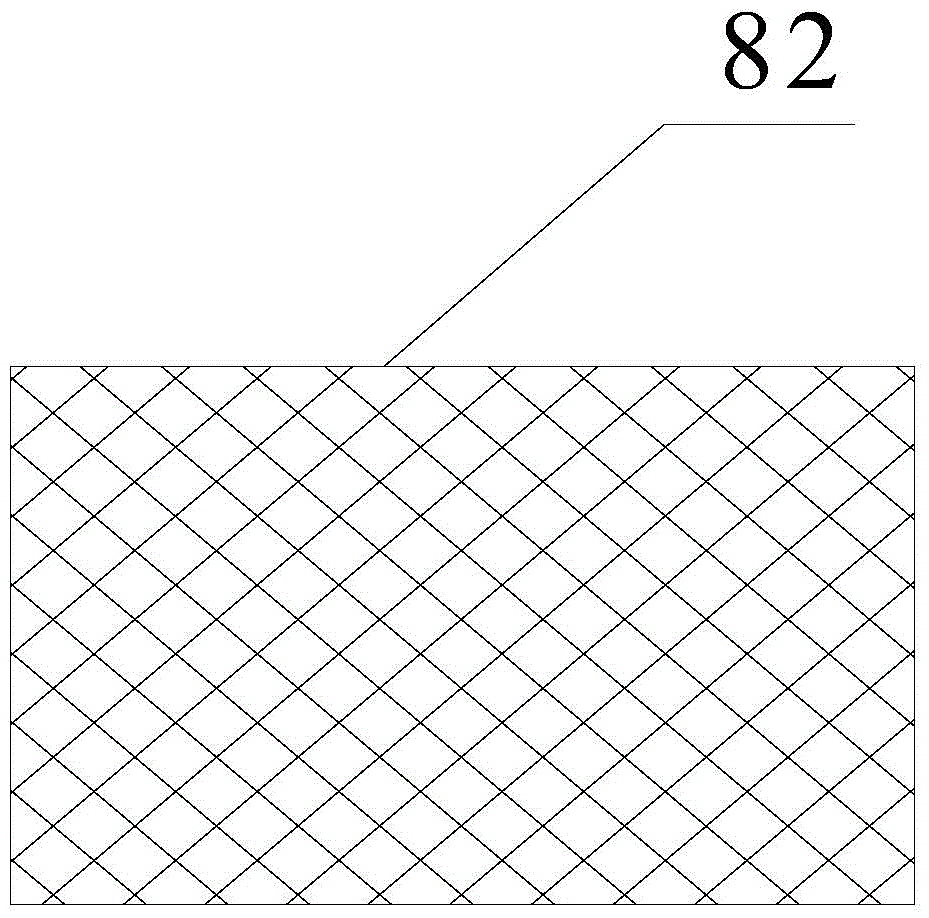

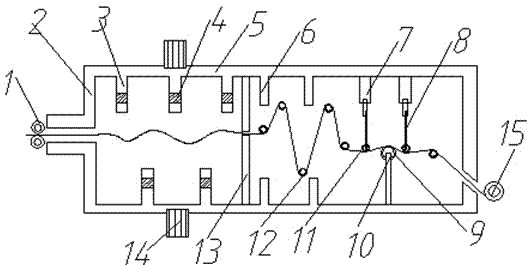

Penetrating type reverse-flow drying device

InactiveCN103471373AStrong penetrating powerLow running costDrying gas arrangementsDrying machines with progressive movementsTransport systemPulp and paper industry

The invention discloses a penetrating type reverse-flow drying device. The penetrating type reverse-flow drying device comprises a heat exchanger, an air heater, a driving drum, a driven drum, a sieve plate type conveying steel belt and a dryer body, wherein an air blower is connected with one side of the upper end of the heat exchanger, the air heater is connected with one side of the lower end of the heat exchanger, the driving drum is connected with a double-stage cycloidal-pin wheel speed reducer through a transmission chain, a material conveying system is formed by the driving drum and the driven drum through the sieve plate type conveying steel belt, a feeding hopper is arranged at one end of the material conveying system, a discharging hopper is arranged at the other end of the material conveying system, the sieve plate type conveying steel belt penetrates through the dryer body, the dryer body is of a sealed structure, a plurality of axial fans are reasonably distributed on the top face and the bottom face of the dryer body, one side of the dryer body is connected with an outlet of the air heater, the other side of the dryer body is connected with an suction fan, and an air outlet of the suction fan is connected with an inlet pipe arranged at the bottom of the heat exchanger. The penetrating type reverse-flow drying device is simple in structure and good in practicability, can achieve rapid and efficient drying of materials, is low in energy consumption and has broad prospects.

Owner:东莞市胜源纸品有限公司

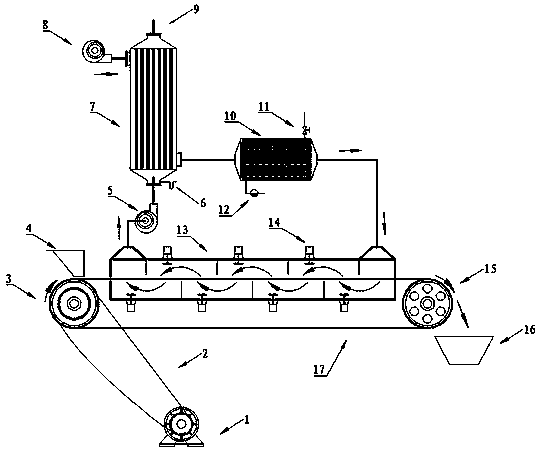

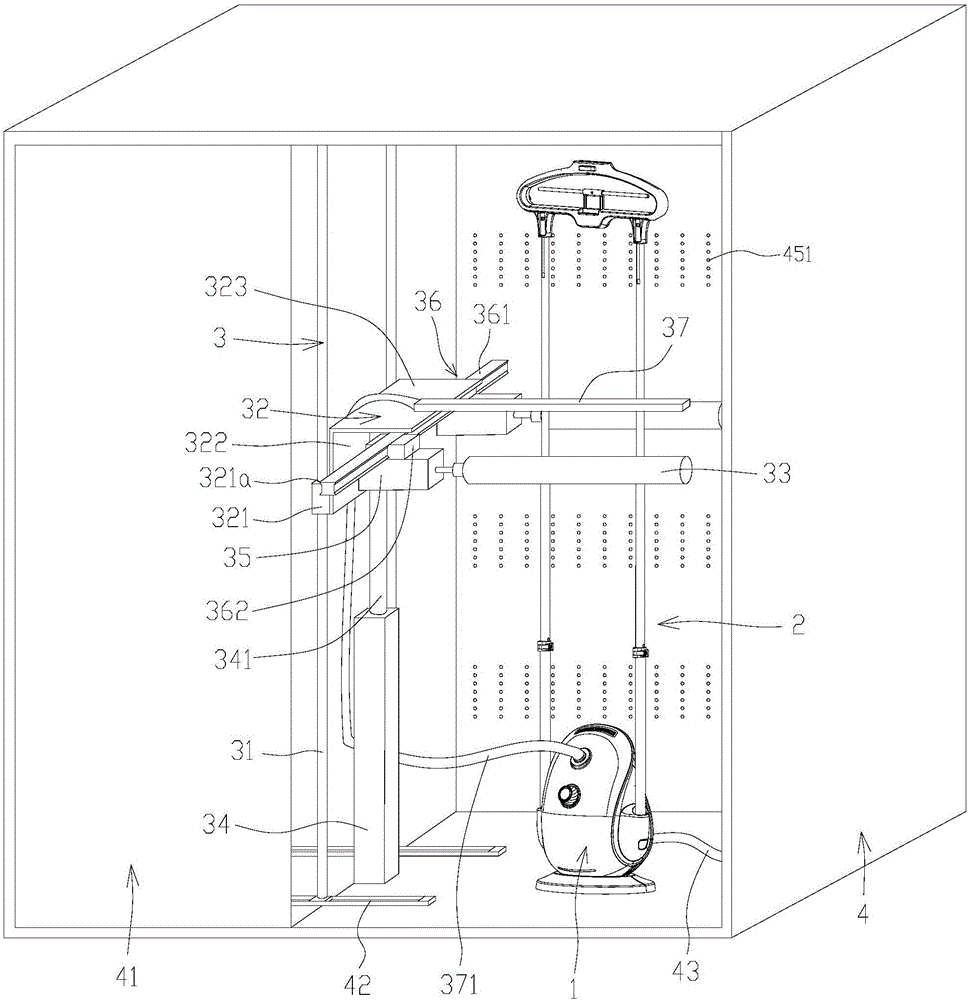

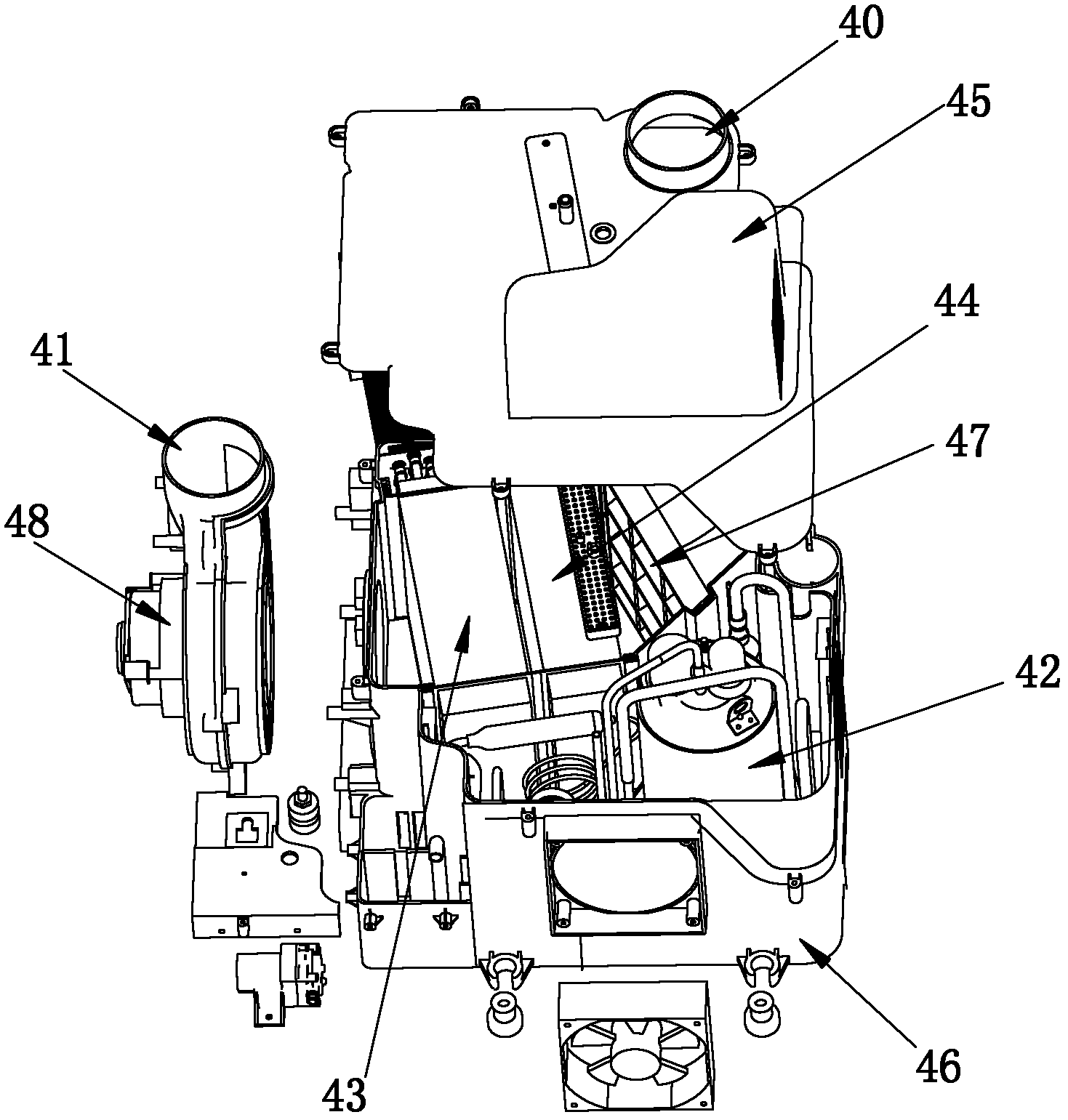

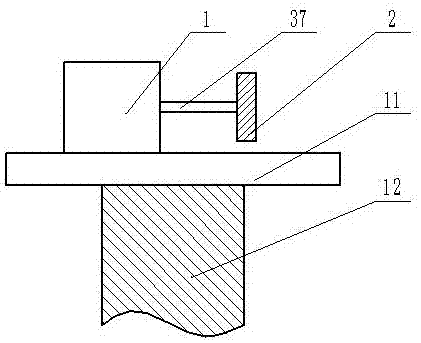

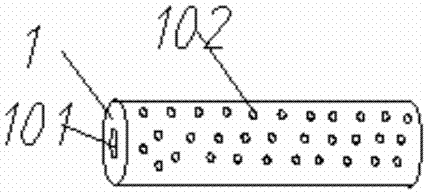

Ironing device

ActiveCN106012461ASimple structureCompact structureIroning apparatusTextiles and paperState of artMechanical engineering

The invention belongs to the technical field of household appliances, and particularly relates to an ironing device. The ironing device comprises a main machine, a hanger assembly and an ironing assembly. A steam generation device is arranged in the main machine and used for delivering steam to ironed clothes. The ironing assembly comprises a guide rod, an installation base, a roller brush, a driving device and a rotating device. The rotating device is arranged on the installation base, and the roller brush is rotationally driven by the rotating device. The installation base is movably connected with the guide rod, an air cylinder serves as the driving device, a push rod of the driving device is connected with the installation base, and the air cylinder drives the installation base to reciprocate in the direction of the guide rod so that the roller brush can brush the clothes hung on the hanger assembly in a reciprocating mode. Compared with the prior art, the ironing device is simple and compact in structure and greatly reduces the operating fatigue of a user; the automatic clothes ironing mode is convenient and fast to implement and good in ironing effect; besides, an air cylinder transmission system is simple in composition, large in output force, high in control precision, high in response speed and low in working noise.

Owner:FOSHAN SHUNDE SINCERE HOME HOME APPLIANCE MFG CO LTD

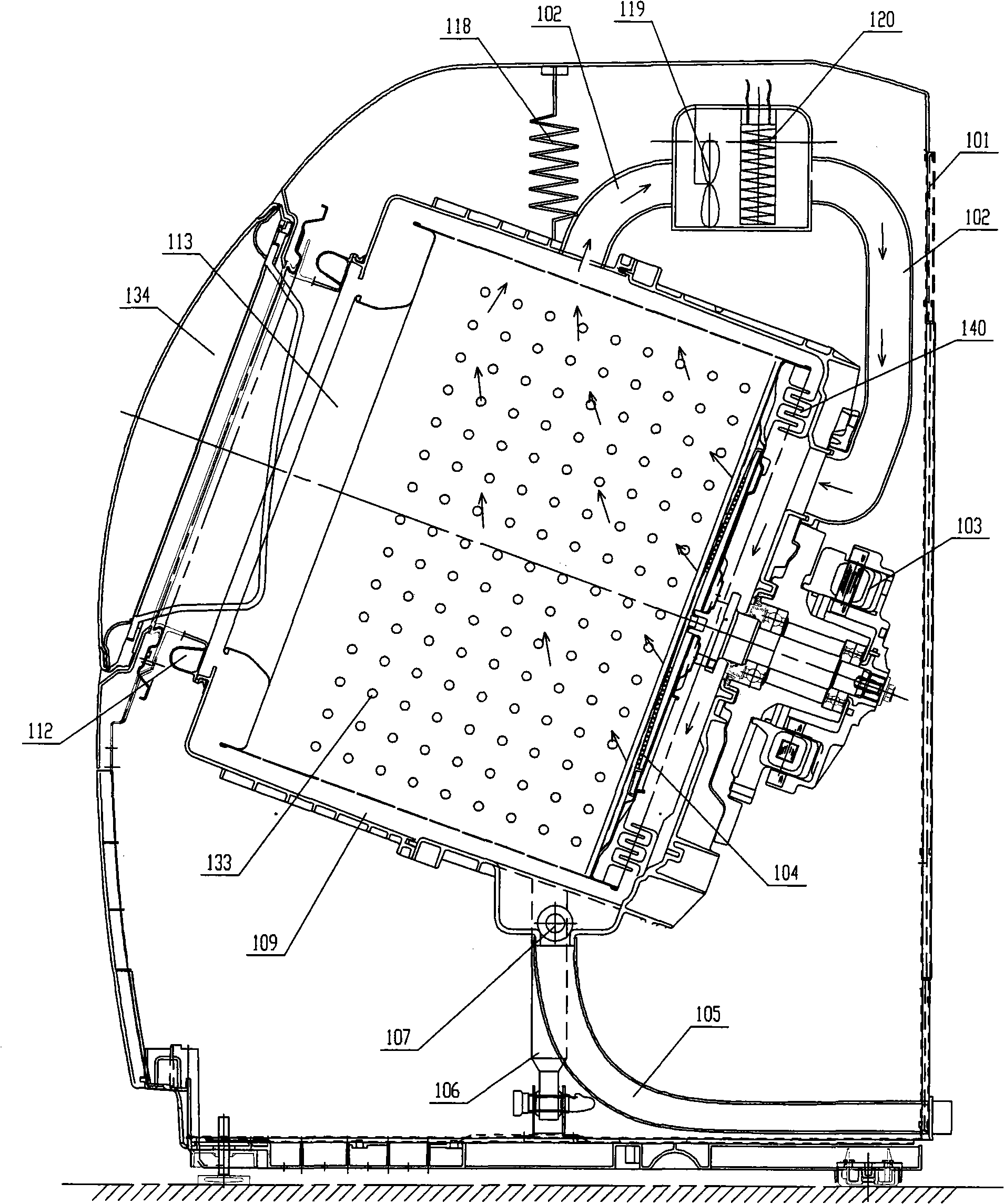

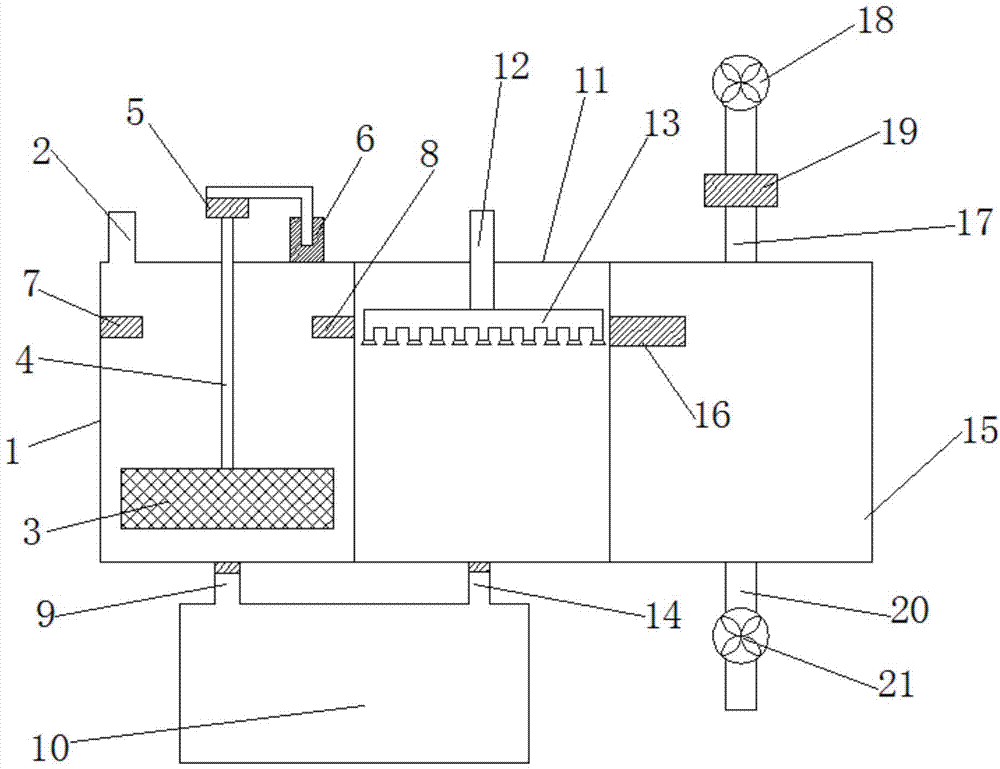

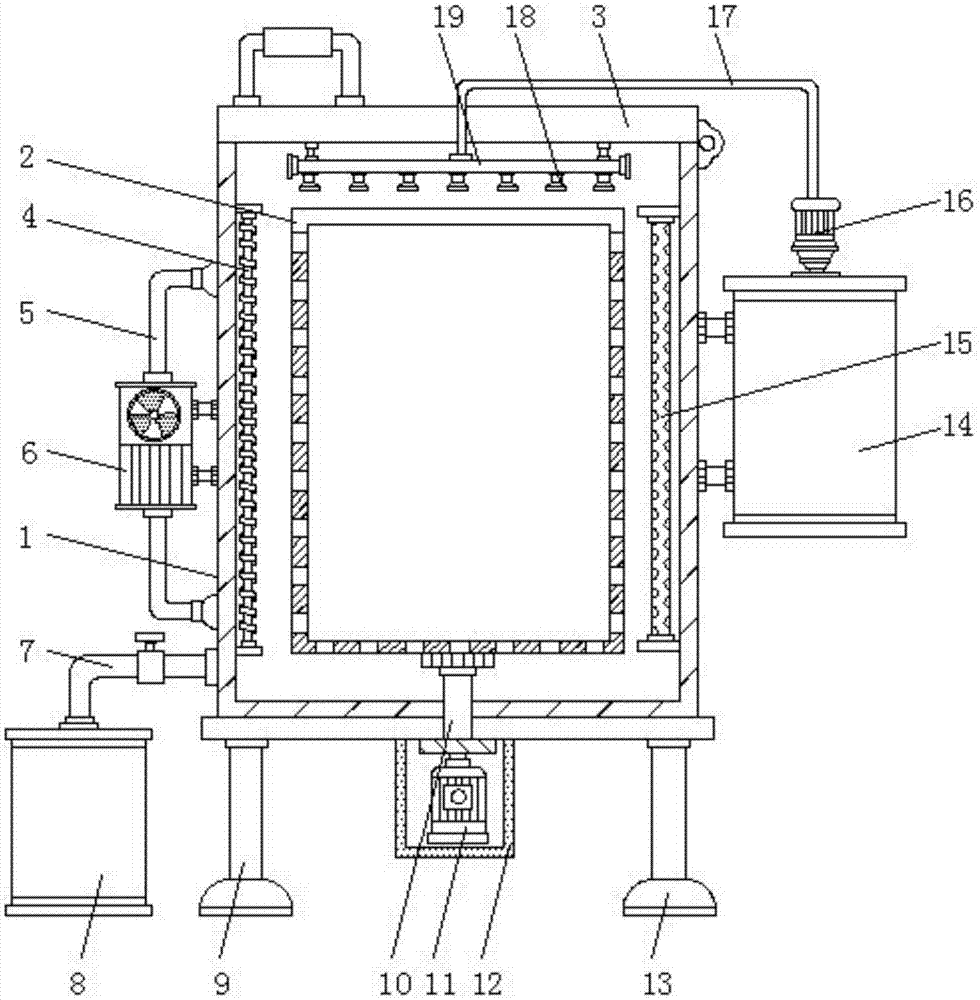

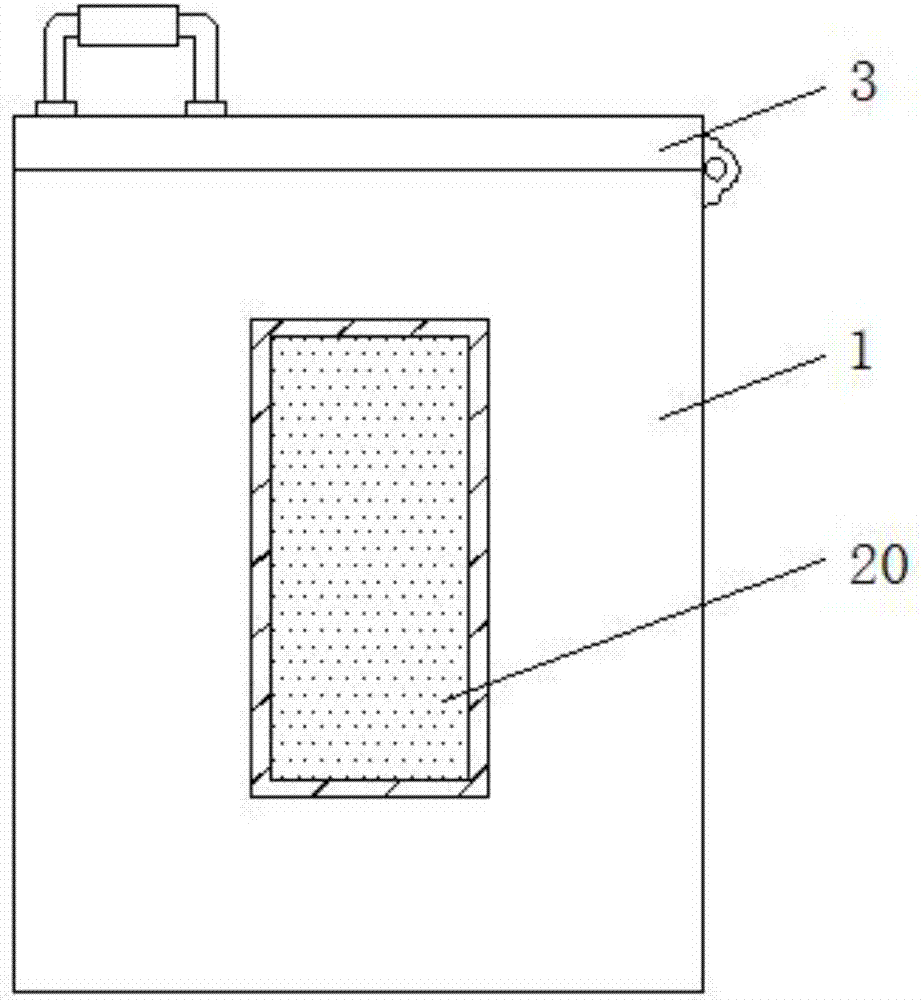

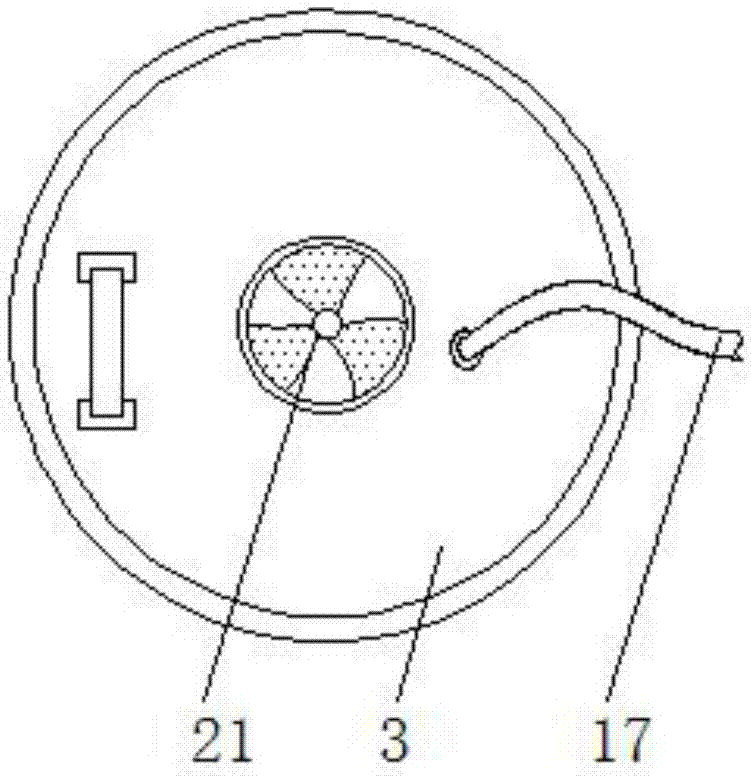

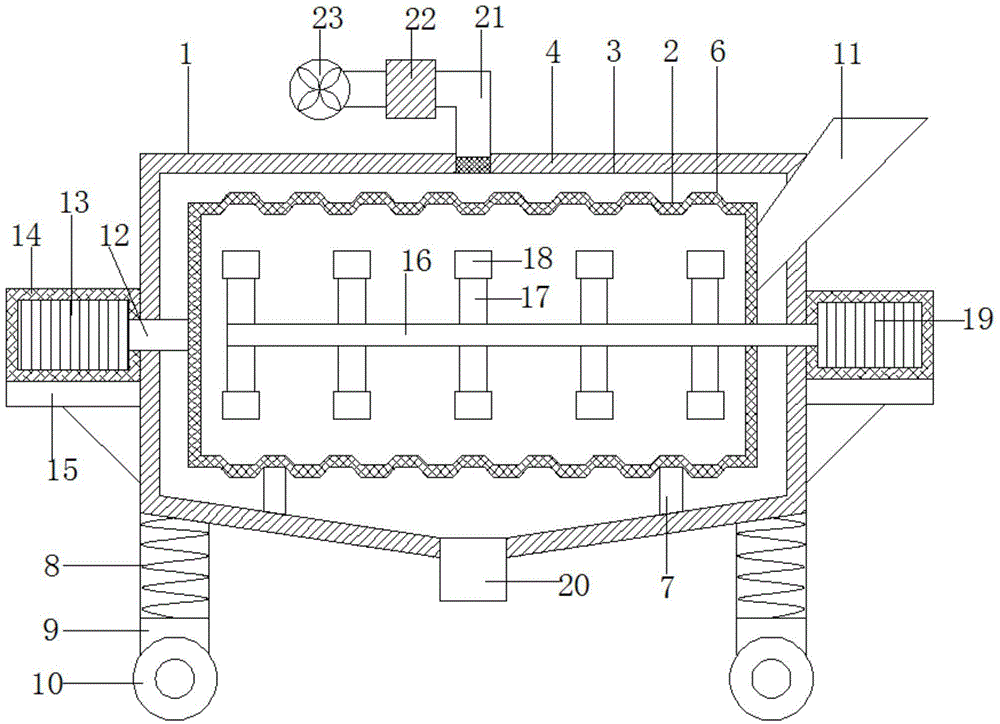

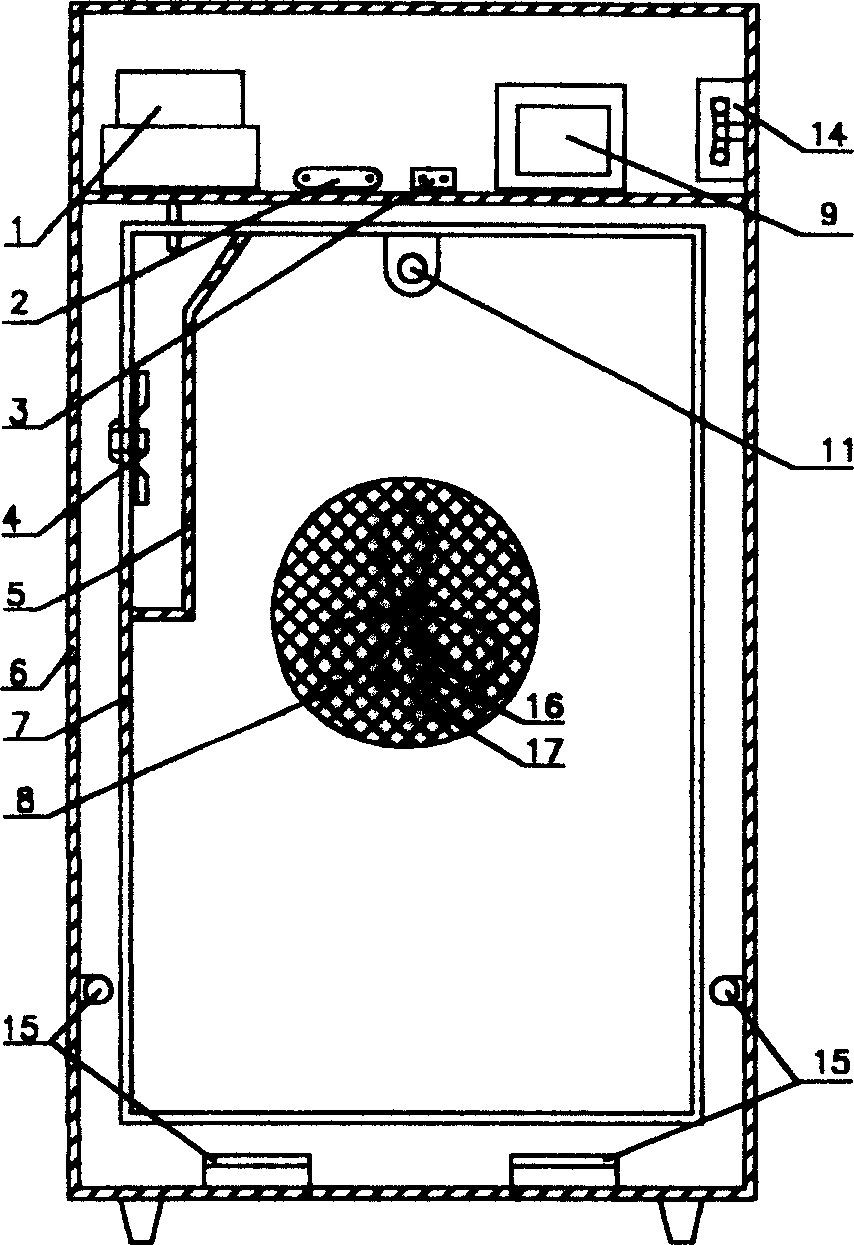

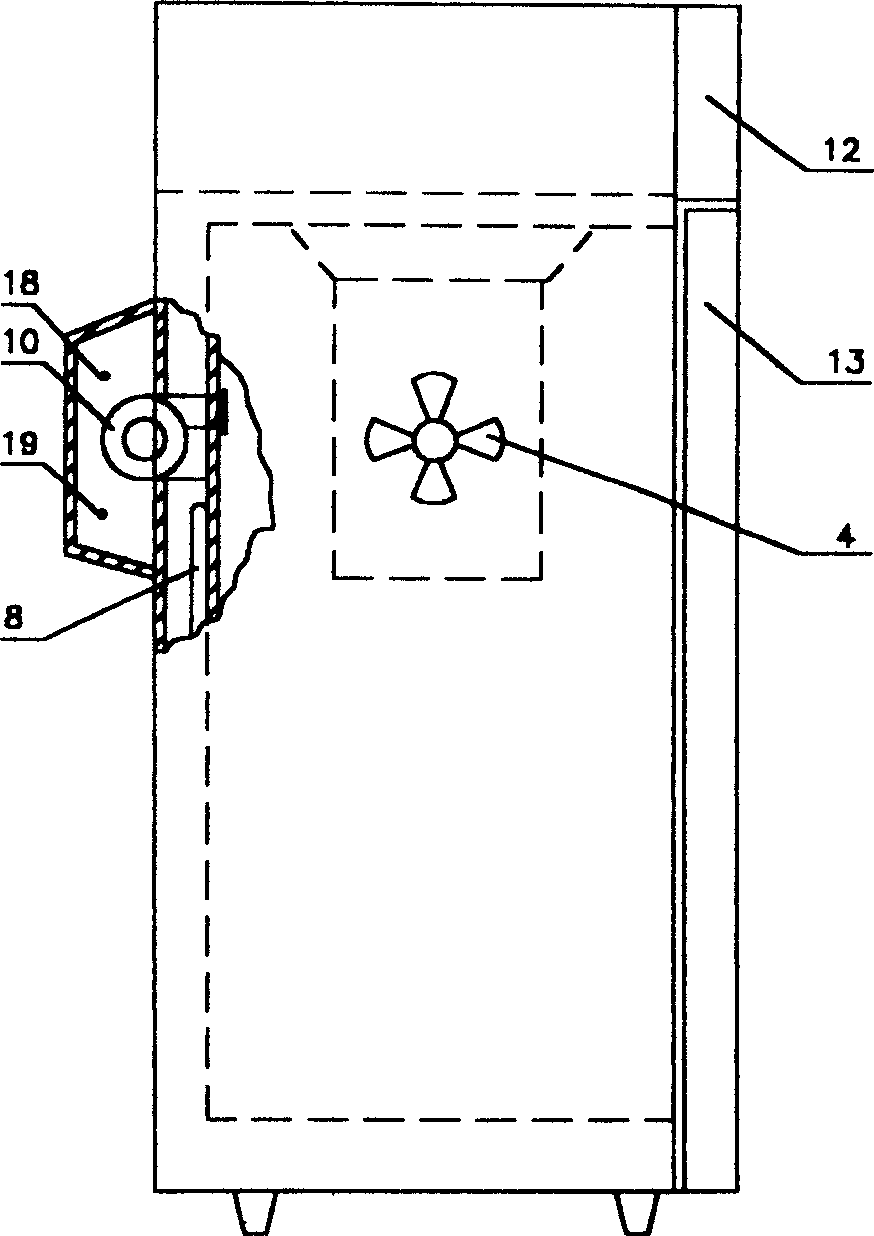

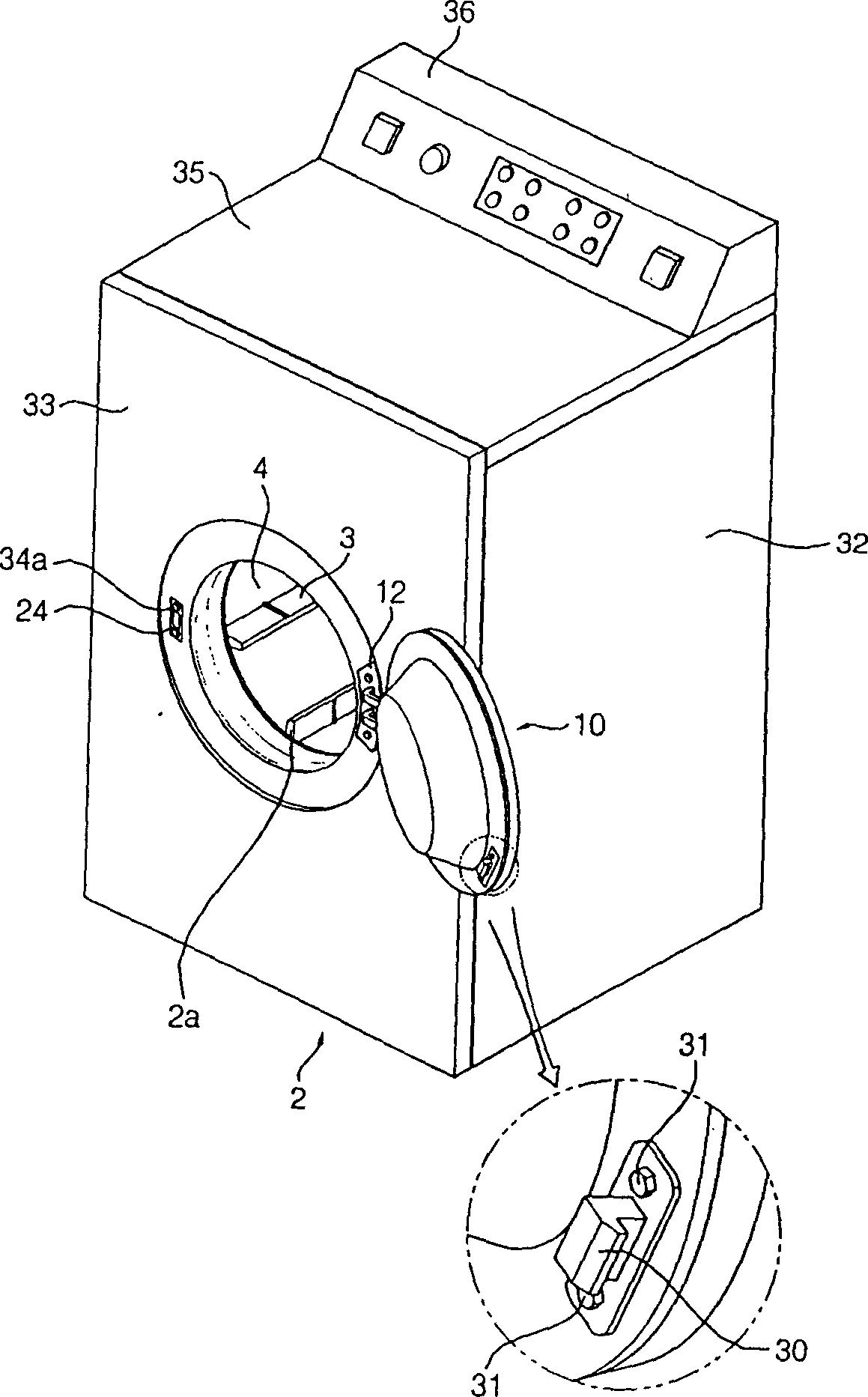

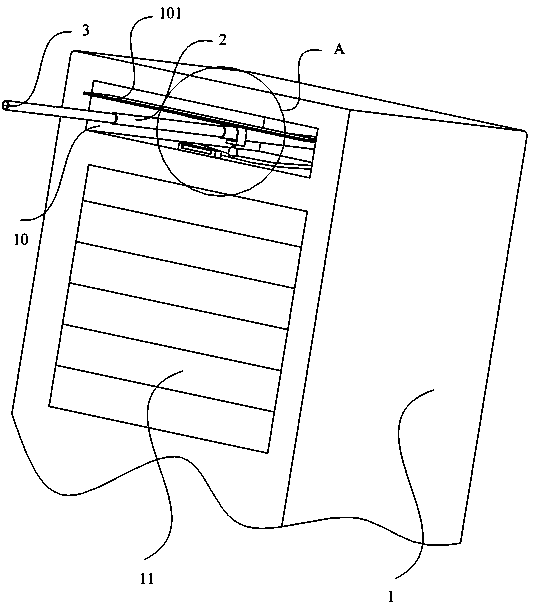

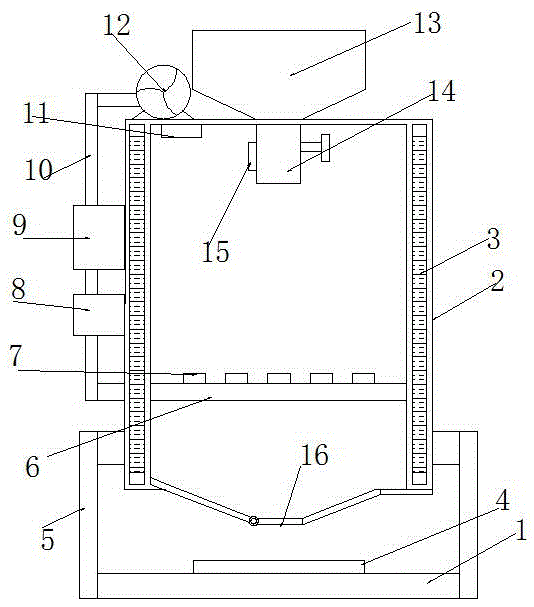

Washing machine with drying device

InactiveCN101343826ASimple designImprove drying effectOther washing machinesWashing machine with receptaclesWater holdingEngineering

The invention discloses a washing machine with the drying device. The washing machine comprises a washing machine casing as the whole frame of the washing machine; a water holding drum which is elastically arranged inside the washing machine casing and at the rear end of which a hot air filling opening is arranged; a circular channel which is arranged at the front end of the water holding drum opening, on the front end surface of which a plurality of air suction holes are arranged, and on the outer side wall of which an air exhaust opening is arranged; a rolling drum which can be arranged inside the water holding drum in a rotary way, on the bottom end of which air holes are arranged, and on the side wall of which a limber hole is arranged; a hot air isolating device which is arranged between the rolling drum front end and the water hold drum front end, and used to isolate the air; a dehumidifying device which is arranged in the circular channel; a drying pipeline which is arranged outside the water hold drum; a condensation water pipe one end of which is connected with the circular channel and the other end of which is connected with the front part of the water draining valve. The drying device in the washing machine of the invention can cause the drying high temperature air flow to evenly enter into the space inside the rolling drum from the rear end and the side wall, to contact with the wet clothes inside the rolling drum, and the drying effect is greatly enhanced.

Owner:PANASONIC HOME APPLIANCES R&D CENT HANGZHOU +1

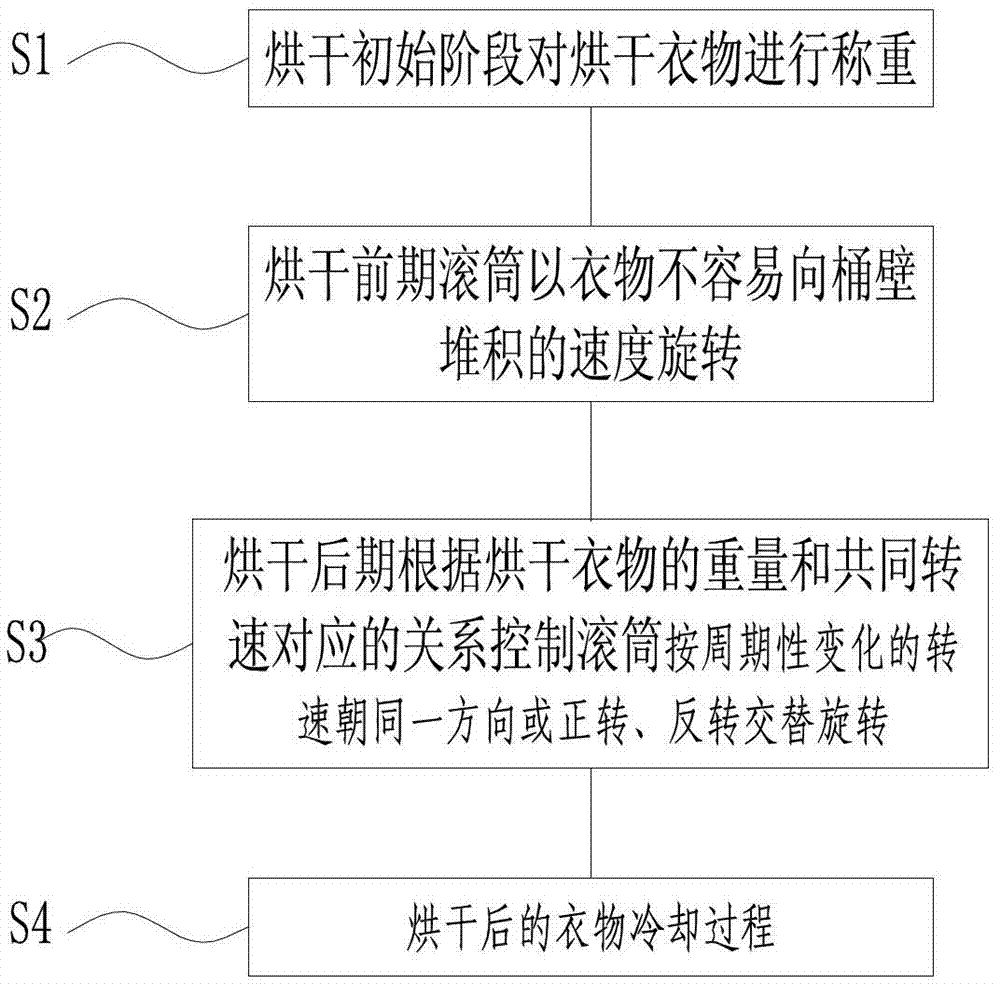

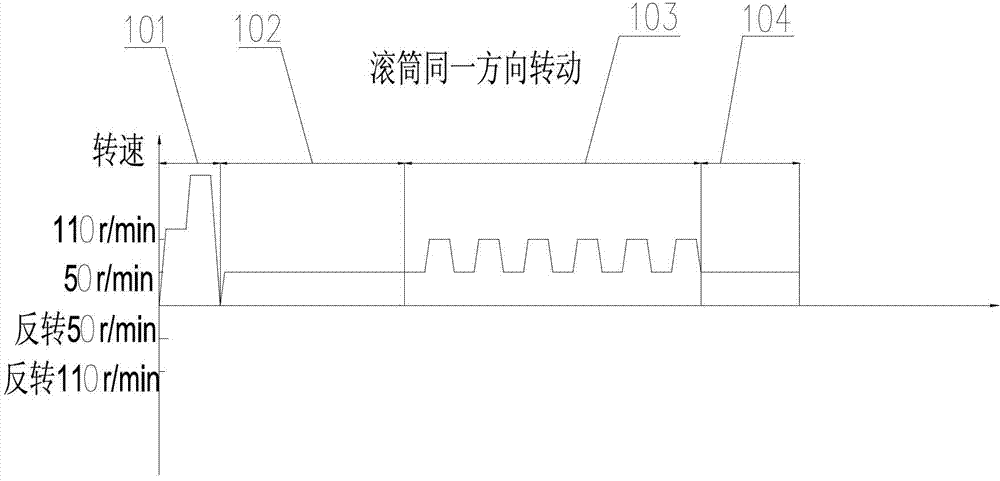

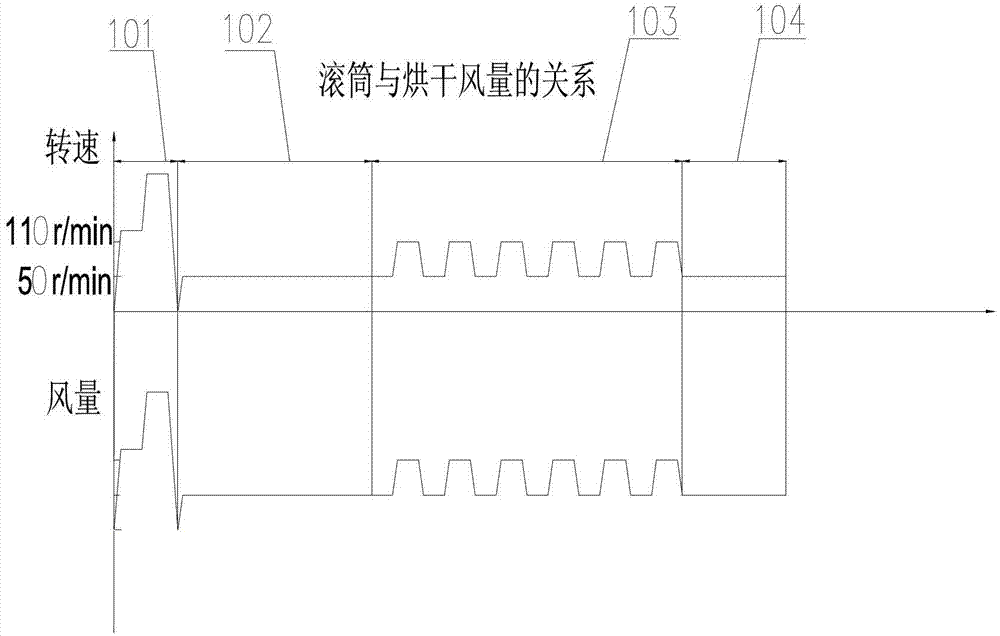

Method for improving drying effect of clothes through speed change of roller and clothes drying machine

ActiveCN102899871AImprove drying effectImprove drying efficiencyTextiles and paperLaundry driersPulp and paper industry

The invention discloses a method for improving drying effect of clothes through speed change of a roller and a clothes drying machine. The method comprises the following steps of: at a primary stage of drying, detecting the weight and / or unit weight of the clothes to be dried; at an earlier stage of drying, due to the fact that the clothes are relatively moist, rotating the roller based on the speed enabling the clothes to uneasily accumulate to a roller wall; at a later stage of drying, controlling the roller to rotate towards the same direction or forwards and backwards rotate alternately according to the periodically changed rotating speed based on the corresponding relation of the weight and / or the unit weight of the clothes and the rotating speed of the roller, wherein the periodically changed rotating speed at least comprises two different kinds of rotating speed; and a process of cooling the dried clothes, according to the method, controlling the roller to rotate towards the same direction or forwards and backwards rotate alternately according to the periodically changed rotating speed by measuring the weight and / or the unit weight of the clothes, and the corresponding relation of the weight and / or the unit weight of the clothes and the rotating speed of the roller, so that the clothes can be completely extended to realize the uniform and complete drying effect of the clothes and further improve the drying effect of the clothes with large weight.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

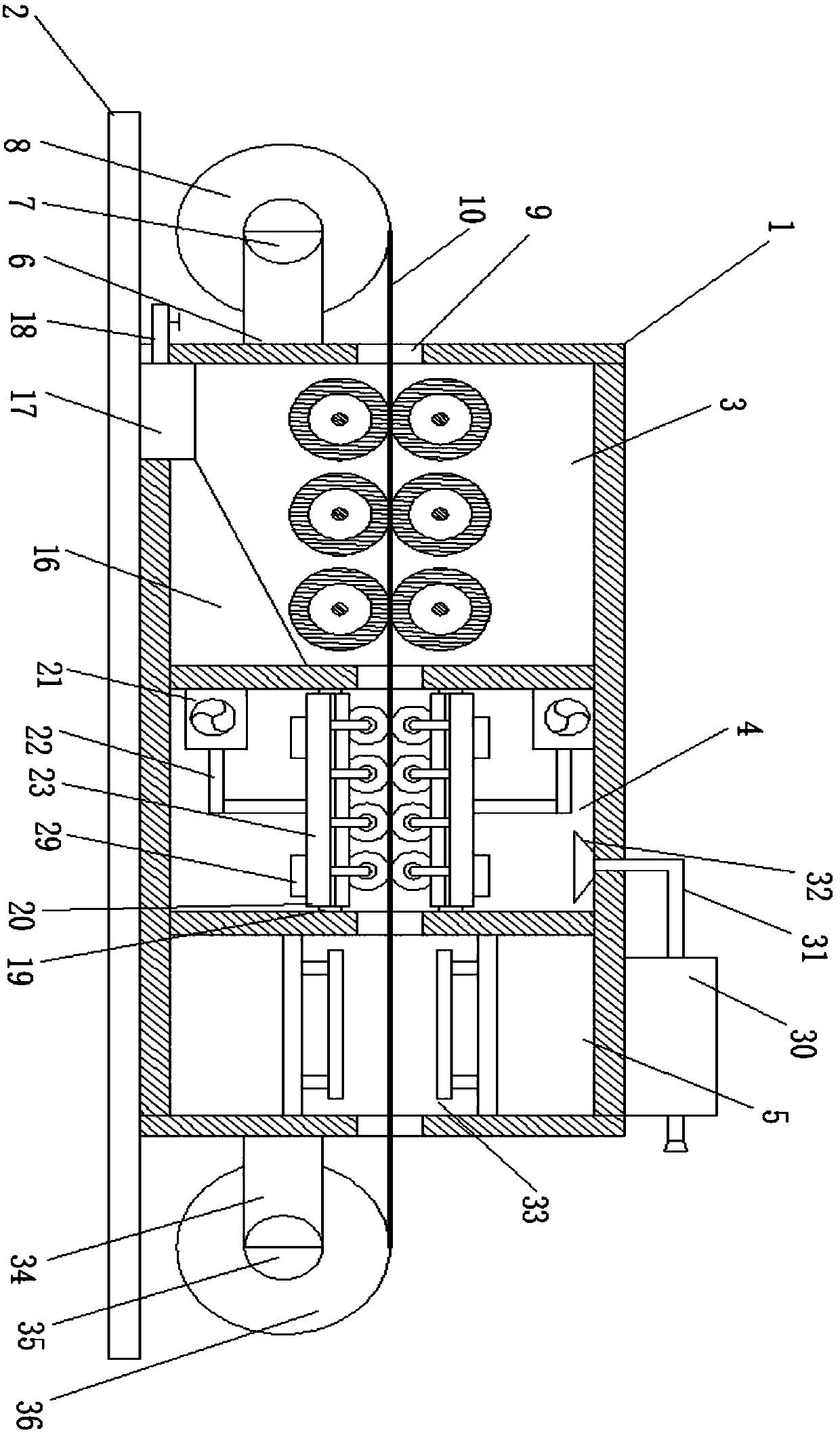

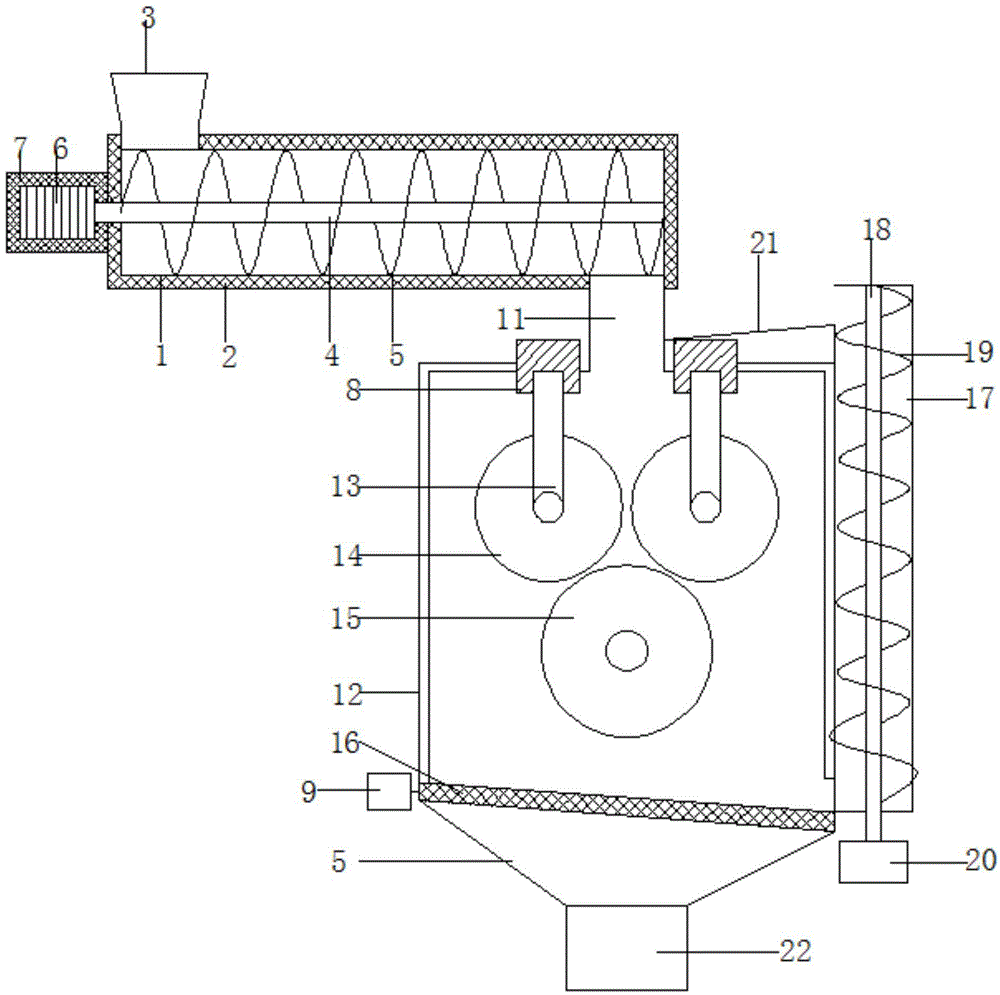

Device for removing copper powder on copper foil and application method of device

ActiveCN105689312ANot easy to damageNot easy to discountCleaning using liquidsHeating arrangementEngineeringCopper foil

The invention discloses a device for removing copper powder on a copper foil and an application method of the device, and belongs to the technical field of copper foil cleaning. The technical points of the device include that a cleaning mechanism and a plurality of drying mechanisms are arranged in order between an unwinding roll and a winding roll along a horizontal direction, and a copper foil orderly passes through the cleaning mechanism and all the drying mechanisms along the horizontal direction. Each drying mechanism is connected with a control unit, and is composed of a housing, a feeding hole and a discharge hole that are separately arranged in two sides of the housing, and an air-floating heating mechanism and a lifting heating mechanism that are arranged in the housing along a housing length direction. The present invention aims at providing the device, which is convenient to use and good in effect, for removing the copper power on the copper foil. The device is used for removing the copper powder on the copper foil.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

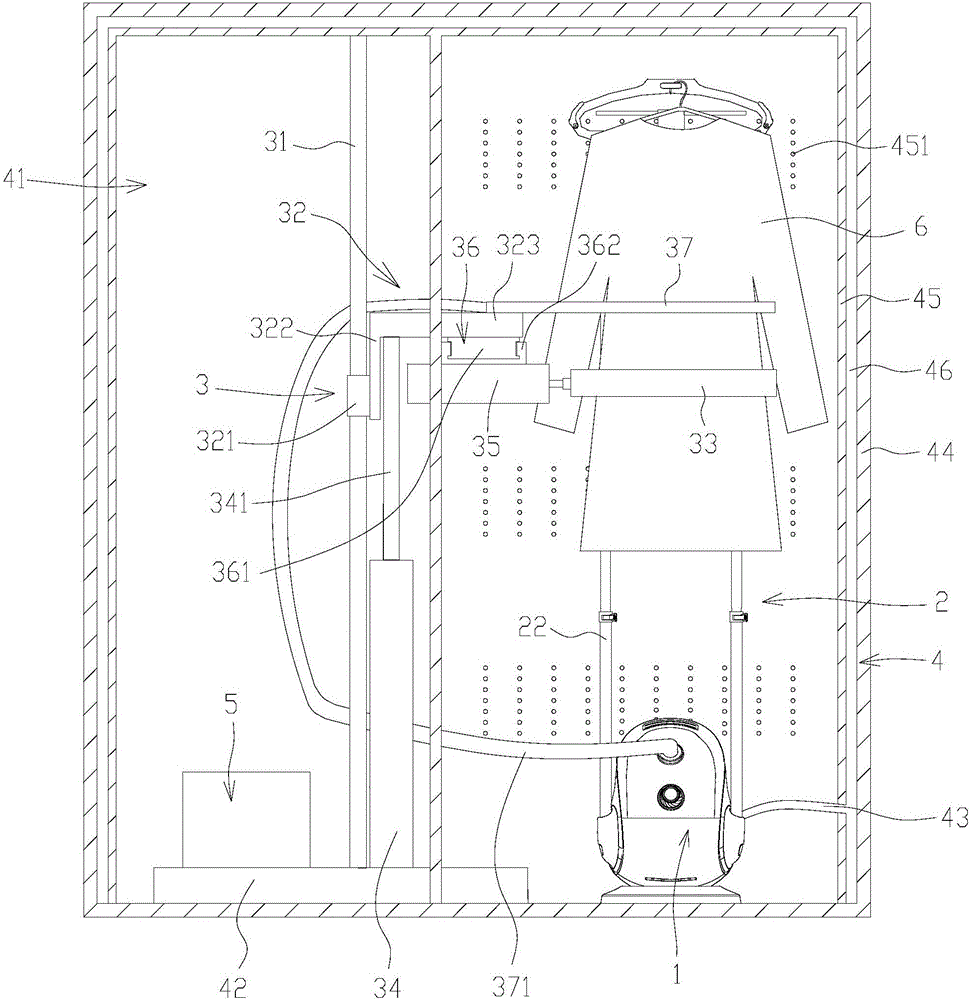

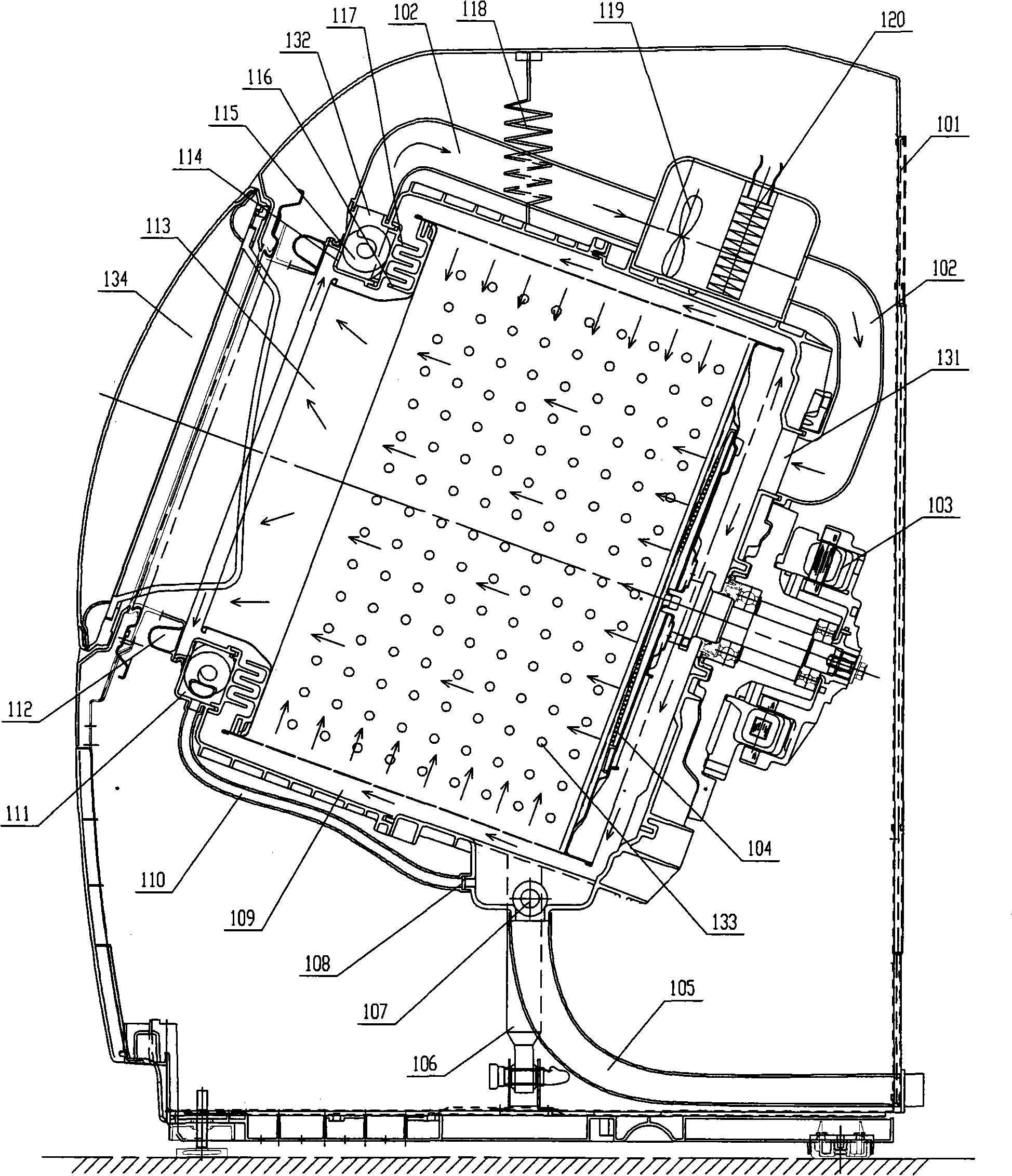

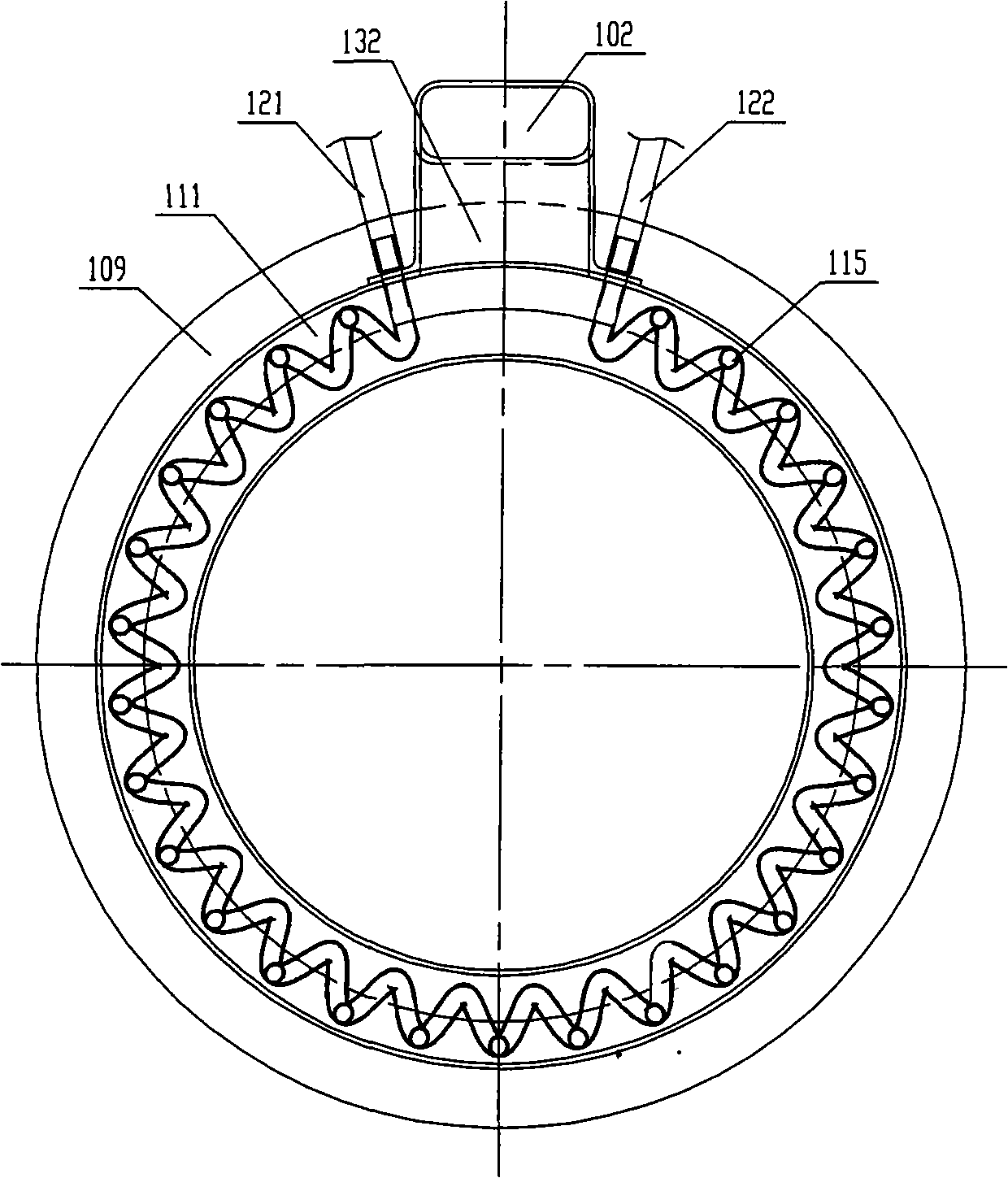

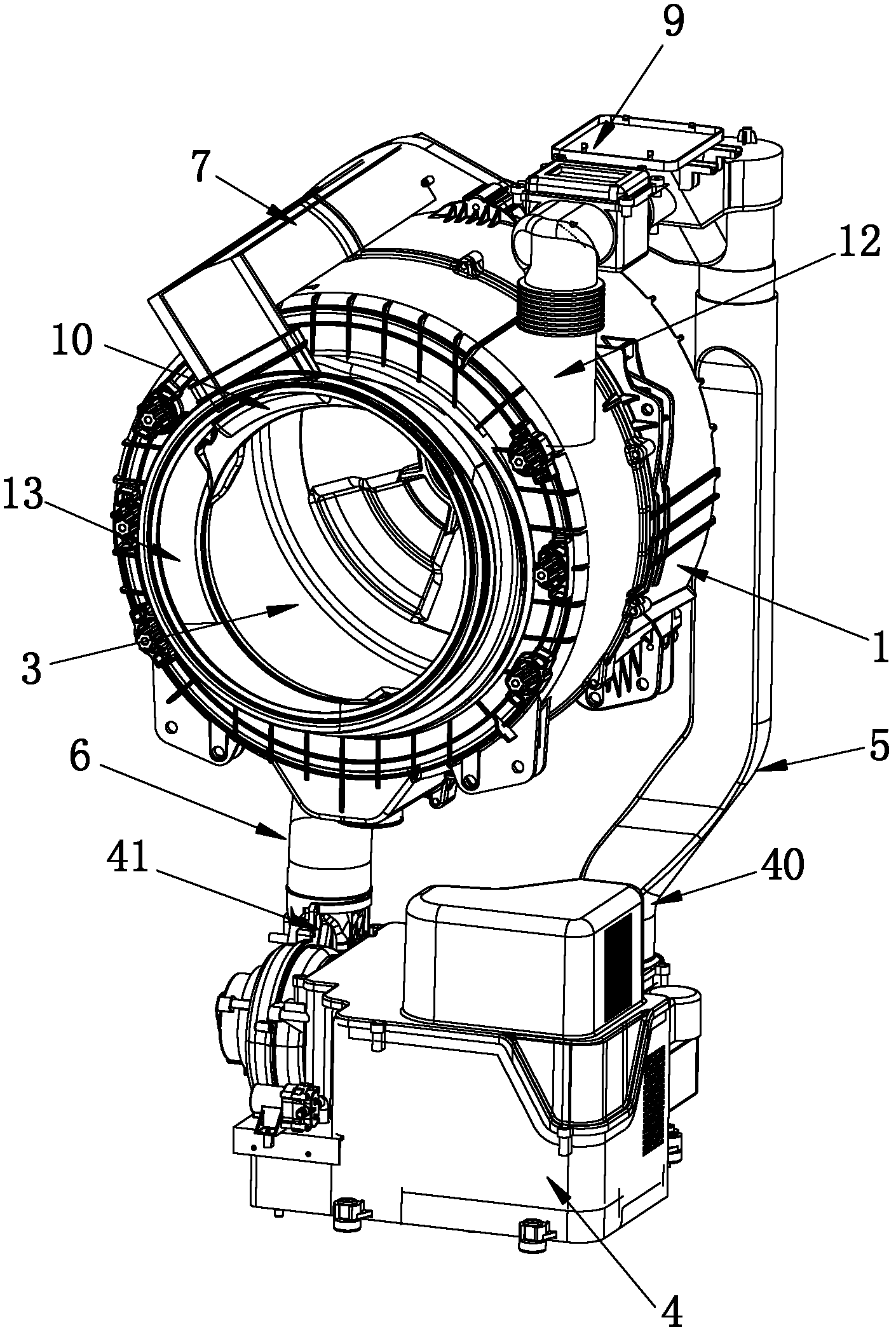

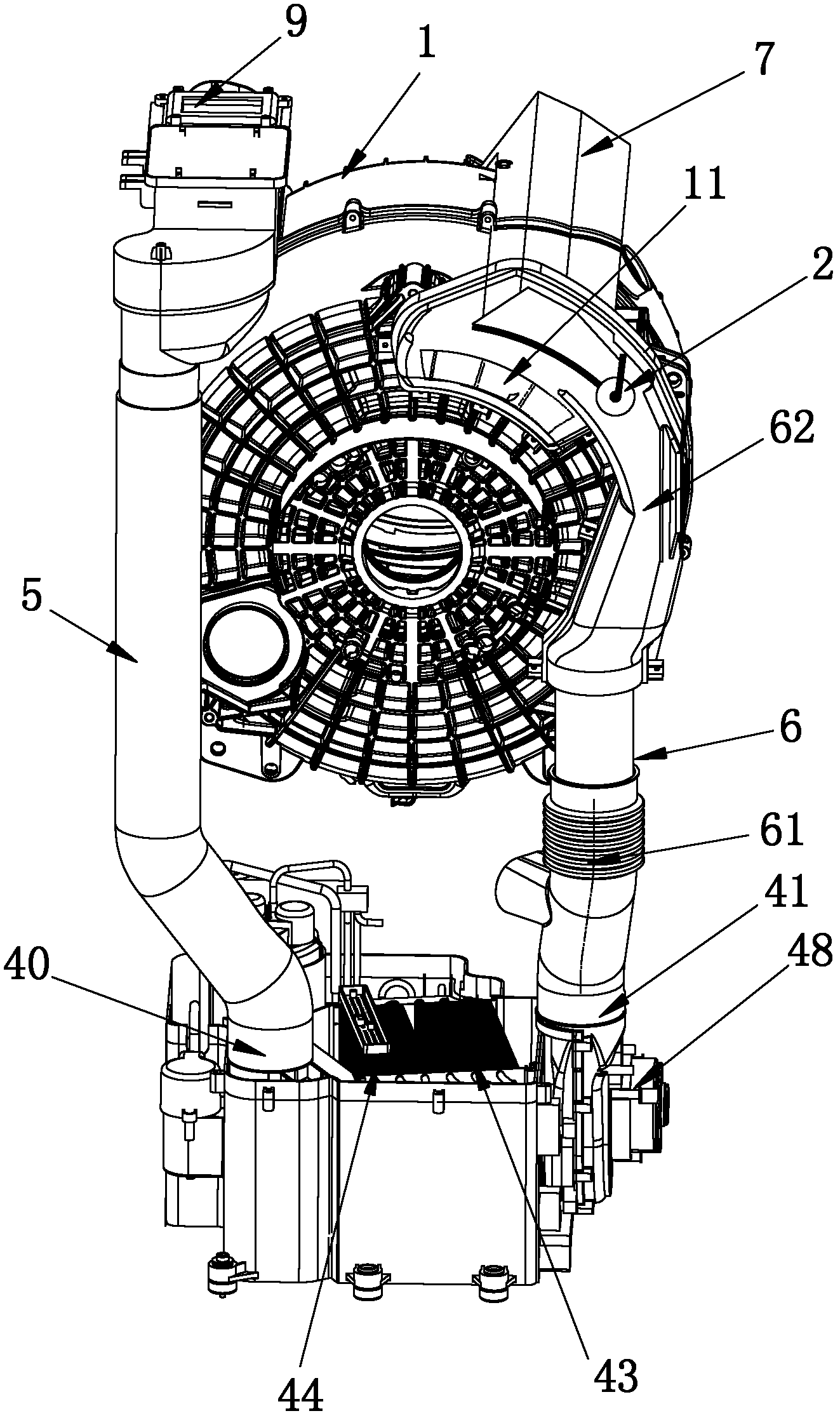

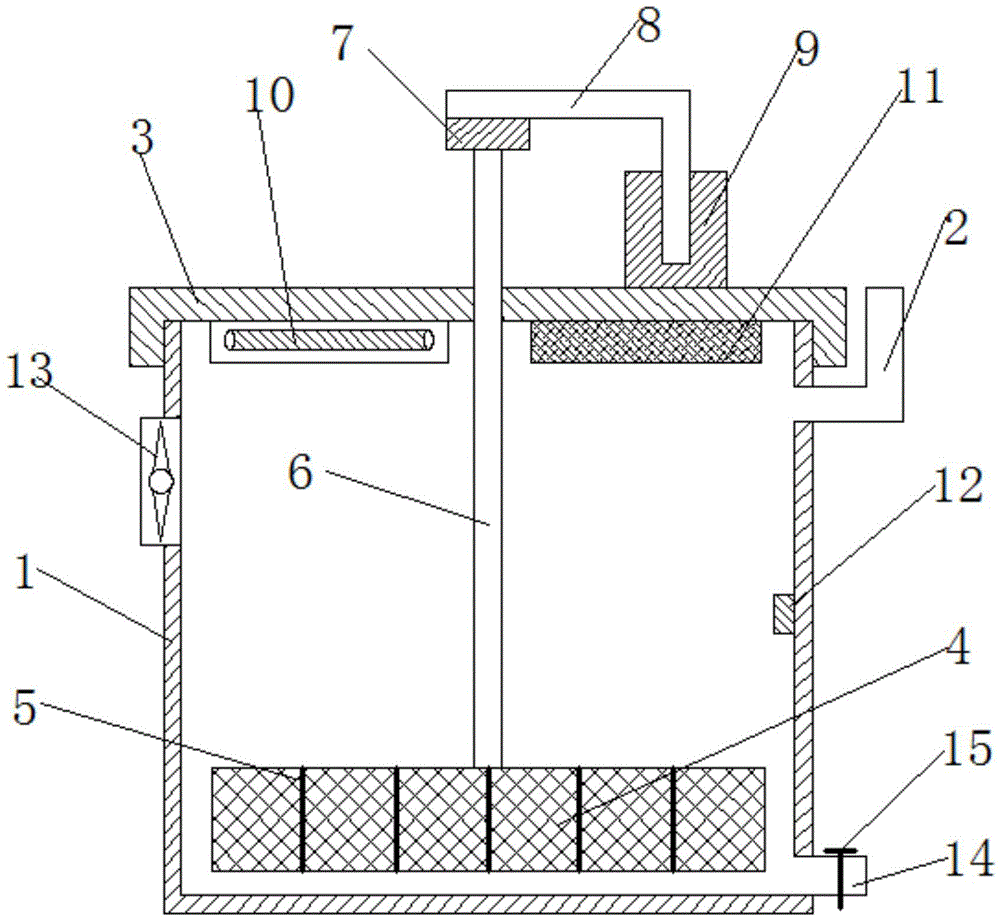

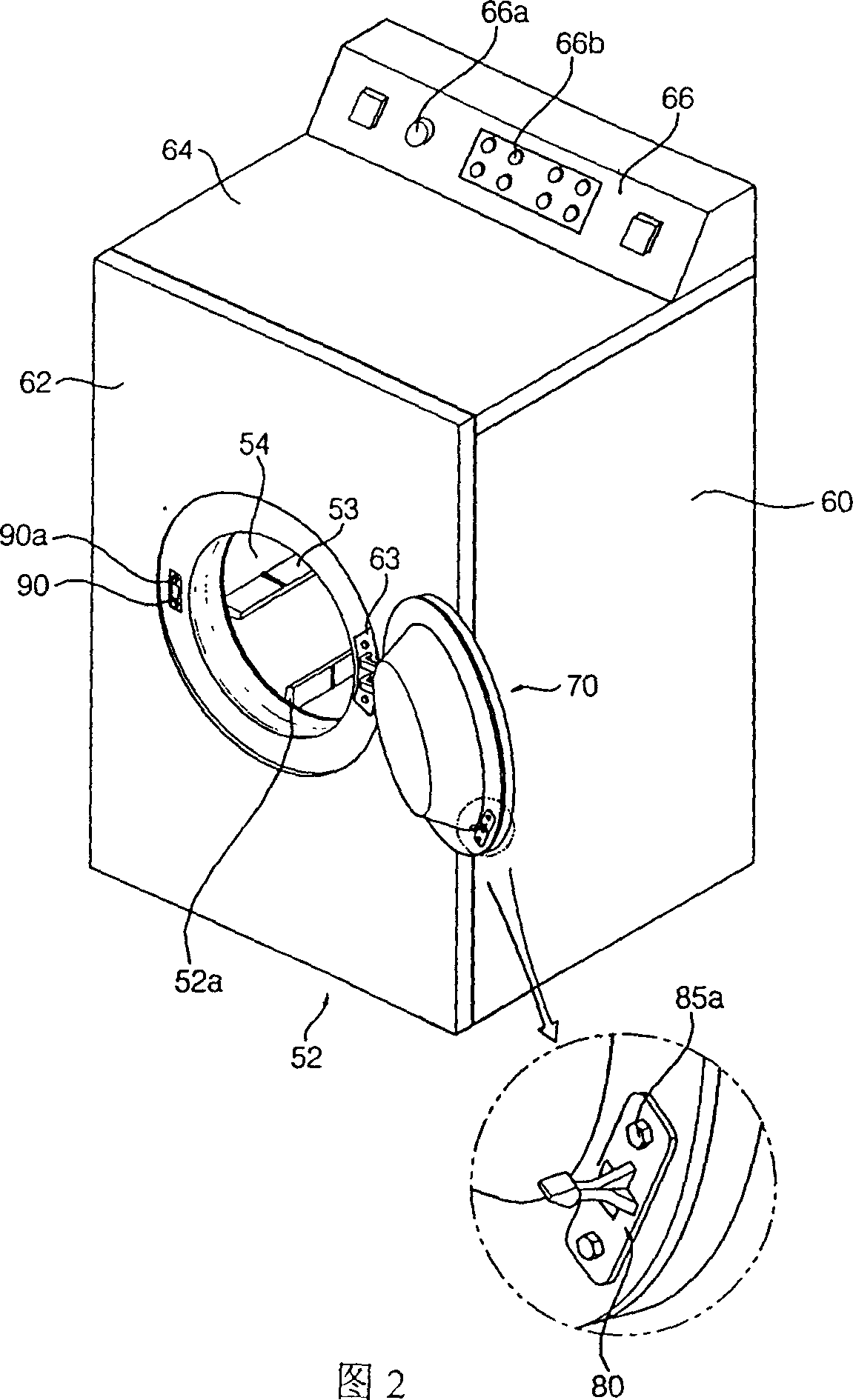

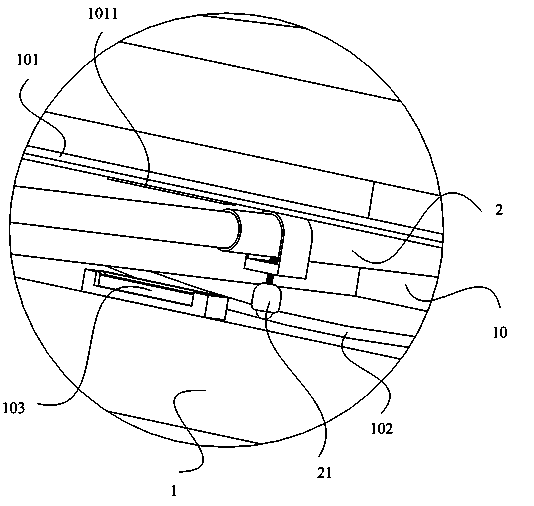

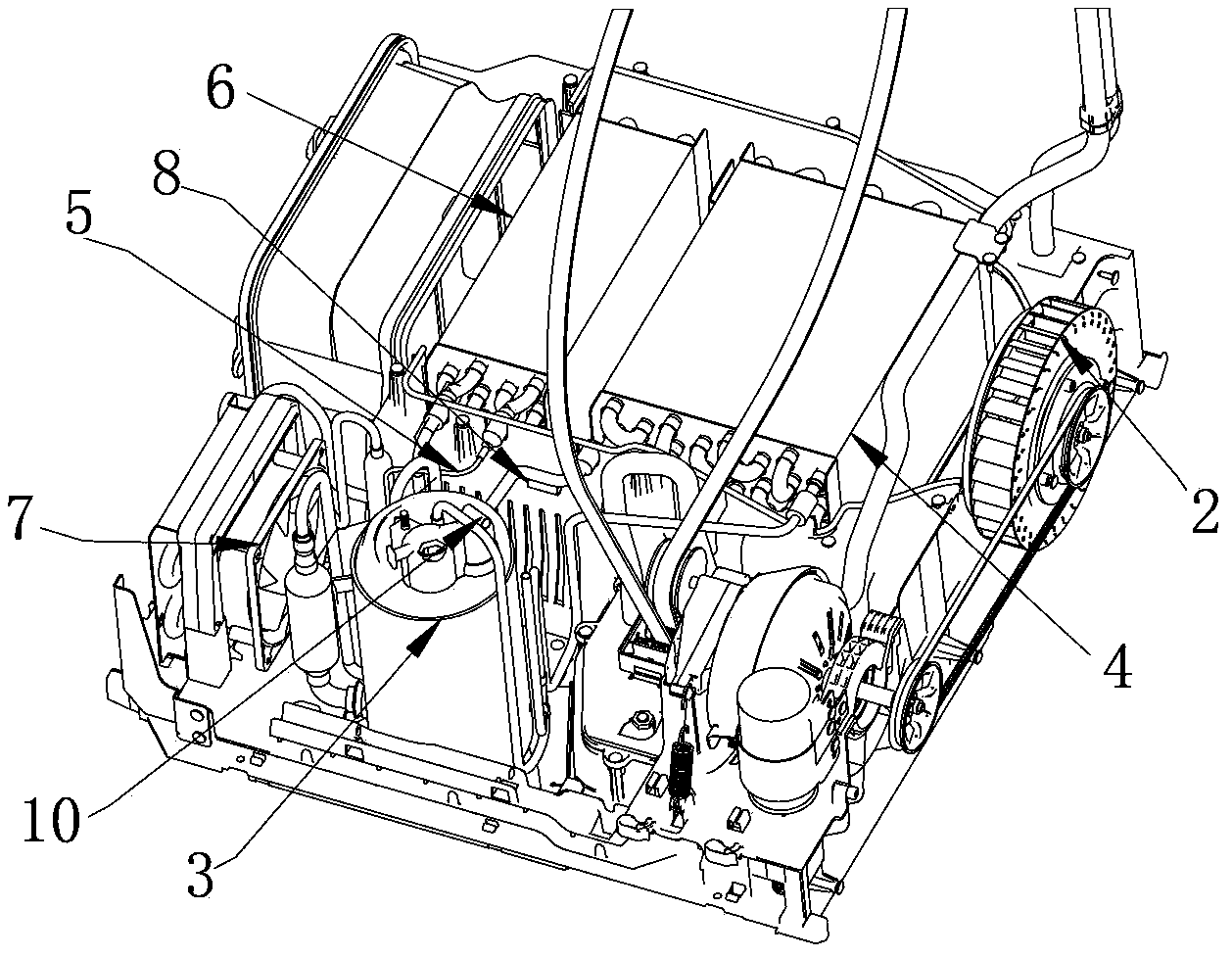

Washing and drying integrated machine with front and rear double drying air inlets and control method thereof

ActiveCN102330316AImprove drying effectDry clothes evenlyControl devices for washing apparatusWashing machine with receptaclesEngineeringMechanical engineering

The invention discloses a washing and drying integrated machine with front and rear double drying air inlets and a control method thereof, and the washing and drying integrated machine comprises a housing, an outer cylinder arranged in the housing, an inner cylinder which is rotatably arranged in the outer cylinder and a heat pump system for drying clothes, wherein the heat pump system comprises a heat pump air inlet and a heat pump air outlet, the front drying air inlet and the rear drying air inlet are respectively arranged above the front part and the rear part of the outer cylinder, a drying air outlet is further arranged above the front part of the outer cylinder, the drying air outlet and the heat pump air inlet are communicated through an air inlet passage, the heat pump air outlet is communicated with the rear drying air inlet through an air supply passage, a second air passage is arranged between the front drying air inlet and the air supply passage, the second air passage clings to the outer wall of the outer cylinder and is integrated with the outer cylinder, and a switching mechanism is used for controlling the heat pump air outlet to be communicated with the front drying air inlet and / or the rear drying air inlet. The washing and drying integrated machine is simple in structure, and controllable in front and rear air inlet modes and has the characteristics of improving the clothes drying efficiency, enhancing the clothes drying effect and achieving more uniform clothes drying effect.

Owner:FOSHAN HAIER DRUM WASHING MACHINE

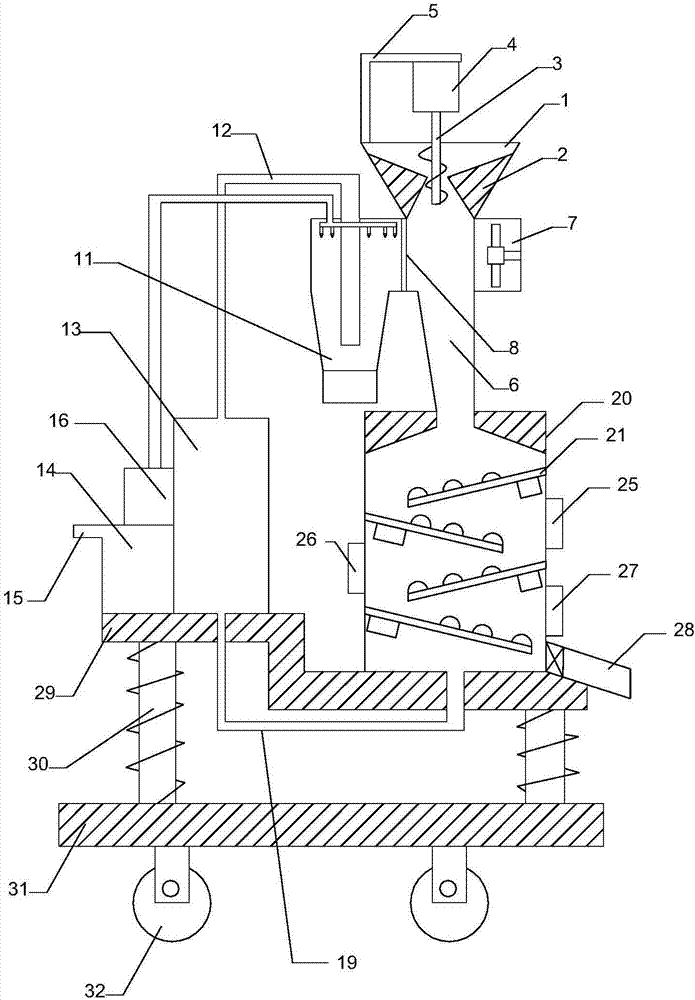

Cleaning and drying integrated device used for mechanical part

InactiveCN105817448AEasy to cleanImprove efficiencyDrying gas arrangementsCleaning using liquidsWater storageDrive wheel

The invention discloses a cleaning and drying integrated device used for a mechanical part. The cleaning and drying integrated device comprises a work box with the top provided with a top cover and the bottom provided with a discharging port, a drive motor, a water storage box and an air heater. A net cylinder is arranged in the work box. A net cover is arranged on the net cylinder. Rotating shafts are arranged on the two sides of the net cylinder. One of the rotating shafts penetrates a shell of the work box and extends to the outer portion of the work box to be fixedly connected with a driven wheel. The driven wheel is in transmission connection with a drive wheel through a belt. The drive wheel is fixedly connected to a rotating shaft of the drive motor. The top of the top cover is provided with a water guide pipe and an air guide pipe. The cleaning and drying integrated device used for the mechanical part is good in cleaning effect, high in efficiency, good in flushing effect and capable of drying the mechanical part after the mechanical part is cleaned, in addition, the drying speed is high, a drying effect is good, cleaning, drying and filtering are integrated, and the later-period use quality of the mechanical part can be ensured.

Owner:CHANGZHOU JINHAILONG MACHINE MFG

Efficient medical instrument disinfection and cleaning device

InactiveCN104840984AFully disinfectedImprove work efficiencyLavatory sanitoryHeatDisinfectantEngineering

The invention discloses an efficient medical instrument disinfection and cleaning device, which comprises a disinfection device, a cleaning device and a storage device, wherein a disinfectant inlet is formed in the upper part of the left side of the disinfection device; an instrument placement frame is arranged on the inner lower side of the disinfection device; a vertical rod is connected to the upper side of the instrument placement frame; a rotating motor is connected to the top end of the vertical rod, and is connected with a lifting device through a connecting rod; a heating probe is arranged on the upper inner wall of the left side of the disinfection device; an ultrasonic probe is arranged on the upper inner wall of the right side of the disinfection device. According to the efficient medical instrument disinfection and cleaning device, a medical instrument can be completely disinfected, cleaned, dried and stored; the lifting device can be rotated to spin-dry and drain the medical instrument after disinfection, so that the working efficiency of the device is greatly improved; waste liquor produced during working can be collected by a waste liquor tank, so that secondary pollution is reduced; in addition, a good hot air drying effect is achieved, so that the working efficiency of the device is further improved.

Owner:苏州福利恒电子科技有限公司

Medical apparatus cleaning and disinfecting device

The invention discloses a medical apparatus cleaning and disinfecting device, which comprises a main cleaning machine body, an upper cover and an apparatus placement rack, wherein a liquid inlet pipe is arranged above the right side of the main cleaning machine body; the upper cover board is arranged on the upper side of the main cleaning machine body; the apparatus placement rack is arranged on the lower side inside the main cleaning machine body; a partition plate is arranged on the apparatus placement rack; a rotating shaft is vertically arranged at the center of the apparatus placement rack; and the top end of the rotating shaft penetrates through the upper cover board and is connected with a rotary motor. According to the medical apparatus cleaning and disinfecting device disclosed by the invention, a medical apparatus can be fully disinfected, sterilized, cleaned and dried; draining of the apparatus is realized by adjusting the height of the apparatus placement rack; the apparatus can be spun by the rotary device in a rotating manner, and can be dried by a heating device at a high temperature; air convection in the device can be increased by a draught fan; and the drying effect and efficiency are improved.

Owner:苏州福利恒电子科技有限公司

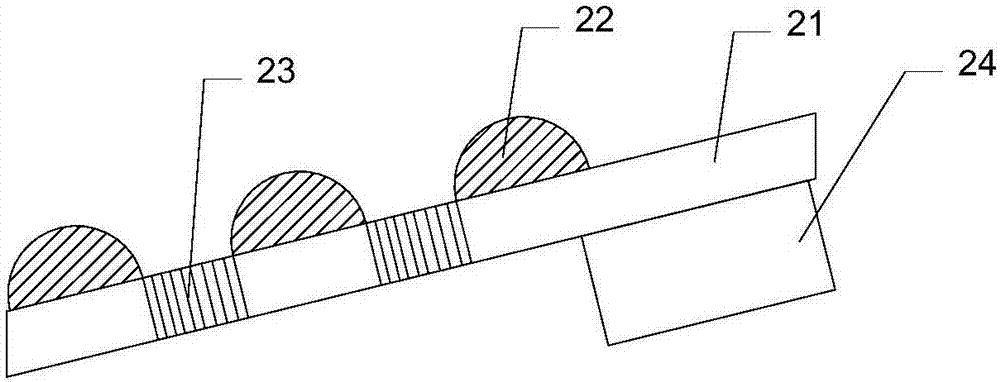

Bearing washing and drying integration device

InactiveCN104550087AReduce the intensity of manual operationImprove work efficiencyDrying gas arrangementsDrying machines with progressive movementsHigh pressureProduction effect

The invention discloses a bearing washing and drying integration device. The bearing washing and drying integration device comprises a washing machine body, a connecting part and a drying machine body, wherein the washing machine body and the drying machine body are communicated with each other through the connecting part to form a whole body, the washing machine body comprises a washing liquid storage box, a high pressure spray head, a baffle plate, a transmission device and a water discharge device, the transmission device is installed inside the washing machine body, the tail end of the transmission device is arranged on the junction of the connecting part and the drying machine body, a discharge baffle plate is arranged in the connecting part, the drying machine body comprises a drying device, conveyor belts, a roller, steering devices and a receiving box, four conveyor belts are arranged inside the drying machine body, each conveyor belt is installed on the roller, the drying device is correspondently installed on the junction of each conveyor belt and the drying machine body, and the steering device is arranged on the steering position of each conveyor belt. By adopting the bearing washing and drying integration device, the washing and drying of a bearing can be completed in one machine, so that the working efficiency is improved, the production effect of the bearing is guaranteed, and the floor occupation area of the machine is reduced.

Owner:XINCHANG LONG HAO BEARING CO LTD

Drying device of long medical gauze

InactiveCN107620185AEasy to moveImprove the extrusion effectLiquid/gas/vapor removal by squeezing rollersIroning machinesGear driveFixed frame

The invention discloses a drying device of long medical gauze. The drying device of the long medical gauze comprises a device case and a base. A first fixing frame and a second fixing frame are installed at the front and back sides of the device case respectively. A delivery rotation shaft and a collection rotation shaft are arranged on the first fixing frame and the second fixing frame respectively in a running-through mode. A delivery wheel disc and a collection wheel disc are mounted on the delivery rotation shaft and the collection rotation shaft respectively. The device case is divided into a dehydration room, a drying room and a disinfection room. Material through holes are formed in all the middles of the front and back walls of the dehydration room, the drying room and the disinfection room. The dehydration room, the drying room and the disinfection room are communicated by the material through holes. The gauze is wound around the delivery wheel disc. The gauze runs through thedehydration room, the drying room and the disinfection room through the material through holes, and the tail end of the gauze is wound around the collection wheel disc. According to the drying deviceof the long medical gauze, a gear drives a squeeze roller to rotate to squeeze the gauze to play the role of fully dehydration; an iron cylinder and the surface of the gauze are in contact, and therefore the role of high-temperature disinfection is further played.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

Tea cleaning and drying device

InactiveCN107965989ARealize the function of cleaning and removing impuritiesSpeed up the flowPre-extraction tea treatmentDrying gas arrangementsWater resourcesAgricultural engineering

The invention discloses a tea cleaning and drying device which comprises a drying box, a rotating tube and a seal cover. The bottom of the drying box is provided with a rotating motor, the rotating motor is connected with the rotating tube through a rotating shaft, two inner walls, close to the rotating tube, of the drying box are provided with a heating pipe and an ultraviolet ray lamp pipe correspondingly, the outer wall, close to the heating pipe, of the drying box is provided with an air blower, the bottom of one side of the drying box is connected with a waste water treatment box througha pollution discharge pipe, the top of the seal cover is provided with an air exhaust fan, and the bottom of the seal cover is provided with a water spray pipe. By means of the tea cleaning and dryingdevice, before agricultural and sideline products are dried, cleaning and impurity removing functions performed on the agricultural and sideline products can be realized, and the quality of dried products is improved; by means of the arrangement of the waste water treatment box, the waste water after cleaning can be filtered and purified, and the recycling of water resources is facilitated; and the tea cleaning and drying device is simple in structure, the efficiency of drying performed on the agricultural and sideline products is high, and the drying is performed more thoroughly.

Owner:WUZHOU YAZHENG AGRI TECH CO LTD

Ball mill provided with pulverizing mechanism and used for producing ceramics

The invention discloses a ball mill provided with a pulverizing mechanism and used for producing ceramics. The ball mill comprises a ball mill body, an inner cylinder and an outer cylinder, wherein the ball mill body comprises the inner cylinder and the outer cylinder disposed outside the inner cylinder, the inner cylinder and the outer cylinder are horizontal cylinders and coaxial, and a sound absorption sponge layer evenly covers the outer wall of the outer cylinder. The ball mill has the advantages that materials are pulverized during ball milling, material pulverizing efficiency and ceramic producing efficiency are increased, a silencing cover and the sound absorption sponge layer can effectively reduce noises, the working environment of operators is improved, ball milling effects are increased by grooves, excessive pulverizing of the materials is avoided, finished product quality is guaranteed, effective vibration reduction is achieved by spring columns, structural stability of the ball mill is increased while noise reduction is achieved, the practicality and convenience of the ball mill are increased by universal wheels, the materials are dried by hot air, good drying effect is achieved, and ceramic producing efficiency is further increased.

Owner:陆丽曼

Processing technology of noodles with four-phase variable-temperature drying method

The invention relates to a processing technology of noodles with four-phase variable-temperature drying method. The processing steps are completely finished in a chain and track type drying room. The chain and track type drying room comprises a cold-blast air zone, a drying zone, a main drying zone and a drying finishing zone, and the producing steps comprise (1) cold-blast, (2) rising temperature drying, (3) high-temperature main drying and (4) falling temperature drying. The invention has the characteristics of low temperature, low speed, steady process, easy mastery, and the like, and dried noodles produced by the process has the advantages of flatness, smoothness, good noodle shape, good product quality and no crisp part. By adopting the different speeds and temperatures of air flows in every zone of the drying room, the invention reasonably achieves the goal of fluent drying, realizes the same speed of inward and outward diffusion of noodles, consequently improves the drying effect, effectively prevents noodles from crazing and getting crisp, ensures the noodle quality and saves the energy at the same time.

Owner:陆昌盛

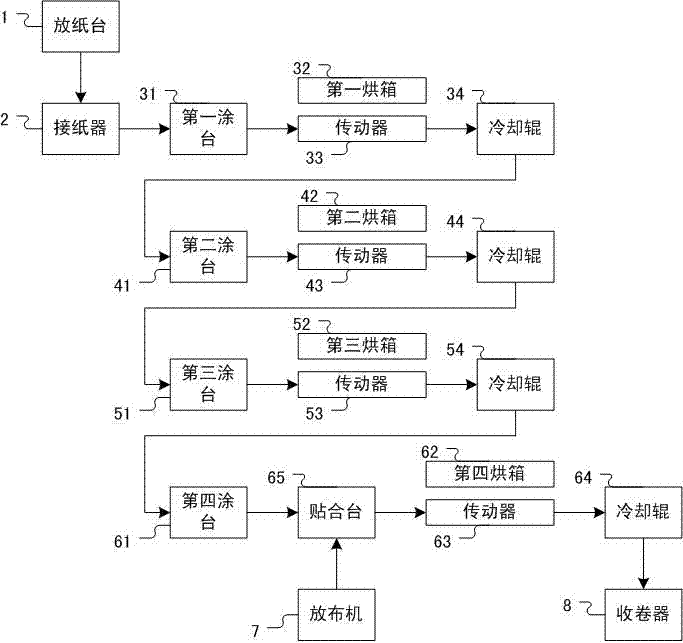

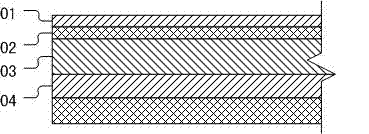

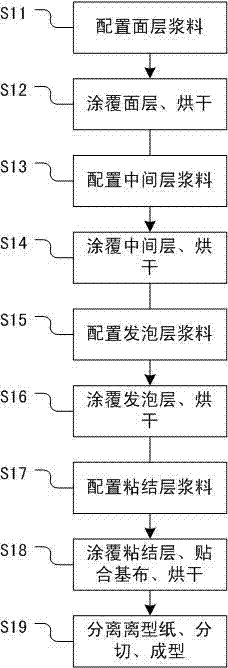

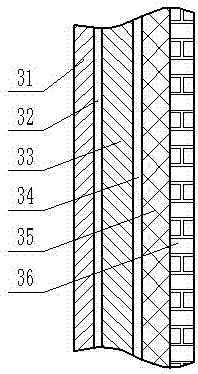

Water-based synthetic leather, and production line and production method thereof

InactiveCN103710995ASolve chromatic aberrationImprove efficiencyLamination ancillary operationsLaminationWater basedProduction line

The invention provides a water-based synthetic leather and a production line thereof. A four-coating four-drying process is adopted, and an intermediate water-based resin coating layer and a foaming water-based resin coating layer are respectively formed. The production line has an integrated production process, has the advantages of relative stability and higher efficiency, and also avoids the problems of low drying efficiency and easy corrugation brought by an excessively thick surface layer. Through partitioning drying boxes and controlling the temperatures of different isothermal regions, drying is uniform, smooth and steady, and the drying effect is good. The synthetic leather is of a five-layer structure, effectively solves the color shading problem brought by large-pattern embossing. At the same time, the invention also provides a production method of the water-based synthetic leather.

Owner:JIANGXI MINGCHUAN SCI & TECH IND

Self-vibrating grain drying and sieving equipment

InactiveCN107339878AImprove the vibration effectPrevent fallingSievingScreeningEngineeringVacuum pump

The invention discloses self-vibrating grain drying and sieving equipment. The equipment comprises a shell, a support and a condensation chamber; the support is arranged outside the shell, sliding blocks are fixedly connected to the middle of the outside of the shell, sliding grooves are formed in both sides of the support, and the sliding blocks are connected with the sliding grooves in a sliding mode; connecting plates are arranged at the upper ends of the sliding grooves, the connecting plates are fixedly connected with the support, and floating devices are arranged between the connecting plates and the sliding blocks; a first sieving net and a second sieving net are fixedly connected to the inner side wall of the shell from top to bottom in sequence, a dehumidification pipe is arranged at the upper end of the shell, a vacuum pump is connected to the middle of the dehumidification pipe, one end of the dehumidification pipe is communicated with the interior of the shell, and the other end of the dehumidification pipe is connected with a condensation pipe in the condensation chamber. According to the self-vibrating grain drying and sieving equipment, the structure is simple, the design is reasonable, sieving of grain is completed through self-vibrating of the shell, and the sieving quality and efficiency are improved; meanwhile, drying equipment is added, the functionality of the device is enhanced, and rapid dehumidification can be conducted, so that the drying efficiency is improved.

Owner:俞纪洪

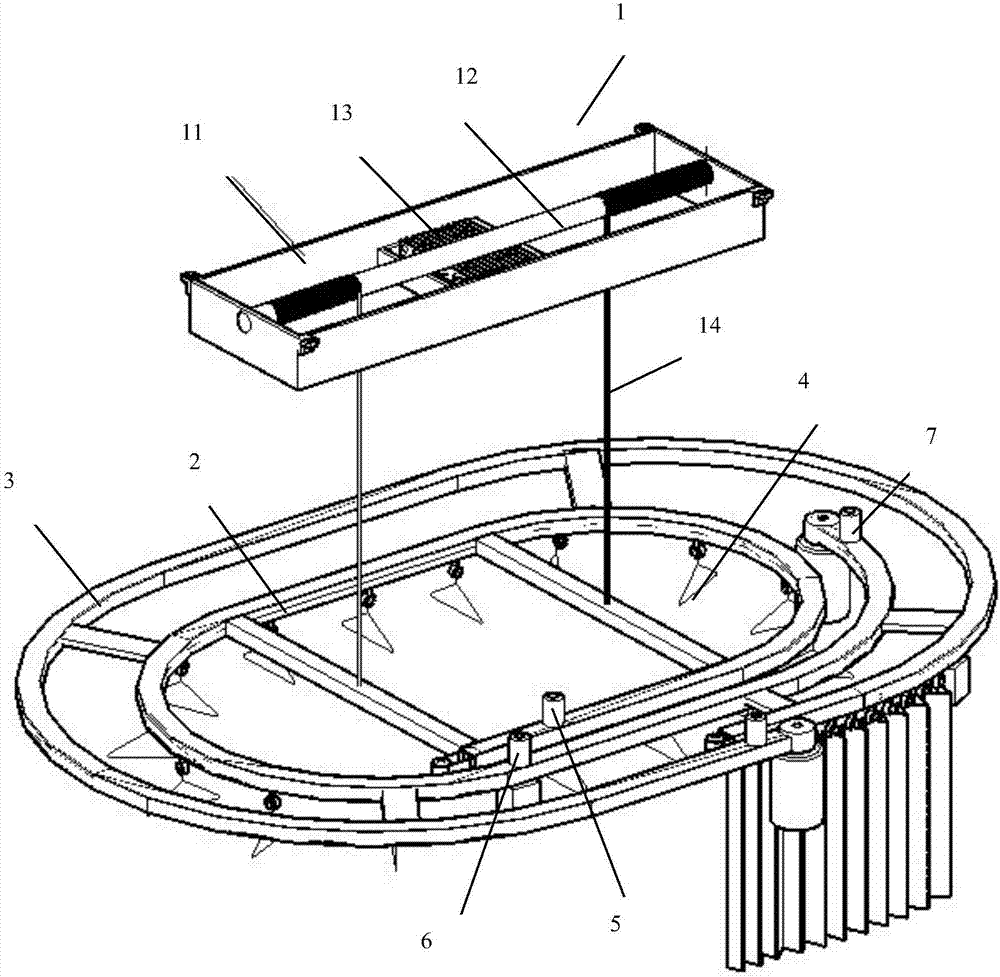

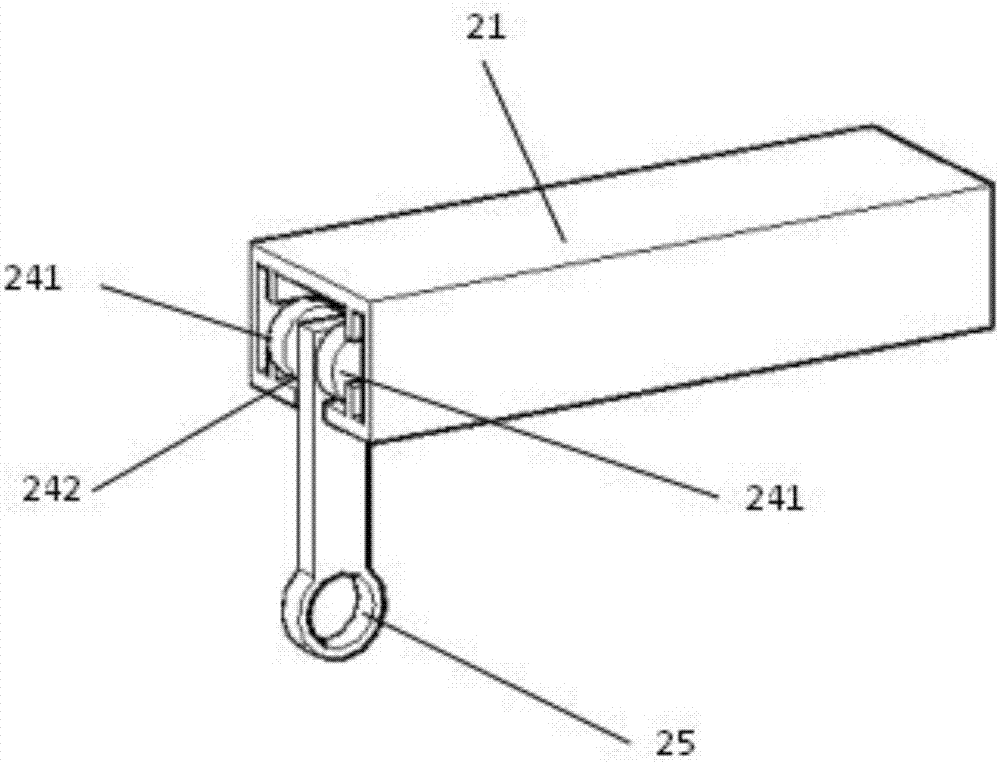

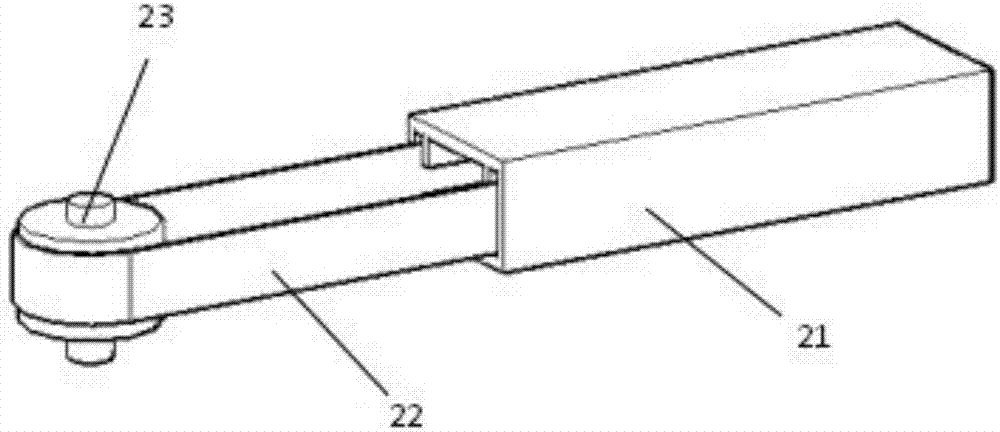

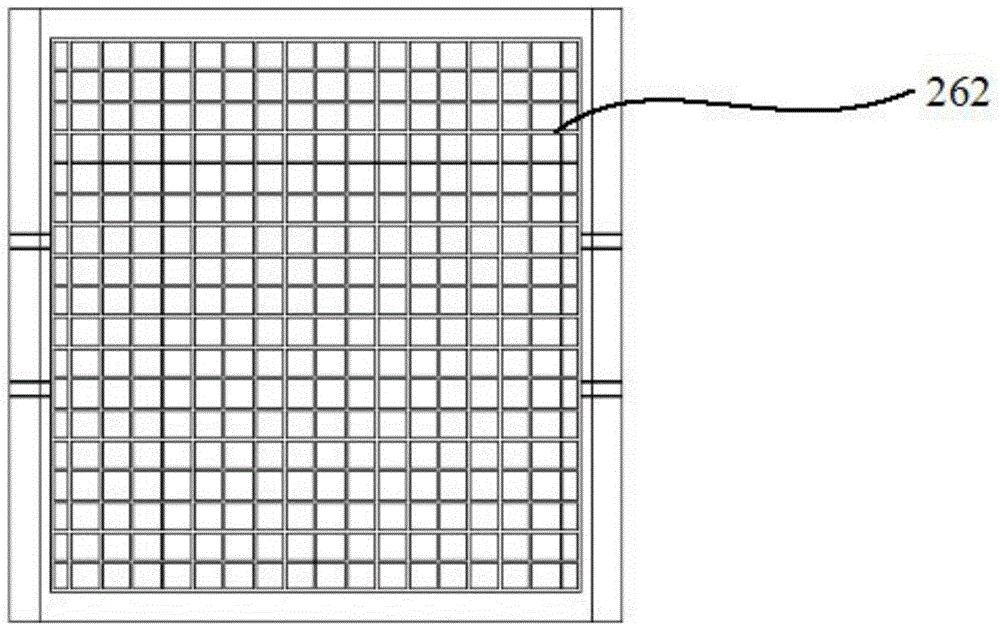

Chinese iris mat spreading, dyeing and drying integrated equipment

ActiveCN103144162AImprove dyeing efficiencyImprove drying efficiencySpraying apparatusWood treatment detailsWork in processMechanical engineering

The invention discloses Chinese iris mat spreading, dyeing and drying integrated equipment comprising a mat spreading device, a dyeing box and a drying box, which are arranged in a straight line, wherein three layers of spaces are arranged up and down in the dyeing box; transfer rollers are arranged on both front and rear sides of each layer of space; dye jetting mechanisms are arranged on the rear sides of the upper-layer space and the middle-layer space of the dyeing box; an inner chamber of the drying box is divided into upper and lower layers by a meshed plate, the lower layer of chamber is a heating chamber and the upper layer of chamber is a drying chamber; and a mat rolling device is arranged on the front side of the drying box for folding and rolling the mat. During operation of the equipment disclosed by the invention, the mat spreading device spreads a semi-finished mat product first, the mat passes through the dye box so that both the front and back surfaces are dyed; the dyed mat is delivered to the drying chamber of the drying box by a mat delivering device, so that the mat is dried, thereby improving the spreading, dyeing and drying efficiency effects.

Owner:苏州盛泽科技创业园发展有限公司

Full intelligent device in multimode of controlling microwave and infrared ray for drying clothes

InactiveCN1626723AReduce use costImprove drying effectTextiles and paperLaundry driersInfraredMicrowave

The invention relates to a multimode all-intelligence controlled microwave and infrared clothes dryer device. It includes external shell, internal cavity, sealed cabinet door, transformer, magnetron, waveguide box, waveguide wheel and electric control circuit. Said electric control circuit includes a control circuit containing microprocessor. Besides, it also includes the components of infrared heating tube group, exhaustor, fan blower, temperature and humidity induction devices and relay group, etc. Said invention also provides the connection method of the above-mentioned all the components.

Owner:罗建华

Hot air circulation grain drying device

InactiveCN107156291AImprove qualityReduce churnDrying gas arrangementsSeed preservation by dryingEngineeringHeat losses

The invention discloses a hot gas circulation grain drying equipment, which comprises a dehumidifier and a drying box; a dust removal channel is arranged above the drying box, and a winnowing device is arranged on the right side of the dust removal channel; the dust removal channel is connected with a cyclone dust collector A drying box is connected under the dust removal channel; a drying plate is arranged in the drying box; a first hot air blower, a second hot air blower and a third hot air blower are arranged between the drying plates. The present invention realizes the full utilization of the hot air and separate drying of the grains with different drying degrees by providing a circulating hot air drying device and hot air blowers with different powers, reducing heat loss and saving energy; the present invention is provided with staggered distribution The drying plate improves the drying efficiency and the drying effect; the invention is equipped with a high-school dust removal device to remove dust and shriveled grains in the grain, improves the quality of the grain, and saves storage space.

Owner:惠安益源信息技术咨询有限公司

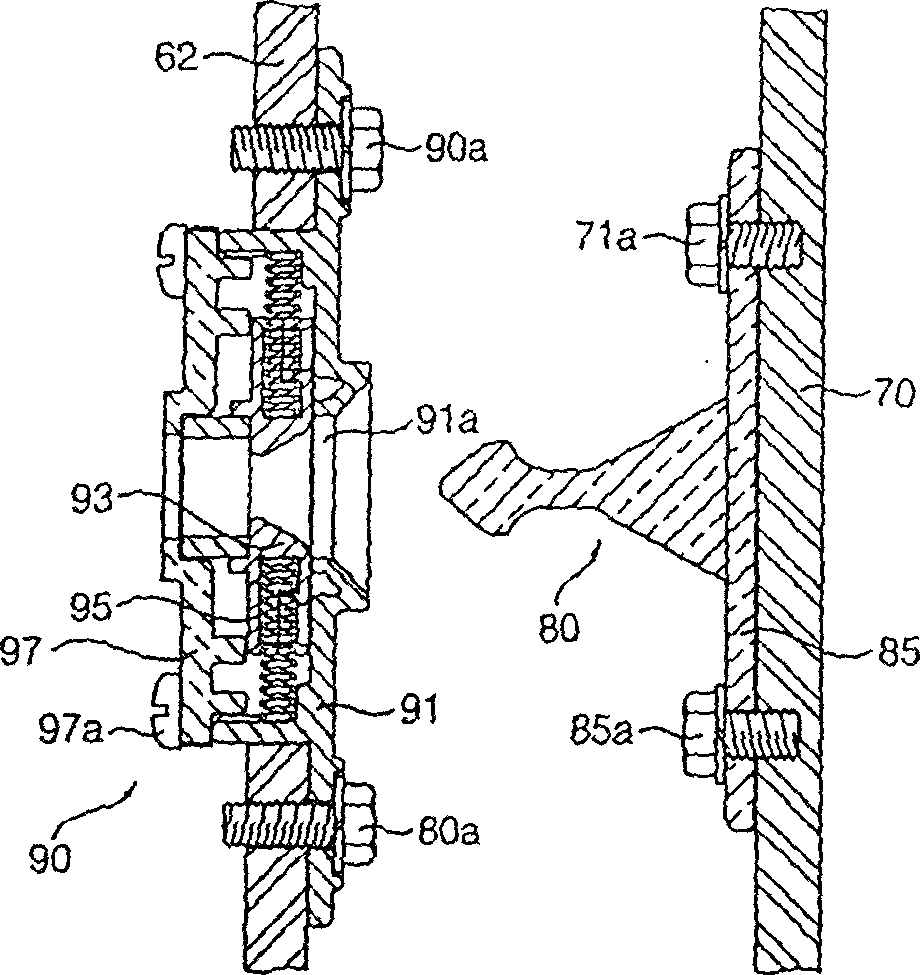

Door Lock assembly

InactiveCN1600968AImprove drying effectEasy to assembleWing fastenersOther washing machinesEngineeringMechanical engineering

A lock device of dryer on washer consists of box body, door with hook, bump lock with support object having hook, hook bulge at hook top, front tilting portion formed at front of hook bulge for pushing support object away to lead it in at time of door closing, back tilting portion at back of front tilting portion for pushing support object away to lead in out at time of door opening.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Textile printing drying and reeling device

InactiveCN104215049AAvoid quality problemsQuality improvementDrying gas arrangementsDrying machines with progressive movementsTextile printerCold air

The invention discloses a textile printing drying and reeling device. A hot air area and a cold air area are arranged for respectively performing hot drying and cold blasting, so that a favorable drying effect can be achieved; furthermore, the temperature of a fabric is cooled by virtue of the cold air area, and then the fabric is reeled, so that the fabric quality problem caused by overhigh fabric temperature during manual fabric reeling is prevented; a tension adjusting device can be used for tensioning the fabric, so that the reeling quality is improved.

Owner:JIANGSU SHUANGYING TEXTILE TECH

Air conditioner with clothes drying function and control method

ActiveCN104279619AAppearance effectEfficient dryingLighting and heating apparatusOther drying apparatusMotor driveEngineering

The invention provides an air conditioner with a clothes drying function and a control method. The air conditioner with the clothes drying function comprises an air conditioner body, an air outlet is formed in the air conditioner body, an installation bin is arranged in the air conditioner body, a baffle capable of being opened and closed is arranged at an opening of the installation bin, a motor and a telescopic rod are arranged in the installation bin, a rotating shaft is arranged at the end of the telescopic rod, the rotating shaft is rotatably connected in the installation bin, and a motor is in transmission connection with the rotating shaft. When clothes need to be dried through the air conditioner, the baffle is opened, the telescopic rod is pulled out of the installation bin, and the motor drives the telescopic rod to swing left and right in a reciprocating mode so that the clothes hung on the telescopic rod can be dried through air blown out of the air outlet; furthermore, under the driving action of the motor, the telescopic rod drives the clothes to swing left and right so that it can be ensured that the clothes are comprehensively and effectively dried, a user does not need to manually adjust the positions of the clothes, the clothes drying efficiency and the control performance are improved, and the clothes drying effect is optimized.

Owner:HAIER GRP CORP +1

Spiral track clothes airing device

PendingCN107476013ASimple structureWide range of drying anglesOther drying apparatusTextiles and paperElectric machineryDrive motor

The invention discloses a spiral track clothes airing device. The spiral track clothes airing device comprises an annular track, a transmission belt, a belt wheel and a drive motor are arranged in the annular track, the transmission belt is connected to the belt wheel and a driving wheel of an output shaft of the drive motor and is tensioned by the belt wheel and the driving wheel, multiple pulley assemblies capable of sliding along the annular track are connected to the inner side of the transmission belt and are connected to one pulling rope, one end of the pulling rope is connected to an elastic telescopic part, and the other end of the elastic telescopic part is fixed to the annular track. According to the spiral track clothes airing device, the track of the clothes airing device is designed to be of an annular non-closed structure overlapped partially, the elastic telescopic part like a spring is connected to one end of the pulling rope, the transmission belt is driven by the drive motor to rotate, and the rotating stroke of the drive motor is adjusted to achieve multi-angle clothes airing. The spiral track clothes airing device is simple in structure and wide in airing angle range, in addition, a rainproof curtain is arranged, it can be avoided that clothes are not put away in a rain to be drenched, and the spiral track clothes airing device is better in clothes airing effect and more intelligent.

Owner:深圳市喵星人科技有限公司

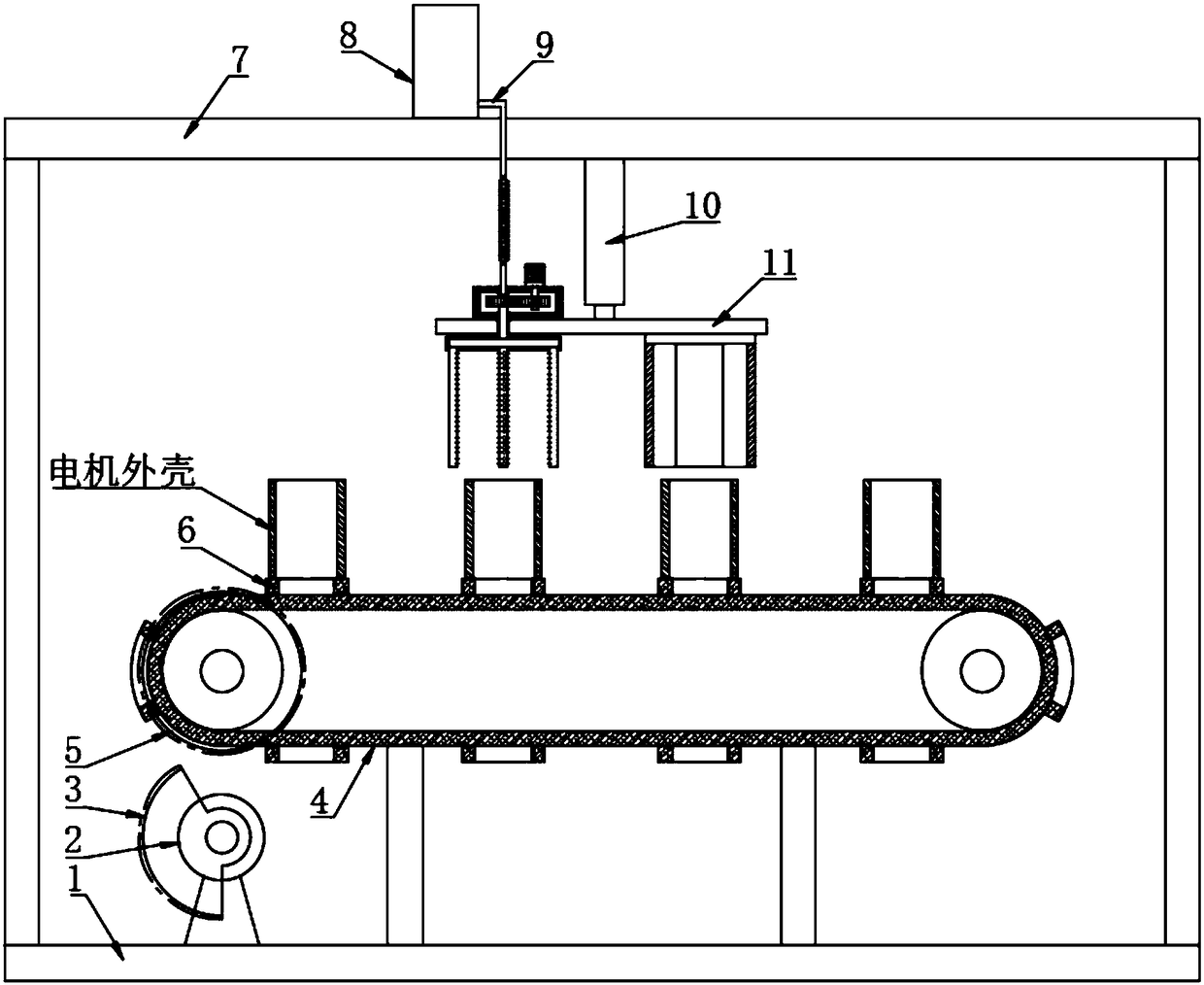

Motor shell painting and drying device

InactiveCN108452990AImprove processing efficiencyEvenly paintedSpray boothsElectric machineryAgricultural engineering

The invention discloses a motor shell painting and drying device. The motor shell painting and drying device comprises a base; a conveying belt is arranged at the top of the base through a bracket; atop plate is fixedly arranged at the top of the base through a bracket; an electric push rod is fixedly arranged at the bottom of the top plate; a push rod at the bottom end of the electric push rod is fixedly connected with a lifting plate; a gear box is fixedly arranged on the left side of the top of the lifting plate; a rotating pipe is arranged in the gear box, and is rotationally connected with the gear box; the bottom end of the rotating pipe penetrates through the lifting plate, and is fixedly connected with a hollow disc; the bottom center of the hollow disc is fixedly connected with an inner spraying pipe; outer spraying pipes are fixedly connected to the left and right sides of the bottom of the hollow disc; a painting pump is arranged at the top of the top plate; a discharge port of the painting pump is connected with a discharge pipe; the discharge pipe is connected with a supply pipe through an extension pipe; and the supply pipe is connected into a rotating pipe. Througharrangement of the outer spring pipes and the inner spraying pipe, the inner and outer walls of motor shells are painted at the same time to achieve high machining efficiency; and the inner and outerspraying pipes are rotated in the painting process to achieve more uniform painting.

Owner:ZHEJIANG OUDAO AUTOMATION EQUIP CO LTD

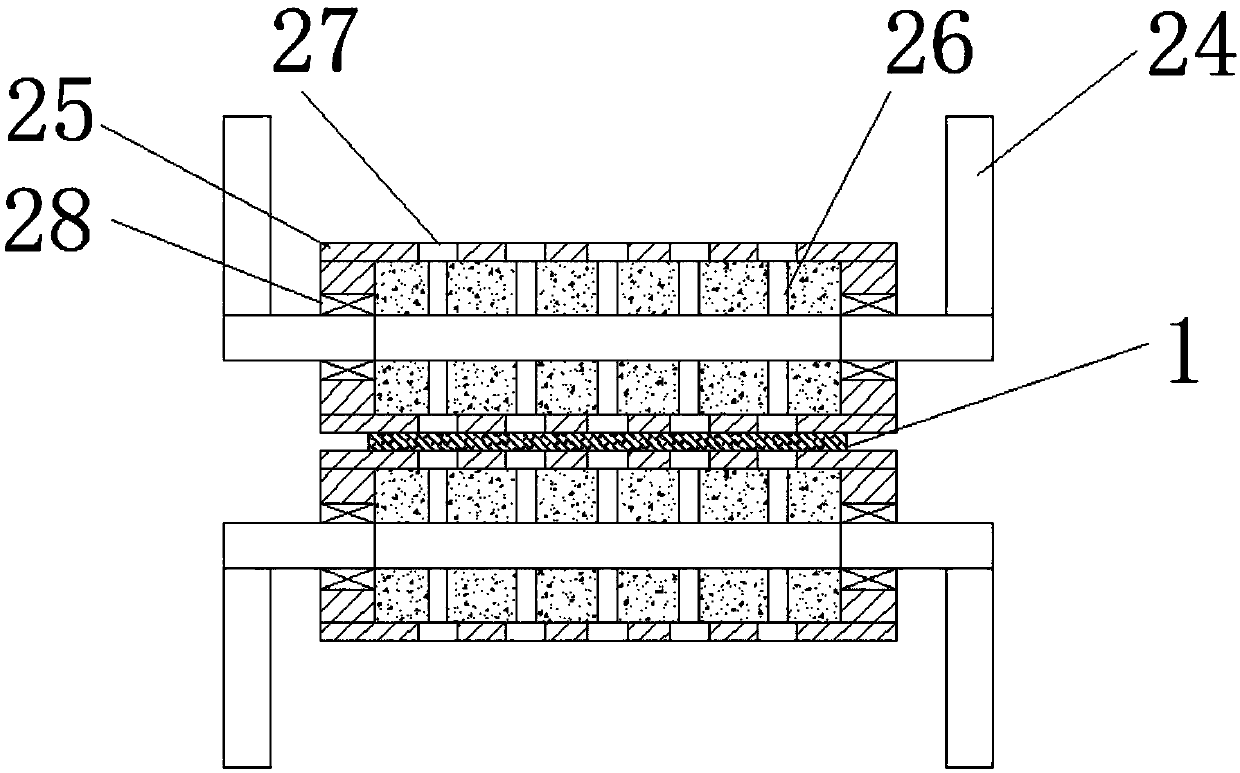

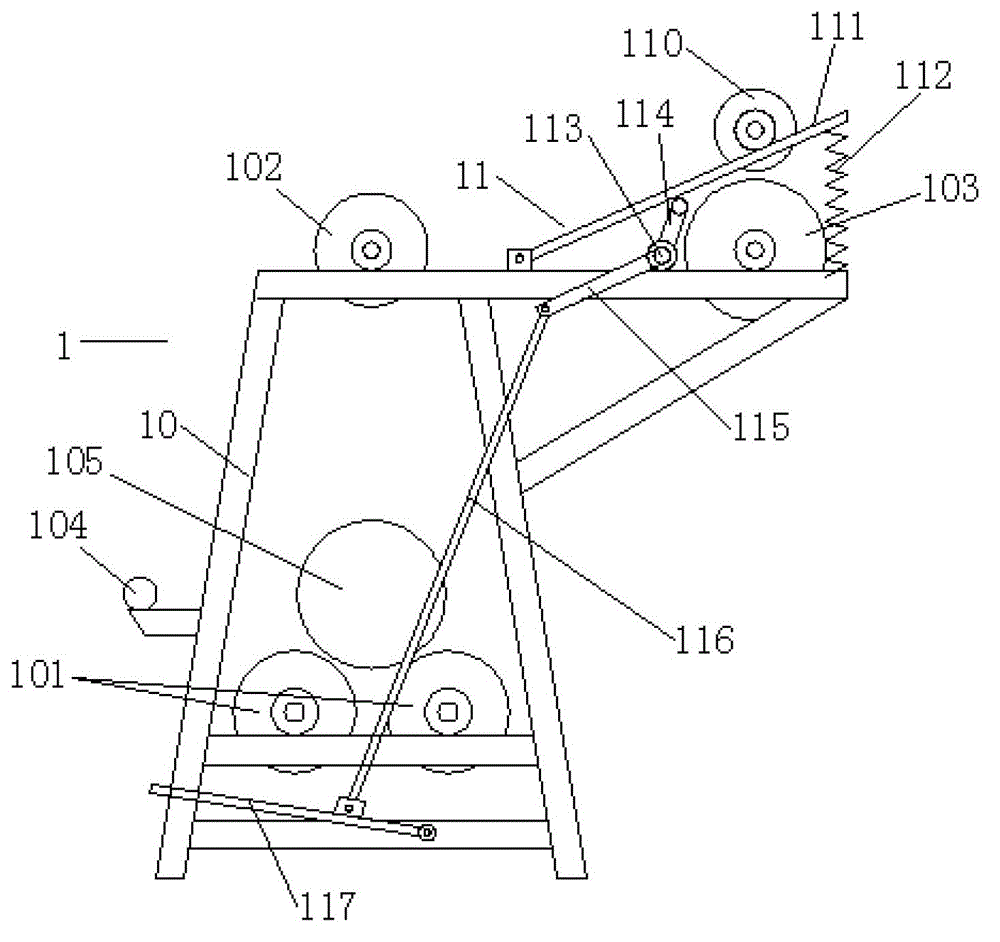

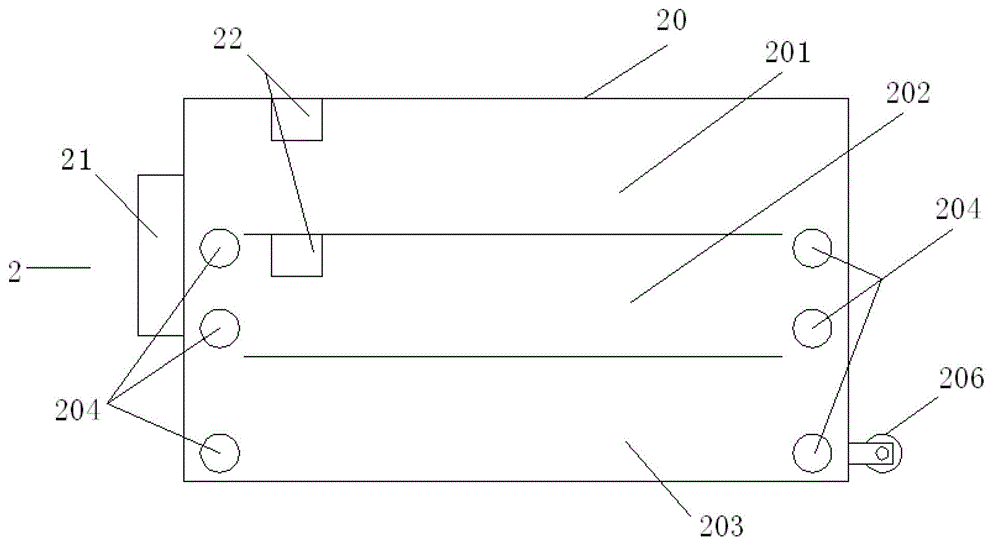

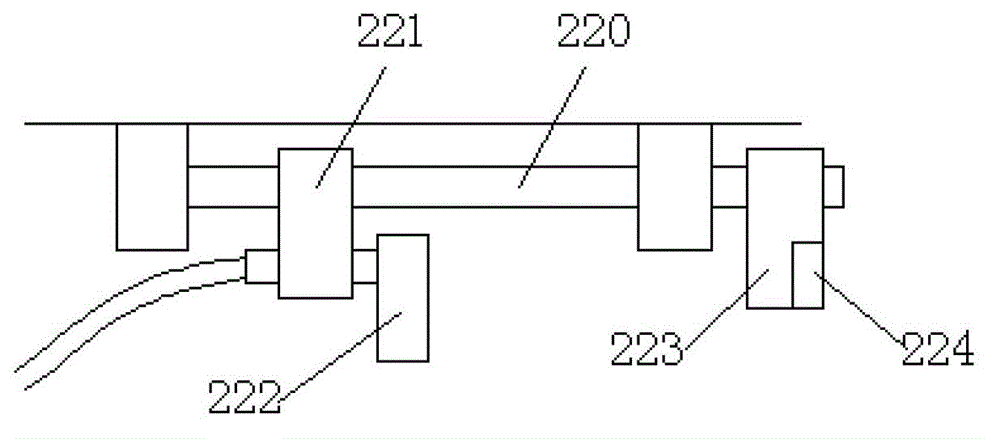

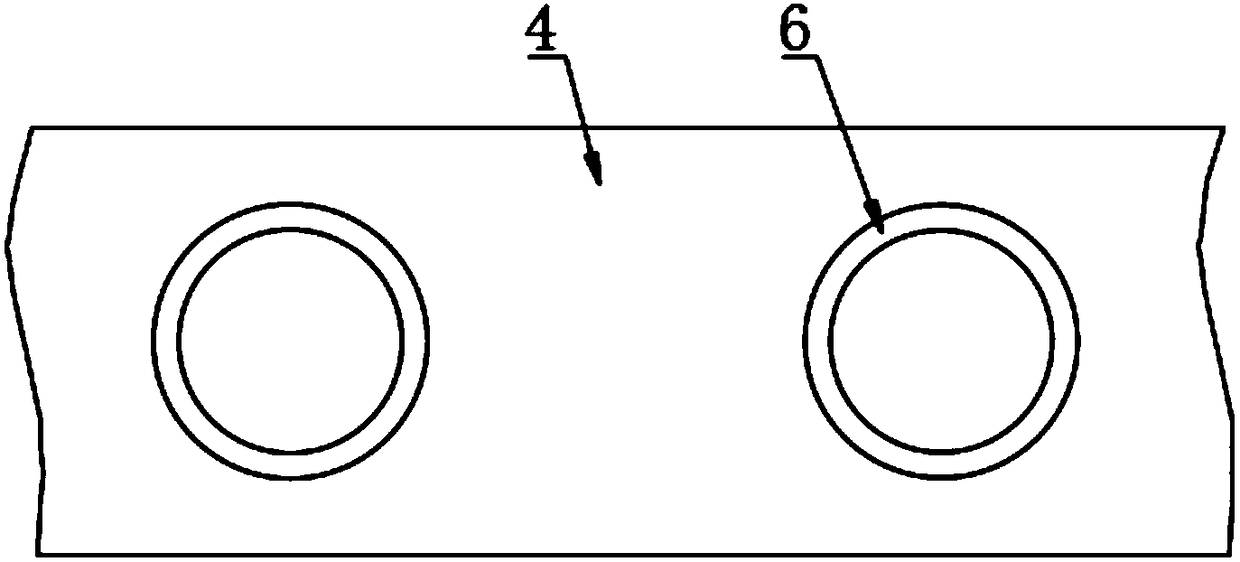

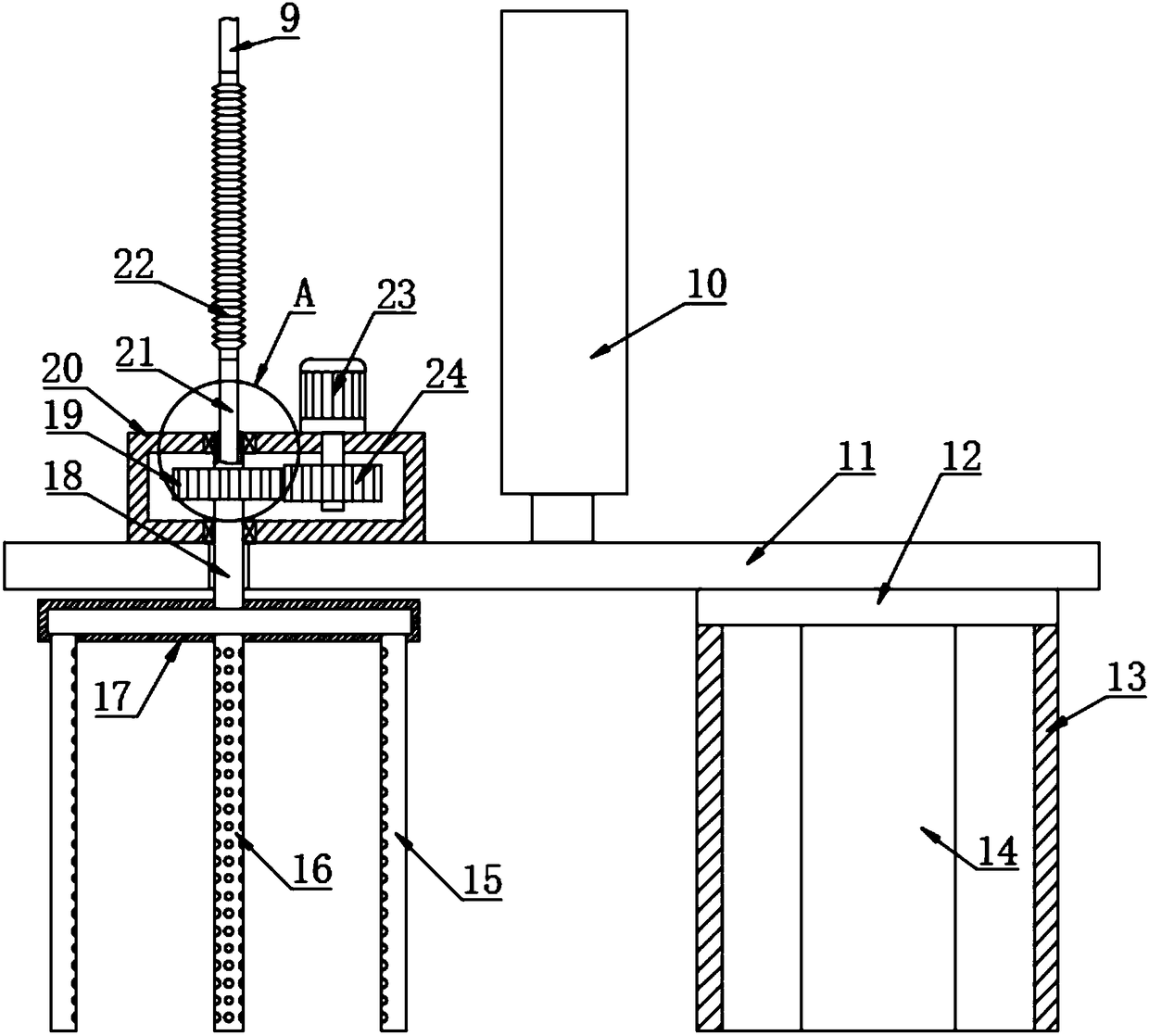

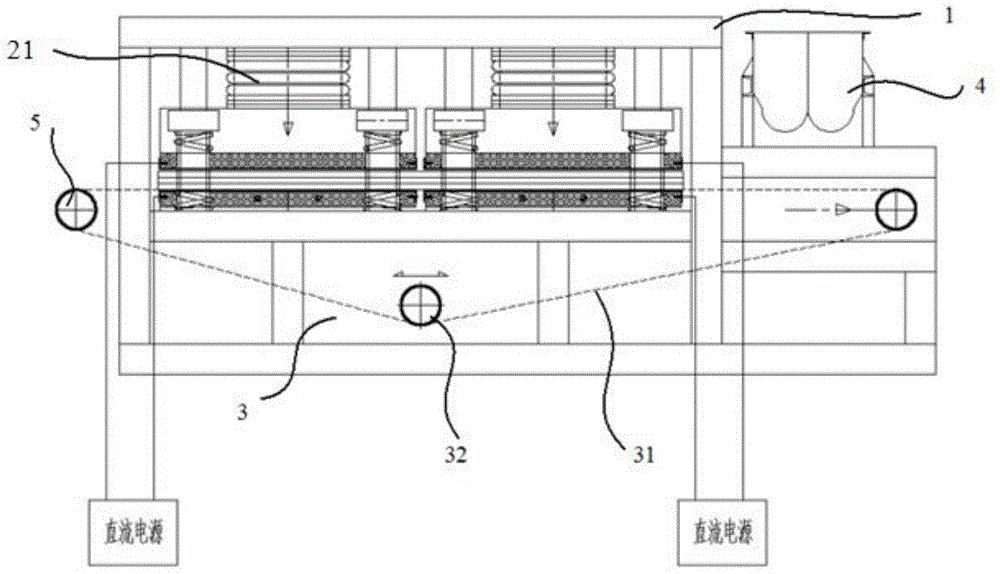

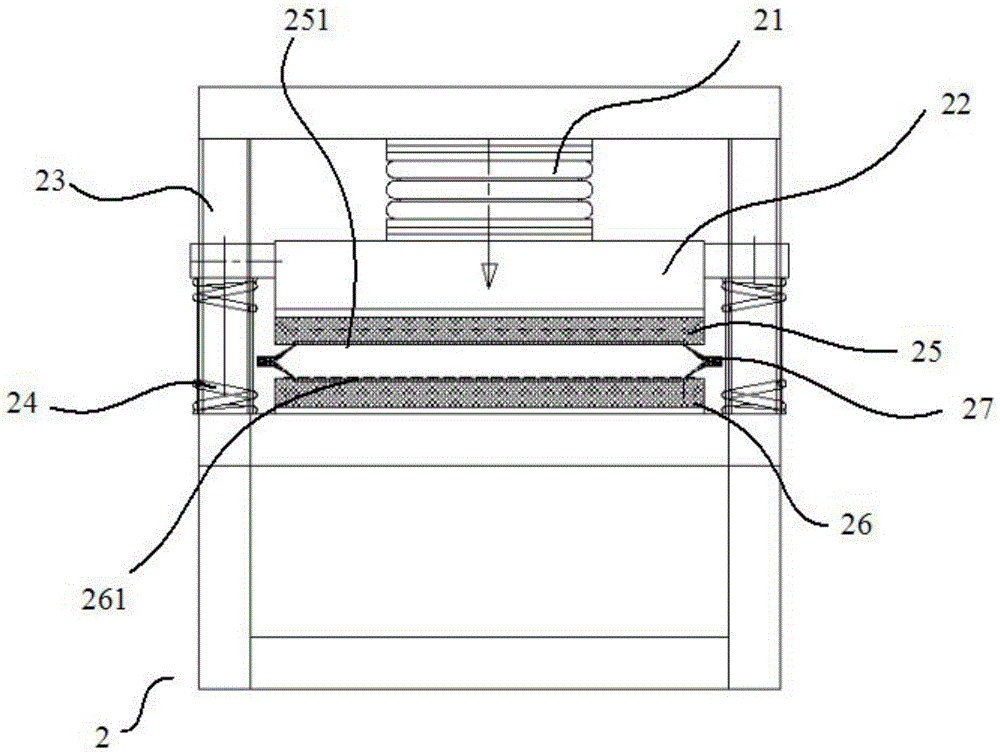

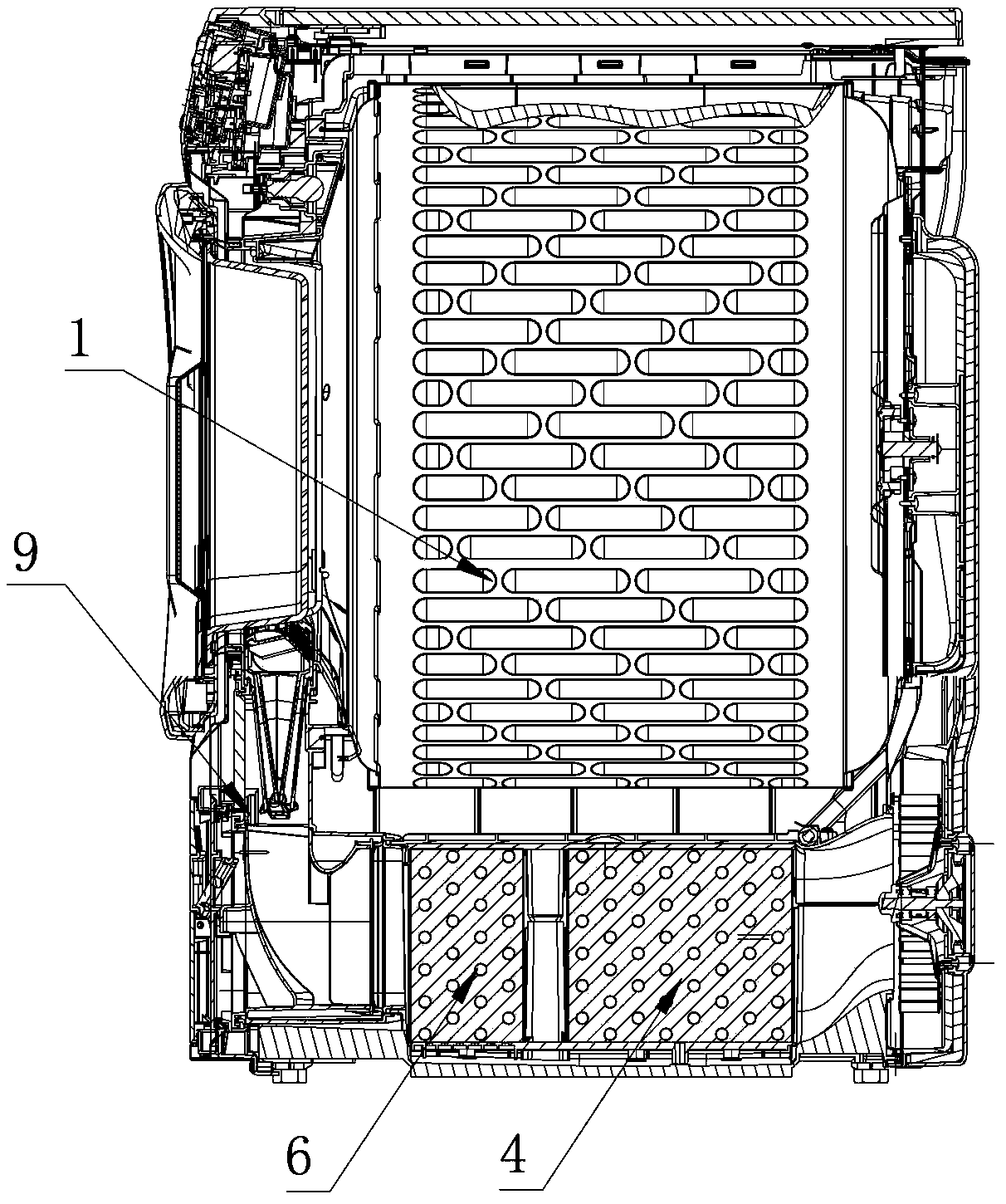

Pressure electric osmosis drier

InactiveCN104817247ASatisfy handlingProcess stabilitySludge treatment by de-watering/drying/thickeningDrying solid materialsElastic componentSludge

The invention provides a pressure electric osmosis drier, and belongs to the technical field of driers. The pressure electric osmosis drier comprises a frame, a module unit, a material conveying device, a distributing device and a discharging device, the module unit is arranged on the frame and comprises a pressurizing device, a pressure-bearing device, a guide column, a reset elastic component, an upper insulation board and a lower insulation board, the pressurizing device is fixed on the frame, two ends of the pressure-bearing device and the reset elastic component are arranged on the guide column in a sleeved manner, the upper insulation board is fixed on the lower portion of the pressure-bearing device, the lower insulation board is arranged below the upper insulation board, a positive electrode board is embedded into the surface of the upper insulation board, and a negative electrode board is embedded into the surface of the lower insulation board. The pressure electric osmosis drier is fine in drying effect and high in safety and can completely meet the requirements of countries for reduction, stabilization, harmlessness and reclamation of sludge treatment, energy is saved, and emission is reduced.

Owner:浙江欧可美科技股份有限公司

Tea leaf drying device

InactiveCN105605889AAvoid damageImprove filtering effectDrying solid materials with heatDrying solid materials without heatPulp and paper industryHeat losses

The invention discloses a tea leaf drying device. The tea leaf drying device comprises a base and a drying box. The drying box is arranged above the base, supporting legs are arranged between the drying box and the base, an electromagnetic heating coil is embedded in the wall of the drying box, a feeding hopper is arranged at the upper end of the drying box, a discharging pipe is arranged at the lower end, located in the drying box, of the feeding hopper, an air jet pipe is arranged in the drying box, an air jet port is formed in the upper side of the wall of the air jet pipe, an exhaust port is formed in the upper left end of the drying box, the air outlet end of the exhaust port is connected with a circulating fan, an air outlet of the circulating fan is connected with the air inlet end of the air jet pipe through an air guide pipe, the air guide pipe penetrates through a filtering box and a dehumidifying box in sequence from top to bottom, a discharging door is further arranged at the bottom of the drying box, and a conveying belt is further arranged on a base at the lower end of the drying box. The tea leaf drying device is simple and reasonable in structure, high in heating efficiency and good in drying effect; heat loss is avoided while dryness of air in the drying box is maintained, and thus the effect of saving energy is achieved.

Owner:廖志标

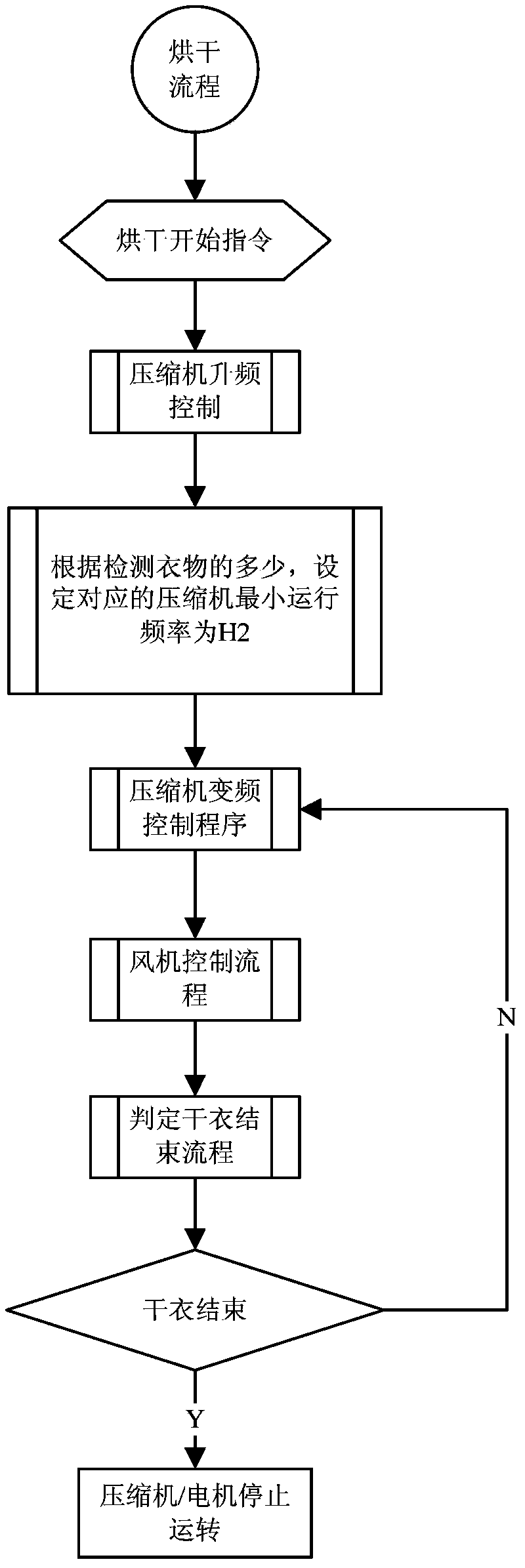

Clothes dryer control method

ActiveCN104120591AIncrease the minimum operating frequencyIncrease drying temperatureTextiles and paperHome appliance efficiency improvementProcess engineeringLaundry

Disclosed is a control method for a laundry dryer. The laundry dryer is a heat-pump laundry dryer, and a compressor is a variable-frequency compressor. According to the amount of laundry, a minimum running frequency of the compressor is set, and the more the laundry is, the greater the set minimum running frequency is. Specifically, when laundry drying is started, the amount of laundry is detected, and according to the detected information, a minimum running frequency, corresponding to the information, of the compressor, is invoked, and a minimum running frequency of the compressor of the current laundry drying process is set. In the improved control method for a compressor in a heat-pump laundry dryer of the present invention, when there is a large amount of laundry, a set minimum running frequency of the compressor is increased, so as to increase the drying temperature inside the cylinder, shorten the drying duration, and eventually achieve a more desirable laundry drying effect; when there is a small amount of laundry, because the laundry is relatively loose, the moisture inside the laundry can easily evaporate, and through comprehensive comparison of the power consumption and drying efficiency of the compressor, a low minimum running frequency of the compressor can be set, thereby lowering energy consumption in comparison.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

High-efficiency crusher for ceramic production

The invention discloses a high-efficiency crusher for ceramic production. The crusher comprises a conveying cylinder, a hydraulic cylinder and a vibrating motor, wherein the outer wall of the conveying cylinder is covered with an electric heating layer; a feed funnel is arranged at the upper side of the left end of the conveying cylinder; a first rotating shaft is horizontally arranged in the internal axes place of the conveying cylinder; and multiple spiral blades are uniformly arranged on the first rotating shaft from left to right. The high-efficiency crusher for ceramic production can crush and dry raw materials for ceramic production, adopts two crushing modes of the spiral blades and crushing rollers to greatly improve the crushing efficiency, can screen materials with unqualified particle size to convey into a crushing cavity for circularly crushing, adopts the vibrating motor to drive a screen to vibrate so as to improve the screening efficiency and effect, guarantees the crushing effect and the finished product quality, improves the adjustment of a gap between the upper and lower crushing rollers to realize the particle size adjustment of the crushed materials, and improves the practicability.

Owner:顾广才

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com