Patents

Literature

232results about How to "Solve chromatic aberration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

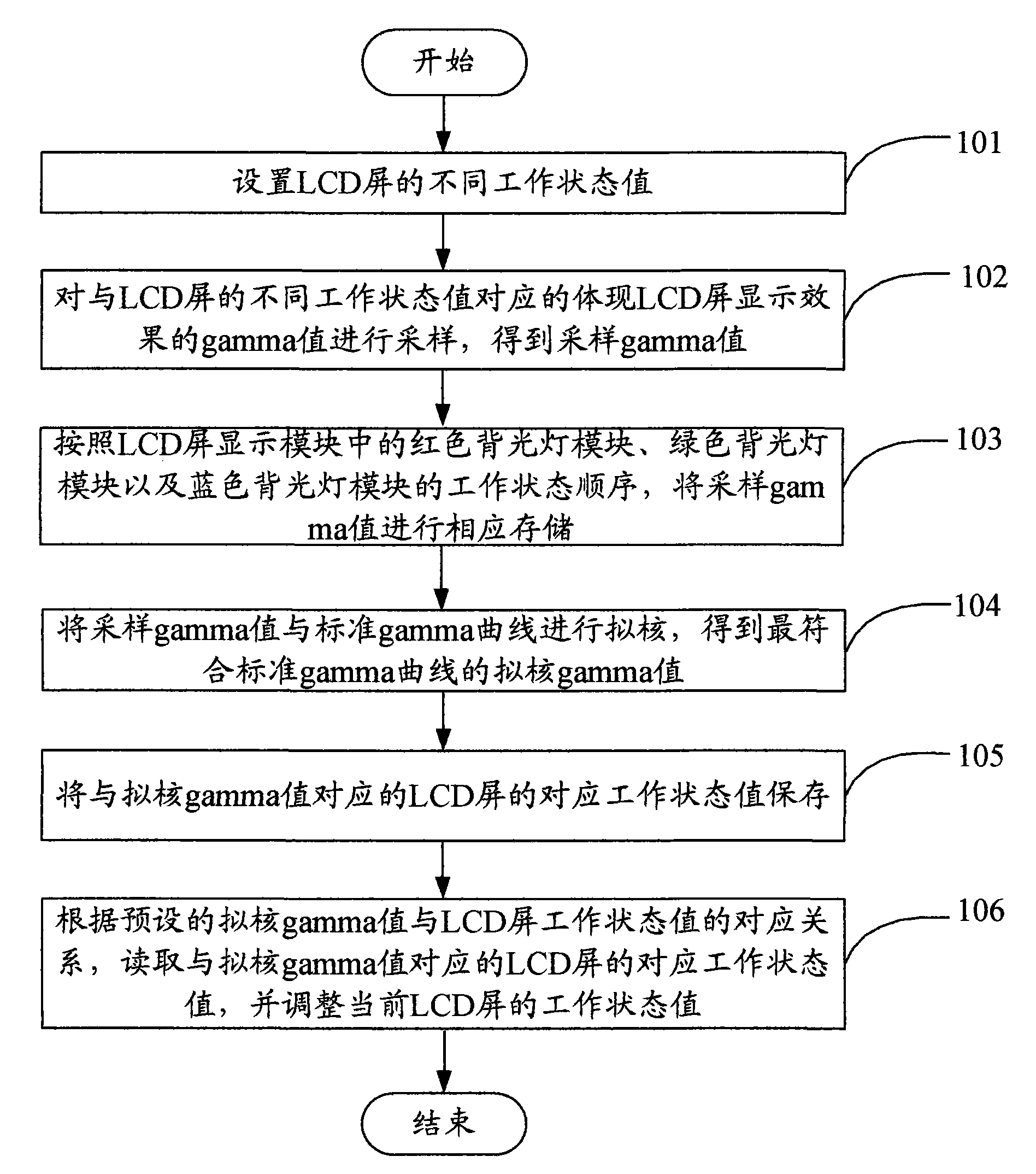

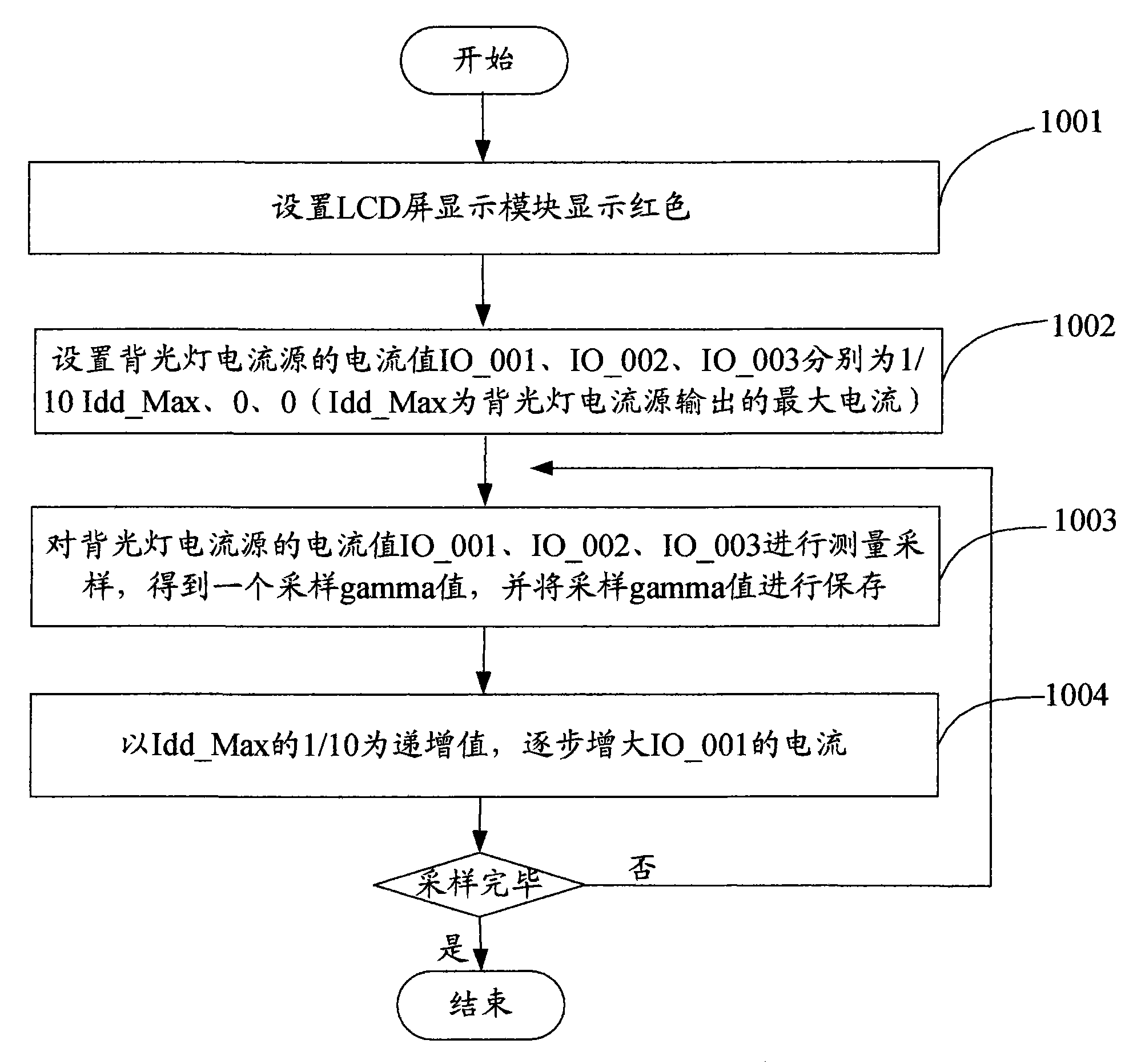

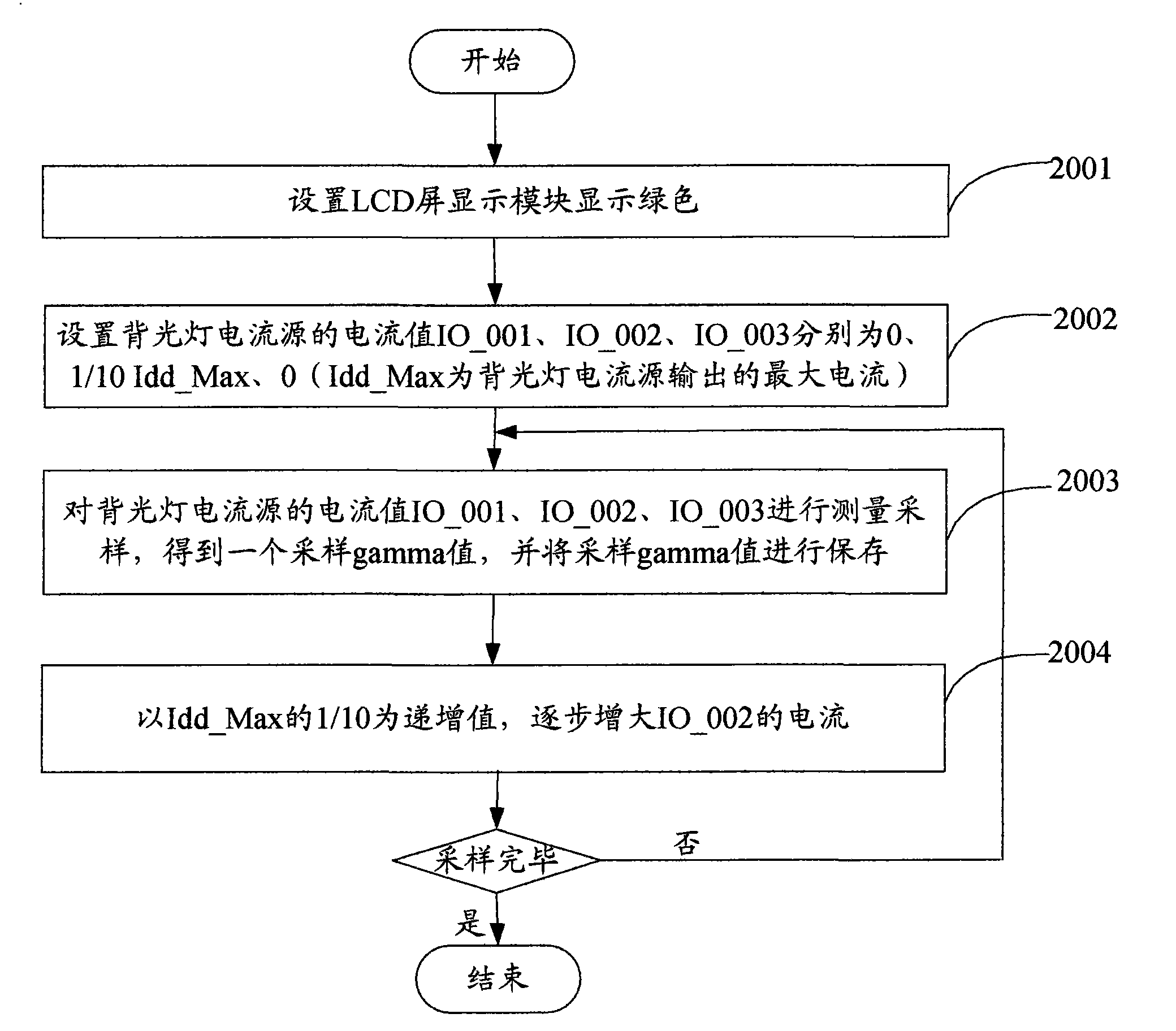

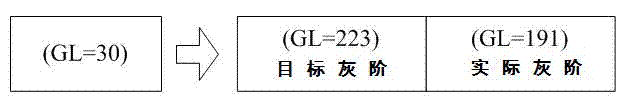

Method and device for correcting gamma value of LCD screen

InactiveCN101840689AImprove the display effectSolve the problem of color castColor signal processing circuitsStatic indicating devicesPhysics

Owner:ZTE CORP

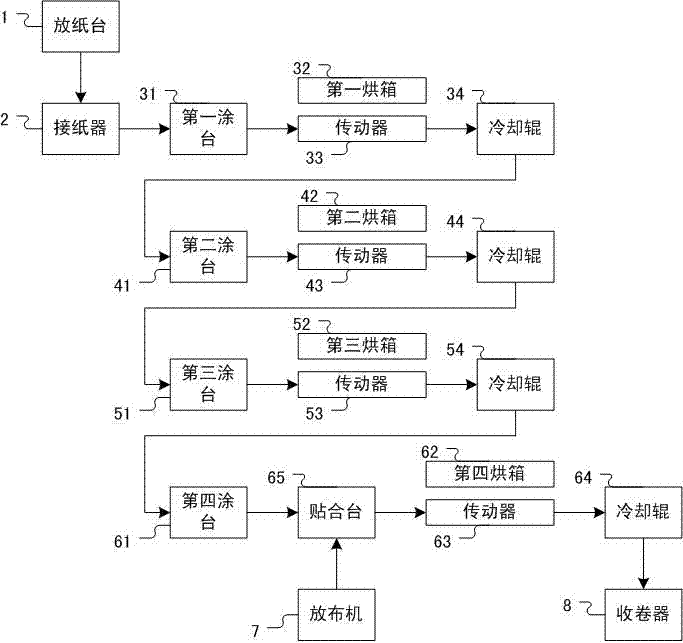

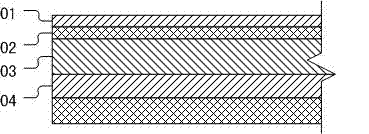

Water-based synthetic leather, and production line and production method thereof

InactiveCN103710995ASolve chromatic aberrationImprove efficiencyLamination ancillary operationsLaminationWater basedProduction line

The invention provides a water-based synthetic leather and a production line thereof. A four-coating four-drying process is adopted, and an intermediate water-based resin coating layer and a foaming water-based resin coating layer are respectively formed. The production line has an integrated production process, has the advantages of relative stability and higher efficiency, and also avoids the problems of low drying efficiency and easy corrugation brought by an excessively thick surface layer. Through partitioning drying boxes and controlling the temperatures of different isothermal regions, drying is uniform, smooth and steady, and the drying effect is good. The synthetic leather is of a five-layer structure, effectively solves the color shading problem brought by large-pattern embossing. At the same time, the invention also provides a production method of the water-based synthetic leather.

Owner:JIANGXI MINGCHUAN SCI & TECH IND

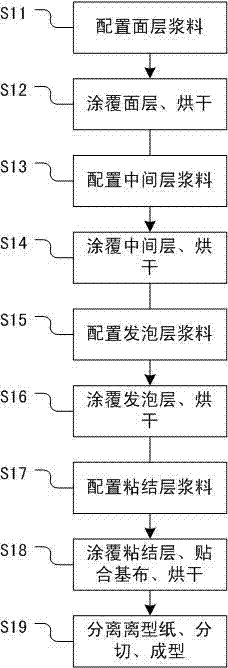

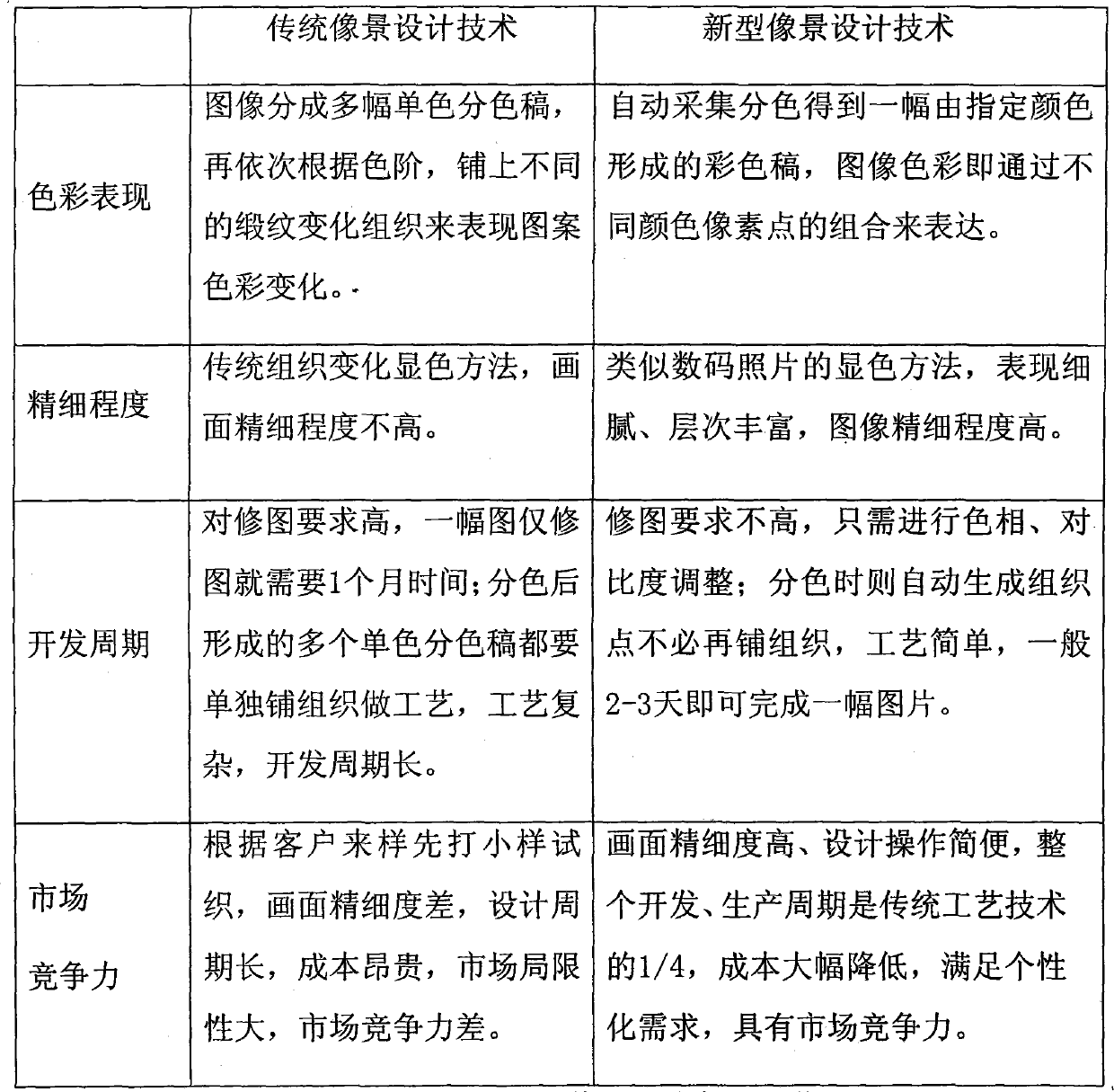

Manufacturing process of full-digital high-fineness image brocade fabrics

InactiveCN102560807AImprove color vibrancyHigh saturationSwivel-woven fabricsLappet-woven fabricsEngineeringDigital printing

A manufacturing process of full-digital high-fineness image brocade fabrics includes the following steps of scanning, image rectifying, color separating and processing. The manufacturing process has the advantages that design and development period is short, production time of conventional jacquard image fabric products is shortened, cost is reduced, expensive individual jacquard fabrics can be popularized in ordinary family, and the requirements of vast customers are met. Meanwhile, the full-digital high-fineness image brocade fabric has more layers and more exquisite styles as compared with conventional image fabrics, solves the problems of few layers and colors and poor fineness of conventional image jacquard fabrics, can be used for developing full-true-color picture works, has simulation effect as digital printing, breaks through limits of original products and can represent original appearance of pictures vividly and record time, events and characters with historical values by a unique presenting manner, thereby making permanent storage of wedding pictures, portraits and historical paintings come true. Further, application field of textiles is expanded and domestic demands of the market can be stimulated.

Owner:TIANJIN TEXTILE ENG RES INST

Milk protein fiber or its filament or its blended yarn dyeing method and coloured woven fabric producing method

ActiveCN1865574ASolve the problem of not being able to dyeHigh dye utilization rateHeating/cooling textile fabricsWoven fabricsAlcoholPolyvinyl acetate

The invention discloses a manufacturing method of milk protein fiber or filament or blended yarn dyeing and yarn-colored product, which is characterized by the following: changing coiling density of yarn; controlling heating temperature; adopting segmented contraction in the cylinder yarn dyeing course; adding self-producing milk protein fiber dyeing specific adjuvant; utilizing polyacrylonitile or polyvinyl acetate alcohol as carrier realize active dyeing technology of milk protein fiber; solving the difficulties of flower color, weak color and bad fastening degree problem to produce excellent washing shrinkage and stable size yarn-dyed product through weaving, shrinking and softening and final disposal.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

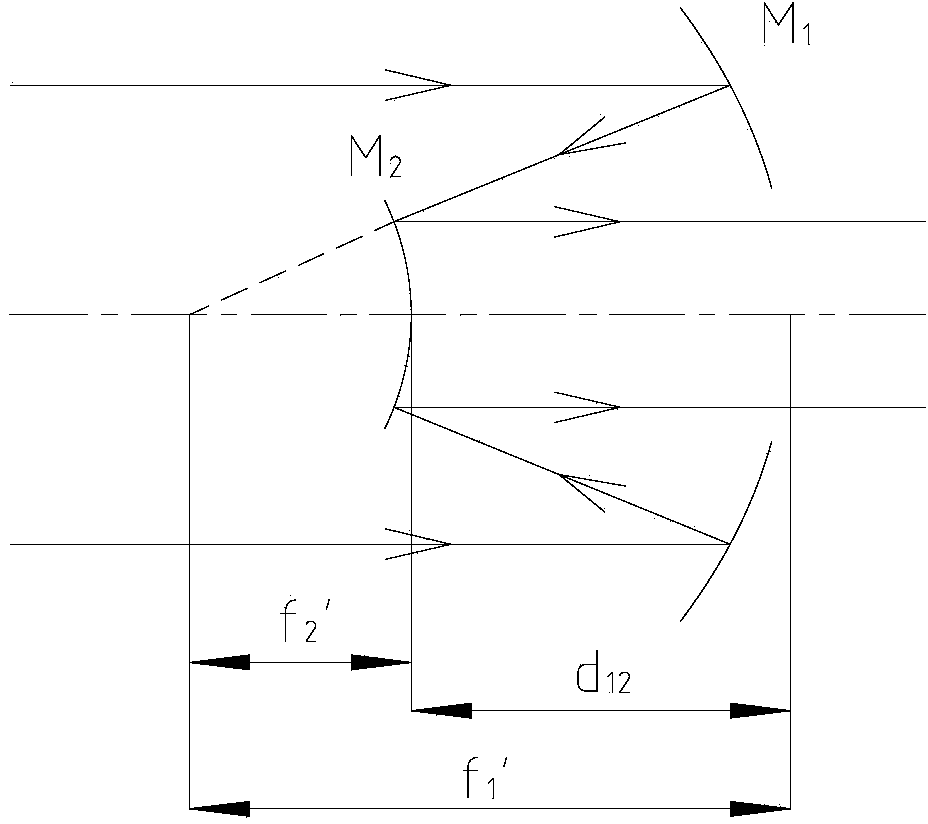

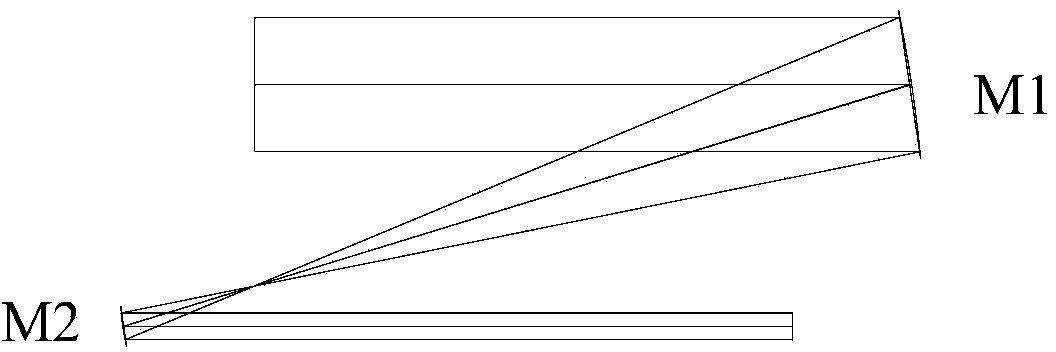

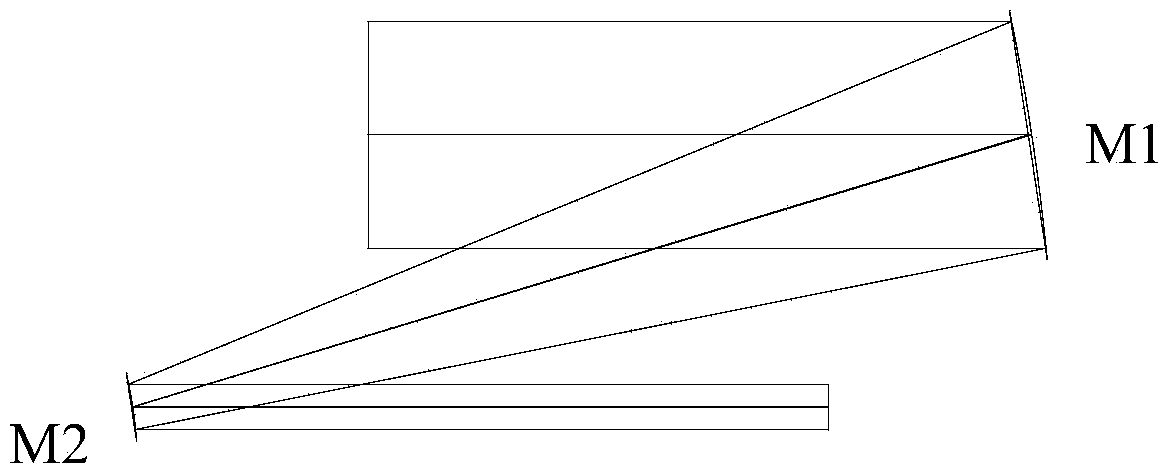

Off-axis blocking-free parallel light system capable of eliminating six types of aberrations

InactiveCN103869491AEliminate aberrationsSolve chromatic aberrationMirrorsBeam expanderOptoelectronics

The invention relates to an off-axis blocking-free parallel light system capable of eliminating six types of aberrations. The off-axis blocking-free parallel light system capable of eliminating six types of aberrations comprises a first reflecting mirror and a second reflecting mirror, the second reflecting mirror is arranged on a reflected light path after reflection of the first reflecting mirror; the first reflecting mirror is arranged on an incident light path; the first reflecting mirror and the second reflecting mirror are paraboloidal reflecting mirrors. The off-axis blocking-free parallel light system capable of eliminating six types of aberrations can be used for a beam expander system or a beam shrinking system or a telescopic system and is capable of simultaneously eliminating six types of aberrations.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Production technology of Tencel cotton willow crepe fabric

ActiveCN107142590AGood shape retentionImprove product added valueWoven fabricsVegetal fibresAdditional valuesEngineering

The invention discloses a production technology of a Tencel cotton willow crepe fabric. The raw materials include combed cotton with 9.7 tex of warps and Tencel cotton with 18 tex of wefts, wherein the blending ratio of the Tencel cotton is 65 / 35 corresponding to Tencel / cotton, and plain weave is used as a basic weave of the fabric. The warp technology process includes the steps of winding, warping, sizing, drafting and weaving; the weft technology process includes the steps of winding, twisting, typing and weaving. According to Tencel cotton willow crepe, fine special cotton yarns are used as the warps, Tencel cotton over-twisted yarns are used as the wefts. Through finishing after high-temperature slacking, patterns like 'inverse willow branches' in the spring are formed on the fabric, and the folding effect is far superior to that of a blister fabric; compared with a pure cotton willow crepe fabric, the fabric is softer, smoother and more elegant, and the conformality is good, so that the fabric is an upscale fashionable underwear fabric, and the additional value of the product is high.

Owner:浙江天骏纺织有限公司

Dyeing method for gossamer/wool gossamer cotton, gossamer/bast and other blended fabric

InactiveCN1512004ASolve color flowerSolve chromatic aberrationFibre treatmentDyeing processWoolProcess engineering

The present invention discloses paint dyeing process for dyeing blended fabric of gossamer with wool, cotton, bast, etc. The blended gossamer fabric material is pre-treated with polyamine polyol as multifunctional compound and dyed with special dyeing adhesive via optimized technological process to obtain destination product. The technological process is simple and low in power consumption, and the dyed blended gossamer fabric product has soft hand feeling, low formaldehyde content, high color fastness and stable product quality. The present invention is suitable for industrial production.

Owner:上海新型纺纱技术开发中心 +1

High temperature scarlet ceramic pigment and production method thereof

The invention provides a high temperature scarlet ceramic pigment and its preparing process, wherein the raw materials comprise (by weight percent) yttrium oxide 63.50-66.50, aluminum oxide 30.50-34.50, chromium hemitrioxide 0.90-1.90, and mineralization agent 1-5. The preparing process consists of weighing raw materials and batching, grinding the batches and sieving, drying and dewatering, synthesizing in a high-temperature electric resistance furnace, thermal insulating and naturally cooling, grinding, rinsing and sieving.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Production process of textile fiber color modifier

The invention relates to a production process of a textile fiber color modifier. The textile fiber color modifier is prepared from the following raw materials in percentage by weight: 52%-68% of swelling agent, 10%-30% of emulsifying and dispersing agent, and 8%-20% of solvent, wherein the swelling agent is one or more of propylene glycol monomethyl ether, phenoxy-1-propanol, cyclohexanol methyl ether, N-normal-butyl-phthalimide, and N-isopropyl-phthalimide; the emulsifying and dispersing agent is one or more of styrylphenol polyoxyethylene ether sulfonate, polyoxyethylene castor oil, iso-tridecanol polyoxyethylene ether, fatty amine polyoxyethylene ether, polyoxyethylene (60) sorbitan monostearate (namely Tween-60), polyoxyethylene (80) sorbitan monostearate (namely Tween-80), and pesticide emulsifier No.600; and the solvent is one or more of water, ethanol, isopropyl alcohol, ethylene glycol, and ethylene glycol monobutyl ether. The production process comprises the following steps of adding all the materials into a reaction kettle and stirring the materials at 30 DEG C to 50 DEG C for 60 to 90 minutes, thereby obtaining the textile fiber color modifier. The textile fiber color modifier can be used for overcoming the dyeing defects of polyester and blended fabrics of the polyester in dyeing, and the dyed fabrics can meet environmental protection standards.

Owner:冯祥茂

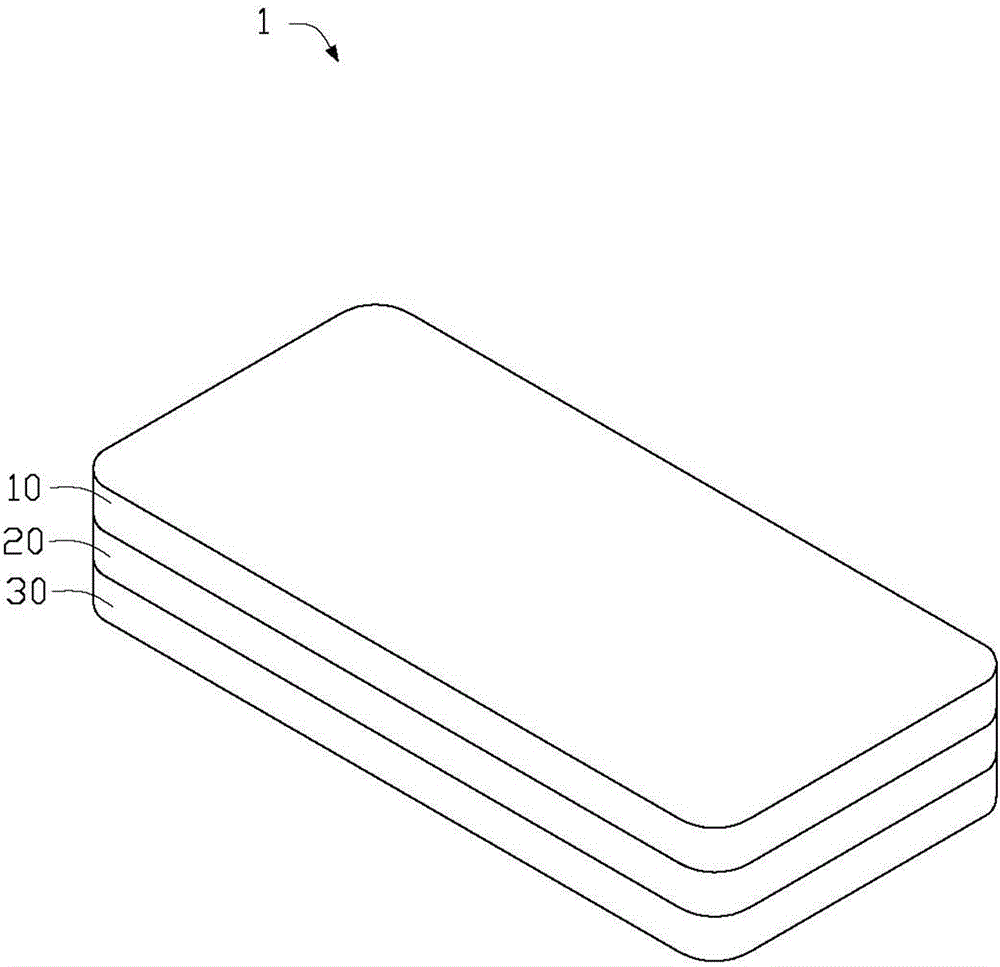

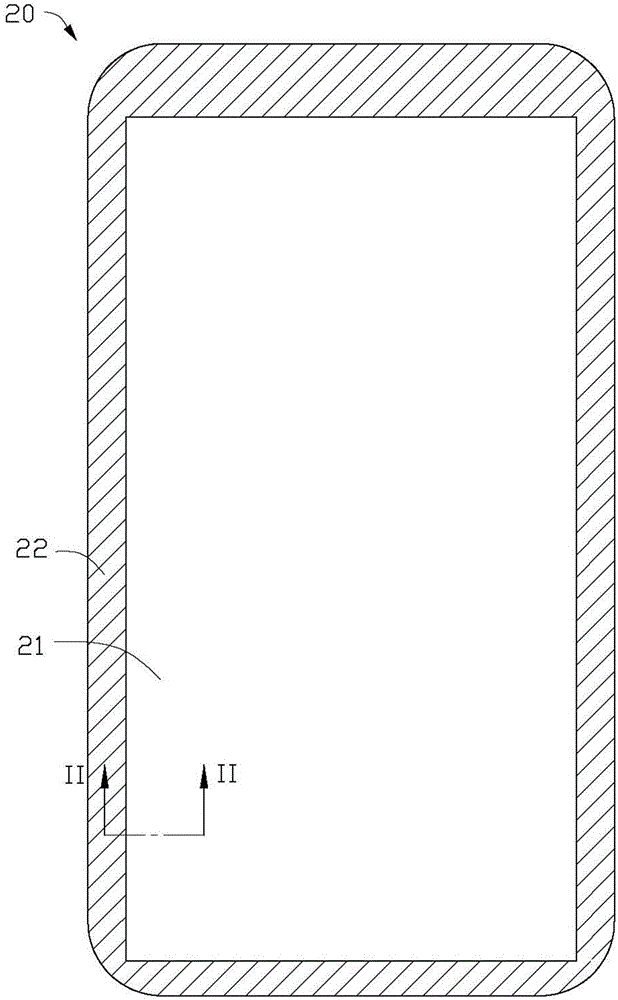

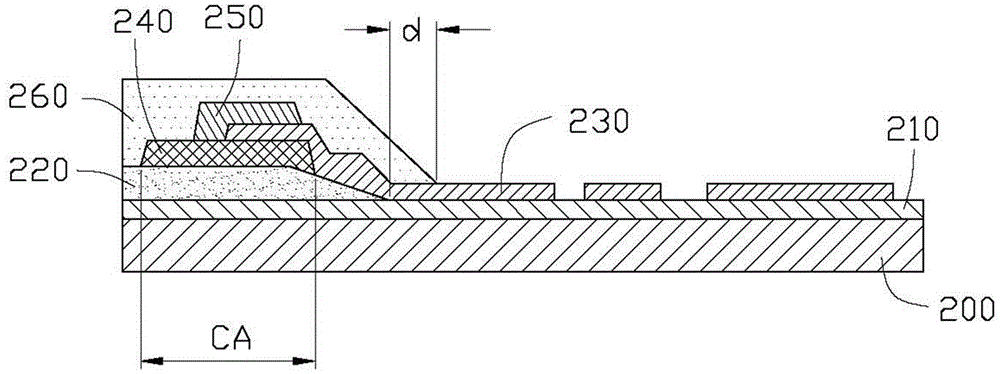

Touch module and manufacturing method thereof

ActiveCN104656990AAvoid damageSolve chromatic aberrationInput/output processes for data processingSignal linesElectrode

The invention relates to a touch module. The touch module comprises a touch region and a wiring region on the periphery of the touch region. The touch module further comprises a substrate, wherein a first light shielding layer is arranged at a position, corresponding to the wiring region, of the substrate, a conductive signal line is laid above the first light shielding layer and a touch electrode is laid at a position, corresponding to the touch region, of the substrate; a protection pad is further arranged above the first light shielding layer to protect the first light shielding layer, the conductive signal line and the touch electrode are respectively extended to the surface of the protection pad to enable the conductive signal line and the touch electrode to be electrically connected at the position of the protection pad. The invention further provides a manufacturing method of the touch module.

Owner:INTERFACE TECH CHENGDU CO LTD +1

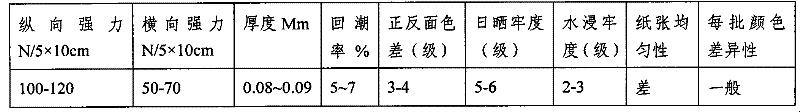

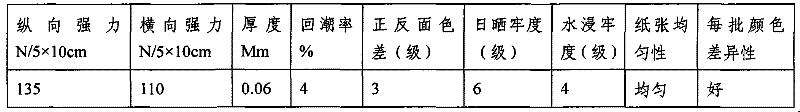

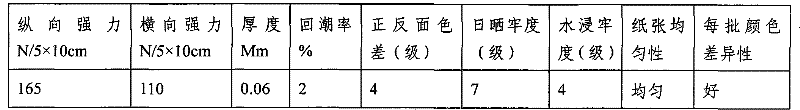

Method for preparing dyed wood pulp paper for nonwoven materials

ActiveCN102230296AChange the dyeing processSolve the fastnessNatural cellulose pulp/paperPaper/cardboardFluff pulpSlurry

The invention discloses a method for preparing dyed wood pulp paper for nonwoven materials, which comprises the following steps of: (1) mixing red pine fluff pulp and coniferous wood pulp to obtain mixed wood pulp; (2) dispersing the pulp, namely putting the mixed wood pulp obtained in the step (1) into a pulp dispersing tank, and adding water for pulping, so that wood pulp fibers are dispersed in the water uniformly; (3) heating, namely heating the water in the pulp dispersing tank; (4) dyeing, namely dyeing dyes in the pulp dispersing tank for 15 to 30 minutes, adding a color fixing agent, and fixing colors for 20 to 30 minutes; and (5) conveying dyed slurry obtained in the step (4) into a fourdrinier part of a papermaking machine for forming, and squeezing, drying, coiling and slittingto obtain the dyed wood pulp paper for the nonwoven materials. Compared with imported wood pulp paper, the dyed wood pulp paper produced by the method has the advantages that: the color fastness to sunlight and water leaching fastness are improved greatly; indexes are higher than the level of foreign products; and the cost is reduced.

Owner:XINLONG HLDG GROUP

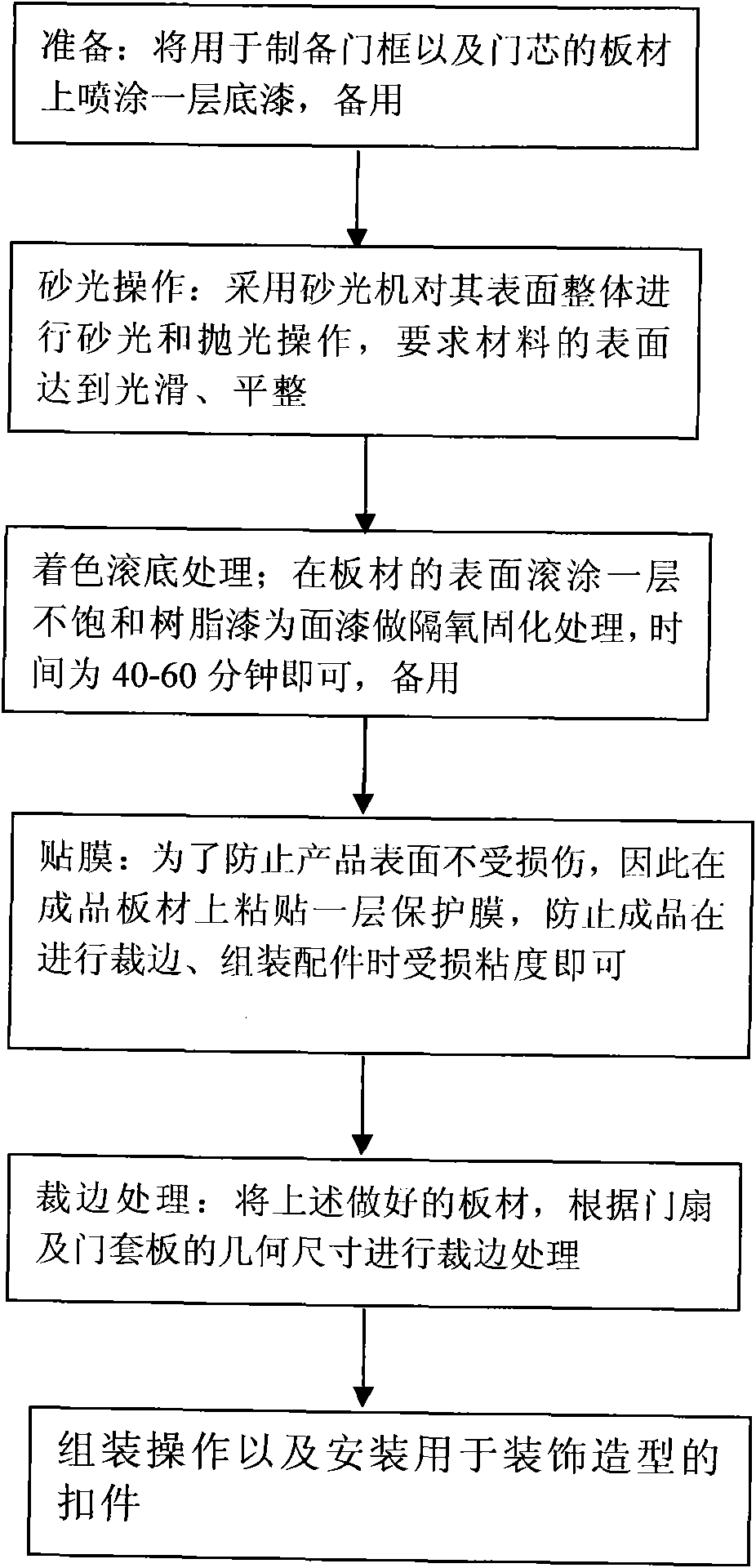

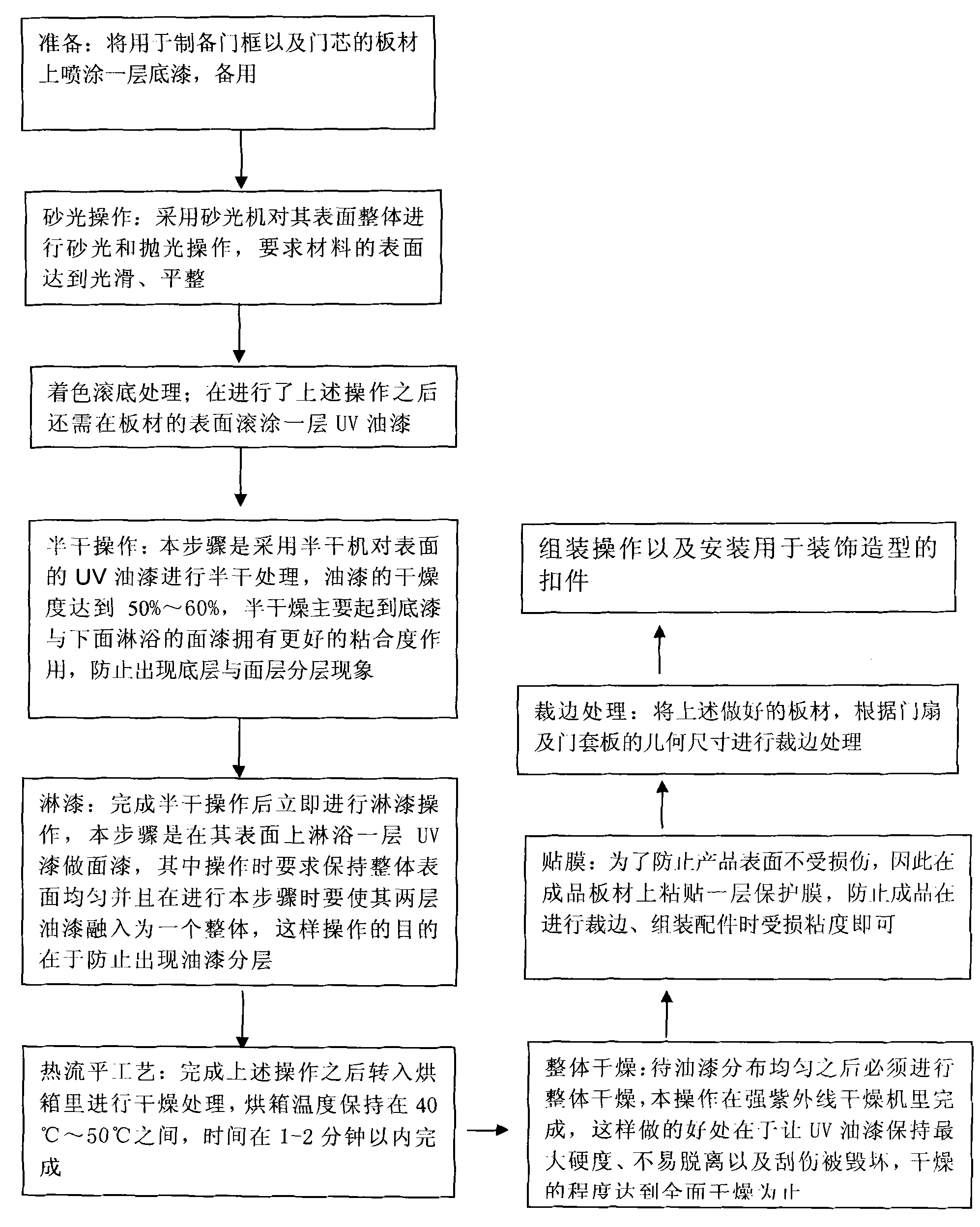

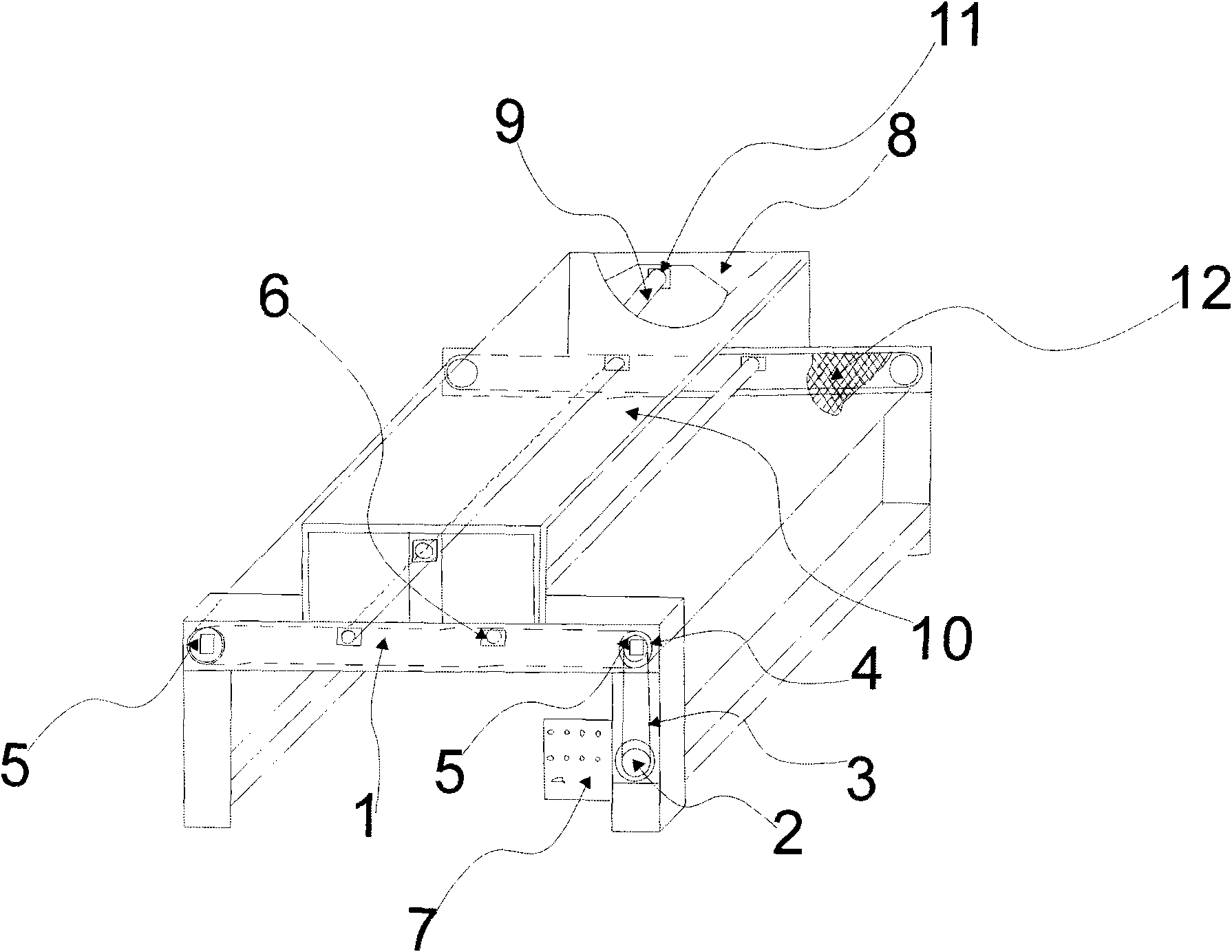

Manufacturing process of wood door and half drying machine

InactiveCN101871307ANot easy to shrinkNot easy to expandPretreated surfacesCoatingsManufacturing engineering

The invention discloses a manufacturing process of a wood door, which is characterized by comprising preparation, sanding operation, colorizing and bottom rolling treatment, lamination, trimming treatment, assembling operation, decorative and shaping fastening piece installation and final entire packaging. The process prevents expansion and contraction in door vertical frame, cross beam and other places. In the invention, the surface oil paint stripping and layering can be prevented by adopting half drying operation, paint spraying, a thermal leveling process and overall drying operation, time is saved and product quality is improved. At the same time, the invention also provides a half drying machine for half drying operation.

Owner:CHENGDU TIANCHENG SHENGMU DOOR

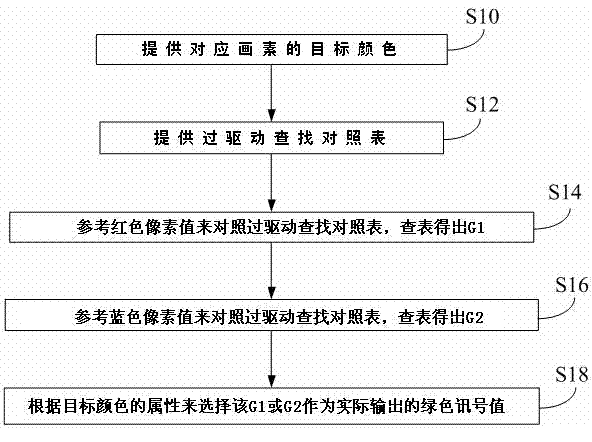

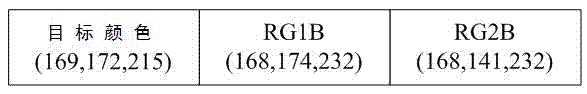

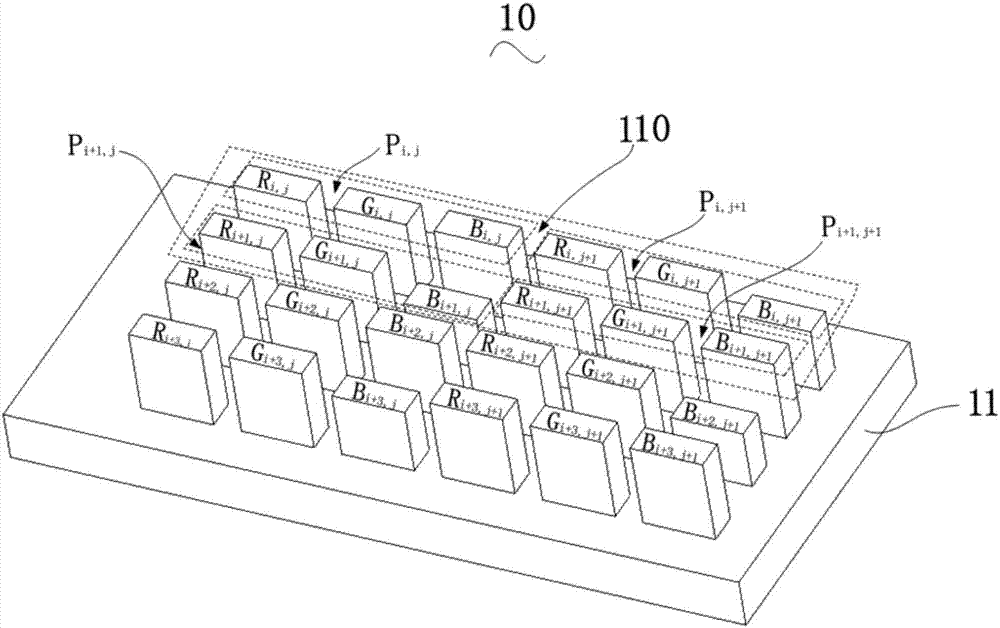

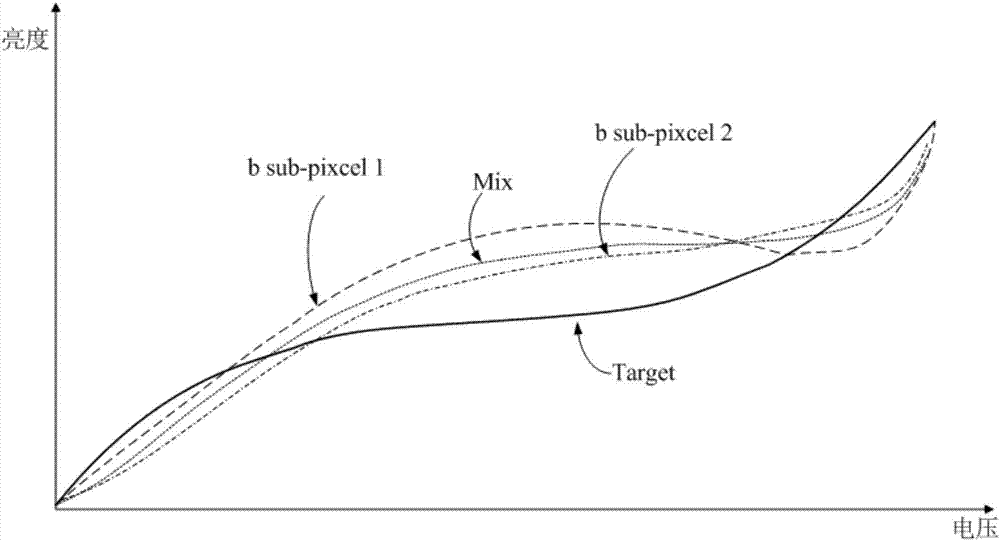

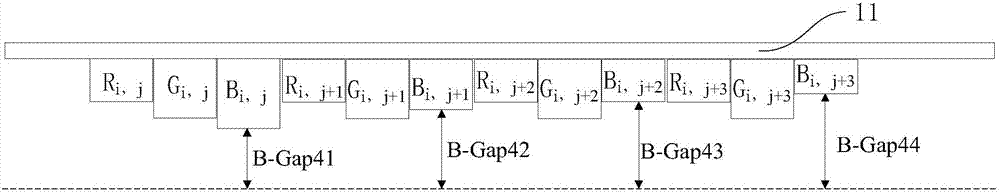

Color display method of color-sequence liquid crystal display

InactiveCN102855857ASolve the problem of color deviationSolve chromatic aberrationStatic indicating devicesLiquid-crystal displayDisplay device

The invention discloses a color display method of a color-sequence liquid crystal display. The problem of color separation is improved by lifting a frequency of opening a green backlight. A reference red pixel or a reference blue pixel is selected according to a color attribute of a target color in an over-drive mode, so as to determine an over-drive value corresponding to a green color field and take the over-drive value as a green signal value which is actually output to a screen of the display, thereby improving the problem of color deviation.

Owner:CPT TECH GRP +1

Array substrate, display panel and display device

ActiveCN107153293ASolve chromatic aberrationSolve the problem of color castNon-linear opticsTransmittanceDisplay device

The invention relates to an array substrate, a display panel and a display device, wherein the array substrate comprises a substrate; a plurality of pixel areas are arranged on the substrate; each pixel area comprises a plurality of pixel units; each pixel unit comprises a red pixel subunit, a green pixel subunit and a blue pixel subunit; a blue light resistance film layer is arranged on the blue pixel subunit; and two adjacent blue pixel subunits in each pixel area are provided with blue light resistance film layers with different thickness. The display device comprises a data receiving chip, a driver board and a display panel, wherein the display panel comprises the array substrate, the driver board comprises a time sequence control circuit, and an initial driving voltage signal of each pixel subunit is processed to ensure that a plurality of blue pixel subunits of an identical row / column in an identical pixel area have a same driving voltage after processing. According to embodiments of the invention, a color cast situation of a lateral view angle can be improved without the requirement of sacrificing a light-permeable opening area, a good panel light transmittance can be kept, and the backlight cost is saved.

Owner:HKC CORP LTD +1

Shredded peduncle dipping type material feeding process

The invention relates to a cabo processing method in the tobacco industry, which comprises the steps of cabo steeping, steam heating, cabo storing, chopping, fountain feeding, drying and swelling, wherein the fountain charging is replaced by impregnated charging, the cabo is fully immersed into the steeping liquor added by feed liquid, dewatering the steeped cabo to next stage (drying and swelling).

Owner:蚌埠卷烟厂

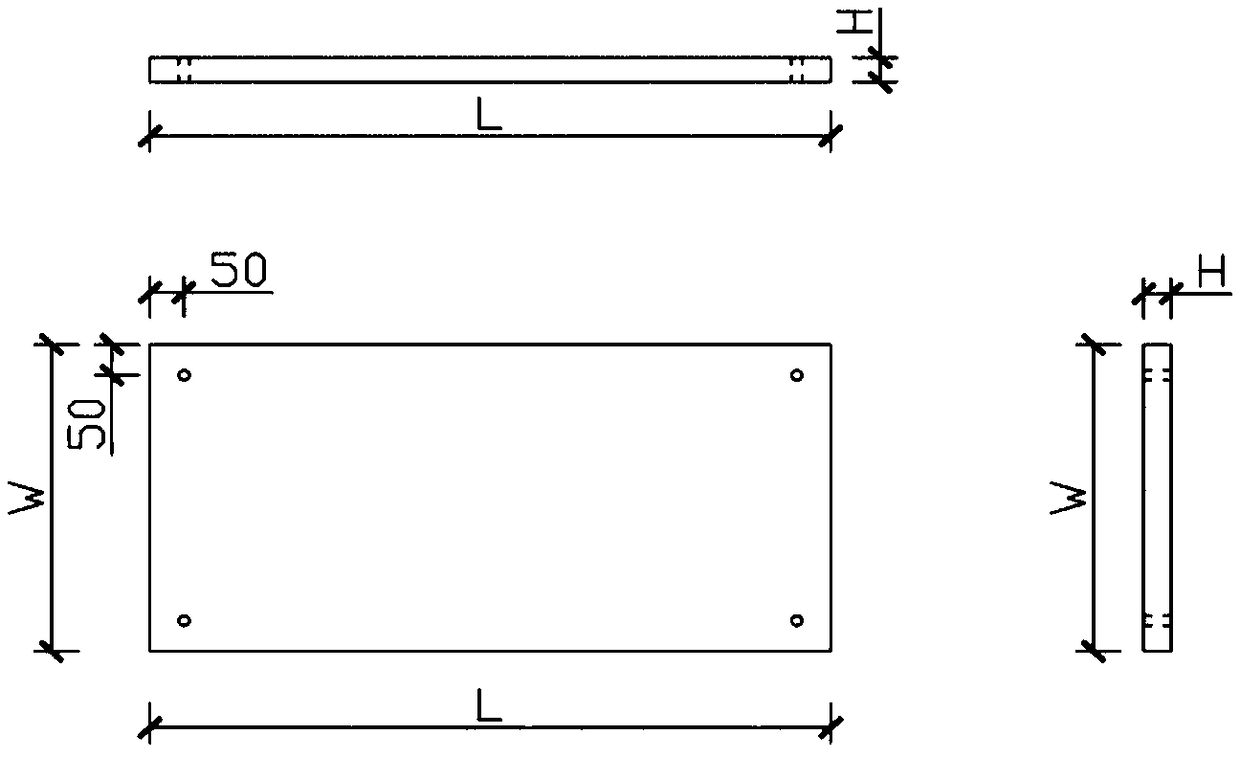

Ultra-high-flexibility concrete inorganic decorative board having pattern-contained surface and preparation method thereof

PendingCN109138310AImprove toughnessSmall shrinkageCovering/liningsCeramic shaping apparatusFlexural strengthCompressive strength

The invention, which relates to the technical field of building decoration materials, discloses an ultra-high-flexibility concrete inorganic decorative board having a pattern-contained surface. The ultra-high-flexibility concrete inorganic decorative board is made of ultra-high-flexibility concrete reinforcement bars by means of prefabrication, wherein the ultra-high-flexibility concrete reinforcement bars have the compressive strength greater than 100 MPa and the bending strength greater than 16 MPa. A decoration pattern is formed on the upper surface of the decorative board; and communicatedmounting bolt holes are formed in the four corners of the decorative board. The reinforcement bars are criss-cross webs; and the adjacent decorative boards are connected by using structural sealants.According to the invention, the inorganic decorative board that is prepared by using ultra-high-flexibility concrete based on vacuum defoaming has characteristics of high flexibility, diversified decorative effects, compact structure without pores, short mold turnover period, relatively low price, good fire-resistant performance, good staining-resistant and waterproof properties, and high durability and is suitable for development and application of green energy-saving decorative materials.

Owner:黄贺明

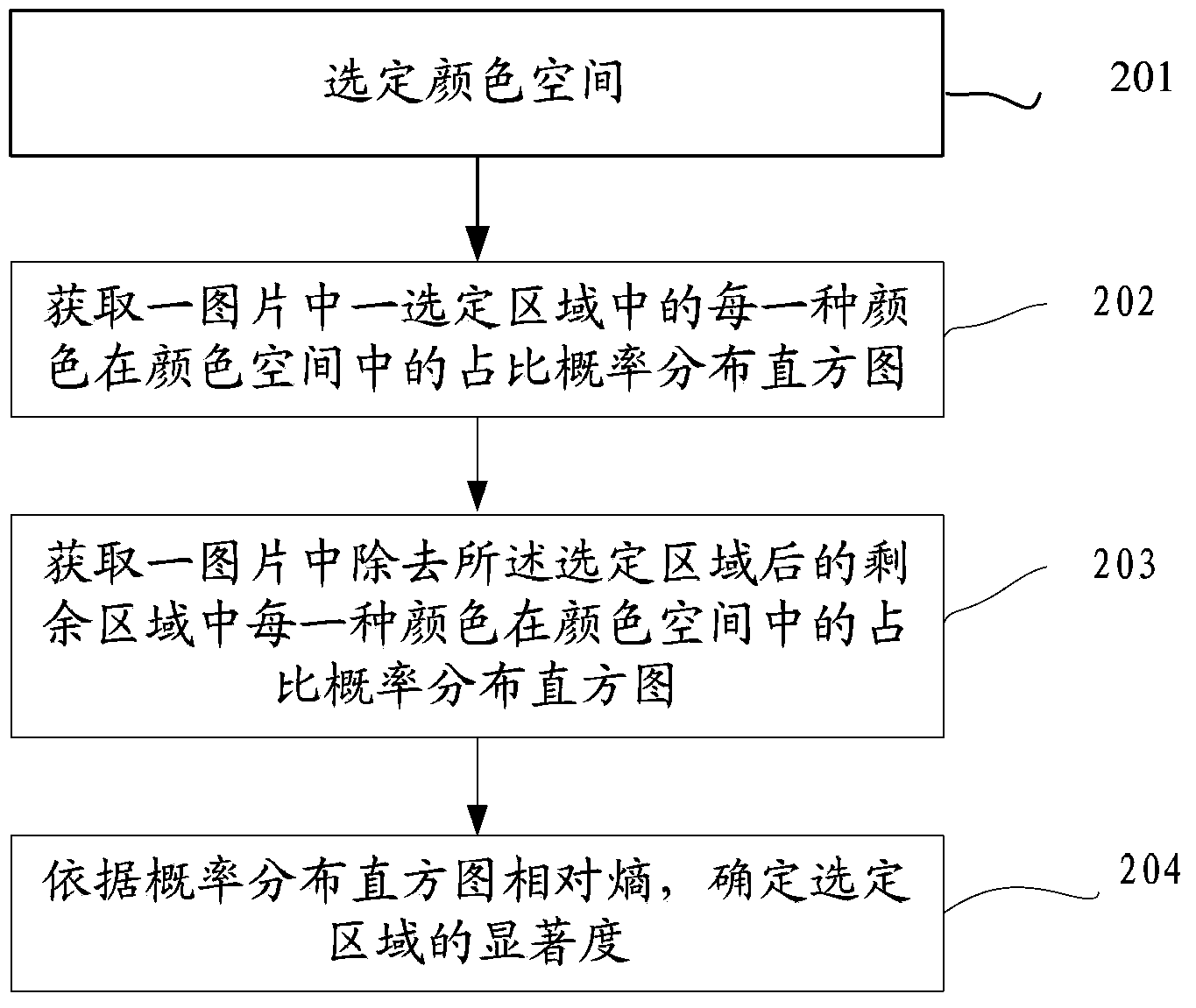

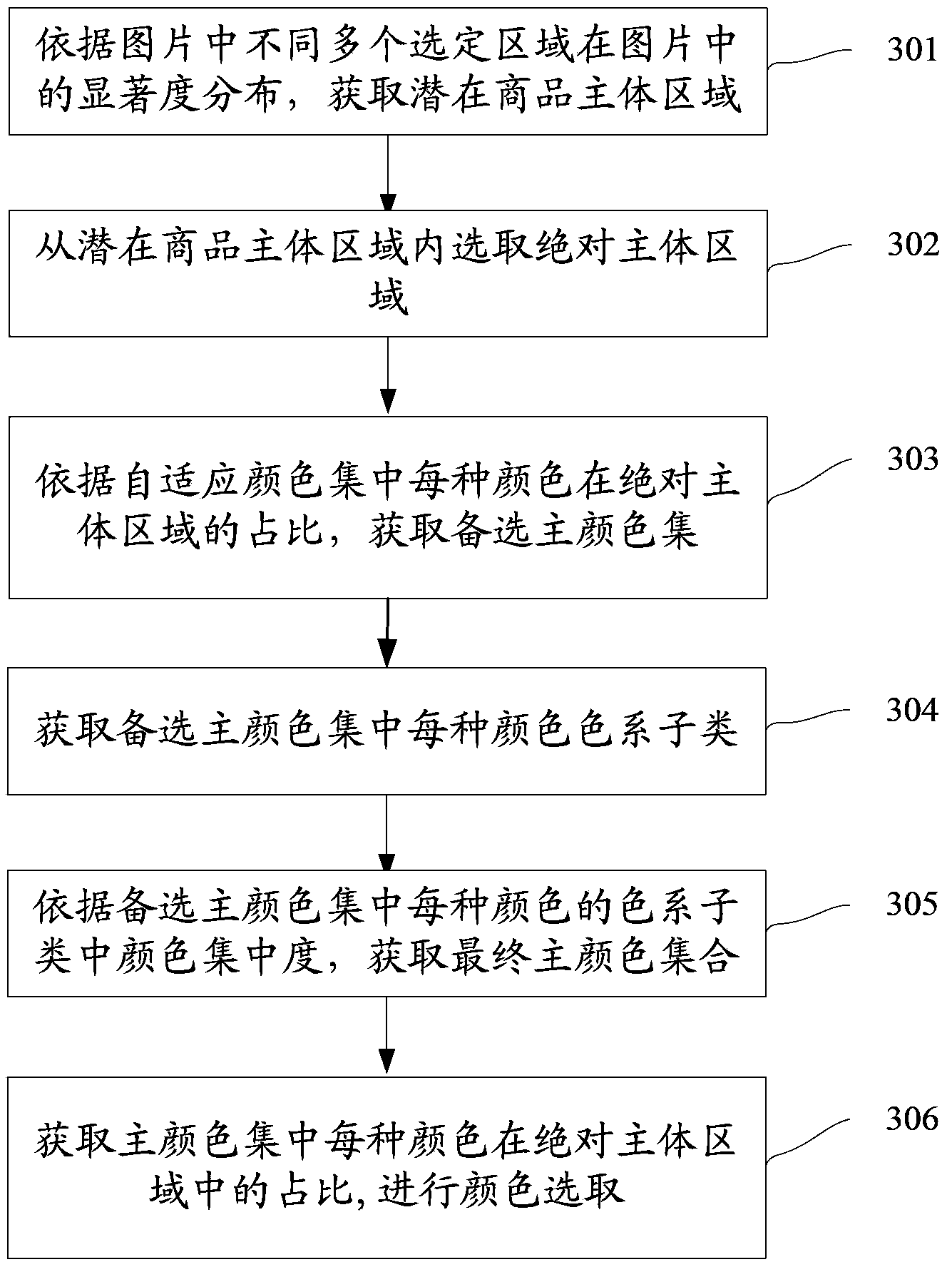

Color selecting method and device

ActiveCN103577993AReduce distractionsSolve chromatic aberrationCommercePattern recognitionSelf adaptive

The invention relates to a color selecting method and device. The method includes the following steps that a selected region with the highest conspicuousness degree is selected in an image and serves as a potential commodity main region. The conspicuousness degrees of all zones of the image corresponding to the picture data are boosted; an absolute main region is selected from the potential commodity main region; the ratio of each color in a self-adaption color set in the absolute main region is obtained; a standby main color set is obtained, an application main color set is obtained; the ratio of each color in the application main color set in the absolute main zone is obtained to carry out color selection. According to the color selecting method and device, background interference can be relieved and the problem of chromatic aberration in color discrimination in the prior art is solved.

Owner:ALIBABA GRP HLDG LTD

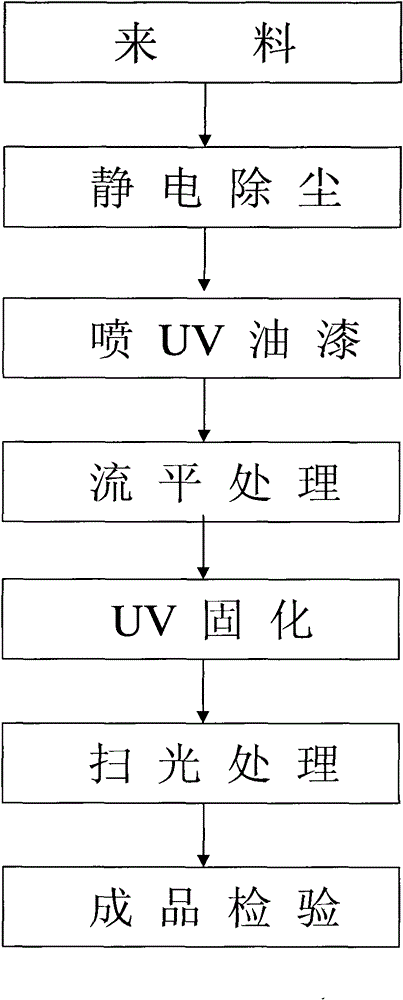

Television shell surface UV (ultraviolet) paint spraying technique

InactiveCN102744192AFix fadingSolve chromatic aberrationPretreated surfacesCoatingsProduct inspectionUltraviolet

The invention relates to a television shell surface UV (ultraviolet) paint spraying technique which comprises the following steps: baiting, electrostatic dust collection, UV oil spraying, UV paint leveling, UV curing, UV photoscanning, and finished product inspection. The concrete operation process comprises the following steps: sanding defective products at a baiting worktable by the operating personnel, and carrying out electrostatic dust collection; sweeping the shell surface, carrying out dust collection again, and sending into a spray chamber; reciprocating scanning in the shell spraying region by a spray gun; after spraying paint on the shell, carrying leveling treatment through a transmission line; after finishing the leveling, carrying out UV irradiation curing by a UV lamp; after finishing UV curing, carrying out electrostatic air blast cooling; and warehousing. The television shell surface UV paint spraying technique can effectively solve the problems of discoloration and color difference in the television shell, enhance the production efficiency, lower the application cost, reduce the environmental pollution and the like.

Owner:FOSHAN NANHAI SZY DIGITAL ELECTRONICS

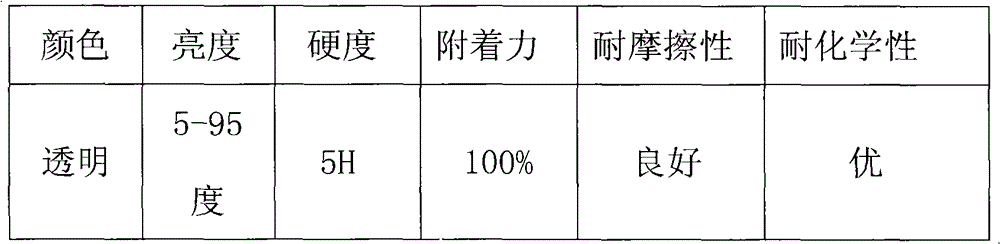

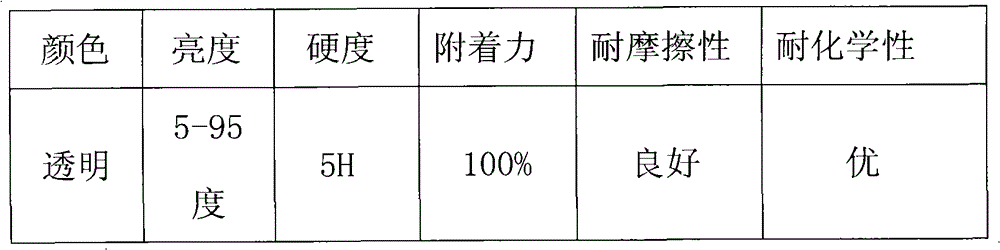

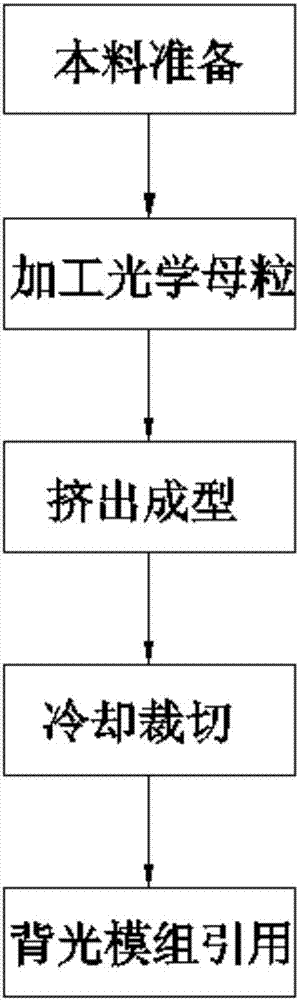

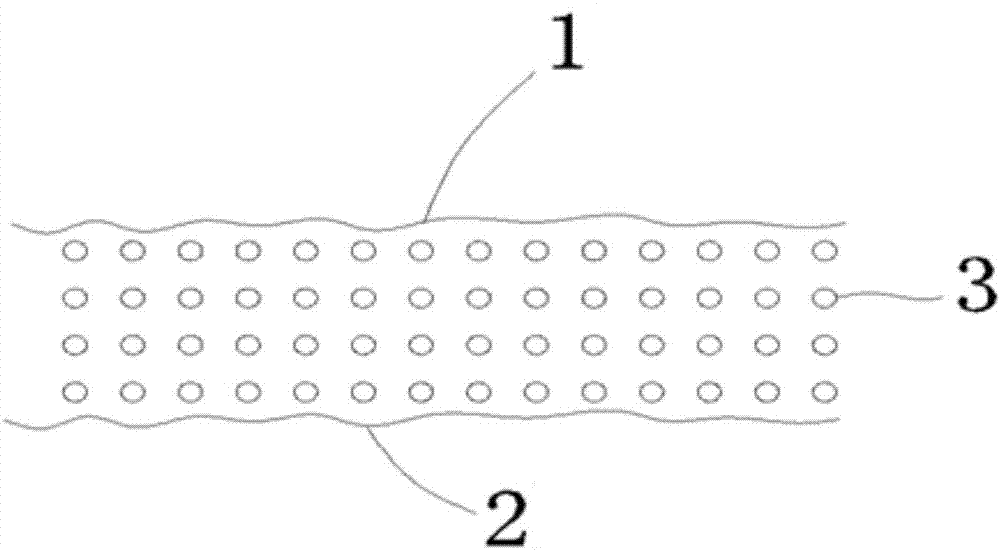

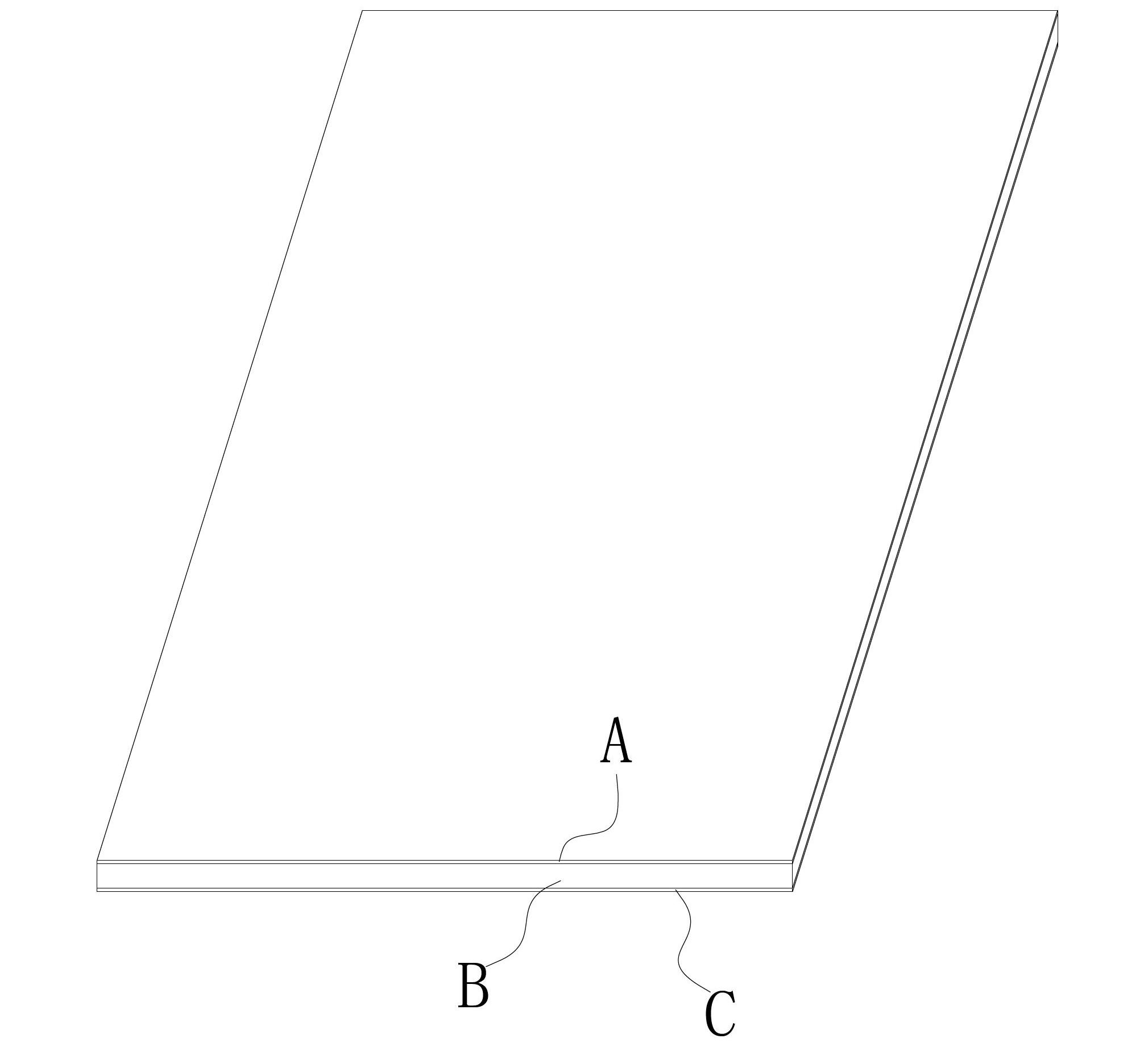

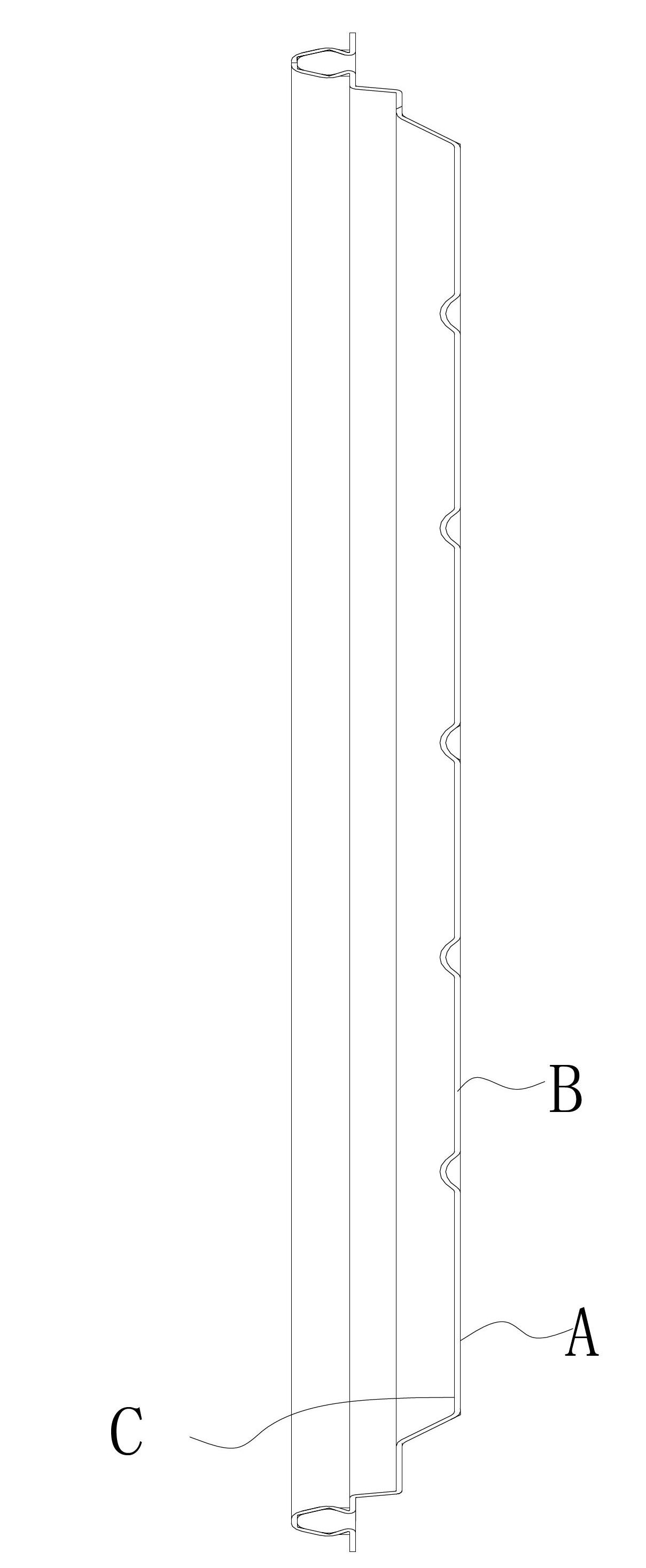

Quantum dot diffusion plate production method

InactiveCN106950750ASmall color differenceSolve chromatic aberrationDiffusing elementsNon-linear opticsQuantum dotColor difference

The invention provides a quantum dot diffusion plate production method. The quantum dot diffusion plate production method comprises following steps: a step 1 of preparing a raw material; a step 2 of making optical master batches: uniformly stirring and mixing a selected mixture of the raw material and pulvis to form the optical master batches; a step 3 of carrying out an extrusion molding process, i.e., uniformly stirring the selected mixture of the raw material, the optical master batches, the quantum dot, GPPS and putting the mixture into an extrusion molding machine, and molding the quantum dot diffusion plate material; and a step 4 of carrying out cooling and cutting processes, i.e., after the extrusion molding step, cooling the quantum dot diffusion plate material through an extrusion line, and cutting the quantum dot diffusion plate material into a quantum dot diffusion plate finished product which adapts to a backlight module in size. According to the invention, quantum dots are fused in the quantum dot diffusion plate extrusion molding process, a white light excitation layer is excited by blue light to generate white light which traverses an inactive region of the quantum dot diffusion plate, white light is emitted from a light emitting surface of the quantum dot diffusion plate, the color difference between the above two kinds of white light is small, the color difference problem of the visible area can be effectively solved, and the color domain uniformity of the backlight module is high.

Owner:青岛国骐光电科技有限公司

Novel 3D stereo printing process

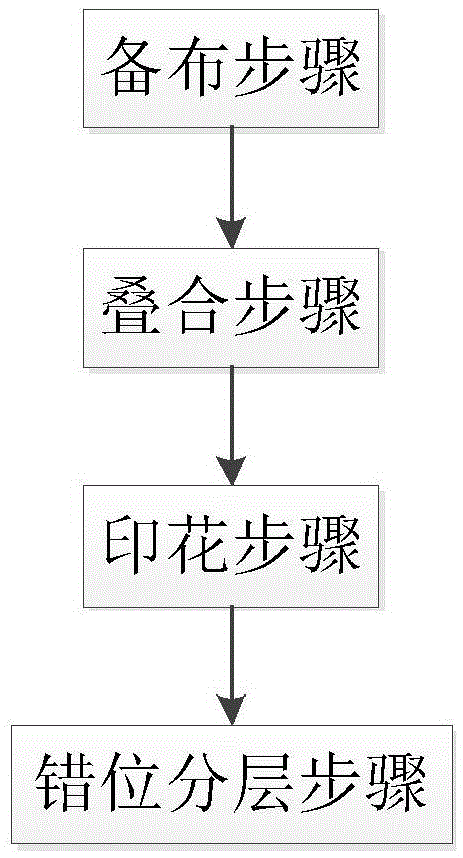

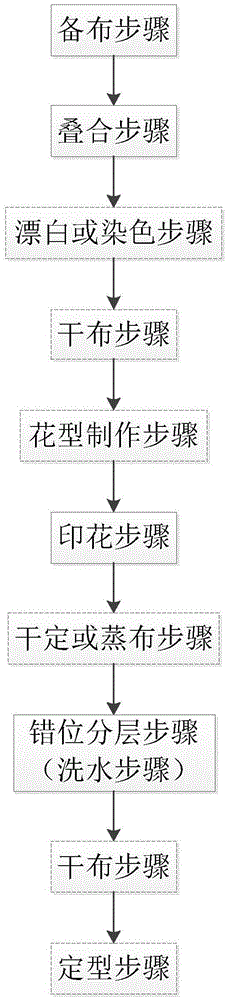

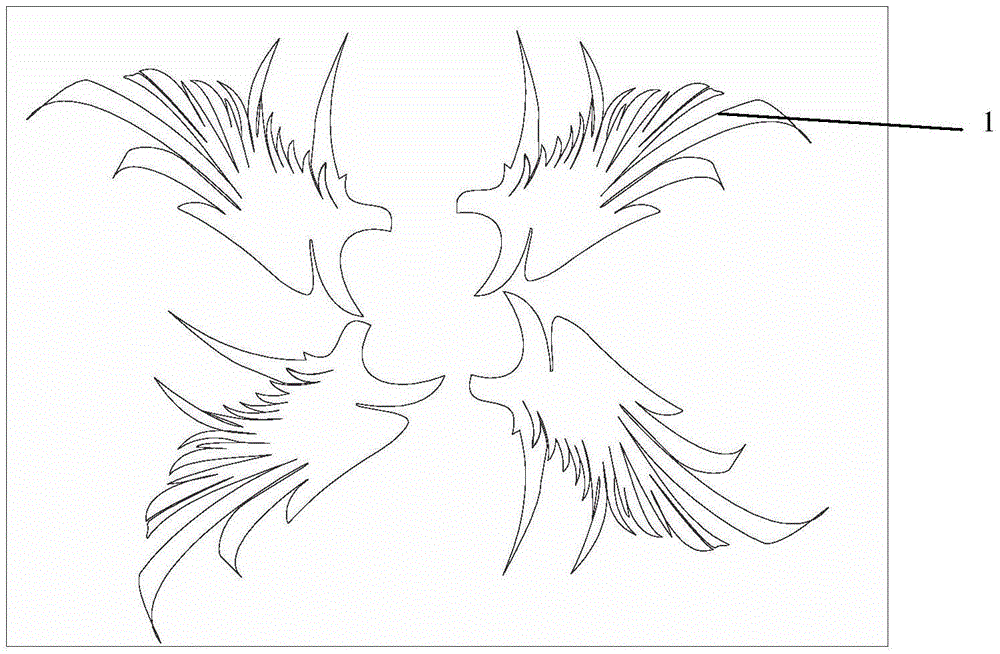

InactiveCN105484061AImprove the level of cleaner productionSolve chromatic aberrationLayered productsTransfer printing processSuperimpositionEngineering

The invention discloses a novel 3D stereo printing process. The 3D stereo printing process comprises the steps of cloth preparation, superimposition, printing and misplaced laying, wherein the printing steps adopts a one-time printing and dyeing process, printing of compound-layer fabrics can be completed through one-time printing and dyeing, and then printed compound-layer fabrics are separated and misplaced, namely the patterns can show multiple-layer overlapped stereo layering sense and the 3D stereo printing effect which can be seen by naked eyes. By the adoption of the printing process, dyes can be saved in production, the cost can be reduced, the technological process can be simplified, and the cleaning production level of enterprises can be improved. In the printing effect, the chromatic aberration problem caused by different temperatures and pressures of different printing batches is avoided due to one-time printing, printing colors can be unified, and the visual effect is good. The process enables the 3D stereo printing effect to be also achieved under the condition of naked eyes, and the costs for 3D stereo glasses are reduced.

Owner:COSMO LADY (CHINA) HOLDINGS

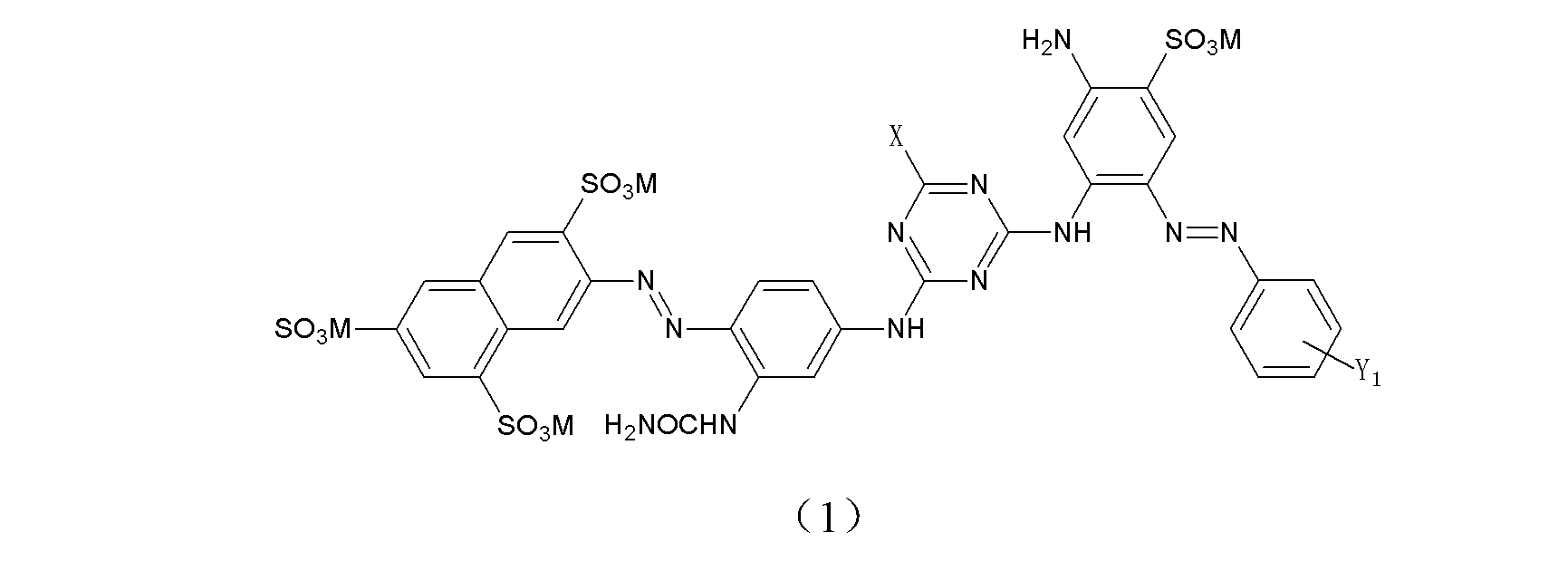

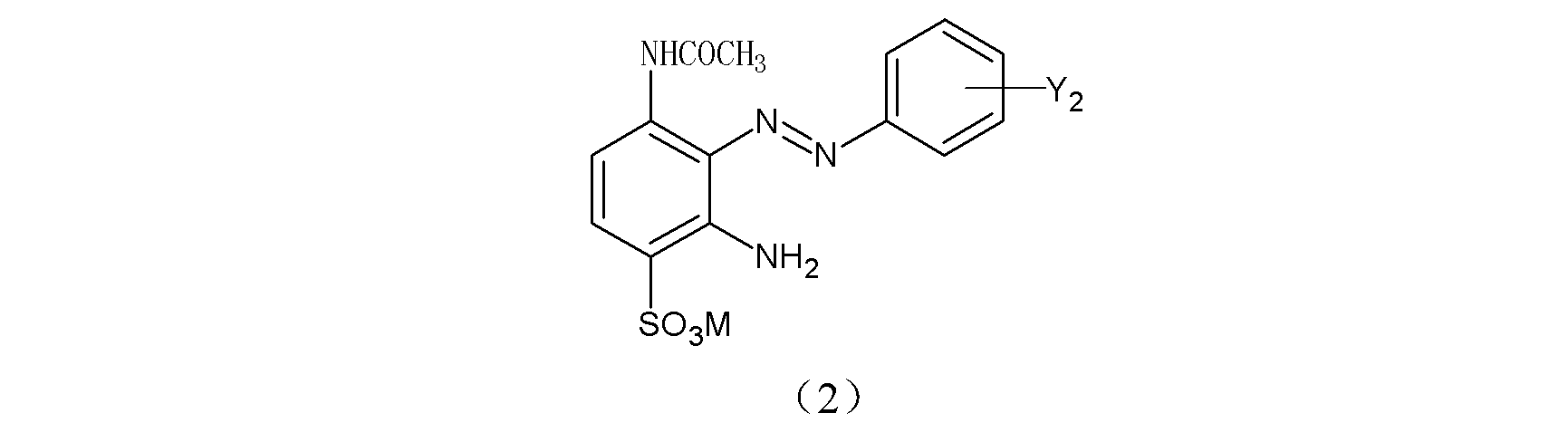

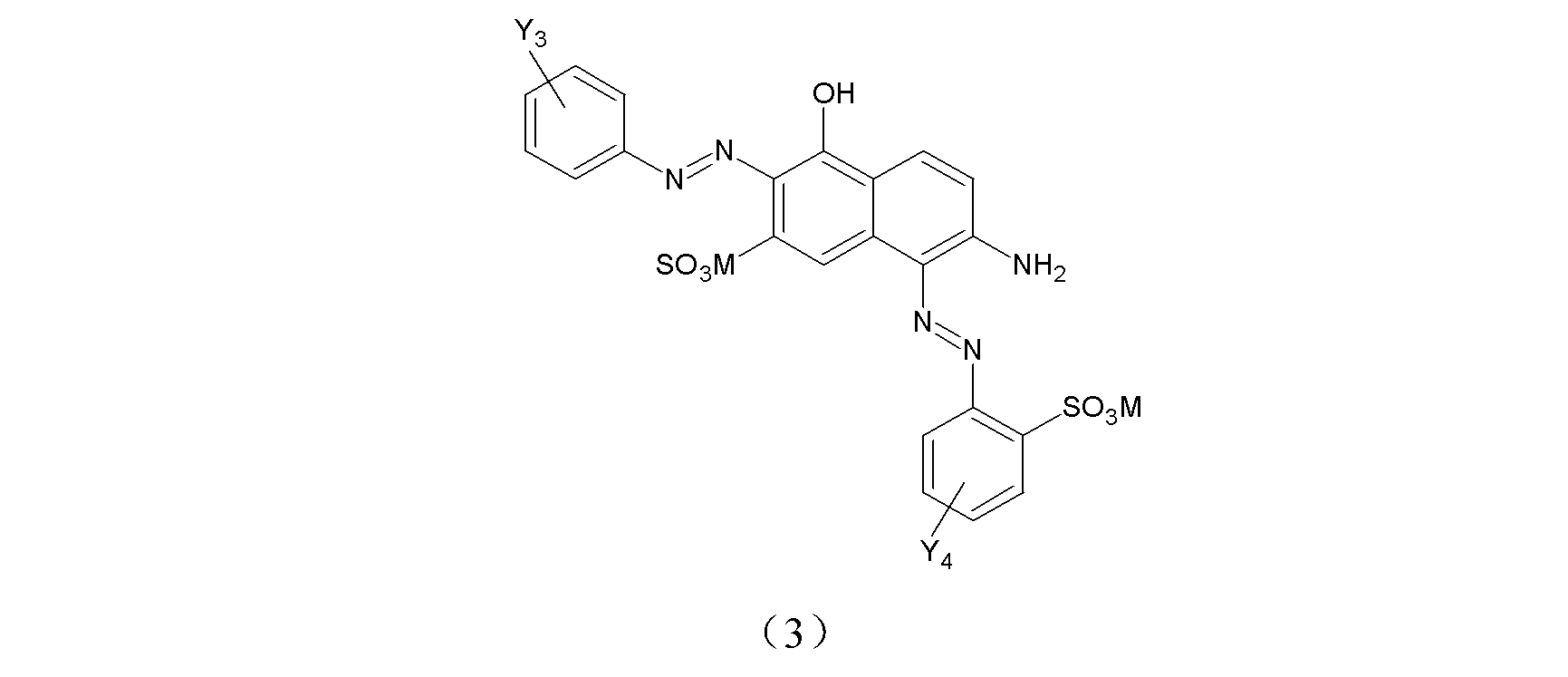

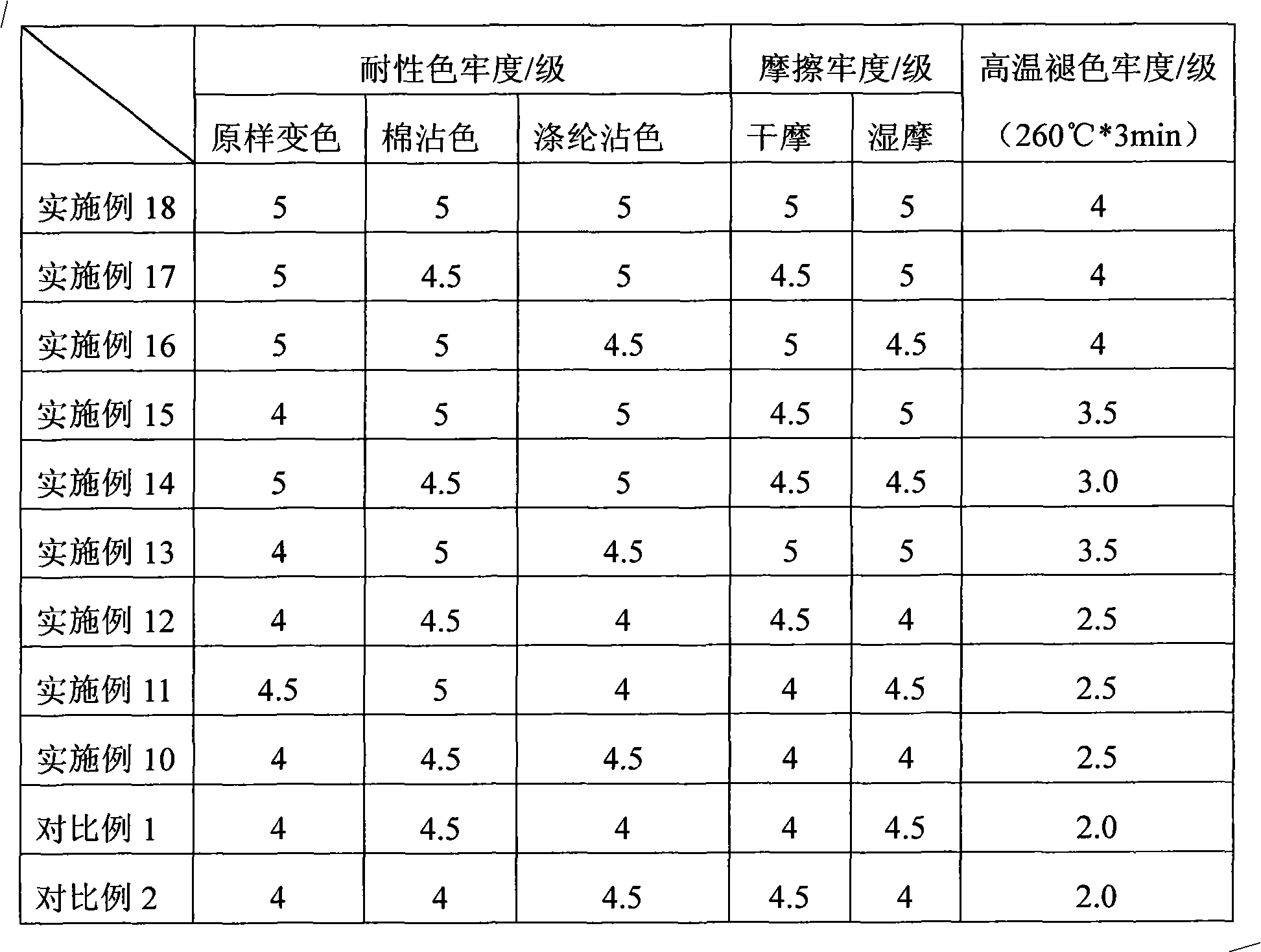

Composite reactive dye composition and use method

InactiveCN103013174AEasy to useGood alkali resistanceOrganic dyesDyeing processReactive dyeAlkali metal

The invention relates to a composite reactive dye composition and a use method. The composite reactive dye composition is characterized by comprising any two or more types of yellow composite reactive dye compositions represented in formulas (1) and (2), red composite reactive dye compositions represented in formulas (3) and (4), a navy blue reactive dye represented in a formula (5) and an orange reactive dye represented in a formula (6), wherein in the formulas (1) to (6), Y1 to Y10 respectively and independently represent SO2CH=CH2 or SO2CH2CH2OSO3M; M represents hydrogen or alkali metal; and X represents Cl or F. The composite reactive dye composition disclosed by the invention has good alkali resistance, can be used for cold-pad-batch dyeing and has high fixation rate and good dyeing stability.

Owner:ZHEJIANG YIDE CHEM

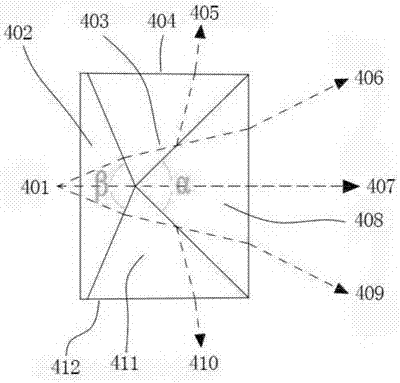

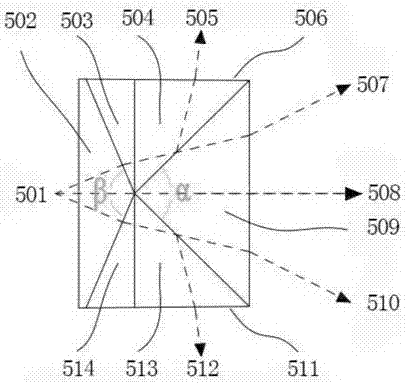

Stereographic projection imaging device and system

ActiveCN106990667ATroubleshoot poor image qualityEliminate stray lightProjectorsStereoscopic photographyImaging qualityPrism

The present invention discloses a stereographic projection imaging device and system with high photosynthetic efficiency capable of performing light path recovery to reduce optical energy loss and improve projection imaging quality and suitable for a low-projection ratio cinema environment. The stereographic projection imaging device comprises a polarization spectrometer, a reflection element, a light beam size regulation module, a linear polarizer, a polarization modulator and a polarization converter. The polarization spectrometer is the polarization splitting prism combination or a polarization beam splitter, the reflection element employs a high-reflection polarization element, the high-reflection polarization element is formed by a protective layer, a reflection layer, an absorption layer and a glass substrate, and the polarization converter has a wavelength bandwidth regulation function. The stereographic projection imaging device can effectively reduce the optical path difference of the reflection light beam and the transmitted light beam to allow the whole structure to be optimized so as to greatly shorten the size of the whole device.

Owner:青岛睿沃丰视觉科技有限公司

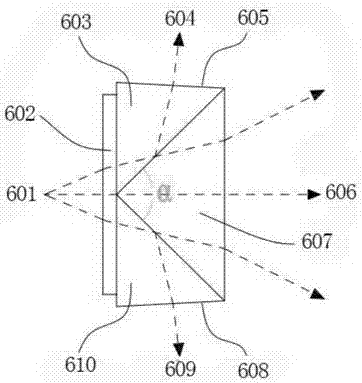

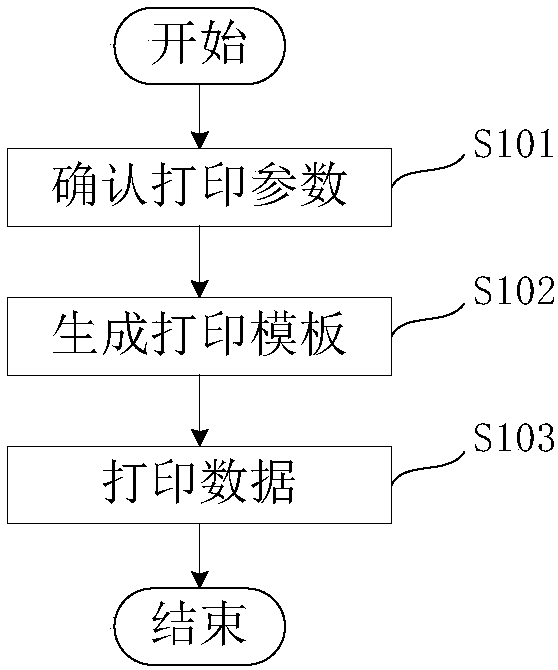

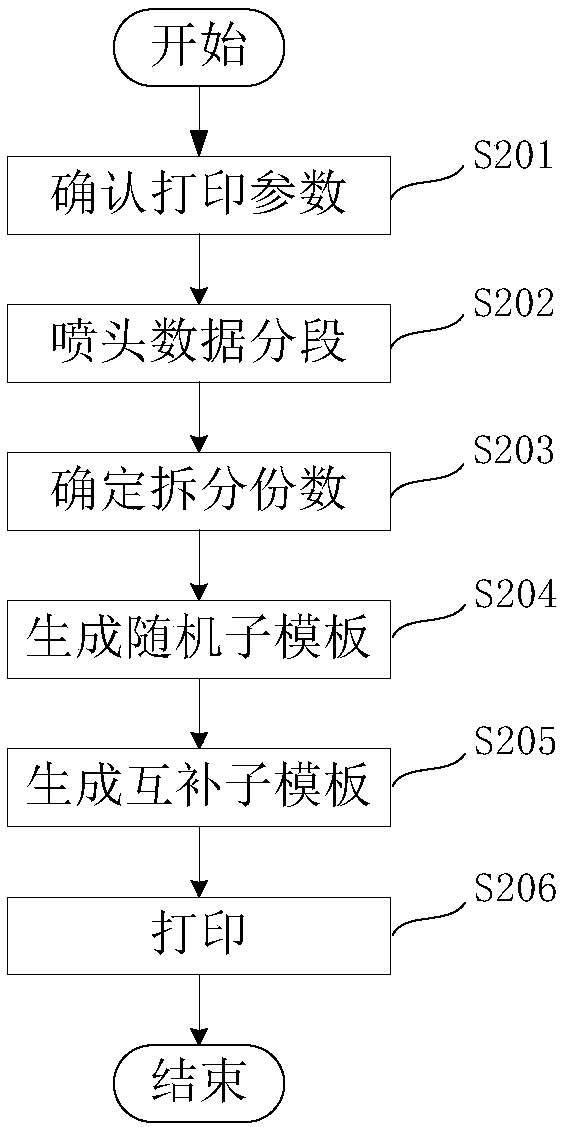

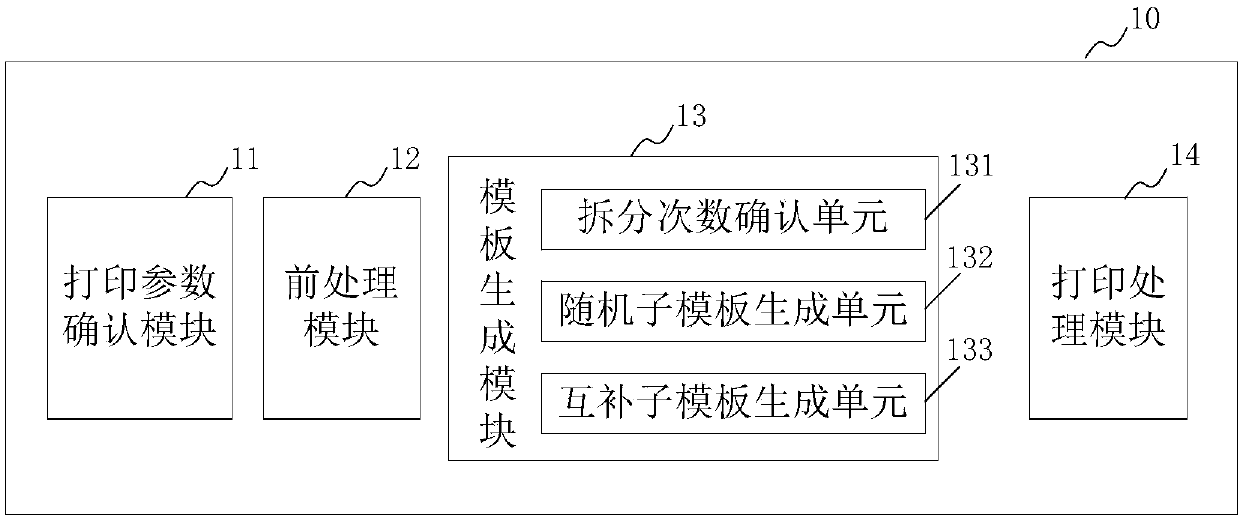

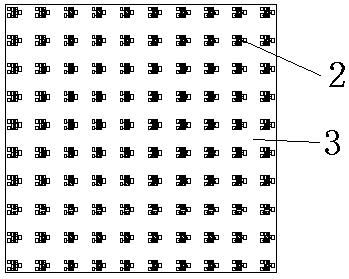

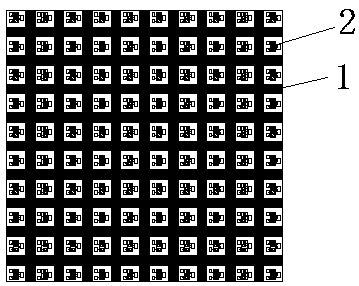

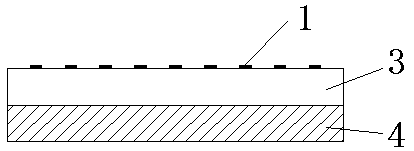

Printing uniformity correction method and device, medium, equipment, system and printer

The invention relates to a printing uniformity correction method. The method includes receiving and confirming printing parameters; generating printing templates used for processing each nozzle data of a printer according to the printing parameters, and dividing, by the printing templates, printing data points into N parts, wherein the N is integers and N >=2; and printing the printing data pointswhich are divided into N parts for N times. Compared with the prior art, the method can effectively disperse errors and enhance printing effects. In addition, a printing uniformity correction device,a medium, equipment, a system and the printer are also related.

Owner:RICOH KK

Ink-jet technology based LED display screen integrative mask

InactiveCN108182888ASolve the patchwork problemSolve chromatic aberrationIdentification meansLED displayColloid

The invention relates to the field of LED display, in particular to an ink-jet technology based LED display screen integrative mask which comprises a PCB substrate with IC; the surface of the PCB substrate is provided with a plurality of COB display screen pixels and is protected by a packaging adhesive in a sealing manner, wherein die bonding and wire bonding are performed on the PCB substrate with the IC; die processing and adhesive sealing are performed on the PCB substrate after wire bonding; graphic ink jetting treatment and printing ink semi-solidification are performed on colloid surface of the packaging adhesive, and an integrative mask is formed among the COB display screen pixels; and then roasting and solidification are performed on printing ink. The ink-jet technology based LEDdisplay screen integrative mask provided by the invention can solve the problems of splicing seams and a color difference among different modules of a COB display screen and can also solve the problem of light breakthrough among the pixels.

Owner:SHENZHEN JINGTAI

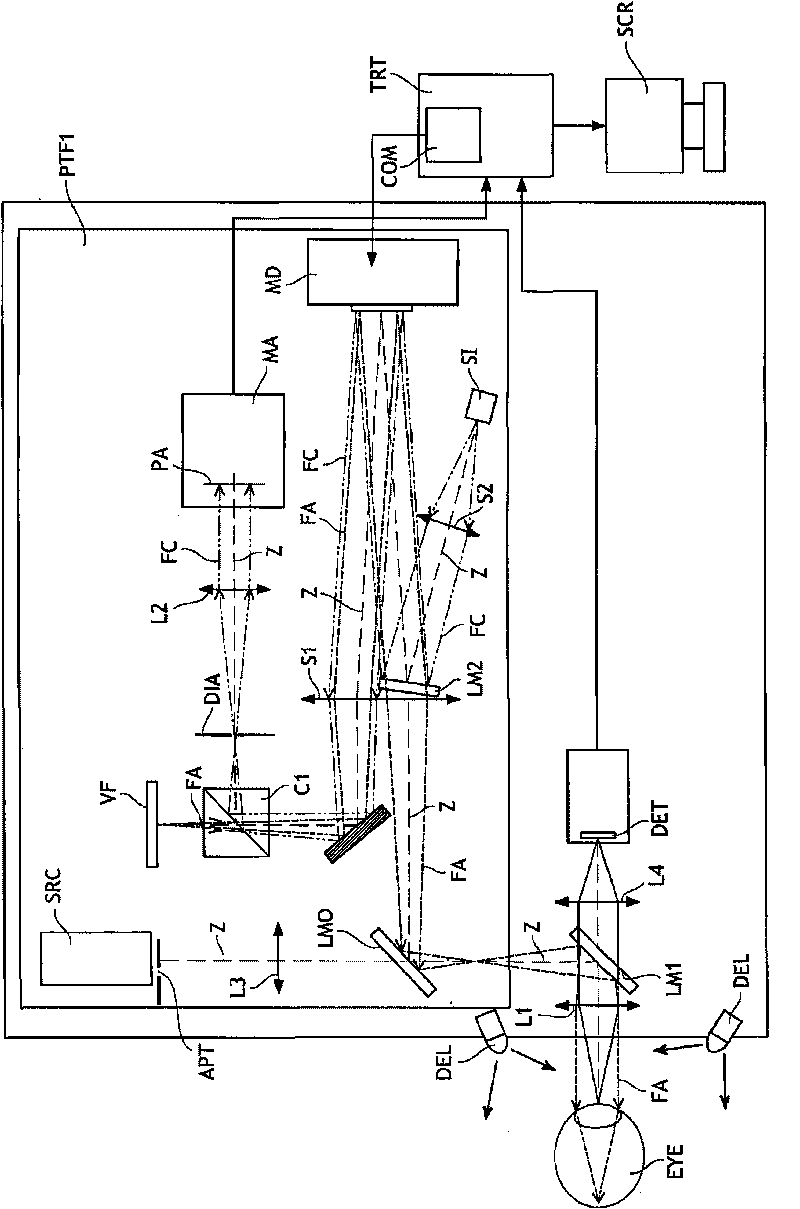

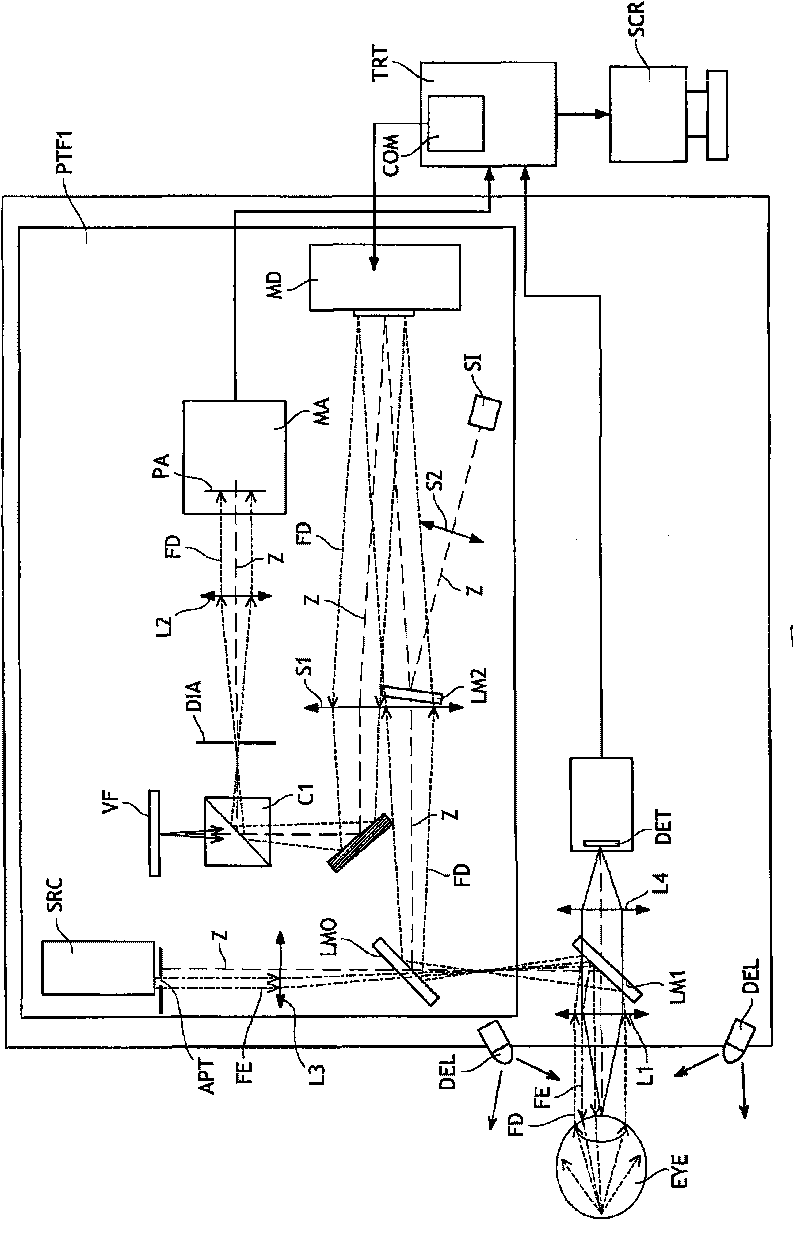

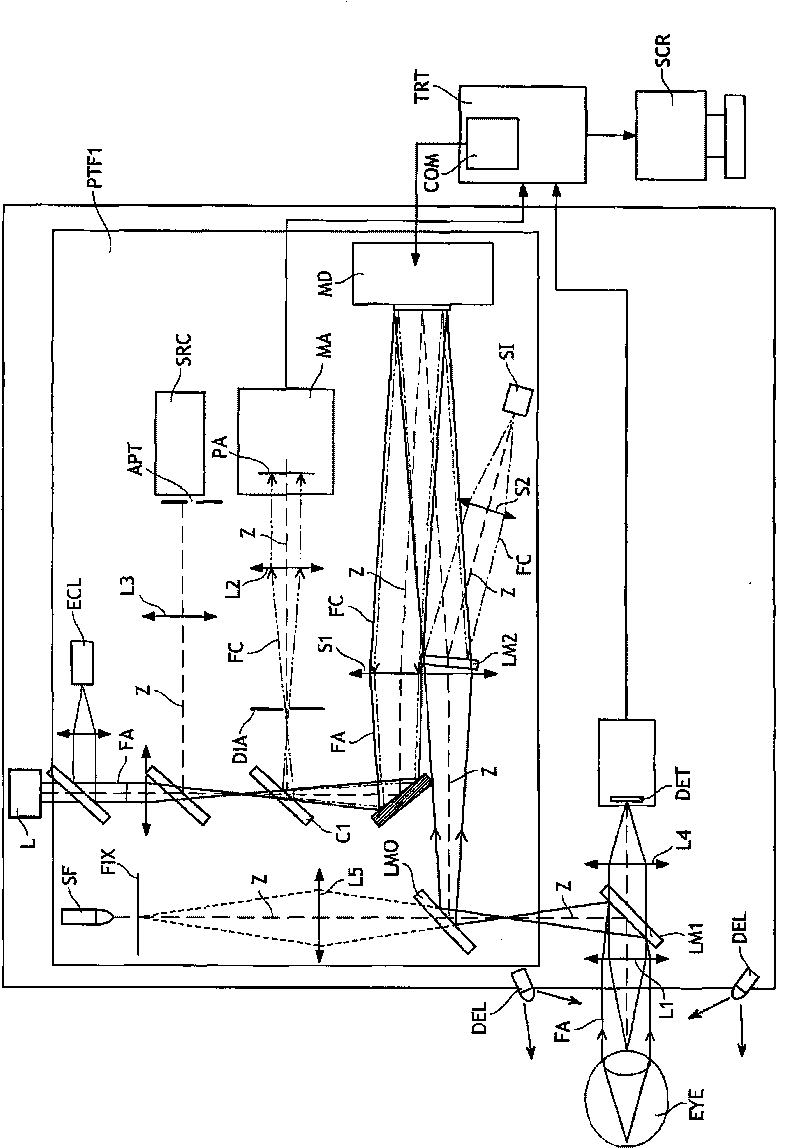

Phase modulation device for an ophthalmic instrument, ophthalmic instruments equipped with such device, and related calibration method

The invention relates to a phase modulation device implemented in an ophthalmic instrument that uses a main light beam (FA) interacting with an eye (EYE), said device comprising: means (MD) for modulating the phase of the wave front of said main light beam (FA); means for controlling the phase modulation means according to a modulation set-point; and means for analysing the modulation thus carried out of the wave front of the main light beam (FA). The device further includes means for emitting a secondary light network (FC), means for directing the secondary light network (FC) along an optical path to the modulation means and then to the wave front analysis means, said optical path extending through the eye.; The control means and the front wave analysis means receiving the modulated secondary light beam (FC) interact during a so-called training period in order to provide response data of the phase modulation means to a set of pre-determined modulation set-points.

Owner:IMAGINE EYES

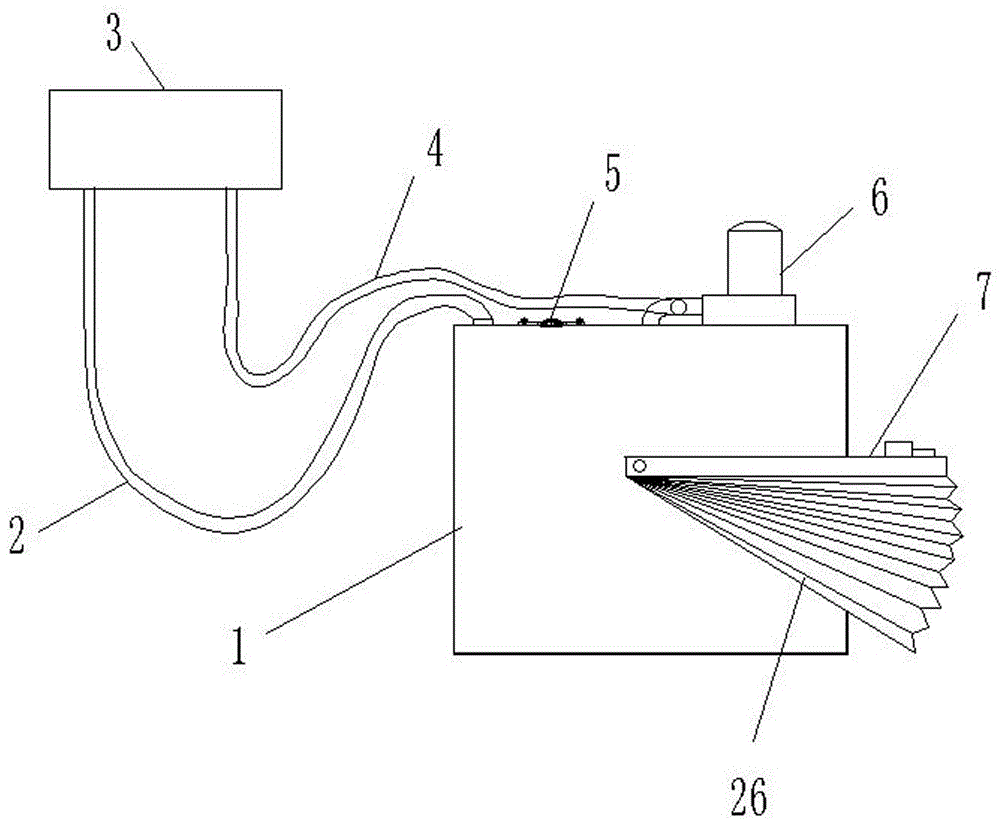

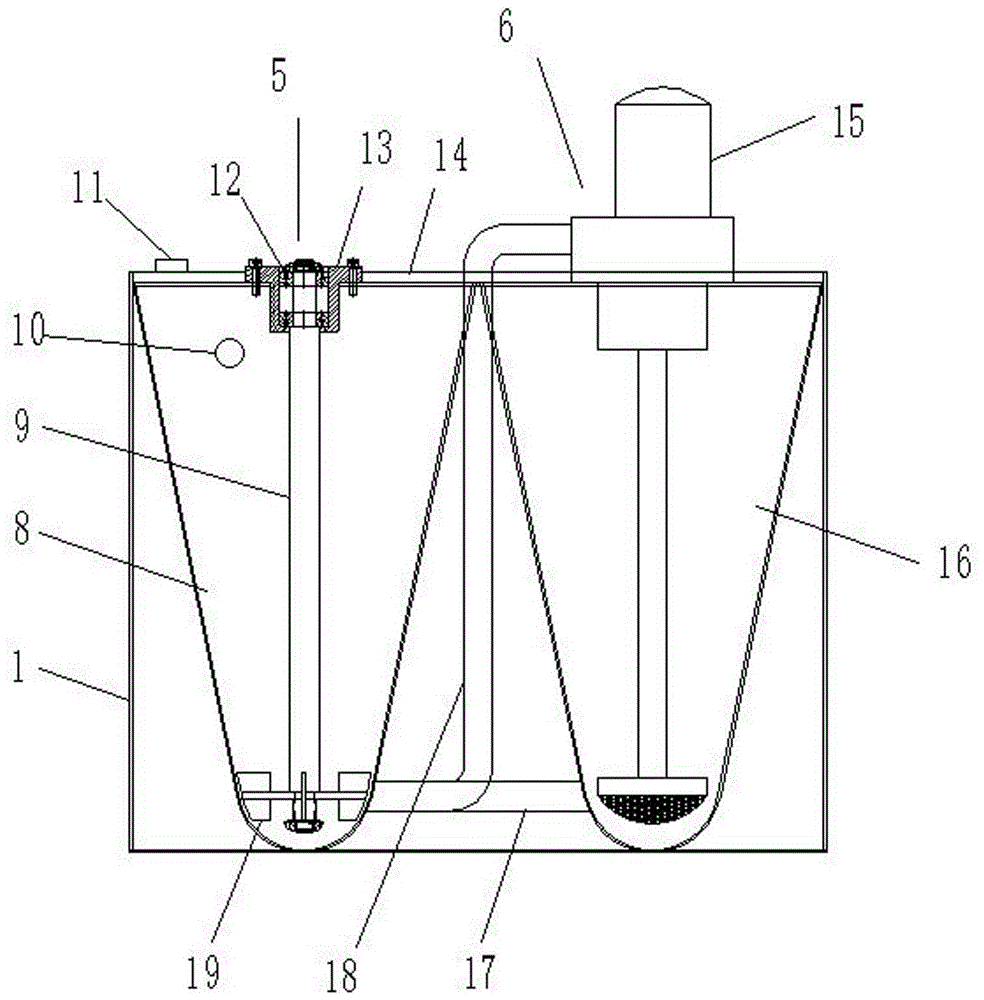

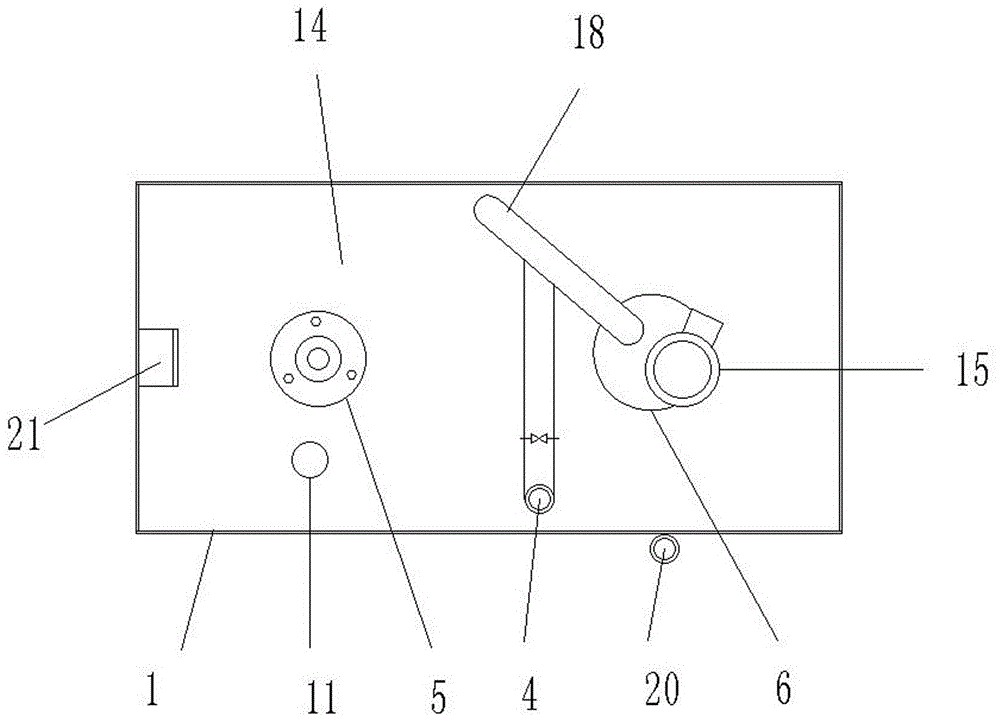

Cyclic ink supply system

The invention discloses a cyclic ink supply system, and relates to the technical field of printing. The cyclic ink supply system comprises an ink supply box and an ink feed box. The ink supply box and the ink feed box are communicated through an ink feed pipe. A return pipe is also arranged between the ink supply box and the ink feed box. The cavity of the ink supply box is divided into an ink storing slot and an ink adding slot. A communicating pipe is arranged between the ink storing slot and the ink adding slot. The ink storing slot is internally provided with a stirring device. The ink adding slot is internally provided with an ink supply device. Ink precipitation and separation can be effectively avoided so that the ink component is ensured to be uniform and consistent, printing aberration can be reduced and the quality and the effect of the printing product can be enhanced.

Owner:HEBEI BAISHA TOBACCO

Inner container of refrigeration equipment and preparation method thereof

InactiveCN102661646AHigh strengthAvoid crackingDomestic cooling apparatusLighting and heating apparatusFoaming agentSurface layer

The invention discloses an inner container of refrigeration equipment and a preparation method thereof. The inner container of the refrigeration equipment is formed by an HIPS (high impact polystyrene) three-layer composite board, the HIPS three-layer composite board comprises a surface layer, a basic layer and a bottom layer, wherein the surface layer is composed of a surface layer HIPS, and the surface layer HIPS is selected from one or more types of natural color HIPS, tinction HIPS and modification extrusion grade HIPS; and the basic layer comprises the natural color extrusion grade HIPS and a feeding material, and the bottom layer is composed of a resistance foaming agent erosion HIPS. According to the inner container of the refrigeration equipment provided by the embodiment of the invention, the HIPS three-layer composite board is adopted to shape, and the surface layer, the basic layer and the bottom layer of the HIPS three-layer composite board are all made of HIPS materials; the different HIPS materials after screening have good consistency, and can be mutually mixed; and the appearance and processing behaviour of the board can not be obviously influenced, the intensity of the board is improved, and the cracking risk is reduced.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Dyeing method for polysulfonamide yarns

ActiveCN102720076AImprove cleanlinessShort lifeFibre typesDry-cleaning apparatus for textilesYarnWater baths

The invention discloses a dyeing method for polysulfonamide yarns, comprising: 1, inverting yarns; 2, processing before dyeing: placing a cylinder yarn into a pretreatment water bath, then heating the water to a temperature between 50 DEG C and 60 DEG C at a speed of 2 DEG C to 3 DEG C per minute, washing the yarn for 5 to 10 minutes, then washing the yarn with clear water, and drying the yarn; Dissolvability of a detergent is 0.8 to 1.2 grams per litter, and the detergent is composed of the following compositions: 3-5 parts of castor oil ethylene oxide condensation products; 15-20 parts of laurinol polyoxyethylene ether; 15-20 parts of sodium dodecyl sulfate; 3-6 parts of dodecyl dimethyl betaine; 3-6 parts of coconut oil amide propyl group hydroxyl sulfobetaines, 3-6 parts of sodium polymethacrylate, 3-5 parts of polyvinylpyrrolidone; 2-4 parts of sodium citrate; 1-2 parts of sodium silicate; 2-4 parts of bentonite; and 50-80 parts of water; 3, dyeing; 4, processing after dyeing. The production process of the invention produces less foam, is easy to operate, has a high color fastness, and the dyed polysulfonamide yarns possess a soft hand feeling.

Owner:SHANGHAI NEW UNION TEXTRA IMPORT & EXPORT

Liner of refrigerating equipment and preparation method thereof

InactiveCN102645071ADoes not significantly affect appearanceDoes not significantly affect processabilityDomestic cooling apparatusLighting and heating apparatusSurface layerEngineering

The invention discloses a liner of refrigerating equipment and a preparation method thereof. The liner of the refrigerating equipment is formed by a HIPS (High Impact Polystyrene) two-layer composite board. The HIPS two-layer composite board comprises a surface layer and a bottom layer, wherein the surface layer is formed by surface layer HIPS; the surface layer HIPS is selected from one or more of natural color HIPS, dyed HIPS and modified extrusion-grade HIPS; and the bottom layer comprises natural color extrusion-grade HIPS and return materials. According to the liner of the refrigerating equipment, which is disclosed by the embodiment of the invention, the HIPS two-layer composite board is adopted to form the liner, both the surface layer and the bottom layer of the HIPS two-layer composite board are made of the HIPS materials, various screened HIPS materials have excellent compatibilities and can be mutually blended without obviously influencing the appearance and the processing performance of the board, and thus, the strength of the board can be improved and the cracking risk can be reduced.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

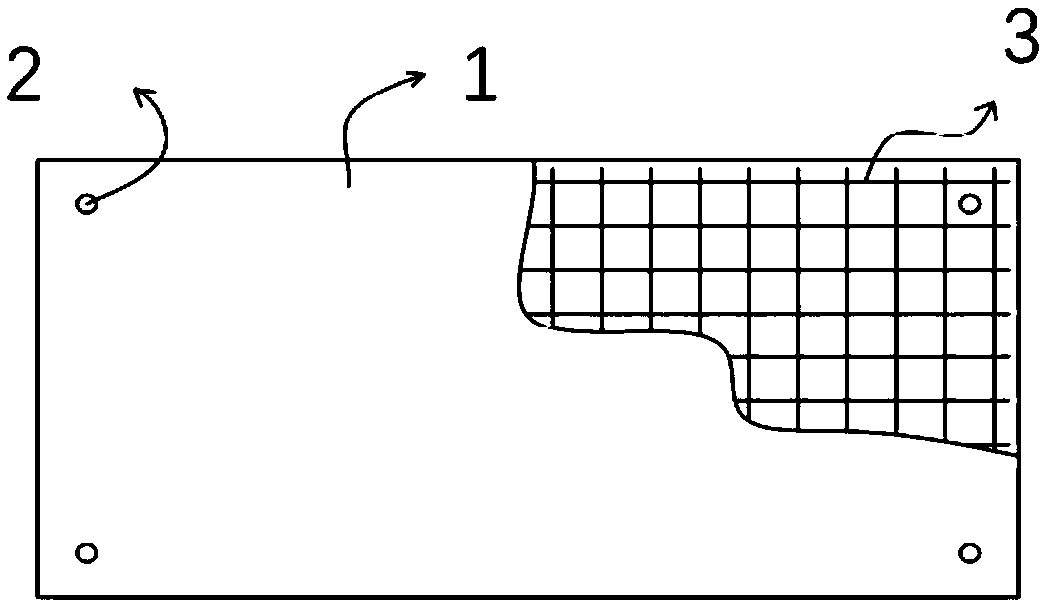

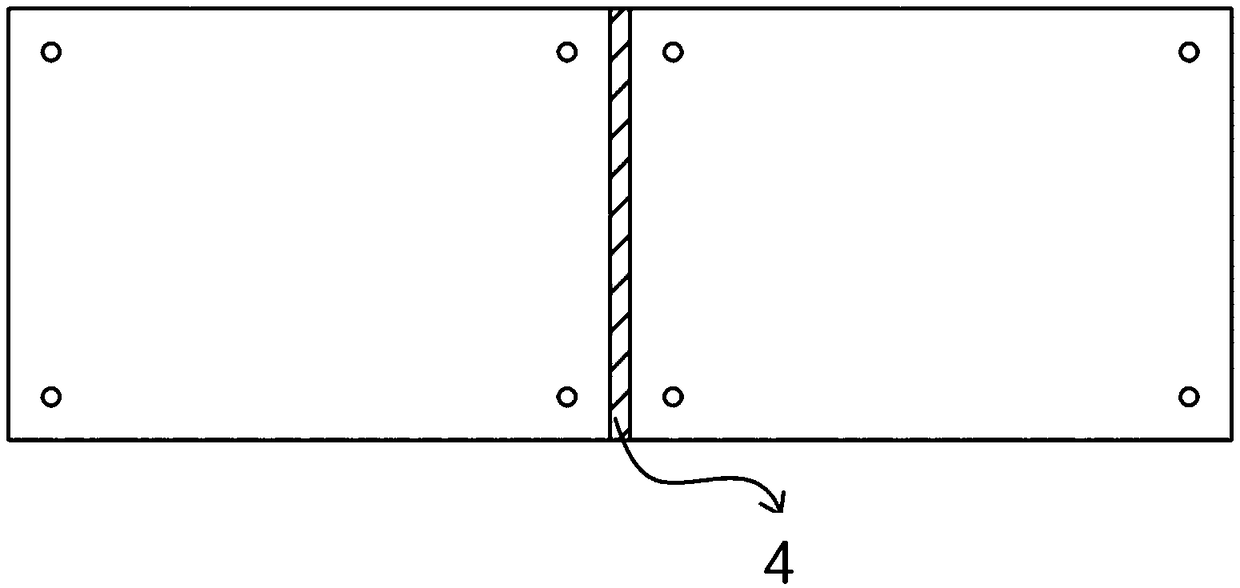

Production and mounting method of nano cement-based composite ultrahigh-strength artificial stone board

InactiveCN108409261AHigh strengthImprove compactnessCovering/liningsShaping press ramWeather resistanceSlag

The invention provides a production and mounting method of a nano cement-based composite ultrahigh-strength artificial stone board. The nano cement-based composite ultrahigh-strength artificial stoneboard comprises a board body material, reinforcing meshes and fibers and T-shaped nuts. The preparation of the board body material uses ultrahigh-strength mortar reaching above C100, and the ultrahigh-strength mortar adopts high-grade cement, silica fume, slag powder, sandstone aggregate with particle size being below 6mm, polycarboxylate superplasticizer and water-binder ratio below 25. Board production equipment has functions of high-frequency vibration, strong compression and vacuumizing and can discharge bubbles in the board, compress and suck moisture in the board and extract gas in the board to increase the density of the board so as to reach the ultralow water-binder ratio needed by ultrahigh-strength concrete. Various defects such as proneness to fading, proneness to breaking, poorfreeze-thaw resistance and short service life caused by the fact that a common-strength cement-based artificial stone board is poor in weather resistance, low in strength and low in density.

Owner:钟兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com