Touch module and manufacturing method thereof

A technology of a touch module and a manufacturing method, applied to instruments, electrical digital data processing, input/output process of data processing, etc., capable of solving problems such as chromatic aberration and damage to the light-shielding layer, and achieving the effect of avoiding chromatic aberration and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

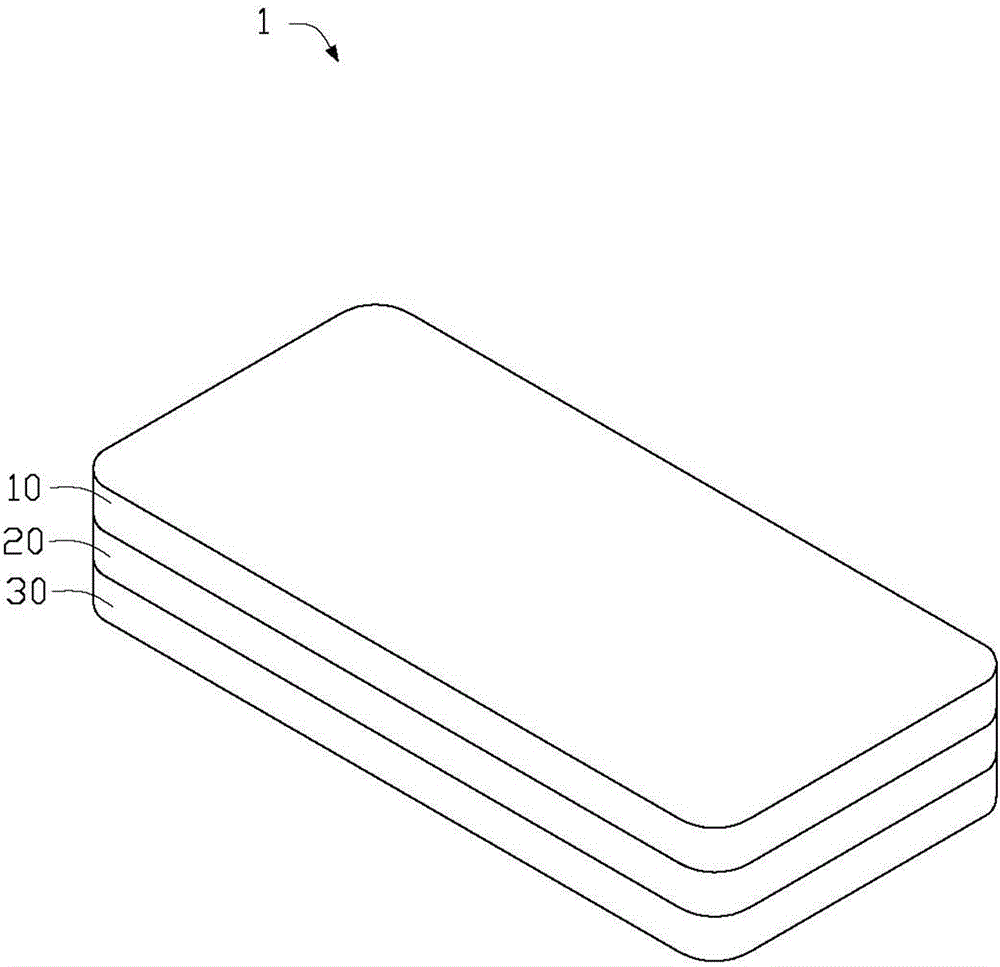

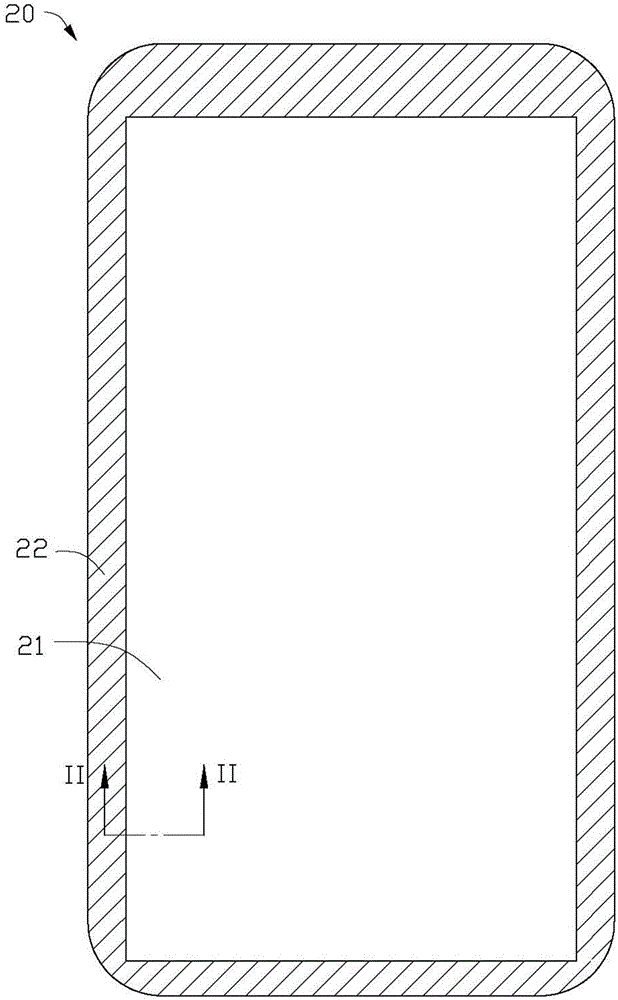

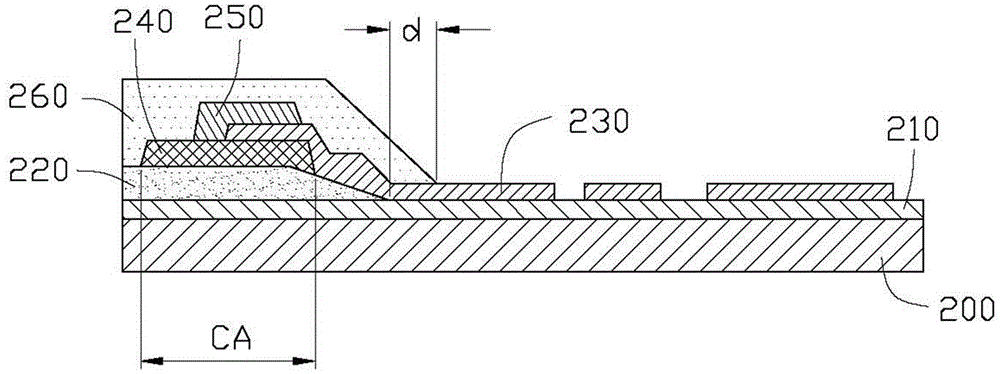

[0020] see figure 1 , figure 1 It is a three-dimensional schematic diagram of the touch display device 1 provided by the present invention. The touch display device 1 includes a cover glass 10 (cover lens / cover glass), a touch module 20 and a display module 30 . The touch module 20 is sandwiched between the cover glass 10 and the display module 30 . In this embodiment, the cover glass 10 and the touch module 20 can be integrated, that is, the cover glass 10 can be used as a substrate of the touch module 20, so that the touch module 20 The touch electrodes are fabricated on the cover glass 10 to form an OGS (one glass solution) or TOL (touch on lens) touch display device. In other embodiments, the touch module 20 may also be glued together with the cover glass 10 and the display module 30 by optical glue. For example, the optical adhesive may be an adhesive with high light transmittance such as optical clear adhesive (Optical Clear Adhesive, OCA) or optical clear resin (Opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com