Patents

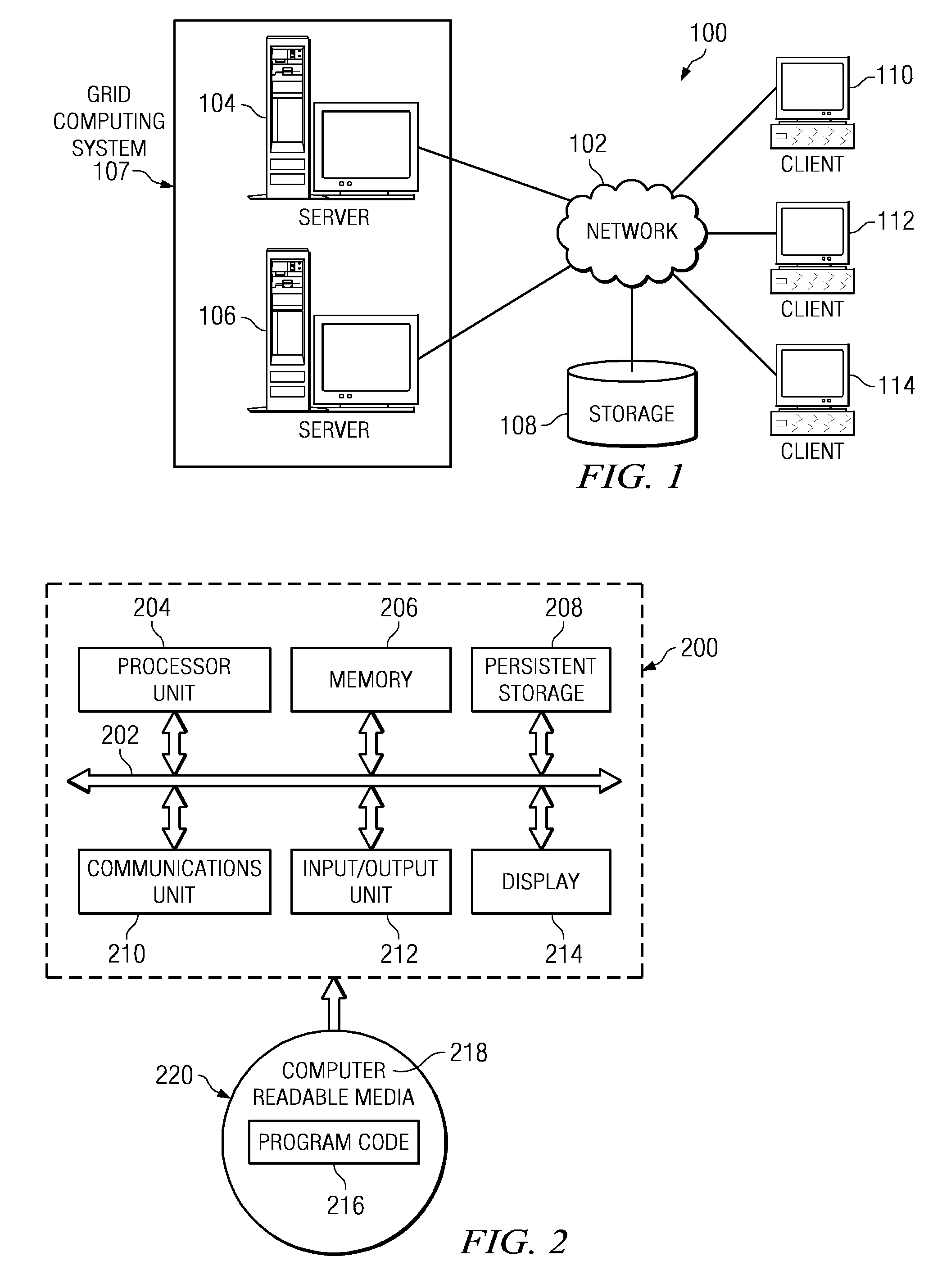

Literature

33 results about "Color modifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A modifier is a word or phrase that explains or describes other words in a sentence. There are two kinds of modifiers: adjectives and adverbs. Phrases and clauses can also be modifiers. Modifiers make writing more colorful.

Lexical classification system with dynamic modifiers

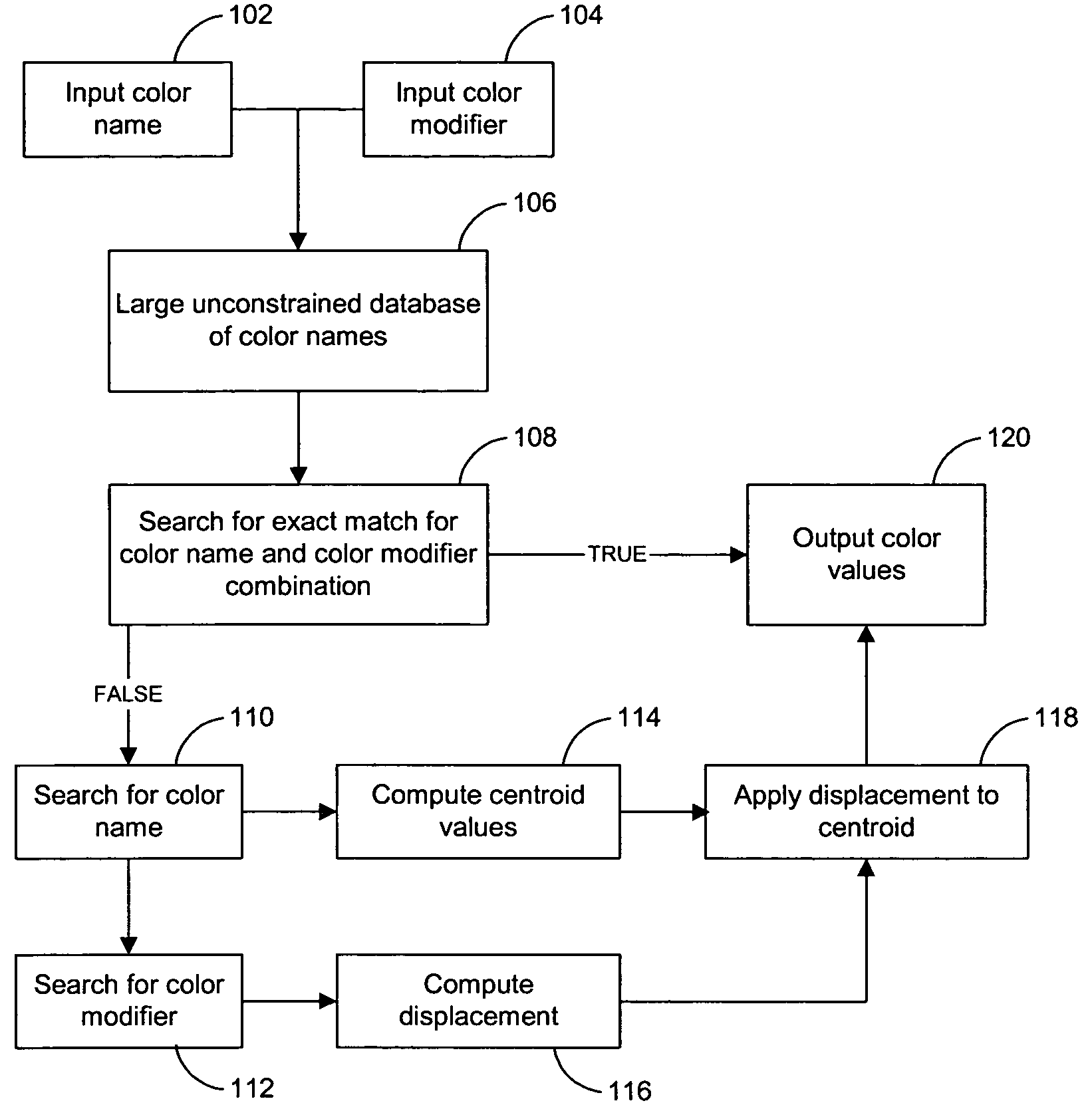

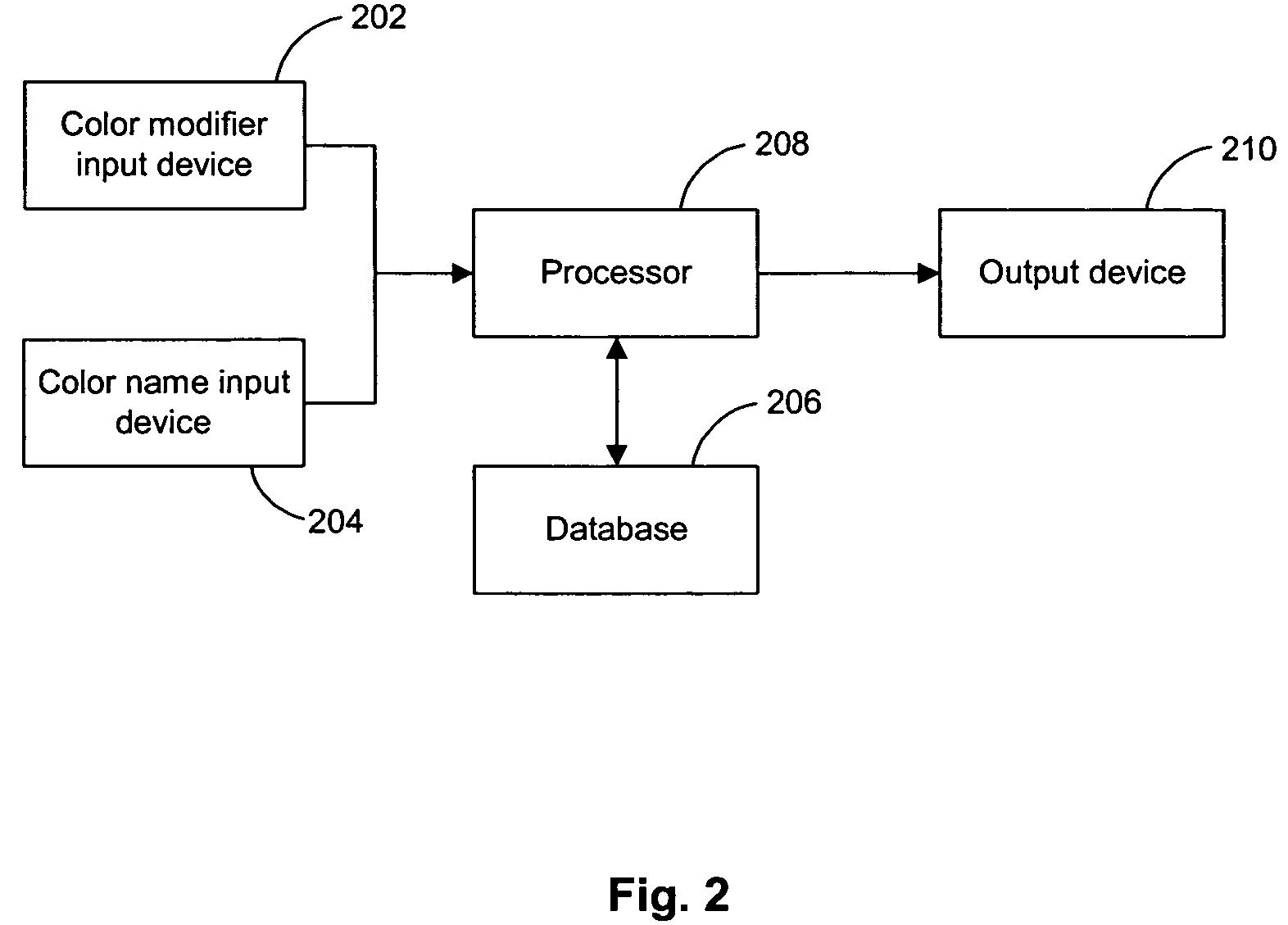

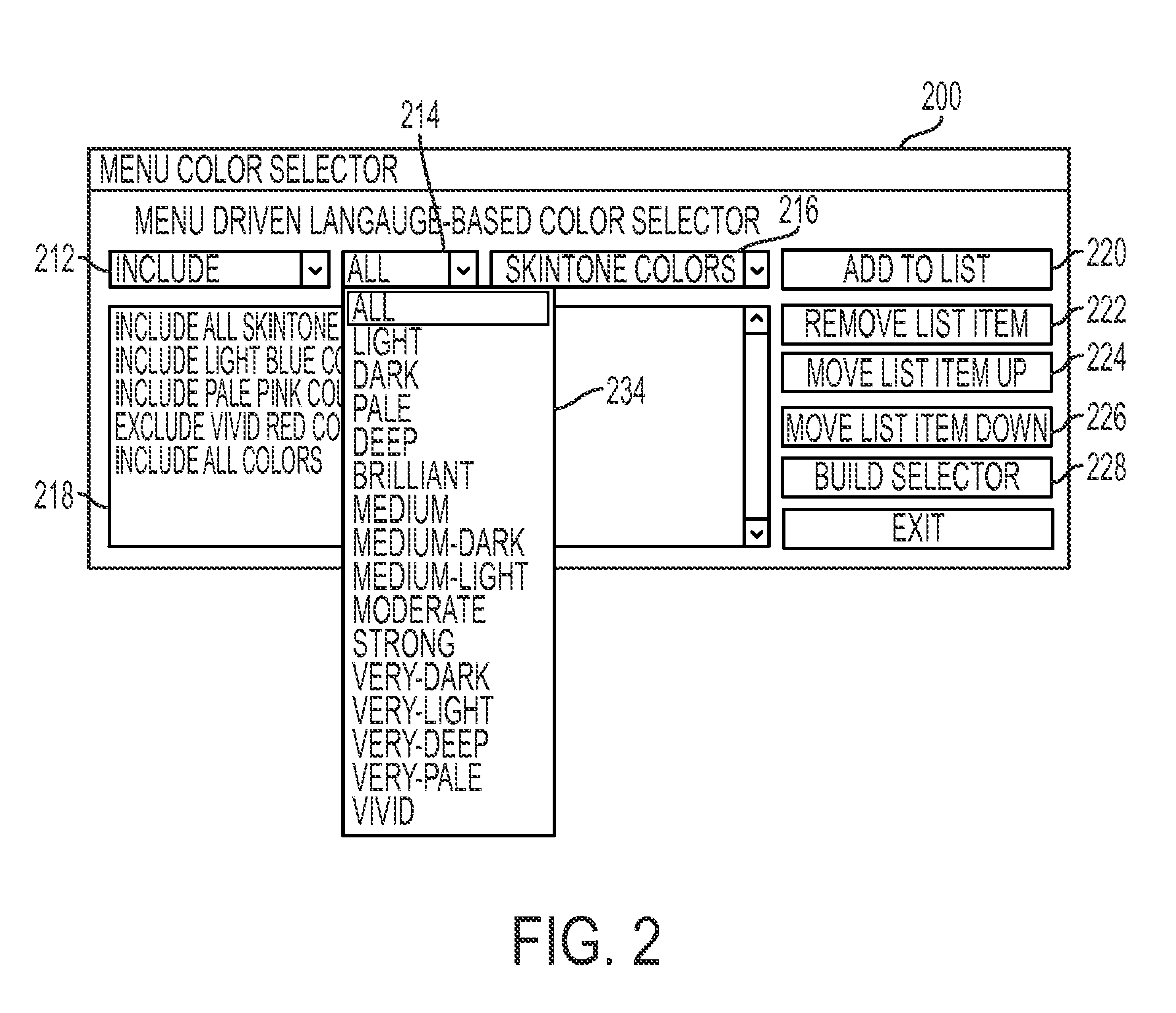

ActiveUS20070100786A1Texturing/coloringCharacter and pattern recognitionComputer visionColor modifier

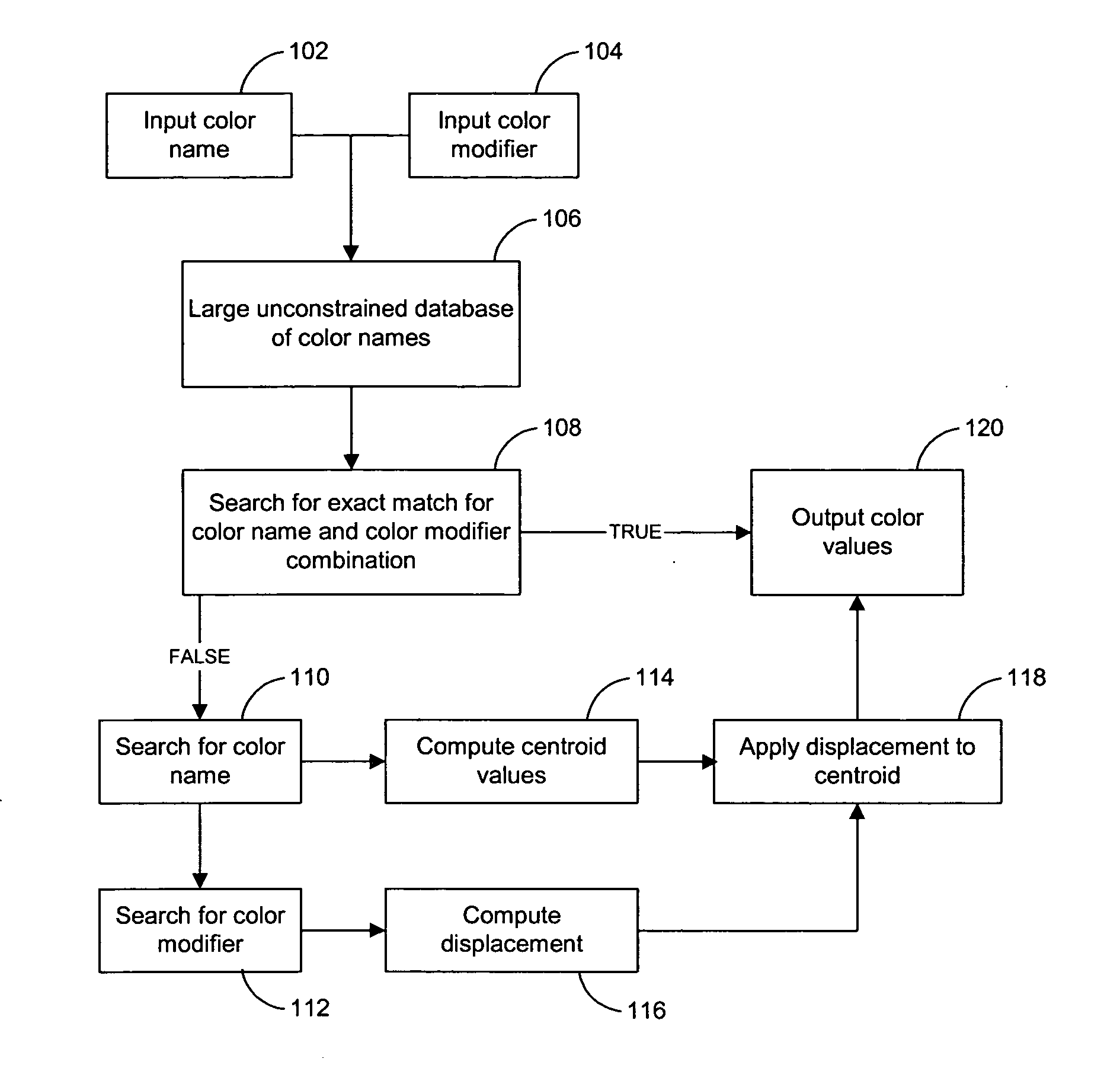

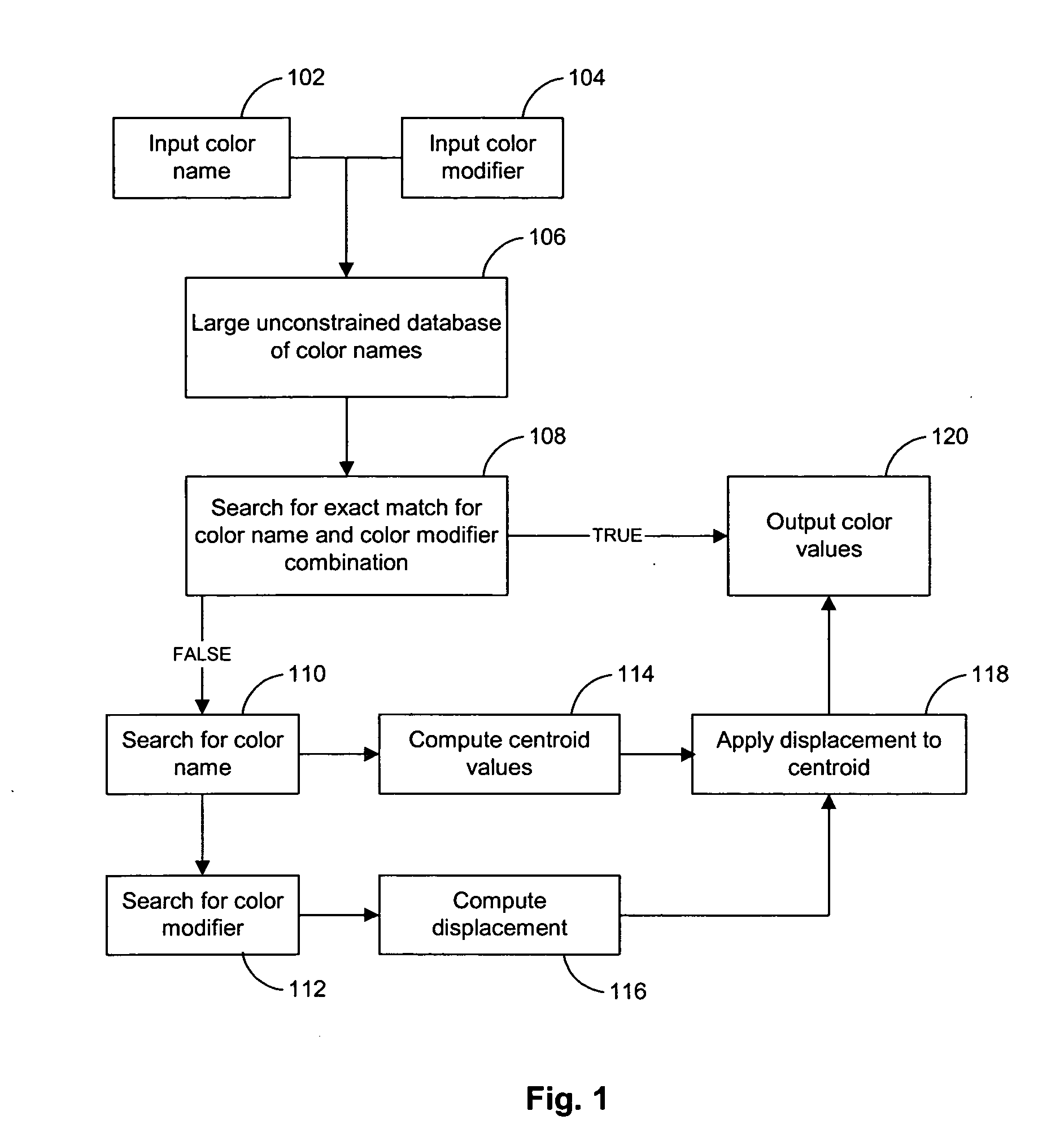

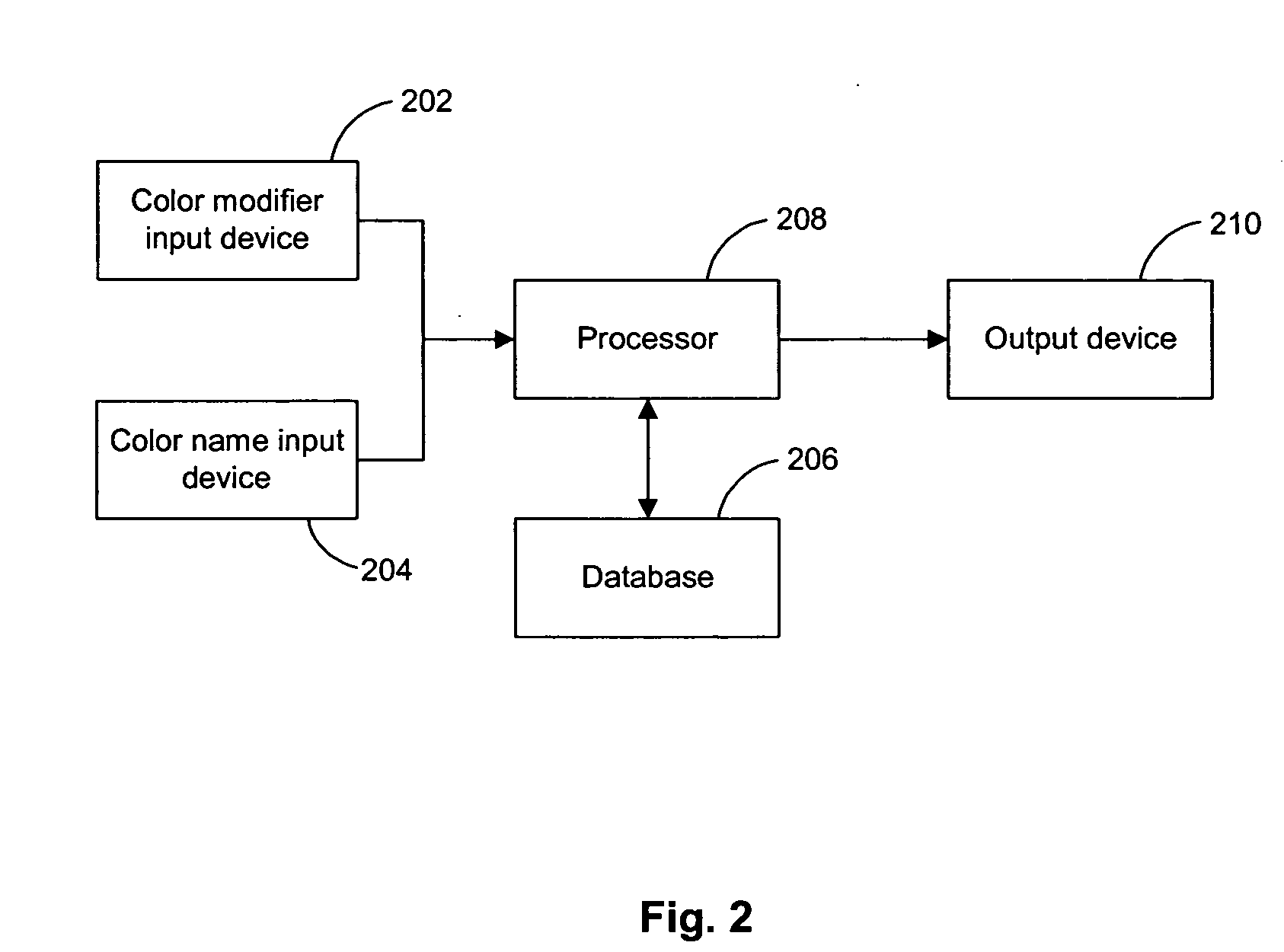

A method of applying a color modifier to a color having a corresponding color name. The method involves receiving a color modifier and a color name and determining a displacement value corresponding to the received color modifier. Determining a displacement value corresponding to the received color modifier involves reference to a color naming database including a set of color modifiers having corresponding color-attribute displacement values. The color modifier is applied to the color name by applying the displacement value to a color value corresponding to the color name.

Owner:HEWLETT PACKARD DEV CO LP

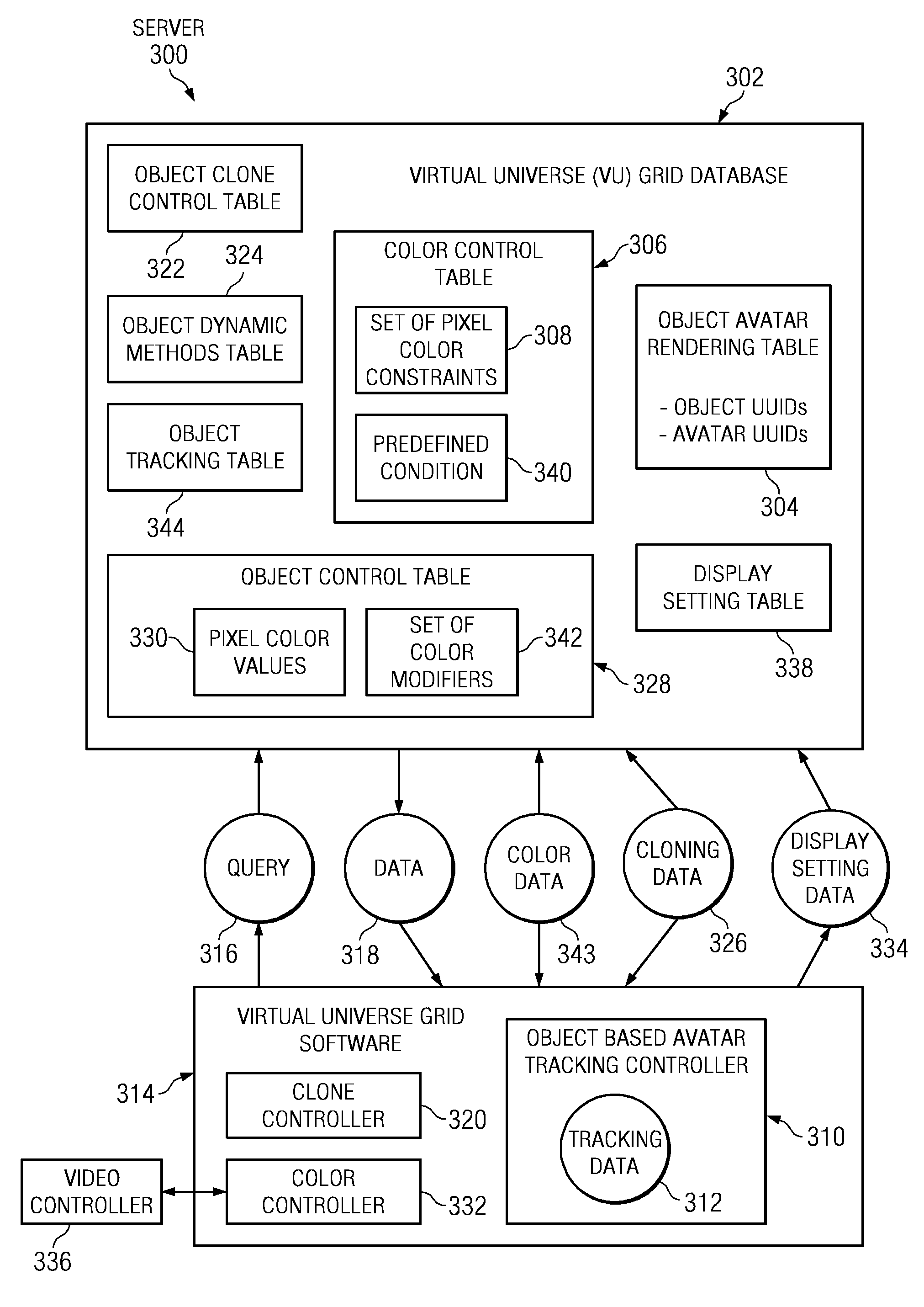

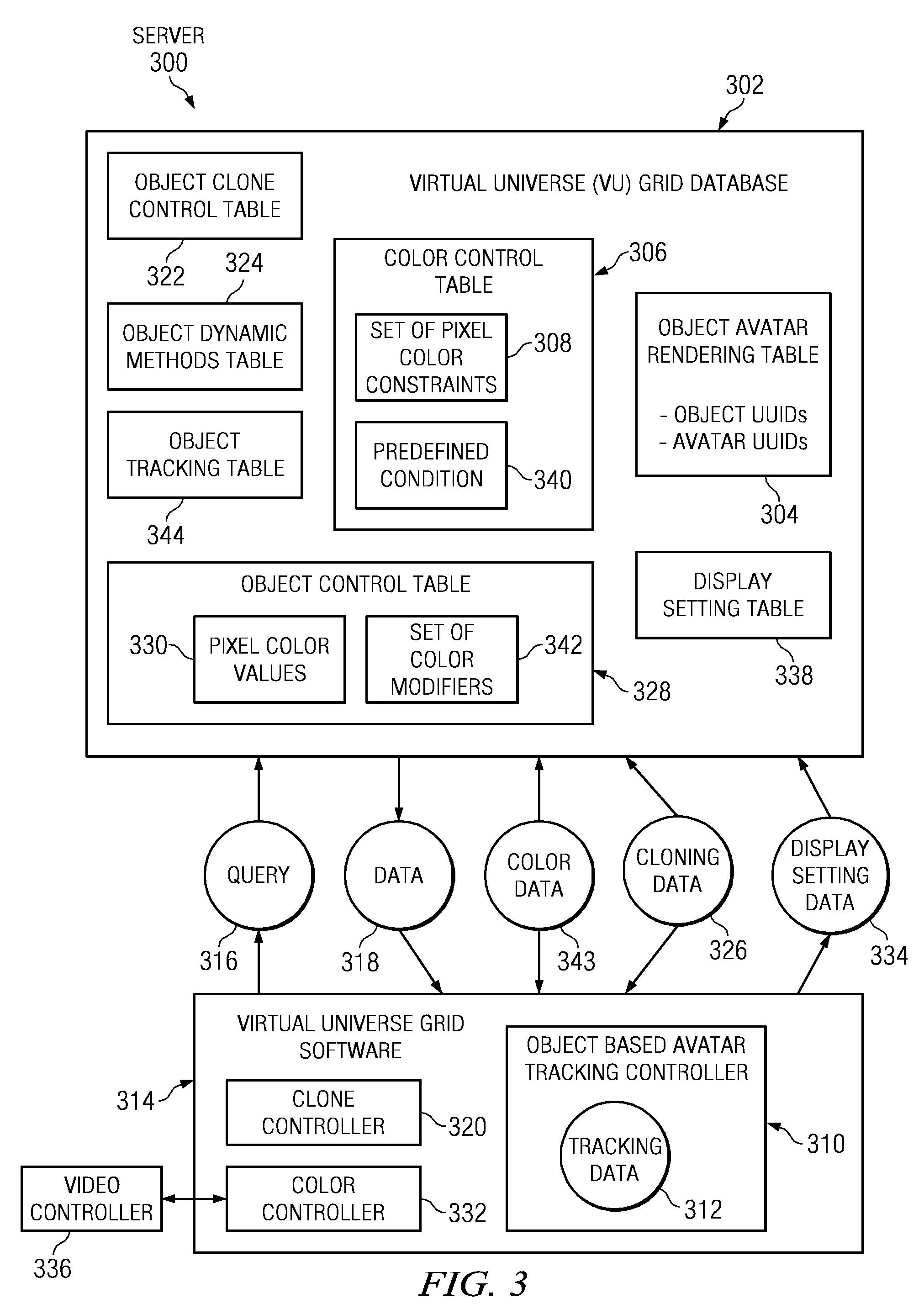

Color Modifications of Objects in a Virtual Universe Based on User Display Settings

A computer implemented method, apparatus, and computer program product for modifying an object. In one embodiment, the process obtains avatar tracking data that identifies a location of an avatar in relation to a range of an object. The range includes a viewable field. The process then selects a data collection method based on the location of the set of avatars. In response to detecting an event for triggering modification of the object, the process calculates a set of color modifiers based on display setting data to form a modified color. Thereafter, the process renders the object using the modified color when the location of the set of avatars is within the range of the object.

Owner:IBM CORP

Lexical classification system with dynamic modifiers

A method of applying a color modifier to a color having a corresponding color name. The method involves receiving a color modifier and a color name and determining a displacement value corresponding to the received color modifier. Determining a displacement value corresponding to the received color modifier involves reference to a color naming database including a set of color modifiers having corresponding color-attribute displacement values. The color modifier is applied to the color name by applying the displacement value to a color value corresponding to the color name.

Owner:HEWLETT PACKARD DEV CO LP

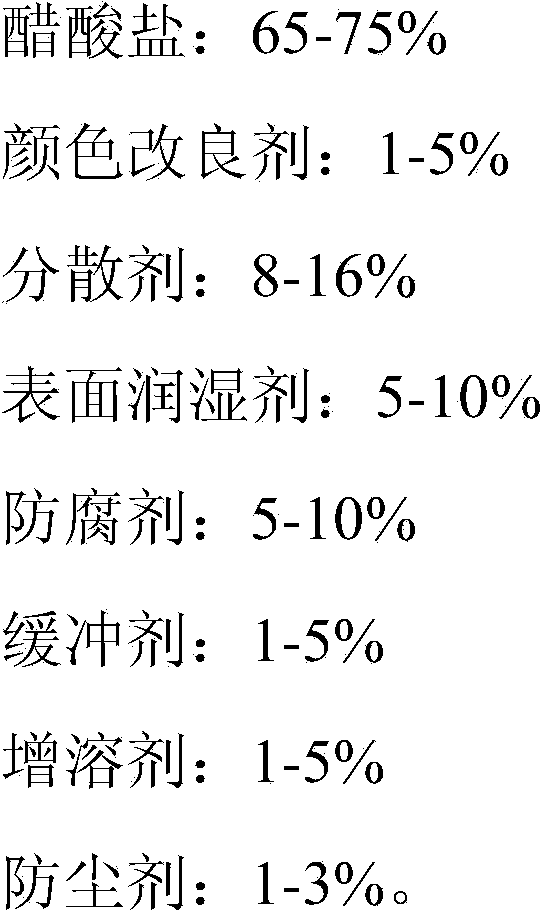

Medium-temperature aluminum oxidation aftertreatment agent

ActiveCN103952743AOvercome management difficultiesOvercoming the impossibility of being used for colorant sealingSurface reaction electrolytic coatingLow speedHazardous substance

The invention discloses a medium-temperature aluminum oxidation aftertreatment agent. The medium-temperature aluminum oxidation aftertreatment agent is prepared by mixing the following components by weight percent: 65-75% of acetate, 1-5% of color modifier, 8-16% of dispersing agent, 5-10% of surface wetting agent, 5-10% of preservative, 1-5% of buffer agent, 1-5% of solubilizer and 1-3% of dust-proof agent. Compared with the prior art, the medium-temperature aluminum oxidation aftertreatment agent has the advantages that the medium-temperature aluminum oxidation aftertreatment agent does not contain harmful substances, is environment-friendly, overcomes the defects that common low-temperature sealants are difficult to manage, can not be used for sealing dyes and have low speeds and the defects that boiling water has high requirements on the quality, is high in energy consumption, easiness in ash generation and long in time, and has relatively strong practicability; an obtained sealing membrane layer is free from pruina and has the characteristics of excellent brightness, smoothness, discoloration prevention property, corrosion resistance, high adhesion and the like.

Owner:苏州禾川化学技术服务有限公司

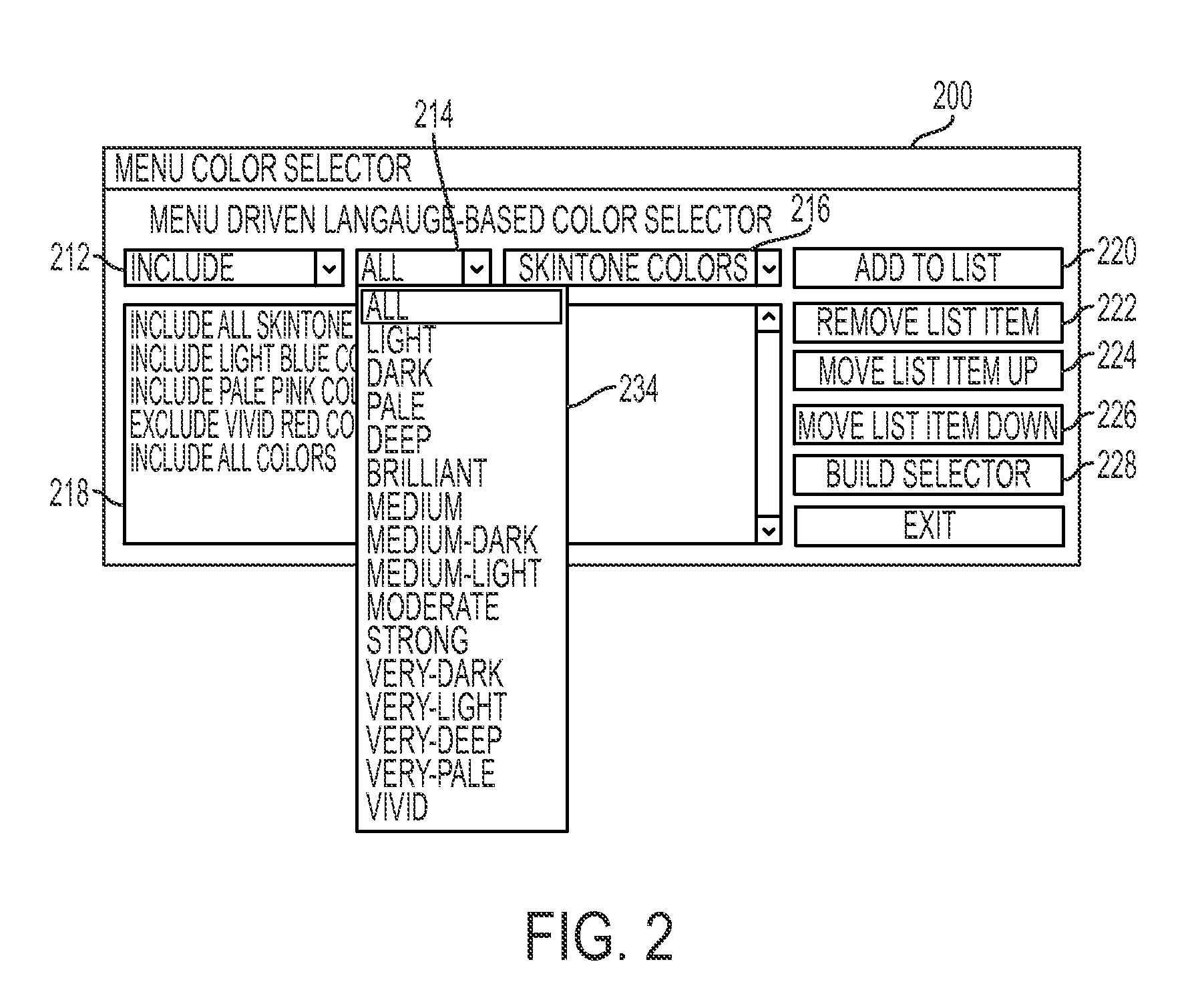

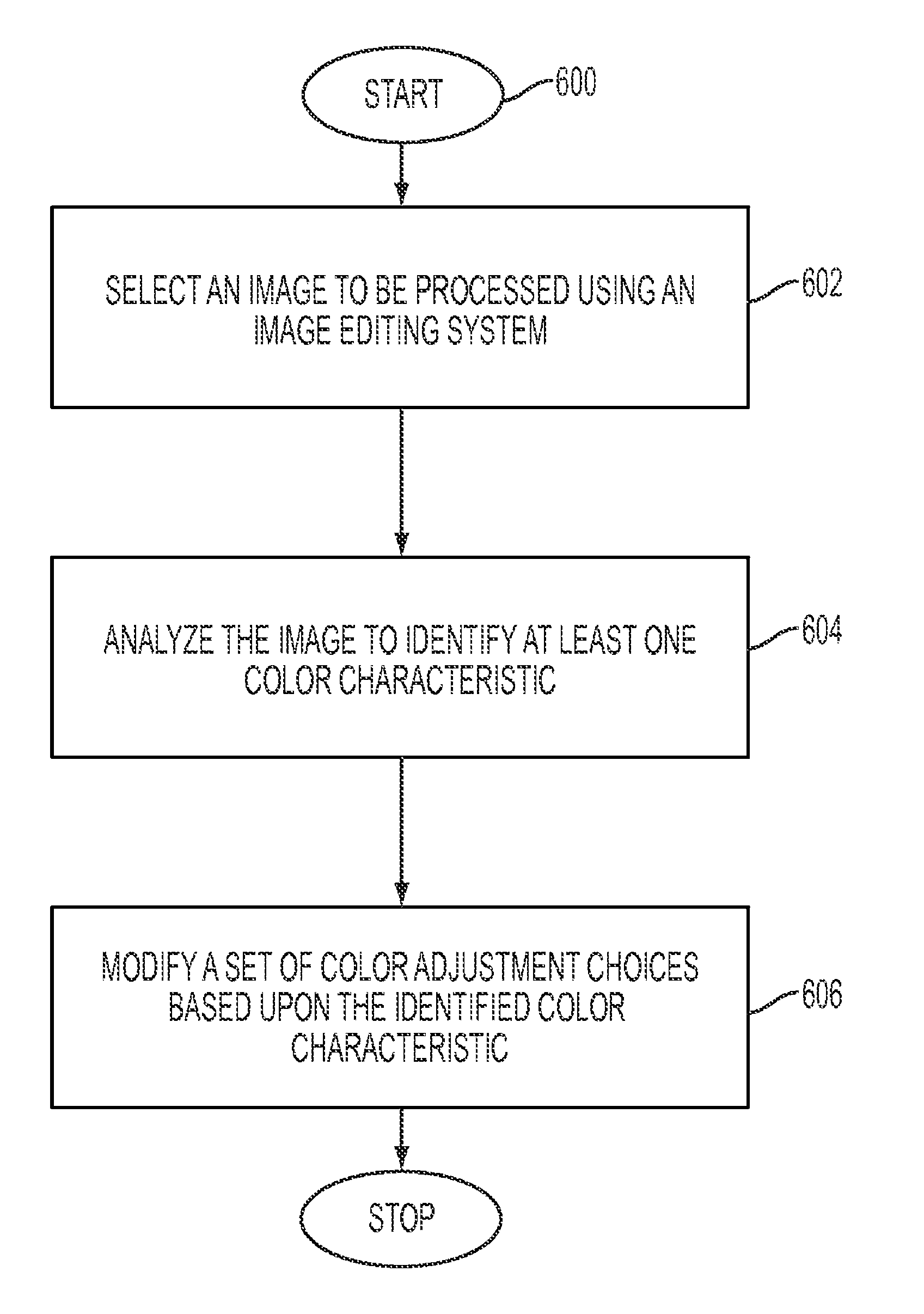

Modifying color adjustment choices based on image characteristics in an image editing system

InactiveUS20120299942A1Reduce decreaseChoose appropriateTexturing/coloringCharacter and pattern recognitionImaging analysisColor modifier

What is disclosed is a system and method for dynamically reducing the number of choices by reordering the selectable menu options in each menu of a color adjustment tool based on image content, selections in other menus, and usage history. Color names and color modifiers are reduced and / or reordered through image analysis, with most frequently occurring colors being placed at the top of the menu and excluding less frequently used or unused colors from the menu. Adjustment adjectives are reduced by eliminating nonsensical or rare color adjustment combinations (e.g. make the grays much more colorful, make the blues yellower), and / or reordered based on usage history, either by the individual user or by aggregating over many users.

Owner:XEROX CORP

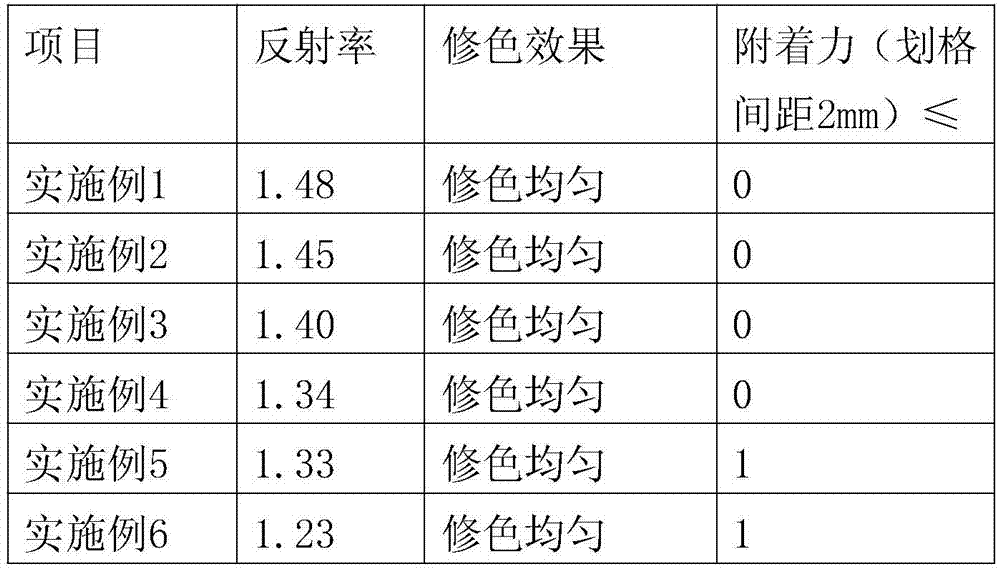

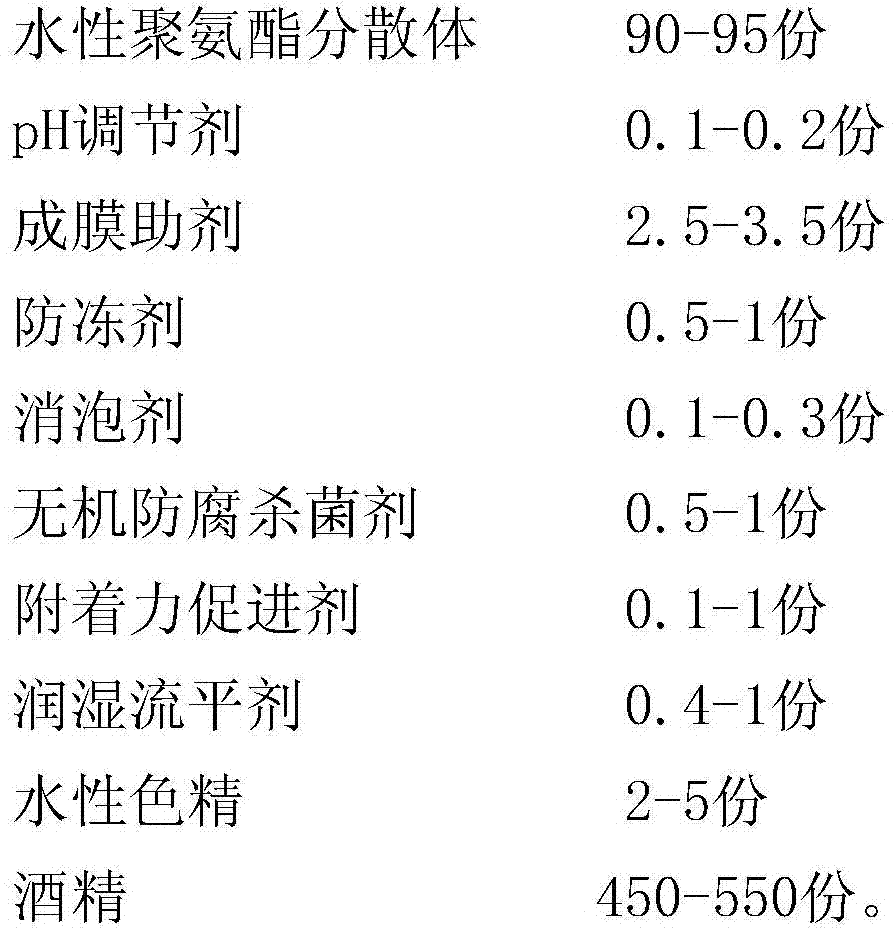

Waterborne woodware surface color modifier

InactiveCN105440925AUniform color correctionGood wood grainAntifouling/underwater paintsPaints with biocidesPolyurethane dispersionAlcohol

The invention relates to a waterborne woodware surface color modifier, which is mainly prepared from the following ingredients (by weight): 90-95 parts of a waterborne polyurethane dispersion, 0.1-0.2 part of a pH regulator, 2.5-3.5 parts of a coalescing agent, 0.5-1 part of an antifreezing agent, 0.1-0.3 part of an antifoaming agent, 0.5-1 part of an inorganic anticorrosion and bactericidal agent, 0.1-1 part of an adhesion promoter, 0.4-1 part of a leveling wetting agent, 2-5 parts of waterborne color concentrate and 450-550 parts of alcohol. The waterborne woodware surface color modifier is used for color modification of waterborne woodenware surface, has advantages of uniform color modification, excellent adhesion to a primer, good transparency and lasting and effective anticorrosion and antibacterial effect, and is green and environmentally friendly.

Owner:SKSHU PAINT

Multifunctional resin coloring modifier and preparation method thereof

InactiveCN105459239ASolve permeabilitySolve level dyeingWood treatment detailsWood impregnation detailsVolumetric Mass DensityFire retardant

The invention belongs to a multifunctional resin coloring modifier and a preparation method thereof. The multifunctional resin coloring modifier comprises, by weight, 10-35 parts of modified melamine urea formaldehyde resin, 1-10 parts of water soluble dye, 1-10 parts of dyeing assistants, 1-10 parts of fire retardants, and 50-80 parts of water. The modified melamine urea formaldehyde resin is prepared from, by weight, 30-50 parts of formaldehyde, 30-50 parts of melamine, 30-50 parts of methyl alcohol, 10-20 parts of urea, 10-20 parts of polymerization inhibitors, and 40-60 parts of water. According to the multifunctional resin coloring modifier and the preparation method thereof, dyeing and functional modifying of wood materials are integrated, the good modified characteristic of the dyed wood is achieved which the dye penetration, leveling property, color fastness, light resistance and the like are achieved. The multifunctional resin coloring modifier and the preparation method thereof have the advantages that operation is easy, implementation is easy, the production cost is low, a dyed material is large in density, high in strength, stable in dimension, resistant to abrasion, resistant to flame, uniform and rich in color, firm and durable, energy is saved in the production process, and environmental friendliness is achieved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Production process of textile fiber color modifier

The invention relates to a production process of a textile fiber color modifier. The textile fiber color modifier is prepared from the following raw materials in percentage by weight: 52%-68% of swelling agent, 10%-30% of emulsifying and dispersing agent, and 8%-20% of solvent, wherein the swelling agent is one or more of propylene glycol monomethyl ether, phenoxy-1-propanol, cyclohexanol methyl ether, N-normal-butyl-phthalimide, and N-isopropyl-phthalimide; the emulsifying and dispersing agent is one or more of styrylphenol polyoxyethylene ether sulfonate, polyoxyethylene castor oil, iso-tridecanol polyoxyethylene ether, fatty amine polyoxyethylene ether, polyoxyethylene (60) sorbitan monostearate (namely Tween-60), polyoxyethylene (80) sorbitan monostearate (namely Tween-80), and pesticide emulsifier No.600; and the solvent is one or more of water, ethanol, isopropyl alcohol, ethylene glycol, and ethylene glycol monobutyl ether. The production process comprises the following steps of adding all the materials into a reaction kettle and stirring the materials at 30 DEG C to 50 DEG C for 60 to 90 minutes, thereby obtaining the textile fiber color modifier. The textile fiber color modifier can be used for overcoming the dyeing defects of polyester and blended fabrics of the polyester in dyeing, and the dyed fabrics can meet environmental protection standards.

Owner:冯祥茂

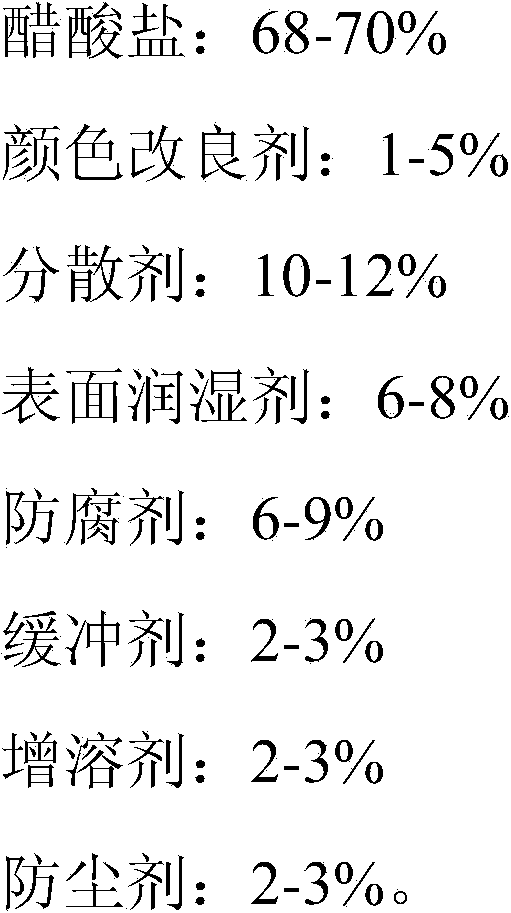

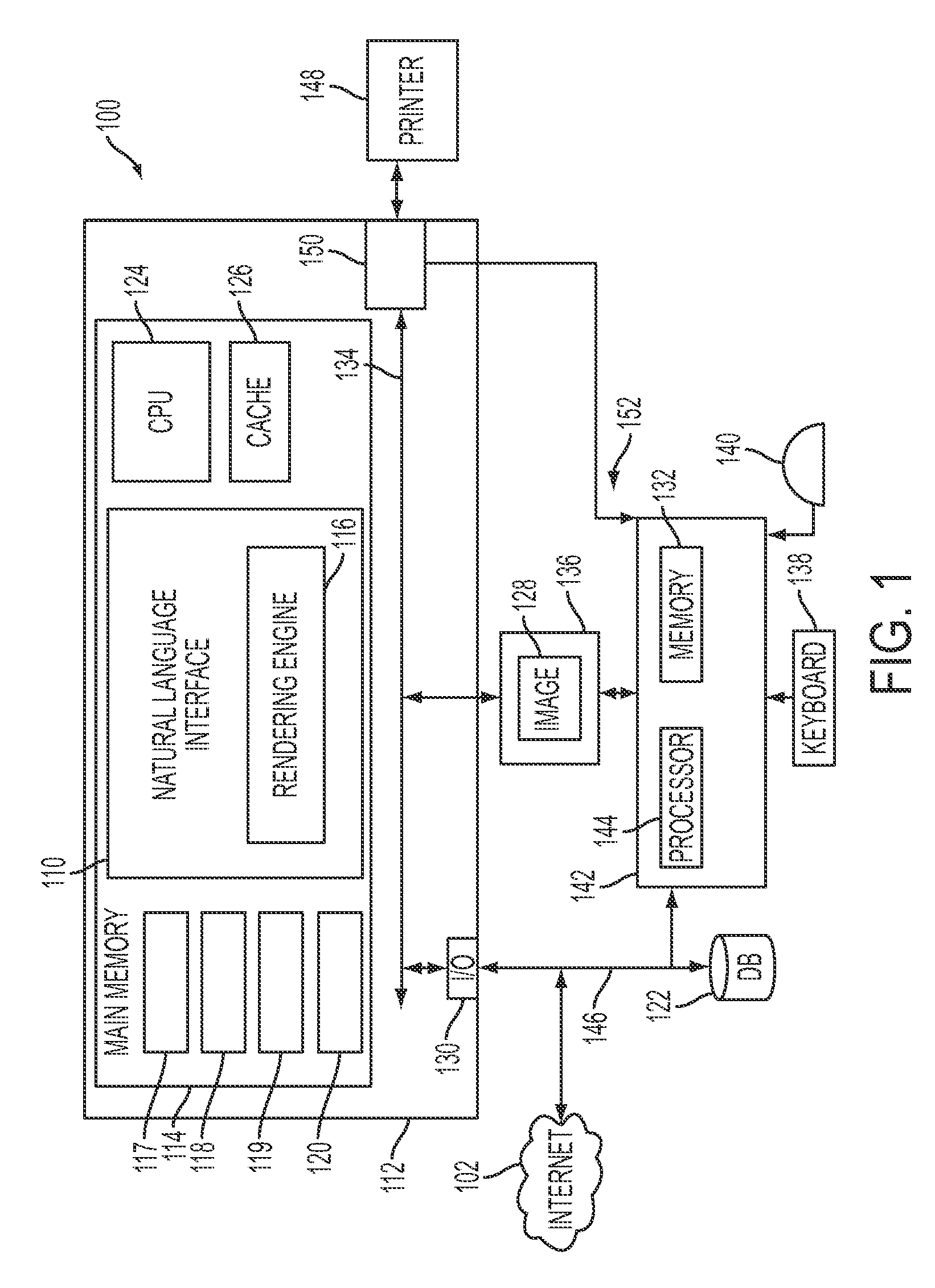

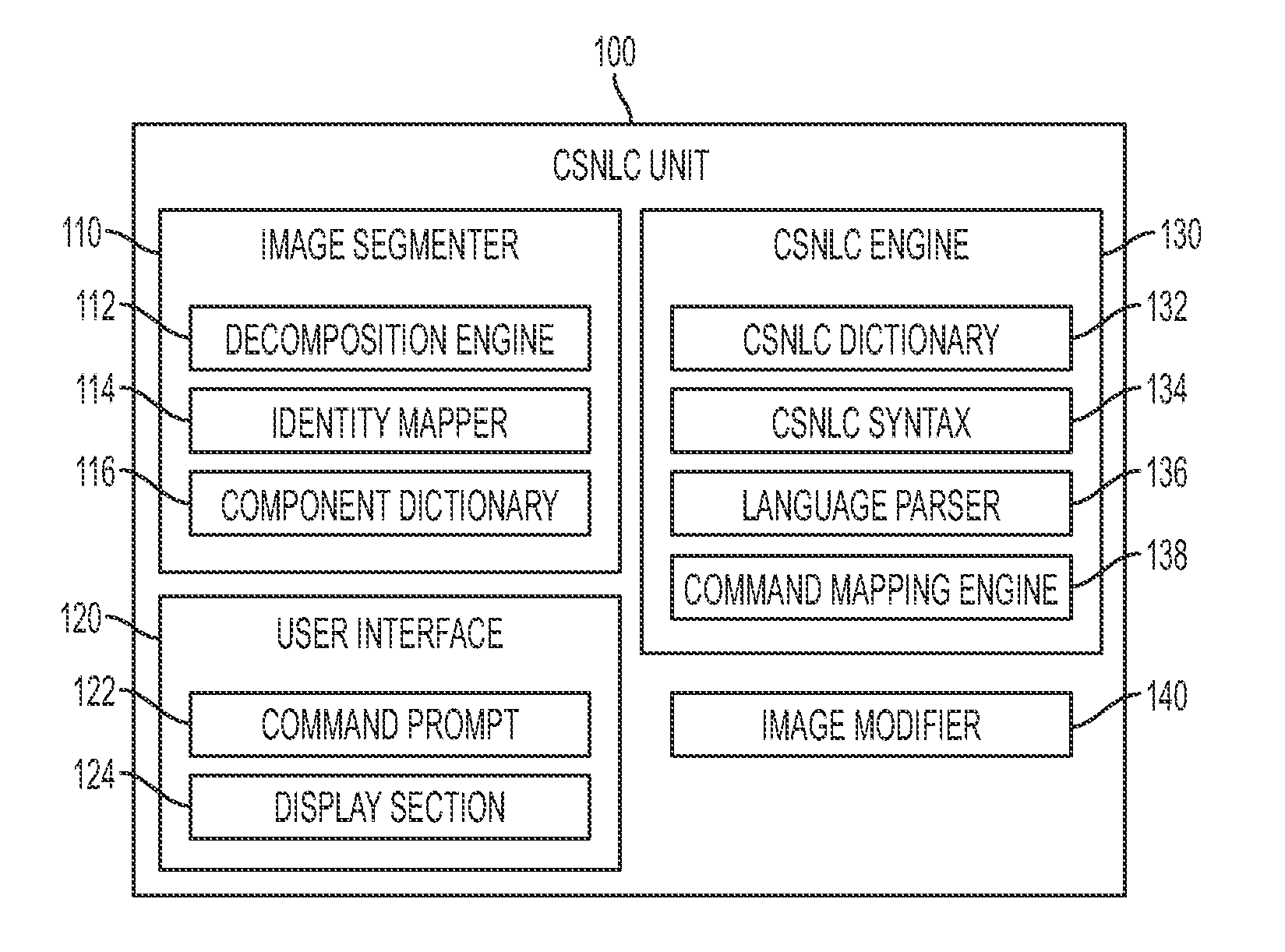

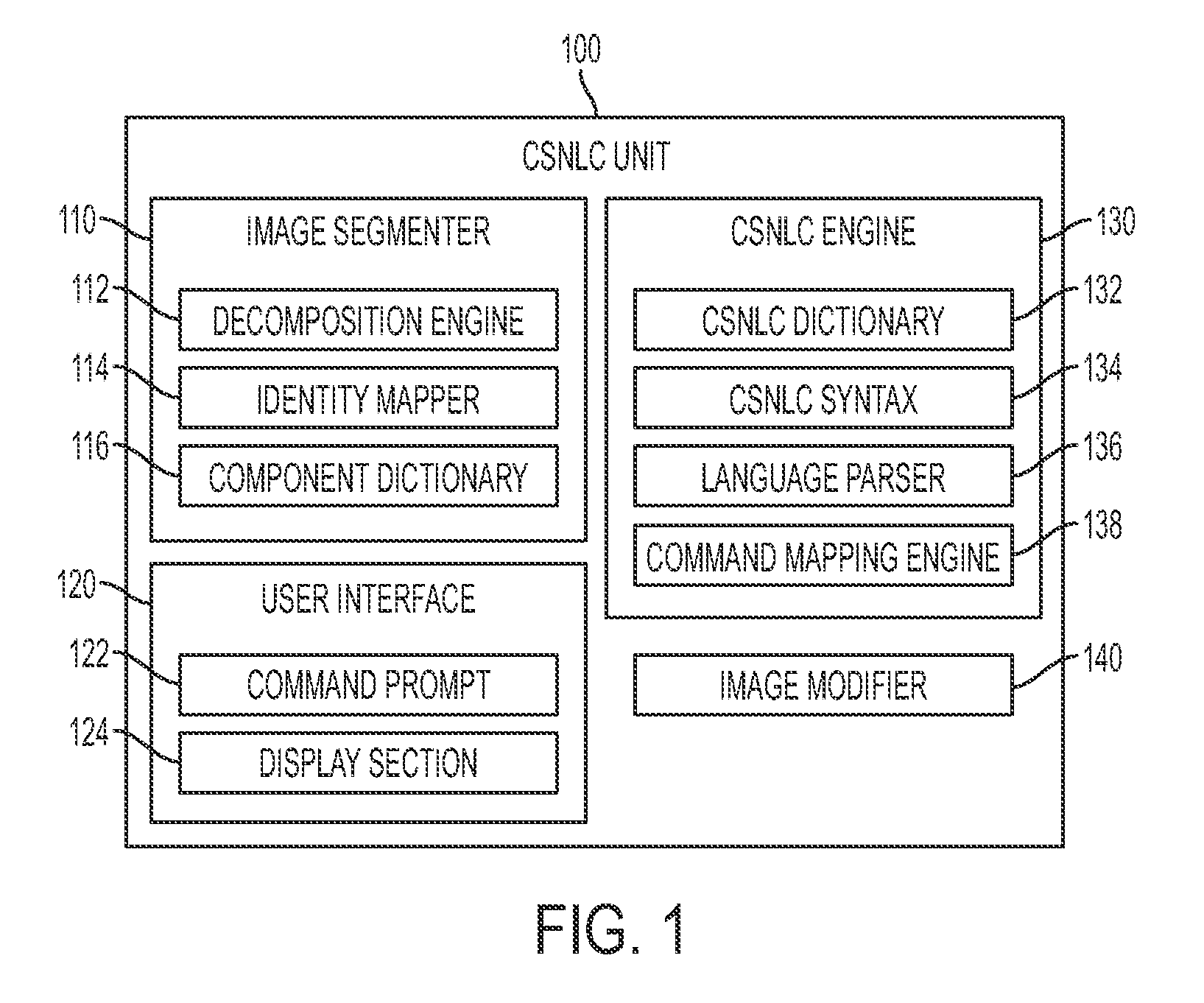

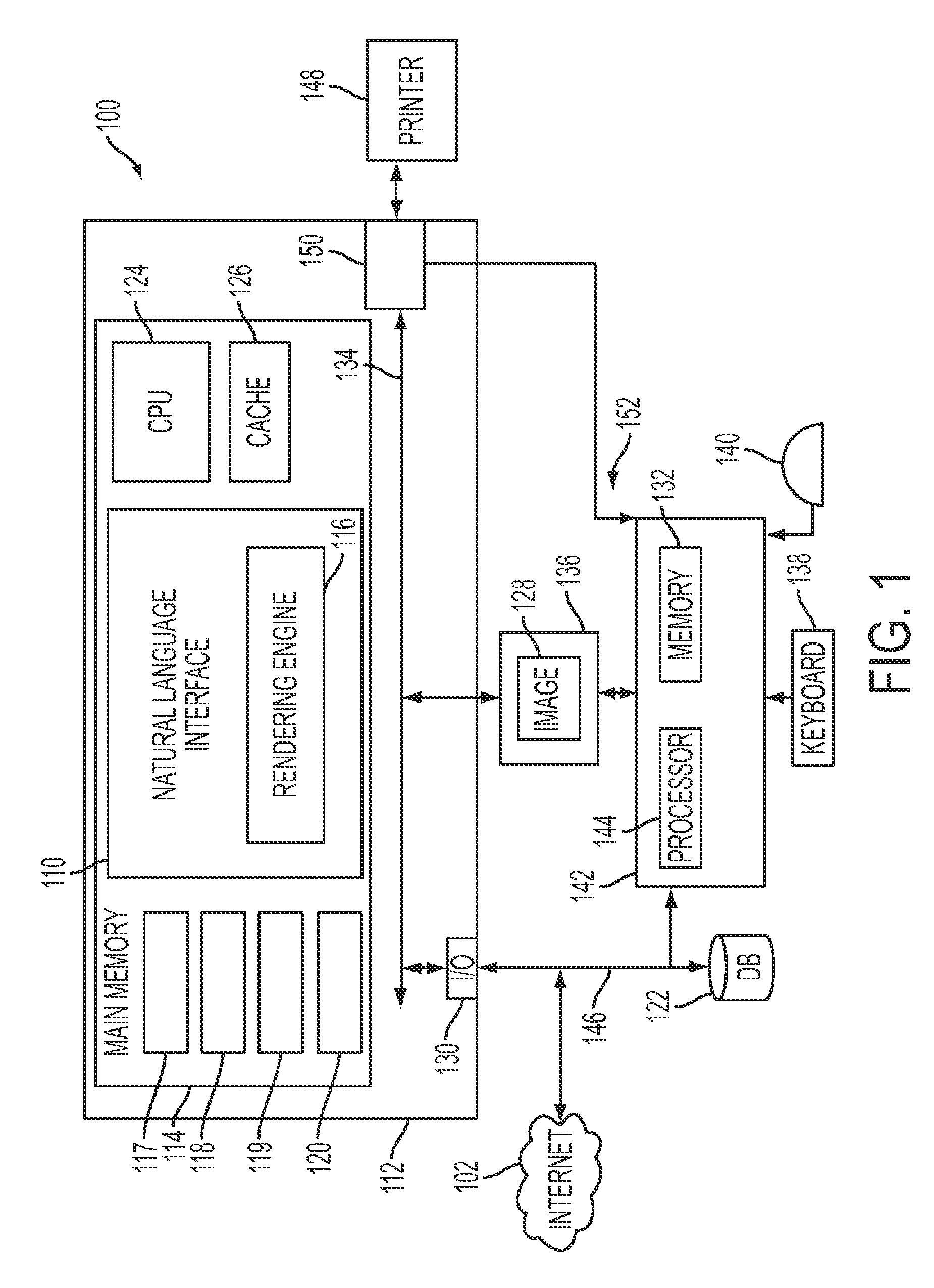

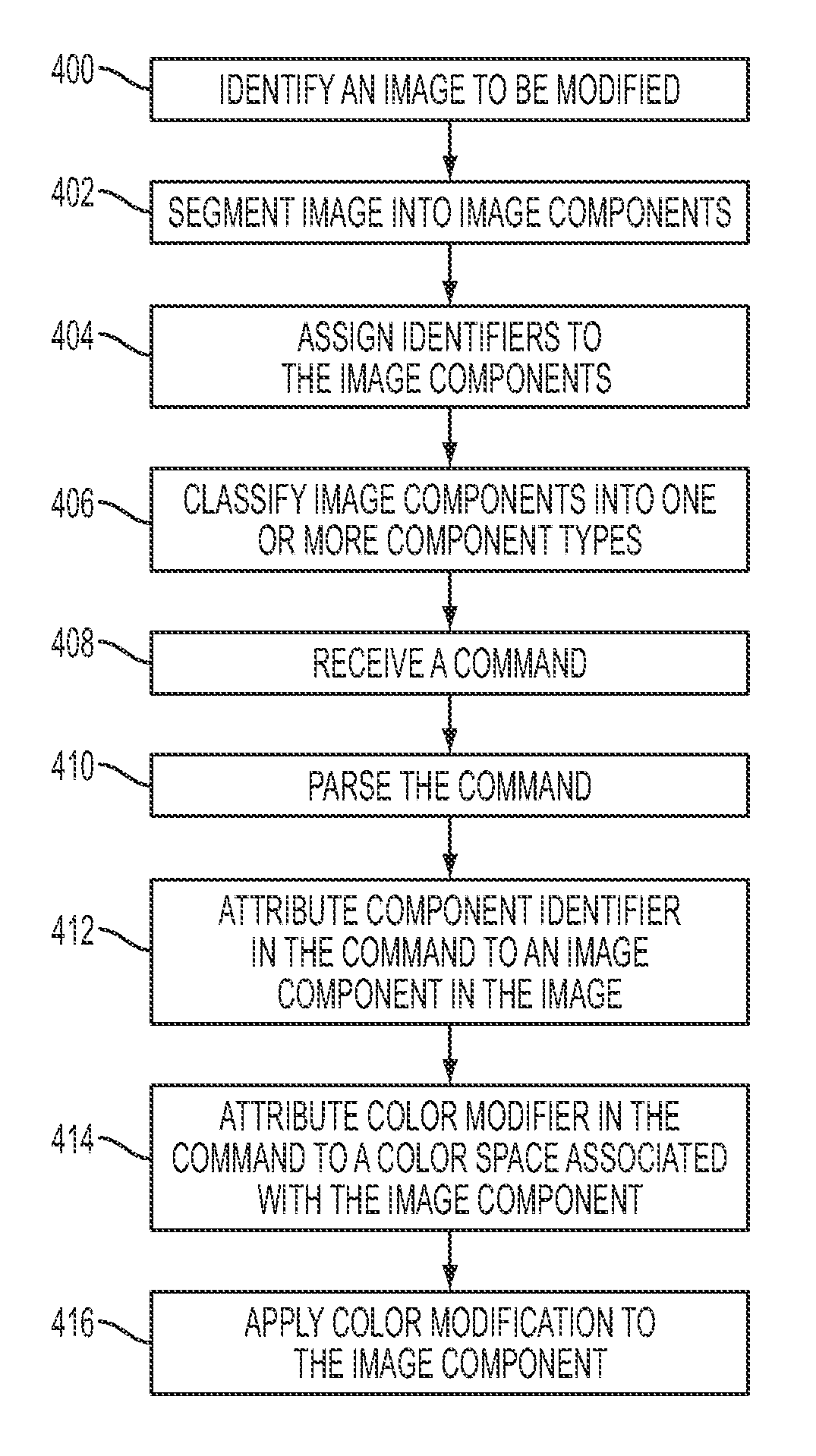

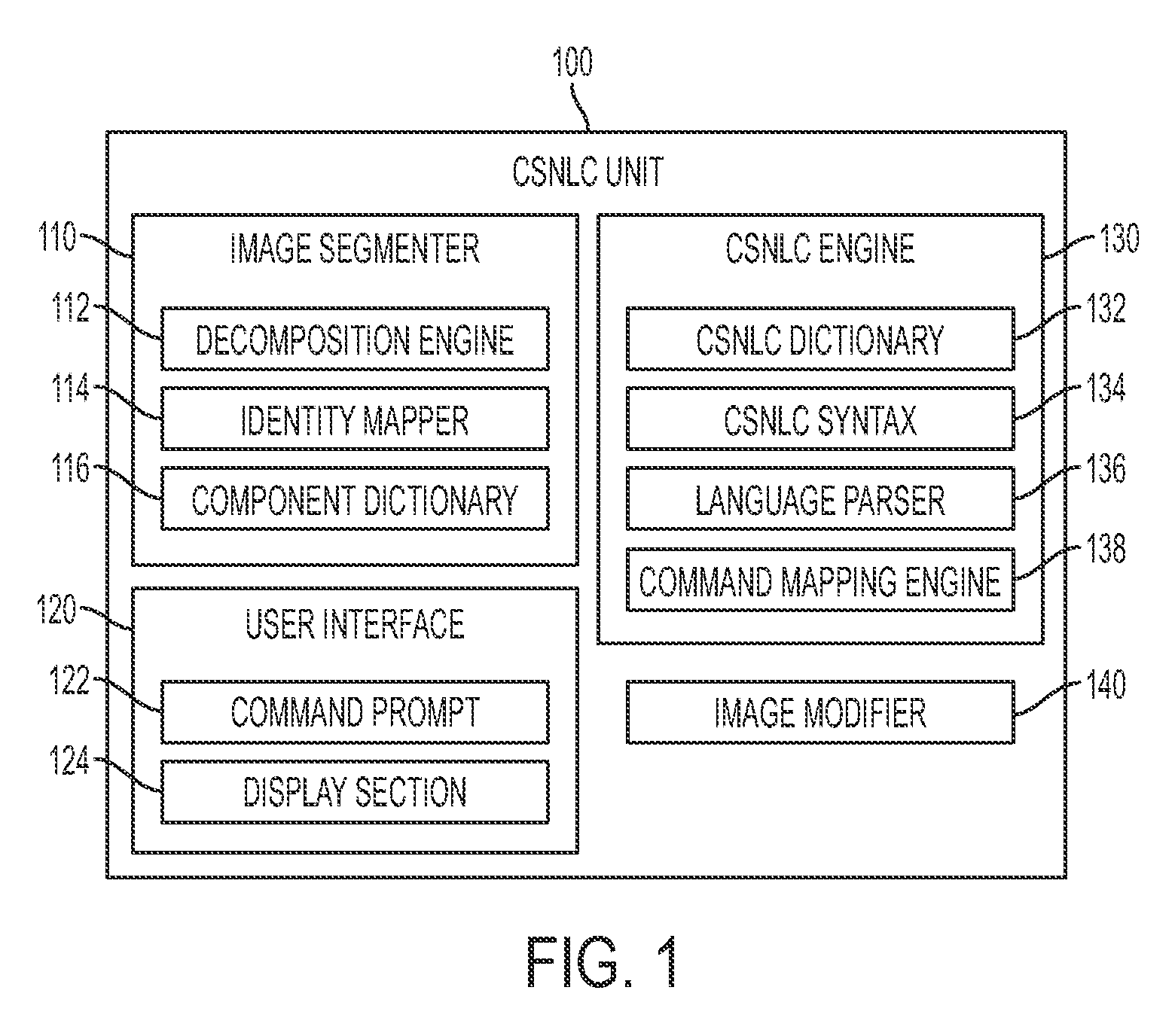

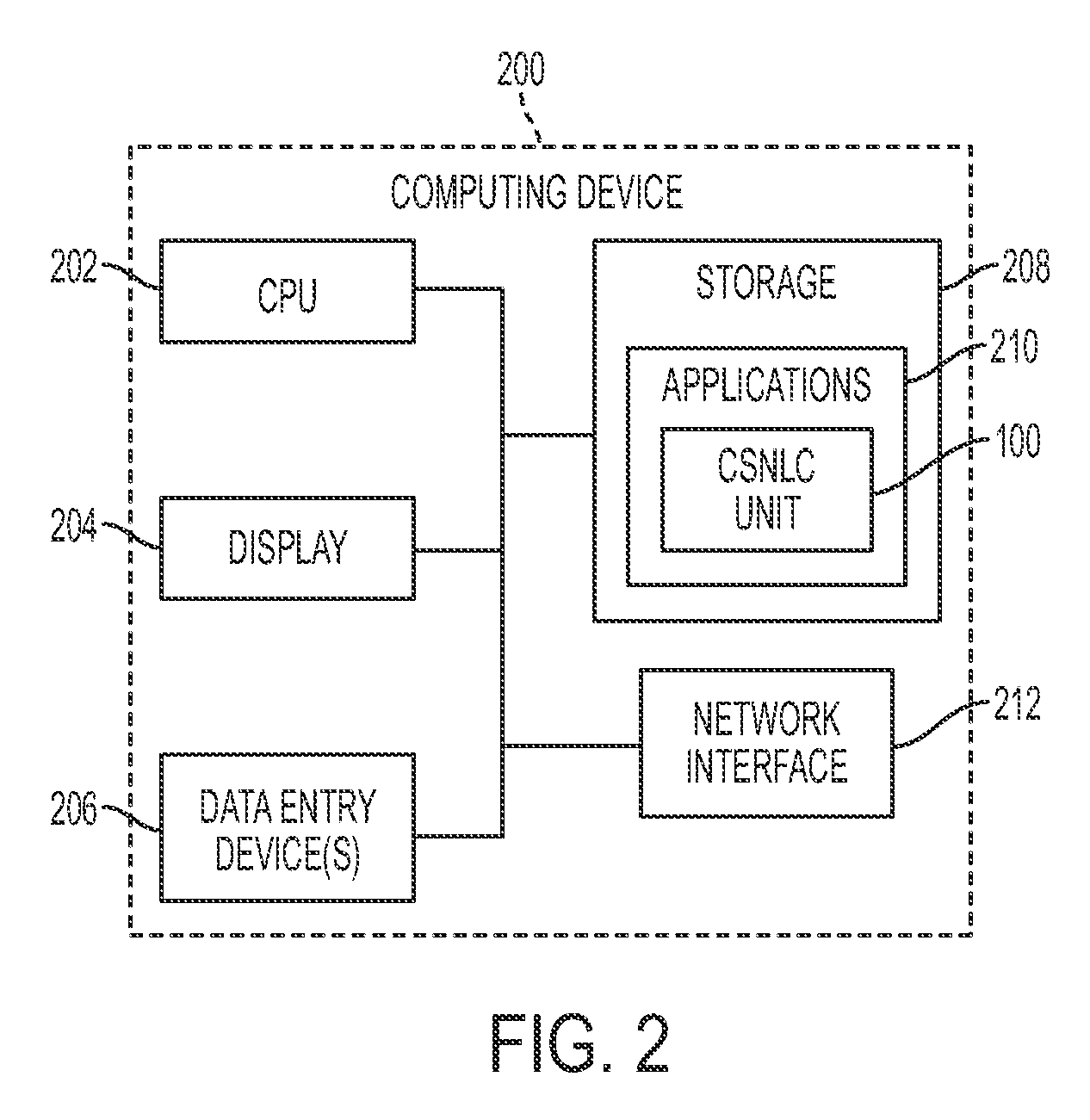

Component specific image modification using natural language color

Embodiments described herein include a component specific natural language color unit for modifying colors of image components in an image using component specific natural language commands. The CSNLC unit can receive a component specific natural language color command for a color modification of an input image. The component specific natural language color command can include a component identifier and a color modifier. The natural language command can be parsed to attribute the component identifier to an image component in the input image and to attribute the color modifier to a predefined color space associated with the image component. The color modifier can indicate the color modification to be performed. The color modification can be applied to the image component to adjust the color of the image component.

Owner:XEROX CORP

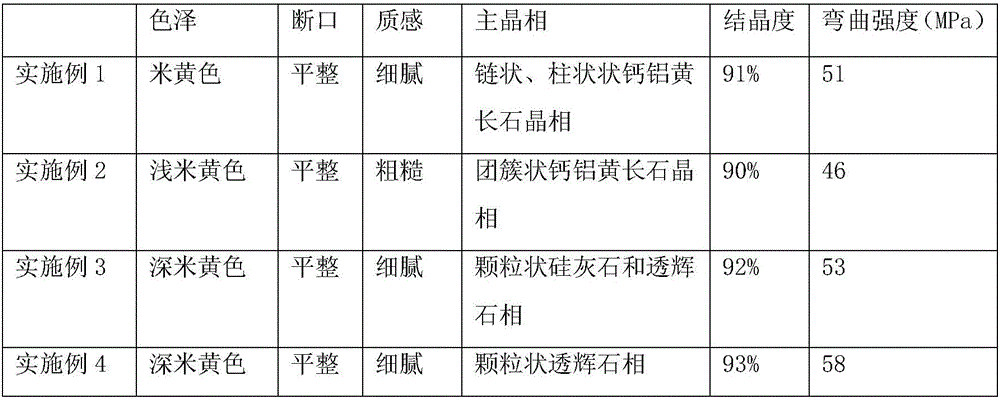

High-titanium blast furnace slag microcrystalline stone material and preparation method thereof

The invention belongs to the field of a stone material manufacturing process and particularly relates to a high-titanium blast furnace slag microcrystalline stone material and a preparation method thereof. Aiming at the problems that an existing microcrystalline stone material prepared from blast furnace slag has poor flatness, rough surface, poor appearance and the like, the invention provides the high-titanium blast furnace slag microcrystalline stone material and the preparation method thereof. The preparation method comprises the following steps: mixing 40-60 parts of high-titanium blast furnace slag, 24-37 parts of a stabilizer, 5-8 parts of a fluxing agent, 5-8 parts of a nucleating agent, 2-4 parts of a crystallization accelerant, 1-3 parts of a color modifier and 1-2 parts of a reducing agent; smelting at 1480 DEG C-1530 DEG C, homogenizing and clarifying to obtain a mixed melt; and calendering to form a sheet material, and nucleating and crystallizing to obtain the microcrystalline stone material. According to the method provided by the invention, the glass viscosity can be reduced; stable molding of glass is accelerated and the chemical stability of the glass is improved; the prepared microcrystalline stone material has a smooth and flat surface, pure color and luster and good quality. The preparation method provided by the invention is simple to operate and the requirements on equipment are not high, so that the preparation method is convenient to popularize and apply.

Owner:PANZHIHUA HUANYE METALLURGICAL SLAG DEV CO LTD

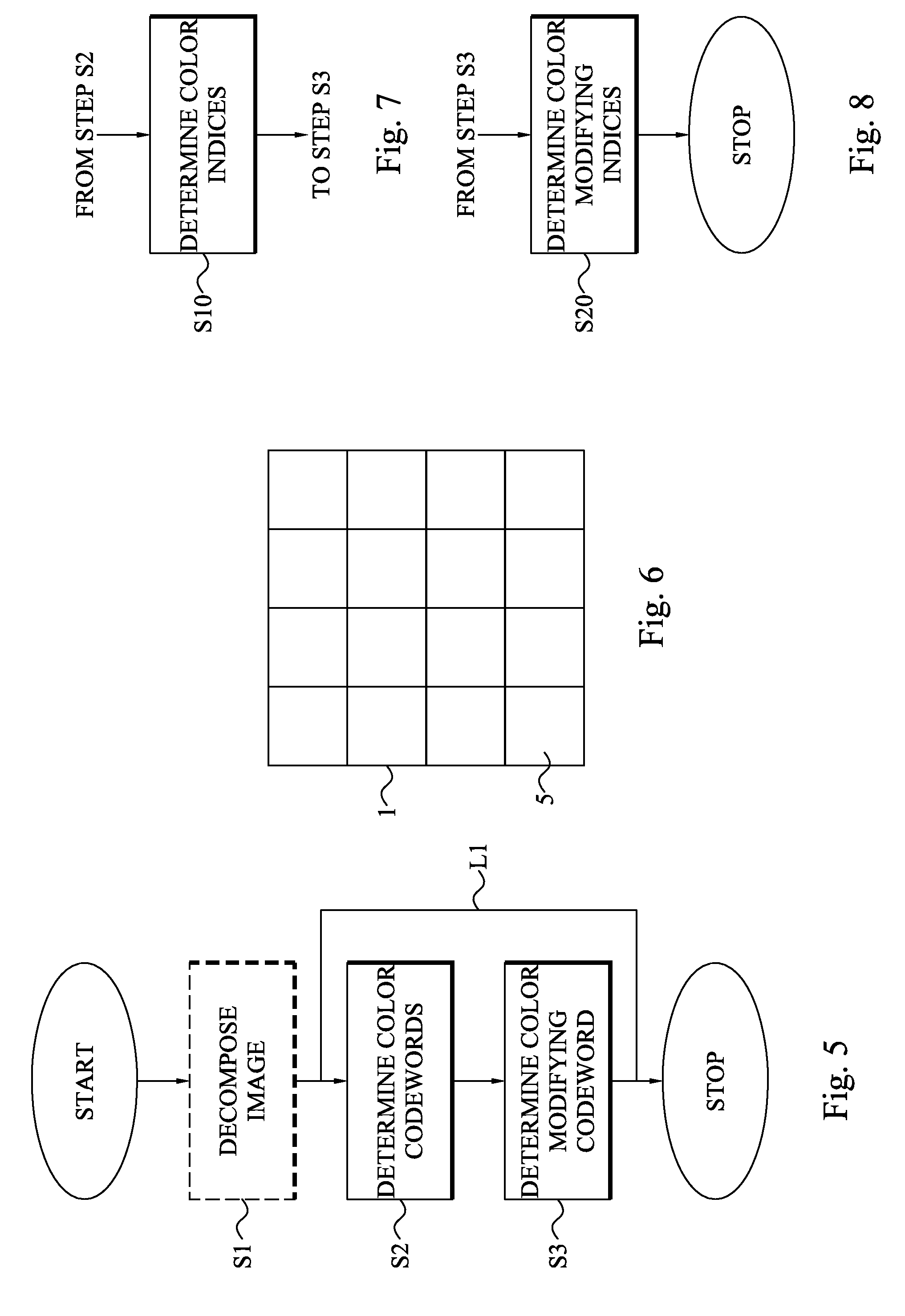

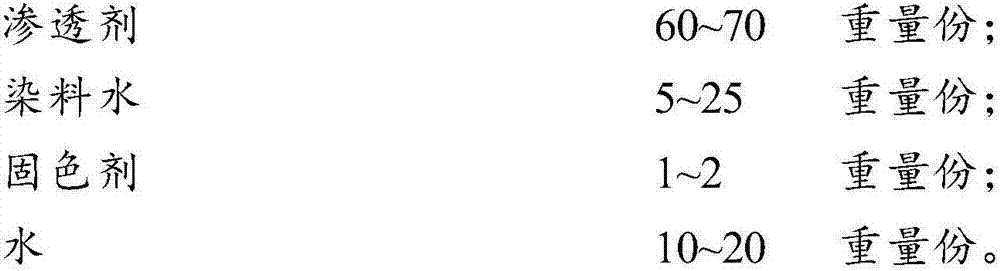

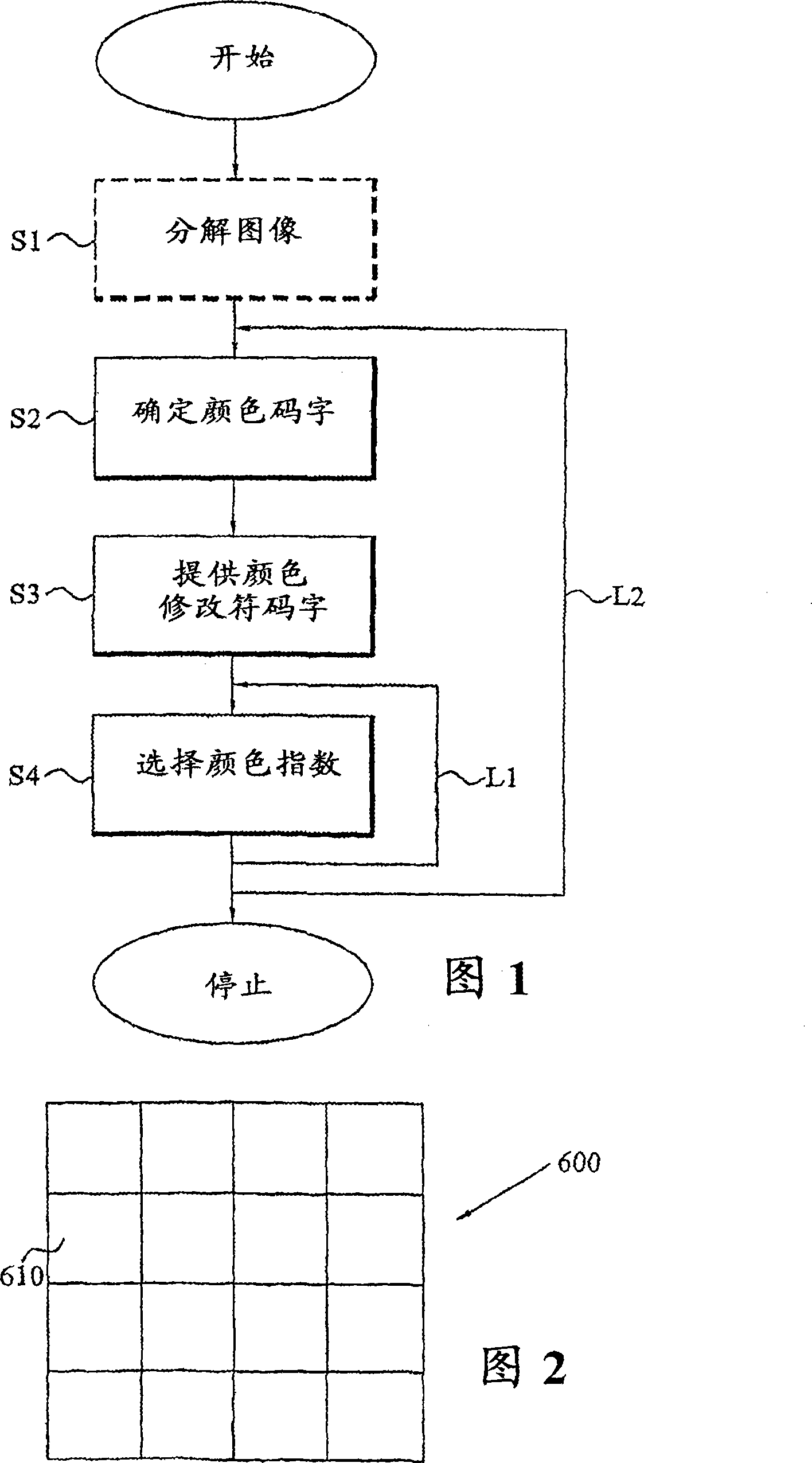

High quality image processing

In a high quality image-encoding scheme an input image is decomposed into several image blocks comprising multiple image elements. The image blocks are encoded into encoded block representations. Such a block representation comprises two color codewords, a color modifying codeword and optionally a sequence of color indices and color modifier indices. The color codewords define multiple discrete color representations along a line in color space. The color modifying codeword represents a set of multiple color modifiers for modifying the multiple color representations along at least one extension vector to obtain, for each color representation, a set of multiple color points. These color points of the multiple sets are located on a surface defined by the multiple color representations and the at least one extension vector. The colors of the image elements in the block are then approximated by these color points on the surface.

Owner:TELEFON AB LM ERICSSON (PUBL)

Organic-inorganic hybridized optical resin composition with high impact resistance, heat resistance and refractive index and preparation method thereof

ActiveCN105482070AImprove impact resistanceImprove heat resistanceCoatingsOptical elementsPolymer scienceHeat resistance

The invention relates to an organic-inorganic hybridized optical resin composition with high impact resistance, heat resistance and refractive index and a preparation method thereof. The optical resin composition comprises the following components by weight: 100% of a mixture A, 0.1-5% of an inorganic material, 0.05-6% of an ultraviolet absorber, 0.01-5% of a mold release agent, 0.01-5% of a polymerization initiator and 0.03-2% of a color modifier. The optical resin composition of the invention can be used for the preparation of optical resin lenses, so that the optical resin lenses have the characteristics of light weight, easy molding, easy dyeing, high transparency and a high Abbe number. After surface spraying, the composition has the advantages of high impact resistance, high heat resistance and high tortuosity ratio.

Owner:JIANGSU QIANYUAN NEW MATERIAL TECH CO LTD

Wood decoration color modifier and method for preparing same

InactiveCN101948645ASimple construction methodUniform color correctionCoatingsChemical industryPhotochemistry

The invention discloses a wood decoration color modifier and a method for preparing the same, which belong to the technical field of chemical industry. The color modifier comprises the following components in percentage by weight: 93 to 96 percent of butyl cellusolve, 0.8 to 3 percent of red color concentrate, 2 to 5 percent of yellow color concentrate and 0 to 0.7 percent of black color concentrate; and a final product is formed by uniformly stirring the components. The wood decoration color modifier has the advantages of simple preparation process, simple and convenient construction method for color modification, uniform color modification and good decoration effect.

Owner:叶明辉

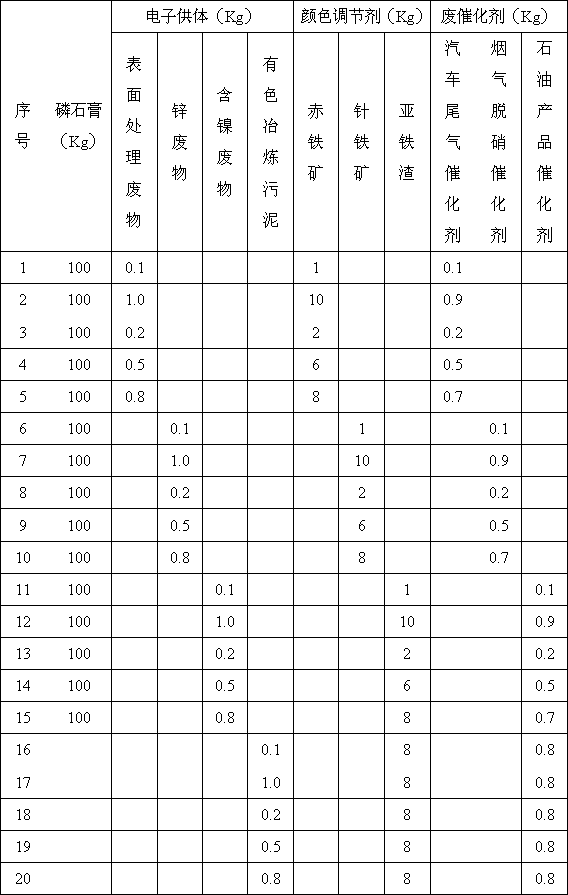

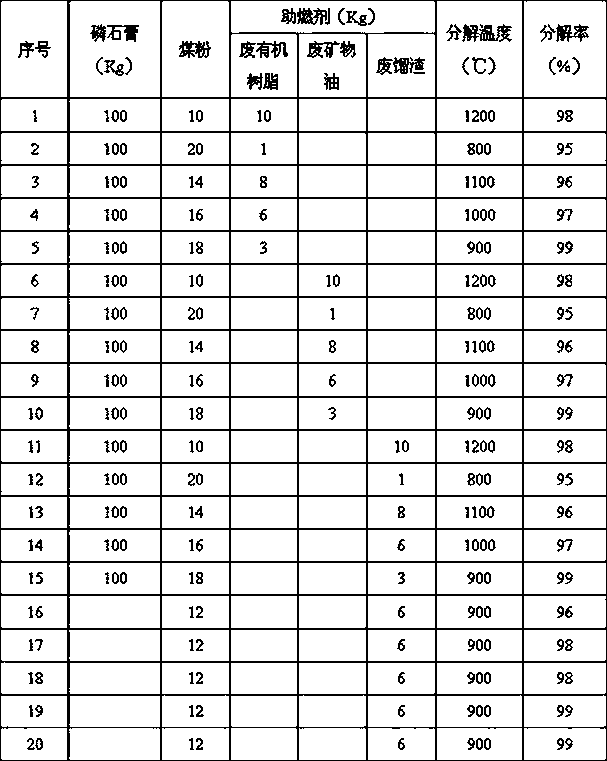

Method for utilizing sulfur and calcium resources in gypsum respectively

ActiveCN109650345ALower decomposition temperatureLow costSulfur compoundsCalcium/strontium/barium oxides/hydroxidesCombustionElectron donor

The invention discloses a method for utilizing sulfur and calcium resources in gypsum respectively, and the method is as follows: adding an electron donor, a color modifier, a waste catalyst and microorganisms into the gypsum, uniformly mixing, aging and drying to obtain a dry material; introducing coal powder and a combustion improver into a boiling furnace to decompose the dry material in the boiling furnace to obtain a sulfur oxide gas and calcium oxide with color. Compared with the prior art, the method has the advantages of low production cost, high production efficiency and thorough decomposition.

Owner:SOUTHWEAT UNIV OF SCI & TECH

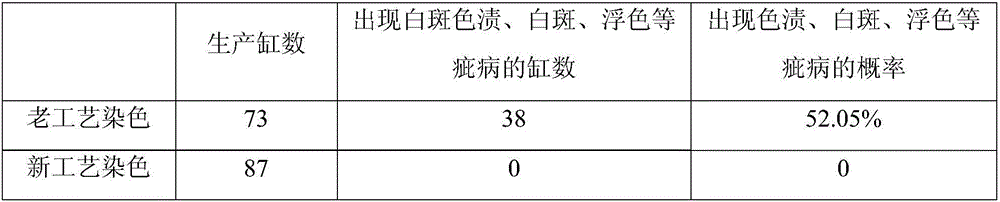

Dyeing method for preventing color spots, hickie and flooding on cloth surface of thin type fabric

InactiveCN105970669AProcess stabilityProcess environmental protectionSucessive textile treatmentsHeating/cooling textile fabricsSodium acetateAcetic acid

The invention relates to a dyeing method for preventing stains, white spots and floating colors on the surface of light and thin fabrics, comprising: pre-treating light and thin fabrics: opening width, pre-shrinking and pre-setting; dyeing: after degreasing once, Add color repair agent HS‑200, high temperature leveling agent, oligomer dispersant, chelating agent, glacial acetic acid and sodium acetate into the dye vat in different batches, the pH of the dye solution is 3.8-4.3, then add dye and disperse After dyeing, wash, dehydrate, arrange, shape, and roll to obtain light and thin fabrics without stains, white spots, and floating colors on the surface of the fabric. The method of the invention greatly improves the problems of color stains, white spots, floating colors and other defects in light and thin fabrics, and the process is stable and simple.

Owner:SHANGHAI CHALLENGE TEXTILE

Modifying color adjustment choices based on image characteristics in an image editing system

InactiveUS8570339B2Choose appropriateReduce colorTexturing/coloringCharacter and pattern recognitionImaging analysisColor modifier

A system and method for dynamically reducing the number of choices by reordering the selectable menu options in each menu of a color adjustment tool based on image content, selections in other menus, and usage history. Color names and color modifiers are reduced and / or reordered through image analysis, with most frequently occurring colors being placed at the top of the menu and excluding less frequently used or unused colors from the menu. Adjustment adjectives are reduced by eliminating nonsensical or rare color adjustment combinations (e.g. make the grays much more colorful, make the blues yellower), and / or reordered based on usage history, either by the individual user or by aggregating over many users.

Owner:XEROX CORP

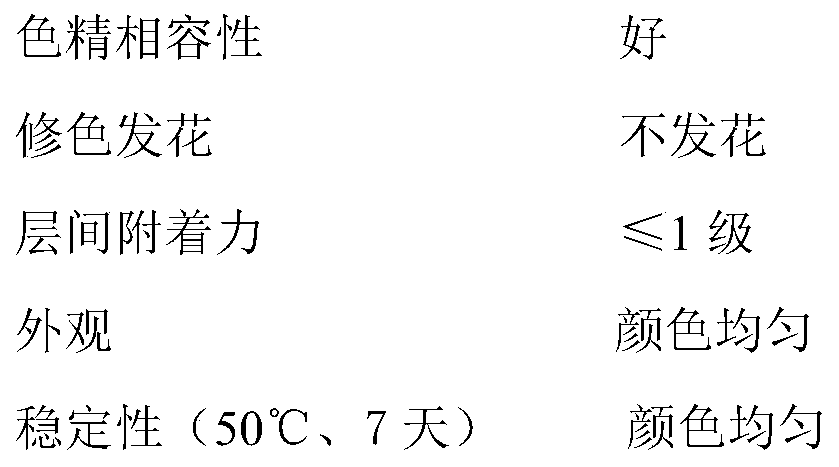

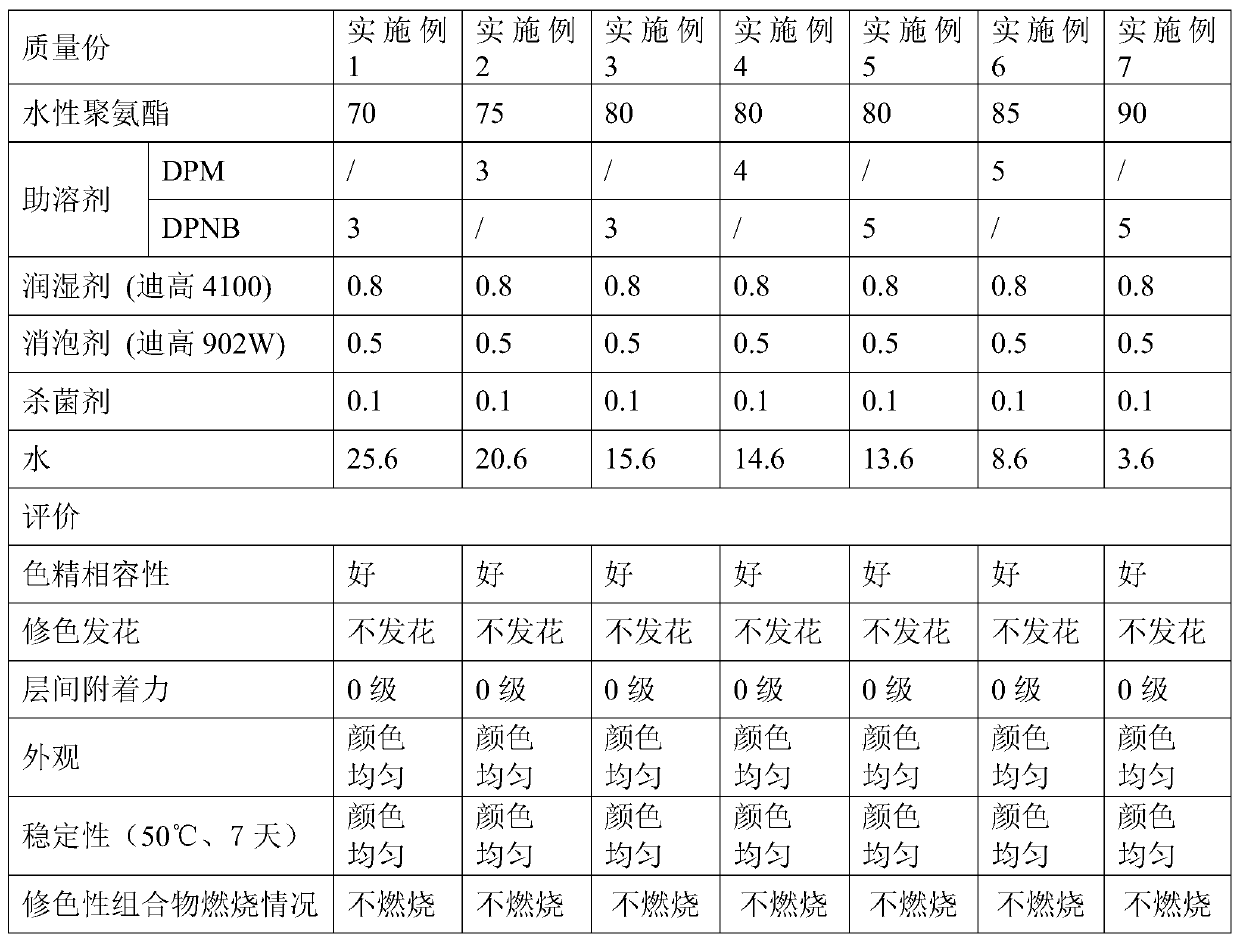

Color repairing composition and preparation method and application thereof

InactiveCN110172295ANo pollution in the processEmission reductionFireproof paintsPolyurea/polyurethane coatingsFoaming agentSolid content

The invention provides a color repairing composition and a preparation method and application thereof. The color repairing composition is prepared from aqueous polyurethane resin, a co-solvent, a wetting agent, an anti-foaming agent, a bactericide and water; the combined quantity of the aqueous polyurethane resin, the co-solvent, the wetting agent, the anti-foaming agent, the bactericide and the water is 100% by weight, wherein the content of the aqueous polyurethane resin is 70-90% by weight, and the solid content of the aqueous polyurethane resin is 32-36%. A color modifier product includingthe color repairing composition is environmentally friendly, free of toxicity and good in flame retardancy, and the fire phenomenon cannot occur during transportation and use.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

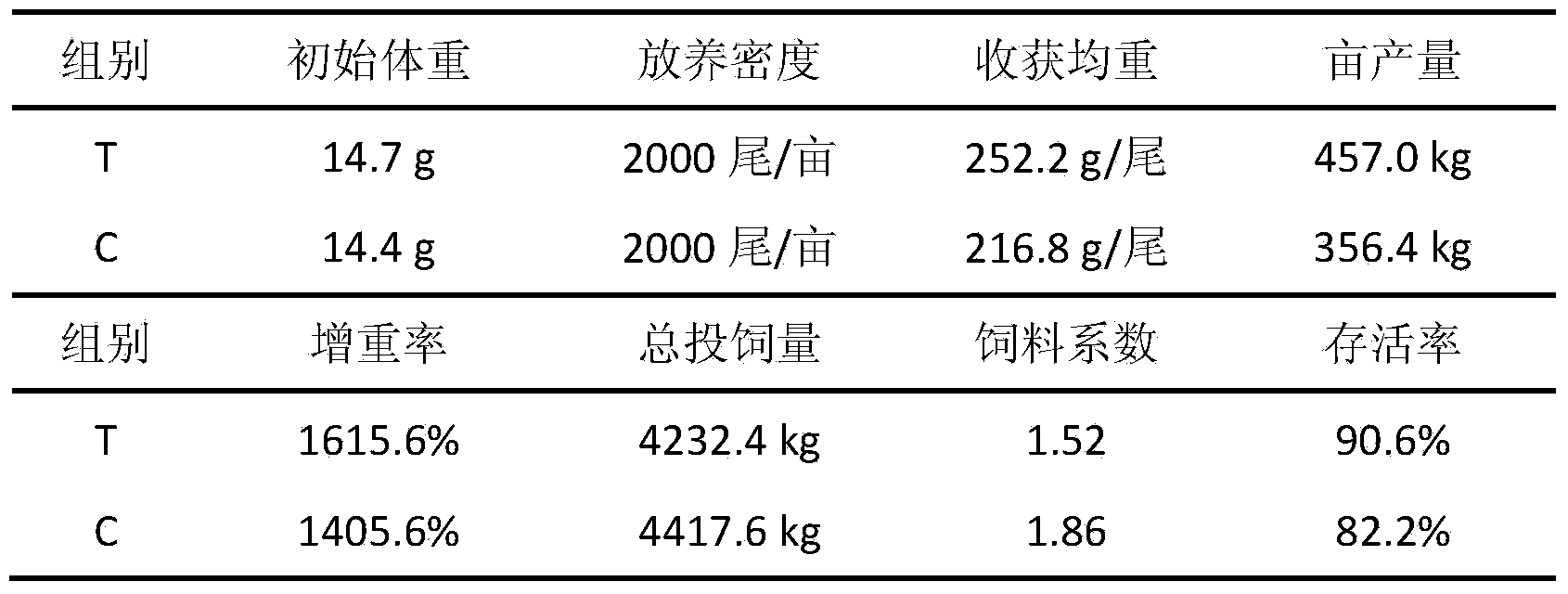

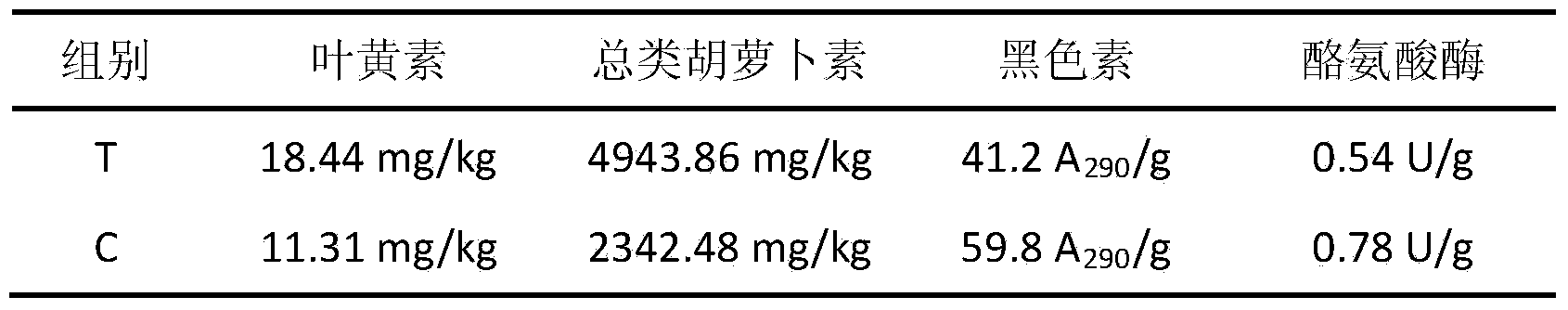

Environment-friendly nutritional compound feed capable of improving body color of sparus latus cultured in pond or net cage

ActiveCN103918949AImprove body colorBody color maintenance and improvementFood processingClimate change adaptationPhytaseVitamin C

The invention discloses environment-friendly nutritional compound feed capable of improving the body color of sparus latus cultured in a pond or a net cage. The compound feed comprises 20%-40% of fish meal, 3%-6% of extruded soybeans, 5%-20% of soybean meal, 5%-15% of peanut meal, 1%-3% of fine bran, 4%-8% of corn protein powder, 15%-30% of flour, 2%-6% of wheat gluten protein, 2%-5% of phospholipid oil, 2%-5% of fish oil, 2%-6% of body color modifier, 0.2%-0.5% of decavitamin, 1%-3% of compound minerals, 0.3%-1% of phagostimulant, 0.05%-0.15% of choline chloride, 0.02%-0.04% of mildew preventive, 0.01%-0.03% of chromium picolinate, 0.2%-0.5% of vitamin C phosphate ester, 0.01%-0.03% of beta-glucan, 0.01%-0.03% of Vitamin E and 0.02%-0.05% of high-temperature-resistant phytase. The environment-friendly nutritional compound feed aims to solve the problem that the body color of the sparus latus is dark when the sparus latus is cultured in the pond or the net cage, promote the sparus latus to grow quickly and enhance the immunity and resistance to diseases of the sparus latus.

Owner:TONGWEI +1

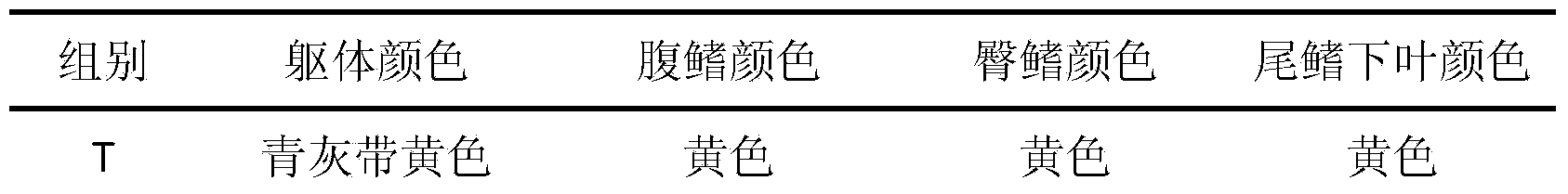

Comprehensive color modifier used for double-face leather and comprehensive color modifying process for double-face leather

The invention provides a comprehensive color modifier used for double-face leather. The comprehensive color modifier comprises a color modifier and a color enhancer; the color modifier comprises 40-70parts by weight of a penetrant, 0.5-1.5 parts by weight of dye water and 30-60 parts by weight of water; the color enhancer comprises 5-20 parts by weight of a penetrant, 5-10 parts by weight of a fatting agent and 70-90 parts by weight of water; and the fatting agent is one or more of a phosphate fatting agent, a lecithin fatting agent, a fish oil type fatting agent and a synthesis fatting agent. The invention also provides a comprehensive color modifying process for the double-face leather. The color modifier and the color enhancer in the specific formula are adopted, the corresponding comprehensive color modifying process is then combined, so that the coloring effect of a leather board is greatly improved, the hand feeling of the leather board is smooth, the oil lubrication feeling isstrong, and the color vividness, and the plumpness and the hand feeling of the surface of the leather board are also improved. In addition, a dye is sufficiently absorbed, the use level of the chemical material is low, the discharge of the three wastes is low, and the process is simple.

Owner:HENAN PROSPER SKINS & LEATHER ENTERPRISE

Method for manufacturing foam material using molten slag

ActiveUS20130161854A1Preserve heatModifies temperatureCeramic shaping apparatusCeramicwareFoaming agentFree cooling

A method for manufacturing a foam material by using a molten slag includes: introducing the molten slag maintained at 1400° C.-1500° C. into a pool for preserving heat, and adding a viscosity modifier and / or a color modifier to the molten slag to adjust a viscosity and / or a color a product manufactured. The molten slag is discharged into a foaming pour while adding a foaming agent to the molten slag, while controlling the foam and mold at 1250° C.-1400° C. The foamed and molded slag is maintained at 800° C.-1000° C. for 20-30 minutes in a non-reducing atmosphere, and then naturally cooled to a room temperature to obtain the foam material. The produced inorganic nonmetal foam material and products thereof have such characteristics as stable color quality, abrasion resistance, pressure resistance, small thermal conductivity, small shrinkage ratio, and excellent sound absorption, adsorption and filtering performances.

Owner:SHANDONG COKING GRP

A kind of multifunctional resin dyeing modifier and preparation method thereof

InactiveCN105459239BHigh densityGood modification characteristicsWood treatment detailsWood impregnation detailsAlcoholWater soluble

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

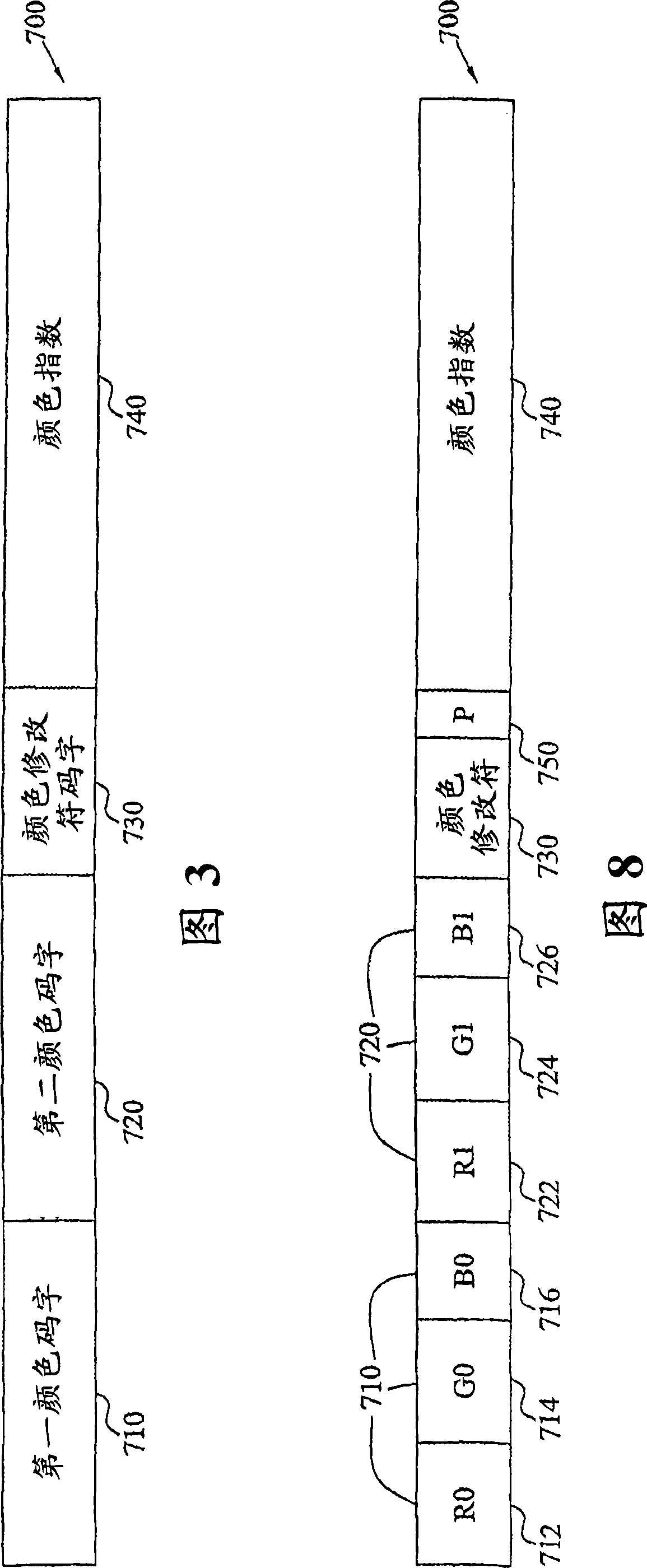

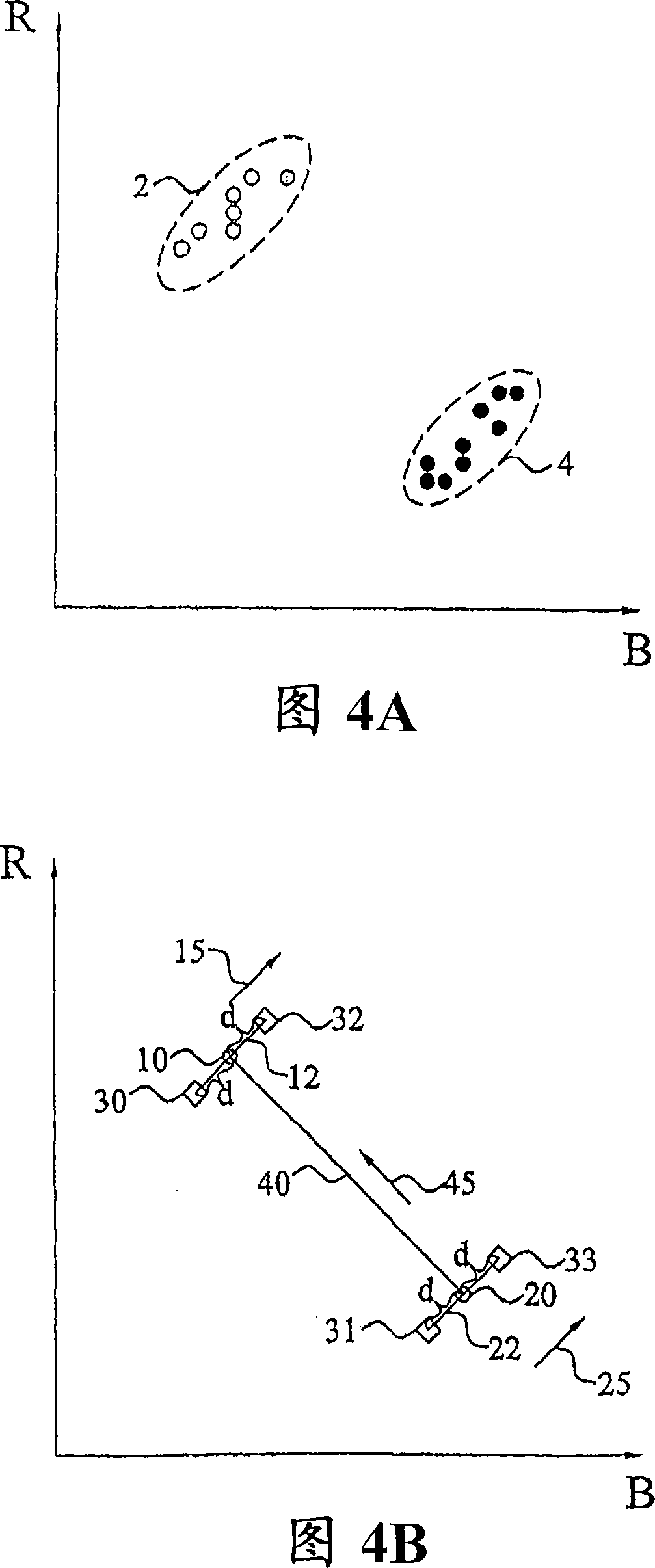

Texture compression based on two hues with modified brightness

In an image-encoding scheme, an input image is decomposed into image blocks (600) comprising multiple image elements (610). The image blocks (600) are then encoded into encoded blocks (700). An encoded block (700) comprises a first color codeword (710), a second color codeword (720), a color modifier codeword (730) and a color index sequence (740). The color codewords (710, 720) are representations of a first and second base color (10, 20) located on a first line (40) in color space. The modifier codeword (730) is a representation of at least one color modifier for modifying the first base color (10) along a second line (12) to obtain multiple color representations (30, 32, 34, 35, 36, 38) along the line (12). The second line (12) has a different direction (15) as compared to the first line (40). The index sequence (740) comprises color indices associated with a color representation selected from i) the representations (30, 32, 34, 35, 36, 38) on the second line (12) and ii) at least one representation (31, 33) based on the second base color (20).

Owner:TELEFON AB LM ERICSSON (PUBL)

Preparation method of floor tile with granite grain

The invention discloses a preparation method of a floor tile with granite grain. The base material of the floor tile is composed of, by weight, 80-85% of phosphogypsum base material, 2-5% of color modifier and the balance water. On the basis of a traditional phosphogypsum-base floor tile, iron-magnesium-aluminum hydrotalcite is added, the floor tile thus has the color of red granite, then the iron-magnesium-aluminum hydrotalcite is mixed with granite and ground together so that the granite grain can be fixed in blocks, and the final prepared floor tile has clear granite grain.

Owner:湖州汇德集团有限公司

Method for manufacturing foam material using molten slag

A method for manufacturing a foam material by using a molten slag includes: introducing the molten slag maintained at 1400° C.-1500° C. into a pool for preserving heat, and adding a viscosity modifier and / or a color modifier to the molten slag to adjust a viscosity and / or a color a product manufactured. The molten slag is discharged into a foaming pour while adding a foaming agent to the molten slag, while controlling the foam and mold at 1250° C.-1400° C. The foamed and molded slag is maintained at 800° C.-1000° C. for 20-30 minutes in a non-reducing atmosphere, and then naturally cooled to a room temperature to obtain the foam material. The produced inorganic nonmetal foam material and products thereof have such characteristics as stable color quality, abrasion resistance, pressure resistance, small thermal conductivity, small shrinkage ratio, and excellent sound absorption, adsorption and filtering performances.

Owner:SHANDONG COKING GRP

Wool coloring modifier

InactiveCN106283744AGood coloring effectImprove dyeing qualityDyeing processPotassium perfluorobutanesulfonatePotassium

The invention relates to a wool coloring modifier, comprising the following components in parts by weight: 9-15 parts of sodium tripolyphosphate, 4-8 parts of fenugreek gum, 3-6 parts of polyethylene glycol, 5-11 parts of hydroxyethyl methylacrylate, 4-7 parts of allyl glycidyl ether, 4-9 parts of sodium oleoyl-N-methyl taurate, 3-6 parts of n-butyl alcohol, and 240-350 parts of water. The wool coloring modifier is characterized by also comprising the following components: polytetrafluoroethylene, polycarbonate, acidic sodium of tungstite, potassium perfluorobutane sulfonate, ethenyl ethanoate, and thermoplastic polyurethane. Compared with the prior art, the wool coloring modifier has the advantages that a wool fabric finished by using the auxiliary agent has better colorability and is high in color fastness after being dyed, and the dyeing quality of the wool fabric is improved.

Owner:江阴市越华毛纺织有限公司

Dyeing technique of beige fabric

InactiveCN103410015ASimple dyeing processMaintain glossDry-cleaning apparatus for textilesDyeing processColour fastnessProduct inspection

The invention discloses a dyeing technique of a beige fabric, which comprises the following steps: raw fabric cylinder matching, pretreatment desizing, hot water cleaning of the raw fabric, heating and dyeing, cooling and cleaning, discharging and waterproof setting, finished product inspection and finished product rolling, wherein the desizing assistant in the pretreatment desizing step is composed of 80kg / l liquid alkali and 2 kg / l desizing agent; in the heating and dyeing step, 0478 gram of 2BLW blue dye, 0.665 gram of E-GL yellow dye and 0.861 gram of 3B red dye are added to every kilogram of fabric; and after the dyes are proportioned, 3kg / l 825 leveling agent, 3kg / l glacial acetic acid and 0.8kg / l color modifier are added to the dyeing assistant. The dyeing technique disclosed by the invention is simple and uses small amounts of assistant, thereby achieving the optimal dyeing effects of uniformity and penetration, ensuring the high dyeing glossiness and high color fastness after dyeing, and obviously enhancing the dyeing intensity and heat and light fastness.

Owner:苏州市富达化纤印染有限公司

Component specific image modification using natural language color

Embodiments described herein include a component specific natural language color unit for modifying colors of image components in an image using component specific natural language commands. The CSNLC unit can receive a component specific natural language color command for a color modification of an input image. The component specific natural language color command can include a component identifier and a color modifier. The natural language command can be parsed to attribute the component identifier to an image component in the input image and to attribute the color modifier to a predefined color space associated with the image component. The color modifier can indicate the color modification to be performed. The color modification can be applied to the image component to adjust the color of the image component.

Owner:XEROX CORP

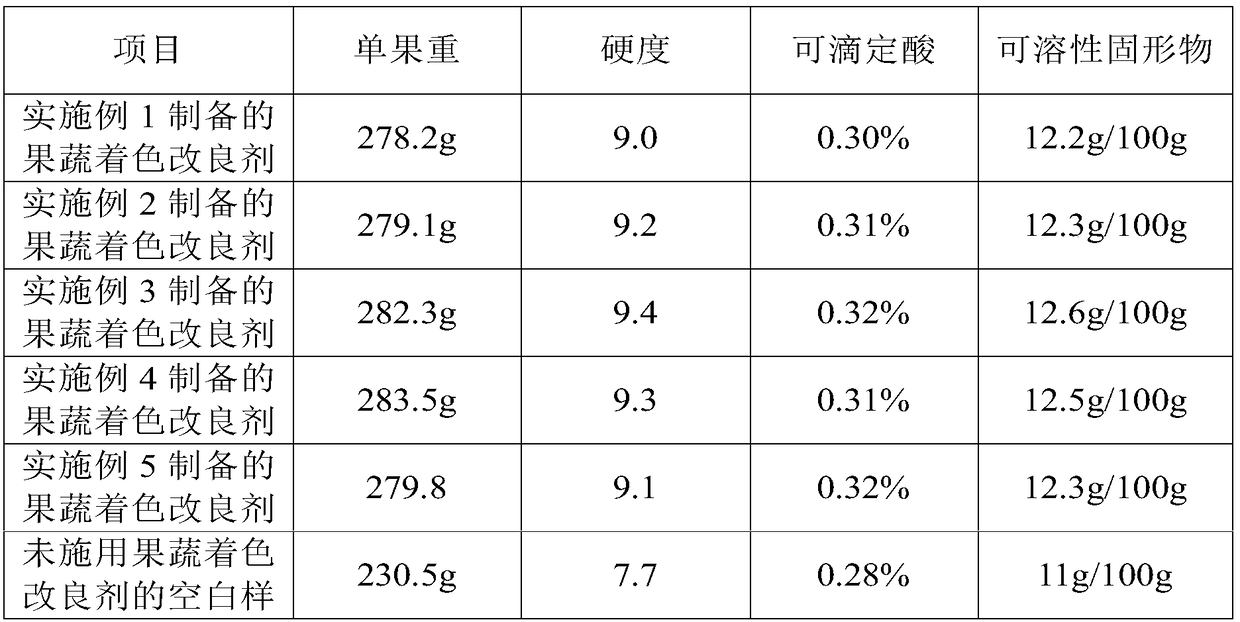

Fruit-vegetable coloring modifier

InactiveCN108835511AGood colorColoring helpsFood ingredient as colourWater bathsUltrasonic dispersion

The invention discloses a fruit-vegetable coloring modifier which comprises the following raw materials: polyphosphate ascorbic acid, alginate polysaccharide, samarium nitrate, calcium phosphate, acetic acid and water. A preparation method of the modifier comprises the following steps: adding water into the samarium nitrate to prepare samarium nitrate solution; weighing alginate polysaccharide, pouring the alginate polysaccharide into a container, adding water into the container for ultrasonic dispersion, transferring the mixture into a constant temperature water bath case for water-curing treatment, dropping the mixture into the samarium nitrate solution, increasing the water bath temperature for reaction for 2h-4h after dropping is ended, so as to obtain a product, and filtering, washingand drying the product, so as to obtain a complex of samarium-alginate polysaccharide; adding the polyphosphate ascorbic acid into water, uniformly stirring the mixture, adding the complex of samarium-alginate polysaccharide into the mixture and uniformly stirring the mixture, so as to obtain the fruit-vegetable coloring modifier. The fruit-vegetable coloring modifier has the advantages of improving appearance of fruits and being safe, environmentally friendly, non-toxic and economic.

Owner:西安日日昕生物科技有限公司

Polypropylene BOPP color modifier

A polypropylene BOPP color modifier is prepared from the following raw materials in parts by weight: 35-55 parts of modified polyvinyl chloride resin, 5-10 parts of high-performance accelerator, 15-20parts of absolute ethanol, 3-8 parts of octadecylamine, 5-10 parts of hydrogen peroxide, 1-3 parts of tallow diamine dioleates, 0.5-1.5 part of polyphenyl phosphite, 5-8 parts of triethylene glycol diheptanoate. The color modifier prepared by the modified PVC resin has excellent stability, good gloss and transparency on the one hand, and will not affect the polypropylene BOPP on the other hand. The content of urethane bond formed by the reaction of cyanate ester group in the accelerator and hydroxyl group increases, the molecular bonding force formed on the surface of the polypropylene BOPP increases, thereby enhancing the adhesion. Therefore, the color modifier prepared by the high-performance accelerator has excellent adhesion to the polypropylene BOPP, and does not affect the transparency and brightness of the color modifier.

Owner:江苏汉光实业股份有限公司

Wooden floor white edge sap stain and preparation method thereof

InactiveCN107020676AConsistent colorFully extractedWood treatment detailsCork treatment detailsRoom temperatureStain

The invention relates to wooden floor white edge sap stain and a preparation method thereof. Bar is cut into a block with the length ranging from 40 mm to 150 mm and the width ranging from 20 mm to 40 mm; the curtal bark is immersed in an alkaline solution with the pH value not smaller than 8.5 for 4-12 hours under the conditions of the normal temperature and shading, stirring is regularly carried out for 1-3 times in the immersing process, and the mass ratio of the bar to the alkaline solution ranges from 1 Kg: 5Kg to 1 Kg: 10 Kg; and the soak solution is filtered, the obtained filtrate is the wooden floor white edge sap stain. According to the wooden floor white edge sap stain and the preparation method therefore, the bar abandoned during wood processing serves as a raw material, the pigment in the bark is extracted through alkaline solution immersing, the leach liquor is smeared to the white edge, equivalently, the white edge is colored, the pigment of the leach liquor is extracted from the bar for making the floor material, and the color of the colored white edge and the color of a core material are basically consistent.

Owner:湖北燕加隆木制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com