Medium-temperature aluminum oxidation aftertreatment agent

A post-treatment agent, aluminum oxidation technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of color fading, poor hardness, short service life of sealed workpieces, etc., to achieve easy dusting, excellent Brightness, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

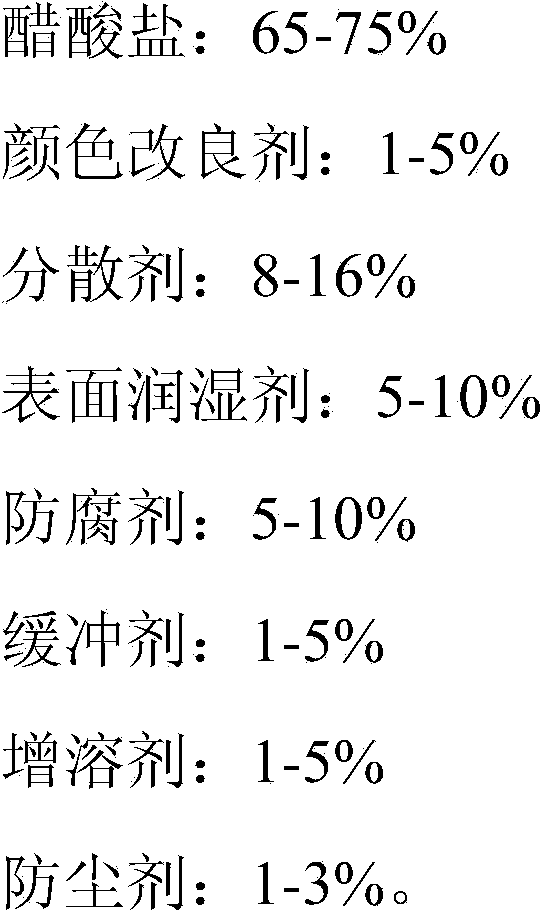

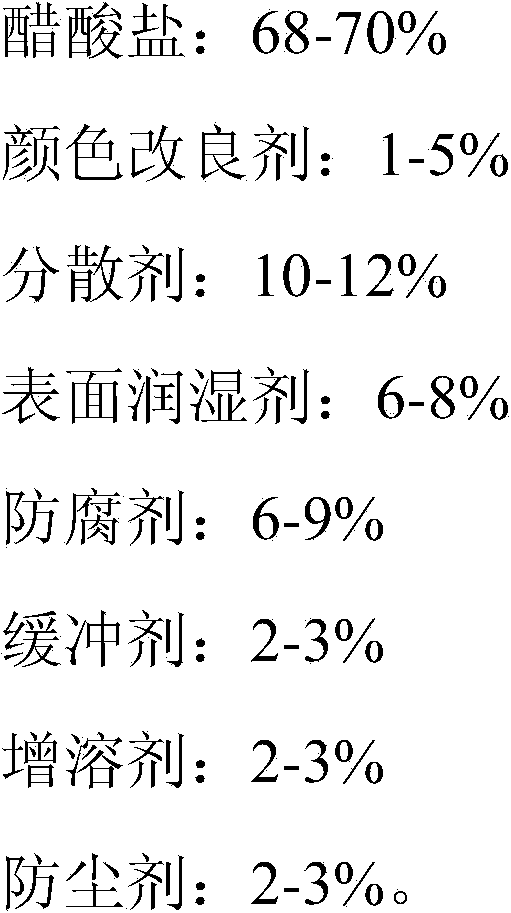

Method used

Image

Examples

Embodiment 1

[0025] 1. Aluminum alloy anodizing process:

[0026] (1) Pretreatment

[0027] Immerse the aluminum alloy as the base material in a 140g / L-180g / L sulfuric acid solution at room temperature for 3-5 minutes, and wash off the degreasing liquid on the surface with clean water.

[0028] Immerse the above-mentioned base material for degreasing and wax removal in 50-60 g / L sodium hydroxide solution (containing alkali etching additive) at 40° C. to 60° C. for 3-8 minutes to complete the alkali etching step. Immerse the alkali-etched sample in 120g / L-150g / L sulfuric acid and 40g / L-50g / L nitric acid solution at room temperature for 2-5 minutes to emit light. Immediately immerse in clean water to wash away any residual acid on the surface.

[0029] (2) Anodizing

[0030] Immerse the sample that has been pretreated in a 150-170g / L sulfuric acid solution at a temperature of 18°C-22°C, and use 1.3A / dm 2 Oxidize at a current density for 30 minutes, and the thickness of the oxide film is ...

Embodiment 2

[0042] A medium-temperature aluminum oxidation post-treatment agent is prepared by mixing the following components by weight percentage:

[0043] Nickel Acetate: 65%, Cobalt Acetate: 1%, Sodium Naphthalene Methylene Sulfonate: 11%, Sodium Naphthalene Methylene Sulfonate: 8%, Benzoic Acid: 9%, Disodium Hydrogen Phosphate: 2%, Polyamide : 2%, sodium polyacrylate: 2%.

[0044] According to the above mass into a solution, Ni 2+ The concentration is 0.8g / L, pH5.8.

[0045] The surface of the aluminum material treated with this treatment agent is smooth and flat, with excellent brightness, and the film pores are free of powder and frost.

[0046] Put the dried sample into the Alizarin Red solution for staining, and select the sealing agent according to the depth of the stained surface. In this example, the coloring effect of the aluminum material is poor, indicating that the sealing effect is good.

[0047] Phosphorus-chromic acid weight loss method is used to detect the sealing...

Embodiment 3

[0049] A medium-temperature aluminum oxidation post-treatment agent is prepared by mixing the following components by weight percentage:

[0050] Nickel acetate: 68%, cobalt acetate: 1%, sodium methylenebisbenzylsulfonate: 10%, sodium cetylbenzenesulfonate: 7%, sodium benzoate: 8%, sodium citrate: 2%, Polyamide: 2%, Polyacrylamide: 2%.

[0051] According to the above mass into a solution, Ni 2+ The concentration is 0.9g / L, pH6.0.

[0052] After being treated with this treatment agent, the surface of the aluminum material is smooth and smooth, with excellent brightness and no powder or frost in the film pores.

[0053] Put the dried sample into the Alizarin Red solution for staining, and select the sealing agent according to the depth of the stained surface. In this example, the coloring effect of the aluminum material is poor, indicating that the sealing effect is good.

[0054] Phosphorus-chromic acid weight loss method is used to detect the sealing quality of the oxide f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com