Method for rapidly repairing and reinforcing high and steep landslide

A fast, high-steep technology, applied in excavation, sheet pile walls, construction, etc., can solve problems such as economic property loss, deep damage, and reinforcement failure, and achieve good theoretical significance and economic value. The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

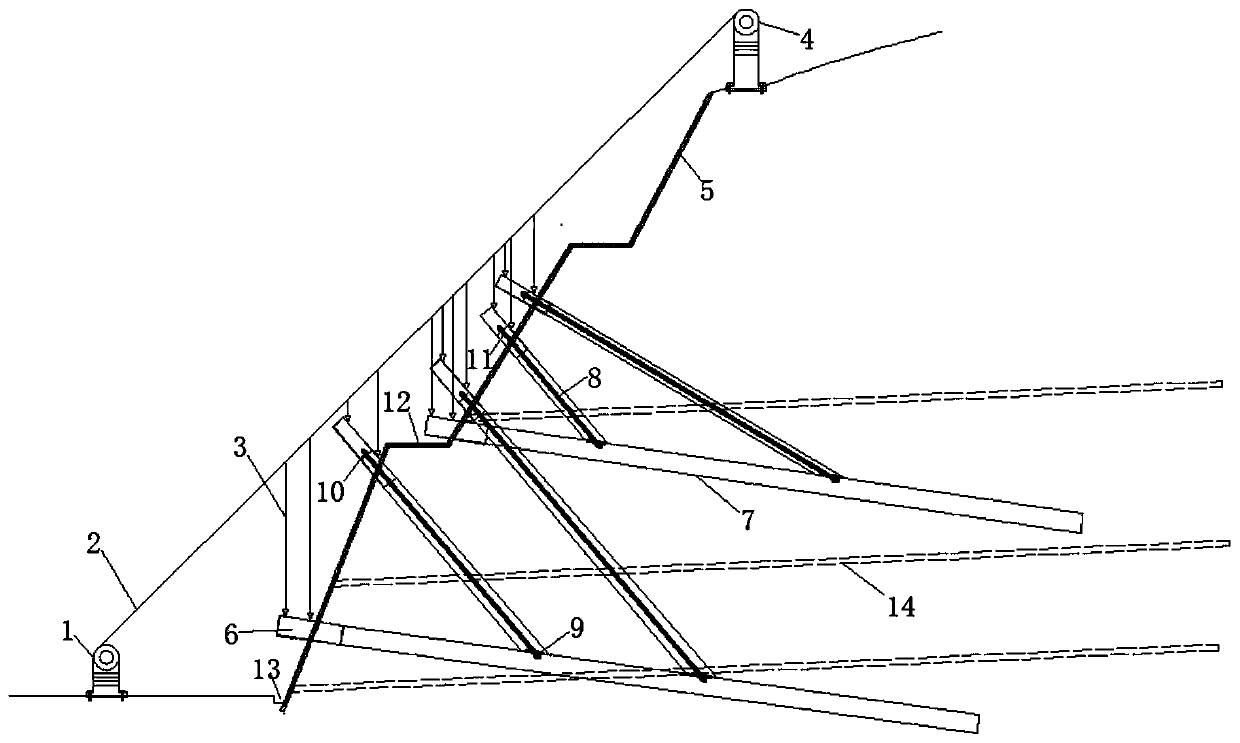

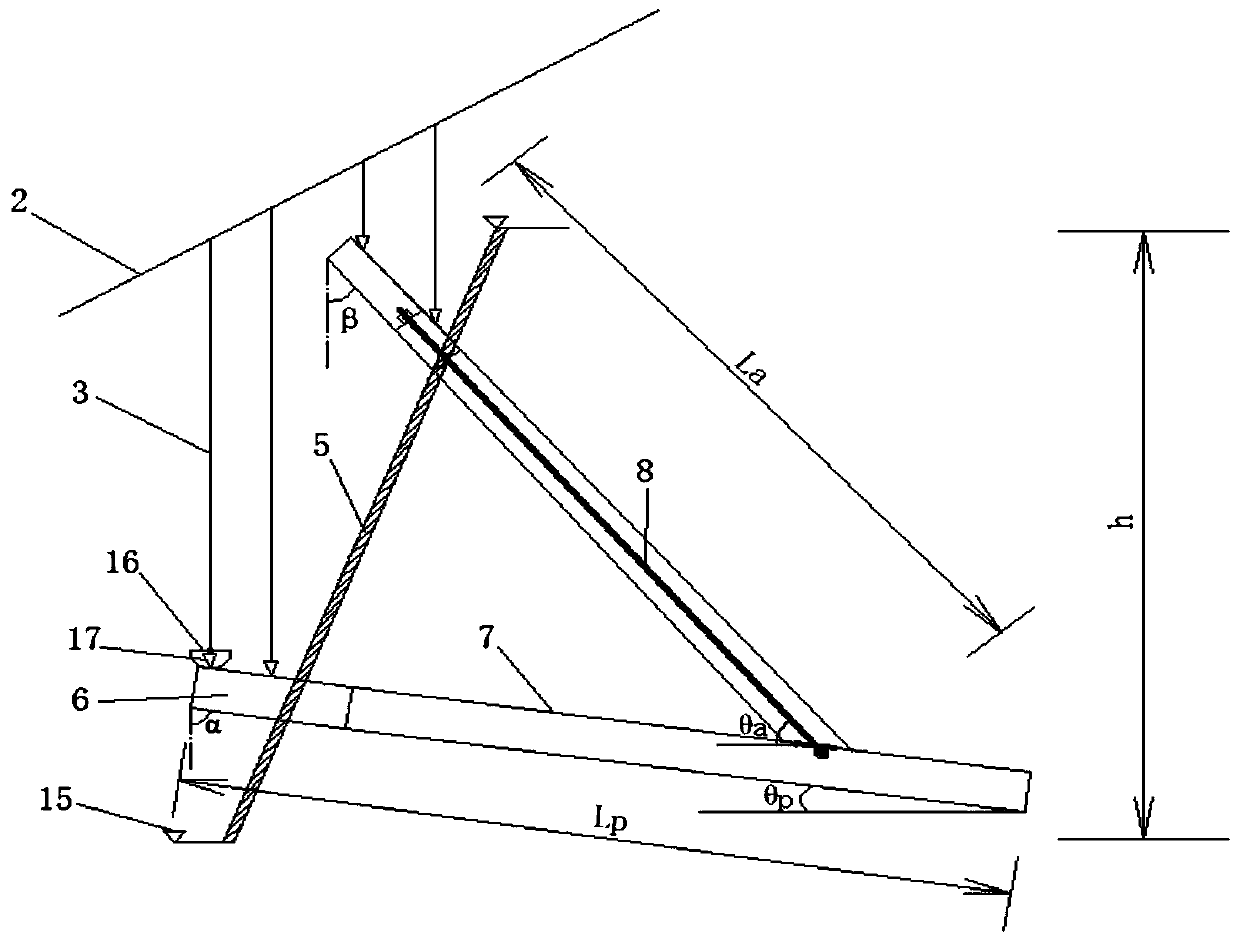

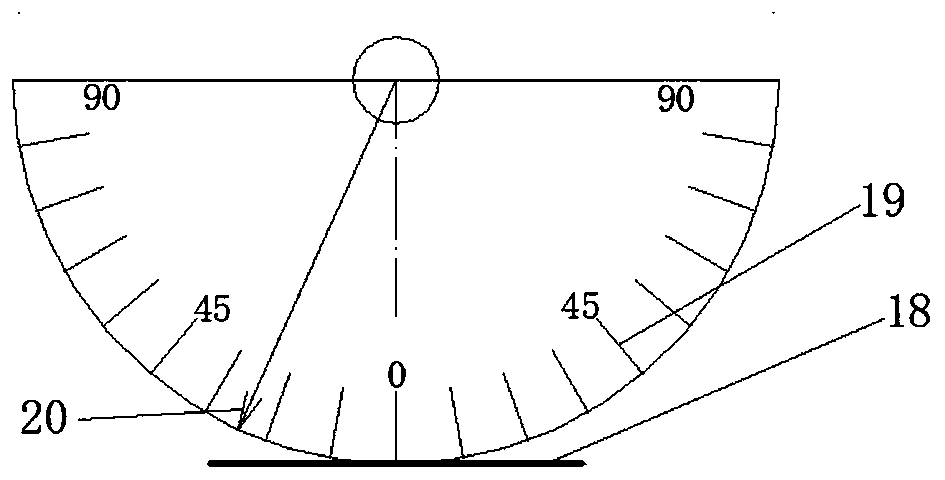

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] see Figure 1 to Figure 6 , the high and steep slope in the present embodiment is an earthy slope structure, and the steps of applying the high and steep landslide rapid repair and reinforcement method of the present invention are as follows:

[0034] (1) Remove the slides accumulated at the bottom of the slope and compact the soil at the bottom of the slope.

[0035] (2) The power frame A1 and the power frame B4 are respectively installed at the stable soil layer at the bottom of the slope and the slope shoulder, and the power frame A1 and B4 are fixed on the steel backing plate 22, and then the steel backing plate 22 and the steel backing plate 22 are connected by the base fixing bolts 23. Slope body, wire rope 2 is installed on power frame A1, B4 again, by power frame A1, B4 top groove 25, rotating runner 24 tightens wire rope 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com