Patents

Literature

233results about How to "Maintain gloss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cigarette tipping paper water-based ink and preparation method

The invention discloses cigarette tipping paper water-based ink and a preparation method, belonging to the technical field of water-based ink. The water-based ink is characterized by consisting of the following raw materials in parts by weight: 50-60 parts of water-based emulsion resin oil, 10-20 parts of iron oxide pigment, 10-20 parts of de-ionized water and 0.5-1.0 part of one or more of auxiliary agents of defoaming agent, anti-sedimentation agent, leveling agent, wetting agent, antibacterial agent, wetting dispersant and surface tension agent. The cigarette tipping paper water-based ink has the advantages of small fineness, high drying speed, high consistency, low viscosity, good dispersion stability, no setting precipitate, no agglomeration, no toxicity, no residual peculiar smell, good wet leveling property, good color development, no brittle fracture at a low temperature, no edge folding during drying, good water resistance, full and clear print, stable color, smooth and glossy surface, good storage stability and wide application range to printing raw paper and printing speed; and the cigarette tipping paper water-based ink can be produced by the method.

Owner:义乌市伟航水性油墨有限公司

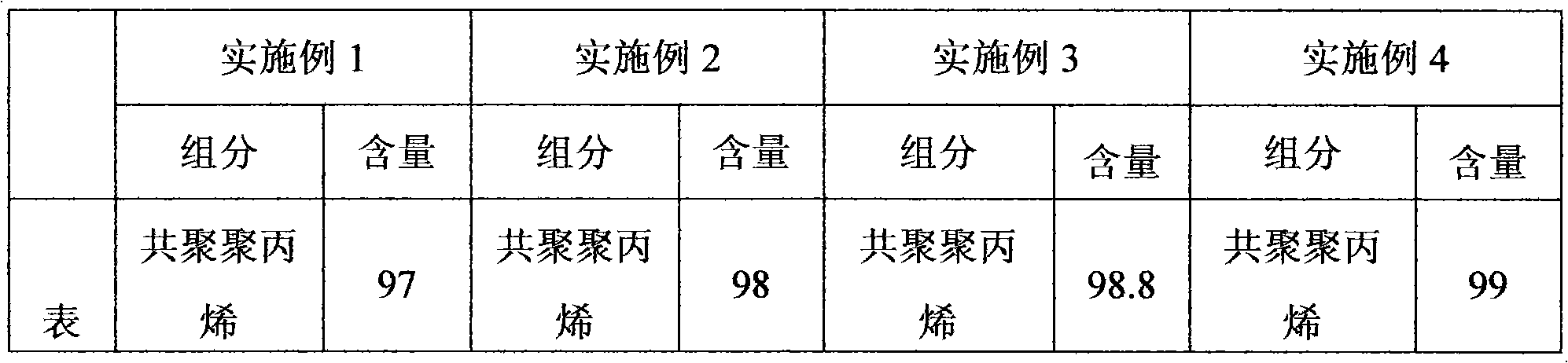

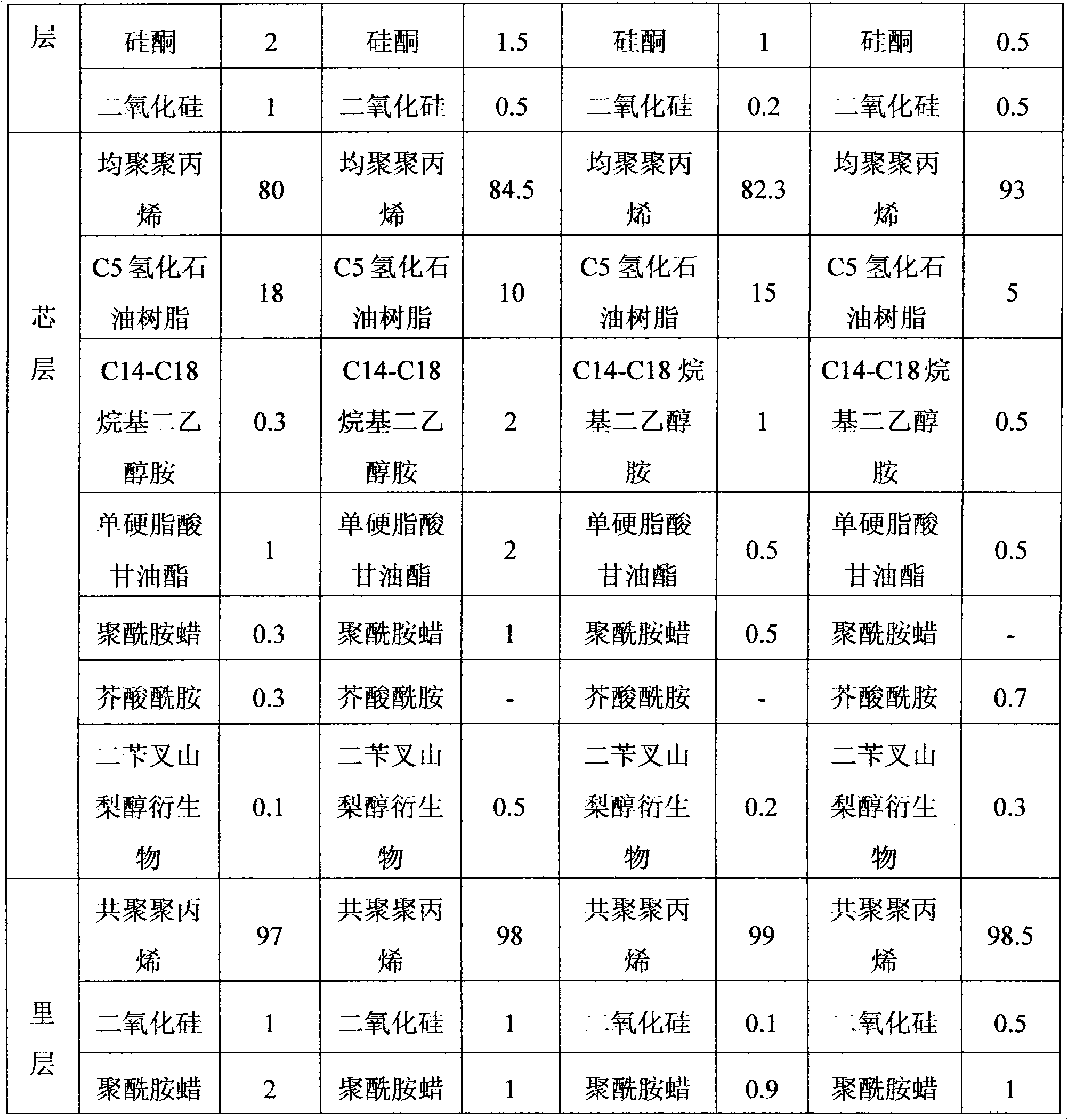

Thermal shrinkage biaxially oriented film

InactiveCN102059836ACrystallization perfectHigh heat shrinkageSynthetic resin layered productsTime changesAcrylic resin

The invention discloses a thermal shrinkage biaxially oriented film which is composed of a surface layer, a sandwich layer and an inner layer, wherein the thickness of the surface layer is 0.5-1.5 micrometers, the thickness of the sandwich layer is 19-22 micrometers, the thickness of the inner layer is 0.5-1.5 micrometers, and the total thickness of the three layers is 20-23 micrometers. The surface layer comprises the following components in percentage by weight: 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The sandwich layer comprises 80-93% of acrylic resin homopolymer, 0.3-3% of anti-static agent, 0.1-0.5% of crystal regulator, 1-2% of surfactant, 5-18% of stiffening agent and 0.5-1% of lubricant. The inner layer comprises 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The film has a stable thermal shrinkage factor which slightly changes as the storage time changes.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

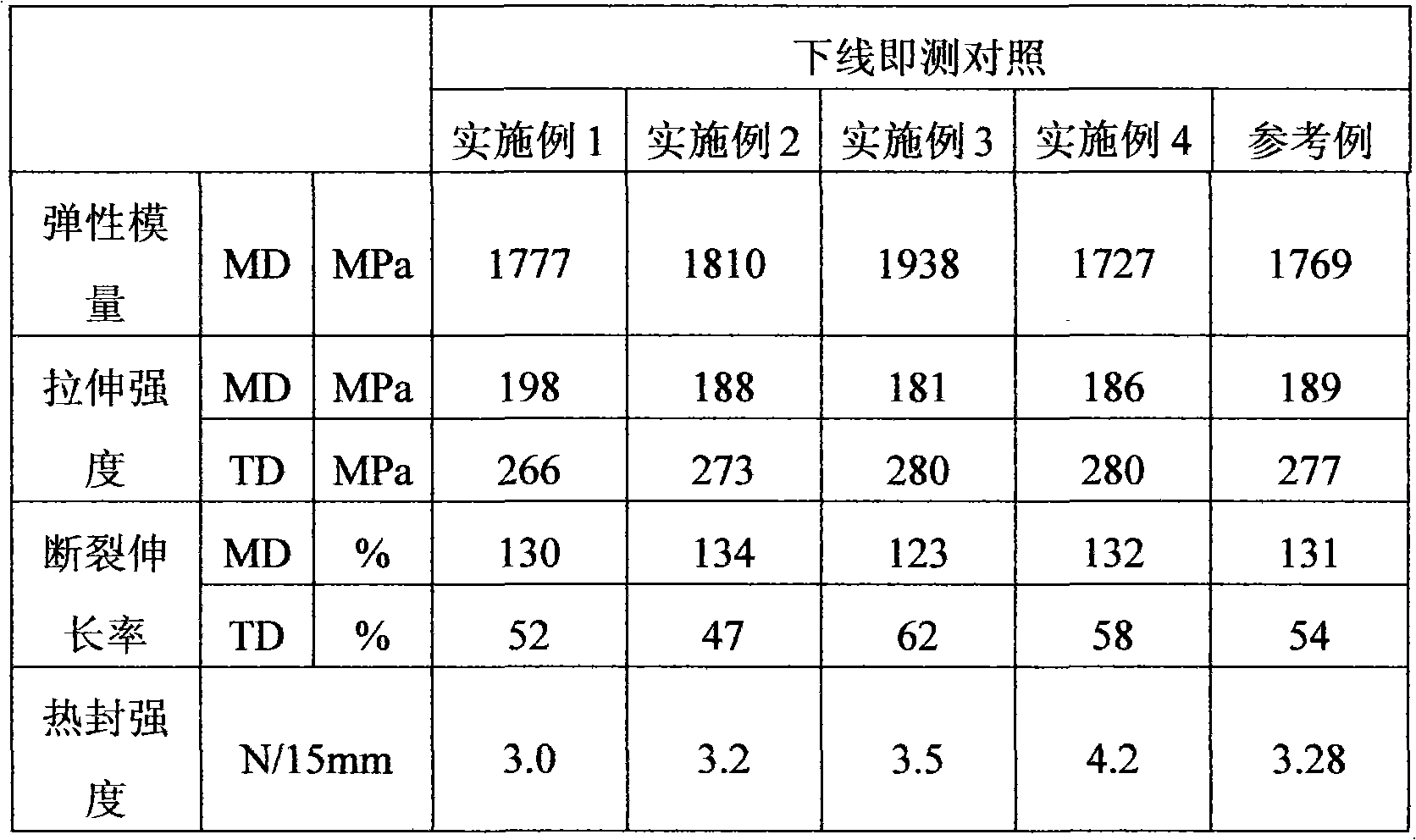

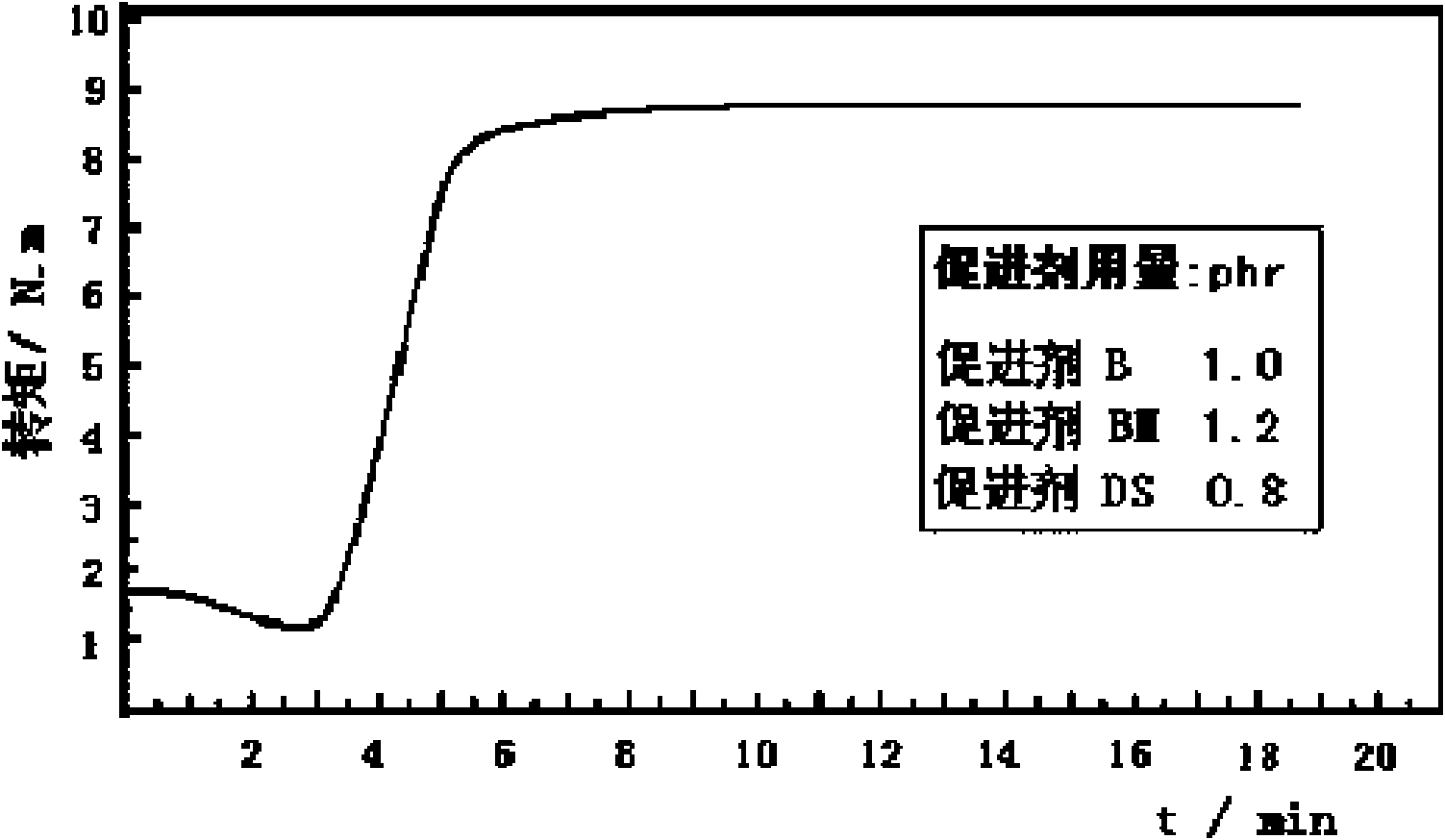

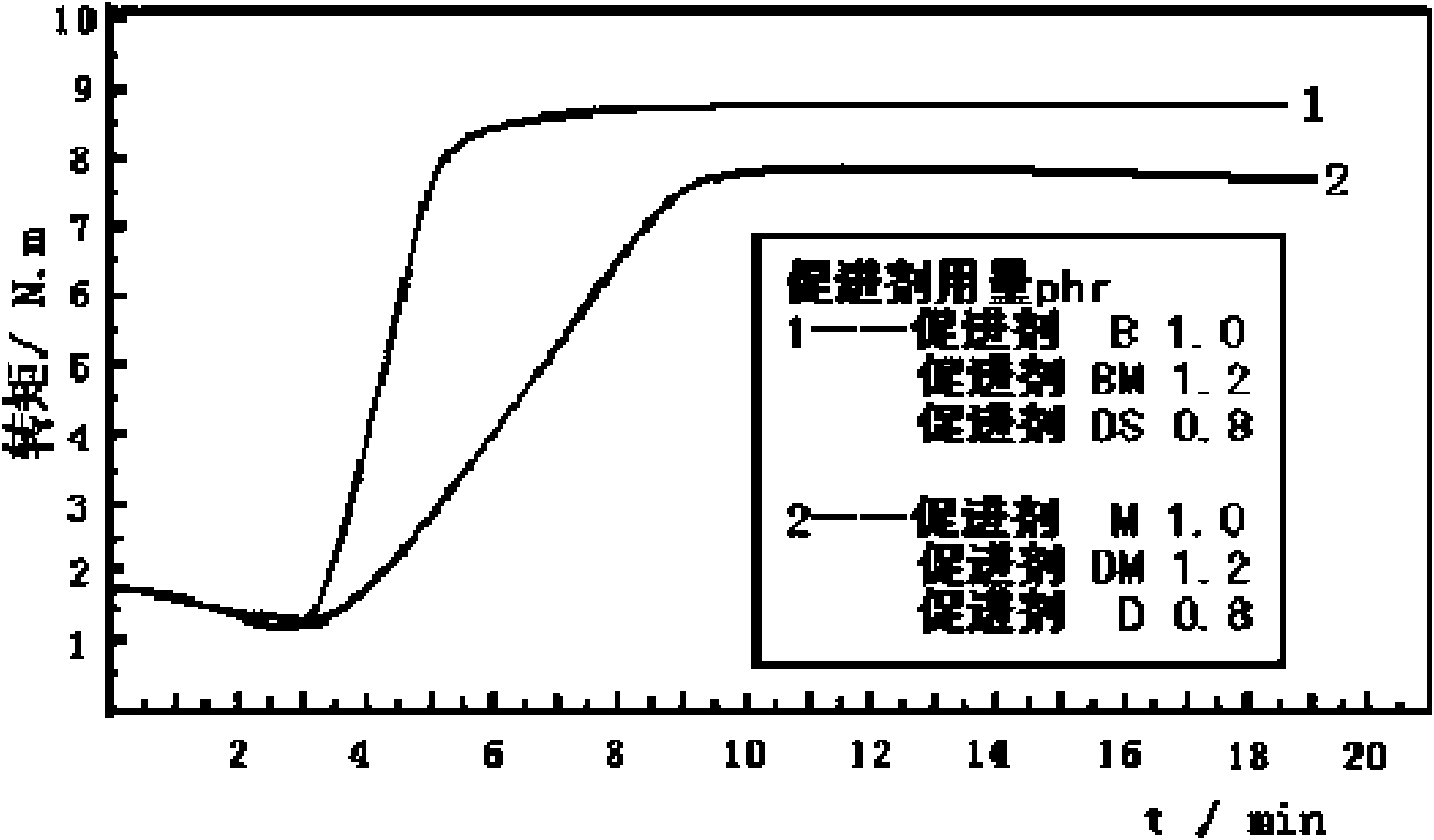

Vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and preparation method and vulcanization process thereof

The invention discloses a vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and a preparation method and a vulcanization process thereof. The vulcanized rubber isprepared from natural rubber, styrene-butadiene rubber, butadiene rubber, accelerator B, accelerator BM, accelerator DS, nanometer zinc oxide, rubber softening oil, sulphur, stearic acid, aging resister CD, carbon black N330, pine tar oil, solid coumarone, reclaimed rubber and pot clay. Compared with the prior art, the vulcanized rubber of the invention has suitable starting time of vulcanization,faster velocity of vulcanization and higher thermal oxidative aging property, the vulcanization efficiency is increased, and the heat-conducting property, processing safety and storage property of the rubber are increased in the vulcanization process; the provided vulcanization process can effectively shorten the vulcanization time, improve the vulcanization quality and increase the vulcanizationefficiency to 2-3 times of the original one.

Owner:JIHUA 3537 SHOE MAKING

Interference-flash-point-free anti-dazzle glass, etching solution preparation method and production technology

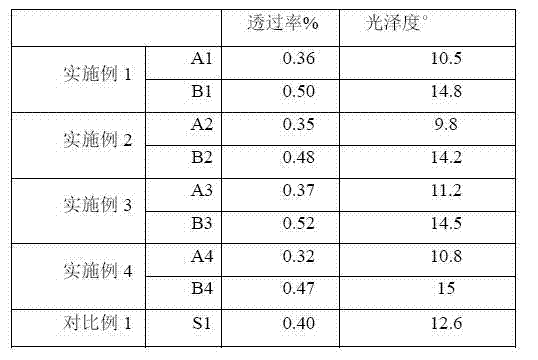

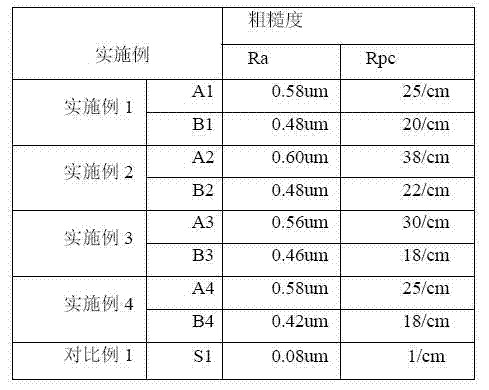

The invention relates to interference-flash-point-free anti-dazzle glass. The glass is characterized by comprising a glass substrate, wherein the glass substrate is provided with a light-in surface, and the other side face, opposite to the light-in surface, of the glass substrate is a light-out surface; the light-out surface of the glass substrate is processed through etching to form a rough surface with a concave-convex structure; according to the definition of surface roughness of the light-out surface, Ra is in the range of 0.06-0.18 micrometer, Rsm is in the range of 15-40 micrometer, andRz is in the range of 0.65-1.5 micrometers; the glossiness of the 60-degree angle of the light-out surface is in the range of 45-85 SGU. The glass has the advantages that the glass is simple in structure, good in wear resistance and long in service life, the glossiness of existing anti-dazzle glass can be kept, and no interference flash point appears during application. The invention further relates to a preparation method of a glass frosting etching solution and a production technology of the interference-flash-point-free anti-dazzle glass.

Owner:佛山市庆通玻璃科技有限公司

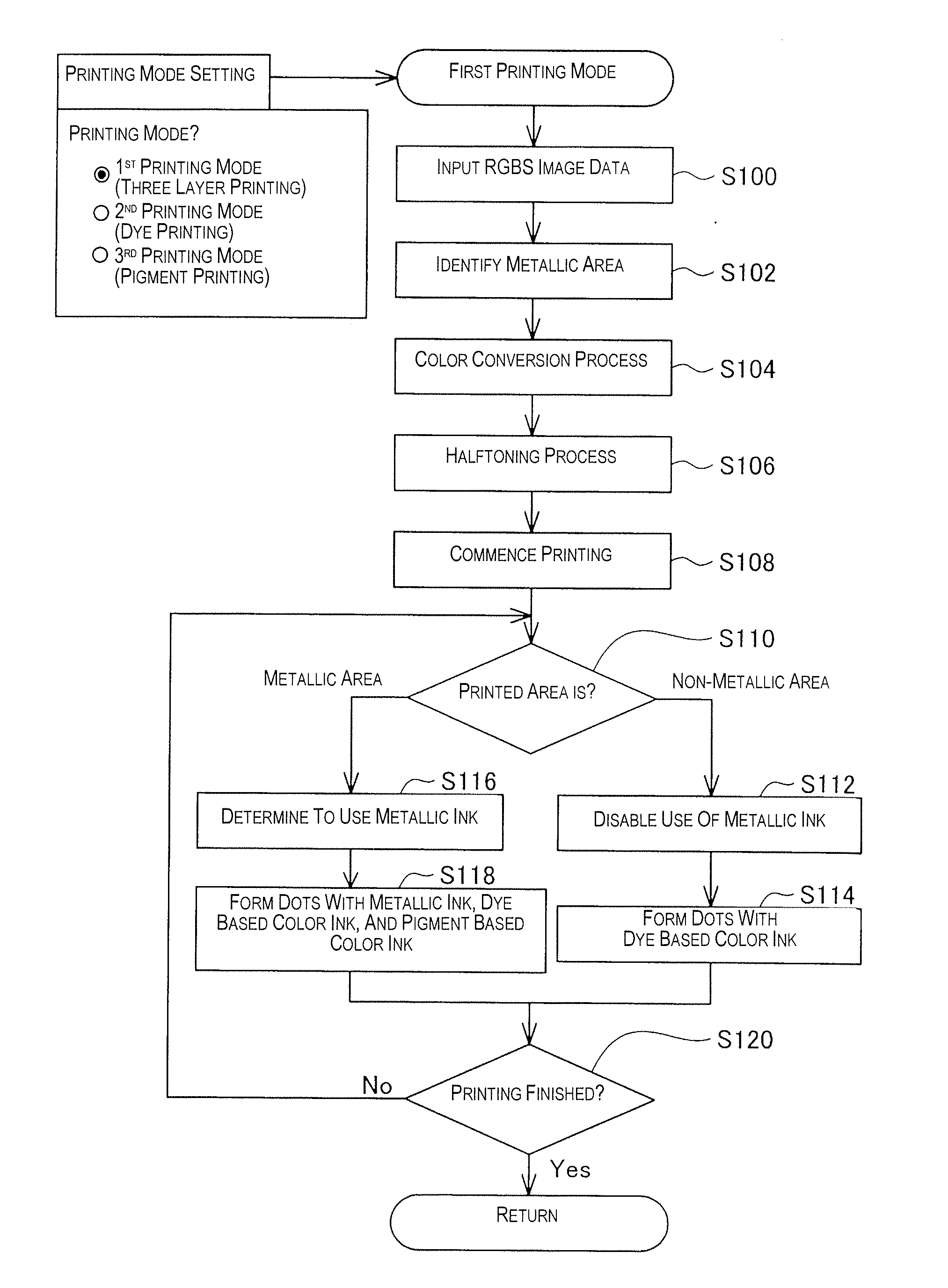

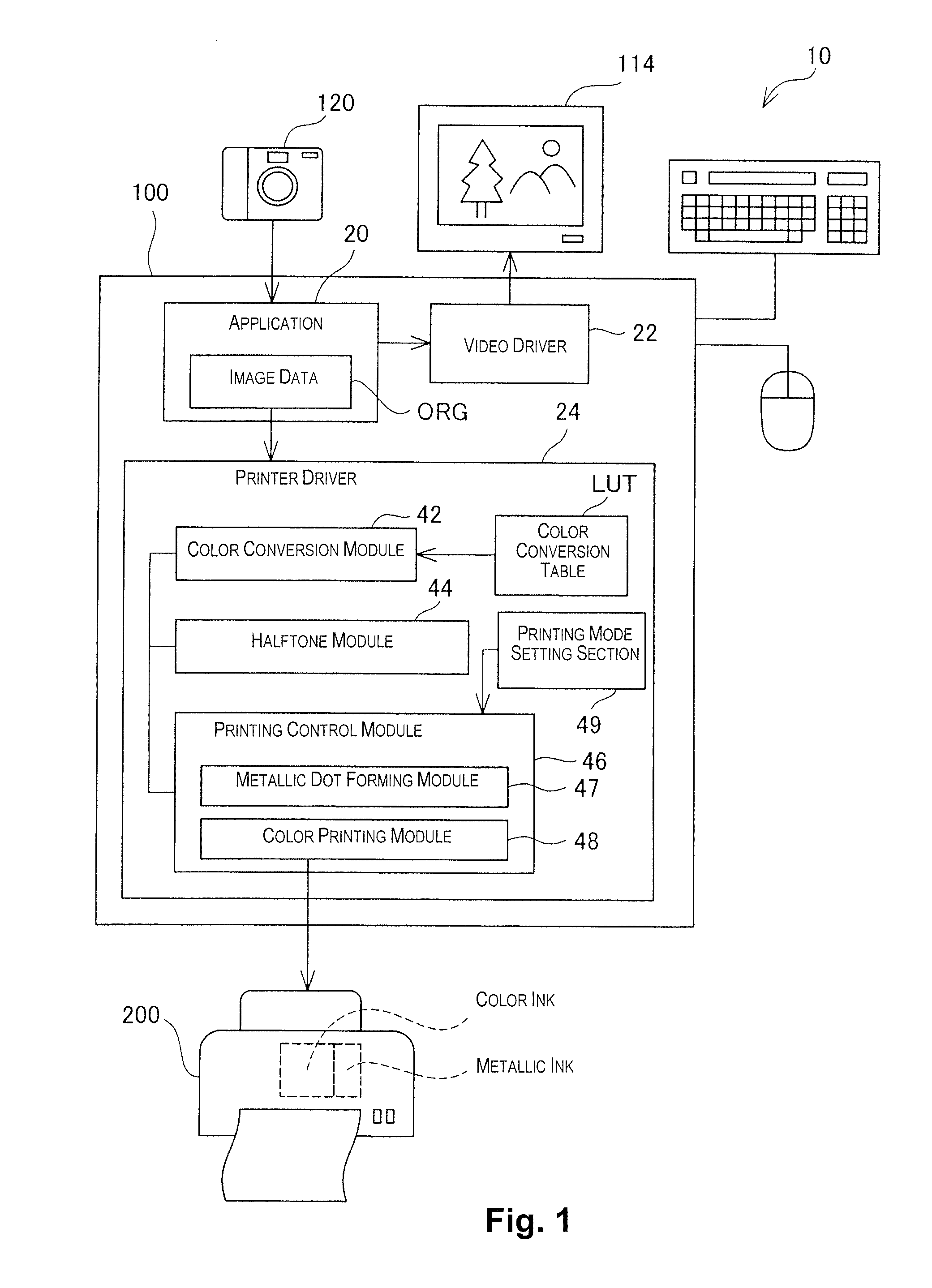

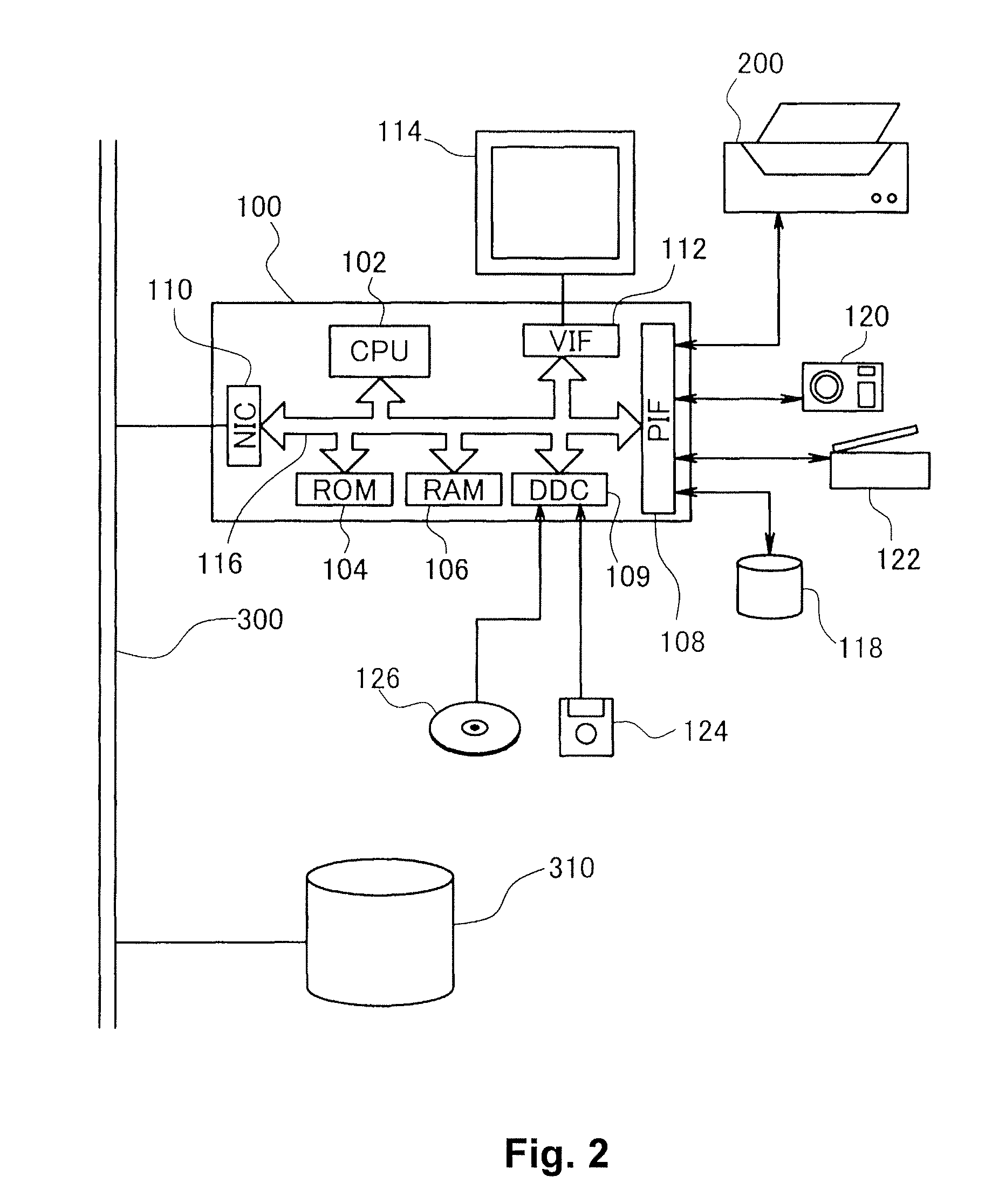

Printing device and printing method

ActiveUS20110221805A1High saturationMaintain glossDuplicating/marking methodsTypewritersEngineeringBlocking layer

The printing device for carrying out printing on a translucent printing medium includes: a print head having a first applying portion for applying a first color material onto the printing medium, a second applying portion for applying a second color material, and a third applying portion for applying an opaque specialty ink; a conveying portion for conveying the printing medium relative to the print head; and a printing control portion configured to execute printing according to a printing mode in which a first color-producing layer of the first color material is formed on the conveying printing medium using the first applying portion, an opaque light-blocking layer of the specialty ink is formed using the third applying portion, and a second color-producing layer of the second color material is formed over the light-blocking layer using the second applying portion after the light-blocking layer is formed.

Owner:SEIKO EPSON CORP

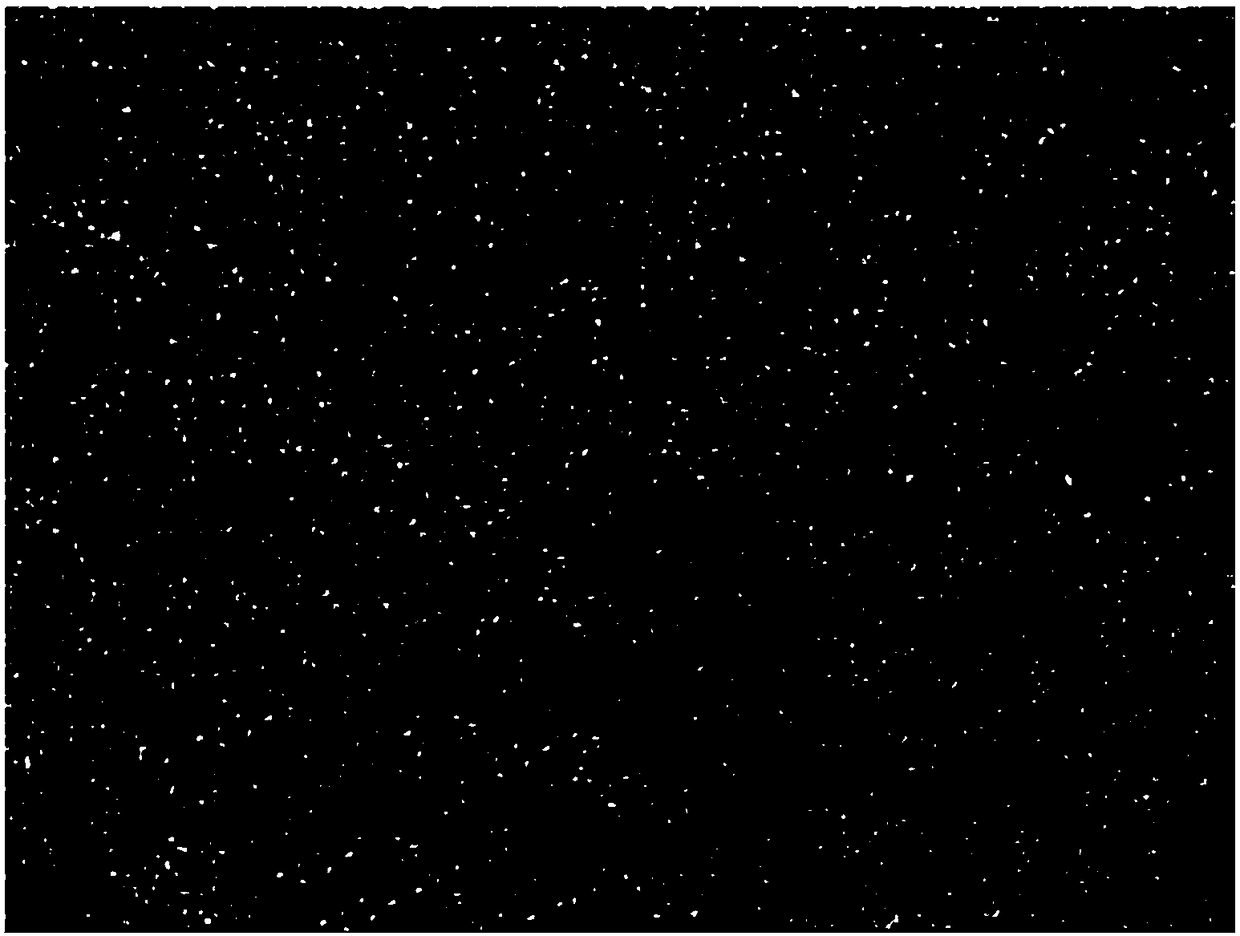

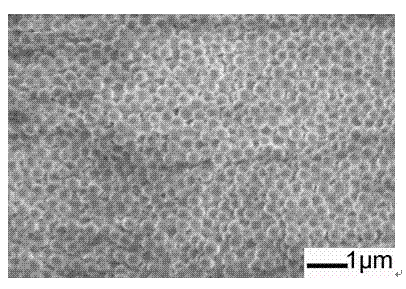

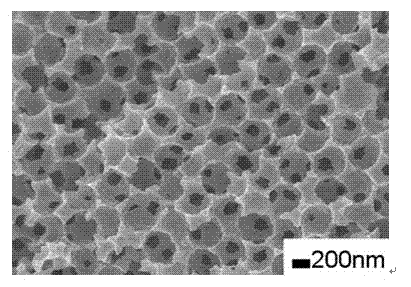

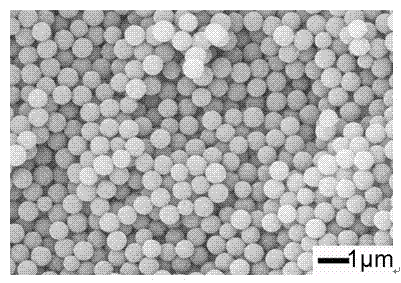

Method for preparing three-dimensional ordered macroporous material by using water-soluble colloidal crystal as template

The invention provides a method for preparing a three-dimensional ordered macroporous material by using a water-soluble colloidal crystal as a template. The method comprises the steps of preparing the colloidal crystal template by using the prepared water-soluble monodisperse polyacrylamide nanoparticles and removing the template by using water as the solvent to obtain the three-dimensional ordered macroporous material. The invention develops a new method for preparing three-dimensional ordered macroporous polymer. Comparing with the traditional hydrofluoric acid etching and calcining, the method provided by the invention can maintain the gloss and chemical structure of the polymer, and is also energy-saving and environment-friendly.

Owner:HEBEI UNIV OF TECH

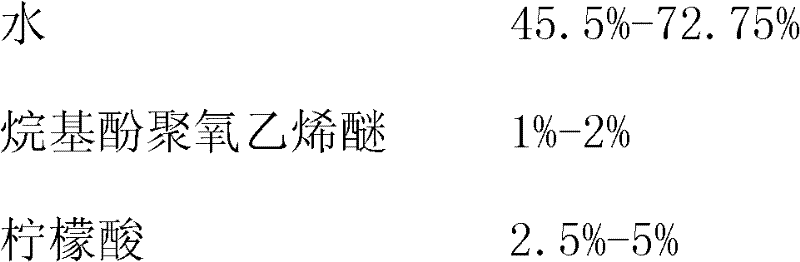

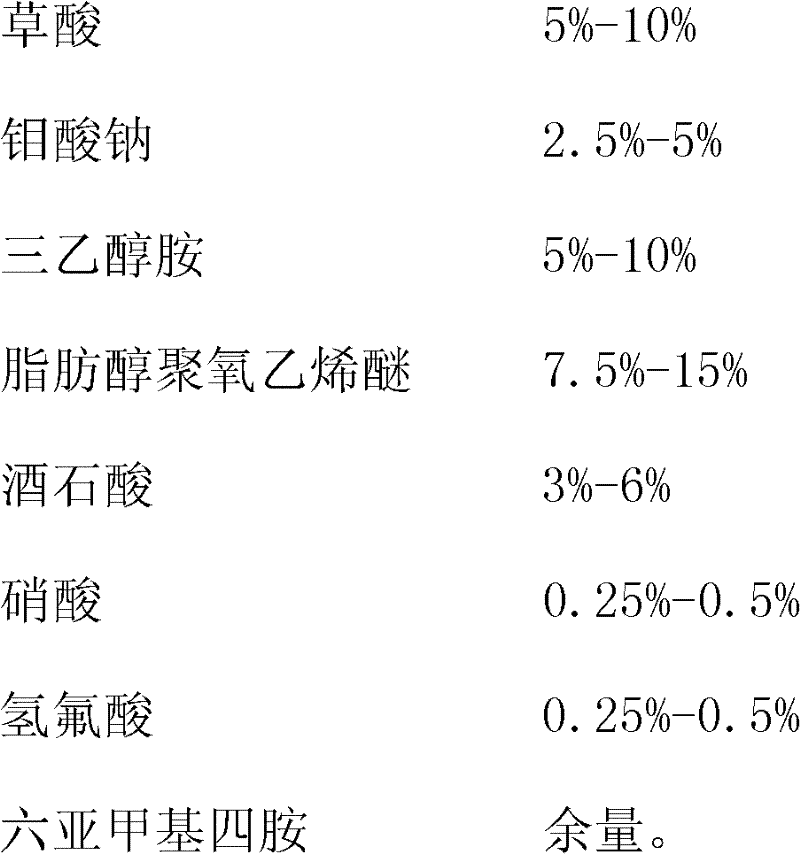

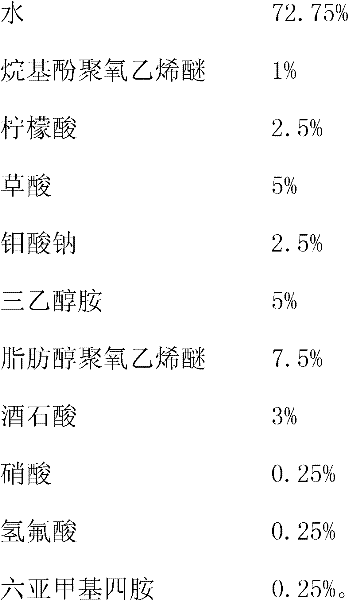

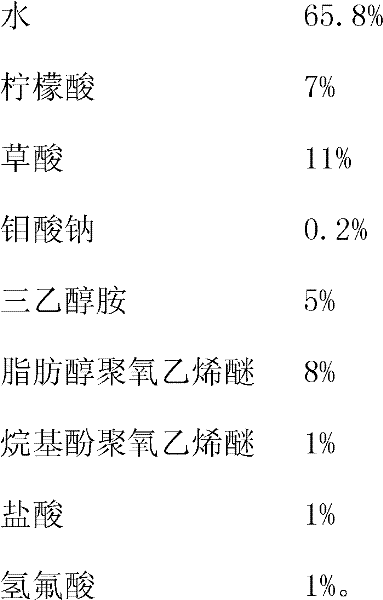

Cleaning agent for stainless steel seamless stay tubes and preparation method for cleaning agent

ActiveCN102400165AMaintain glossContact no harmMetallic material coating processesHexamethylenetetramineAlkylphenol

The invention relates to the technical field of chemical cleaning, in particular to a cleaning agent for stainless steel seamless stay tubes and a preparation method for the cleaning agent. The cleaning agent for the stainless steel seamless stay tubes is prepared by mixing the following raw materials in percentage by weight at normal temperature: 45.5 to 72.75 percent of water, 1 to 2 percent of alkylphenol polyoxyethylene, 2.5 to 5 percent of citric acid, 5 to 10 percent of oxalic acid, 2.5 to 5 percent of sodium molybdate, 5 to 10 percent of triethanolamine, 7.5 to 15 percent of fatty alcohol-polyoxyethylene ether, 3 to 6 percent of tartaric acid, 0.25 to 0.5 percent of nitric acid, 0.25 to 0.5 percent of hydrofluoric acid and the balance of hexamethylenetetramine. The cleaning agent for the stainless steel seamless stay tubes has novel process, is easy to operate and strong in cleaning force, does not need to be heated, can be reused, can be used for cleaning the stainless steel seamless stay tubes without corroding the surface of stainless steel, and keeps the glossiness of the stainless steel; and the cleaning agent for the stainless steel seamless stay tubes has no injury to the skin, is low-carbon and environment-friendly, has high cost performance, and saves the cost.

Owner:云霄县食品快检中心

Strong-base corrosion-resistant ceramic glaze and preparation method thereof

The invention discloses a strong-base corrosion-resistant ceramic glaze. The ceramic glaze comprises the following components: a boron frit, quartz powder, spodumene, calcined zinc oxide, calcined talcum powder, kaolin, zirconium silicate, a toner and the like. The preparation method comprises the following steps: preparing materials according to mass parts of the components, carrying out ball milling to obtain glaze, sieving the glaze discharged out of a ball mill to obtain glaze slurry, adding water and an electrolyte to respectively adjust the concentration and thixotropy of the glaze slurry, dipping a glaze blank in the glaze slurry, carrying out drying, then putting the glaze blank into a roller kiln, and carrying out firing at a temperature of 1210-1240 DEG C to obtain a high-densityborosilicate glass body. Various pigments are wrapped in the glass body for protection, the firing temperature is low, compactness of the fired glaze is guaranteed, a complete glaze glass body with high density, high gloss and pore-free glaze surface is achieved, and Si-O bonds formed in the glaze glass are protected from being damaged, so that corrosion of strong bases can be resisted.

Owner:HUNAN HUALIAN CHINA IND

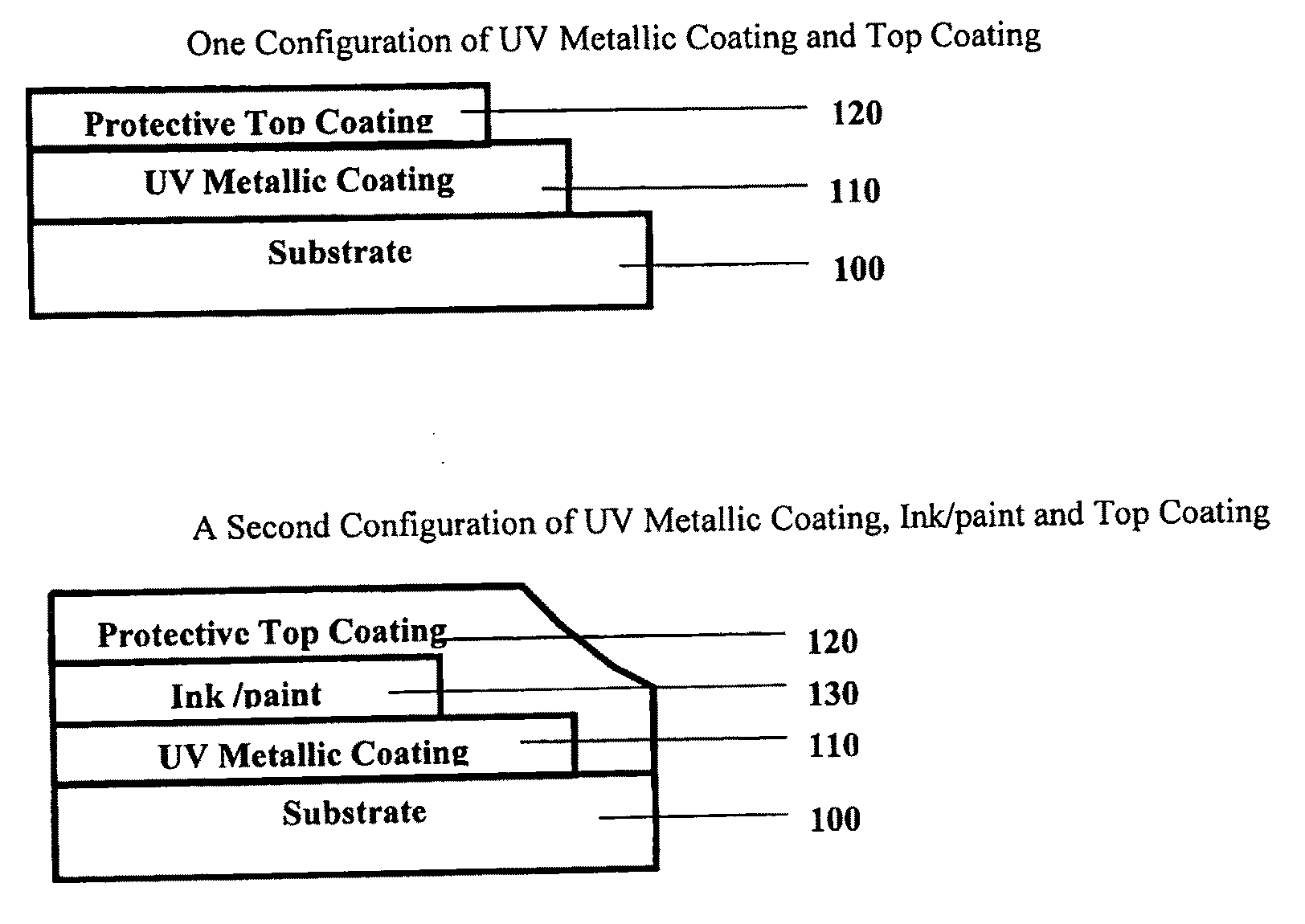

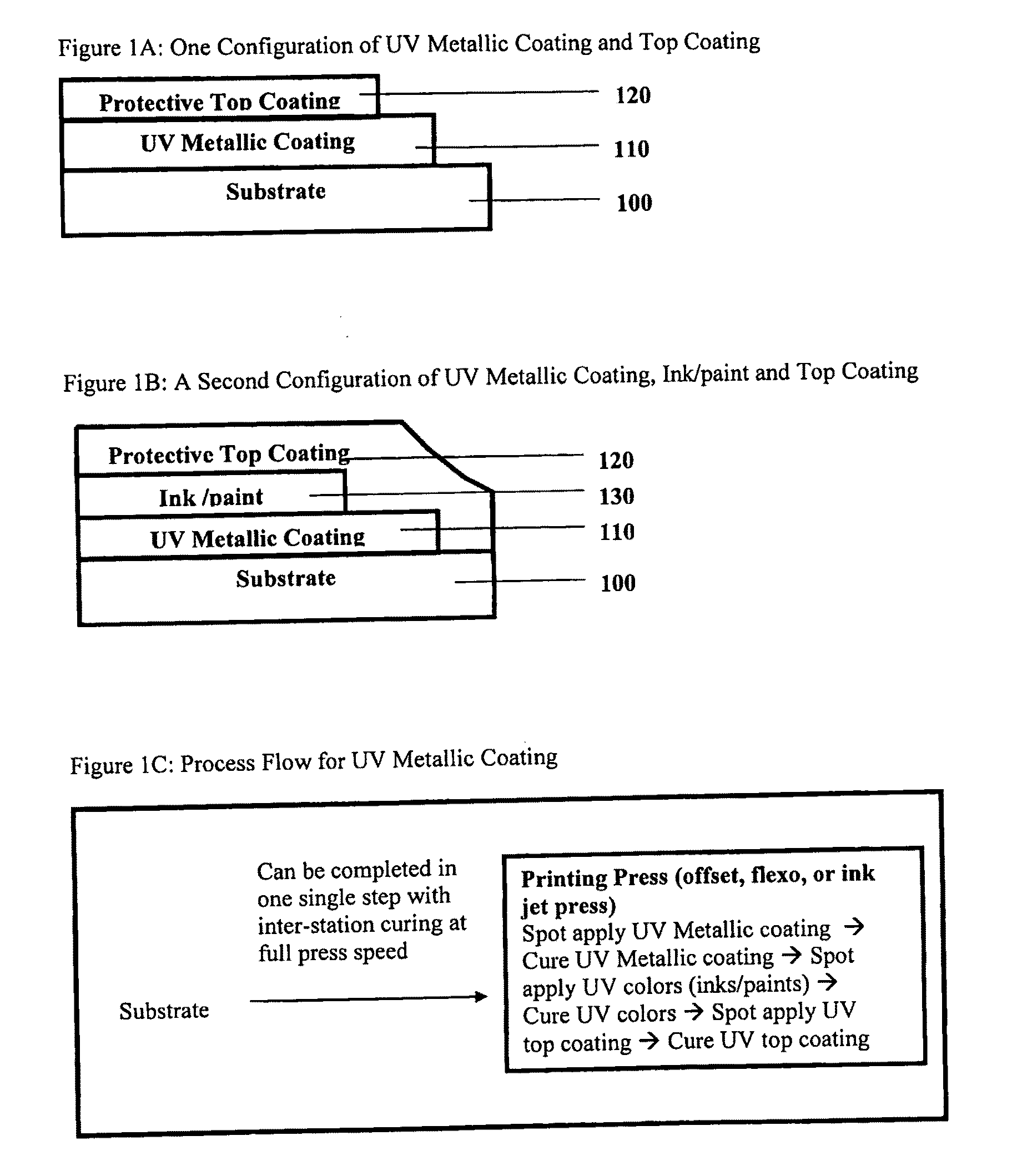

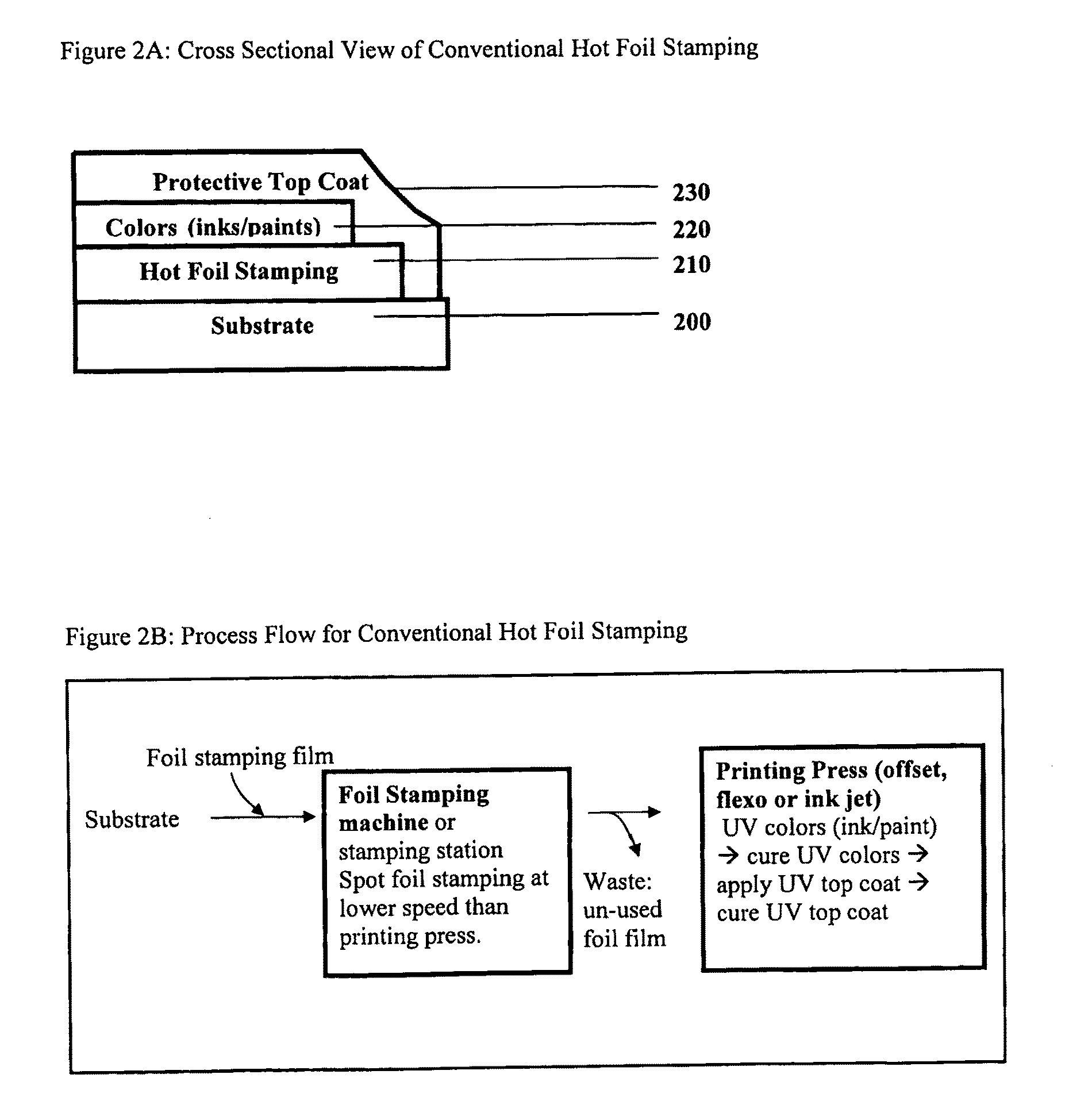

UV curable metallic decorative compositions

ActiveUS20150344722A1High glossMaintain press stabilityRadiation applicationsSynthetic resin layered productsUltraviolet lightsOrganic chemistry

The invention provides an ultraviolet light curable metallic composition, and articles made therewith. The UV-curable metallic compositions provide a high gloss metallic finish, retain the gloss level over storage duration, and maintain press and shelf stability, while maintaining fast cure speeds. The metallic finishes of the instant compositions have gloss above 190 GU measured at 60°.

Owner:ACTEGA NORTH AMERICA TECH INC

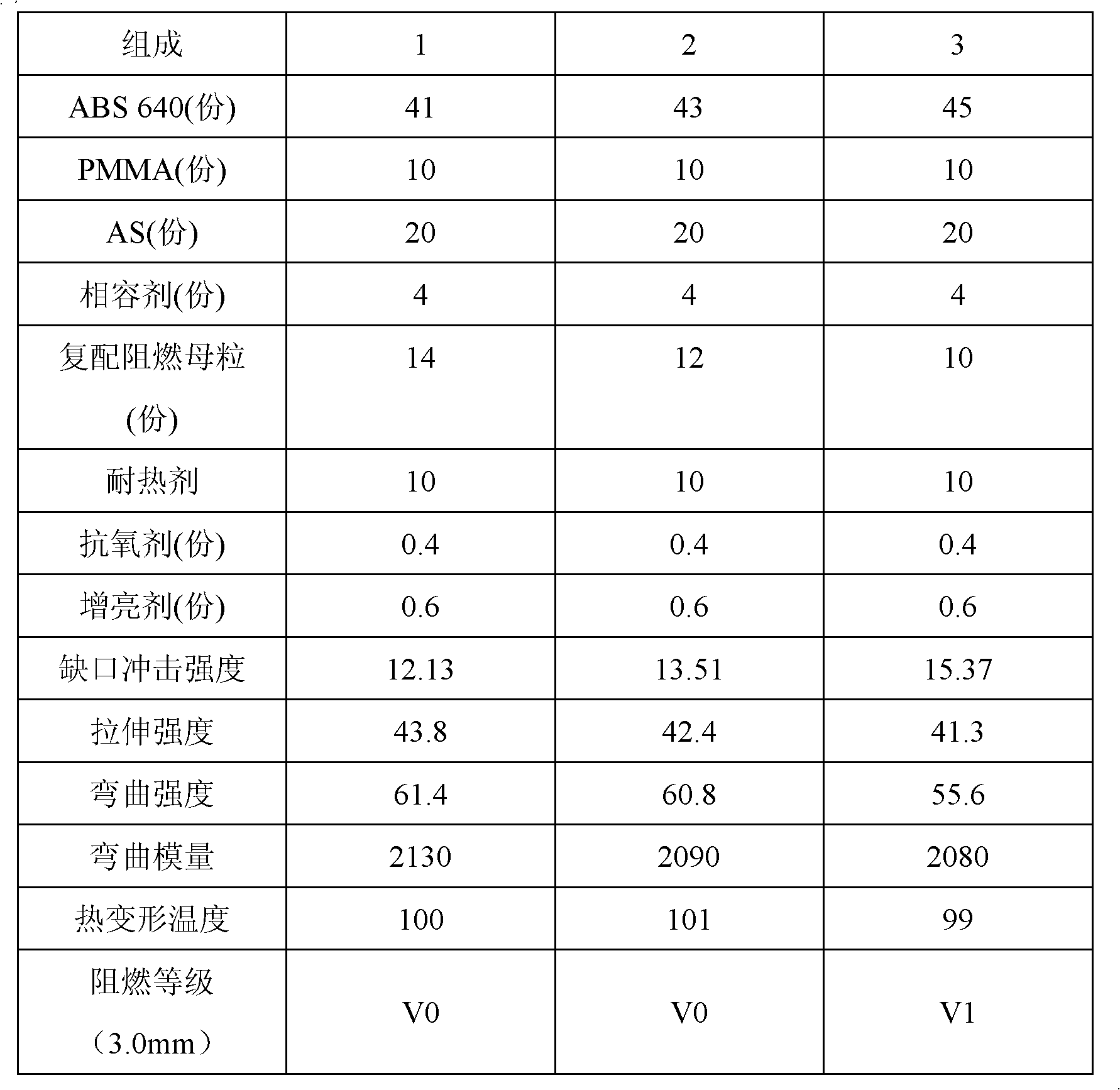

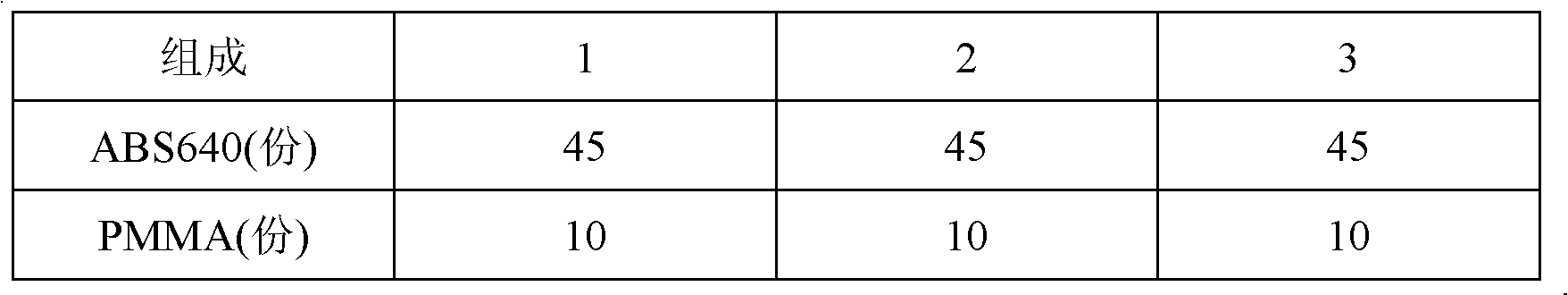

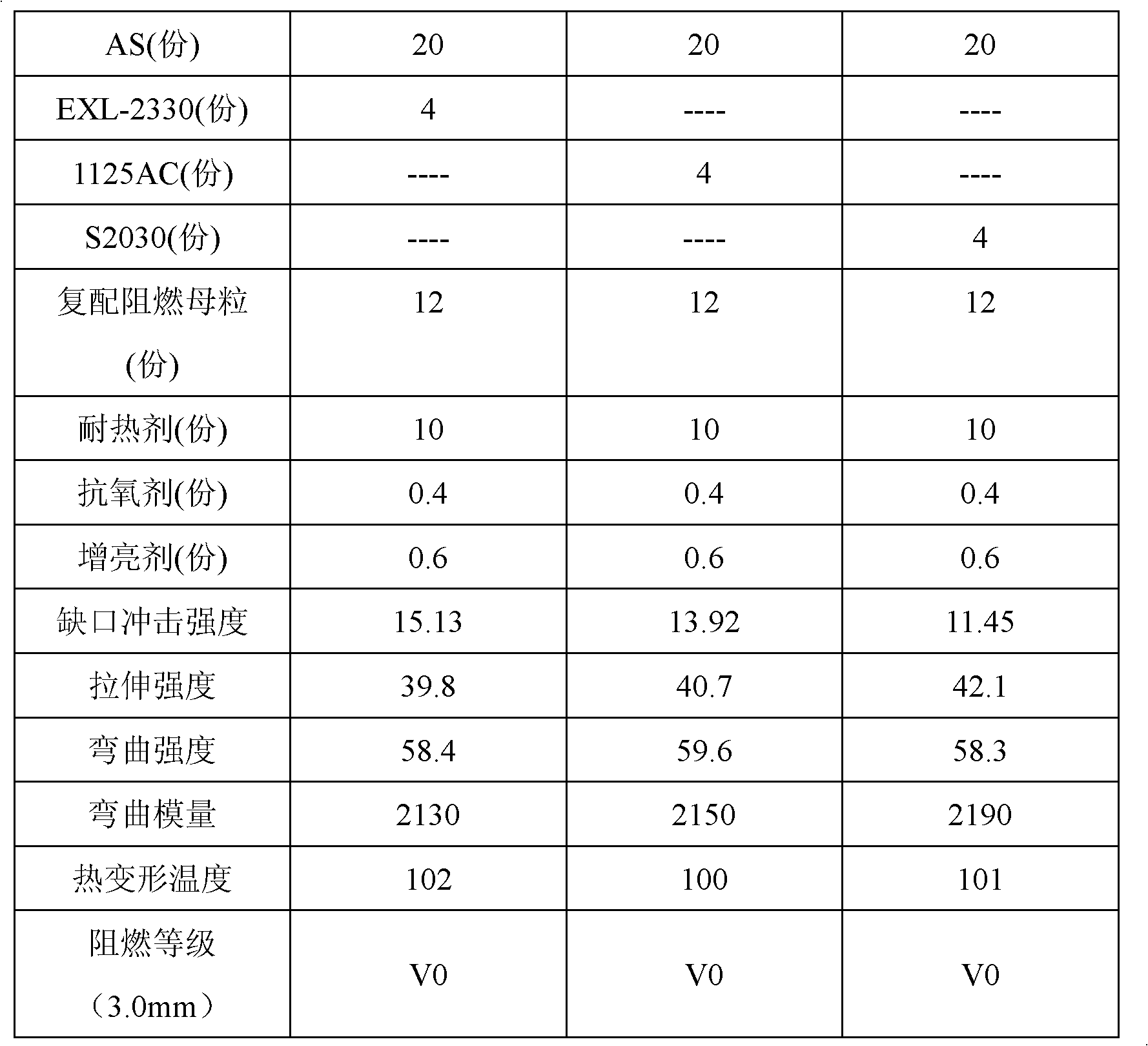

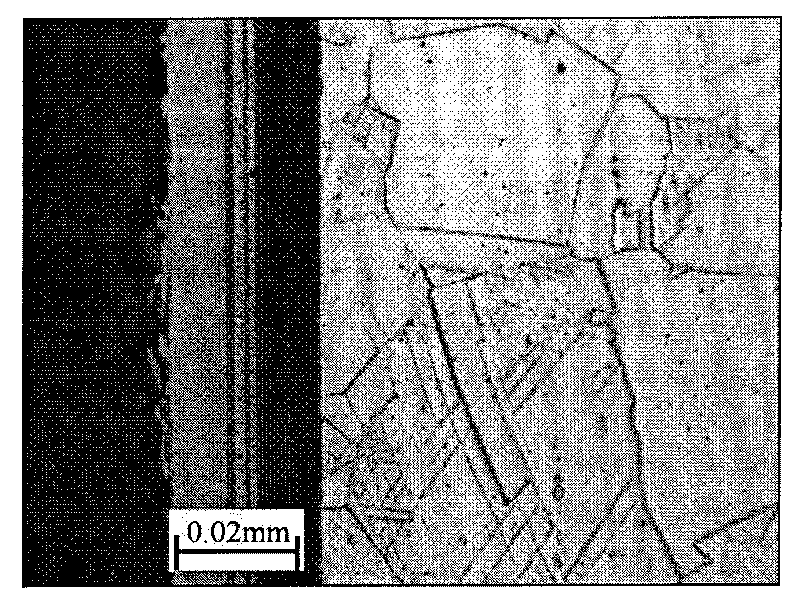

High-gloss, flame-retarding and heat-resistance ABS alloy and preparation method thereof

InactiveCN102101932AMaintain glossSimple preparation processHeat deflection temperatureHeat resistance

The invention discloses a high-gloss, flame-retarding and heat-resistance acrylonitrile-butadiene-styrene (ABS) alloy and a preparation method thereof. The invention provides a high-gloss, flame-retarding and heat-resistance ABS modified resin, which comprises an ABS resin, a PMMA resin, an AS resin, a compound flame-retarding master batch, a compatilizer, a heat resistant agent, an antioxygen and a brightener. The alloy retains the high physical properties of ABS resin and has high flame-retarding performance, high surface gloss and high thermal deformation temperature. The high-gloss, flame-retarding and heat-resistance ABS can be widely used in automobile, home appliance and electronic appliance industries and other industries.

Owner:福建奥峰科技有限公司

Surface treatment method for improving wear resistance and corrosion resistance of austenitic stainless steel shell

InactiveCN101709463AContent controlImprove bindingLiquid/solution decomposition chemical coatingChemical platingSand-paper

The invention discloses a surface treatment method for improving wear resistance and corrosion resistance of an austenitic stainless steel shell, which comprises the following steps: sanding the austenitic stainless steel shell with sand paper; deoiling, and washing with water to remove residual deoiling solution; and washing with acid to remove the film, activating the surface, washing with cold water and preheating, putting the austenitic stainless steel shell in a prepared plating solution to carry out plating for 1-2 hours, taking out, washing with hot water and cold water alternately to remove the residual plating solution on the sample surface, and finally drying to obtain the plating. The invention adopts the chemical plating technique to obtain the good-quality amorphous Ni-W-P ternary alloy plating on the surface of the austenitic stainless steel shell, thereby obviously improving the wear resistance of the product on the premise that the original silvery color and favorable glossiness of stainless steel are ensured.

Owner:SOUTH CHINA UNIV OF TECH

Metal surface treatment agent

The invention relates to a metal surface treatment agent and in particular relates to an environment-friendly non-ferrous metal surface treatment agent, belonging to the technical field of metal surface cleaning and surface rust-proof treatment. The metal surface treatment agent comprises corrosion inhibitors, surfactants, chitosan, antioxidants, titanium dioxide, silicon dioxide and water. When the metal surface treatment agent is used, nano titanium dioxide and nano silicon dioxide form a protective film on the metal surface; nano F-doped titanium dioxide and nano silicon dioxide can decompose bacteria on the metal surface when exposed to the sun, have high hydrophilicity and more fully protect the metal surface from being eroded by bacteria and rainwater, thus not only is the metal surface well cleaned but also the protective film is formed on the metal surface so as to protect the gloss of the metal surface.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Production method for lining paper for cigarette

ActiveCN102899957AGood paper evennessUniform moistureWater-repelling agents additionPaper/cardboardPaper sheetHardwood

The invention discloses a production method for a lining paper for a cigarette. The production method comprises the following steps: A) preparing grinding pulp, and then allocating the pulp which contains 15-30 wt.% of bleached needle bush pulp, 55-75 wt.% of bleached hardwood pulp and 10-15 wt.% of straw pulp, separately pulping, and then mixing the grinding pulp, and controlling pulp intensity at 30-40 OSR and wet weight being 2.5-5.5g; B) adding padding and a degassing agent before primarily slushing the pulp, and then entering into multi-stage deslagging; C) adding pulp glue and starting the secondary slushing; D) after ending the secondary slushing, adding a sizing agent, placing into a pressure screen for treating, and adding a retention agent at an outlet of the pressure screen; E) pouring the pulp into a pulp flowing box, loading a net and preparing paper with the pulp; F) extracting and dewatering; G) drying; H) performing soft calendaring dual-pressing treatment; and I) coiling, rewinding and cutting, packaging and putting into a storage. The lining paper for the cigarette produced according to the production method has the beneficial effects: the paper sheet uniformity is excellent; the horizontal width rated difference is small; the tensile force is high; the lining paper is easy to cut; the front surface of the paper sheet has higher smoothness; and the back surface of the paper sheet has certain smoothness.

Owner:XIANHE CO LTD

Ink-jet printing dyestuff ink

InactiveCN101186770AIncreased reflection densityStability has no effectInksPrintingDrying timePolymer chemistry

Disclosed is pigment ink for ink-jet printing, which is composed by mixing color paste, resin, pH regulating agents and de-ionized water and is characterized in that the weight percent of the color paste is 10-50%, the weight percent of the resin is 0.1-3%, the weight percent of the pH regulating agents is 0.1-2%, and the rest is the de-ionized water. The advantages and technical effects of the invention are in that satisfied scuff resistance can be achieved by changing the added resin, fingers can smear on the surface of printed materials without leaving any marks after printing is finished, strong luster sensation is achieved together with the scuff resistance, and stability and drying time of the ink can not be influenced after the resin is added.

Owner:天津兆阳纳米科技有限公司

Spray type mildew-proof leather polishing agent and preparation method thereof

The invention discloses a spray type mildew-proof leather polishing agent which is characterized by comprising the following components in parts by weight: 5-15 parts of aloe fibroin collagen humectant, 30-50 parts of carnauba wax, 5-7 parts of castor oil, 5-20 parts of dimethyl silicon oil, 0.1-0.5 part of mildew preventive, 0.5-2 parts of cationic surfactant, 0.01-0.1 part of essence and 20-30 parts of water. The spray type mildew-proof leather polishing agent is simple and convenient to use, and the cleaning, maintenance and polishing are finished at one time; the spray type mildew-proof leather polishing agent has strong antifouling ability, does not generate static electricity and prevents dust; the spray type mildew-proof leather polishing agent is neutral and phosphorus-free, contains a benzoic acid preservative and can suppress mildew reproduction; the spray type mildew-proof leather polishing agent resists ultraviolet under strong light and prevents aging and cracking; and with natural aloe component, the spray type mildew-proof leather polishing agent can keep the fullness, elasticity and gloss of leather for long time.

Owner:SUZHOU XIELU NETWORK TECH

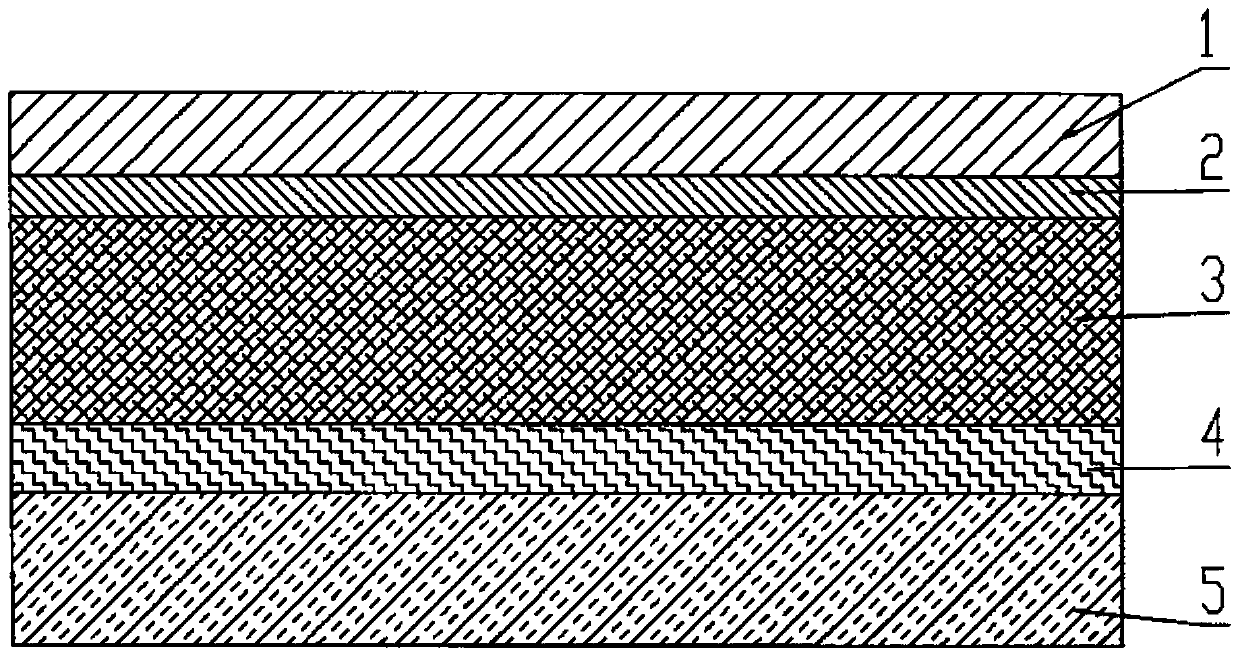

Invisible car cover protective film with TPU substrate and preparation process

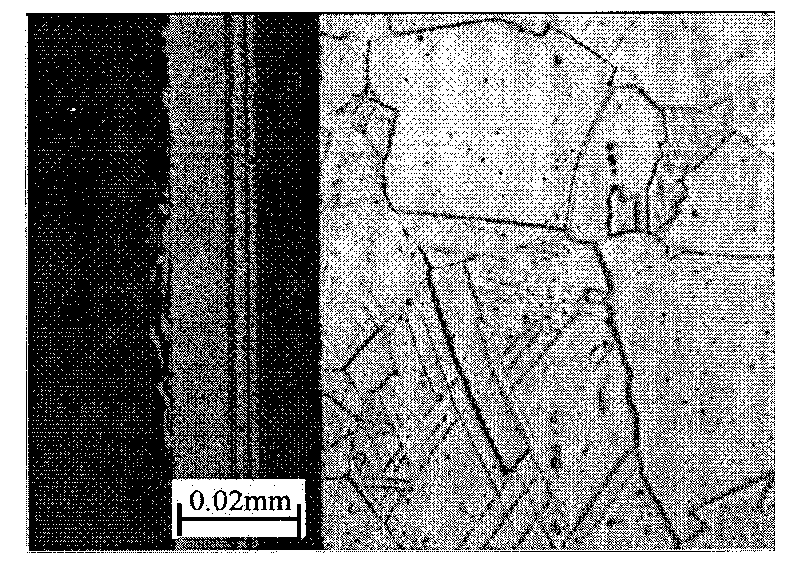

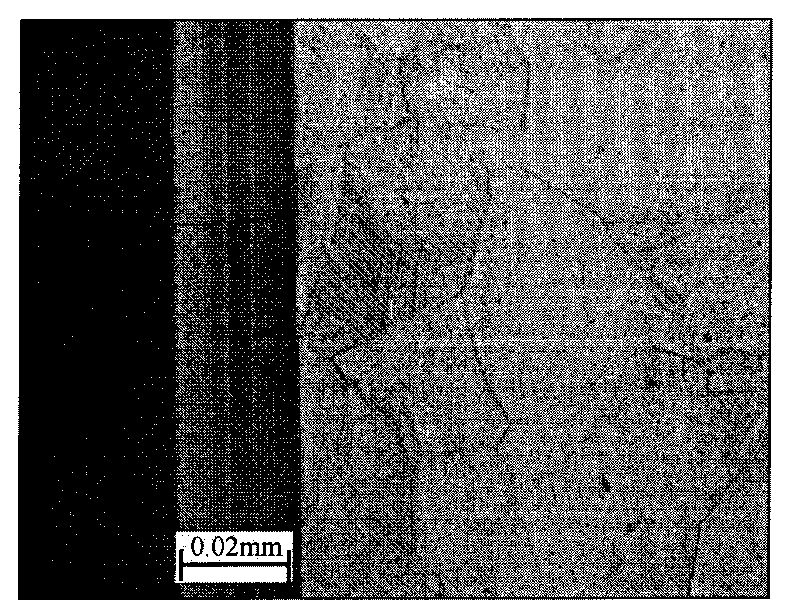

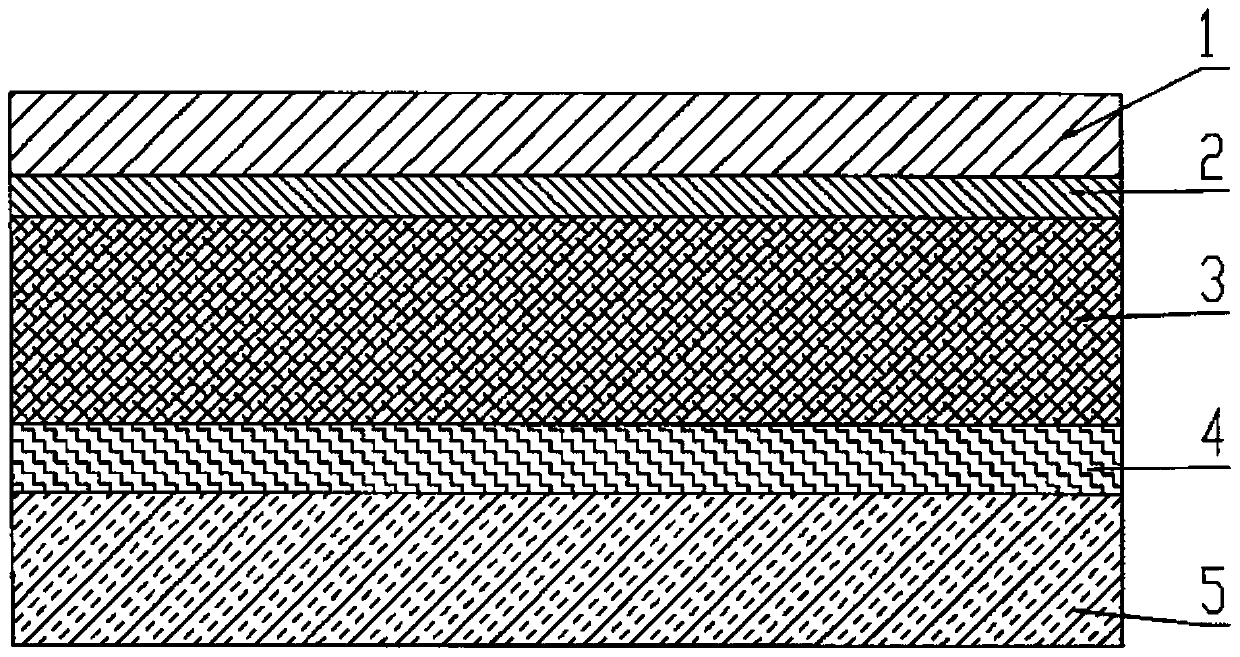

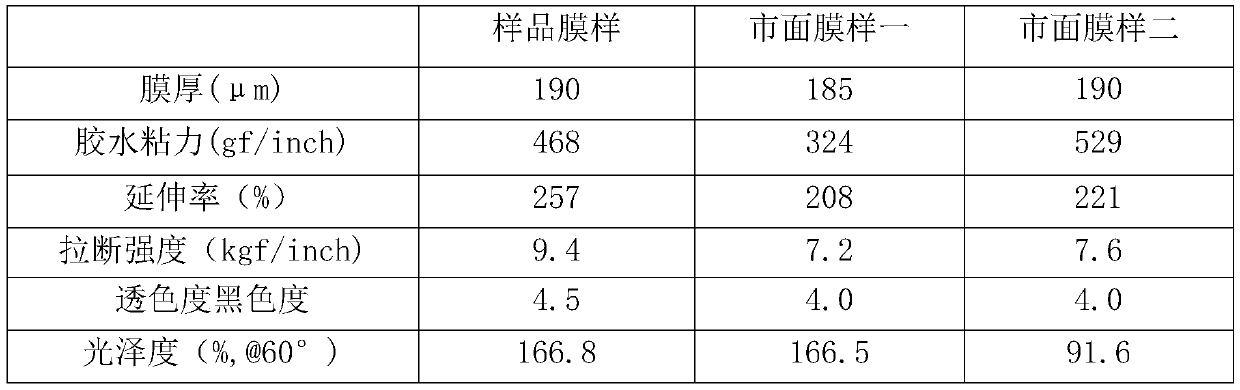

InactiveCN110218525AImprove bindingIncrease profitPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolyesterTectorial membrane

The invention discloses an invisible car cover protective film with a TPU substrate. The invisible car cover protective film comprises a protective layer, a substrate layer and a release layer, wherein the protective layer is prepared from PET, the substrate layer is prepared from a polyester / polyether copolymer system, and the release layer is prepared from PET; a lower adhesive layer and an upper adhesive layer are separately adhered to main surfaces on both sides of the substrate layer, an aliphatic pressure-sensitive adhesive is coated on the surface of the release layer, and then the lower adhesive layer is adhered to one main surface of the substrate layer in a film transfer mode; and the upper adhesive layer is directly coated on the other main surface of the substrate layer. The invention also provides a preparation process of the invisible car cover protective film with the TPU substrate, and the preparation process comprises the steps: (1) preparing the TPU substrate layer, (2) pretreating the substrate layer, (3) preparing the lower adhesive layer, (4) performing film transfer, (5) preparing the upper adhesive layer, and (6) preparing the protective layer. The bonding force between the adhesive layers and the substrate layer is good, a high product strength and a high utilization rate of raw materials are achieved, and automatic repair of scratches can be achieved through polyurethane microcapsule particles in the adhesive layers.

Owner:NINGBO JIAHUA NEW MATERIAL TECH CO LTD

Trackpad and manufacturing method thereof

ActiveCN102898030AGuaranteed roughnessGood touchInput/output processes for data processingTouch SensesEngineering

The invention provides a manufacturing method of a trackpad. The method comprises: step 1, providing a glass substrate; step 2, conducting etching on the surface of the glass substrate with silk print etching ink; and step 3, immersing the etched glass substrate in a glass polishing solution to carry out polishing, thus obtaining the trackpad. The invention also provides the trackpad obtained by the method. Employment of the method disclosed in the invention to manufacture the trackpad can ensure the touchpad certain roughness, improve the touch sense of existing trackpads, and can endow the trackpad with certain light transmittance and guarantee its glossiness. Therefore, the method is conducive to improve the quality of the trackpad, thus further improving the use performance of electronic products.

Owner:BYD CO LTD

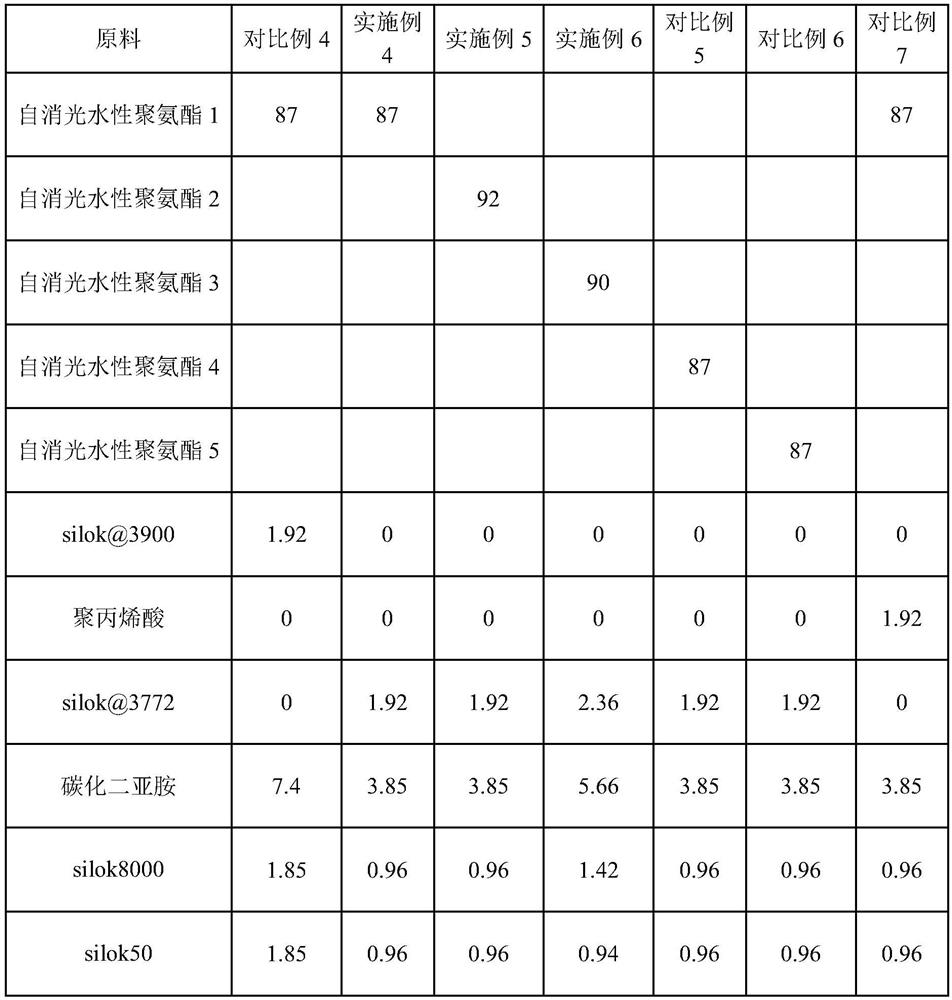

Water-based self-extinction polyurethane dispersion, and preparation method and composition thereof

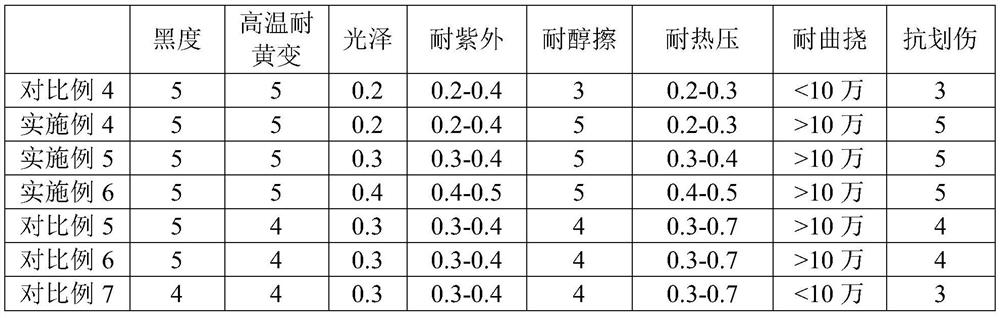

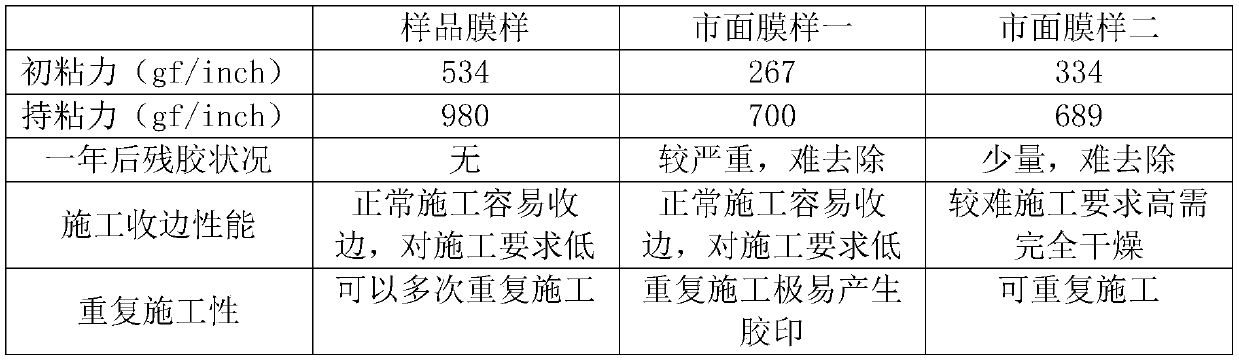

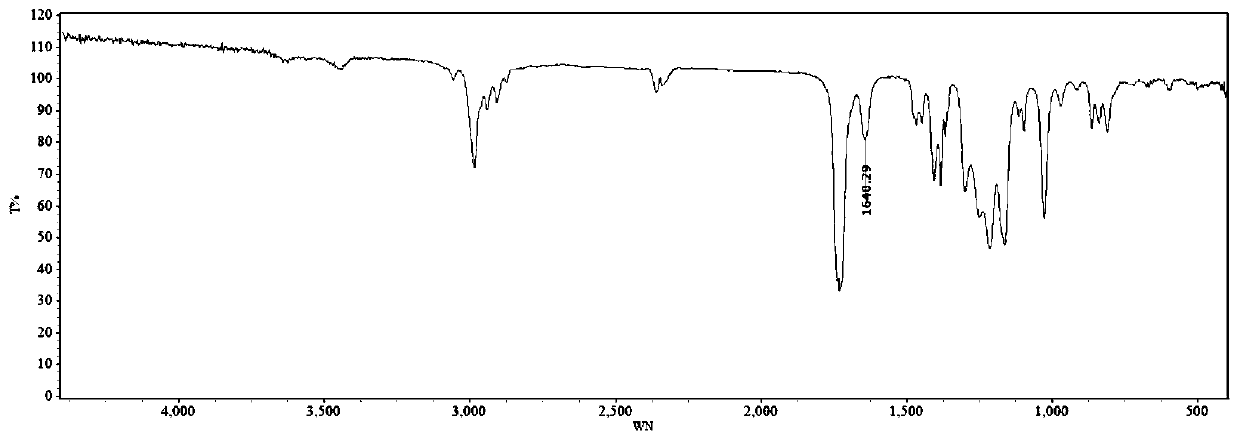

ActiveCN111944111AAvoid hydrolysisHigh hardnessPolyurea/polyurethane coatingsPolyurethane dispersionPolymer science

The invention provides a water-based self-extinction polyurethane dispersion, and a preparation method and a composition thereof. According to the waterborne self-extinction polyurethane dispersion, the trihydric alcohol and the silane coupling agent are used and are further compounded with the polycarbonate polyol and other raw materials for use, so the waterborne self-extinction polyurethane dispersion has more excellent mechanical properties, thermal stability, hydrolysis resistance, chemical resistance and weather resistance. The composition is based on the waterborne self-extinction polyurethane dispersion, and comprises: (a) the waterborne self-extinction polyurethane dispersion; (b) a carboxyl crosslinking agent; (c) carboxyl group-containing macromolecular siloxane; (d) a wetting agent; and (e) a feeling agent. The composition obtained in the invention has good blackness, scratch resistance and flexing resistance on PVC leather.

Owner:WANHUA CHEM GRP CO LTD +1

Plastic surface treatment technique

InactiveCN104017231AMaintain glossImprove appearance gradeMolten spray coatingGrit blastingSurface finishing

The invention relates to a plastic surface treatment technique which comprises the following steps: plastic degreasing, plastic swelling, plastic surface coarsening, primary grit blasting, spraying treatment, hole sealing treatment, secondary grit blasting (carrying out grit blasting on the plastic surface by using a high-pressure spray gun and a sand material), and water washing and drying. The treatment technique is simple, shortens the treatment time, and enhances the high-temperature oxidation resistance and corrosion resistance of the plastic; and the plastic has higher surface smoothness and is beautiful.

Owner:CHUZHOU HONGYUAN SPRAYING

Production technology of TPU-substrate invisible car cover protection film

InactiveCN110183985AImprove bindingIncrease profitFilm/foil adhesive primer layersPressure sensitive film/foil adhesivesPolyesterTectorial membrane

The invention discloses a production technology of a TPU-substrate invisible car cover protection film. The TPU-substrate invisible car cover protection film is produced according to the following steps: (1), forming a TPU substrate layer; (2), pretreating the substrate layer; (3), forming a lower adhesive layer; (4), performing film transfer; (5), forming an upper adhesive layer; (6), forming a protective layer. In the TPU-substrate invisible car cover protection film, the protective layer is made of PET, the substrate layer is made of a polyester-polyether copolymer system, and a release layer is made of PET; the lower adhesive layer is an aliphatic pressure-sensitive adhesive, and the upper adhesive layer is aliphatic polyurethane or carbamate-acrylic based surface coating. A TPU substrate of the of TPU-substrate invisible car cover protection film has relatively high modulus and strength, so that good weather resistance, gloss, transparency, crystal flow pattern and other requirements are guaranteed; the adhesive layers have strong adhesion to the substrate layer and have high raw material utilization rate, and during using, the adhesive layers provide suitable initial adhesionand permanent adhesion for the surface of car paint, so that the advantage that glue does not remain on the paint surface is achieved.

Owner:NINGBO JIAHUA NEW MATERIAL TECH CO LTD

Aspartate resin of novel structure, polyurea coating as well as preparation method and application of polyurea coating

ActiveCN109912442AAvoid formingEliminate Stability IssuesOrganic compound preparationAmino-carboxyl compound preparationRoom temperatureHardness

The invention provides aspartate resin of a novel structure and a preparation method of a polyurea coating containing the aspartate resin. According to a synthesis method of the aspartate resin of thenovel structure, unsaturated binary carboxylic ester and unsaturated monocarboxylic ester are used in the aspartate resin of the novel structure to have a Michael addition reaction with a primary amino compound, wherein the unsaturated binary carboxylic ester is alkyl acrylate or alkyl methacrylate. The novel polyurea coating is characterized in that the coating is cured and formed at the room temperature in a form of double components, wherein the component A is a common isocyanate curing agent, and the component B is a mixture at least containing the aspartate resin of the novel structure,which is prepared according to claim 3 or 4. Acrylate (methacrylate) with a smaller space volume is introduced into one end of a molecular chain, the internal plasticization effect after the coating is cured is reduced, and the hardness of the coating is increased.

Owner:郁维铭 +1

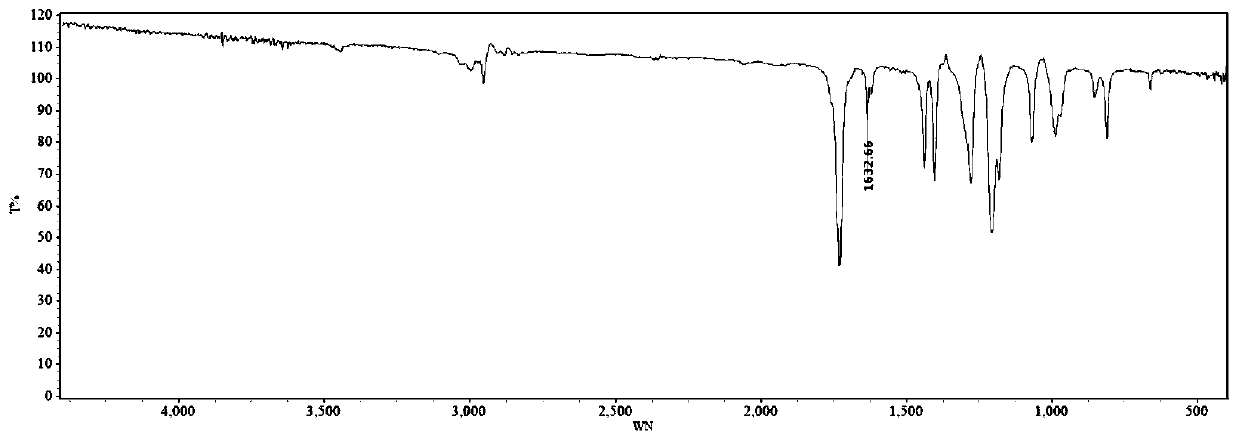

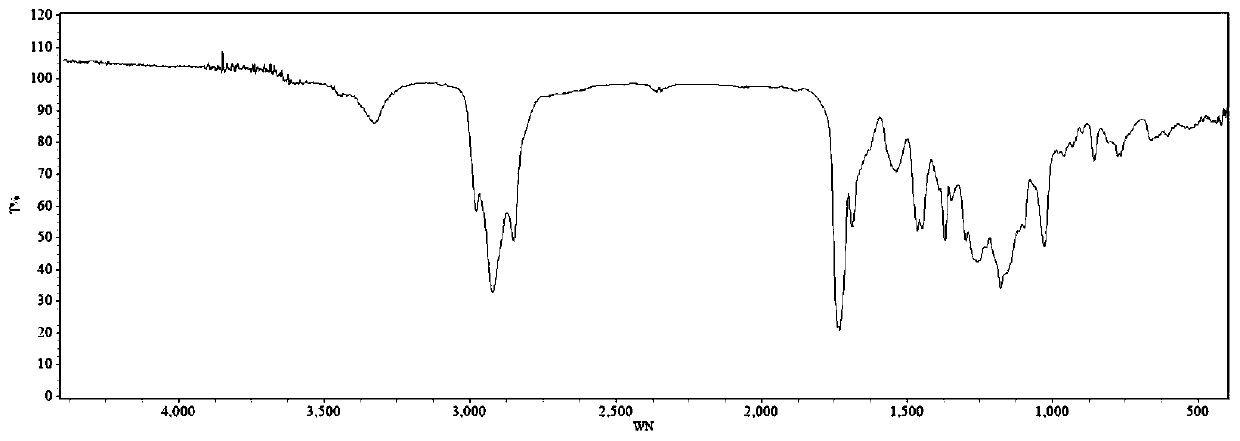

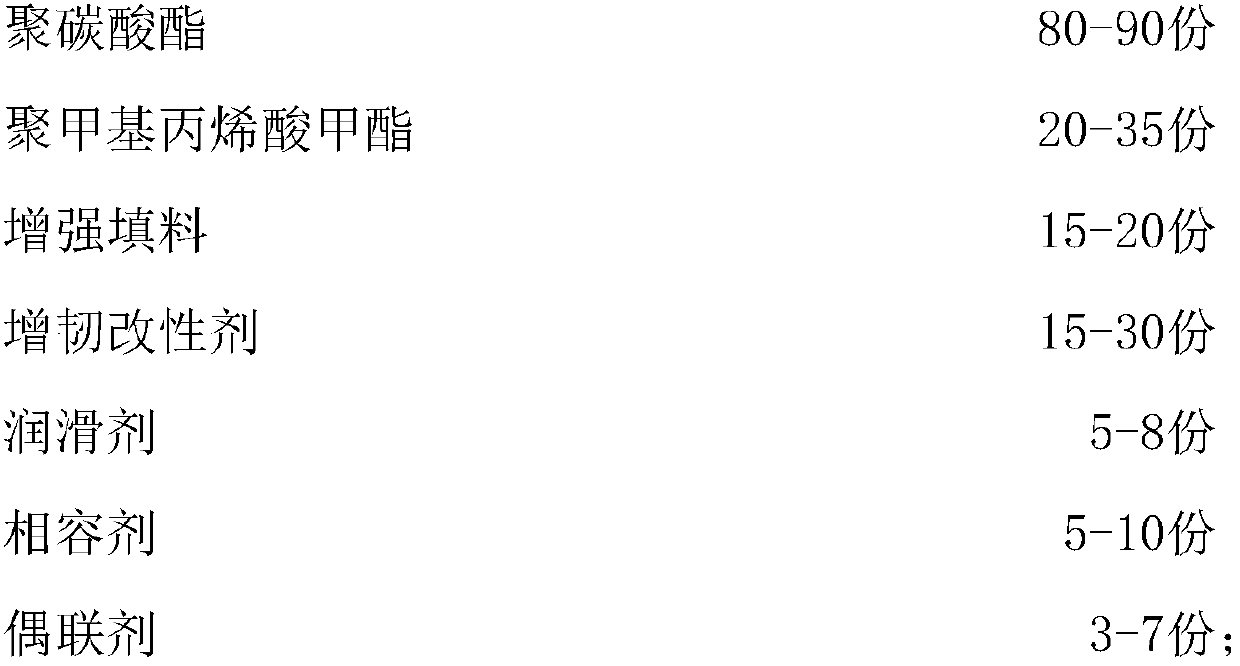

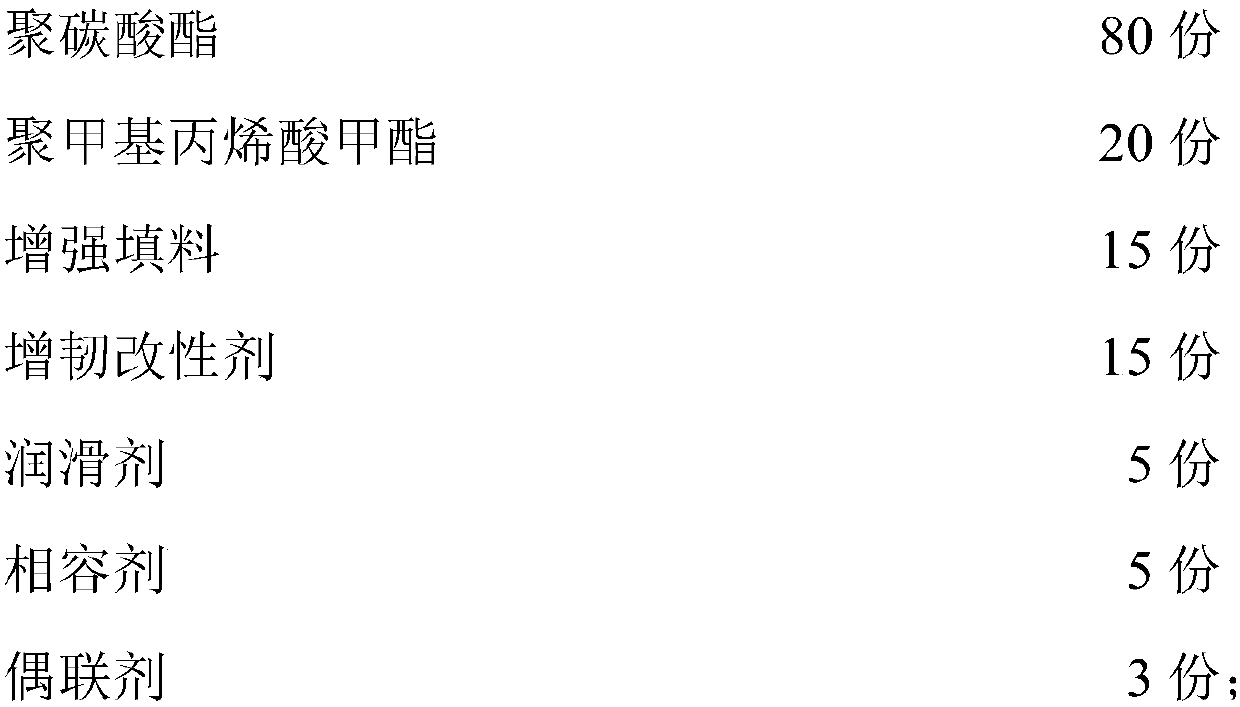

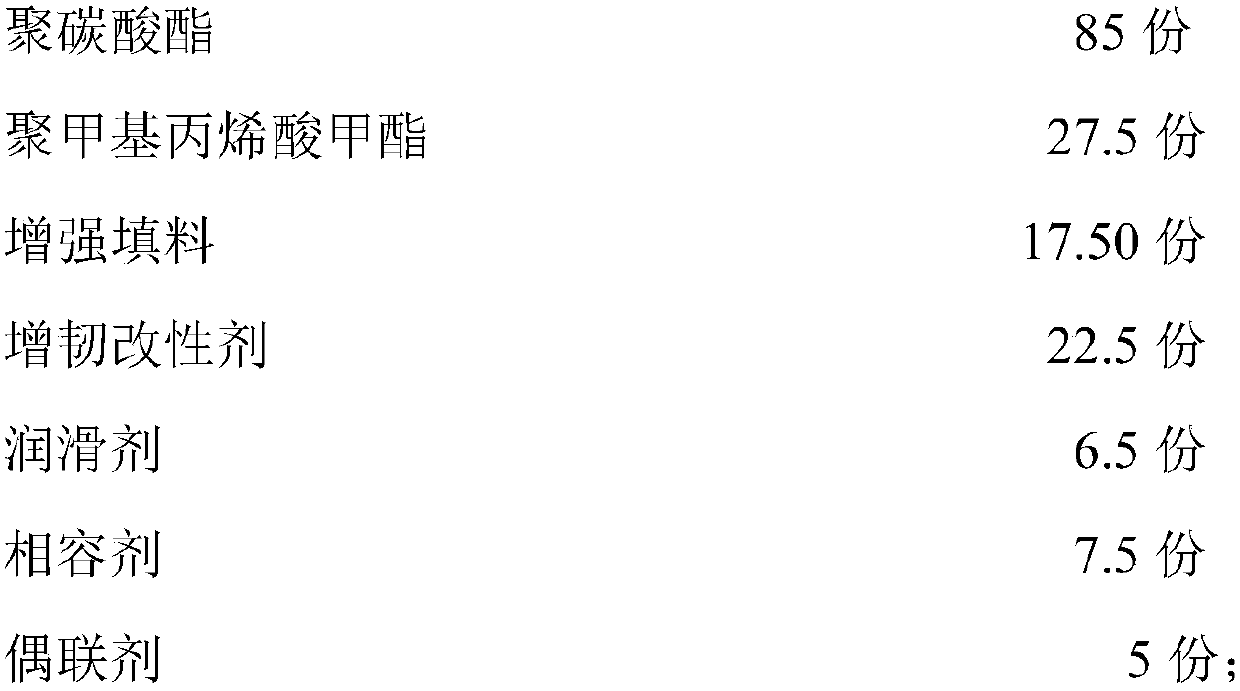

High-toughness and high-hardness composite material and preparation method thereof

The invention relates to the technical field of materials, particularly to a high-toughness and high-hardness composite material and a preparation method thereof, wherein the high-toughness and high-hardness composite material comprises the following raw materials by weight: 80-90 parts of polycarbonate, 20-35 parts of polymethyl methacrylate, 15-20 parts of a reinforcing filler, 15-30 parts of atoughening modifier, 5-8 parts of a lubricant, 5-10 parts of a compatibilizer, and 3-7 parts of a coupling agent, wherein the reinforcing filler is a mixture of hollow glass microspheres and nanometerboron fibers, and the toughening modifier is a mixture of a styrene-butadiene thermoplastic elastomer and high-density polyethylene grafted maleic anhydride, such that the toughness and the hardnessof the PC-PMMA composite material can be simultaneously increased, the impact resistance and the tensile strength of the PC-PMMA composite material can be increased, the wear resistance is good, the scratch is not easily generated on surface of the product, the fluidity is high, and the processing molding is easy.

Owner:GUANGDONG GERUI NEW MATERIALS CO LTD

Anti-virus thin film and biaxial tension technique

An antibacterial film is prepared from polyacrylic resin, assistant and antibacterial mother particles through bidirectional drawing. Its advantages are high and durable bacteria killing and suppressing effect and antimildew effect, high strength, uniformity, transparency, and thermal stability, and high safety.

Owner:GUILIN PRENOVO ANTIBACTERIAL MATERIAL CO LTD

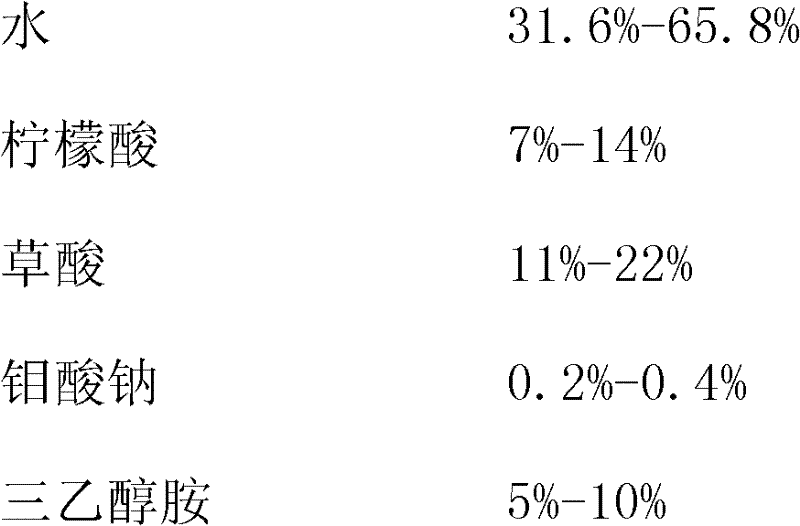

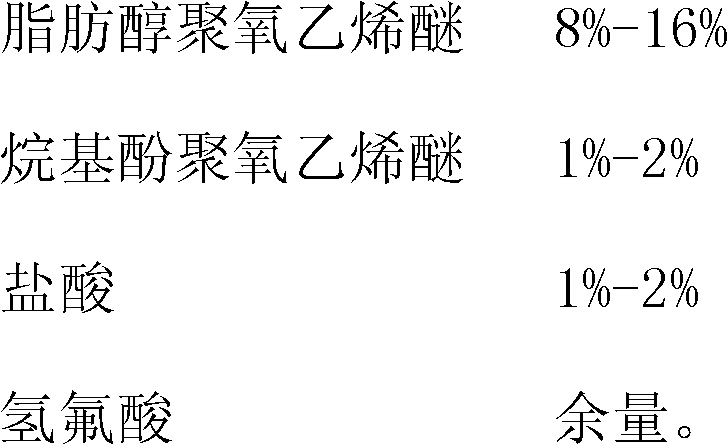

Cleaning agent for stainless steel cold-rolling piece and preparation method thereof

The invention relates to the technical field of chemical cleaning, in particular to a cleaning agent suitable for a stainless steel cold-rolling piece and a preparation method thereof. The cleaning agent for the stainless steel cold-rolling piece is manufactured at normal temperature by mixing the following raw materials by weight percentage: 31.6 percent to 65.8 percent of water, 7 percent to 14 percent of citric acid, 11 percent to 22 percent of oxalic acid, 0.2 percent to 0.4 percent of sodium molybdate, 5 percent to 10 percent of triethanolamine, 8 percent to 16 percent of fatty alcohol-polyoxyethylene ether, 1 percent to 2 percent of alkylphenol ethoxylates, 1 percent to 2 percent of hydrochloric acid and the balance of hydrofluoric acid. The chemical cleaning and the preparation method have the advantages that the operation is simple, the cleaning effect is good, the surface of the stainless steel cold-rolling piece cannot be corroded at the same time, and the glossiness of the stainless steel cold-rolling piece is maintained; the cleaning agent for the stainless steel cold-rolling piece can be repeatedly used and cannot harm skin when being contacted with the skin; and as not containing zinc or nitrogen, the cleaning agent is low-carbon and environmentally friendly, and the cost is saved.

Owner:响水巨合金属制品有限公司

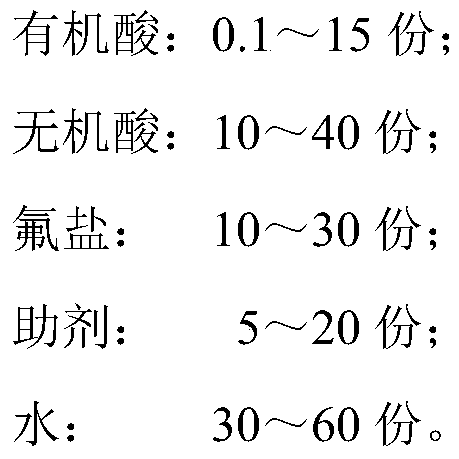

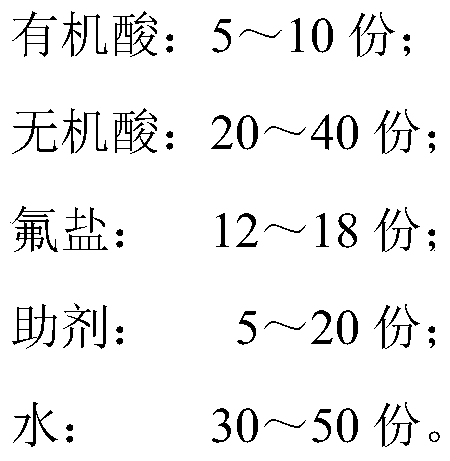

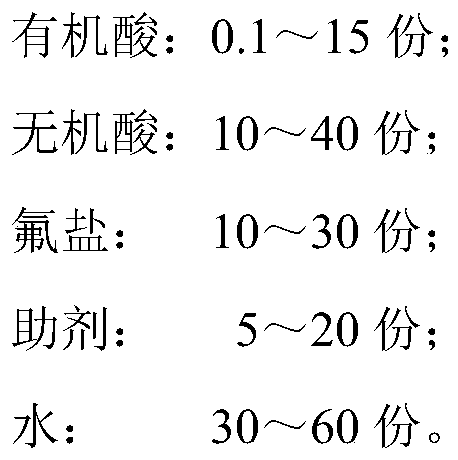

Safe, environment-friendly and stain-resistant antislipping agent and preparation method therefor

The invention relates to the technical field of antislipping products and particularly relates to a safe, environment-friendly and stain-resistant antislipping agent and a preparation method therefor.The safe, environment-friendly and stain-resistant antislipping agent comprises the following ingredients in parts by weight: 0.1-15 parts of organic acid, 10-40 parts of inorganic acid, 10-30 partsof fluoride, 5-20 parts of auxiliaries and 30-60 parts of water. According to the safe, environment-friendly and stain-resistant antislipping agent and the preparation method therefor, a system formedby the organic acid, the inorganic acid, the auxiliaries and the fluoride is in synergism and forms nanoscale holes, of which the size is uniform and the depth is uniform, on floor tiles, and thus, the antislipping coefficient of the floor tiles is increased. After the floor tiles are treated with the antislipping agent disclosed by the invention, matte cannot be caused, subsequent polishing treatment is not required, the floor tiles keep glossiness, and the effect is durable. The antislipping agent disclosed by the invention is safe, environmentally friendly and stain-resistant.

Owner:上海地宝防滑防护科技有限公司

Processing method of nutrient rice

The invention discloses a processing method of nutrient rice. The processing method comprises the following steps that 1, rice screening is conducted through adopting a drum primary cleaning sieve anda vibrating screen; 2, impurities are removed; 3, solutions are mixed. The water, edible alkali, carrageenan, protease k and sodium citrate are uniformly mixed, and the mixture is heated to 60-70 DEGC for later usage; 4, soaking is conducted, the rice with the impurities removed in 2 is put into the 60-70 DEG C solution obtained in 3 and the soaking lasts for 20-40 minutes; 5, drying is conducted; 6, the rice is shelled; 7, the husked rice separation machine is adopted for separating the husked rice from the unhulled rice; 8, rice milling is conducted, the husked rice with the water contentof 18% is subjected to roughening and whitening by adopting a rice milling machine; 9, the rice cooling is conducted, the rice obtained in 8 after roughening and whitening is placed in a cooling ricebin to stand for 24 hours; 10, polishing is conducted; and 11, packaging into bags is conducted. According to the method, the flavor and the nutritive value of the nutrient rice can be improved.

Owner:湖南侗都米业股份有限公司

A cleaning agent for stainless steel and iron member composite boards and a preparation method of the cleaning agent

The invention relates to a cleaning agent for stainless steel and iron member composite boards. The cleaning agent comprises following components by weight: 40%-50% of water, 12%-18% of a polyoxyethylene alkyl ether, 0.5%-2% of an alkylphenol ethoxylate, 4%-6% of citric acid, 2%-4% of tartaric acid, 9%-11% of a corrosion inhibitor, 8%-12% of hexamethylenetetramine, 4%-6% of a metal complexing agent, 0.5%-1.5% of hydrochloric acid, 1%-3% of hydrofluoric acid and 0.5%-1.5% of sodium molybdate. The invention also provides a preparation method of the cleaning agent. The cleaning agent is simple and safe to use, and has good effects of removing sinter, oxide scale, grease and dirt. The cleaning agent is capable of cleaning iron steel plates in a non-excessive corrosion manner, removing the sinter, the grease, the dirt, etc. on stainless steel plates, and guaranteeing the glossiness of the stainless steel plates and the iron steel plates.

Owner:SUZHOU YIFANG METAL SURFACE TREATMENT TECH

Metal surface treatment method

InactiveCN103668257ANot corrodedEasy to cleanMetallic material coating processesSurface cleaningMegasonic cleaning

The invention relates to a metal surface treatment method, in particular to an environment-friendly non-ferrous metal surface treatment method, belonging to the technical field of surface cleaning and surface rust prevention treatment of metal. The method comprises the steps of diluting a metal surface treatment agent with water which is 8-9 times as much as the metal surface treatment agent; adding an acidifying or alkalizing agent to control the PH value of working solution to be 8.0-9.0, and cleaning the surface of non-ferrous metal for 3-4min by ultrasonic waves or in a spraying mode at normal temperature or 50-60 DEG C and drying in a temperature range from 10 DEG C to 120 DEG C; when the method is adopted, nanoscale titanium dioxide and nanoscale silicon dioxide form a protective membrane layer on the surface of the metal, and nanoscale F-doped titanium dioxide and nanoscale silicon dioxide can decompose bacteria on the surface of the metal under the irradiation of sunlight and have high hydrophilcity, so as to fully protect the surface of the metal from being eroded by bacteria and rainwater; therefore, the surface of the metal is protected very well and the protective membrane is formed on the surface of the metal to protect the glossiness of the metal surface.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Wear-resistant and scratch-resistant polypropylene composite with high gloss as well as preparation method and application of polypropylene composite

The invention relates to a wear-resistant and scratch-resistant polypropylene composite with high gloss as well as a preparation method and an application of the polypropylene composite. The polypropylene composite comprises the following main raw materials: polypropylene, a silicone rubber-silane coupling agent-hollow glass bead reactant, filler and an additive packet. In the prepared wear-resistant and scratch-resistant polypropylene composite with high gloss, molecular weight distribution of polypropylene is narrow, hollow glass beads and silicone rubber are mainly distributed on the material surface, a workpiece has high surface gloss, good processability and low shrinkage, and an injection molded workpiece is not prone to production of flow marks and can replace workpieces such as ABSwith higher requirements for gloss, wear resistance and scratch resistance of home appliance housings, automobile trim strips, automobile door handles and the like.

Owner:WANHUA CHEM GRP CO LTD +1

Surface treatment method of nonferrous metal workpiece

InactiveCN107747113AImprove surface propertiesMaintain glossAnodisationAnti-corrosive paintsNonferrous metalSilicon dioxide

The invention discloses a surface treatment method of a nonferrous metal workpiece. The surface treatment method of the nonferrous metal workpiece comprises the steps of chemical polishing, surface treating agent dipping, drying, anode oxidation treatment and polishing and the like. By the adoption of the surface treatment method of the nonferrous metal workpiece, burrs and material marks on the surface of the nonferrous metal workpiece are removed, a silicon dioxide protective film is formed on the surface of the nonferrous metal, the surface corrosion rate of the nonferrous metal is lowered,surface discoloring and crystal precipitation of the nonferrous metal are prevented, the glossiness of the surface of the nonferrous metal is kept, and the comprehensive performance of the surface ofthe nonferrous metal is improved.

Owner:宝鸡市铭坤有色金属有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com