Patents

Literature

39results about How to "Improve appearance grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic surface treatment technique

InactiveCN104017231AMaintain glossImprove appearance gradeMolten spray coatingGrit blastingSurface finishing

The invention relates to a plastic surface treatment technique which comprises the following steps: plastic degreasing, plastic swelling, plastic surface coarsening, primary grit blasting, spraying treatment, hole sealing treatment, secondary grit blasting (carrying out grit blasting on the plastic surface by using a high-pressure spray gun and a sand material), and water washing and drying. The treatment technique is simple, shortens the treatment time, and enhances the high-temperature oxidation resistance and corrosion resistance of the plastic; and the plastic has higher surface smoothness and is beautiful.

Owner:CHUZHOU HONGYUAN SPRAYING

Puí»er chrysanthemum Tuo tea

The invention provides a Pu-erh chrysanthemum packaged tea, and consists of 90 percent of Pu-erh tea leaves and 10 percent of chrysanthemum, wherein, the Pu-erh tea leaves is green Pu-erh tea or cooked Pu-erh tea made by a conventional processing method and is provided with unique fragrance of the cooked Pu-erh tea as well as freshness of the chrysanthemum and medicinal values of depressurization and lipid expelling by the Pu-erh tea and liver calming, fire purging, sputum eliminating and producing the effect toward clear vision and refreshment by the chrysanthemum. The invention is prepared by adopting natural materials, has simple technique and low cost and ensures that effective health-care components are not damaged; the product has high-grade appearance, flavored taste and health functions of cooling, quenching the thirst, calming the liver, purging fire, alleviating fatigue and improving immunity. In addition, long-term drinking of the tea is easy to be accepted by most of people and has certain health protection effect on human bodies, can get rid of fatigue, enhance the immunity and is easy to be accepted by most people.

Owner:黄泽明

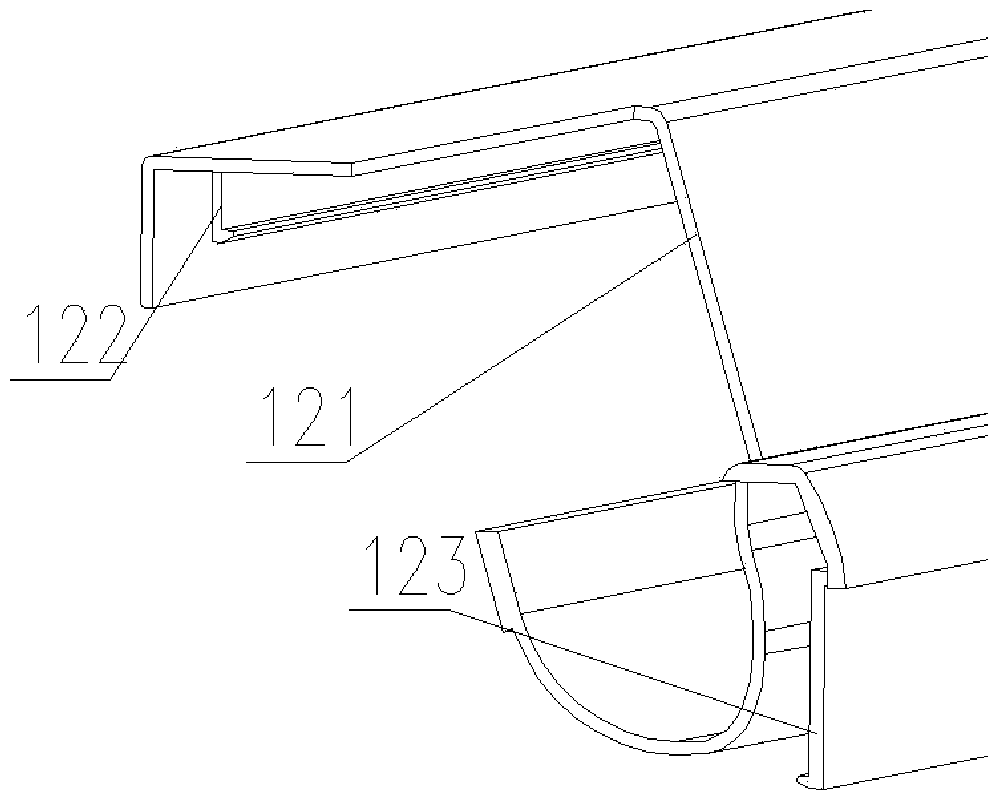

Refrigerator door body

ActiveCN105928305AImprove appearance gradeStrong metal feelingLighting and heating apparatusCooling fluid circulationAlloyEngineering

The invention discloses a refrigerator door body and belongs to the technical field of refrigerating equipment. The refrigerator door body comprises a door frame, a glass plate and a door lining, wherein the door frame consists of an upper decorative bar, a left end stop, a right end stop, a left insert and a right insert; the upper decorative bar is an aluminum alloy extruded part; the left end of the upper decorative bar is provided with a first blocking hook, a second blocking hook and a fifth blocking slot; the top of the left end stop is provided with a first blocking slot matched with the first blocking hook and a second blocking slot matched with the second blocking hook; the left insert is blocked into the fifth blocking slot; the right end of the upper decorative bar is provided with a third blocking hook, a fourth blocking hook and a sixth blocking slot; the top of the right end stop is provided with a third blocking slot matched with the third blocking hook and a fourth blocking slot matched with the fourth blocking hook; and the right insert is blocked into the sixth blocking slot. The refrigerator door body is simple in structure, and is convenient to mount; by virtue of the decorative bars made of the aluminum alloy material, the door body has stronger metallic appearance, so that the appearance level of a refrigerator is improved; and meanwhile, high mould charge of a plastic mould is saved.

Owner:AUCMA

Printing ink with tough effect and surface finishing technology for paper packing boxes

InactiveCN108059874AImprove appearance gradeStrong friction resistanceInksOther printing apparatusSurface finishingPOLYETHYLENE WAX

The invention relates to the field of packing and printing, and especially relates to a printing ink with a tough effect and a surface finishing technology for paper packing boxes. The printing ink comprises following raw materials in percentage by weight: 43 to 53% of polyurethane resin, 15 to 25% of epoxy resin, 3 to 6% of tri(propylene glycol) diacrylate, 3 to 6% of polyethylene wax, 1 to 3% ofphoto initiator TPO, 1 to 3% of photo initiator 369, 4 to 10% of silica, 4 to 8% of talcum powder, and 6 to 10% of bentonite. The printing ink is used to decorate the surface of a paper packing box by the provided surface finishing technology. The surface of the processed paper packing box has dark luster. People can feel flannelette touch when touching the surface of the paper packing box. The appearance of the paper packing box is upgraded, and the wear resistant performance of the surface of the paper packing box is strengthened.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

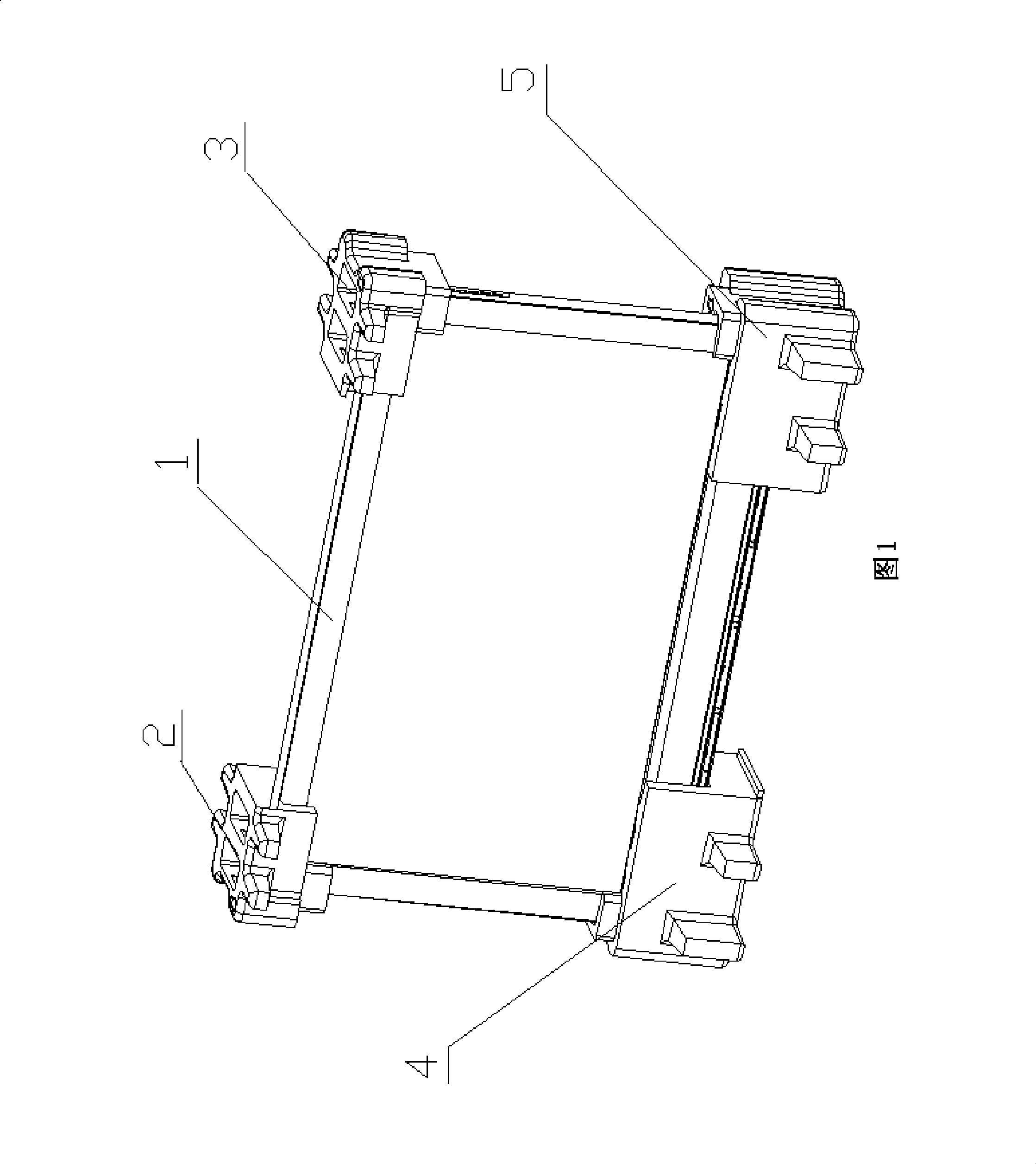

Protection gasket for plane TV package

InactiveCN101423136AThe overall thickness is thinReduce usageContainers to prevent mechanical damageDamagable goods packagingLogistics managementEngineering

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Color crystal glass having three-dimensional effect

InactiveCN102416818AImprove appearance qualityImprove appearance gradeSpecial ornamental structuresGlass/slag layered productsScreen printingPrinting ink

Owner:JIANGSU OBON PLASTIC

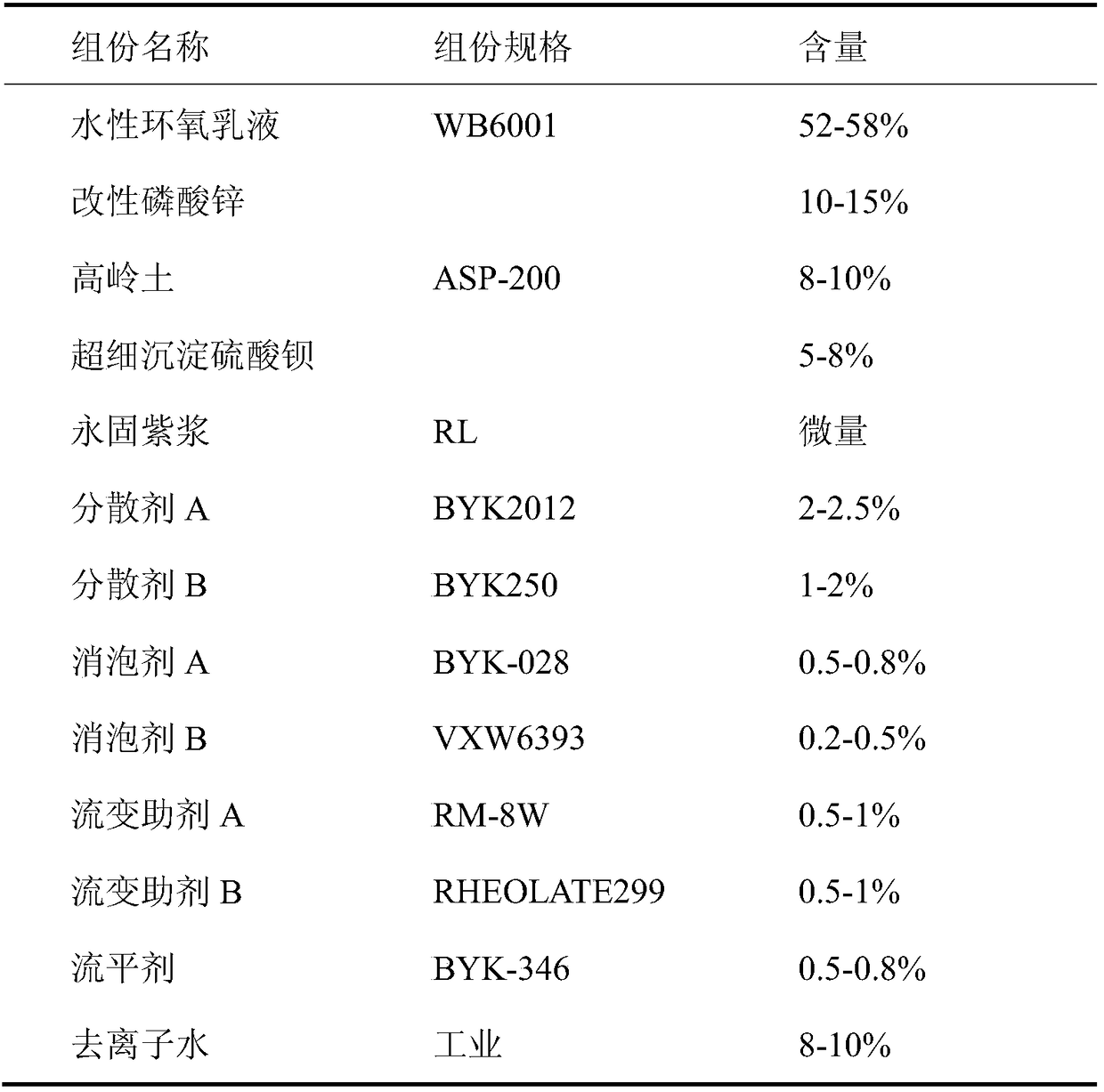

High-performance waterborne double-component epoxy resin with relatively high solid content and preparation method

InactiveCN108395811AImprove bindingImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

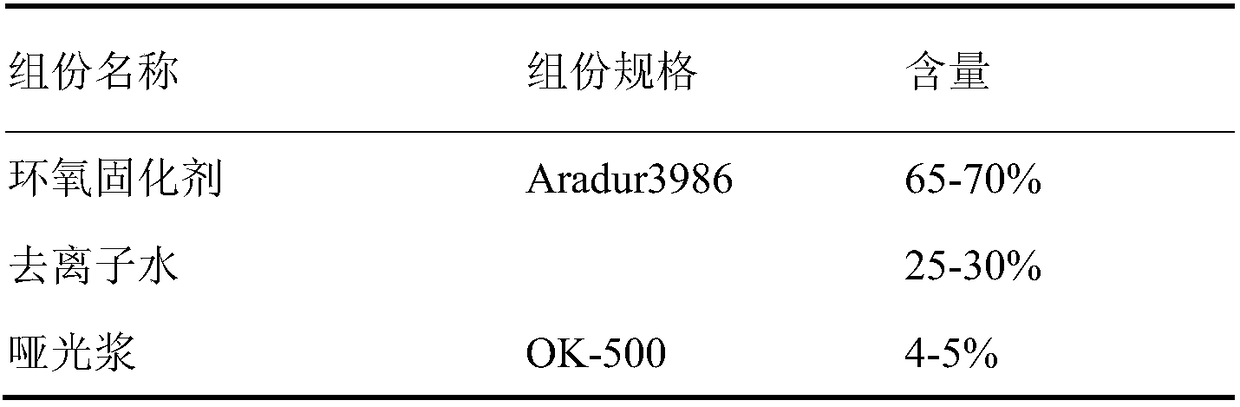

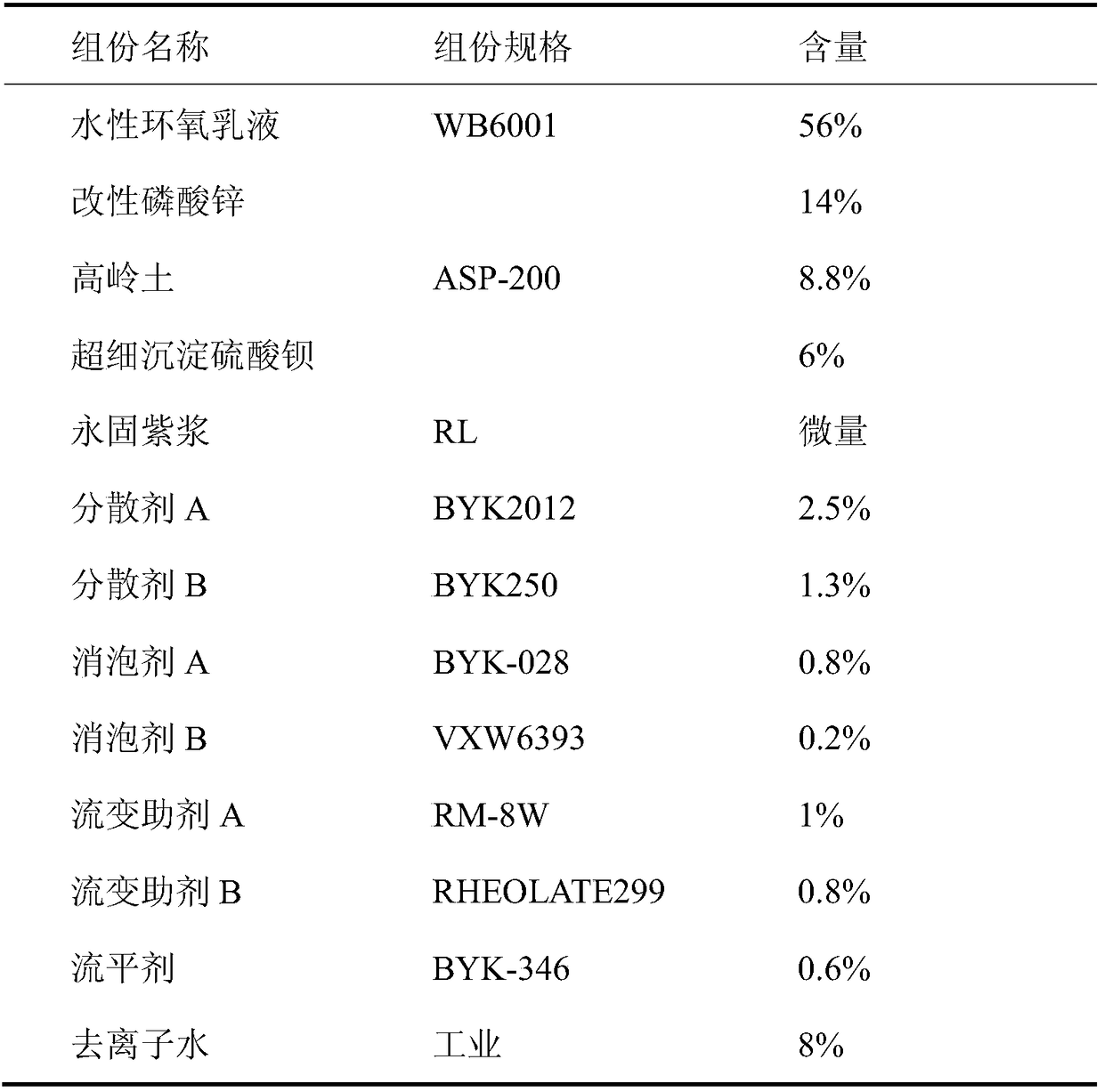

The invention discloses high-performance waterborne double-component epoxy resin with relatively high solid content and a preparation method. The high-performance waterborne double-component epoxy resin is prepared from a component A and a component B, wherein the component A is prepared from the following components: waterborne epoxy emulsion, modified zinc phosphate, kaolin, ultrafine precipitated barium sulfate, permanent violet slurry, a dispersant A and a dispersant B, a de-foaming agent A and a de-foaming agent B, a rheological auxiliary agent A and a rheological auxiliary agent B, a flatting agent and de-ionized water; the component B is prepared from the following components: an epoxy curing agent, de-ionized water and matte slurry; the component A and the component B are mixed according to the ratio of 2.7 to 1. The product disclosed by the invention has a strong binding force with a matrix and has relatively high corrosion prevention performance; the product has a relativelygood adhesive force and certain decoration performance on a machining surface of a metal part; relatively thick coating film thickness can be formed in one step; a coating film on the product is transparent and matte; the high-performance waterborne double-component epoxy resin can be blended according to different color requirements and integrates corrosion resistance, mechanical properties and adecoration function into a whole; the production cost is reduced and the emission of VOC (Volatile Organic Compounds) is reduced.

Owner:SINO TRUK JINAN POWER

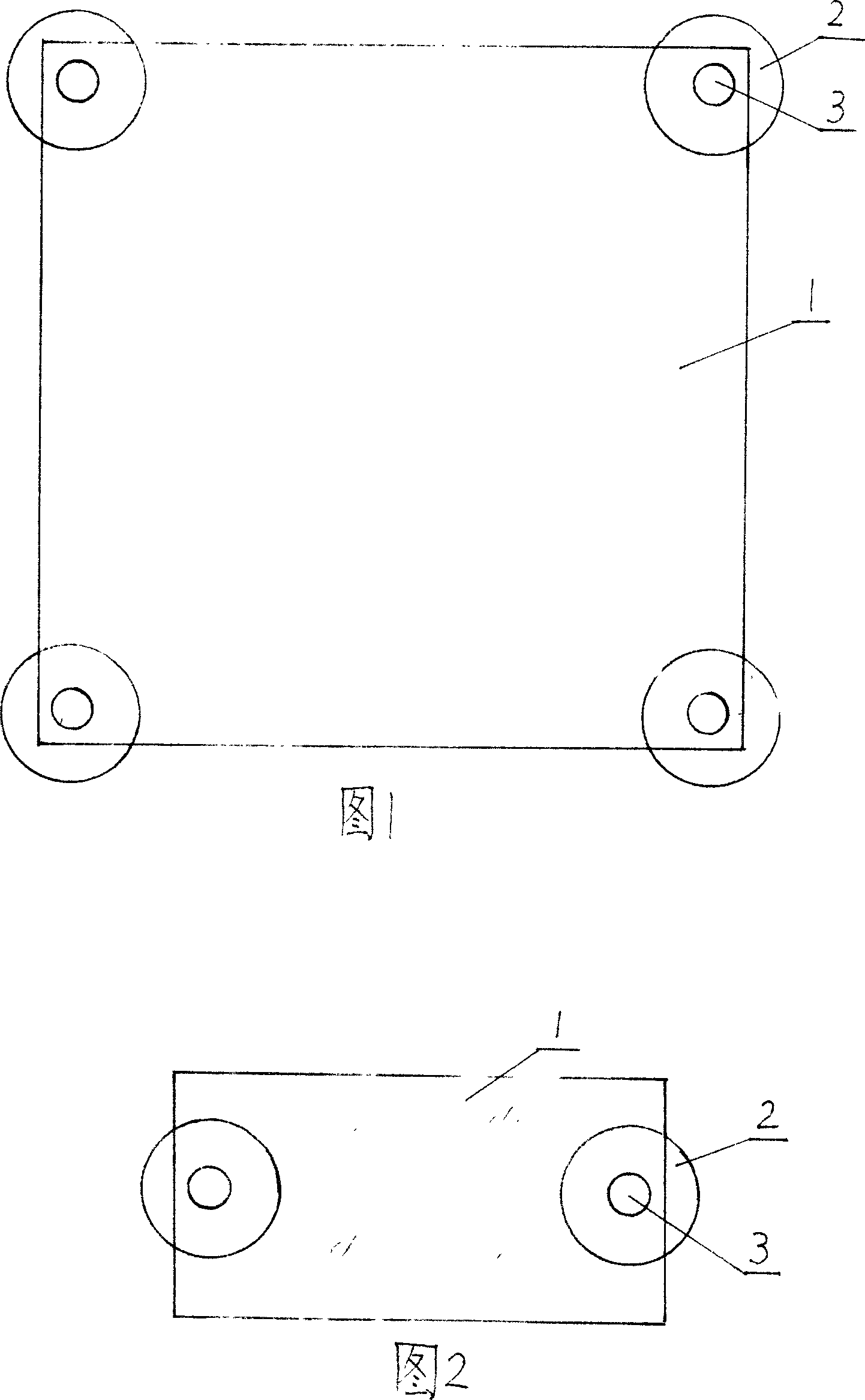

A cupule pasting method and cupule suspending plate

This invention relates to one attracted add method and its hanging board, which comprises the following steps: processing round hole in edge of five to ten millimeter in film board four angles with round hole match with attracted top end ball handle or column handle; then adding the disc to gate, window glass board, stainless board or clear complete wall, wherein, the disc number and their distance and round hole number are relative covered on top of disc and loads the slice load with font or pattern onto film board.

Owner:杨生

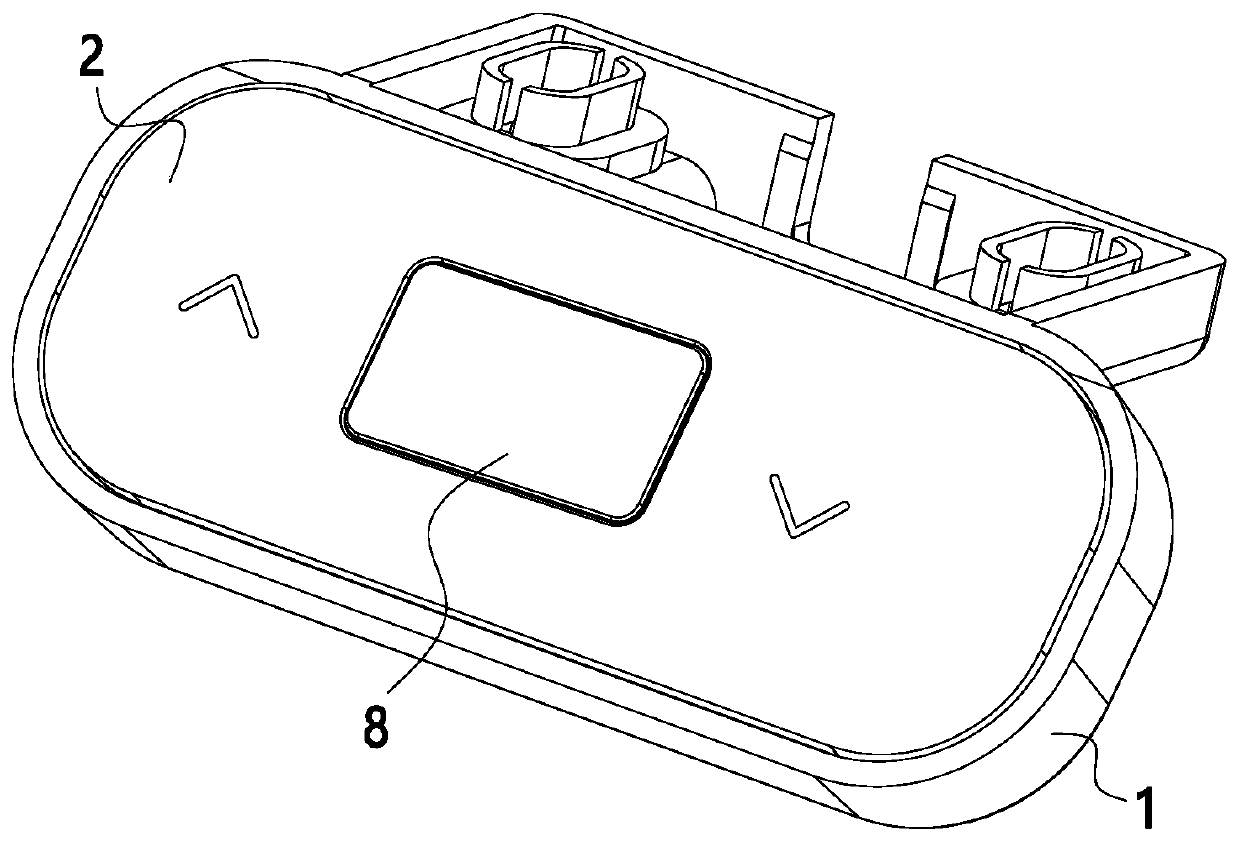

Operator for controlling electrically adjustable furniture

PendingCN110677148AImprove operational safetyReduce the probability of misuseElectronic switchingManipulatorOperation safety

The invention discloses an operator for controlling electric adjustable furniture and belongs to the field of manipulators, the invention discloses an operator for controlling electric adjustable furniture. The operator comprises a shell and an actuating panel, the actuating panel is movably supported in the shell and forms a cover body of the shell; a circuit board is arranged in the shell, the circuit board comprises a main control unit for detecting an actuating signal; a first switch for generating a first actuating signal and a second switch for generating a second actuating signal are arranged between the actuating panel and the main control unit; a third switch for generating a third actuating signal is arranged between the bottom wall of the shell and the main control unit; when the main control unit detects the first actuating signal and the second actuating signal at the same time, the main control unit sends out a first command, and when the main control unit detects the first actuating signal, the second actuating signal and the third actuating signal at the same time, the main control unit sends out a second command, so that the misoperation rate is reduced, and the operation safety of the electric adjustable furniture is improved.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

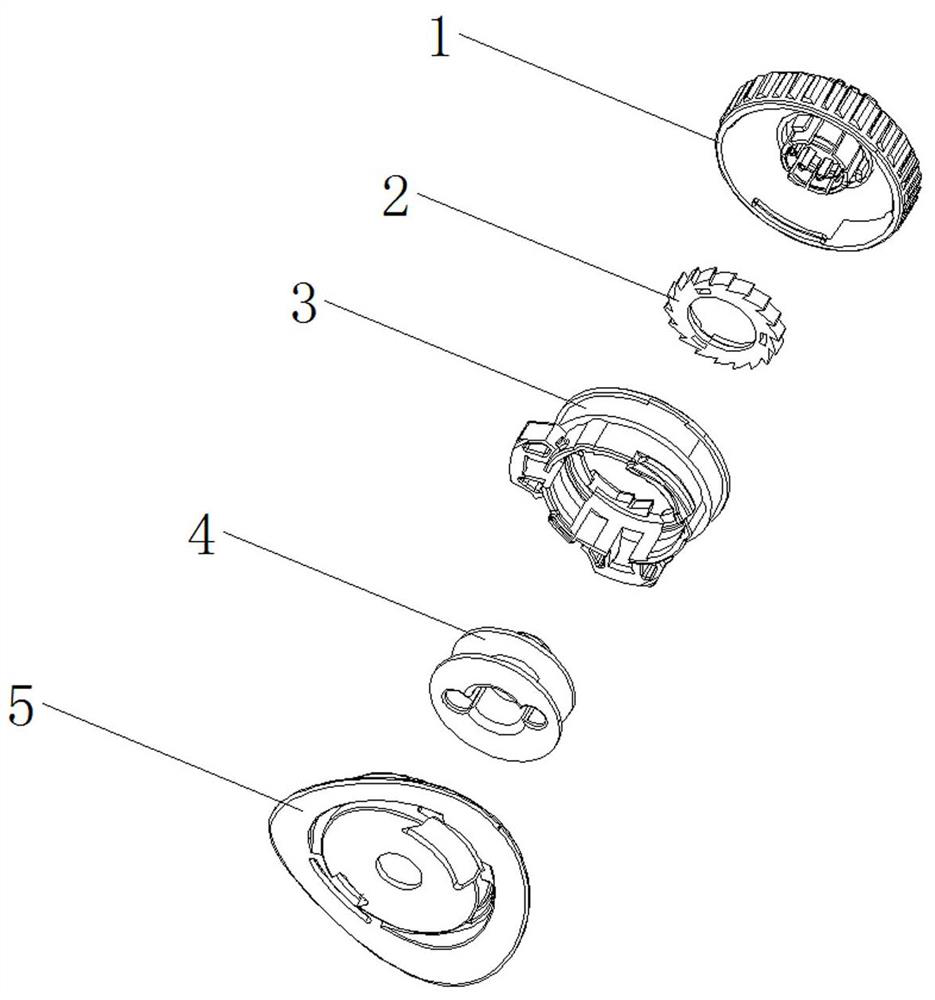

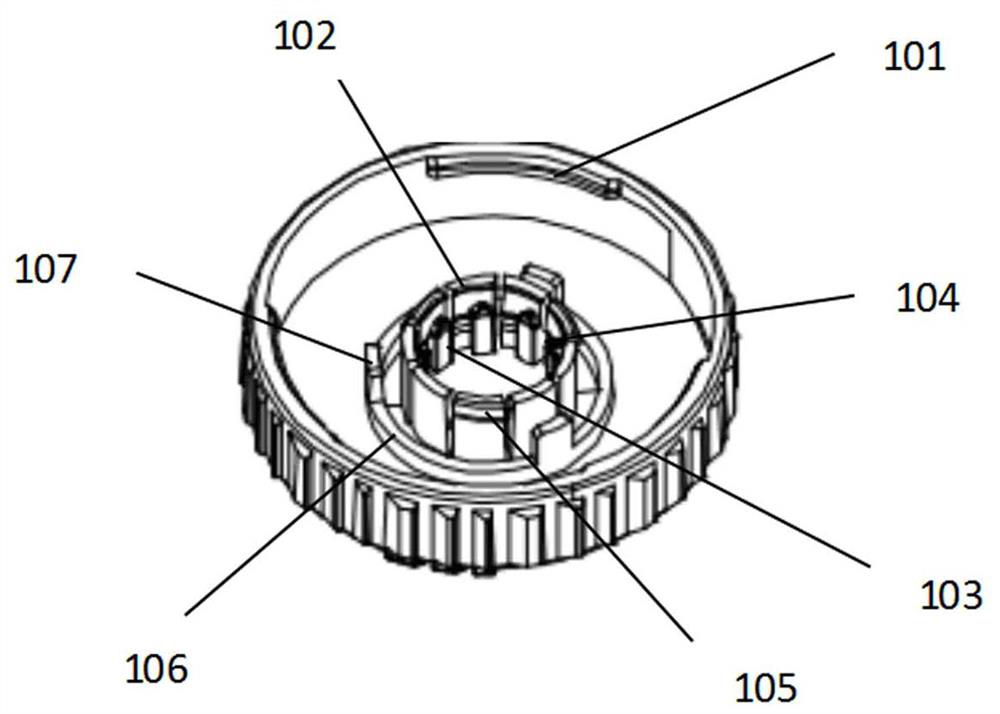

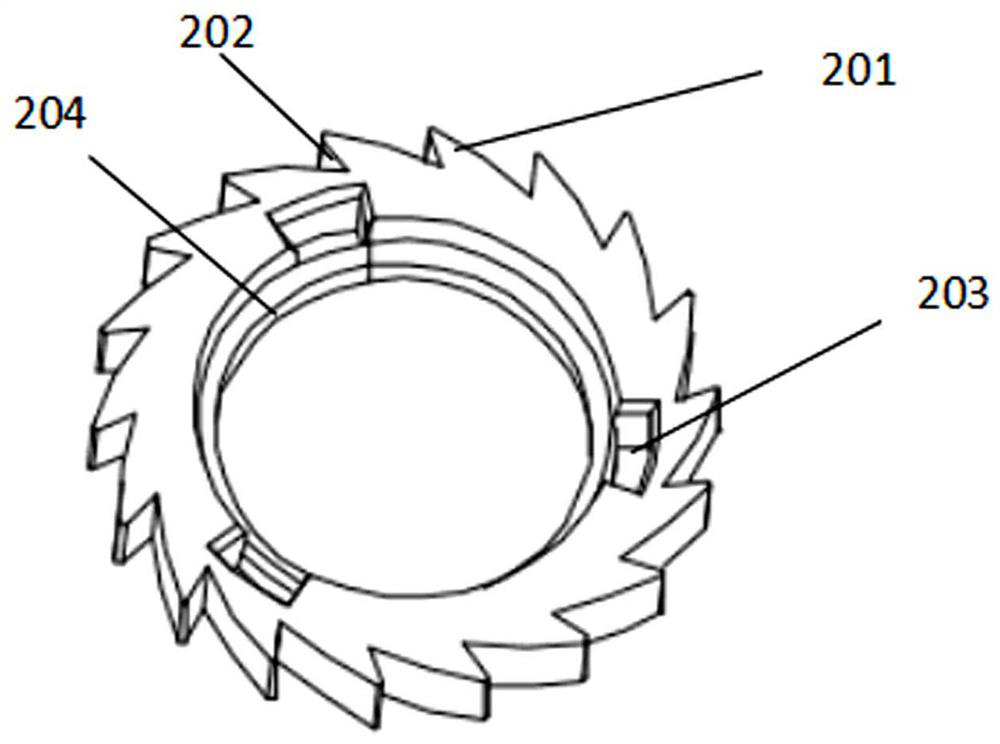

Knob device

The invention provides a knob device. The knob device comprises a knob, a wheel bin, a line wheel, a base and a shoelace, wherein the base is sewn on the side surface of an upper or a tongue; a buttonposition is arranged on the inner circumferential edge of the knob; a plurality of square holes are formed in the circumferential edge of the wheel bin; a plurality of rope penetrating holes I are formed in the lower part of the outer circle of the wheel bin; a line groove is formed in the middle of the line wheel; a plurality of rope penetrating holes are formed in the line wheel; a counter borestructure is arranged in the center of the bottom of the line wheel; the knob device further comprises a gear ring; clamping teeth capable of preventing the gear ring from rotating are arranged on the gear ring; and a blocking mechanism corresponding to the clamping teeth arranged on the gear ring is arranged on the wheel bin. The knob device is better in reliability; when a pawl arm on the wheelbin is stressed reversely, the pawl arm deforms towards the centrifugal direction, pawl teeth and ratchets on the pawl arm are tightly attached together, circumferential teeth and ratchet teeth on the pawl arm are tightly attached together, and the stress states of the pawl arm, the ratchets, the circumferential teeth and the ratchet teeth are very ideal, so that the structure is higher in reliability when stressed reversely.

Owner:李付德

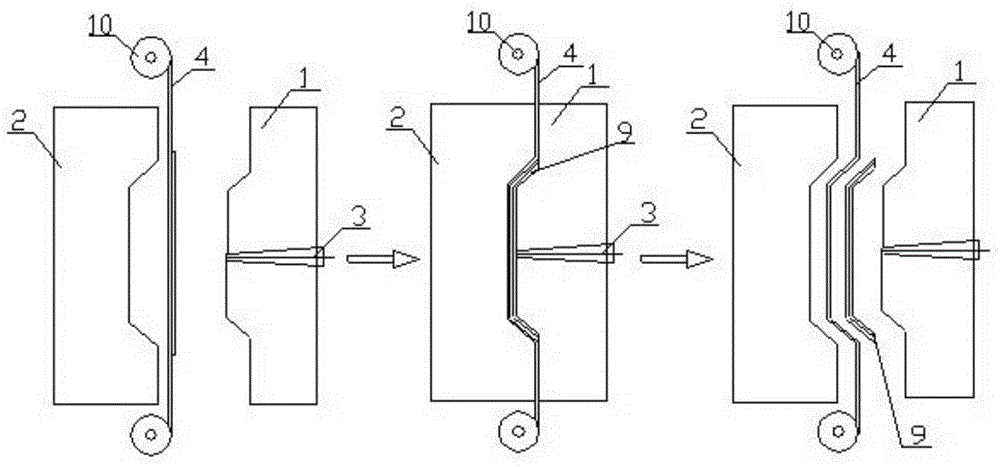

Production method for plastic product with customized pattern, plastic product and diaphragm

InactiveCN105291673ARealize personalized customizationLow costSynthetic resin layered productsSpecial ornamental structuresEngineeringDigital printing

The invention relates to a production method for a plastic product with a customized pattern and the plastic product. The production method comprises the following steps: A, printing a user-customized pattern on the surface of a base-layer film of a diaphragm in a digital printing mode; B, putting the diaphragm which is printed with the pattern into a mould cavity of a mould, and positioning the diaphragm; C, injecting molten plastics into the mould cavity, and enabling the diaphragm to be tightly combined on the surface of the plastic product; D, opening the mould after cooling, removing the diaphragm by peeling, and taking out the plastic product printed with the customized pattern. According to the production method, a photo, a creativeadvertisement picture, a creative topic picture and the like provided by a user can be directly used, so that the picture source is wide; and the pattern provided by the user is printed on the surface of the product, so that the preference of the user can be adapted better, the effect shown by the product is better, user customization needs are completely met, and mass production further can be realized.

Owner:QINGDAO HAIER MOLDS

Processing method for three-phase asynchronous motor terminal welding

InactiveCN106602799AImprove appearance gradeQuality improvementManufacturing dynamo-electric machinesCopper wireEngineering

The invention provides a processing method for three-phase asynchronous motor terminal welding. The method comprises: step (a), tools and materials are prepared; to be specific, a heat gun, a welding stand, a tin wire, a wiring terminal and a piece of cloth are prepared; step (b), a lead wire is protected by the cloth to ensure correct and proper protection and avoid the potential quality hazard, wherein the copper wire length allowance of the lead wire is controlled to be 8mm to 11mm; step (c), the end portion of the lead wire is coated with a soldering paste, the wiring terminal sleeves the processed end portion, and the to-be-welded lead wire is coated by a piece of slightly wet cloth, so that any burning or damage of the lead wire can be prevented; and step (d), the wiring terminal and the lead wire copper wire are heated locally; when the copper wire in the wiring terminal becomes red, the tin wire is added and thus heat is transferred to the tin wire to enable the tin wire to be heated and melted, so that a weld joint is filled. And the appearance is required to be plumb and flat without any missing and weld beading. With the method provided by the invention, raw materials can be saved; the efficiency can be improved; the overall appearance is beautiful and consistent; and the quality problem is solved during the application process of the method.

Owner:QINGDAO SANLI INTELLIGENT POWER

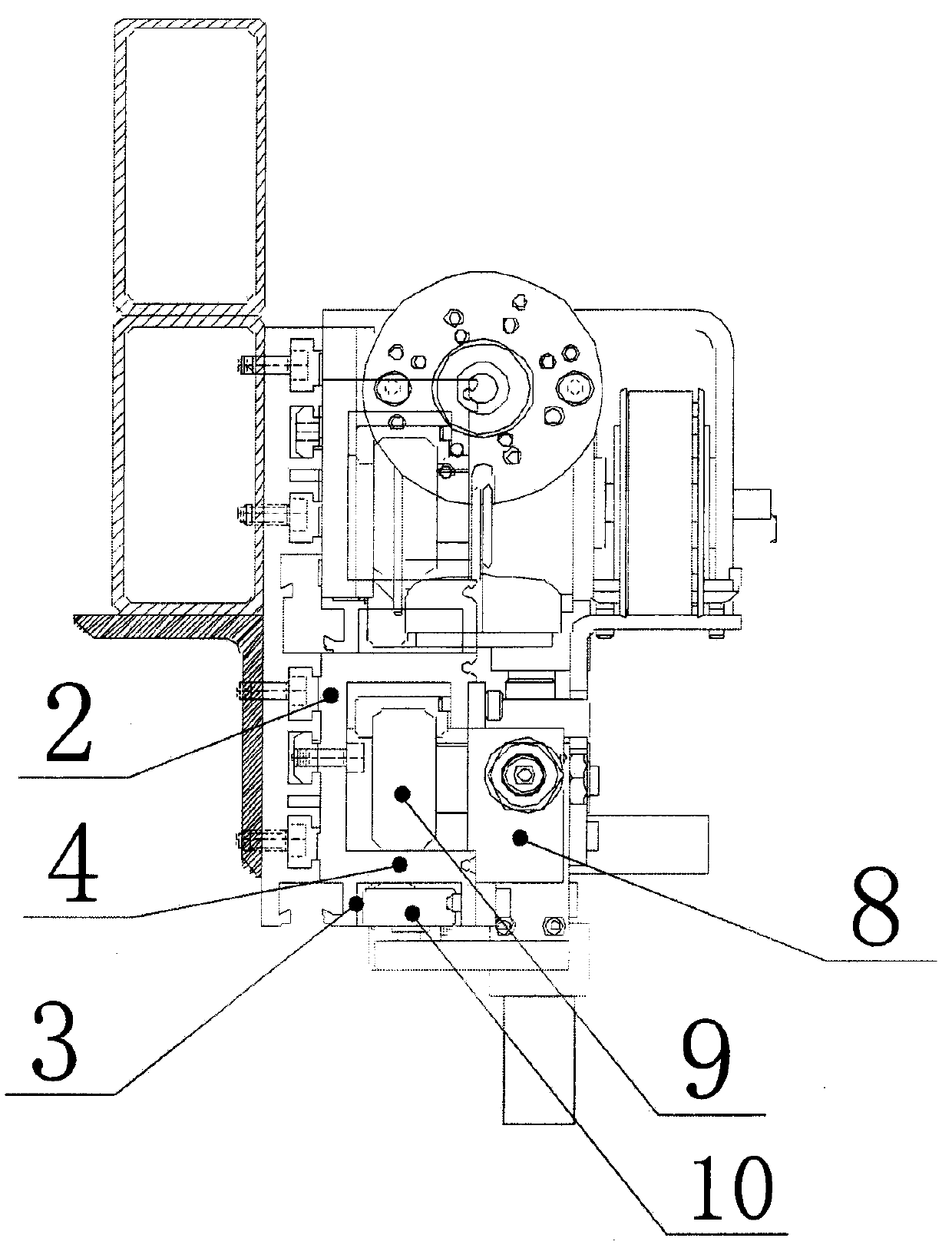

Electric sliding-plug door window

InactiveCN110528989AImprove appearance gradeSmart fashion temperamentPower-operated mechanismSealing arrangementsWindow openingEngineering

The invention relates to an electric sliding-plug door window which comprises a structure frame body, a door window blade, a track component and a driving component, wherein the track component comprises a front track unit, a rear track unit and a bottom track unit which are arranged on the structure frame body. The door window blade is arranged on the track component through a plurality of sliding blocks, the track component can limit the sliding of the door window blade, and therefore the plug and pull out of the door window blade on a door opening or a window opening is realized. The electric sliding-plug door window is suitable for a variety of building structures and can also be extended to the use of broken bridge aluminum door window systems. The electric sliding-plug door window has the advantages as follows: a door leaf or the door window blade can be perfectly flush with the walls on the two sides after being closed, thus the design appearance and size requirements are met, and the overall appearance grade of a building is improved; the door leaf or the door window blade blends with the surroundings of the building perfectly, adding a smart and fashionable atmosphere to the building and indoor decoration, and being another model that technology builds architectural aesthetic feeling.

Owner:中拓门业(天津)有限公司

Water outlet opening processing process for producing connector pressure castings

The invention discloses a water outlet opening processing process for producing connector pressure castings, which comprises a plurality of steps for finally realizing water taking openings of the connector pressure castings. The process has the advantages that the processed connector pressure castings have high surface smoothness and high appearance grade, the fraction defective is reduced by more than five times, and compared with the prior art, the invention improves the production efficiency by more than ten times.

Owner:DONGGUAN XINGHE PRECISION DIECASTING MOLD CO LTD

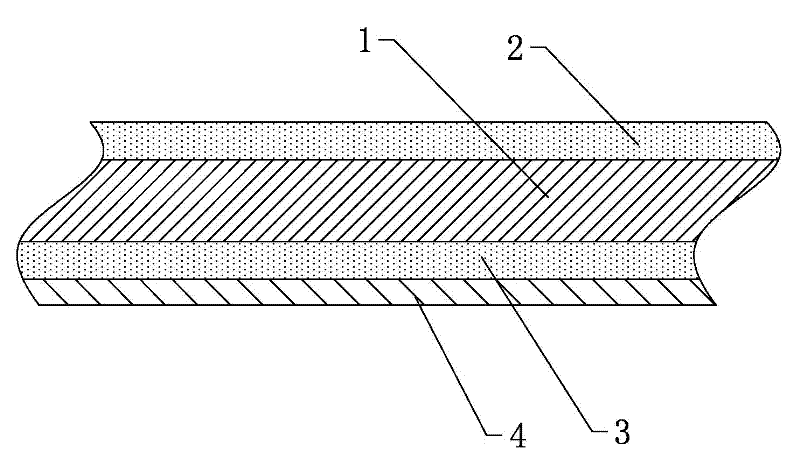

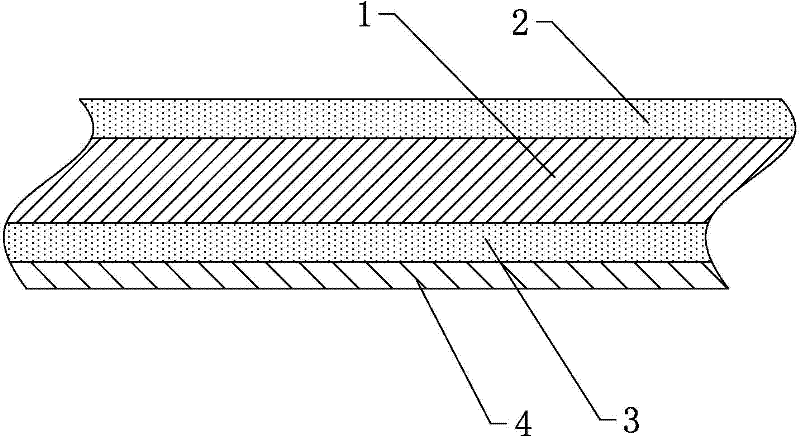

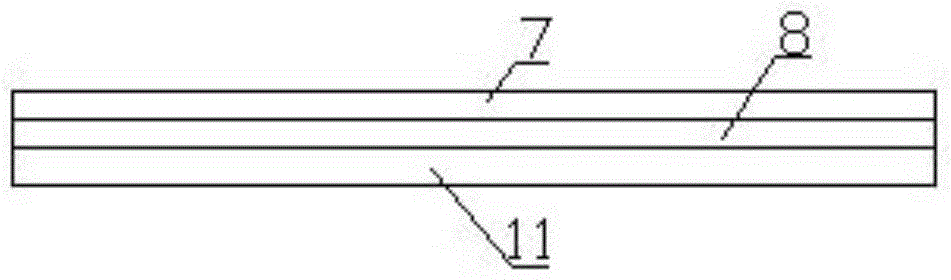

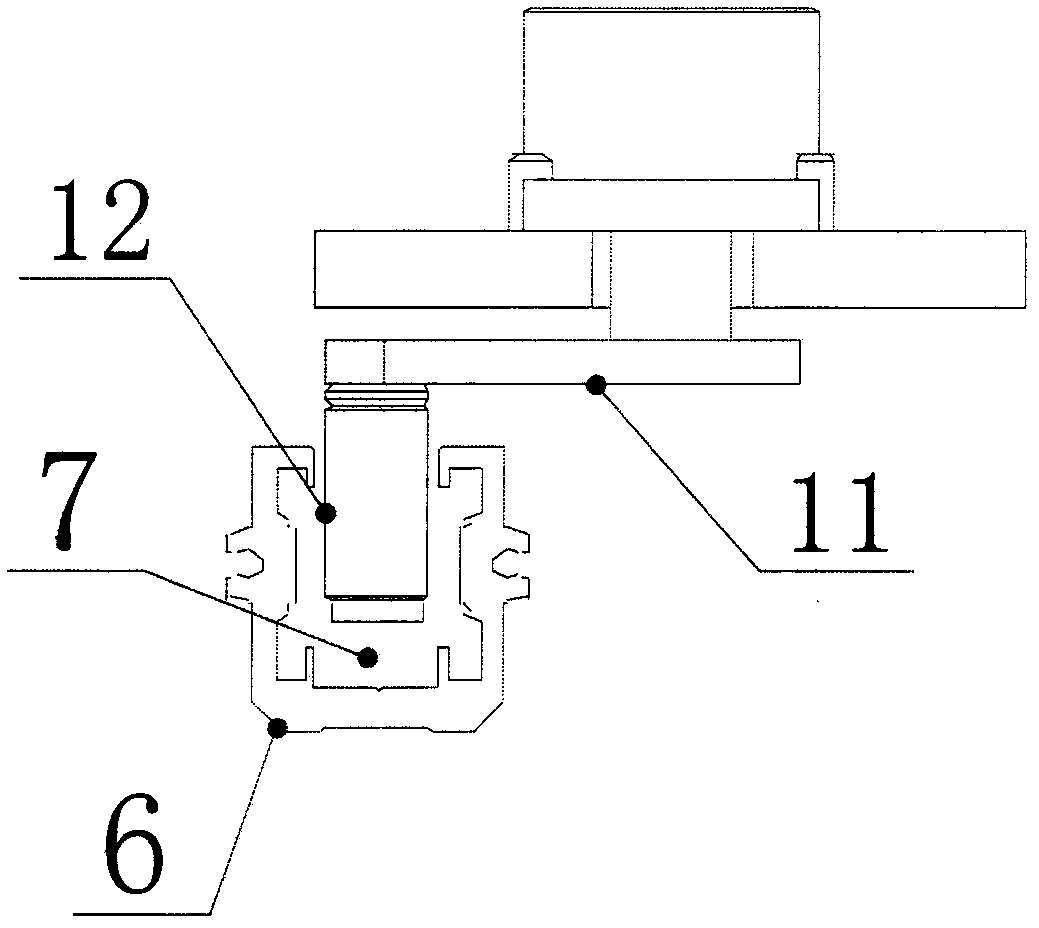

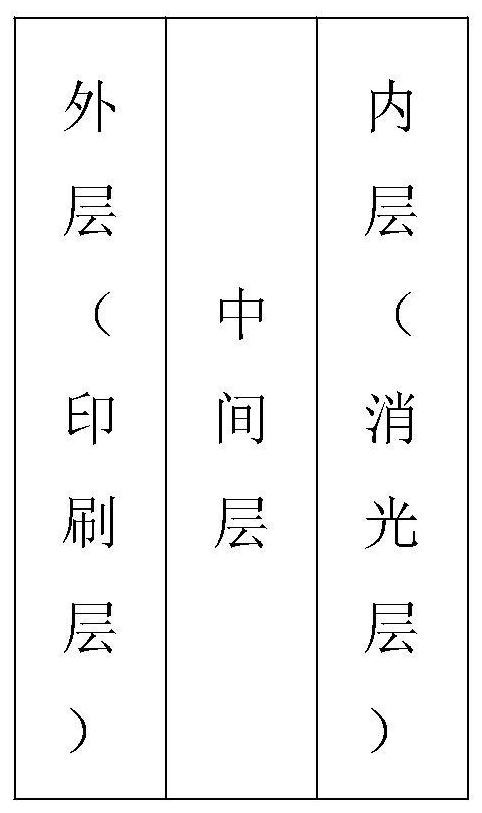

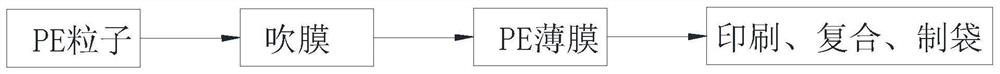

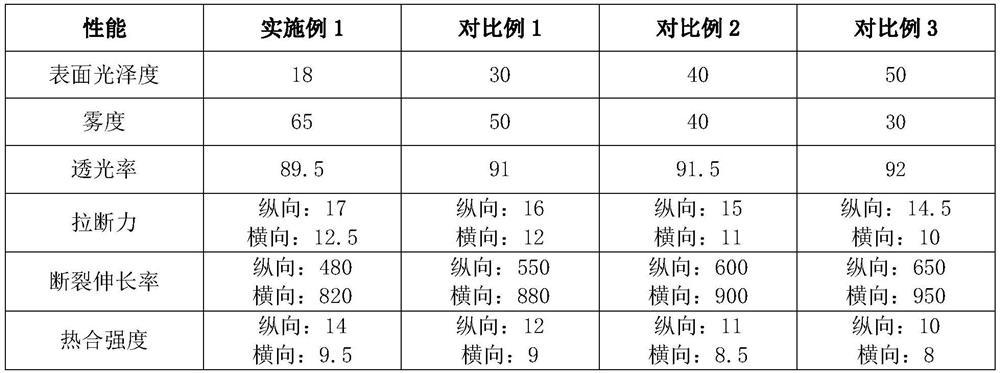

Matt polyethylene film suitable for intaglio printing and preparation process thereof

PendingCN113059879AHigh heat sealing strengthEasy to bagFlexible coversWrappersLow-density polyethylenePolymer science

The invention relates to a matt polyethylene film suitable for intaglio printing and a preparation process thereof, and belongs to the technical field of packaging, wherein the matt polyethylene film comprises an outer layer, a middle layer and an inner layer which are prepared by an intaglio printing process and are connected in sequence; the outer layer comprises 97.5 parts by mass of low density polyethylene, 1.5 parts by mass of a processing aid and 1 part by mass of a slipping agent; the middle layer comprises 100 parts by mass of low density polyethylene; and the inner layer comprises 98.5 parts by mass of low-density polyethylene, 1 part by mass of a processing aid and 0.5 part by mass of a slipping agent. The inner layer is made of resin with the grade of FB2230, so that the surface glossiness is effectively improved, and the extinction effect is achieved; and the resin is enhanced polyethylene resin, has higher heat sealing strength, is easier for bag making, and does not generate the bad problems of knife sticking, wire rising and the like.

Owner:HUANGSHAN NOVEL

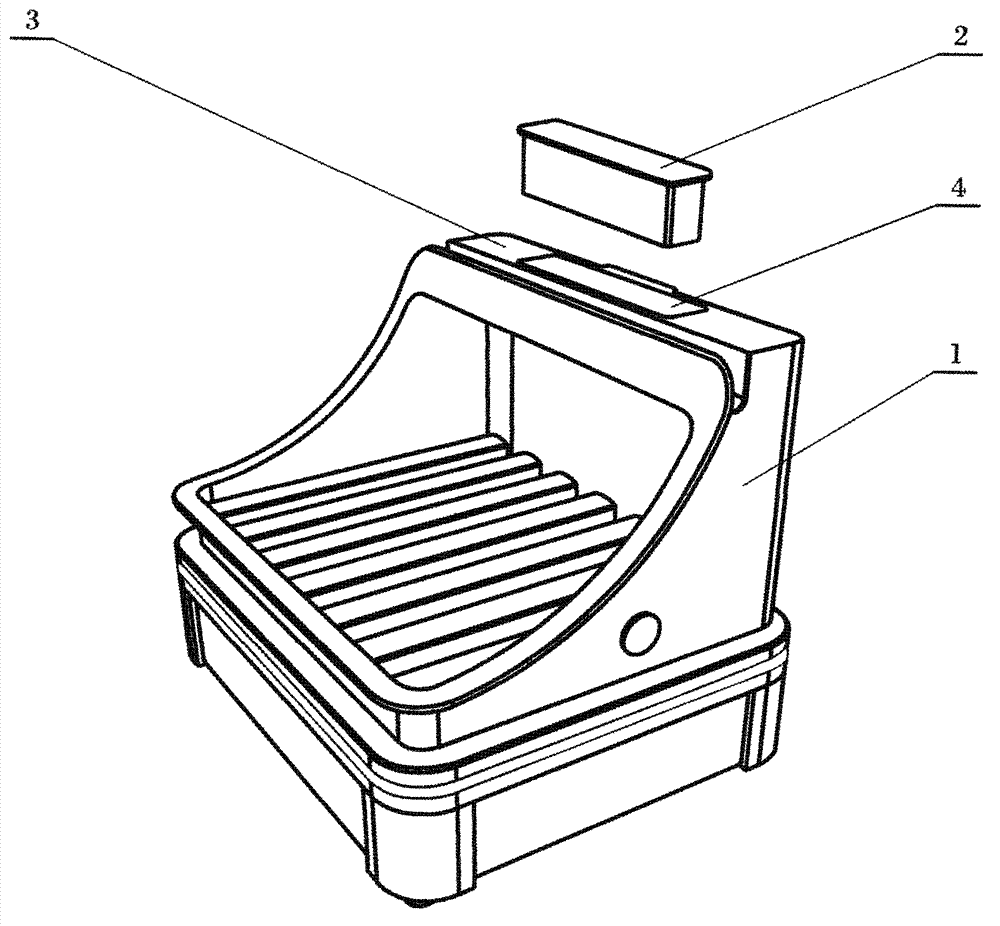

Foot warming box with upper electric control box

InactiveCN102895058AGood lookingImprove applicabilityTherapeutic coolingTherapeutic heatingEngineeringElectric control

This invention relates to a foot warming box with an upper electric control box, belonging to the technical field of household electric heaters. The foot warming box with the upper electric control box consists of a box body and the electric control box and is characterized in that the upper part of the box body is provided with an upper platform; an electric control box hole is formed in the upper platform; and the electric control box is embedded in the electric control box hole. The foot warming box has the advantages that the electric control box of the foot warming box is upgraded to an upper device, the appearance grade of products is improved, and the comfort is obviously improved when the electric control box is operated for warming, so that the appearance and the applicability of the foot warming box have breakthrough improvement, and the foot warming box has an extremely good market prospect.

Owner:遵义航阳电器厂

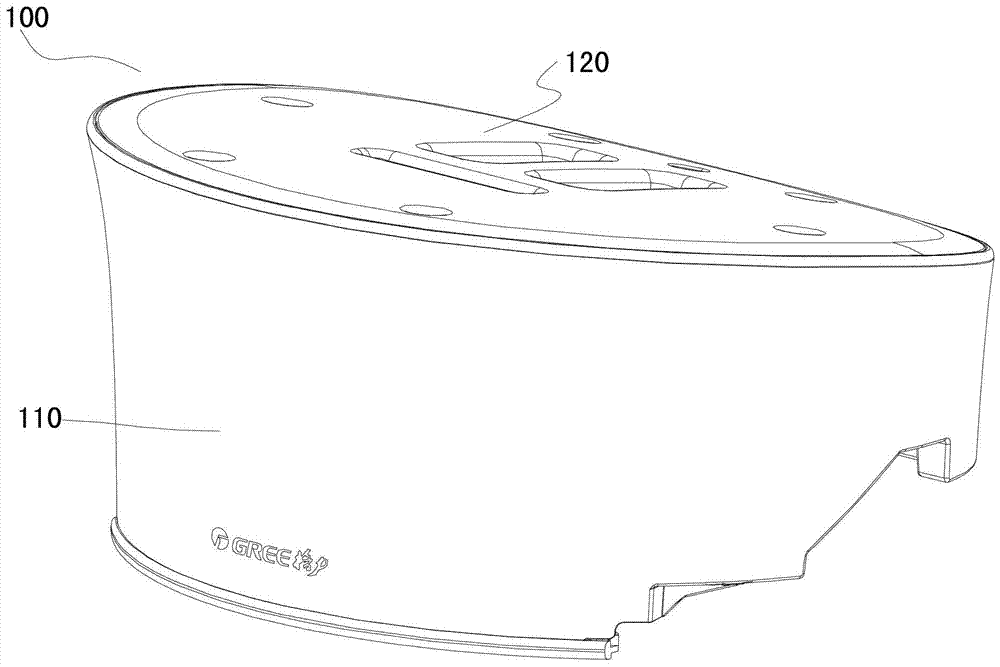

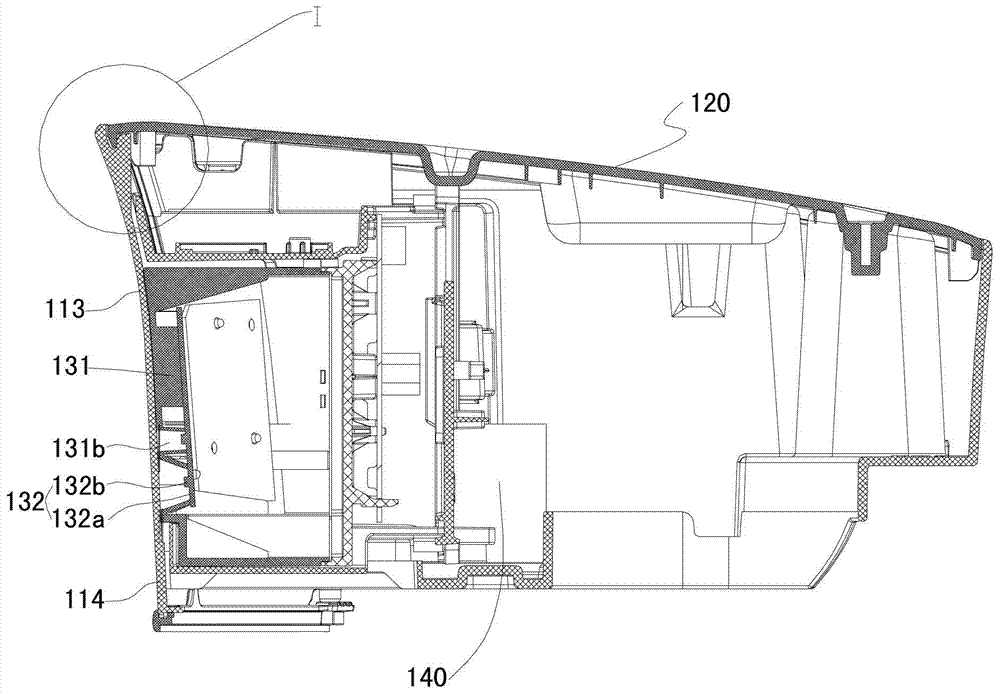

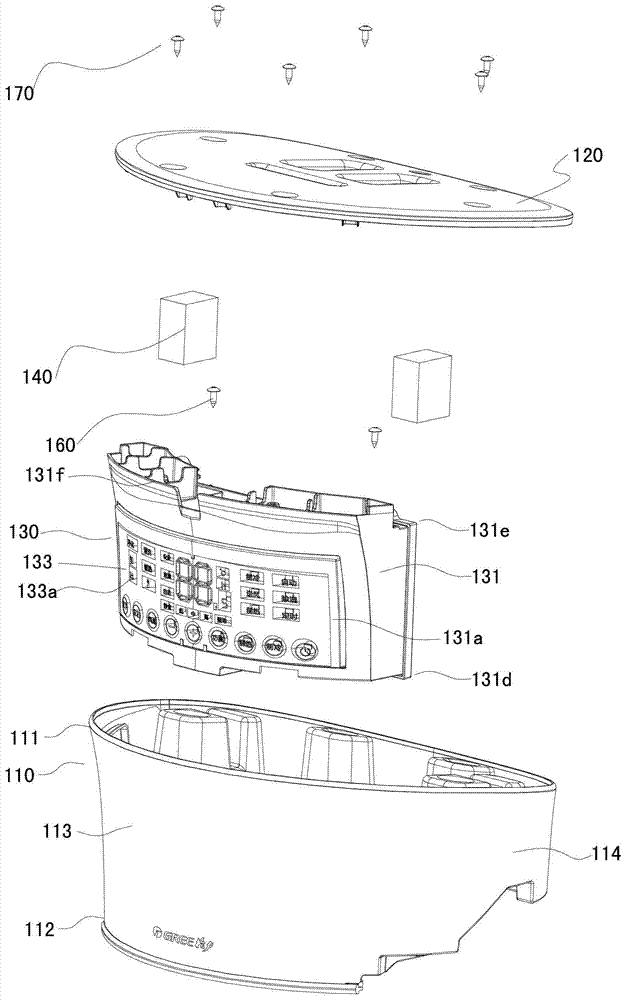

Display device and air conditioner with same

ActiveCN104154641BAchieve transformationImprove appearance gradeMechanical apparatusHeating and ventilation casings/coversDisplay deviceSpeckle pattern

The invention discloses an air conditioner display device and an air conditioner with the display device. The air conditioner display device includes a display panel and a display assembly. The display assembly includes a display mask and a light source module. The display panel is provided with a projection surface, the pattern transmits light, and the light emitted by the light source module is projected onto the projection surface after passing through the pattern. Since the display device provided by the present invention adopts the above-mentioned structure, when the power is turned on, the light emitted by the light source module passes through the pattern and then projects onto the projection surface to form a light spot of a corresponding pattern. The displayed pattern can be seen on the screen, thus realizing the transformation of the display mode without increasing the cost. Moreover, since the display panel is non-transparent, the pattern on the display mask is invisible when the power is off, which improves the overall appearance of the product.

Owner:GREE ELECTRIC APPLIANCES INC

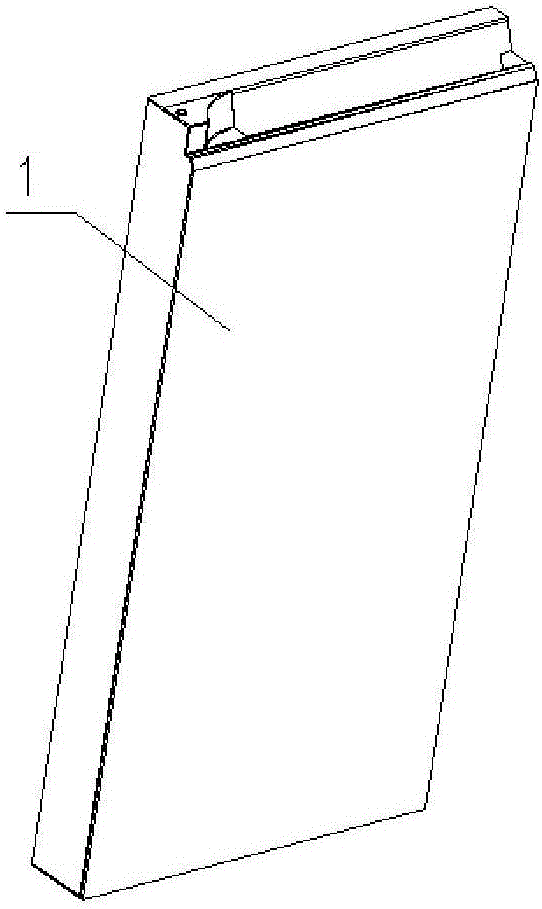

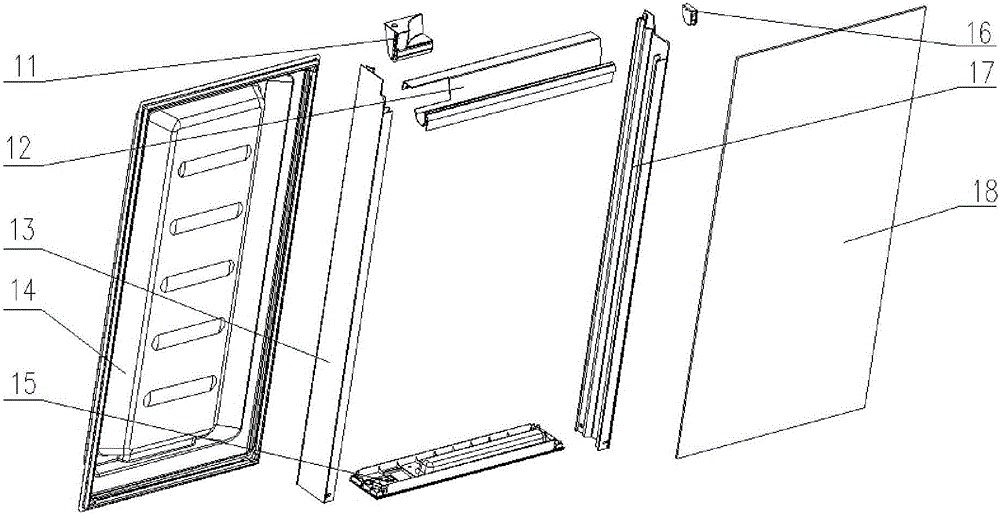

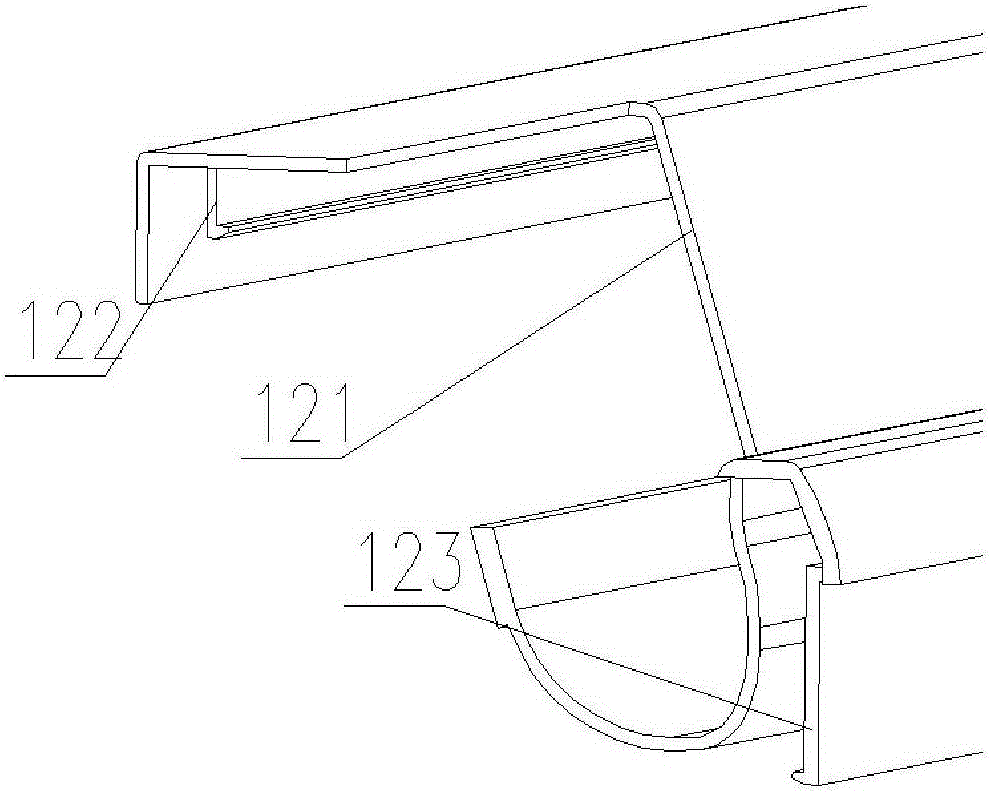

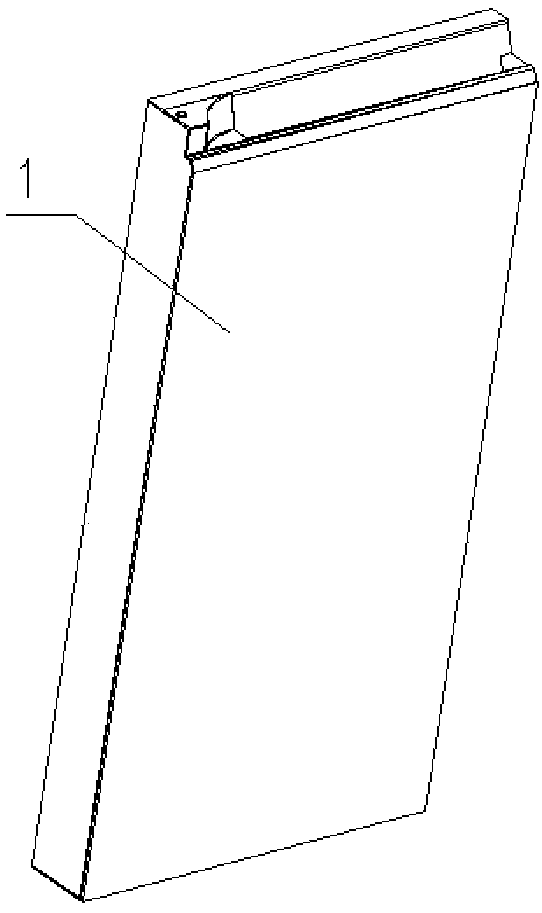

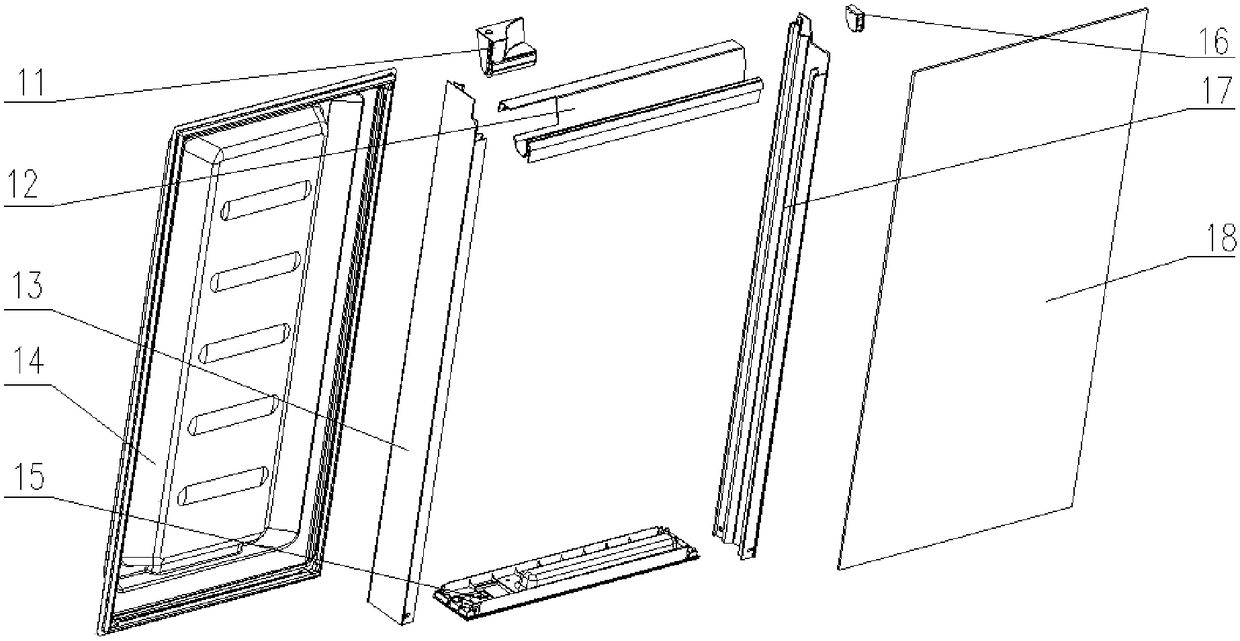

A refrigerator door

ActiveCN105928305BImprove appearance gradeStrong metal feelingLighting and heating apparatusCooling fluid circulationAlloyEngineering

The invention discloses a door body of a refrigerator, which belongs to the technical field of refrigeration equipment, and comprises a door frame, a glass plate and a door liner. Aluminum alloy extruded parts, the left end of the upper decorative strip is provided with a first hook, a second hook and a fifth slot; the top of the left end is provided with a first slot matching the first hook and a The second hook is matched with the second hook; the left insert is snapped into the fifth slot; the right end of the upper decorative strip is provided with a third hook, a fourth hook and a sixth slot; The top of the right end file is provided with a third slot matching with the third hook and a fourth slot matching with the fourth hook; the right insert is snapped into the sixth slot. The invention has simple structure and convenient installation, and the decorative strip made of aluminum alloy makes the door body have a stronger metal feeling, improves the appearance grade of the refrigerator, and saves high mold costs for opening plastic molds at the same time.

Owner:AUCMA

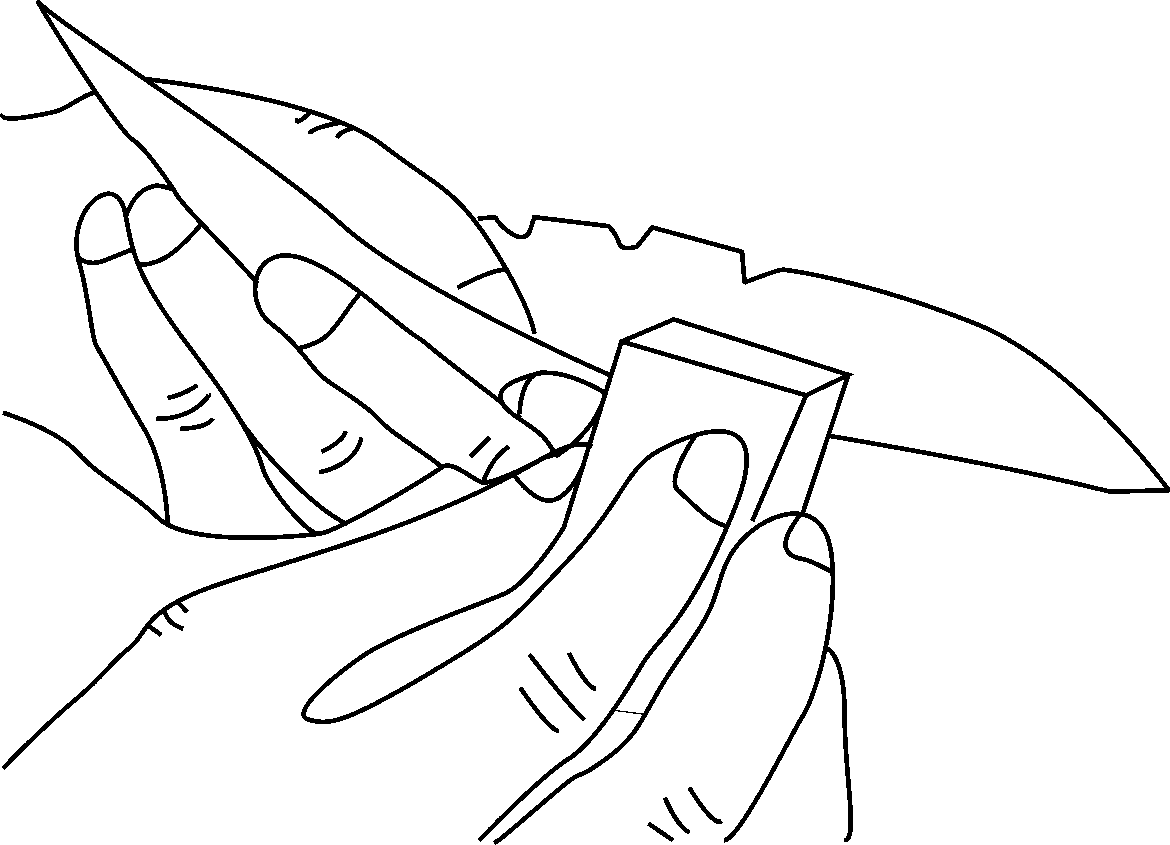

Novel shoemaking part exposed burr processing technology

The invention provides novel shoemaking part exposed burr processing technology. The novel shoemaking part exposed burr processing technology comprises following steps: singeing, wherein cut off leather part exposed burrs are removed through singeing, exposed leather fiber is broken through singeing until no burr is left; coating of a beautifying agent, wherein leather fractures are coated with the beautifying agent uniformly without stacking; polishing and waxing, wherein a bristle wheel with polishing wax is used for polishing and waxing of the coated leather fractures. According to the novel shoemaking part exposed burr processing technology, the appearance of finished products produced using the novel shoemaking part exposed burr processing technology is fine; the leather fractures arebright, and are not too swanking. The novel shoemaking part exposed burr processing technology is convenient in operation, is capable of providing leather exposed fiber with viscosity, so that bonding of the exposed fiber is realized, smoothening of large piece leather is realized, fiber fixing is realized, the rough appearance is eliminated after fiber floating inhibition, and finished shoe appearance grade is increased.

Owner:JIHUA 3515 LEATHER & SHOES

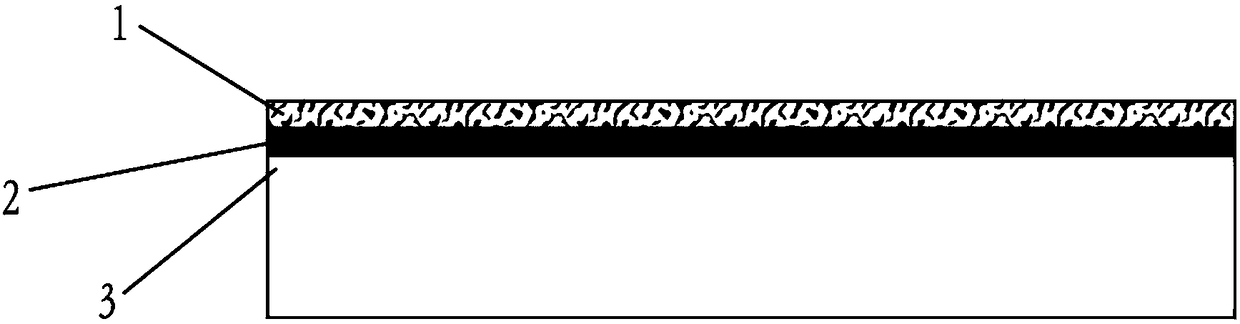

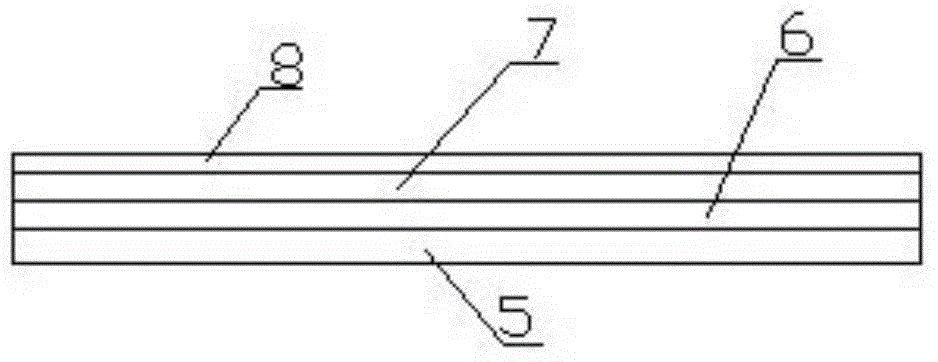

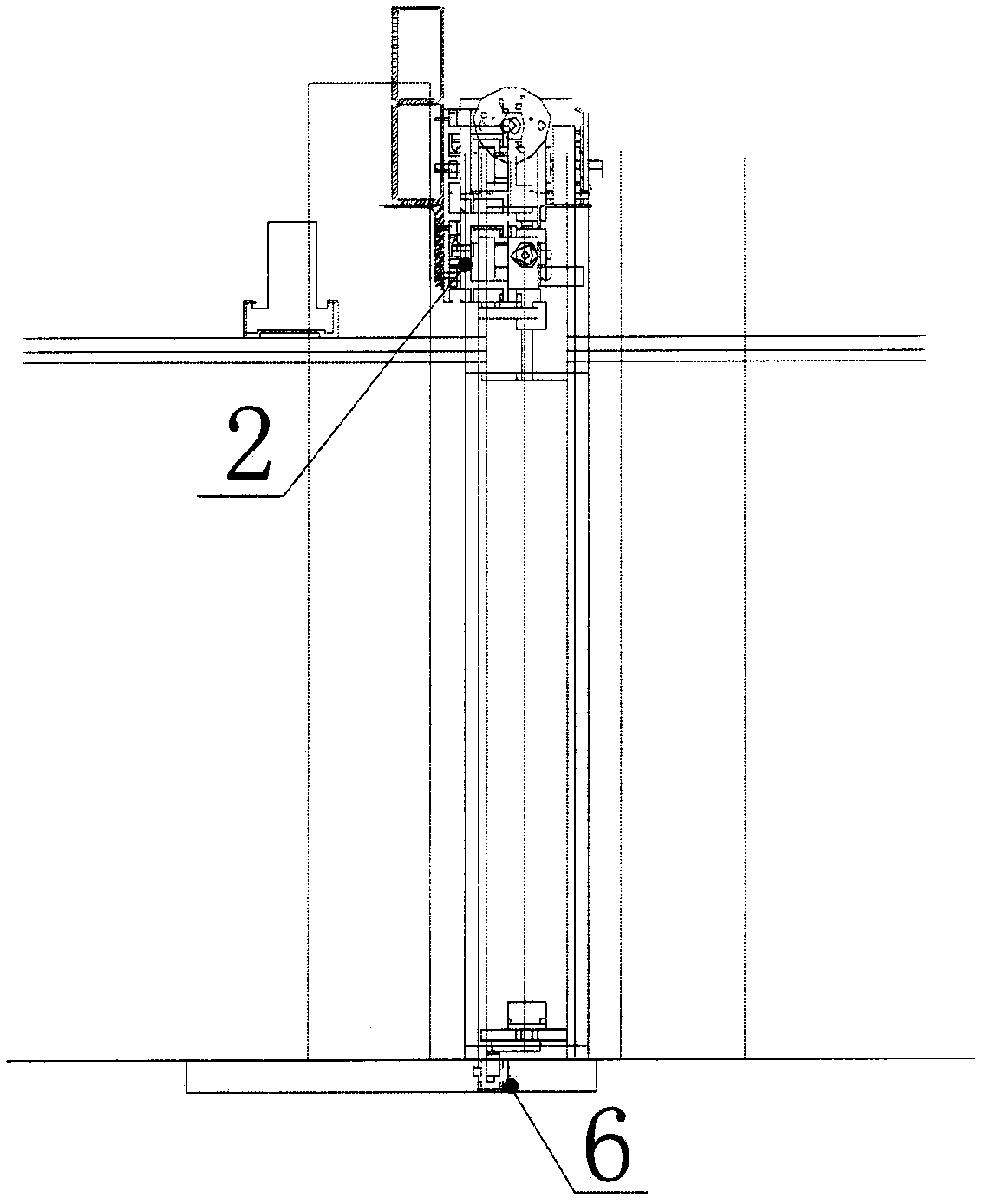

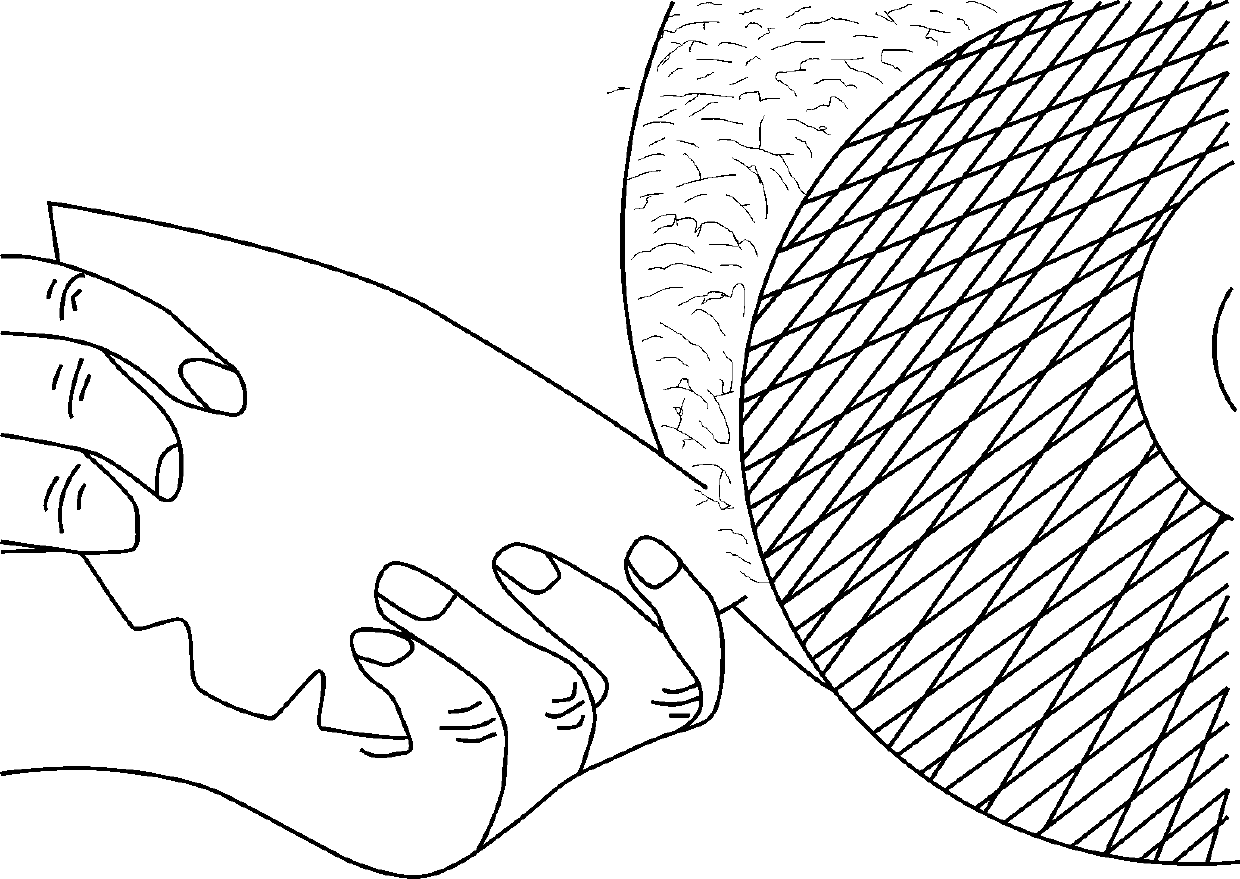

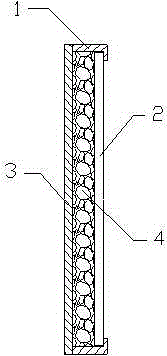

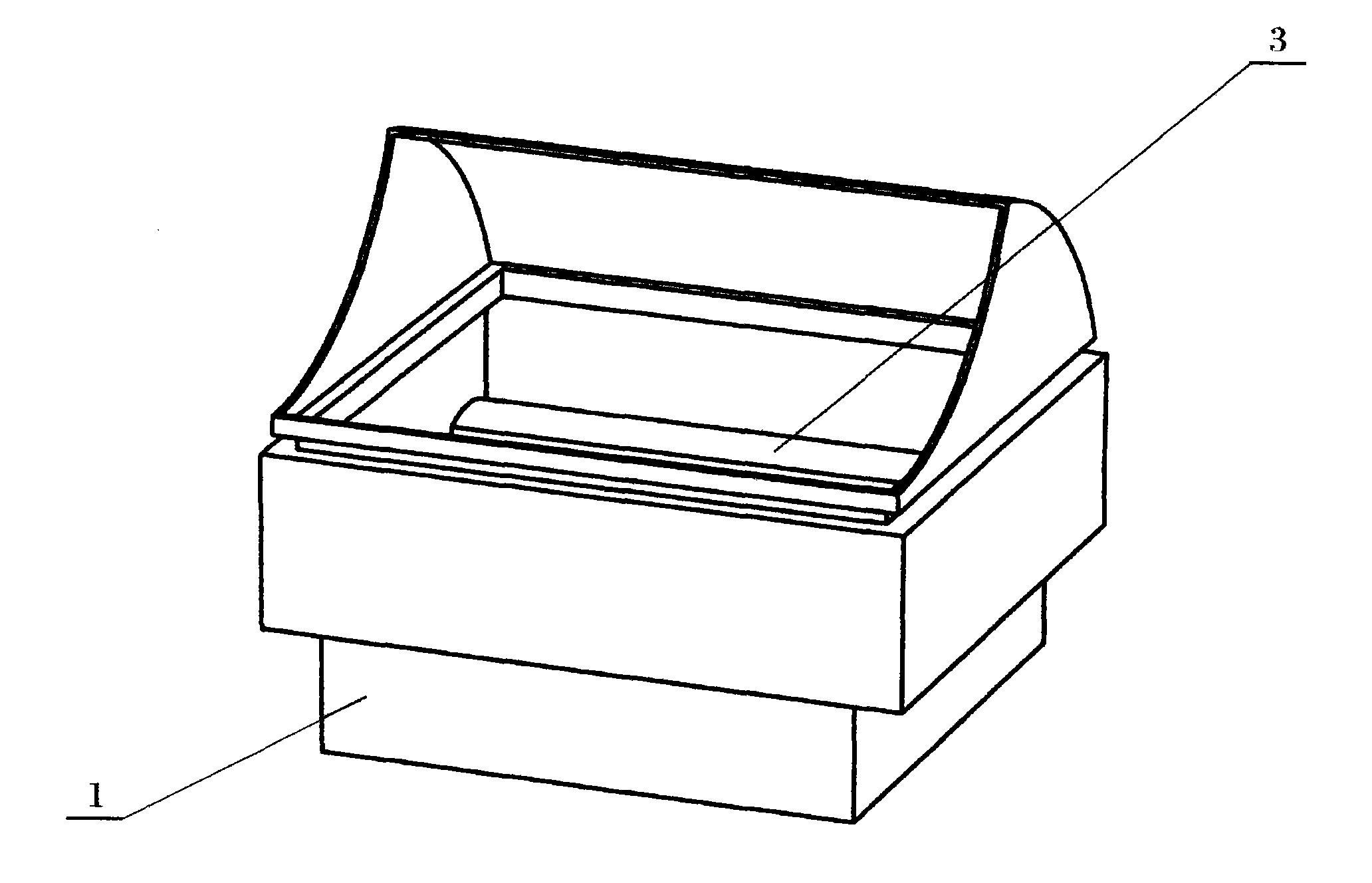

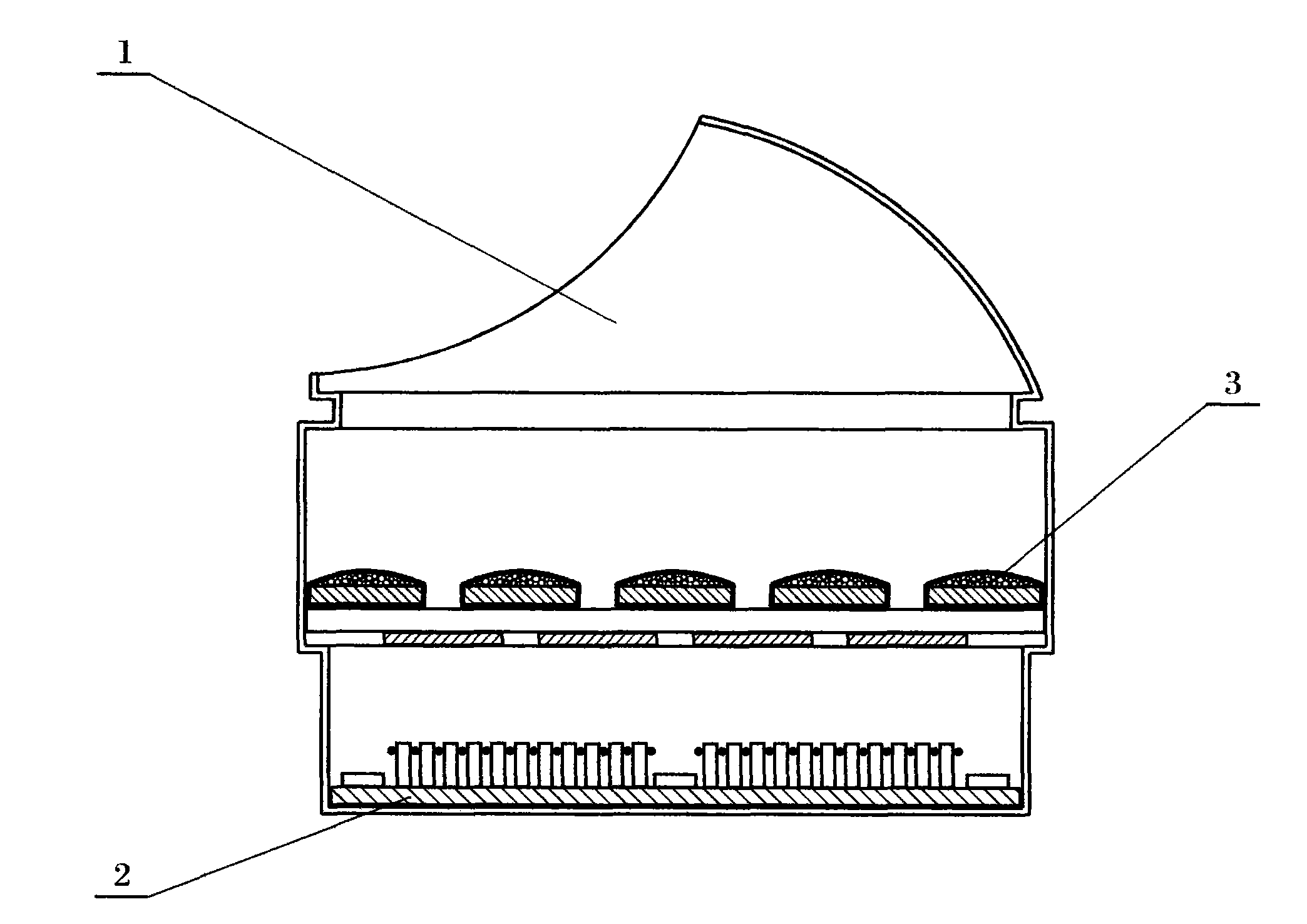

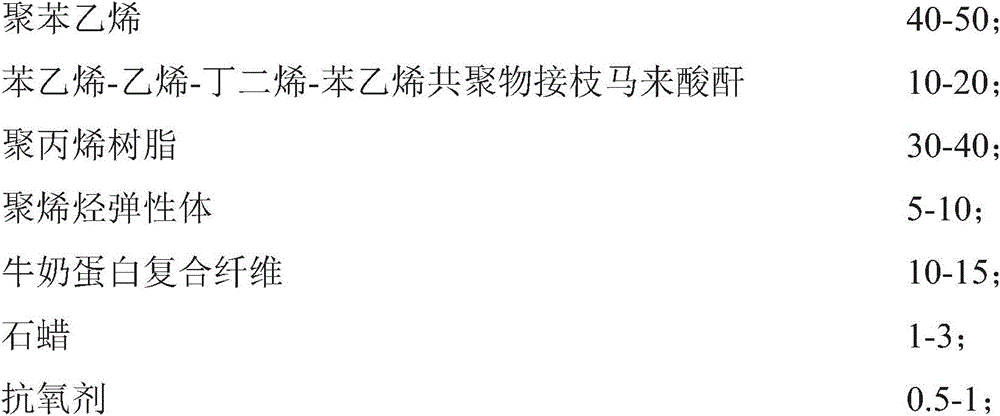

Front frameless glass refrigerator door and preparation method thereof

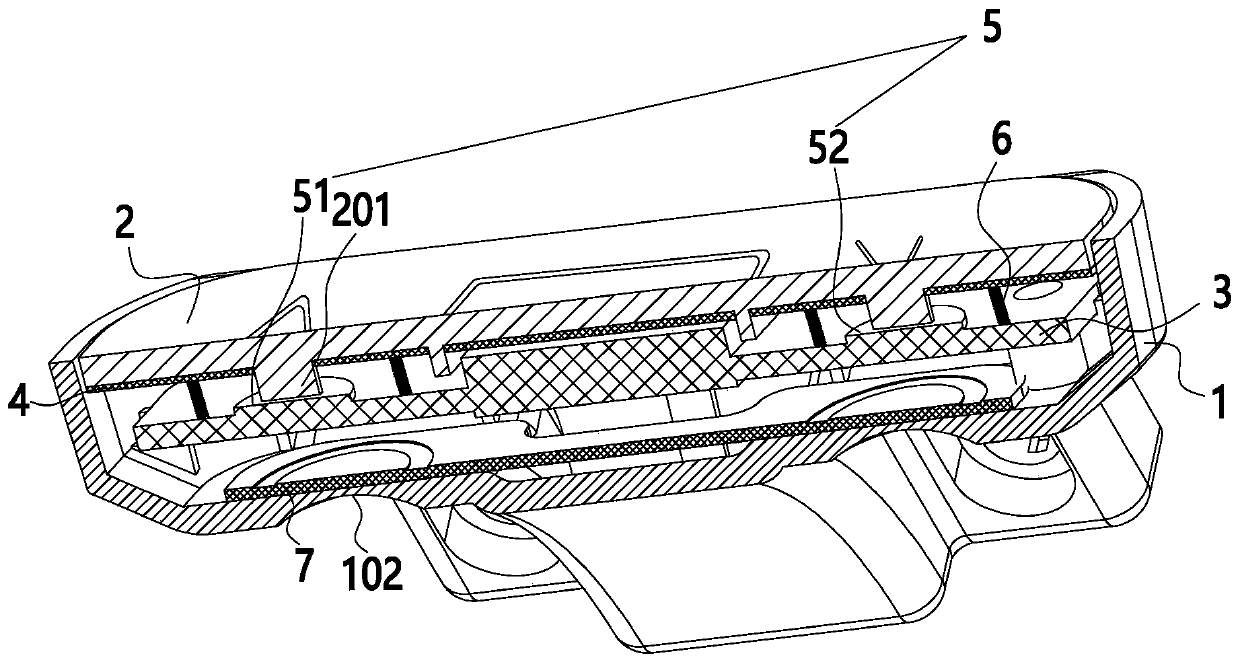

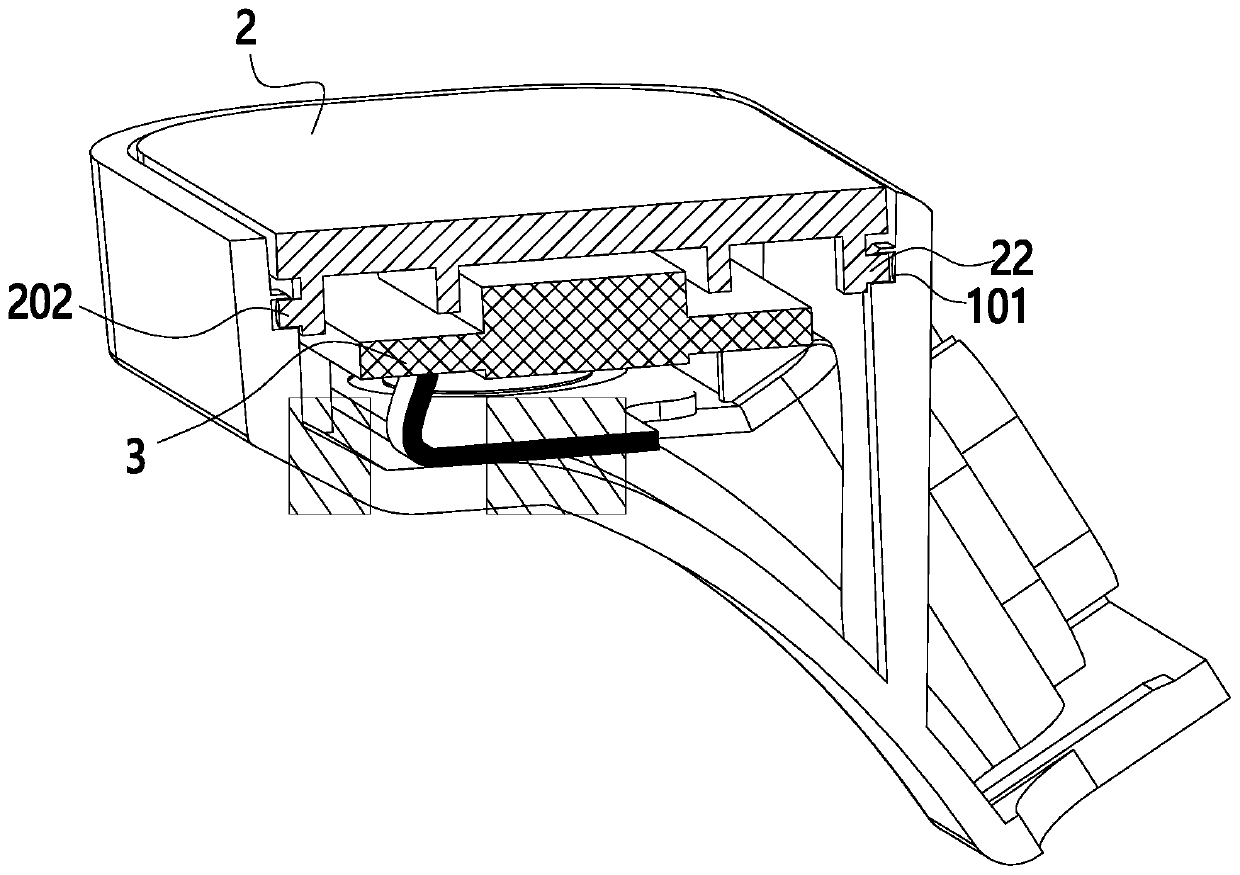

ActiveCN102840730BNot easy to ageImprove appearance gradeDomestic cooling apparatusLighting and heating apparatusRefrigerator carEngineering

The invention relates to a glass refrigerator door without a frame on a right side. The glass refrigerator door comprises a refrigerator door frame body (1), wherein a glass panel (2) and a door body back plate (3) are respectively arranged at the right side and back side of the refrigerator door frame body (1); foaming layers (4) are filled between the refrigerator door frame body (1), the glass panel (2) and the door body back plate (3); the glass refrigerator door is characterized in that the glass panel (2) is cladded on the right side of the refrigerator door frame body (1); and the refrigerator door frame body (1) is molded by injection. The preparation method comprises the following steps: 1. molding the refrigerator door frame body; 2. installing the door body back plate at the back side of the refrigerator door frame body; 3. adding a foam material to foam; and 4. cladding the glass panel on the right side of the refrigerator door frame body. The product disclosed by the invention has good beautiful performance and longer service life; and with the adoption of the product, the cost can be reduced in a production process; the production efficiency is improved, and the rejection rate is reduced.

Owner:江阴市龙龙金属塑胶有限公司

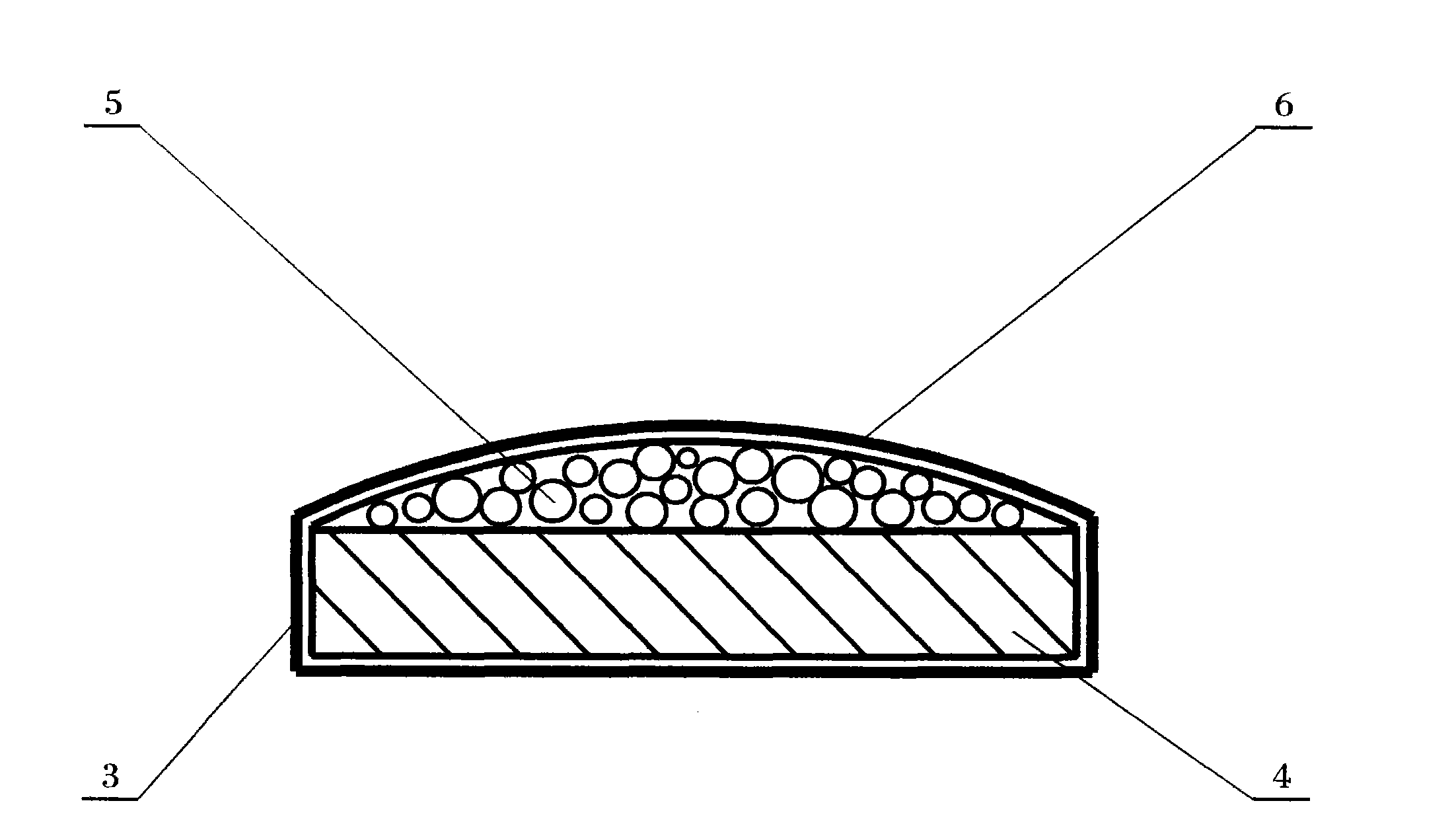

Comfortable foot warming box

InactiveCN102138837AImprove appearance gradeImprove comfortTherapeutic coolingTherapeutic heatingSoft FootCost performance

The invention discloses a comfortable foot warming box, and belongs to the technical field of household electric heaters. The comfortable foot warming box consists of an external box body, a heating unit and a foot pedal, and is characterized in that: the foot pedal consists of a foot pedal substrate, a soft resilient filler and a decorative cladding layer; the soft resilient filler is placed on the foot pedal substrate; and the decorative cladding layer packs the soft resilient filler on the foot pedal substrate tightly. The invention has the advantages that: the hard foot pedal of the foot warming box is upgraded to the flexible soft foot pedal, so the appearance grade of a product is improved, and the comfortableness of the foot on the foot pedal is obviously improved when the foot is warmed; and the comfortable foot warming box has high cost performance and good market prospect.

Owner:田双阁

Processing method for motor rotor paint spraying

InactiveCN106533074AImprove appearance gradeImprove insulation performanceLiquid surface applicatorsManufacturing stator/rotor bodiesLacquerVarnish

The invention provides a processing method for motor rotor paint spraying, which is characterized by comprising the steps of: a) preparing materials including diamond aluminum powder paint, a quick drying agent, varnish and rotor coating paint; b) blending the diamond aluminum powder paint, the quick drying agent and varnish according to a corresponding proportion; c), spraying the rotor coating paint on the surface of a rotor silicon steel sheet from left to right, so that the thickness of an insulating paint film on the surface of a rotor is uniform; d), and spraying the blended diamond aluminum powder paint on the surface of a cast aluminum end ring of the rotor, so that the cast aluminum end ring and the rotor silicon steel sheet are distinctive in spraying and clear in layered sense. By adopting the processing method for motor rotor paint spraying, the rotor appearance level can be effectively improved, and the insulativity of the rotor is improved.

Owner:QINGDAO SANLI INTELLIGENT POWER

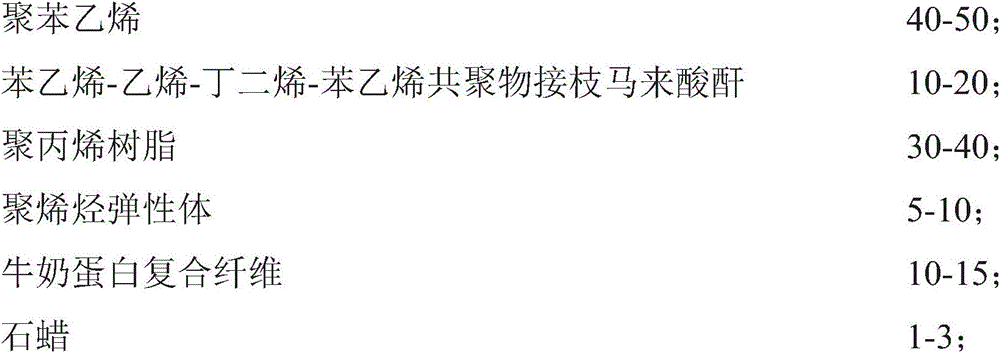

A kind of preparation method and product of milk silky fiber earphone wire

ActiveCN104485160BHigh fastnessSilky and softCommunication cablesFlexible cablesStyrene ethylene butadiene styreneChemistry

Owner:DONGGUAN YINGTONG WIRE +1

Non-negative-pressure equipment surface decorating process

InactiveCN105522861ASimple surface treatmentLow costDecorative surface effectsAngle grinderBlast effects

The invention relates to a non-negative-pressure equipment surface decorating process. The technological process mainly comprises: (a) determining the specifications and model of equipment and the specific position of publicity word information on the equipment, manufacturing rubber words and rubber strips (with the specifications, the model and the publicity words of the equipment), and pasting double-sided adhesive tape on the back surfaces of the rubber words and the rubber strips; (b) grinding the determined specific position by an 80# flap wheel, a 120# flap wheel, a 240# flap wheel, a 320# flap wheel and a 400# flap wheel in sequence; (c) repeatedly polishing the region with polishing paste by using an angle grinder provided with a felt wheel until a mirror surface effect is achieved; (d) pasting and compacting the rubber words and the rubber strips pasted with the double-sided adhesive tape in the previously-determined position of the equipment; (e) conducting shot blasting on the equipment to enable the overall shot blasting effect of the equipment to be consistent; (f) removing the rubber words and the rubber strips on the surface and the double-sided adhesive tape on the surface of the equipment thoroughly after the completion of shot blasting; and (g) conducting secondary shot blasting on the equipment within a short time.

Owner:QINGDAO SANLI ZHONGDEMEI WATER EQUIP

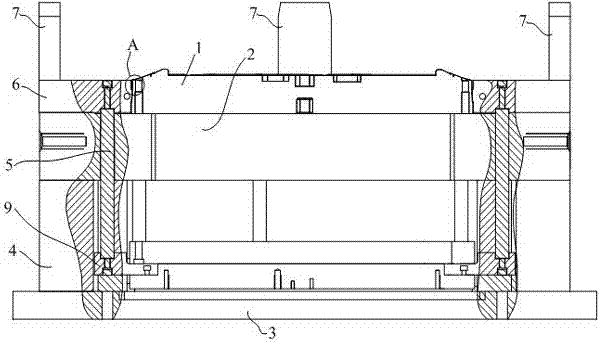

An injection mold for a product without a draft angle on the outer side of the edge of the side wall

Owner:QINGDAO HISENSE MOLD

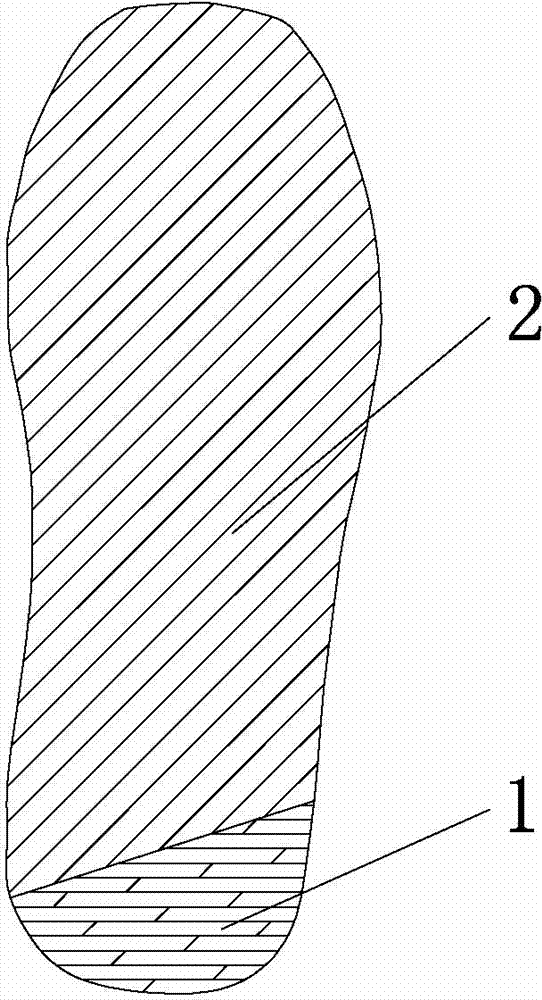

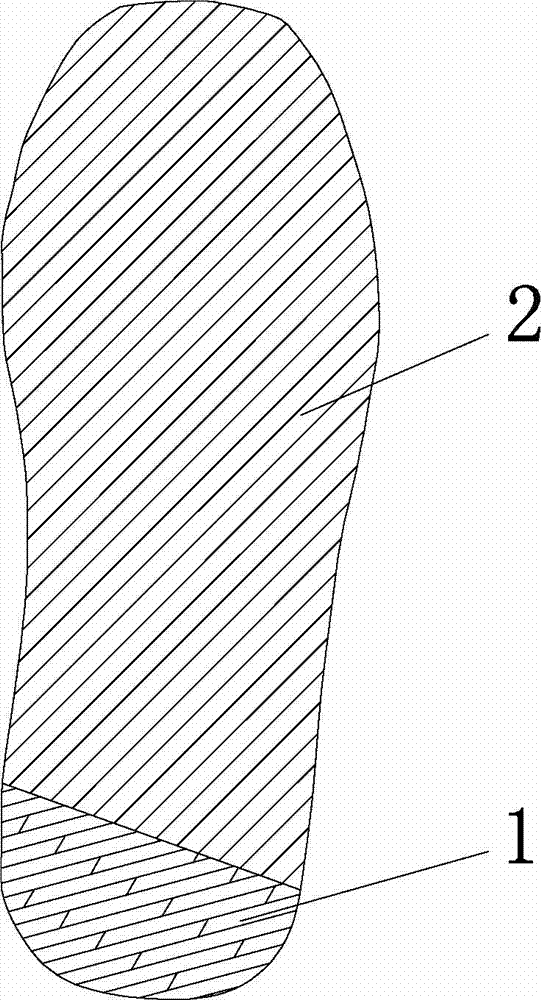

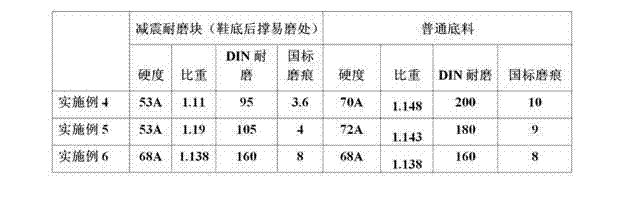

Double-hardness and double-physical-property rubber sole and preparation technology thereof

Owner:DEZHOU XINHUARUN TECH CO LTD

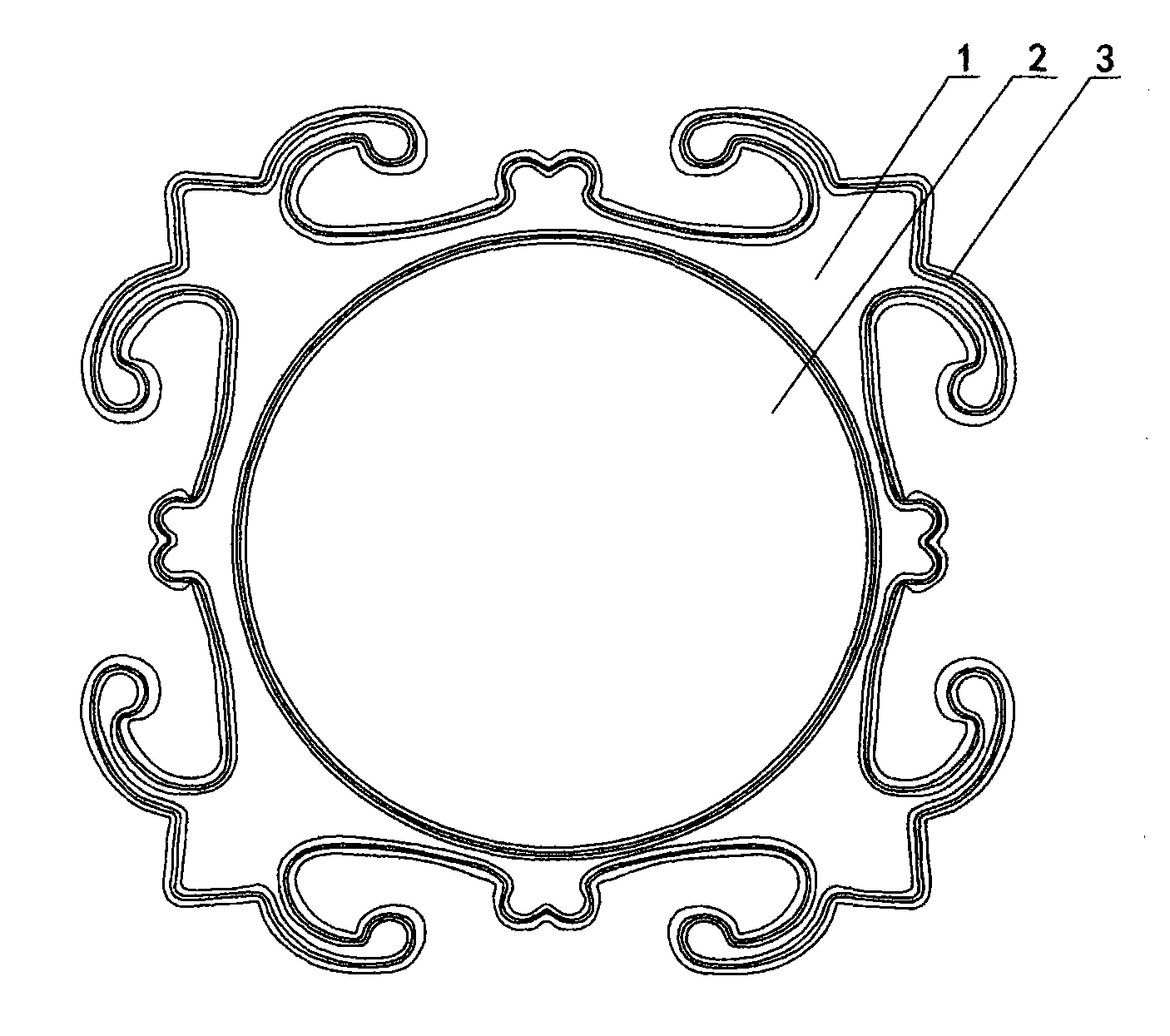

LED lantern decorative accessory

ActiveCN103640392AIncreased durabilityGood light transmissionSpecial ornamental structuresIsosceles trapezoidEngineering

The invention relates to an LED lantern decorative accessory, which includes a decorative part body, the outer edge of which is provided with an annular array type decorative layer structure composed of four groups of wavy bosses. Every two adjacent wavy bosses are connected. A cambered surface extends respectively out of two sides of each wavy boss, and each cambered surface bends towards the central point of the decorative part body. A lamp band slot is disposed surrounding the wavy bosses' outer edges of the decorative part body and each cambered surface outer edge, and the outer wall surface of the lamp band slot inclines inward so as to clamp a lamp band in the slot. The longitudinal section of the lamp band slot is an isosceles trapezoid or right trapezoid structure. Also, the decorative part body and the lamp band slot are both made of silica gel. The lantern decorative accessory composed of silica gel has the advantages of low temperature resistance, durability, good light transmission and the like. At the same time, the lamp band slot is disposed on the inner edge of the decorative accessory, thus helping to improve the decoration level and make the lantern more beautiful.

Owner:王桂强

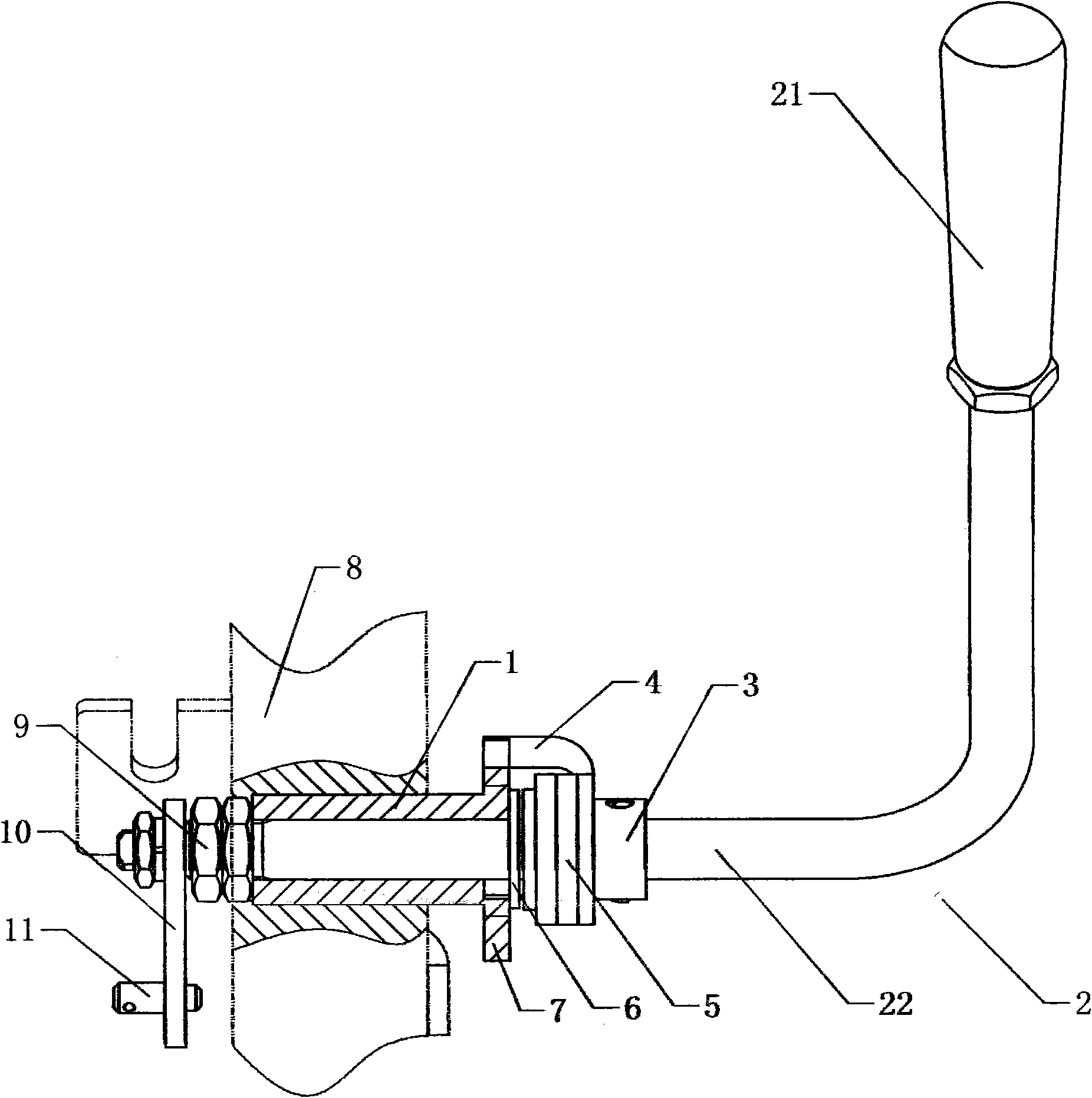

Hand throttle operation mechanism

ActiveCN102022195BSmooth handlingConducive to manipulationFuel-injection pumpsMachines/enginesControl theoryThrottle

The invention discloses a hand throttle operation mechanism, comprising: a sleeve, which is used for the fixation on a vehicle body and is rotatably equipped with a hand throttle operating lever for the connection with an engine throttle pulled line; a locking anti-loosening device, which is used for automatically locking the hand throttle operating lever upon the rotation of the hand throttle operating lever and is installed between the hand throttle operating lever and the sleeve; and a limiting device, which is used for limiting a rotation angle of the hand throttle operating lever and is installed between the hand throttle operating lever and the sleeve. The hand throttle operation mechanism is simple in structure and convenient and reliable in operation, and can freely control the opening angle of the engine oil pump pulled by the pulled line in order to realize the accurate positioning of the rotating speed of engine, in addition, the hand throttle operation mechanism is easy inbeing processed and low in manufacturing cost.

Owner:LOVOL HEAVY IND CO LTD

Treatment process for stainless steel surface

The invention relates to a treatment process of stainless steel and provides a process for overcoming the defects in an existing widely-applied process for stainless steel surface, such as an acid cleaning and passivation process, metallic luster of the stainless steel surface is reduced, the stainless steel surface subjected to shot blasting is rough and is not resistant to dirty, and the stainless steel surface is not easy to clean after long time. According to the treatment process disclosed by the invention, the stainless steel surface is subjected to mechanical polishing and sand blasting treatment, so that the defects of a substrate are eliminated, and the appearance of the stainless steel surface is enabled to be uniform and consistent; on the basis, the treatment effect of the stainless steel surface can be blacker and brighter, uniform and attractive by adopting electrolytic polishing treatment, so that the defects that a stainless steel part is rough and has no metal luster can be overcome; and after treatment, the stainless steel surface is glossy black and is strong in metallic texture.

Owner:QINGDAO SANLI ZHONGDEMEI WATER EQUIP

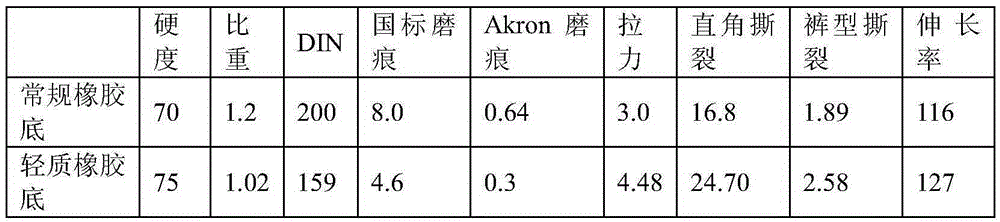

A kind of light rubber sole and preparation method thereof

The invention provides light rubber and a preparation method of the light rubber as well as a shoe sole prepared by using the rubber. The rubber is mainly prepared from SBS-I, SBS-II, butadiene styrene rubber, white carbon black, di-(3-triethoxyl silane propyl)-tetrasulfide, stearic acid, PEG 4000, zinc oxide and dicumyl peroxide. The shoe sole produced by using the rubber provided by the invention is light in weight, and the physical indicators meet the national test standard. Meanwhile, the problem on loss of gloss of conventional shoe sole is solved, the brightness of the bright matt finish is enhanced, and the overall effect on appearance is attractive so as to satisfy the demands of different crowds, so that not only is the appearance grade of the product shoe sole produced enhanced, but also the product shoe sole has the characteristics of lightness, comfort and the like.

Owner:DEZHOU XINHUARUN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com