Refrigerator door body

A refrigerator door body and door frame technology, which is applied to cooling fluid circulation devices, lighting and heating equipment, household appliances, etc., can solve the problems of low strength, deformation, and high cost of plastic parts, so as to save mold costs, facilitate installation, and be strong. metallic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

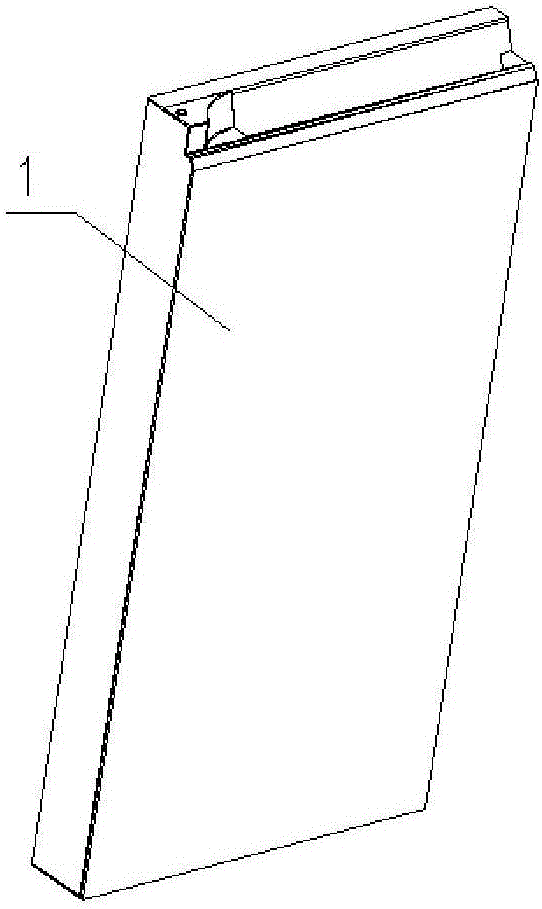

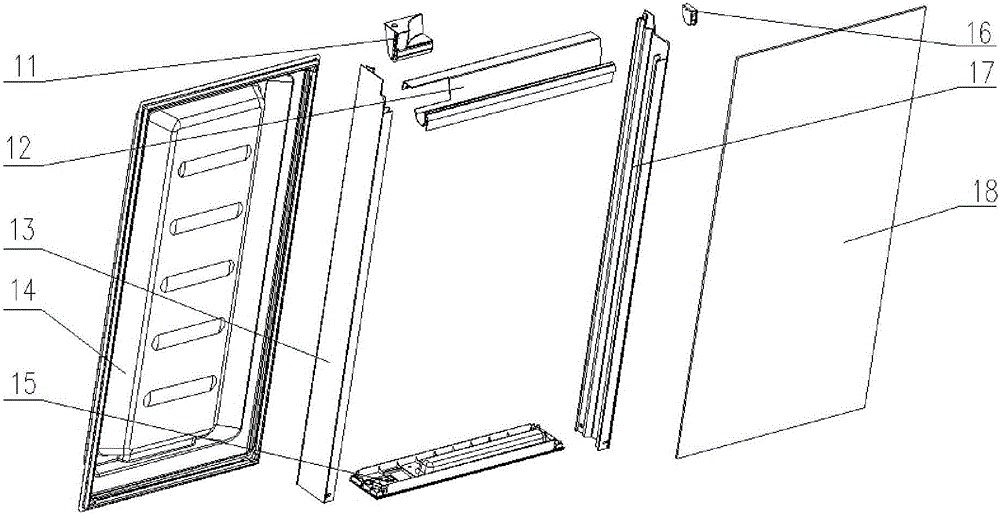

[0025] Such as Figure 1-2 As shown, the side-opening door body 1 includes a door frame, a first glass plate 18 and a first door liner 14 . The side door frame is assembled by the first upper trim strip 12 , the first lower trim strip 15 , the first left end rail 13 , the first right end rail 17 , the first left insert 11 and the first right insert 16 . The first left end rail 13 and the first right end rail 17 can be plastic or aluminum alloy extruded parts, and the first upper trim strip 12 is an aluminum alloy extruded part. Wherein the first left end file 13 and the first right end file 17 are the same extruded profile, the tops of the first left end file 13 and the first right end file 17 are cut out with the first upper trim 12, the first left insert 11 and the first The right insert 16 fits the structure.

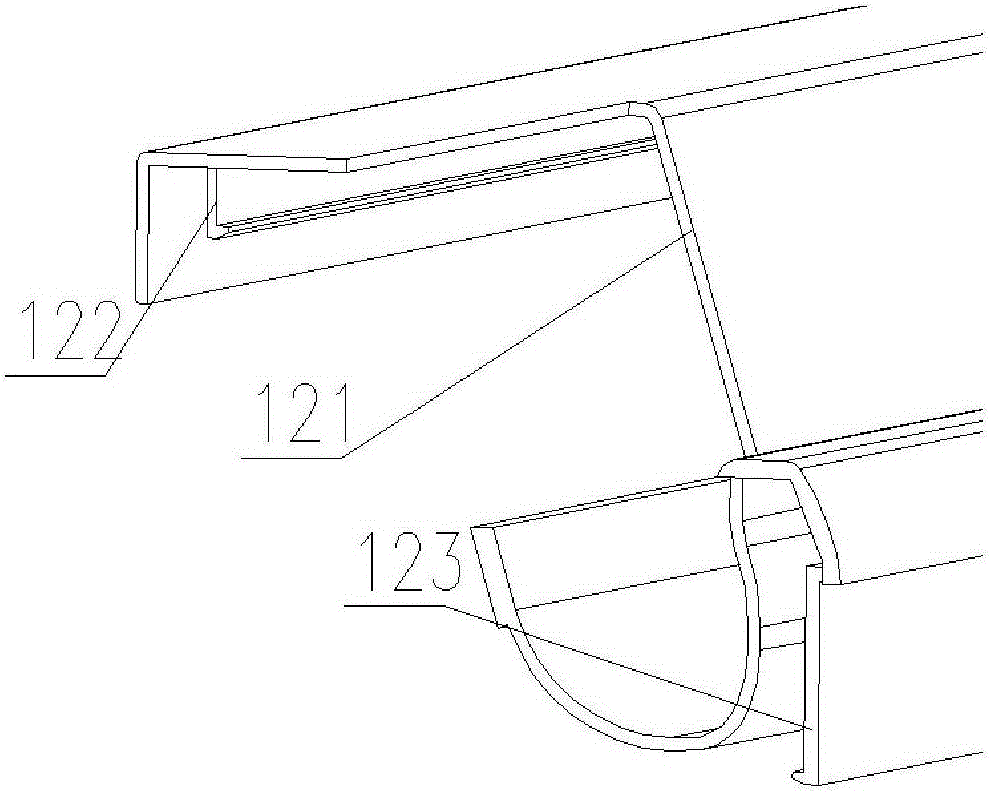

[0026] Such as image 3 Two hooks, a first hook 122 and a second hook 123 , are extruded on the first upper decorative strip 12 shown.

[0027] The first hook 12...

Embodiment 2

[0030] Such as Figure 6-7 As shown, the drawer type door body 2 is a symmetrical structure. Wherein the second left insert 21 and the second right insert 26 have a symmetrical structure, and the second left end stop 23 and the second right end stop 27 have a symmetrical structure. The structure of the left end of the second upper trim strip 22 and figure 2 The middle structure is the same, and the right structure is the mirror image of the left structure; the second lower trim strip 25 and the door liner 24 are also left-right symmetrical structures. The door frame of the drawer-type door body 2 is assembled by the second upper trim strip 22, the second lower trim strip 25, the second left end rail 23, the second right end rail 27, the second left insert 21, and the second right insert 26. , the assembly structure is the same as the left assembly structure of the above-mentioned side-opening door frame. The second glass plate 28 and the second door lining 24 are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com