Patents

Literature

101results about How to "Strong metal feeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet aluminium-silver size coating with light curing

A ultraviolet light solidified aluminium silver slurry coating consists of acrylic resin 20-50wt%, acrylic ester monomer 10-50wt%, light initiating agent 3-10wt%, aluminium silver slurry 2-15wt%, aluminium silver slurry orienting agent 4-15wt%, assistants 0.3-2.5wt% and solvent 15-30wt%. It achieves fast curing speed, less organic volatile substances, higher production efficiency, better adhesion, hardness and abrasive-resistant performance.

Owner:CHINA LUCKY FILM CORP +1

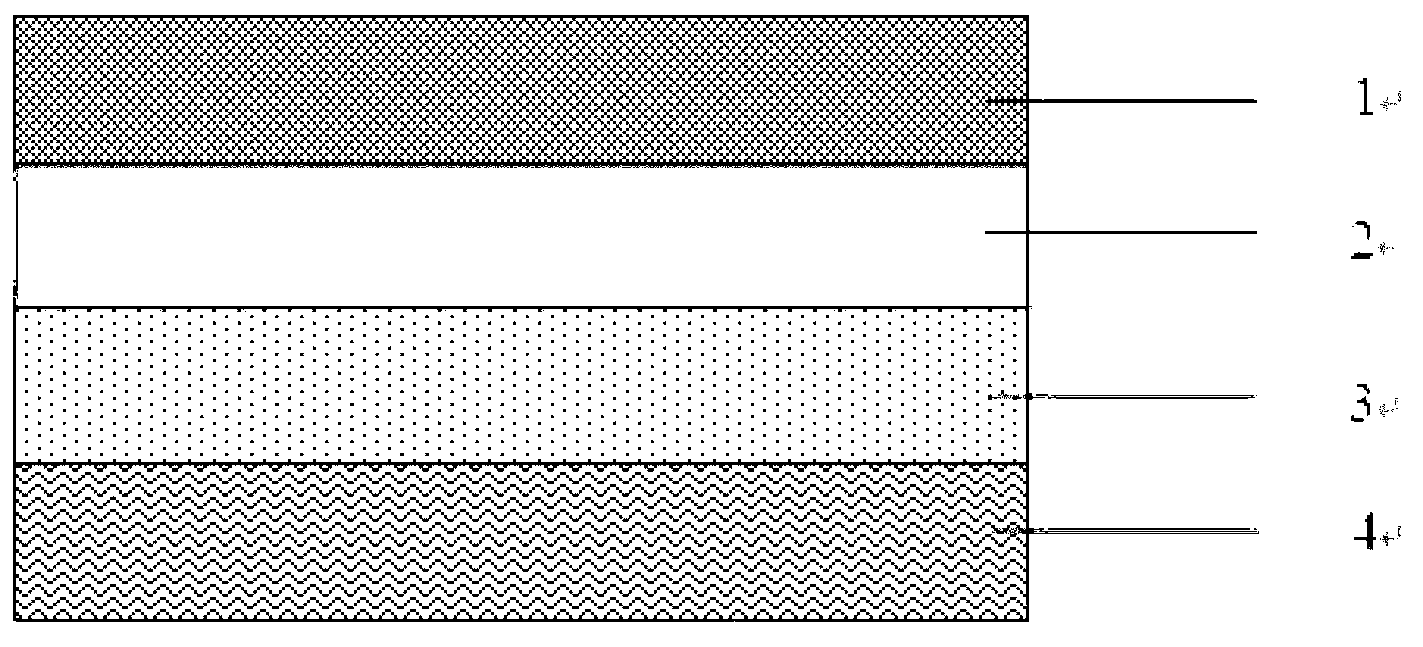

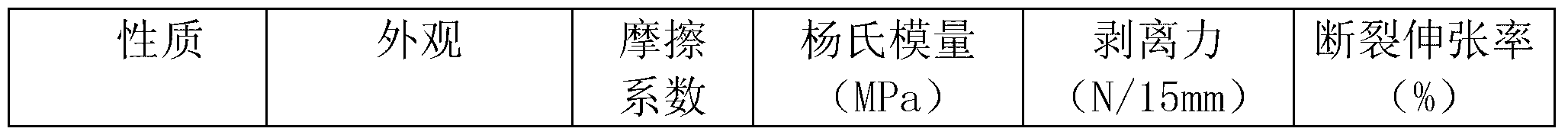

Seamless PET (polyester) laser transfer membrane and preparation method thereof

ActiveCN103317874AStrong metal feelingImprove mechanical propertiesSynthetic resin layered productsCoatingsPolyesterWater based

The invention relates to a seamless PET (polyester) laser transfer membrane which comprises a carrier PET base membrane, a protection layer, an imaging layer and an aluminum layer, wherein the protection layer is a transfer coating layer, a transfer coating is prepared by adopting raw materials by weight percent: 12-40 percent of water-based resin system, 6-10 percent of ionic copolymerization monomer, 3-7 percent of a diluent, 40-68 percent of dispersion medium, 1-5 percent of a pH modifier and 4-8 percent of a crosslinking agent. The invention also relates to a preparation method of the seamless PET laser transfer membrane. The seamless PET laser transfer membrane provided by the invention is strong in metal luster and excellent in mechanical property, moisture prevention and weather resistance. The surface of the seamless PET laser transfer membrane adapts to various printing processes, and thus various artistic designs can be printed.

Owner:HAINAN SHINER IND

One-component PU low-temperature curing hardware coating and preparation method thereof

The invention relates to a single-component poly urethane (PU) low-temperature cured hardware coating and a preparation method. Vernix is prepared from hydroxy acrylic resin serving as a main ingredient, part of hydroxyl polyester resin and amino resin and a mixed solvent, an acid catalyst, a defoamer and a flatting agent which serve as auxiliary materials. The preparation method comprises the following steps of: preparing, dispersing, and blending. The single-component PU low-temperature cured hardware coating has the characteristics of simple construction process, long service life, high metal texture of prepared metallic paint, energy conservation and low cost, and is mainly applied to hardware substrates.

Owner:深圳市深赛尔股份有限公司

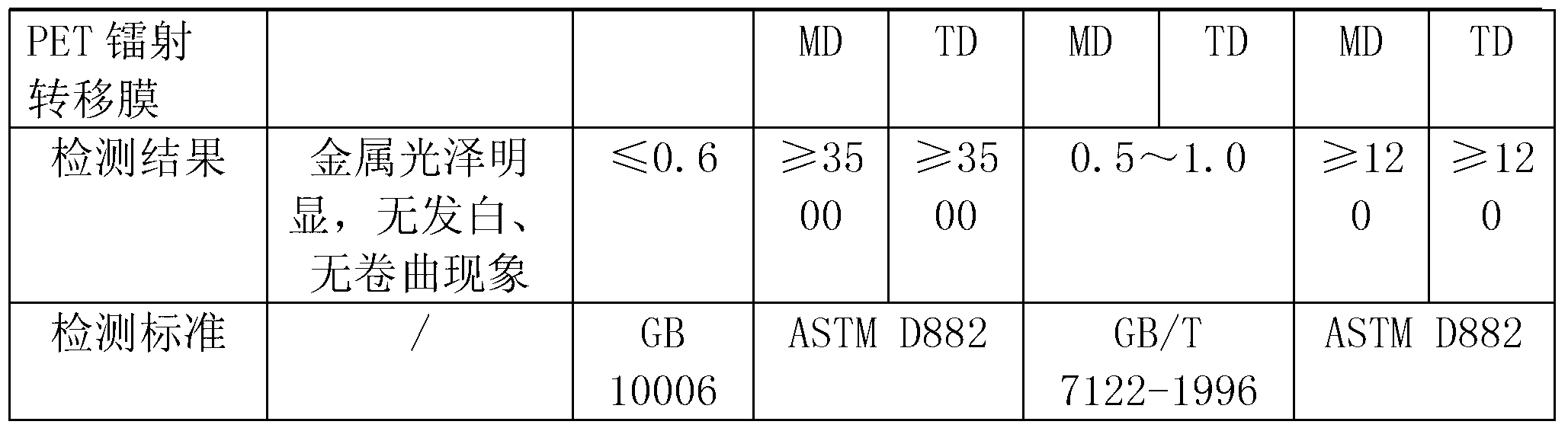

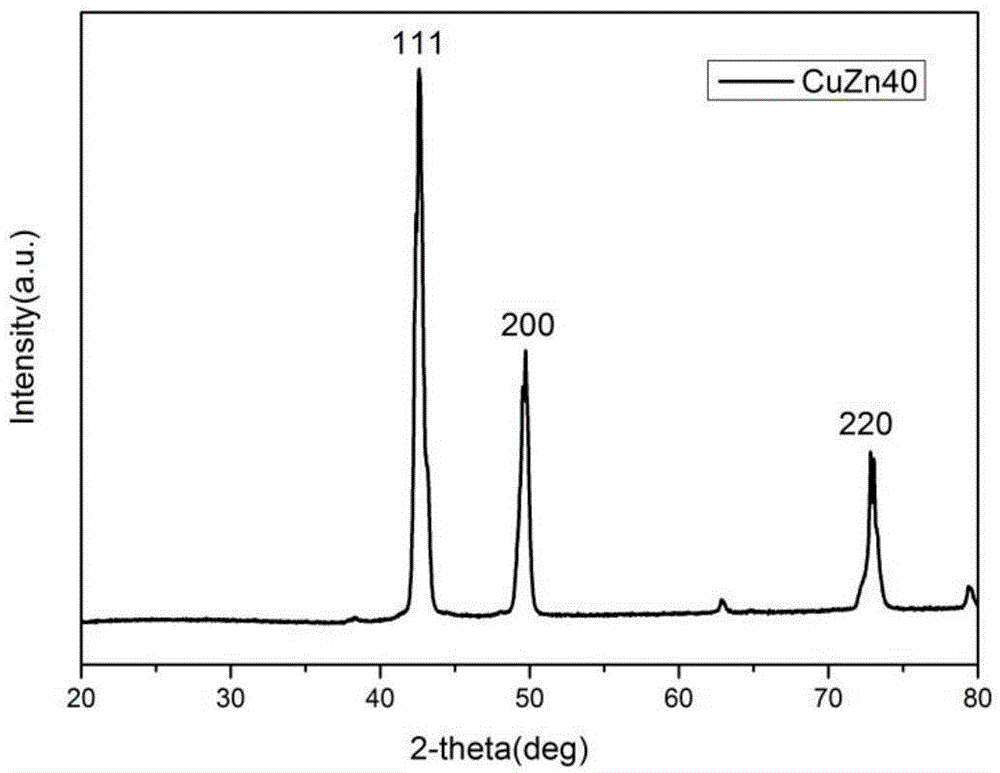

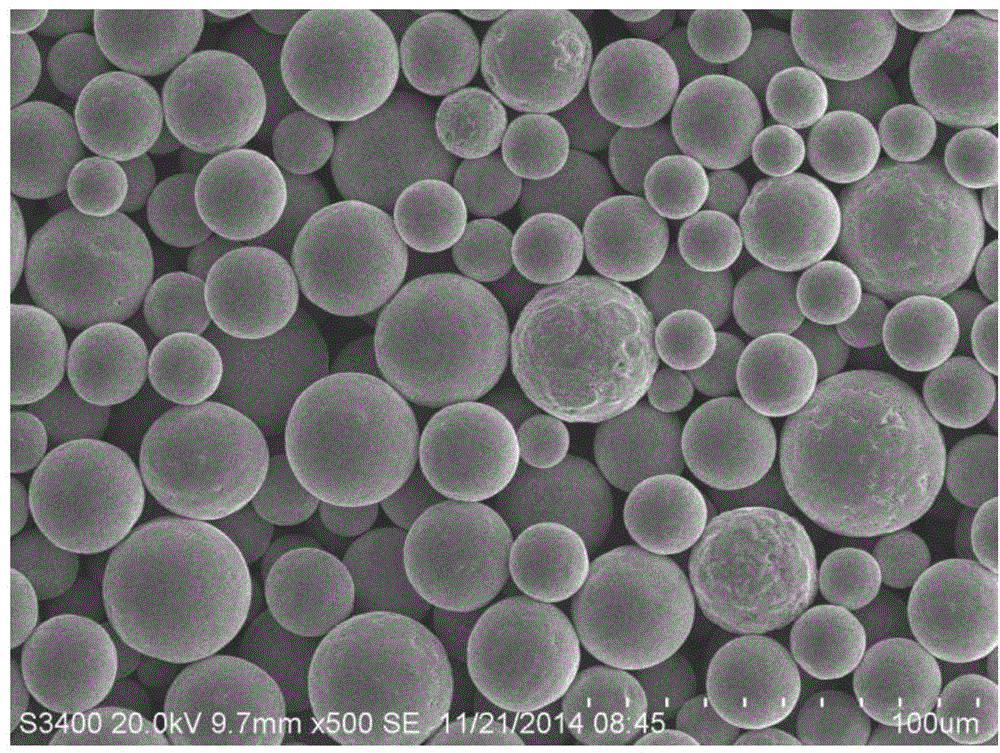

Spherical brass alloy powder manufacture method

The invention discloses a spherical brass alloy powder manufacture method. The method is characterized by including 1, preparing brass alloy powder; 2, preparing evenly-mixed powder of brass alloy powder and carbon material powder or ceramic material powder; 3, performing high temperature treatment, melting the brass alloy, solidifying, obtaining metal spheres, and cooling rapidly; 4, separating the carbon material powder or ceramic material powder, and obtaining micron or nano brass alloy spherical powder. The temperature of high temperature treatment is equal to or higher than that of metal melting, preferably, the temperature of high temperature treatment ranges from 10 to 80 DEG C higher than that of the brass alloy melting point. According to the method, process is simple, cost is low, and the method is adaptive to large scale production; the brass alloy powder is free of macro segregation, the surface metal sense is strong, and application of metal three-dimensional printing, print painting decoration, spraying (brazing) welding metal powder and metal filters can be met.

Owner:NANJING UNIV

Metallic powder coating

The invention discloses a power coating strengthening metal effect, belonging to the technical field of chemical powder coating product. It adds extinction agent, polish and wax powder in the basic material (polyester / epoxy) system and then make the three matters interact to obtain the powder coating. It is adapted on all kinds of home and universal electrical apparatus and household utensils.

Owner:广州擎天粉末涂料实业有限公司

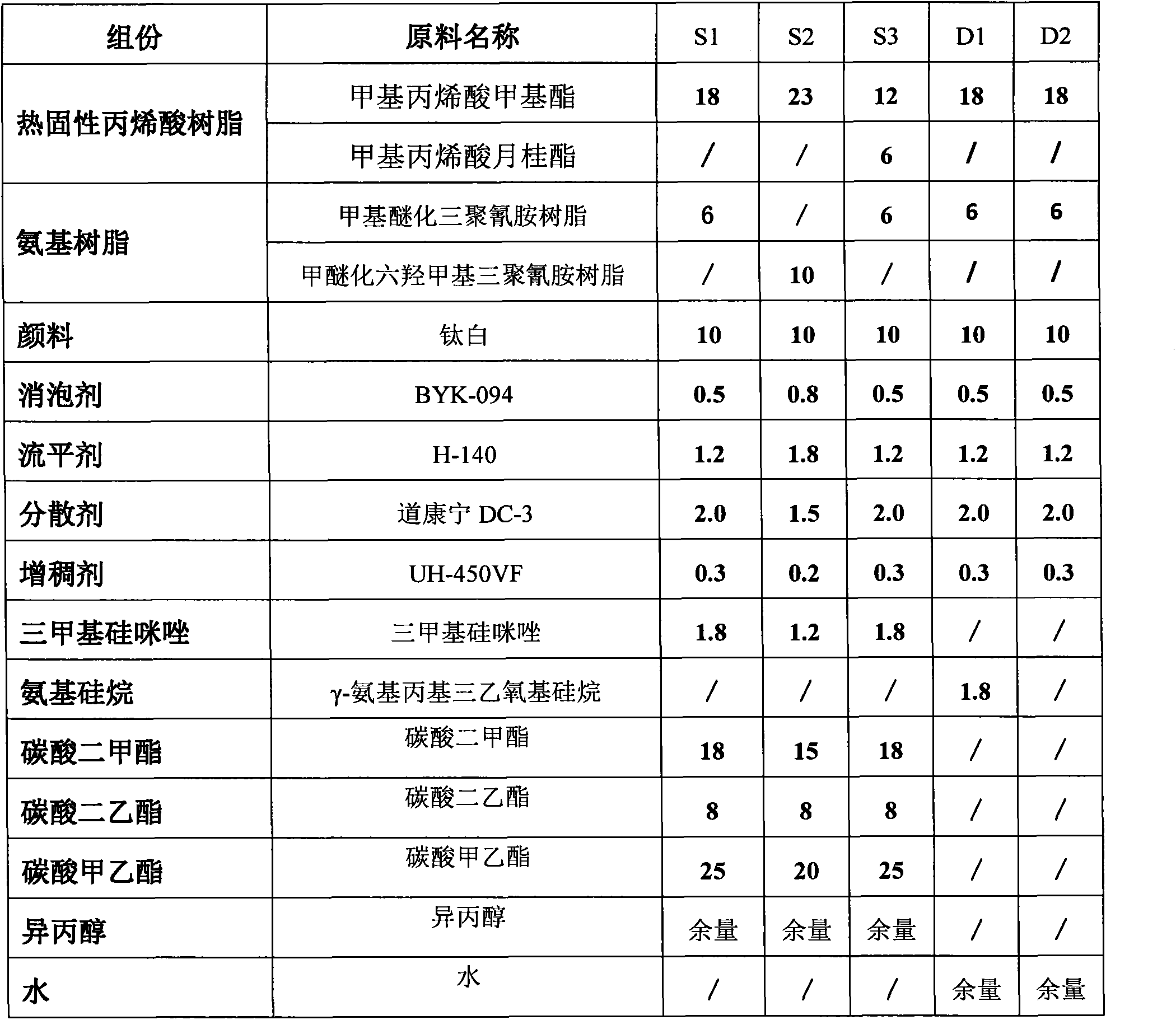

Thermosetting acrylic metallic paint

The invention relates to a thermosetting acrylic metallic paint. The metallic paint comprises the following components: 18-23wt% of thermosetting acrylic resin, 13-16wt% of amino resin, 8-12wt% of pigments, 3.5-5.0wt% of aids and 45-60wt% of solvent. The thermosetting acrylic metallic paint has the beneficial effects that the thermosetting acrylic metallic paint has excellent adhesiveness and solvent resistance and is suitable for coating the surfaces of bicycles, motorcycles, cars, refrigerators, washing machines, electric fans, instruments, meters, precision machinery and IT products; and the coatings formed by coating the paint have bright colors, high hardness, good lusters, strong sense of metal of the metallic paint and excellent abrasion resistance, weather resistance, adhesiveness and solvent resistance.

Owner:DANYANG JIAMEI CHEM

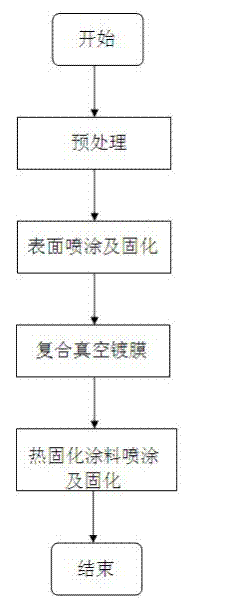

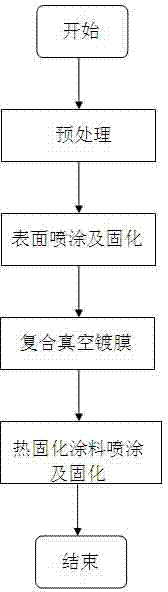

Composite vacuum plating method

ActiveCN102383101AHigh densityStrong metal feelingVacuum evaporation coatingSputtering coatingSputteringPre treatment

The invention discloses a composite vacuum plating method and belongs to the technical field of surface treatment. The method comprises steps of surface pretreatment of a base material, surface spraying and solidification, vacuum plating, spraying of thermocuring paint and solidification. The vacuum plating comprises nickel plating through magnetron sputtering, nickel-chromium plating through combination of magnetron sputtering and chrome plating through ion plating and cathode arc ion. The invention omits an onerous furbisher process, simplifies technical flow, increases production efficiency and mitigates labor intensity of workers; secondly, a mixed film plating technology of magnetron sputtering and ion plating is employed that the obtained product film has high film density and strong metal feel; thirdly, preparations of a metal layer and a metal mixed coating are carried out in a same vacuum furnace, so as to facilitate operation, guarantee good bond of the film and enhance product quality.

Owner:HUZHOU BIAOLI ENERGY SAVING TECH CO LTD

Hotpressed or embossed artificial leather and preparation method thereof

The invention relates to hotpressed or embossed artificial leather, which comprises a surface layer, a foaming layer and a base cloth layer in sequential arrangement, wherein the surface layer is a polyurethane surface layer; the polyurethane surface layer is prepared from the following preparation raw materials in parts by weight: 95 to 105 parts of polyurethane resin, 0.1 to 0.3 part of flattingagents, 15 parts of antiaging agents, 1 to 10 parts of coloring agents and 100 parts of compound organic solvents. The invention also relates to a preparation method of the hotpressed or embossed artificial leather. The hotpressed or embossed artificial leather has the advantage that the hand feeling and the exquisite feeling of the leather after the stamping are improved.

Owner:FUJIAN POLYTECH TECH CO LTD

Gravure copper gold powder preparation method

InactiveCN106424742AStrong metal feelingNot easy to change colorTransportation and packagingMetal-working apparatusCopperTemperature resistance

The invention discloses a gravure copper gold powder preparation method for solving the problems of weak oxidation resistance high-temperature resistance and easy color change of copper gold powder in the prior art. The gravure copper gold powder preparation method comprises the steps of raw material weighing, raw material fusion, preparation of metal powder by water atomization, drying, ball milling, polishing and screening; the prepared copper gold powder resists oxidation through adding ball milling assistant in the ball milling process and adding polishing assistant in the polishing process; and the prepared product is high in metal luster, excellent in product quality, excellent in high-temperature resistance, high in production process stability and high in production efficiency.

Owner:RUIAN CHENGXUAN IND & TRADE CO LTD

Outdoor decorative metal powdery paints

InactiveCN101157819AImprove the decorative effectReduce construction costsPowdery paintsPolyester coatingsColor effectMetal coating

The invention discloses a metal powder coating used for outdoor decoration, pertaining to the coating technique field. A preparation method thereof comprises high-speed mixing, melting extrusion, press crushing, grinding and dry mixing treatment; raw materials are according to the following weight proportion: 40 to 60 percent of outdoor pure polyester resin, 4 to 5 percent of TGIC curing agent, 3 to 5 percent of flow agent, 1 to 2 percent of PCR214 metal pigment, 0.1 to 0.3 percent of PC100 metal pigment, 0 to 2 percent of PCR212 metal pigment, 0 to 30 percent of filler, 0.1 to 5 percent of conventional pigment, 0.2 to 0.4 percent of benzoin, and 0.1 to 0.2 percent of fumed silica. The invention has the advantages that the coloring effect can be adjusted by adjusting the pigment portions of base materials powder to form the metal coating with different ground colors; in addition, the invention has the advantages of primary coating film forming, low operation cost, good decoration effect, good weatherability and being applicable for long time outdoor.

Owner:XUZHOU ZENITH COATING

Sand grain metal powder paint

The sand grain metal powder paint consists of resin and curing leveling system 60-80 wt%, sand grain agent 0.1-0.5 wt%, pigment 0-20 wt%, stuffing 0-30 wt%, metal pigment 0.5-5 wt%, and powder flowing promoter 0.1-0.2 wt%. It is prepared through the technological process including the steps of high speed stirring to mix, fusing and extruding, tabletting and crushing, grinding into powder and sieving, and dry mixing.

Owner:XUZHOU ZENITH COATING

3D effect surface treatment process

ActiveCN105543933ARich structureStrong metal feelingSurface reaction electrolytic coatingAnodic oxidationSurface finishing

The invention relates to the technical field of electronic equipment, in particular to a 3D effect surface treatment process. According to the 3D effect surface treatment process, anodic oxidation is carried out after the surface of an aluminum alloy is subjected to shielding sand blasting for two times at least by a shielding jig on the basis of conventional sand blasting. Through at least two times of sand blasting by the shielding jig, sand thicknesses and pressures of adjacent patterns are different, structure layers of surfaces of products are enriched, and through anodic oxidation, the 3D effect is achieved. Products manufactured by the process have excellent metallic appearance, are good in smudginess resistance, and are quite suitable to be used as appearance products of electronic and communication equipment.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

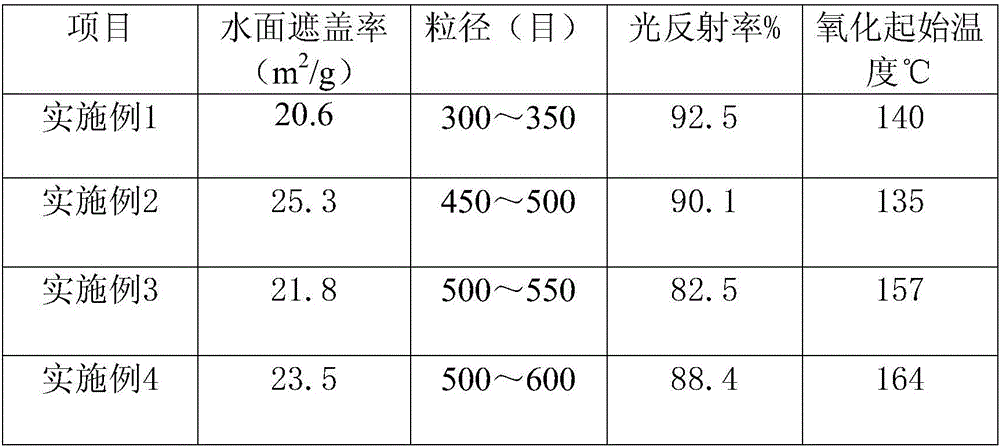

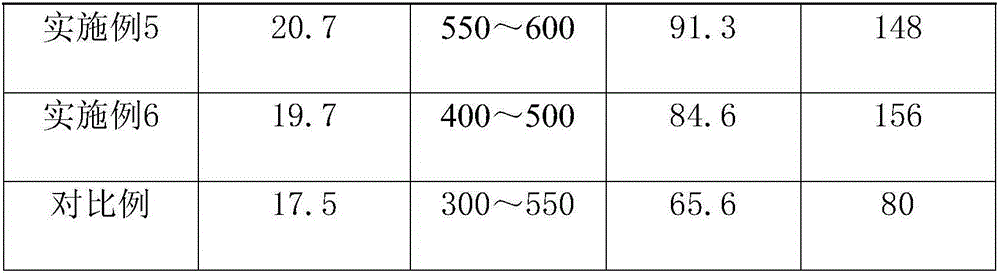

Artificial copper paint for aluminium profile and preparation method thereof

ActiveCN106883764ARealistic simulated copper effectRealistic imitation plating effectAnti-corrosive paintsCross-linkSolvent

The invention discloses an artificial copper paint for an aluminium profile. The artificial copper paint for the aluminium profile is prepared by the raw materials of electroplate silver resin for baking varnish, polyester resin, mixed solvent, cross-linked amino resin, oriented anti-settling agent, crystal pearlescent pigment, color mixing pigment and coupling agent; the electroplate silver resin for the baking varnish is obtained by combining solid electroplate silver resin and a mixed solvent according to a proportion. A preparation method for the artificial copper paint for the aluminium profile comprises the steps of adding the electroplate silver resin for the baking varnish and the polyester resin to a mixing tank to be uniformly mixed; adding 80-90% of the mixed solvent to the mixing tank during mixing; adding the cross-linked amino resin to the mixing tank during mixing and uniformly dispersing the cross-linked amino resin; adding the coupling agent and the oriented anti-settling agent to the mixing tank in sequence; stirring materials in the mixing tank till the materials are uniformly mixed; adding the crystal pearlescent pigment and the color mixing pigment to the mixing tank during mixing to mix the color; adding the rest mixed solvent to the mixing tank and adjusting the viscosity of the materials in the mixing tank; mixing the materials till the materials are uniformly mixed; cooling the materials to a room temperature; filtering and packaging the materials to obtain the artificial copper paint for the aluminium profile.

Owner:ZHEJIANG XIZERONG PAINT CO LTD

Directional arraying agent for waterborne effect pigment, and preparation method and application thereof

The invention relates to the technical field of directional arraying agents, specifically to a directional arraying agent for a waterborne effect pigment, and a preparation method and application thereof. The directional arraying agent for the waterborne effect pigment comprises the following raw materials by weight: 10 to 50 parts of monomer, 1 to 10 parts of an emulsifier, 0.5 to 5 parts of an initiator and 50 to 100 parts of deionized water. The preparation method comprises a first step of emulsifying the monomer, the emulsifier, the initiator and deionized water in a reaction vessel and a second step of carrying out free radical polymerization so as to obtain the directional arraying agent for the effect pigment. The waterborne directional arraying agent has zero VOC discharge; the waterborne effect pigment can be directionally arrayed in paint and presents strong metal sensation; and the preparation method is simple in process and favorable for large-scale production. Excellent flashing effect can be obtained by only adding 0.2 to 3% of the directional arraying agent for the waterborne effect pigment into waterborne paint.

Owner:东莞市隆海新材料科技有限公司

Water dispersible fluorine silicone modified acrylic resin coating and preparation and application in aluminum profile

The invention belongs to the technical field of water dispersible fluorine silicone modified acrylic resin coating, and discloses water dispersible fluorine silicone modified acrylic resin coating and preparation method thereof and an application in an aluminum profile. The coating comprises black primer and varnish, and the preparation method includes the following steps that carbon black, water and a dispersing agent are mixed and dispersed to obtain black wash; water dispersible fluorine silicone modified acrylic resin is mixed with amino resin, naphthalene sulfonic acid catalyzer is added, after mixture is stirred evenly, the water, talcum powder and the black wash are added to disperse and filtrate, the black primer is obtained; the water dispersible fluorine silicone modified acrylic resin is mixed with the amino resin, the naphthalene sulfonic acid catalyzer and flatting agent are added, after the mixture is stirred evenly, the water, a defoaming agent, propylene glycol monomethyl ether and ethyl alcohol are added to disperse and filtrate, and the varnish is obtained. Double coating water-based paint is formed by the coating, the coating has decorative effects that the color is rich, the feeling of metal is strong and the gloss is high, the weather ability is excellent, green and environmental protection are achieved, the cost is low, and the coating can be applied to aluminum profile coating.

Owner:GUANGZHOU HUMAN CHEM

Glass decoration picture

InactiveCN104476973AWith auto-illuminationStrong metal feelingSpecial ornamental structuresMetal stripsPrinting ink

A disclosed glass decoration picture comprises a glass base plate, a glass-base-plate front surface, a glass-base-plate back surface, a pattern contour, a concave groove, a metal strip contour and a backboard layer; the glass-base-plate back surface is provided with the pattern contour of the concave groove; a metal strip is embedded into the inner wall of the concave groove through gluing for forming the metal strip contour, and the metal strip is a flat metal strip; the concave groove is filled with colorful sand, and the colorful sand is formed by mixing an aqueous printing-ink fluorescent liquid and polyurethane glue; and the backboard layer is pasted on the glass-base-plate back surface. The glass decoration picture is strong in metal sense, is relatively beautiful, has embossment effect by employing the colorful sand as a filler, and is relatively strong in stereoscopic impression. The fluorescent liquid has automatic luminescent property, and another artistic wall painting effect can be generated under the conditions of night or dim light.

Owner:SUZHOU JUTONGYUAN ARTWORK DECORATION

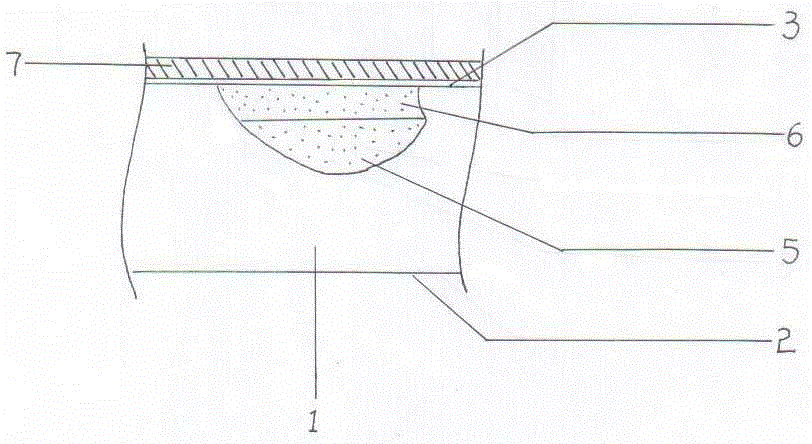

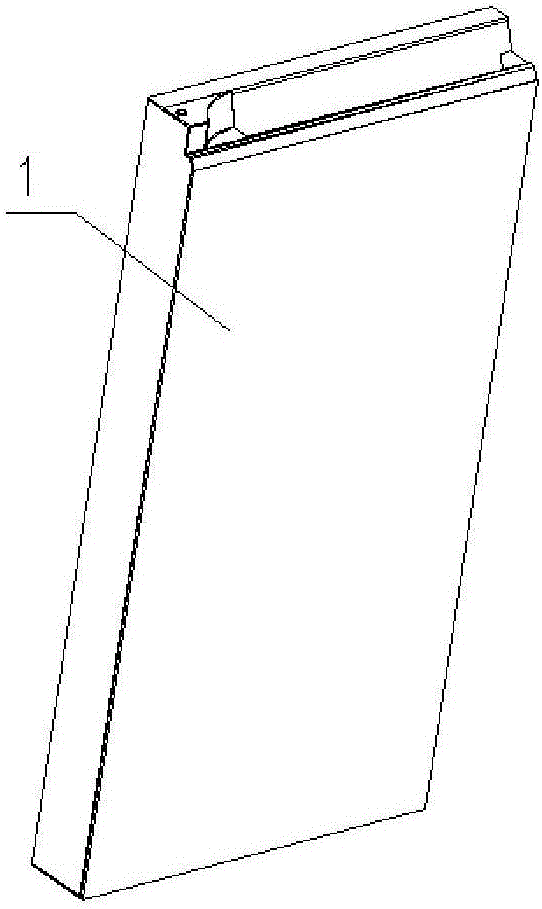

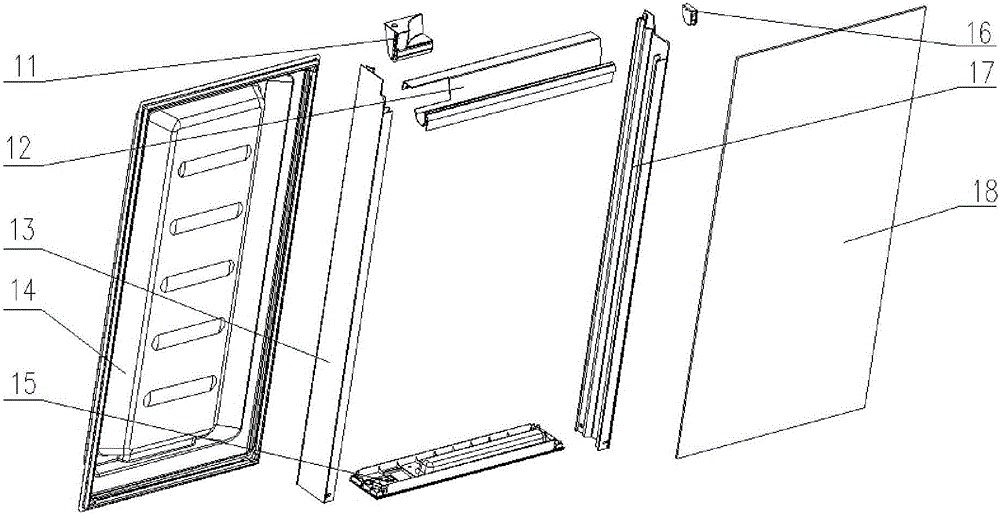

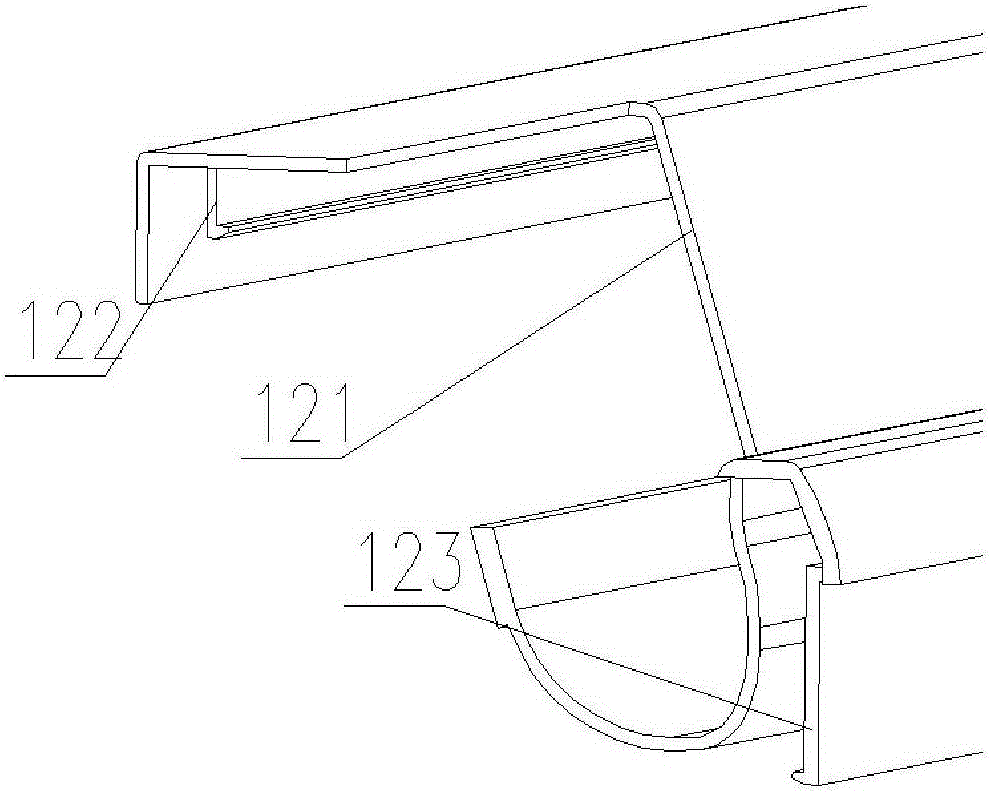

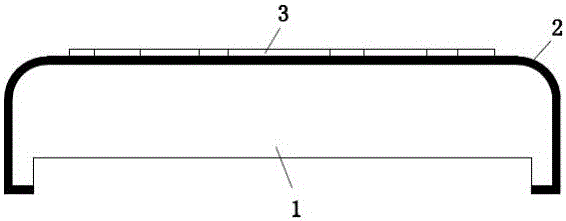

Refrigerator door body

ActiveCN105928305AImprove appearance gradeStrong metal feelingLighting and heating apparatusCooling fluid circulationAlloyEngineering

The invention discloses a refrigerator door body and belongs to the technical field of refrigerating equipment. The refrigerator door body comprises a door frame, a glass plate and a door lining, wherein the door frame consists of an upper decorative bar, a left end stop, a right end stop, a left insert and a right insert; the upper decorative bar is an aluminum alloy extruded part; the left end of the upper decorative bar is provided with a first blocking hook, a second blocking hook and a fifth blocking slot; the top of the left end stop is provided with a first blocking slot matched with the first blocking hook and a second blocking slot matched with the second blocking hook; the left insert is blocked into the fifth blocking slot; the right end of the upper decorative bar is provided with a third blocking hook, a fourth blocking hook and a sixth blocking slot; the top of the right end stop is provided with a third blocking slot matched with the third blocking hook and a fourth blocking slot matched with the fourth blocking hook; and the right insert is blocked into the sixth blocking slot. The refrigerator door body is simple in structure, and is convenient to mount; by virtue of the decorative bars made of the aluminum alloy material, the door body has stronger metallic appearance, so that the appearance level of a refrigerator is improved; and meanwhile, high mould charge of a plastic mould is saved.

Owner:AUCMA

Technology for directly printing pattern on plastic electroplated key cap

ActiveCN105931912ADimensionally stableEasy to processElectric switchesOther printing apparatusKey pressingMetallic materials

The invention relates to the technical field of keys of electronic products, and especially relates to a technology for directly printing a pattern on a plastic electroplated key cap. The technology comprises the steps: 1, carrying out the injection moulding of a key cap; 2, coating the insulating cap with insulating oil; 3, carrying out the electroplating of a metal film; 4, washing an insulating oil layer at the bottom of the key cap; 5, printing ink on the surface of the key cap; 6, carrying out assembly. Because the surface of the key cap after injection moulding is coated with the metal film, compared with a mode of employing a pure metal material to process the key in the prior art, the technology is low in production cost, can achieve batch production, and is stable in size of a produced key cap. Moreover, the technology can guarantee the good adhesive force between the printed character or pattern and the metal film, and the printed character or pattern is good in surface hardness, is good in performance of wear resistance, and is resistant to corrosion and oxidation.

Owner:DONGGUAN SINCO ELECTRONICS

Composite zinc alloy film coating process

InactiveCN103668071AHigh densityStrong metal feelingVacuum evaporation coatingSputtering coatingZinc alloysFilm coating

The invention discloses a composite zinc alloy film coating process, and belongs to the technical field of surface treatment. The process sequentially comprises the steps of substrate surface pre-treatment, surface spraying and curing, vacuum film coating and heat-curable coating spraying and curing, wherein the vacuum film coating step comprises magnetron sputtering nickel plating, magnetron sputtering-ion plating mixed nickel-chromium plating and cathodic arc ion chromium-plating. According to the process, a heavy polishing procedure is eliminated, the process flow is simplified, the production efficiency is improved, and the labor intensity of a worker is reduced; in addition, a magnetron sputtering-ion plating mixed film coating technology is adopted, and an obtained product is high in film layer density and highly metallic; moreover, a metal layer and a metal mixed coating are prepared in the same vacuum furnace, so that the process is easy to operate, high bonding force of a film layer is ensured, and the quality of the product is improved.

Owner:WUXI HUIMING ELECTRONICS TECH

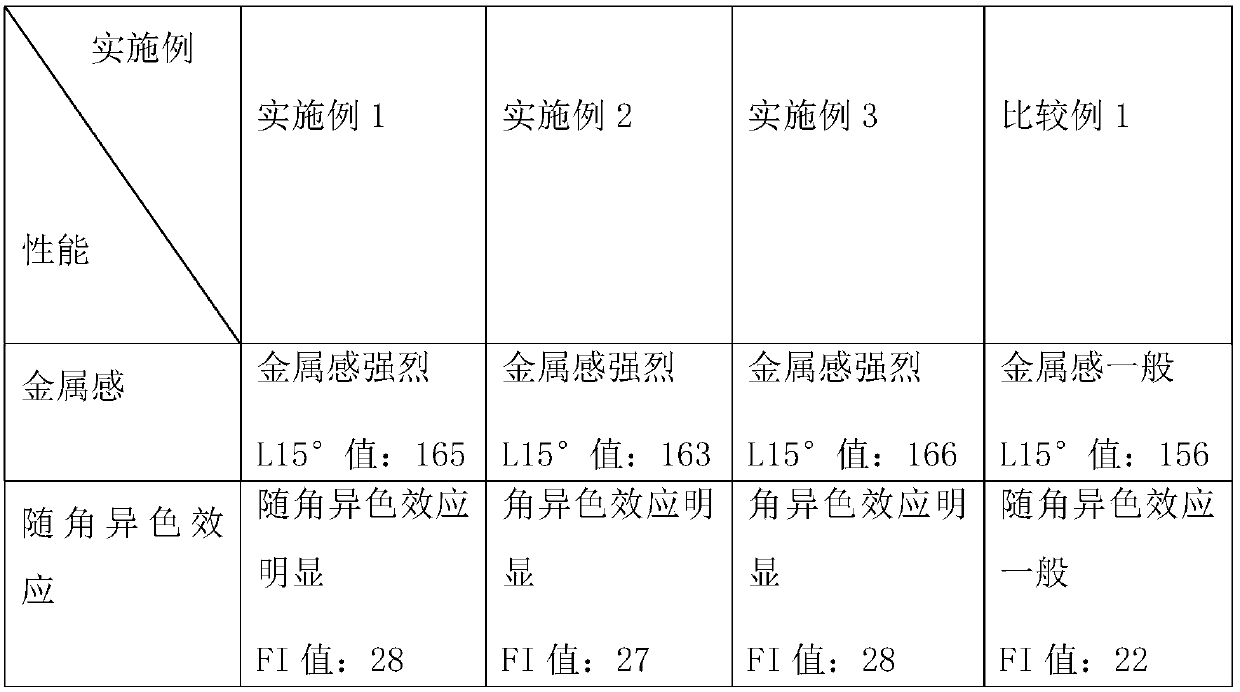

Modified aluminum pigment and preparation method thereof, and coating containing same

InactiveCN109694591AStrong metal feelingExcellent color flop effectCoatingsPigment physical treatmentOrganic solventFatty acid formation

The invention provides a modified aluminum pigment comprising, based on the total weight of the modified aluminum pigment, 60-70 wt% of flake aluminum powder, 3-5 wt% of a compound formed by nano-titanium dioxide and fatty acid, and 25-35 wt% of an organic solvent, wherein the weight ratio of nano-titanium dioxide to fatty acid is (0.5-5):100. The invention also provides a corresponding preparation method of the modified aluminum pigment and a coating containing the modified aluminum pigment. Compared with traditional aluminum pigments, the modified aluminum pigment has better metal sensationand better angle-dependent optical effect.

Owner:长沙族兴新材料股份有限公司

Nickel-imitative metallic powder coating and preparation method thereof

InactiveCN107057535AStrong metal feelingRealistic decorative metal nickel plate effectPowdery paintsEpoxy resin coatingsEpoxyTitanium

The invention discloses a nickel-imitative metallic powder coating, which is prepared from the following raw-material components in parts by weight: 90 to 110 parts of polyester resin, 65 to 72 parts of epoxy resin, 0.5 to 1.8 parts of antifoaming agent, 2.5 to 4 parts of luster enhancing agent, 3.5 to 4.3 parts of flatting agent, 1.5 to 2.5 parts of scratch resisting agent, 90 to 120 parts of filling, 8 to 15 parts of titanium pigment, 0.3 to 0.5 part of carbon black, 6 to 7 parts of iron oxide yellow, 0.6 to 0.7 part of iron oxide red, 0.62 to 0.72 part of HR yellow, 0.3 to 1.1 parts of flow anti-caking agent, 0.6 to 1.4 parts of silver powder and 0.025 to 0.075 part of aluminum powder diffusion and arrangement auxiliary. The invention also discloses a preparation method of the powder coating.

Owner:江西杰克西新材料有限公司

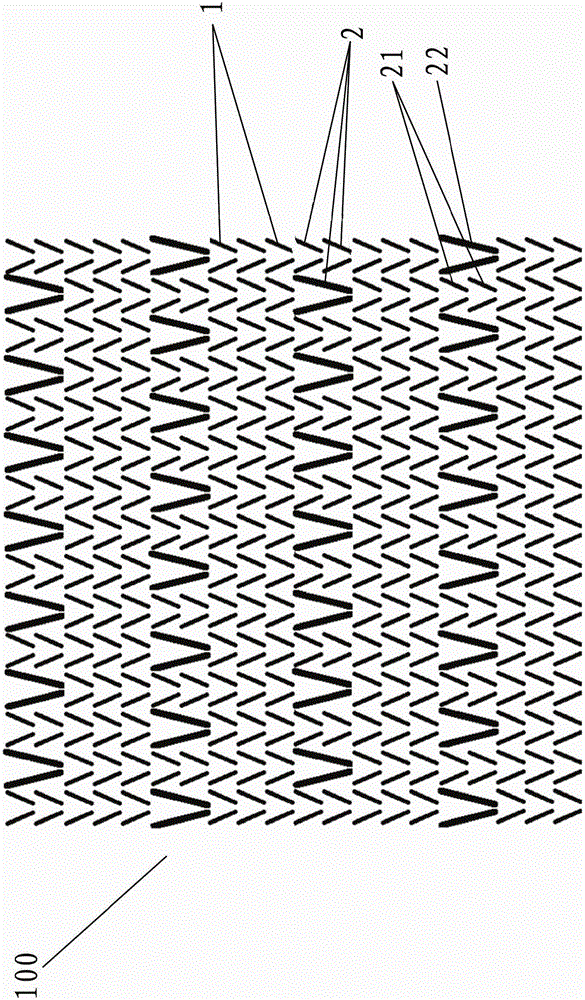

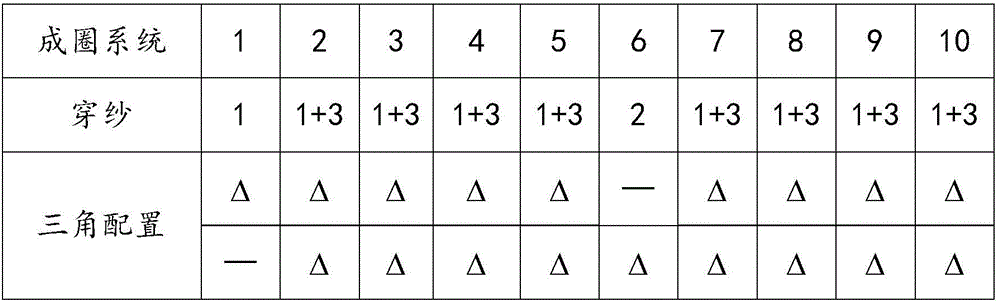

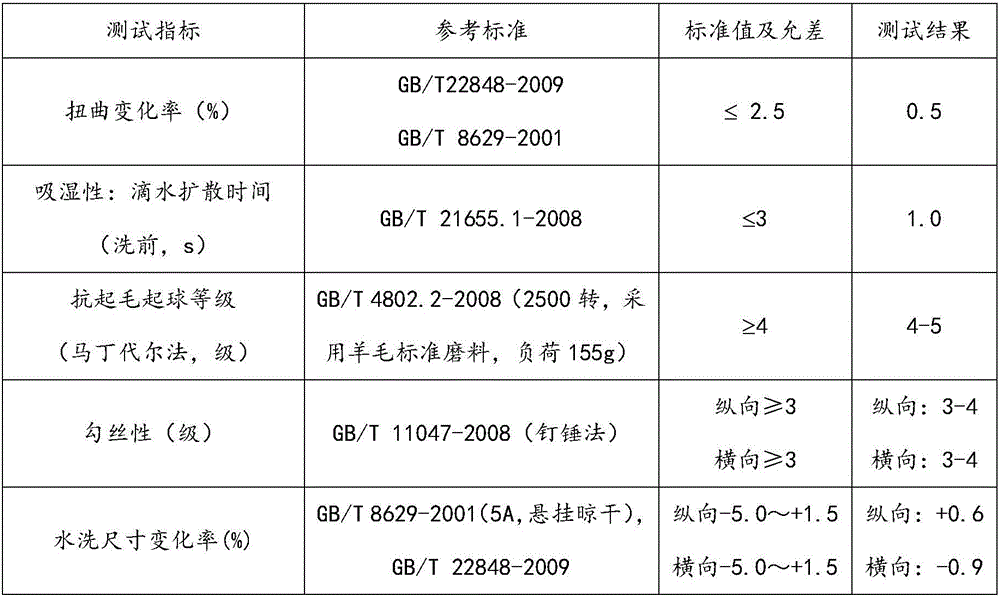

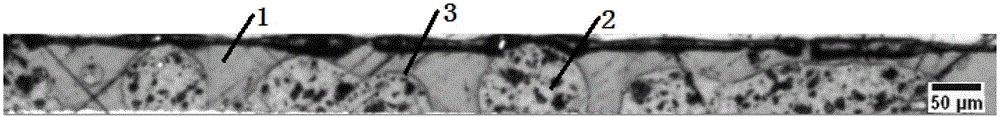

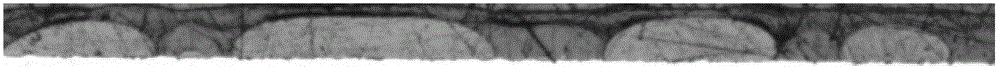

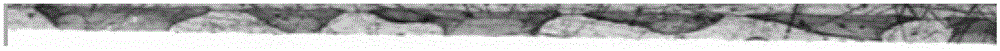

Single-sided weft-knitted fabric with cross-stripe effect and production method of single-sided weft-knitted fabric

ActiveCN106480589AGood bar effectRich fabric surfaceWeft knittingHeating/cooling textile fabricsPolyesterEngineering

The invention provides single-sided weft-knitted fabric with the cross-stripe effect. The single-sided weft-knitted fabric comprises a fabric body with the cross-stripe structure, the cross-stripe structure is formed by first coil rows and second coil rows, the first coil rows and the second coil rows are longitudinally and alternatively arranged, each second coil row behind each first coil row performs 1-stitch displacement, the first coil rows are composed of coils by knitting of three continuous cross-row looped coils protruding the front side of the fabric body, the second coil rows are formed by alternative knitting of looped coils of two cross-row coils protruding the front side of the fabric body and one longitudinal floating-thread stretched coil, the first coil rows are woven by cationic polyester filament and spandex in a doubling manner, and the second coil rows are knitted by half-matting polyester filament. Compared with the prior art, the single-sided weft-knitted fabric has the advantages of remarkable stripe experience, good cross elasticity and extension, good resistance to pilling and the like. The invention further provides a production method of the single-sided weft-knitted fabric with the cross-stripe effect.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

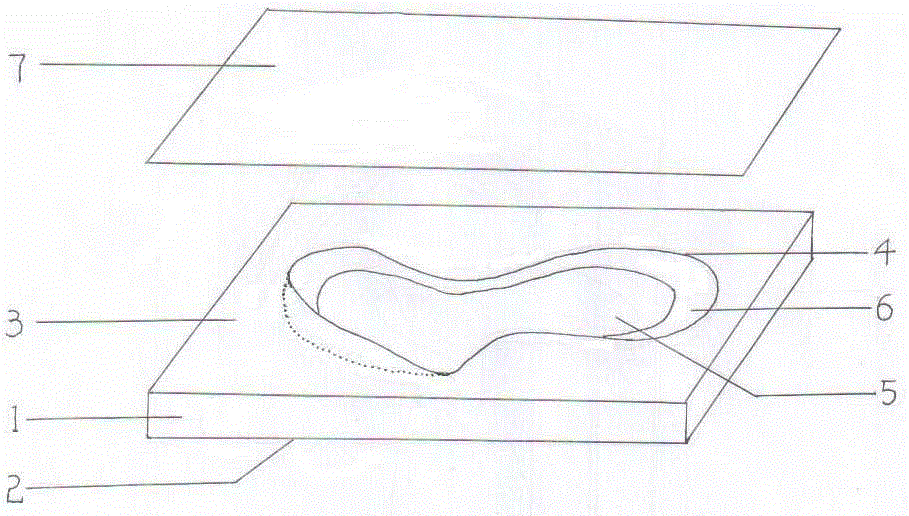

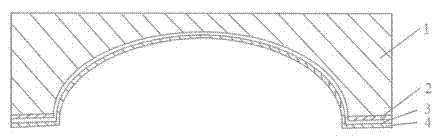

LOGO with internal stereoscopic effect for vehicle and preparation method thereof

ActiveCN103692978AStrong metal feelingThere are no problems such as deformationVehicle componentsUltravioletProtection layer

The invention discloses a LOGO product with an internal stereoscopic effect. A LOGO white part is prepared by injection molding of a high-transparency thermoplastic high polymer material, one face of the LOGO white part is a smooth plane, the other face of the LOGO white part is concave, a concave body is a LOGO overall profile, a multilayer functional layer structure is arranged on one face of the concave body and comprises a thermoplastic high polymer material body transparent layer, a colorful transparent layer and a UV (Ultraviolet) back cover protection layer. The LOGO product with the internal stereoscopic effect, which is provided by the invention, has a simple process of a preparation technology and environmental friendliness. According to the product prepared by the method, ray is reinforced and reflected by a bottom processing layer, the LOGO is arranged in a transparent part and has the effects of strong stereoscopic impression and extremely strong metal sense; by adopting a special integrated structure, an electroplated layer of a bottom liner of the lining LOGO is protected by the transparent part, the appearance problem cannot be influenced by fading, scratch and the like; through adopting the integrated structure, the LOGO has no problem of deformation due to external stress action.

Owner:CHUZHOU HONGYUAN SPRAYING

Metal alike art type powder coating and preparation method thereof

ActiveCN103146288ACorrosion resistanceWith destructionPolyurea/polyurethane coatingsEpoxy resin coatingsFluorocarbonParticle system

The invention belongs to the field of a powder coating and particularly relates to a metal alike art type powder coating. The metal alike art type powder coating comprises an epoxy resin particle system and a fluorocarbon resin particle system, wherein the epoxy resin particle system contains epoxy resin, an adaptive curing agent A and a flatting agent A; the fluorocarbon resin particle system contains fluorocarbon resin, an adaptive curing agent B and a flatting agent B; and the weight part ratio of the epoxy resin particle system to the fluorocarbon resin particle system is (6-4):(4-6). According to the metal alike art type powder coating, the incompatibility of the flatting agent, the epoxy resin and the fluorocarbon resin is utilized for controlling the distribution the flatting agent, the epoxy resin and the fluorocarbon resin in coating layers, so that the flatting agent is evenly dispersed between the epoxy resin layer and the fluorocarbon resin layer to generate a visual effect of alternative dark and bright, and then a metal alike effect is achieved.

Owner:NINGBO SOUTH SEA CHEM

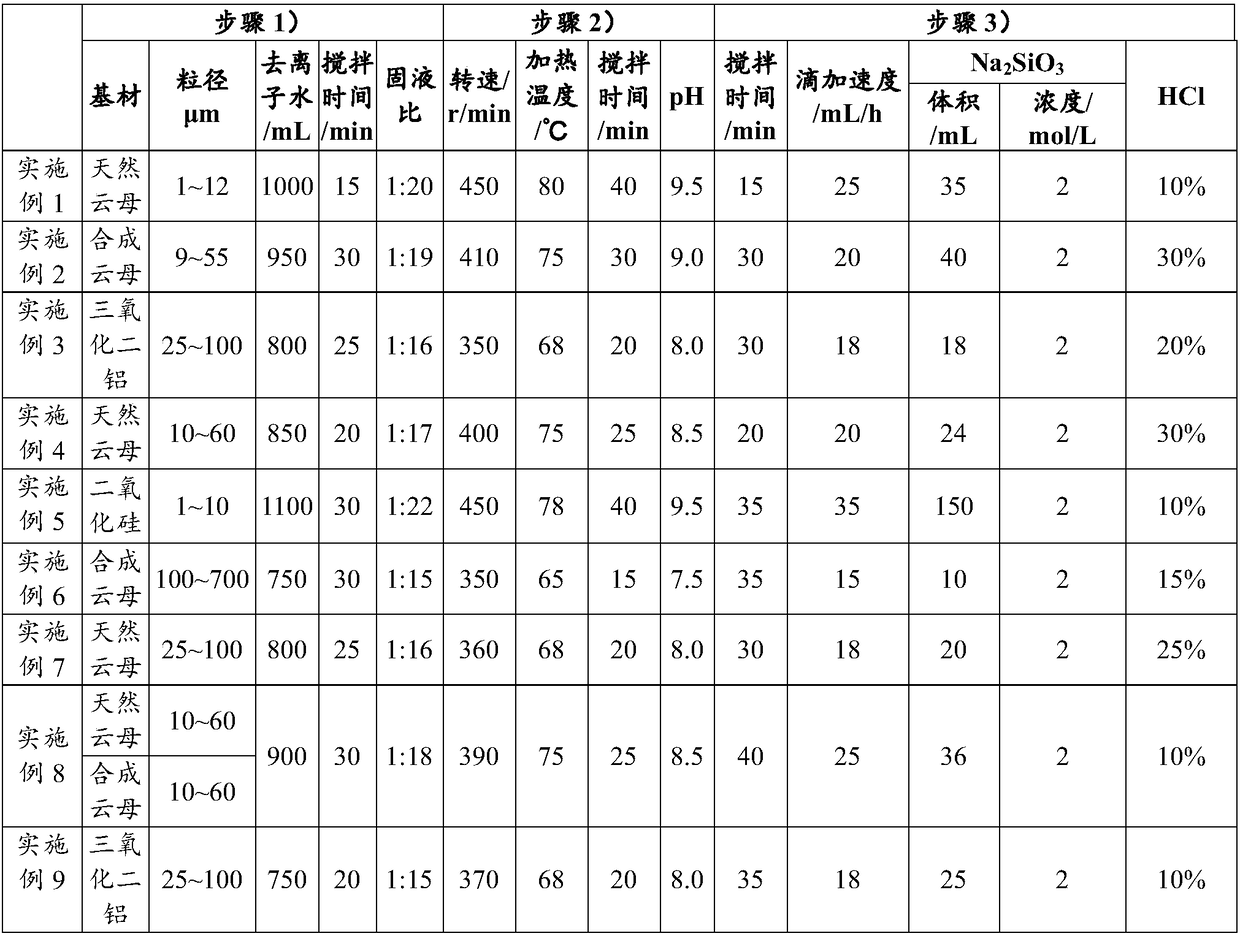

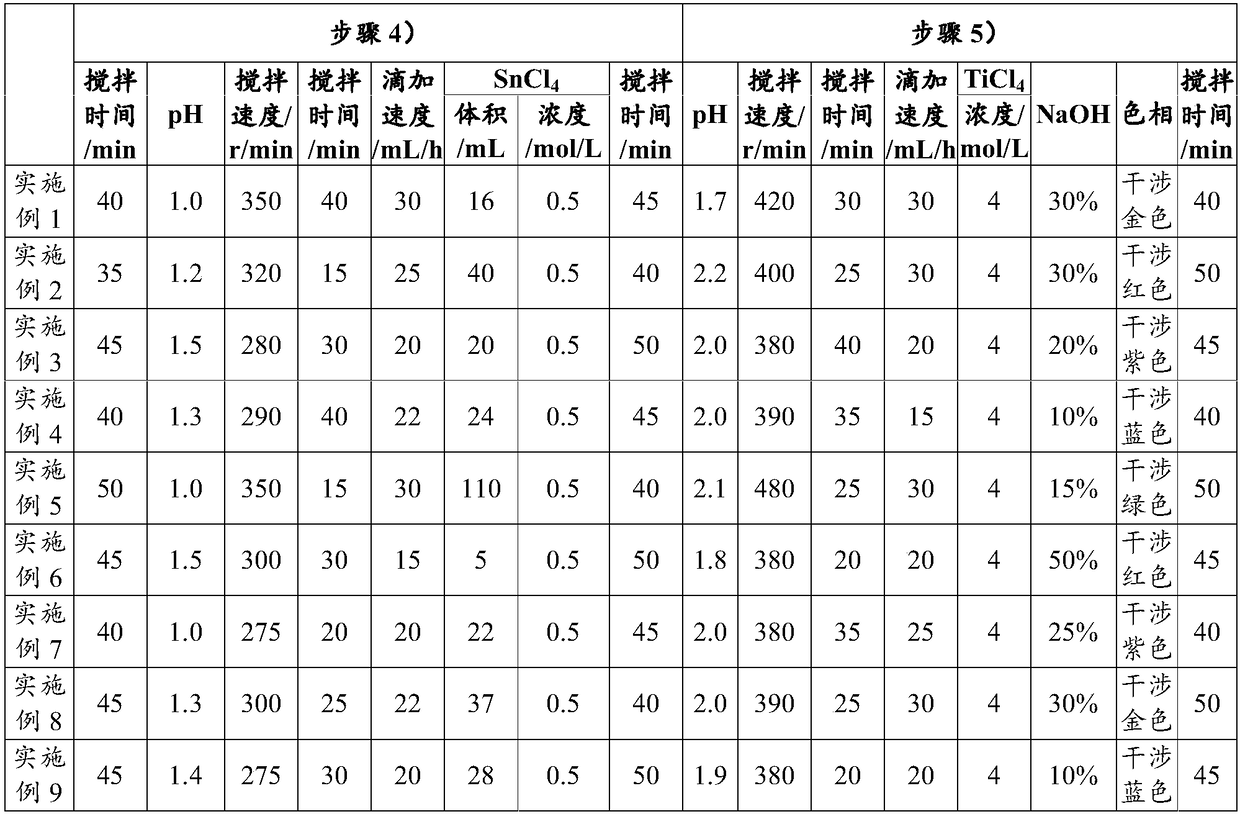

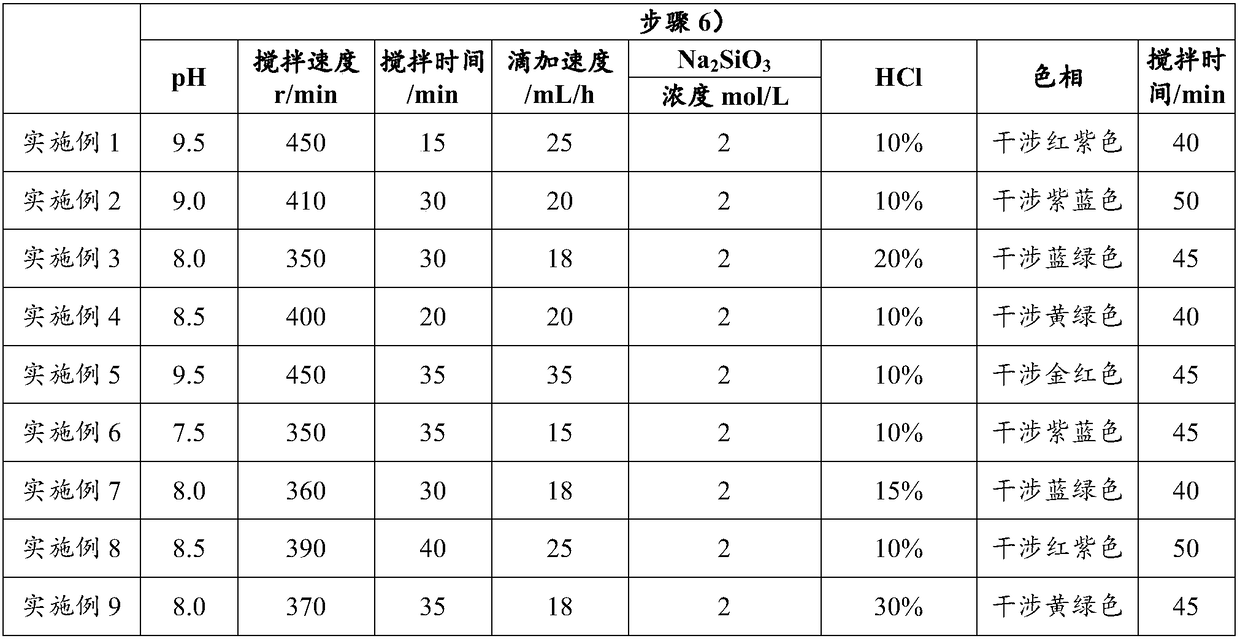

Pearlescent pigment containing rutile and anatase type TiO2 layer, and preparation method of pearlescent pigment

ActiveCN108276806ASimple coating processEasy to operateInorganic pigment treatmentCoated surfacePhysical chemistry

The invention discloses pearlescent pigment containing rutile and an anatase type TiO2 layer. The pearlescent pigment comprises a layer structure consisting of the following layers: (A) a base material; (B) a first SiO2 coating on the surface of the base material; (C) a second SnO2 coating on the surface of the first SiO2 coating; (D) a third TiO2 coating on the surface of the second SnO2 coating;(E) a fourth SiO2 coating on the surface of the third TiO2 coating; (F) a fifth TiO2 coating on the surface of the fourth SiO2 coating. Compared with the prior art, the pearlescent pigment provided by the invention has the characteristics of being high in color saturation, good in brightness and strong in metallic feeling, the use value of the pearlescent pigment is increased, and the pearlescentpigment can meet the use demands in the fields such as automobiles, paint, leather, textile, plastic, electronics, ink and cosmetics. In addition, the invention also discloses a preparation method ofthe pearlescent pigment. The method is simple in process and easy to operate; the obtained product has high purity, and the final hue of the product can be controlled by adjusting the thickness of coating layers of the oxides.

Owner:GUANGXI CHESIR PEARL MATERIAL CO LTD

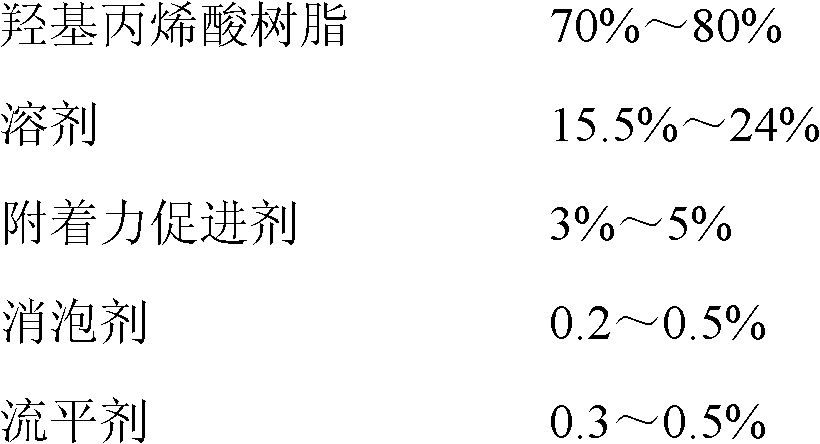

Adhesion enhancement priming paint used for surface of gold and silver foil, and preparation method and application thereof

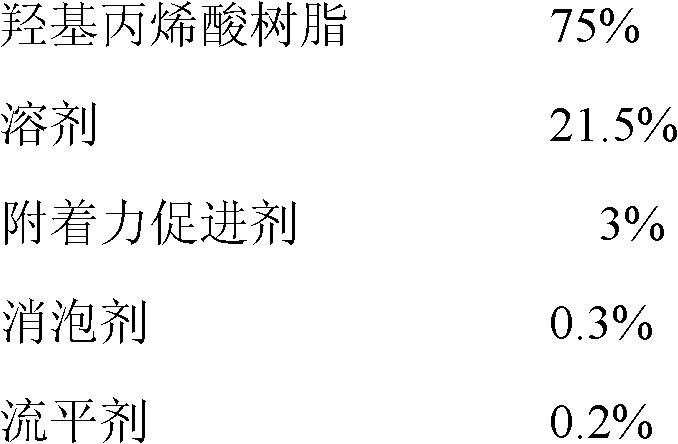

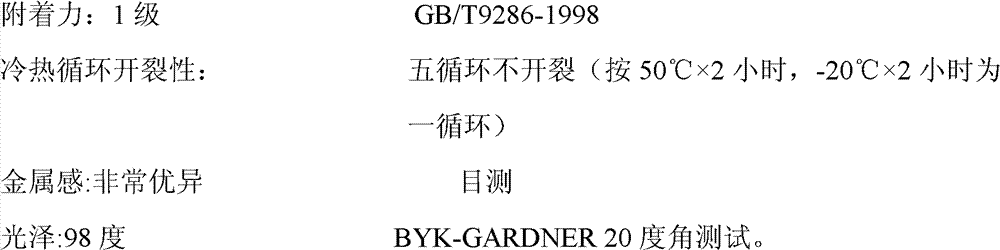

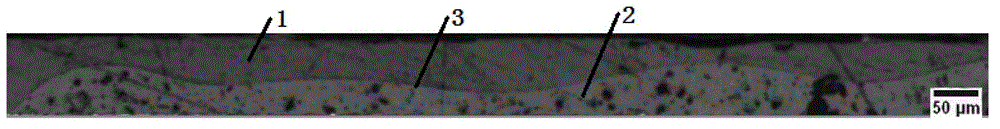

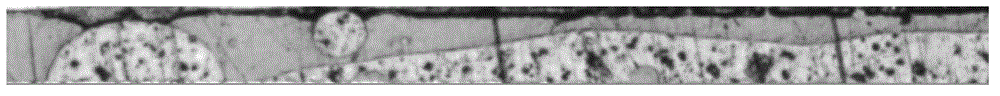

InactiveCN103113814AStrong adhesionStrong metal feelingPolyurea/polyurethane coatingsSpecial surfacesAcrylic resinSolvent

The invention discloses an adhesion enhancement priming paint used for the surface of a gold and silver foil, and a preparation method and an application thereof. The priming paint is composed of a component A and a component B, the component A comprises 70-80wt% of a hydroxy acrylic resin, 15.5-24wt% of a solvent, 3-5wt% of an adhesion promoter, 0.2-0.5wt% of an antifoaming agent and 0.3-0.5wt% of a leveling agent, and the component B comprises 40-45wt% of hexamethylene diisocyanate biuret and 55-60wt% of the solvent. The enhancement priming paint can be dried at normal temperature, and can be coated onto the surfaces of house furnishings or handicrafts or other surfaces plastered with the gold and silver foil after the match with a curing agent to reach extremely-strong adhesion, excellent metal sensation and hot-cold cracking resistance in order to reach excellent decoration and protection purposes.

Owner:上海展辰涂料有限公司 +2

Waterborne gravure silver ink and production process thereof

The invention discloses waterborne gravure silver ink and a production process of the waterborne gravure silver ink. The formula of the waterborne gravure silver ink comprises the following components in parts by weight: 30 to 40 parts of deionized water, 10 to 20 parts of ethanol, 0.1 to 1 part of a surfactant, 0.5 to 1 part of a directional arrangement additive, 40 to 55 parts of waterborne resin solutions, and 10 to 20 parts of waterborne aluminum silver paste. The waterborne gravure silver ink and the production process of the waterborne gravure silver ink disclosed by the invention have the advantages of excellent water resistance, difficult oxidation stain and good anti-settling performance.

Owner:HUNAN HULIDA PAINT TECH

Powder coating with imitation anodic oxidation effect and preparation method thereof

ActiveCN103146287AGood weather resistanceBright colorsPowdery paintsEpoxy resin coatingsAnodic oxidationChemistry

The invention belongs to the field of powder coating and in particular relates to a powder coating with an imitation anodic oxidation effect. The powder coating comprises an epoxy resin granule system containing epoxy resin, a correspondingly matched curing agent A and dye, and a fluorocarbon resin granule system containing fluorocarbon resin and a matched curing agent B, wherein the ratio of the epoxy resin granule system to the fluorocarbon resin granule system in parts by weight is (6-4): (4-6). The powder coating with the imitation anodic oxidation effect is a novel powder paint for art, which not only maintains the metallic luster of coating base materials, but also endows the coating base materials with bright color, and also has good weather resistance, the coating has excellent appearance decorative effect, the quality stability of the product of each batch is strong, and the product is durable and is very applicable to high end decorative fields.

Owner:NINGBO SOUTH SEA CHEM

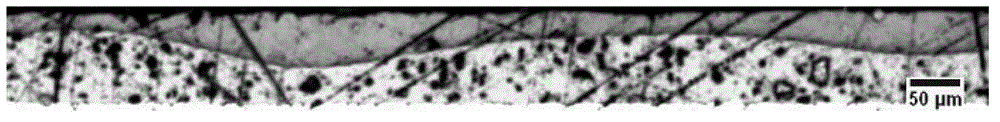

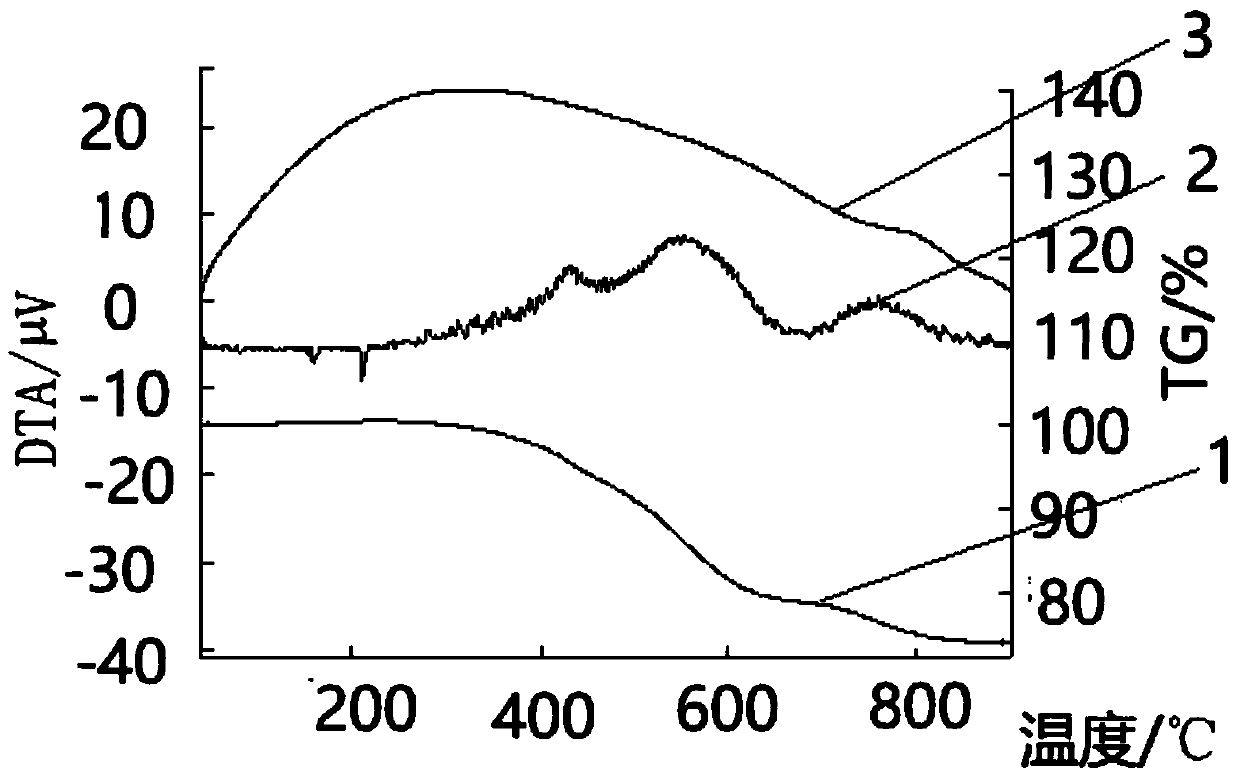

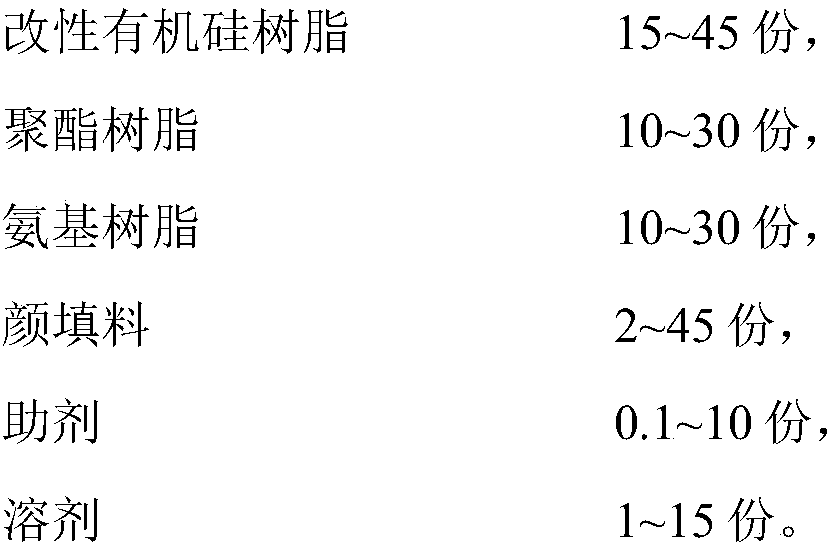

Temperature-resistant coating for coiled material household appliances and preparation method thereof

InactiveCN109536016ANot easy to yellowGuaranteed flexibilityAnti-corrosive paintsPolyester resinHome appliance

The invention discloses a temperature-resistant coating for coiled material household appliances. The temperature-resistant coating includes the following components in parts by weight: 15 to 45 partsof modified organic silicone resin, 10 to 30 parts of polyester resin, 10 to 30 parts of amino resin, 2 to 45 parts of pigment and filler, 0.1 to 10 parts of an auxiliary agent, and 1 to 15 parts ofa solvent. The invention discloses a preparation method of the temperature-resistant coating. The temperature-resistant coating has high temperature resistance and excellent processing performance, and has the advantages of decorative properties and corrosion resistance of home appliance coatings.

Owner:NIPPON PAINT IND COATINGS SHANGHAI

Aluminium alloy for household appliance handle and purification method of melt of aluminium alloy

ActiveCN104233019AIncrease extrusion speedImprove surface qualityRare-earth elementPurification methods

The invention relates to an aluminium alloy for a household appliance handle and a purification method of melt of the aluminium alloy. The aluminium alloy is characterized by comprising the following chemical components in percentage by weight: 1.0%-1.12% of Mg, 0.16%-0.22% of Si, 0.1%-0.5% of La+Ce, less than 0.25% of Fe, no more than 0.02% of Cr, no more than 0.02% of Mn, no more than 0.03% of Zn, no more than 0.02% of Cu, no more than 0.02% of each of other impurity elements, and the balance of Al, wherein the total content of the other impurity elements is not more than 0.15%. By adding rare earth elements La and Ce, the aluminium alloy for the household appliance handle is capable of improving the surface quality of an aluminium alloy section and improving the extrusion speed of the aluminium alloy. The household appliance handle produced by adopting the aluminium alloy for the household appliance handle disclosed by the invention has the advantages of being smooth in surface, strong in metal feel, environment-friendly and durable, collision-resistant, corrosion-resistant, high in strength, good in mechanical property and the like.

Owner:ALNAN ALUMINIUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com