Metal alike art type powder coating and preparation method thereof

A technology of powder coating and metal imitation, which is applied in the field of powder coating and can solve the problems of instability, easy oxidation and rubbing off of metal powder coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

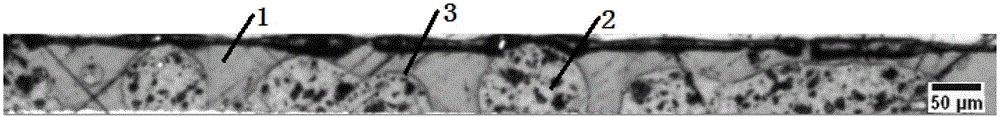

Image

Examples

Embodiment 1

[0070] The metal-like art powder coating described in this embodiment includes an epoxy resin particle system and a fluorocarbon resin particle system with a weight ratio of 1:1.

[0071] The epoxy resin particle system consists of the following components by weight:

[0072] Bisphenol A epoxy resin (E-12) and dicyandiamide curing agent (DYHARD 100S) 80 copies in total;

[0073] Leveling agent-1.5 parts of amide modified polyether oligomer;

[0074] 13.2 parts of pigments and fillers, including pigments and fillers. The fillers are selected from barium sulfate such as W-44HB, and the pigments are selected from titanium dioxide CR826. The pigments and fillers can be added according to the requirements of those skilled in the art. In the example, the adding ratio of the pigment and the filler is 1:1;

[0075] 3.8 parts of auxiliary agent A, the auxiliary agent A includes corner coverage modifier Kuraray 0.5 part of Mowital, 1.5 part of curing accelerator BASF2-MI, wetting and dispersin...

Embodiment 2

[0087] The metal-like art powder coating described in this embodiment includes an epoxy resin particle system and a fluorocarbon resin particle system with a weight ratio of 6:4.

[0088] The epoxy resin particle system consists of the following components by weight:

[0089] A total of 40 copies of bisphenol A epoxy resin NPES-903 and substituted dicyandiamide curing agent (CASAMID 710 from THOMAS SWAN);

[0090] Leveling agent-2 parts of amide modified polyether oligomer;

[0091] 0.8 part of pigments and fillers, including pigments and fillers, the filler is made of aluminum hydroxide such as Portafill A40, the pigment is carbon black 330R, wherein the pigment and filler can be added according to the requirements of the person skilled in the art. In this embodiment, the addition ratio of the pigment and the filler is 2:1;

[0092] 10 parts of auxiliary agent A, which includes corner coverage modifier Kuraray 2.5 parts of Mowital, 2.5 parts of curing accelerator BASF2-MI, wetting an...

Embodiment 3

[0103] The metal-like art powder coating described in this embodiment includes an epoxy resin particle system and a fluorocarbon resin particle system with a weight ratio of 4:6.

[0104] The epoxy resin particle system consists of the following components by weight:

[0105] Phenolic epoxy resin (KUKDO YDPN series) and phenolic hydroxyl resin curing agent (KUKD OKD-420 total 98.7 parts;

[0106] Leveling agent-0.5 part of amide modified polyether oligomer;

[0107] 60 parts of pigments and fillers, including pigments and fillers, the filler is made of aluminum hydroxide such as Portafill A40, the pigment is carbon black 330R, wherein the pigment and filler can be added according to the requirements of those skilled in the art for the product. In this embodiment, the addition ratio of the pigment and the filler is 1:2;

[0108] 2 parts of auxiliary agent A, the auxiliary agent A includes corner coverage modifier (Kuraray Mowital) 0.5 part, curing accelerator (BASF2-MI) 0.5 part, wetti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com