Preparation method of graphene composite conductive fiber

A graphene composite and conductive fiber technology, which is applied in fiber processing, fiber type, textiles and papermaking, etc., can solve the problems of high cost of precious metal silver, lower fiber conductivity, and poisoning of precious metals, and achieve low price, light fiber specific gravity, Environmental and human body non-polluting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

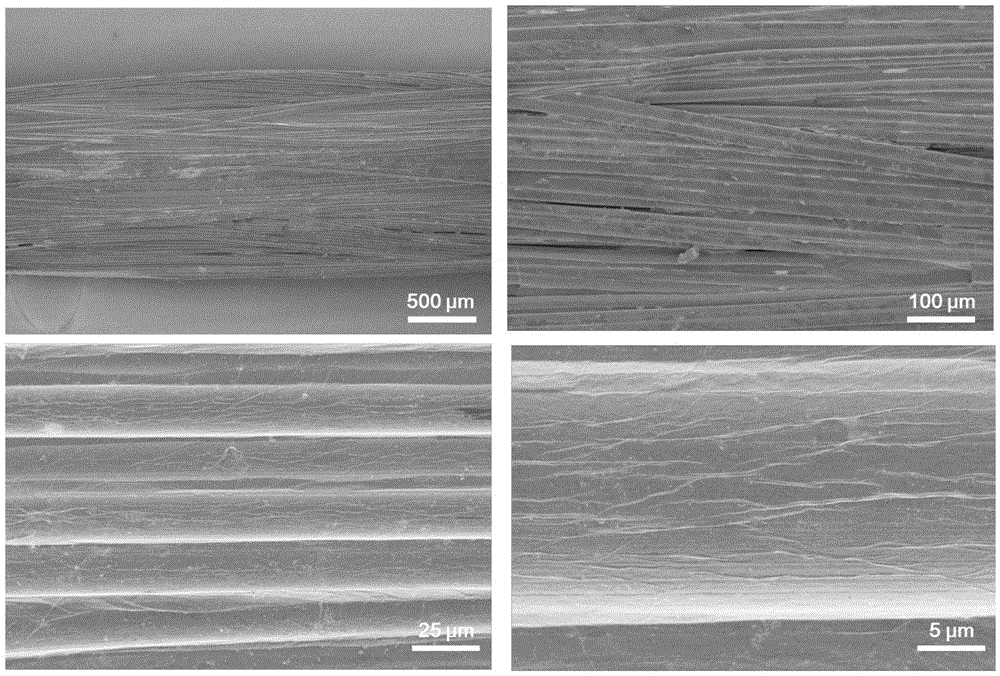

Image

Examples

Embodiment 1

[0033] (1) Take common textile polyester fibers, soak them in acetone at room temperature for 1 hour, remove surface oils and impurities, wash them with pure water, and dry them.

[0034] (2) Then soak in 0.5M NaOH solution, soak for 30min at room temperature, wash with pure water, and dry.

[0035] (3) Soak the textile fiber obtained in step (2) in a 0.3% (wt) graphene oxide solution, soak for 30 minutes, wash with water, and dry to obtain a textile fiber whose surface is impregnated with graphene oxide.

[0036] (4) The obtained textile fibers are coated with 0.3% (wt) graphene oxide solution on the surface. Place it on a hot table and dry it to obtain a polyester composite fiber with a graphene oxide coating. The number of times of padding and coating is 2 times. The hot stage drying temperature is 60°C.

[0037] (5) Place the obtained polyester / graphene oxide composite fiber in reducing agent HI, and reduce it at 90° C. for 1 hour to obtain polyester / graphene composite f...

Embodiment 2

[0039] (1) The steps are the same as step (1) in Example 1.

[0040] (2) Then soak in 1M NaOH solution, soak for 30min at room temperature, wash with pure water, and dry.

[0041] (3) The steps are the same as step (3) in Example 1.

[0042] (4) The steps are the same as step (4) in Example 1.

[0043] (5) The steps are the same as step (5) in Example 1.

Embodiment 3

[0045] (1) The steps are the same as step (1) in Example 1.

[0046] (2) Then soak in 2M NaOH solution, soak for 30min at room temperature, wash with pure water, and dry.

[0047] (3) The steps are the same as step (3) in Example 1.

[0048] (4) The steps are the same as step (4) in Example 1.

[0049] (5) The steps are the same as step (5) in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com