Adhesion enhancement priming paint used for surface of gold and silver foil, and preparation method and application thereof

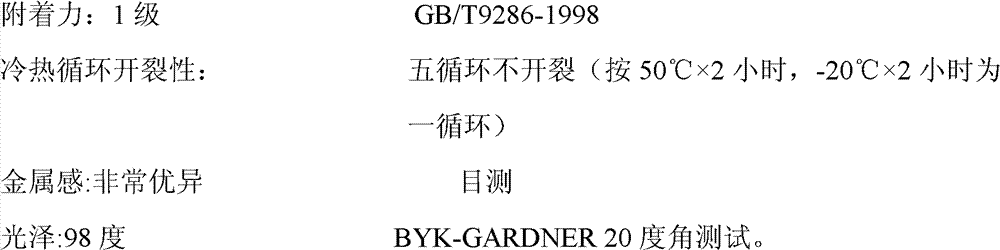

A gold-silver, primer technology, used in devices that apply liquid to surfaces, special surfaces, polyurea/polyurethane coatings, etc., can solve problems such as poor adhesion, cracking, loss, etc. Adhesion, excellent metallic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

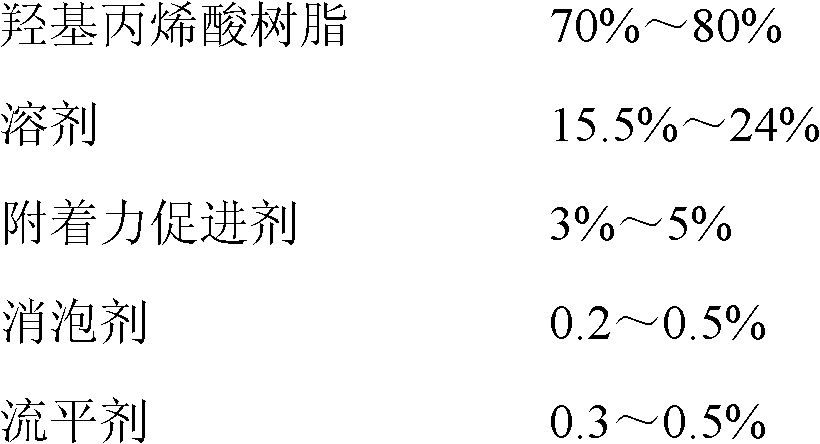

[0032] Group A formula: (weight)

[0033]

[0034] B component formula: (weight)

[0035] Hexamethylene diisocyanate biuret: 40%

[0036] Solvent 60%

[0037] Hydroxy acrylic resin can be used as Deqian's FS-2050

[0038] The solvent in component A is butyl acetate from Taixing Jinjiang;

[0039] Adhesion promoter is epoxy modified polyester resin, technical requirements: hydroxyl value: 30±2mgKOH / g, acid value: 25±5mgKOH / g, LTW from German EVONIK company can be used;

[0040] The defoamer is polysiloxane-polyether copolymer, BYK066 from BYK Company of Germany;

[0041] The leveling agent is a fluorine-modified polyacrylate copolymer, using Deqian's LEVELOL837;

[0042] The hexamethylene diisocyanate biuret in component B is N75 from Bayer, Germany;

[0043] The solvent in component B is butyl acetate from Taixing Jinjiang;

[0044] Preparation:

[0045] Part A

[0046] (1) First put the acrylic resin into the dispersion tank, add 50% of the total weight of the sol...

Embodiment 2

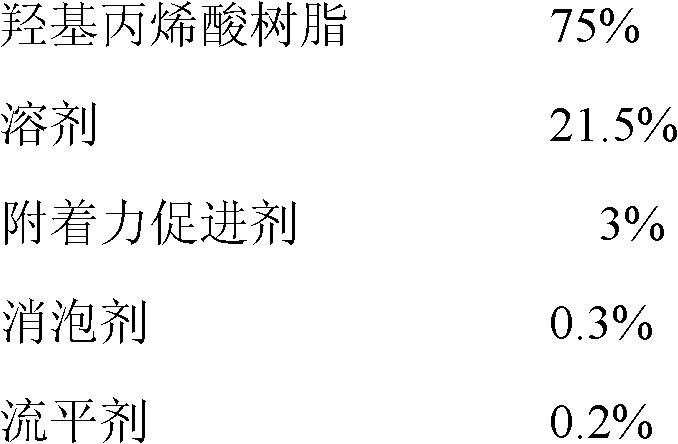

[0057] Group A formula: (weight)

[0058]

[0059] B component formula: (weight)

[0060] Hexamethylene diisocyanate biuret 45%

[0061] Solvent 55%

[0062] Hydroxy acrylic resin can be used as Deqian's FS-2050

[0063] The solvent in component A is butyl acetate from Taixing Jinjiang;

[0064] Adhesion promoter is epoxy modified polyester resin, technical requirements: hydroxyl value: 30±2mgKOH / g, acid value: 25±5mgKOH / g, LTW from German EVONIK company can be used;

[0065] The defoamer is polysiloxane-polyether copolymer, BYK066 from BYK Company of Germany;

[0066] The leveling agent is a fluorine-modified polyacrylate copolymer, using Deqian's LEVELOL837;

[0067] The hexamethylene diisocyanate biuret in component B is N75 from Bayer, Germany;

[0068] The solvent in component B is butyl acetate from Taixing Jinjiang;

[0069] Preparation:

[0070] Part A

[0071] (1) First put the acrylic resin into the dispersion tank, add 30% of the total weight of the solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com