Pearlescent pigment containing rutile and anatase type TiO2 layer, and preparation method of pearlescent pigment

A pearlescent pigment, anatase type technology, applied in the field of pearlescent pigments, can solve the problems of difficult to achieve color saturation and brightness, affecting the use effect, etc., to achieve the effect of brilliant color, good brightness and strong metallic feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

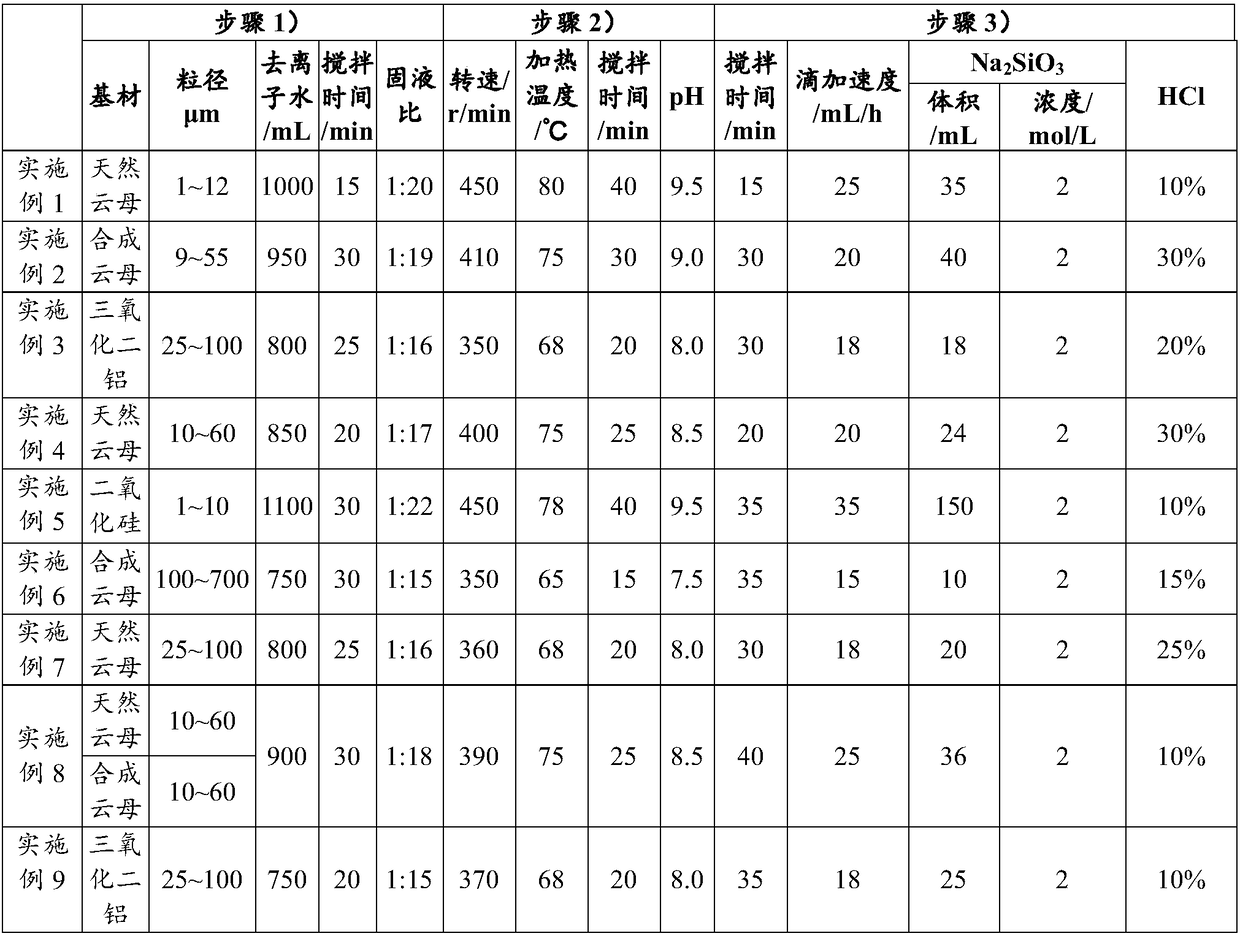

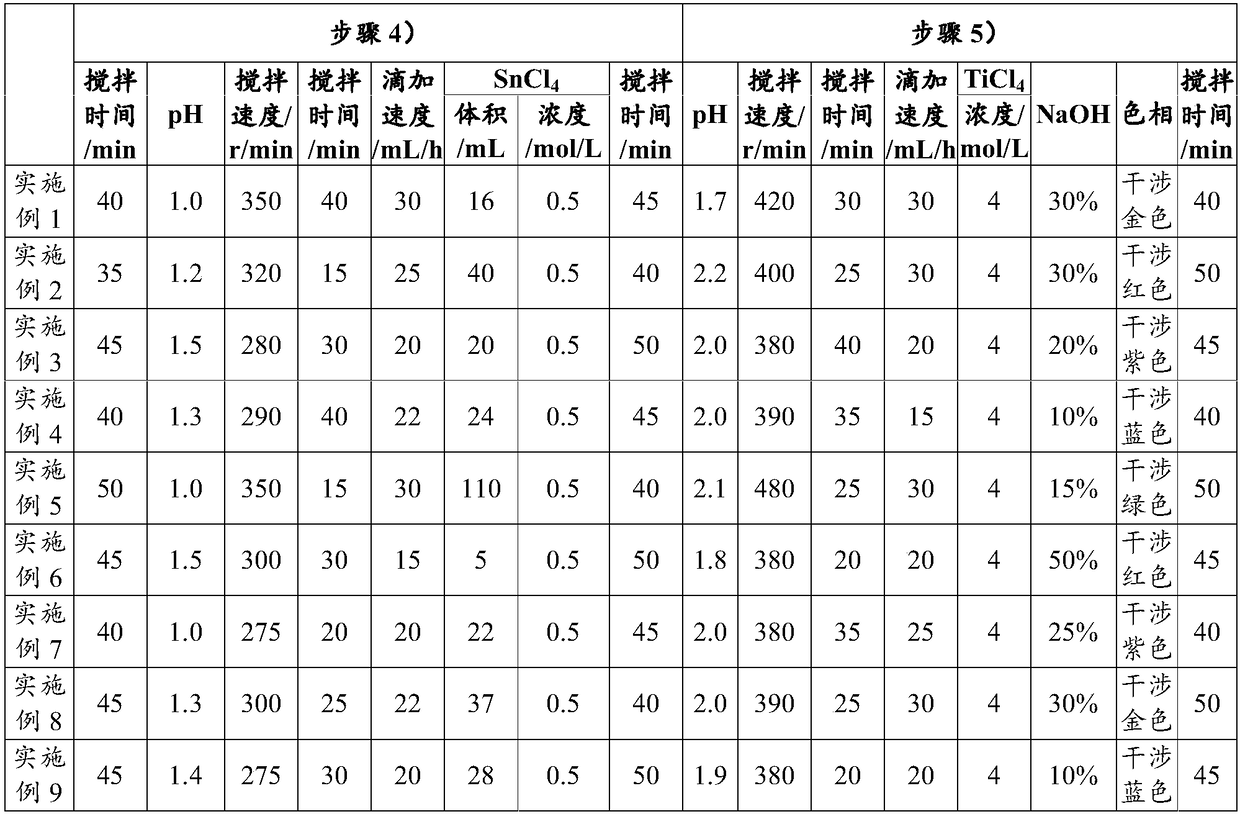

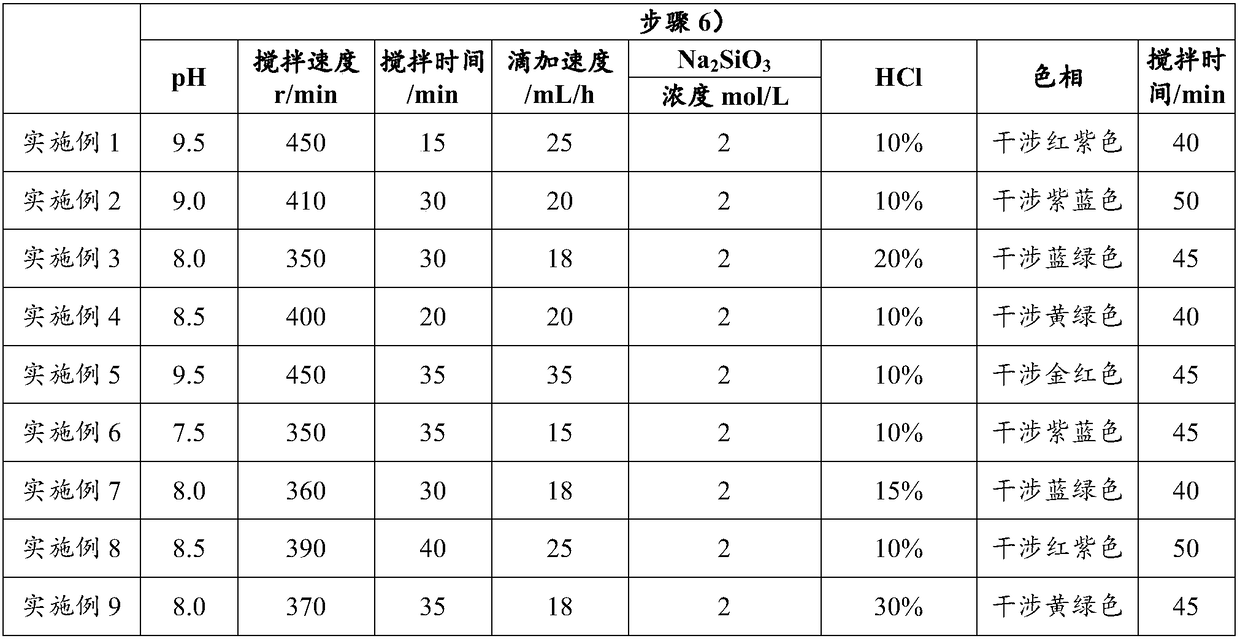

Embodiment 1

[0045] 1) Weigh 50 g of natural mica with a particle size of 1-12 μm in a 2L reaction kettle, add 1000 mL of deionized water with a conductivity of less than 20 μS / cm, and stir for 15 minutes to form the first suspension with a solid-to-liquid ratio of 1:20;

[0046] 2) At a stirring speed of 450r / min, heat the first suspension to 80°C, continue stirring for 40 minutes, adjust the pH value of the suspension to 9.5, and obtain the second suspension;

[0047] 3) After stirring for 15min, add 35mL of 2mol / L Na in the second suspension at a rate of 25mL / h 2 SiO 3 The solution is hydrolyzed and coated, and at the same time, 10% dilute hydrochloric acid is added dropwise to maintain the stability of the pH value of the suspension to obtain a third suspension;

[0048] 4) in Na 2 SiO 3 After the dropwise addition of the solution, continue stirring at constant temperature for 40 minutes, adjust the pH value of the third suspension to 1.0, and after stirring for 40 minutes at a stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com