Patents

Literature

66 results about "Potassium perfluorobutanesulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Features and Applications. 1. Potassium perfluorobutane sulfonate is characterized by ultra high stability of both chemical and thermal properties. It can resist over 450℃ of temperature. This sulphonated flame retardant is applicable for the engineering plastics that need to be processed at high temperature.

Heatproof anticorrosion wear resistant powdery paint, preparation method and application

ActiveCN103073972AImprove anti-corrosion performanceHigh temperature resistanceLiquid surface applicatorsAnti-corrosive paintsPotassium perfluorobutanesulfonatePolyvinyl butyral

The invention relates to a heatproof anticorrosion wear resistant powdery paint, a preparation method and an application. The powdery paint comprises the following raw materials by weight: 80-100 parts of phenol novolac epoxy, 25-35 parts of bisphenol A-epoxy resin matrix, 4.0-5.5 parts of dicyandiamide, 80-120 parts of cast stone powder, 10-40 partsof polypropylene, 5-8 parts of graphite, 5-8 parts of component A, 2-5 parts of aluminum hydroxide, 1-3 parts of magnesium oxide, 5-7 parts of ethyl lactate, 1-3 parts of polyvinyl butyral, 5-8 parts of copper oxide, 1-5 parts of carbon nanotube, 0.1-2 parts of 2,4,5-trichlorobenzene sulfonate, 0.2-1 part of potassium perfluorobutanesulfonate and 0.1-0.4 parts of phenylsulfonyl benzene sulfonic acid potassium. According to the invention, phenol novolac epoxy is taken as a base, the bisphenol A-epoxy resin matrix is added, the carbon nanotube is added in the anticorrosion paint, the heatproof and anticorrosion performances of the paint can be enhanced, and the coating process is simple.

Owner:BEIJING SINOPERM TECH

A preparing method of an environmental friendly flame-retardant polycarbonate composite material

InactiveCN105348763AChange surface propertiesGood compatibilityPotassium perfluorobutanesulfonatePhosphate

A preparing method of an environmental friendly flame-retardant polycarbonate composite material is disclosed. The method includes mixing nanometer zinc oxide, nanometer titanium dioxide, nanometer aluminium hydroxide, glass fibre, kaolin, nanometer zinc stannate, ferrocene, zinc molybdate, basic sodium aluminium carbonate, calcium stearate, zinc stearate and a silane coupling agent KH-540 to obtain a modified filler; melting and extruding polyvinyl butyral, polyvinylidene fluoride, octafluoro-diphenyl diglycidylether, styrene-acrylonitrile copolymer, melamine resin and the modified filler in a twin-screw extruder to obtain dispersed master batch; adding polycarbonate, the dispersed master batch, tris(2,4-diisobutyl) phosphate, hexaphenoxycyclotriphosphazatriene, potassium perfluorobutanesulfonate, bisphenol A bisphthalonitrile, a plasticizer and an oxidant into a twin-screw extruder, melting and extruding. The composite material prepared by the method is good in heat resistance and excellent in flame retardance.

Owner:ANHUI GUANGYUAN TECH DEV

Antibacterial type high-density polyethylene tube

InactiveCN103554608AImprove antibacterial propertiesImprove impact resistanceEpoxyPotassium perfluorobutanesulfonate

The invention discloses an antibacterial type high-density polyethylene tube. The antibacterial type high-density polyethylene tube is prepared from the following raw materials in parts by weight: 80-84 parts of high-density polyethylene, 0.8-1 part of polycarbodiimide, 1-2 parts of epoxy tetra hydro dioctyl phthalate, 1-2 parts of captan, 2-3 parts of oxidized polyethlene wax, 2-3 parts of cellulose acetate fiber, 0.7-2 parts of potassium perfluorobutanesulfonate, 0.5-1 part of N-hydroxymethyl acrylamide, 1-2 parts of ethyl naphthol, 0.2-0.4 parts of waste scrap iron, 4-6 parts of wollastonite powder and 10-13 parts of compound filler. The tube disclosed by the invention has good antibacterial effect, good impact resistance and heat resistance; the physical performances of the tube are greatly improved by the added compound filler; moreover, the antibacterial type high-density polyethylene tube has good ring stiffness and extensive applicability.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

High-strength transparent cable sheath material

InactiveCN105602082AReduce manufacturing costHigh transparencyPlastic/resin/waxes insulatorsInsulated cablesPotassium perfluorobutanesulfonatePolyethylene terephthalate glycol

The invention discloses a high-strength transparent cable sheath material which comprises the following raw materials in parts by mass: 50-80 parts of ethylene-vinyl acetate copolymer containing 18-20% of vinyl acetate, 20-40 parts of polyethylene terephthalate-1,4-cyclohexanedimethanol, 1-2 parts of plasticizer cyclohexane 1,2-di(2-propylheptyl) diformate, 20-50 parts of nitrile silicone rubber, 5-12 parts of nano silicon dioxide, 3-8 parts of calcium carbonate, 2-6 parts of acrylonitrile-butadiene-styrene terpolymer, 0.1-0.2 part of potassium perfluorobutanesulfonate, 5-10 parts of paraffin oil and 0.2-0.6 part of reinforcing agent DH-3. The sheath material disclosed by the invention has good transparency; in use, troubleshooting for the wire shielding damage is easy to realize, and the tracking of parallel wires and a connector and a circuit is simpler and easy to implement; and the sheath material disclosed by the invention has good transparency as well as relatively high mechanical strength and comprehensive performance and good stability.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

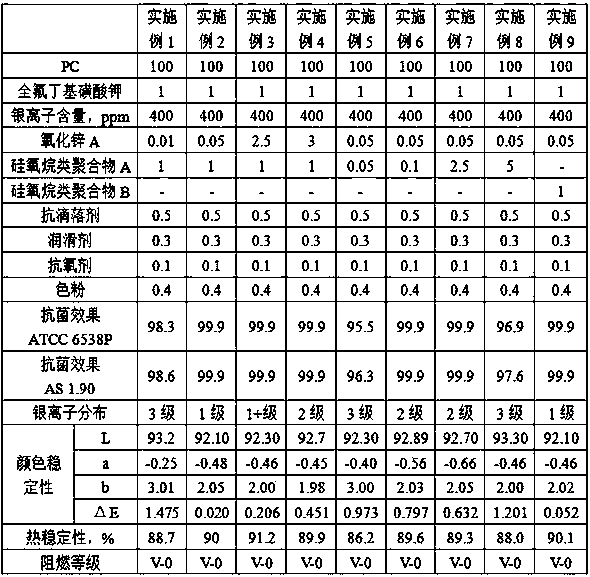

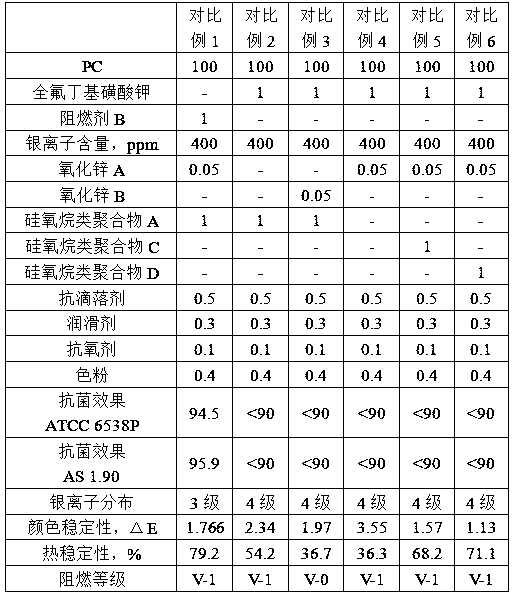

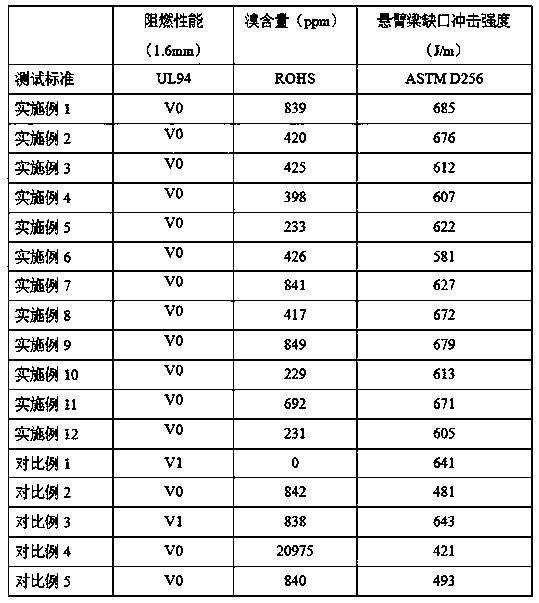

Antibacterial fire-retardant polycarbonate composite material and preparation method thereof

ActiveCN109486153AGood sustained antibacterial effectImprove durabilityPotassium perfluorobutanesulfonateNano zinc oxide

The invention discloses an antibacterial fire-retardant polycarbonate composite material. The antibacterial fire-retardant polycarbonate composite material is composed of, by weight part, 100 parts ofpolycarbonate, 0.1-10 parts of potassium perfluorobutanesulfonate, 0.01-5 parts of nano-zinc oxide and 0.01-5 parts of siloxane polymer with a molecular weight of 200-300 thousand; based on the totalweight of the antibacterial fire-retardant polycarbonate composite material, the content of silver ions is 200-600 ppm. According to the antibacterial fire-retardant polycarbonate composite material,the nano-zinc oxide and the siloxane polymer with a molecular weight of 200-300 thousand synergize to achieve dispersing and migrating effects, the concentration of the silver ions from inside to surface is increased in a gradient mode, and meanwhile, along with surface abrasion of the antibacterial fire-retardant polycarbonate composite material, the internal silver ions can migrate to the surface at a uniform speed along with the siloxane polymer with a molecular weight of 200-300 thousand to maintain good and continuous antibacterial effects of the antibacterial fire-retardant polycarbonate composite material; besides, the antibacterial fire-retardant polycarbonate composite material has the advantages of good color stability, good antibacterial performance, high fire resistance and the like.

Owner:KINGFA SCI & TECH CO LTD +1

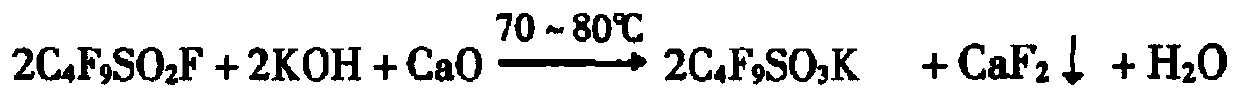

Preparation method of potassium perfluorobutanesulfonate

ActiveCN111170898AIncrease productivityHigh puritySulfonic acids salts preparationPotassium perfluorobutanesulfonateCalcium hydroxide

The invention discloses a preparation method of potassium perfluorobutanesulfonate. The method adopts continuous fluid reaction to replace batch-type kettle reaction, and comprises the following steps: (i) providing a tubular reactor; (ii) continuously adding perfluorobutyl sulfonyl fluoride and aqueous slurry of potassium hydroxide and calcium hydroxide into the tubular reactor at a reaction temperature of 70-100 DEG C under a pressure sufficient to keep the perfluorobutyl sulfonyl fluoride in a liquid state; (iii) drying the reaction mixture to obtain a solid containing calcium fluoride andpotassium perfluorobutanesulfonate; (iv) carrying out high-temperature dissolution on the solid by adopting ethanol, wherein the dissolution temperature is 65-76 DEG C; and (v) crystallizing the dissolved ethanol solution containing potassium perfluorobutanesulfonate to obtain potassium perfluorobutanesulfonate.

Owner:INNER MONGOLIA WANHAO FLUOROCHEM +1

Electric conduction pbt material

ActiveCN104140647ALower surface resistivityImprove conductivityMethacrylatePolytetramethylene terephthalate

The invention discloses an electric conduction pbt material. The electric conduction pbt material comprises, by weight, 72-80 parts of polybutylene terephthalate, 2-3 parts of ethyldiol methacrylate, 1-2 parts of tea saponin, 5-10 parts of graphene, 2-3 parts of brominated polystyrene, 0.8-1 part of potassium perfluorobutanesulfonate, 3-4 parts of epoxidized soybean oil, 1-2 parts of 1H-Imidazole-1-ethanol, 0.1-0.2 part of sodium persulfate, 2-3 parts of polyethylene glycol 1000, 0.6-1 part of polyimide and 1-2 parts of processing agents. The graphene is added in the pbt material, the surface specific resistance of a finished matrix can be effectively reduced, the electric conduction performance is superior, and the electric conduction pbt material is especially suitable for automobiles, electric products, mechanical parts and the like.

Owner:东莞市冬驭新材料股份有限公司

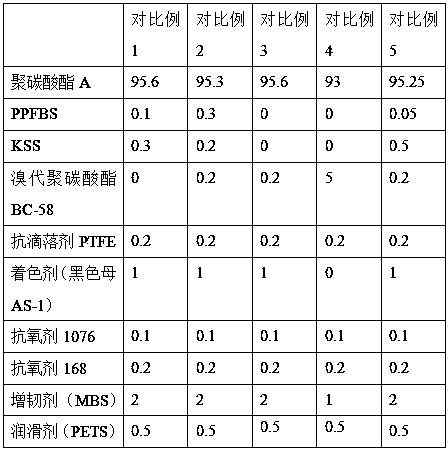

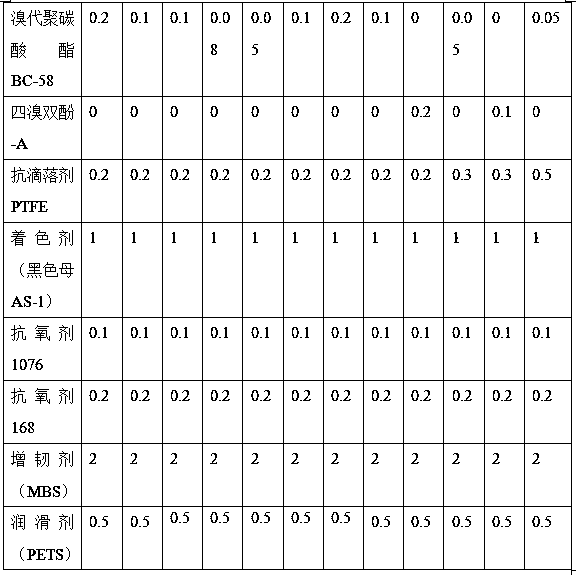

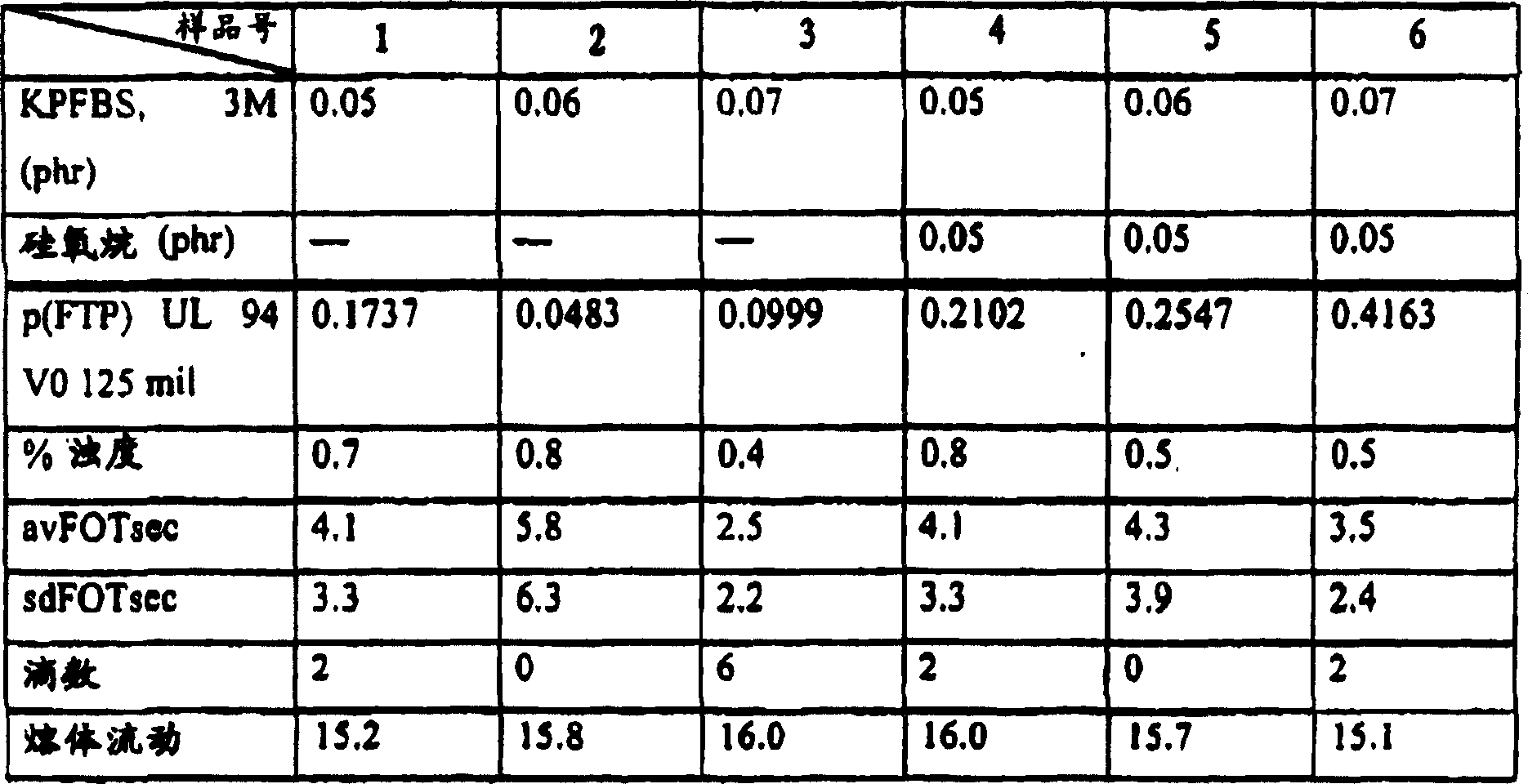

Low-bromine, high-efficiency and environment-protection flame retardant polycarbonate

ActiveCN108299814AGood mechanical propertiesImprove thermal performancePotassium perfluorobutanesulfonateBromine

The invention provides a low-bromine, high-efficiency and environment-protection flame retardant polycarbonate and a preparation method thereof. The flame retardant polycarbonate comprises, by weight,93-98 parts of polycarbonate, 0.2-0.5 part of a sulfonate flame retardant, 0.05-0.2 part of a bromine-based flame retardant, 0.1-0.5 part of an anti-dripping agent and 0-6 parts of an assistant, wherein the sum of the parts by weight of above five components is 100 parts; and the sulfonate flame retardant is a compound of potassium perfluorobutanesulfonate and potassium diphenylsulfonesulfonate,and a weight ratio of the potassium perfluorobutanesulfonate to the potassium diphenylsulfonesulfonate to the bromine-based flame retardant is 1:(1-6):(0.5-2). The compound formed by compounding the potassium perfluorobutanesulfonate and potassium diphenylsulfonesulfonate and the bromine-based flame retardant have synergistic flame retardation effects, so the addition amounts of the flame retardants are greatly reduced, the flame retardation efficiency is high, and the mechanical properties and the thermal properties of polycarbonate are slightly affected, thereby the finally obtained polycarbonate meets ROSH and halogen-free environmental protection requirements, the bromine content is controlled at 900 ppm or below, and the flame retardation grade reaches 1.6 mm UL94 V0.

Owner:GUANGDONG KINGFA TECH CO LTD

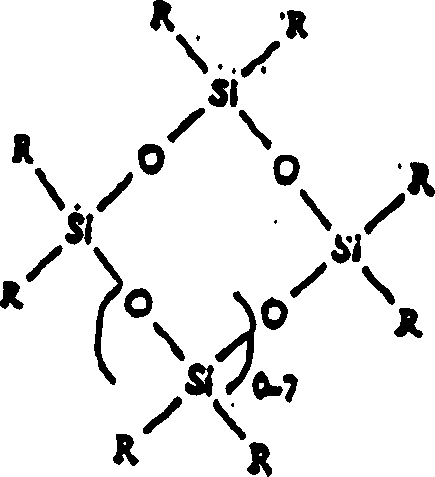

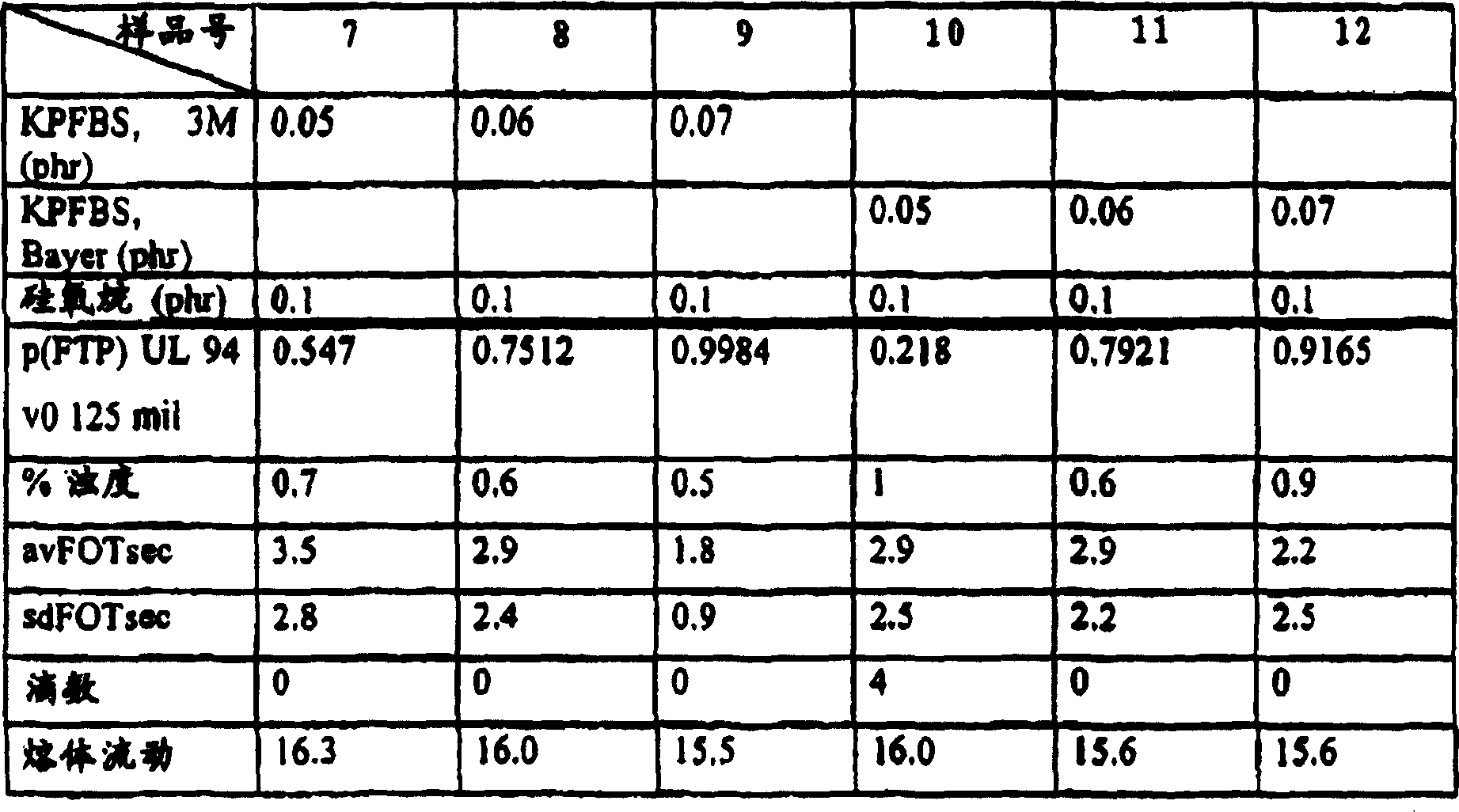

Fire-retarded polycarbonate resin composition

Improved fire-retarded properties can be imparted to polycarbonate resin composition by incorporating into the polycarbonate a fire-retardant component containing a perfluoroalkane sulfonate such as potassium perfluorobutane sulfonate and a cyclic siloxane such as octaphenylcyclotetrasiloxane. The fire-retardant component is suitably added at levels to form a polycarbonate composition in which the perfluoroalkane sulfonate is present in an amount of from 0.02 to 0.1 phr relative to the composition as a whole, and the cyclic siloxane is present in an amount of at least 0.02 relative to the composition as a whole.

Owner:SABIC GLOBAL TECH BV

Copper and copper alloy dedicated metal surface treatment agent

InactiveCN104818479APlay a protective effectHigh tensile strengthMetallic material coating processesPotassium perfluorobutanesulfonateSodium bicarbonate

The invention discloses a copper and copper alloy dedicated metal surface treatment agent which is composed of the following raw materials, by weight, 2-3 parts of mercaptobenzothiazole, 0.8-1.2 parts of ferrous sulphate, 0.1-0.2 part of dimethyl acetamide, 10-15 parts of polyvinyl alcohol, 0.01-0.02 part of p-hydroxybenzoic acid, 4-6 parts of sericin, 0.07-0.1 part of boric acid, 0.05-0.1 part of yttrium nitrate hexahydrate, 0.4-1 part of a silane coupling agent KH-550, 2-3 parts of barium petroleum sulfonate, 0.3-0.4 part of phytosterol, 160-200 parts of water, 0.5-1 part of potassium perfluorobutanesulfonate and 0.6-1 part of sodium bicarbonate. According to the invention, water-soluble polymer polyvinyl alcohol and sericin are mixed, and then silanization treatment is carried out. After hydrolysis of silane, an adsorption type film can be formed on metal surface so as to isolate water molecules and oxygen molecules in the environment, thus having a protective effect. Through boric acid modification, tensile strength and heat stability of blend films can be enhanced.

Owner:BENGBU TIMES ELECTRONICS

Titanium sol modified flame-retardant optical cable material and preparation method thereof

InactiveCN105924850AHigh thermal decomposition temperatureIncrease char formationPotassium perfluorobutanesulfonateAluminate

The invention discloses a titanium sol modified flame-retardant optical cable material, which is prepared from the following raw materials in parts by weight: 10 to 13 parts of talcum powder, 1 to 2 parts of calcium aluminate, 4 to 5 parts of polytetrafluoroethylene wax, 0.4 to 1 part of potassium perfluorobutanesulfonate, 2 to 3 parts of epoxidized soybean oil, 100 to 130 parts of polyvinyl chloride, 20 to 27 parts of polystyrene, 3 to 4 parts of sodium hypophosphite hydrate, 2 to 3 parts of paraformaldehyde, 0.2 to 0.3 part of 35-37-percent hydrochloric acid, 4 to 6 parts of dichloropentate, 5 to 7 parts of aluminum chloride hexahydrate, 0.1 to 0.2 part of triethylamine, 2 to 3 parts of tetrabutyl titanate, 0.1 to 0.4 part of polyglycerol fatty acid ester, 1 to 2 parts of magnesium sulfate, 0.8 to 1 part of hydroxyethyl cellulose, 2 to 3 parts of calcium lactobionate and 1 to 2 parts of acetic acid. The titanium sol modified flame-retardant optical cable material has the advantages that the effects of diluting flame and reducing temperature in a burning region can be achieved; in addition, free radicals generated during polystyrene chain segment cracking can be captured through some phosphorous oxide free radials and the like generated during the cracking; the thermal stability of the material is improved; the heat release value of the material is reduced.

Owner:安徽电信器材贸易工业有限责任公司

Rust-proof waterborne epoxy coating material and preparation method thereof

InactiveCN108047879AGood water solubilityGood compatibilityAnti-corrosive paintsEpoxy resin coatingsPotassium perfluorobutanesulfonateEpoxy

The invention discloses a rust-proof waterborne epoxy coating material. The rust-proof waterborne epoxy coating material is prepared from the following raw materials in parts by weight: 0.7 to 2 partsof wood creosote, 3 to 4 parts of dodecenylsuccinic acid, 0.7 to 1 part of zinc diricinoleate, 3 to 4 parts of tributyl borate, 2 to 5 parts of wool grease, 0.6 to 1 part of potassium perfluorobutanesulfonate, 10 to 16 parts of isopropanol, 1 to 2 parts of ammonium molybdate, 2 to 4 parts of magnesium chloride, 100 to 110 parts of epoxy dispersion liquid and 0.1 to 0.2 part of 2,4-imidazolidinone. According to the rust-proof waterborne epoxy coating material disclosed by the invention, the zinc diricinoleate, the ammonium molybdata, the wool grease, the dodecenylsuccinic acid and the like which are added in the rust-proof waterborne epoxy coating material have very good rust-proof performance, and a very good synergistic rust prevention effect can be obtained.

Owner:季雅佩

Charger shell material and preparation method thereof

InactiveCN106947231AAvoid the risk of damage to the device or even a fireImprove thermal conductivityHeat-exchange elementsPotassium perfluorobutanesulfonateSilanes

The invention discloses a charger shell material and a preparation method thereof. The charger shell material comprises, by weight, 120-150 parts of polycarbonate resin, 4-8 parts of vinyl tris(beta-methoxyethoxy)silane, 5-10 parts of vinyltriethoxysilane, 30-50 parts of acetone, 15-40 parts of anhydrous ethanol, 0.1-1 part of potassium perfluorobutanesulfonate, 0.5-5 parts of polytetrafluoroethylene, 10-20 parts of nano-alumina, 5-10 parts of nanometer zinc oxide, 5-15 parts of nanometer boron nitride, 5-20 parts of magnesium hydroxide and 5-20 parts of thermally conductive silicone grease. The charger shell material has the advantages of high thermal conduction coefficient, high impact resistance, good flame-retardant performance, low cost, easily available raw materials, simple preparation method and good application prospect.

Owner:合肥仁德电子科技有限公司

Polymer waterborne polyurethane coating and preparation method thereof

InactiveCN105925165AHigh tensile strengthPromote absorptionAntifouling/underwater paintsPaints with biocidesPotassium perfluorobutanesulfonateDispersity

The invention discloses a polymer waterborne polyurethane coating. The polymer waterborne polyurethane coating is composed of the following raw materials in parts by weight: 0.1 to 0.3 part of konjac glucomannan, 0.1 to 0.3 part of ascorbic acid, 10 to 14 parts of titanium tetrachloride, 0.3 to 0.7 part of hexahydrated ferric chloride, 30 to 40 parts of a hydrogen peroxide solution with a concentration of 28 to 30%, 600 to 700 parts of poly epsilon-caprolactone glycol, 470 to 500 parts of isophorone diisocyanate, 20 to 30 parts of acetone, 13 to 20 parts of dimethylolpropionic acid, 4 to 6 parts of diethylene glycol, 0.1 to 0.16 part of stannous octoate, 5 to 7 parts of triethylamine, 1 to 3 parts of polyether glycol, 1.4 to 2 parts of sodium polyacrylate, 0.4 to 1 part of potassium perfluorobutanesulfonate, 0.07 to 0.1 part of octadecyl isocyanate, 2 to 4 parts of titanium dioxide and 0.2 to 0.6 part of n-salicylanilide. The coating provided by the invention is added with polymer materials like sodium polyacrylate, so the dispersity of nano-sized molecules in the polymer is effectively improved, and the stability of a finished coating film is enhanced.

Owner:李强

Fluorinated self-cleaning plastic plate and preparation method thereof

InactiveCN106496870ALower surface energyReduce surface activityPotassium perfluorobutanesulfonateAluminum ammonium sulfate

The invention discloses a fluorinated self-cleaning plastic plate. The fluorinated self-cleaning plastic plate is prepared from, by weight, 0.3-1 part of polyglycerol-10 oleate, 6-8 parts of montmorillonoid, 0.7-1 part of sodium alkyl benzene sulfonate, 0.4-1 part of n-salicylanilide, 10-14 parts of titanium tetrachloride, 3.7-4 parts of ferric chloride, 6-8 parts of 25%-30% of hydrogen peroxide, 7-9 parts of methyl methacrylate, 0.1-0.2 part of azodiisobutyronitrile, 100-130 parts of polyvinyl chloride, 0.7-1 part of silane coupling agent kh560, 0.6-1 part of 2-bromine-4-methylphenol, 0.3-1 part of trimethylolpropane, 2-3 parts of aluminum ammonium sulfate, 0.7-1 part of potassium perfluorobutanesulfonate and 2-3 parts of calcium fluoride. Added iron-doped titanium dioxide has good photocatalysis capacity, pollutants attached to the surface of the plate can be degraded and removed, and therefore self-cleaning performance is achieved.

Owner:ANHUI BEIMA TECH CO LTD

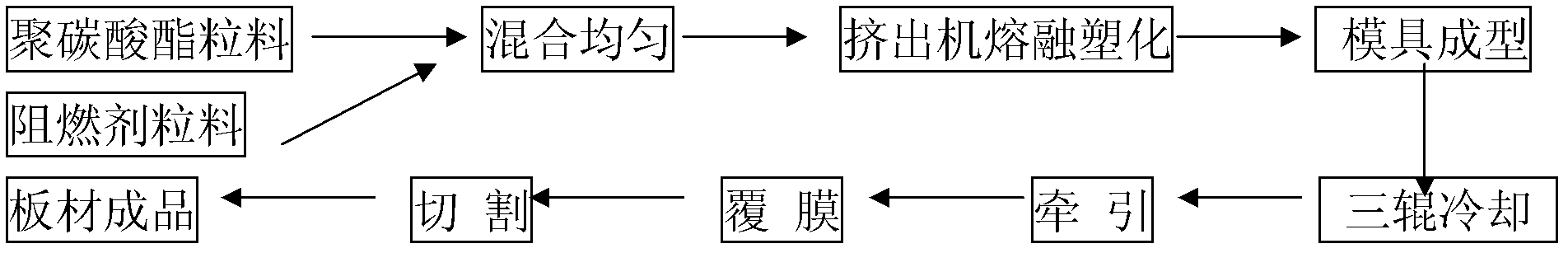

Polycarbonate flame retardant endurance plate and preparation method thereof

InactiveCN103183948AHigh strengthHigh toughness, high light transmittancePotassium perfluorobutanesulfonateNon toxicity

The invention relates to a polycarbonate flame retardant endurance plate. The flame retardant endurance plate is composed of the following components, by weight, 95%-99.5% of polycarbonate and 0.5%-5% of a flame retardant, wherein the flame retardant is modified potassium perfluorobutanesulfonate. A preparation method of the flame retardant endurance plate comprises the steps of (1) mixing carbonate particles and flame retardant particles uniformly, melting and plasticizing the mixture in an extruder; (2) shaping the plasticized material in a mold and cooling by a three-roller method; and (3) drawing, coating and cutting the cooled model. The polycarbonate flame retardant endurance plate provided by the invention has the advantages of thin thickness, high strength, strong toughness, high transparency, non-toxicity and harmlessness, etc. The polycarbonate flame retardant endurance plate can not release toxic and harmful gas to the environment, and fits ROHS environment-protecting directives.

Owner:SHANGHAI HUILI TUVGAL SHEETAB

Organosilicon weathering agent for external spray coating for elevated support formwork

InactiveCN106634145AImprove protectionGood weather resistanceCoatingsPotassium perfluorobutanesulfonateSlag

The invention discloses an organosilicon weathering agent for an external spray coating for an elevated support formwork, and relates to the technical field of the coating weathering agent. The organosilicon weathering agent is prepared from the following raw materials in parts by weight: 10-15 parts of an organosilicon polymer, 5-9 parts of ultrafine polyimide resin powder, 3-6 parts of brominated butyl rubber, 3-6 parts of hydrogenated rosin pentaerythritol ester, 2-4 parts of chlorinated polyethylene, 2-4 parts of briquette slag, 2-4 parts of asbestos wool, 1-2 parts of polyaluminum ferric chloride, 1-2 parts of potassium perfluorobutanesulfonate, 1-2 parts of rice chaff ash, 1-2 parts of sulfurized lard, 0.5-1 part of 3-pyrroline and 0.5-1 part of vanadium oxide. The weathering agent as an additive is exclusively used in the external spray coating for the elevated support formwork and can significantly enhance the weatherability of a formed coating, and the weatherability of the coating can be improved by 20%-35% compared a coating containing a conventional ultraviolet absorber additionally.

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

PTT polyester based weather resistant flame retardant composite material

InactiveCN104845243AImprove flame retardant performanceImprove stabilityPolyesterPotassium perfluorobutanesulfonate

The invention discloses a PTT polyester based weather resistant flame retardant composite material. The material comprises the following components by mass: 80%-95% of PTT, 5%-20% of an inorganic filler, 0.1%-0.5% of a coupling agent, 0.1%-0.3% of a composite flame retardant, 0.5%-2% of an ultraviolet stabilizer, 0.1%-0.5% of a nucleating agent, 0.1%-0.5% of an antioxidant, and 0.1%-1% of a lubricant. The composite flame retardant is a compound of an iodate flame retardant potassium perfluorobutanesulfonate and a melt drip resistant agent polytetrafluoroethylene in a mass ratio of 1:1. The PTT polyester based weather resistant flame retardant composite material provided by the invention has good flame retardant properties and weathering stability, also has good strength, rigidity and heat resistance, good flame retardant effect, and limiting oxygen index up to over 32%, and is in accordance with the requirements of no halogen, high efficiency, melt drip resistance and UL94V-0 grade flame retardance.

Owner:王妮娜

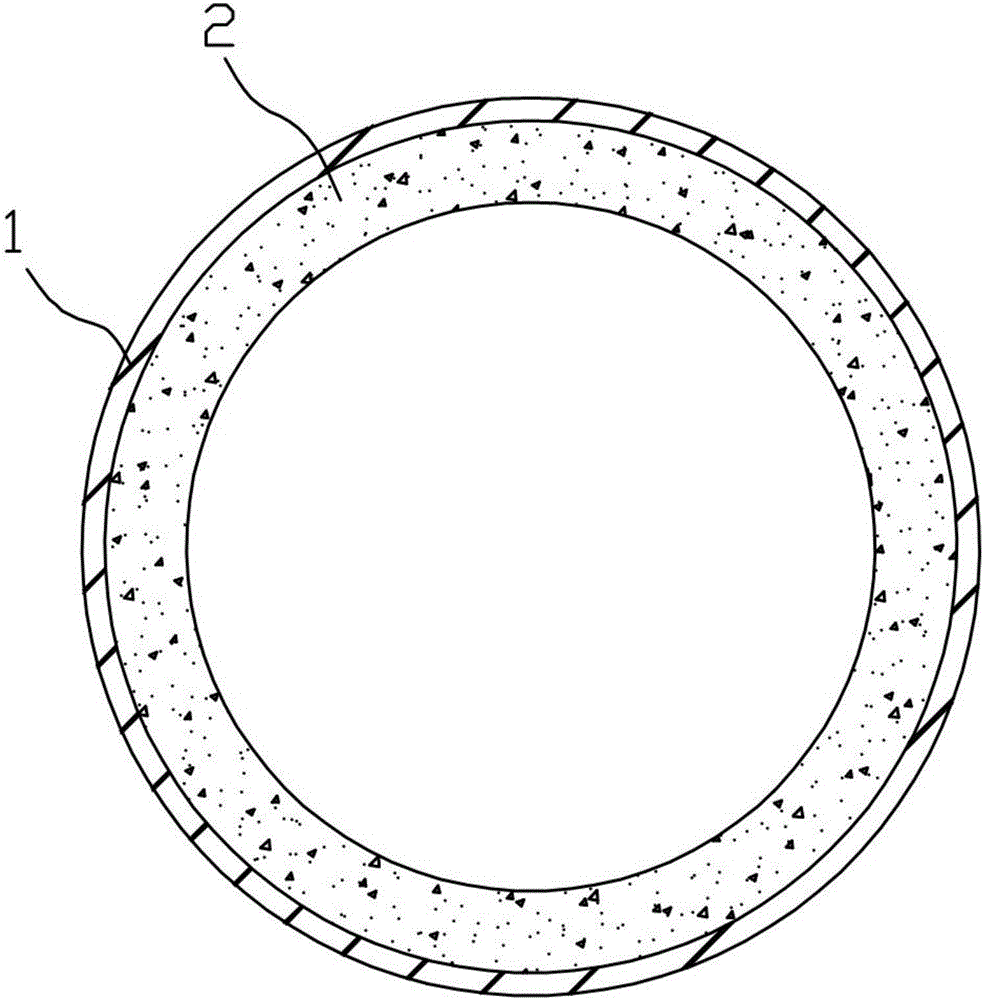

Energy-saving and environmental-friendly photovoltaic solar street light pole

InactiveCN106369531AHigh strengthImprove toughnessMechanical apparatusLighting support devicesPotassium perfluorobutanesulfonateAntioxidant

An energy-saving and environmental-friendly photovoltaic solar street light pole comprises a cylindrical street light pole body. The energy-saving and environmental-friendly photovoltaic solar street light pole is characterized in that the street light pole body is formed by an inner pipe and an outer pipe arranged on the outer wall of the inner pipe through injection molding, the inner pipe is a steel pipe, and the outer pipe is a modified plastic pipe; and the modified plastic pipe is made from, by weight, 100kg of modified recycled plastic, 1.2kg of polyvinyl cyclosilane, 0.8kg of triazine charring agents, 2.5kg of glass fiber, 0.7kg of potassium perfluorobutanesulfonate, 0.5kg of nano-titania, 0.5kg of nanoscale ceramsite powder, 0.1kg of antimony oxide, 0.2kg of vulcanizers, 0.5kg of di-isobutyl hexahydrophthalate, 0.2kg of antioxidants, 5.2kg of polytrifluorochloroethylene and 0.05kg of graphene nanoplatelets. By additionally arranging the modified plastic pipe, the surface of the street light pole body is protected against rust, colors are deployed at will, the maintenance cost is low, and the service life is long.

Owner:界首市绿暄照明科技有限公司

Flame retardation PC/PBT alloy and preparation method therefor

InactiveCN104861624AImprove mechanical propertiesEasy to processPotassium perfluorobutanesulfonateSulfonate

The invention discloses a flame retardation PC / PBT alloy and a preparation method therefor. The flame retardation PC / PBT alloy comprises the following ingredients, by weight, 40%-60% of PC, 20%-30% of PBT, 5%-15% of modified filling materials, 3%-8% of flexibilizers, 0.1%-1% of flame retardant, 0.1%-1% of triphenyl phosphate, 0.5%-2% of compatilizers, 0.1%-0.5% anti-oxidants and 0.1 %-1% of lubricants. The flame retardant is one selected from potassium perfluorobutanesulfonate, potassium dibenzyl sulfonyl sulfonate and potassium trifluoromethyl sulfamide. The beneficial effects are that the flame retardation PC / PBT alloy has excellent mechanical properties and processing performances, the intensity is high, the impact resistance is high, the cost is low, the flame retardation performance is good, and the flame retardation PC / PBT alloy is suitable for popularization and application.

Owner:QINGDAO TONGCHUANG ENERGY SAVING ENVIRONMENTAL PROTECTION ENG

Modified polycarbonate material for processing of shell of capacitor of locomotive

The invention relates to a modified polycarbonate material for processing of a shell of a capacitor of a locomotive. The modified polycarbonate material is prepared from the following raw materials in part by weight: 56 to 75 parts of polycarbonate, 15 to 25 parts of acrylonitrile-butadiene-styrene (ABS) resin, 2 to 4 parts of ABS-g-maleic anhydride (MAH) compatilizer, 3 to 8 parts of toughening agent methyl methacrylate-butadiene-styrene (MBS), 3 to 4 parts of flame-retardant potassium perfluorobutanesulfonate (PPFBS), 3 to 4 parts of organosilicon flame retardant, 0.1 to 0.5 part of epoxy resin, 0.1 to 0.3 part of composite antioxidant B225 and 2 to 5 parts of light calcium carbonate powder. The shell of the capacitor of the locomotive which is processed by using the material has the characteristics of light weight, difficulty in deformation and high dielectric strength, and cost is low.

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Non-halogenated flame retardant polycarbonate compounds

Owner:AVIENT CORP

Flame retardation PTT polyester fiber and preparation method therefor

InactiveCN104862813AImprove flame retardant performanceImprove heat resistanceFlame-proof filament manufactureMonocomponent polyesters artificial filamentTextile fiberPotassium perfluorobutanesulfonate

The invention discloses a flame retardation PTT polyester fiber and a preparation method therefor. The flame retardation PTT polyester fiber comprises the following ingredients, by weight, 80%-95% of PTT, 2%-8% of flame retardant monomers, 2%-6% of polyethylene glycol, 0.5%-2% of benzyl silicone, 0.1%-0.5% of potassium Perfluorobutanesulfonate, 0.1%-0.5% of stabilizing agents, 0.1%-0.5% of anti-oxidants and 0.1%-1% of lubricants. The PTT is polytrimethylene terephthalate prepared from terephthalic acid and 1,3-propylene glycol as raw materials and with an intrinsic viscosity of 0.7-0.9dL / g. The flame retardant monomers are 2-hydroxyethyl (phenyl) phosphinic acid. The beneficial effects are that the flame retardation PTT polyester fiber has excellent flame retardation performance and heat resistance, the limit oxygen index can reach more than 38%, the hand feeling is soft, the serviceability is strong, and the flame retardation PTT polyester fiber is suitable for the textile fabric field.

Owner:QINGDAO XINZHAN PLASTIC

Anti-termite corrugated pipe

InactiveCN104059289AGood antibacterial and insecticidal effectImprove removal effectAluminatePotassium perfluorobutanesulfonate

The invention discloses an anti-termite corrugated pipe. The anti-termite corrugated pipe is produced from the following raw materials in parts by weight: 1-2 parts of ammonium tungstate, 0.5-1 part of distearoyl isopropoxy aluminate, 2-3 parts of calcium ricinoleate, 1-2 parts of sodium pentachlorophenate, 2-3 parts of tetrabutyl titanate, 7-10 parts of sea-foam stone powder, 1-2 parts of butylcellosolve, 0.2-0.5 part of potassium perfluorobutanesulfonate, 2-3 parts of magnesium silicate, 1-2 parts of phenothiazine, 0.5-1 part of ground pepper, 1-2 parts of brominated polystyrene, 2-3 parts of palm wax, 93-100 parts of polypropylene and 7-10 parts of compound auxiliaries. The corrugated pipe has excellent antimicrobial and insecticidal efficacy, and in particular has an excellent effect on removing termites; as a result, the spoilage of the pipe is reduced, the service life of the pipe is prolonged, the repair rate is reduced and the cost is saved.

Owner:ANHUI HAINA SICHUAN PLASTICS TECH

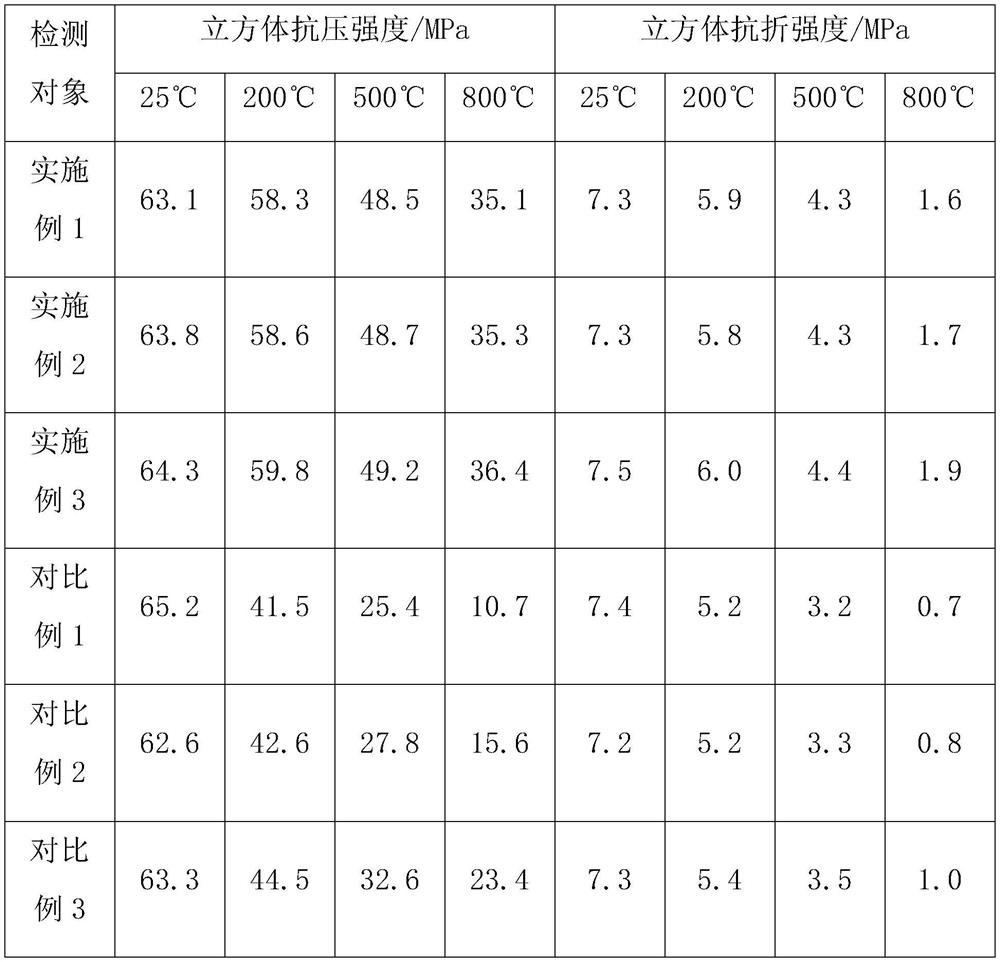

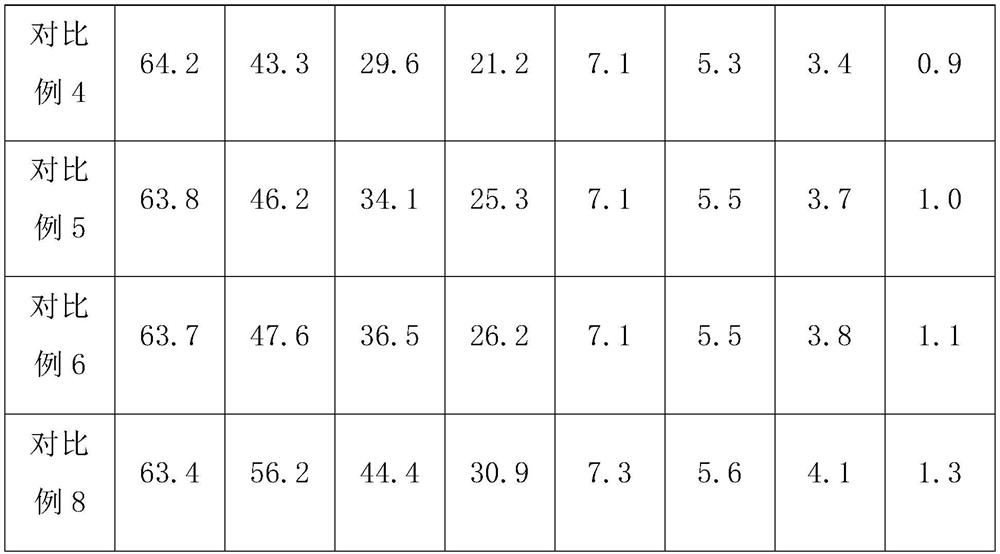

Lightweight aggregate concrete and preparation method thereof

ActiveCN114149205AImprove high temperature resistanceReduce coefficient of frictionSolid waste managementPotassium perfluorobutanesulfonateOrganic film

The invention relates to the field of building materials, and particularly discloses lightweight aggregate concrete and a preparation method thereof. The lightweight aggregate concrete is prepared from the following raw materials in parts by weight: cement, an admixture, machine-made sand, stone powder, surface modified ceramsite, fine stone, polytetrafluoroethylene fibers, water and a water reducing agent, the surface modified ceramsite is obtained by performing surface modification on ceramsite through fireproof resin and potassium perfluorobutanesulfonate; the preparation method comprises the following steps: mixing and stirring the cement, the admixture, the machine-made sand, the stone powder and the fine stone to obtain a solid mixture; adding the rest raw materials except the surface modified ceramsite and the polytetrafluoroethylene fiber into the solid mixture, and stirring to obtain concrete slurry; and adding the surface modified ceramsite and polytetrafluoroethylene fiber into the concrete slurry, and stirring to obtain the concrete. According to the lightweight aggregate concrete disclosed by the invention, the high-temperature resistance of the concrete is improved; according to the preparation method, the possibility that an organic film on the surface of the surface modified ceramsite is abraded is reduced.

Owner:陕西泾港沣环保建材有限公司

Polyether type polyurethane sponge with flame-retardant function

InactiveCN107556447AWith slow resilienceImprove flame retardant performancePotassium perfluorobutanesulfonateSodium bicarbonate

The invention belongs to the technical field of polyurethane sponge. The invention discloses polyether type polyurethane sponge with a flame-retardant function. The polyether type polyurethane spongeis prepared from the following raw materials: first polyether polyol, second polyether polyol, third polyether polyol, a first catalyst, a second catalyst, silicone oil, rubber, water, a composite foaming agent, MDI isocyanate, and the like, wherein the composite foaming agent is prepared from surface-coated sodium bicarbonate, surface-coated ammonium carbonate and azodicarbonamide; the surface-coated sodium bicarbonate is prepared by coating the surface of sodium bicarbonate with an organic silicon quaternary ammonium salt antibacterial agent; the surface-coated ammonium carbonate is preparedby coating the surface of ammonium carbonate with potassium perfluorobutanesulfonate. The polyether type polyurethane sponge provided by the invention has slow resilience, is moderate in hardness andhas a good flame-retardant effect; special antibacterial treatment is carried out on pores of the polyether type polyurethane sponge, so that the problem that harmful microorganisms such as bacteriaeasily grow and enrich in the pores of the sponge can be solved.

Owner:德清舒华泡沫座椅有限公司

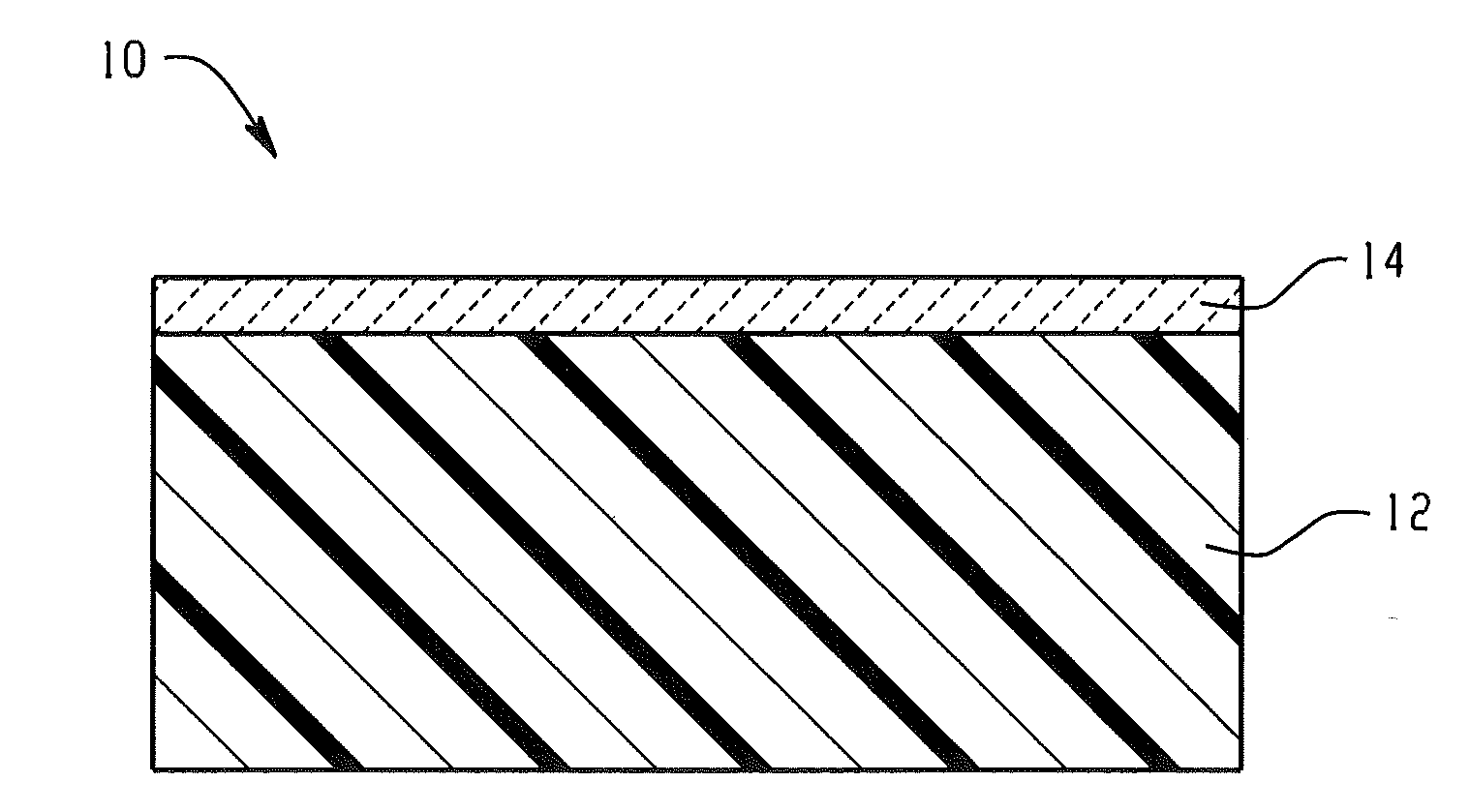

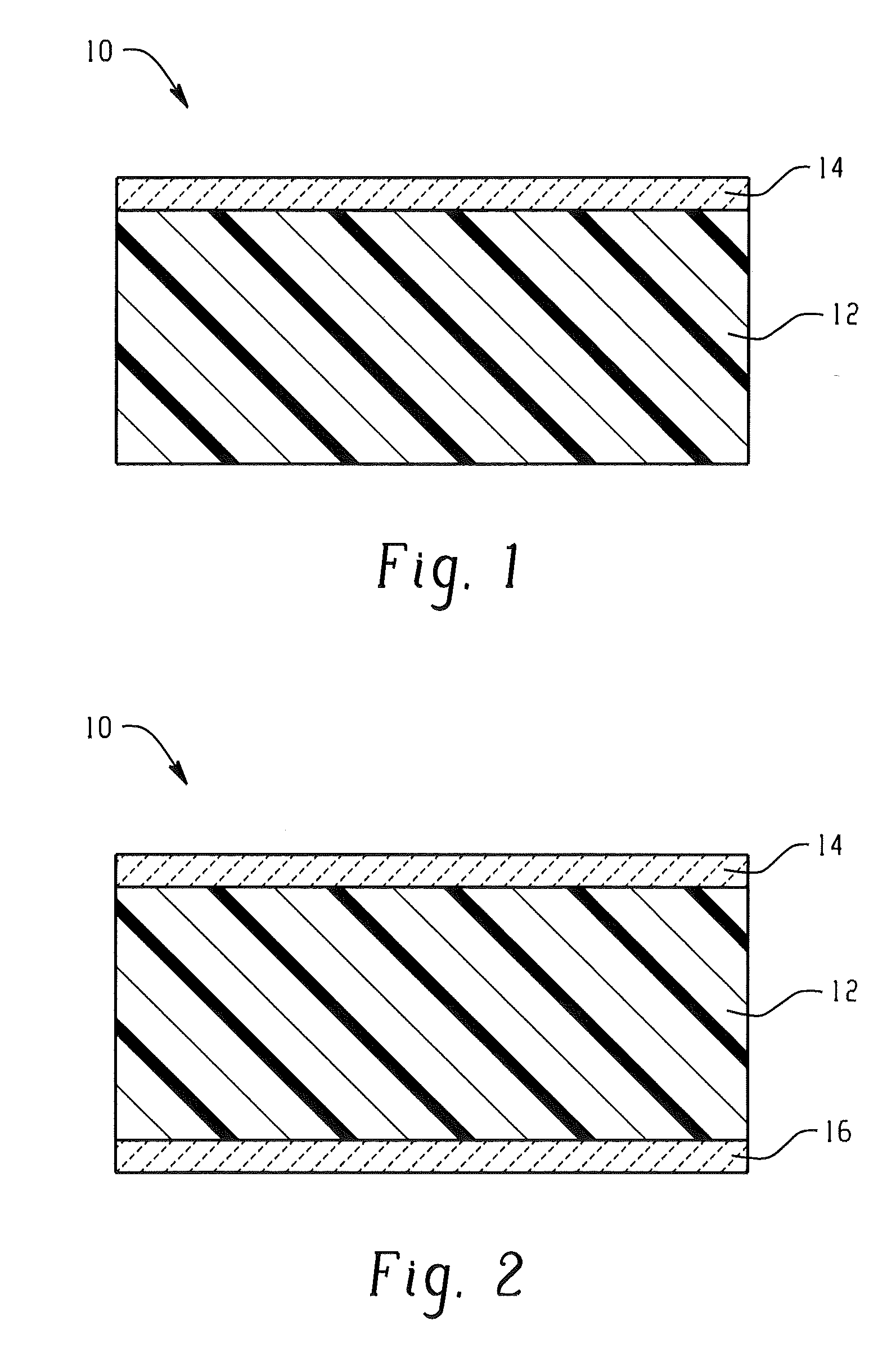

Multilayer sheet and methods of making and articles comprising the multilayer sheet

ActiveUS20110293927A1Liquid surface applicatorsFilm/foil adhesivesPotassium perfluorobutanesulfonatePotassium

In some embodiments, a multilayer sheet comprises: a first cap layer formed from a first cap composition comprising polycarbonate and potassium perfluorobutane sulfonate; a second cap layer formed from a second cap composition comprising polycarbonate and potassium perfluorobutane sulfonate; and a core layer formed from a core composition comprising polycarbonate and without potassium perfluorobutane sulfonate. The core layer is disposed between the first cap layer and the second cap layer.

Owner:SABIC GLOBAL TECH BV

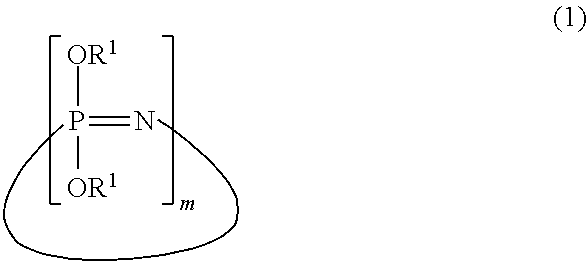

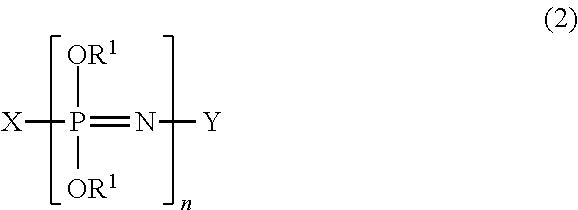

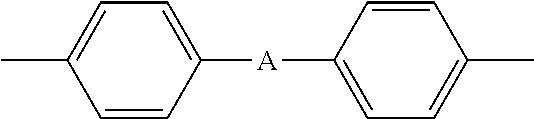

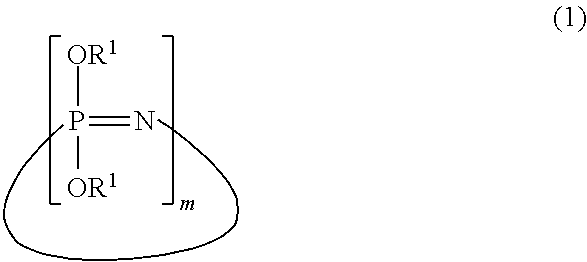

Non-halogenated flame retardant polycarbonate compounds

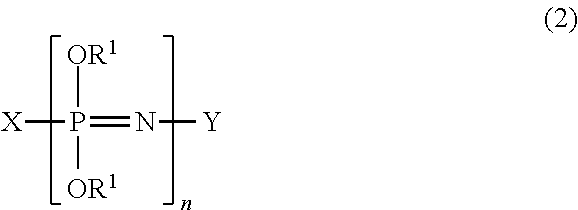

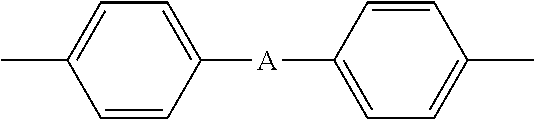

ActiveUS20140163137A1Antifouling/underwater paintsPaints with biocidesPotassium perfluorobutanesulfonateCompound a

A flame retardant polycarbonate compound is disclosed. The compound comprises a polycarbonate and non-halogenated polyphosphazene as a flame retardant, along with talc, polytetrafluoroethylene, and optionally, a potassium salt of perfluorobutane sulfonic acid. The compound can achieve a UL 94 rating of V-0 at two different thicknesses of less than 1 mm.

Owner:AVIENT CORP

Material for electric meter box shells and preparation method thereof

InactiveCN105086413AImprove flame retardant performanceIncrease loading capacityPotassium perfluorobutanesulfonateFiber

The invention discloses a material for electric meter box shells and a preparation method thereof, belonging to the technical field of materials and solving the problem that existing materials for meter boxes have poorer comprehensive properties. The material comprises the following raw materials in parts by weight: 120-140 parts of polycarbonate, 70-80 parts of glass fibers, 30-40 parts of epoxy silicone oil, 10-20 parts of polyethylene, 10-30 parts of glycidyl methacrylate, 1-3 parts of potassium perfluorobutanesulfonate, 10-20 parts of styrene, 1-3 parts of antioxidant 168, 2-4 parts of antioxidant 1010, 1-3 parts of light stabilizer 770, 1-3 parts of ultraviolet light absorber, 2-10 parts of oxidized polyethylene wax and 0.2-0.6 part of pentaerythritol stearate. The preparation method comprises the following steps: weighing the raw materials according to the parts by weight, adding the raw materials to a high-speed mixer to be mixed, then granulating the mixture with a twin-screw extruder, and drying and then injection-molding the obtained granules, thus preparing the material. The material can be widely used for the electric meter box shells.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Automobile backdoor wire harness fixing rubber sheath

InactiveCN103756062AEasy to installNot easy to fall offPotassium perfluorobutanesulfonatePhosphoric acid

The invention discloses an automobile backdoor wire harness fixing rubber sheath. The automobile backdoor wire harness fixing rubber sheath is prepared from following raw materials, by weight, 94 to 100 parts of chloroprene rubber S40V, 7 to 10 parts of superfine barium sulfate, 1 to 2 parts of aluminium triphosphate, 1 to 2 parts of molybdenum boride, 4 to 6 parts of tailing, 0.4 to 1 part of Potassium Perfluorobutanesulfonate, 2 to 3 parts of diammonium tetraborate, 2 to 3 parts of polyisoprene, 3 to 5 parts of acrylate levelling agent, 5 to 7 parts of epoxidized soybean oil, 1 to 2 parts of ammonium dihydrogen phosphate, 1 to 2 parts of anti-aging agent RD, 1 to 1.3 parts of sulphur, 2 to 3 parts of Hydrated zinc borate, 1 to 2 parts of promoter CA, and 20 to 25 parts of a composite filling material. The automobile backdoor wire harness fixing rubber sheath possesses dust prevention effect, water resistance, wear resistance, and excellent protective effect; can be installed firmly; is not easy to fall off or break; and is easy to bend; and friction with wire harness is small.

Owner:WUHU JINYING MACHINERY SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com