Low-bromine, high-efficiency and environment-protection flame retardant polycarbonate

A technology of flame-retardant polycarbonate and polycarbonate, which is applied in the field of low-bromine, high-efficiency and environmentally friendly flame-retardant polycarbonate, can solve the problem of high brominated flame retardant addition, achieve high flame-retardant efficiency, reduce the amount of addition, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

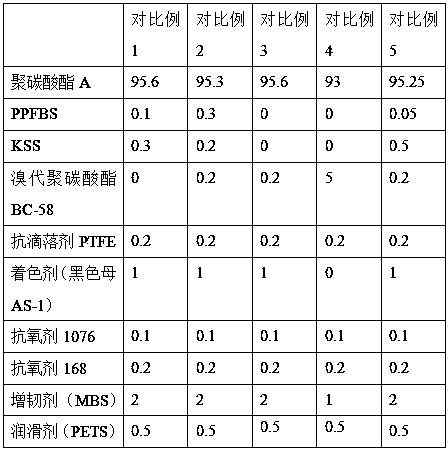

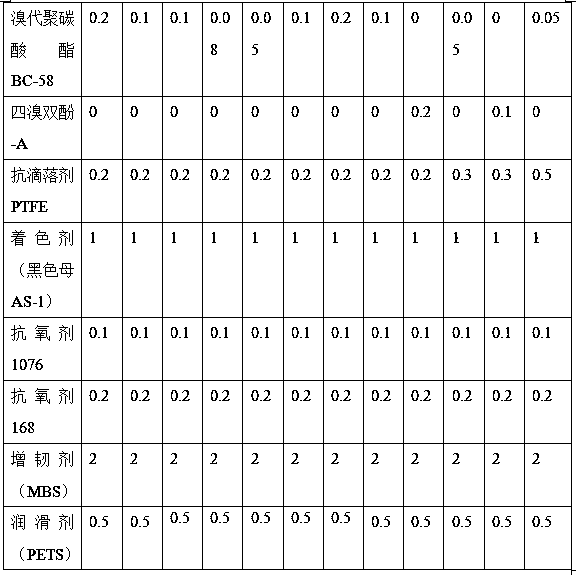

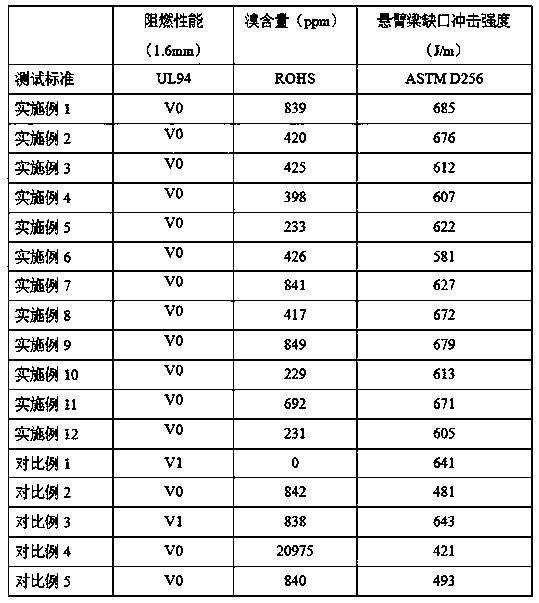

[0031] The present invention will be described in further detail below in conjunction with specific examples and comparative examples, but the present invention is not limited to the following examples.

[0032] In the examples, the raw materials not specified in particular are all conventional commercially available commodities.

[0033] Polycarbonate A, aromatic polycarbonate, melt index 10 g / 10min (PC 1300-10NP LG Chem);

[0034] Polycarbonate B, an aromatic polycarbonate with a melt index of 15 g / 10min; which consists of a melt index of 10 g / 10min (PC1300-10NP LG Chem) and a melt index of 22 g / 10min (PC 1300-22NP LG Chem) Two kinds of composites are obtained;

[0035] Potassium perfluorobutane sulfonate (PPFBS), purchased from 3M Company;

[0036] Potassium diphenylsulfonesulfonate (KSS), purchased from Metro, India;

[0037] Brominated polycarbonate BC-58, purchased from Great Lakes, USA;

[0038] Tetrabromobisphenol-A was purchased from the Dead Sea, Israel.

[0039...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com