Patents

Literature

418 results about "Retardation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This type of retardation is caused by a purely mental issue suffered from the depression or manic depression. The effects include the slowing down of thought and a reduction of physical movements in an individual that is affected by the mental illness.

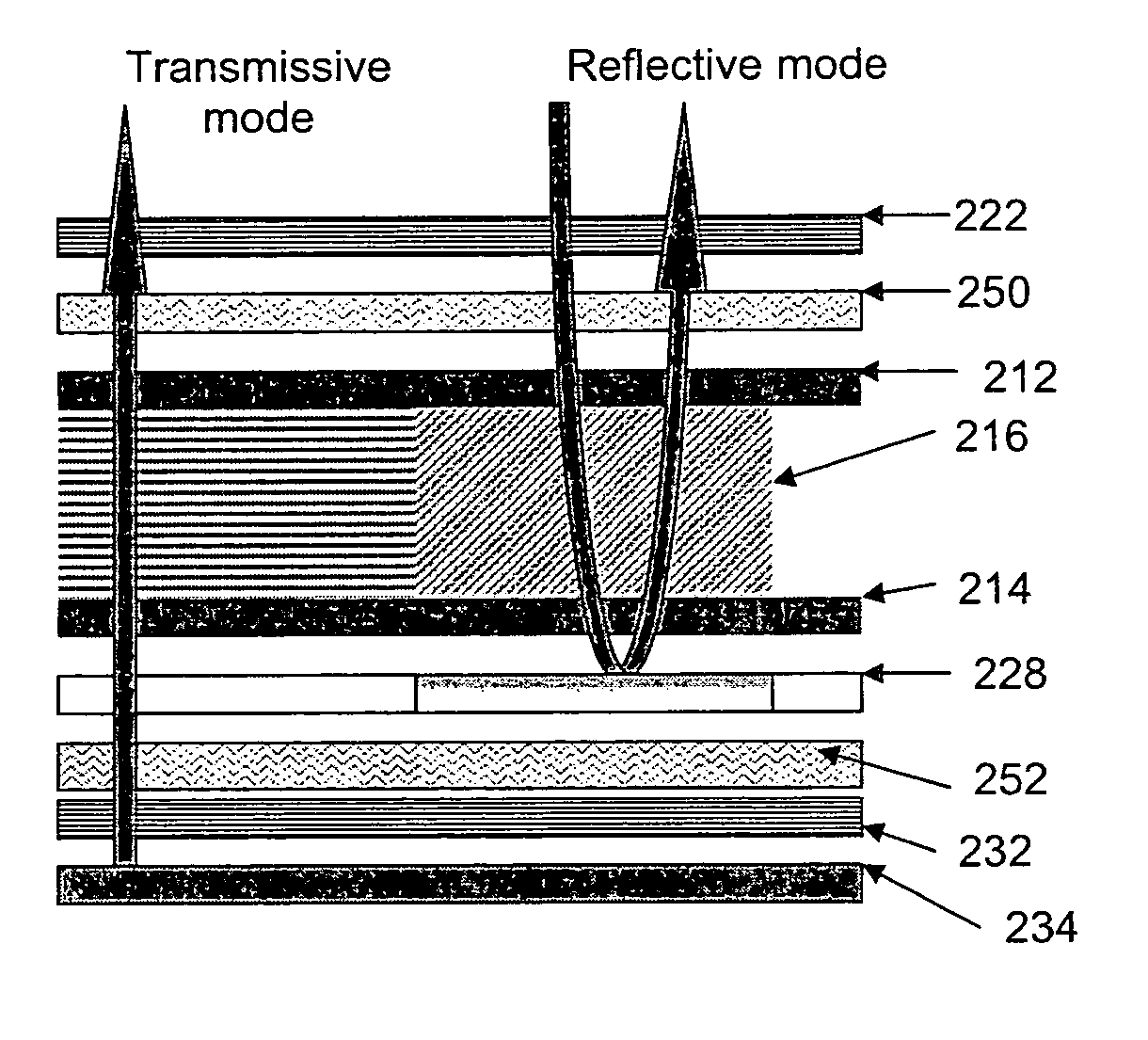

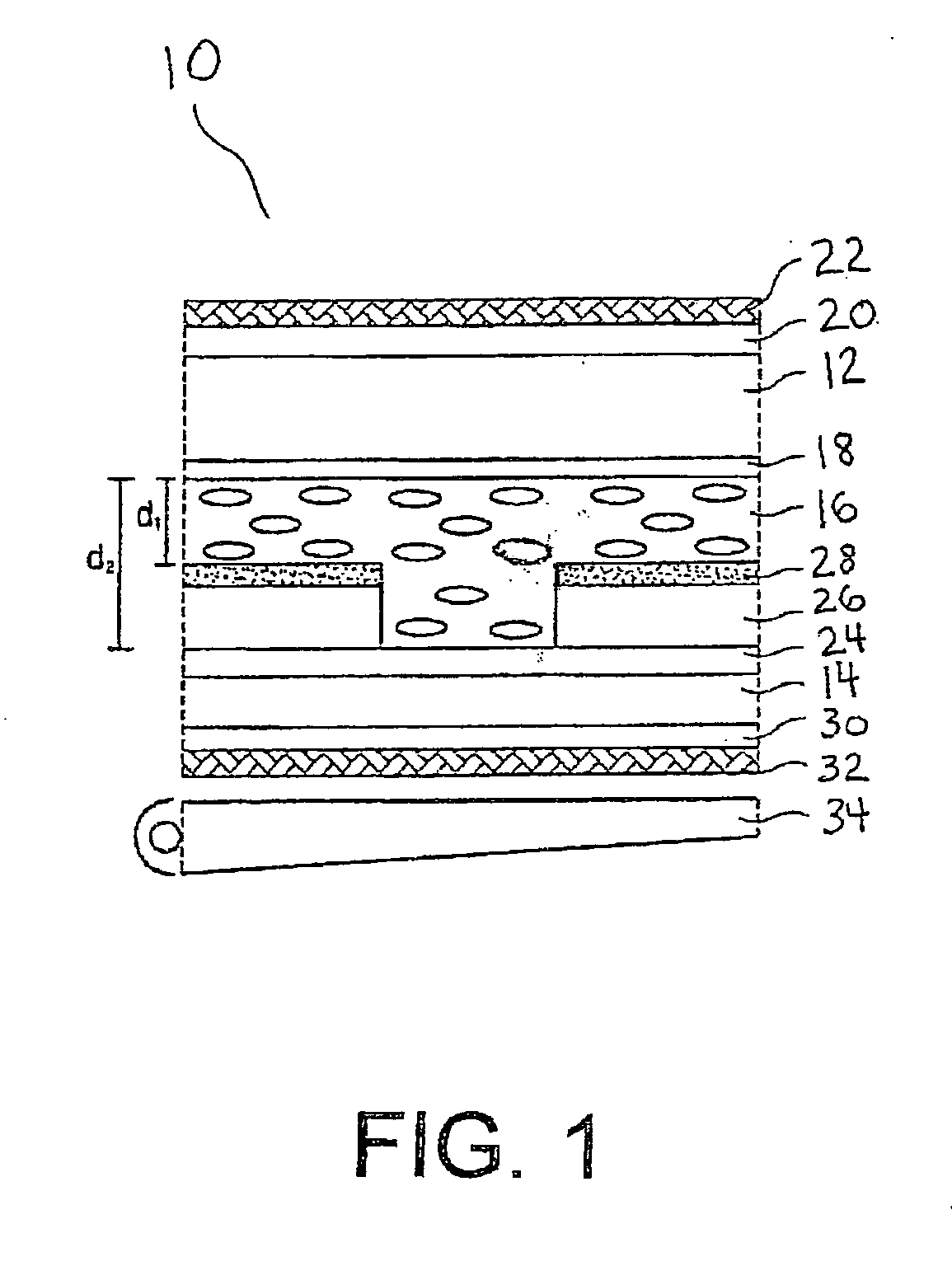

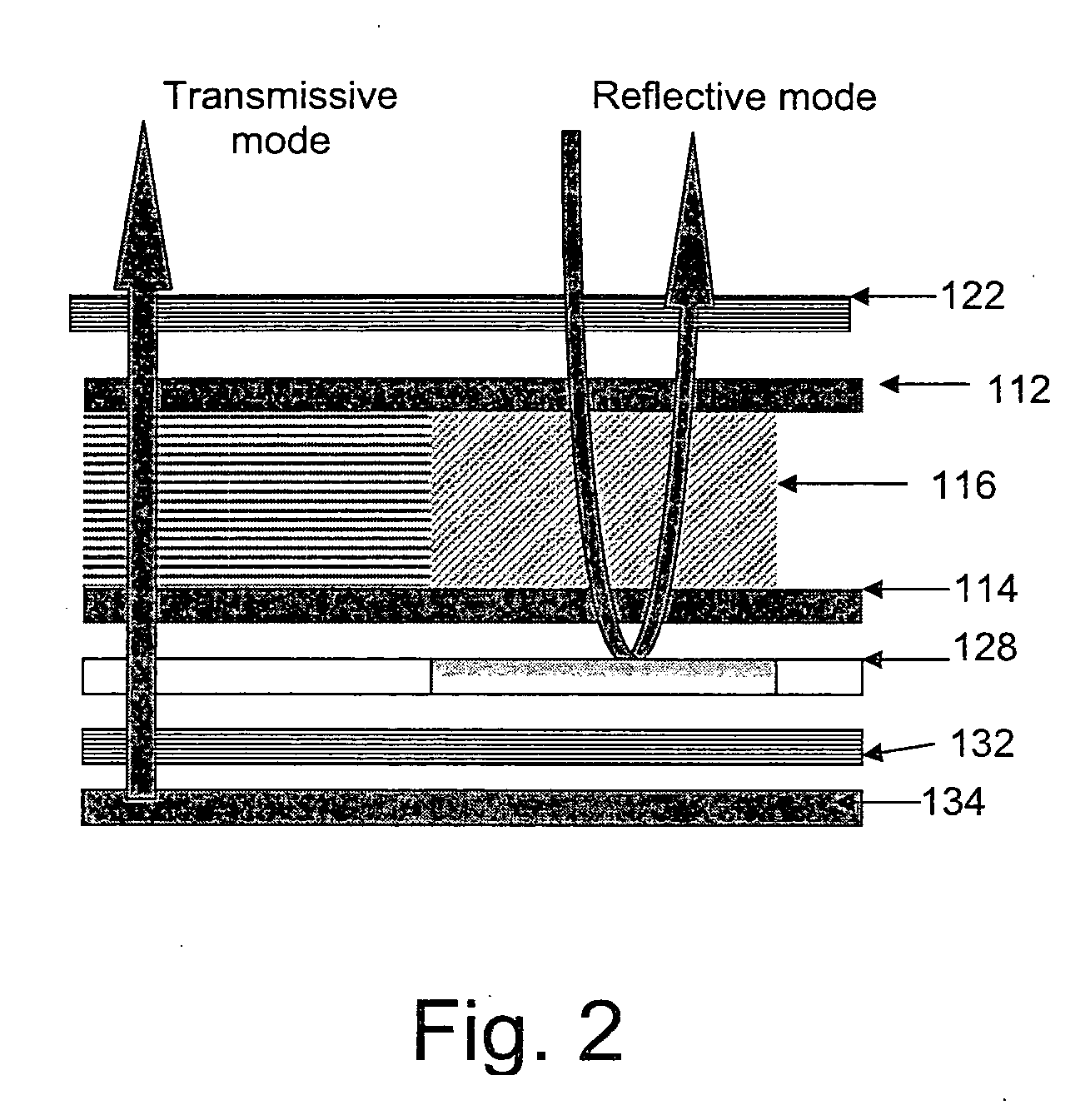

Polymer stabilized electrically controlled birefringence transflective LCD

ActiveUS20060023146A1Improve device stabilityUseful for developmentNon-linear opticsDisplay deviceLiquid crystal

A transreflective display in which the thickness of the liquid crystal layer is the same for both transmissive and reflective modes. The transmissive and reflective pixels are stabilized in two different liquid crystal configurations with different birefringences. The light retardation effect of one path in the transmissive pixels is close to or equals the retardation effect of two paths in the reflective pixels, resulting in synchronization of the two modes.

Owner:KENT STATE UNIV

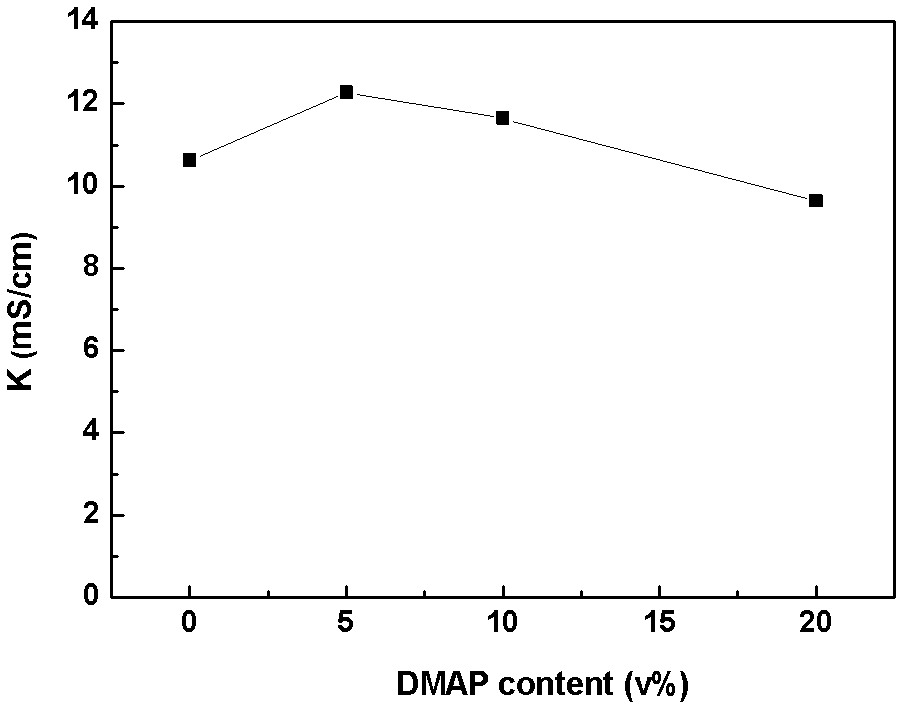

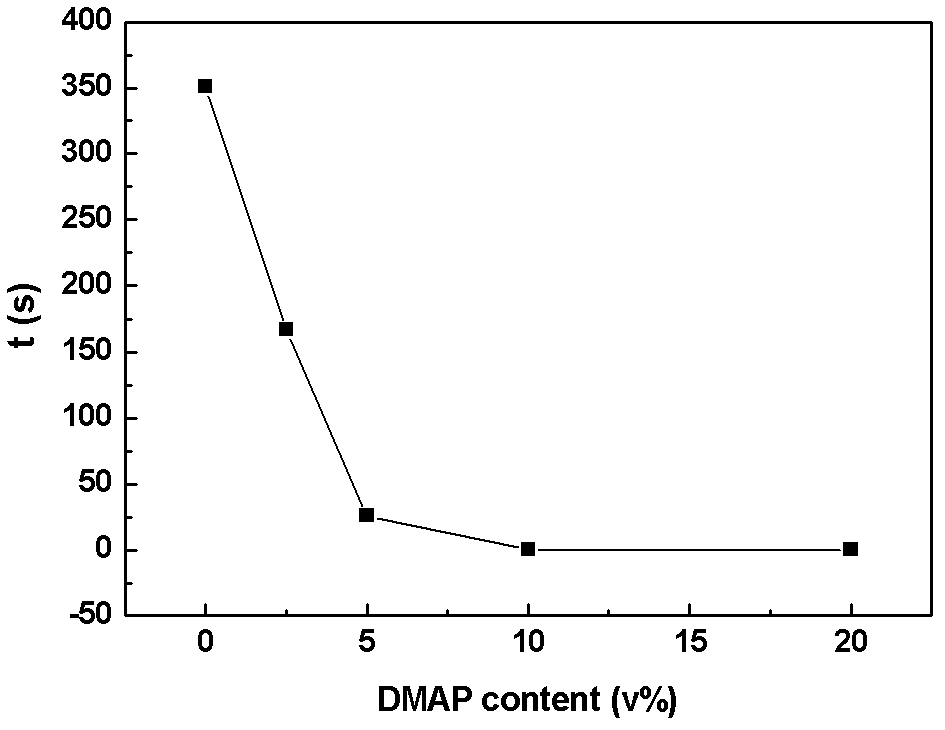

Double-functional lithium battery electrolyte additive and preparation method thereof

InactiveCN102386441AImprove flame retardant performanceGood flame retardancy and even non-combustibilityGroup 5/15 element organic compoundsSecondary cellsOrganic solventPhosphate

The present invention provides a double-functional lithium battery electrolyte additive and a preparation method thereof, and relates to the lithium battery electrolyte. The present invention provides the double-functional lithium battery electrolyte additive and the preparation method thereof, wherein the double-functional lithium battery electrolyte additive has a flame retardant performance, even a totally non-combustible characteristic. The double-functional lithium battery electrolyte additive is alkenyl phosphate. Phosphite trimester and alkenyl alkylogen are used as raw materials and react in organic solvent for preparing the double-functional lithium battery electrolyte additive. The double-functional lithium battery electrolyte additive and the routine lithium ion battery electrolyte can form the lithium ion battery electrolyte with double functions. The double-functional lithium battery electrolyte additive belongs to a double-functional additive and has the advantages of: higher phosphorus content and better flame retardation effect, wherein the existence of double bonds causes prior film forming of the double-functional lithium battery electrolyte additive in a discharging process. Compatibility between the electrolyte and a cathode is improved, and thermal stability of the cathode SEI layer is obtained.

Owner:XIAMEN UNIV

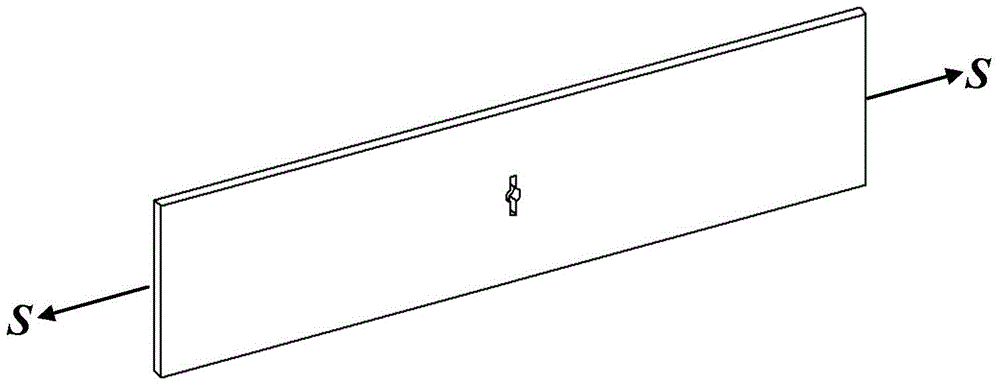

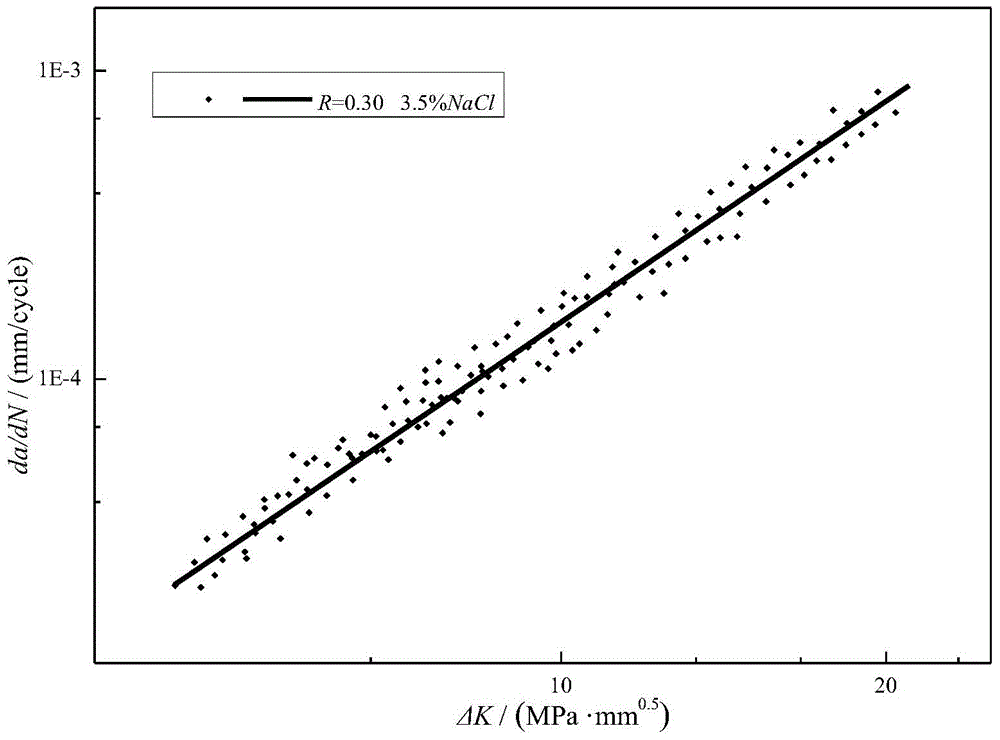

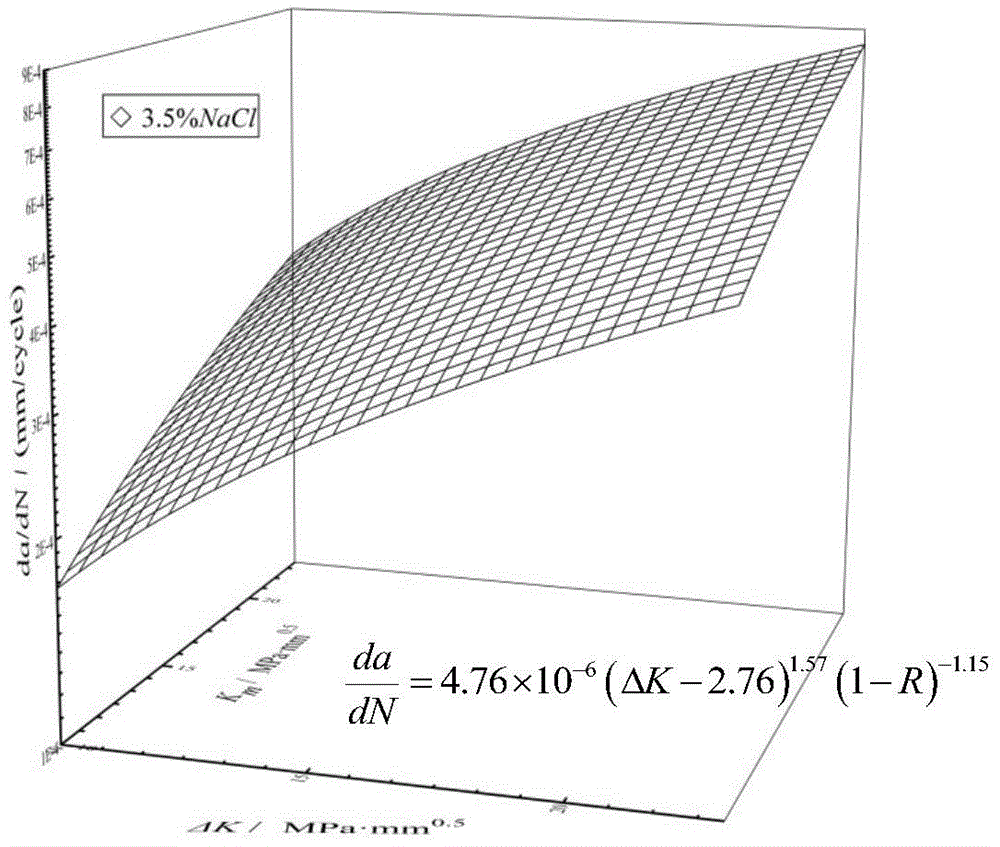

Corrosion crack expansibility characterization and life estimation method

A corrosion crack expansibility characterization and life estimation method comprises the following steps: 1, obtaining the corrosion crack expansibility da / dN-deltaK curve of a material through constant load test; 2, considering influences of corrosion on the fracture threshold value, correcting a Walker formula, fitting the da / dN-deltaK curve through combining a binary linear regression theory, and constructing a corrosion crack expansibility characterization model; and 3, considering the interaction between the retardation effect and load under spectrum load, and estimating the corrosion spectrum-loaded crack expansion life of the material by adopting a Willenborg-Chang model and an accumulation integration technology. The method is simple and practical, allows the corrosion crack expansibility characterization model to be constructed and the spectrum-loaded crack expansion life to be estimated only through using the constant load crack expansibility curve and the actually measured flight load spectrum of the material in corrosion environment, and has great scientific significance and engineering application values.

Owner:北京睦邦仁科技有限公司

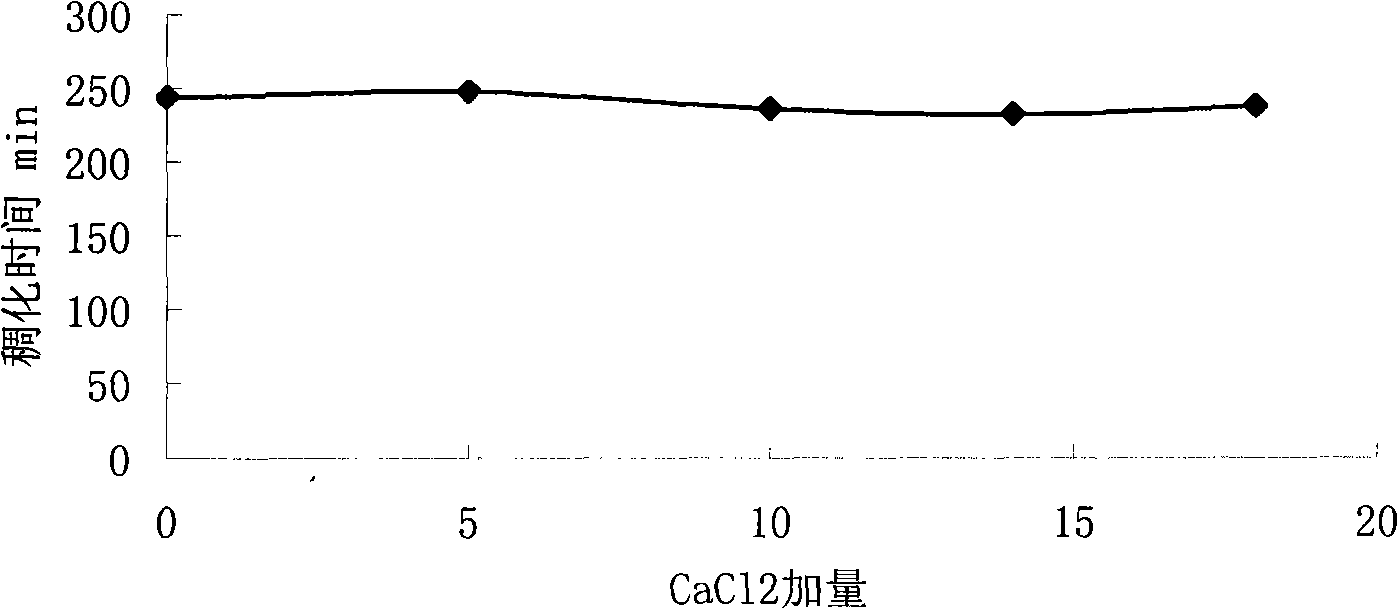

Well cementing high-temperature inhibiting agent for oil gas well and preparation method

InactiveCN101402849AMeet the needs of safe constructionThickening time adjustableDrilling compositionItaconic acidWell cementing

The invention discloses a novel cement high temperature retarder used for cementing an oil (gas) well as well as a preparing method thereof. The invention relates to a macromolecular polymer which has high temperature resistance and is prepared by using an acetone liquid to deposit and wash an itaconic acid, 2-acrylamide-2-methyl propane sulfonic acid (AMPS), benzoperoxide and the like which are taken as materials. The novel cement high temperature retarder added into a cement pulp has the characteristics of good retardation effect, good fluidity as well as salt and calcium resistance under high temperature and the like. The invention can meet the demands of safe construction on cementing depth wells and ultra-deep wells.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Halogen-free resin composition, bonding sheet and copper-clad laminate

ActiveCN102732029AHigh glass transition temperatureImprove heat resistanceFilm/foil adhesivesSynthetic resin layered productsHeat resistanceGlass transition

The invention provides a halogen-free resin composition, a bonding sheet and a copper-clad laminate. The halogen-free resin composition comprises the following components of: by weight, 10-90 parts of polybenzoxazine resin, 10-90 parts of polyepoxides, 1-50 parts of a curing agent, 0.01-1 part of a curing accelerator, 10-100 parts of a filling material, and 0-80 parts of a fire retardant. The bonding sheet prepared from the halogen-free resin composition has high glass-transition temperature, excellent heat resistance and low water absorption. The copper-clad laminate prepared from the bonding sheet has high glass-transition temperature, excellent heat resistance, good flame retardation effect and low water absorption. In addition, the technology for making the copper-clad laminate is simple to operate and requires low cost.

Owner:GUANGDONG SHENGYI SCI TECH

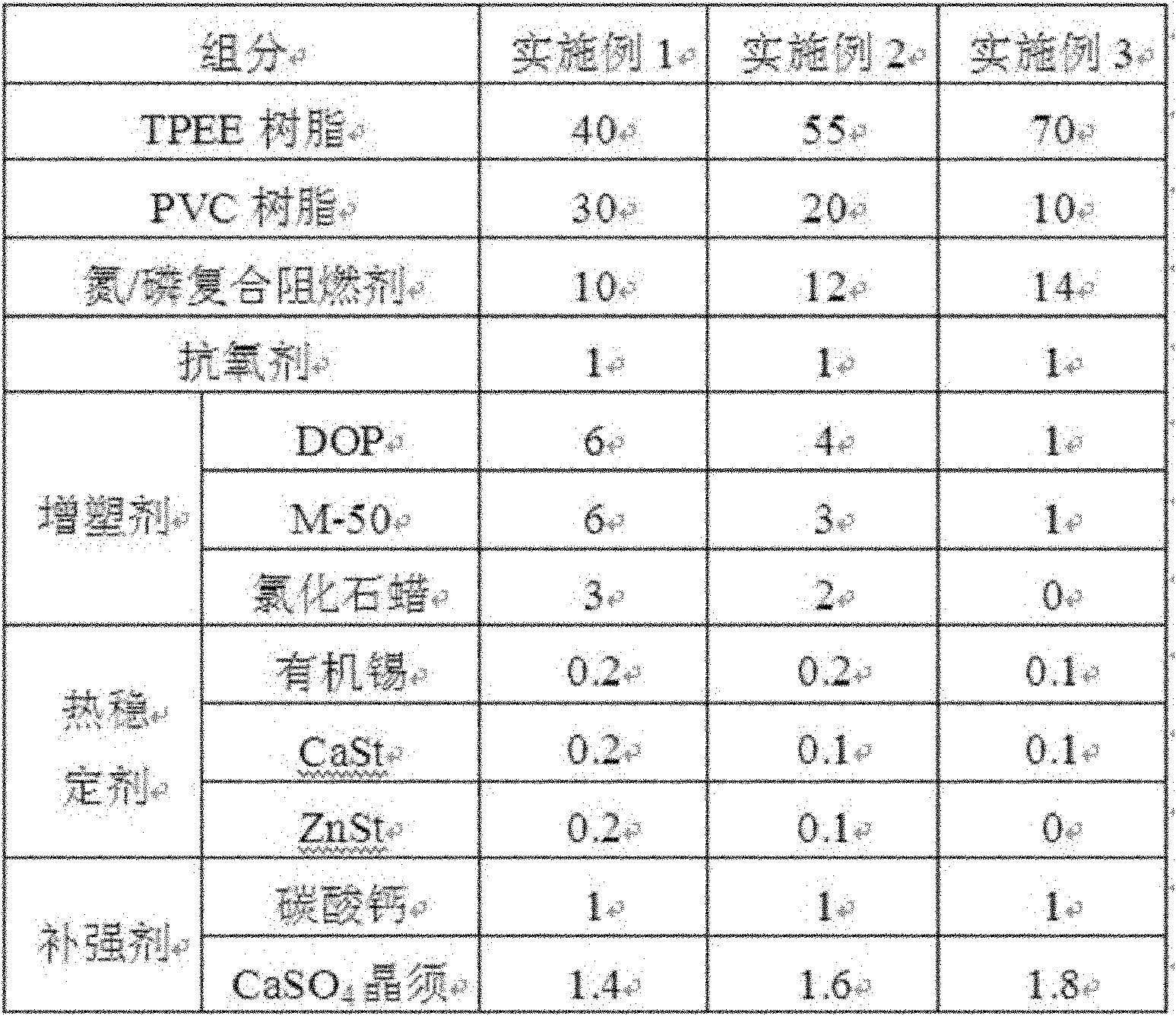

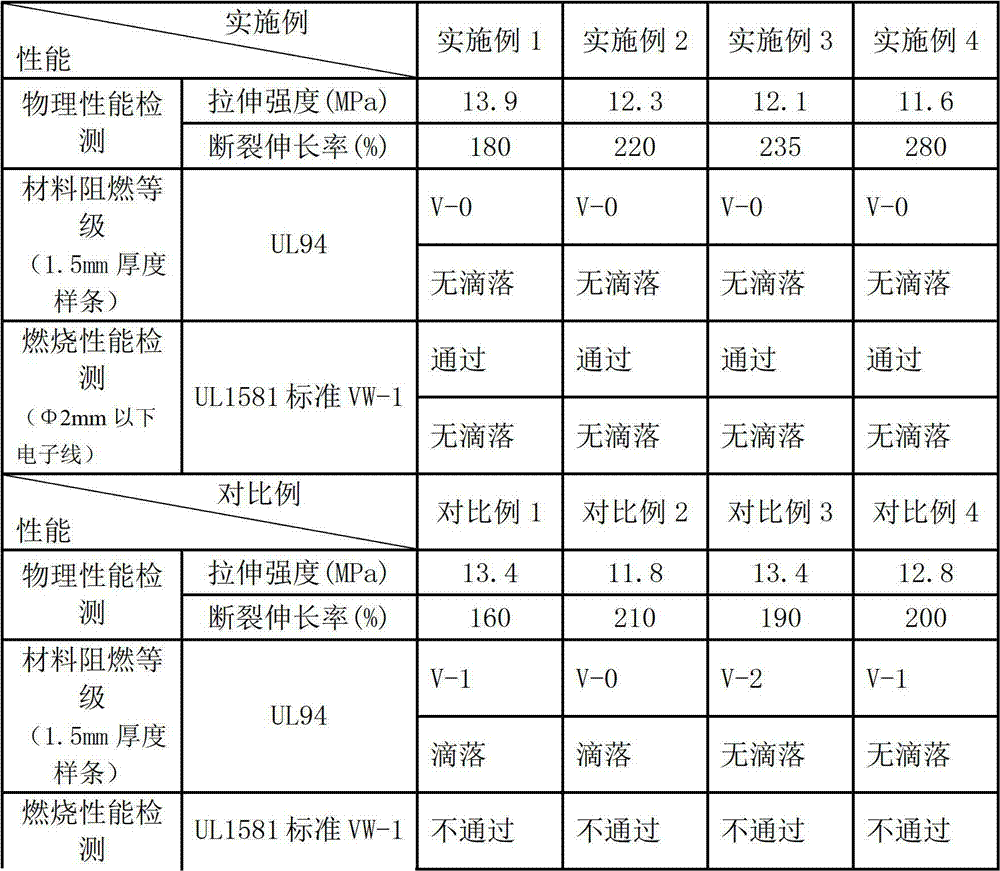

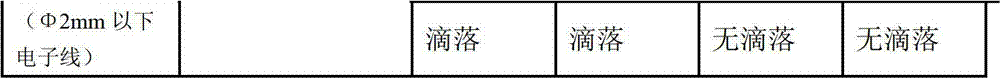

Environment-friendly flame-retardant cable material and preparation method thereof

ActiveCN102485792AImprove flex resistanceGood compatibilityInsulated cablesInsulated conductorsEnvironmental resistanceFire retardant

The invention discloses an environment-friendly flame-retardant cable material which comprises, by weight, 40 to 70 of thermoplastic elastomers, 10 to 30 of a PVC resin, 10 to 14 of a nitrogen / phosphorus composite fire retardant, 0.5 to 2 of an anti-oxidant, 2 to 15 of a plasticizer, 0.2 to 0.6 part of a heat stabilizer and 2 to 3 of a strengthening agent. According to the invention, TPEE and PVC are mixed to prepare the cable material, and thus, low temperature flexibility of PVC is improved, tensile strength, elongation, hardness and tear strength are enhanced, an ideal flame retardation effect can be obtained without addition of a great amount of the fire retardant since PVC can improve flame retardation of a composite, and cost can be reduced because PVC is much cheaper than TPEE; the fire retardant is obtained by compounding a nitrogen fire retardant and a phosphorus flame retardant, and the strengthening agent is added so as to improve mechanical properties of the composite cable material, so the cable material can be used in the field of high and mid grade sheaths for electric wires, cables and optical fibers.

Owner:HEFEI GENIUS NEW MATERIALS

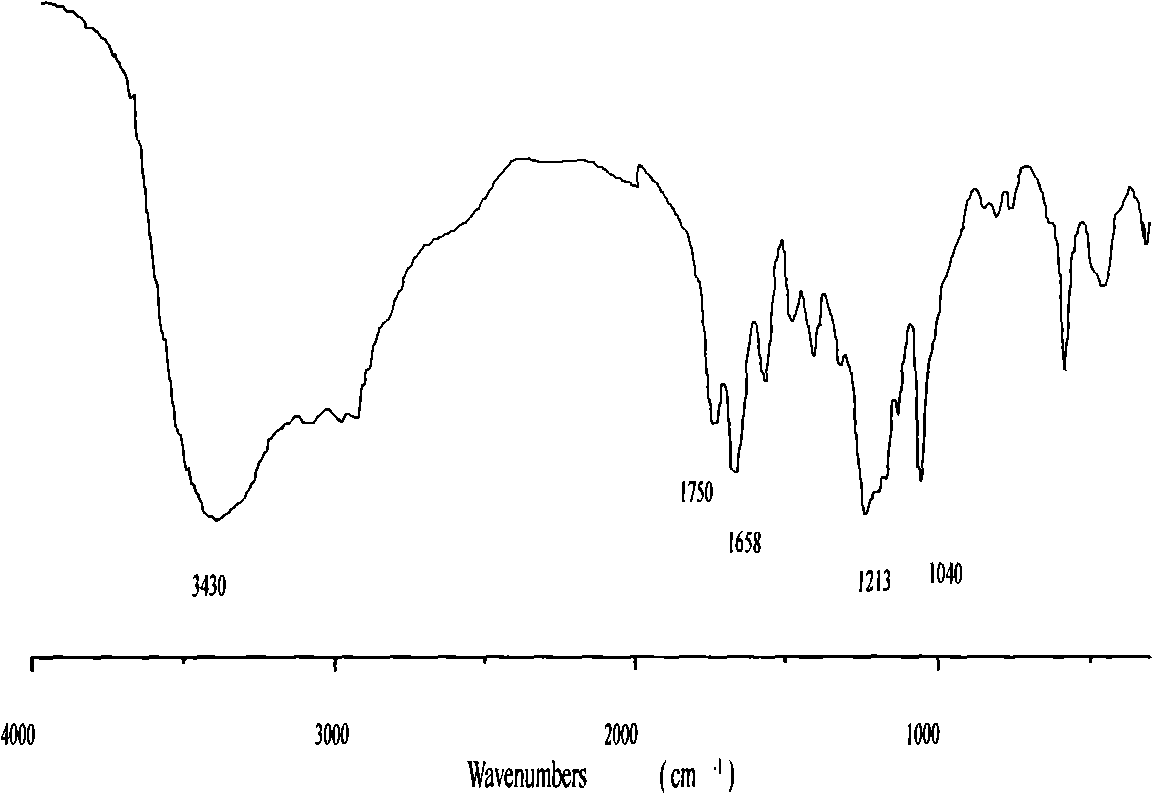

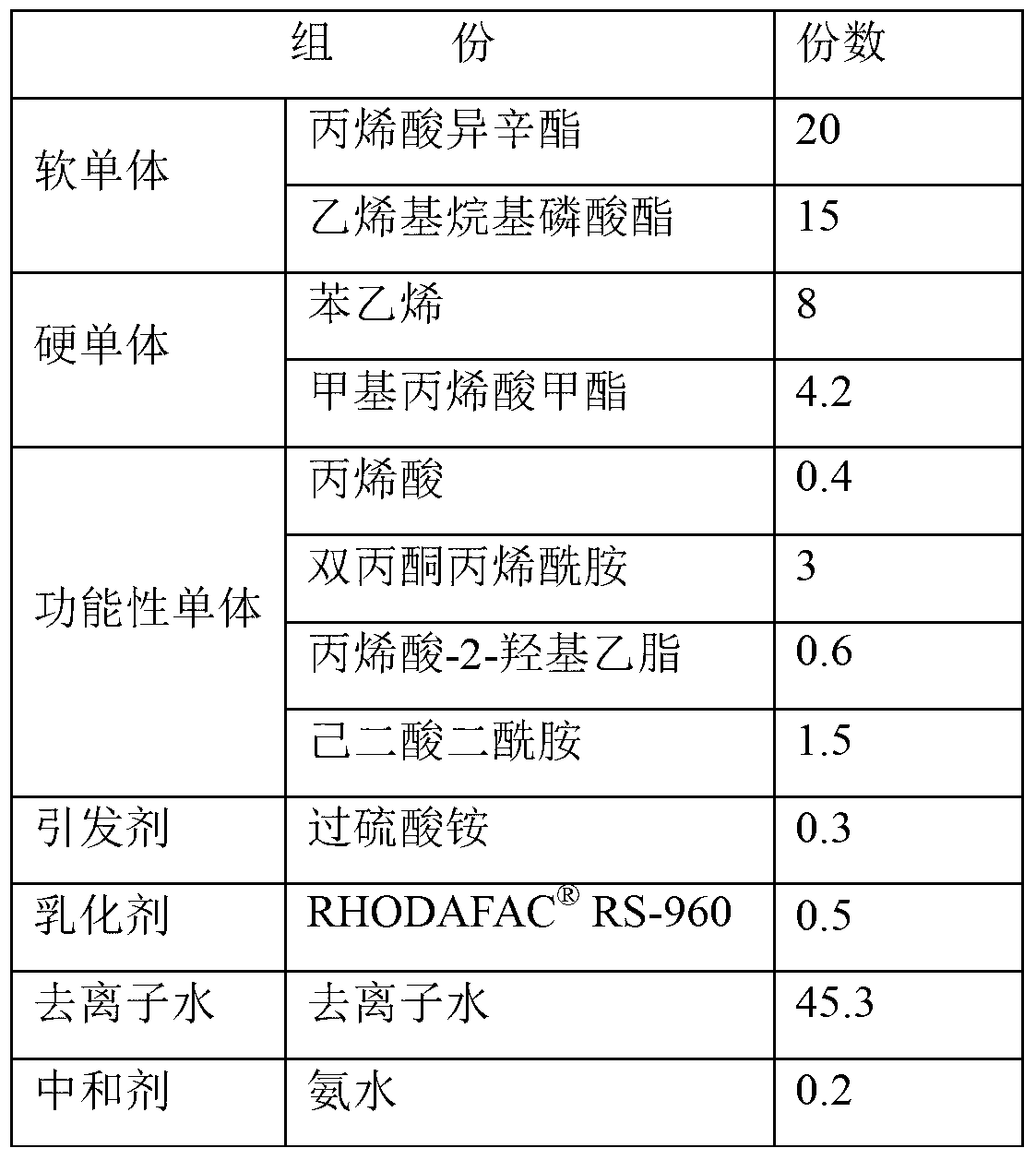

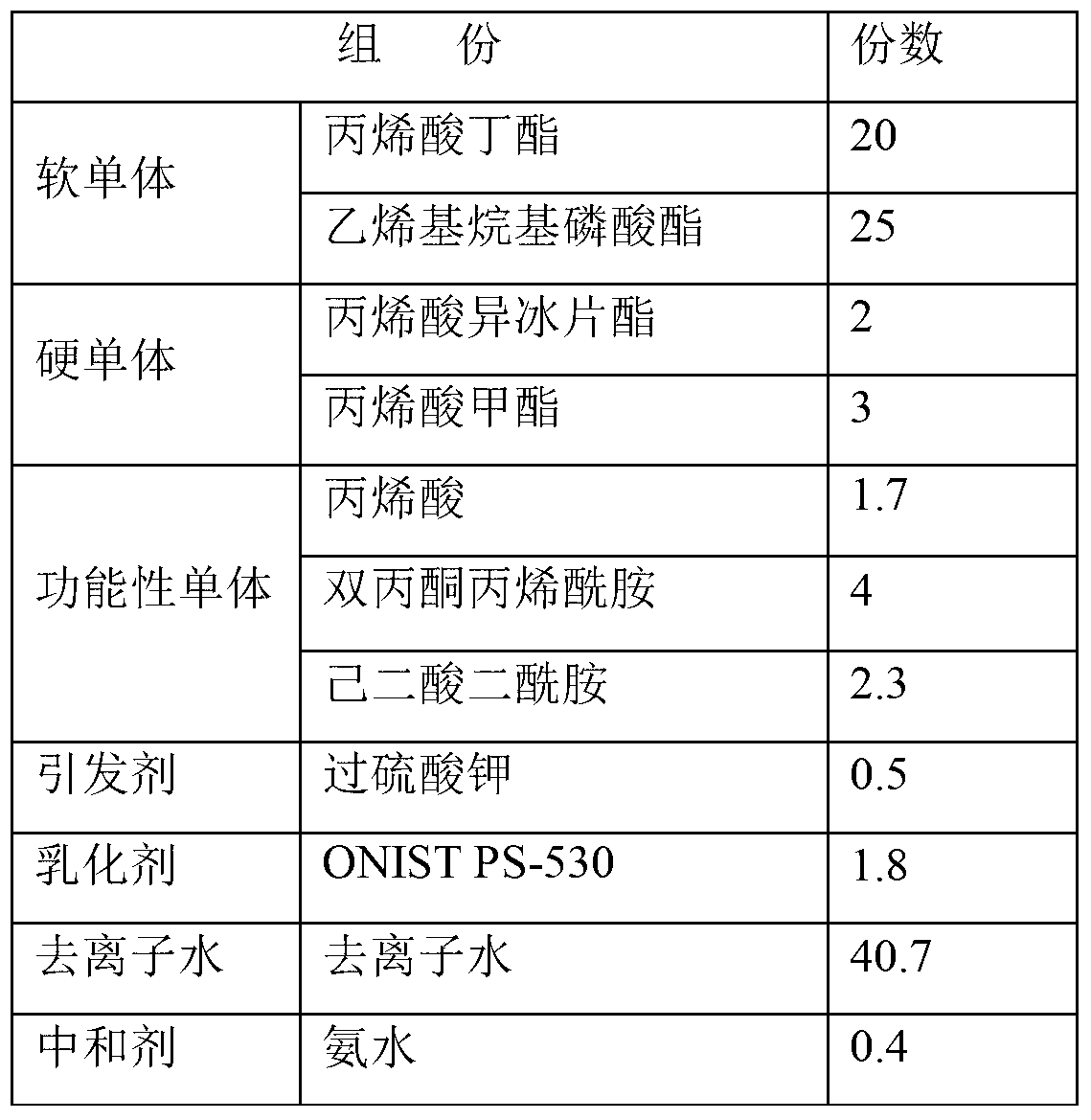

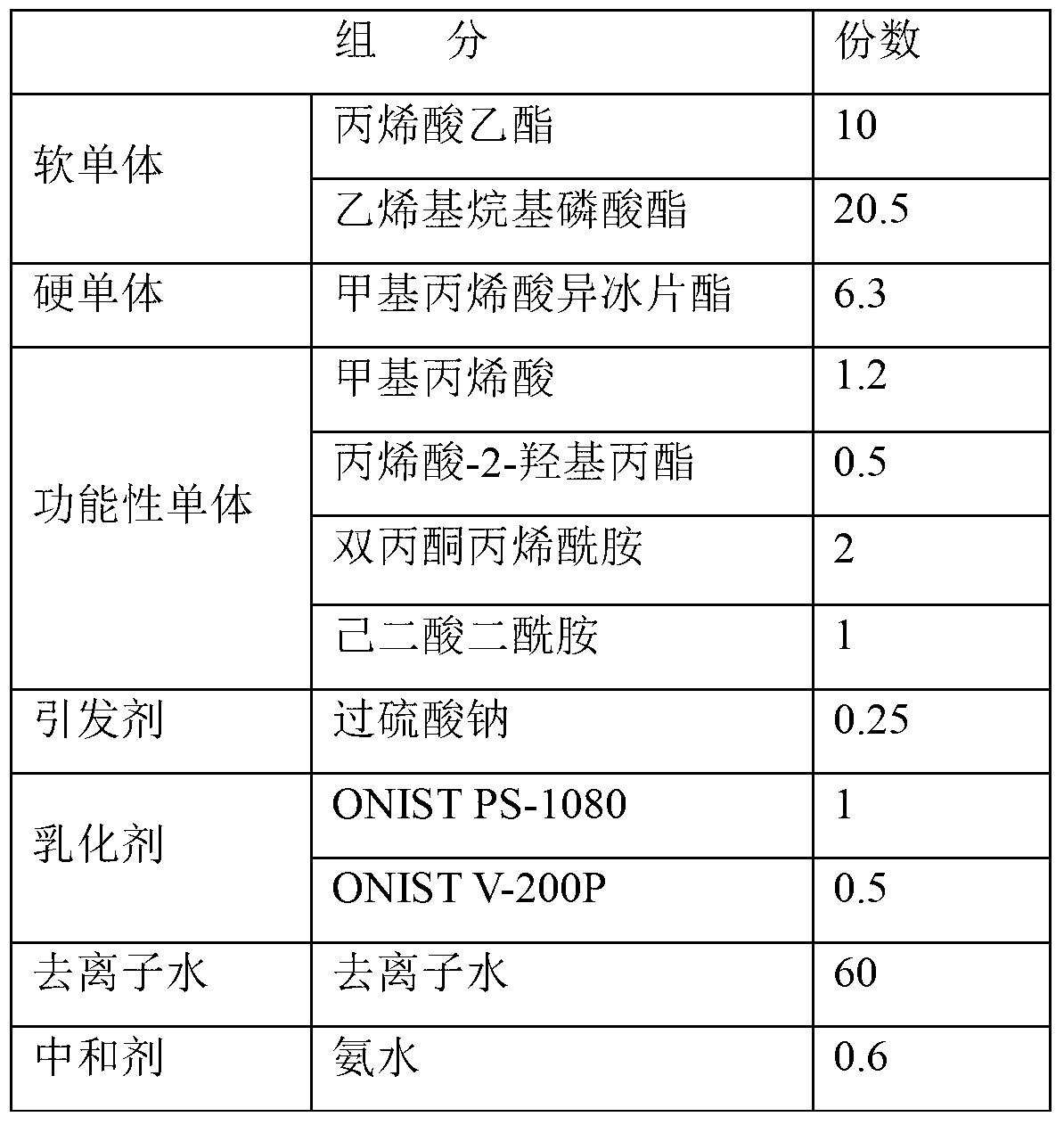

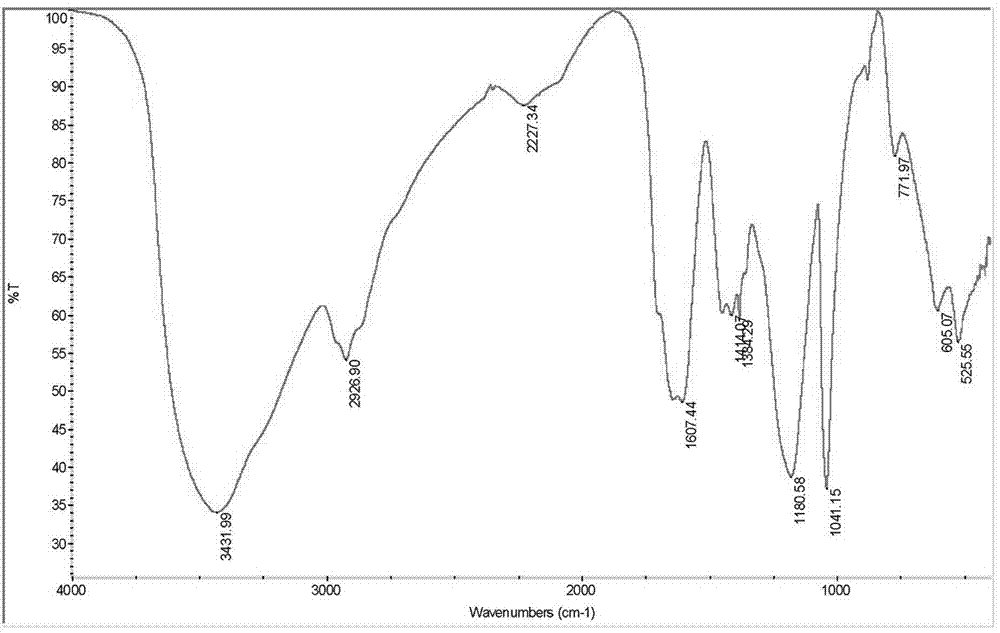

Environmental protection fire retardation type textile printing coating material and preparation method thereof

ActiveCN103225215AImprove flame retardant performanceFeel goodDyeing processTextile printerEngineering

The present invention discloses an environmental protection fire retardation type textile printing coating material and a preparation method thereof. According to the present invention, a fire retardation type acrylate is adopted as a main base material to prepare a fire retardation type coating material for textile printing, wherein the prepared fire retardation type coating material self-extinguishes within 5 seconds after leaving fire, and has characteristics of good fire retardation effect, good elasticity, low cost, excellent washing fastness resistance, and excellent color fastness; during a production process and a use process of the product, no formaldehyde is released, an environmental protection characteristic is provided, and the product does not contain heavy metals and alkyl phenol substances, and is an environmentally friendly and green product; and the preparation method has characteristics of easy production process control, high production efficiency and stable system, and is suitable for industrial scale production.

Owner:连云港百利合新材料发展有限公司

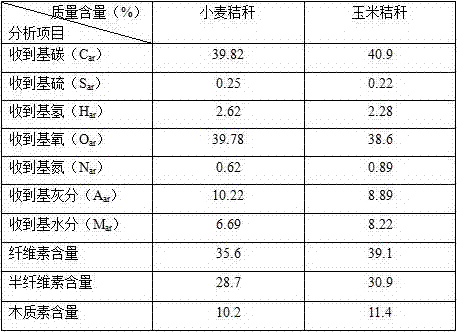

A kind of aliphatic water reducing agent prepared by utilizing straw and preparation method thereof

The invention relates to the technical field of preparation of water reducers of construction engineering, in particular to an aliphatic water reducer prepared from straw and a preparation method thereof. The water reducer is prepared in the steps of washing straw with acid, modifying an aliphatic water reducer with the straw and the like. The defect that an existing biologic water reducer product is low in water reduction rate is overcome, the defect that when the aliphatic water reducer is used, concrete separation, weepage and retardation effects are poor is overcome, environmental friendliness and economic efficiency are good, and application and popularization prospects are good. The water reducer has the technical advantages that waste straw resources are effectively used, the defect that the existing aliphatic water reducer is poor in retardation effect is overcome, the application range of the aliphatic water reducer is widened, reaction conditions and the proportion of reactants in the preparation process of the aliphatic water reducer are optimized, stability of product quality can be better protected, and production cost is reduced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Multilayer coated red phosphorus low smoke halogen-free flame retardant polyolefin cable sheath material and preparation method thereof

ActiveCN102731888AGood halogen freeImprove flame retardant performanceInsulated cablesInsulated conductorsElastomerPolymer science

The present invention belongs to the technical field of a new material, and provides a multilayer coated red phosphorus low smoke halogen-free flame retardant polyolefin cable sheath material and a preparation method thereof. The sheath material comprises the following components, by weight, 30-70 parts of a matrix resin A, 30-70 parts of a matrix resin B, 5-30 parts of a compatibilizer, 5-40 parts of a flame retardant agent A, 10-40 parts of a flame retardant agent B, 0.1-2 parts of a lubricant, and 0.1-1 part of an antioxidant. The preparation method comprises the following steps: A, extruding; and B, carrying out granulation on the extruded material by a granulator to obtain the sheath material finished product. Advantages of the material of the present invention are that: the sheath material is prepared by matching the flame retardant agent A and the flame retardant agent B with the polyolefin elastomer raw material, such that characteristics of halogen-free property and good low smoke flame retardation effect are provided, and advantages of good physical property, good water resistance and less dripping are provided; and the preparation method has a simple preparation process, and is suitable for large-scale industrial production.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

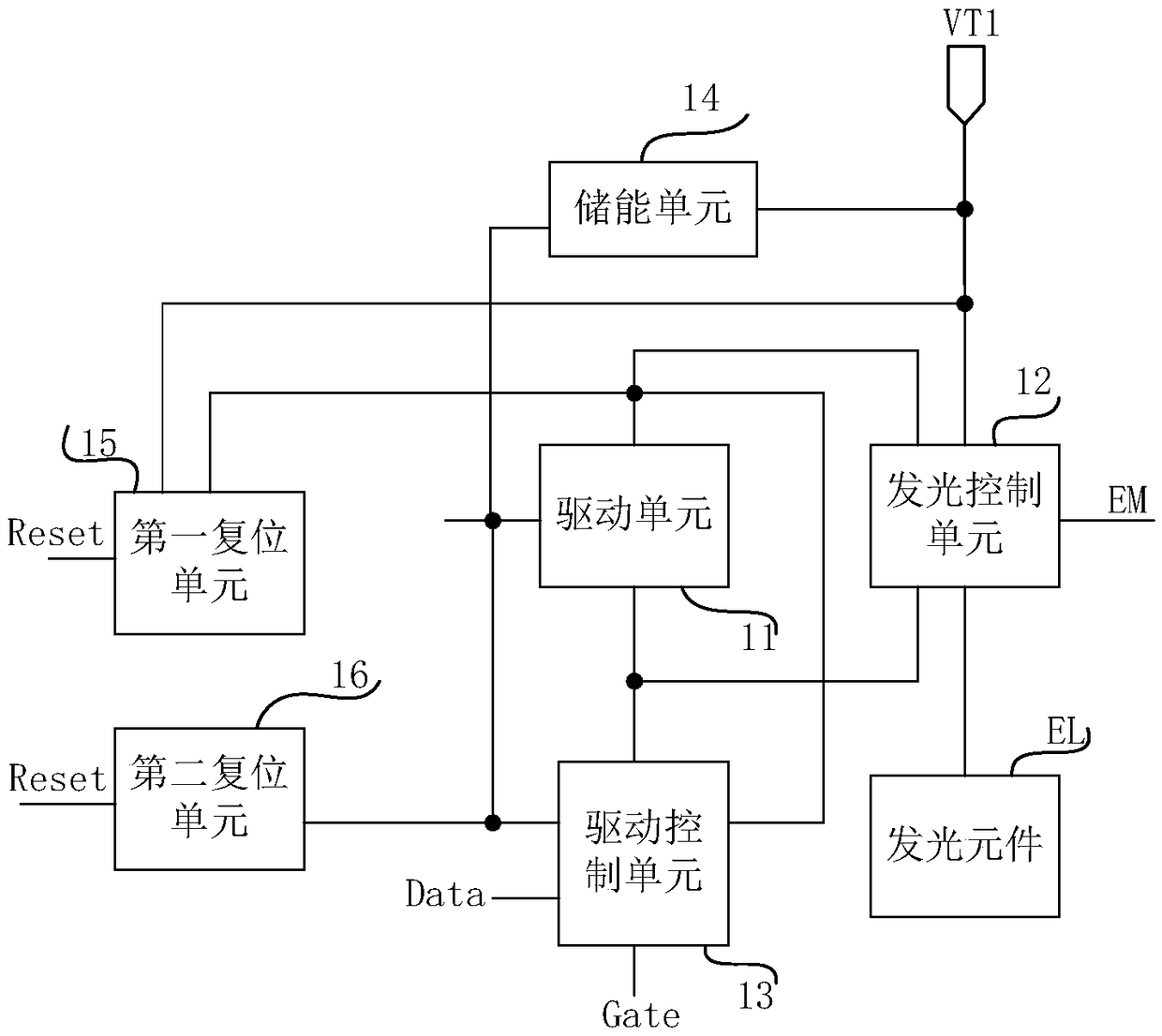

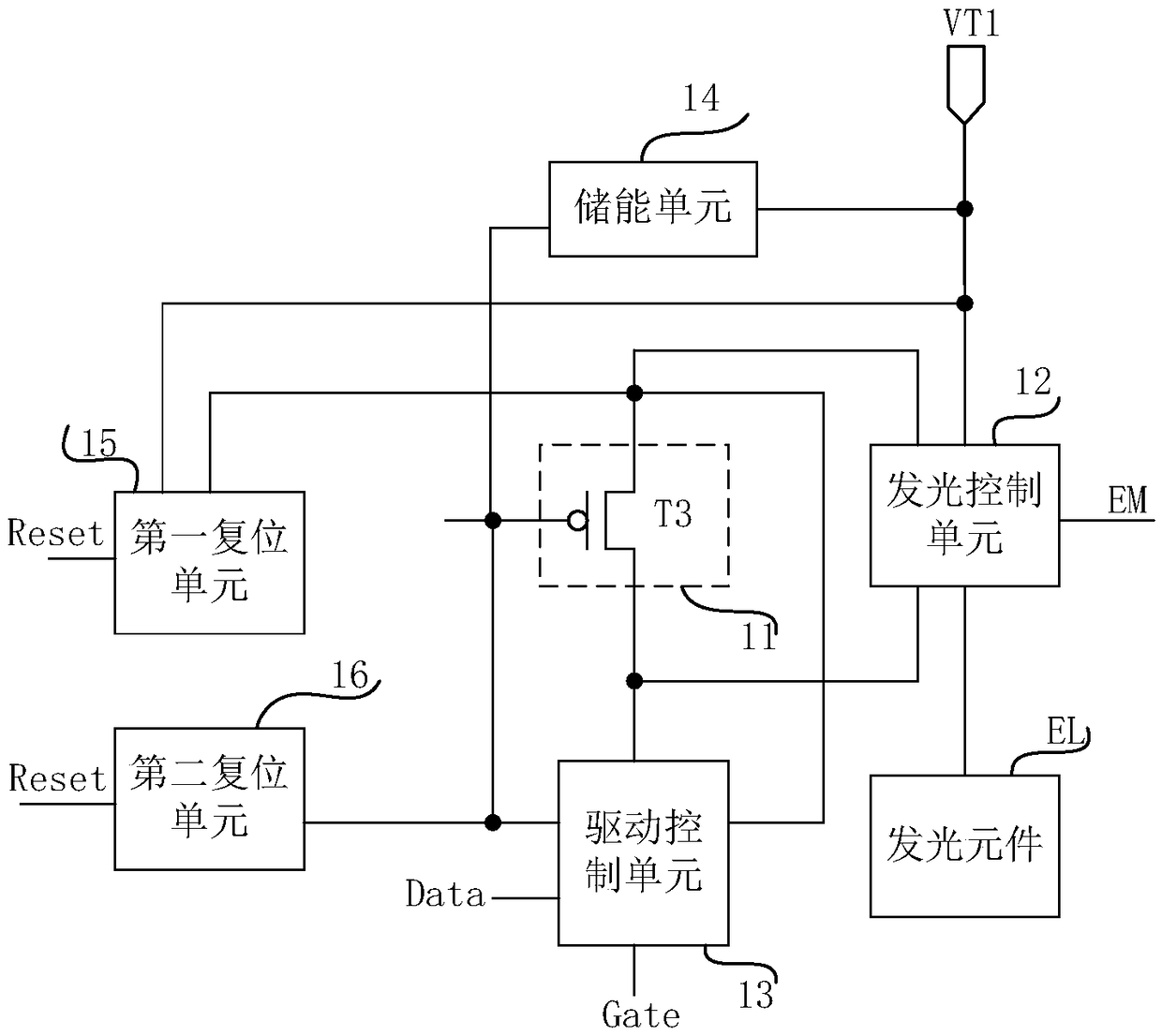

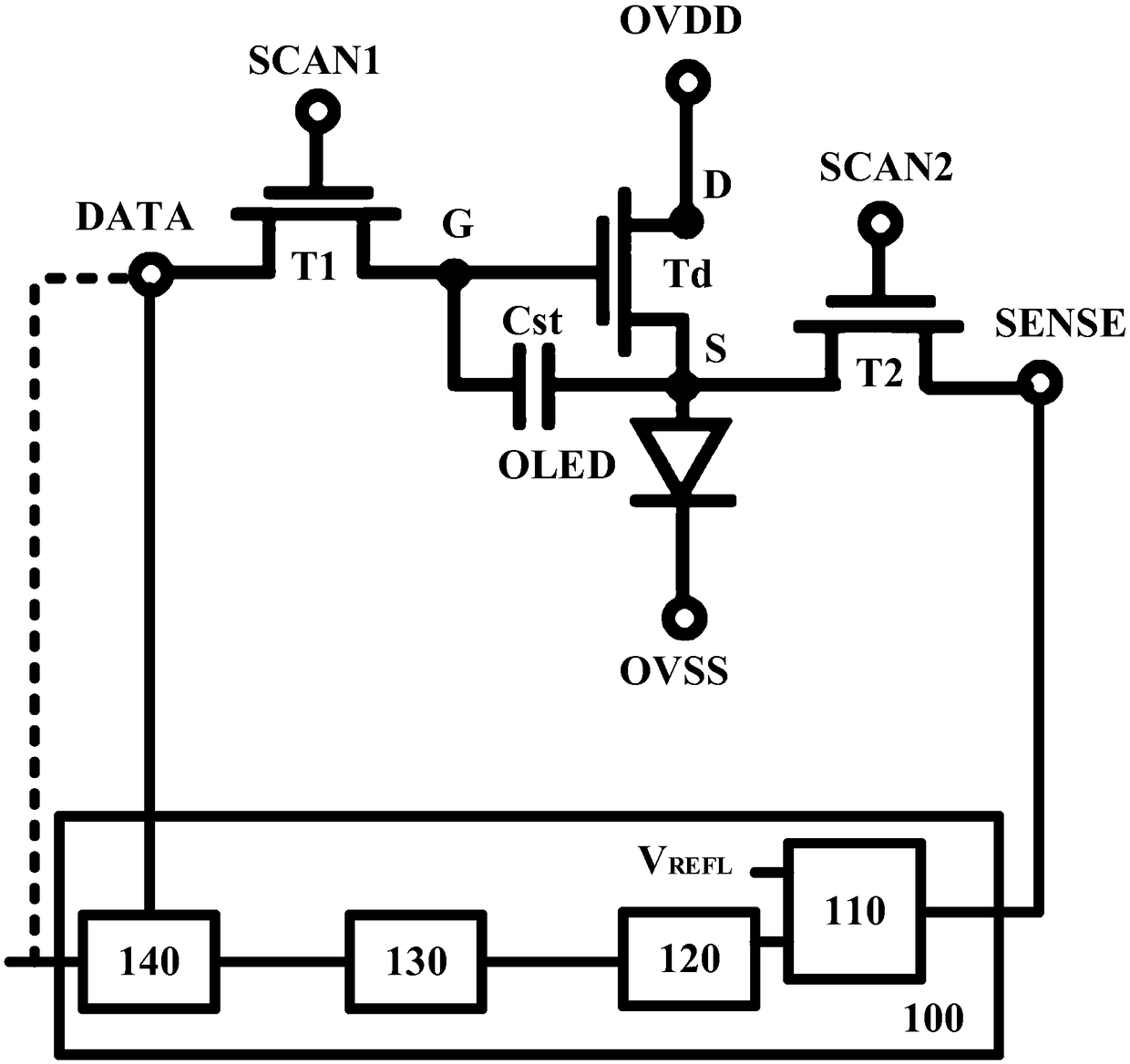

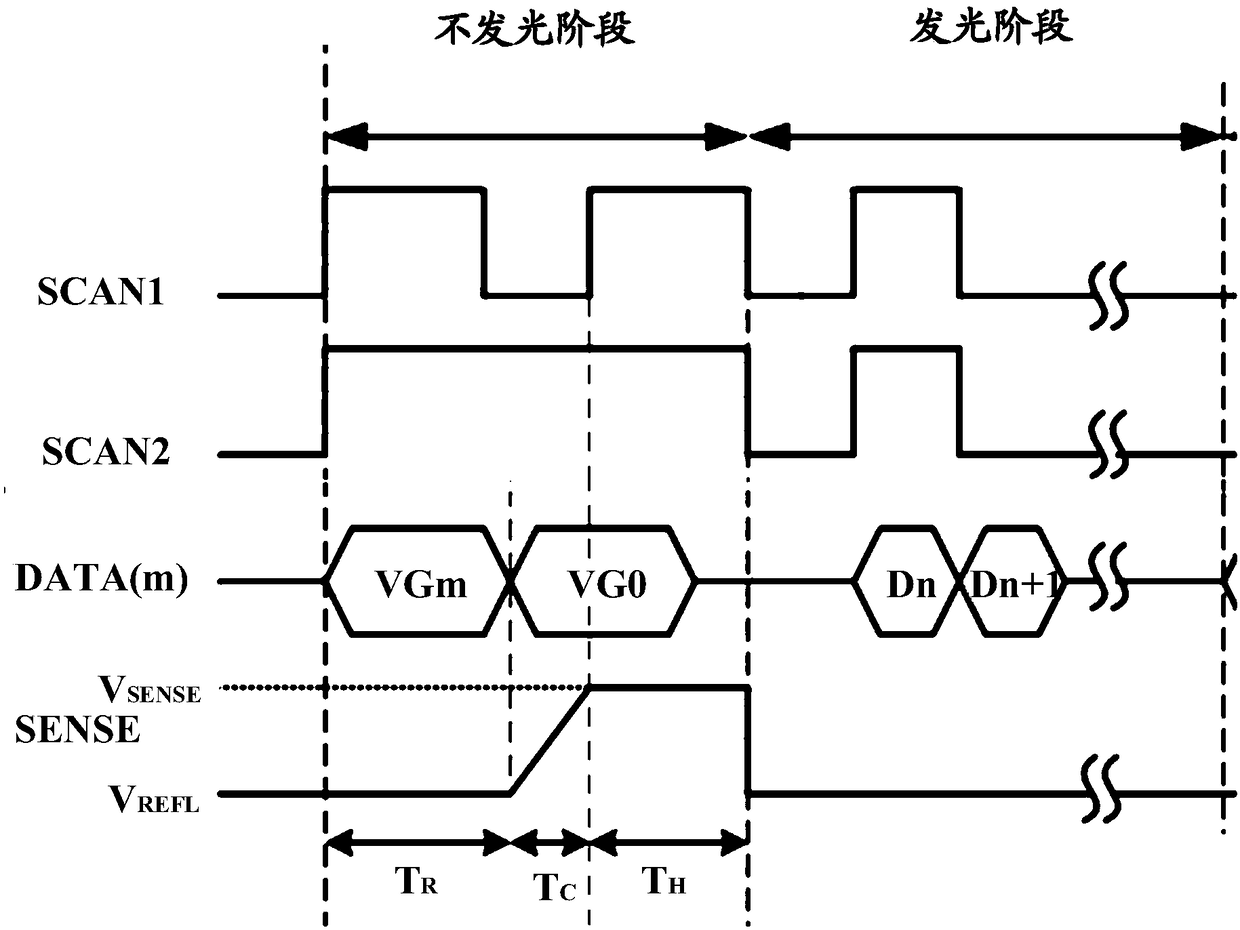

Pixel circuit, pixel drive method and display device

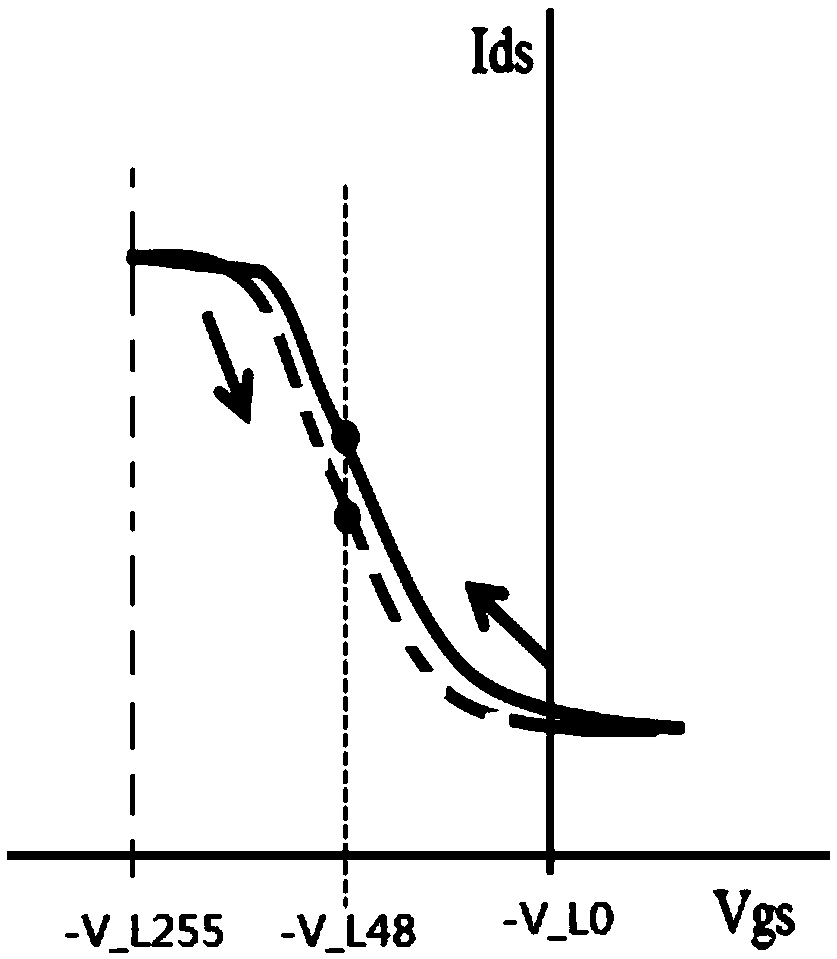

InactiveCN109256094AReduce hysteresisImprove afterimage problemStatic indicating devicesControl lineDisplay device

The invention provides a pixel circuit, a pixel drive method and a display device. The pixel circuit comprises a light-emitting element, a drive unit, a light emitting control unit, a drive control unit, an energy storage unit, a first reset unit and a second reset unit, wherein the first reset unit is used for controlling first voltage output by a first voltage line to be written into a first endof the drive unit under the control of a rest control line; the second reset unit is used for controlling initial voltage output by an initial voltage line to be written into a control end of the drive unit under the control of the rest control line; and the drive unit is used for driving the light-emitting element to emit light under the control of the control end of the drive unit. With the pixel circuit, the pixel drive method and the display device, the problem of residual image display caused by the retardation effect of a drive transistor of the drive unknit in the prior art is solved.

Owner:BOE TECH GRP CO LTD +1

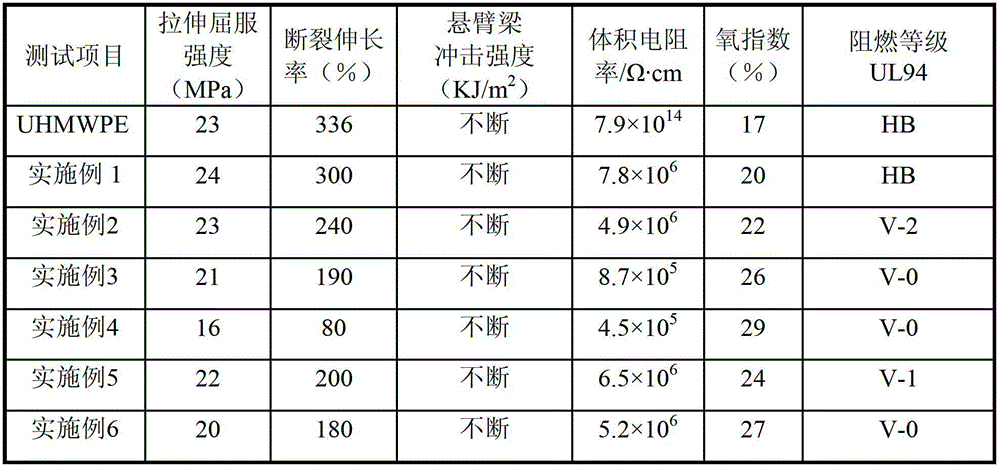

Antistatic halogen-free fire retardation ultra-high molecule weight polyethylene material and preparation method thereof

The present invention discloses an antistatic halogen-free fire retardation ultra-high molecule weight polyethylene material, which comprises, by weight, 100 parts of ultra-high molecule weight polyethylene, 5-40 parts of expanded graphite, 5-20 parts of a synergistic fire retardation agent, 0.1-2 parts of a coupling agent, 0.1-10 parts of a flowing modifier, 0.1-1 part of a nucleating agent, 0.1-1 part of an antioxidant, and 0.1-5 parts of an antistatic agent. According to the present invention, the large particle size (general tens or even hundreds of mum) expanded graphite is added to the ultra-high molecule weight polyethylene material, such that the disadvantage of fire retardation effect reduction due to non-uniform dispersion of the halogen fire retardation agent and the traditional halogen-free fire retardation agent in the ultra-high molecule weight polyethylene substrate is solved; and the graphite itself is a good electric conduction material, such that surface electric resistance and volume electric resistance of the material can be significantly reduced so as to solve disadvantages of the halogen fire retardation agent and the traditional halogen-free fire retardation agent in the ultra-high molecule weight polyethylene, wherein the disadvantages comprise that the halogen fire retardation agent and the traditional halogen-free fire retardation agent can not concurrently have an antistatic performance and a fire retardation performance.

Owner:CHANGZHOU RUIJIE NEW MATERIAL TECH CO LTD

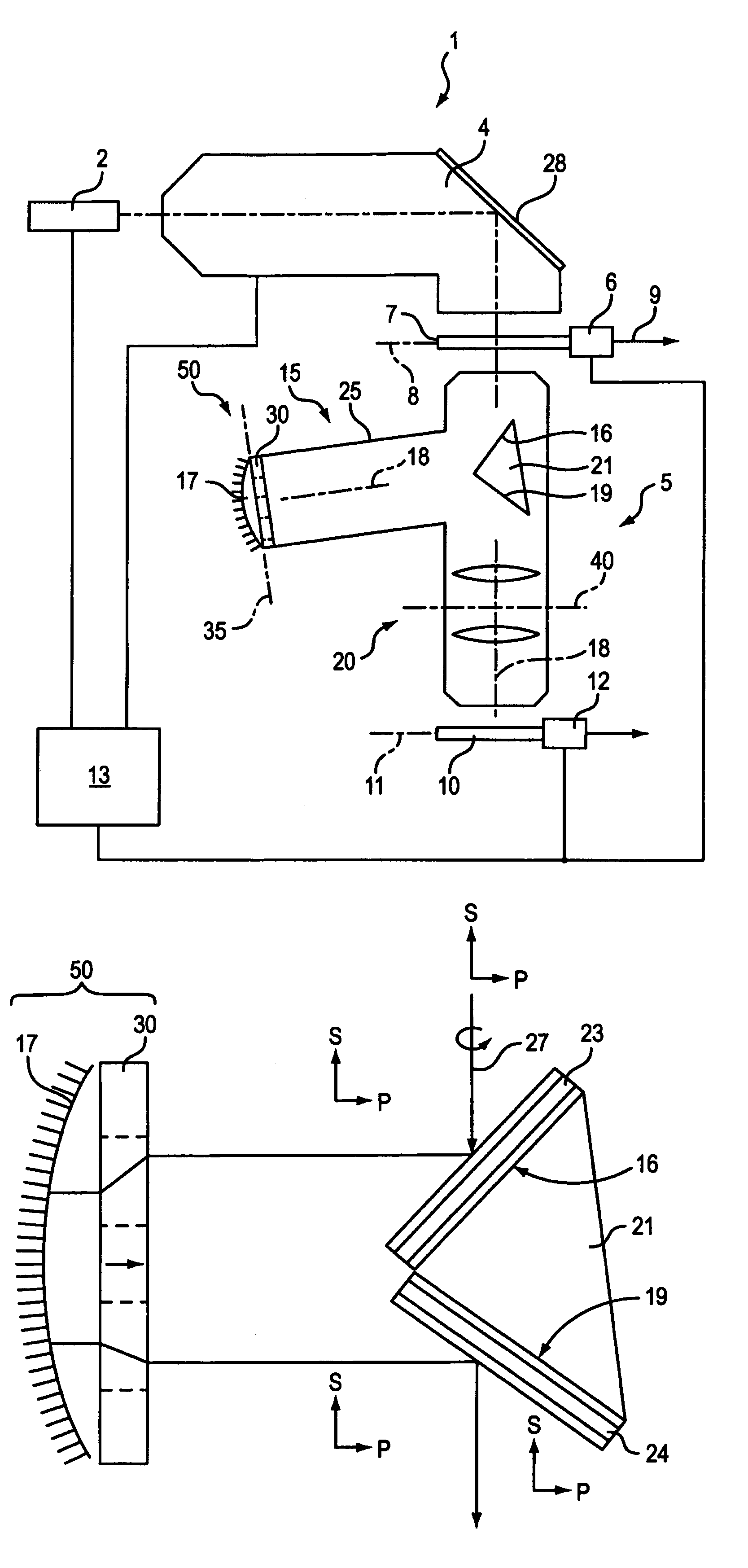

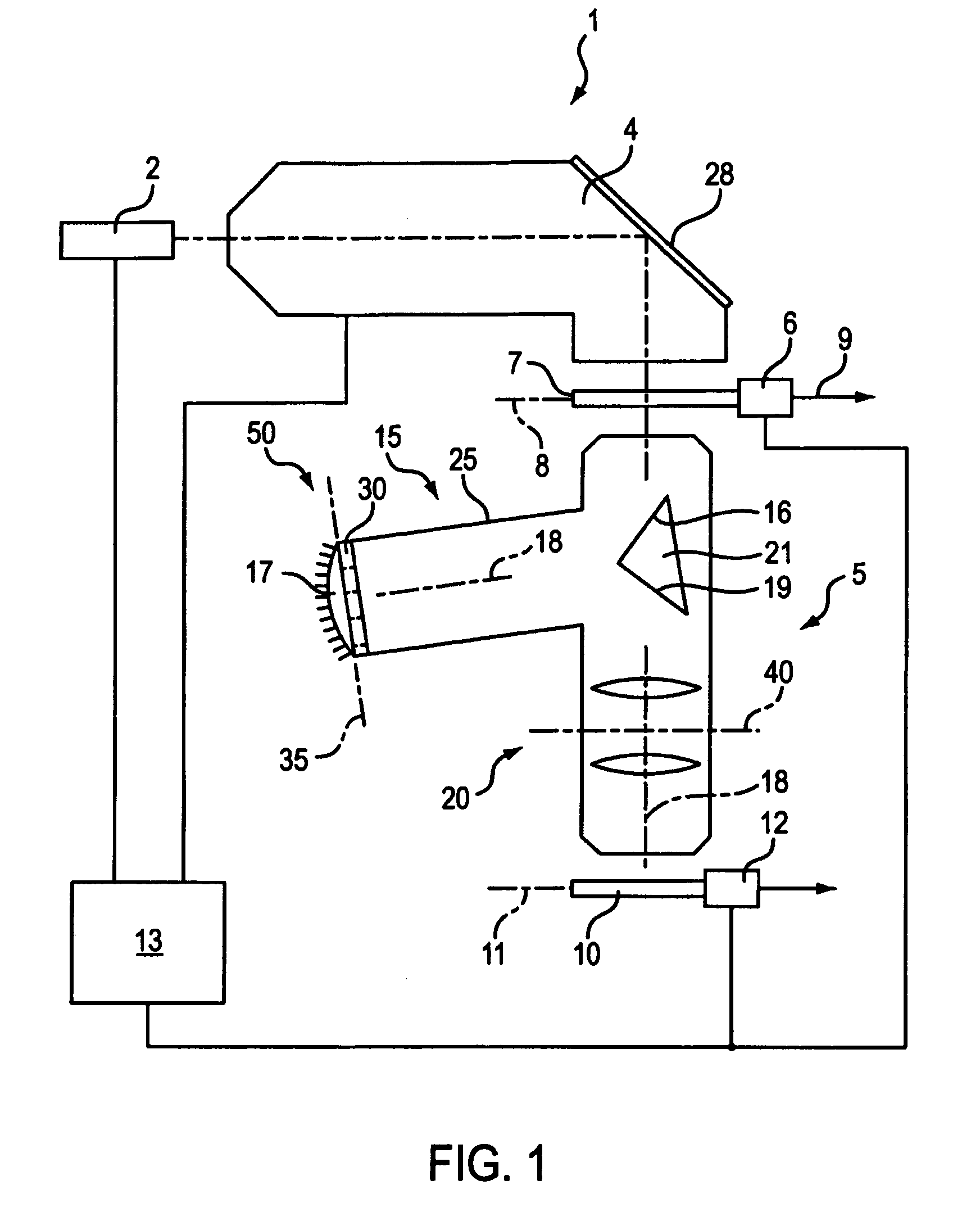

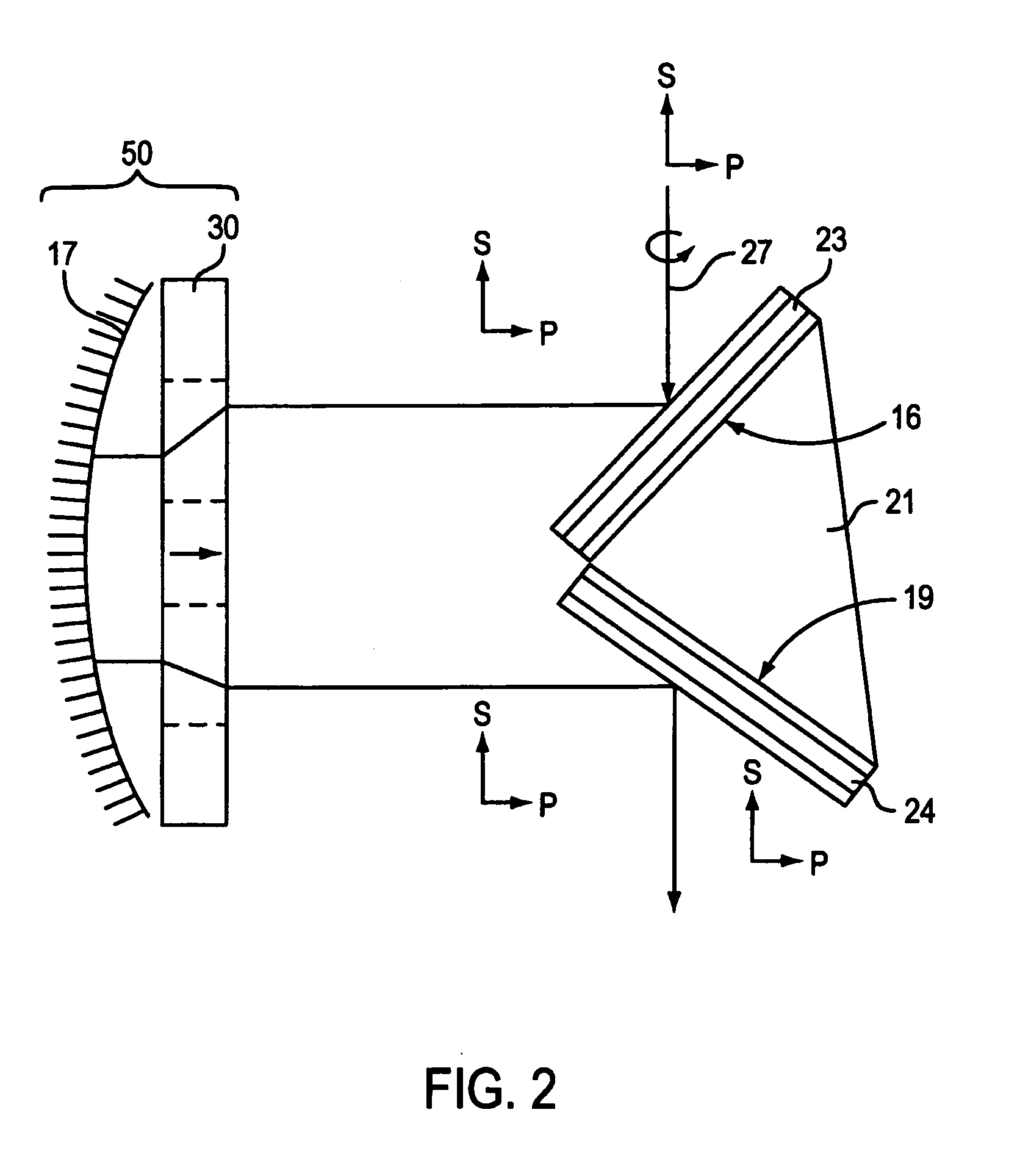

Optically polarizing retardation arrangement, and microlithography projection exposure machine

InactiveUS7053988B2Different effectPolarising elementsDiffraction gratingsOptoelectronicsOptical polarization

A retardation arrangement for converting an input radiation beam, incident from an input side of the retardation arrangement, into an output radiation beam which has over its cross section a spatial distribution of polarization states which can be influenced by the retardation arrangement and differs from the spatial distribution of polarization states of the input radiation, is designed as a reflective retardation arrangement. A useful cross section of the retardation arrangement has a multiplicity of retardation zones of different retardation effect. Such a mirror arrangement having a retardation effect varying as a function of location can be used to compensate undesired fluctuations in the polarization state over the cross section of an input radiation beam and / or to set specific output polarization states, for example in order to set radial or tangential polarization.

Owner:CARL ZEISS SMT GMBH

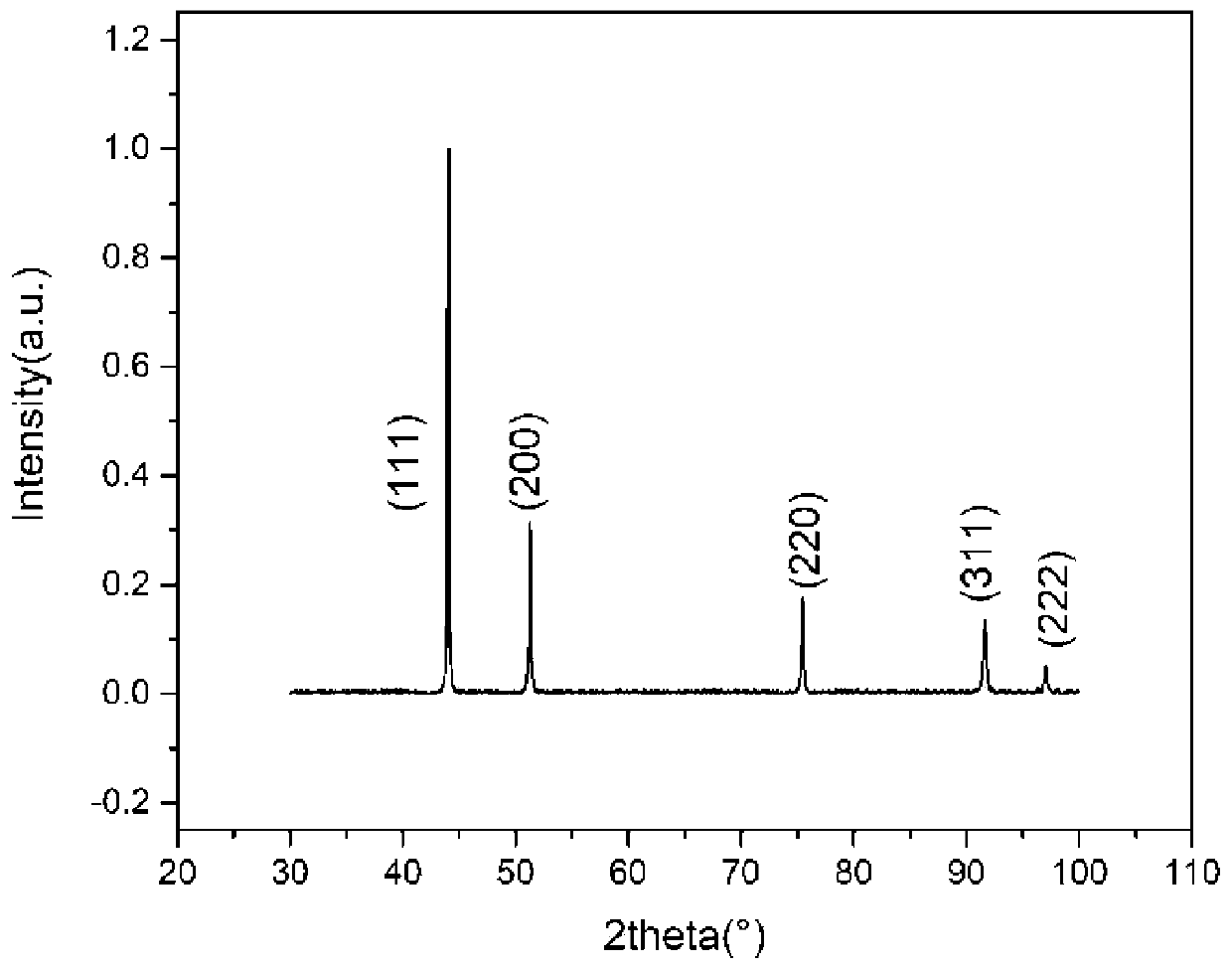

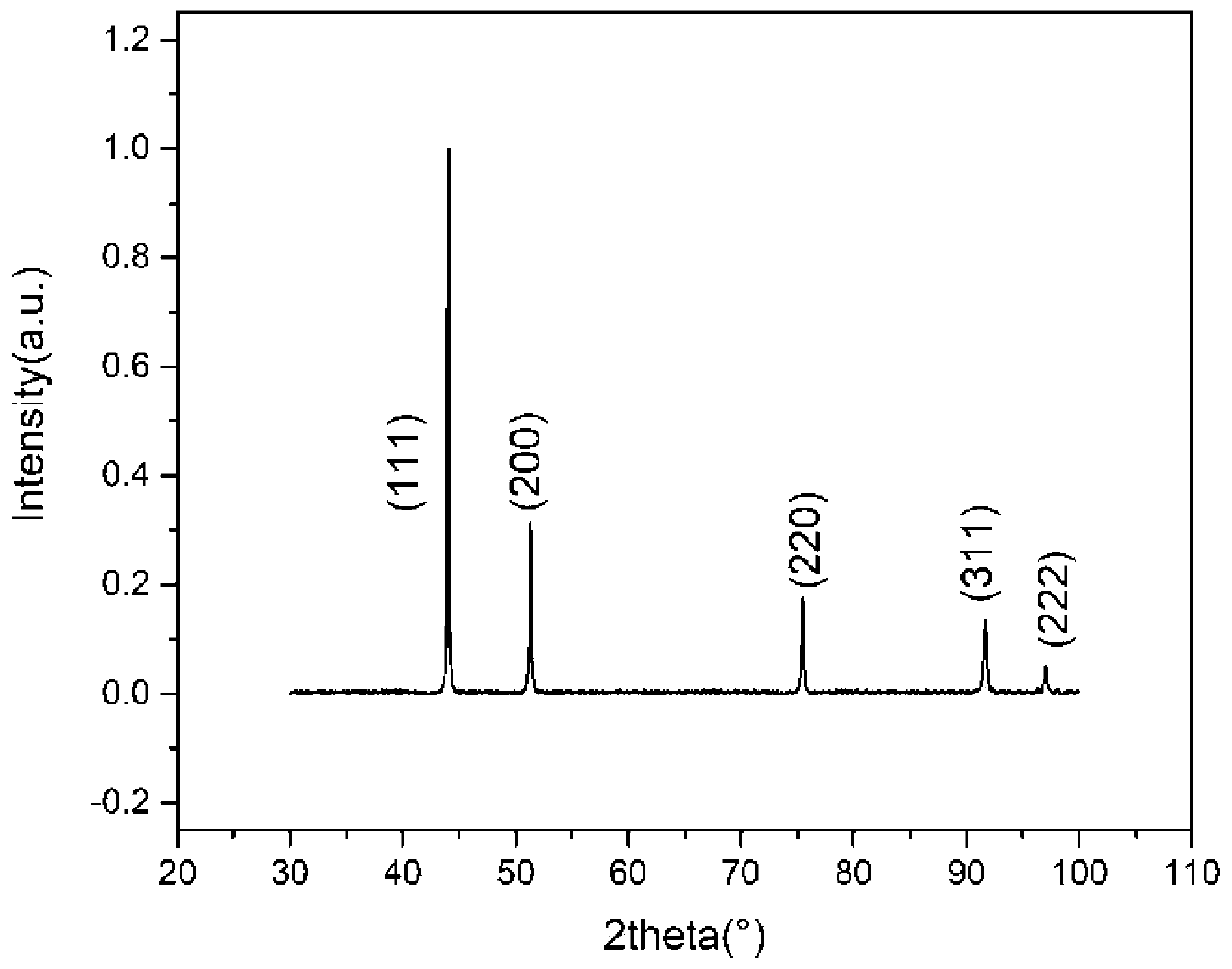

Medium entropy alloy material for additive manufacturing and application method of medium entropy alloy material

ActiveCN109972019AHigh strengthStrong matchAdditive manufacturing apparatusArc welding apparatusWire cuttingSolid solution strengthening

The invention discloses a medium entropy alloy material for additive manufacturing and an application method of the medium entropy alloy material, and relates to the field of additive manufacturing. The medium entropy alloy material for additive manufacturing is characterized in that the material components comprise Cr, Co and Ni, and the atomic percentages are separately 20%-50%. The applicationmethod comprises the following steps that a metal substrate with appropriate size is selected, each component is melted by using a heat source, a scanning path file of a 3D model of a workpiece is input into a robot control computer to scan in a given path, the workpiece is separately from the substrate by using wire cutting after all scanning and cooling, and the workpiece is cleaned, shined andpolished. According to the medium entropy alloy material for additive manufacturing and the application method of the medium entropy alloy material, the strong solid solution strengthening effect in amedium entropy alloy is utilized to obtain a printed workpiece with high strength and good toughness matching, and meanwhile, the diffusion retardation effect is utilized to delay or even prevent thediffusion of substrate materials and prevent the formation of various brittle mesophase; and meanwhile, less elements are involved, simple preparation and easy realization of industrial production are achieved, and the medium entropy alloy material for additive manufacturing and the application method of the medium entropy alloy material have the advantages of low cost, environmental friendlinessand the like.

Owner:SHANGHAI JIAO TONG UNIV +1

Heat-preservation fireproof board and preparation method thereof

ActiveCN103951369AGood heat insulationHigh ignition pointSolid waste managementSilicon dioxideFire prevention

A heat-preservation fireproof board is prepared by the following raw materials: 80-100 parts by weight of magnesium oxide, 2-3 parts by weight of dimethyl silicone oil, 4-6 parts by weight of aluminum nitride powder, 20-30 parts by weight of anhydrous magnesium chloride, 3-5 parts by weight of hollow glass beads, 8-12 parts by weight of tetrapod-shaped zinc oxide whiskers, 3-6 parts by weight of aerosil, 3-5 parts by weight of polyvinyl acetate emulsion, 20-30 parts by weight of refractory materials, 3-6 parts by weight of rock wool, 3-5 parts by weight of methylisothiazolinone, 2-4 parts by weight of ferriferrous oxide, 5-8 parts by weight of methyl sodium silicate, 1-2 parts by weight of sodium dodecyl benzene sulfonate, and 130-150 parts by weight of water. By virtue of adding the multiple types of refractory materials, the board can be high in burning point and good in flame retardation effect; and with the addition of the fly ash hollow beads, the board can be good in heat insulation effect and fine in fireproof effect. In brief, the board of the invention is a novel inorganic heat-preservation and heat-insulation building material integrating characteristics of heat preservation, heat insulation, high strength, fire prevention, water proofing, sound absorption, sound insulation, and decoration.

Owner:安徽颐鑫节能材料有限公司

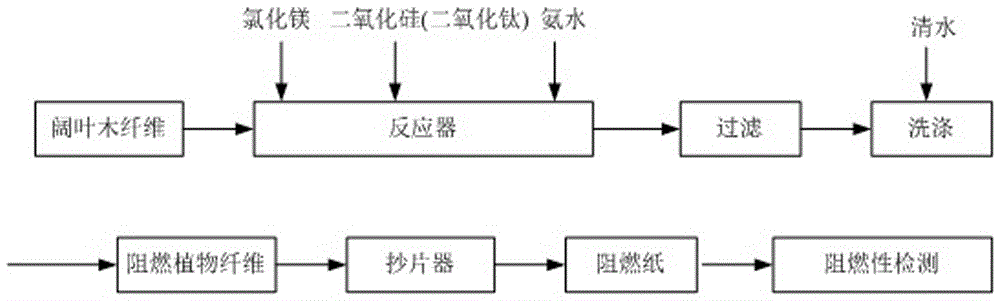

Flame-retardant plant fiber and flame-retardant paper

The invention relates to the field of a flame-retardant material, and especially relates to flame-retardant plant fiber and a piece of flame-retardant paper. The flame-retardant plant fiber comprises plant fiber slurry and a fire retardant; a preparation method of the flame-retardant plant fiber comprises the following steps: a magnesium chloride solution whose concentration is 0.8-1.4mol / L is added into a reactor with heating and stirring, the temperature is controlled at 50-70 DEG C, the plant fiber pulp and an ultrafine filling material are added, stirring is carried out for 20-40 minutes, ammoniacal liquor whose mass fraction is 2.0-2.5% is added, stirring is carried out for 10-30 minutes, the plant fiber pulp is filtered and washed with clear water, and the flame-retardant plant fiber is obtained. The flame-retardant paper which is made from the flame-retardant plant fiber has the advantages of good flame retardation effects, low influence on physical strength of paper, low production cost, and environment protection.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

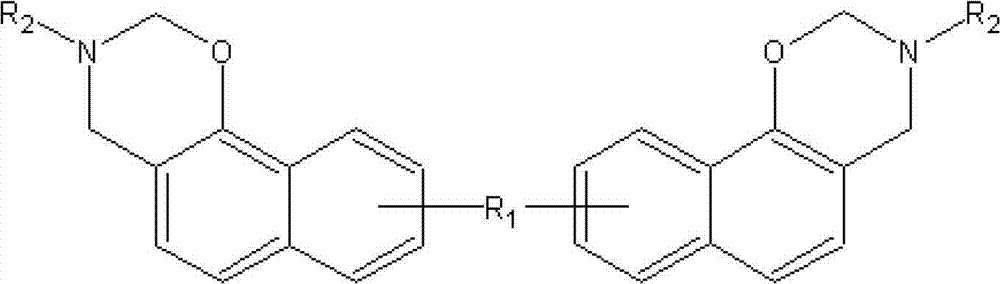

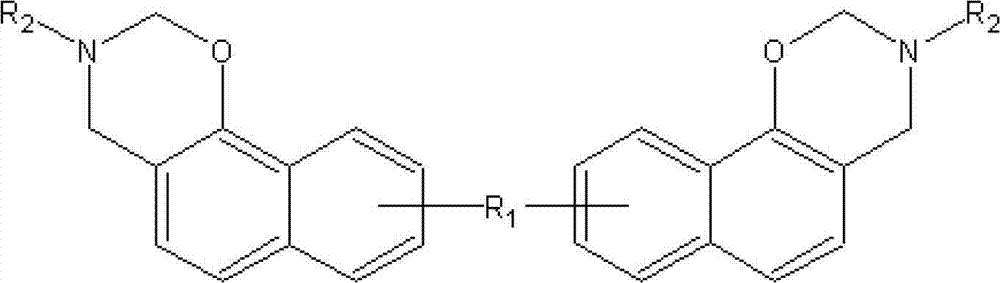

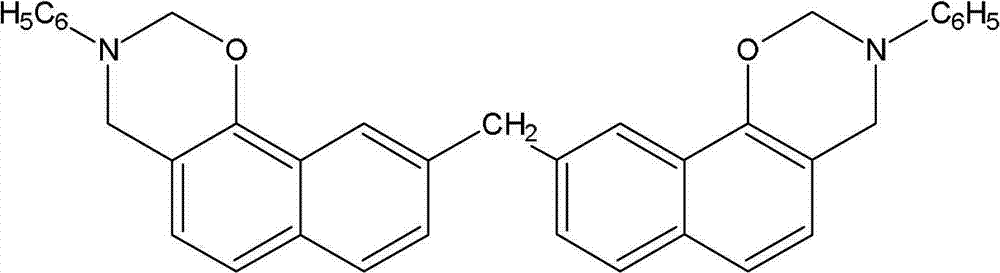

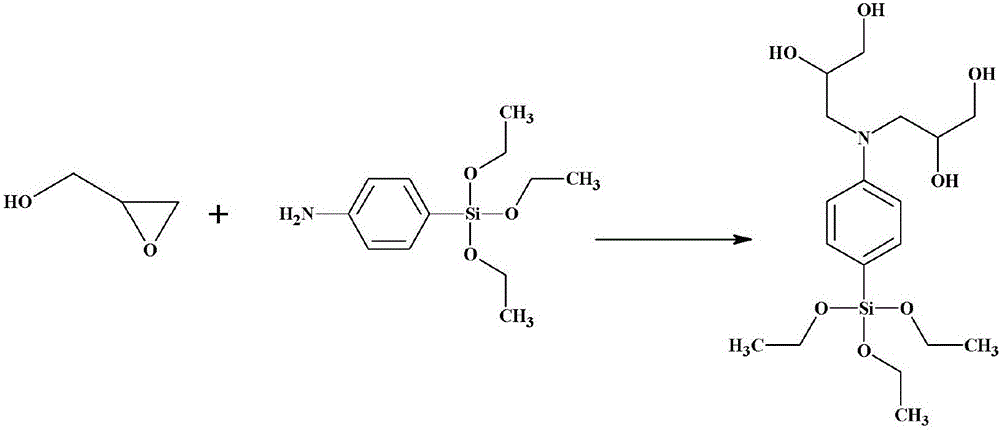

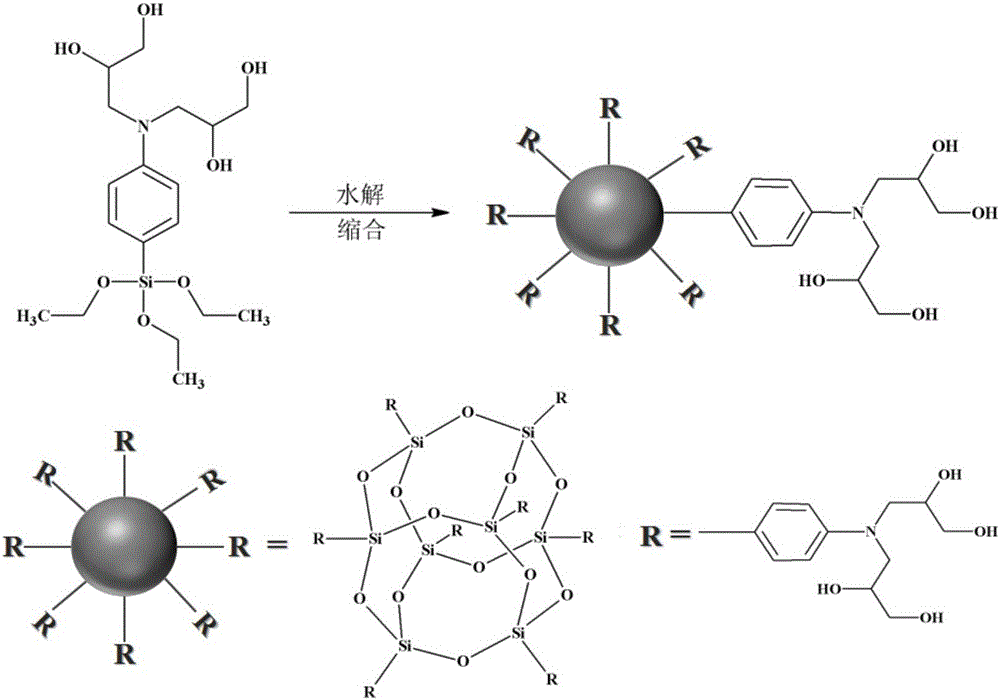

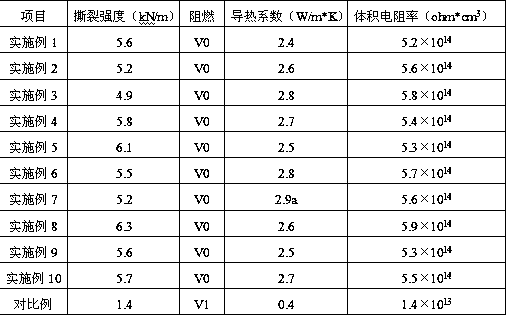

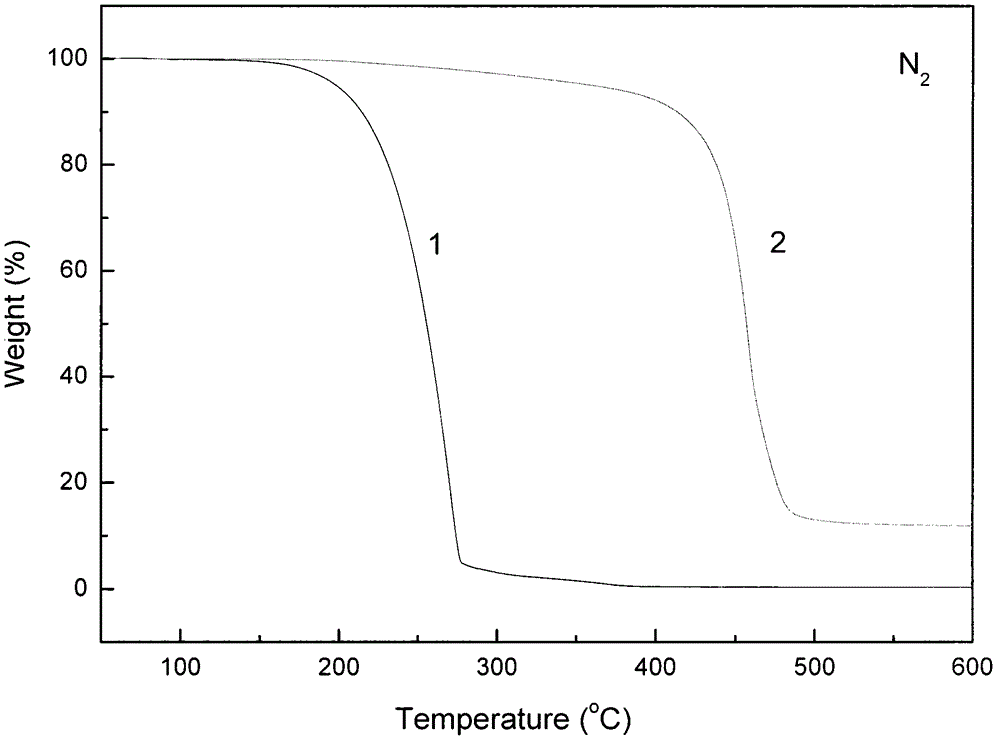

Polyhydroxyalkylphenyl polysilsesquioxane and preparation method and application thereof

InactiveCN106750308AImprove heat resistanceSynthetic reaction conditions are mildCarbamateFire retardant

The invention discloses polyhydroxyalkylphenyl polysilsesquioxane. The polyhydroxyalkylphenyl polysilsesquioxane has the following structures as shown in description, and can be used for preparing a polysilsesquioxane modified polyurethane hard foaming material. The hard foaming material is prepared from A component and B component; the A component comprises organic polyols, the foaming agent, the stabilizing agent, catalyst, crosslinking agent, polyhydroxyalkylphenyl polysilsesquioxane POSS, and flame retardant; the B component comprises polyisocyanates. In the polyurethane material, the polyhydroxyalkylphenyl polysilsesquioxane POSS is added, the polyhydroxyalkyl POSS monomer is reacted with the polyisocyanates to form a carbamate bond, the POSS in rigid structure is crosslinked into a molecular chain of the polyurethane material so as to enhance the mechanical property and the heat resistance of the polyurethane material. The boron inorganic flame retardant and the silicon-containing POSS produce the synergistic fire retardation effect, and a good smoke inhibition effect is formed at the same time. The reaction process is simple, the operation is convenient, and the POSS is suitable for the industrial production. The invention further discloses the preparation of the POSS.

Owner:NANJING UNIV

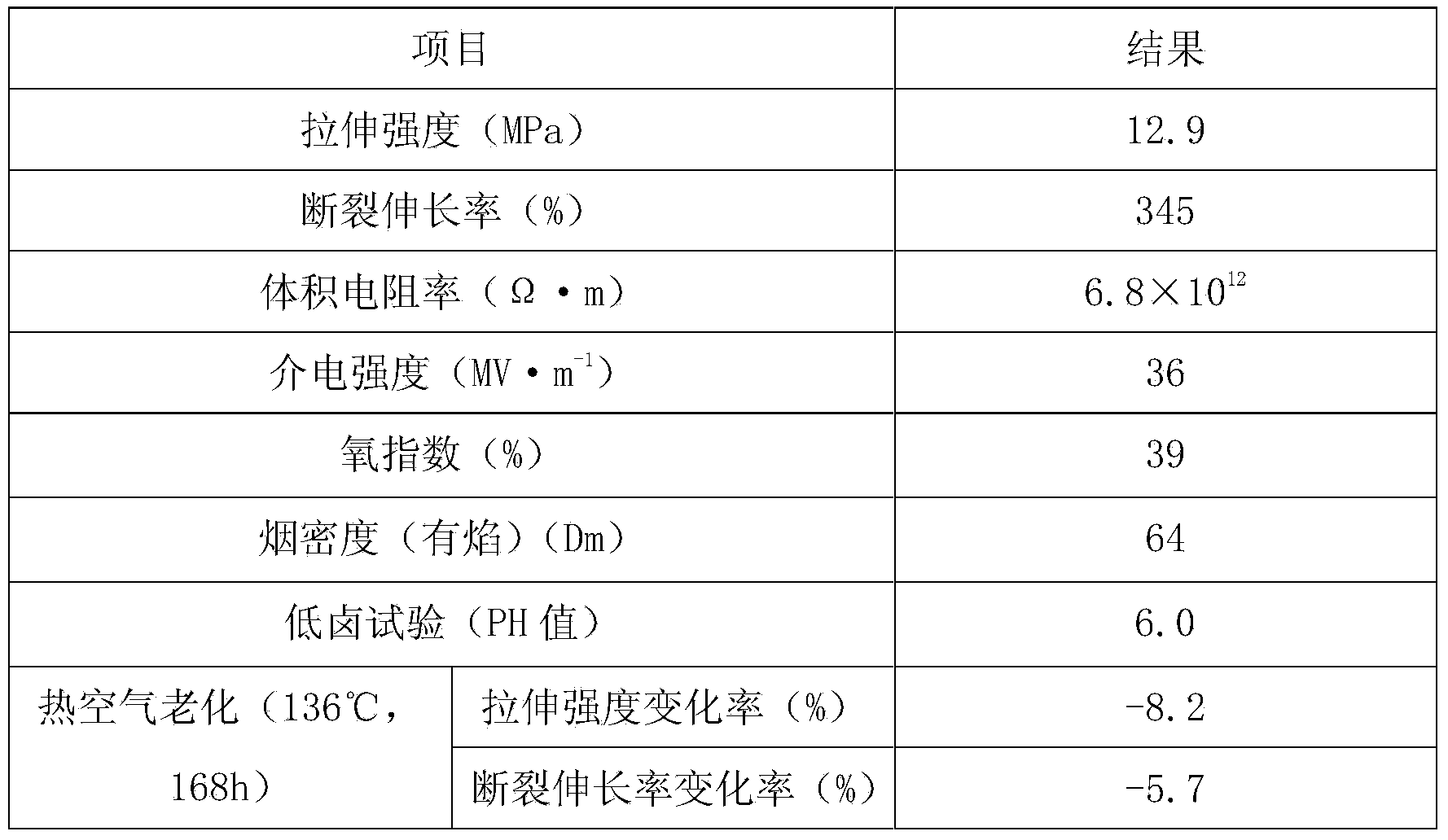

Insulation silica gel material and silicon fabric used for new-energy vehicle battery heater

InactiveCN108178929AExcellent electrical insulation propertiesImprove flame retardant performanceFiberElectrical battery

The invention relates to an insulation silicon material and a silicon fabric used for a new-energy vehicle battery heater. The insulation silicon material comprises the following raw materials in parts by weight: 90-120 parts of silicone rubber, 15-40 parts of a composite fire retardant, 40-60 parts of a filling material, 2-6 parts of a lubricant, 1-5 parts of a promoter, and 2-12 parts of a vulcanizing agent; the silicon fiber comprises a glass fiber cloth, a sulfurated insulation silicon layer arranged at one surface of the glass fiber cloth, an un-sulfurated insulation silicon layer arranged at the other surface of the glass fiber cloth, and a PE membrane. Compared with the prior art, the silicon material has excellent electrical isolation characteristic, good flame retardation effect,and protruded heat conduction effect, the silicon fabric prepared by the insulation silicon material has good flexibility and compression performance, can tightly attach on the surface of a power battery, has the advantages of good shock resistance, good aging-resistant performance, and convenient installation and dismounting, is repeatedly usable, and has good application prospect.

Owner:无锡市辉英电力电子有限公司

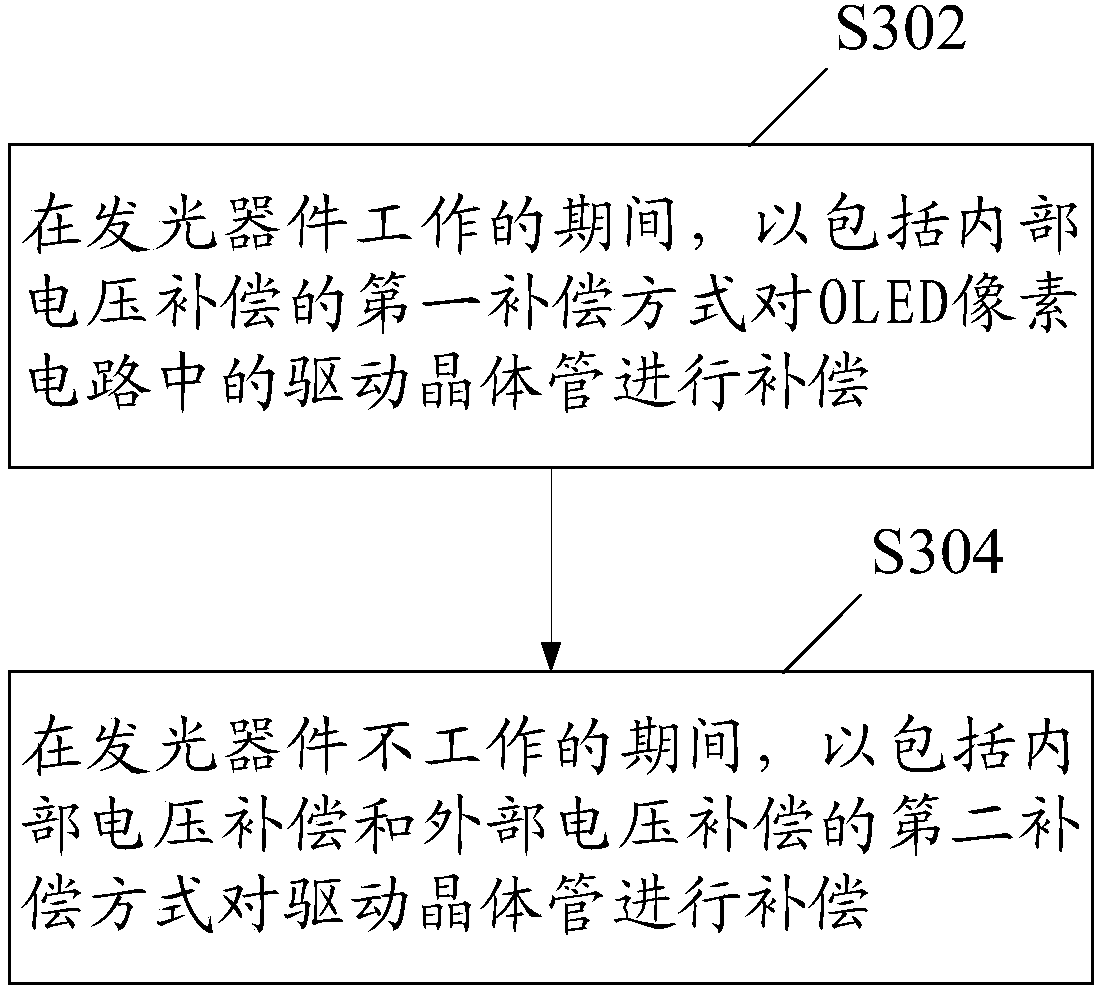

OLED pixel circuit compensation method

The embodiment of the invention provides an OLED pixel circuit compensation method comprising the following steps: using a first compensation mode that contains internal voltage compensation to compensate a driving transistor in an OLED pixel circuit in a luminescent device working period in the OLED pixel circuit; using a second compensation mode that contains internal voltage compensation and external voltage compensation to compensate the driving transistor in a luminescent device non-working period. The method can compensate threshold-voltage drift of the driving transistor, thus improvingthe OLED pixel circuit yield rate, preventing the external voltage compensation retardation effect, and accelerating a sensing charging rate in the external voltage compensation.

Owner:BOE TECH GRP CO LTD

PET/PP alloy material and preparation method thereof

The invention discloses a PET / PP alloy material and a preparation method thereof. The invention discloses a PET / PP alloy material, which is prepared from the following components according to the mass percentage proportions: 20-50% of PET, 20-50% of PP, 3-8% of compatibilizer, 10-30% of reinforcing agent, 15-20% of composite fire retardant, 0.5-2% of lubricant, and 0.1-1% of anti-oxidant. The beneficial effects reside in that: the PET / PP blending alloy material provided by the invention has both advantages of PET and PP, has excellent comprehensive properties; simultaneously, proper amounts of reinforcing agent and composite fire retardant are added, in order to effectively improve mechanical properties and flame retardation performance of the PET / PP alloy material, and make the PET / PP blending alloy material have advantages of high notch impact strength, excellent bendability, and good flame retardation effect; and the PET / PP blending alloy material is widely applied in the fields of automobile, household electrical appliance, toy and machinery, and has a wide application prospect.

Owner:QINGDAO XINZHAN PLASTIC

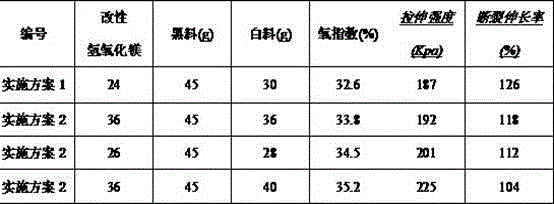

Preparation method of halogen-free flame retardant rigid polyurethane foam insulation material for exterior wall insulation

The present invention relates to a preparation method of halogen-free flame retardant rigid polyurethane foam insulation material for exterior wall insulation, and belongs to the field of energy-saving environment-friendly building insulation materials. The material is prepared by mixing a black material and a combined white material. The black material is isocyanate; the combined white material comprises 20-40 parts of polyol, 10-40 parts of a modified flame retardant, 1-10 parts of a synergistic flame retardant, 0.5-5 parts of a catalyst, 1-5 parts of a foaming agent and 0.5-3 parts of a stabilizer. The modified flame retardant employed by the present invention is magnesium hydroxide treated by a special coupling agent, has excellent flame retardation effect and fire rating of up to B1 grade; and the combined white material prepared from the flame retardant is not easy to produce stratification or precipitation, and can be placed for 30 days. The insulation material provided by the invention meets the needs of industrial production, plays a role in energy conservation and environmental protection, and is superior to the existing organic flame retardant insulation materials on the market.

Owner:大连亚泰科技新材料股份有限公司

105 DEG C low-smoke zero-halogen flame-retardant ethylene-propylene-diene monomer cable material and preparation method thereof

InactiveCN103509257AImprove flame retardant performanceLow smoke productionRubber insulatorsInsulated cablesDehydroacetic acidMicrocrystalline wax

The invention discloses a 105 DEG C low-smoke zero-halogen flame-retardant ethylene-propylene-diene monomer cable material and a preparation method thereof. The cable material is prepared from the following raw materials in parts by weight: 75-95 parts of ethylene-propylene-diene monomer, 30-40 parts of SG-4 type PVC resin, 10-15 parts of PBT resin, 1-2 parts of antiager DM, 1-2 parts of antiager RD, 2-3 parts of zinc oxide, 3-6 parts of titanium dioxide, 4-8 parts of microcrystalline wax, 10-15 parts of aluminium hydroxide, 5-10 parts of molybdenum trioxide, 8-12 parts of zinc borate, 1-2 parts of promoter TMTD, 2-3 parts of stearic acid, 15-20 parts of fumed silica, 10-15 parts of ultrafine powdered steatile, 10-15 parts of nanometer potter's clay, 1-2 parts of dehydroacetic acid, 5-10 parts of acetyl triethyl citrate, 4-8 parts of tributyl citrate, 2-3 parts of sulphur and 3-5 parts of a composite filler. The cable material of the invention is excellent in flame retardation effect, extremely less in smoke generating amount during combustion, none in generated toxic gas, none in generated corrosive gas, completely environment-friendly, good in high-temperature resistance, usable at 105 DEG C for a long time without deformation or scorch, capable of normally transmitting signals or electric energy, and durable.

Owner:安徽天民电气科技有限公司

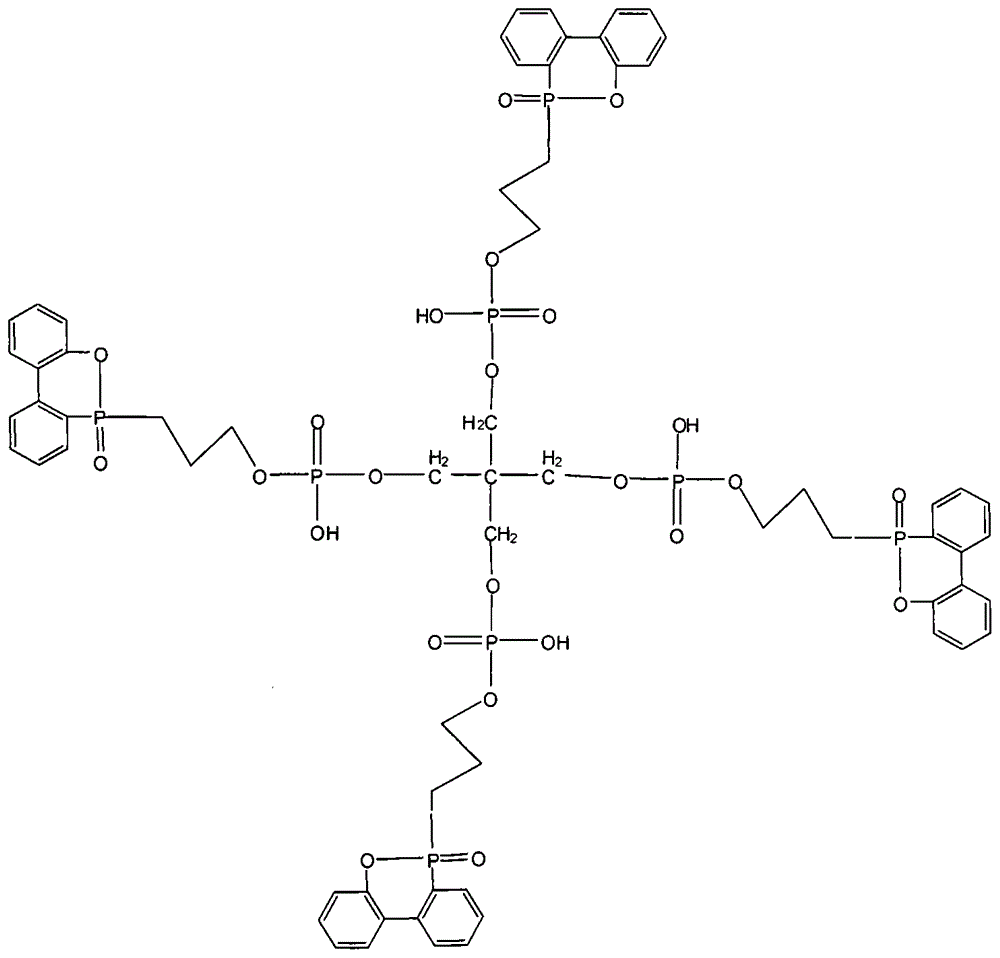

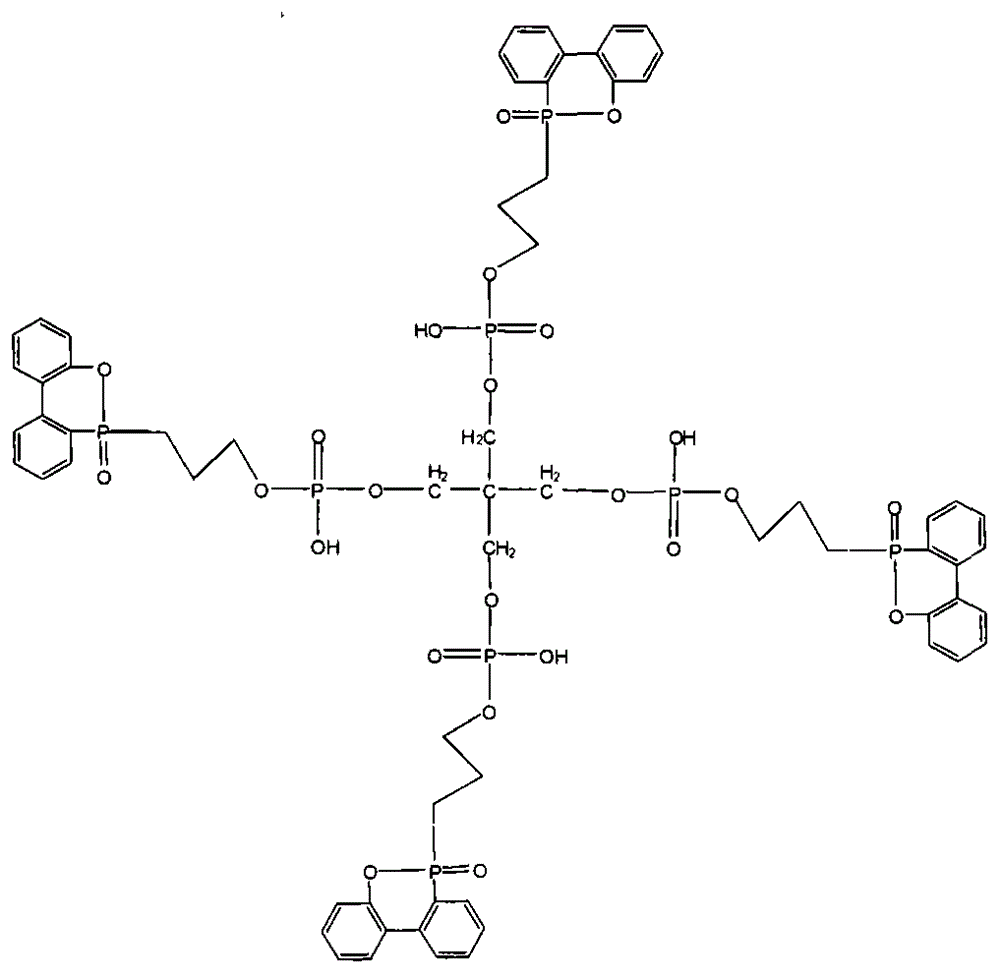

Flame retardant containing DOPO groups and preparation method of flame retardant

InactiveCN104629086AHigh molecular weightImprove thermal stabilityGroup 5/15 element organic compoundsPolymer scienceGas phase

The invention relates to a flame retardant which contains DOPO groups and has gas phase and solid phase flame retardation effects and a preparation method of the flame retardant. The flame retardant is a novel flame retardant, can be added into a polymer material as an improved auxiliary agent, and belongs to the technical field of processing auxiliary agents. The flame retardant disclosed by the invention has high molecular weight and good thermal stability, is high in carbon residue rate after degradation, is stable in flame retardant efficiency, can be used for improving the flame retardant properties of the material by virtue of a gas phase and a solid phase, and can be used for improving the flame retardant properties of high molecular materials after the flame retardant is added into the high molecular materials; and the method disclosed by the invention is simple, adopts a one-pot process, and is high in efficiency.

Owner:国建工材(北京)科技有限公司

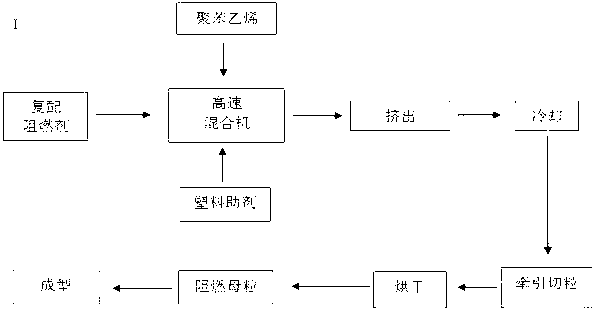

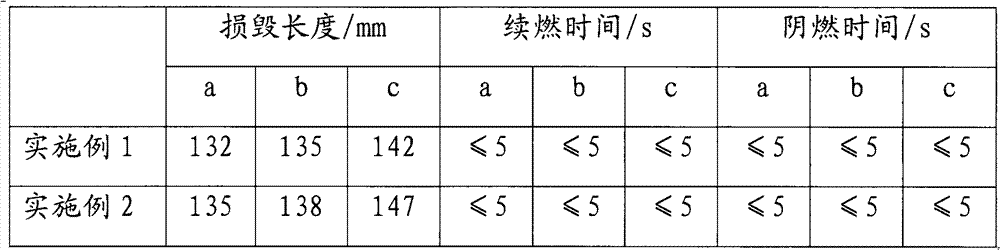

Compounding flame retardation polystyrene composition and preparation method thereof

The invention relates to a compounding flame retardation polystyrene composition and a preparation method thereof. The composition comprises polystyrene resin, complex flame retardant, lubrication dispersant, flexibilizer and anti-oxidant. The method comprises the steps of: adding all the components into a high speed mixer, mixing the components uniformly, extruding the mixed components by using a double-screw extruder, and granulating the mixed components by using a pelleter to obtain polystyrene composition pellets. According to the invention, compounding is carried out by using environment-friendly decabromodiphenylethane, antimony trioxide, zinc borate and thermoplastic phenol resins; toxic polybrominated dibenzdioxan and toxic polybrominated dibenzofurans are not generated when combustion of the composition is carried out; relatively expensive antimony trioxide is partially replaced by cheap zinc borate; not only price is low, but also smoke concentration in combustion process can be effectively reduced, and combustion molten drops are inhibited, thereby synergistic flame retardation effect of the compounding flame retardant is obvious, and flame retardation effect is good.

Owner:TAIYUAN UNIV OF TECH +1

Waterborne polyurethane coating and preparation process

InactiveCN106634530AImprove flame retardant performanceHarm reductionFireproof paintsAntifouling/underwater paintsFire retardantPolyurethane coating

The invention discloses waterborne polyurethane coating and a preparation process thereof. The waterborne polyurethane coating is prepared from modified waterborne polyurethane, an expansive fire-retardant system, a flame retardant synergist, water, filler, a dispersing agent, an antifoaming agent, a thickening agent, a curing agent, a mildew-proof bactericide, a coalescing agent and a penetrating agent. The preparation process is simple, feasible and low in preparation cost, and the coating prepared according to the method is great in flame retardation effect, nontoxic and free of environment pollution.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Fire-retardant finishing method of terylene fabric

InactiveCN102851944AImprove flame retardant performanceDoes not affect colorFibre typesCouplingFire retardant

The invention discloses a fire-retardant finishing method of a terylene fabric. The method comprises the following steps: dipping the terylene fabric in a dipping liquid containing a composite fire retardant at 80-95DEG C for 5-30min; and carrying out temperature maintenance of the terylene fabric at 115-130DEG C for 0.5-2h, wherein the composite fire retardant comprises 30-45 parts by weight of an organophosphorus compound, 50-70 parts by weight of zirconium oxide, and 2-5 parts by weight of an aluminum-zirconium coupling agent. The method has a substantial fire retardation effect to the terylene fabric, so the finished terylene fabric has a good fire retardation endurance, and the color, the appearance, the hand feel and other physical and mechanical performances of the fabric are not affected.

Owner:KUNSHAN TIENIU SHIRT FACTORY

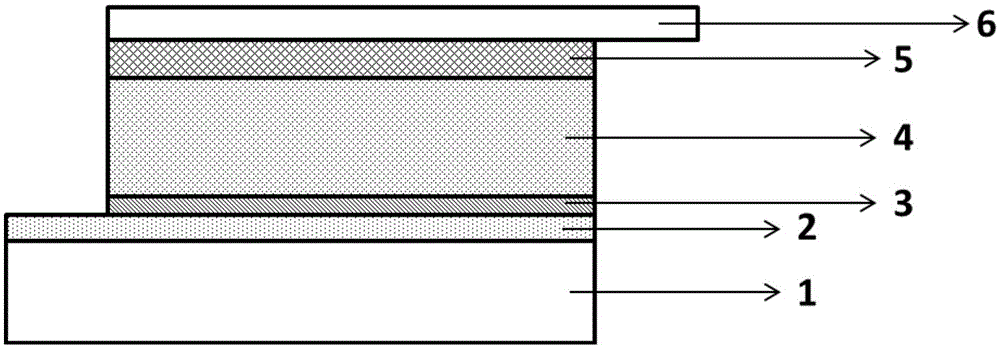

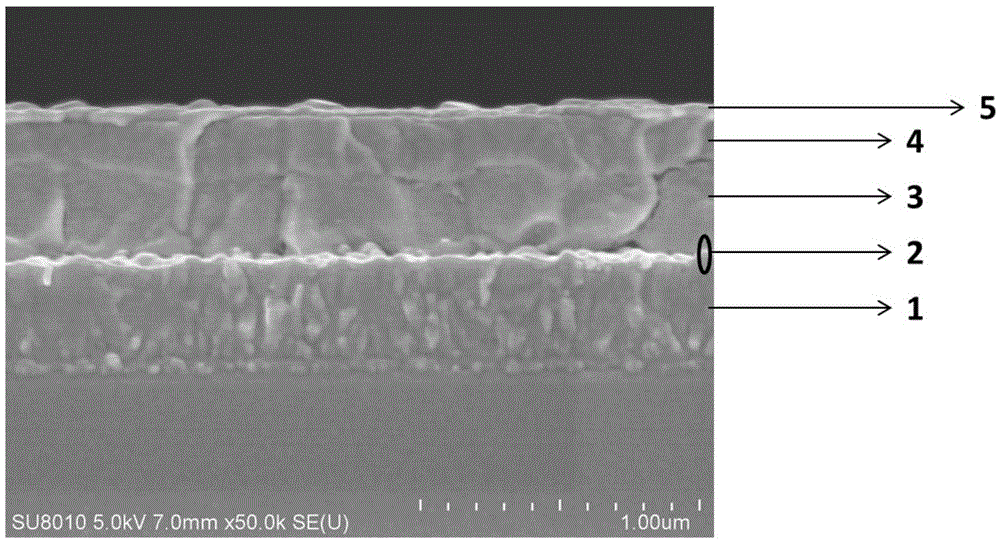

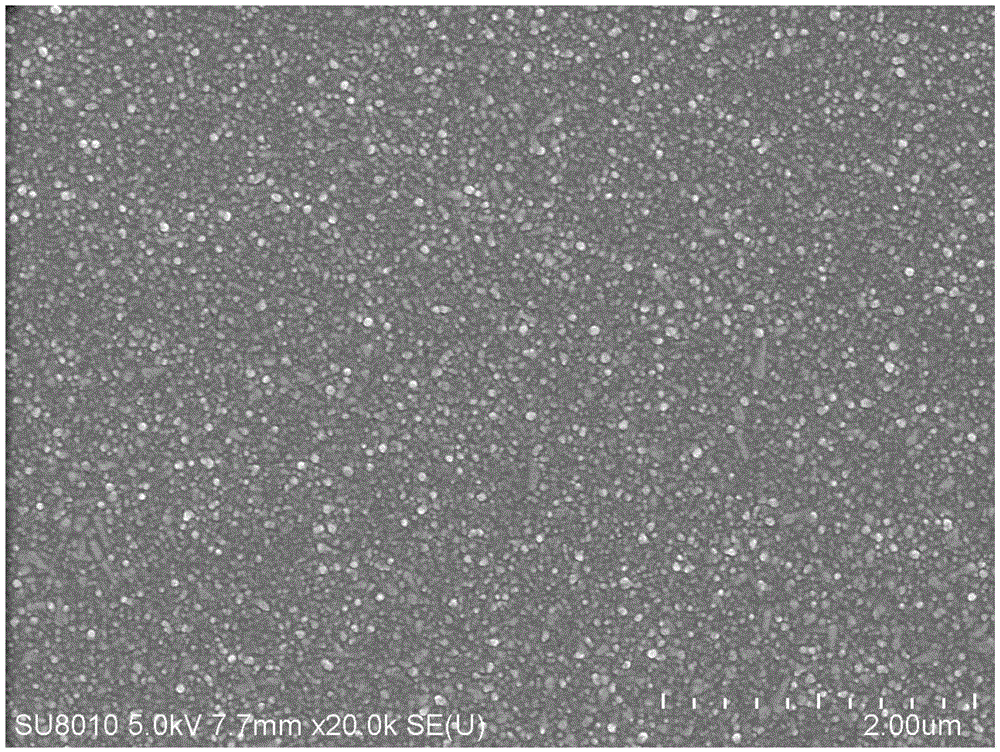

Method for preparing interface modified perovskite solar cell through vapor auxiliary solution method

InactiveCN105576131AQuality improvementImproved interface contactSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellSpins

The invention discloses a method for preparing an interface modified perovskite solar cell through a vapor auxiliary solution method, and belongs to the technical field of solar cells. Electron transmission material is spin-coated on a clean FTO substrate, and a barrier layer is obtained through thermal treatment; then a C60 organic solution is spin-coated on the barrier layer, and an interface modification layer is obtained through thermal treatment; a perovskite light absorption layer is prepared on the interface modification layer by using the vapor auxiliary solution method; and finally a hole transmission layer is spin-coated on the perovskite light absorption layer and then vacuum vapor plating of a counter electrode is performed so that the perovskite solar cell is obtained. According to the method, the perovskite light absorption layer is prepared by using the vapor auxiliary solution method, and the interface between the barrier layer and the perovskite light absorption layer is modified so that the retardation effect of the perovskite solar cell can be reduced and photoelectric conversion efficiency and electrical performance of the perovskite solar cell can be enhanced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

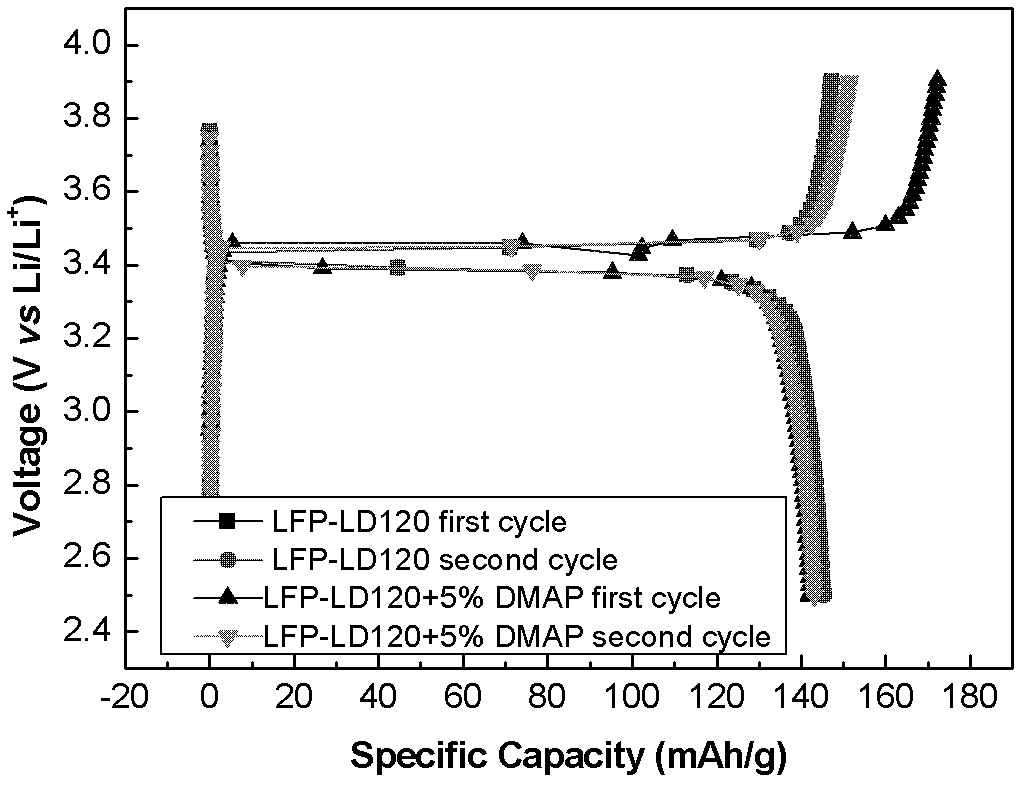

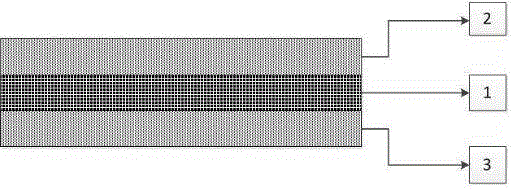

Lithium ion battery

ActiveCN102368565AImprove securityIncrease current densitySecondary cellsNon-aqueous electrolyte accumulator electrodesRetardation effectPhosphoric acid

The invention relates to the technical field of lithium ion batteries, and especially relates to a high safety lithium ion battery. The lithium ion battery is characterized in that: the lithium ion battery comprises a cathode plate, an anode plate, a separation film and an electrolyte, and two ends of the anode plate in a length direction are respectively provided with at least one tab; the electrolyte comprises a phosphate ester flame retardant additive; and the electrolyte comprises a film forming additive, and the head and the tail of the anode plate are respectively welded with one or more tabs which have shunting effects. So the prepared monomeric battery has a multi-tab structure. The electrolyte in the battery of the invention, which has a good flame retardation effect, allows the safety of the battery to be effectively improved; and the introduction of the film forming additive and the current optimization by the two tabs allow the compatibility of the anode plate and the electrolyte to be improved, and the anode plate to be prevented from being destroyed by the flame retardant additive.

Owner:DONGGUAN AMPEREX TECH +1

Fire retardation coating material, preparation method and uses thereof

The present invention discloses a fire retardation coating material, a preparation method and uses thereof. The coating material comprises, by weight, 20-40% of a polyvinyl chloride paste resin, 5-10% of a polytetrafluoroethylene suspension resin, 20-30% of an auxiliary agent part (a plasticizer, a heat stabilizer, an anti-ultraviolet agent, a sterilization agent, and a fire retardation agent), 5.0-10% of titanium dioxide, 3-5% of calcium carbonate, and the balance of a solvent part. According to the present invention, the polyvinyl chloride paste resin, the polytetrafluoroethylene suspension resin, the plasticizer, the heat stabilizer, the anti-ultraviolet agent, the sterilization agent, the fire retardation agent, the titanium dioxide and the calcium carbonate are adopted as the raw materials, and titanium dioxide slurry preparing, mixing, viscosity adjusting and a series of processes are performed to prepare the fire retardation coating material; and the PET textile cloth coated with the coating material of the present invention can be used in the field of PET tarpaulins, and has the good fire retardation effect.

Owner:SHANGHAI NAR INDAL

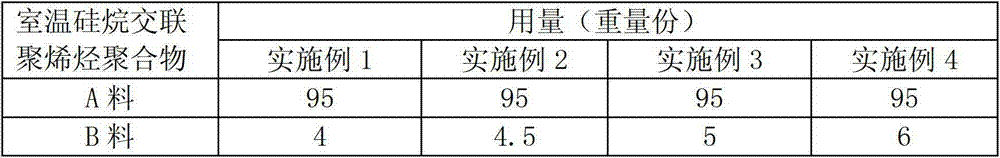

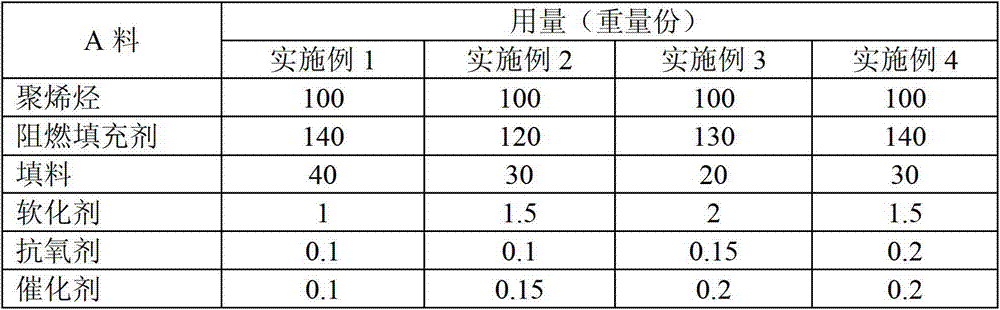

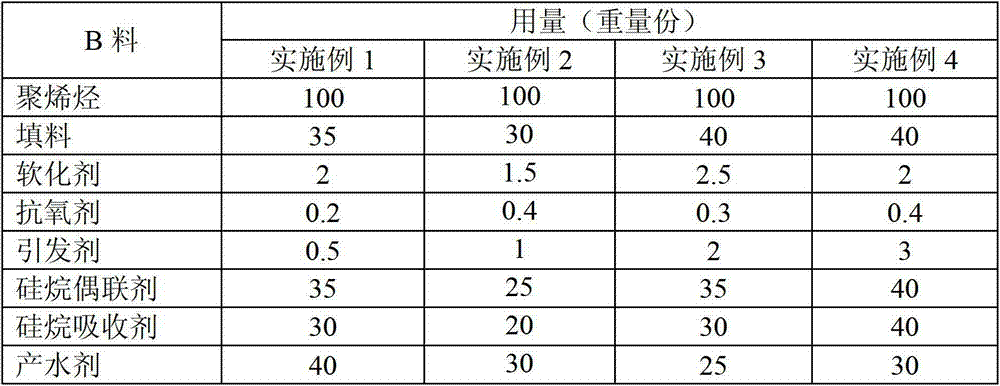

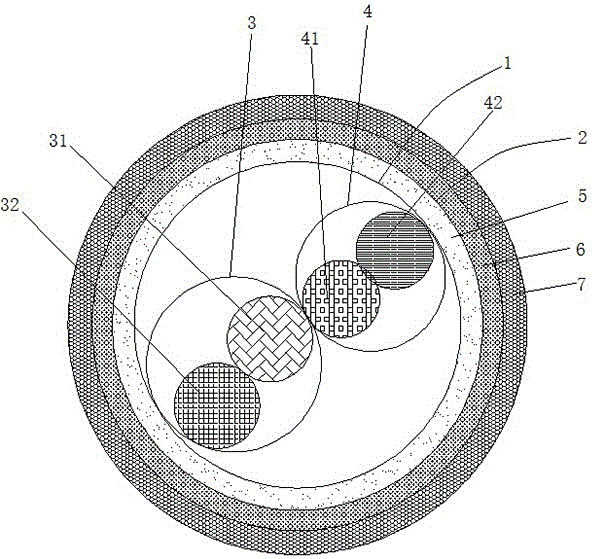

Room-temperature silane cross-linked polyolefin and its preparation method

The invention discloses a room-temperature silane cross-linked polyolefin and its preparation method. The preparation method comprises the following steps: mixing polyolefin in a 80-100DEG C open mill, rolling, sequentially adding a flame retardant filler, a filler, a softener and an antioxidant, mixing for 5-15min, adding a catalyst, mixing for 2-6min, and taking down to obtain a material A; mixing polyolefin in a 60-90DEG C open mill, rolling, sequentially adding a filler, an antioxidant and a water bringing agent, mixing for 5-15min, adding a silane coupling agent / silane absorbent mixture, mixing for 2-5min, and taking down to obtain a material B; and uniformly mixing the catalyst material A with the base material B according to a weight ratio of 95:4-6 at 60-90DEG C, mixing for 4-8min for tabletting, tabletting with a press vulcanizer at 165-175DEG C for 10-20min, and disposing the prepared sample at normal temperature for 24-120h to obtain the silane cross-linked polyolefin. The preparation method has the advantages of omitting of a water boiling cross-linking or water vapor bath cross-linking link, technology simplification and cost reduction, and a wire and cable sheath material prepared through using the silane cross-linked polyolefin has the advantages of good elasticity and flexibility, good flame retardation effect, and strong heat resistance and ageing resistance.

Owner:上海驰程化工工贸有限公司

Antibiotic flame-retardant yarn and production process thereof

ActiveCN106555265AImprove antibacterial propertiesImprove flame retardant performanceYarnYarnSurface layer

The invention provides an antibiotic flame-retardant yarn and a production process thereof. The yarn comprises a core layer and a surface layer wrapping the outer wall of the core layer, the core layer is formed by intertwining an antibiotic strand and a flame-retardant strand, and the surface layer comprises an antibiotic coating, a heat insulation fibrous layer and a flame-retardant coating which are successively arranged at the surface of the core layer from the inside to the outside; the antibiotic strand is formed by blending a nanometer titanium dioxide catalyst fiber with a bamboo charcoal fiber; and the flame-retardant strand is formed by blending a PPT fiber with a polytetrafluoroethylene fiber. According to the invention, the yarn is formed by intertwining the antibiotic strand and the flame-retardant strand, the antibiotic strand is formed by blending the nanometer titanium dioxide catalyst fiber with the bamboo charcoal fiber, and the flame-retardant strand is formed by blending the PPT fiber with the polytetrafluoroethylene fiber, through compounding of the multiple fibers and configuration of the antibiotic coating, the heat insulation fibrous layer and the flame-retardant coating arranged on the surface layer, the yarn is enabled to have quite good antibiotic and flame retardation effects, the preparation cost of the yarn is low, the economic benefits are good, and large-scale production is facilitated.

Owner:杭州缤丽纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com