Antibiotic flame-retardant yarn and production process thereof

The technology of yarn and antibacterial strand is applied in the field of antibacterial and flame retardant yarn and its production technology, which can solve the problems of single efficacy and the like, and achieve the effect of low preparation cost, good economic benefit and good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below through specific examples, but the examples do not limit the protection scope of the present invention.

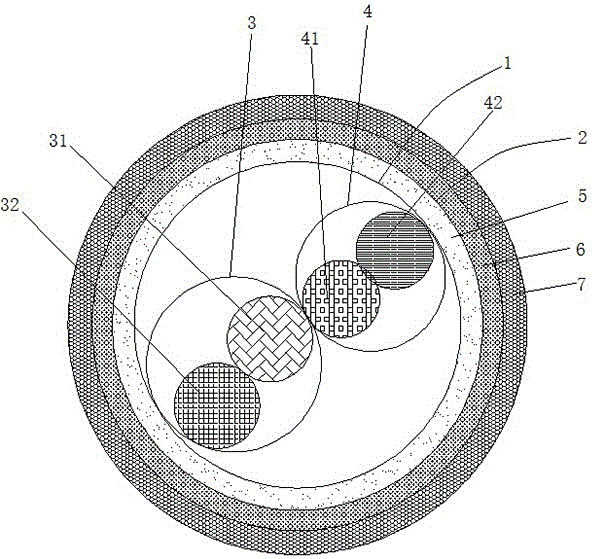

[0045] refer to figure 1 , a kind of antibacterial flame-retardant yarn of the present invention, described yarn comprises: core layer 1 and the surface layer 2 that is coated on the outer wall of core layer 1, and described core layer 1 is made of antibacterial strand 3 and flame-retardant strand 4. Formed by cross-twisting, the surface layer 2 includes an antibacterial coating 5, a heat-insulating fiber layer 6 and a flame-retardant coating 7 that are sequentially arranged on the surface of the core layer 1 from inside to outside; the antibacterial strand 3 is composed of nano-titanium dioxide catalyst fibers 31 and Bamboo charcoal fibers 32 are blended; the flame retardant strand 4 is formed by blending PPT fibers 41 and polytetrafluoroethylene fibers 42 .

[0046] Further, the antibacterial coating 5 is an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com