Fire-retardant finishing method of terylene fabric

A polyester fabric, flame retardant finishing technology, used in fiber processing, textiles and paper making, etc., to achieve good flame retardant durability, strong durability, and significant flame retardant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

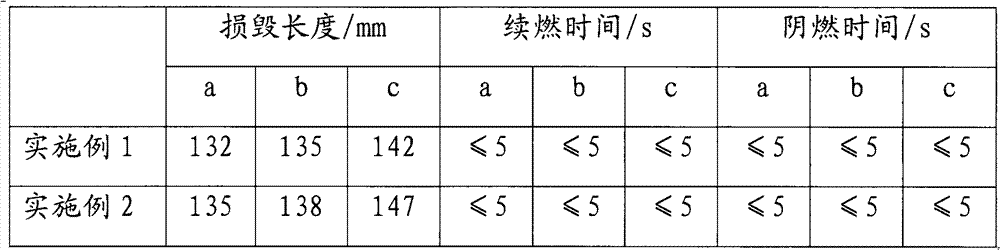

Embodiment 1

[0015] Preparation of composite flame retardant:

[0016] Add 35 grams of cyclic phosphonate, 60 grams of zirconia, and 5 grams of aluminum zirconate coupling agent into water and mix to prepare an impregnation solution with a mass solid content of 40%.

[0017] Finishing of flame retardant polyester fabric:

[0018] The polyester fabric was immersed in the dipping solution containing the above-mentioned composite flame retardant at 95° C. for 30 minutes, and then the polyester fabric was kept at a constant temperature of 120° C. for 1 hour.

Embodiment 2

[0020] Preparation of composite flame retardant:

[0021] 40 grams of tetrakis hydroxymethyl phosphine chloride, 55 grams of zirconia, and 2 grams of aluminum zirconate coupling agent were added into water and mixed to prepare an impregnation solution with a mass solid content of 20%.

[0022] Finishing of flame retardant polyester fabric:

[0023] The polyester fabric was immersed in the dipping solution containing the above-mentioned composite flame retardant at 80°C for 20 minutes, and then the polyester fabric was kept at a constant temperature of 115°C for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com