Patents

Literature

191results about How to "Improve device stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

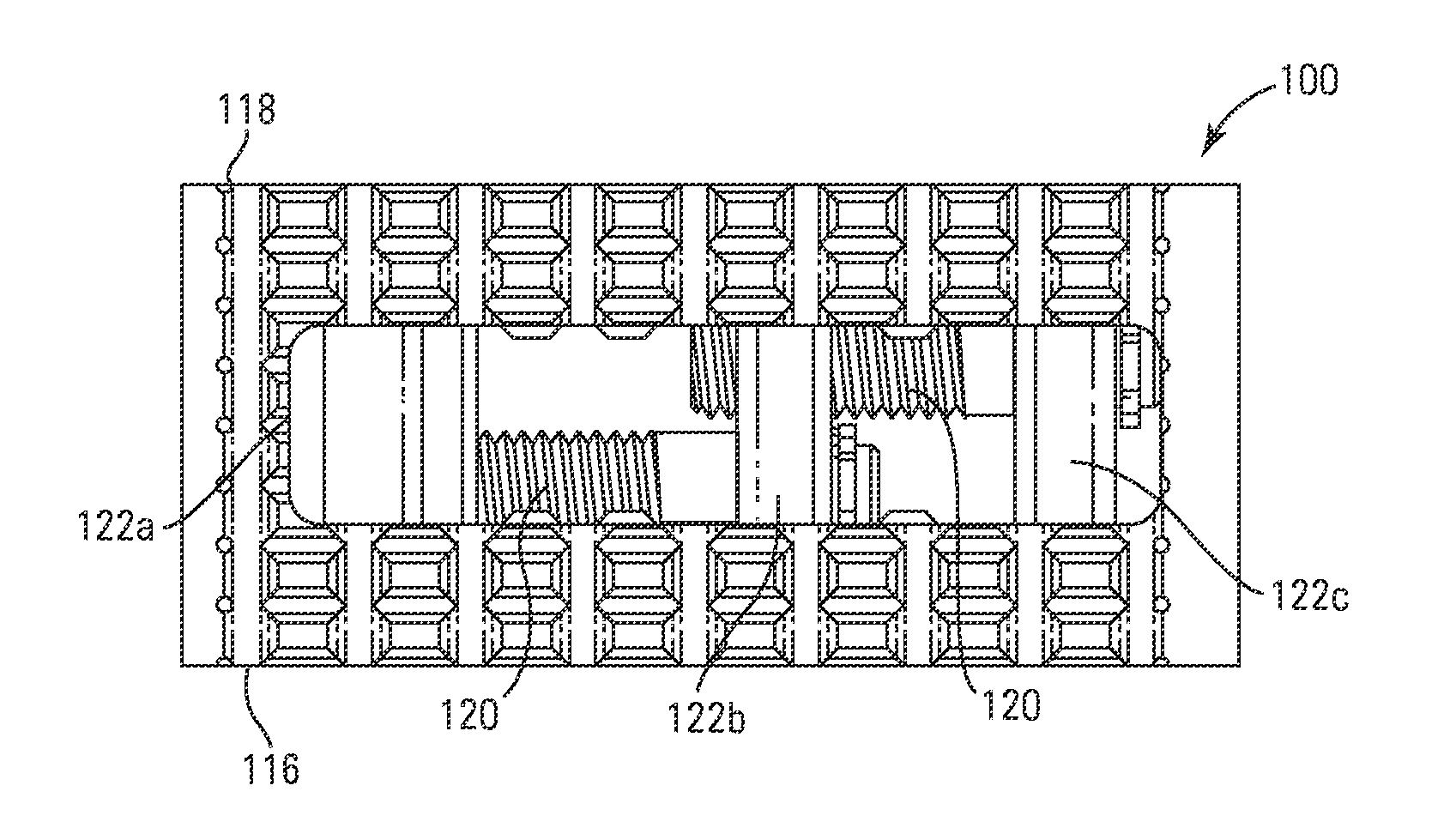

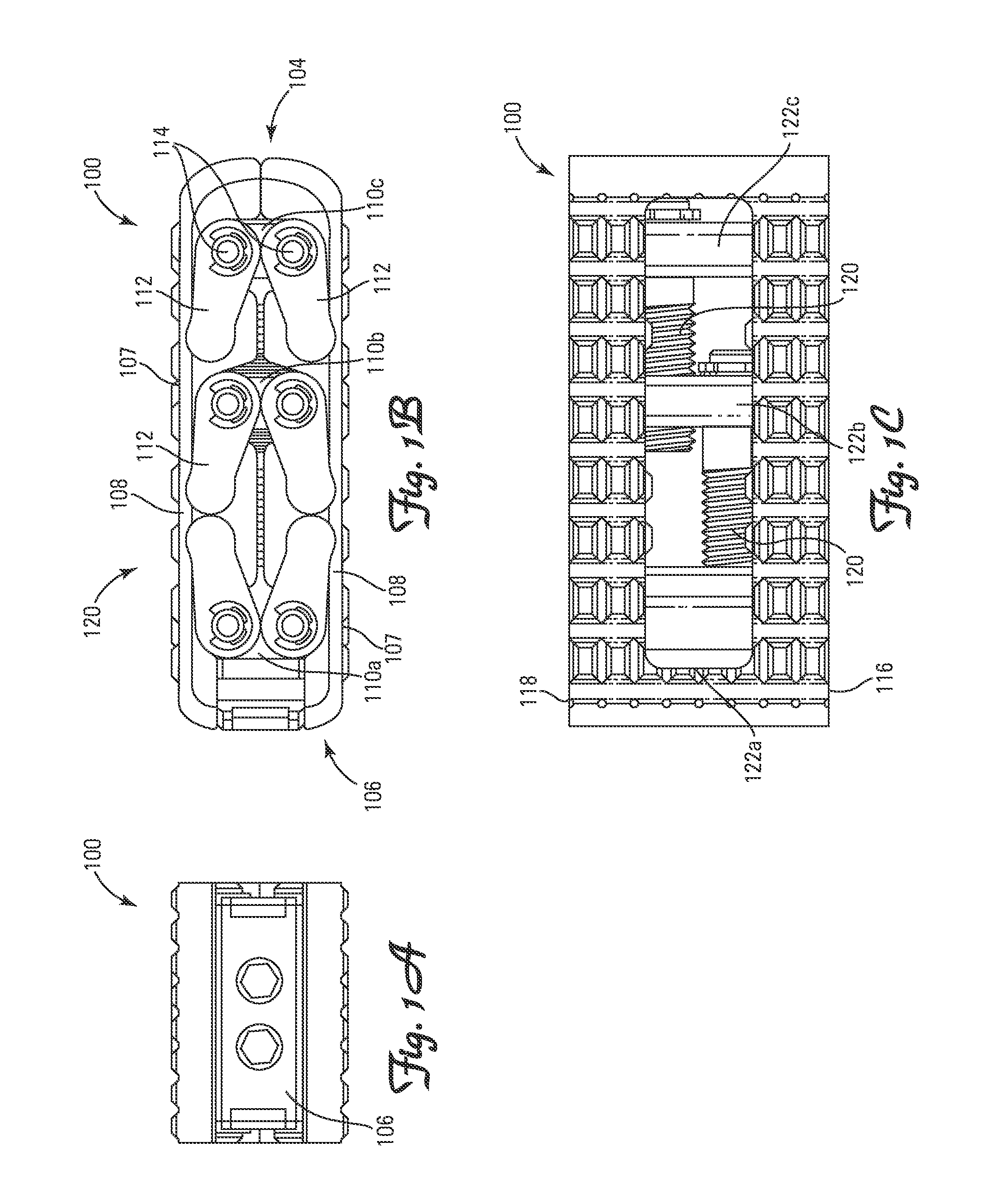

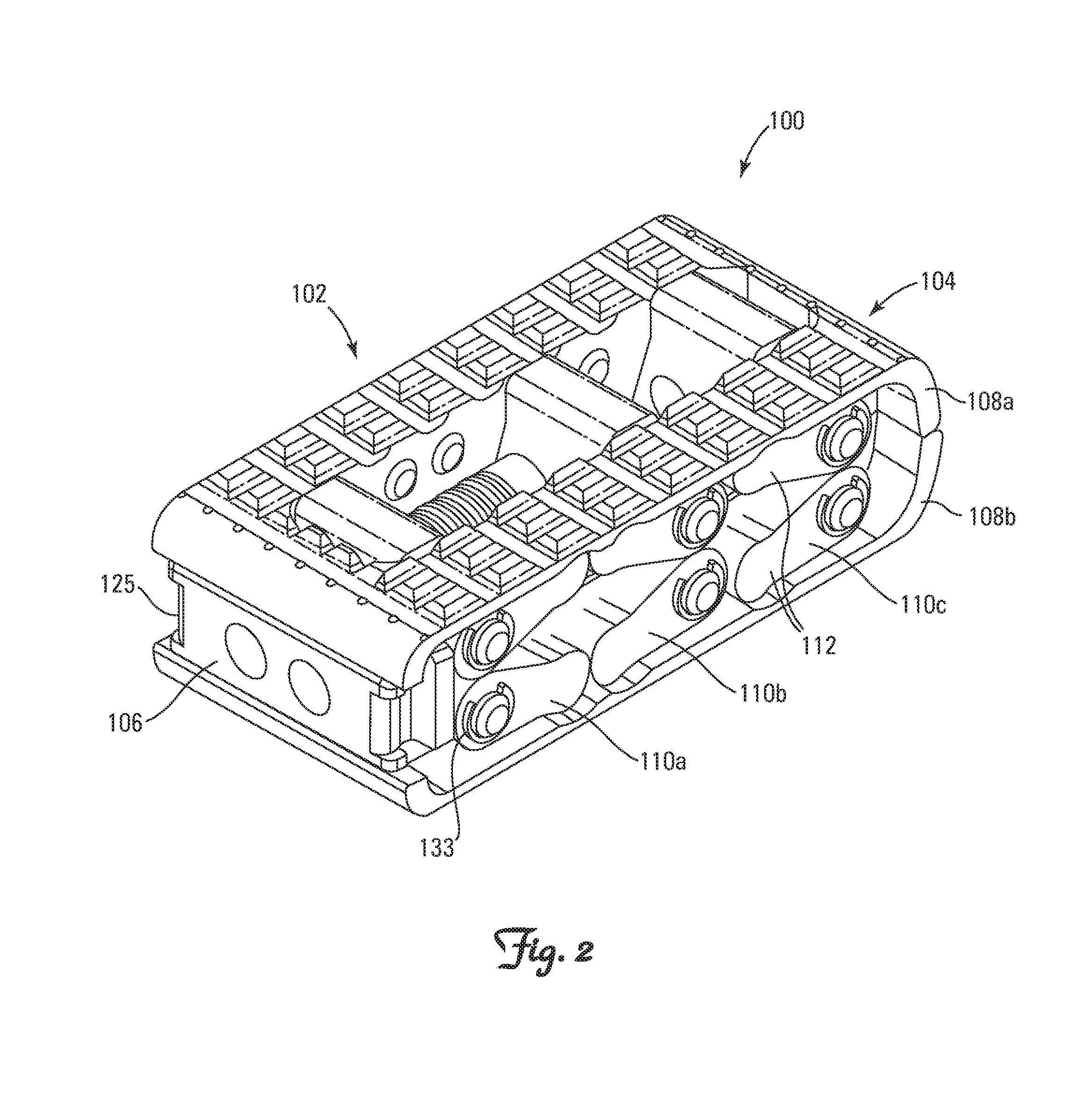

Expandable intervertebral cage

An expandable intervertebral cage adapted to be implanted into an intervertebral disc space in a patient's body, the expandable intervertebral cage including first and second base plates having outer surfaces configured to interface with vertebra in the intervertebral disc space, a first, second and third arm assembly hingedly connected to first and second base plates, and first and second actuation members, wherein rotation of the first actuation member pulls the second arm assembly towards the first arm assembly and rotation of the second actuation member pulls the third arm assembly towards the second arm assembly, the first actuation member and the second actuation member capable of being actuated independently of each other.

Owner:SPINEX TEC

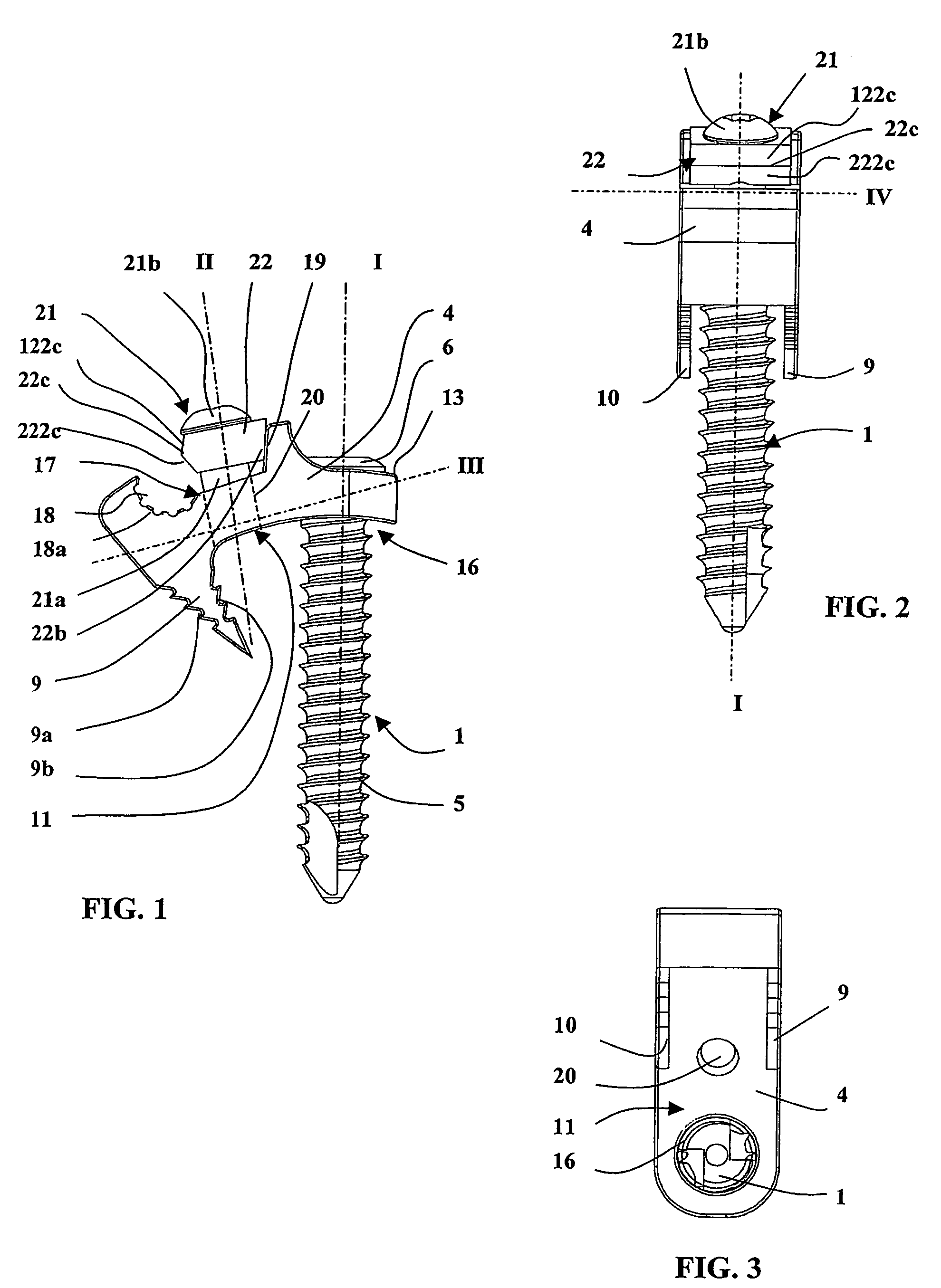

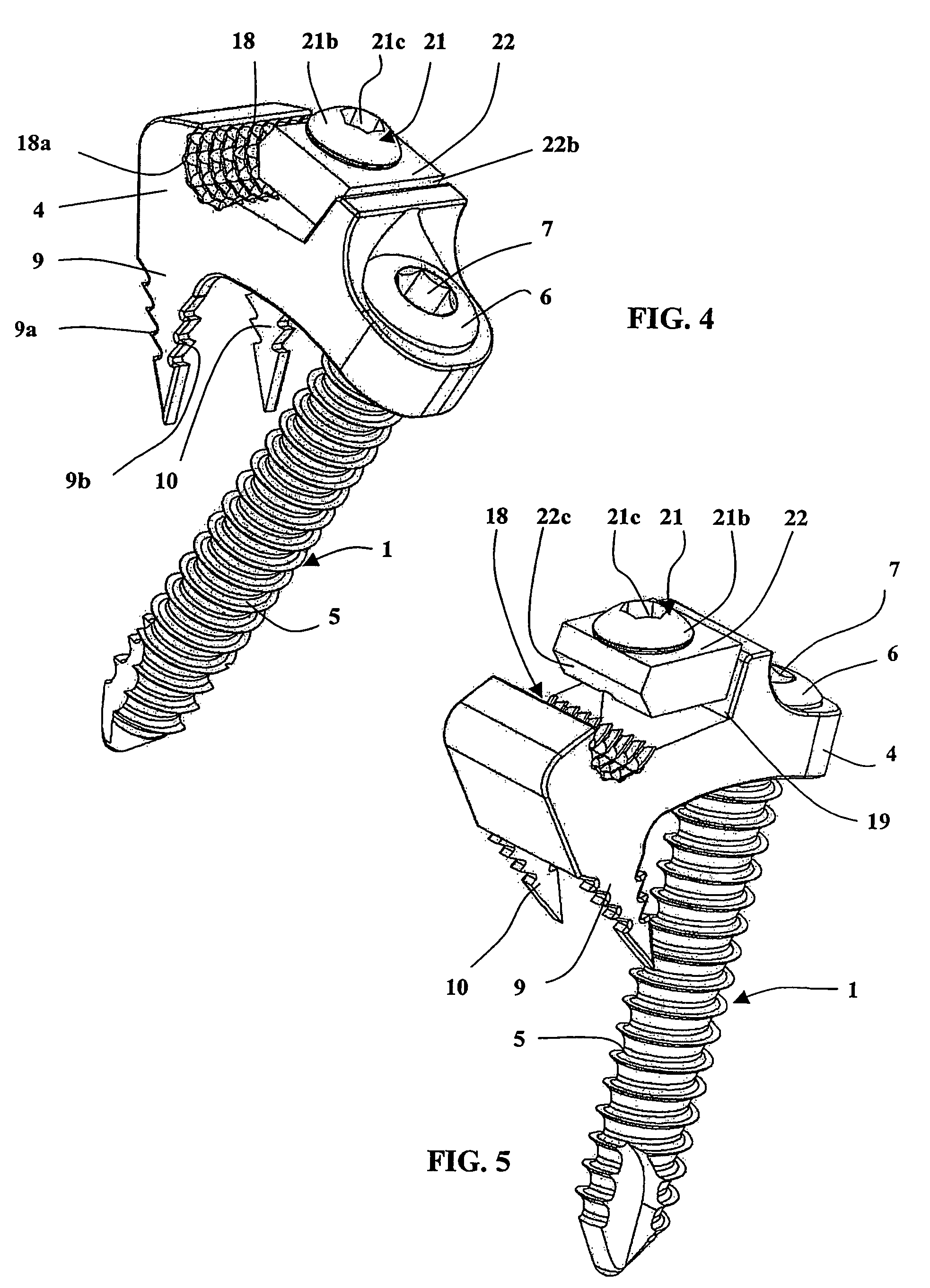

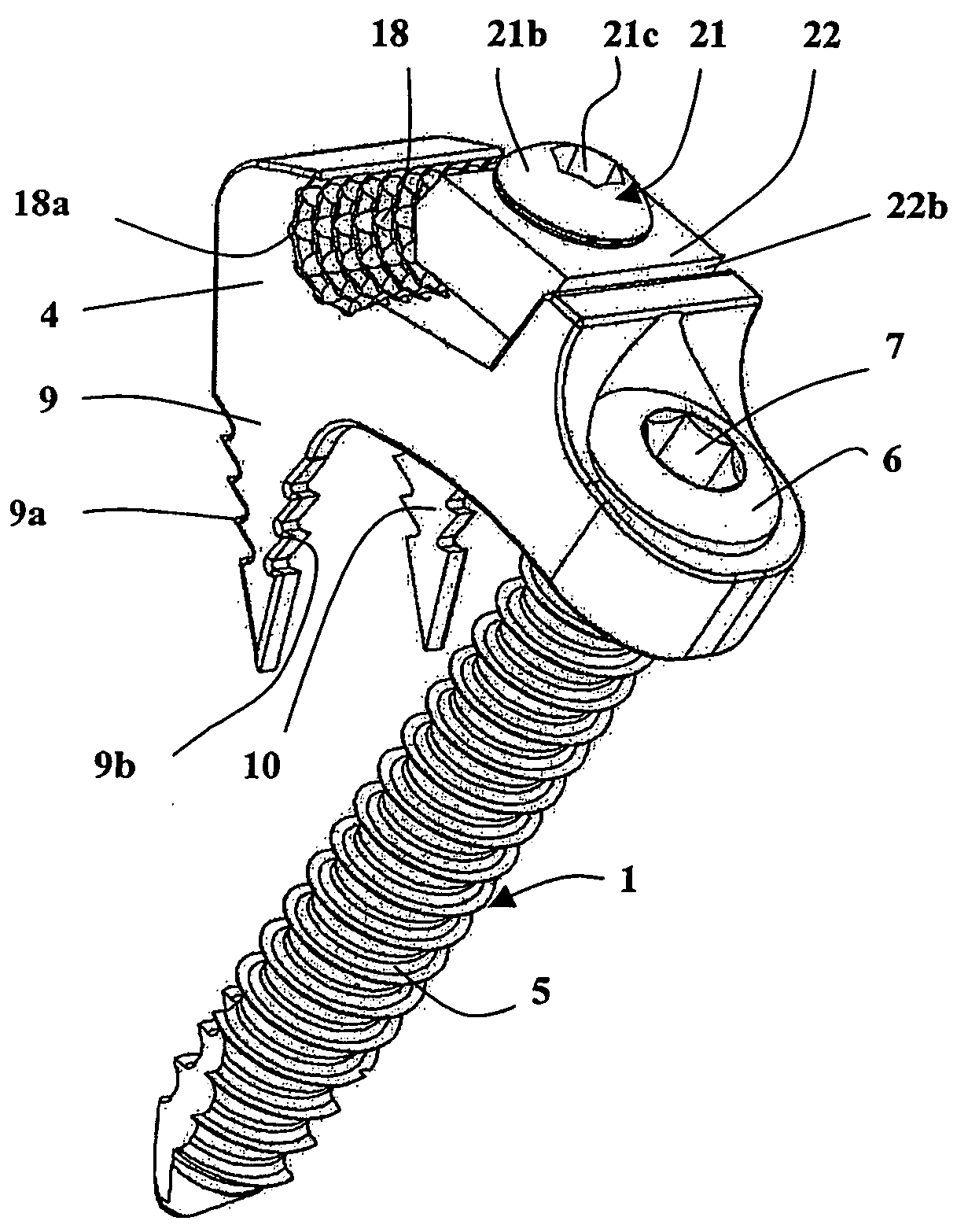

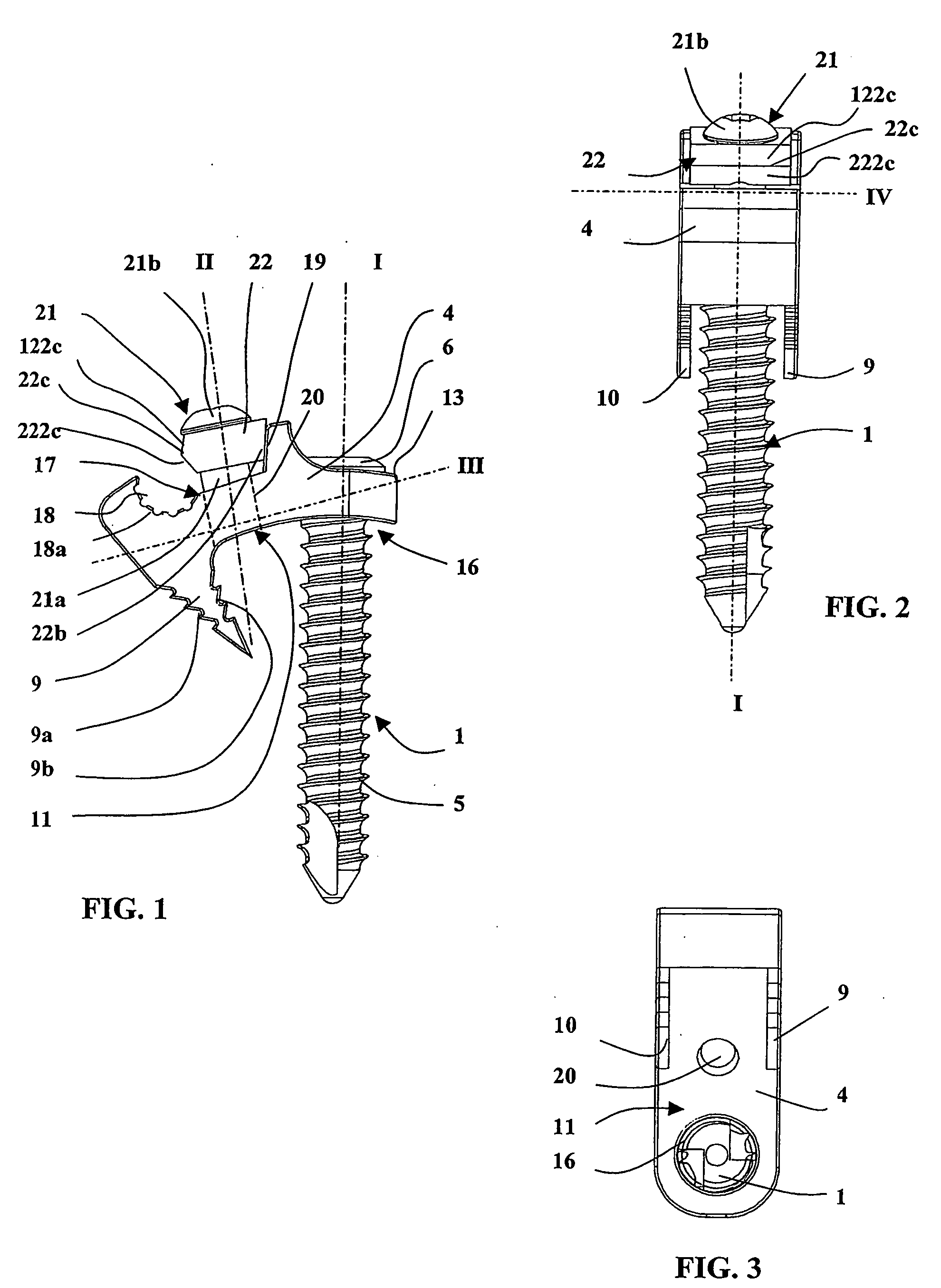

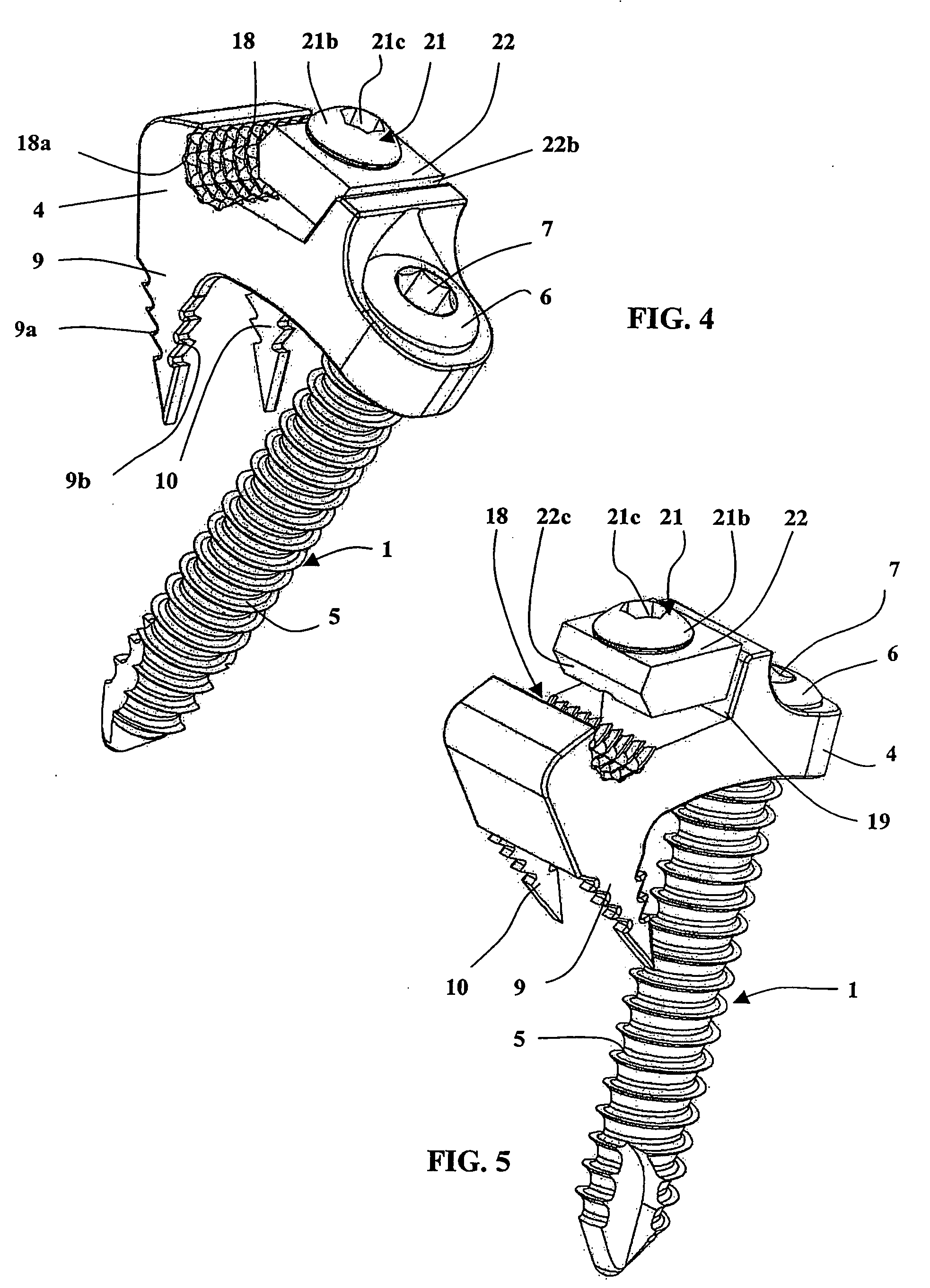

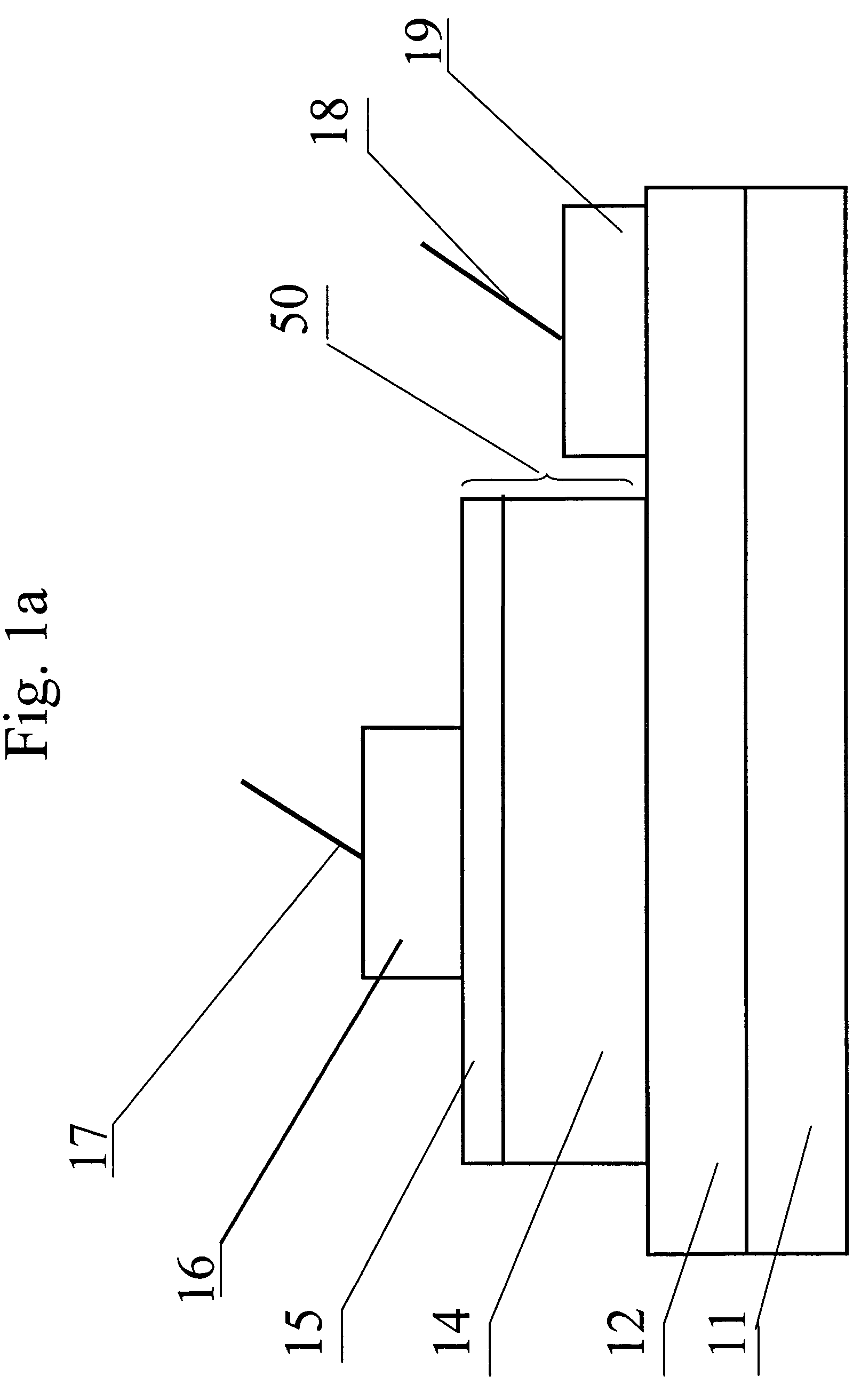

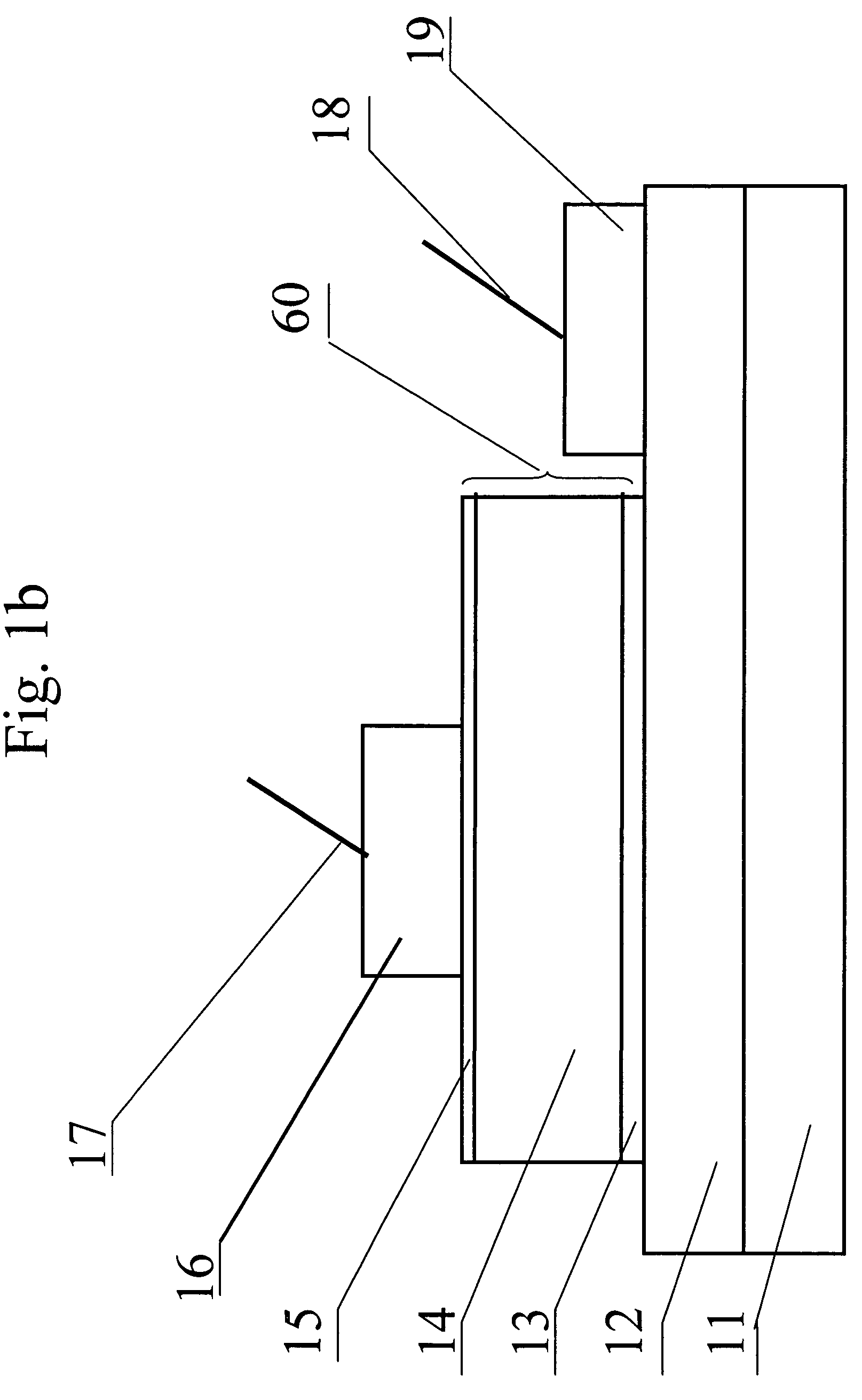

Device comprising anterior plate for vertebral column support

ActiveUS7455684B2More effective fastening of the vertebraeImprove fitInternal osteosythesisJoint implantsEngineeringAnterior plate

Owner:LAPE MEDICAL

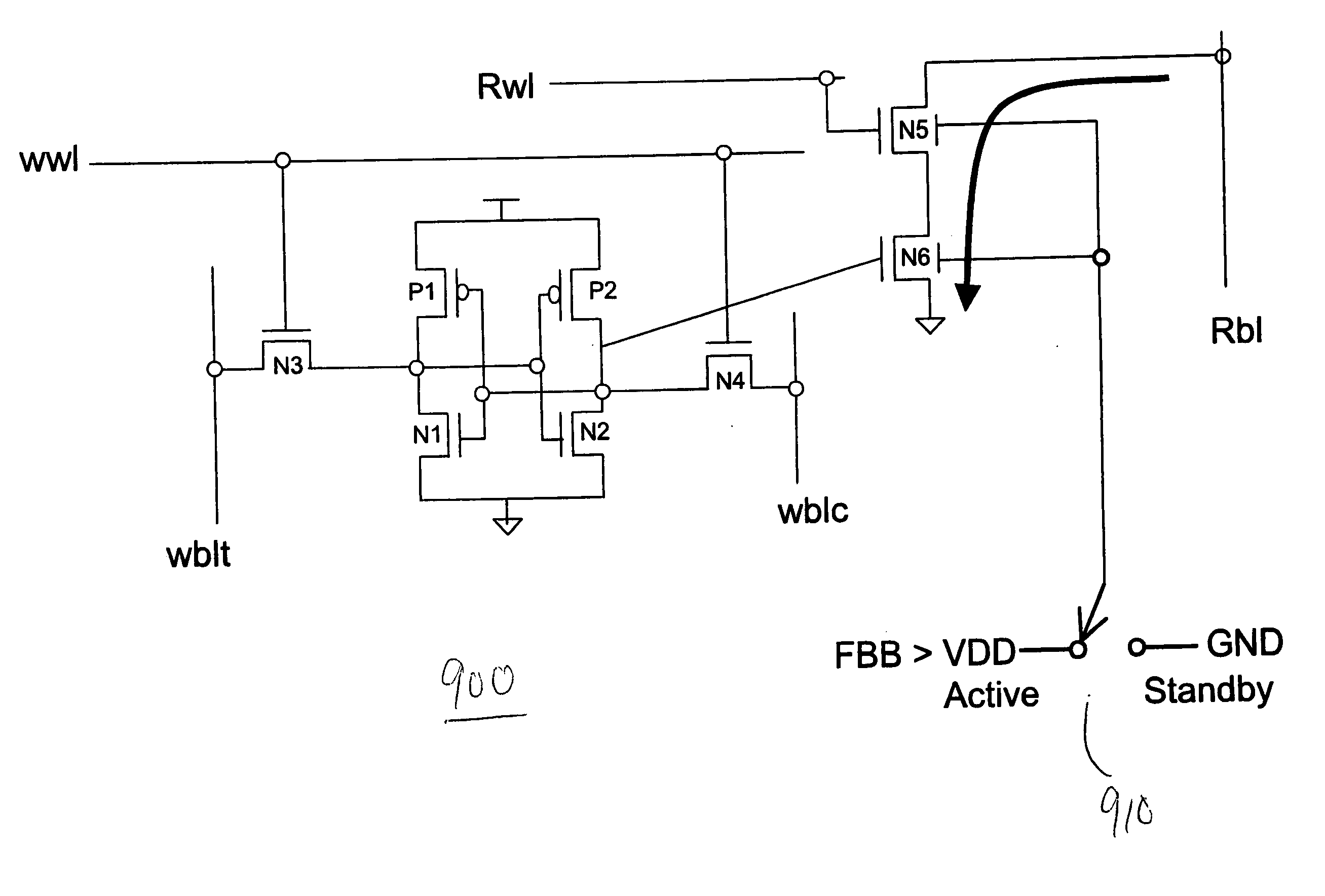

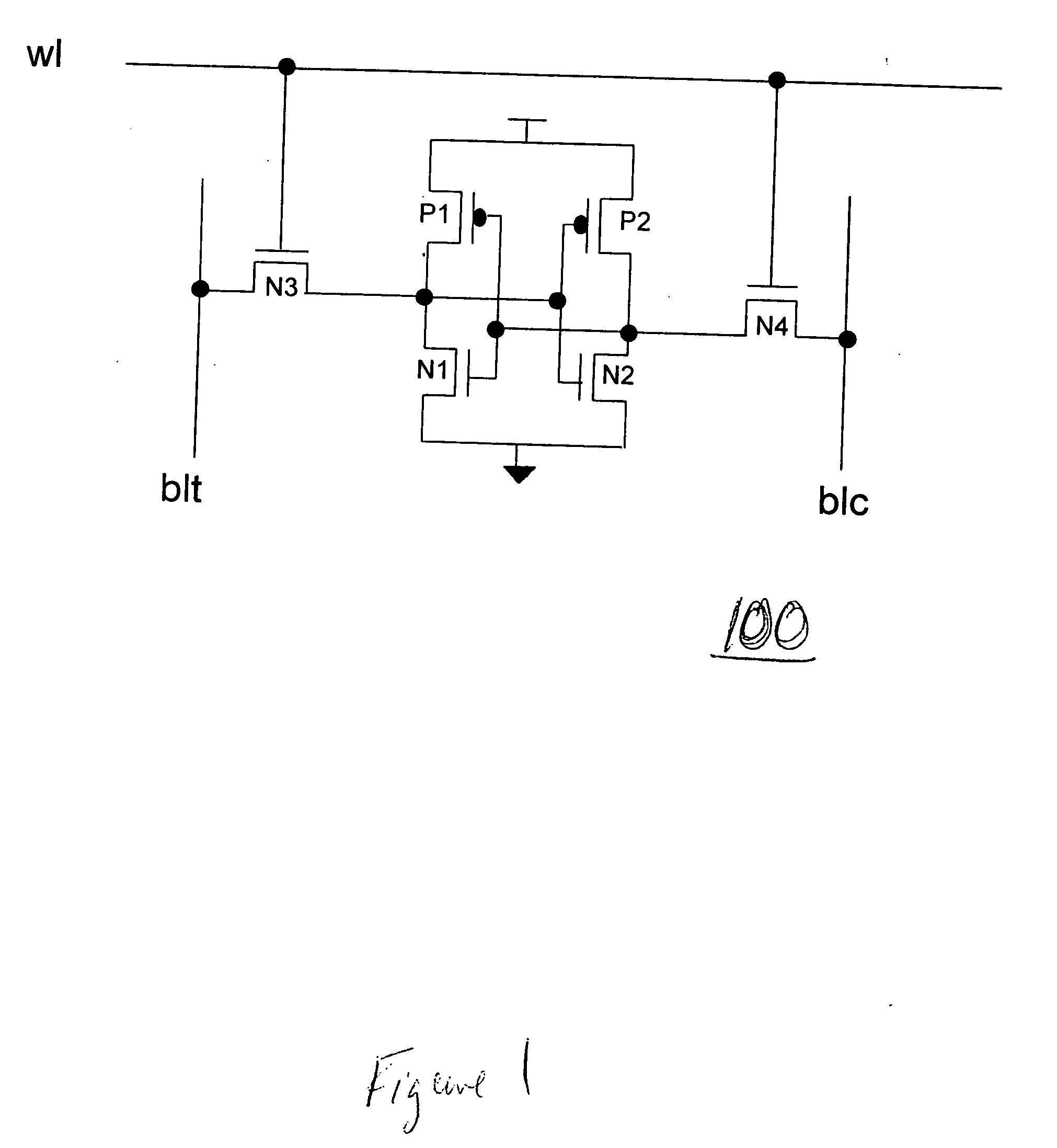

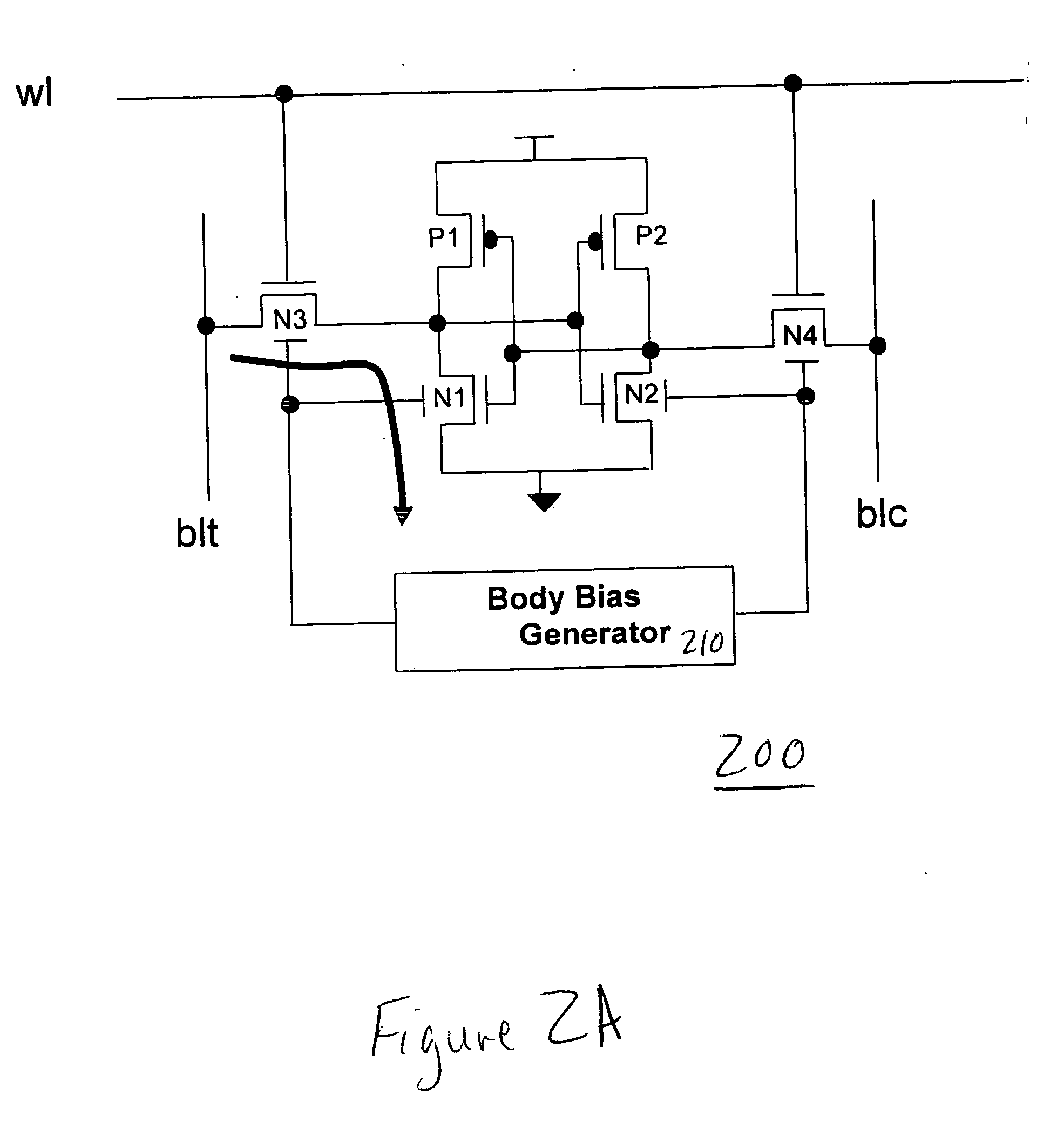

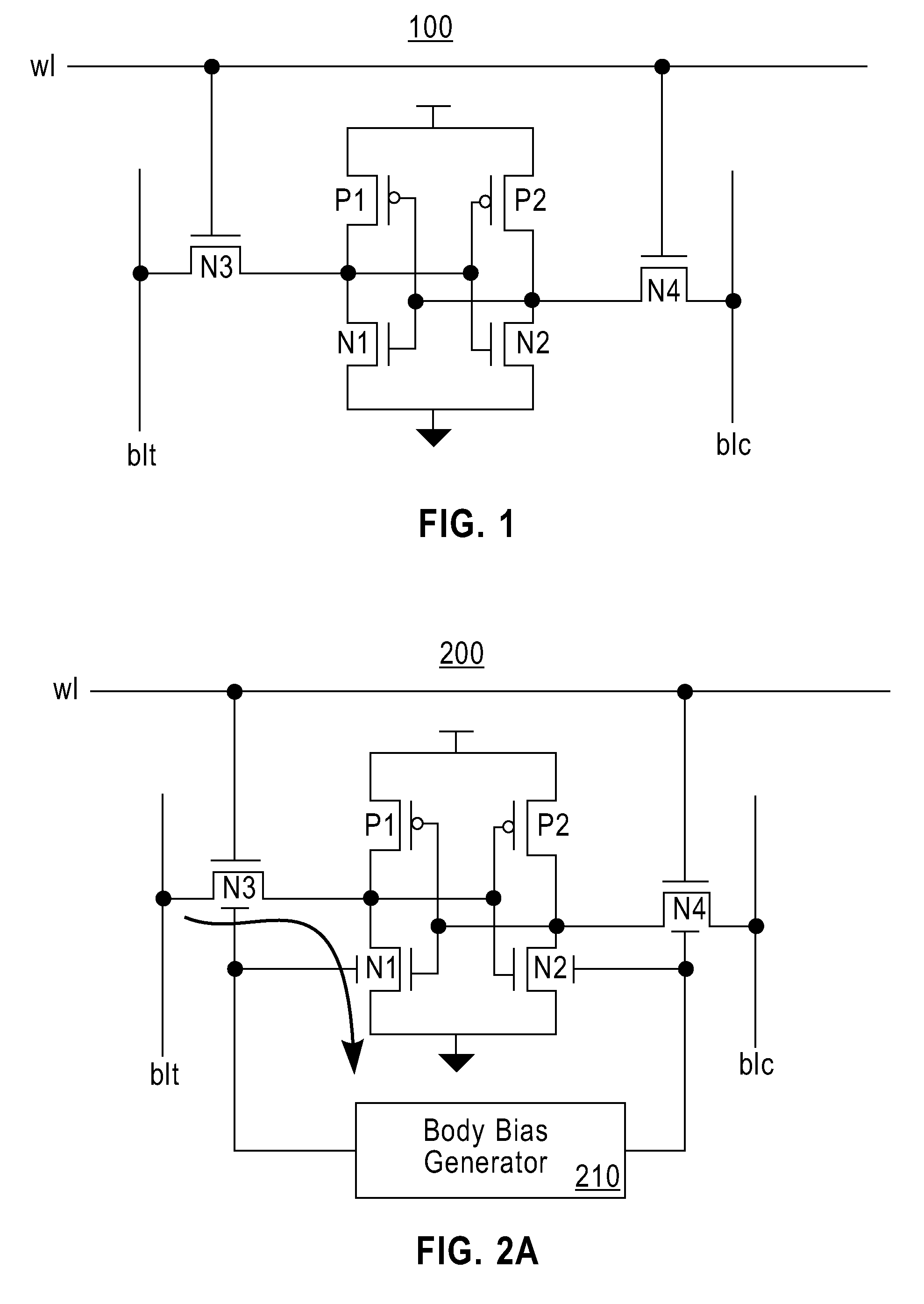

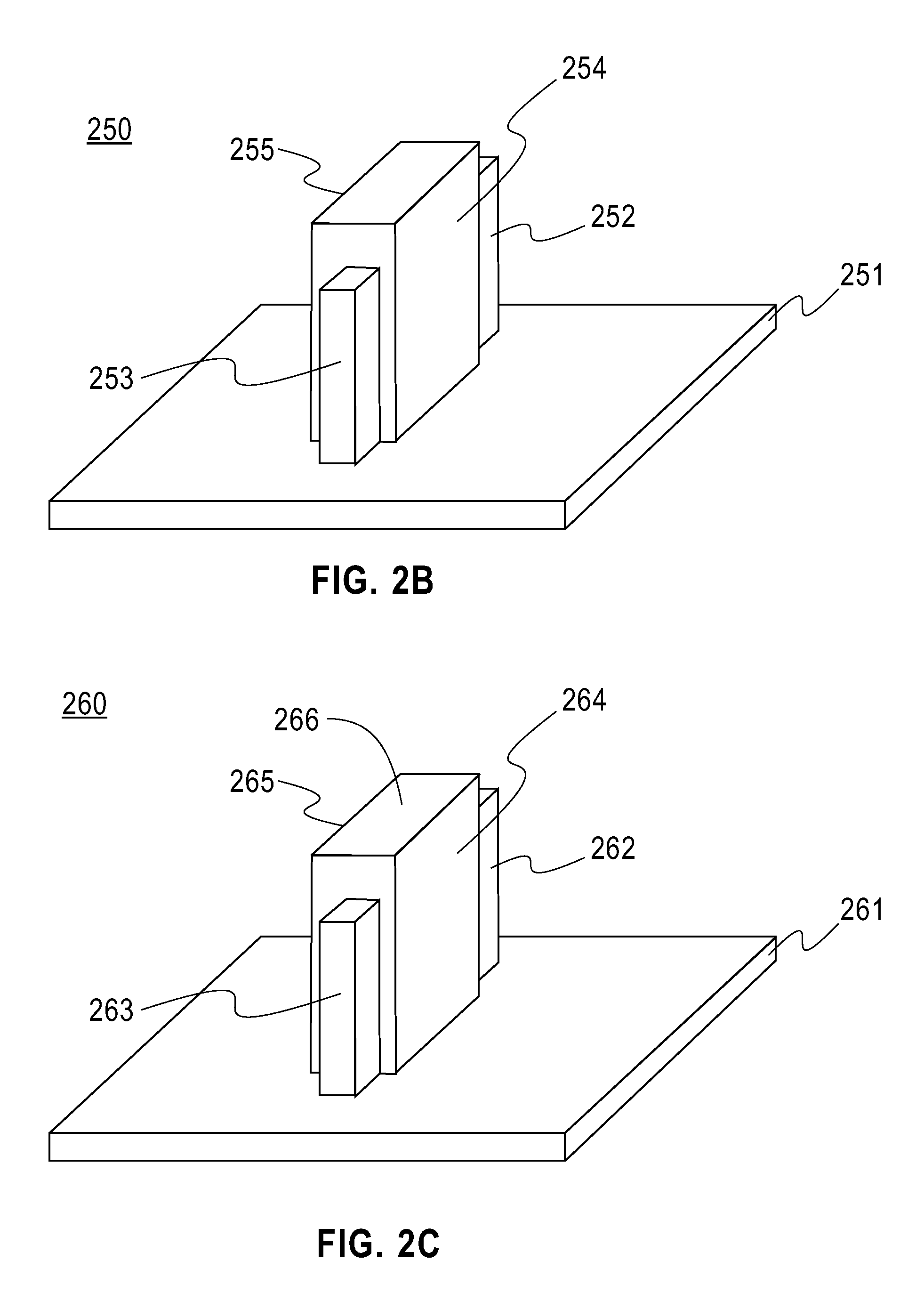

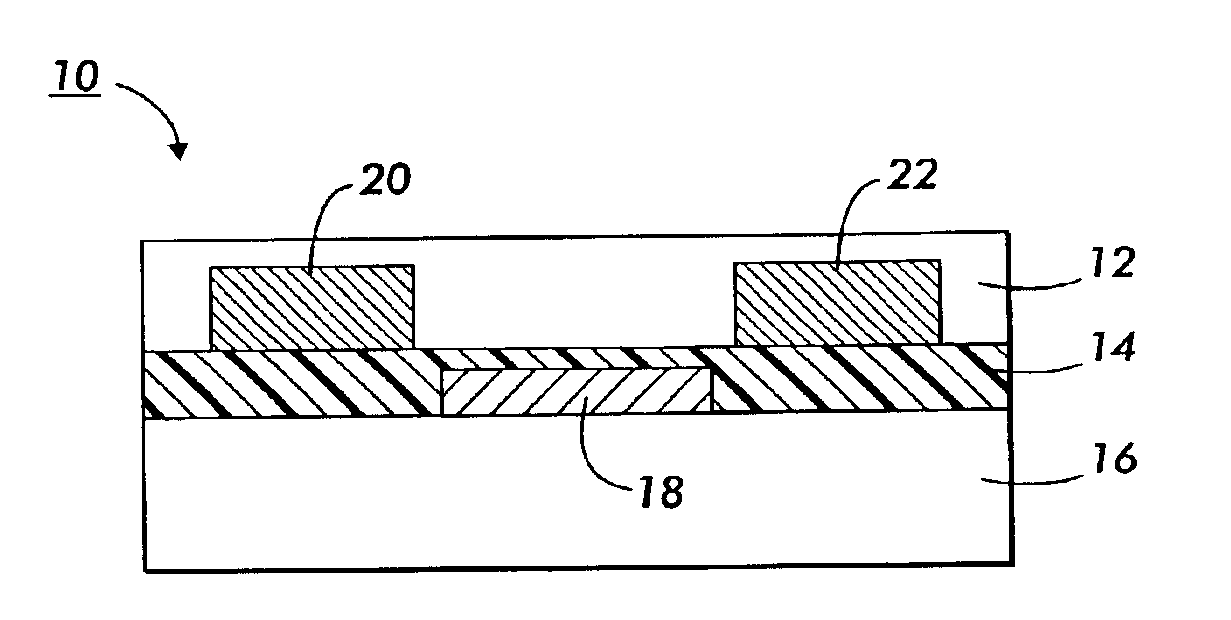

Semiconductor device including back-gated transistors and method of fabricating the device

ActiveUS20060274569A1Improve device densityImprove device stabilityTransistorSolid-state devicesStatic random-access memoryDevice material

A memory cell (e.g., static random access memory (SRAM) cell) includes a plurality of back-gated n-type field effect transistors (nFETs), and a plurality of double-gated p-type field effect transistors (pFETs) operatively coupled to the plurality of nFETs.

Owner:GLOBALFOUNDRIES US INC

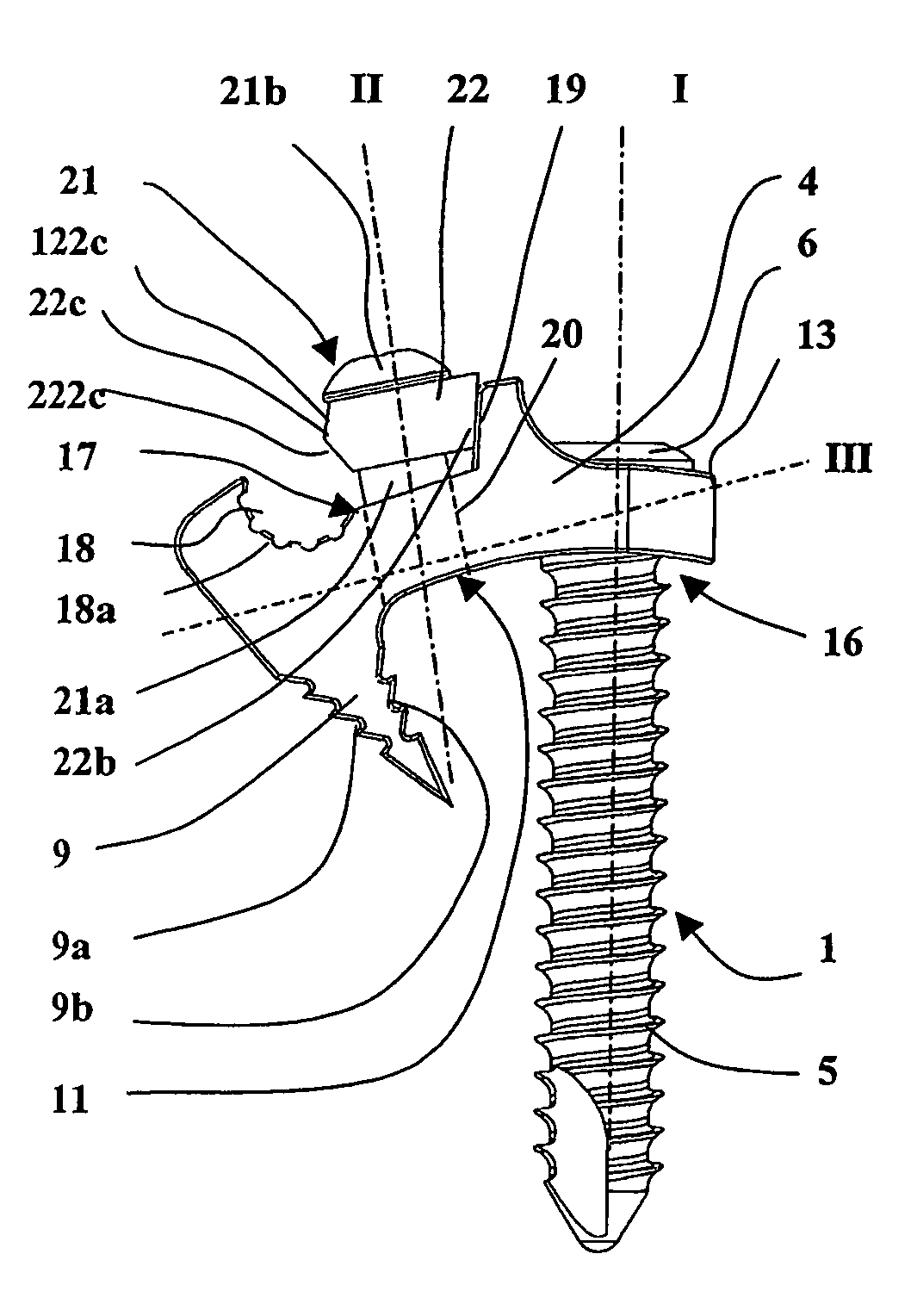

Device comprising anterior plate for vertebral column support

ActiveUS20060116676A1Improve fitEasy to adjustInternal osteosythesisJoint implantsAnterior plateVertebra

In a device including an anterior plate for vertebral column support, there is at least one connecting sliding piece which is used to connect an anchoring screw to a securing rod. The securing rod is inserted into a cylindrical bearing and is fixed using a tightening device including a small clamp and a tightening screw. The connecting sliding piece includes at least one tip which extends away from the cylindrical bearing for the securing rod, in a direction which converges with the axis of the anchoring screw. In this way, the connecting sliding piece is provisionally fixed by pressing same against a vertebra, the anchoring screw is subsequently screwed in place and, finally, the securing rod is inserted laterally into the cylindrical bearing before being tightened using the small clamp and the tightening screw. The device is designed for anterior implantation on a vertebral column.

Owner:LAPE MEDICAL

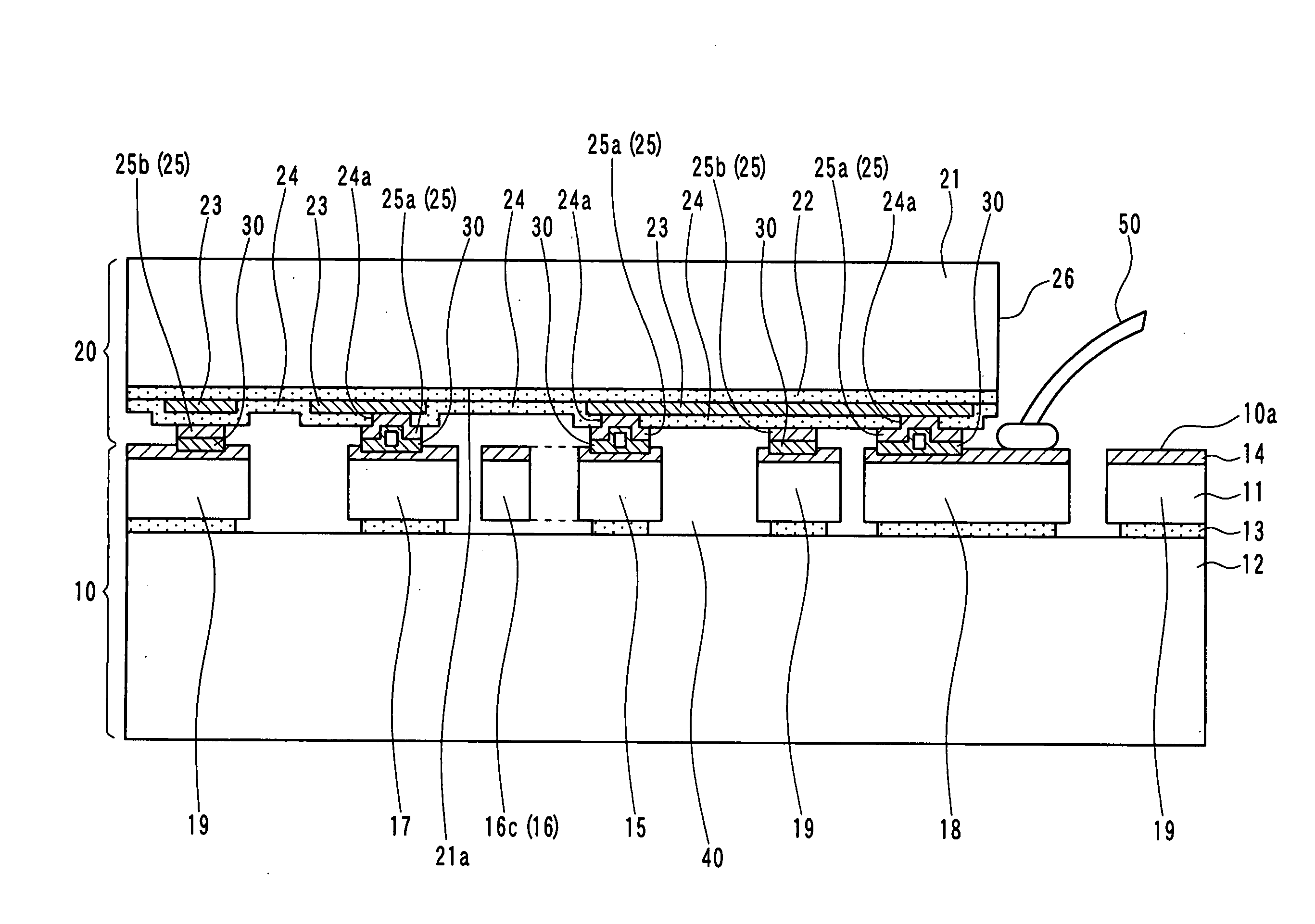

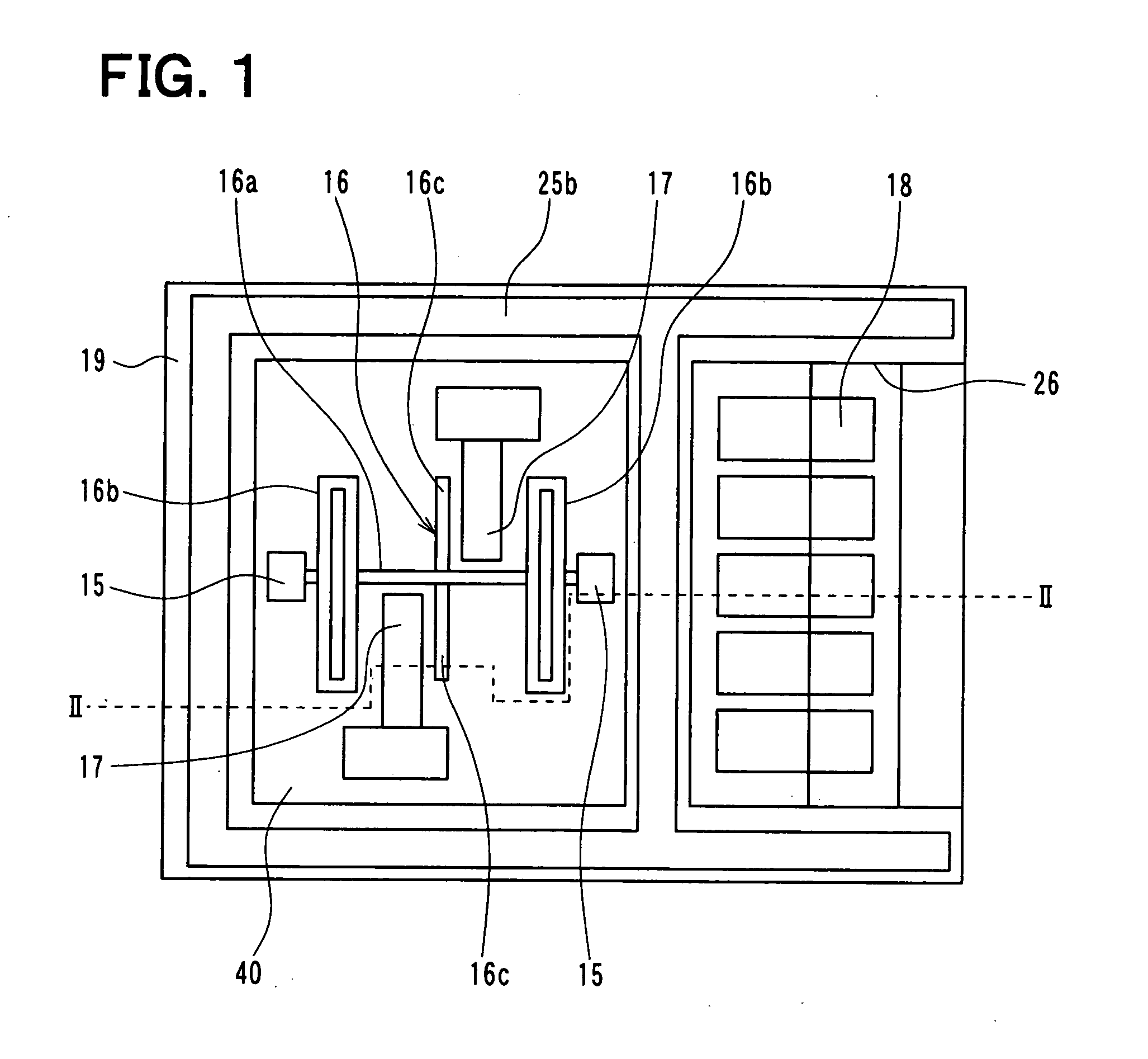

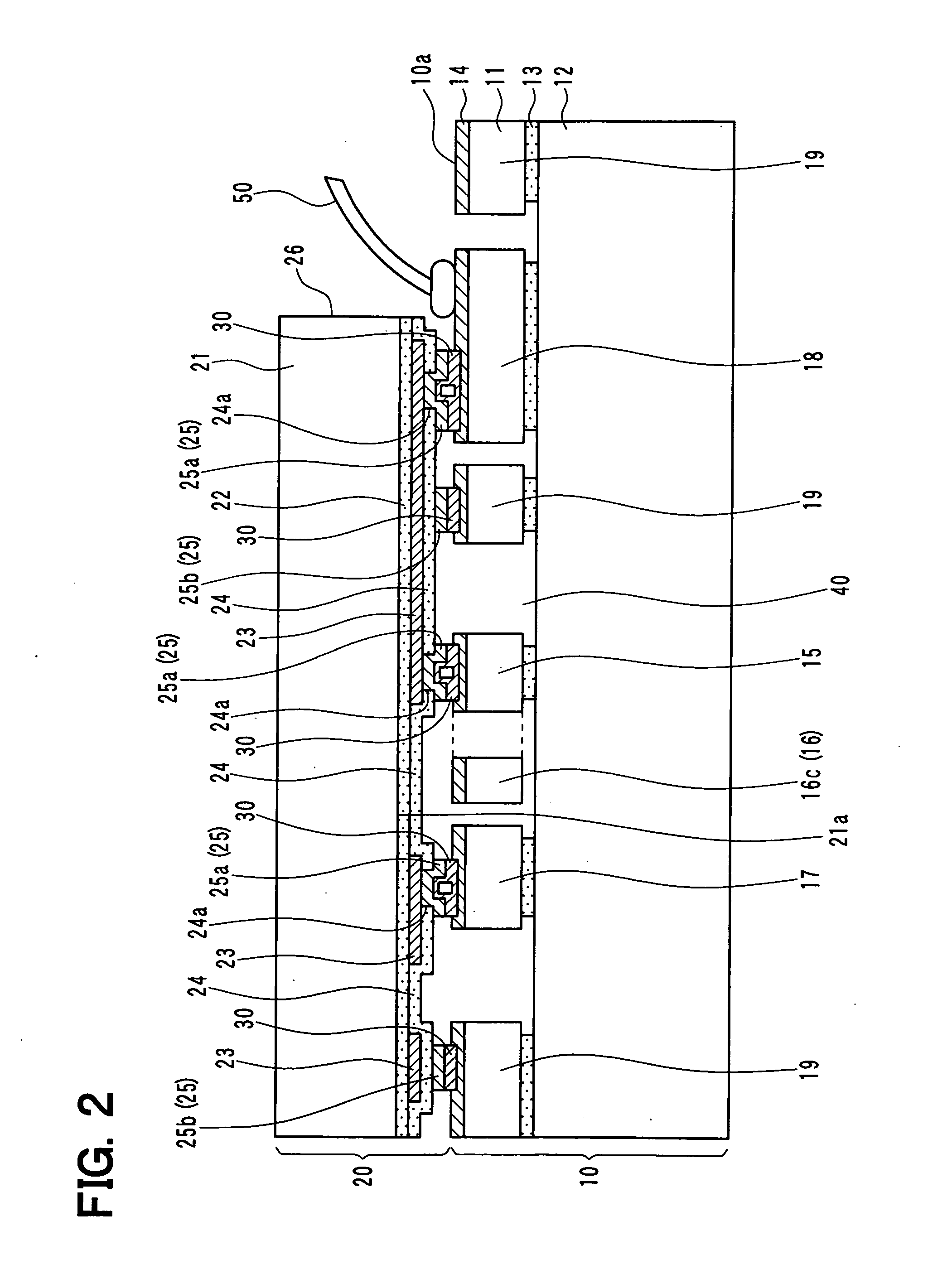

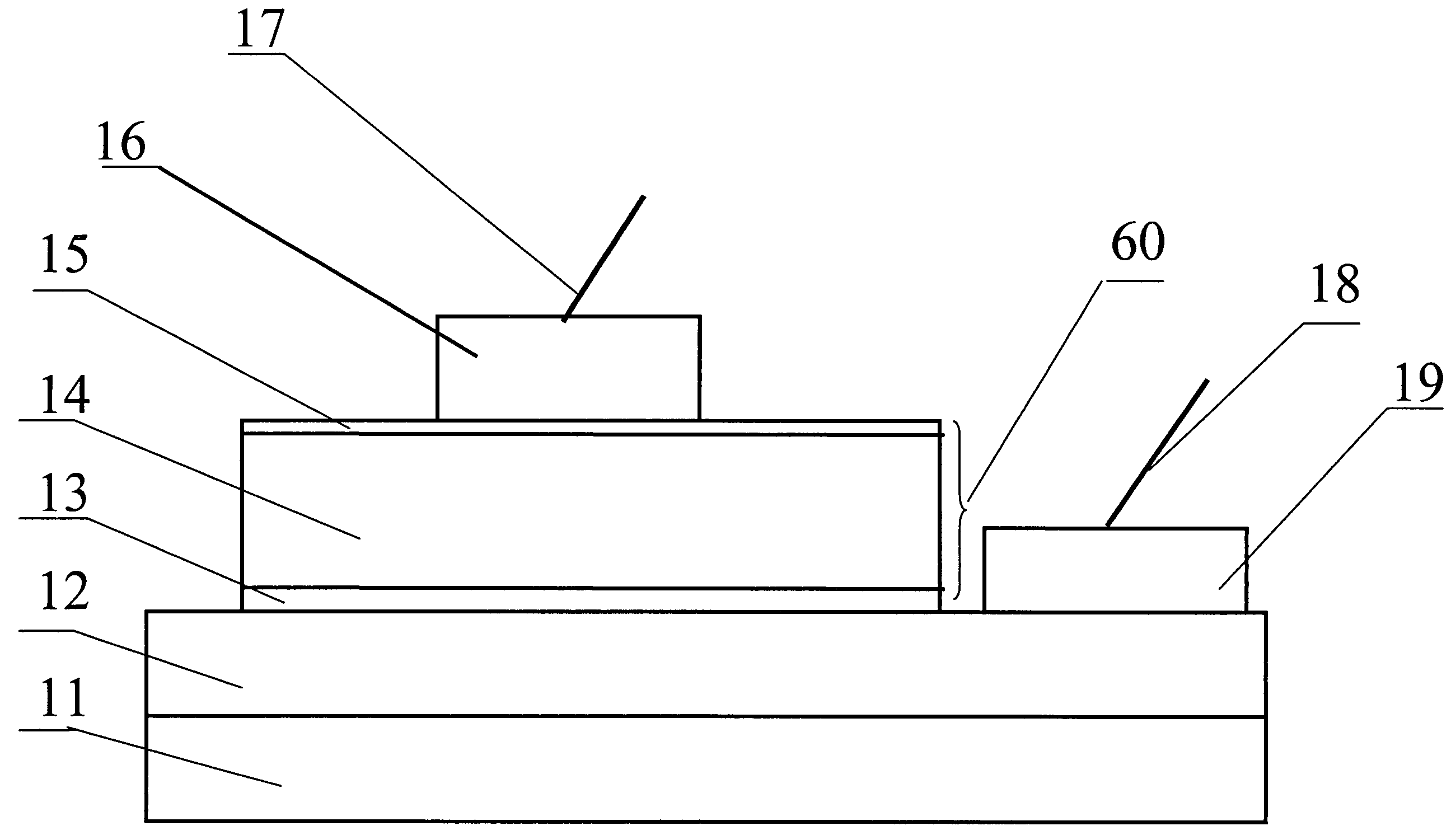

Semiconductor device and method for manufacturing the same

ActiveUS20100148341A1Bonding strengthImprove productivitySemiconductor/solid-state device detailsSolid-state devicesAlloyEngineering

A semiconductor device includes: a sensor including a sensor structure on a first side of the sensor and a periphery element surrounding the sensor structure; and a cap covering the sensor structure and having a second side bonded to the first side of the sensor. The cap includes a first wiring layer on the second side of the cap. The first wiring layer steps over the periphery element. The sensor further includes a sensor side connection portion, and the cap further includes a cap side connection portion. The sensor side connection portion is bonded to the cap side connection portion. At least one of the sensor side connection portion and the cap side connection portion provides an eutectic alloy so that the sensor side connection portion and the cap side connection portion are bonded to each other.

Owner:DENSO CORP

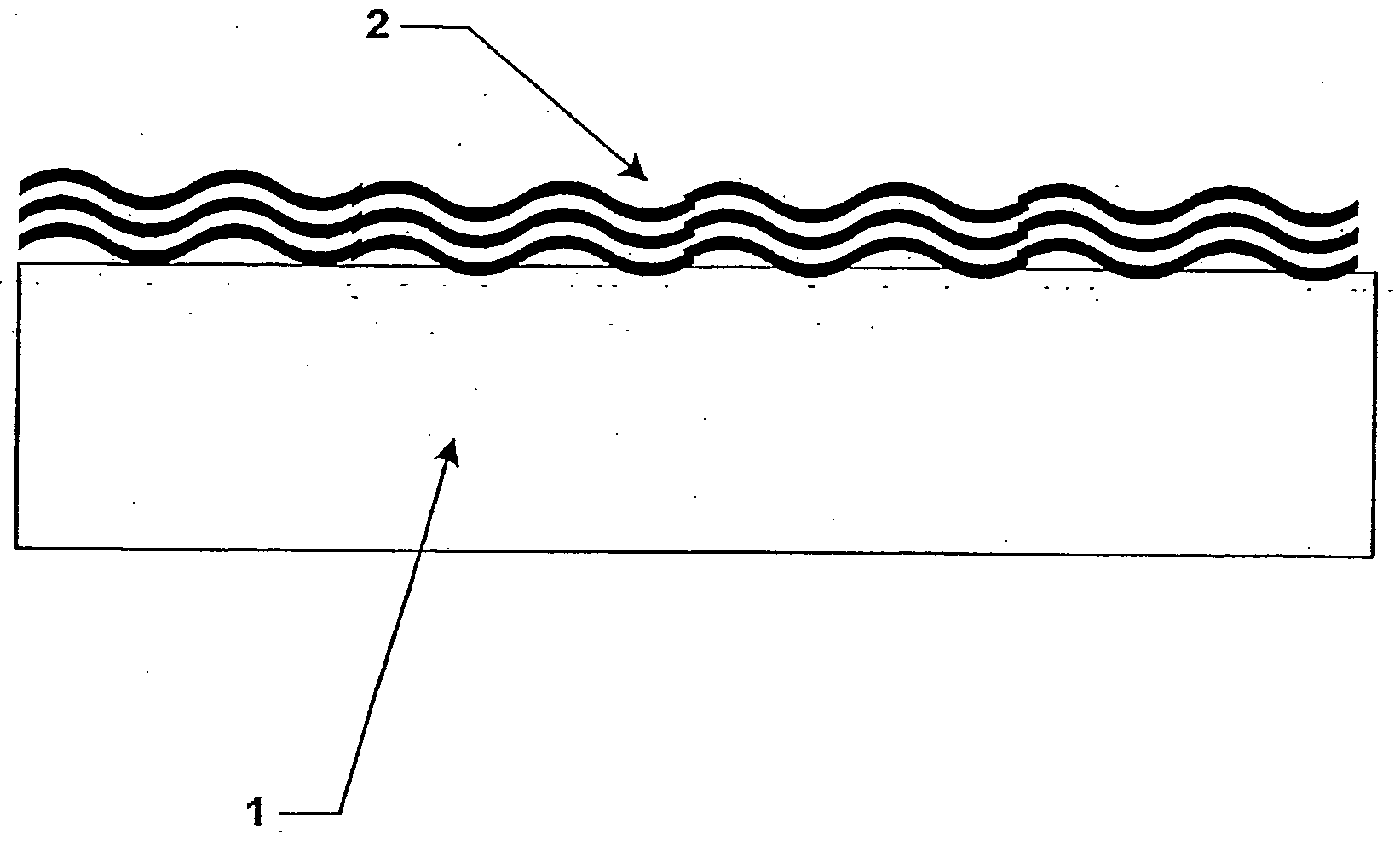

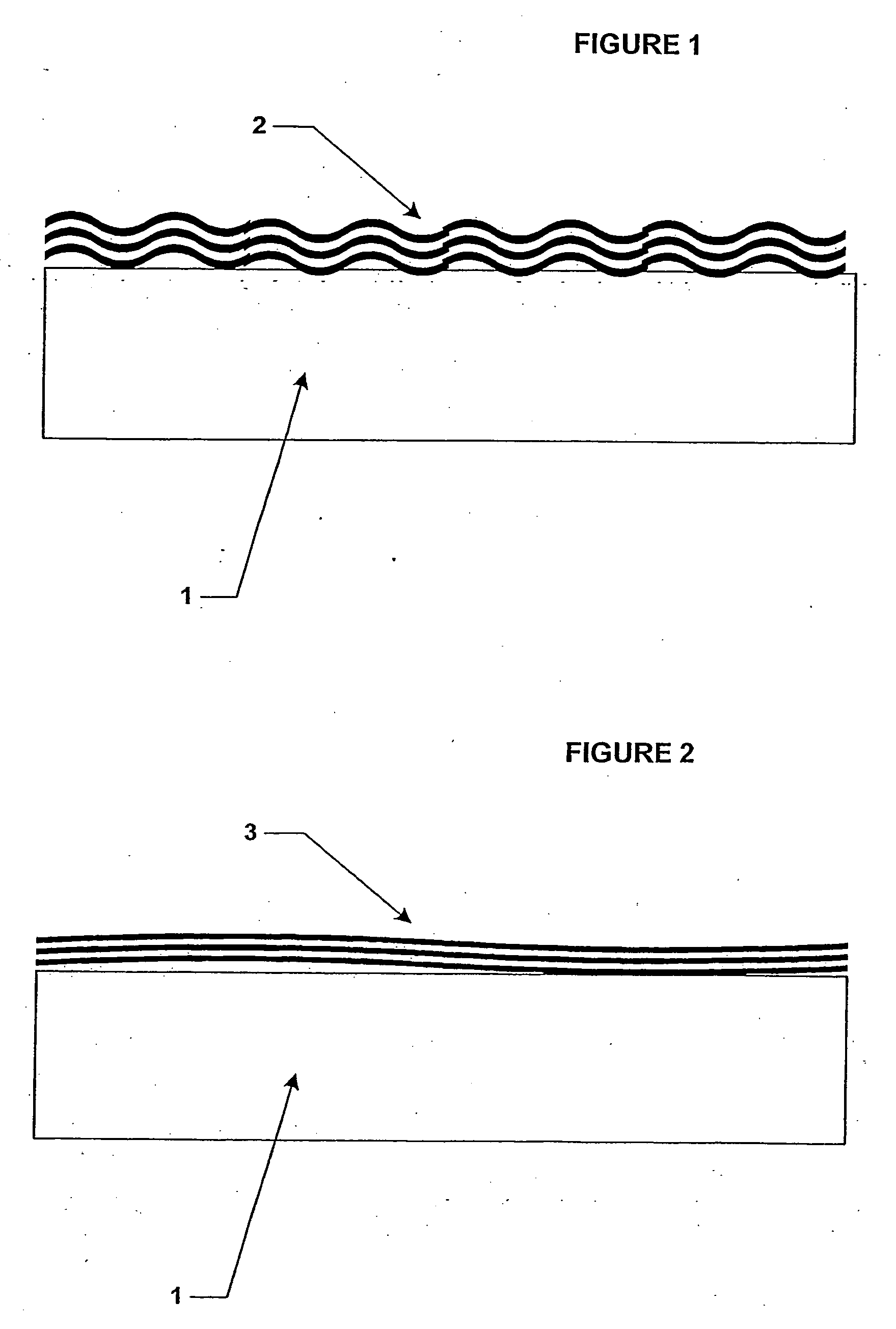

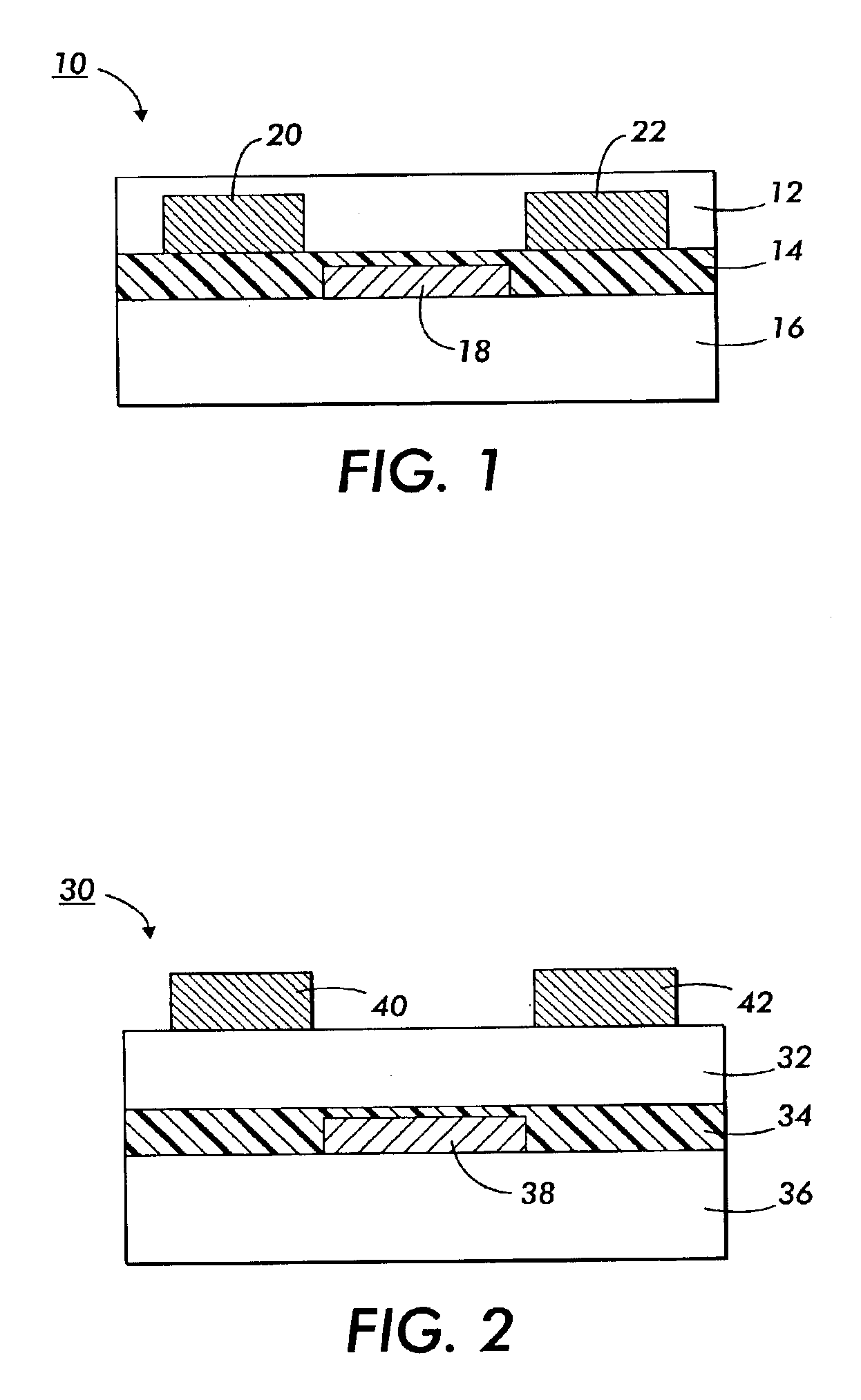

Switchable resistive perovskite microelectronic device with multi-layer thin film structure

ActiveUS7608467B2Reduce voltageImprove configurationSemiconductor/solid-state device manufacturingDigital storageElectrical resistance and conductanceMagnification

A switchable resistive device has a multi-layer thin film structure interposed between an upper conductive electrode and a lower conductive electrode. The multi-layer thin film structure comprises a perovskite layer with one buffer layer on one side of the perovskite layer, or a perovskite layer with buffer layers on both sides of the perovskite layer. Reversible resistance changes are induced in the device under applied electrical pulses. The resistance changes of the device are retained after applied electric pulses. The functions of the buffer layer(s) added to the device include magnification of the resistance switching region, reduction of the pulse voltage needed to switch the device, protection of the device from being damaged by a large pulse shock, improvement of the temperature and radiation properties, and increased stability of the device allowing for multivalued memory applications.

Owner:UNIV HOUSTON SYST

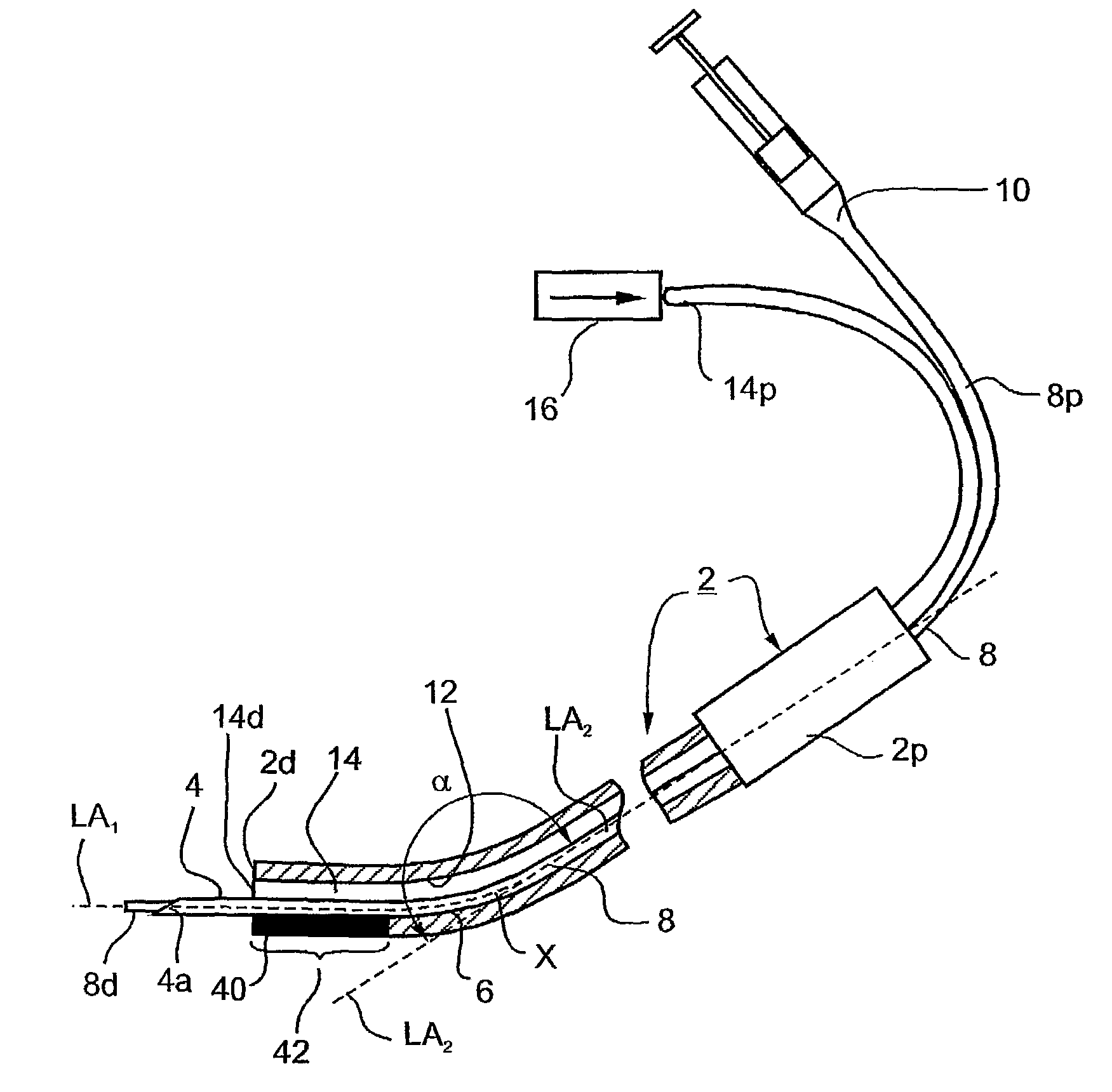

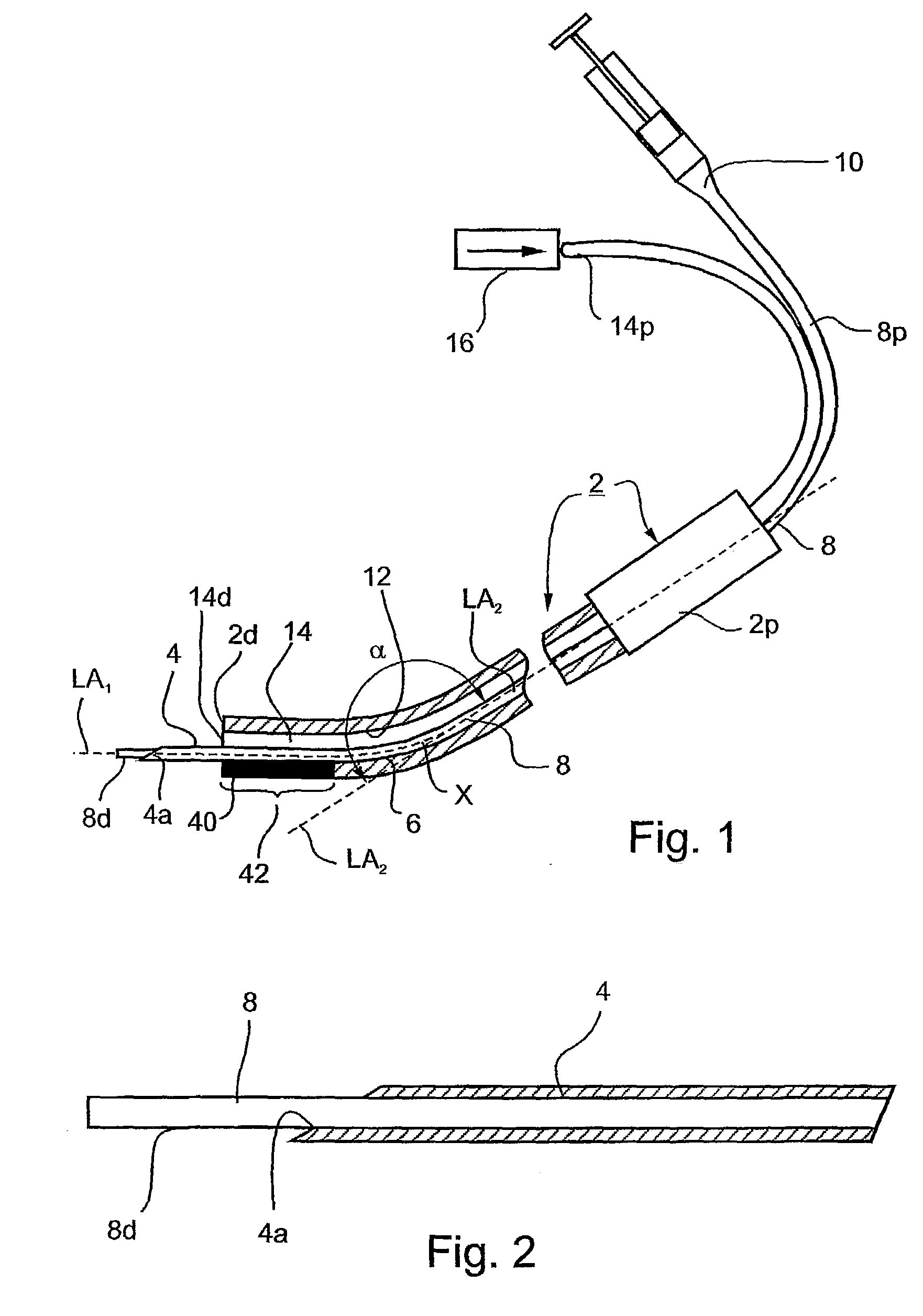

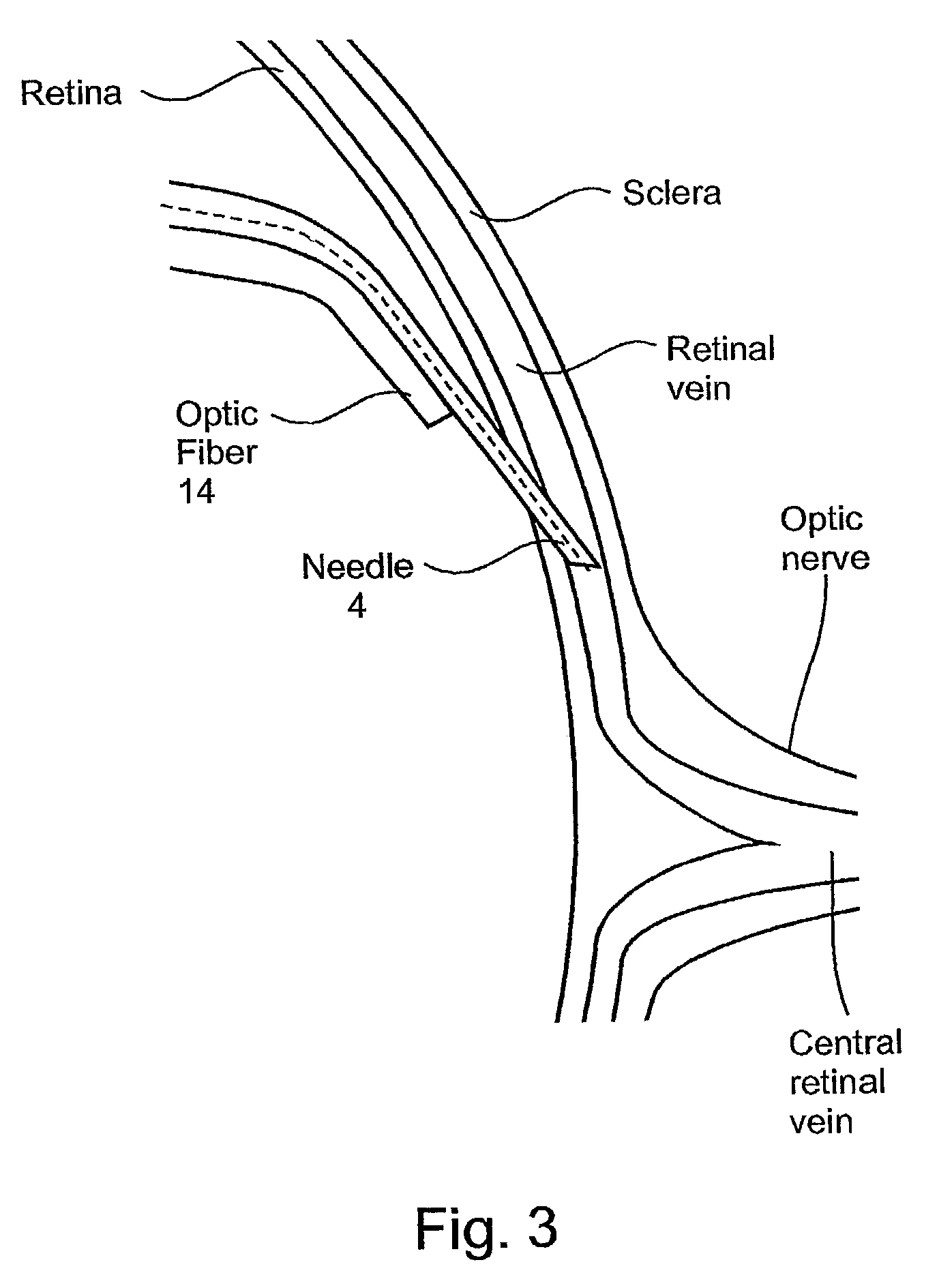

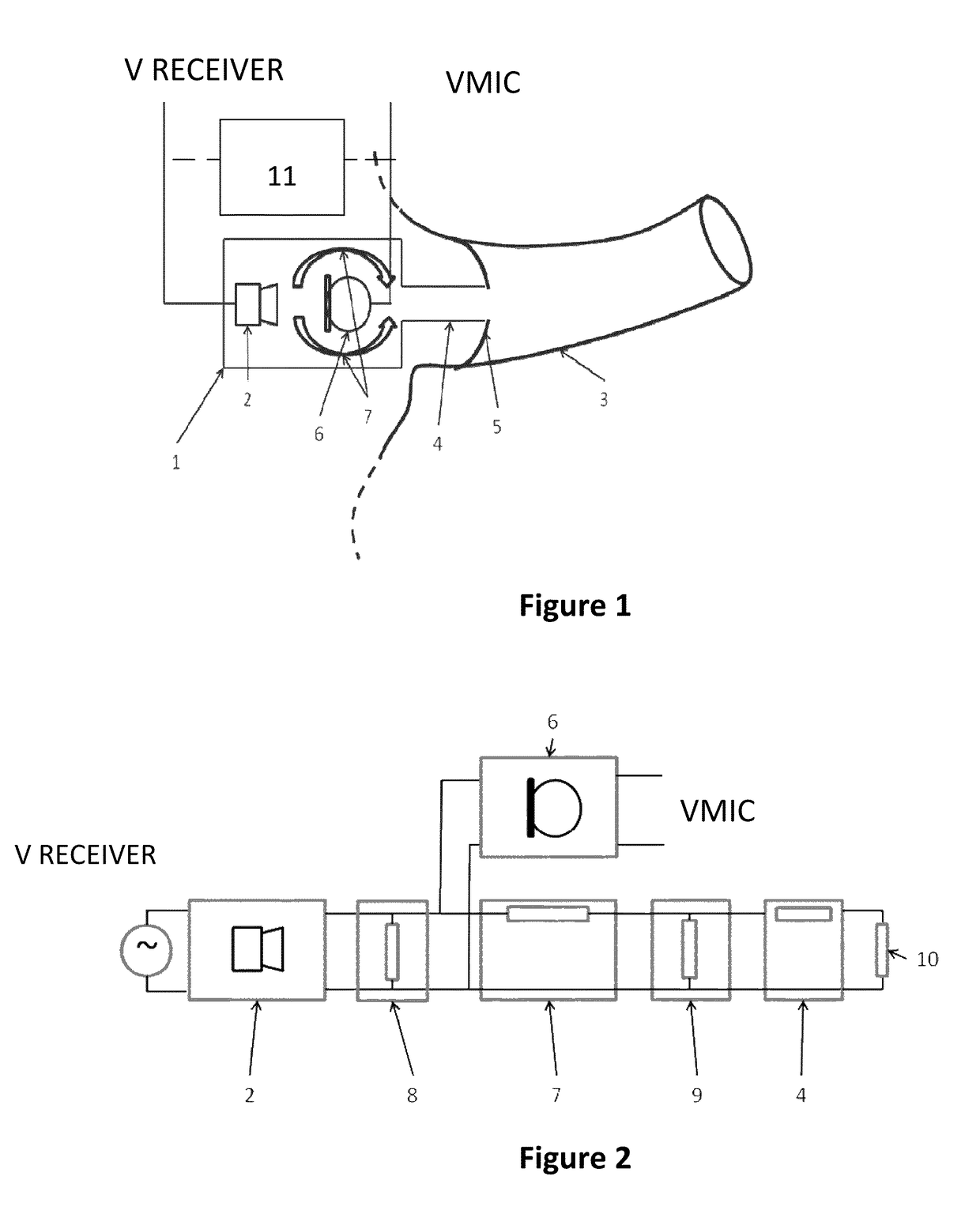

Microsurgical injection and/or distending instruments and surgical method and apparatus utilizing same

InactiveUS20030171722A1Facilitate orienting the needle coaxialFacilitate penetrating the blood vesselInfusion syringesDiagnosticsRetinaSurgical department

A microsurgical injection instrument particularly useful by a physician for injecting a liquid substance or a suspension into a blood vessel in the retina of a subject's eye, includes a handpiece carrying a hollow needle at its distal end, for penetrating the blood vessel. The longitudinal axis of the distal end of the handpiece and of the needle is at an angle of from 90°-180°, preferably about 145°, to the longitudinal axis of the proximal end of the handpiece to facilitate orienting the needle substantially tangentially to the plane of the subject's retina coaxially to a blood vessel for penetrating the blood vessel. The instrument may also be used to treat an occluded blood vessel by moving a flexible tube through the hollow needle, after the needle has penetrated the blood vessel, to enter and catheterize the blood vessel.

Owner:PAQUES MICHEL +1

Electrode for an energy storage device

InactiveUS20050118440A1Improve electrochemical stabilityImprove voltage stabilityHybrid capacitor electrodesLiquid electrolytic capacitorsCarbon coatingDopant

An electrode for an energy storage device, including a substrate of at least one metal that forms a native oxide layer; and a treated layer formed on the substrate from the native oxide layer, the treated layer having a resistance that is less than the resistance of a native oxide layer. In some embodiments, the treated layer possesses at least one of the following properties: includes one or more dopants, is thinner than the native oxide layer, has a carbon coating that is applied to the treated layer which improved adhesion characteristics, and others. Further, there is an energy storage device having two or more of such electrodes, wherein the device has a low initial ESR and / or a low ESR at various intervals. Moreover, disclosed is a low resistance metal including a substrate of at least one metal that forms a native oxide layer; and a treated layer formed on the substrate from the native oxide layer, the treated layer having a resistance that is less than the resistance of a native oxide layer. Additionally, methods relating to the above devices are also disclosed.

Owner:CAP XX LTD

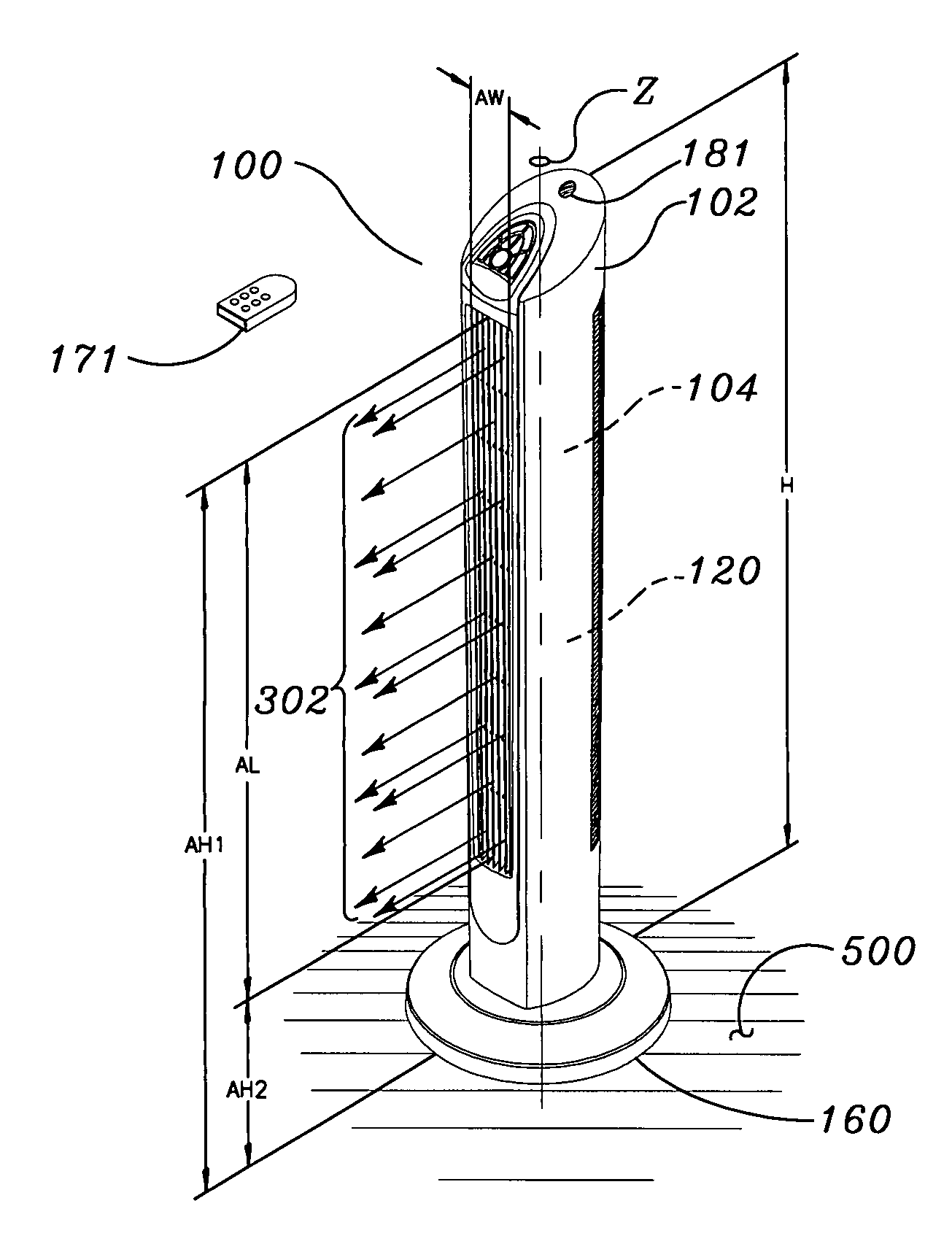

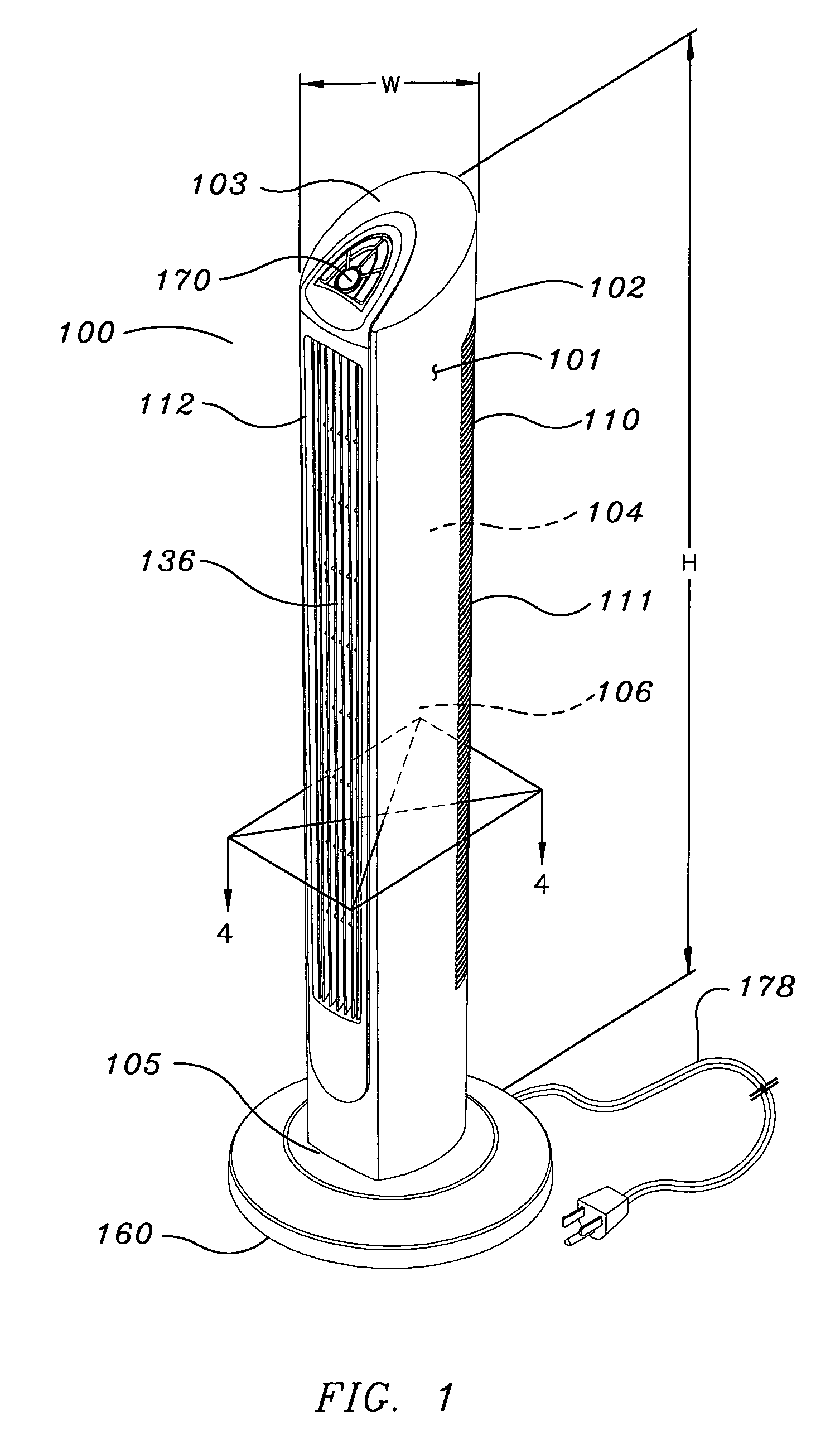

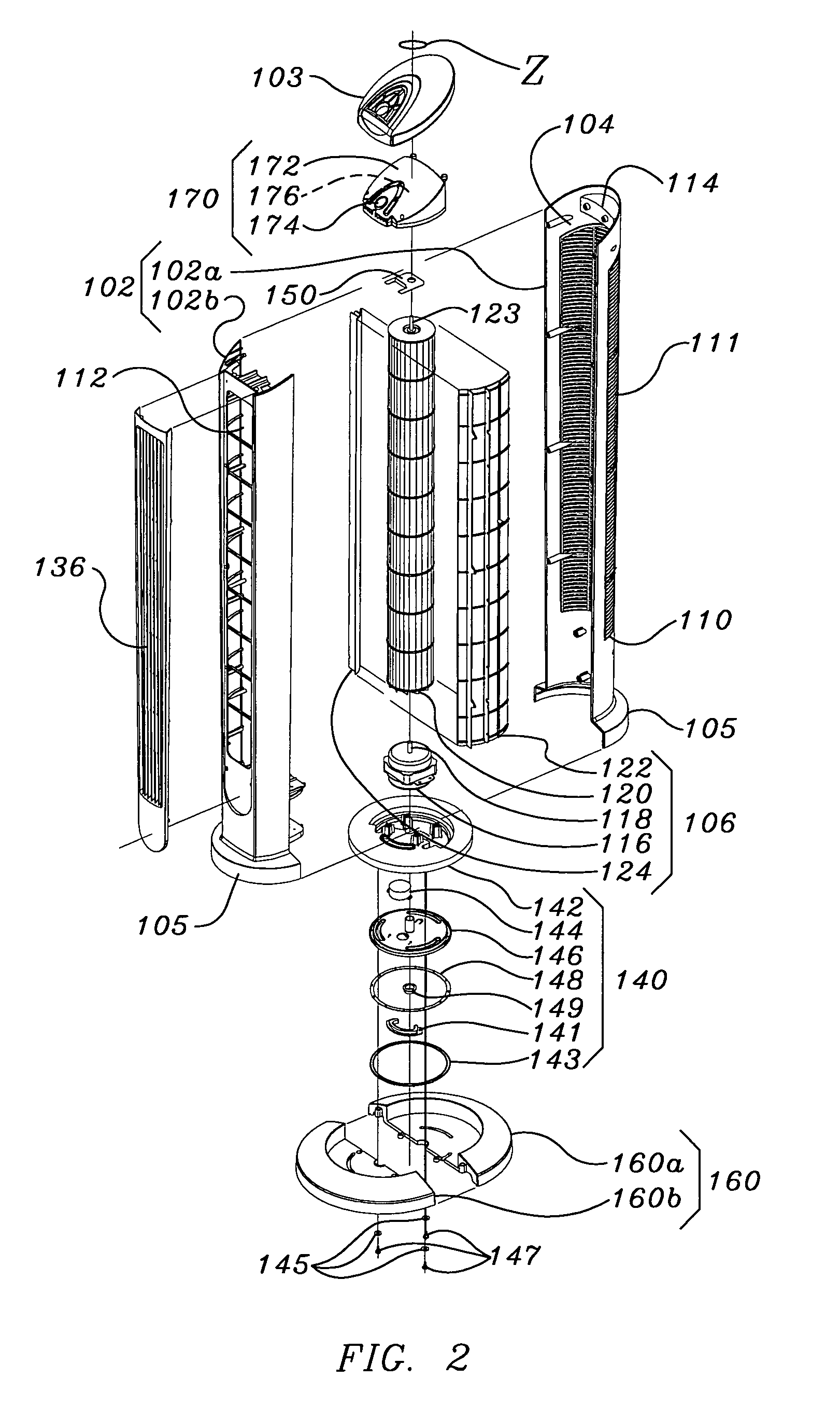

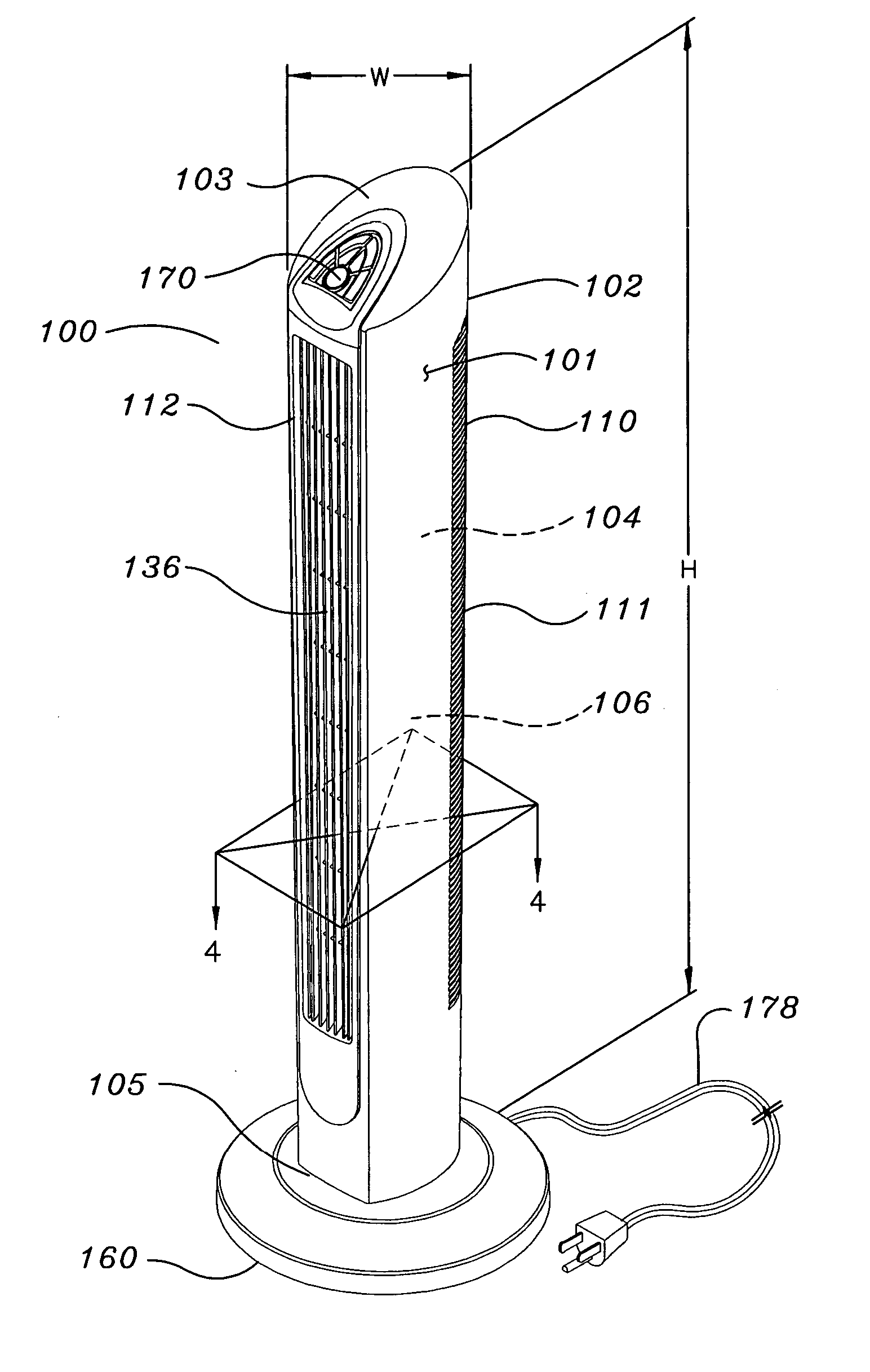

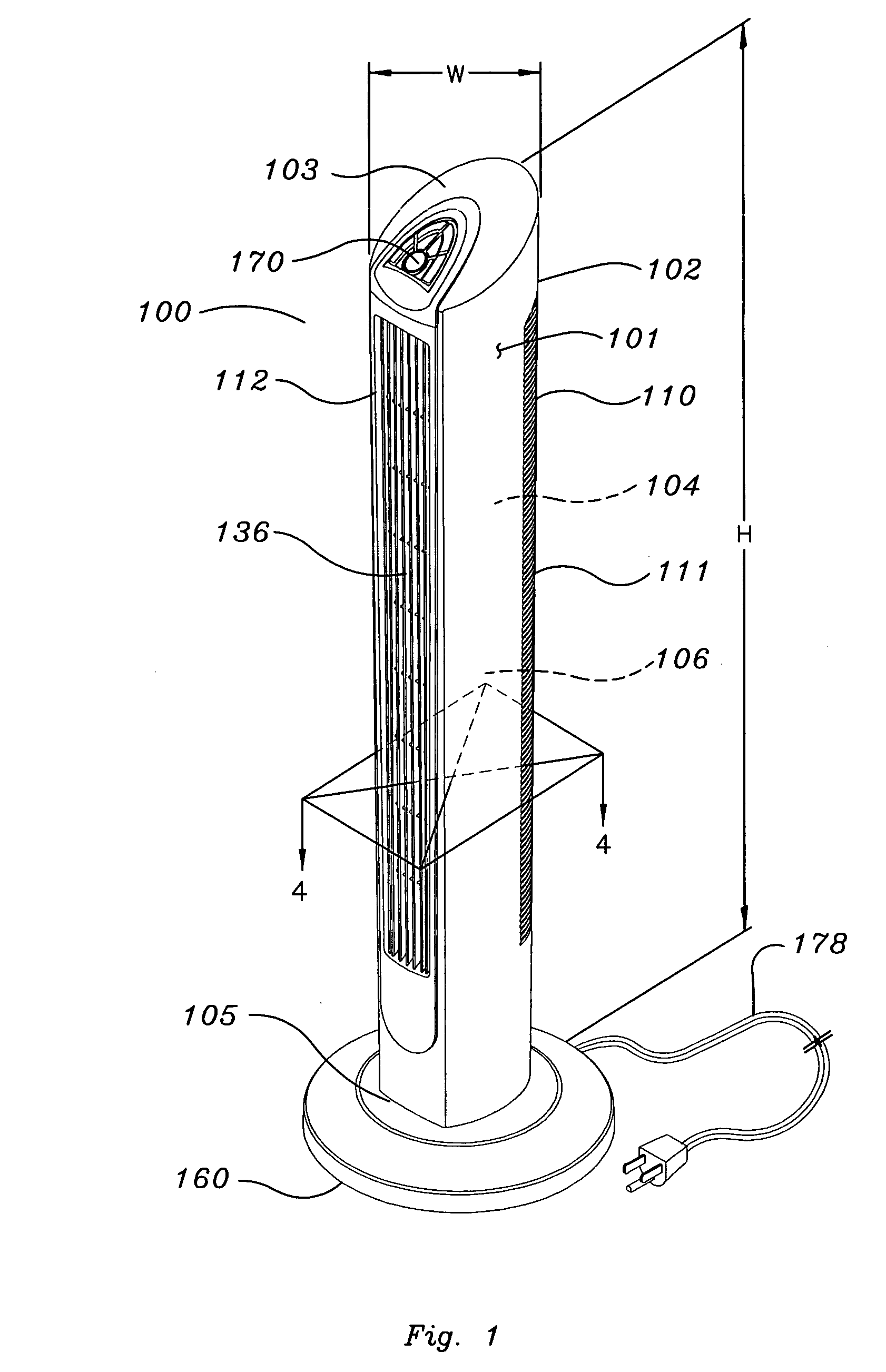

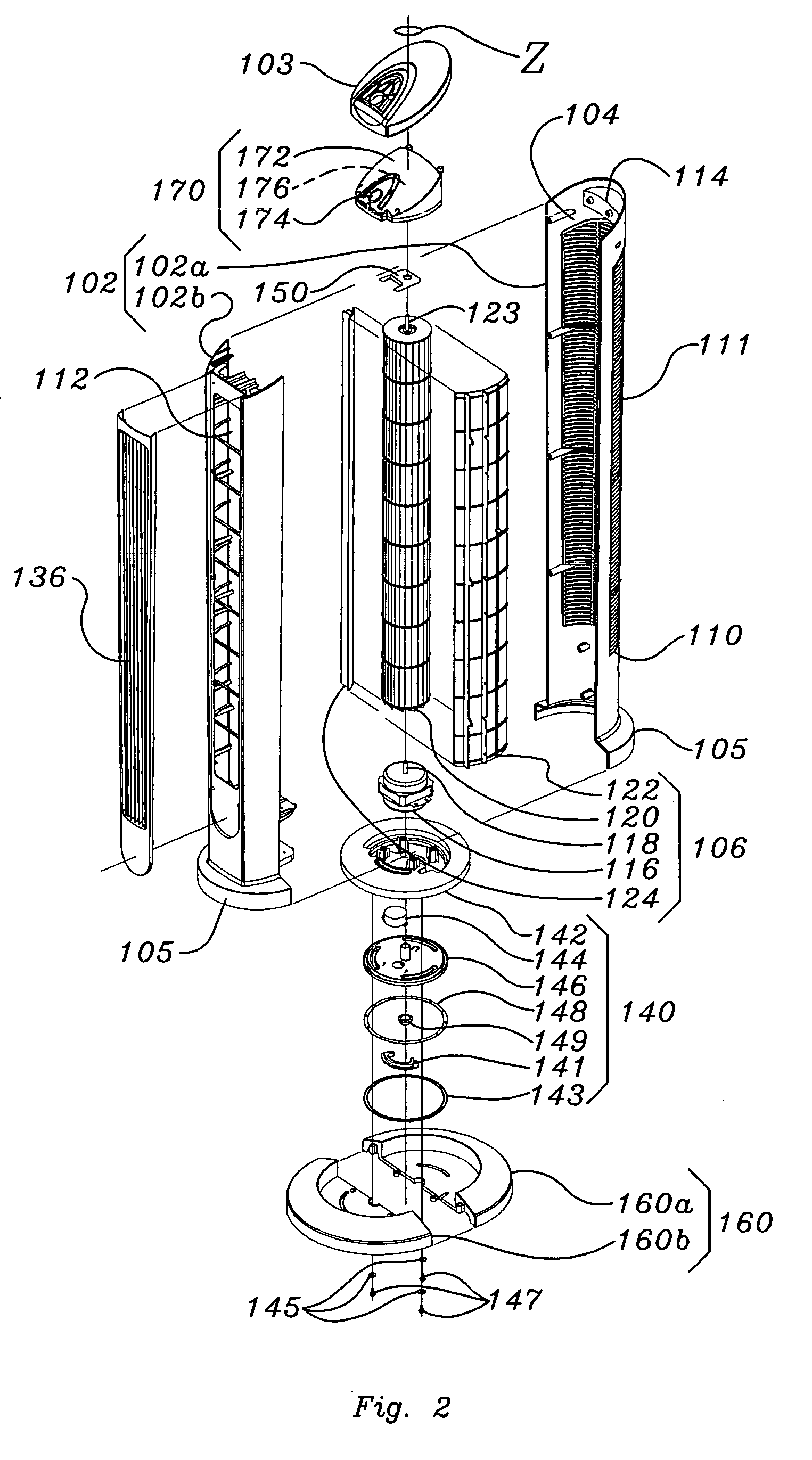

Vertical tower fan

A portable, vertical tower fan capable of generating a vertically oriented exhaust air stream that conforms better to a user at an elevation above a support surface. The device includes an vertically elongated housing, an air blower assembly located within the elongated housing and a base provides a space saving design.

Owner:LASKO OPERATION HLDG LLC

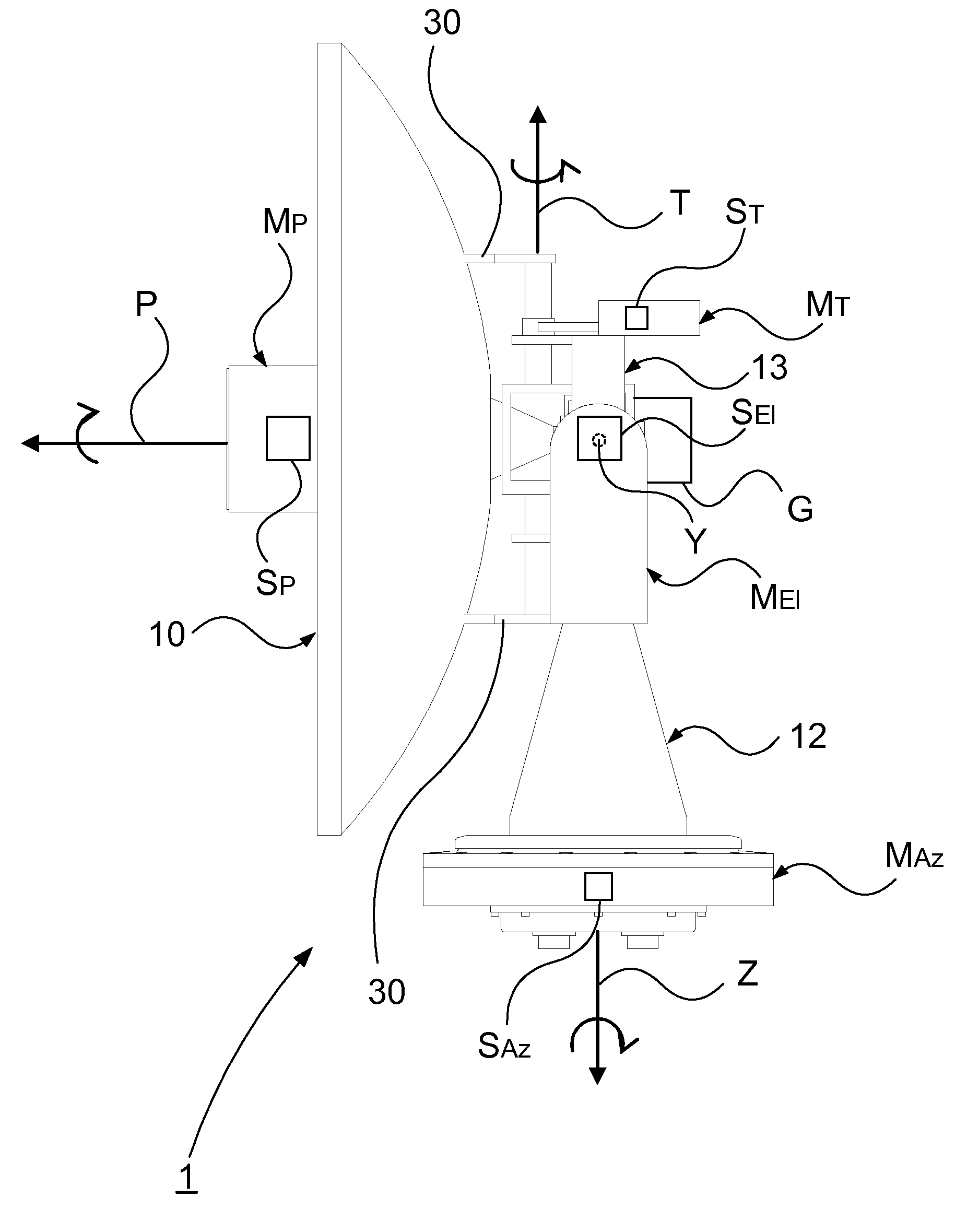

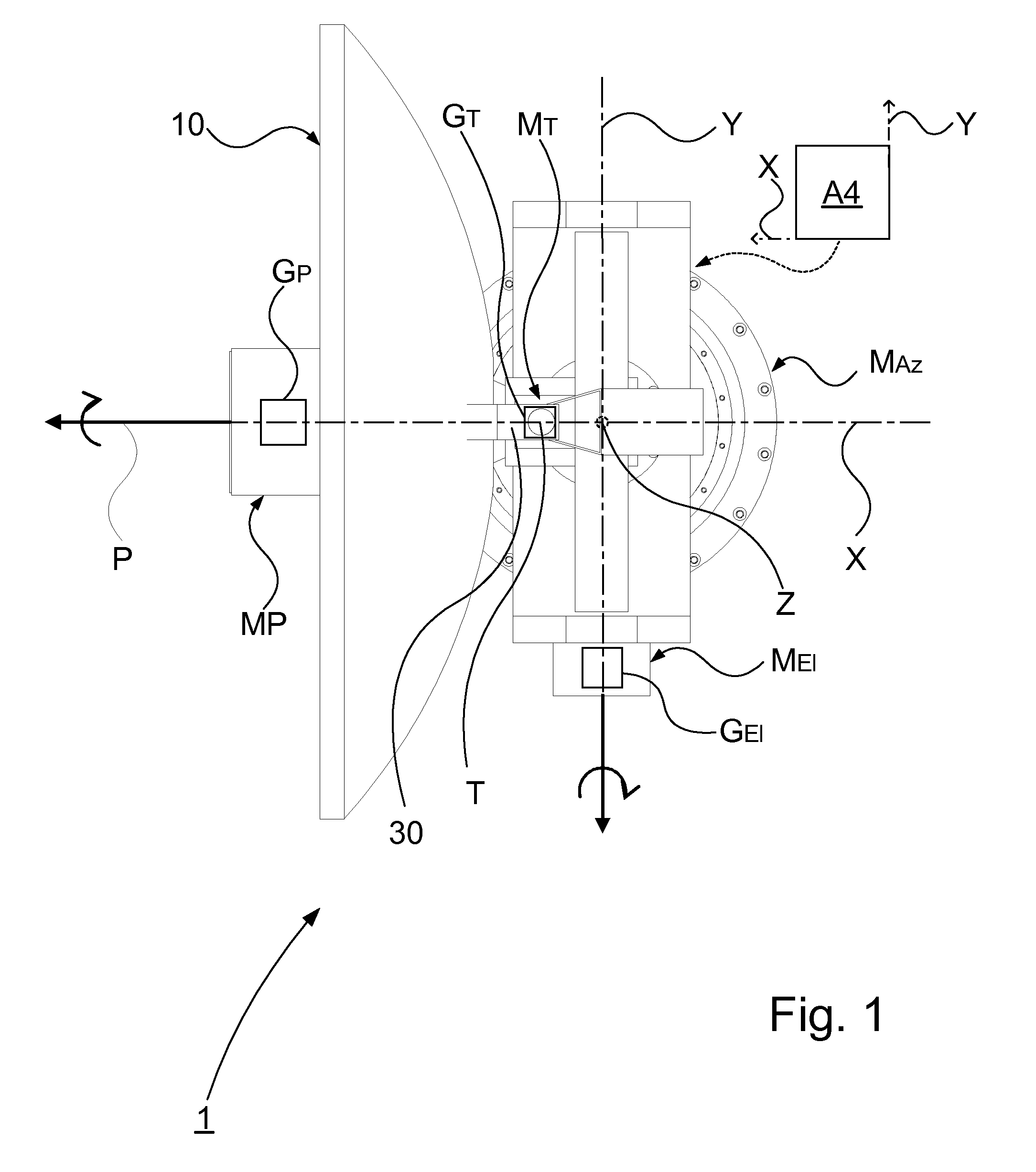

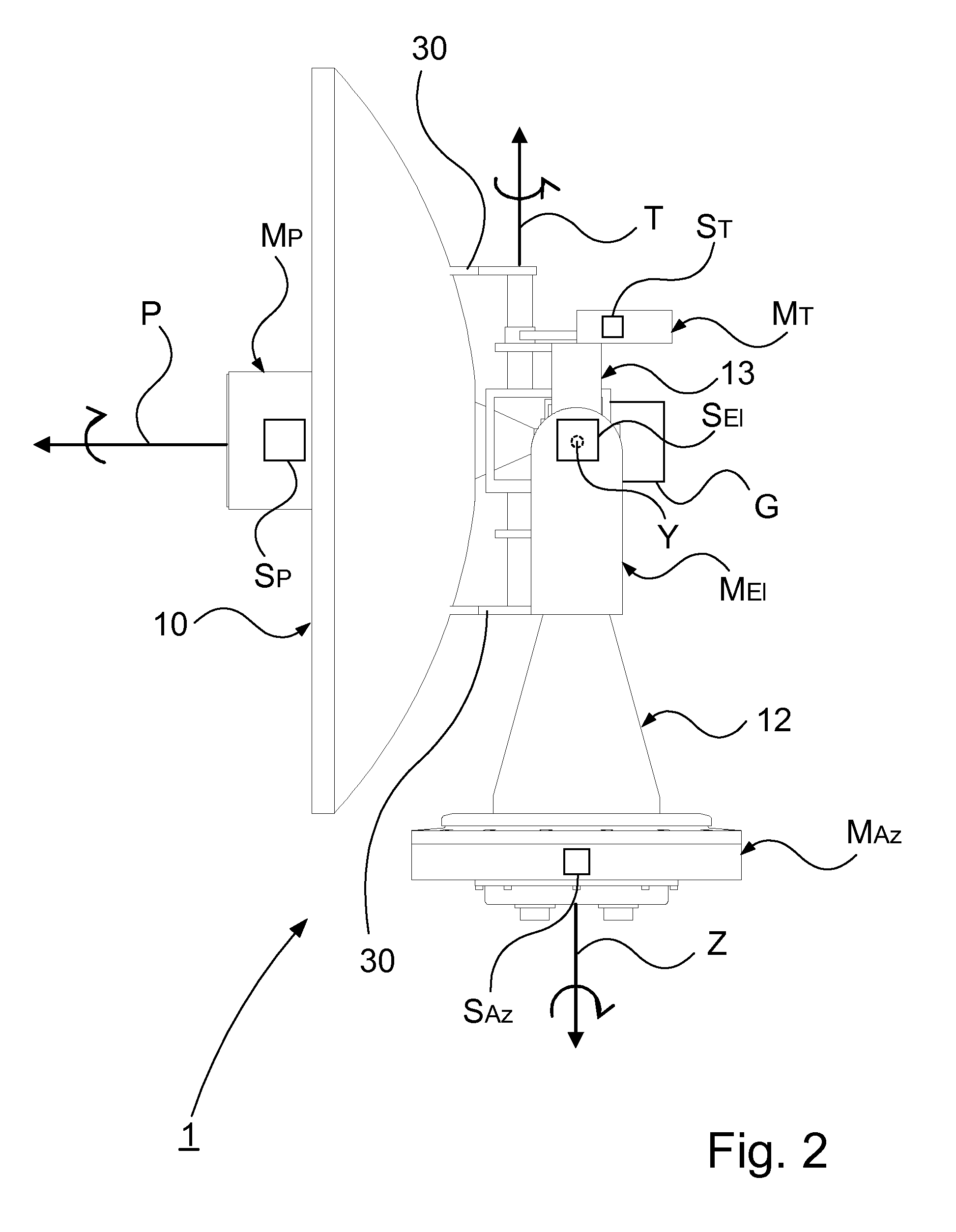

Device and method for controlling a satellite tracking antenna

ActiveUS20100201589A1Improve abilitiesImprove device performanceAntenna adaptation in movable bodiesElevation angleRotational freedom

A device for controlling a satellite tracking antenna. An azimuth drive is configured to impart an azimuthal rotational motion to the antenna about an azimuth axis. An elevation axis drive is configured to impart a rotational motion to the antenna about an elevation axis orthogonal to the azimuth axis. A tilt axis drive is configured to impart a rotational motion to the antenna about a tilt axis. The tilt axis is connected to the elevation axis in such a way that the rotational freedom of motion of the antenna about the tilt axis is dependent on the elevation angle such that: at an elevation angle of 0° the rotational freedom of motion of the antenna about the tilt axis corresponds to the azimuthal rotational motion; at an increasing elevation angle the rotational freedom of motion about the antenna successively transcends into a roll rotation; and at an elevation angle of 90° the rotational freedom of motion of the antenna about the tilt axis corresponds to a roll rotation about a roll axis orthogonal to the azimuth axis and to the elevation axis. A control controls the operation of the azimuth axis drive, the elevation axis drive, and the tilt axis drive. The control includes a true north seeking gyro for tracking position, orientation, direction and speed of movement of the device. The control further includes an additional gyro comprising an elevation gyro axis arranged to sense the elevation movement and a tilt gyro axis arranged to sense the tilt movement, so as to minimize the angular velocity of the antenna pointing vector. A method for controlling a satellite tracking antenna, and a vessel including the device.

Owner:SAAB AB

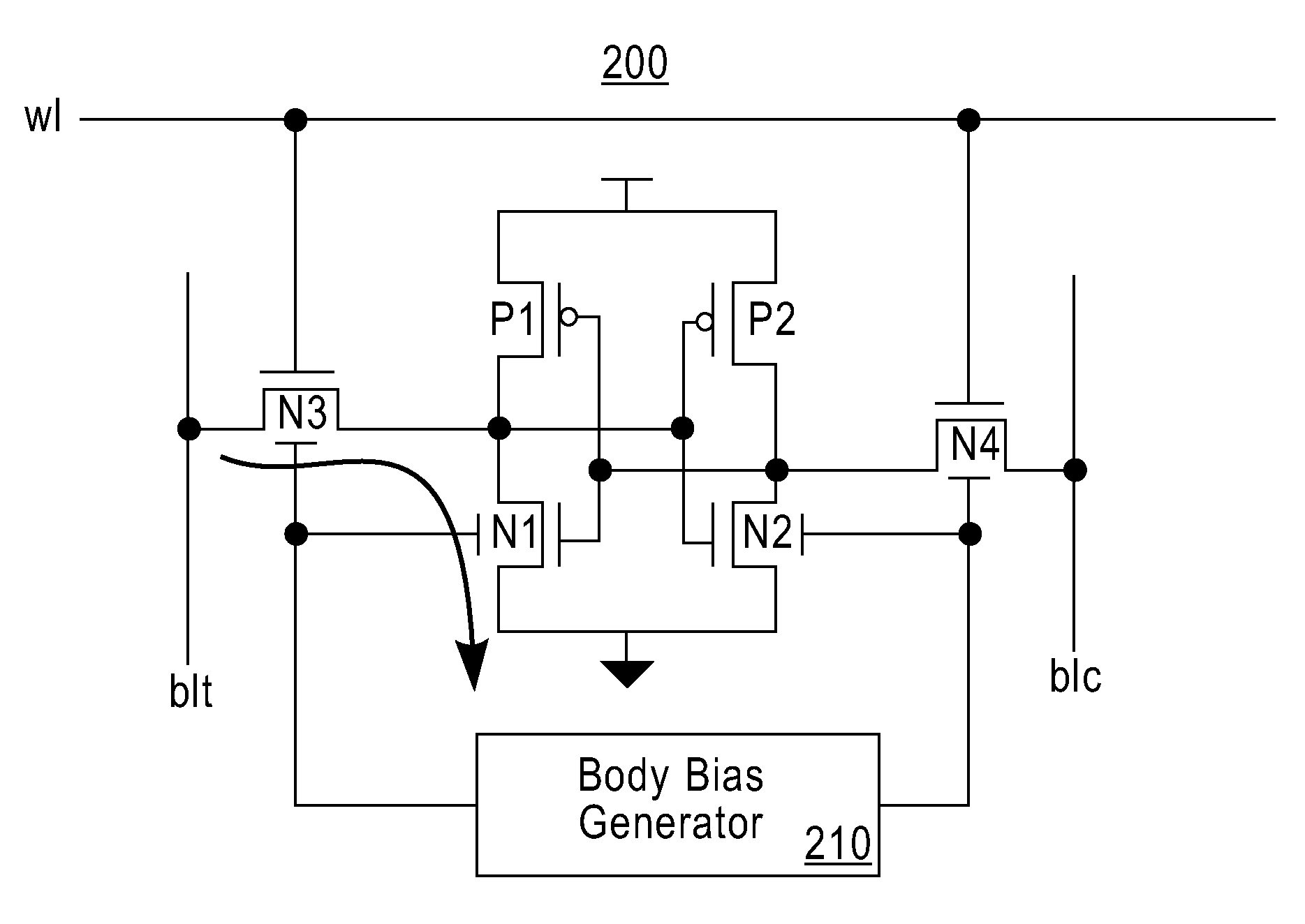

Semiconductor device including back-gated transistors and method of fabricating the device

ActiveUS7532501B2Improve device densityImprove device stabilityTransistorSolid-state devicesStatic random-access memoryEngineering

A memory cell (e.g., static random access memory (SRAM) cell) includes a plurality of back-gated n-type field effect transistors (nFETs), and a plurality of double-gated p-type field effect transistors (pFETs) operatively coupled to the plurality of nFETs.

Owner:GLOBALFOUNDRIES U S INC

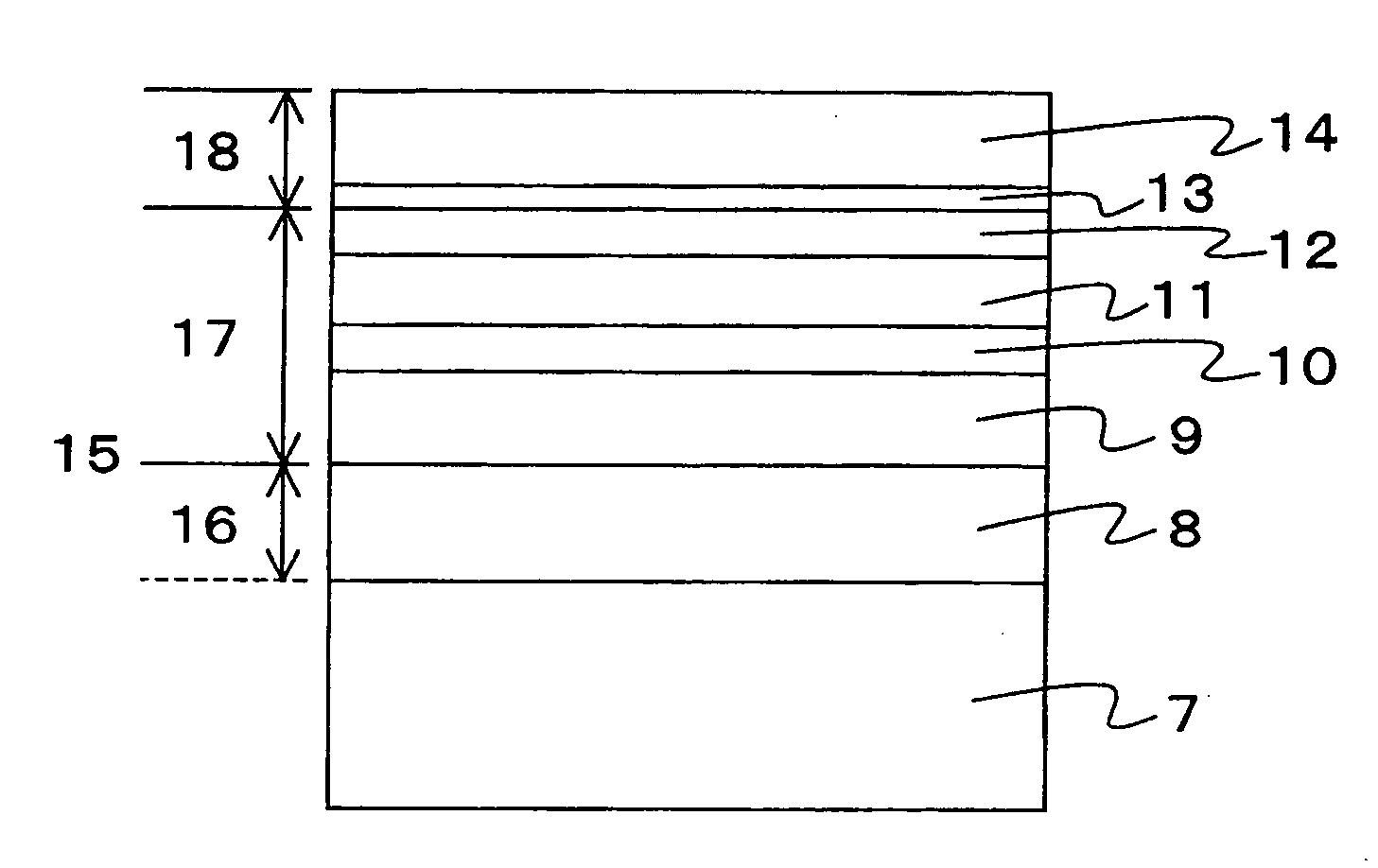

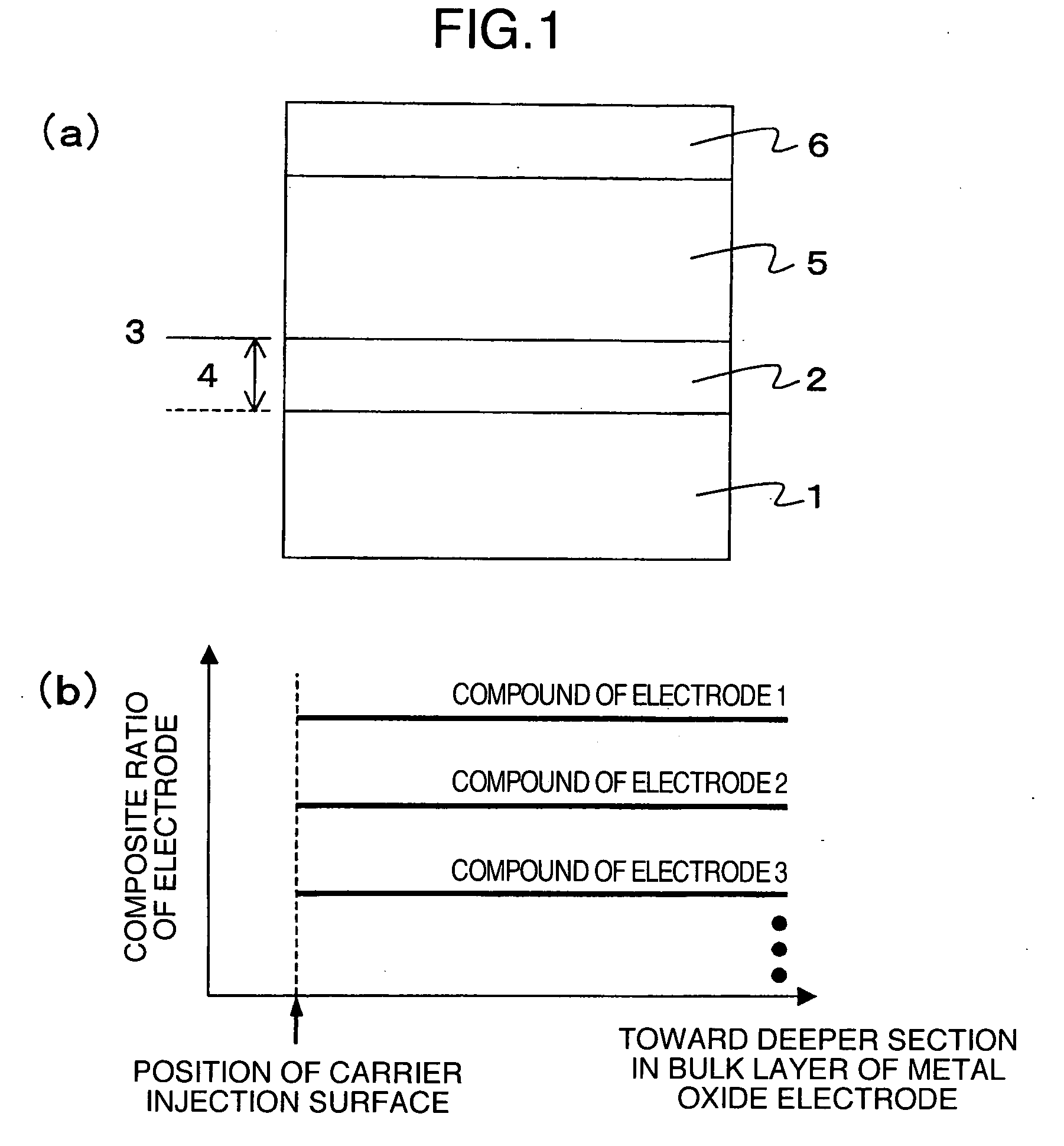

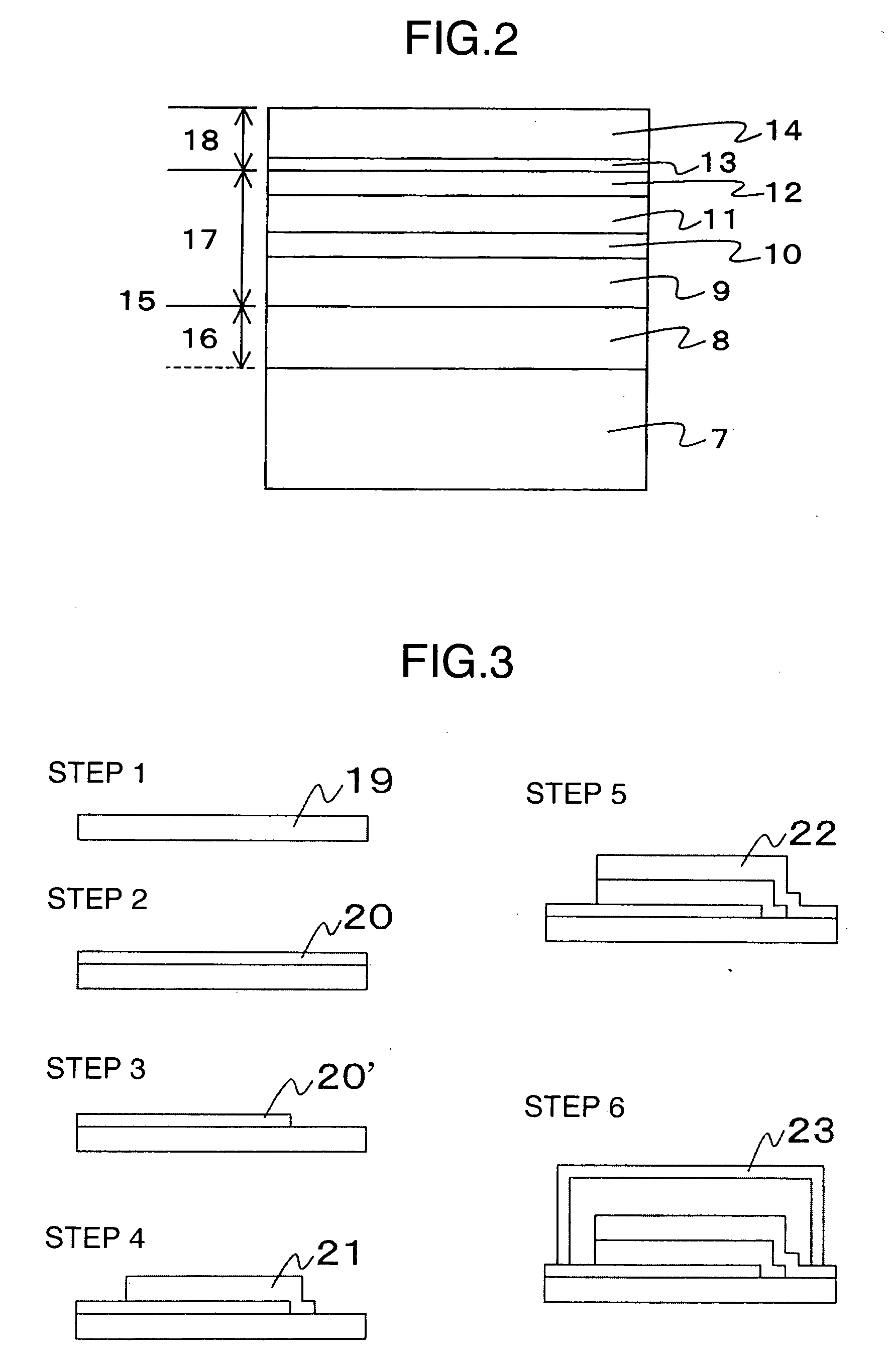

Organic electroluminescence device and organic electroluminescence system

ActiveUS20060255722A1Solution to short lifeReduce total powerDischarge tube luminescnet screensElectroluminescent light sourcesPhysicsOrganic electroluminescence

An organic electroluminescence device is provided which employs a metal oxide electrode having particular composition distribution of elements to extend the life. A conventional approach for extending the life of an electroluminescence device is not provided by considering the degradation mechanism of how the organic electroluminescence device is degraded by the driving with electric current. The composite ratio of compounds of an electrode made of metal oxide forming part of the organic electroluminescence device is substantially uniform from a surface through which the carriers are injected from the electrode toward a deeper section in a bulk layer of the electrode. Thus, the electrode has stoichiometrically stable composition to prevent the degradation of electrode materials and diffusion into the organic layer, thereby providing a longer life.

Owner:SAMSUNG DISPLAY CO LTD +1

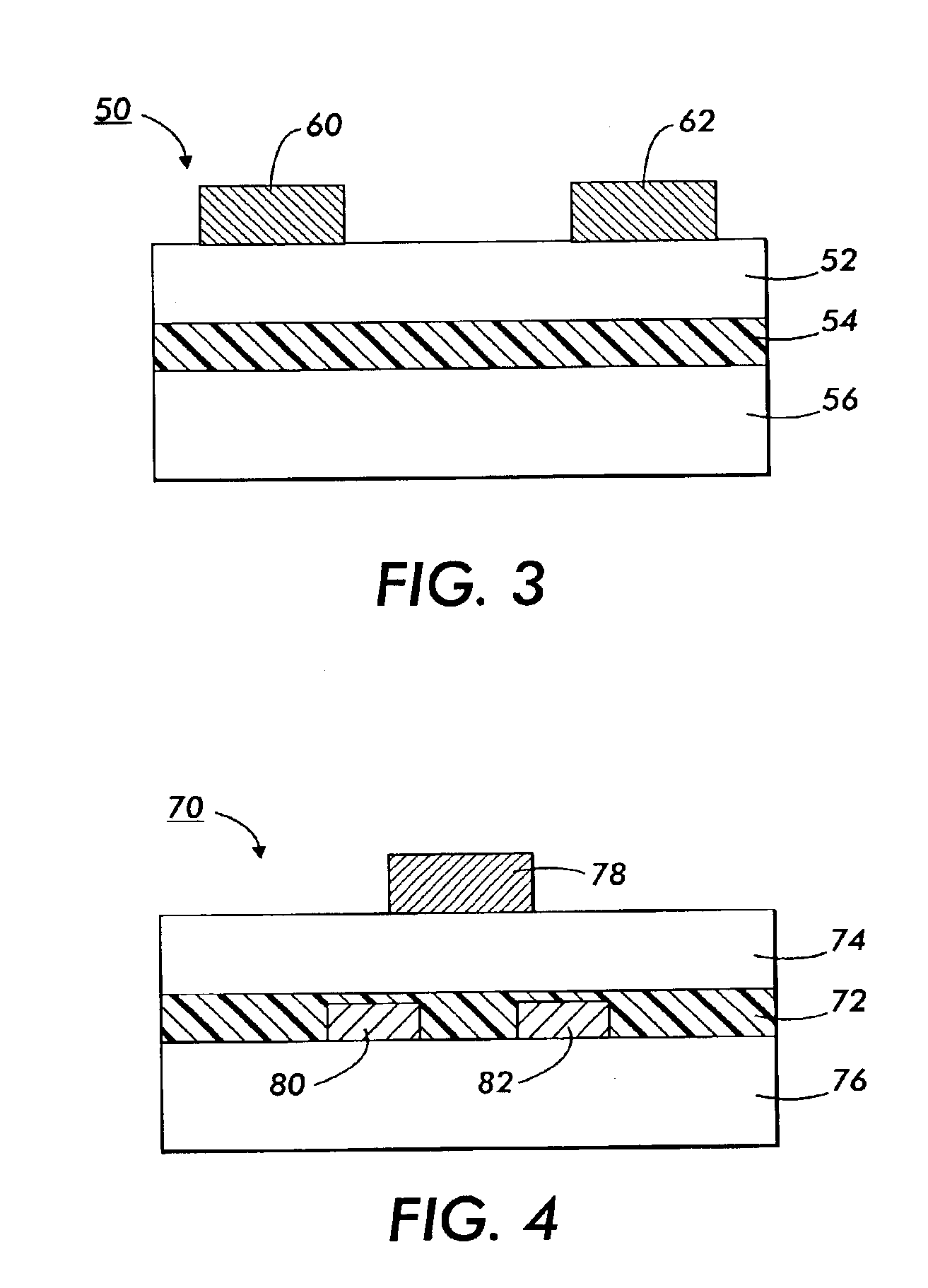

Fluorinated polythiophenes and devices thereof

InactiveUS6855951B2Reduce manufacturing costImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingMole fractionChemistry

An electronic device containing a polythiophene wherein R is an alkyl alkoxy; x represents the number of R groups; R′ is CF3, alkoxy, alkyl, or optionally alkylene; y and z represent the number of segments; and a and b represent the mole fractions of each moiety, respectively, wherein the sum of a+b is equal to about 1.

Owner:XEROX CORP

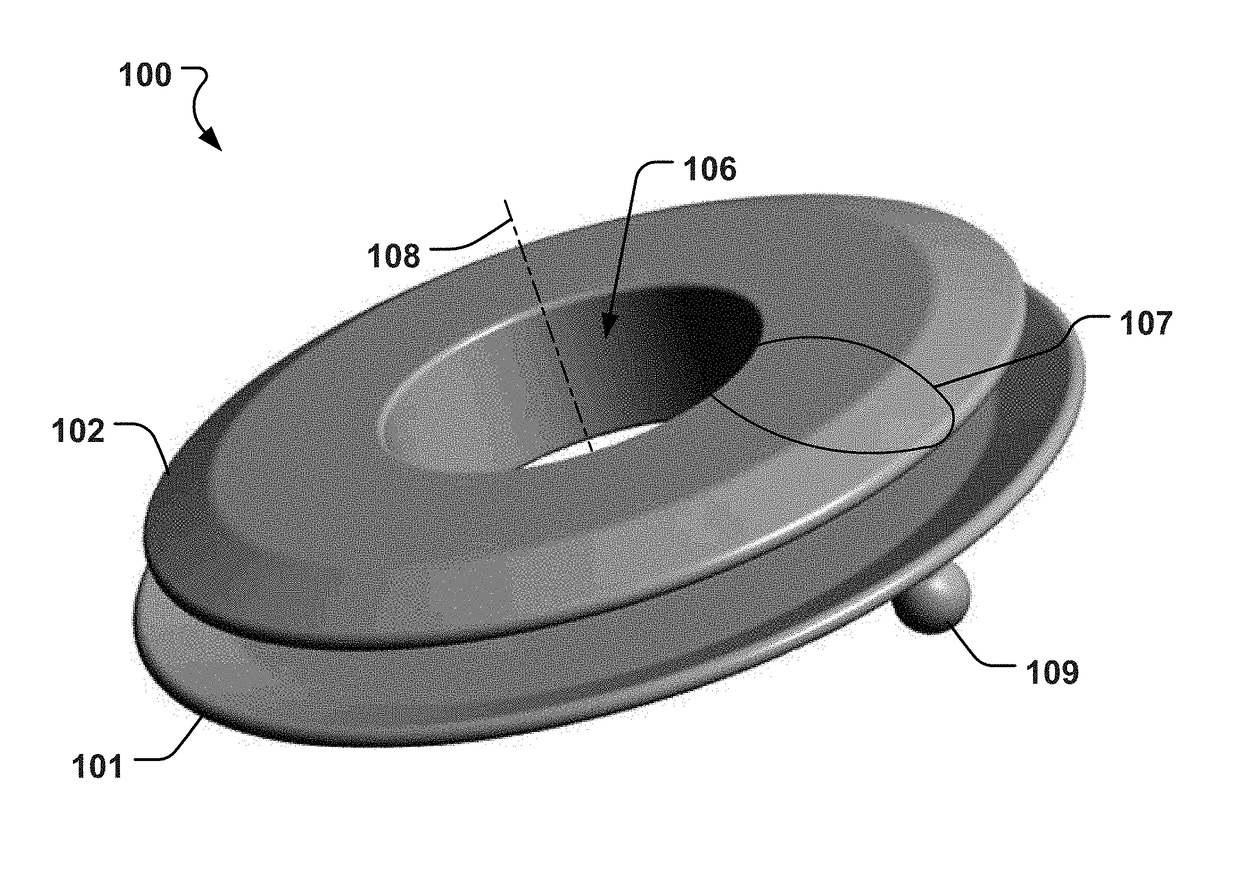

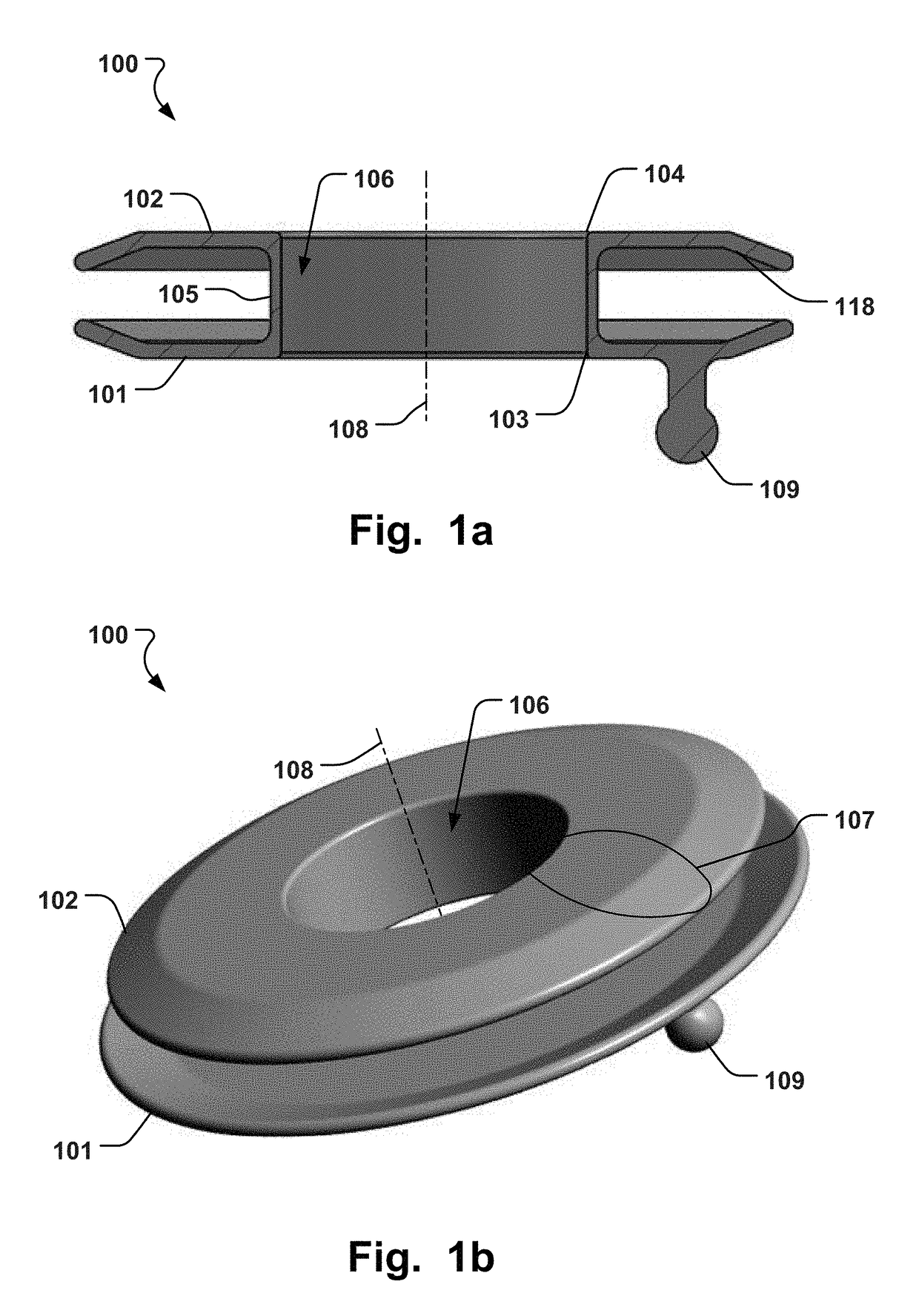

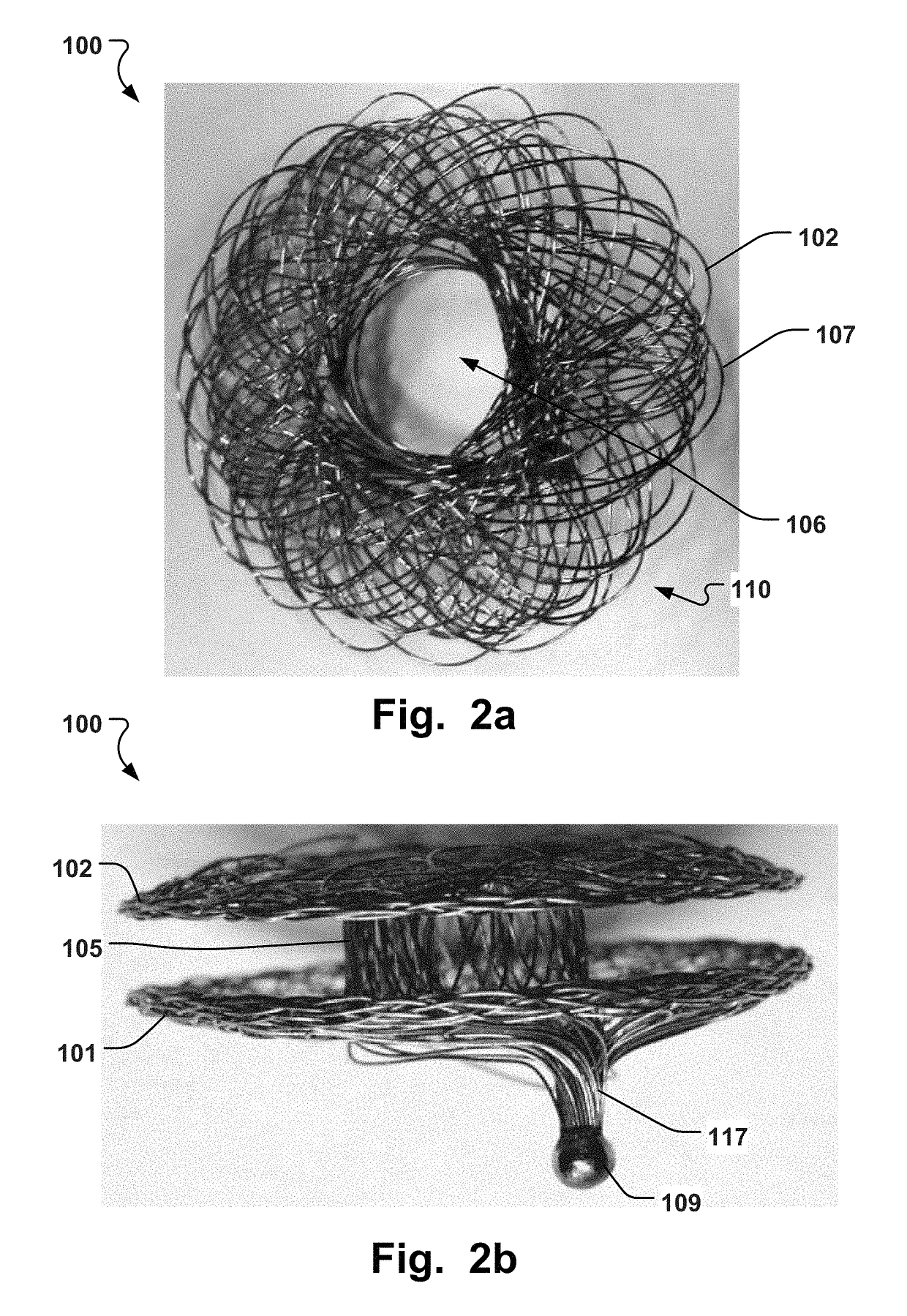

A Flow Regulating Device In The Heart

A blood flow regulator for creating a shunt in the heart, comprising; a proximal element having a general disc-shape, defined by a braid of one or more wires extending about a central aperture of the proximal element; a distal element having a general disc-shape, defined by a braid of one or more wires extending about a central aperture of the distal element; and a third element defining a neck section intermediate the proximal and distal elements and forming a cavity having a diameter no greater than a diameter of each of the distal and proximal elements, wherein said distal element comprises at least one loop of a wire extending radially outwardly from a center of the distal element and returning towards said center of said distal element.

Owner:OCCLUTECH GMBH

Vertical tower fan

A portable, vertical tower fan capable of generating a vertically oriented exhaust air stream that conforms better to a user at an elevation above a support surface. The device includes an vertically elongated housing, an air blower assembly located within the elongated housing and a base provides a space saving design.

Owner:LASKO OPERATION HLDG LLC

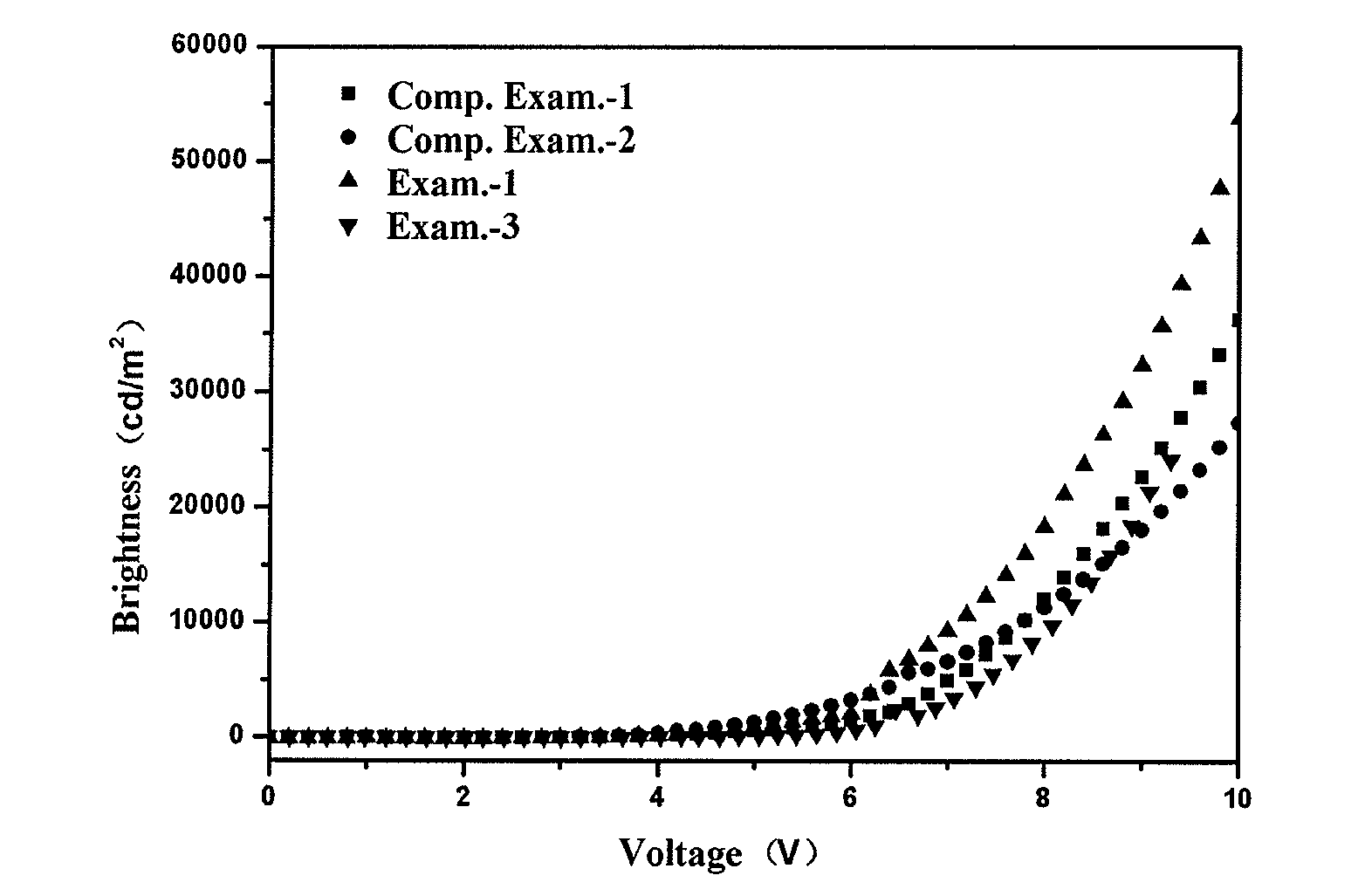

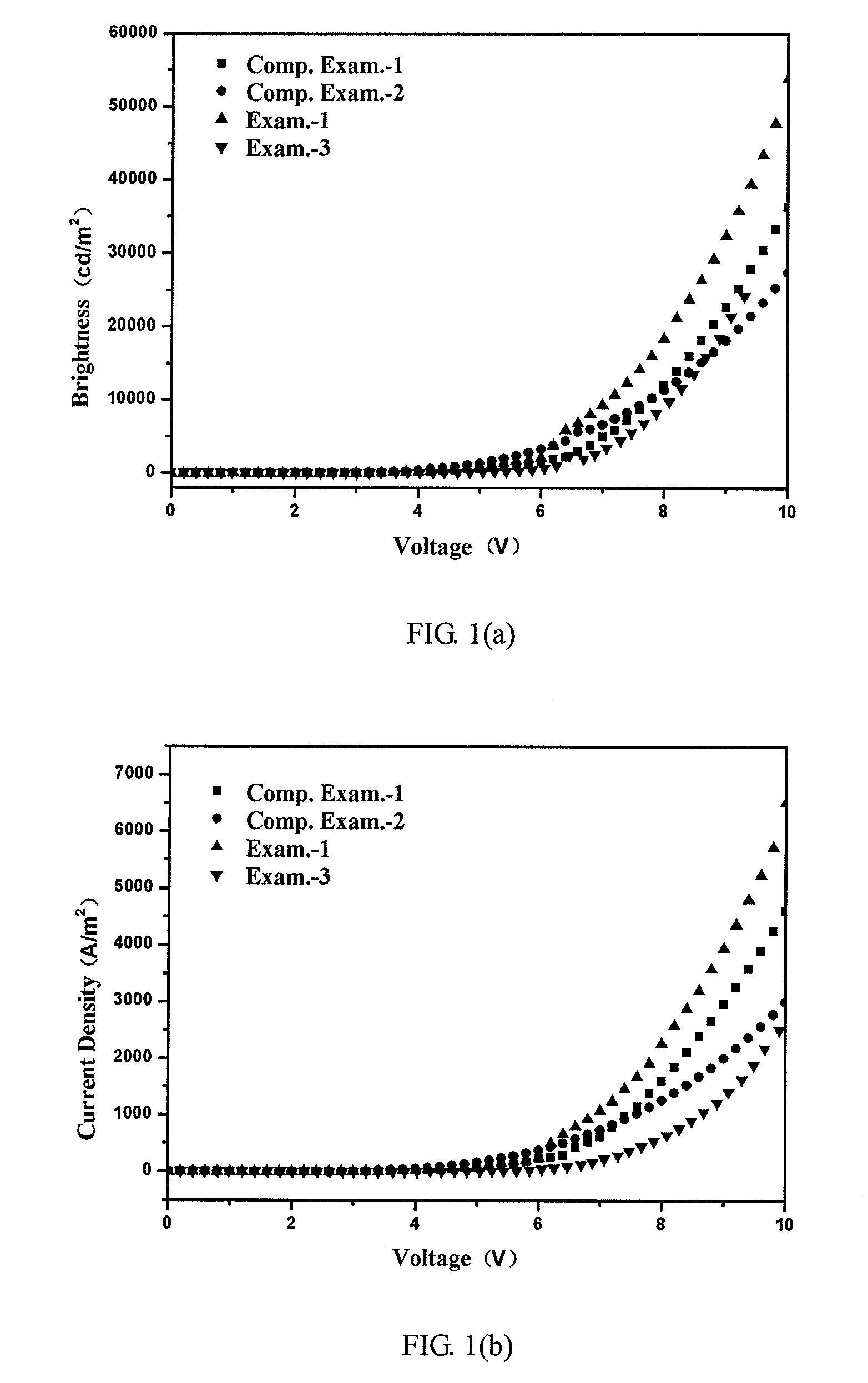

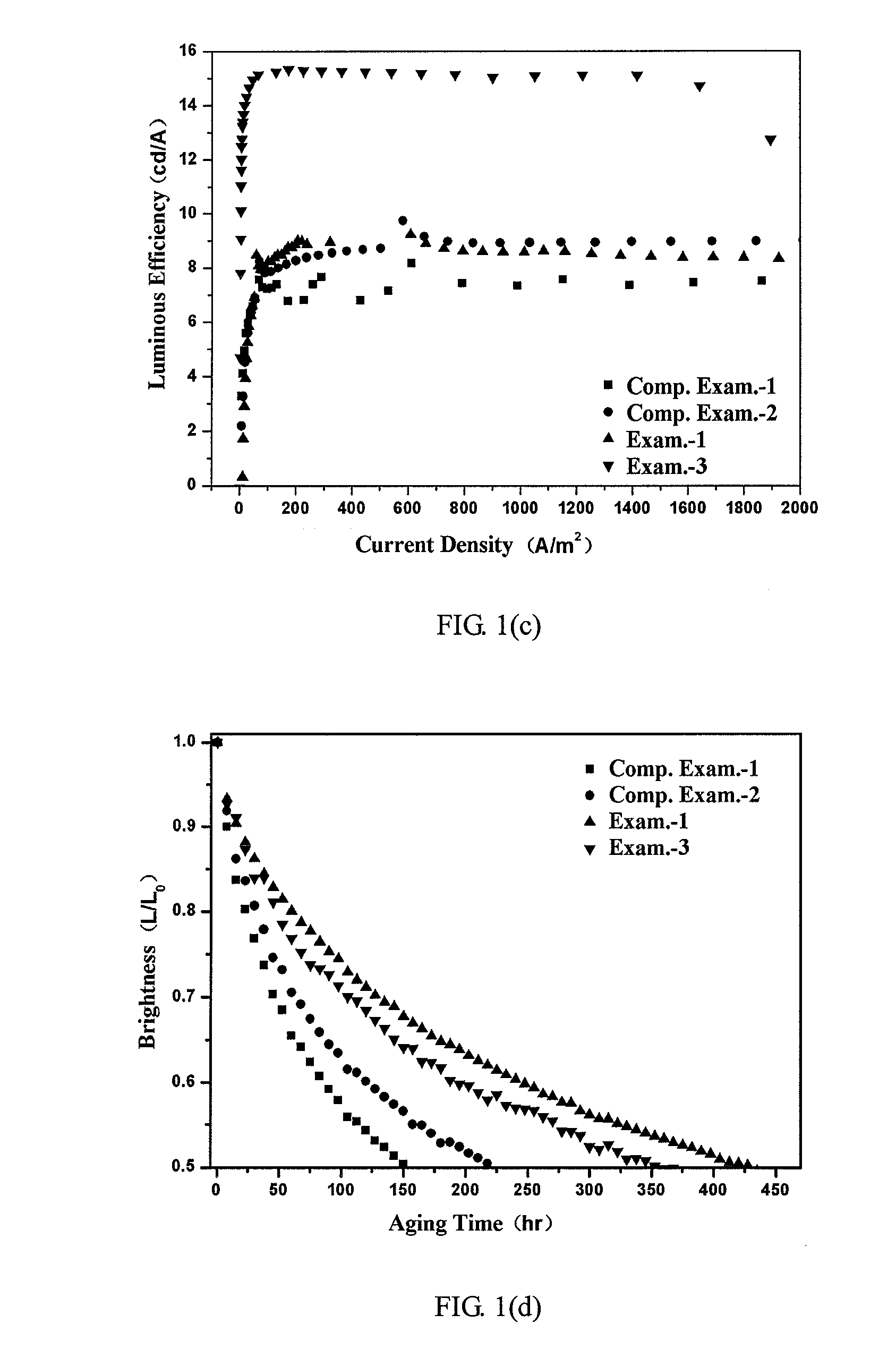

Organic electroluminescent device

InactiveUS20090001878A1Improve luminous efficiencyGood balanceDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceOxide

An organic electroluminescent device includes an anode, a cathode and an organic functional layer between the anode and the cathode, in which at least one of hole injection layer, hole transport layer and electron transport layer includes a host material and an inorganic inactive material doped in the host material, and the inorganic inactive material is a halide, oxide or carbonate of metal.

Owner:TSINGHUA UNIV +2

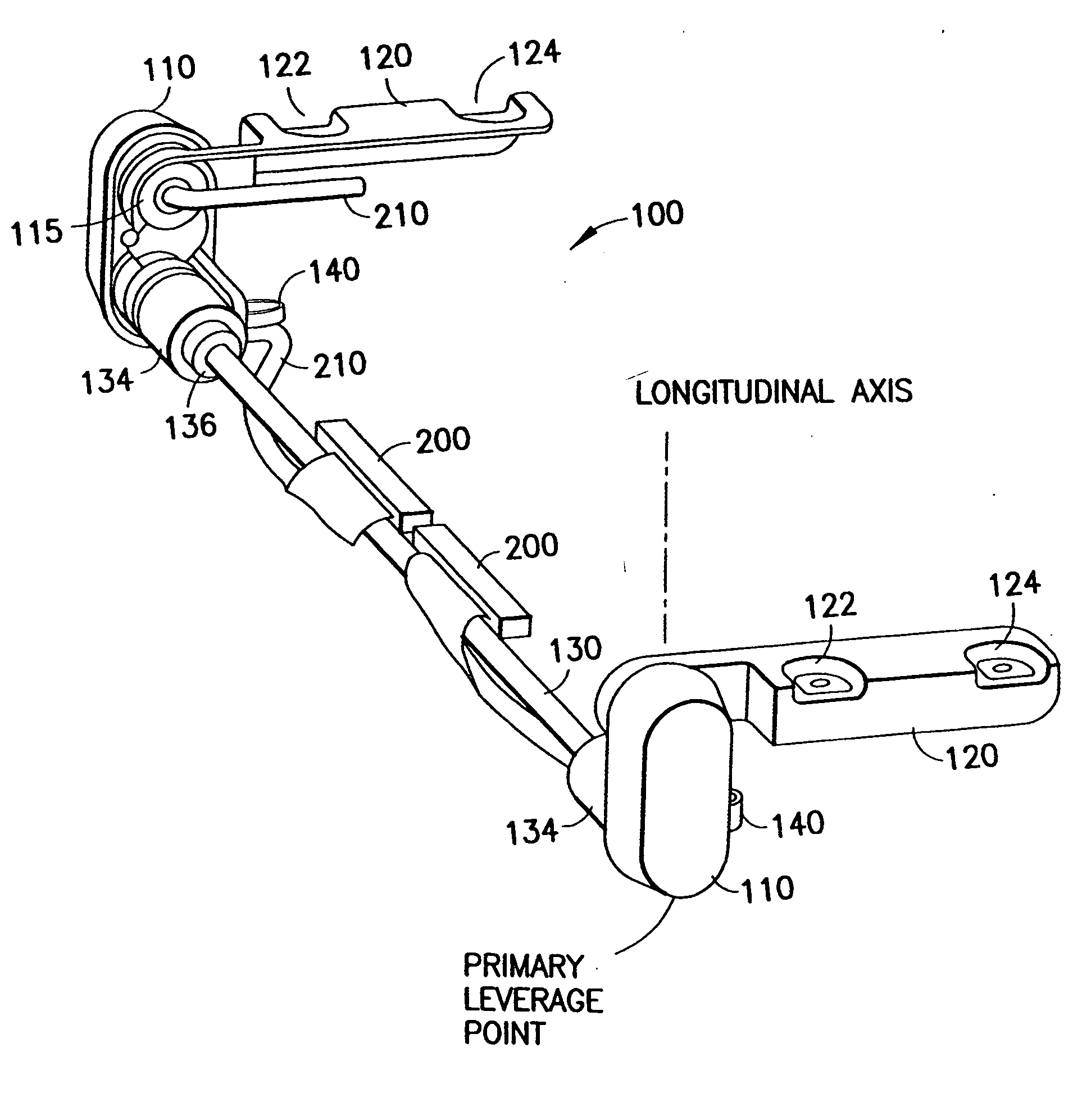

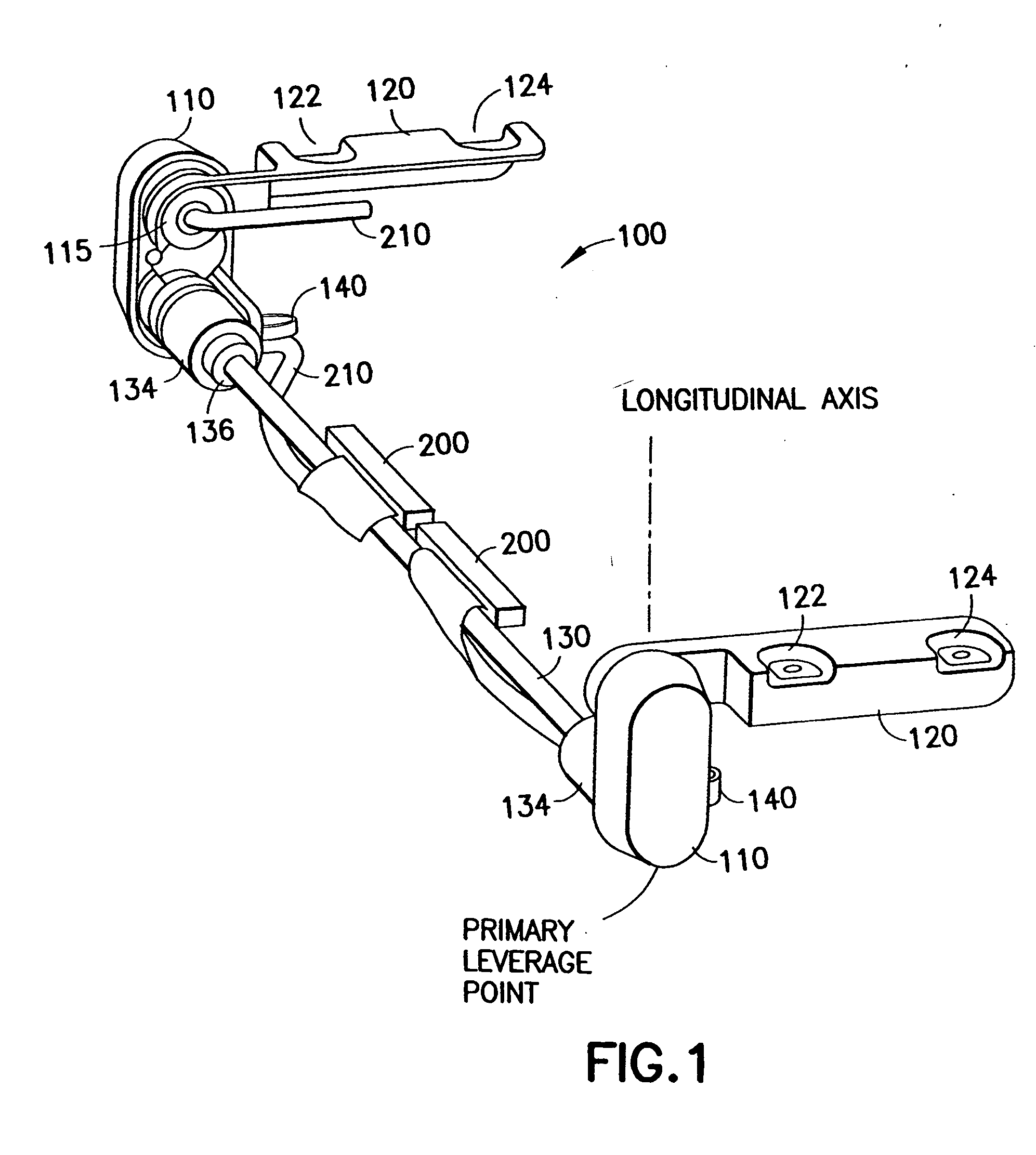

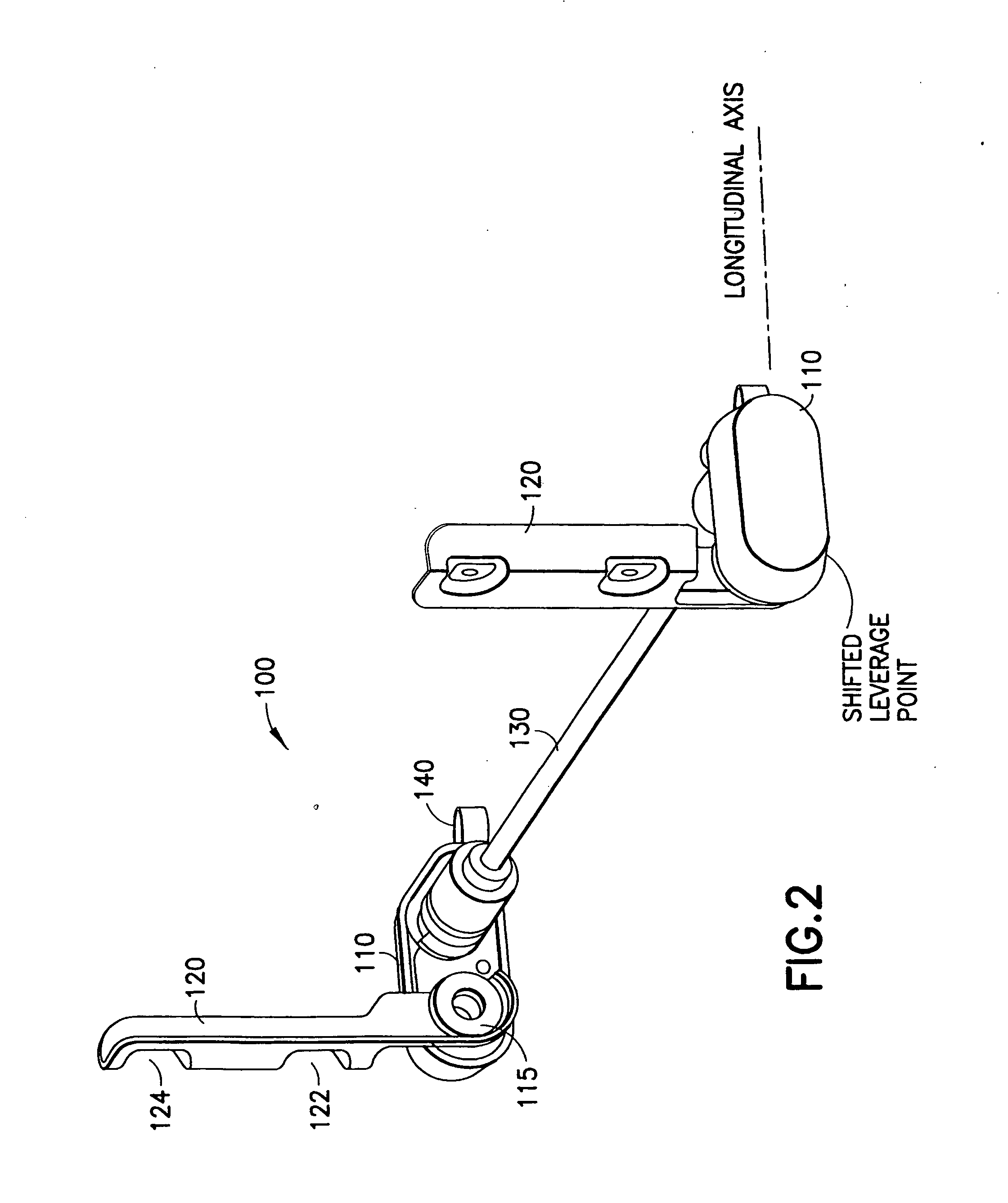

Double-axis hinge for use in electronic devices

InactiveUS20070234521A1Improve device stabilityImprove stabilityDetails for portable computersSubstation equipmentRotational axisControl theory

A hinge has two hinge arms for rotatably mounting a lower part of an electronic device of a clamshell design at a first rotational axis and for rotatably mounting an upper part of the electronic device at a second rotational axis. When the angle between the lower and second parts is within a first angular range, the hinge arms are rotated against the lower part in order to change the angle and the hinge leverage point is located substantially below the first rotational axis. When the angle is in a second angular range beyond the first angular range, the hinge arms are rotated against the upper part in order to change the angle and to move the leverage point away from the lower part. As such, the stability of the electronic device when the angle is in the second angular range.

Owner:NOKIA CORP

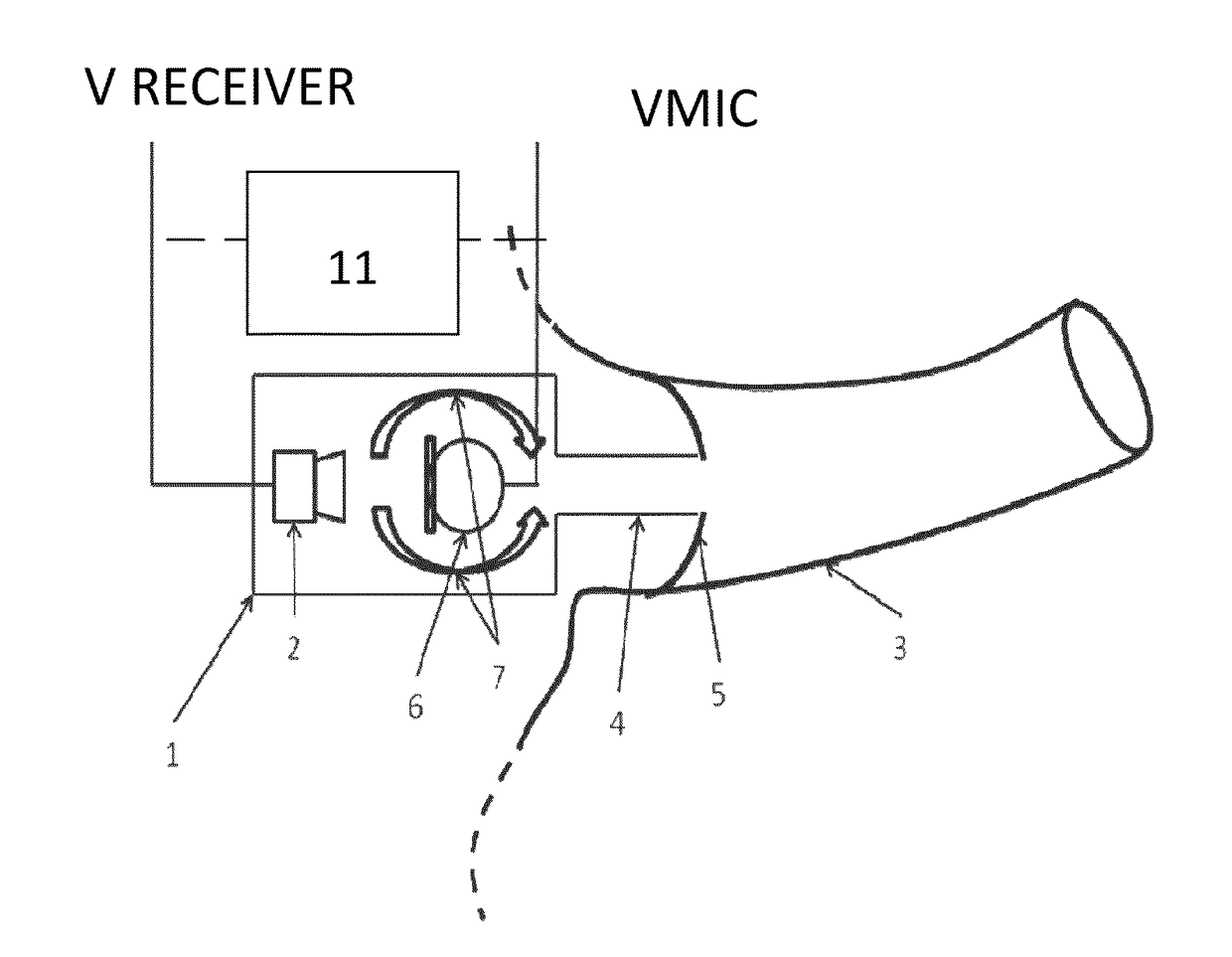

In-ear device incorporating active noise reduction

InactiveUS9654854B2Improved active noise cancellation performanceImprove device stabilityEar treatmentHearing device active noise cancellationEngineeringNoise reduction

Owner:PHITECK SYST LTD

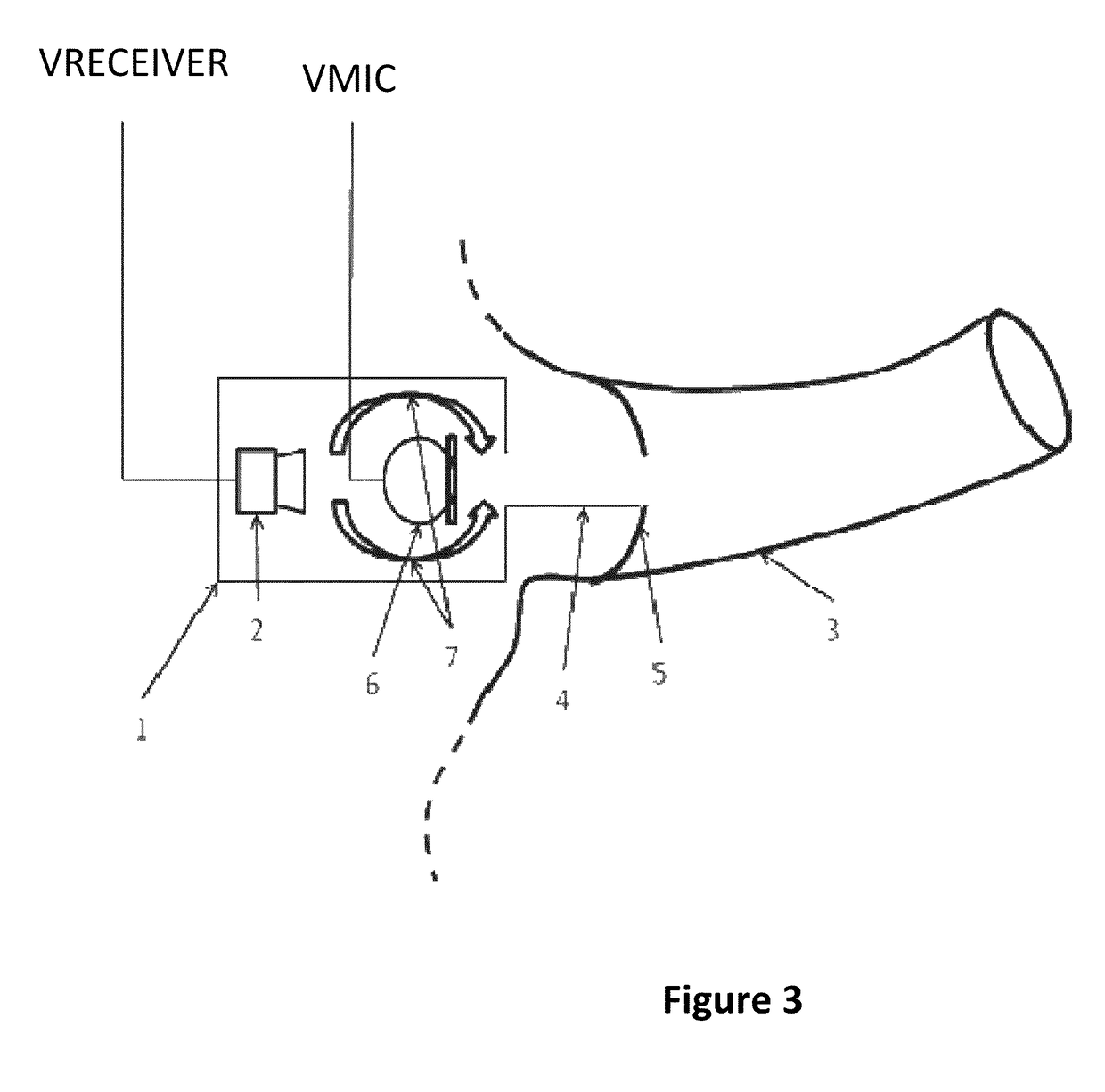

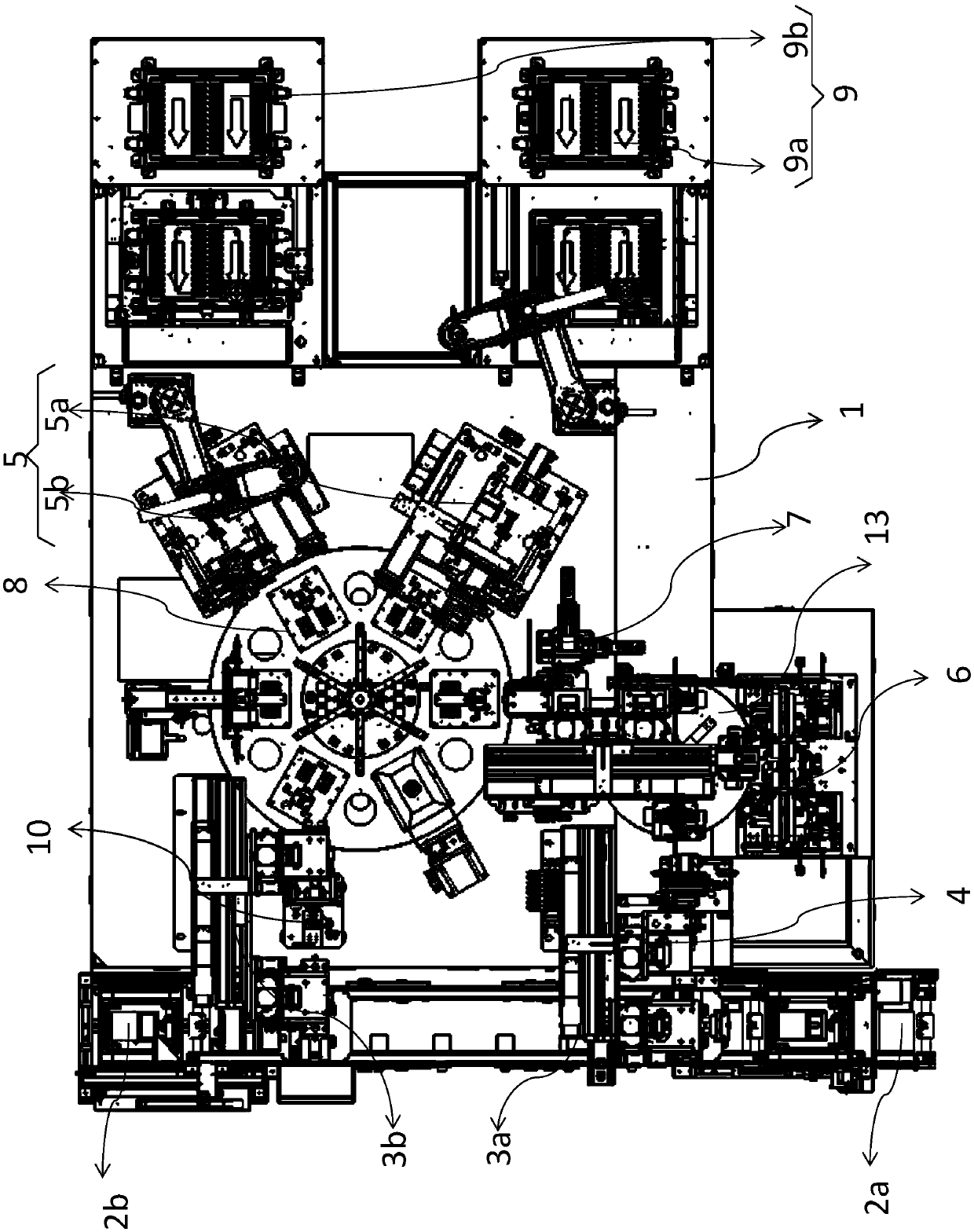

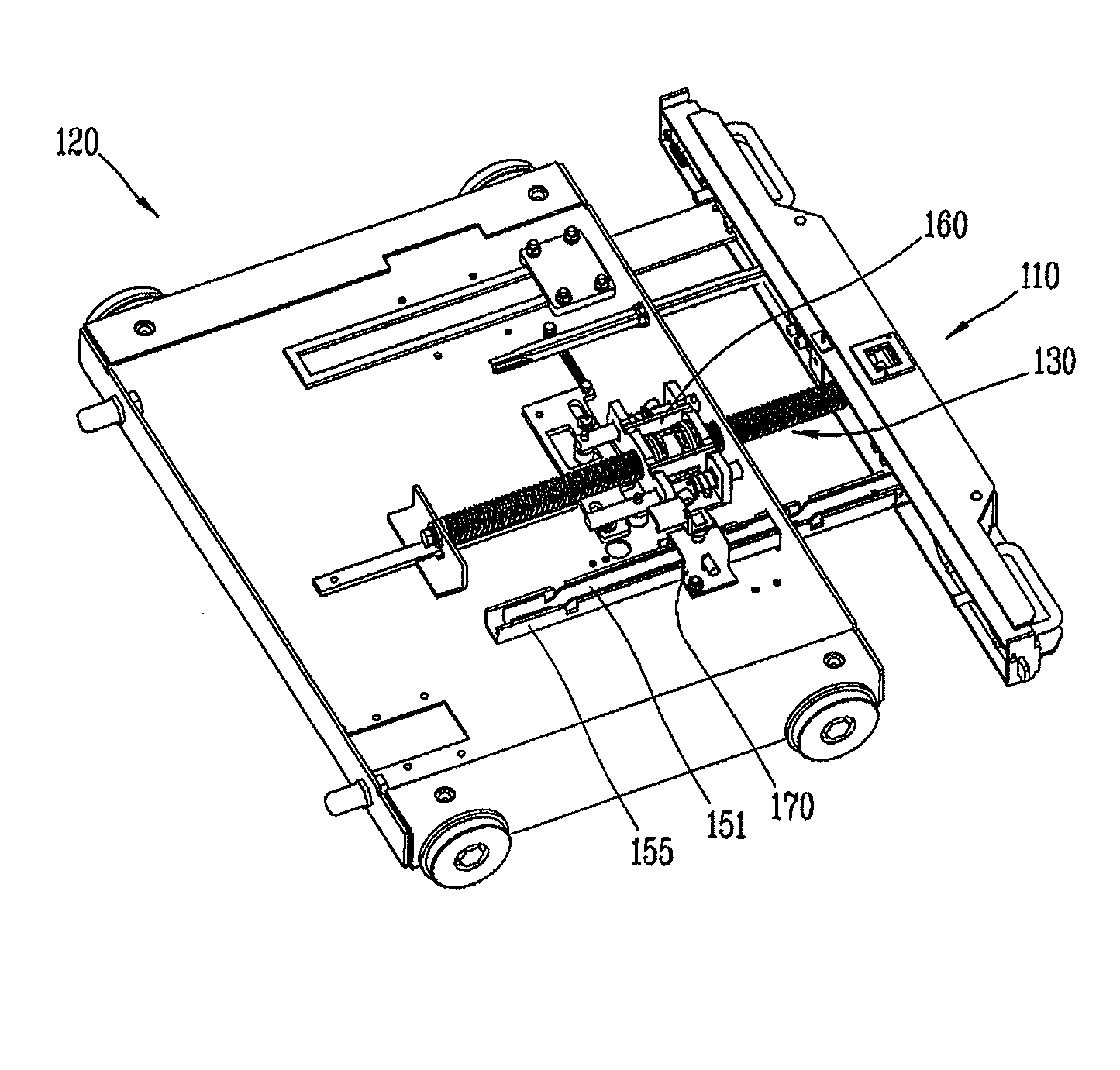

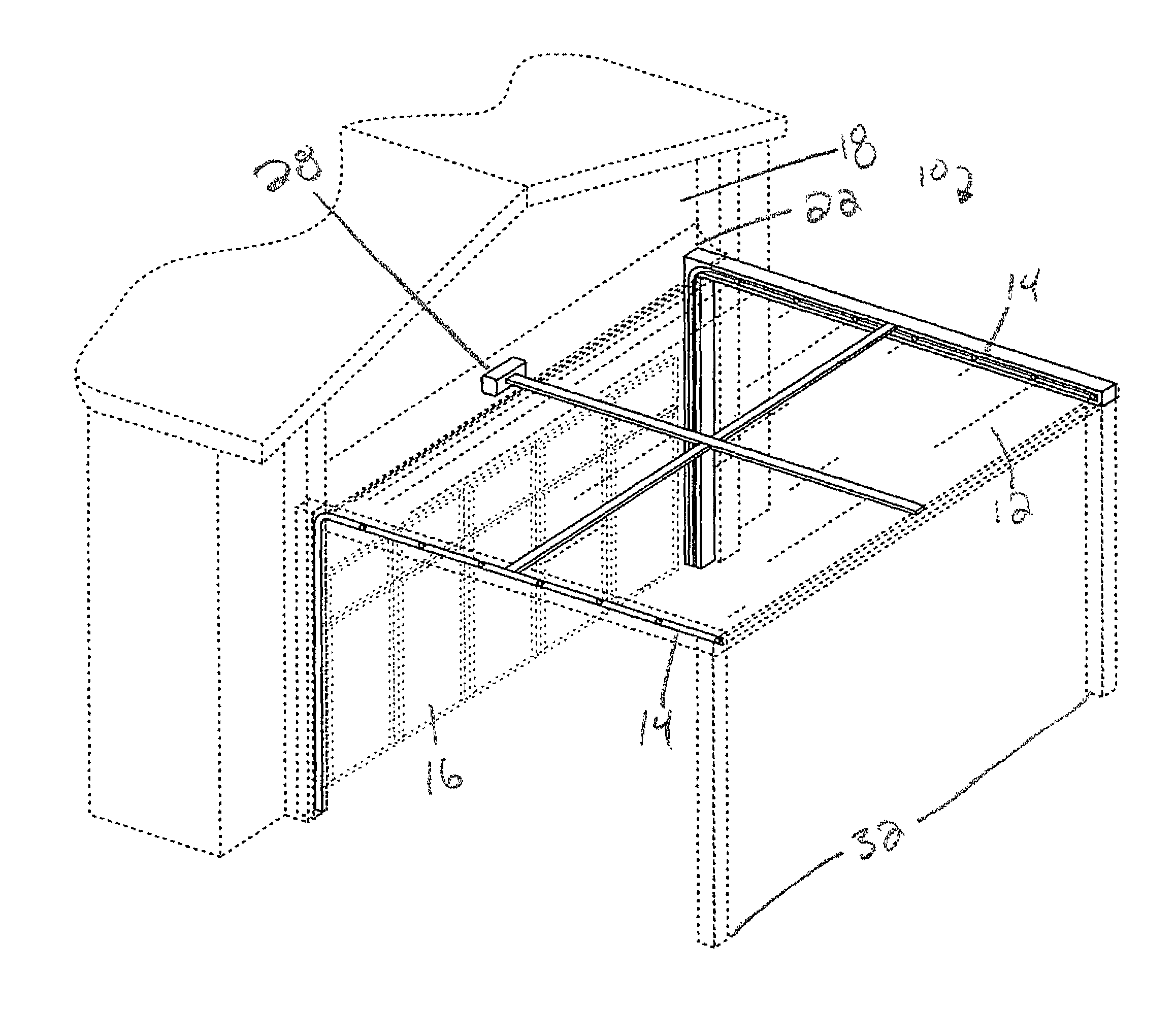

Battery cell holding rack mounting equipment

PendingCN107768725AReduce labor costsImprove job accuracyFinal product manufactureElectrolyte accumulators manufactureEngineeringLine structure

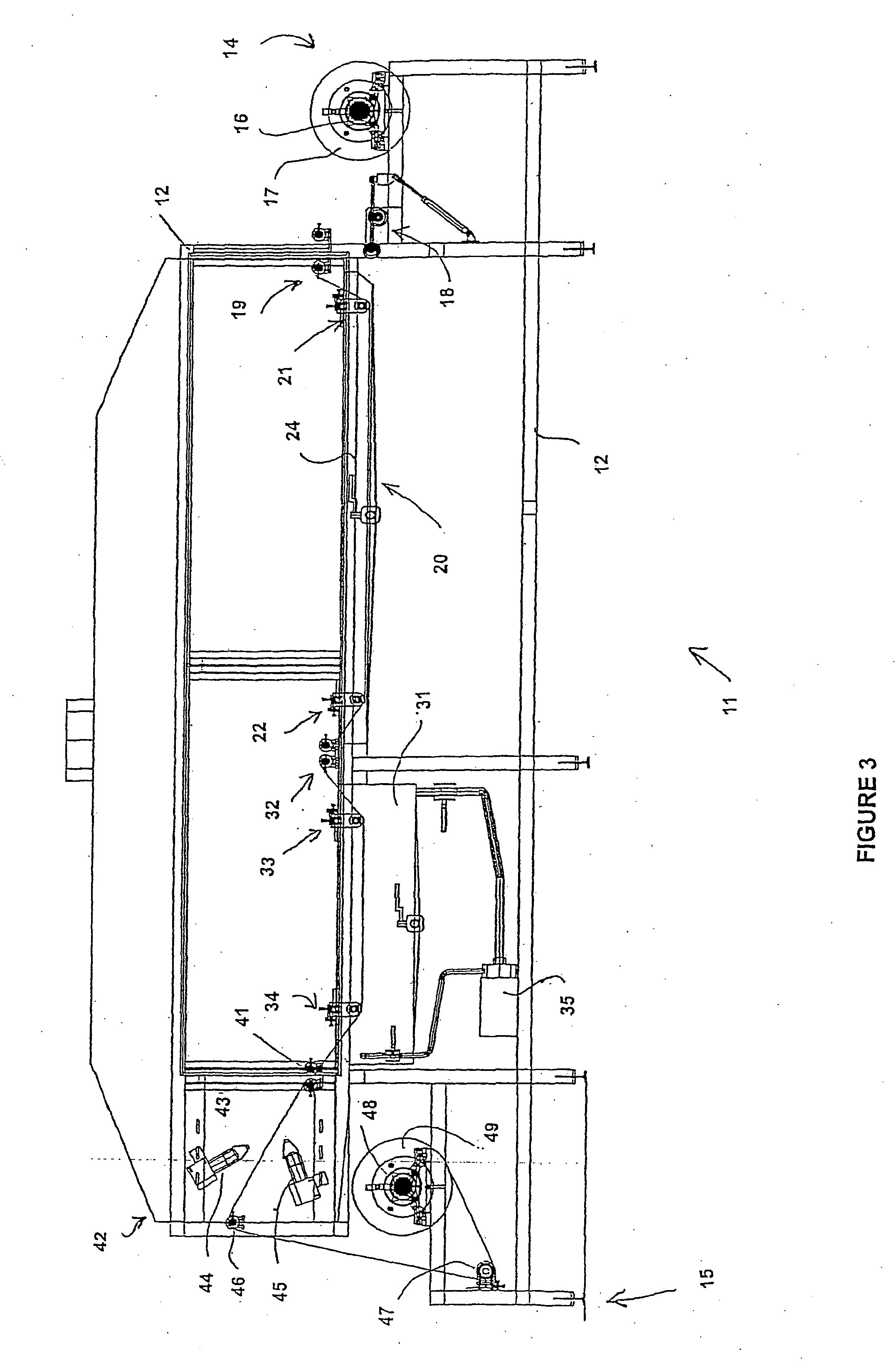

The invention relates to battery cell holding rack mounting equipment which comprises a feeding device, a gluing device, a rotating disc conveying device, a holding rack feeding device and a dischargedevice, wherein the feeding device, the gluing device, the rotating disc conveying device, the holding rack feeding device and the discharge device are mounted on a rack base according to a processing sequence to form a complete processing stream line. Due to adoption of an automatic line structure for loading and unloading materials, and a rotating disc multi-station conveying mechanism, the space can be relatively well utilized; the gluing mechanism, a detection mechanism, a holding rack pressing mechanism and the like are correspondingly arranged on the rotating disc multi-station conveying mechanism, then multi-station production is achieved, and relatively good automation of production is achieved; meanwhile, gluing and detection of electrode lug welding parts and mounting of a holding rack are achieved, full-automatic continuous product is achieved, the labor cost is reduced, high operation precision is achieved, different stations are compactly arranged and associated, the overall production efficiency and the equipment stability are improved, and automatic continuous line production is achieved.

Owner:海目星(江门)激光智能装备有限公司

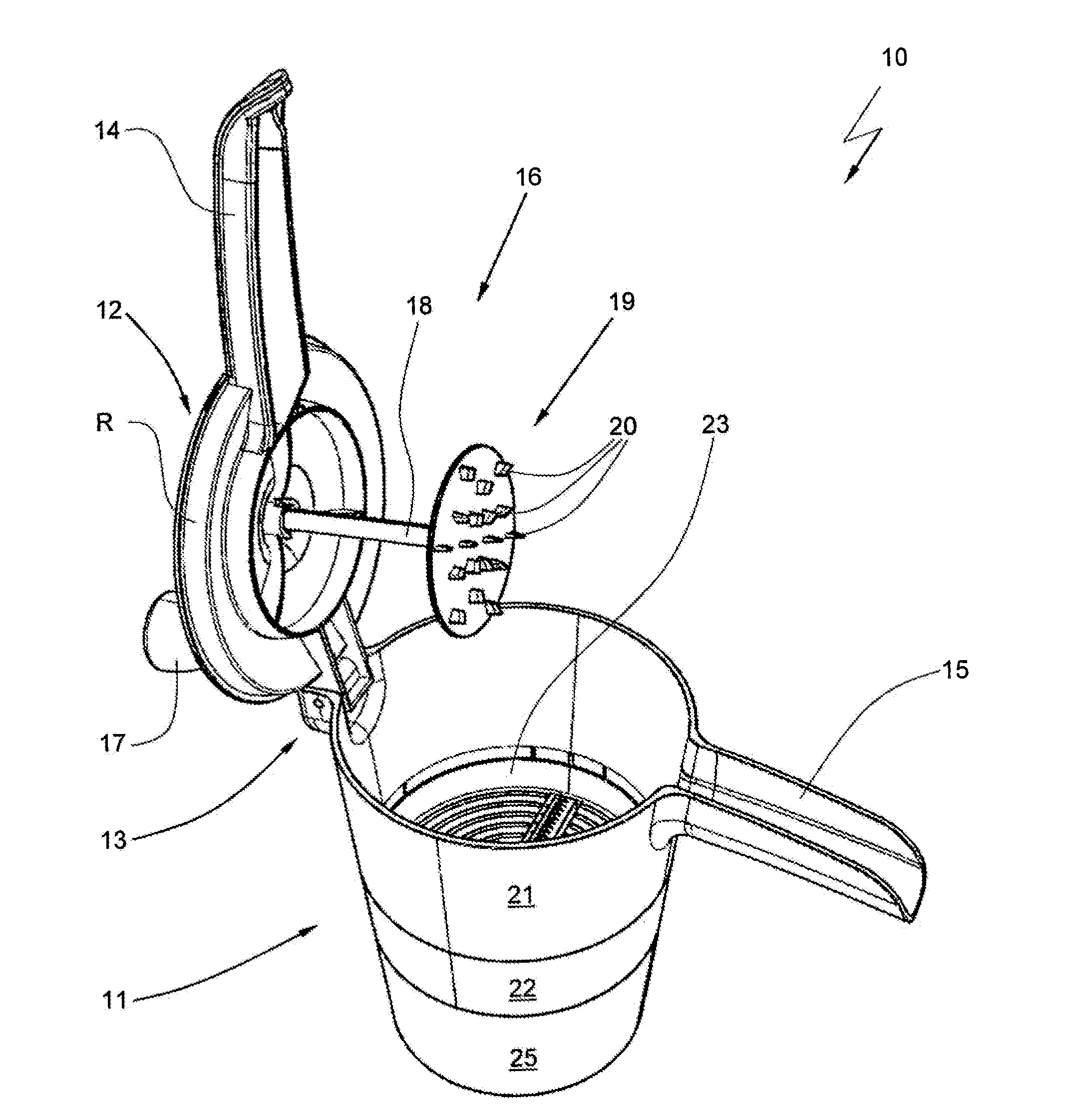

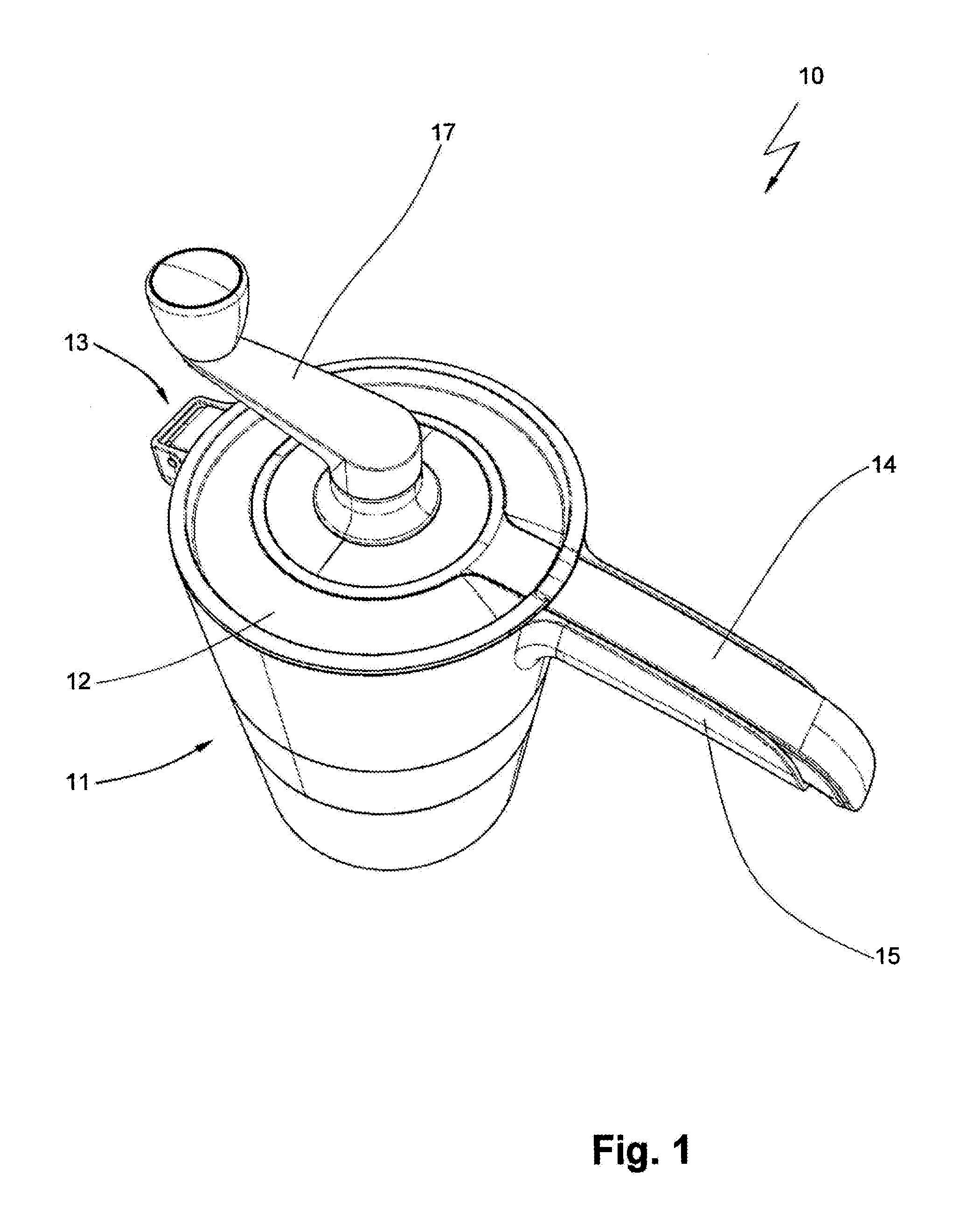

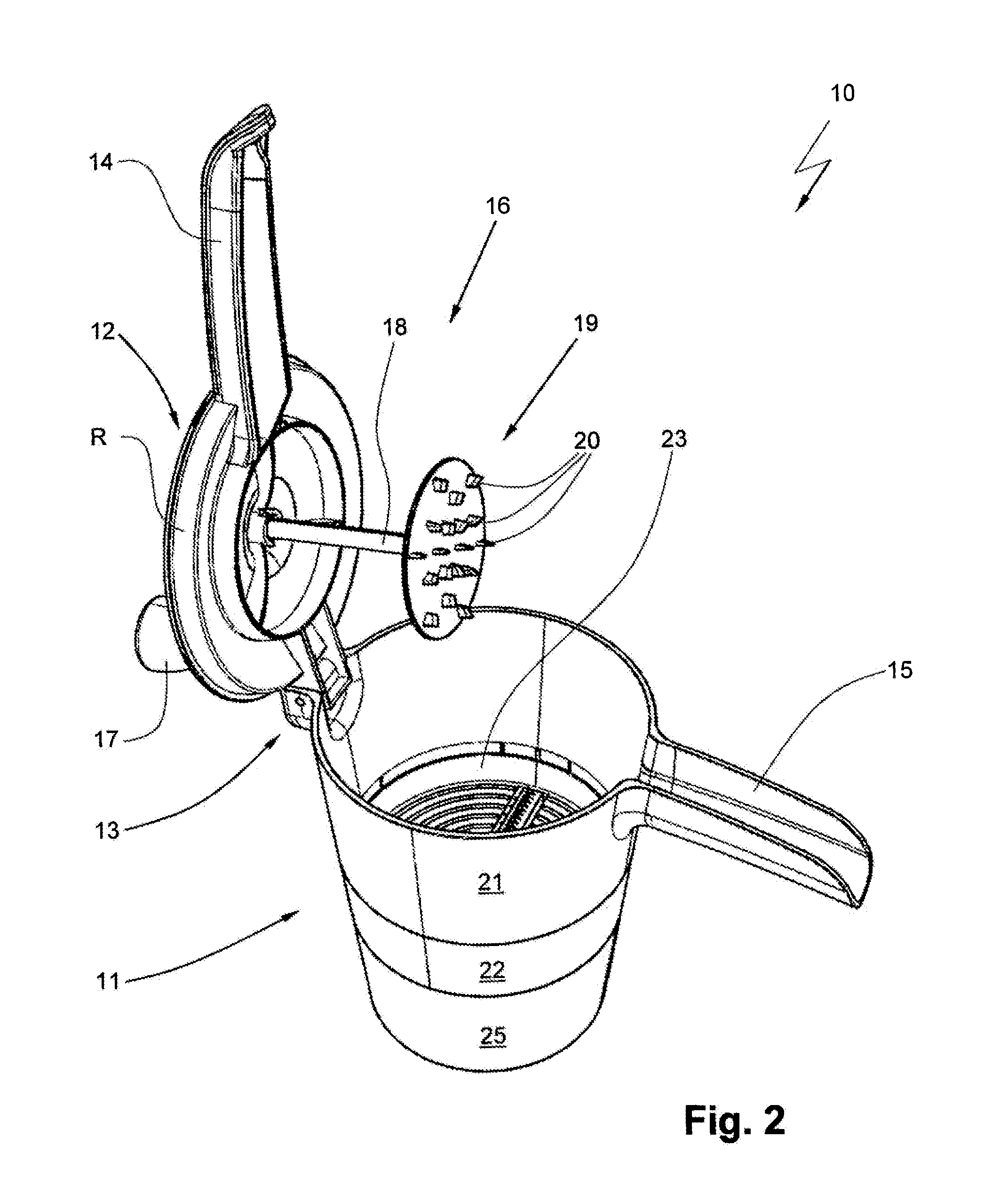

Device for Spiral Cutting Fruit and Hard Vegetables

ActiveUS20140165408A1Improve usabilitySubstantial ergonomic advantageThrusting weaponsWeapon componentsEngineeringCucumber family

A device for spiral cutting fruit and hard vegetables like apples, radishes, carrots, beets and cucumbers, comprising: a cutting device; and a hand operated fixation and drive device for the cutting material which hand operated fixation and drive device is arranged above the cutting device, wherein a housing is configured as a can and includes a cover arranged on the housing, wherein which the fixation and drive device is supported in the cover, and wherein the cover is provided with an extension that is handle shaped and arranged at a circumference of the cover.

Owner:GEFU KUCHENBOSS

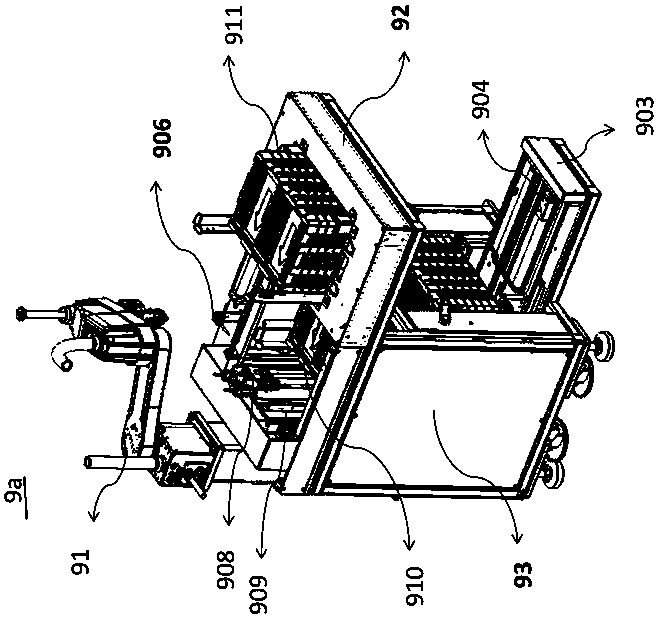

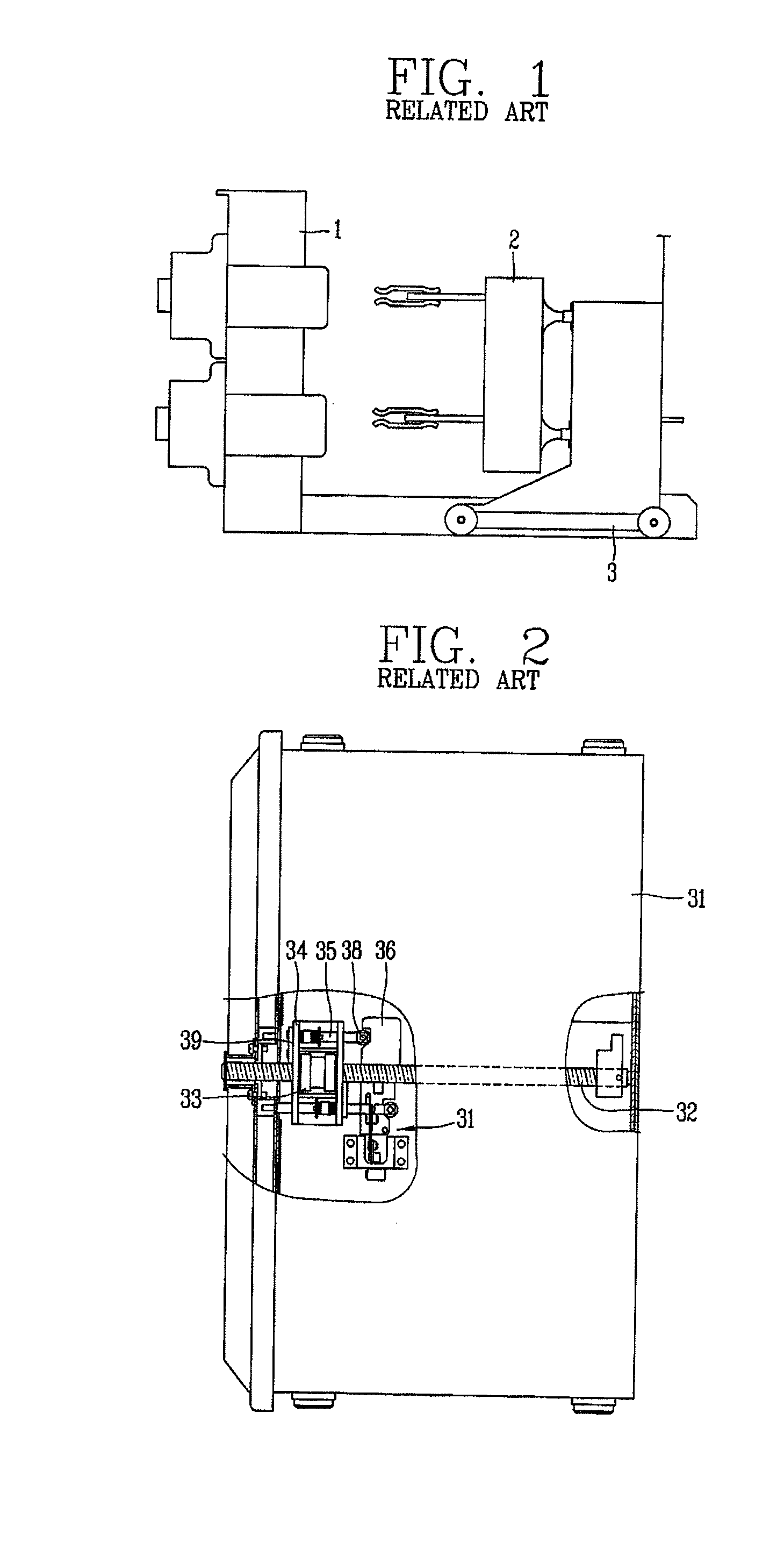

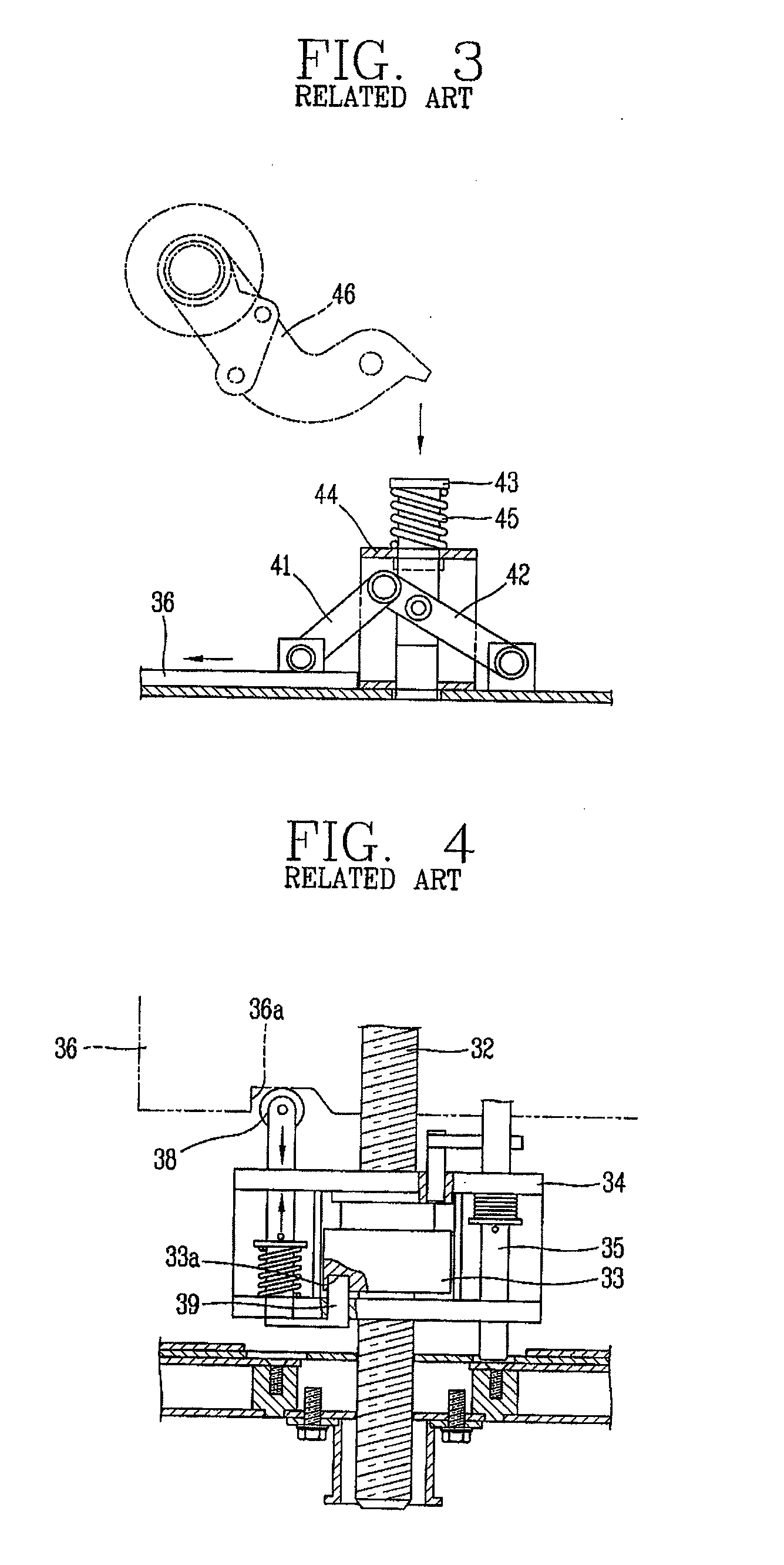

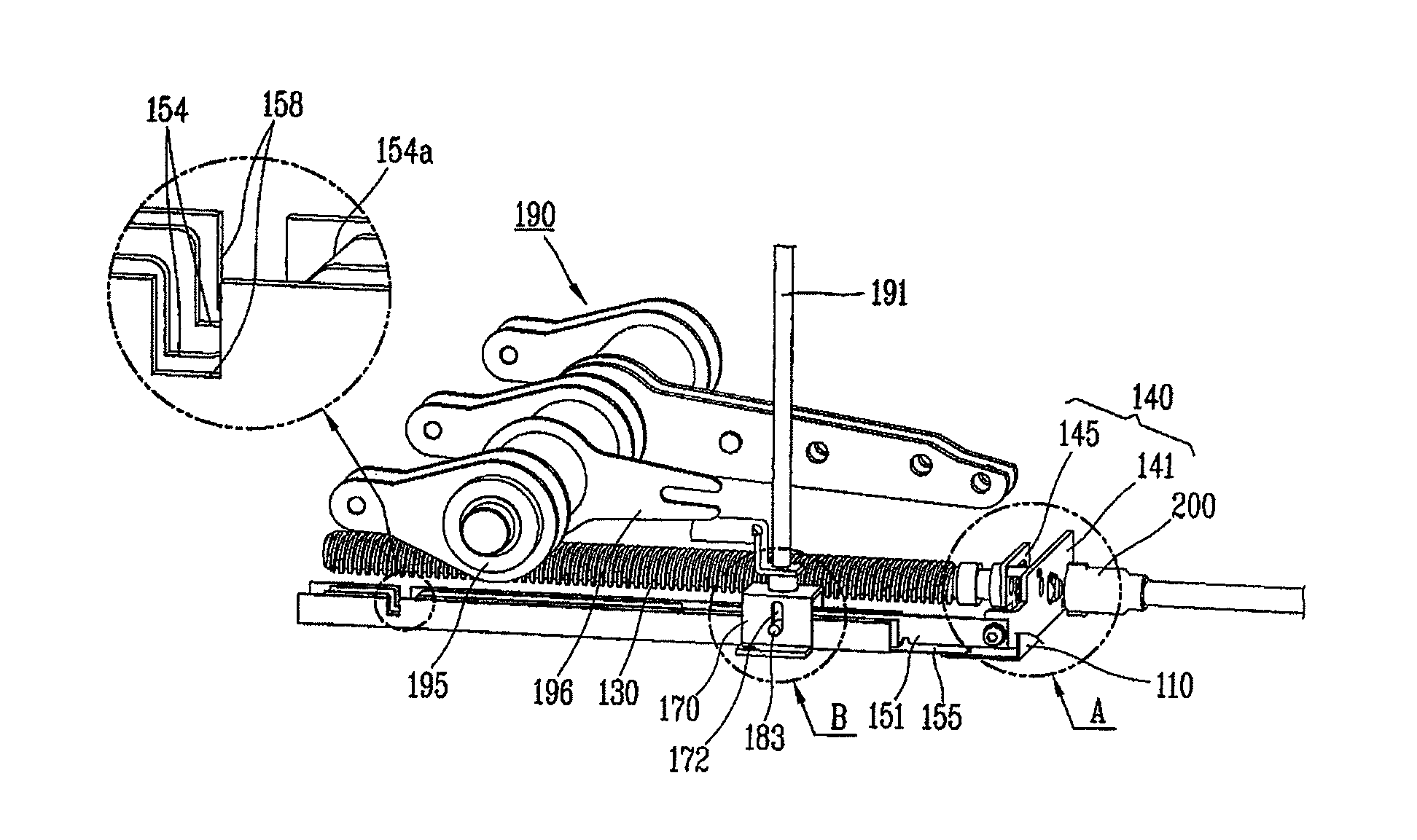

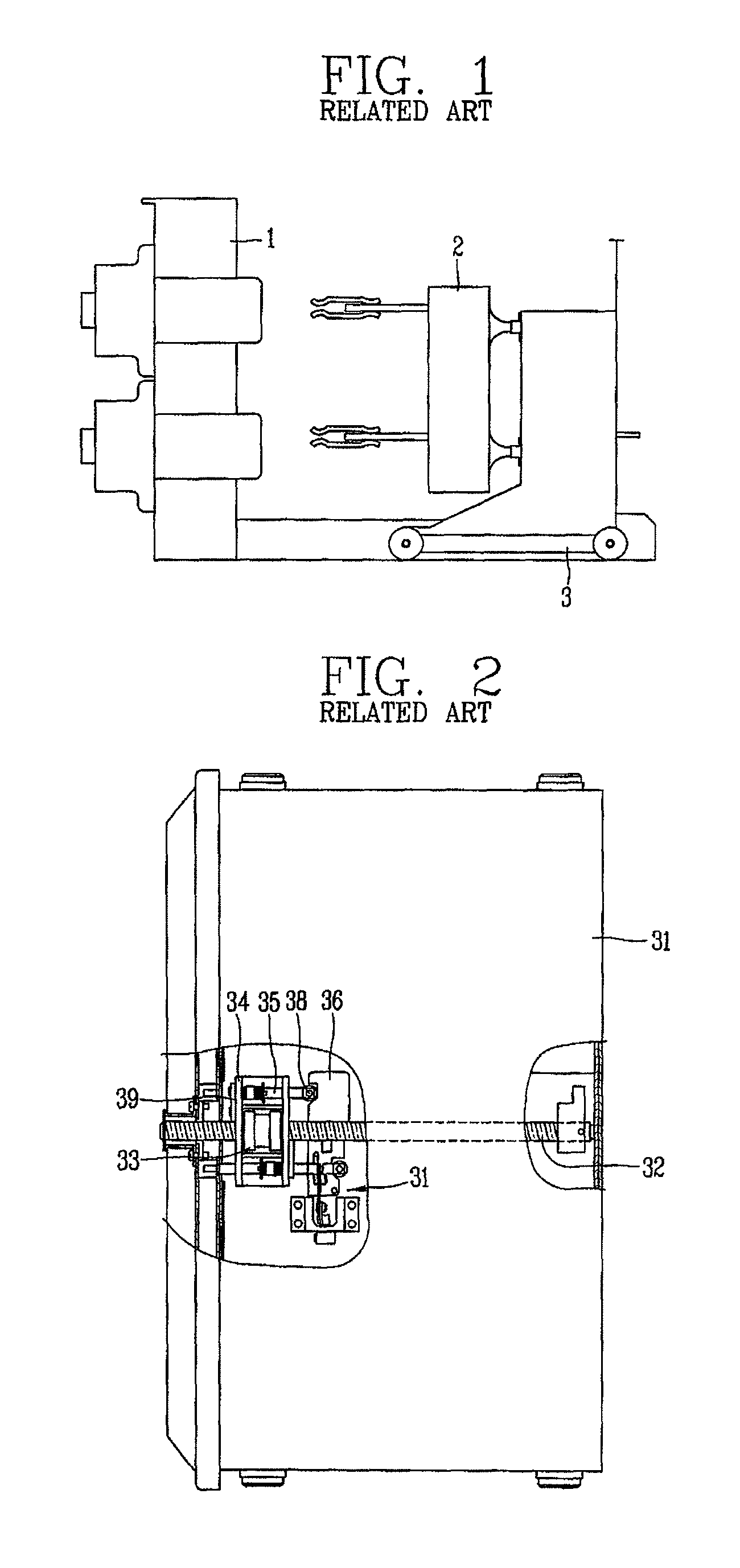

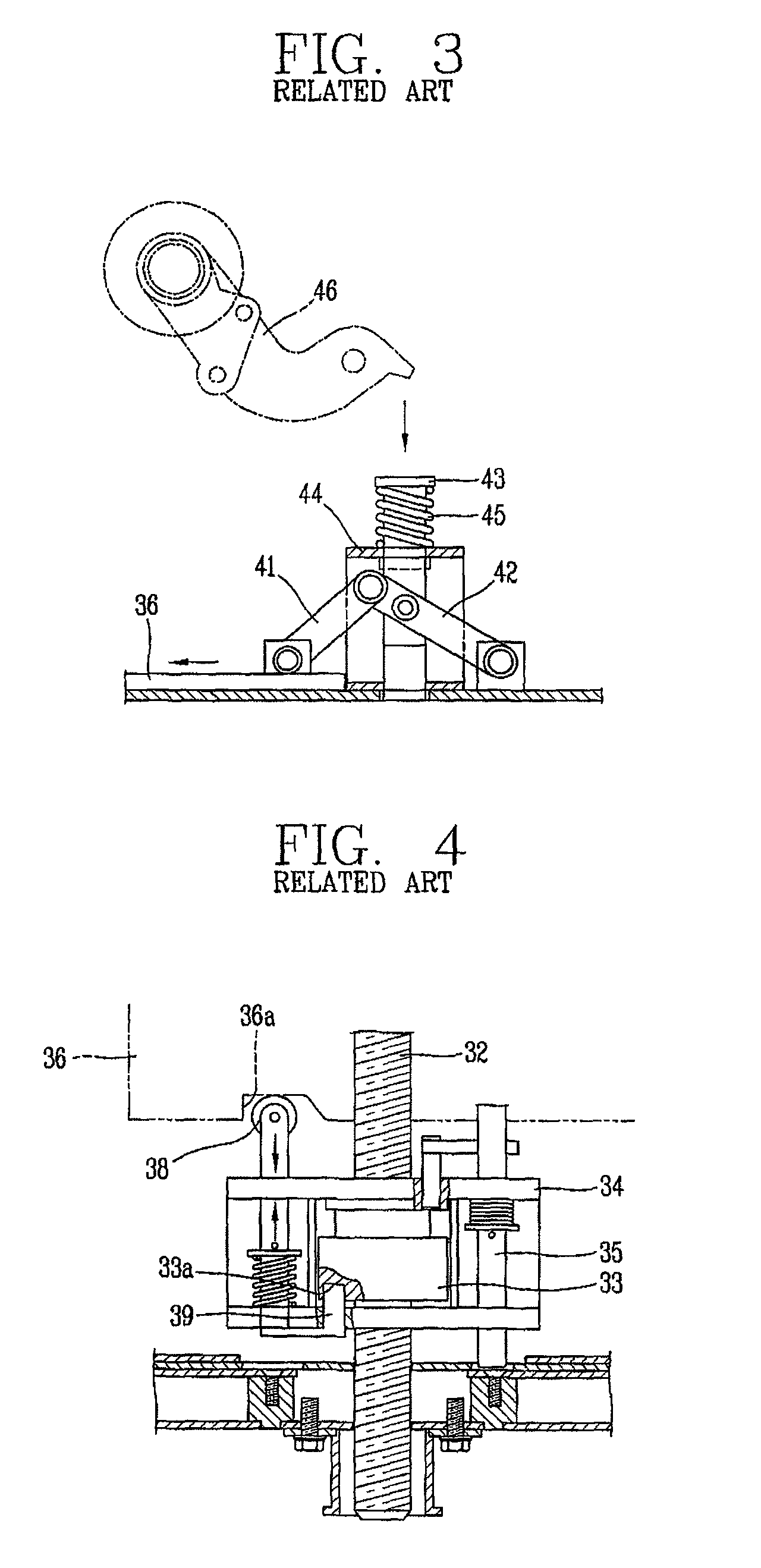

Apparatus for preventing withdrawing or inserting of carriage in circuit breaker

ActiveUS20100230256A1Improve device stabilityAvoid damageNon-enclosed substationsSwitchgear with withdrawable carriageEngineeringContact resistance

An apparatus for preventing withdrawing and insertion of a carriage of a circuit breaker is disclosed. When a circuit breaker main body is inserted, an interlocking unit operates by interworking with the carriage withdrawing and inserting preventing apparatus, and while the circuit breaker is being closed, a withdrawal and insertion handle prevents a lead screw from being rotated by the interlocking unit. Thus, when the circuit breaker performs a closing operation, unnecessary withdrawing and inserting operation of the carriage is basically prevented to thus prevent various safety accidents, a contact resistance, a temperature increase, and damage to a device resulting from a breakdown.

Owner:LS IND SYETEMS CO LTD

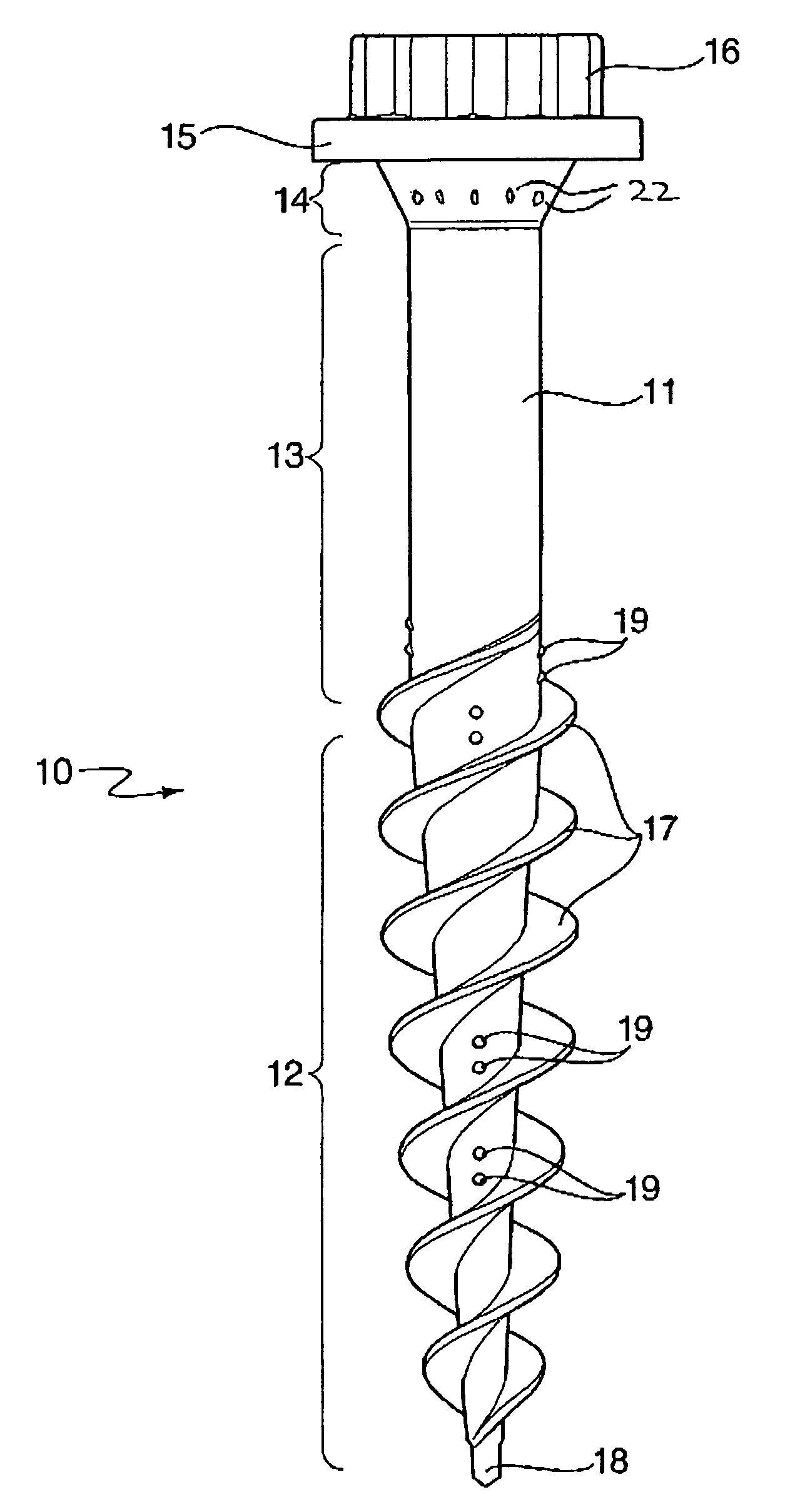

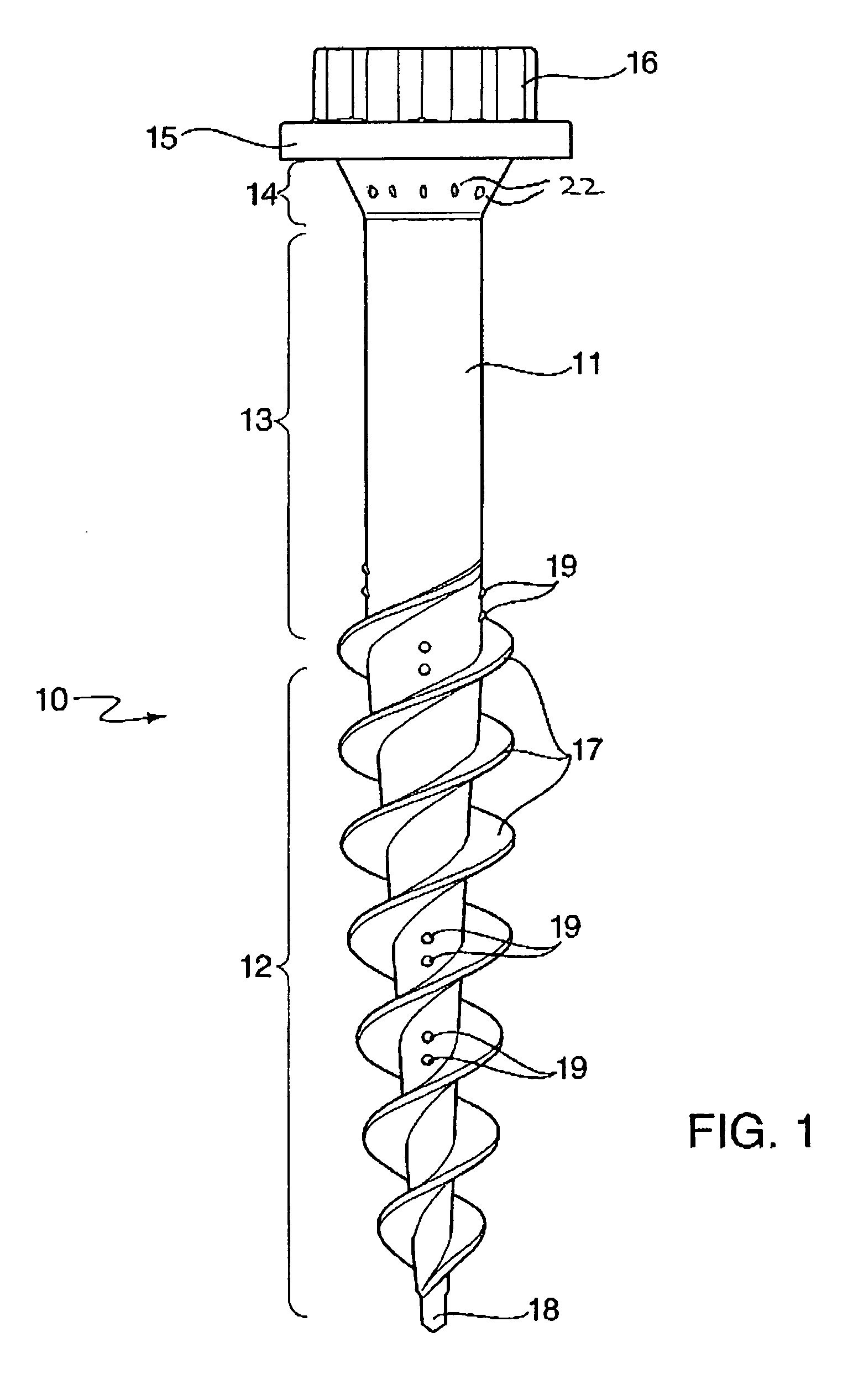

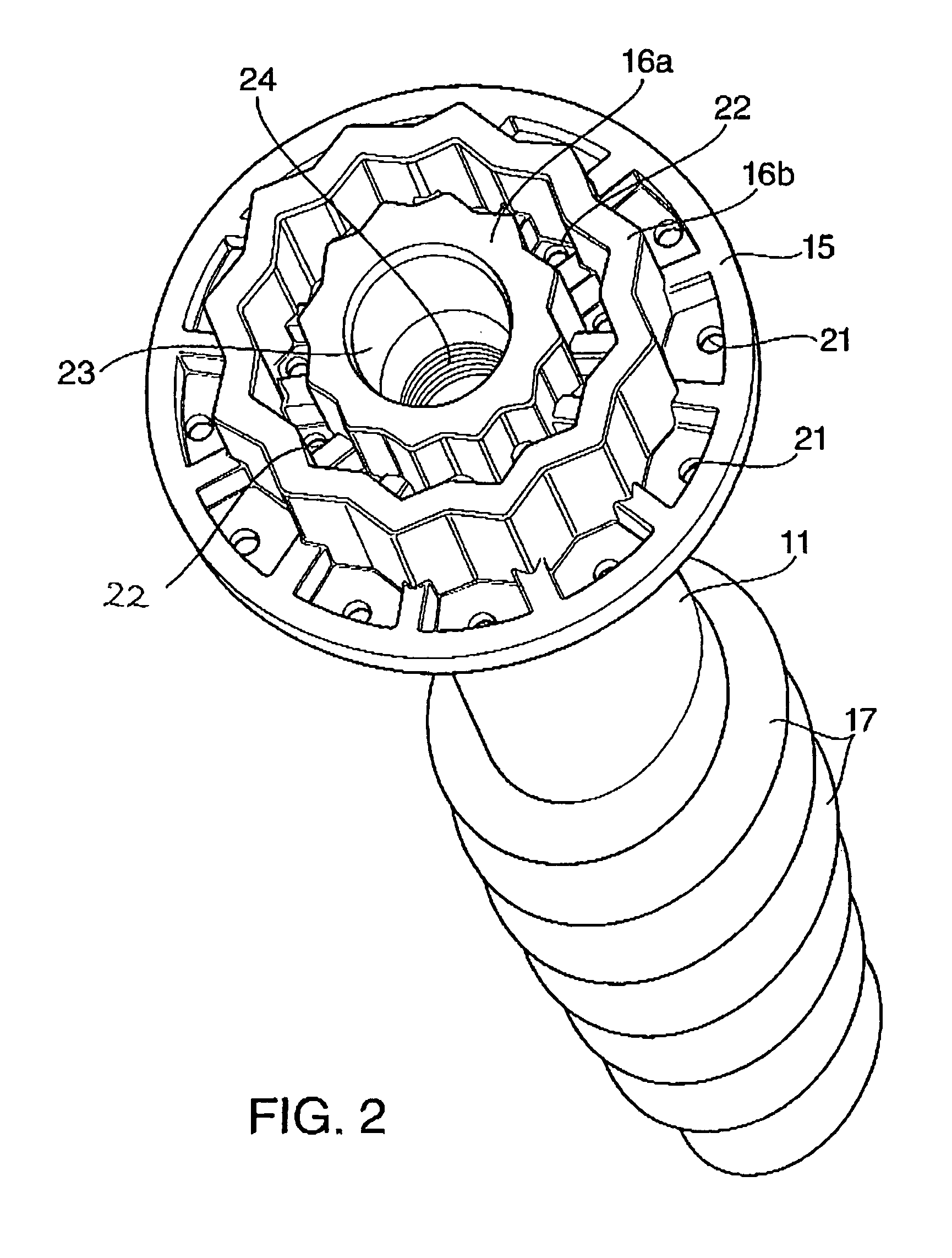

Anchoring device

InactiveUS20080008555A1Improve device stabilityPrevent lateral movementScrewsTowersEngineeringMechanical engineering

An anchoring device comprising a shaft, at least part of whose length comprises a tapered portion, with at least one helical flange which runs substantially along the length of said tapered section and an engagement means to allow the device to engage with a lever wherein in use rotation of the lever about the axis of the shaft results in rotation of the device such that the tapered portion and the helical flange co-operate to drive the device into the ground.

Owner:ARDERN FERGUS JOHNATHAN

Apparatus for preventing withdrawing or inserting of carriage in circuit breaker

ActiveUS8198557B2Improve device stabilityAvoid safety accidentsNon-enclosed substationsSwitchgear with withdrawable carriageContact resistanceCircuit breaker

An apparatus for preventing withdrawing and insertion of a carriage of a circuit breaker is disclosed. When a circuit breaker main body is inserted, an interlocking unit operates by interworking with the carriage withdrawing and inserting preventing apparatus, and while the circuit breaker is being closed, a withdrawal and insertion handle prevents a lead screw from being rotated by the interlocking unit. Thus, when the circuit breaker performs a closing operation, unnecessary withdrawing and inserting operation of the carriage is basically prevented to thus prevent various safety accidents, a contact resistance, a temperature increase, and damage to a device resulting from a breakdown.

Owner:LG IND SYST CO LTD

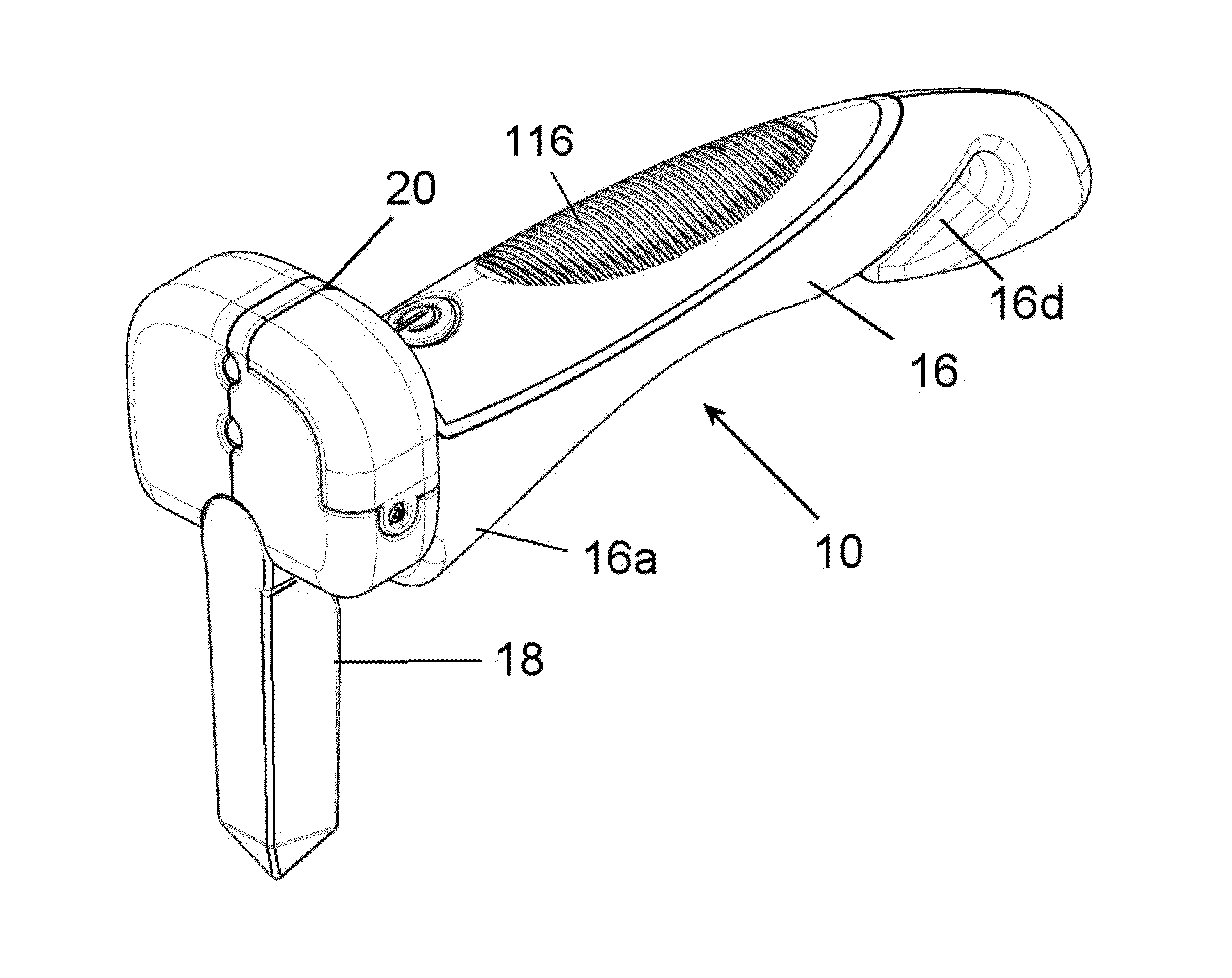

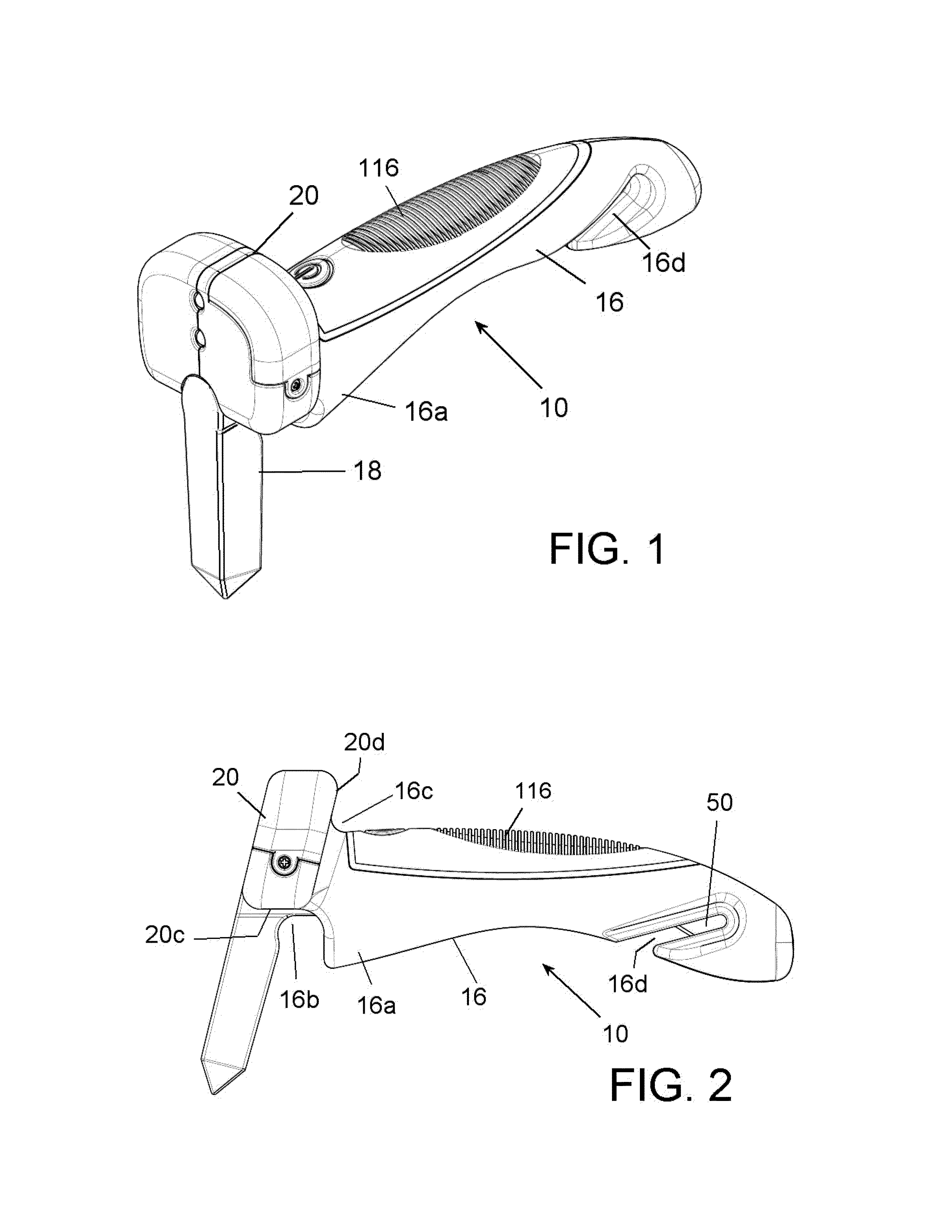

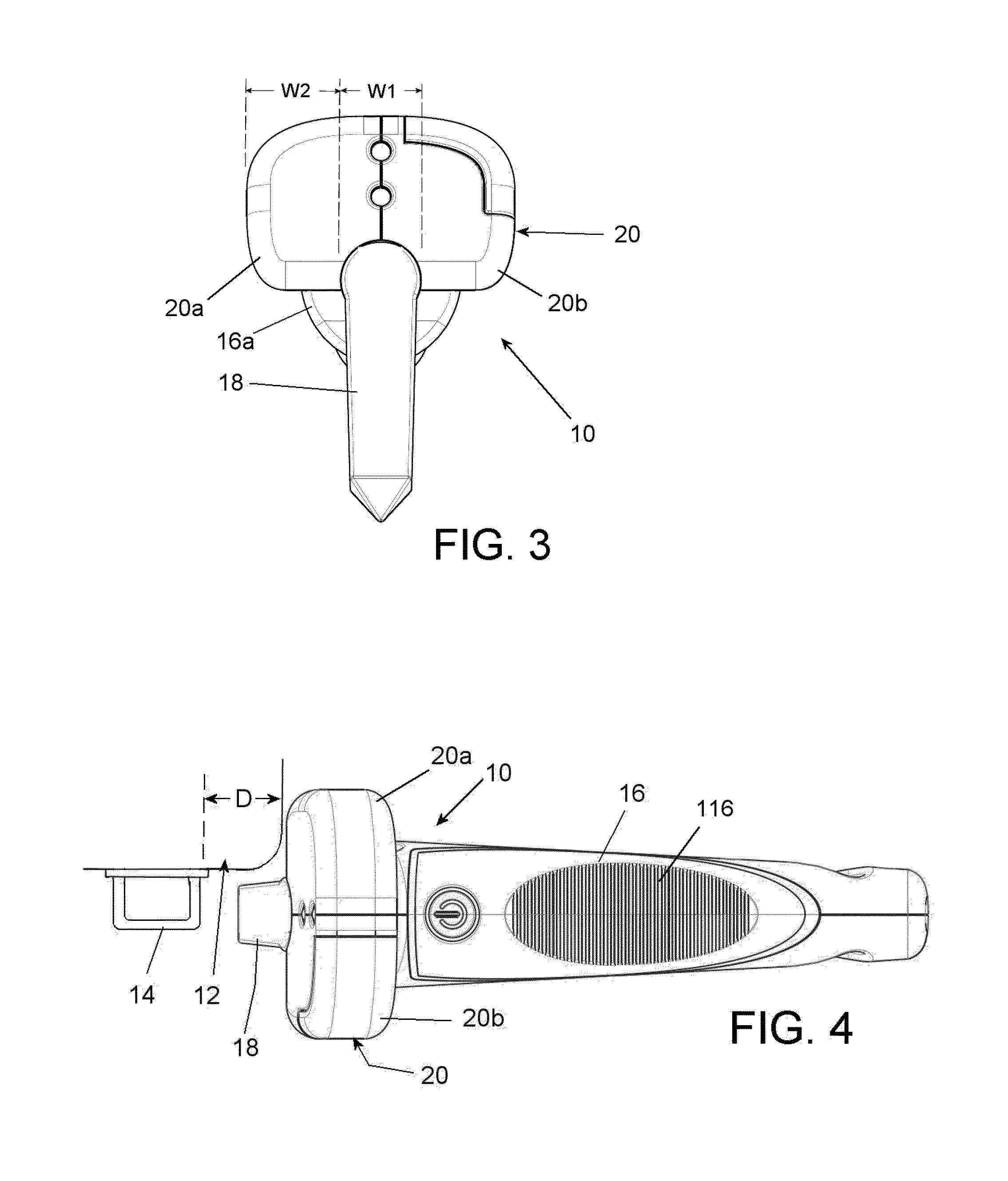

Vehicle entry/egress assistance device

ActiveUS9403466B1Improve device stabilityVehicle arrangementsLighting support devicesMechanical engineeringEngineering

An assistance device for entering and leaving a vehicle includes a handle member for supporting at least part of the weight of the user grasping a handle of the handle member, a striker pin insertion post for extending into the opening of a striker pin in the door frame, for supporting at least part of the weight of a user grasping the handle, and a pair of outrigger side portions extending transversely outwardly of the insertion post, on respective opposite sides of the handle member and insertion post, each having a transverse width greater than a transverse width of the insertion post for impeding entry of the insertion post into the opening of the striker pin when the handle member is outside the plane of the door frame.

Owner:E MISHAN & SONS

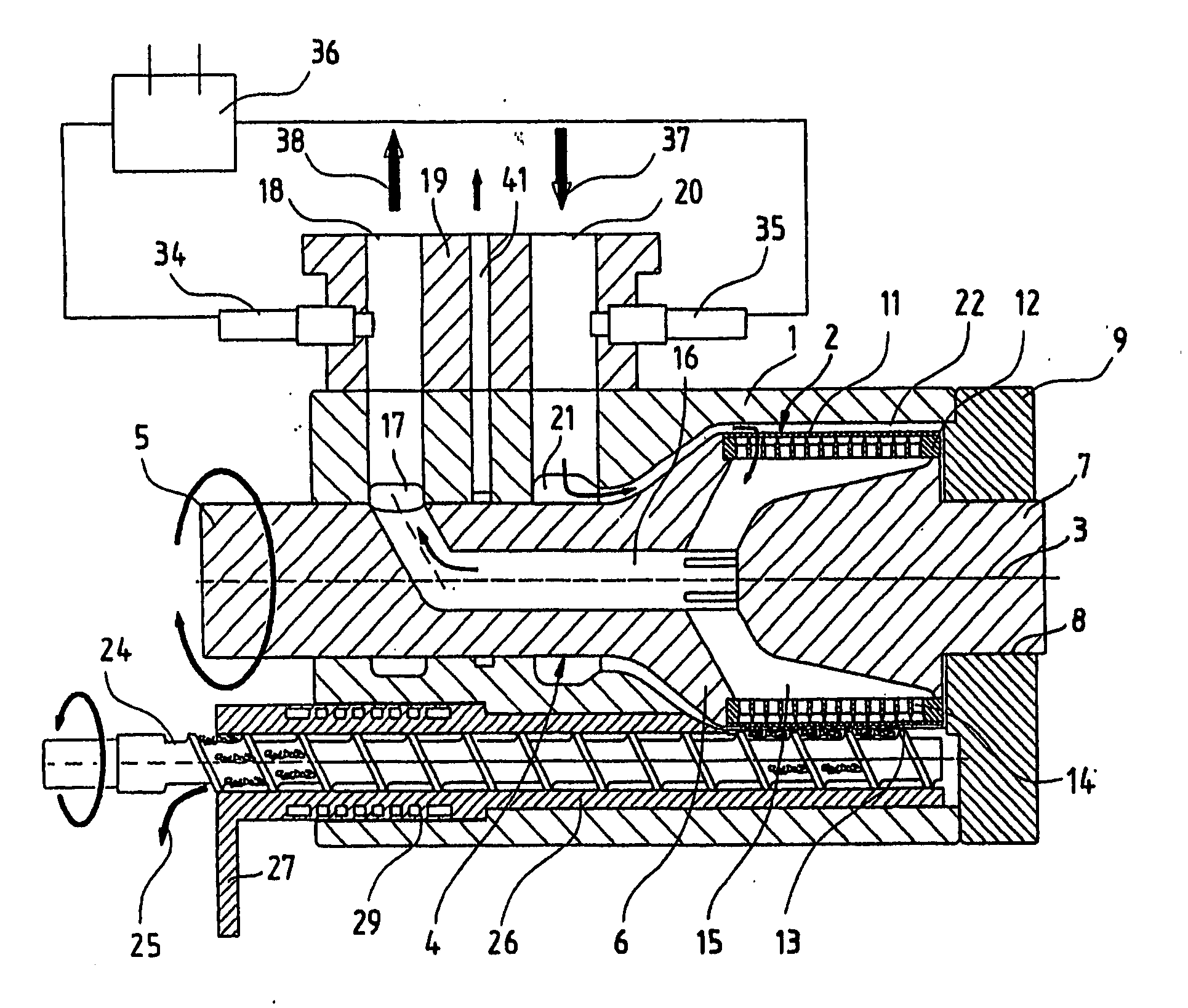

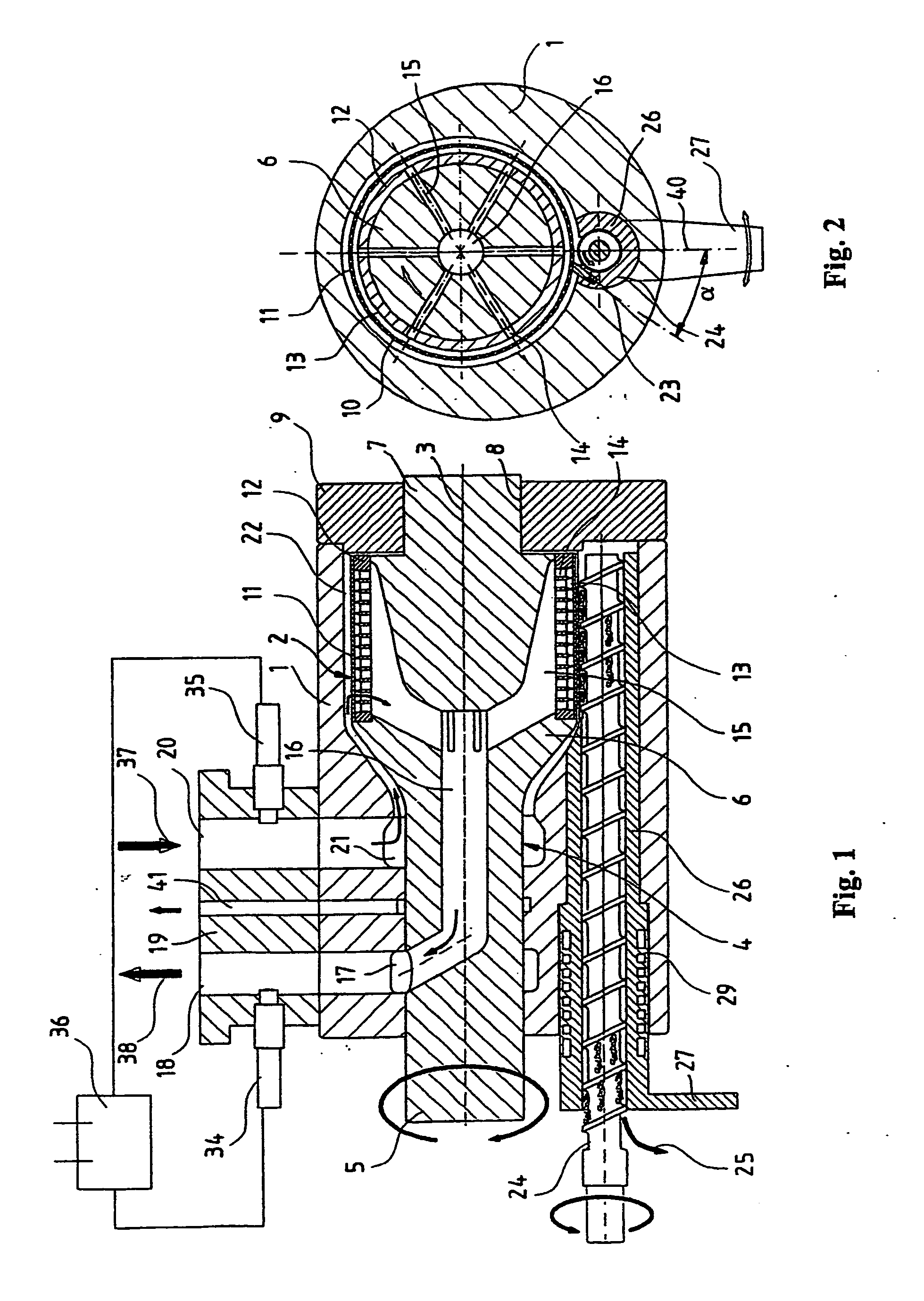

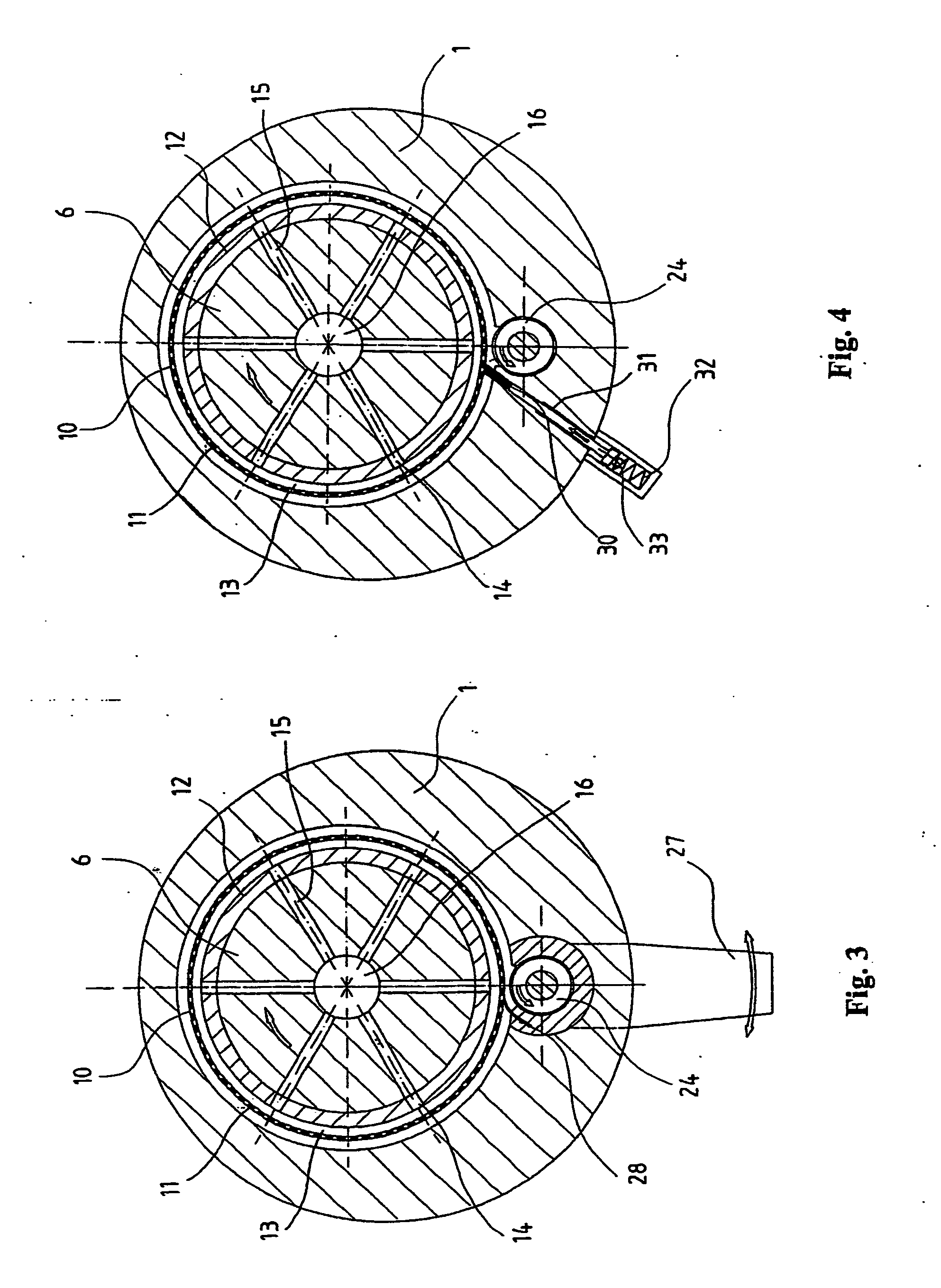

Device for continuous filtration of material blends

ActiveUS20050161391A1Reduce wearReduce tearingWrappingMoving filtering element filtersMotor driveFiltration

A device for the continuous filtration of material blends, in particular for separating impurities from plastic melts. A housing has a hollow cylindrical filter disposed inside. An inside chamber is disposed inside the filter. An annular chamber is defined by the outer surface of the filter and an inside wall of the housing. A cleaning device removes the impurities retained on the filter by a motor driving about an axis coupled to pivot the filter inside the housing. The cleaning device has at least one wiper for removing in the radial direction impurities retained on the filter. A conveying device transports off the impurities removed from the filter by the wiper. The motor-driven filter and the conveying device are driven separately of each other.

Owner:ETTLINGER KUNSTSTOFFMANSCHINEN GMBH

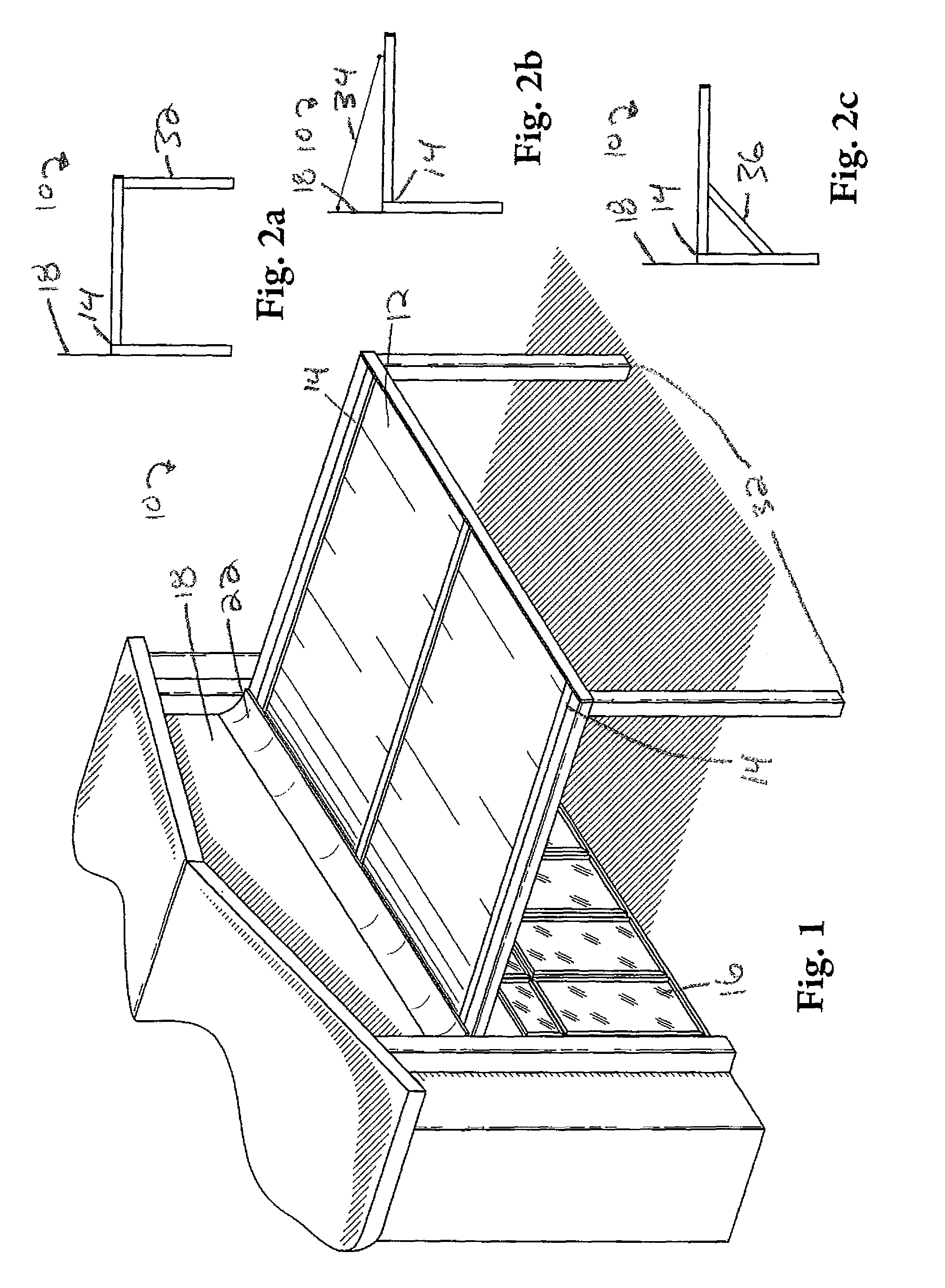

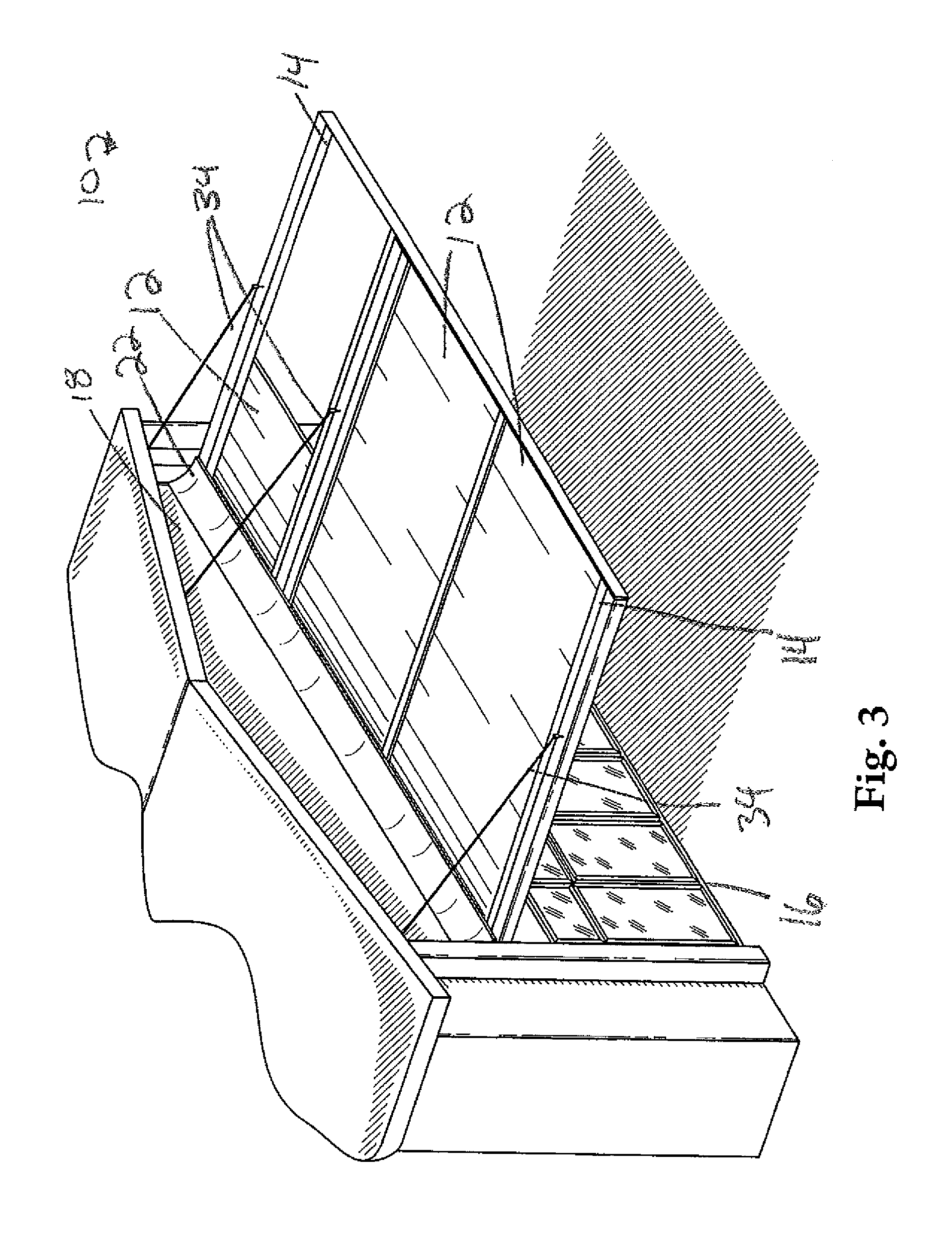

Patio cover and storm protection device

InactiveUS7748429B2Improve device stabilityProtect the interiorBuilding roofsSunshadesRemote operationStorm

Owner:HALLER ETHEL F

Dynamic welding method of laser welding machine

ActiveCN104722922AReduce labor intensityImprove equipment efficiencyWelding/soldering/cutting articlesMetal working apparatusThree-dimensional spaceEngineering

The invention discloses a dynamic welding method of a laser welding machine. Through the dynamic welding method of the laser welding machine, it can be well guaranteed that welding joints are linear. The head edge and the tail edge of a front stainless steel roll and the head edge and the tail edge of a rear stainless steel roll are fed to a welding machine, it is guaranteed that the edges to be welded to are located in the actual welding area of the welding machine, shears of the welding machine shear the edges of strip steel, the width of the strip steel is measured through an external sensor, and the adjustment process of a center line is achieved; accurate welding parameters are called according to actual material specifications, and a laser head moves from the driving side to the operating side so that the welding process of the strip steel can be completed. First, data of the actual welding joints are acquired; second, the data are analyzed and screened, and calculation of deviation points is performed; third, displacement adjustment reference data are generated according to data deviation. The dynamic welding method of the laser welding machine has the advantages that it is guaranteed that the welding joints are linear, a longitudinal traction track of a welding gun vertically coincides with the welding joints in a three-dimensional space, the labor intensity of production and operation staff is relieved, efficiency and stability of equipment are improved, the welding success rate is increased, and the automation degree is improved.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

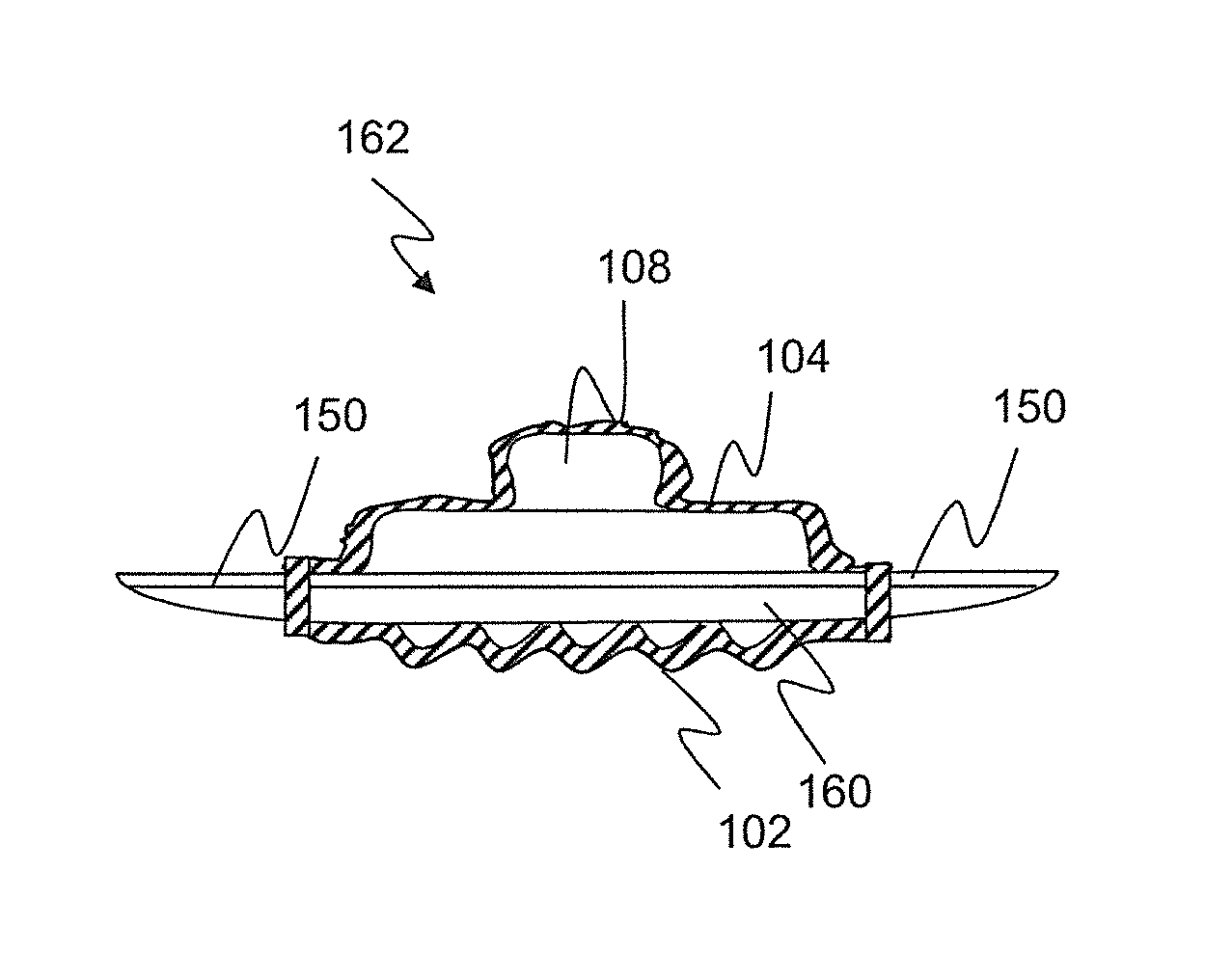

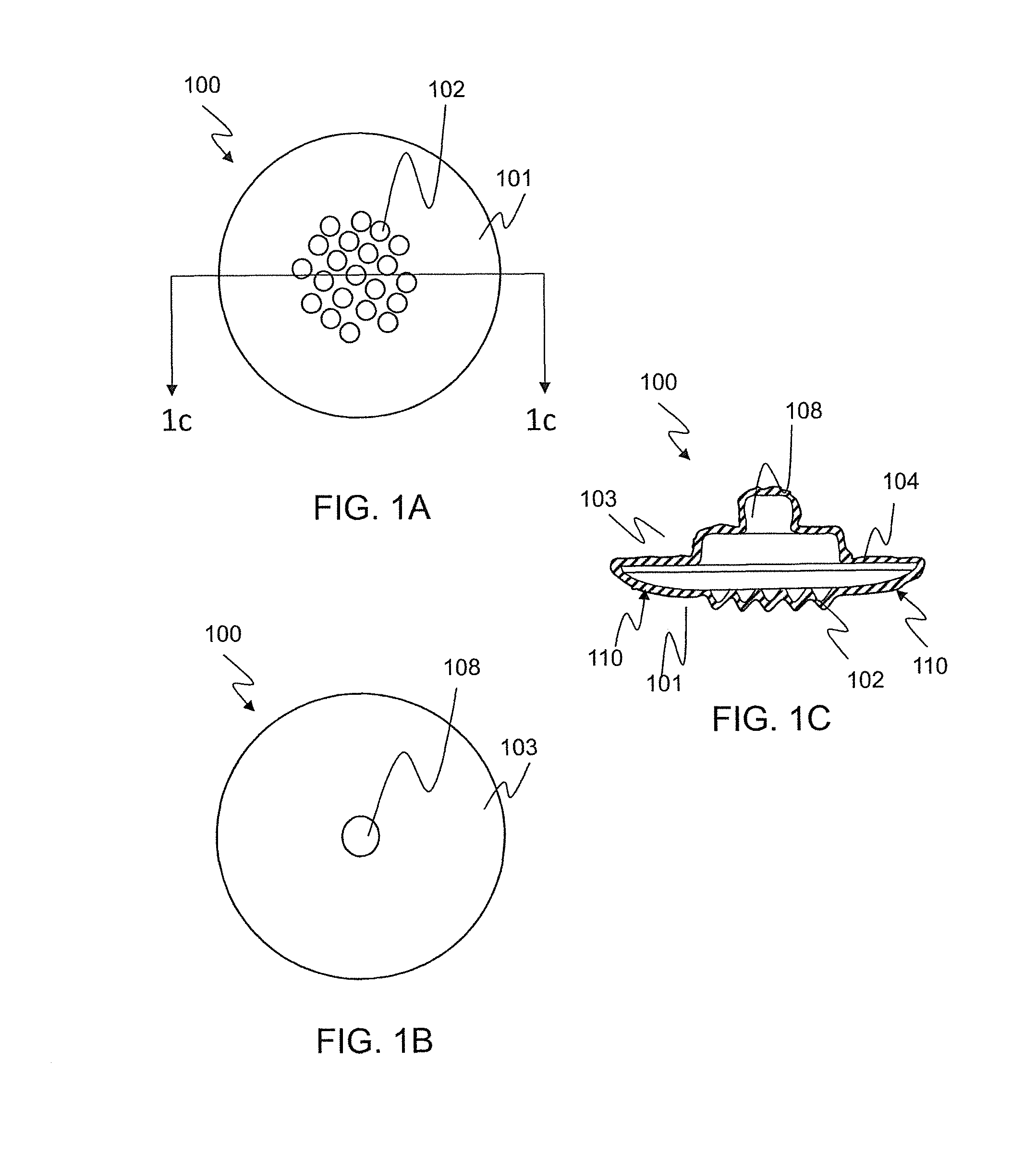

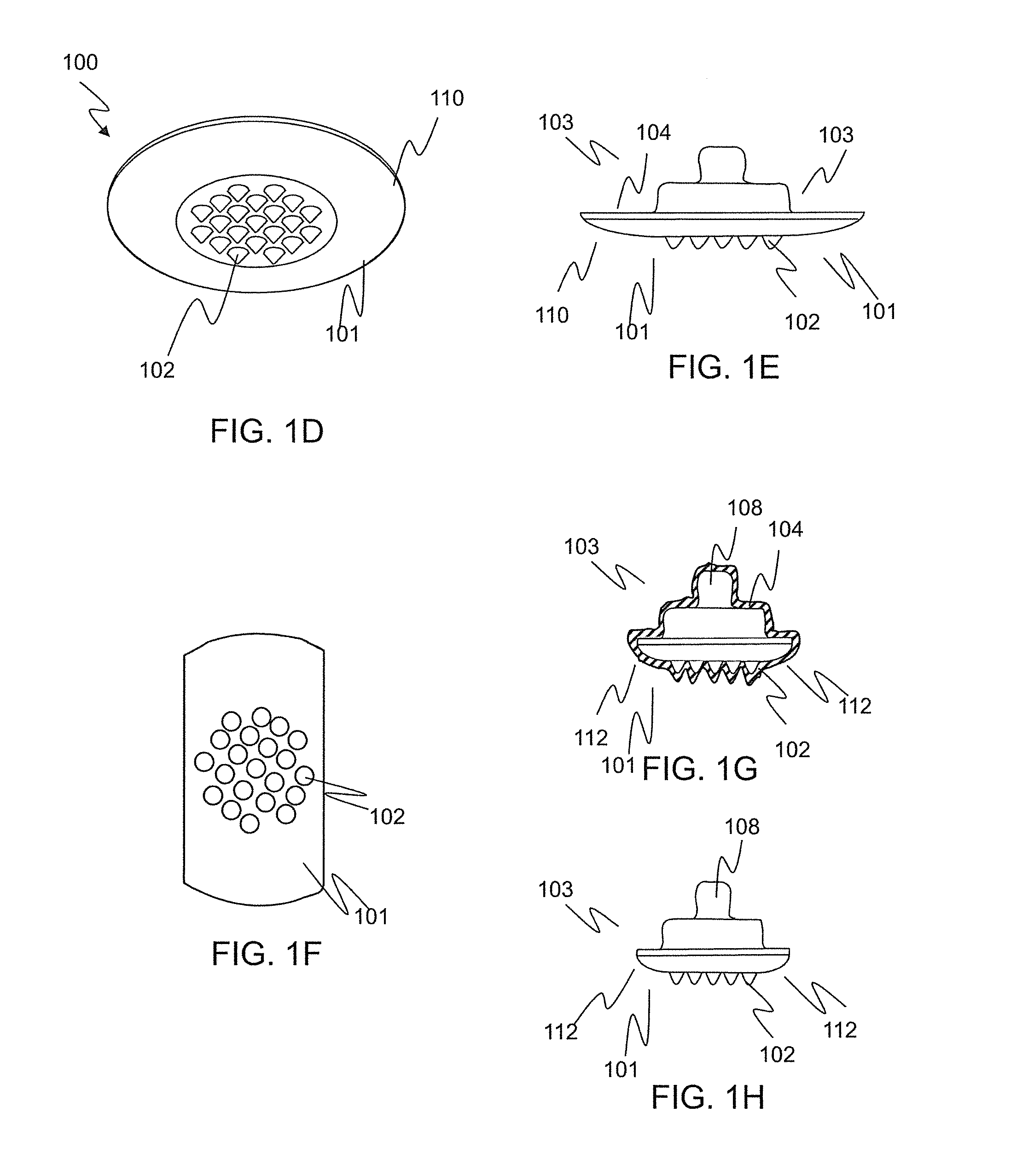

Dry physiological recording device and method of manufacturing

ActiveUS9192313B1Reduce material costsBetter electrical signalElectrocardiographyElectromyographyElectric signalBiomedical engineering

The present invention is directed to a physiological recording device and, more particularly, to a physiological recording device that can be used without skin preparation or the use of electrolytic gels. The invention is further directed to an encouragement ring which stabilizes and helps situate the physiological recording device on a subject's skin to help provide a better electrical signal, increase surface area, and reduce and minimize noise and artifacts during the process of recording or monitoring a physiological signal. The invention is still further directed to surface features on a surface of the physiological recording device with a size and shape that will not substantially bend or break, which limits the depth of application of the recording device, and / or anchors the recording device during normal application. The invention is even further directed to a method for manufacturing a physiological recording device, and minimizing cost of manufacture.

Owner:ORBITAL RES

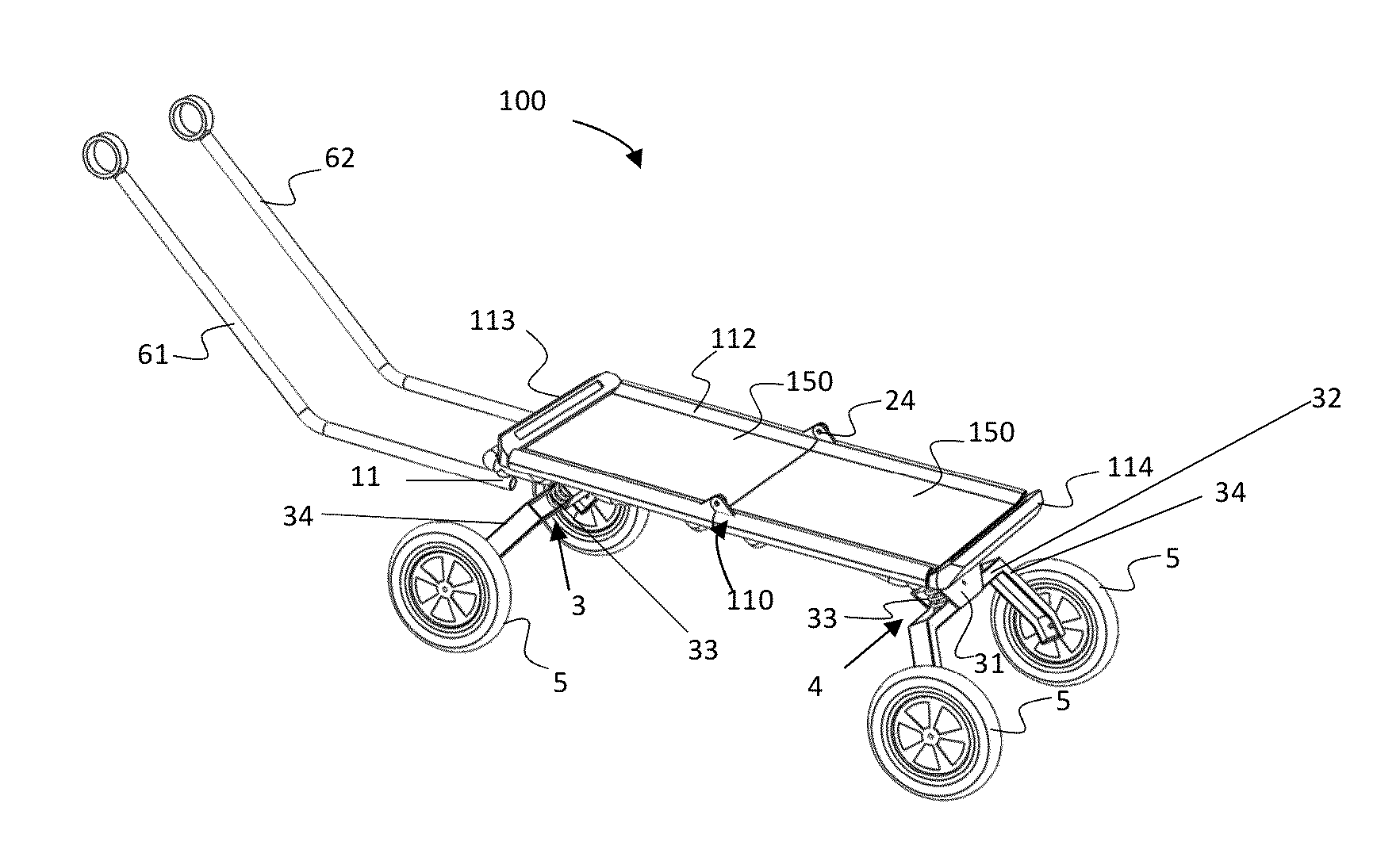

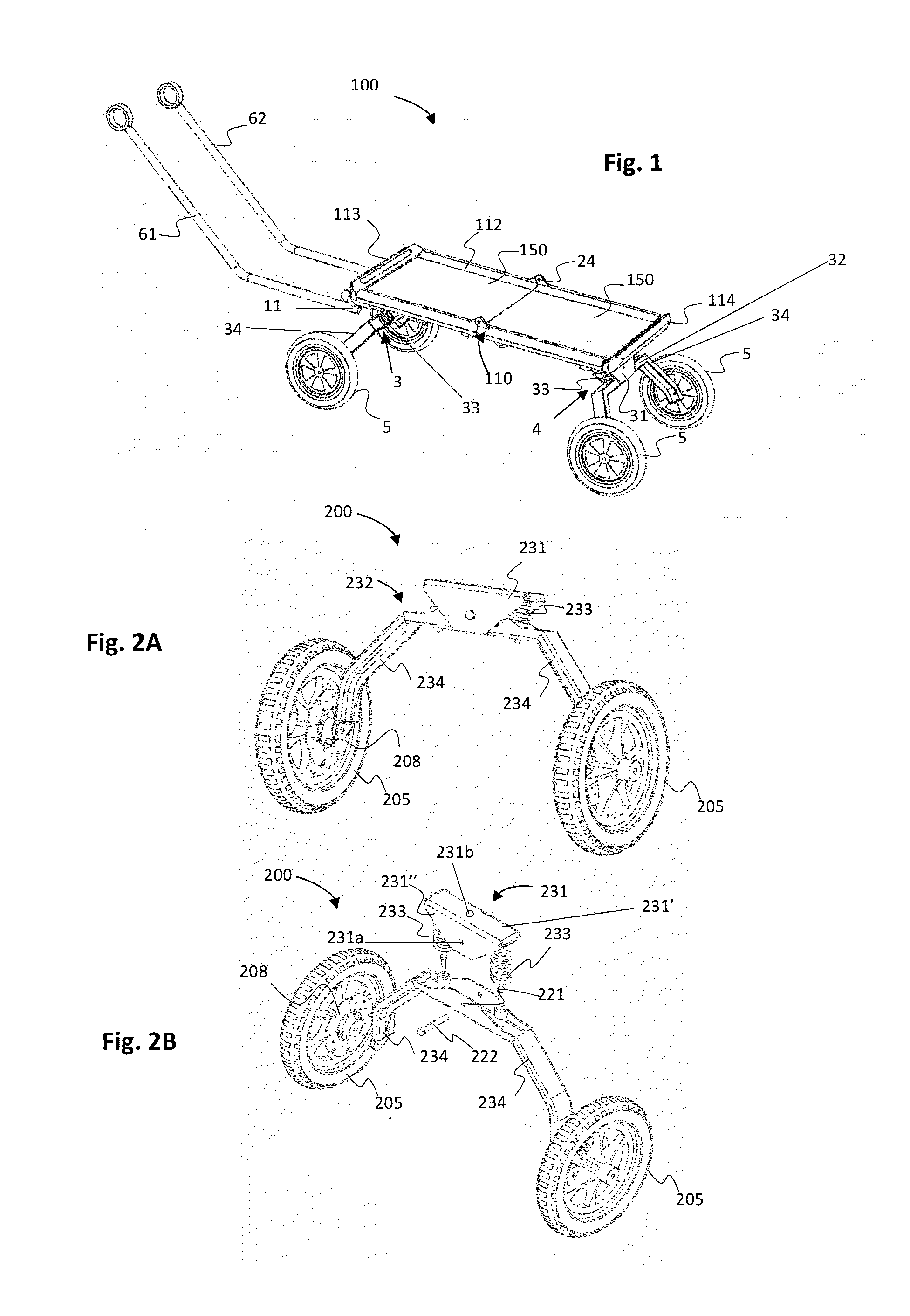

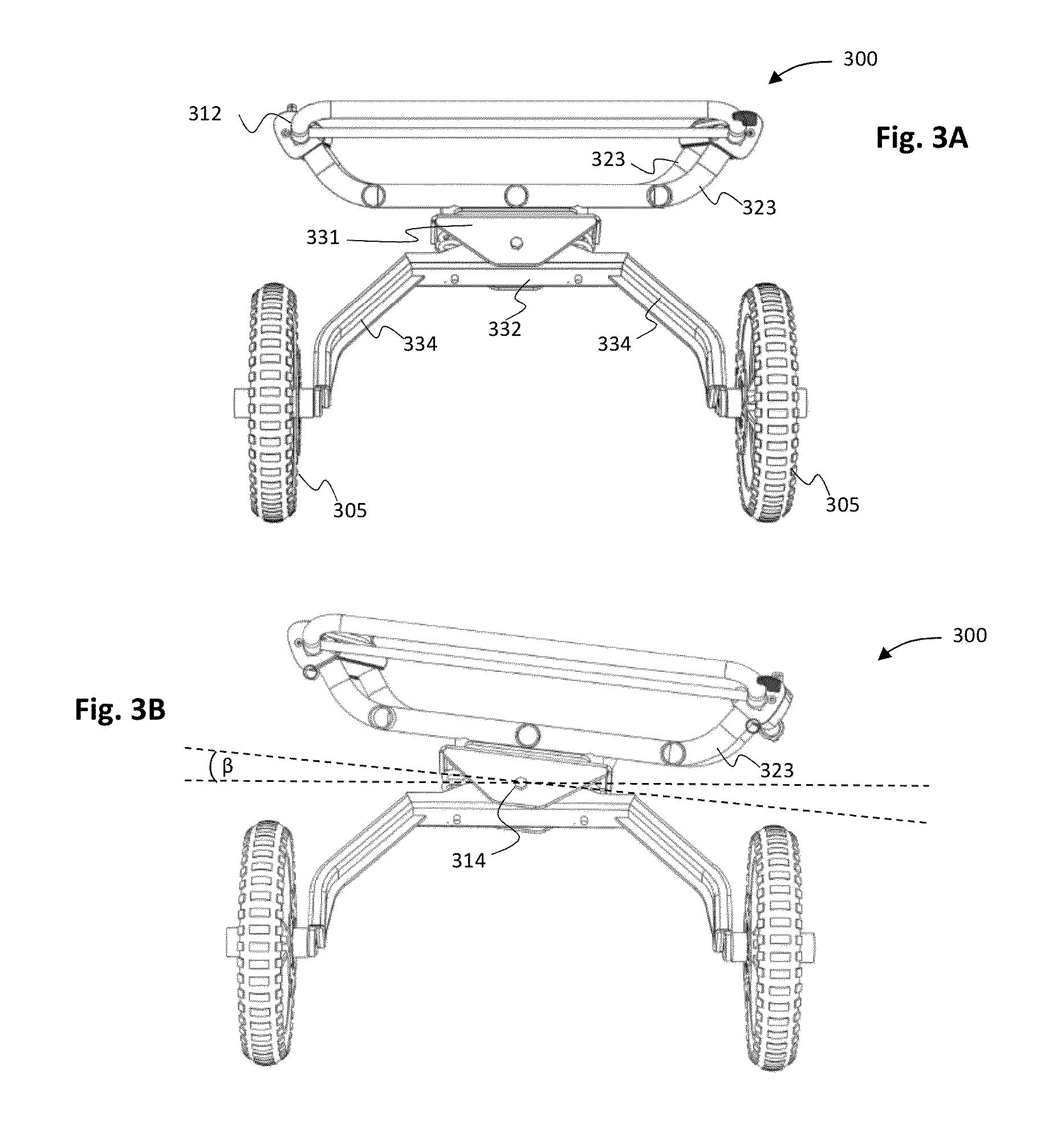

Wheeled carrying device

ActiveUS20140284902A1Improve device stabilityCarriage/perambulator accessoriesCarriage/perambulator with multiple axesUnsurfaced roadEngineering

A man-powered (e.g. manually pulled or pushed) multipurpose wheeled carrying device with ground clearance for transporting people, animals, equipment and goods over unsurfaced roads or tracks. The carrying device may include a chassis, a front dependent suspension and a rear dependent suspension, wherein each of the dependent suspensions comprises a legged solid axle, a connector, springs, and wheels. The legged solid axles of the dependent suspensions are adapted to keep the chassis at least 6 inches above the ground surface. The dependent suspensions are tiltable around a longitudinal axis of the chassis to keep the chassis leveled while all of the wheels are in contact with the ground, and to provide ground clearance during use.

Owner:NOY ILAN BAR

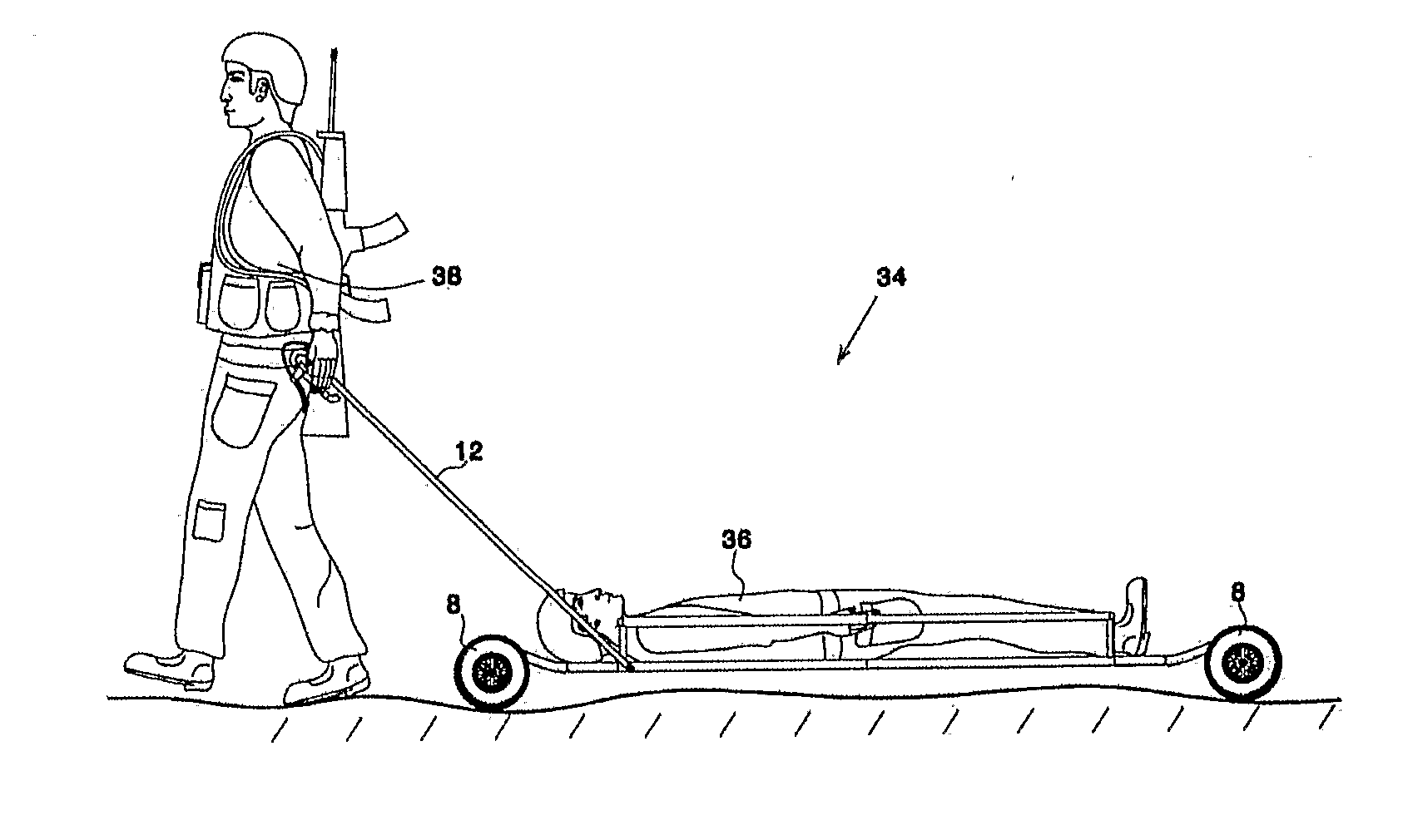

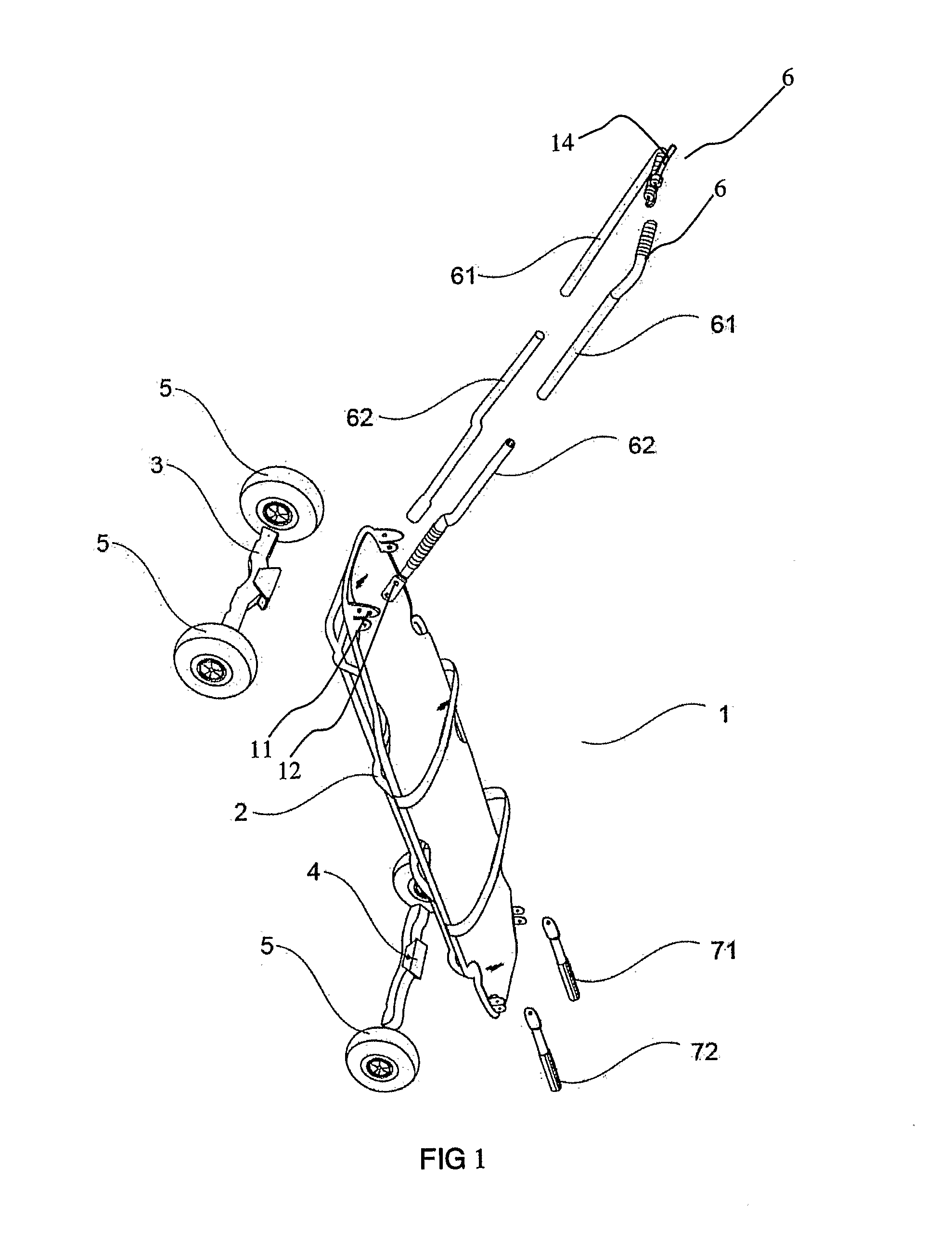

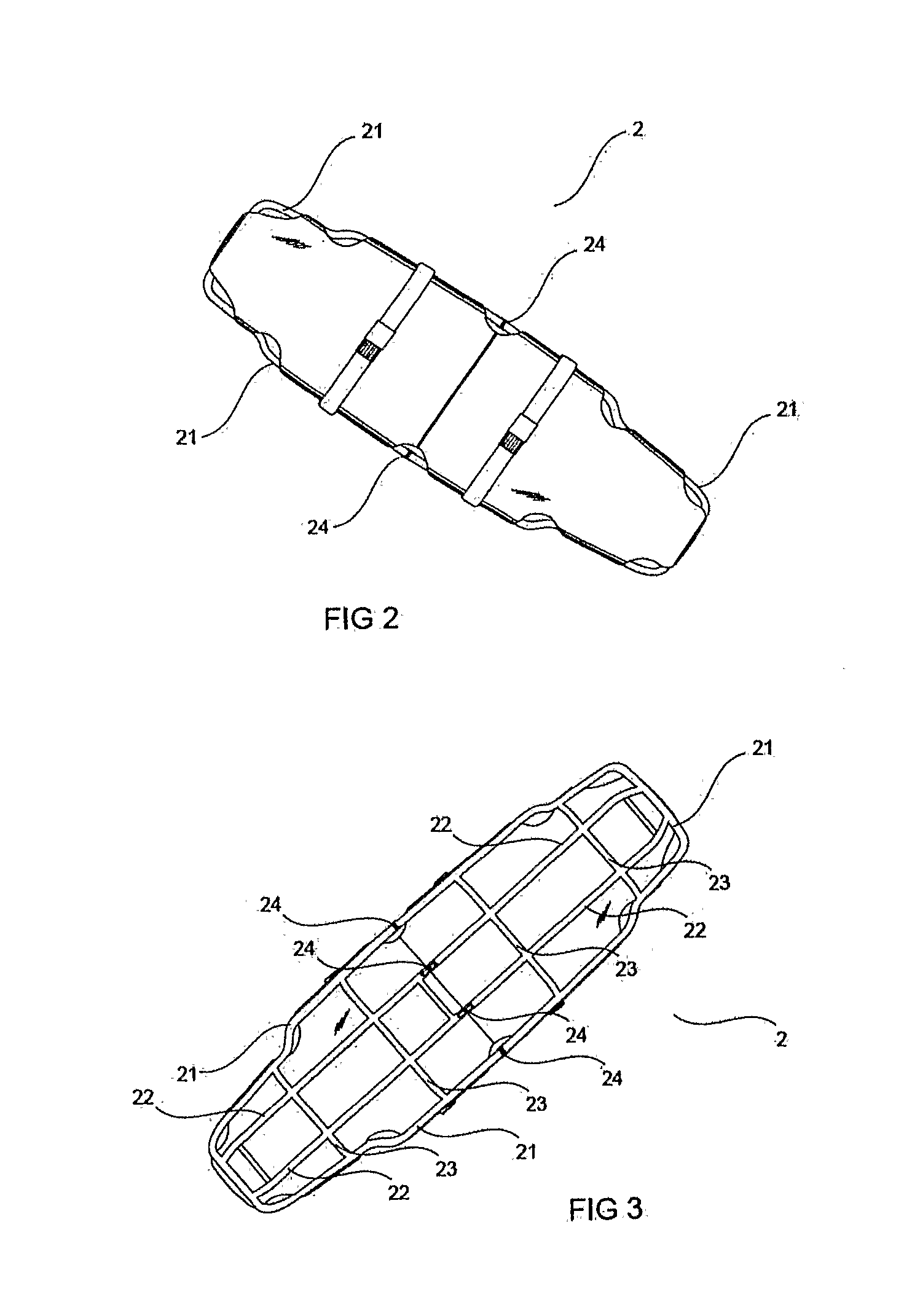

Collapsible Wheeled Stretcher

InactiveUS20120007340A1Improve device stabilityCarriage/perambulator accessoriesStretcherTerrainEngineering

The present invention discloses a foldable collapsible wheeled stretcher on wheels, having handles for pulling and steering. The device is provided with dependent suspensions allowing mobility in rough and bumpy terrain while maintaining the stability of stretcher surface, reducing tilt and vibration that reach the wounded person being transported upon the stretcher. It is provided with folding or telescopic means allowing it to be carried upon the back or stowed in a small volume. The device enables rescue of injured people in an improved manner from (for example) regions which are not passable by vehicles, and may be pulled by a single rescuer instead of being carried by two to four. The device may be further used to transport material.

Owner:NOY ILAN BAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com