Patents

Literature

569 results about "Load spectrum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

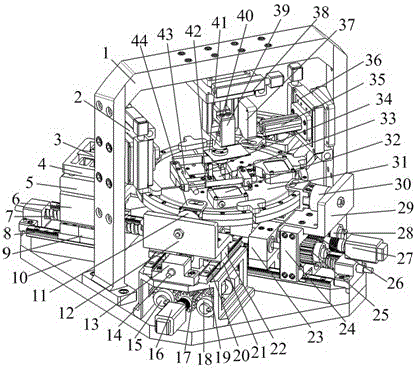

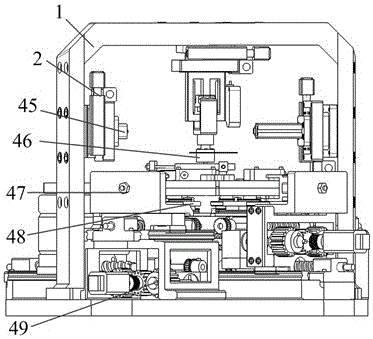

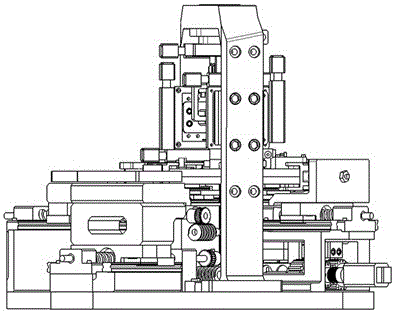

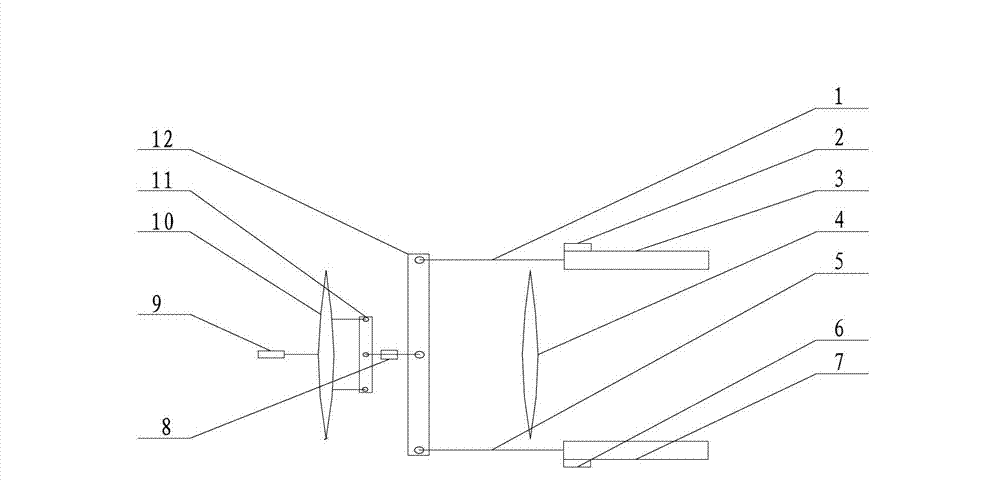

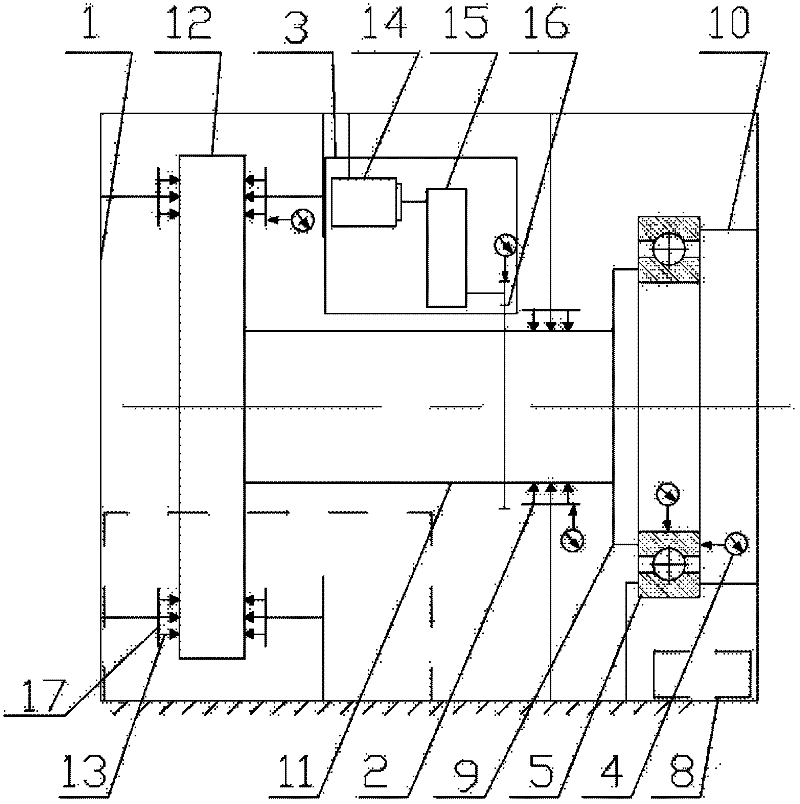

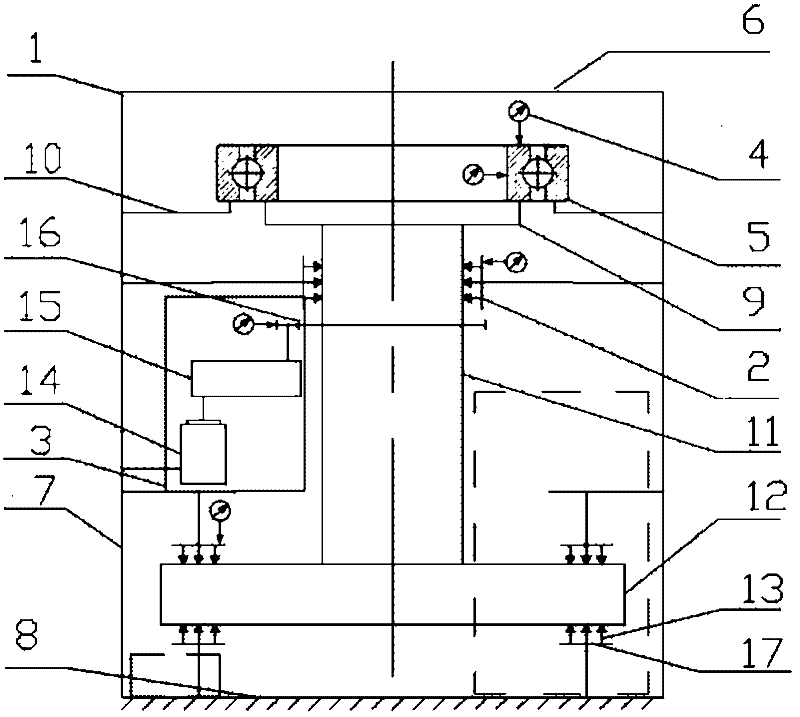

Material mechanical property in-situ testing system and method in dynamic and static load spectrum

ActiveCN106226152AImprove compatibilityCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesEngineeringMultiple modes

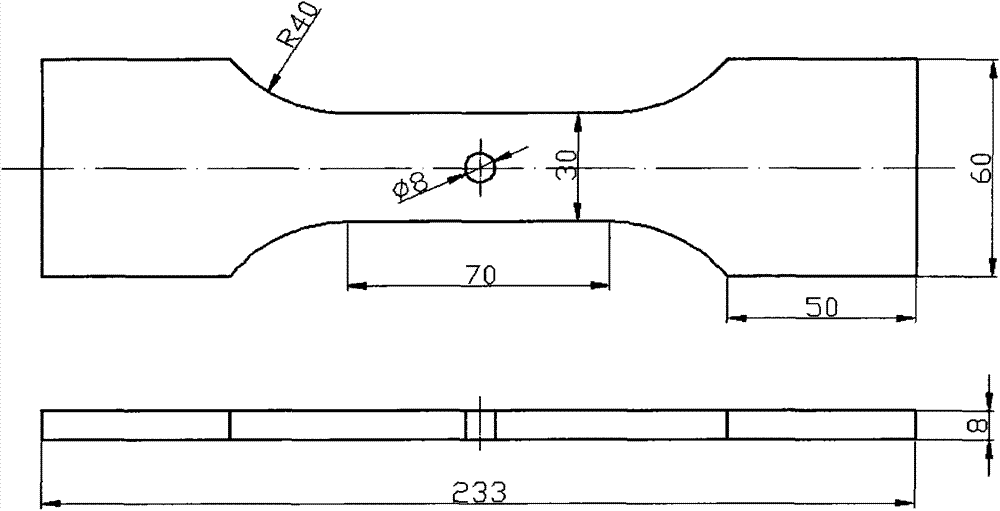

The invention relates to a material mechanical property in-situ testing system and method in a dynamic and static load spectrum, and belongs to the field of mechanical tests. The system integrates the following functions: a static testing function of biaxial drawing and shearing in an orthogonal plane, a shearing static testing function, a double shaft pull-pull mode fatigue testing function, and a static / dynamic press testing function. A complicated static / dynamic load spectrum can be established. Multi-mode composite load mechanical property evaluation can be performed on a film material or a block material, for example: high-cycle fatigue tests based on double-shaft pre-stretching load and impact press tests based on double-shaft stretching-shearing pre-load. At the same time, special defects are pre-fabricated on the central area and cross shaped arm area of a test piece; the analysis functions of a variable-zoom optical imaging system or a digital speckle strain analysis system can be utilized; the provided system and method can also be used to research the deformation behavior and cracking expansion rules of micro defects in a component under a multi-dimensional stress, and an evaluation tool is provided for performance degradation rules of products and optimized preparation method of materials.

Owner:JILIN UNIV

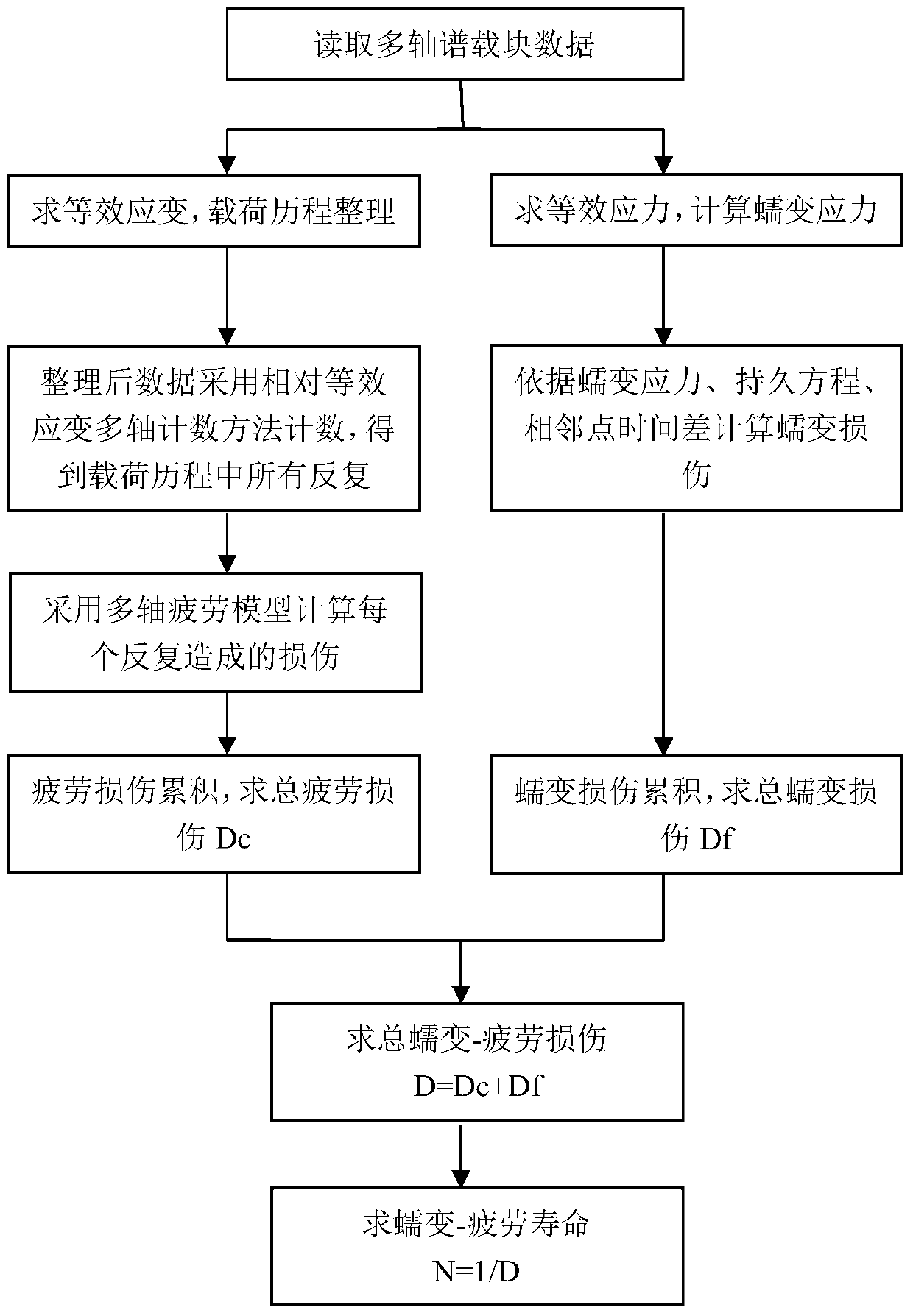

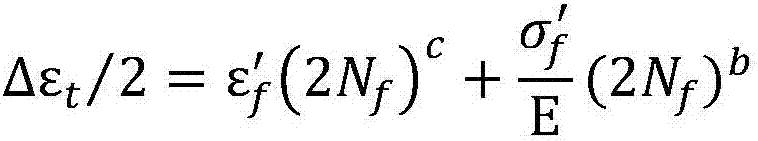

Low-cycle creep and fatigue life evaluation method under conditions of high temperature and multiaxial spectrum load

ActiveCN103926152AEasy accessReduce testing costsMaterial strength using tensile/compressive forcesFatigue damageCreep stress

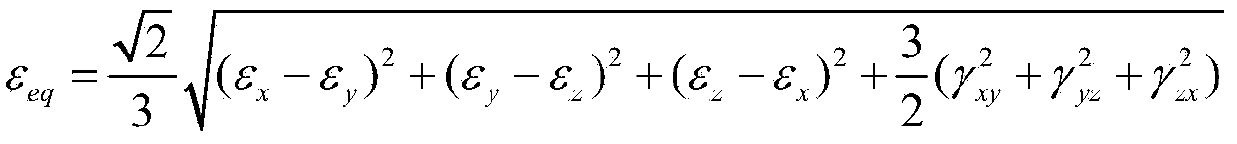

The invention relates to a low-cycle creep and fatigue life evaluation method under the conditions of high temperature and multiaxial spectrum load. The method comprises the following steps of reading a stress strain history in a multiaxial loading spectrum data block, working out equivalent strain, and finishing a loading history; repeatedly extracting by adopting a relative equivalent strain multi-axis counting method; working out all repeated fatigue damage by adopting a unified multiaxial fatigue damage life prediction model; accumulating the fatigue damage to work out the total fatigue damage; working out equivalent creep stress by utilizing the original loading history; working out creep damage Dc according to the equivalent creep stress and the stress history by combining a creep lasting equation; working out the total damage D caused by a multiaxial load spectrum block at the high temperature; and estimating the multiaxial creep and fatigue life. According to the method, the fatigue damage under the multiaxial stress and the creep damage under the multiaxial stress can be respectively calculated in the whole loading spectrum data block, the fatigue material constant at the room temperature is adopted in the calculation of the fatigue damage, and lasting equation material constant recommended by specification is adopted in the calculation of the creep damage; through experimental verification, the method has a good prediction effect.

Owner:BEIJING UNIV OF TECH

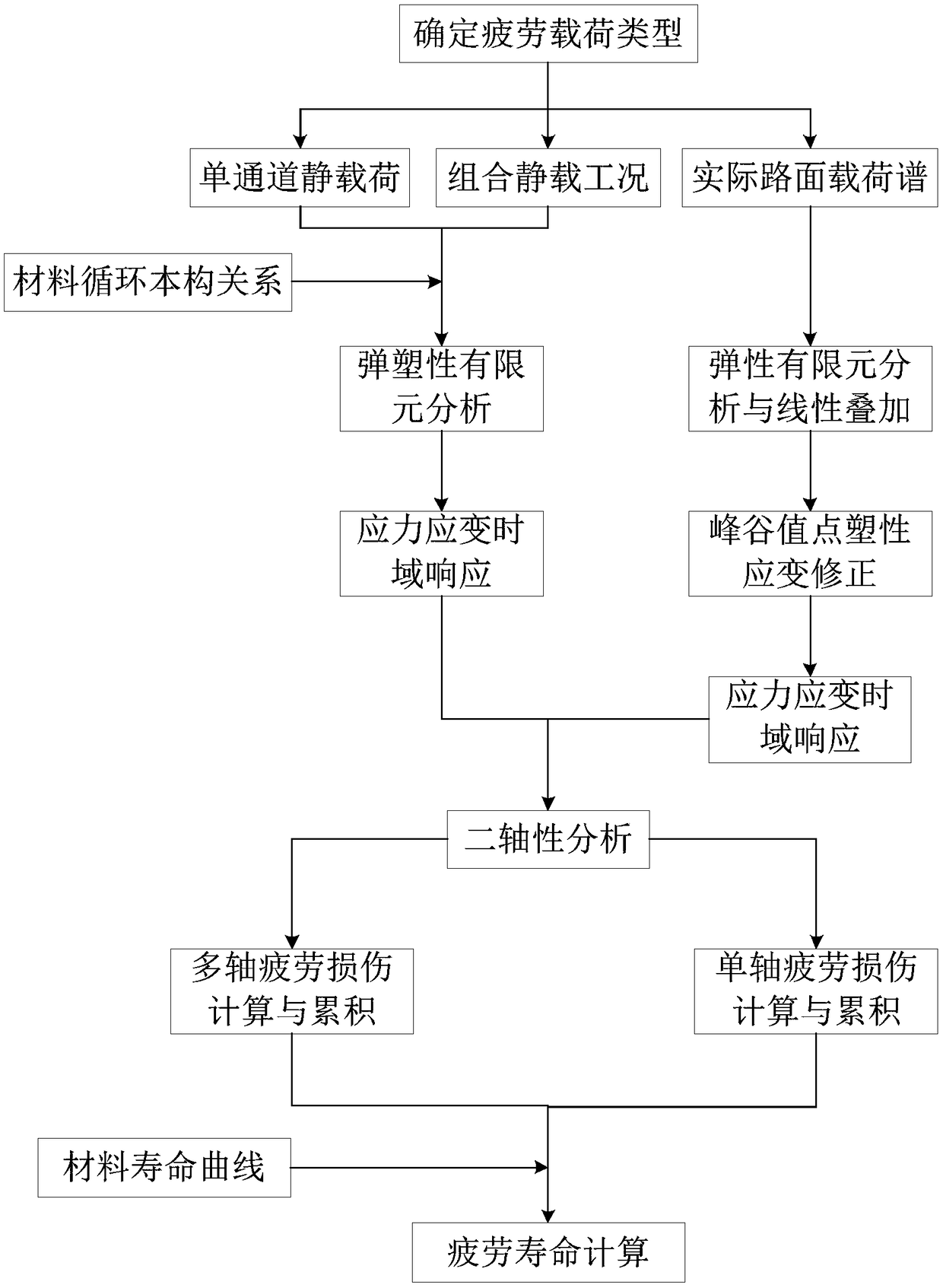

Damage calculation method for low-cycle fatigue and high-strength impact coupling based on local stress strain method

InactiveCN103344515AAccurate fatigue damage analysis resultsMaterial strength using repeated/pulsating forcesFatigue damageFatigue loading

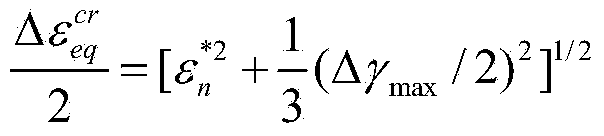

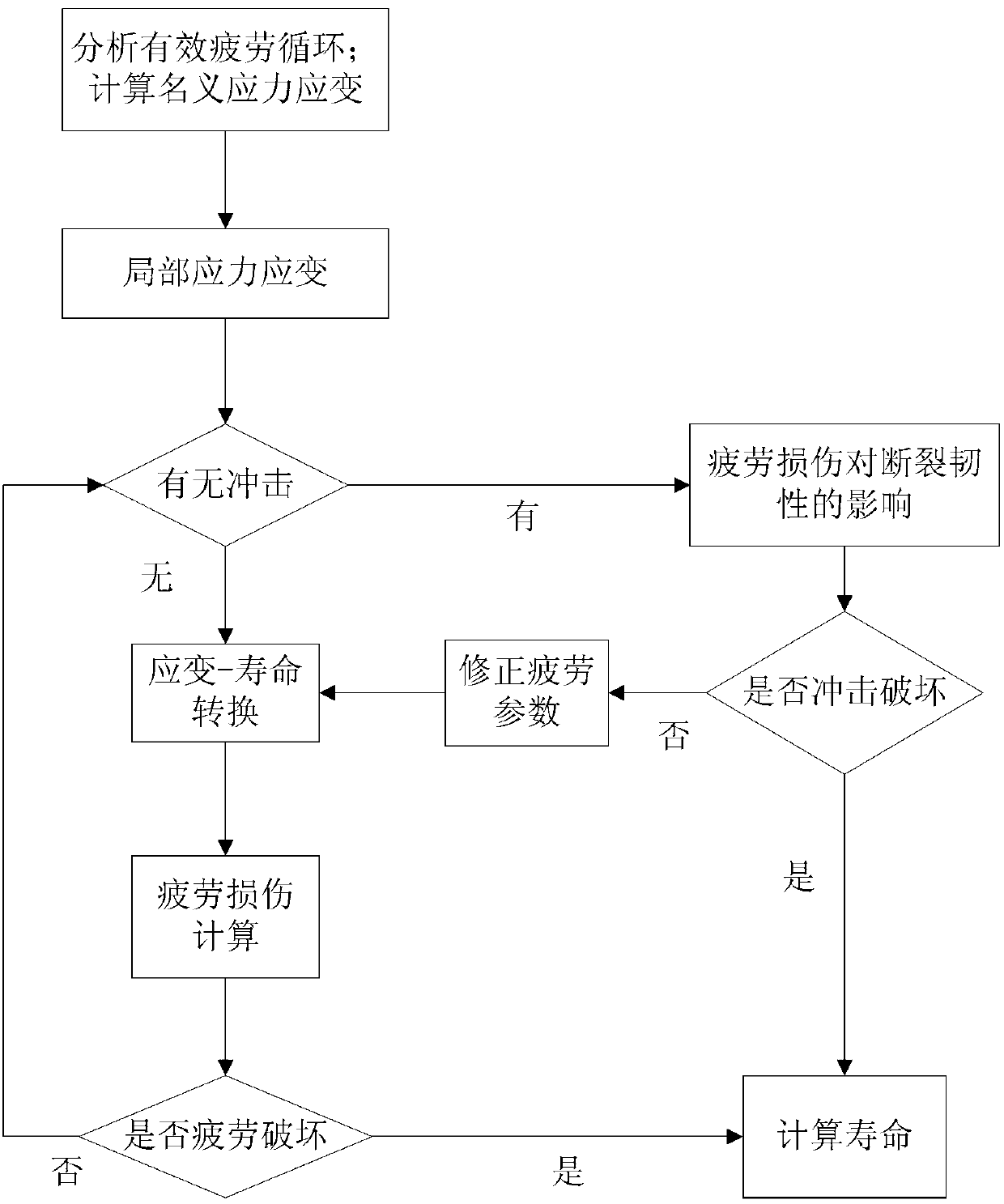

The invention relates to a damage calculation method for low-cycle fatigue and high-strength impact coupling based on a local stress strain method. The damage calculation method comprises the following steps of: (1) analyzing a fatigue load spectrum, calculating nominal stress strain of each stage of multiple stages of amplitude-variable fatigue load spectra, and converting the nominal stress strain into local stress strain; (2) calculating fatigue life and damage corresponding to each stage of fatigue load local strain when a product is impacted; (3) calculating the fatigue life and the damage corresponding to each stage of the fatigue load local strain when the product is impacted and the impact is in an influence range, and considering the damage probability in a fatigue circulation unit when the product is impacted; (4) calculating impact performance influenced by fatigue accumulated damage; and (5) calculating comprehensive degree of reliability. Compared with a conventional fatigue damage calculation method, the damage calculation method has the advantages that the influence of high-strength impact on the fatigue damage, the influence of fracture failure caused by direct impact to the life of the product and the influence of the fatigue accumulated damage to the shock resistance of the product are considered, and the fatigue-impact life and the degree of reliability of the product can be well evaluated under a complex environment.

Owner:BEIHANG UNIV

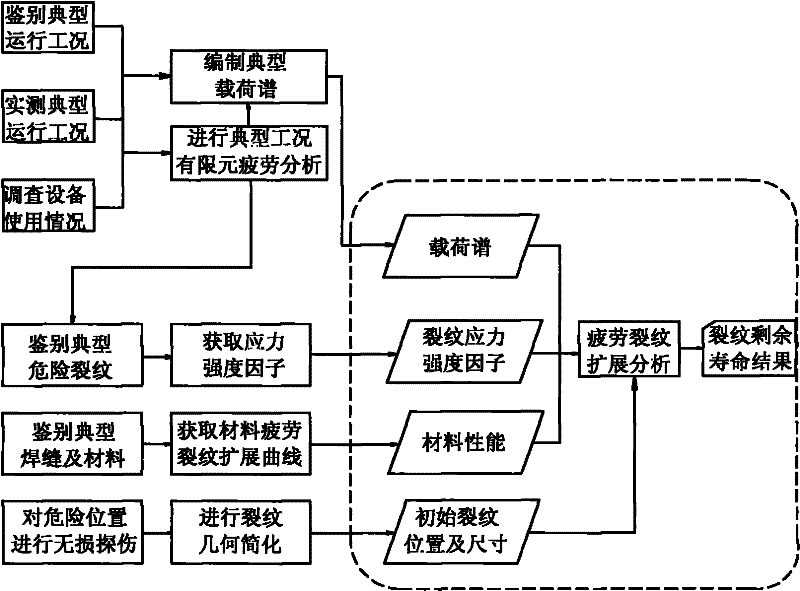

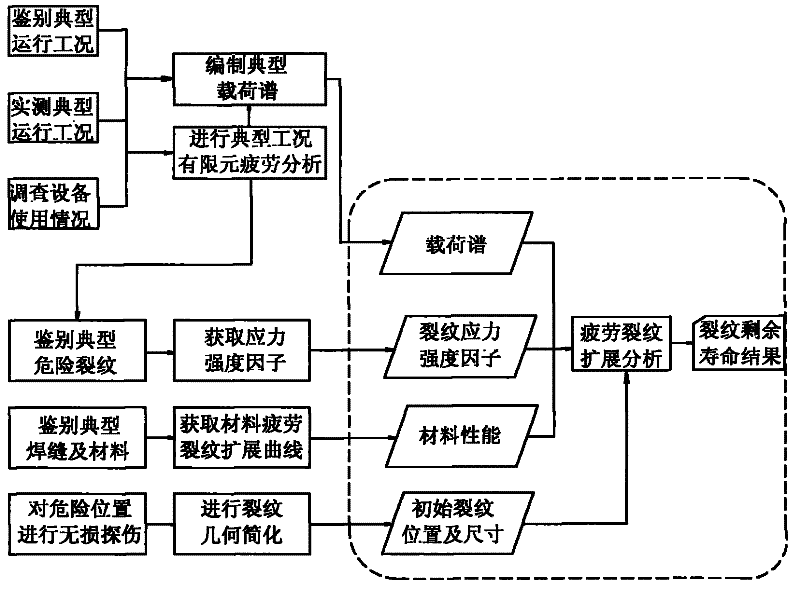

Method for estimating remaining fatigue life of main metal structure of crane

InactiveCN102221473AReflect duty cycleEstimating Fatigue LifeStructural/machines measurementUsing wave/particle radiation meansEstimation methodsEngineering

The invention relates to a method for estimating the remaining fatigue life of a main metal structure of a crane. The method is applied to the compiling of actually measured load spectrums, the measurement of material fatigue crack propagation curves, the nondestructive detection of hazardous locations and the estimation of the remaining fatigue life of the main metal structures of the large cranes at relatively higher working levels in shipyards, ports and the like, and is also applied to the estimation of the remaining fatigue life of the cranes of other types. The method comprises the following steps of: (1) acquisition of the load spectrum; (2) measurement of material performance; (3) detection of an initial crack location and an initial crack size; (4) acquisition of a crack stress intensity factor; and (5) estimation of the remaining fatigue life. In the method, factors such as the existence of a crack in the structure, the detection of the location and size of the actually crack, and the like are taken into account, and the nondestructive detection is performed on the hazardous location; therefore, the remaining fatigue life of the metal structure of the crane can be accurately estimated.

Owner:GUANGZHOU ACAD OF SPECIAL EQUIP INSPECTION& TESTING

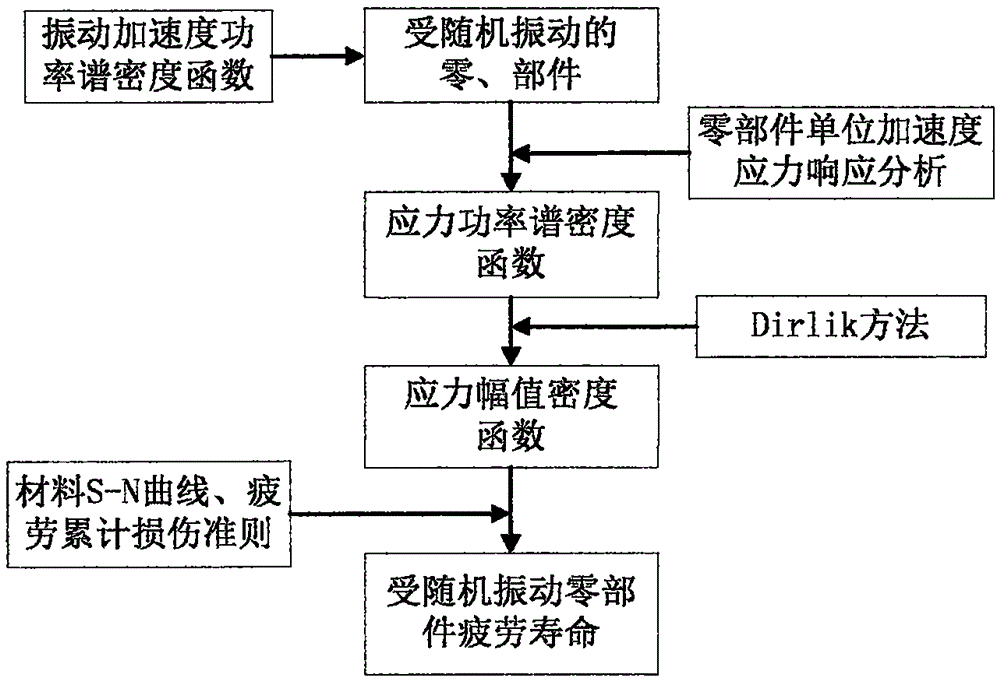

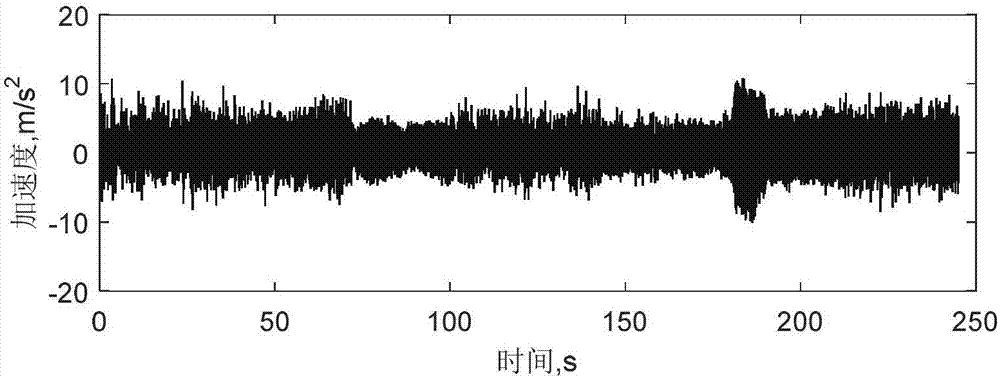

Analysis method for testing fatigue life of components based on vibration signals

InactiveCN105651478ASolve the problem that it is difficult to directly obtain structural stress amplitude informationExtended service lifeVibration testingLoad timeEngineering

Owner:QINGDAO R & D INST XIAN JIAOTONG UNIV

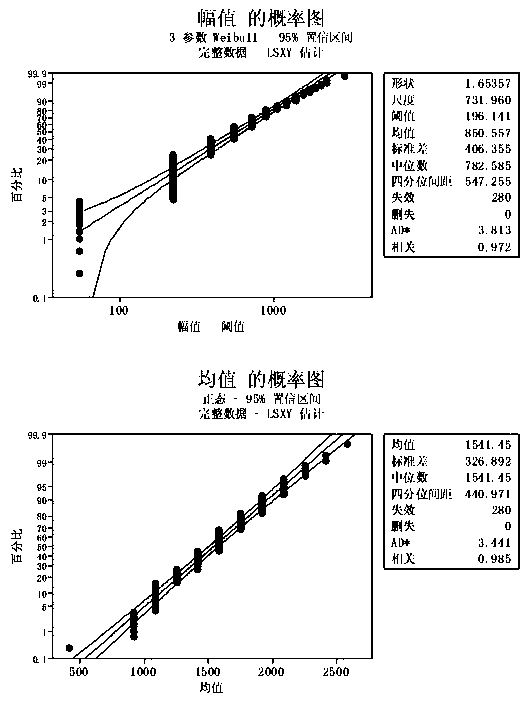

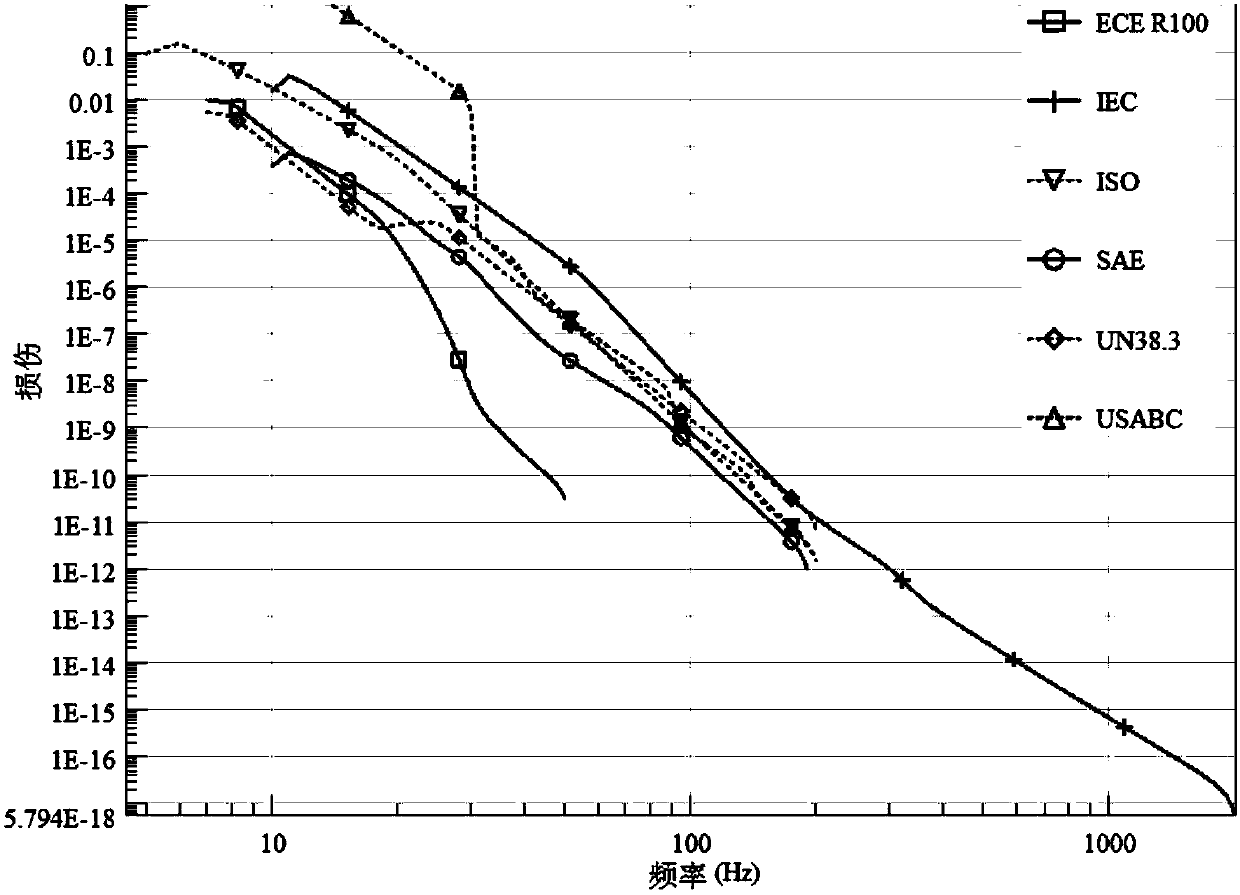

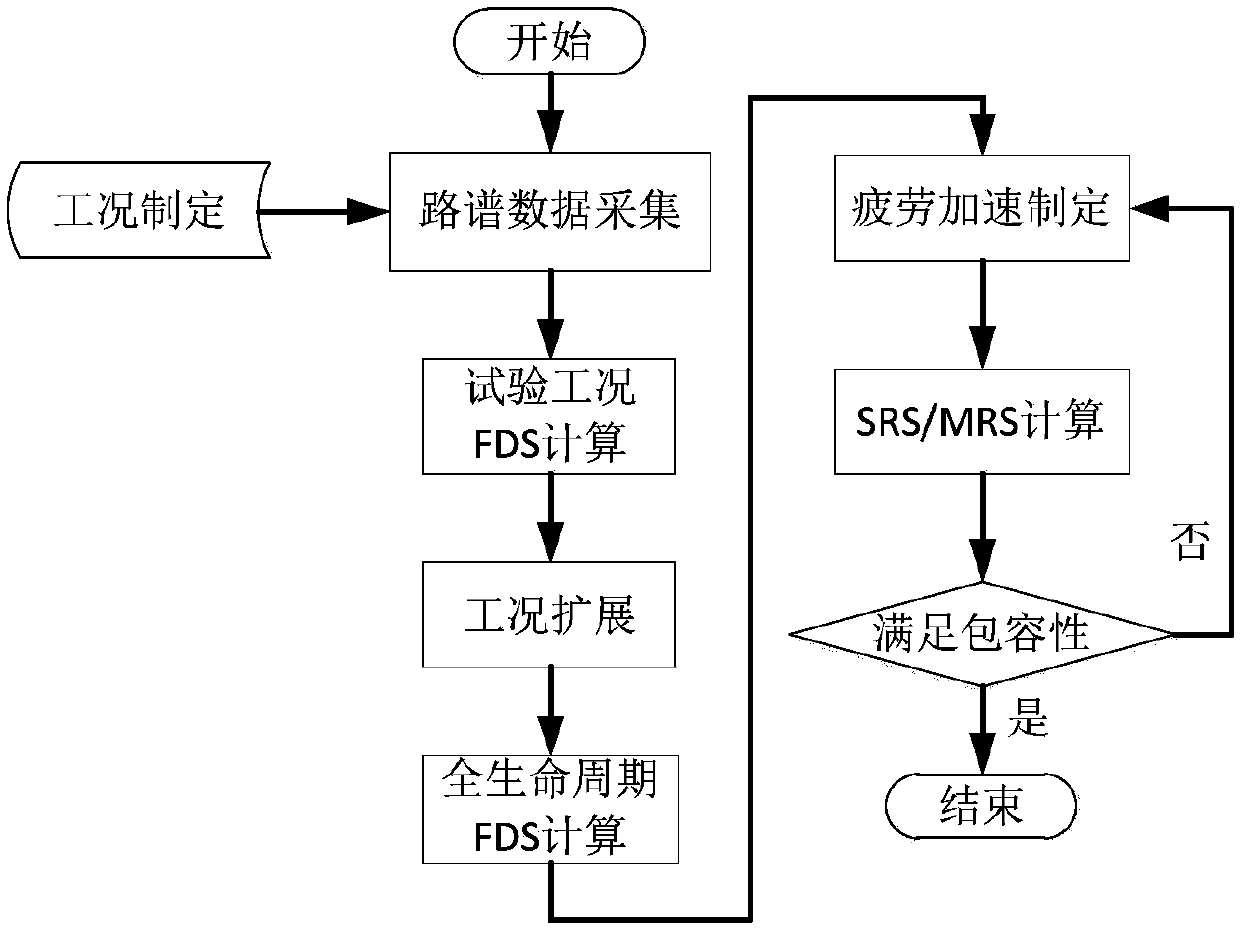

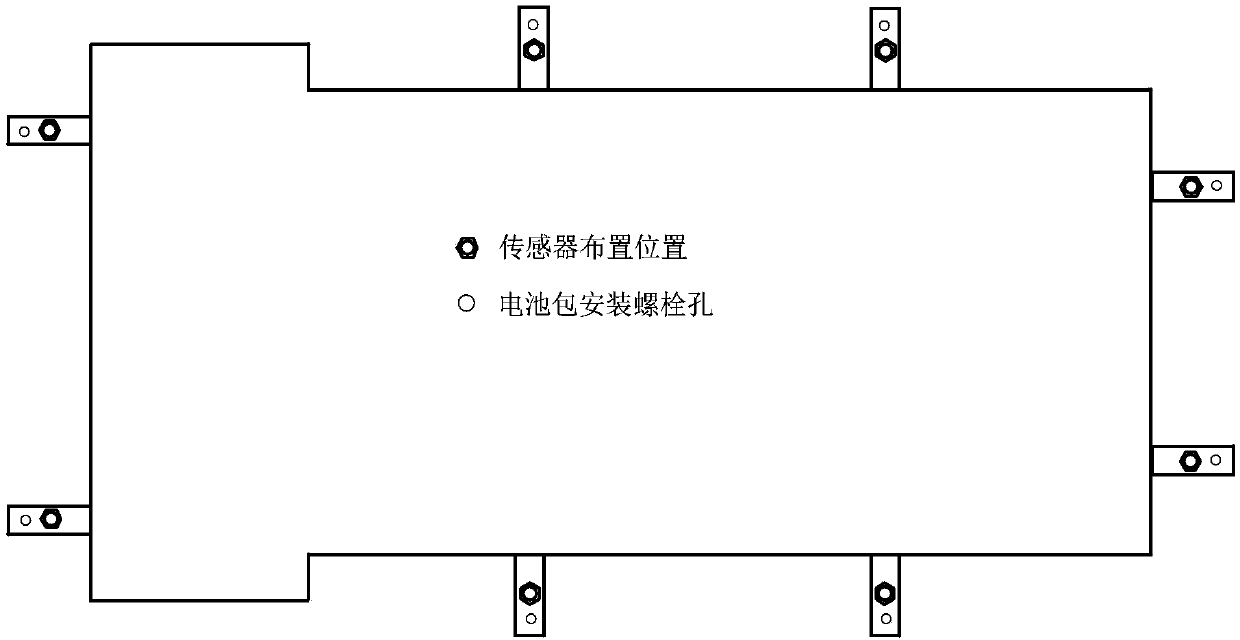

Real road spectrum based electric automobile battery pack structure fatigue life prediction method

InactiveCN107991103AGuaranteed accuracyStrong engineering practicabilityVehicle testingDynamic modelsAutomotive battery

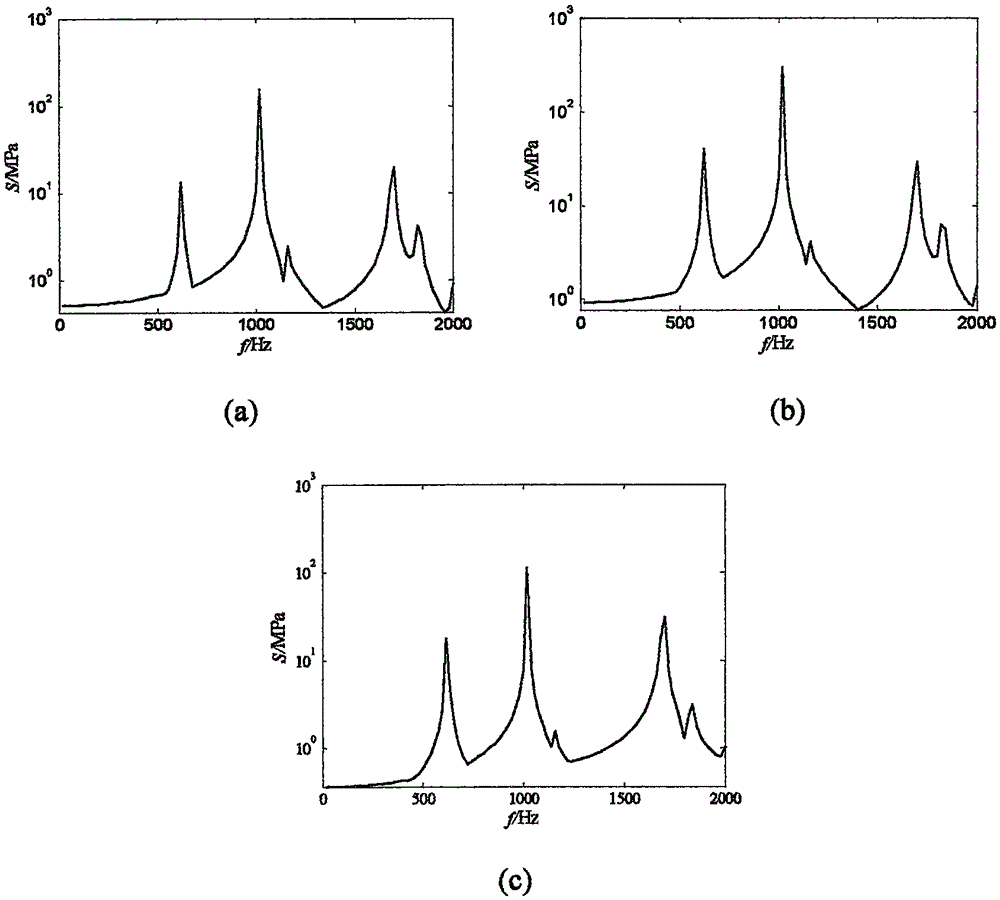

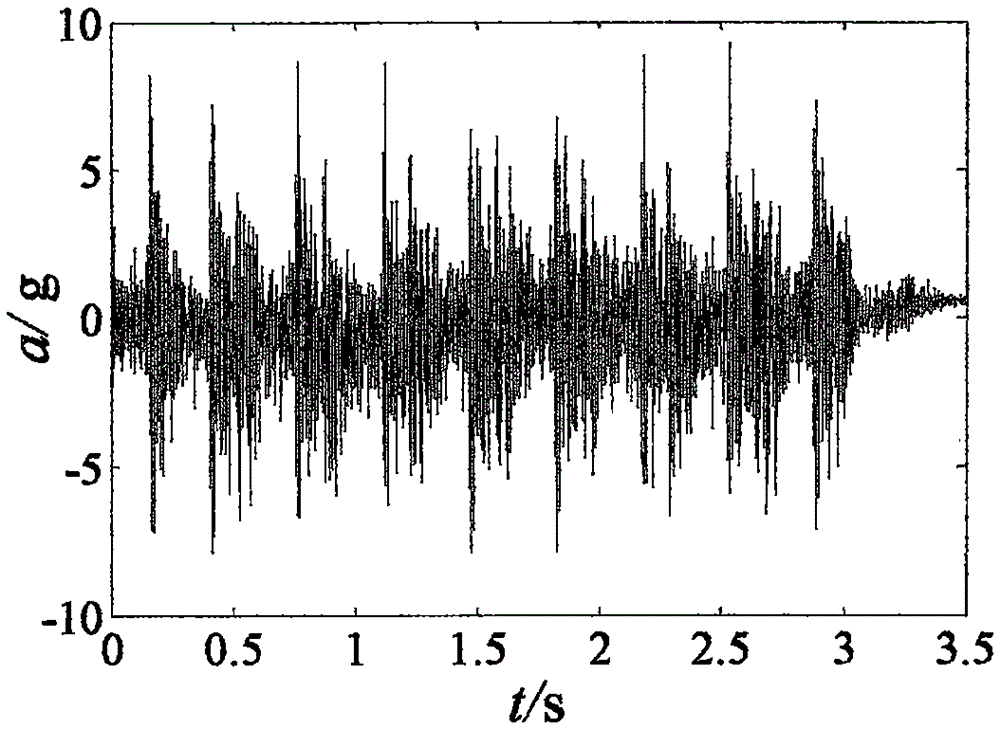

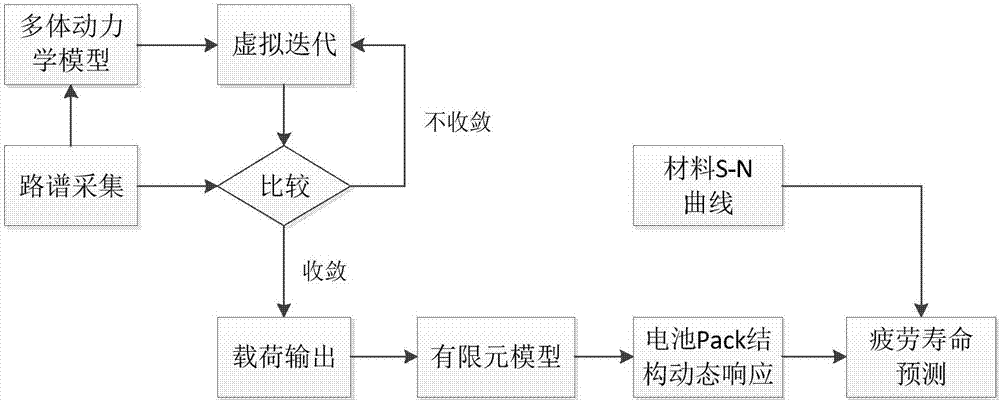

The invention discloses a real road spectrum based electric automobile battery pack structure fatigue life prediction method. The method mainly includes electric automobile road load condition setting, road load spectrum acquisition and analysis, integral automobile multi-body dynamic model establishment, multi-body dynamic model transfer function acquisition and load spectrum iteration and fatigue life prediction. By adoption of a half-testing half-simulation iteration method, a real load spectrum of an electric automobile is obtained, battery pack structural load accuracy is guaranteed, highengineering practicality is realized, and expensive bench equipment input is avoided, so that low cost is realized. By battery pack structure fatigue life prediction according to a multi-axial fatigue theory and a broadband random fatigue life prediction method, low calculation amount and high prediction precision are realized.

Owner:开沃新能源汽车集团股份有限公司

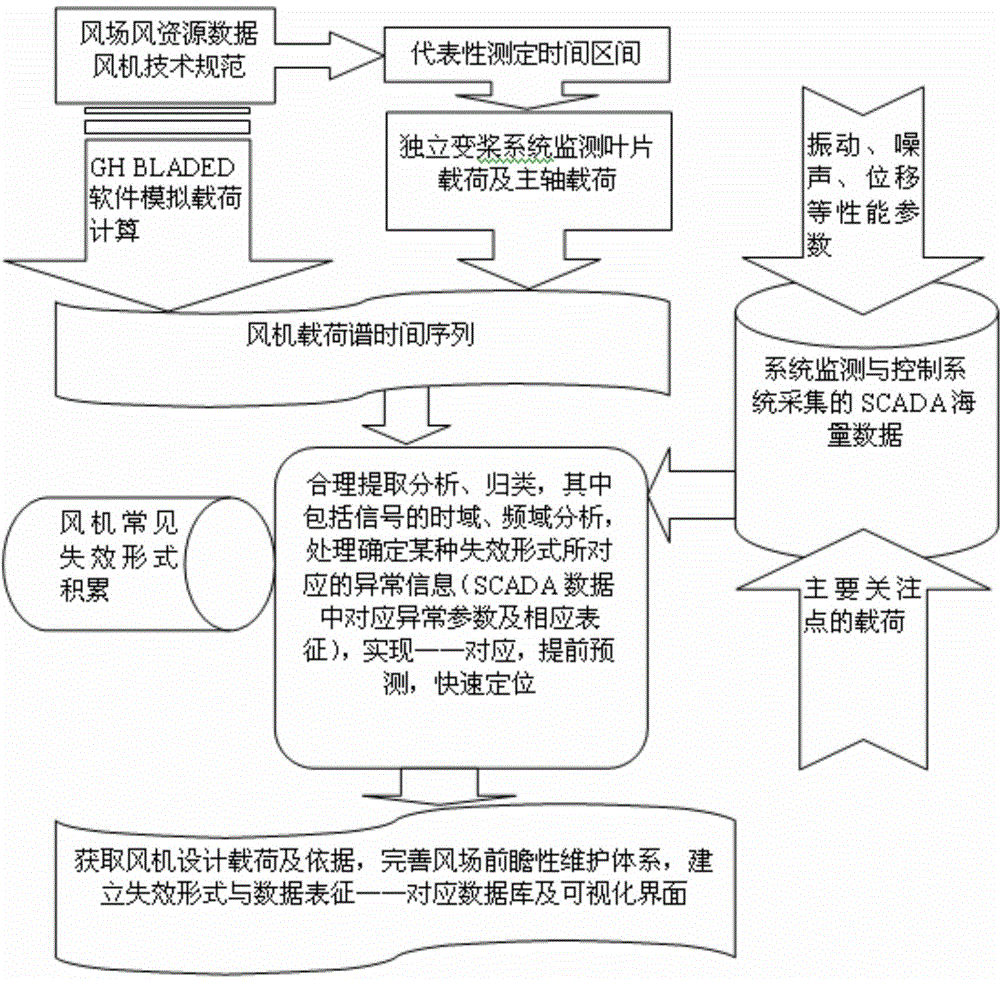

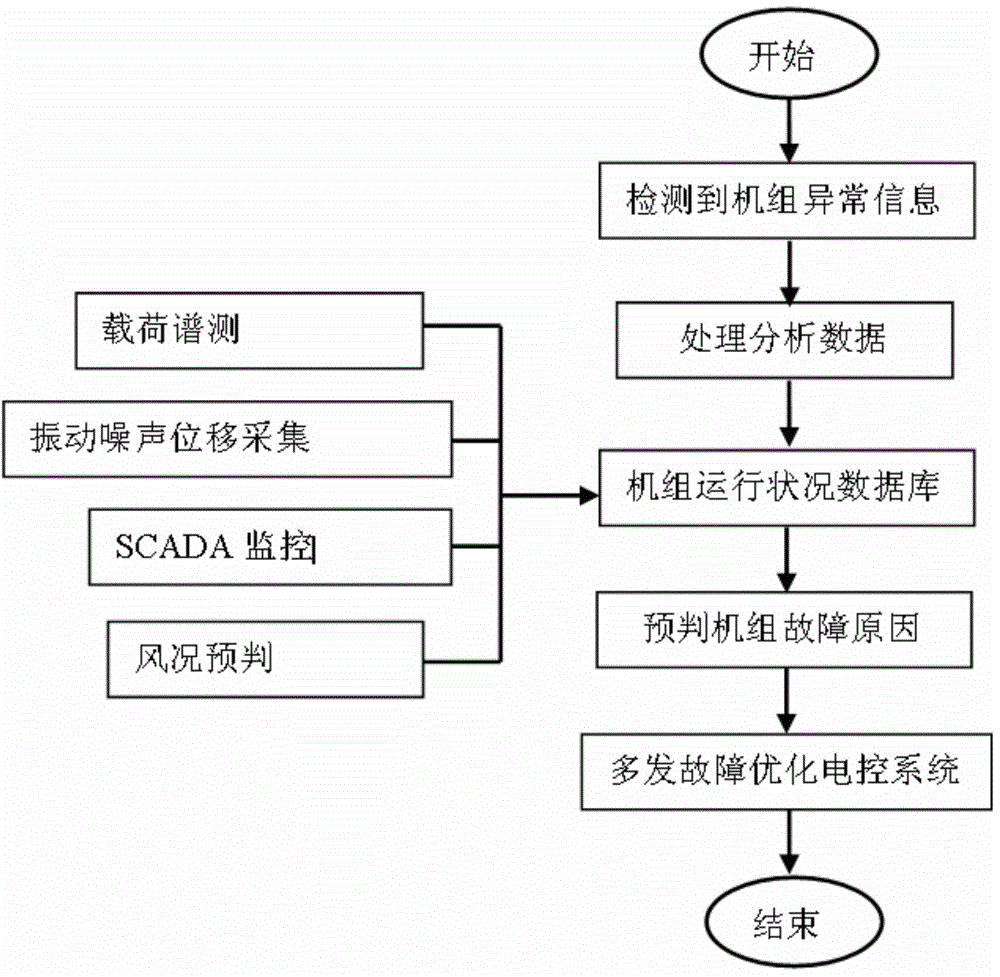

Load spectrum determination and proactive maintenance system of wind generating set

ActiveCN104019000AProactive maintenance implementationWind energy generationWind motor componentsWind drivenElectricity

The invention relates to a load spectrum determination and proactive maintenance system of a wind generating set. The load spectrum determination and proactive maintenance system comprises a data acquisition and monitoring control system and is characterized in that a main engine of the data acquisition and monitoring control system is in connection with a main control system of the wind generating set for communication so as to obtain running and alert data of the wind generating set; the main engine also is in connection with a load spectrum determination unit of the wind generating set for communication so as to determine the running load spectrum of the wind generating set, is in connection with a transmission chain acquisition unit of the wind generating set for communication so as to acquire vibration, noise and displacement of a transmission chain of the wind generating set, and is connected with a wind power plant wind-resource distribution data unit. By detecting the running state of wind driven generators, the system establishes a running condition database, studies the mechanism of main failure forms of a fan, and realizes proactive maintenance for the wind generating set.

Owner:NINGXIA YINXING ENERGY

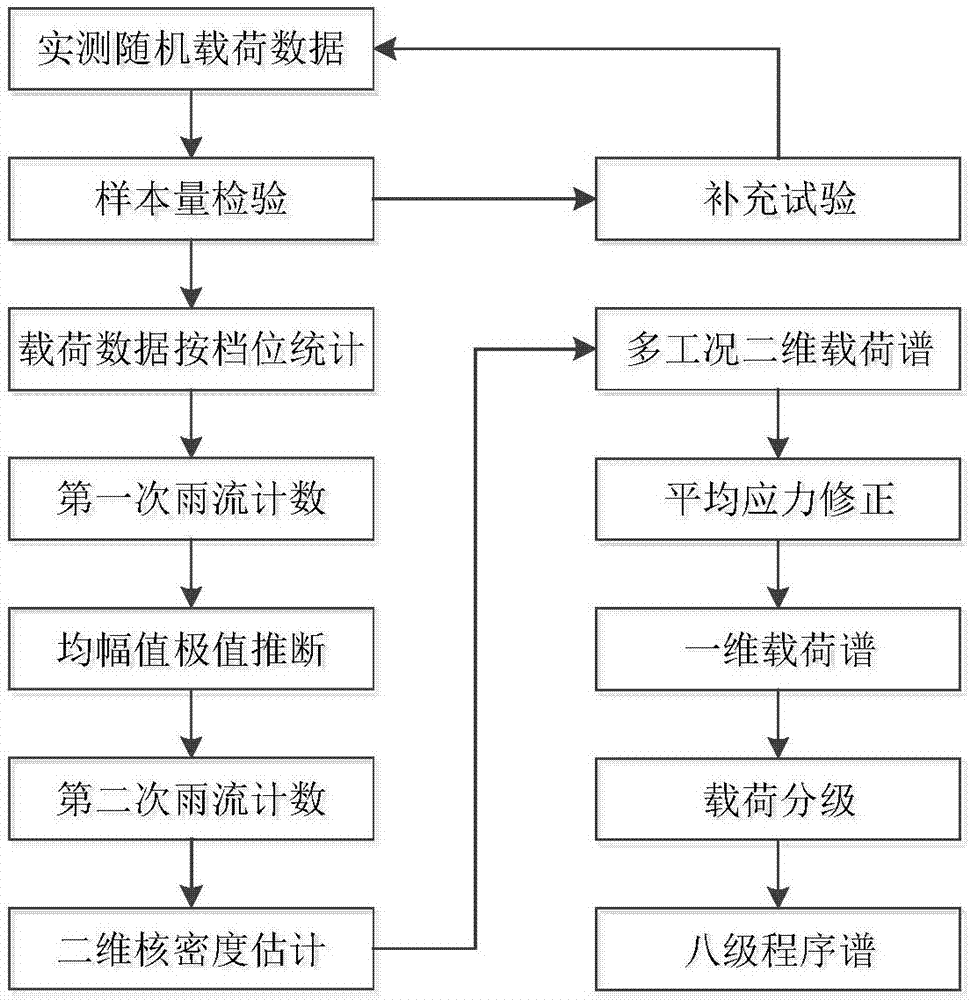

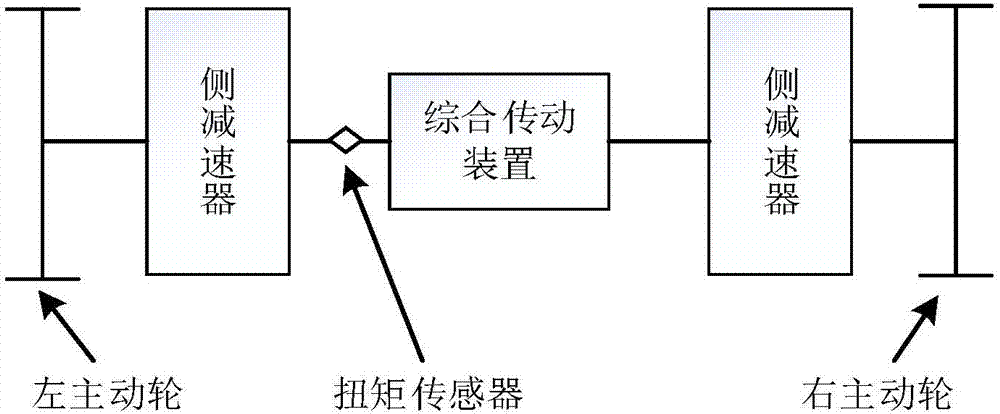

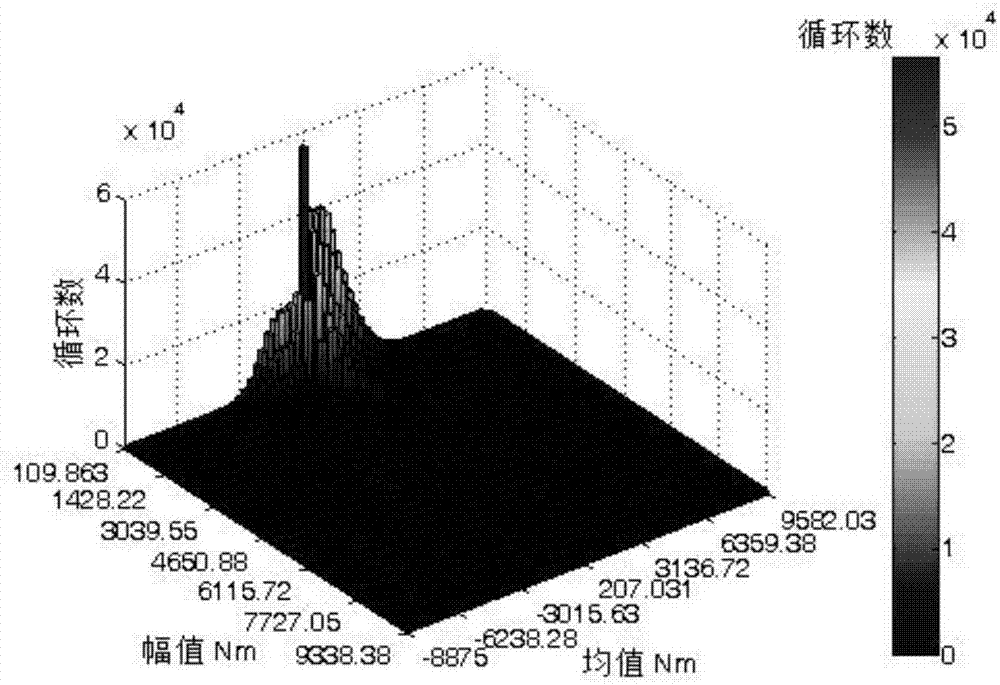

Kernel density estimation-based load spectrum compilation method for transmission shaft of tracked vehicle

ActiveCN106886638ARaise the confidence levelRealize reasonable extrapolationGeometric CADSpecial data processing applicationsSpectral density estimationDrive shaft

The invention relates to a kernel density estimation-based load spectrum compilation method for a transmission shaft of a tracked vehicle. The method comprises the following steps of S1, collecting and preprocessing torque load sample data of the tracked vehicle; and S2, generating a two-dimensional load spectrum through first two-time rain flow counting, mean amplitude extremum inference, second rain flow counting, two-dimensional kernel density estimation, multi-condition synthesis and extrapolation in sequence. According to the method, the two-time rain flow counting is adopted; a first rain flow counting result is used for the mean amplitude extremum inference; a second rain flow counting result is used for the kernel density estimation; mean amplitude distribution can be well fitted; and an actually measured rain flow matrix can be reasonably extrapolated. The load spectrum compiled by adopting the method and the actually measured rain flow matrix have highly similar probability density distribution, reasonable extrapolation of the actually measured rain flow matrix is realized, and an expected effect is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

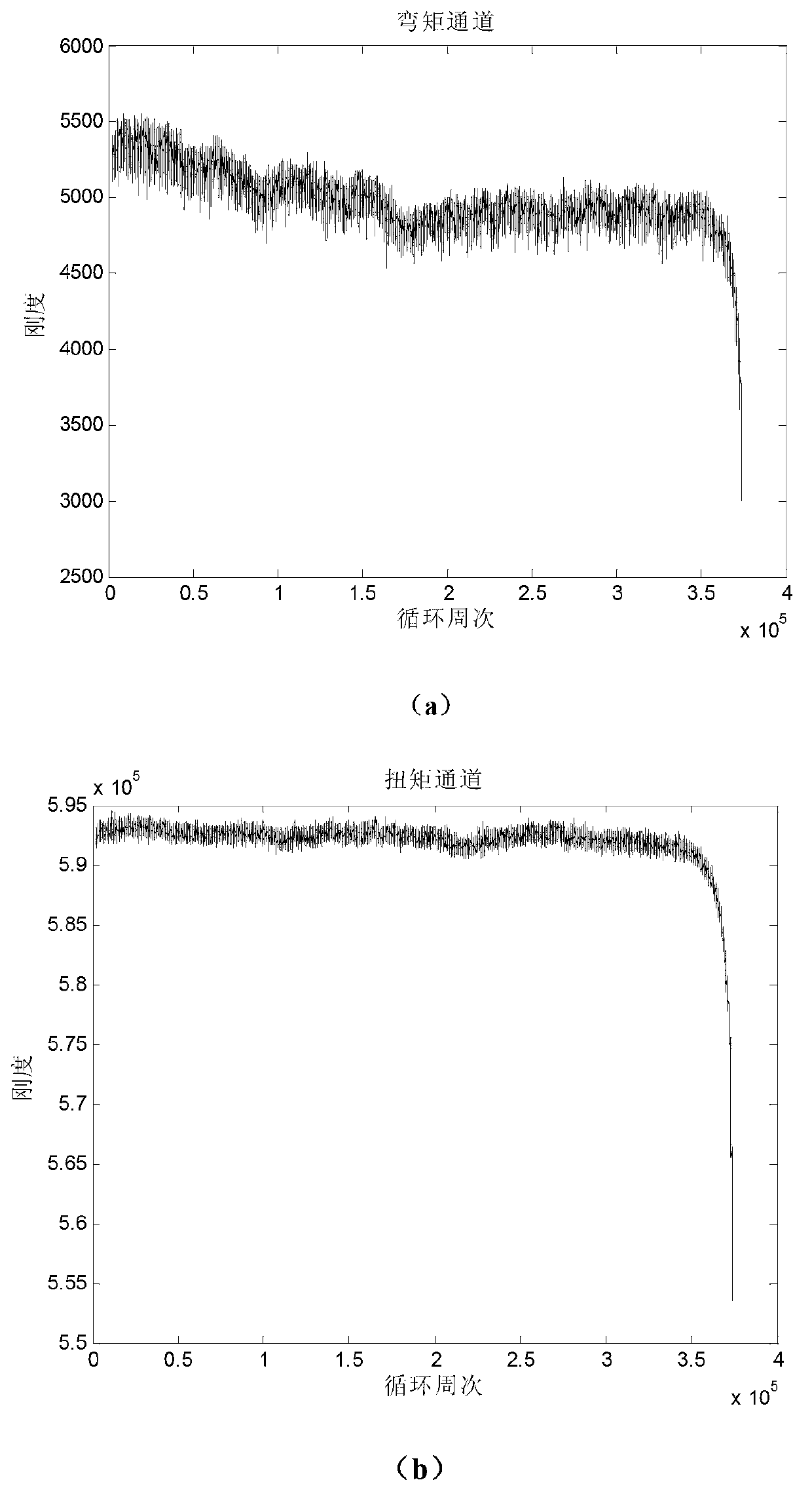

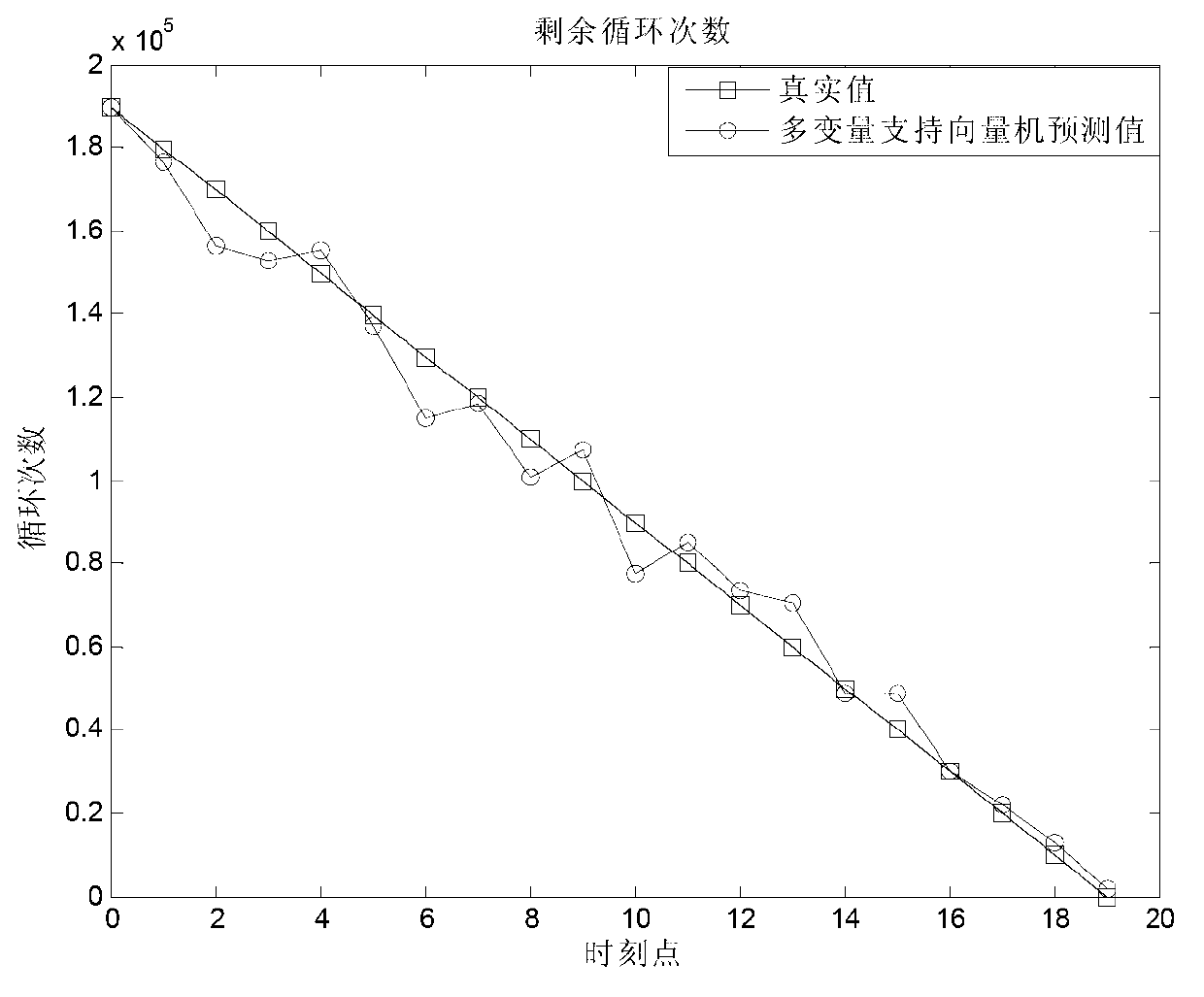

Multivariable support vector machine prediction method for aero-engine rotor residual life

ActiveCN103217280AOvercome the limitations of under-appliedOvercome the defect of insufficient diggingMachine part testingAviationSupport vector machine

The invention provides a multivariable support vector machine prediction method for aero-engine rotor residual life. According to the method, service time, a load spectrum, rotation speed and vibration signal characteristics of an aero-engine rotor are selected to be as input parameters of a life prediction model. A multivariable support vector machine prediction model for the residual life is established based on a multivariable prediction method, sample parameters are input to the model to be trained and then output, and prediction for the residual life of the aero-engine rotor is achieved under a small sample condition. The method is simple and practical, reliable in result, good in instantaneity and is suitable for quantitatively calculating the residual life of the aero-engine rotor under the small sample condition.

Owner:XI AN JIAOTONG UNIV

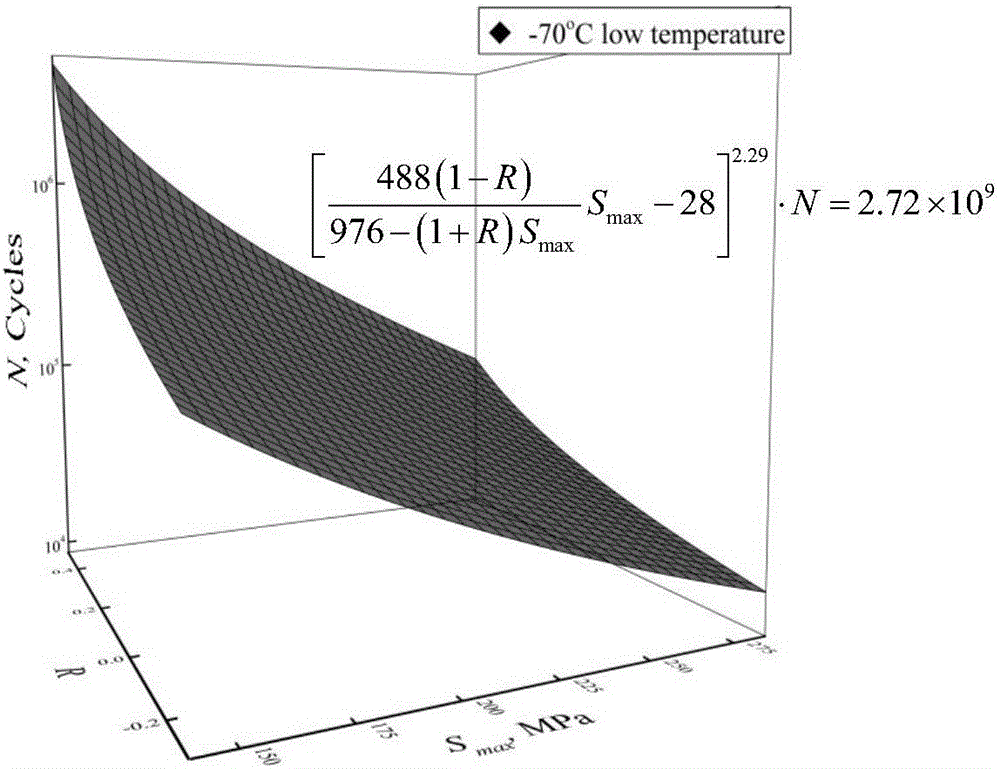

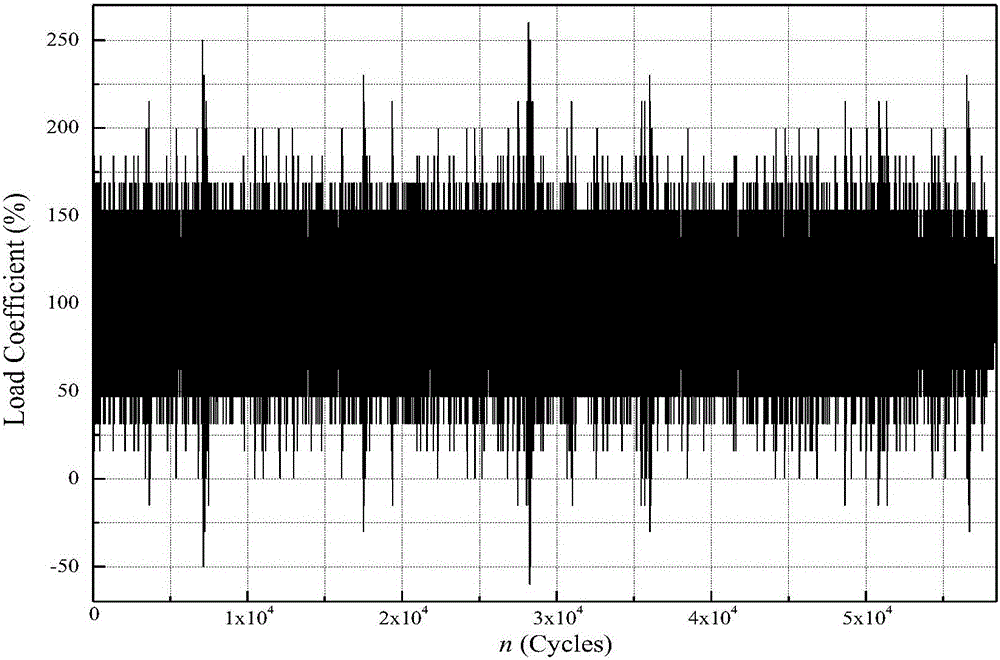

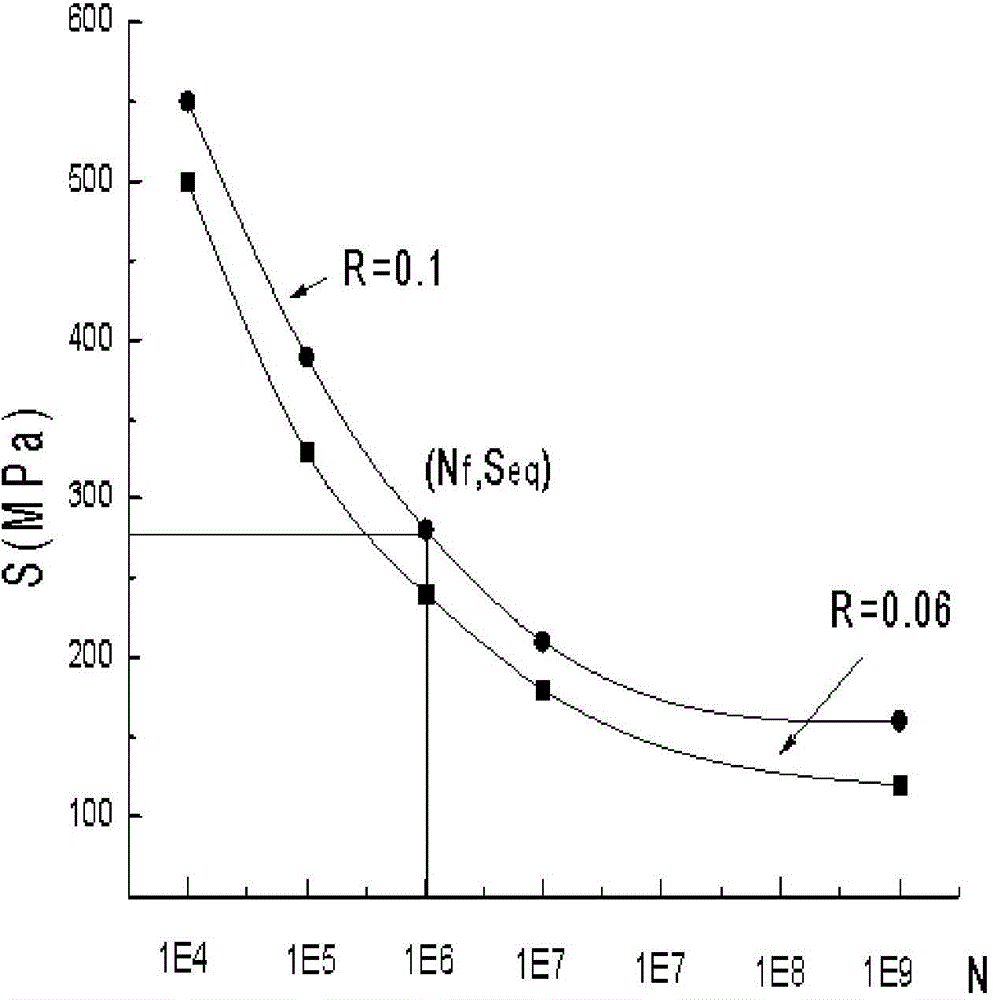

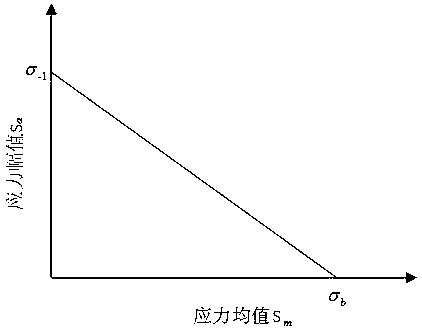

Low-temperature fatigue property characterization and life estimation method

The invention discloses a low-temperature fatigue property characterization and life estimation method. The method comprises three major steps of step 1, through considering the influence of a stress ratio, deriving an S-N-R curved surface characterizing the fatigue property by adopting a Goodman equilife curve based on a three-parameter power function expression, and performing data processing by virtue of a linear regression theory; step 2, through considering an interaction effect of loads under spectrum loading, proposing a corrected spectrum loading fatigue life estimation model based on a Willenborg / Chang model and a crack tip plastic zone theory, and giving out a fatigue damage increment representation method; and step 3, calculating the low-temperature spectrum loading fatigue life of a material by adopting an accumulative damage theory. The method is simple and practical; and a low-temperature fatigue property characterization model can be constructed only by a constant-load fatigue property curved surface and an actually measured flight load spectrum of the material in a low-temperature environment, and the spectrum loading fatigue life is estimated, so that the method has important academic meanings and engineering application values.

Owner:BEIHANG UNIV

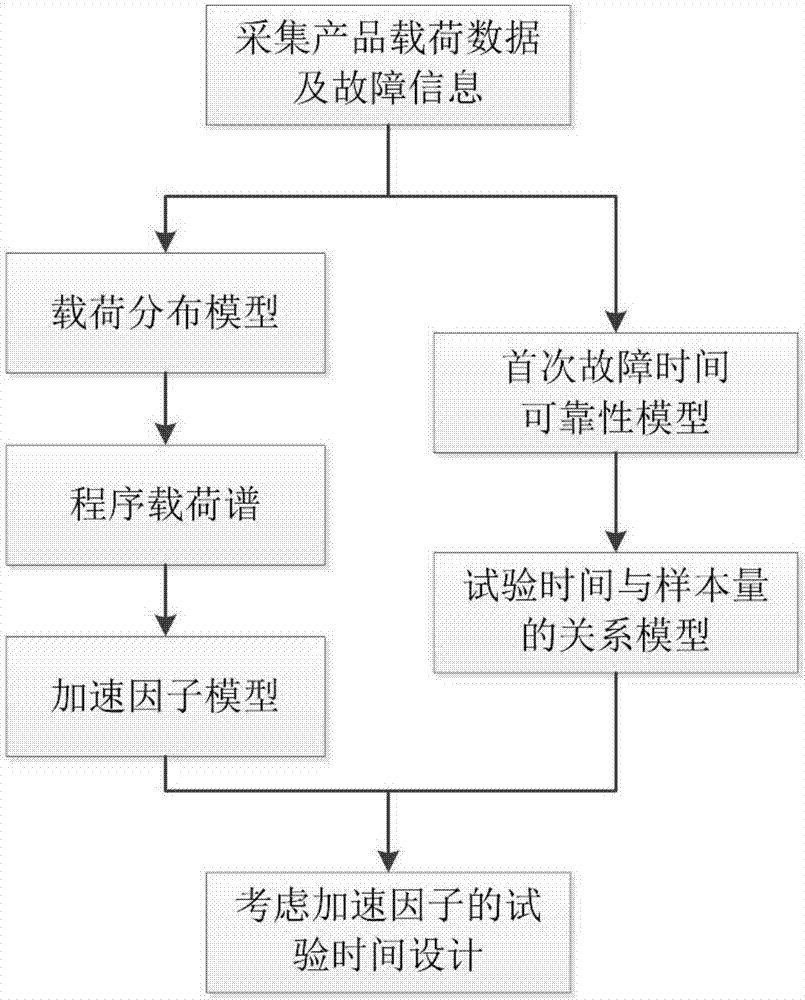

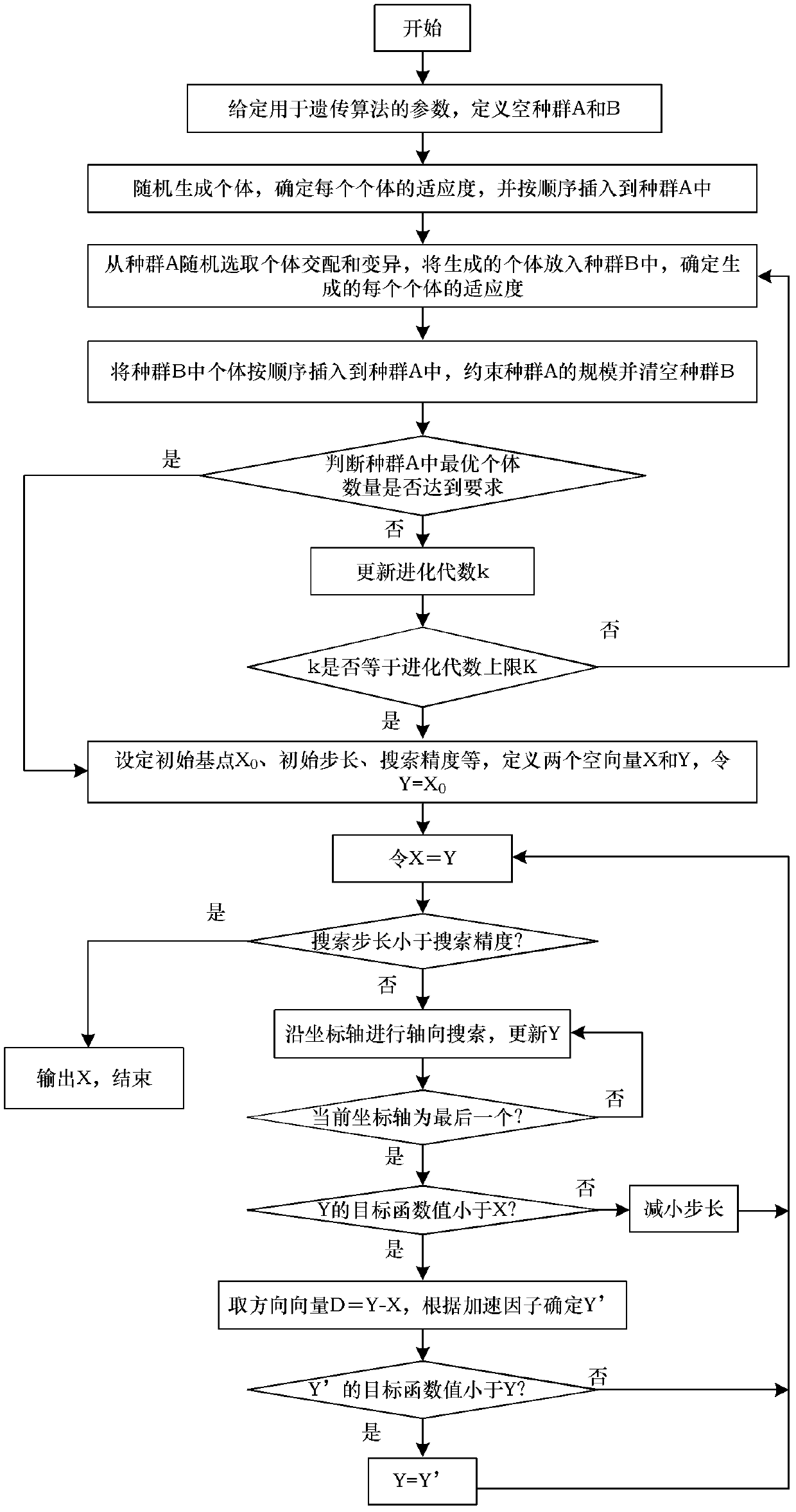

Motorized spindle accelerated life testing time design method

InactiveCN106874582AImprove accuracyGeometric CADSpecial data processing applicationsNumerical controlRelational model

The invention belongs to the technical field of numerical control machine tool and relates to a motorized spindle accelerated life testing time design method. The method includes the steps that firstly, product load data and fault information are collected; secondly, a load distribution model is established; thirdly, a program load spectrum is designed; fourthly, a product service life estimated formula is determined on the basis of the Miner fatigue accumulation damage theory, and an accelerated life testing accelerating factor model is built on the basis of the formula; fifthly, based on the fault information, a first fault time reliability mode is built through model hypothesis, parameter estimation and hypothesis testing; sixthly, testing time design is conducted on the basis of the first fault time, the first fault time corresponding to an acceptable reliability degree serves as a standard, and a relational model of motorized spindle testing time and the sample capacity is established; seventhly, an accelerating factor is considered for testing time design, and the creditability of the testing time design is verified. The relational model of the testing time and the sample capacity is considered, the accelerating factor model is established on the basis of the modification Miner theory, the modeling accuracy is improved, and the method better conforms to actual conditions.

Owner:JILIN UNIV

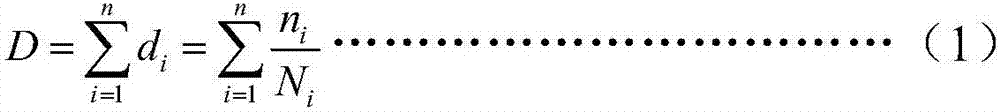

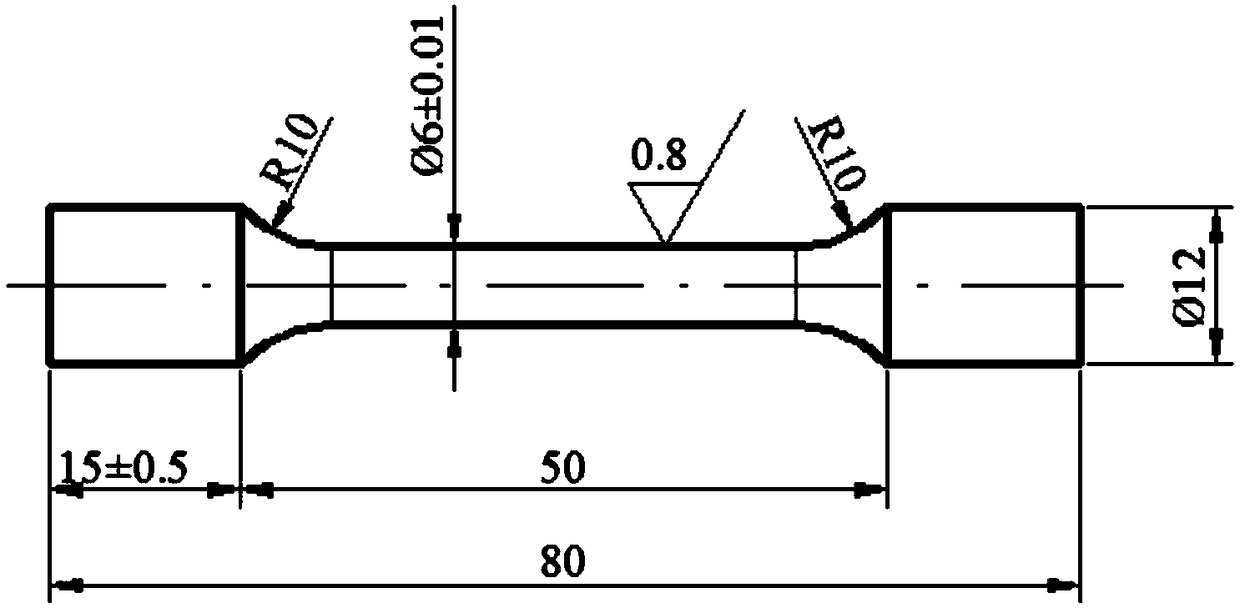

A method for analyzing fatigue life of steering knuckle

ActiveCN109214078ATime-consuming to solveAccurate fatigue analysis resultsGeometric CADSustainable transportationFatigue loadingProblem of time

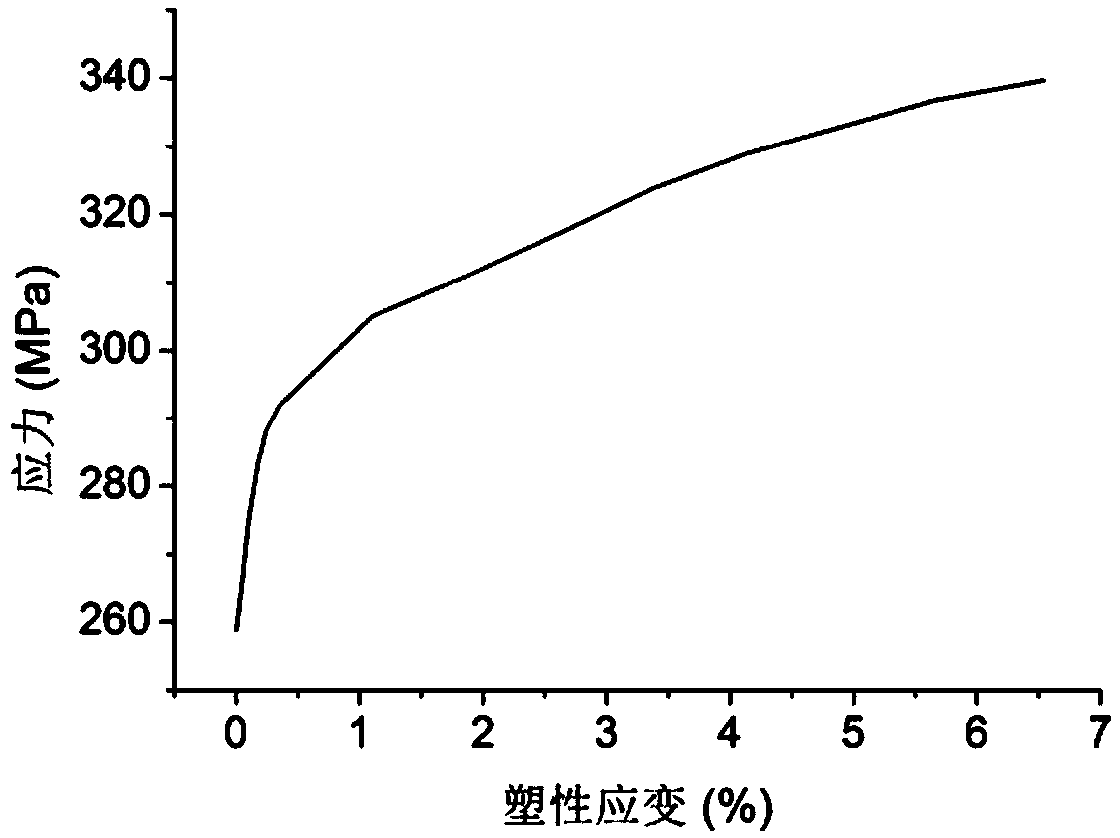

The invention discloses a method for analyzing the fatigue life of a steering knuckle, comprising the following steps: 1) obtaining the fatigue load of the steering knuckle; 2) carrying out uniaxial tensile material test on the use material; 3) if the fatigue load is under the static load condition, the elastic-plastic finite element analysis method is adopted to solve the problem; or, if it is the actual pavement load spectrum, the elastic-plastic finite element analysis is carried out on the points exceeding the yield strength by elastic finite element method and linear superposition method,and the modified stress-strain results are obtained. 4) analyzing the biaxiality of the obtained stress response in time domain to determine the load state of the steering knuckle; 5) calculating thedamage accumulation and life of steering knuckle. The present invention solves the problem of time-consuming finite element solution under the input of actual pavement load spectrum, at the same time, the stress and strain of the material entering the plastic phase are considered, so that the result is more accurate, and fatigue analysis is carried out by combining the static load condition or the single channel static load condition, and more references are provided in the design phase.

Owner:SOUTH CHINA UNIV OF TECH

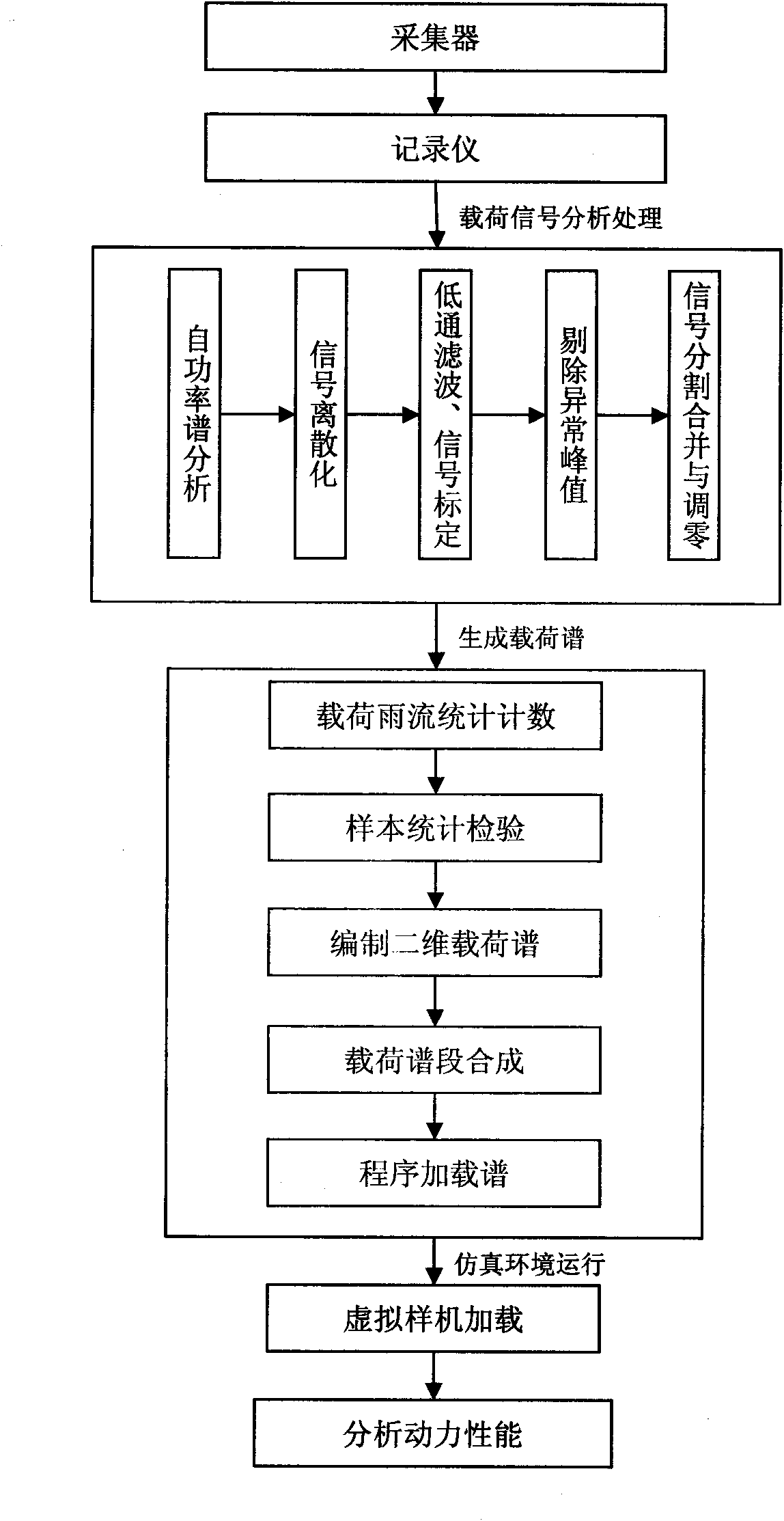

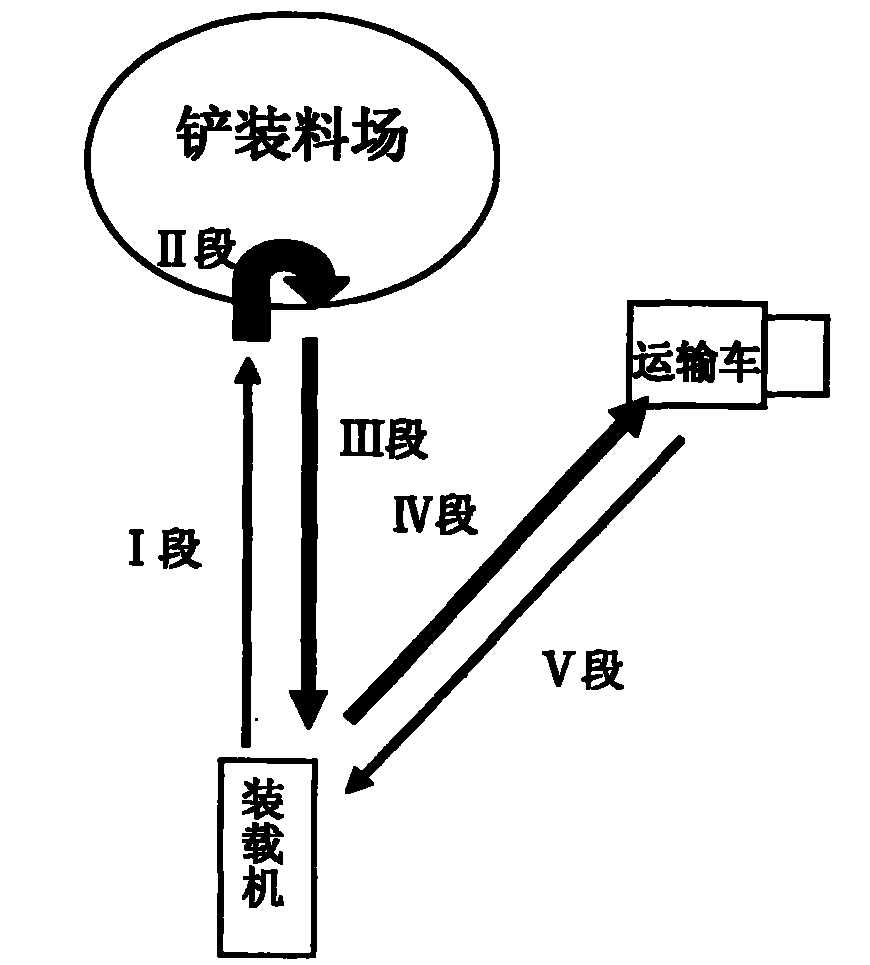

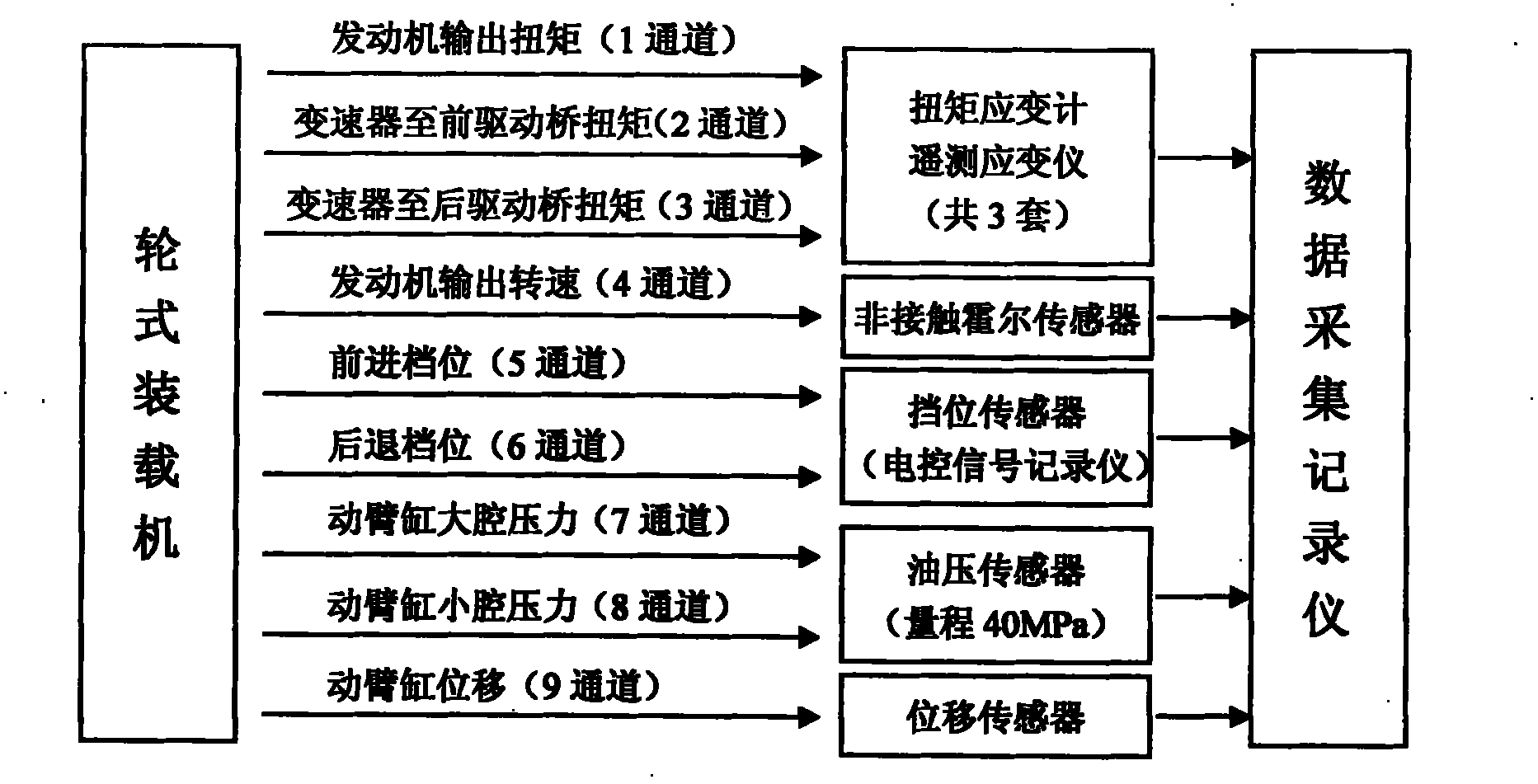

Transmission system load signal testing, analyzing and processing method of wheel-type loader

InactiveCN101788398AEasy to analyzeGuaranteed accuracyMachine gearing/transmission testingMechanical machines/dredgersComputer moduleWorking environment

The invention discloses a transmission system load signal testing, analyzing and processing method of a wheel-type loader; the transmission system load signal testing of the wheel-type loader is completed by a transmission system load signal testing module; a signal acquisition device and a recorder which are mutually connected form the transmission system load signal testing module; load signal analysis and processing are completed by a load signal analyzing and processing module, and the load signal analyzing and processing module analyzes and processes the load signal recorded by the recorder; the method solves the problems of transmission system load on-line actual measurement and load testing signal processing of the wheel-type loader, reduces the interference of pseudo-signals with load spectrum generation as possible, realizes the truth of the transmission system load spectrum, uses the transmission system load spectrum in the virtual test of the power performance optimization design of the wheel-type loader so that the precision is close to the real working environment of the loader, greatly shortens the performance testing time of the wheel-type loader, and improves the optimization design precision.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

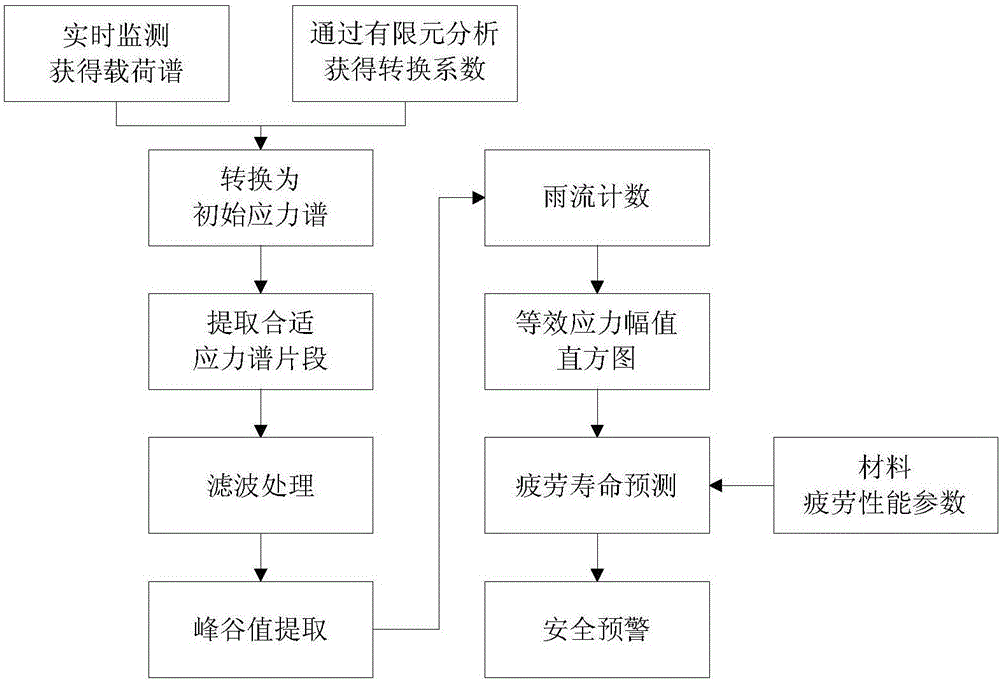

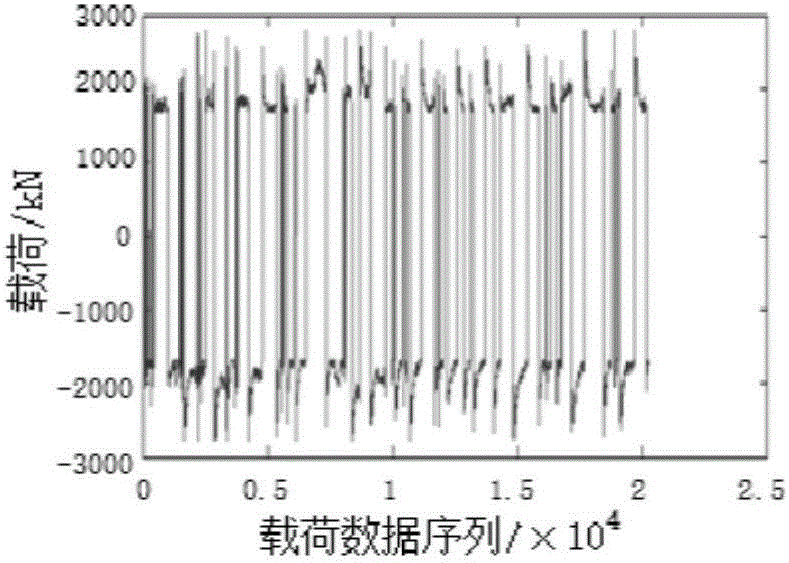

Rolling mill transmission system key component fatigue life early warning method based on load spectrum analysis

InactiveCN106644464APredict fatigue lifeSolve the large amount of calculationMachine gearing/transmission testingConversion coefficientsOperability

The invention discloses a rolling mill transmission system key component fatigue life early warning method based on load spectrum analysis. The method is characterized by comprising the following steps: 1, obtaining a rolling mill transmission system key component load spectrum through real-time monitoring in a rolling mill working process; 2, based on a computer simulation technology, obtaining a stress distribution and conversion coefficient of a rolling mill transmission system key component; 3, obtaining a corresponding stress spectrum by performing conversion processing on the load spectrum measured in the first step; 4, compiling an equivalent stress amplitude histogram by performing statistics on the stress spectrum after processing in the third step by use of a cyclic rain flow counting method; and 5, calculating fatigue life circulation frequency of a transmission part by use of a correction Miner method, and converting the fatigue life circulation frequency into a fatigue life taking a year as a unit. The method solves the problems of large calculation amount and high calculation complexity in a conventional fatigue life calculation method, has quite high applicability and operability and is high in engineering practicality.

Owner:NANJING UNIV OF TECH

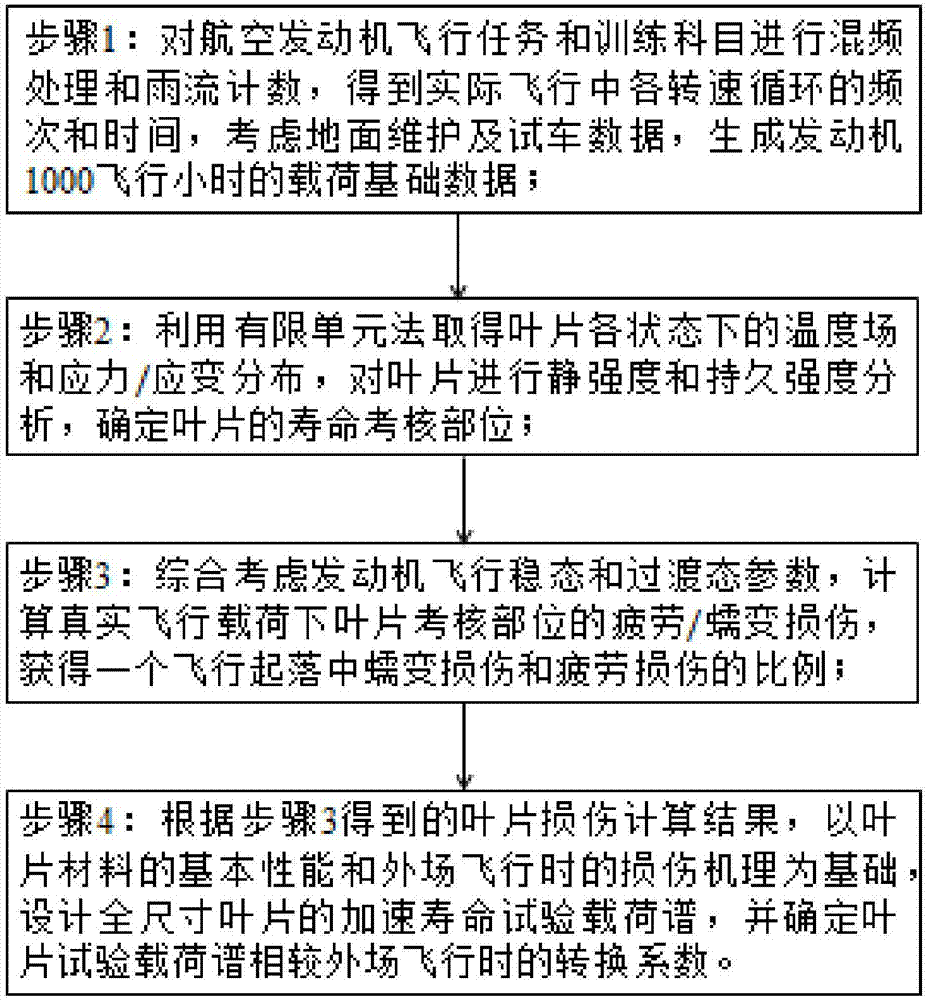

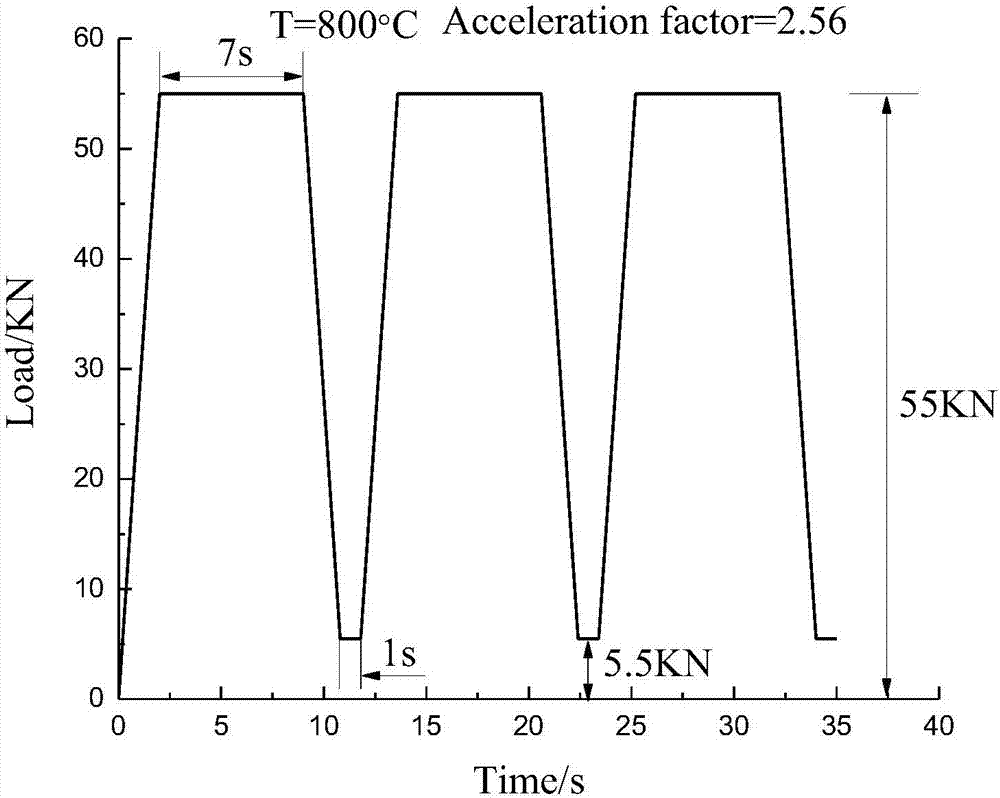

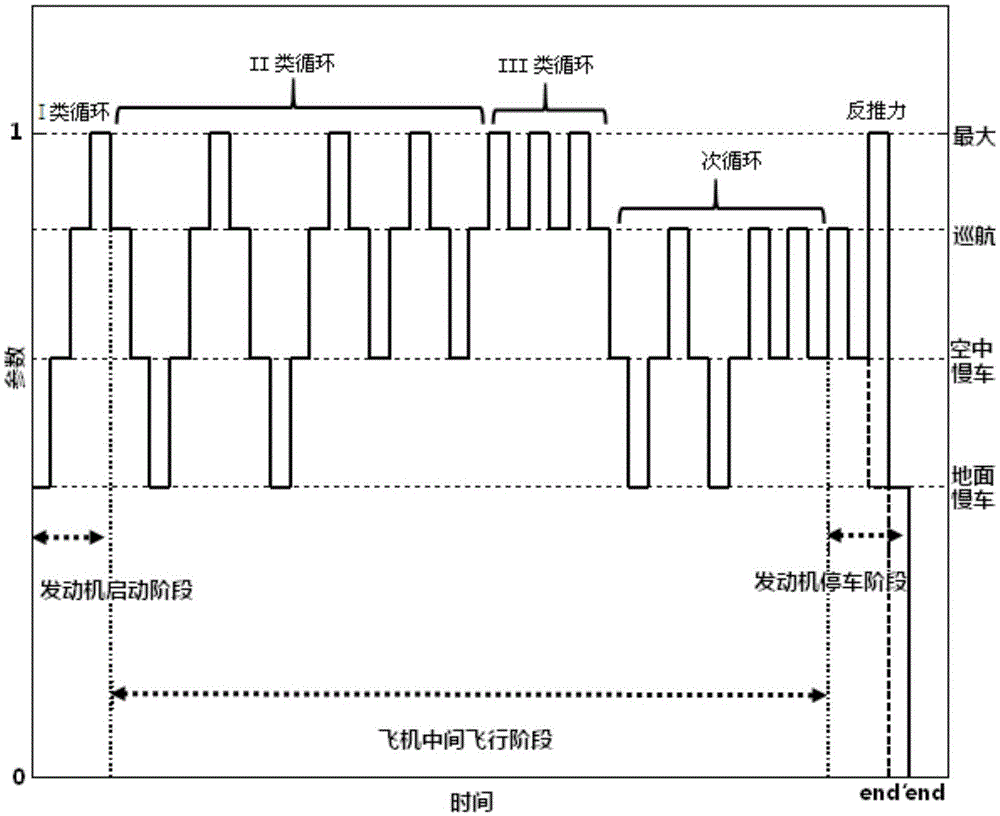

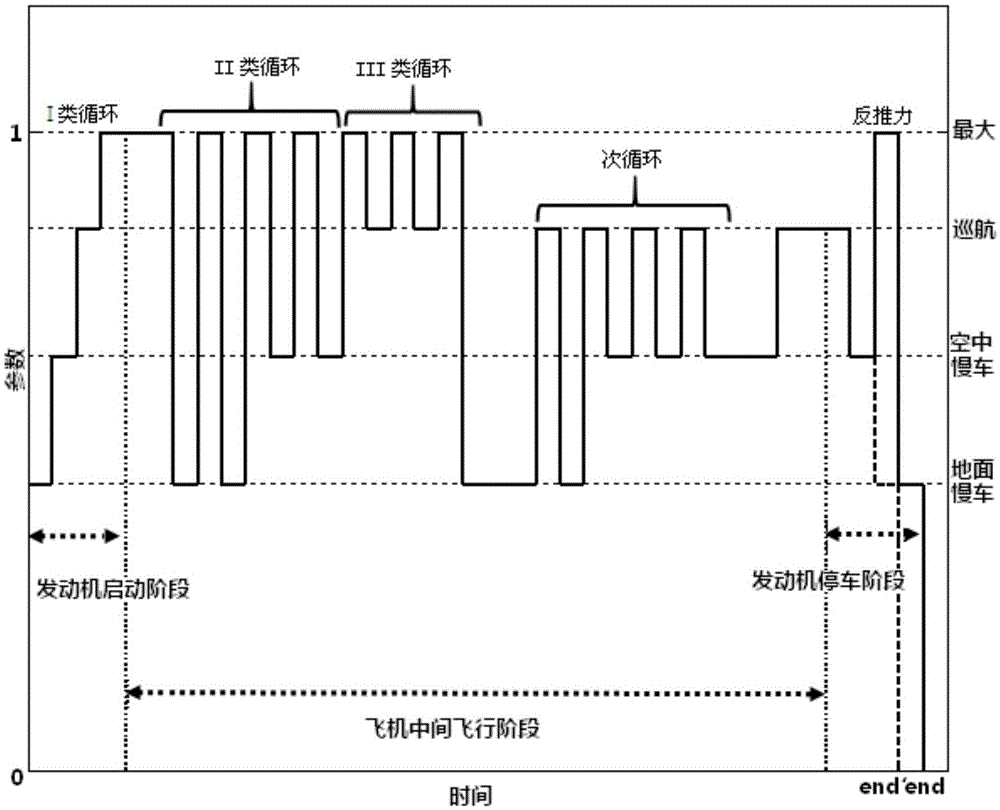

Turbine rotor blade accelerated life test load design method taking regard of flight damage

PendingCN107247002ADamage reasonably characterizedLife assessmentMaterial strength using tensile/compressive forcesDesign optimisation/simulationFatigue damageAviation

The invention relates to a turbine rotor blade accelerated life test load design method taking regard of flight damage. The method includes: 1) conducting frequency mixing treatment and rain flow counting on aeroengine flight missions and training subjects to acquire the frequency and time of each rotation speed cycle in actual flight, thus obtaining the load basic data of an engine within certain flight hours; 2) acquiring the temperature field and stress strain distribution of the blade under all states by finite element method, analyzing the blade static strength and endurance, and determining a lifetime testing part of the blade; 3) calculating the fatigue damage and creep damage of the blade testing part under a true flight load to acquire a ratio of creep damage and fatigue damage during rise and fall of a flight; and 4) designing a accelerated life test load spectrum of a full-size blade, and determining a conversion coefficient of the blade test load spectrum relative to out-field flight. The method provided by the invention can be used for acquiring the technical life of the blade and studying the remaining life of the blade, and saves time and economic cost for the fatigue-creep lifetime test of the blade.

Owner:BEIHANG UNIV

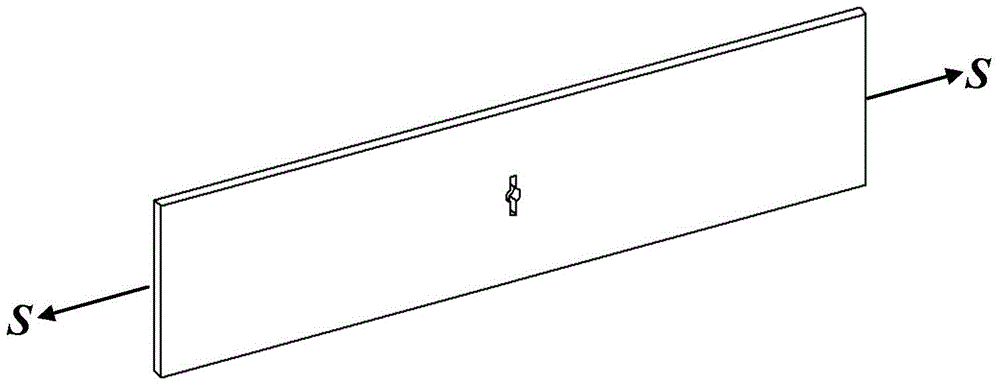

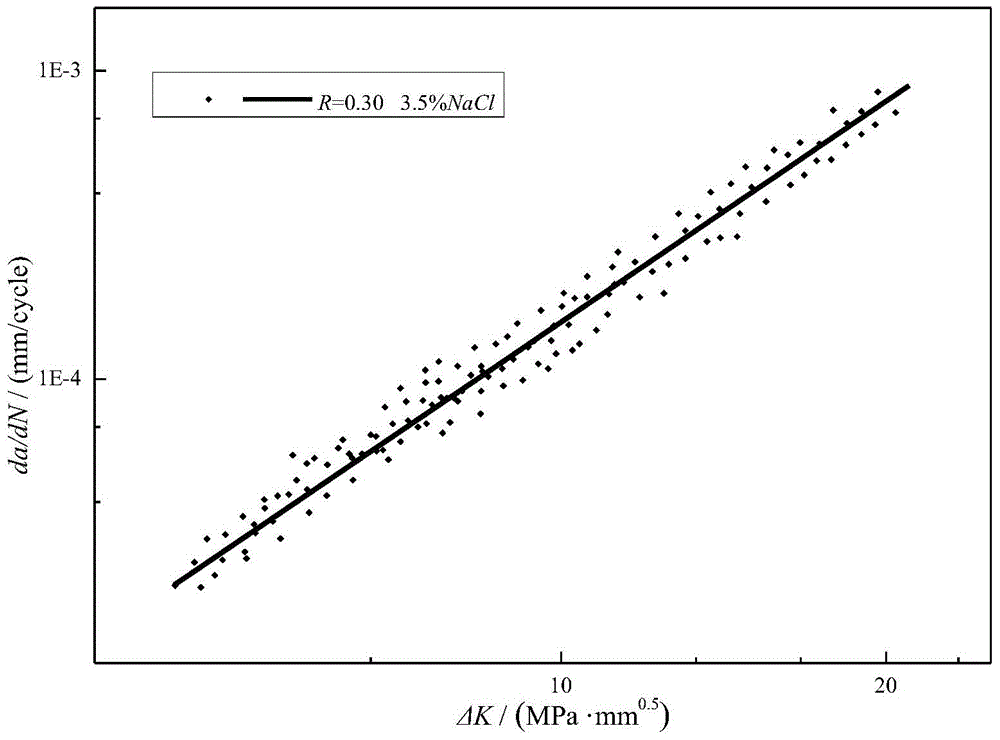

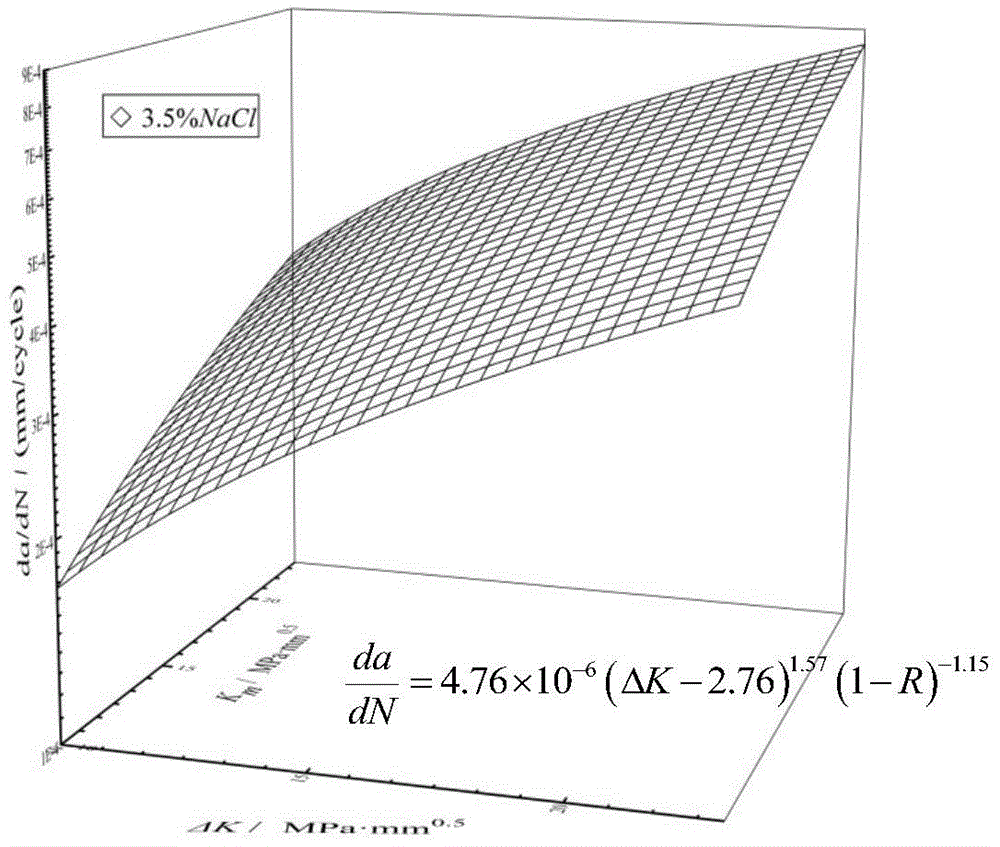

Corrosion crack expansibility characterization and life estimation method

A corrosion crack expansibility characterization and life estimation method comprises the following steps: 1, obtaining the corrosion crack expansibility da / dN-deltaK curve of a material through constant load test; 2, considering influences of corrosion on the fracture threshold value, correcting a Walker formula, fitting the da / dN-deltaK curve through combining a binary linear regression theory, and constructing a corrosion crack expansibility characterization model; and 3, considering the interaction between the retardation effect and load under spectrum load, and estimating the corrosion spectrum-loaded crack expansion life of the material by adopting a Willenborg-Chang model and an accumulation integration technology. The method is simple and practical, allows the corrosion crack expansibility characterization model to be constructed and the spectrum-loaded crack expansion life to be estimated only through using the constant load crack expansibility curve and the actually measured flight load spectrum of the material in corrosion environment, and has great scientific significance and engineering application values.

Owner:北京睦邦仁科技有限公司

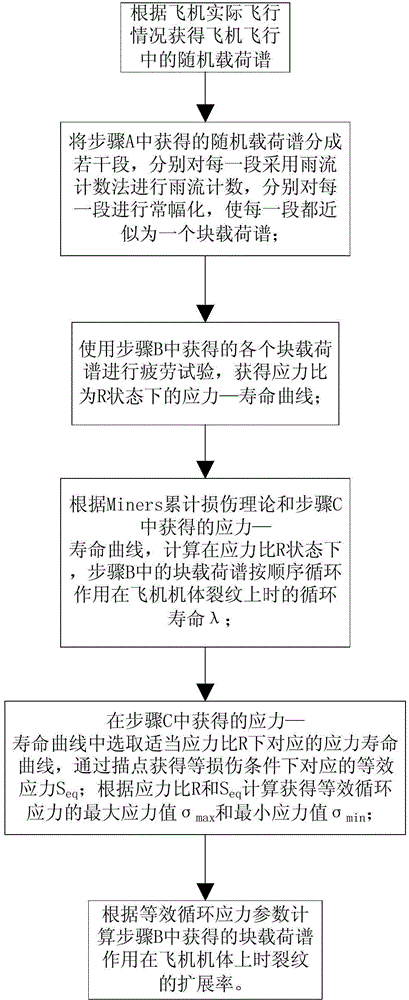

Prediction method of crack propagation life of aircraft body

ActiveCN104792633AAvoid frequent updatesAvoid repartitioningMaterial strength using repeated/pulsating forcesStress ratioEngineering

The invention discloses a prediction method of a crack propagation life of an aircraft body. The prediction method comprises the following steps: obtaining a random loading spectrum of an aircraft in flight according to the practical flight situation of the aircraft; dividing the obtained random loading spectrum into a plurality of sections, and respectively performing rain-flow counting and constant amplitude on each section, so that each section is approximated as a block loading spectrum; according to an Miners progressive damage theory, calculating a cycle life lambda effected on a crack of each block loading spectrum under the state of a corresponding stress ratio R, performing a fatigue test under the suitable stress ratio, and obtaining a corresponding stress-life curve; according to an equal defect theory, selecting the correspondence life curve under the suitable stress ratio R in the stress-life curve, and obtaining the equivalent stress Seq corresponding to the same life by a point tracing method; then, according to the R and the Seq, obtaining a maximum stress value sigma max and a minimum stress value sigma min of the equivalent cyclic stress; according to parameters of the equivalent cyclic stress, calculating the propagation rate of the crack when the obtained block loading spectrum is acted on the aircraft body.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

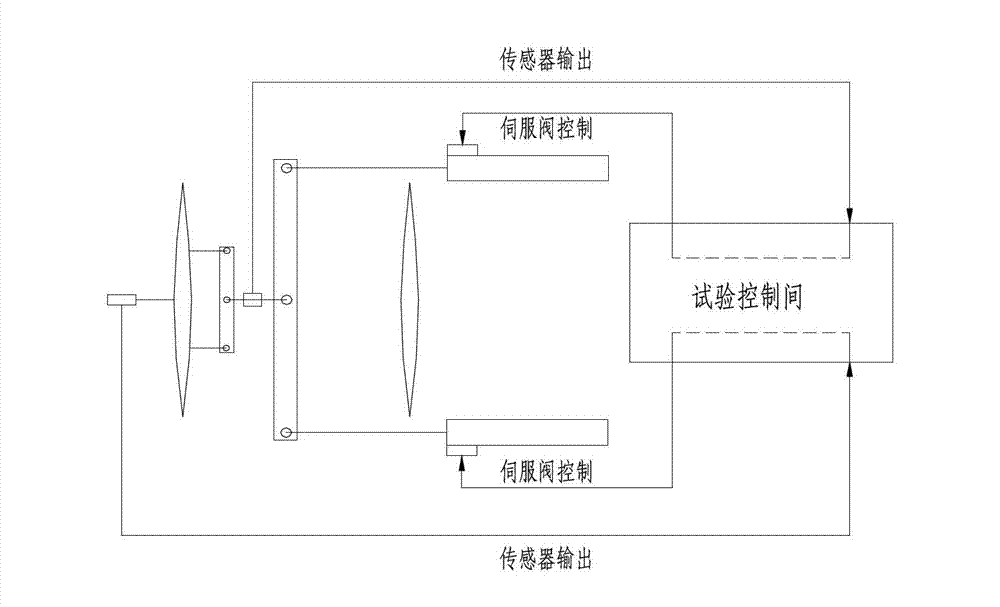

Load system and method combining force control and position control and used for airplane structural strength tests

ActiveCN103043225AAvoid interferenceTaking into account the needs of the testAircraft components testingActuatorPosition control

The invention relates to a load test technology and in particular to a load system and method combining force control and position control and used for airplane structural strength tests. The load system combining force control and position control comprises a force control actuator cylinder, a position control actuator cylinder, a force control sensor, a displacement sensor, a control module, load devices used for connection and a load device used for crossing interference pieces. Two ends of the load device used for crossing interference pieces are respectively provided with the load devices used for connection, each load device used for connection is respectively connected with the force control actuator cylinder and the position control actuator cylinder, the force control actuator cylinder is provided with a load module controlling load and the force control sensor, and the position control actuator cylinder is provided with the control module used for control load. The load system and method combining force control and position control controls the force control actuator cylinder and the position control actuator cylinder to respectively perform load on two ends of loading devices according to control commands of load spectrums, the load devices can move along deformation of test pieces, and interference of the load devices and the test pieces during testing process can be avoided.

Owner:CHINA AIRPLANT STRENGTH RES INST

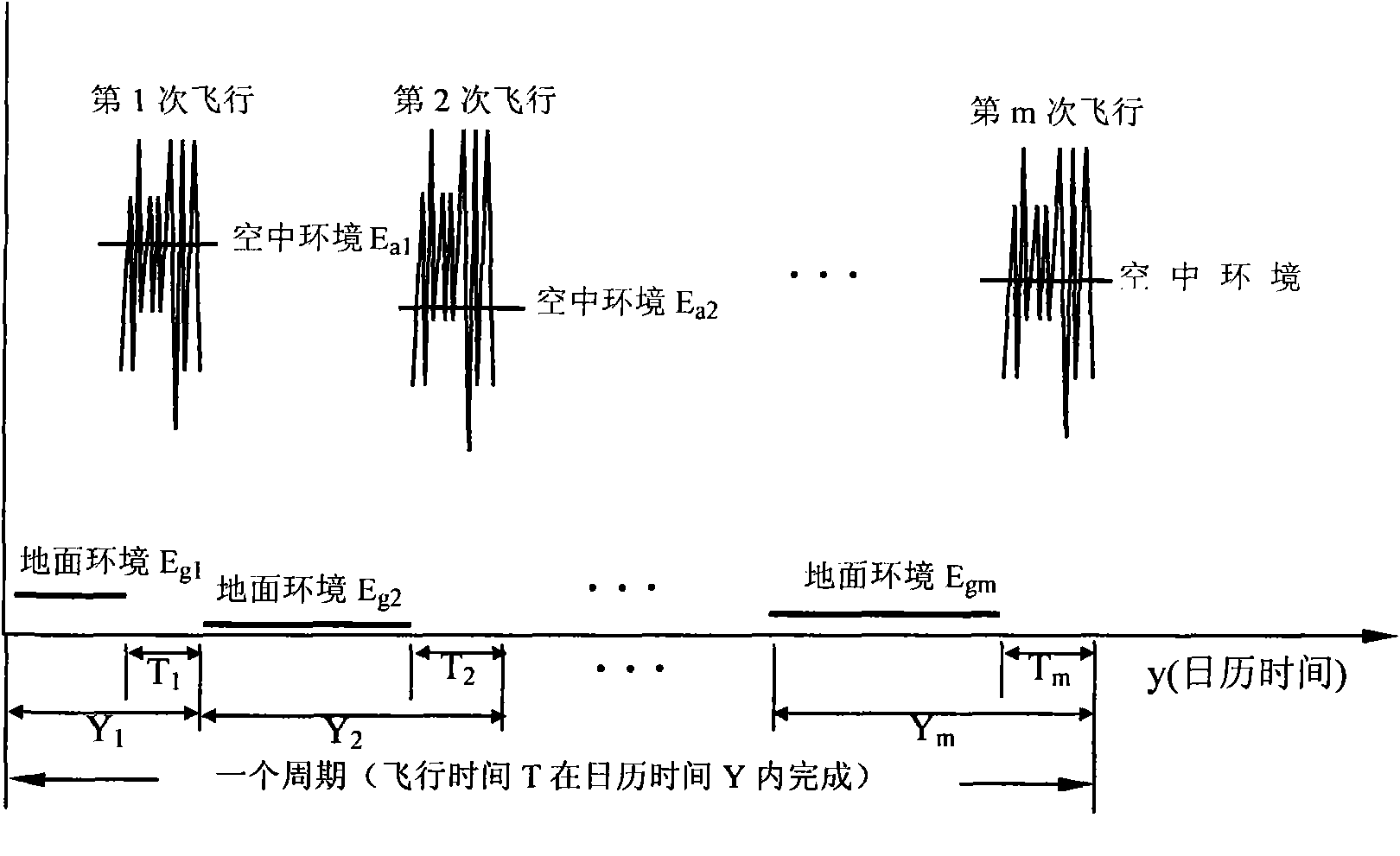

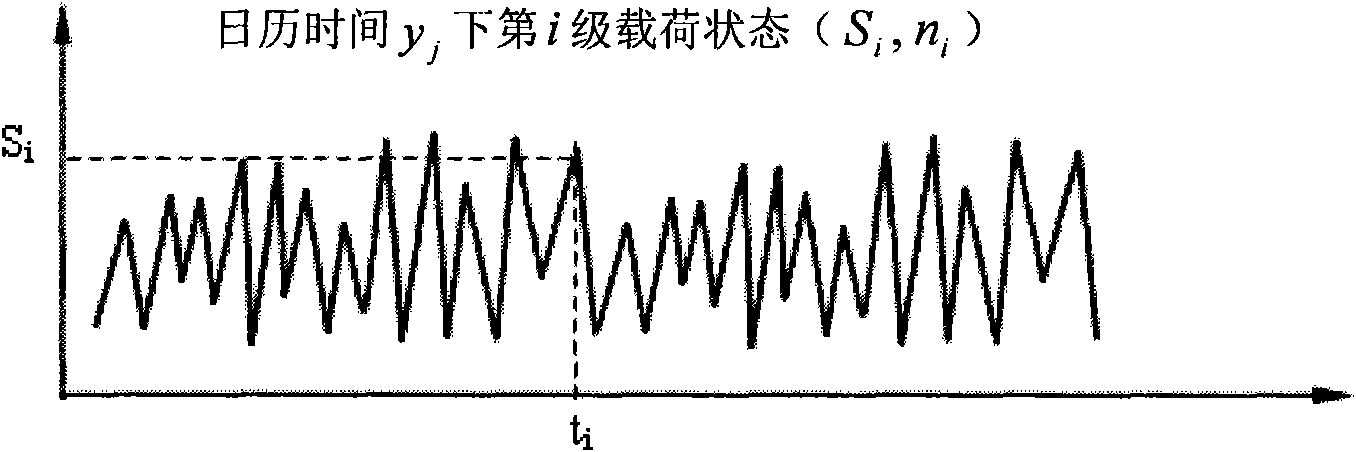

Method for estimating calendar life of aircraft structure

InactiveCN102184326AFew parametersPromote engineering applicationSpecial data processing applicationsFatigue loadingCalendar time

The invention discloses a method for estimating calendar life of an aircraft structure, belonging to the technical field of aircraft life estimation and particularly relating to improvement on the method for estimating the calendar life of the aircraft structure. The method mainly comprises three steps of: 1, compiling a fatigue load spectrum under the condition of considering influence of calendar time; 2, establishing relation between the calendar time and fatigue life; and 3, estimating the calendar life of the structure by using a linear accumulated damage theory. The method has the advantages that: influences of the calendar time and an environmental factor are simultaneously considered during estimation of fatigue life; a load-environment process which is actually suffered by the aircraft structure can be really reflected; a few parameters are required to be determined; and engineering application is facilitated.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

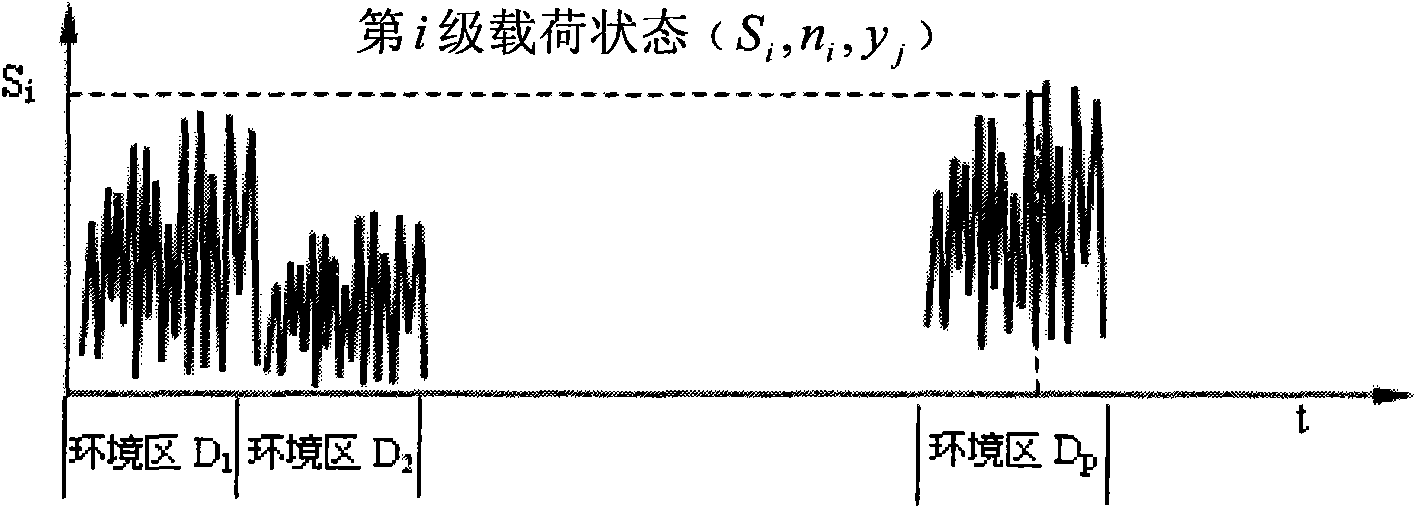

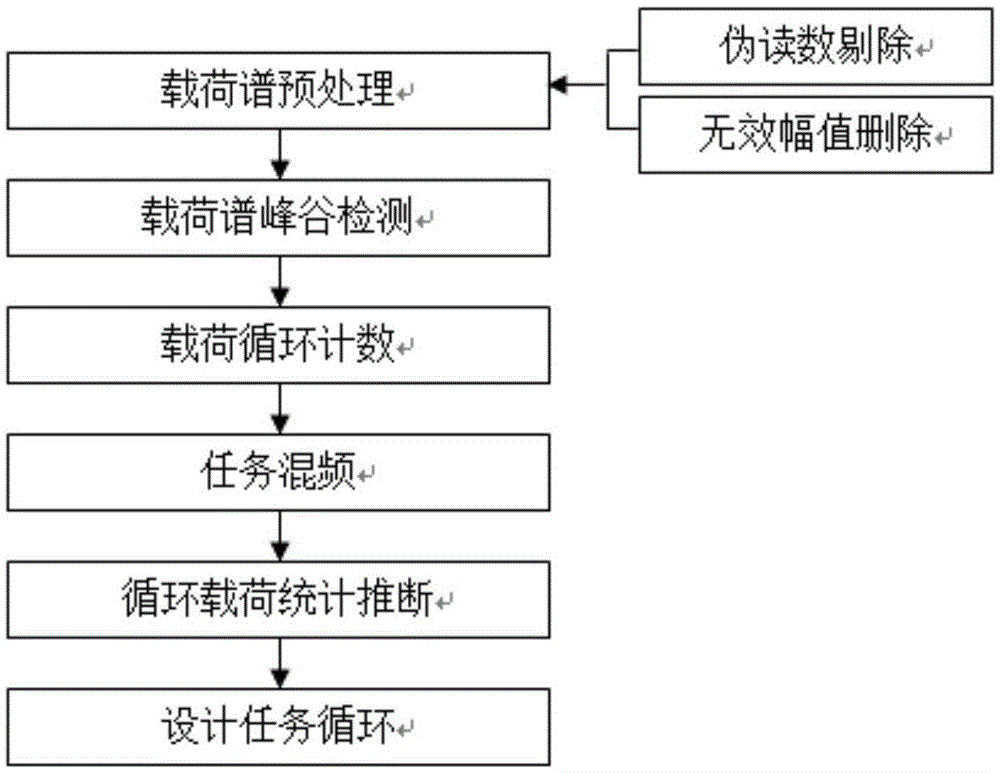

Compilation method for general standard test load spectrum of aero-engine

ActiveCN105574247ASimplify the compilation processLife PredictionGeometric CADEngine testingAviationCompilation error

The invention discloses a compilation method for a general standard test load spectrum of an aero-engine. The method comprises the following main steps: (1) standardizing a mission profile load parameter; (2) generating a mission profile load parameter sequence; (3) generating a load parameter standard test spectrum of a single mission profile of the aero-engine; and (4) compiling the general standard test load spectrum of the aero-engine by frequency mixing of flight missions. The test load spectrum of the aero-engine, compiled with the method, can serve as a main part life test load of the aero-engine; and based on an original aero-engine load spectrum compilation technology, load requirements of an aircraft in all periods and test conditions during actual flight are comprehensively considered. The test load spectrum of the aero-engine, compiled based on the general standard test load spectrum of the aero-engine, can not only really reflect the change of the load parameter of the aero-engine along with the flight time but also simplify a test load spectrum compilation process and improve the working efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for analyzing service life of high maneuverability aircraft base on detail fatigue rating

InactiveCN104809321AEasy to understandEasy to masterSpecial data processing applicationsStrength propertiesStructural reliabilityStress level

The invention belongs to the field of an aircraft fatigue theory and relates to a method for analyzing service life of a high maneuverability aircraft base on detail fatigue rating. The analyzing method comprises the following steps: step1, preparing load spectrum analyzed based on the DFR (detail fatigue rating) of the high maneuverability aircraft; step2, analyzing the reference value of the DFR; step3, calculating the DFR0 value; step4, calculating the fatigue rating coefficient RC of the component; step5, confirming the allowable value [DFR] of the structure DFR; step6, calculating the allowable stress [sigma max]; step7, calculating and assessing the fatigue strength margin; step8, calculating the reliable lifetime of the structure; step9, creating a stress level control curve and providing the allowable stress value of the objective service life. The analyzing method has the advantages that the process of performing fatigue design and service life assessment by the DFR method is relatively simple, the calculation workload is relatively low, the operating efficiency of the whole department can be dramatically improved, and thus the analyzing method has the important significance to shorten the research period of a new machine and to save the research cost, and the economic benefit is obvious.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

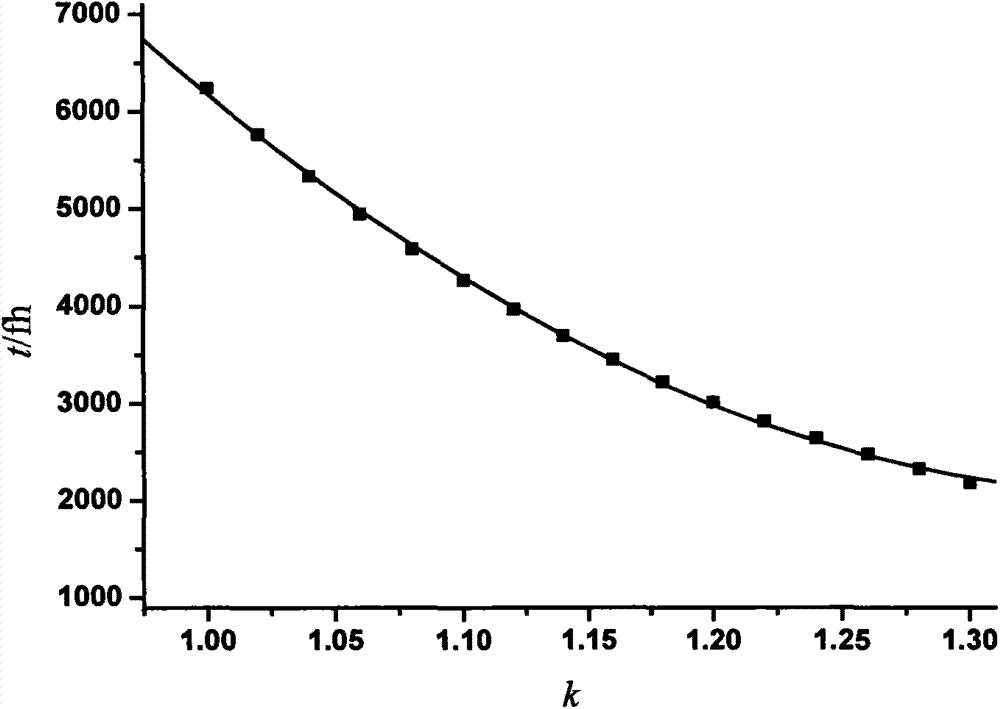

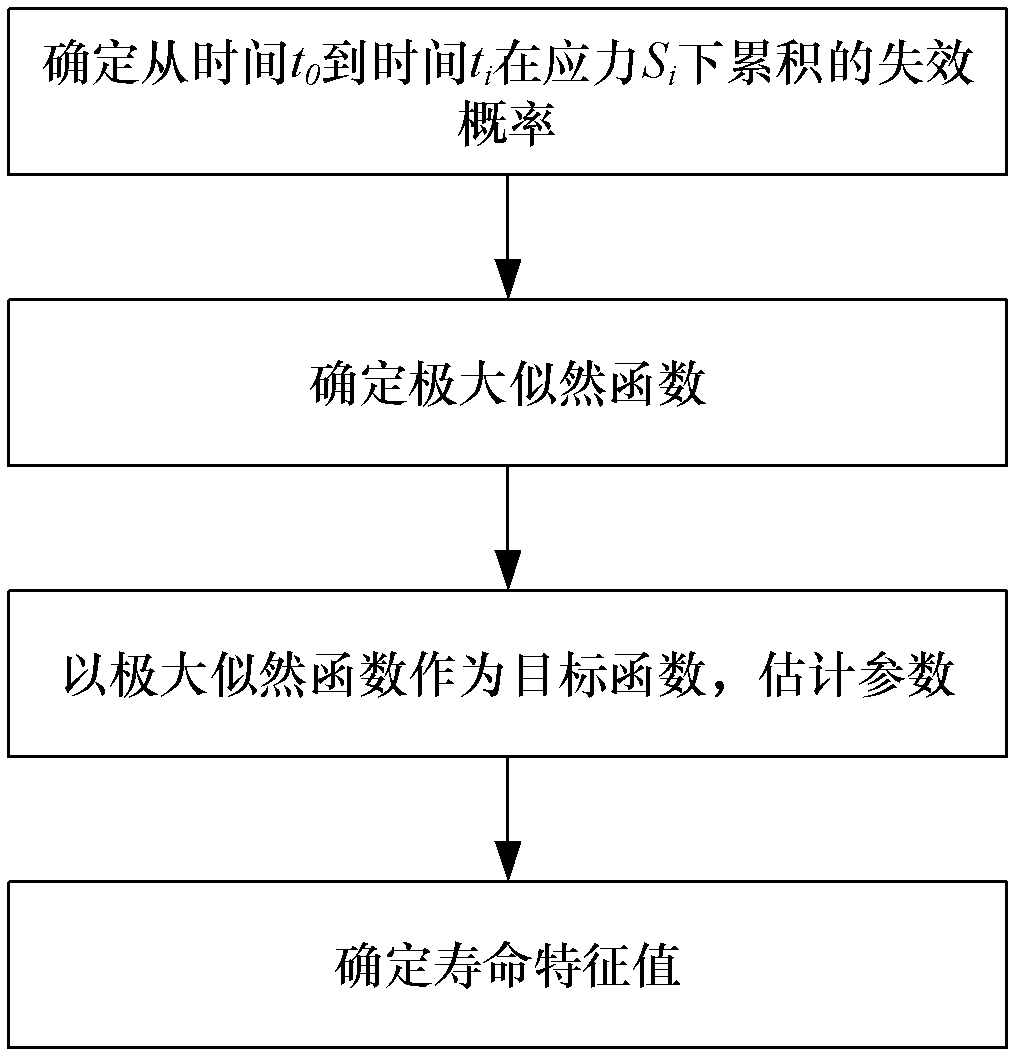

Modeling method for combined stress accelerated life test damage accumulation model of space driving assembly

InactiveCN102509023ALife assessmentSolve the problem of small number of samples in accelerated life testBiological modelsSpecial data processing applicationsStart timeModel method

The invention provides a modeling method for a combined stress accelerated life test damage accumulation model of a space driving assembly and belongs to the field of reliability and service life evaluation of the space driving assemblies. The modeling method comprises the following steps of: carrying out an accelerated lift test on the space driving assembly with a main fault mode as fatigue by adopting combined stress; analyzing test data to determine the failure probability accumulated under the stress from start time t0 to time ti; then determining a combined stress acceleration model of a failure sample and a truncated sample to obtain a maximum likelihood function of the acceleration model; and finally, estimating relevant parameters in the model to obtain a final acceleration model, wherein a life value under any load spectrum can be determined according to a generalized Eyring model. The modeling method disclosed by the invention is suitable for the combined stress accelerated life test of the space driving assembly; and according to the modeling method, test time can be shortened; test expenses are saved; a test sample and the truncated sample subjected to a conventional life test can be effectively utilized; and the life of the space driving assembly can be evaluated accurately.

Owner:BEIHANG UNIV

Method for rapidly and nondestructively prediction of residual strength and residual lifetime

InactiveCN101231222APredictive science and accuracyStrength propertiesResidual strengthPredictive methods

The invention discloses a method for predicting the residual intensity and the residual service life rapidly and intactly, comprising the following steps that: firstly, the stress-service life curve of a material or a part, i.e. the S-N curve, is measured; secondly, the corresponding relation between the surface hardness and the residual intensity of the material or the part under a random load spectrum of reinforcing, damaging and considering small load strengthening is established; thirdly, the surface hardness in the process of using the material or the part is measured, according to the corresponding relation between the surface hardness and the residual intensity of the material or the part, the residual intensity of the material or the part is predicted rapidly and intactly; forthly, the residual service life of the material or the part under the different load spectrum is predicted rapidly and intactly by adopting the predicted residual intensity and the stress-service life curve of the material or the part, that is the S-N curve. The rapid and intact prediction of the residual intensity and the residual service life of the material or the part can be realized by the simple measurement of the surface hardness by adopting the method.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

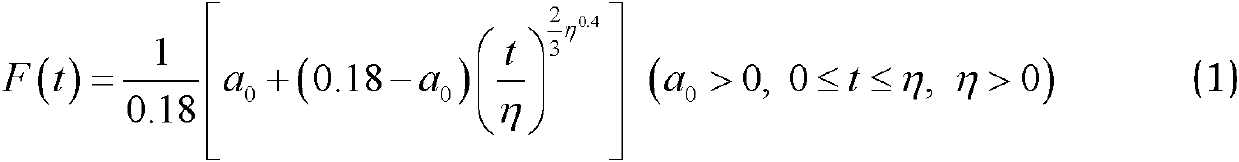

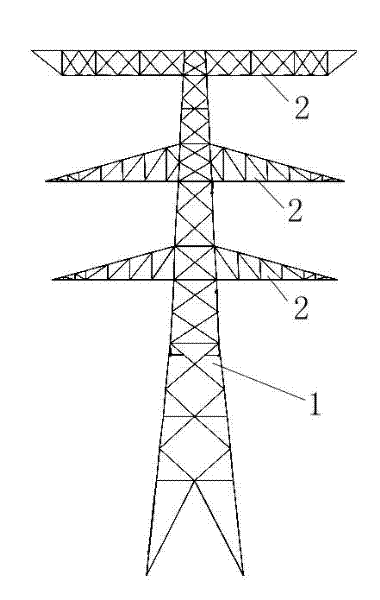

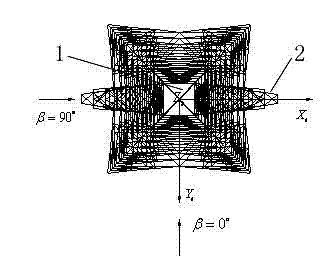

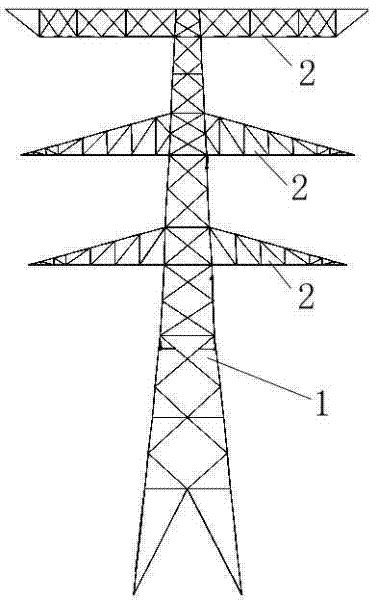

Three-dimensional wind-resistant design method for power transmission tower

InactiveCN102609579AEnsure safetyGuaranteed economyTowersSpecial data processing applicationsRigid modelEstimation methods

A three-dimensional wind-resistant design method for a power transmission tower includes the steps: carrying out a rigid model balance force measurement wind tunnel test by means of increasing and decreasing components of cross arms, and measuring shape coefficients of a power transmission tower body with the overlong cross arms and all direction wind angles of the cross arms; and obtaining wind load cross-power spectrums, based on a base response force spectrum, of a downwind direction, an across-wind direction and a reversing direction of each node by means of a height sectioning estimation method of power transmission tower node wind load spectrums, and obtaining three-dimensional equivalent node wind load directly used for power transmission tower wind-resistant design by the aid of a load-response correlation method based on the node wind load cross-power spectrums. The three-dimensional wind-resistant design method for the power transmission tower takes the influence of different wind direction angles on the shape coefficients into consideration, truly measures shape coefficient values of the overlong cross arms serving as special components, breaks through normative limitations, and takes full account of characteristics of the power transmission tower with the overlong cross arms, wind induced response of the power transmission tower in the downwind direction is calculated, and simultaneously wind induced response of the power transmission tower in the across-wind direction and the reversing direction is calculated, so that safety, economy and reliability in design of the power transmission tower with the overlong cross arms are guaranteed.

Owner:STATE GRID CORP OF CHINA +2

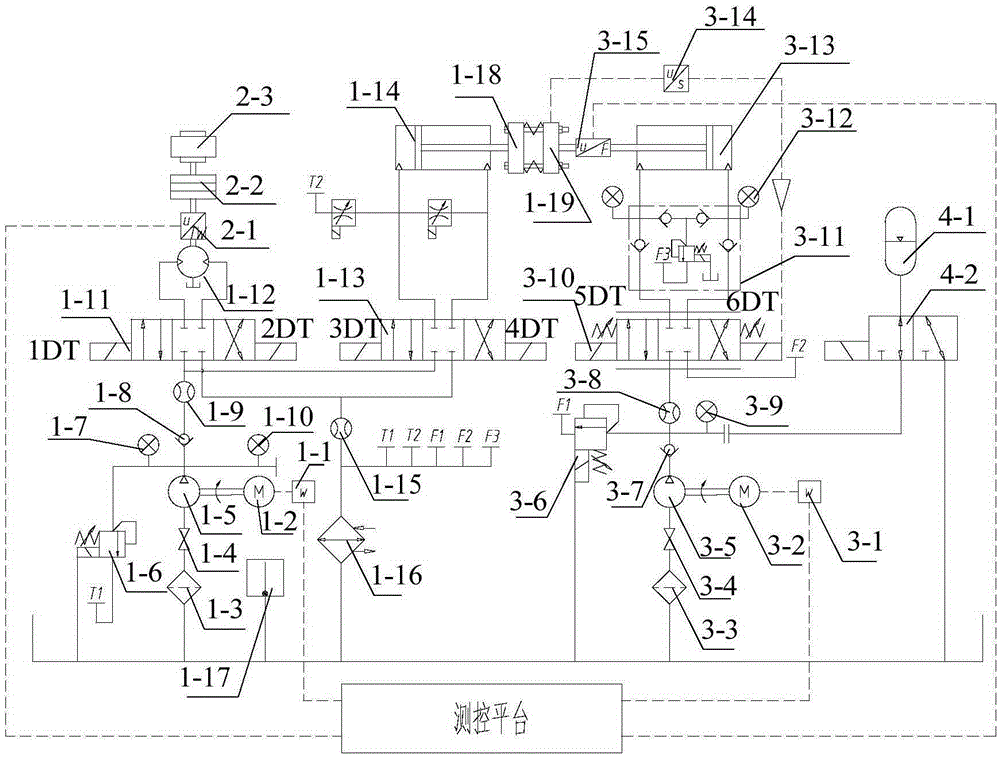

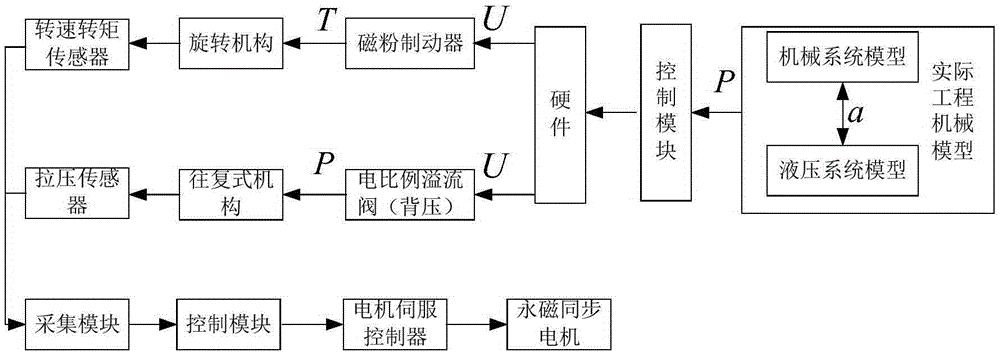

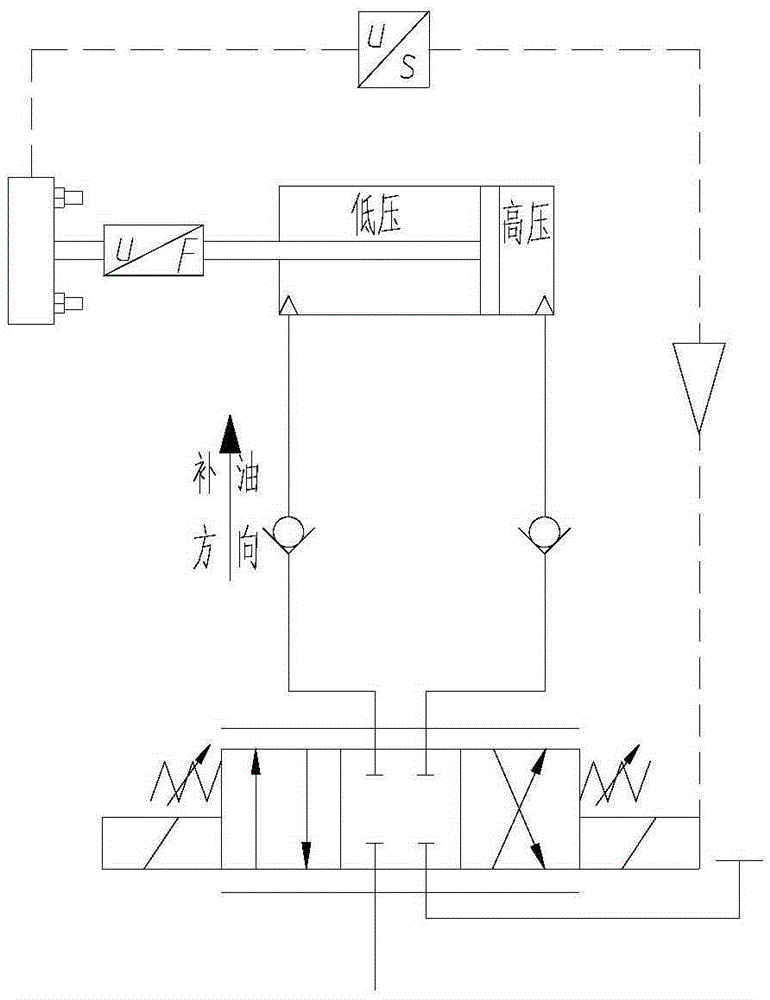

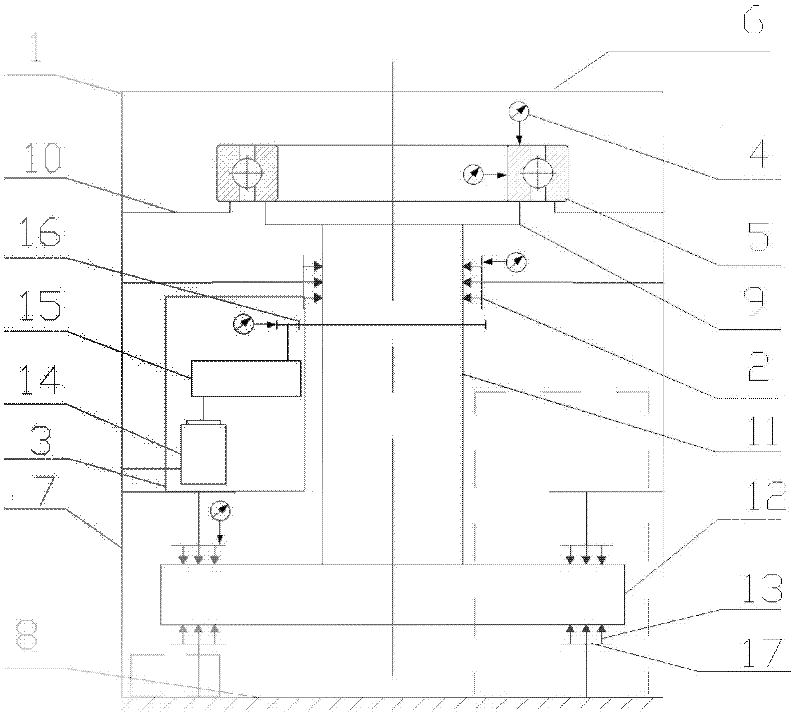

Experiment platform and experiment method for virtual loading and controlling of engineering mechanical work conditions

ActiveCN105298991AGuaranteed uptimeEasy for secondary developmentFluid-pressure actuator testingMechanical modelsPermanent magnet synchronous motor

The invention discloses an experiment platform and an experiment method for virtual loading and controlling of engineering mechanical work conditions. The experiment platform comprises a movable support, an oil tank, a driving hydraulic loop, a reciprocating loading loop, a rotary loading system and an experiment platform measuring and controlling system. The measuring and controlling system is internally provided with various engineering mechanical models, load spectrums in the operation process of the measuring and controlling system are converted into electric signals through an industrial personal computer to be output to an electromagnetic proportional overflow valve in a reciprocating loading loop or a magnetic powder brake in the rotary loading system through practical working condition simulation, and therefore force and torque loading of a hydraulic cylinder or a hydraulic motor in the driving hydraulic loop is achieved. Closed-loop rotation speed control is conducted on a permanent magnet synchronous motor of a driving system with the combination of running states of a system, and pressure and flow in the system are adjusted. According to the experiment platform and the experiment method for the virtual loading and controlling of the engineering mechanical work conditions, development of the experiment platform in a laboratory environment with the combination of the engineering practice is achieved, the practical engineering significance is achieved, operation is convenient, and the secondary development capacity is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

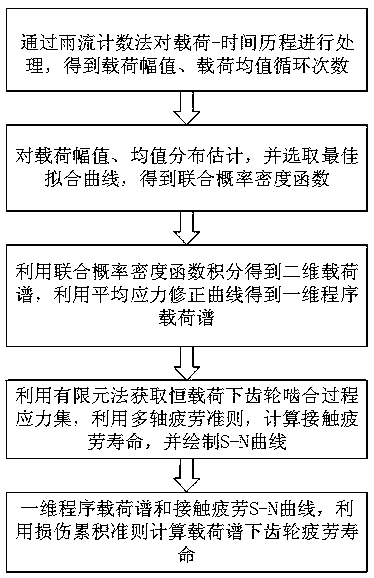

Gear contact fatigue life prediction method based on load spectrum

ActiveCN110147624AImprove accuracyImprove efficiencyGeometric CADDesign optimisation/simulationFatigue damageConstant load

The invention discloses a gear contact fatigue life prediction method based on a load spectrum. The gear contact fatigue life prediction method comprises the following steps: 1, compiling a load spectrum for limited load-time history obtained by measurement, and performing function fitting on the load of the whole life cycle by utilizing a parameter extrapolation method through a statistical result of a rain flow counting method to obtain a two-dimensional load spectrum of the whole life cycle; 2, converting the two-dimensional load spectrum into a one-dimensional load spectrum; 3, simulatingthrough a finite element method to obtain a time-varying stress-strain process of the gear, predicting the contact fatigue life under a constant load by combining a multi-axis fatigue criterion, and drawing the contact fatigue S-N curve of the gear; 4, calculating the contact fatigue life of the gear under the load spectrum according to the Palmgmn-Miner fatigue damage accumulation criterion. Themethod has the advantages that the accuracy of predicting the contact fatigue life of the gear is improved, the test cost is saved, and the efficiency is improved.

Owner:CHONGQING UNIV

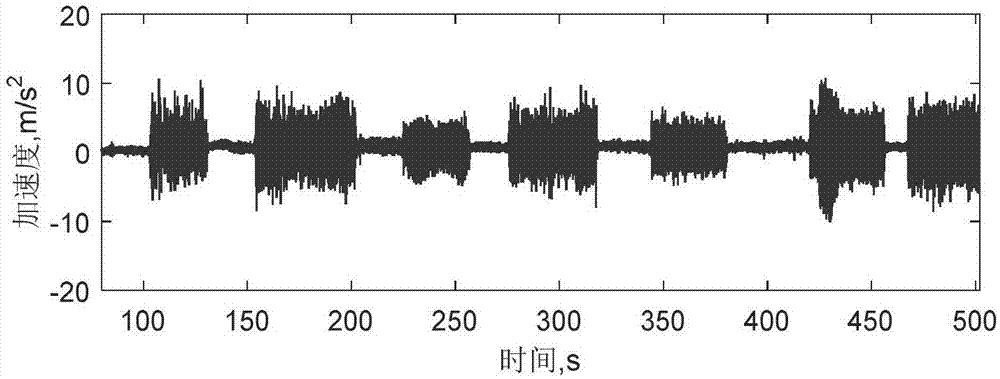

Electric automobile battery pack random vibration fatigue acceleration method based on real road spectrum

InactiveCN108036908AGuaranteed accuracyStrong engineering practicabilityVibration testingShock testingFatigue damageCar driving

The invention discloses an electric automobile battery pack random vibration fatigue acceleration method based on a real road spectrum. The method comprises the steps of (1) acquisition and analysis of the road load spectrum; (2) calculation of full life circle fatigue damage spectrum of the battery pack; and (3) formation of battery pack vibration fatigue acceleration (laboratory standard). Electric automobile battery pack laboratory stand vibration fatigue acceleration is performed for different installing positions of different automobile battery packs according to the actually measured road spectrum of the electric automobile driving so that the problem of single evaluation standard can be solved, and the China's electric automobile operation condition can be further met on the basis of the domestic road condition and the battery manufacturing level of the domestic enterprise.

Owner:开沃新能源汽车集团股份有限公司

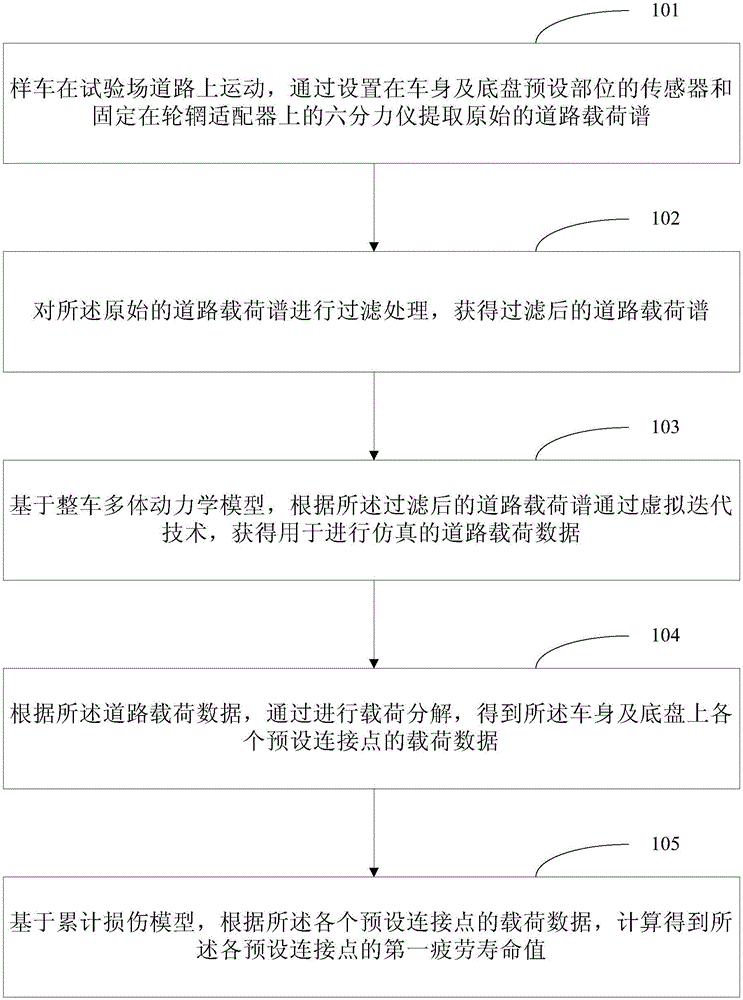

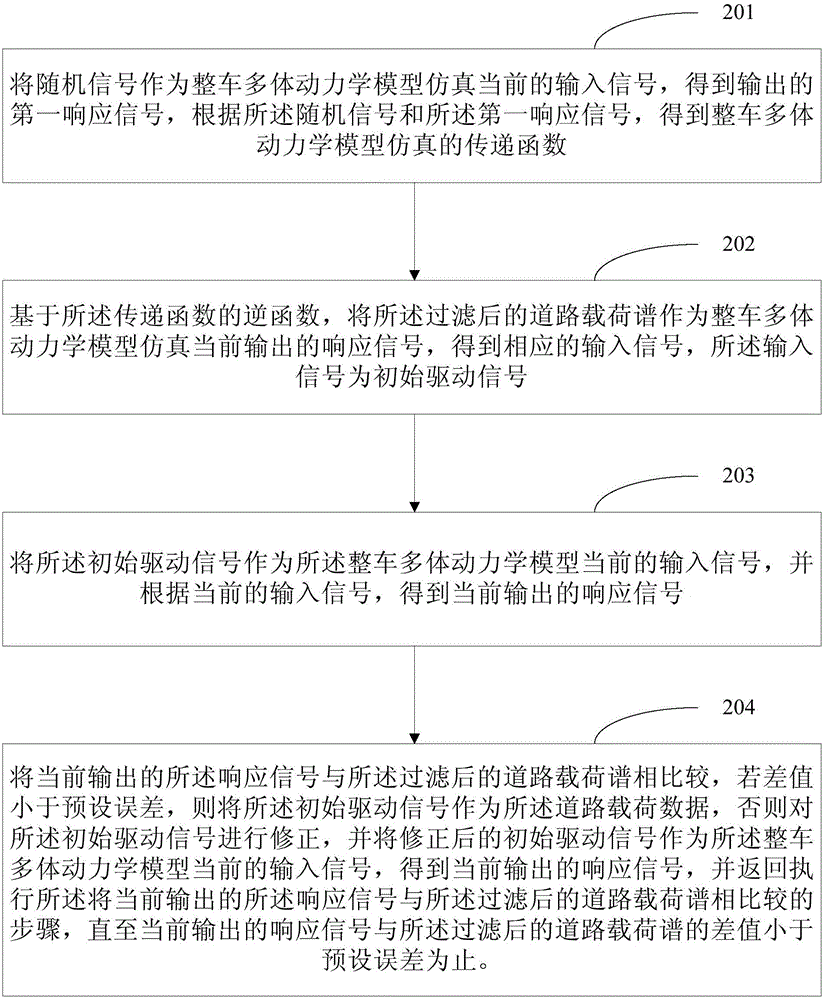

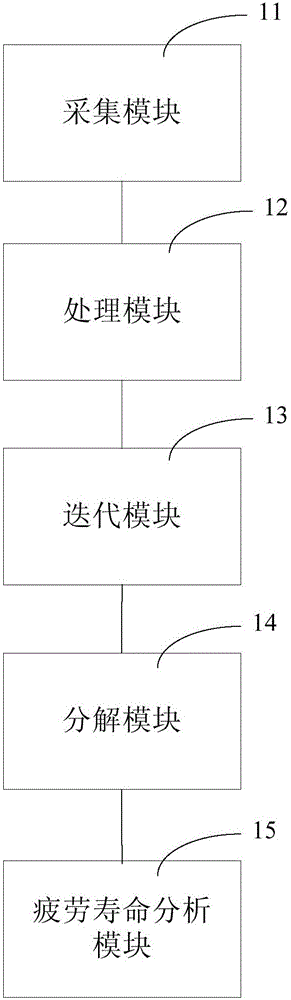

Road load test method and system

ActiveCN105092261AAccurate Fatigue Life PredictionImprove fatigue durabilityVehicle testingIn vehicleDecomposition

The invention discloses a road load test method and system. The method comprises the steps of: with a sample vehicle running on roads on a test site, extracting an original road load spectrum; filtering the original road load spectrum, and obtaining the road load spectrum which has been filtered; based on a multi-body dynamics automobile model and in accordance with road load spectrum which has been filtered, obtaining the road load spectrum for carrying out the simulation through virtual iteration technology; through load decomposition, obtaining load data at each preset connection point of the vehicle body and a chassis; and based on the load data, calculating a first fatigue endurance value of each preset connection point. The method can obtain the actual original road load spectrum on different test sites, and based on the actual original road load spectrum, can calculate the fatigue life value, and can further predict a more accurate fatigue life of the vehicle, which can effectively increase the fatigue endurance of the vehicle body and provide the effective basis for the optimization and improvement of a vehicle structure in vehicle design.

Owner:BAIC MOTOR CORP LTD

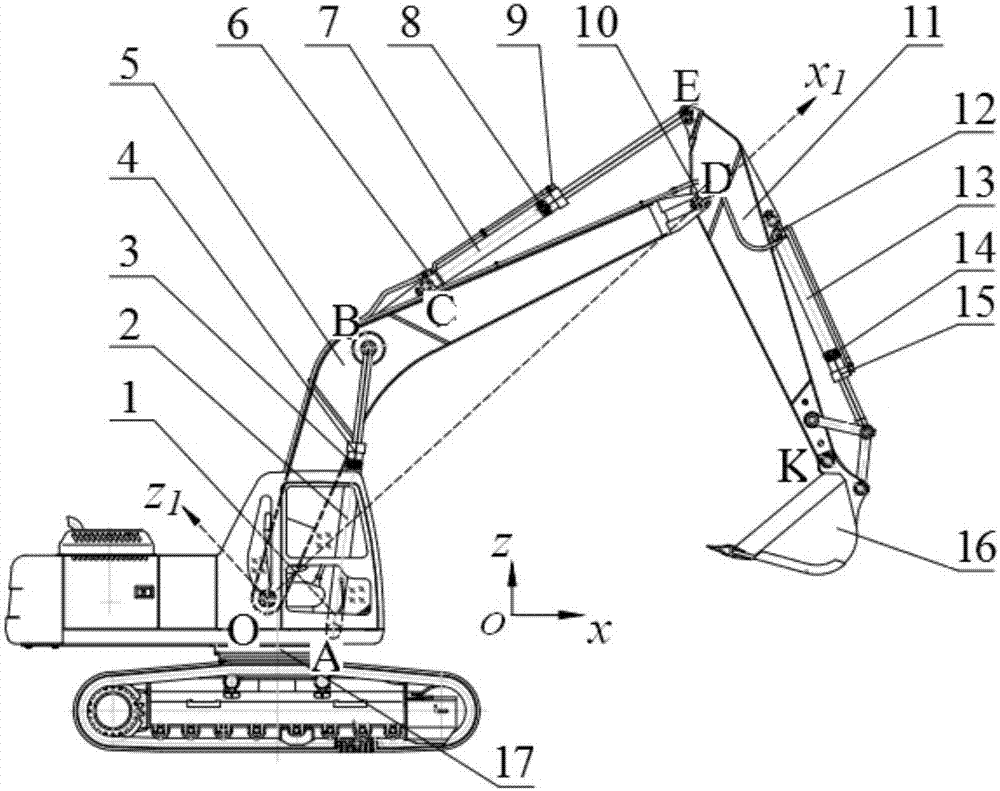

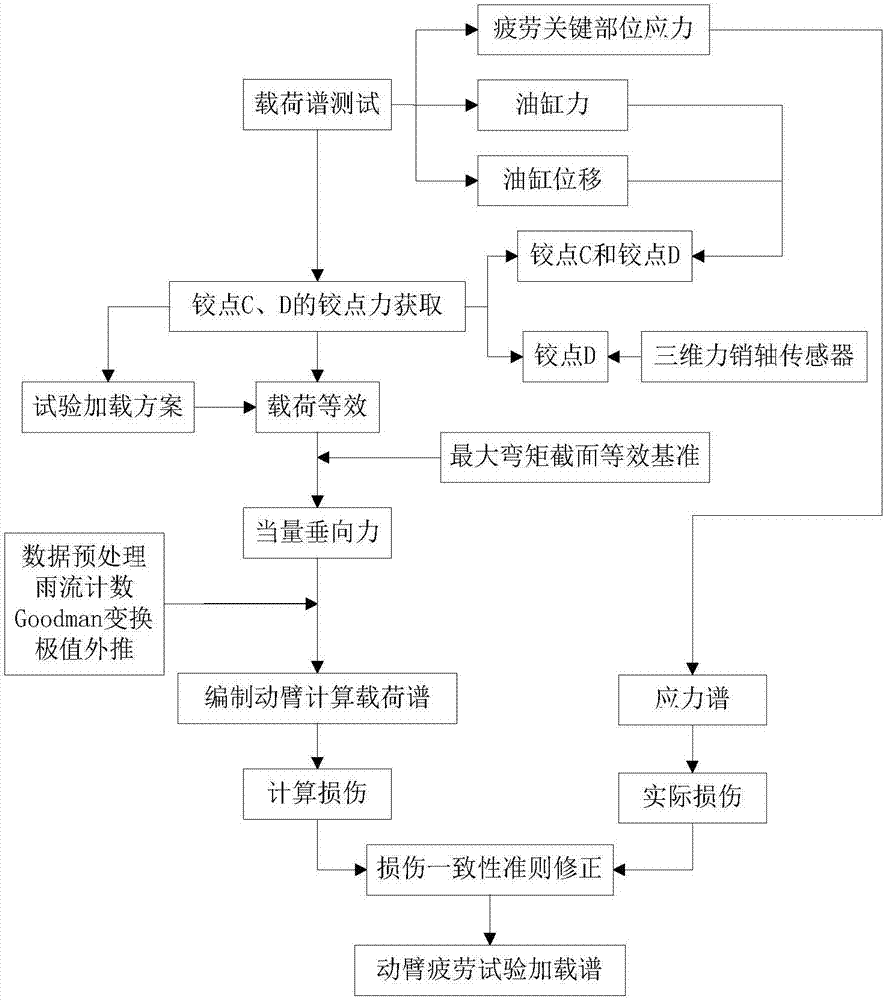

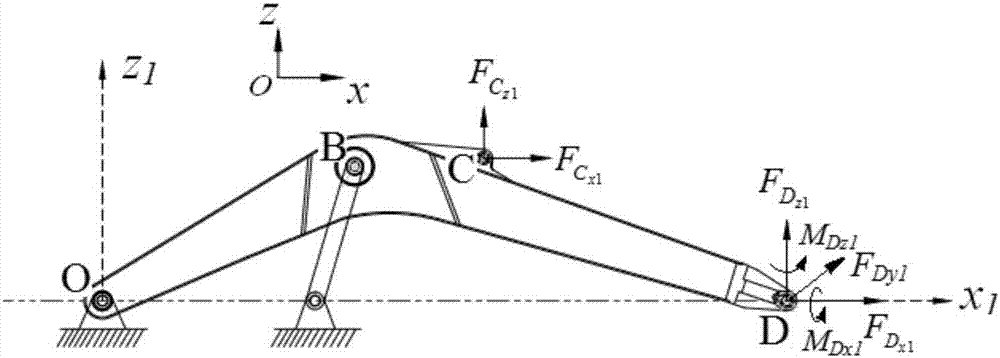

Excavator's boom fatigue test program spectrum managing and test loading method

ActiveCN106885691AAvoid experimental errorImprove test accuracyMachine part testingStress measuresEngineering

The invention discloses an excavator's boom fatigue test program spectrum managing and test loading method. The method comprises the concrete processes of 1, preparing basic data for compiling a load spectrum; 2, determining an excavator's boom fatigue test loading scheme; 3, taking the maximum bending moment of the boom as the load equivalent basis, and calculating the equivalent vertical load; 4, compiling the equivalent vertical force-time history into a boom calculation load spectrum; and 5, adopting the damage consistence principle at the fatigue key part stress measuring point to correct the calculation load spectrum, and finally obtaining the boom fatigue test program spectrum. The method is based on the actually-measured load, simplifies the fatigue test and represents the actual stress state of the boom to the greatest extent.

Owner:CHANGAN UNIV

A Large Bearing Test Bench with Static Pressure Loading and Closed Structure

ActiveCN102288410AIncrease stiffnessReduce volumeMachine bearings testingReduction driveControl system

The invention belongs to the technical field of bearing test and relates to a bearing test table, which consists of four parts, namely a closed mechanical structure, a hydrostatic loading system, a driving system and a measurement and control system, wherein the closed mechanical structure consists of a test bearing, a test table end cover, a connecting part, a vertical column, a base and the like, and a loading disk, the test bearing, the end cover, the vertical column and the base form an internal closed structure; the hydrostatic loading system realizes radial loading, axial loading and overturning moment loading by an axial loading seat and an oil cylinder and a radial loading seat and the oil cylinder and performs application according to a test bearing load spectrum; a motor, which is fixed on the base, of the driving system drives the loading disk and the test bearing to rotate by a speed reducer and a driving gear; and the measurement and control system comprises a sensor, a computer, a control cabinet, the sensor, an actuator and the like. By using a floating hydrostatic loading technology, the influence of a test table bearing on the performance data of the test bearing is reduced. The test table is high in rigidity, small in volume and low in cost.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com