Multivariable support vector machine prediction method for aero-engine rotor residual life

An aero-engine and support vector machine technology, which is used in the testing of mechanical components, the testing of machine/structural components, and measuring devices, etc., can solve problems such as difficult prediction problems, high costs, and complex service conditions of aero-engine rotors.

Active Publication Date: 2013-07-24

XI AN JIAOTONG UNIV

View PDF6 Cites 36 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When studying a certain phenomenon or predicting a certain change, it is necessary to observe and record multiple indicators at the same time, and comprehensively predict the development of the whole thing according to the change law of multiple variables and the interdependence between variables. However, the traditional multivariate forecasting method deals with small The problem of forecasting under sample conditions still has some difficulties

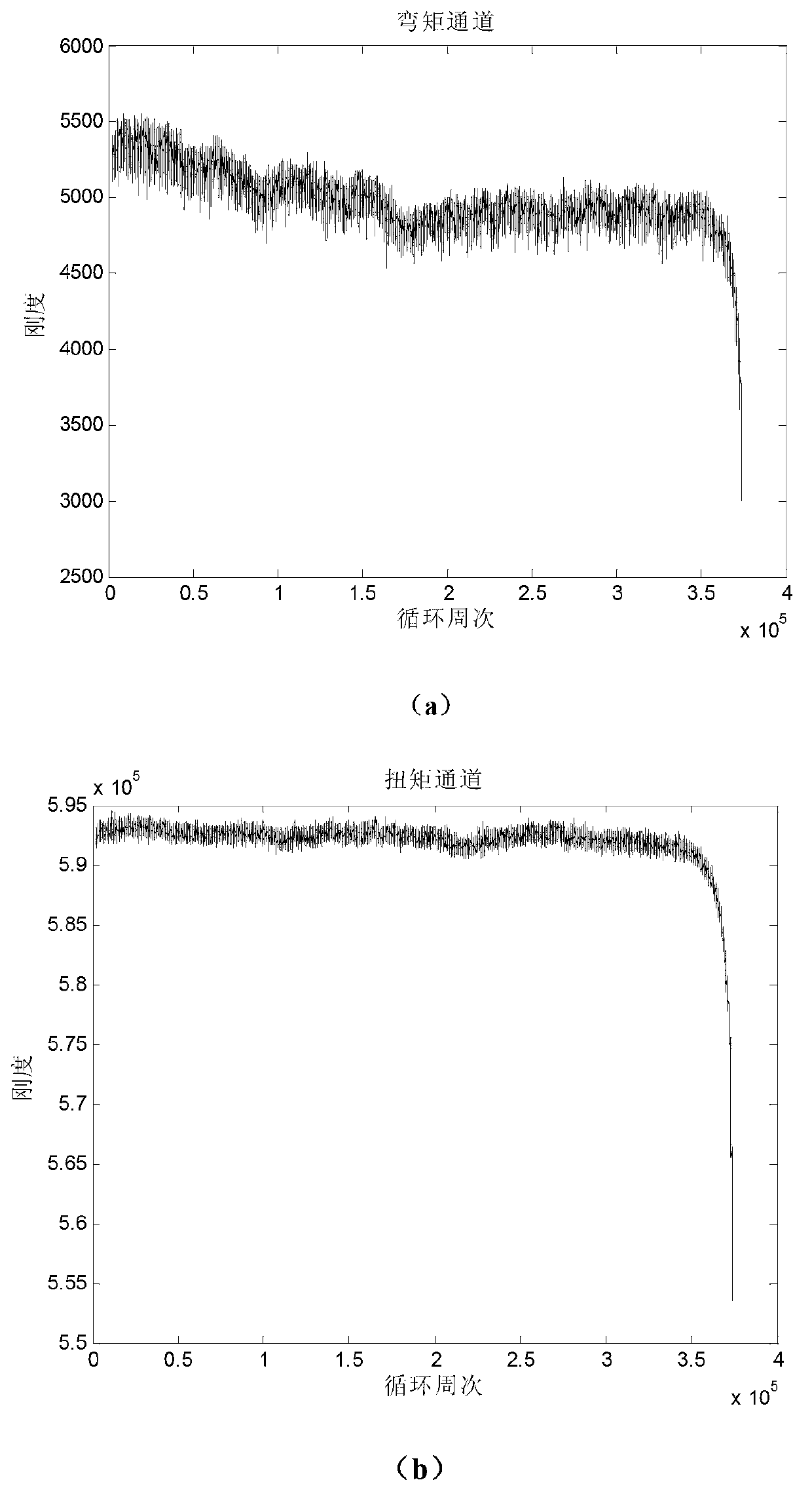

The service conditions of aero-engine rotors are complex, and its fatigue damage is a problem affected by various factors, and it becomes a small-sample problem due to the limitations of long test period and high cost. Therefore, it is necessary to develop a life prediction method for aero-engines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

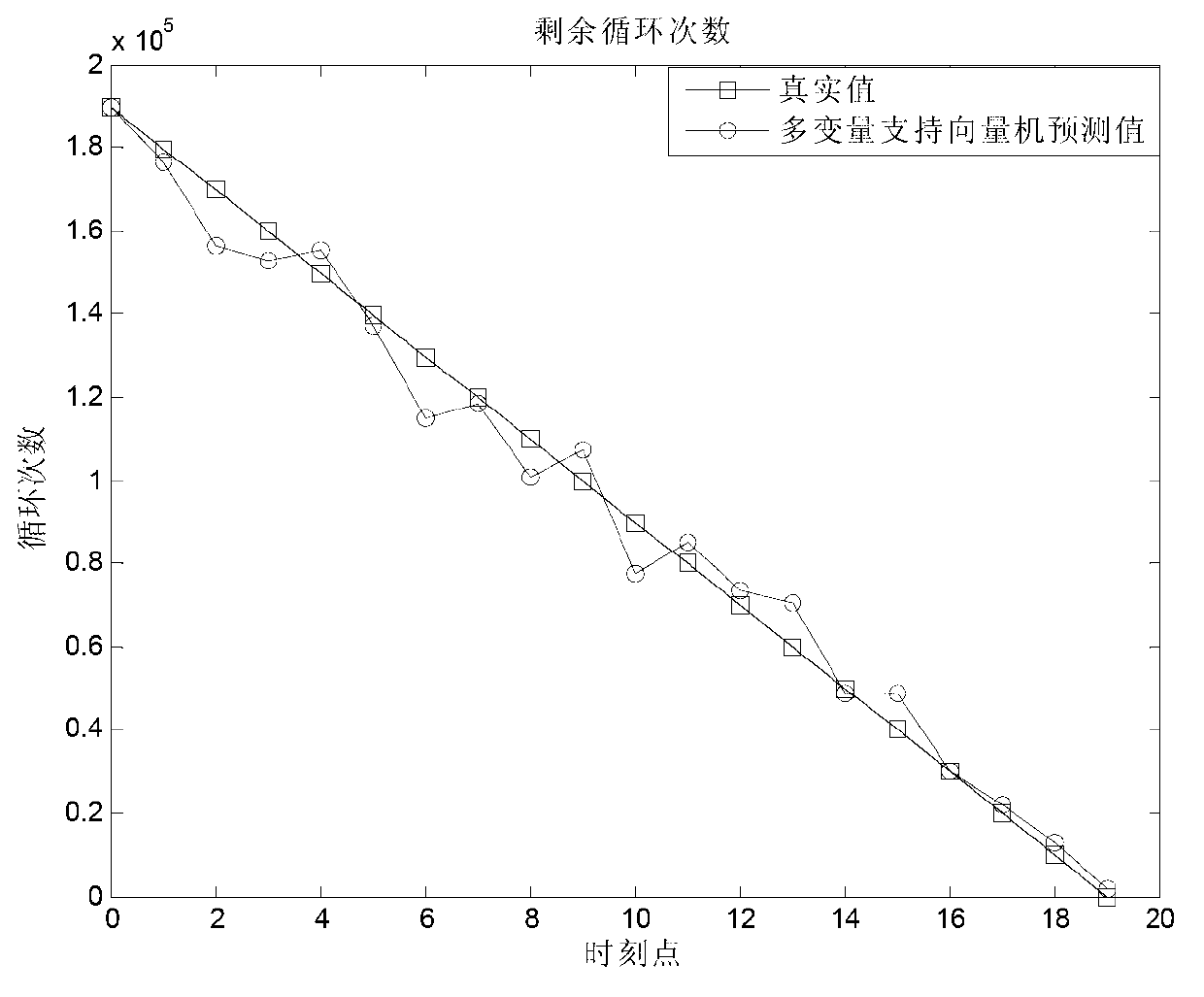

[0074] This embodiment provides the specific implementation process of the present invention in the test piece test of the rotor of an aero-engine, and at the same time verifies the effectiveness of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

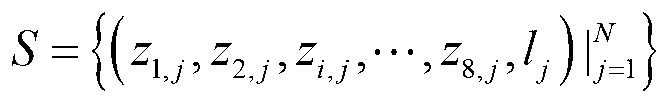

The invention provides a multivariable support vector machine prediction method for aero-engine rotor residual life. According to the method, service time, a load spectrum, rotation speed and vibration signal characteristics of an aero-engine rotor are selected to be as input parameters of a life prediction model. A multivariable support vector machine prediction model for the residual life is established based on a multivariable prediction method, sample parameters are input to the model to be trained and then output, and prediction for the residual life of the aero-engine rotor is achieved under a small sample condition. The method is simple and practical, reliable in result, good in instantaneity and is suitable for quantitatively calculating the residual life of the aero-engine rotor under the small sample condition.

Description

technical field [0001] The invention belongs to the field of life prediction, and in particular relates to a multivariate support vector machine prediction method for the remaining life of an aeroengine rotor. Background technique [0002] At present, all countries and major airlines in the world attach great importance to the research of aero-engine safety technology. Various models of Boeing and Airbus aircraft are equipped with a complete condition monitoring and fault diagnosis system, with an average of 15 monitoring parameters. Although condition monitoring and fault diagnosis systems are relatively common in the analysis of aero-engines, in-flight parking accidents caused by fatigue cracks and bearing failures have emerged in an endless stream. Therefore, in-depth research on the expansion of rotor cracks and the realization of rotor condition monitoring and remaining life prediction can lay a solid theoretical foundation for improving the safety and reliability of a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M13/00

Inventor 陈雪峰罗腾蛟辛伟何正嘉

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com