Motorized spindle accelerated life testing time design method

A technology of accelerated life test and design method, applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems of lack of test data, slow failure of samples, large sample size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

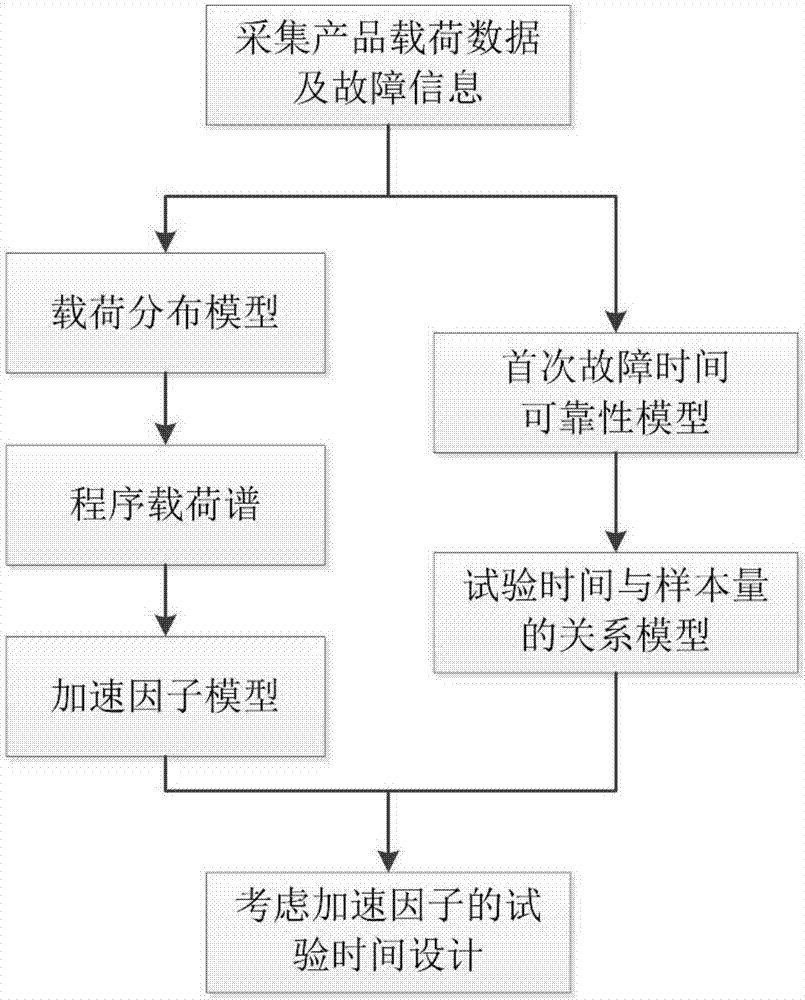

Method used

Image

Examples

Embodiment

[0146] Taking a certain type of electric spindle as an example, combined with the reliability data collected during the operation of the enterprise, the cutting load spectrum of the electric spindle was analyzed and established, and the accelerated life test acceleration factor was evaluated based on the revised Miner theory.

[0147] The following takes milling as an example to expand the calculation, and its load spectrum obeys the two-parameter Weibull distribution of m=0.782, η=0.105, that is, the distribution function of the relative number of cycles is The program load spectrum is constructed based on the classification of light load, light medium load, medium load, medium heavy load, and heavy load, as shown in Table 1.

[0148] Table 2-1 Load spectrum of electric spindle milling program

[0149]

[0150] If the material coefficient of the main shaft is m=2.94, then α=0.85m=2.5. test damage factor statistic

[0151] Similarly, the actual damage factor statistics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com