Real road spectrum based electric automobile battery pack structure fatigue life prediction method

A fatigue life prediction, electric vehicle technology, applied in the testing of machine/structural components, vehicle testing, measuring devices, etc., can solve the problem that the real load spectrum of the battery pack structure cannot be obtained, to ensure accuracy and engineering practicability Strong, low-computation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

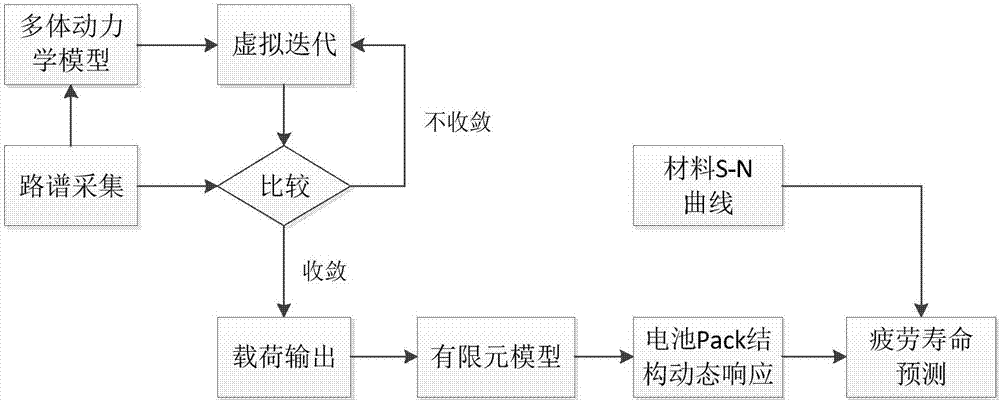

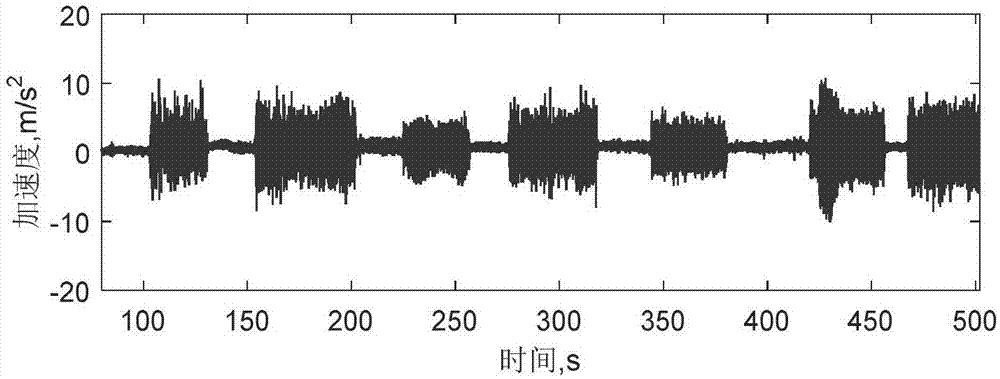

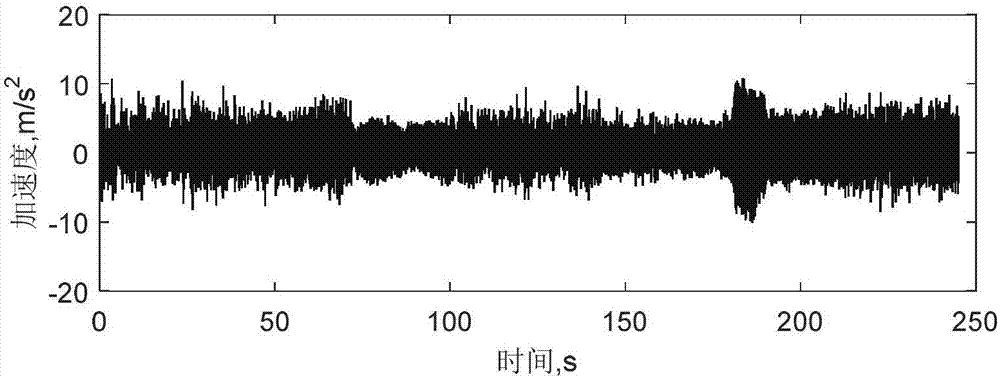

[0032] The structural failure of the battery pack is mostly caused by structural fatigue, that is, during the normal driving of the electric vehicle, the battery pack is subjected to cyclic alternating loads, and the stress level is low, usually lower than the structural yield limit, and eventually the structural fatigue fails due to the accumulation of fatigue damage. From the analysis of the excitation source, the battery pack mainly bears the random vibration load from the ground. For this type of random load, it is very beneficial to use the vibration fatigue analysis method to analyze and predict the fatigue life of the battery pack structure. Only the PSD (power spectral density) of the response is used to avoid the huge amount of calculation of the transient analysis. This method uses the transfer function between the input load signal and the dynamic stress of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com