Patents

Literature

140 results about "Yield limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yield limit - Point which signifies the start of plastic deformation. But this does not signify the end of limit of elastic deformation. End of elastic limit is signified by elastic limit. Thus, there is a small elasto plastic region between the elastic and yield limit where deformation is neither true elastic nor true plastic.

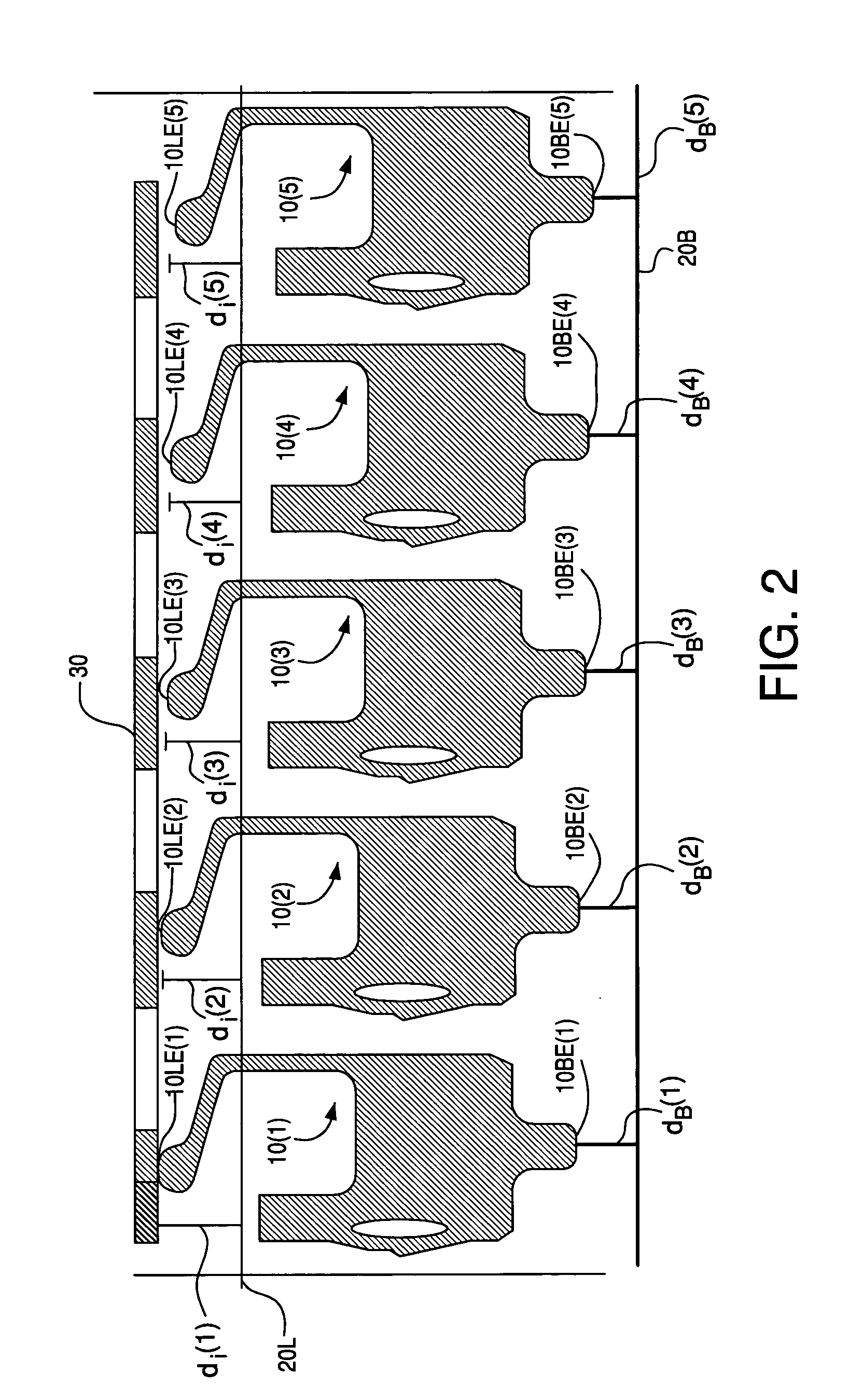

Multidimensional Process Corner Derivation Using Surrogate Based Simultaneous Yield Analysis

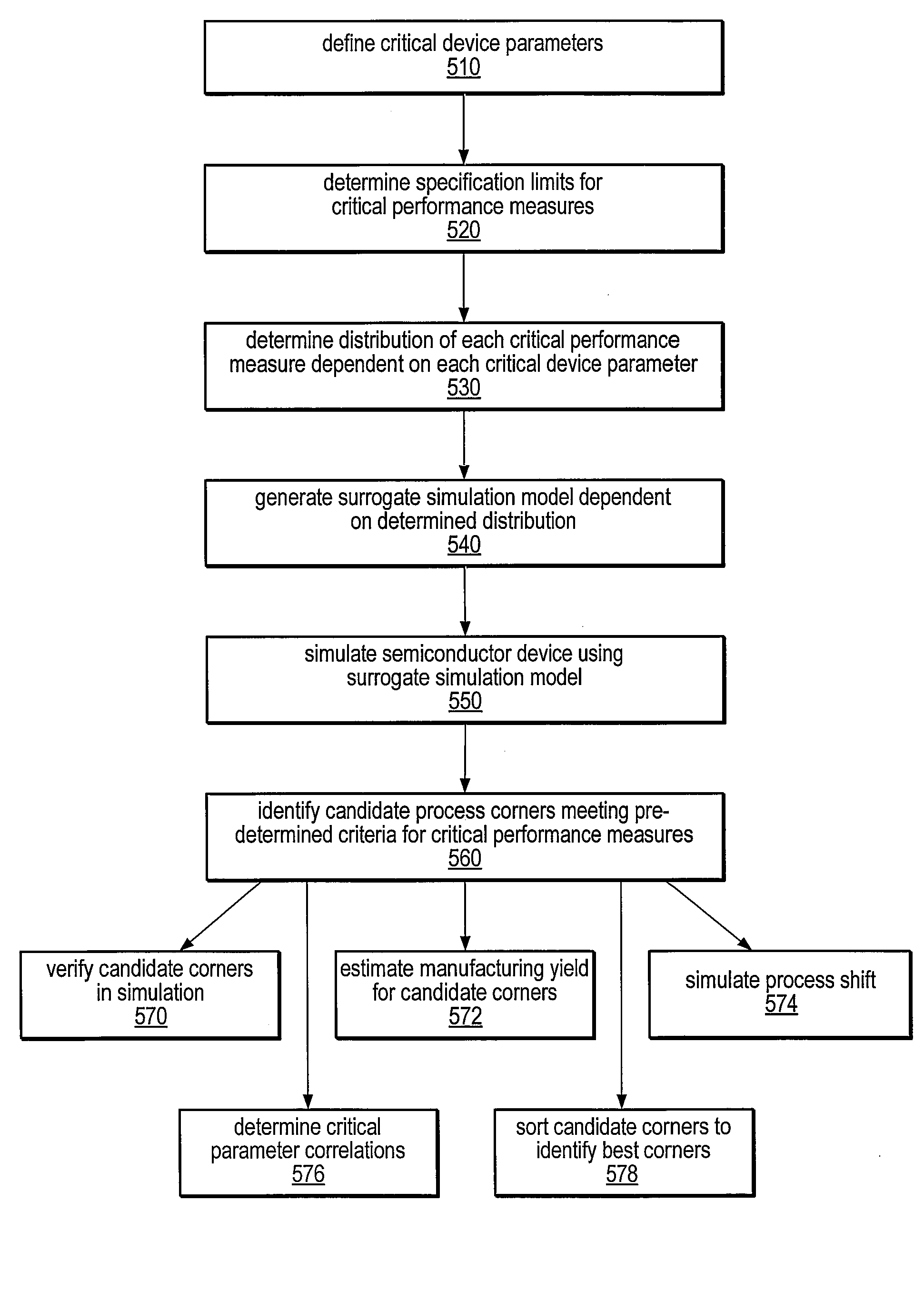

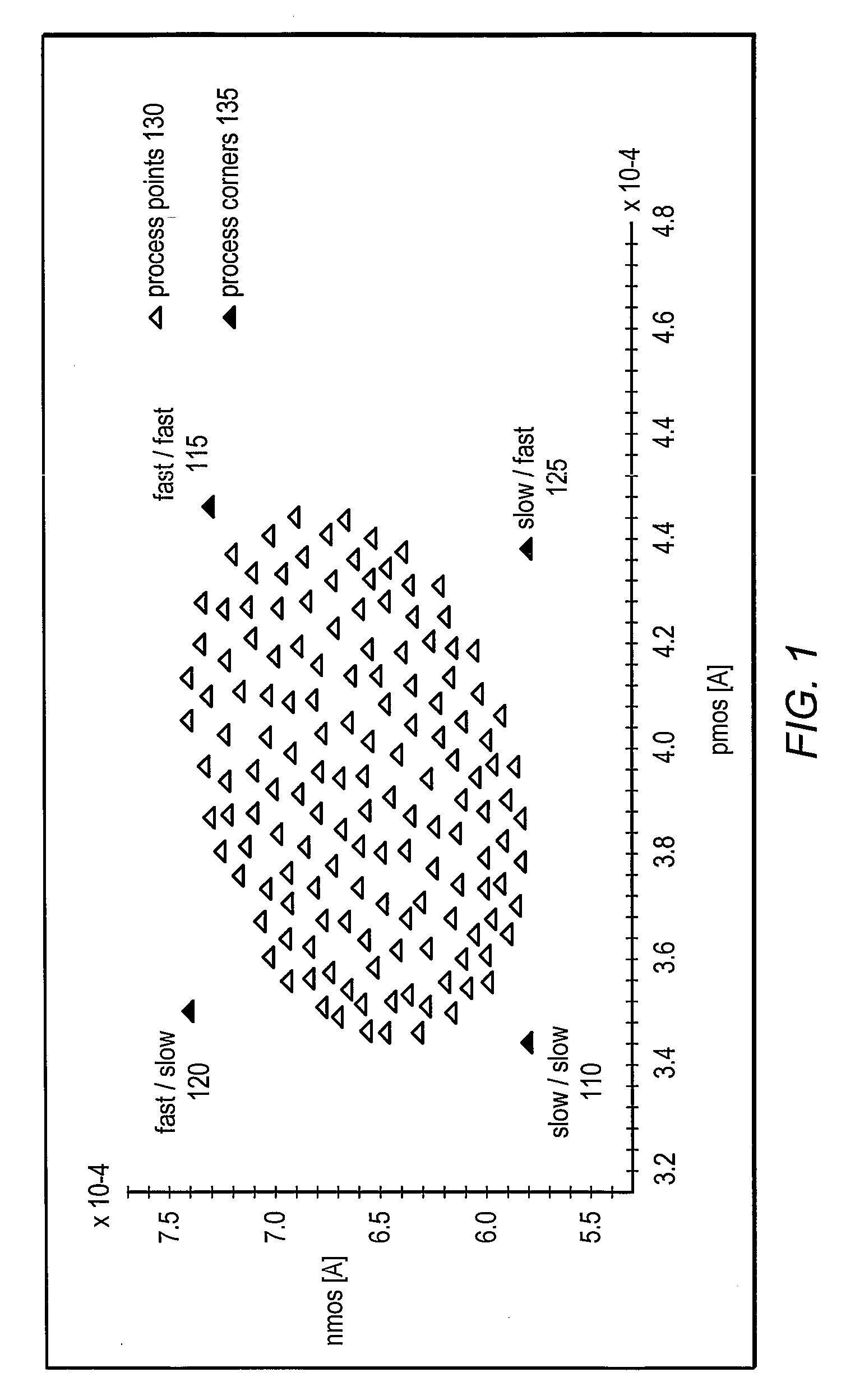

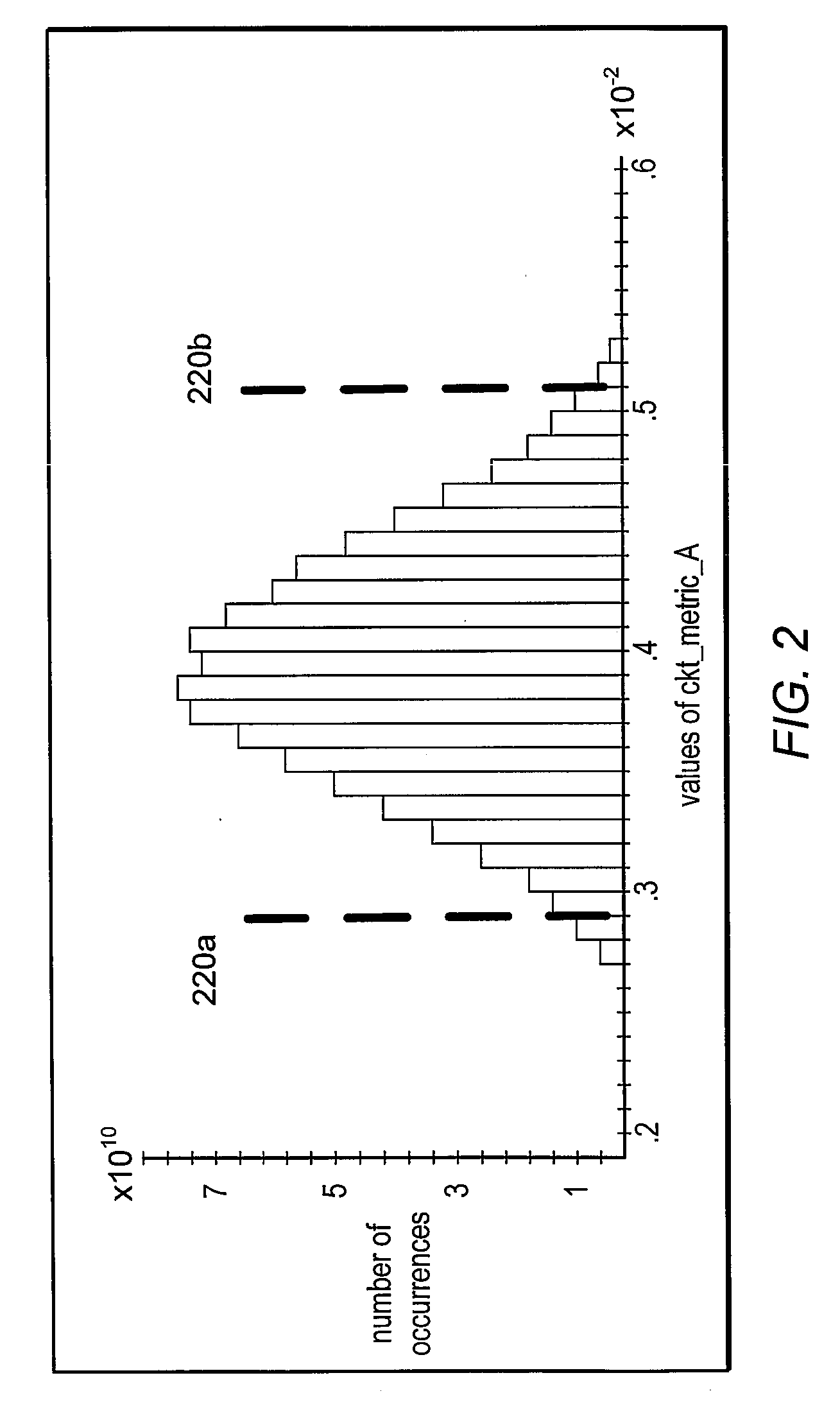

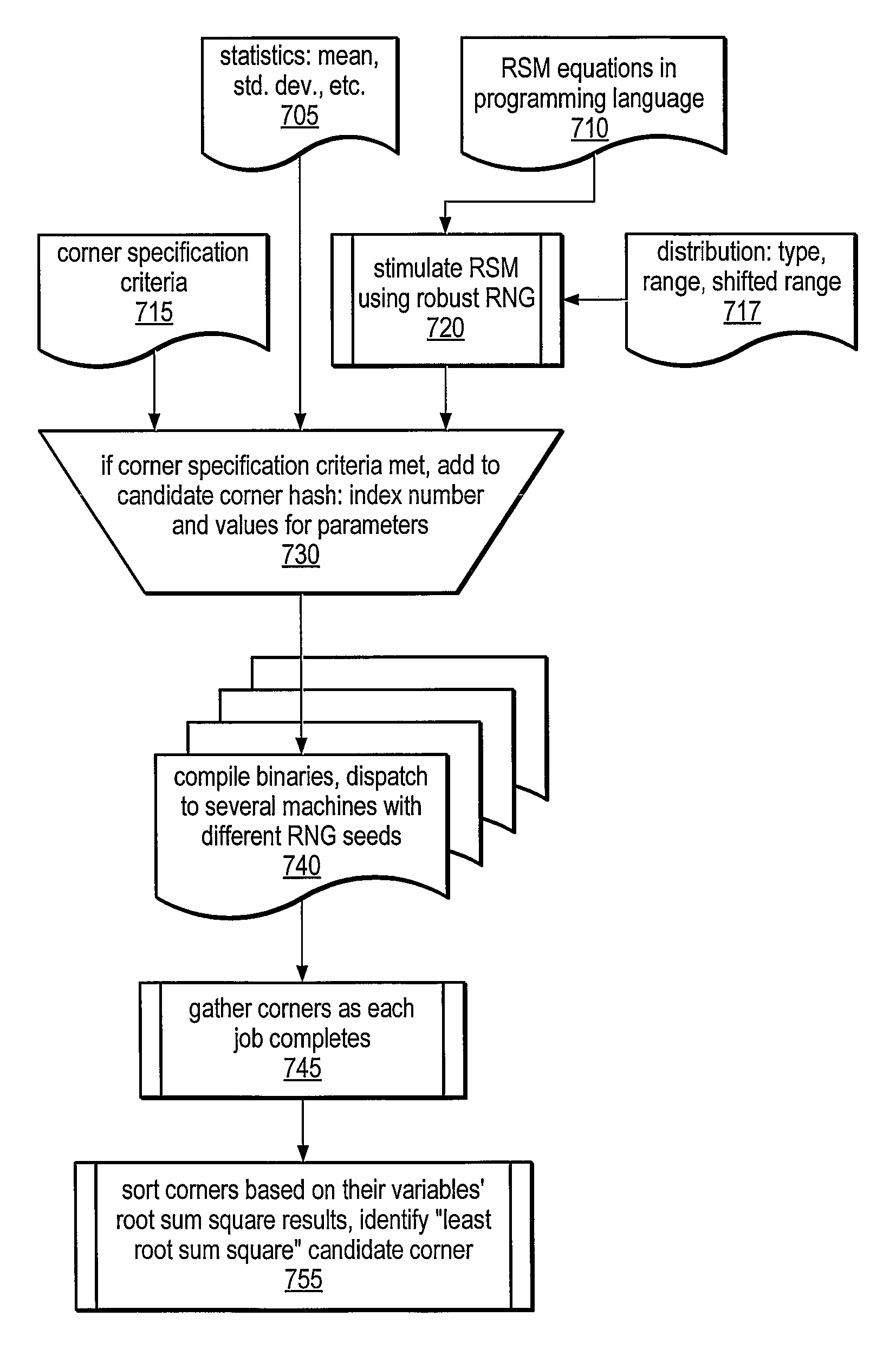

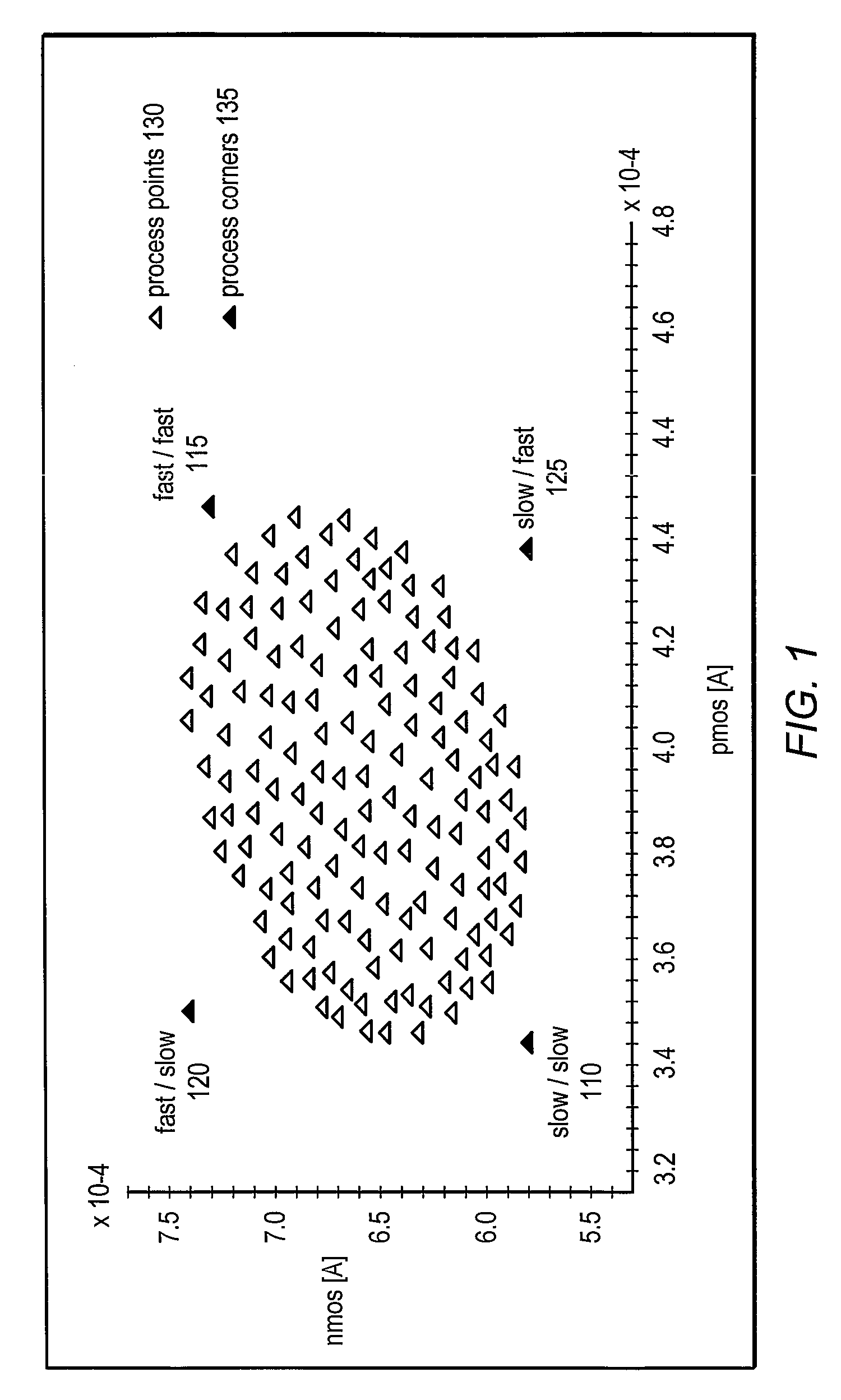

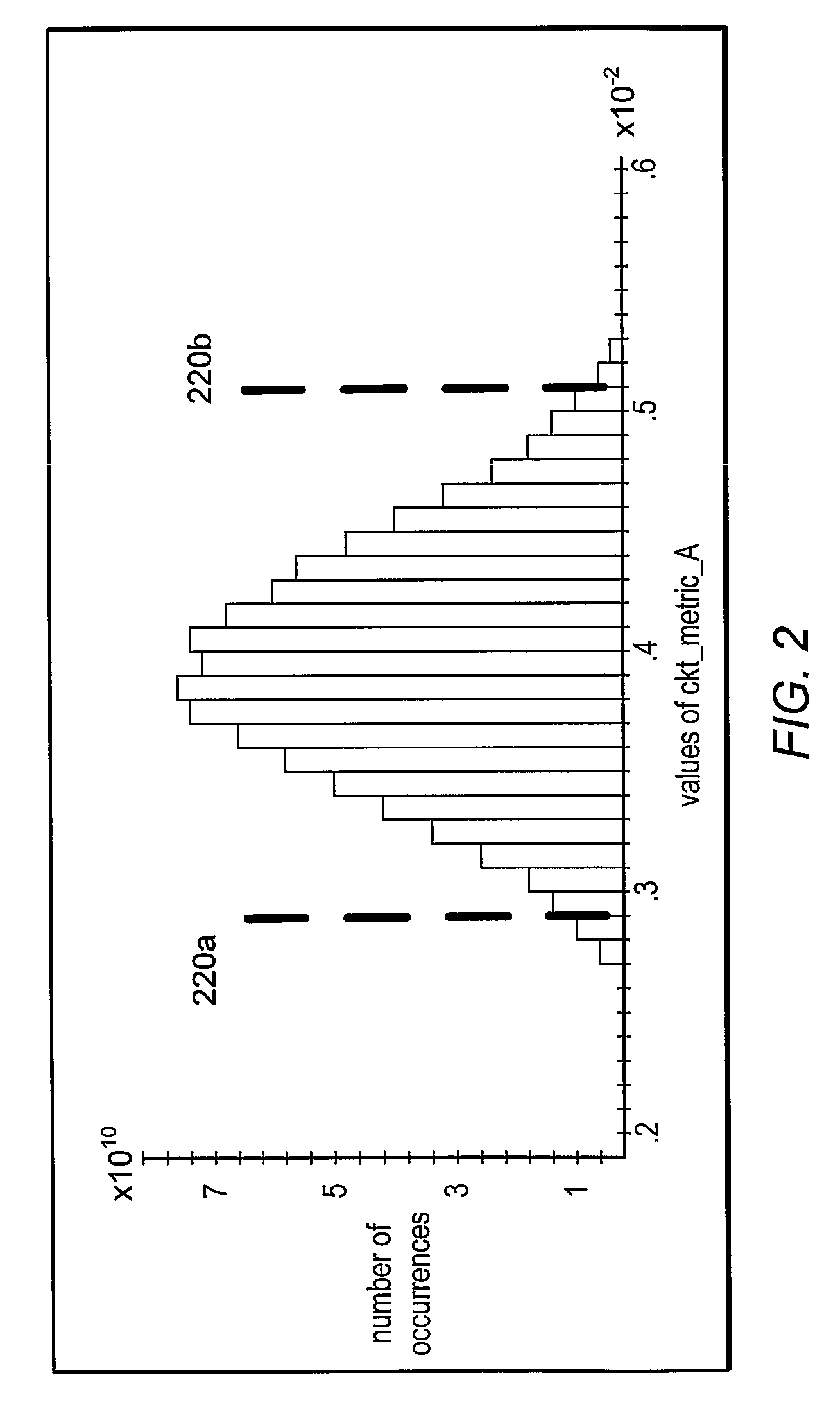

A system and method for deriving semiconductor manufacturing process corners using surrogate simulations is disclosed. The method may be used to determine individual performance metric yields, the number of out-of-specification conditions for a given number of simulation samples, and a total yield prediction for simultaneous multi-variable conditions. A surrogate simulation model, such as a Response Surface Model, may be generated from circuit simulation data or parametric data measurements and may be executed using a large number of multi-variable sample points to determine process corners defining yield limits for a device. The model may also be used to simulate process shifts and exaggerated input ranges for critical device parameters. In some embodiments, the derived process corners may better represent physically possible worst-case process corners than traditional general-purpose process corners, and may address differences in process sensitivities for individual circuits of the device.

Owner:ORACLE INT CORP

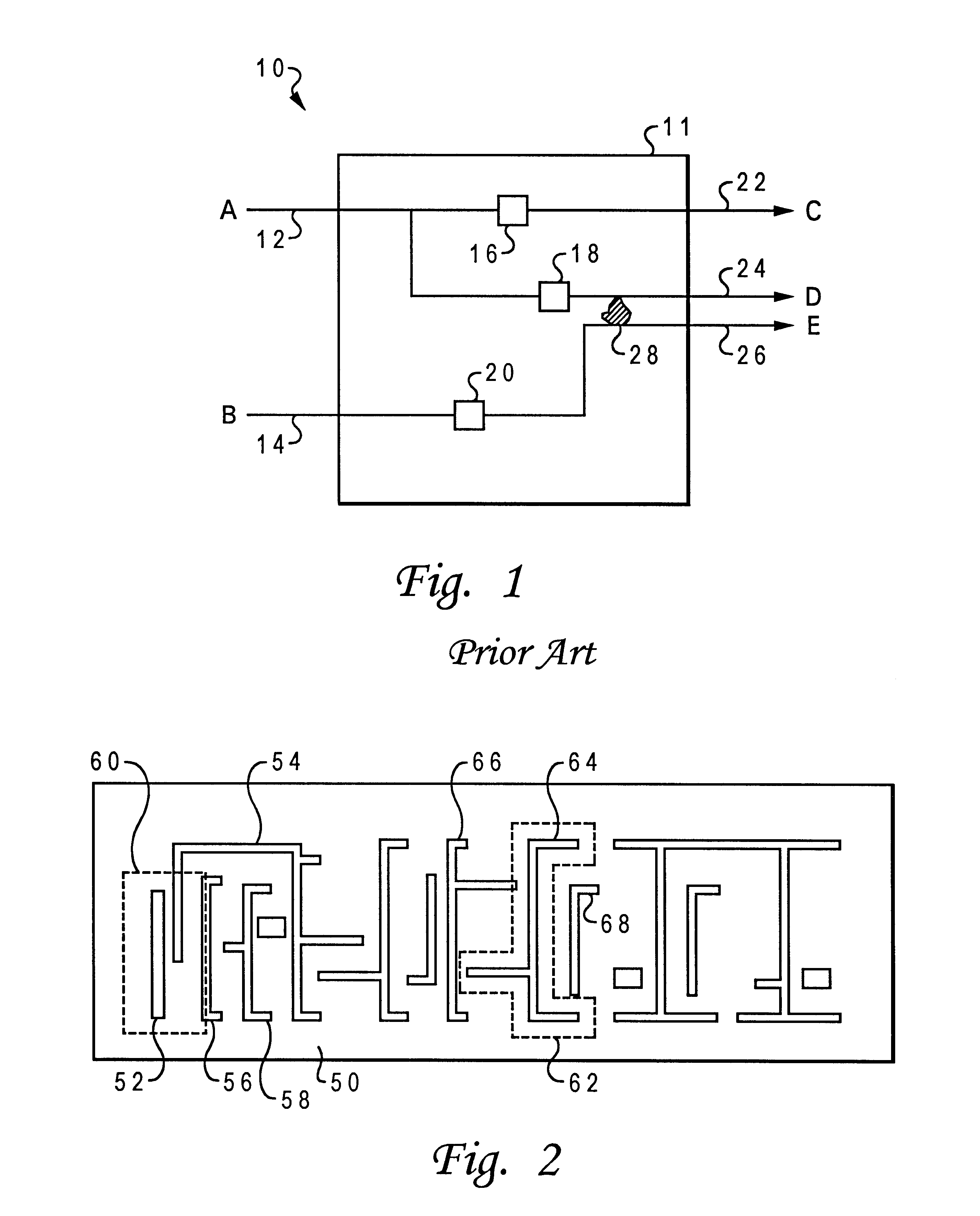

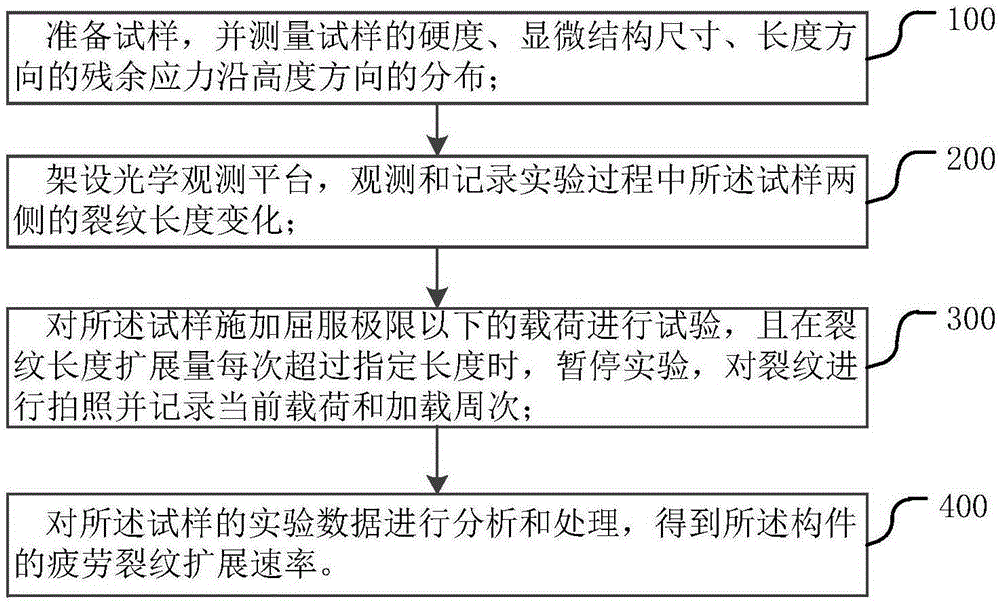

Method and system for improving yield of semiconductor integrated circuits

InactiveUS6507930B1Semiconductor/solid-state device testing/measurementSolid-state devicesEngineeringYield limit

A method and system are disclosed for improving a yield of circuits produced from a semiconductor wafer. A plurality of design rules are established for designing a layout of the circuit within the wafer. A yield-limiting set of the plurality of design rules are selected. Adherence to each of the set of rules throughout all of the layout reduces the yield. For each one of the set of rules, a recommended value is determined. A percentage of occasions each one of the set should be exceeded within the layout is also determined. The layout is then designed so that each one of the set of the plurality of design rules meets or exceeds the recommended value more often than the percentage.

Owner:IBM CORP

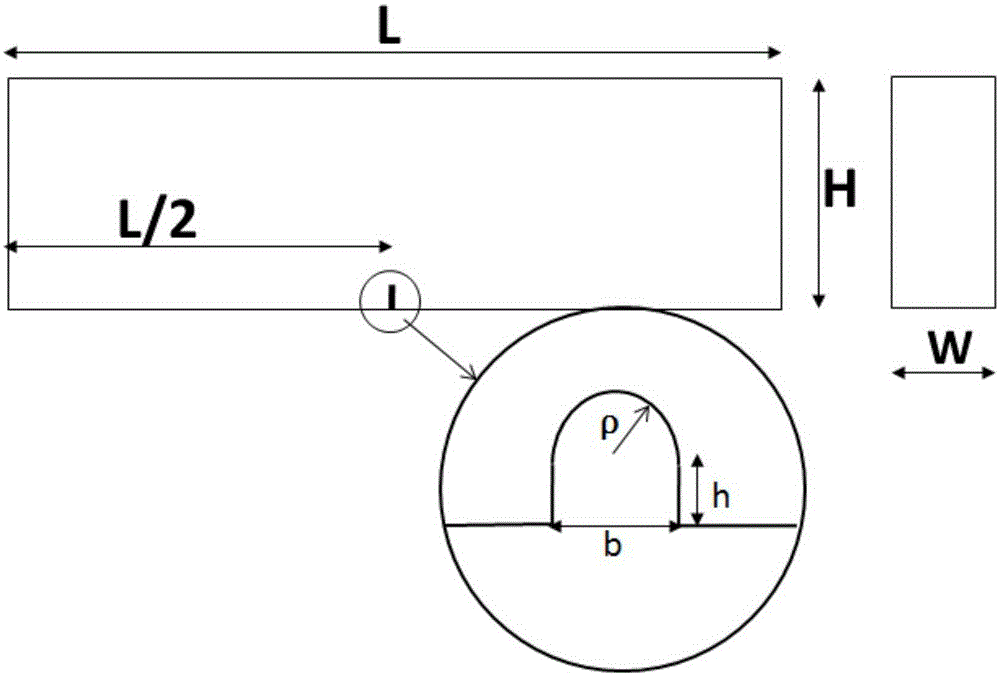

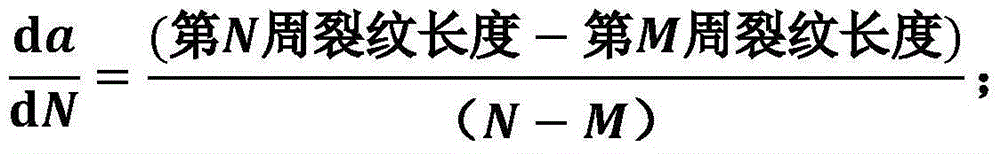

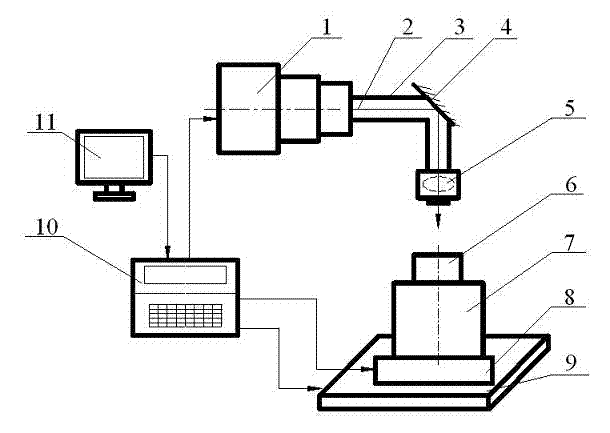

Measuring method for surface strengthening member fatigue crack expansion rate

ActiveCN105181492AEnsure consistencyRealize determinationMaterial strength using repeated/pulsating forcesCurrent loadTested time

The invention provides a measuring method for a surface strengthening member fatigue crack expansion rate. The method comprises the following steps: sample preparation is carried out, and hardness, a microscopic structure size, distribution of a residual stress in the length direction along the height direction of a sample are measured; an optical observation platform is erected, crack length changes of two sides of the sample during the test process are observed and recorded; a load less than a yield limit is applied to the sample for test, when the crack length expansion amount exceeds an appointed length every time, the test is paused, the cracks are shot and the current load and loading cycles are recorded; the test data of the sample is subjected to analysis and processing, and the fatigue crack expansion rate of the member is obtained. In the measuring method, a sample is cut from a whole-size member directly, and the consistency of the sample and the member is kept. The problems are solved effectively that whole-size member test time is long, the material cost is high, a lot of test data is difficult to obtain, and measuring of the surface strengthening member fatigue crack expansion rate is achieved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

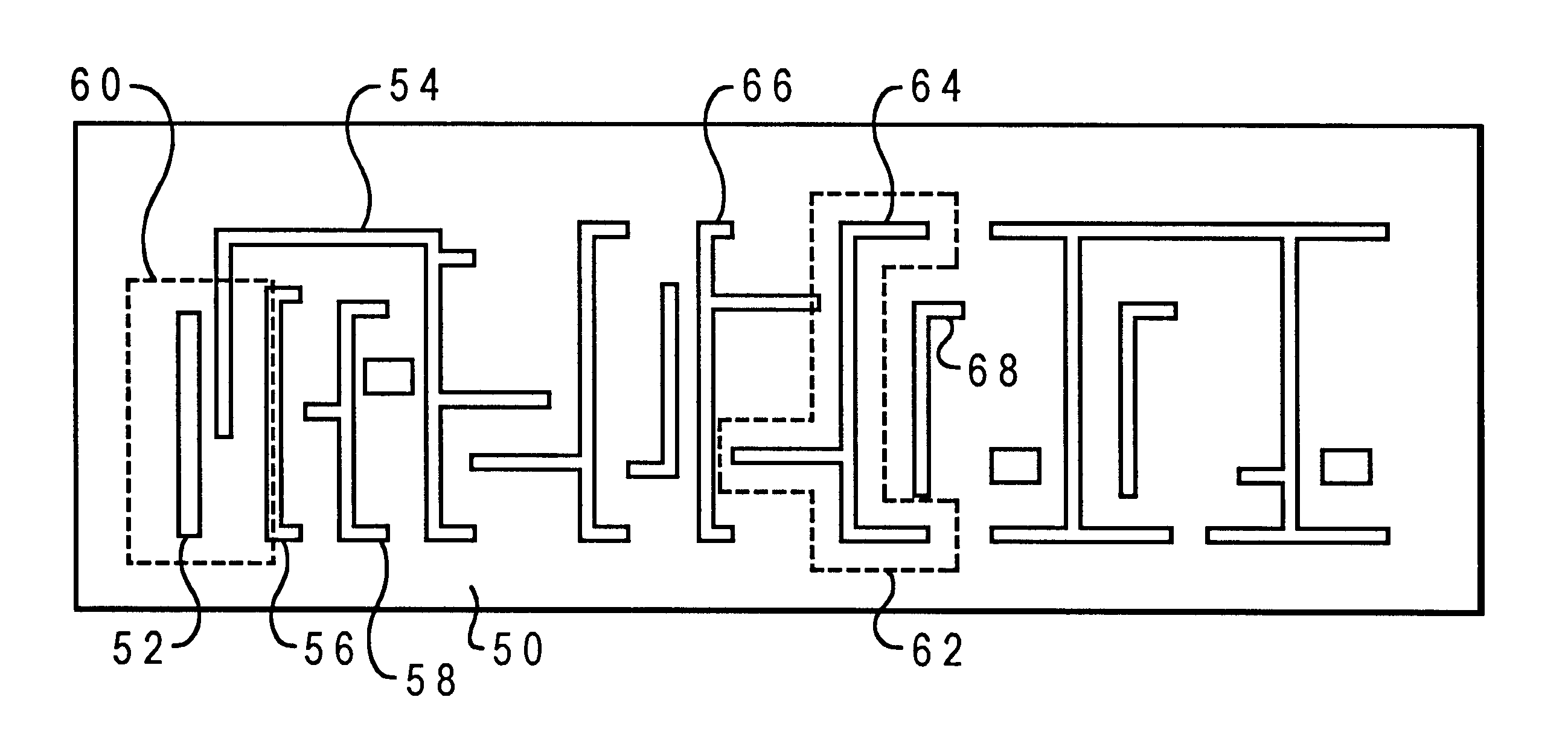

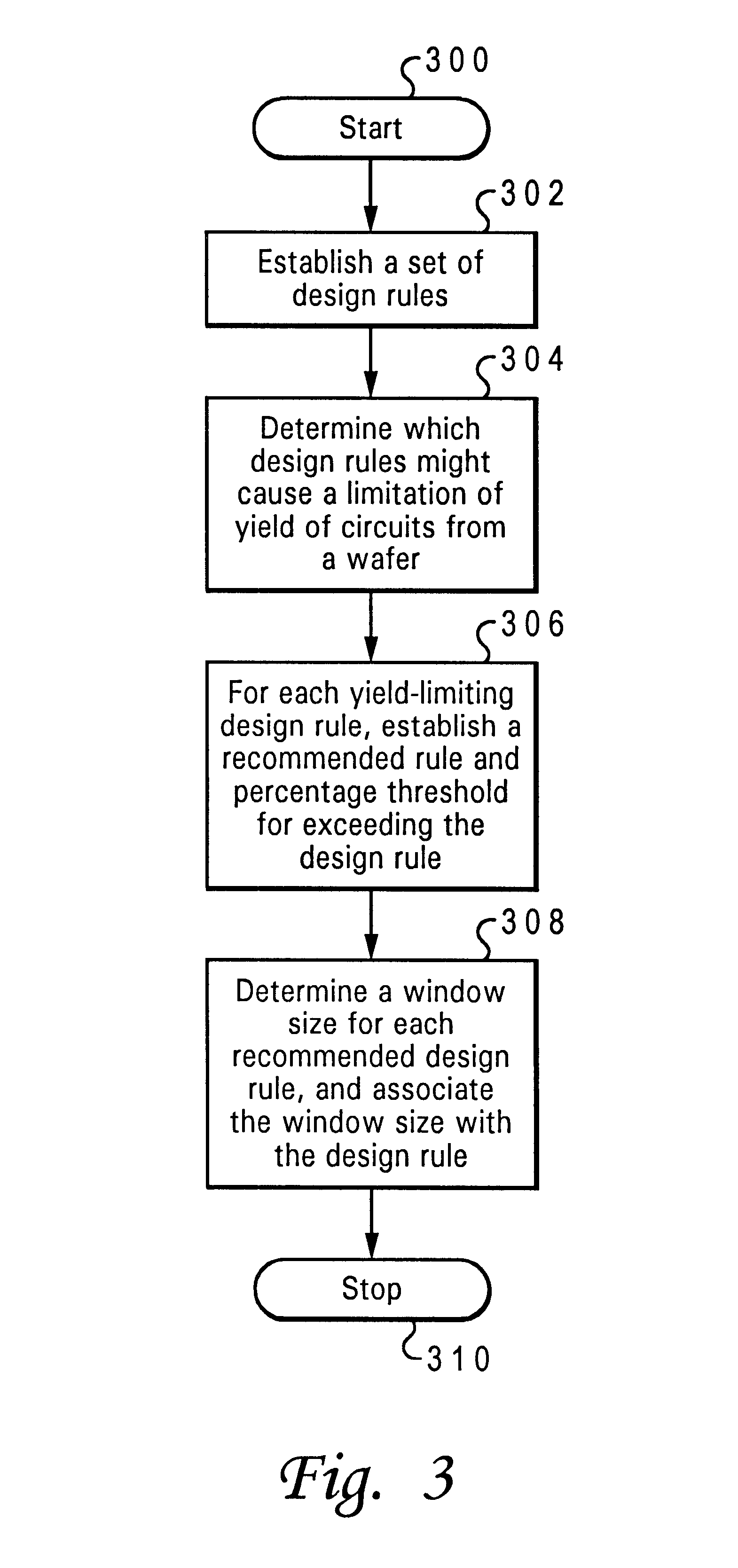

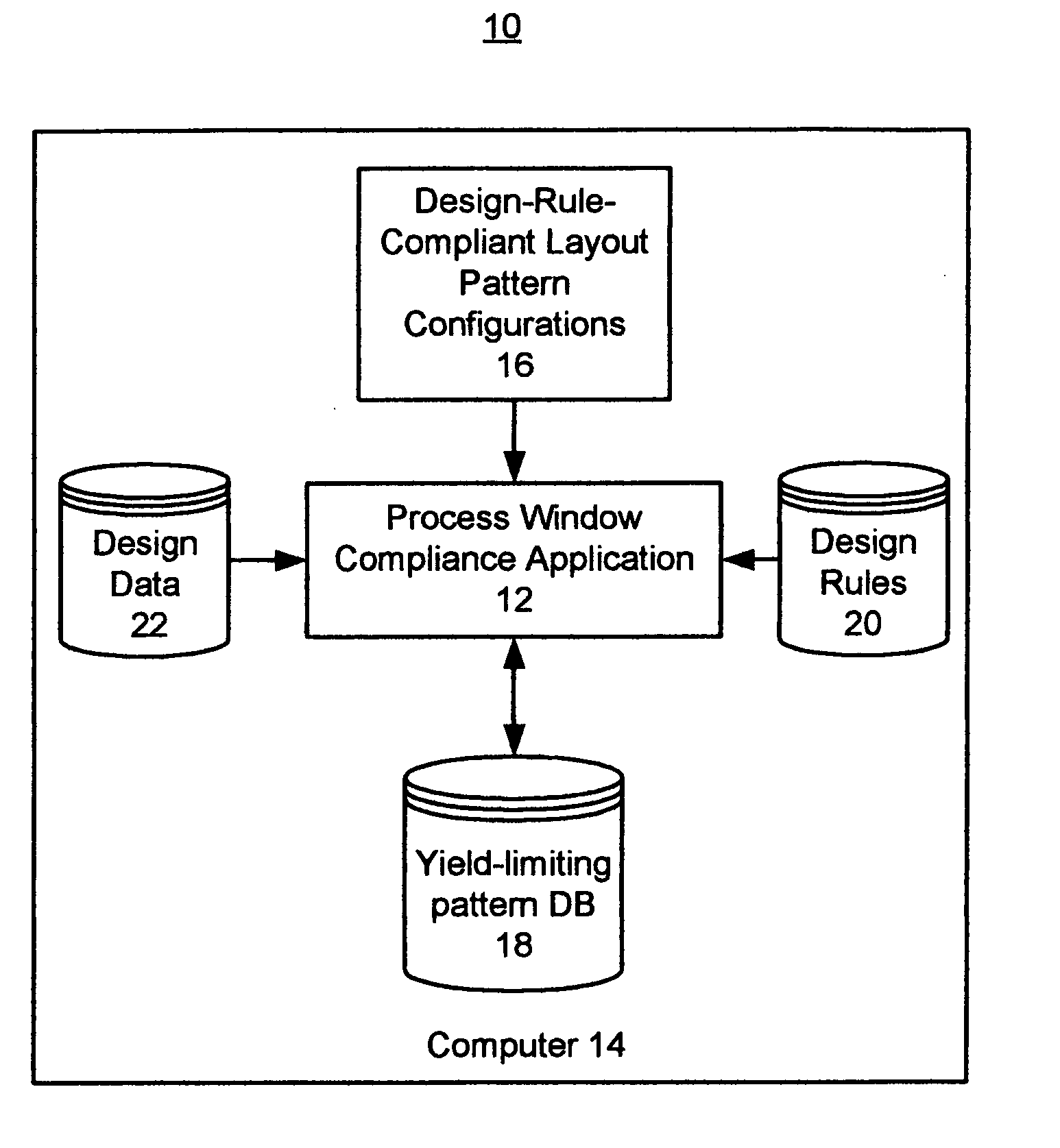

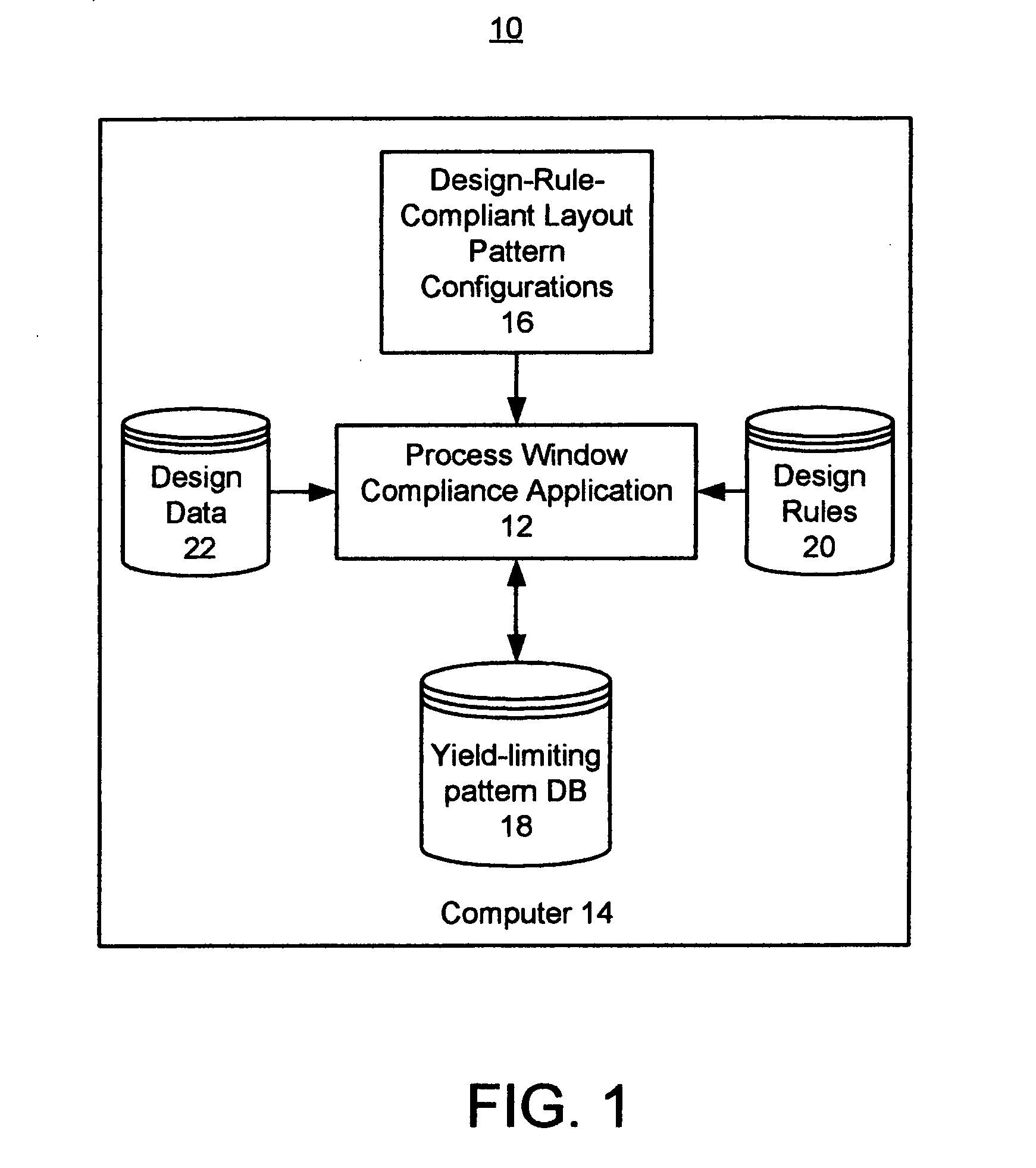

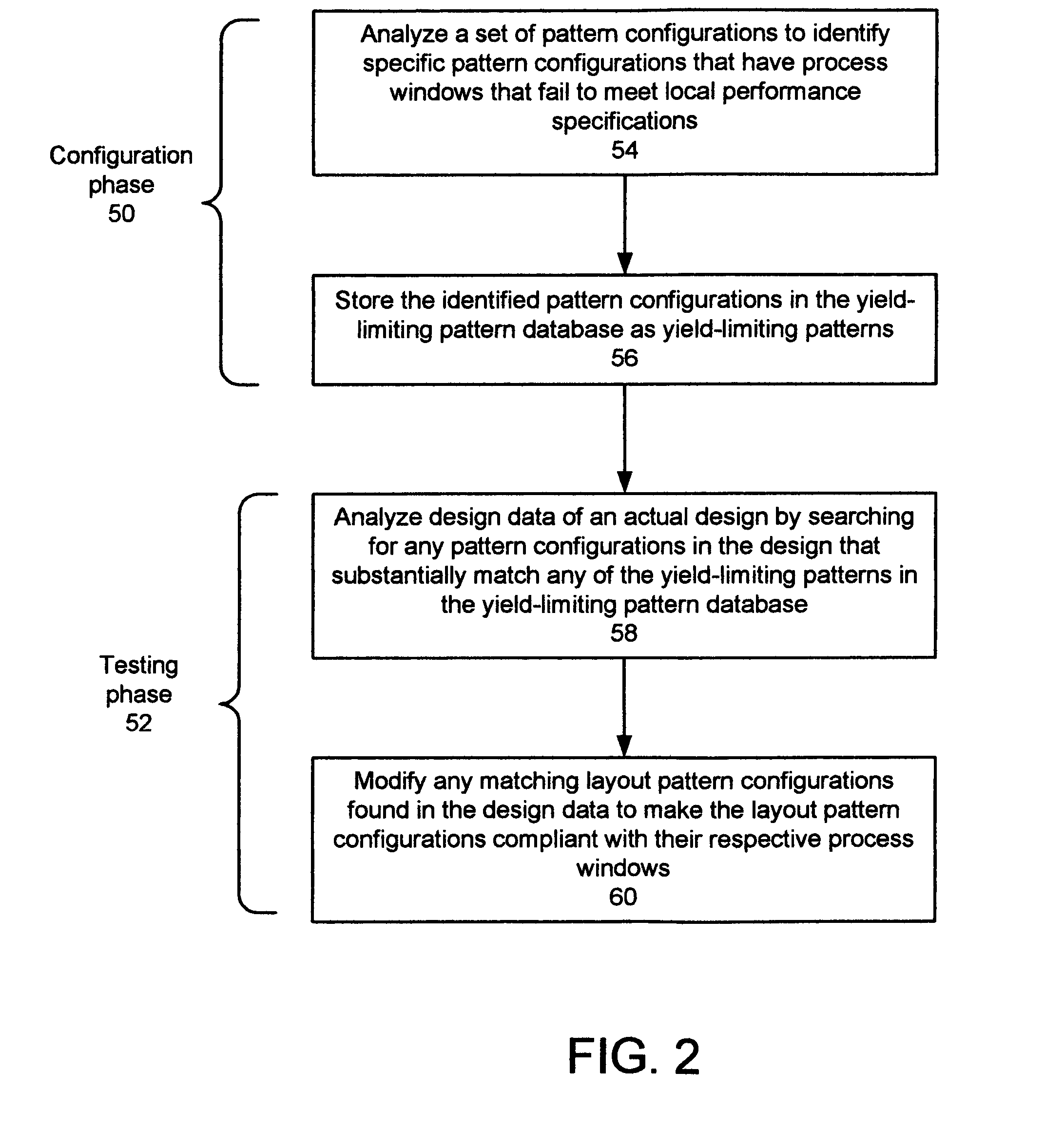

Yield-limiting design-rules-compliant pattern library generation and layout inspection

InactiveUS20070157153A1Computer aided designSpecial data processing applicationsEngineeringPerformance specification

A method and system is provided for analyzing process window compliance of an integrated circuit design. Aspects of the present invention include identifying layout pattern configurations that have process windows that fail to meet respective local performance specifications; searching for any layout pattern configurations in a design that substantially match any of the identified layout pattern configurations; and modifying any matching layout pattern configurations found in the design to make the layout pattern configurations compliant with their respective process windows.

Owner:BELL SEMICON LLC

Multidimensional process corner derivation using surrogate based simultaneous yield analysis

A system and method for deriving semiconductor manufacturing process corners using surrogate simulations is disclosed. The method may be used to determine individual performance metric yields, the number of out-of-specification conditions for a given number of simulation samples, and a total yield prediction for simultaneous multi-variable conditions. A surrogate simulation model, such as a Response Surface Model, may be generated from circuit simulation data or parametric data measurements and may be executed using a large number of multi-variable sample points to determine process corners defining yield limits for a device. The model may also be used to simulate process shifts and exaggerated input ranges for critical device parameters. In some embodiments, the derived process corners may better represent physically possible worst-case process corners than traditional general-purpose process corners, and may address differences in process sensitivities for individual circuits of the device.

Owner:ORACLE INT CORP

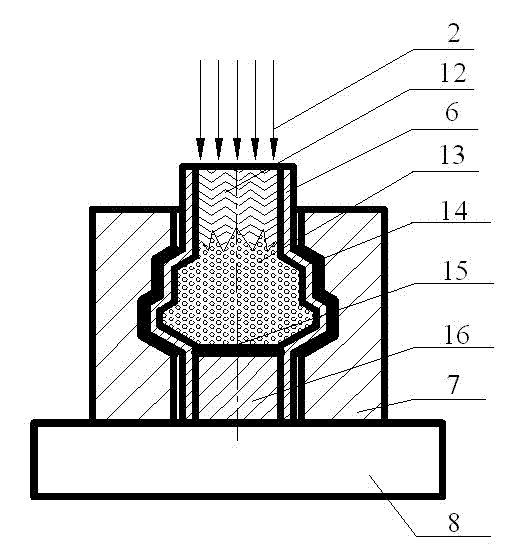

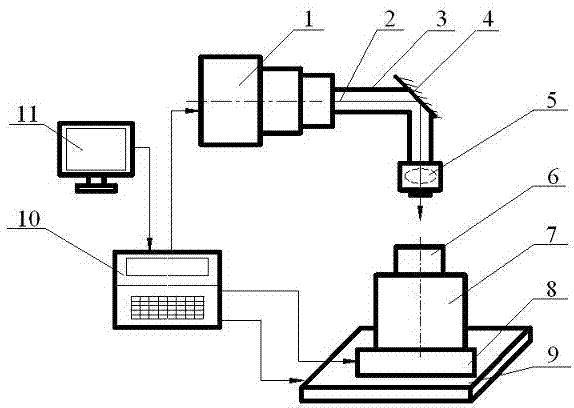

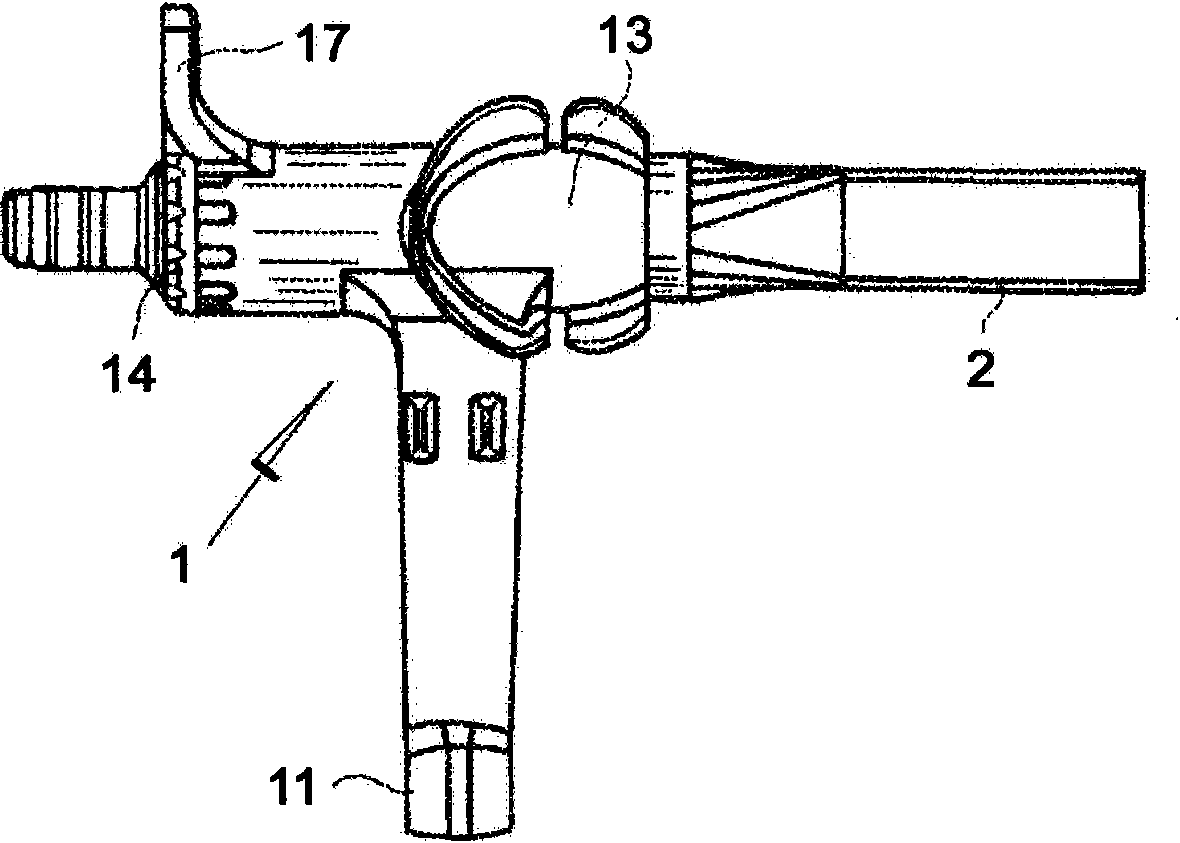

Method and device for forming metal reducer pipe based on laser shock wave technology

ActiveCN102225491AImprove flexibilityHigh value for high flexibilityLaser beam welding apparatusShock waveLaser processing

The invention discloses a method and device for forming a metal reducer pipe based on a laser shock wave technology and belongs to the technical field of laser processing. In the invention, the upper end part, separated from a pipe fitting, of a plugging rod is coated with a laser energy absorption layer; a laser beam enters the interior of a pipe billet to be formed along the axis of the pipe billet, thereby irradiating on the absorption layer on the upper end part of the plugging rod; the absorption layer absorbs laser energy so as to be gasified and ionized, thus forming high-voltage plasmas; and the high-voltage plasmas quickly expand to form a high-amplitude shock wave, thereby promoting the expansion of the pipe billet until the pipe billet is jointed with the profile of a mould, therefore the deformed shape of the pipe billet is in accordance with the profile of the mould. In the invention, the laser shock wave controlled in parameter is utilized as a power source for internal high pressure forming of the pipe billet, and good safety is provided; and the method and device provided by the invention are suitable for not only forming the pipe billet of a material extremely low in yield limit, but also forming the pipe billet with high yield strength; besides, continuous multi-pulse laser irradiation can be performed and uninterrupted multi-impact can be carried out; and high production efficiency is ensured.

Owner:马鞍山市安工大智能装备技术研究院有限公司

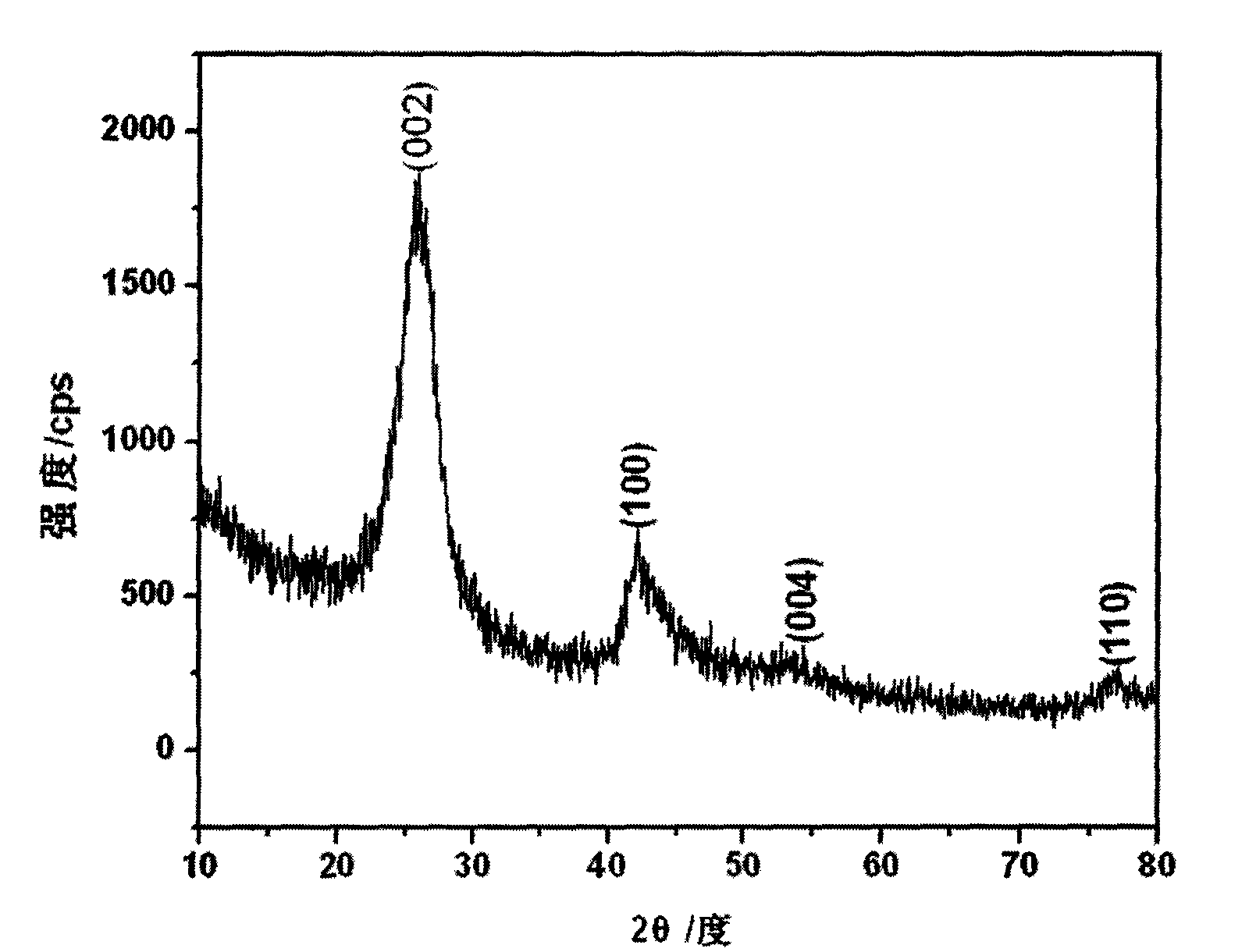

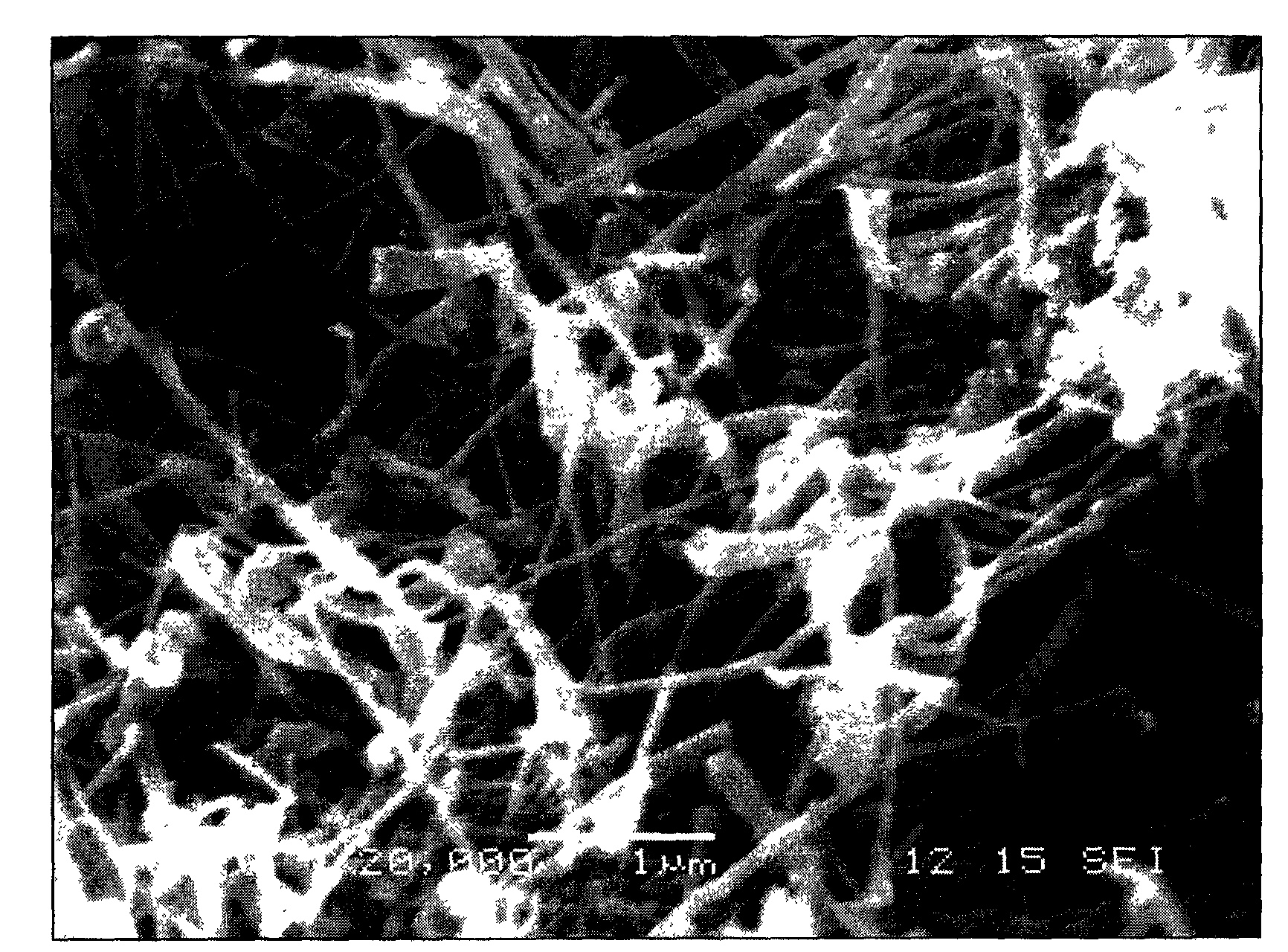

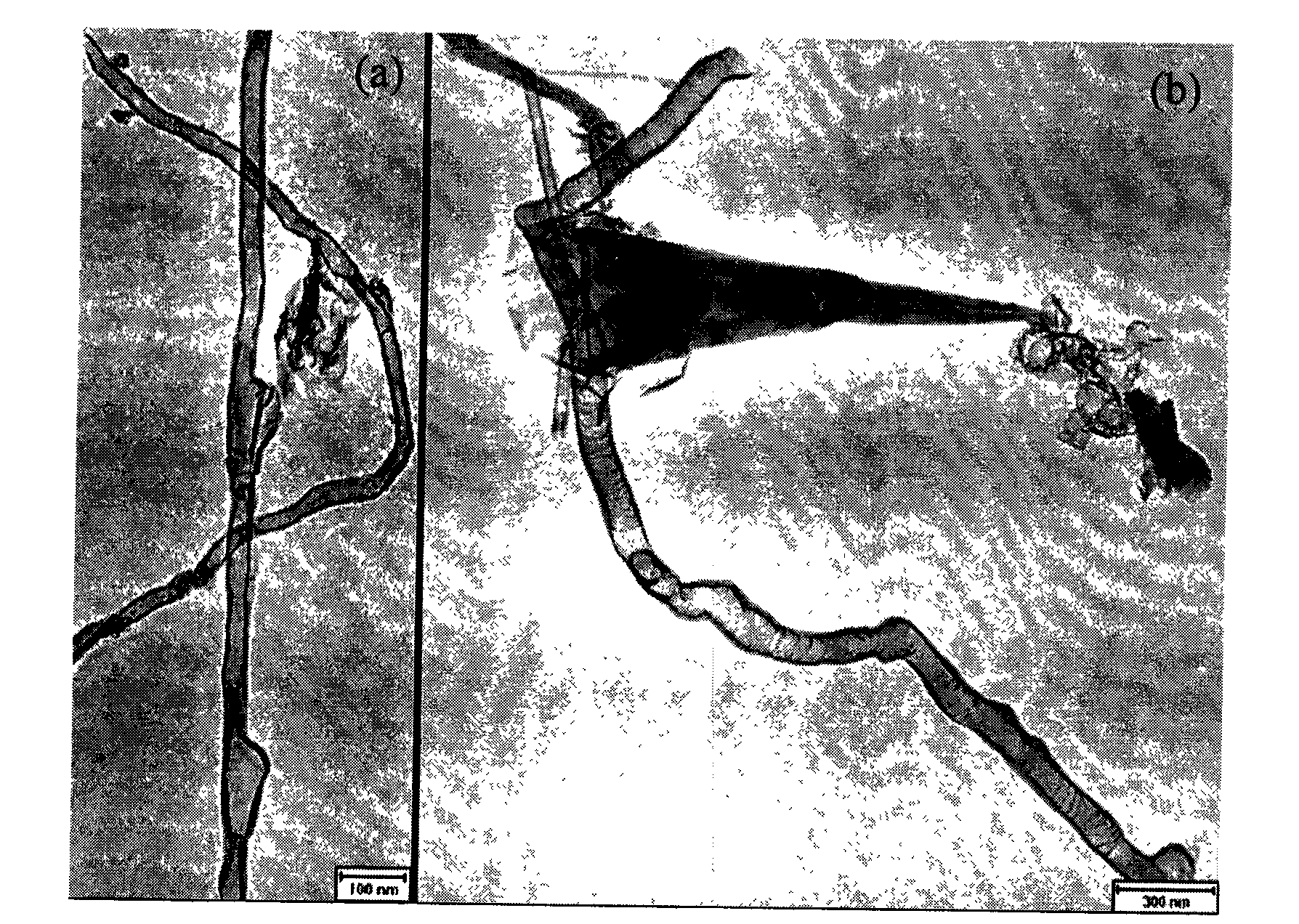

Method for preparing boron nitride nanotubes by annealing of inorganic boracic precursor

InactiveCN101580236ASimple preparation processChemically stableNanostructure manufactureNitrogen compoundsBoron nitrideBoron

The invention relates to a novel method for preparing boron nitride nanotubes by annealing of an inorganic boracic precursor, comprising annealing the inorganic boracic precursor for 5-50h at the temperature of 800-1200 DEG C to obtain boron nitride nanotubes. The beneficial effects of the invention comprise that 1) annealing reaction of the boracic precursor is adopted to prepare boron nitride nanotubes, boron element is sintered with catalyst to form porous solid, the problem that the yield and the purity of boron nitride nanotubes are low is solved, the preparation yield limit of boron nitride nanotubes is surmounted, the preparation process is simple, the product yield of boron nitride nanotubes is above 80% and the purity is above 85%; 2) the chemical property of the prepared inorganic boracic precursor is stable which is applicable to batch manufacturing boron nitride nanotubes with low cost and high purity; the reaction condition of preparing precursor is mild, the process is simple, and the energy consumption and the cost are low, which is applicable to industrialized production and the precursor can be directly used to prepare boron nitride nanotubes.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Process for quenching-distribution heat treatment on 60Si2CrVA steel spring for trains

InactiveCN101597680AHigh yield limitImprove fatigue strengthIncreasing energy efficiencyFurnace typesYield ratioRound bar

The invention discloses a process for quenching-distribution heat treatment on 60Si2CrVA steel spring for trains. The process comprises the following steps: polishing a 60Si2CrVA steel round bar with diameter less than or equal to 50mm, and heating the steel round bar to a temperature of between 960 and 1,060 DEG C through an inductive heating mode; then, wrapping the 60Si2CrVA steel round bar into a spring in the temperature state; cooling the wrapped spring to a temperature of between 810 and 900 DEG C, quenching the spring at a temperature of between 130 and 210 DEG C, and keeping constant temperature for 10 to 60 seconds; quickly placing the spring in a medium at a temperature of between 280 and 350 DEG C, maintaining for 50 to 800 seconds, and placing the spring into water or oil for cooling; and tempering the spring at a temperature of between 250 and 470 DEG C for 60 to 120 minutes. The 60Si2CrVA steel spring product has the advantages of high yield limit and fatigue strength, good quenching harden ability, high tensile strength and yield ratio, high toughness and the like.

Owner:GUIZHOU UNIV

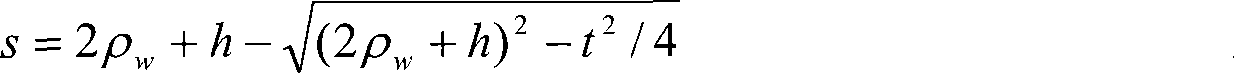

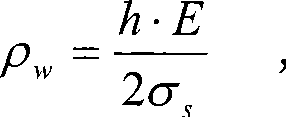

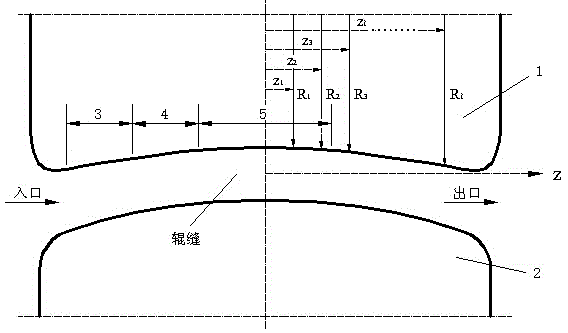

Straightening scheme of metal plate-belt roll type combination straightening machine

InactiveCN101417297AThe same degree of bendingSame speedRoll force/gap control deviceEngineeringYield limit

The invention discloses a straightening proposal of a metal slab band roller-typed combined straightener, which belongs to the technical field of the metal slab band straightener and is the improvement aiming at the existing straightening proposal. The invnetion is characterized in that in a roller system combined by a small roller system and a big roller system, a 'parallel straightening proposal' with equal rolling reduction both in a front roller system and a rear roller system is adopted, the rolling reduction thereof is as follows: s equals to 2rhow plus h-(2rhow plus h)<2>-t<2> / 4, wherein, 2rhow is the curvature radius of the bend of the slab band, rhow equals to (h question mark E ) / 2 sigmas, h is the thickness of the slab band, E is the elastic modulus of the slab band, sigmas- is the yield limit of the slab band, and t is the roller nip of the big roller system.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

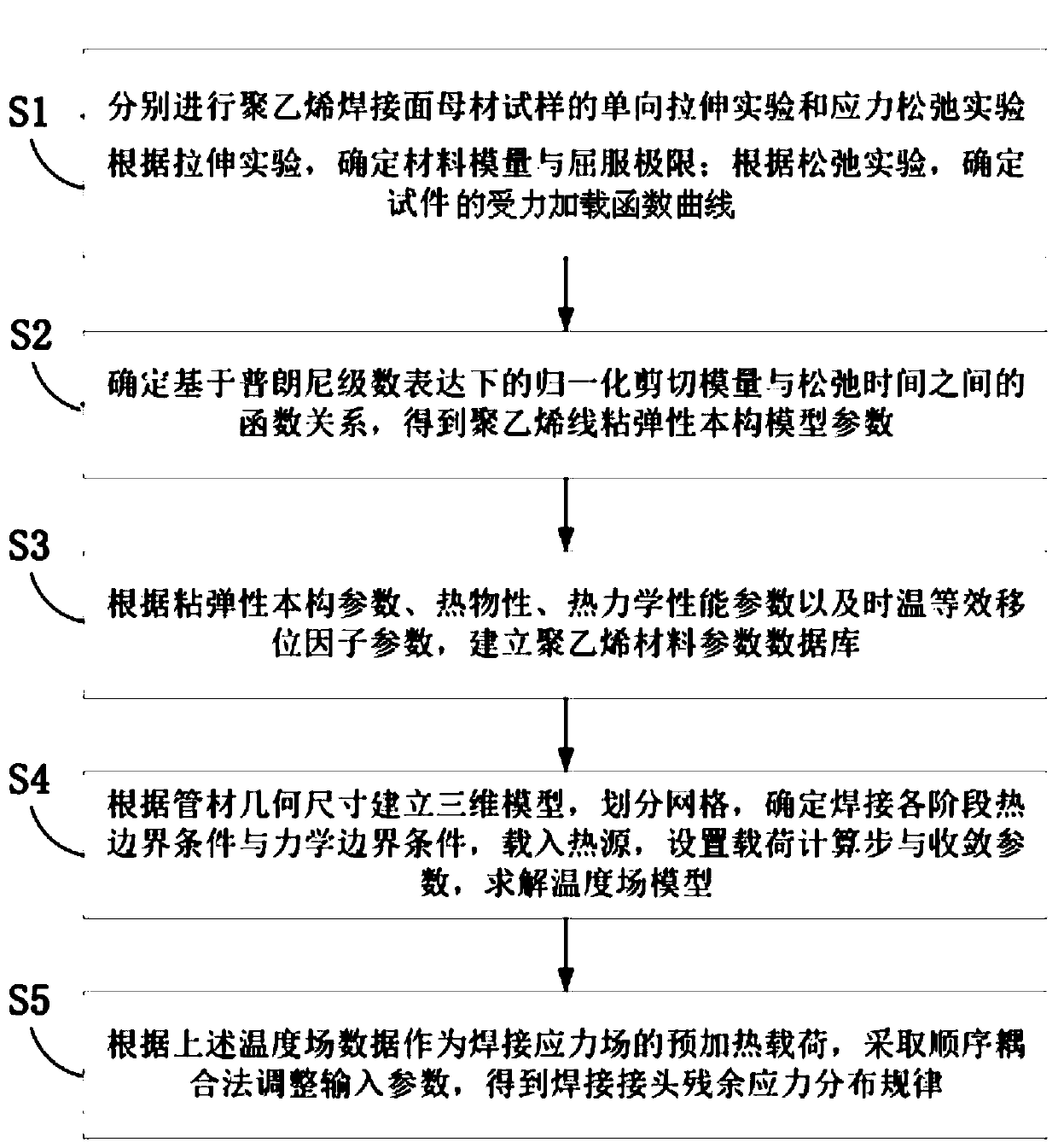

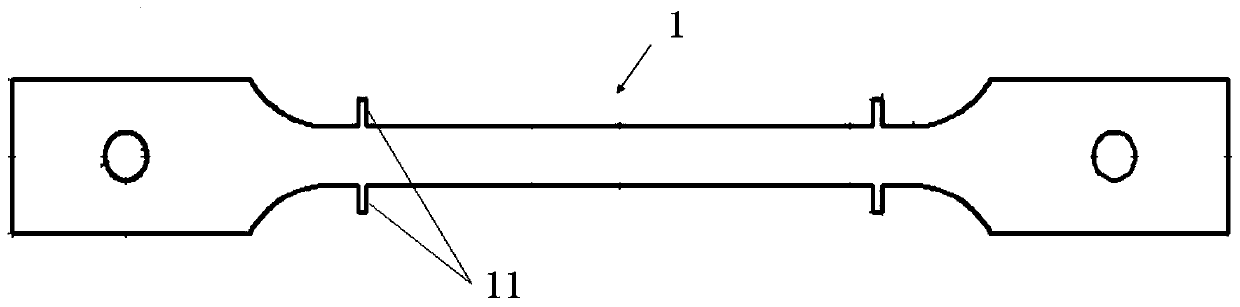

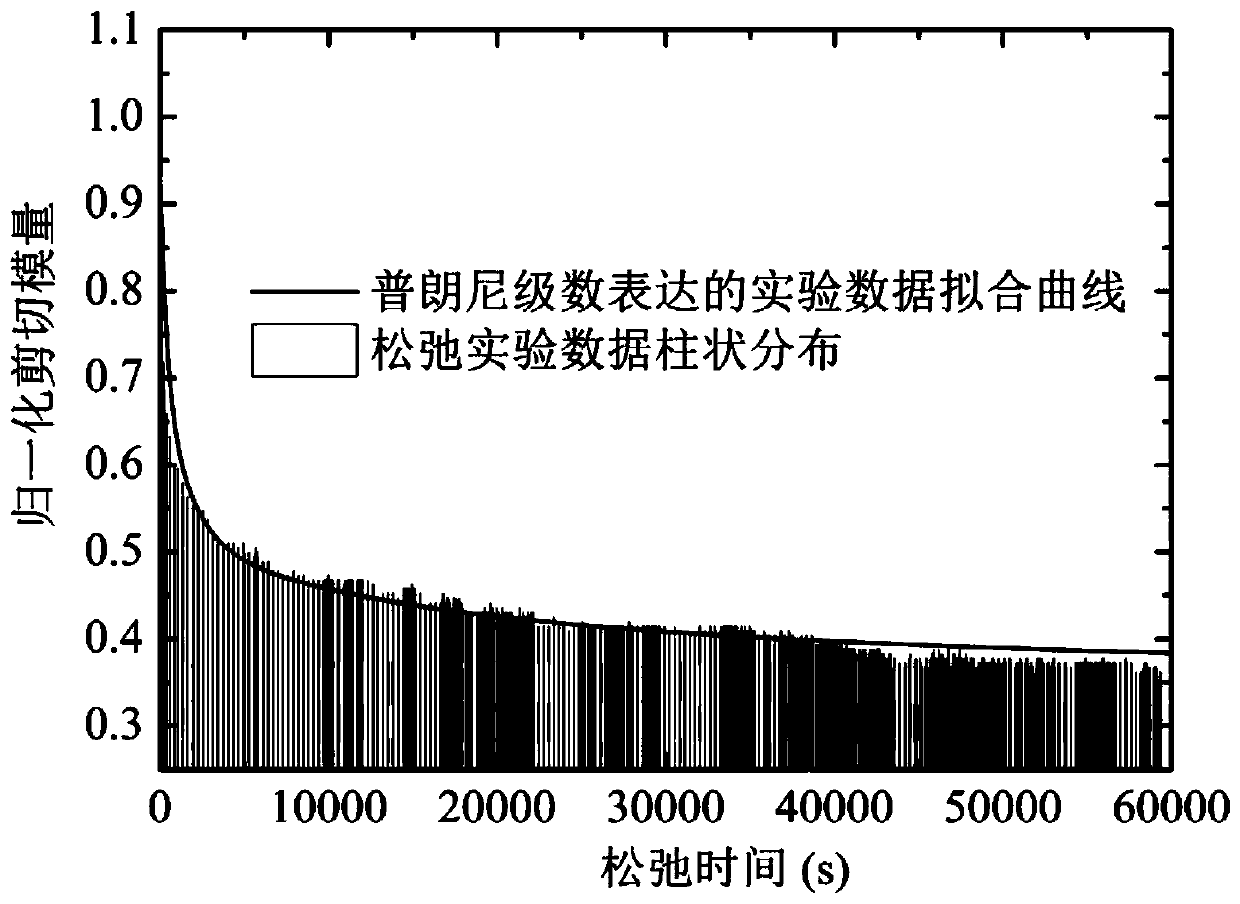

Method for analyzing residual stress of polyethylene pipe welded joint

ActiveCN110188451ASolve problems with less precisionEfficient analysisDesign optimisation/simulationProcess efficiency improvementNondestructive analysisCurve fitting

The invention provides a method for analyzing residual stress of a polyethylene pipe welded joint. The method comprises the following steps: carrying out a unidirectional stretching experiment and a stress relaxation experiment to obtain a tangent modulus and a yield limit value of a base material sample and a stress loading function curve of the base material sample under unit strain; establishing a viscoelastic constitutive model based on a generalized Maxwell equation and Pluronic series, and fitting the curve by adopting the model to obtain parameters of the model; establishing a basic material database of the polyethylene material according to the parameters, the thermophysical parameters and the thermodynamic parameters; establishing a geometric model, dividing grids, inputting thermal boundary conditions and force boundary conditions of each welding stage, and setting load steps and convergence parameters to obtain instantaneous temperature field data; and taking the instantaneous temperature field data as a preheating load, and adjusting input parameters by adopting a sequential coupling method to obtain the distribution condition of the residual stress. According to the method for analyzing residual stress of a polyethylene pipe welded joint, nondestructive analysis of the residual stress of the joint after the welding process is accurately and quickly realized.

Owner:EAST CHINA UNIV OF SCI & TECH

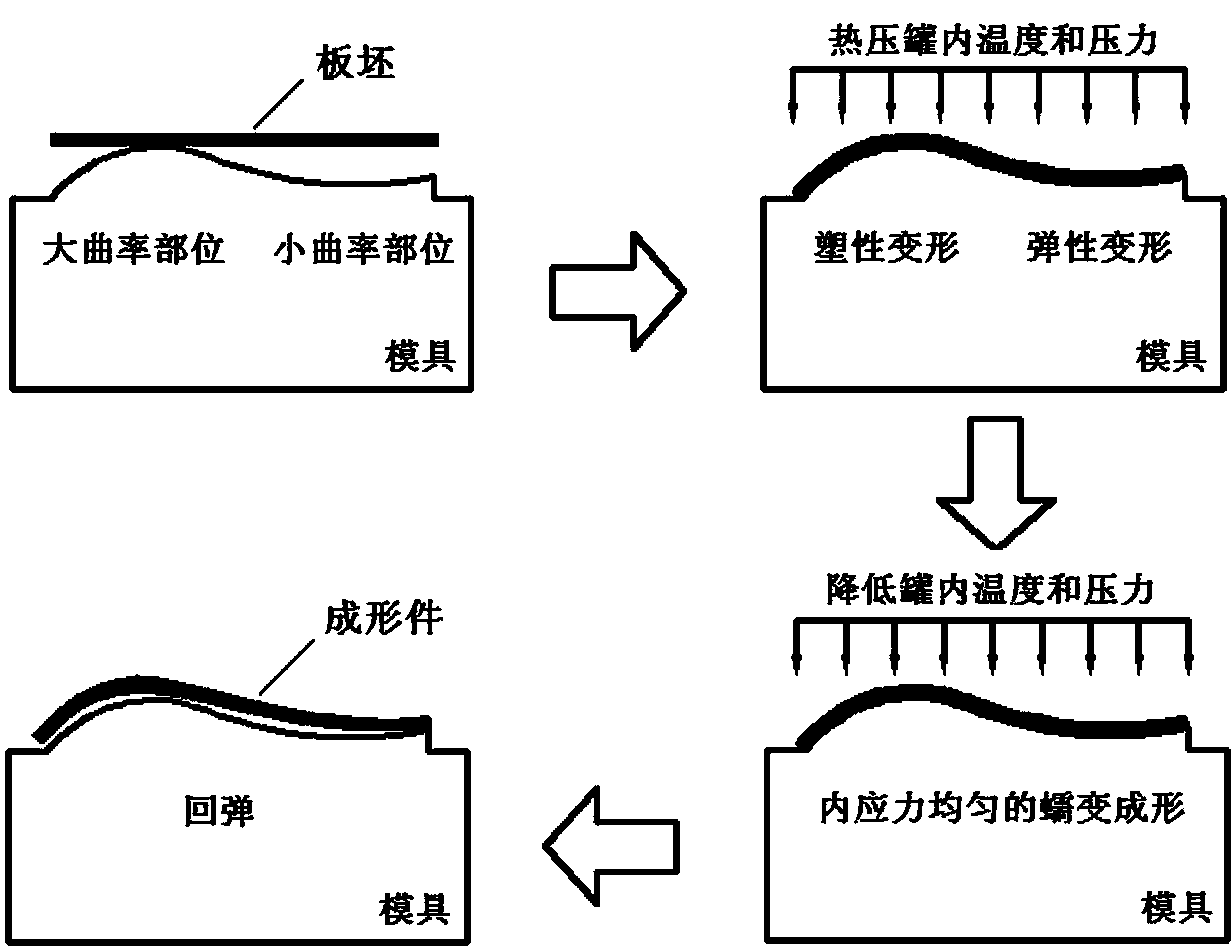

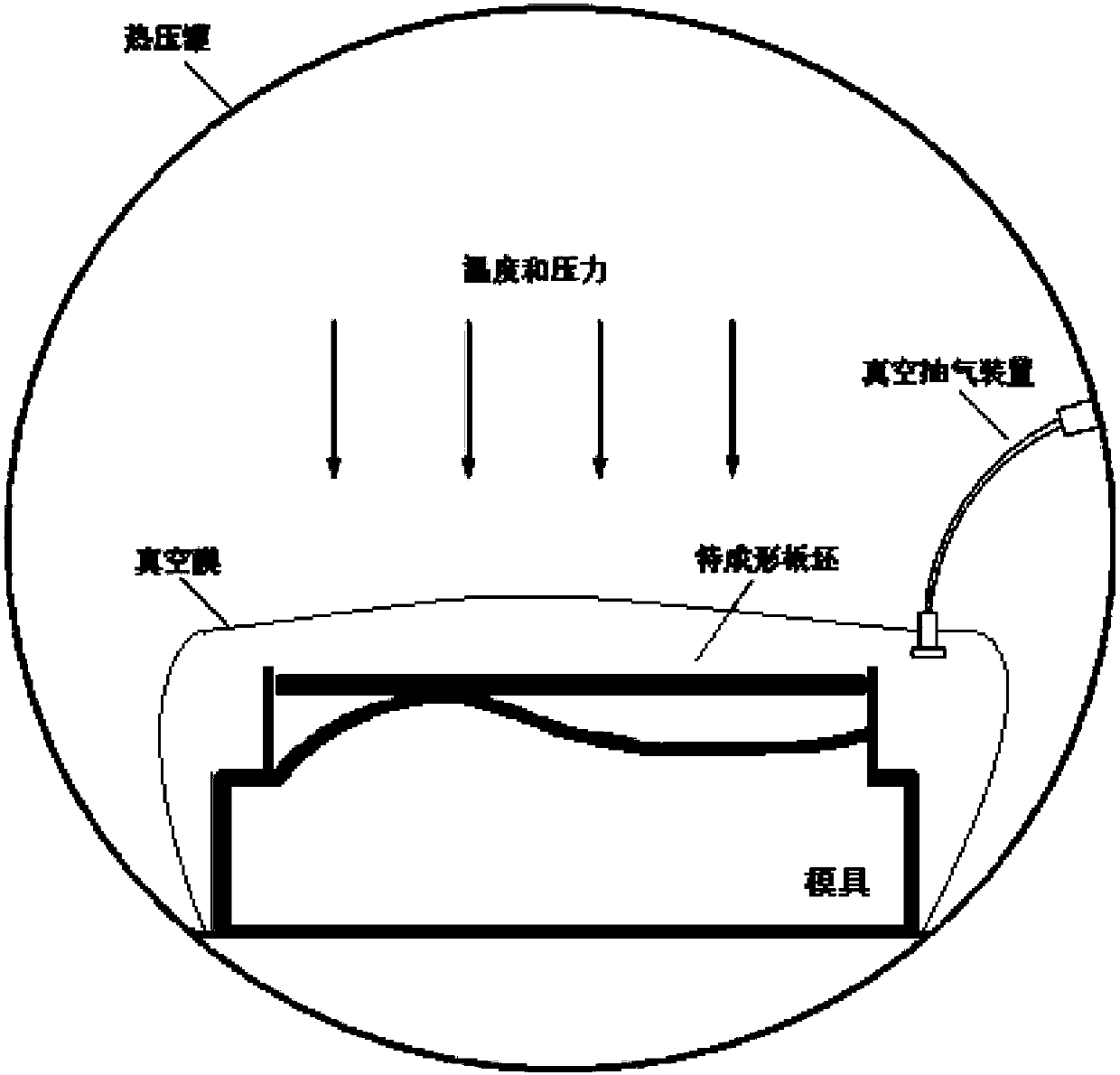

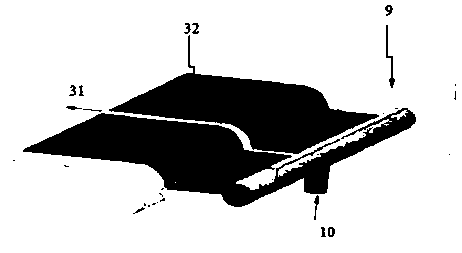

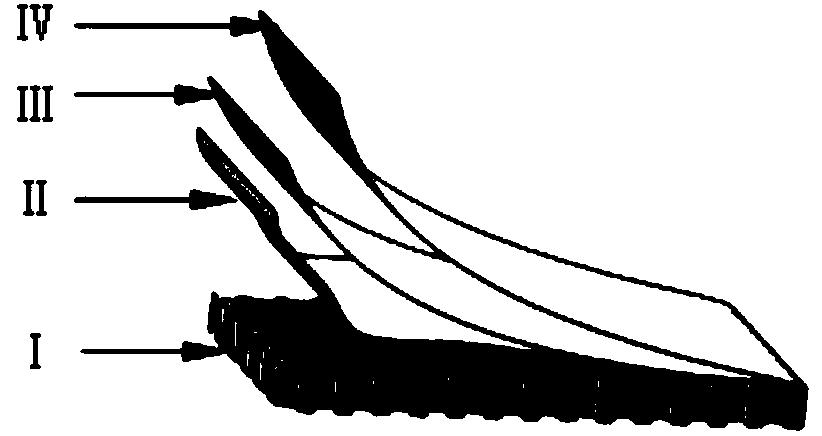

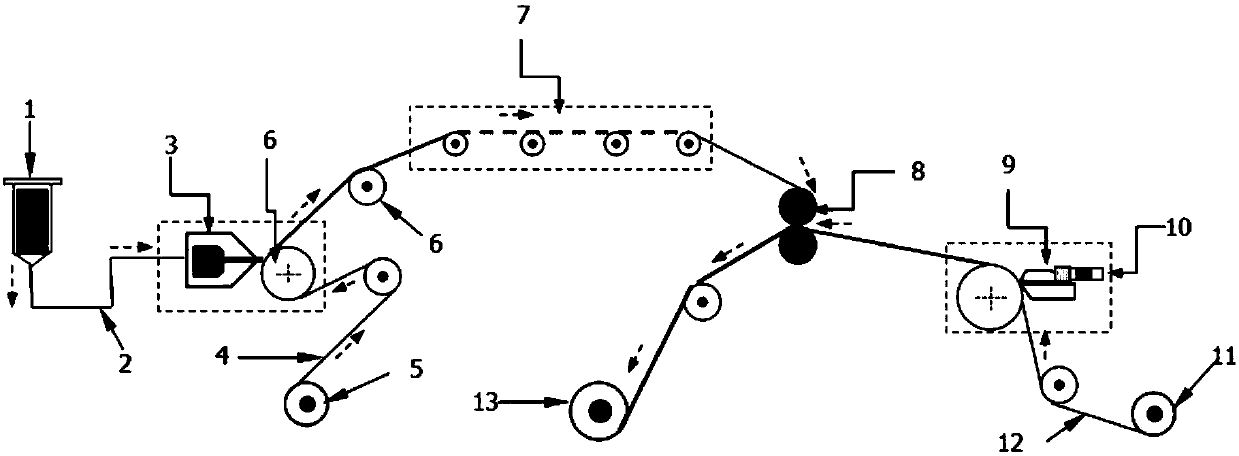

One-step shaping method for non-aging reinforced aluminum alloy whole wallboard based on autoclave

InactiveCN104190777AImprove performance uniformityEliminate performance differencesFurnace typesHeat treatment furnacesAtmospheric pressureInternal stress

The invention relates to a one-step shaping method for a non-aging reinforced aluminum alloy whole wallboard based on an autoclave. Firstly, an aluminum alloy plate blank is fixed onto a shaping die, is sealed in a vacuum state, and is placed into the autoclave; the temperature inside the autoclave is then raised to the full annealing temperature of the aluminum alloy, the pressure inside the autoclave is increased to the pressure required by contact molding of a component, and plastic deformation of a large-curvature area material occurs when the yield limit is reached; the temperature and the pressure are lowered slightly, so that the component is kept at the contact molding state and creep deformation occurs; finally, pressure and temperature in the autoclave is released, the required component shape and surface are obtained after the plate blank rebounds. The method adopts local plastic deformation and creep deformation to release a great amount of internal stress, so that residual stress of the formed workpiece is reduced, and uneven performance caused by difference of local internal stress of the workpiece is eliminated; the production period is shortened, the final rebound amount is obviously reduced, the tooling is simple, only one set of lower die is required for realization, and die cost is greatly saved.

Owner:CENT SOUTH UNIV

Liquid metal flexible shielding material and preparation method thereof

ActiveCN107901534AGood radiation absorption performanceThe overall thickness is thinProtective equipmentFibre treatmentLiquid metalRadiation shield

The invention provides a liquid metal flexible shielding material and a preparation method thereof. The liquid metal flexible shielding material includes a substrate layer, a liquid metal layer and ananti-aging layer which are sequentially arranged from bottom to top. The liquid metal flexible shielding material has an excellent shielding performance and a thin thickness, is nontoxic, has a far better yield limit than traditional lead-containing particle radiation shielding materials, can achieve extremely excellent stretchable radiation shielding materials, and has excellent values in the fields of flexible shielding gloves, shielding clothes and even X-ray lithography.

Owner:YUNAN JINGCHUANG LIQUID METAL THERMAL CONTROL TECH RES & DEV CO LTD

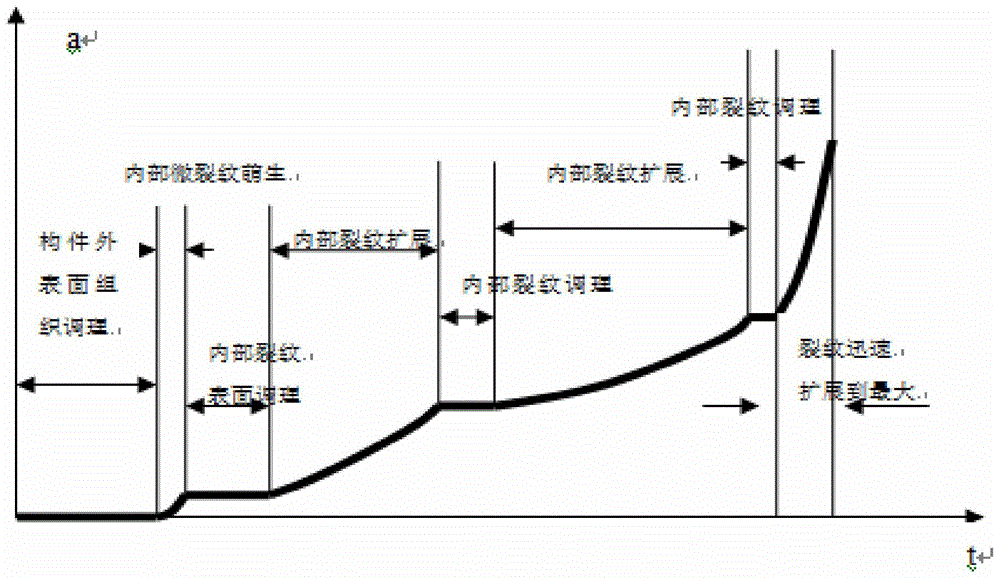

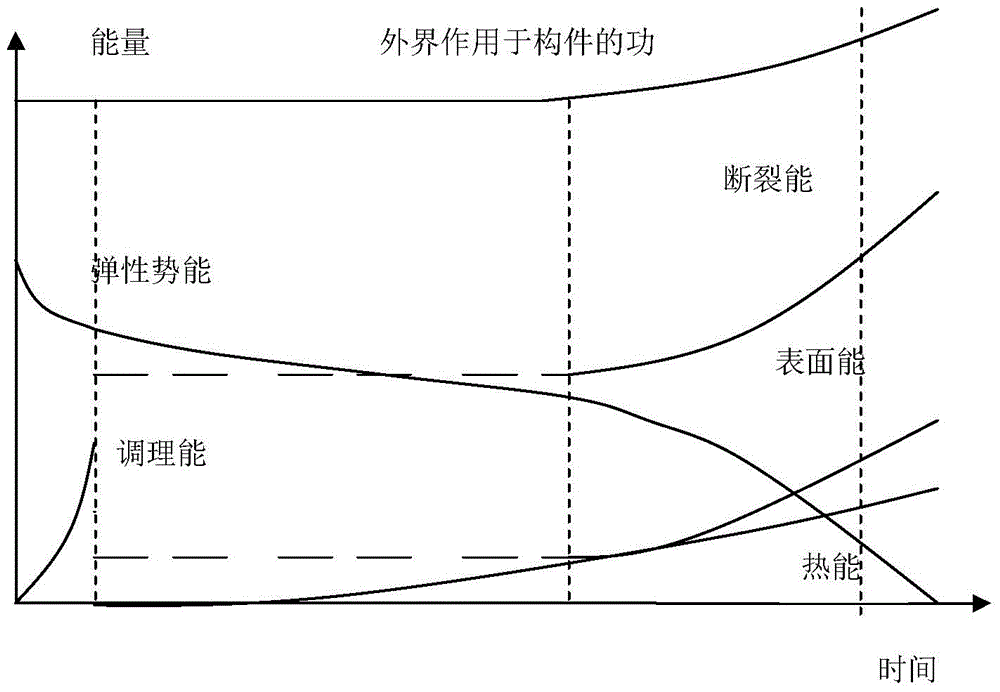

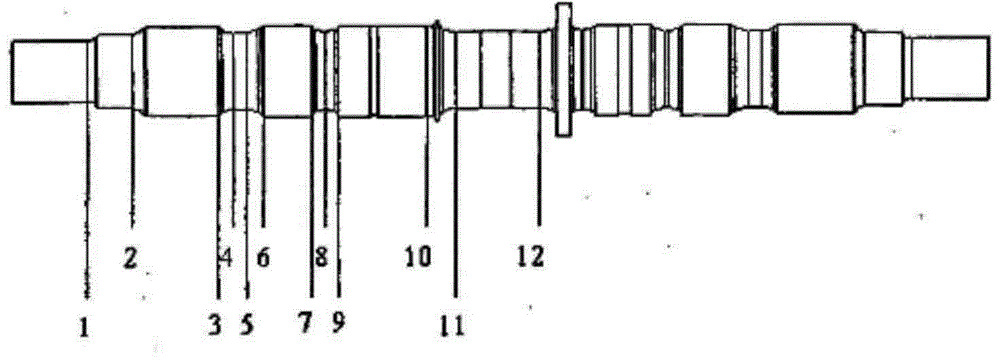

Method for calculating ultrahigh-cycle fatigue crack initiation time

The invention belongs to the fields of quantitative description and life calculation and analysis of ultrahigh-cycle fatigue damage coupling mechanisms of iron system materials and in particular relates to a method for calculating ultrahigh-cycle fatigue crack initiation time. The method comprises the following steps: by adopting principles such as an energy conservation principle, elastic mechanics and fracture mechanics, taking a hollow shaft as an example, establishing a three-dimensional transient temperature field, providing a quantitative model and time calculation method in the ultrahigh-cycle fatigue crack initiation process under the coupling effect, giving novel crack initiation basis, and performing allowable stress design reasoning. The propagation of cracks is discontinuous, the change of outside action time and change of the crack length are in the same direction, and the change speed is influenced by surface energy and yield limit. The scheme has the advantages that the method is based on the quantitative model of the crack initiation under the multi-factor coupling effect when the material interior crack size is zero. The method directly contributes to estimating the observable crack scale and crack initiation time in actual production and is scientific.

Owner:SOUTHEAST UNIV +1

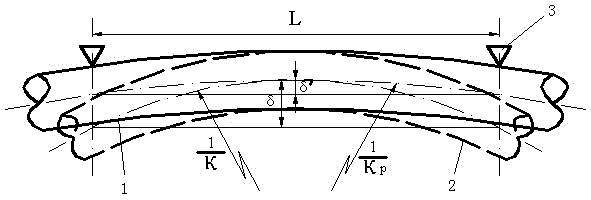

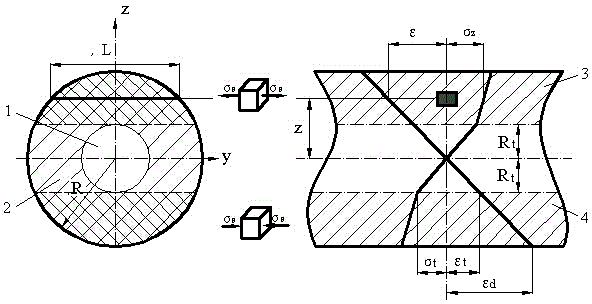

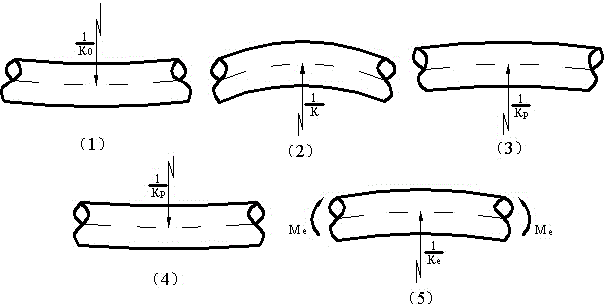

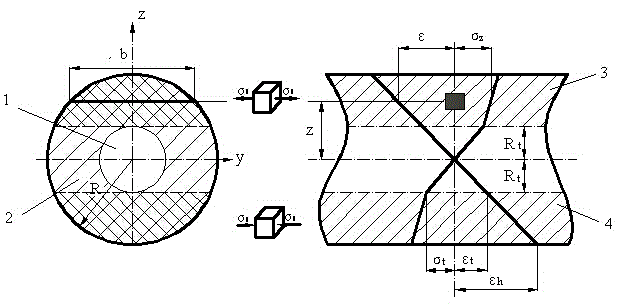

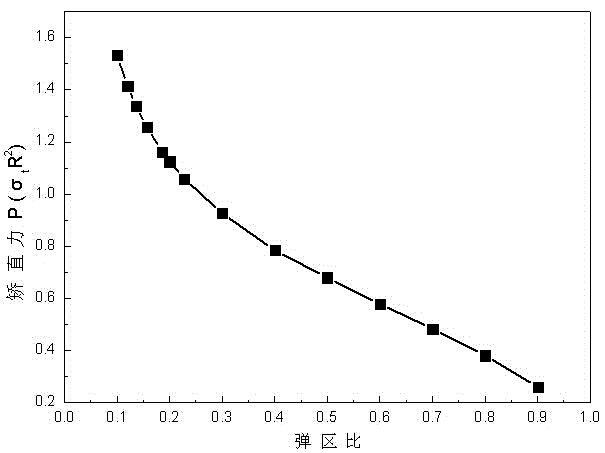

Model for predicting resilience of bar subjected to two roll straightening

ActiveCN104866641AAccurately reflectAccurately describe the stress-strain relationshipSpecial data processing applicationsStress distributionTension compression

The invention relates to a method for predicting resilience of a bar subjected to two roll straightening, and belongs to the technical field of two-roll straightening machines. The method comprises the followings steps: firstly, determining the offset of a stress neutral layer when the rod is subjected to straightening; then, determining a deformation-hardening coefficient and tension-compression stress distribution according to different straightening processes and deformation characteristics of rods in different specifications; finally, determining the model for predicting rebound bending moment and straightening rebound deflection by combining a pure bending and rebound theory, wherein the rebound deflection delta is related to the following variables of R, sigma<t>, lambda, xi, psi, kappa, I, E, L, B, n, R0, Rw, P and tau; R represents a rod radius; sigma<t> represents the yield limit; lambda represents a hardening coefficient; xi represents an elastic region ratio; psi represents a neutral layer offset radius ratio; k represents an anti-bend rate; I represents rod section moment of inertia; E represents modulus of elasticity; L represents the distance between the two end points in three-point bending; B represents a plastic coefficient; n represents a hardening index; R0 represents an initial bending radius; Rw represents an anti-bend radius; P represents straightening force; tau represents a correction coefficient. According to the method, a straightening and deformation process can be truly reflected, and the straightening theory can be perfected; resilience in the straightening process can be accurately predicted, and bases for the roll shape design and process parameter establishment are provided.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

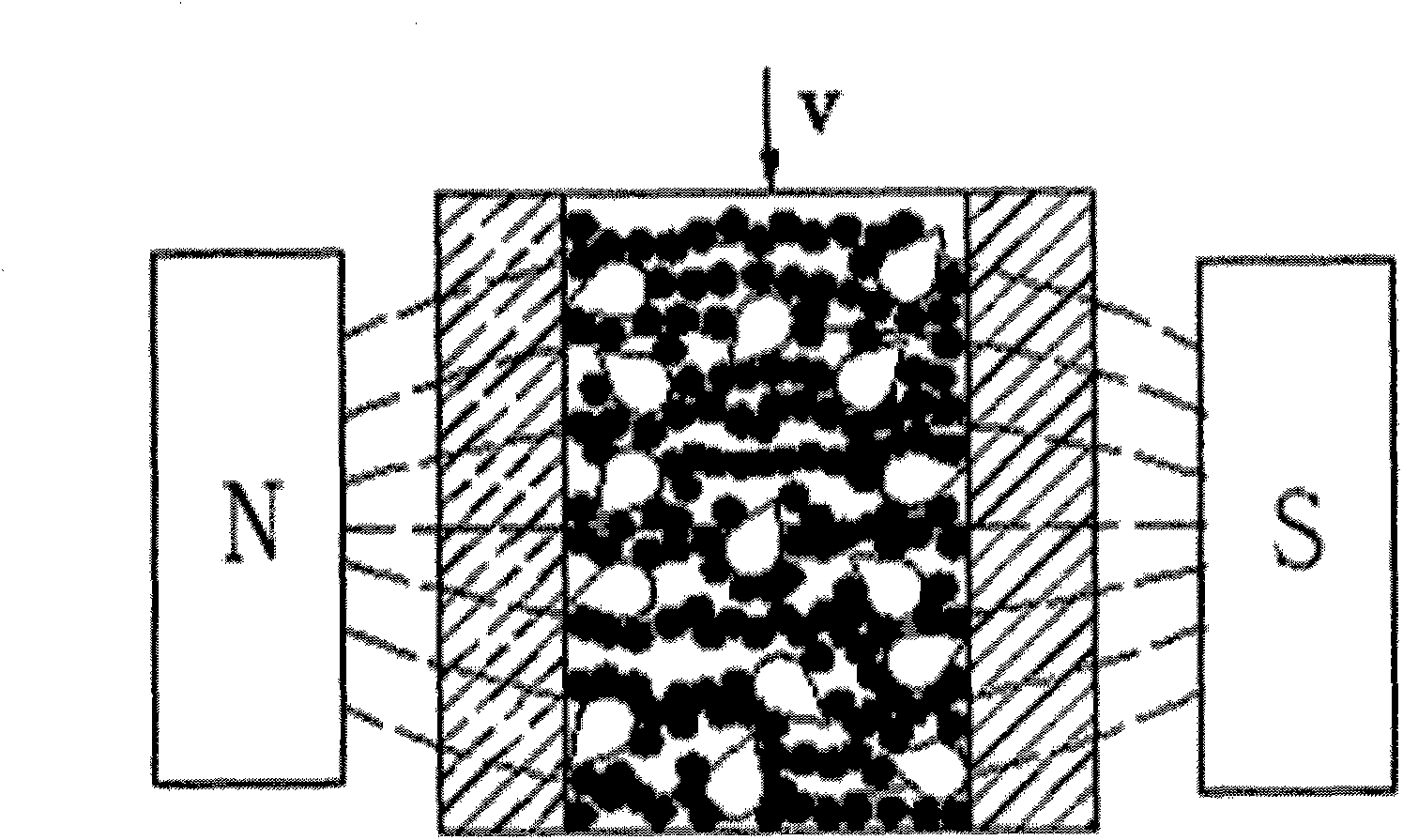

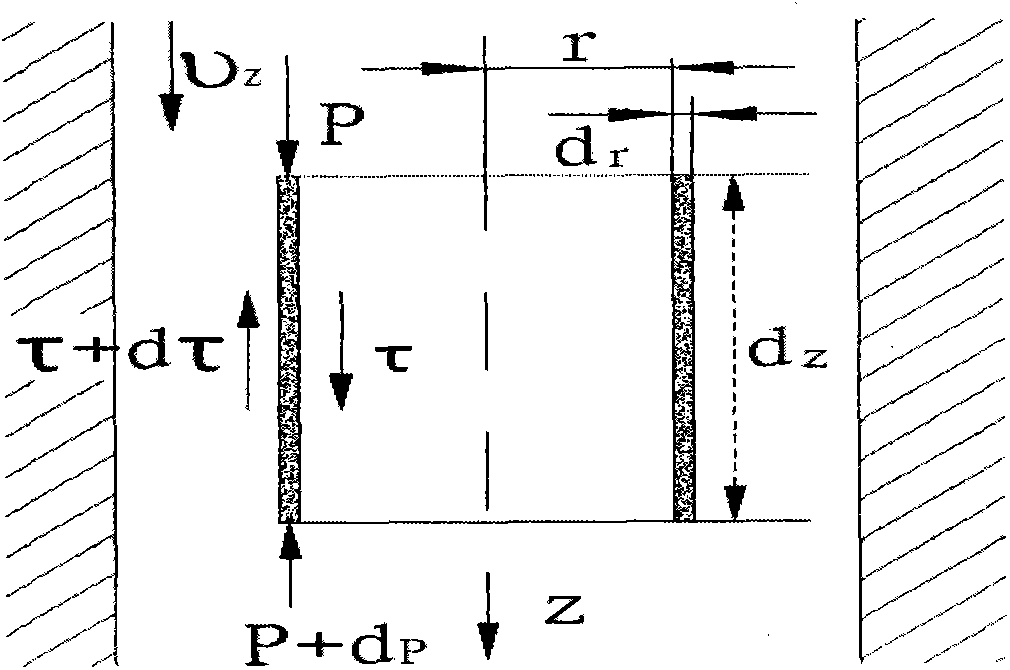

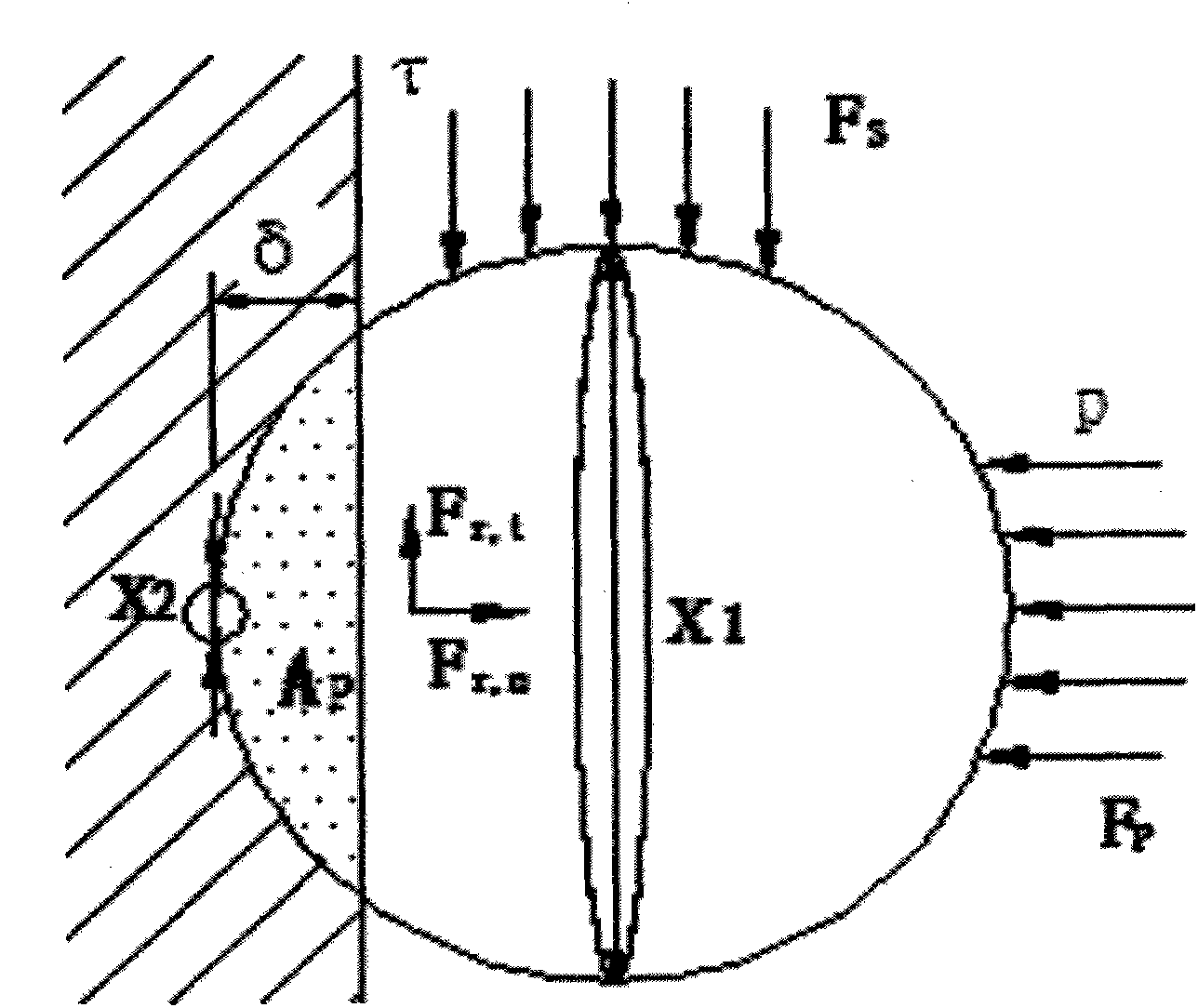

Method for calculating material removal rate for liquid magnetic grinding tool small hole finishing processing

ActiveCN103831673AImprove removal efficiencyImprove surface qualitySpecial data processing applicationsMaterial removalEngineering

The invention relates to a method for calculating a material removal rate for liquid magnetic grinding tool small hole finishing processing. According to magneto-rheological features of a liquid magnetic grinding tool, a material removal mechanism of liquid magnetic grinding tool small hole finishing processing is explained from a microcosmic point of view. A double-blade circle radius model is adopted to serve as a cutting model of a single abrasive particle for research, a mathematical expression of the material removal rate of small hole finishing processing is deduced, theoretical analysis is carried out on influence factors of the mathematical expression, and accordingly it is concluded that the material removal rate of finishing processing is in direct proportion to the square of the diameter of the abrasive particle, shearing stress of the liquid magnetic grinding tool and fluid pressure, and is in inverse proportion to the yield limit of a workpiece material. In a certain range, removal efficiency of the material can be improved by increasing the diameter of abrasive particles, inlet pressure and current intensity, and quality of surfaces obtained after the surfaces are processed for a period of time is correspondingly improved.

Owner:TAIYUAN UNIV OF TECH

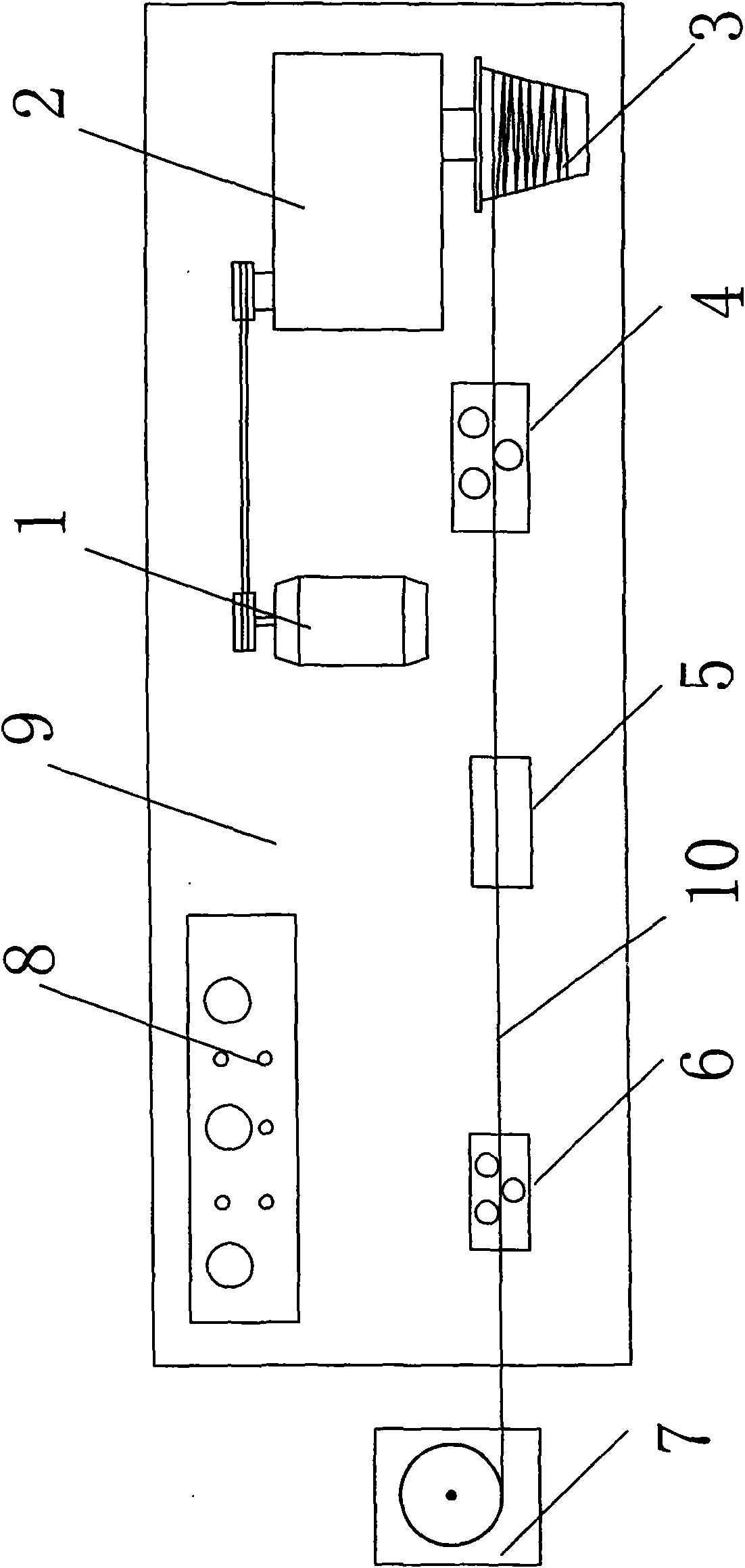

Spiral hoop reinforcement manufacturing machine

InactiveCN101564812AUnique structural designSimple structureOther manufacturing equipments/toolsMetal working apparatusLow speedReduction drive

The invention relates to a spiral hoop reinforcement manufacturing machine, wherein a motor output shaft drives and is connected with a speed reducer, the low-speed end of the speed reducer is connected with a forming disc, a disc round steel wire arranged on a charging tray is dynamically connected with the forming disc through a straightener, a wire drawing machine and a counter, and the forming disc performs wire drawing and hoop reinforcement manufacture while rotating. The spiral hoop reinforcement manufacturing machine has unique structure design, simple and practical structure and low cost, skillfully combines the wire drawing with the spiral hoop reinforcement manufacture to achieve multiple functions by one machine, and performs square and polygon cold enwinding by using drawing force close to a steel wire yield limit generated in the cold drawing process of the steel wire; and because the drawing force is close to the steel wire yield limit, after the cold enwinding and forming, elastic deformations are not generated so that the dimension is stable and unchanged and the spiral hoop reinforcement is formed after continuous enwinding. The spiral hoop reinforcement manufacturing machine not only reduces the production cost, but also improves the production working efficiency by more than 10 times, thus the machine can achieve production increment, synergy, consumption reduction and energy conservation.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

Production technology of longitudinal beam of high-strength heavy load truck

InactiveCN101602165AOvercome insurmountable problemsNoveltyOther manufacturing equipments/toolsVehicle frameHeavy load

The invention relates to a production technology of a longitudinal beam of a high-strength heavy load truck, comprising the following steps of: A, coiling materials; B, uncoiling; C, slitting; D, leveling; E, carrying out rolling shaping; F, carrying out quenching heat treatment, wherein the quenching temperature is 840 to 870 DEG C; G, punching, wherein the punching diameter is less than or equal to two times of that of the plate thickness; H, cutting holes which can not be punched by laser; and I, transferring into other procedures. Based on the existing technology, a quenching heat treatment technology is added before punching so as to achieve the aim of producing a high-strength longitudinal beam. If high-strength materials are directly adopted and purchased, the production technology at present is very difficult to realize, so all manufacturers do not adopt single-beam truck frames at present. By adopting the technology to carry out heat treatment, the mechanical property of the longitudinal beam is enhanced, and especially the yield limit can reach 800 to 900MPa. As the high-strength longitudinal beam is used, the strength of the car frame can be greatly enhanced by plate materials with the same thickness, a secondary beam can be cancelled simultaneously, so the total weight of the car frame can be reduced.

Owner:SINO TRUK JINAN POWER

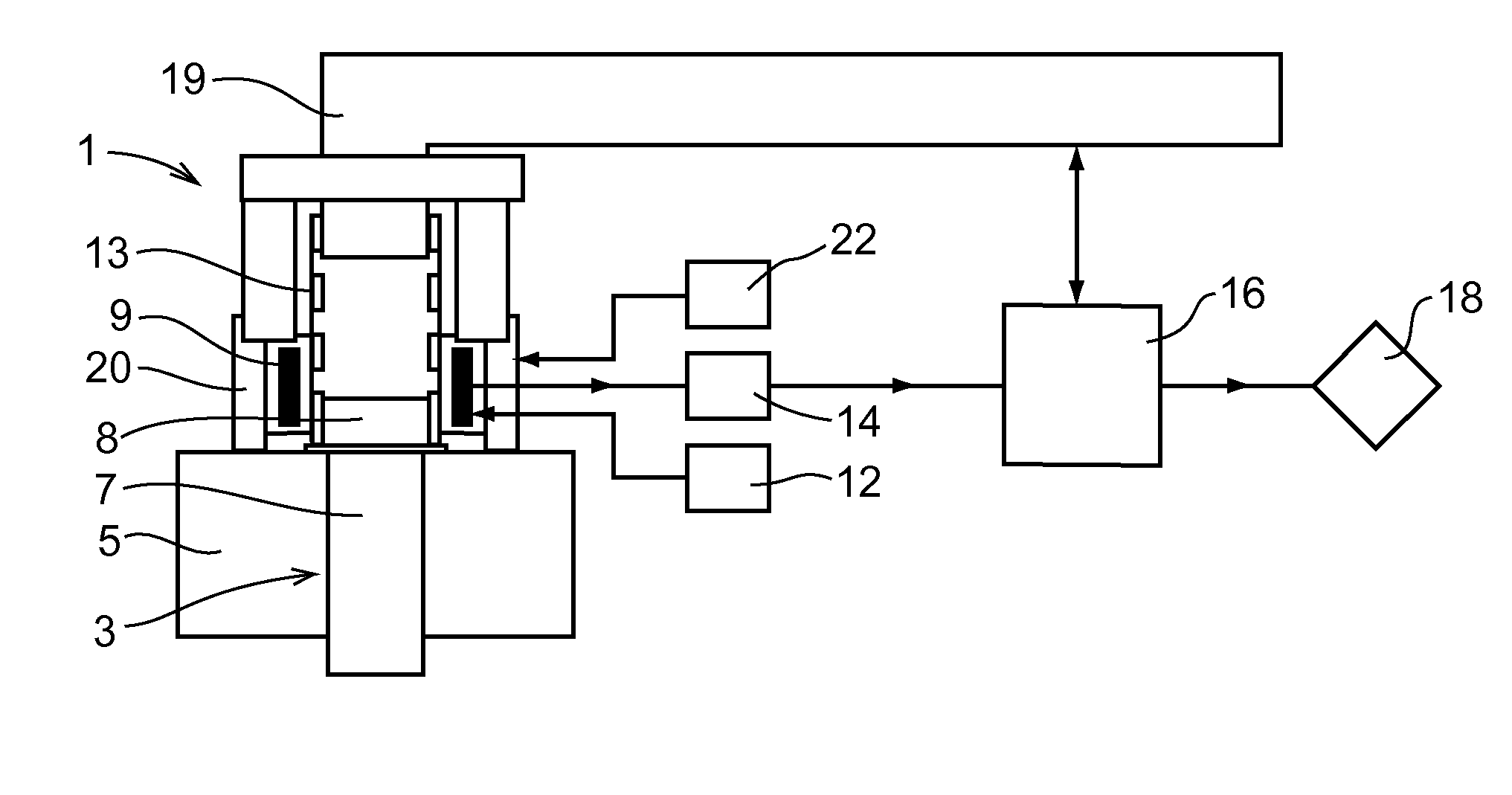

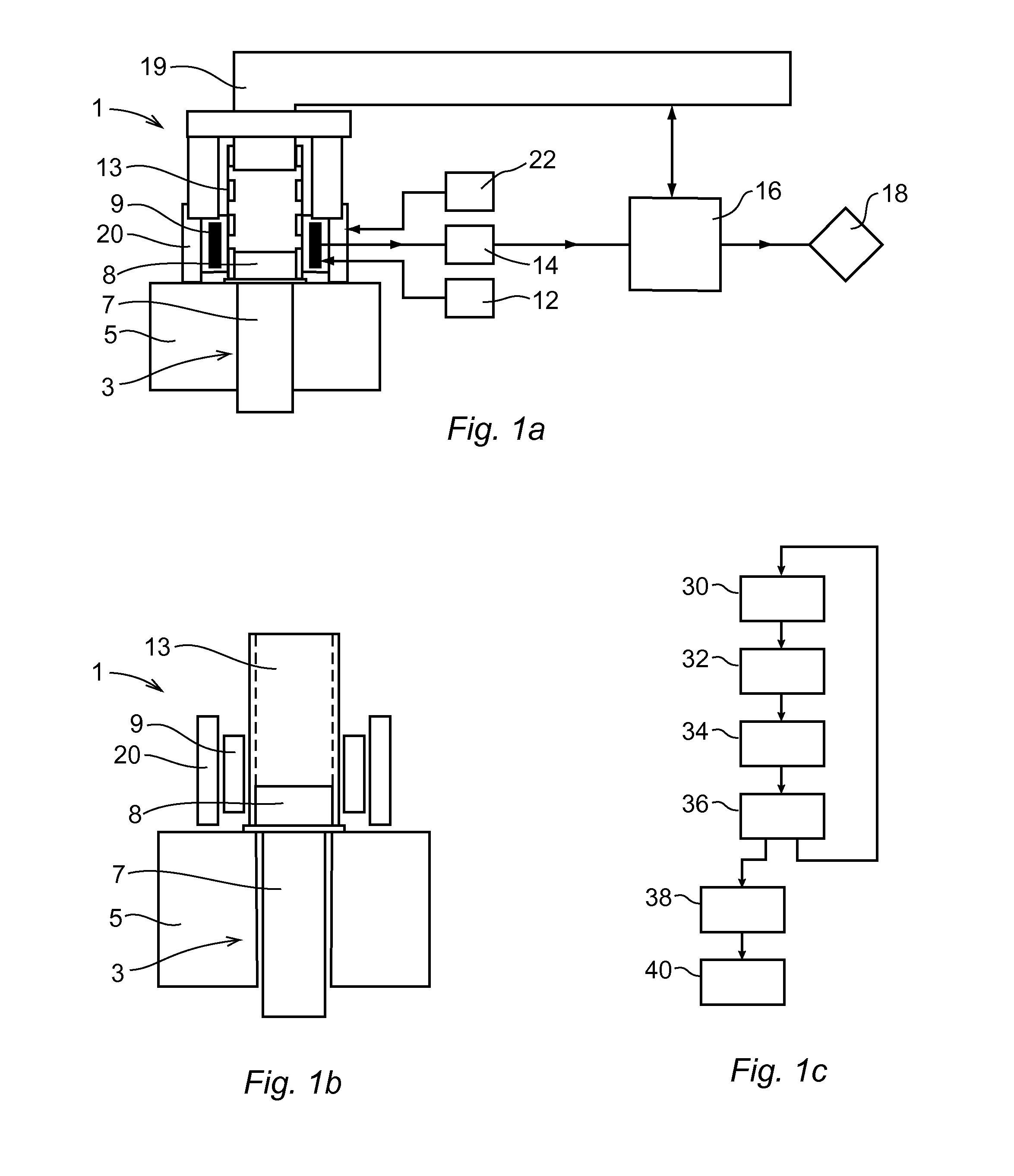

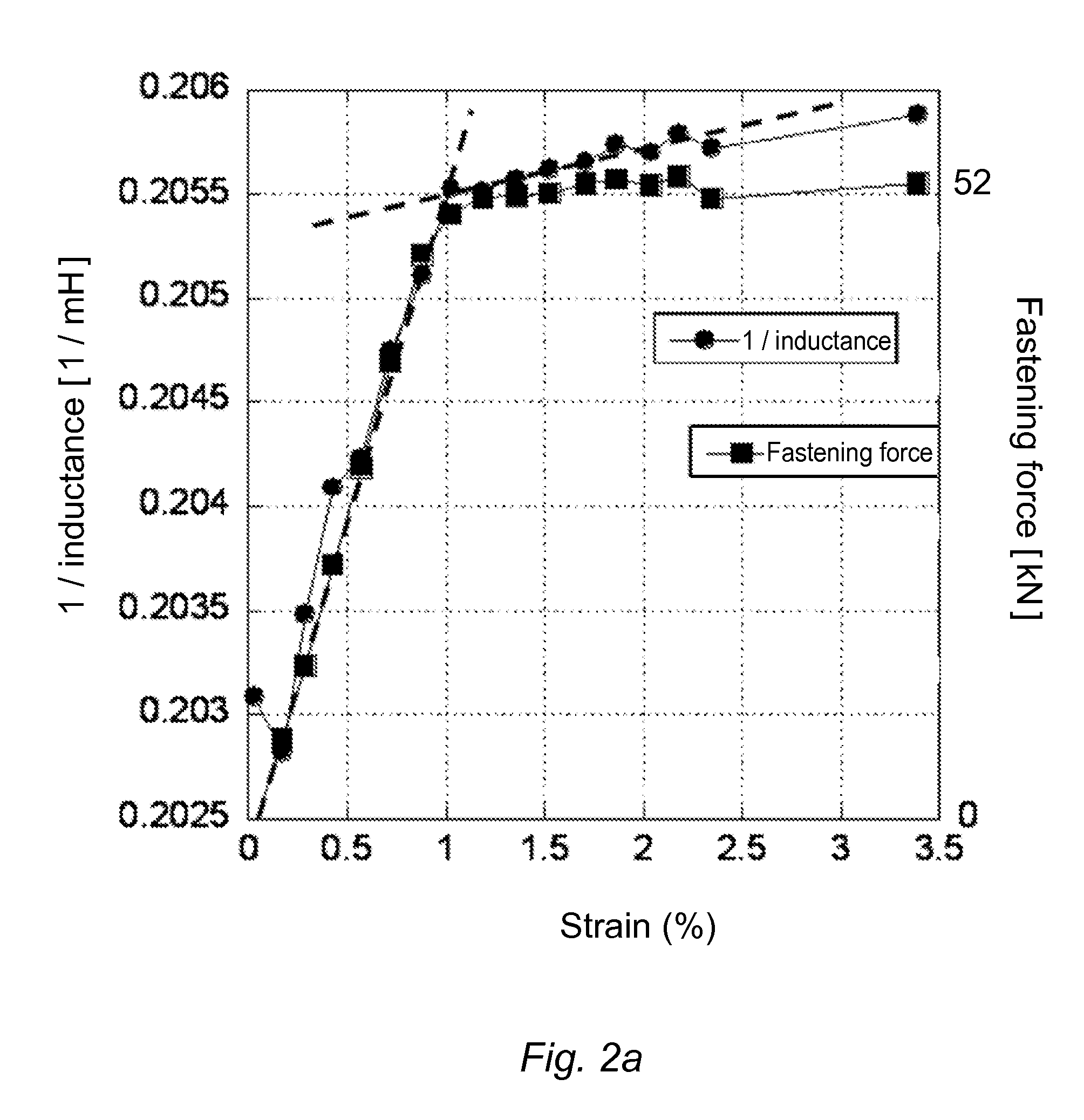

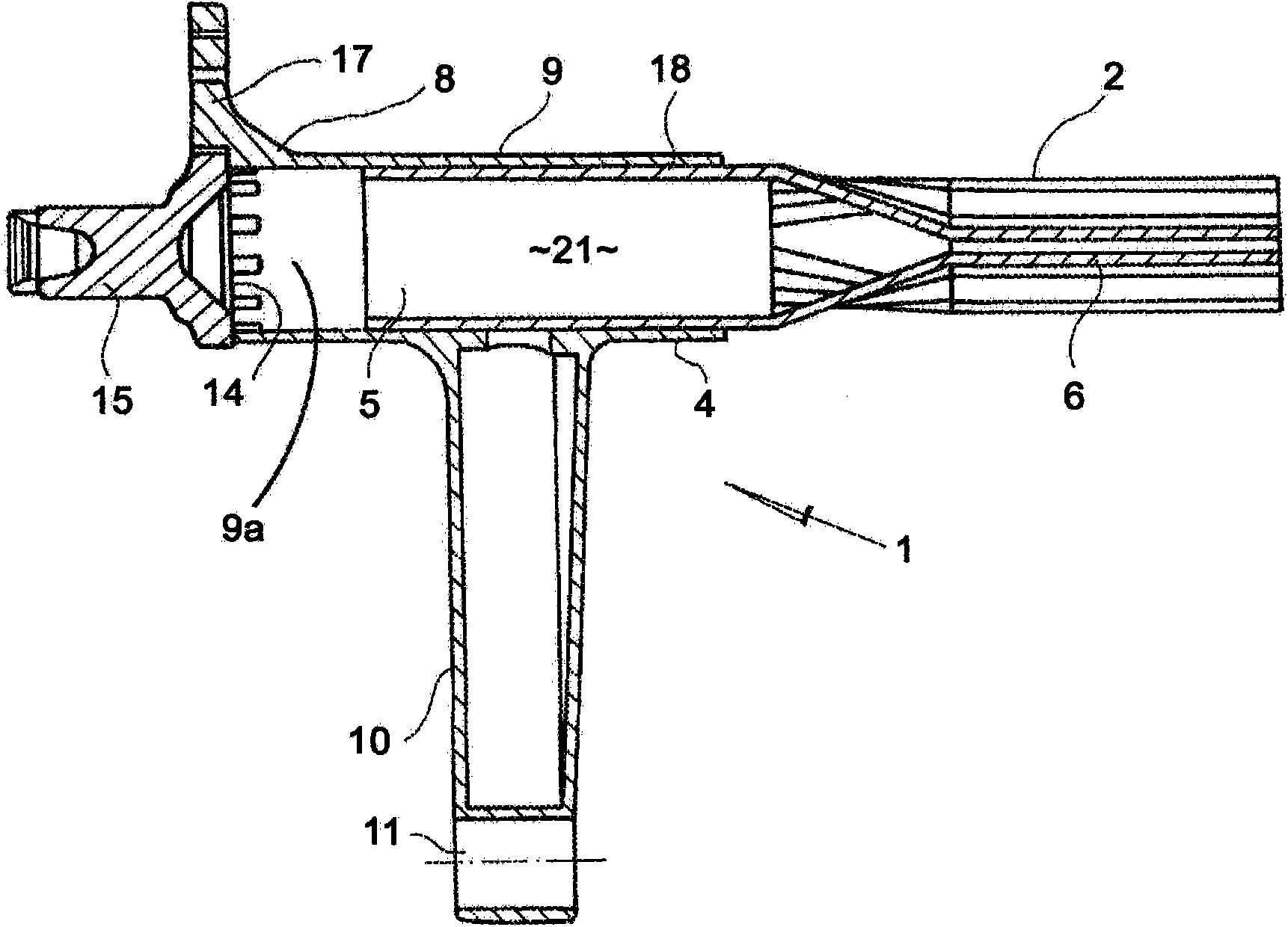

Device and method for indicating if a fastening element has reached a tensile yield limit load

ActiveUS8910526B2Simple structureReduce riskForce measurement by measuring magnetic property varationWrenchesMagnetic susceptibilityEngineering

A device and method for indicating if a fastening element upon fastening to a piece has reached a tensile yield limit load. The fastening element includes a threaded shaft having a magnetostrictive material. The device includes a mechanism for generating an alternating magnetic field that penetrates the shaft, a mechanism for measuring a physical quantity that depends on the momentary magnetic susceptibility of the shaft and a control unit adapted to detect a significant change of the physical quantity and determine and indicate if the shaft of the fastening element has reached the tensile yield limit load.

Owner:CARBON COMPENSATE SCANDINAVIA AB (ID 556784 0847)

Method for optimizing tension system of cold continuous rolling unit by taking crack control as target

ActiveCN109550791AGuarantee product qualityIncrease productivityGeometric CADTension/compression control deviceAttenuation coefficientUltrasound attenuation

The invention discloses a method for optimizing a tension system of a cold continuous rolling unit by taking crack control as a target. The method comprises the following steps (a) parameters of equipment and processes of the cold rolling unit are collected, wherein the parameters comprise radii of rack working rollers, surface line speed of the rack working rollers, original roughness of the rackworking rollers, rough degree attenuation coefficients of the working rollers and rolling kilometers of the rack working rollers after roller exchange; and (b) rolling process parameters of strip steel are collected, and the rolling process parameters comprise elastic modulus of the strip steel, the poisson ratio of the strip steel, the width of the strip steel, the strip steel inlet thickness ofeach rack, the strip steel outlet thickness of each rack, the press-down rate, the inlet speed of the strip steel before each rack, strip steel deformation resistance and strip steel shear yield limit. According to the method, a proper tension system optimization value is given by combining equipment and process characteristics of the cold continuous rolling unit, the quality of strip steel products in the high-speed rolling process of the cold continuous rolling unit is guaranteed, and the production efficiency of plate and strip production enterprises is improved.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

Machining process for internal combustion engine expansion breaking connecting rod

The invention discloses a machining process for an internal combustion engine expansion breaking connecting rod. The machining process includes the steps of forging and pressing forming, wherein a blank is formed to be a workblank of the internal combustion engine expansion breaking connecting rod; normalizing, wherein the workblank of the internal combustion engine expansion breaking connecting rod meets mechanical property requirements for the workblank; shot blasting and flaw detection, wherein oxide skin on the surface of the workblank of the internal combustion engine expansion breaking connecting rod and generated due to heating in the forging and pressing forming is removed, and it is guaranteed that flaw and folding defects do not exist in the surface of a product; chipping machining, wherein the workblank of the internal combustion engine expansion breaking connecting rod is machined to be an internal combustion engine expansion breaking connecting rod finished product. According to the machining process, parameters of mechanical properties such as the tensile strength, the yield limit, elongation and percentage reduction of area of the connecting rod are all increased to some extent, the mechanical properties of the connecting rod are improved on the whole, the tensile property and the impact resistance degree are greatly improved compared with those of existing materials, and the connecting rod can be well adapted to operating needs of high-power internal combustion engines.

Owner:ZHEJIANG YUEJIN MACHINERY

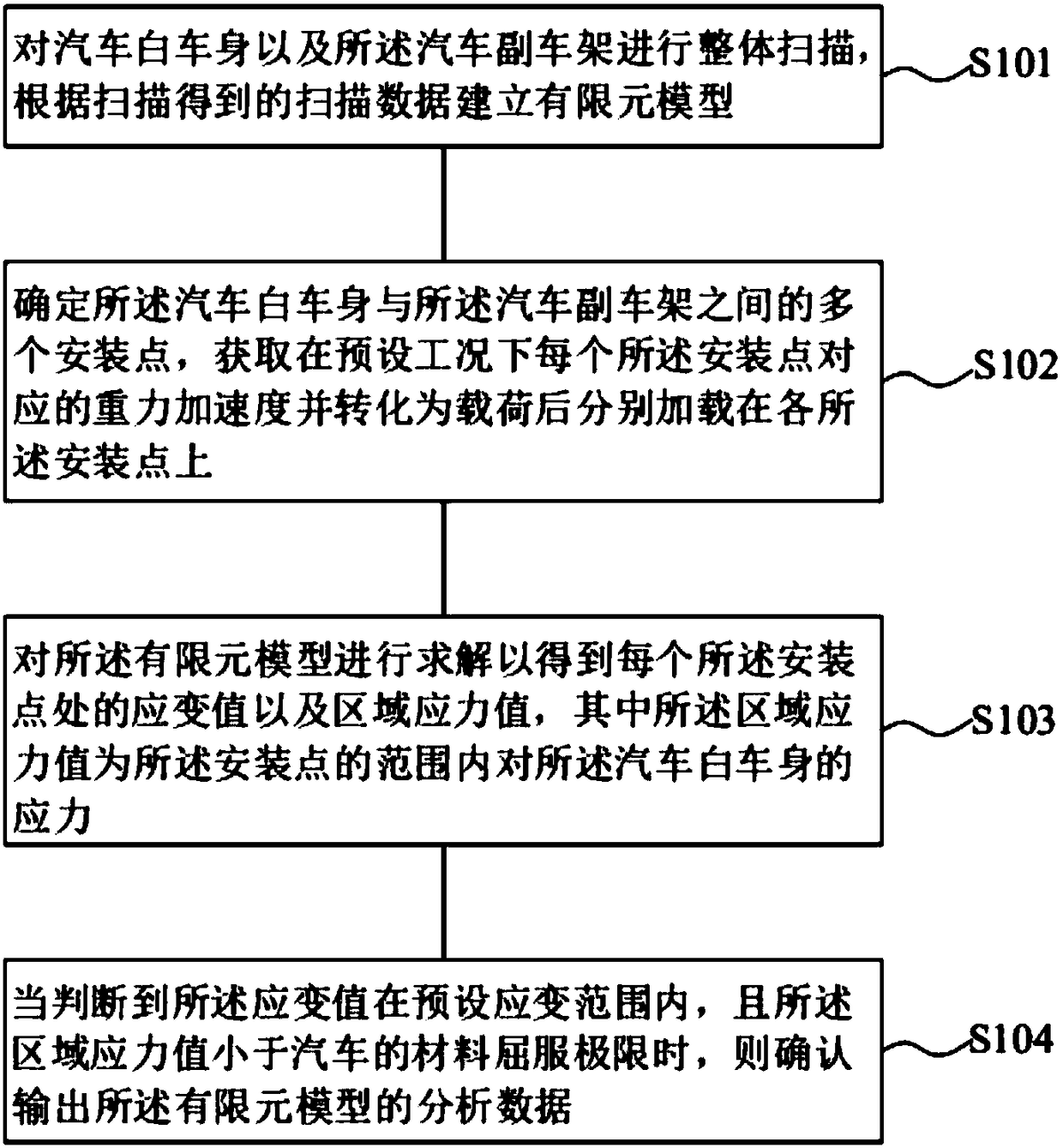

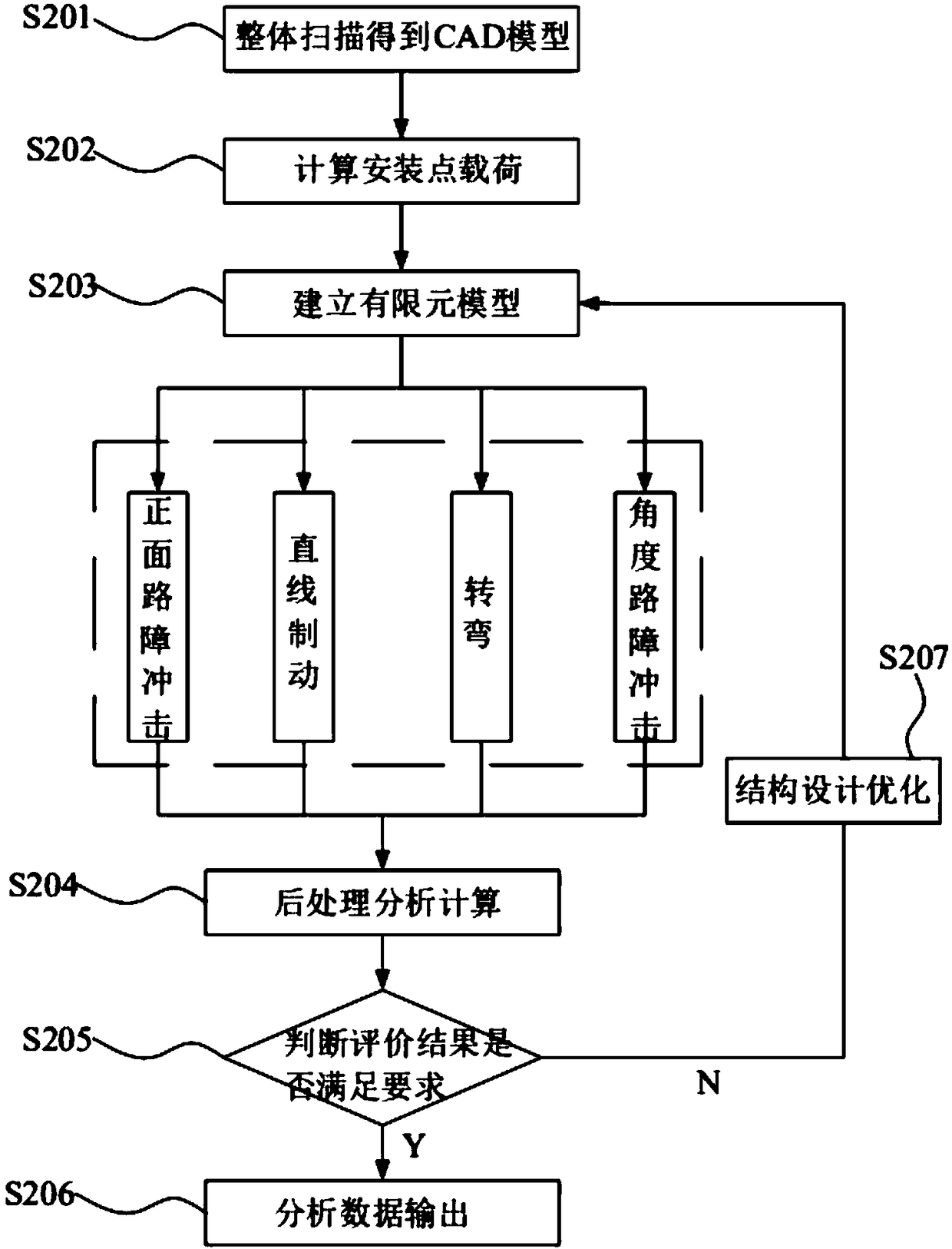

Analysis method of installation point strength of automobile sub-frame

PendingCN108520119ASolve the problem that the accuracy still needs to be improvedGeometric CADDesign optimisation/simulationElement modelAnalysis data

The invention discloses an analysis method of installation point strength of an automobile sub-frame. The method comprises the steps that overall scanning is conducted on an automobile body-in-white and the automobile sub-frame to establish a finite element model according to scanning data obtained through scanning; multiple installation points between the automobile body-in-white and the automobile sub-frame are determined, and corresponding acceleration of gravity of each installation point under preset working conditions is obtained, converted into loads and loaded on each installation point respectively; the finite element model is solved to obtain strain values and regional stress values of each installation point, wherein the regional stress values are the stress on the automobile body-in-white within ranges of the installation points; when it is detected that the strain values are within preset strain ranges and the regional stress values are smaller than the yield limit of materials of an automobile, the outputting of the analysis data of the finite element model is confirmed. By means of the analysis method, it is ensured that strength data of each installation point conforms to preset standards, and the overall safety coefficient of a product is improved.

Owner:JIANGLING HLDG

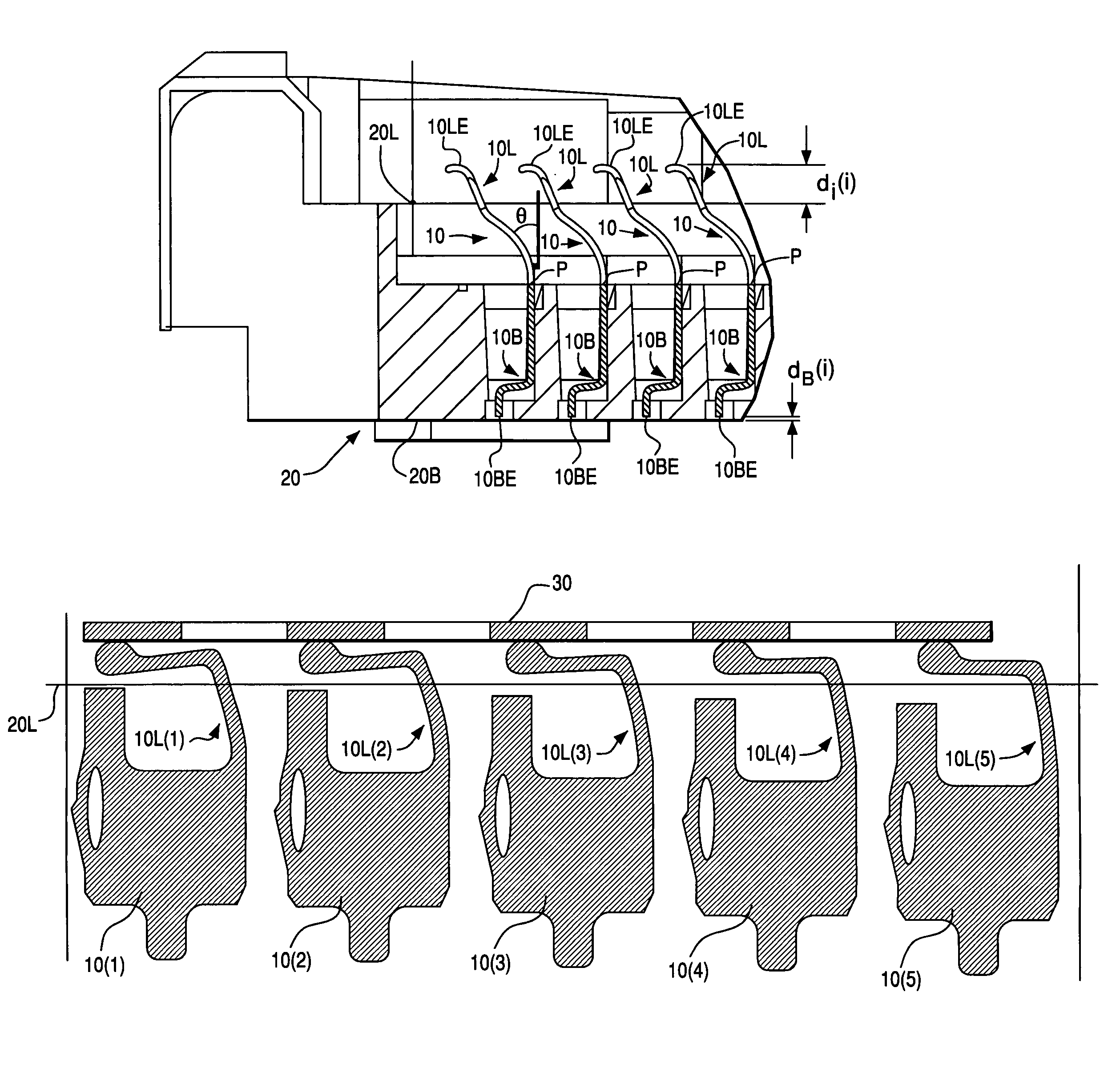

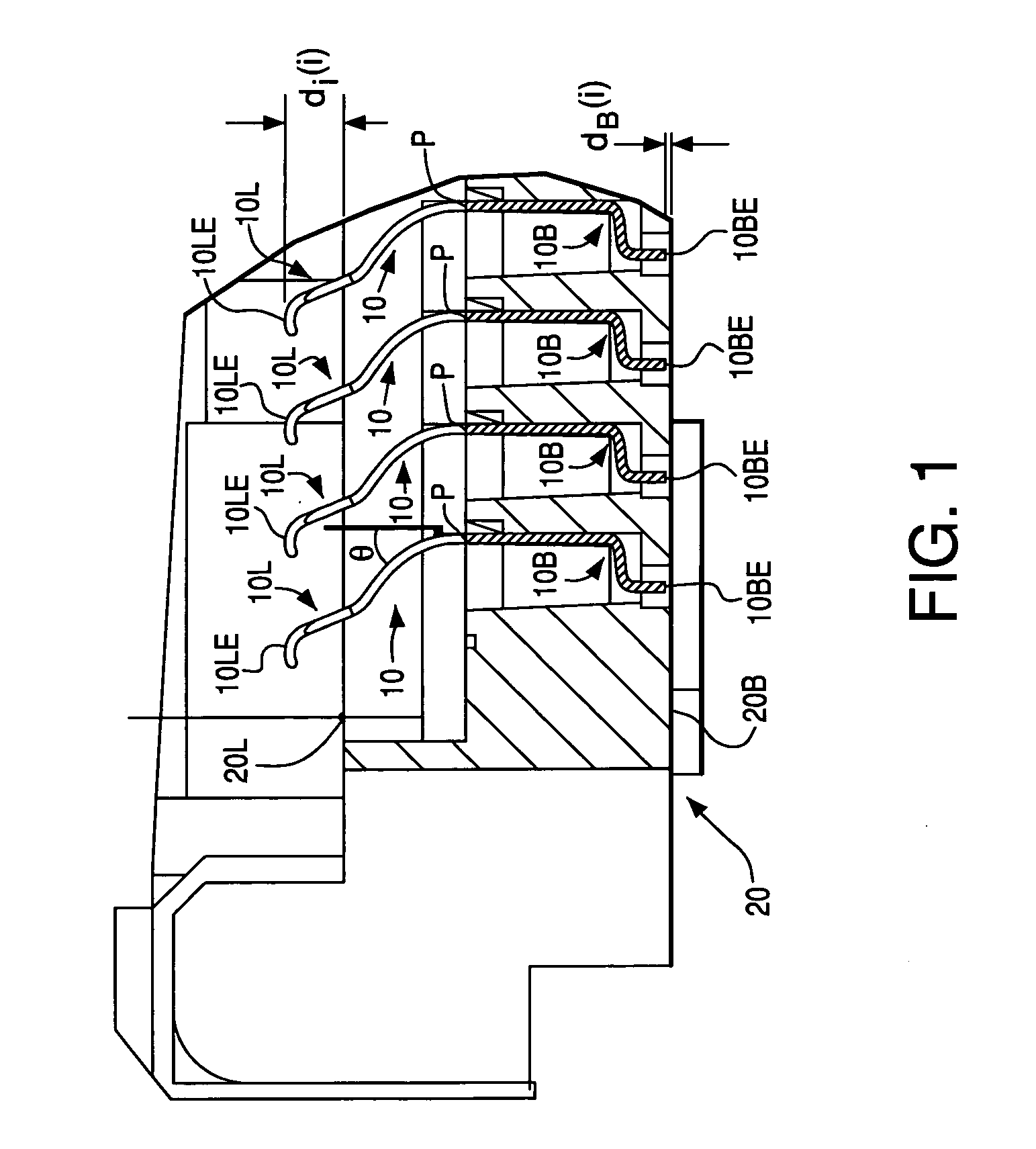

Methods for controlling contact height

InactiveUS7210225B2Reduce variationElectrical apparatus contructional detailsConnection formation by deformationEngineeringElectrical connector

Methods for setting contact height in an electrical connector are disclosed. Each of a plurality of electrical contacts may be seated in a connector housing such that each contact has a respective initial height relative to the housing. At least one of the contacts is pressed on such that, after the pressing, each of the contacts has approximately the same height relative to the connector housing. The pressing may bend the at least one contact at least until it has set. Before the pressing, the initial contact heights have a first tolerance. After the pressing the pressed contact heights have a second tolerance that is smaller than the first tolerance. The pressing operation bends the contacts to a point that exceeds the yielding limit of the contact material, and may deform the contacts such that the several contacts have about the same contact height relative to the connector housing.

Owner:FCI AMERICAS TECH LLC

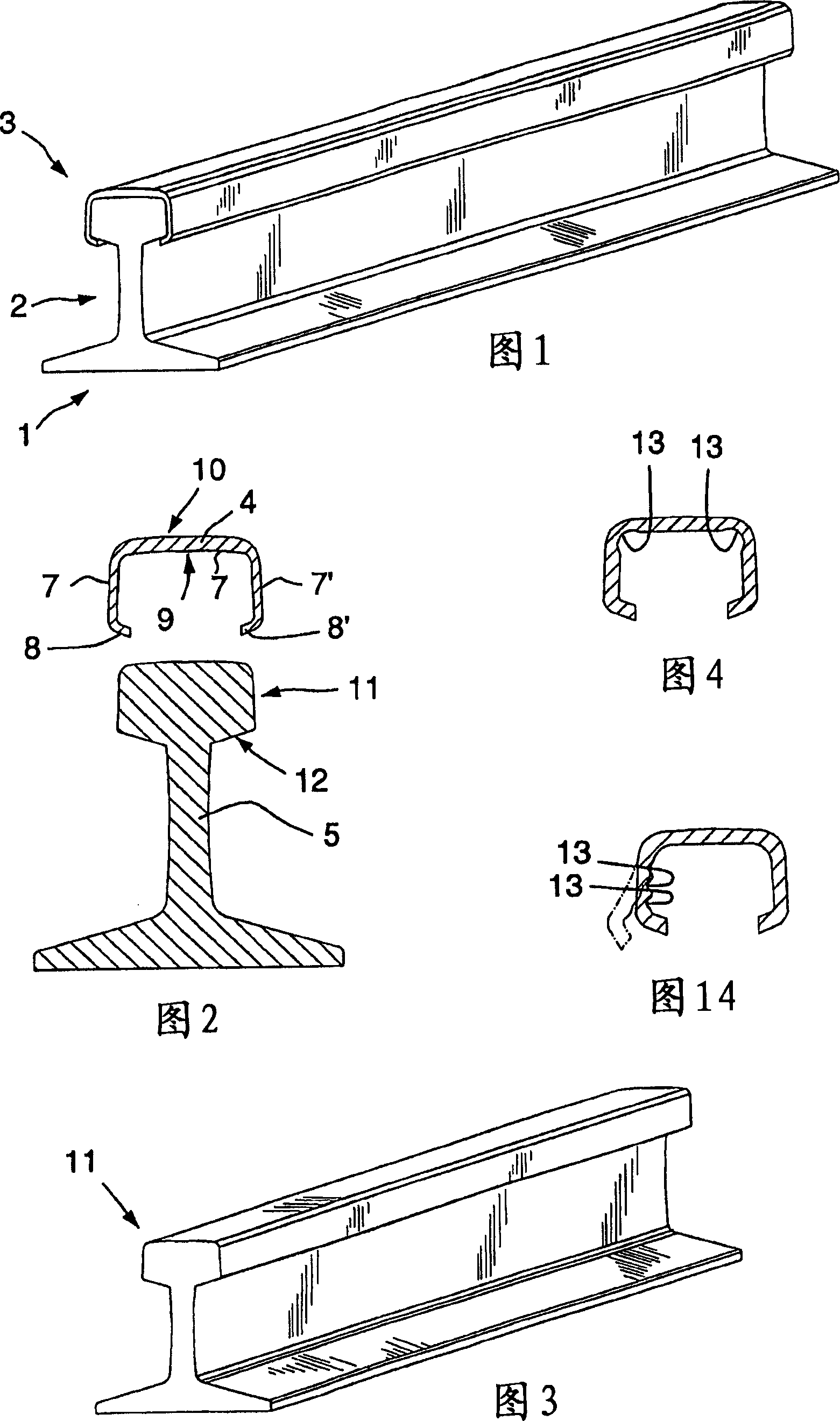

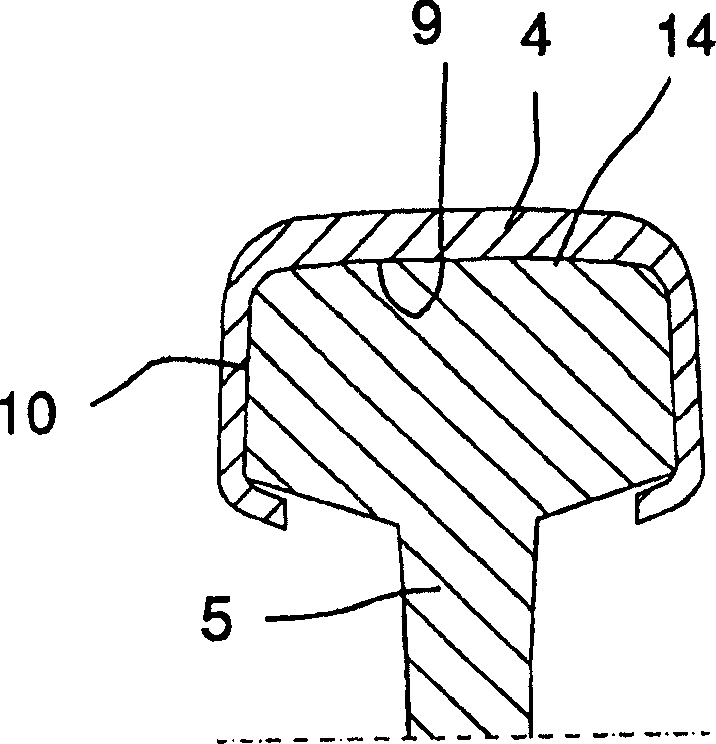

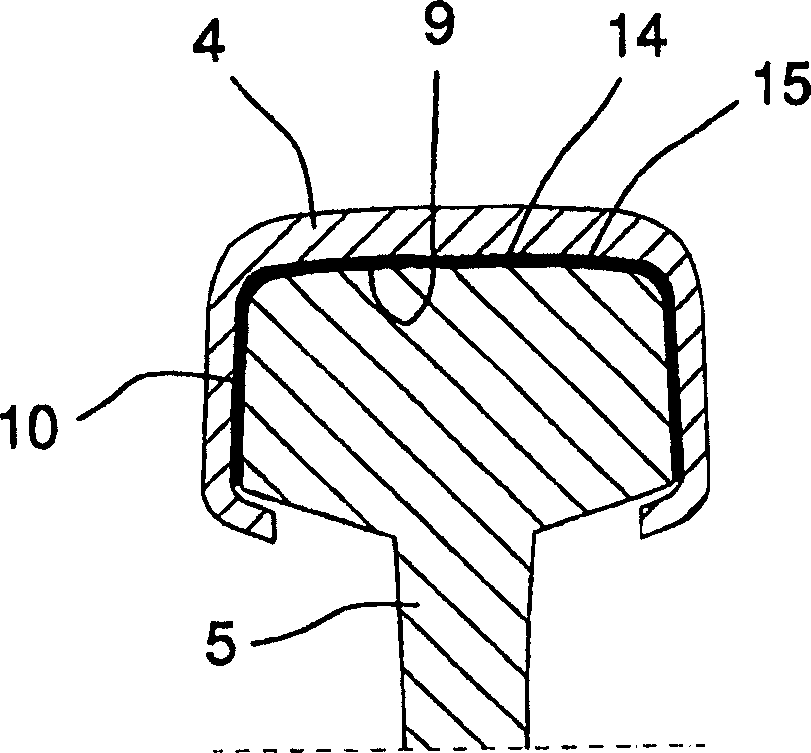

Guide rail of compound type and a method for manufacturing such a rail

The invention concerns a guide rail of compound type and a method of manufacturing such a guide rail. The guide rail is made like a railway rail or similar and intended for guiding interaction with a wheel of a unit travelling along the rail, comprising a long outer rail (4) made of sheet metal exhibiting the shape of a longitudinal open channel with defined inside (9) and outside (10), a long base rail (5) exhibiting a foot (1) for mounting the rail to a surface, a web (2) extending from the foot supporting a main part (3), which, in comparison to the web, is thicker and serves as a receptacle (11) for receiving and supporting the outer rail, whereby the outer rail has an outer profile that has been chosen to provide a guiding interaction with the wheel. According to the invention, the inside (9) of the outer rail (4) and the receptacle section (11) exhibit opposing section shapes, that the outer rail (4) has a yield limit exceeding that of the base rail (5) and that both parts are joined together by adhesive binding such as welding or gluing.

Owner:安德斯 松德格伦

Method for preventing lining plate of ball grinder from cracking

InactiveCN101623746AReduce downtimeIncrease effective volumeFoundry mouldsFurnace typesEngineeringLost-foam casting

The invention relates to a method for preventing a lining plate of a ball grinder from cracking, which is suitable for improving the lining plate of the prior ball grinder and aims to enhance the yield limit of the lining plate of the ball grinder. The method adopts high manganese steel materials, such as ZGMn13Cr2Mo and ZG32Mn9SiCr2MoRe or ZGMn9Cr2ReSi, containing metallic elements, i.e. Cr, Mo, and the like to manufacture an end lining plate, a cylinder body lining plate and a grid lining plate of the ball grinder by a lost foam casting method and needs to carry out heat processing for cast and formed lining plates before the lining plates are installed to be used. The method comprises the following steps: firstly, placing the lining plates into a furnace to be heated to 200 DEG C-300 DEG C, and preserving the temperature of the lining plates for 1-2 hours; then heating the lining plates to 650 DEG C-680 DEG C according to the speed of 40 DEG C-50 DEG C / hour, and preserving the temperature of the lining plates for 4.5-5 hours; then heating the lining plates to 1060 DEG C-1090 DEG C according to the speed of 60 DEG C-70 DEG C / hour, and preserving the temperature of the lining plates for 3.0-4.0 hours; taking the lining plates out of the furnace, placing the lining plates into water to subject to water toughening processing, then placing the lining places into a tempering furnace to be heated to 300 DEG C-350 DEG C according to the speed of 40 DEG C-50 DEG C / hour, and preserving the temperature of the lining plates for 6-8 hours; then cooling the lining plates at the speed of 1.5-2.5 min / mm; tempering the lining plates into the furnace, and controlling the temperature of the lining plates below 150 DEG C.

Owner:TAIYUAN IRON & STEEL GROUP

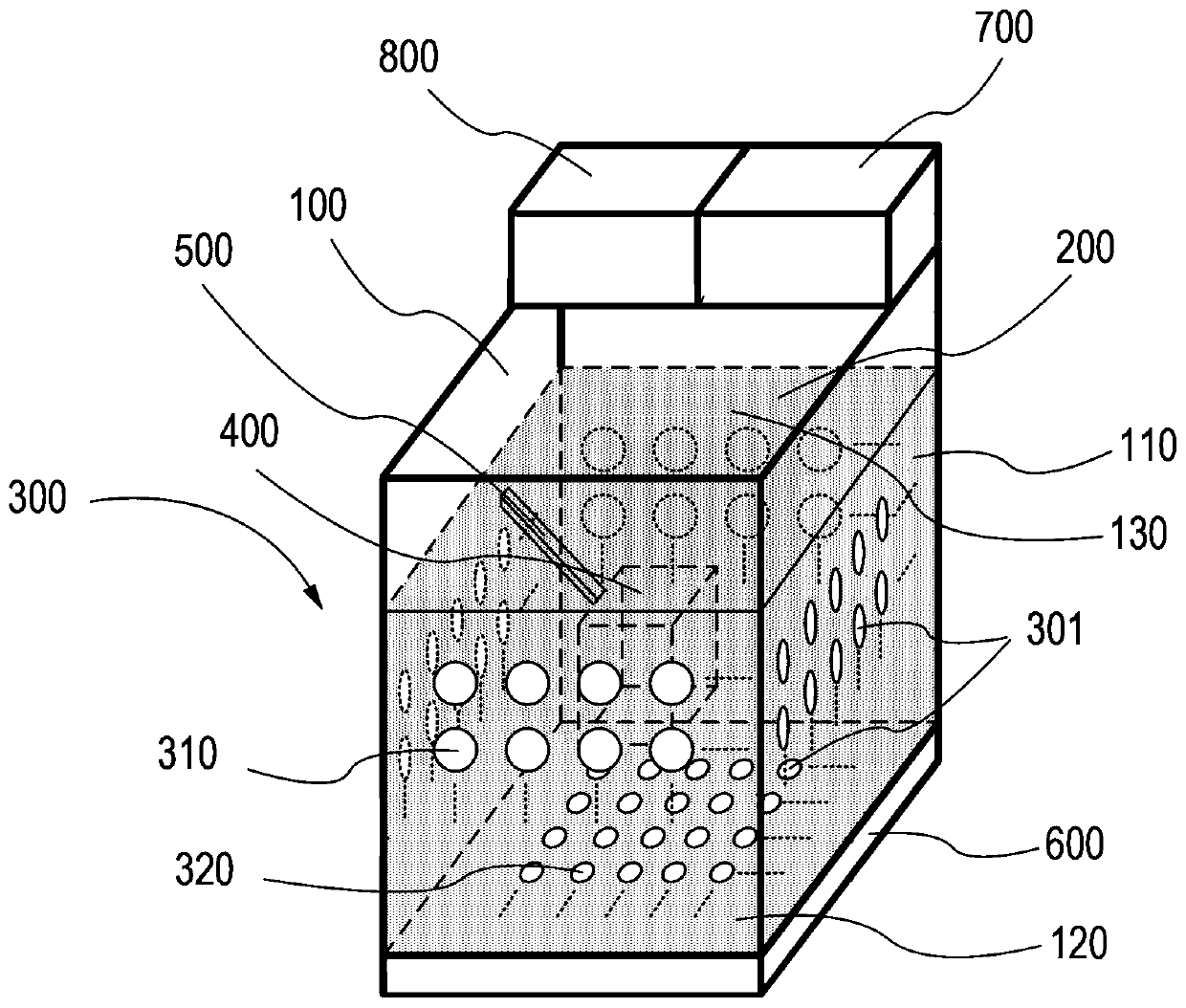

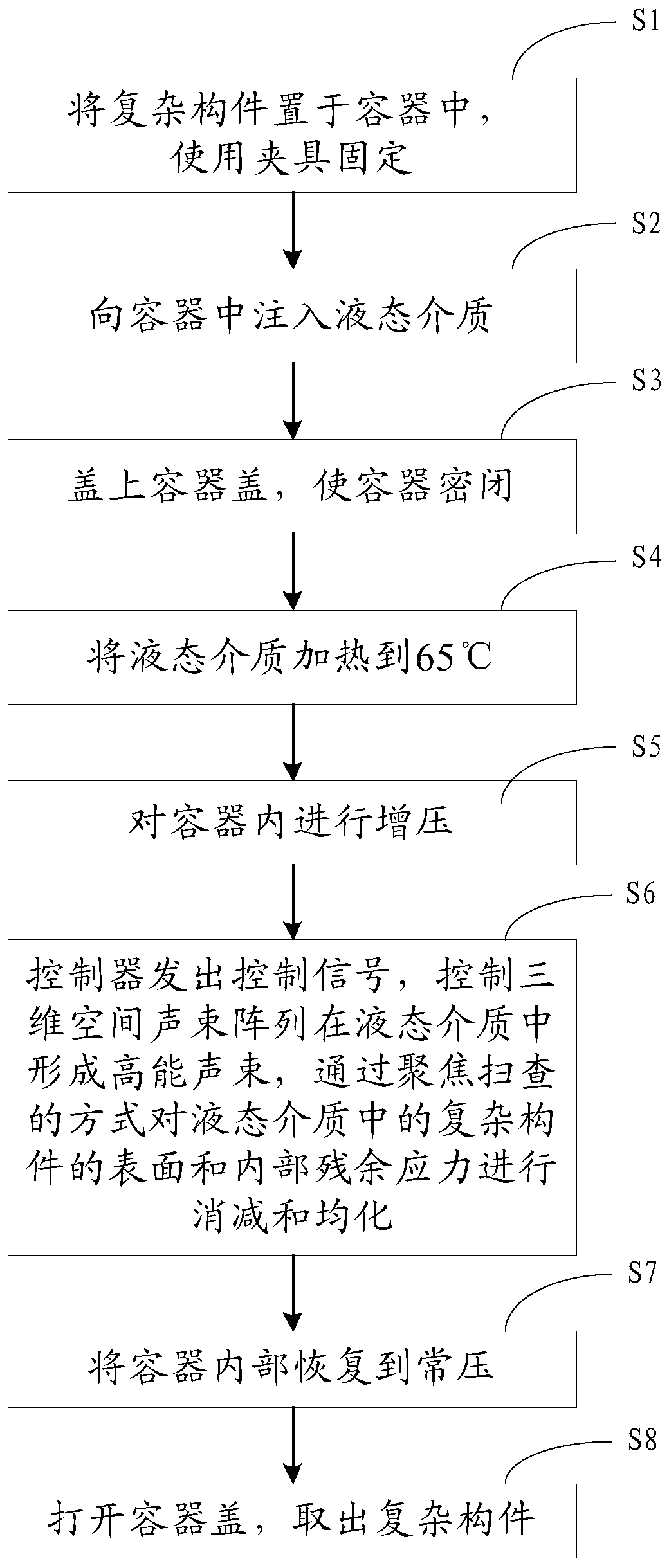

Device and method for reducing and homogenizing residual stresses of complex component

ActiveCN110172566AReduce residual stressProcess efficiency improvementMechanical componentsHigh energy

The invention discloses a device and method for reducing and homogenizing the residual stresses of a complex component. The complex metal or nonmetal mechanical component with residual stresses distributed on the surface and interior are placed in a liquid fluid medium or soft medium with high-energy acoustic beams; the high-energy acoustic beams generated by high-energy ultrasonic transducer arrays radiate to the surface and interior of the complex structural component; alternating dynamic stresses and residual stresses, which are applied to residual stress concentration areas by high-energyelastic waves in the component, are superposed by means of focused scanning; and when the total of the stresses is greater than the yield limit of the material, the component generates plastic deformation, and finally the residual stresses inside the component are reduced and homogenized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

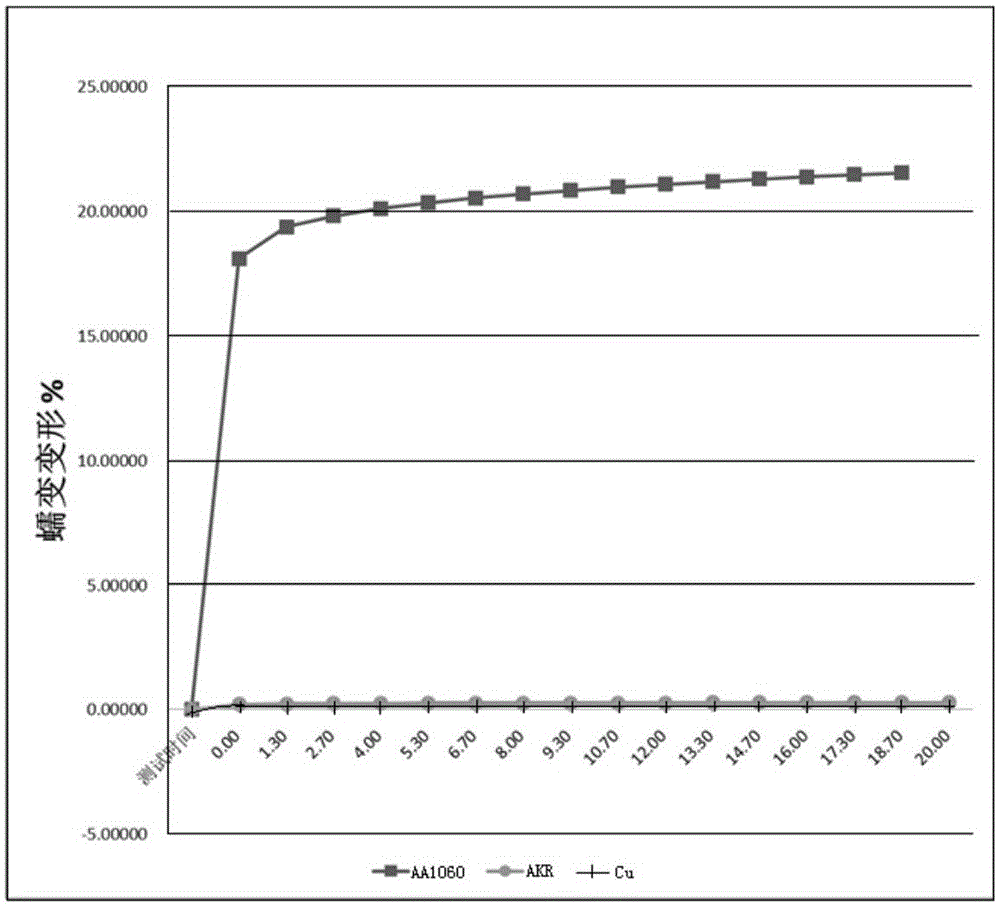

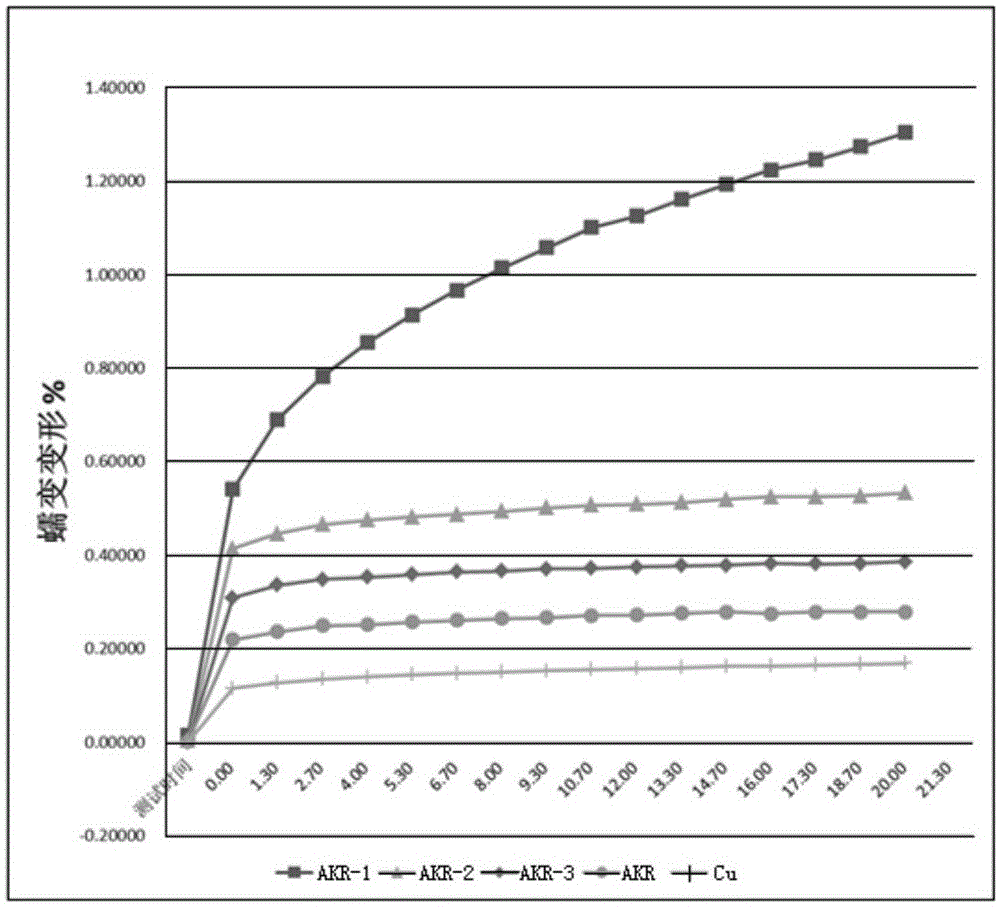

High-conductivity compressive-creep-resistant aluminum alloy and manufacturing method thereof

ActiveCN105132767AHigh tensile strengthHigh yield limitMetal/alloy conductorsCompressive creepRare earth

The invention discloses a high-conductivity compressive-creep-resistant aluminum alloy. The high-conductivity compressive-creep-resistant aluminum alloy comprises the following components in percentage by mass: 0.25%-2.5% of copper, 0.3%-2.8% of magnesium, 0.03%-0.5% of rare earth, 0.3%-1.2% of iron and the balance of aluminum. The invention further discloses a manufacturing method for the high-conductivity compressive-creep-resistant aluminum alloy. The manufacturing method comprises the following steps: (1) pre-treating an alloy raw material; (2) carrying out batching, melting and in-furnace treatment on the alloy raw material; (3) carrying out online refining treatment on a molten aluminum alloy; and (4) casting and forming the alloy. The obtained aluminum alloy material not only has high tensile strength and yield limit, but also has excellent electrical conductivity, and good thermal stability of a resistor at a high temperature; more importantly, at the high temperature, the aluminum alloy material has very excellent compressive creep resistance, is a major breakthrough of replacing copper with aluminum in the electrotechnical industry, greatly solves the defect caused by creep property difference in an aluminum alloy conductor material application process, and meets performance requirements of the aluminum alloy material while applied in the electrotechnical industry.

Owner:深圳阿尔泰克轻合金技术有限公司

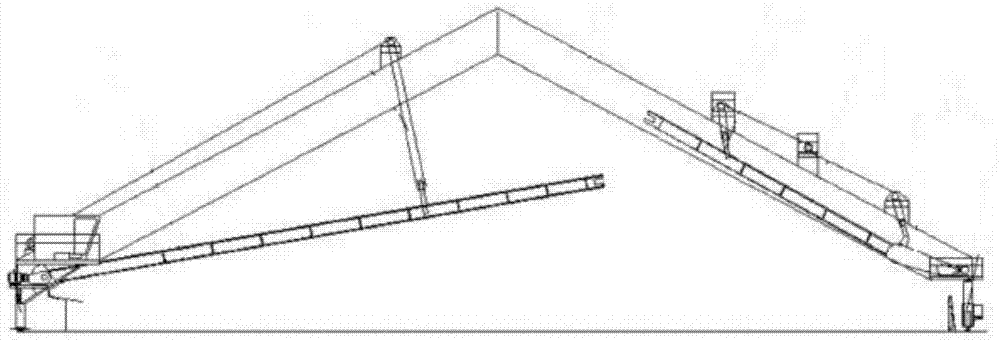

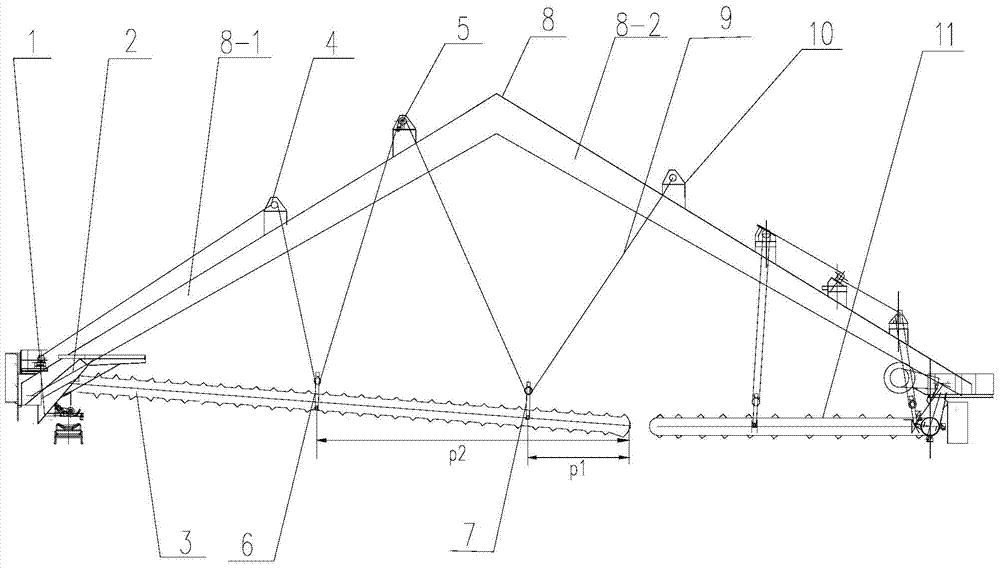

Steady long-span gantry raking machine

ActiveCN103482373AExtended service lifeIncrease the maximum yield limitLoading/unloadingEngineeringLong span

The invention relates to the technical field of chemical production equipment, in particular to a steady long-span gantry raking machine comprising a gantry, a main raking arm and an auxiliary raking arm. The main raking arm and the auxiliary raking arm are movably connected to two support ends of the gantry, the gantry support end provided with the main raking arm is a first gantry end, and an electric rope winch is mounted at the first gantry end. Taking the highest point of the gantry as a boundary, a section close to the main raking arm is a first gantry section, and a section close to the auxiliary raking arm is a second gantry section. Two static pulley blocks are mounted on the first gantry section, two static pulley blocks are also mounted on the main raking arm, a fixing device is mounted on the second gantry section, and a wire rope leading out from the electric rope winch is wound of the pulley blocks. Two suspension pivots are adopted to uniformly disperse stress on the main raking arm, so that maximum yield limit of a material of the main raking arm is increased, running is stable, and service life of the raking machine is prolonged.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

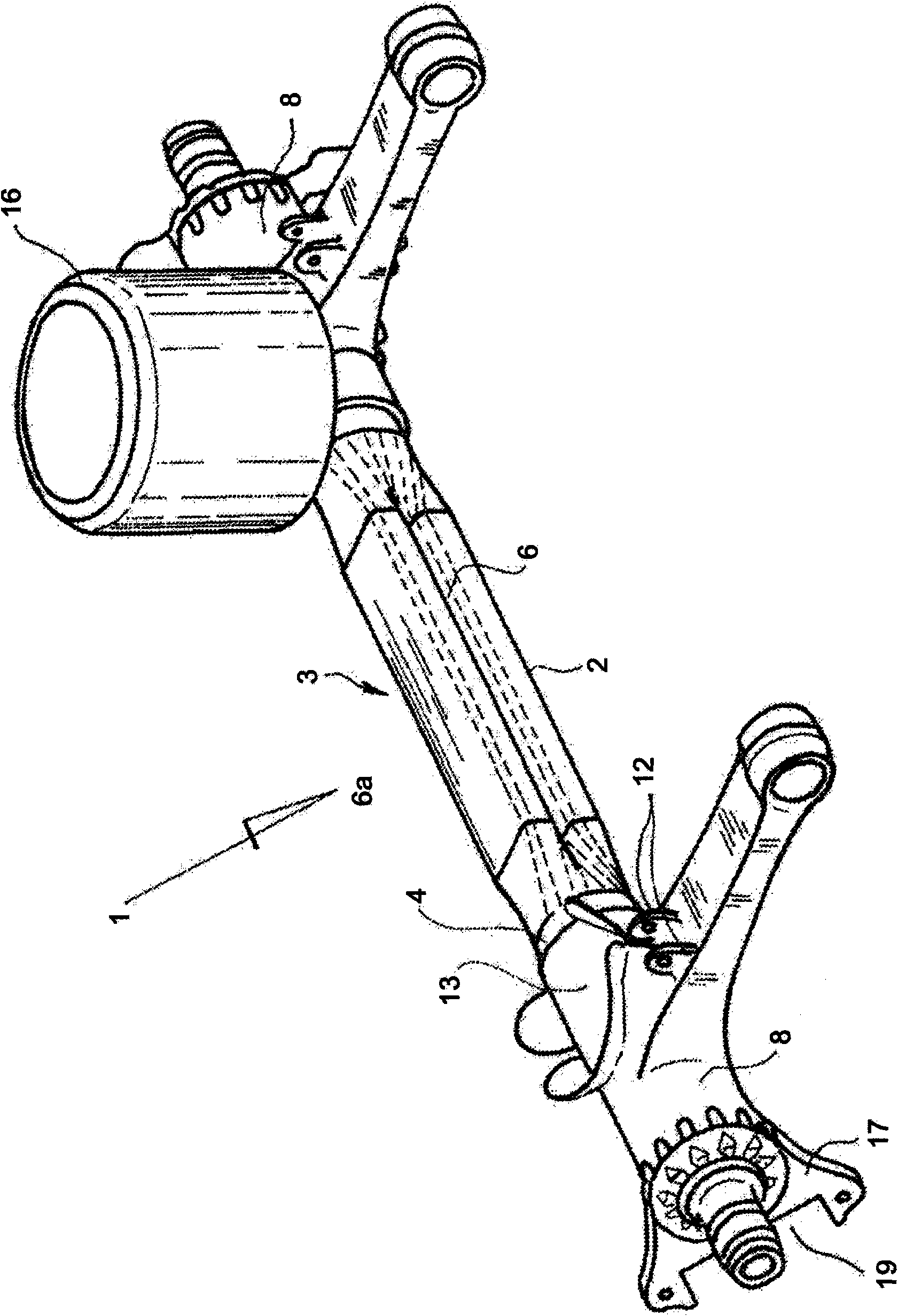

Axle assembly for a commercial vehicle and method for producing said axle assembly

InactiveCN101878125AFree space is not limited by thisLimited available spaceInterconnection systemsResilient suspensionsBreaking strengthTrailing arm

Owner:SCHMITZ CARGOBULL

Method for designing roller shape of two-roller straightener concave roller

ActiveCN104615824AImprove straightening qualityMeet the requirements of high precision straighteningSpecial data processing applicationsClassical mechanicsEngineering

The invention relates to a method for designing a roller shape of a two-roller straightener concave roller and belongs to the technical field of two-roller straighteners. The method comprises the following steps that firstly, stress distribution of bar material straightening actual deformation is determined; secondly, a formula of a straightening reverse bending ratio is determined according to bar material straightening deformation characteristics; thirdly, on the basis, combining abrasion of straightening force on a roller face, residual stress and influence of an elastic core on hidden danger deflection, the reverse bending ratio of a roller lumbar segment is determined; finally, the reverse bending ratios of the roller lumbar segment and a roller thoracic segment are determined by a remnant curvature formula. The reverse bending ratios of all segments are related with the following variates : Cw = {delta, eta, sigma<t>, sigma<6> epsilon<t>}, wherein the delta is an elastic region ratio, the eta is a ratio of the maximum deformation stress to yield limit, the sigma<t> is the yield limit, and the sigma<6> epsilon<t> is the straightening maximum deformation stress corresponding to the <6> epsilon<t>. On the premise of ensuring the stable straightening quality, the straightening straightness accuracy of the bar materials is improved, the abrasion on the rollers is reduced, the import amount of foreign straightening rollers is reduced, and the enterprise cost is saved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Collapse strength prediction method

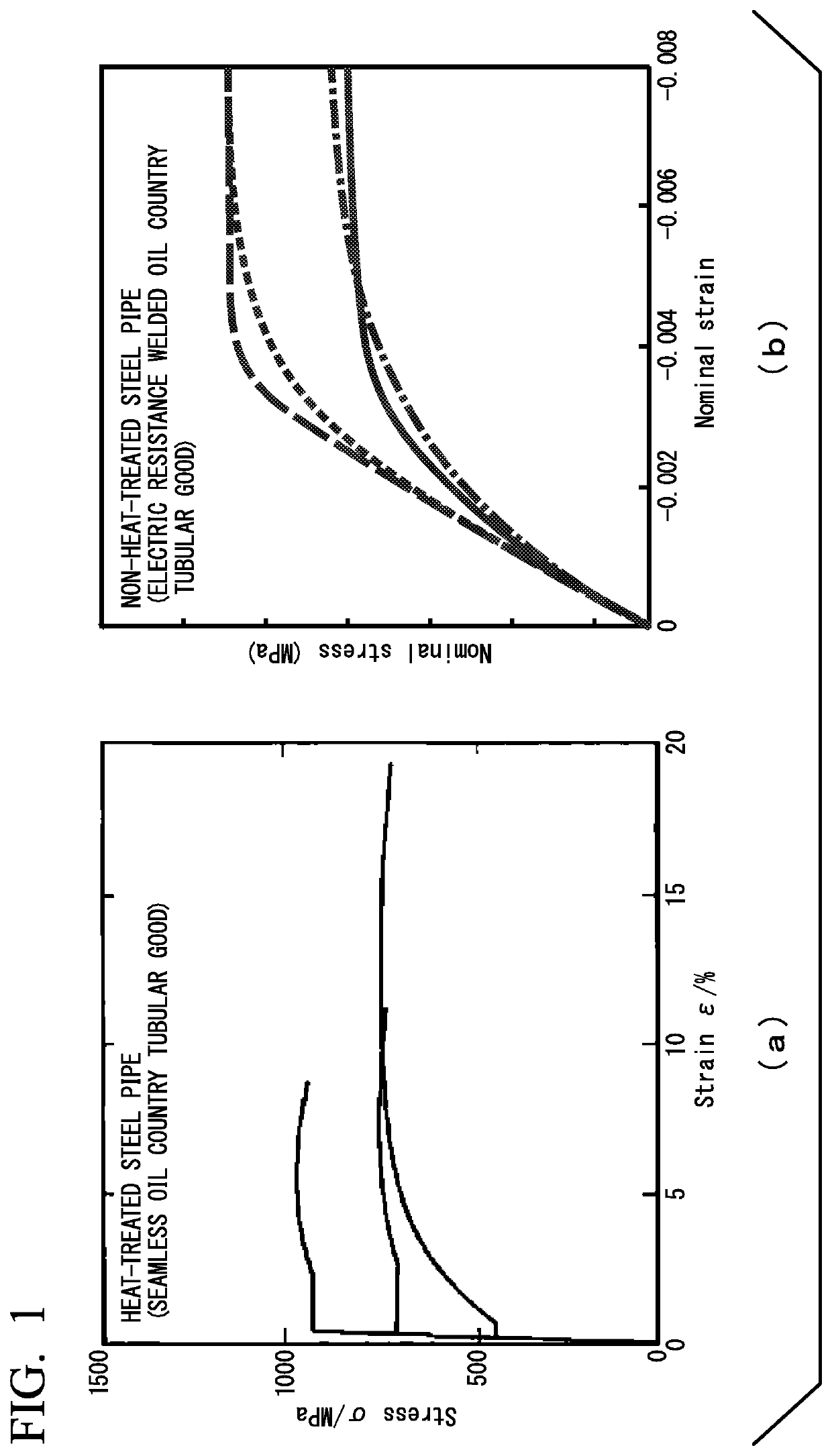

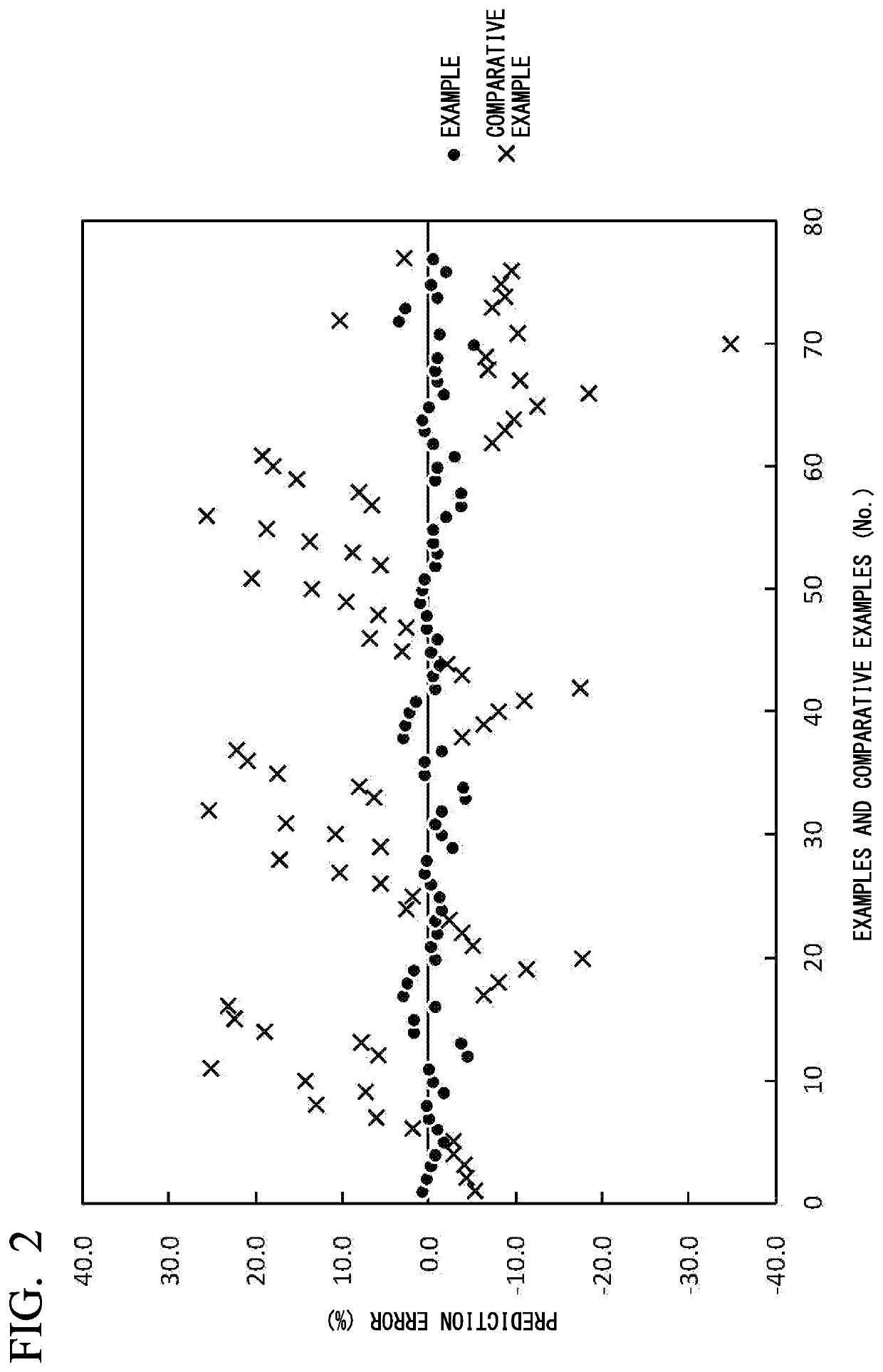

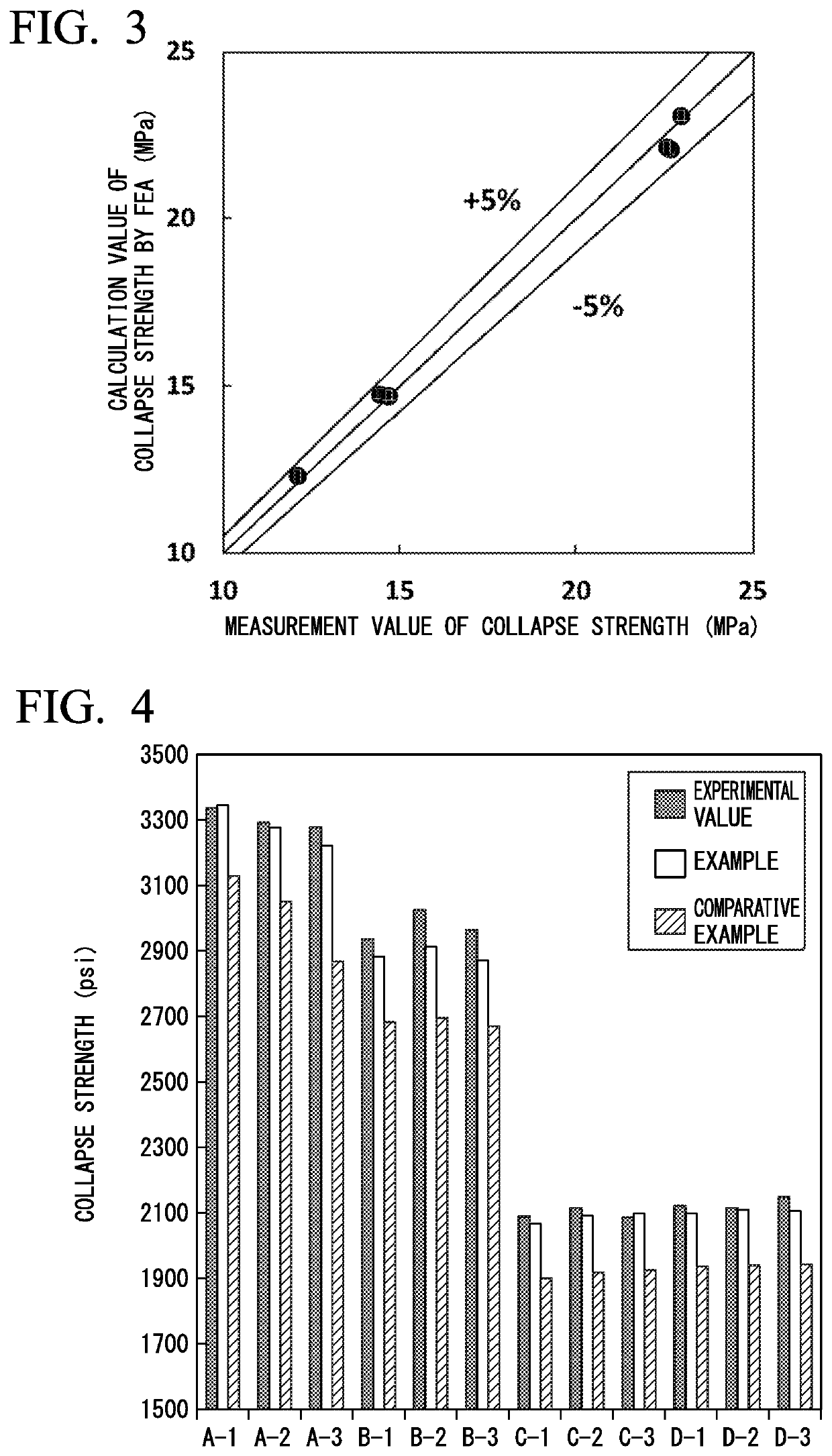

ActiveUS20200034403A1Accurately collapse strengthExact strengthGeometric CADMaterial strength using tensile/compressive forcesPipeUltimate tensile strength

A collapse strength prediction method of a steel pipe includes deriving a prediction equation indicating a relationship among D / t obtained by dividing an outer diameter D (mm) by a thickness t (mm), material characteristics, a collapse strength dominant factor, and a collapse dominant proof stress (σCDOS) of the steel pipe using a plurality of reference steel pipes collapse whose strengths have been obtained in advance, obtaining D / t, material characteristics, a collapse strength dominant factor, and a predicted collapse strength of a steel pipe that is an evaluation subject, obtaining a compressive stress-strain curve in a circumferential direction of the steel pipe that is the evaluation subject, obtaining a stress that causes a permanent strain to be generated in the steel pipe that is the evaluation subject as the collapse dominant proof stress on the basis of the compressive stress-strain curve, and computing the predicted collapse strength of the steel pipe that is the evaluation subject from the D / t, the material characteristics, the collapse strength dominant factor, and the collapse dominant proof stress, which have been obtained, on the basis of the prediction equation, and the permanent strain is set according to a value of the D / t of the steel pipe that is the evaluation subject.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com