One-step shaping method for non-aging reinforced aluminum alloy whole wallboard based on autoclave

An aging-strengthening, integral wall panel technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as increasing production costs and cycles, large residual stress of workpieces, and reducing workpiece performance, so as to eliminate the problem of uneven performance and improve performance. Performance uniformity, the effect of reducing the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The siding material is 5A06 aluminum alloy hot-rolled plate, the length of the slab is 800mm, the width is 200mm, and the thickness is 10mm. The target shape surface is continuously distributed along the length direction of the wall plate with a bending radius of 800 mm to 15000 mm, showing a streamlined shape. The mold surface includes a large curvature range: R / t=80~90, a small curvature range: R / t=130~1500, and an intermediate curvature range: R / t=90~130.

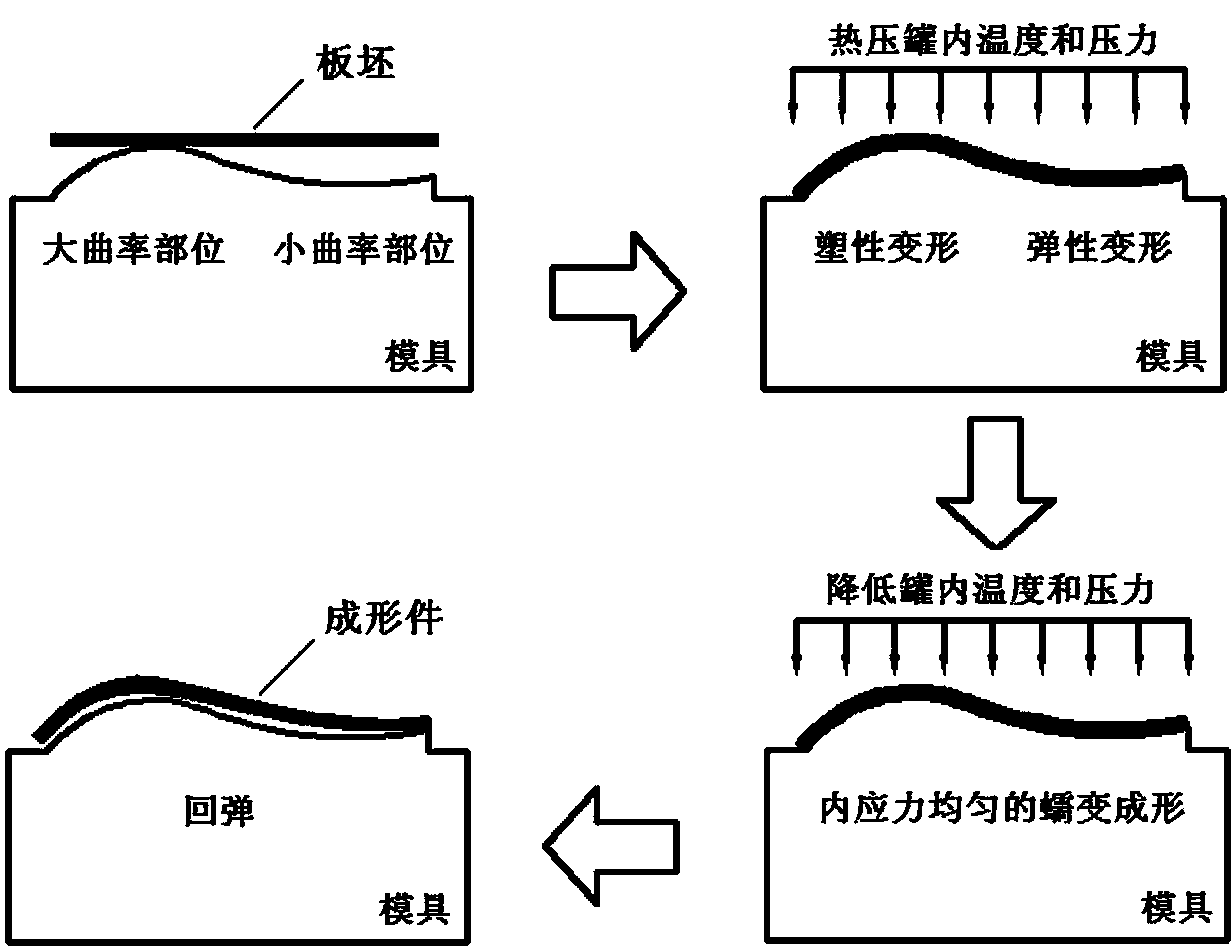

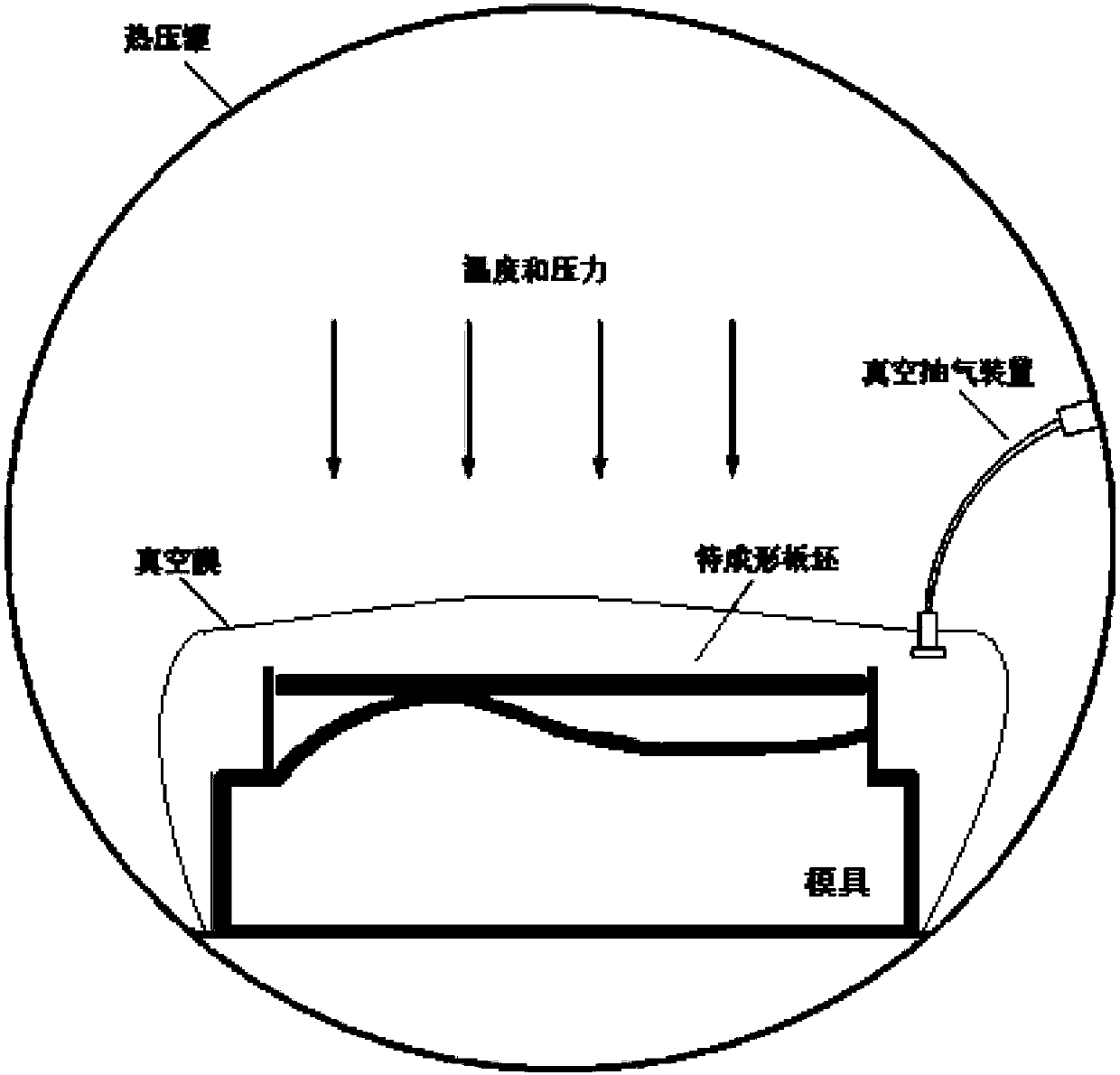

[0025] First place the slab on the forming mold and fix it, then apply a vacuum film to make the mold and the slab in a vacuum-enclosed environment, and then put it into the autoclave. Raise the temperature in the autoclave to 350°C, and increase the pressure in the tank to 5 Bar to make the slab and the mold fit together. At this time, the material reaches the yield limit at the large curvature part and undergoes plastic deformation. After keeping for 2 hours, the pressure in the tank dropped to 2Bar, and the te...

Embodiment 2

[0027] The wall plate material is 5052 aluminum alloy cold-rolled plate, the length of the slab is 1800mm, the width is 900mm, and the thickness is 8mm. The target shape surface along the length direction of the wallboard is ellipse with long and short semi-axes of 378mm and 126mm respectively, and the width direction is straight without bending. The mold surface includes a large curvature range: R / t=0~172, a small curvature range: R / t>260, and an intermediate curvature range: R / t=172~260.

[0028] First place the slab on the forming mold and fix it, then apply a vacuum film to make the mold and the slab in a vacuum-enclosed environment, and then put it into the autoclave. Raise the temperature in the autoclave to 345°C, and increase the pressure in the tank to 4Bar to make the slab and the mold fit together. At this time, the material reaches the yield limit at the large curvature part and undergoes plastic deformation. After keeping for 2 hours, the pressure in the tank dro...

Embodiment 3

[0030]The wall plate material is 5083 aluminum alloy O-state plate, the length of the slab is 1000mm, and the width is 580mm. The thickness of the web is 3mm, and ribs with a height of 15mm and a thickness of 4mm are provided on one side of the web. The ribs have a rectangular cross-section and are distributed in a grid. There are 9 cells in total, and the size of each cell is 300mm×160mm. The target shape surface along the width direction of the wall panel has a single curvature radius of 800mm, R / t=44.4, which belongs to the large curvature range.

[0031] First place the slab on the forming mold and fix it, then stick a vacuum film to make the mold and the slab in a vacuum-enclosed environment, and then put it into the autoclave. Raise the temperature in the autoclave to 400°C, and increase the pressure in the tank to 5 Bar to make the slab and the mold fit together. At this time, the material reaches the yield limit at the large curvature part and undergoes plastic deform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com