Patents

Literature

223results about How to "Small amount of rebound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

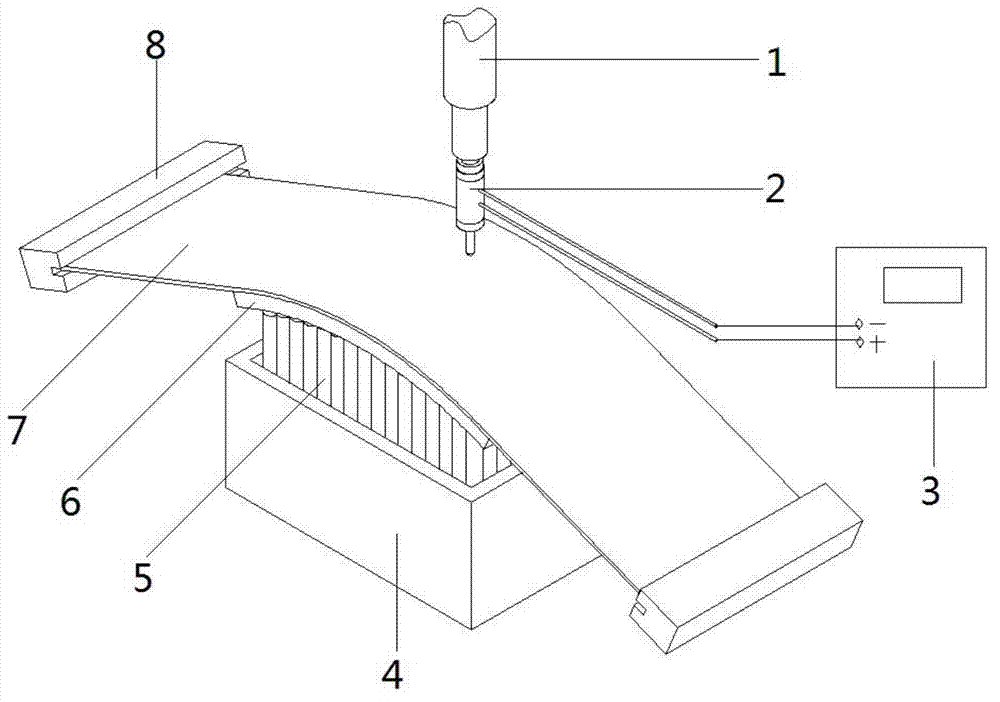

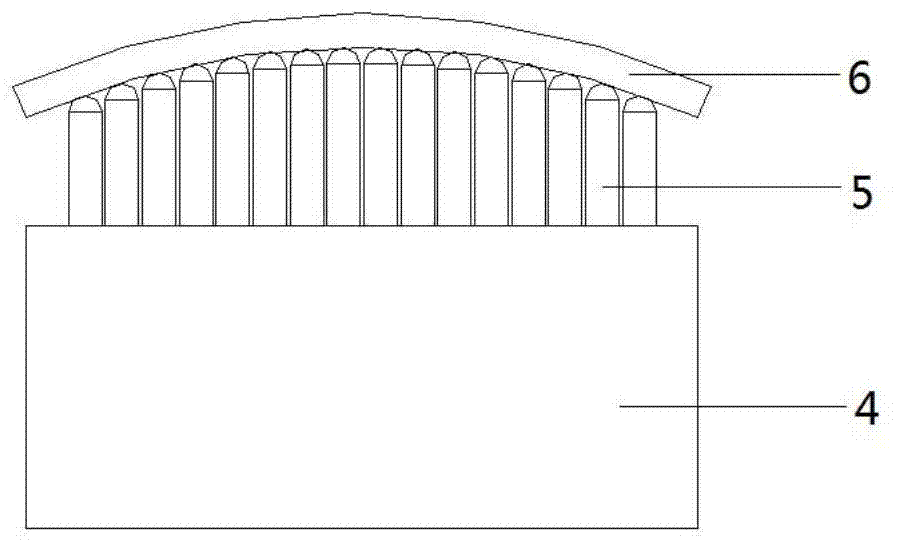

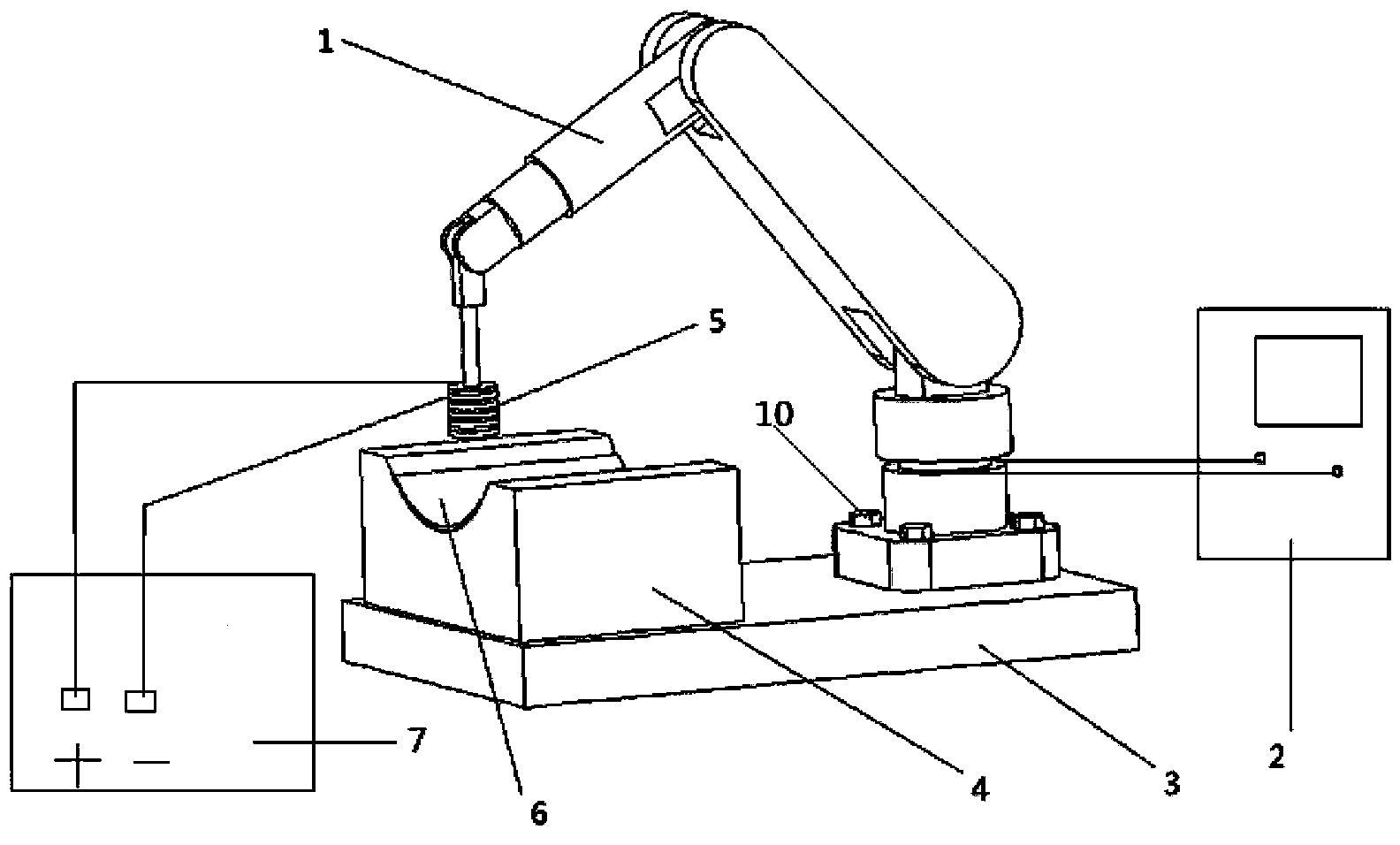

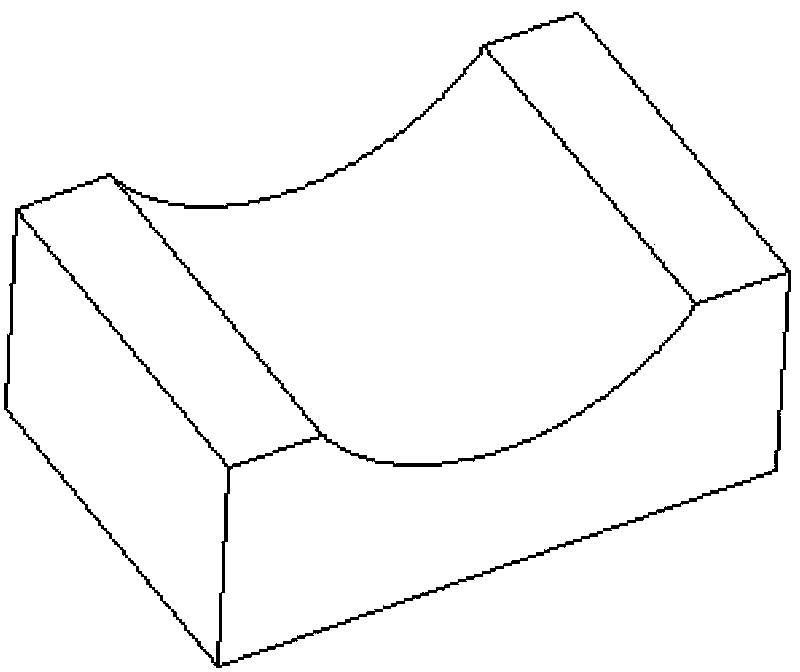

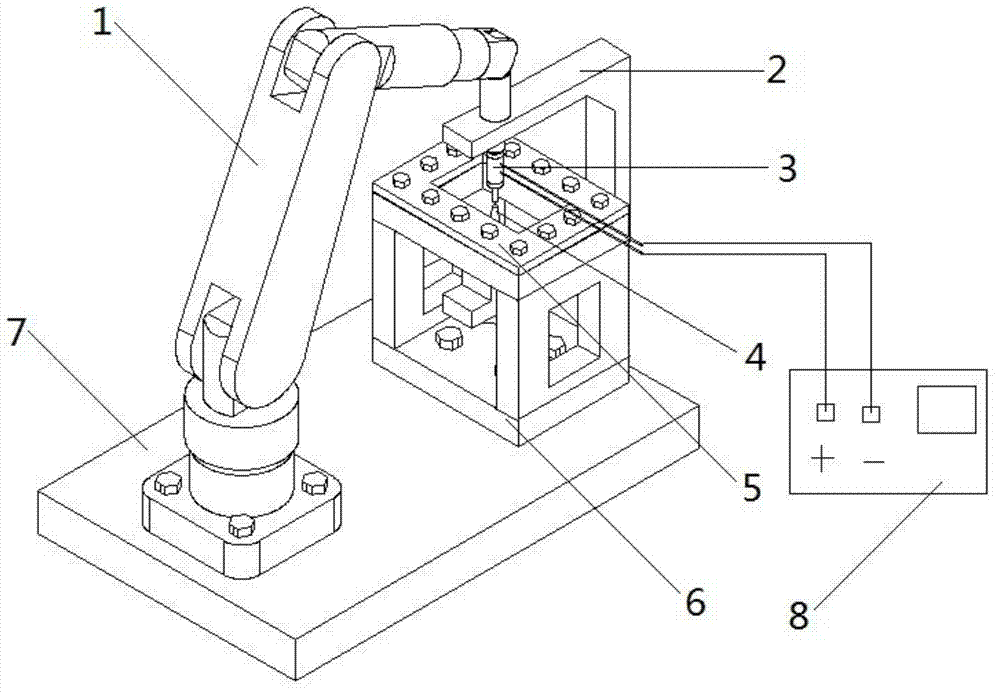

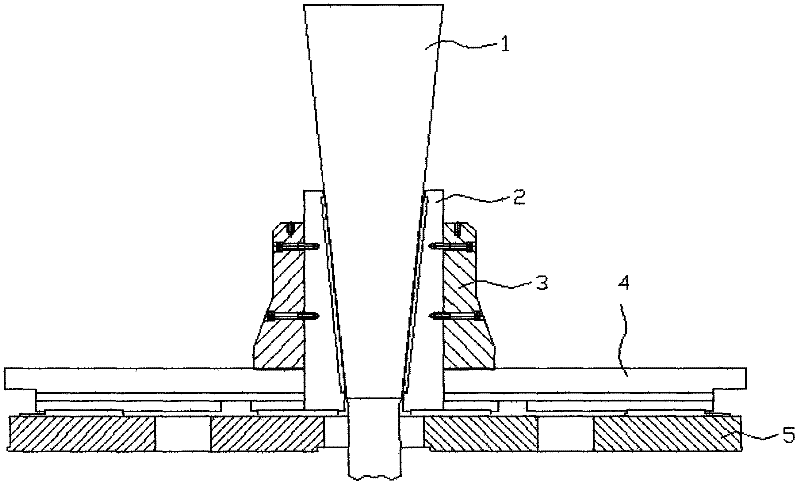

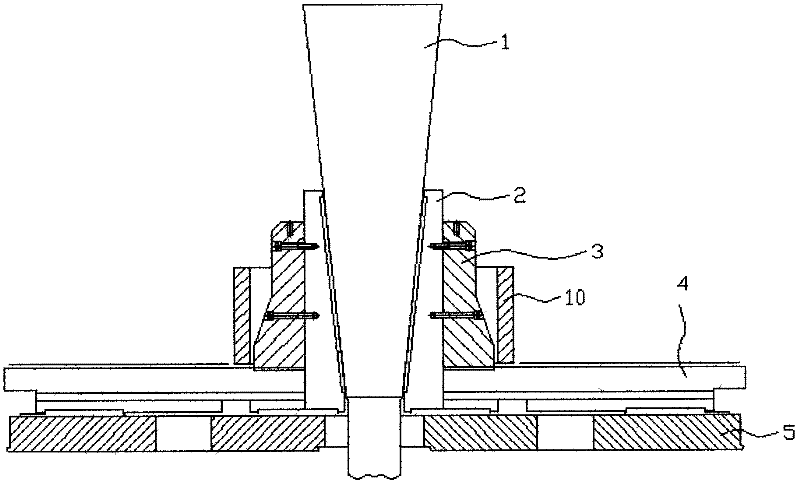

Flexible stretch-forming device and method for carrying out stretch-forming on plate by utilizing same

InactiveCN103480713AReduce deformation resistanceHigh forming precisionShaping toolsIndustrial machineIndustrial manipulator

The invention discloses a flexible stretch-forming device and a method for carrying out stretch-forming on a plate by utilizing the flexible stretch-forming device and solves the technical problem that the stretch-forming accuracy of a flexible stretch-forming device for the molded surface of a reconfigurable unidirectional continuous die is low. The technical scheme includes that the flexible stretch-forming device comprises an industrial manipulator, a heating forming head, a power supply, a multipoint die, a nail post and a polyurethane elastic cushion. The nail post is mounted on the base of the multipoint die, the polyurethane elastic cushion is positioned above the nail post, the lower surface of the polyurethane elastic cushion is attached to the discrete surface formed by the nail head of the nail post, the plate is positioned above the polyurethane elastic cushion, the lower surface of the plate is attached to the upper surface of the polyurethane elastic cushion, the heating forming head is positioned above the plate, and the spherical head surface of the heating forming head is contacted with the upper surface of the plate. According to the flexible stretch-forming device and the method for carrying out stretch-forming on the plate by utilizing the flexible stretch-forming device, the electromagnetic induction heating forming head is adopted to locally heat the plate in the stretch-forming process, the local heat effect of the region can reduce the deformation resistance of the plate, the plasticity is improved, the resilience value is reduced, and the forming accuracy of the plate is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

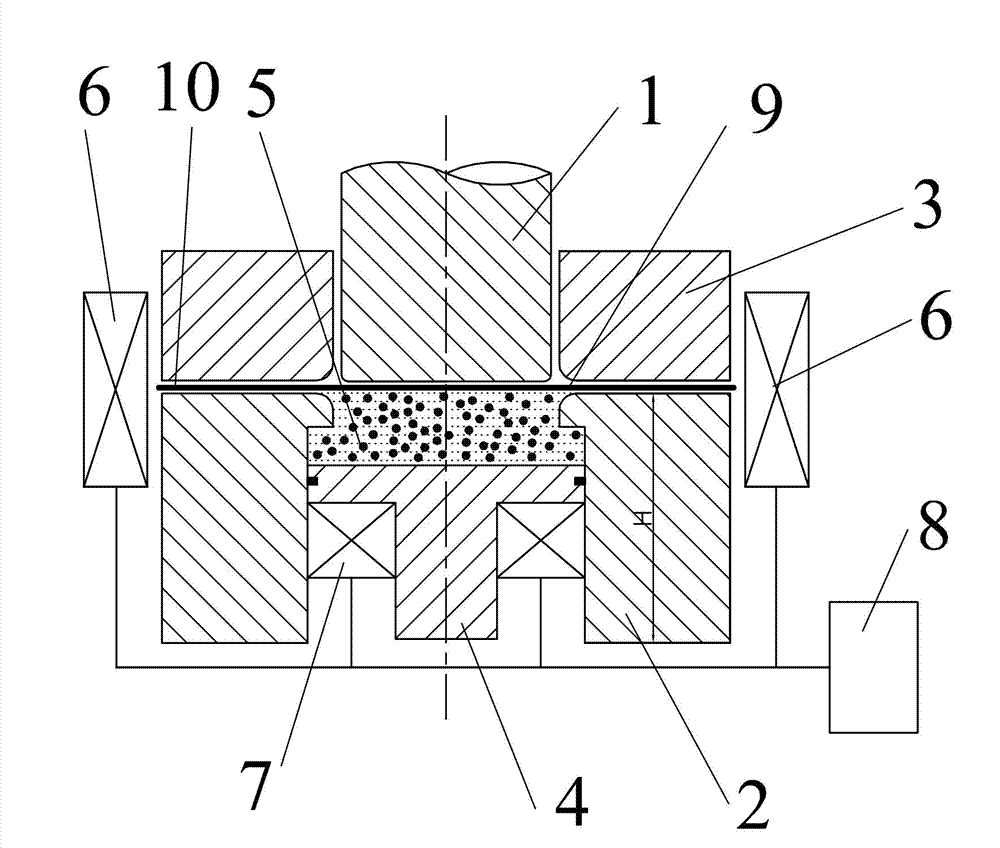

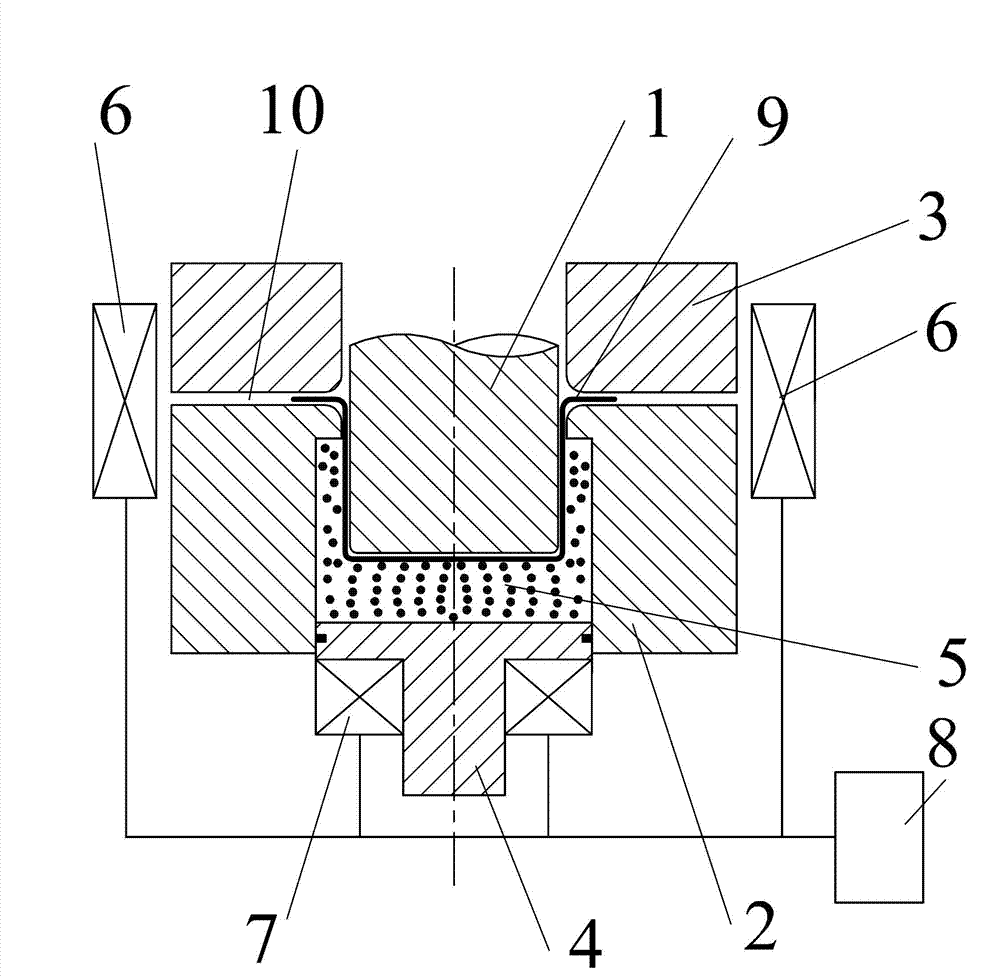

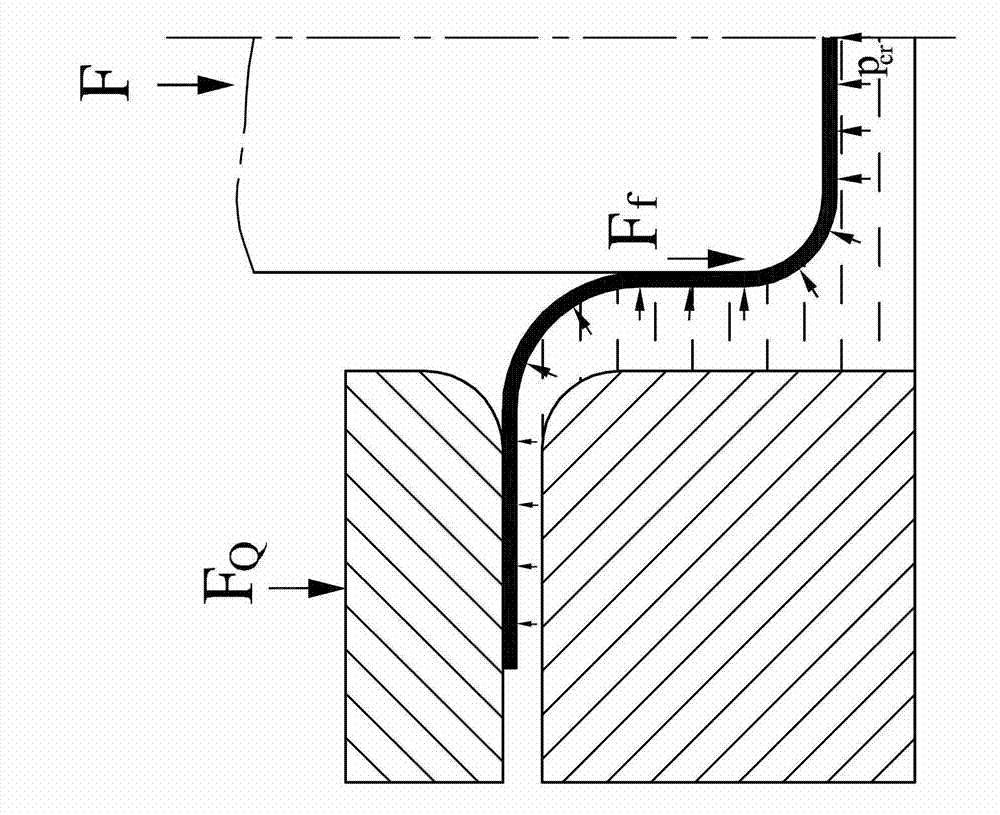

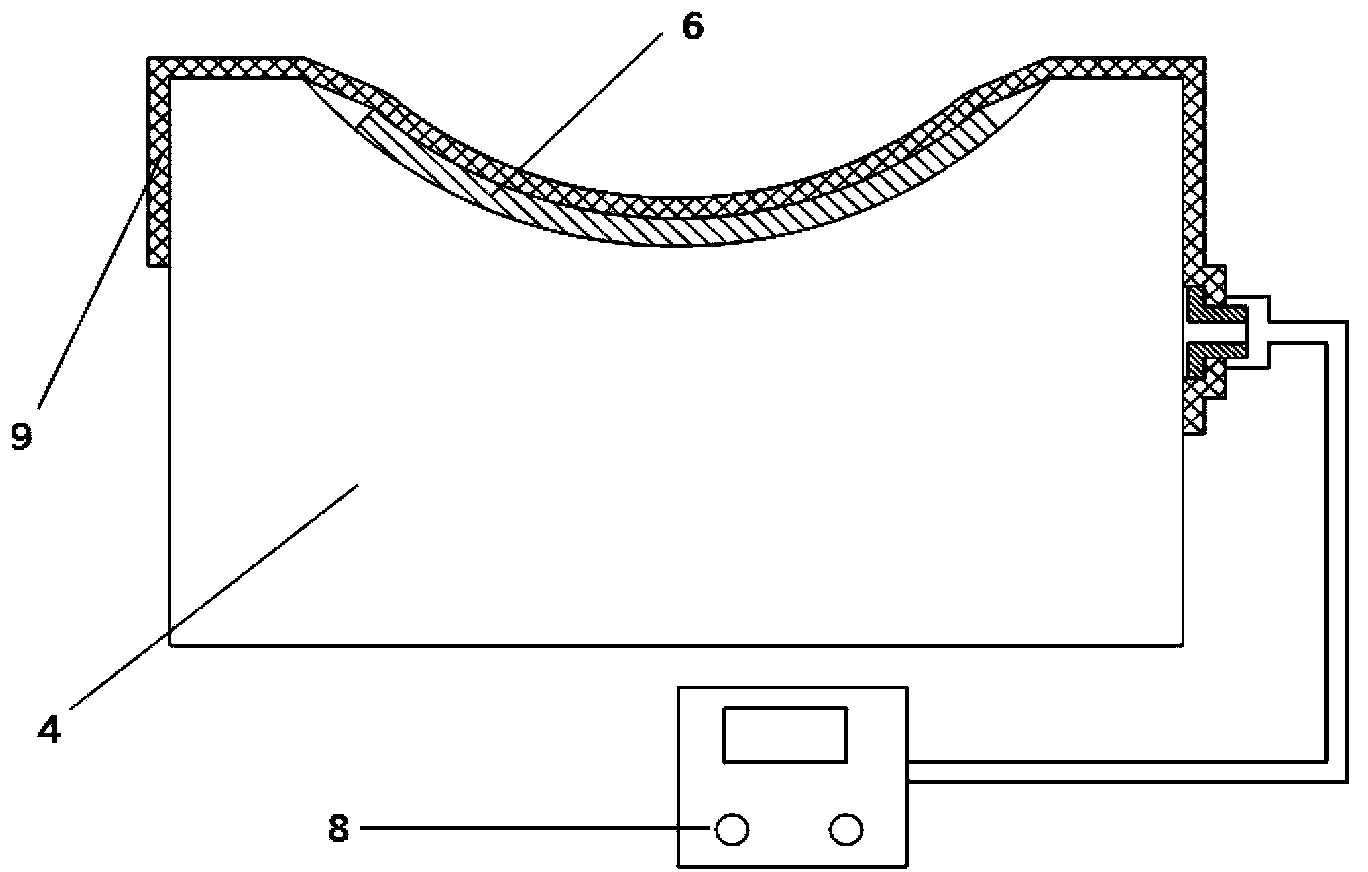

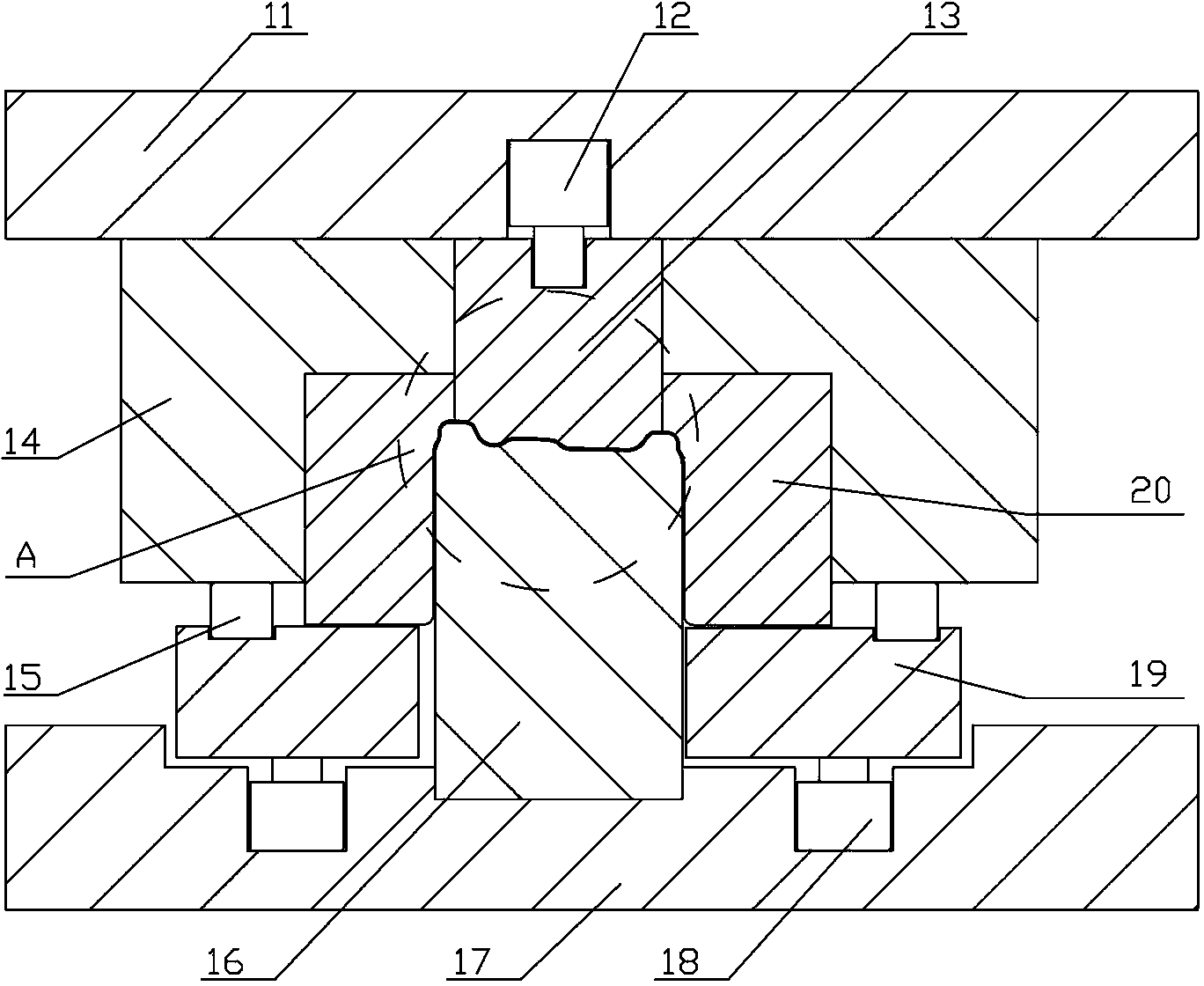

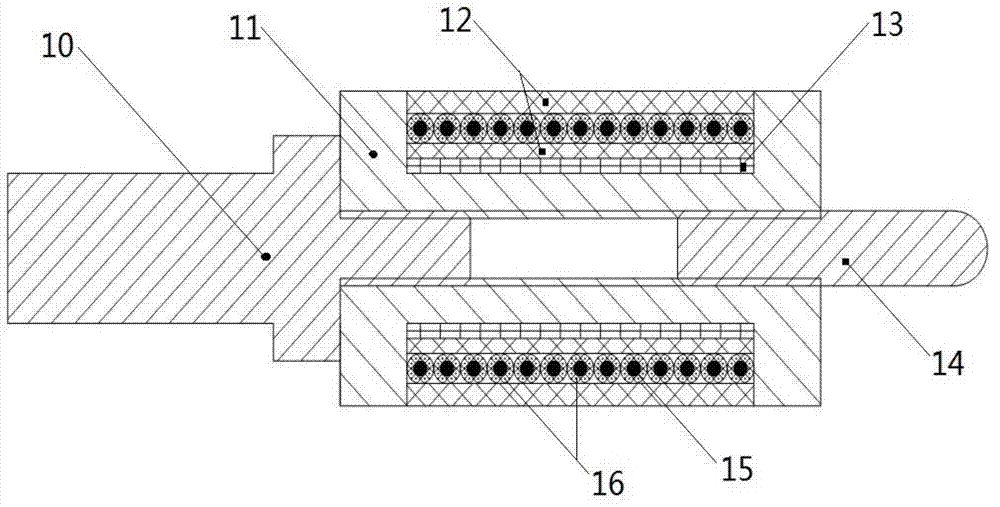

Sheet material hydro-mechanical deep drawing forming device and method using magnetic medium to pressurize

The invention provides a sheet material hydro-mechanical deep drawing forming device and a sheet material hydro-mechanical deep drawing forming method using a magnetic medium to pressurize, belongs to the technical field of hydro-mechanical deep drawing, and solves the technical problems in a traditional sheet material hydraulic forming process that wrinkles are formed, the deformation uniformity is poor and the like, caused by the reason that overflowing pressure of a flange region is reduced, when a sealing ring is not used in order to realize overflowing and lubrication. A sealed hydraulic chamber formed by a concave die and a lower plunger piston is used for containing the magnetic medium; a convex die can penetrate through an edge pressing ring to drive a plate blank to move downwards to enter the sealed hydraulic chamber formed by the concave die and the lower plunger piston; a first coil is arranged on the periphery of the outer side of the flange region formed by the concave die and the edge pressing ring; a second coil is arranged on a pull rod of the lower plunger piston; and a magnetic control unit is used for controlling the sizes of magnetic fields generated by the first coil and the second coil. Firstly, a certain amount of the magnetic medium is poured into the hydraulic chamber and the edge pressing ring is moved downwards after the plate blank is placed; the viscosity and the pressure value of the magnetic mediums on a flange and in the hydraulic chamber are respectively adjusted and controlled through the magnetic fields; and a punching head is moved downwards until a plate piece is formed. The sheet material hydro-mechanical deep drawing device and the sheet material hydro-mechanical deep drawing method using the magnetic medium to pressurize are suitable for hydro-mechanical deep drawing formation of a sheet material.

Owner:HARBIN UNIV OF SCI & TECH

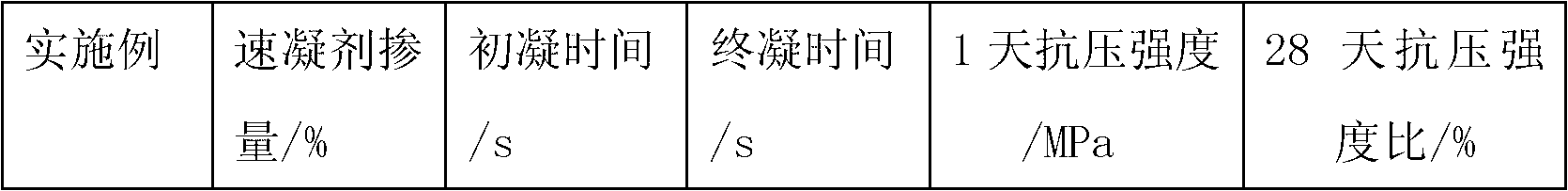

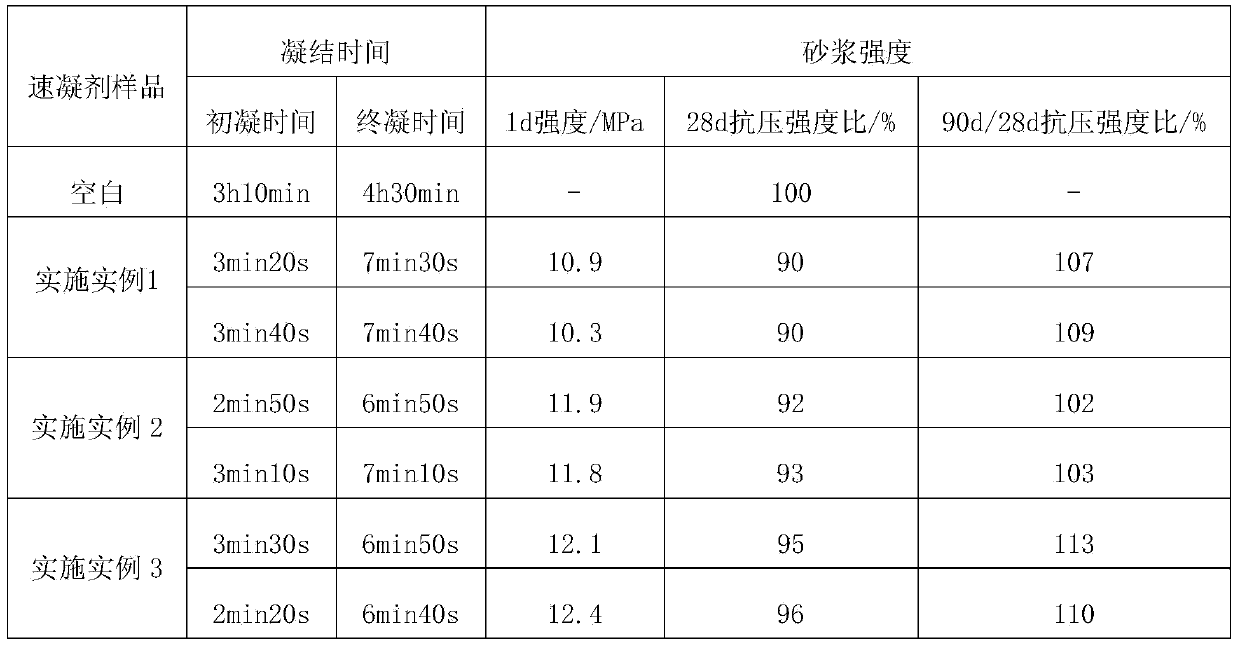

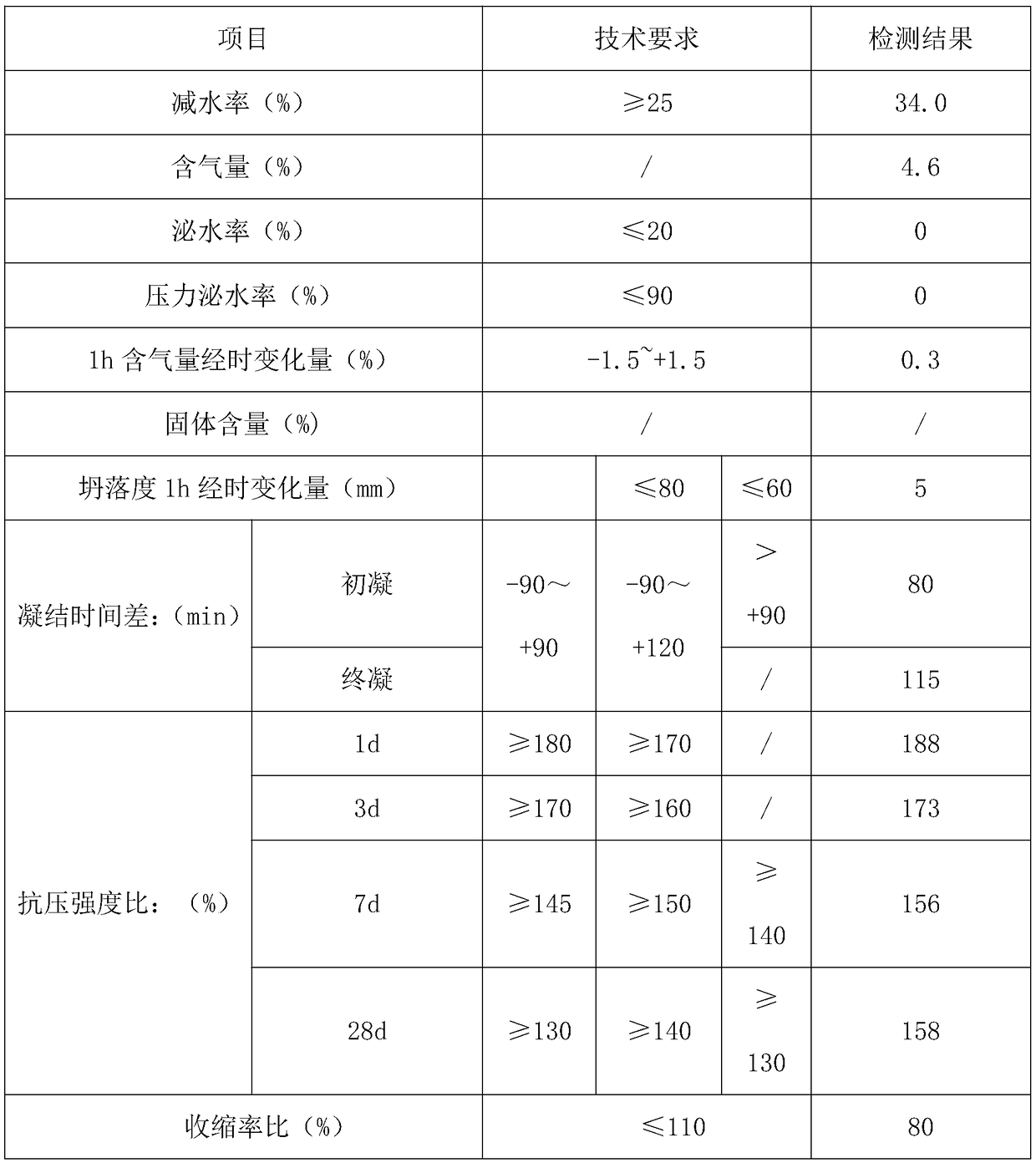

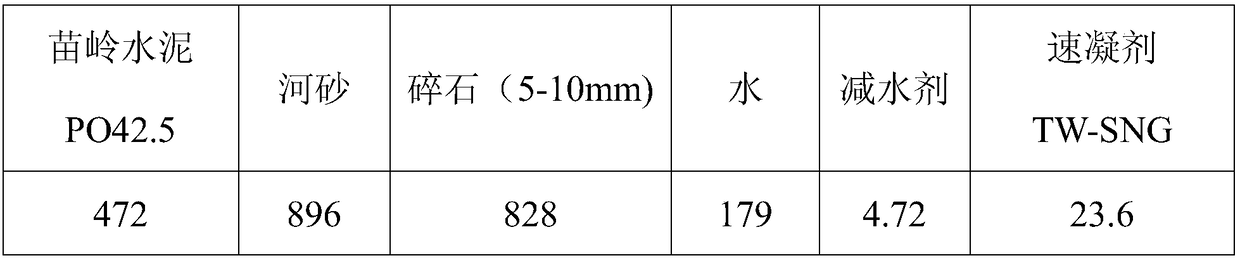

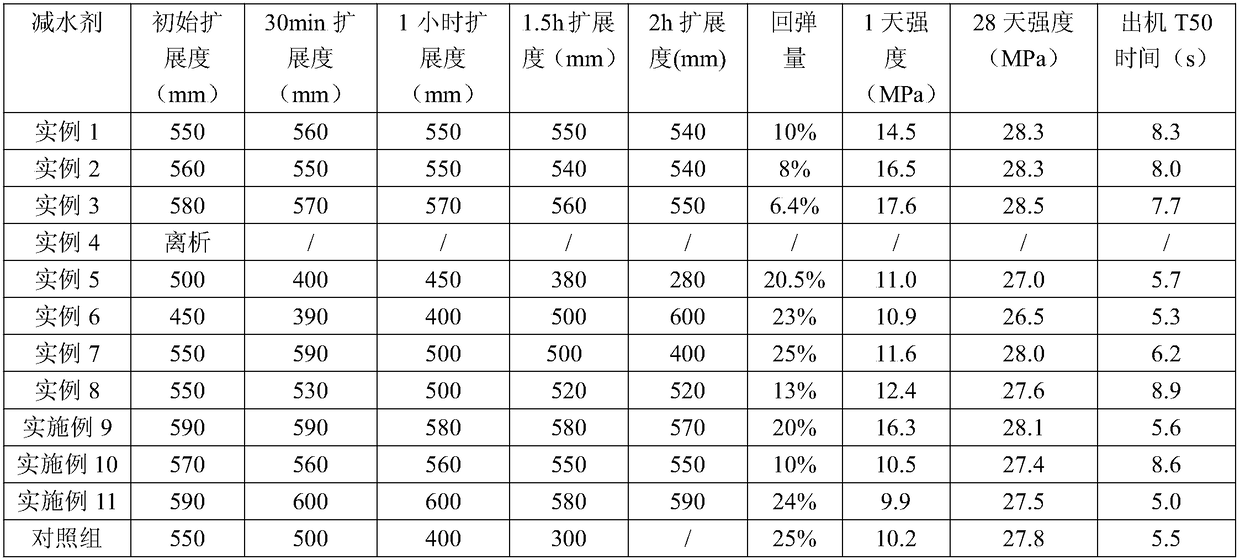

Alkali-free liquid accelerator and preparation method and application thereof

The invention discloses an alkali-free liquid accelerator, which is free of alkali in raw materials and preparation. The accelerator is composed of 30-80% of aluminum sulfate, 1-10% of hydroxy carboxylic acid, 4-15% of organic amine, 3-10% of polyhydric alcohols, 1-5% of inorganic acid and the balance of water. The accelerator disclosed by the invention is high in early strength, low in long-term strength loss, good in caking property and low in resilience value; as a result, environment-friendly no-pollution construction can be realized; the synthetic process of the accelerate is simple and moderate in reaction conditions; and therefore, the accelerate is an excellent-performance alkali-free liquid accelerator.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

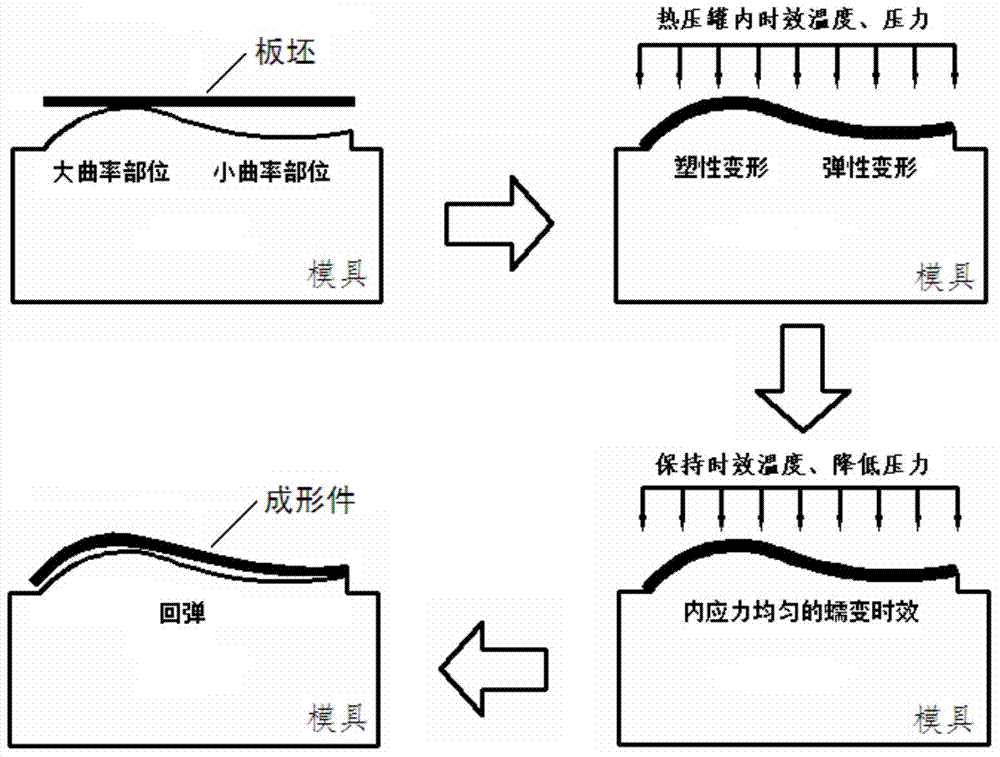

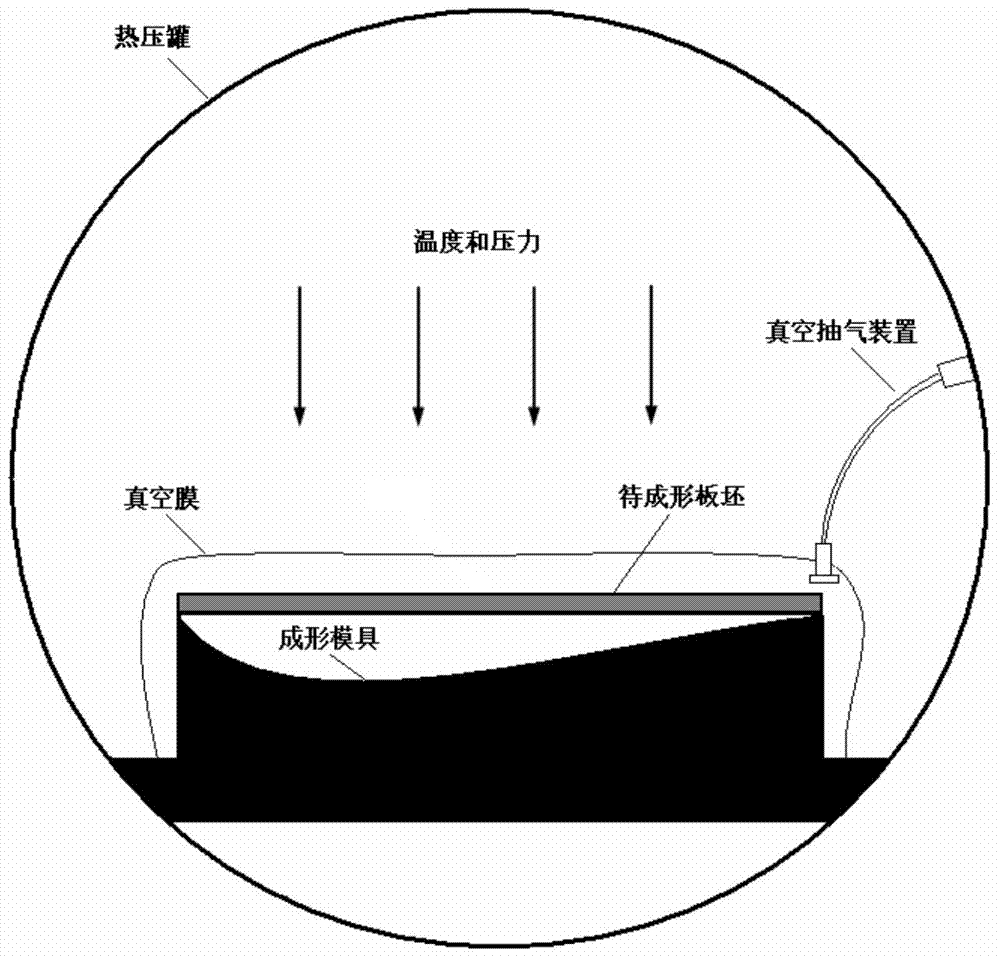

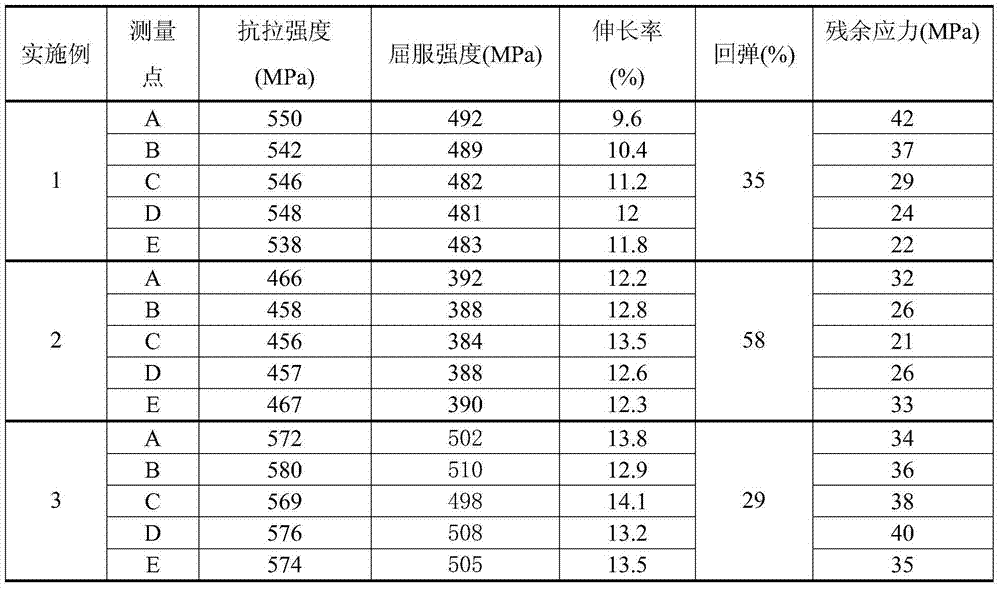

Age hardenable aluminum alloy integral panel one-step forming method based on autoclave

ActiveCN103691793AEliminate internal stress differencesShorten the production cycleInternal stressAluminium alloy

The invention discloses an age hardenable aluminum alloy integral panel one-step forming method based on an autoclave. The method includes the steps: firstly, fixing an aluminum alloy plate blank on a forming die, and placing the aluminum alloy plate blank into the autoclave after the aluminum alloy plate blank and the forming die are sealed in a vacuum manner; secondly, providing temperature needed by aluminum alloy aging and pressure needed by component laminating inside the autoclave, and enabling heavy-curvature portion materials to reach yield limit and enter a creep aging stage by keeping a laminating state after plastic deformation. Internal stress distribution is adjusted by local plastic deformation, so that the problem of non-uniform performance caused by internal stress difference in the creep aging process can be eliminated, production cycle and rebound are decreased by combining plastic deformation with creep deformation, and the height of the die can be decreased. The process method can be implemented in the autoclave with enough capacity, the highest working pressure is not lower than 10Bar, and the using temperature can range from 100 DEG C to 200 DEG C. The method is simple and convenient to operate, can be implemented only by one set of female die and has an actual industrial production application value, a tool is simple, and cost is saved.

Owner:CENT SOUTH UNIV +1

Low-resilience and low-alkaline liquid accelerator for sprayed concrete and preparation method thereof

The invention relates to a low-resilience and low-alkaline liquid accelerator for sprayed concrete and a preparation method thereof. The accelerator is prepared from the following raw materials: an aluminate mother liquid, a modifier, hydramine and a stabilizer, wherein the mass ratio of the modifier and the aluminate mother liquid is 1: (1-5), the dosage of hydramine is 0.5-2.5% of the sum of the modifier and the aluminate mother liquid in mass, the dosage of the stabilizer is 0.3-2% of the sum of the modifier and the aluminate mother liquid in mass; the stabilizer is one of vinylon glue, EDTA (Ethylene Diamine Tetraacetic Acid) and xanthan gum. The preparation method comprises the following steps: preparing the aluminate mother liquid; preparing the modifier; and preparing the low-alkaline liquid accelerator. The adulterate amount of the accelerator provided by the invention is 3-6% mass of cement, the initial setting time is 3 minutes and the final setting time is 8 minutes, and the requirements of JC477-2005 accelerator for sprayed concrete are satisfied. The accelerator is uniform and stable and strong in adaptability with cement, can be used for effectively reducing resilience and dust amount in construction of prayed concrete, and is short in setting time and less in loss of long-term strength.

Owner:刘翠芬

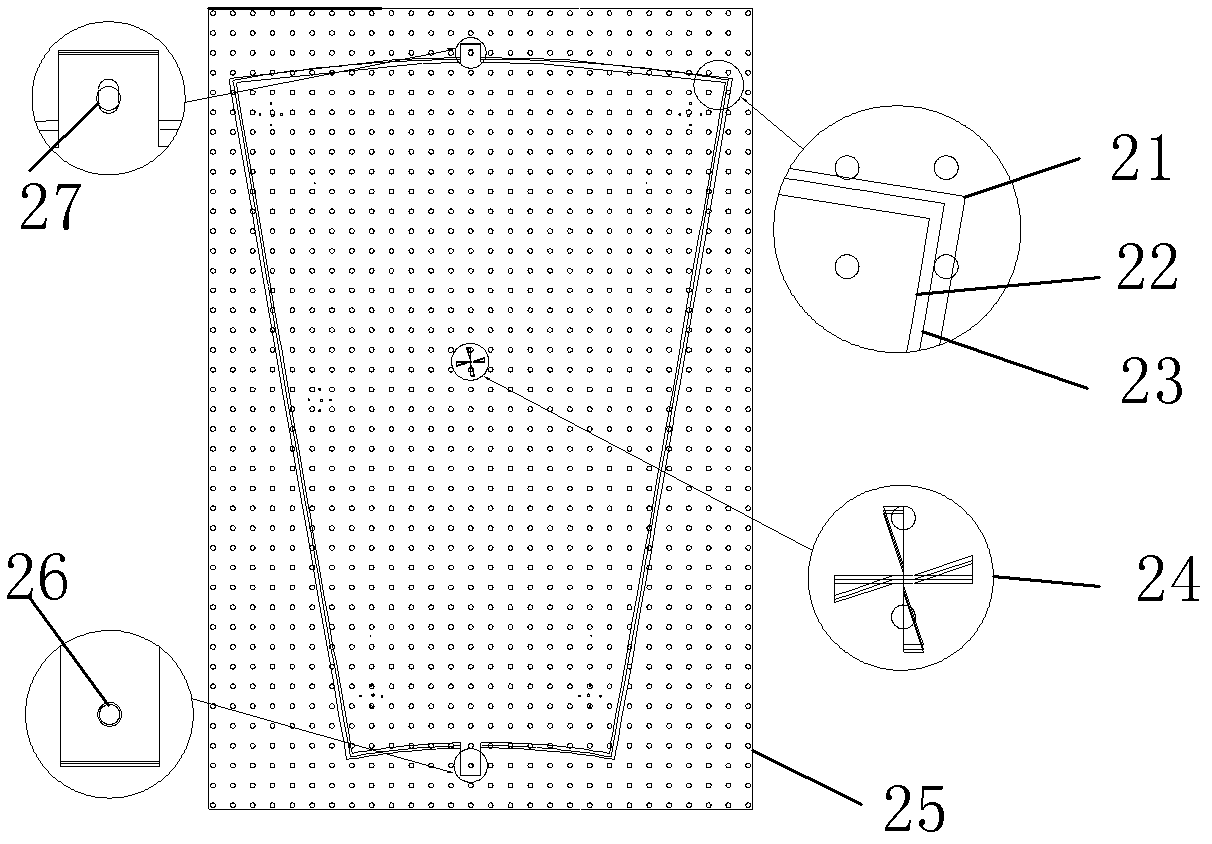

Compound forming method for large-curvature double-curve-degree high-accuracy antenna panel

ActiveCN102569984AEasy maintenanceImprove the sticking degreeAntenna supports/mountingsRadiating elements structural formsLaser processingHoneycomb

The invention relates to a compound forming method for a large-curvature double-curve-degree high-accuracy antenna panel. The antenna panel particularly comprises three layers of pre-stretched aluminum plates, two layers of durable honeycomb cores and a plurality of pre-embedded pieces for connecting a back rack, wherein the three layers of aluminum plates comprise a pre-stretched working plate, a pre-stretched middle connecting plate and a pre-stretched back plate, which are cut and trimmed according to sample plates. The forming method at least comprises the following main steps of: performing three-dimensional modeling of the three layers of plates of the large-curvature double-curve-degree high-accuracy antenna panel; performing spacial geometric unfolding of the three layers of plates, and positioning the three layers of plates on a nail bed; performing laser processing of the sample plates of the three layers of aluminum plates; manufacturing an entity mould according to a moulding surface of the working plate; performing pre-stretching forming of the three layers of aluminum plates, and cutting and trimming the three layers of aluminum plates according to the sample plates; calculating the nail height, and positioning the three layers of pre-stretched plates on a high-accuracy nail bed; and manufacturing the large-curvature double-curve-degree high-accuracy antenna panel by laying sandwich structures layer by layer.

Owner:BEIHANG UNIV

Fireproof material for mending furnace as well as preparation method and using method thereof

The invention discloses a fireproof material for a mending furnace as well as a preparation method and a using method thereof. The fireproof material for the mending furnace comprises magnesia, magnesium powder, aluminium oxide, calcium oxide and sodium hexametaphosphate, wherein the total weight of the fireproof material for the mending furnace is used as a reference, the total content of the magnesia and the magnesium powder accounts for 80-90 percent by weight; the content of the aluminium oxide accounts for 3-7 percent by weight; the content of the calcium oxide accounts for 3-7 percent by weight; the content of the sodium hexametaphosphate accounts for 3-7 percent; and the main components of the magnesia and the magnesium powder are MgO. The fireproof material for the mending furnace is high in adhesive ratio, good in stickiness, solidification and hardness, and low in resilience value during mending; and therefore, a mending layer formed by the fireproof material for the mending furnace is good in anti-erosion performance and long in service life.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

Manufacturing method of elastic concave-convex warp knitted fabric and warp knitted fabric

The invention provides a manufacturing method of an elastic concave-convex warp knitted fabric. The method comprises the steps of weaving preparation, guide bar configuration, knitting and the like. When a convex area of a concave-convex pattern is woven, GB4 is subjected to yarn laying and looping on a rear needle bed of a double-needle-bed warp knitting machine, and because low-elasticity yarn or non-elastic yarn serves as the GB4 for embroidering, the resilience amount of the woven yarn is relatively small or the woven yarn is not resilient. When a concave area of the concave-convex pattern is woven, GB3 is subjected to yarn laying and looping on the rear needle bed of the double-needle-bed warp knitting machine, the woven yarn is relatively large in resilience amount because spandex core-spun yarn serves as the GB3, and the yarn contracts to a bottom layer, so that a surface layer is sunken downward to the bottom layer, and the formed concave-convex structure has certain elasticity. Compared with a traditional technical scheme, the concave-convex warp knitted fabric can be directly woven without subsequent treatment, the process is simple, and the production cost is relatively low.

Owner:SINCETECH FUJIAN TECH CO LTD

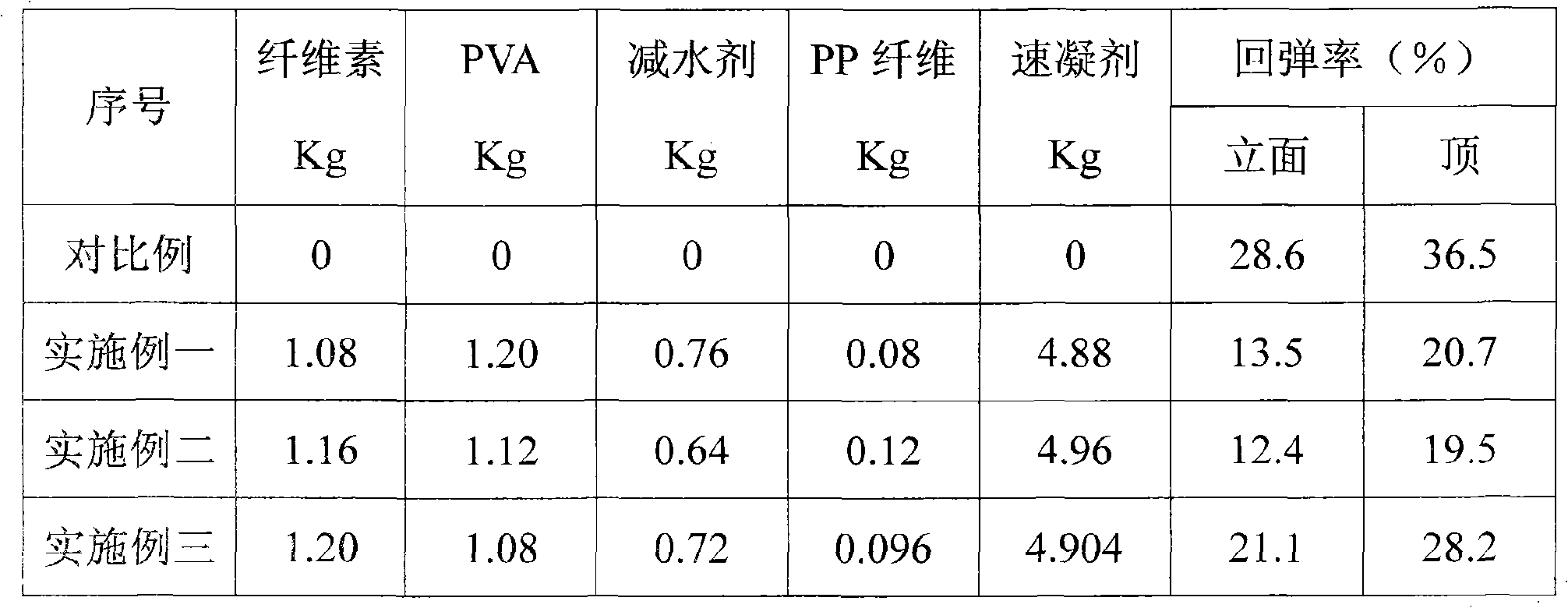

Concrete spraying additive

The invention discloses a shotcrete admixture, comprising: 13 to 15 parts by weight of cold water quick dissolving powdery methylcellulose ether or cold water quick dissolving powdery hydroxyethyl cellulose ether, 13 to 15 parts by weight of cold water quick dissolving powdery polyvinyl alcohol, 8 to 11 parts by weight of naphthalene-series powdery water-reducing agent, 1 to 2 parts by weight of mesh polypropylene fiber and 58 to 62 parts by weight of cement accelerator. The shotcrete admixture is prepared by adding the constituents into the concrete together for increasing the cohesion of concrete and viscosity of early-stage slurry, the slurry initial setting time is short, and the resilience amount of concrete can be reduced by 30 to 50 percent.

Owner:山东科技大学教育服务有限公司

Forming device and forming method of electromagnetic induction assisting prestress

InactiveCN103406419AEasy to transformAchieving Electroplastic Bending FormingMetallic materialsEngineering

The invention discloses a forming device and a forming method of electromagnetic induction assisting prestress. A forming mold and a manipulator are fixed on the upper portion of a base. An electromagnetic coil is mounted at the chuck part of the manipulator, wire connecting of an electromagnetic induction control system is completed correspondingly, the electromagnetic coil is ensured to generate a pulsed magnetic field successfully in the forming process, and induced current is generated on a sheet material. The sheet material is placed on the mold, and a vacuum bag is placed on the sheet material and is evacuated through an evacuating device, so that the sheet material is pressed on the mold tightly, and effect of vacuum compaction is achieved. A computer control system is operated to form the electromagnetic induction assisting prestress. According to the forming device, when the pulsed magnetic field of the inducing coil penetrates a workpiece, the workpiece generates the induced current, plastic deformation capacities of metal materials are improved by the current, crystallizing process of amorphous alloy is promoted, solidification structure of the alloy is refined, deforming resistance during the forming process is reduced, springback amount is reduced, forming accuracy and comprehensive mechanical properties are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

High-tension board forming device

The invention discloses a high-tension board forming device. The high-tension board forming device is characterized by comprising an upper die base, an upper die pressing plate, an upper die forming punch pin, a lower die forming punch pin, a lower die base and a lower die pressing plate, wherein the upper die pressing plate is connected with the upper die base, the upper die forming punch pin is arranged on the two sides of the upper die pressing plate, the lower die pressing plate is connected with the lower die base, the lower die forming punch pin is arranged in the middle of the lower die pressing plate, two outer side walls of the lower die forming punch pin are respectively provided with at least two convex hulls, and two inner side walls of the upper die forming punch pin are provided with grooves corresponding to the convex hulls. According to the high-tension board forming device, due to the convex hull structure, in the bending process, interior molecules of a plate flow along the outer walls of the convex hulls to have plastic deformation, the increased convex hulls can absorb materials accumulated in the bending process, the tension of the plate located at the bending position is dispersed, and springback of the plate is reduced; meanwhile, in the bending process, the bending pressure is increased due to the arrangement of the lower die pressing plate and a balance weight, and the situation that the plate wrinkles in the bending process is reduced.

Owner:RAINBOW METAL TECH

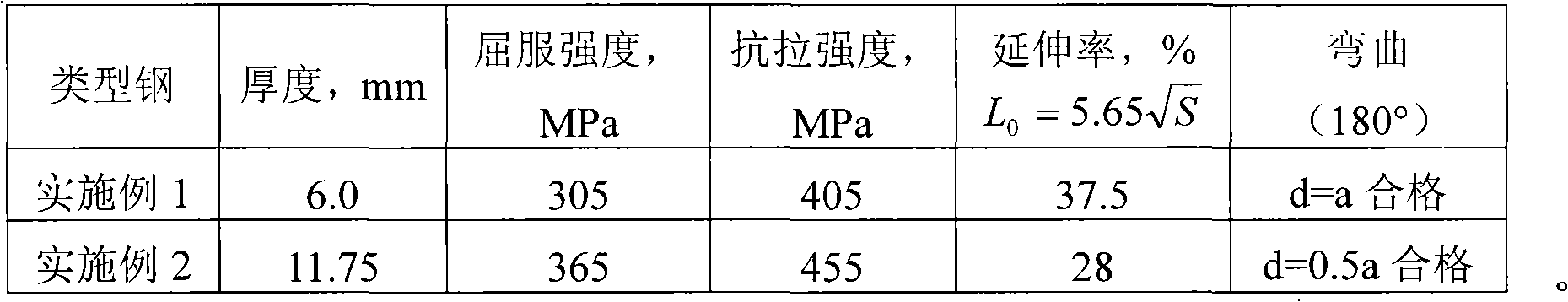

Steel belt for spoke of vehicle wheel and manufacturing method thereof

InactiveCN101280389AGood welding performanceStable controlTemperature control deviceManufacturing convertersChemical compositionSteel belt

The invention relates to a steel strip for the wheel spoke of the vehicle and the manufacturing method thereof. The chemical composition of the steel strip has the following weight percentage: C is larger than 0 and lower than or equal to 0.26 percent, Si is lower than or equal to 0.50 percent, Mn is larger than 0 and lower than or equal to 2.0 percent, P is lower than or equal to 0.035 percent, S is lower than or equal to 0.035 percent, Al is larger than 0 and lower than or equal to 0.10 percent, Nb is larger than 0 and lower than or equal to 0.060 percent, and the residue is Fe and micro impurities. The steel strip of the invention adopts molten iron desulphurization, converter smelting, LF ladle refining, slab continuous casting, rolling by hot continuous rolling mill, which has superior welding performance and molding performance, the mechanical property is uniform, the processing of the spinning spoke of vehicle wheels in varied specifications can be performed, and the finished product rate is high. The steel strip for the wheel spoke of the vehicle of the invention has the advantages that the cost is low, the producing operation is easy, and the industrialization is easy.

Owner:SHANDONG IRON & STEEL CO LTD

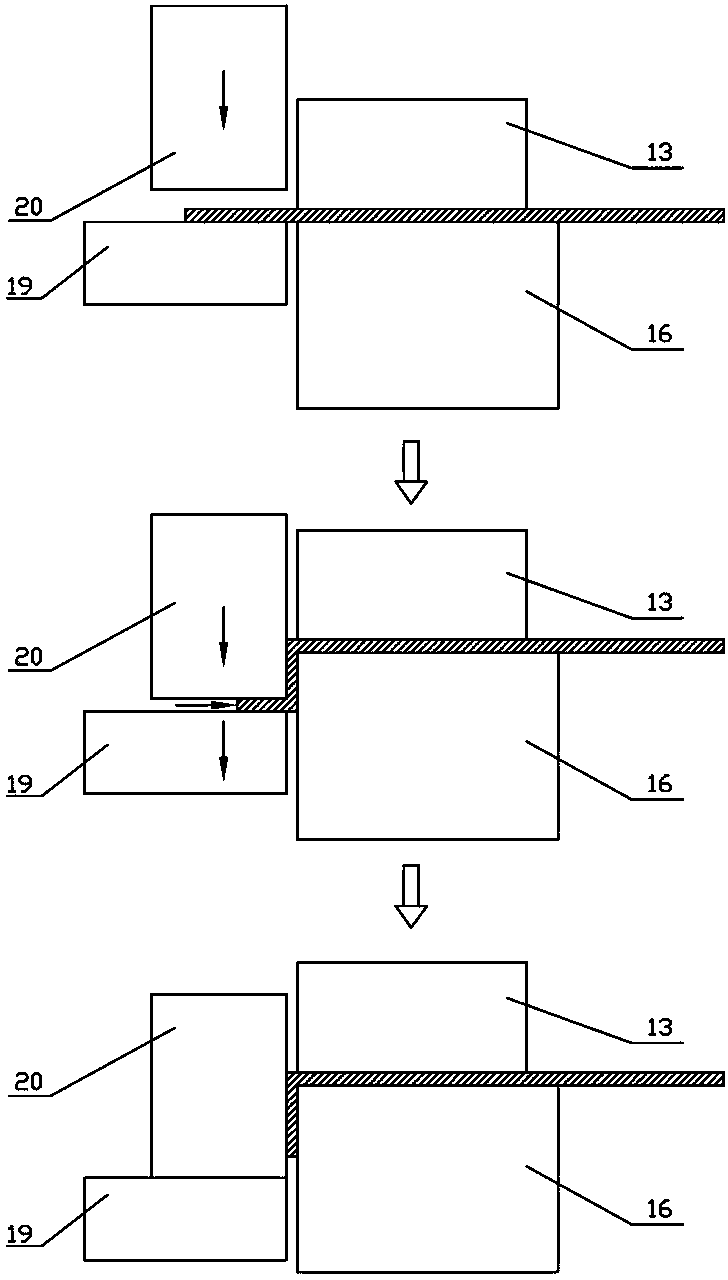

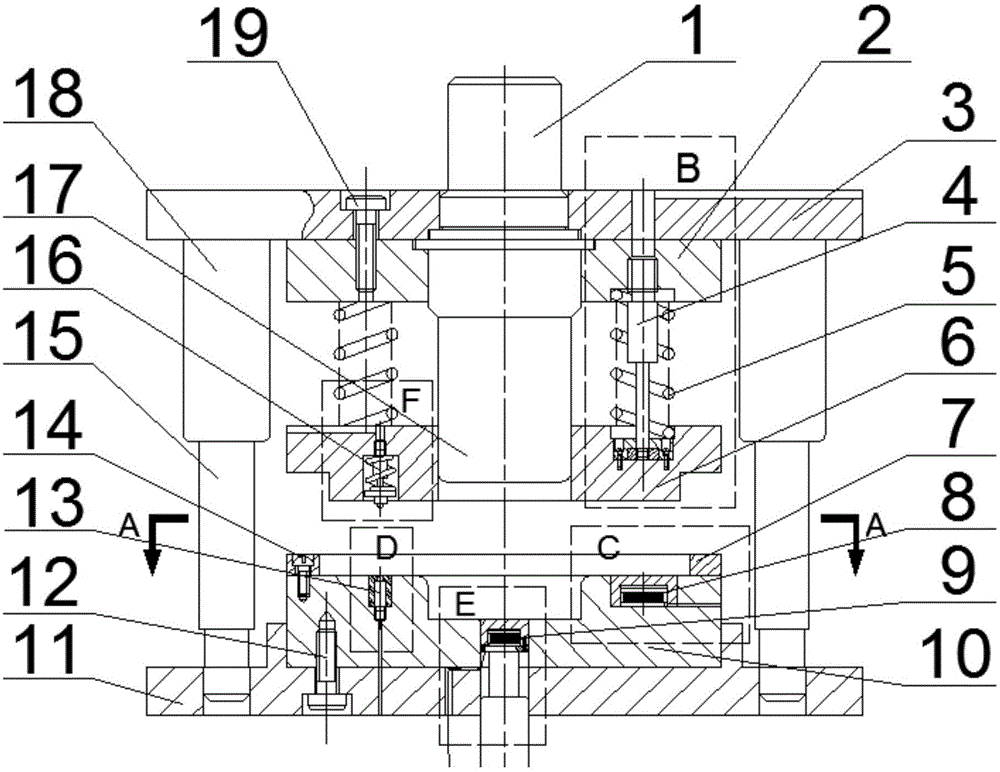

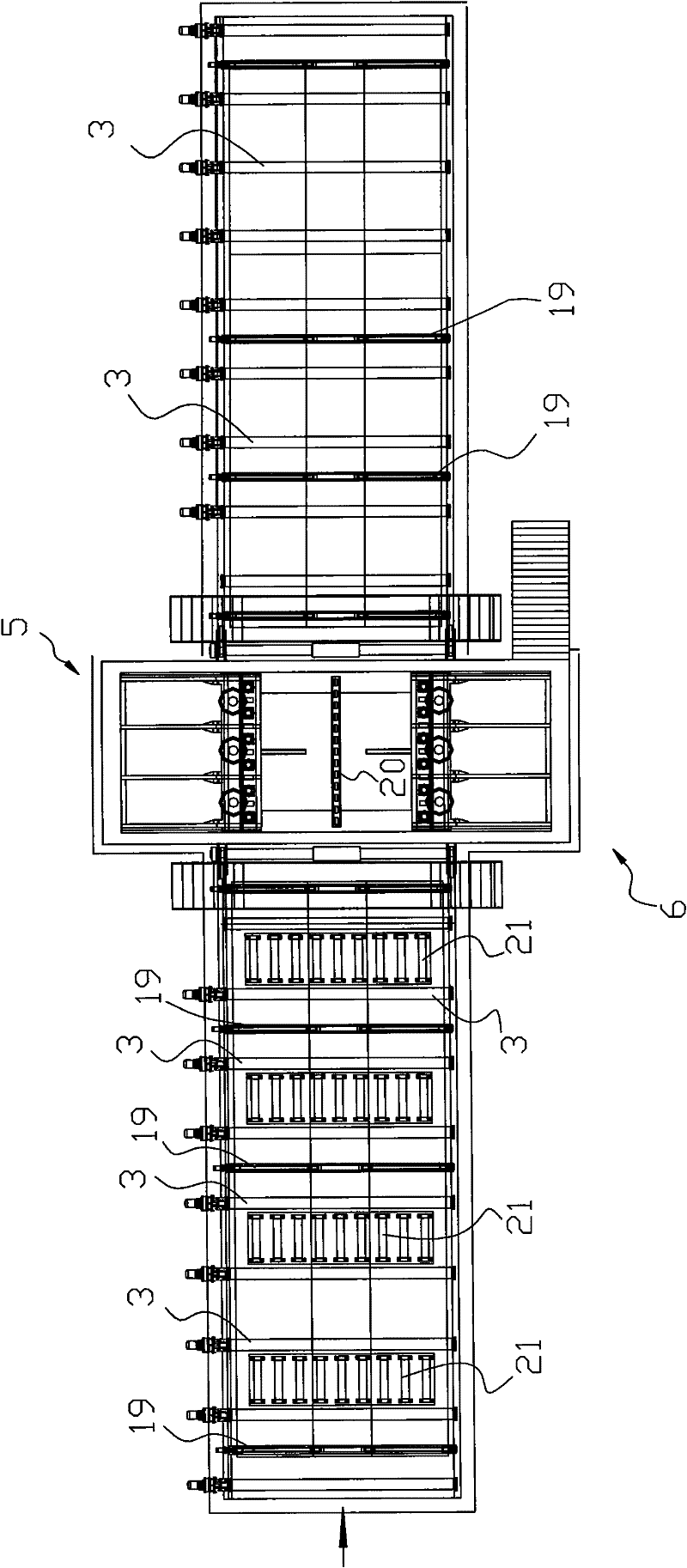

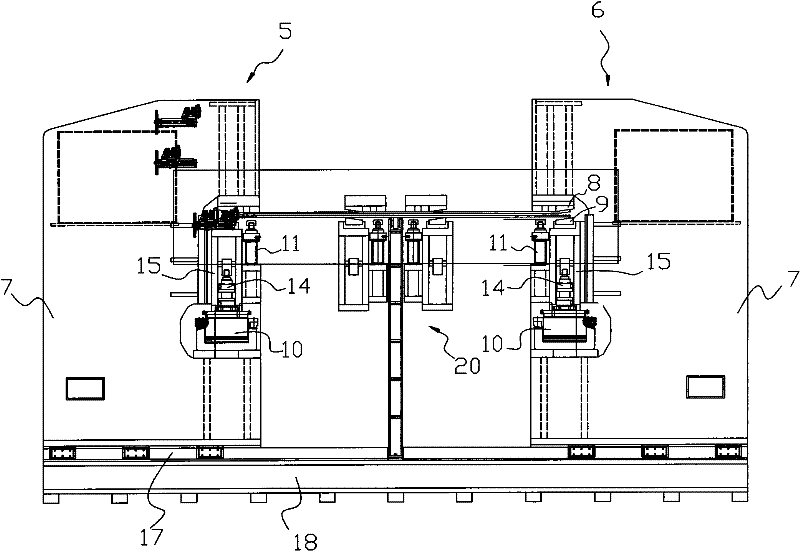

Sheet part stamping/welding integrated manufacturing device

ActiveCN104889736AIncrease productivityReduce production energy consumptionShaping toolsMetal-working feeding devicesEngineeringSpot welding

The invention provides a sheet part stamping / welding integrated manufacturing device. The sheet part stamping / welding integrated manufacturing device comprises a concave die and a convex die; the concave die is fixed on a lower plate; the convex die is connected to an upper plate; the lower plate and the upper plate are connected together by use of a guide column and a guide sleeve; a plurality of first magnetorheological dampers are connected to the lower surface of a convex die fixed plate; a blank holder is connected to the lower ends of the first magnetorheological dampers; a plurality of second magnetorheological dampers are mounted on the lower part of the blank holder; the lower ends of the second magnetorheological dampers are connected with a spot-welding upper electrode; a plurality of stop-welding lower electrodes are mounted at the outer edge of the concave die; a first electromagnet is mounted in the central position of the concave die; more than two second electromagnets are mounted at the outer edge of the concave die; the mounting positions of the second electromagnets are all located in a circle determined on the basis of the center of the spot-welding lower electrode, and distributed alternately with the stop-welding lower electrodes. The sheet part stamping / welding integrated manufacturing device is integrated with stamping and welding; sheet parts machined by use of the device are low in resilience, low in consumed energy source and high in machining efficiency.

Owner:XI AN JIAOTONG UNIV

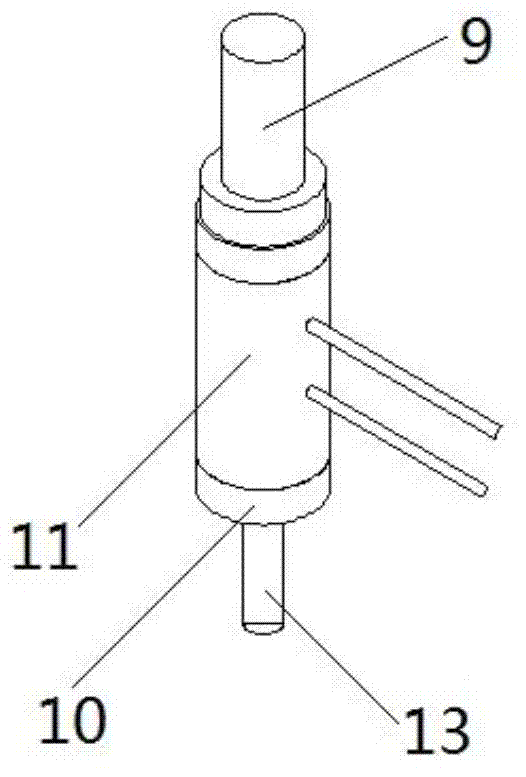

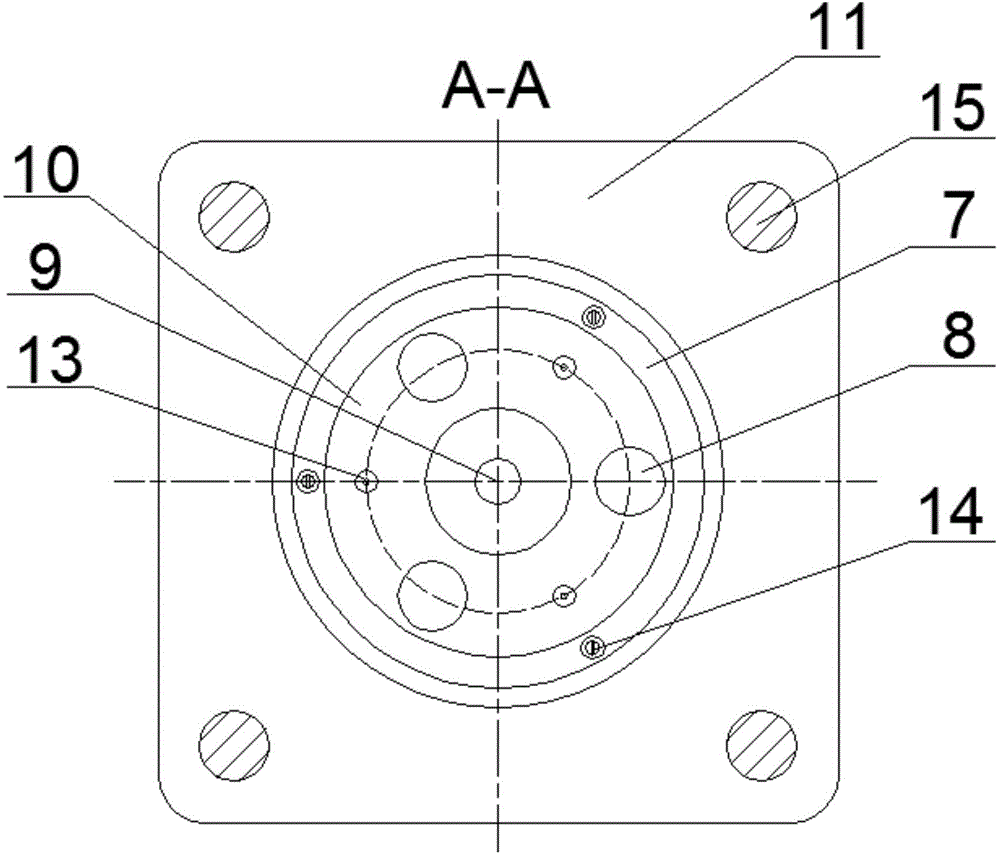

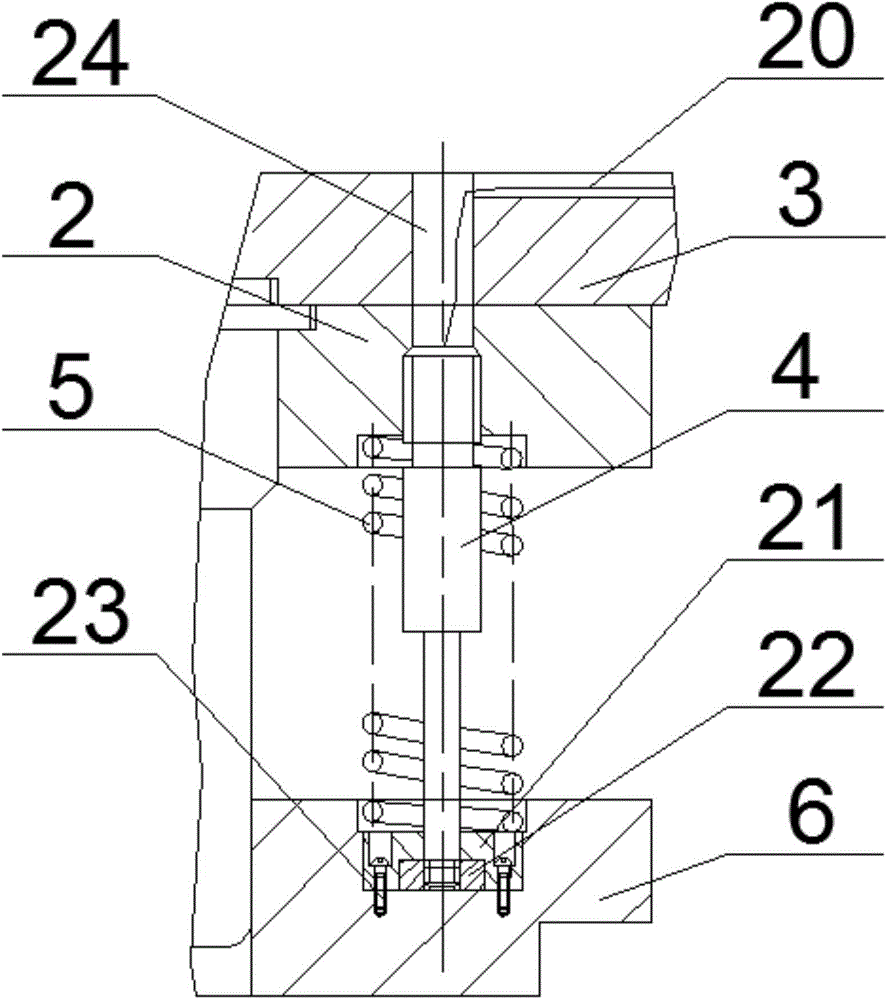

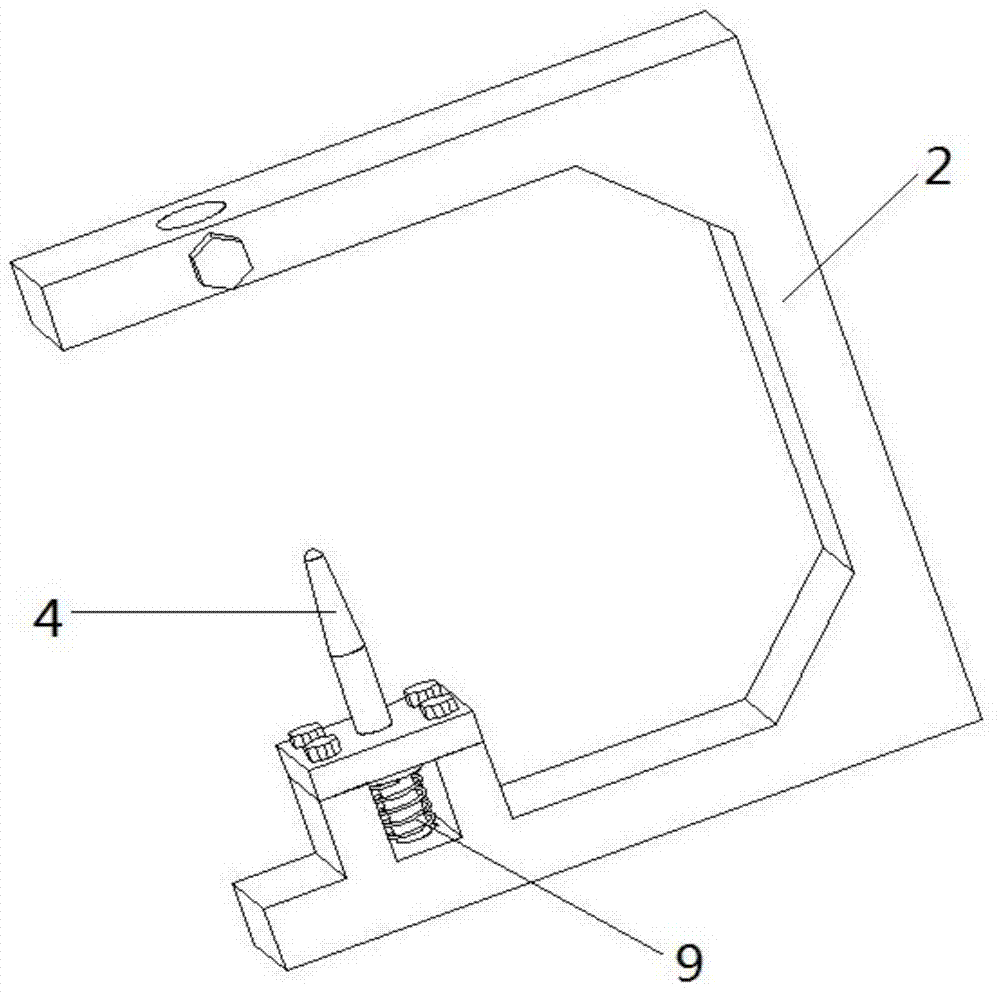

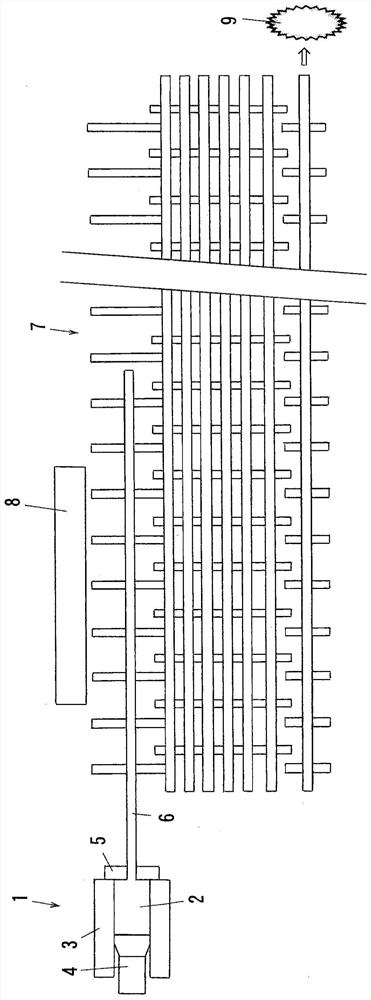

Increment forming device and method for performing increment forming by utilizing increment forming device

InactiveCN103480751AAchieve stretch deformationImprove surface qualityShaping toolsHigh energyControl system

The invention discloses an increment forming device and a method for performing increment forming by utilizing the increment forming device and solves the technical problem of poorer forming precision of the existing panel movable ring electromagnetic incremental forming device. The technical scheme is that an industrial manipulator and a C-shaped frame are respectively fixed two ends of a base; a clamping frame is positioned at the opening of the C-shaped frame; a heating forming head is mounted at the clamping end of the industrial manipulator; a control system for the heating forming head is connected with a high-energy pulse power supply. During heating forming, a panel is placed on the clamping frame to be clamped, then the C-shaped frame is mounted on the industrial manipulator and the heating forming head is well mounted, the panel is subjected to an extruding force by a compression spring, and meanwhile, the heating forming head is enabled to be consistent and harmonious in moving due to the C-shaped frame. As the heating forming head adopts electromagnetic induction for heating, the deforming resistance of a material is reduced by the local heat effect of the contacting deforming area between the heating forming head and the panel, the plasticity is improved and the forming precision is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

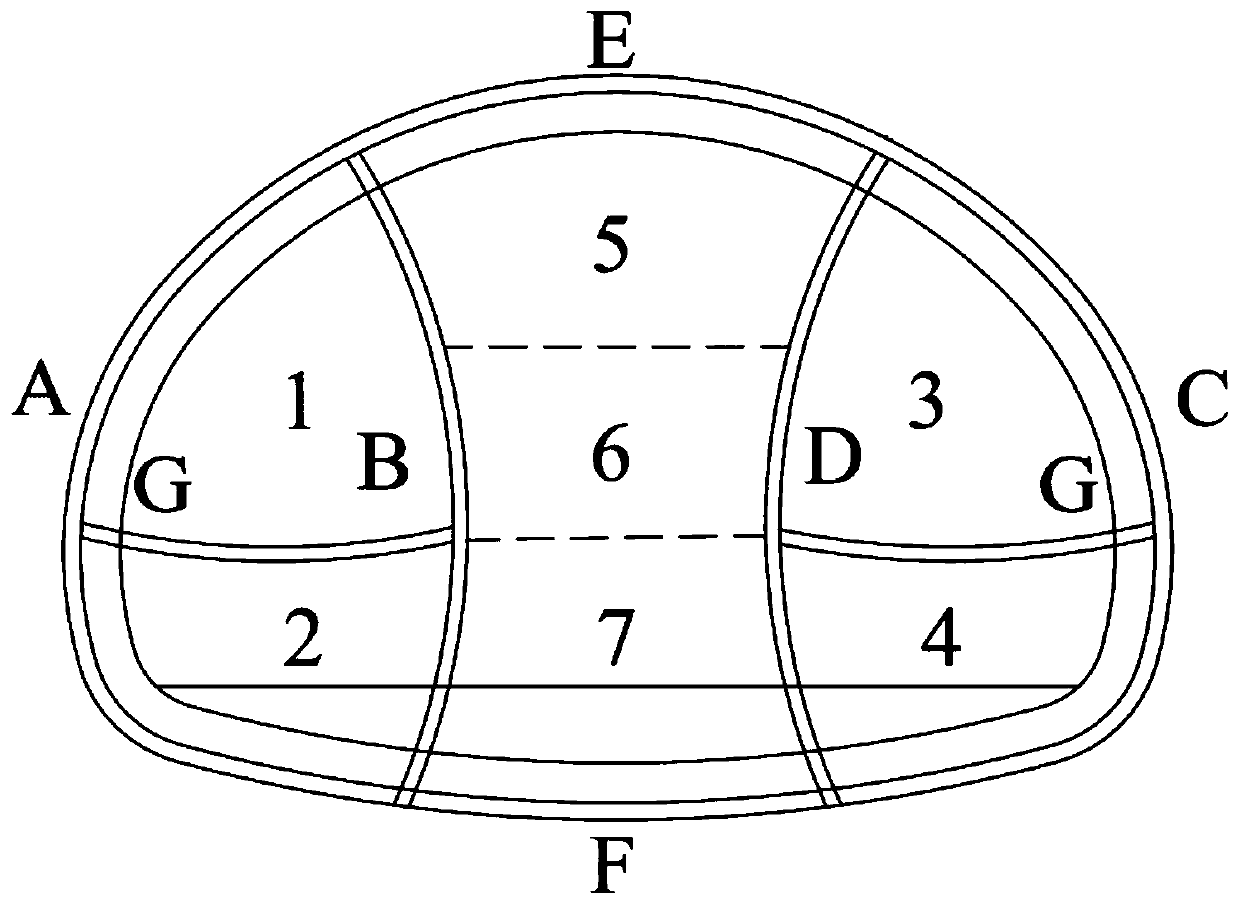

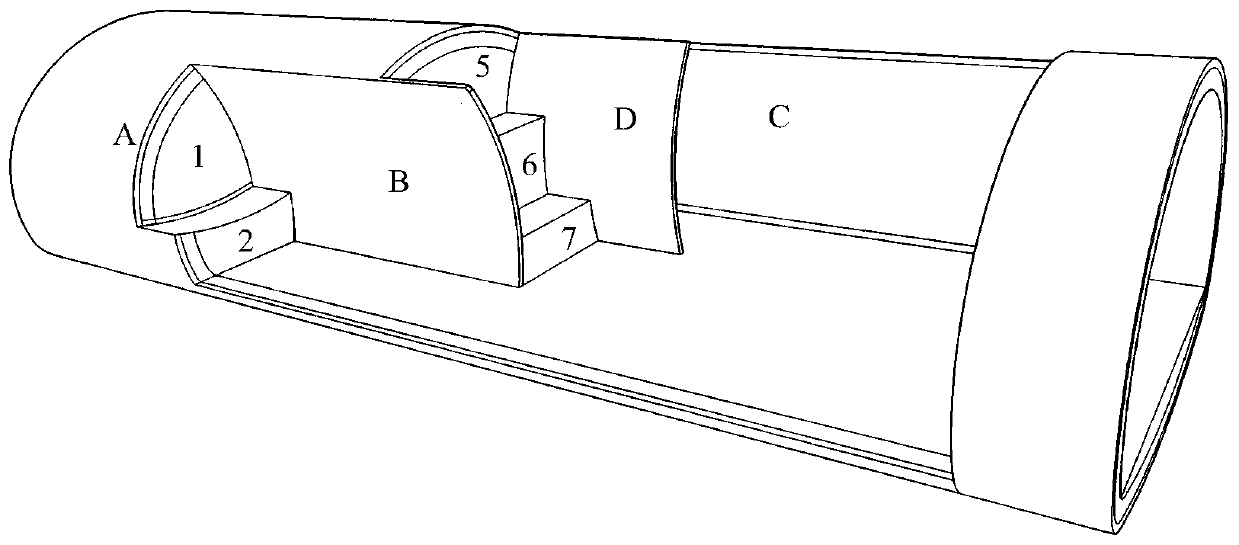

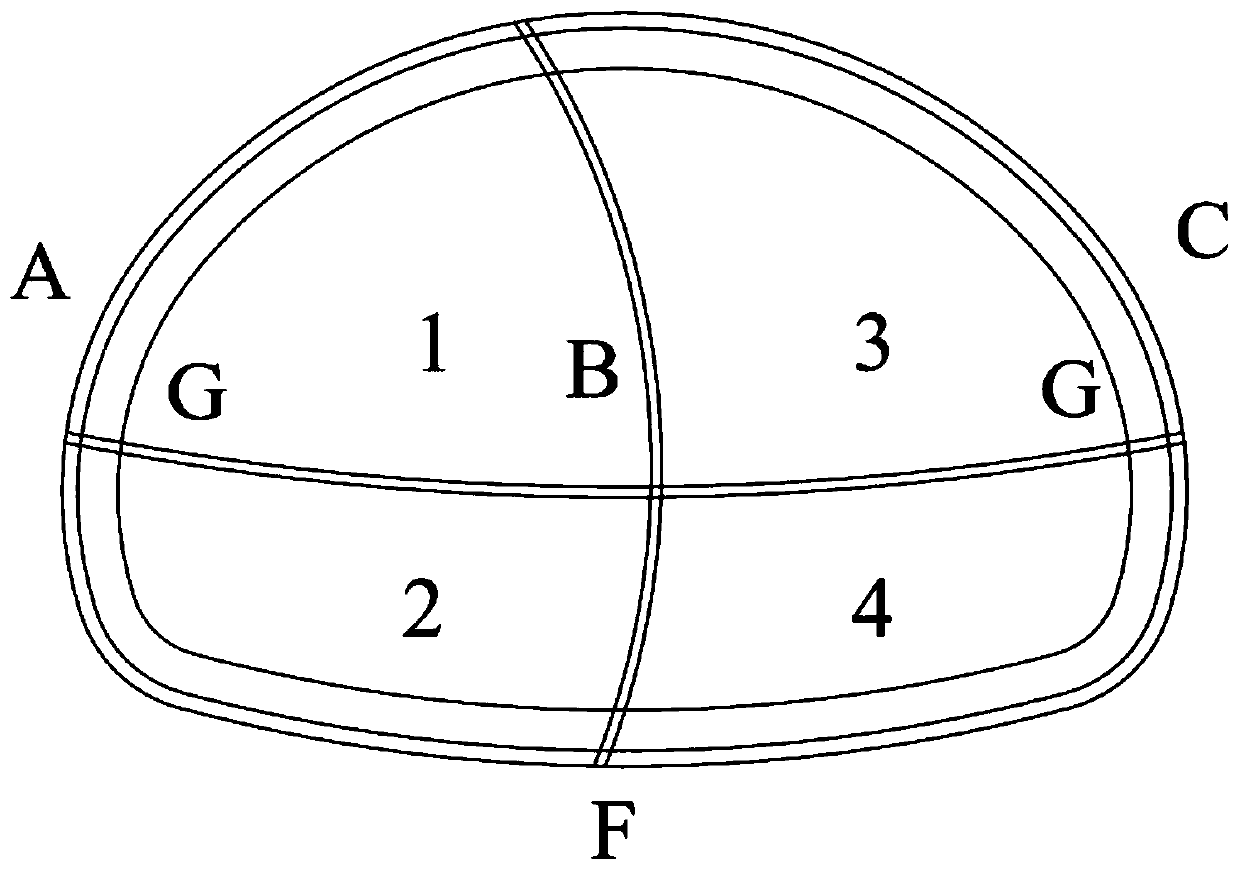

Construction method conversion construction method of super-large-span tunnel in V-level to IV-level surrounding rock section

ActiveCN109989757AReduce disturbanceAvoid intervalsUnderground chambersTunnel liningTunnel constructionBuilding construction

The invention discloses a construction method conversion construction method of a super-large-span tunnel in a V-level to IV-level surrounding rock section. The elevation of an excavation arching lineis controlled to be consistent; in transition section construction, a left pilot tunnel temporary middle wall and a right pilot tunnel temporary middle wall on the two sides of a pilot and a rear pilot in a surrounding rock double-side-wall pilot tunnel method simultaneously move towards the middle of the tunnel until the left pilot tunnel temporary middle wall is in contact with the right pilottunnel temporary middle wall, and foot locking anchor rods are applied to the two sides of a temporary inverted arch; and then the right pilot tunnel temporary middle wall is removed, and the left pilot tunnel temporary middle wall is reserved as a middle temporary middle wall of a CRD method. According to the method, a double-side-wall pilot tunnel method is transversely transited to the CRD method through a gradual change method, the time interval between construction method conversion is avoided, and disturbance of later removal of temporary supports of the double-side-wall pilot tunnel method to surrounding rock is reduced; and therefore the construction speed is increased, the construction period is shortened, enforced idleness due to poor organization of work is avoided, and economicbenefits of tunnel construction are improved.

Owner:CHANGAN UNIV

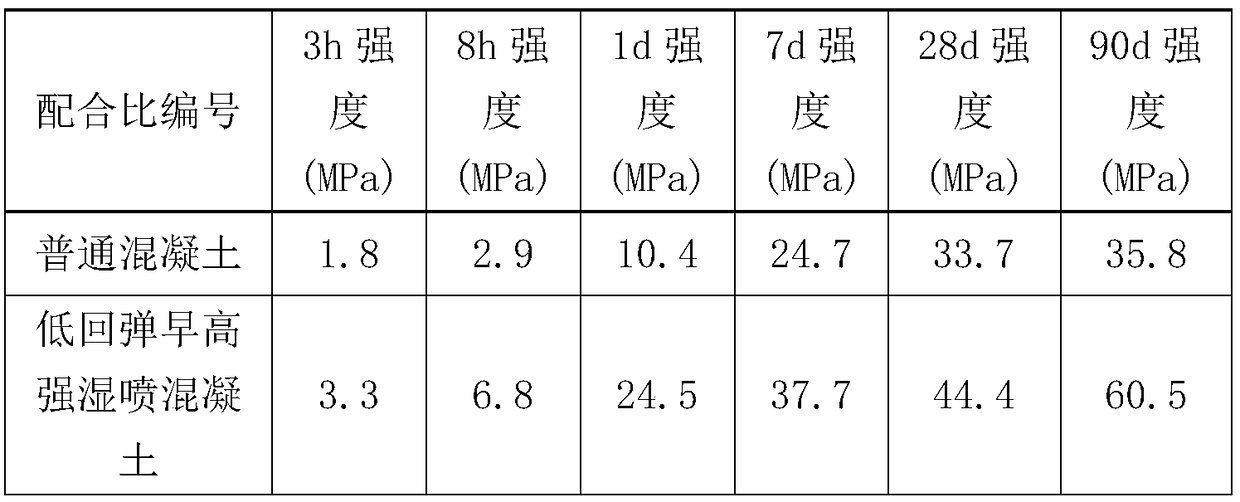

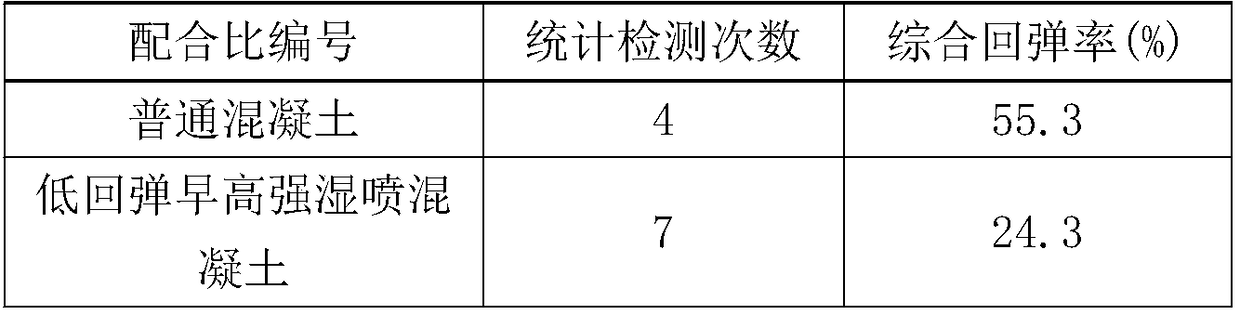

Low-resilience, early-strength and high-strength wet-spraying concrete and application thereof

The invention relates to the field of building materials and in particular provides low-resilience, early-strength and high-strength wet-spraying concrete and application thereof. The low-resilience,early-strength and high-strength wet-spraying concrete is prepared from the following raw materials in parts by weight: 380 to 500 parts of cement, 800 to 1000 parts of sand, 650 to 800 parts of crushed stone, 10 to 30 parts of a setting accelerator, 160 to 200 parts of water, 20 to 30 parts of a high-strength ultra-micro additive and 40 to 50 parts of fly ash. According to the low-resilience, early-strength and high-strength wet-spraying concrete prepared by the invention, the binding force is greatly improved and the resilience rate of the concrete is reduced; the concrete can be normally sprayed in a water-rich region and a result reaches the advanced level in China; the low-resilience, early-strength and high-strength wet-spraying concrete can be directly applied to primary supportingconstruction of tunnels and a novel technical way is explored for the primary supporting construction of the tunnels.

Owner:TRANSTECH ENG CORP

Pre-bending machine

The invention discloses a pre-bending machine comprising a material conveying mechanism, a main machine, a lubricating system and an electronic control system. The pre-bending machine is characterized in that the material conveying mechanism comprises a first material conveying unit and a second material conveying unit, the first material conveying unit and the second material conveying unit bothcomprise material conveying rollers, centring devices and clamping material conveying devices, wherein the material conveying rollers are sequentially arranged, and the clamping material conveying devices are close to one side of the main machine; the main machine comprises a first main machine unit and a second main machine unit which are separately erected at both sides of the main machine, thefirst main machine unit and the second main machine unit both comprise C-shaped stands, upper moulds, lower brackets and upper clamping rollers, wherein the lower brackets can carry lower moulds to move up and down; a main machine width adjusting device is arranged between the first main machine unit and the second main machine unit and comprises transmission screw rods and sliding rails, whereinthe transmission screw rods are respectively fixedly connected to the C-shaped stands through corresponding nuts, and the stands are connected with the sliding rails through slide blocks. The invention has the advantages of small resilience amount of preformed steel plate workpieces, high forming speed, high efficiency, undamaged workpieces, good bending quality, and the like.

Owner:QINGDAO WUXIAO GRP

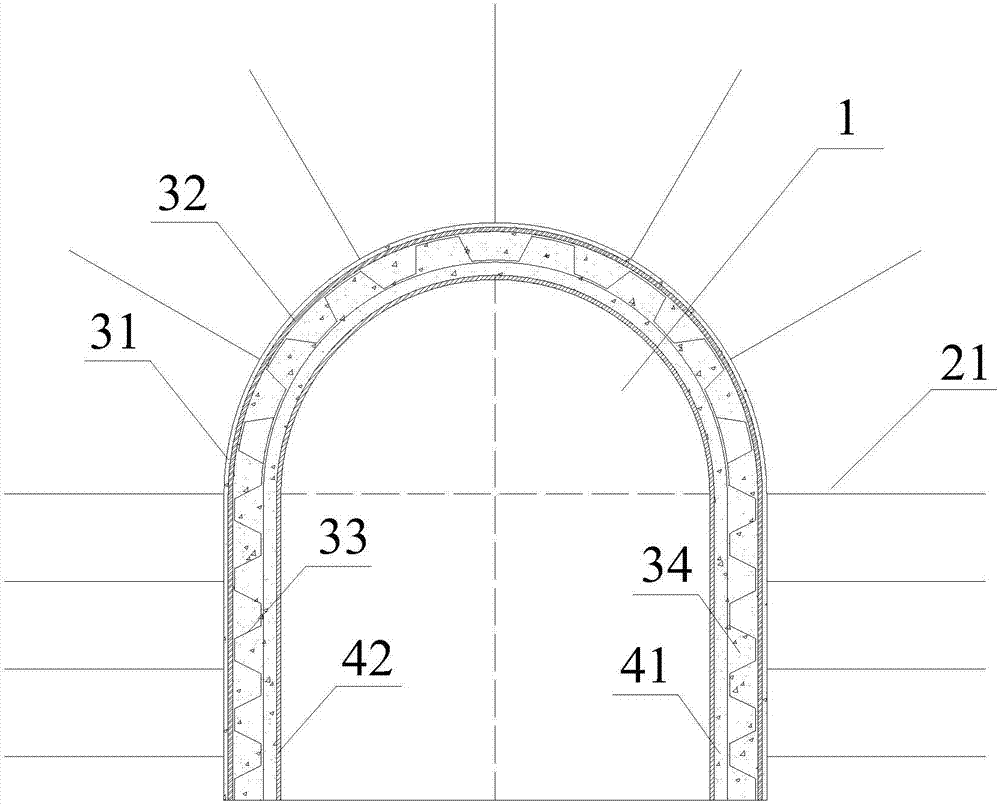

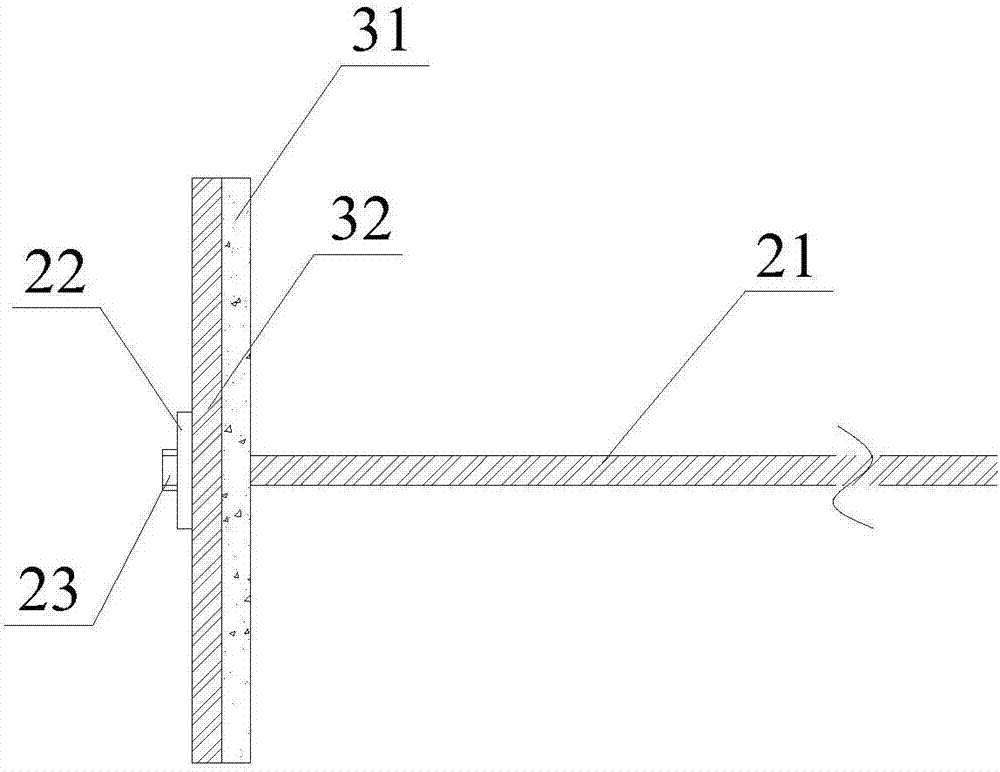

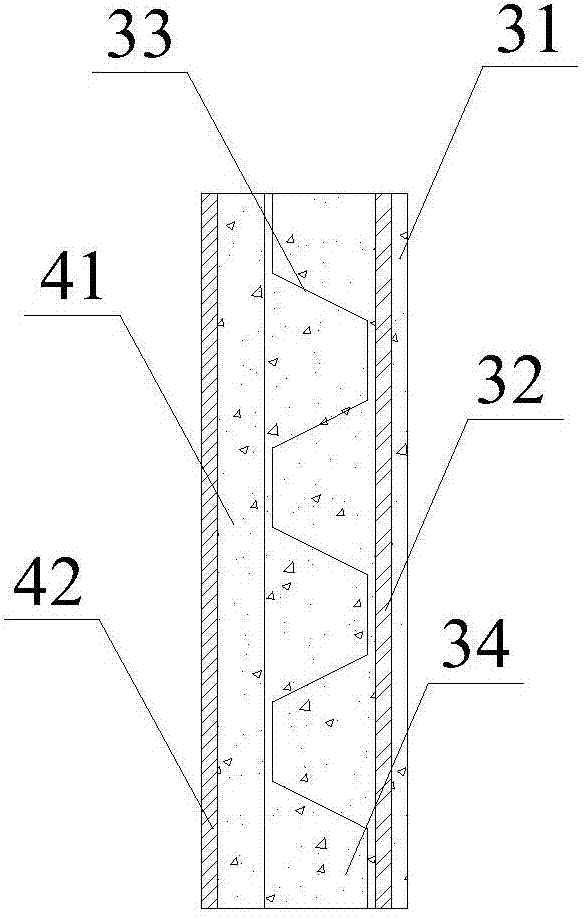

Deep high-ground-temperature roadway heat-insulation lining structure and construction method thereof

ActiveCN106988769ARealization of thermal insulation liningHigh strengthUnderground chambersTunnel liningInsulation layerArchitectural engineering

The invention discloses a deep high-ground-temperature roadway heat-insulation lining structure and a construction method thereof. The lining structure comprises a grouting heat-insulation ring, a primary lining heat-insulation layer and a secondary lining heat-insulation layer. Firstly, a heat-insulation grout material is injected through a hollow grouting anchor rod to form a grouting heat-insulation ring; the primary lining heat-insulation layer is distributed to form a primary support, wherein the primary lining heat-insulation layer comprises a first jet ceramsite concrete layer, a reinforcing mesh layer, a metal support and a second jet ceramsite concrete layer; after roadway deformation is stabilized, the secondary lining heat-insulation layer is constructed, and construction of the structure is completed, wherein the secondary lining heat-insulation layer comprises a third jet ceramsite concrete layer and a heat-insulation plate. By means of the structure and existing common support means and according to the current situation that deep mining high-temperature damage is severe, the stability of a roadway support structure is ensured by reasonably improving supporting materials and increasing the heat-insulation plates; by means of multiple heat-insulation measures, heat is effectively prevented from spreading into a roadway, and the application and popularization value is good.

Owner:ANHUI UNIV OF SCI & TECH

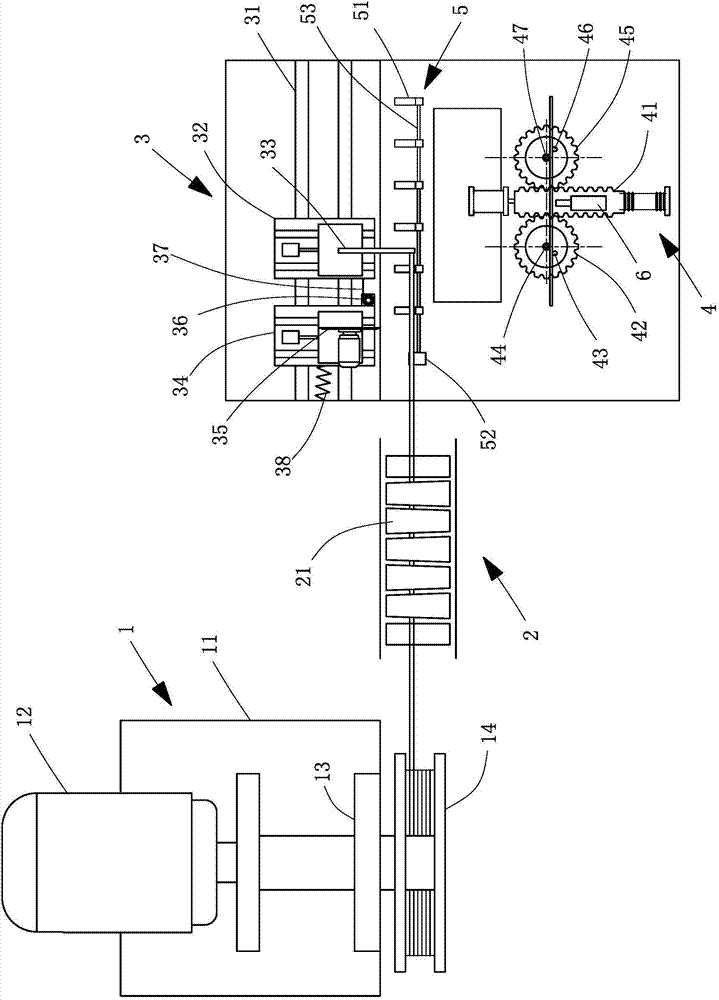

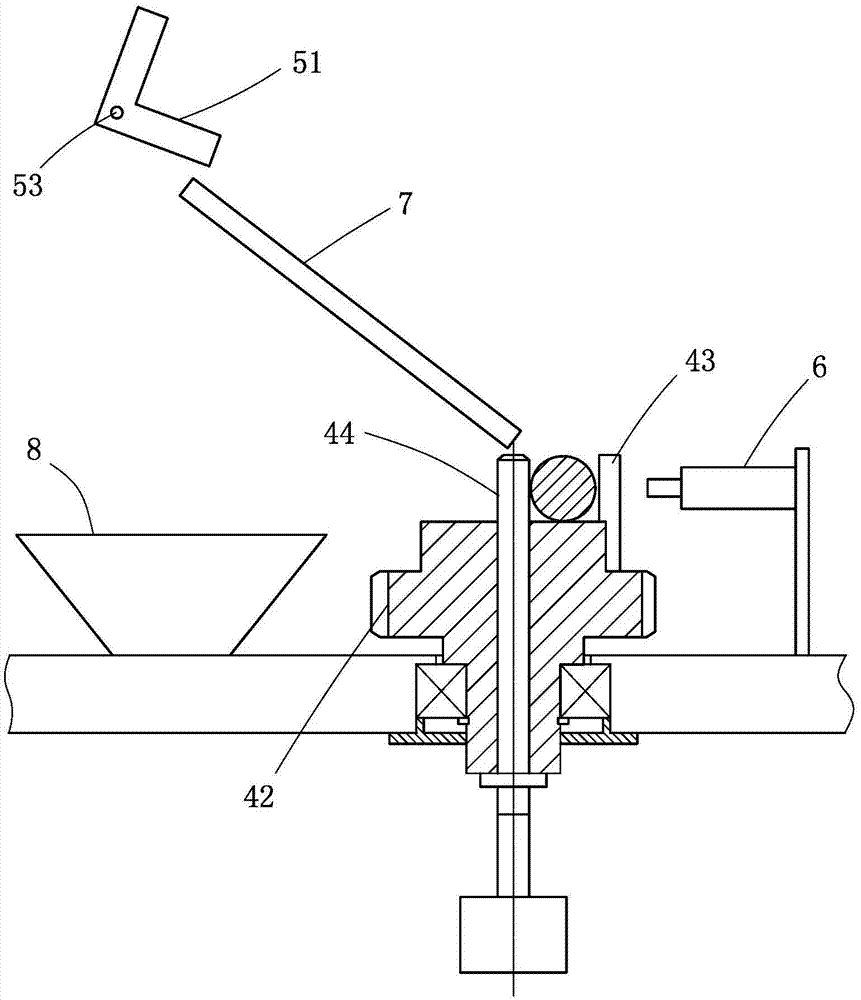

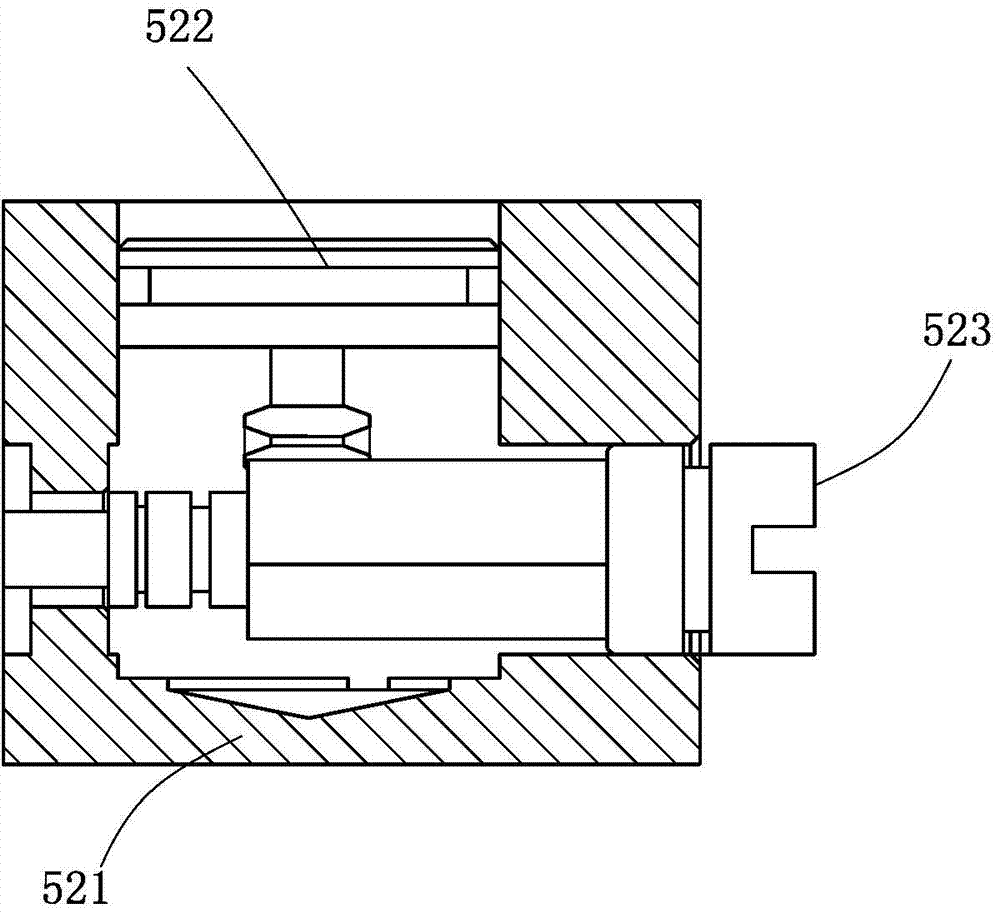

U-shaped double-head bolt processing equipment

ActiveCN103522073AIncrease productivityLabor savingOther manufacturing equipments/toolsMetal working apparatusEngineeringRebar

The invention discloses U-shaped double-head bolt processing equipment and belongs to the technical field of non-standard bolt processing equipment. The U-shaped double-head bolt processing equipment mainly comprises a decoiling device, a straightening device, a fixed-length cutting device, a bending device, a thread processing device and a thermal treating device. The fixed-length cutting device comprises a slide rail identical with the folding direction of a reinforcing steel bar, a fixed-length slide bench and a cutting slide bench are arranged on the slide rail in a sliding mode, the fixed-length slide bench and the cutting slide bench are connected through a flexible cable, the flexible cable is connected with a torsion spring, a tension spring is arranged between the cutting slide bench and the slide rail, accordingly online continuous fixed-length cut can be achieved without shutdown, the equipment is prevented from being started frequently to generate damage, and the equipment can automatically return after cutting. The U-shaped double-head bolt processing equipment improves production efficiency of U-shaped double-head bolt processing, reduces production cost and is widely applied to processing and manufacturing of U-shaped double-head bolts.

Owner:NINGBO HAOBO IND & TRADE

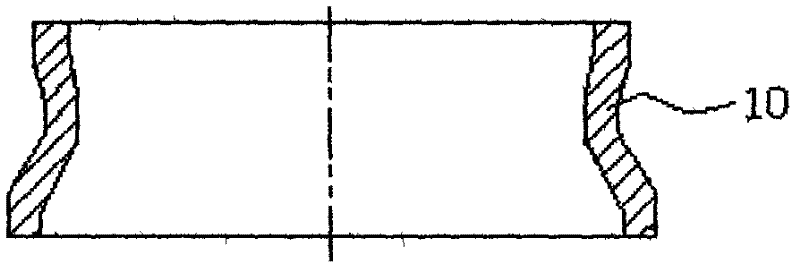

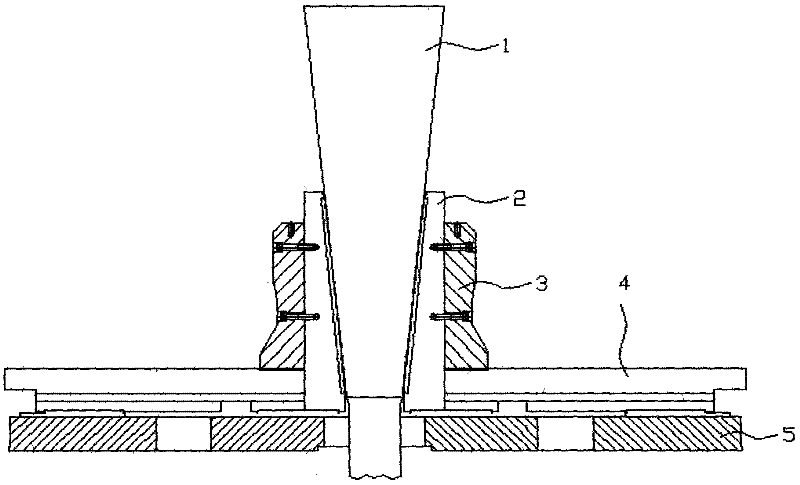

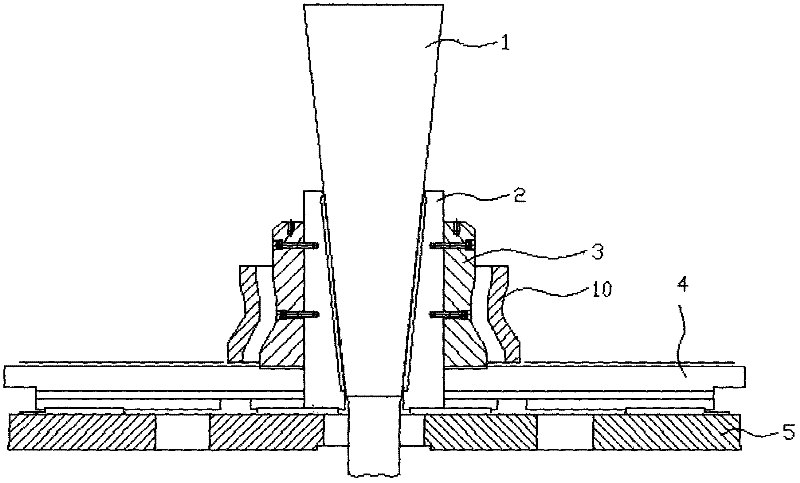

Thermal bulging process for special-shaped high-temperature-alloy rolled ring workpieces

The invention discloses a thermal bulging process for special-shaped high-temperature-alloy rolled ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a special-shaped high-temperature-alloy rolled ring workpiece which is treated by thermal rolling is sleeved on the periphery of a preheated bulging block in a bulging machine, and the bulging block squeezes the ring workpiece axially along the inner circumference of the rolled ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 820 DEG C to 860 DEG C, the bulging time ranges from 20s to 30s, the pressure holding time ranges from 10s to 11s, and the deflection ranges from 0.7% to 0.9%. The primary rotation is completed by rotating the rolled ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 790 DEG C to 830 DEG C, the bulging time ranges from 20s to 30s, the pressure holding time ranges from 16s to 18s, and the deflection ranges from 0.8% to 1 %. The second rotation is completed by rotating the ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 760 DEG C to 800 DEG C, the bulging time ranges from 30s to 40s, the pressure holding time ranges from 25s to 28s, and the deflection ranges from 0.9% to 1.1%. The dimensional precision of the rolled ring workpiece can be 1%. to 2%. of the corresponding precision after the rolled ring workpiece is bulged, and the rolled ring workpiece is mainly used for the fields of space navigation and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

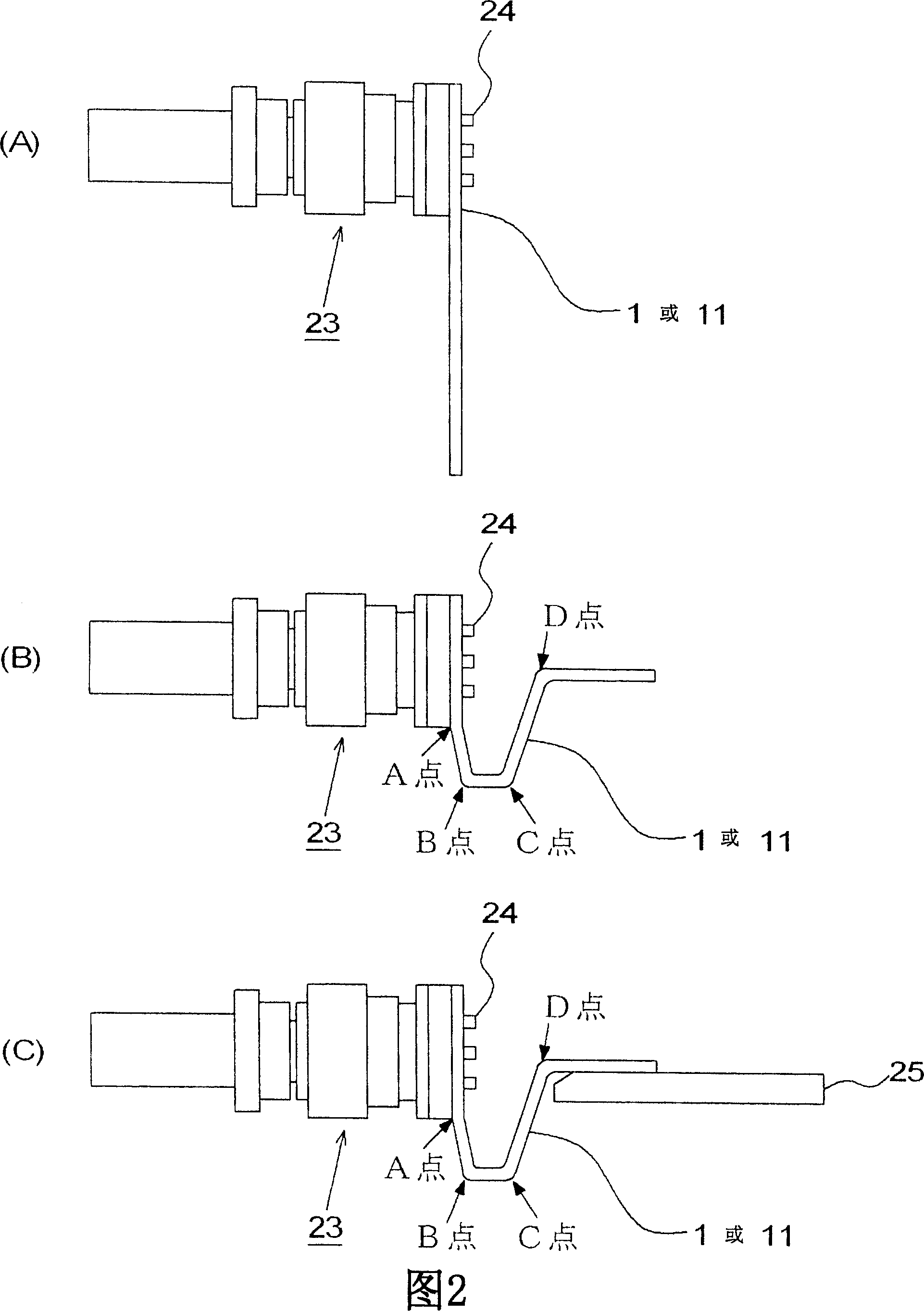

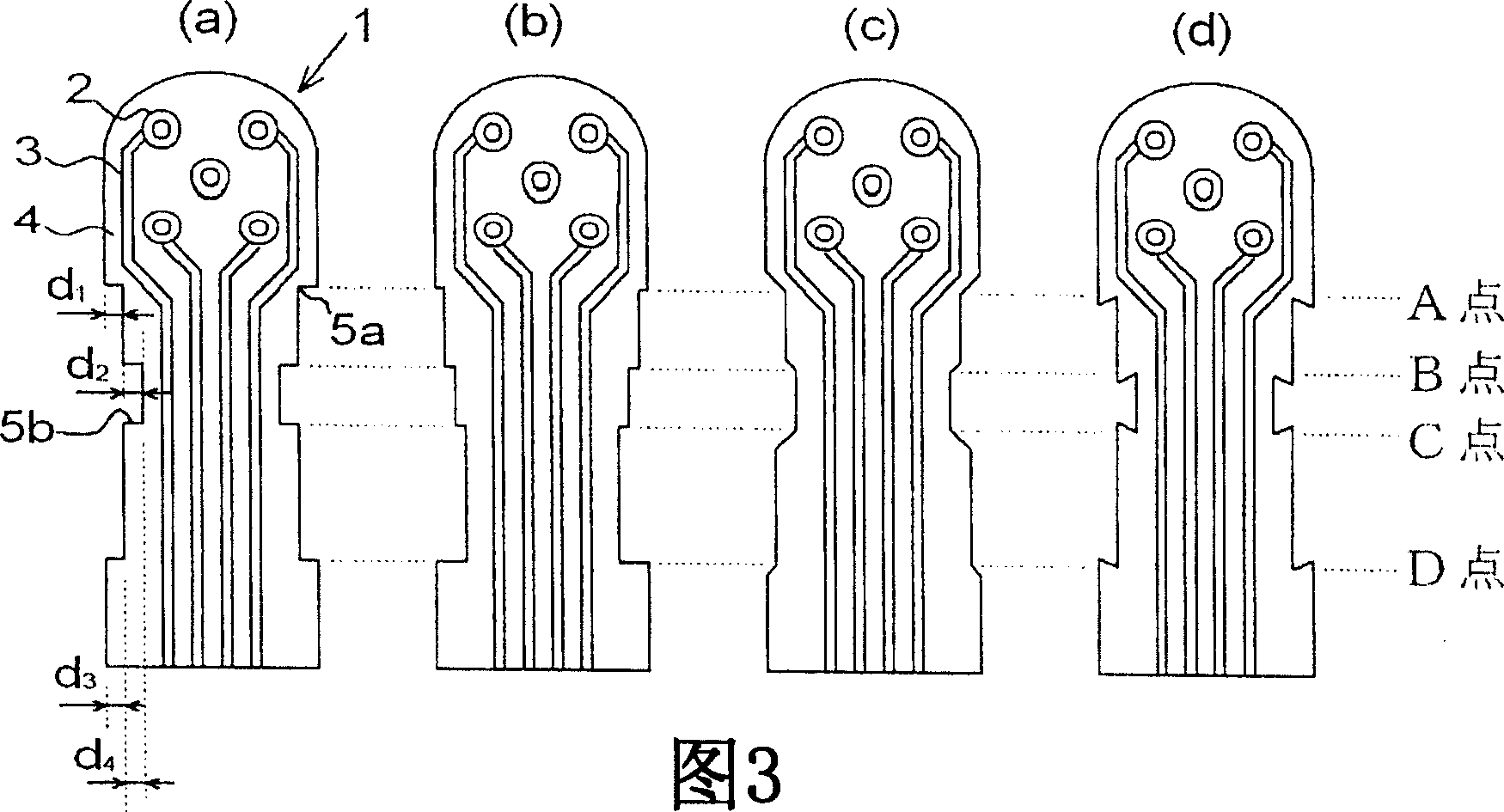

Flexible board

InactiveCN1956619AEasy to adjustWith configurationPrinted circuit aspectsElectrical connection printed elementsElectrical conductorEngineering

A flexible board capable of being bent easily and precisely a plurality of times at desired positions has insulating layer exhibiting flexibility, a conductor layer and recessed angular portions situated in both side edges of the board so as to oppose each other. Three of more of these angular portions are disposed on each side edge of the board. More specifically, the flexible board has at least one constricted portion that reduces the width of the board. The constricted portion is situated on both side edges of the board in such a manner that the constricted portions oppose each other, and has at least one of a step portion having a step-like shape and a cut-out portion having a V- or U-like shape. Three or more step-like portions and cut-out portions are situated together on each side edge the board.

Owner:NEC ELECTRONICS CORP

Special water reducer for railway tunnel construction sprayed concrete

The invention belongs to the technical field of new concrete materials, and particularly relates to a special water reducer for a railway tunnel construction sprayed concrete. An adverse effect of a retarder on an accelerator is eliminated; without influencing a setting performance of the concrete, longer-time stability of a working performance of the concrete is maintained; through adding a viscosity modifier and adjusting the air content, the sprayed concrete has better cohesiveness and can be easily adhered onto a tunnel rock wall, so that the number of rebound and drop of the sprayed concrete is reduced, and the aims of reducing the waste of the sprayed concrete and improving the durability of the concrete are achieved; meanwhile, through appropriately adding an organic early strengthcomponent, the early strength of the sprayed concrete is improved.

Owner:贵州天威建材科技有限责任公司

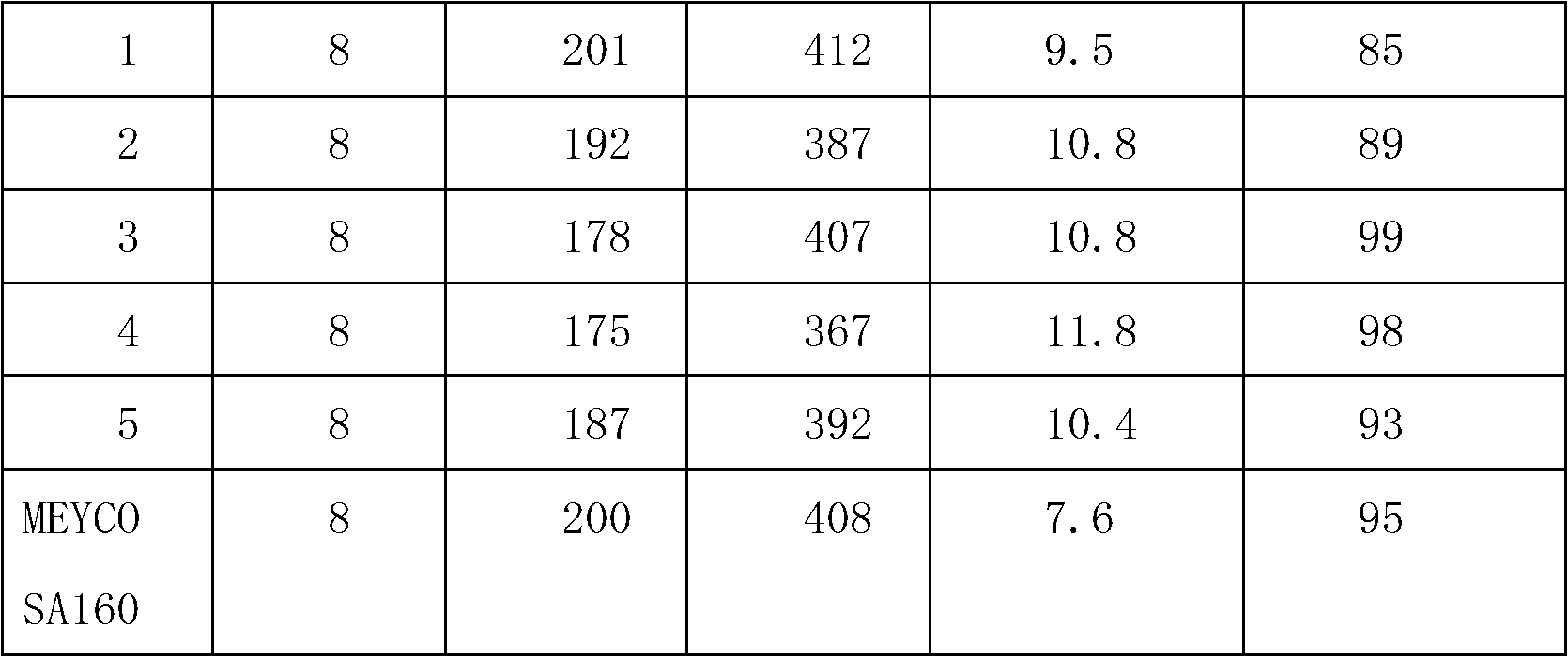

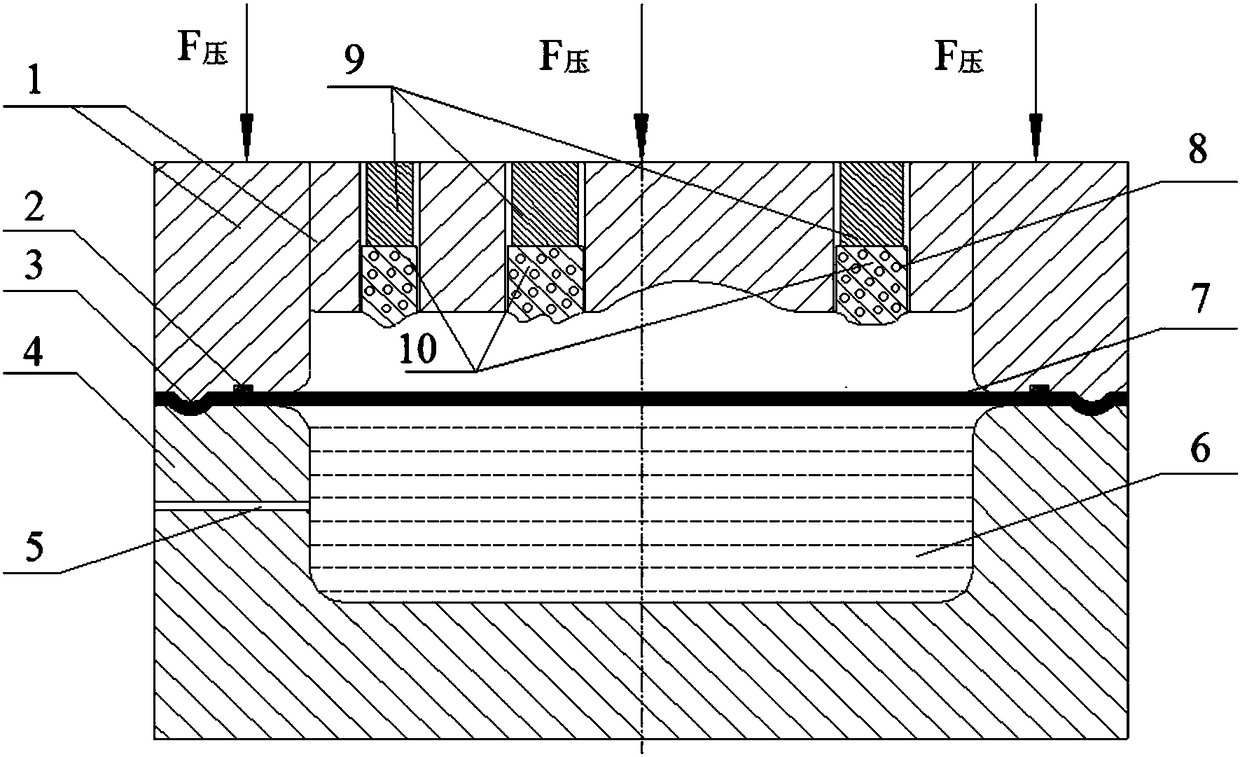

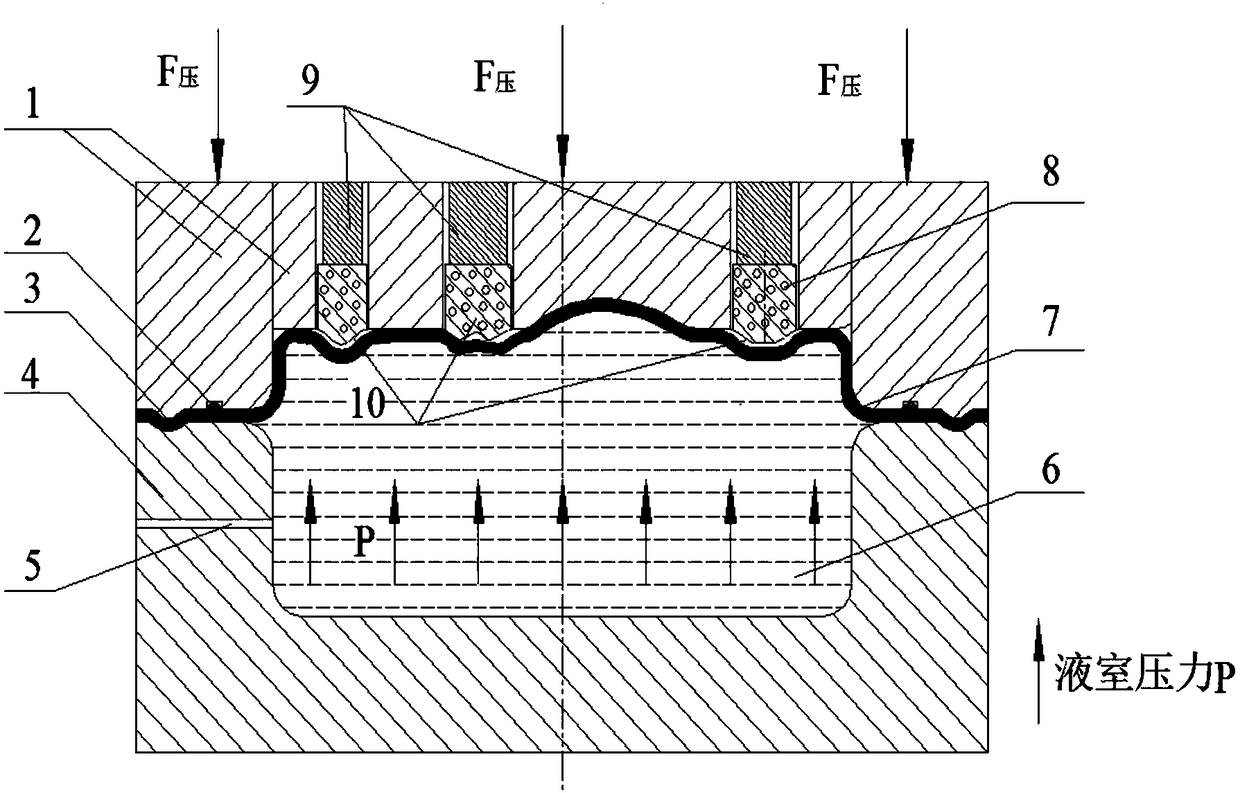

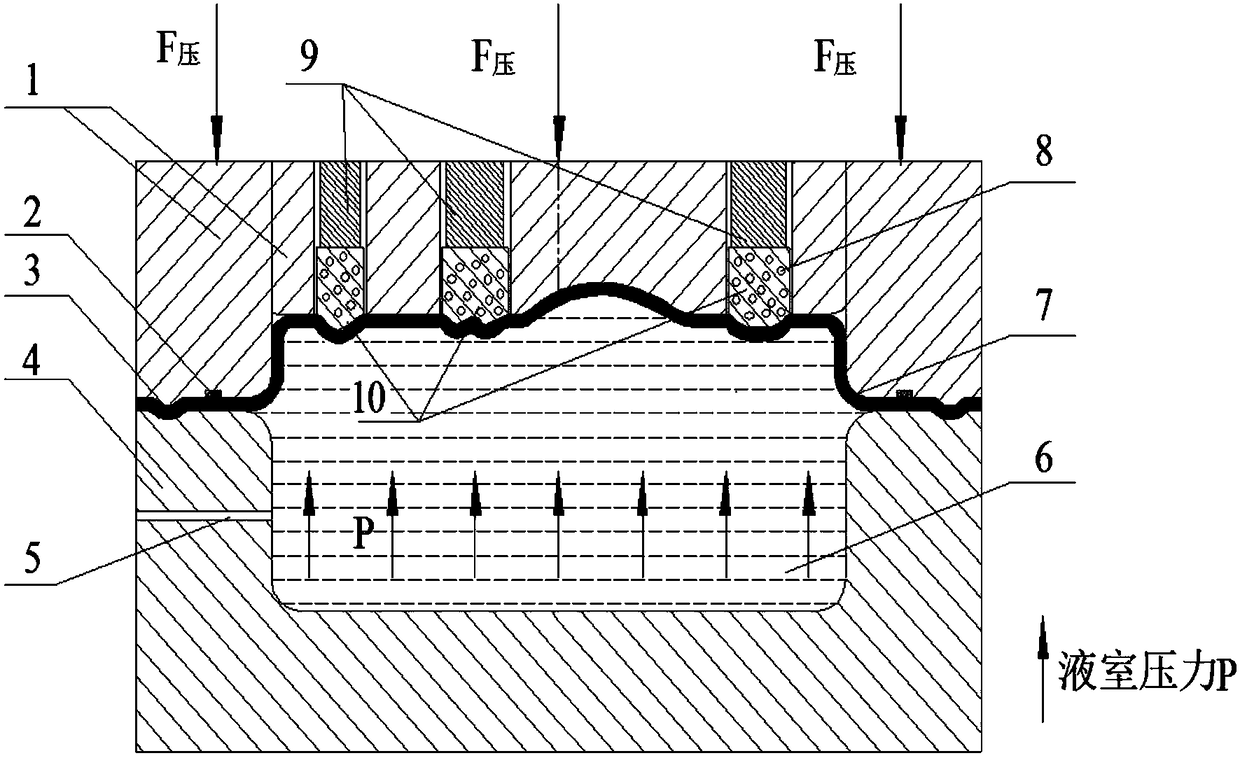

Cold-hot sequential coupling forming technology of large-scale aluminium alloy complex structural members

A cold-hot sequential coupling forming technology of large-scale aluminium alloy complex structural members is a novel forming technology which is derived from the intersection and fusion of liquid-filled forming technology and hot-stamping forming technology. The novel forming technology has the characteristics of liquid filling forming and hot stamping forming at the same time. The cold-hot sequential coupling forming technology comprises the steps that the upper and lower dies are closed, according to adjusting the blank holder force, a panel veneer is impacted between the dies; the panel veneer is attached to die profiles in function of high pressure liquid in a liquid chamber, the forming of most features is completed; and after forming the liquid-filled, according to the characteristic of the thermoplasticity of materials, the hot-stamping technology process is carried out by using heated movable insert blocks, the forming of local features is completed, sequential forming of different part features is completed, and final product parts are obtained. The dies are installed in one time, and two forming processes are realized, and thus the time-consuming of switching the dies is reduced, and the accuracy requirements of global forming and external dimensions of the product parts are guaranteed. At the same time, the movable insert blocks are convenient to install and easy to replace, so the time of repairing dies is reduced and the production efficiency is improved. The sequential forming technology has the unique advantages of in the forming of aerospace, automotive and other fields of complex structural alloy members, and has wide application prospect.

Owner:BEIHANG UNIV

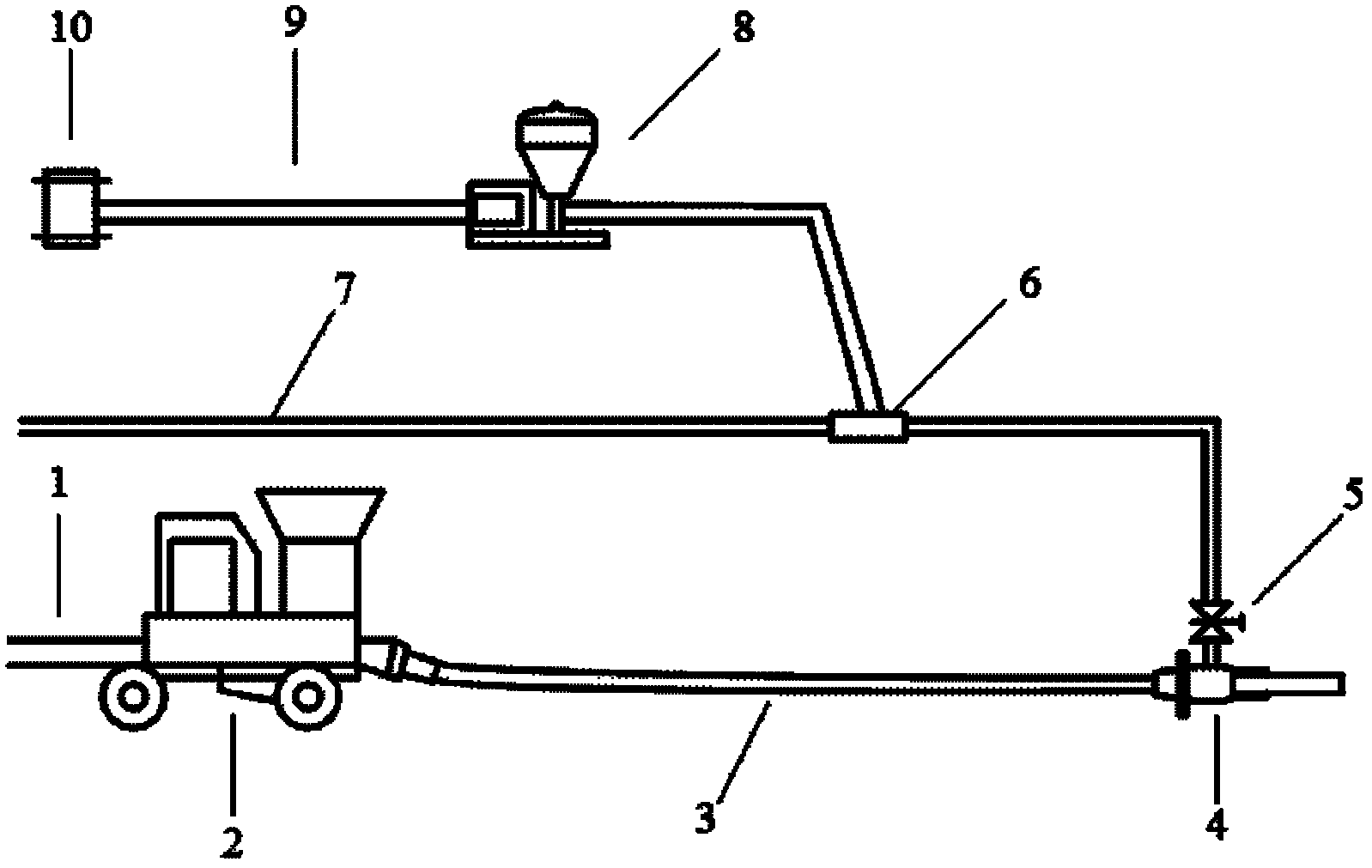

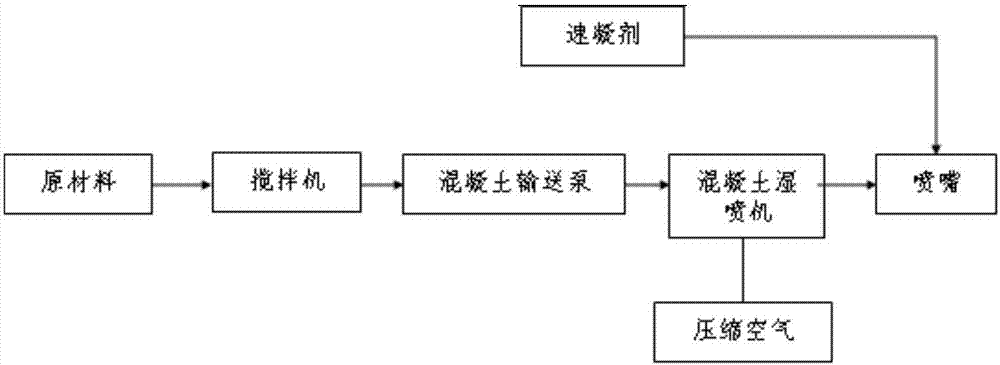

High-pressure hydraulic injection system

ActiveCN102635373ASmall amount of reboundReduce generationUnderground chambersTunnel liningWorking environmentEngineering

The invention discloses a high-pressure hydraulic injection system. The high-pressure hydraulic injection system comprises an injection machine, a setting accelerator container, a liquid setting accelerator feeder, a setting accelerator mixing pipe and a nozzle, wherein the injection machine is connected with the nozzle through a material conveying hose, the setting accelerator container is connected with the liquid setting accelerator feeder through a setting accelerator material conveying pipe, the setting accelerator mixing pipe has a tee structure with three openings, namely a feed port I, a feed port II and a discharge port I, the liquid setting accelerator feeder is connected with the feed port I of the setting accelerator mixing pipe through a material conveying hose, the feed port II is connected with a high-pressure water pipe, and the discharge port I is connected with the nozzle through the high-pressure water pipe. The high-pressure hydraulic injection system has the following advantages: 1. the high-pressure hydraulic injection system enables liquid setting accelerator to be applied, and the liquid setting accelerator can effectively reduce the resilience and dust capacity of concrete in construction, improve the working environment and save cost; and 2. a dry injection technology is changed to wet injection, the equipment is simple and flexible, the construction is simple and convenient, and the operation is easy.

Owner:SHANDONG UNIV

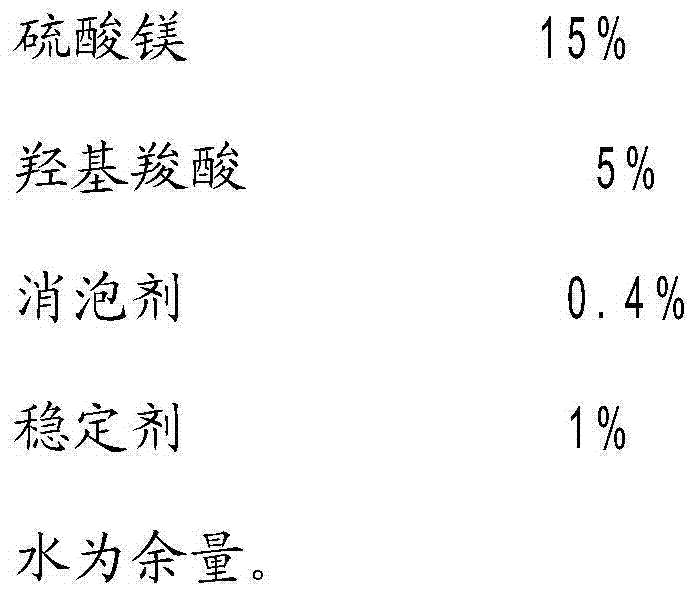

Liquid accelerator and preparation method thereof

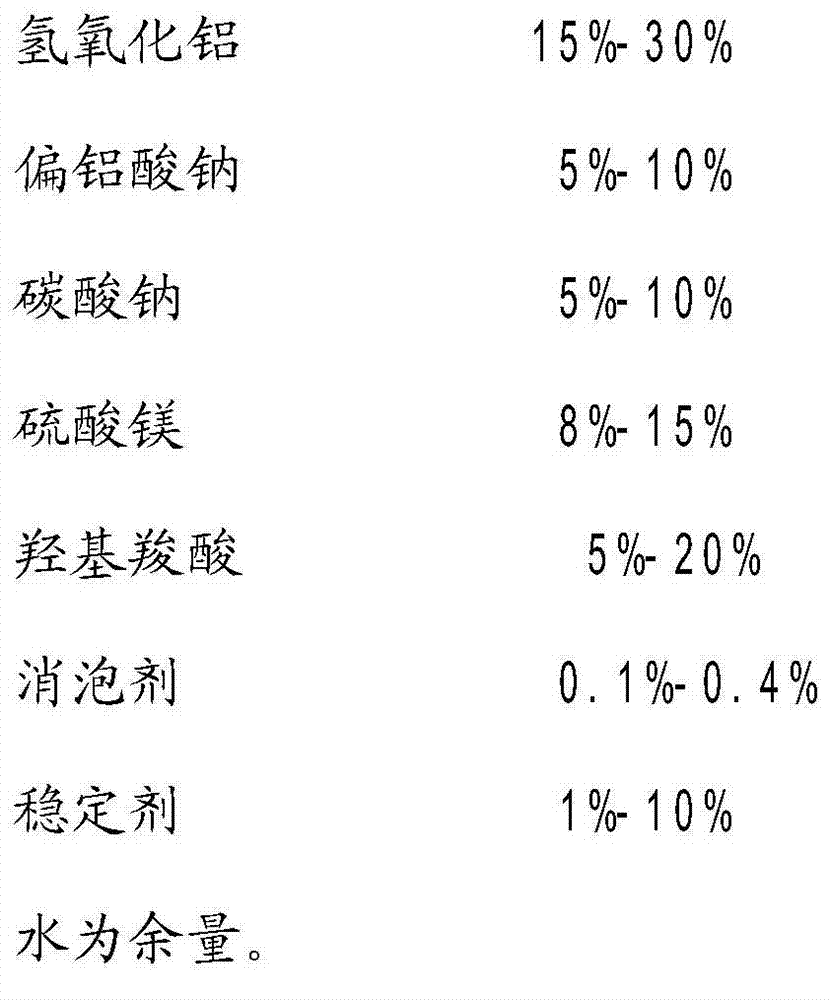

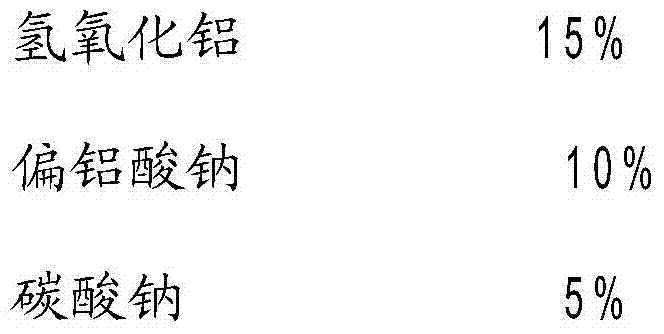

The invention discloses a liquid accelerator and a preparation method thereof. The liquid accelerator is composed of the following components by weight percentage: 15-30% of aluminium hydroxide, 5-10% of sodium metaaluminate, 5-10% of sodium carbonate, 8-10% of magnesium sulfate, 5-20% of hydroxy carboxylic acid, 0.1-0.4% of defoamer, 1-10% of stabilizer and the balance of water. The liquid accelerator has rapid sprayed concrete setting time and obvious effect for the early strength and the 30-day compressive strength, is good in caking property, low in resilience value, simple in synthetic process, mild in reaction condition and excellent in performance and can realize the green environment-protection non-pollution construction. The effect is better than that of the market liquid accelerator.

Owner:张萍

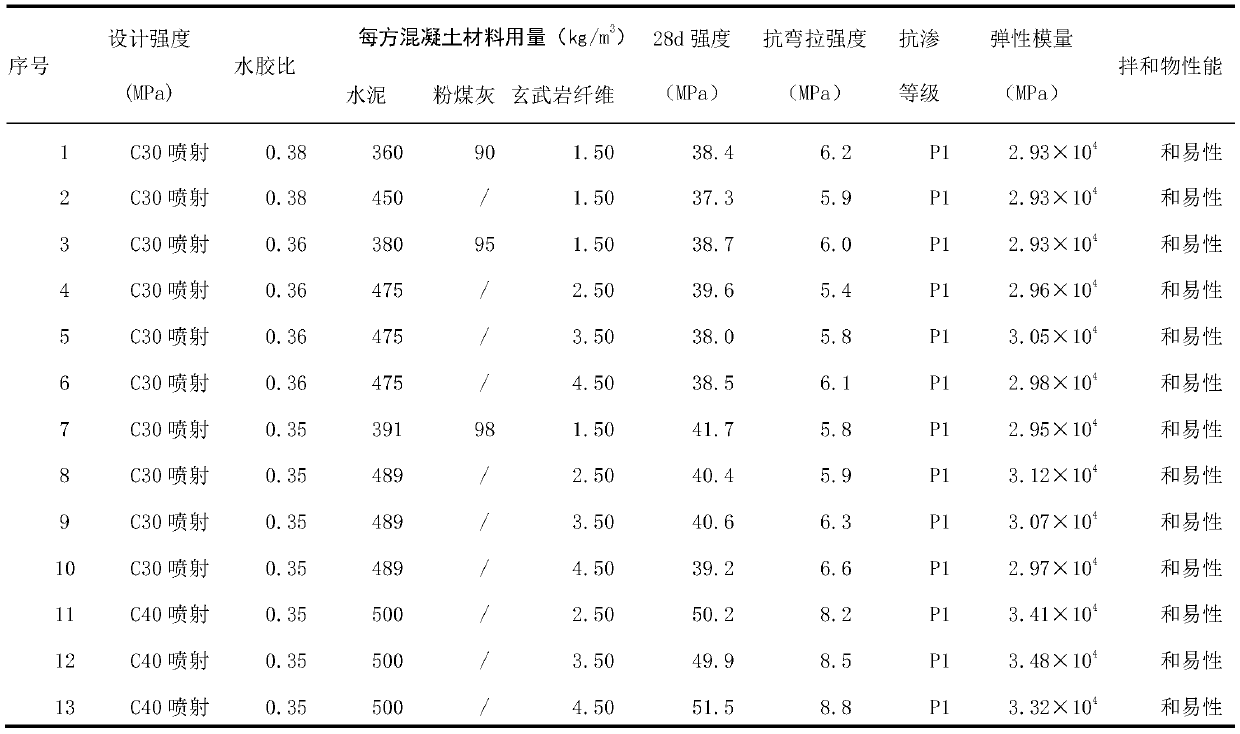

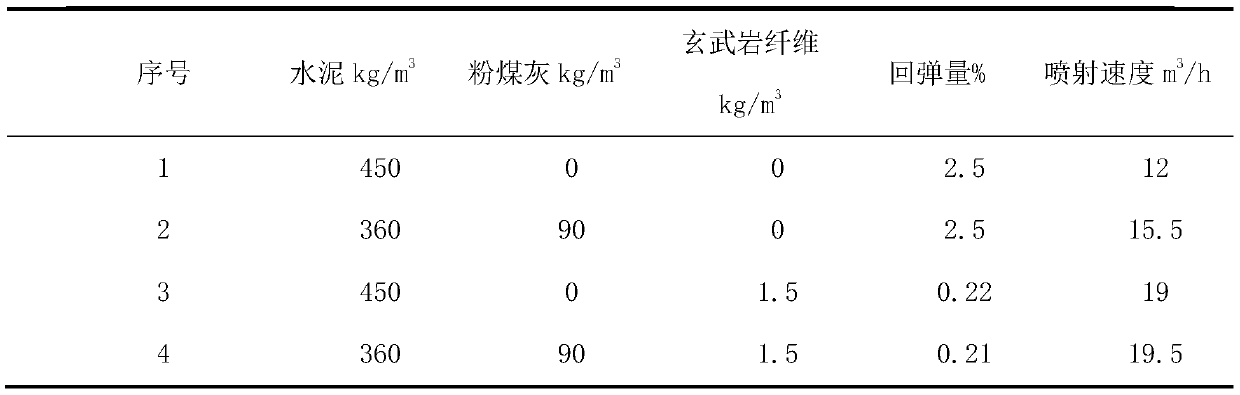

Tunnel sprayed concrete and preparation method thereof

InactiveCN110590258AHigh strengthImprove flexural strengthSolid waste managementShotcreteHigh stress

The invention relates to the technical field of tunnel construction, and particularly discloses a tunnel sprayed concrete. The tunnel sprayed concrete comprises the components based on the volume of tunnel sprayed concrete of 360-500 kg / m3 of cement, 818-890kg / m3 of coarse sand, 789-817kg / m3 of broken stone, 1.5-4.5kg / m3 of basalt fiber, 90-98kg / m3 of fly ash, 8-20kg / m3 of accelerator and 5-10kg / m3 of water reducing agent. The invention also discloses a preparation method of the tunnel sprayed concrete. By adding the fly ash, the strength, the bending strength and the permeability resistance of the concrete are improved; meanwhile, the compactness of the concrete is effectively improved, the effect of preventing weak base water damage can be achieved, and the durability of the concrete isimproved; through the addition of basalt fiber doping, the bending strength is gradually improved, the condition that concrete is cracked under a high stress section can be effectively prevented, theconcrete construction performance is good, the spraying speed is high, and the rebound amount is small; and compared with common sprayed concrete, the concrete doped with basalt fibers can save 1 / 3 ofspraying time.

Owner:GUIZHOU HIGHWAY ENG GRP

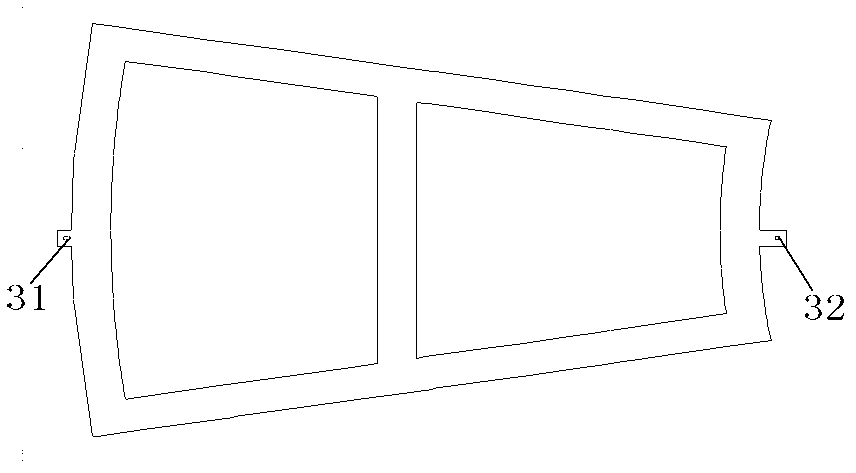

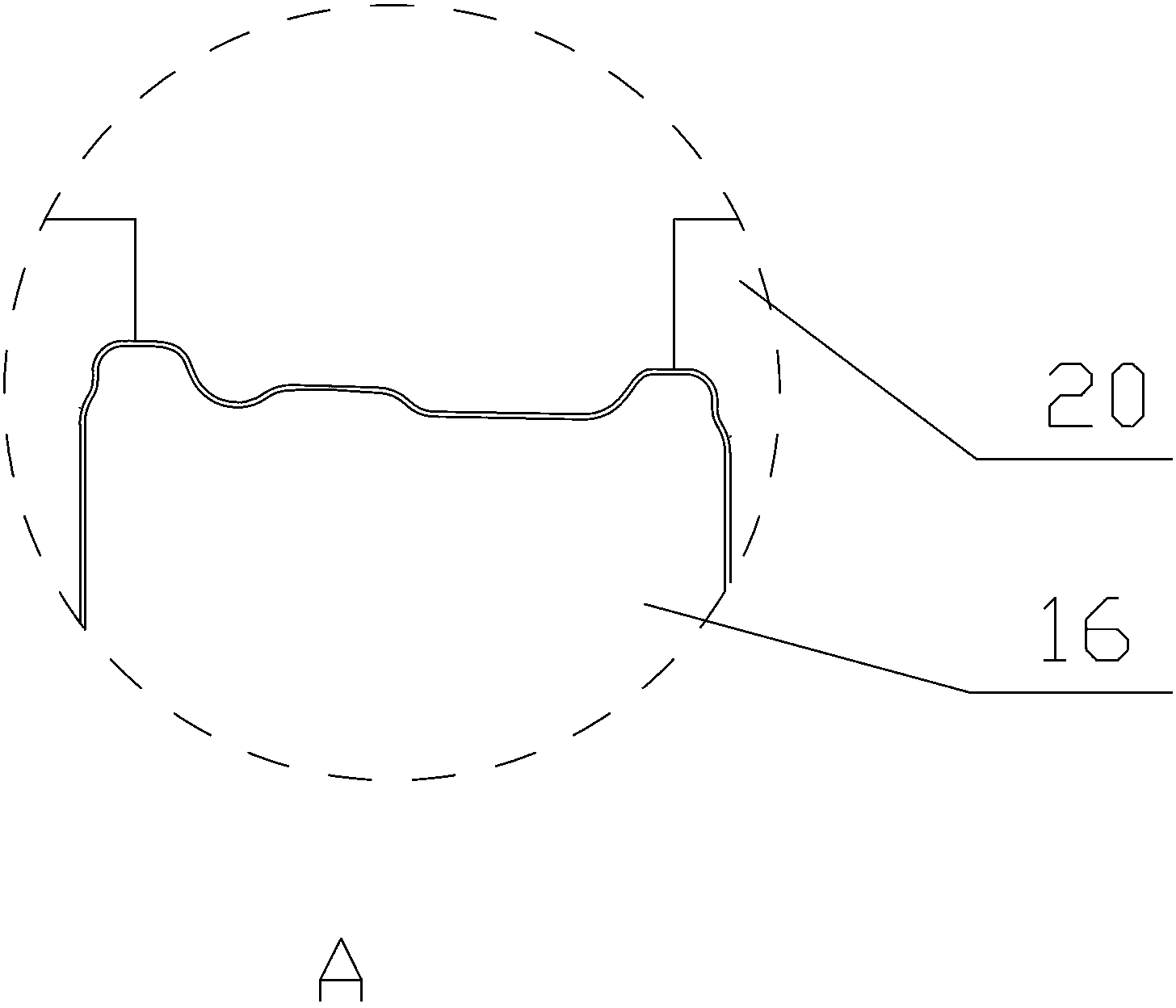

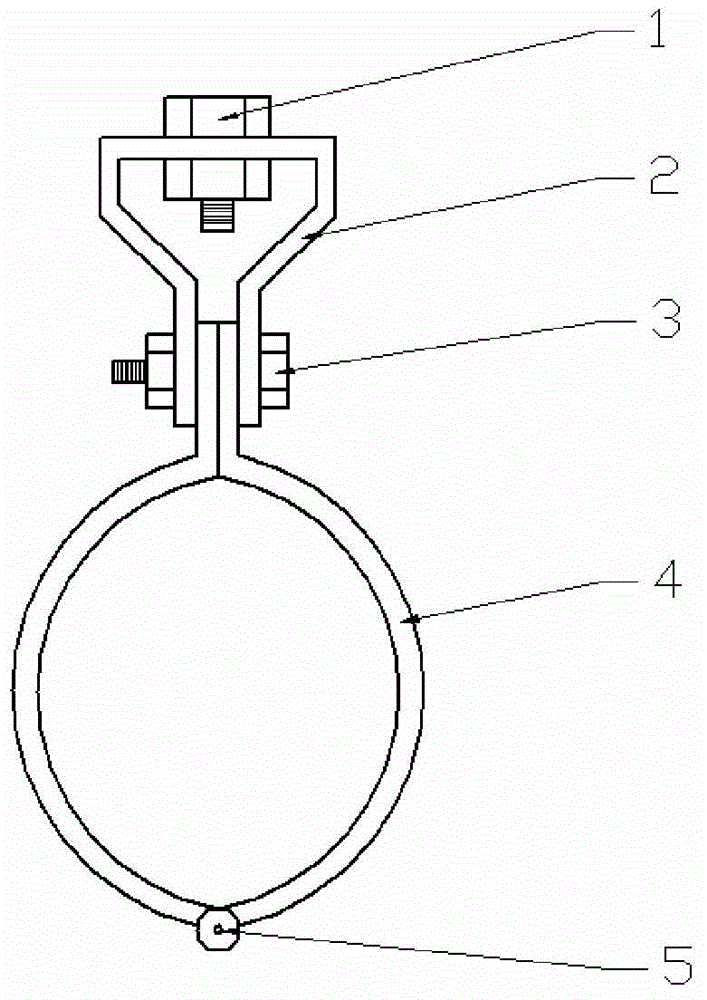

Corrosion-resistant high-strength support/hanger assembly and manufacturing technology thereof

ActiveCN105042191AGood plastic deformation stabilityUniform materialPipe supportsManufacturing technologyEngineering

The invention discloses a corrosion-resistant high-strength support / hanger assembly. The support / hanger assembly comprises a tube clamp and a connecting part arranged at the lower end part of the tube clamp, wherein the tube clamp comprises two clamp pliers which are in the same shape and are symmetrically arranged; each clamp plier comprises a connecting end, a circular arc section and a clamping section; the connecting ends of the two clamping pliers are connected together in a rotating manner; the arc mouth ends of the circular arc sections of the two clap pliers are oppositely arranged; fastening holes are respectively formed in the clamping sections of the two clamp pliers, and the two fastening holes correspond to each other. The invention further discloses a manufacturing technology of the corrosion-resistant high-strength support / hanger assembly. The support / hanger assembly disclosed by the invention is simple and reasonable in tube clamp structure, scientific in design, high in strength, hardness and toughness, resistant to acid and alkaline corrosion, not liable to deform under high temperature and high pressure, and long in service life.

Owner:BEIDELI ENERGY EQUIP JIANGSU CO LTD

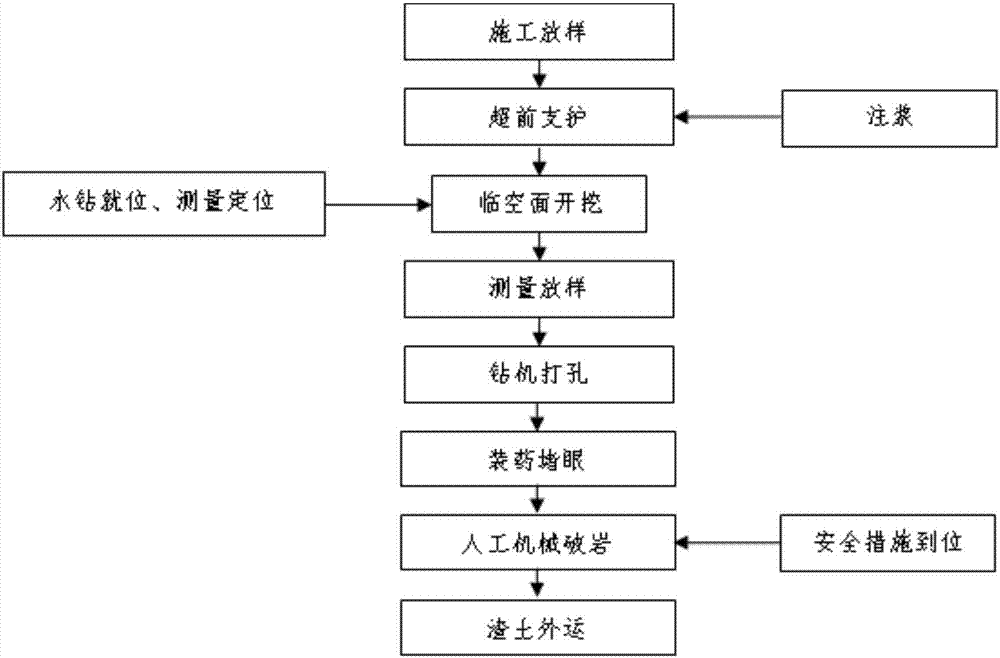

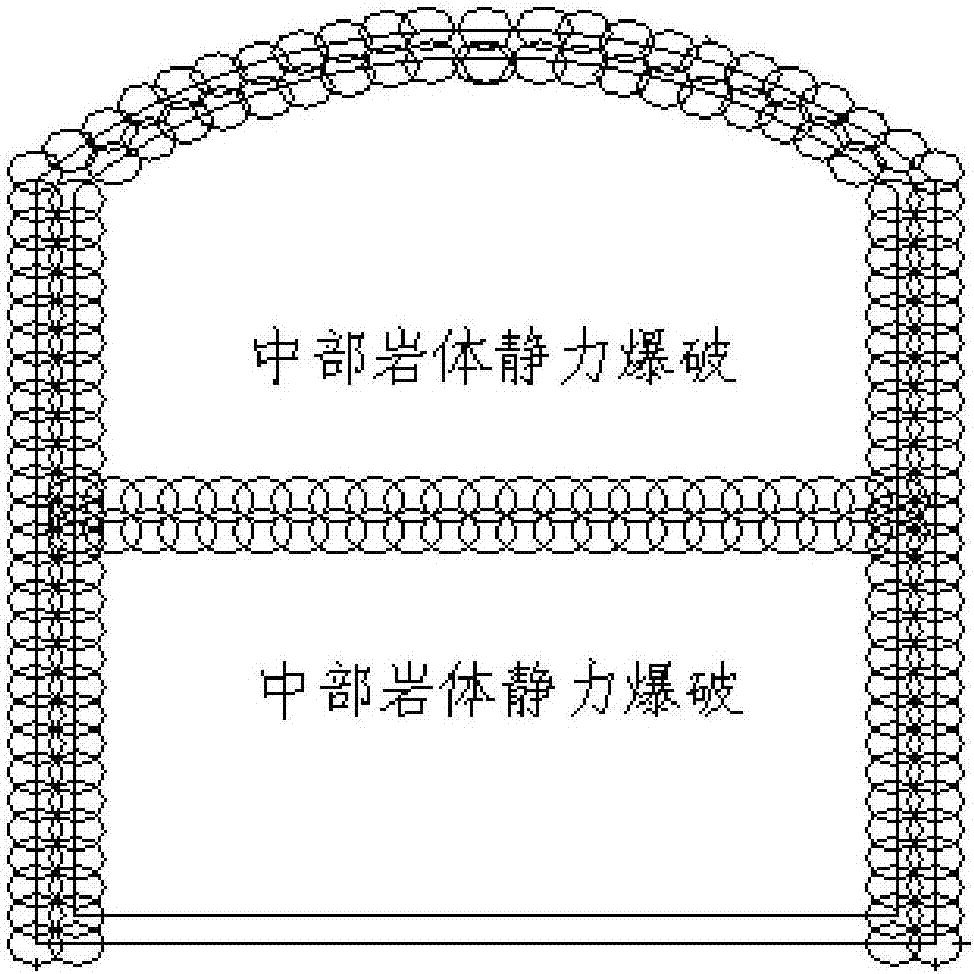

Narrow area ultra-deep channel inclined well back excavation construction method

InactiveCN107060779AReduce areaGuaranteed normal passageUnderground chambersTunnel liningBedrockMain channel

The invention discloses a narrow area ultra-deep channel inclined well back excavation construction method. The narrow area ultra-deep channel inclined well back excavation construction method comprises the following steps of (1), construction lofting, (2), advance support, (3) freeing surface excavation, (4), measurement lofting, (5), static blasting, (6), rock breaking and residue soil outward transporting and (7), primary support. According to the back excavation construction method, excavation is conducted from bottom to top, the occupied ground road area is small, normal traffic of a road can be guaranteed, and additional pressure is not brought to transportation; residue soil in the inclined well construction process can be transported out directly with residue soil in a main channel, so that the secondary carrying process is omitted, used equipment is simple, personnel input is less, cross operation can be conducted, the construction period is shortened, and the cost is reduced by a large margin; and after rock breaking is conducted through static blasting, manual work and a machine are matched to conduct clear-up and excavation, the residue soil is directly loaded into a vehicle through an excavator after blasting and directly transported to a residue field through a main tunnel, disturbance of inclined well excavation to tunnel bedrock on the two sides and an upper rock stratum is reduced, and construction safety is guaranteed.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

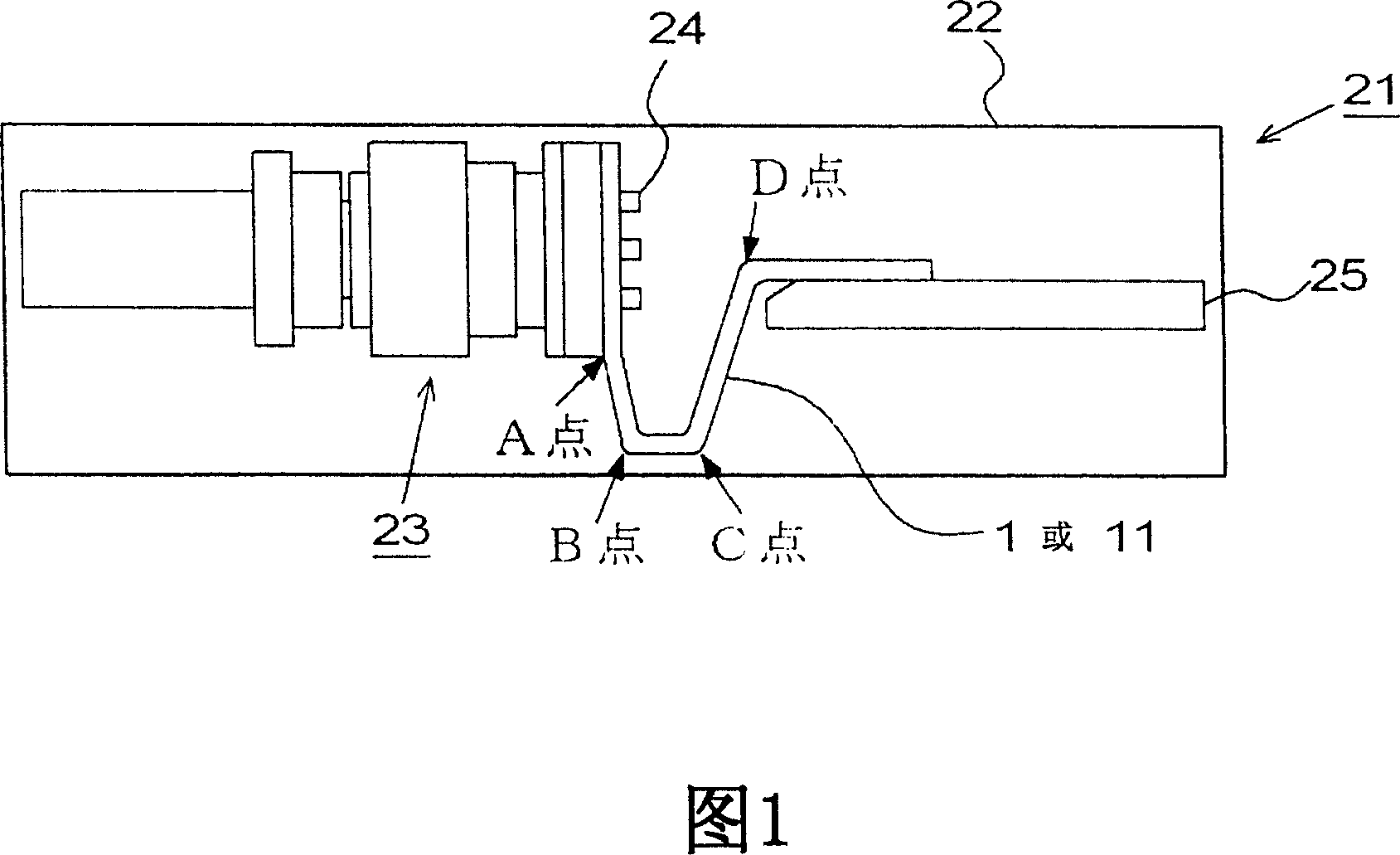

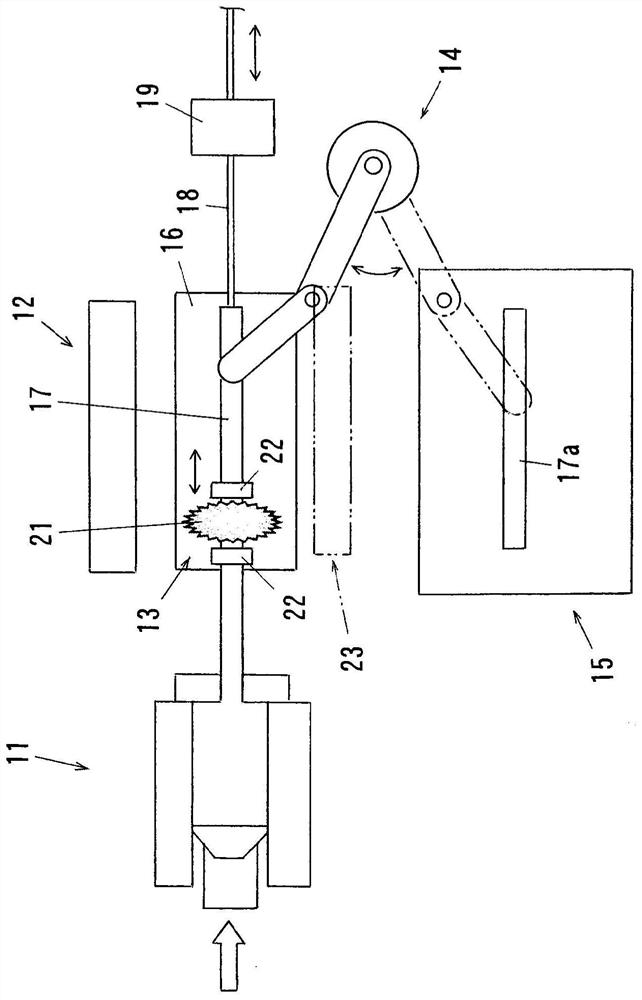

Method and system for manufacturing aluminum alloy part

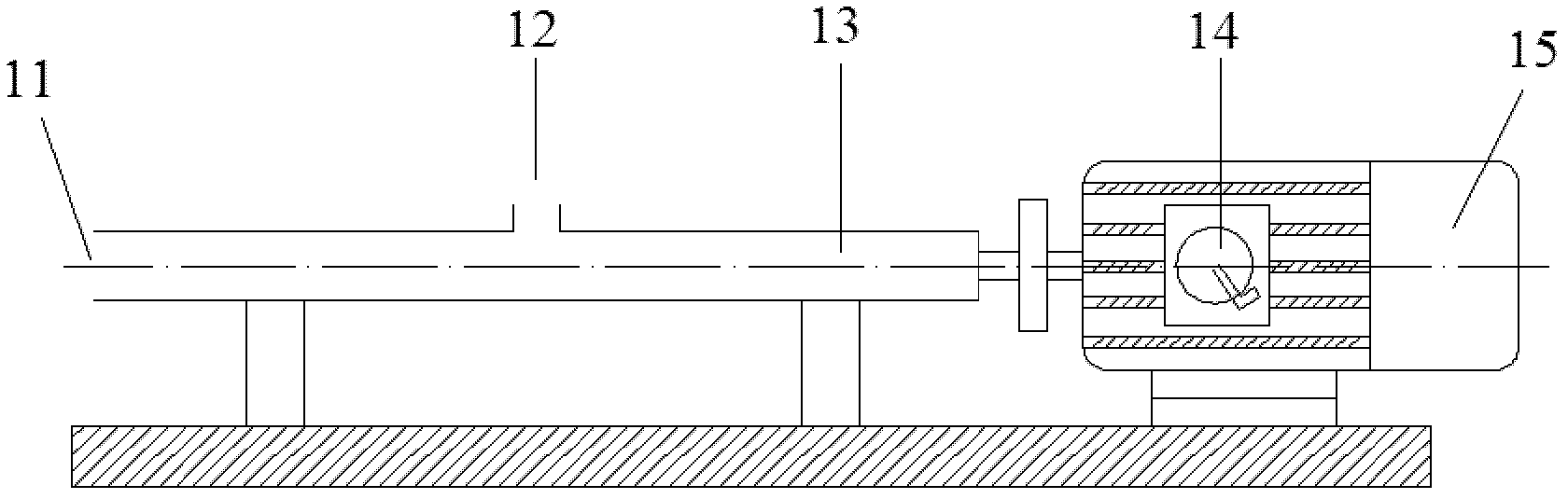

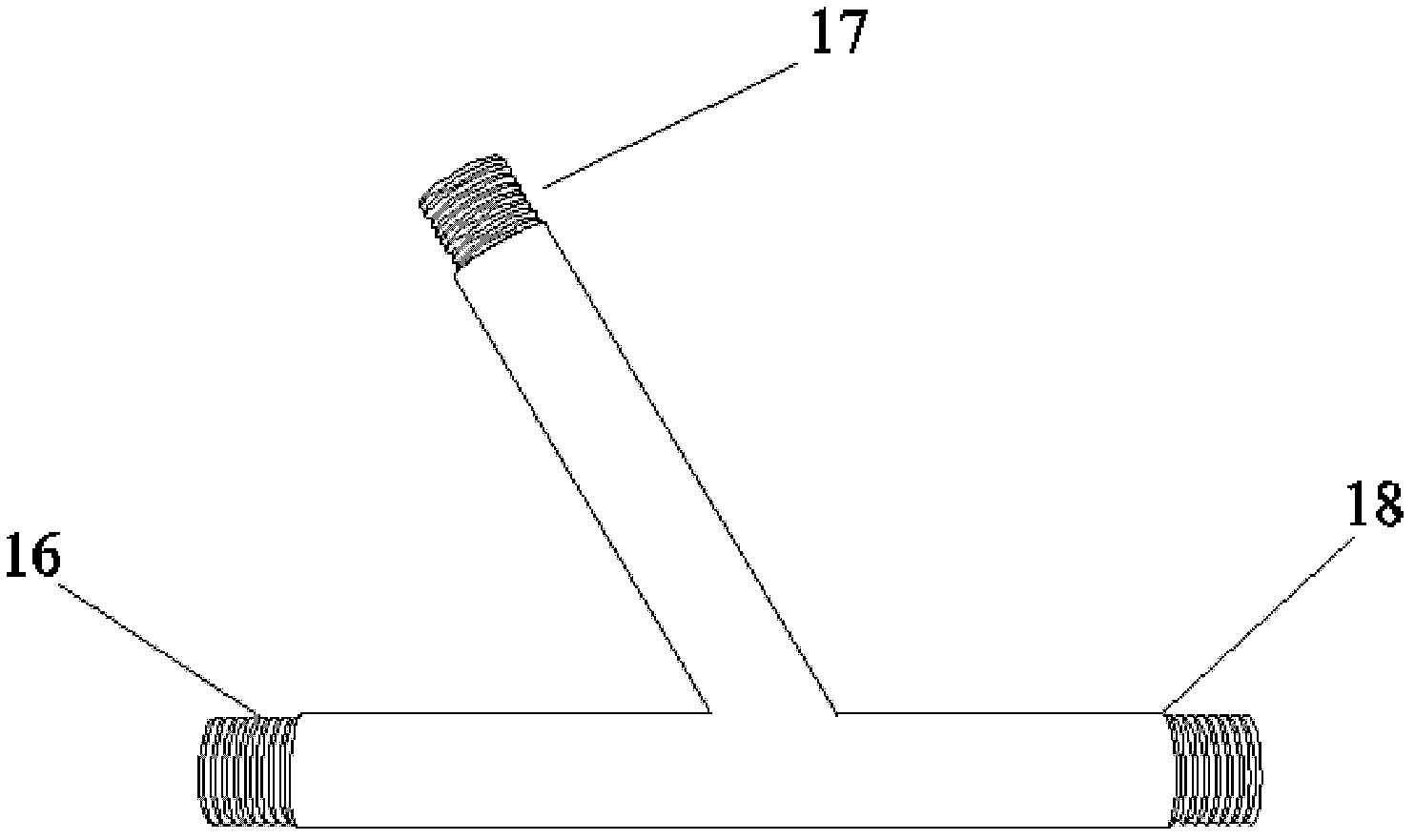

The invention provides a method for manufacturing an aluminum alloy part. When an aluminum alloy part is manufactured by subjecting a heat-treated aluminum alloy extruded material to plastic working,the method prevents the occurrence of cracks during plastic working at a lower cost than methods involving solution treatment or retrogression treatment. A manufacturing apparatus includes an extruderdevice (11) that performs hot extrusion processing on a heat-treated aluminum alloy; a cutting device (13) that is disposed on the output side of the extruder device (11), cuts the extruded material(17) to a predetermined length, and cuts the extruded material away from the extruder device (11); and a conveyance device (14) and a plastic working device (15) which are provided in the extruder device (11). The conveyance device (14) conveys the extruded material (17a) cut into a predetermined length by the cutting device (13) to the plastic working device (15), and the plastic working device (15) performs plastic working on the extruded material (17a) conveyed by the conveyance device (14) to form an aluminum alloy part.

Owner:KOBE STEEL LTD

Method for forming irregular ring piece by utilizing stainless-steel rectangular ring rolled piece through thermal bulging

ActiveCN102513457AHigh dimensional accuracyPrecise control of bulge sizeShaping toolsAbnormal shapedAerospace

The invention discloses a method for forming an irregular ring piece by utilizing a stainless-steel rectangular ring rolled piece through thermal bulging, comprising the following steps of: sleeving the heated stainless-steel rectangular ring rolled piece on the periphery of a pre-heated bulging blockin a bulging machine; starting the bulging machine so that the ring rolled piece is squeezed by the bulging block in a radial direction along the inner circumference surface of the ring rolled piece and becomes the irregular ring blank after being deformed for 11-13%, thus completing primary bulging; rotating the irregular ring blank for 45 degrees along an center axis, thus completing primary rotation; carrying out secondary bulging with the deformation amount of 1.8-2% and secondary rotation on the irregular ring blank according to the previous steps; carrying out tertiary bulging with the deformation amount of 1.4-1.6% and tertiary rotation on the irregular ring blank according to the previous steps; and carrying out quartus bulging with the deformation amount of 1.2-1.4% and quartus rotation on the irregular ring blank according to the previous steps, so as to obtain the irregular ring piece. The size precision of the irregular ring piece can reach 0.1-0.2% of the corresponding size. The irregular ring piece formed by using the method disclosed by the invention is mainly used for fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com