Patents

Literature

176results about How to "Solve wrinkle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

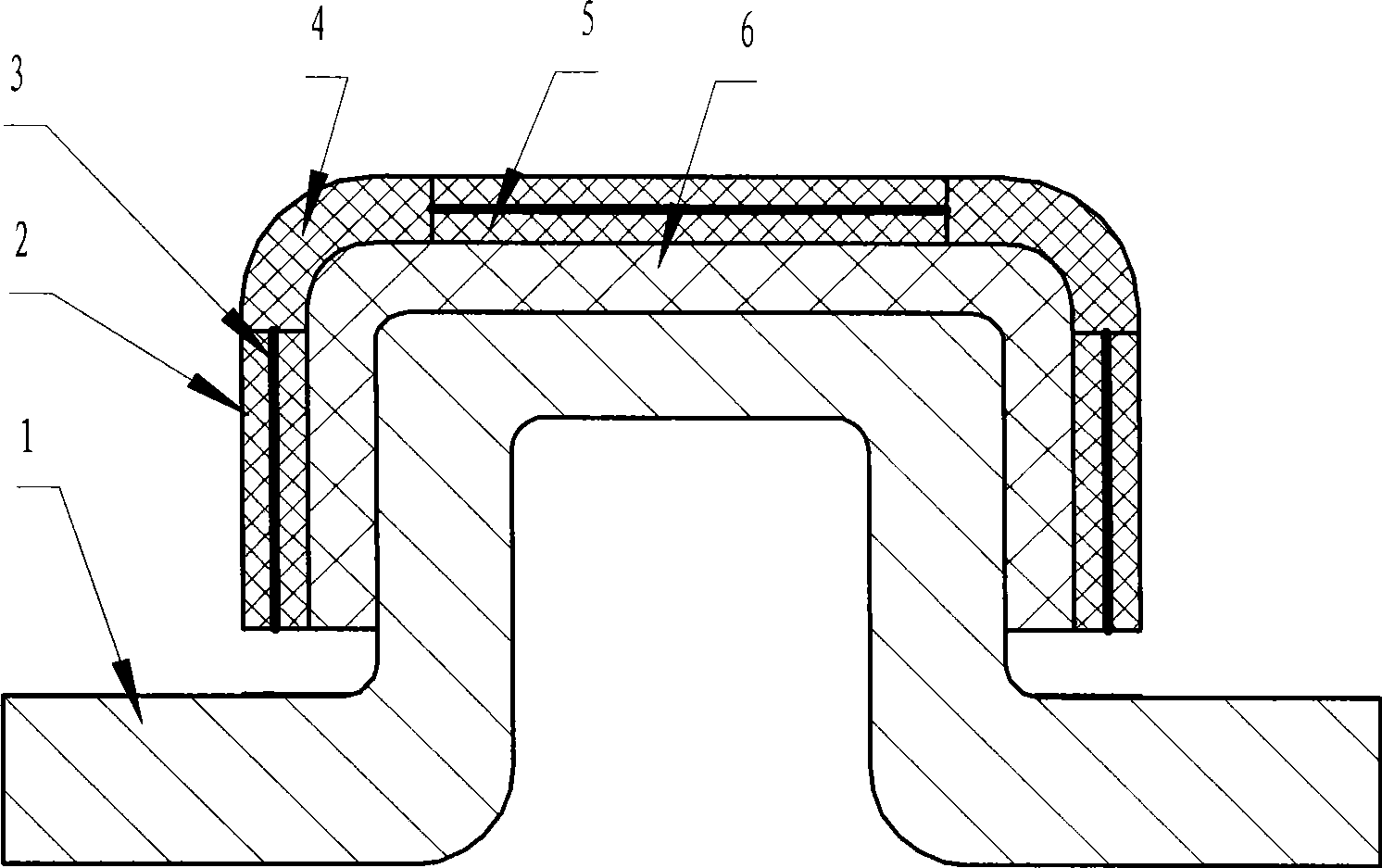

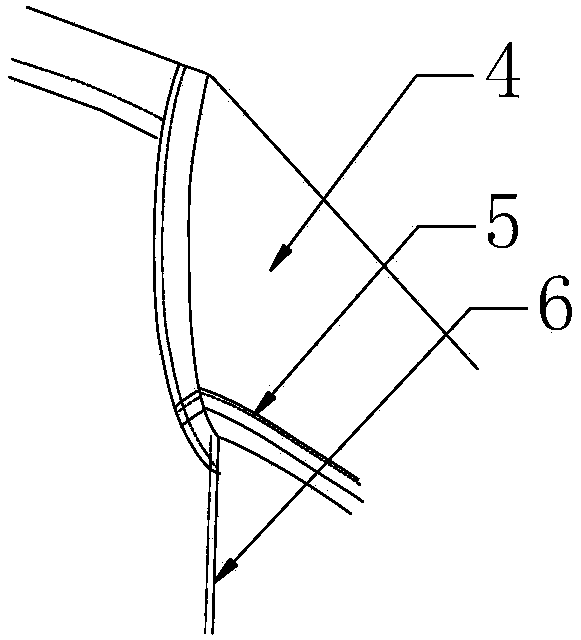

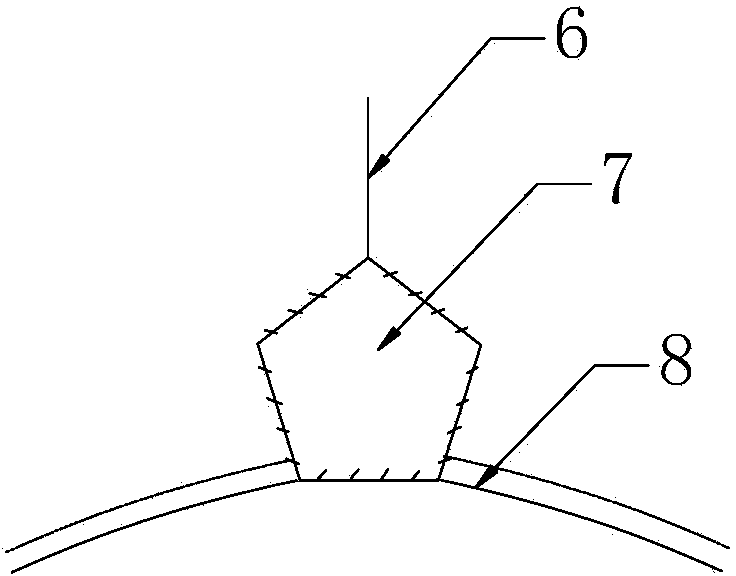

Curing formation method for non-flat plate composite product and shaping mould

The invention discloses a curing forming method and a forming die used for a non-slab composite material part. The method comprises the steps as follows: composite material part blank is arranged on a rigid die body which has the same shape with the processing shape and gluing and layer-paving are carried out according to the required dimension; after the layer-paving is finished, the composite material part blank is arranged on the rigid die body; furthermore, surfaces with plane are provided with elastic soft layers; corner pure rubber layers which are connected with elastic soft layer joint seams are arranged at corner profile so as to form a soft die surface; subsequently, vacuum bag auxiliary material is arranged on the soft die surface so as to prepare the vacuum bag curing forming composite material part. By the flexible soft die consisting of rubber-fabrics, the method arranges the composite material part blank on the surface of the soft die after the layer-paving is finished; the method for preparing the vacuum bag curing forming part solves the surface quality problems in the prior art that the non-die surface of the bag-pressing forming composite material part is crapy, accidented and has no gloss and the like, and improves the working efficiency.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

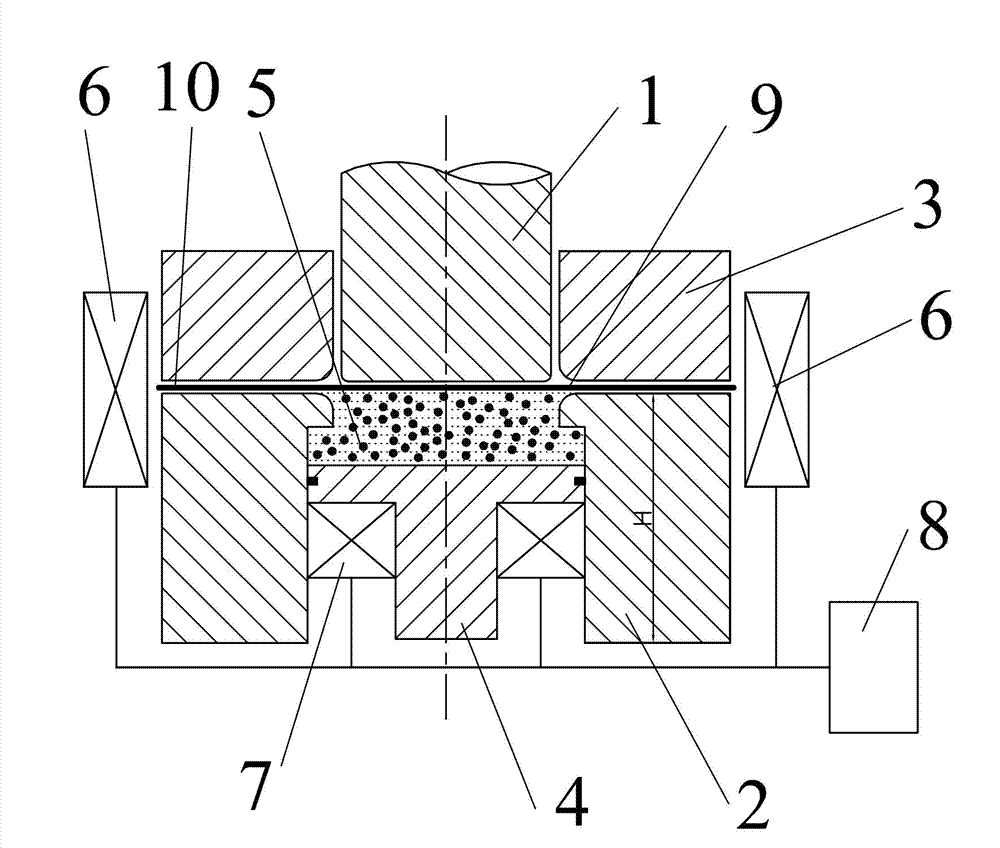

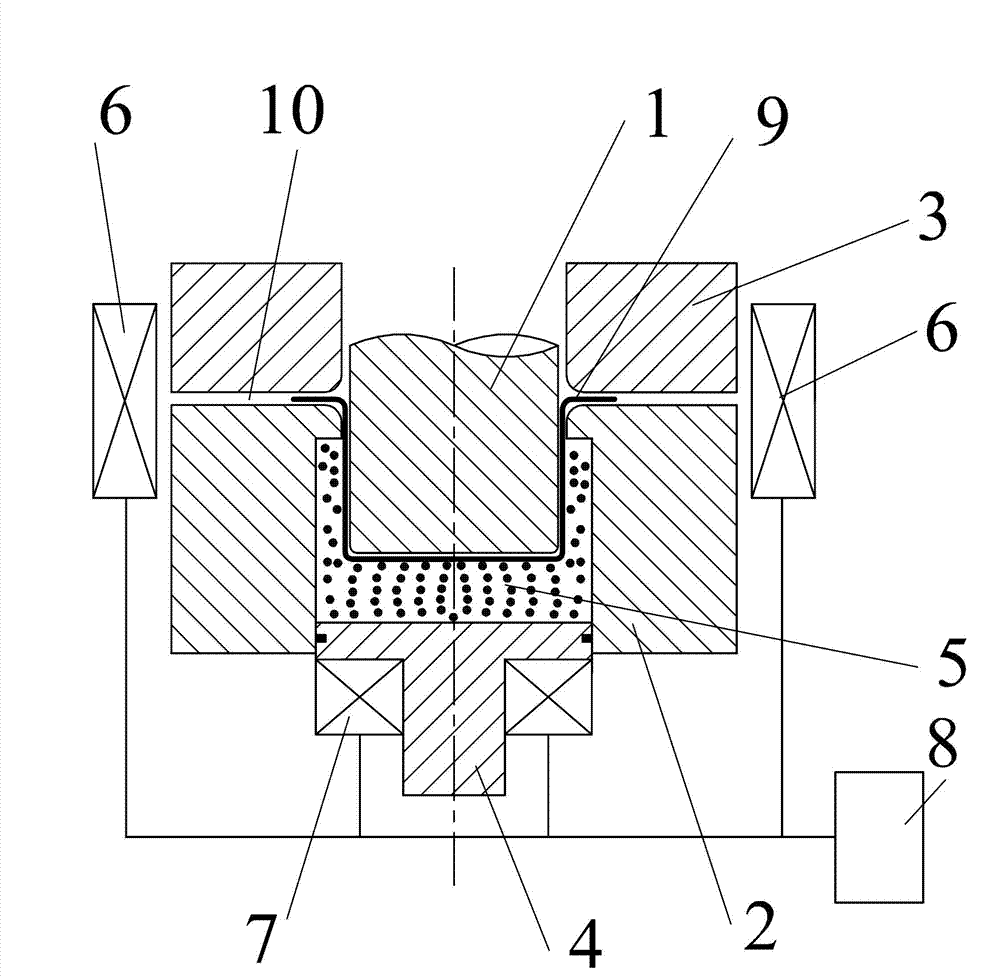

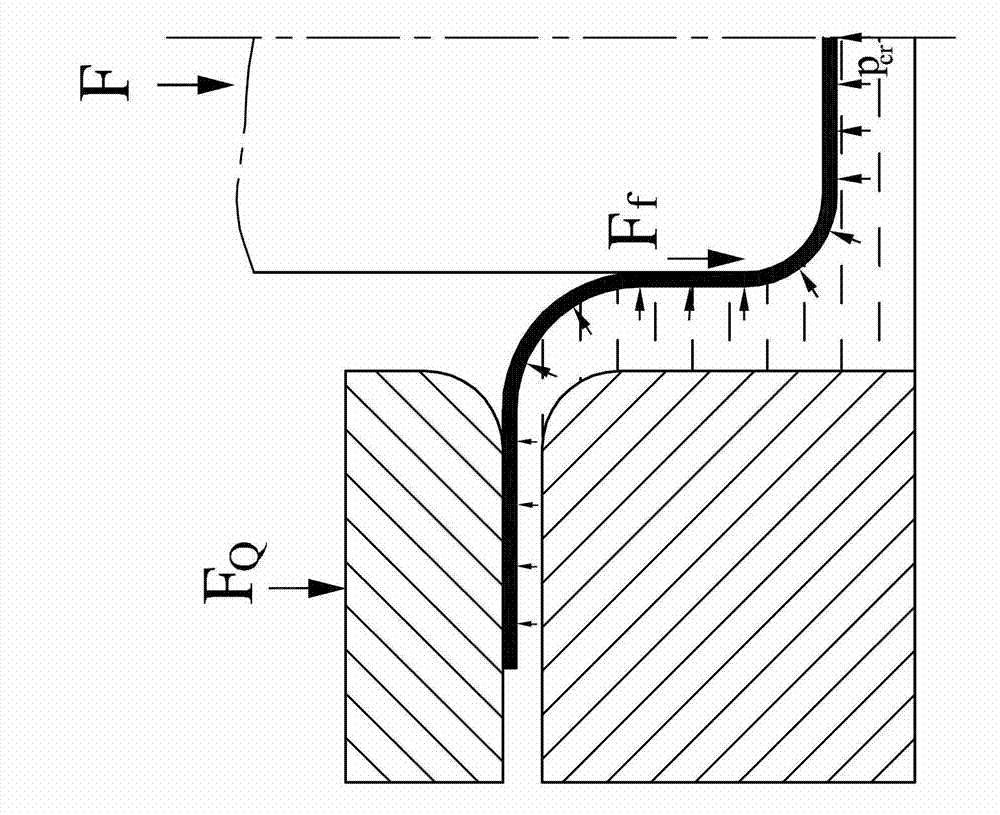

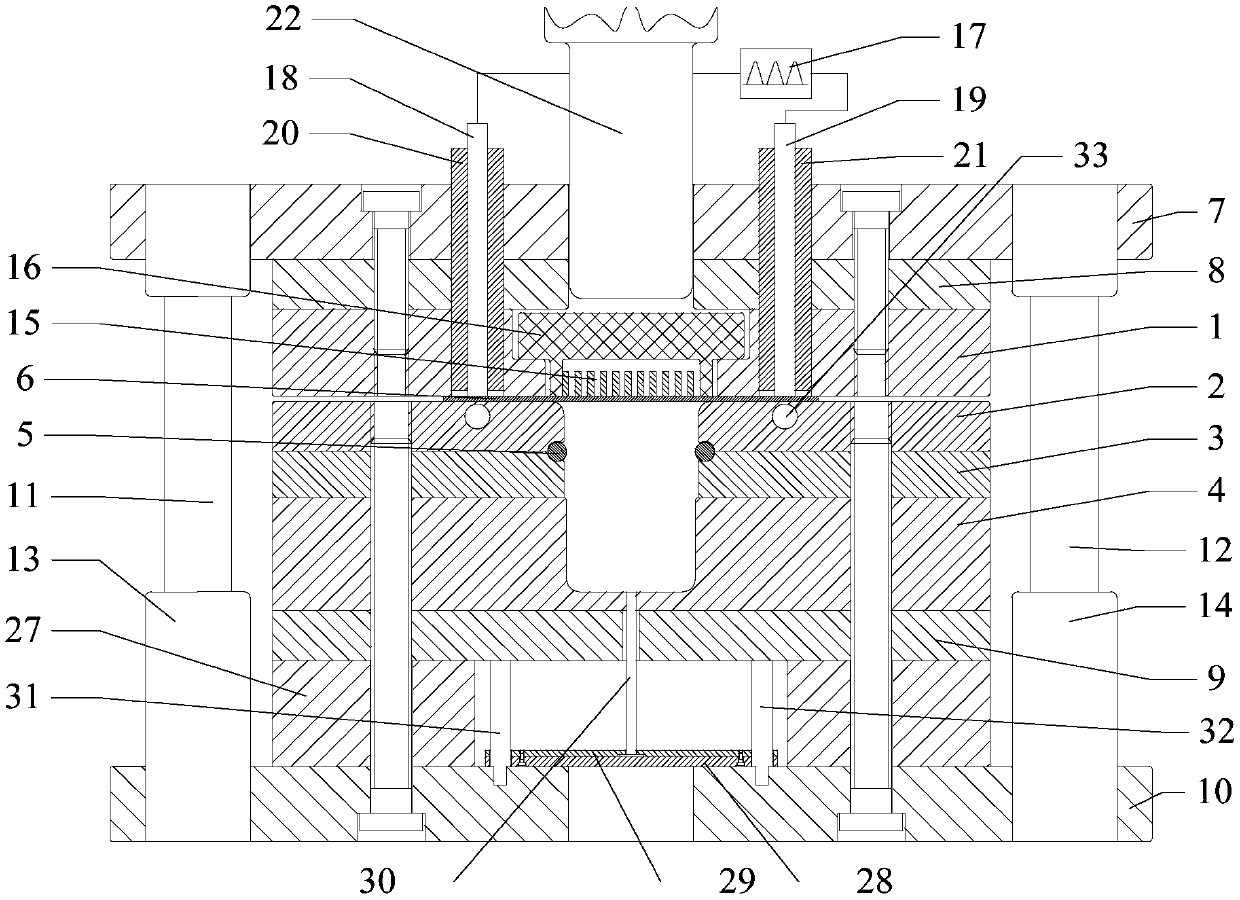

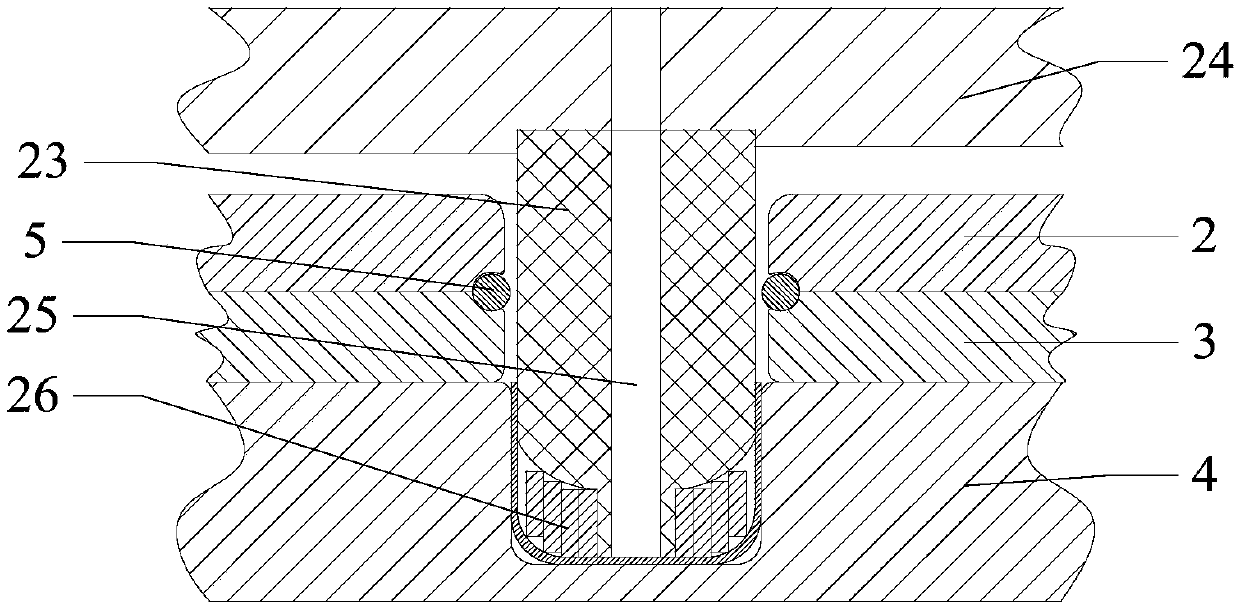

Sheet material hydro-mechanical deep drawing forming device and method using magnetic medium to pressurize

The invention provides a sheet material hydro-mechanical deep drawing forming device and a sheet material hydro-mechanical deep drawing forming method using a magnetic medium to pressurize, belongs to the technical field of hydro-mechanical deep drawing, and solves the technical problems in a traditional sheet material hydraulic forming process that wrinkles are formed, the deformation uniformity is poor and the like, caused by the reason that overflowing pressure of a flange region is reduced, when a sealing ring is not used in order to realize overflowing and lubrication. A sealed hydraulic chamber formed by a concave die and a lower plunger piston is used for containing the magnetic medium; a convex die can penetrate through an edge pressing ring to drive a plate blank to move downwards to enter the sealed hydraulic chamber formed by the concave die and the lower plunger piston; a first coil is arranged on the periphery of the outer side of the flange region formed by the concave die and the edge pressing ring; a second coil is arranged on a pull rod of the lower plunger piston; and a magnetic control unit is used for controlling the sizes of magnetic fields generated by the first coil and the second coil. Firstly, a certain amount of the magnetic medium is poured into the hydraulic chamber and the edge pressing ring is moved downwards after the plate blank is placed; the viscosity and the pressure value of the magnetic mediums on a flange and in the hydraulic chamber are respectively adjusted and controlled through the magnetic fields; and a punching head is moved downwards until a plate piece is formed. The sheet material hydro-mechanical deep drawing device and the sheet material hydro-mechanical deep drawing method using the magnetic medium to pressurize are suitable for hydro-mechanical deep drawing formation of a sheet material.

Owner:HARBIN UNIV OF SCI & TECH

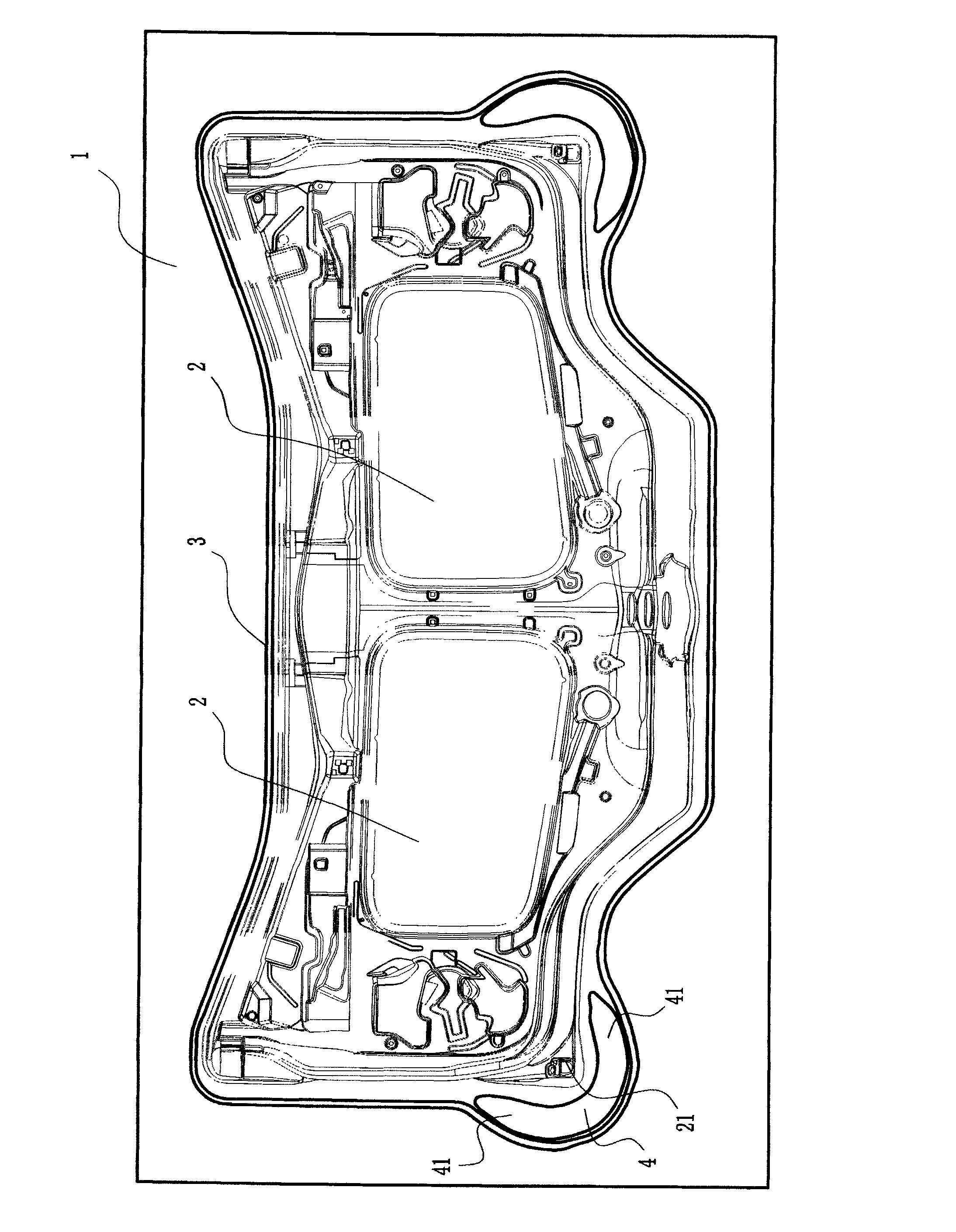

Punching method for preventing plate corner part in car door from wrinkling

The invention discloses a punching method for preventing a plate corner in a car door from wrinkling. In the method, craft rib supplement is added in modeling by a drawing procedure to completely draw out the shape of the plate corner in the car door, and only a root fillet needs to be machined in subsequent reshaping, thus reducing the reshaping load in the subsequent procedure, changing the technical problems of the existing business such as shallow drawing, a traditional great shaping process method and easy drawing but difficulty in reshaping, and effectively solving the problem of wrinkling of products which troubles the traditional process for a long time and can not be solved.

Owner:SHANDONG WEIFANG FOTON MOLD

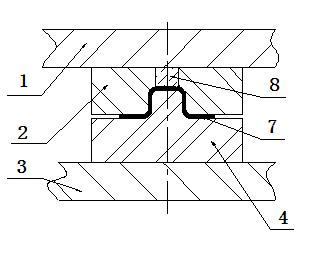

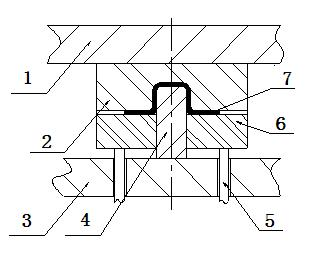

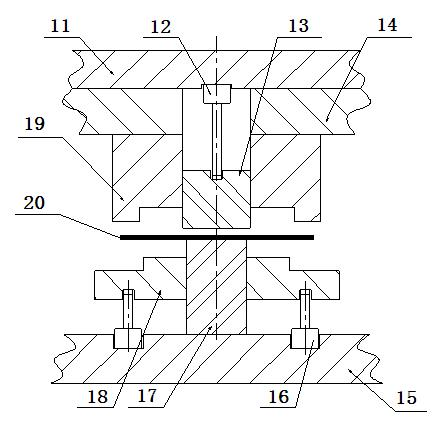

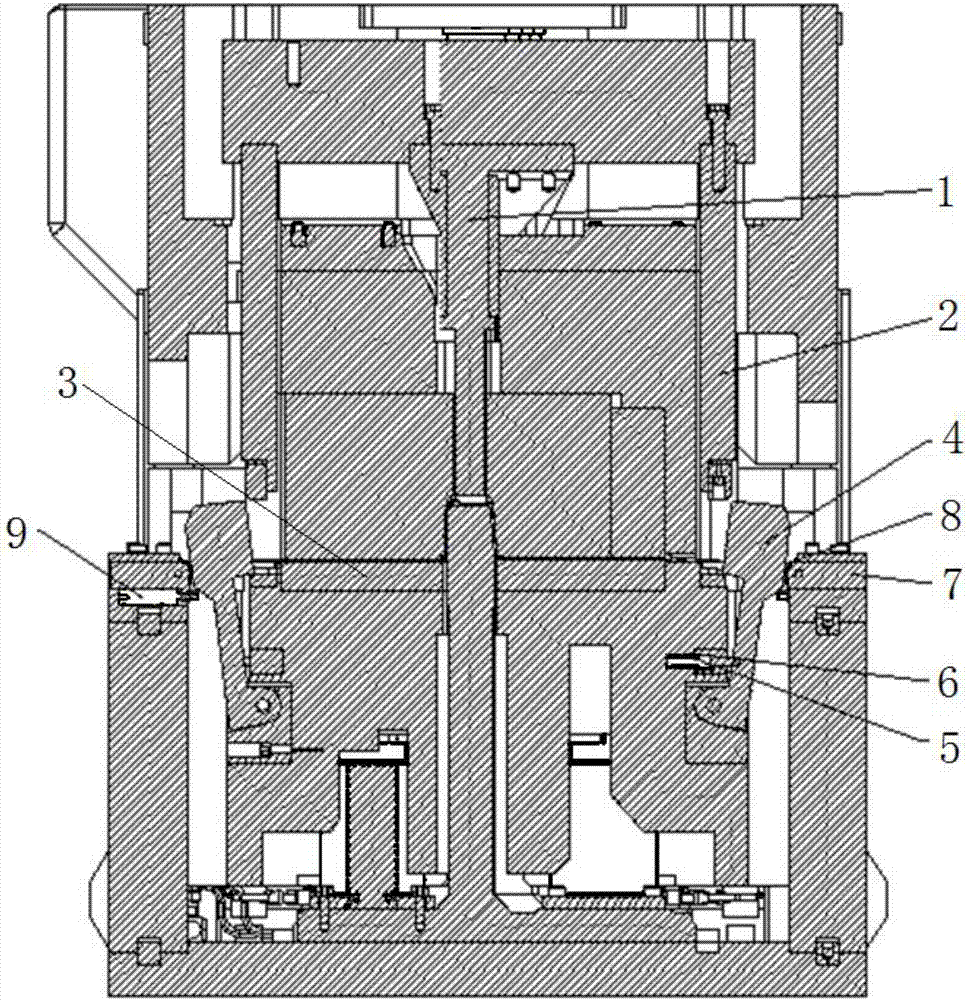

Molding die for processing high-tension plate parts

ActiveCN102310147ASolve molding difficultiesSolve insufficient plastic deformation during moldingShaping toolsEngineeringNitrogen gas

The invention relates to a molding die for processing high-tension plate parts, which comprises an upper die seat (11), a material press core (13), an upper die fixing plate (14), a lower die seat (15), a convex die (17), a material press plate (18) and an upper die knife block (19), wherein the upper die fixing plate (14) is arranged between the upper die seat (11) and the upper die knife block (19), at least one nitrogen spring (12) is arranged between the material press core (3) and the upper die seat (11), at least two nitrogen springs (16) are arranged between the material press plate (18) and the lower die seat (15), a locking unit (21) is manufactured on the material press plate (18) and the upper die knife block (19), a material plate (20) locked between the material press core (13) and the locking unit (21) in molding can be fully stretched for plastic deformation, and the large springback amount after molding is overcome.

Owner:CHERY AUTOMOBILE CO LTD

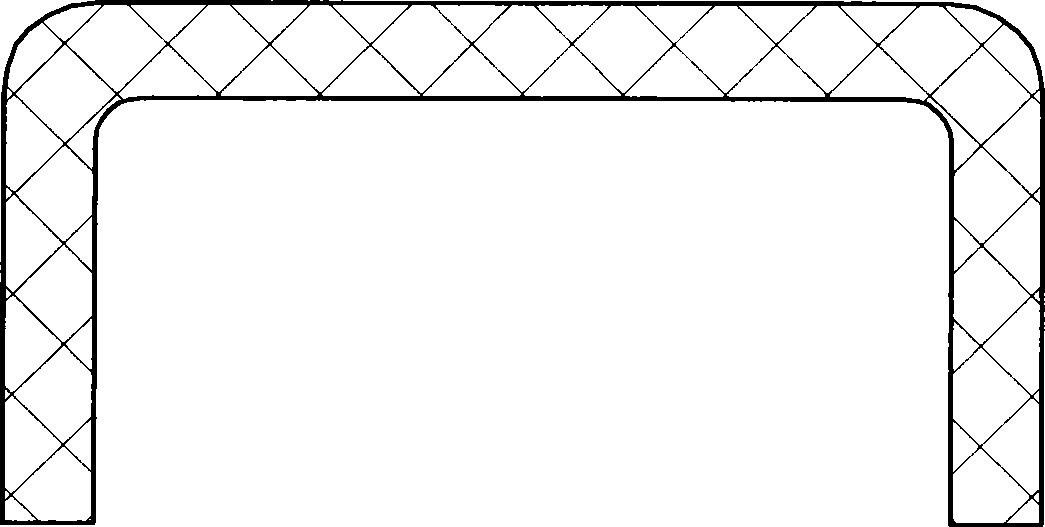

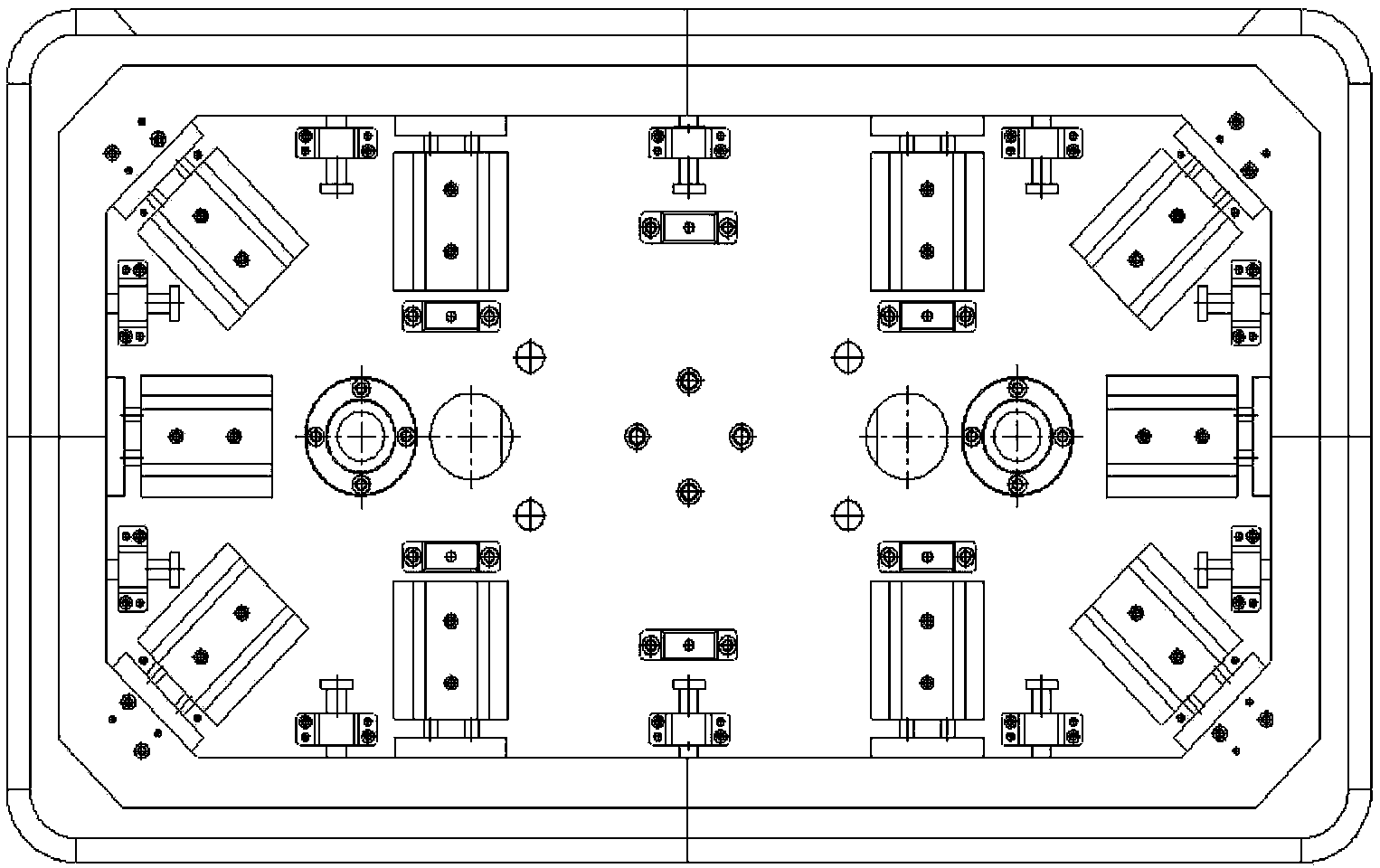

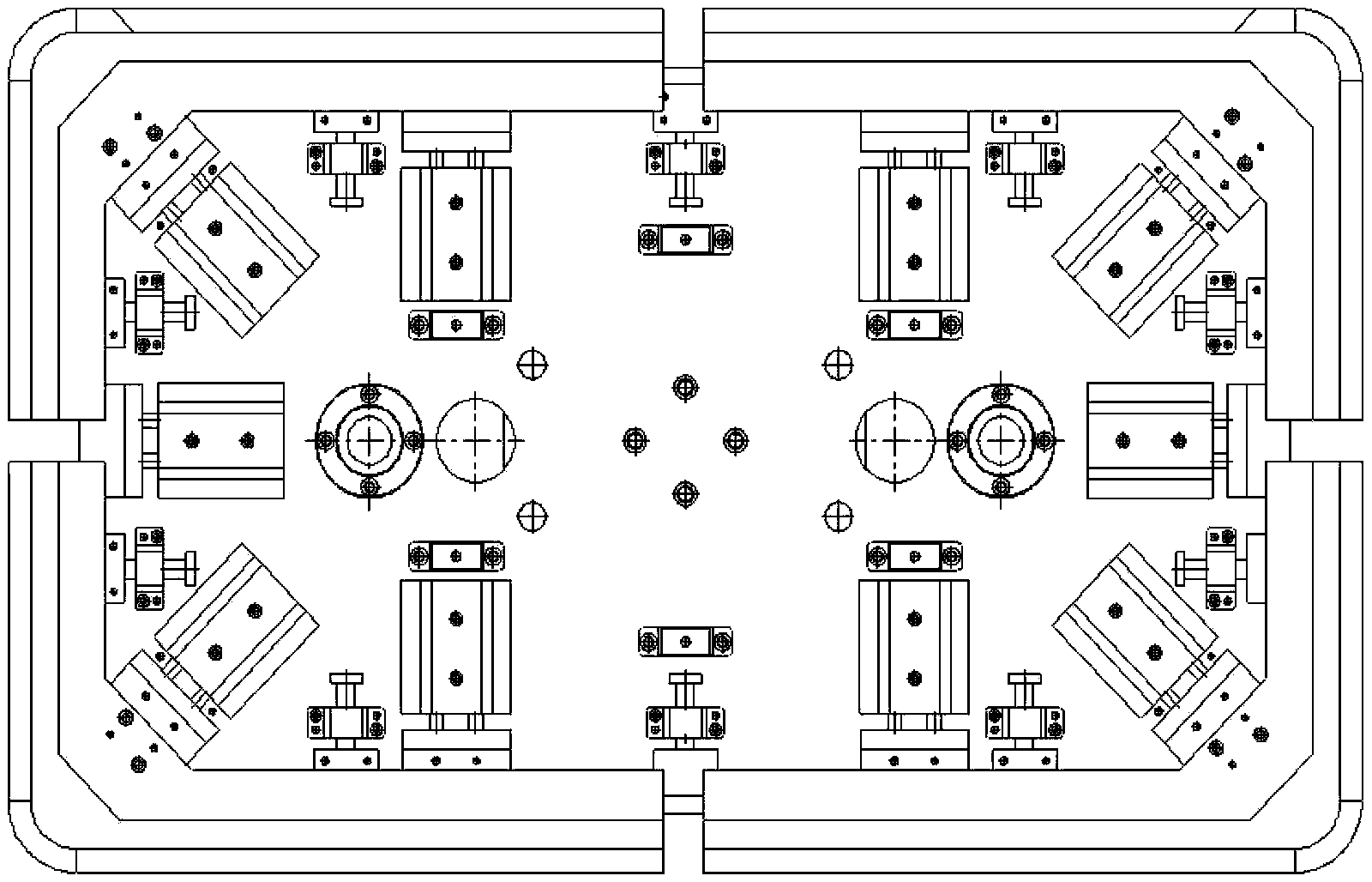

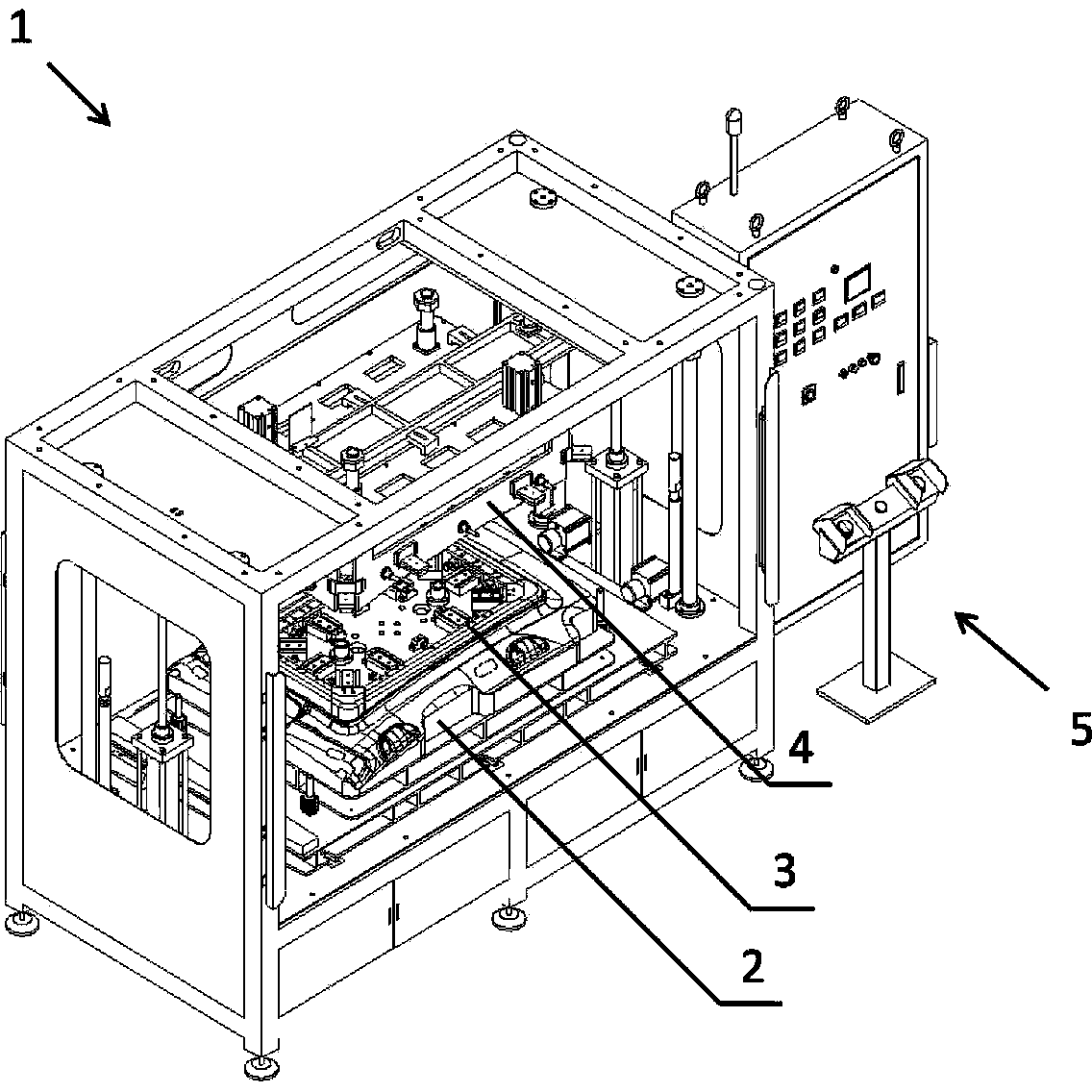

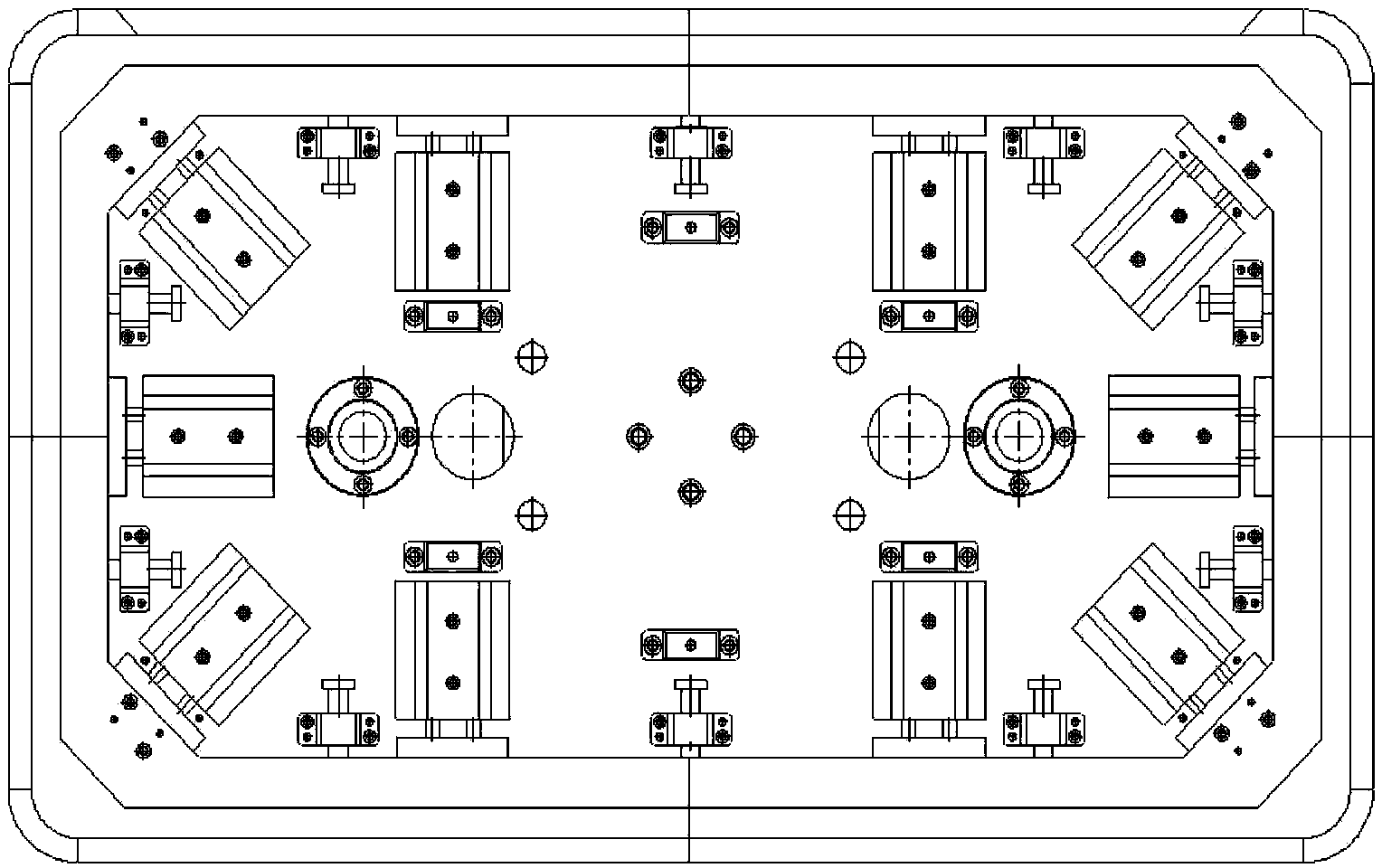

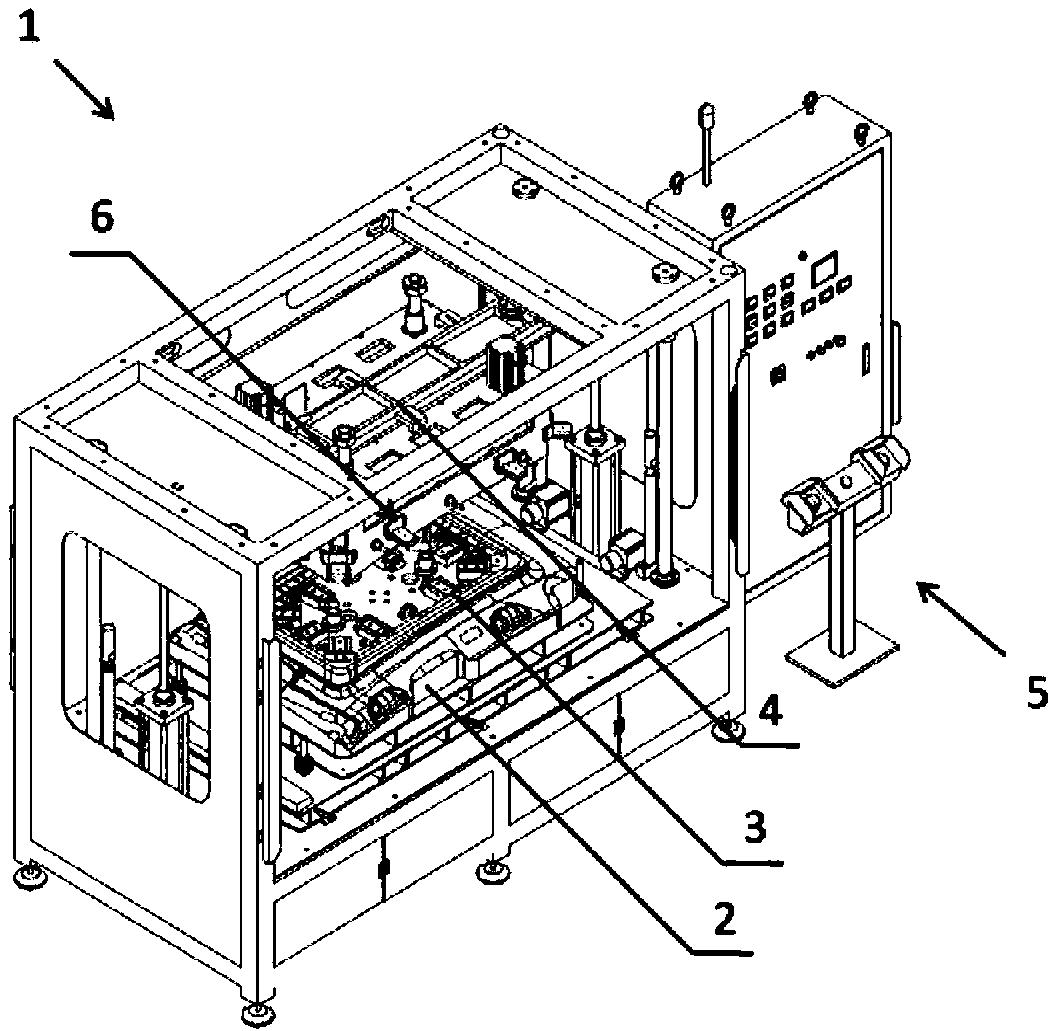

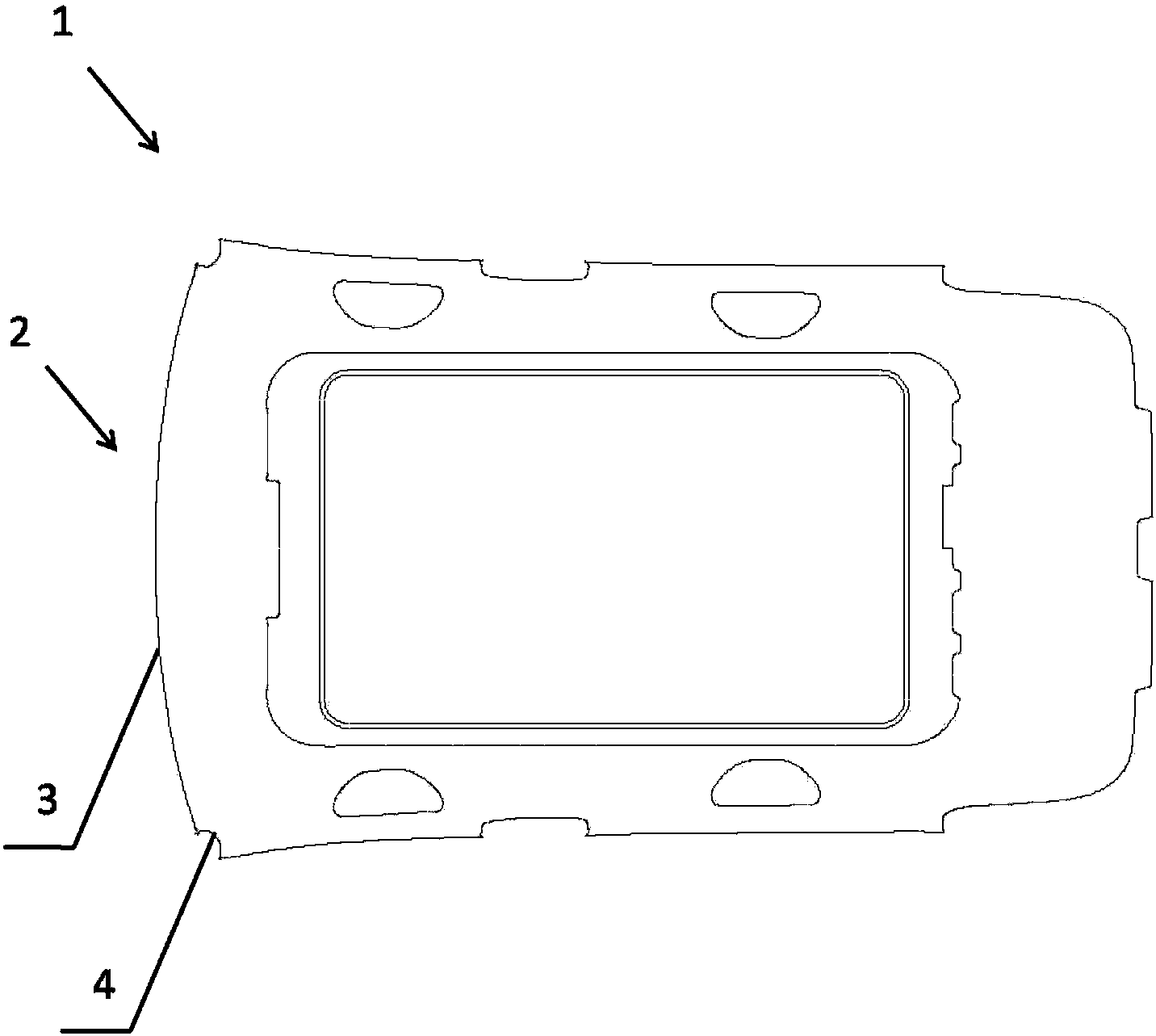

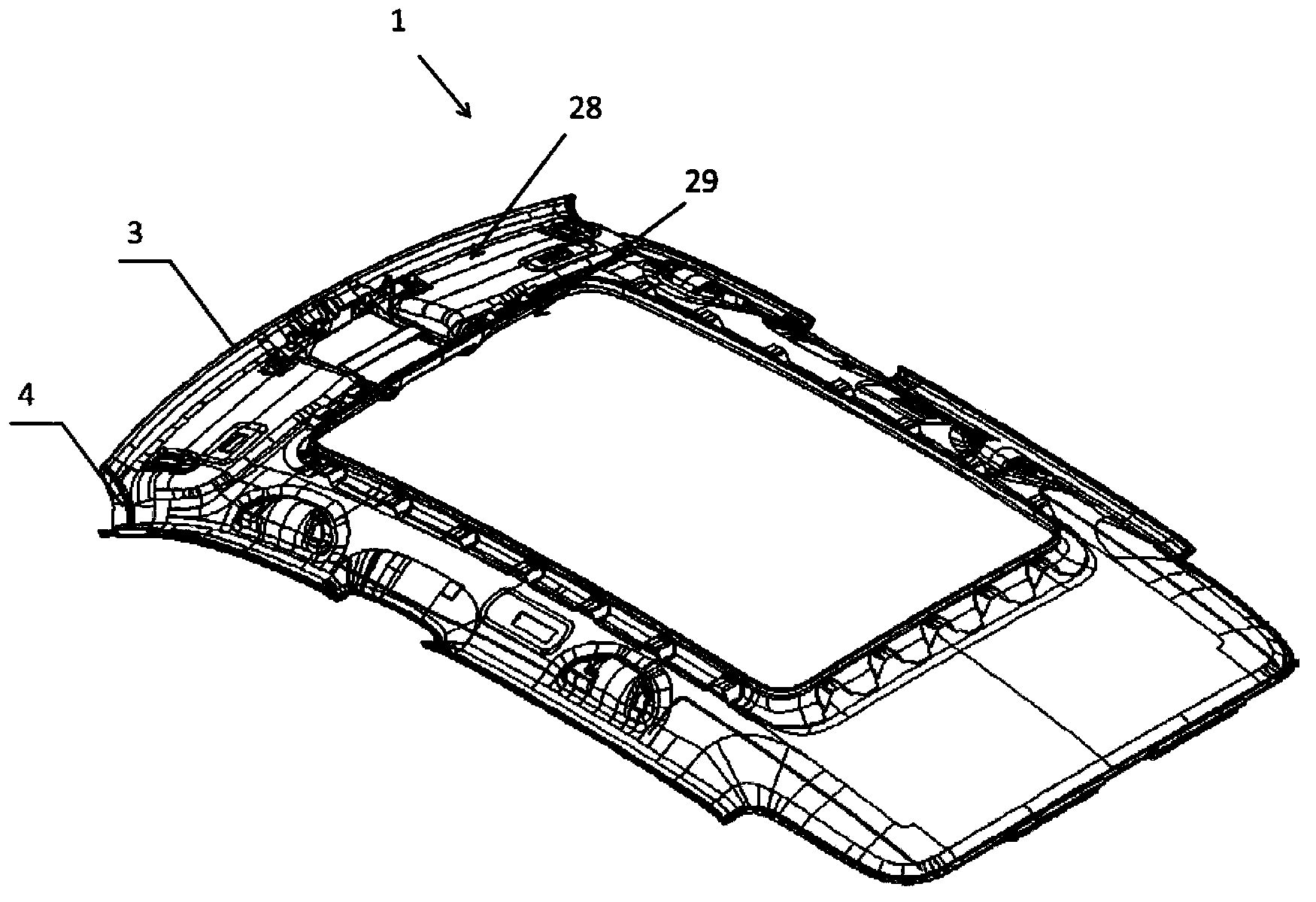

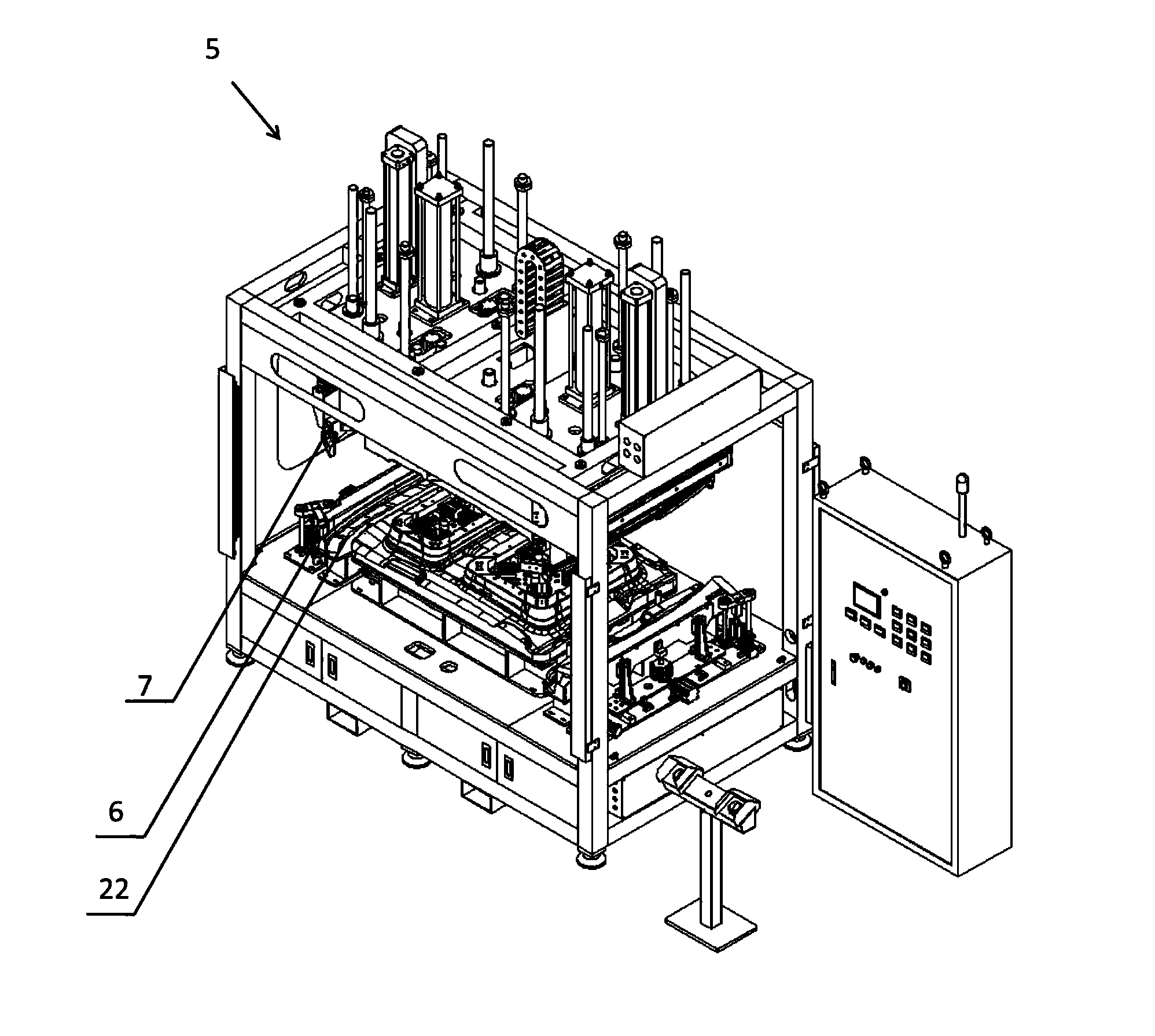

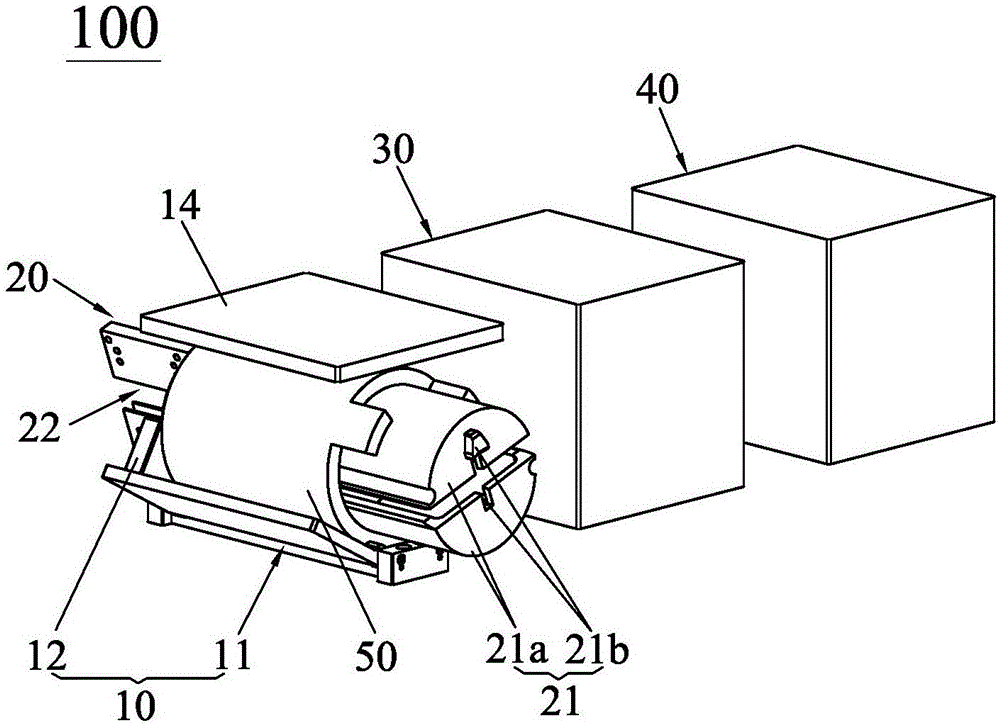

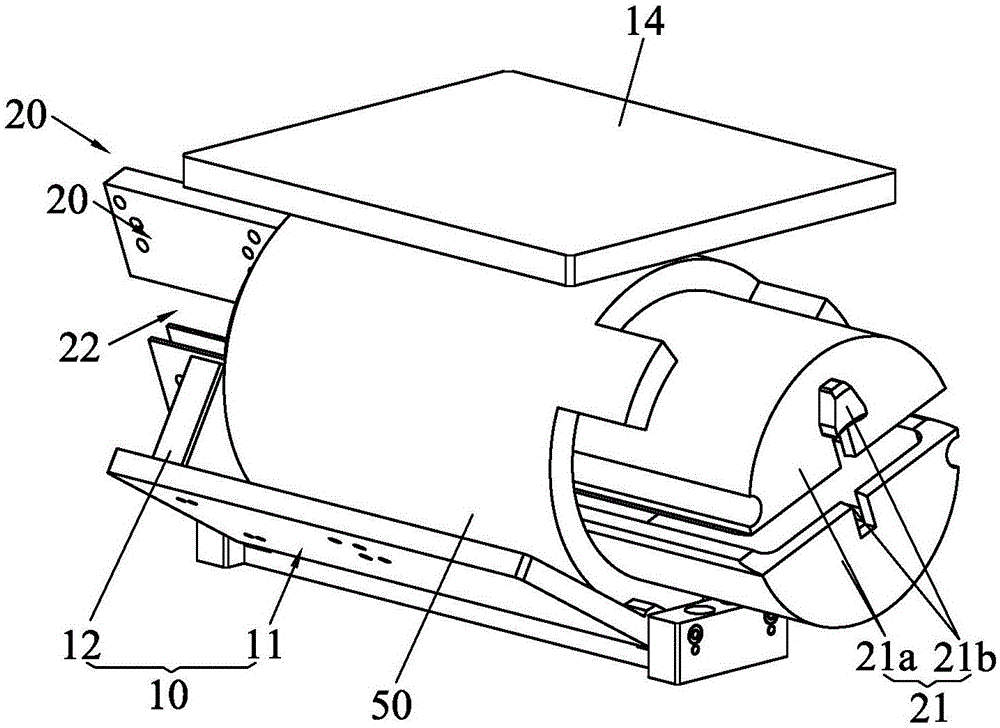

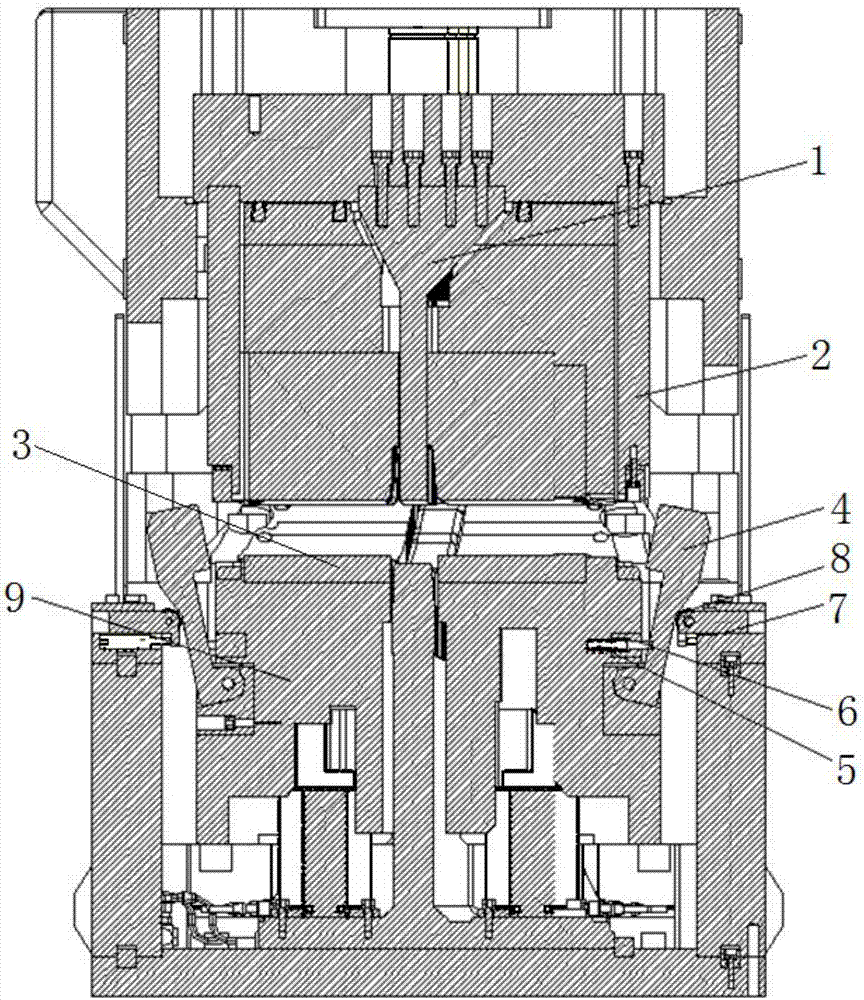

Turning device and edge covering equipment

ActiveCN104162976AGuaranteed aestheticsSolve wrinkleLaminationLamination apparatusMechanical engineeringSunroof

The invention relates to a turning device and edge covering equipment. The turning device is used for outwards turning a decorative fabric glued on the inner surface of the skylight opening part of a vehicle interior ceiling and gluing the decorative fabric to the outer surface of the skylight opening part. The turning device comprises a frame mechanism and a control mechanism, wherein the size of the frame mechanism corresponds to that of the skylight opening part; the control mechanism controls the frame mechanism to operate; the frame mechanism comprises four corner turning blocks and four edge turning blocks, the corner turning blocks are matched with shapes of corners of the skylight opening part, the edge turning blocks are matched with shapes of edges of skylight opening part, and the corner turning blocks and the edge turning blocks are contacted through inclined surfaces. During turning, the corner turning blocks and the edge turning blocks can turn the fabrics at the corners and the fabrics on the edges respectively, so that the problem of wrinkling after the fabrics at the corners are turned is solved, and the integral attractiveness of a finished product of the interior ceiling can be kept.

Owner:CENMOY AUTOMATION TECH SHANGHAI CO LTD

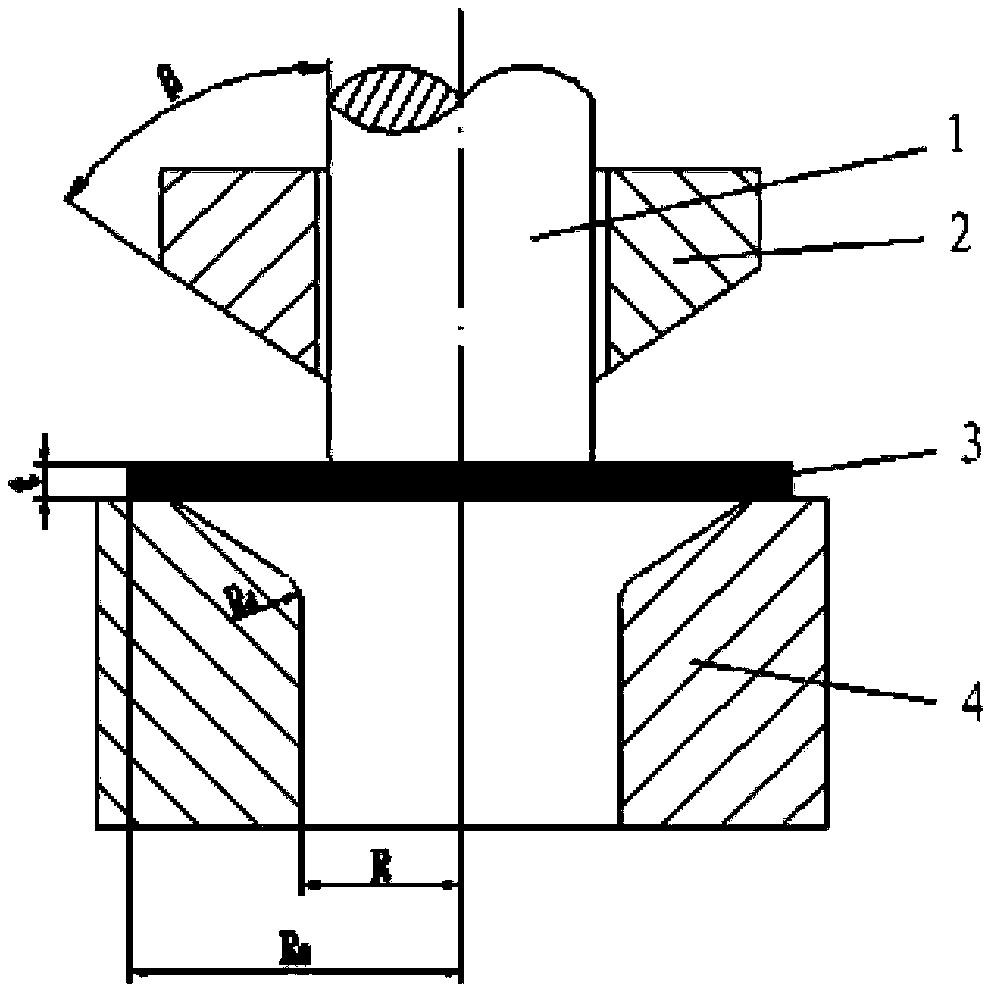

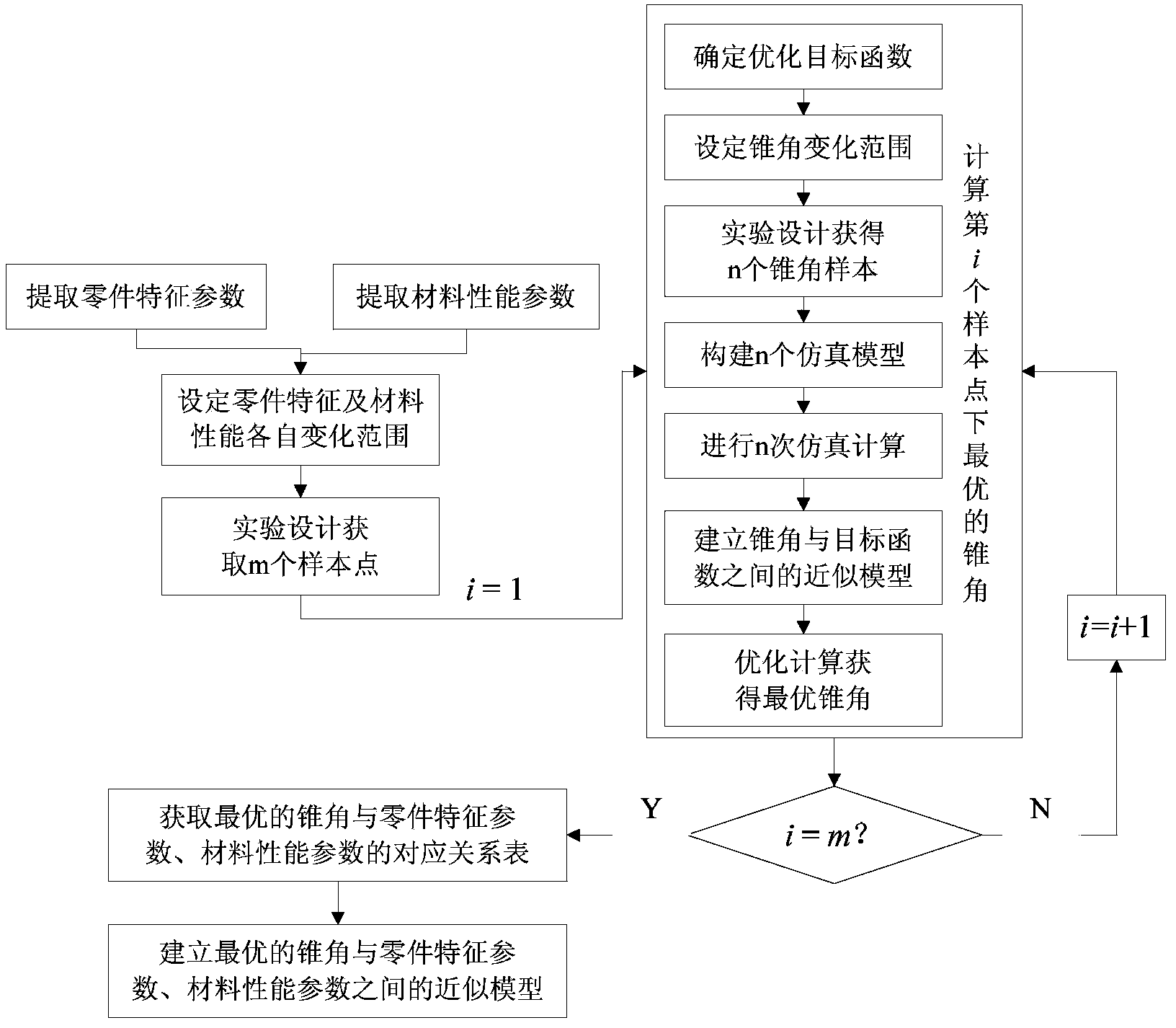

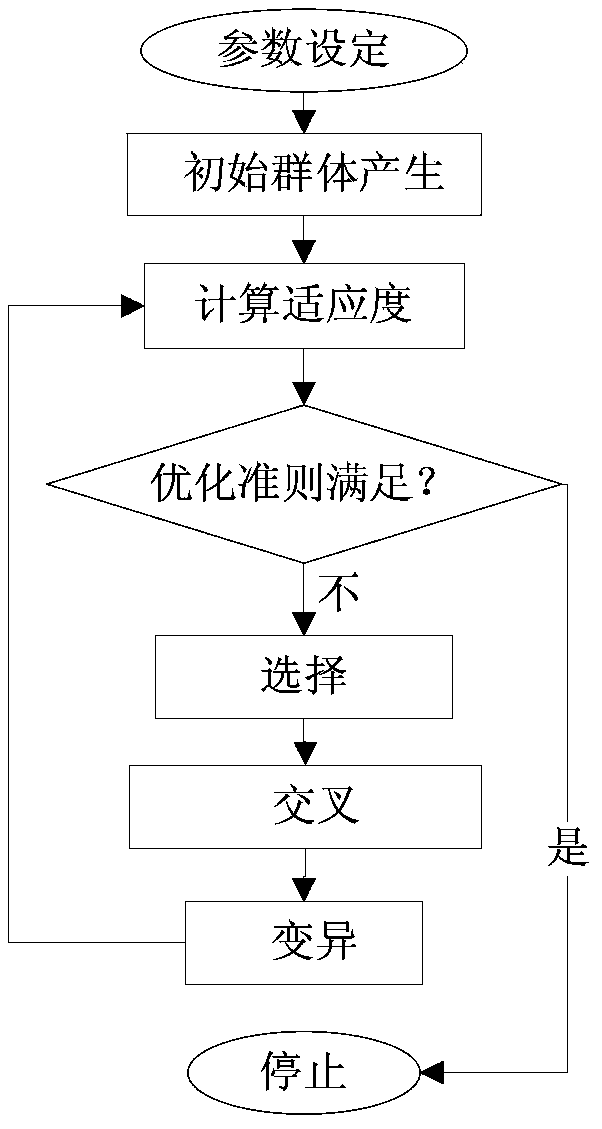

Taper blank-holding and deep-drawing stamping method

The invention relates to a taper blank-holding and deep-drawing stamping method for a cylindrical piece and belongs to the technical field of stamping forming. A deep-drawing die is manufactured to enable a blank to form a tapered recess falling into a tapered concave of a female die, and a required cylinder is deep-drawn in the center of the tapered concave till the cylinder reaches the predetermined depth, wherein the taper angle of the blank holder tapered concave of the deep-drawing die is an optimal taper angle calculated by a computer. By adopting the method, the problems of wrinkling and tension fracturing of a deep-drawing piece in the stamping process are effectively solved to ensure that the manufactured deep-drawing die can be deep-draw high-quality deep-drawing pieces.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

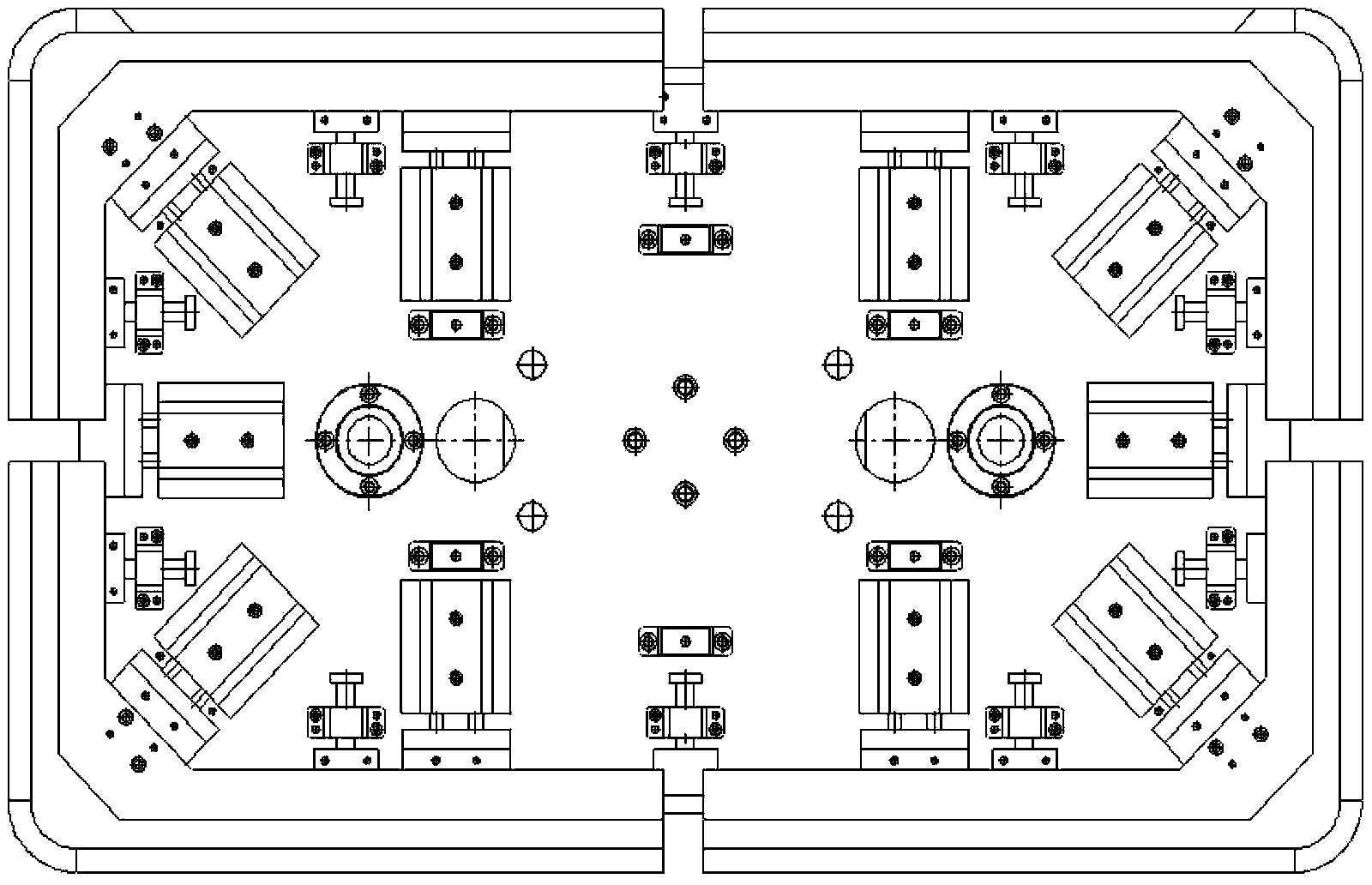

Compressing device and edge wrapping equipment

The invention relates to a compressing device and edge wrapping equipment comprising the compressing device. The compressing device comprises four angle compressing units as well as four edge compressing units, wherein the angle compressing units are provided with angle compressing blocks conforming to angle part shapes of automobile interior ceiling skylight opening parts; the edge compressing blocks are provided with edge compressing blocks conforming to edge part shapes of automobile interior ceiling skylight opening parts. According to the compressing device and the edge wrapping equipment, because the compressing device is arranged for the edge wrapping equipment newly, when an edge turning device turns edges of angle part fabrics and edge part fabrics of the skylight opening part, the angle compressing blocks and the edge compressing blocks can respectively compress the angle part fabrics and the edge part fabrics tightly together with the edge turning device, so that the angle part fabrics and the edge part fabrics always keep the balanced state in the subsequent heating process; the problem of wrinkling of the angle part fabrics after edge turning is solved; and the integral beauty of manufactured finished interior ceiling products can be kept.

Owner:CENMOY AUTOMATION TECH SHANGHAI CO LTD

Bedding fabric with antibacterial and cool functions and post-finishing process thereof

InactiveCN103132196AGood hygroscopicityRefreshingSolvent-treatmentBiochemical fibre treatmentPolymer scienceSpinning

The invention discloses bedding fabric with antibacterial and cool functions and a post-finishing process thereof. The bedding fabric is formed by weaving blended yarn with antibacterial and cool functions. The blended yarn with antibacterial and cool functions is formed by blending linen fiber, chitin fiber staple and polyester filament yarn according to sirofil spinning technology. In the blended yarn with antibacterial and cool functions, the linen fiber and the chitin fiber staple are both wrapped on the surface of the polyester filament yarn. The post-finishing process includes the following steps: desizing and scouring-singeing-bleaching repeatedly through chlorine oxygen-cellulase washing-dying-washing and gentle stretching-preshrinking-finished products. The fabric finished products has cool touch, excellent antibacterial performance and good crease resistance. Compared with pure linen fabric, the fabric is soft. Simultaneously compared with chitin fabric, the fabric has a certain body and is appropriate for bedding fabric in spring and summer.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Turning device and edge covering equipment

ActiveCN104162975ASolve wrinkleGuaranteed aestheticsLaminationLamination apparatusEngineeringBlock match

Owner:CENMOY AUTOMATION TECH SHANGHAI CO LTD

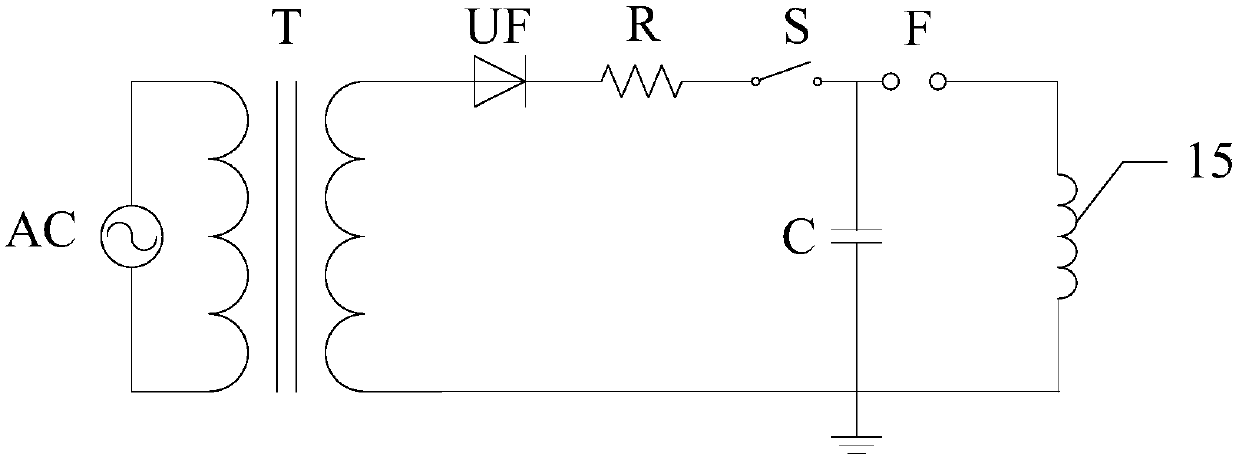

Preparation device for 4.5 microns ultrathin electrolytic copper foils and preparation process thereof

ActiveCN111155150ASolve the edge tearing problemSolve wrinkleElectroforming processesElectrolytic agentManufacturing technology

The invention discloses a preparation device for 4.5 microns ultrathin electrolytic copper foils and a preparation process thereof to achieve the purpose through the following technical scheme. The preparation device comprises an anode tank, a cathode roller, a conductive device, a online grinding mechanism, a water washing mechanism, a stripping and trimming mechanism, an oxidation preventing mechanism, a drying fan cooling mechanism, and a winding mechanism. The preparation process enables each performance of products to meet related index requirements mainly through control of the electrolyte flow, the electrolyte temperature, the electrolyte major constituents, the electrolyte micro-components, the direct current amount and the additive process. The invention effectively solves the edge tearing problem of the cathode roller and the corrugation problem of copper foils in the production process, and meanwhile, improves the tensile strength and ductility of products and meets the demands of high-end customers to key physical indexes of the copper foils through the research and development breakthrough on the key technologies such as an electrolyte preparation technology and a rawfoil manufacturing process.

Owner:TAIXING SHENGDA COPPER IND CO LTD

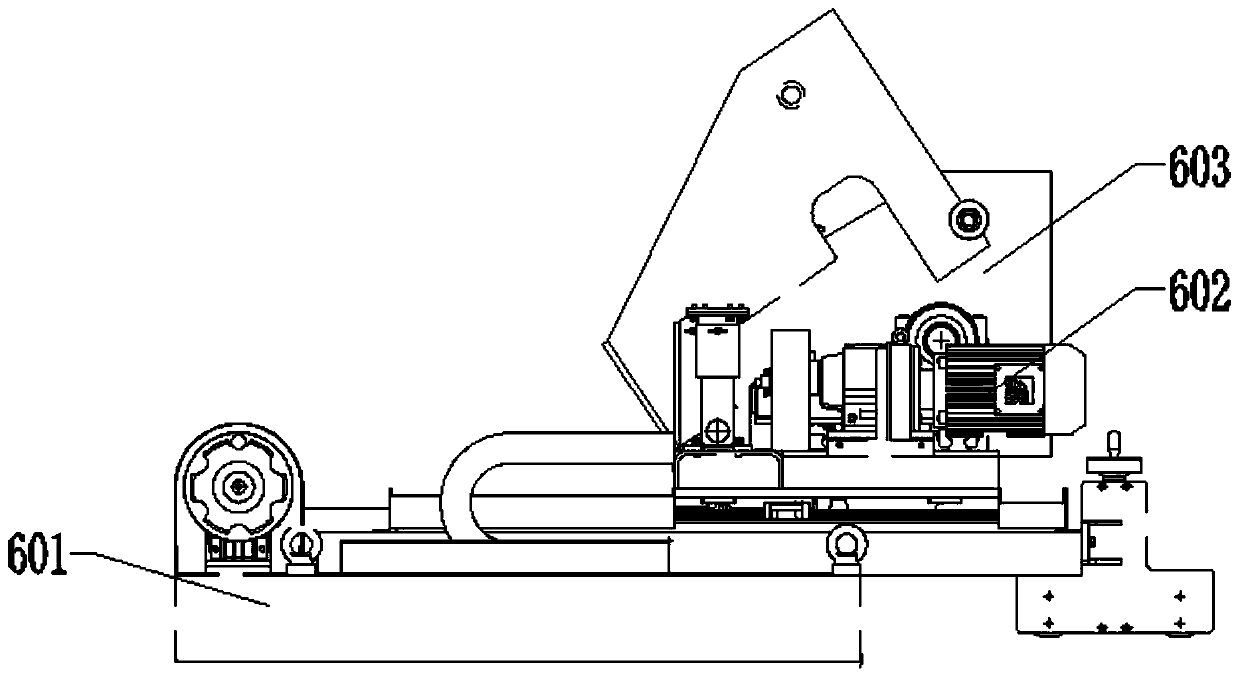

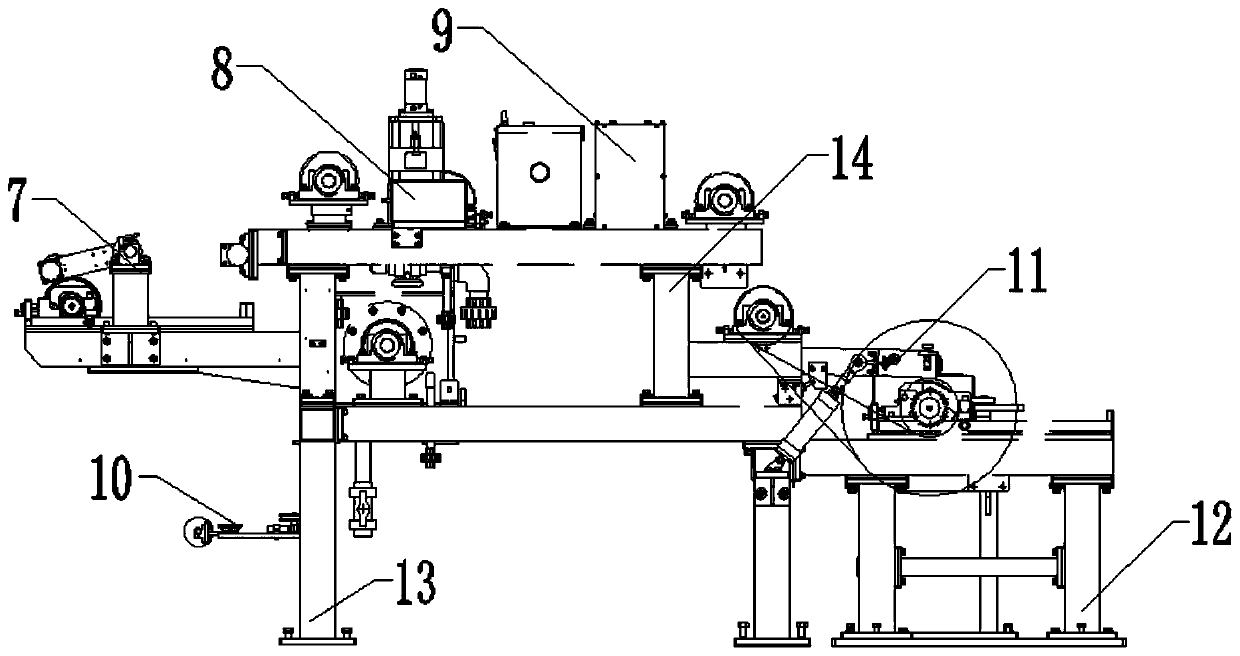

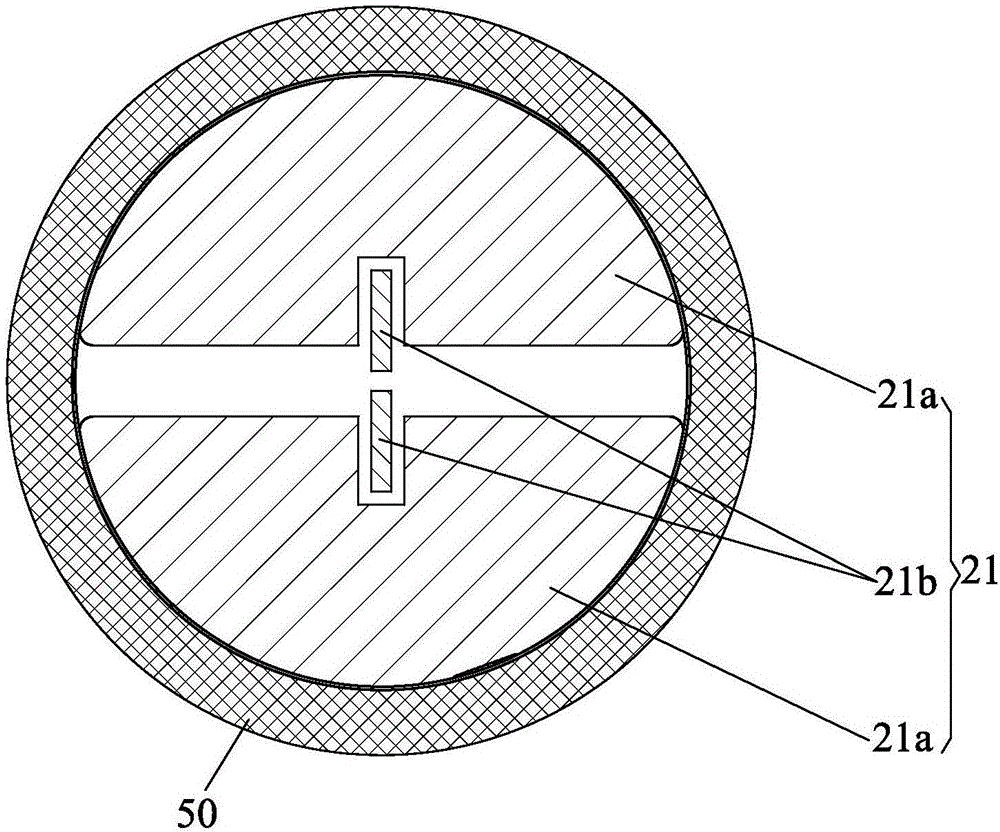

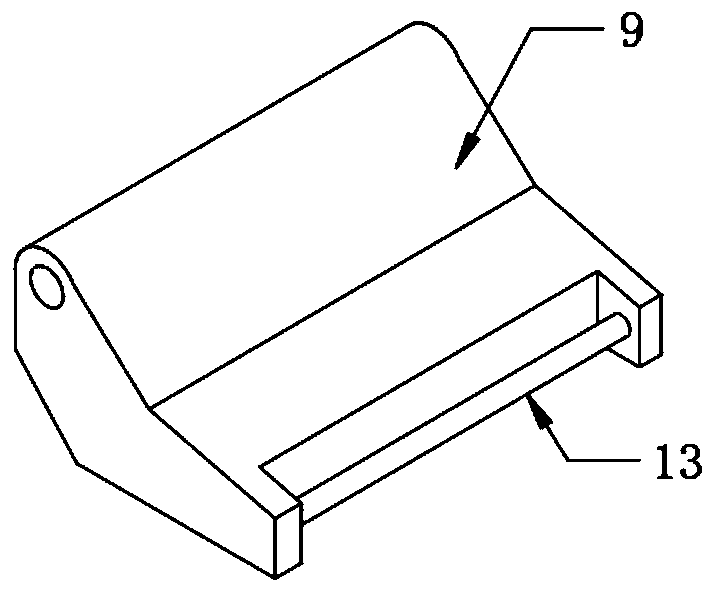

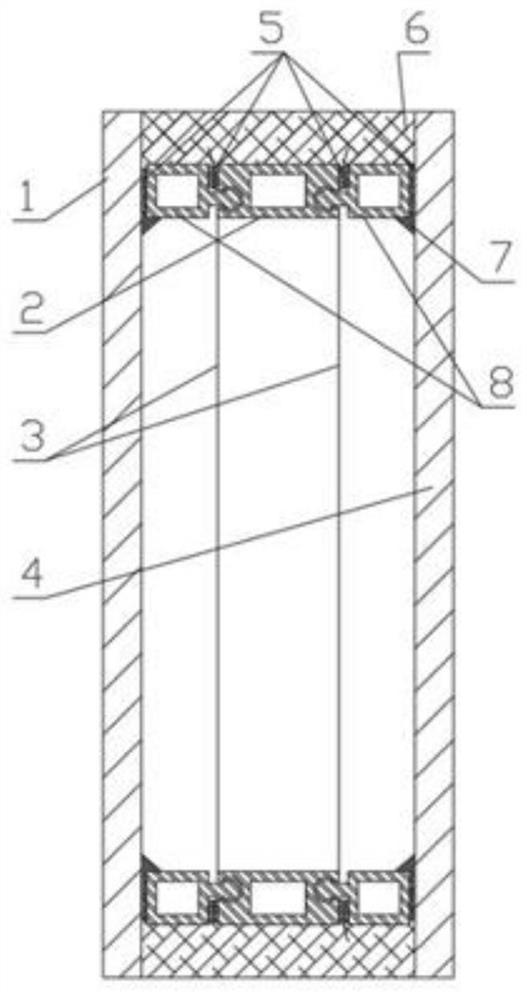

Auxiliary unloading device for circular wound needle, cable core winding equipment and cable core forming method

ActiveCN106711491ASolve the unloading problemQuality assuranceAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

Owner:东莞市博拓锂电科技有限公司

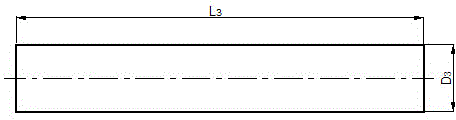

Bend forming method of large-angle pipeline with high precision, large pipe diameter and small bending diameter ratio

The invention discloses a bend forming method of a large-angle pipeline with high precision, a large pipe diameter and a small bending diameter ratio, and belongs to the technical field of machining. Metal or alloy materials with the low melting temperature are machined to be a core rod, the core rod is assembled into an inner hole of the large pipeline to be bent, the large pipeline and the core rod are simultaneously bent through bend forming, pipe blank which is subjected to bend forming is heated to be at the temperature higher than the melting temperature of the alloy core rod, at a certain temperature below the AC1 temperature of a bent pipe material (or the heating temperature at which the performance of the pipe blank material can not drop obviously), a core rod material in the bent pipe is molten and flows out, and the large bent pipe with the bent section ovality being small, the inner hole surface being smooth and the inner arc being capable of not wrinkling is acquired. The bent pipe low-melting-point core rod technology is suitable for the bend forming of the large-angle pipeline which is high in forming precision requirement, thick in wall, large in pipe diameter and small in bending diameter ratio.

Owner:CHINA FIRST HEAVY IND

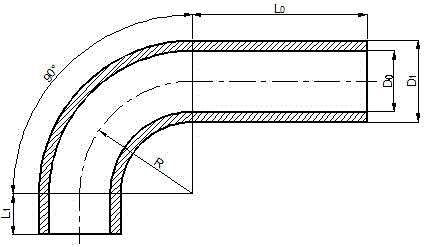

Semi-hand-sewing method for shirt

The invention relates to a semi-hand-sewing method for a shirt. The method includes the first step of cutting out a front shirt piece, a back shirt piece, yokes, sleeve pieces, cuffs and a collar of the shirt, the second step of sewing side seams of the front shirt piece and the back shirt piece, sewing the yokes and back shoulder portions of a shirt body and sewing the sleeve seams and side seams of the sleeve pieces, and carrying out processing on the sleeve pieces and the cuffs in a machine processing mode, the third step of carrying out sewing processing on the yokes of the shirt with the shift body in a hand sewing mode, the fourth step of carrying out sewing processing on shirt sleeves with the processed shirt body in a hand sewing mode, the fifth step of sewing pentagonal attached cloth on joints between the front shirt piece and the back shirt piece of the shift body, and the sixth step of sewing shirt buttons on the front fly portion of the shirt body in a hand sewing mode. According to the method, hand processing and machine processing are combined, the production efficiency of the shirts is guaranteed, and the processing quality is improved.

Owner:青岛酷特智能股份有限公司

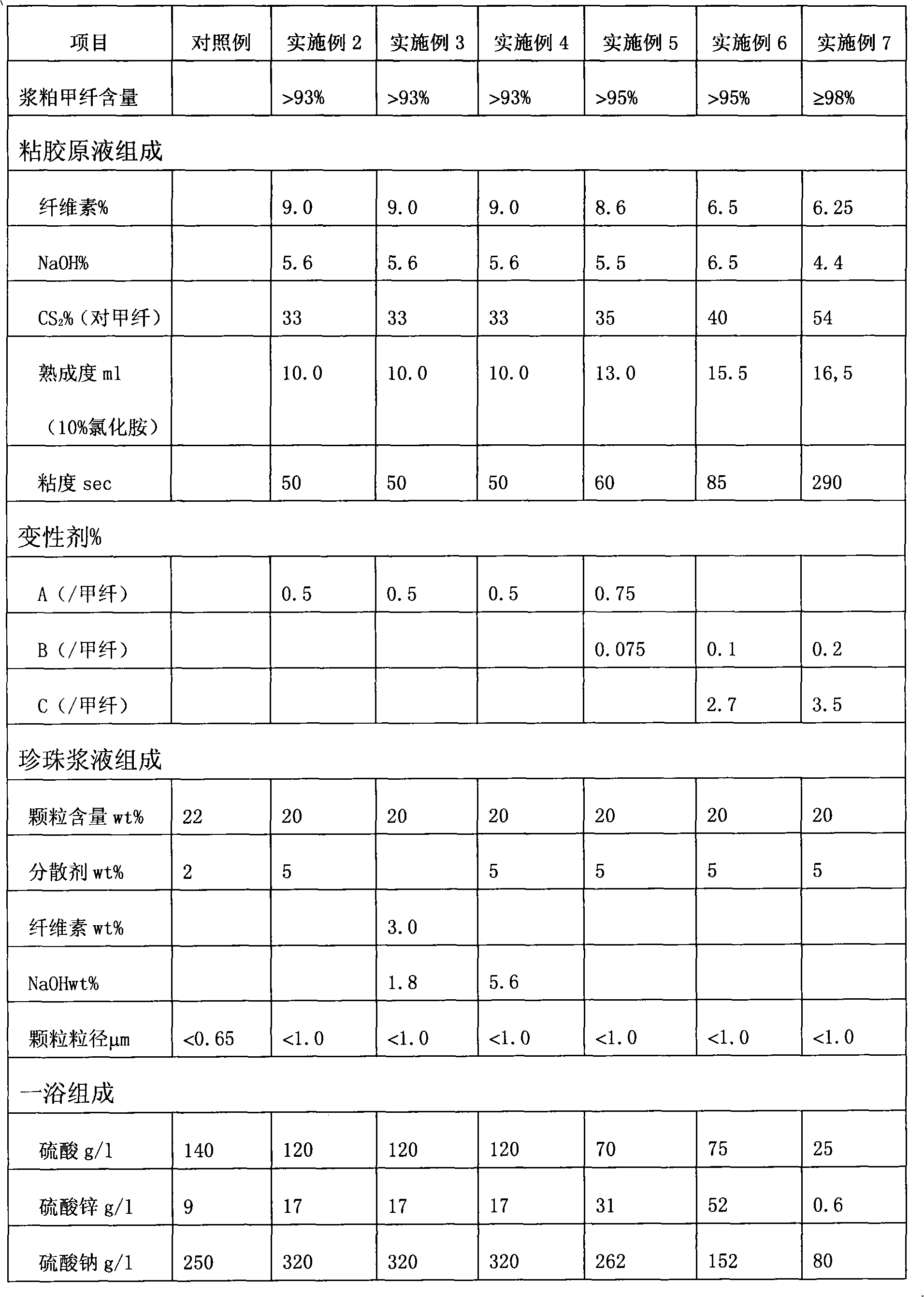

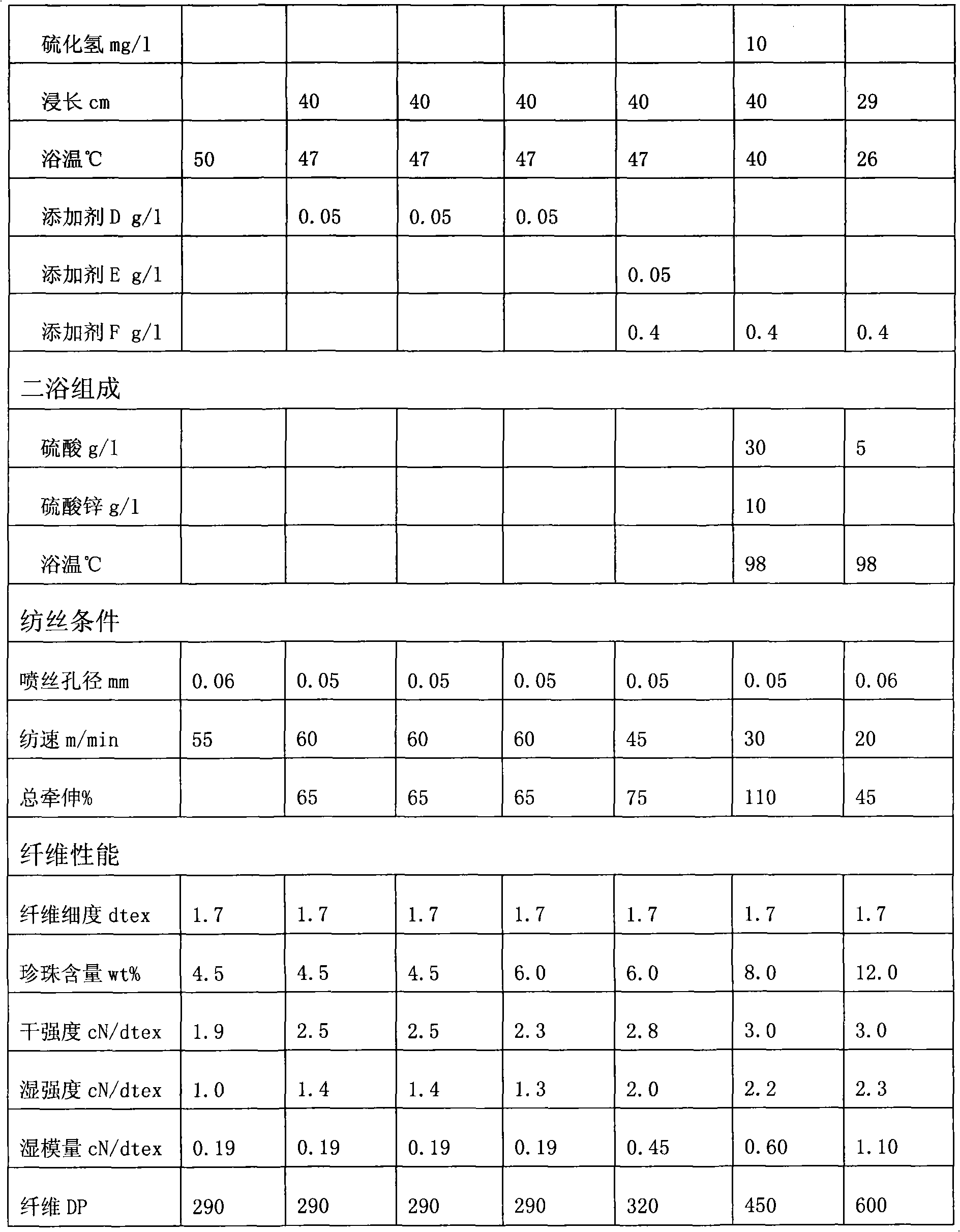

Improved viscose fiber containing pearl particles and manufacturing method thereof

InactiveCN101514496ASolve washing deformationSolve wrinkleMonocomponent cellulose artificial filamentSpinning solutions preparationCellulosePolymer science

The invention relates to improved viscose fiber containing pearl particles and a manufacturing method thereof. The fiber is reinforced, high-wet-modulus or rich and strong viscose fiber, the total amount of the fiber comprises 0.1 to 15.0 weight percents of the pearl particles, 0.2 to 6.0 weight percent of denaturant, and 79.0 to 99.7 weight percents of cellulose, the dry rupture strength of the fiber is more than or equal to 2.2 cN / dtex, and the wet rupture strength of the fiber is more than or equal to 1.2 cN / dtex. The mixture of one or more components selected from the copolymer of fatty amines, polyamines compounds, alcohol amine, polyoxyethylene and the aliphatic amine thereof, fatty acid, fatty alcohol, amide condensation compounds, ethylene oxide and propylene oxide, quaternary ammonium, pyrrolidine dithiocarbamate, dithioglycol, imidazole and derivatives thereof, is adopted as the denaturant. The manufacturing method for the fiber comprises the steps of: (1) the preparation of a viscose stock solution; (2) the preparation of slurry of the pearl particles; (3) the injection mixing of the slurry of the pearl particles and the viscose stock solution through a pre-spinning injection system; (4) spinning; and (5) post-treatment.

Owner:上海士林纤维材料有限公司

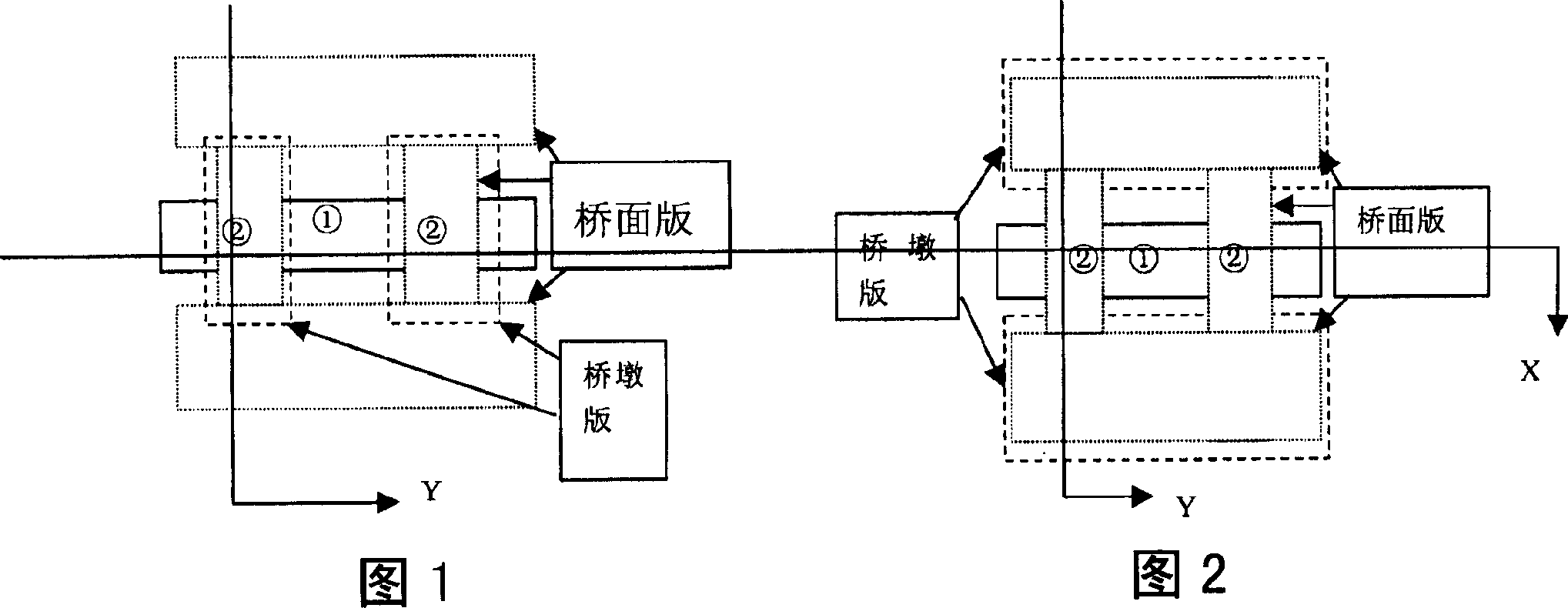

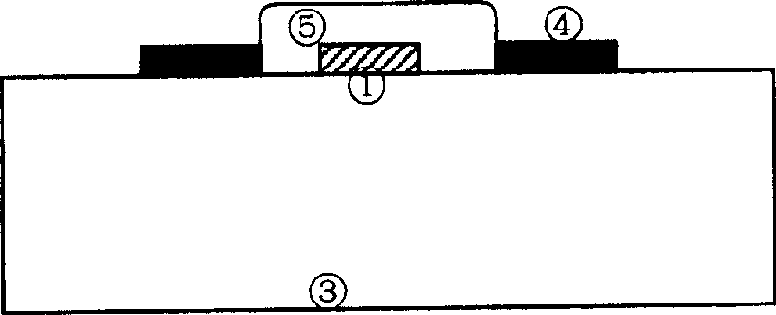

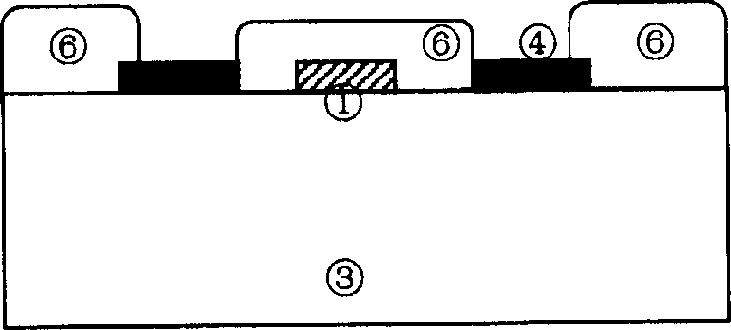

Method for manufacturing air bridge by composite glue electric-plating

InactiveCN1641837AAvoid corrosionSolve wrinkleSemiconductor/solid-state device manufacturingConductive material chemical/electrolytical removalEtchingAir bridge

The invention relates to a compound glue electroplating making air bridge method. Its features are that it including the following steps that the compound glue is plated on the base piece, and photo etching pier; high temperature roasting to make the rim angle of the compound glue smooth; start coating is spattered on the compound glue; the start coating is coated second photoresist, and photo etching floor; after this, the start coating is plated metal; peeling off the start coating under the photo etching to make it reveal the tow side base piece to form air bridge.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

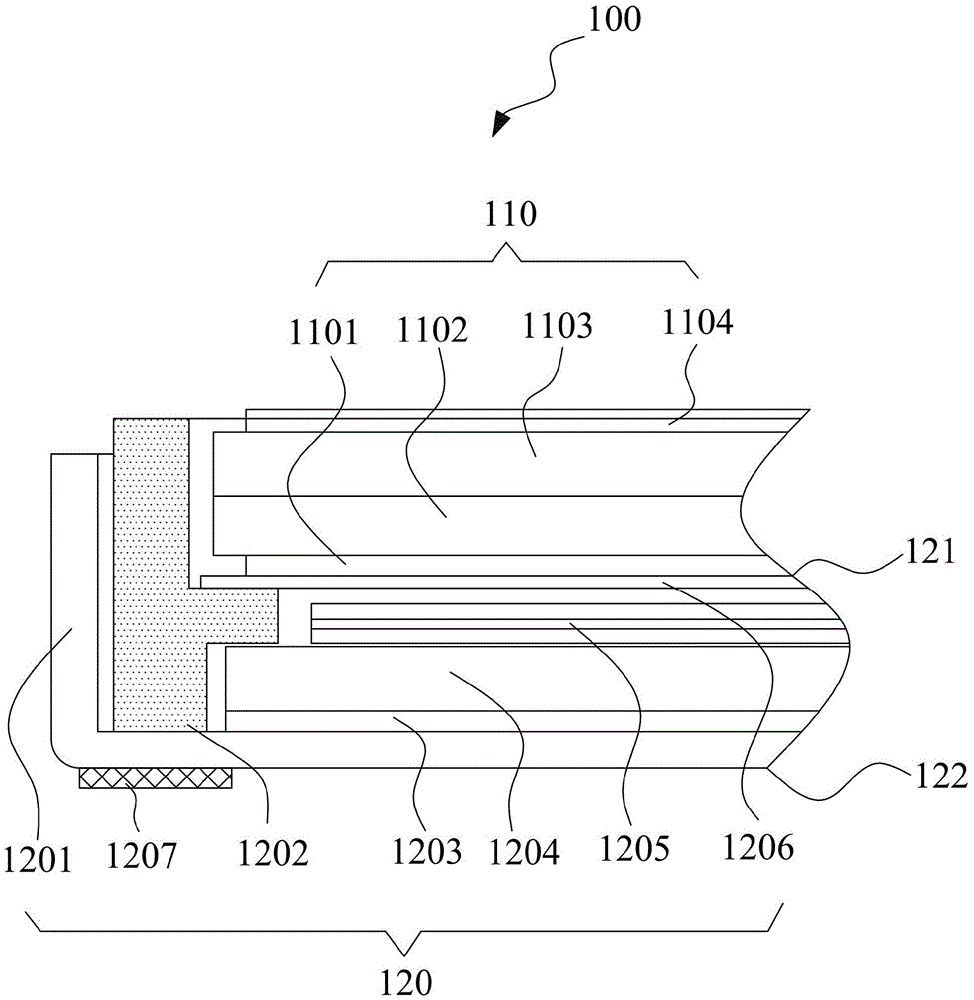

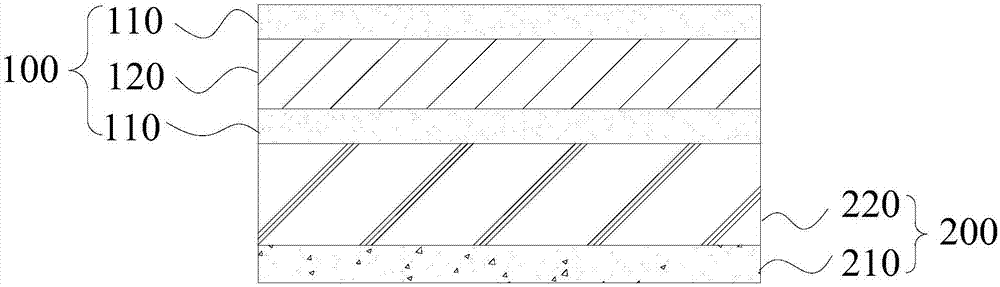

Liquid crystal display module and liquid crystal display device

ActiveCN105467645AEasy to assemblePrevent plastic frame deformationNon-linear opticsPolarizerFilm material

The invention discloses a liquid crystal display module. The liquid crystal display module comprises a liquid crystal display screen and a backlight module. The backlight module comprises a first surface and a second surface opposite to the first surface, and the liquid crystal display screen is attached to the first surface of the backlight module. The liquid crystal display screen comprises a lower polarizer, a CF screen, a TFT screen and an upper polarizer, wherein the lower polarizer, the CF screen, the TFT screen and the upper polarizer are sequentially laminated. The backlight module comprises an iron frame, a rubber frame, a reflecting film, a light guide plate, an optical film material and lightproof rubber, wherein the reflecting film, the light guide plate, the optical film material and the lightproof rubber are sequentially laminated, and the liquid crystal display screen, the reflecting film, the light guide plate, the optical film material and the lightproof rubber are arranged inside the rubber frame; the iron frame is arranged outside the rubber frame, the rubber frame is provided with metal powder, and a magnetic thin film is arranged on the second surface of the backlight module. The invention further provides a liquid crystal display device with the liquid crystal display module. By means of the liquid crystal display module, deformation of the rubber frame in the temperature test can be avoided, the liquid crystal display module is easy to assemble, the corrugated problem of the film material can be solved, and the liquid crystal display module is further easy to repair.

Owner:万年联创显示科技有限公司

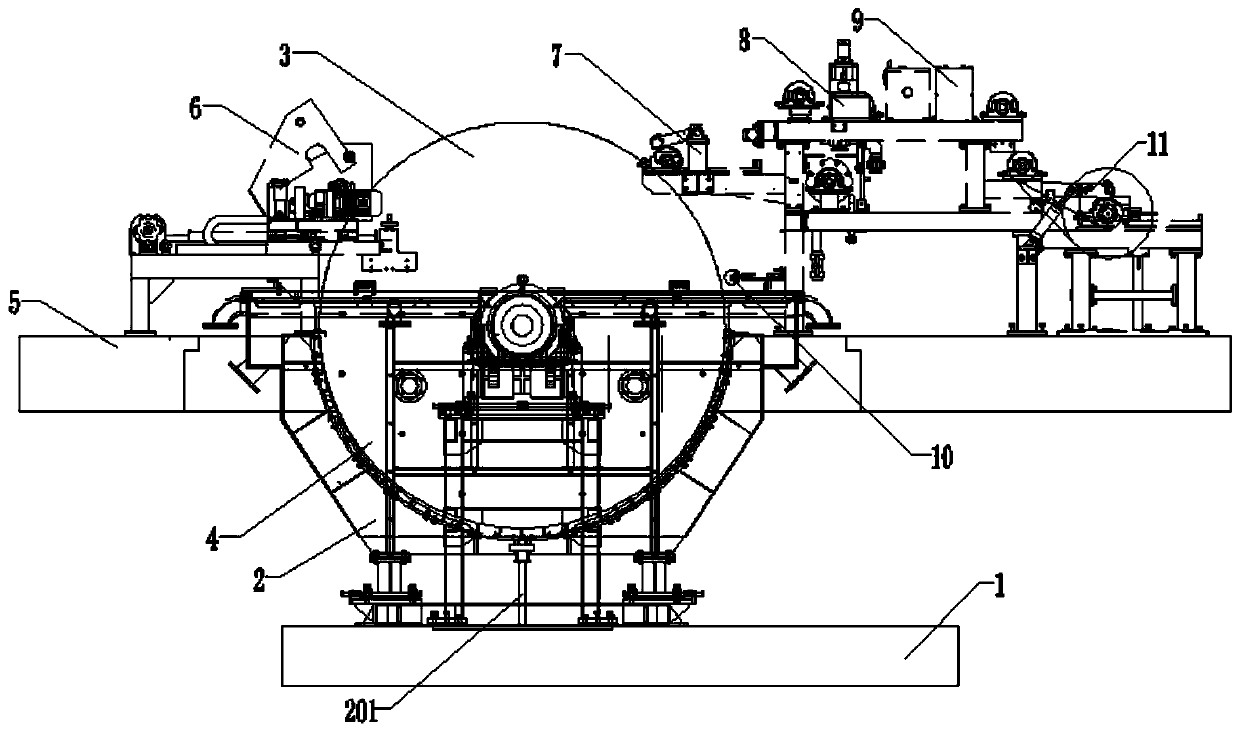

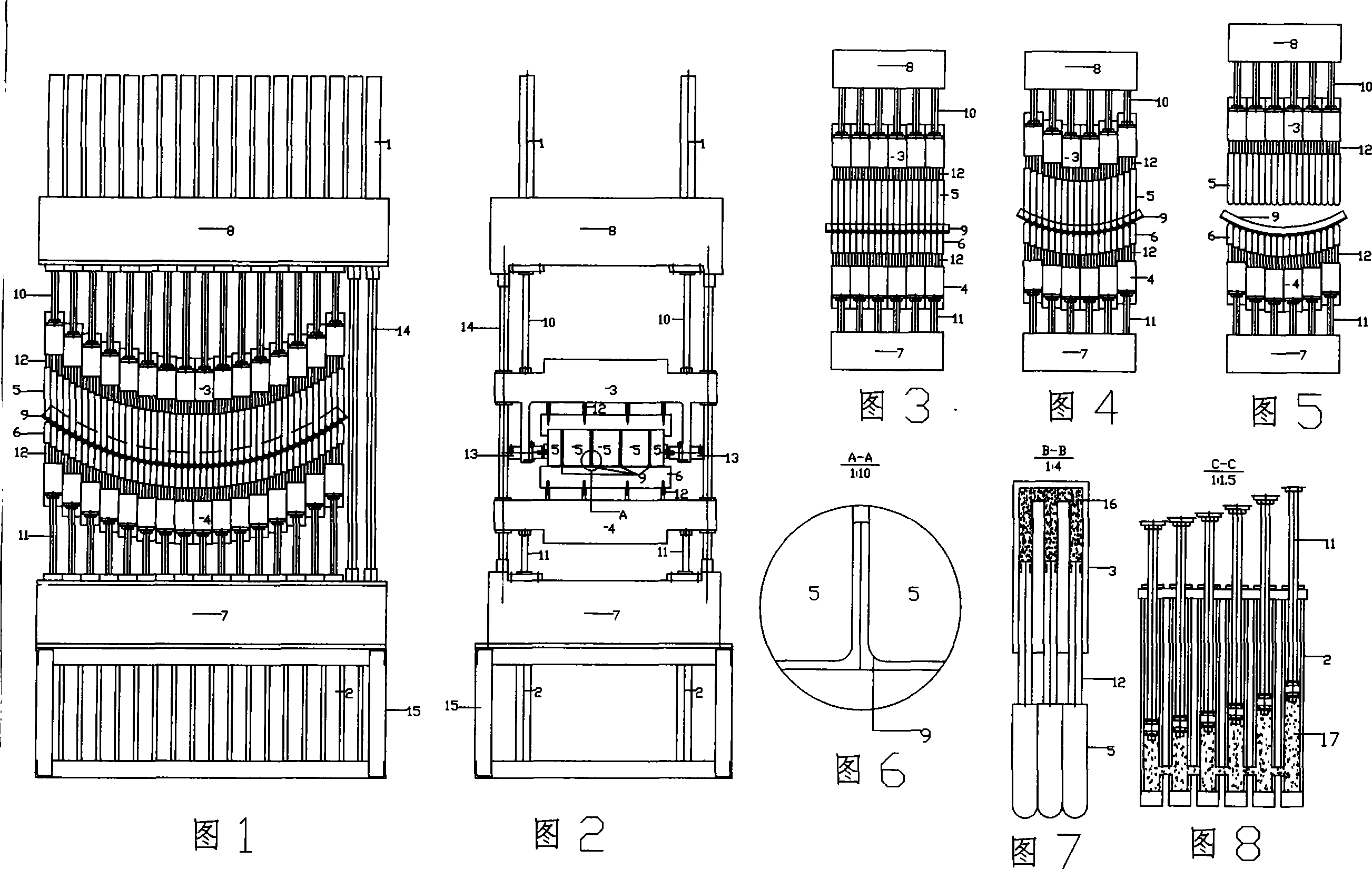

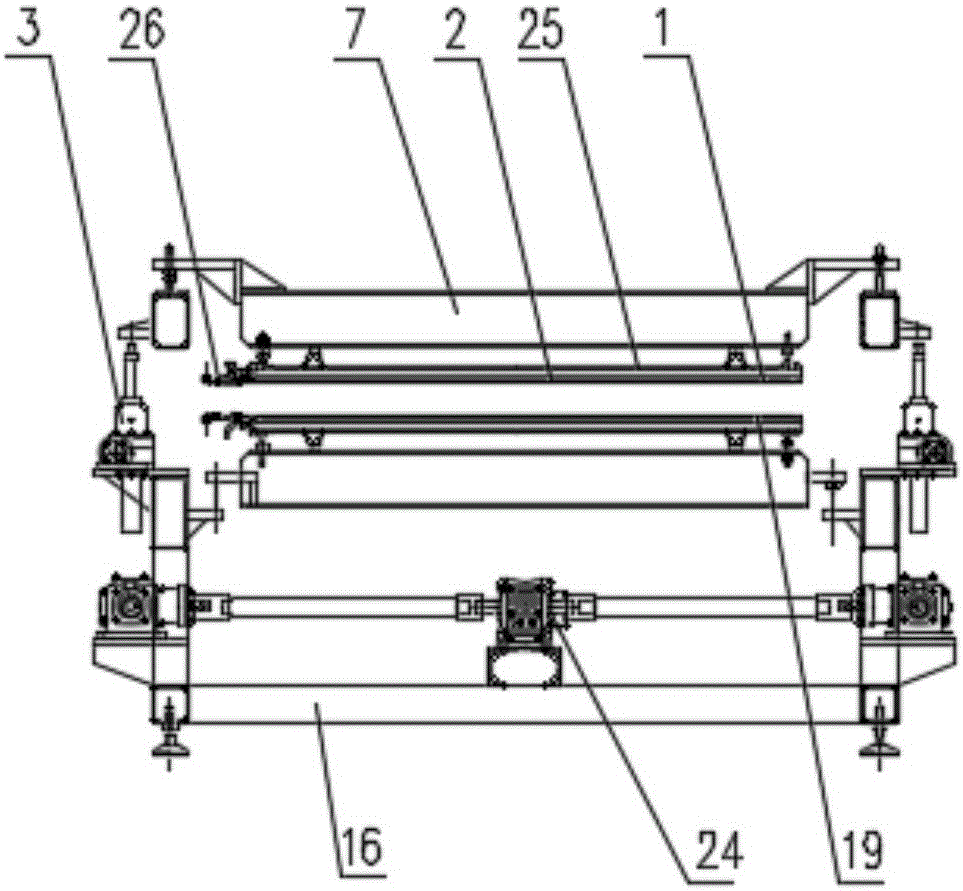

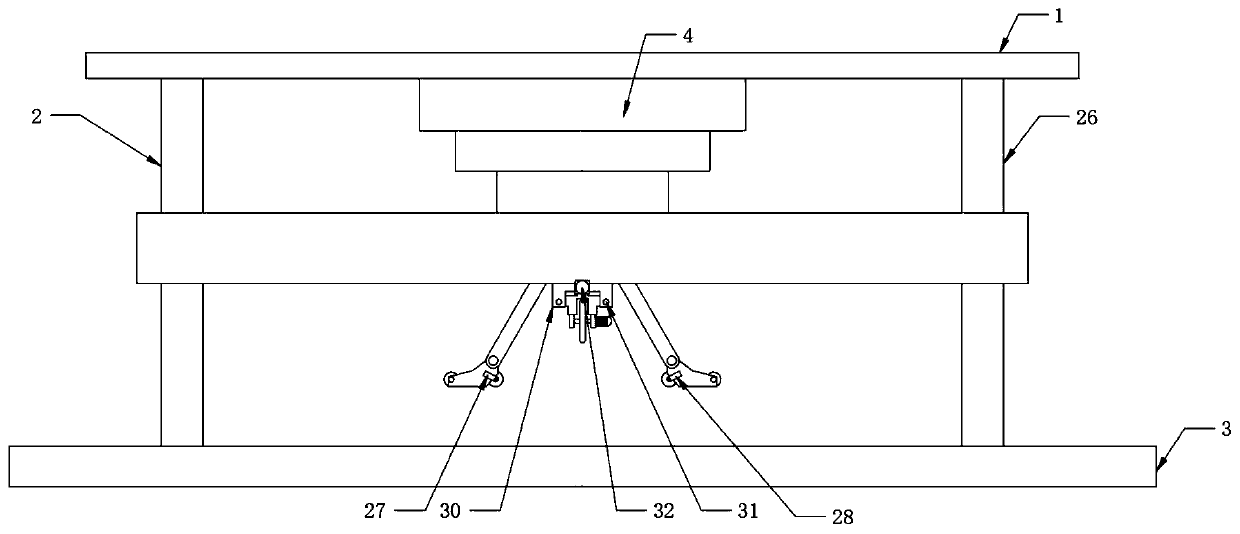

Sectional material dynamic controllable forming device

The invention relates to a device which can carry out plastic working on proximate matter, in particular to a dynamic controllable forming device for proximate matter including a hydraulic frame. The hydraulic frame is provided with a fixed upper cross beam and a lower cross beam. A guiding column is arranged between the upper cross beam and the lower cross beam. The guiding column is provided with an upper active cross beam and a lower active cross beam that can slide up and down. The upper cross beam is provided with a loading hydraulic cylinder the lower end of a piston rod of which is fixedly connected with the upper active cross beam. assistant hydraulic cylinders are arranged in the upper and lower active cross beams and the lower end of a piston rod of the upper and lower active cross beams is provided with a die head. The lower cross beam is provided with a bearing hydraulic cylinder. The oil cylinders of neighboring cylinders are mutually communicated. The upper end of the piston rod is fixedly connected with the lower active cross beam. The die head adopts a sheet-shaped die head with an arc working surface and is fixedly formed by a plurality of active die heads that can move horizontally. A workpiece to be processed is clamped between the active die heads. The invention is controlled by computer and leads the proximate matter to realize controllable deformation by utilizing a plurality of regularly arranged and highly adjustable die heads. The invention can process more than ten workpieces for once.

Owner:王江武

Non-crease cotton costume making process

InactiveCN1739419ASolve the burningSimple processSewing apparatusClothes making applicancesShrinkage rateEngineering

The new non-crease costume making process includes the following steps: 1. adding double-sided glue strip into the folded part of costume, and 2. ironing the folded part. Before the step 1, one ironing step may be added to form crease in the folded part, so that the double-sided glue strip may be inserted along the crease. The making process includes also sewing step with 220# Dacron coated string. Adding double-sided glue strip and ironing can adhere two layers of material together like one layer. The said process increases the hardness of the adhered parts to avoid crease, and using 220# Dacron coated string can reduce the shrinkage rate difference for further preventing crease.

Owner:BEIJING SICHUANG APPAREL

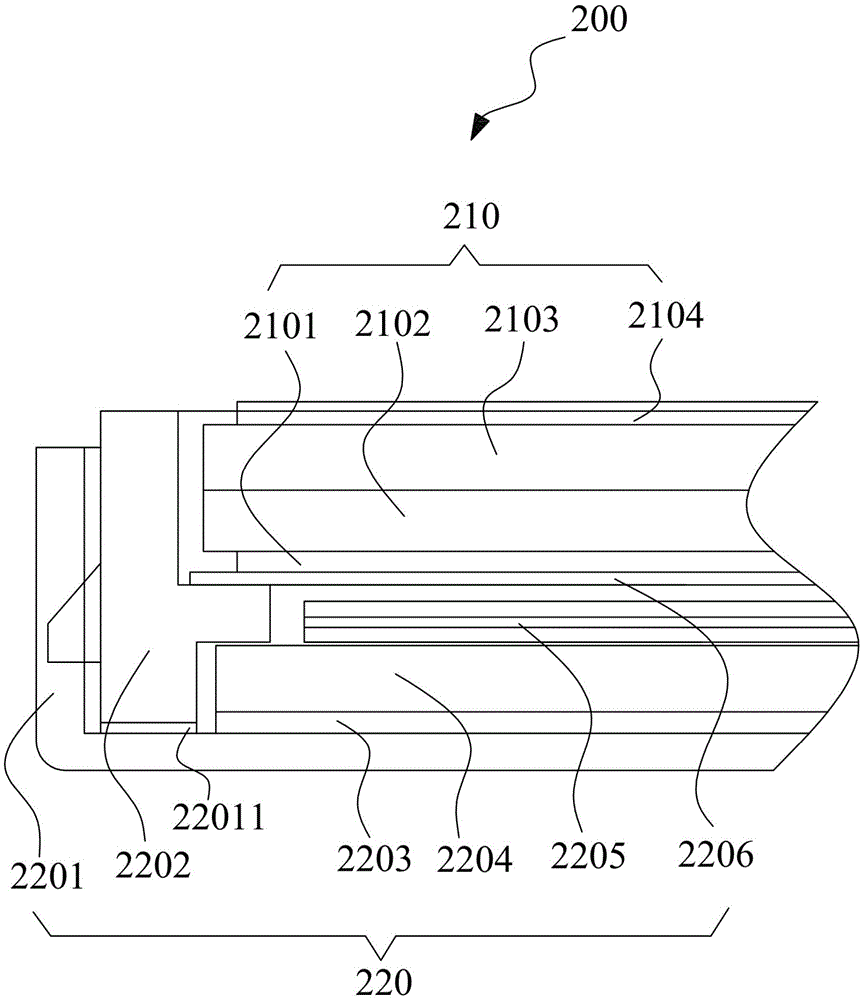

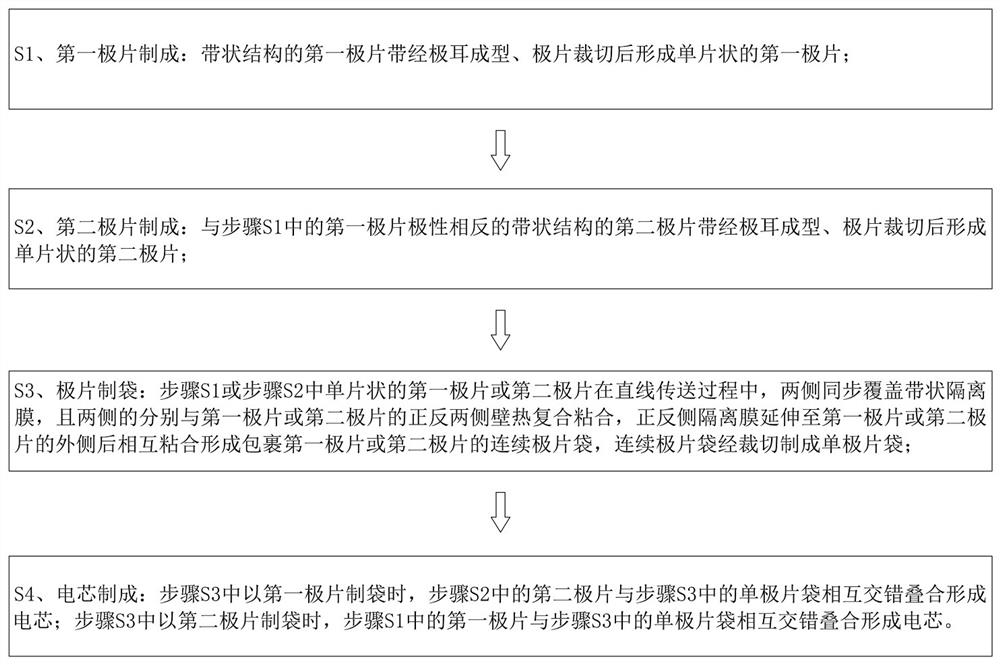

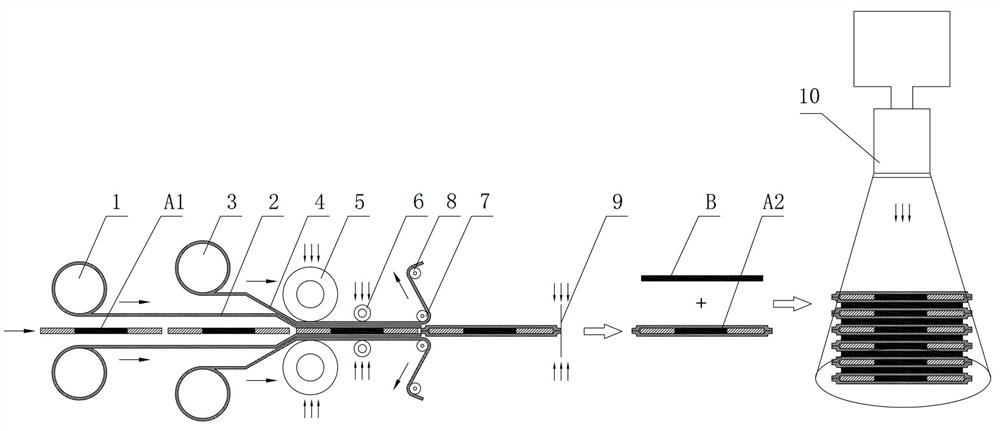

Thermal compounding manufacturing process of battery cell

ActiveCN113782838AGuaranteed Position AccuracyImprove lamination efficiencyFinal product manufactureCell component detailsManufacturing engineeringPole piece

The invention discloses a thermal compounding manufacturing process of a battery cell. The thermal compounding manufacturing process comprises the following process steps that: a pole piece is manufactured, namely, single pole pieces are formed after a pole piece belt with a belt-shaped structure is subjected to pole lug forming and pole piece cutting; pole piece bags are manufactured, namely, a single-sheet-shaped first pole piece or a single-sheet-shaped second pole piece is bonded to the front side wall and the back side wall through diaphragms on the two sides in a thermal compounding mode respectively, diaphragms on the front side and the back side extend to the outer side of the first pole piece or the outer side of the second pole piece and then are bonded to form a continuous pole piece bag, and the continuous pole piece bag is cut into single pole piece bags; and a battery cell is formed, namely, the single pole pieces and the single pole piece bags are mutually staggered and overlapped to form a battery cell. According to the invention, the problem of wrinkling of the diaphragms is solved, the position precision between the positive and negative pole pieces is ensured, the single diaphragm alignment process of the traditional lamination is simplified by adopting diaphragms larger than the pole pieces, the lamination efficiency is effectively improved, combustion caused by short circuit is reduced, and the safety coefficient of the battery is improved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

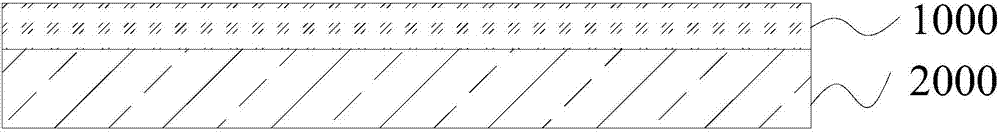

Packaging adhesive, backlight module and display device

ActiveCN107340652ASolve wrinkleSolve the problem of light leakageNon-linear opticsWrinkle skinAdhesive belt

The invention discloses a packaging adhesive, a backlight module and a display device. The packaging adhesive comprises a first adhesive tape and a second adhesive tape, wherein the first adhesive tape and the second adhesive tape are arranged in an overlapped manner; the thicknesses of the first adhesive tape and the second adhesive tape are equal; the first adhesive tape comprises a first substrate and two first adhesive surfaces distributed on two sides of the first substrate; the second adhesive tape comprises a second substrate and two second adhesive surfaces; the first adhesive tape is arranged on one side, far away from the second adhesive surface, of the second adhesive tape. The backlight module and a display panel are connected through the packaging adhesive, the problems that the backlight module has wrinkles and light leakage can be solved, furthermore the quality of a display is improved, and the pass percent of the display is increased.

Owner:BOE TECH GRP CO LTD +1

Stamping and drawing die

InactiveCN107243562ASolve wrinkleGuaranteed uniformityShaping toolsEjection devicesEngineeringMechanical engineering

The invention relates to a stamping and drawing die which comprises an upper die and a lower die matched with the upper die. A material pressing plate is arranged on an upper bottom plate of the upper die and located in the concentrated flowing position of stamping part panels of the upper bottom plate. The material pressing plate is provided with an ejector rod arranged vertically. The top end of the ejector rod is fixed to the material pressing plate. The bottom end of the ejector rod is suspended and is close to the edge of the lower die. A blank holder is arranged on the edge of the lower die. A swing wedge mechanism used for abutting against the ejector rod is arranged on the lower die and is close to the blank holder. In the process that the upper die and the lower die are assembled, the swing wedge mechanism abuts against the ejector rod. According to the stamping and drawing die, while the effect that stamping parts are not damaged due to pressing during normal production of the die is guaranteed, due to the fact that the upper material pressing plate is arranged in the over-concentrated flowing position of the stamping part panels, the stamping parts are formed in the compressed state, the flowing uniformity of materials is guaranteed, and the problem that the stamping parts are wrinkled is well solved.

Owner:DIGITAL DIE STAMPING TECH WUHAN

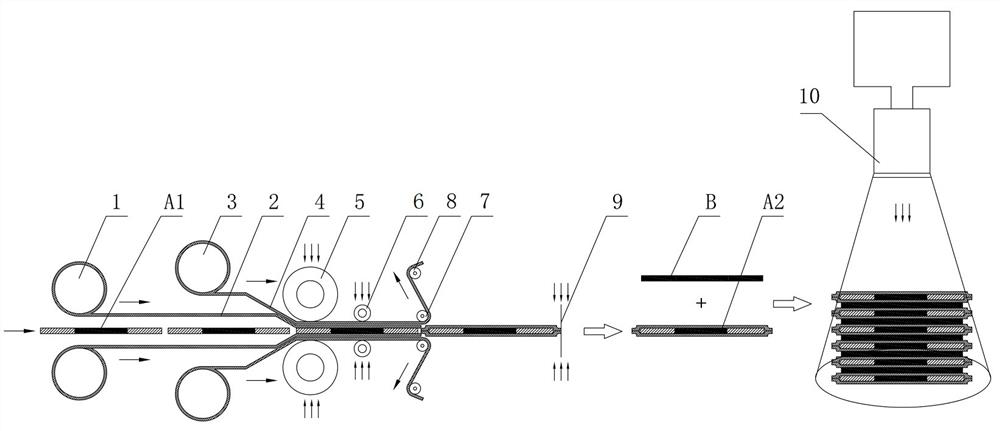

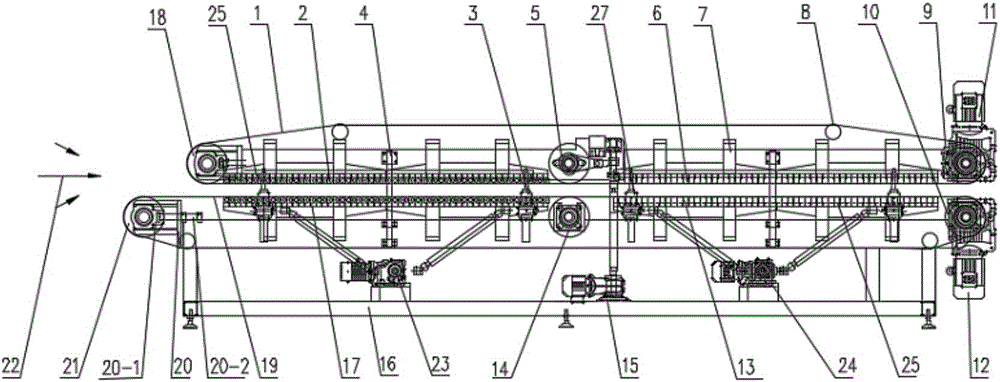

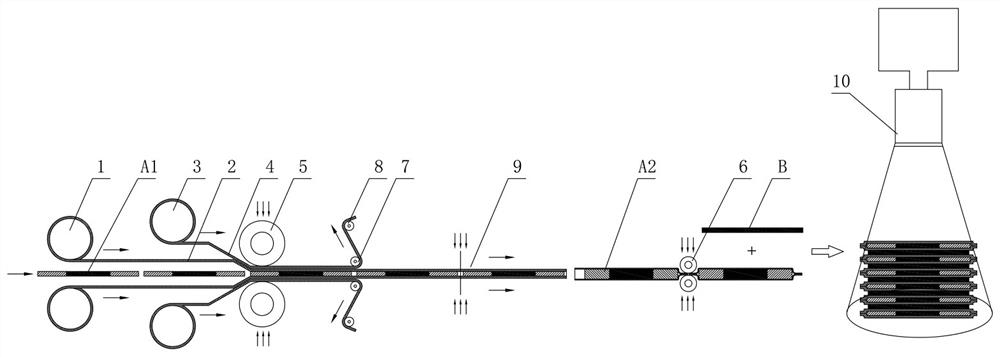

Flat belt type composite process and equipment

ActiveCN106113885AEvenly heatedAccurate temperature monitoringLaminationLamination apparatusHigh intensityUltimate tensile strength

The invention belongs to the field of material composition, and particularly relates to a flat belt type compounding process. According to the process, firstly, high-temperature heating is performed through a strip-shaped heating plate; the temperature is uniformly conducted onto a Teflon flat belt; further, the composite materials on the Teflon flat belt and glue attached onto the composite materials are preheated and prepressed; then, the composite materials are pressed again through a pair of press rollers; then, the composite materials are cooled and shaped by the strip-shaped cooling plate; finally, materials are conveyed out through the Teflon flat belt; the total compounding of the materials is completed. The invention also provides equipment used for realizing the process. According to different composite materials, through controlling the temperature, the speed and the pressure, the materials are perfectly attached and have high intensity; the upper and lower Teflon flat belts achieve uniform gaps and precise gap regulation; the flatness and no drape of the surface composite materials are ensured.

Owner:JIANGSU HONGYE MACHINERY

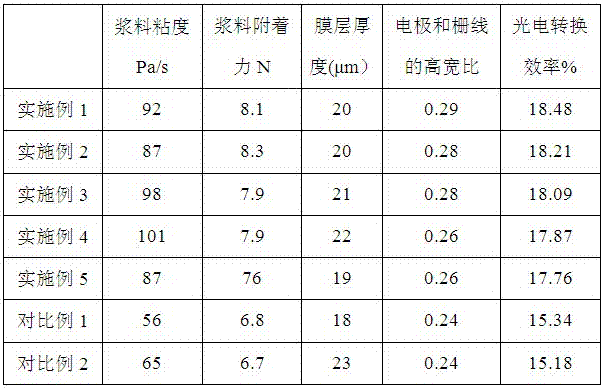

Organic carrier used for solar cell silver paste and preparation method for organic carrier

ActiveCN107045897AEasy to prepareImprove consistencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteOrganic solvent

The invention belongs to solar cell silver paste, and particularly relates to an organic carrier used for the solar cell silver paste and a preparation method for the organic carrier. The silver paste comprises the organic carrier used for the solar cell silver paste, and the organic carrier comprises the following materials in parts by weight: 70-90 parts of organic solvent, 5-15 parts of glass powder, 0.5-3 parts of hydrogenated castor oil, 5-15 parts of thickening agent, 0.1-0.8 parts of cationic surface active agent, and 3-6 parts of coupling agent. The preparation method for the organic carrier is simple, and the prepared organic carrier is efficient and high in consistency; by virtue of optimization of the organic carrier used for the solar cell silver paste, quite high linear moulding capability is achieved, the silk-screen quality of the silver paste on a silicon wafer is improved, the depth-width ratio of an electrode to a grid line after sintering can be improved and the occupied light-receiving area is reduced, thereby improving the efficiency of the solar cell.

Owner:JIANGSU RUIDE NEW ENERGY TECH

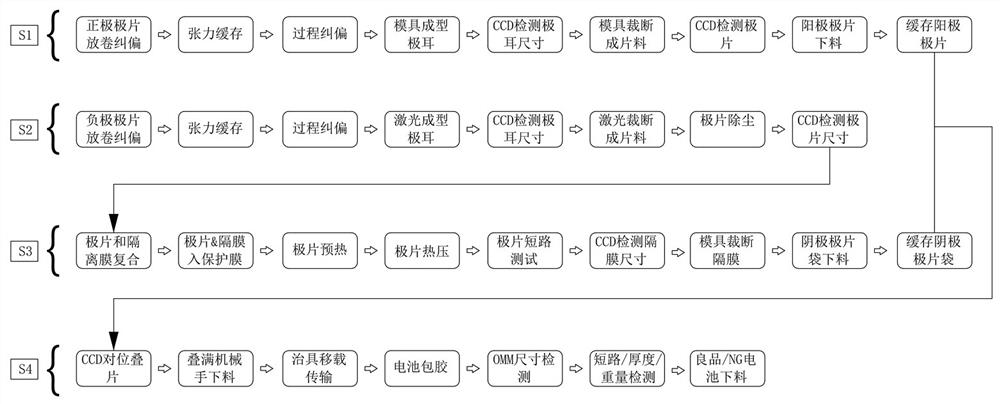

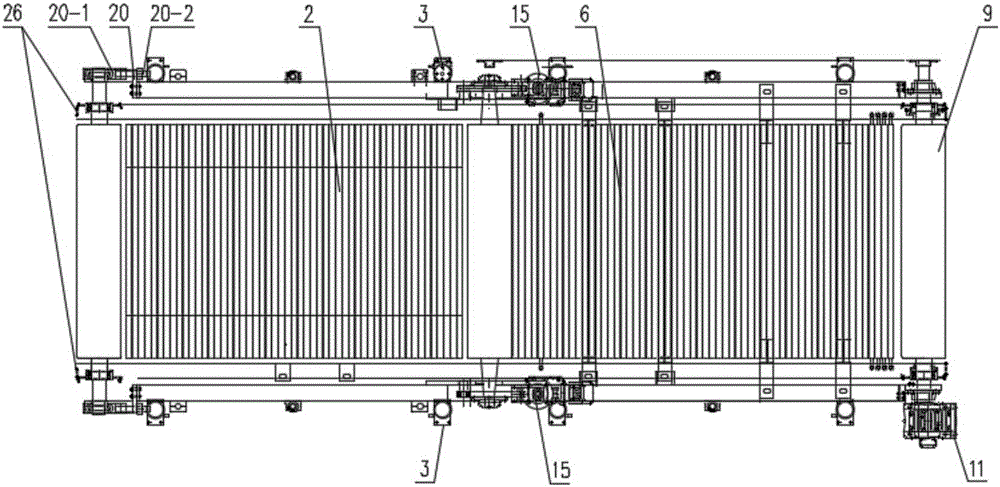

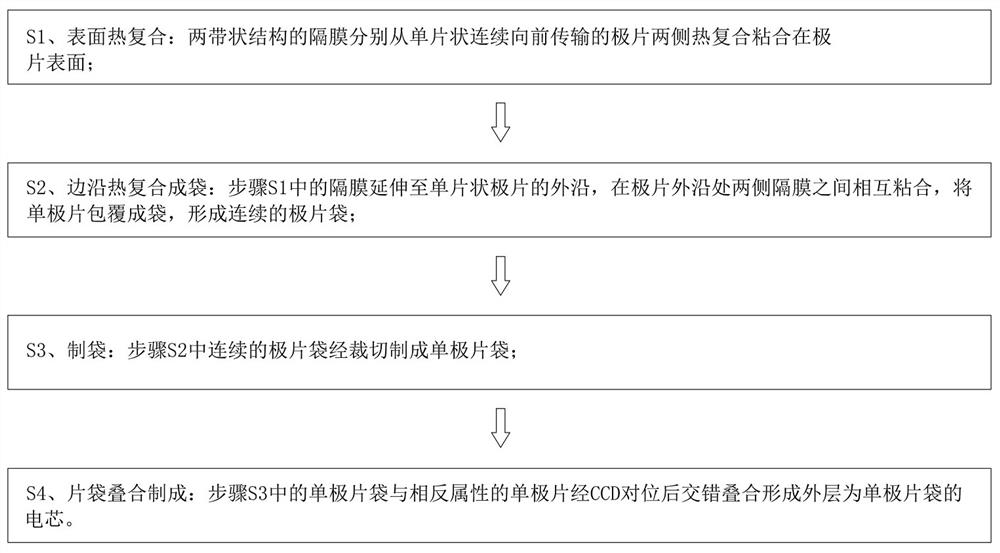

On-line type pole piece bag-making and laminating process and bag-making and laminating production line thereof

ActiveCN113782839ASolve wrinkleSolve problems that affect the quality of batteriesFinal product manufactureCell component detailsProduction linePole piece

The invention discloses an on-line type pole piece bag-making and laminating process and a bag-making and laminating production line thereof. The process comprises the following process steps of: S1, surface thermal compounding: bonding two diaphragms with belt-shaped structures onto the surfaces of single pole pieces continuously conveyed forwards in a thermal compounding manner from the two sides of the pole pieces; S2, edge thermal compounding to form a bag: extending the diaphragms in the step S1 to the outer edges of the single pole pieces, mutually bonding the diaphragms on the two sides of the outer edges of the pole pieces, and wrapping the single pole pieces into a continuous pole piece bag; S3, bag making: cutting the continuous pole piece bag in the step S2 into single pole piece bags; and S4, piece bag laminating and manufacturing: aligning the single pole piece bags in the step S3 and single pole pieces with opposite properties through a CCD (Charge Coupled Device), and laminating in a staggered manner to obtain a battery cell. According to the invention, the problem of wrinkling of the diaphragms is solved, the position precision between the positive and negative pole pieces is ensured, the single diaphragm alignment process of the traditional lamination is simplified by adopting the diaphragms larger than the pole pieces, the lamination efficiency is effectively improved, combustion caused by short circuit is reduced, and the safety coefficient of a battery is improved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

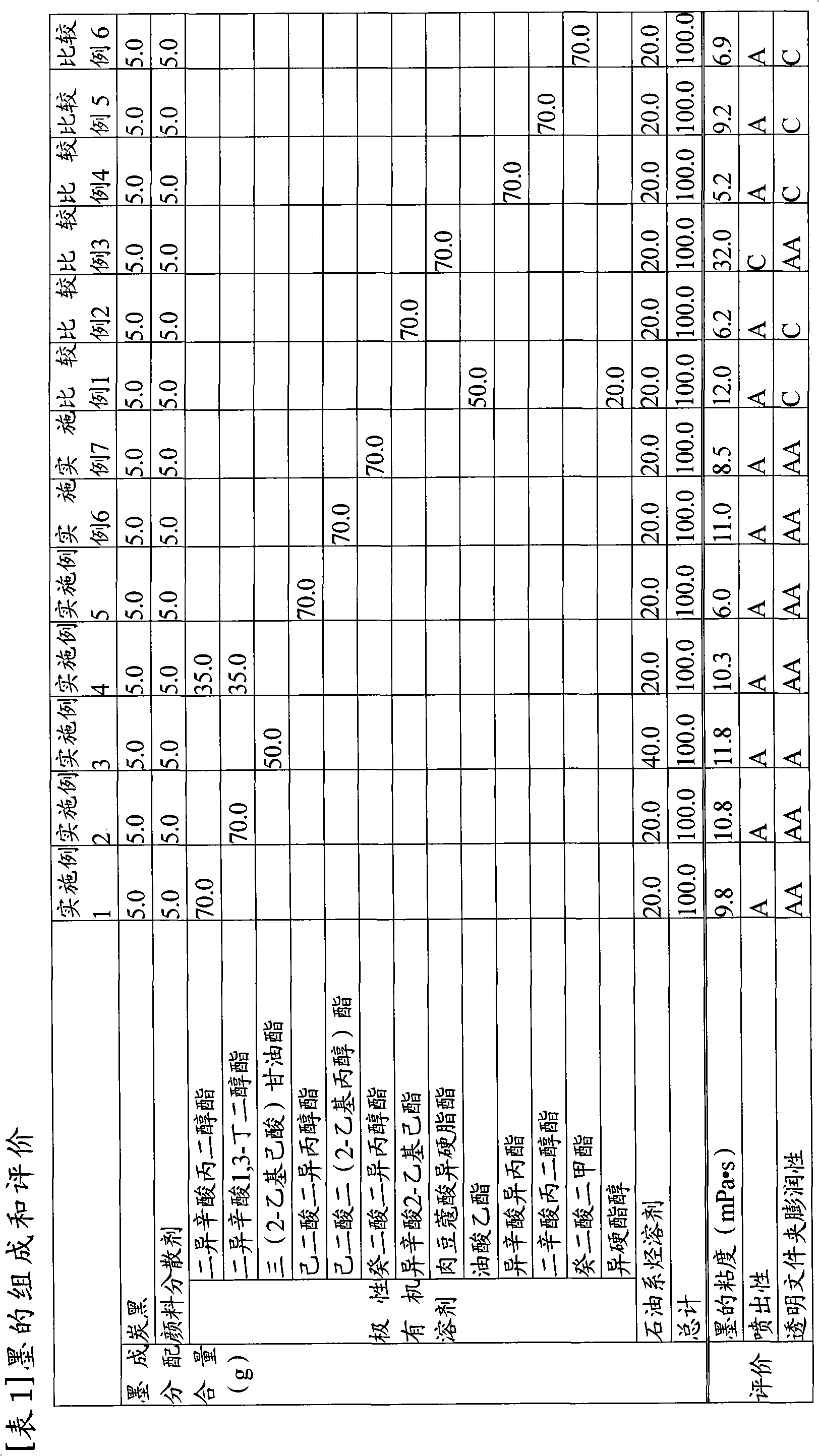

Non- water pigment ink

The invention relates to a non-water pigment ink, comprising pigment, pigment dispersant and non-water dissolvant. the non-water dissolvant contains esters above dyadic ester of polyatomic alcohol and branched fatty carboxyl acid, or esters above dyadic ester of branched fatty alcohol and multi-fatty carboxyl acid.

Owner:RISO KAGAKU CORP

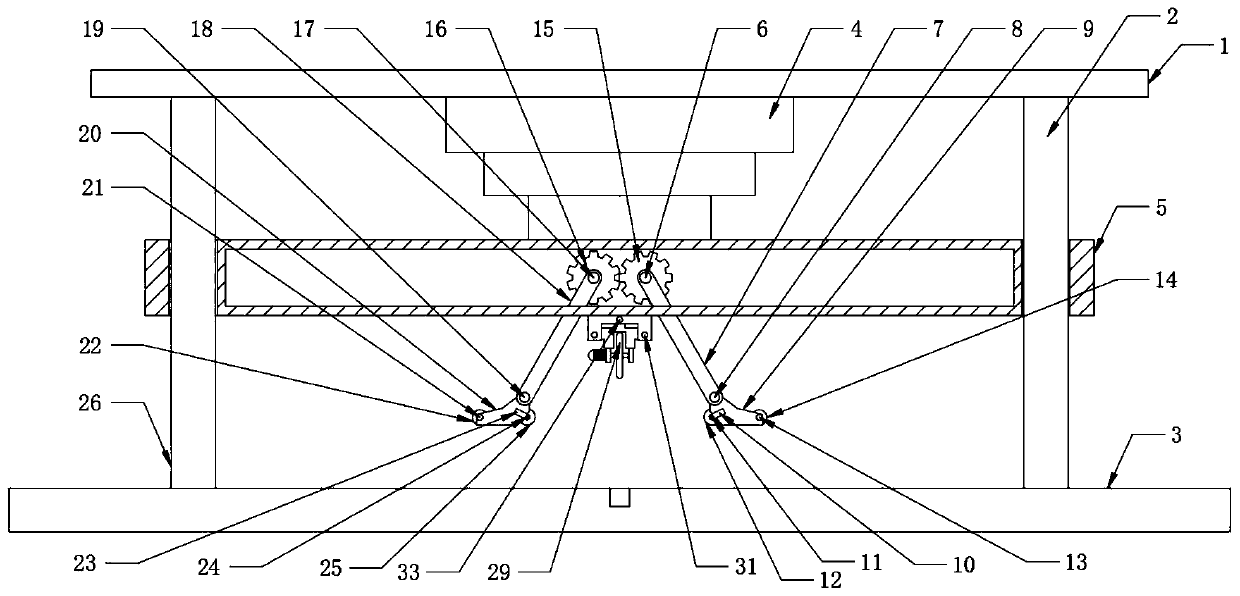

Aluminum alloy battery box composite forming device

ActiveCN109590405AImprove plasticityAvoid the problem of self-strength reductionShaping toolsHollow articlesAutomotive batteryElectric-vehicle battery

The invention provides an aluminum alloy battery box composite forming device, belongs to the field of metal material processing and forming, and solves the problem that an existing electric vehicle battery box forming process easily leads to poor quality of the formed part. The forming device lies in that a supporting plate, a preforming concave die and a pressing plate are stacked on a forming concave die sequentially from bottom to top; a first through cavity, a preforming through cavity, a second through cavity and a forming cavity form a vertically communicating cavity; a to-be-formed aluminum alloy sheet is clamped between the pressing plate and the preforming concave die; an electromagnetic pulse preforming unit is used for preforming the aluminum alloy sheet in the performing through cavity; an electroplastic element makes the preformed aluminum alloy sheet generate an electroplastic effect; a stamping forming unit is used for secondary forming of the aluminum alloy sheet withelectroplastic effect in the forming cavity; and an electromagnetic pulse rectifying unit is used for performing electromagnetic pulse forming on a fillet region of the reformed aluminum alloy sheet,so that the fillet region of the aluminum alloy sheet is further adhered to the fillet region of the forming cavity.

Owner:XIANGTAN UNIV

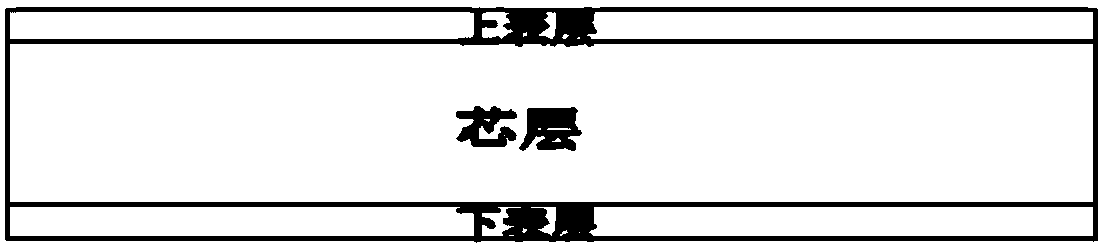

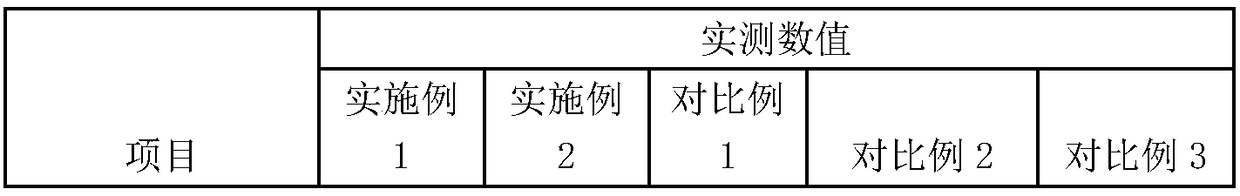

BOPP film capable of resisting crease and resisting cigarette packet deformation as well as preparation method thereof

InactiveCN108715070AImprove heat resistanceAvoid deformationSynthetic resin layered productsSurface layerPolypropylene

The invention provides a BOPP film capable of resisting crease and resisting cigarette packet deformation as well as a preparation method thereof. The BOPP film is prepared by directly coextruding andlaminating a three-layer structure of an upper surface layer, a core layer and a lower surface layer; the upper surface layer comprises the following components: a copolymer polypropylene, a slippingagent master batch and an anti-sticking agent master batch; the core layer comprises the following components: a homopolymer polypropylene, a stiffening agent master batch and an electrostatic agentmaster batch; and the lower surface layer comprises the following components: a copolymer polypropylene, a slipping agent master batch and an anti-sticking agent master batch. According to the productand the process, the technical problems of crease and cigarette packet deformation in soft packet cigarette film packaging.

Owner:ZHANJIANG PACKAGING MATERIAL ENTERPRISES

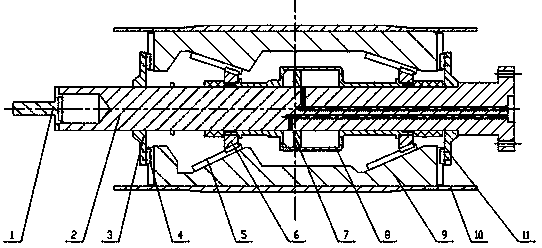

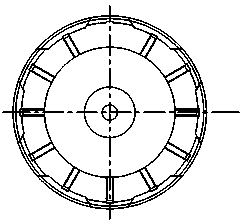

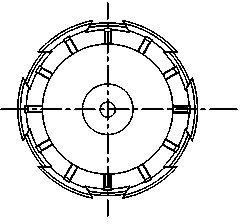

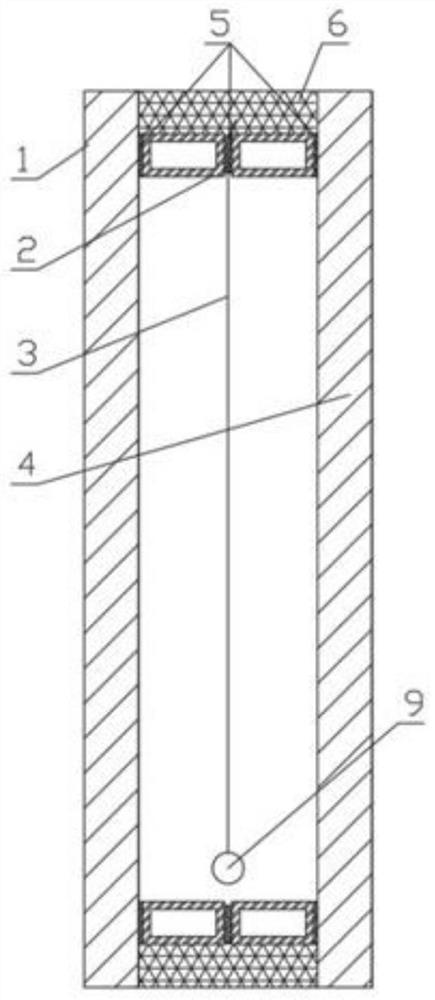

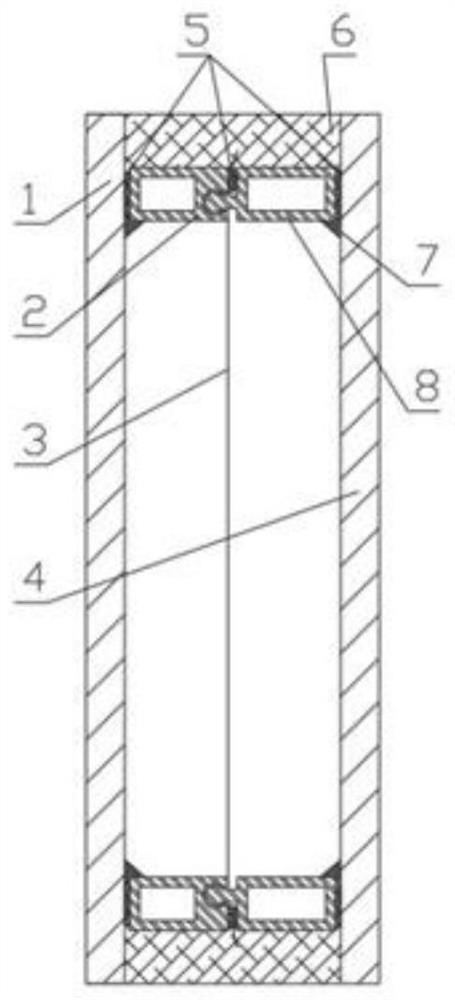

Tyre body fitting drum

The invention provides a tyre body fitting drum. The tyre body fitting drum is composed of a main shaft and a drum body, wherein the main shaft is fixedly provided with a left supporting disc and a right supporting disc; a hidden cylinder which can slide on the main shaft is arranged between the two supporting discs, cone-shaped bodies are sleeved on the outer edges of the two ends of the hidden cylinder, and the middle part and the main shaft can form a sealing air chamber; a piston is fixed on the main shaft and can divide the sealing air chamber into two parts, two air channel holes are formed in the main shaft, and the two air channel holes are respectively connected to the two parts of the sealing air chamber; the drum body comprises an angle plate and drum tiles covered on the outer side surface of the angle plate, and the two ends of the angle plate are respectively connected with the left supporting disc and the right supporting disc through radial guide rails so as to enable the angle plate to slide along the radial guide rails; the inner side surface of the angle plate and the cone-shaped bodies are in movable fit through slant guide rails. The tyre body fitting drum provided by the invention has the advantages that the angle plate drives the drum tiles to realize the shrinking movement of the tyre body fitting drum, a gap is not generated among the drum tiles, the rolling effect is good, the structure is simple, the energy utilization rate is high, and the tyre body fitting drum is used in an all steel truck radical tyre secondary method type forming machine.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND +1

Textile fabric cutting device

The invention relates to the technical field of textile equipment, and discloses a textile fabric cutting device. The textile fabric cutting device comprises a top seat, a first guide rod and a base,wherein the bottom of the top seat is fixedly connected with the top end of the first guide rod; the bottom end of the first guide rod is fixedly connected with the top end of the base; and the bottomend of the top seat is fixedly connected with an air cylinder. According to the textile fabric cutting device, a transmission gear, a driven gear, a first transmission arm, a second transmission arm,a first pressing plate, a second pressing plate, a first right press roller, a second right press roller, a first left press roller, a second left press roller and the like are arranged; and after atransmission seat performs descending, and when the first pressing plate and the second pressing plate are in contact with the surface of cloth, the first pressing plate and the second pressing plateare pushed by the first transmission arm and the second transmission arm to simultaneously move towards the two ends of the cloth, and the cloth is straightened while the cloth is pressed, so that thecloth is prevented from wrinkling, the problem that the cloth needs to be pressed and fixed separately when the cloth is cut is solved, and the problem that the cutting area of the cloth is prone towrinkling is avoided.

Owner:南通市联缘染业有限公司

Suspended film hollow glass, manufacturing method, continuous production device and application

PendingCN111827845ASimple processEasy to manufactureSolar heating energyDomestic cooling apparatusAdhesiveHigh productivity

The invention belongs to the technical field of hollow glass, and discloses suspended film hollow glass, a manufacturing method, a continuous production device and application. Spacer frames are bonded to corresponding peripheral positions of front glass and rear glass, the edge of the upper end of a suspended film is fixed between every two adjacent spacer frames in a bonding or welding or clamping manner, the lower end of each suspended film is fixedly connected with a bottom rod with the length matched with the width of the suspended film, and the bottom rods are fixed to the lower ends ofthe spacer frames. Cavities are formed between the suspended films and the front and rear glass and between the suspended films respectively. Spaces formed by the front glass, the rear glass and the outer sides of the spacer frames are fully covered with a structural adhesive, and the double-cavity or multi-cavity suspended film hollow glass is formed after solidification of the structural adhesive. The suspended film hollow glass can be conveniently manufactured by a simple process at a low cost and high productivity and has good heat insulation and sound insulation effects, the packaging width of the glass edge is equivalent to that of existing hollow glass, and the inherent breathing phenomenon of the hollow glass can be effectively relieved.

Owner:WEIHAI RUNFENG GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com