Taper blank-holding and deep-drawing stamping method

A deep drawing and tapered technology, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of difficult implementation, high cost, complex structure of stamping equipment with variable blank holder force method, etc., and achieve a convenient and reasonable solution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

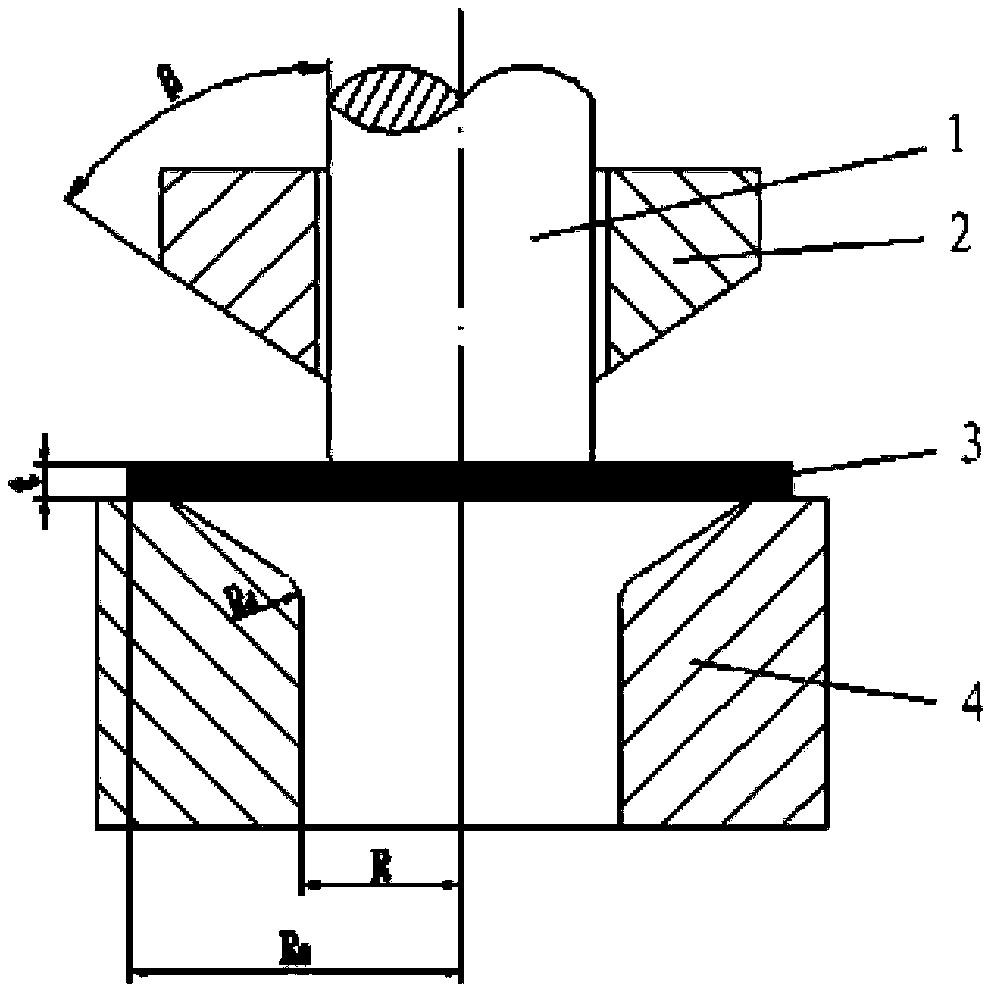

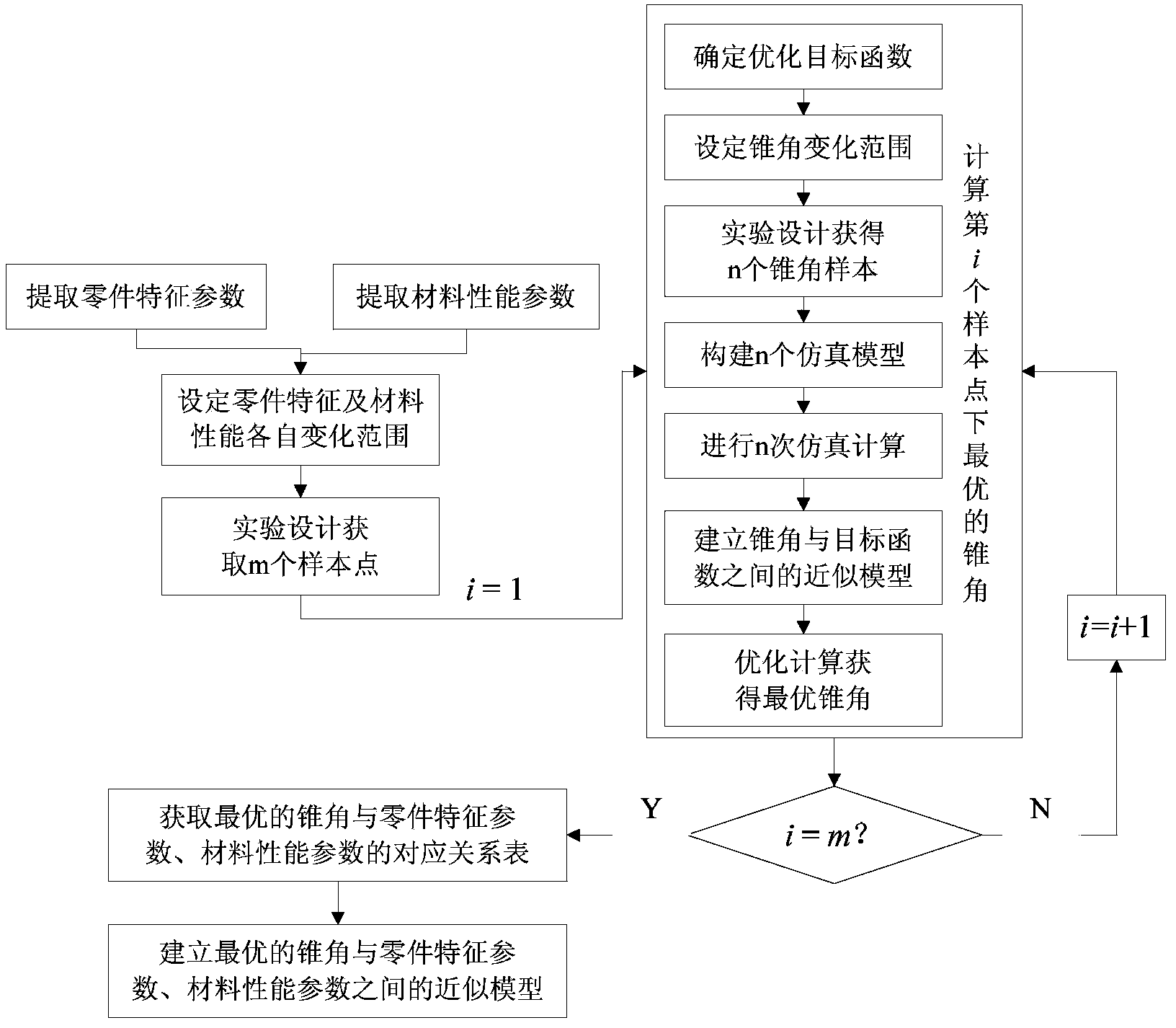

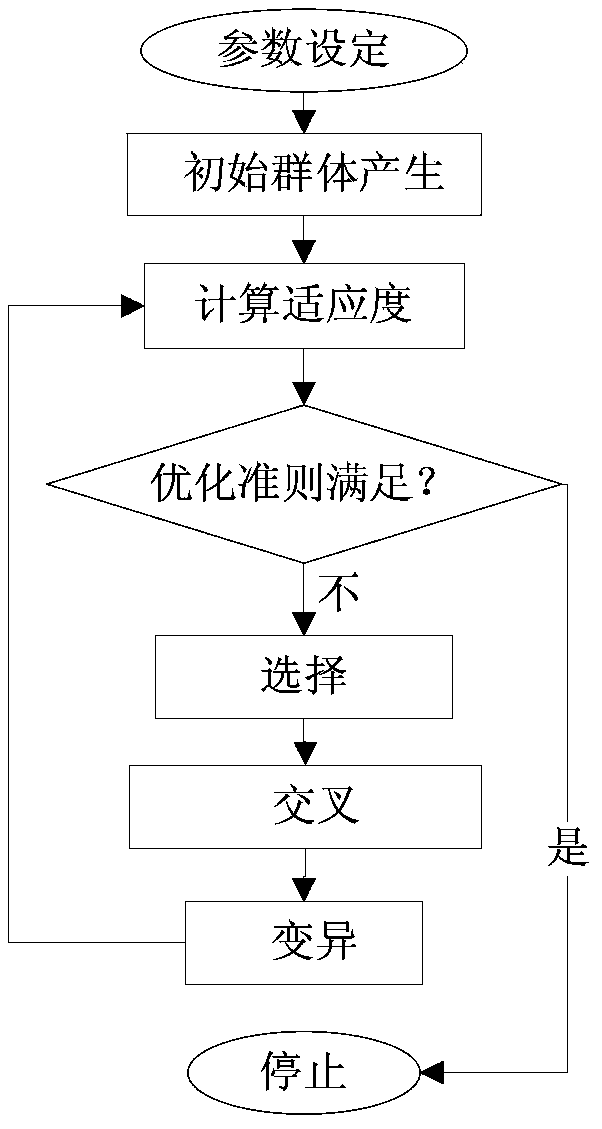

[0034] The specific implementation manner will be further described below in conjunction with the accompanying drawings. This embodiment is aimed at a tapered blank holder for a cylindrical part of an air conditioner compressor shell, and its stamping and stretching adopts a tapered blank holder, such as figure 1 As shown, 1 is a punch, 2 is a workpiece, 3 is a blank holder, and 4 is a die. The basic process is (see figure 2 ):

[0035] The first step is to manufacture a drawing die consisting of a punch, a die and a blank holder, wherein the outer diameter of the punch matches the inner diameter of the cylinder of the drawn part, and the die has a diameter that matches the outer diameter of the drawn part The upper end of the inner hole has a conical concave with a machining allowance, and the lower end of the blank holder has a conical head that matches the conical concave and has a machining allowance; it will be processed after the optimal cone angle value is determined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com