Patents

Literature

312results about How to "Solve the problem of light leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

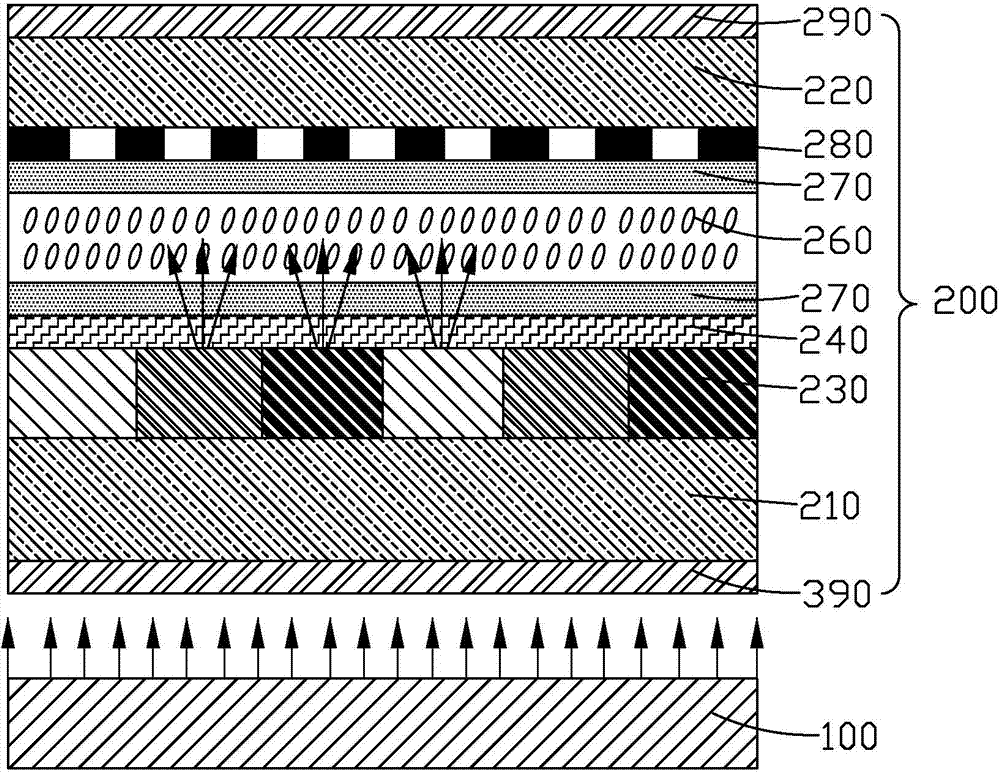

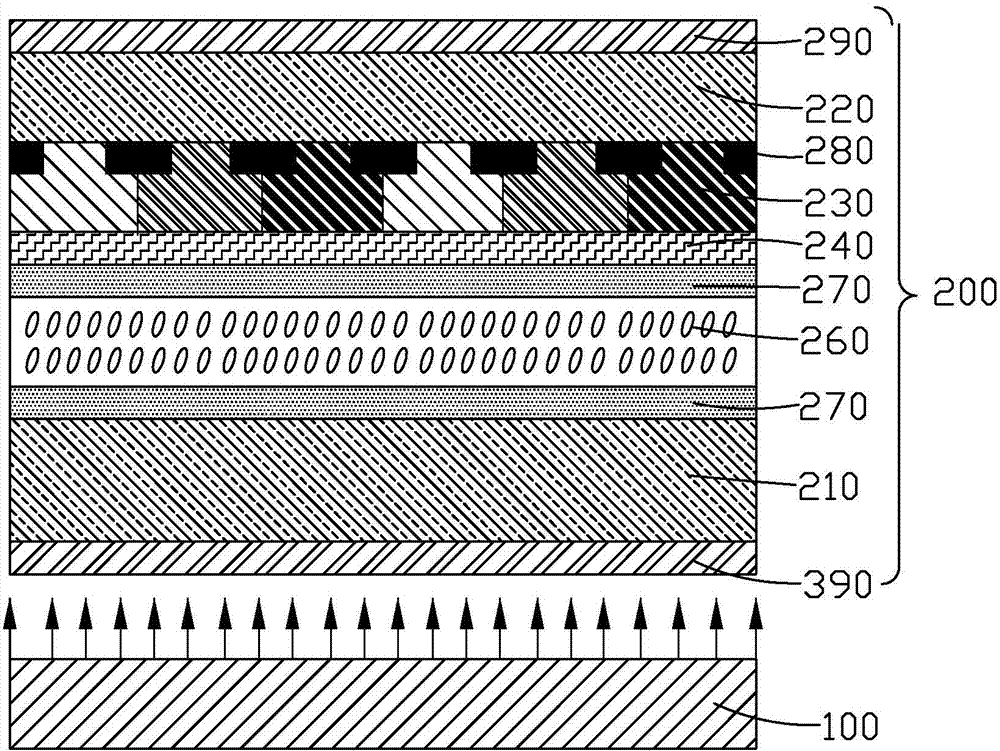

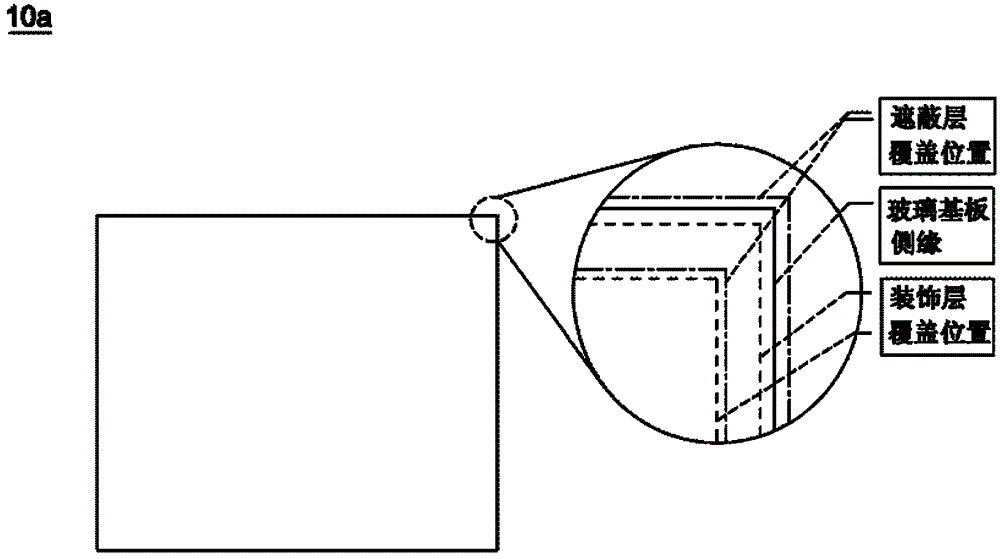

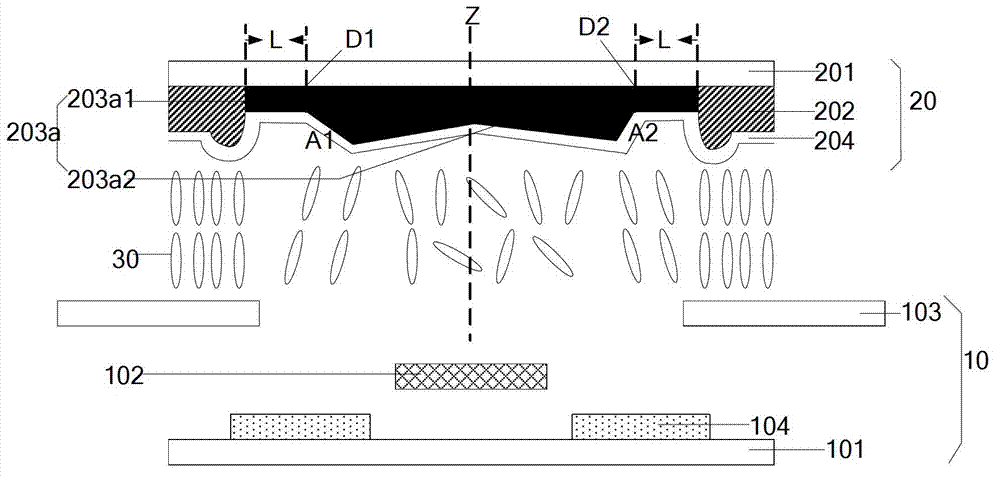

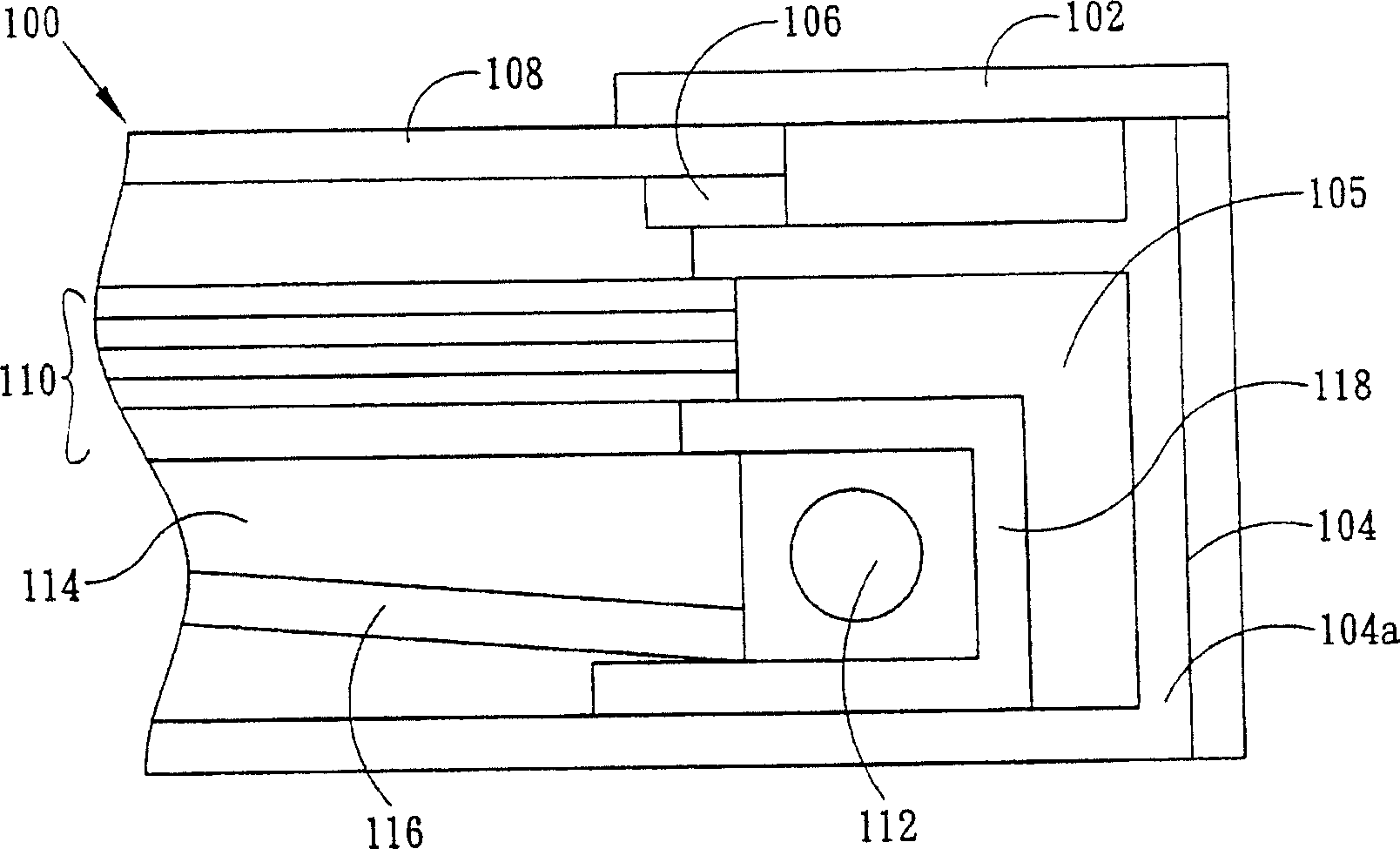

Display panel and display device

ActiveCN103926739ASolve the problem of light leakageQuality improvementNon-linear opticsIdentification meansDisplay deviceEngineering

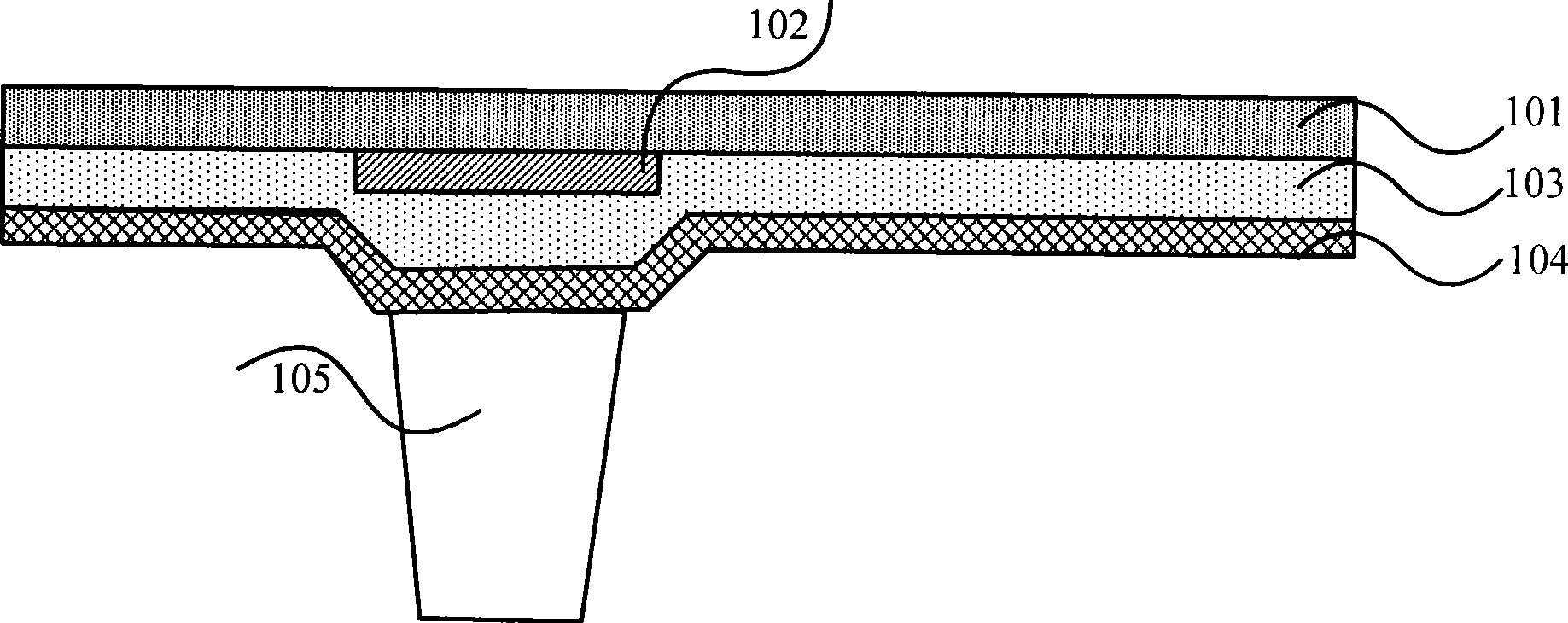

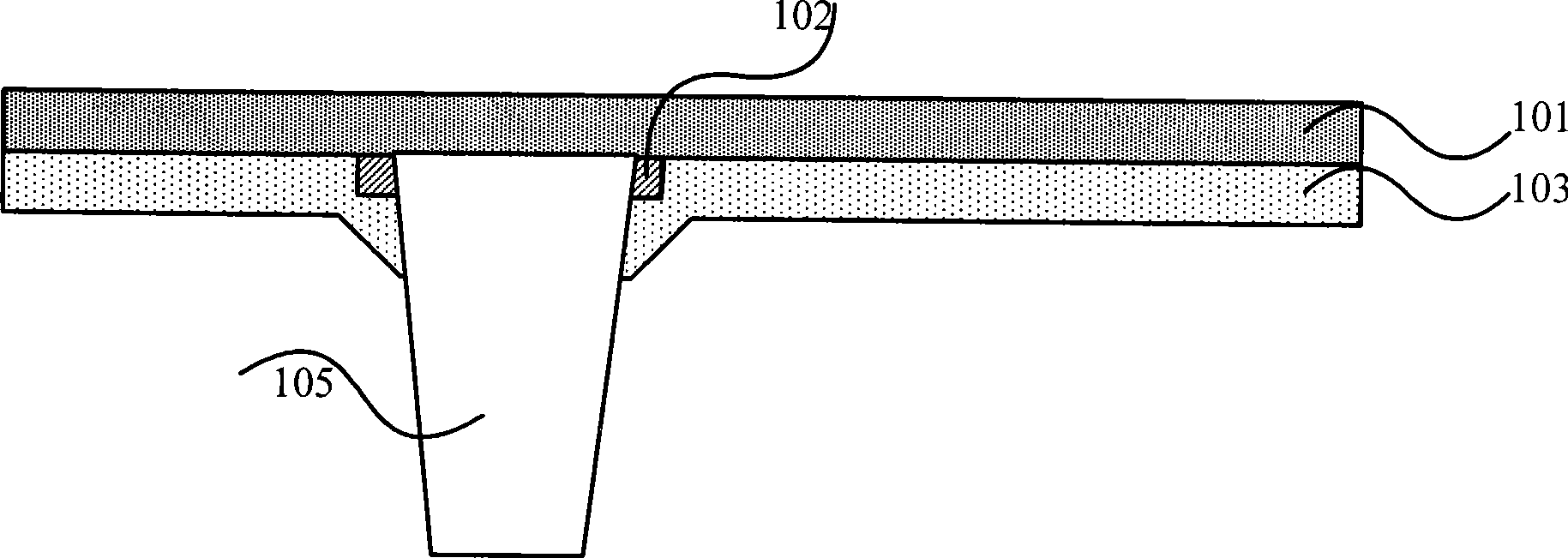

The invention provides a display panel and a display device. The display panel comprises a first substrate and a second substrate which are arranged oppositely. A first black matrix and a second black matrix are formed on one face, facing the second substrate, of the first substrate, the first black matrix is positioned in a display area, the second black matrix is positioned in a non-display area, the first black matrix and the second black matrix are enabled to be disconnected by arranging a first slit between the same, a light shading layer and a light absorbing layer are sequentially arranged on one face, facing the first substrate, of the second substrate in a manner of being from far to near relatively to the first substrate, and shadows, of the light absorbing layer and the light shading layer, on the first substrate along a direction perpendicular to the first substrate cover the first slit. By the display panel and the display device, display picture quality can be improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

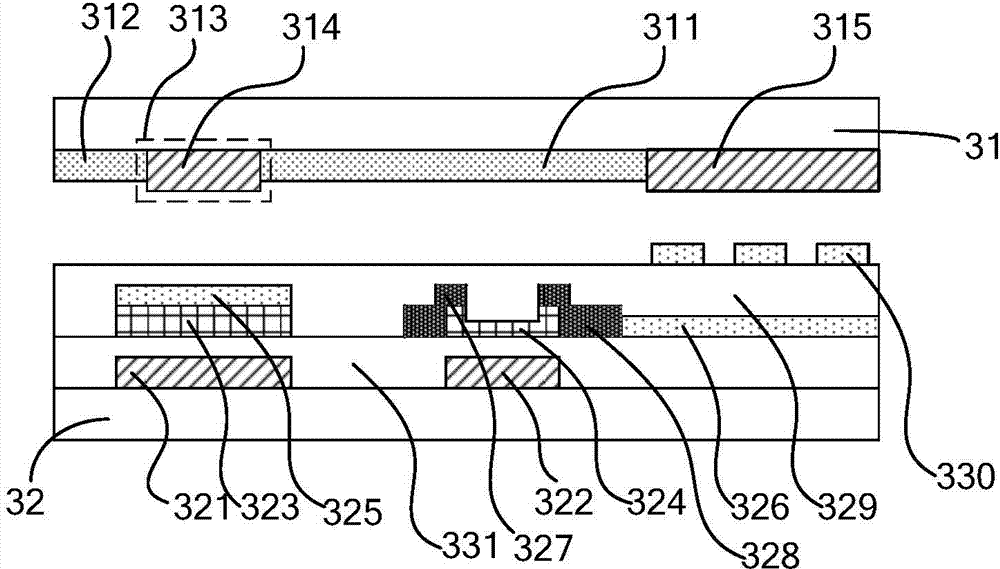

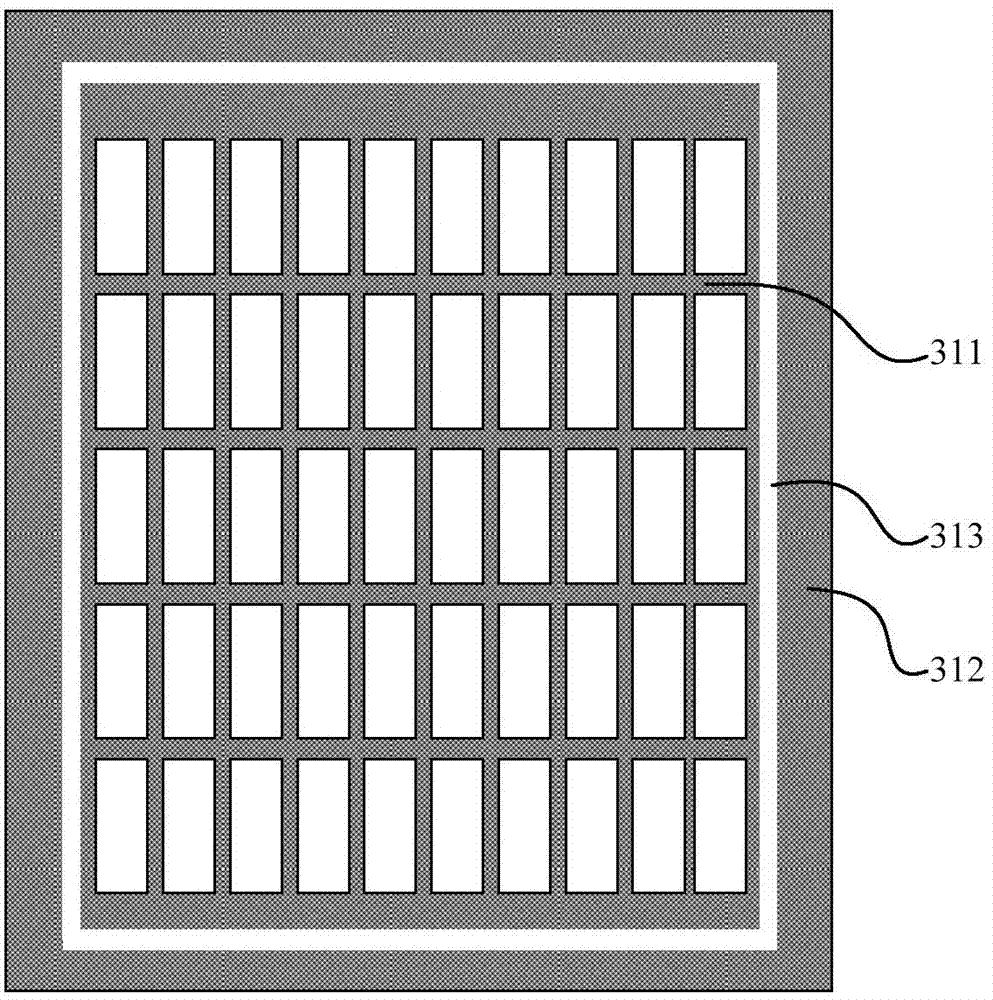

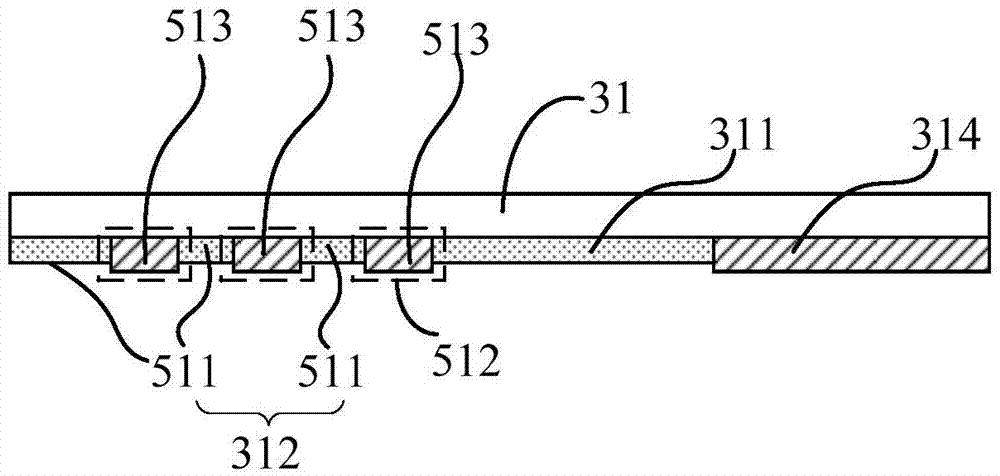

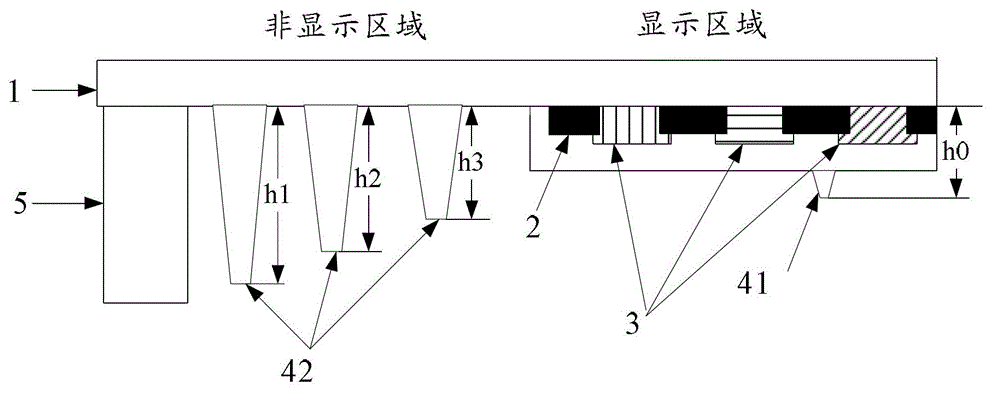

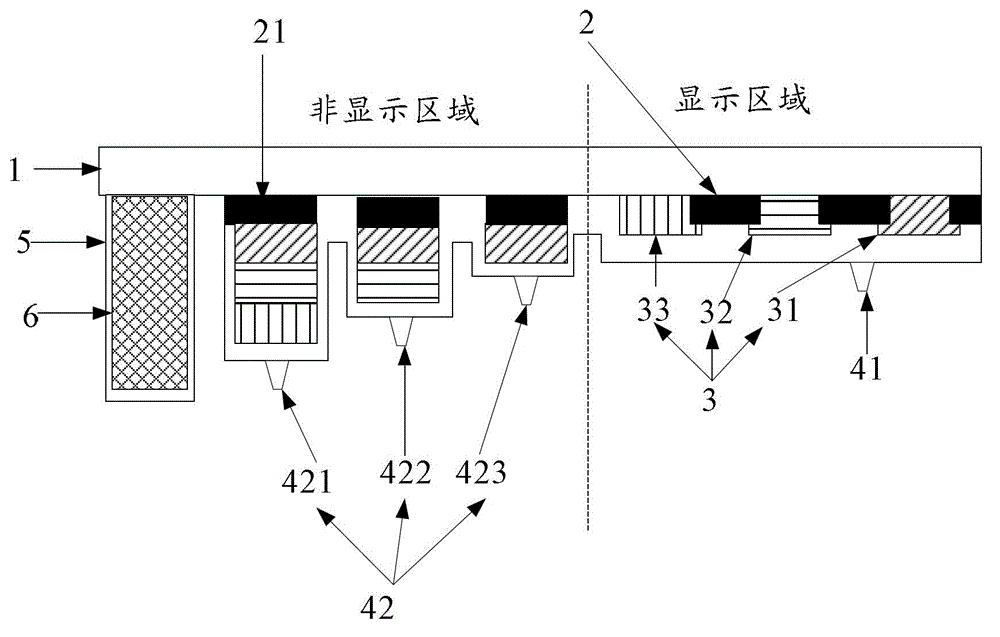

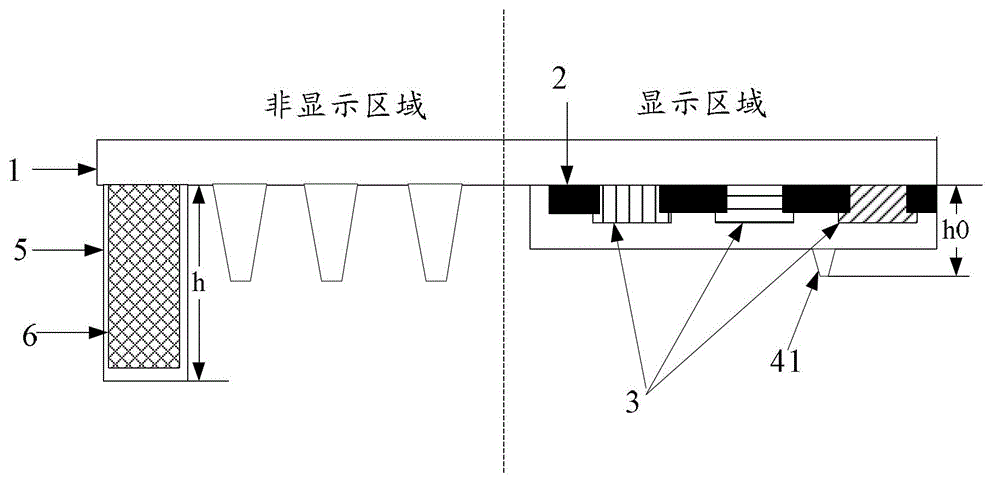

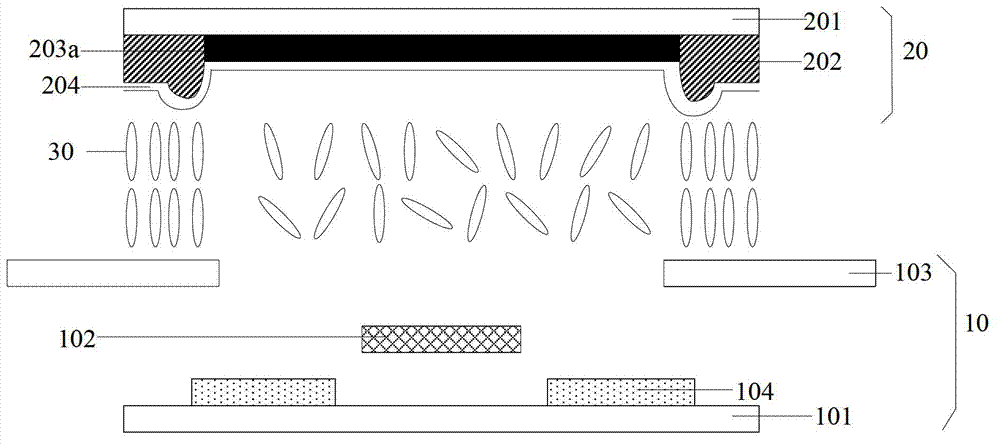

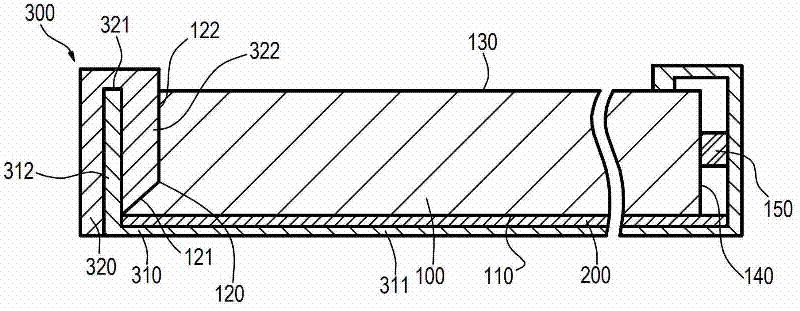

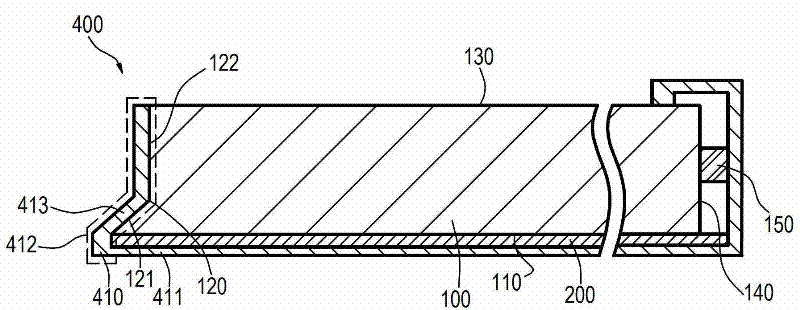

Color film substrate as well as manufacturing method and display device thereof

ActiveCN103149729AIncrease heightImprove display qualityNon-linear opticsLiquid-crystal displayColor film

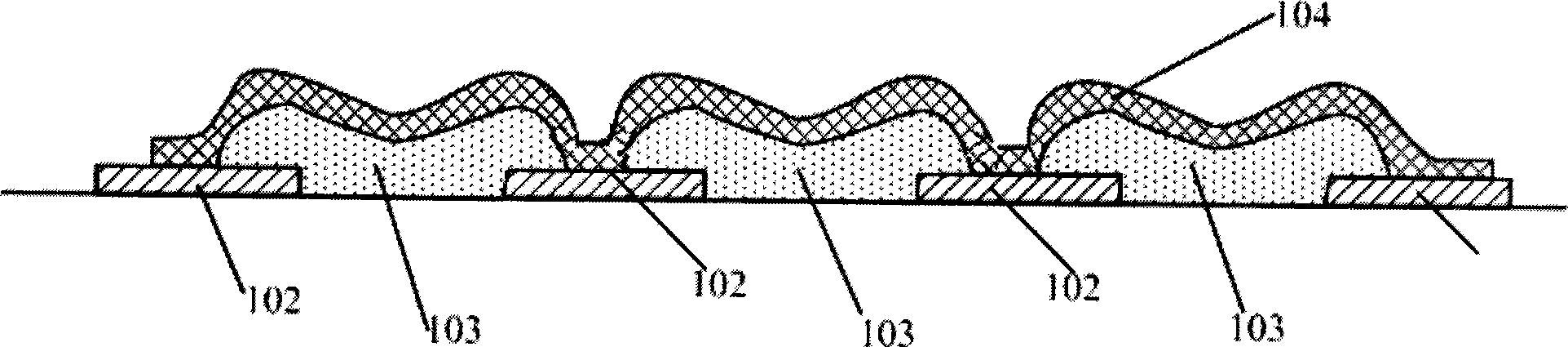

The embodiment of the invention provides a color film substrate as well as a manufacturing method and a display device thereof, relates to the technical field of display, can solve the problem of light leakage at the periphery of a display panel, and improves the display quality of liquid crystal display equipment. The color film substrate comprises a transparent substrate as well as black matrixes and color films which are arranged on the transparent substrate, wherein a display area spacer is arranged in the display area of the color film substrate; at least one type of boundary spacer is arranged in the non-display area of the color film substrate; and the height value from the top end of the at least one type of boundary spacer to the inner surface of the transparent substrate is greater than that from the top end of the display area spacer to the inner surface of the transparent substrate.

Owner:BOE TECH GRP CO LTD

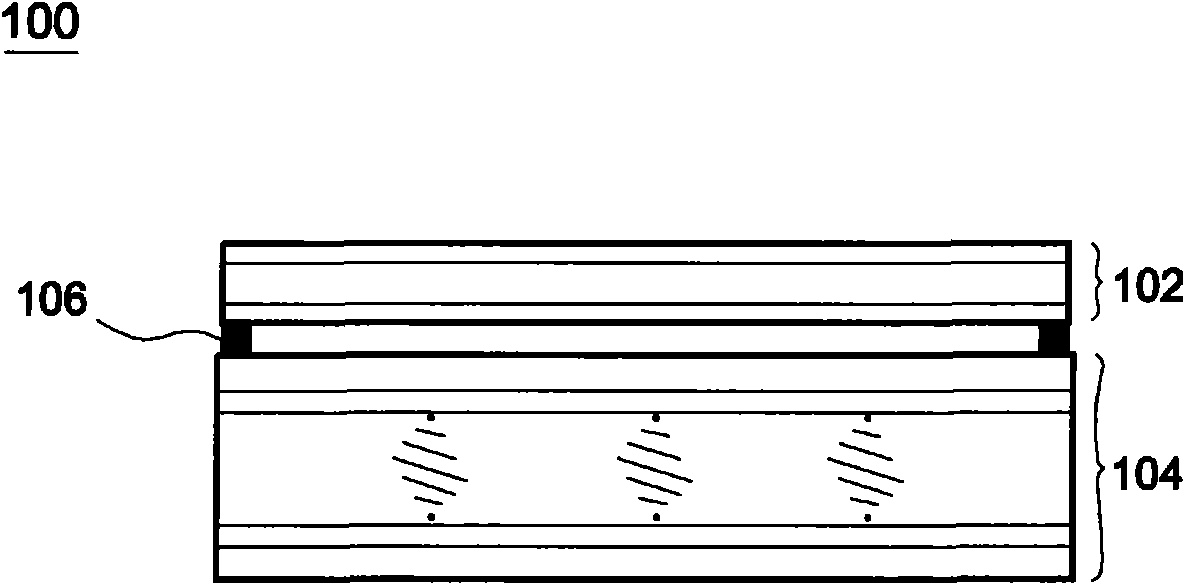

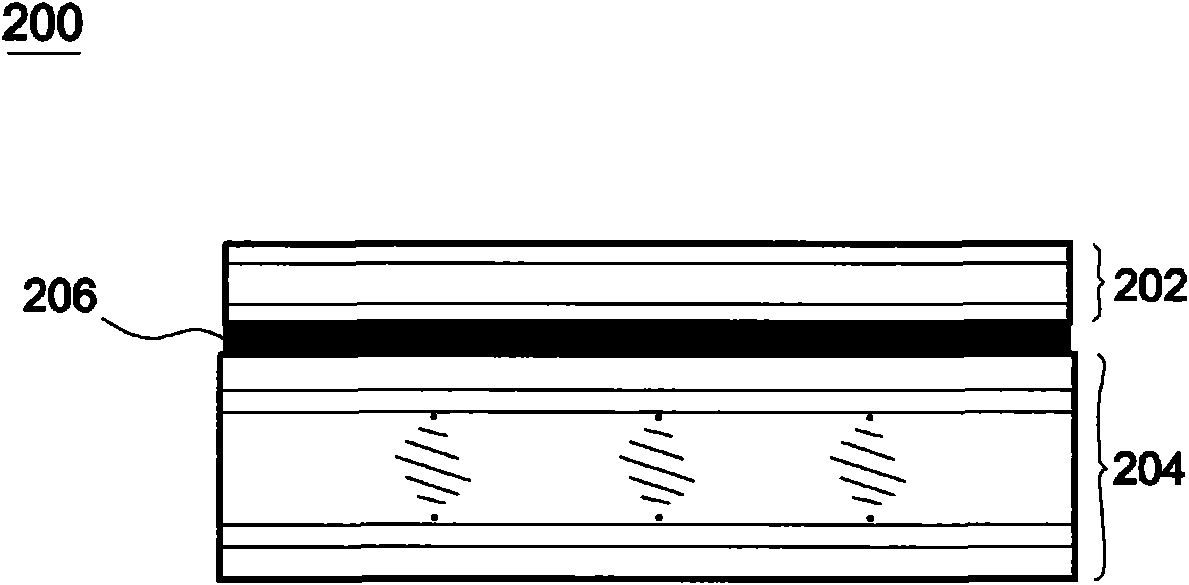

Liquid crystal display

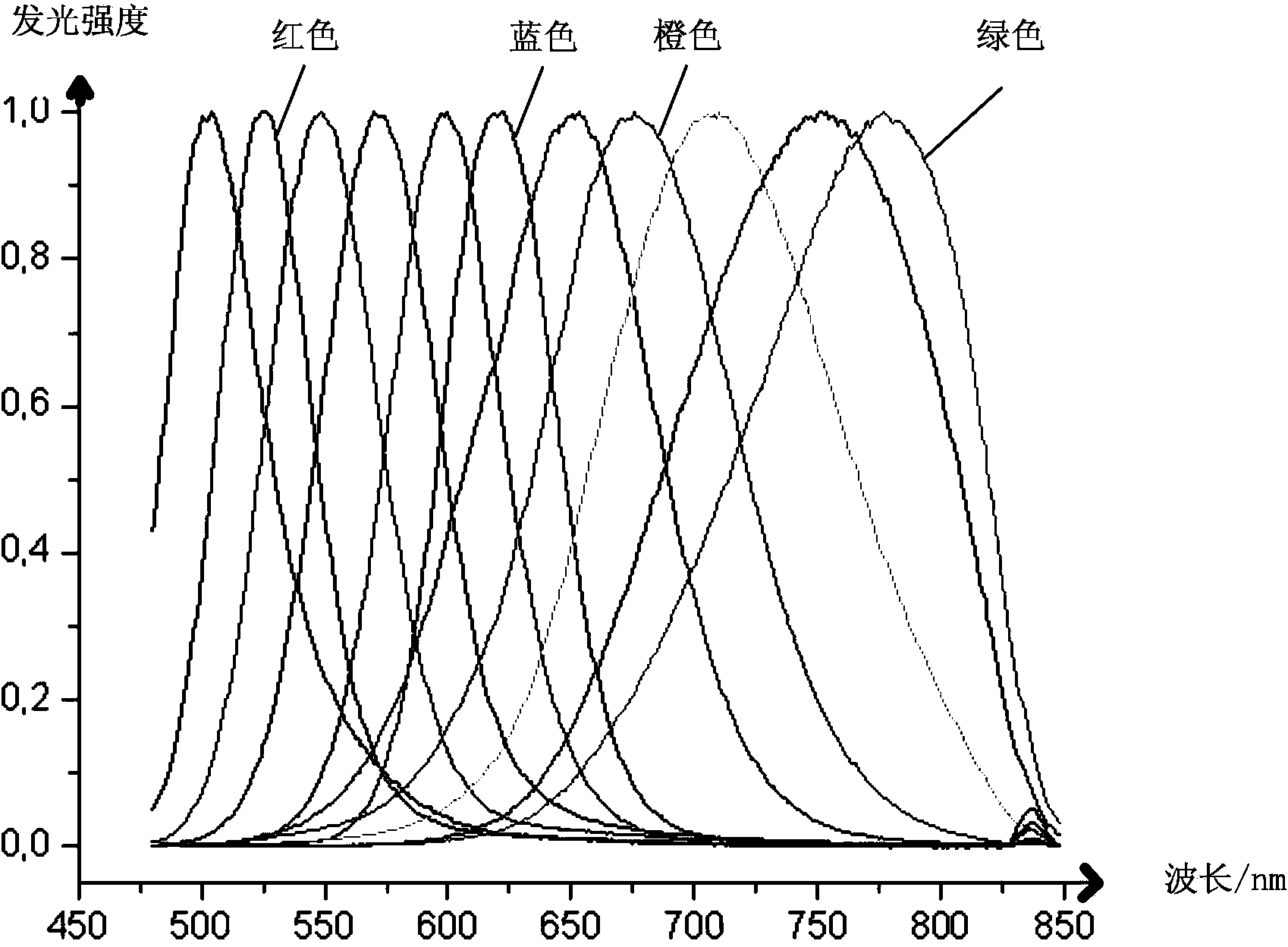

ActiveCN104765187ASolve the problem of light leakageIncrease contrastNon-linear opticsLiquid-crystal displayOrganic dye

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

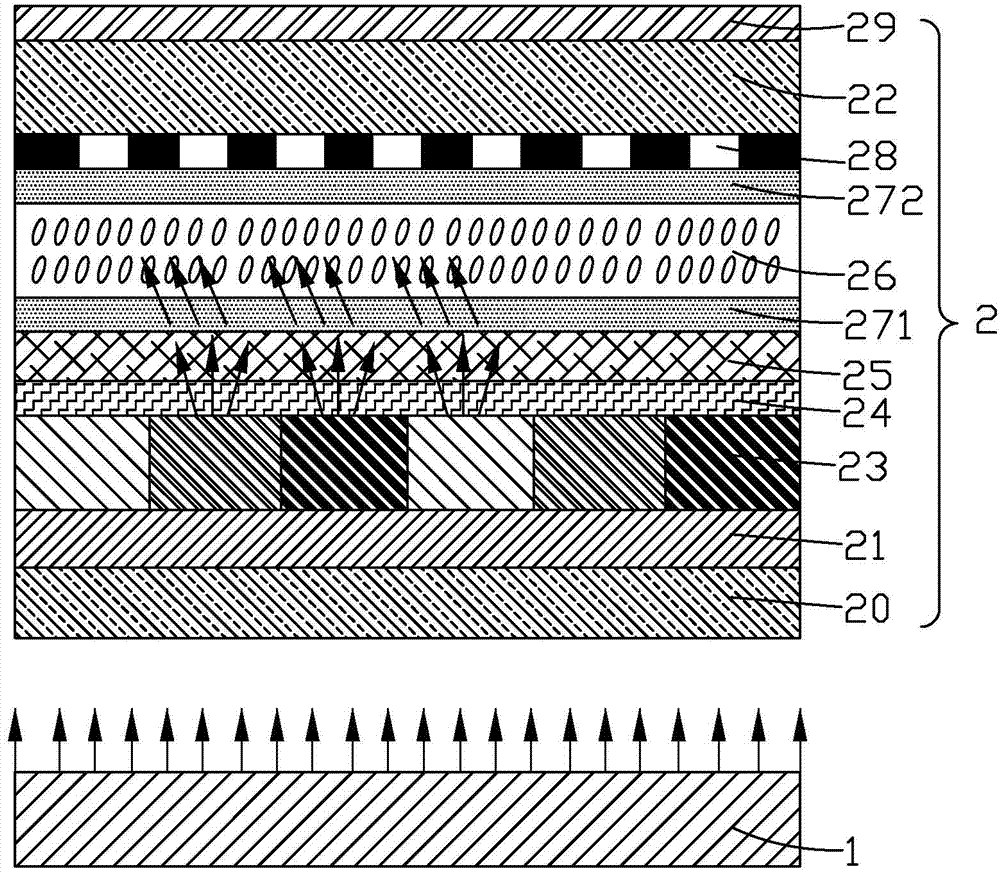

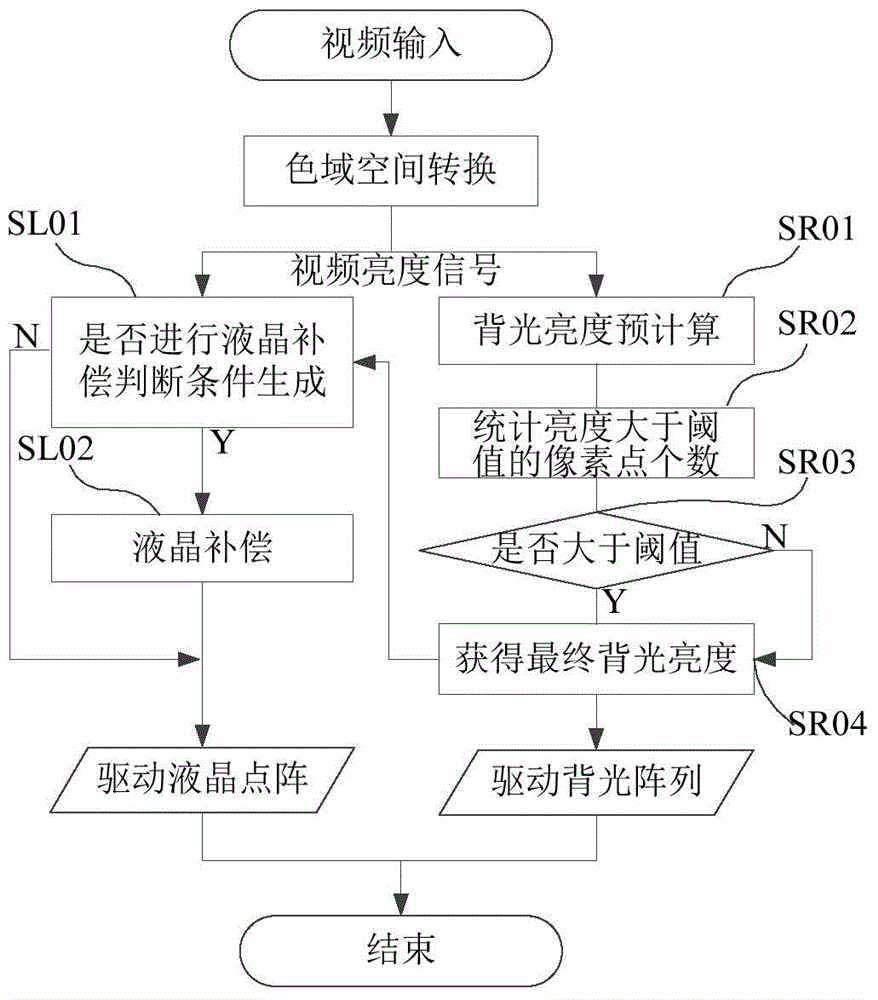

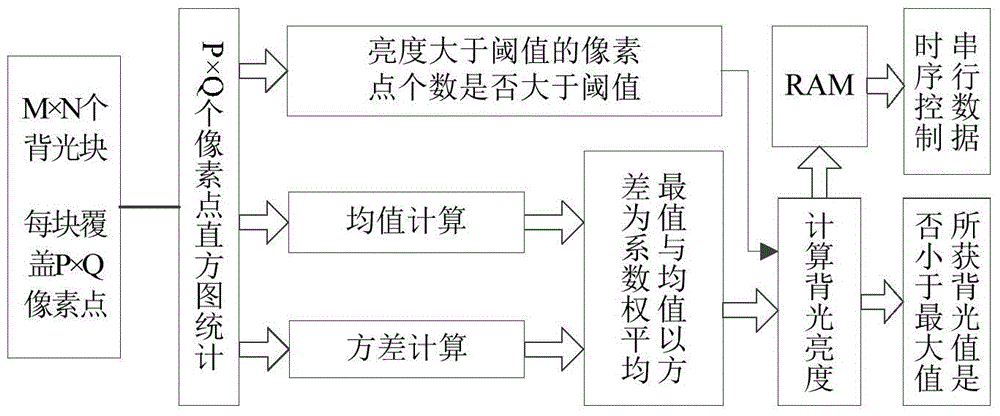

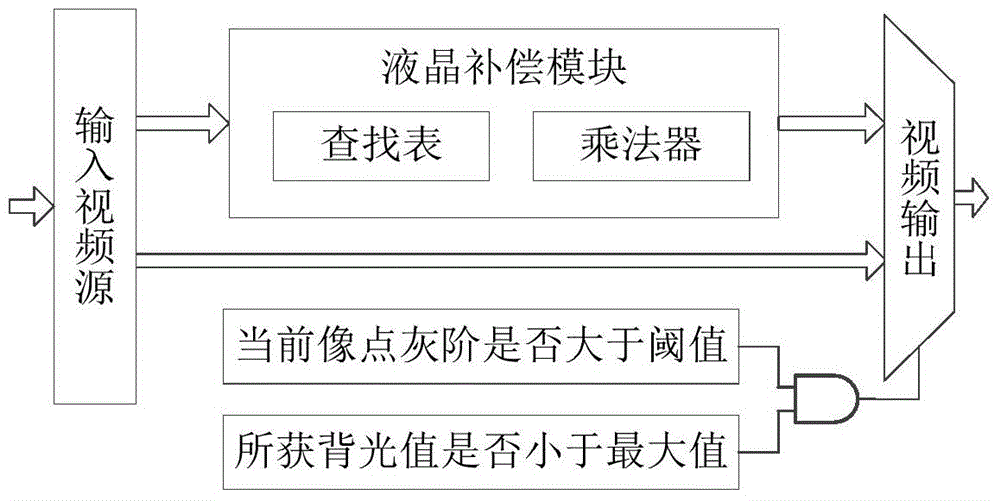

Self-adapting dynamic backlight control system and method based on image content

InactiveCN105047140ASolve the problem of light leakageImprove static contrastStatic indicating devicesDistortionSelf adaptive

The invention discloses a self-adapting dynamic backlight control system and method based on image content. According to image content, a plurality of backlight regions are control independently, therefore the effects are achieved that power consumption is lowered and frame contrast is raised. A video stream is divided into two paths: one path is used for calculating backlight brightness, and the other path carries out liquid crystal compensation. In the backlight brightness calculation path, a histogram statistic module carries out statistics of image brightness, weighted average of the maximum value and the average value of the corresponding regions is carried out and backlight brightness information of the current region is obtained. Through a set threshold determination condition, the brightness is adjusted, final brightness information is obtained, adjustment by an output control module is carried out, and output through a serial data flow is carried out. In addition, because an image content distortion phenomenon can happen after backlight modulation, compensation of the original video signal is carried out according to the obtained backlight brightness information in the liquid crystal compensation path, and screening display as a final video signal is carried out.

Owner:XI AN JIAOTONG UNIV

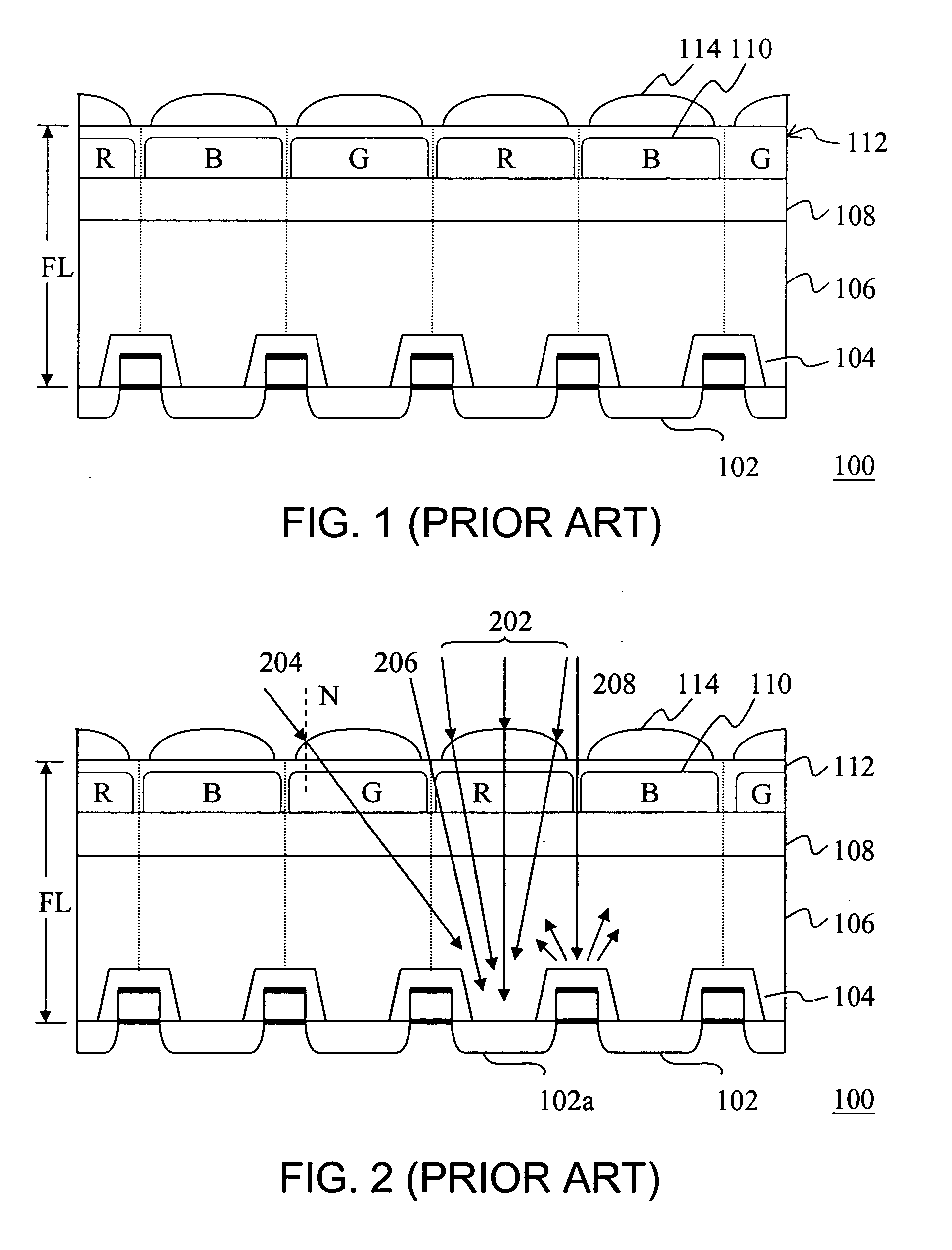

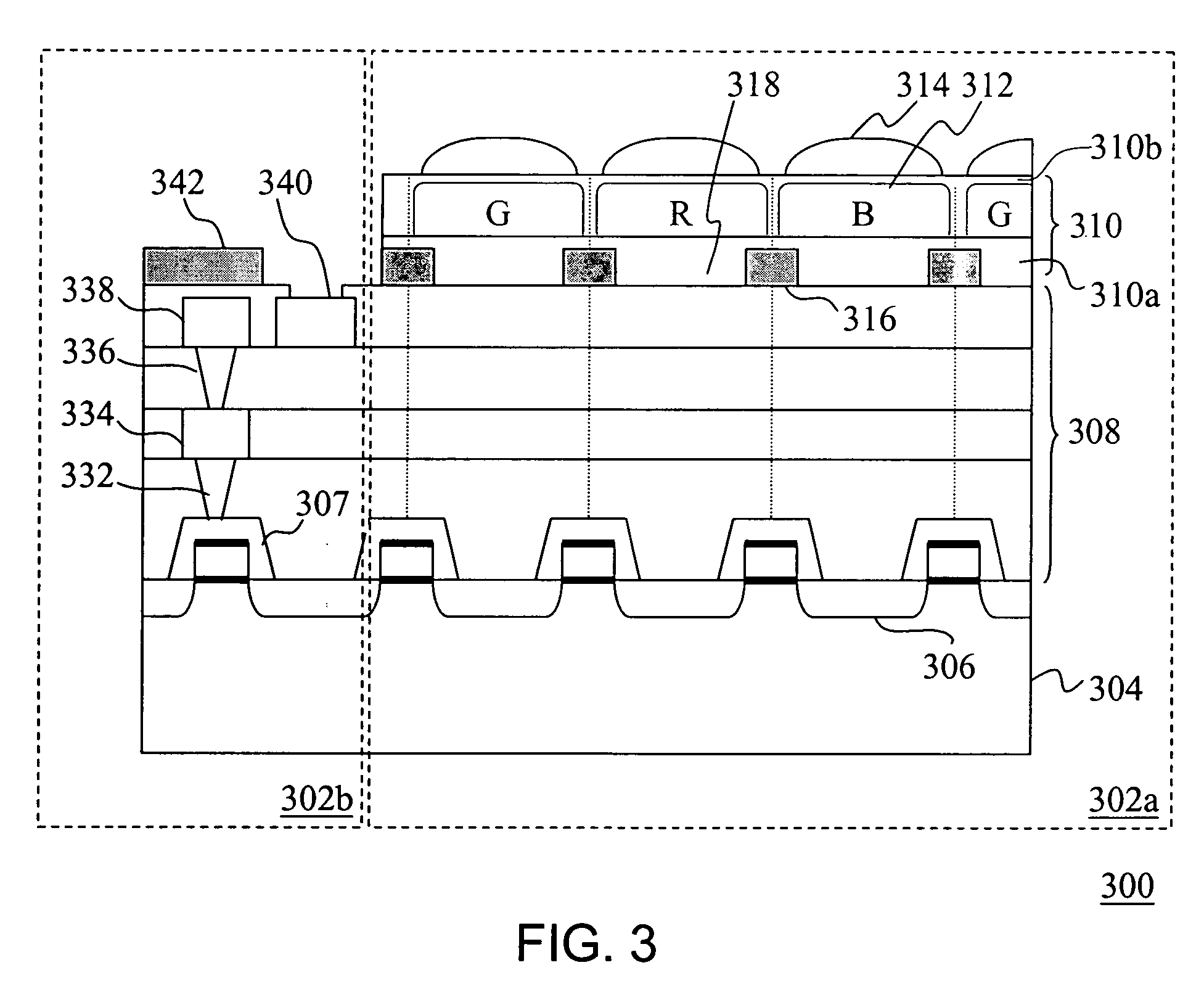

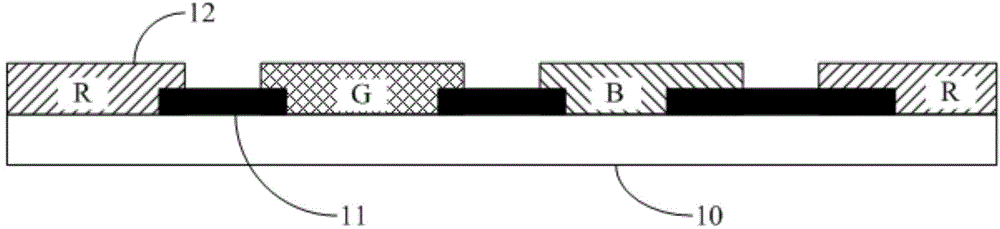

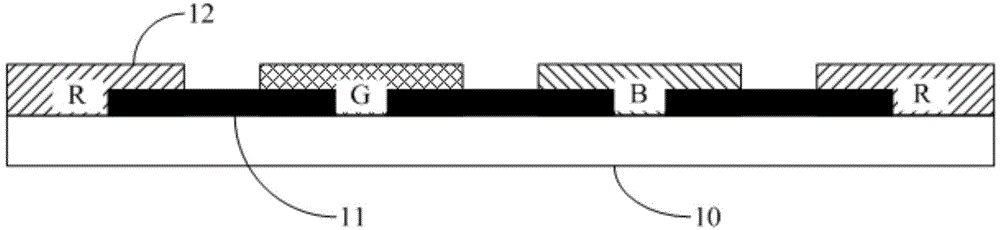

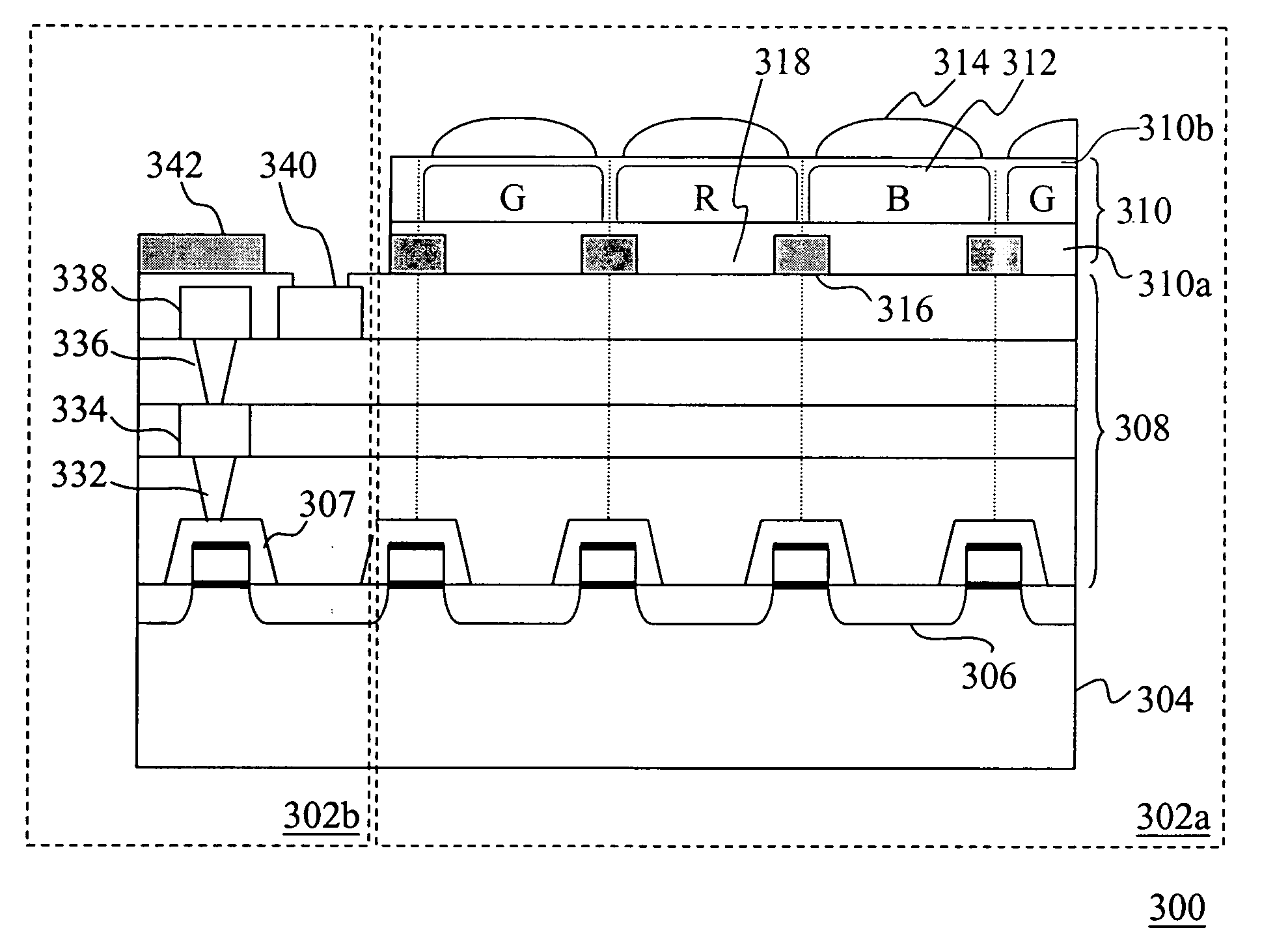

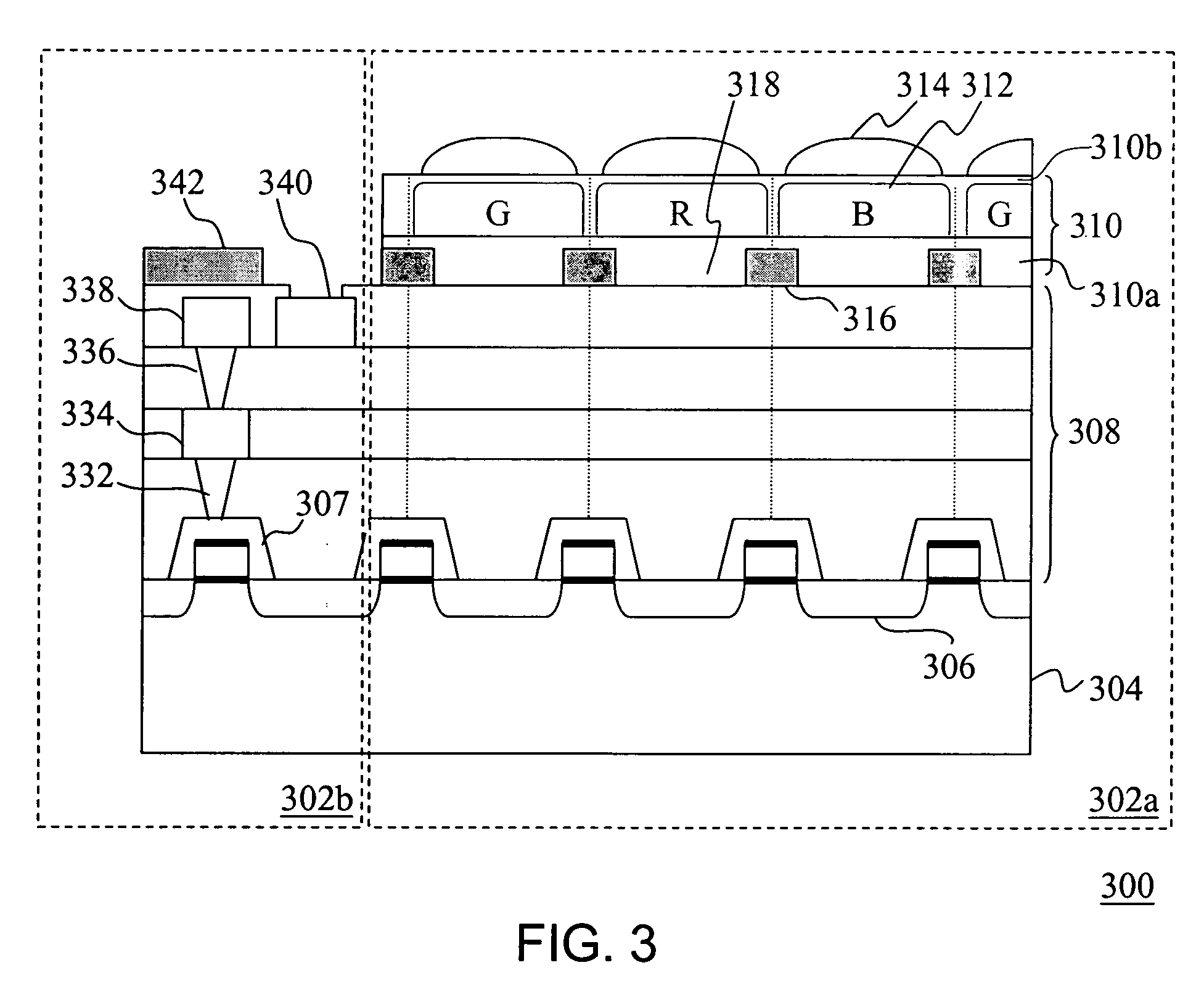

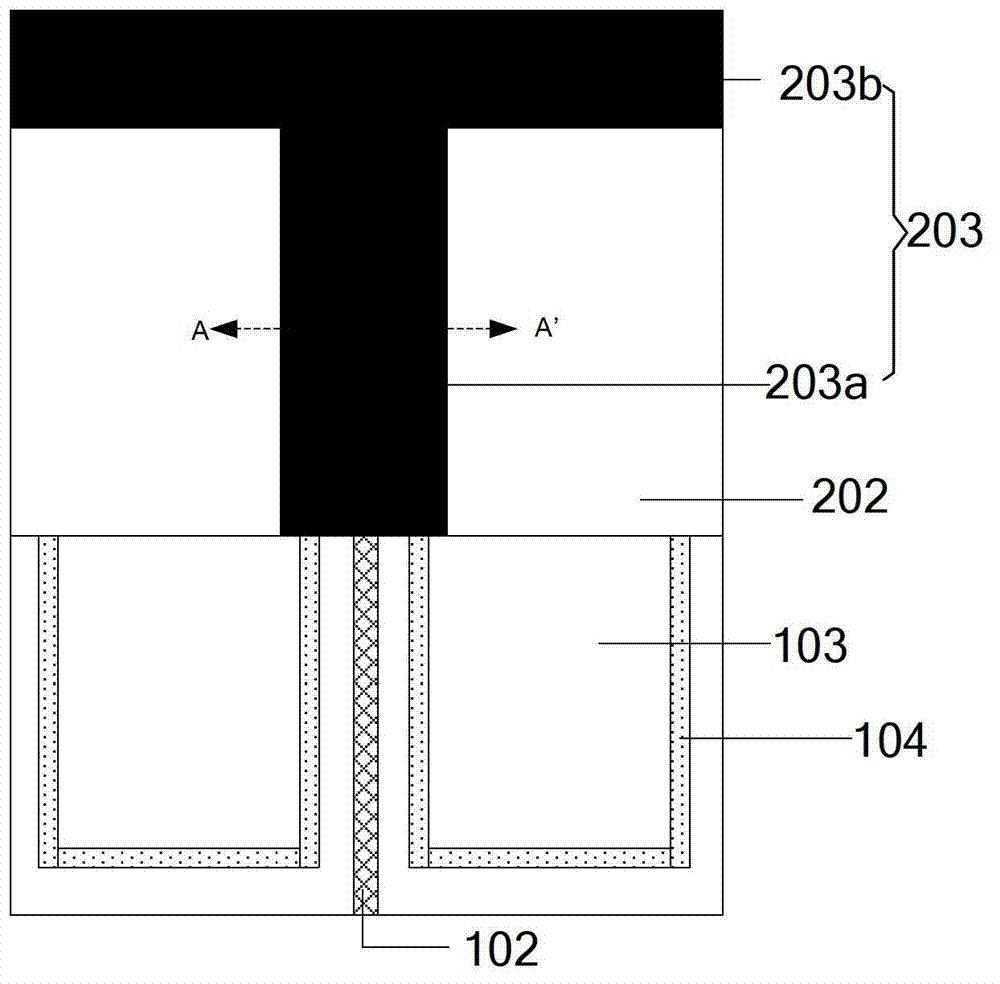

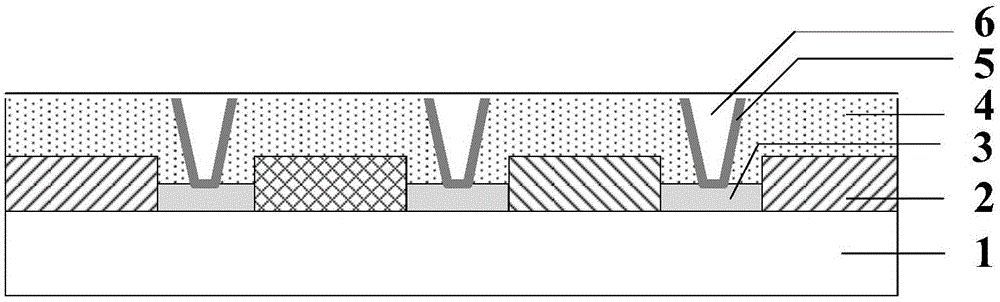

Image sensor device with color filters and manufacturing method thereof

ActiveUS7180044B2Contrasting colorsHigh sensitivitySolid-state devicesMaterial analysis by optical meansDielectric layerMicrolens

An image sensor device including a substrate, a plurality of photo sensors, a dielectric layer, a planar layer, a plurality of color filters, a plurality of microlenses, and a shield layer is provided. The photo sensors are disposed in the substrate, and the dielectric layer is disposed over the photo sensors and the substrate. The planar layer is disposed over the dielectric layer. The color filters are disposed in the planar layer, wherein each of the color filters is disposed over each of the photo sensors. The microlenses are disposed over the planar layer, wherein each of the microlenses is disposed over each of the color filter. The shield layer including a plurality of openings is disposed in the planar layer and is disposed under or over the color filters, wherein each of the openings is disposed over each of the color filters.

Owner:MARLIN SEMICON LTD

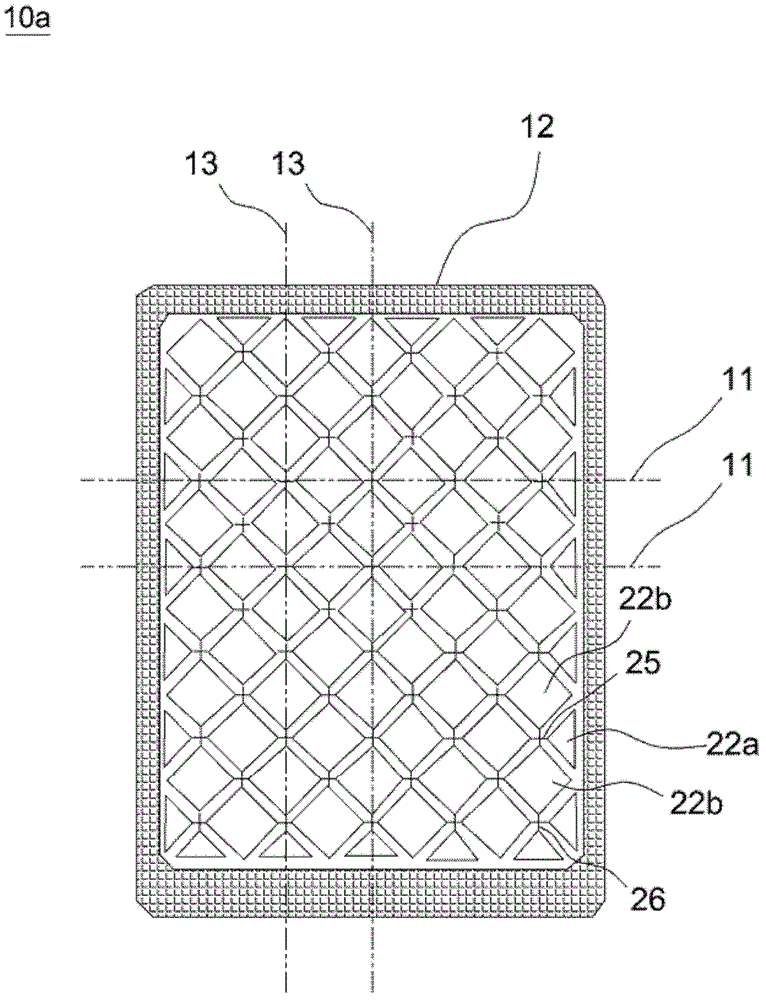

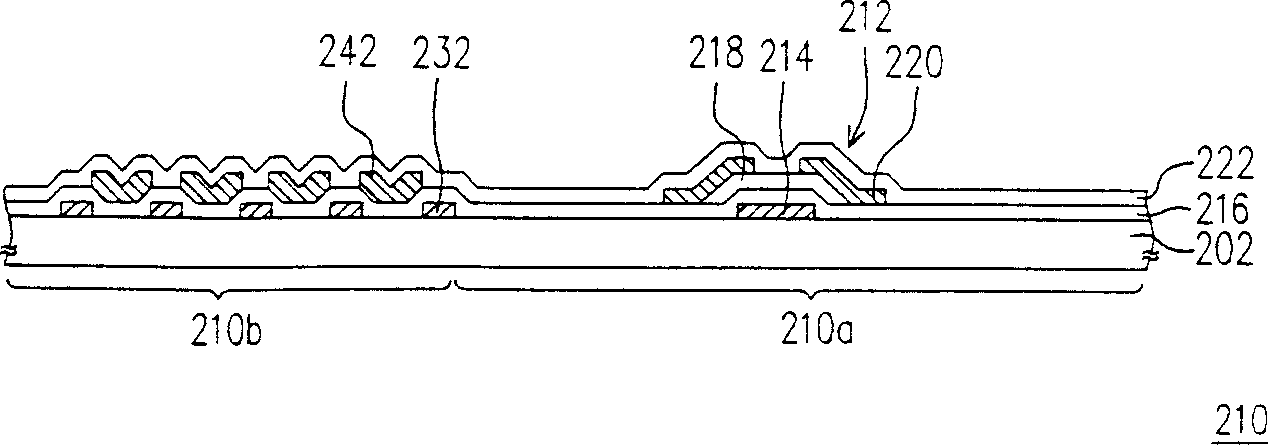

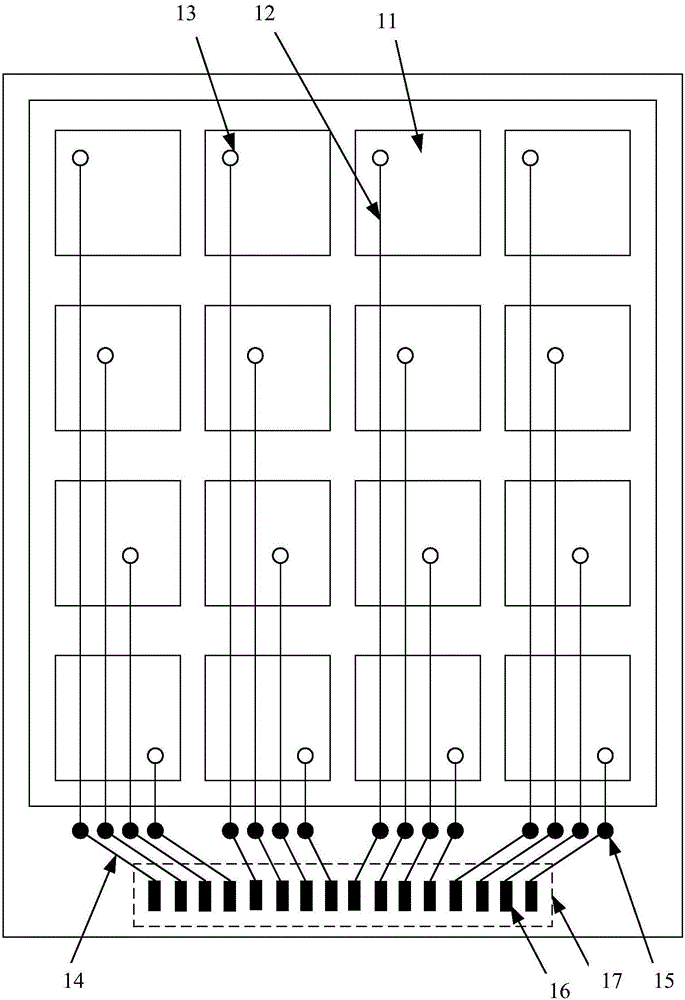

Touch displaying device and substrate

ActiveCN104238222ASolve the problem of light leakageSolve the display effectNon-linear opticsDisplay deviceEngineering

The invention provides a touch displaying device and substrate. A plurality of data lines, a plurality of gate lines, a plurality of pixel electrodes, a plurality of common electrodes and covering electrodes are included. The gate lines and the data lines are in insulation crossing. In the extending direction of the gate lines and / or the data lines, a carving seam is formed between two adjacent common electrodes. The covering electrodes are placed above the carving seams. At a displaying stage, common voltage is applied to the covering electrodes. The projection of the carving seams on the touch displaying substrate and the projection of the data lines and / or the gate lines on the touch displaying substrate comprise coinciding parts. The projection of the covering electrodes on the touch displaying substrate at least covers the data lines and / or the gate lines of the coinciding parts. Accordingly, voltage fluctuation on the data lines and / or scanning lines can be screened through the covering electrodes, and the problems of light leakage and poor image displaying effect caused by voltage fluctuation are solved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

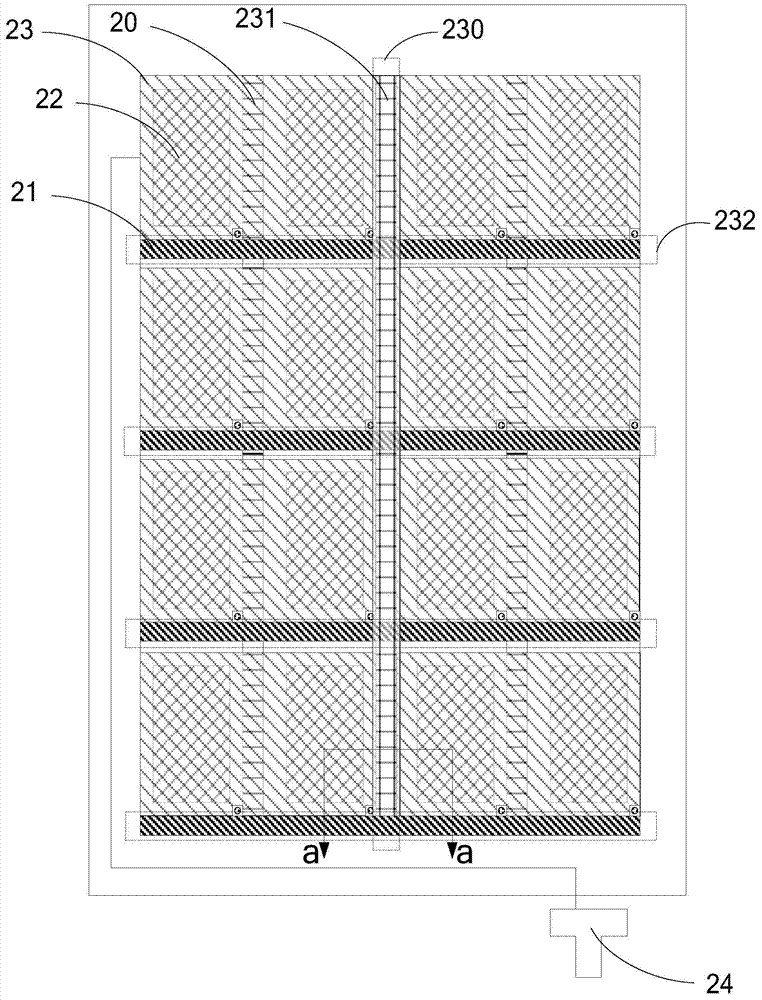

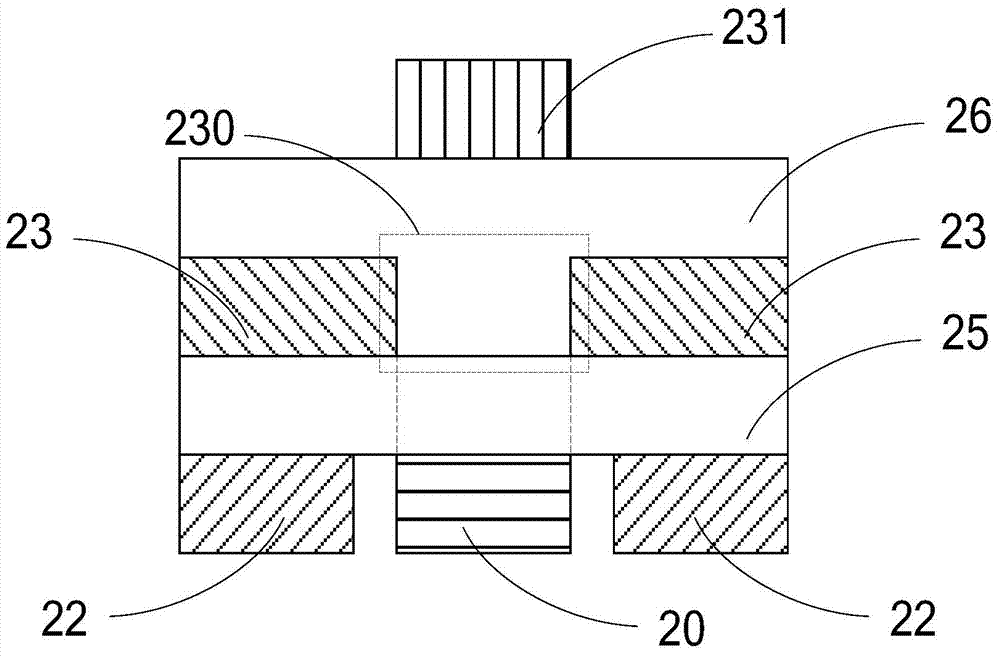

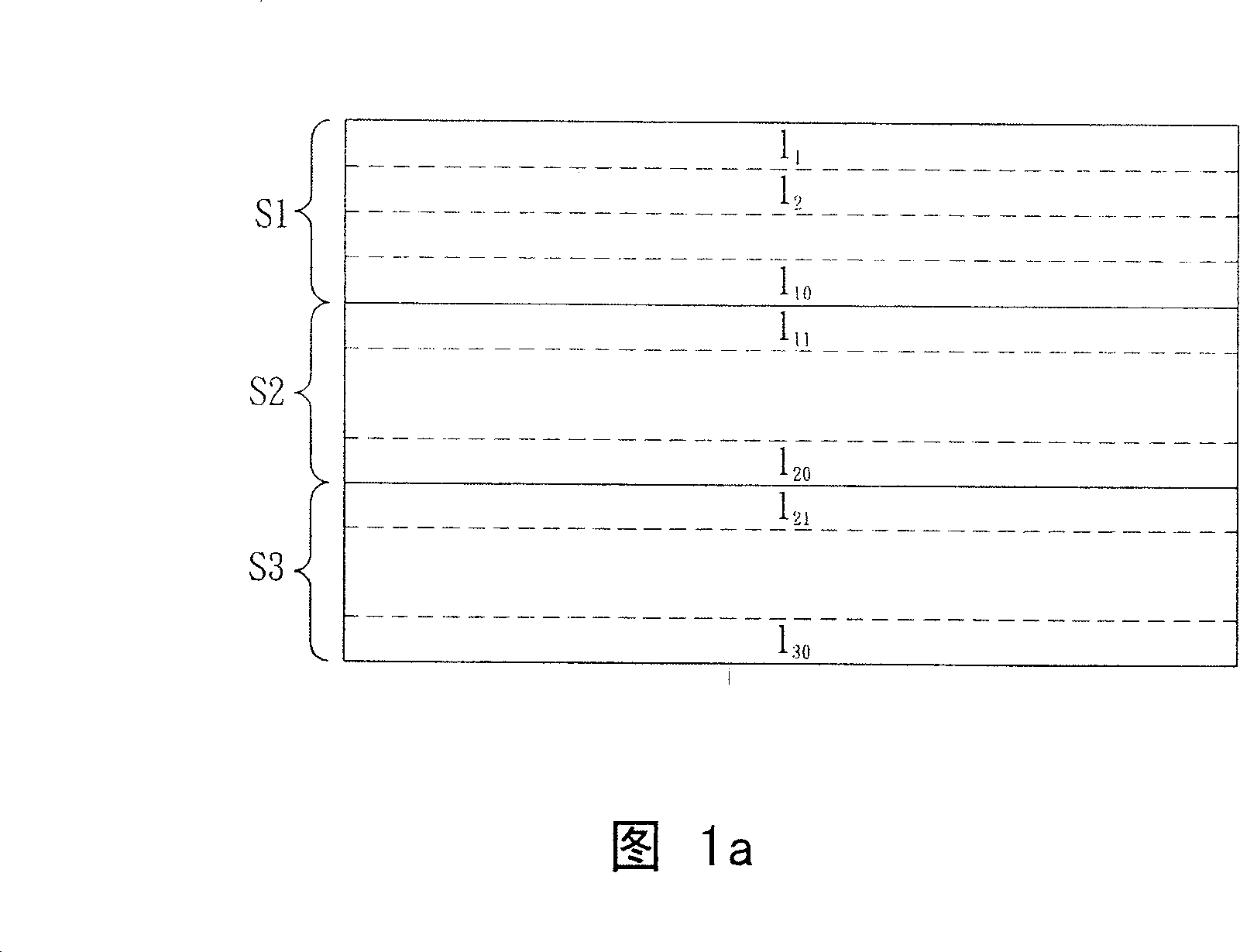

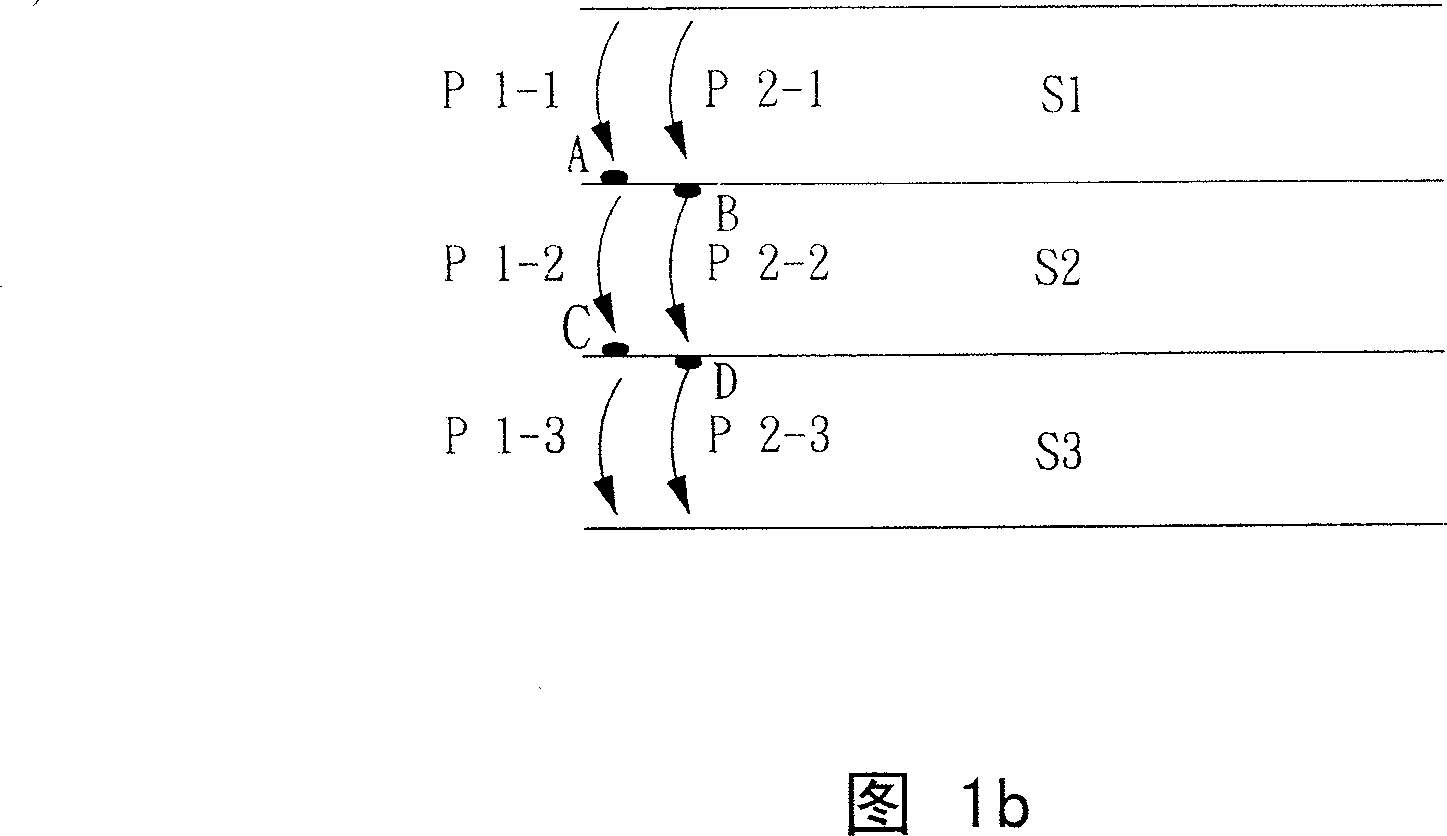

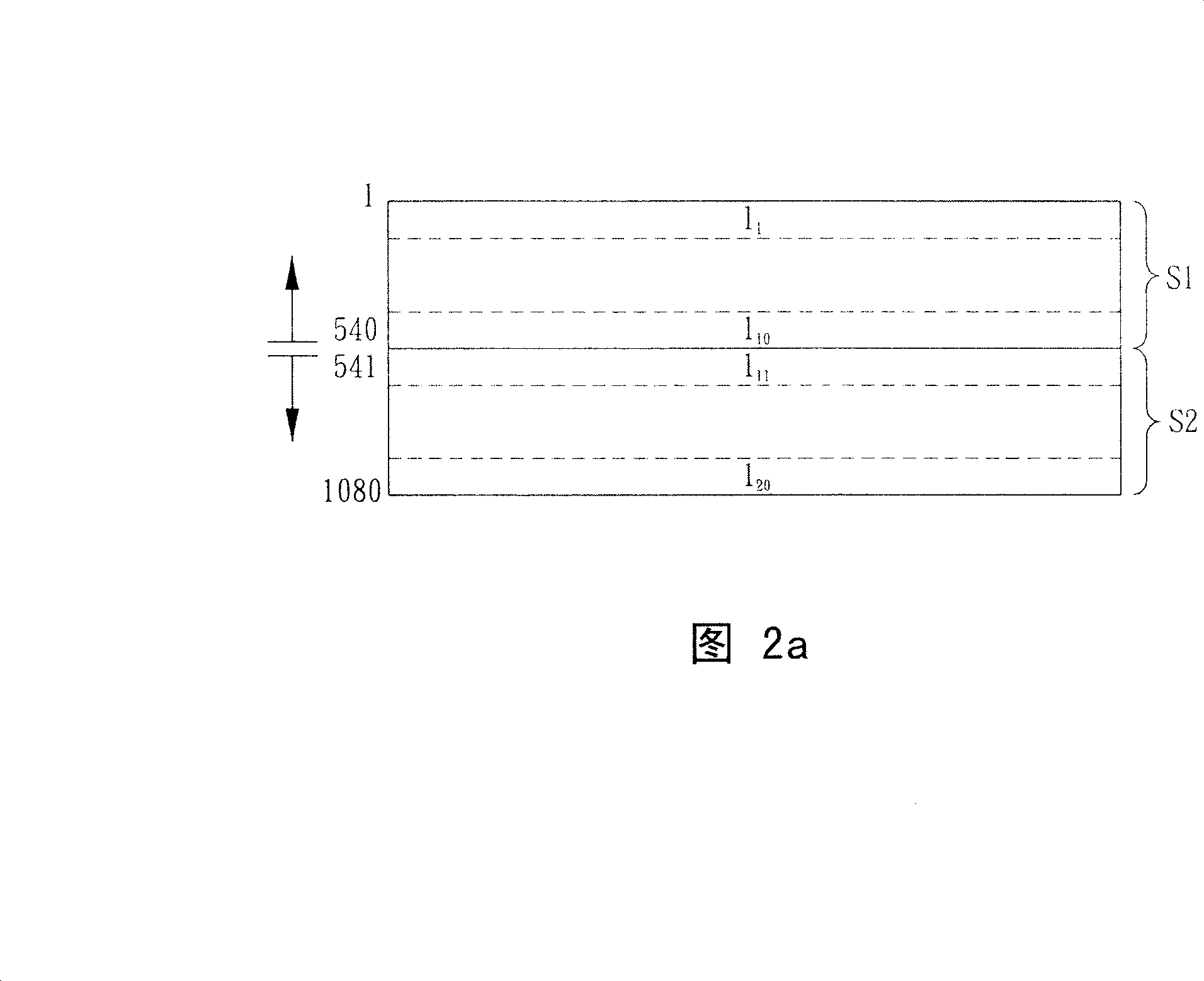

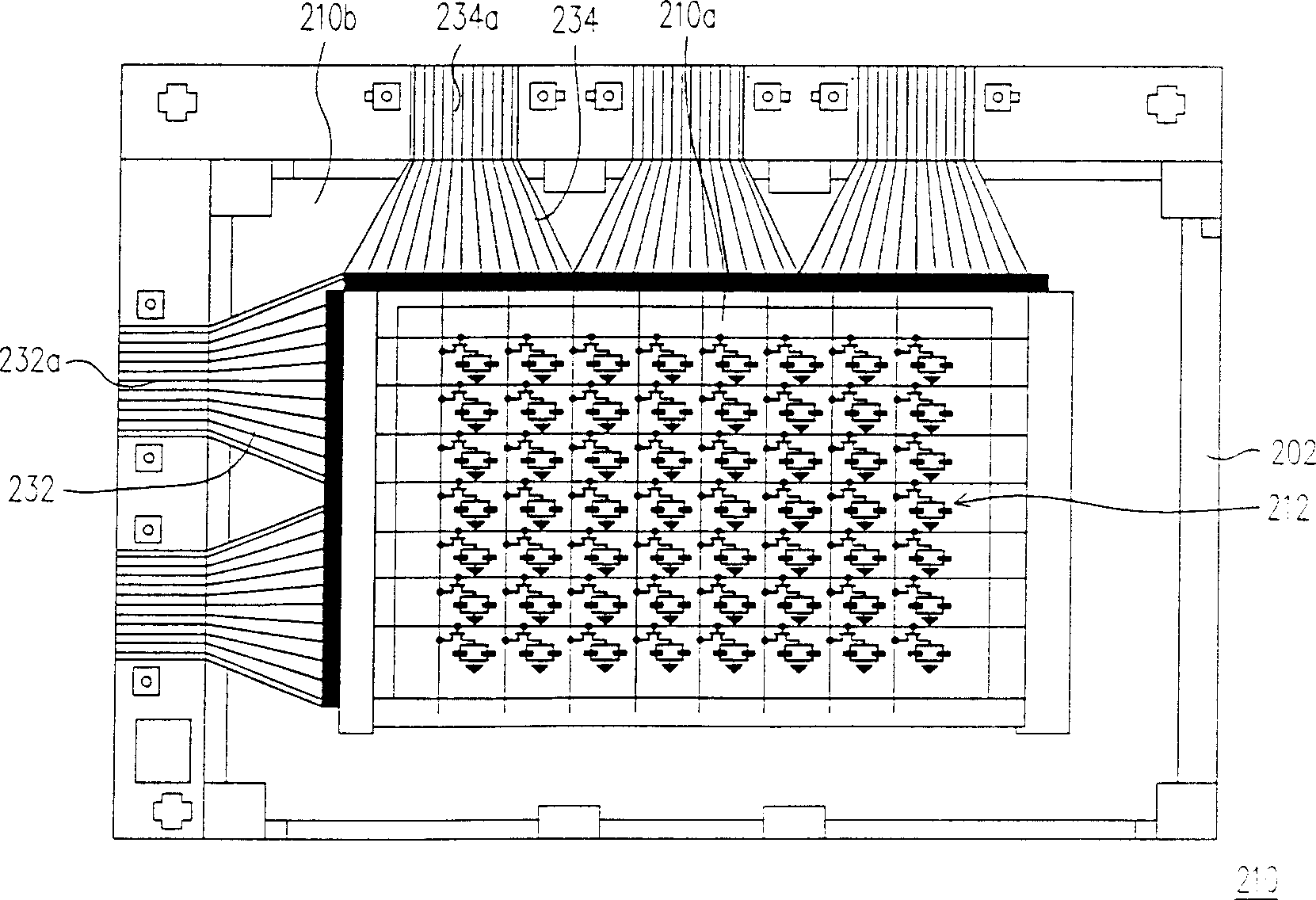

LCD device and scanning method

ActiveCN101114426AAvoid discontinuitiesSolve the problem of light leakageStatic indicating devicesColor gelLight source

The invention provides a liquid crystal display device as well as a relative scanning method. One implementation example of the invention is a colorless filter, and a liquid crystal display device which uses a red light emitting diode, a green light emitting diode and a blue light emitting diode as back light source, as well as a relative scanning method. The device is characterized in that a panel scanning line is divided into a plurality of scanning areas in the direction parallel to the scanning line, and each scanning area is further divided into at least one small zone. A back light module provides a corresponding group of light emitting diodes behind each small zone, and each group of light emitting diodes comprises a red light emitting diode, a green light emitting diode and a blue light emitting diode in proper sequence; wherein, when a color separated sub-picture is displayed, the scanning order of neighbor scanning areas is in the direction of facing a juncture or in the opposite direction of leaving the juncture. When the scanning of a small zone is finished, and after liquid crystal molecules finish the reaction, the corresponding group of light emitting diodes behind the small zone is lightened, thus avoiding the discontinuous phenomenon of dynamic pictures.

Owner:DYNASCAN TECH

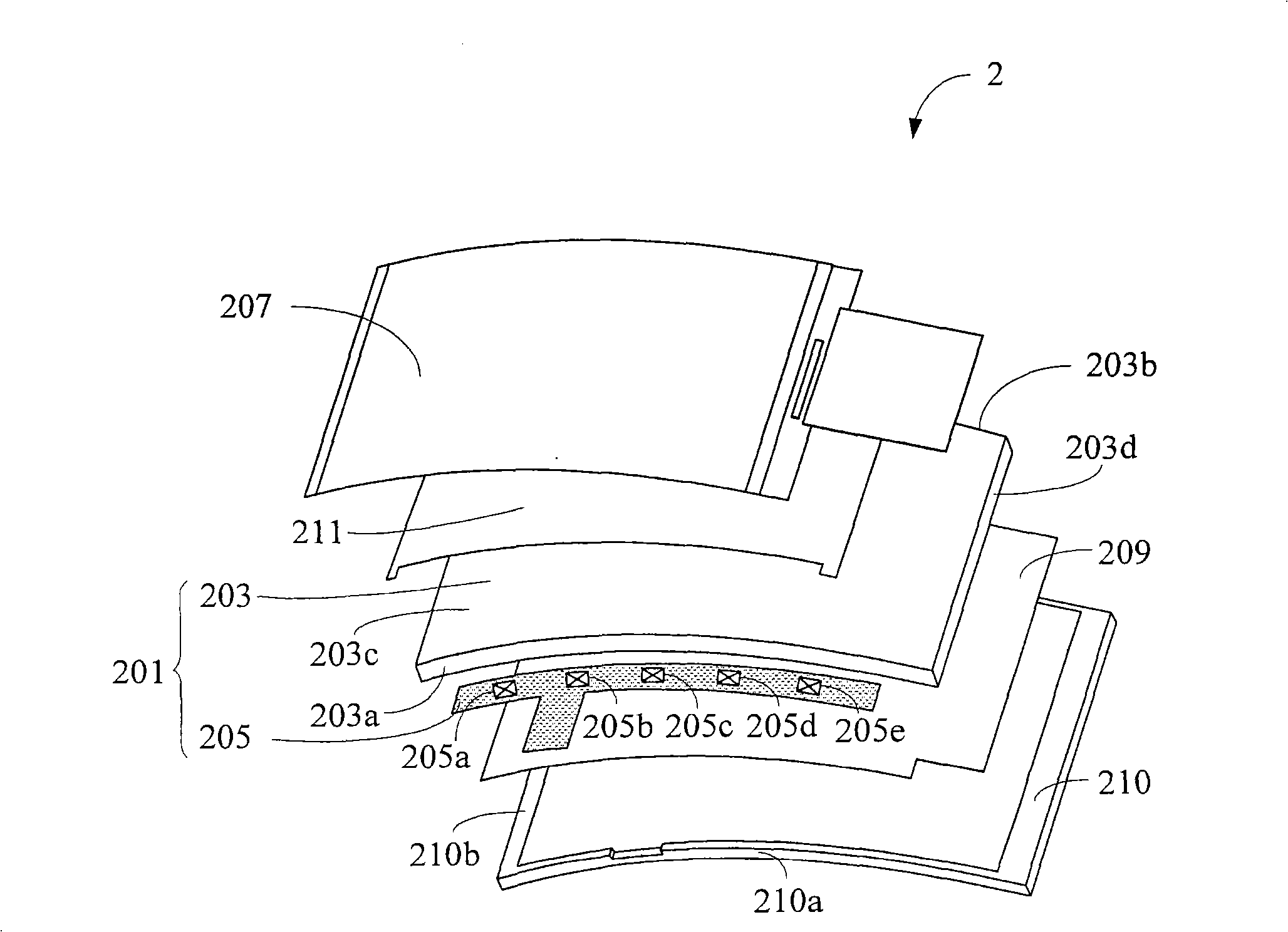

Color film substrate and production method, display panel and display device of color film substrate

ActiveCN104808384AChange widthSolve the problem of light leakageNon-linear opticsLiquid mediumElectrophoresis

The invention discloses a color film substrate and a production method, a display panel and a display device of the color film substrate used for solving the problems that a curve-flat conversion display panel leaks light or the transmittance is descended. The color film substrate comprises a substrate base plate, a black matrix and a color film layer including color sub pixels in matrix arrangement; the color film substrate also comprises a plurality of electrophoresis units and a flat layer; each electrophoresis unit comprises a first control electrode, a second control electrode, opaque charged particles, a transparent electrophoretic liquid medium and a transparent retaining wall; the transparent retaining wall is used for limiting the opaque charged particles and the transparent electrophoretic liquid medium in a first preset area; the area comprises the first control electrode and the second control electrode; the first control electrode and the second control electrode are respectively used for receiving different voltage signals to form a voltage difference, so that the opaque charged particles move towards the direction of the first control electrode or the second control electrode in a gathering way, and the width of a shading area between two adjacent color sub pixels is changed; the flat layer covers the whole substrate base plate and is used for sealing the electrophoresis units.

Owner:BOE TECH GRP CO LTD +1

Colorful film substrate and method for manufacturing same

ActiveCN101398562AIncrease the lengthIncrease the effective elasticityPhotomechanical apparatusNon-linear opticsLiquid-crystal displayBlack matrix

The invention relates to a colorful film substrate and a preparation method thereof; wherein, the colorful film substrate comprises a glass substrate and a column-shaped cushion article, a black matrix and a pixel resin which are sequentially arranged on the glass substrate; the preparation method of the colorful film substrate comprises the steps as follows: firstly, the column-shaped cushion article is formed on the glass substrate; subsequently, the black matrix is formed on the glass substrate where the column-shaped cushion article is formed; subsequently, the pixel rein is formed on the glass substrate where the column-shaped cushion article and the black matrix are formed. The colorful film substrate and the preparation method thereof effectively increase the length and elasticity of the column-shaped cushion article by forming the column-shaped cushion article on the glass substrate, thus improving the stability of the box thickness and ensuring the quality of the liquid crystal display.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

LED packaged piece and manufacturing method thereof

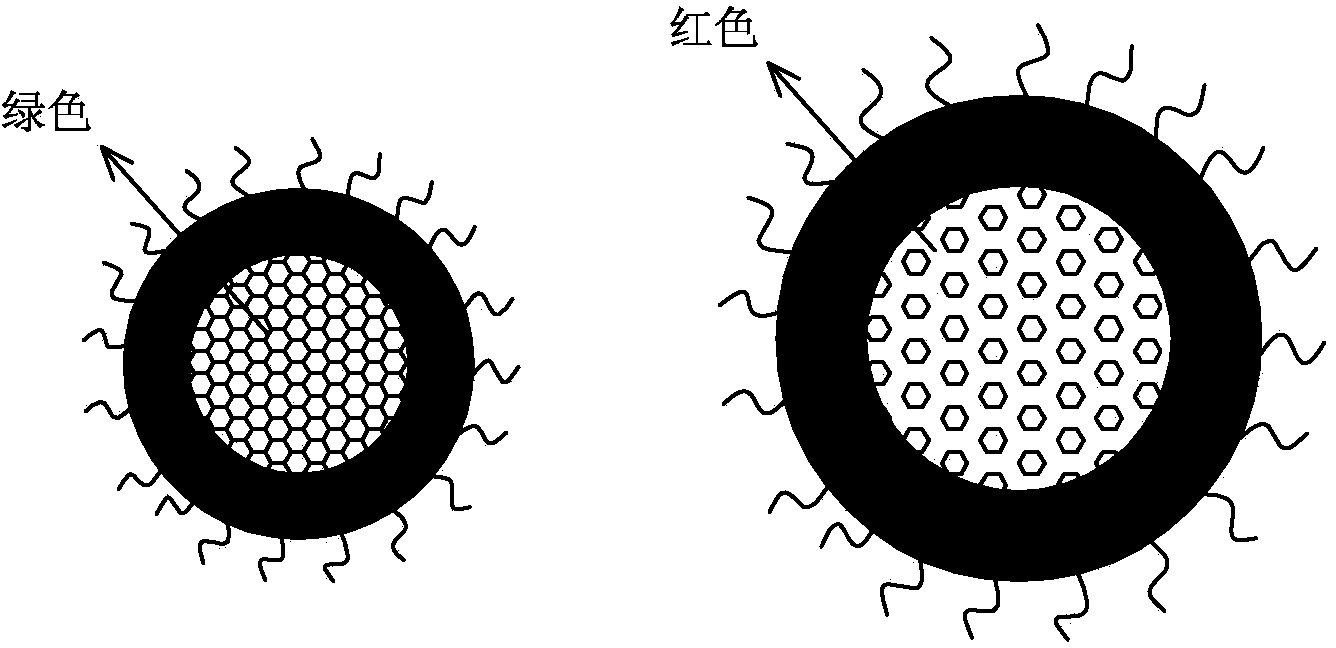

ActiveCN103681990AReduce the difficulty of assemblySolve the problem of light leakageSolid-state devicesSemiconductor devicesAdhesiveQuantum dot

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

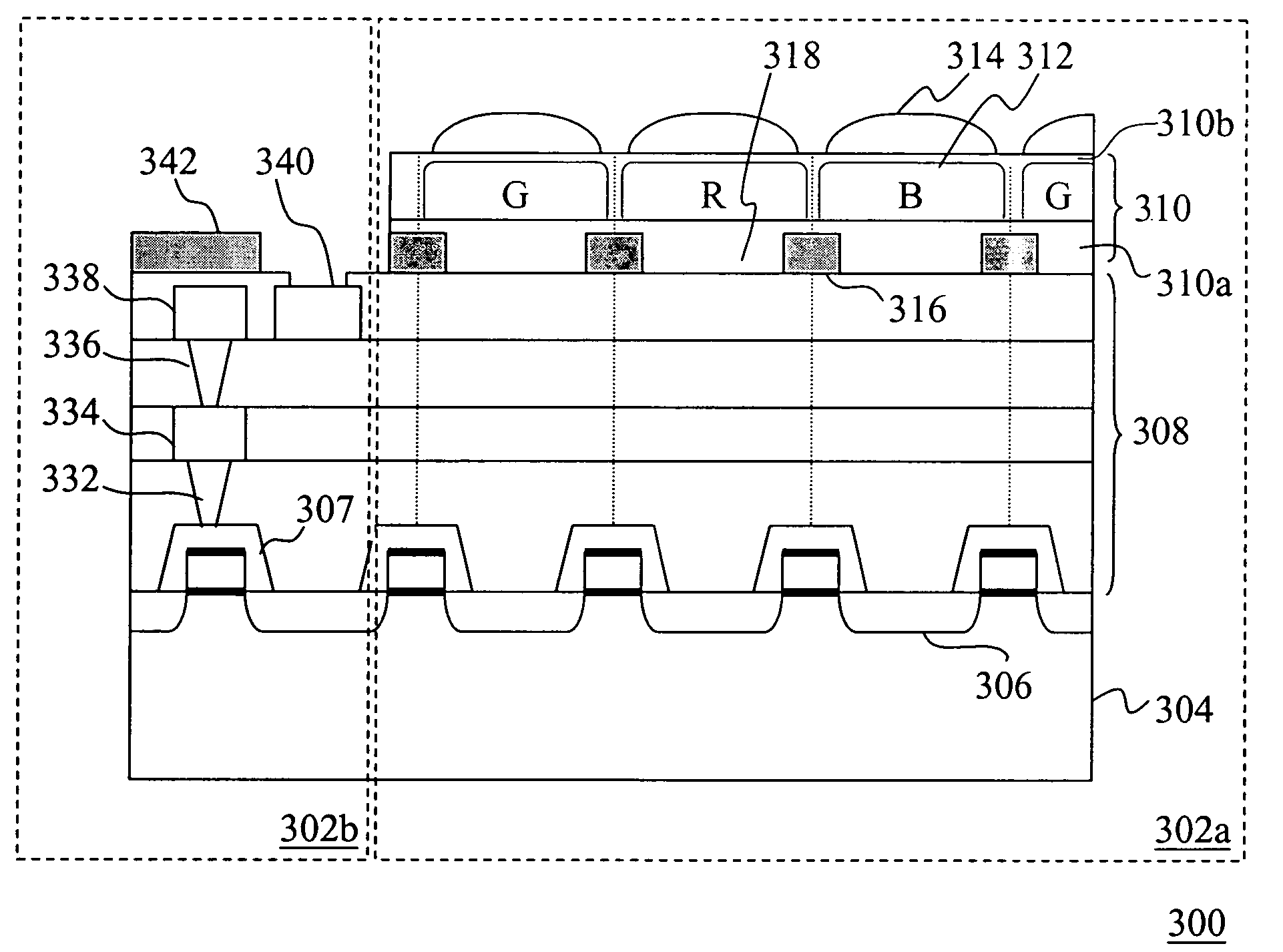

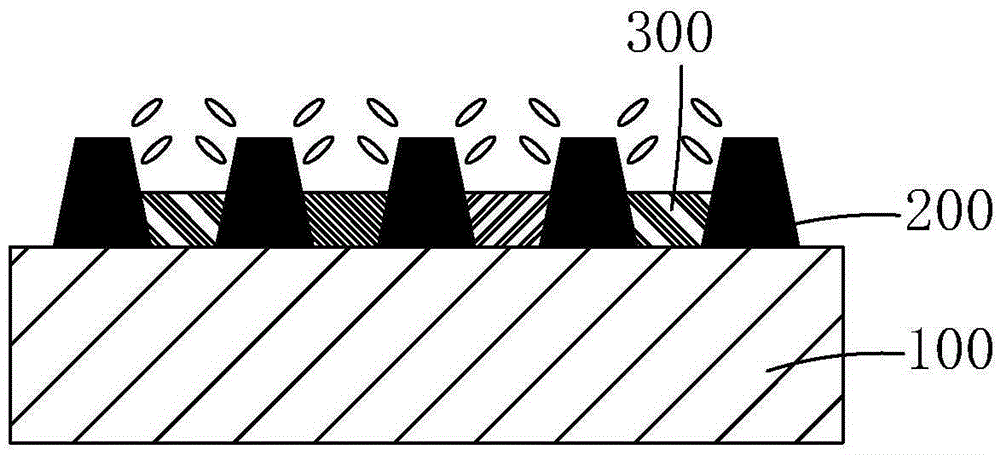

Image sensor device and manufacturing method thereof

ActiveUS20060118698A1Contrasting colorsHigh imaging sensitivitySolid-state devicesMaterial analysis by optical meansDielectric layerMicrolens

An image sensor device including a substrate, a plurality of photo sensors, a dielectric layer, a planar layer, a plurality of color filters, a plurality of microlenses, and a shield layer is provided. The photo sensors are disposed in the substrate, and the dielectric layer is disposed over the photo sensors and the substrate. The planar layer is disposed over the dielectric layer. The color filters are disposed in the planar layer, wherein each of the color filters is disposed over each of the photo sensors. The microlenses are disposed over the planar layer, wherein each of the microlenses is disposed over each of the color filter. The shield layer including a plurality of openings is disposed in the planar layer and is disposed under or over the color filters, wherein each of the openings is disposed over each of the color filters.

Owner:MARLIN SEMICON LTD

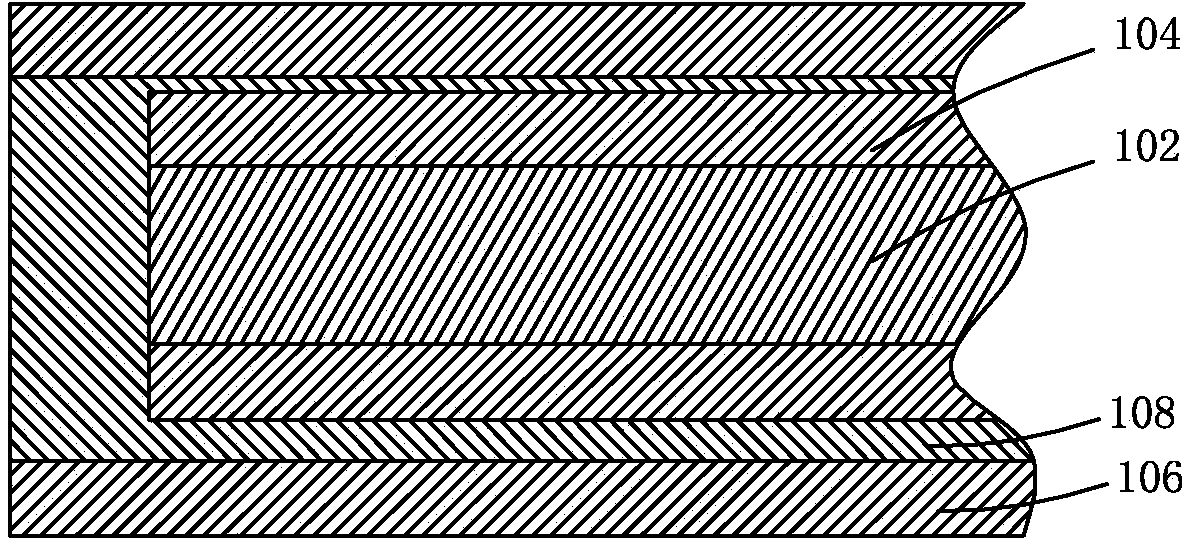

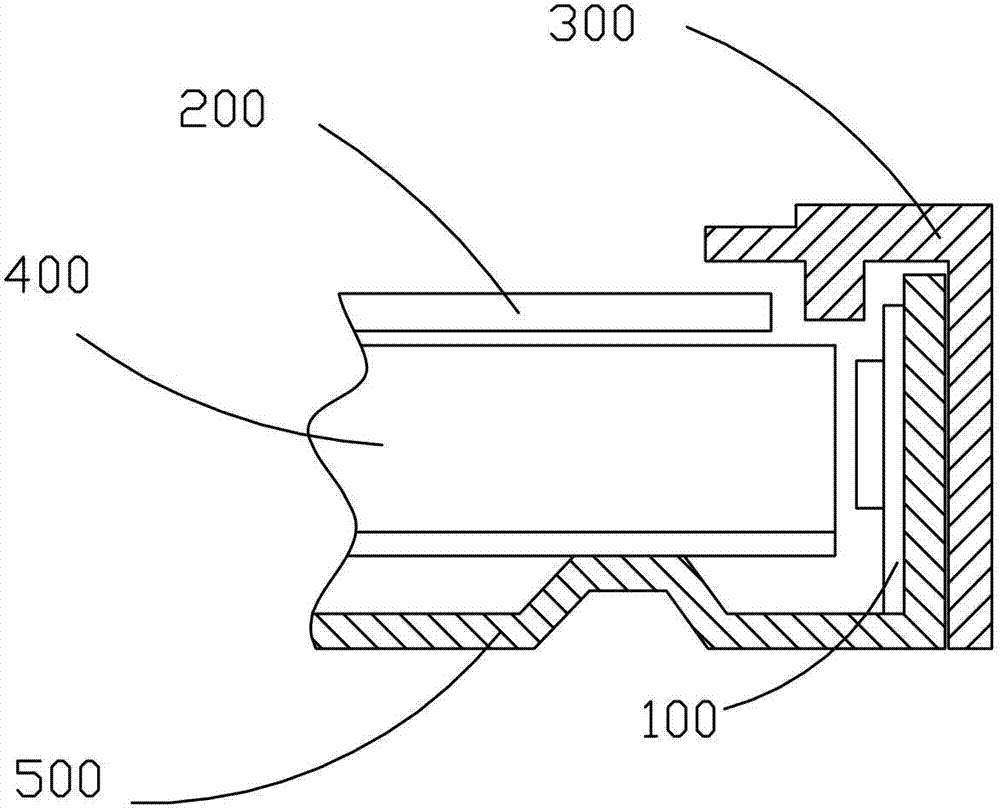

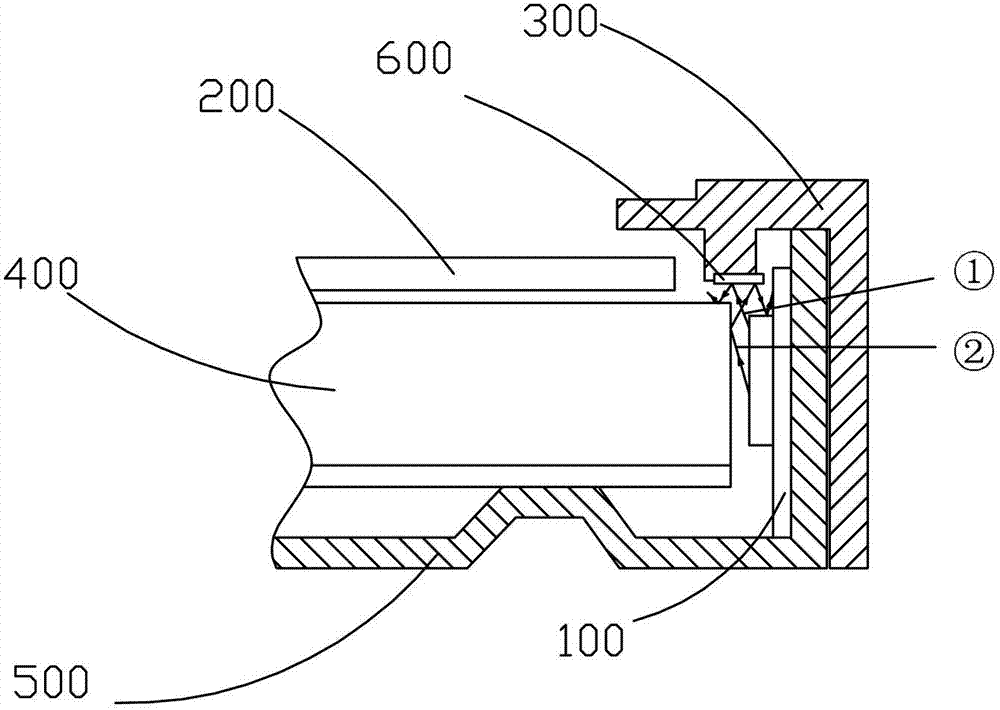

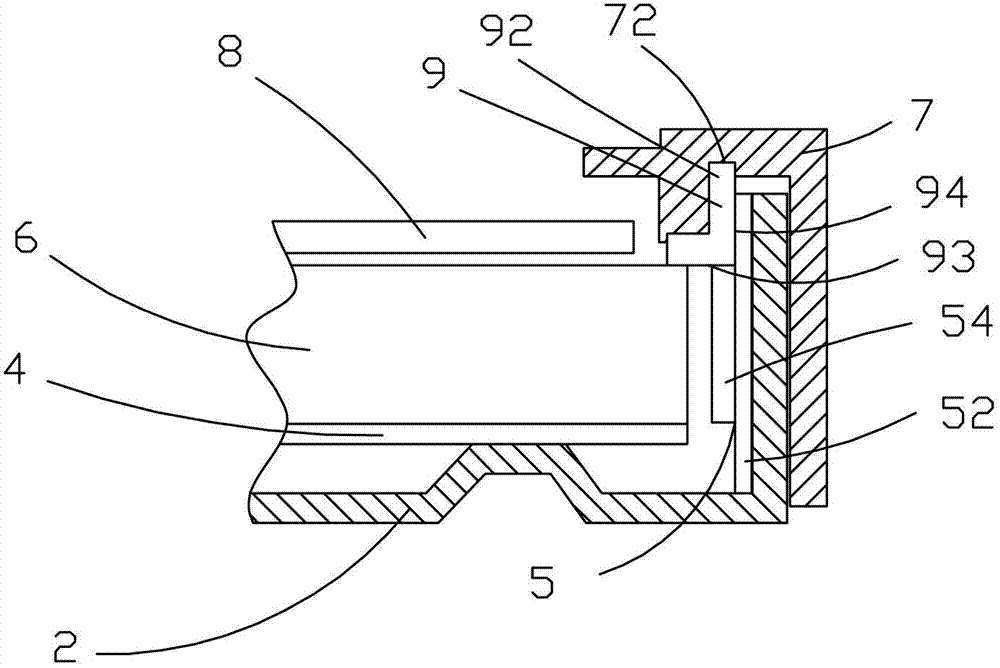

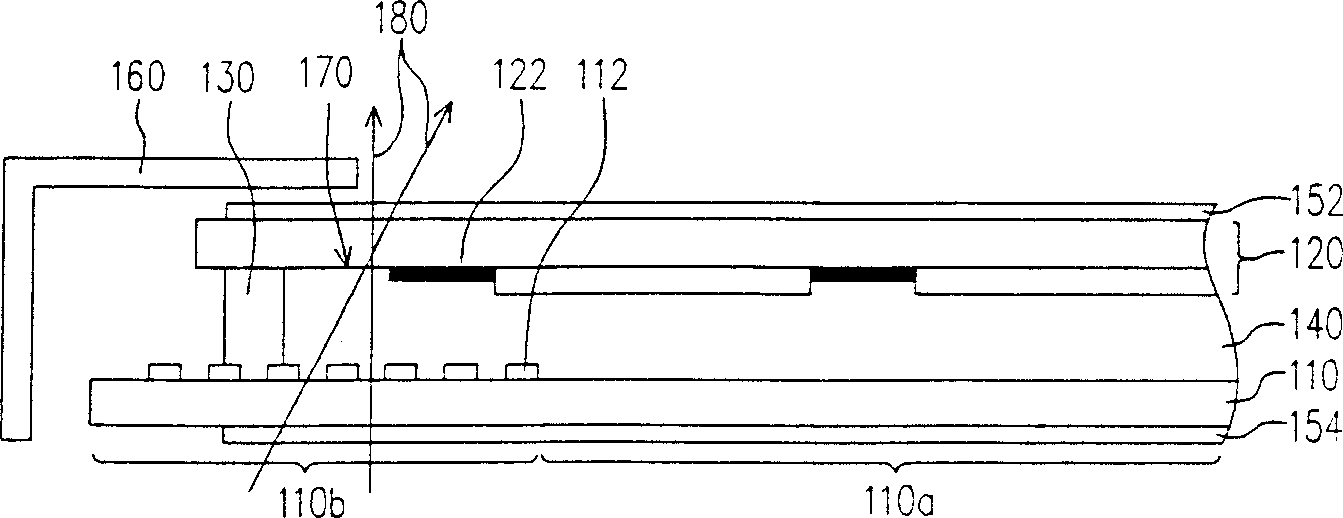

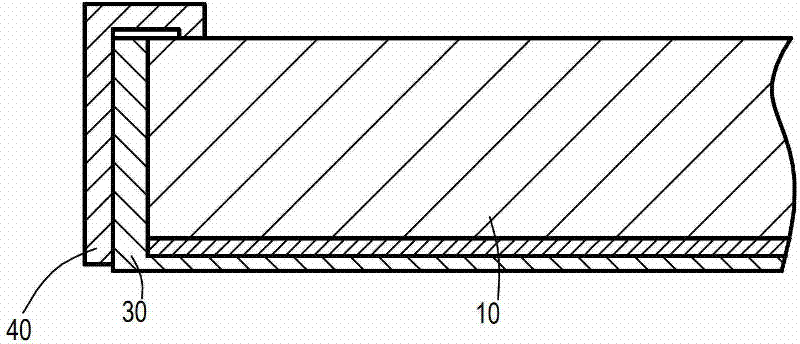

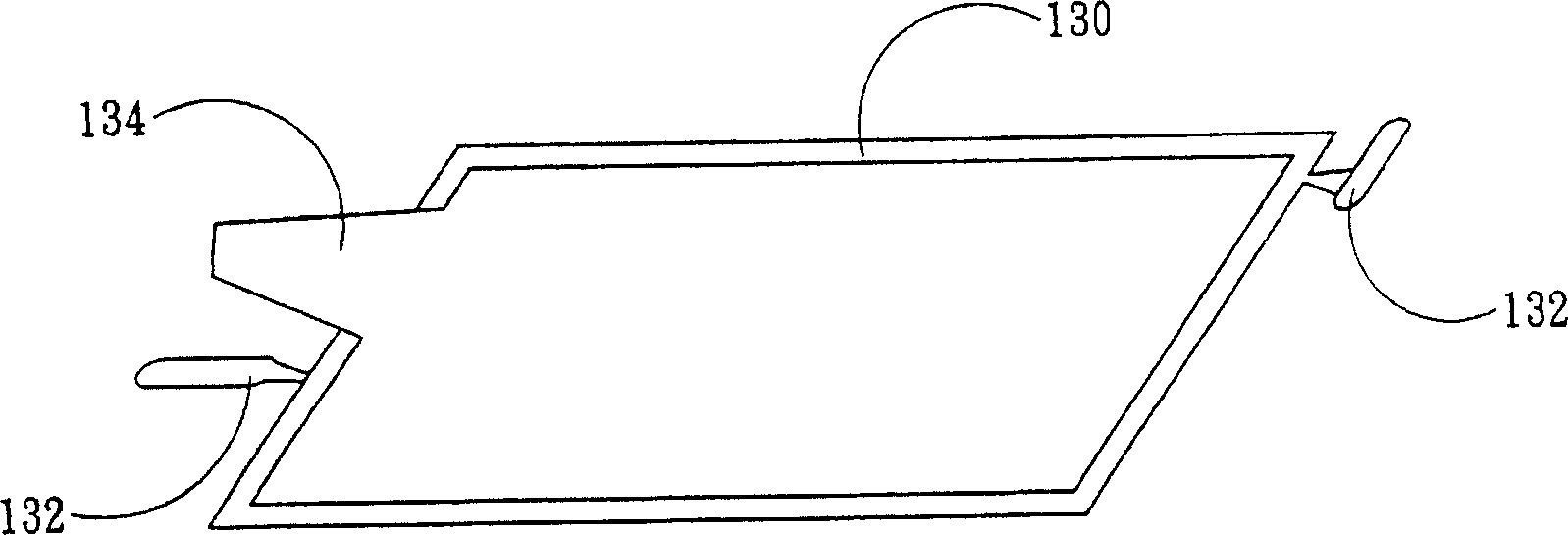

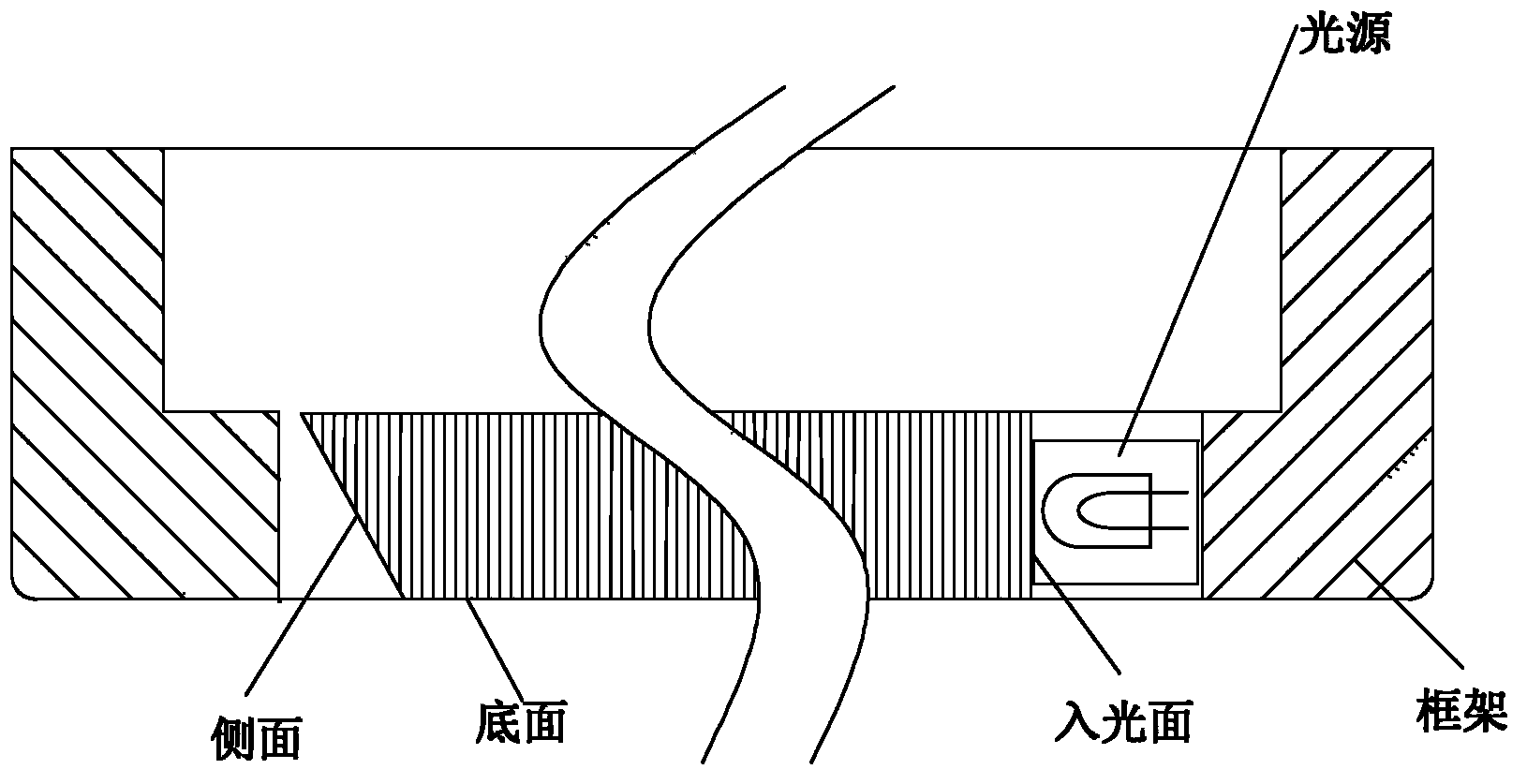

Backlight module

ActiveCN102889523ASolve the problem of light leakageImprove lighting efficiencyPoint-like light sourcePlanar/plate-like light guidesLight guideEngineering

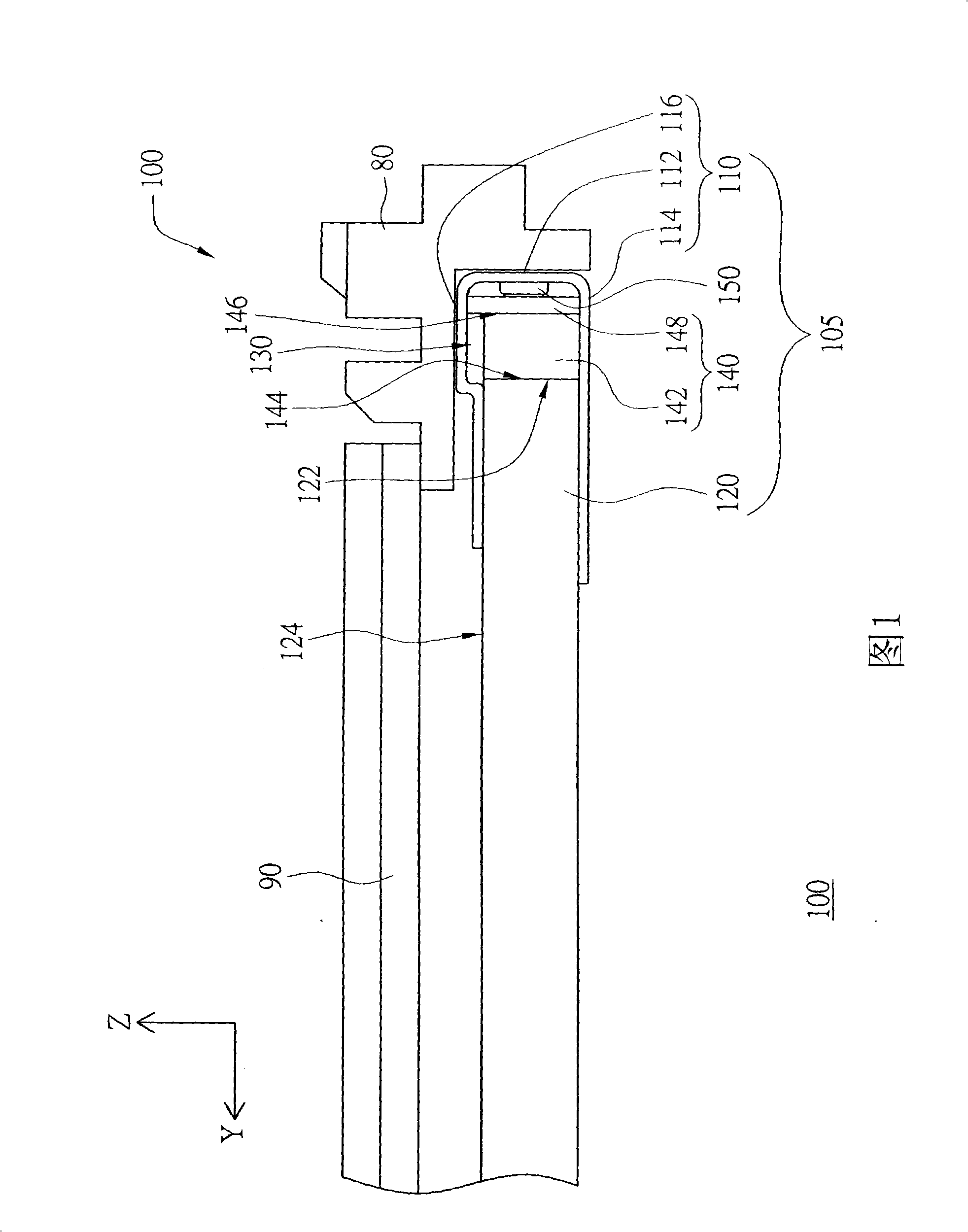

The invention provides a backlight module. The backlight module comprises a back plate, a reflecting sheet arranged in the back plate, a light guide plate arranged on the reflecting sheet, an optical membrane assembly arranged on the light guide plate, a backlight source arranged in the back plate and facing the light guide plate, a frame arranged on the back plate, and an elastic retaining wall arranged above the light incident end of the backlight source and the light guide plate and fixed on the frame in a plugging, attaching or clamping manner, wherein the elastic retaining wall includes a bottom surface and a side surface vertical to the bottom surface; and the bottom surface and the side surface keep close contact with the upper surface of the light guide plate and the backlight source. The elastic retaining wall made of white rubber and having elasticity is fixed on the frame in the plugging, attaching or clamping manner and keeps close contact with the light guide plate and the upper surface of an LED (light emitting diode) lamp, so that the elastic retaining wall can reflect light back to the light guide plate to well prevent the light from being emitted from a gap on the light incident side, thereby solving the problem of incident-side light leakage of the backlight module and improving the light efficiency of the backlight module.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

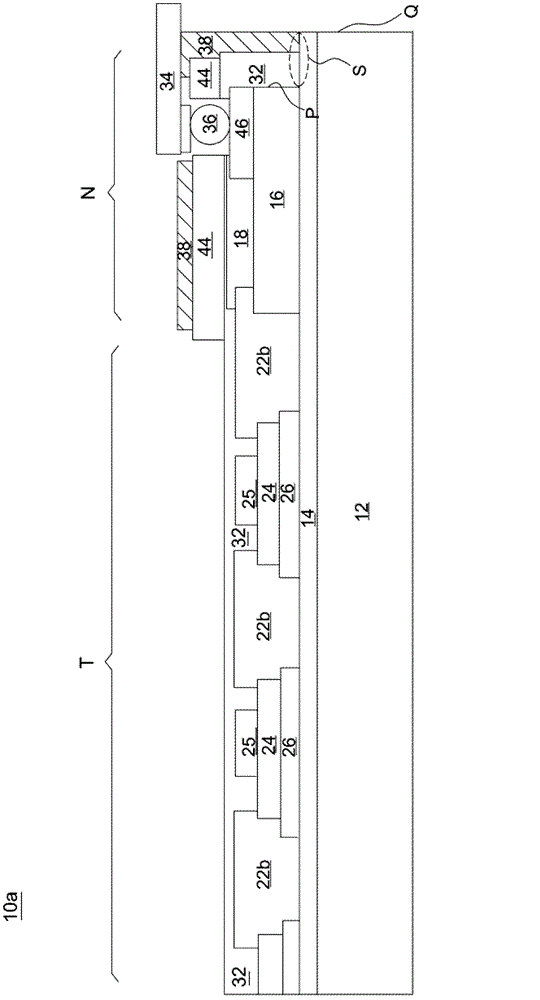

Touch device and touch display device

InactiveCN102799295AAvoid problems such as scratches and puncturesSolve the problem of light leakageInput/output processes for data processingTouch SensesDisplay device

The invention provides a touch device and a touch display device. The touch device comprises a transparent substrate, a touch sensing structure, a decorative layer, a routing layer, a protective layer and a shielding layer, wherein the decorative layer is arranged on the transparent substrate and is located in a non-contact area; and the routing layer is arranged on the decorative layer, the protective layer is arranged on the transparent substrate and at least covers the touch sensing structure and the routing layer, and the shielding layer is at least arranged on the protective layer and is located in the non-contact area.

Owner:WINTEK CORP

Liquid crystal display panel and display device

ActiveCN102789088ASolve the problem of light leakageImprove display qualityNon-linear opticsVertical planeLiquid-crystal display

The embodiment of the invention provides a liquid crystal display panel and a display device and relates to the technical field of the liquid crystal display. The light leakage problem caused by inferior alignment of a colored film substrate and an array substrate is solved. The liquid crystal display panel comprises the colored film substrate and the array substrate, wherein the array substrate comprises a first transparent substrate, a data line and a grid line; the colored film substrate comprises a second transparent substrate, colored resin, a first black matrix parallel to the data line, a second black matrix parallel to the grid line, and a common electrode covering the colored resin, the first black matrix and the second black matrix; the first black matrix comprises a bottom plane and a raised structure on the bottom plane; side walls of the raised structure in first positions are inclined walls; the inclined walls are inclined to a central vertical plane of the first black matrix along the data line direction from the first positions; and the first positions are intersected positions between the bottom plane and two side walls of the raised structure closest to a boundary position of the first black matrix and the colored resin. The liquid crystal display panel provided by the embodiment of the invention is used for increasing the display quality.

Owner:BOE TECH GRP CO LTD +1

Thin film transistor array substrate and fabricating method thereof

InactiveCN1763948ASolve the problem of light leakageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMetal

The manufacture method for a TFT array base comprises: while manufacturing the TFT for pixel zone, forming light-screening layer between lead wires in round circuit by metal layer to shield zone easy leak light between source / drain layer or grid layer; besides, adding out stabilization voltage on light-screening layer to reduce signal disturbance of wires. Thereby, it can detect the TFT array and whether there is a short circuit between lead wire and light-screening layer by said out-added voltage simultaneously.

Owner:CHUNGHWA PICTURE TUBES LTD

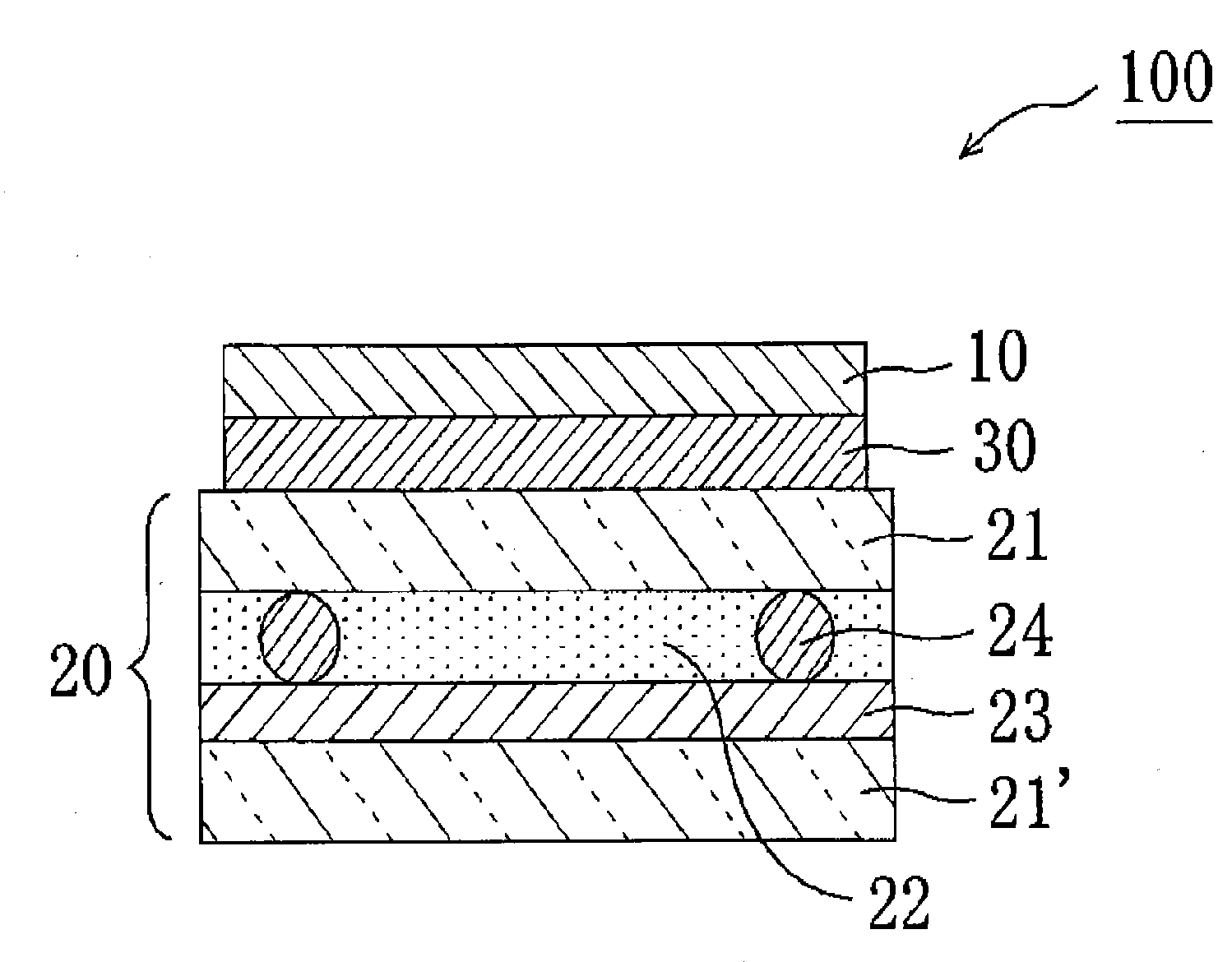

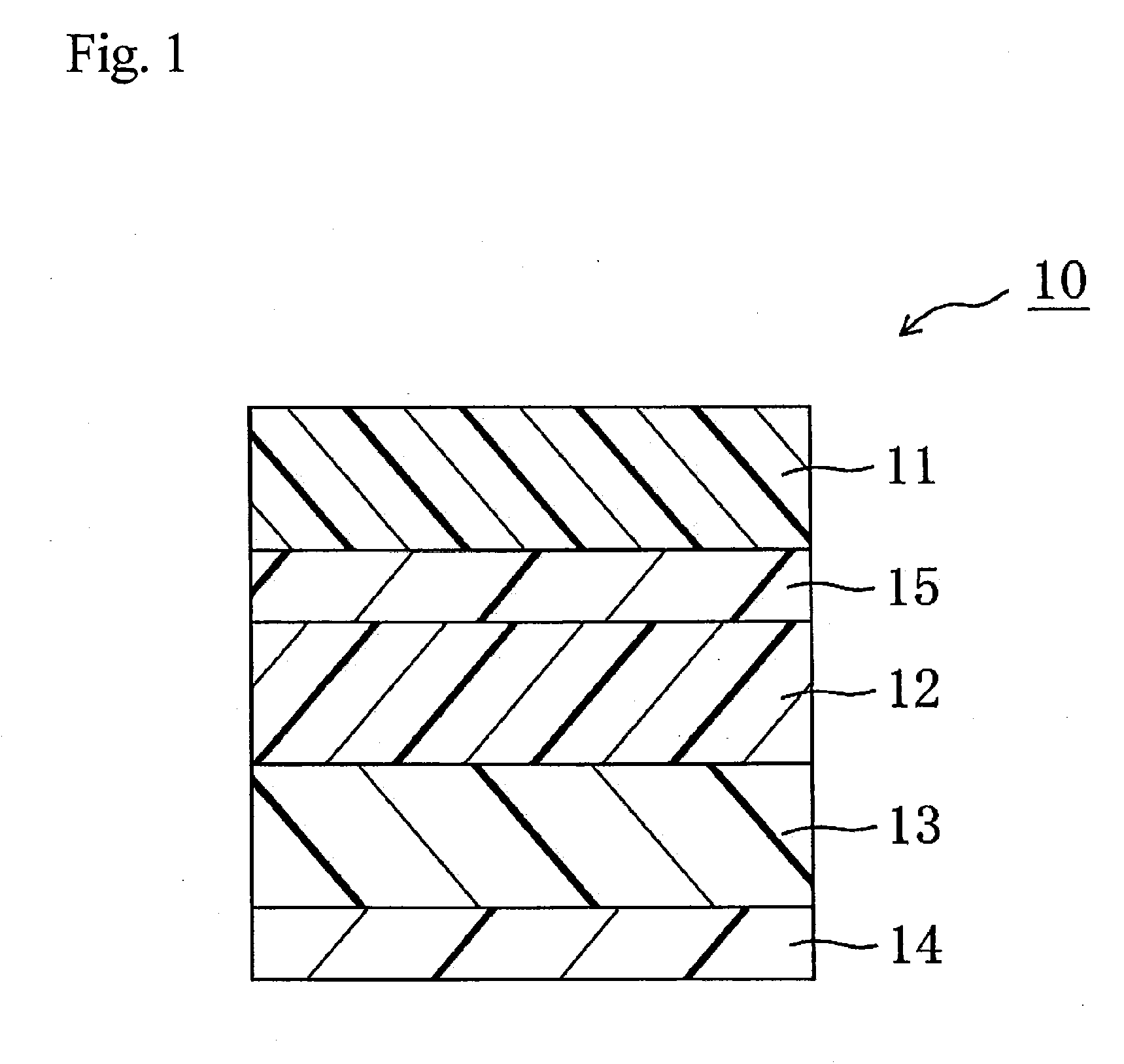

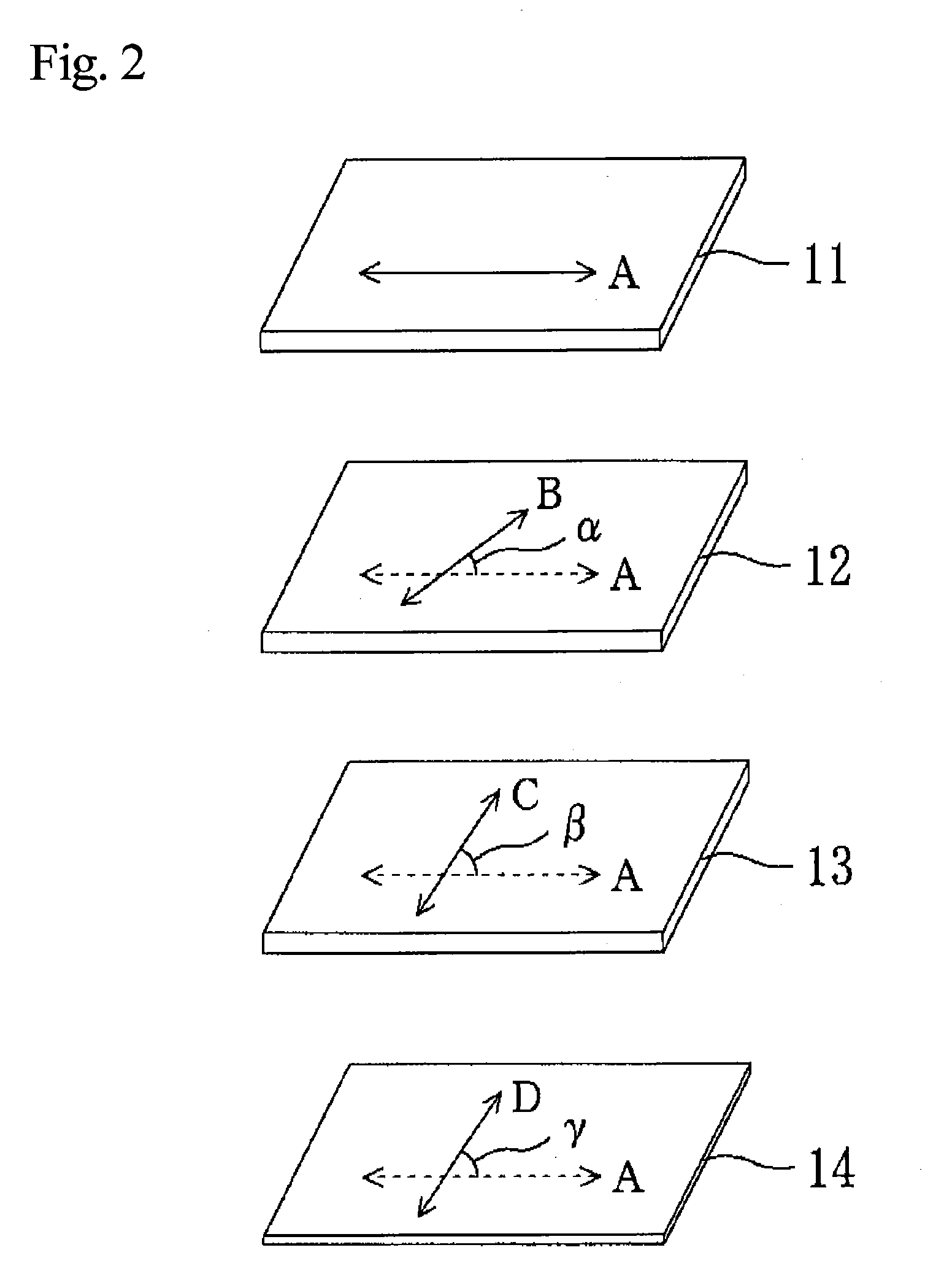

Polarizing plate with an optical compensation layer and image display apparatus using the same

InactiveUS20090122236A1Degradation of optical propertyRelieve pressurePolarising elementsNon-linear opticsShear modulusOptical property

There are provided a polarizing plate with an optical compensation layer capable of suppressing the degradation in optical properties due to the use under a high-temperature environment, and an image display apparatus using the polarizing plate with an optical compensation layer.The polarizing plate with an optical compensation layer includes a polarizer, a pressure-sensitive adhesive layer and at least one optical compensation layer, in the stated order. The pressure-sensitive adhesive layer has a dynamic storage shear modulus (G′) at 100° C. of 1.0×104 to 6.0×104 Pa.

Owner:NITTO DENKO CORP

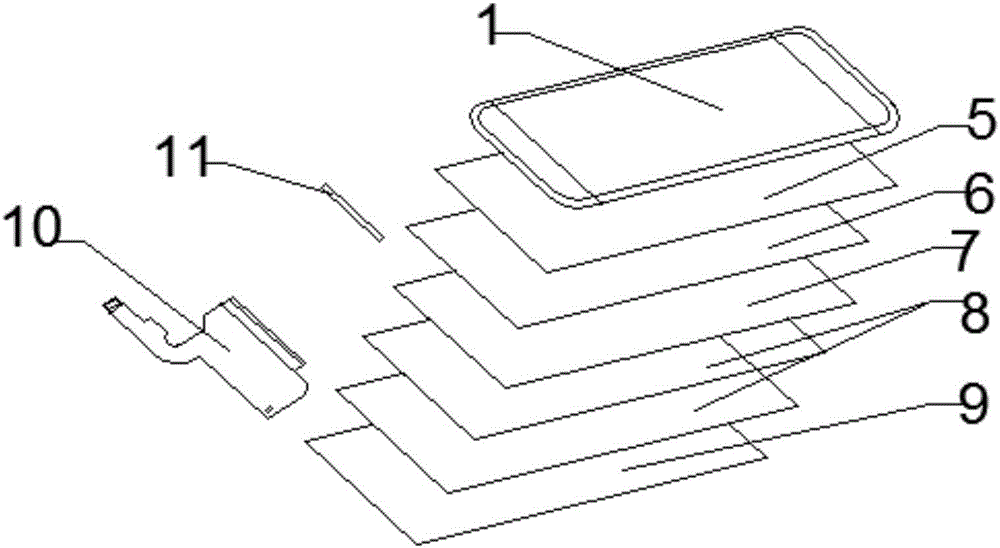

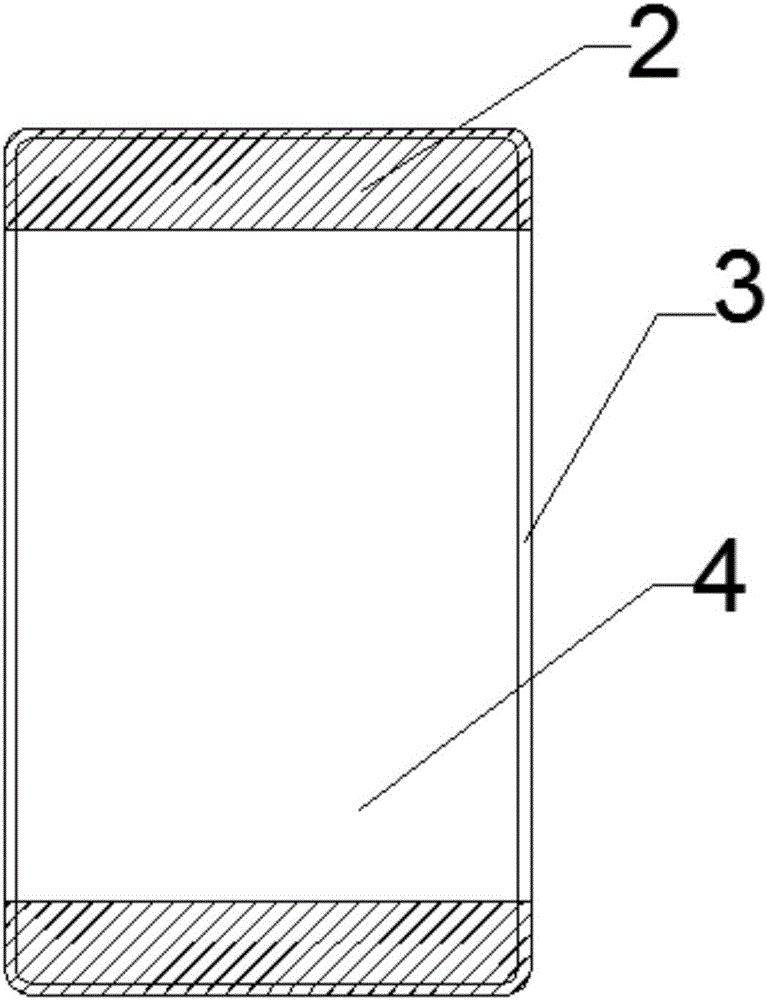

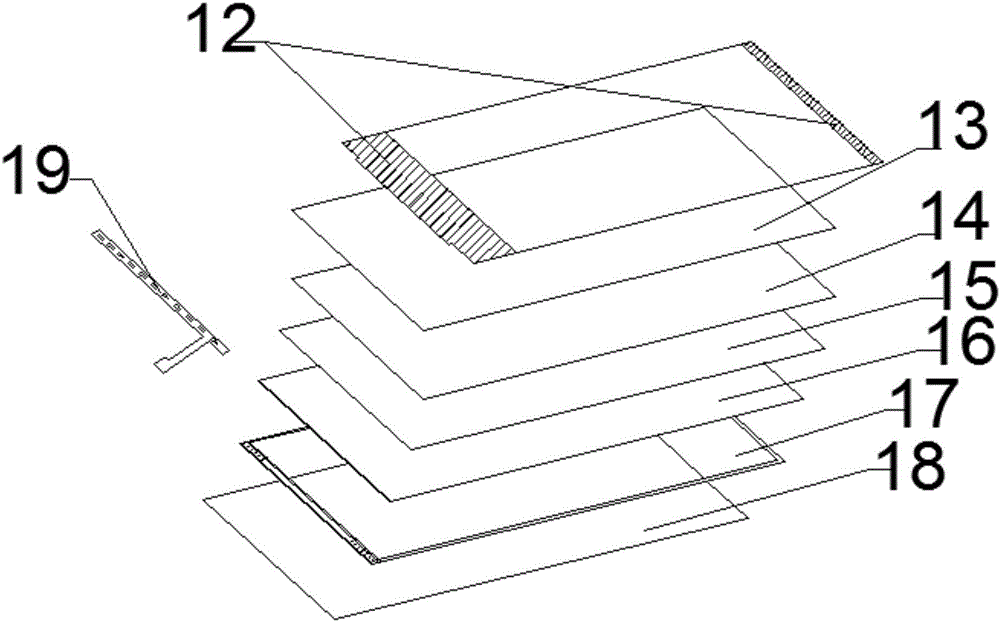

Frameless liquid crystal display module and implementation process thereof

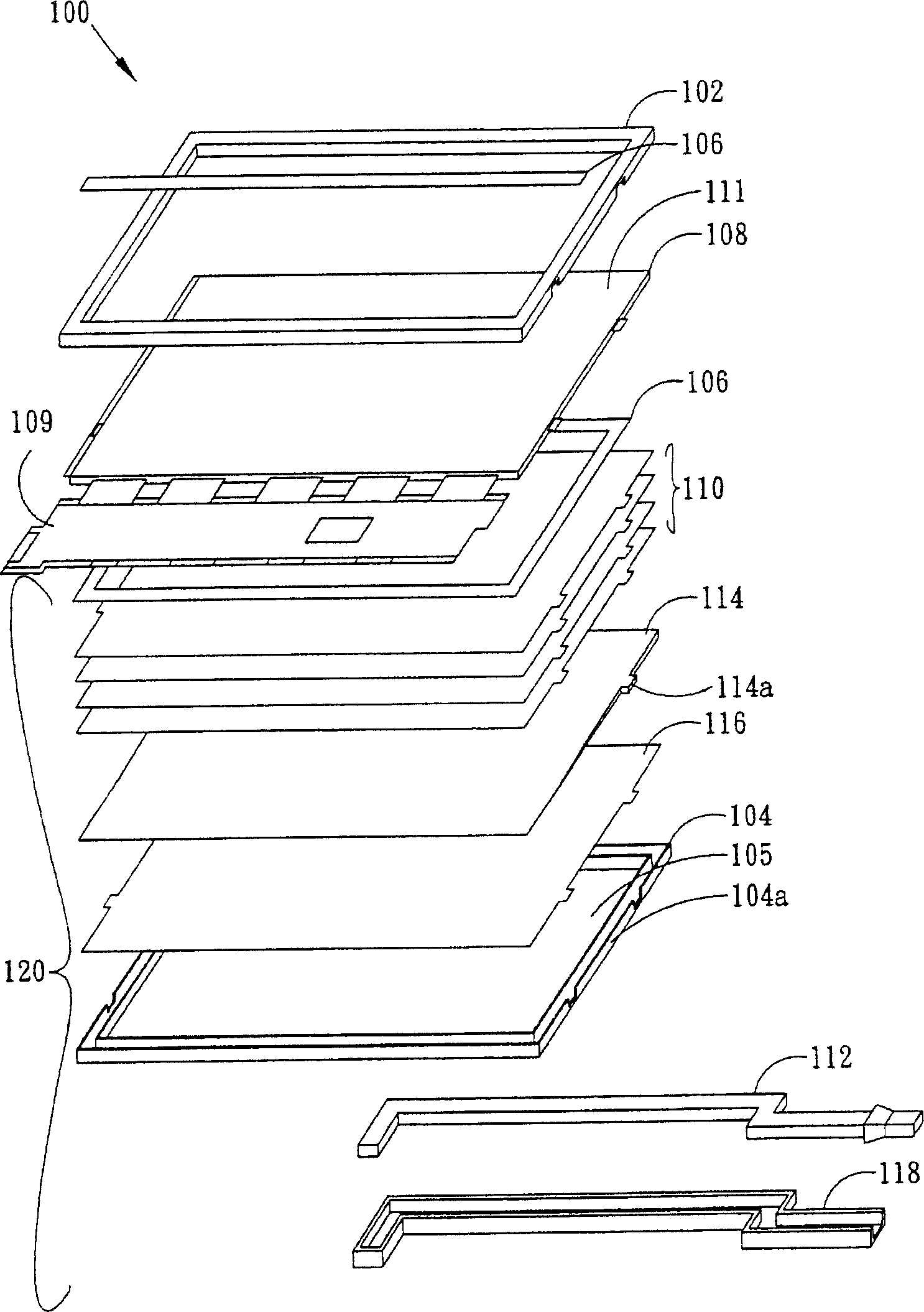

ActiveCN106647007AReasonable process designSolve the problem of light leakageStatic indicating devicesNon-linear opticsLiquid-crystal displayAdhesive

The invention discloses a frameless liquid crystal display module and an implementation process thereof. The frameless liquid crystal display module comprises a frameless cover plate, a silk-screen ink area, an edge cambered surface area, a transparent window area, optical cement, an upper polarizer, a lower polarizer, ultra-narrow-frame liquid crystal display glass, a backlight module, a flexible circuit board, a drive IC, black shading tape, an upper brightness enhancement film, a lower brightness enhancement film, a diffuser, a light guide plate, a rubber frame and lower iron frame, a reflector plate, an LED lamp bar group, an ultra-narrow-frame liquid crystal display glass component and adhesive. The frameless liquid crystal display module has the advantages that the semi-finished product of the frameless liquid crystal display module is formed by the frameless cover plate matched with the ultra-narrow-frame liquid crystal display glass, the frameless cover plate is thick and has a cambered surface at the edge, the cambered surface can reflect light, the semi-finished product is assembled with the frameless backlight module, then further adhering is performed by spraying the adhesive, and a frameless display effect is achieved by the light reflection of the edge of the frameless cover plate.

Owner:安徽帝晶光电科技有限公司

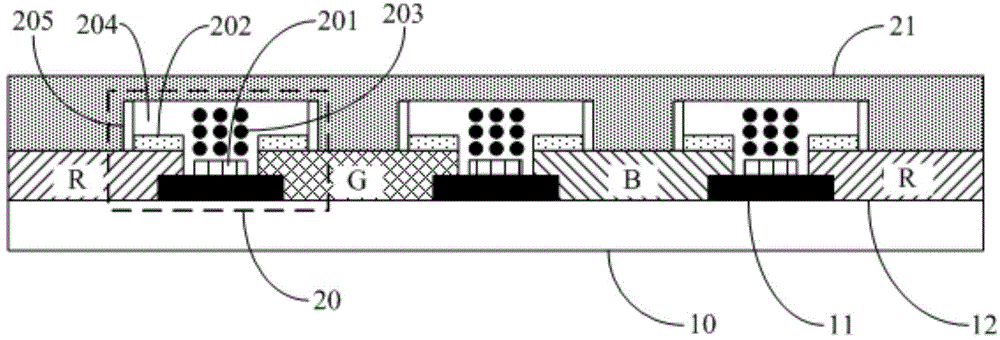

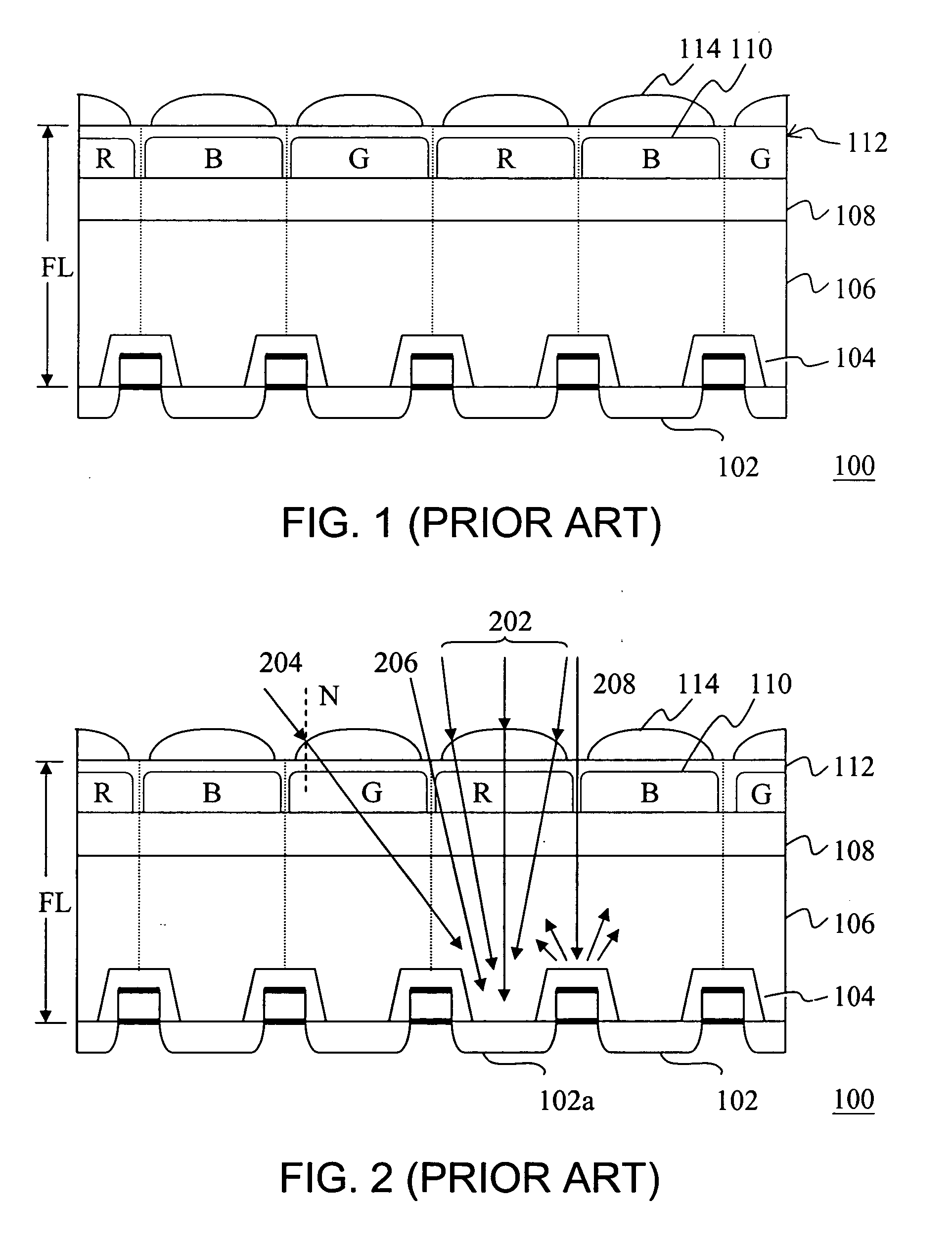

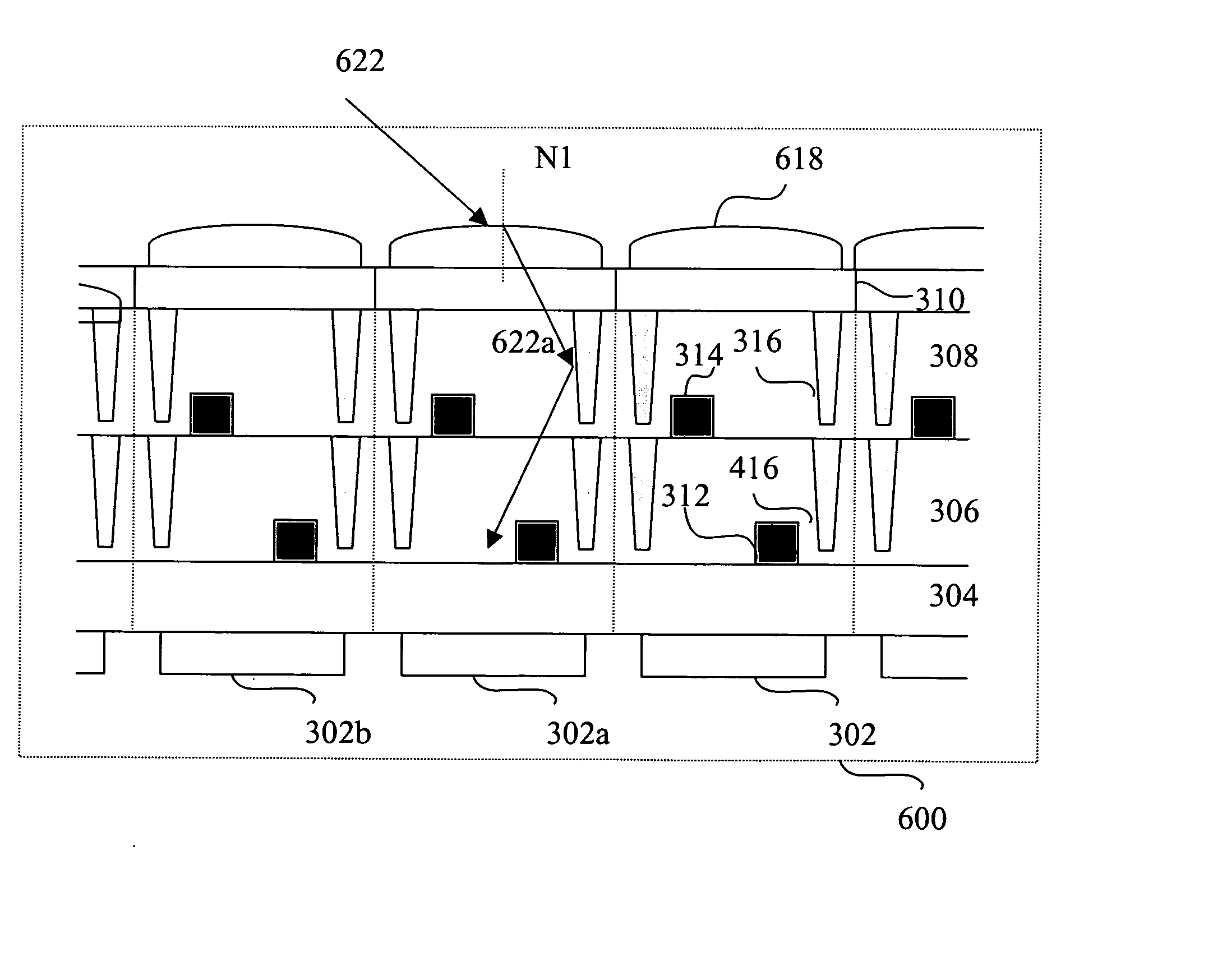

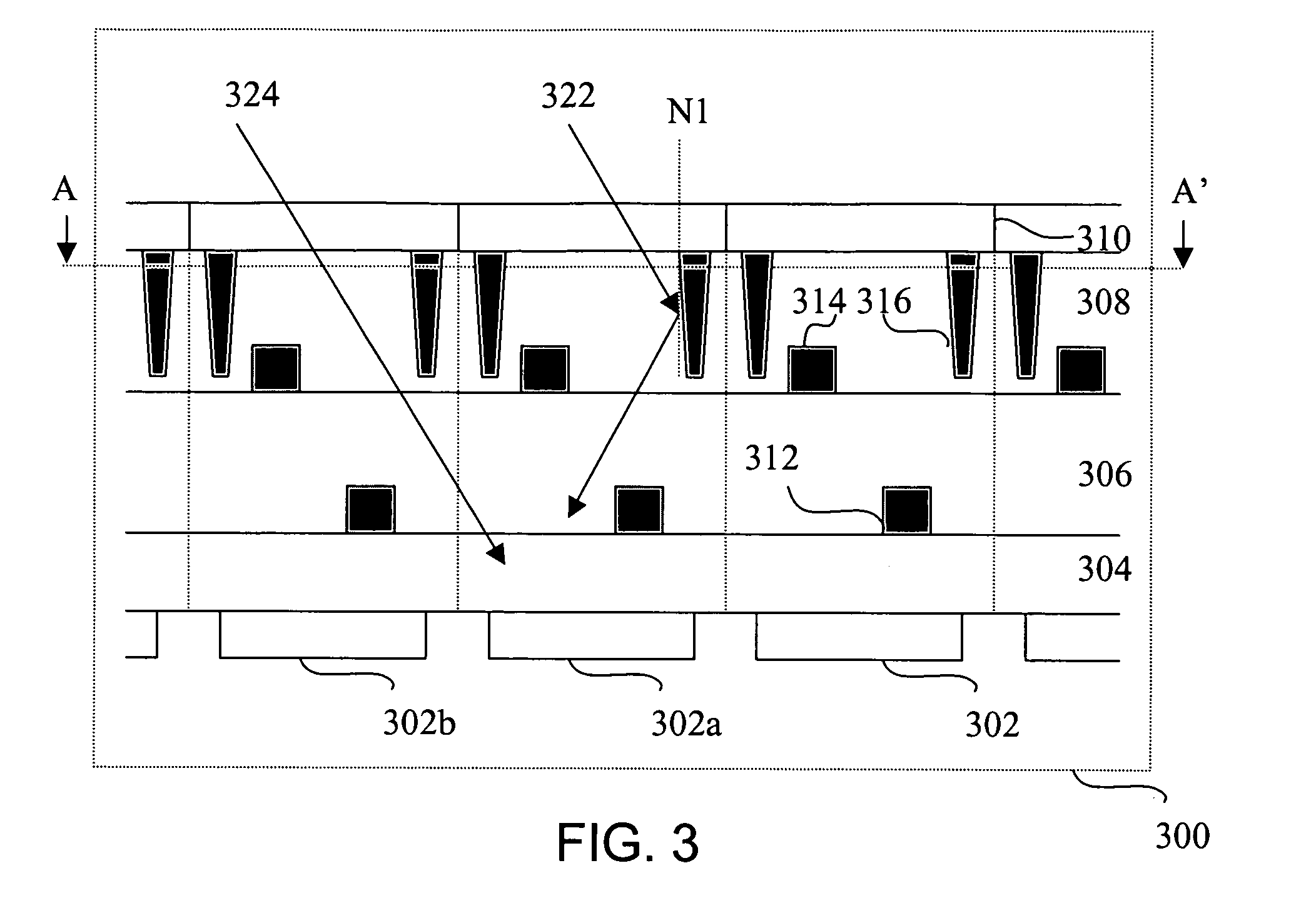

Image sensor device and manufacturing method thereof

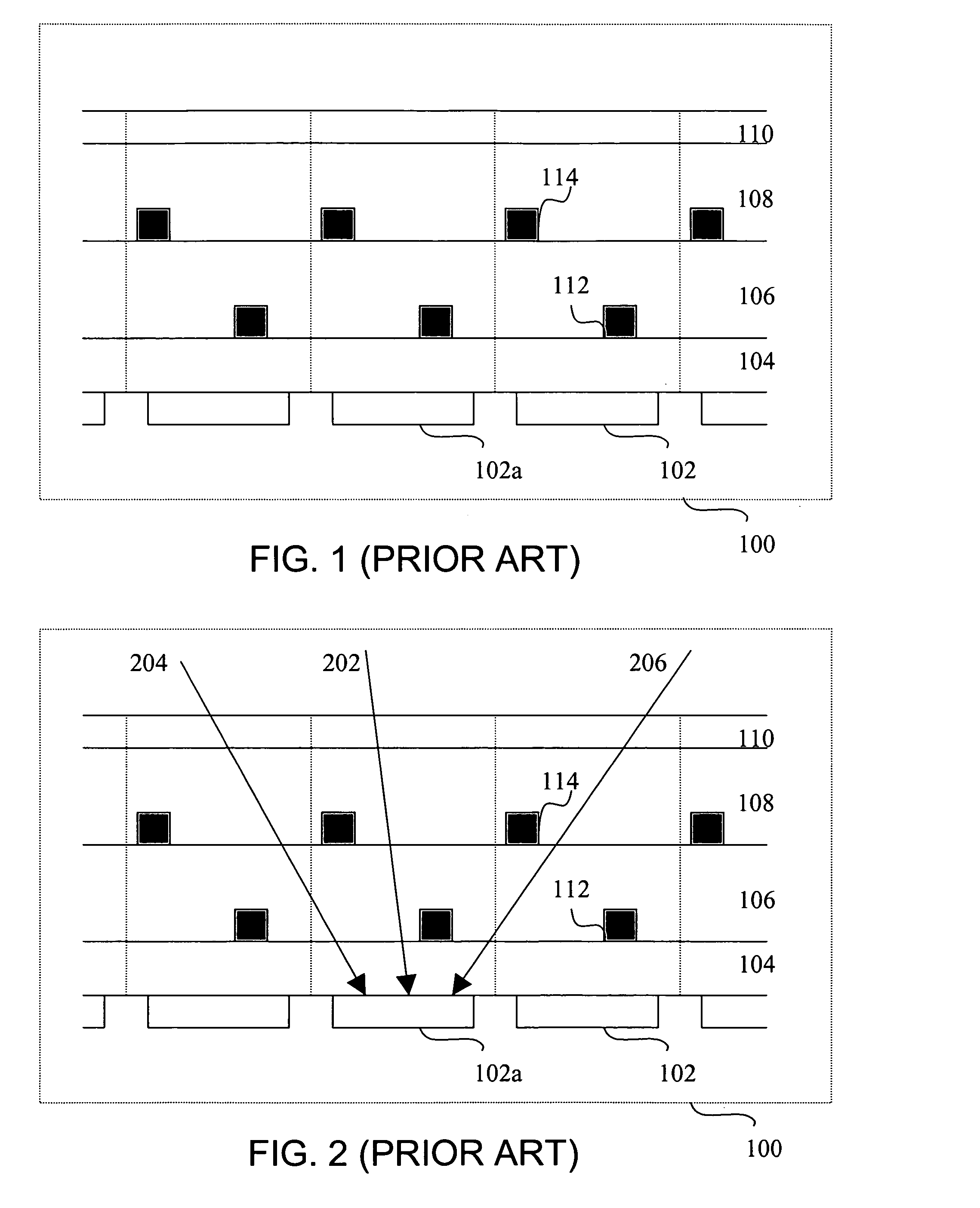

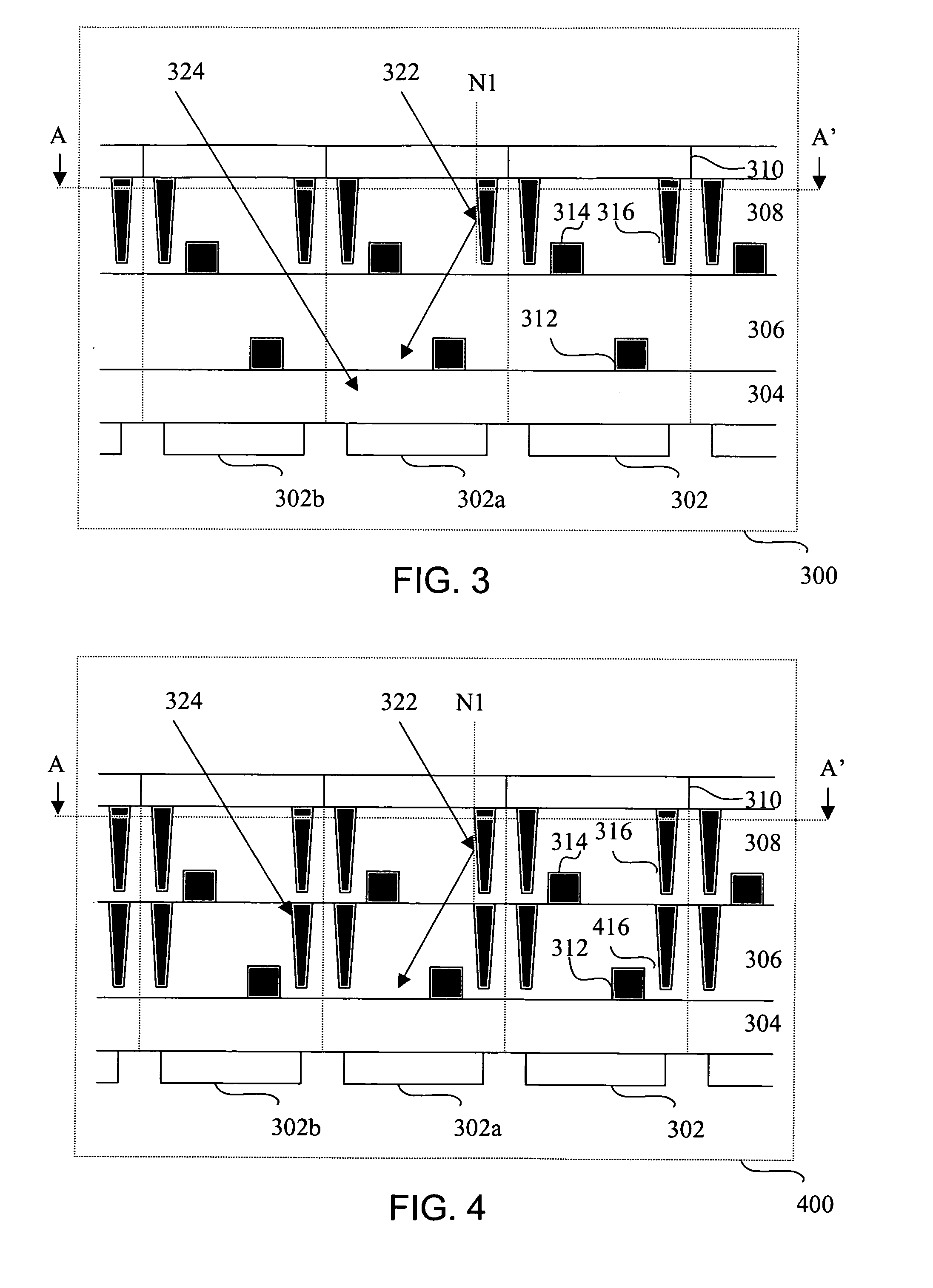

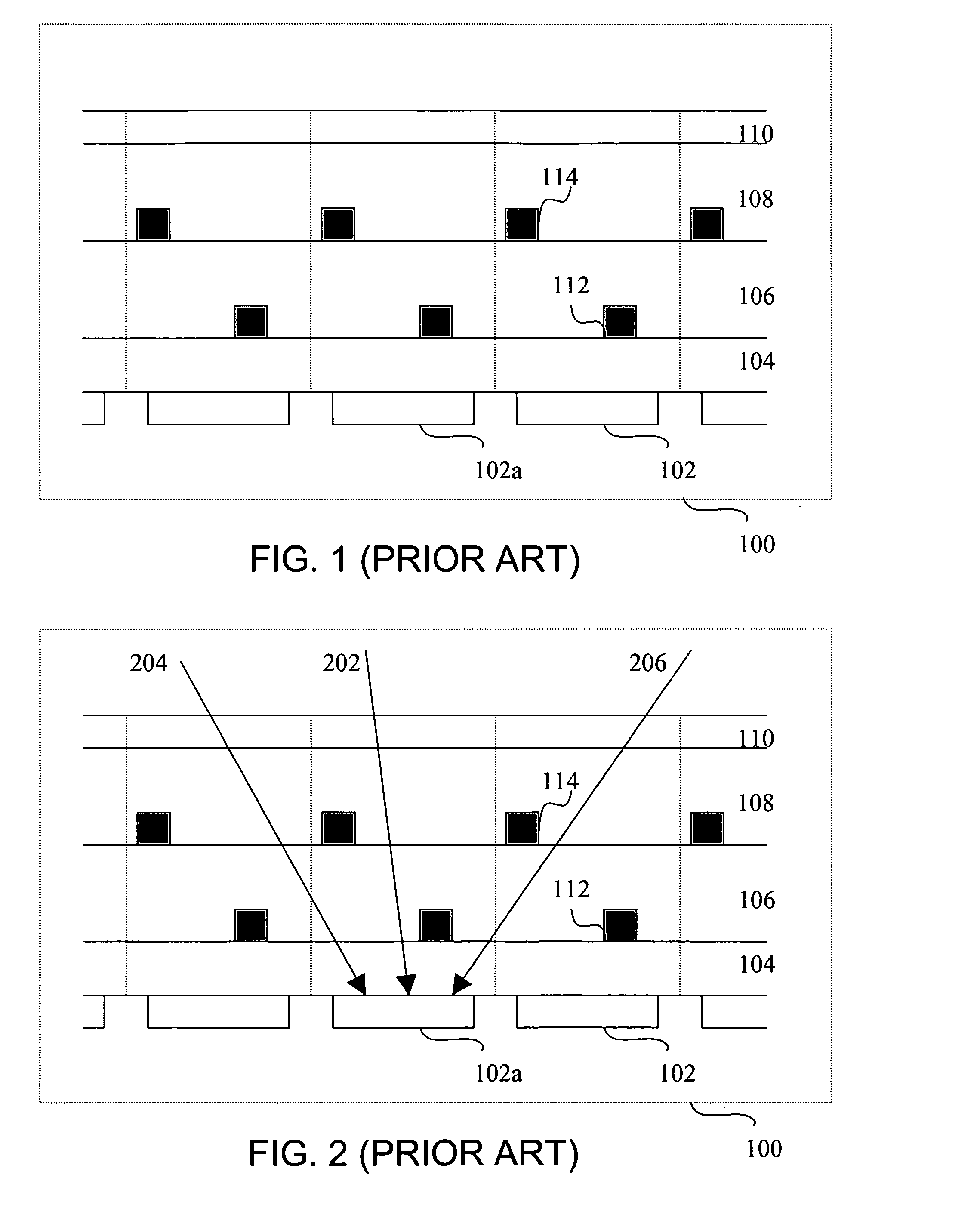

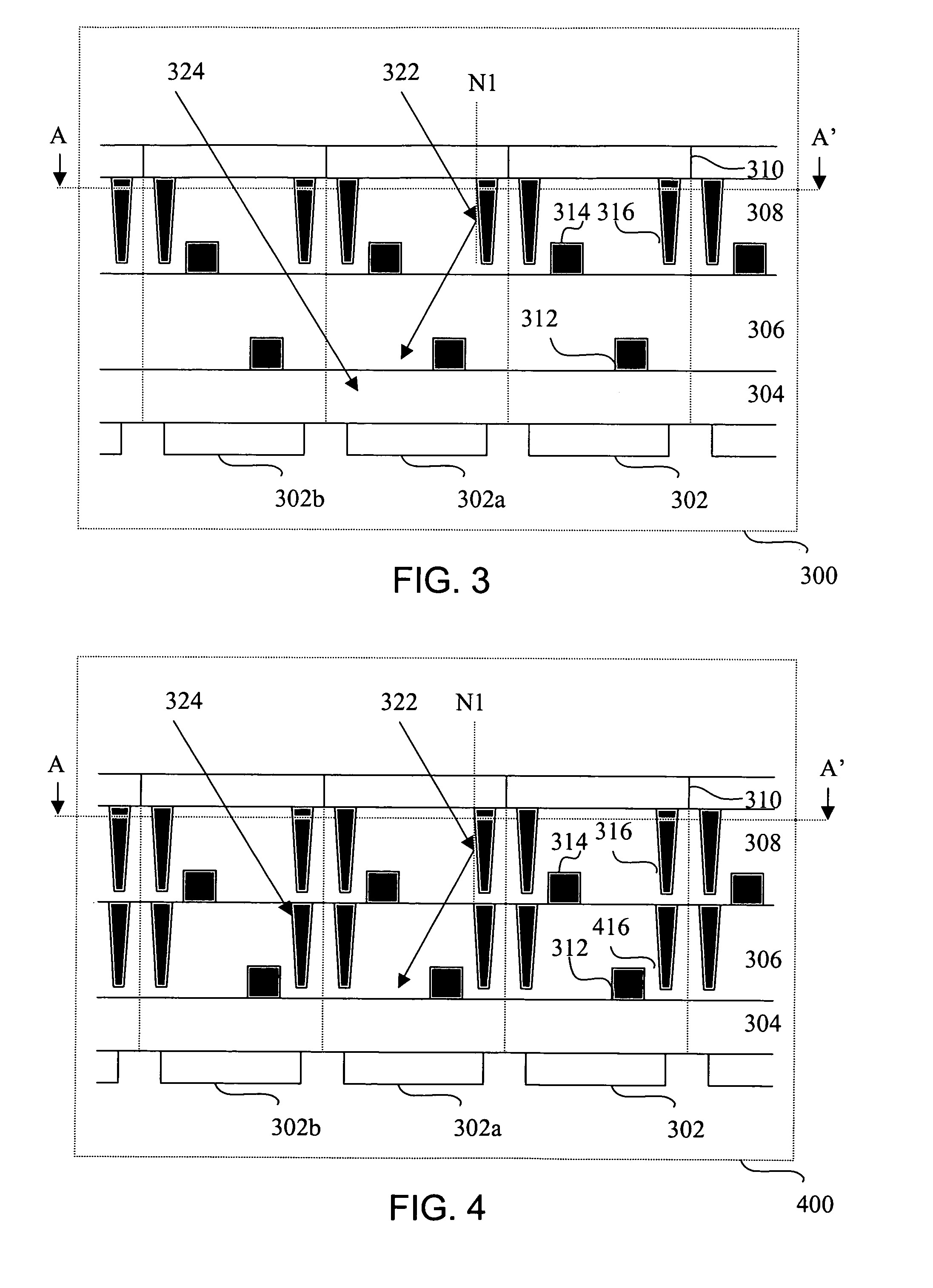

ActiveUS20050247963A1Spatial resolution is lowLow image sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingInter layerImage resolution

An image sensor and a manufacturing method thereof are provided. The image sensor includes a plurality of sensors, an inter-layer dielectric layer formed over the sensors, a first inter-metal dielectric layer formed over the inter-layer dielectric layer, and a plurality of first via walls formed in the first inter-metal dielectric layer, wherein each of the first via walls is formed around each of the sensors. In addition, the image sensor further includes a second inter-metal dielectric layer formed over the first inter-metal dielectric layer and a plurality of second via walls formed in the second inter-metal dielectric layer, wherein each of the second via walls is formed around each of the sensors. Therefore, the light leakage between different pixels and the problem of crosstalk are solved, and the spatial resolution and the photo sensitivity of the image sensor are enhanced.

Owner:MARLIN SEMICON LTD

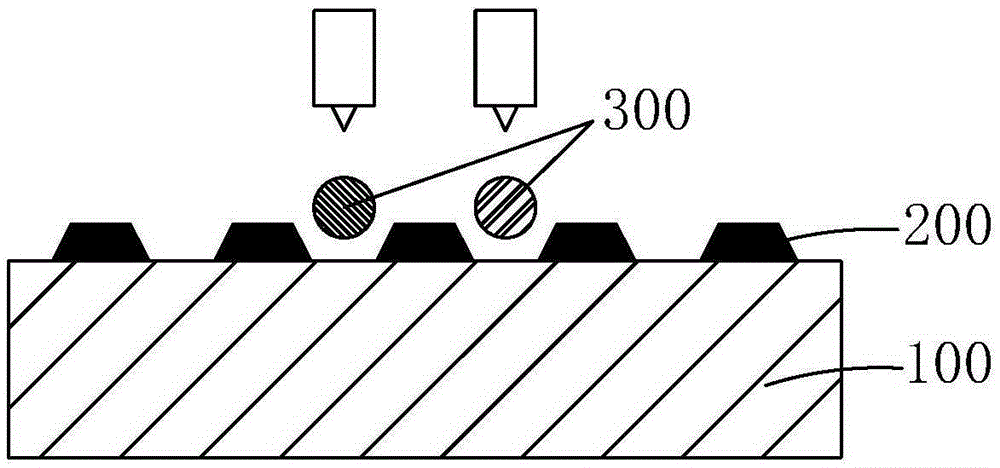

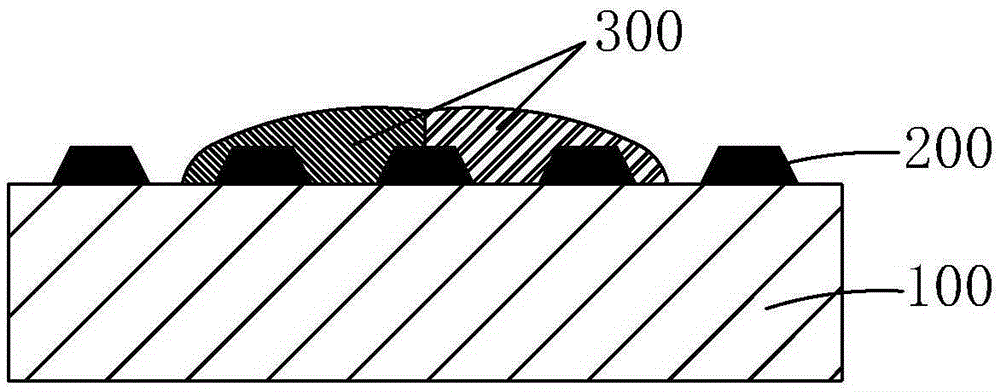

Manufacturing method for color filter substrate

InactiveCN105259696AImprove flatnessFunction as a retaining wallPhotomechanical apparatusTypewritersQuantum dotColor mixing

The invention provides a manufacturing method for a color filter substrate. According to the manufacturing method for the color filter substrate, a light resistance stop wall is formed on a black matrix before quantum dot glue is dropwise added to a sub-pixel area through a positive light resistor to play a stop wall role when the quantum dot glue is dropwise added, and the light resistance stop wall is removed after the stop wall role is played; accordingly, the problems that in an existing manufacturing method for the color filter substrate, color mixing occurs due to free flowing of the quantum dot glue due to the fact that the height of a stop wall is too small, and light leaking occurs due to disorder distribution of liquid crystals due to the fact that the height of the stop wall is too large are solved; the technology is simple, and the flatness degree of the manufactured color filter substrate is better.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Backlight module and liquid display device thereof

ActiveCN102691933ASolve the problem of light leakageAchieve designOptical light guidesLight fasteningsLiquid-crystal displayLight guide

The invention discloses a liquid crystal display device which comprises a panel module, a backlight module, a frame and a light source. The backlight module comprises a light guide plate which comprises a bottom surface, an emergent face opposite to the bottom surface, at least one lateral incident face and at least one lateral face. The lateral faces include a clamping face. The frame is used for containing the light guide plate and is provided with an abutting part corresponding to the clamping face, and the abutting part is tightly abutted to the clamping face of the light guide plate to fix the same. The light source is contained in the frame and faces the lateral incident face to allow light to emerge.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Lampshade structure and backlight module

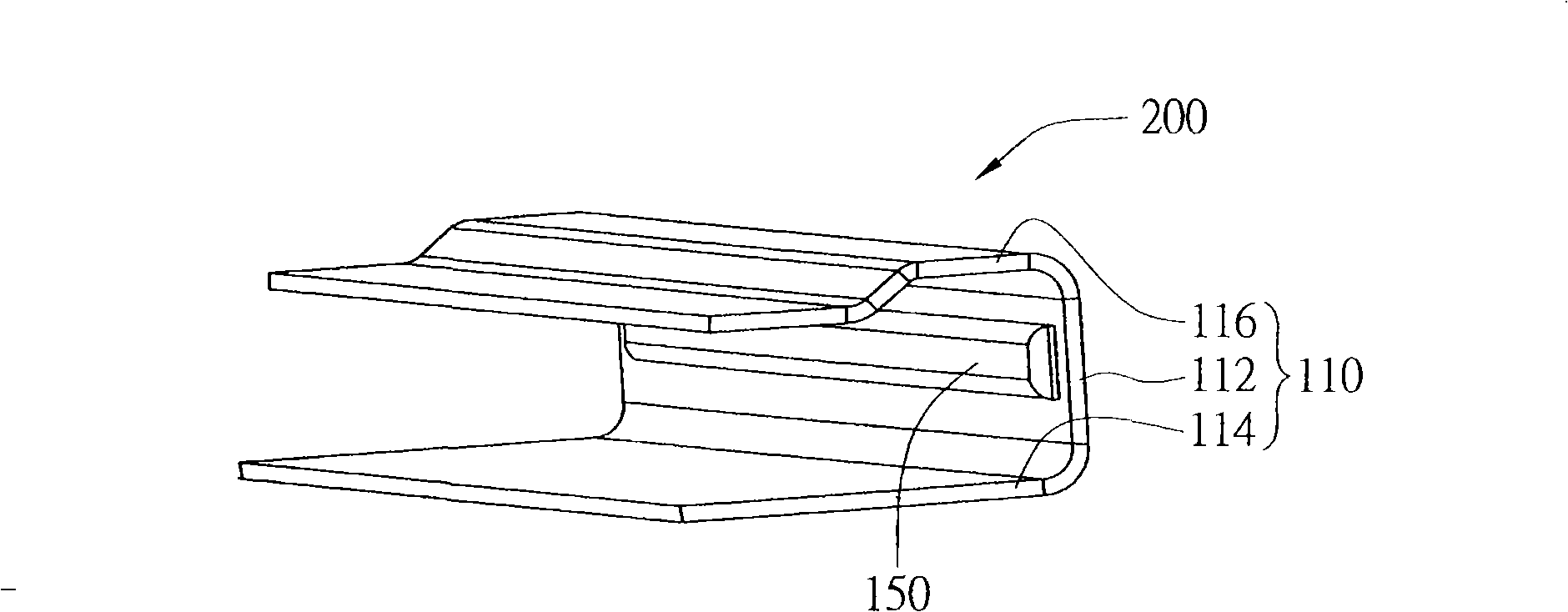

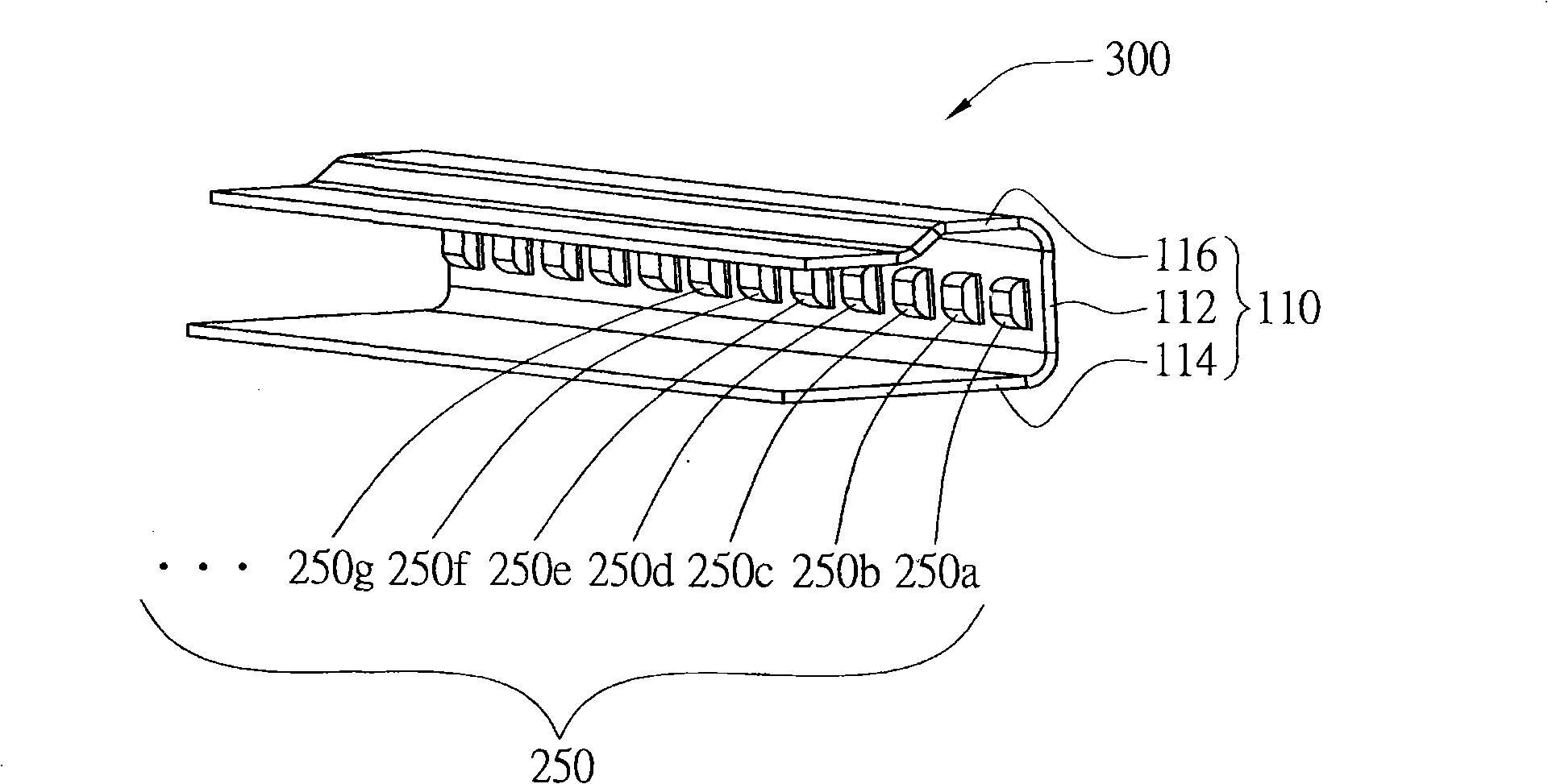

InactiveCN101255971AAvoid skewSolve the problem of light leakageMechanical apparatusPoint-like light sourceLight guideEngineering

The invention discloses a backlight module comprising a metal component, a light guiding plate, a luminous assembly and a projecting structure. The metal component comprises a substrate and two side plates disposed at the two sides of the substrate and facing each other. The light guiding plate, the substrate plate and two side plates surround an accommodation space in which the luminous assembly is disposed. The luminous assembly comprises at least a LED and a printed circuit board. The projecting structure is disposed between the substrate and the printed circuit board. A lamp shied structure is also disclosed.

Owner:AU OPTRONICS CORP

Backlight module structure

Owner:AU OPTRONICS CORP

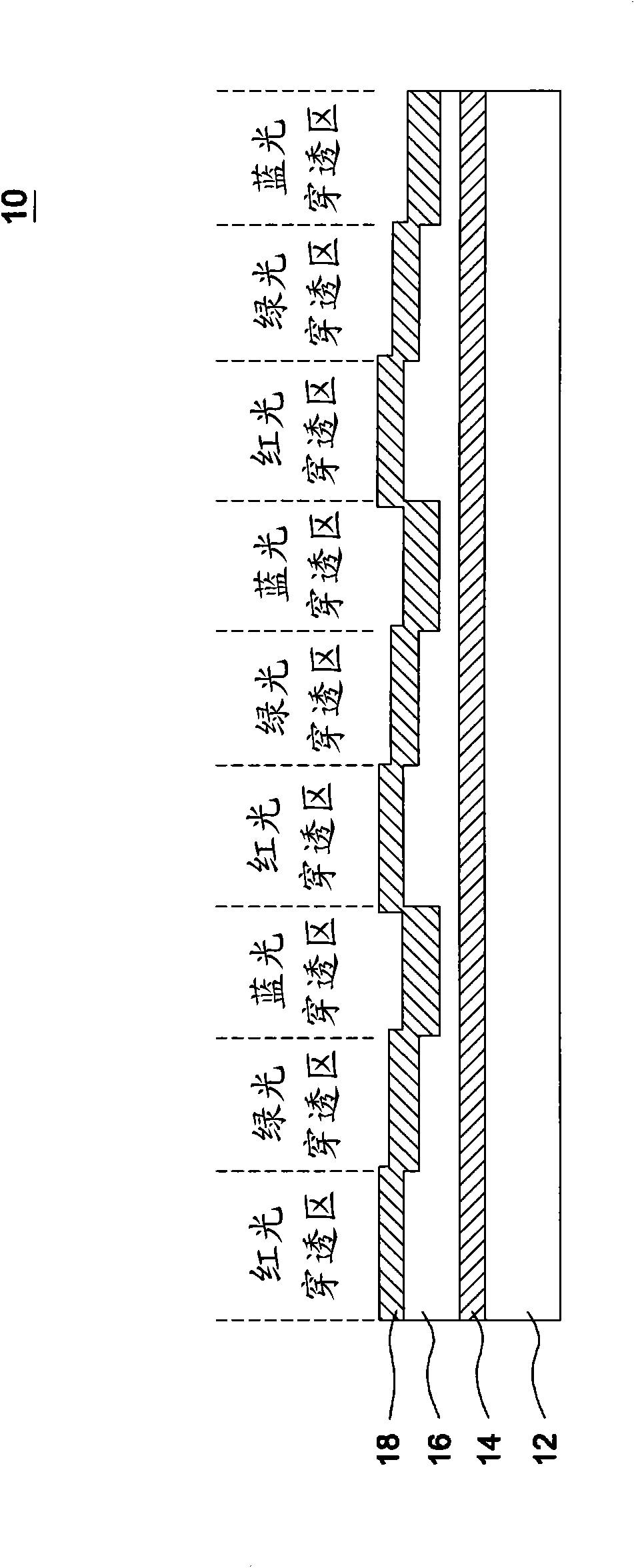

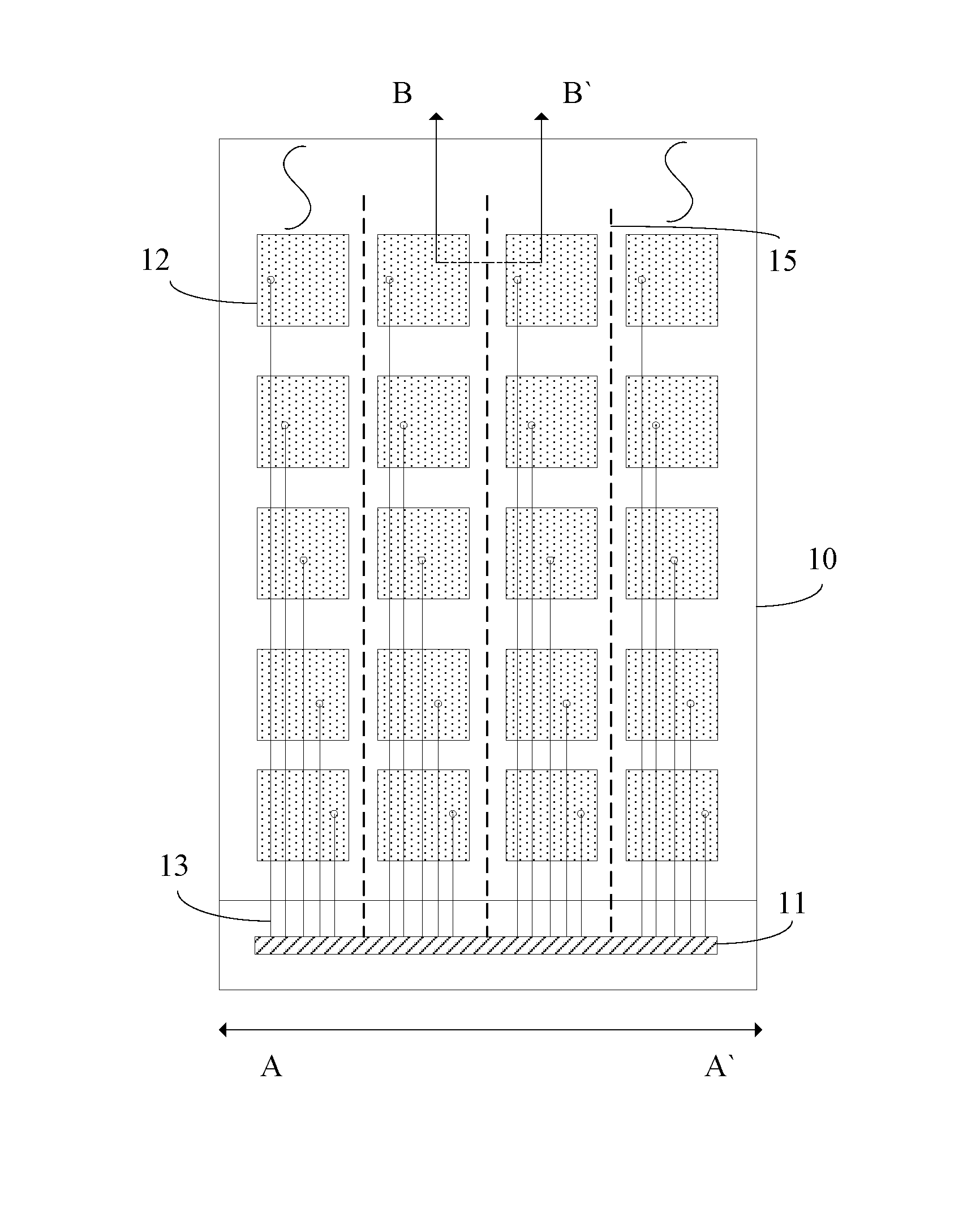

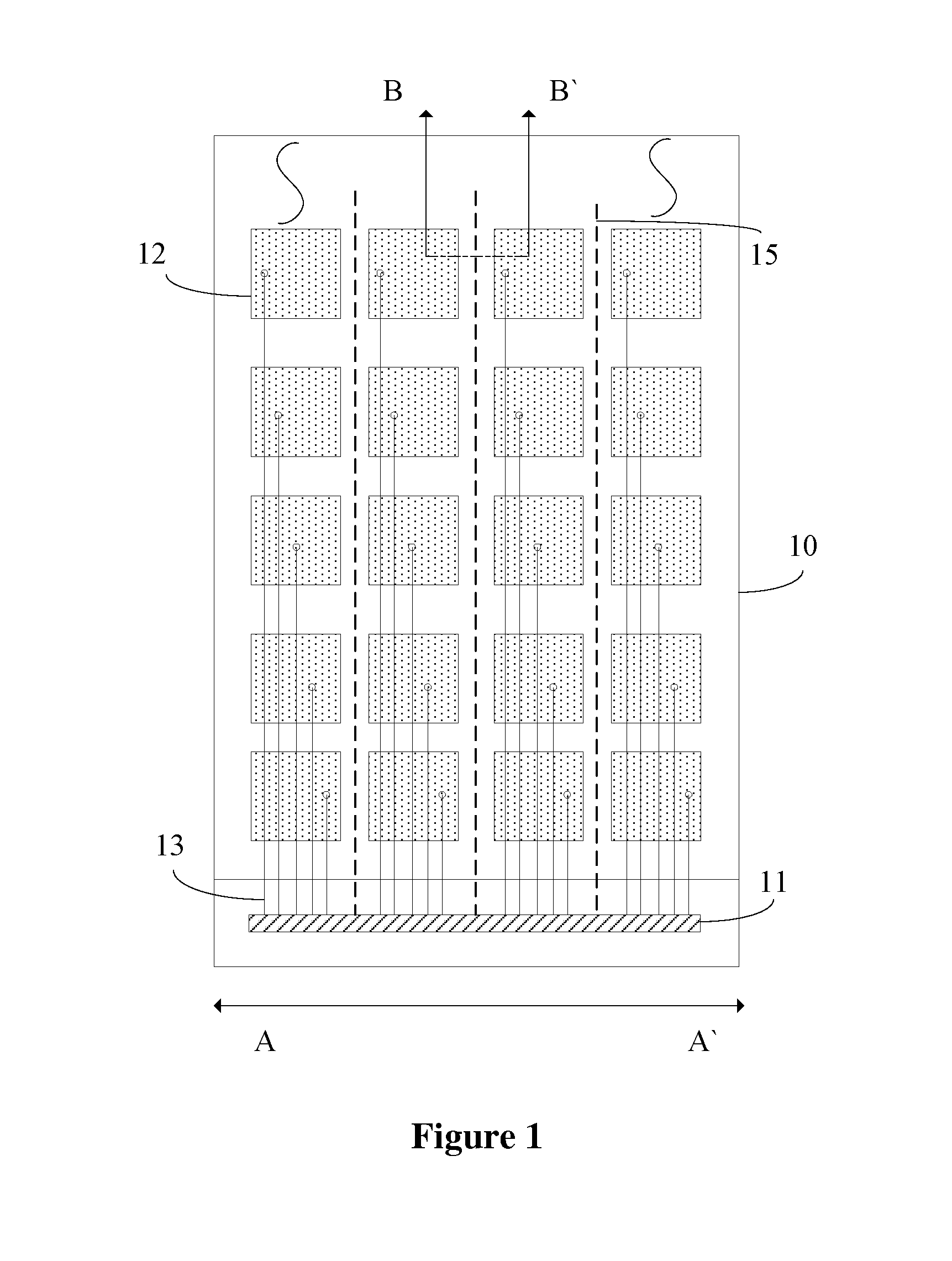

Colorful filter with touch function and liquid crystal display device

InactiveCN101551544AFacilitate thinningSolve the problem of light leakageNon-linear opticsInput/output processes for data processingColor gelLight filter

The invention relates to a colorful filter with touch function, comprising: a transparent substrate, a conductive layer, a filter layer and a protective layer, wherein the conductive layer is formed on the transparent substrate to sense a touch signal and provided with boundary electrodes on the periphery thereof, the filter layer is formed on the conductive layer, and the protective layer is formed on the filter layer. The filter layer comprises a plurality of red light penetrating zones, green light penetrating zones and blue light penetrating zones, and a pixel unit of a liquid crystal display device at least covers one red light penetrating zone, a green light penetrating zone and a blue light penetrating zone respectively.

Owner:WINTEK CORP

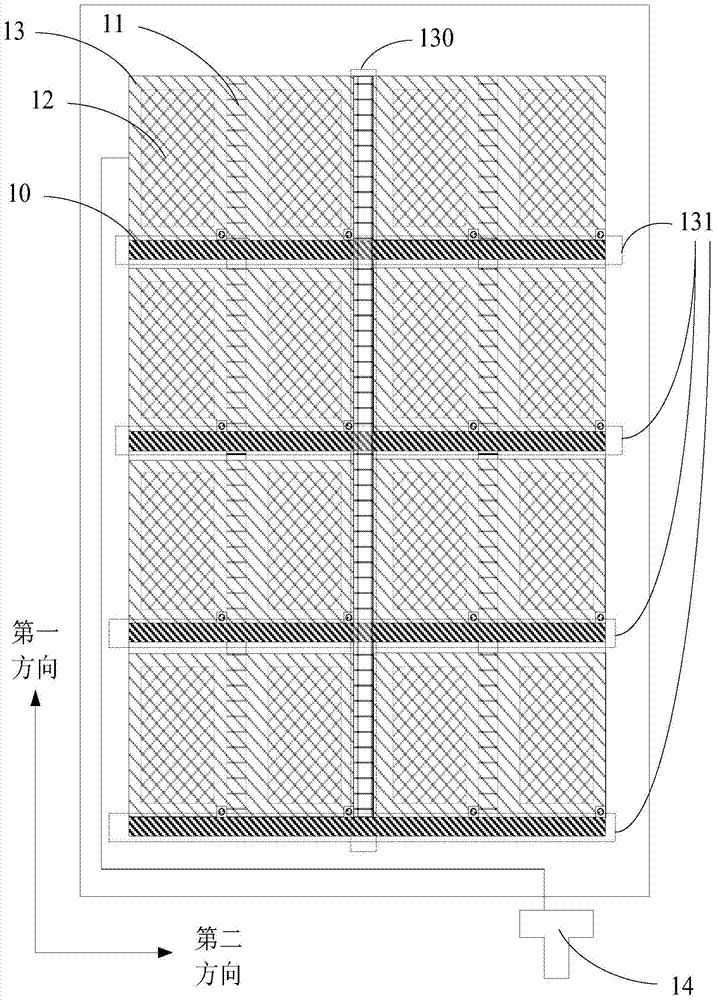

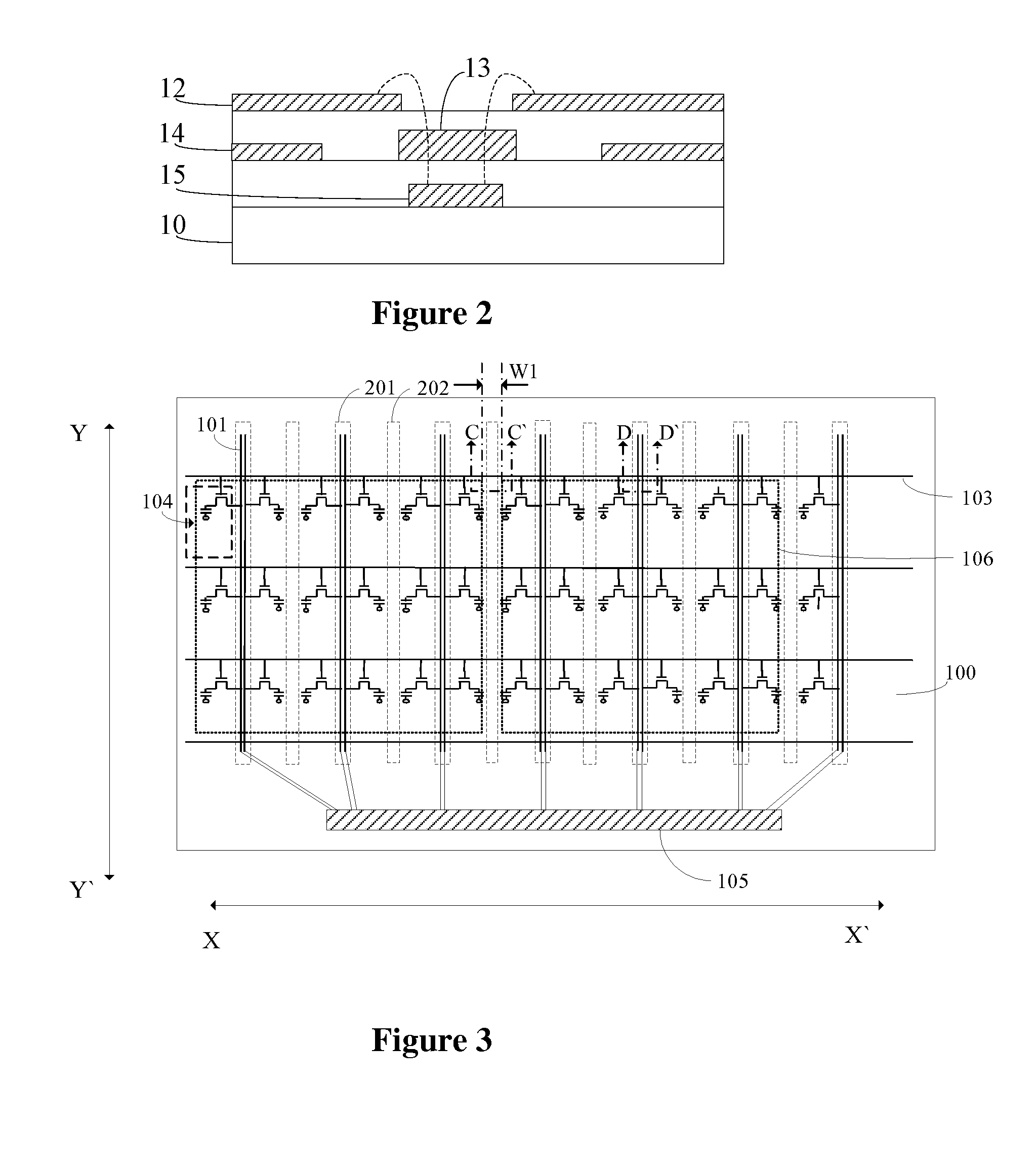

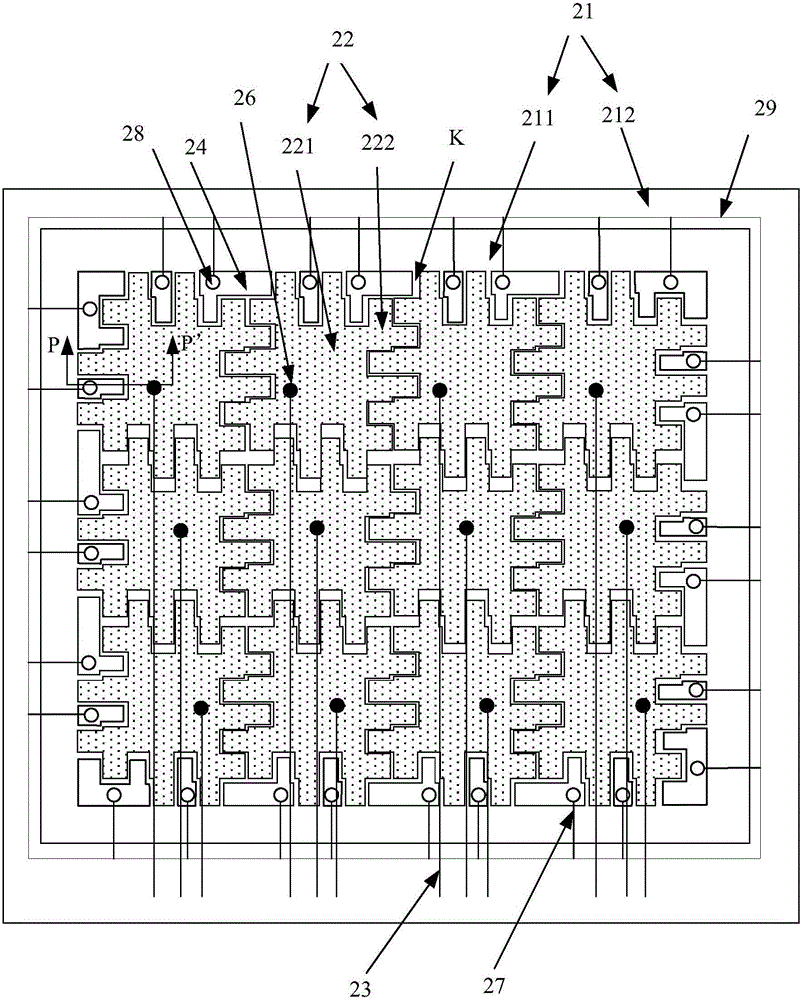

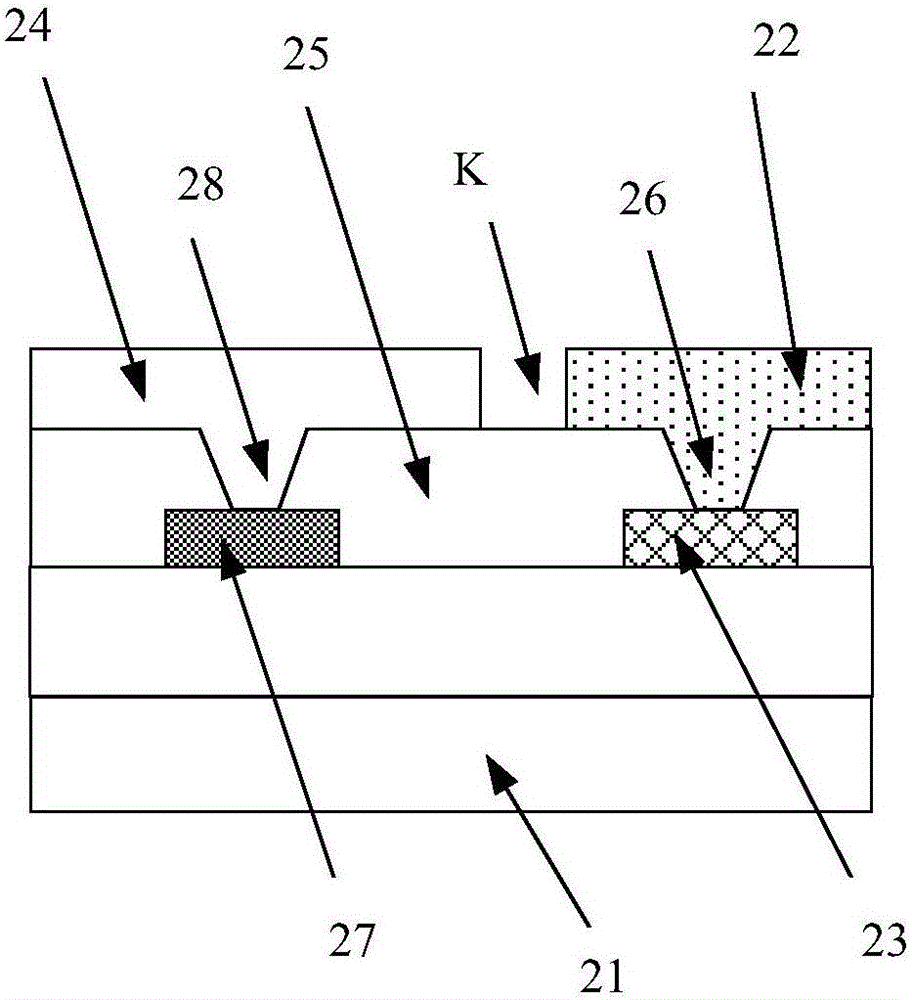

Array substrate, method for fabricating the same, and display apparatus

ActiveUS20160291776A1Avoid light leakageWell display effectNon-linear opticsInput/output processes for data processingData linesComputer science

An array substrate, a method for fabricating the same and a display apparatus are provided. The array substrate includes first non-display areas and second non-display areas, where the first non-display areas and the second non-display areas are respectively areas between adjacent columns of the pixel units and are arranged alternately in the first direction; two data lines are disposed in each first non-display area, the two data lines are electrically connected to two columns of pixel units on two sides of the first non-display area where the two data lines are located; a gap is provided between two electrode units adjacent in the first direction, and the gap is located above a part of the second non-display area.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

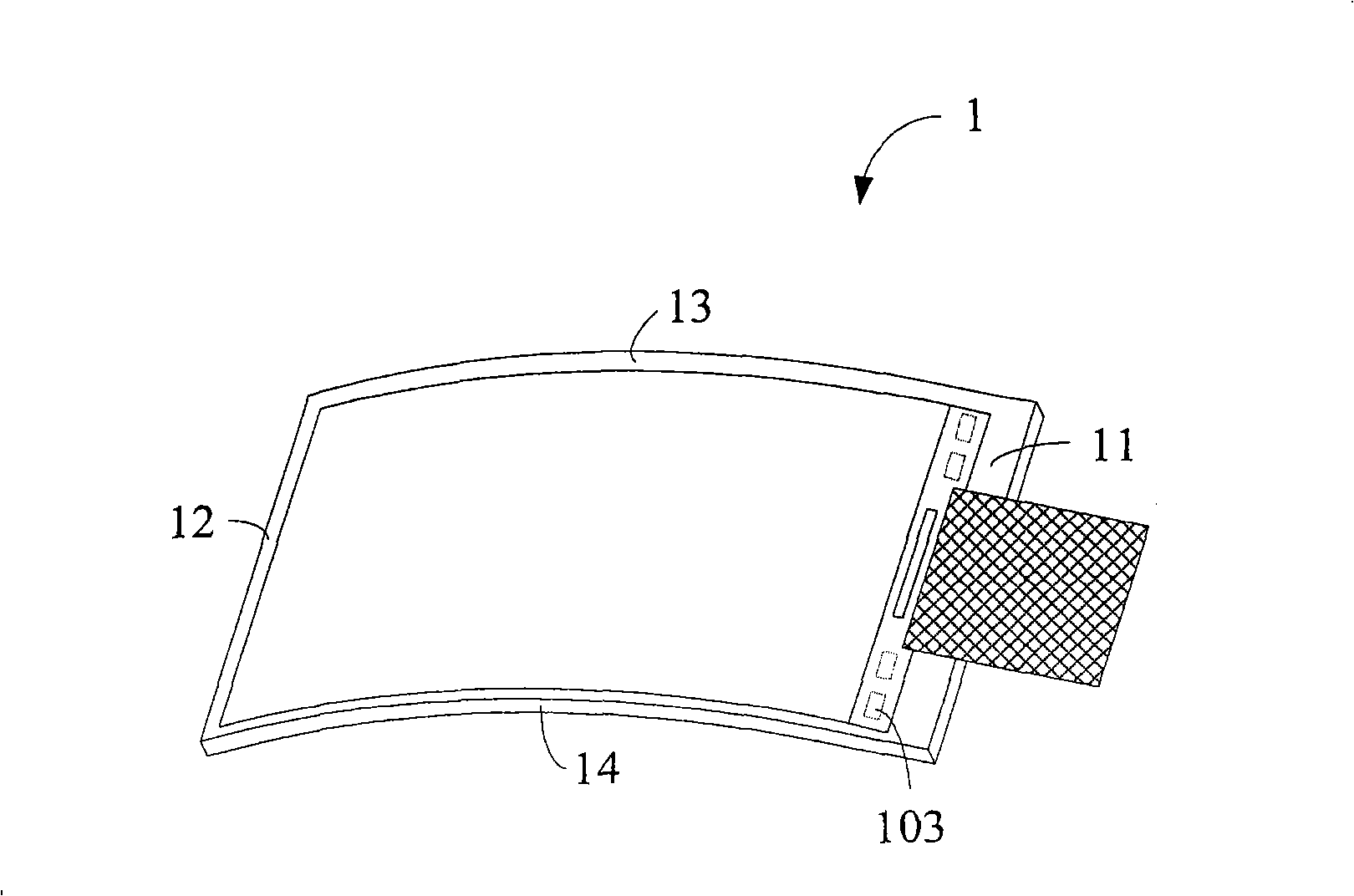

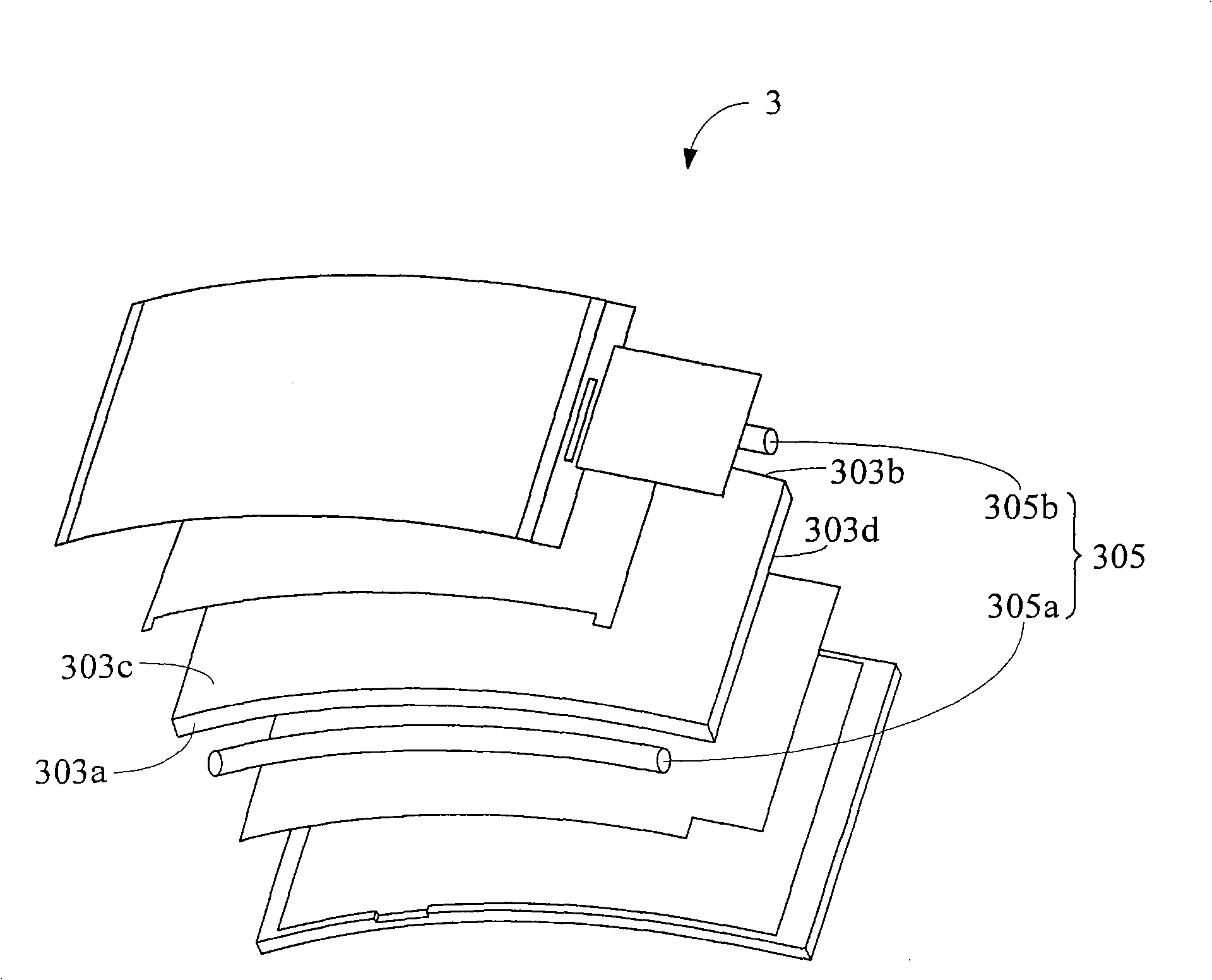

Light guiding device for thin type display and the thin type display thereof

InactiveCN101493209ASolve the problem of light leakageMechanical apparatusStatic indicating devicesLight guideDisplay device

The invention discloses a light conducting device for a thin-type display and a thin-type display thereof. The thin-type display comprises a light conducting device, a panel and a frame, wherein, the frame is equipped with two opposite arc-shaped side frames and two opposite side frames, the light conducting device is equipped with a light conducting plate and a light source device; the light conducting plate is equipped with a top camber, a bottom camber, a first arc-shaped side and a second arc-shaped side; the top camber and the bottom camber are relatively connected with the first arc-shaped side and the second arc-shaped side on the two sides of the top camber and the bottom camber, the first arc-shaped side and the second arc-shaped side are relatively arranged in the two arc-shaped side frames; the light source device is arranged between one of the two arc-shaped sides and one of the two arc-shaped side frames; and the panel is arranged in the frame and on the light conducting device.

Owner:AU OPTRONICS CORP

Touch screen and touch display electronic device

ActiveCN105760033ASolve the problem of light leakageGuaranteed display effectInput/output processes for data processingVisibilityOptoelectronics

The invention discloses a touch screen and a touch display electronic device. The touch screen comprises a substrate, an auxiliary electrode layer, a common electrode layer and a routing layer, wherein the auxiliary electrode layer, the common electrode layer and the routing layer are arranged on the same side of the substrate, and the common electrode layer and the routing layer are oppositely arranged in the direction perpendicular to the substrate. The common electrode layer comprises a plurality of common electrode blocks which are the same. Each common electrode block comprises a center electrode and a sawtooth electrode electrically connected with the center electrode. The opposite sawtooth electrodes of every two adjacent common electrodes are nested. The routing layer comprises a plurality of first wires electrically and correspondingly connected with the common electrode blocks in a one-to-one mode. The auxiliary electrode layer comprises a plurality of auxiliary electrode blocks. The sawtooth electrodes adjacent to the edge of the substrate and the auxiliary electrode blocks are nested. When the common electrode blocks input common voltage signals for image display control, the auxiliary electrode blocks input common voltage signals. The touch screen improves the touch detection precision, and prevents the problems of visibility of edge images and light leakage of pixel electrodes near to the edge of the substrate.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Color film substrate, manufacturing method thereof, display panel and display device

The invention belongs to the field of display technology, in particular to a color film substrate, a manufacturing method thereof, a display panel and a display device. The color film substrate comprises a substrate and a color filter layer arranged on the substrate. The color filter layer comprises color fitter units which are of at least two colors and distributed in an array. A black matrix is between adjacent color fitter units. A flat layer is arranged on the color filter layer. Grooves corresponding to black matrixes are arranged on the flat layer. Light-blocking layers are arranged in the grooves. Due to the light-blocking layers, mix-color light is blocked so that one color can be observed at the lateral angle so that color mixture and light leakage are solved.

Owner:BOE TECH GRP CO LTD

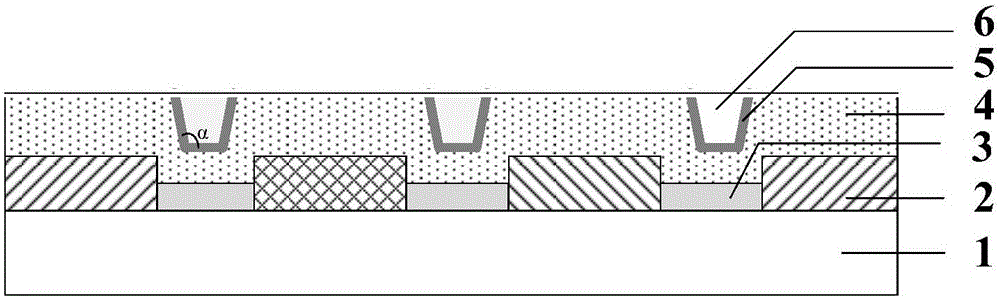

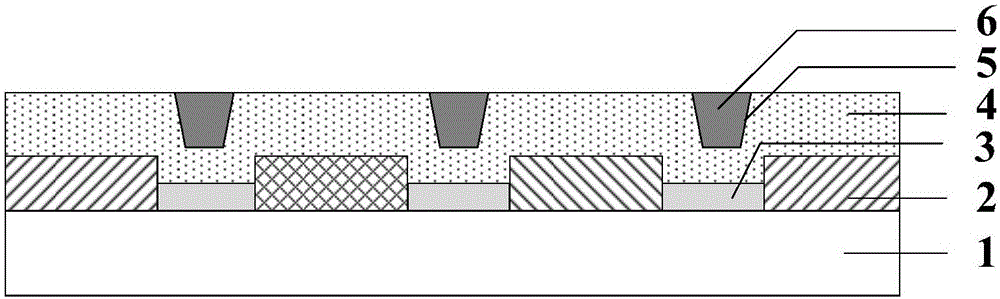

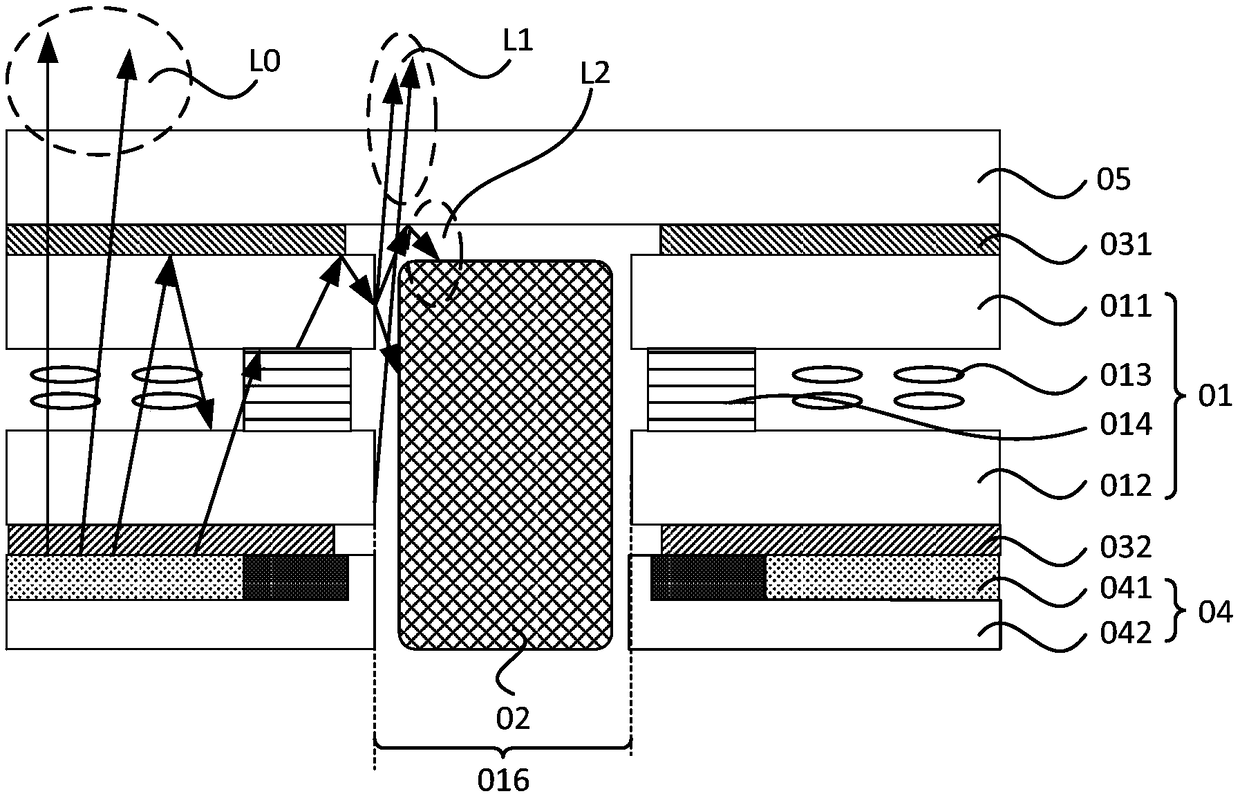

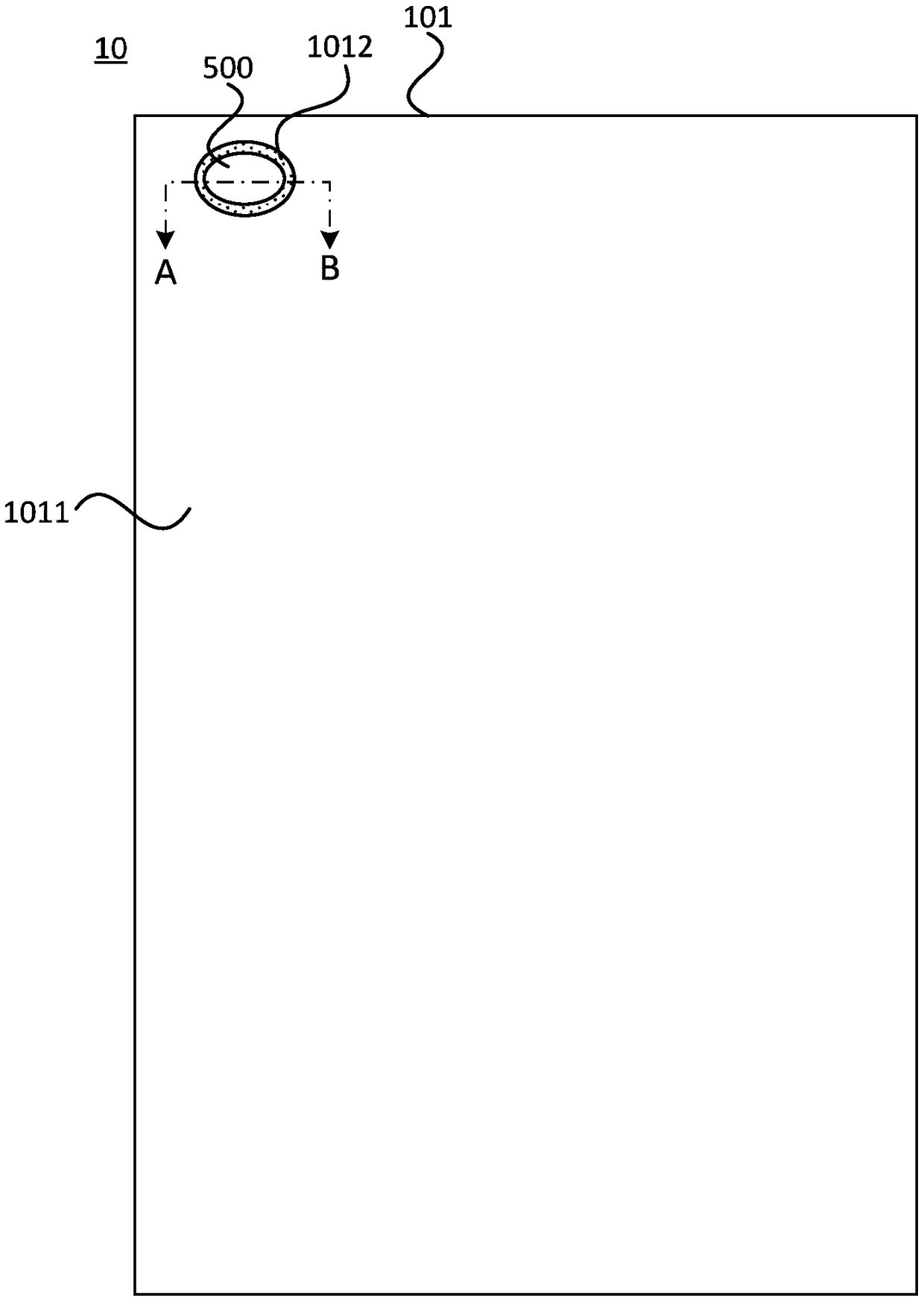

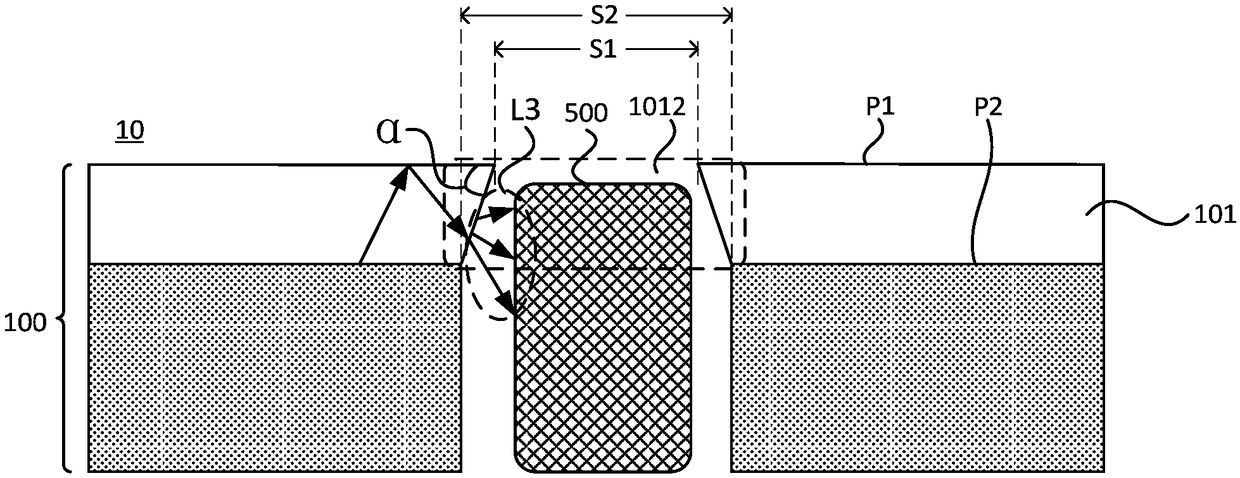

Display device

ActiveCN108828823AAvoid light leakageSolve the problem of light leakageNon-linear opticsAcute angleDisplay device

The embodiment of the invention discloses a display device. The display device comprises a display panel and a functional module. The display panel comprises a first substrate, the first substrate islocated on the light outlet side of the display panel and comprises a display zone and at least one first via hole, and the display zone surrounds the first via holes. The first substrate comprises afirst surface and a second surface opposite to the first surface, the first surface is the surface close to the light outlet side of the display panel, the opening area of the first via holes on the first surface is smaller than that of the first via holes on the second surface, an included acute angle formed by the inner side wall of the first via holes and the first surface is alpha and is greater than or equal to 30 degrees but is smaller than 90 degrees, and the functional module is located below orthographic projections of the first via holes on the first surface. The display device can make light emitted from the edges of the first via holes offset in the direction of deviating from the light outlet side of the display panel, and accordingly the intensity of light pointing to the light outlet side of the display panel can be reduced, namely light leakage on the edges of the first via holes is decreased.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

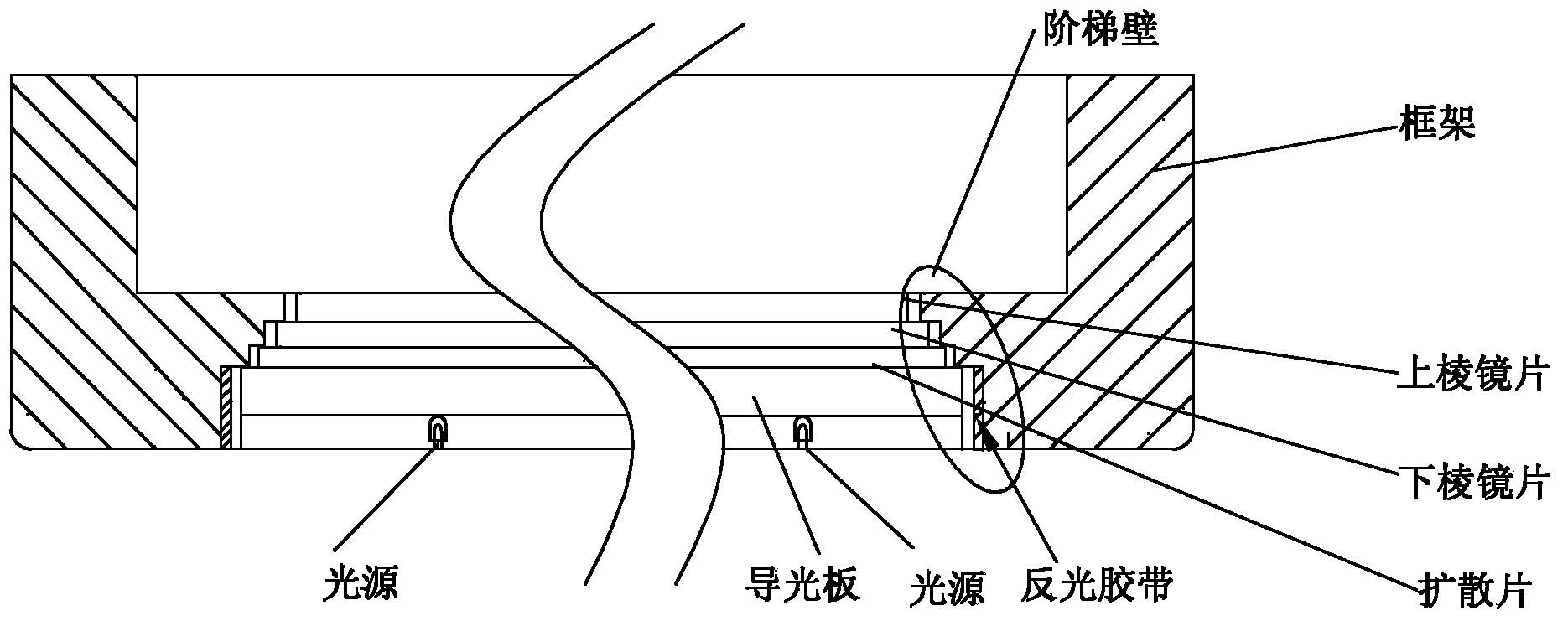

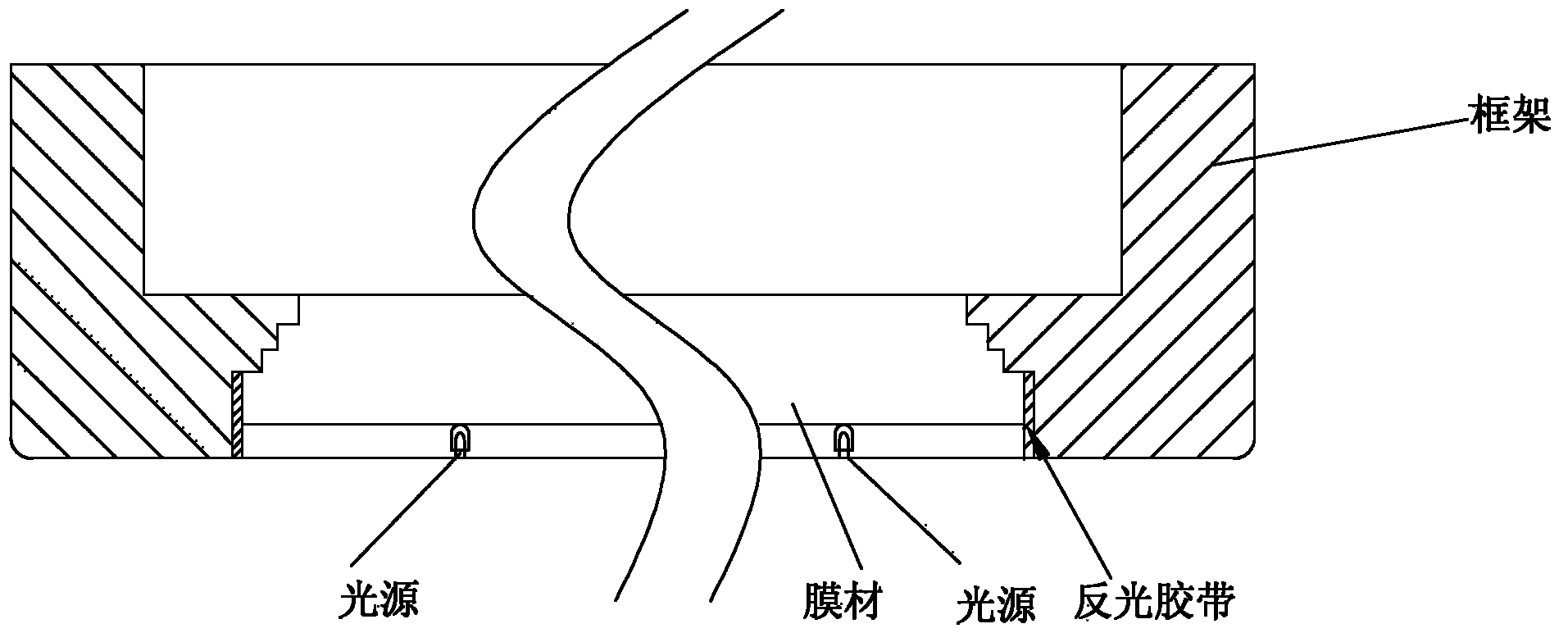

Backlight module and liquid crystal display device

InactiveCN103912819ASolve the problem of light leakageSolve the problem of bright linesLight fasteningsNon-linear opticsLiquid-crystal displayBright line

The invention discloses a backlight module and a liquid crystal display device. The backlight module comprises a light source, a frame and a membrane for transforming the light source into a uniform area light source. The light source and the membrane are accommodated in the frame, the face for guiding emission of light is a light emitting face, and the face opposite to the light emitting face is a bottom. At least one of the sides, which intersect with the light emitting face in the membrane, is step-shaped. The step-shaped sides expand outwards successively along the direction from the light emitting face to the bottom. Correspondingly, the sides opposite to the step-shaped sides of the membrane in the frame are in step shapes matched with the step shapes of the membrane. By means of the backlight module and the liquid crystal display device, the problem of peripheral light leakage and bright lines of traditional backlight module matched visual areas can be solved, and the brightness of the backlight module can be improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Image sensor device and manufacturing method thereof

ActiveUS7235833B2Spatial resolutionHigh sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingInter layerImage resolution

An image sensor and a manufacturing method thereof are provided. The image sensor includes a plurality of sensors, an inter-layer dielectric layer formed over the sensors, a first inter-metal dielectric layer formed over the inter-layer dielectric layer, and a plurality of first via walls formed in the first inter-metal dielectric layer, wherein each of the first via walls is formed around each of the sensors. In addition, the image sensor further includes a second inter-metal dielectric layer formed over the first inter-metal dielectric layer and a plurality of second via walls formed in the second inter-metal dielectric layer, wherein each of the second via walls is formed around each of the sensors. Therefore, the light leakage between different pixels and the problem of crosstalk are solved, and the spatial resolution and the photo sensitivity of the image sensor are enhanced.

Owner:MARLIN SEMICON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com