Backlight module and liquid display device thereof

A liquid crystal display device and backlight module technology, which is applied in the direction of lighting devices, fixed lighting devices, lighting device components, etc., can solve the problems of too thick frames, light leakage, and the inability to realize narrow frames, etc., and achieve the effect of improving the appearance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further details will be given below in conjunction with the preferred embodiments shown in the accompanying drawings.

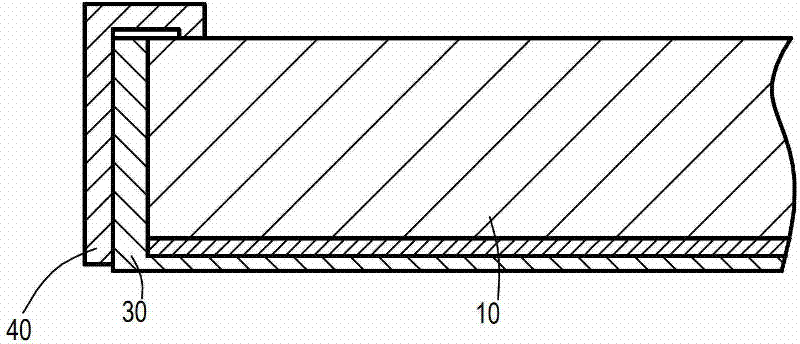

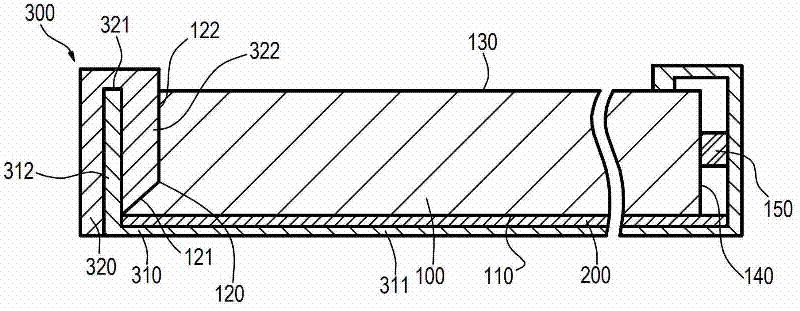

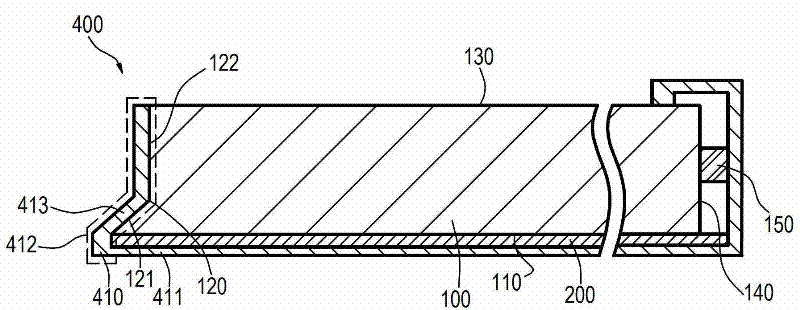

[0022] see figure 2 It is a side sectional view of the backlight module of the first embodiment of the present invention. The backlight module disclosed in this embodiment includes: a light guide plate 100, the light guide plate 100 includes a bottom surface 110, and a light emitting surface 130 opposite to the bottom surface , at least one side toward the light incident surface 140 and at least one side surface, wherein the side surface includes a clamping surface 120, and the clamping surface 120 includes an upper portion 122 and a lower portion 121, wherein the lower portion 121 is a first Inclined surface, the first inclined surface forms an acute angle with the bottom surface 110, the upper surface 122 is a plane perpendicular to the top surface, and the plane shrinks toward the center of the light guide plate 100, the lower surface 121 and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com