Patents

Literature

547 results about "Bright line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

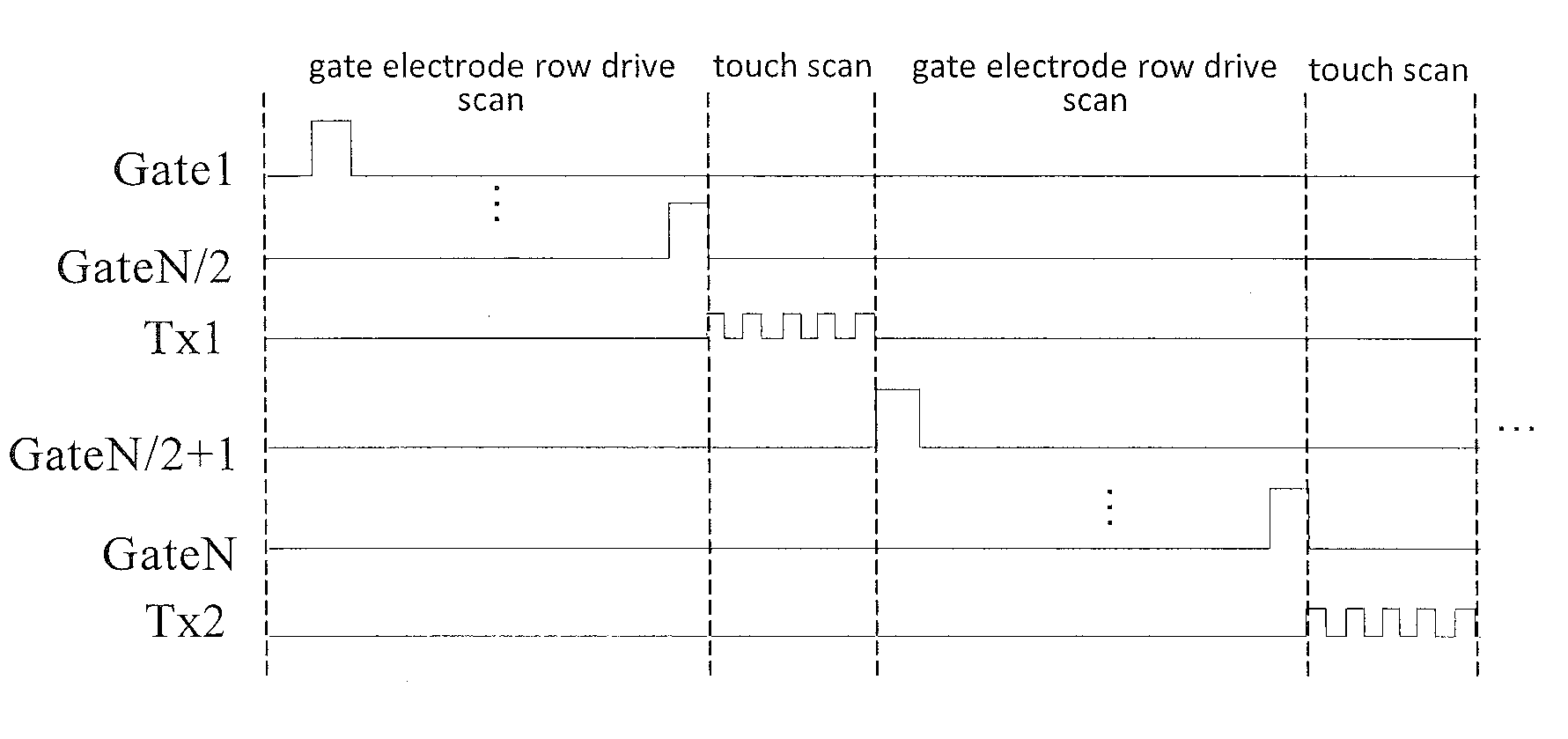

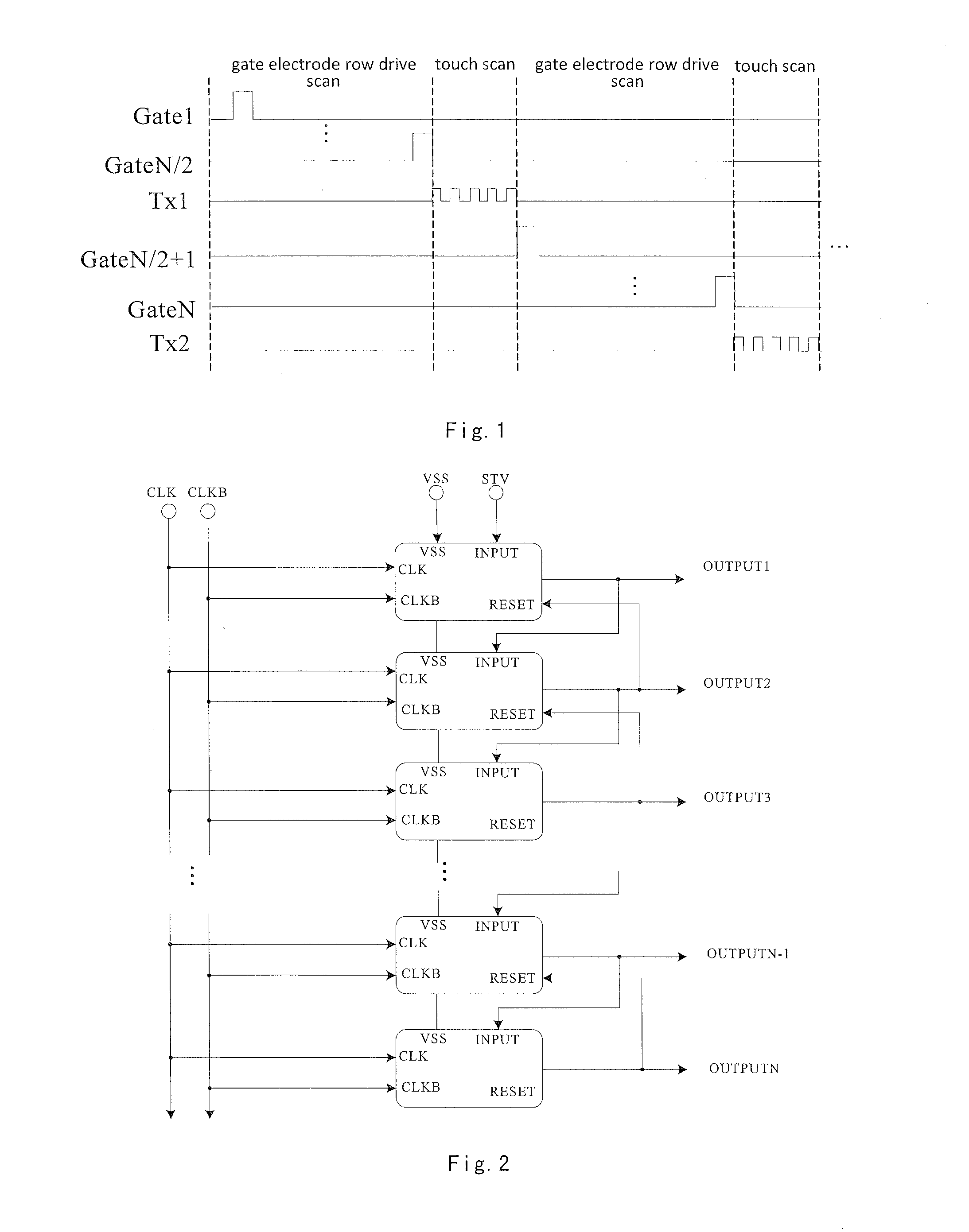

Gate drive circuit and method and display device

ActiveCN103943055APrevent leakageAvoid the defect of insufficient charge rateStatic indicating devicesDigital storageShift registerLevel shifting

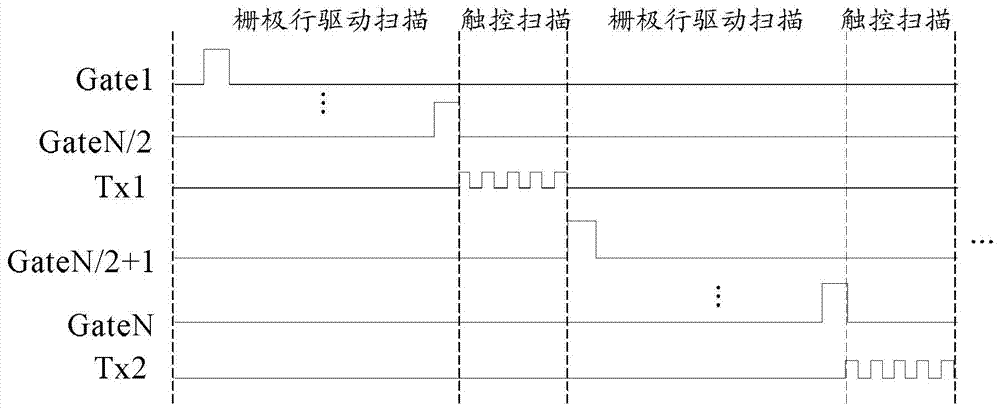

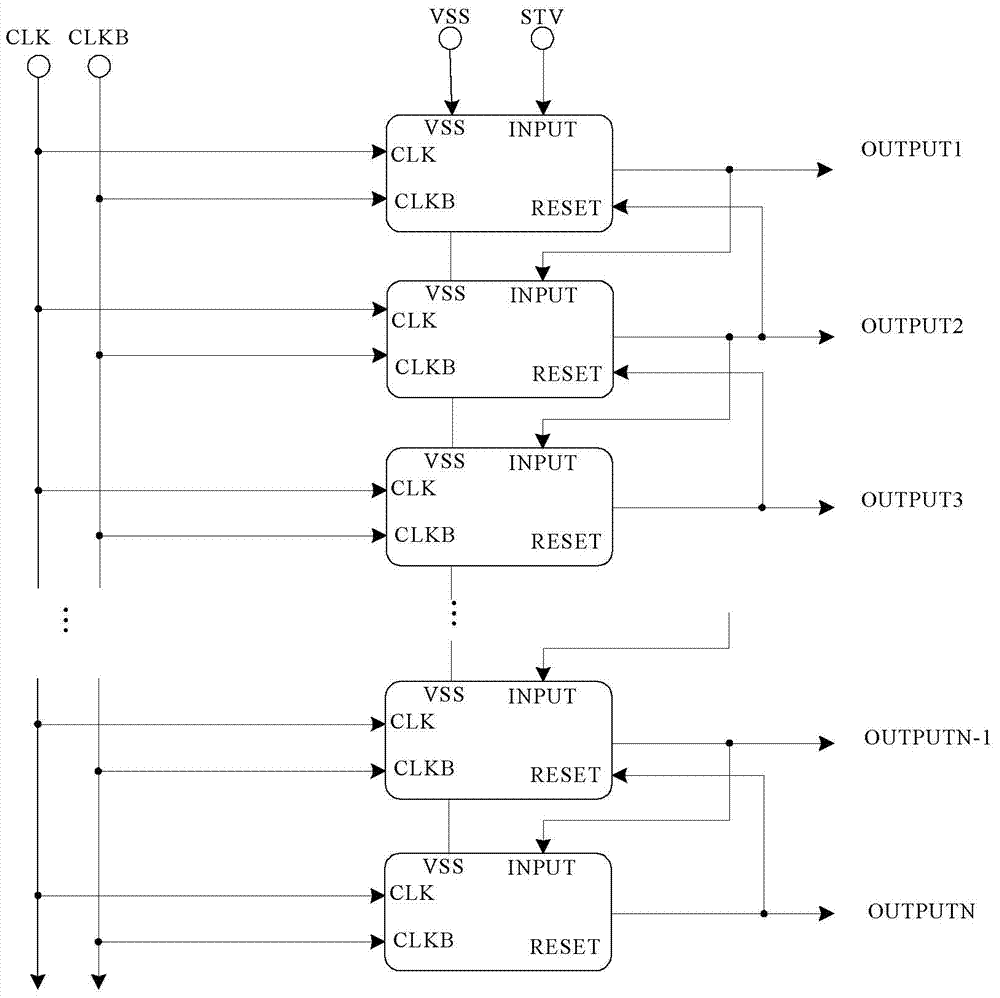

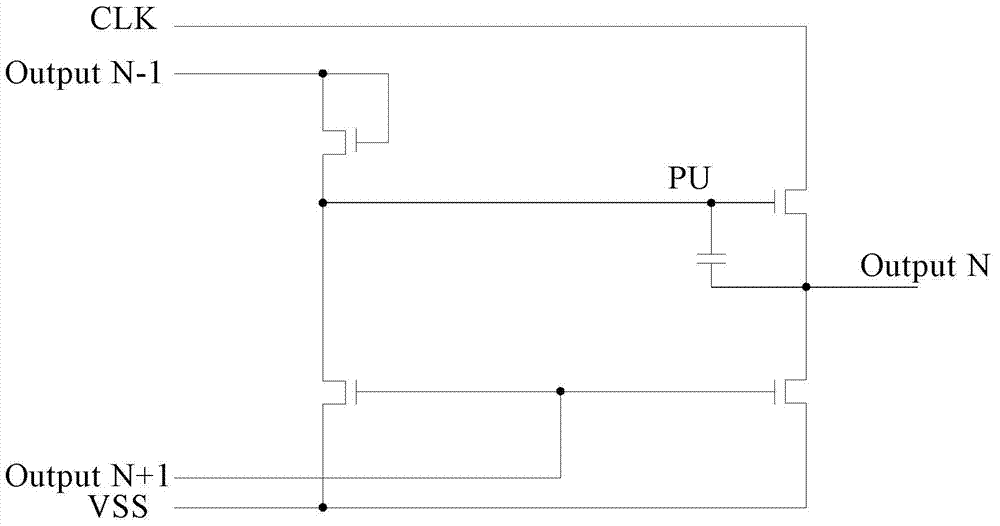

The invention provides a gate drive circuit and method and a display device and relates to the technical field of display. The method includes the steps that gate row drive scanning is performed on shifting register units located in a first area in the gate drive circuit; after gate row drive scanning of the shifting register units in the first area is finished, touch scanning is performed; after touch scanning is finished, the last-level shifting register unit located in the first area is scanned again so that the last-level shifting register unit located in the first area can be used for pre-charging a first-level shifting register unit located in a second area; gate row drive scanning is performed on shifting register units located in the second area in the gate drive circuit, and the last-level shifting register unit located in the first area is in cascade connection with the first-level shifting register located in the second area. The method can overcome the defect that the row pixel charging rate is insufficient and solve the problem of dark lines or poor bright lines.

Owner:BOE TECH GRP CO LTD

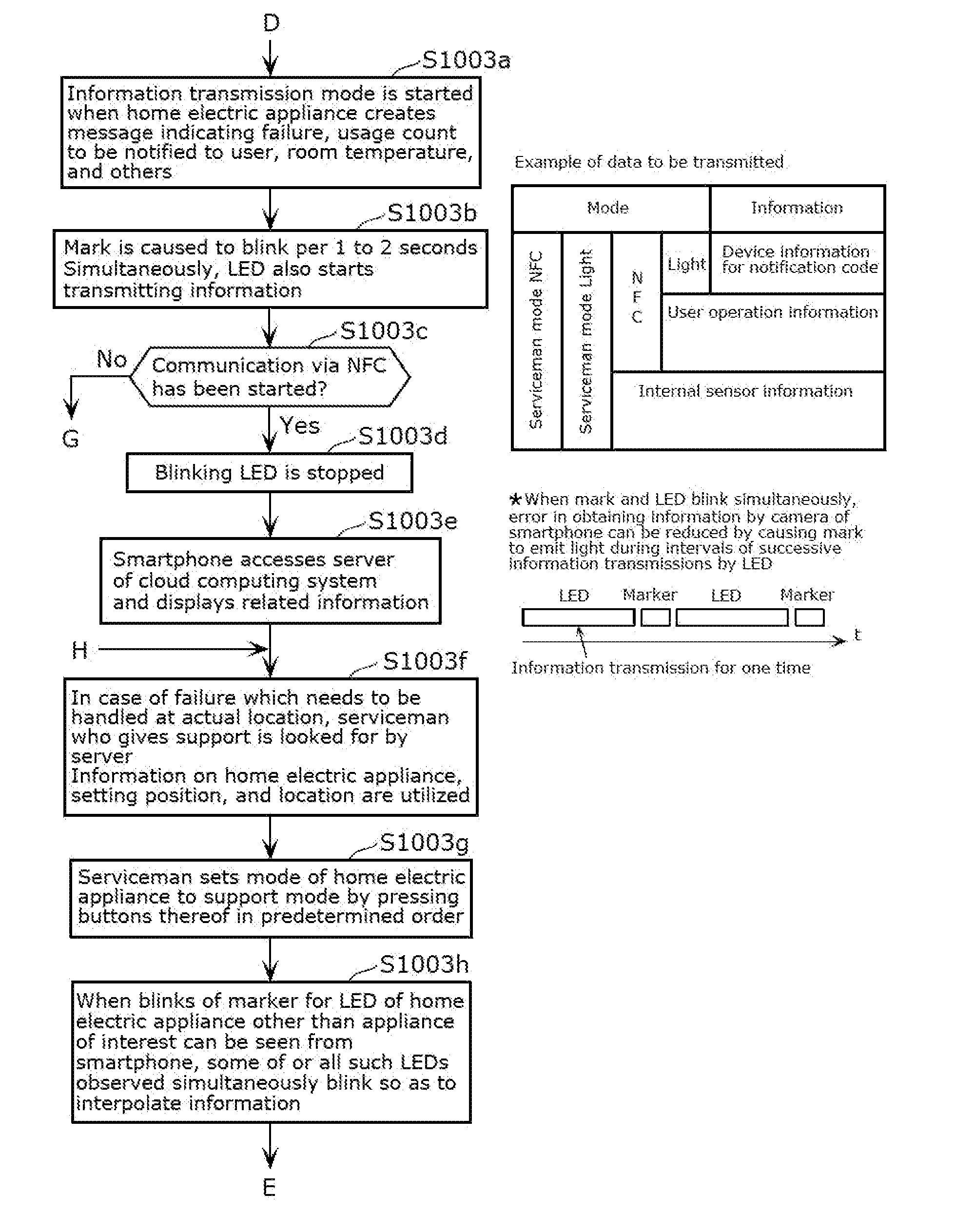

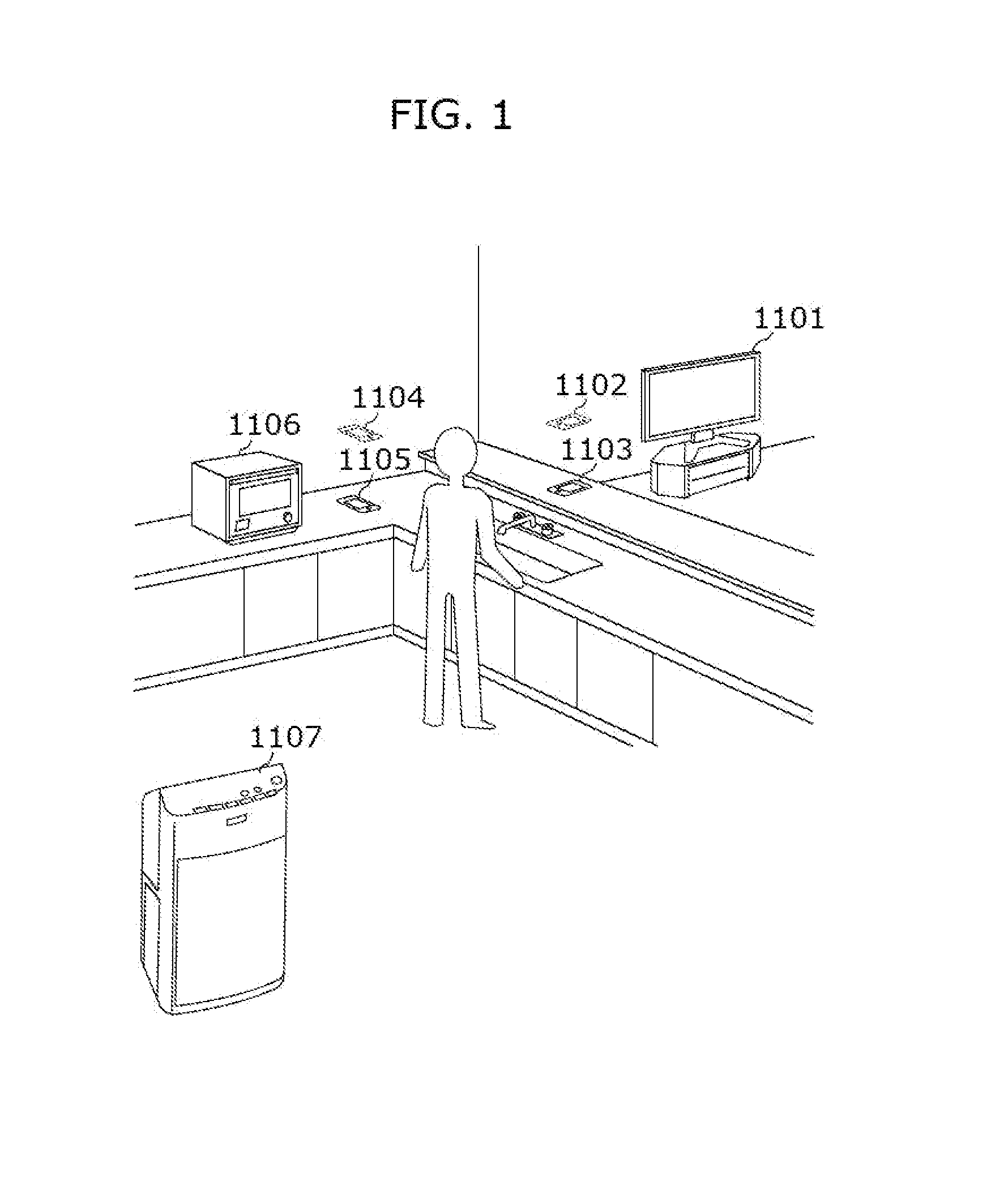

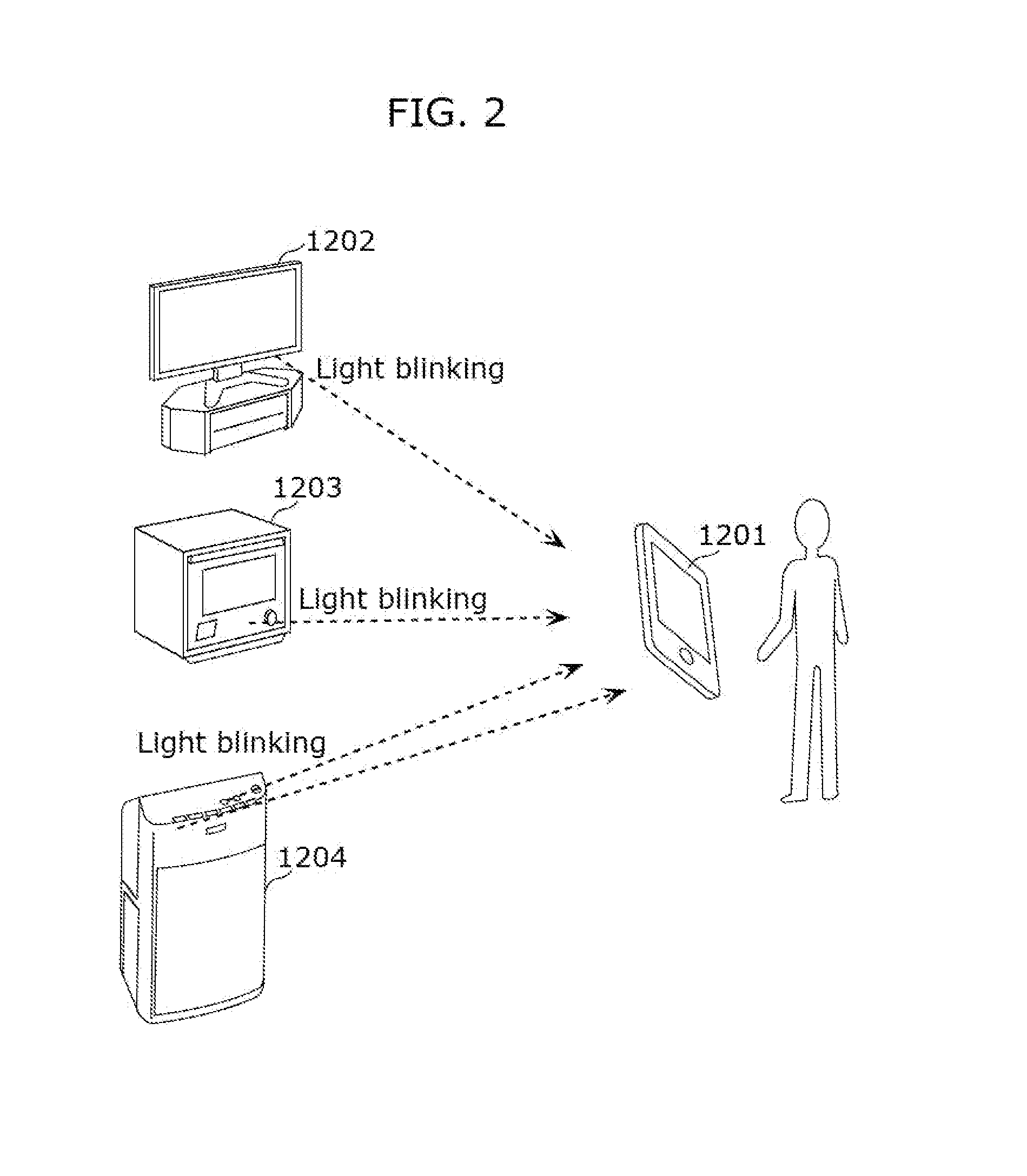

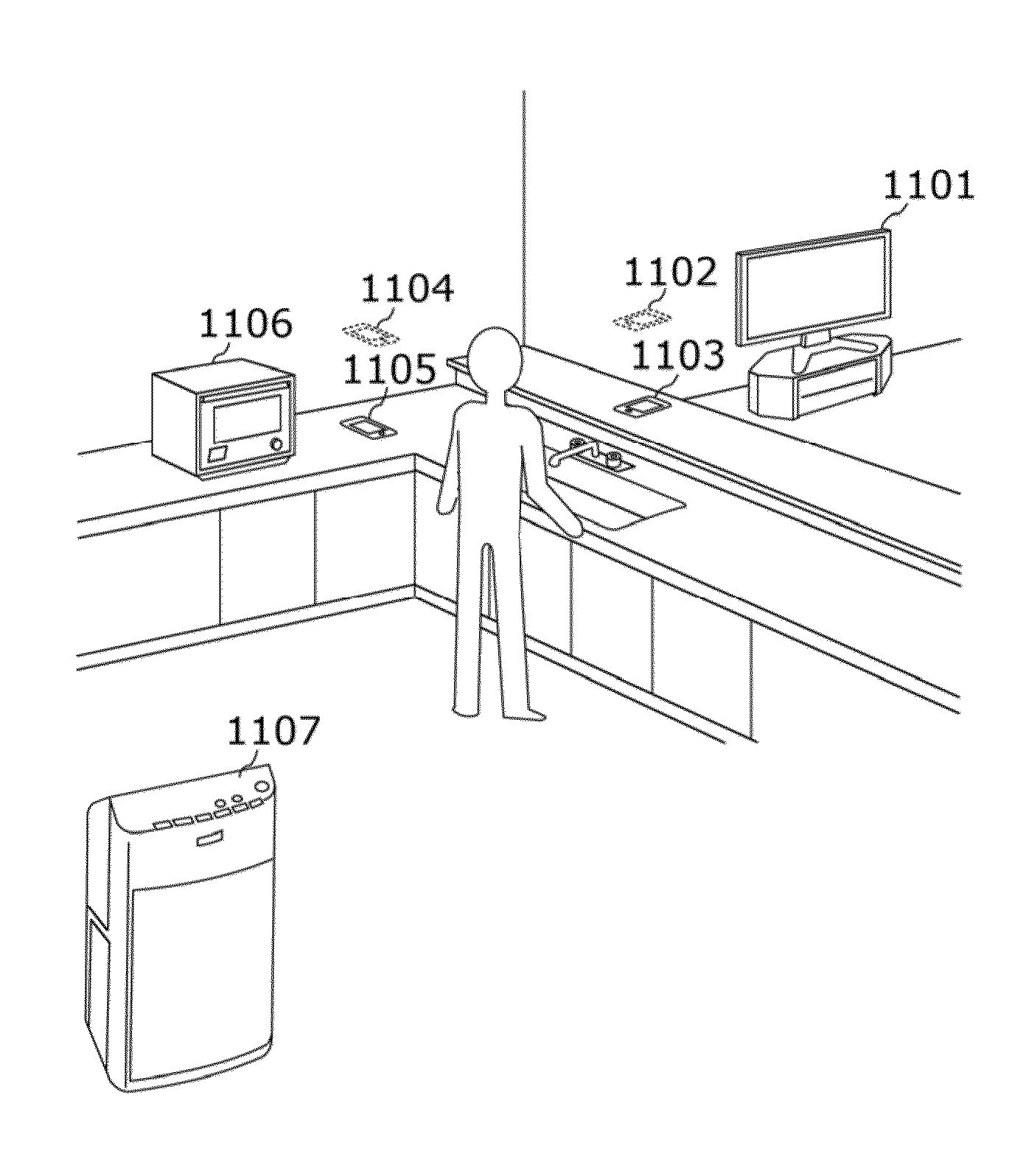

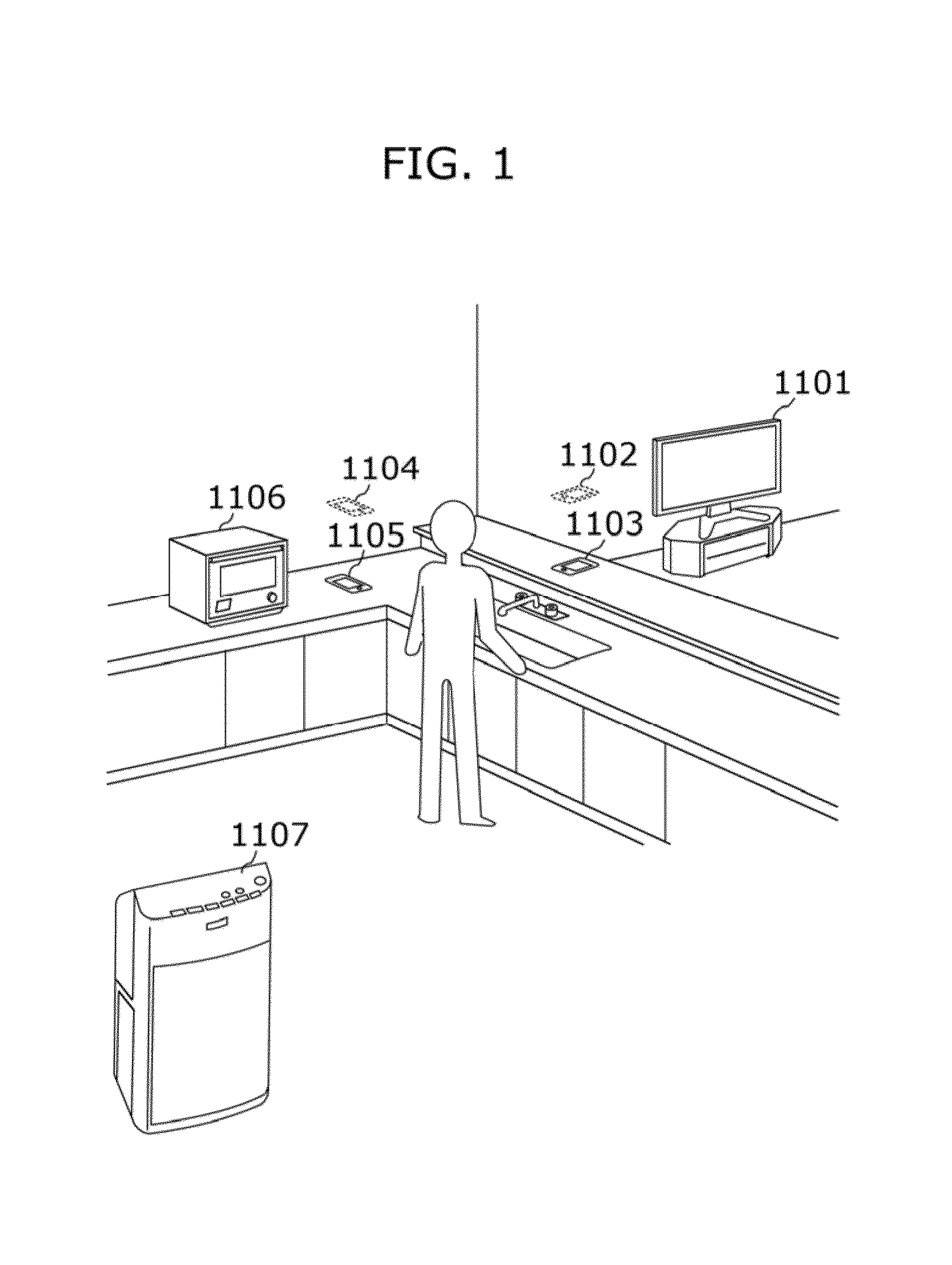

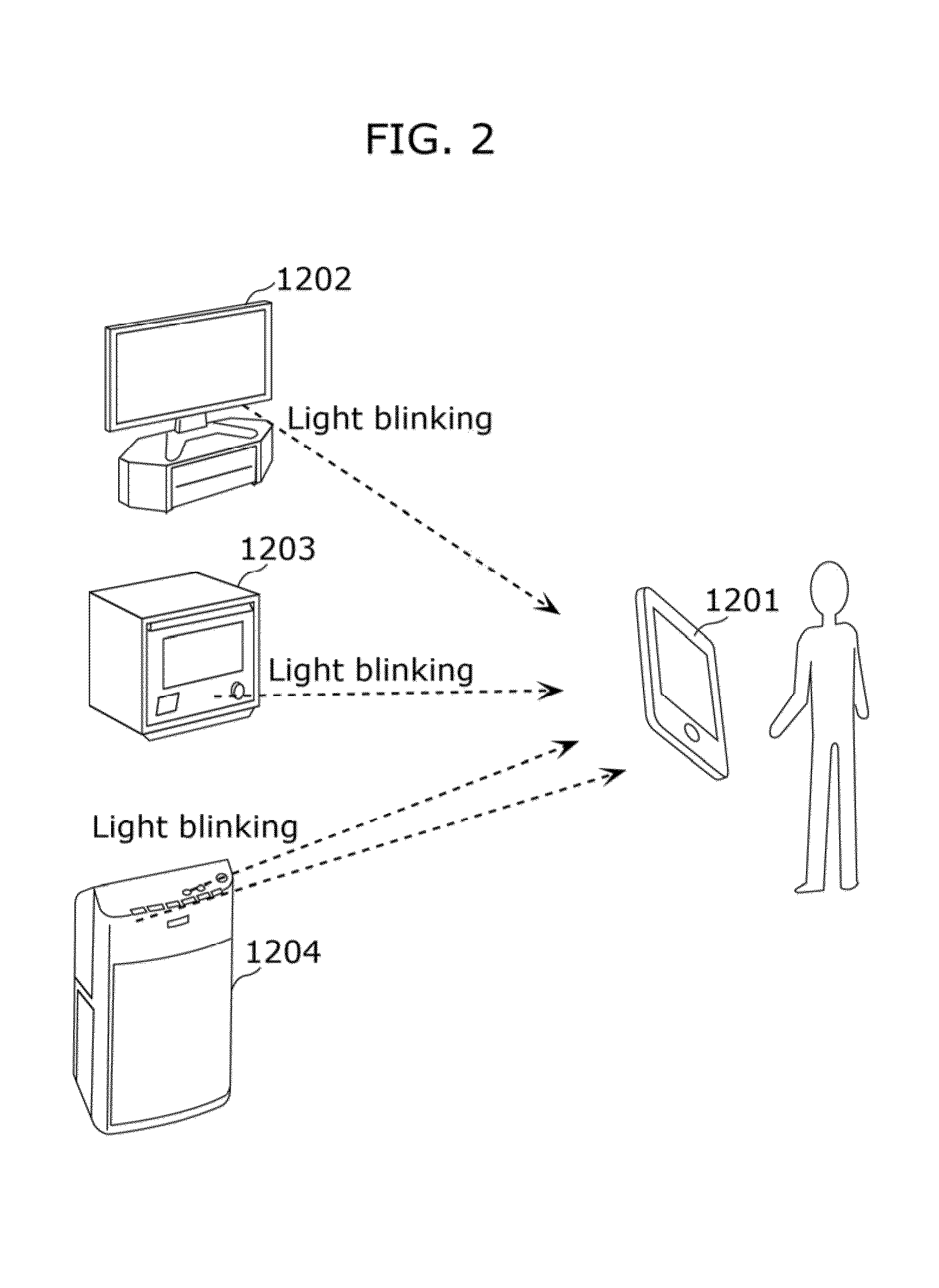

Information communication device

ActiveUS20130337787A1Low computing performanceTelevision system detailsService provisioningExposure Elapsed TimeComputer science

An information communication method includes: setting an exposure time of an image sensor to less than or equal to 1 / 2000 second so that, in an image obtained by capturing a subject by the image sensor, a stripe bright line parallel to a plurality of exposure lines included in the image sensor appears according to a change in luminance of the subject; obtaining the image including the stripe bright line parallel to the plurality of exposure lines by, using the set exposure time, starting exposure sequentially for the plurality of exposure lines each at a different time; and obtaining information by demodulating data according to, in a pattern of the bright line included in the obtained image, a brightness change in a direction perpendicular to the plurality of exposure lines.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

Information communication method

ActiveUS20140307156A1Low computing performanceTelevision system detailsColor television detailsTerminal equipmentVisible light communication

An information communication method selects between a visible light communication mode in which information is obtained from a subject using an image sensor having a plurality of exposure lines and a normal imaging mode. The method includes obtaining first image data by image capture with a first exposure time in the normal imaging mode. When an image is presented that prompts a user of a terminal device including the image sensor to move the terminal device to enable the information to be obtained, second image data is obtained by image capture with a second exposure time, shorter than the first exposure time, in the visible light communication mode. The information is obtained by demodulating data specified by a direction in a pattern of a bright line appearing in the second image data and corresponding to the exposure lines that is substantially perpendicular to the exposure lines.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

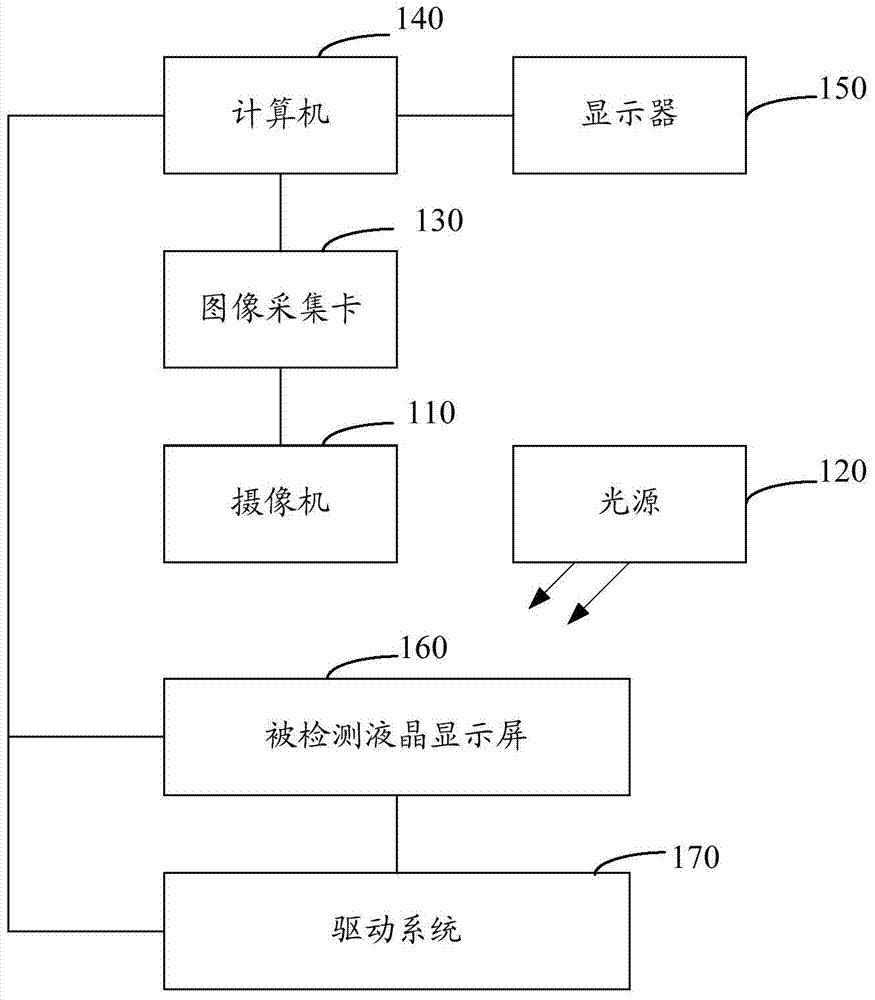

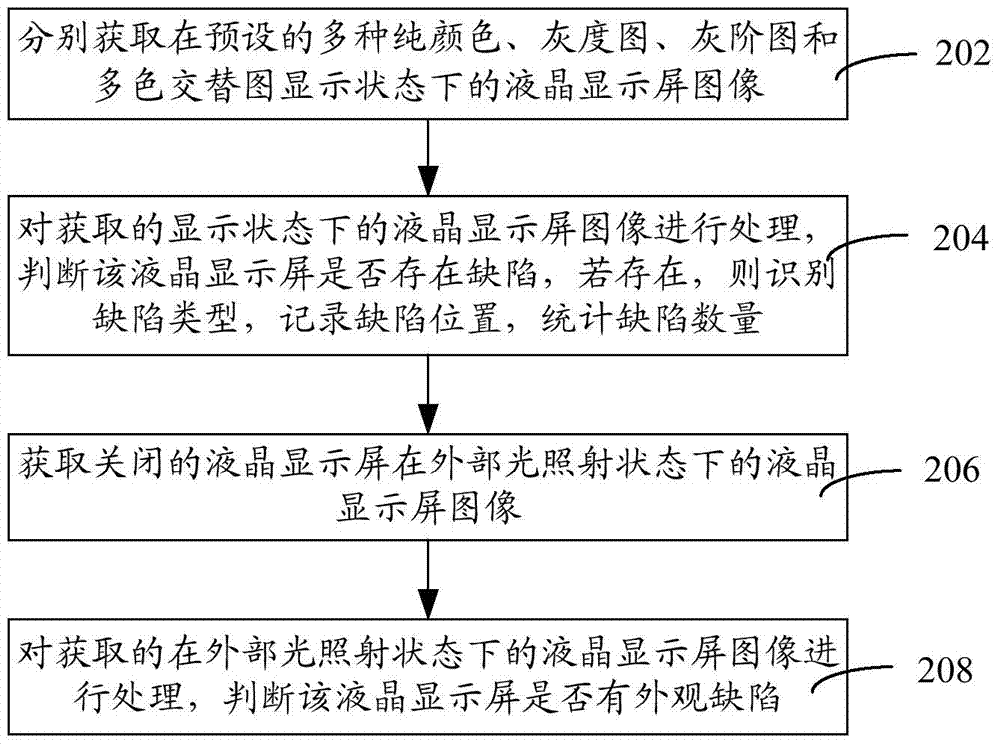

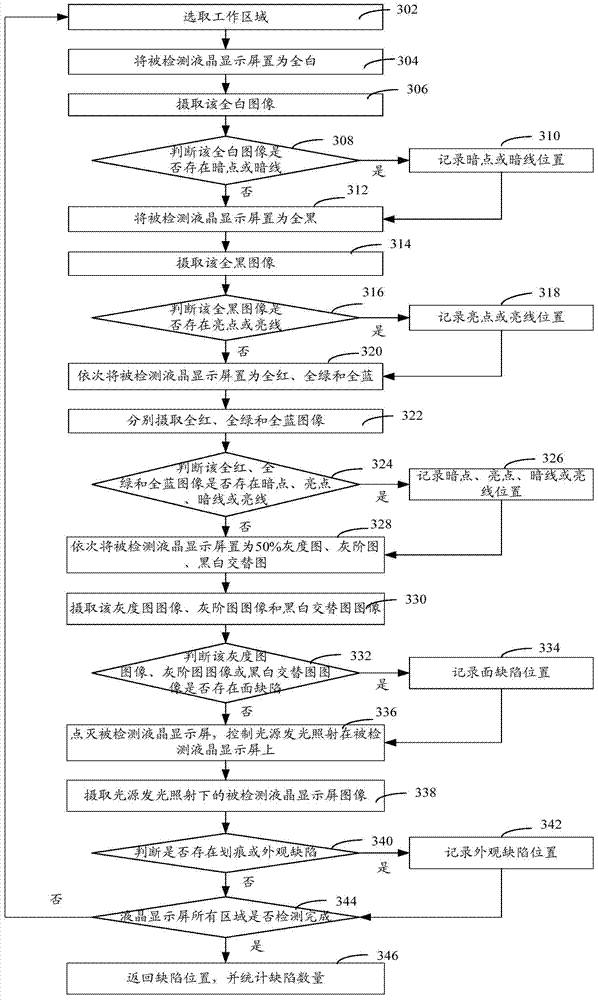

Automatic optical detection method and automatic optical detection system

ActiveCN104749184AQuality improvementImprove yieldOptically investigating flaws/contaminationNon-linear opticsProduction lineLight irradiation

The invention relates to an automatic optical detection method and an automatic optical detection system. The method comprises the following steps: obtaining liquid crystal screen images in preset display states of multiple pure colours, grey-scale images, grey-level images and multi-colour alternating images respectively; processing the liquid crystal screen images in the obtained display states, judging whether a liquid crystal screen has defects or not, if so, then identifying the types of the defects, recording the positions of the defects, and counting the number of the defects; obtaining the liquid crystal screen images of the turned-off liquid crystal screen in an external light irradiation state; processing the liquid crystal screen images in the obtained external light irradiation state, and judging whether the liquid crystal screen has appearance defects or not. According to the automatic optical detection method and the automatic optical detection system provided by the invention, brightness, dark spots, bright lines, dark lines, surface defects and appearance defects can be detected, defect detection types are increased, unqualified products are reduced, the quality of the liquid crystal screen is improved, a production line can be improved, and the production yield of the liquid crystal screen can be increased.

Owner:EVOC SMART IOT TECH CO LTD

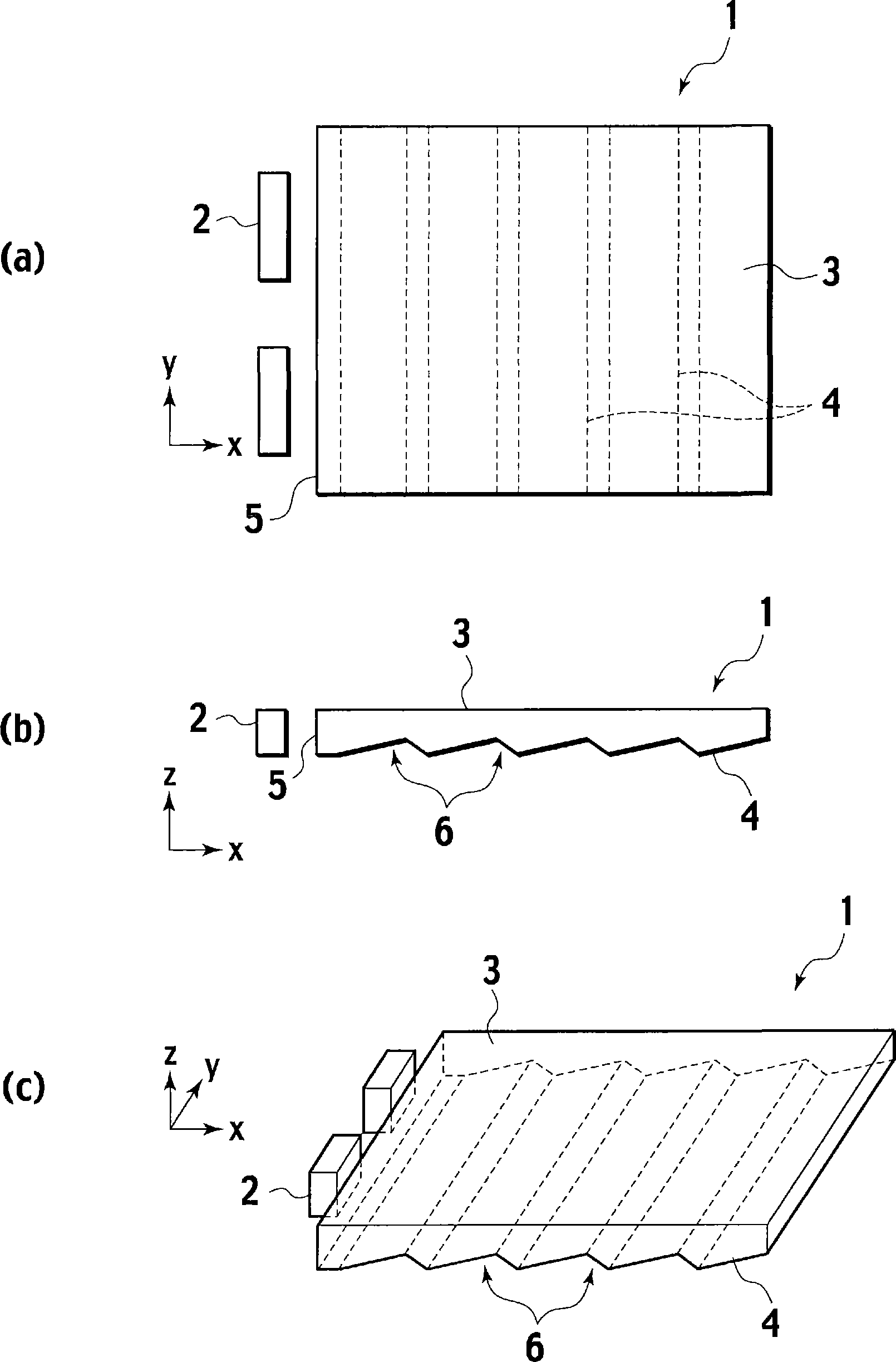

Image display apparatus

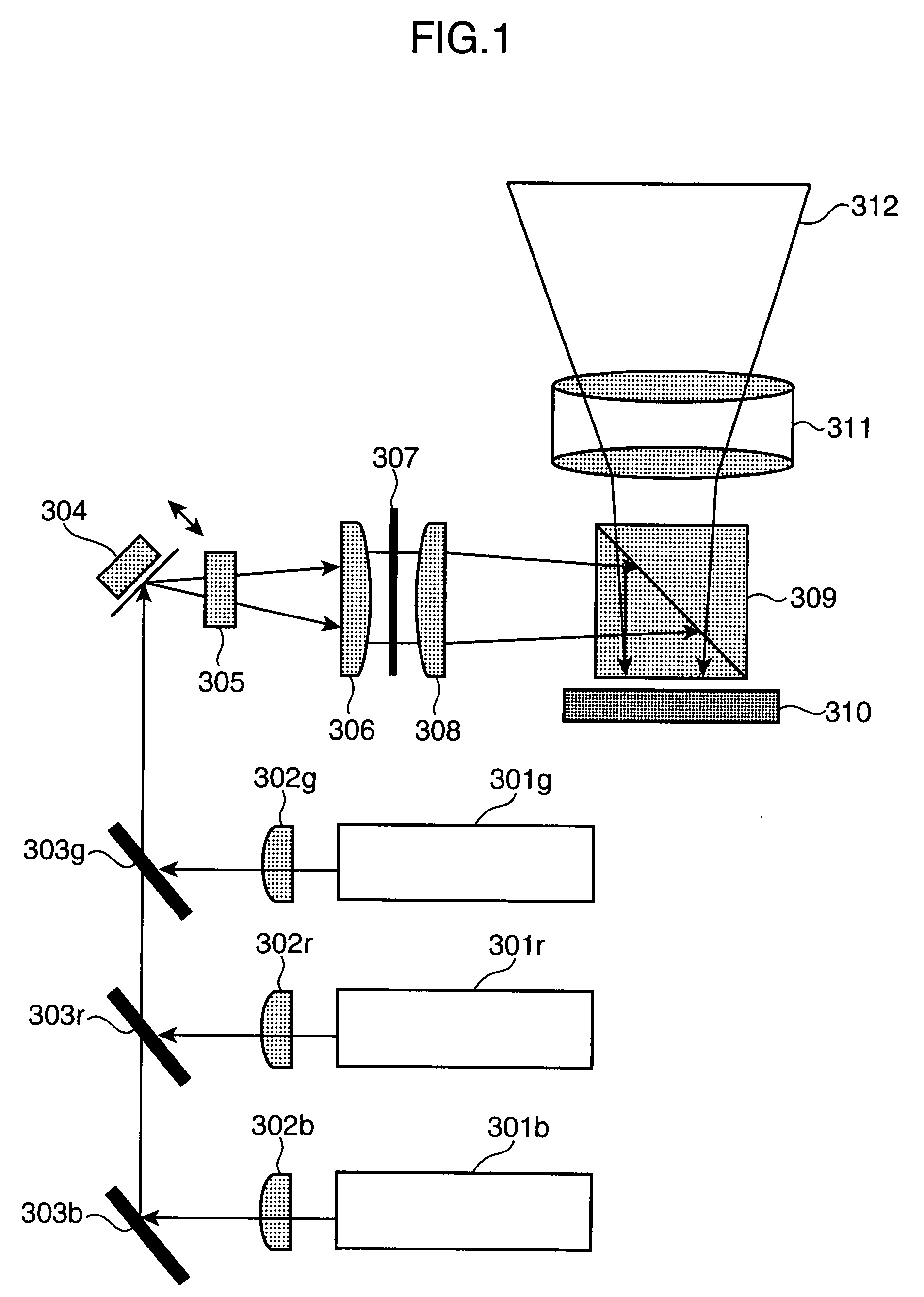

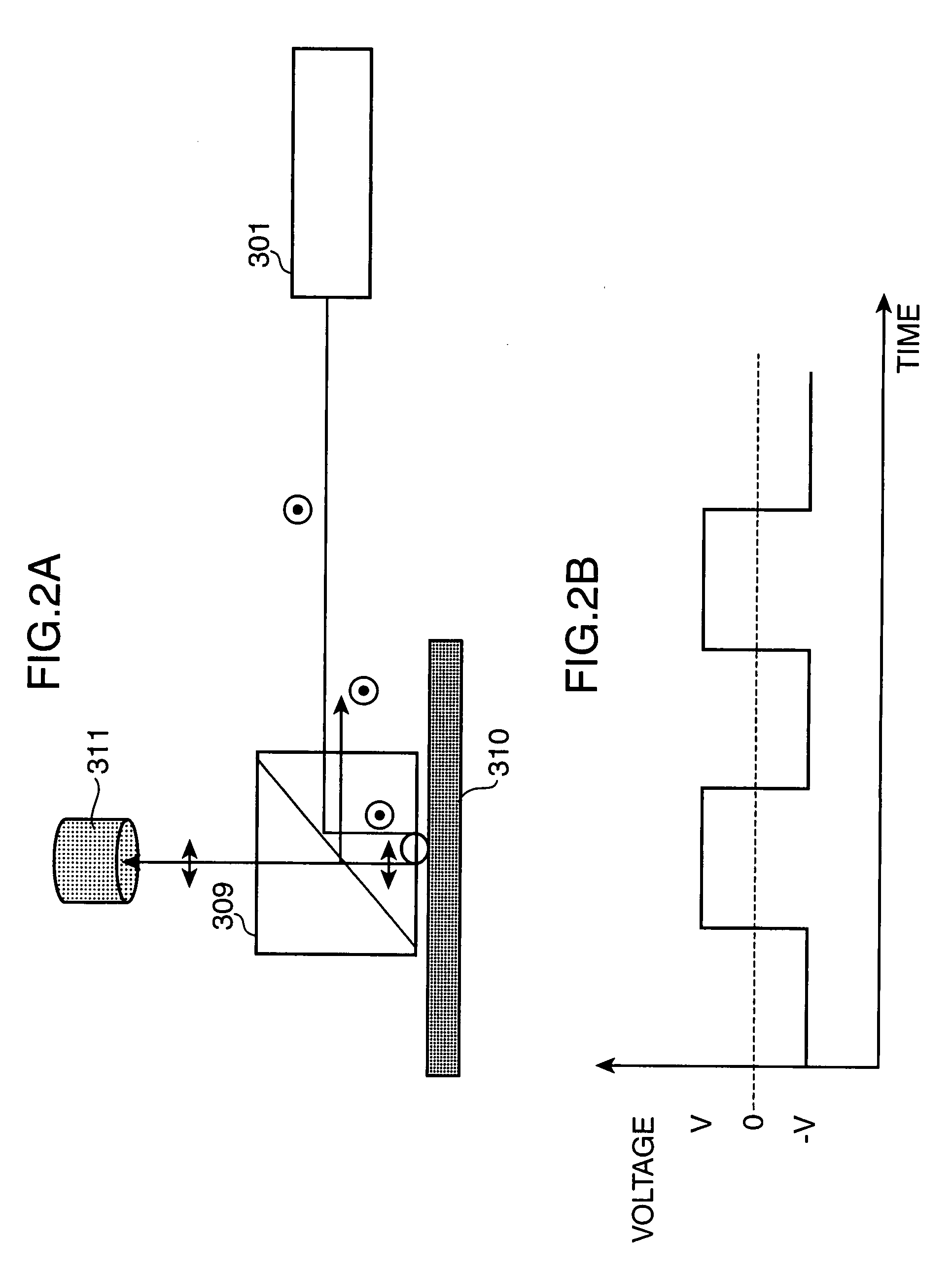

InactiveUS20070252918A1Improve portabilityHigh-accuracy displayTelevision system detailsProjectorsSpatial light modulatorBeam scanning

A 2D image display apparatus using a laser light source. By controlling the timing of a scan by a beam scan portion in response to the characteristic of a laser light source and by setting a light emitting time of the laser light source to an integral multiple of a scan cycle of the beam scan portion, it is possible to illuminate a spatial light modulator homogeneously with a laser beam. It is thus possible to display an image at high accuracy without causing a bright line, irregularities in brightness, and contrast deterioration.

Owner:PANASONIC CORP

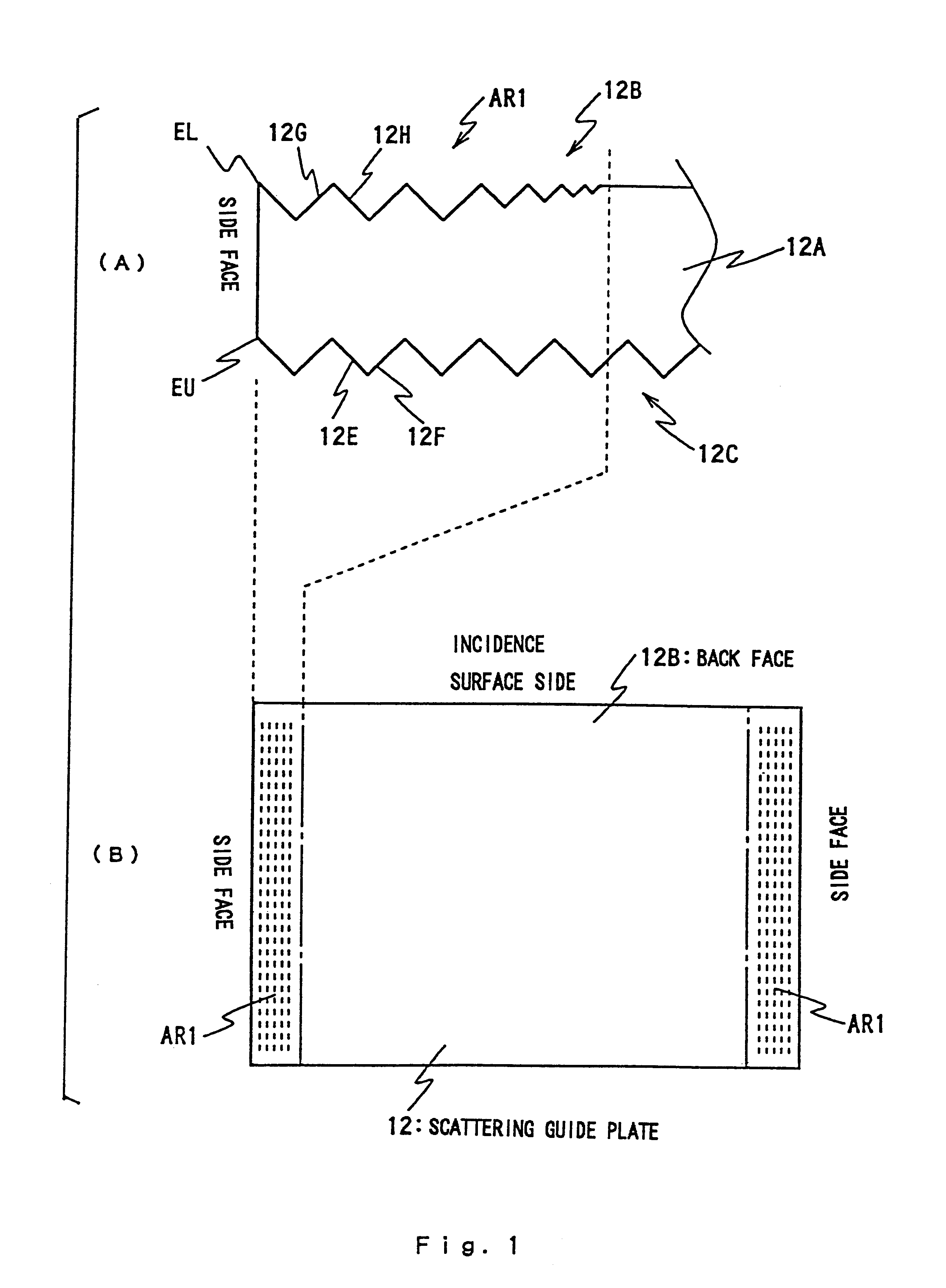

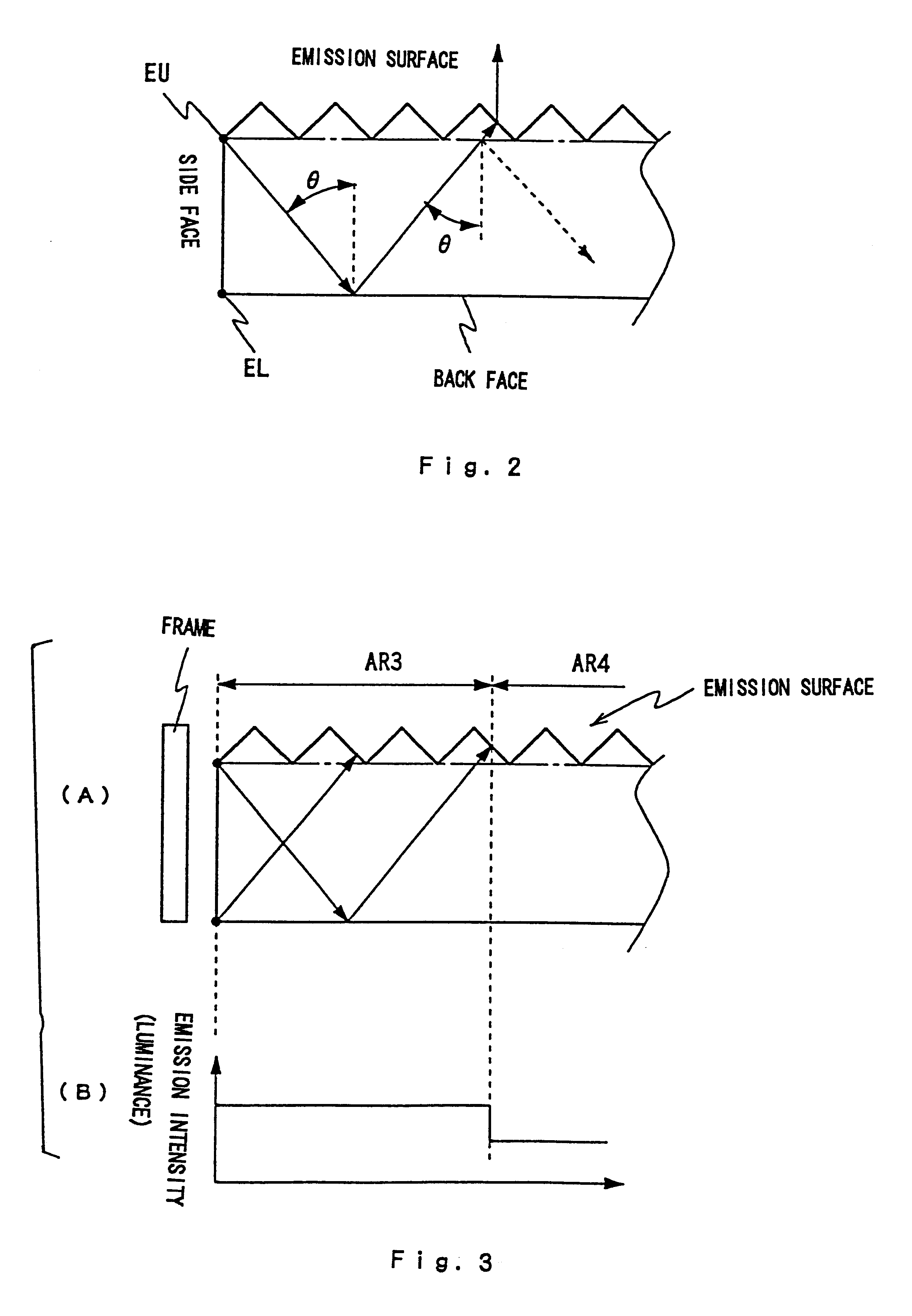

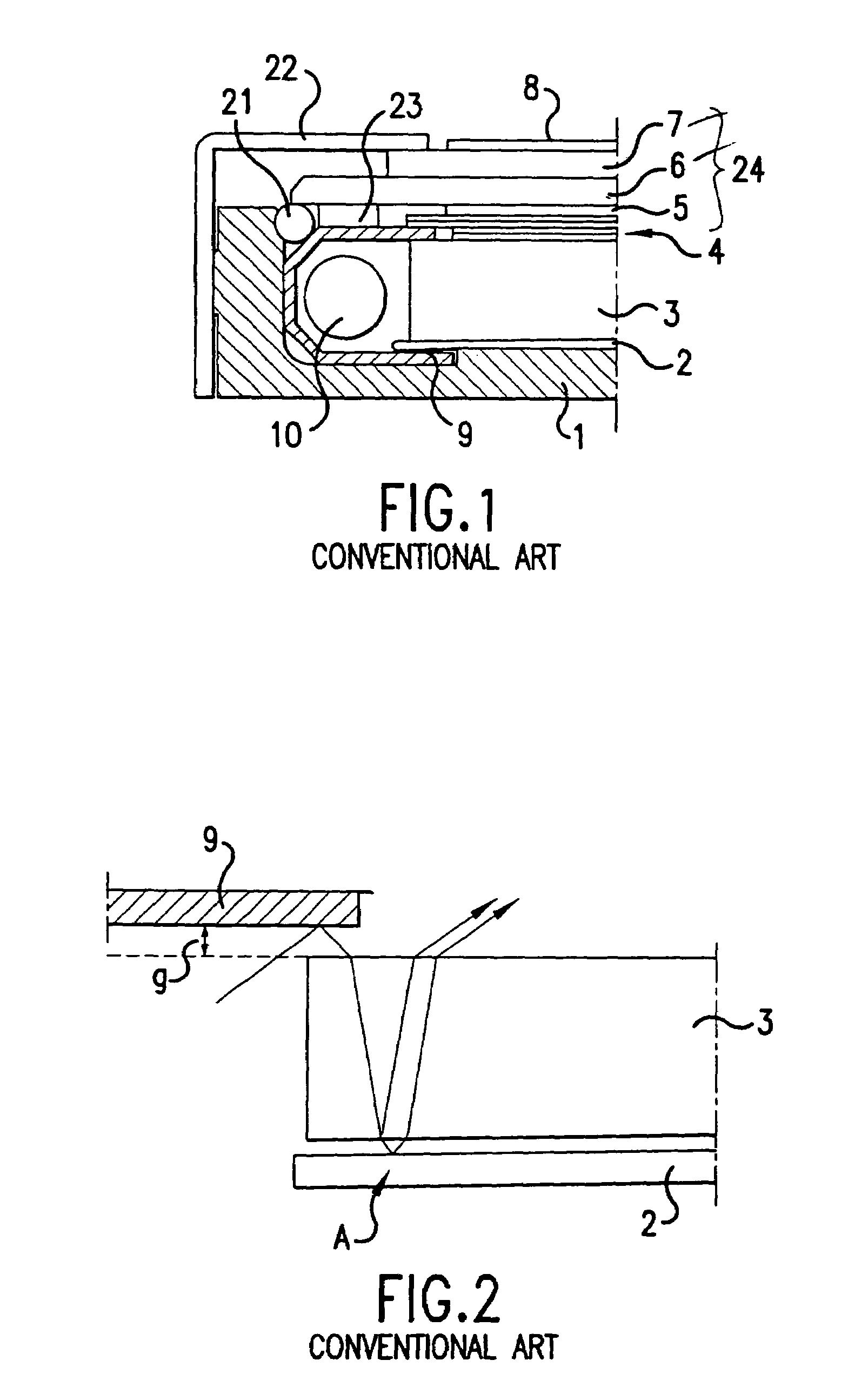

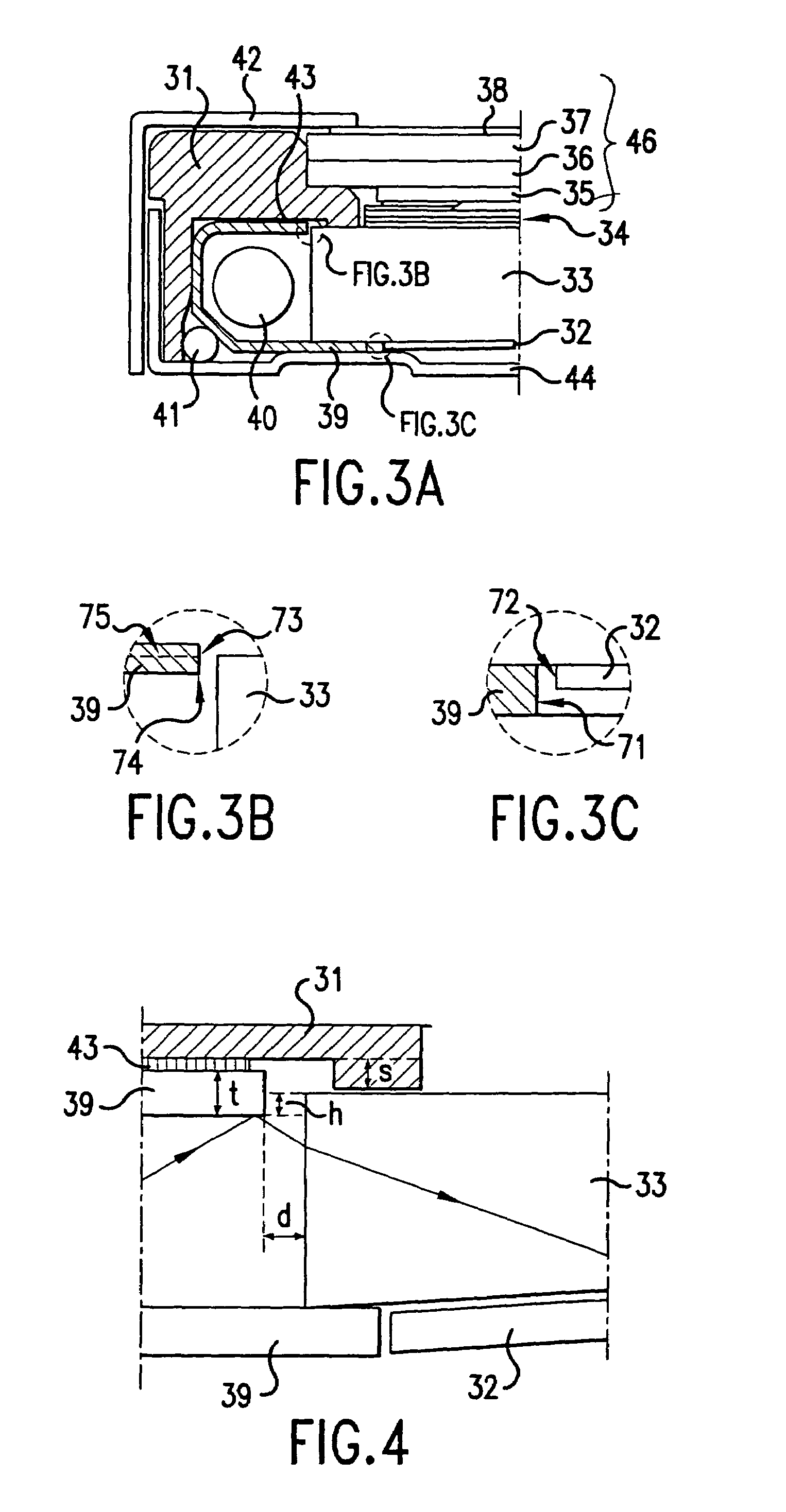

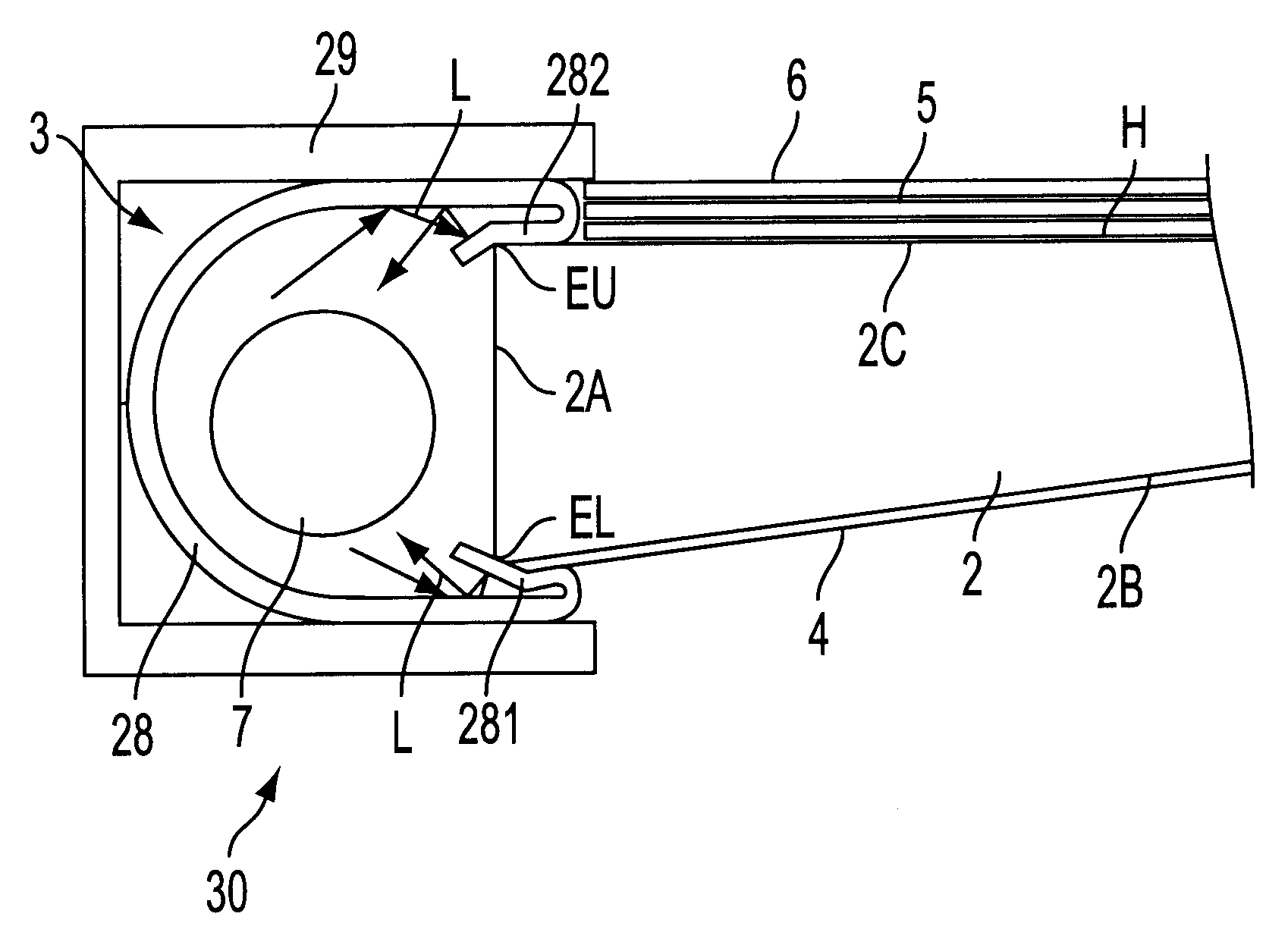

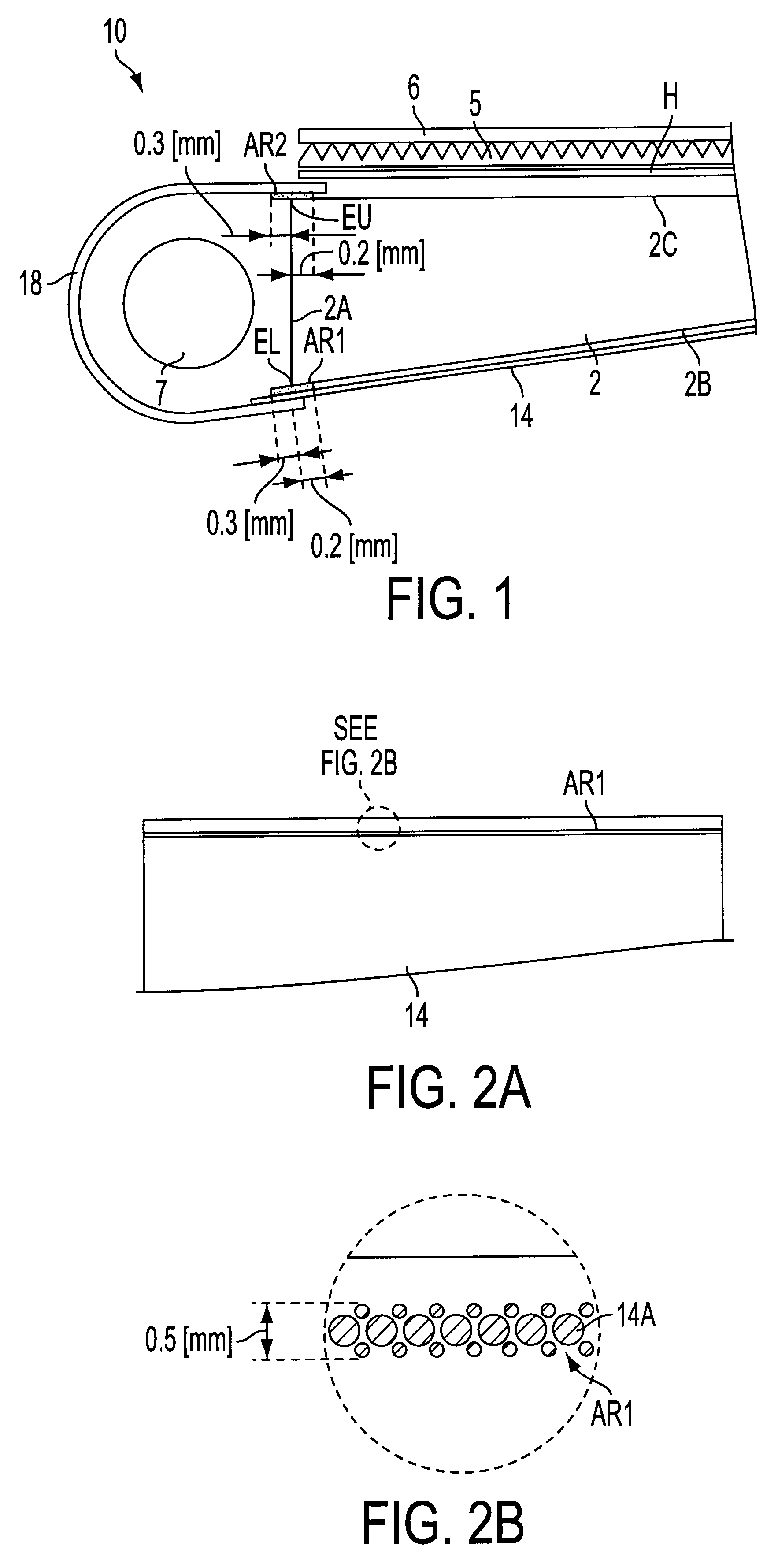

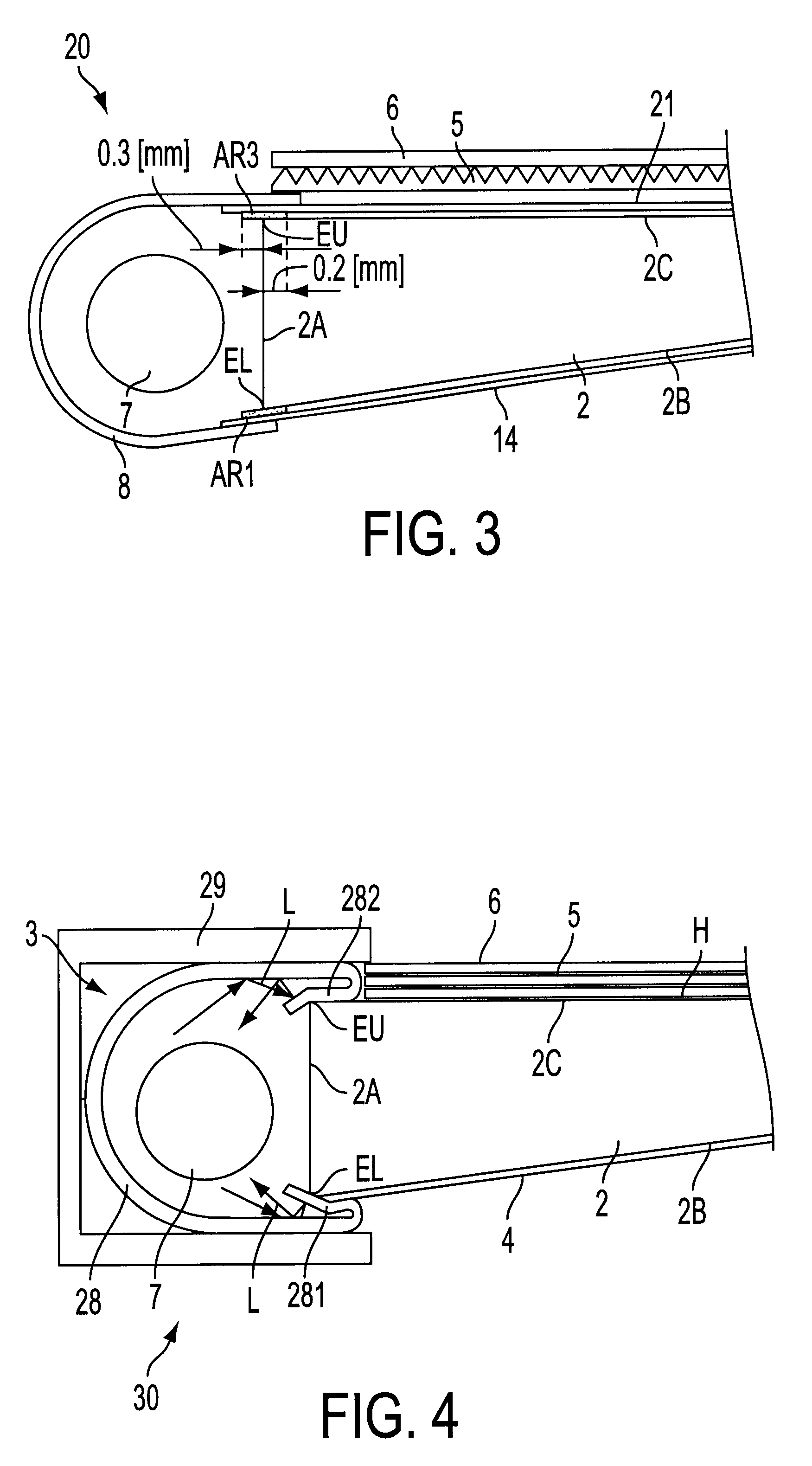

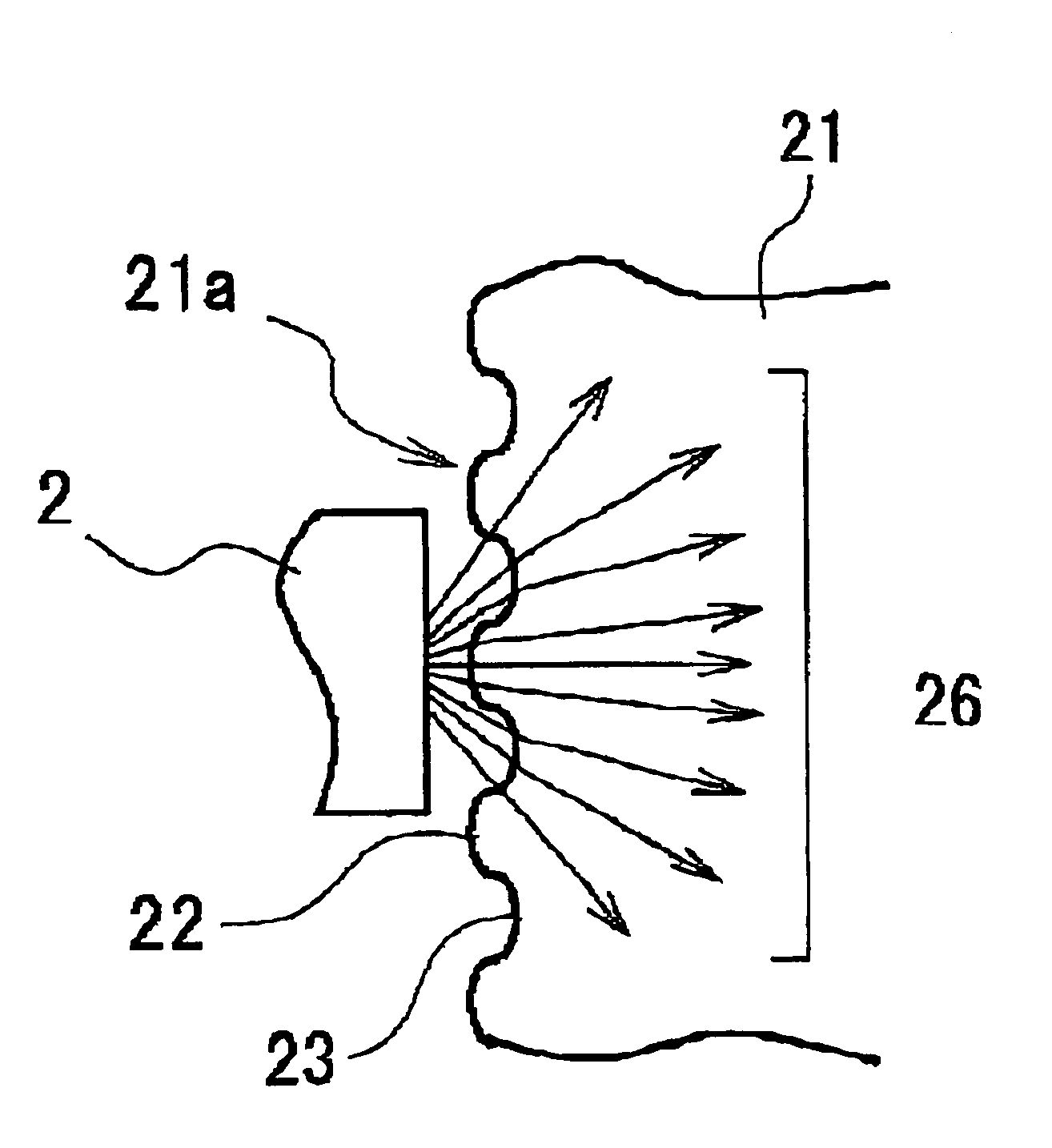

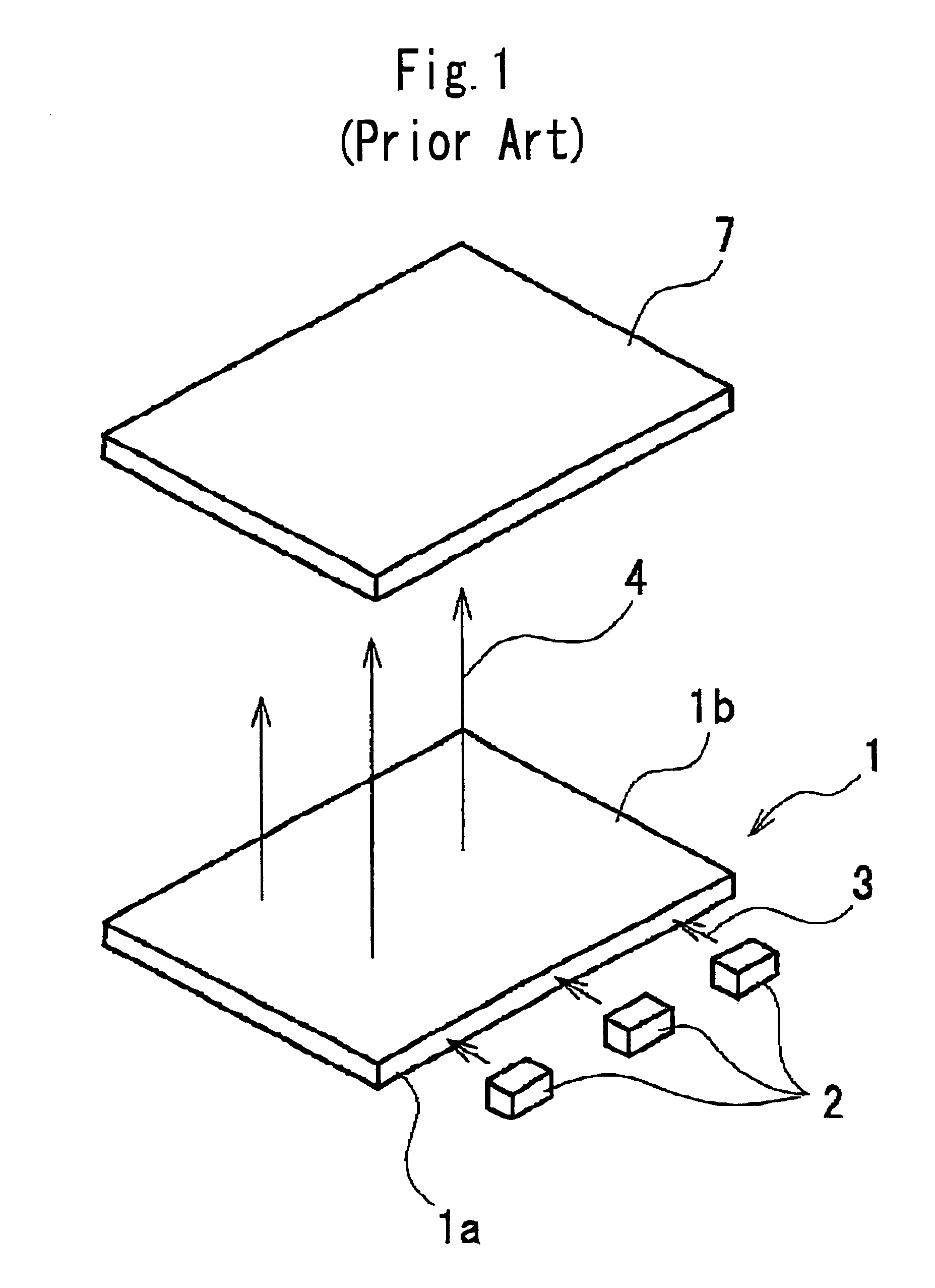

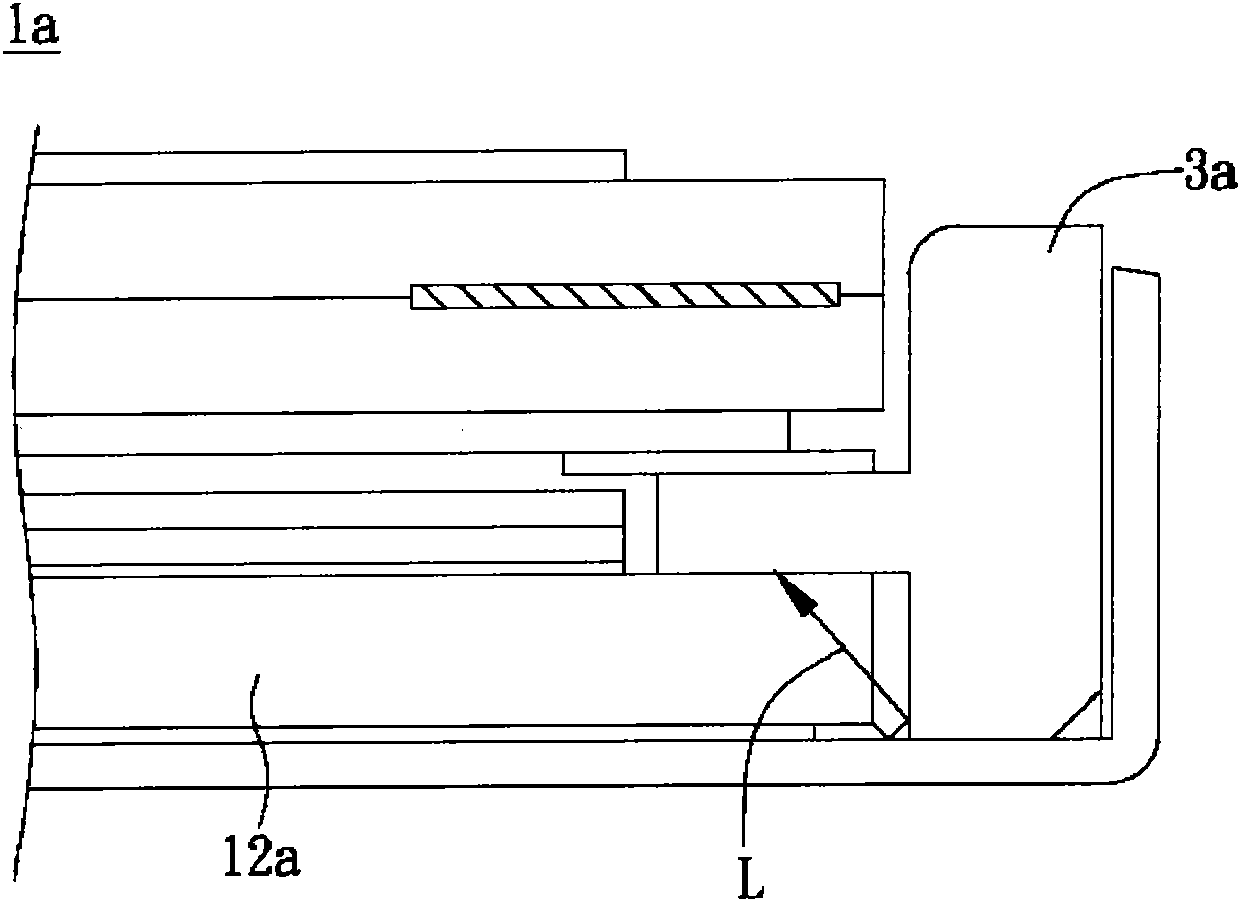

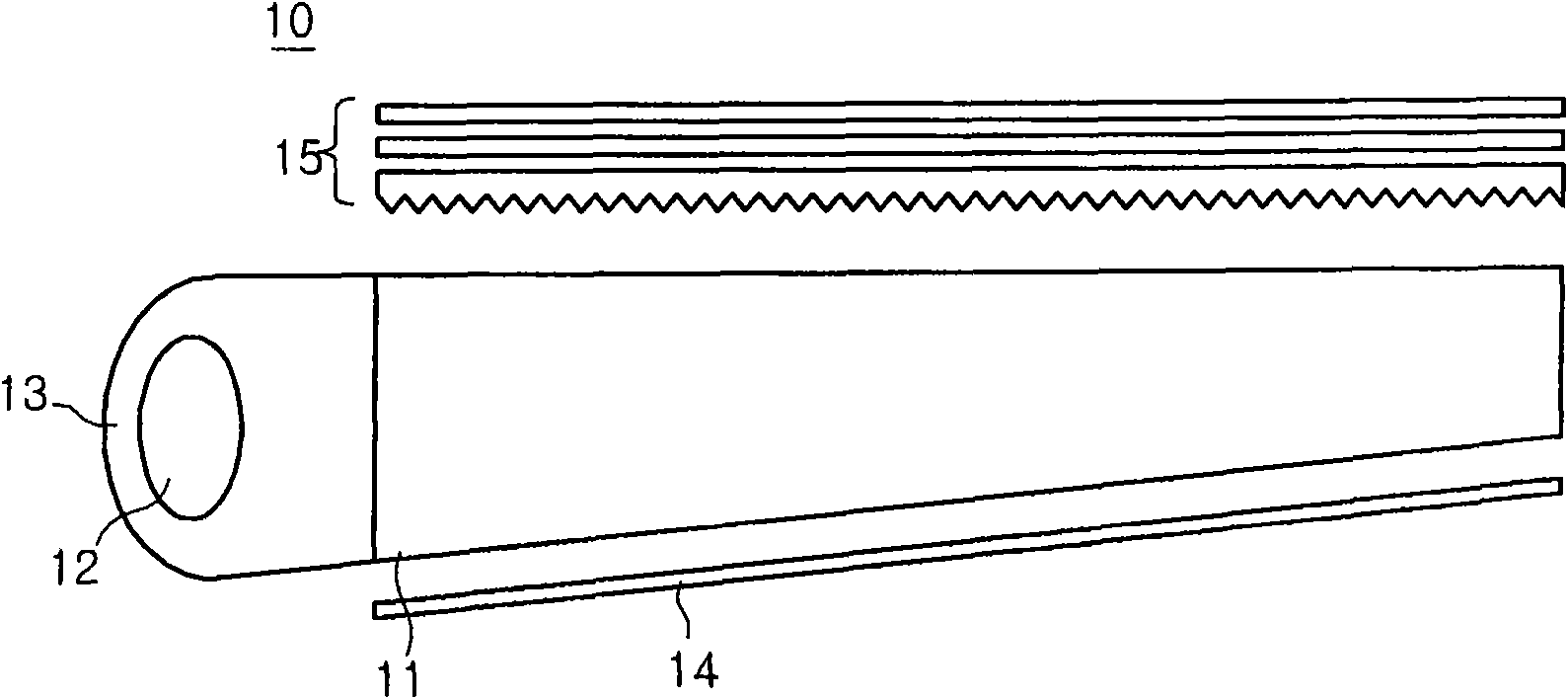

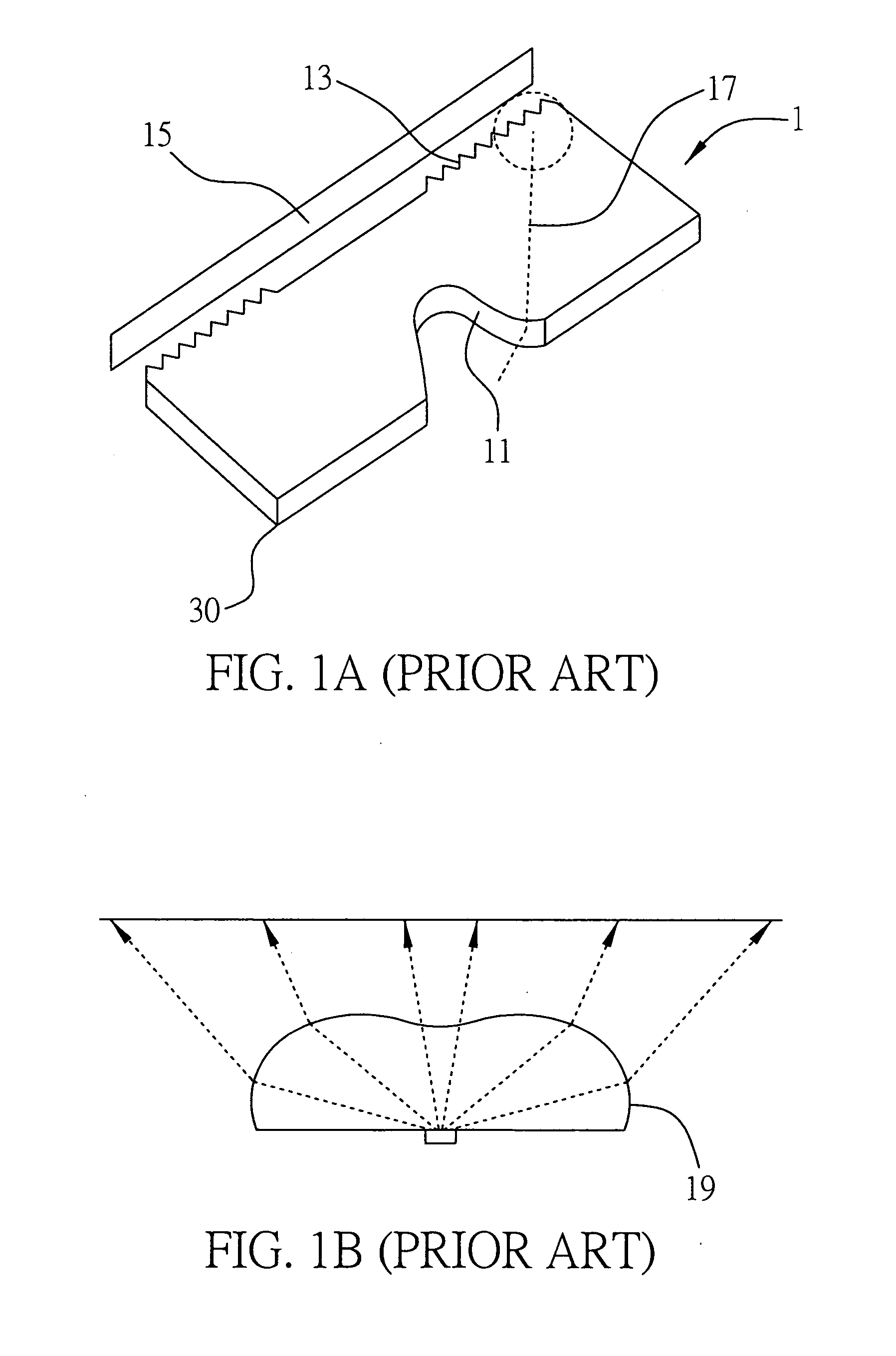

Surface light source device of side light type

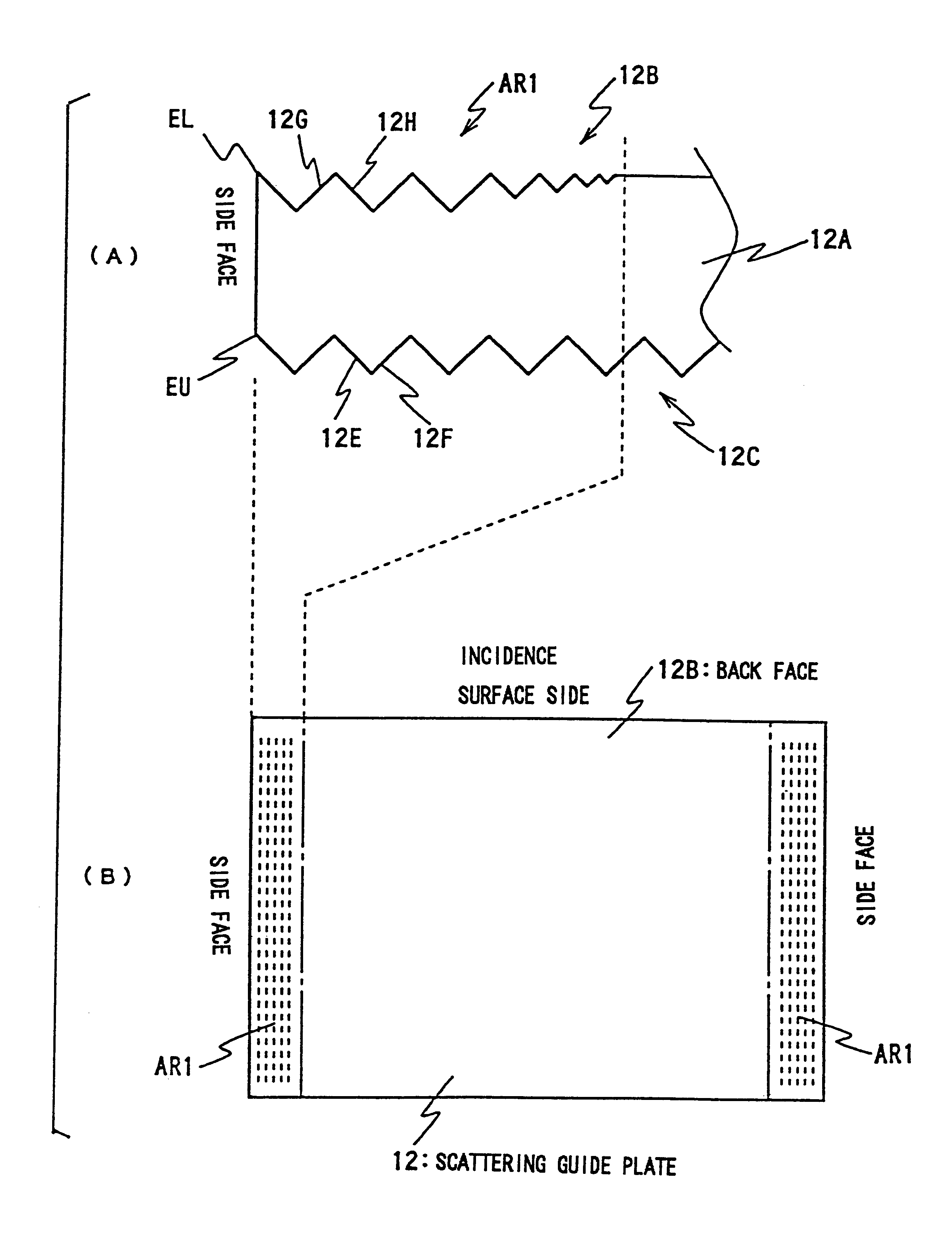

InactiveUS6406158B1Avoid it happening againPrevent surfaceMeasurement apparatus componentsMachines/enginesPrismBright line

Illuminating light, supplied from a primary light source of a surface light source device of side light type, passes through an incidence surface (12A) and enters a wedge-shaped scattering guide plate (12). Inside the guide plate (12), the illuminating light propagates toward the end while being repeatedly reflected between a back face (12B) and an emission surface (12C). During this process, the illuminating light receives scattering action of particles or the like in the guide plate (12). The emission surface (12C) provides a prism surface. The back face (12B) comprises a plurality of projections in a belt region (AR1) along an edge (EL). The projections run generally parallel to the edge (EL) and each has a pair of slopes (12G and 12H). The height of the projections (that is, depth of the troughs) or the inclination of the slopes (12G and 12H) preferably decrease according to distance from the edge (EL). The projections diffuse light propagation direction, thereby preventing generation of bright lines around the edge (EU) of the emission surface.

Owner:ENPLAS CORP +1

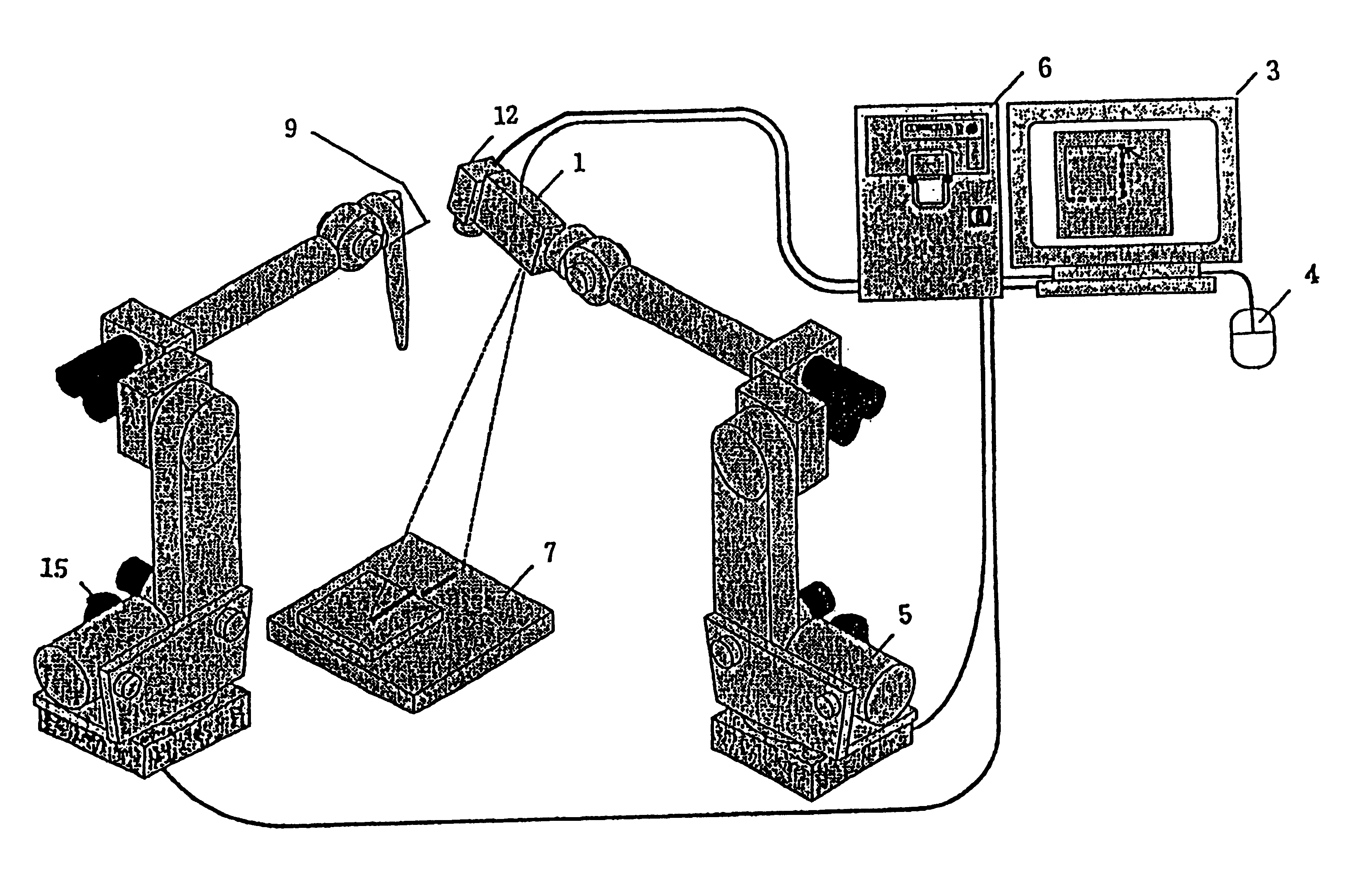

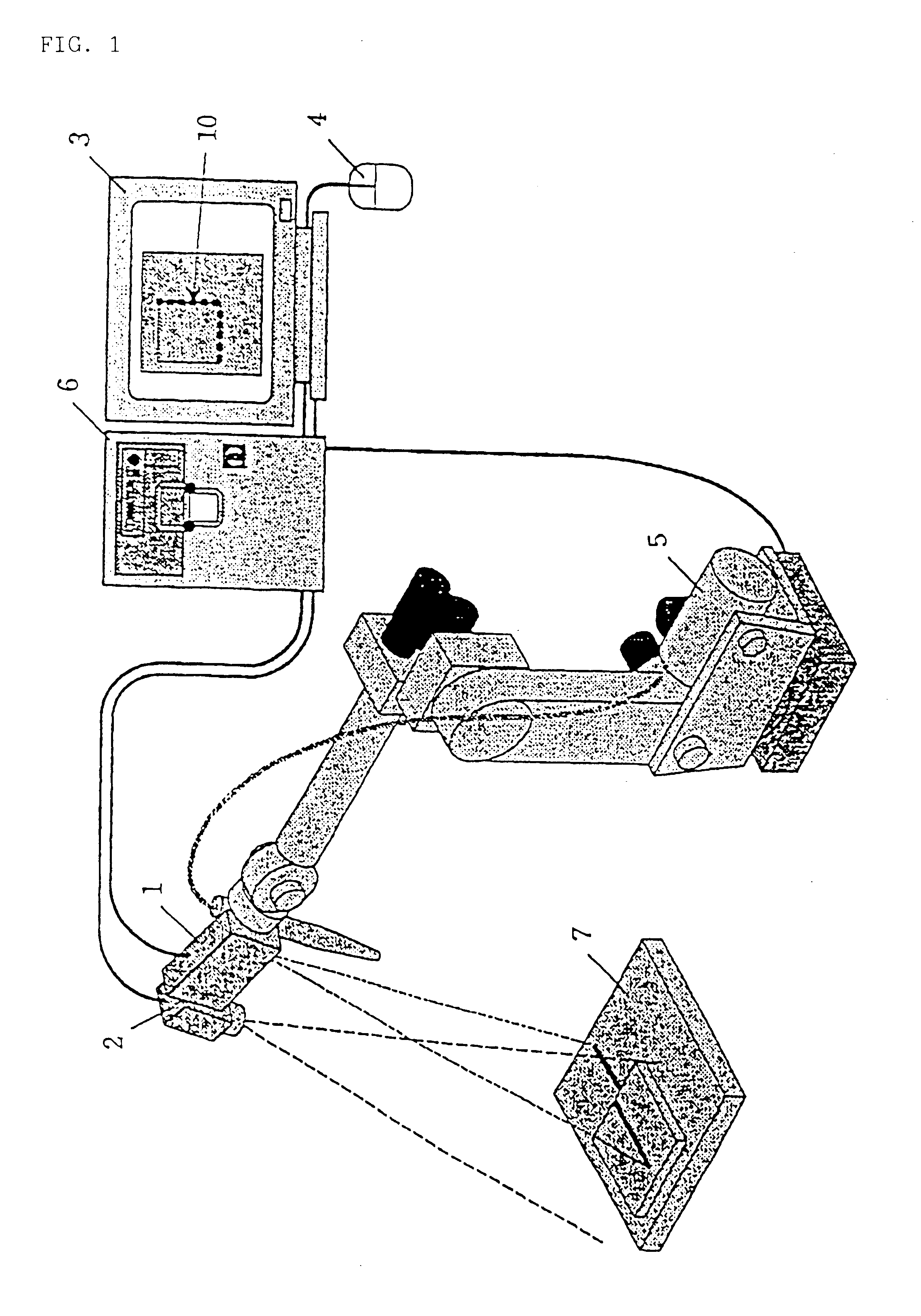

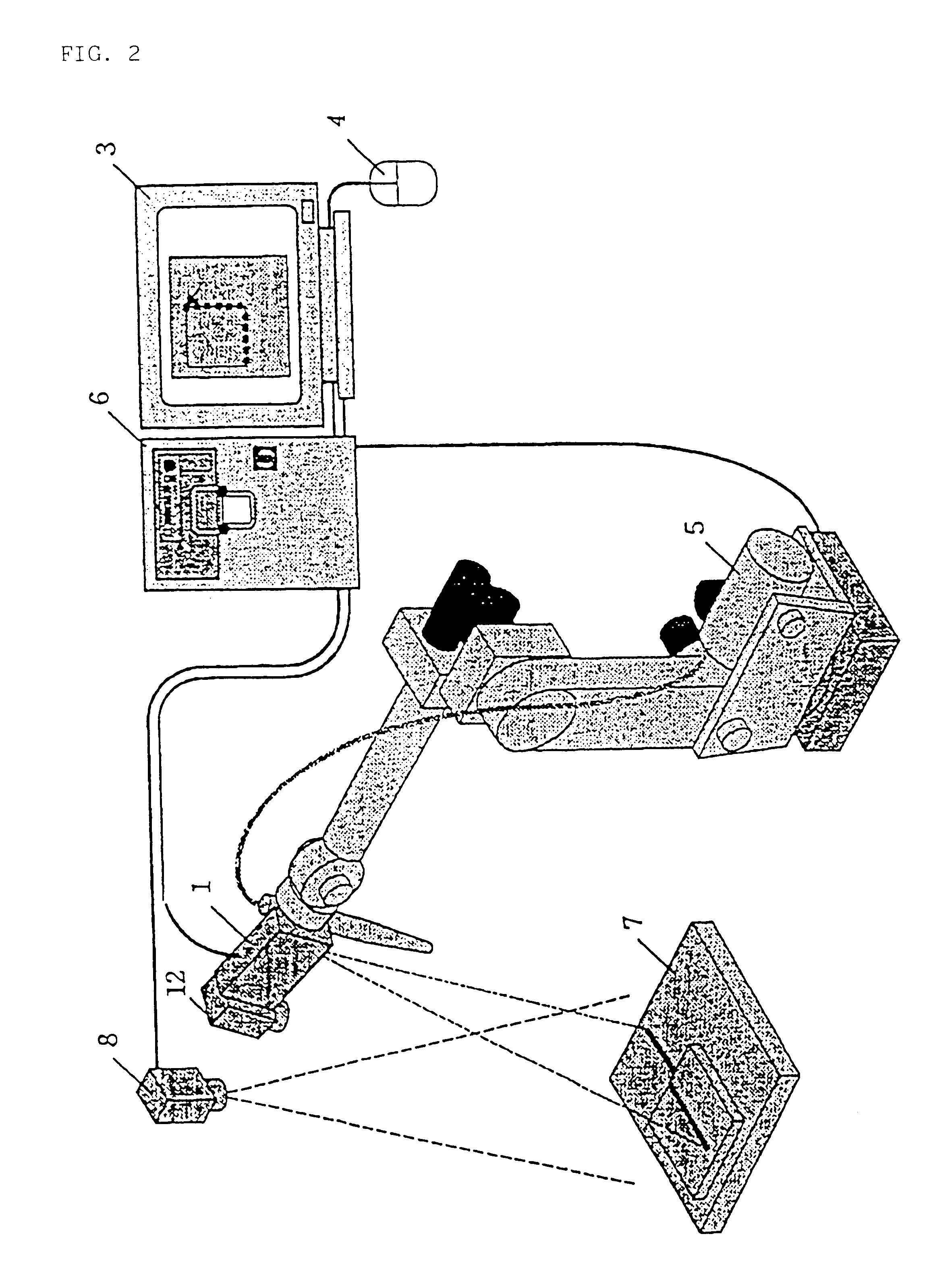

Robot teaching apparatus

InactiveUS6763284B2Unnecessary to performEasy to implementProgramme-controlled manipulatorLevel controlPointing deviceBright line

Owner:FANUC LTD

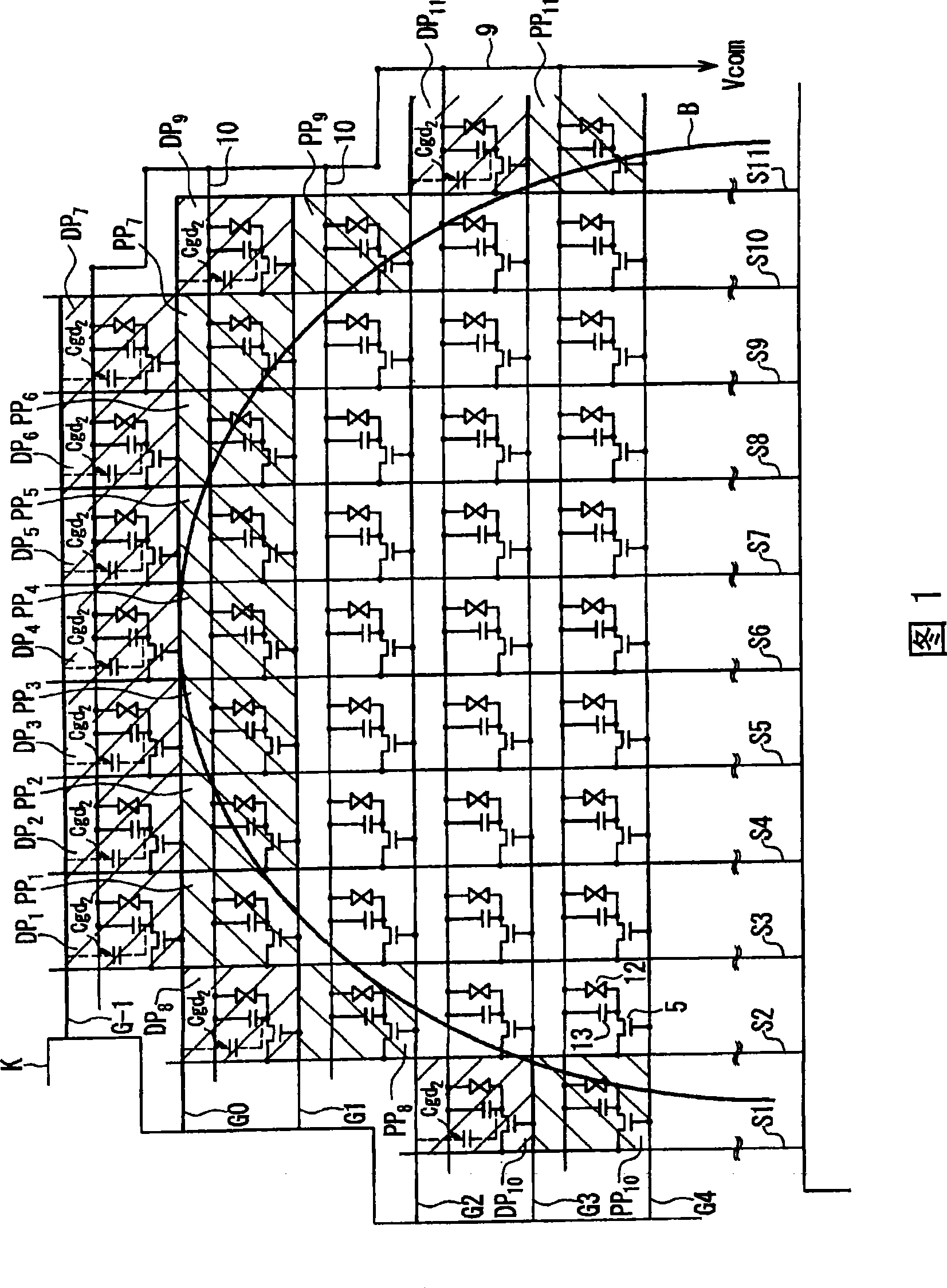

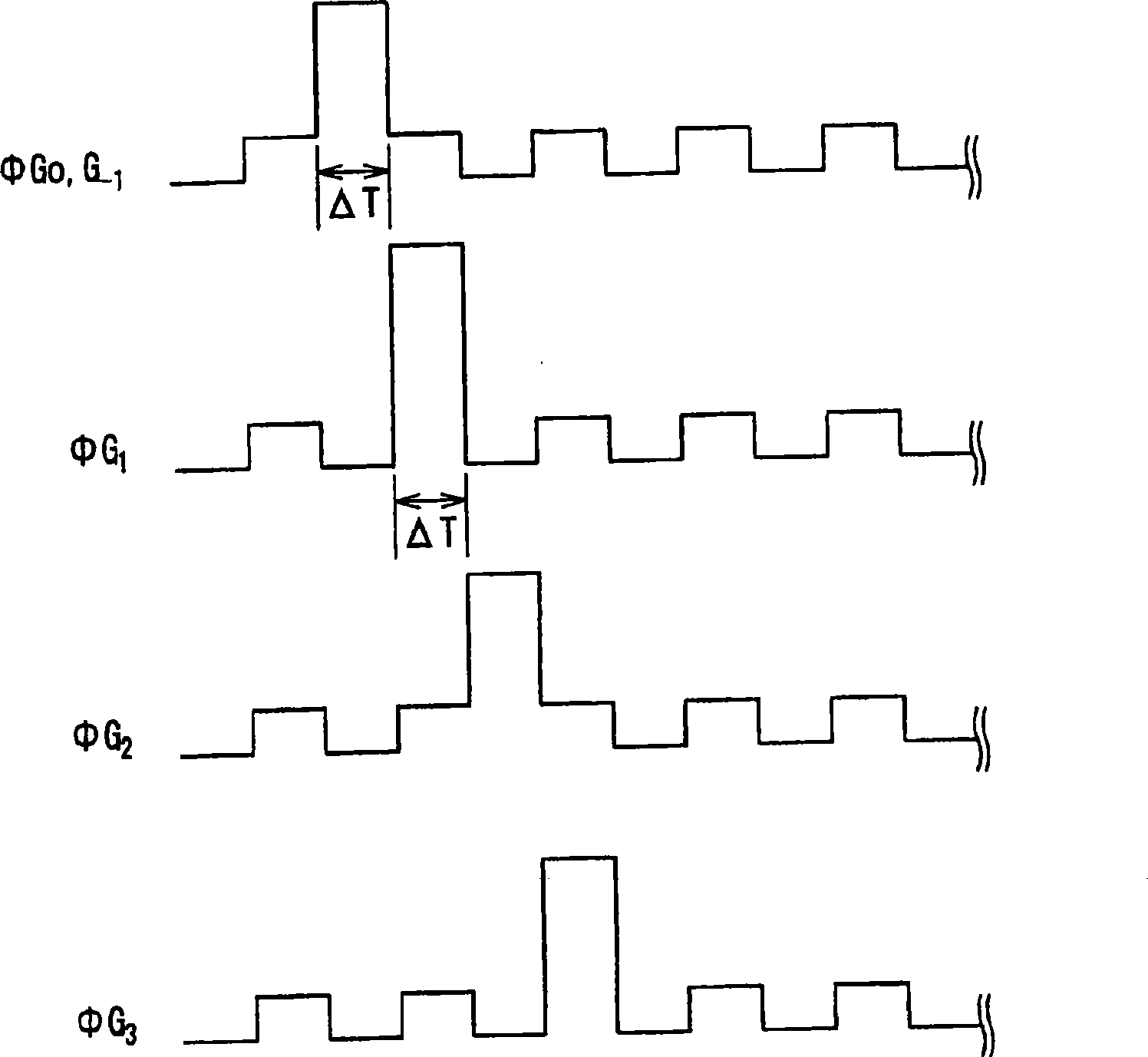

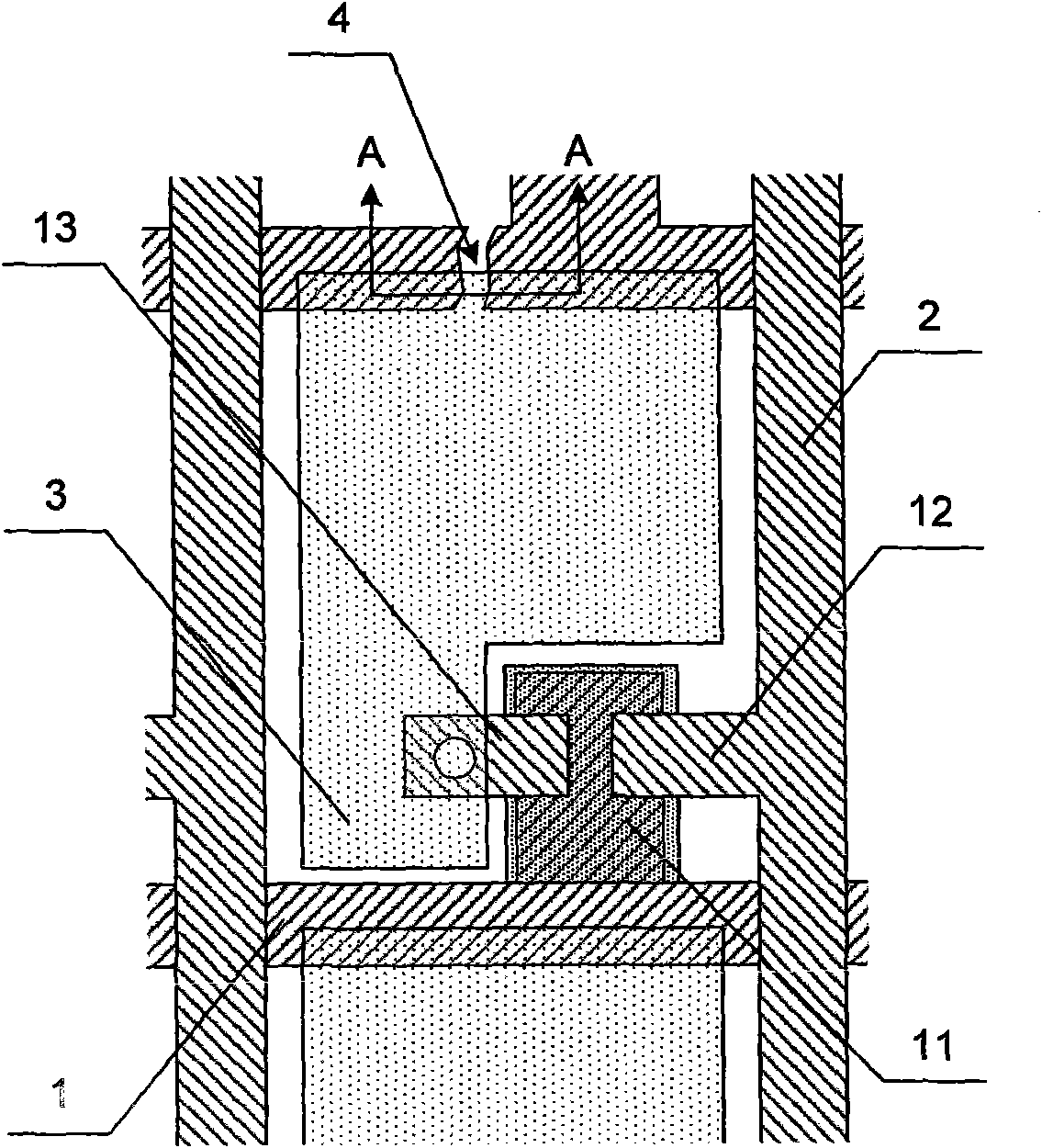

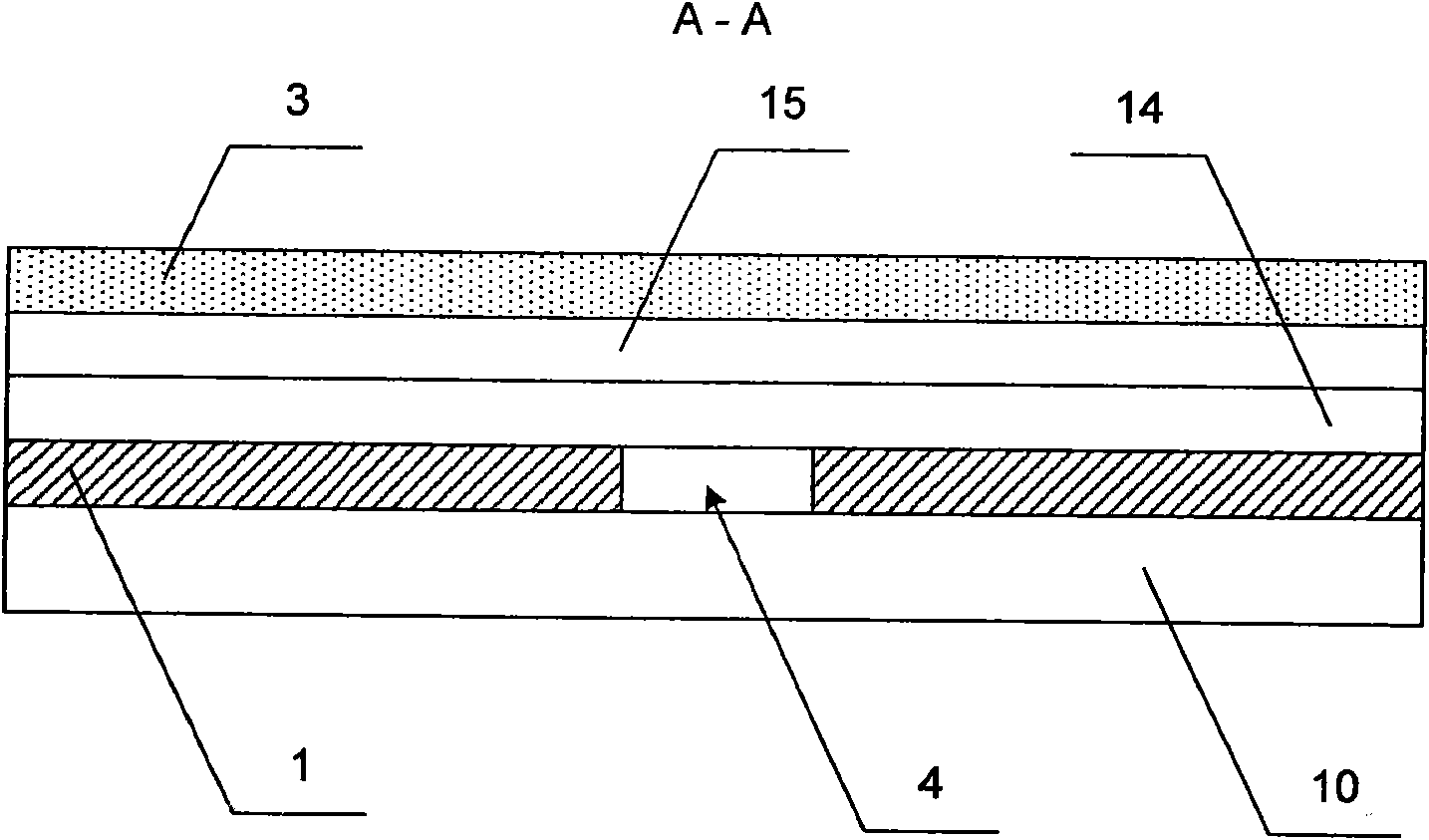

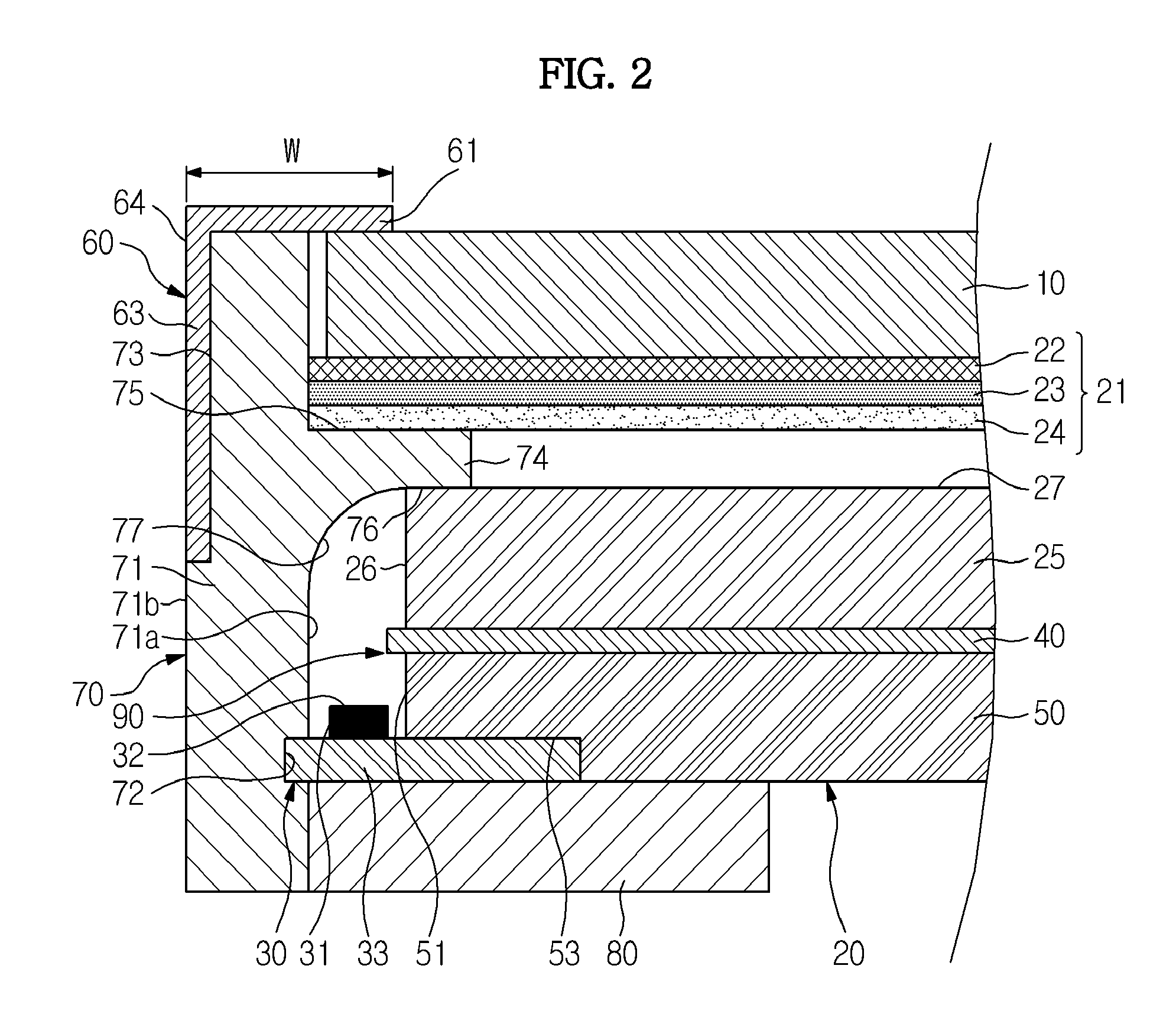

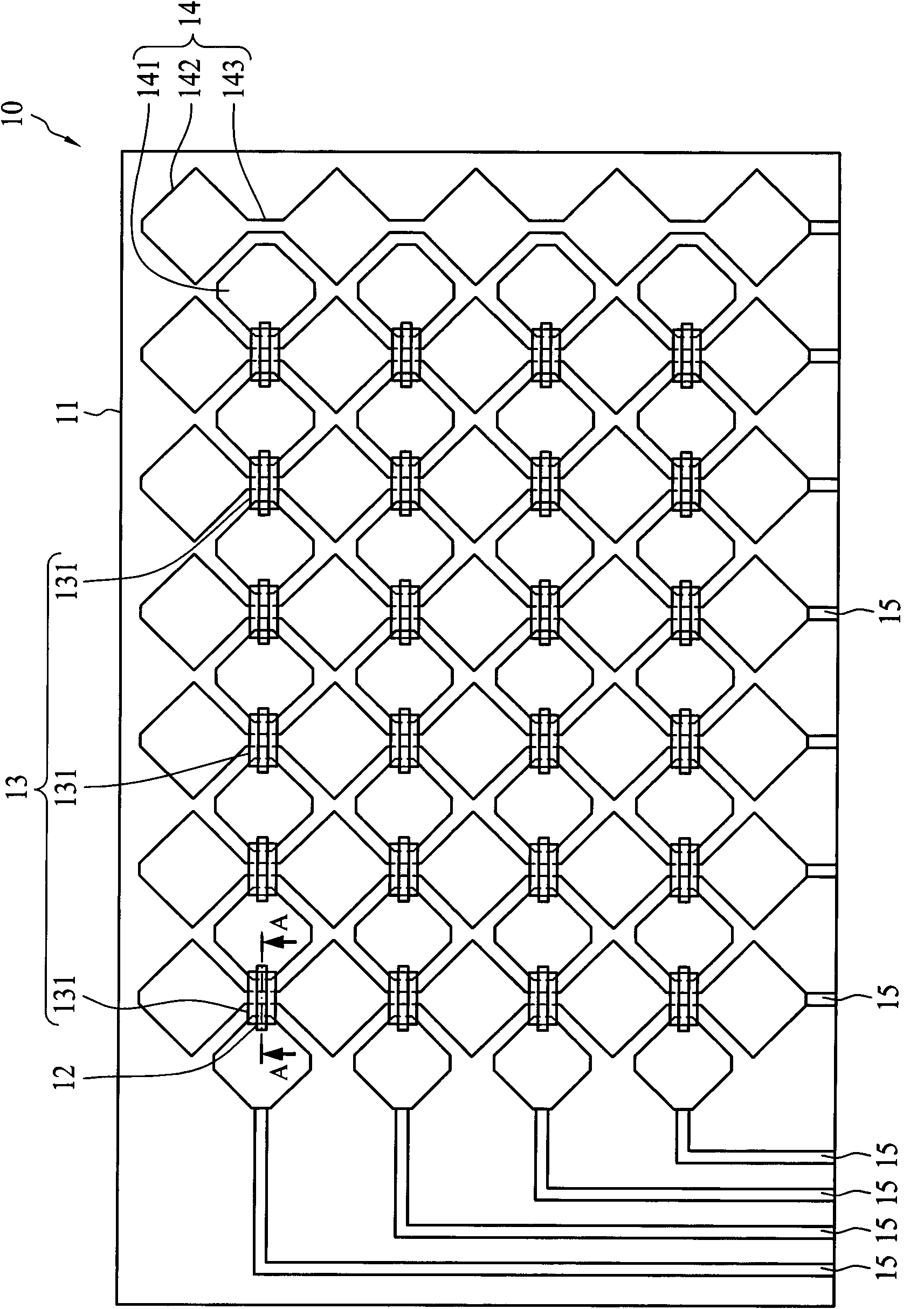

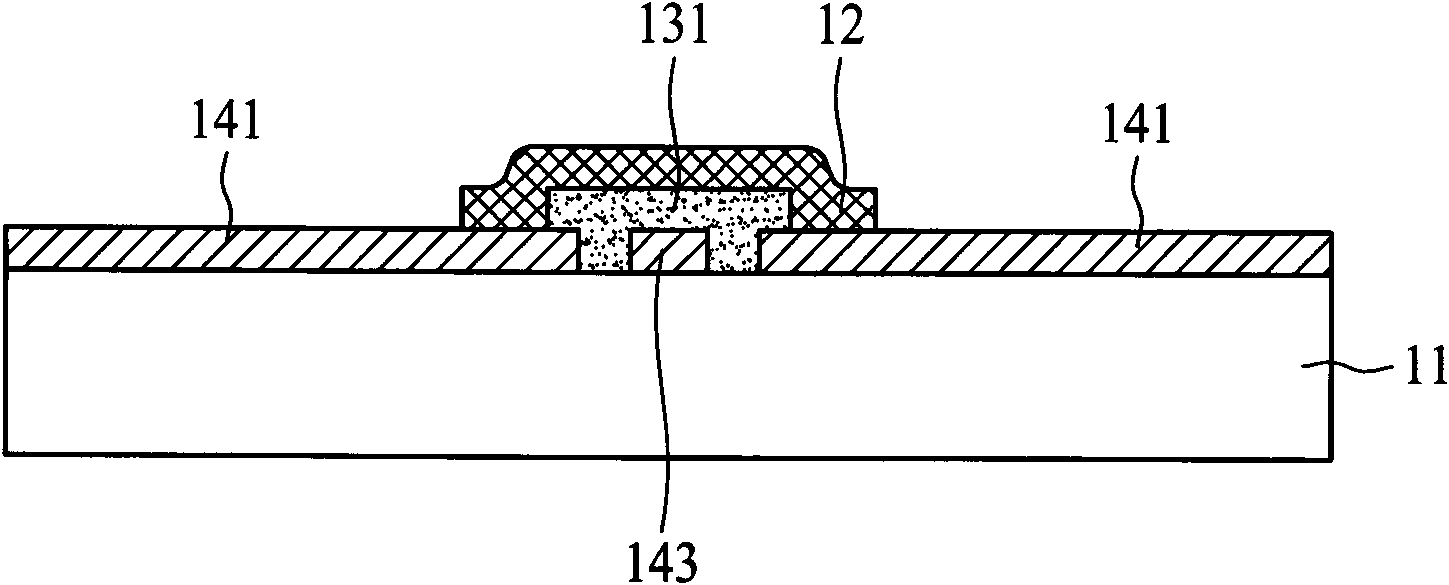

Active matrix substrate and display device using the same

InactiveCN101401143AImprove qualityPrevents defects such as damage display qualityStatic indicating devicesNon-linear opticsActive matrixDisplay device

An irregular shape display device that is not rectangular in display area is provided to prevent from disadvantages of poor display dignity, and the like, due to bright lines formed by pixels at specific portions. In an active matrix substrate used as an display substrate in which a distribution region of pixel electrodes corresponding to a display region has an irregular shape other than a rectangle, at least one dummy scanning line (dummy scanning lines G0, G-1) is formed at a more outer side than a scanning line (G1) positioned at the edge portion on a scanning initiation side; and upper scanning lines are provided to extend to positions opposite to scanning lines between which a scanning line (G2) and the most outlying peripheral pixels (PP) are put and with which TFT's (5) of the most outlying peripheral pixels (PP) are connected. The dummy pixels (DP) are provided preferably at upper portions of the screen than each of the most outlying peripheral pixels (PP).

Owner:SHARP KK

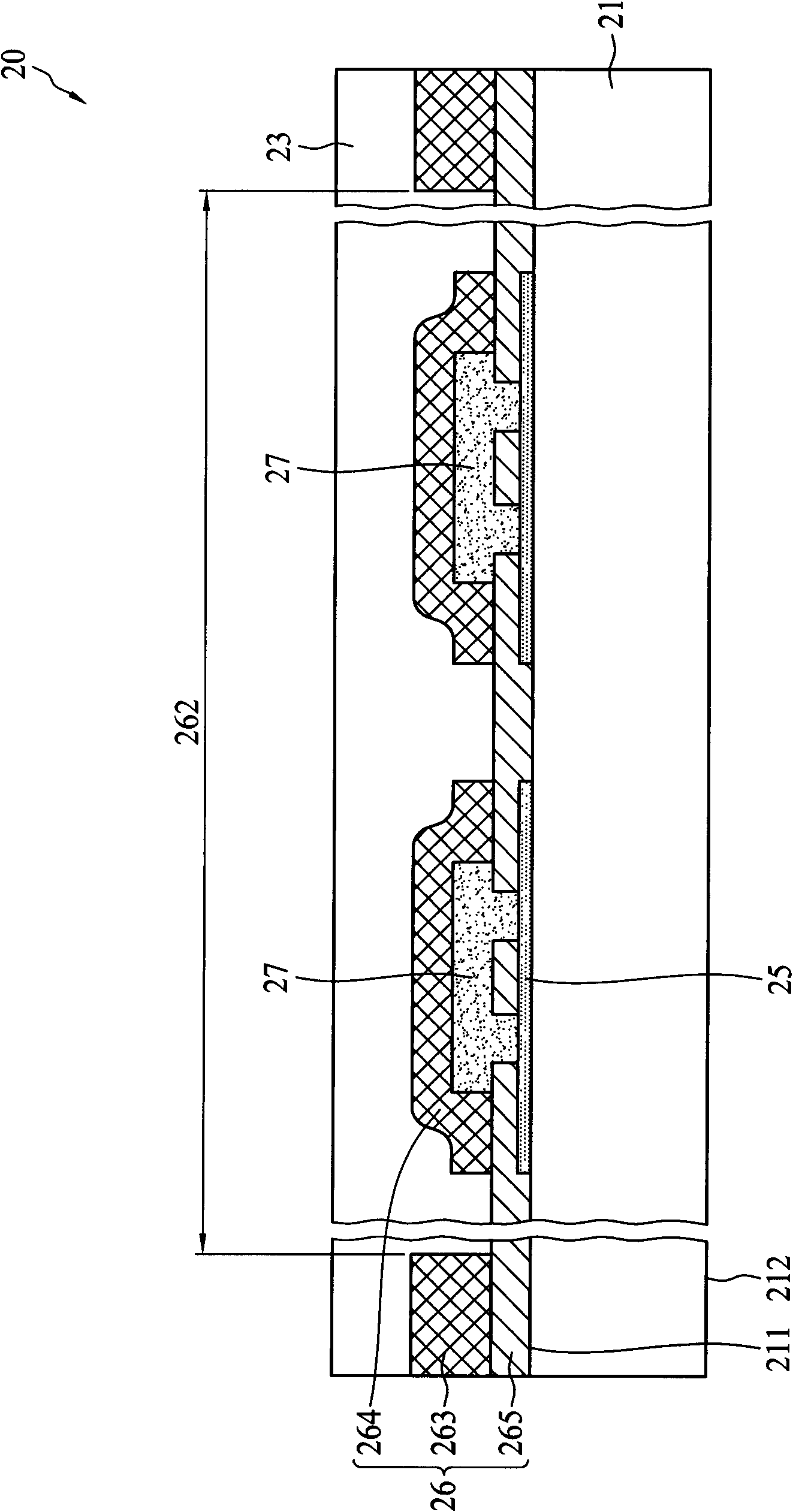

Liquid crystal display device and backlight thereof

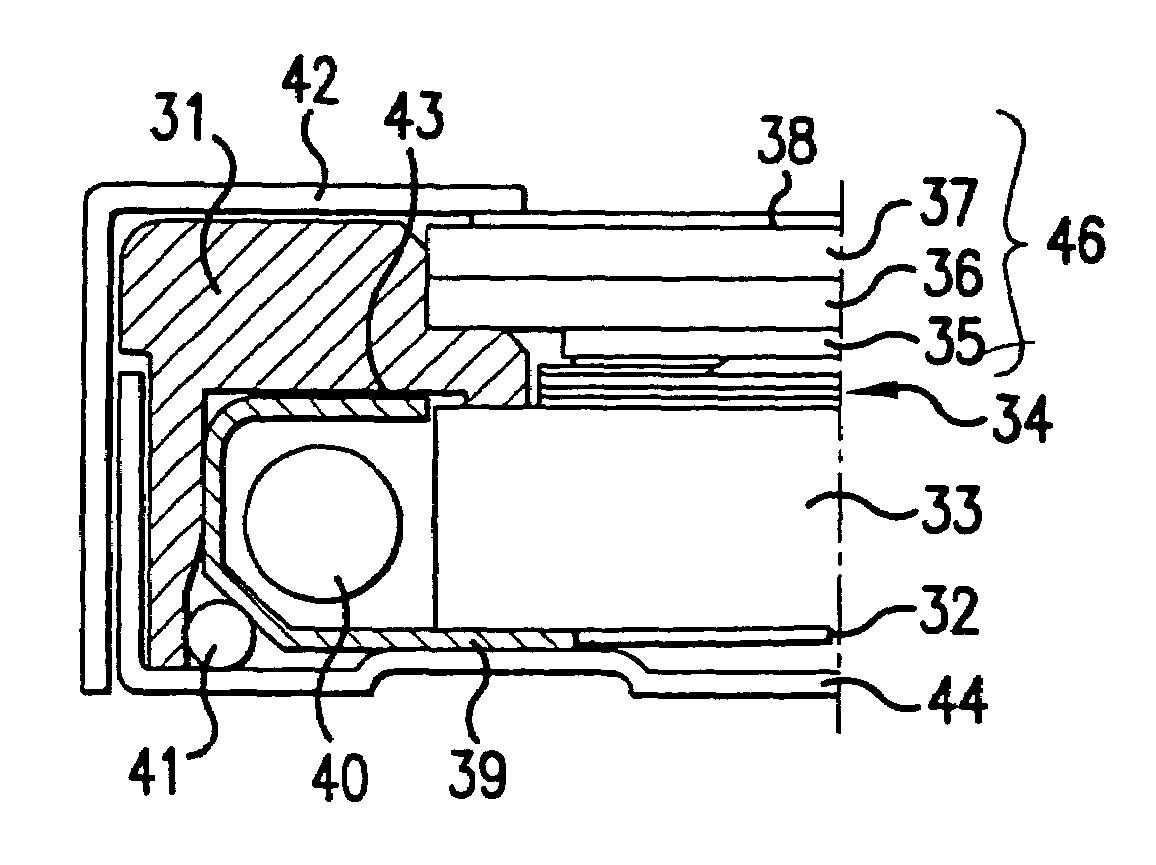

InactiveUS7083318B2Avoid it happening againInhibit generation of wrinkleShow cabinetsMechanical apparatusWrinkle skinLiquid-crystal display

In a liquid crystal display device according to the present invention, an upper end portion of a lamp housing is fixed on a main supporter so that the lamp housing can be made to face a side edge of a light guide. Light that can cause bright lines is eliminated or minimized through absorption or scattering by a main supporter. The main supporter is also thermally insulating and is placed between the lamp housing and a liquid crystal panel. Further, a thermally conducting bottom cover is placed under the backlight. Therefore, heat generated from the lamp is effectively channeled away from the light guide to prevent liquid crystal panel deterioration. Still further, although the upper and lower surfaces of the light guide is tightly fit between the lamp housing and the main supporter, wrinkles on a sheet reflector are prevented because the sheet reflector is not stacked between the lamp housing and a lower surface of the light guide.

Owner:LG DISPLAY CO LTD

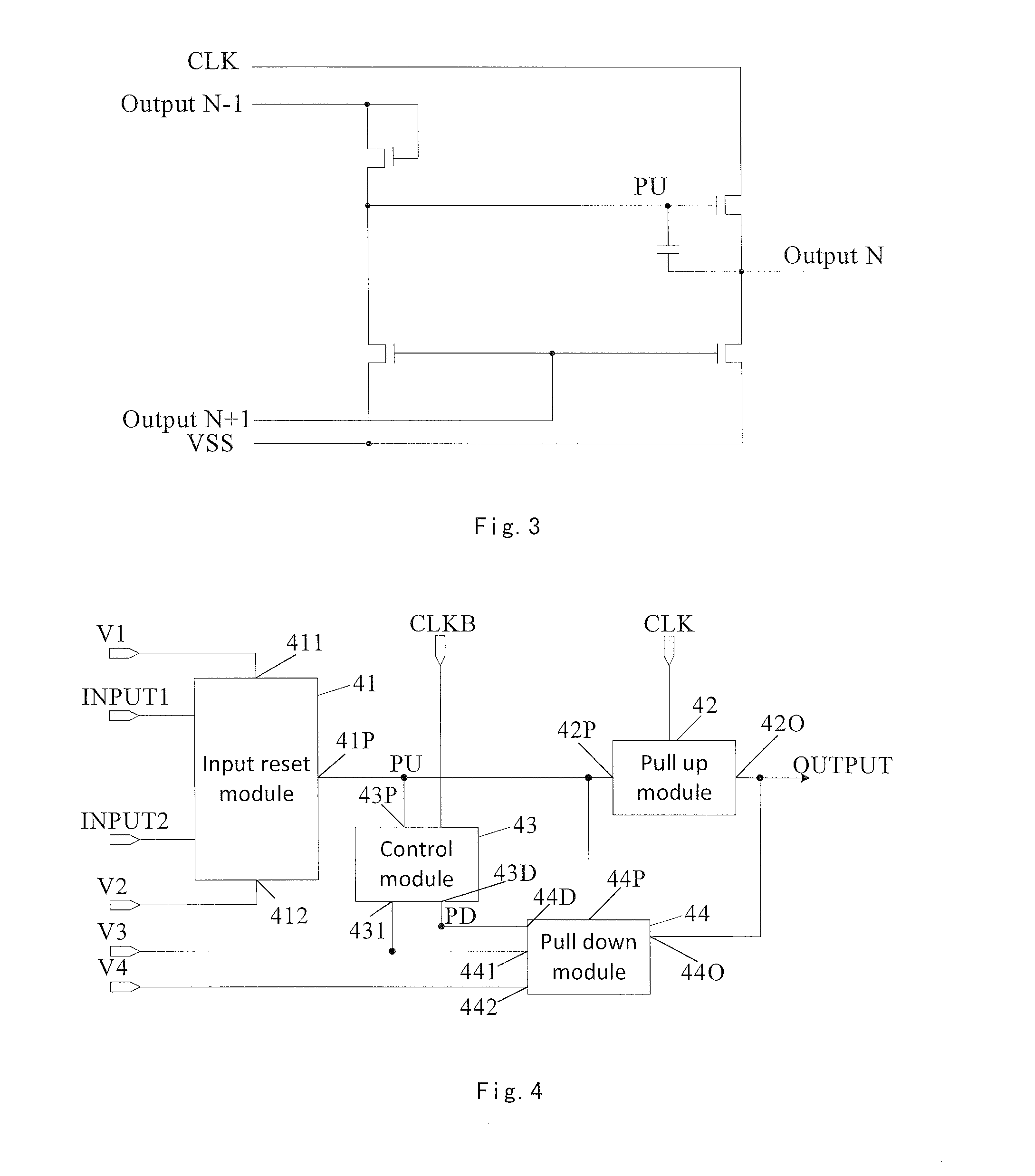

Shift register unit, gate electrode drive circuit and display apparatus

ActiveUS20160049126A1Suppress dark lines or bad bright linesImprove reporting rateStatic indicating devicesDigital storageShift registerProcessor register

The present disclosure provides a shift register unit, a gate electrode drive circuit and a display apparatus, which relates to a technical field of display. The shift register unit includes an input reset module, a pull up module, a control module and a pull down module. By inputting a high level into the second signal input end of the input reset module in the touch scan to maintain the level at the pull up control node, the electrical leak effects at the pull up control node may be avoided efficiently. In this way, the defects of insufficient charging rate of the row pixels may be avoided and the dark lines or bad bright lines may be suppressed.

Owner:BOE TECH GRP CO LTD

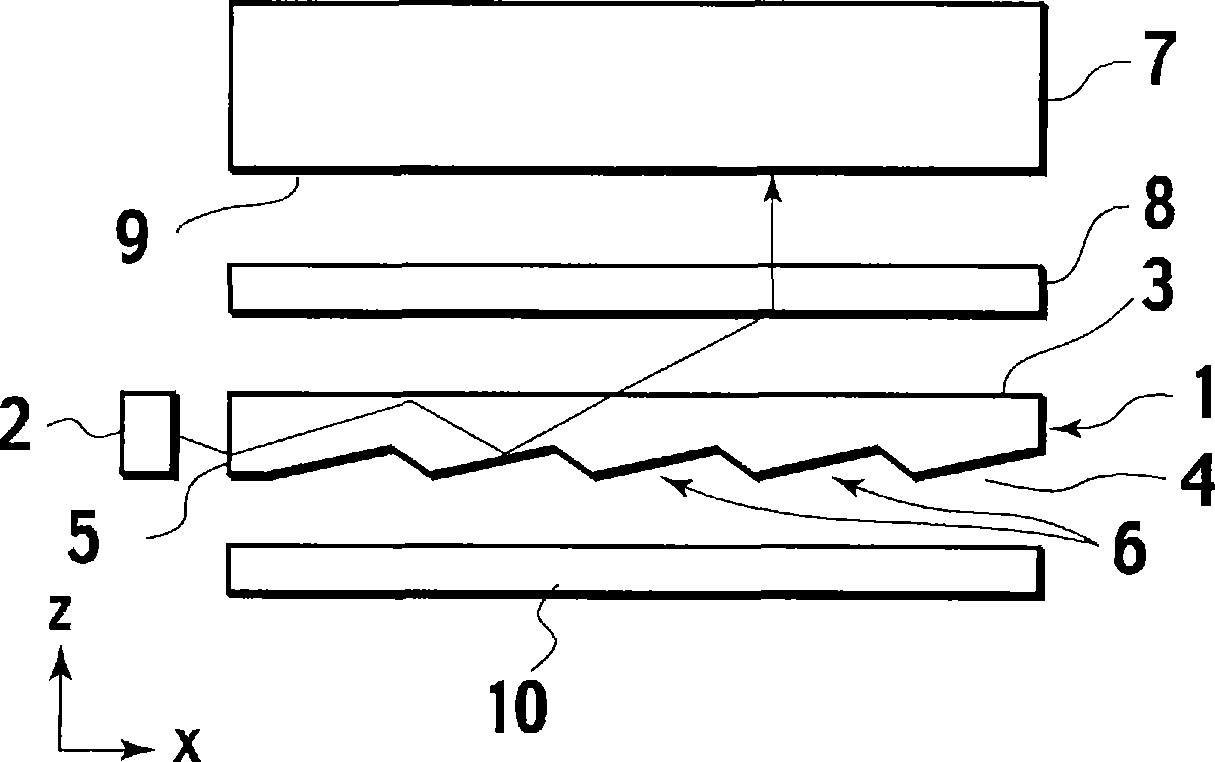

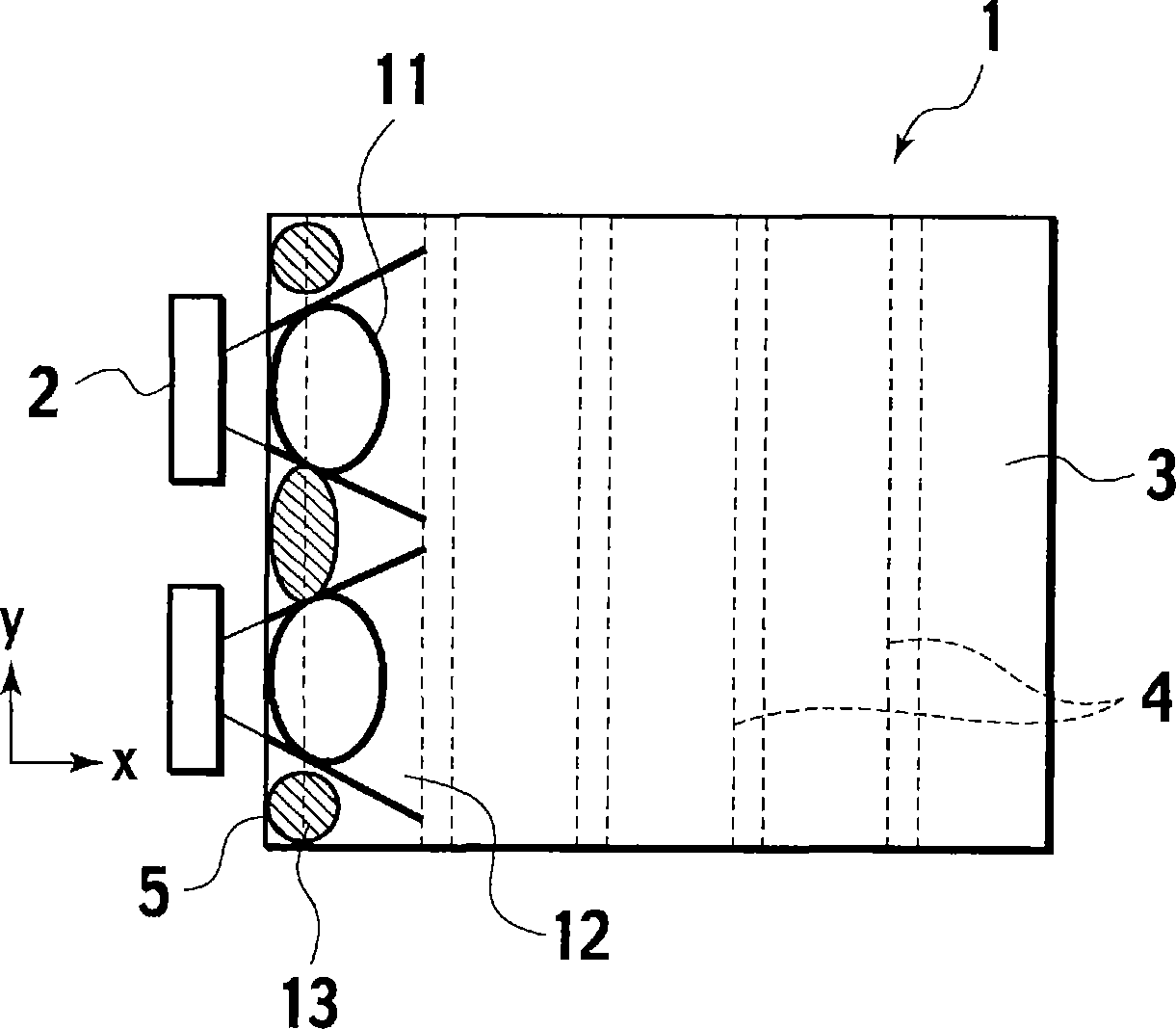

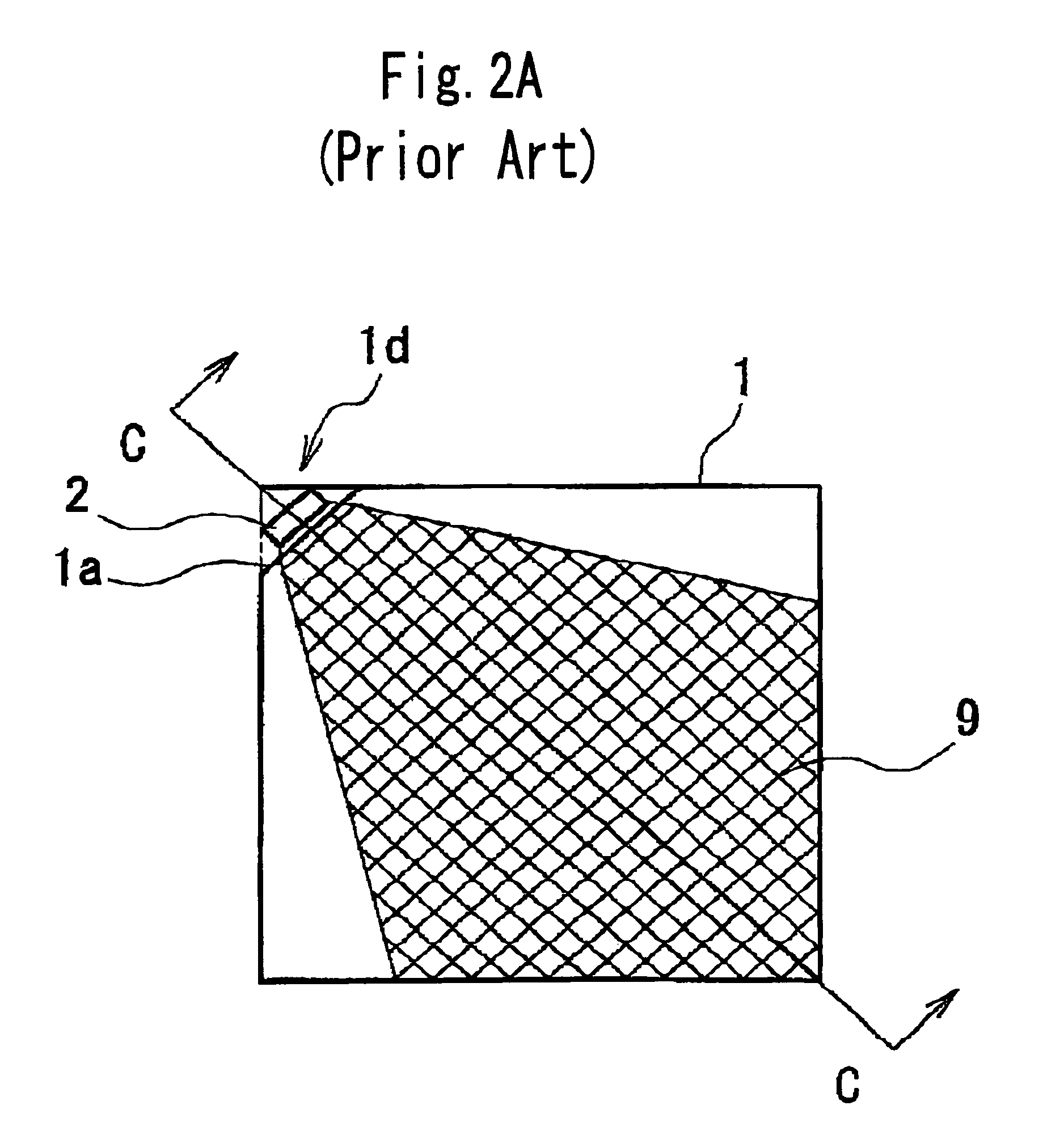

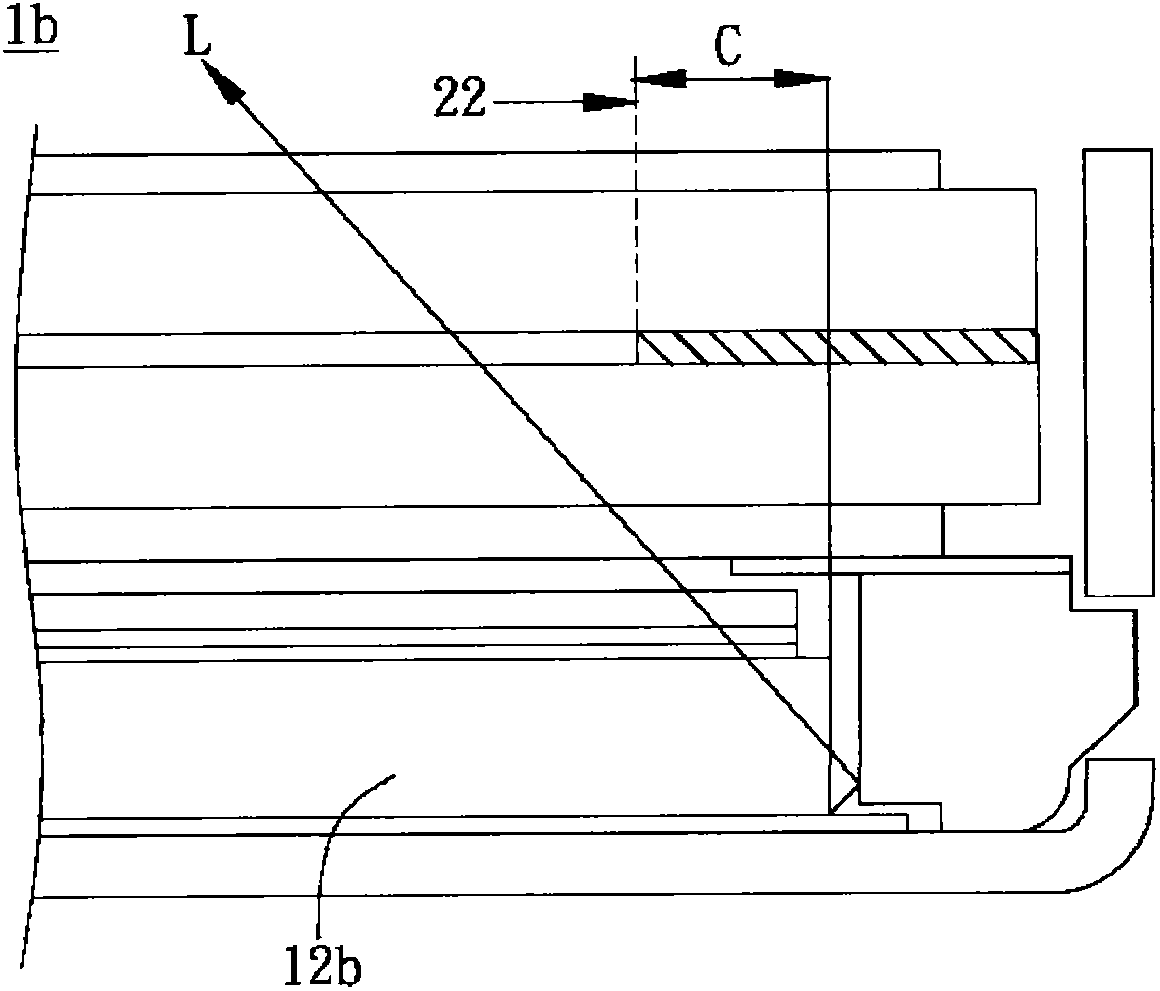

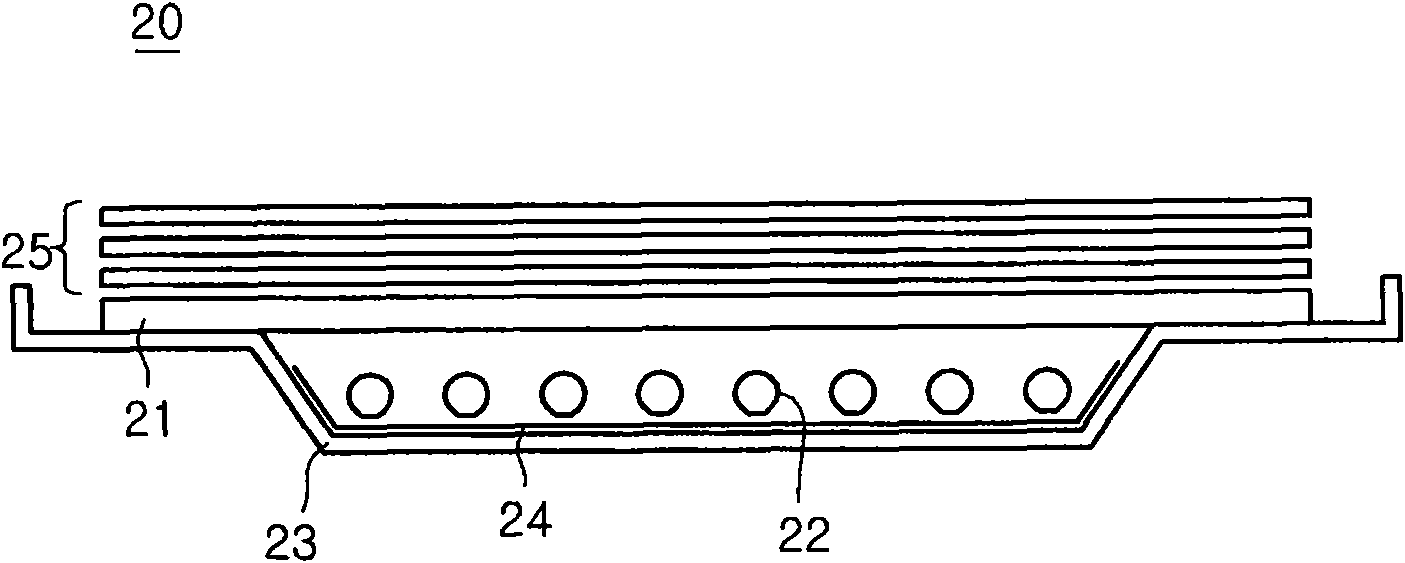

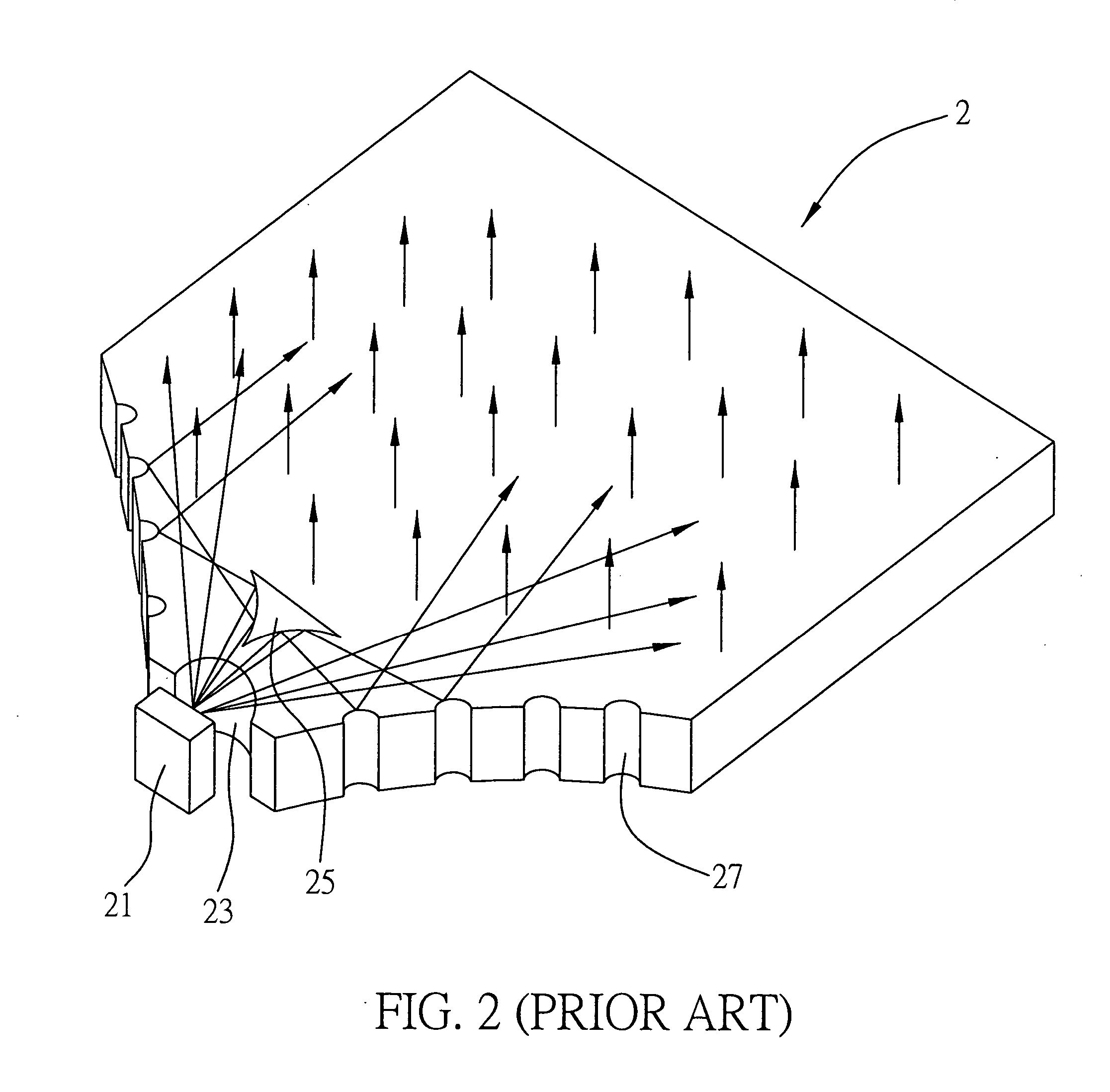

Surface light source device of side light type

InactiveUS6435685B2Improve uniformityPreventing bright linePlanar/plate-like light guidesMachines/enginesOptoelectronicsBright line

A surface light source device of side light type has a guide plate, a primary light source for supplying illuminating light through an incidence surface, first and second edges at which major surfaces respectively intersect the incidence surface, and one or plural additive members arranged in direct contact with the emission surface and / or the back surface thereon in the vicinity of the first edge and / or the second edge. At least one of the additive members has a shield for preventing illuminating light from being incident to the first or second edge. For example, the shield includes absorptive areas formed on the additive members. Each of the absorptive areas is formed so that each of the absorptive areas crosses the first or second edge. A distal end of a reflector arranged in the primary light source or frame blocks incidence of light to the first and / or second edge. The light incidence block to each edge prevents luminance irregularities in the form of a bright line.

Owner:ENPLAS CORP

Reflector and backlight device

A back light device realizing improvement in hotspots and bright line in the region of light incidence and of darkness arising in between light sources is provided by forming the reflective surface of the reflector as a structured face comprising an iteration of prism elements of trapezoidal section.

Owner:HITACHI CHEM CO LTD

Light guide plate

ActiveUS7357557B2Improve display image qualityHigh quality imagingMechanical apparatusPlanar/plate-like light guidesEmberLight guide

Owner:CITIZEN ELECTRONICS CO LTD

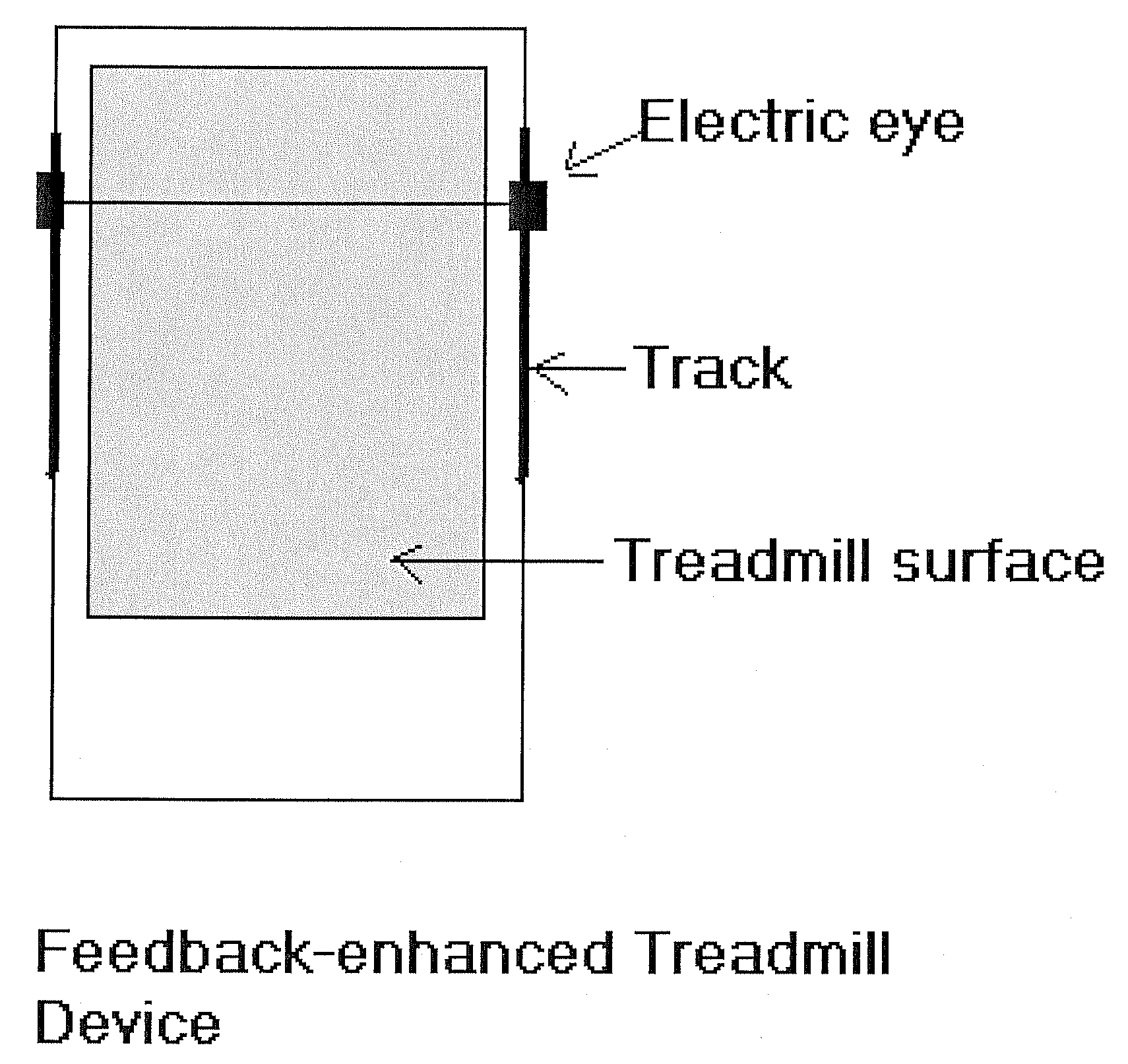

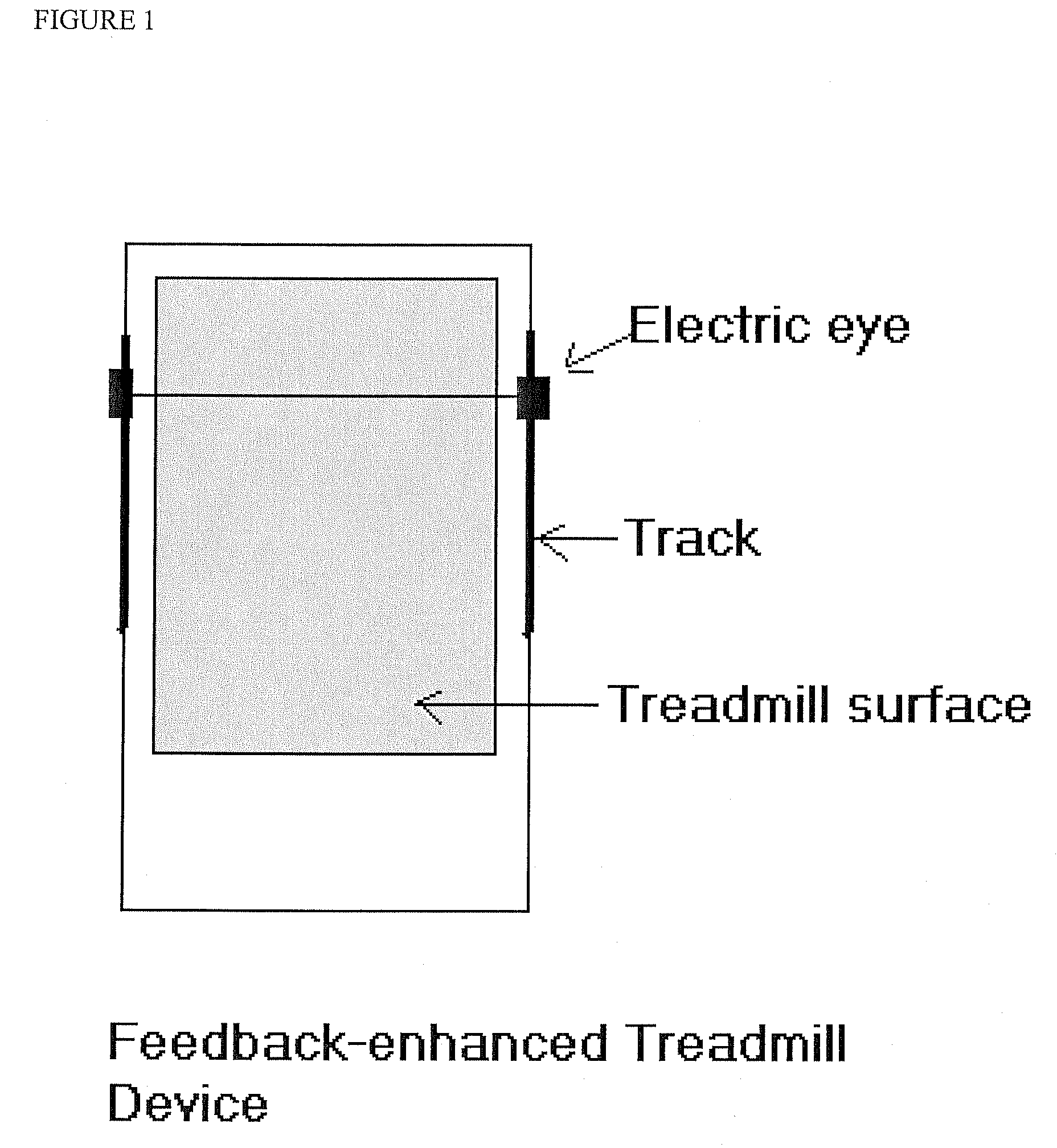

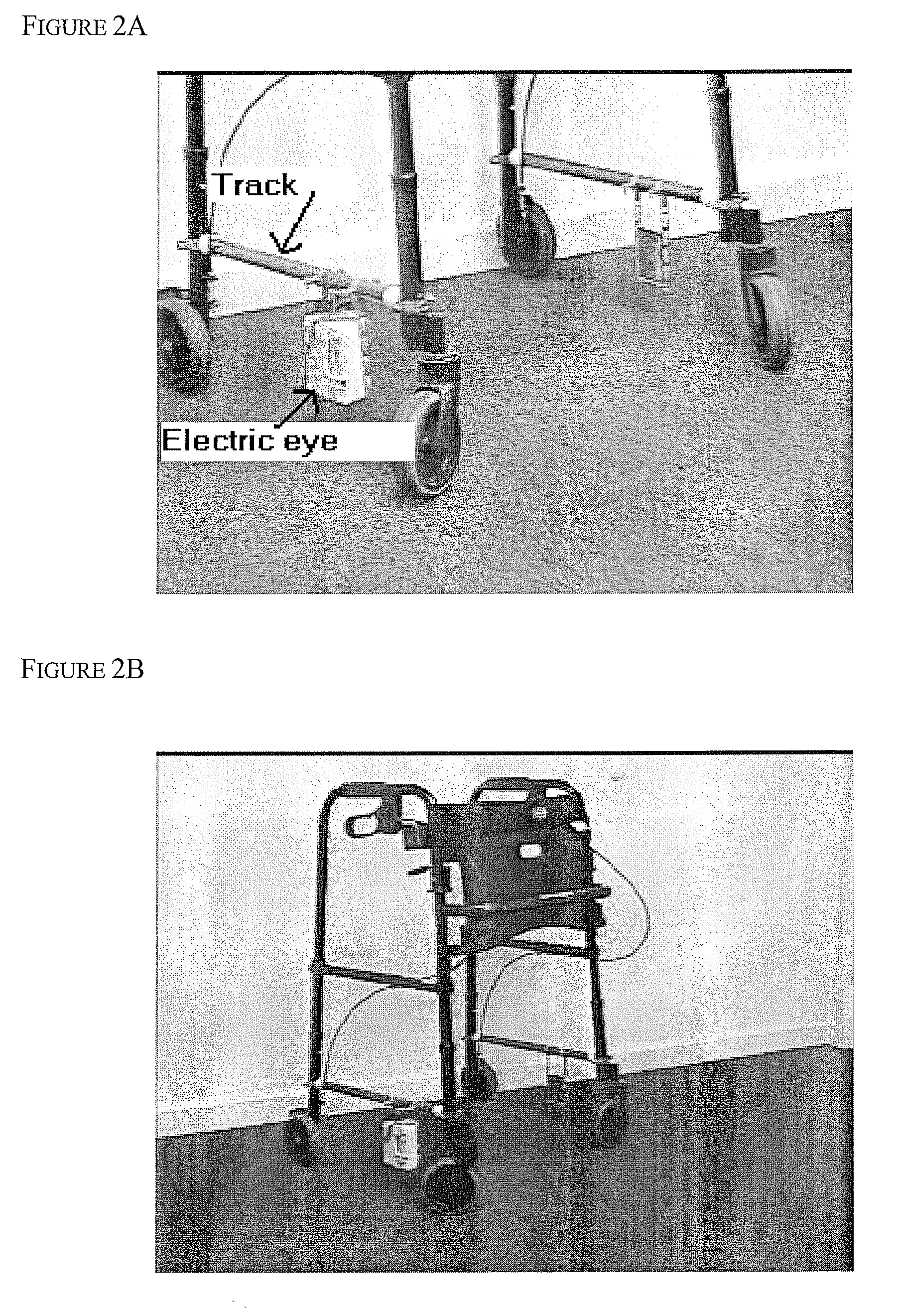

Products and methods for motor performance improvement in patients with neurodegenerative disease

InactiveUS20070255186A1Improve gait performancePerson identificationWalking aidsDiseaseStride length

The present invention is drawn to products and methods to improve the gait performance of subjects with neurodegenerative disease before and after feedback-enhanced training. The present invention has the goal of producing larger stride length in patients with neurodegenerative disease. The method includes patients walking on a treadmill while a bright line is shown at increasing distances from their center of gravity, and encouraging them to take larger steps. The present invention also includes a walking assistance appliance, including, a walker, cane, and so forth.

Owner:DE NOVO TECH

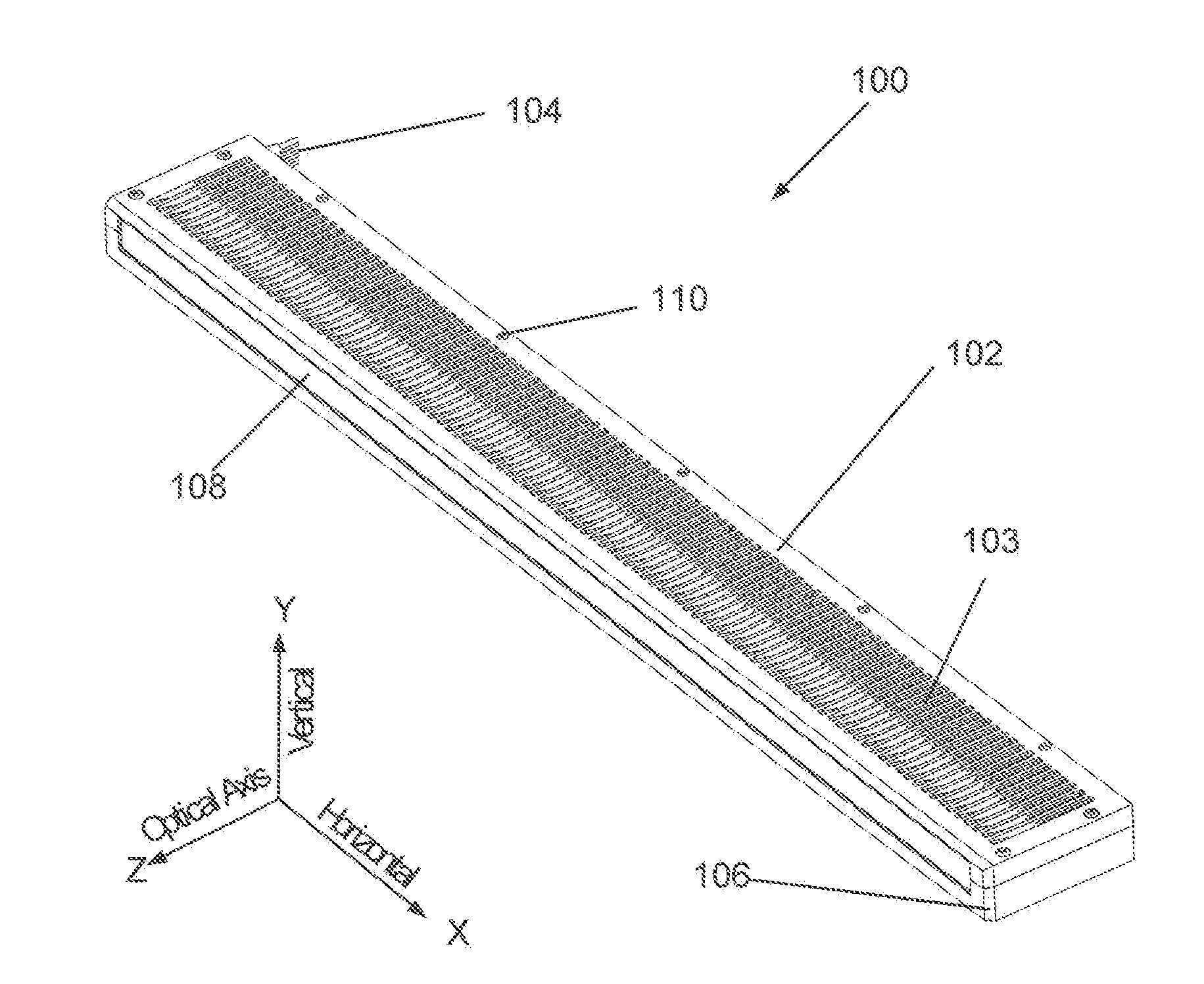

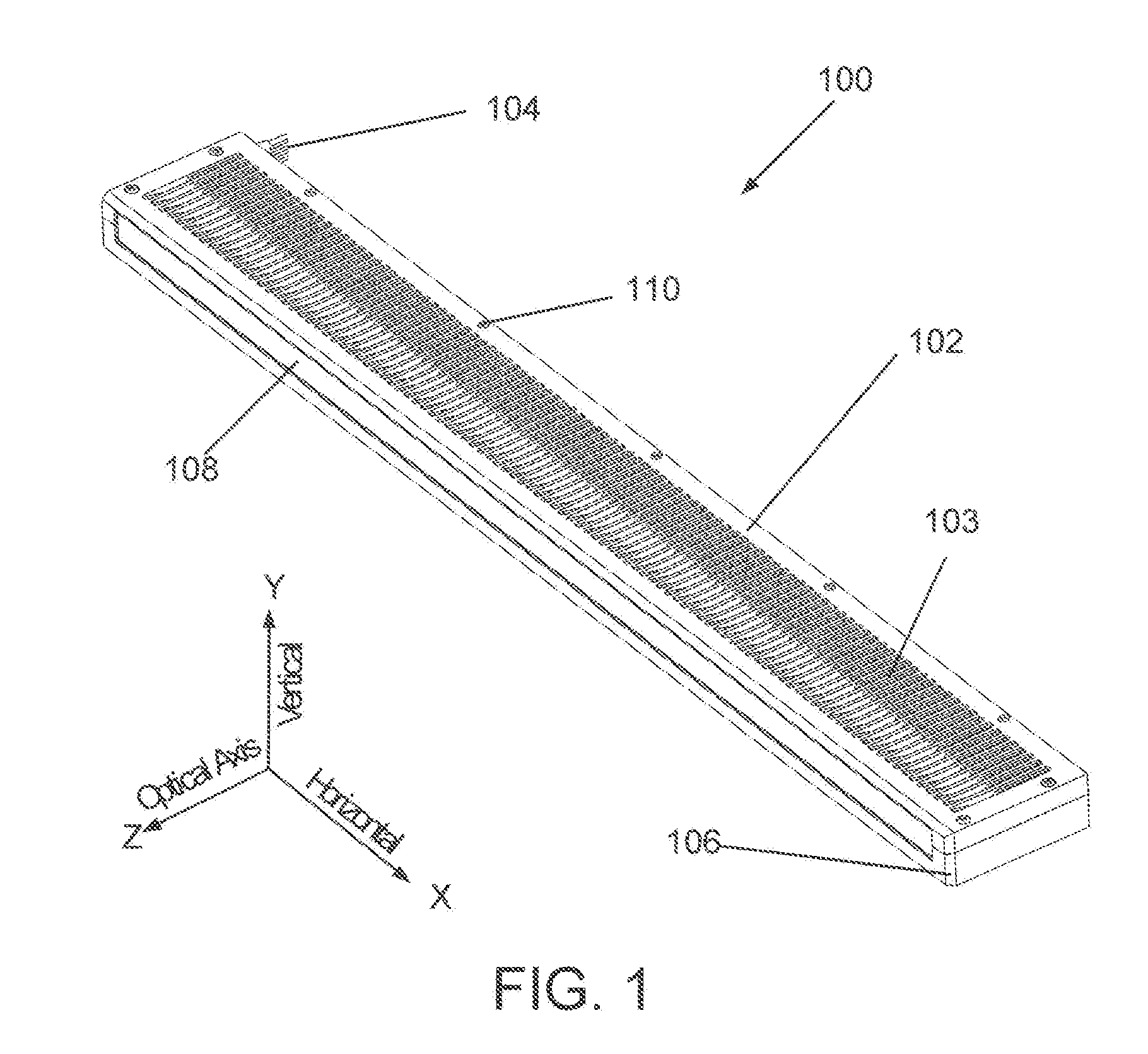

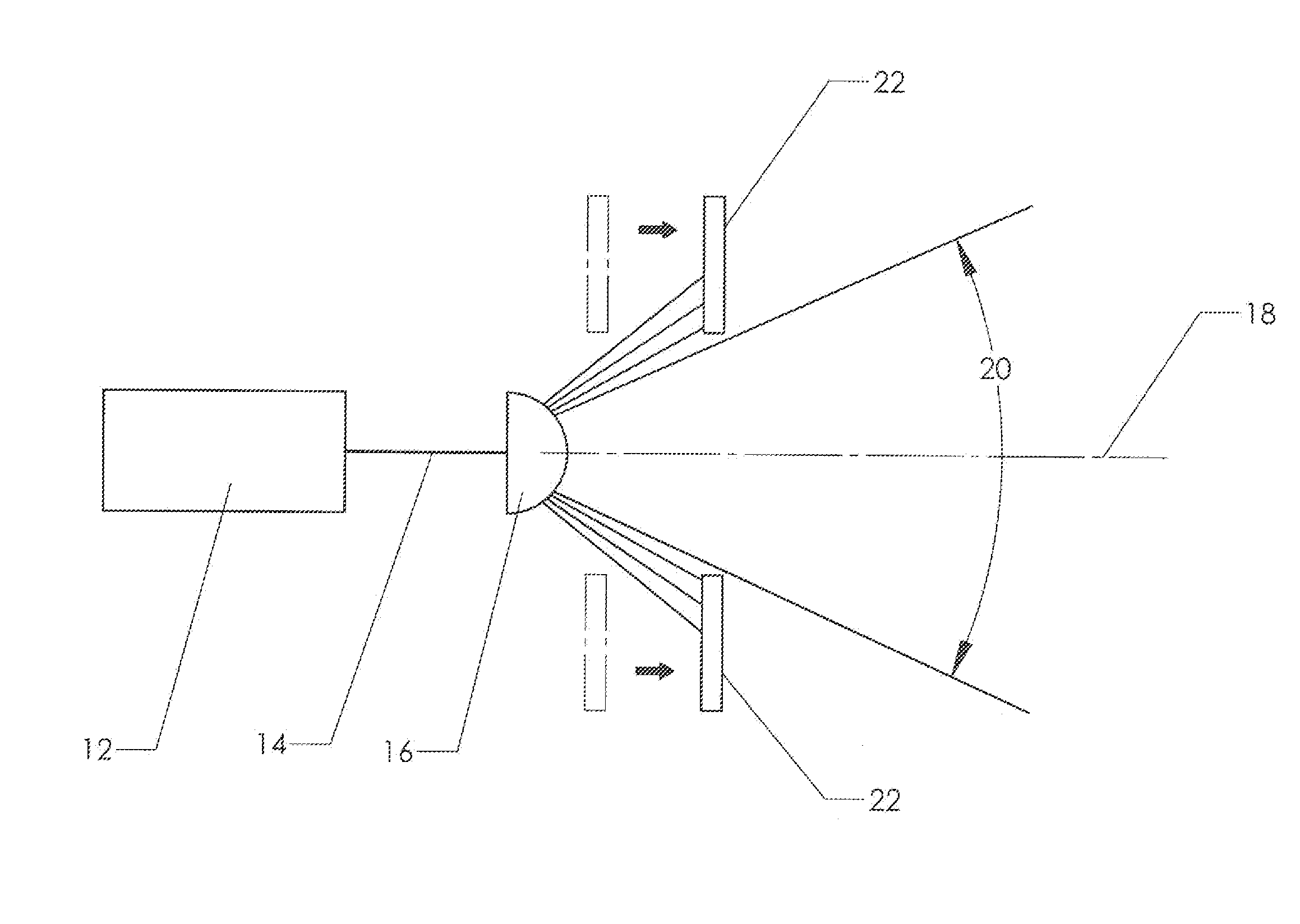

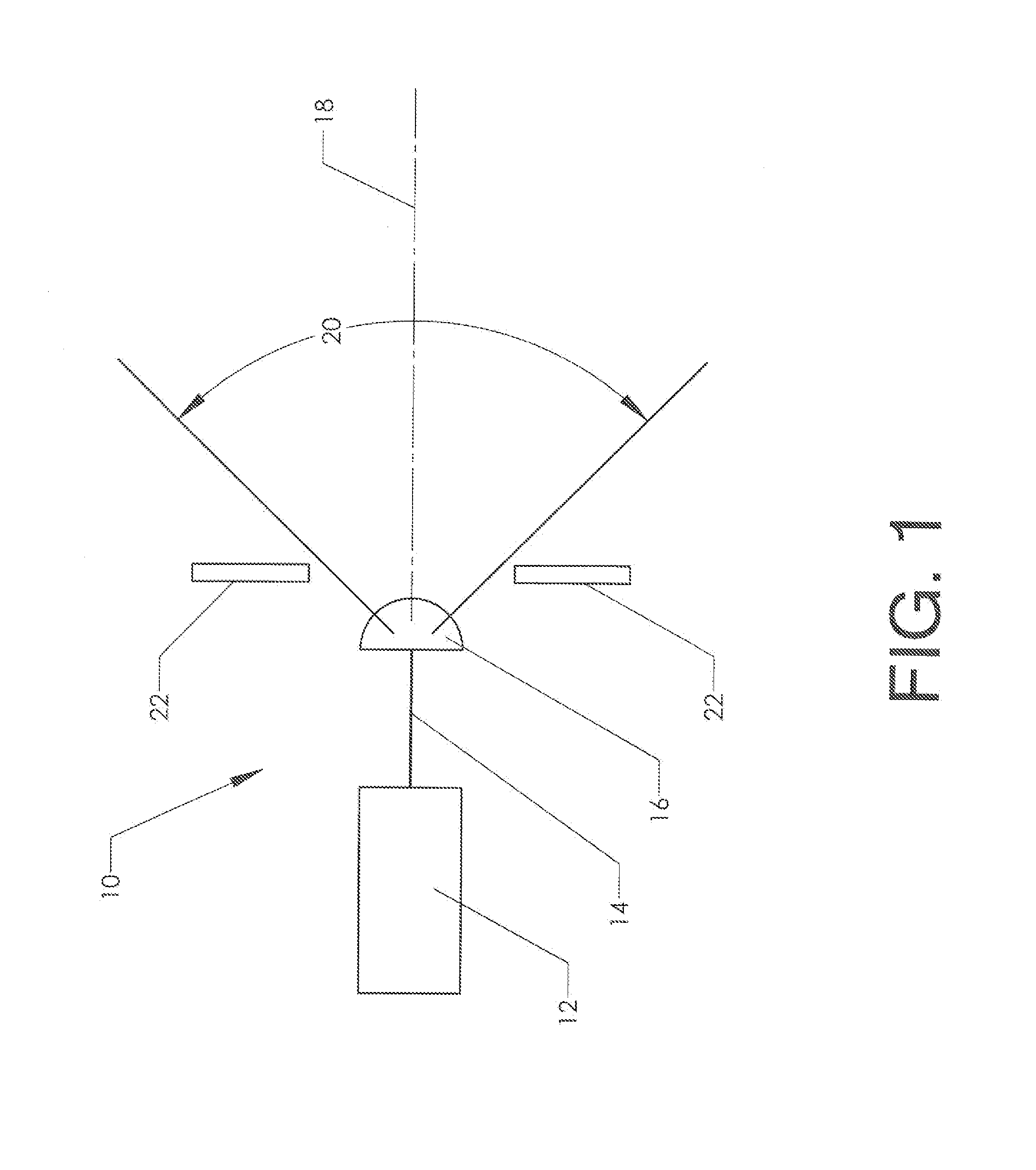

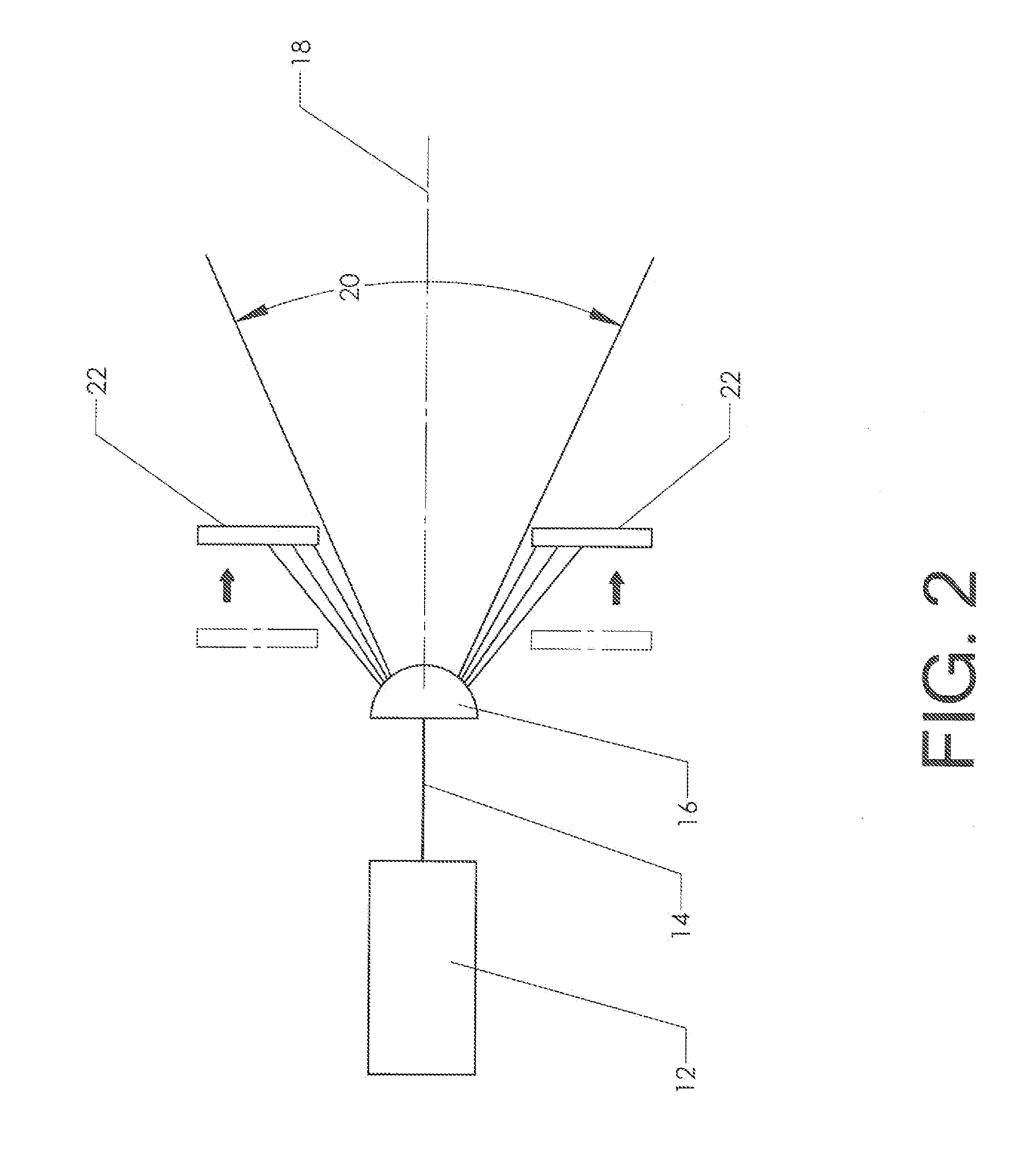

Light emitting diode linear light for machine vision

ActiveUS20100188017A1Minimizing cost of systemLow costLighting support devicesPoint-like light sourceMachine visionEngineering

The invention herein comprises a linear lighting system which incorporates light emitting diode (LED) light sources with one or more distinct colors including broad band white light. The LED die or die arrays are mounted to a high thermal conductivity circuit board comprising COB technology which can include both the LED die and electronic drive components resulting in a more compact and reliable design with improved thermal and optical performance at lower cost. In conjunction with high efficiency imaging collection optics and aberration corrected cylindrical optics, the output of the LED sources are imaged to a bright line suitable for use in machine vision applications and the like.

Owner:INNOVATIONS & OPTICS

Reflective sheet and method of manufacturing the same

ActiveUS20150146436A1Improving good picture quality of imageReduce manufacturing costMirrorsNon-linear opticsManufacturing cost reductionEngineering

A reflective sheet with a dot-cut pattern for preventing both bright line and bright spot, and a method of manufacturing the same, is provided. The reflective sheet and method of manufacturing the same may be capable of reducing a manufacturing cost and also improving a manufacturing efficiency. The reflective sheet may include a bottom part including a hole for exposing a light source, the bottom part provided on a bottom surface of a cover bottom; a lateral part extending from the bottom part, the lateral part provided at a lateral surface of the cover bottom; a half-cut pattern formed in the boundary between the bottom part and the lateral part; and a plurality of dot-cut patterns formed at the lateral part.

Owner:LG DISPLAY CO LTD

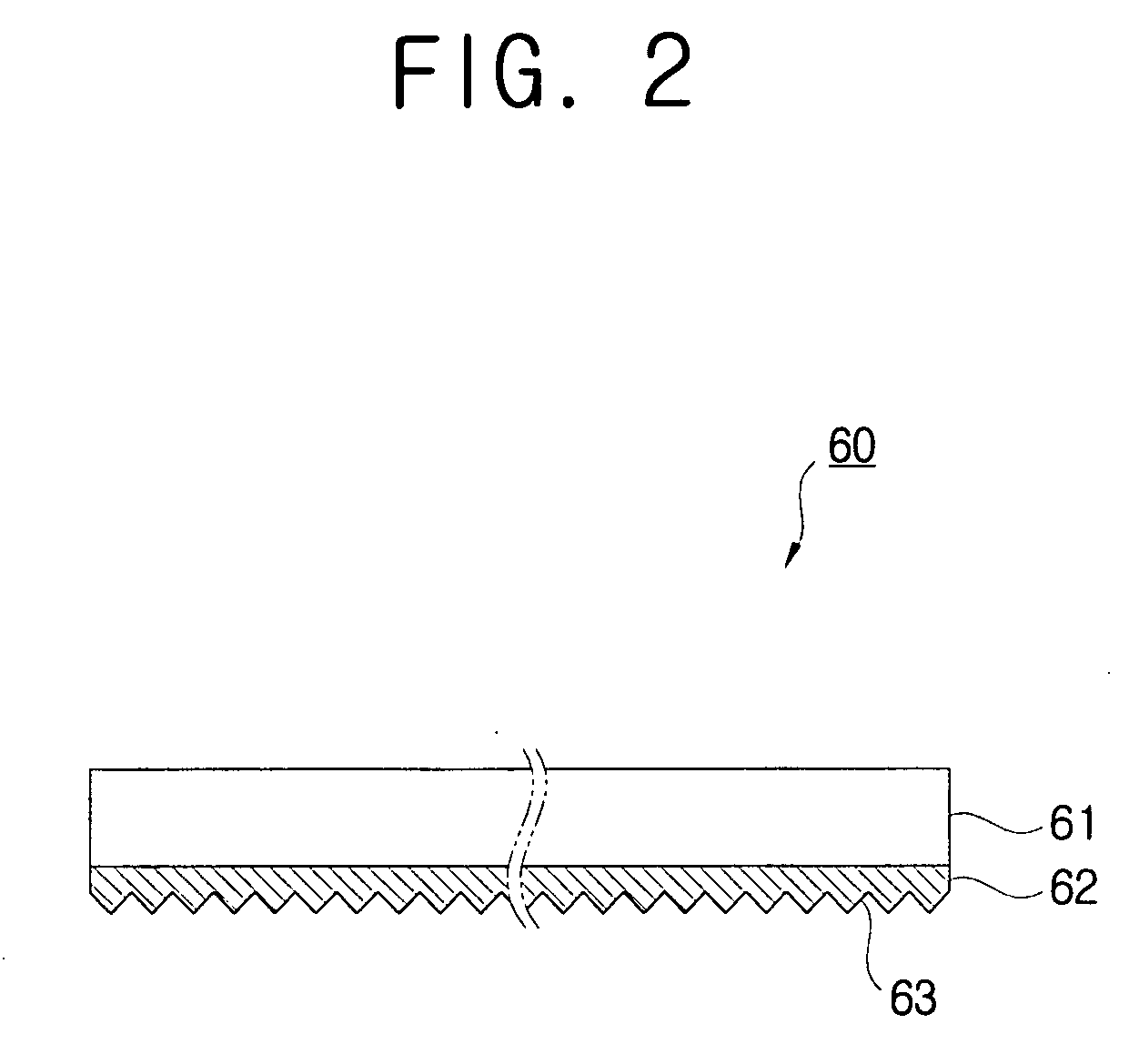

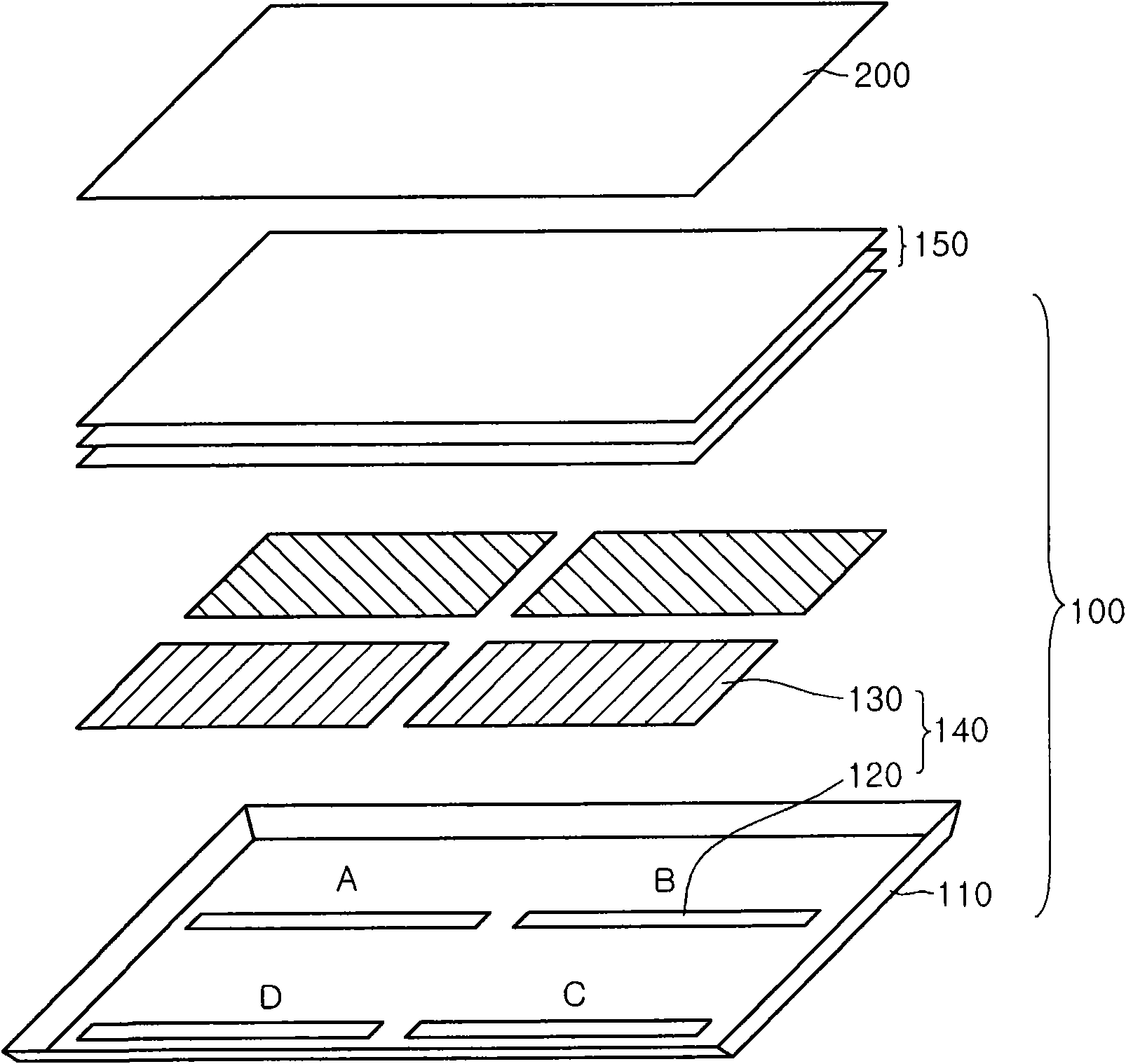

Optical sheet and LCD apparatus using the same

ActiveUS20050007513A1Increase brightnessBright-line is decreasedPrismsMechanical apparatusLight guideEngineering

The present invention relates to an optical sheet and an LCD apparatus using the same. An LCD apparatus according to the present invention comprises an LCD panel to display a picture thereon; a lamp unit emitting light; a light guide plate to guide the light from the lamp unit toward the LCD panel evenly; an optical sheet provided between the LCD panel and the light guide plate and including a condensing layer condensing the light from the light guide plate on the LCD panel, and a reflective polarizing layer attached to the surface of the condensing layer facing the LCD panel and selectively transmitting and reflecting the light condensed by the condensing layer. With this configuration, the present invention provides an optical sheet and an LCD apparatus using the same, in which a bright-line is decreased, brightness are enhanced, and the optical sheet is prevented from shrinking.

Owner:SAMSUNG DISPLAY CO LTD

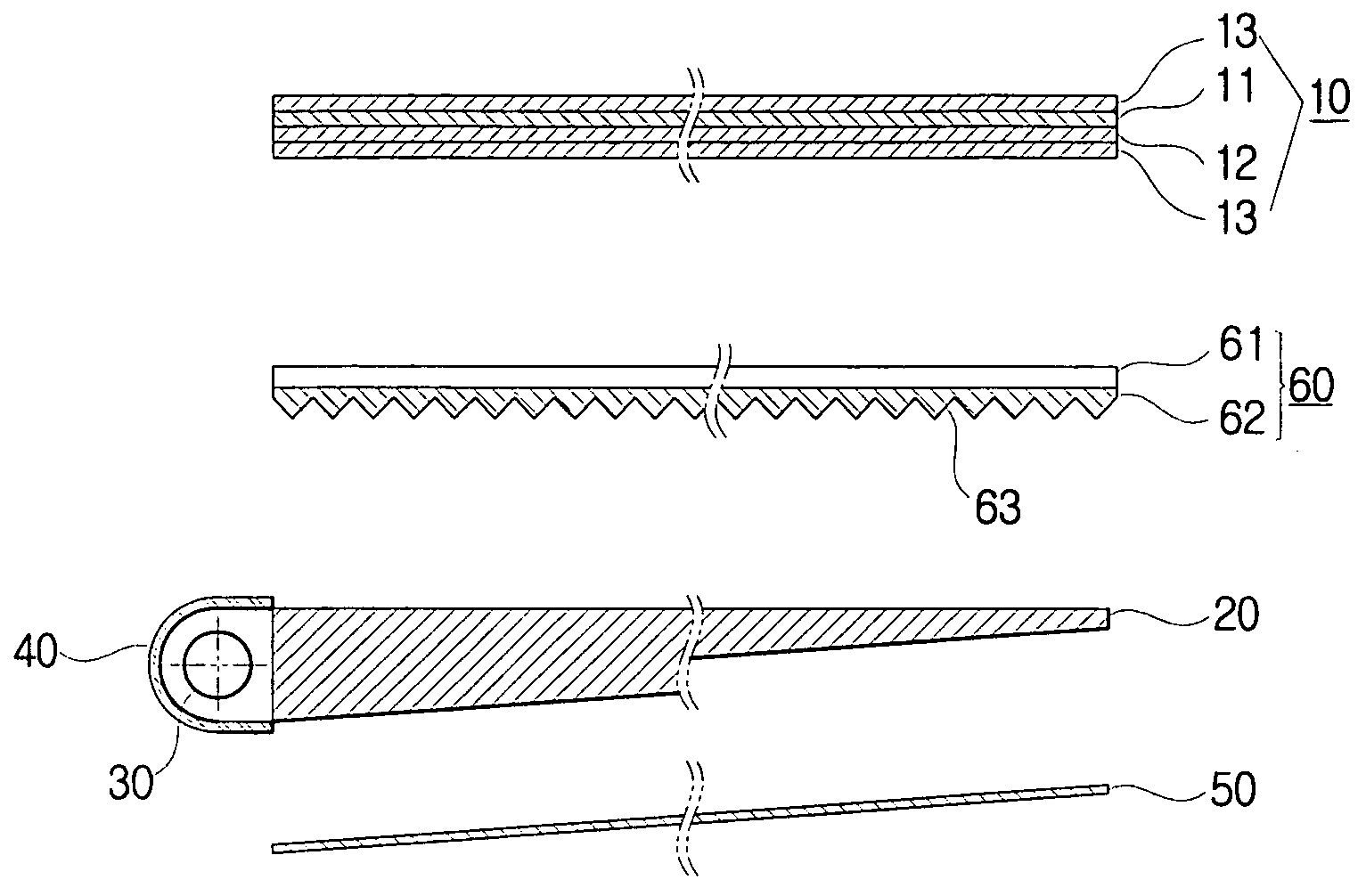

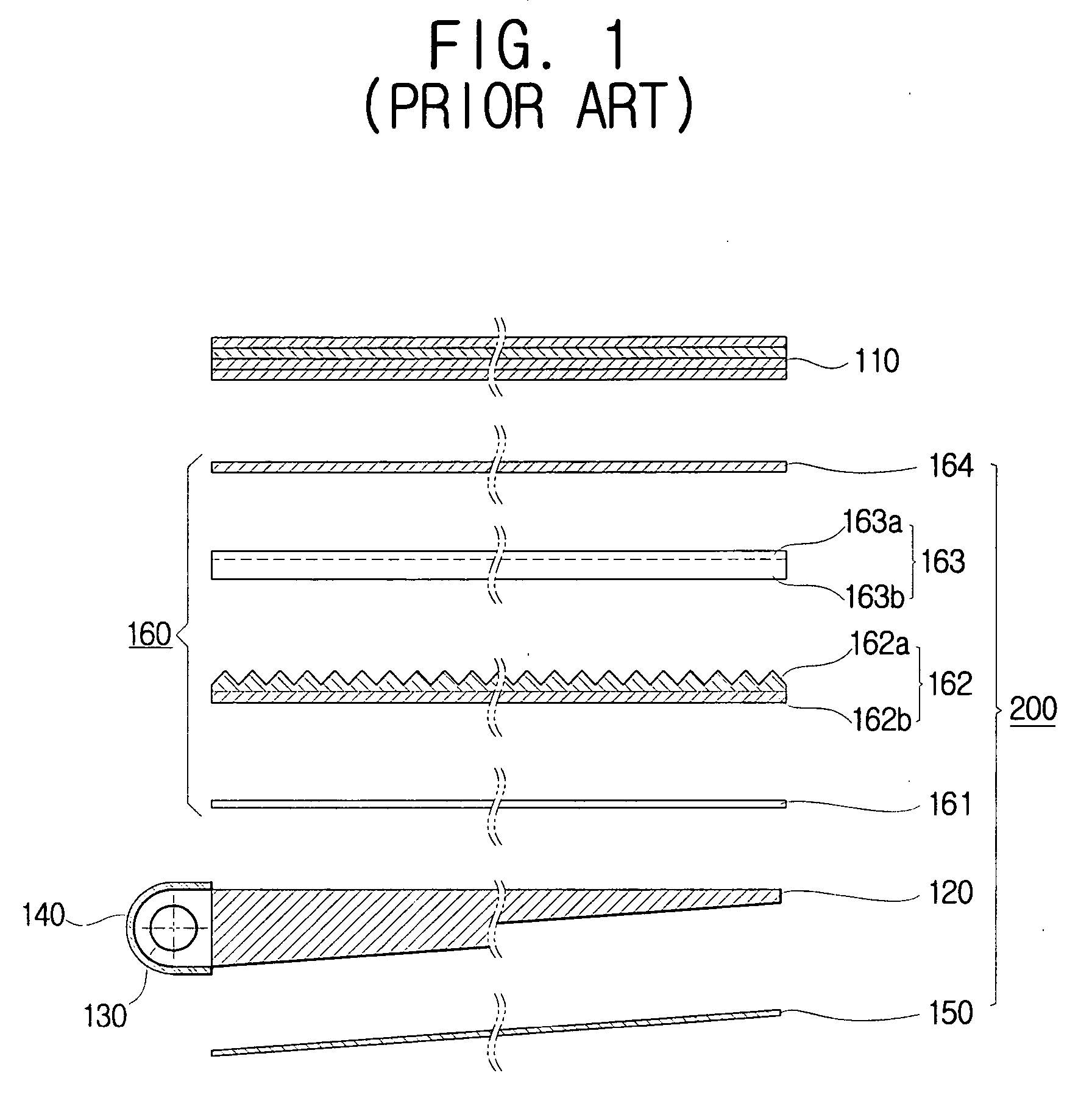

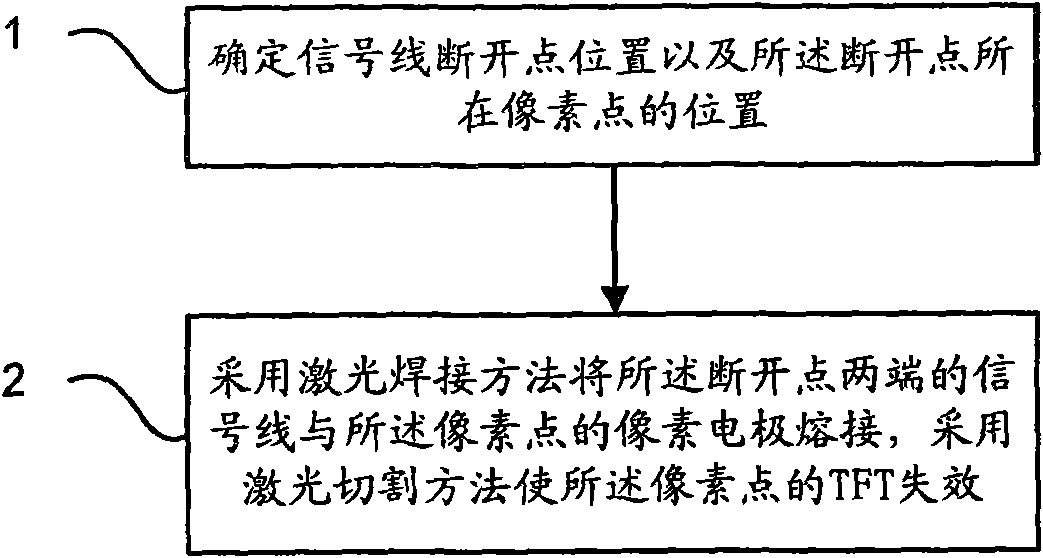

Liquid crystal display and method for restoring broken wires

InactiveCN101581840AImprove the level ofAvoid wastingNon-linear opticsLiquid-crystal displayLaser cutting

Owner:BOE TECH GRP CO LTD +1

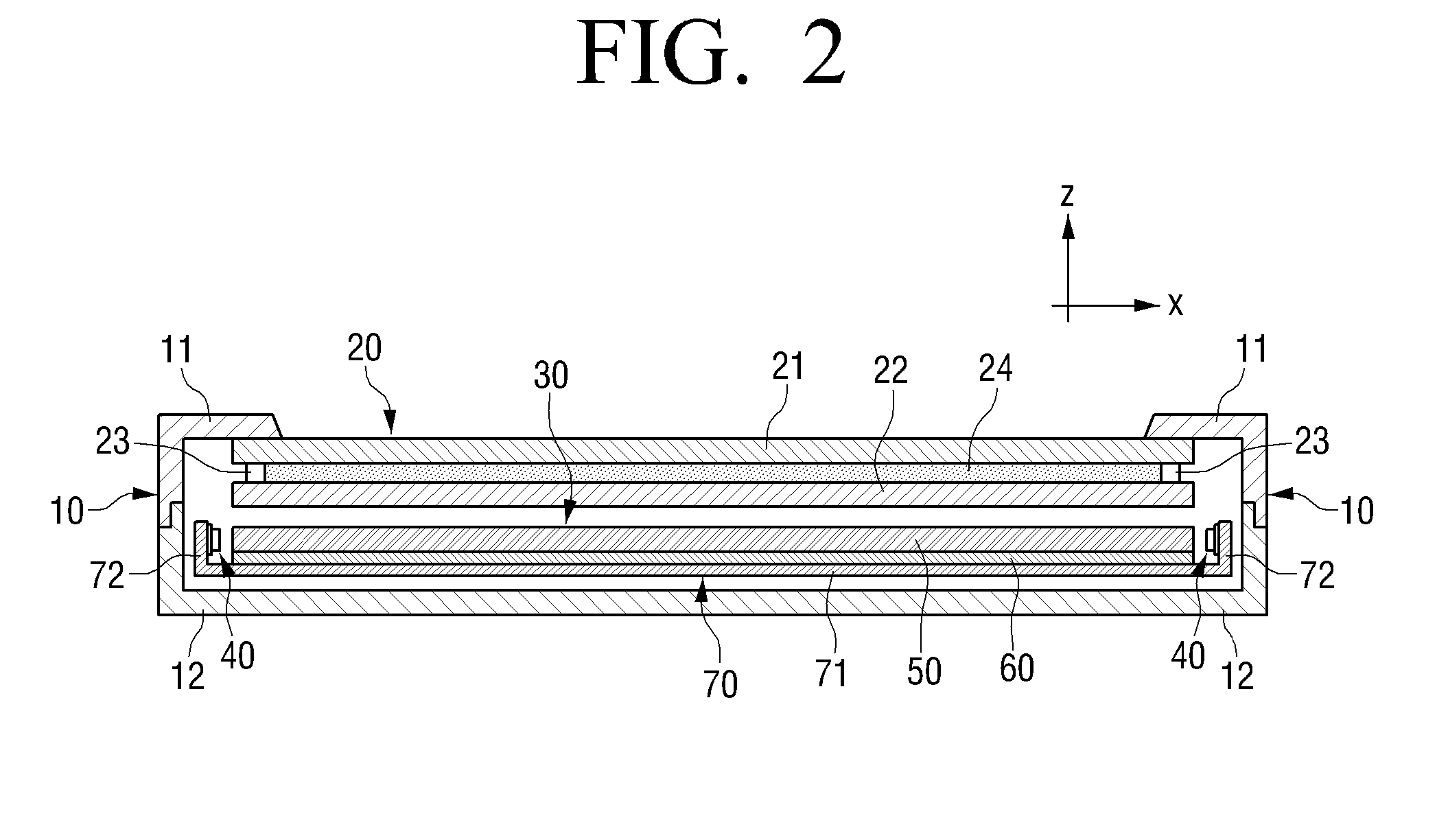

Liquid crystal display device

InactiveUS20120050635A1Improve reliabilityReduce border widthOptical light guidesNon-linear opticsLiquid-crystal displayLight guide

A liquid crystal display device is provided. The liquid crystal display device includes a light-shielding member to prevent light irradiated upward from a light-emitting surface of a plurality of light-emitting diodes from being incident on a lower edge of an incident surface of a light-guide portion. As a result, a bezel surrounding a liquid crystal display panel may be made thinner, and a bright line defect, hot spot, may be prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

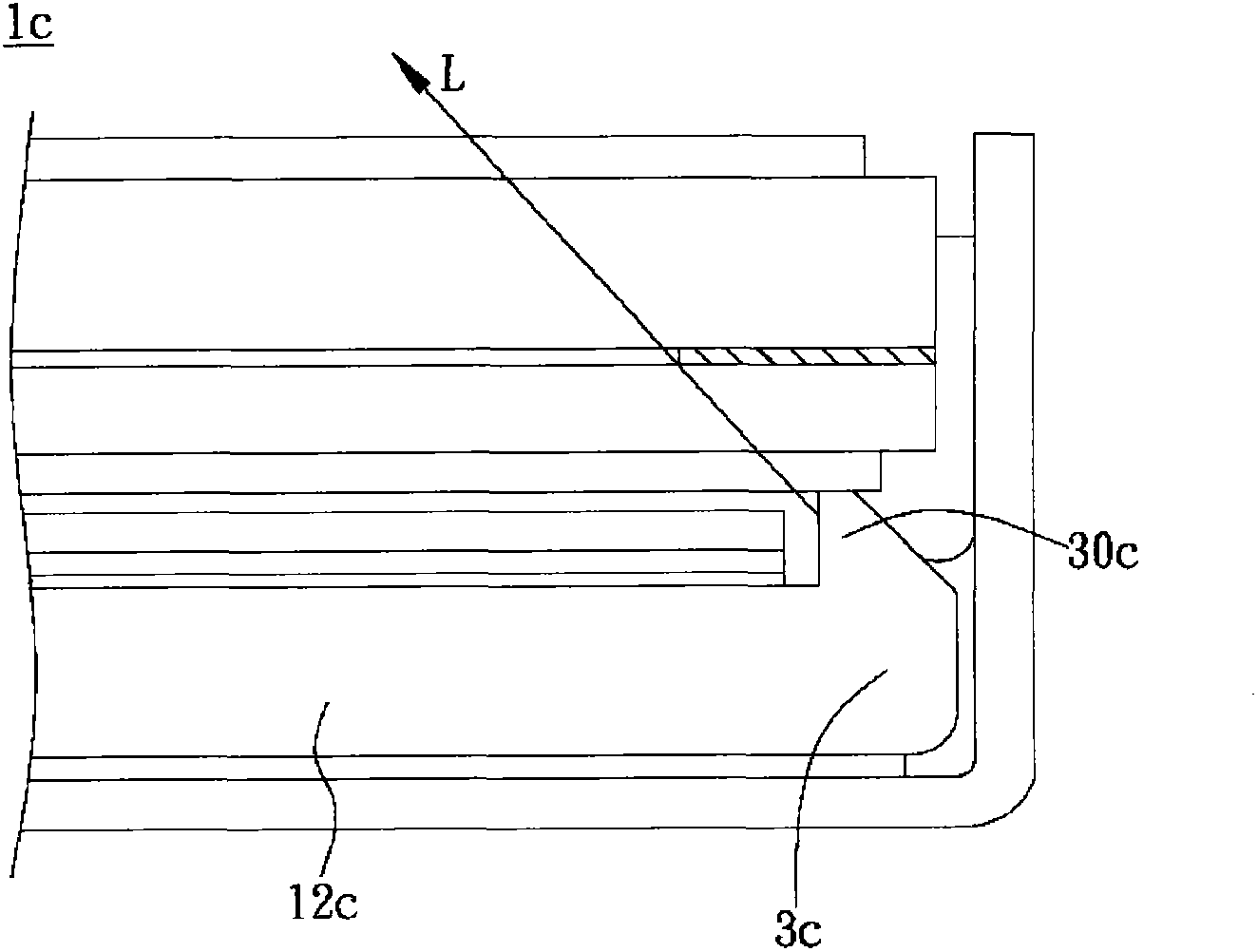

Light guide plate with supporting rib and display module comprising same

InactiveCN102354014AAvoid bright linesAvoid light leakageMechanical apparatusLight guides for lighting systemsLight guideOptoelectronics

The invention relates to a light guide plate with a supporting rib and a display module comprising the same. The light guide plate is used for a backlight module. The light guide plate comprises a light exiting region and a light shading region, wherein the light shading region is arranged at one side of the light exiting region, at least protrudes out of the plane of the light exiting region, the light exiting region is formed by the body of the light guide plate, the body comprises a light exiting surface and a first end having a first thickness, the light shading region comprises at least part of the supporting rib of the light guide plate, the supporting rib is arranged at the first end of the body and extends along the first end, at least part of the supporting rib protrudes out of the light exiting surface, at least part of the supporting rib is formed by non-transmitting bodies, the supporting rib has a shading width inward from the first end, and the shading width is no smaller than the first thickness. The light guide plate can avoid bright lines or leaked light caused by border refracted light.

Owner:AU OPTRONICS CORP

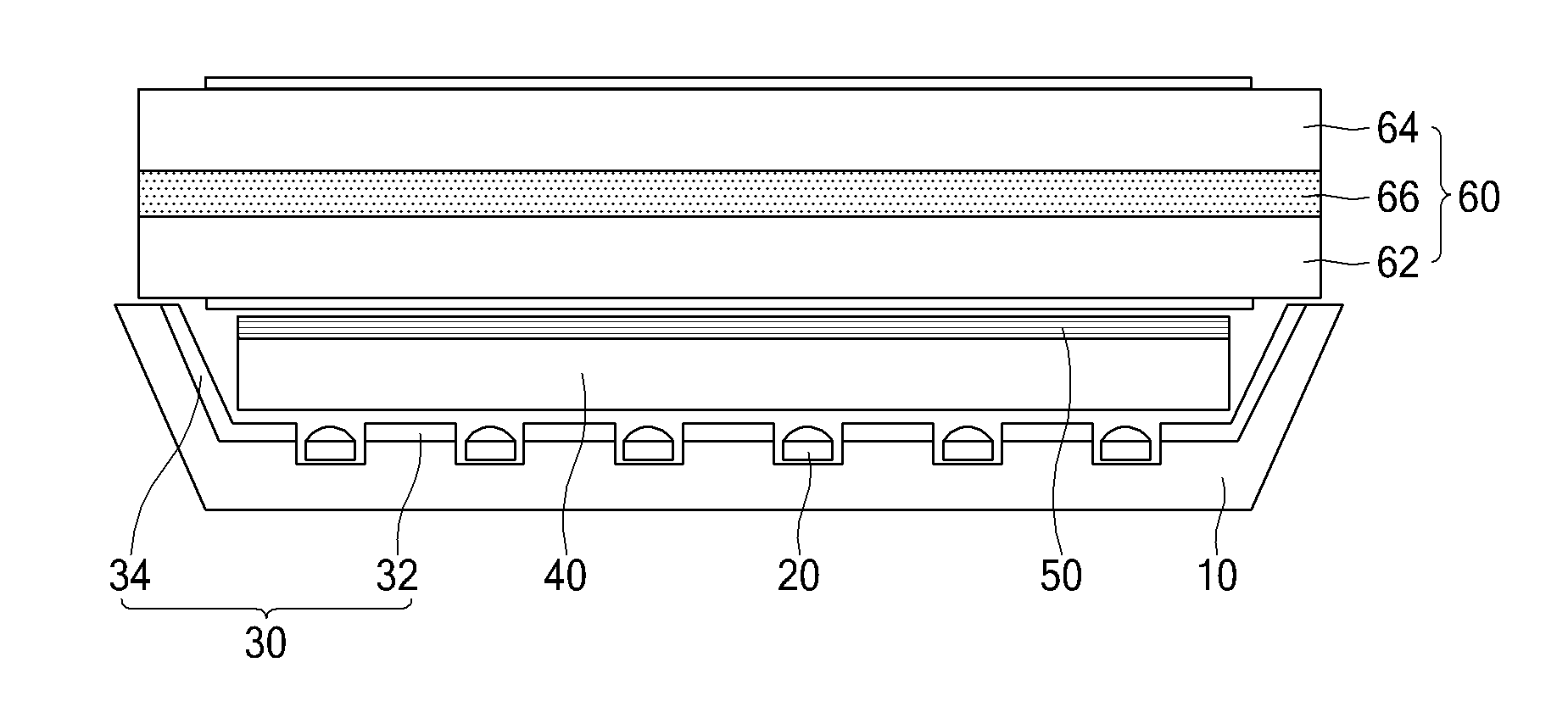

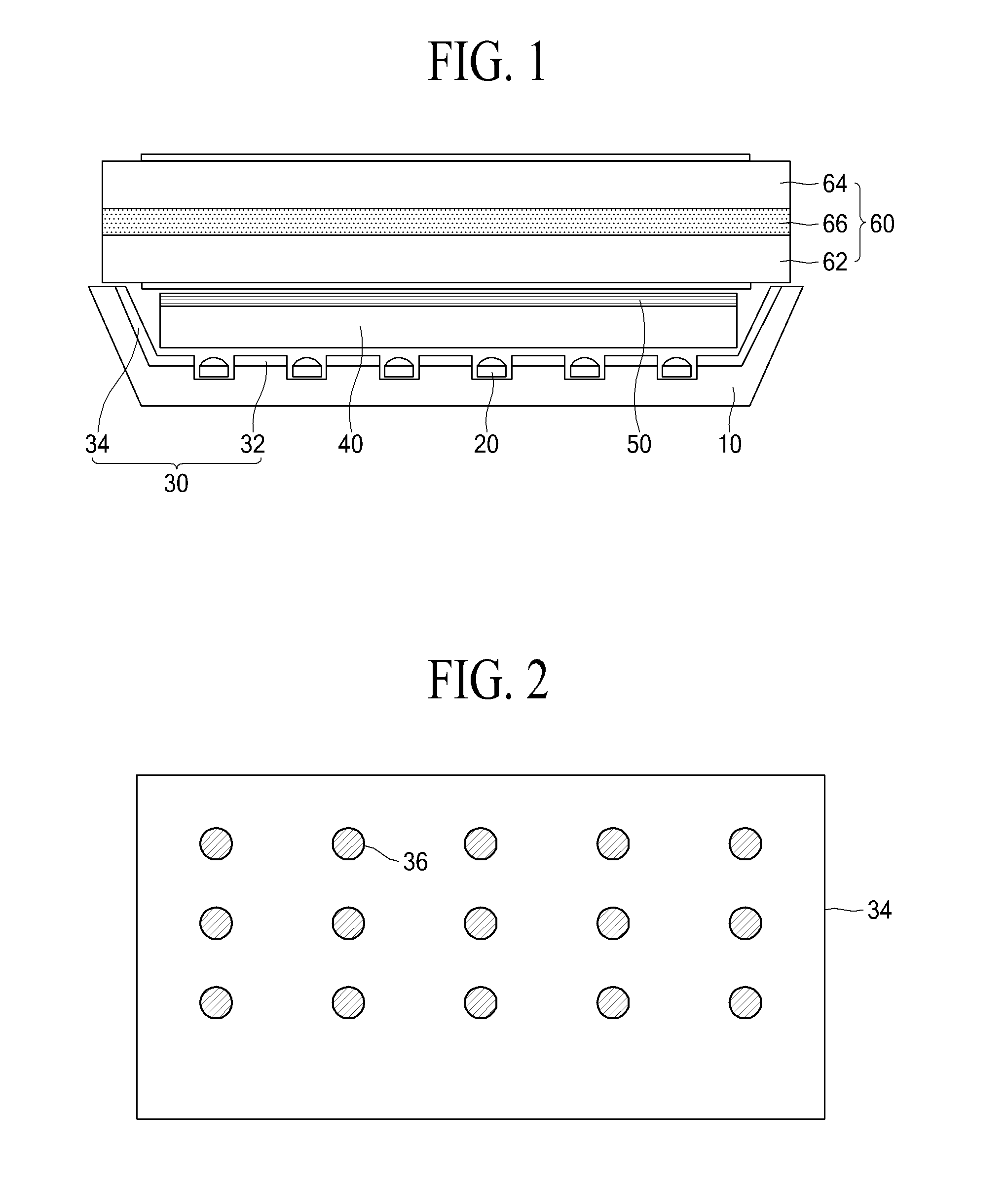

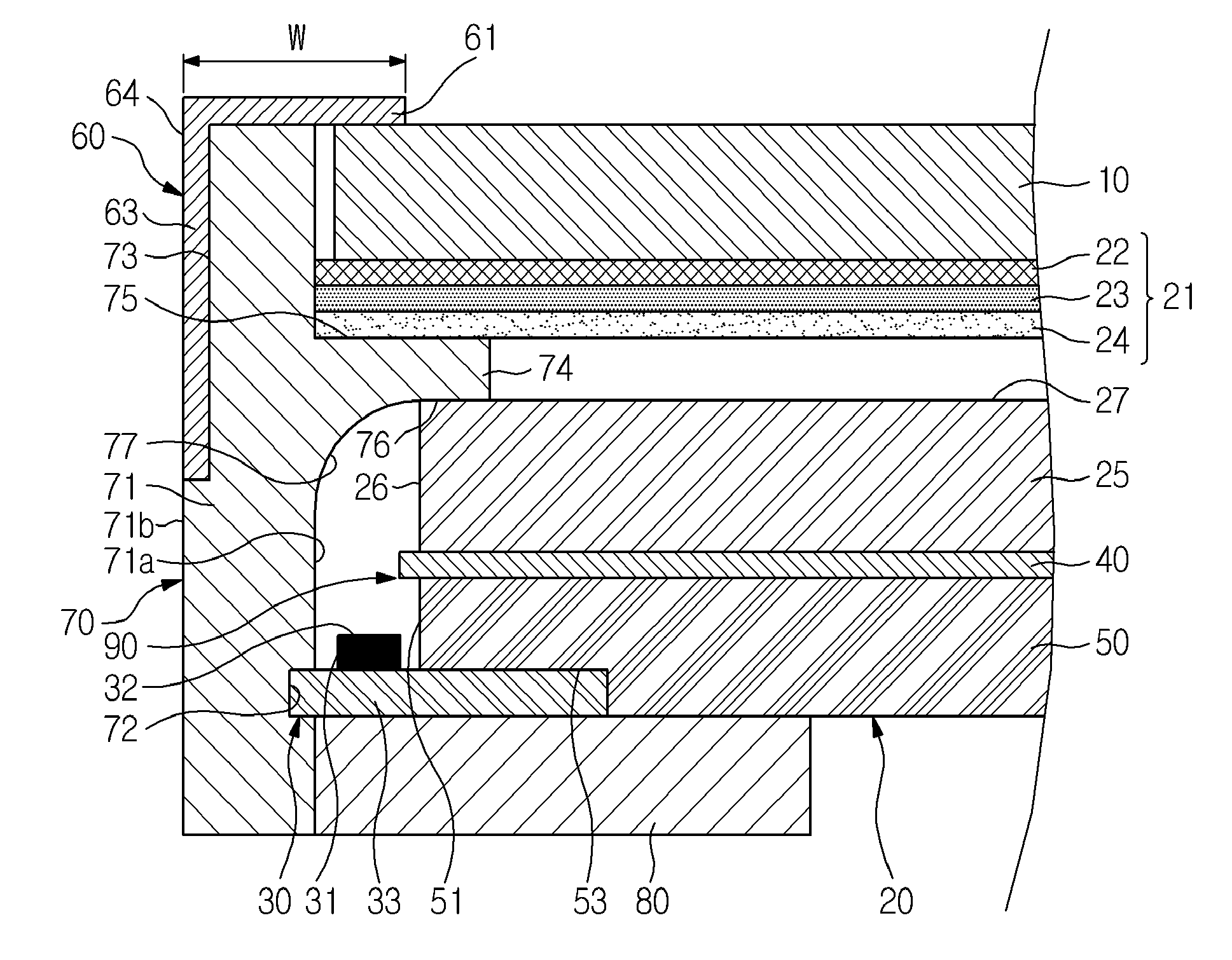

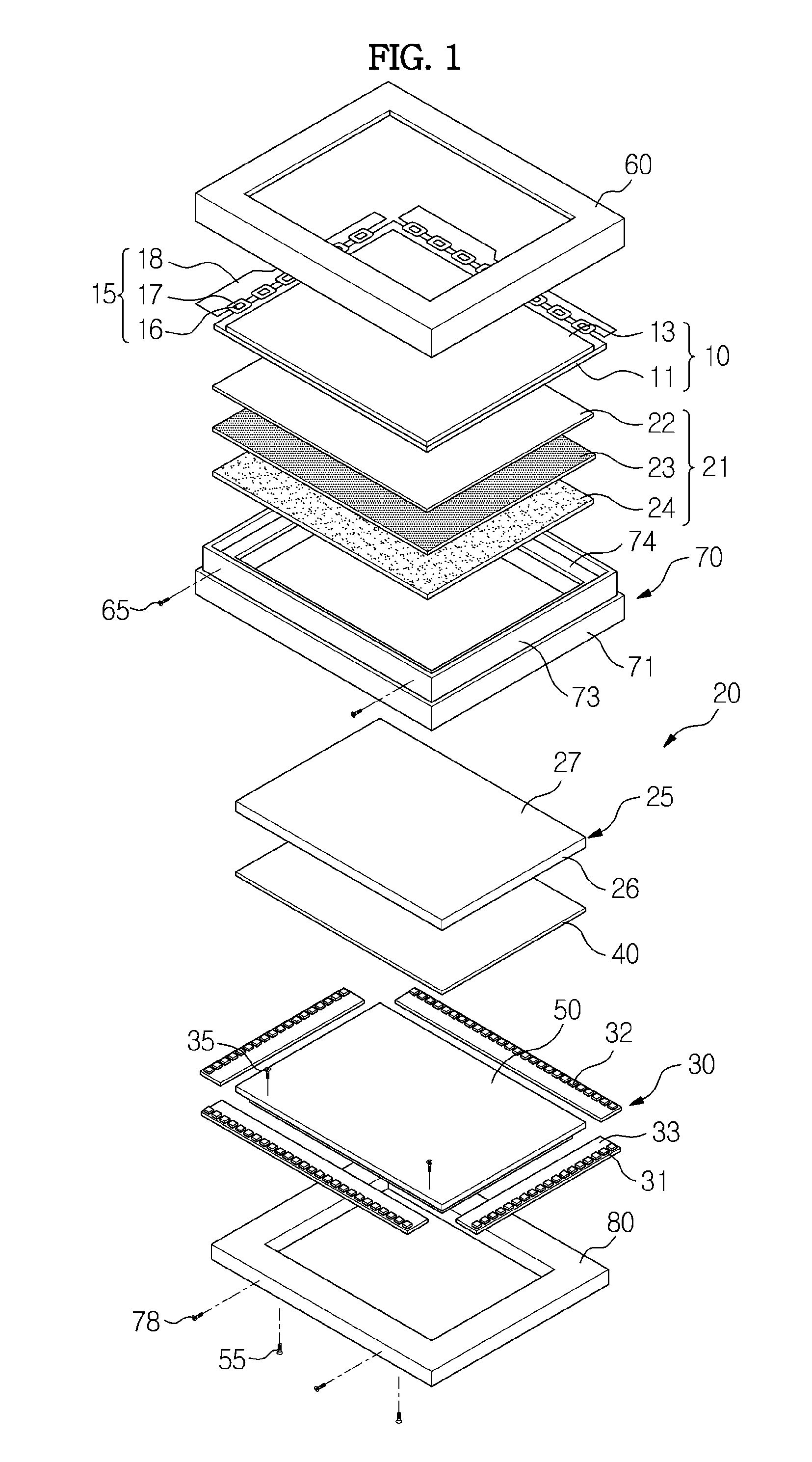

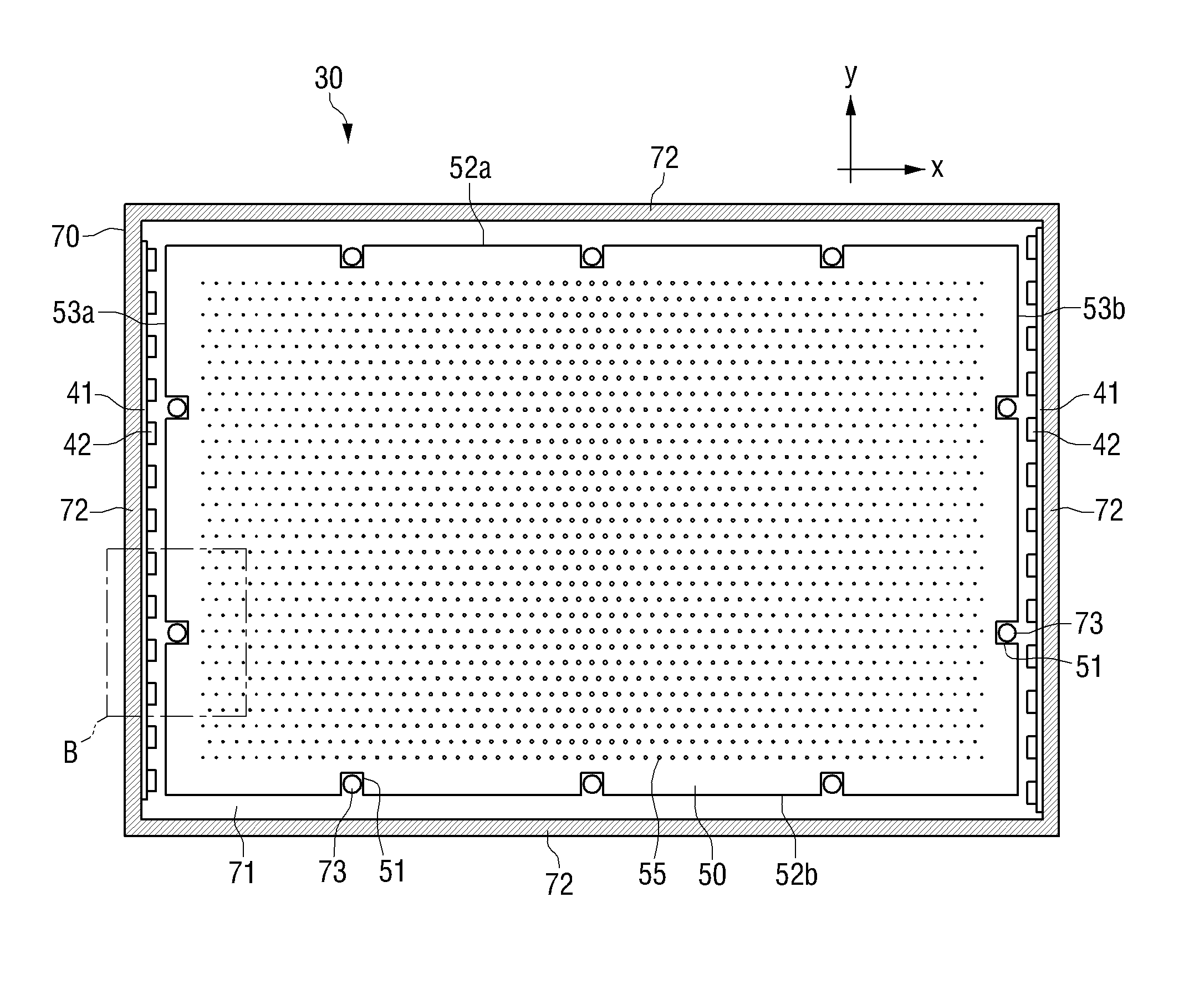

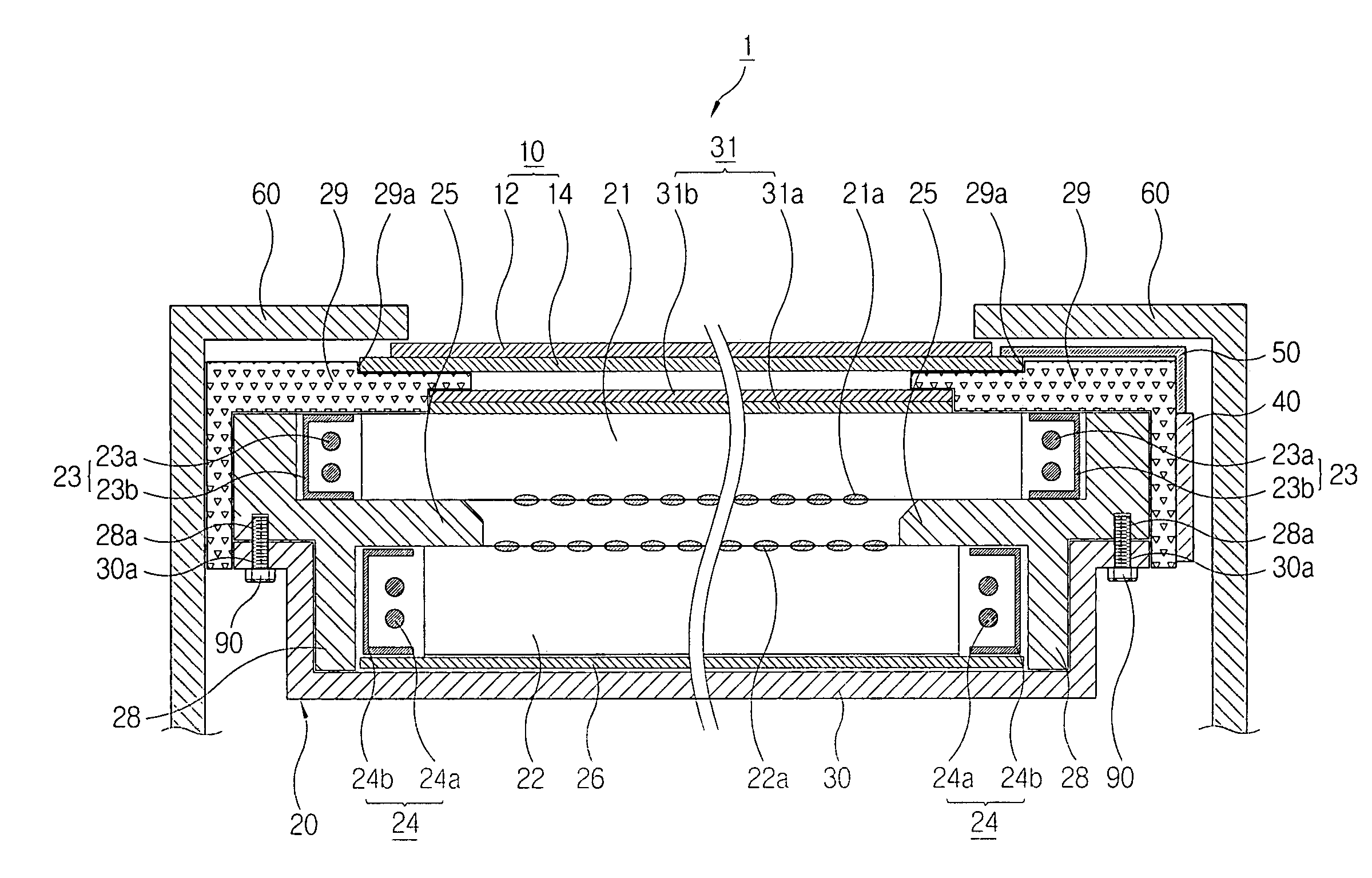

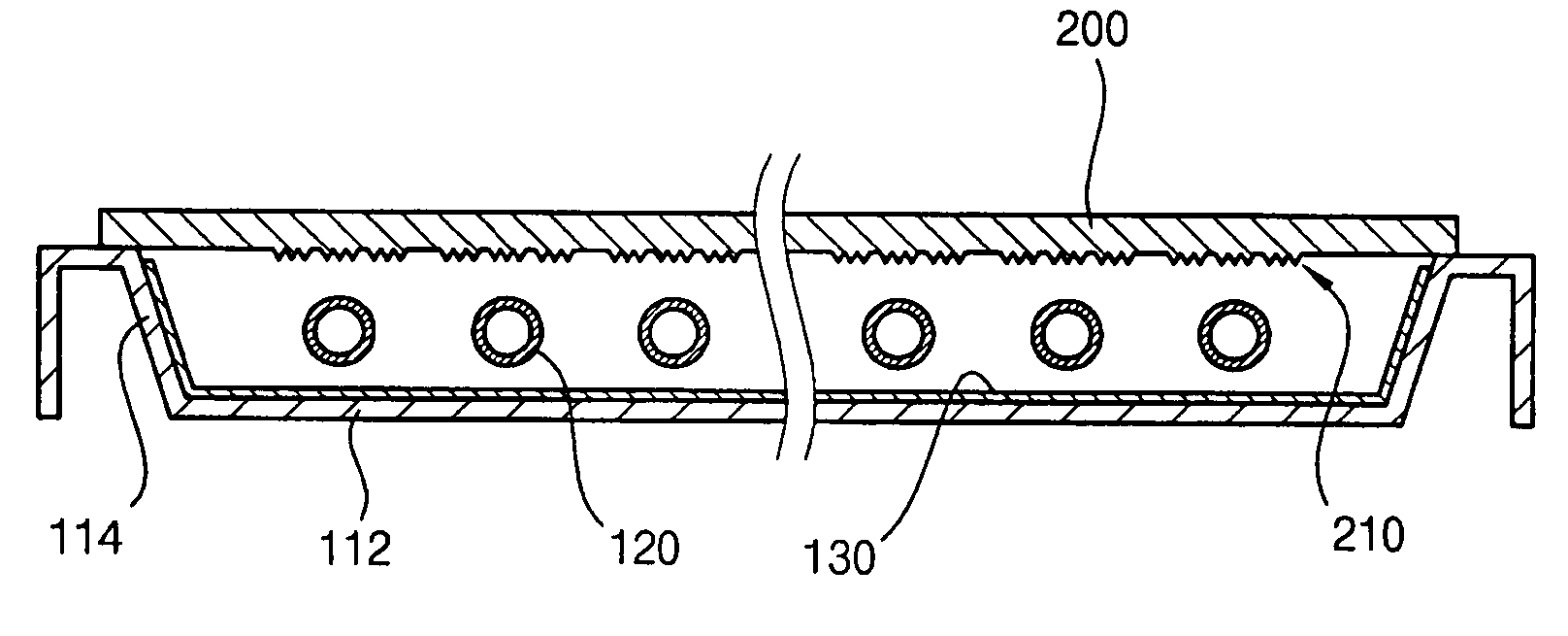

Backlight unit and liquid crystal display device having the same

ActiveCN101660689AUniform brightnessMechanical apparatusPoint-like light sourceLiquid-crystal displayLed array

A backlight unit and an LCD device produce a more uniform brightness by reducing or preventing bright lines occurring at the location of each LED device. The backlight unit includes a bottom cover defining a plurality of luminescent regions in first and second directions perpendicular to each other; a plurality of light source modules arranged in the plural luminescent regions and each including alight guide plate and an LED array disposed at the side of the light guide plate in a boundary region adjacent at least one of the luminescent regions; an optical sheet disposed over the light sourcemodules including a first light source module and a second light source module. The second light guide plate of the second light source module overlaps an incident portion of first light guide plateof the first light source module to cover a first LED array of the first light source module. Accordingly, the backlight unit can prevent the generation of bright lines and hot spots caused when the light guide plate does not cover the LED array. As a result, the LCD device may improve images of uniform brightness.

Owner:LG DISPLAY CO LTD

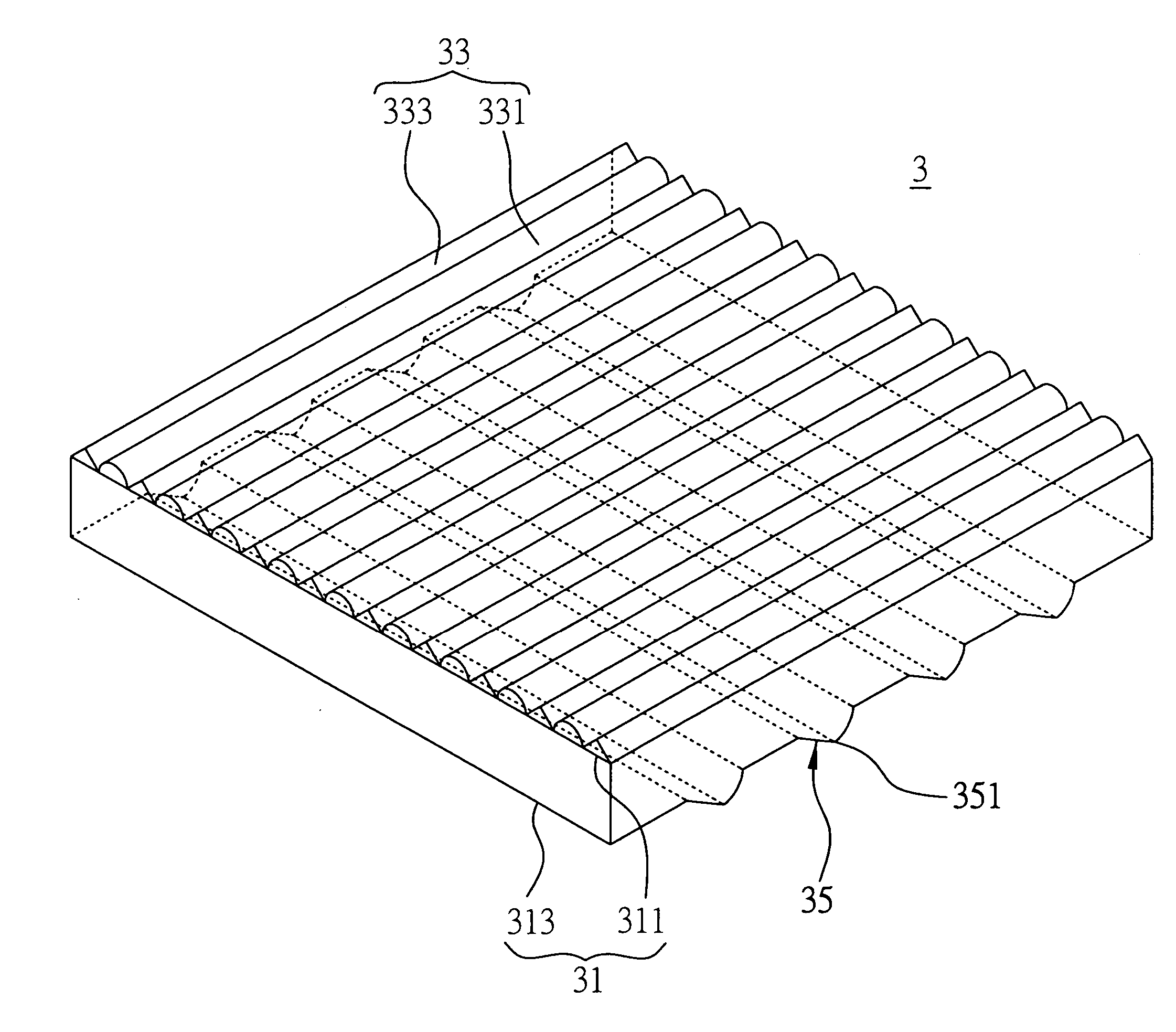

Light guide plate having two micro structures and back light unit having the light guide plate

InactiveUS20070047258A1Increase brightnessImprove evennessOptical light guidesReflectorsMicro structureLight guide

A light guide plate is provided. The light guide plate has a transparent substrate having a first optical face and a second optical face, a first micro structure and a second micro structure respectively corresponding to the first optical face and the second optical face. The first micro structure has a tunable composite optical effect with light collection and diffusion functions so as to increase brightness and evenness of exit light. The second micro structure has a design of curved face to destroy total reflection of light, such that bright lines can be effectively prevented from occurrence by avoiding the light outputting from the direction over against the first optical face. A back light unit having the light guide plate is further provided in the present invention.

Owner:IND TECH RES INST

Capacitive touch panel

InactiveCN101989160AEliminate or reduce the problem of reflected lightInput/output processes for data processingCapacitanceEngineering

The invention discloses a capacitive touch panel, comprising a transparent substrate, a light shielding layer and a capacitive induction circuit element, wherein the capacitive induction circuit element is arranged above one surface of the transparent substrate and comprises a sensing zone and multiple metal wires; the sensing zone comprises multiple conductive bridging lines; the multiple metal wires are arranged around the sensing zone and are electrically connected with the sensing zone; and the light shielding layer and the multiple conductive bridging lines are vertically overlapped. When a user observes and uses the capacitive touch panel, the conductive bridging lines are shielded by the light shielding layer so as to eliminate or reduce the probability that the conductive bridging lines reflect light, so that no bright spots or bright lines can be generated in the sensing zone, and the user is free of troubles in viewing a display screen and uncomfortable vision.

Owner:RITFAST CORP

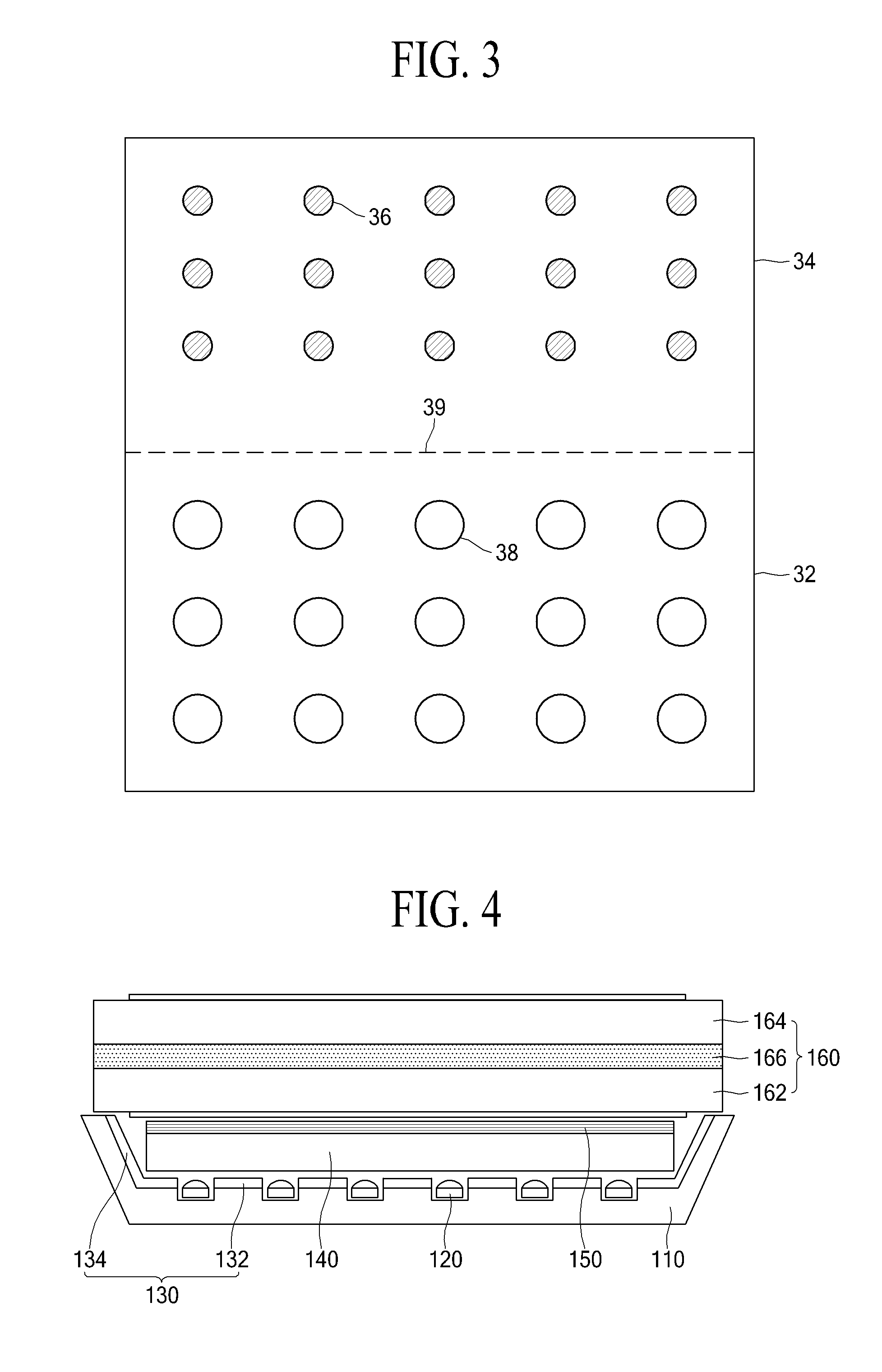

Backlight unit and liquid crystal display apparatus having the same

InactiveUS20100296021A1Improve image qualityConvenient amountPlanar/plate-like light guidesIlluminated signsLiquid-crystal displayLight guide

A backlight unit, light guide panel, and liquid crystal display (LCD) apparatus having the same are provided. The backlight unit includes a light guide panel which comprises a plurality of patterns to scatter light forward on a bottom surface, and one or more fixing grooves on an edge area; a light source unit which is disposed on a side surface of the light guide panel, and emits light towards the light guide panel; and a supporting member which supports the light guide panel, and comprises one ore more fixing protrusions being inserted into the fixing groove, wherein the amount of patterns formed on a darkness occurring area adjacent to the fixing groove is increased compared to that on an adjacent area, and the amount of patterns formed on a bright line occurring area adjacent to the fixing groove is decreased compared to that on an adjacent area.

Owner:SAMSUNG ELECTRONICS CO LTD

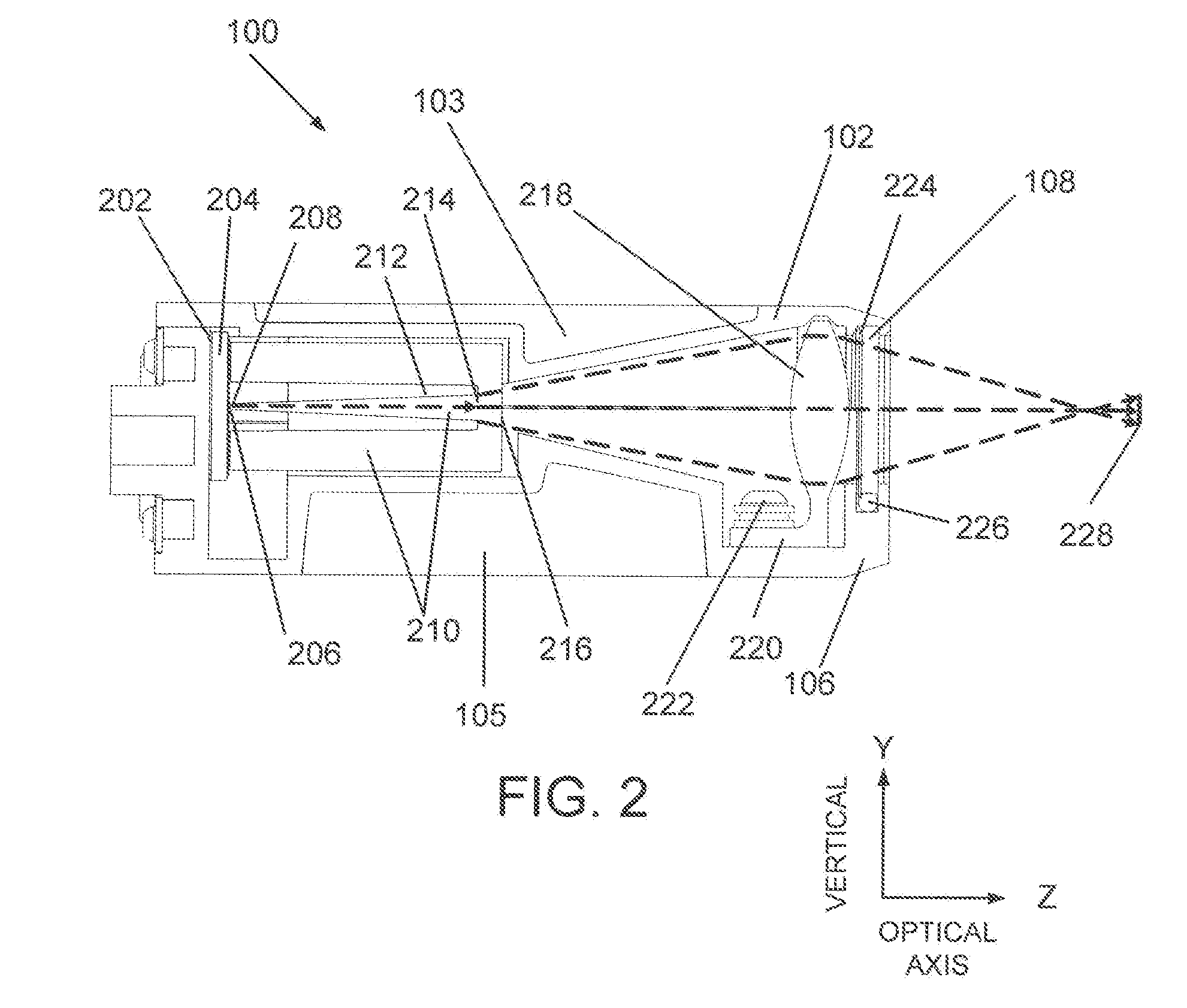

Line projection system

InactiveUS20140207326A1Position/course control in two dimensionsDistance measurementFactory floorLaser light

Owner:QUNOMIC VIRTUAL TECH

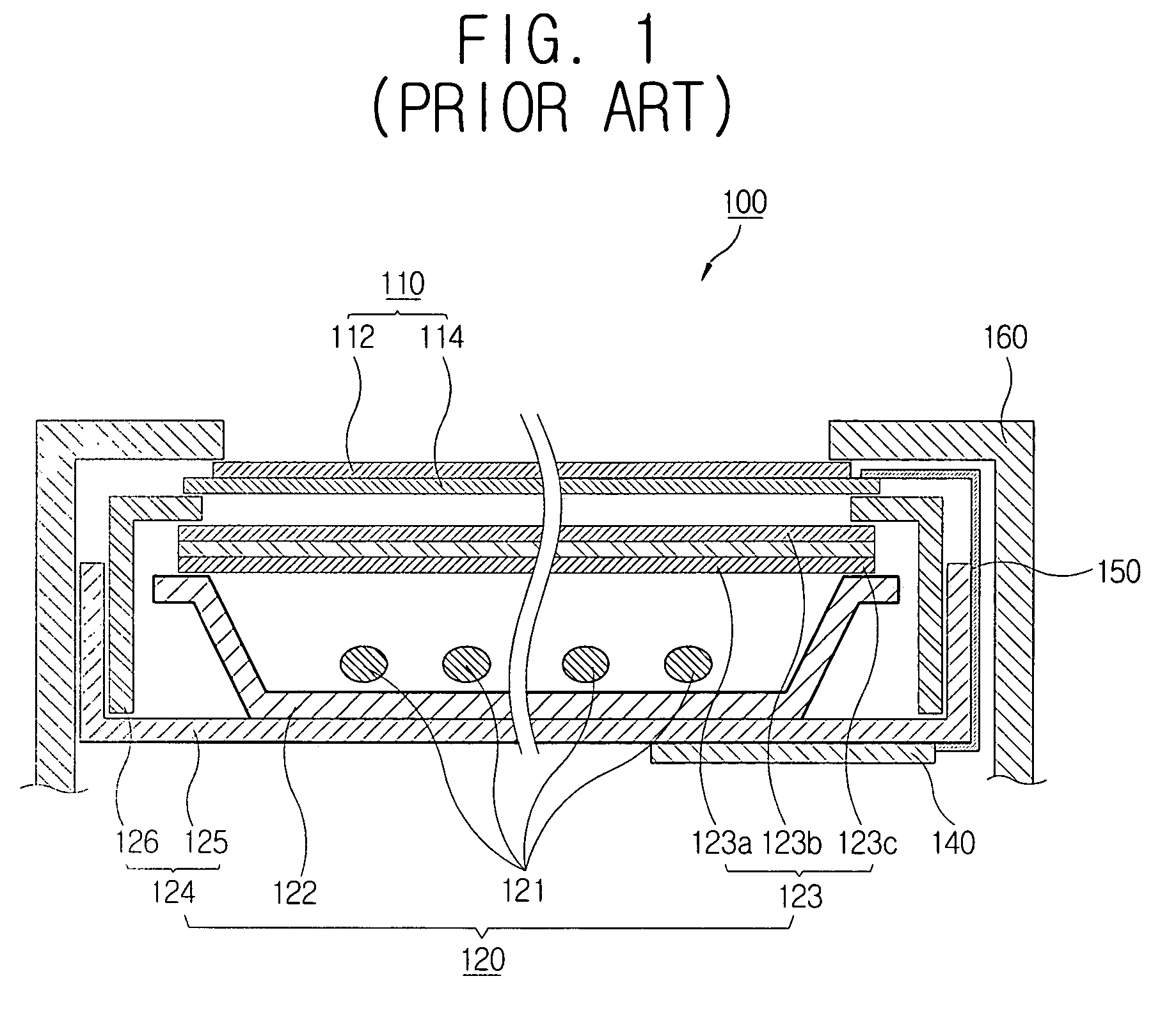

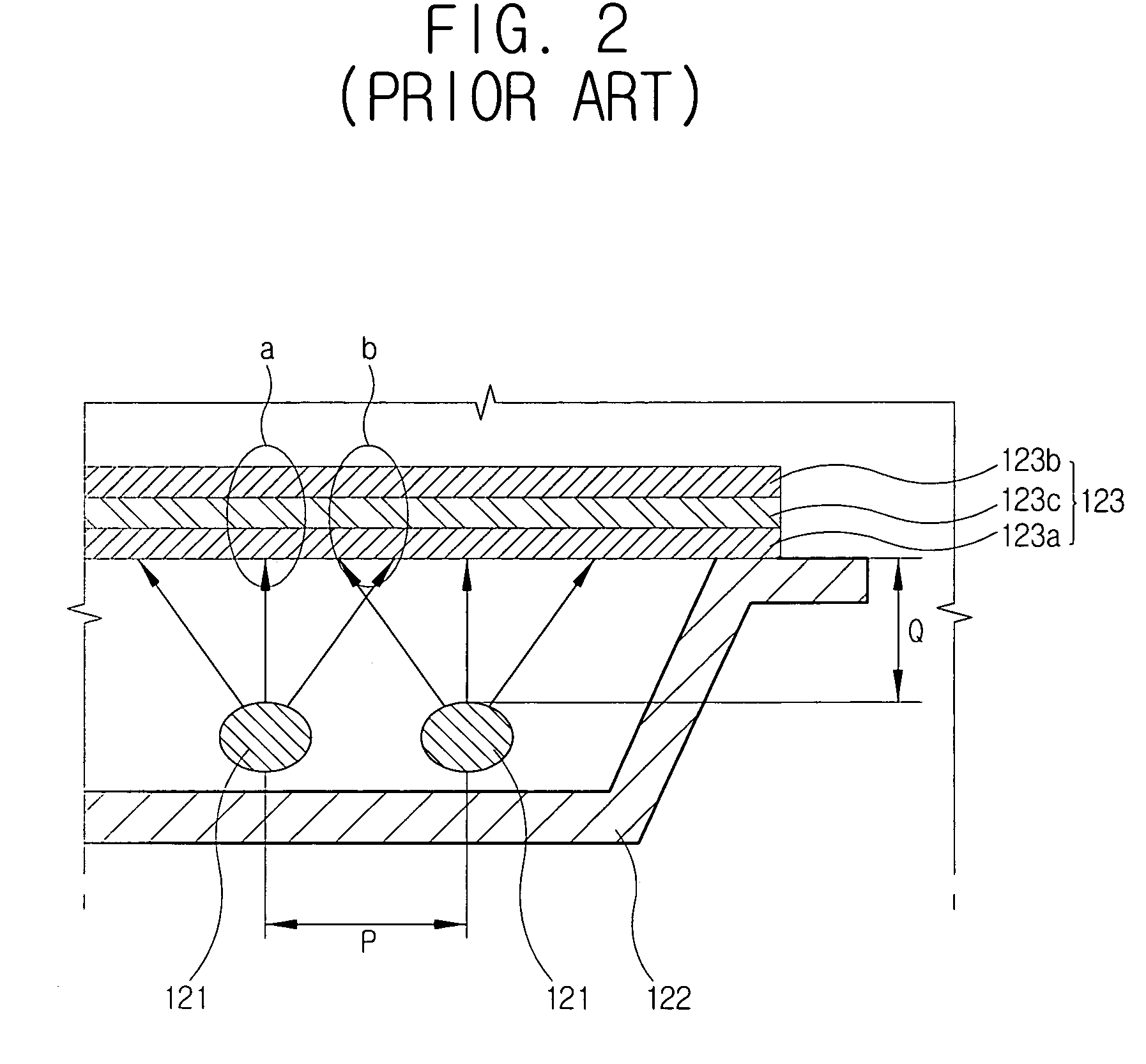

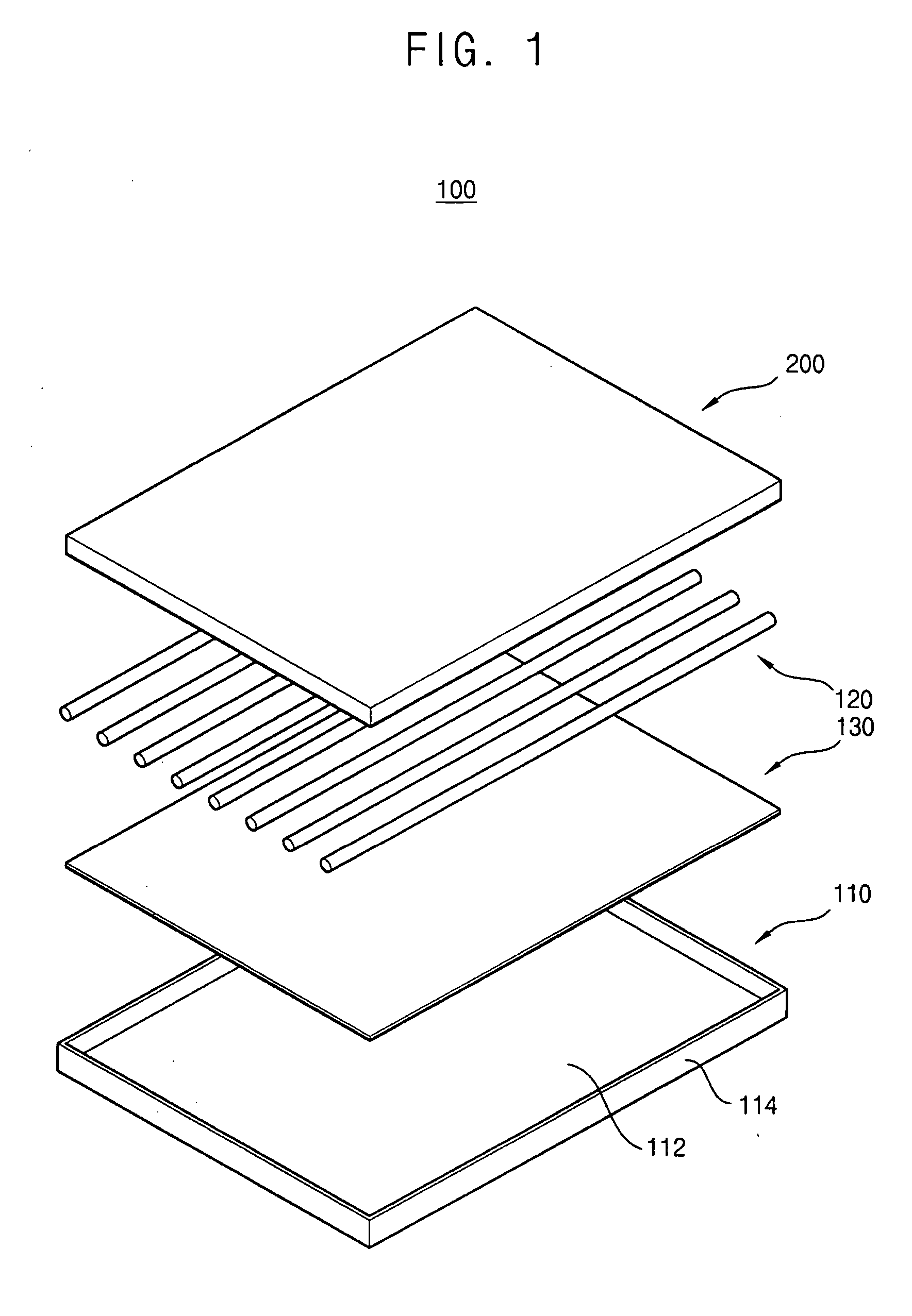

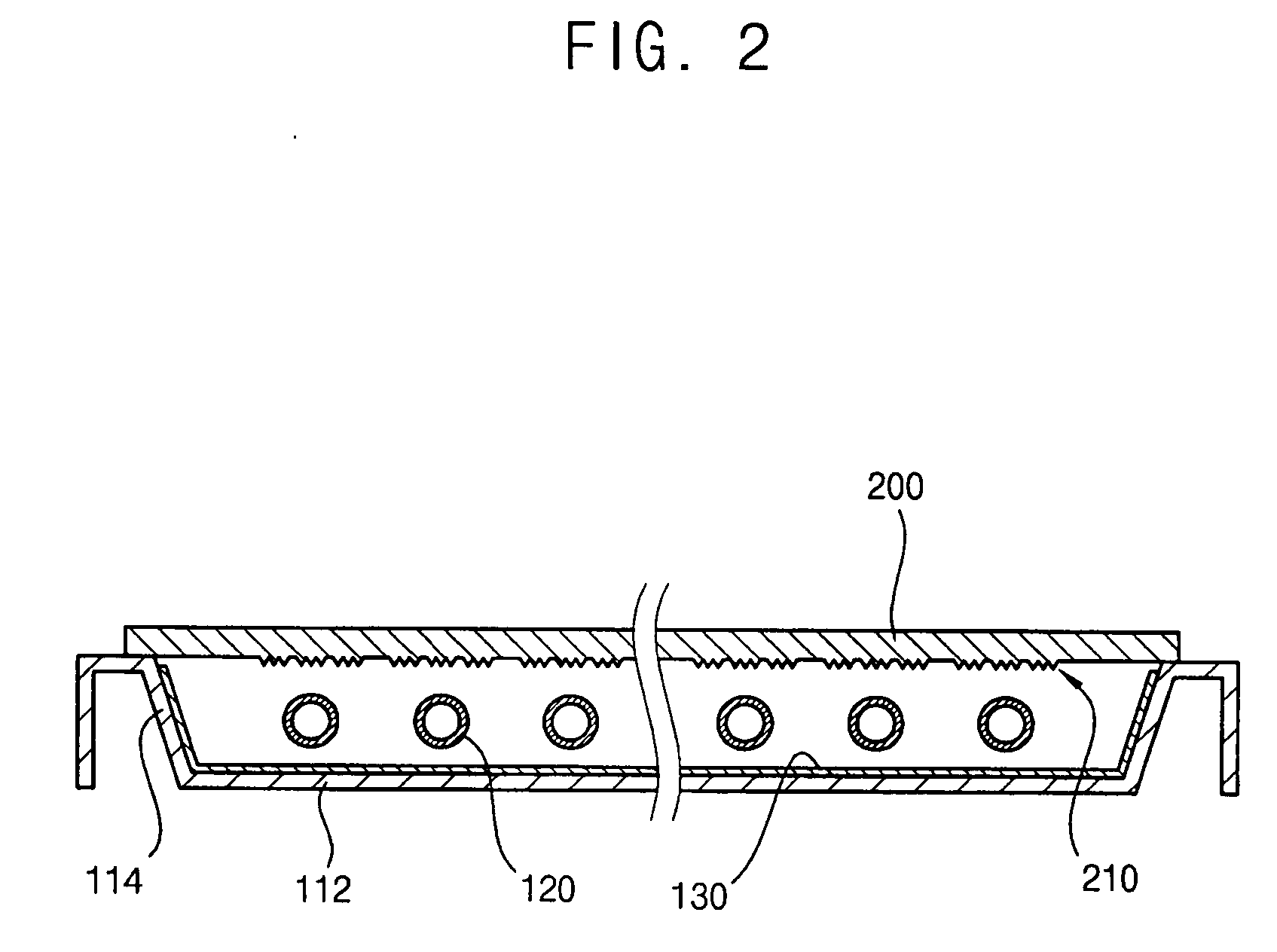

Back light assembly, liquid crystal display apparatus and manufacturing method thereof

InactiveUS7154570B2Increase brightnessReduce thicknessMechanical apparatusElongate light sourcesLight guideEngineering

A iquid crystal display apparatus that comprises: a liquid crystal display panel that displays a picture; a plurality of light guide plates that are installed on a rear of the liquid crystal display panel and are spaced from each other; and a back light assembly with a lamp assembly that emits light toward each light guide plate. As described above, the present invention provides the back light assembly and the liquid crystal display apparatus improving the brightness, reducing the thickness, removing the bright lines and the waterfall on the liquid crystal display panel, and lowering the manufacturing cost.

Owner:SAMSUNG DISPLAY CO LTD

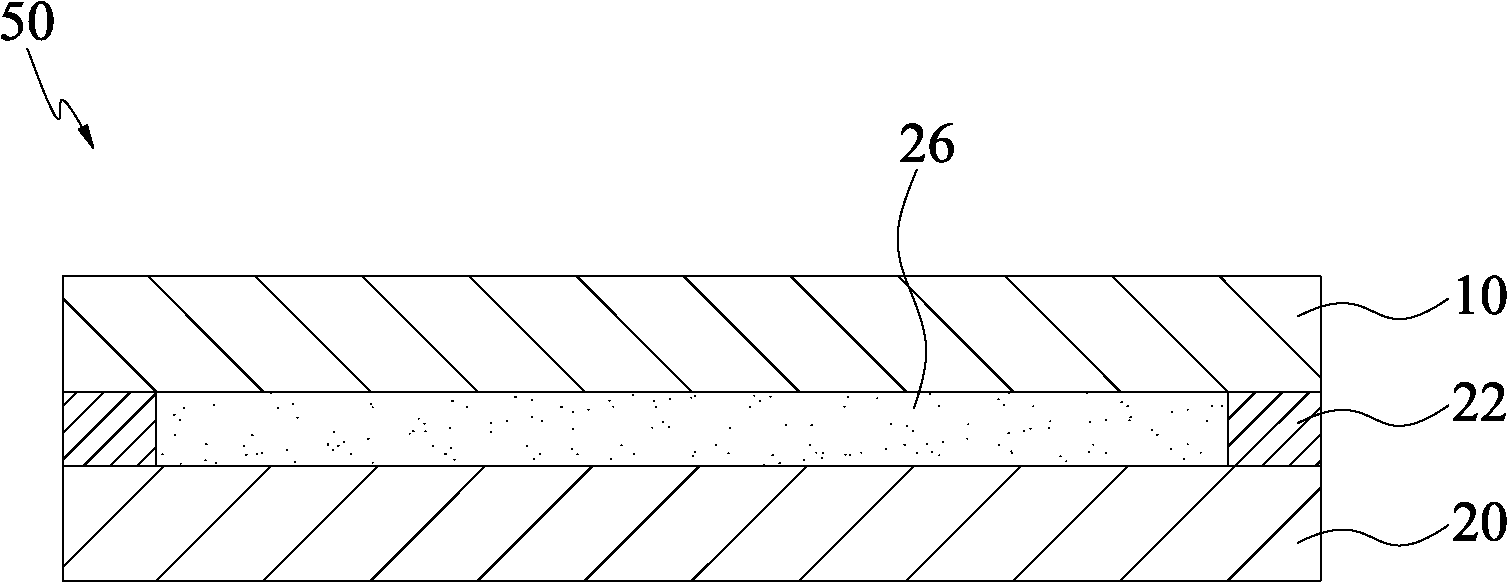

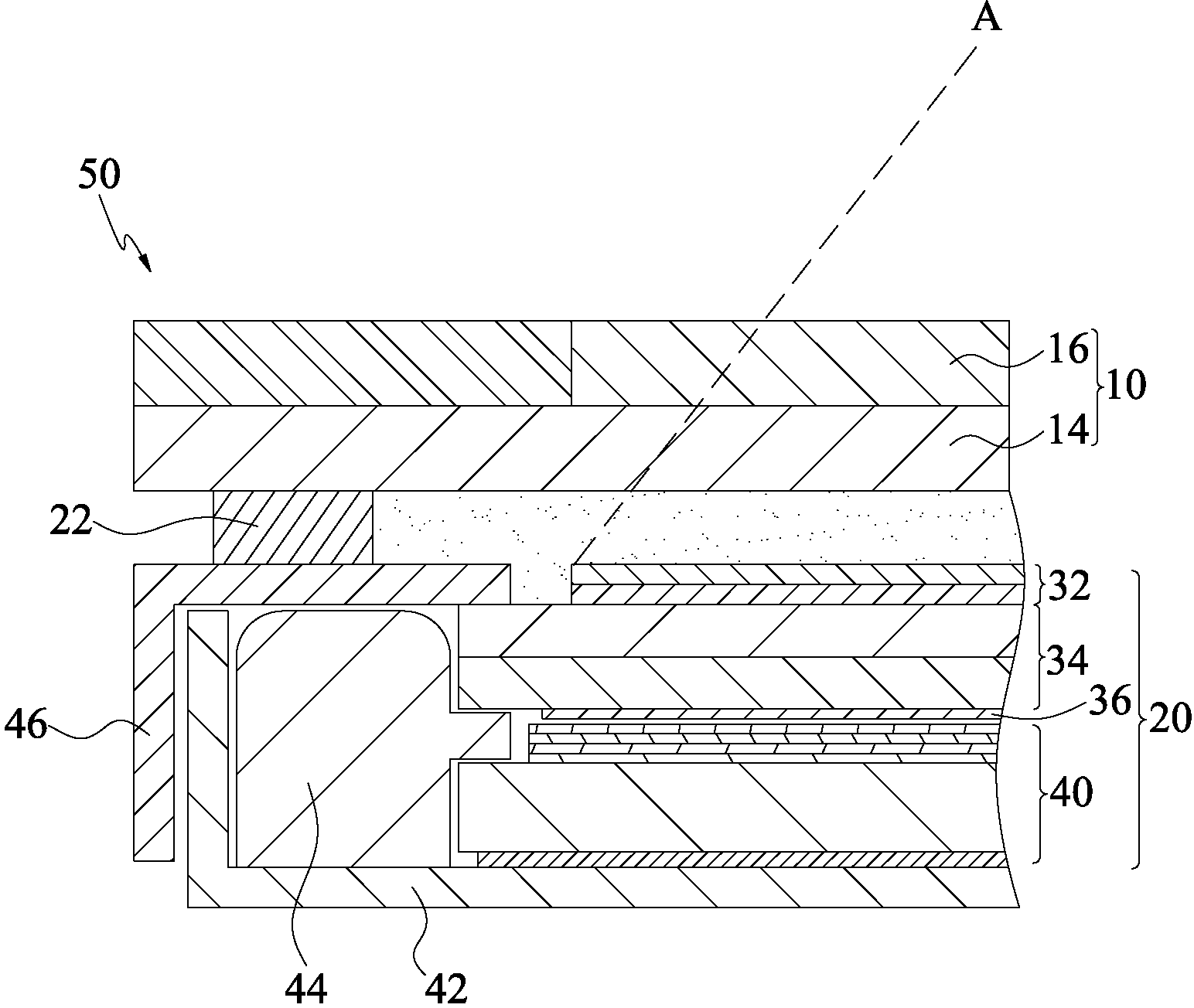

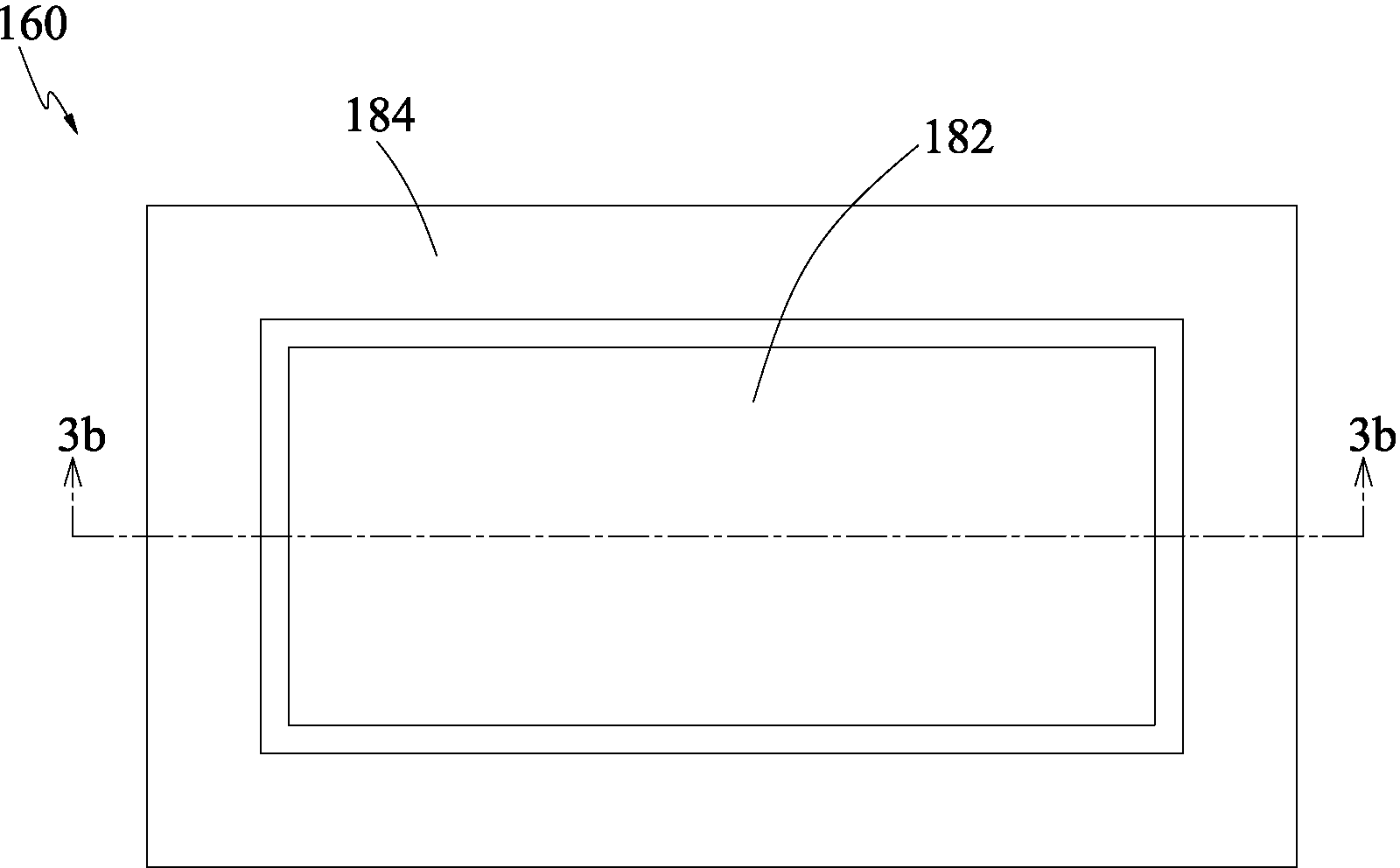

Backlight assembly and liquid crystal display device having the same

InactiveUS20060256580A1Improve image display qualityReduce assemblyMechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayDisplay device

A backlight assembly includes a receiving container, a plurality of lamps, and a diffusion plate. The lamps are received in the receiving container and are arranged substantially in parallel with each other to generate light. The diffusion plate on the lamps includes a plurality of light diffusing parts each having a plurality of embossed patterns corresponding to the lamps. Each of the embossed patterns has a circular shape or a polygonal shape in plan view and a substantially triangular cross-section or a semi-circular cross-section. Each of the embossed patterns is recessed or protruded from a surface of the diffusion plate to form a concave or convex shape, respectively. Therefore, a bright line of the backlight assembly is decreased to improve an image display quality of a display device.

Owner:SAMSUNG ELECTRONICS CO LTD

Polaroid, display module, touch control type display device, and manufacturing method thereof

InactiveCN103033867ALight emitting surface is flatImprove bonding yieldStatic indicating devicesSynthetic resin layered productsLiquid-crystal displayDisplay device

The invention discloses a polaroid, a display module, a touch control type display device, and a manufacturing method thereof. The touch control type display device includes a touch control panel; a liquid crystal display module including a liquid crystal panel; an upper polaroid and a lower polaroid which are configured on the first and second surfaces of the liquid crystal panel, wherein the upper Polaroid includes a polarized substrate layer; an adhesive layer which is configured on one surface of the polarized substrate layer and includes a middle area and a periphery area, wherein the middle area and the periphery area are separated from each other, the middle area of the adhesive layer is made of a first optical transparent glue, and the middle area is attached to the liquid crystal panel; a circular frame glue formed between the periphery area of the upper polaroid of the liquid crystal display module and the touch control panel; and a second optical transparent glue fully filled in the circular frame glue. The touch control type display device provided can prevent white bright lines caused by the reflection of the edge residue glue of the upper polaroid, thereby preventing visual difference.

Owner:HANNSTAR DISPLAY CORPORATION

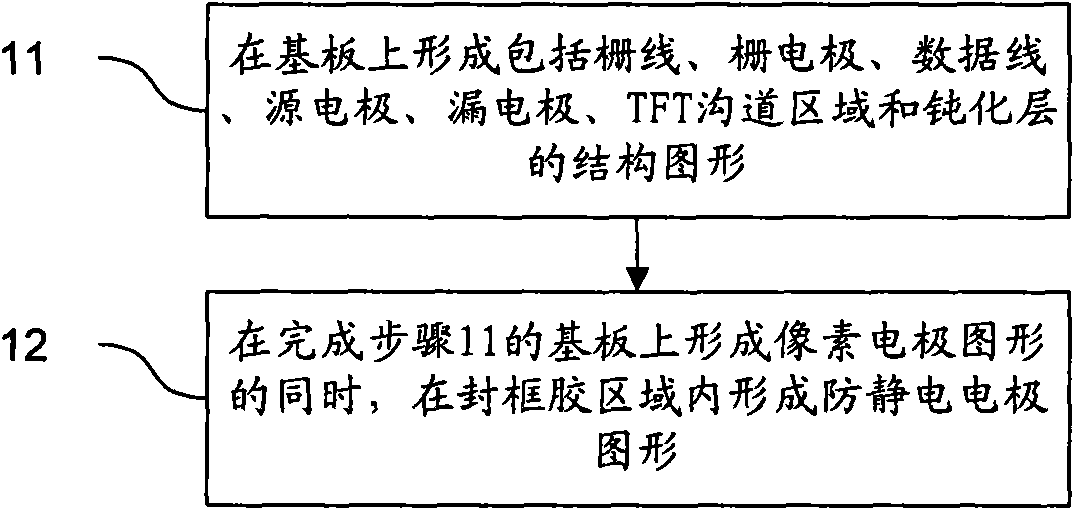

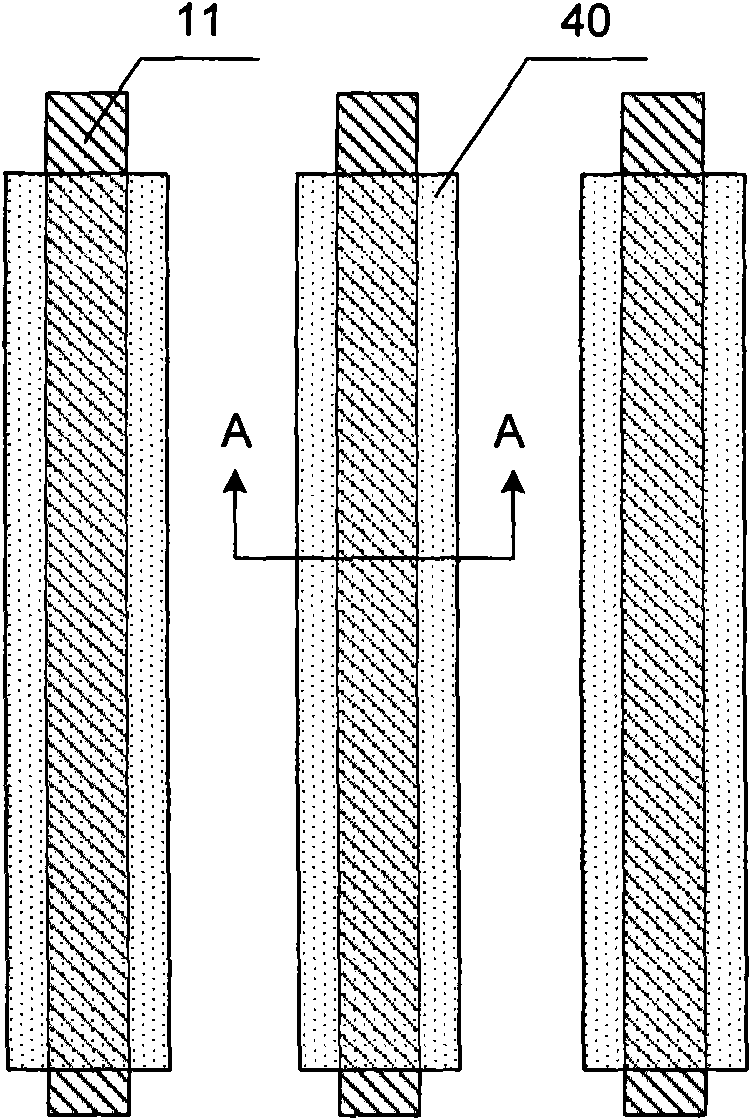

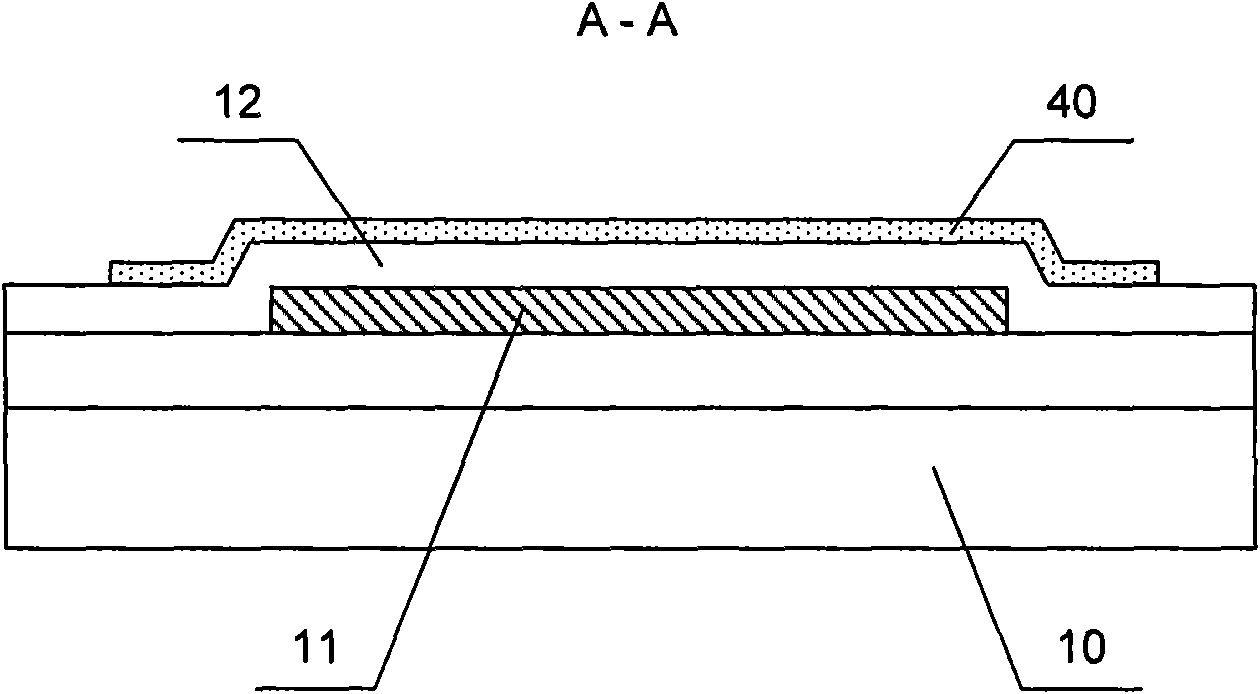

Liquid crystal display array substrate and manufacturing method thereof

InactiveCN101661198APrevent bright line defectsIncrease the areaSolid-state devicesPhotomechanical apparatusLiquid-crystal displayEngineering

The invention relates to a liquid crystal display array substrate and a manufacturing method thereof. The manufacturing method comprises the following steps: forming a structural figure comprising a grid line, a gate electrode and an active layer on a substrate; forming a structural figure comprising a data wire, a source electrode, a drain electrode and a TFT channel area, wherein the two sides of the data wire are in a slope shape or a stepped shape for preventing the aggregation of static electricity; forming the figure of a passivation layer; and forming the figure of a pixel electrode, and forming the figure of an anti-static electrode simultaneously in a frame sealant area. The two sides of the data wire are in the slope shape or the stepped shape preventing the aggregation of the static electricity, thus electrostatic discharge possibly caused by the edges and corners of the data wire is dispersed effectively; and simultaneously, the anti-static electrode is formed in the framesealant area to reduce the density of the static electricity accumulated on the surface of a golden ball, so the electrostatic discharge between the data wire and the golden ball can be avoided, and the defect of imperfect bright line caused by a short circuit between the data wire and the golden ball can be effectively prevented.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

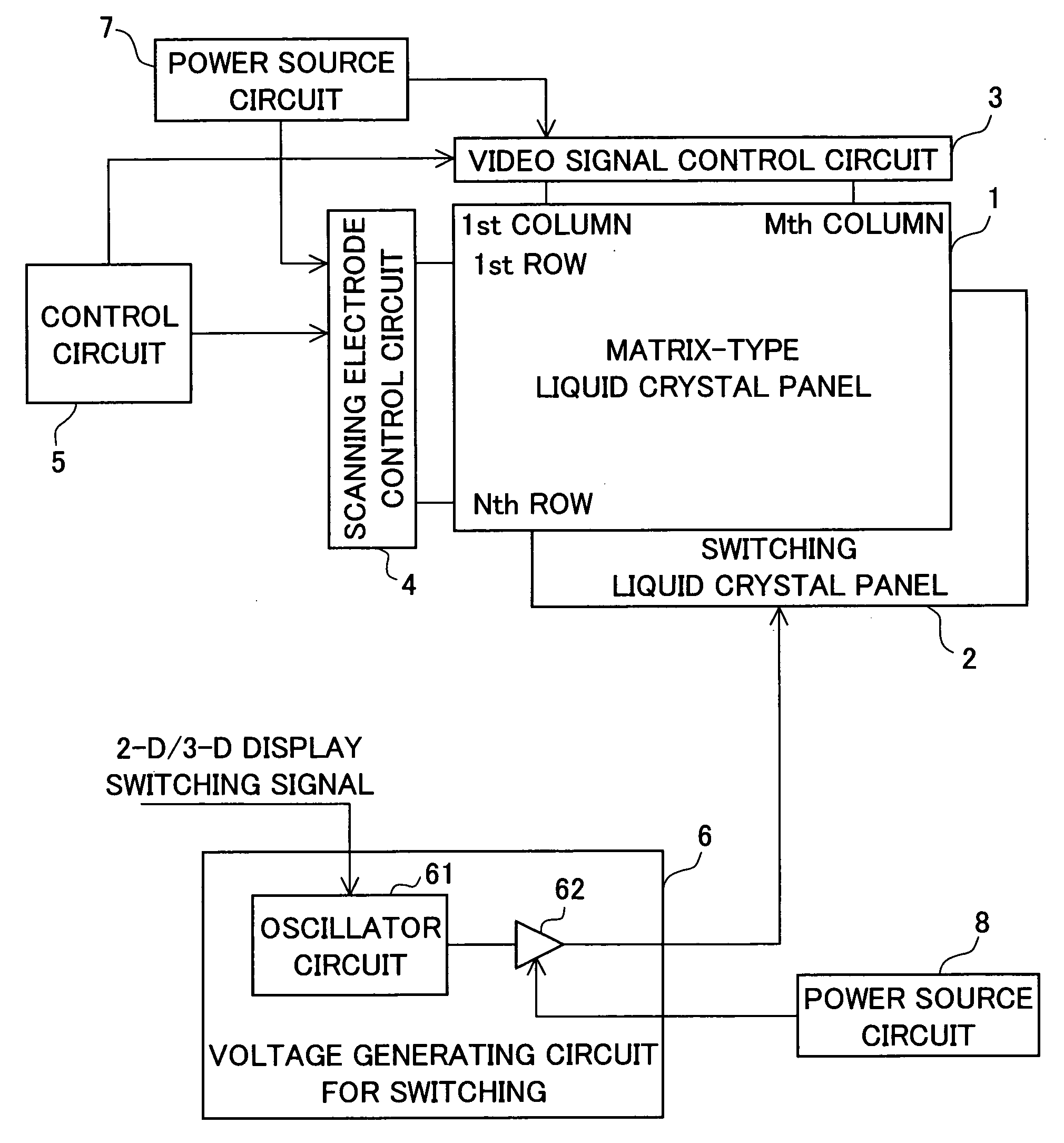

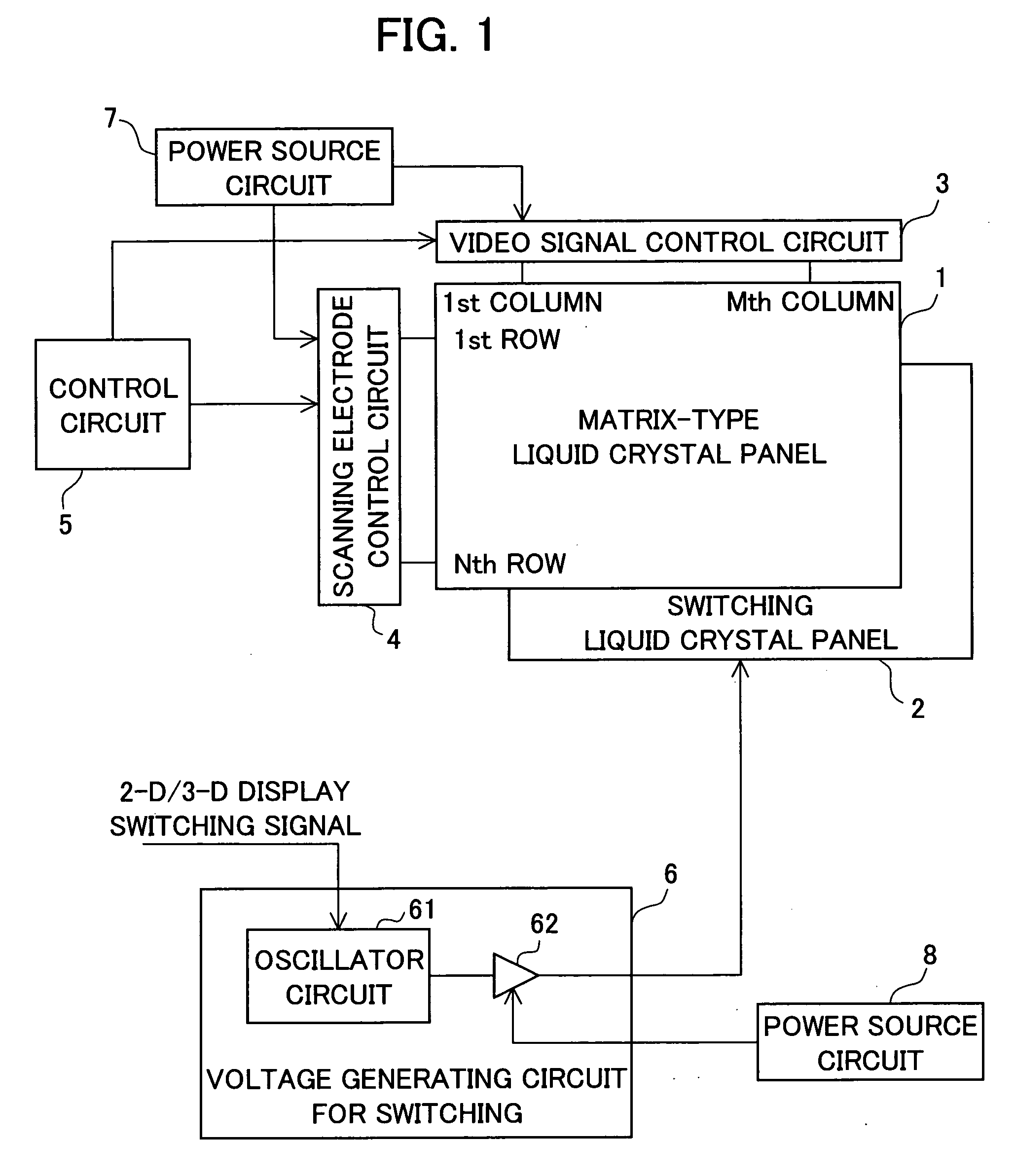

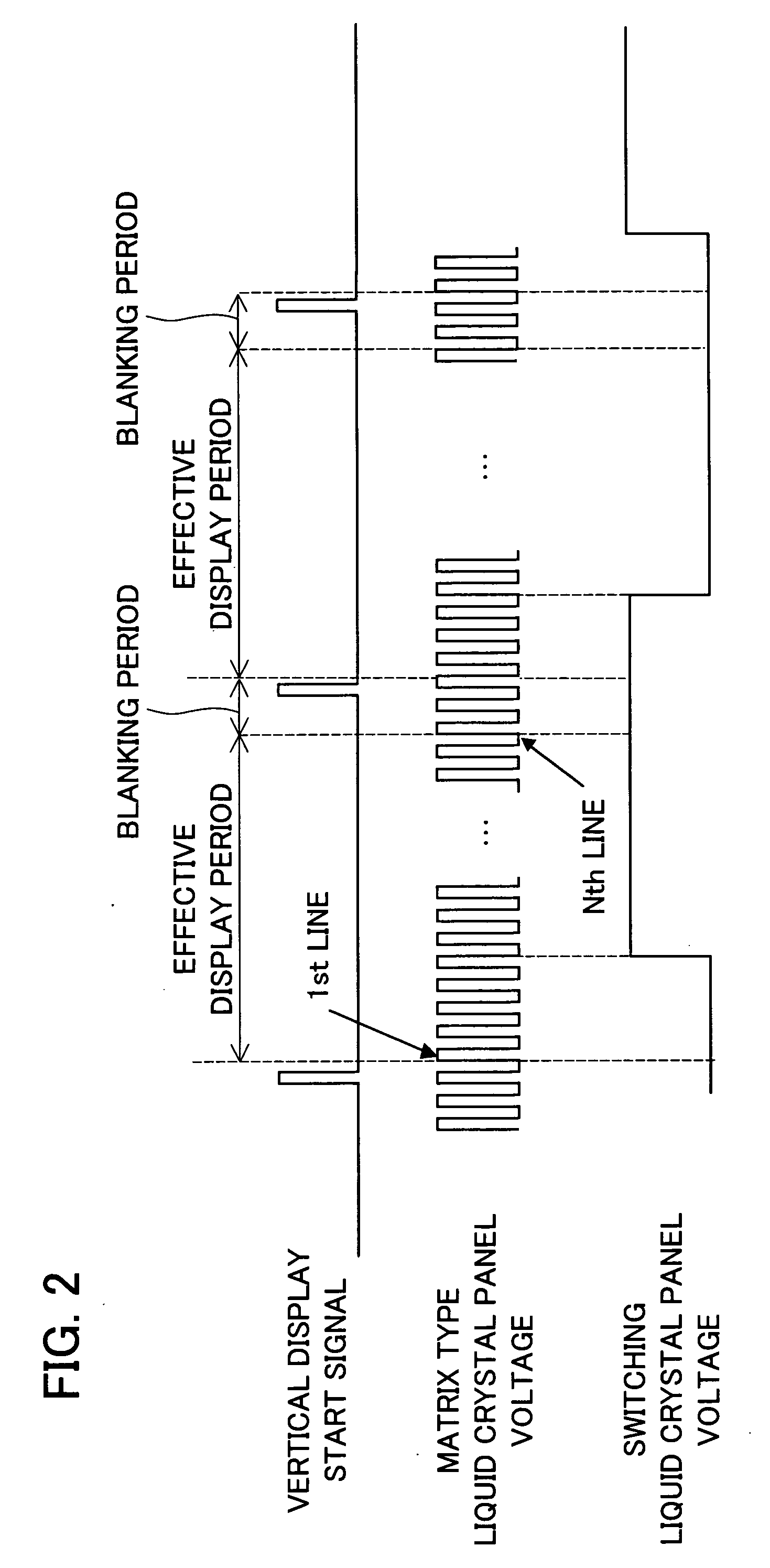

Method of driving display apparatus and display apparatus

ActiveUS20050212744A1Avoid display qualityQuality improvementStatic indicating devicesSteroscopic systemsElectrical polarityEngineering

A display apparatus according to the present invention is provided with a matrix-type liquid crystal panel and a switching liquid crystal panel, the matrix-type liquid crystal panel and the switching liquid crystal panel assembled together. In the display apparatus, a polarity of a voltage applied on an electrode pair of the switching liquid crystal panel is inverted once in substantially one vertical period or in one or more vertical period. With this arrangement, it is possible to reduce a number of bright line or dark line. This attains display quality improvement and power consumption reduction.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com