Liquid crystal display array substrate and manufacturing method thereof

A liquid crystal display and array substrate technology, which is applied in semiconductor/solid-state device manufacturing, instruments, electric solid-state devices, etc., and can solve problems such as bad bright lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

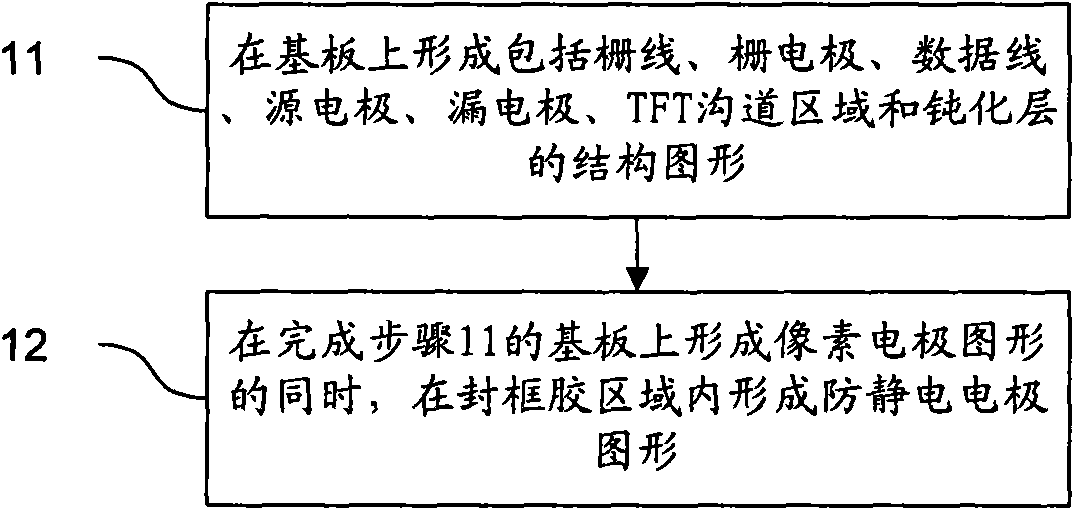

[0046] figure 1 It is a flow chart of the first embodiment of the manufacturing method of the liquid crystal display array substrate of the present invention, specifically including:

[0047] Step 11, forming a structural pattern including gate lines, gate electrodes, data lines, source electrodes, drain electrodes, TFT channel regions and passivation layers on the substrate;

[0048]Step 12: While forming the pixel electrode pattern on the substrate completed in step 11, an antistatic electrode pattern is formed in the sealant area.

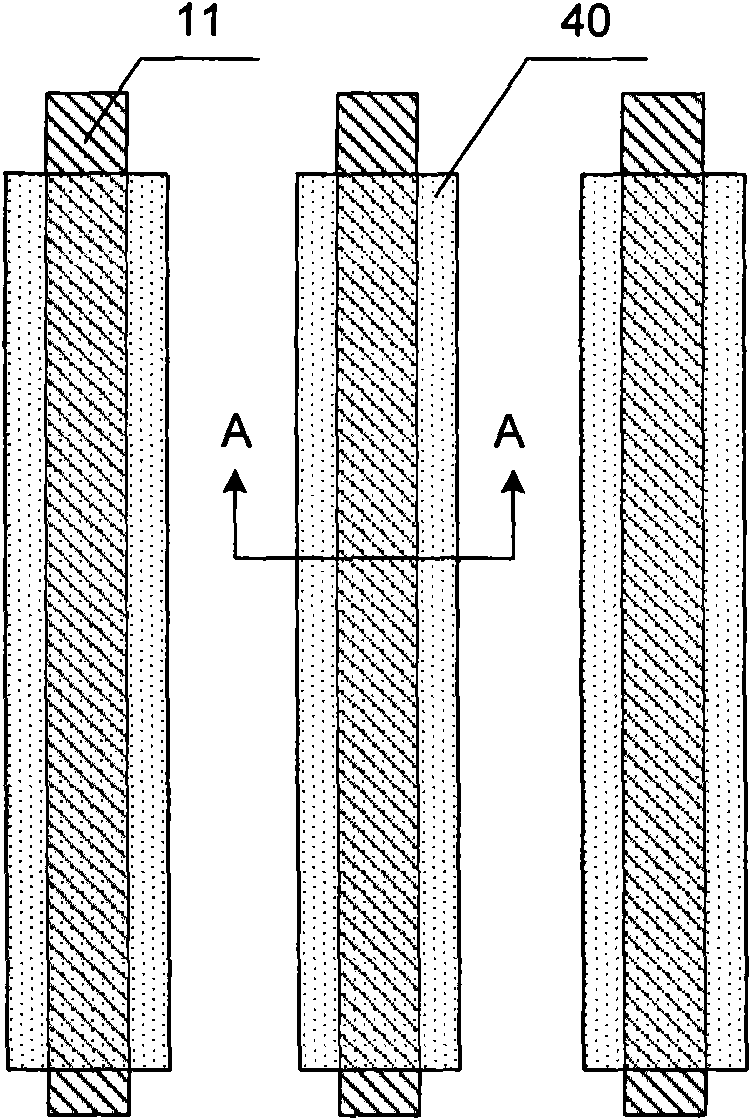

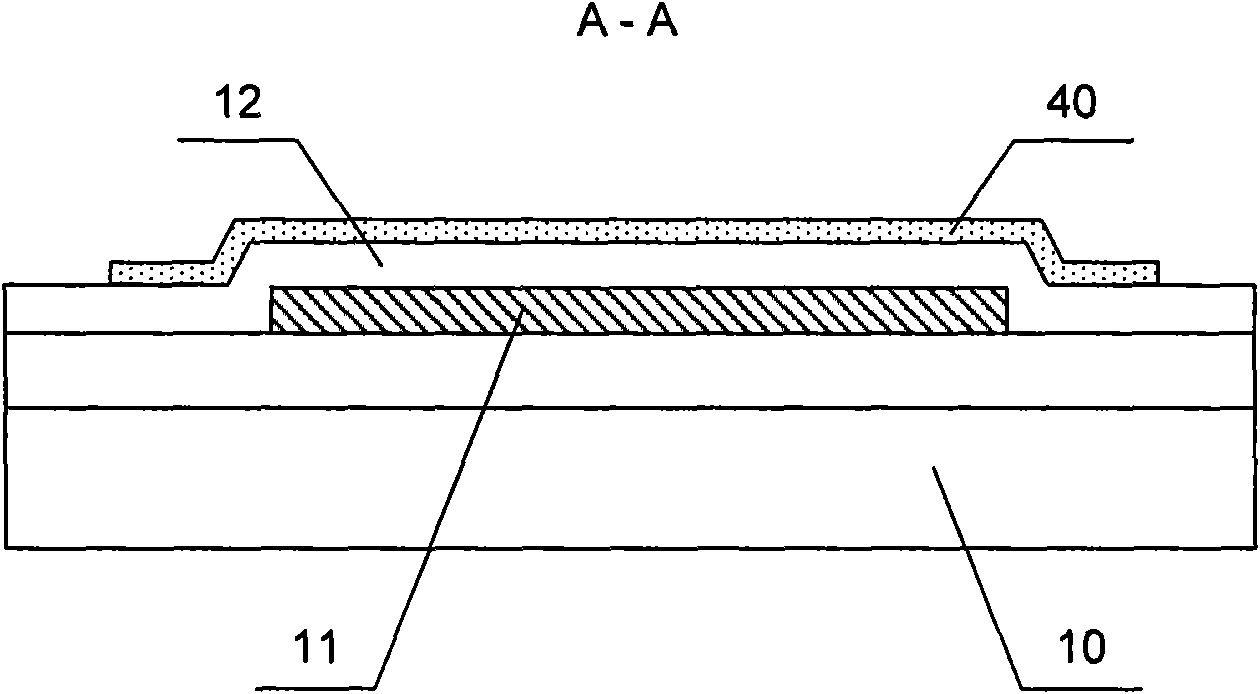

[0049] This embodiment provides a method for manufacturing an array substrate of a liquid crystal display. An antistatic electrode is formed at the same time as the pattern of the pixel electrode is formed, and the antistatic electrode is located in the frame sealing area, which is the subsequent array substrate and color filter substrate. The area where the sealant is applied when the box is aligned, and the sealant contains gold balls. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com