Reflector and backlight device

A technology of backlight device and reflector, applied in the field of backlight device and reflector, can solve the problem of insufficient light distribution and achieve the effect of high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

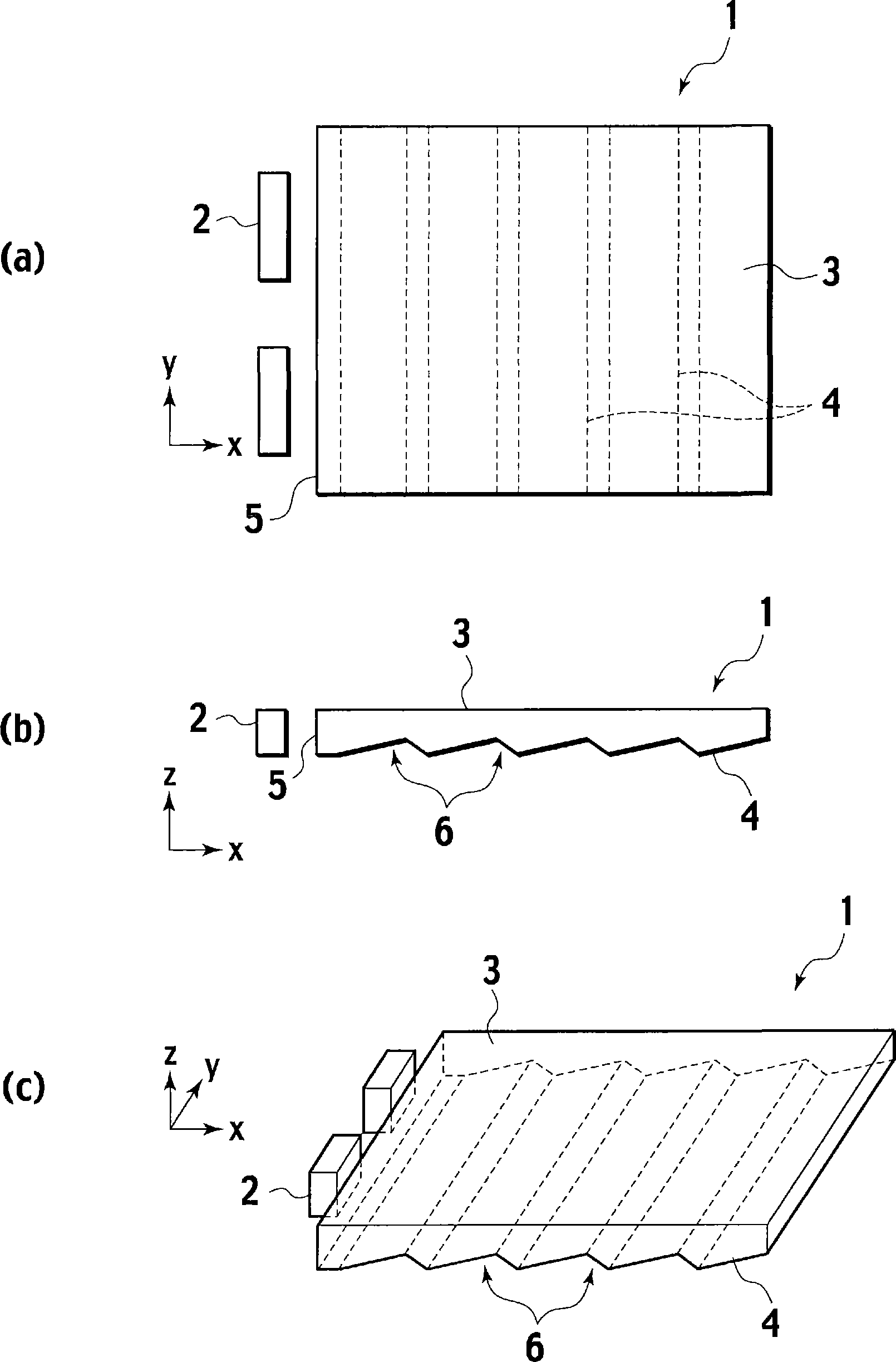

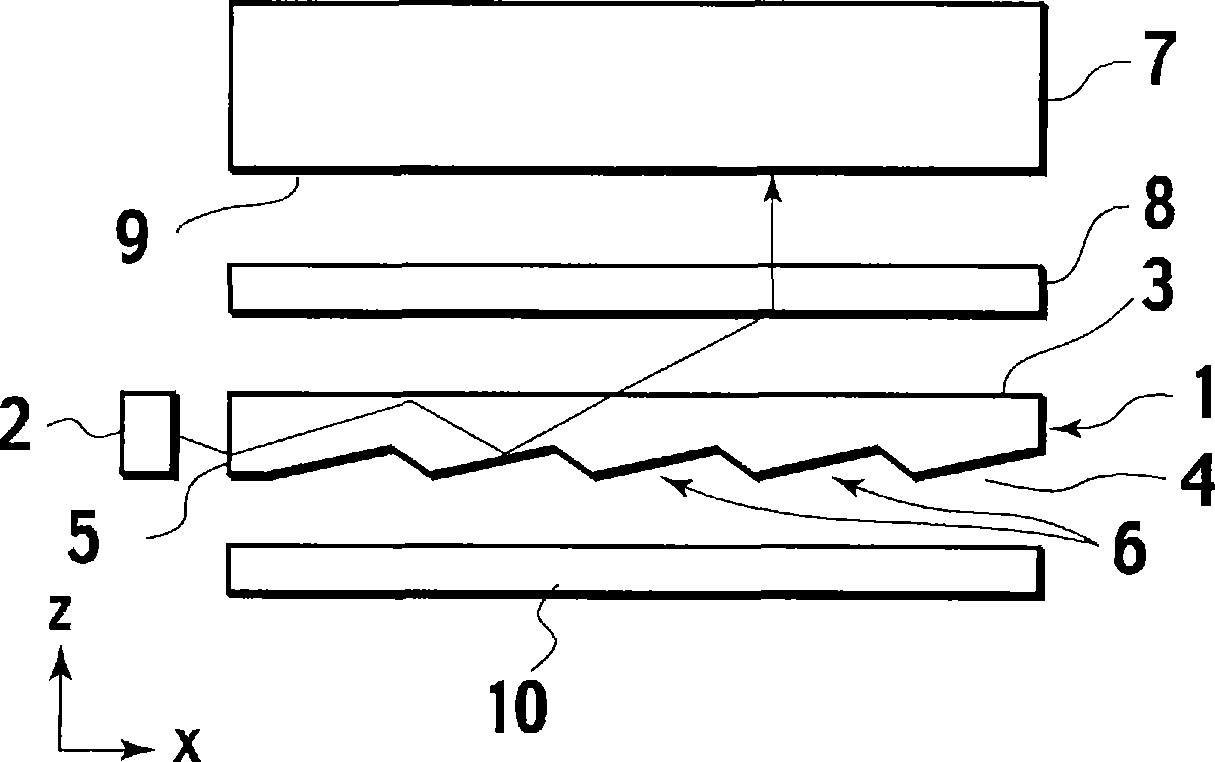

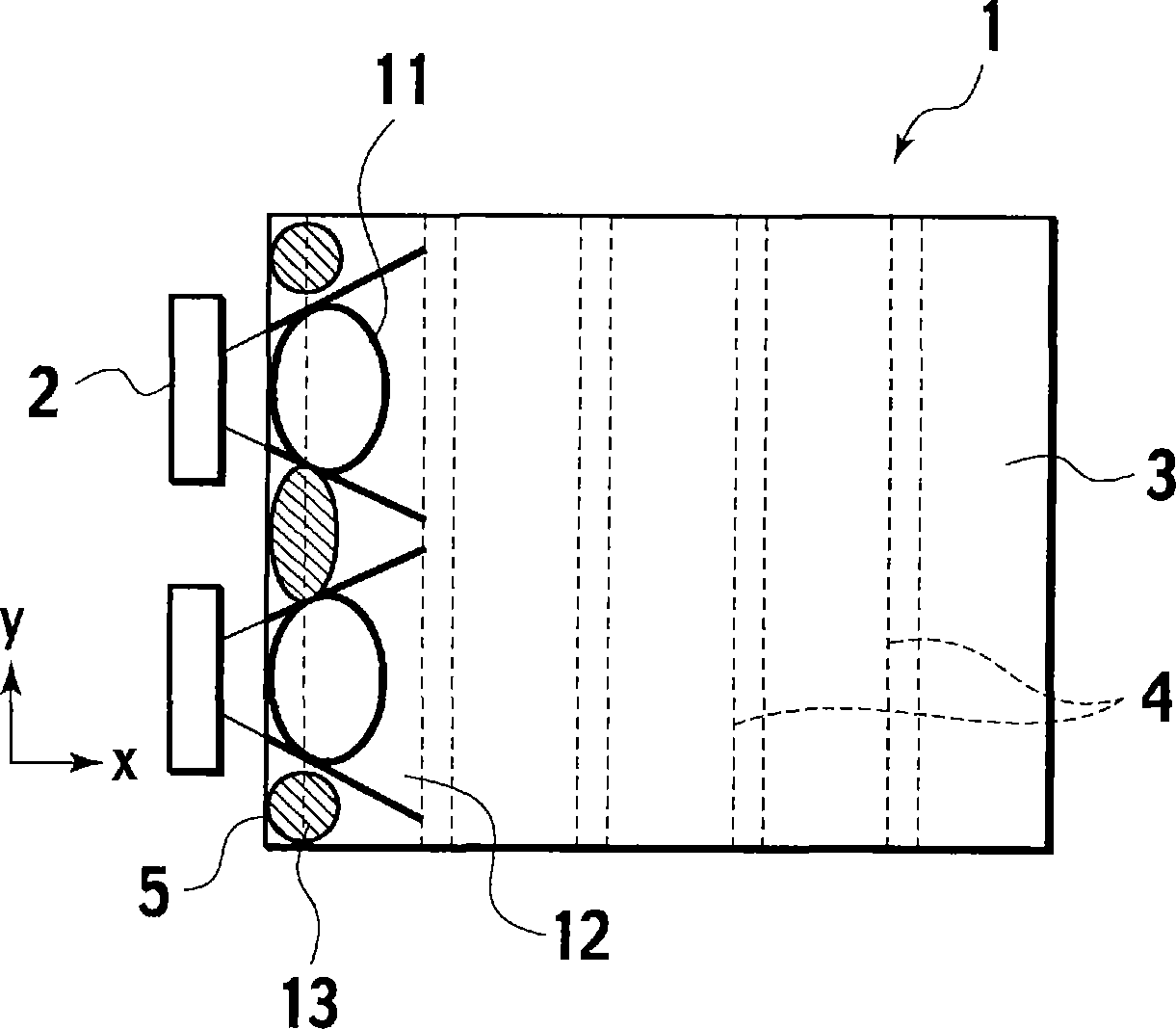

[0037] Next, embodiments of the reflector and the backlight device of the present invention will be described in detail with reference to the drawings.

[0038] In this embodiment, for the sake of simplicity, the same components are denoted by the same reference symbols in several different drawings. In addition, the drawings of this embodiment are used for explaining the content of the present invention, and do not accurately reflect the ratio of the dimensions of each part.

[0039] In addition, for convenience of reference, an xyz rectangular coordinate system is set in the figure. The x-axis and the y-axis are set along the two upper and lower sides of the light guide plate in the light traveling direction of the light guide plate, and the z-axis is set along the normal direction of the emitting surface. In addition, the positive and negative directions of the z axis are referred to as up and down.

[0040] Figure 4 is a reflector showing the first embodiment. Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com