Light guide plate with supporting rib and display module comprising same

A light guide plate and support rib technology, which is applied in the field of light guide plate design, can solve problems such as bright line light leakage, and achieve the effect of avoiding bright line or light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

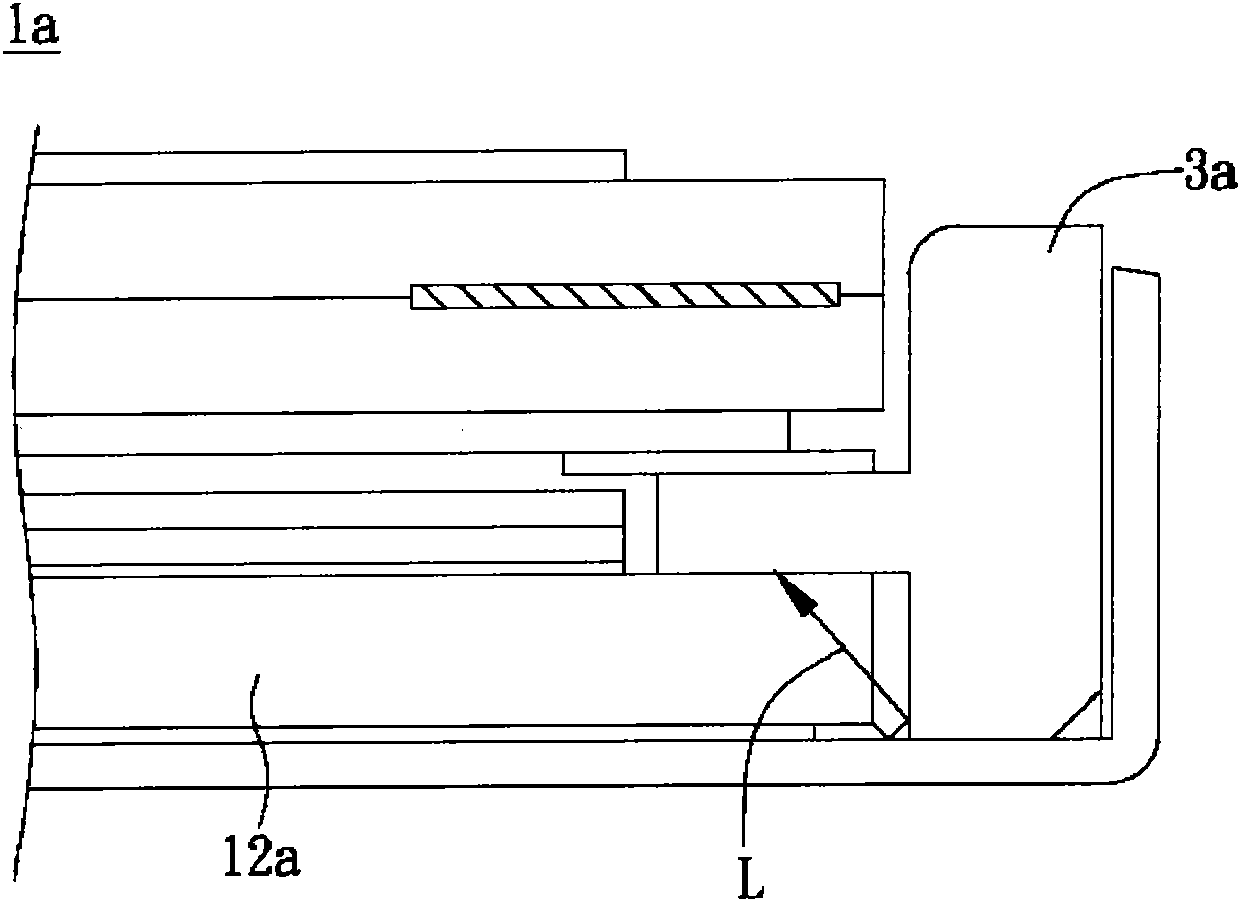

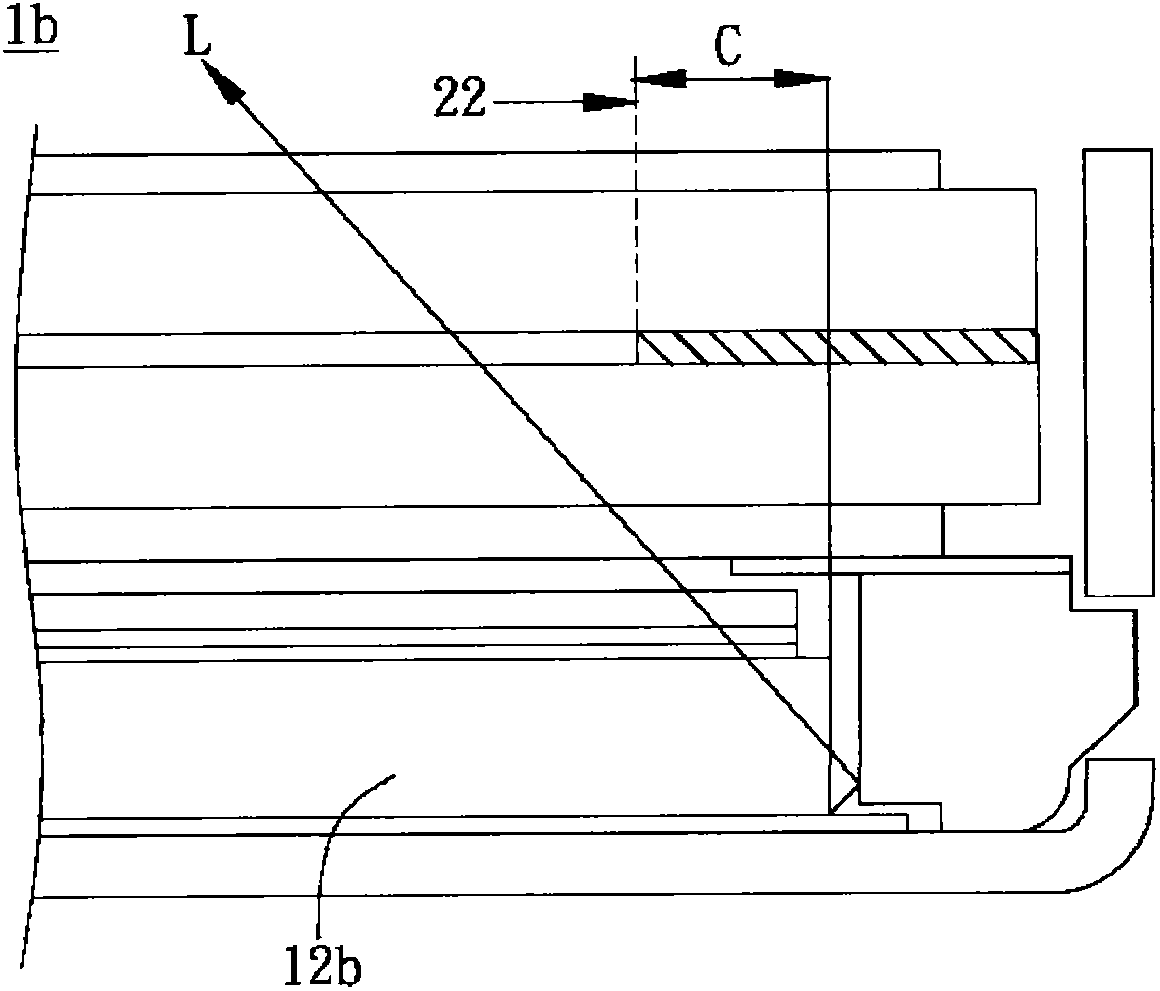

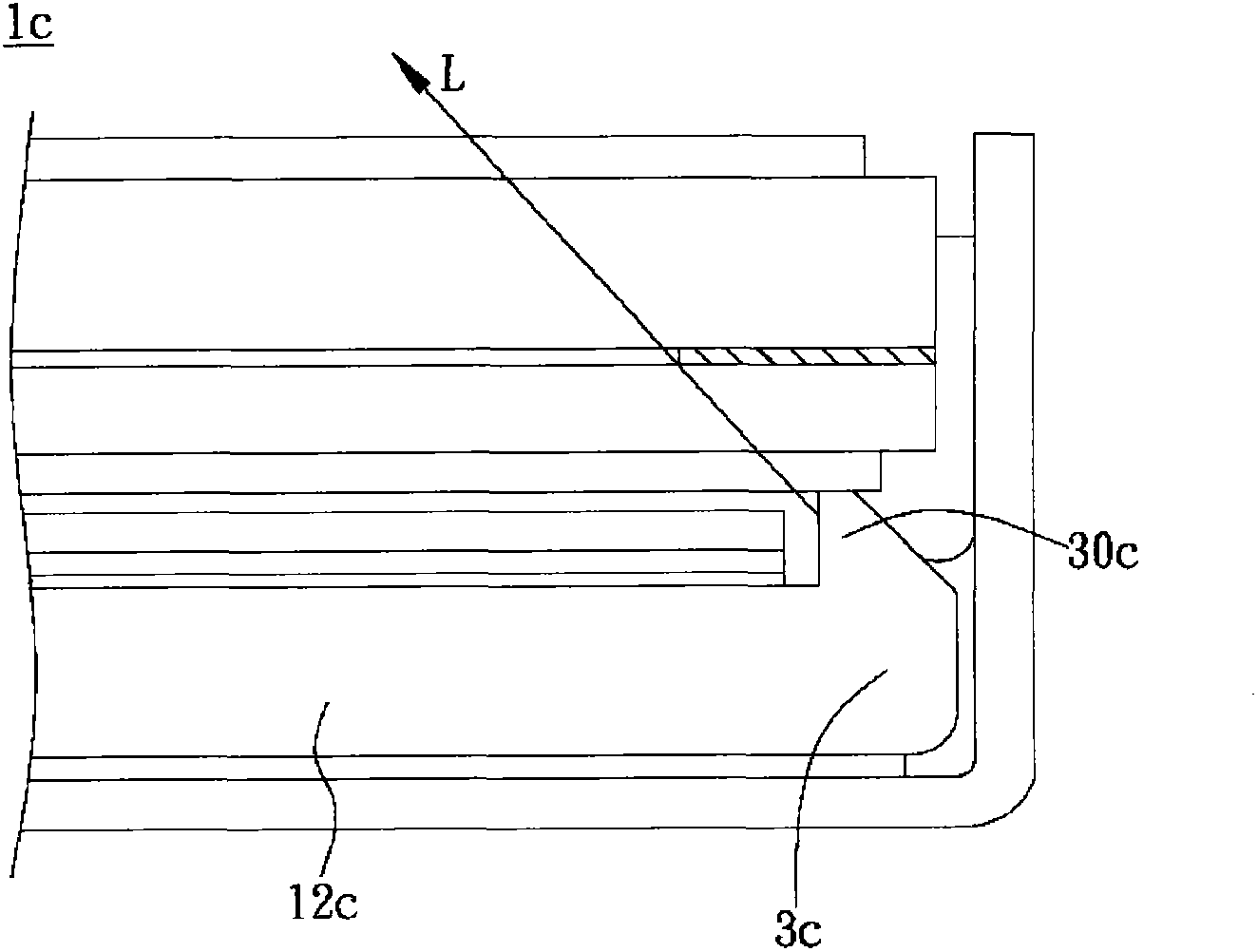

[0065] like Figure 2A As shown, the light guide plate 100 used in the backlight module of the present invention includes a light emitting area A and a light shielding area B. like Figure 2B-Figure 2C As shown, the light emitting area A usually includes a plane, and the light shielding area B is located on one side of the light emitting area A, and is at least partially higher than the plane of the light emitting area A or protrudes on the plane of the light emitting area A. In this embodiment, the plane of the light-exiting area A is usually the light-exiting surface of the light-exiting area A. Specifically, as Figure 2A and Figure 2B As shown, the light exit area A is formed by the body 110 of the light guide plate 100 . The body 110 has a light emitting surface 116 and a first end 1101, and has high light transmittance. Wherein, the first end 1101 is located on one side of the light emitting surface 116 , for example, on the side of the light emitting surface 116 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com