Light guide plate and backlight module using same

A backlight module, light guide plate technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of no diffusion function, poor light uniformity effect, etc., to improve the brightness and uniformity of light output, and avoid bright lines. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

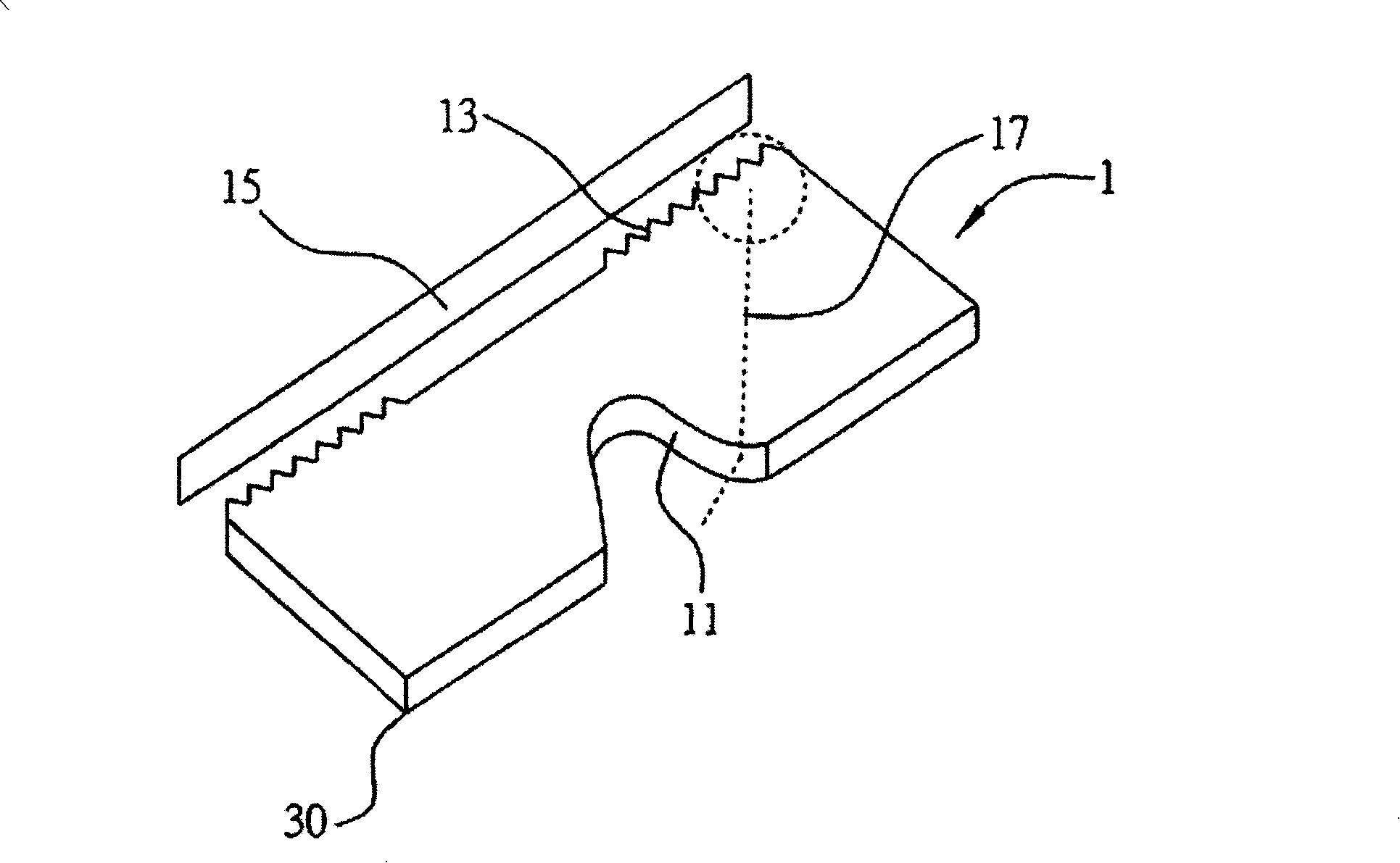

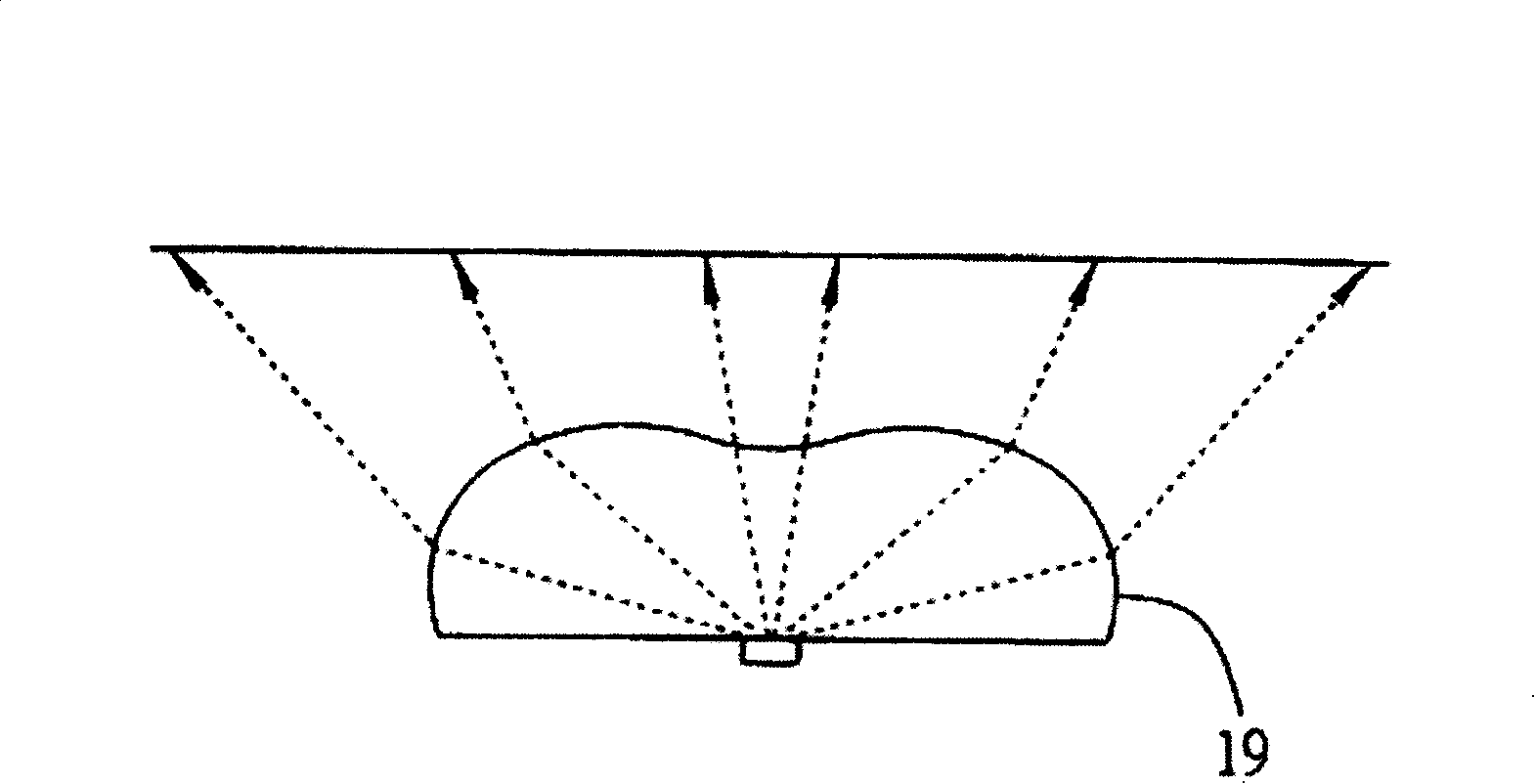

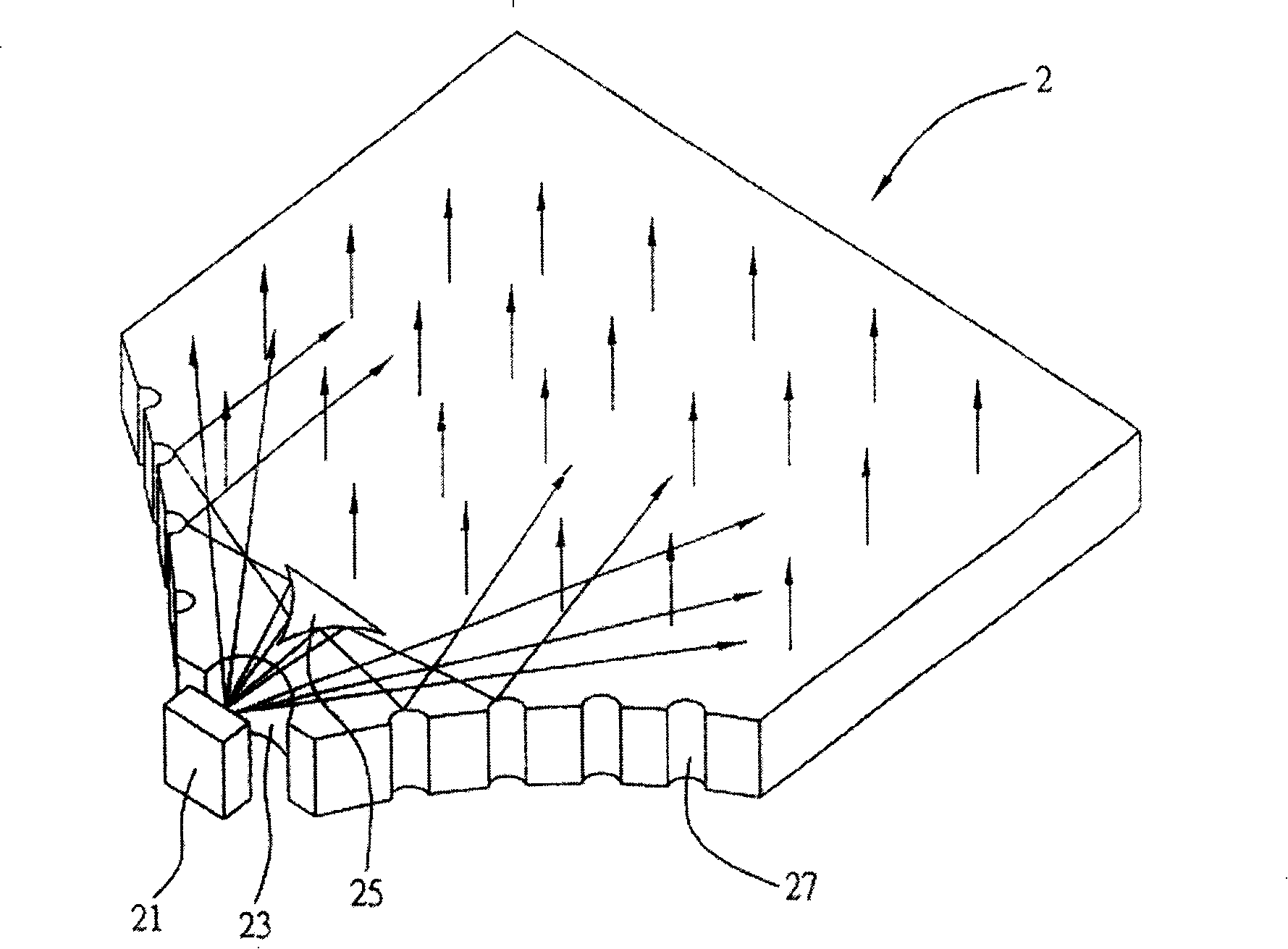

[0049] Figure 3A 8B is drawn according to Embodiment 1 of the light guide plate and the backlight module having the light guide plate of the present invention.

[0050] see Figure 3A , which is a three-dimensional schematic diagram of the structure of the light guide plate in Embodiment 1. The light guide plate 3 as shown in the figure includes a light-transmitting substrate 31 , a first microstructure 33 and a second microstructure 35 .

[0051] Such as Figure 3A As shown, the transparent substrate 31 has a first optical surface 311 and a second optical surface 313 opposite to each other. In this embodiment, the transparent substrate 31 may be a transparent substrate or other equivalent transparent components.

[0052] The first microstructure 33 is disposed on the first optical surface 311, and is made of, for example, a light-transmitting material, and has a diffuser 331 and a light-collecting part 333 juxtaposed to each other. The diffuser 331 and the light-collectin...

Embodiment 2

[0066] Figure 9 It is drawn according to Embodiment 2 of the light guide plate and the backlight module with the light guide plate of the present invention. Wherein, the same or similar components as in Embodiment 1 are represented by the same or similar component symbols, and detailed descriptions are omitted to make the description of this case clearer and easier to understand.

[0067] The biggest difference between Embodiment 2 and Embodiment 1 is that in the light guide plate of Embodiment 2, the first microstructure is provided with at least one diffused light-collecting composite part, instead of having a diffused part and a light-collecting composite part as in Embodiment 1. department.

[0068] Such as Figure 9 The shown light guide plate 3 includes a transparent substrate 31 , a first microstructure 33 and a second microstructure 35 . The light-transmitting substrate 31 and the second microstructure 35 can choose the same structure as the light-transmitting subs...

Embodiment 3

[0072] Figure 10 It is drawn according to Embodiment 3 of the light guide plate and the backlight module with the light guide plate of the present invention. Wherein, the same or similar components as those in the above-mentioned embodiments are represented by the same or similar component symbols, and detailed descriptions are omitted.

[0073] The biggest difference between the third embodiment and the above-mentioned embodiments is that the first microstructure is provided with a diffused light-collecting recombination part and a light-collecting part juxtaposed to each other.

[0074] see Figure 10 In the light guide plate 3 of this embodiment, the first microstructure 33 is provided with a diffused light-collecting recombination part 335 and a light-collecting part 333 which are spaced and juxtaposed to each other for the function of diffusing and collecting light. Same as the above-mentioned embodiment, the light-diffusing composite part 335 also has an arcuate surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com