Patents

Literature

207results about How to "Improve bonding yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of creating defect free high Ge content (>25%) SiGe-on-insulator (SGOI) substrates using wafer bonding techniques

ActiveUS7235812B2Improve bonding yieldReduce defect densitySolid-state devicesSemiconductor/solid-state device manufacturingBond interfaceOptoelectronics

Owner:GLOBALFOUNDRIES US INC

Method of creating defect free high Ge content (>25%) SiGe-on-insulator (SGOI) substrates using wafer bonding techniques

ActiveUS20060054891A1Improve bonding yieldReduce defect densitySolid-state devicesSemiconductor/solid-state device manufacturingBond interfaceOptoelectronics

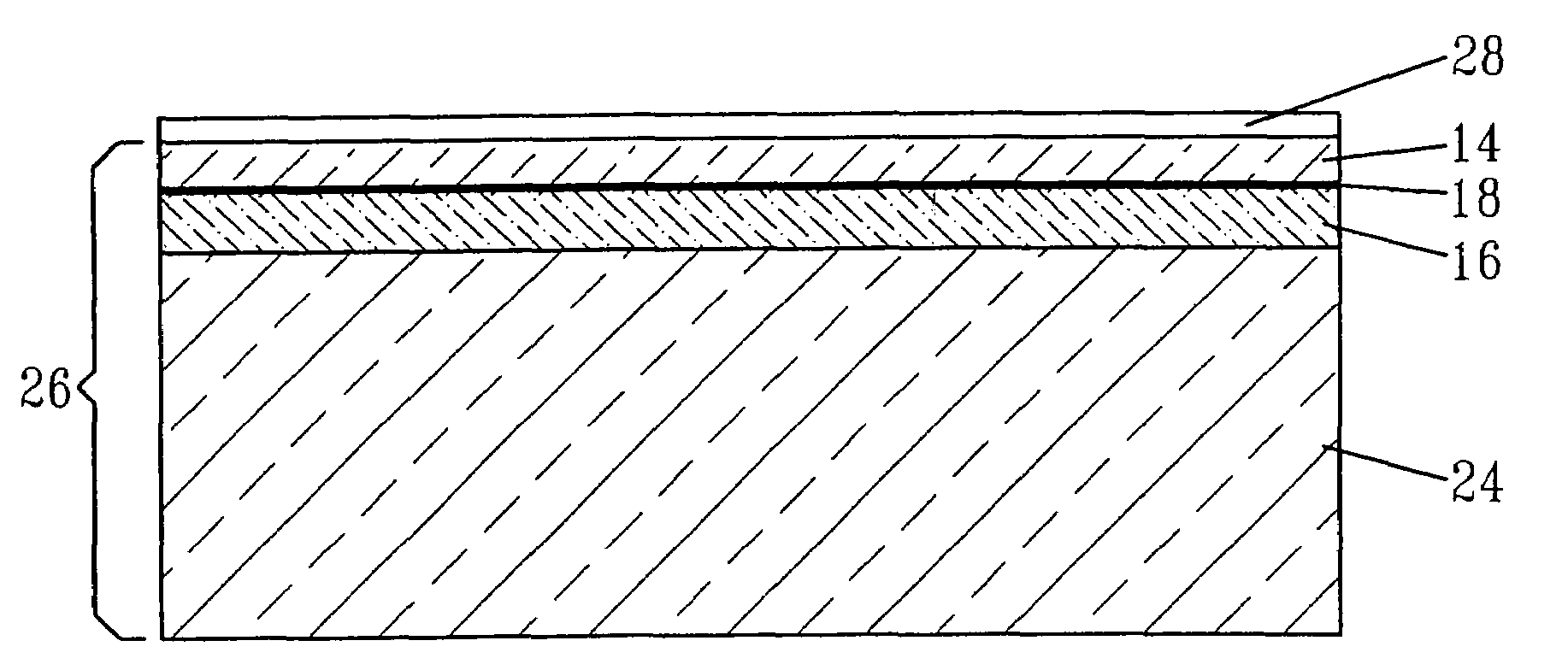

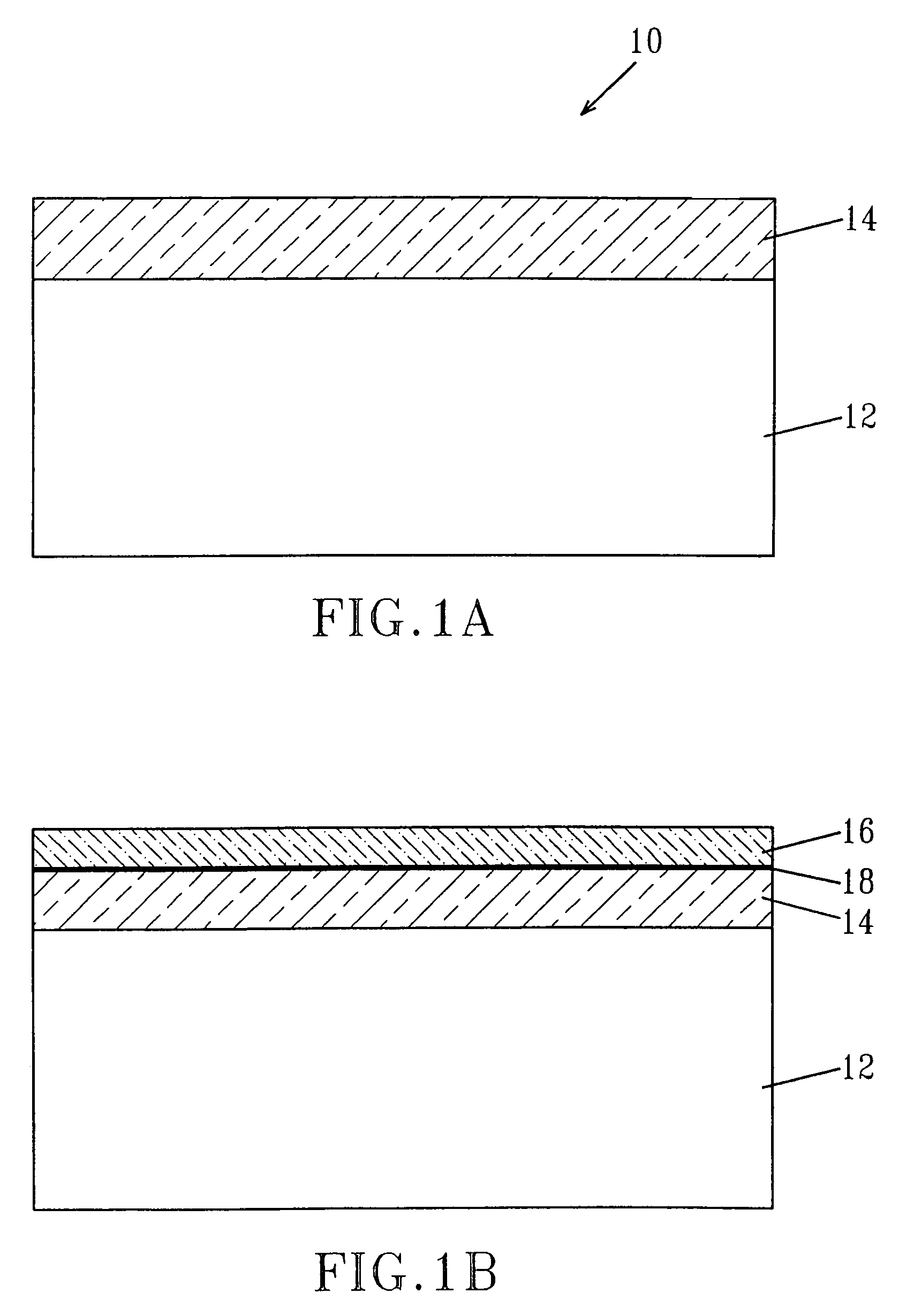

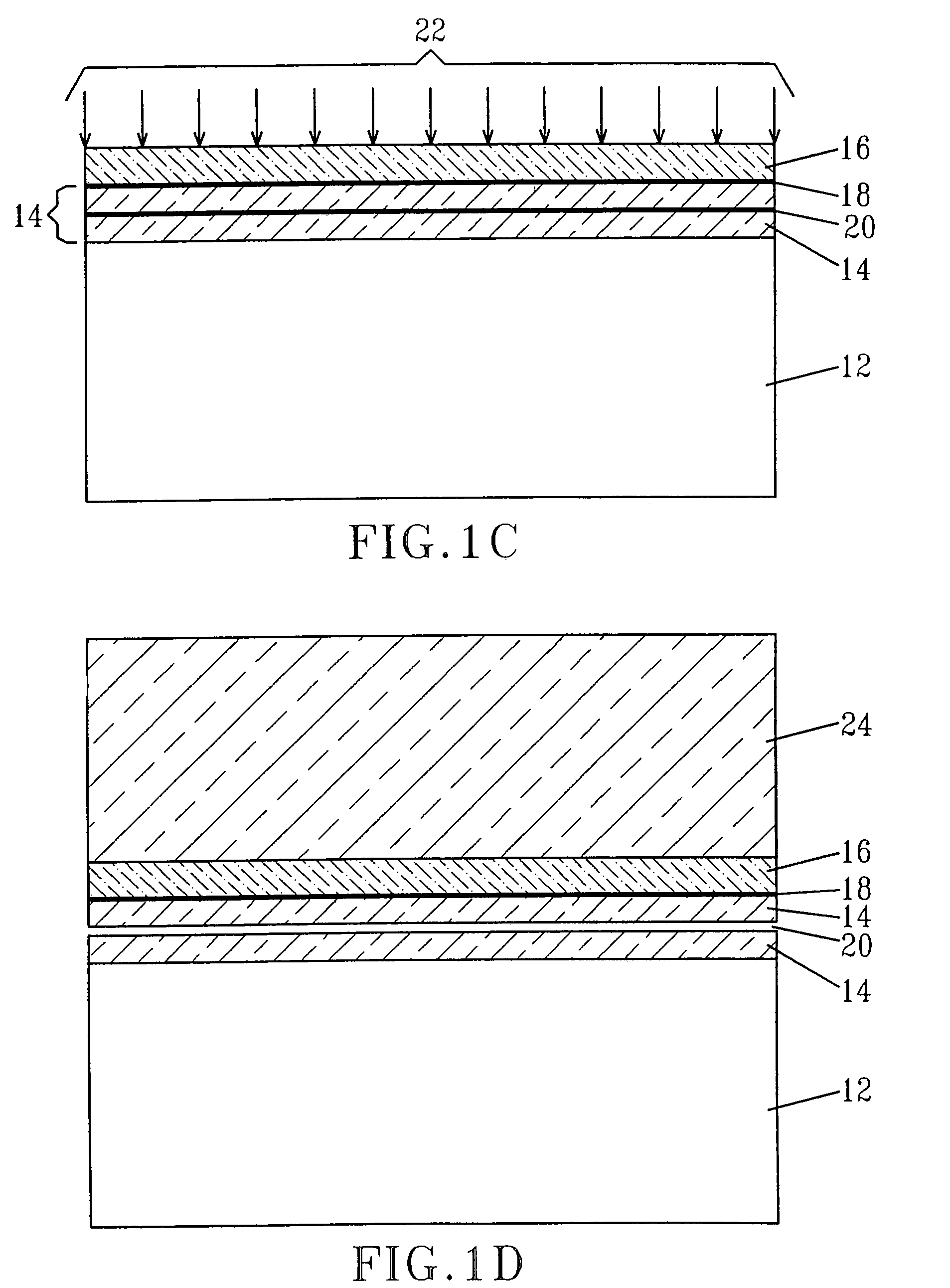

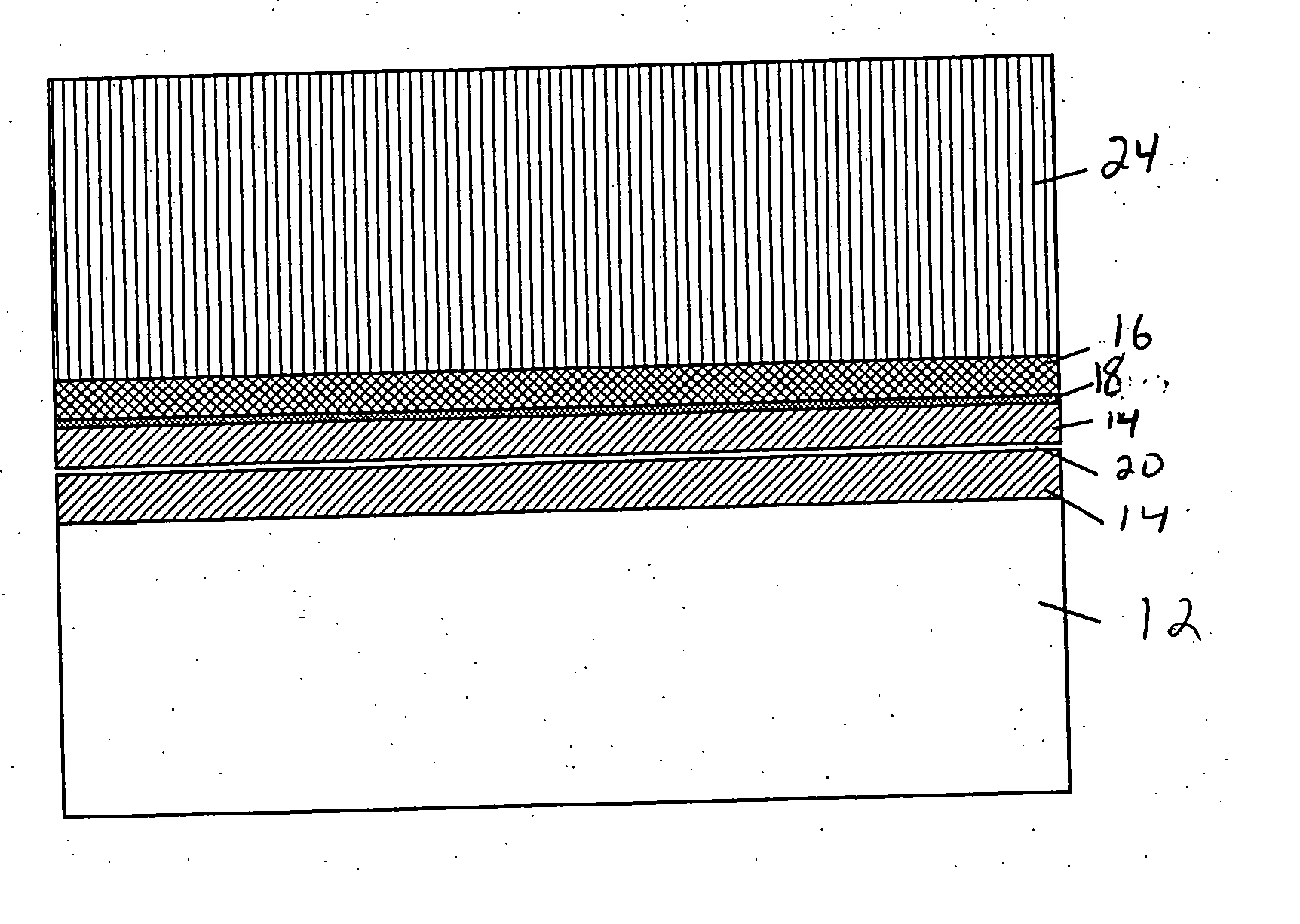

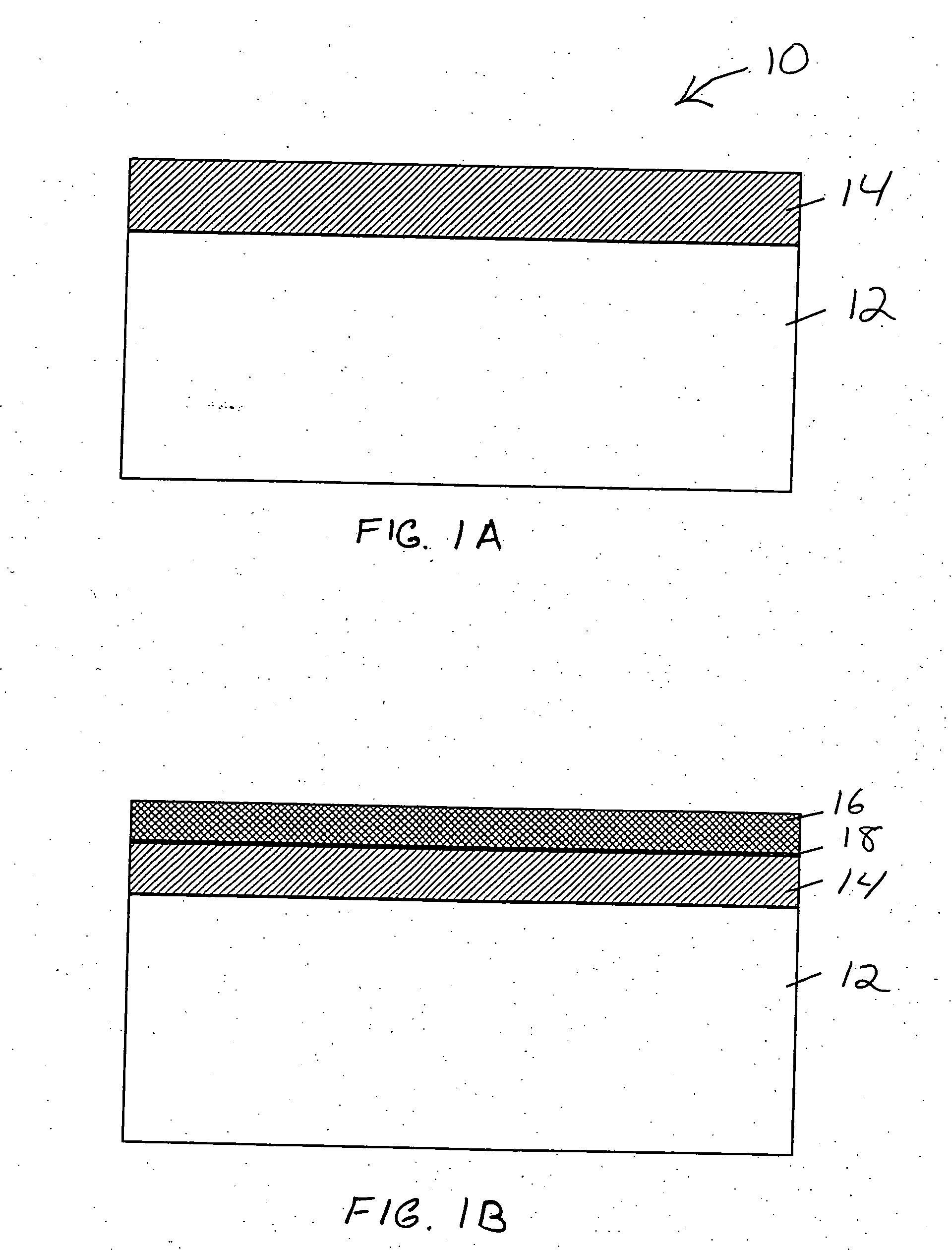

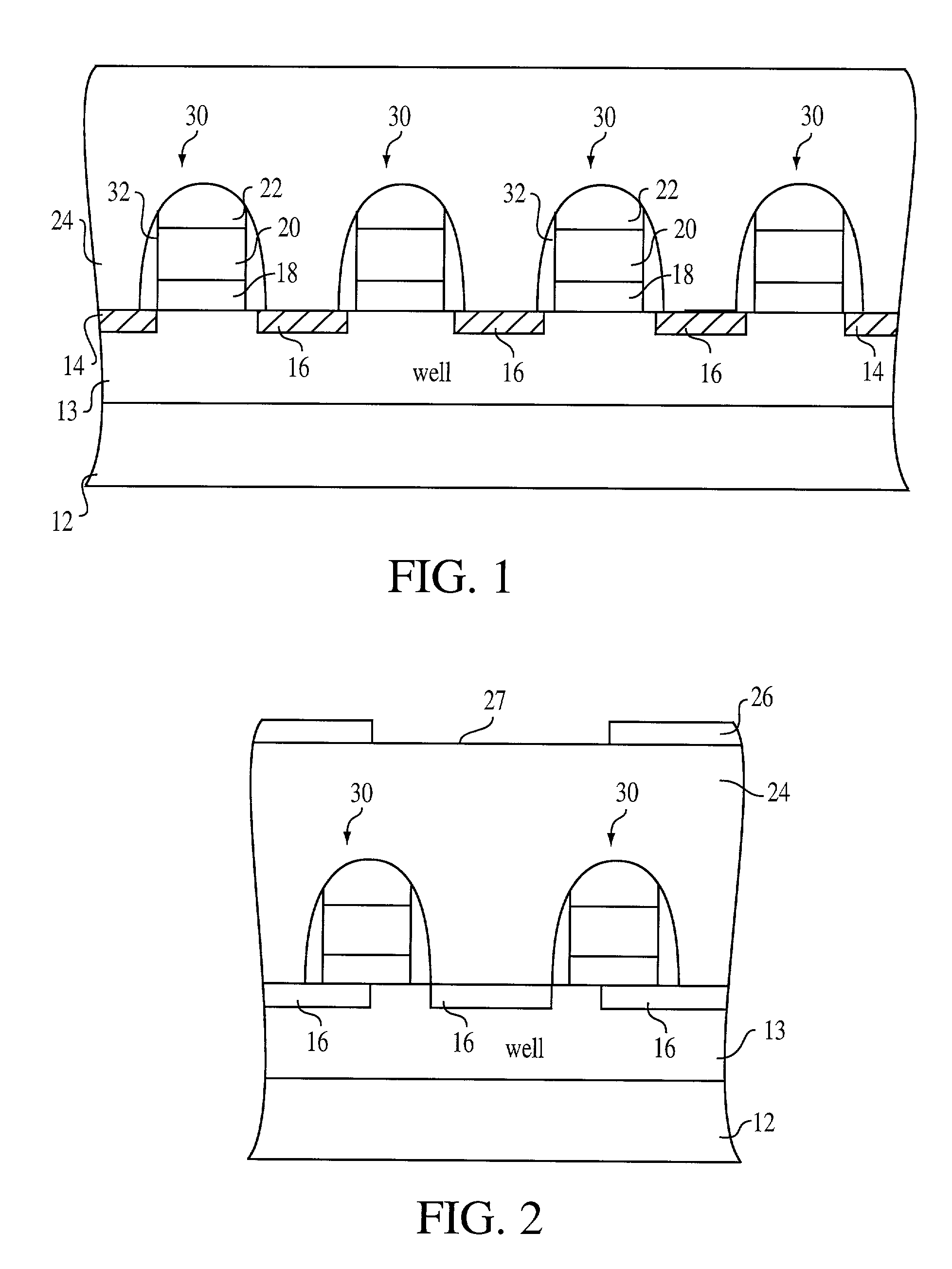

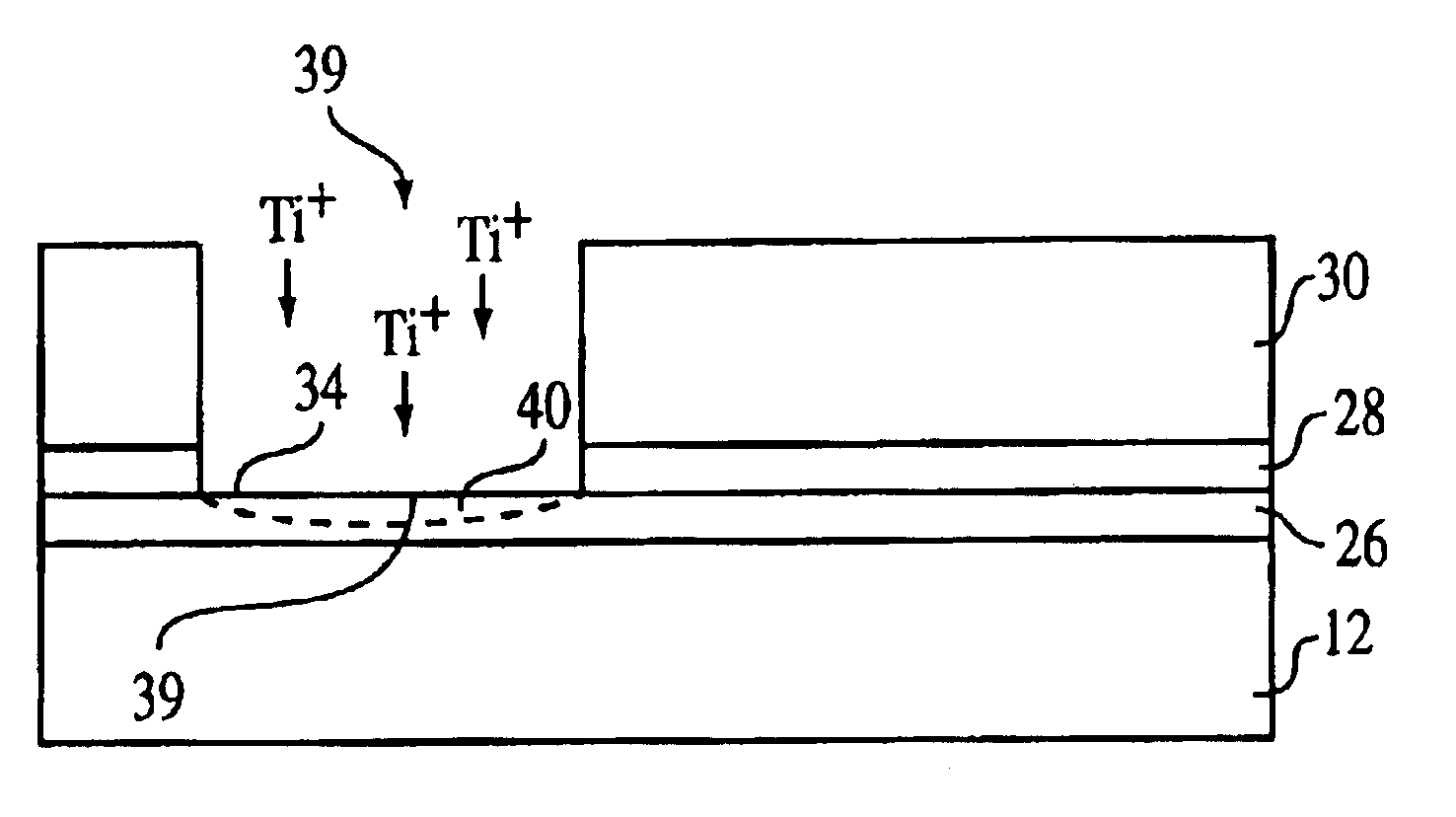

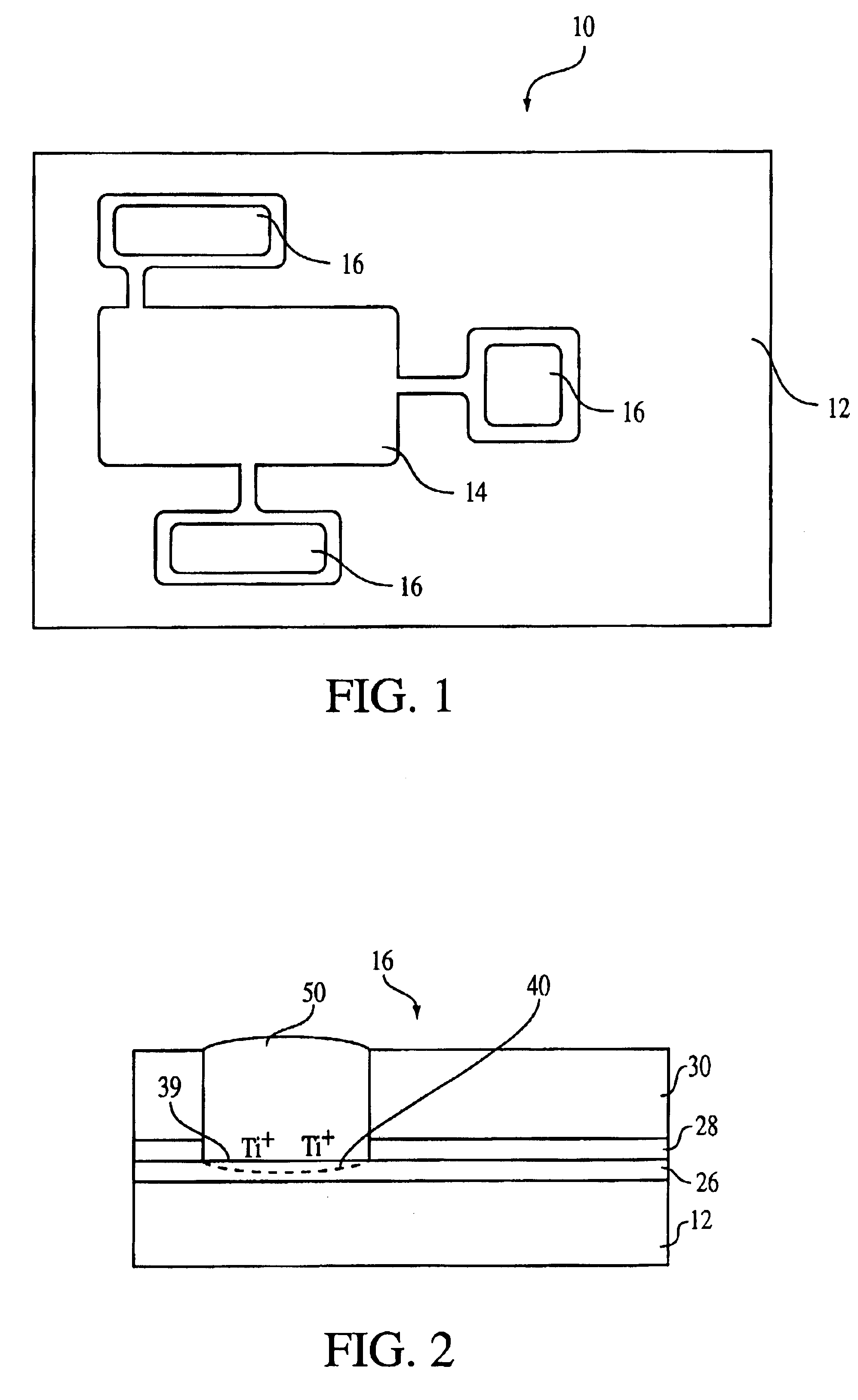

A method for achieving a substantially defect free SGOI substrate which includes a SiGe layer that has a high Ge content of greater than about 25 atomic % using a low temperature wafer bonding technique is described. The wafer bonding process described in the present application includes an initial prebonding annealing step that is capable of forming a bonding interface comprising elements of Si, Ge and O, i.e., interfacial SiGeO layer, between a SiGe layer and a low temperature oxide layer. The present invention also provides the SGOI substrate and structure that contains the same.

Owner:GLOBALFOUNDRIES US INC

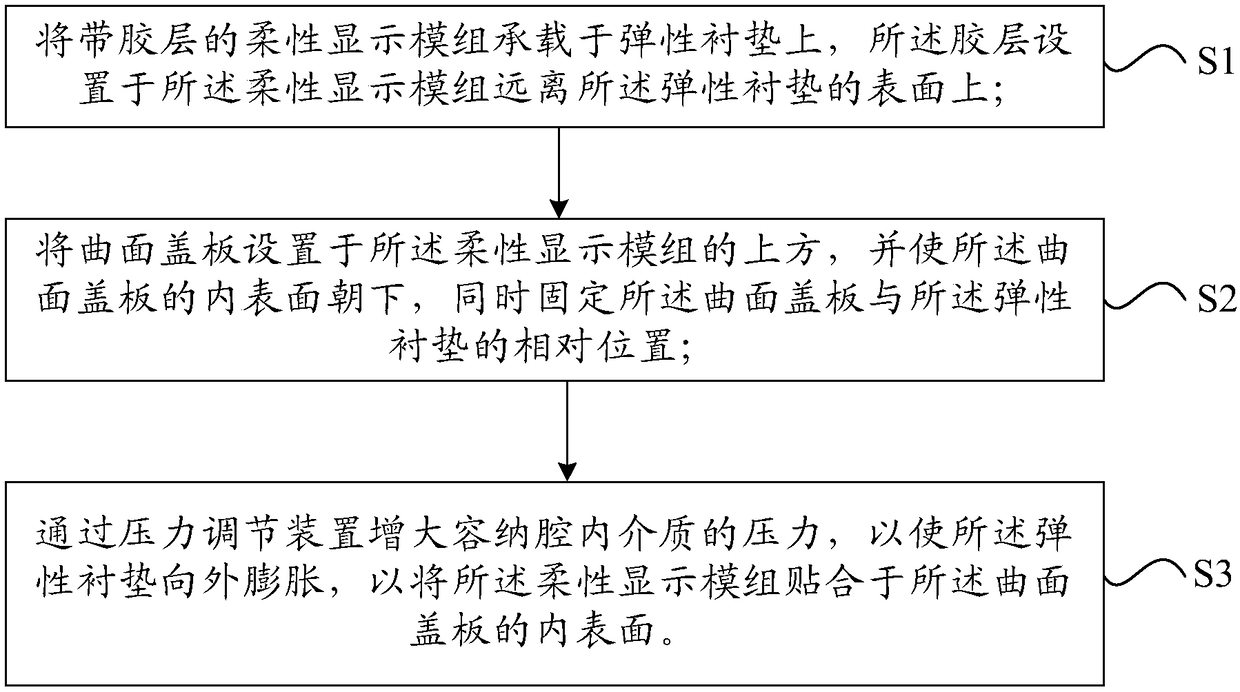

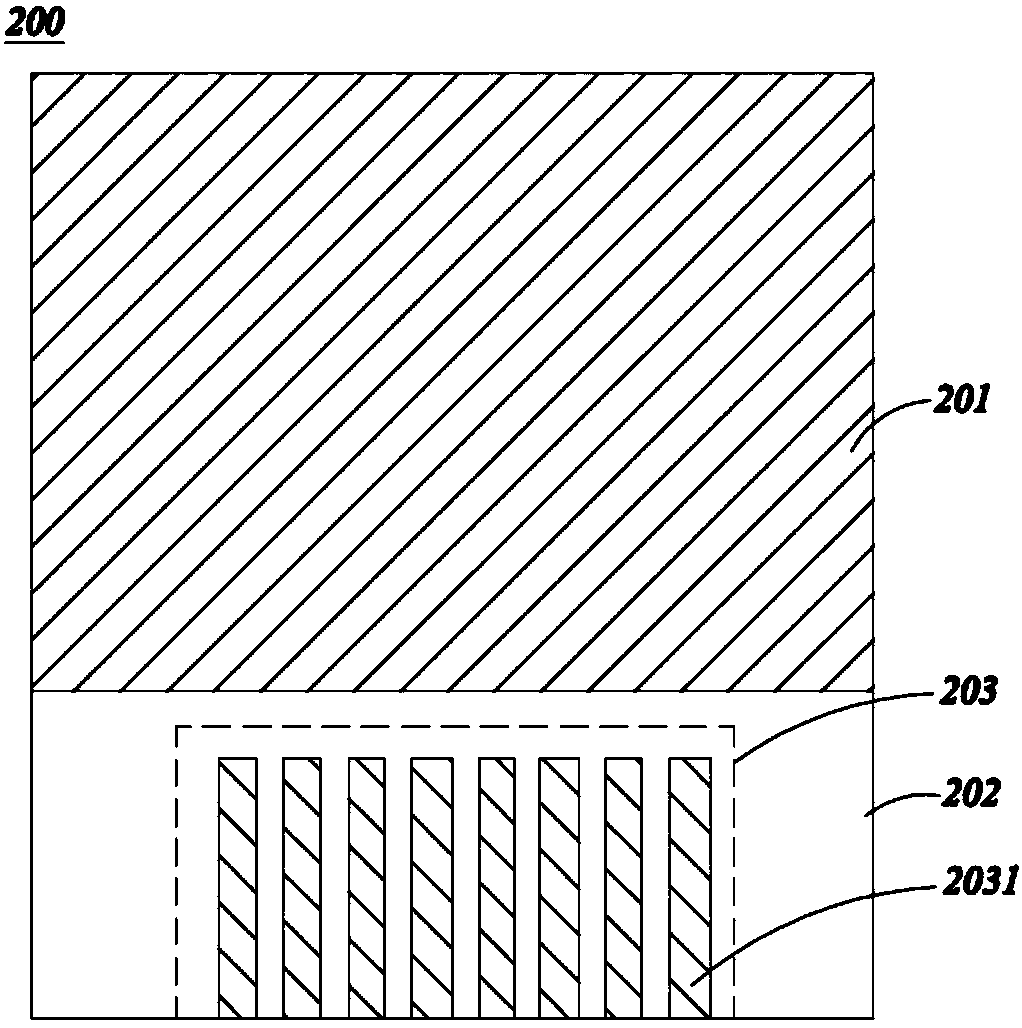

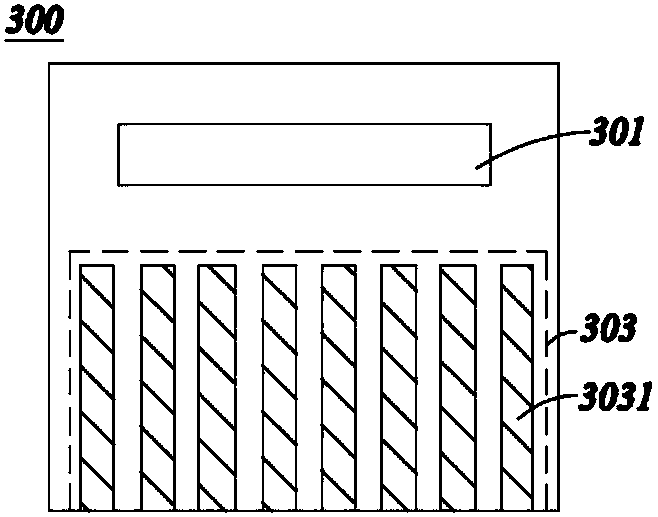

Laminating device and method for applying same

InactiveCN108198515AImprove versatilityImprove bonding yieldIdentification meansSurface displayEngineering

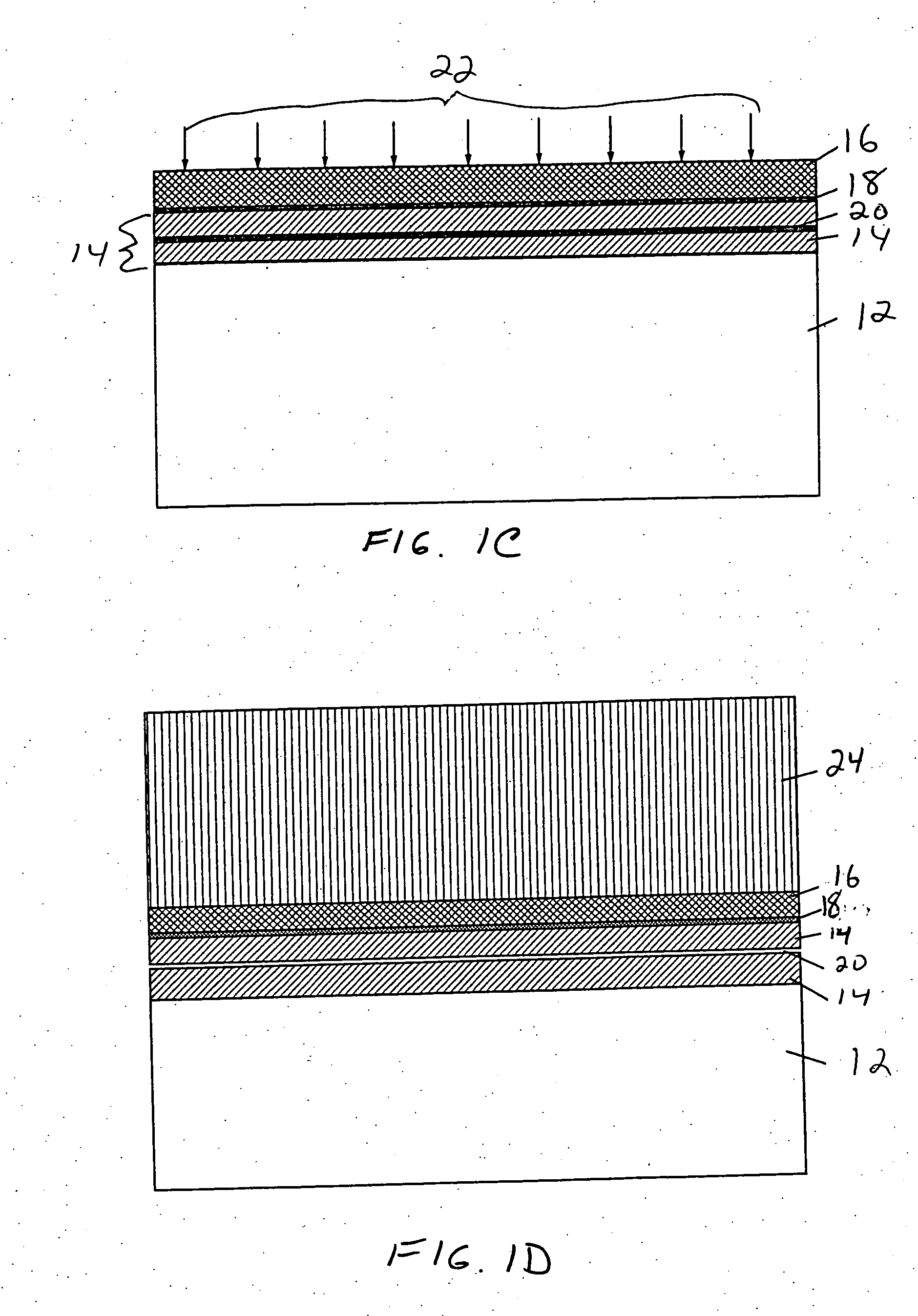

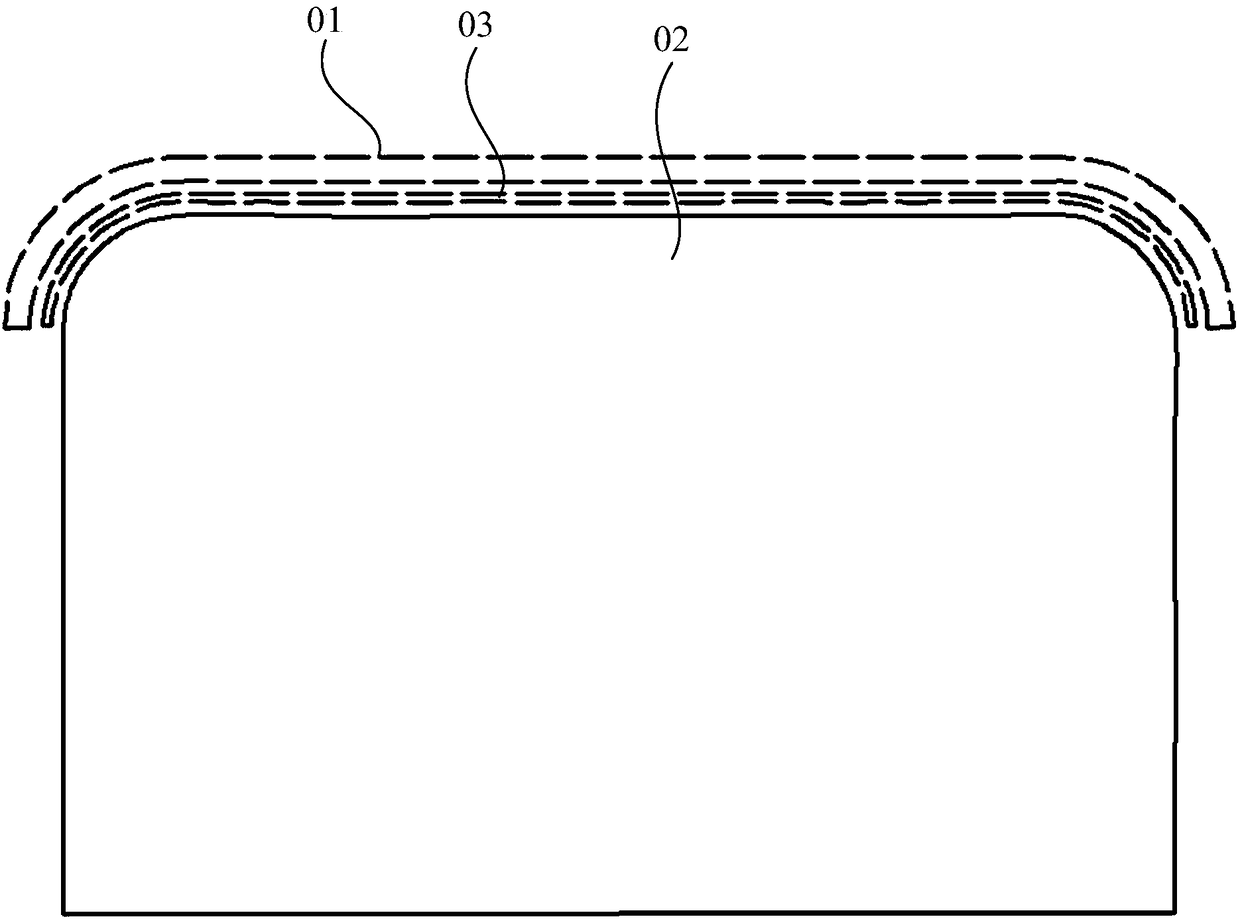

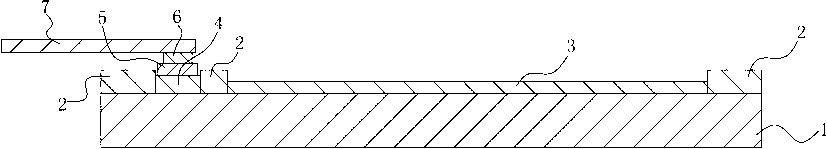

The invention discloses a laminating device and a method for applying the same, and relates to the technical field of processing of curved-surface display devices. The laminating device comprises an elastic lining and a pressure regulating device. An accommodating cavity is formed in the elastic lining and is filled with media, and the pressure regulating device is used for regulating the pressures of the media in the accommodating cavity, so that the elastic lining can be outwardly expanded or inwardly contracted. The laminating device and the method have the advantages that the problems of poor universality and lamination yield of laminating equipment for flexible display modules and curved-surface cover plates can be solved by the aid of the laminating device and the method; the laminating device is used for laminating flexible display modules on the inner surfaces of curved-surface cover plates.

Owner:BOE TECH GRP CO LTD +1

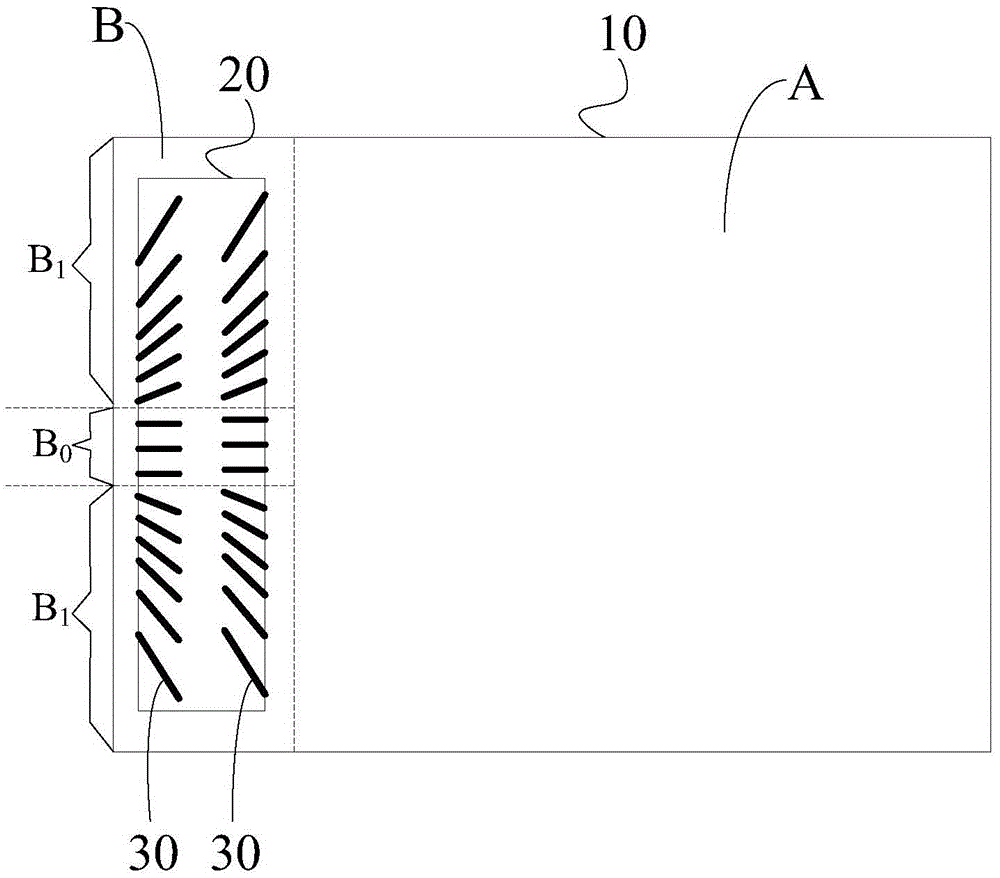

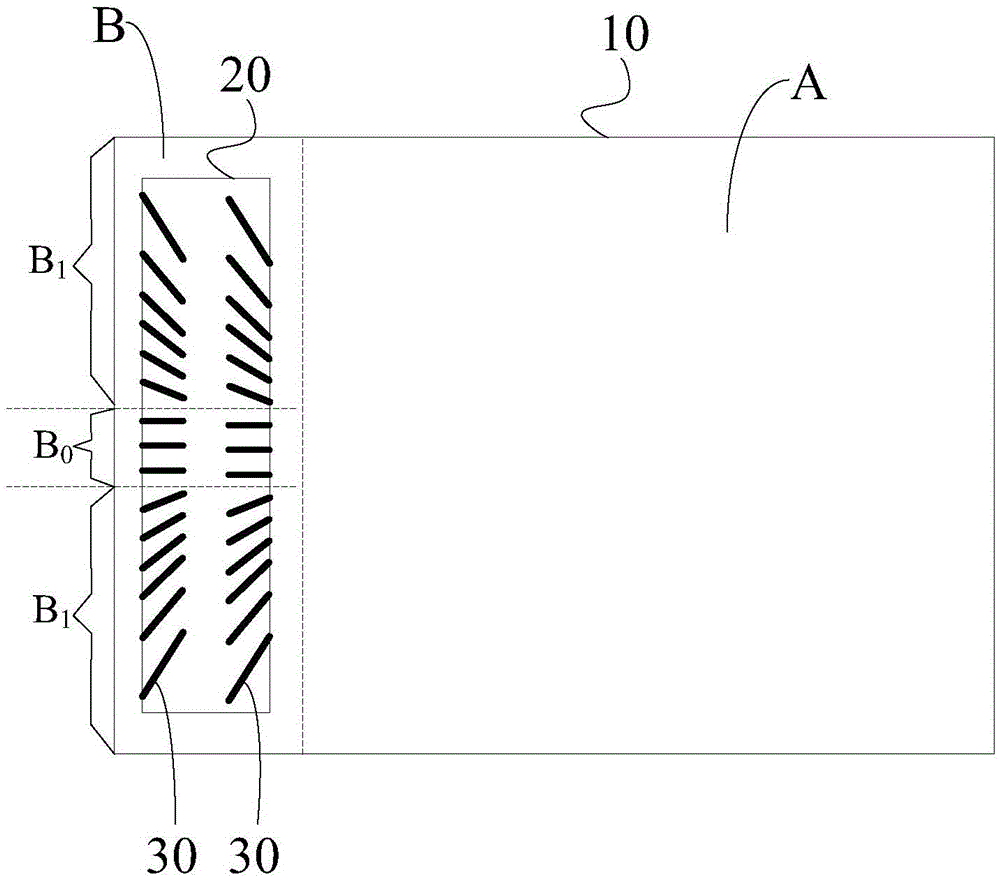

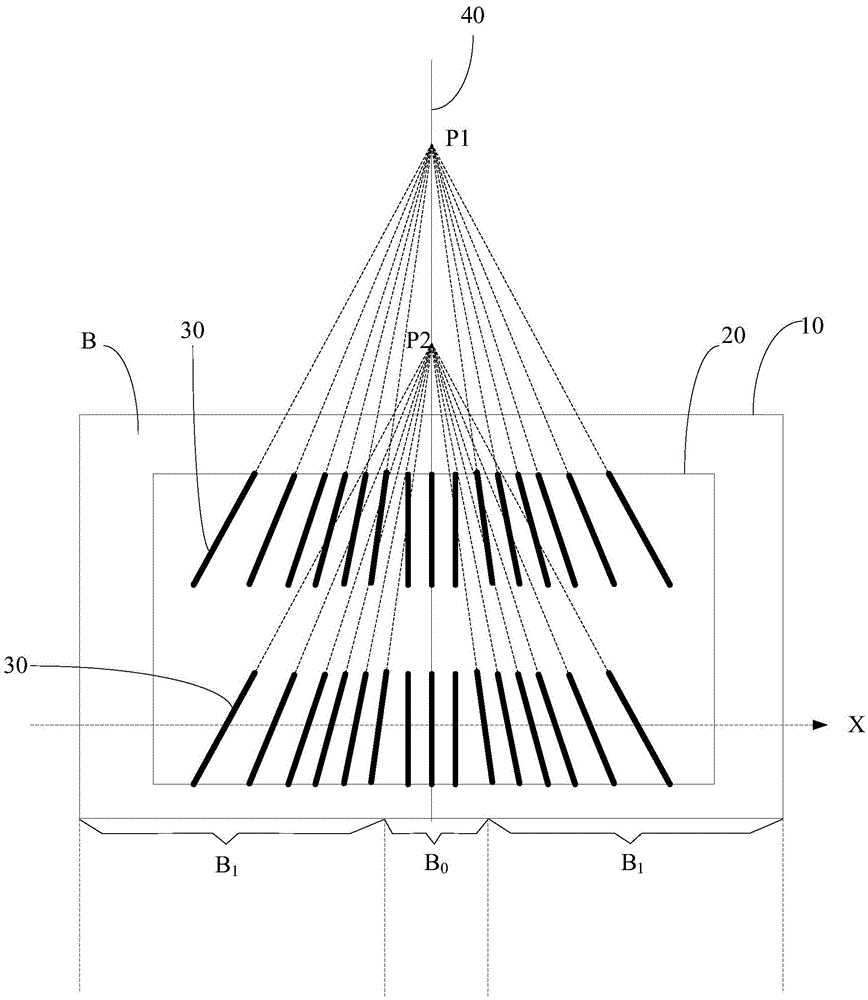

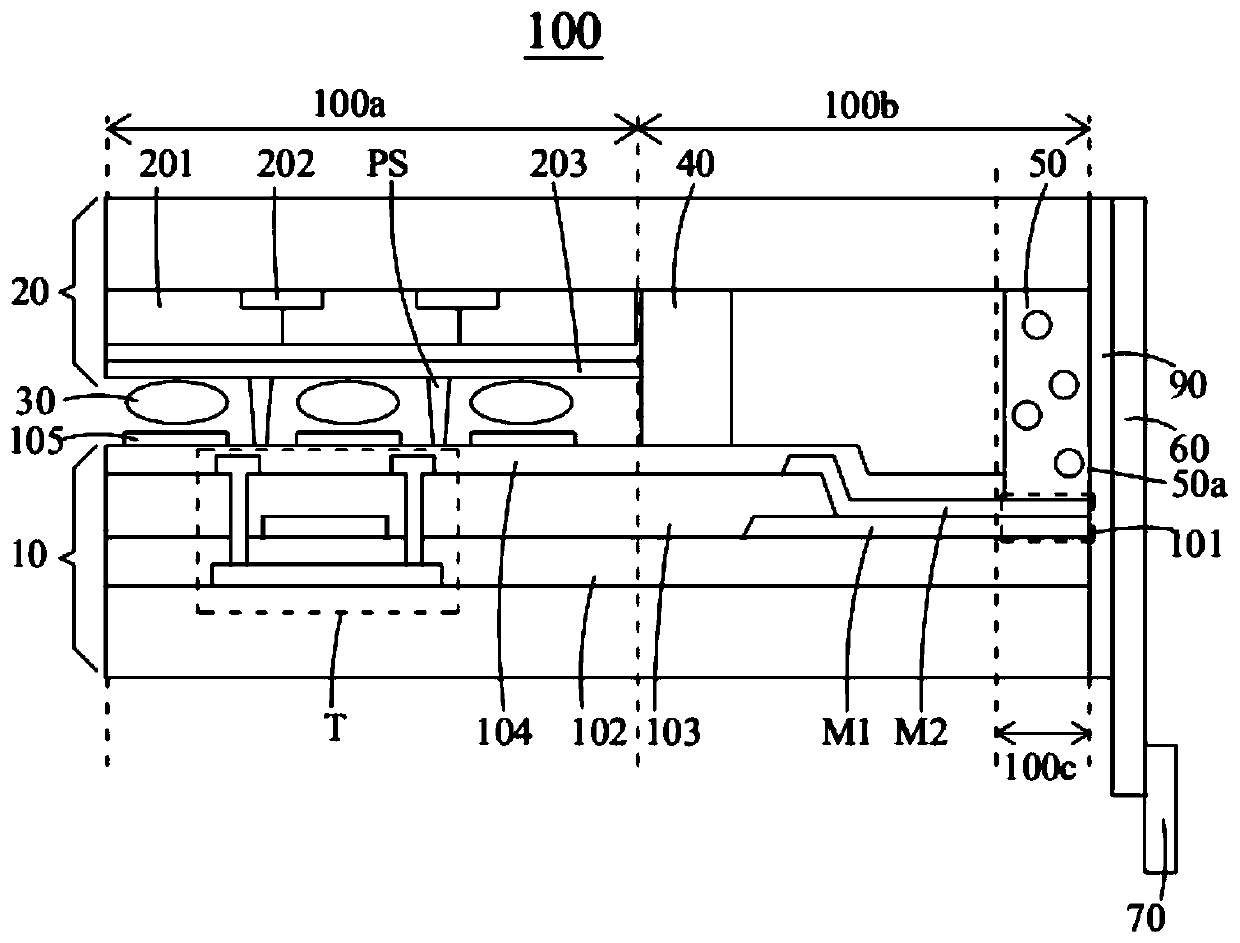

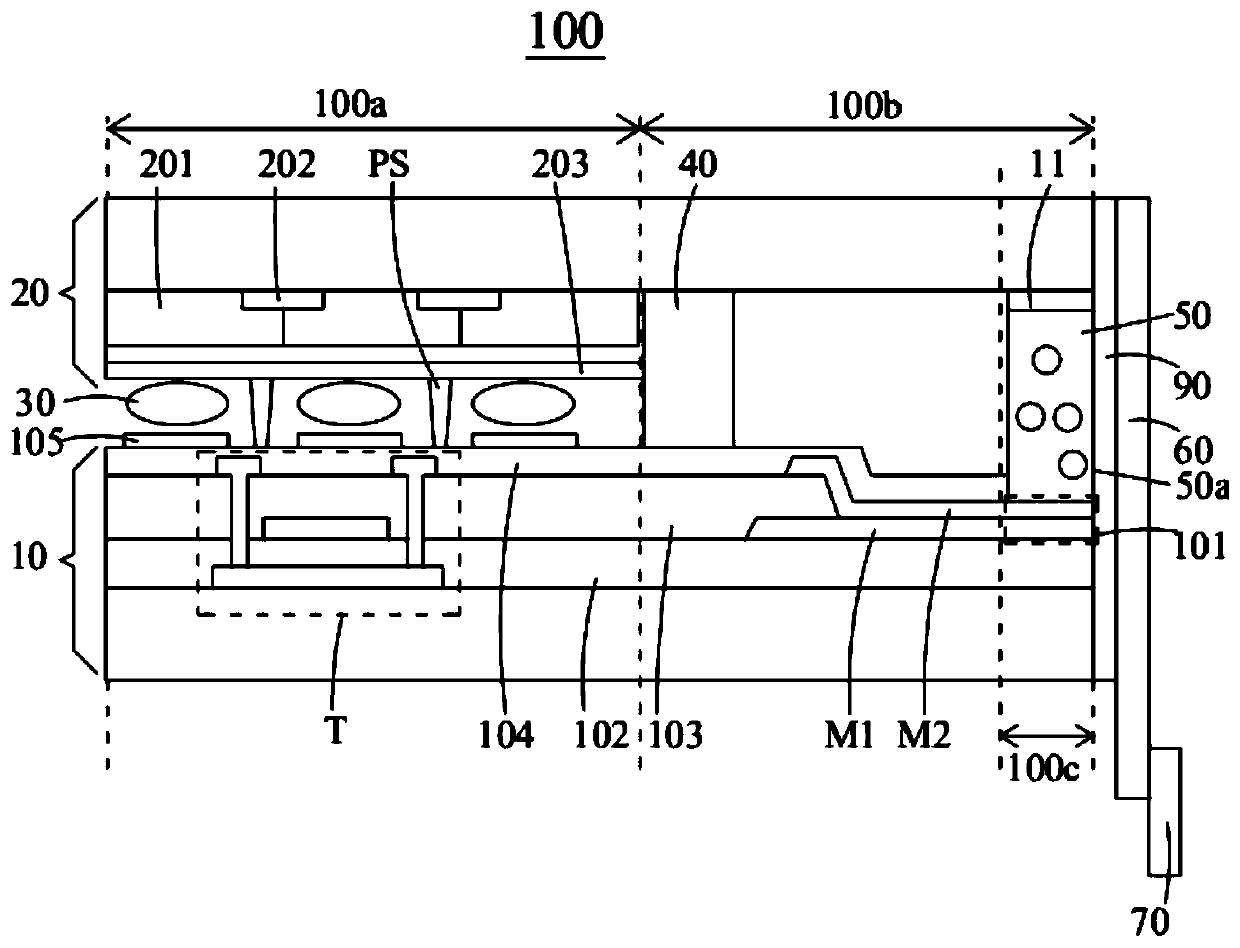

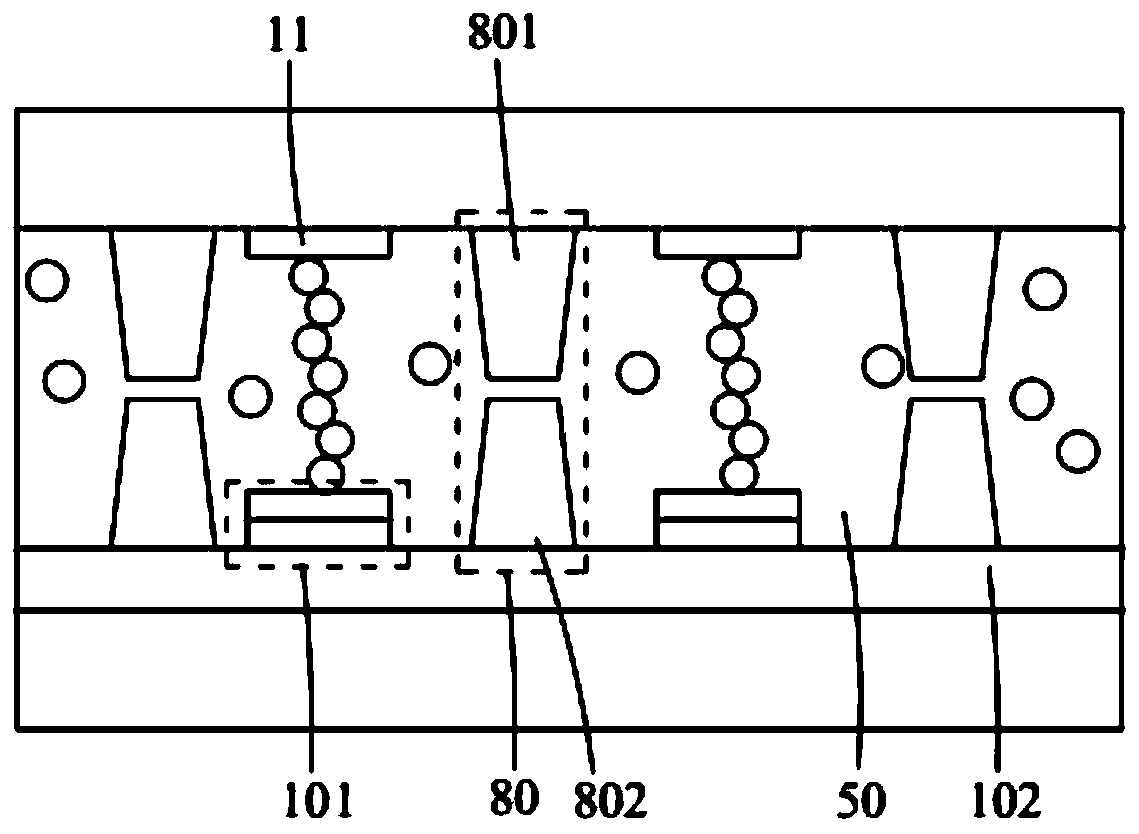

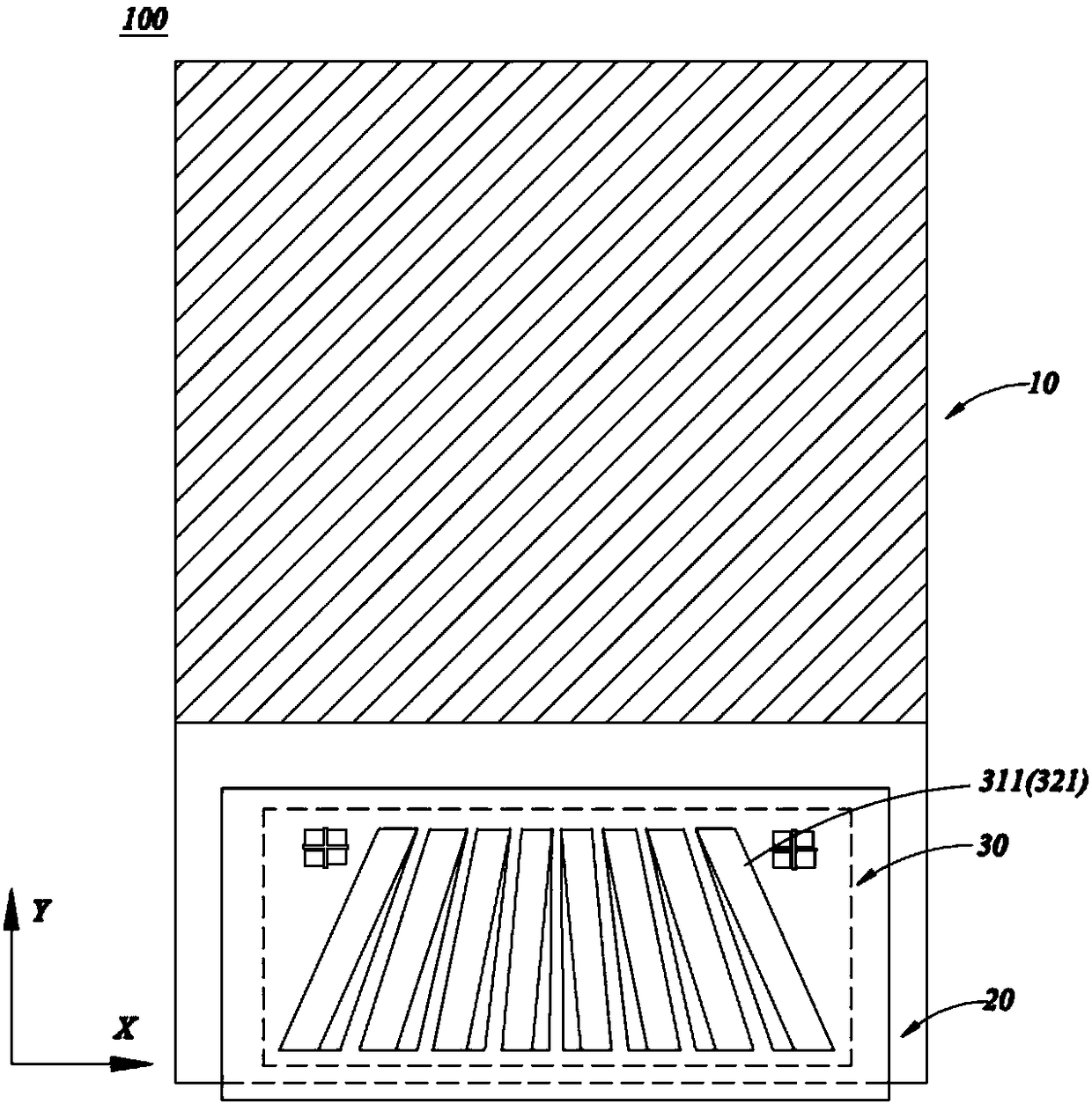

Display device and chip binding method thereof

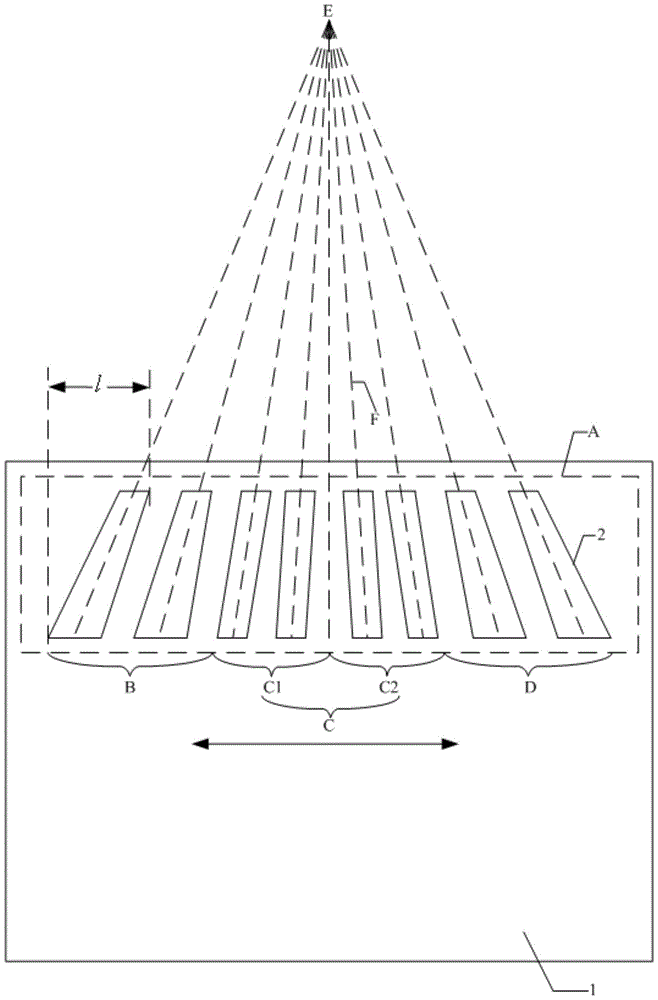

InactiveCN105654856AImprove bonding yieldAchieve correct alignmentStatic indicating devicesSemiconductor/solid-state device detailsSize changeEngineering

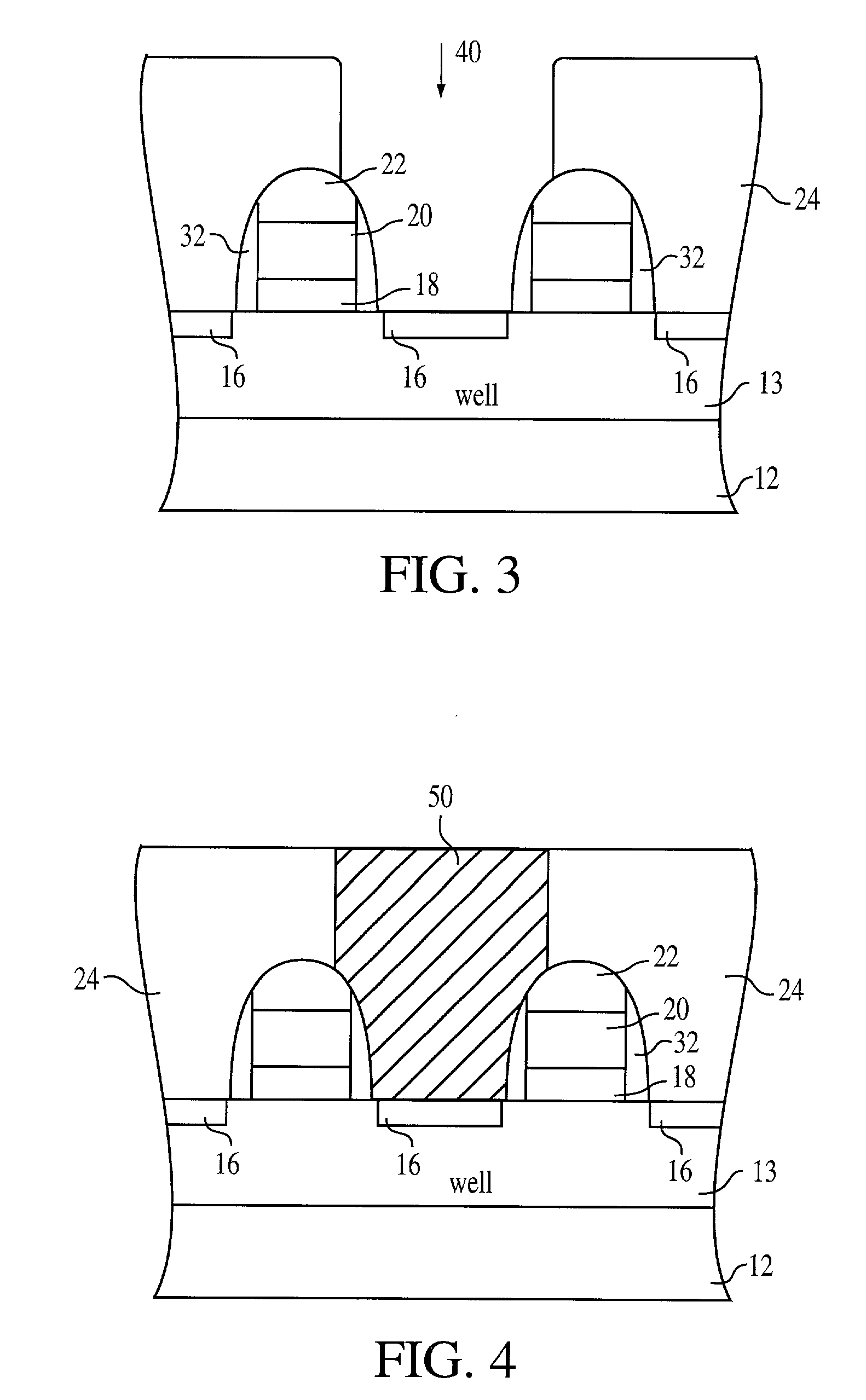

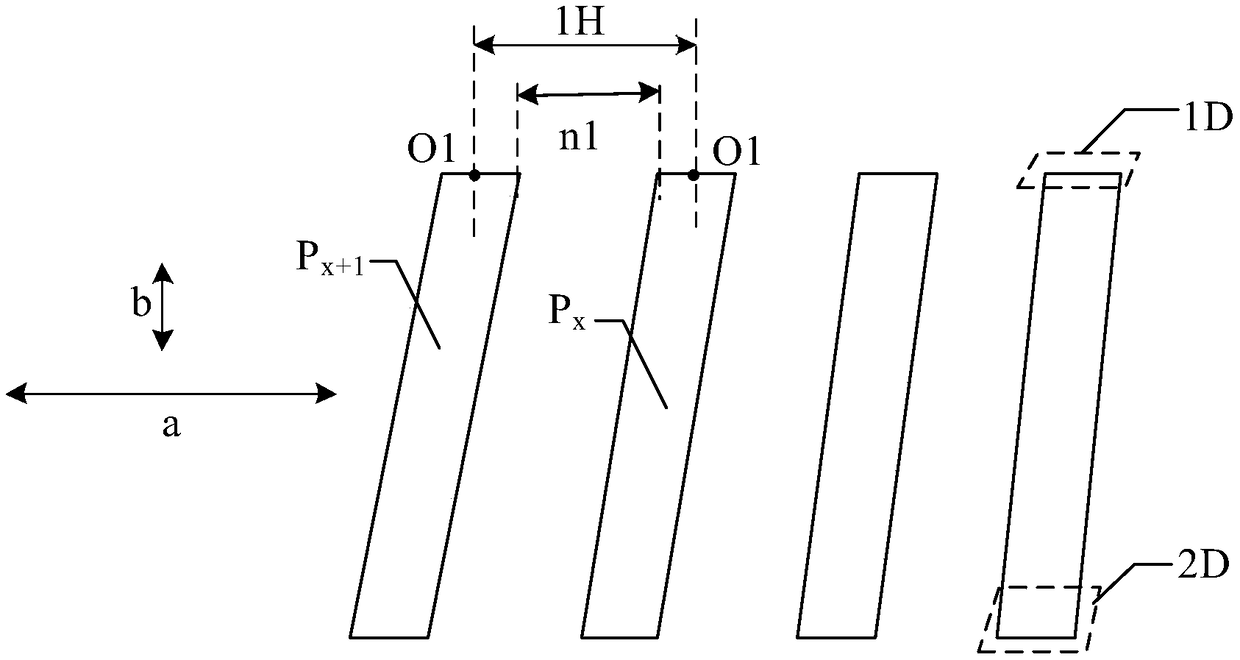

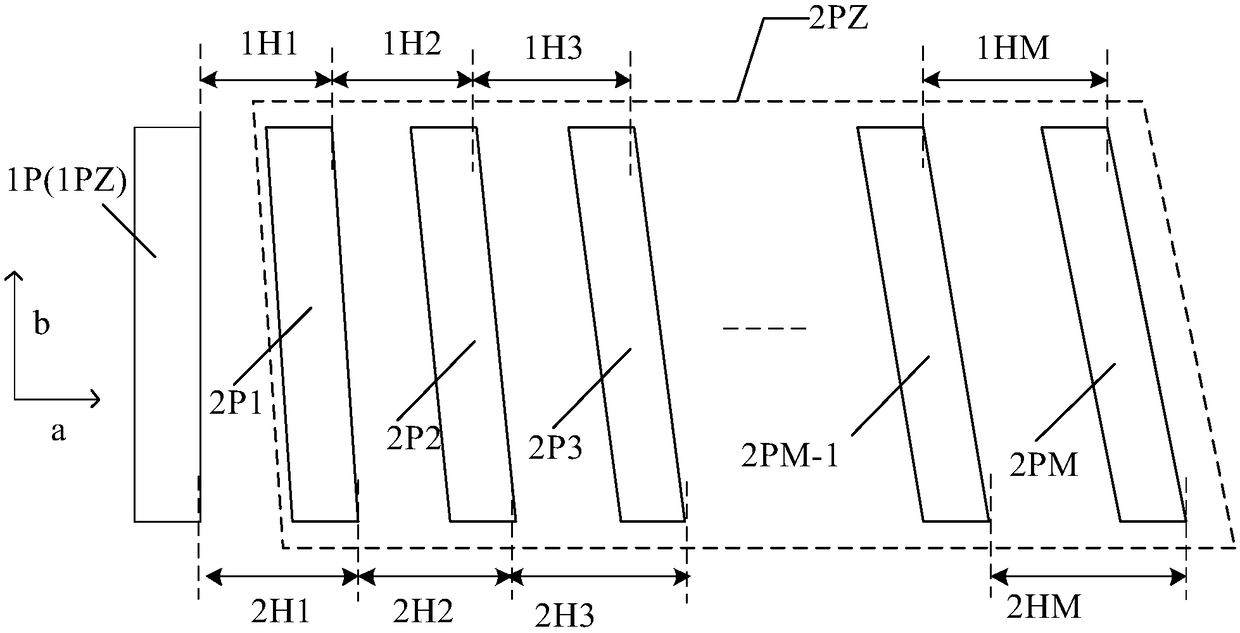

The invention discloses a display device and a chip binding method thereof. The display device comprises a flexible display panel and a chip bound on a non-display region of the flexible display panel. Due to the fact that extension directions of all pins meet the following condition that in each row of pins, at least the pins located on the side region are converged on the same point in a datum line along extension lines at the same end according to the regions of the pins, and the included angles between respective extension lines of the two pins belonging to the same pin set and the datum line are equal. Thus, when the size of the flexible display panel is changed in the first direction, the flexible display panel and the chip can be bound after the relative positions, perpendicular to the first direction, of the flexible display panel and the chip are adjusted, and therefore it is guaranteed that correct alignment of the pins of the chip and the pins of the flexible display panel can be achieved as long as the size change of the flexible display panel in the first direction is within a certain range, and the chip binding yield of the display device is increased.

Owner:BOE TECH GRP CO LTD

Touch control display device

InactiveCN104777943AIncrease the gapImprove curing yieldLaminationLamination apparatusFlexible circuitsUltraviolet lights

The invention discloses a touch control display device. The touch control display device comprises a display flexible circuit board and a touch control flexible circuit board which are bound to different sides of the touch control display device respectively. The touch control display device can effectively enlarge a gap between a seal cover plate and a display panel during adhesion of the seal cover plate, so that ultraviolet light illuminates optical cement more easily, the curing yield of the optical cement is improved, and the follow-up cement overflow defect is avoided. In addition, avoidance of the structures including a black array, a polaroid and the like is designed on a binding area of the touch control flexible circuit board so that the binding state of the touch control flexible circuit board can be monitored under a microscope after binding of the touch control flexible circuit board is completed, and the binding yield is improved.

Owner:BOE TECH GRP CO LTD +1

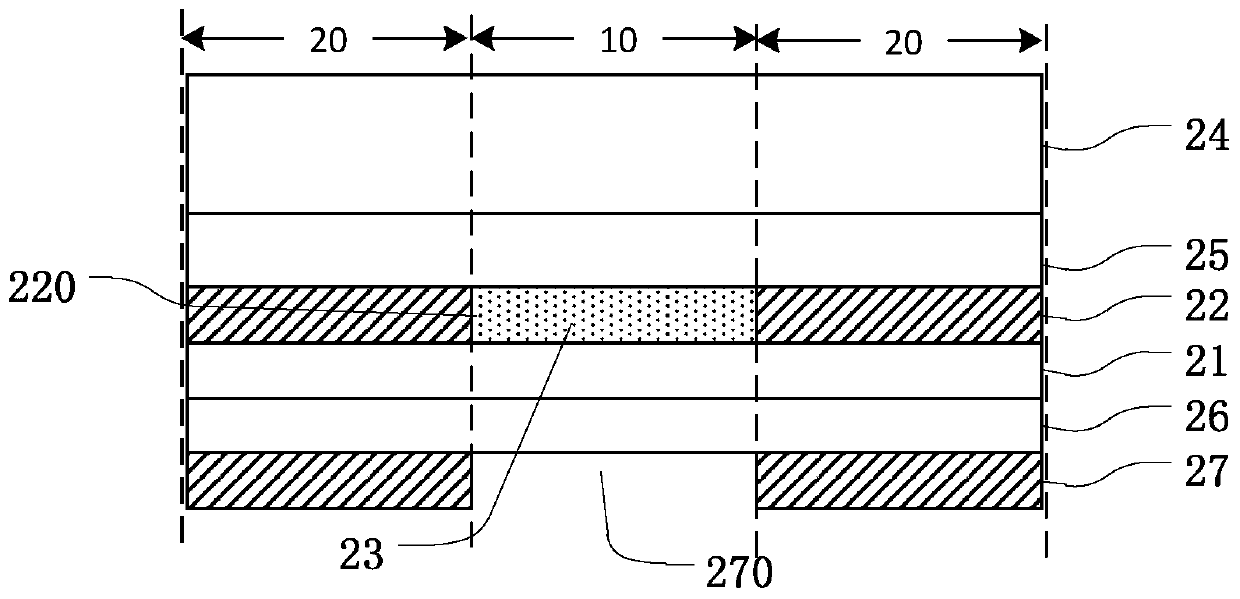

Chip on film, flexible display panel and display device

ActiveCN105720028AAvoid misalignmentImprove bonding yieldStatic indicating devicesSemiconductor/solid-state device detailsChip on filmDisplay device

The invention discloses a chip on film, a flexible display panel and a display device. When a swelling amount of a middle area in a binding area of the flexible display panel is smaller than swelling amounts of areas on both sides, input pad distances in the middle area are smaller than input pad distances in the areas on both sides. In the chip on film disclosed by the invention, output pads positioned in different areas are set into different shapes, namely, the output pads in the middle area are set into shapes to occupy small space while the output pads in the areas on both sides are set into shapes to occupy relatively large space, so that the chip on film can adapt to deformation at different positions in the binding area of the flexible display panel; a compression joint area between the chip on film and the binding area of the flexible display panel is increased; the problem of misalignment between the output pads of the chip on film and input pads in the binding area of the flexible display panel is solved; and a binding yield between the chip on film and the flexible display panel is increased.

Owner:BOE TECH GRP CO LTD

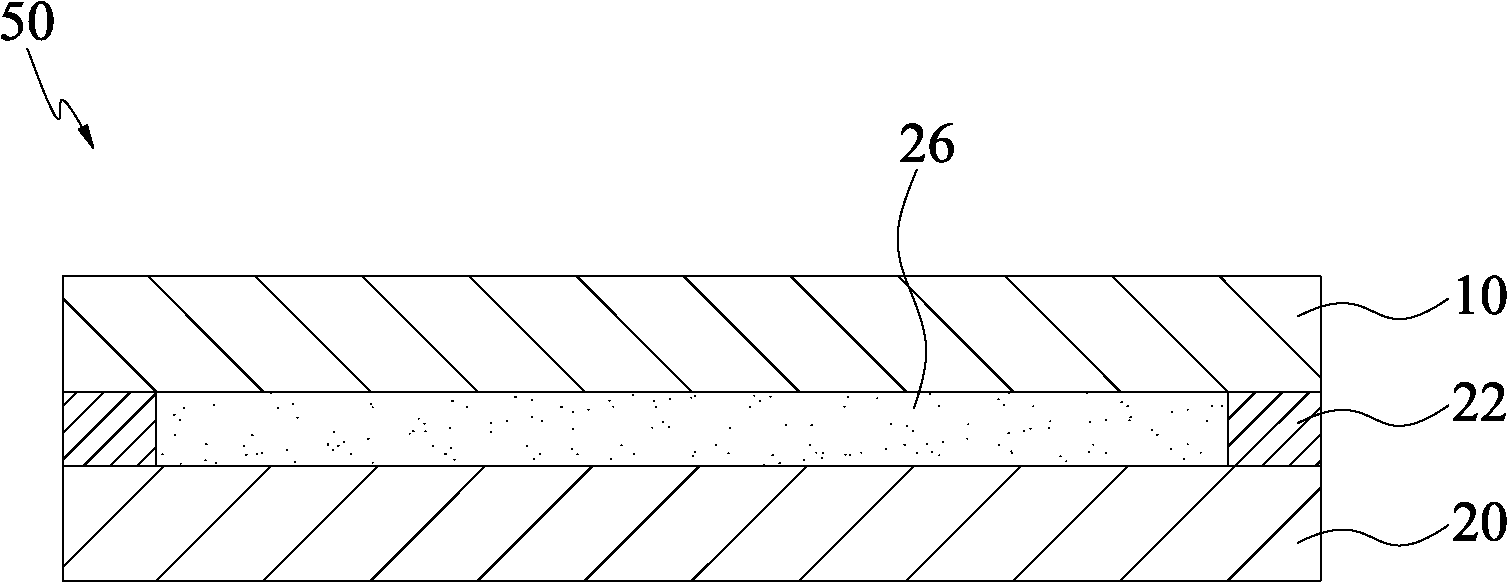

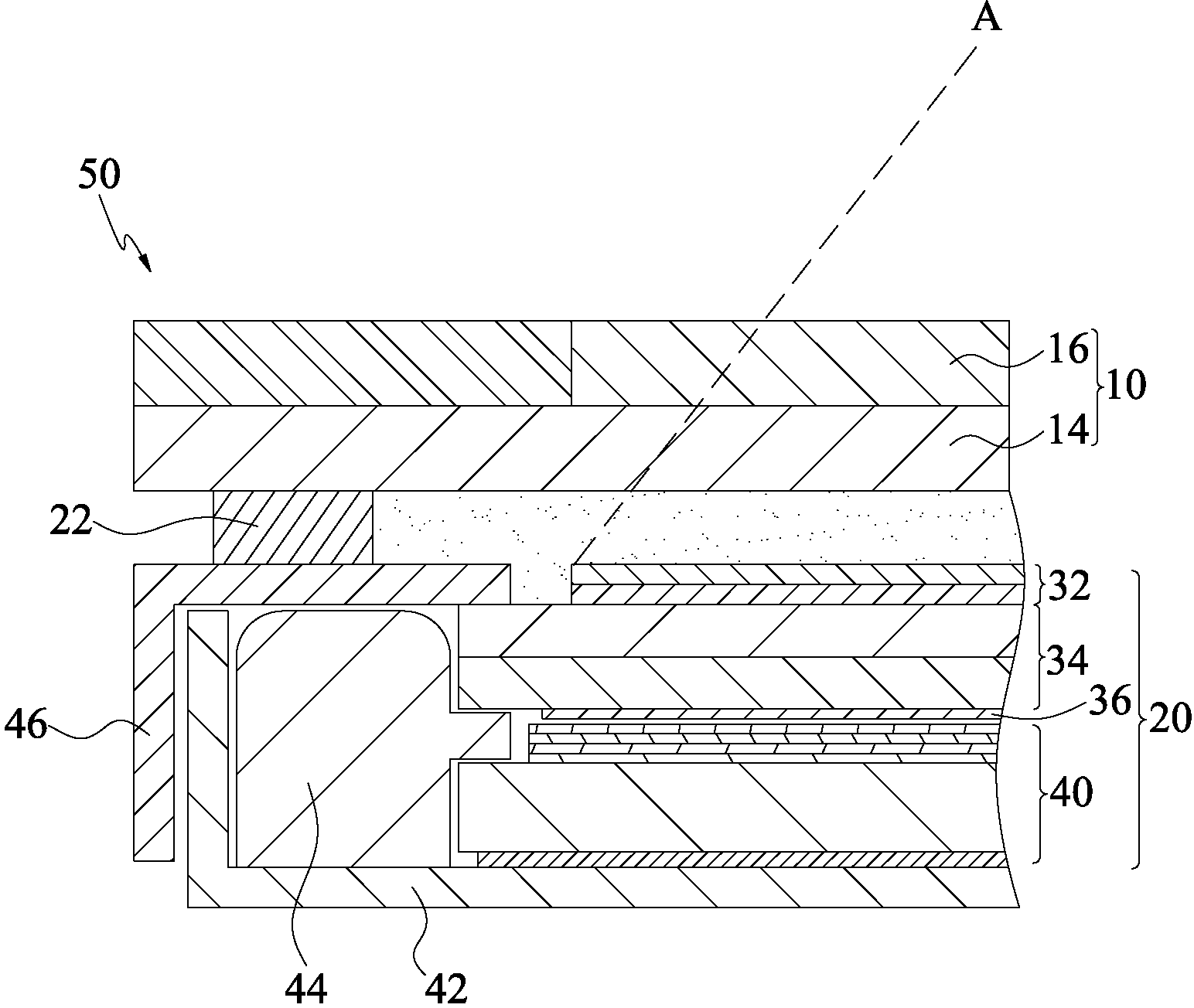

Polaroid, display module, touch control type display device, and manufacturing method thereof

InactiveCN103033867ALight emitting surface is flatImprove bonding yieldStatic indicating devicesSynthetic resin layered productsLiquid-crystal displayDisplay device

The invention discloses a polaroid, a display module, a touch control type display device, and a manufacturing method thereof. The touch control type display device includes a touch control panel; a liquid crystal display module including a liquid crystal panel; an upper polaroid and a lower polaroid which are configured on the first and second surfaces of the liquid crystal panel, wherein the upper Polaroid includes a polarized substrate layer; an adhesive layer which is configured on one surface of the polarized substrate layer and includes a middle area and a periphery area, wherein the middle area and the periphery area are separated from each other, the middle area of the adhesive layer is made of a first optical transparent glue, and the middle area is attached to the liquid crystal panel; a circular frame glue formed between the periphery area of the upper polaroid of the liquid crystal display module and the touch control panel; and a second optical transparent glue fully filled in the circular frame glue. The touch control type display device provided can prevent white bright lines caused by the reflection of the edge residue glue of the upper polaroid, thereby preventing visual difference.

Owner:HANNSTAR DISPLAY CORPORATION

Display device, display backboard and production method

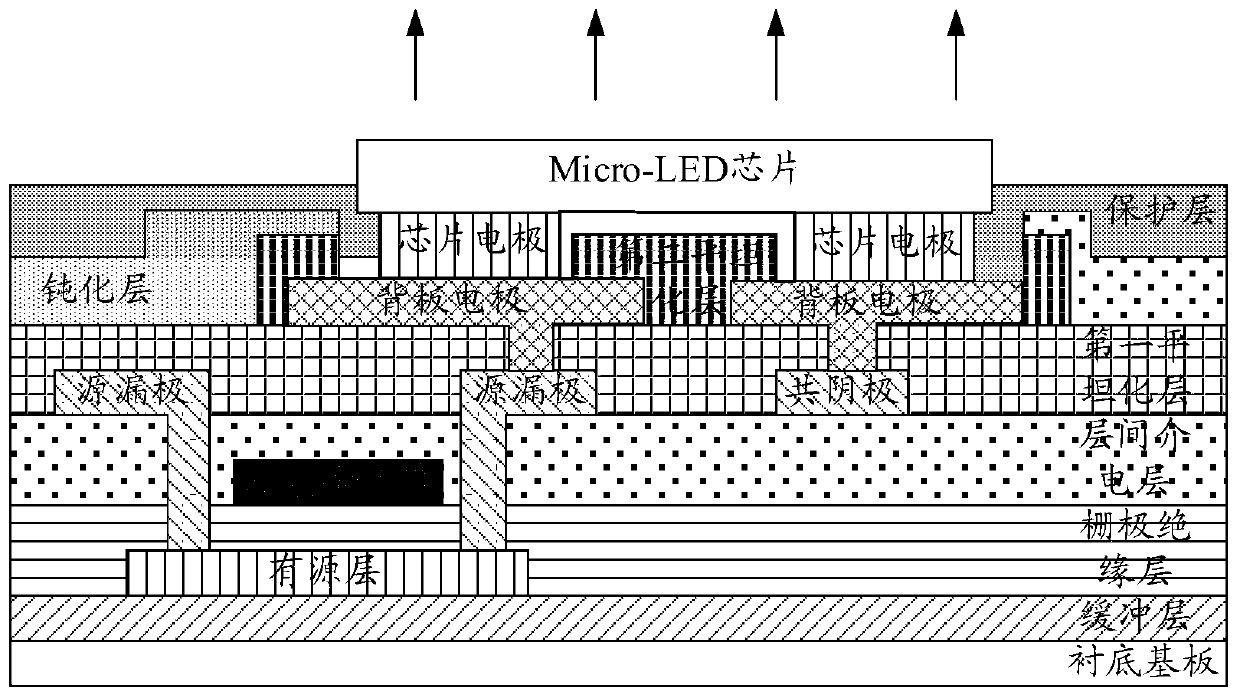

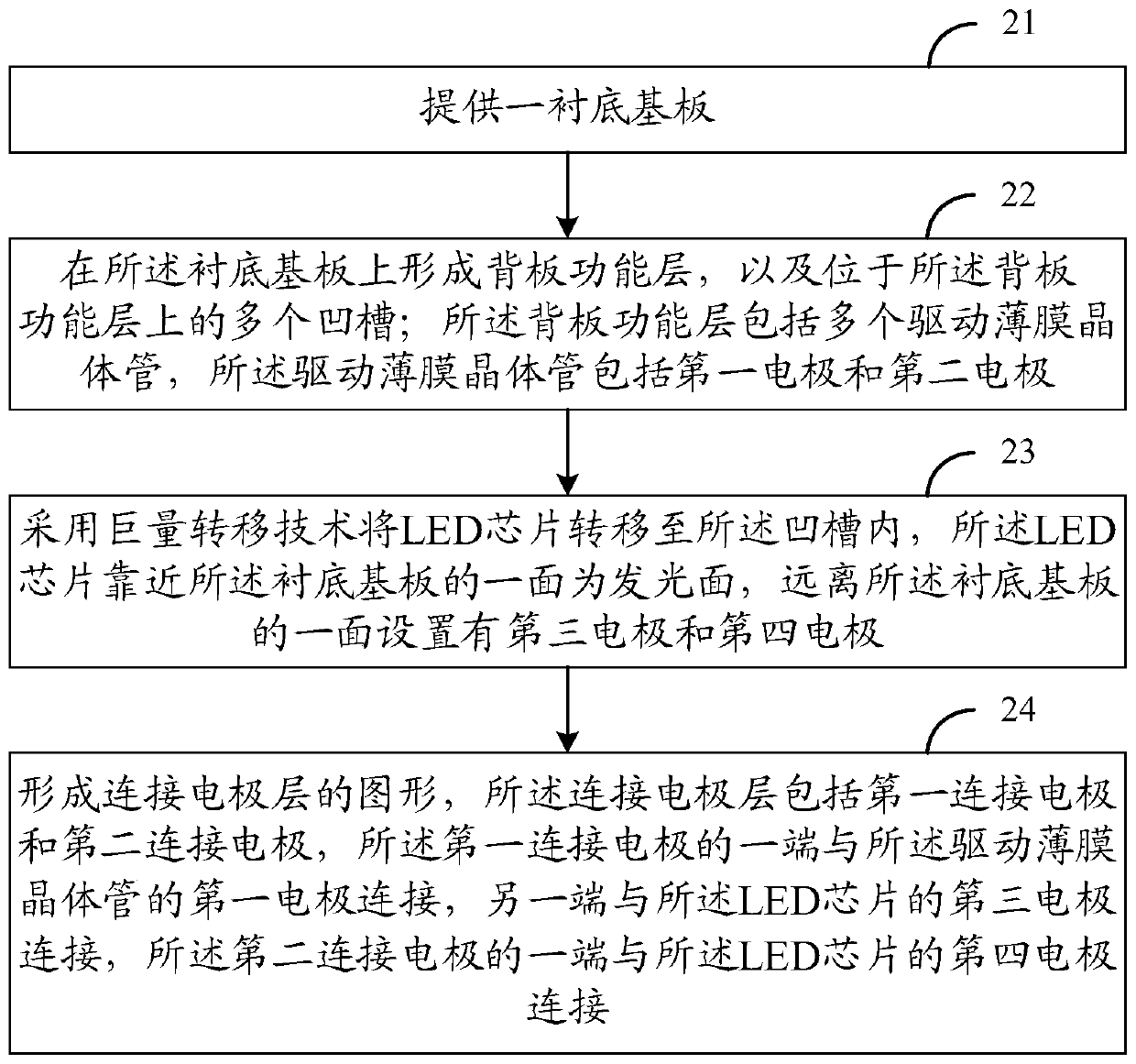

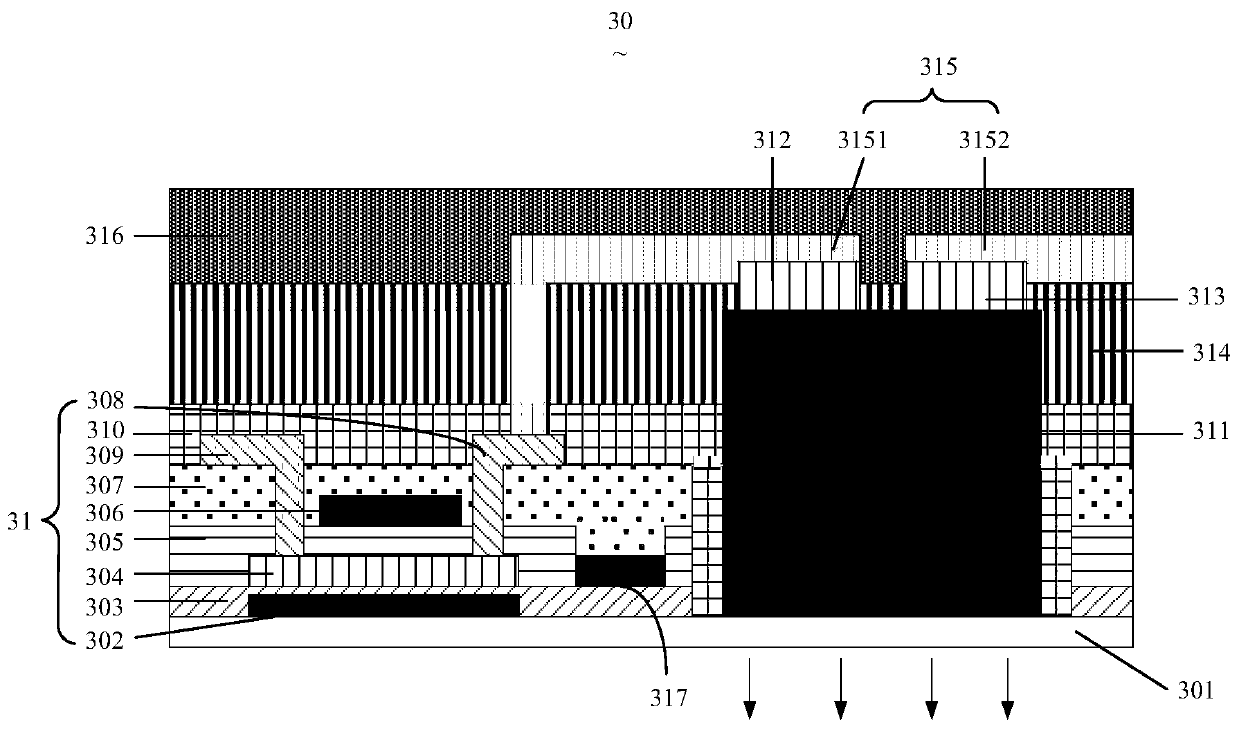

ActiveCN109786421ASimple processImprove binding efficiencySolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention provides a display device, a display backboard and a production method and relates to the technical field of display. The production method comprises the steps of providing a substrate base plate; forming a backboard function layer on the substrate base plate, and forming a plurality of grooves located on the backboard function layer, wherein the backboard function layer comprises aplurality of drive thin film transistors, and the drive thin film transistors comprise first electrodes and second electrodes; transferring LED chips to the grooves through adoption of a mass transfertechnology, wherein faces of the LED chips close to the substrate base plate are light emitting faces, and third electrodes and fourth electrodes are set on the faces of the LED chips away from the substrate base plate; and forming a graph of a connection electrode layer, wherein the connection electrode layer comprises first connection electrodes and second connection electrodes, one end of thefirst connection electrodes is connected with the first electrodes of the drive thin film transistors, the other end is connected with the third electrodes of the LED chips, and one end of the secondconnection electrodes is connected with the fourth electrodes of the LED chips. Binding efficiency and binding yield of the LED chips can be improved, and production cost is reduced.

Owner:BOE TECH GRP CO LTD

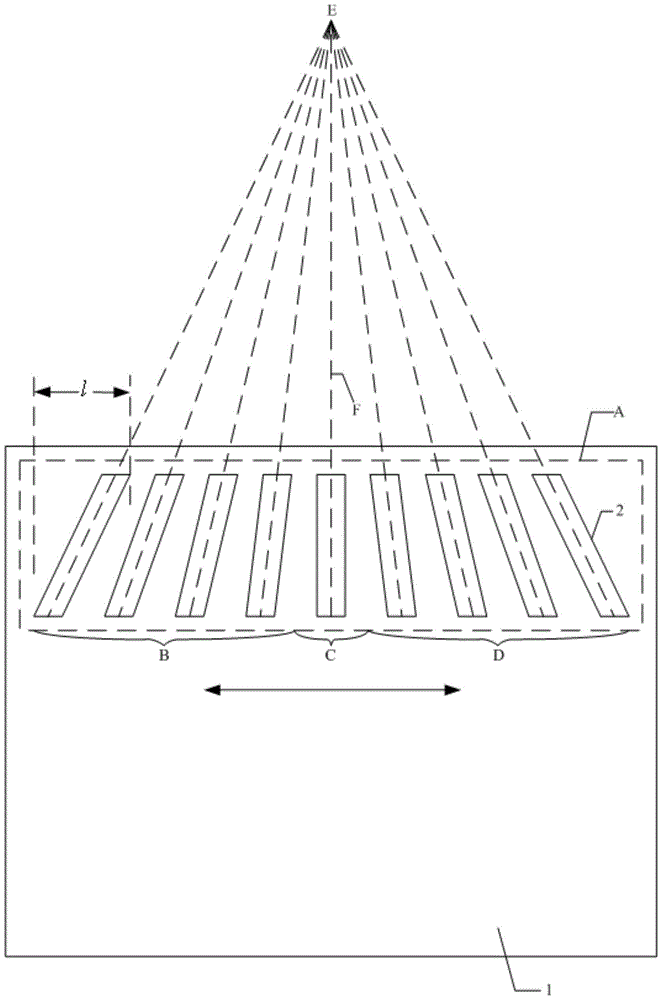

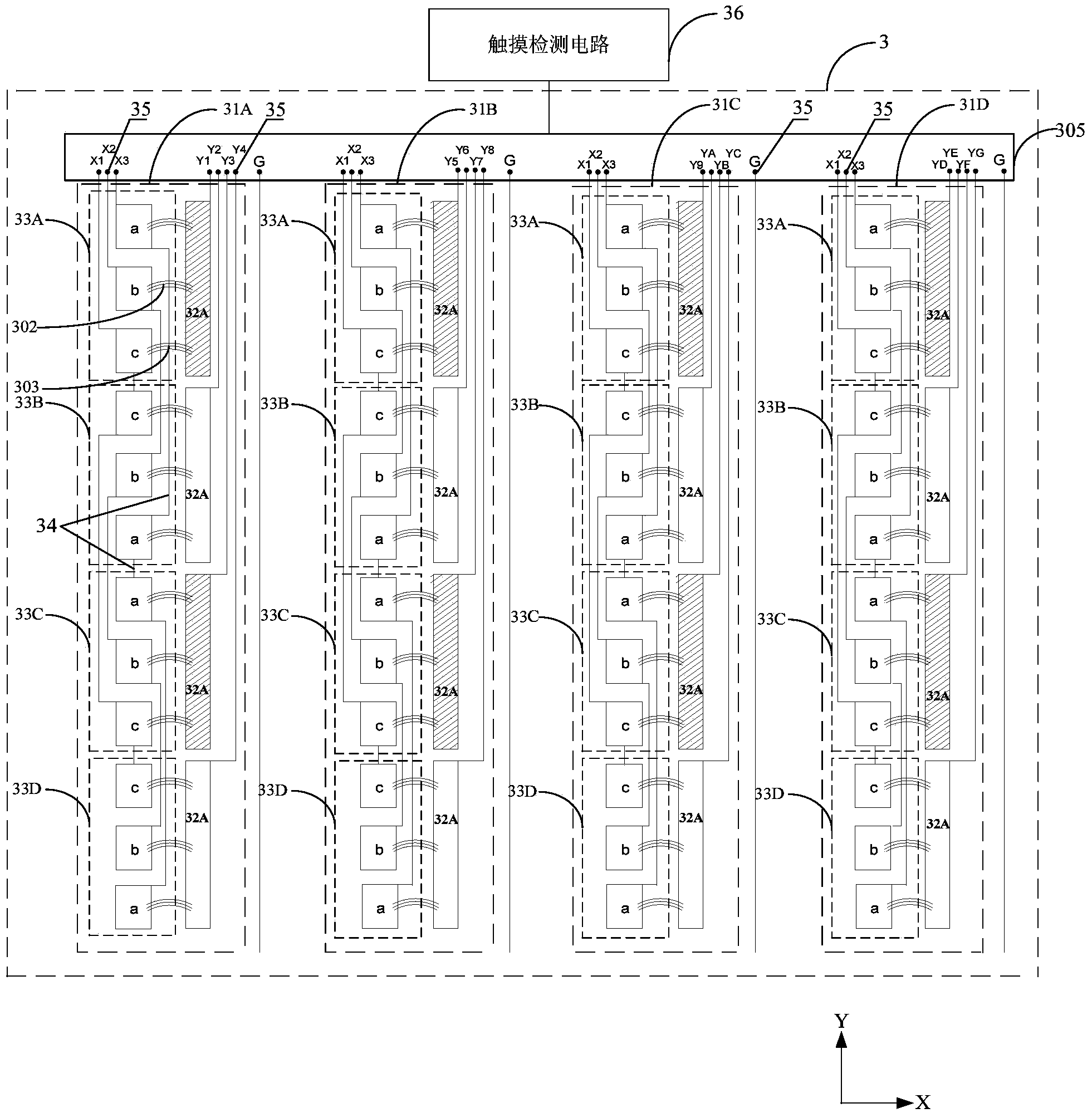

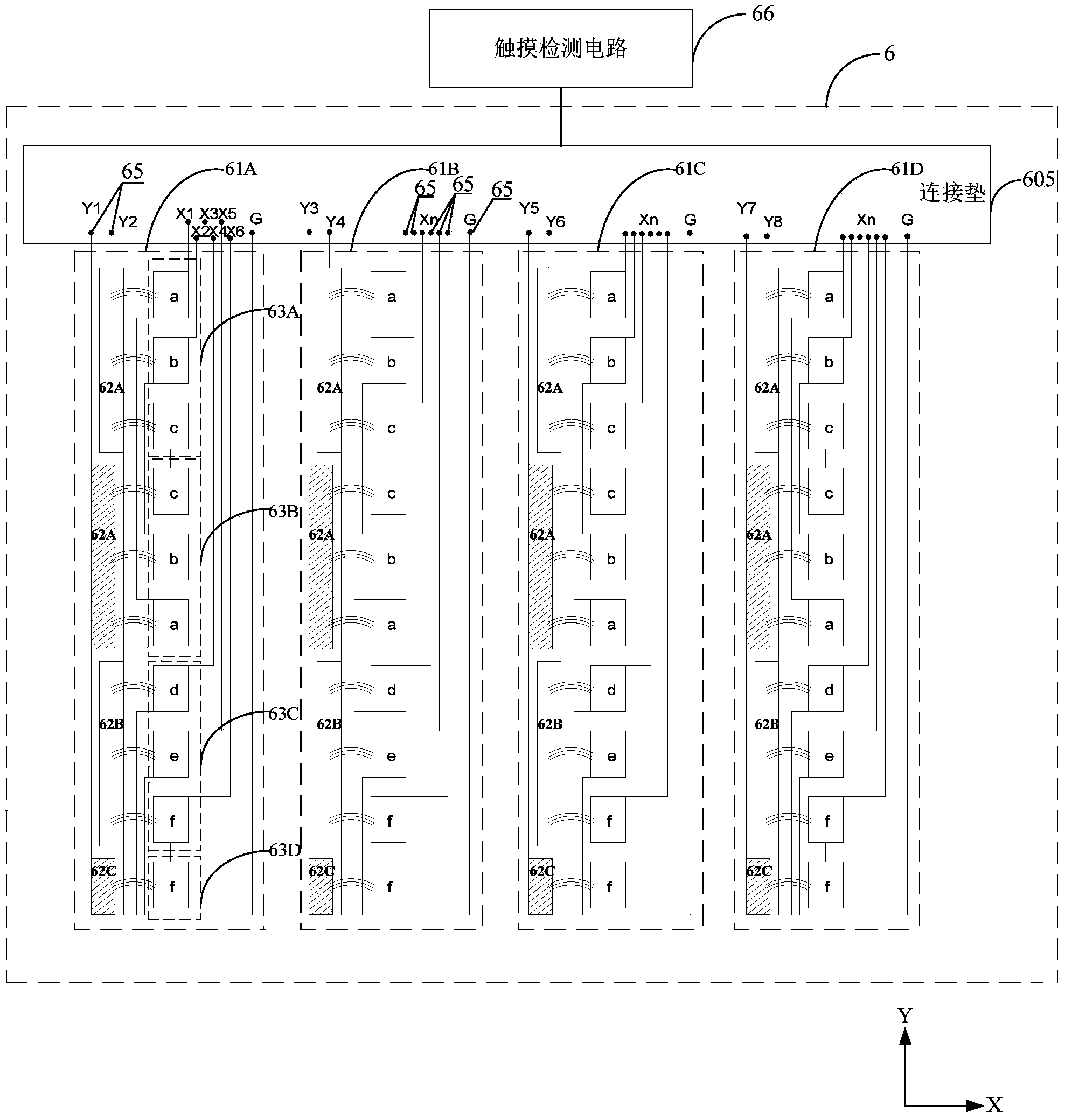

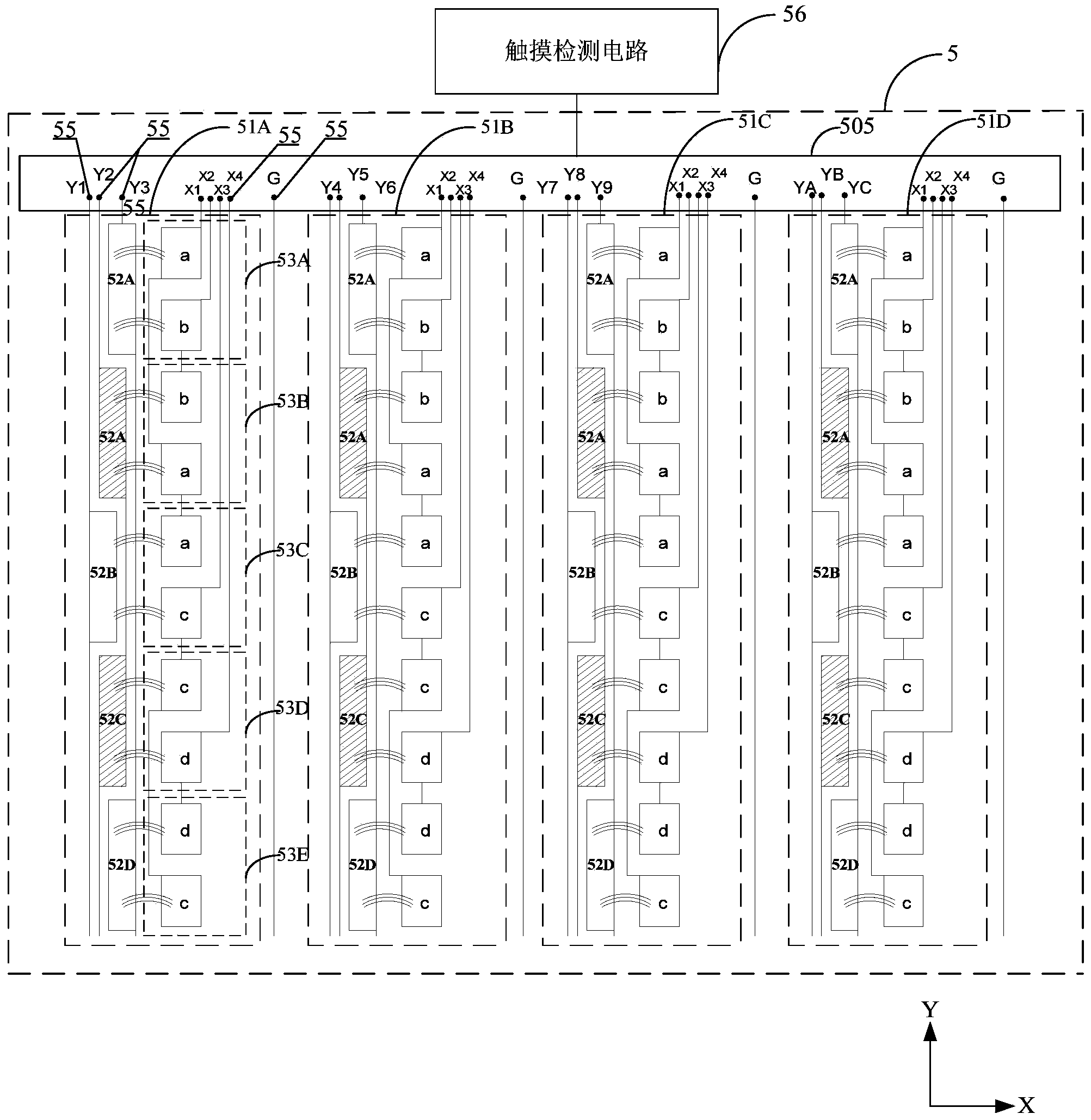

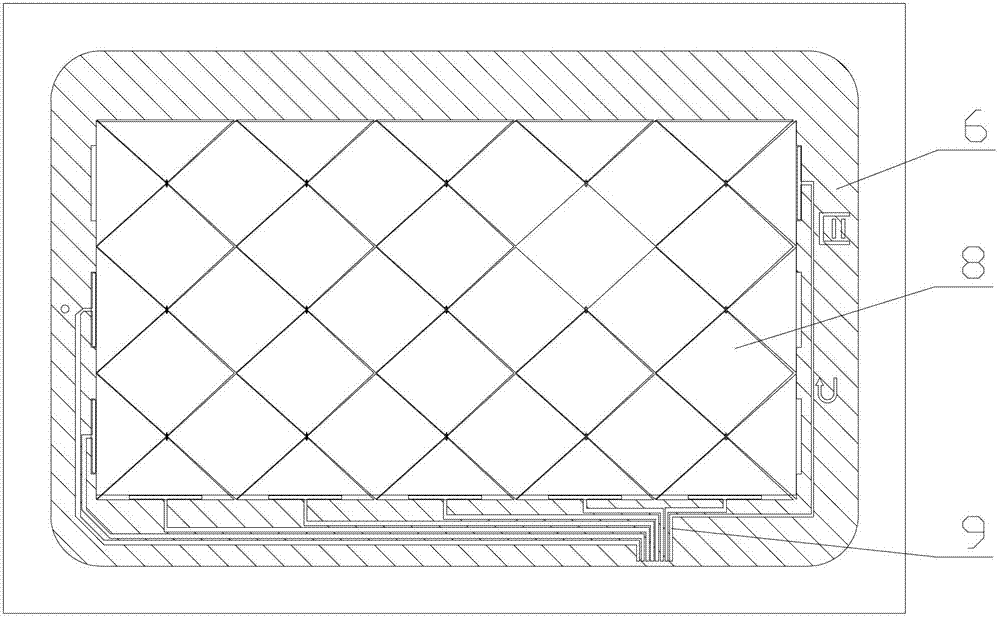

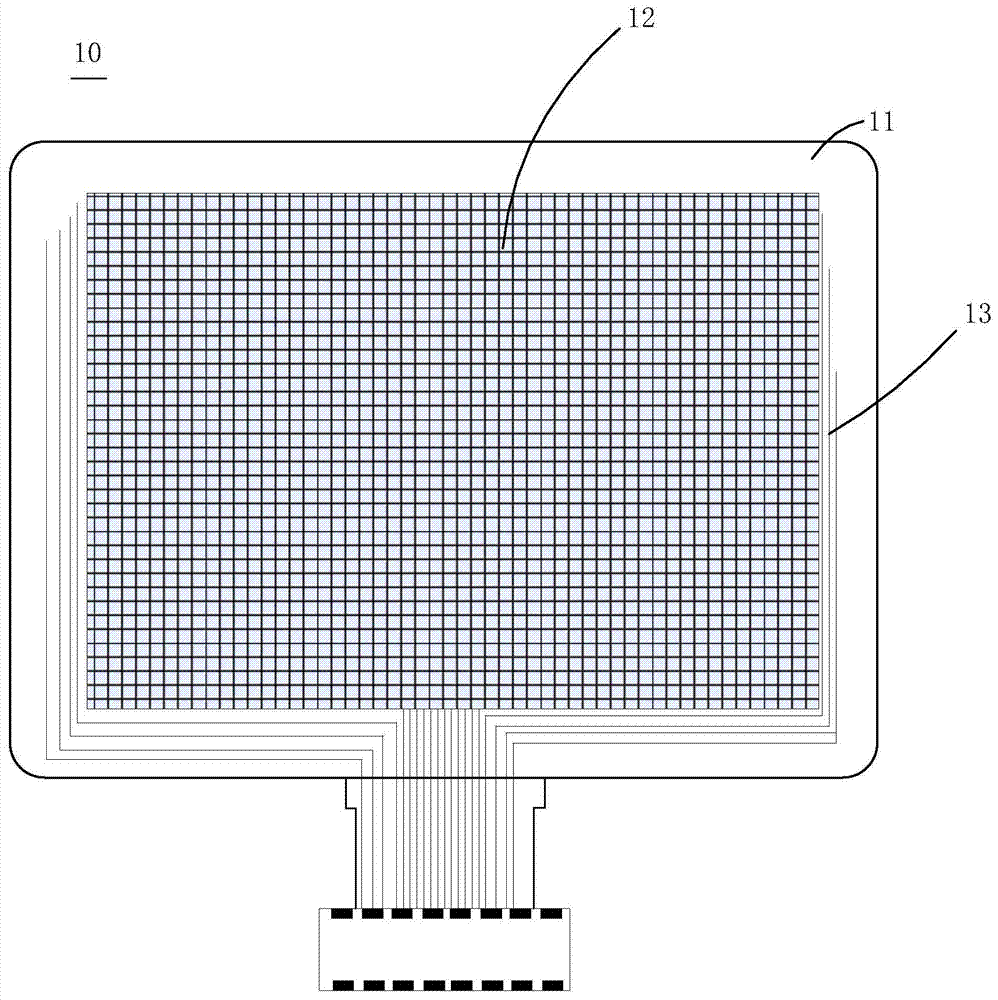

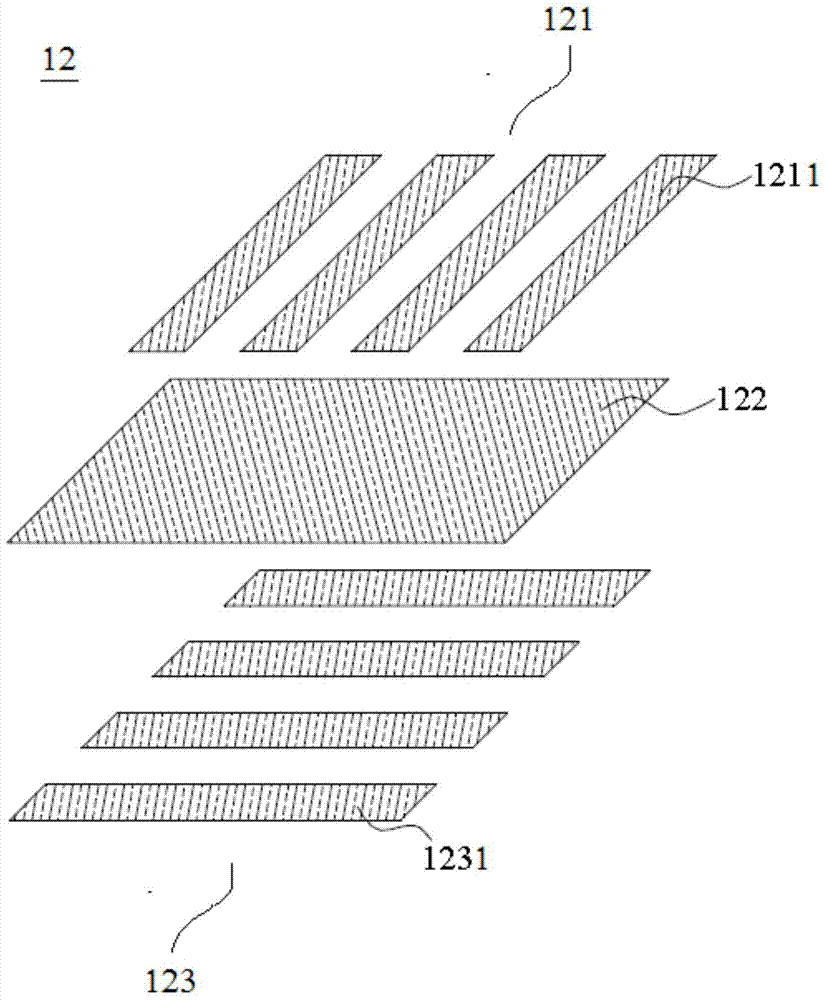

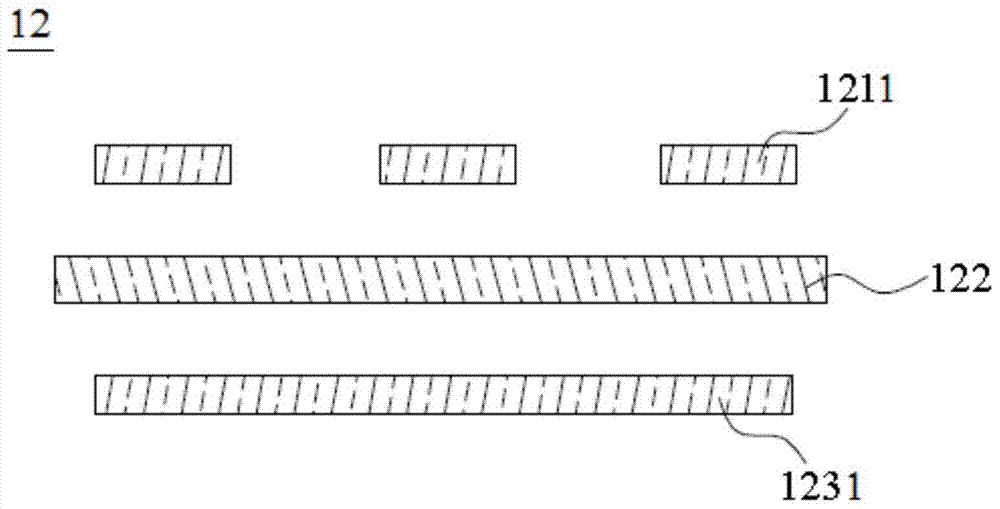

Single-layer mutual capacitance touch screen, touch screen device and equipment

ActiveCN104375725AReduce in quantityReduce areaInput/output processes for data processingPhysicsMutual capacitance

The invention is applied to the field of touch control technologies and provides a single-layer mutual capacitance touch screen, a touch screen device and equipment. The touch screen comprises a binding bonding pad and induction electrode units distributed side by side, wherein the binding bonding pad is connected with a touch detection circuit; each induction electrode unit comprises a first electrode, a first electrode set and a second electrode set, each first or second electrode set comprises a plurality of second electrodes, the first electrode and the second electrodes of each induction electrode unit are coupled to form induction nodes, the first electrodes are connected through first lead wires, and the second electrodes are connected through second lead wires; each first electrode set corresponds to the corresponding first electrode, and each second electrode set corresponds to another first electrode; the second electrodes in the two electrode sets of each induction electrode unit are distributed in a mirror symmetry mode, and each second electrode of each electrode set is connected with the binding bonding pad through a second lead wire. Through arrangement and combination of drive electrodes and reception electrodes, the number of leads and the number of PADs to be bound are reduced, the binding yield is increased, linearity, precision and reliability of binding are improved, and the area and cost of an FPC are reduced.

Owner:ORISE TECHNOLOGY CO LTD

Method of forming an interconnect structure for a semiconductor device

InactiveUS20070042596A1Improve thermal conductivityImprove bonding yieldSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectDevice material

Owner:MICRON TECH INC

Manufacturing method of OGS touch screen

ActiveCN103257746ANot afraid of scratchesSimple processInput/output processes for data processingSputteringSilver paste

The invention discloses a manufacturing method of an OGS touch screen. The manufacturing method comprises the following steps: a. a shadow-removing layer is sputtered on the back of a glass substrate through the method of vacuum coating; b. a conductive layer is sputtered on the back of the shadow-removing layer through the method of vacuum coating; c. an electrode pattern and driving routings are manufactured through an exposure process or a silkscreen process; d. an ink layer for covering the routings is printed on the back of the glass substrate, and thus an outer frame pattern is formed; e. a conductive ink layer is printed on a blank area of a conductive metal foot; f. silver pasted lines are printed on the conductive ink layer; g. the shape of the touch screen is processed, PFC lead feet are pasted on the silver pasted lines, and thus the touch screen is finished. According to the manufacturing method of the OGS touch screen, the conductive layer is arranged on the surface of the glass substrate directly, the conductive ink is conducted, therefore, the problems of breakage of the coating film layers caused by coating film steps and breakage of the FPC hot-pressed conducting layer are solved, the gluing yield is improved, and the touch screen is durable.

Owner:SUN VIEW TECH HUIZHOU CO LTD

Liquid crystal display panel

ActiveCN110888276AIncrease electrical contact areaImprove bonding yieldNon-linear opticsLiquid-crystal displayColor film

The invention provides a liquid crystal display panel. The conductive frame adhesive is arranged between a plurality of terminals of an array substrate and a color film substrate, chip-on films are bound on side surfaces of the conductive frame adhesive and terminals in the thickness direction so as to increase the electrical contact area when the chip-on films are bound, and thereby the binding yield of the chip-on films is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

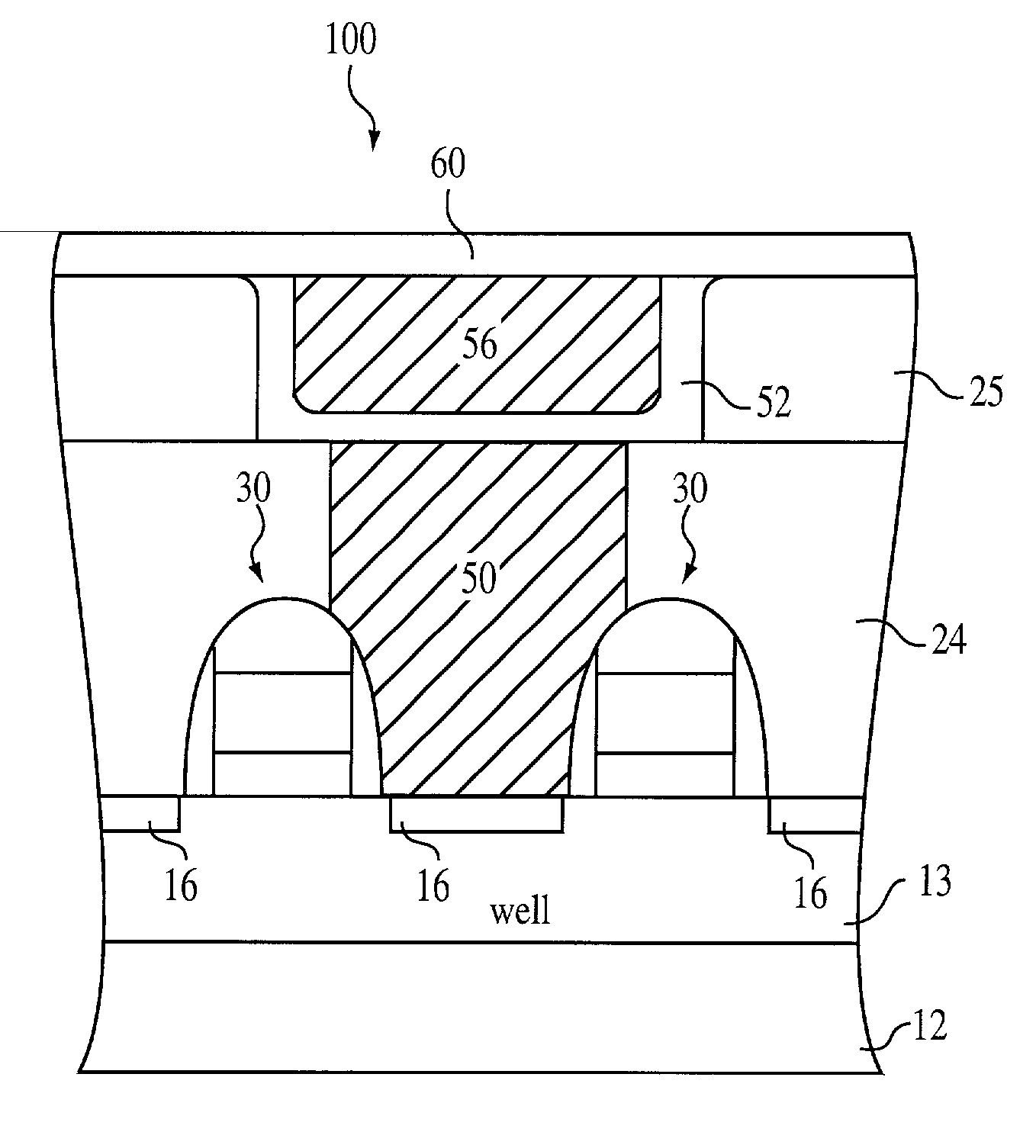

Method of forming a multi-layered copper bond pad for an integrated circuit

InactiveUS6841478B2Improve bonding yieldImprove contact adhesionSemiconductor/solid-state device detailsSolid-state devicesNitrogenSolder ball

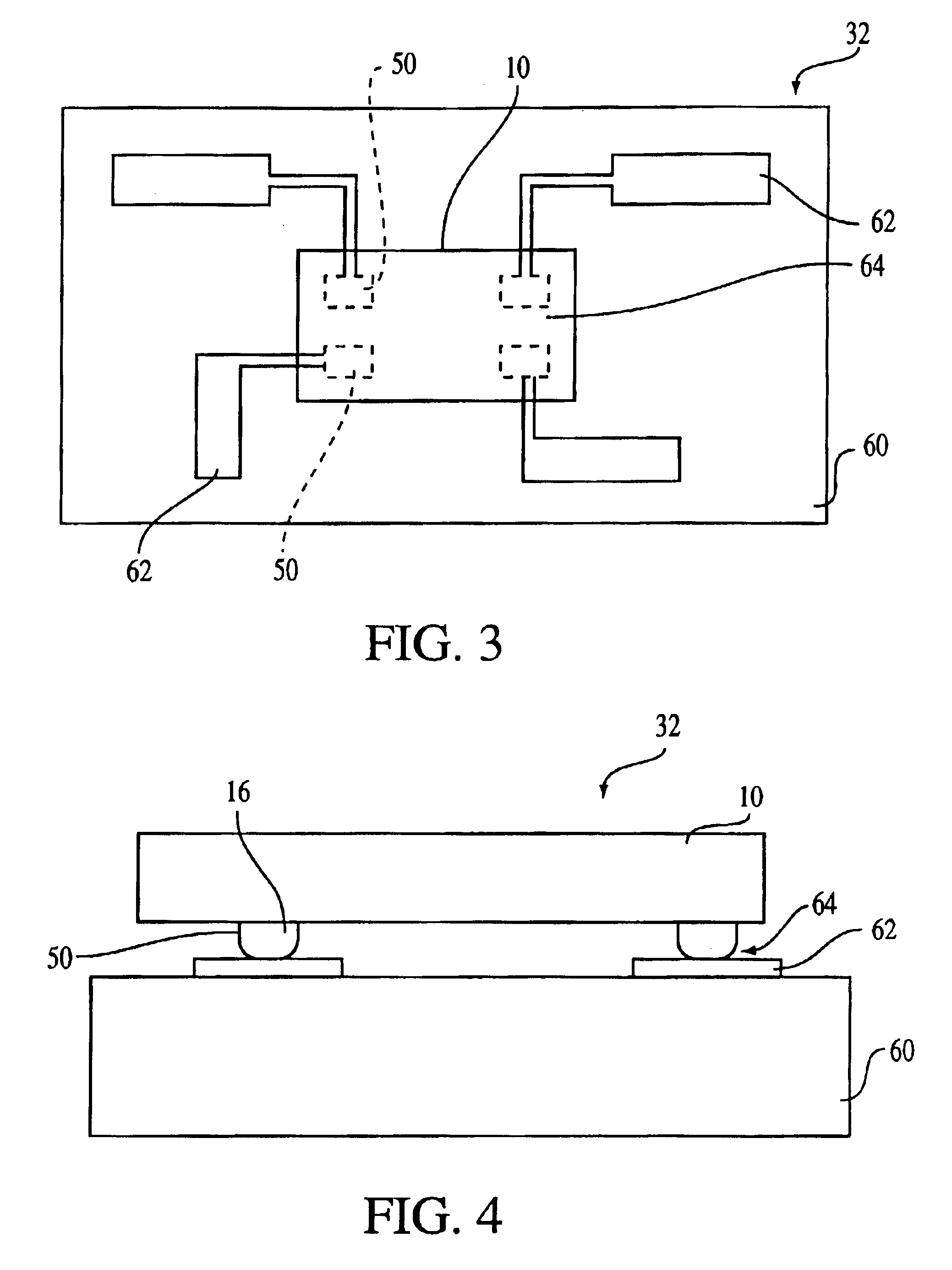

A multi layered copper bond pad for a semiconductor die which inhibits formation of copper oxide is disclosed. A small dose of titanium is implanted in the copper surface. The implanted titanium layer suppresses the copper oxide growth in the copper bond pad by controlling the concentration of vacancies available to the copper ion transport. An interconnect structure such as a wire bond or a solder ball may be attached to the copper-boron layer to connect the semiconductor die to a lead frame or circuit support structure. In another embodiment, a titanium-aluminum passivation layer for copper surfaces is also disclosed. The titanium-aluminum layer is annealed to form a titanium-aluminum-copper alloy. The anneal may be done in a nitrogen environment to form a titanium-aluminum-copper-nitrogen alloy.

Owner:MICRON TECH INC

Production method of temperature-resistant pressure-resistant capacitive touch screen panel

InactiveCN102830871AReduce manufacturing costImprove absorption rateInput/output processes for data processingCapacitanceFlexible circuits

The invention discloses a production method of a temperature-resistant pressure-resistant capacitive touch screen panel. The production method includes the steps: firstly, cleaning and drying a glass substrate; secondly, forming a removable local shade layer; thirdly, vacuum-plating a black titanium carbide film or black titanium carbonitride film; fourthly, vacuum-plating a silica film on the surface of the titanium carbide film or titanium carbonitride film; fifthly, removing the local shade layer and the portions of the films thereon to obtain the glass substrate with a metal film wire black-film masking frame and a transparent visual area; sixthly, on the back of the glass substrate, forming a transparent ITO (indium tin oxide) conducting film on the transparent visual area, forming a metal film wire connected with the transparent ITO conducting film on the black film masking frame, and forming an OC (over coat) protective layer on the metal film wire; and seventhly, forming the touch screen panel. The temperature-resistant pressure-resistant capacitive touch screen panel is capable of effectively resisting high temperature and high pressure, bonding yield of the touch screen panel and a flexible circuit board is increased, and production cost of OGS (one glass solution) capacitive touch screen modules is reduced greatly.

Owner:WUHU TOKEN SCI

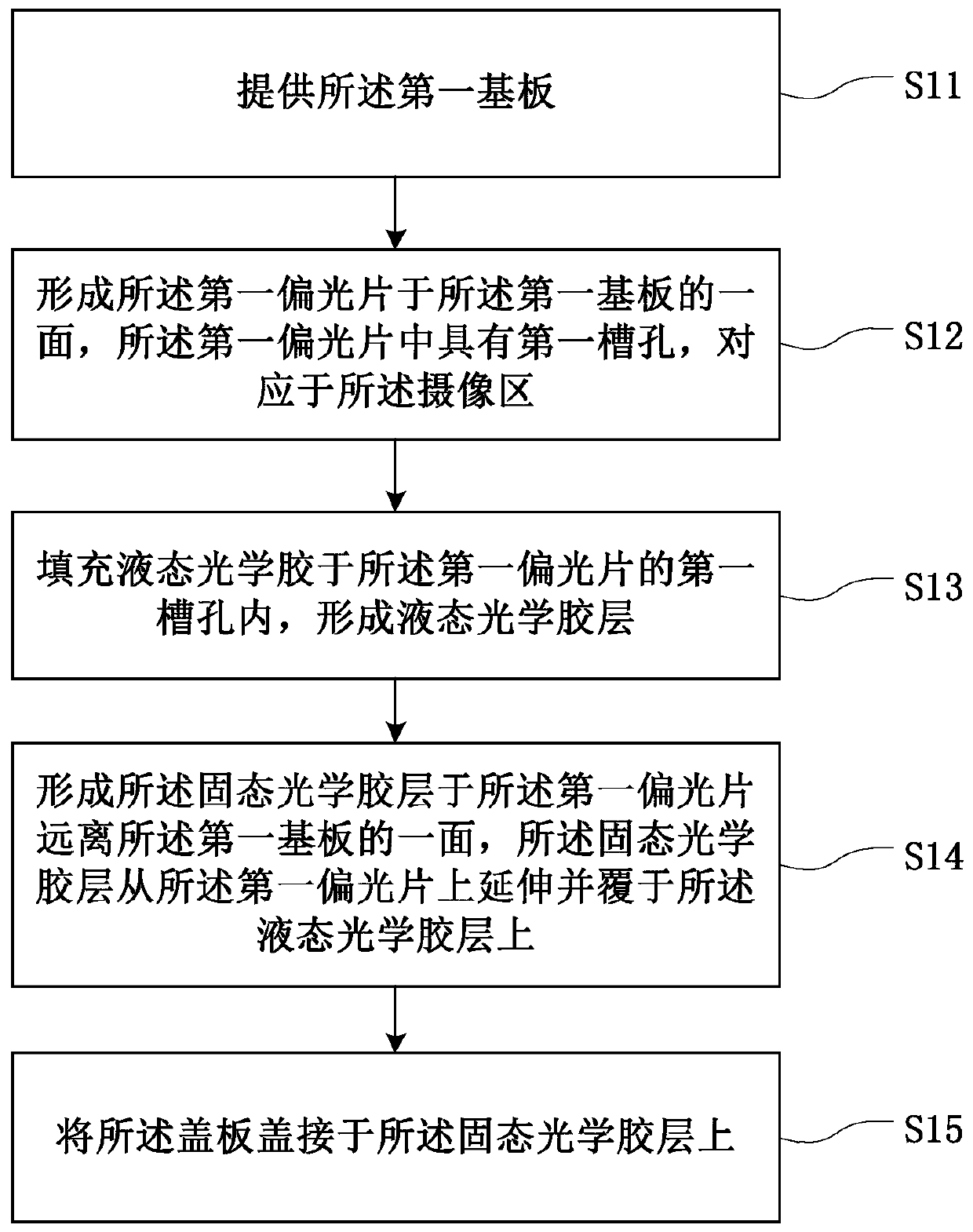

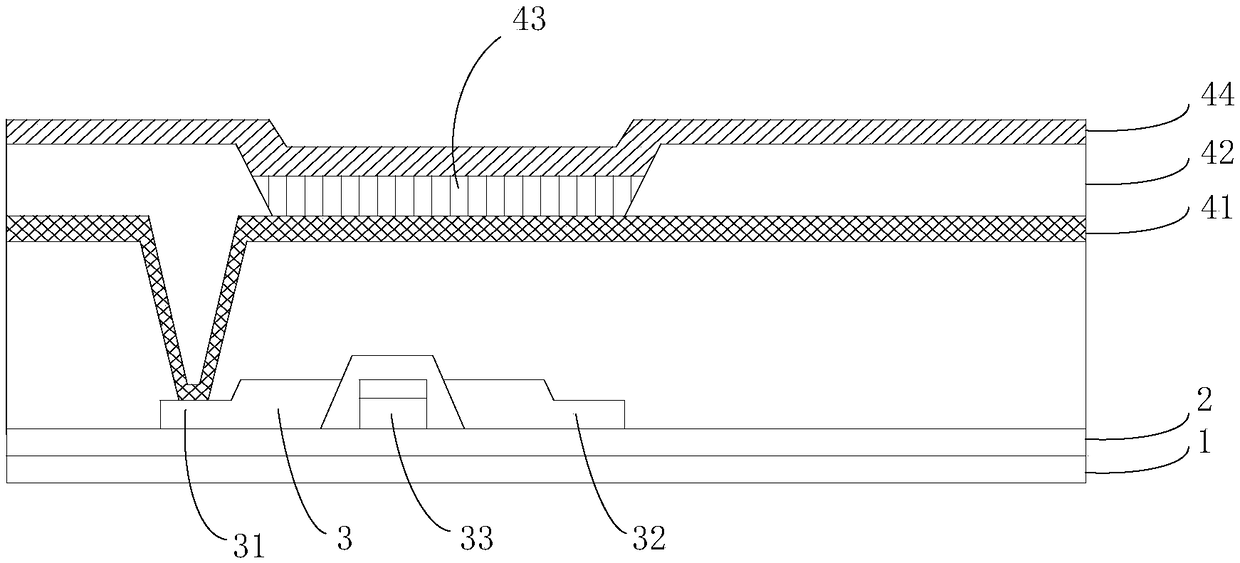

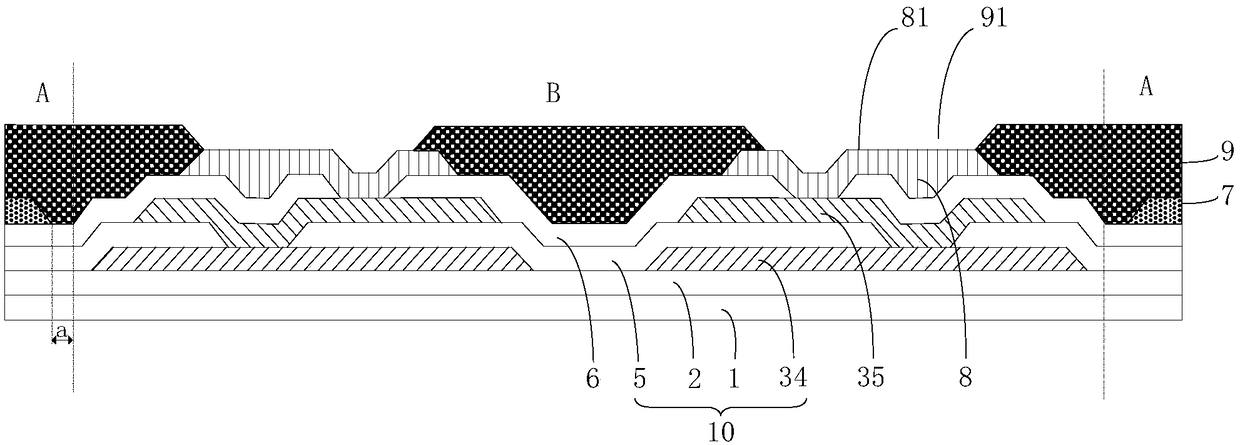

Display panel and preparation method thereof

InactiveCN110908163AImprove qualityIncrease absorbanceTelevision system detailsColor television detailsTransmittanceEngineering

The invention provides a display panel and a preparation method thereof. The display panel comprises a camera shooting area, a display area surrounding the camera shooting area, a first substrate, a first polarizer, a liquid optical adhesive layer, a cover plate and a solid optical adhesive layer. The first polaroid is arranged on one surface of the first substrate; the first polaroid is providedwith a first slotted hole corresponding to the camera shooting area; the first slotted hole is filled with the liquid optical adhesive layer; the cover plate is connected to the face, away from the first substrate, of the first polaroid in a covering mode. The solid optical adhesive layer is at least arranged between the cover plate and the first polaroid. The invention has the technical effects;according to the display panel and the preparation method thereof provided by the invention, the liquid optical adhesive is used for replacing the solid optical adhesive to fill the slotted hole of the corresponding camera shooting area, so that the phenomenon of bubbles when the slotted hole is filled with the solid optical adhesive is avoided, the laminating yield is improved, the light absorption rate of the optical adhesive at the slotted hole is improved, the light transmittance of the camera shooting area is improved, and the quality of the display panel is further improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Display panel and display device

ActiveCN109309101AIncrease the exposed areaIncrease the number ofSolid-state devicesSemiconductor devicesDisplay deviceOrganic layer

The invention provides a display panel and display device. The display panel includes a display area and a bonding area connected to the display area; the bonding area includes a substrate layer set,first metal layers formed on the substrate layer set, passivation layers formed on the first metal layers, second metal layers formed on the passivation layers, and protective layers formed on the second metal layers; the second metal layers are electrically connected to the first metal layers through the contact holes in the passivation layers; the protective layers have multiple through holes; and the parts of the second metal layers corresponding to the through holes are exposed to form multiple contact electrodes. Through the large area etching on first organic layers, third connection electrodes can have larger bare areas, and therefore, bonding areas can be enlarged, the number of ACF particles can be increased, bonding resistance can be reduced, and the yield rate of bonding can beimproved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Electronic assembly and display device

ActiveCN108470727AEffective correction of alignment deviationImprove stabilitySemiconductor/solid-state device detailsSolid-state devicesDisplay deviceStructural engineering

The invention relates to an electronic assembly and a display device; the electronic assembly comprises a first binding zone and a second binding zone mutually matched; the first and second binding zones respectively comprise a plurality of first and second pins arranged at intervals, wherein the first pin has a first end and a second end, and the second pin has a third end and a fourth end; in the arrangement direction of the first pins, a first distance between the most outer sides of two first ends of the two most outer first pins is smaller than a second distance between the most outer sides of the two second ends; a first width ratio is formed between the first and third ends of at least one corresponding first pin and second pin, and a second width ratio is formed between the secondand fourth ends, wherein the first width ratio and the second width ratio are different. The contraposition deviations between the plurality of first and second pins can be effectively rectified; theavailable binding zone is relatively large in area, thus greatly improving the binding yield rate.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

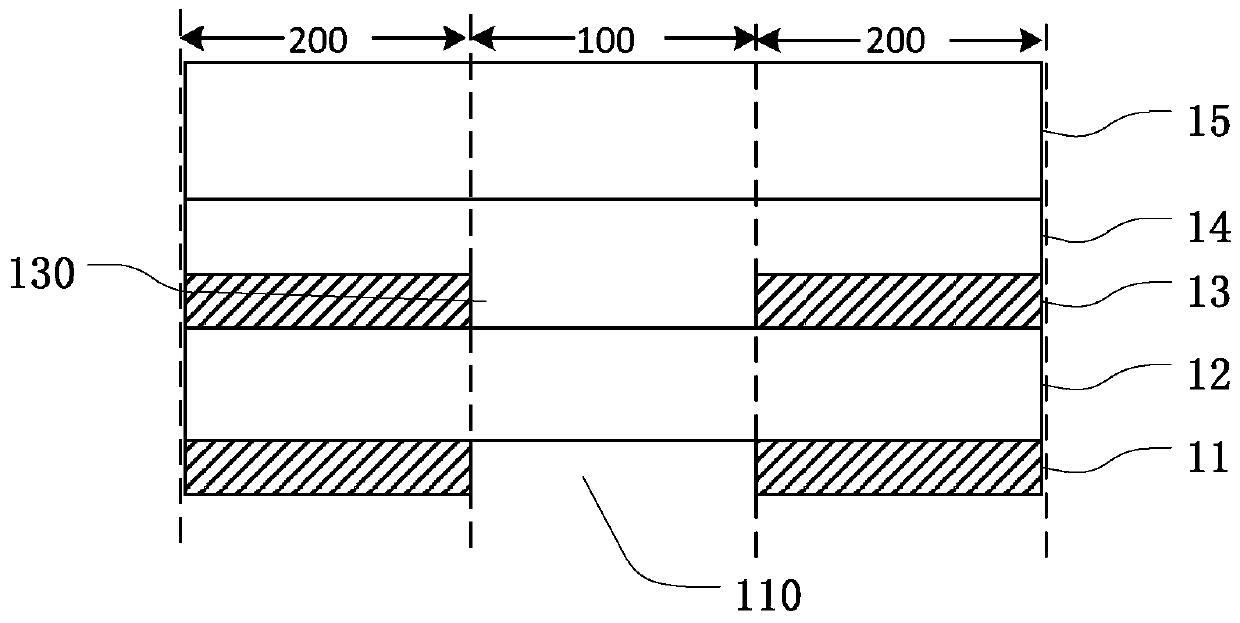

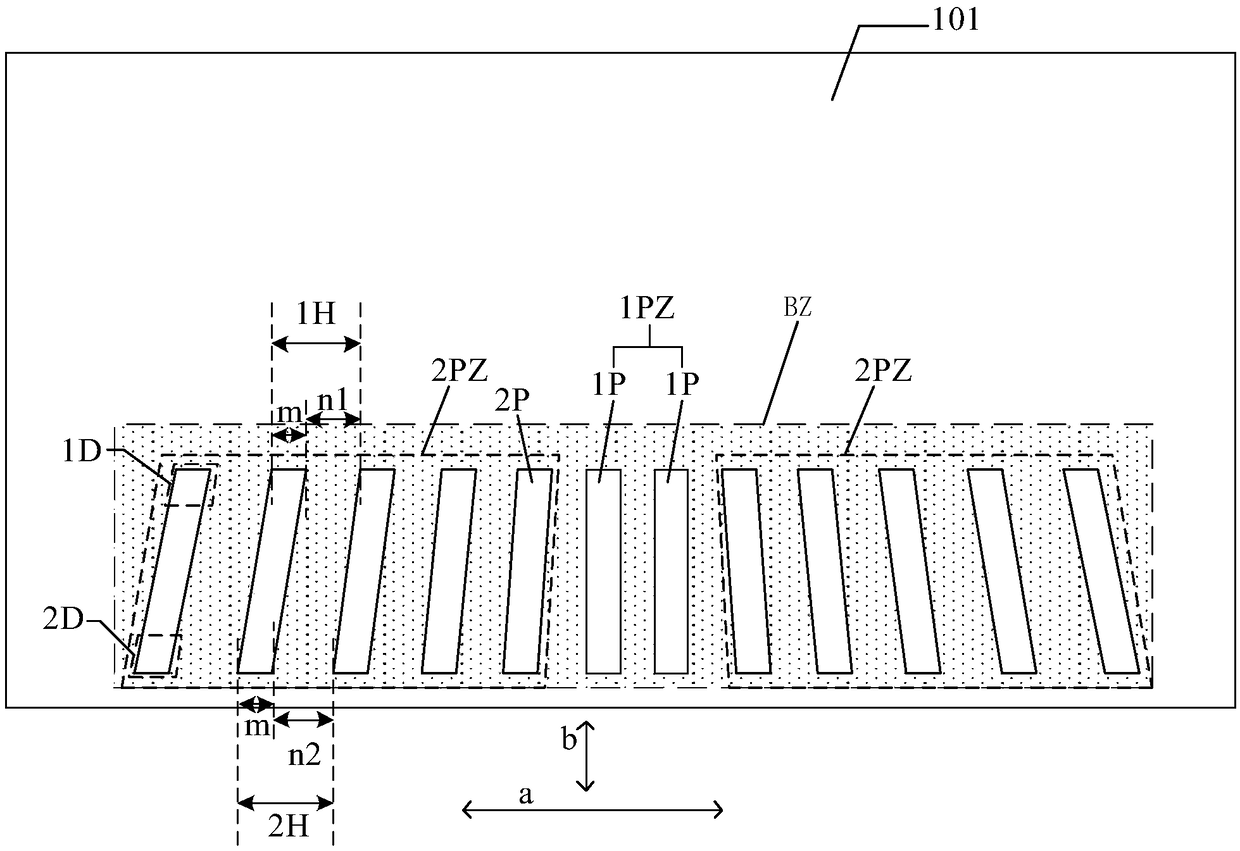

Display panel, flexible circuit board and display module

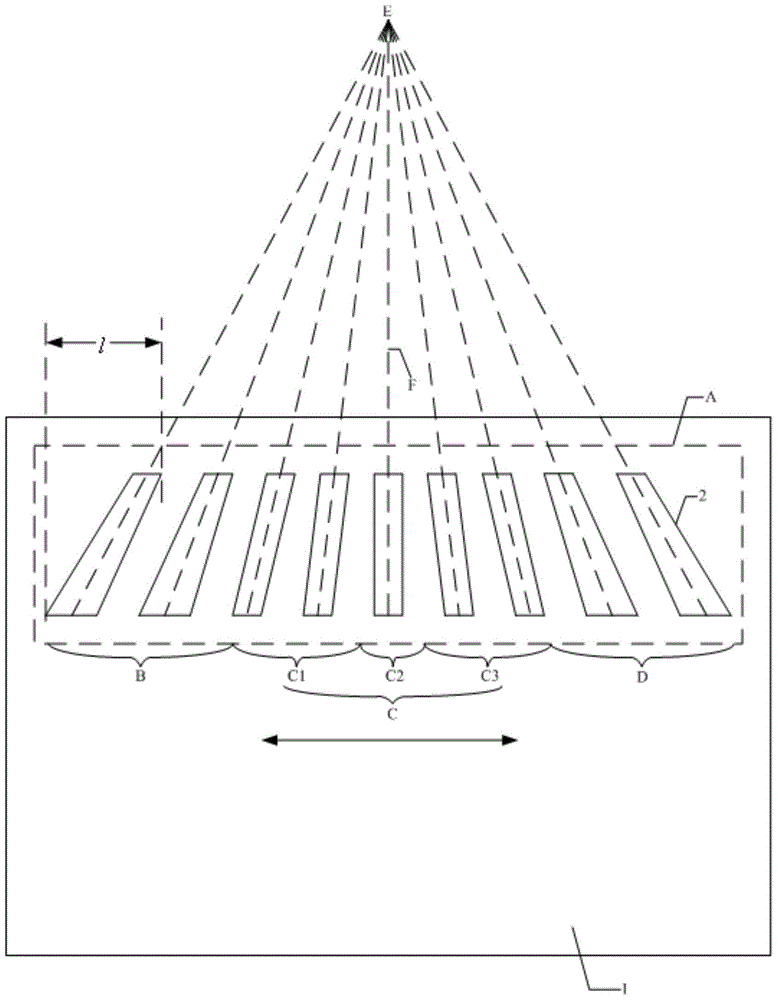

ActiveCN109451660AReduce misalignmentImprove bonding yieldSemiconductor/solid-state device detailsPrinted circuit aspectsFlexible circuitsDislocation

The invention discloses a display panel, a flexible circuit board and a display module. The display panel comprises a substrate and at least one row of input bonding pads arranged in a first direction, arranged in a binding region of the substrate; the first input bonding pads extend in a second direction; the second input bonding pads form second input bonding pad groups; the two second input bonding pad groups are located on the two sides of a first input bonding pad group respectively; each input bonding pad comprises a first end and a second end; an interval between any two adjacent inputbonding pads includes a first interval and a second interval; in each second input bonding pad group, the first interval and the second interval between the two adjacent second input bonding pads arenot equal; the first input bonding pad groups point to the second input bonding pad groups; and from the first input bonding pads and the second input bonding pads, which are adjacent, the first intervals are gradually increased in sequence, and the second intervals are gradually increased in sequence. The dislocation between the input bonding pads and output bonding pads in the binding process can be effectively reduced, thereby improving the binding yield.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

OGS (one glass solution) capacitive touch screen and method for manufacturing same

InactiveCN103294313ASufficient and secure connection conductionMeet the appearance qualityInput/output processes for data processingSilver pasteScreen printing

The invention discloses an OGS (one glass solution) capacitive touch screen and a method for manufacturing the same. The method for manufacturing the OGS capacitive touch screen includes chemically strengthening the surfaces of a glass substrate, and then coating a transparent conducting film layer on one surface of the glass substrate; etching a circuit on the transparent conducting film layer to obtain a conducting glass substrate with distributed conducting film layer patterns; performing screen printing on positions, except for small conducting holes, of a frame by insulating printing ink, curing the printing ink and forming a black insulating film layer; performing screen printing on the small conducting holes by conducting printing ink and nano-silver paste; adhering the nano-silver paste with a flexible printed circuit to obtain the touch screen. The frame is arranged on the surface, which is coated with the transparent conducting film layer, of the glass substrate. A viewing area is arranged inside the frame. The OGS capacitive touch screen and the method have the advantages that requirements on the appearance quality (namely, coloring of the frame of the touch screen) and the functional quality (in other words, edge electrodes of the touch screen are sufficiently and firmly connected and conducted with the flexible printed circuit) of the OGS capacitive touch screen can be met simultaneously, the bonding strength of the small conducting holes and the flexible printed circuit is improved, accordingly, the conductivity of the OGS capacitive touch screen is improved, the product yield is increased, and the production cost is reduced.

Owner:城步新鼎盛电子科技有限公司

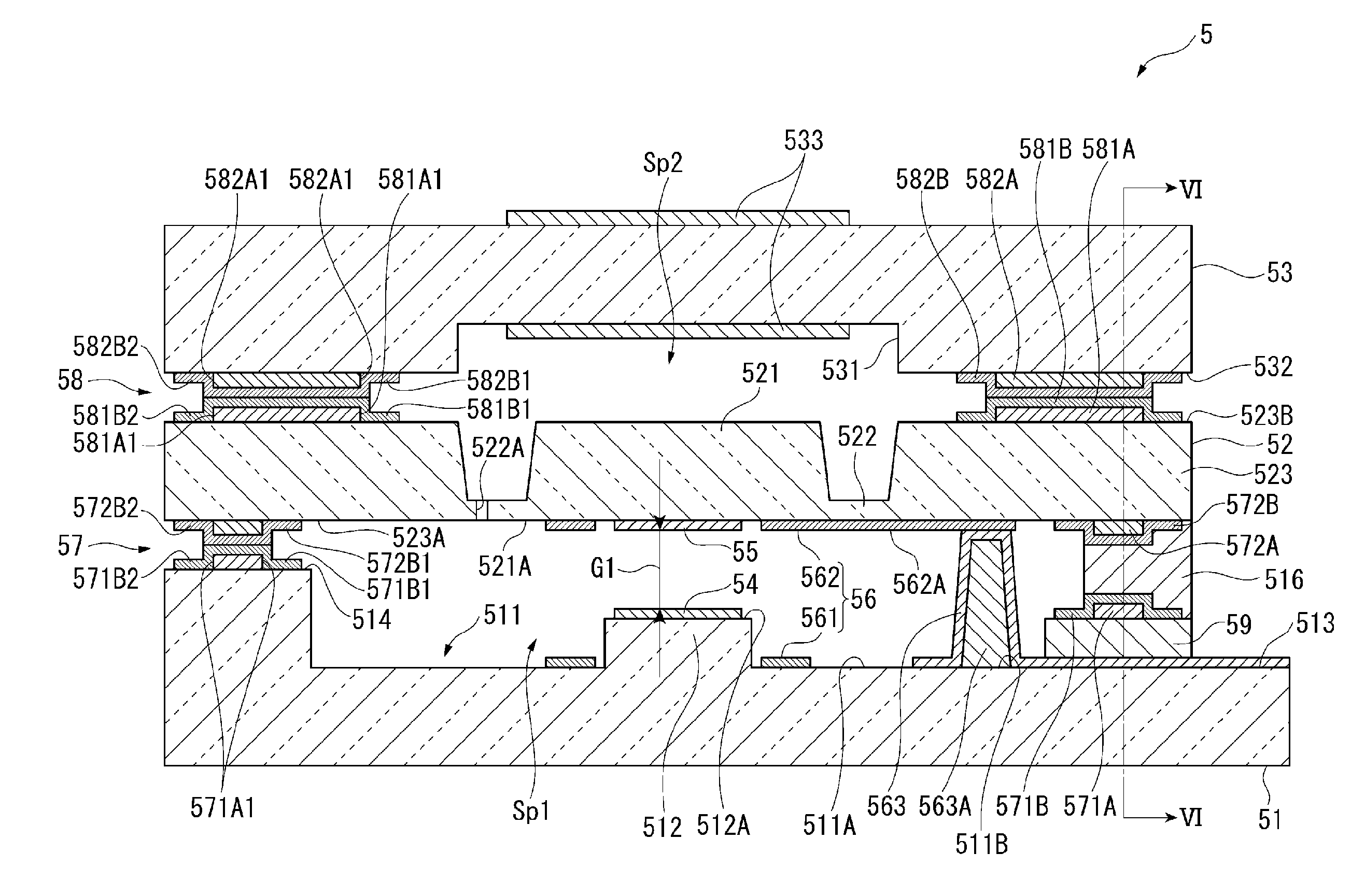

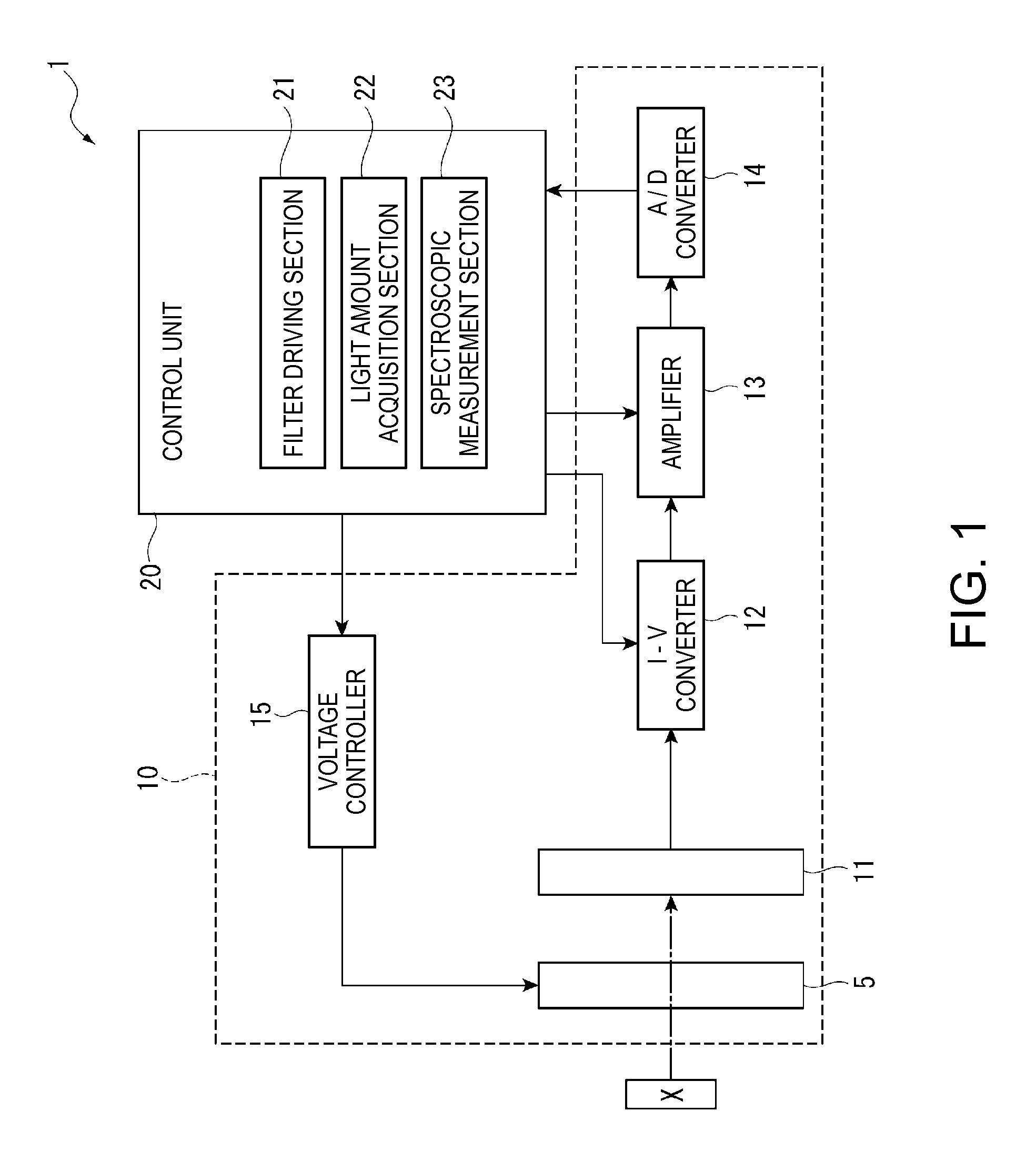

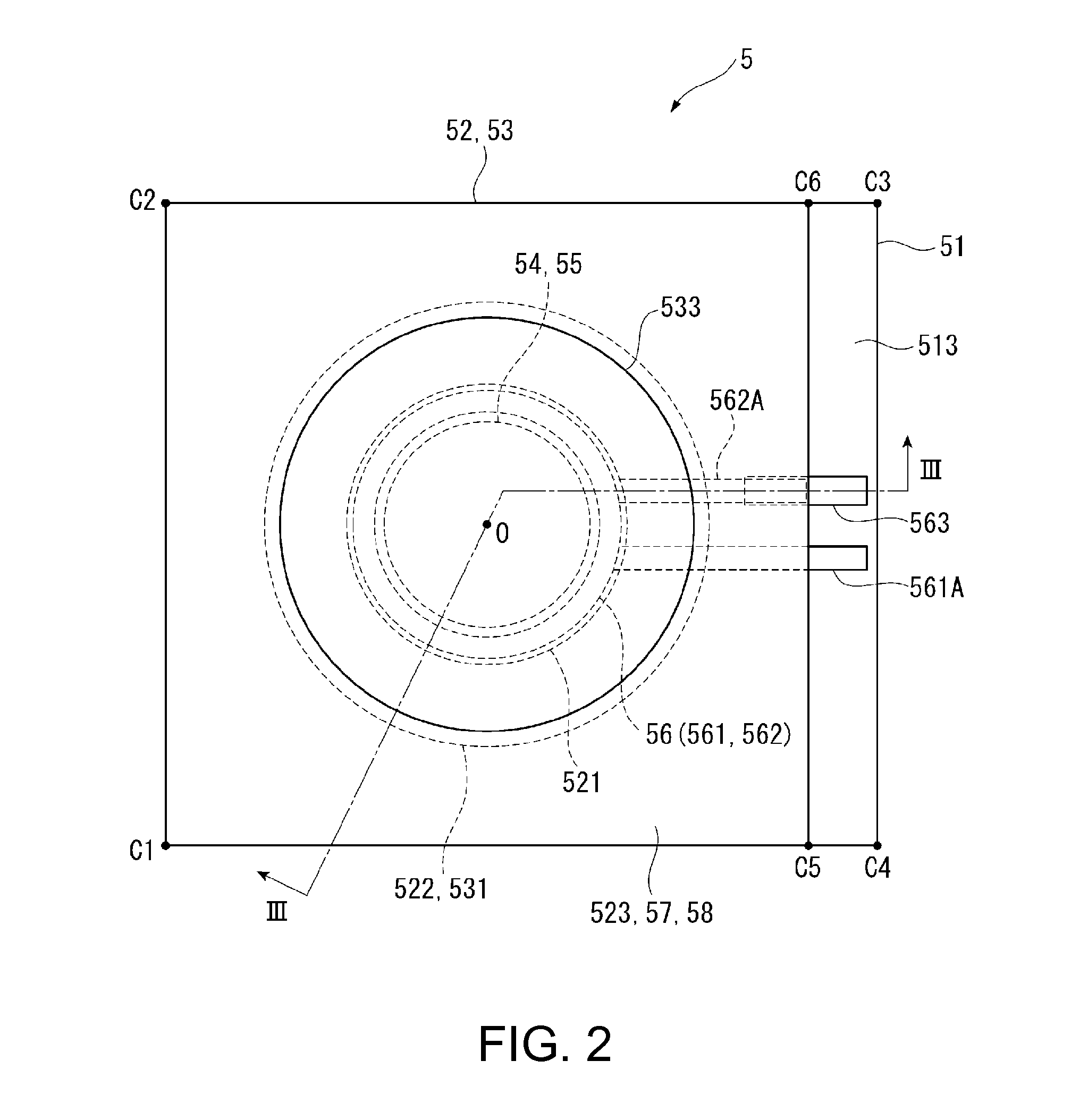

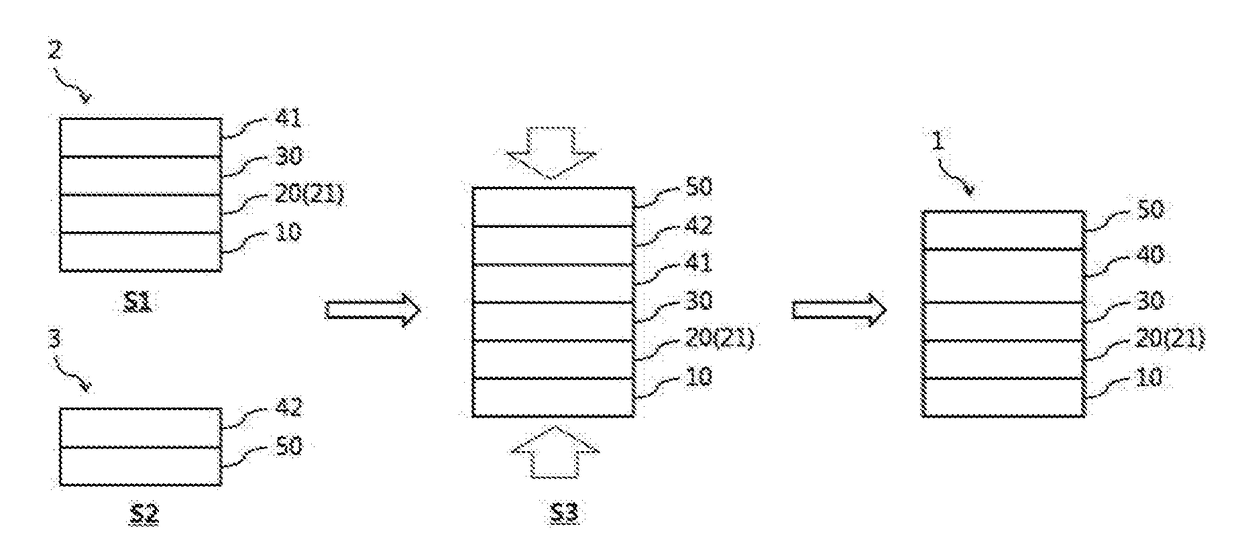

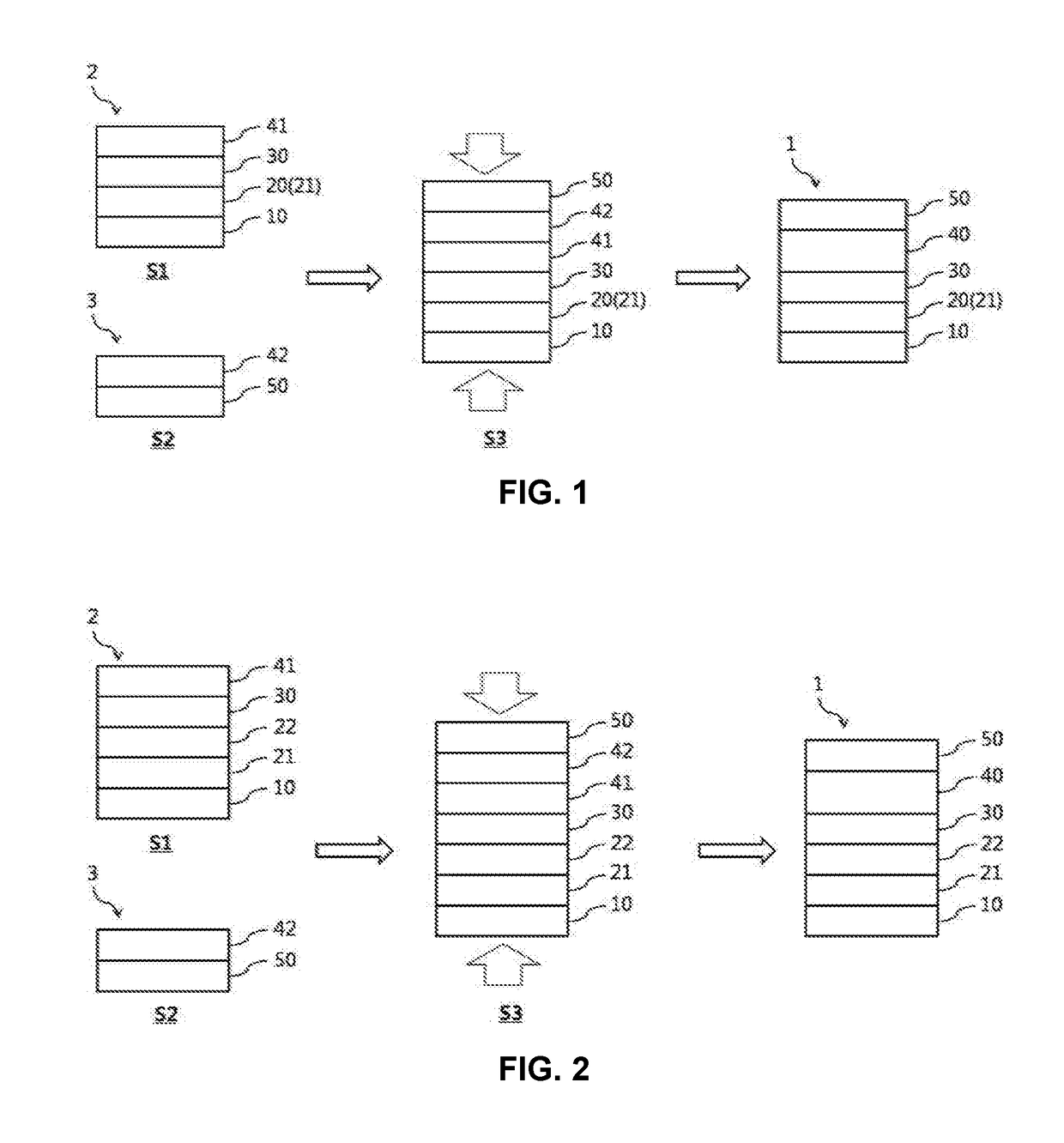

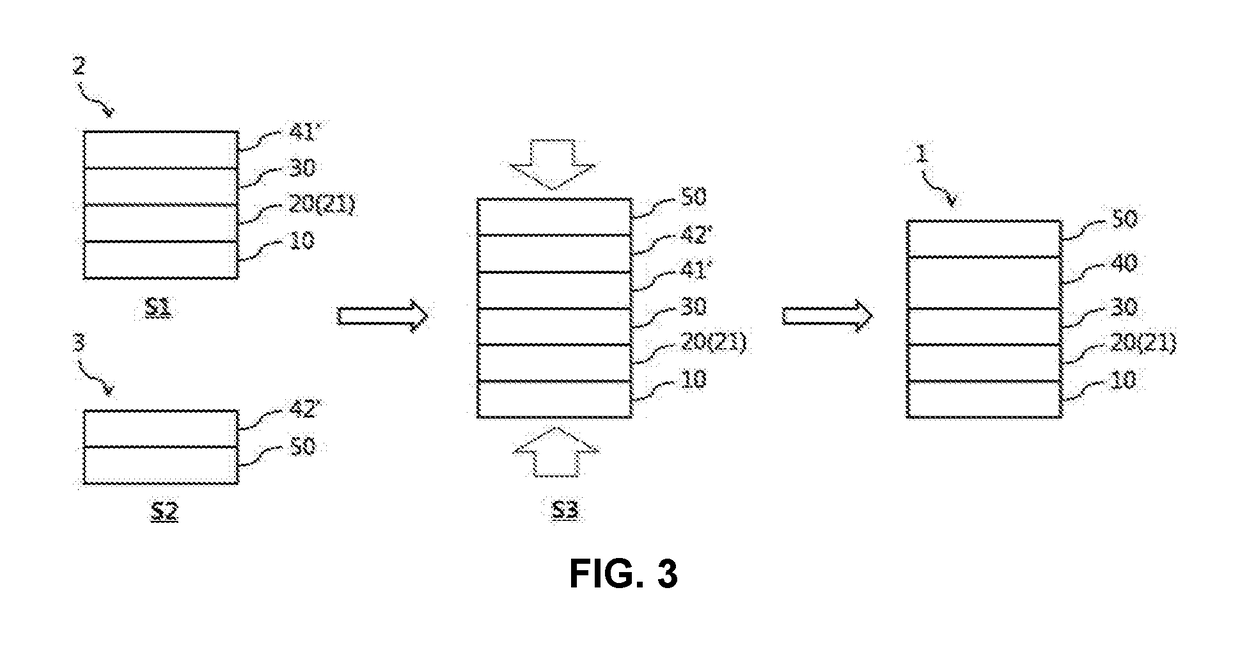

Interference filter, interference filter manufacturing method, optical module, electronic apparatus, and bonded substrate

InactiveUS20140268344A1Suppress influenceHigh airtightnessLamination ancillary operationsLaminationOptical ModuleInterference filter

A wavelength tunable interference filter includes a fixed substrate, a movable substrate, a fixed reflective film provided on the fixed substrate, a movable reflective film provided on the movable substrate so as to face the fixed reflective film, and a first bonding portion that bonds the fixed substrate and the movable substrate to each other. The first bonding portion includes a resin layer provided on the fixed substrate, a metal layer that is provided on the fixed substrate so as to cover the resin layer and that has smaller plasticity than the resin layer, and another metal layer that is provided on the movable substrate and that is bonded to the metal layer.

Owner:SEIKO EPSON CORP

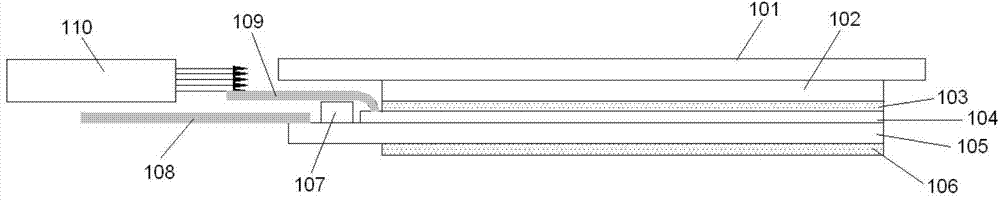

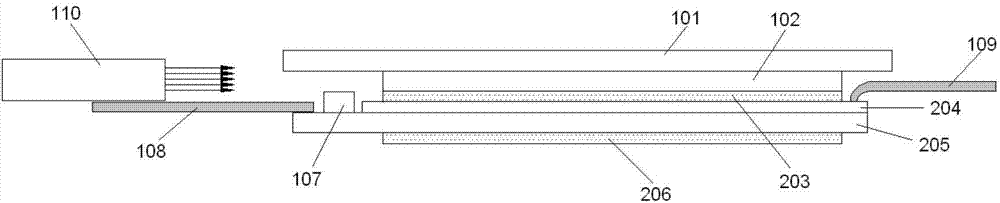

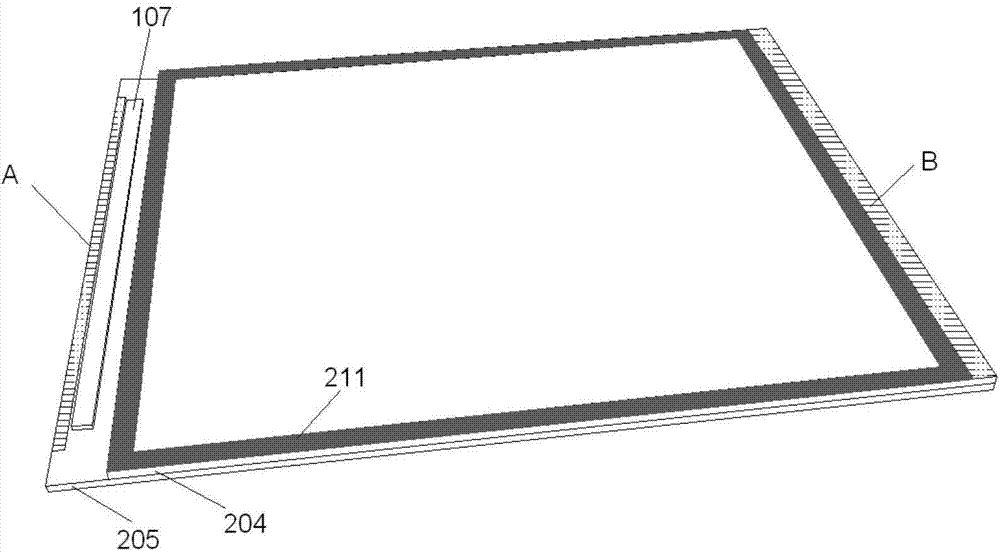

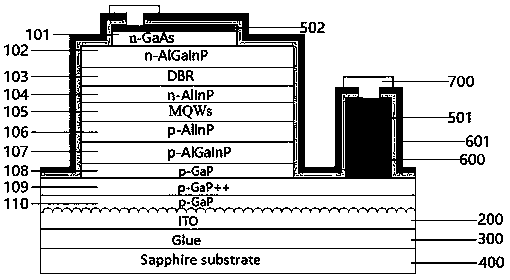

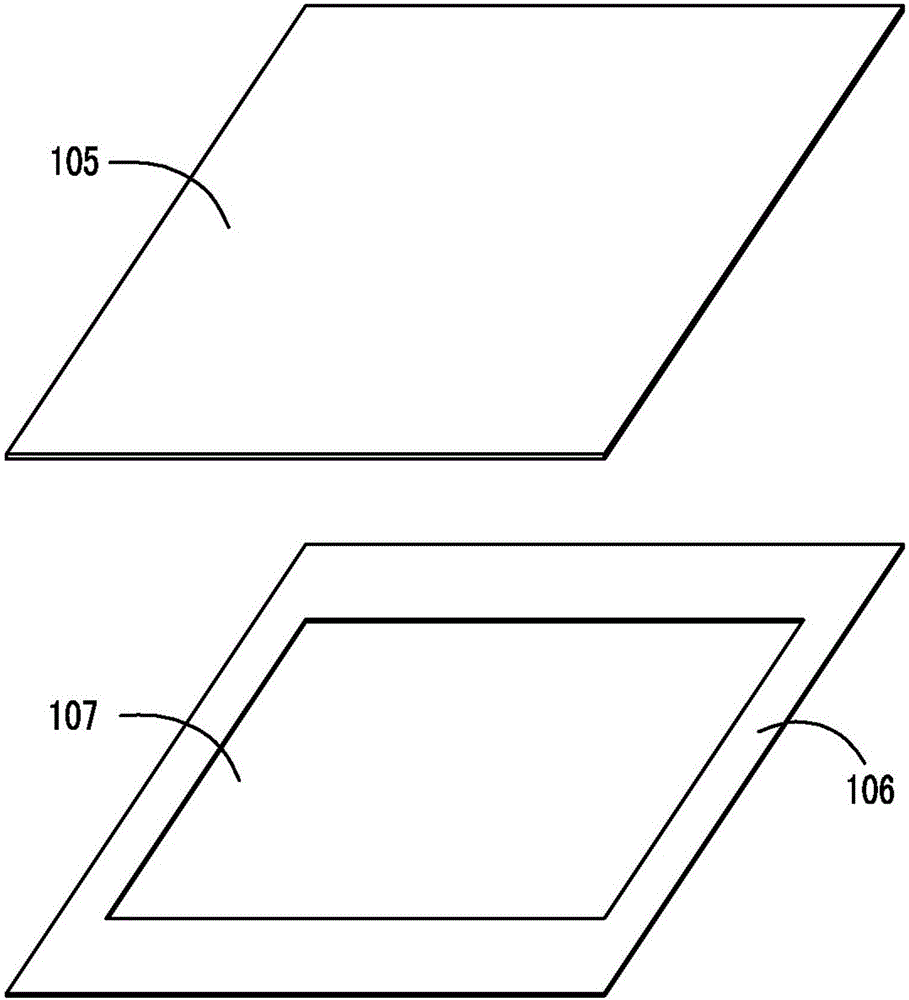

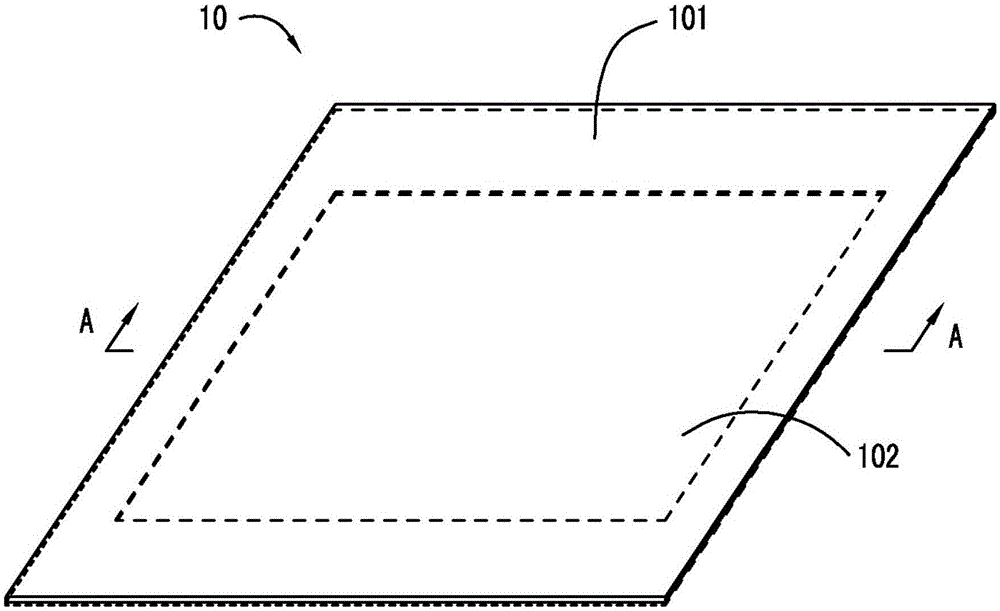

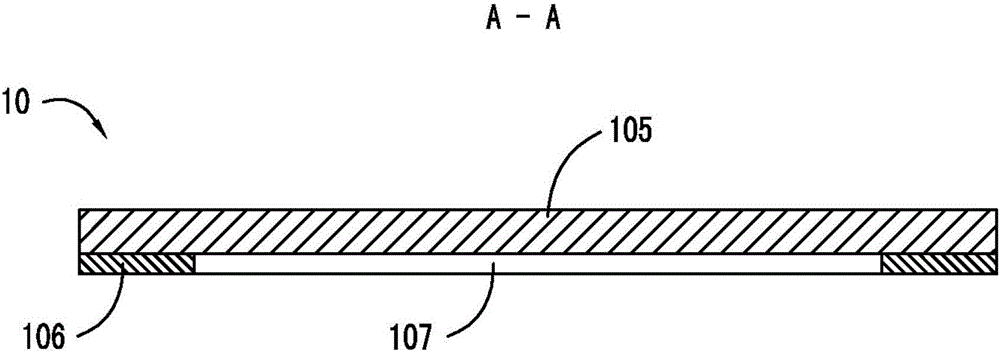

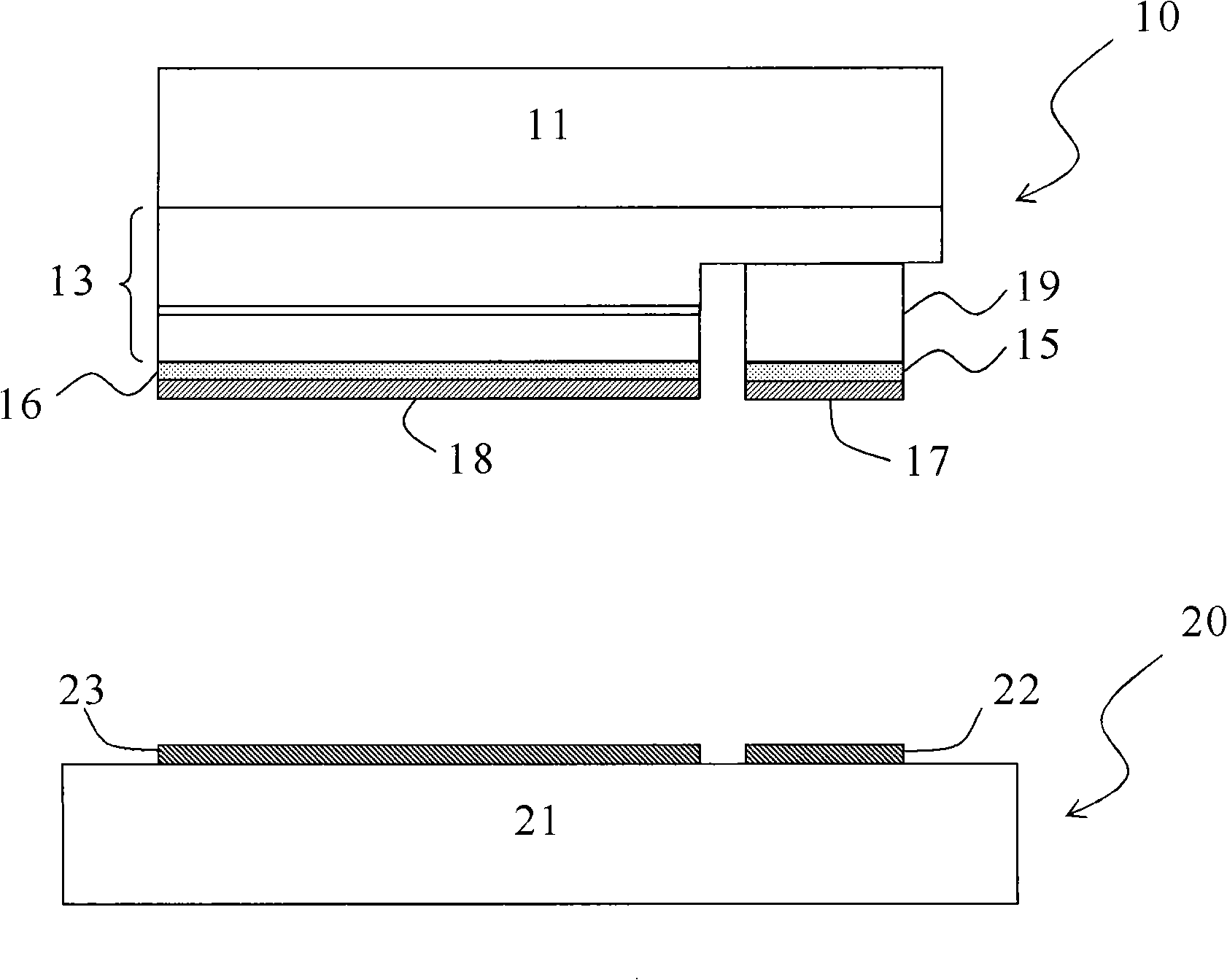

A flip-chip AlGaInP red light Micro-LED and a preparation method thereof

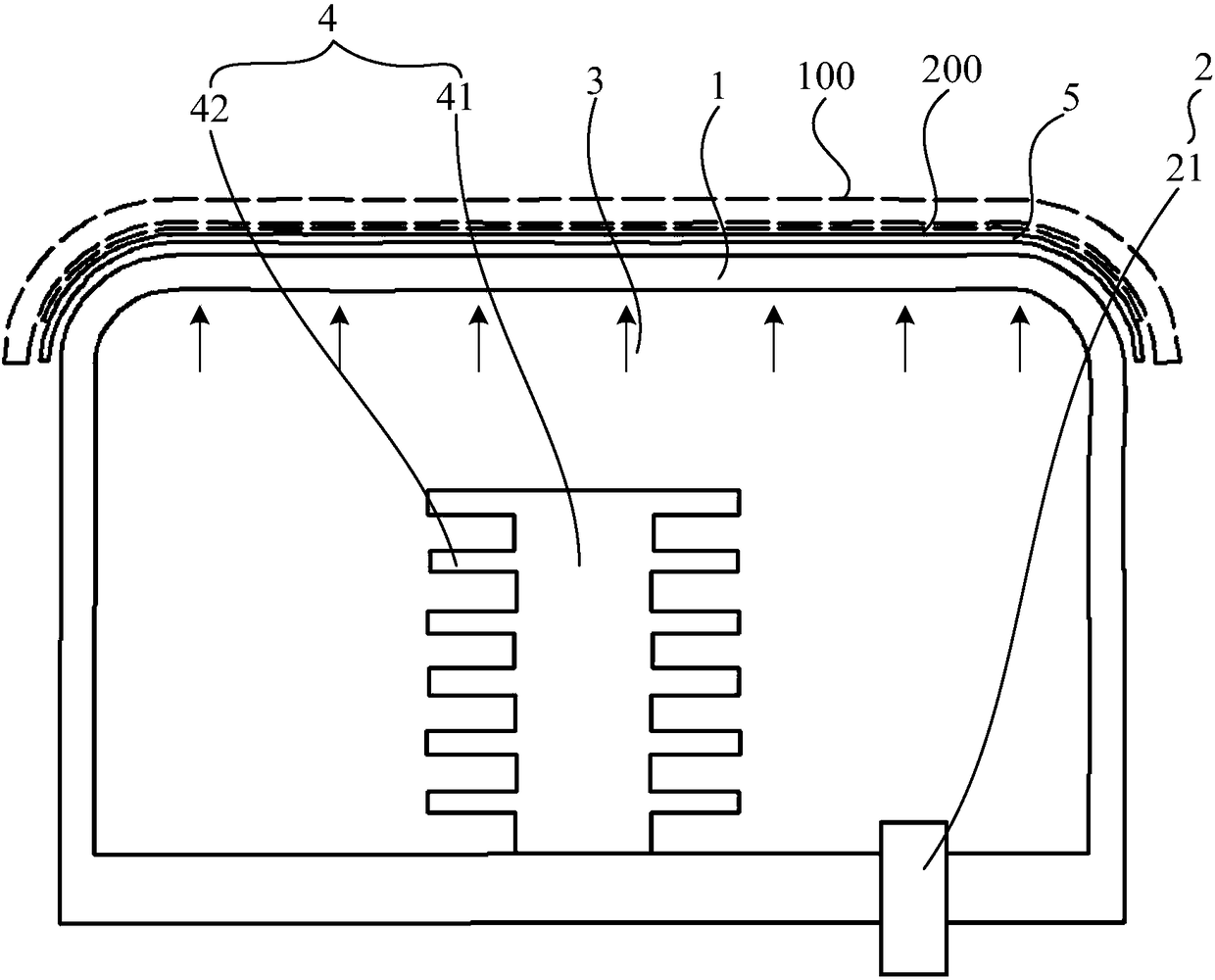

The invention belongs to the technical field of LED production and manufacture, and relates to a flip-chip structure AlGaInP red light Micro-LED and a preparation method thereof. The flip-chip structure AlGaInP red light Micro-LED includes an n-GaAs ohmic contact layer 101, an n-AlGaInP expansion layer 102, a DBR layer 103, an n-AlInP confinement layer 104, a light emitting layer 105, a p- AlInP confinement layer 106, a p- AlGaInP extended layer 107, a p-GaP current spread layer 108, a p-GaP ohmic contact lay 109, a p-GaP coarse bonding lay 110, an ITO layer 200, a cured layer 300, a substrate400, an electrode layer 501, a first metal layer 502, a protective layer 600, an ODR layer 601 and a second metal layer 700 ; the structure is novel, the working principle is clear, and the light emitting efficiency is improved; As that bonding layer between indium tin oxide (ITO) and the ultraviolet cure optical adhesive is used as a bonding layer connecting the sapphire, the bonding yield can be improved, and the technical route of the invention is reliable, the technical foundation is mature, the raw materials are easy to obtain, and the invention is favorable for batch production.

Owner:肖和平

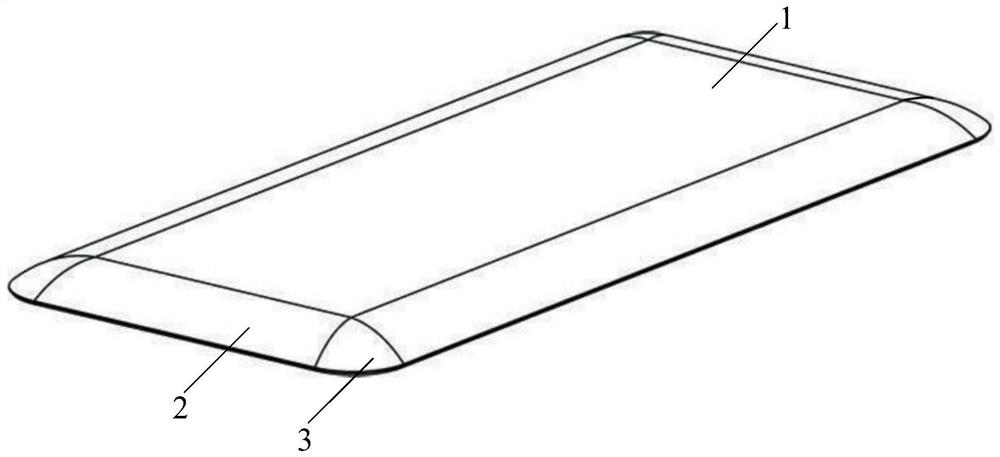

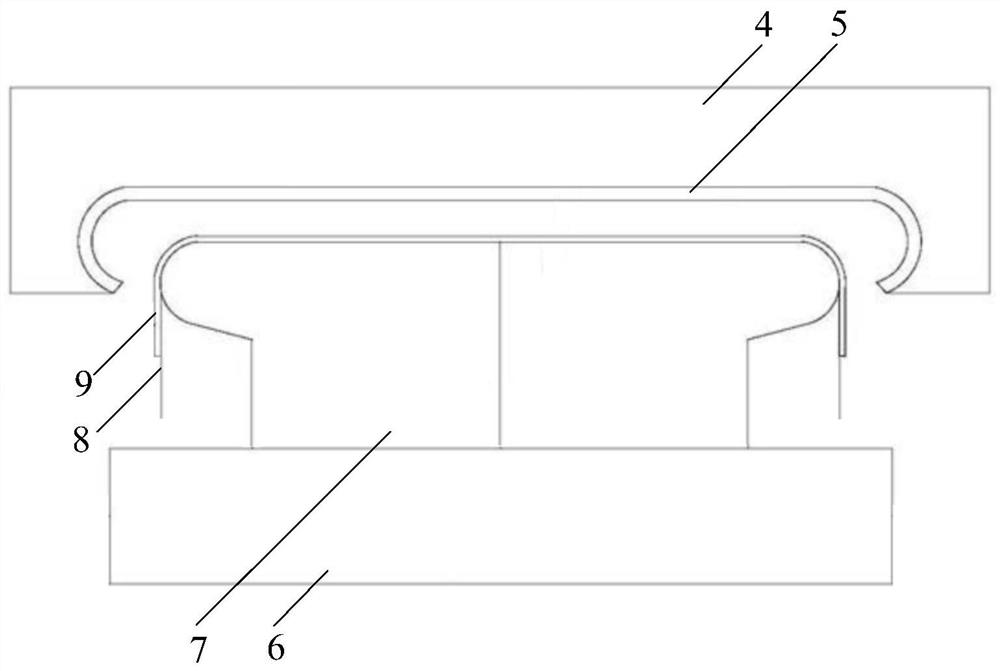

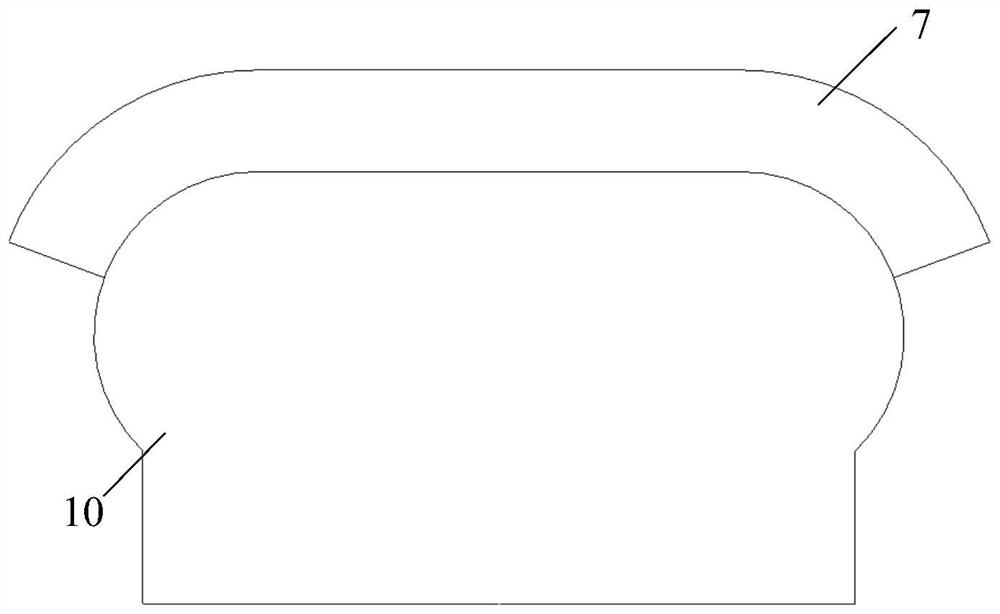

Profiling equipment, laminating device, laminating method and display device

ActiveCN113053245AAvoid the problem of insufficient profilingReach recovery forceDomestic articlesIdentification meansDisplay deviceEngineering

The embodiment of the invention provides profiling equipment, a laminating device, a laminating method and a display device. The profiling equipment comprises a profiling jig and an acting device. The profiling jig is made of a shape memory material and has a first state and a second state. The profiling jig in the first state comprises an attaching surface, and the attaching surface is used for attaching a flexible display panel. The profiling jig in the second state comprises a profiling surface, and the profiling surface corresponds to the target shape of the flexible display panel. The acting device acts on the profiling jig to change the state of the profiling jig. In the profiling process of the profiling equipment, the action device enables the profiling jig to be switched from the first state to the first state, the flexible display panel attached to the attaching face deforms along with the shape memory material, full profiling can be achieved, the problems of wrinkles, bubbles, no display, abnormal display and the like during fitting with a curved surface cover plate can be avoided, a better laminating effect can be ensured, and the laminating yield and reliability are improved.

Owner:BOE TECH GRP CO LTD +1

Biometric feature recognition sensor and electronic equipment comprising same

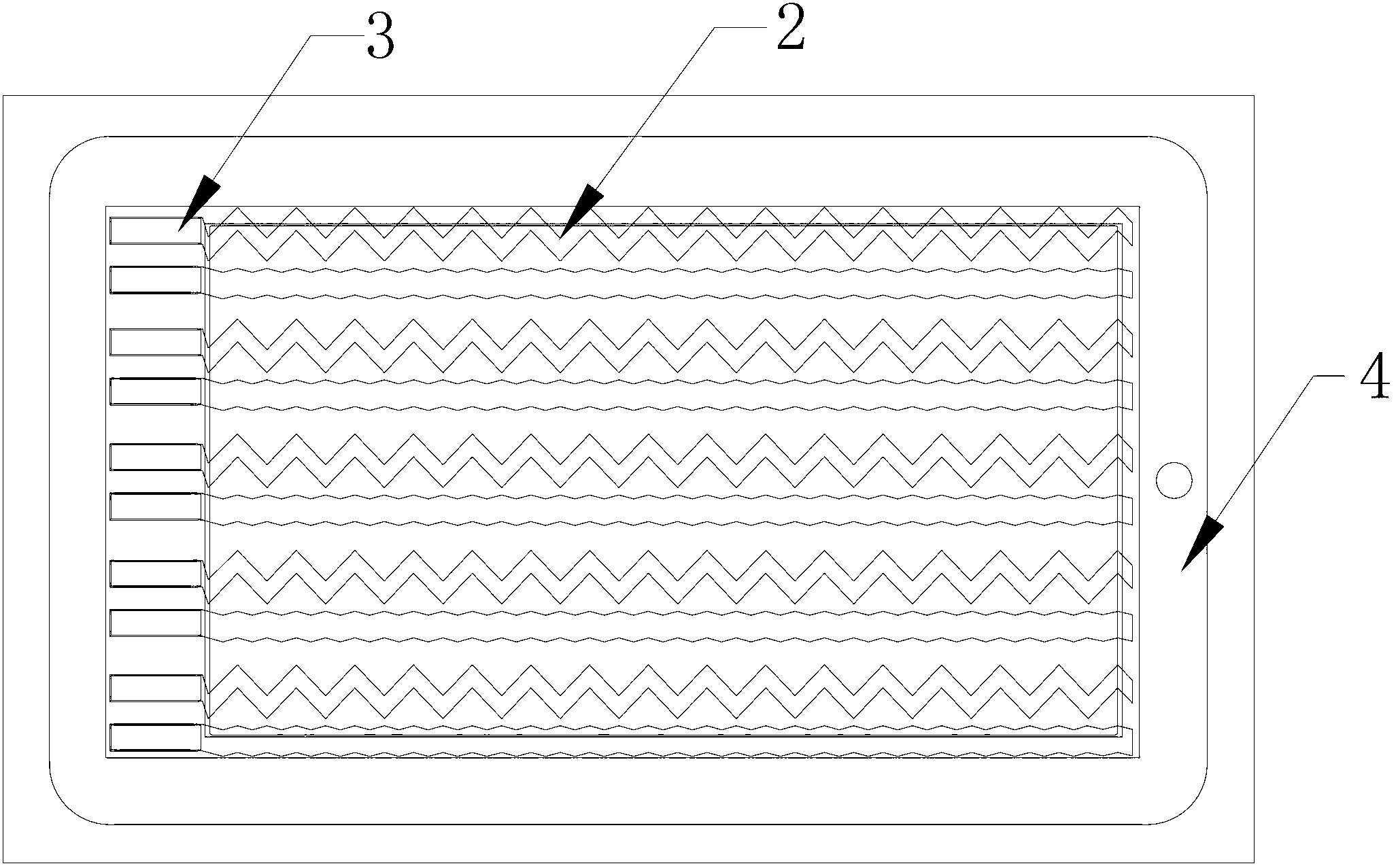

ActiveCN103942534AReduce the numberShorten the lengthCharacter and pattern recognitionFeature recognitionPhysics

The invention discloses a biometric feature recognition sensor and electronic equipment comprising the same. The sensor comprises a substrate, a conductive circuit and a plurality of lead wires. The conductive circuit is formed on the substrate and comprises a first conductive layer, a second conductive layer and an insulating layer, wherein the first conductive layer comprises a plurality of first electrodes distributed in a mutually-insulated mode, the second conductive layer comprises a plurality of second electrodes distributed in a mutually-insulated mode, the insulating layer is arranged between the first conductive layer and the second conductive layer in a clamped mode, and projections, on the plane where the second electrodes are located, of the first electrodes intersect with the second electrodes. The lead wires comprise at least one first electrode set lead wire and at least one second electrode set lead wire, wherein first electrode sets composed of the first electrodes are connected with the first electrode set lead wires one to one, and second electrode sets composed of the second electrodes are connected with the second electrode set lead wires one to one. The areas of a plurality of overlapping portions formed by the projections, on the plane, of the first electrodes in the first electrode sets and the second electrodes in the second electrode sets are different.

Owner:NANCHANG VIRTUAL REALITY RES INST CO LTD

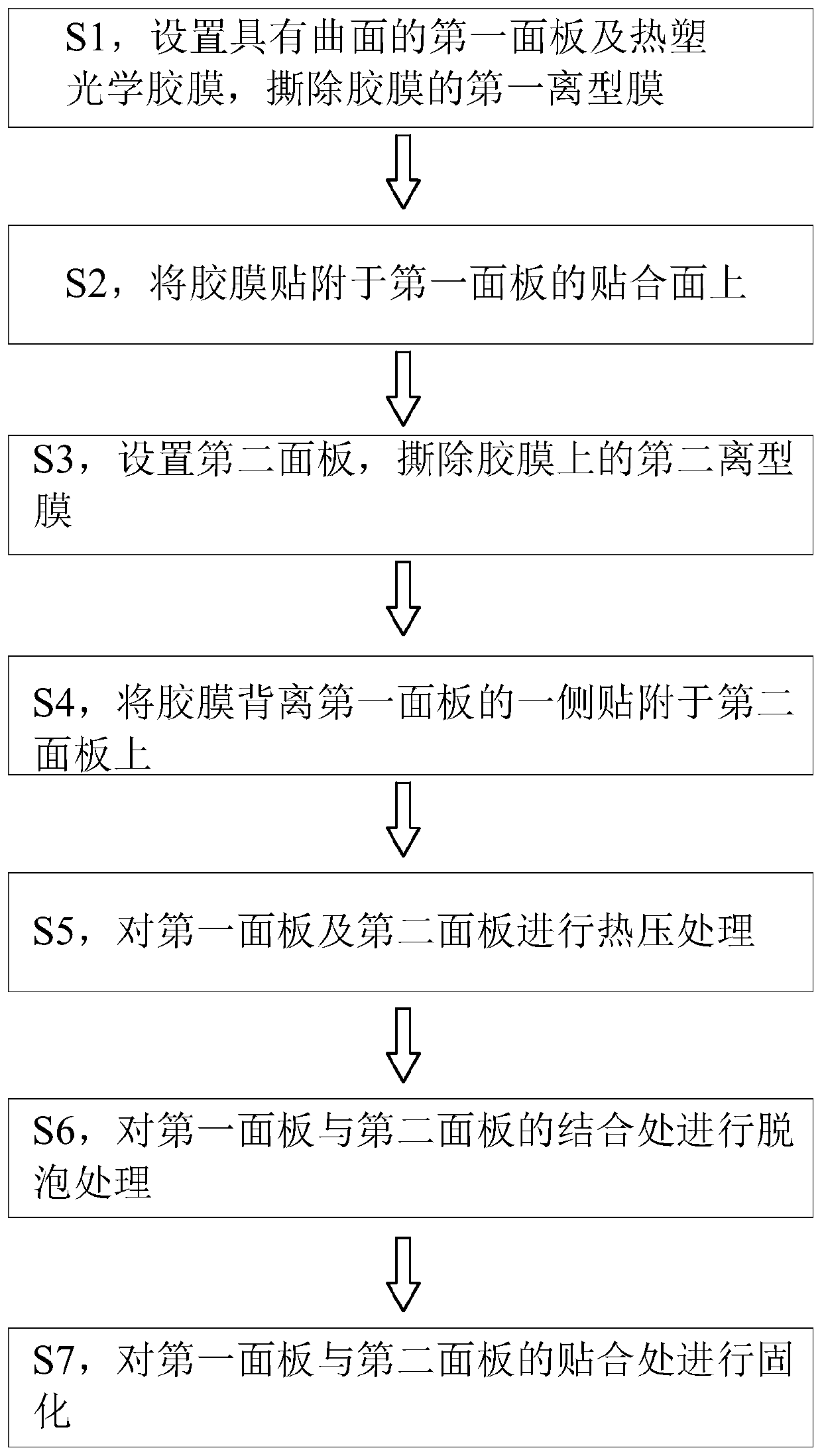

Adhesion method based on curved-surface flexible screen and display device

The invention relates to the technical field of displays and display adhesion. The invention relates to an Adhesion method based on a curved surface flexible screen. The adhesion method based on the curved surface flexible screen comprises the steps of providing a first panel with a curved surface and an optical thermoplastic adhesive film, tearing off the first release film of the adhesive film,attaching the adhesive film to the surface of the first panel, arranging a second panel, tearing off the second release film, attaching one side, opposite to the first panel, of the adhesive film to the second panel, carrying out hot pressing and defoaming treatment on the first panel and the second panel, and curing the joint of the first panel and the second panel. The display device is manufactured by the film adhesion method. The adhesive film provided by the invention can be quickly attached to the first panel and the second panel; according to the display device, bubbles generated in thehot pressing process of the adhesive film are eliminated, stress at the attaching position of the first panel and the second panel is absorbed, the adhesive film is prevented from rebounding, the first panel and the second panel are prevented from deforming, the attaching yield between the first panel and the second panel is increased, the display effect of the display device is improved, and theservice life of the display device is prolonged.

Owner:深圳一鑫新材料有限公司

Capacitive touch screen cover plate and production process thereof

InactiveCN106648274AImprove the situationImprove bonding yieldInput/output processes for data processingSilver pasteTectorial membrane

The invention relates to the technical field of touch screens, in particular to a capacitive touch screen cover plate and a production process thereof. The problem that in an existing cover plate, gaps are caused by ink steps and lead to bubbles is solved. According to the cover plate, an ink frame layer is arranged on a glass substrate, the middle of the ink frame layer is hollow and forms a window region, and a transparent ink layer is arranged in the window region; a glue layer is arranged between the ink frame layer and a conducting layer as well as between the transparent ink layer and the conducting layer, a silver paste layer is formed on the periphery of the bottom face of the conducting layer, an organic transparent insulating material layer is formed on the bottom face of the silver paste layer, a first protective film is arranged between the conducting layer and the silver paste layer, and a second protective film is arranged on the insulating layer. The production process includes the steps that ink, the transparent ink layer and the glue layer are sequentially printed on the glass substrate in a silk screen mode, an ITO film is formed on the glue layer and etched, the protective film is plated on the periphery of the bottom face of the conducting layer, silver paste is printed on the bottom face of the first protective film in a silk screen mode, and an insulating material is printed on the silver paste layer in a silk screen mode; the second protective film is plated on the insulating layer and irradiated with ultraviolet light.

Owner:JIANGXI PINGBO ELECTRONICS

Functional membrane, mobile terminal, hot pressing molding method of functional membrane and tool for hot pressing molding

InactiveCN106738804AImprove bonding yield and finished product qualityReduce processDigital data processing detailsTelephone set constructionsHot pressingCivil engineering

The invention relates to a functional membrane, a mobile terminal, a hot pressing molding method of the functional membrane and a tool for hot pressing molding. The functional membrane is applied to a curved surface cover plate and is provided with a shading region and a light transmitting region, one surface of the cover plate back to a user is the back surface of the cover plate, when the functional membrane is attached to the back surface of the cover plate, the region, corresponding to the shading region, on the cover plate forms a non-display region, the region, corresponding to the light transmitting region, on the cover plate forms a display region, and the shape of the functional membrane is matched with the shape of the back surface of the cover plate. The mobile terminal applies the functional membrane above. The hot pressing molding method of the functional membrane is used to manufacture the functional membrane. The tool for hot pressing molding is used to implement the hot pressing molding method of the functional membrane. The functional membrane is prefabricated into a curved surface model suitable for the curved surface cover plate before attaching, which is favorable for solving the defect problem occurring when a flat functional membrane is attached, such that the attaching yield and finished product quality are improved.

Owner:VIVO MOBILE COMM CO LTD

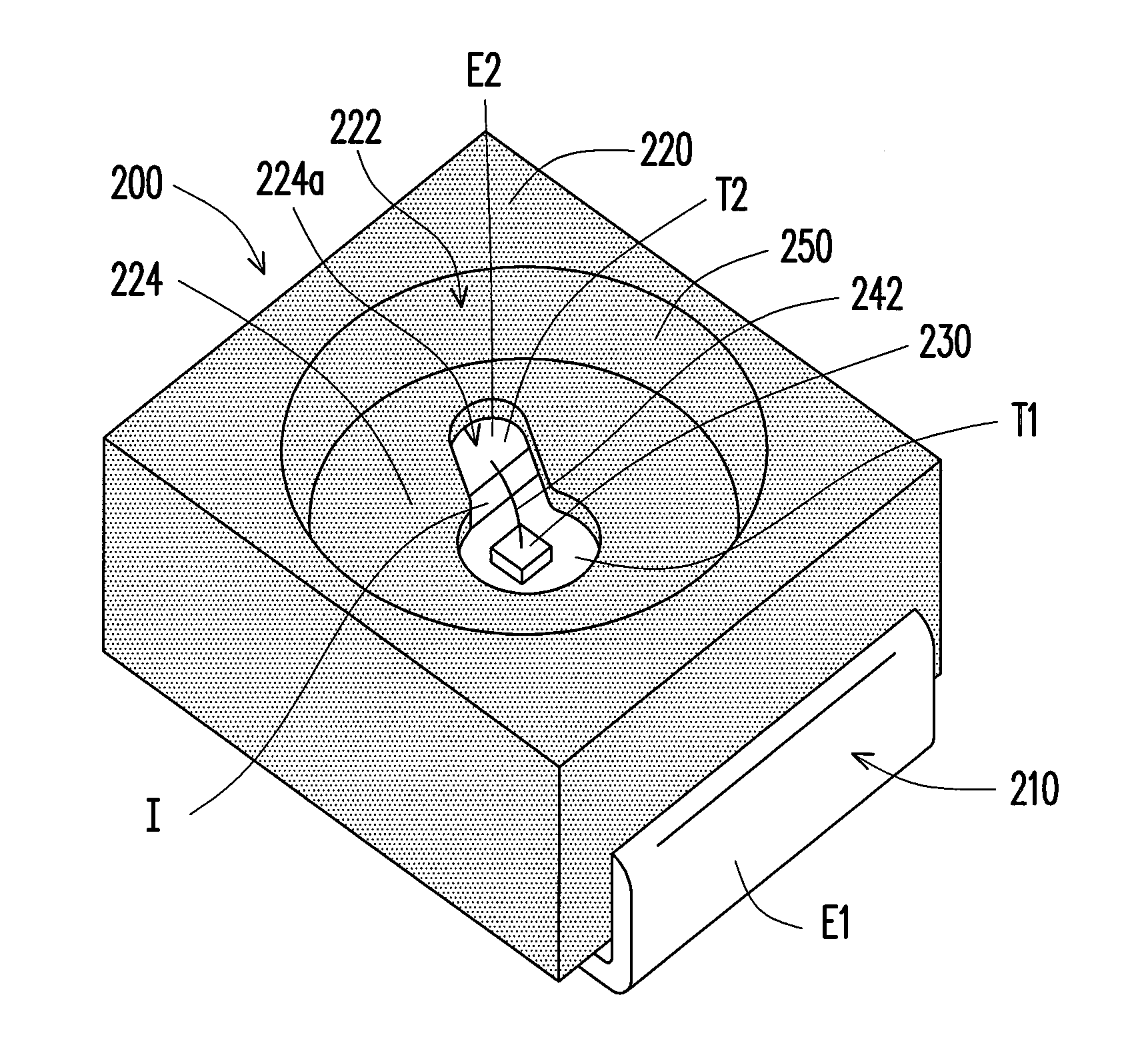

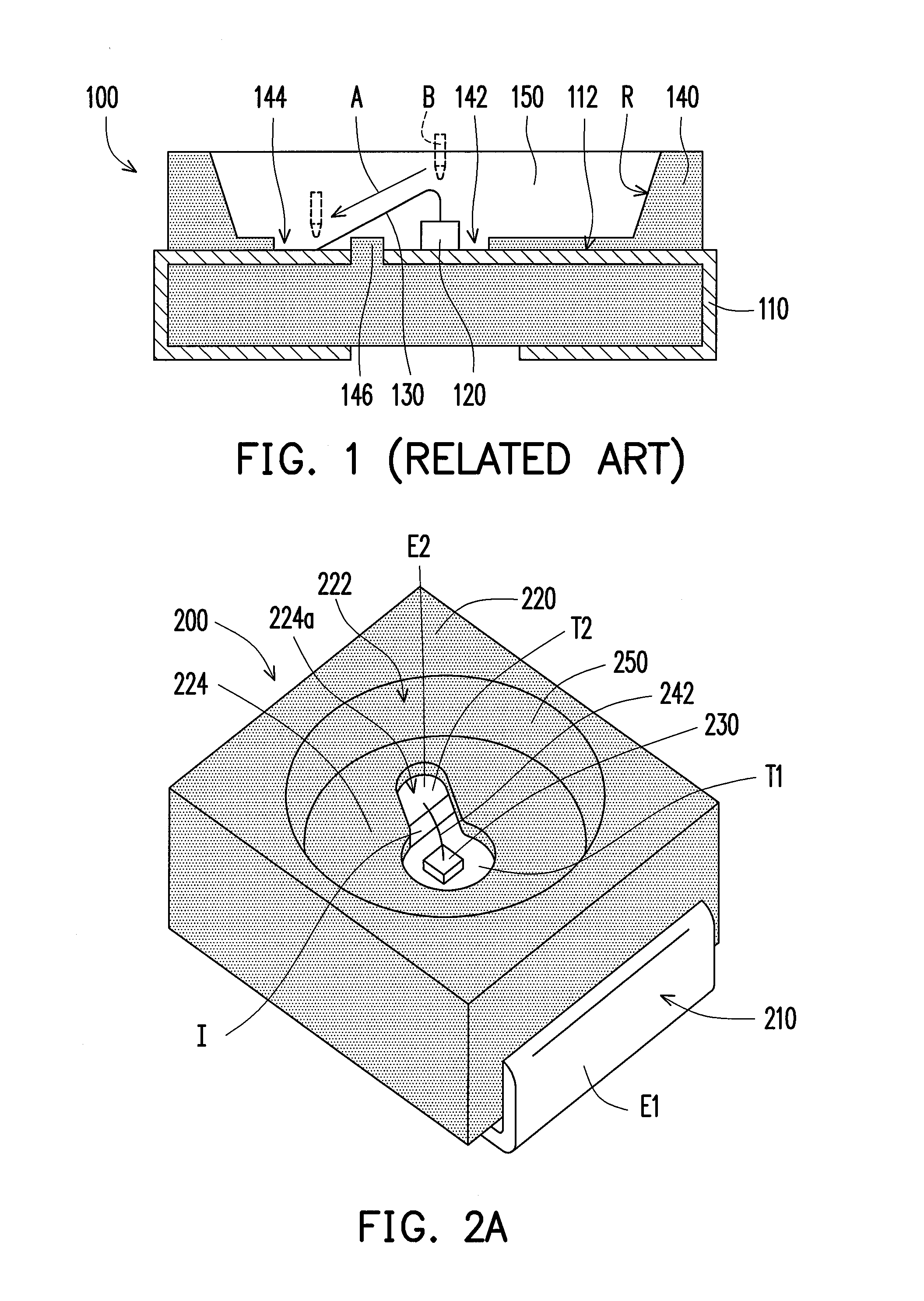

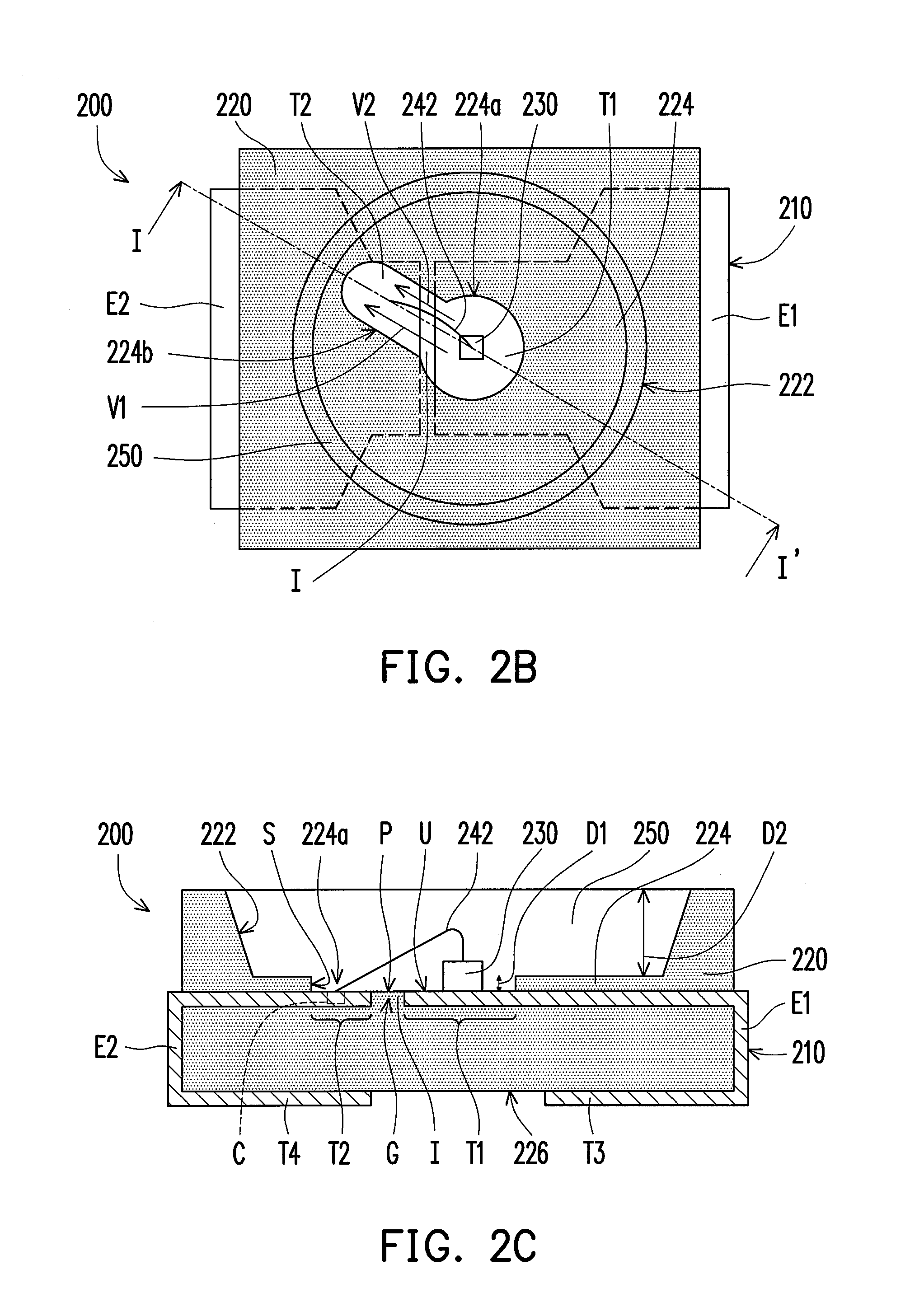

Light element device and method for manufacturing same

ActiveCN101359704AIncrease joint areaImprove bonding yieldSemiconductor/solid-state device detailsSolid-state devicesLight-emitting diodeDiode

The invention discloses a luminous element and a fabrication method thereof. The luminous element comprises a luminous diode and a pedestal; wherein the luminous diode is composed of electrodes and a junction layer formed on the electrodes, and the pedestal comprises a junction pad and a plurality of lug bosses and / or pits which are formed on the junction pad. The method for fabricating the luminous diode includes the following steps: providing a luminous diode which has electrodes and a junction layer which is arranged on the electrodes; providing a pedestal which comprises at least a junction pad; forming a plurality lug bosses and / or pits on the junction pad; and jointing the luminous diode and the pedestal.

Owner:EPISTAR CORP

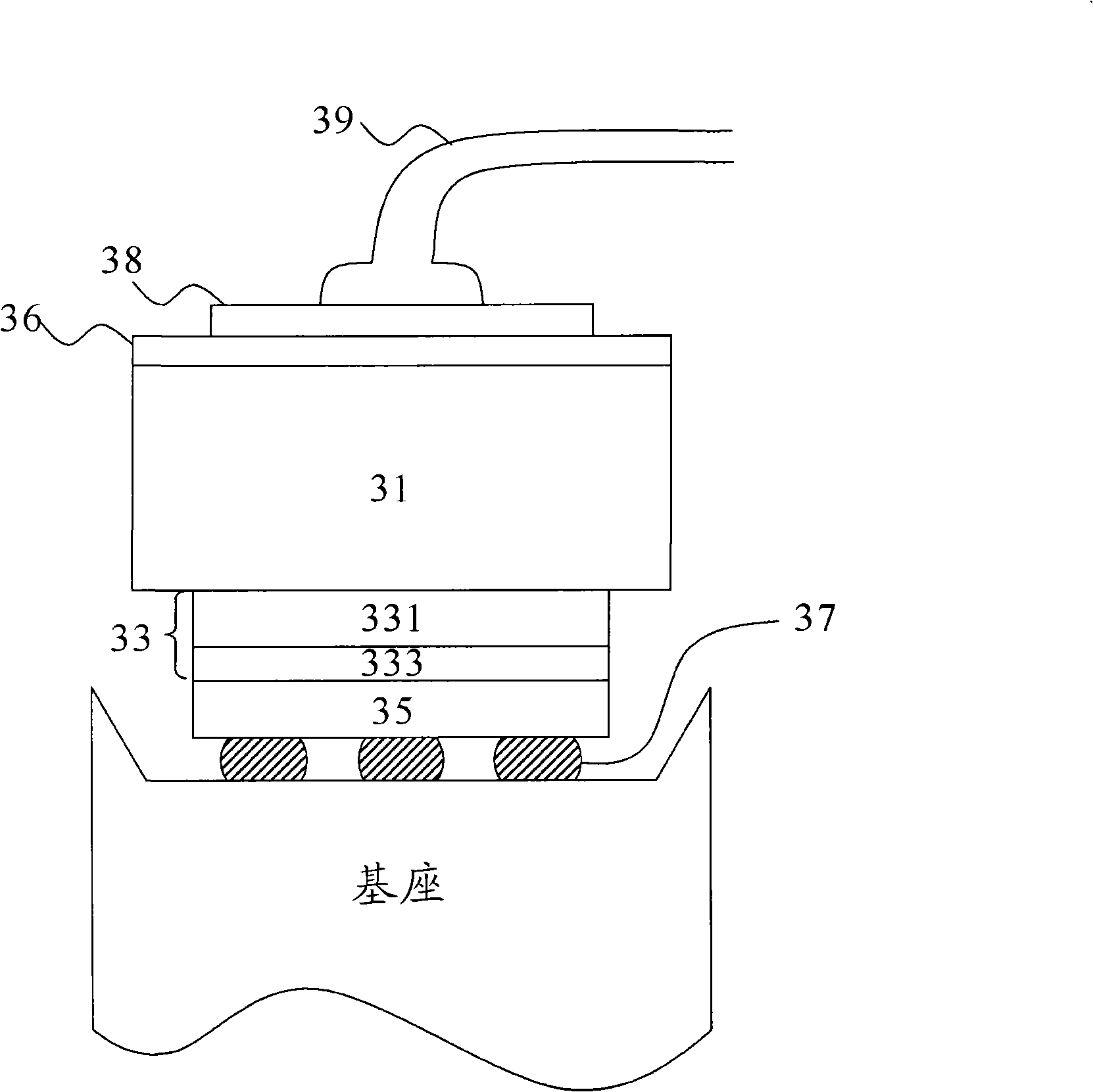

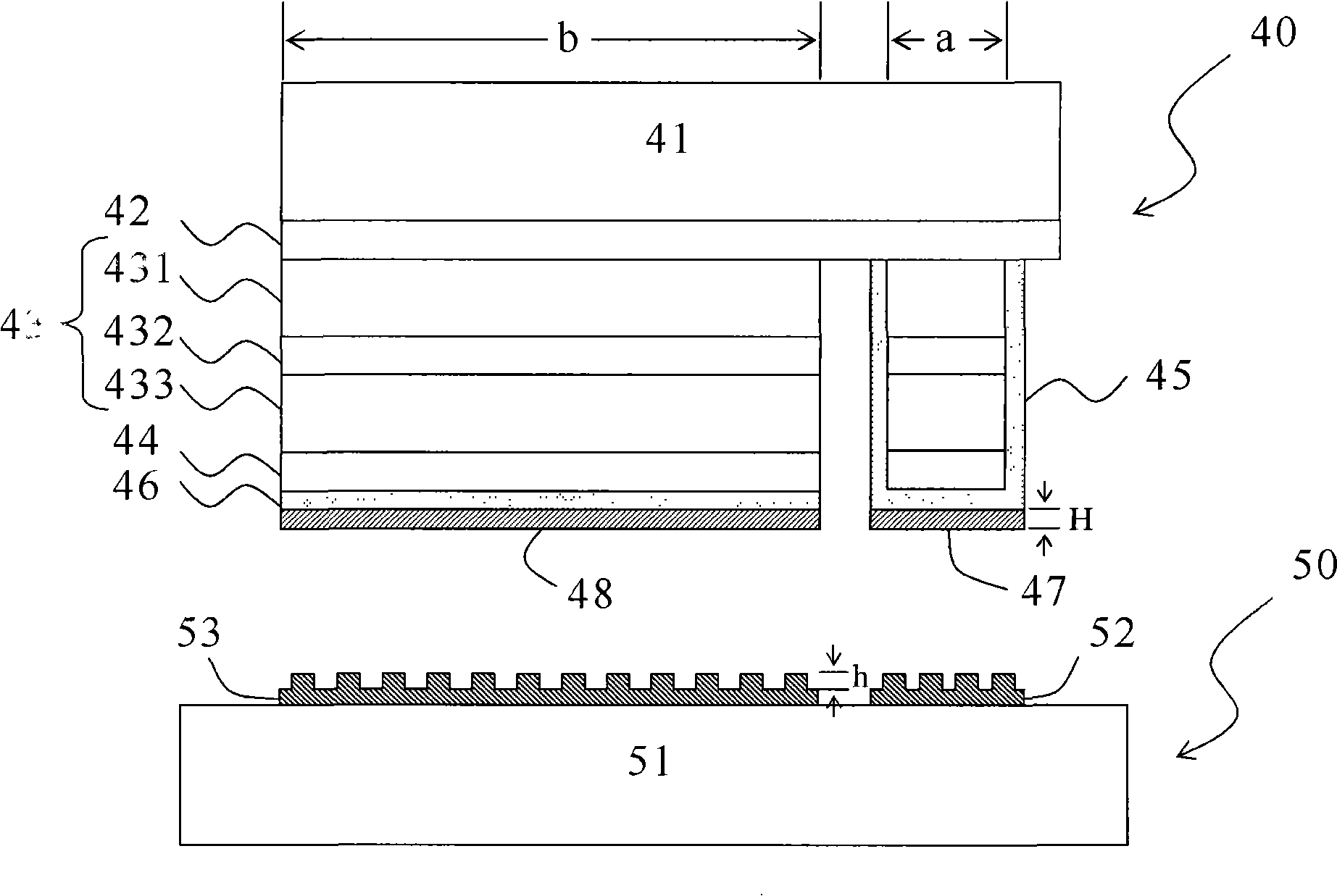

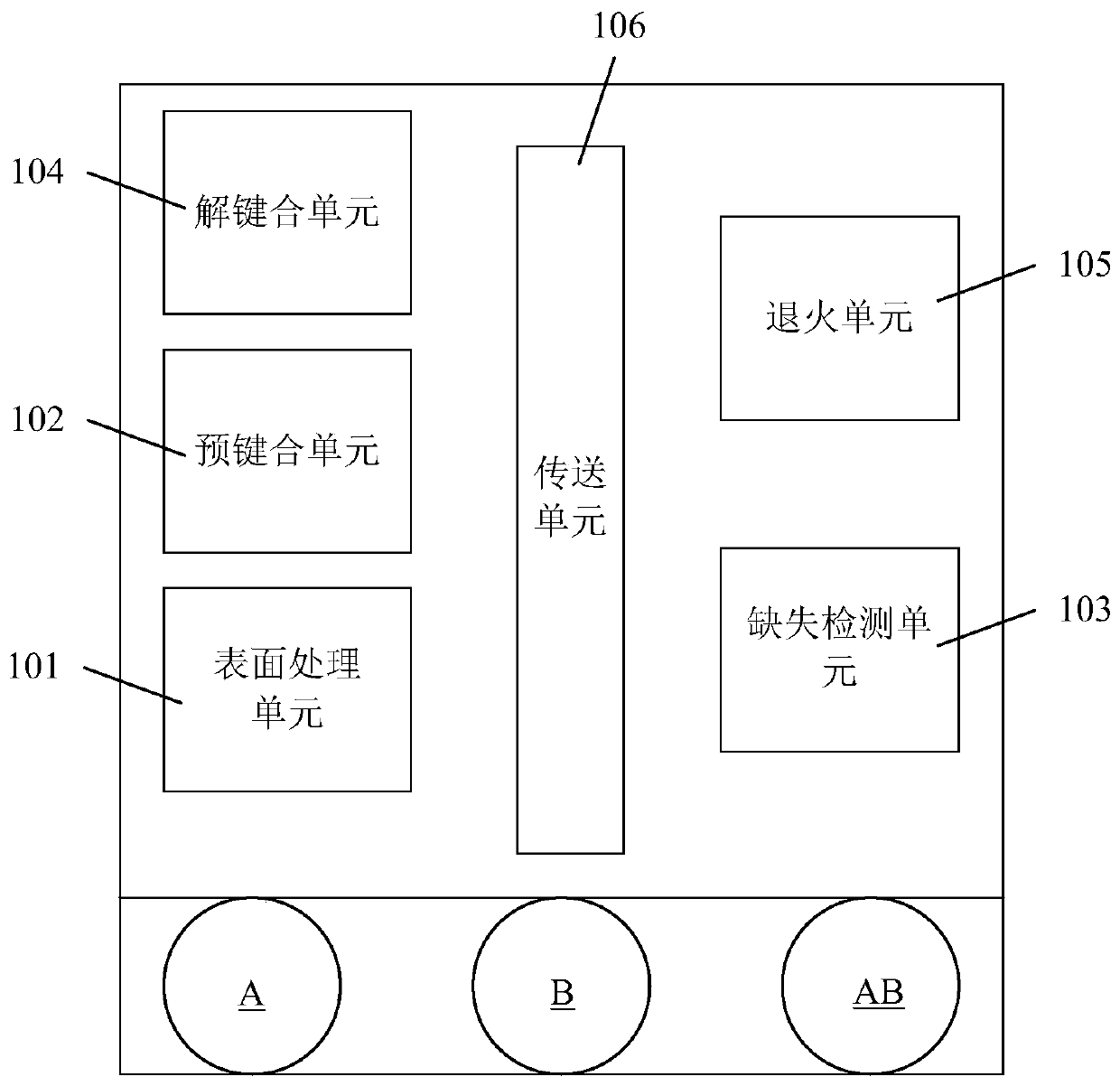

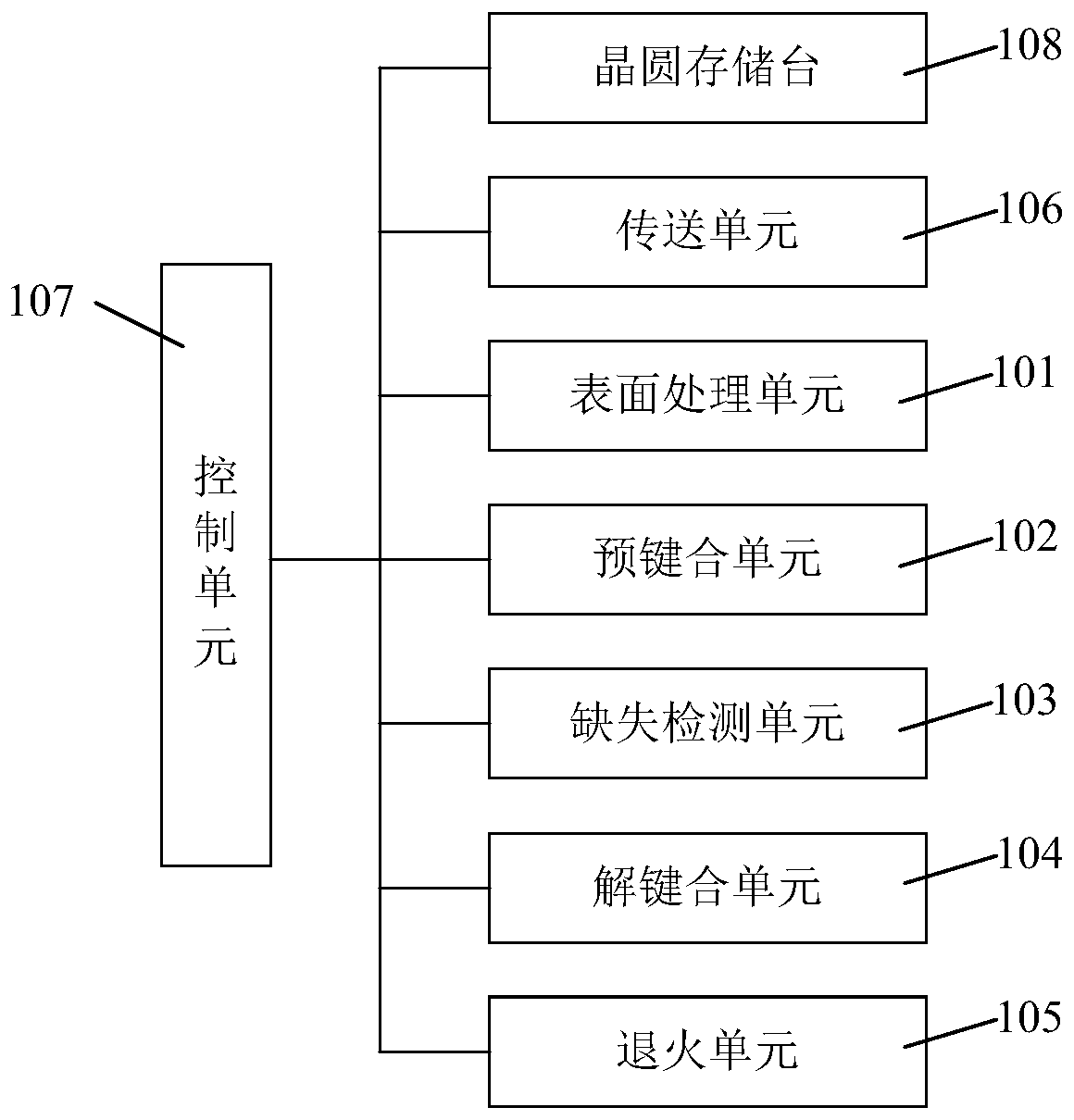

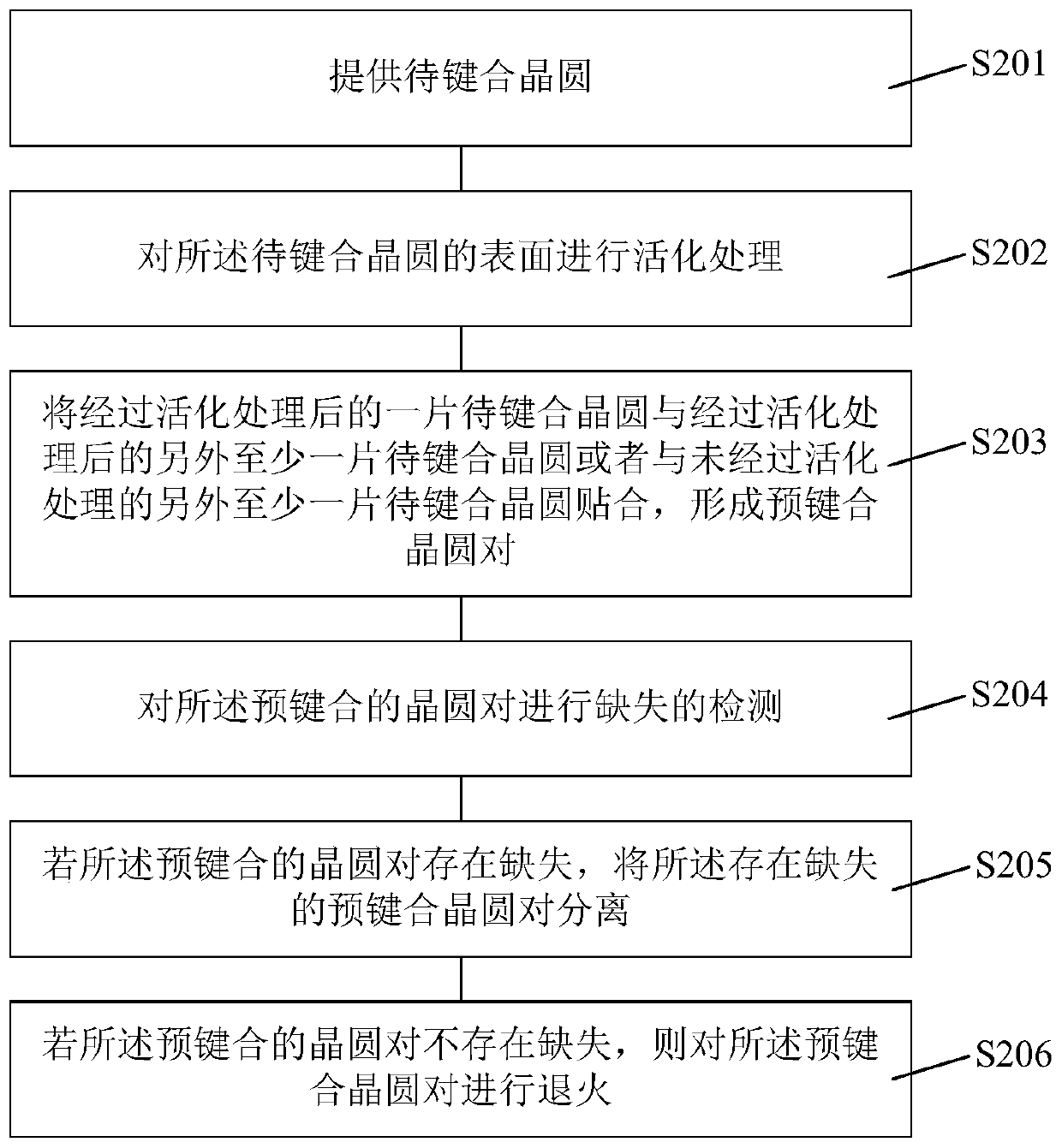

Low-temperature wafer direct bonding machine and wafer bonding method

ActiveCN110098140AAvoid scrappingAvoid lostSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringWafer bonding

A low-temperature wafer bonding machine and a wafer bonding method are provided. The low-temperature wafer bonding machine comprises a surface treatment unit used for activating the surfaces of to-be-bonded wafers, a pre-bonding unit used for bonding one activated to-be-bonded wafer to at least one other activated to-be-bonded wafer or at least one other unactivated to-be-bonded wafer to form a pre-bonded wafer pair, a missing detection unit used for detecting whether the pre-bonded wafer pair is missing, and a de-bonding unit used for separating the missing pre-bonded wafer pair. The successrate of de-bonding of the low-temperature wafer bonding machine of the invention is improved.

Owner:ICLEAGUE TECH CO LTD

Light emitting diode package structure

InactiveUS20100148211A1Improve yieldIncrease productionSolid-state devicesSemiconductor devicesEngineeringLight-emitting diode

A light emitting diode (LED) package structure including a leadframe, a housing, a LED chip and a light-transmissive encapsulant is provided. The leadframe has a first electrode and a second electrode separated from each other. The housing wraps the first electrode and the second electrode and includes a recess having a bottom and a sidewall. The bottom of the recess has a cover layer covering the leadframe and having an opening exposing an end of the first electrode, an end of the second electrode and a spacer disposed therebetween and connected thereto wherein the spacer, the end of the first electrode and the end of the second electrode are substantially coplanar. The LED chip is disposed in the recess and electrically connected to leadframe. The light-transmissive encapsulant is filled in the recess.

Owner:EVERLIGHT ELECTRONICS

Method for preparing a bonded type perovskite solar cell

ActiveUS20180122584A1Low processing costEnhance price competitivenessLight-sensitive devicesSolid-state devicesPerovskite solar cellOptoelectronics

A method for preparing a perovskite solar cell by a non-deposition method is provided. Particularly, the method includes preparing a first substrate by forming a hole transport layer on a light absorbing layer in a semi-dried state and pressurizing and drying a second substrate including an opposing electrode to the first substrate.

Owner:HYUNDAI MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com