Laminating device and method for applying same

A bonding device and heating device technology, applied to identification devices, instruments, etc., can solve problems such as poor bonding yield and low versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The medium in the containing cavity is a gas medium, and the pressure regulating device is a temperature regulator installed in the containing cavity, and the temperature regulator is used to adjust the temperature of the medium gas, thereby adjusting the pressure of the medium gas. This structure is simple and easy to implement.

Embodiment 2

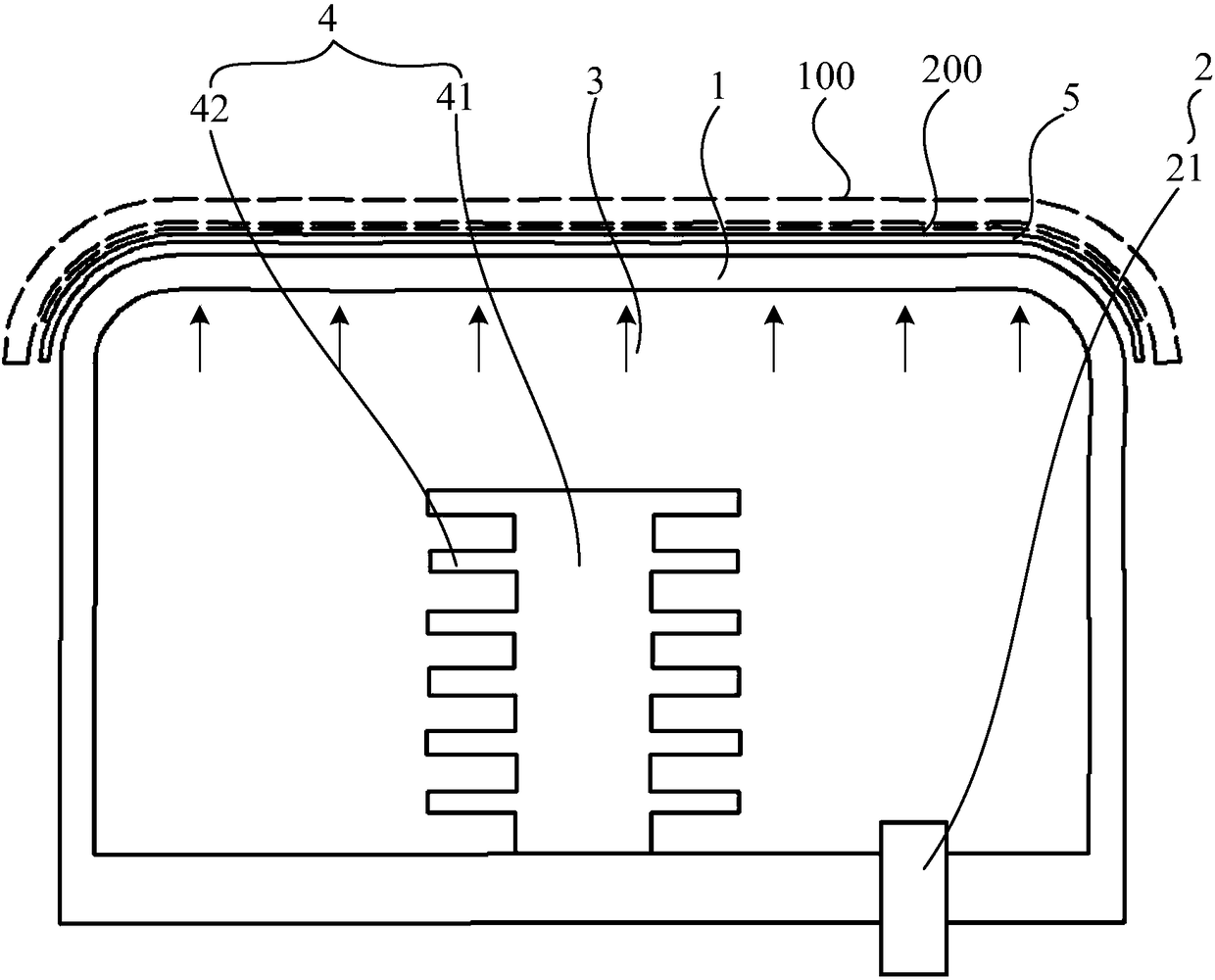

[0031] Embodiment two: if figure 2 As shown, the pressure regulating device 2 includes a power pump 21 connected to the chamber 3, a pressure relief port (not shown in the figure) opened on the side wall of the chamber 3, and a pressure relief valve ( not shown in the figure), the power pump 21 is used to charge the medium into the accommodation chamber 3, the pressure relief port is used to discharge the medium in the accommodation chamber 3, and the pressure relief valve is used to open or close the pressure relief port. Therefore, the amount of the medium in the accommodation chamber 3 can be adjusted by controlling the opening or closing of the power pump 21 and the pressure relief valve, thereby adjusting the pressure of the medium in the accommodation chamber 3 . This structure is simple, and the adjustment range of the medium pressure is large, the adjustment efficiency is high, and the expansion requirement of the elastic gasket 1 can be met.

[0032] exist figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com