Light element device and method for manufacturing same

A technology for light-emitting components and manufacturing methods, which is applied to electrical components, electrical solid-state devices, semiconductor devices, etc., and can solve problems such as failure, overflow light-emitting diodes, and extrusion of bonding layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

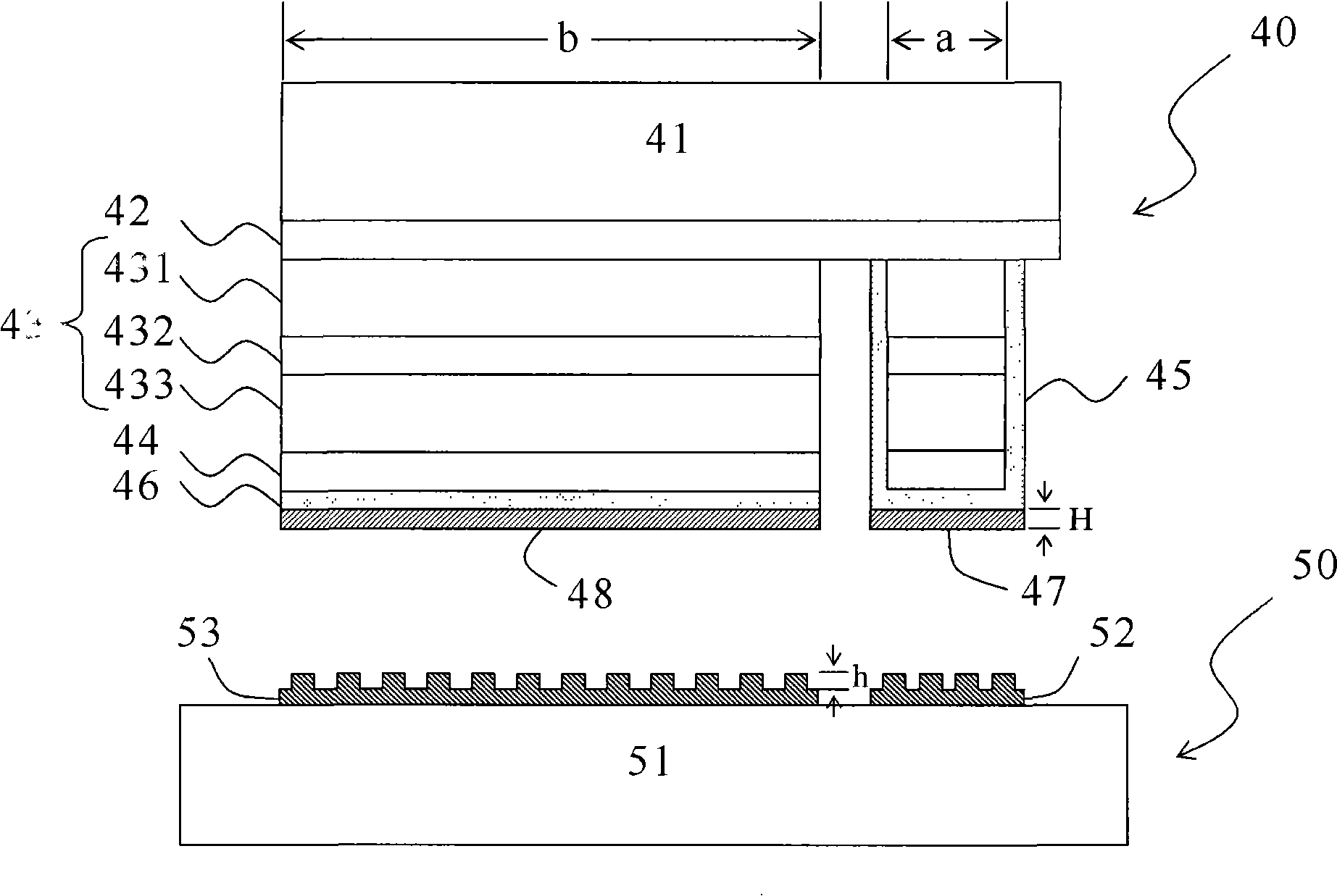

[0022] Please refer to Figure 3A The light-emitting device according to the present invention includes a light-emitting diode 40 and a base unit 50. The light emitting diode 40 includes a transparent substrate 41 whose material is, for example, Al 2 O 3 , GaN, glass, GaP, SiC, or CVD diamond; the first contact layer 42 is formed on the transparent substrate 41, the first contact layer 42 has a first area a and a second area b; the light-emitting stack 43 is substantially formed on the first A first area a and a second area b on a contact layer 42. The light emitting stack includes a first electrical type semiconductor layer 431, an active layer 432, and a second electrical type semiconductor layer 433 in sequence. The layer 43 emits light when driven by voltage, and its material can be red, yellow, or green light (Al z Ga 1-z ) 0.5 In 0.5 P quaternary series, or Al that emits blue or purple light x In y Ga (1-x-y) N gallium nitride series; the second contact layer 44 corresponds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com