Composite monofilament applied to material filtering base cloth and preparing method thereof

A technology of composite monofilament and base fabric, which is applied in the manufacture of rayon, complete sets of equipment for producing rayon, conjugated synthetic polymer rayon, etc., can solve the problem of increasing the porosity of the composite monofilament and the high cost of the composite monofilament. , low filtration efficiency and other problems, to achieve the effect of good grip, high porosity, and improved filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

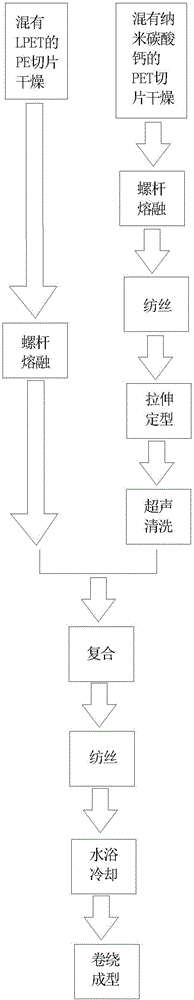

[0033] figure 1 It is the process flow chart of the preparation method of composite monofilament applied to filter material base cloth provided by the present invention; as shown in the figure, the preparation method of composite monofilament applied to filter material base cloth provided by the present invention includes:

[0034] (1) The PET chips mixed with nano-calcium carbonate are dried, screw melted, spinning, stretched and shaped, and ultrasonically cleaned into a core layer monofilament;

[0035] (2) PE chips mixed with LPET are dried and screw melted to form a skin layer;

[0036] (3) The core layer monofilament and skin layer produced in step (1) and step (2) are composited and spun, and then cooled in a water bath, and finally wound and formed into composite monofilament for filter base fabric .

[0037] Among them, in step (1), 8%-15% of nano-calcium carbonate is mixed in PET; during drying treatment, pre-crystallization: 45-80°C (1 to 4 hours), heating: 81-125°C (1~ 6 ...

Embodiment 1

[0048] 1. Preparation of PET core layer:

[0049] The preparation steps of the core layer include: drying the PET chips mixed with nano calcium carbonate, and then performing screw melting, spinning, stretching and setting, and ultrasonic cleaning; wherein the addition amount of nano calcium carbonate is 8%; the core layer is single The diameter of the wire is 0.05 mm. The process parameters in the preparation step are specifically: slice drying: pre-crystallization: 45-80°C (1 hour); temperature rise: 81-125°C (1 hour); heat preservation: 125°C (5 hours). Screw melting: extruder supply: 200g / min; pressure: 50kg / cm2; preheating zone temperature: 255°C; melting zone temperature: 280°C; metering zone temperature: 280°C. Spinning: template temperature: 280°C; spinning speed: 50m / min. Stretching setting: stretching ratio: 3; setting temperature: 120°C. Ultrasonic cleaning: ultrasonic tank length: 10 meters; power: 0.15KW.

[0050] 2. Preparation of PE skin:

[0051] The preparation ...

Embodiment 2

[0055] 1. Preparation of PET core layer:

[0056] The preparation steps of the core layer include: drying the PET chips mixed with nano calcium carbonate, and then performing screw melting, spinning, stretching and setting, and ultrasonic cleaning; wherein the addition amount of nano calcium carbonate is 15%; the core layer is single The diameter of the wire is 3.2 mm. The process parameters in the preparation step are specifically: slice drying: pre-crystallization: 45-80°C (4 hours); temperature rise: 81-125°C (5 hours); heat preservation: 125°C (8 hours). Screw melting: extruder supply: 550g / min; pressure: 150kg / cm2; preheating zone temperature: 255°C; melting zone temperature: 285°C; metering zone temperature: 285°C. Spinning: template temperature: 300°C; spinning speed: 200m / min. Stretching setting: stretching ratio: 5.5; setting temperature: 160℃. Ultrasonic cleaning: Ultrasonic water tank length: 15 meters; power: 1.5KW.

[0057] 2. Preparation of PE skin:

[0058] The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com