Micro light emitting diode wafer

A technology of light-emitting diodes and chips, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as difficulty in manufacturing, limitations, and unsuitability for miniature light-emitting diode chips, and achieve the effect of reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

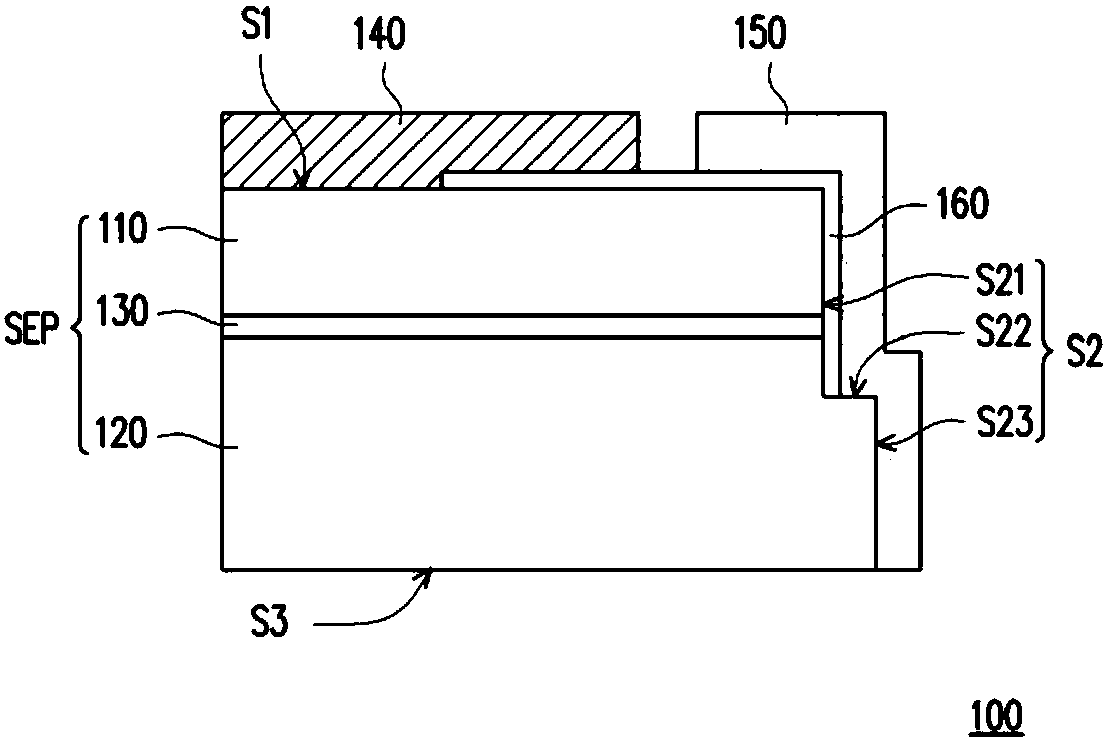

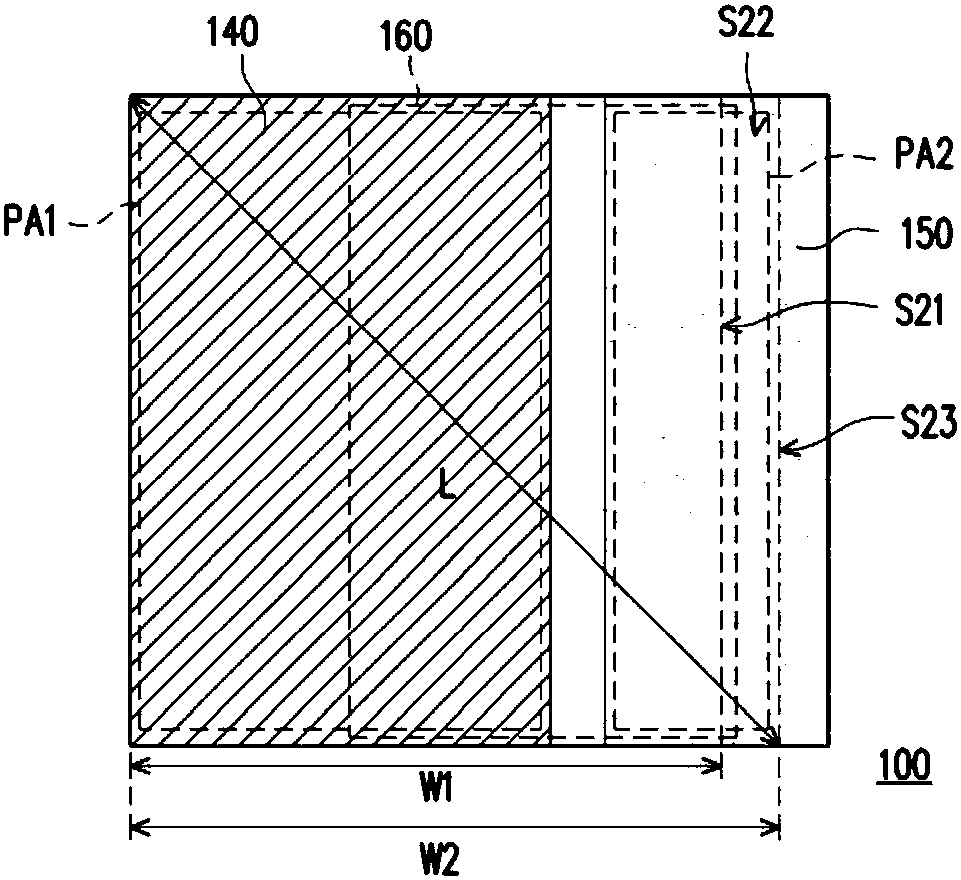

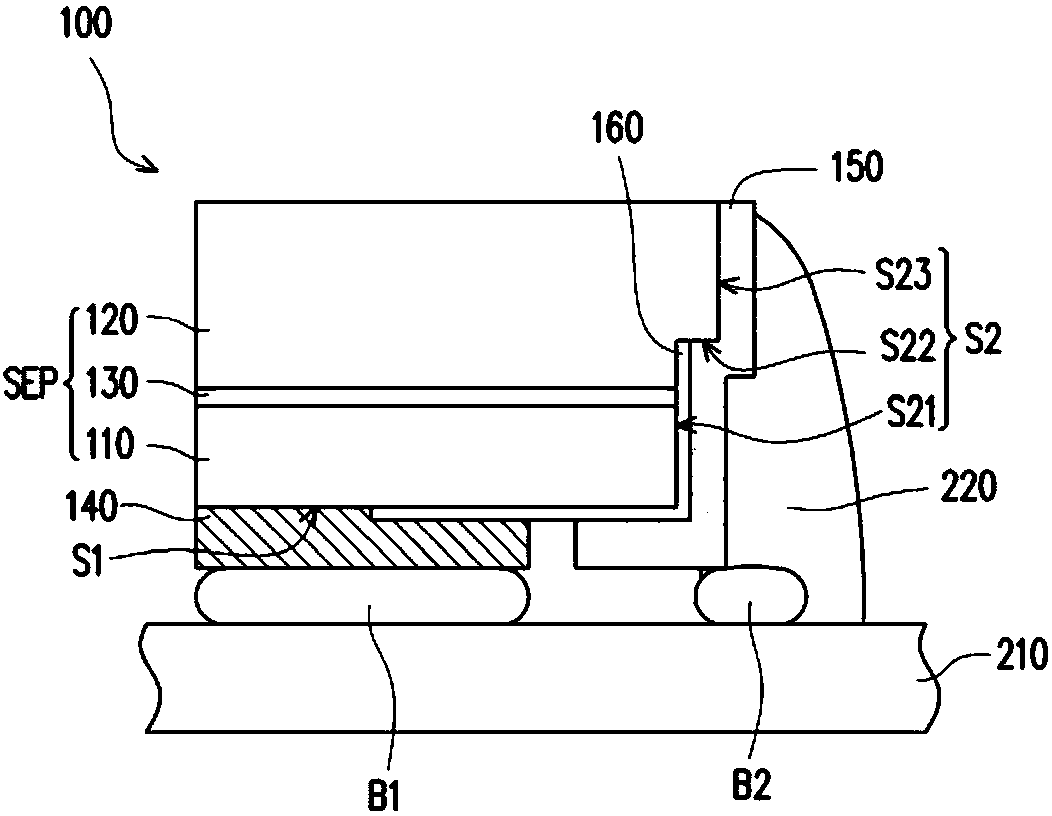

[0048] Figure 1A A cross-sectional schematic diagram showing a micro light emitting diode chip according to an embodiment of the present invention, please refer to Figure 1A . In this embodiment, the Micro Light-Emitting Diode (μLED) chip 100 includes an epitaxial structure SEP, an insulating layer 160, a first electrode 140 and a second electrode 150. Specifically, the epitaxial structure SEP has a first type doped semiconductor layer 110, a second type doped semiconductor layer 120, and a light emitting layer 130, and the light emitting layer 130 is located between the first type doped semiconductor layer 110 and the second type doped semiconductor layer 110. Between the semiconductor layers 120. The material of the semiconductor epitaxial structure SEP may be, for example, gallium nitride (GaN), indium gallium nitride (InGaN) or other semiconductor materials suitable for electroluminescence. The present invention does not limit the material of the semiconductor epitaxial str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com