Patents

Literature

397results about How to "Large luminous area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

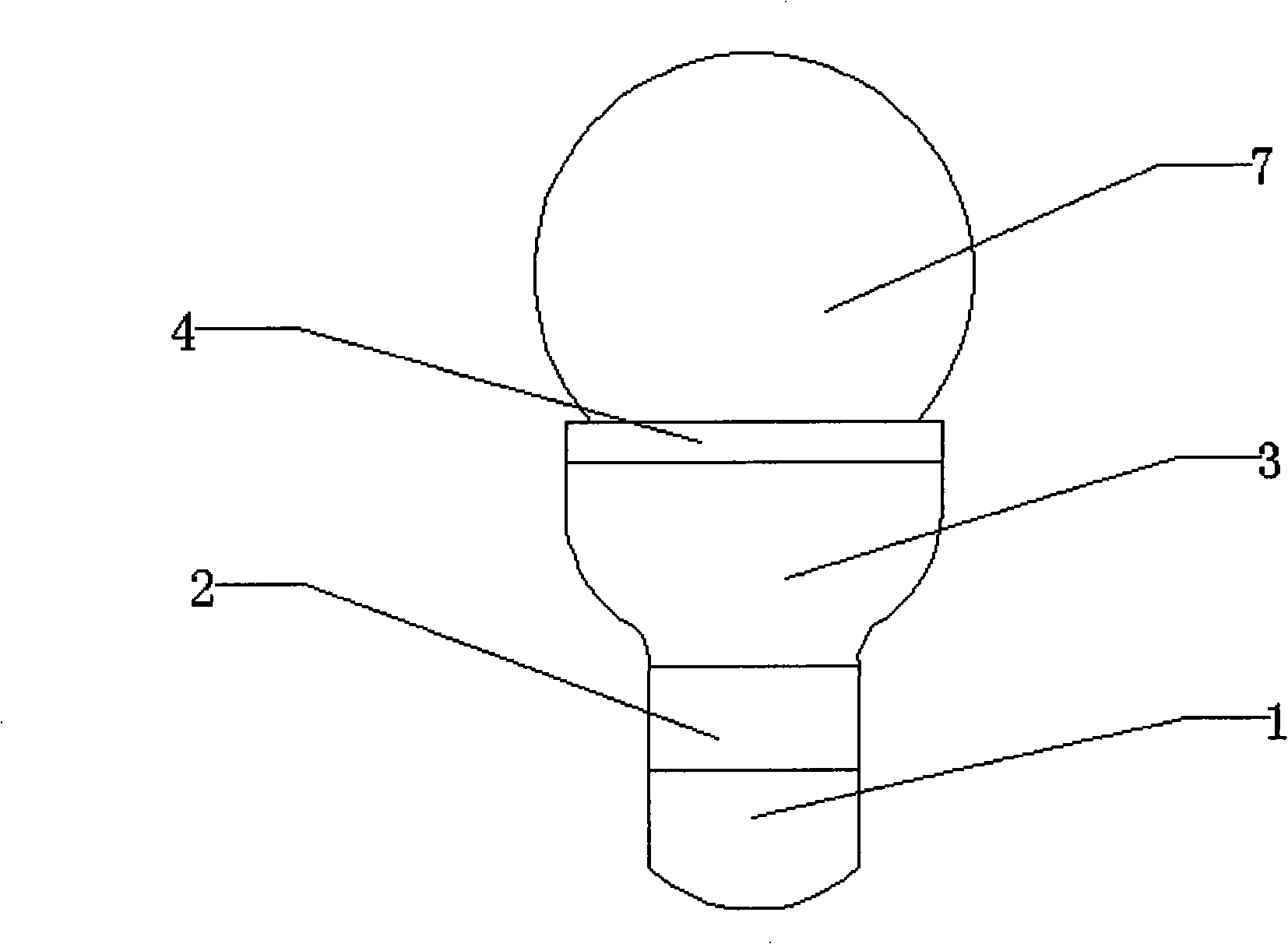

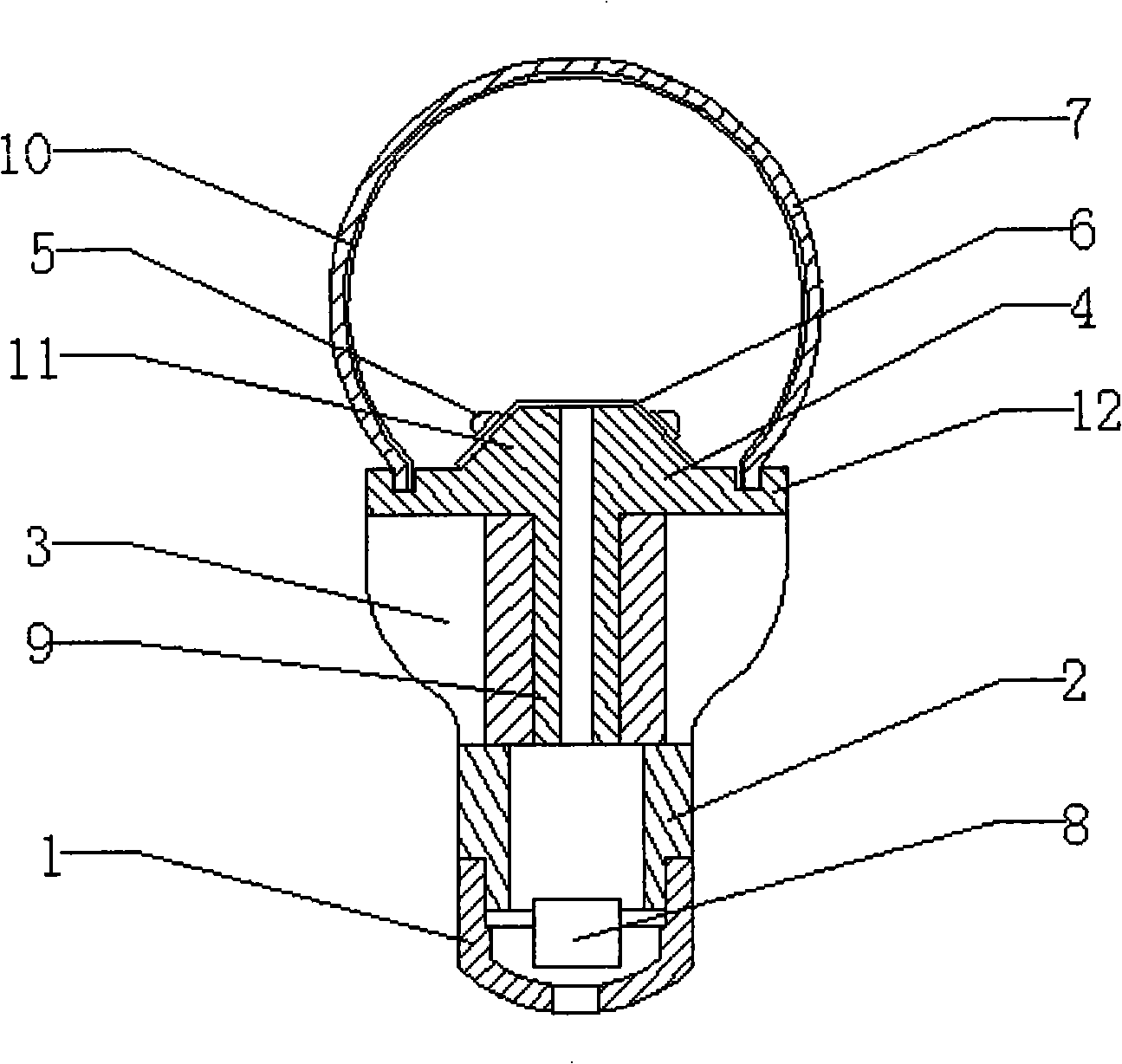

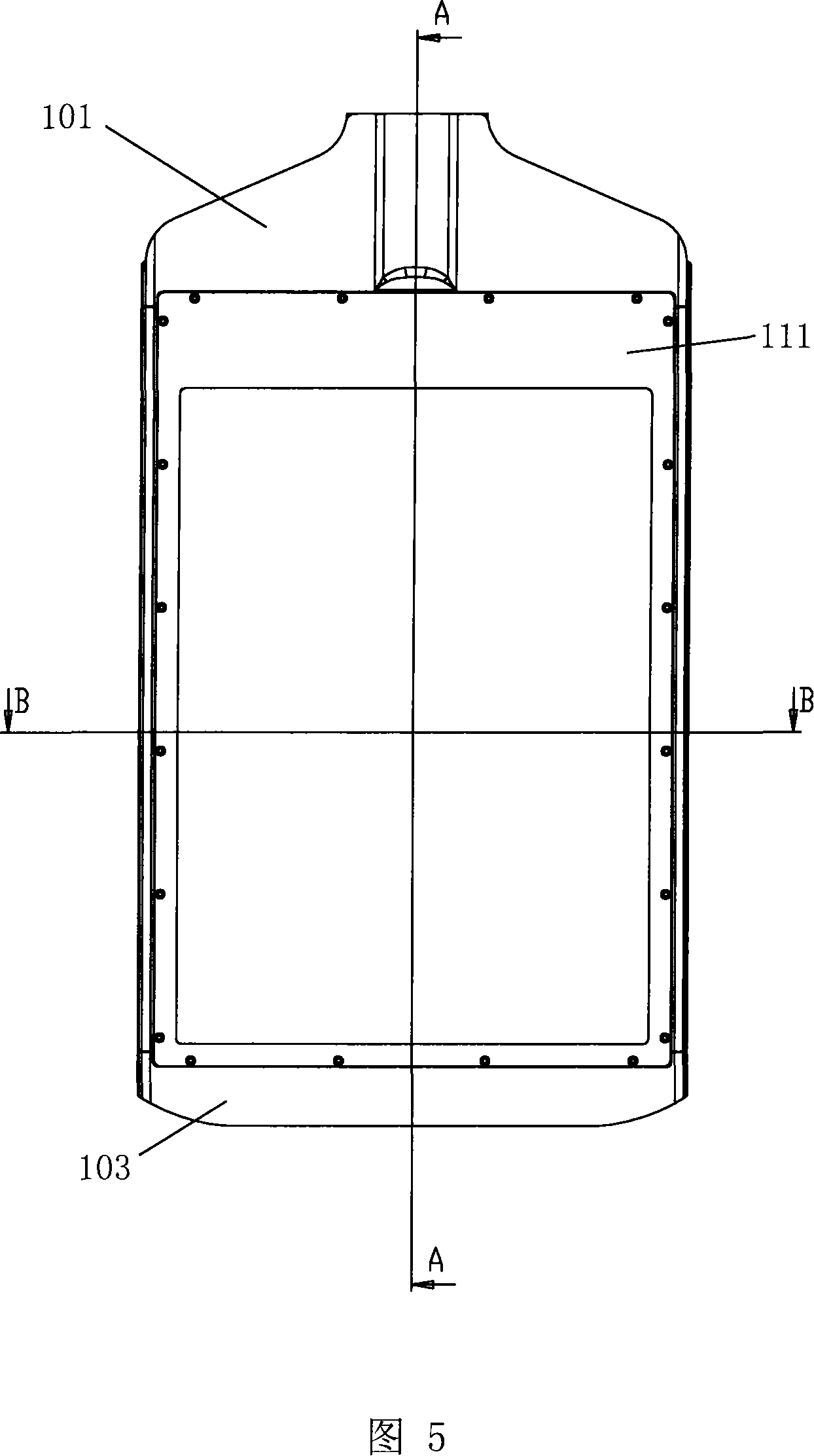

LED lighting bulb

InactiveCN101307887AReduce surface temperatureImprove securityPoint-like light sourceLighting heating/cooling arrangementsEffect lightEngineering

The invention relates to a LED lighting bulb, which comprises a socket, a separating pillar, a radiator, a light source base, a plurality of LED lamps, insulated aluminum base plates and a glass lamp housing, wherein, the socket is connected with the separating pillar connected with the radiator; the radiator which is round is connected with the light source base, and the center of the radiator is provided with a via hole; a thermal conductive pillar connected to the via hole is arranged at the back end of the light source base; the insulated aluminum based plates uniformly provided with a plurality of LED lamps are connected with the front end center of the light source base; the glass lamp housing, the inner surface of which is coated with a layer of reflection grinding powder, is connected with the light source base. The invention has the advantages of large luminous area, soft light, low power consumption without mercurial pollution, good heat dissipation, low surface temperature of the lamp, good safety, convenient operation and long life, without needing to install accessories of the prior fluorescent lamp such as ballasts, starters, etc., and the start-up of the bulb free from influence of temperatures and on-off times.

Owner:穆学利

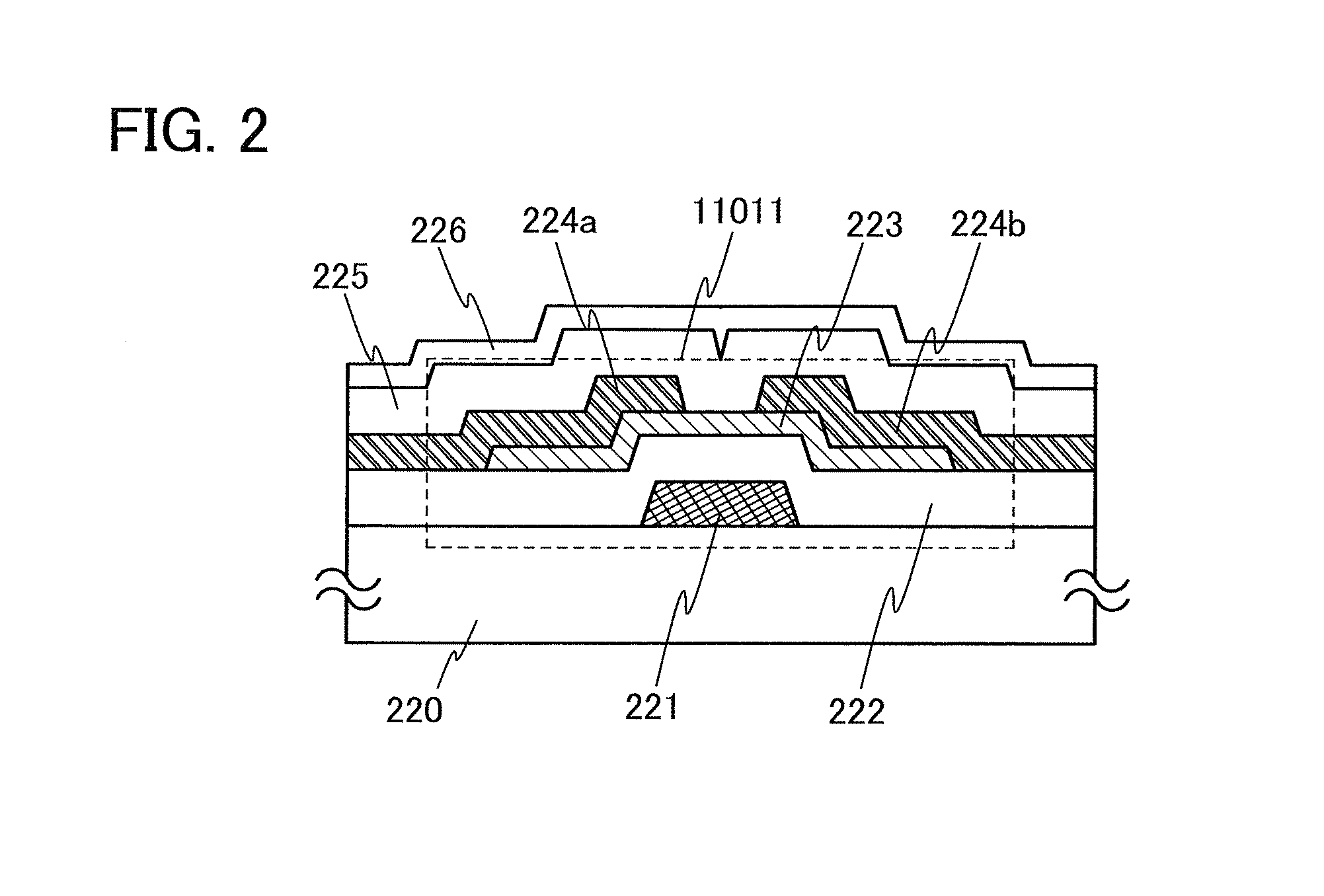

Organic el display panel

ActiveCN101681997AIncrease opening ratioSolution to short lifeElectroluminescent light sourcesSolid-state devicesHole injection layerOptoelectronics

Disclosed is an organic EL display panel with an organic light emitting layer of a uniform film thickness. The organic EL display panel comprises a substrate, a line-shaped bank that is arranged on the substrate and defines line-shaped regions on the substrate, and two or more organic EL elements arranged in a row in each of the line-shaped regions. Each of the organic EL elements includes an anode arranged on the substrate, a hole injection layer arranged on the anode and comprised of a metal oxide, an organic light emitting layer arranged on the hole injection layer, and a cathode arranged on the organic light emitting layer. The hole injection layer is formed in a concave or convex shape, a part of the hole injection layer is arranged below the bank, and the organic light emitting layeris formed by coating the line-shaped regions with an organic light emitting material.

Owner:JOLED INC

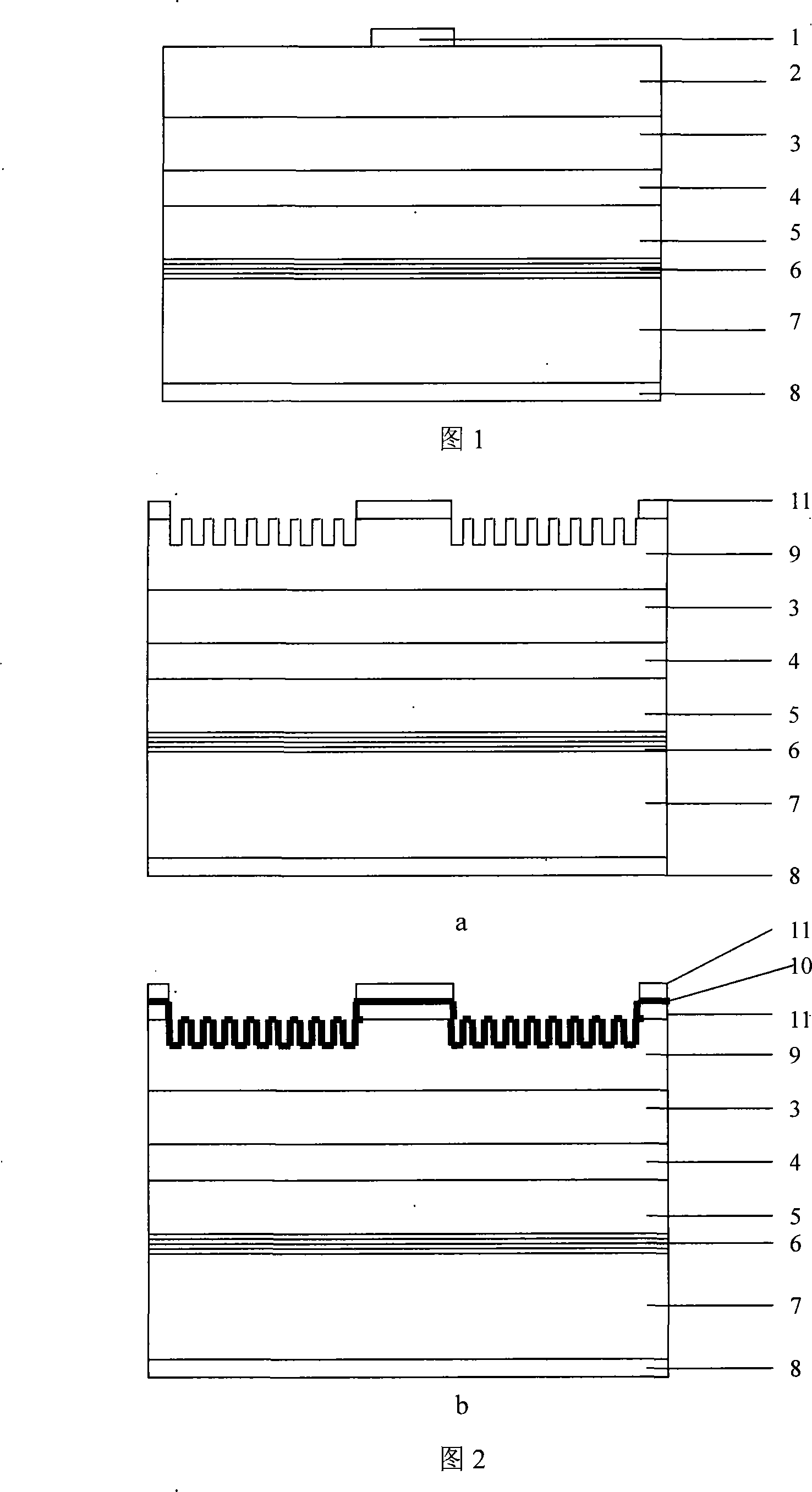

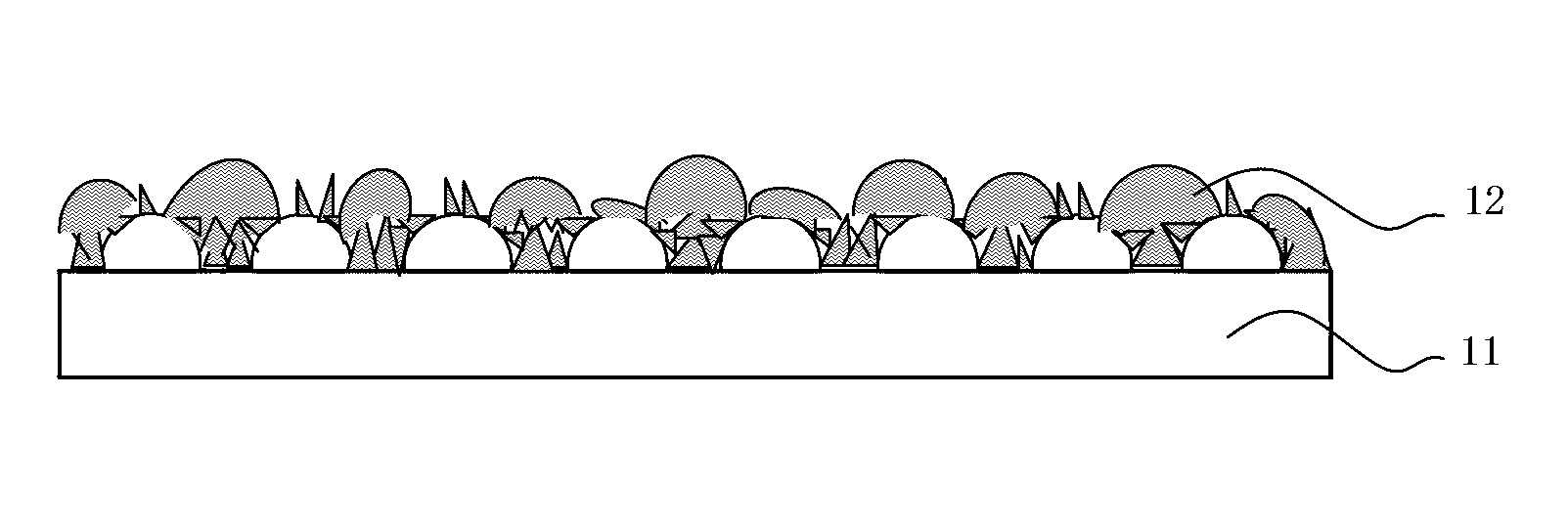

Emitting surface semiconductor LED with nanostructure and its preparing process

InactiveCN101159307AReduce reflectionLarge luminous areaSemiconductor devicesLight reflexManufacturing technology

The invention relates to the technical field of semiconductor photoelectronic device manufacturing, in particular to a semiconductor light emitting diode (LED) with a nanometer light emitting surface. The inventive method comprises growing a dielectric layer (12) and a metal layer (13) on a GaP layer (2) of the conventional LED, and sequentially using the metal layer (13) as a mask to etch the dielectric layer (12) and the parts outside a P type electrode (11) on the upper surface of the GaP layer (2) to obtain the LED with the nanometer light emitting surface. The method also comprises coating a layer of indium tin oxide (ITO) conducting film (10) on the nanometer light emitting surface and the upper surface of the P-type electrode (11), and preparing a P-type electrode (11) with the same structure on the P-type electrode (11) coated with the ITO conducting film (10). The invention reduces light reflex, improves device performance, and can be used in various semiconductor LEDs. Meanwhile, the invention has the advantages of simple process, low cost, and applicability to batch production.

Owner:BEIJING UNIV OF TECH

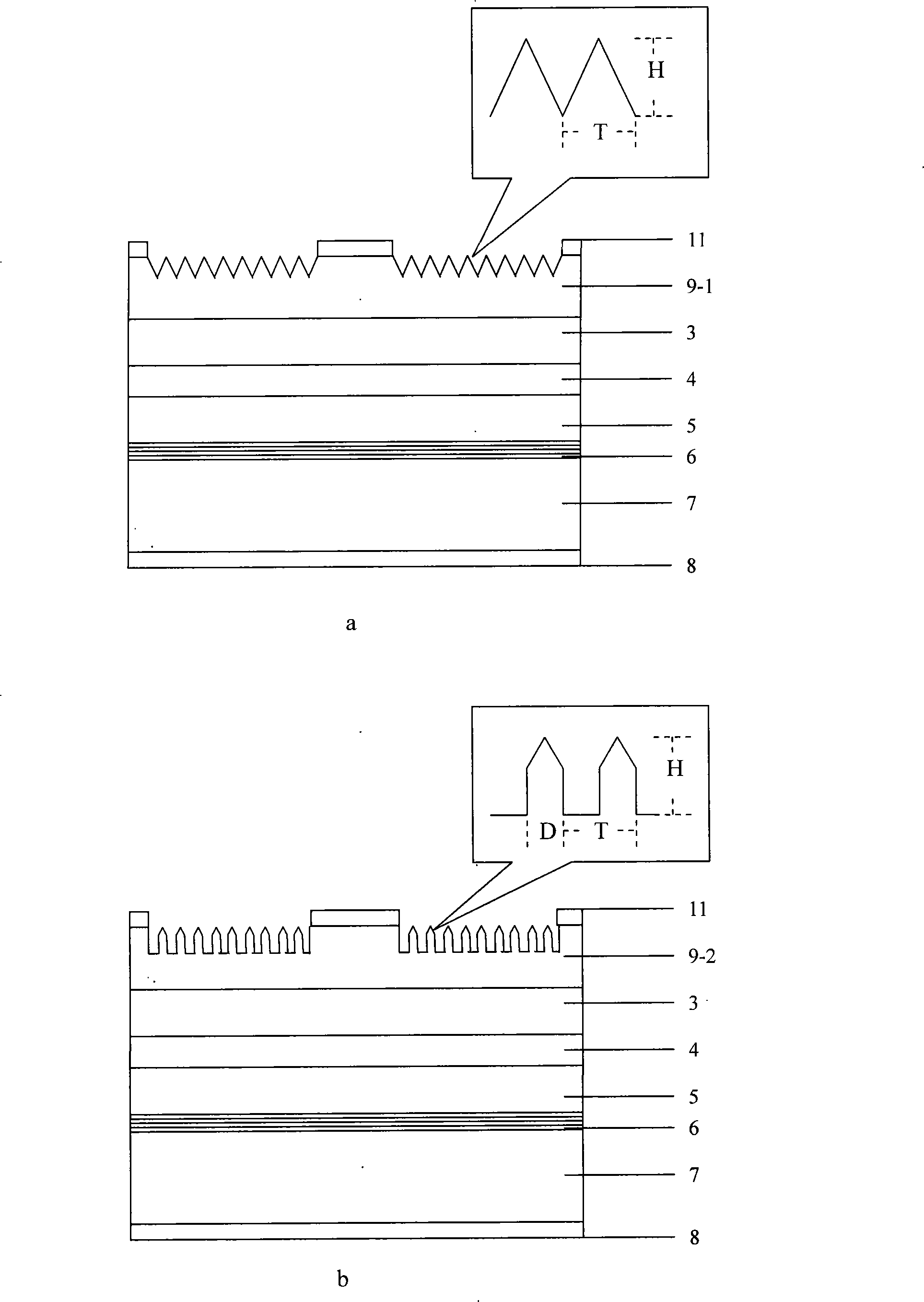

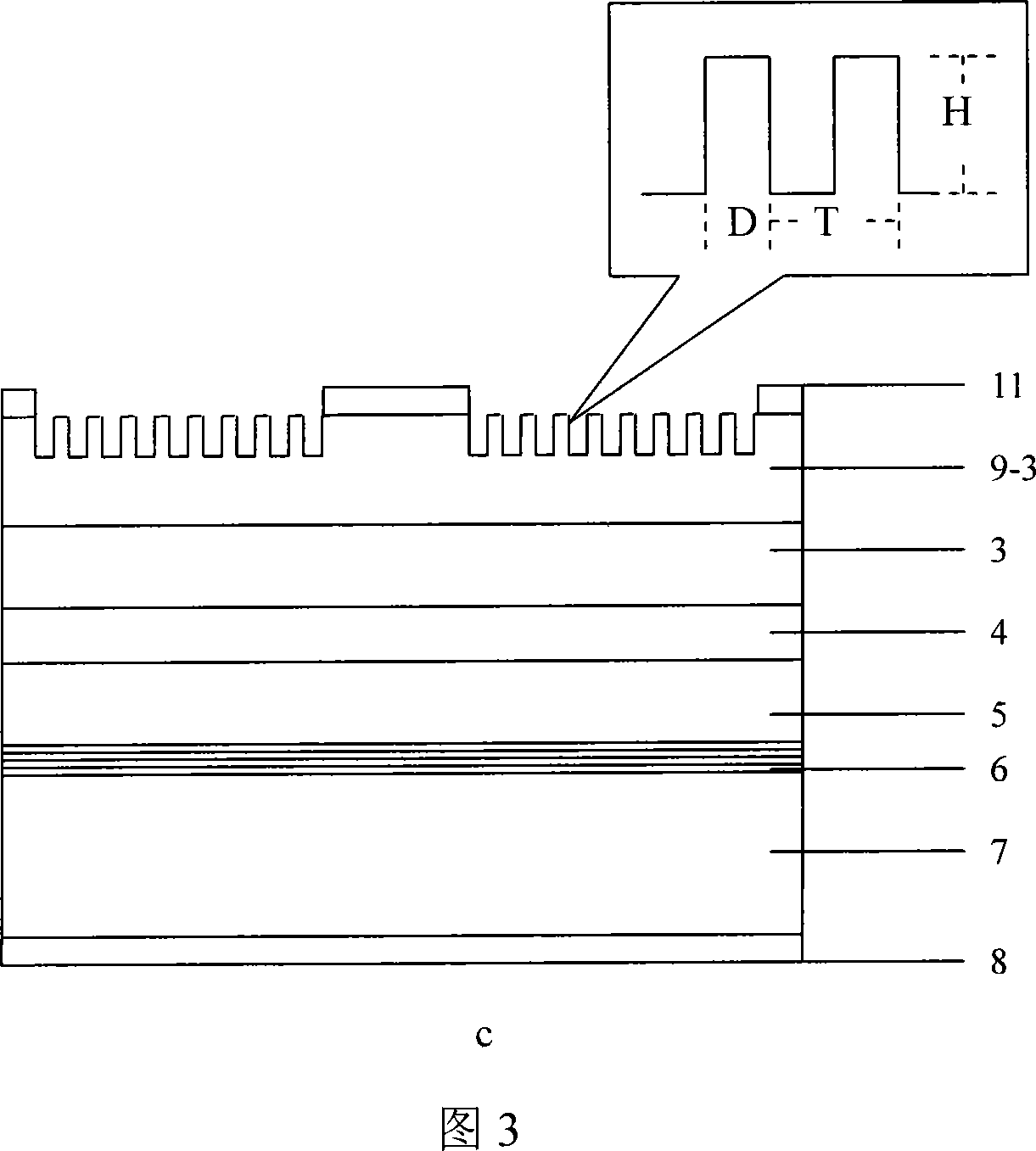

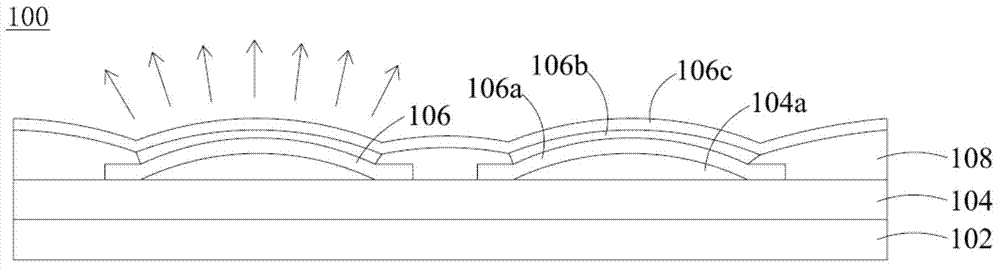

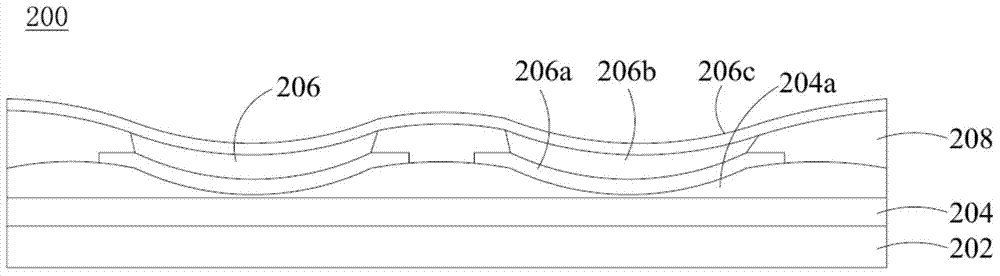

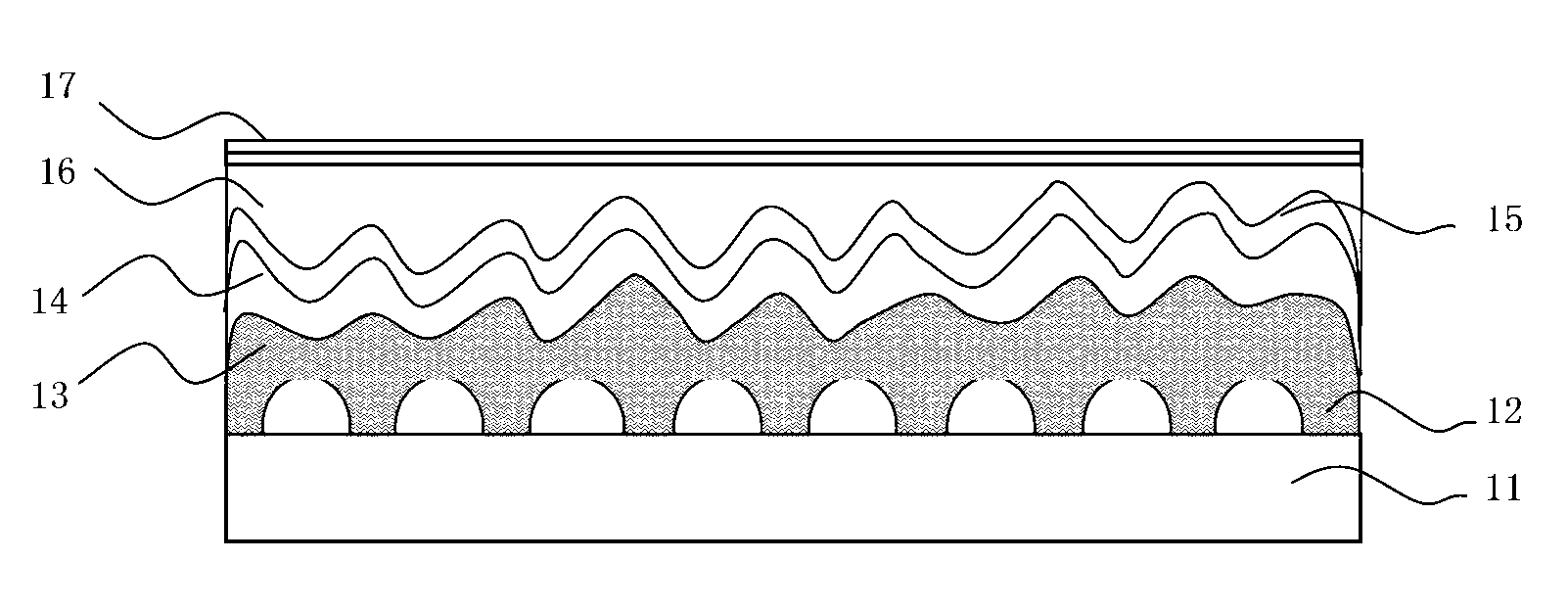

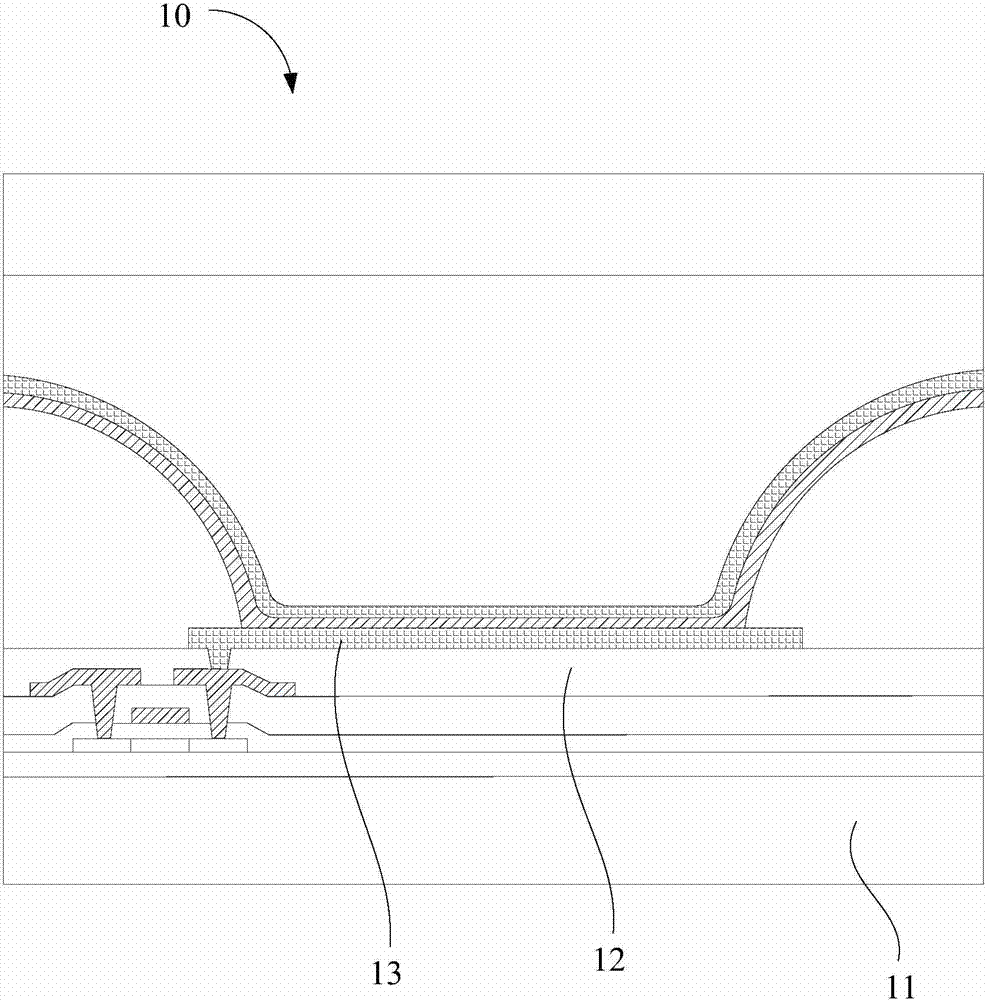

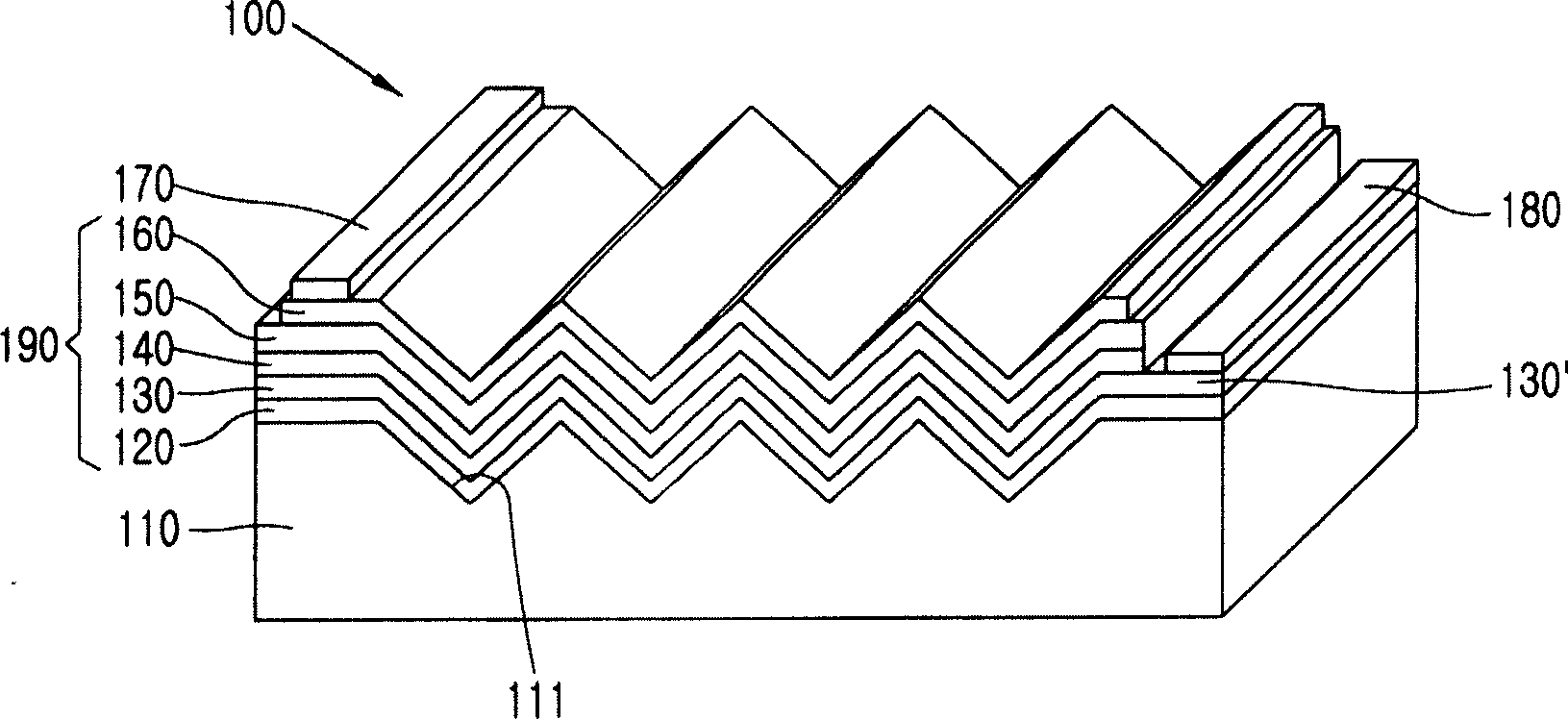

OLED light-emitting device and manufacturing method thereof

InactiveCN103928626AIncrease opening ratioImprove luminous brightnessPlanar light sourcesFinal product manufactureEngineeringContact position

The invention relates to an OLED light-emitting device and a manufacturing method of the OLED light-emitting device. The OLED light-emitting device comprises a substrate, a planarization layer and a plurality of light-emitting units, wherein the planarization layer is located on the substrate and provided with a plurality of bending parts which are arranged at intervals; the light-emitting units are located on the planarization layer, and each light-emitting unit is located on the corresponding bending part and has a shape corresponding to that of the bending part. Each light-emitting unit comprises a first electrode, a light-emitting structure located on the first electrode and a second electrode located on the light-emitting structure. A cross section of each bending part has an arc-shaped outline as a whole. According to the OLED light-emitting device and the manufacturing method of the OLED light-emitting device, by arranging the bending parts in the contact positions of the light-emitting units and the planarization layer, the planar planes of the light-emitting units are turned into bending surfaces, the aperture rate of organic light-emitting diodes is substantially increased, light-emitting area is enlarged, and thus the luminance of the OLEDs is improved, power consumption is reduced, and the service life of the product is prolonged.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

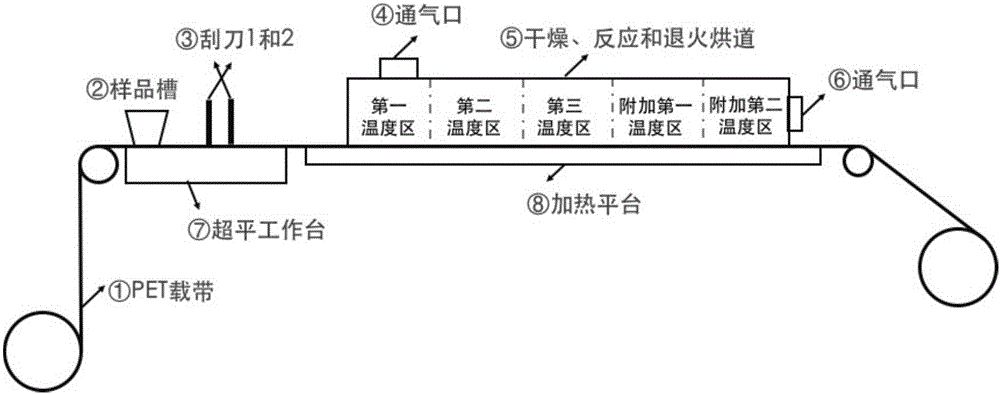

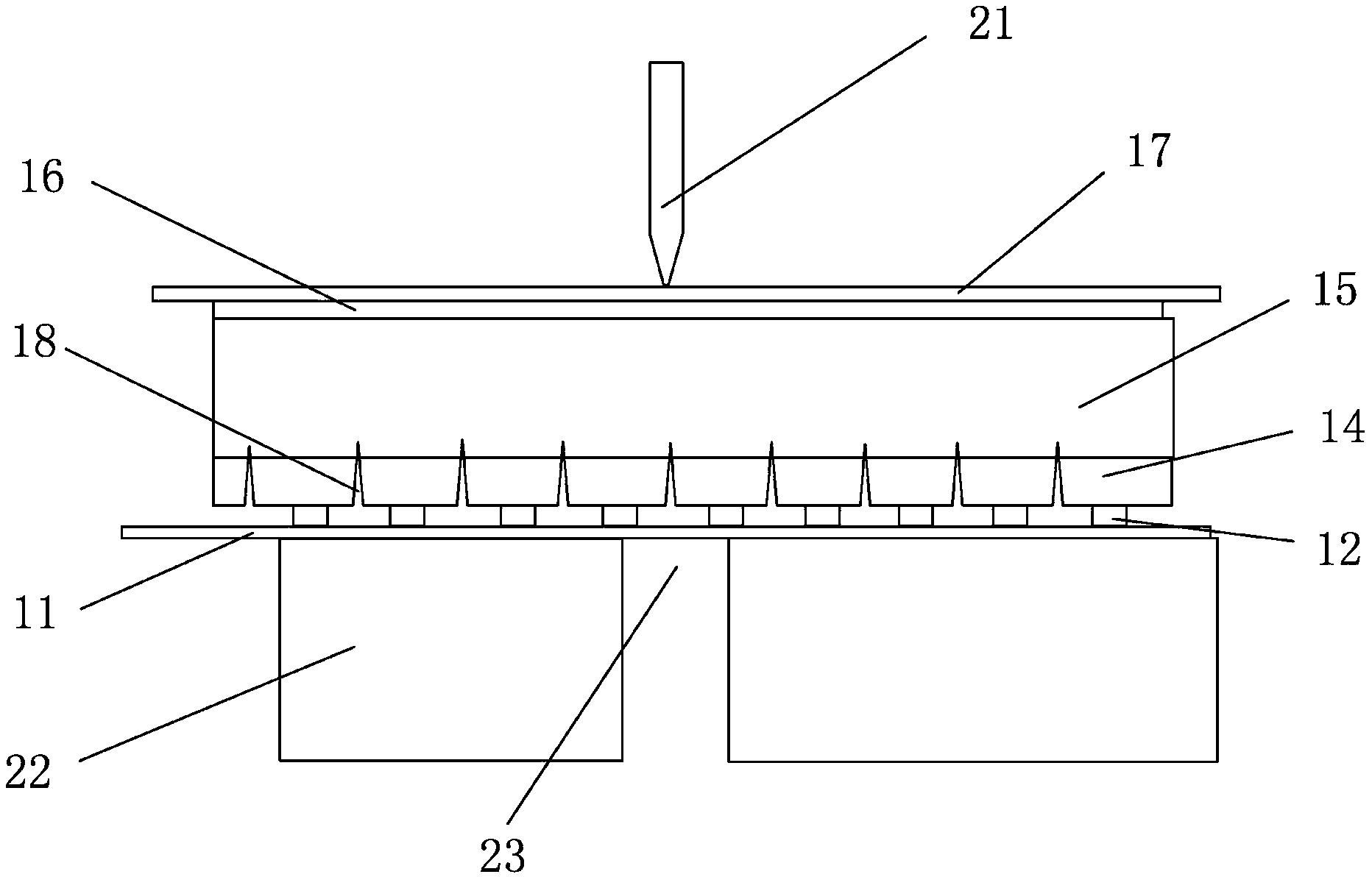

Preparation method of perovskite quantum dot/polymer composite fluorescent film

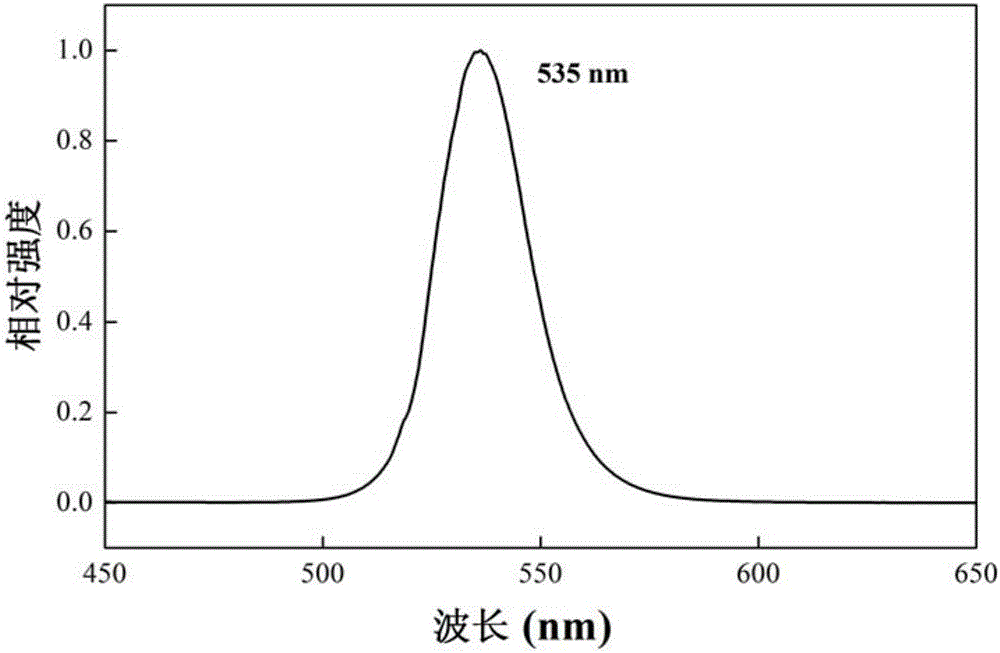

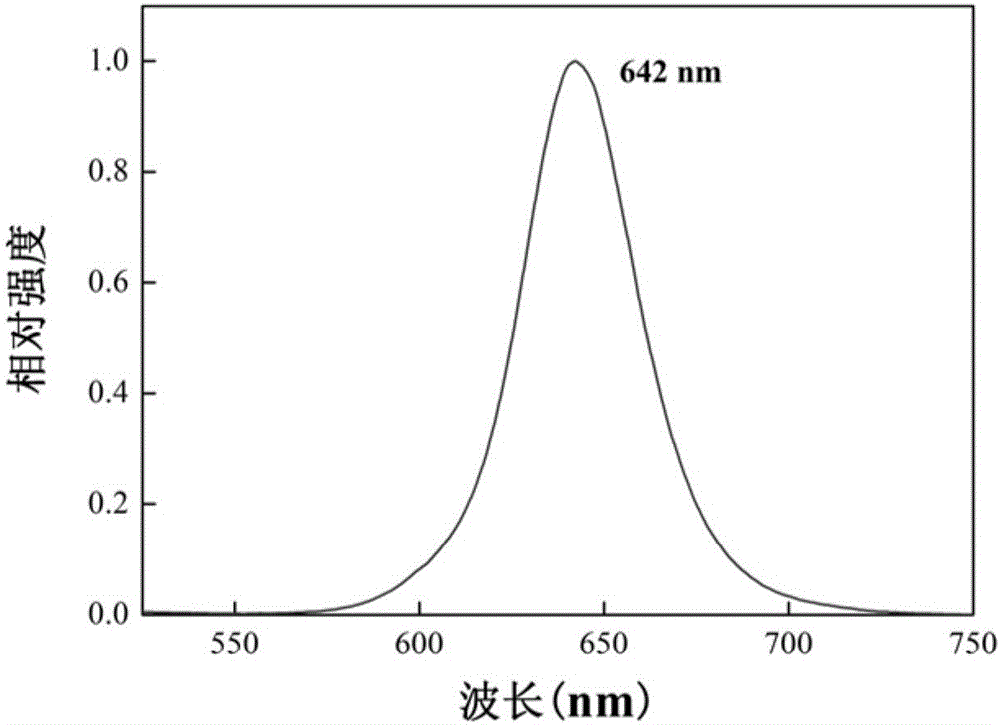

ActiveCN106750427AFacilitate continuous productionGood film formingLuminescent compositionsOrganic solventFluorescence

The invention provides a preparation method of a perovskite quantum dot / polymer composite fluorescent film. The method comprises the following steps that S1, perovskite raw material ingredients and polymer ingredients are dissolved in an organic solvent to obtain a film forming solution; S2, a substrate material is coated with the film forming solution; S3, the substrate material coated with the film forming solution continuously passes through a plurality of temperature regions to be heated; the perovskite quantum dot / polymer composite fluorescent film is generated. The preparation method provided by the invention has the advantages that a multi-section heating drying mode is used; the fluorescent quality of the quantum dot optical film can be better controlled; the method can be used for continuously and industrially producing the composite fluorescent film; the production flow process can be obviously simplified; the production efficiency is improved; the cost is reduced.

Owner:ZHIJING NANOTECH CO LTD

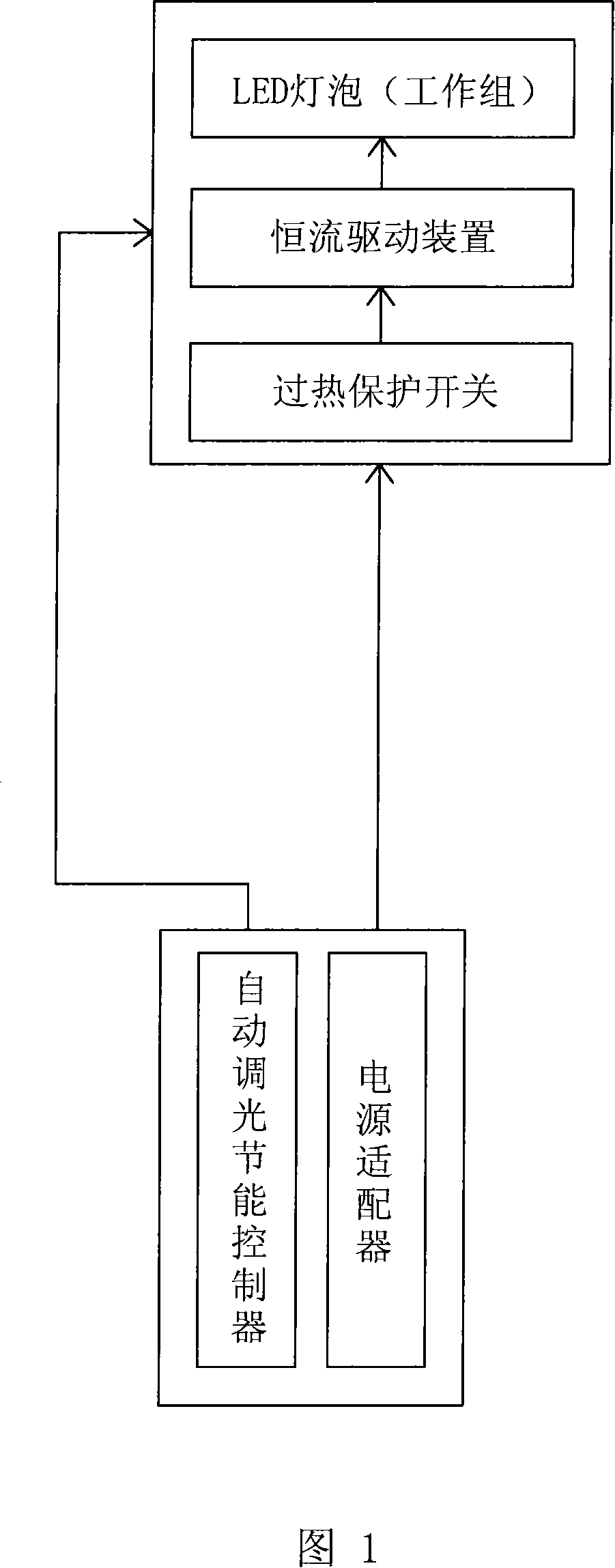

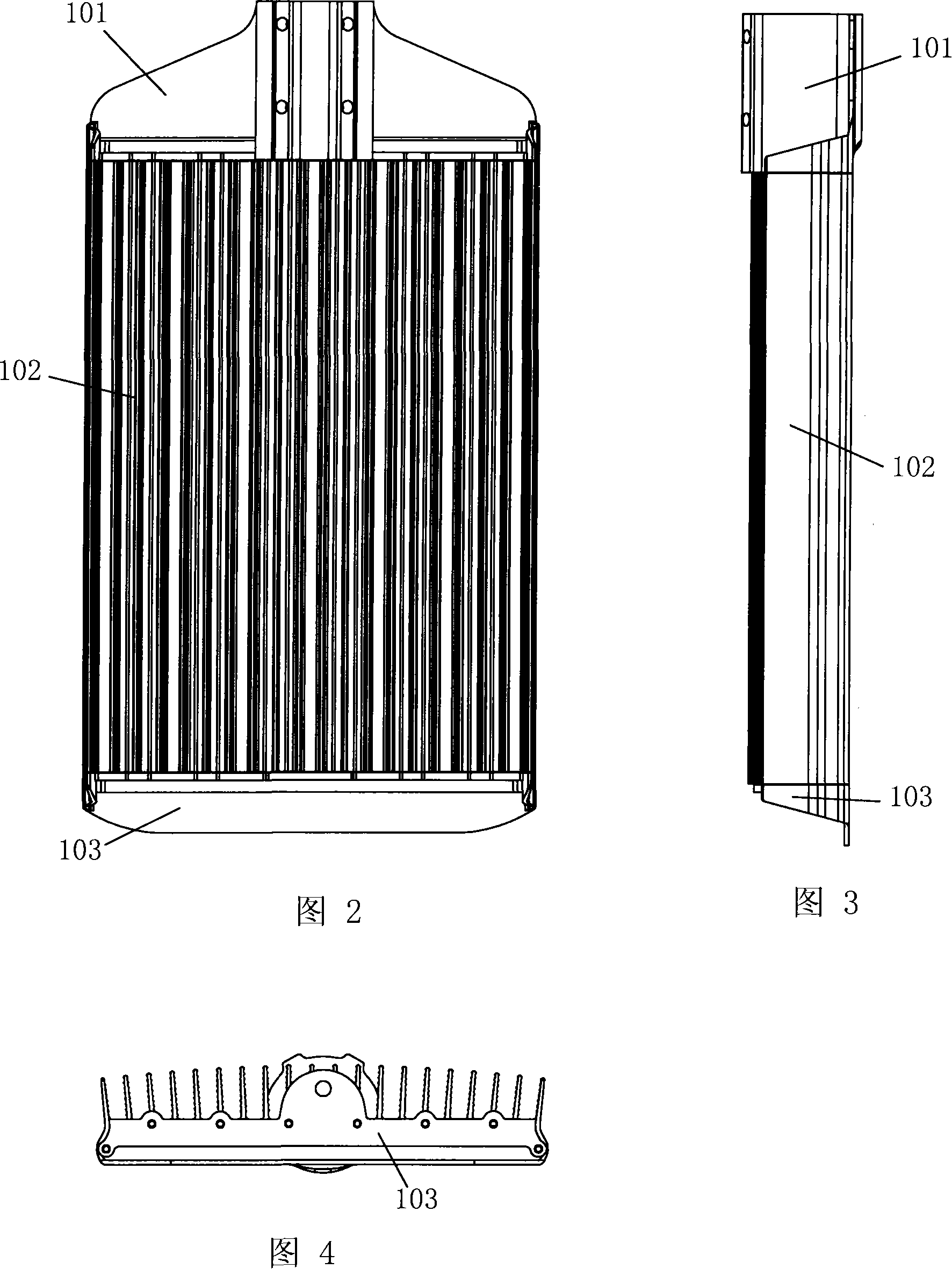

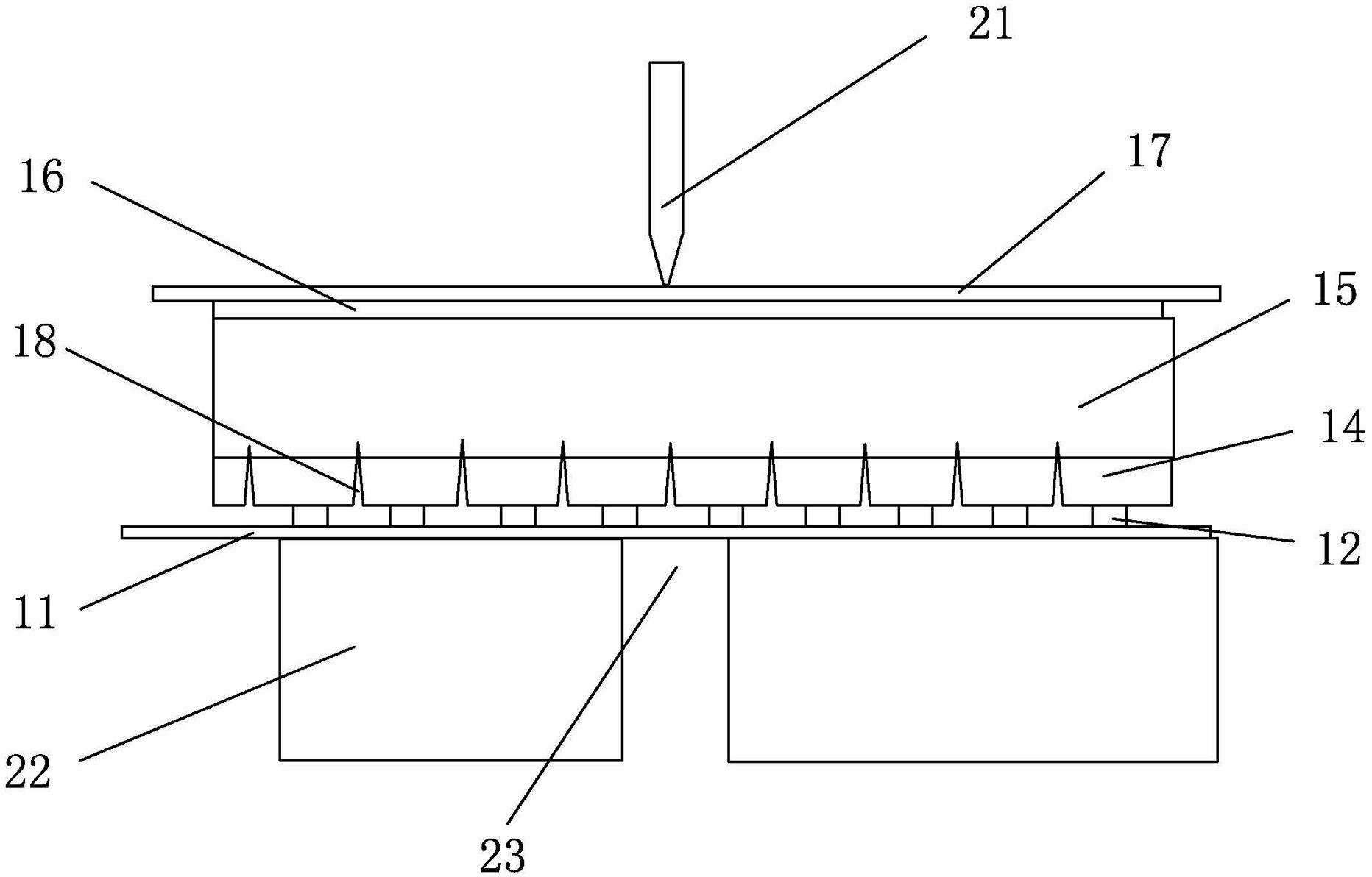

LED road lamp and LED road lamp radiation area expansion method

The invention relates to a LED street lamp, in particular to an expandable LED street lamp and a method for expansion of luminous surface of LED street lamp. The LED street lamp comprises a lamp body equipped at the top of a lamp post of the LED street lamp. The invention is characterized in that a plurality of dismountable and independent LED working modules are equipped in the lamp body, each working module is composed of a piece of heat conducting substrate and a LED lamp bulb equipped on the front side of the LED heat conducting substrate, and a printed circuit is disposed on the heat conducting substrate; the lamp body also comprises a plurality of independent constant current driving devices, one constant current driving device corresponds to one LED working module, and the constant current driving devices supply power to the LED working modules. The method for expansion of luminous surface of LED street lamp comprises adding the LED working modules. The invention provided an expandable LED street lamp and a method for expansion of luminous surface of LED street lamp.

Owner:DONGGUAN KINGSUN OPTOELECTRONIC CO LTD

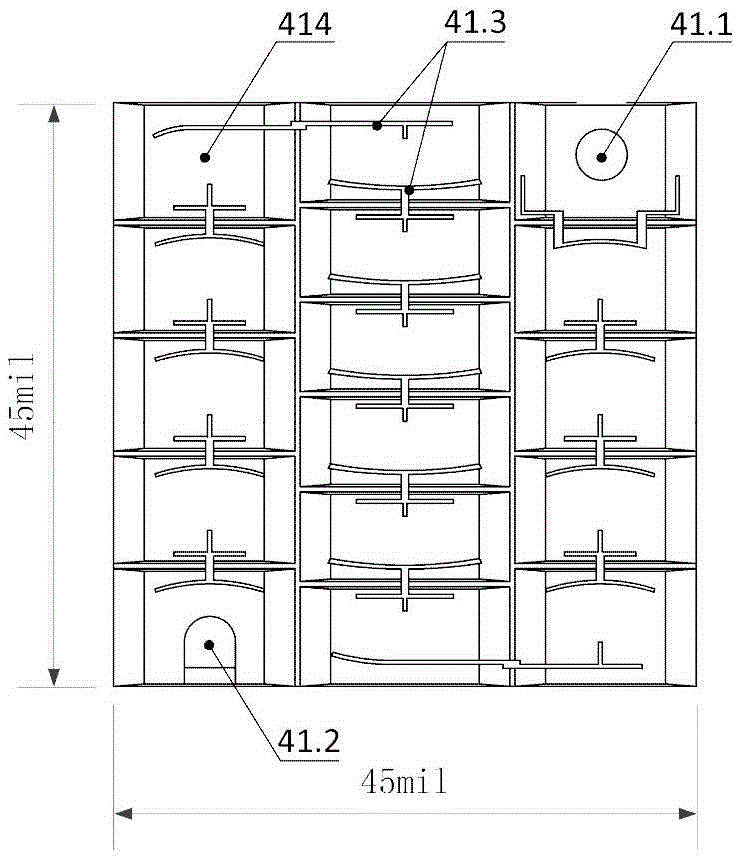

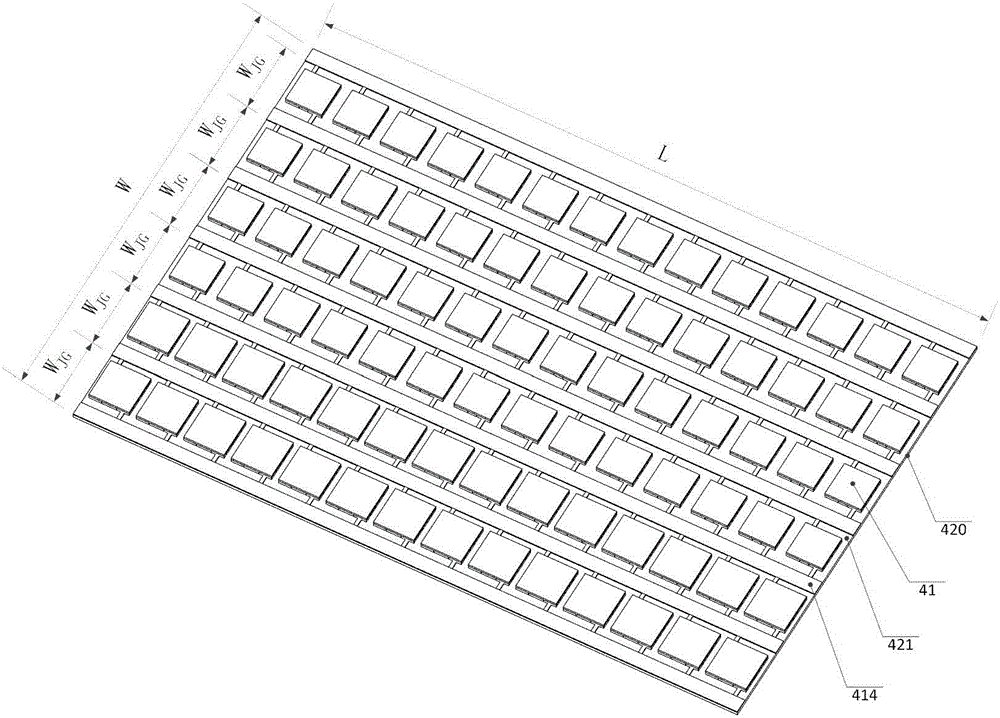

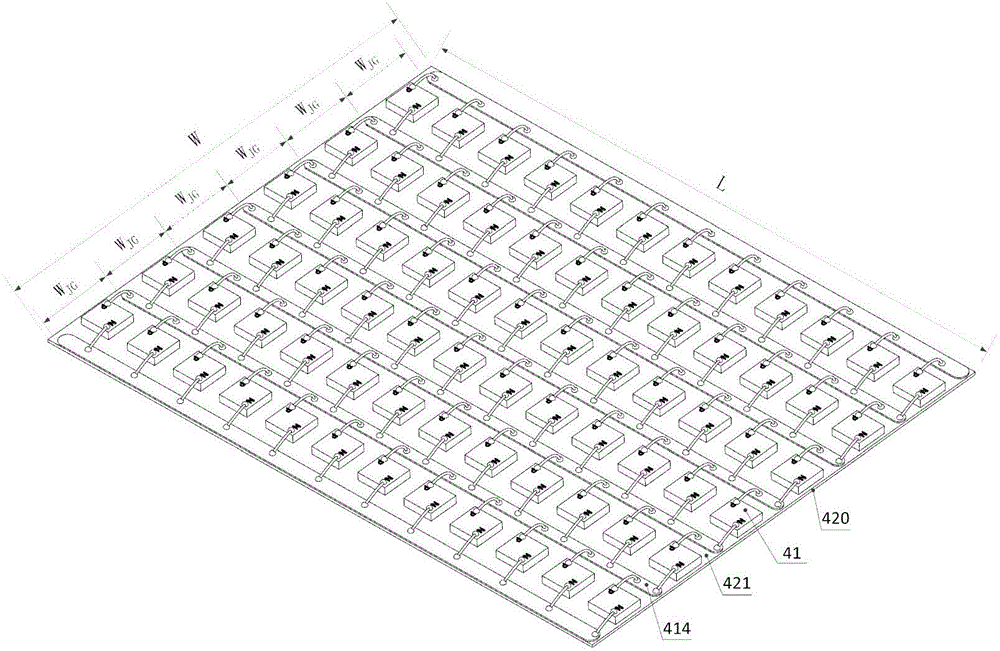

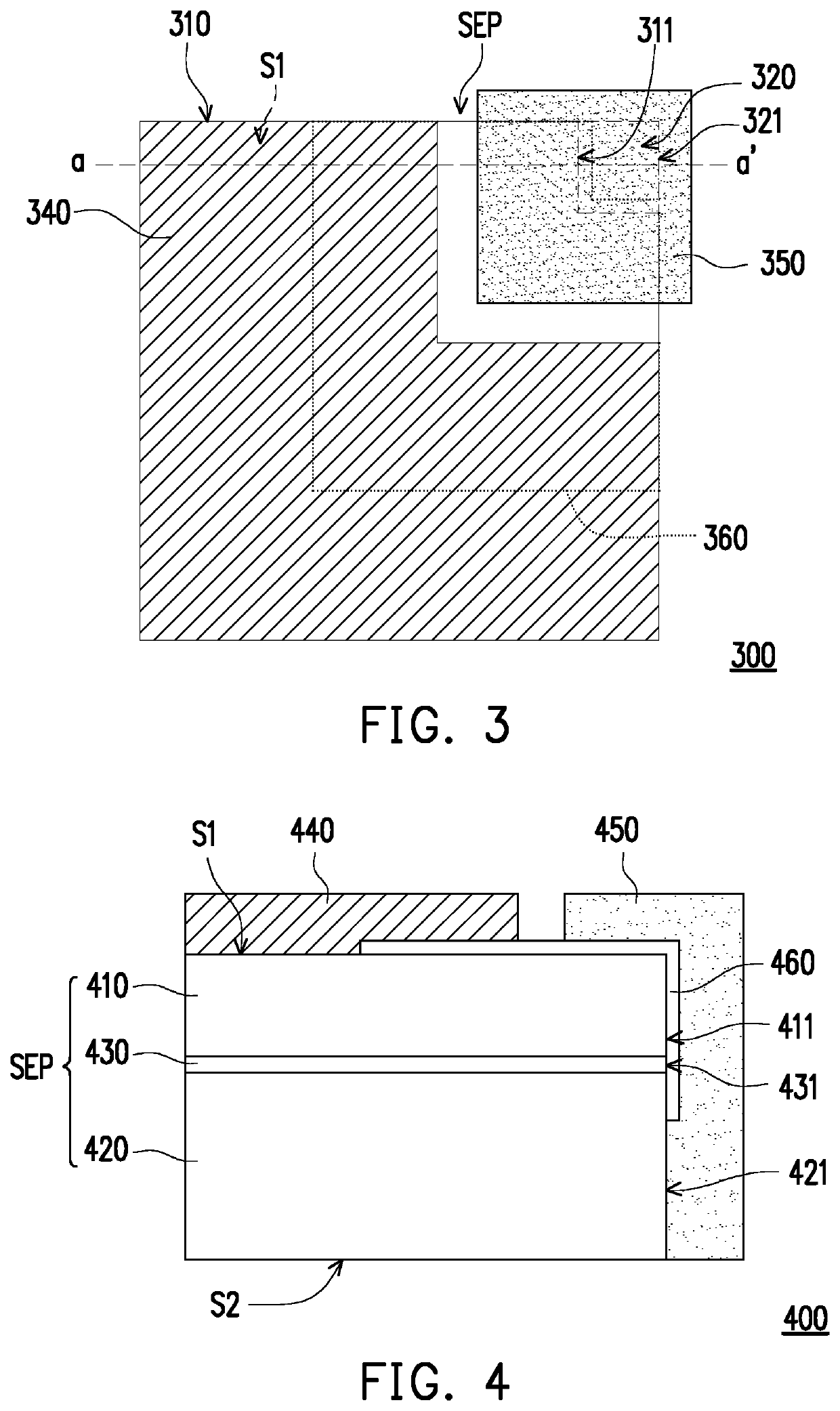

Large chip for LED lighting

ActiveCN103985809AReduce manufacturing costThe production process is short and simplePlanar light sourcesPoint-like light sourceEngineeringMaterials science

The invention discloses a large chip for LED lighting. The large chip comprises a first transparent substrate (421) with a fixed width W, N+1 parallel interface wires are arranged on the first transparent substrate (421), LED chip series connection sets formed by N LED chips (41) are arranged on the first transparent substrate (421), each LED chip (41) is located between two adjacent interface wires, the distance between the two adjacent interface wires is WJG, wherein the WJG=(W-the with of the interface wire) / N, and the positive pole and the negative pole of each LED chip (41) are respectively connected to the two adjacent interface wires. Meanwhile, the multiple LED series connection sets are in series connection, so that an N-column and multi-row LED chip array capable of extending in the length direction of the first transparent substrate (421) is formed in the first transparent substrate (421), wherein N is an integer ranging from 3 to 7.

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

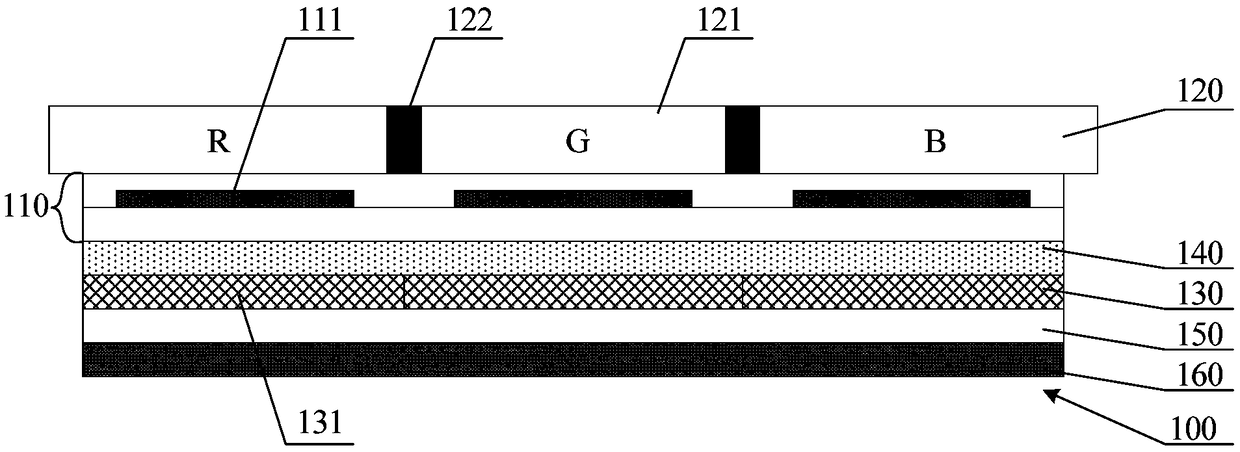

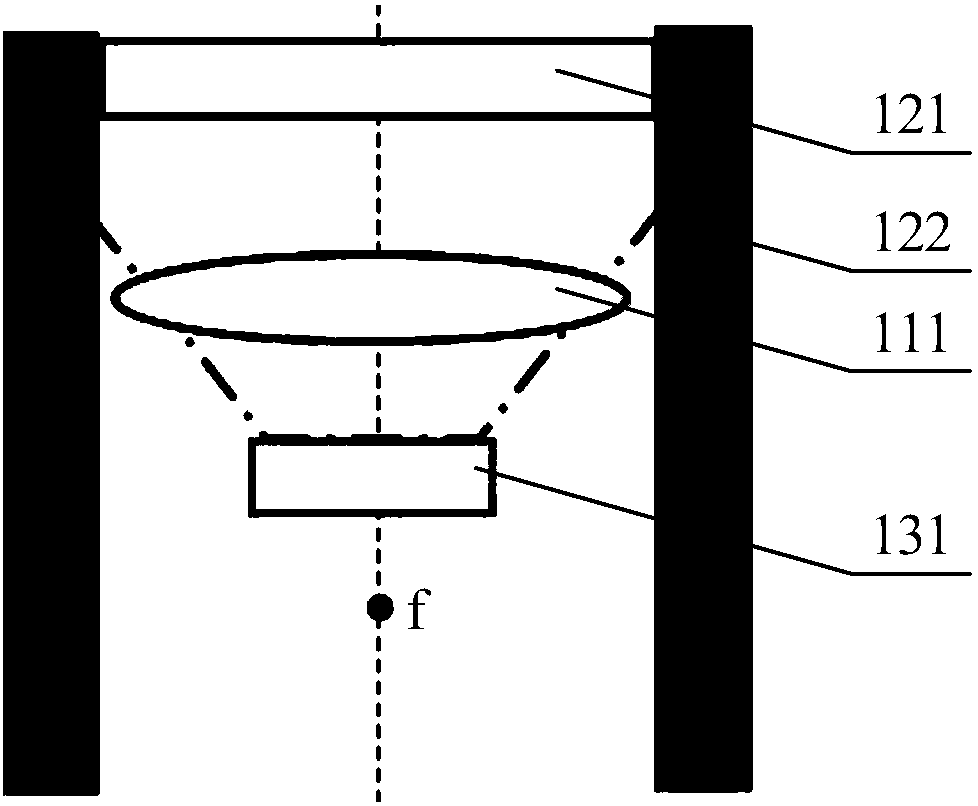

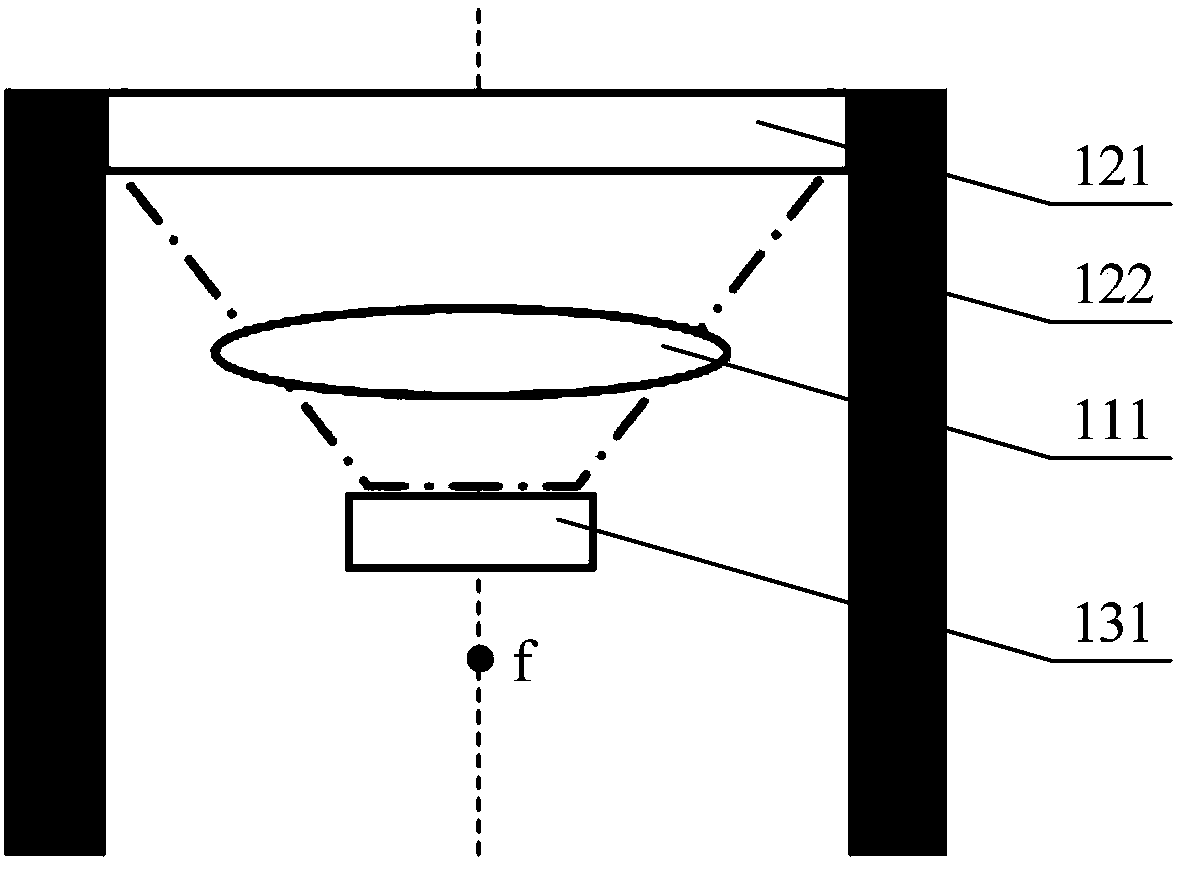

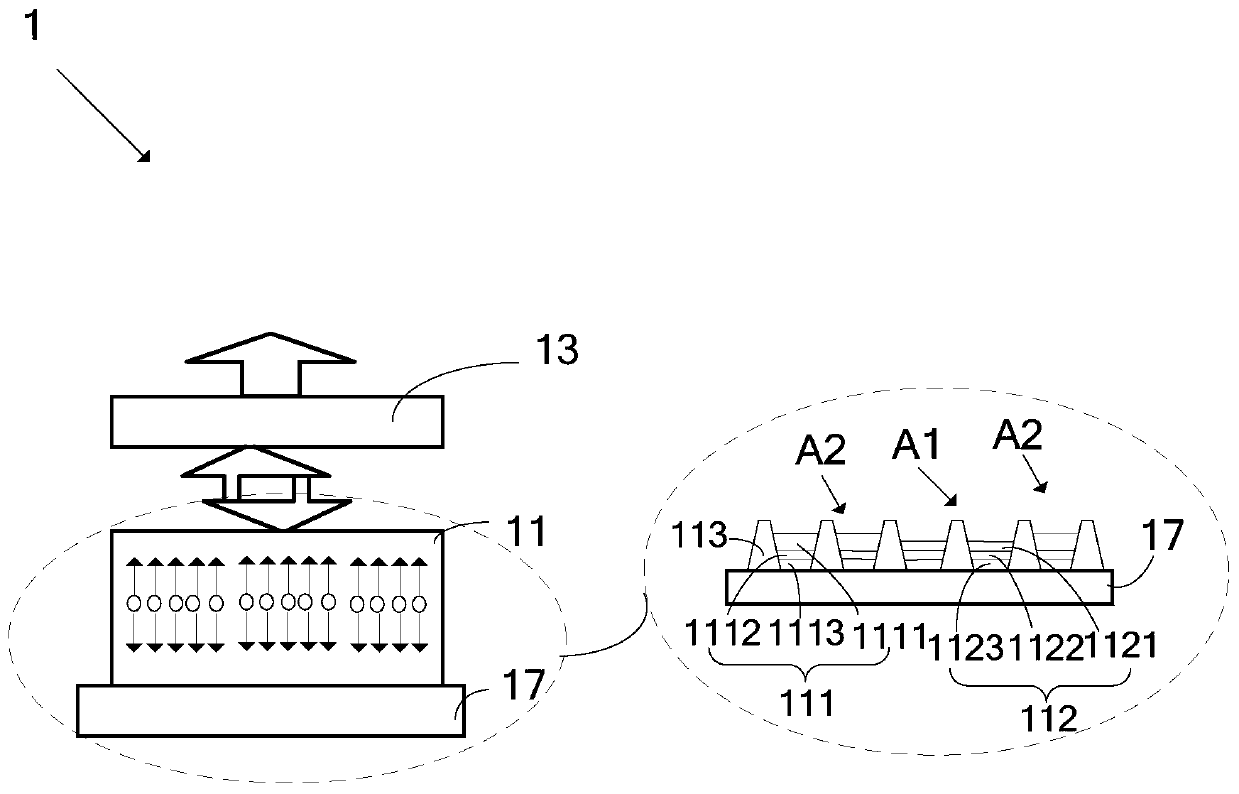

Flexible display panel, flexible display device and manufacturing method of flexible display panel.

ActiveCN108598125ALarge luminous areaImprove brightness reductionFinal product manufactureSolid-state devicesLight spotDisplay device

The embodiment of the invention discloses a flexible display panel, a flexible display device and a manufacturing method of the flexible display panel. The flexible display panel comprises a flexiblesubstrate, a display device layer arranged at one side of the flexible substrate and including multiple light-emitting units, a lens layer and a color filtering layer orderly arranged at the light-emergent side of the display device layer, wherein the color filtering layer comprises a black matrix, and multiple filtering units defined by the black matrix, the area of each filtering unit is enlarged when the filtering unit is in the stretching state, the lens layer comprises lenses arranged between the light-emitting units and the corresponding filtering units, and each lens is used for formingenlarged light spot through the light ray sent from the light-emitting unit and penetrating the lens, the area of the light spot is greater than the area before stretching of the filtering unit. Through the flexible display panel disclosed by the embodiment of the invention, the problem that the brightness is reduced since the aperture ratio of the display panel is reduced when the existing flexible display device is stretched and the problem that the brightness is non-uniform since the display panel is in non-uniform stretching are dealt with to a certain degree.

Owner:BOE TECH GRP CO LTD

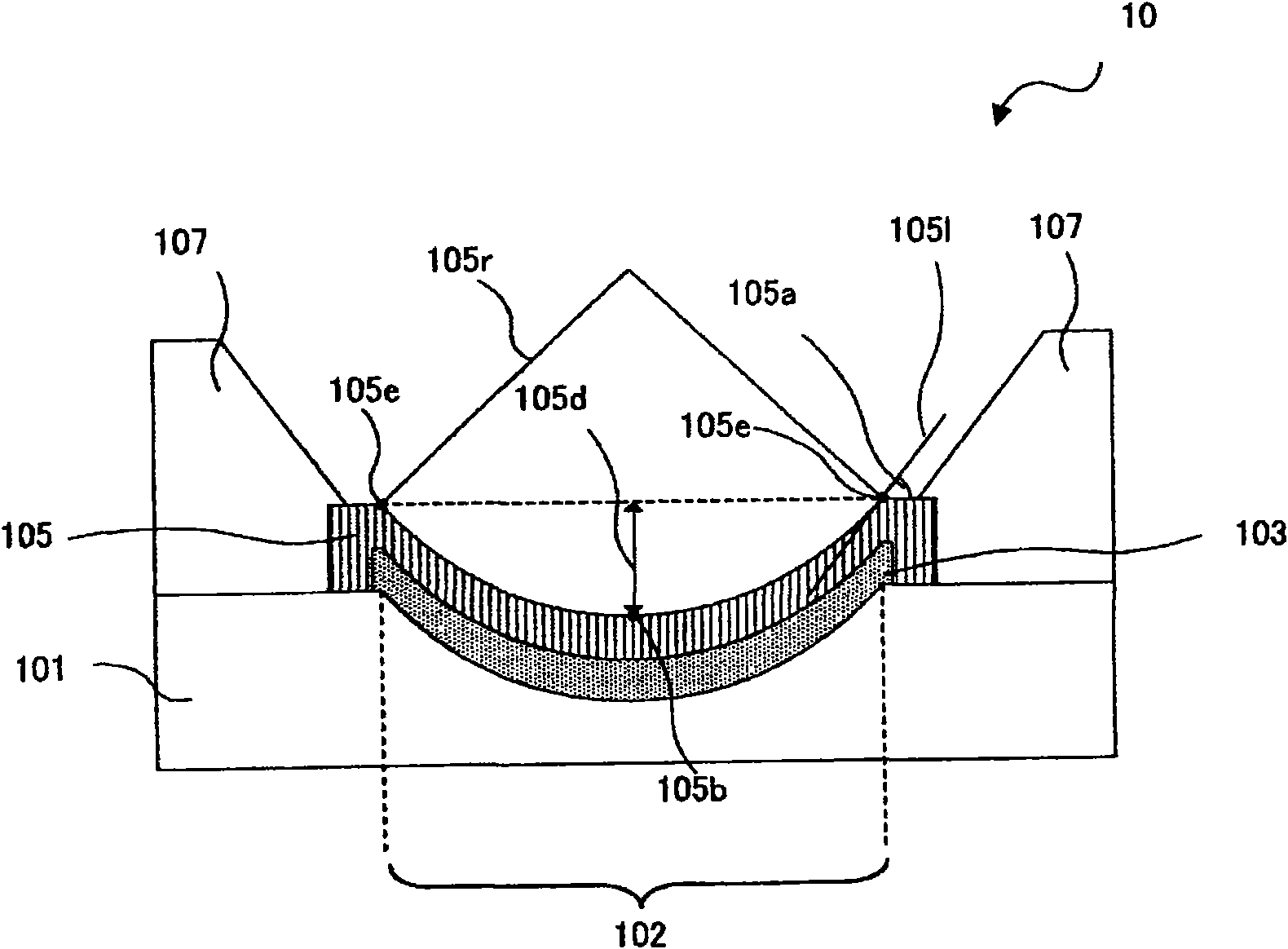

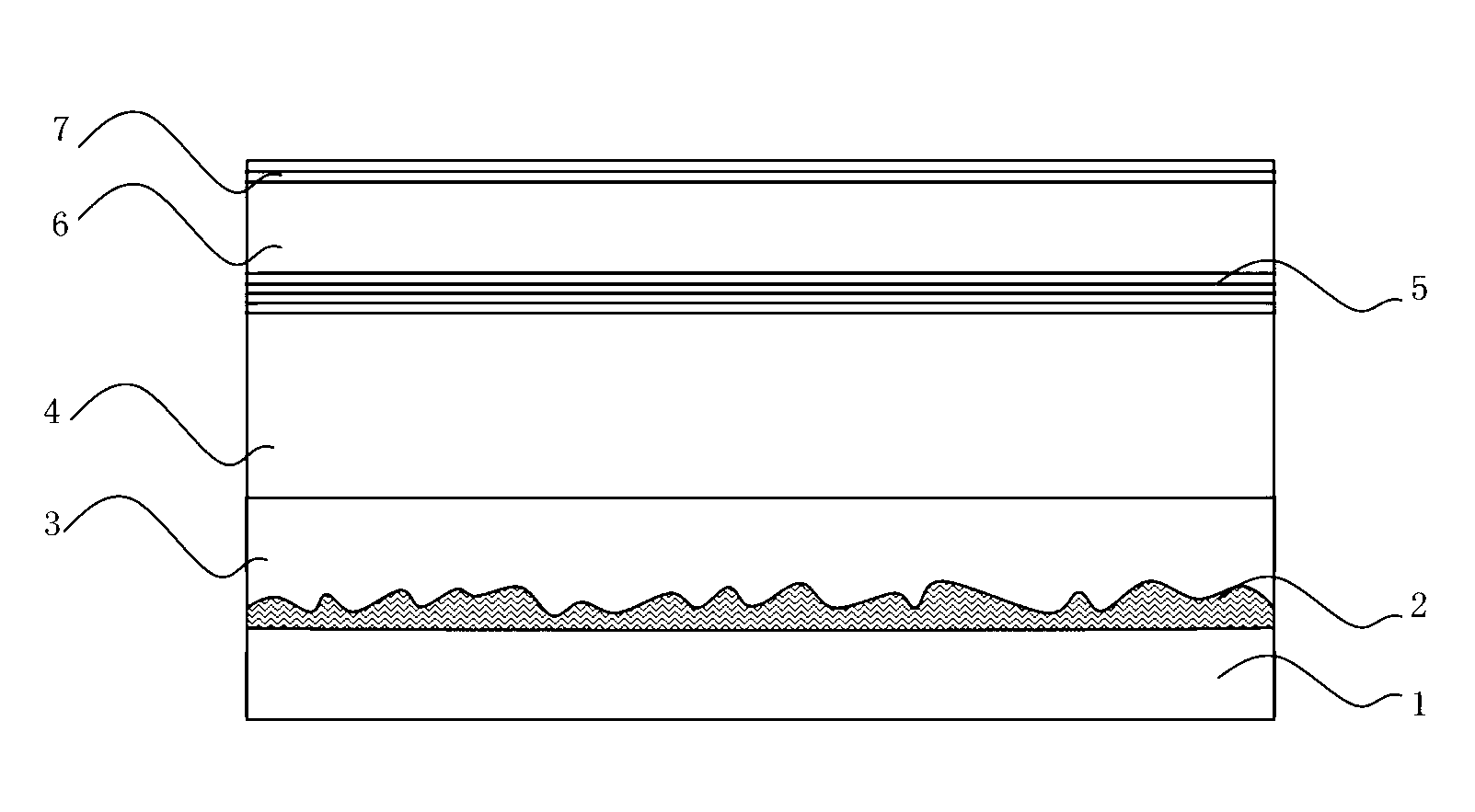

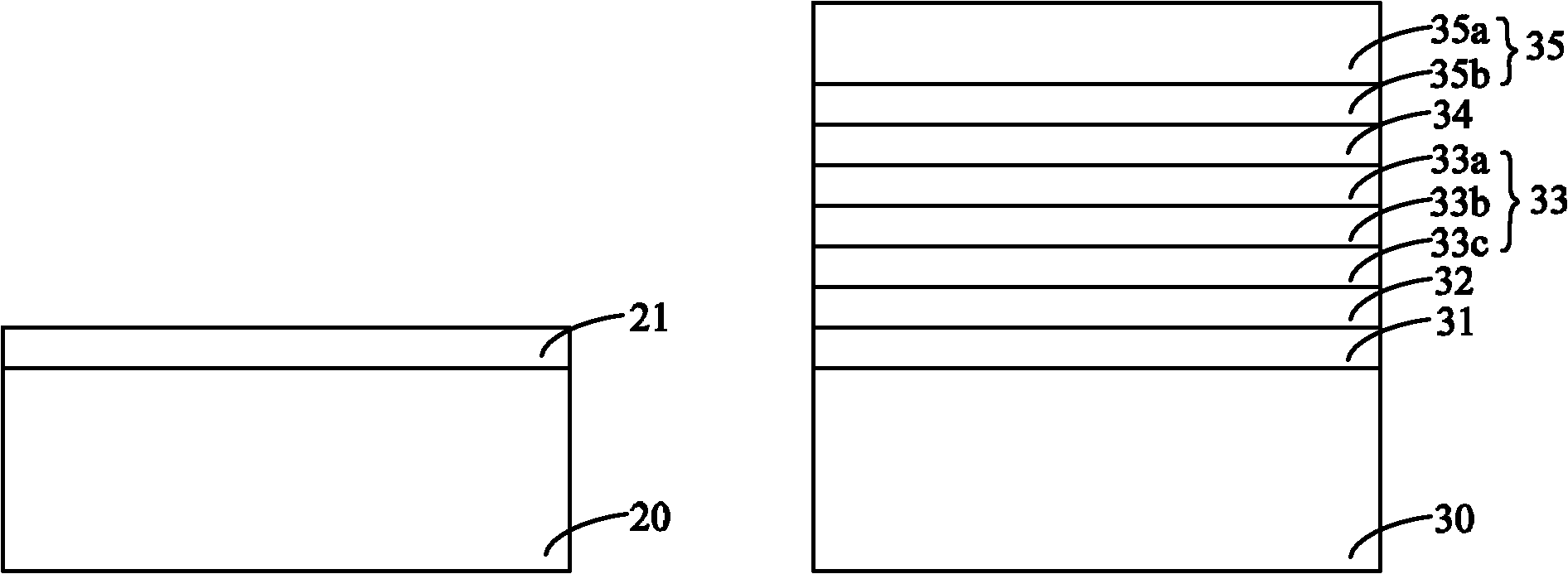

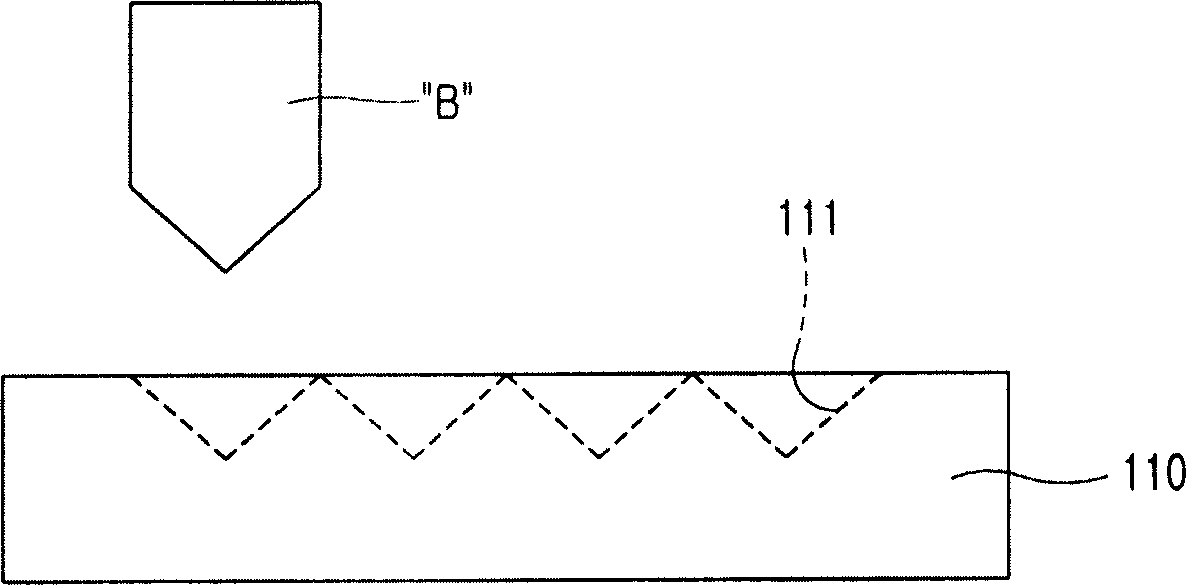

epitaxial wafer structure of gallium nitride-based LED (Light-Emitting Diode) and preparation method thereof

ActiveCN102842660ALarge luminous areaImprove luminous efficiencySemiconductor devicesQuantum efficiencyQuantum well

The invention relates to a process of growing a nucleating layer on the surface of a patterned substrate at a low temperature to form an uneven surface. The invention overcomes the problem that in a conventional LED (Light-Emitting Diode) device structure, an active layer has a superstrong depolarization field, and thus, an energy band of a quantum well is inclined, an electron hole wave function is separated in space and the radiative recombination efficiency is reduced, so that the internal quantum efficiency of a LED is reduced. The invention also provides an epitaxial wafer structure of a gallium nitride-based LED and a preparation method of the epitaxial wafer structure, wherein the epitaxial wafer structure has high crystalline quality and a nonplanar active layer structure is implemented on a weak polarity surface of the epitaxial wafer structure. Therefore, the internal quantum efficiency of the LED is improved.

Owner:EPITOP PHOTOELECTRIC TECH

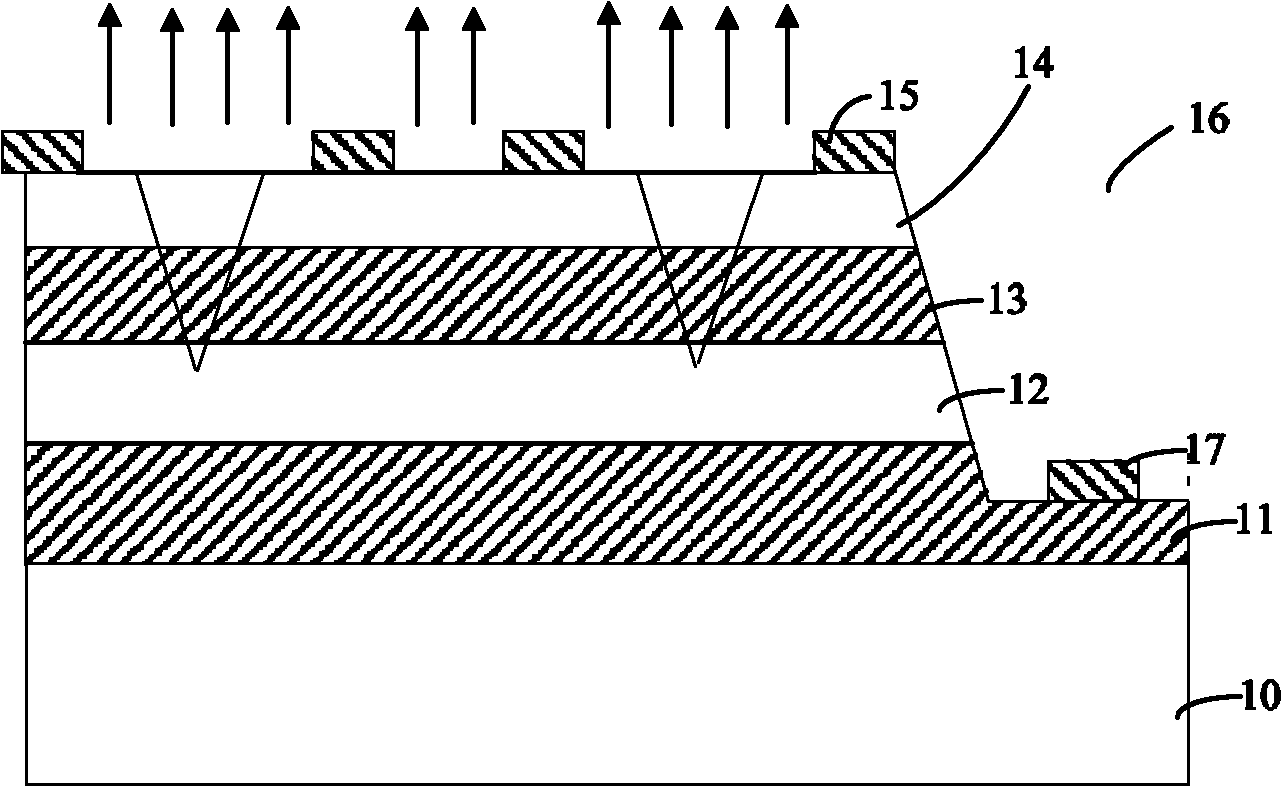

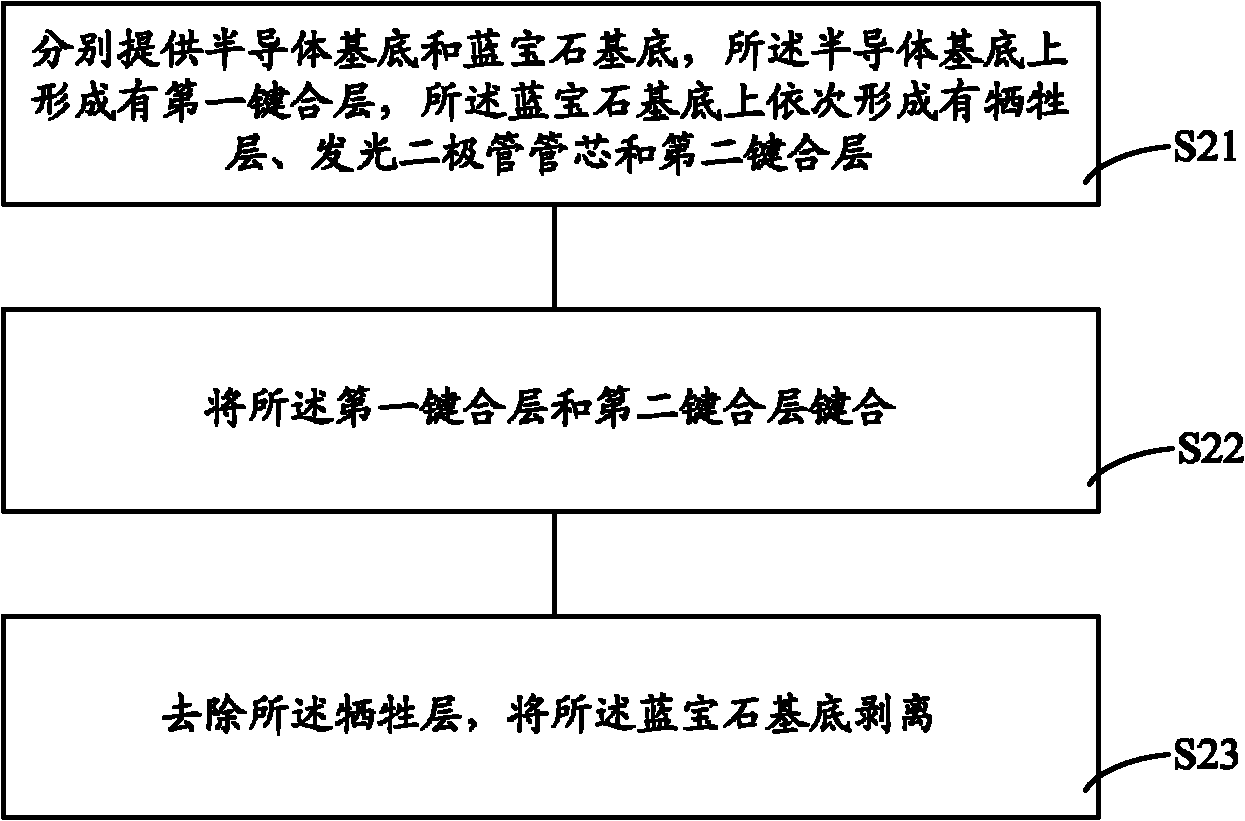

Light emitting diode and making method thereof

ActiveCN101964385AImprove thermal conductivityHelps dissipate heatSemiconductor/solid-state device manufacturingSemiconductor devicesLight-emitting diodeSemiconductor

The invention provides a light emitting diode and a making method thereof. The making method of the light emitting diode comprises the following steps of: separately providing a semiconductor substrate and a sapphire substrate, wherein a first bonding layer is formed on the semiconductor substrate, and a sacrifice layer, a light emitting diode core and a second bonding layer are formed on the sapphire substrate in sequence; bonding the first bonding layer and the second bonding layer; removing the sacrifice layer and stripping the sapphire substrate. The invention increases the effective light emitting area of the light emitting diode, improves the heat radiating and enhances the light emitting efficiency.

Owner:JADE BIRD DISPLAY SHANGHAI LTD

Organic light emitting display and manufacturing method thereof

ActiveCN104733632ALarge luminous areaImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPolarizerMirror reflection

The invention discloses an organic light emitting display and a manufacturing method thereof. The organic light emitting display comprises a flatness layer and an organic light emitting element, wherein the first surface of the flatness layer comprises a flat area and a rugged area connected with the flat area, and the flat area and the rugged area are arranged in a stagger and interval mode; the organic light emitting element comprises an organic light emitting layer and a reflection layer; the organic light emitting layer and the reflection layer are stacked on the rugged area; and the part, corresponding to the rugged area, of the reflection layer is provided with a diffuse reflection part with the same shape as that of the rugged area. According to the above organic light emitting display, the reflection layer with the same shape is formed on the rugged area on the organic light emitting element, and mirror reflection can be effectively controlled; as the reflection layer has a rugged shape, the light emitting area is increased, and the light emitting efficiency per unit area is improved; and in addition, as the reflection layer can effectively control mirror reflection, circular polarizers can be saved or reduced, and the light extraction efficiency is greatly improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Light-emitting device

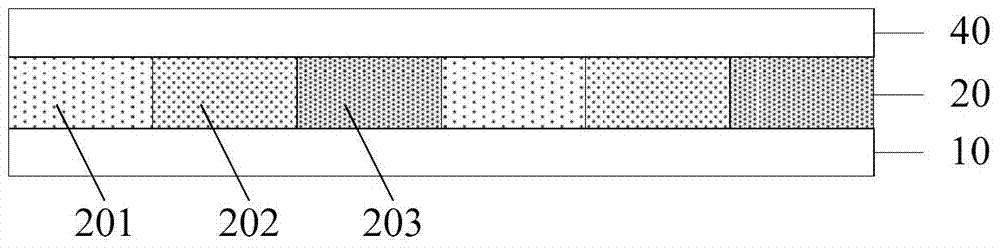

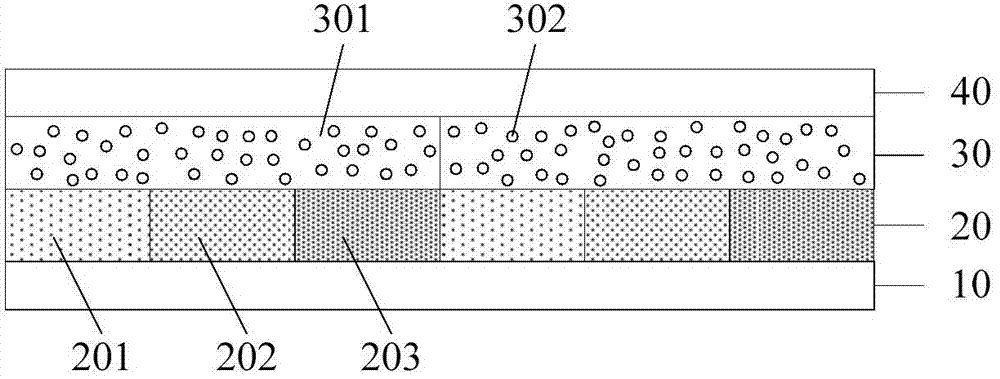

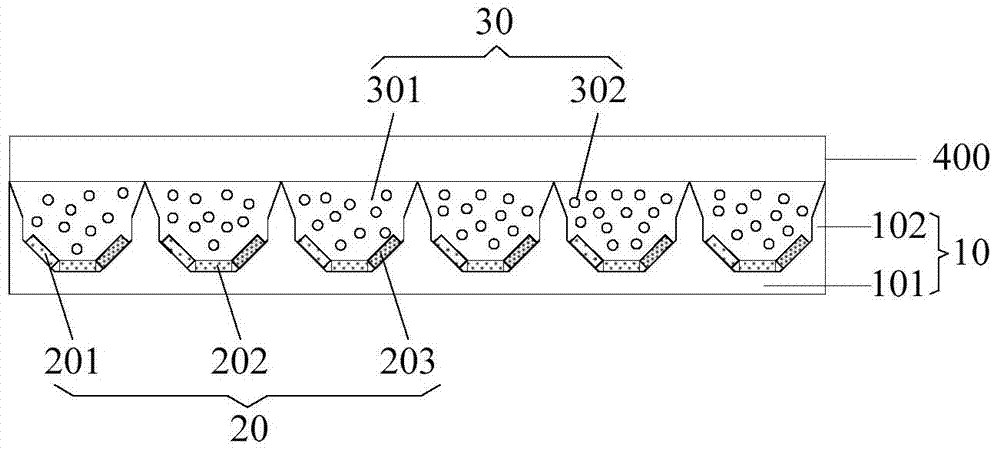

InactiveCN103928594AImprove brightness unevennessAchieve mutual mixingLight source combinationsPoint-like light sourceDisplay deviceEngineering

The embodiment of the invention provides a light-emitting device, and relates to the technical field of display and illumination. The light-emitting device can increase the light-emitting area and achieve uniform and mixed light emergence. The light-emitting device comprises a back plate, a packaging structure, a light-emitting structure and a scattering layer, wherein the light-emitting structure and the scattering layer are arranged between the back plate and the packaging structure, the scattering layer is located at a light emergence side of the light-emitting structure, the light-emitting structure is separated into a plurality of light-emitting units, the scattering layer is separated into a plurality of scattering units, and the multiple light-emitting units correspond to the multiple scattering units one to one. Each light-emitting unit comprises a first light-emitting sub-unit, a second light-emitting sub-unit and a third light-emitting sub-unit and is applied to manufacturing of a display device and an illumination lamp.

Owner:BOE TECH GRP CO LTD

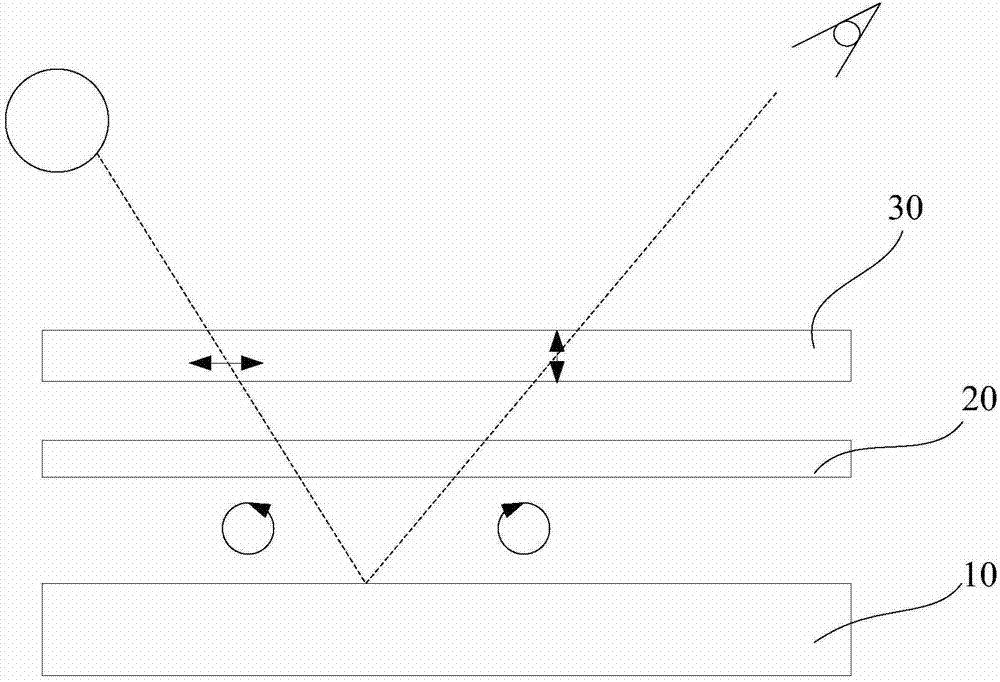

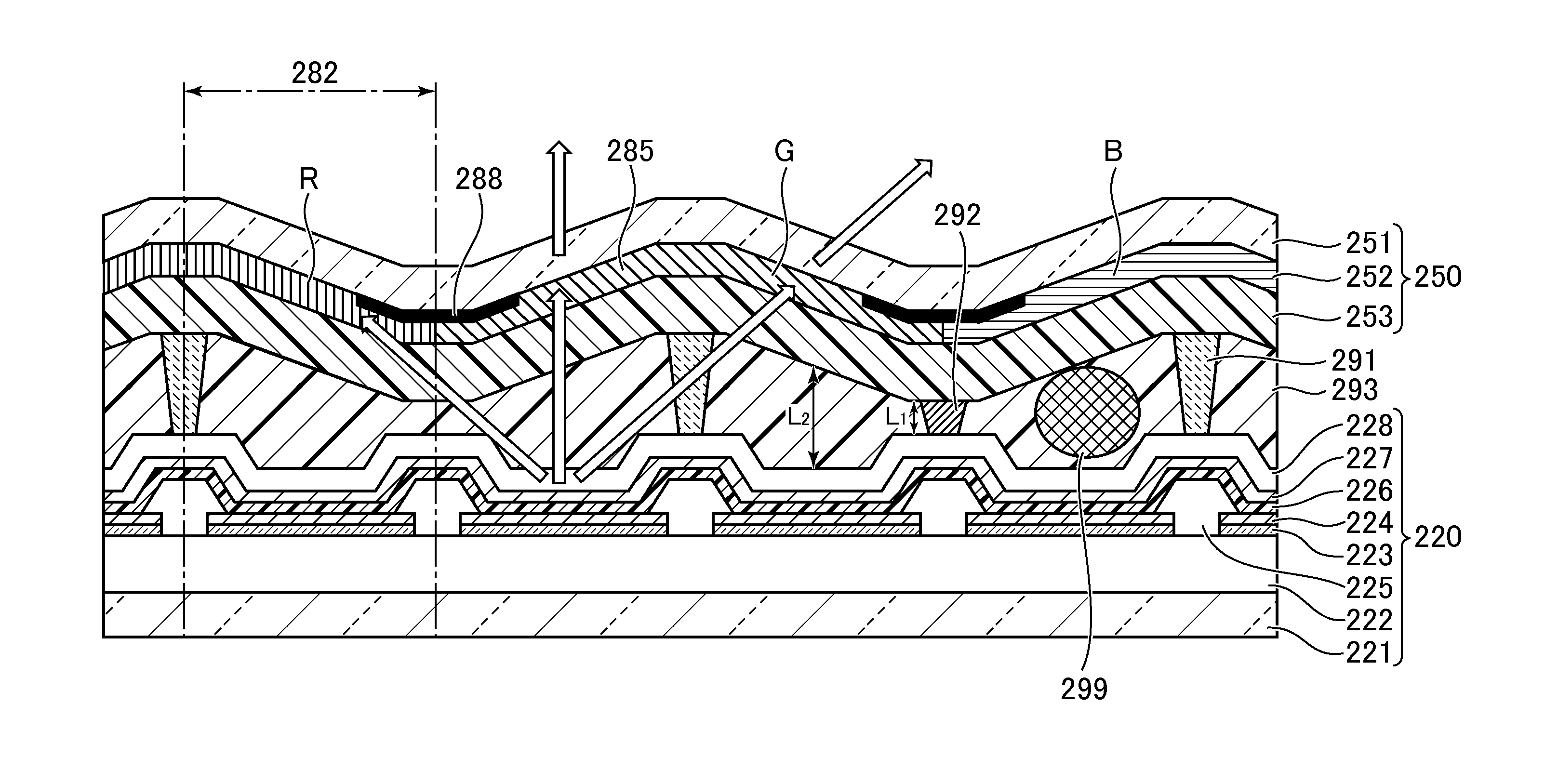

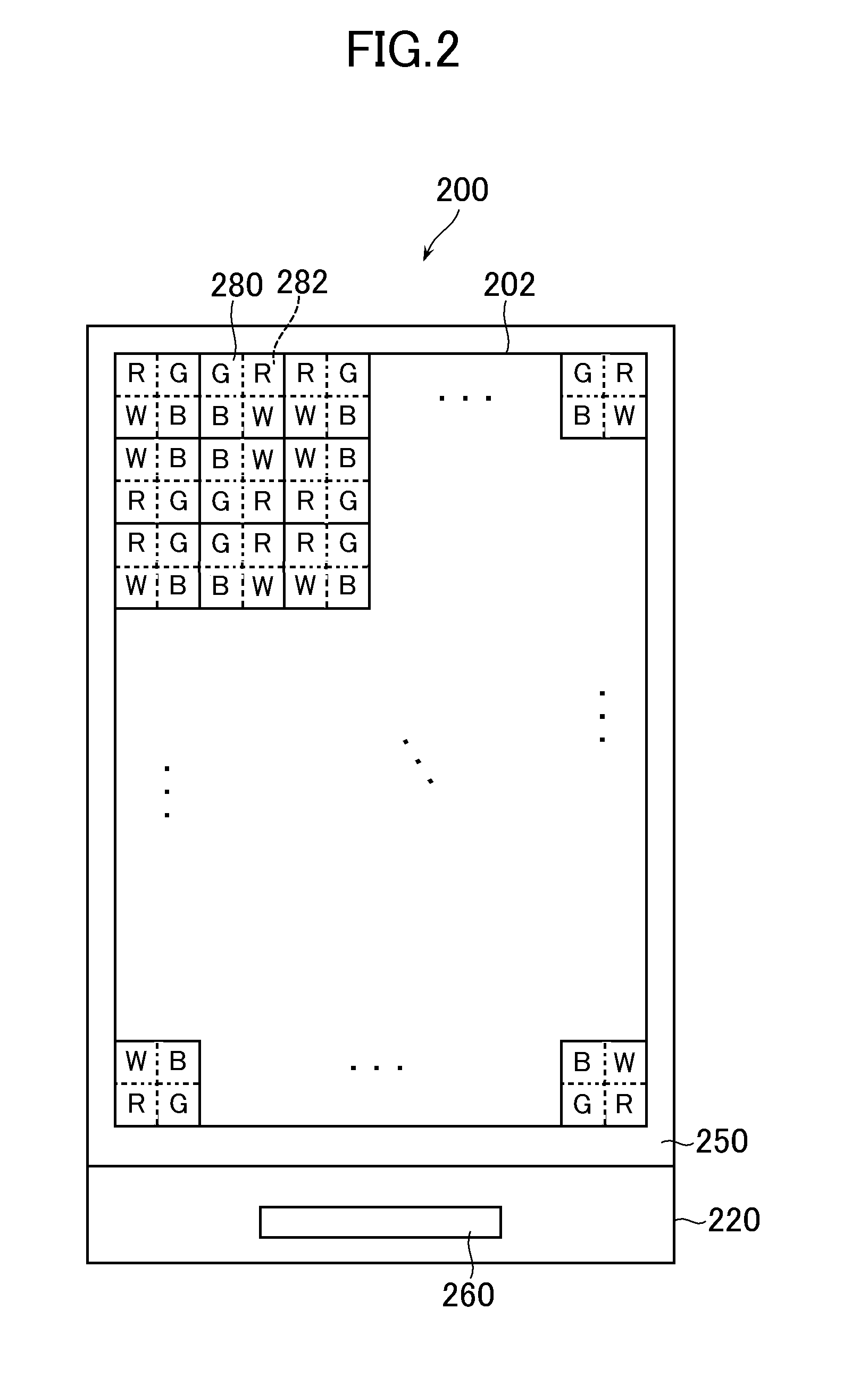

Organic el display device

ActiveUS20150162386A1Large luminous areaColor can be suppressedSolid-state devicesSemiconductor/solid-state device manufacturingColor gelDisplay device

An organic EL display device includes a thin film transistor substrate in which a light-emitting element is provided for each of plural sub-pixels constituting each pixel, a counter substrate provided with a coupled color filter which is a color filter arranged to be extended over plural adjacent sub-pixels and allowing light in one wavelength region to pass through and a light-shielding film which is arranged on a boundary between adjacent color filters to allow lights in different wavelength regions to pass through and shields light, a filler arranged between the thin film transistor substrate and the counter substrate and made of a transparent organic material, and a filler thickness adjustment part which adjusts to cause a thickness of the filler in a region where the light-shielding film is provided to be thinner than a thickness of the filler in a region where the light-emitting element is provided.

Owner:JAPAN DISPLAY INC

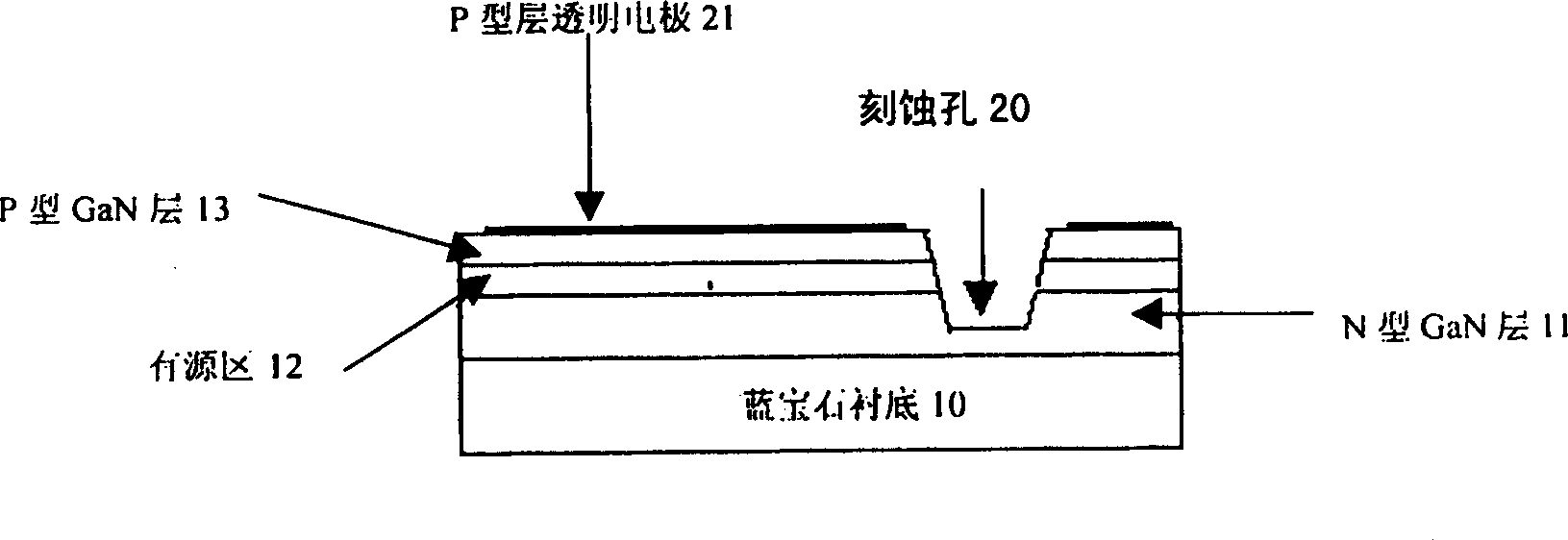

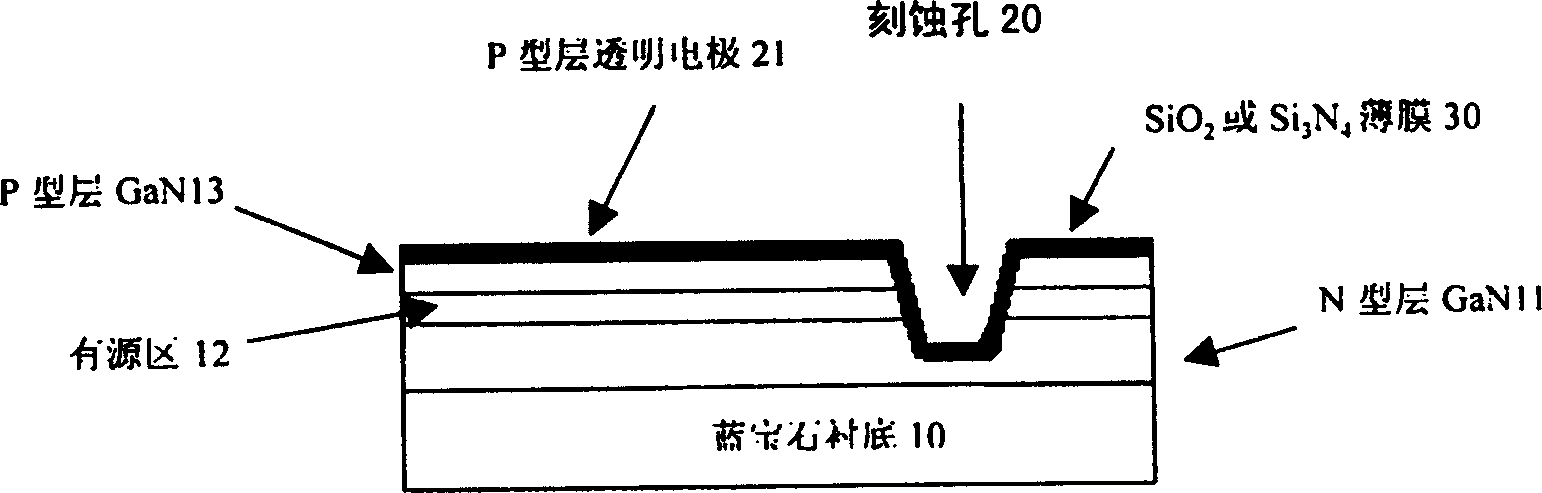

Method for producing N-type layer ohmic contact electrode of GaN LED

InactiveCN1525577ALarge luminous areaIncrease luminous powerSemiconductor devicesEvaporationContact layer

The invention is a manufacturing method for gallium nitride base brightening dioxide N type ohm contact electrode. It includes following steps: 1)etches out circle or rectangular or any shape hole whose diameter or side length is less than 50 um on the N electrode area of designed pipe core with dry etching method or humidity corroding method on the extension structure of gallium nitride base brightening dioxide on the sapphire substrate, etches to the N type contact layer; 2) produces a layer of P type transparent electrode on P type gallium nitride layer; 3) evaporates insulating film such as silicon dioxide or silicon nitride on the sample; 4) corrodes off the insulating film on N type layer etched or corroded with the photoetching method or corrosion method, and exposes N type layer, maintains the insulating film whose diameter or side length is about 100 um on the platform or side walls of the hole; 5) finally uses photoetching and evaporation or spattering method to produce N electrode, forms the gallium nitride base brightening dioxide N type ohm contact electrode.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

LED (Light Emitting Diode) structure and manufacturing method thereof

InactiveCN102447016AReduce difficultyImprove light extraction rateSemiconductor devicesEngineeringReflective layer

The invention discloses an LED (Light Emitting Diode) structure and a manufacturing method thereof. The LED structure comprises a base plate, a light emitting epitaxy structure, a first electric contact layer, a second electric contact layer, a transparent insulating layer, a first reflection layer, a second reflection layer, a first barrier layer, a second barrier layer, a first electric electrode and a second electric electrode. The first electric contract layer and the second electric contact layer are respectively arranged on a first electric semiconductor layer and a second electric semiconductor layer which are in a light emitting epitaxy structure. The transparent insulating layer covers the light emitting epitaxy structure, the first electric contact layer and the second electric contact layer and comprises a first contact window and a second contact window which respectively expose the first electric contact layer and the second electric contact layer. The first reflection layer and the second reflection layer respectively cover the first contact window and the second contact window and extend on the transparent insulating layer. The first barrier layer and the second barrier layer respectively cover the first reflection layer and the second reflection layer. The first electric electrode and the second electric electrode are respectively arranged on the first barrier layer and the second barrier layer and fully fill the first contact window and the second contact window.

Owner:佛山市奇明光电有限公司 +1

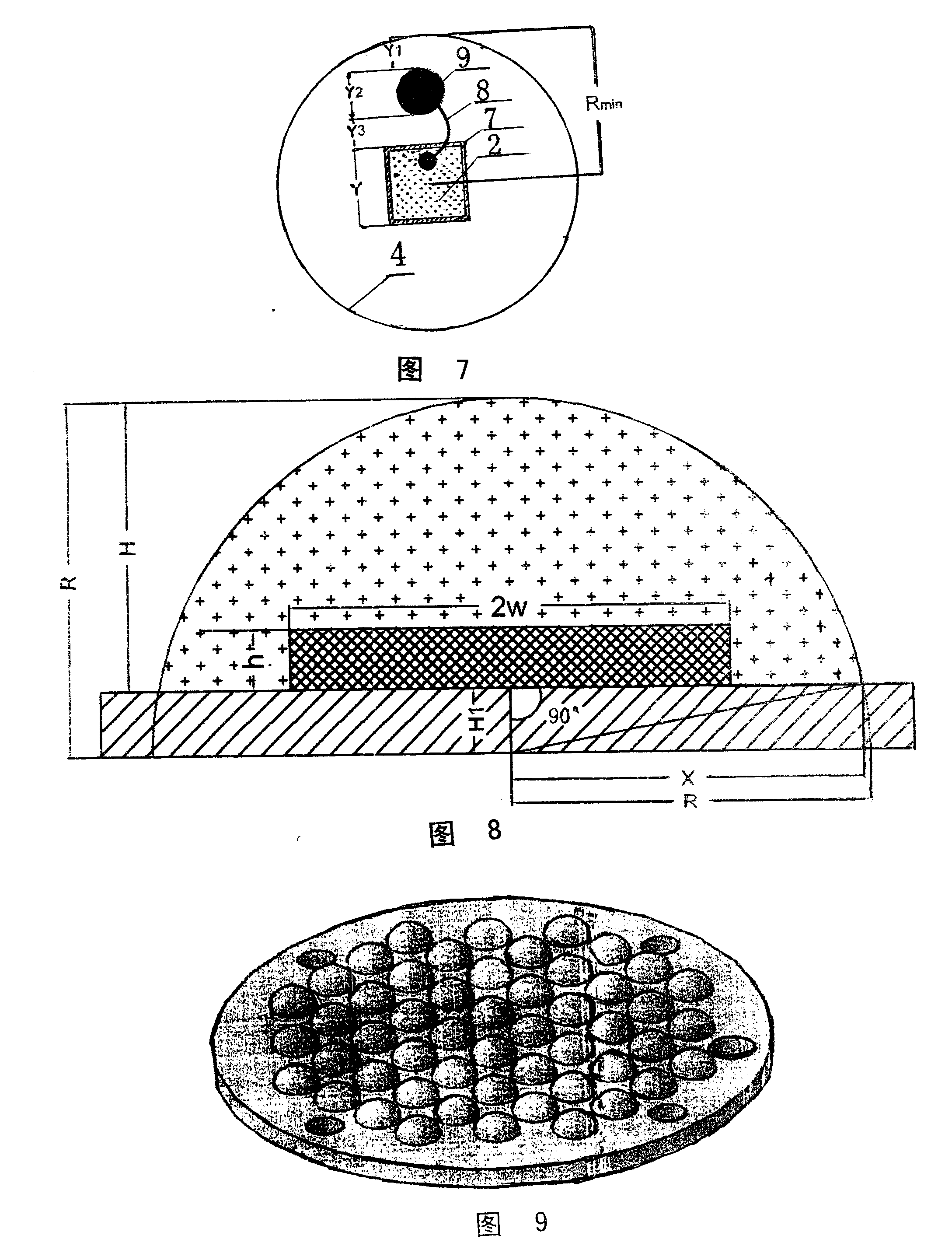

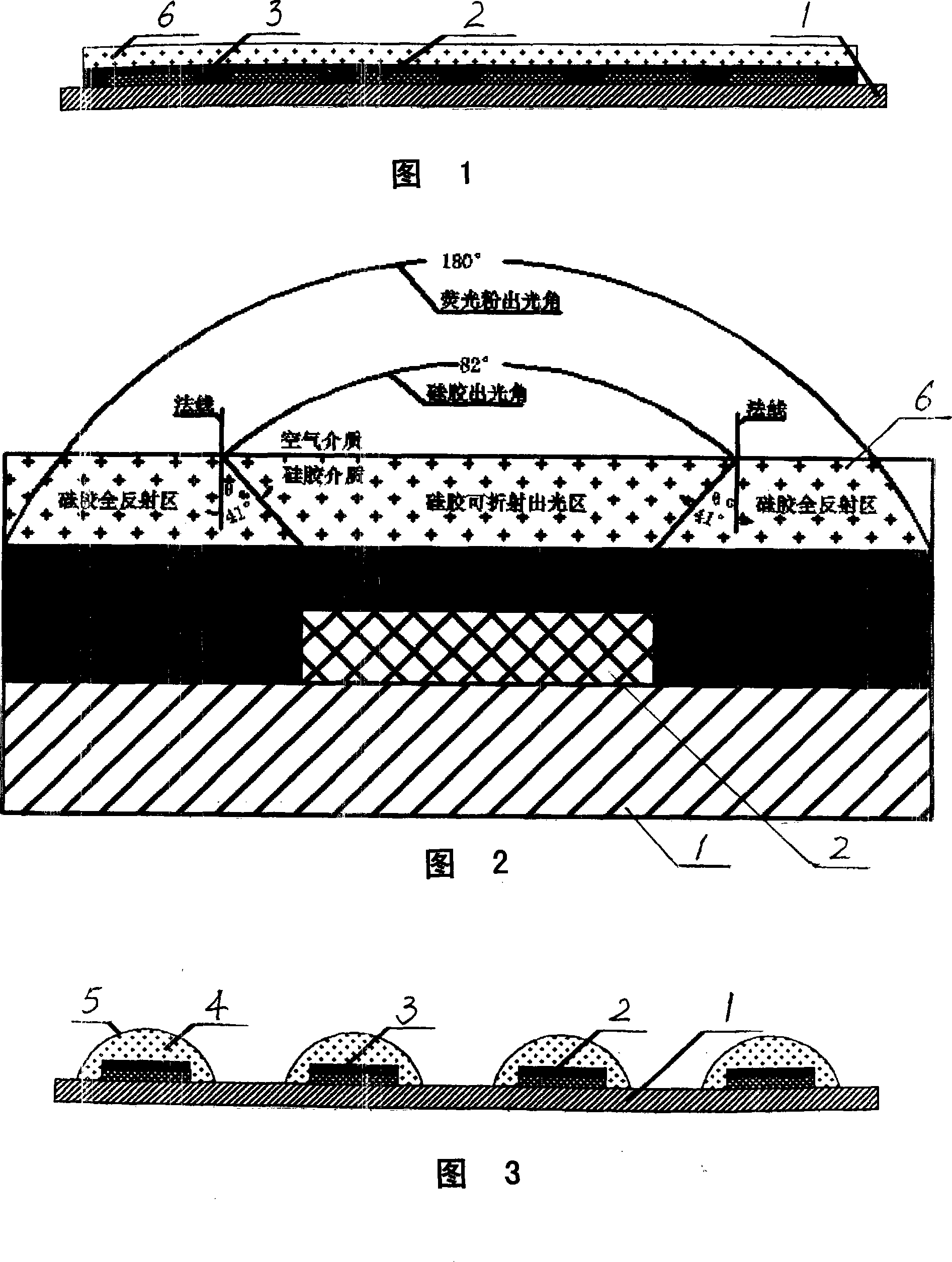

Non-reflection high light extracting rate unit WLED power expanding type high power WLED light source

InactiveCN101173758AIncreased beam angleLight interference is smallElectrical apparatusPoint-like light sourceEffect lightSilica gel

The invention relates to a no-reflection high-efficient-luminescence unitary-WLED power-capacity-expansion high-power light source. A plurality of blue-light BLED chips are welded on a radiating base plate. The surfaces of the BLED chips are coated with silica gel phosphor powder, which forms white-light WLED illuminants. The high-light-transmittance and high-intensity industrial plastic PC is made into a thin isopachous hemisphere-shaped casing. The PC casing is filled with high-transparency silicon gel which has the same light transmittance as the PC, which forms a silica gel hemispherical lens. The silica gel lens is packaged above the phosphor powder along the centre to form the no-reflection and high-efficient-luminescence unitary WLED light source. A plurality of unitary WLED light sources are assembled to a high-power WLED light source by capacity expansion. The light source can be make into a street lamp, an emergency lighting lamp, a safety lighting lamp for mine roadway, a mine cap lamp, a safety lighting lamp for subway and airport, an indoor lighting lamp and other WLED lighting lamps. The invention has the advantages of scientifically reasonable structure, low production cost, good radiating property, low power consumption, high efficient luminescence, long service life and other advantages.

Owner:西安锐泽克斯光电科技有限公司

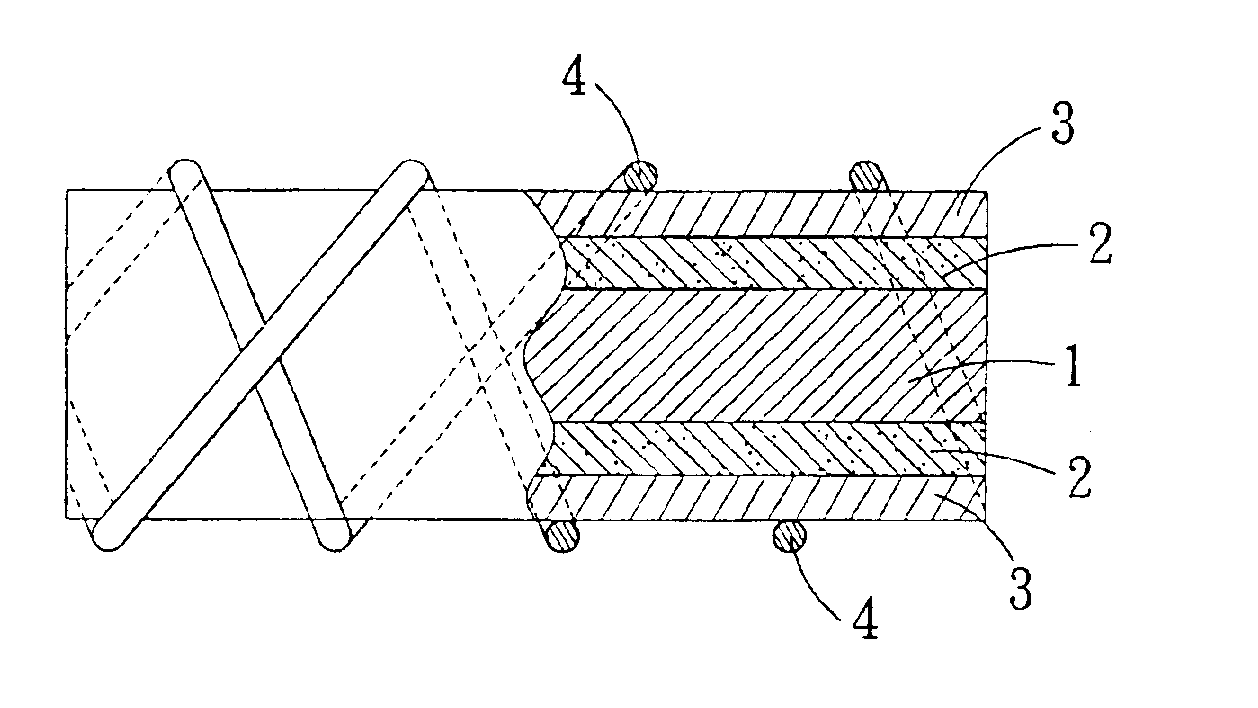

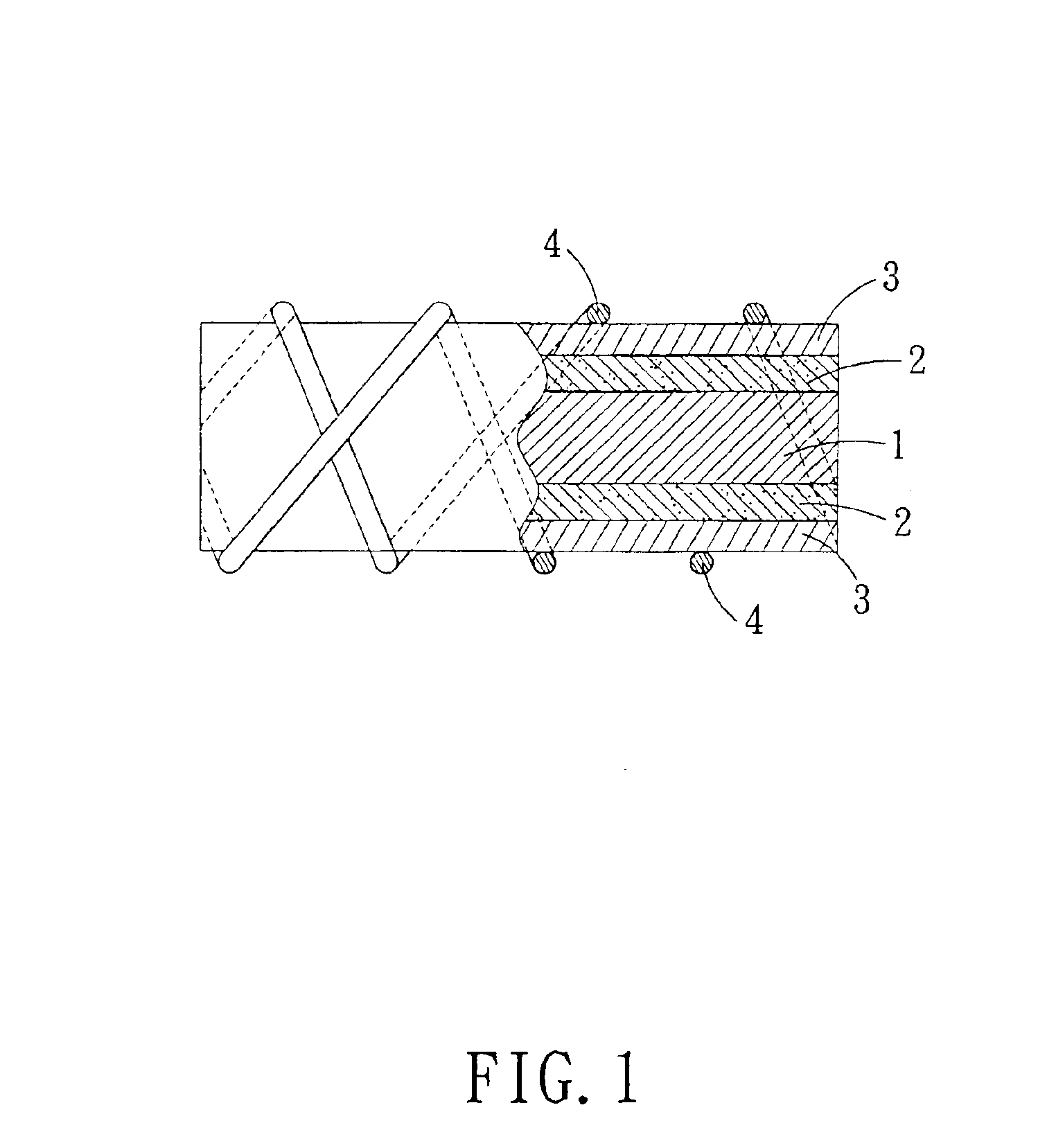

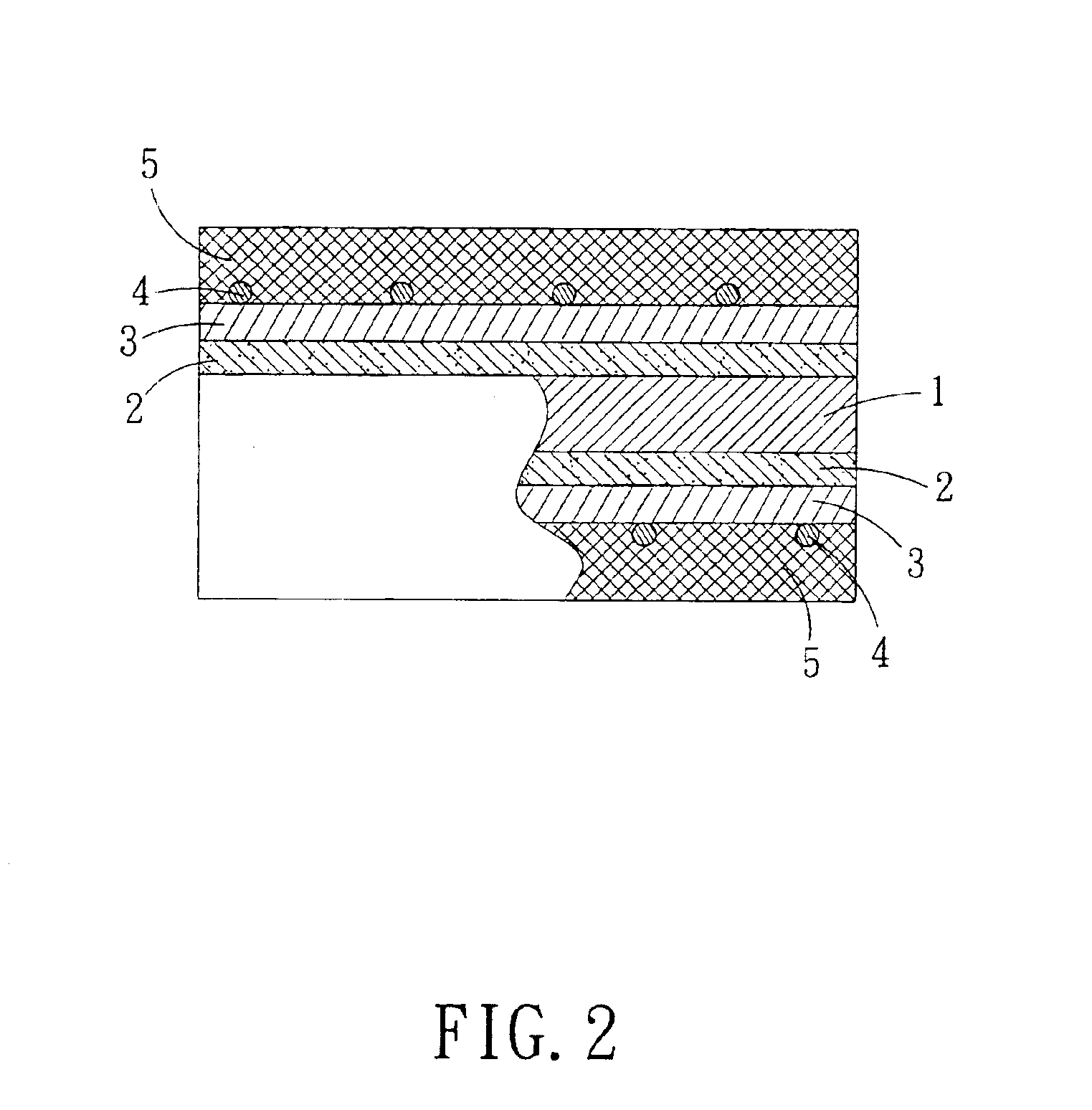

Electroluminescence (EL) tube and wire and manufacturing method

InactiveUS6960725B2Increase the areaSimple manufacturing processElectroluminescent light sourcesPower cables with screens/conductive layersSynthetic resinElectroluminescent wire

An electroluminescent wire core having a flexible central electrode, a luminescent layer and a transparent, conductive layer. An outer surface of the central electrode is coated with the luminescent layer and the transparent, conductive layer respectively. In the transparent, conductive layer is disposed luminescent power which is covered by thermoplastic macromolecular polymer and synthetic resin.

Owner:SHENZHEN EL LIGHTING TECH CO LTD

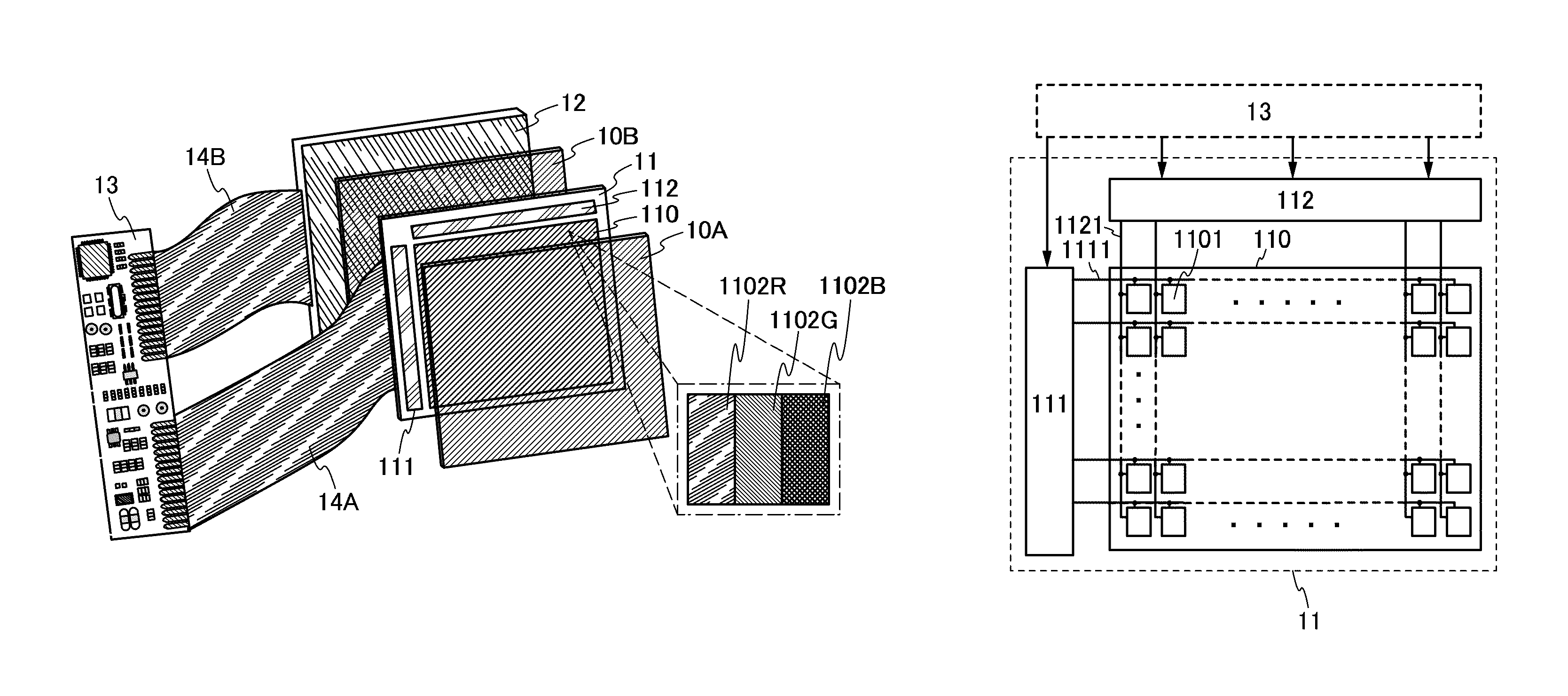

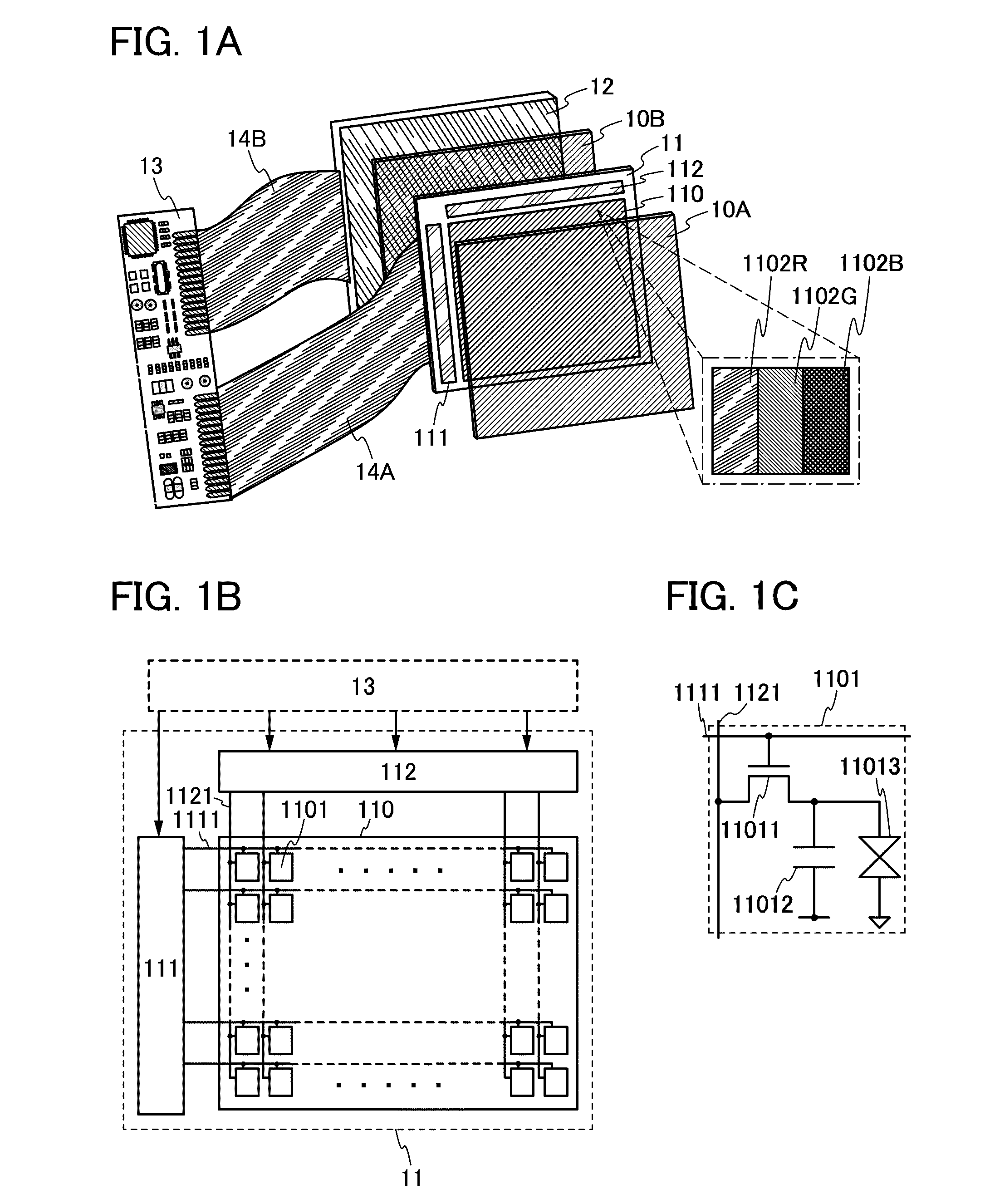

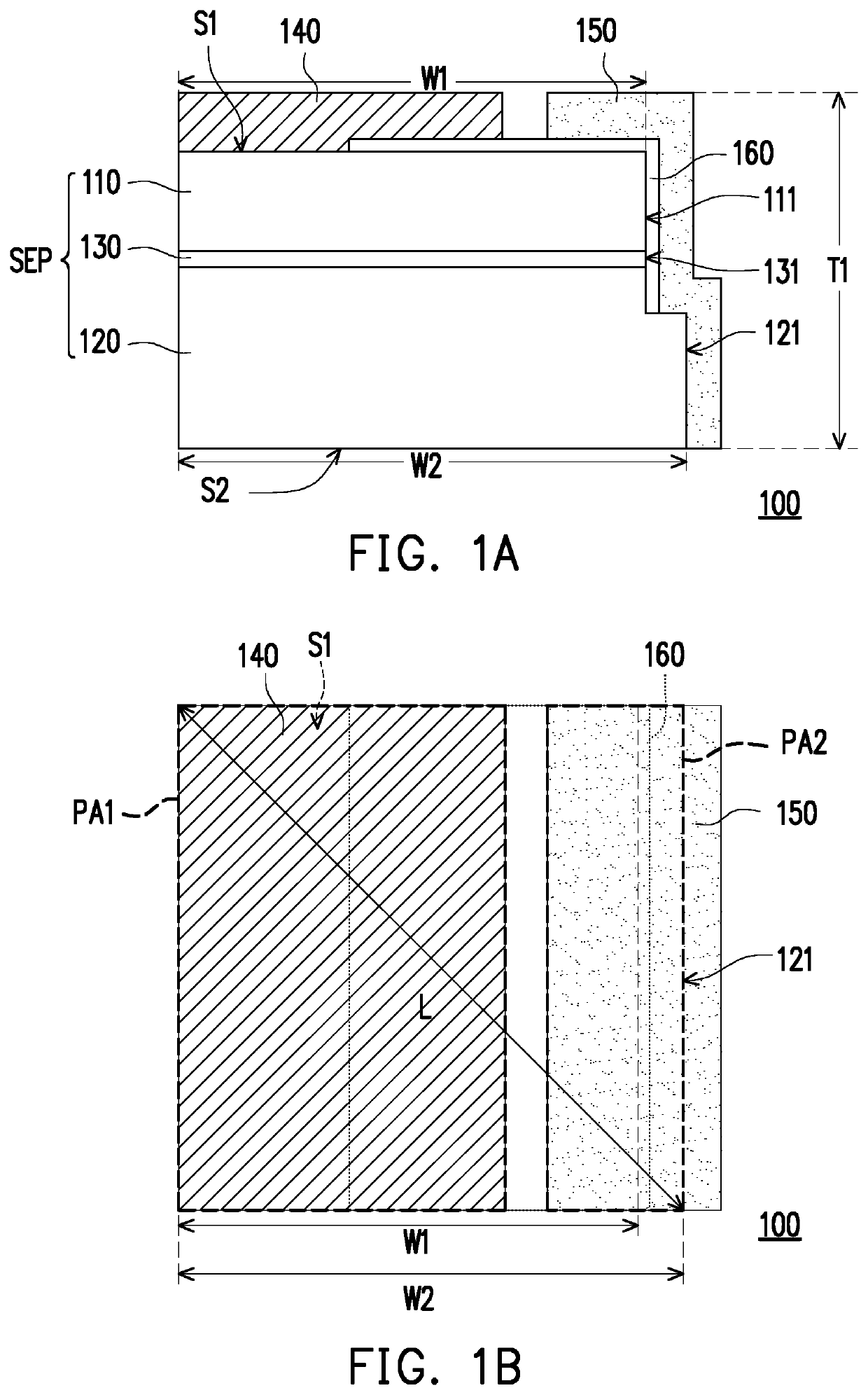

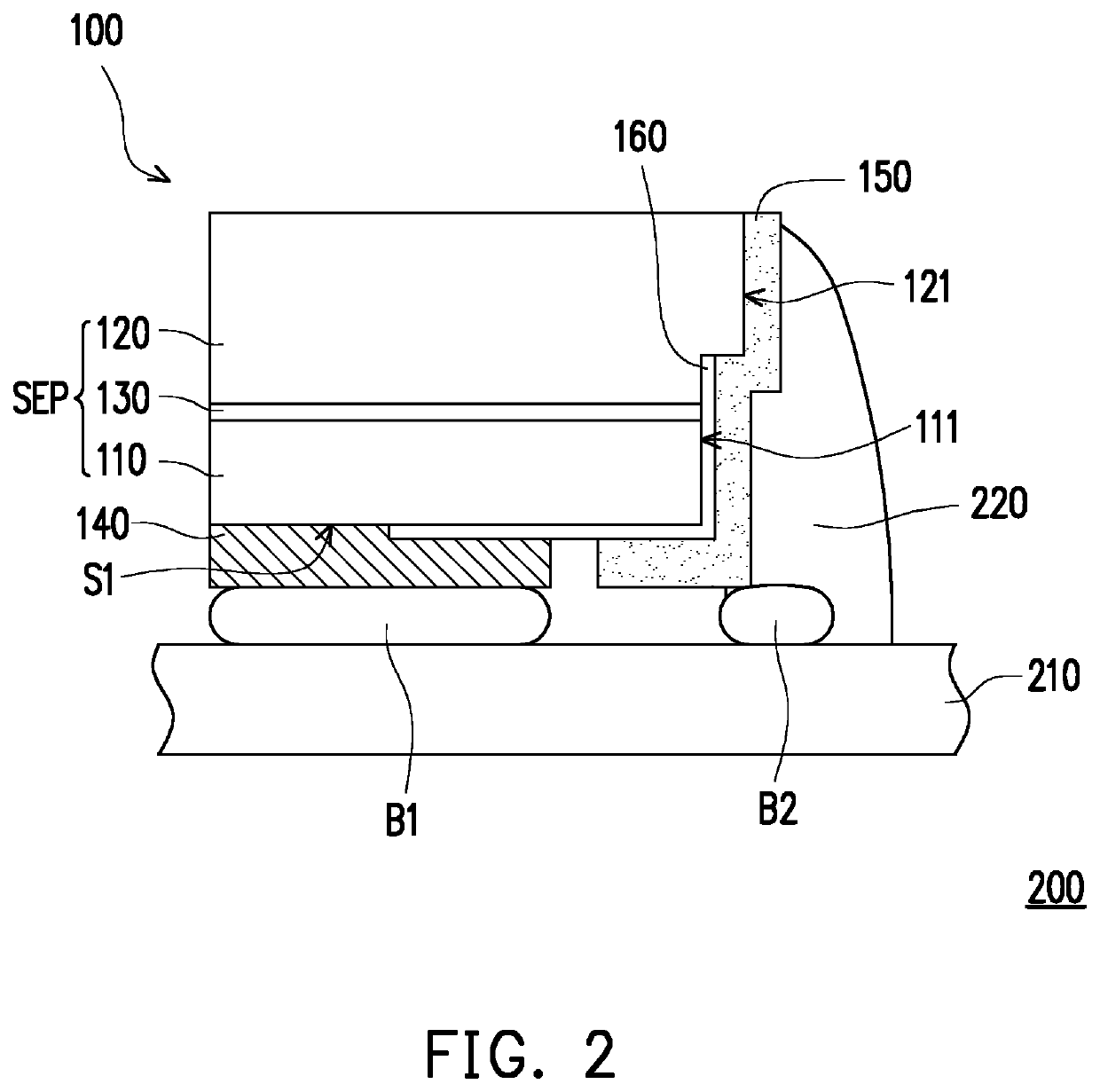

Liquid crystal display device and electronic device

ActiveUS9349325B2Reduce power consumptionDeterioration in display quality is suppressedElectrical apparatusElectroluminescent light sourcesLiquid-crystal displayLight emission

It is an object to provide a transmissive liquid crystal display device in which power consumption is reduced and deterioration in display quality is suppressed. As a backlight, a surface-emission light source is employed. The light source is a light source which performs surface light emission, so that the light emission area is large. Accordingly, the backlight can effectively radiate heat. Thus, even in the case where an image signal is not input to a pixel for a long period, the pixel can hold the image signal. In other words, both a reduction in power consumption and a suppression of deterioration in display quality can be realized.

Owner:SEMICON ENERGY LAB CO LTD

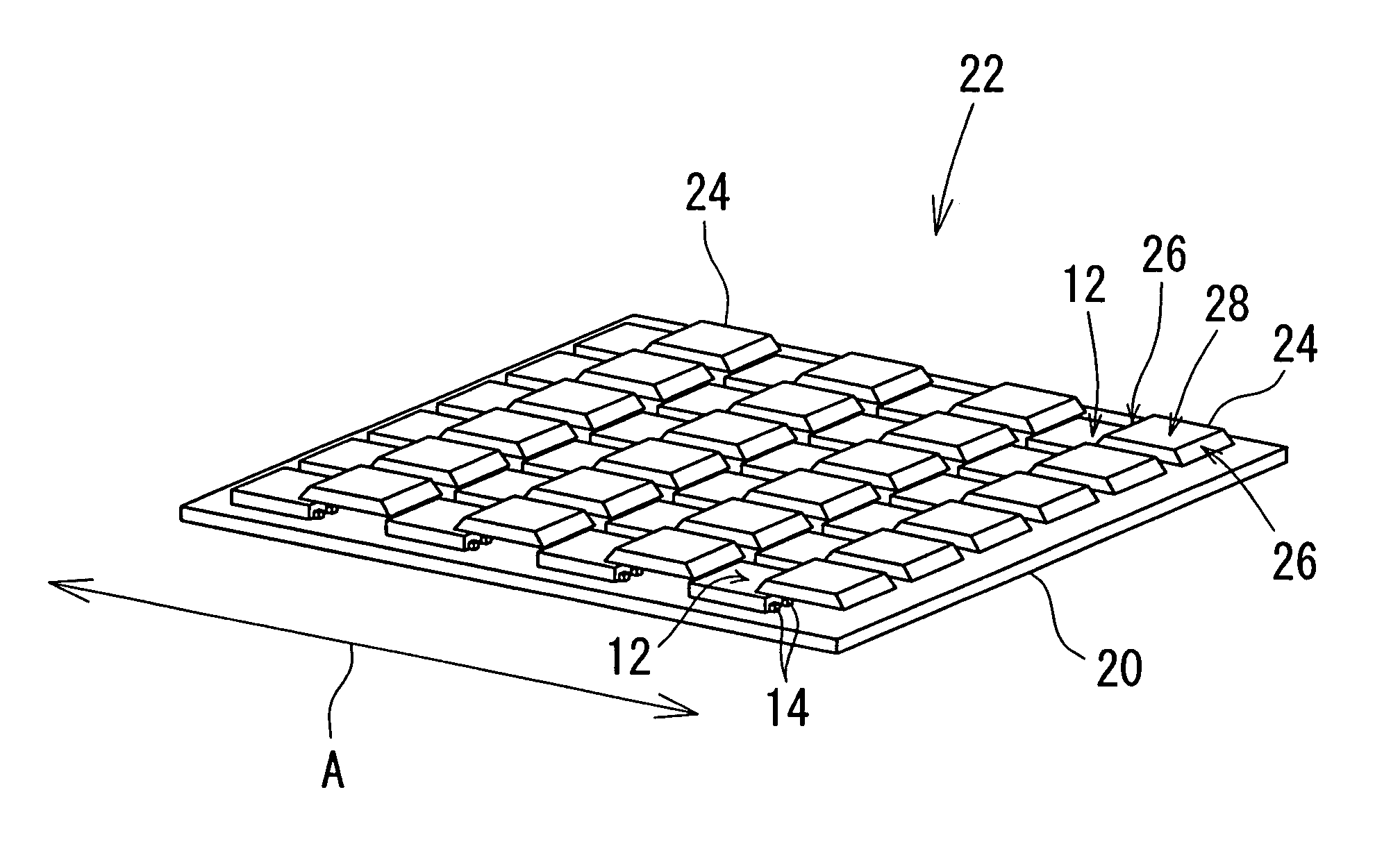

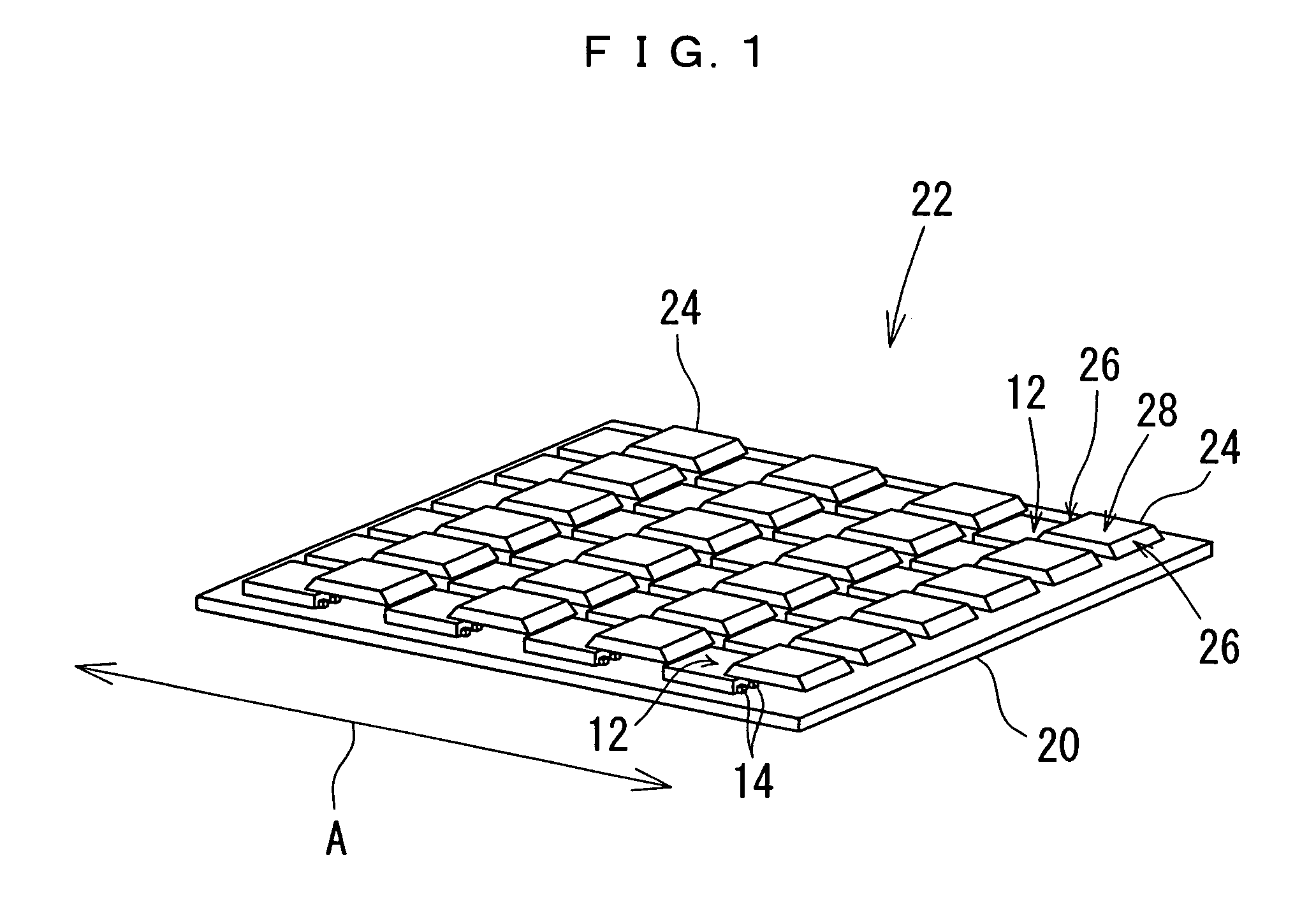

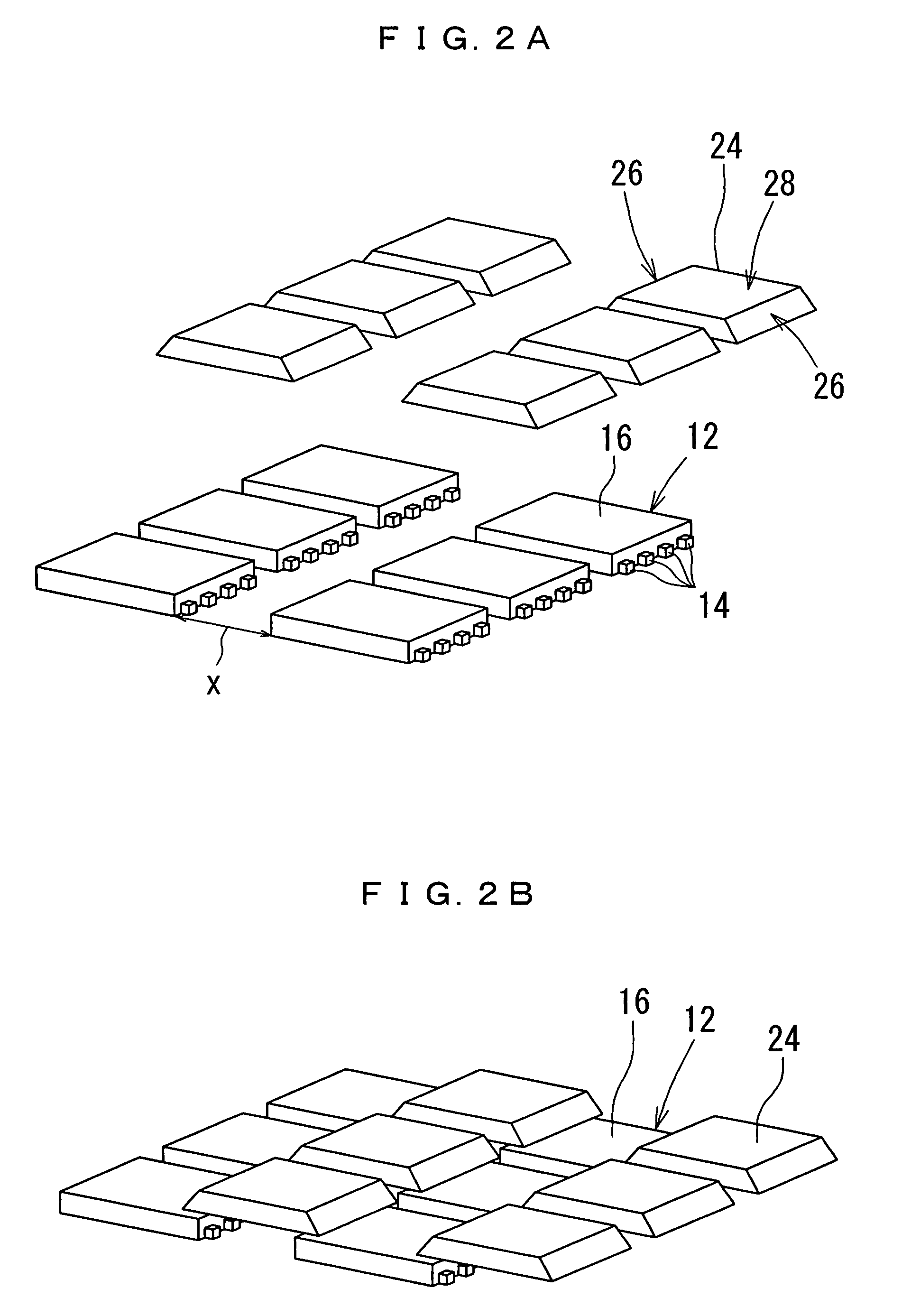

Spread illuminating apparatus of multiple panel type

InactiveUS7588364B2Reduce power consumptionUniform brightnessShow cabinetsNon-electric lightingEffect lightStray light

Owner:MINEBEAMITSUMI INC

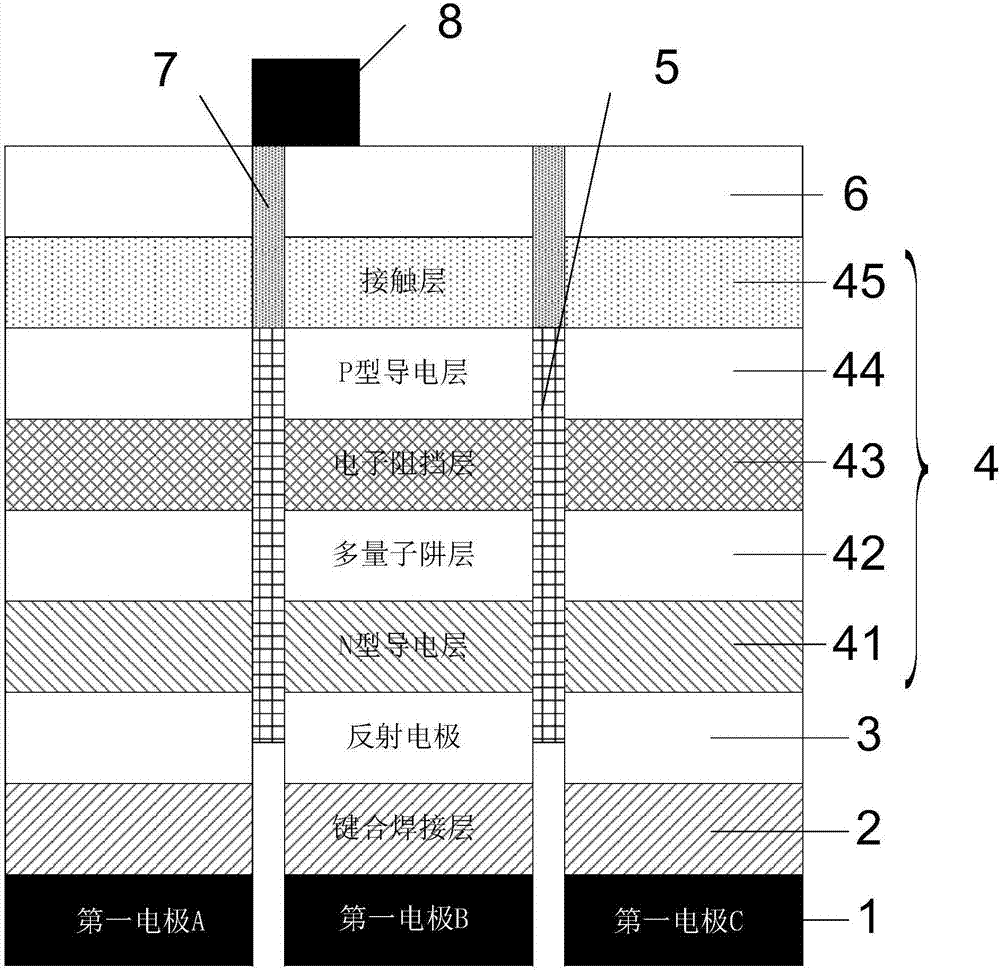

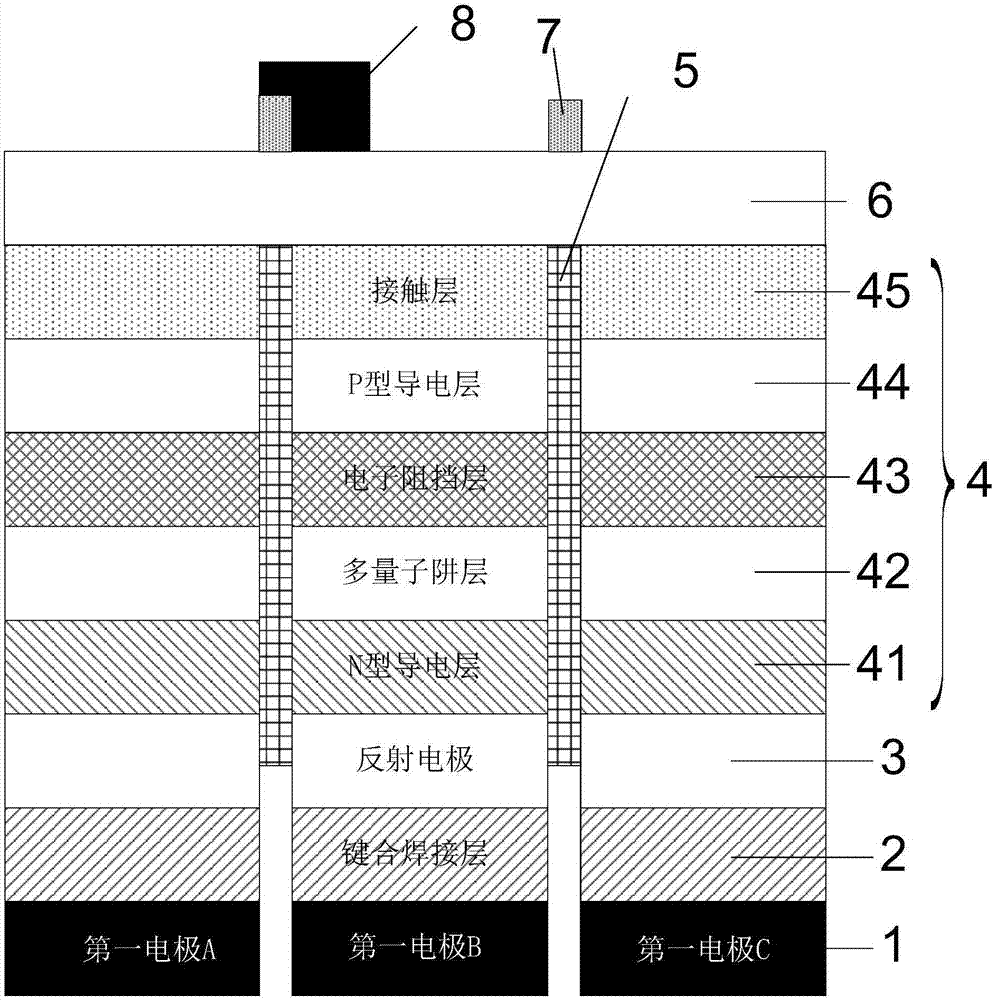

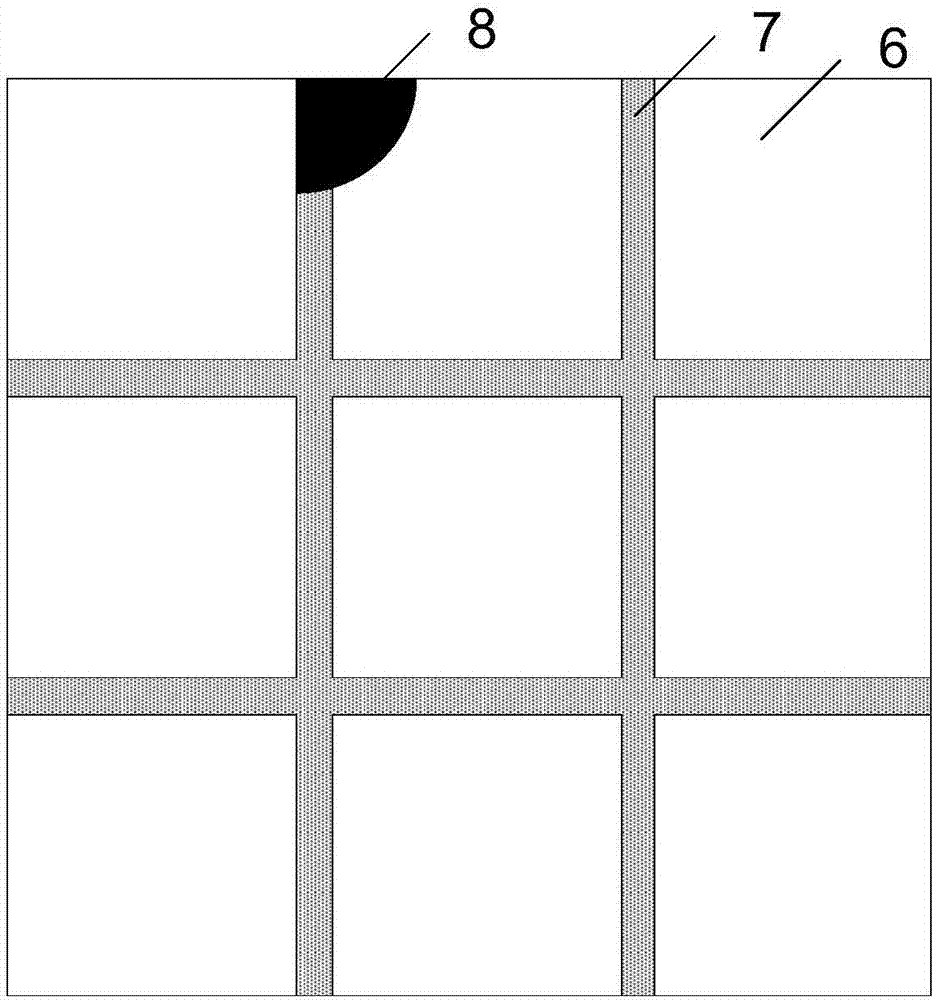

Micro LED chip, manufacturing method thereof, and Micro LED array substrate

ActiveCN107331741AImprove luminous efficiencyAvoid the problem of low luminous efficiencySemiconductor devicesLed arrayIsolation layer

The application provides a Micro LED chip, a manufacturing method thereof, and a Micro LED array substrate. The Micro LED chip uses a vertical structure. A first electrode and a second electrode are manufactured on different sides respectively. By arranging an electrode net with a grid structure on an isolation layer, multiple Micro LED sub-chips can emit light independently as long as only one second electrode is electrically connected with the electrode net and there is no need to provide a second electrode for each Micro LED sub-chip for light emitting control. The electrode net is arranged on the isolation layer, and the position of the electrode net is opposite to the position of the isolation layer to avoid the blocking of the effective light-emitting area by the electrode net, thereby greatly reducing the light-blocking area of the electrode. Compared with the prior art, the Micro LED chip increases light-emitting area and improves light-emitting efficiency.

Owner:XIAMEN CHANGELIGHT CO LTD

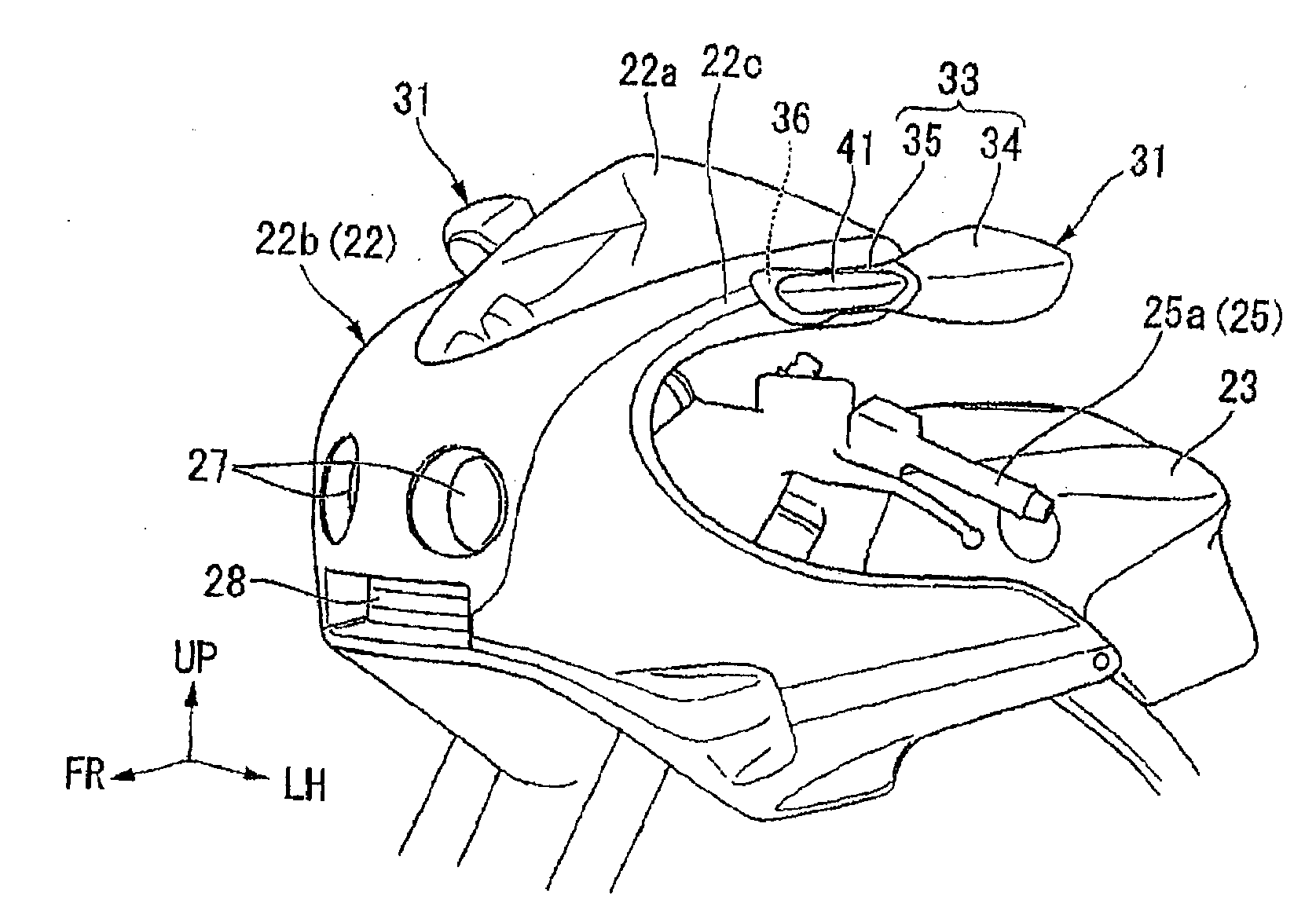

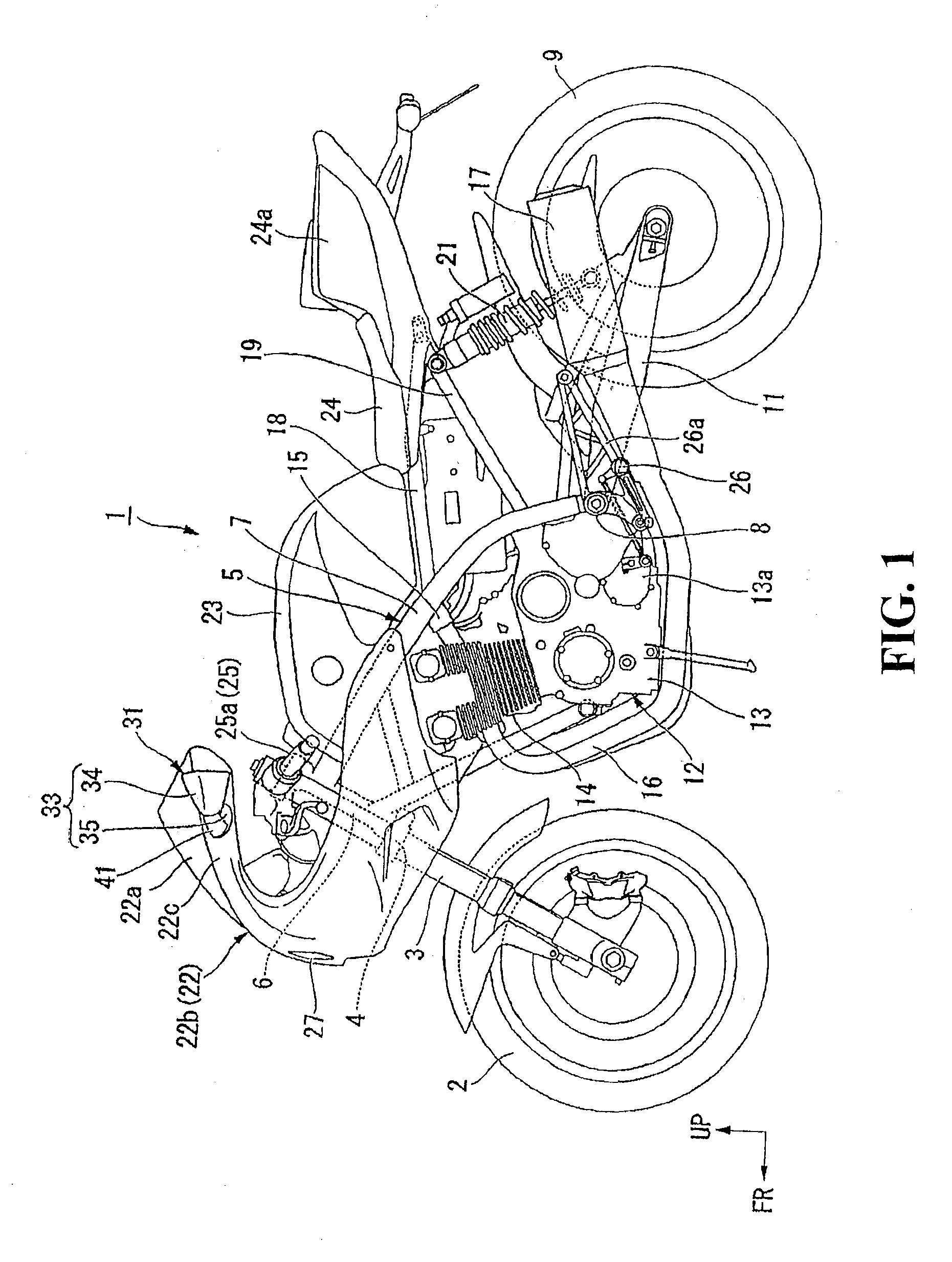

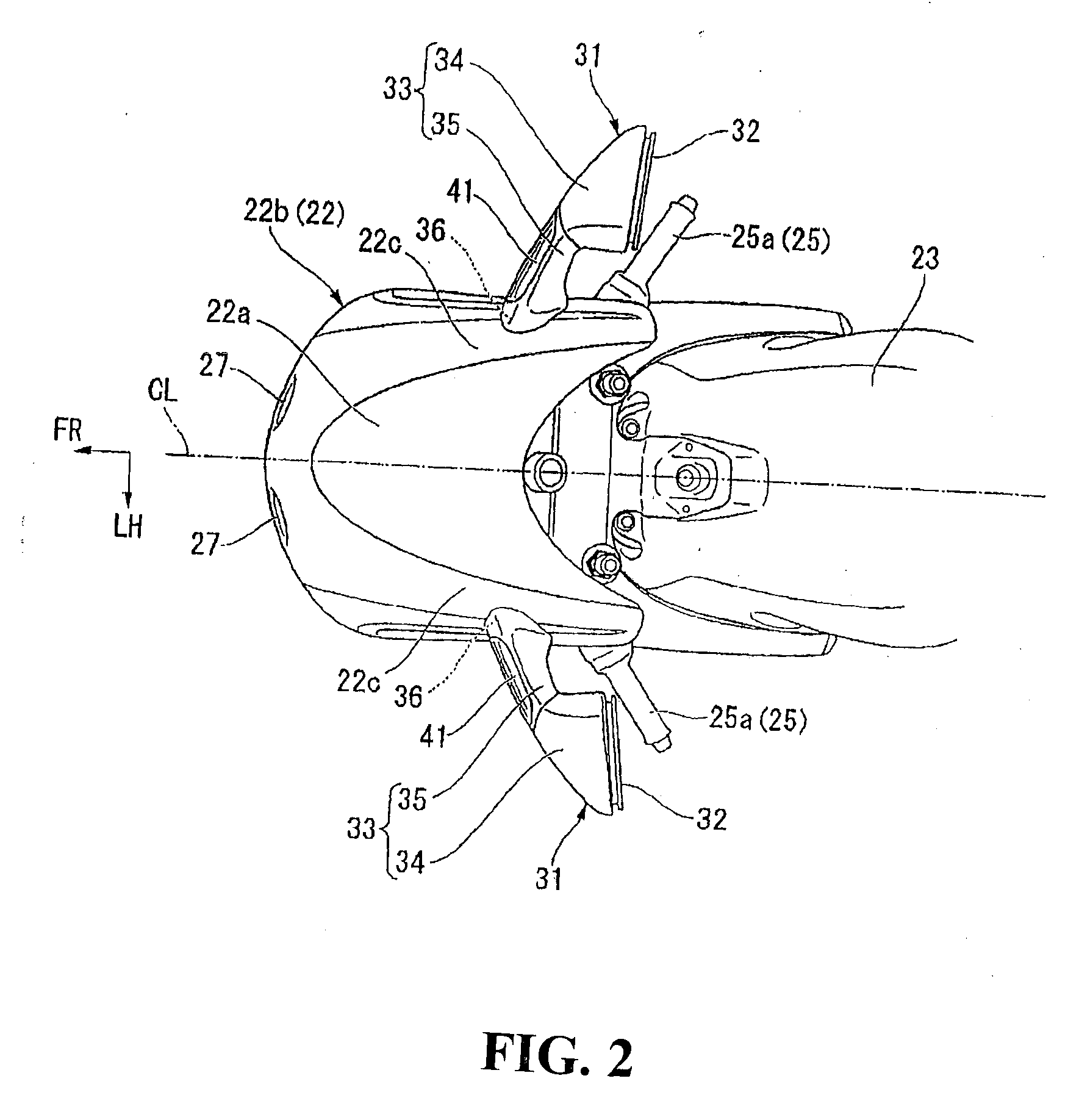

Blinker integrated rear-view mirror of saddle-ride type vehicle

InactiveUS20090073704A1Convenient ArrangementIncrease flexibilityOptical signalLighting elementsEngineeringRear-view mirror

A saddle-ride type vehicle includes a vehicle body, a housing body holding a rear-view mirror, and a stay structure provided between the vehicle body and the housing body. The stay structure secures the housing body to the vehicle body. A front blinker is provided in the stay structure.

Owner:HONDA MOTOR CO LTD

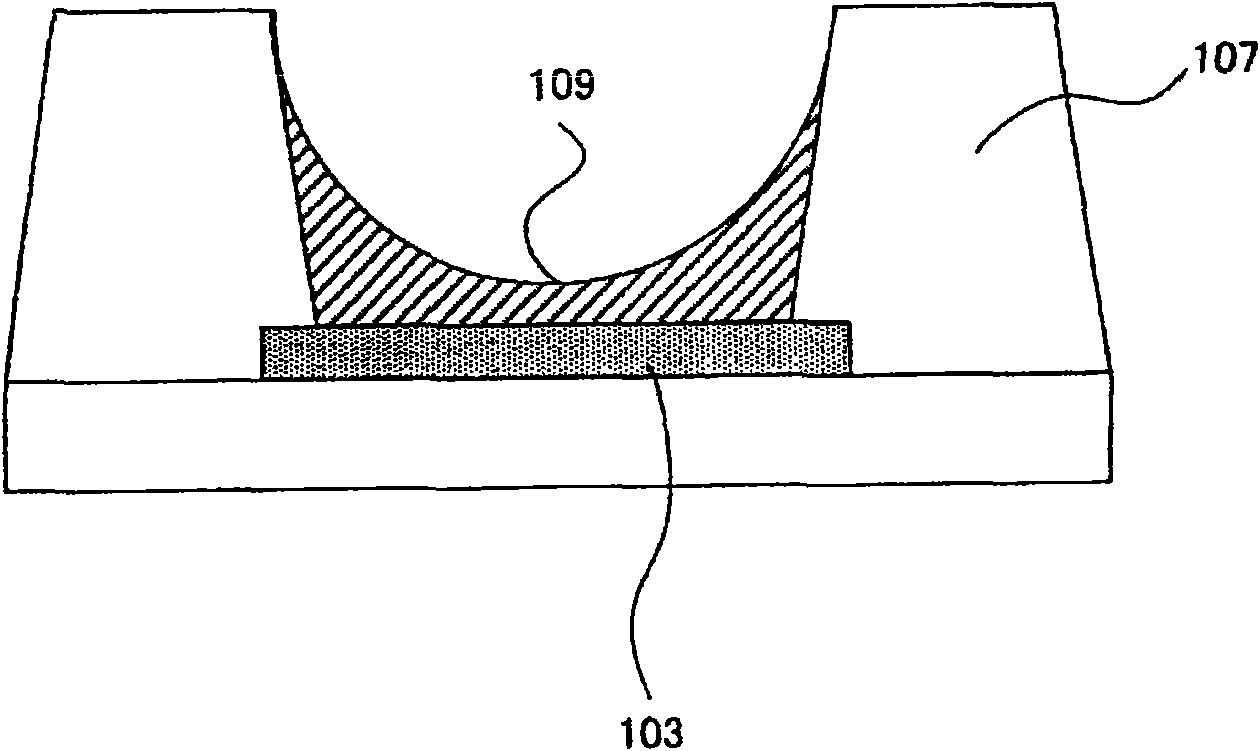

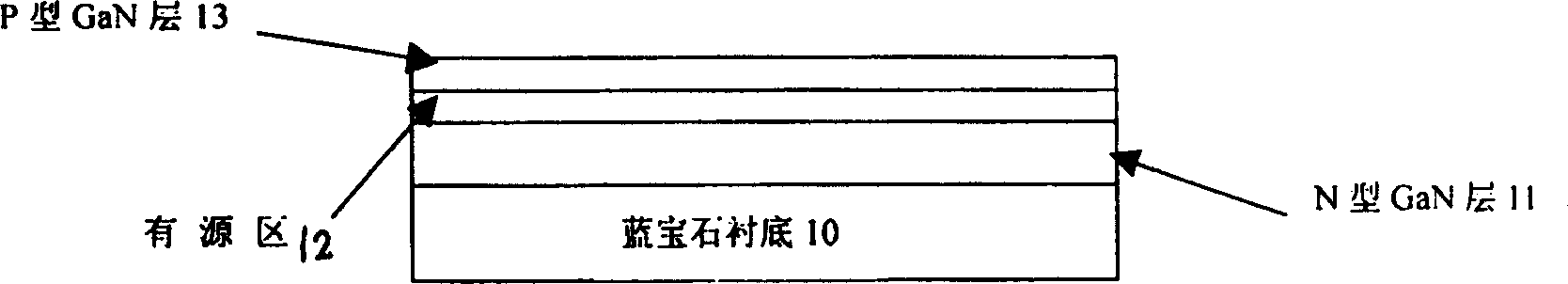

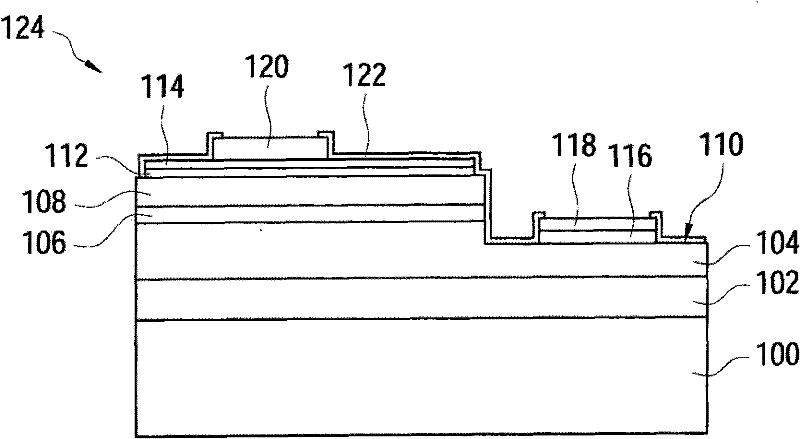

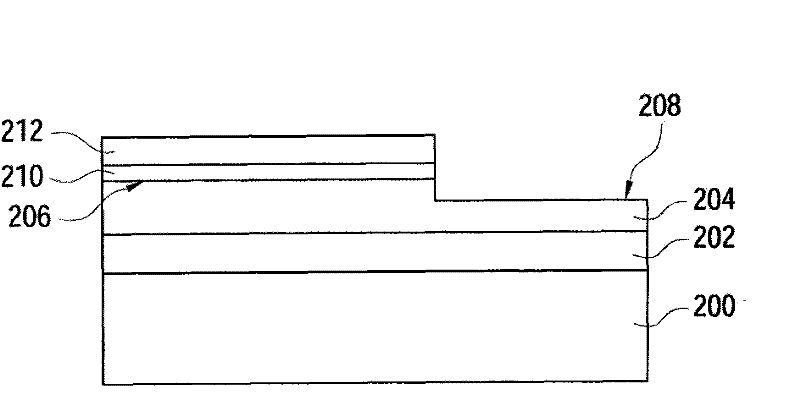

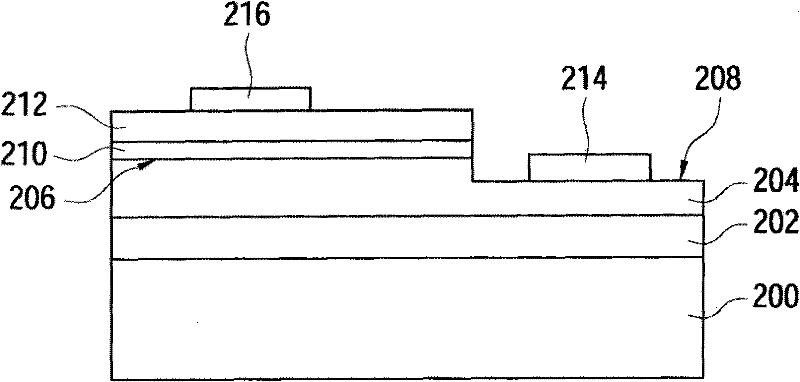

Light emitting device and manufacturing method thereof

InactiveCN1638162ALarge luminous areaReduce manufacturing costLaser active region structureSemiconductor devicesContact layerActive layer

The invention discloses a light emitting device and a manufacturing method thereof. A groove is formed on the substrate of the light-emitting device, and a buffer layer, an n-contact layer and an active layer are sequentially deposited on the groove, thereby increasing the light-emitting area of the active layer. Therefore, the luminous efficiency is improved, and high-brightness light can be obtained with a substrate of the same size, thereby reducing production costs.

Owner:LG ELECTRONICS INC

Method for producing an organic light emitting device (OLED) and structure produced thereby

InactiveUS20020117663A1Easy to useEasy and low-cost manufactureSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorOrganic light emitting device

An organic light emitting device (and a method for producing the device) includes a multilayered structure with a substrate layer providing a first electrode layer, a second electrode layer and at least one layer of light emitting organic material between the first and second electrode layers. The second electrode layer includes at least two separate layers, a layer of a semi-transparent metal electrode and a layer of light transparent lateral conductor, is deposited onto the layer of light emitting organic material such as depositing the semi-transparent metal electrode layer onto the layer of light emitting organic material, depositing subsequently at least one protection layer thereupon and depositing the light transparent lateral conductor layer onto the protection layer.

Owner:INNOLUX CORP

AlGaInP light-emitting diode (LED) chip and cutting method for same

InactiveCN102709409ASimple structureImprove luminous efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesLight-emitting diodeDiode

The invention discloses an AlGaInP light-emitting diode (LED) chip, which comprises a GaAs substrate serving as an epitaxial layer substrate. An epitaxial layer is arranged on one surface of the GaAs substrate, and serves as a PN junction of the LED chip. An Au thin film is plated on the other surface of the GaAs substrate, and serves as the cathode end of the LED chip. BeAu thin films arranged at equal intervals are deposited on the epitaxial layer, and an Au thin film is deposited on the BeAu thin films to form the anode ends of the LED chip. A cutting method for the AlGaInP LED chip specifically comprises the following steps of: (1) half-cutting the LED chip on one surfaces of the anode ends of the LED chip by using a diamond cutter to form cutting channels to separate the uniformly arranged anode ends of the LED chip, wherein the LED chip is 100 to 300 mu m thick; (2) coating a blue film at the anode ends of the LED chip, and coating a Mylar film at the cathode end of the LED chip; and (3) placing the LED chip on a cleaving table of a cleaver in a way that the anode end of the LED chip is downward and the cathode end of the LED chip is upward, and pressing and breaking the LED chip along the cutting channels by using a cleaving knife of the cleaver, so that the LED chip forms independent crystal grains.

Owner:东莞洲磊电子有限公司

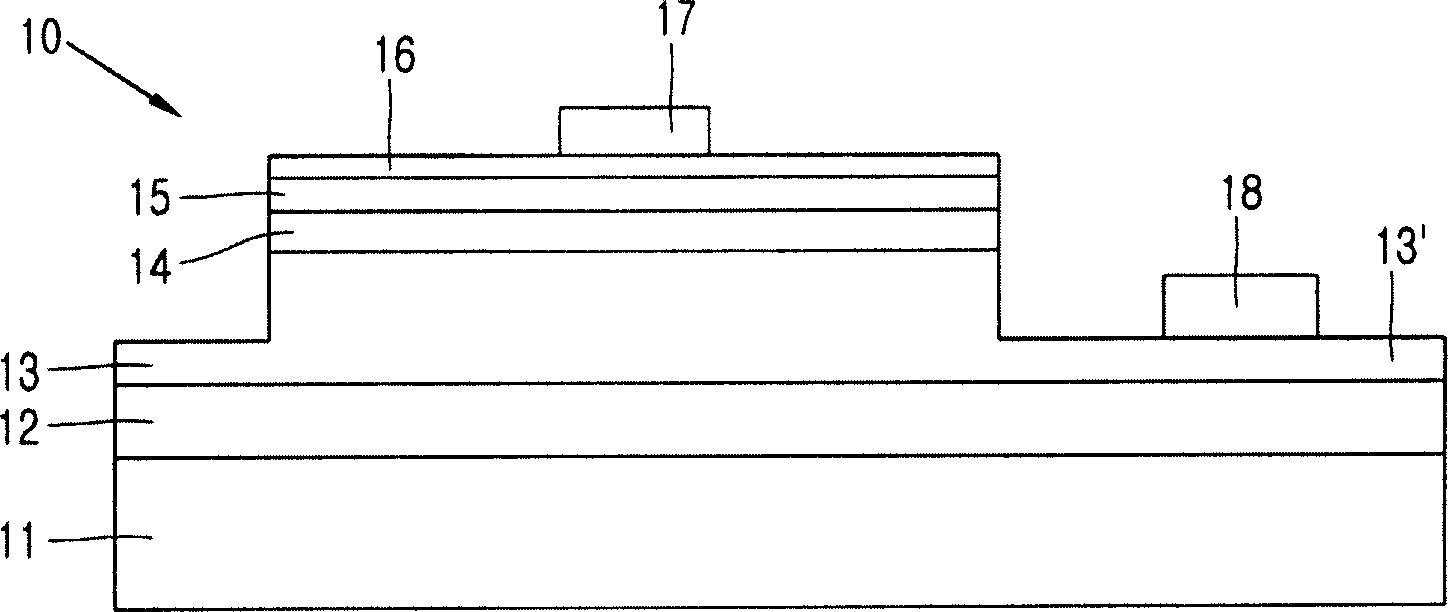

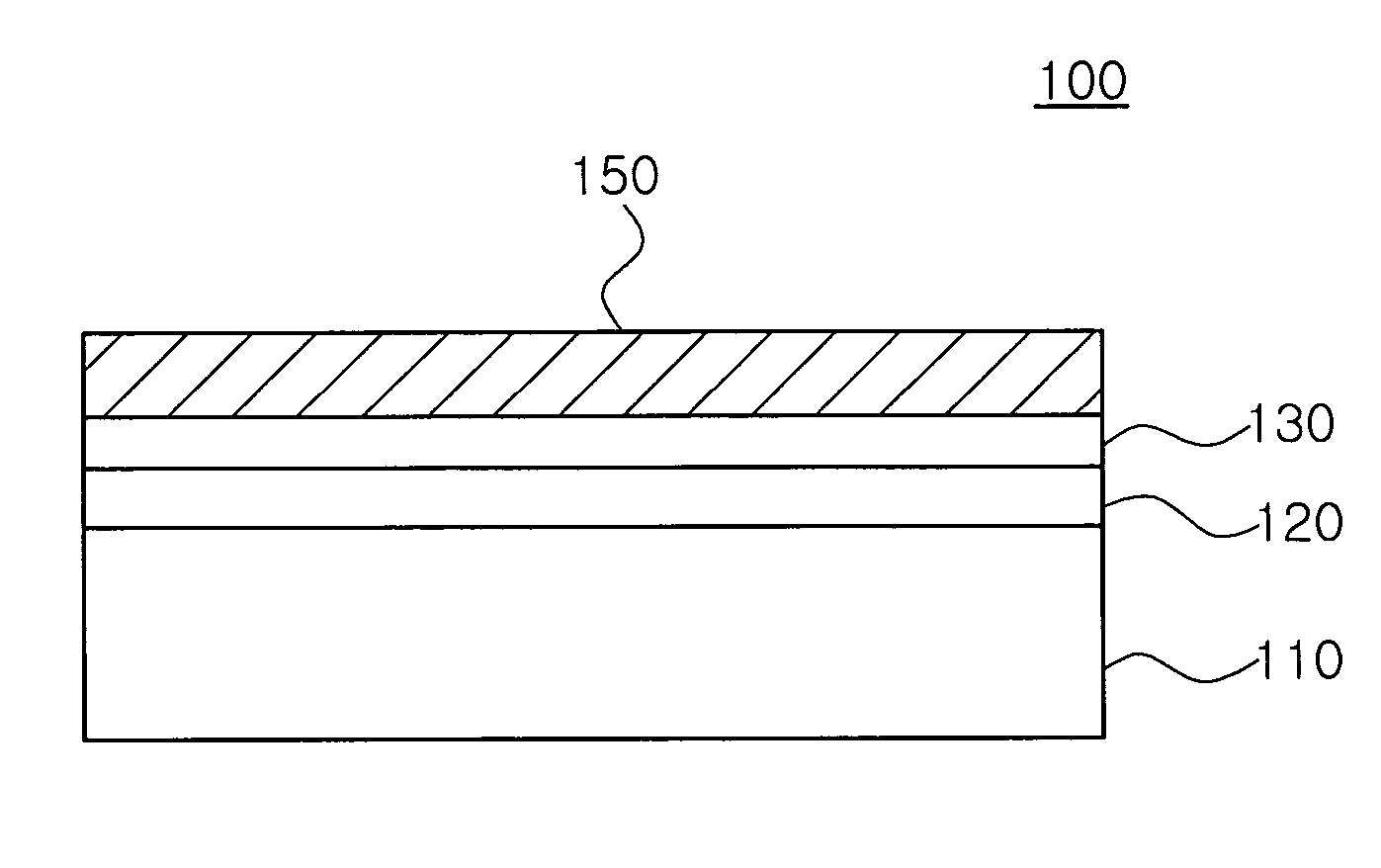

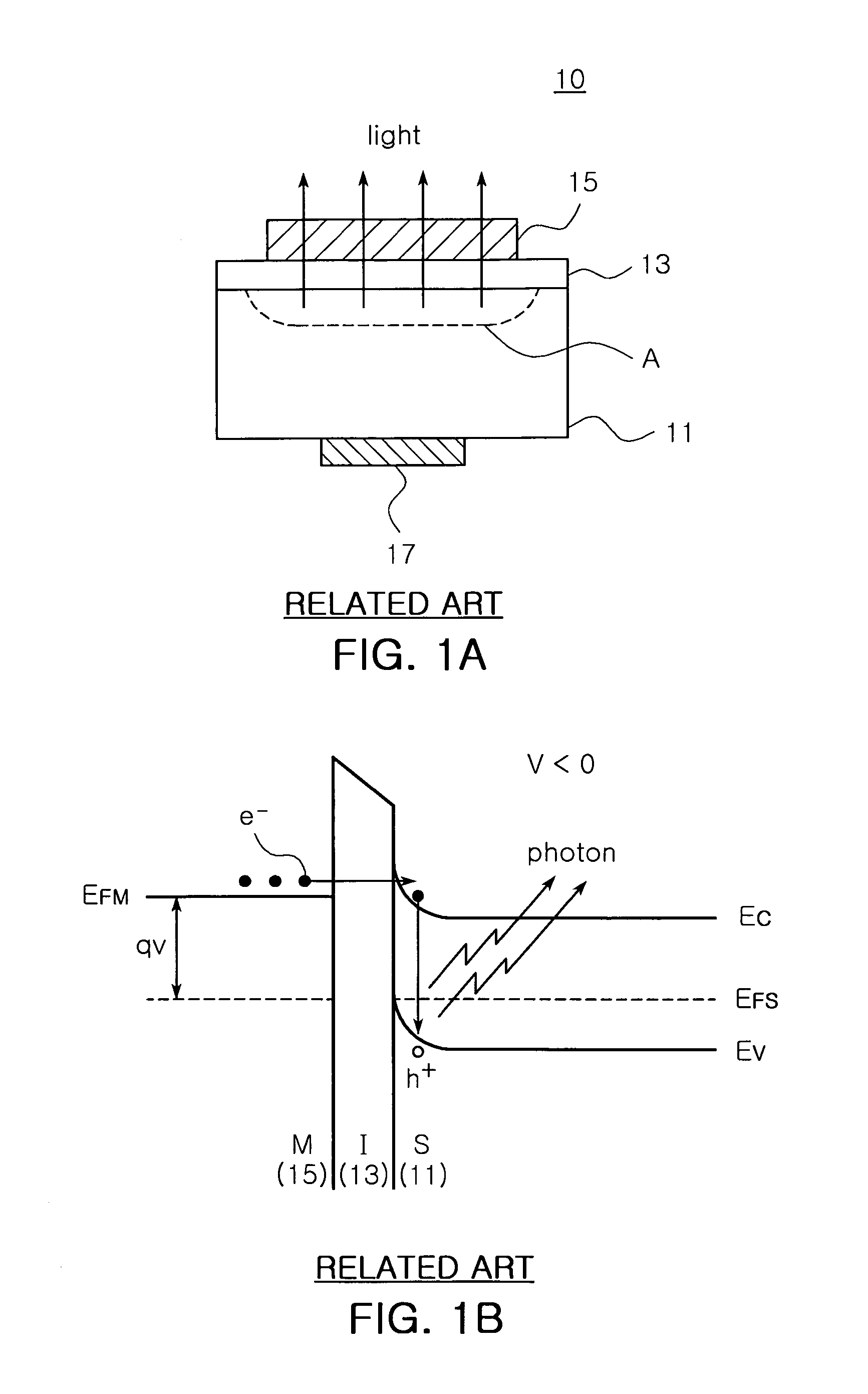

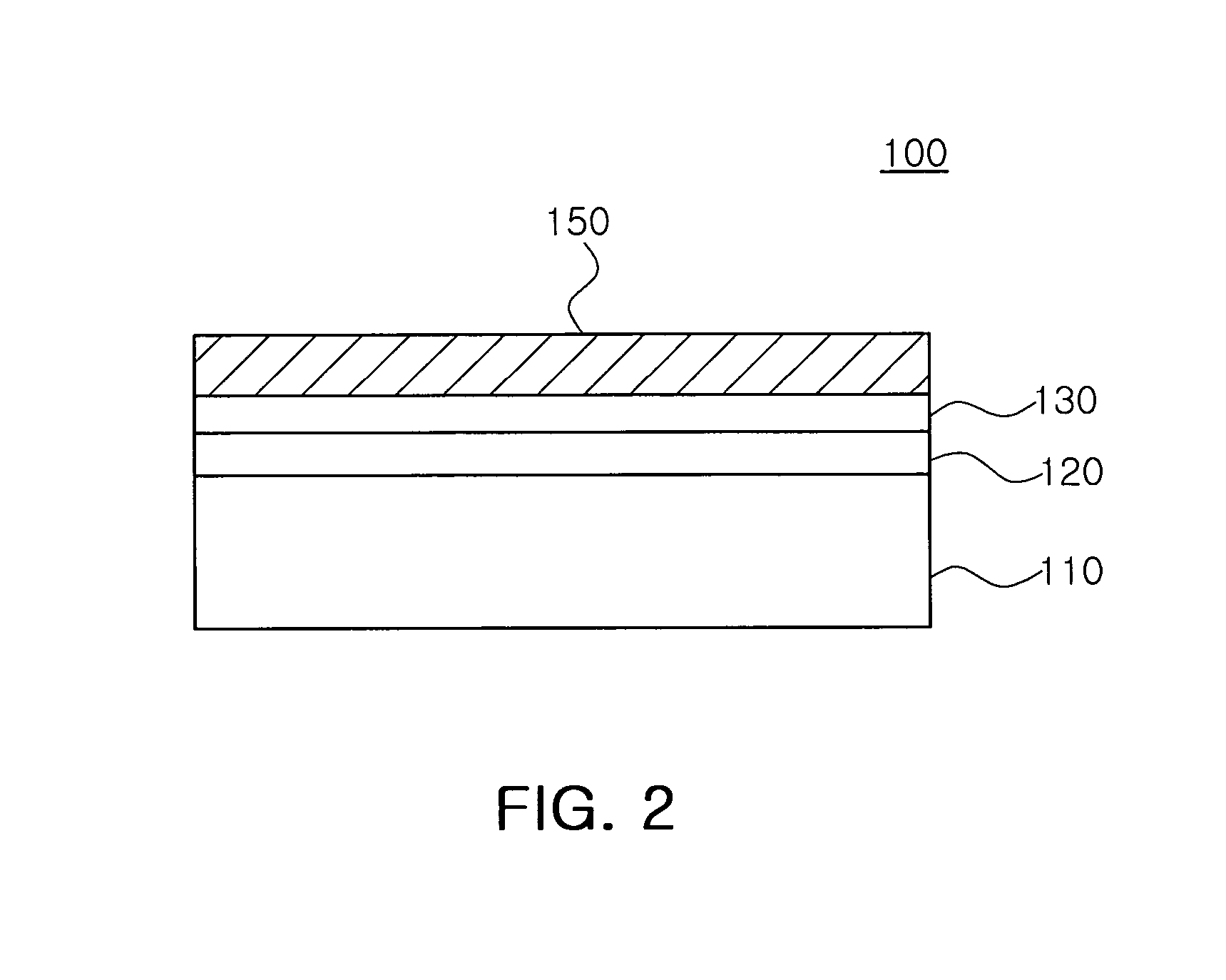

Light emitting device

InactiveUS20080142782A1Simple structureLarge luminous areaNanotechSolid-state devicesQuantum wellQuantum dot

There is provided a light emitting device of a simpler structure, capable of ensuring a broad light emitting area and a high light emitting efficiency, while manufactured in a simplified and economically efficient process. The light emitting device including: a semiconductor layer; an active layer formed on the semiconductor layer, the active layer comprising at least one of a quantum well structure, a quantum dot and a quantum line; an insulating layer formed on the active layer; and a metal layer formed on the insulating layer.

Owner:SAMSUNG ELECTRONICS CO LTD

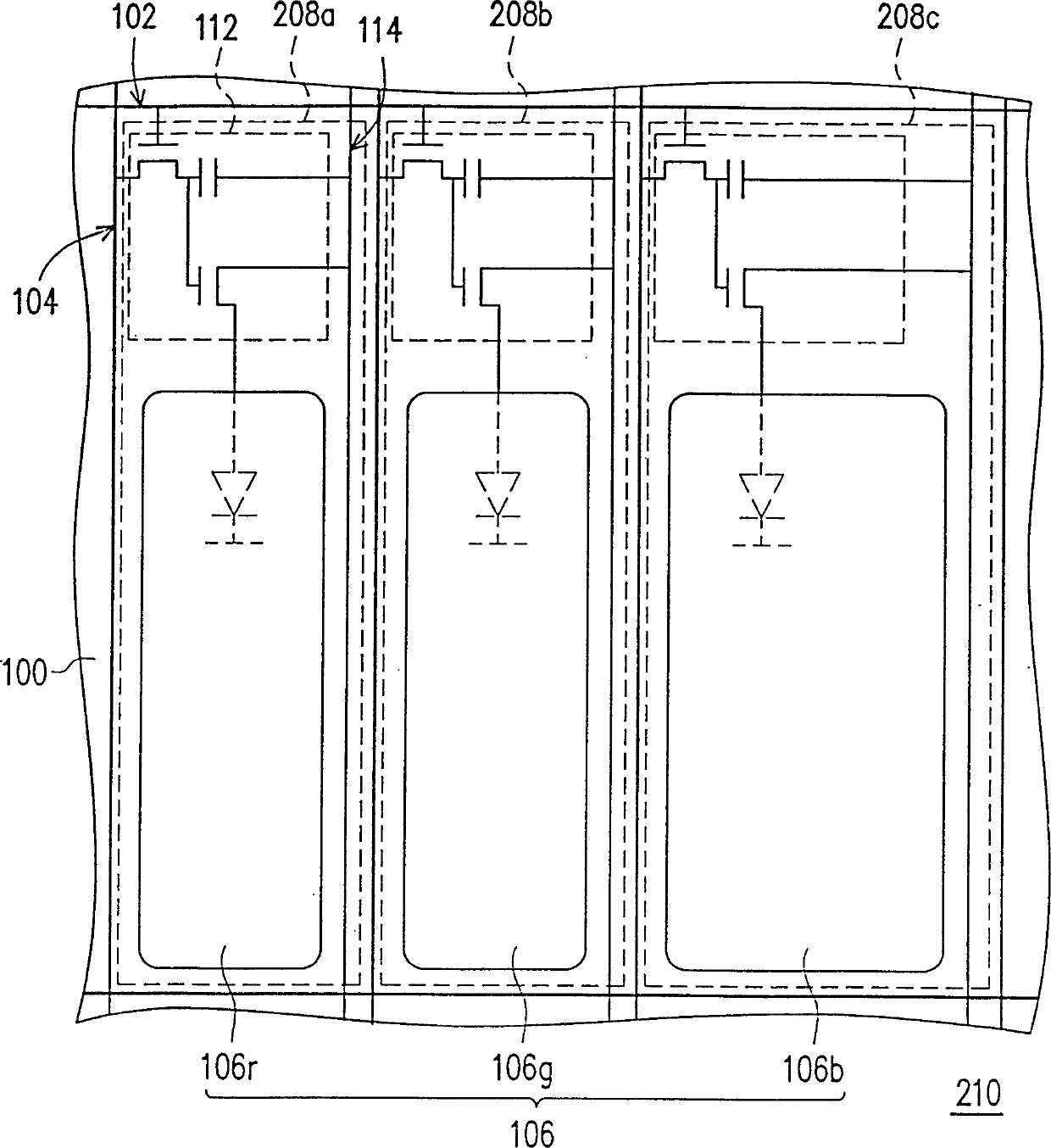

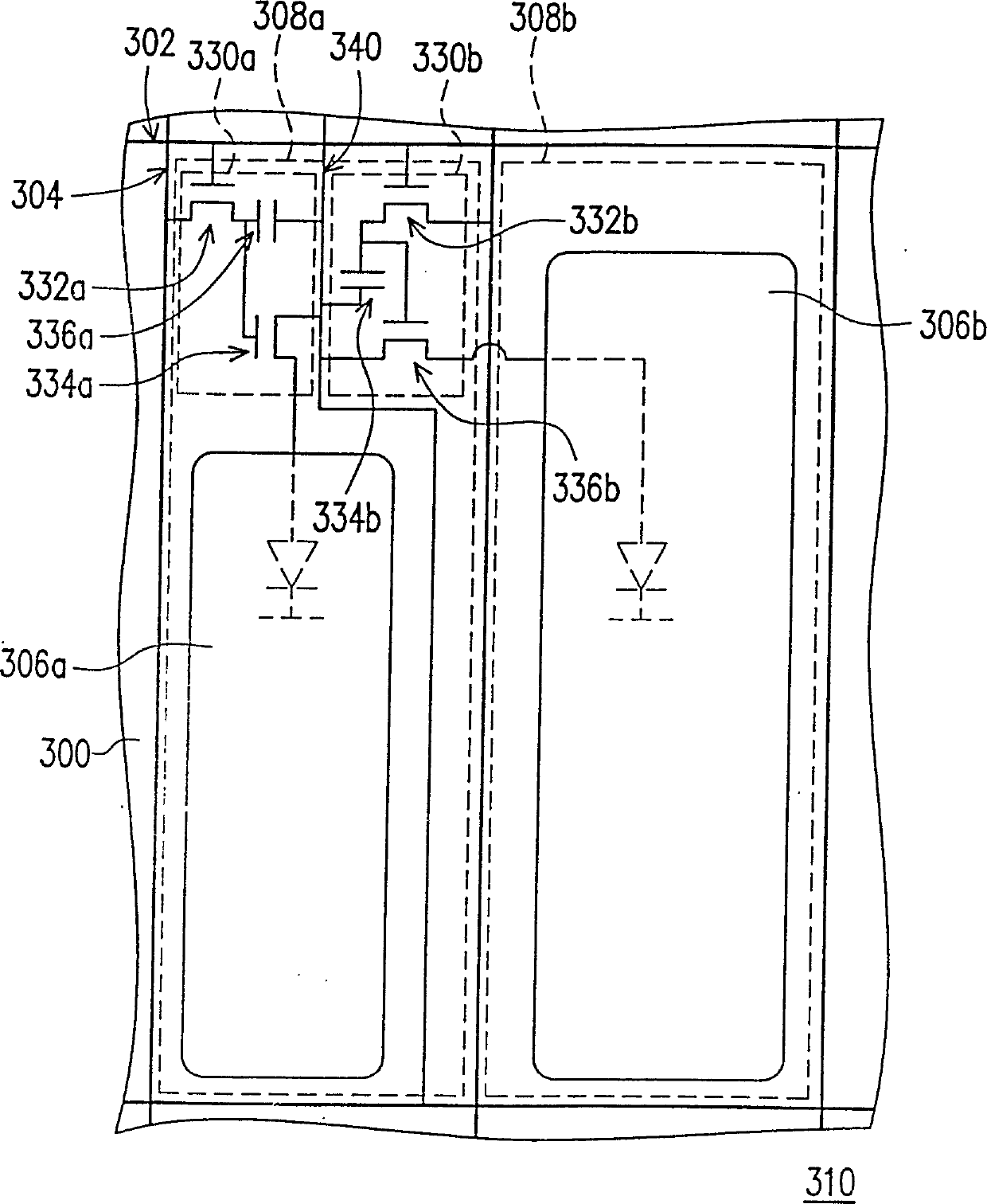

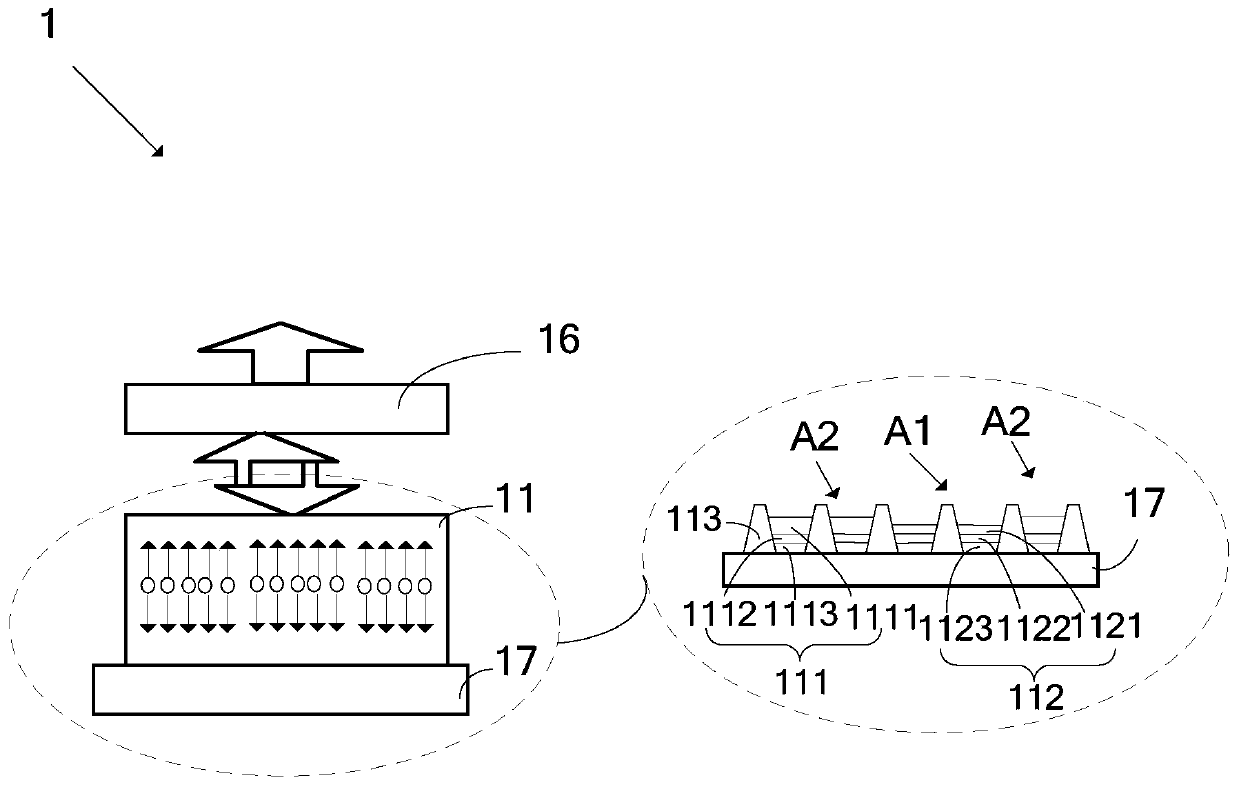

Active organic electroluminescent element array

InactiveCN1774147ALarge luminous areaSmall light emitting areaElectrical apparatusElectroluminescent light sourcesElectricityEngineering

An organic electroluminescence element array of active type consists of the first pixel zone and the second pixel zone being divided out by scan wiring and data wiring separately. It is featured as setting the first luminous element, the first control unit and the second control unit in each first pixel zone and setting the second luminous element in each second pixel zone; connecting the first control unit to the first luminous element in electricity for driving the first luminous element and the second control unit to the second luminous element in electricity for driving the second luminous element.

Owner:CHUNGHWA PICTURE TUBES LTD

Micro light-emitting diode chip

ActiveUS20200075805A1Easy to manufactureOptimized areaSolid-state devicesSemiconductor devicesEngineeringLight-emitting diode

A micro light-emitting diode chip includes an epitaxial structure, a first electrode, and a second electrode. The epitaxial structure includes a first type doped semiconductor layer, a light emitting layer, and a second type doped semiconductor layer, and the epitaxial structure further includes a first surface, a side surface and a second surface opposite to the first surface. The side surface of the epitaxial structure connects to an outer edge of the first surface and an outer edge of the second surface. The first electrode is disposed on the first surface, and is electrically connected to the first type doped semiconductor layer and contacts the first type doped semiconductor layer on a portion of the first surface. The second electrode is disposed on and surrounds the side surface, and electrically connected to the second type doped semiconductor layer, and directly contacts the second type doped semiconductor layer on a portion of the side surface. A length of a diagonal of the micro light-emitting diode chip is greater than 1 micrometer and is less than or equal to 140 micrometers, and a thickness of the micro light-emitting diode chip is great than 1 micrometer and is less than 10 micrometers.

Owner:PLAYNITRIDE

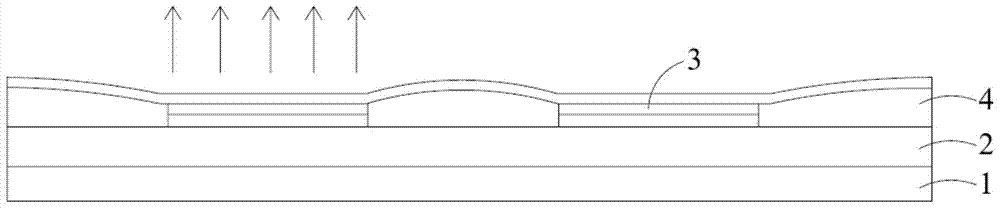

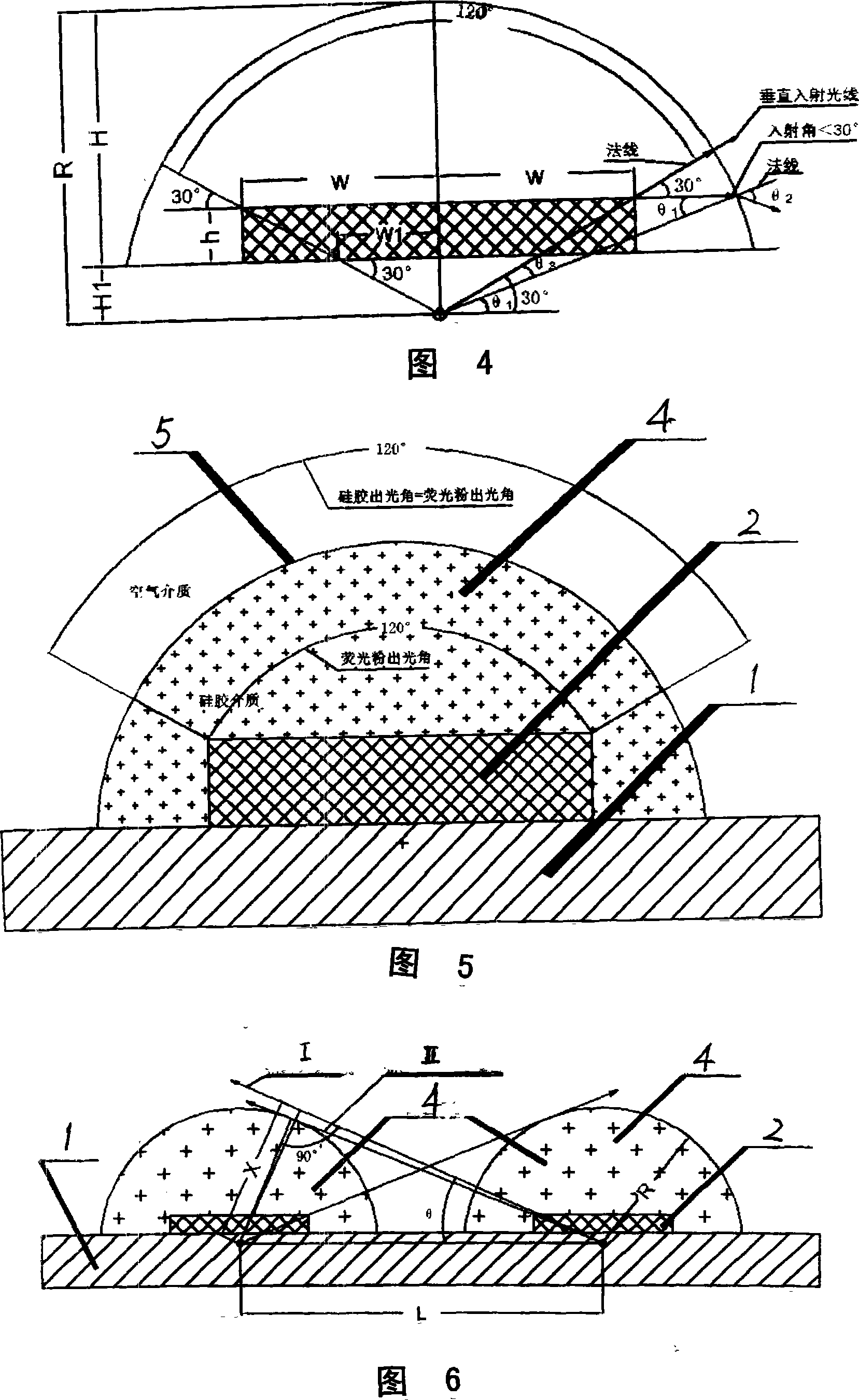

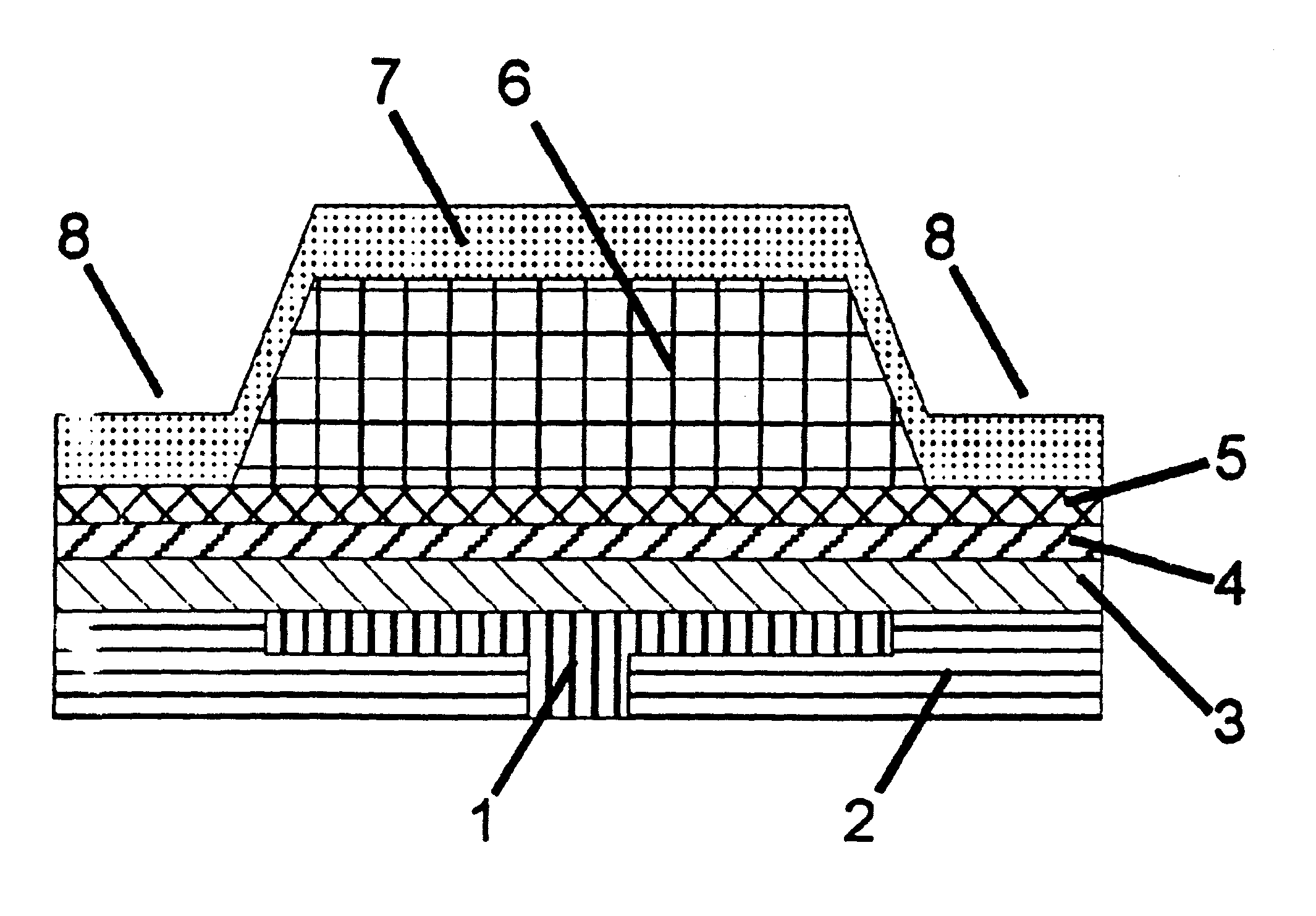

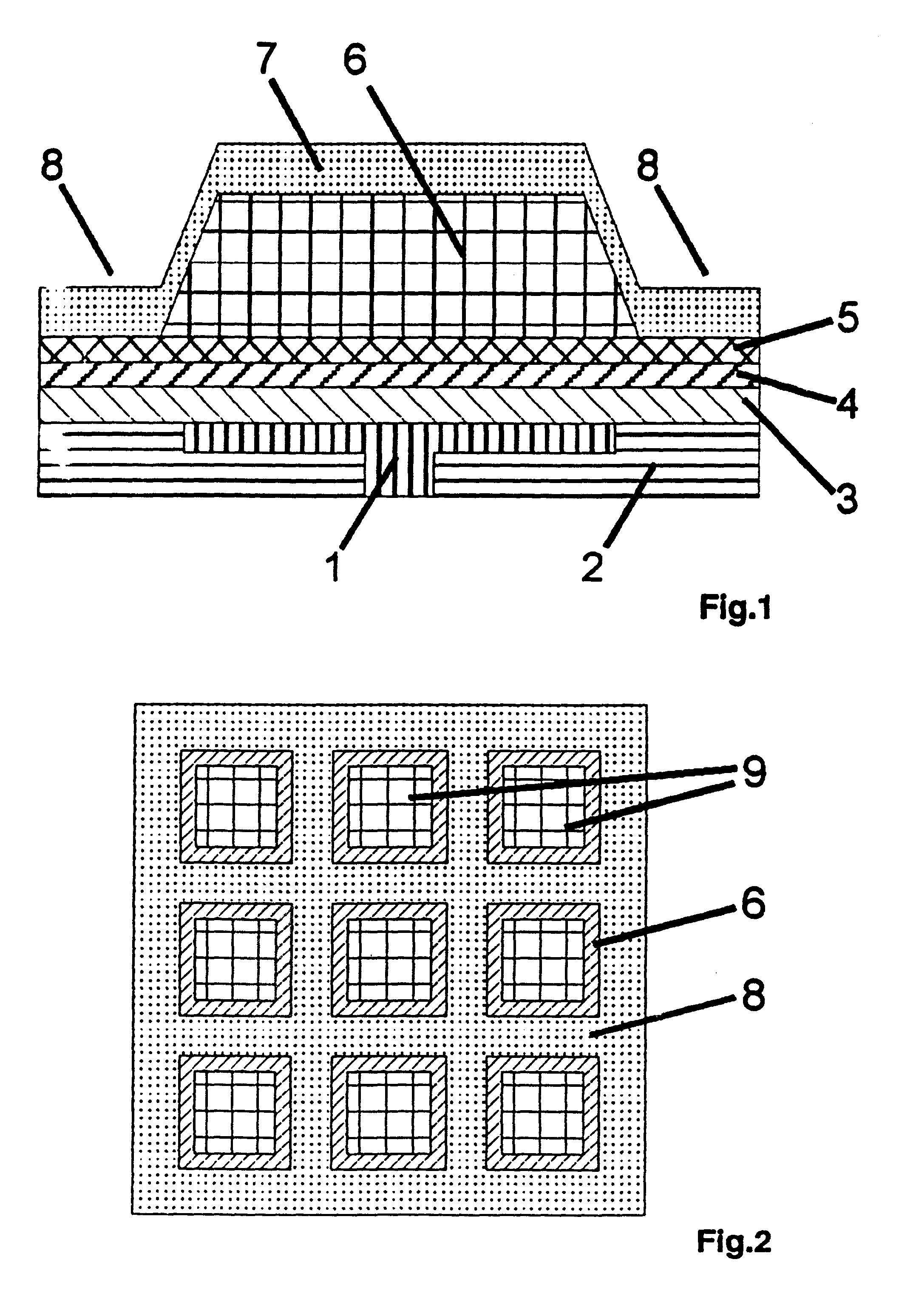

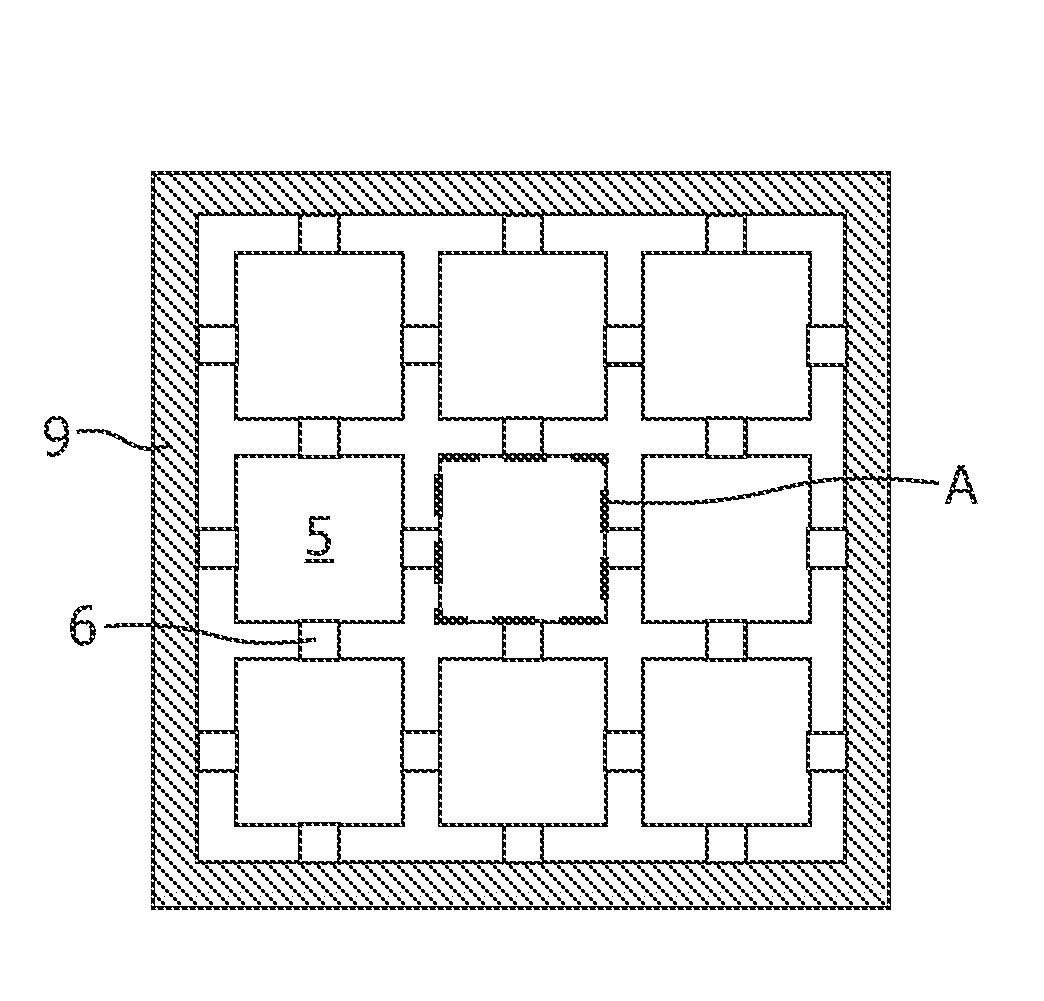

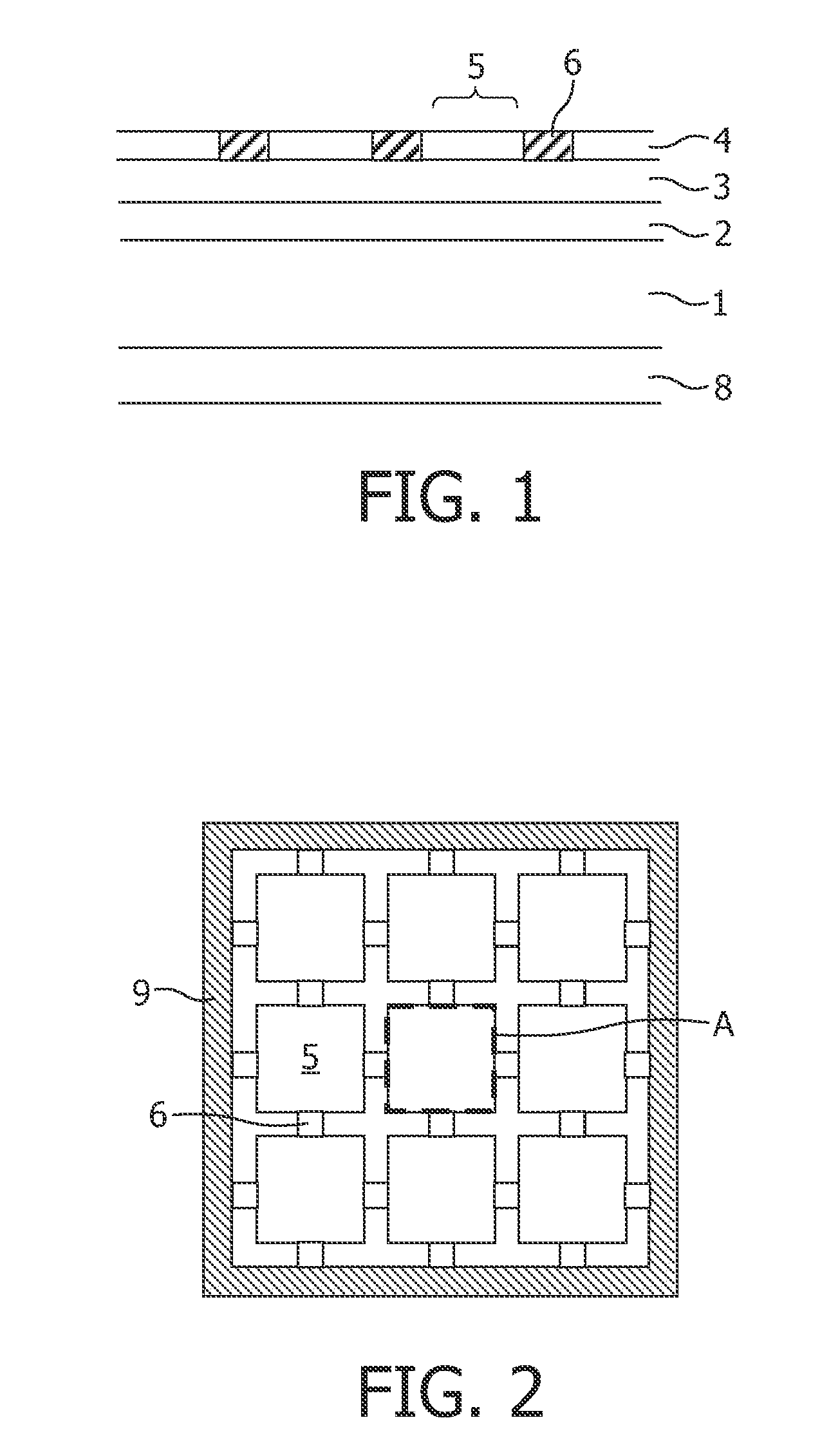

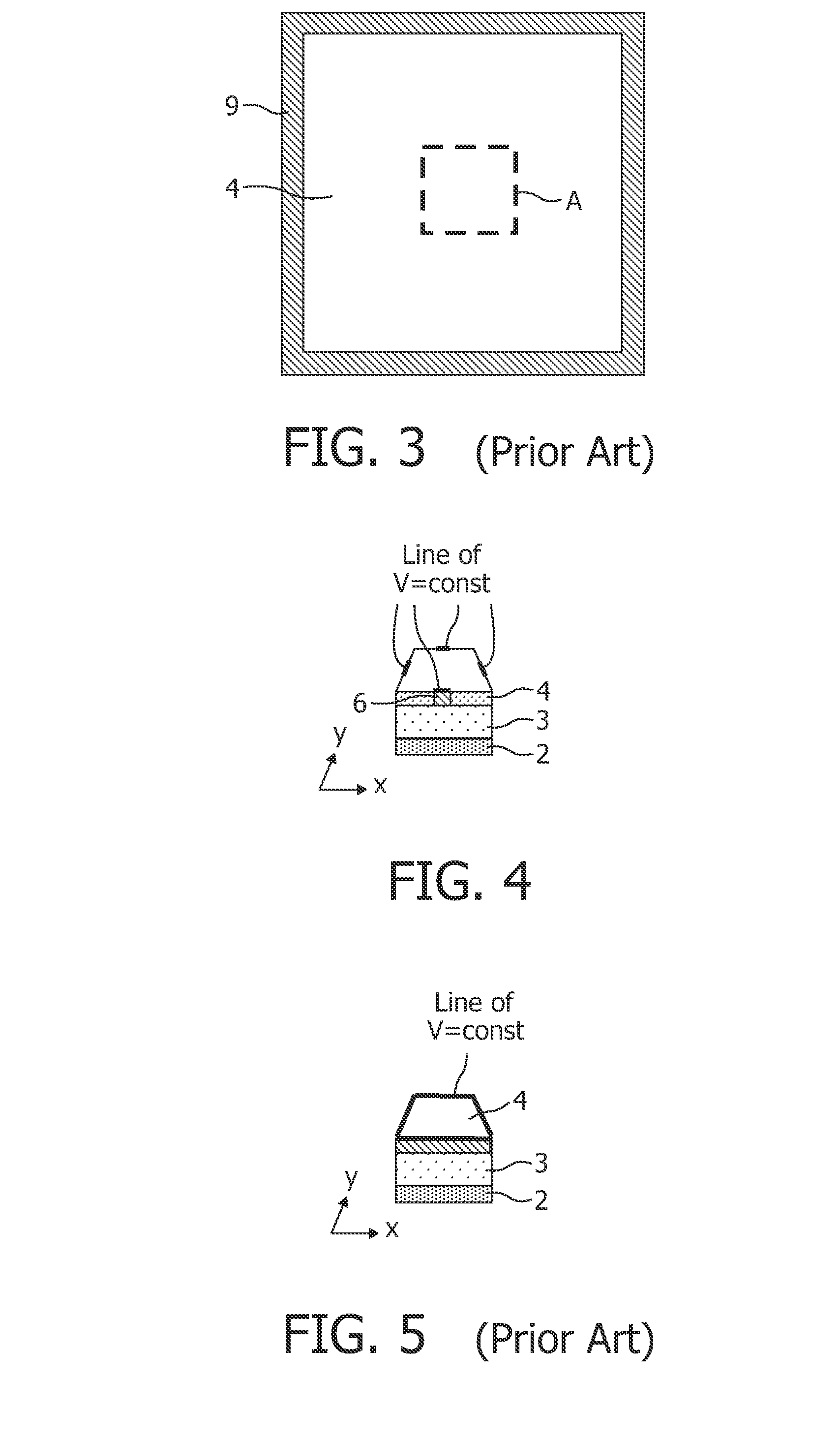

Large area light emitting diode light source

InactiveUS20100140598A1Avoid smallWithout risk of failureSolid-state devicesSemiconductor/solid-state device manufacturingNear neighborElectrical connection

The present invention relates to a LED light source comprising at least one layer of light emitting material (3), in particular organic light emitting material, sandwiched between two electrode layers (2, 4). At least one of the electrode layers (2, 4) is structured to form a pattern of electrode segments (5), each electrode segment (5) being in electrical contact with at least three of its nearest neighbor electrode segments (5) via direct electrical connections (6), which are designed to act as electrical fuses between the electrode segments (5). The invention allows the design of a large area LED light source having a homogeneous light density without the risk of failure of larger light emitting areas.

Owner:OLEDWORKS GMBH

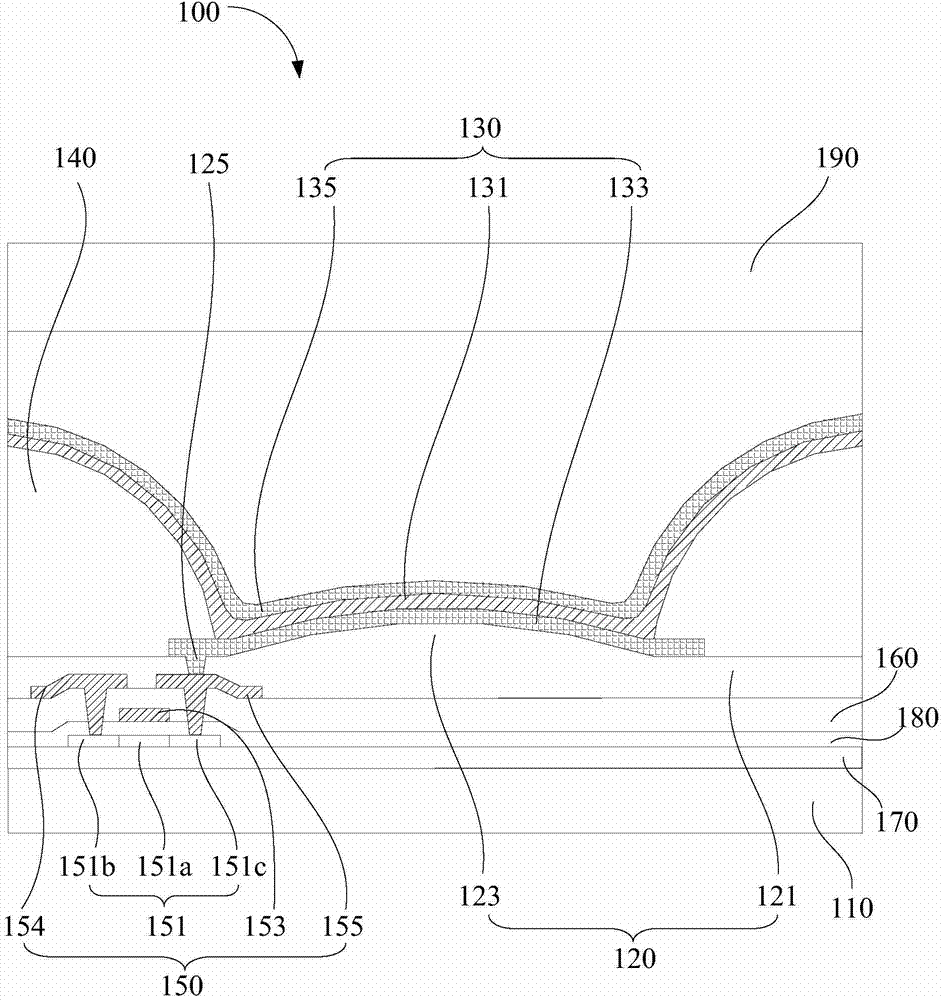

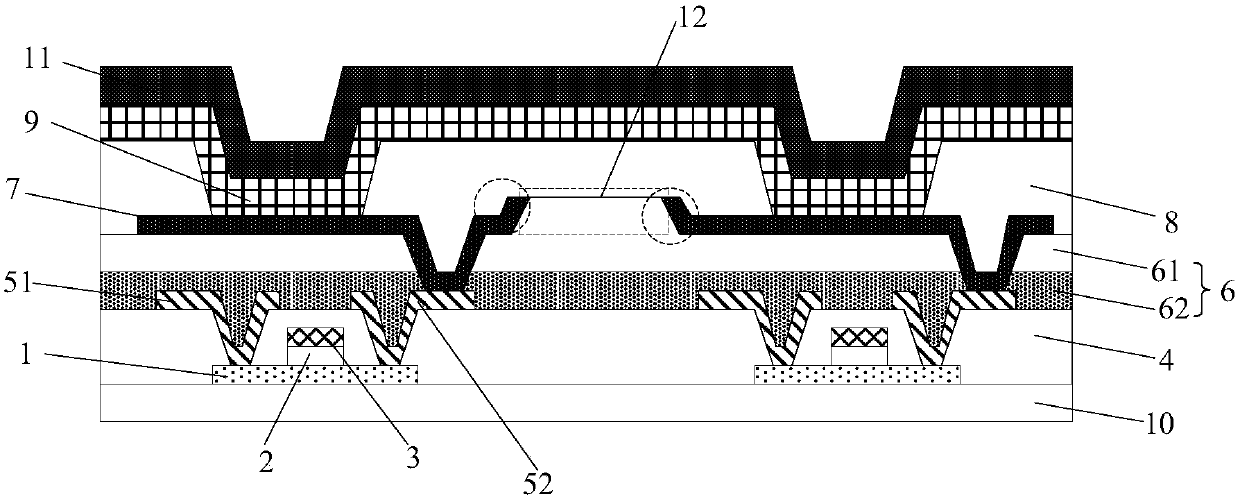

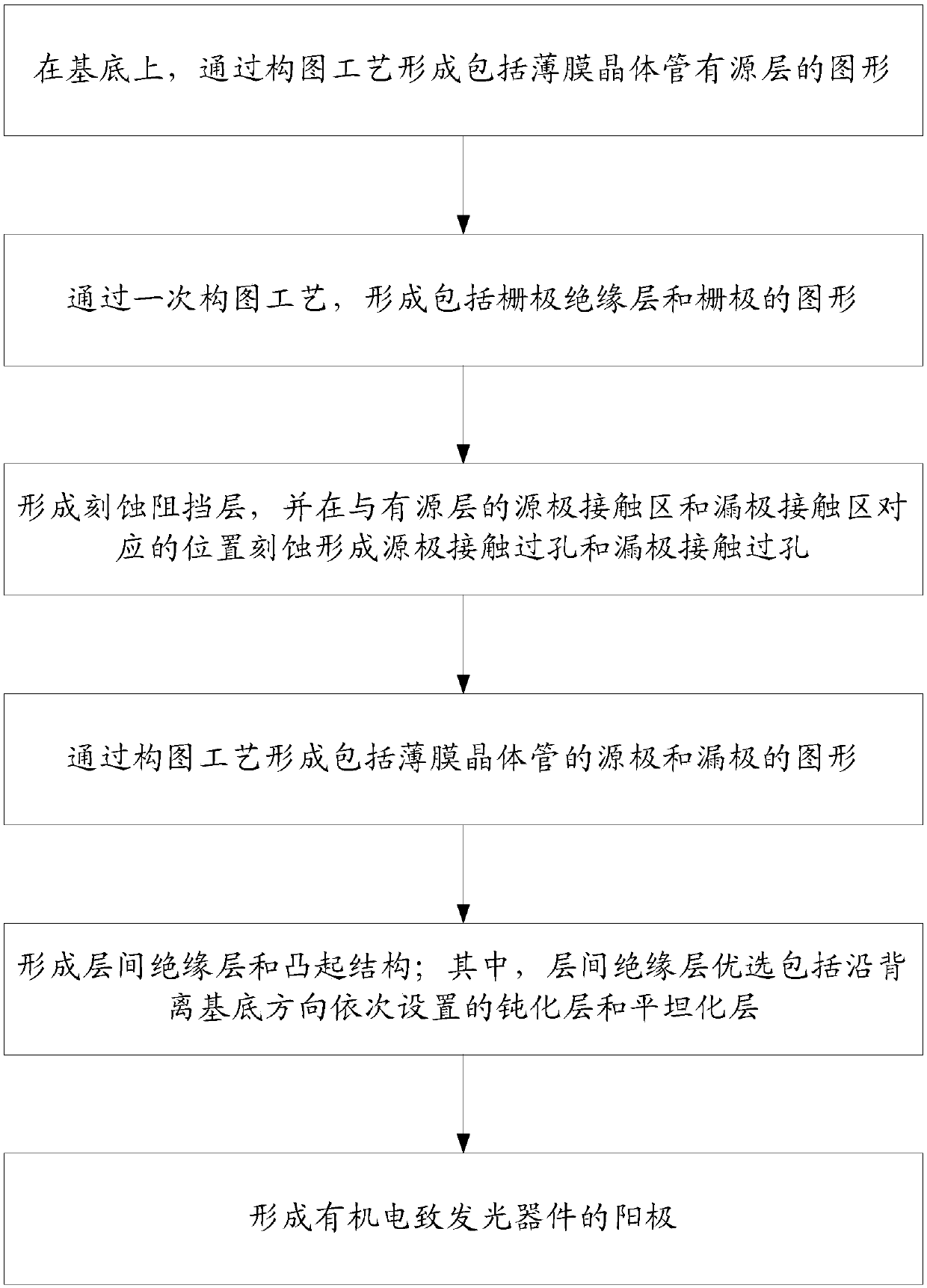

Array substrate, fabrication method thereof and display device

PendingCN107681063ALarge luminous areaImprove light stabilitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceOptoelectronics

The invention provides an array substrate, a fabrication method thereof and a display device, and belongs to the technical field of display. By the array substrate, the problem that a threshold voltage of a thin film transistor is greatly drifted due to irradiation of an existing organic light emitting device on the thin film transistor can be solved. The array substrate comprises a substrate anda plurality of pixel units, wherein the plurality of pixel units are arranged on the substrate, each pixel unit comprises an organic light emitting device, the organic light emitting device comprisesa first pole, a light emitting layer and a second pole which are sequentially arranged along a direction deviating from the substrate, the material of the first pole comprises a reflection material, aprotruding structure is arranged between the first poles of arbitrary two adjacent organic light emitting devices, and the first pole of each organic light emitting device extends to a side wall of the protruding structure.

Owner:BOE TECH GRP CO LTD

Display panel, mask plate and manufacturing method of display panel

ActiveCN111524460ALarge luminous areaHigh light transmittanceVacuum evaporation coatingSputtering coatingMaterials scienceLight transmission

The invention provides a display panel, a mask plate and a manufacturing method of a display panel. The display panel comprises a display area, the display area comprises a mounting area and a non-mounting area, the mounting area is used for mounting a preset assembly, and the non-mounting area is an area, except the mounting area, of the display area. The display panel also comprises a pixel layer. The pixel layer comprises a plurality of first sub-pixels, wherein the plurality of first sub-pixels are arranged in the non-mounting area, and each first sub-pixel comprises a first cathode; a plurality of second sub-pixels arranged in the mounting area, wherein each second sub-pixel comprises a second cathode, and the thickness of the second cathode is smaller than that of the first cathode.According to the scheme, the light transmittance of the mounting area in the display panel is improved by reducing the thickness of the cathodes in the mounting area.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com