Method for producing N-type layer ohmic contact electrode of GaN LED

A technology of ohmic contact electrodes and light-emitting diodes, which is applied to circuits, electrical components, semiconductor devices, etc., and can solve problems such as not being on the same plane, affecting yield, and difficulty in bonding and flip-chip technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

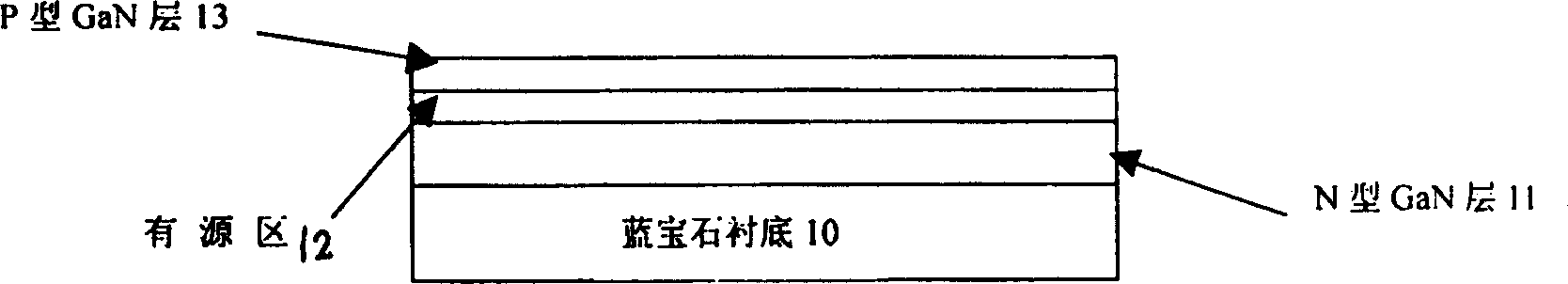

[0022] see figure 1 As shown, the fabrication method of the N-type layer ohmic contact electrode of the GaN-based light-emitting diode of the present invention generally includes forming an N-type GaN layer 11, an active layer 12 and a P-type GaN layer 11 on a sapphire substrate 10 by means of epitaxy. GaN layer 13.

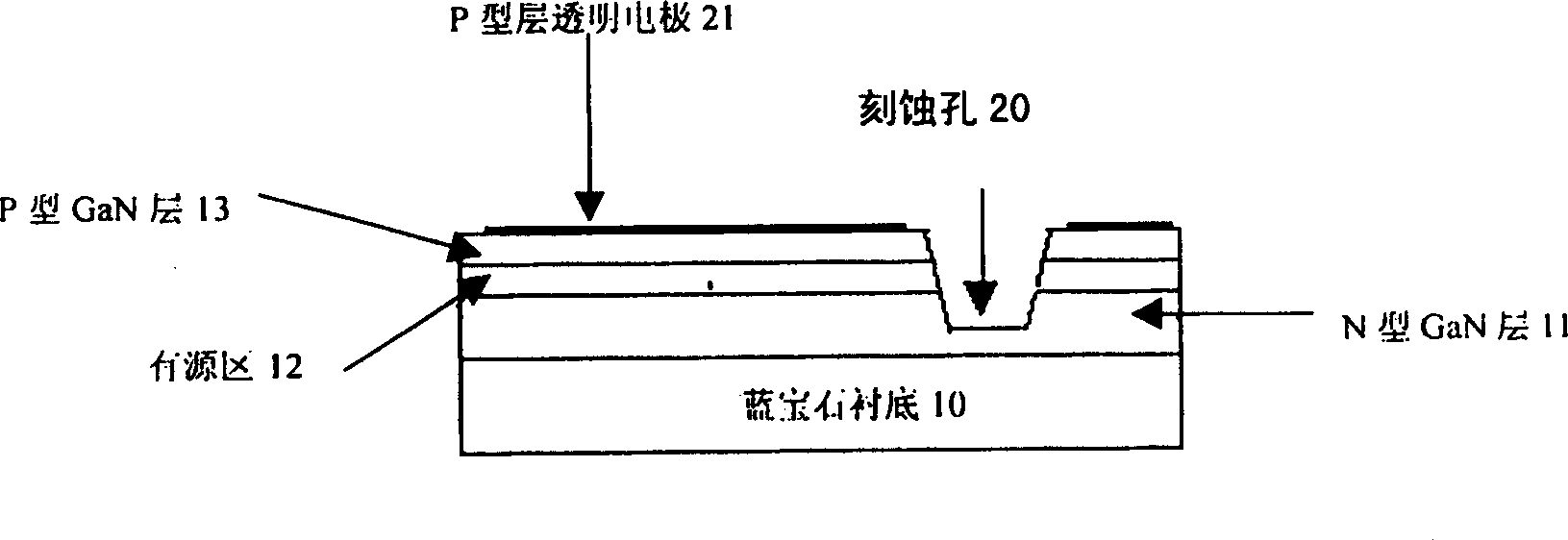

[0023] First etch or corrode an etching hole 20 with a diameter of 30 microns at the N electrode position of the tube core design until the N-type layer 11 is exposed, and prepare the P-type layer transparent electrode 21 by photolithography and evaporation or sputtering, such as figure 2 shown;

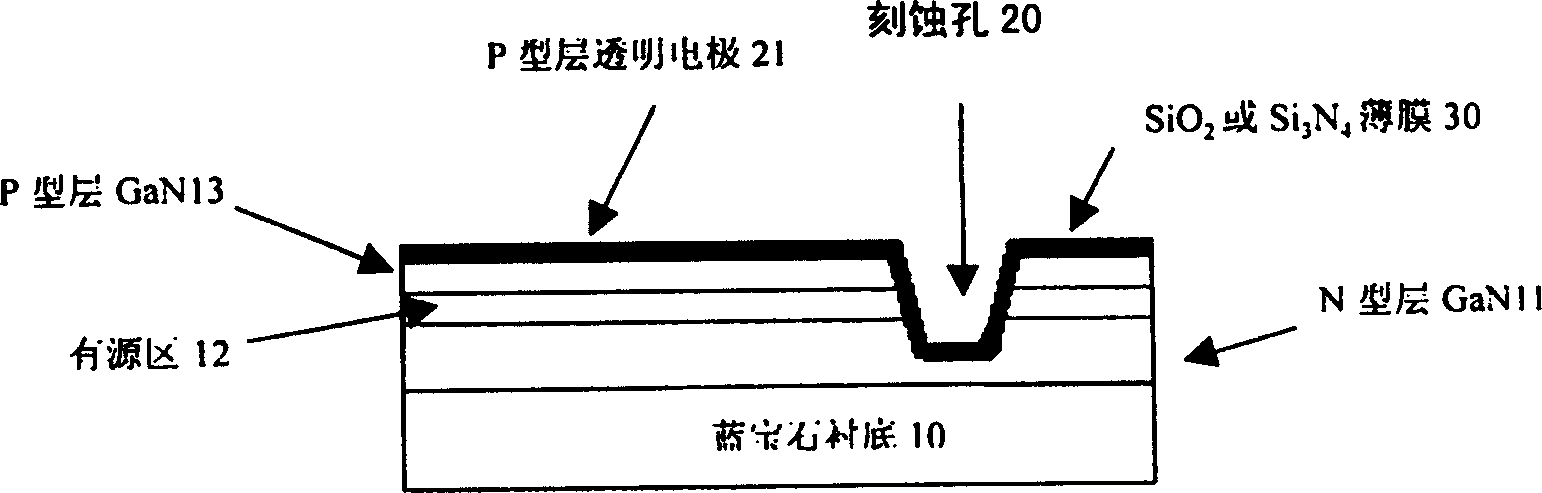

[0024] Then use the CVD method to vapor-deposit a 0.10 micron silicon dioxide film 30 on the surface of gallium nitride, such as image 3 shown;

[0025] Then use photolithography and chemical etching to etch away the insulating film 30 on the surface of the N-type layer 11 and the area other than the N electrode. The diameter of the remaining insulating film 30 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com