epitaxial wafer structure of gallium nitride-based LED (Light-Emitting Diode) and preparation method thereof

A light-emitting diode, gallium nitride-based technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of decreasing radiation recombination efficiency, reducing the internal quantum efficiency of LEDs, etc., to achieve the effect of increasing the light-emitting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

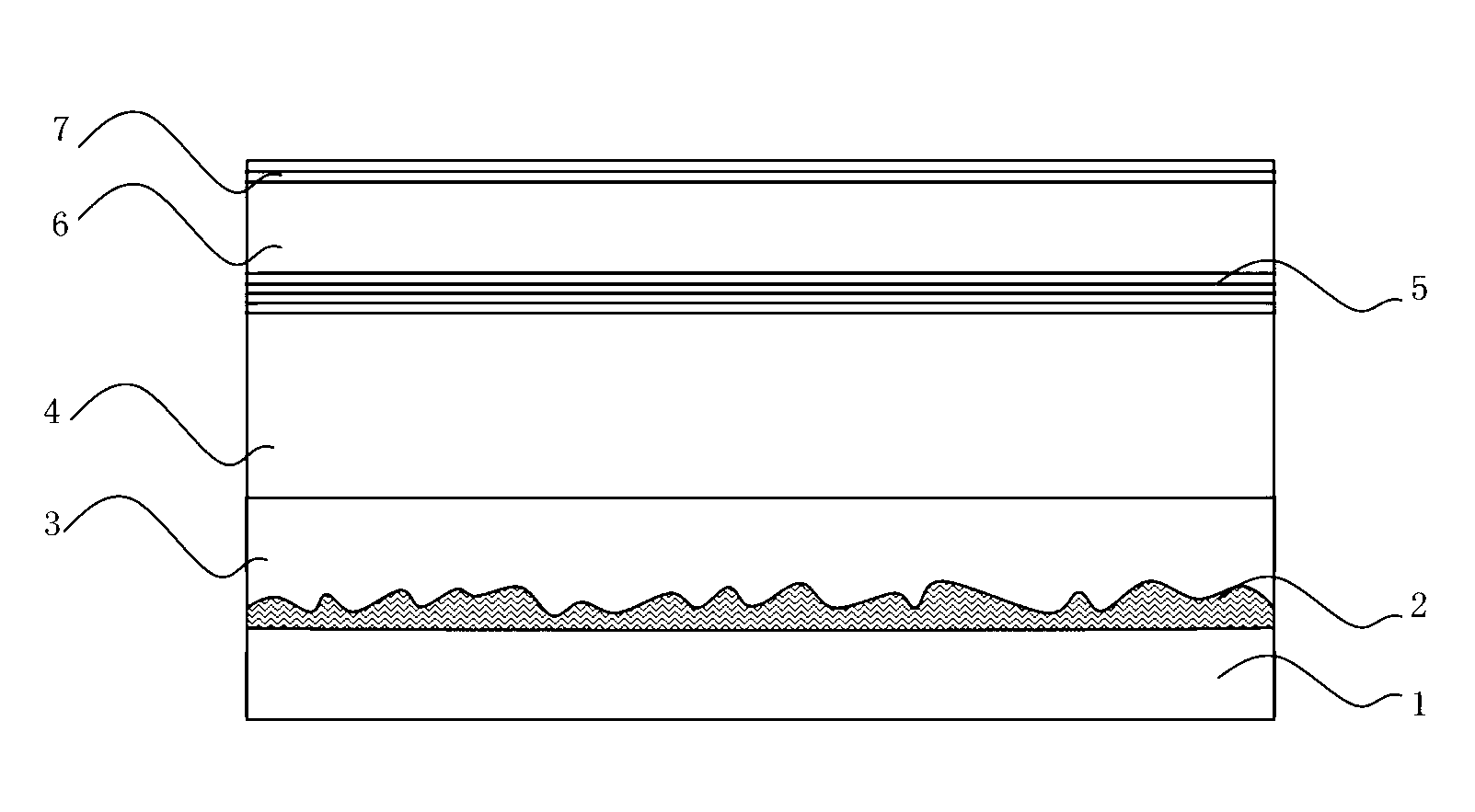

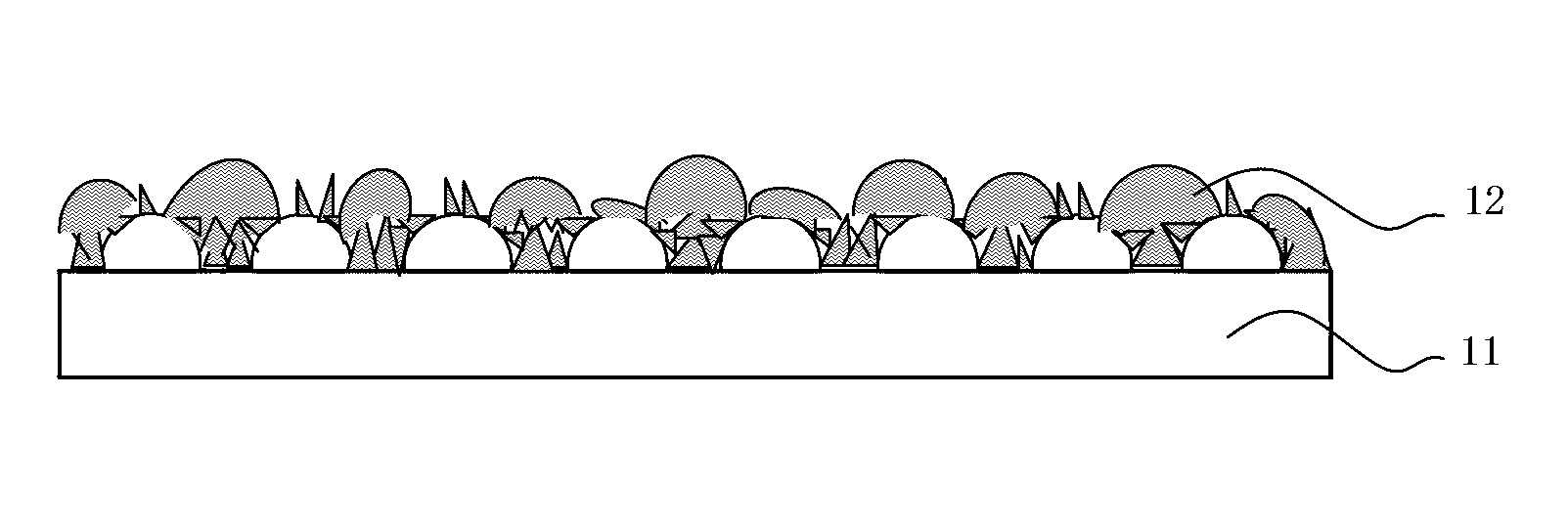

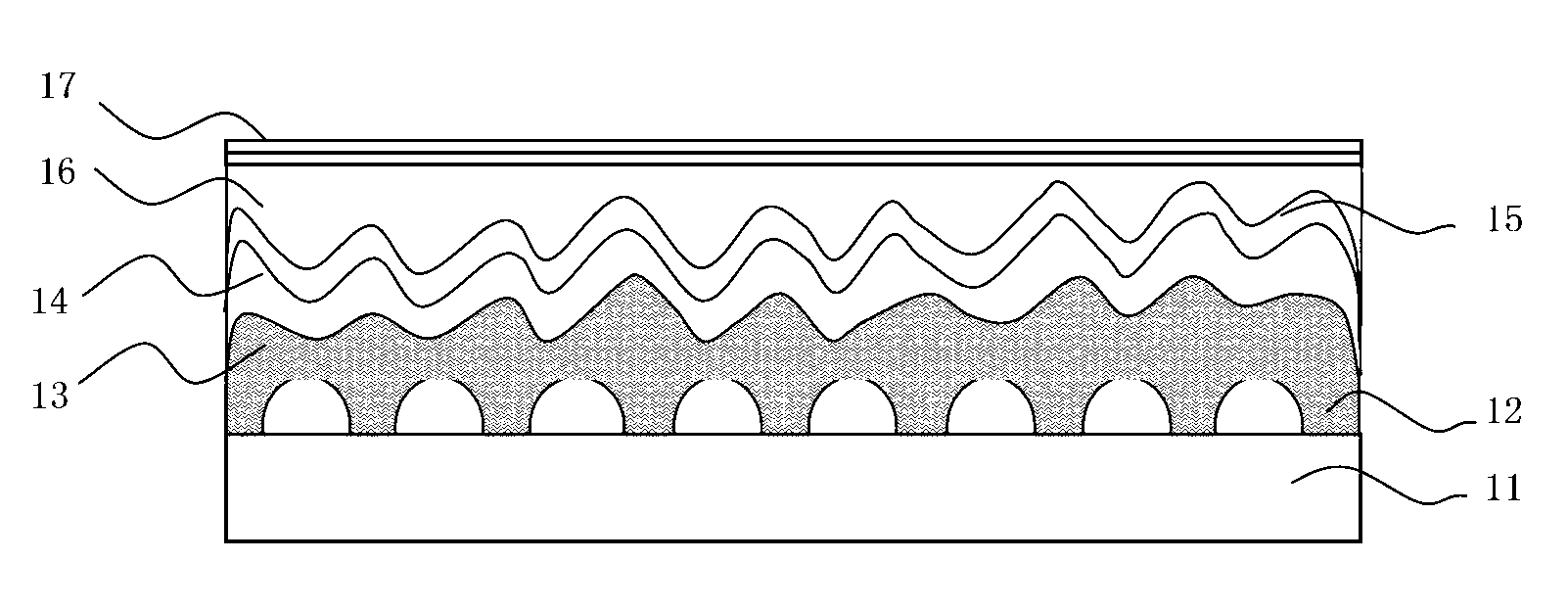

[0026] The specific implementation of the structure of a GaN-based light-emitting diode epitaxial wafer on a weakly polar surface and its preparation method provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0027] attached figure 2 And attached image 3 Shown is a schematic diagram of the process of the method of the present invention. The specific steps of the method for preparing the epitaxial wafer structure of a gallium nitride-based light-emitting diode on a weakly polar surface according to the present invention are as follows:

[0028] 1) Load the graphic substrate 11 into the reaction chamber, and 2 Heating to above 1050°C in the atmosphere for heat treatment of the substrate for 10-20 minutes; then cooling down at 500-650°C to grow a nucleation layer with a thickness of 15-100nm, the material is Al x In y Ga 1-x-y N, where 0≤X≤1, 0≤Y≤1.

[0029] 2) High-temperature annealing at 900-1100°C to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com