Large chip for LED lighting

A technology of LED lighting and LED chips, which is applied in the direction of lighting devices, lighting and heating equipment, components of lighting devices, etc., and can solve the problems of small area of LED chips and related circuits, small batches of manufacturers, thick optical-mechanical templates, etc. , to achieve the effect of facilitating standardized operations, simple production process, and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the drawings and embodiments, but it is not a basis for limiting the present invention.

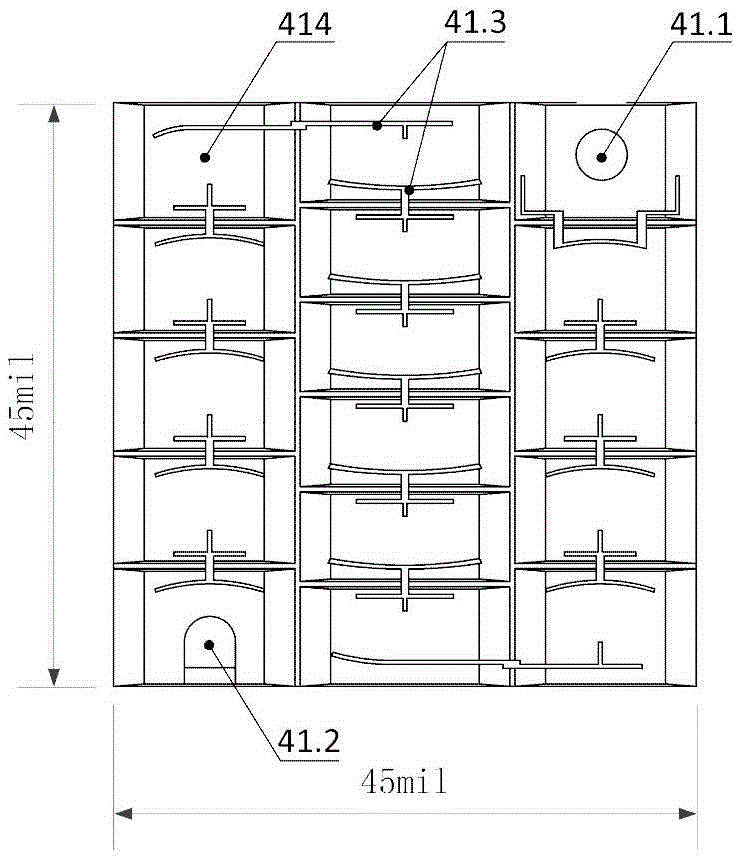

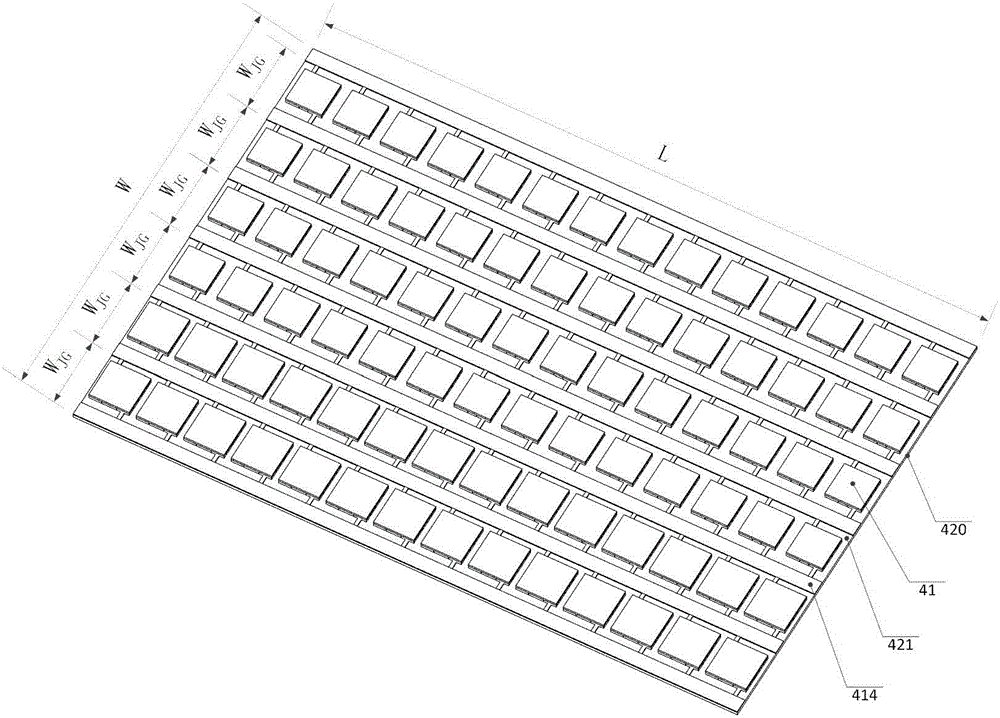

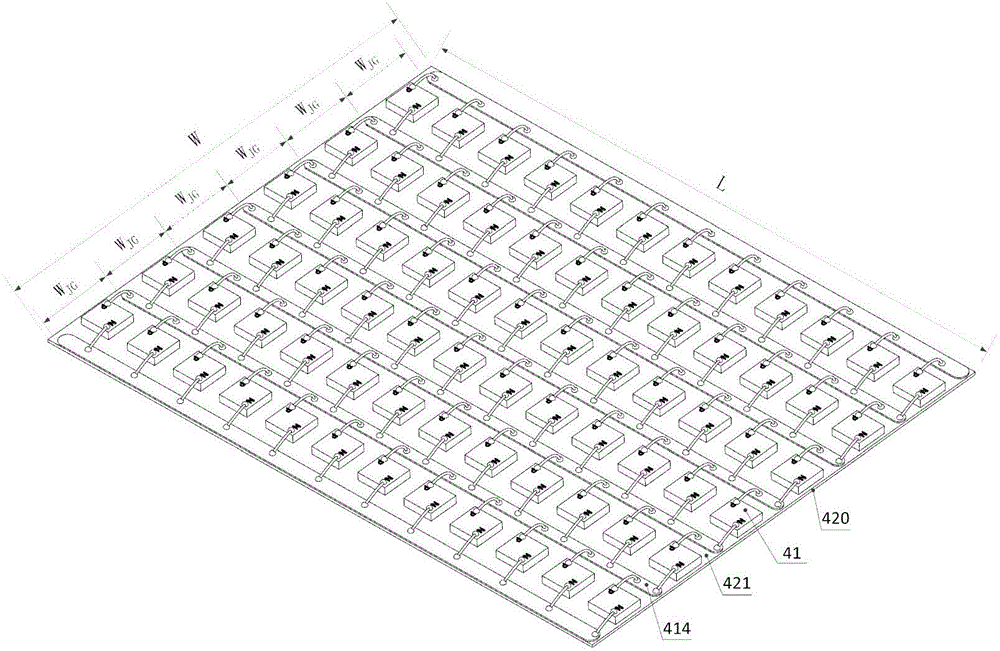

[0046] Examples. LED lighting chip, such as Figure 1 to 3 Shown: It includes a first transparent substrate 421 with a fixed width of W. N+1 parallel interface wires are provided on the first transparent substrate 421, and N LED chips 41 are provided on the first transparent substrate 421 to form a series of LED chips. Group, each LED chip 41 is located between two adjacent interface wires, and the distance between two adjacent interface wires is W JG Equal to W minus the interface wire width and then divided by N(W JG =(W-interface wire width) / N), and the positive and negative poles of each LED chip 41 are respectively connected to two adjacent interface wires; and multiple LED series groups are connected in parallel at the same time, so that the first transparent substrate 421 An array of N columns and multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com