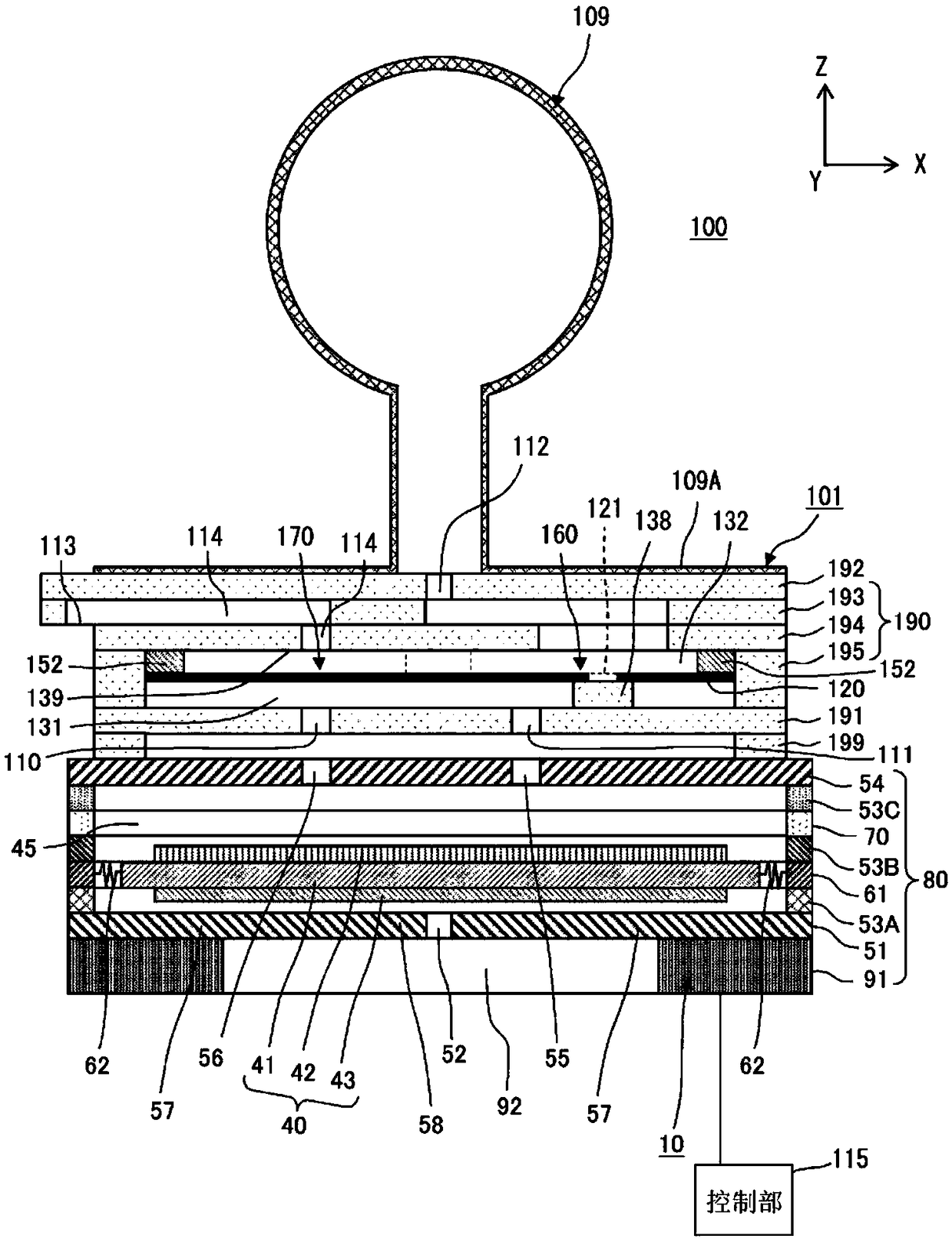

Valve, gas control device, and sphygmomanometer

A control device and gas technology, applied in the field of sphygmomanometers, can solve the problems of direct bonding of large containers with a large amount of air, and the second plate cannot have a large bonding area, etc., to achieve the effect of large bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

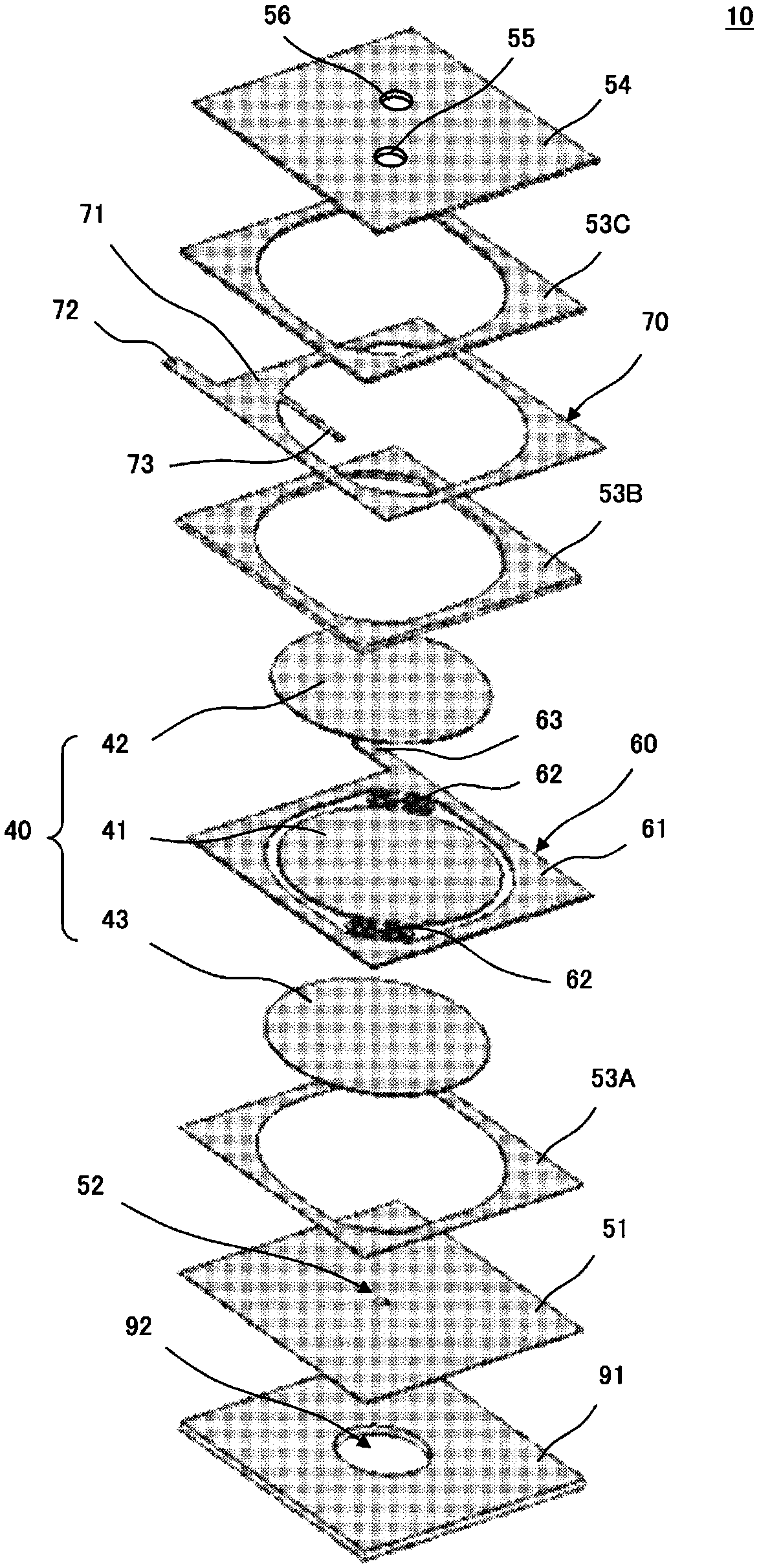

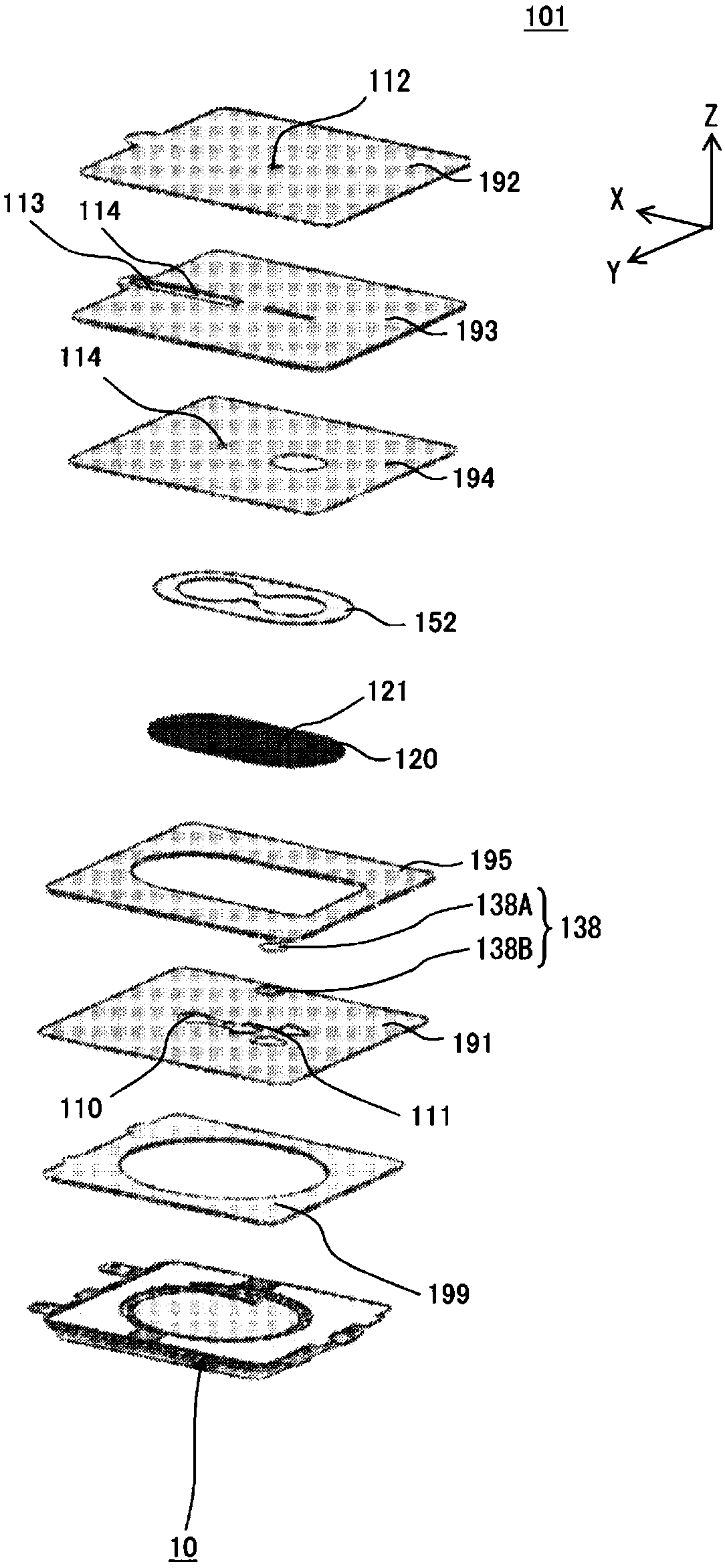

Method used

Image

Examples

other Embodiment approach

[0100] In addition, in the foregoing embodiments, air is used as the gas, but it is not limited thereto. In practice, as the gas, a gas other than air can also be used.

[0101] In addition, the pump 10 of the above-mentioned embodiment includes the actuator 40 that performs bending vibration in the unimorph type, but it may also include the actuator 40 that performs bending vibration in the bimorph type by attaching piezoelectric elements on both sides of the vibrating plate. the actuator.

[0102] In addition, although the pump 10 of the above-mentioned embodiment includes the actuator 40 that bends and vibrates due to expansion and contraction of the piezoelectric element 42, the present invention is not limited thereto. For example, an actuator that performs bending vibration by electromagnetic drive may be provided.

[0103] In addition, although the pump 10 of the above-mentioned embodiment is equipped with the discharge hole 55 and the discharge hole 56, it is not lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com