Patents

Literature

56results about How to "Increase electrical contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

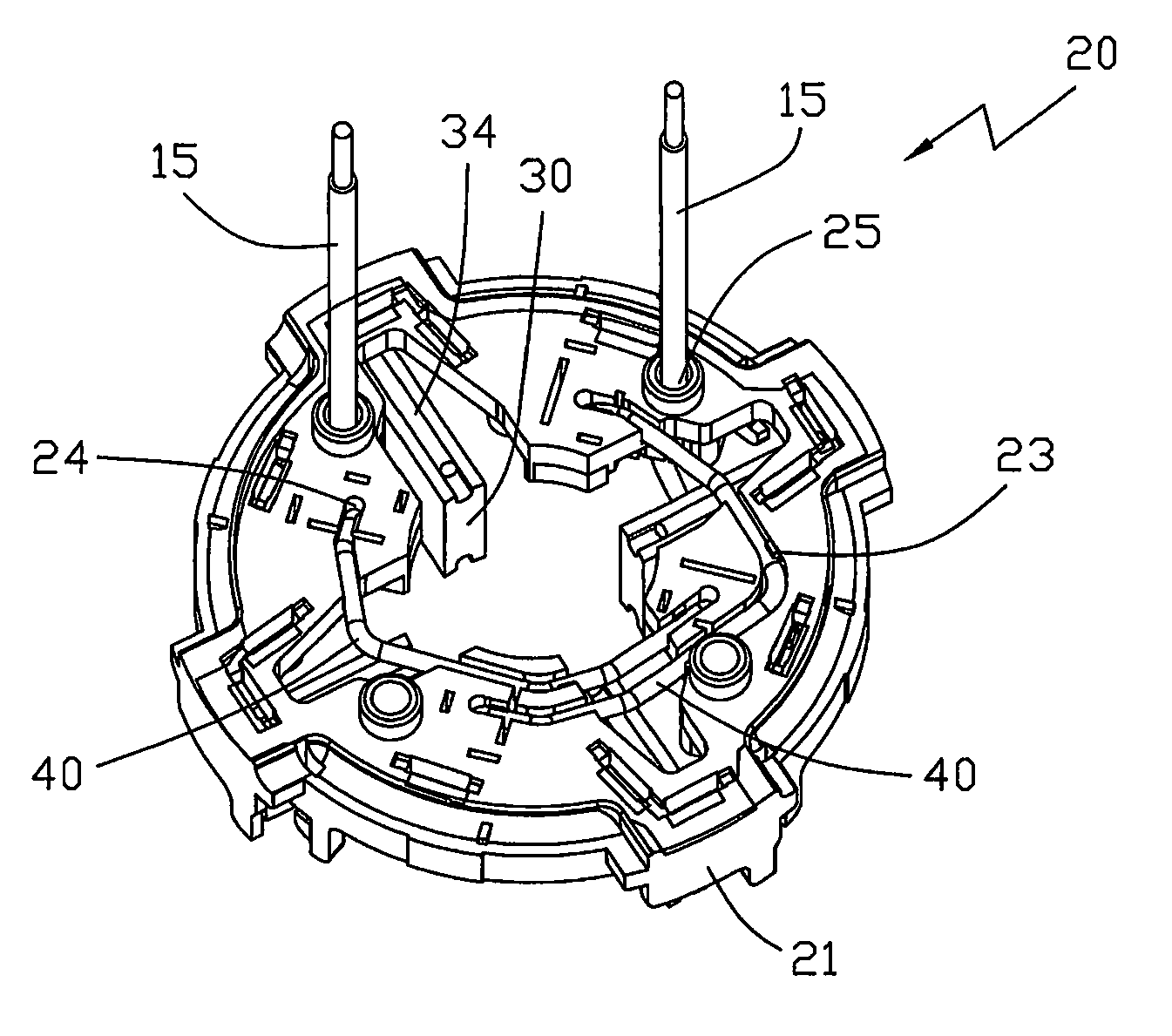

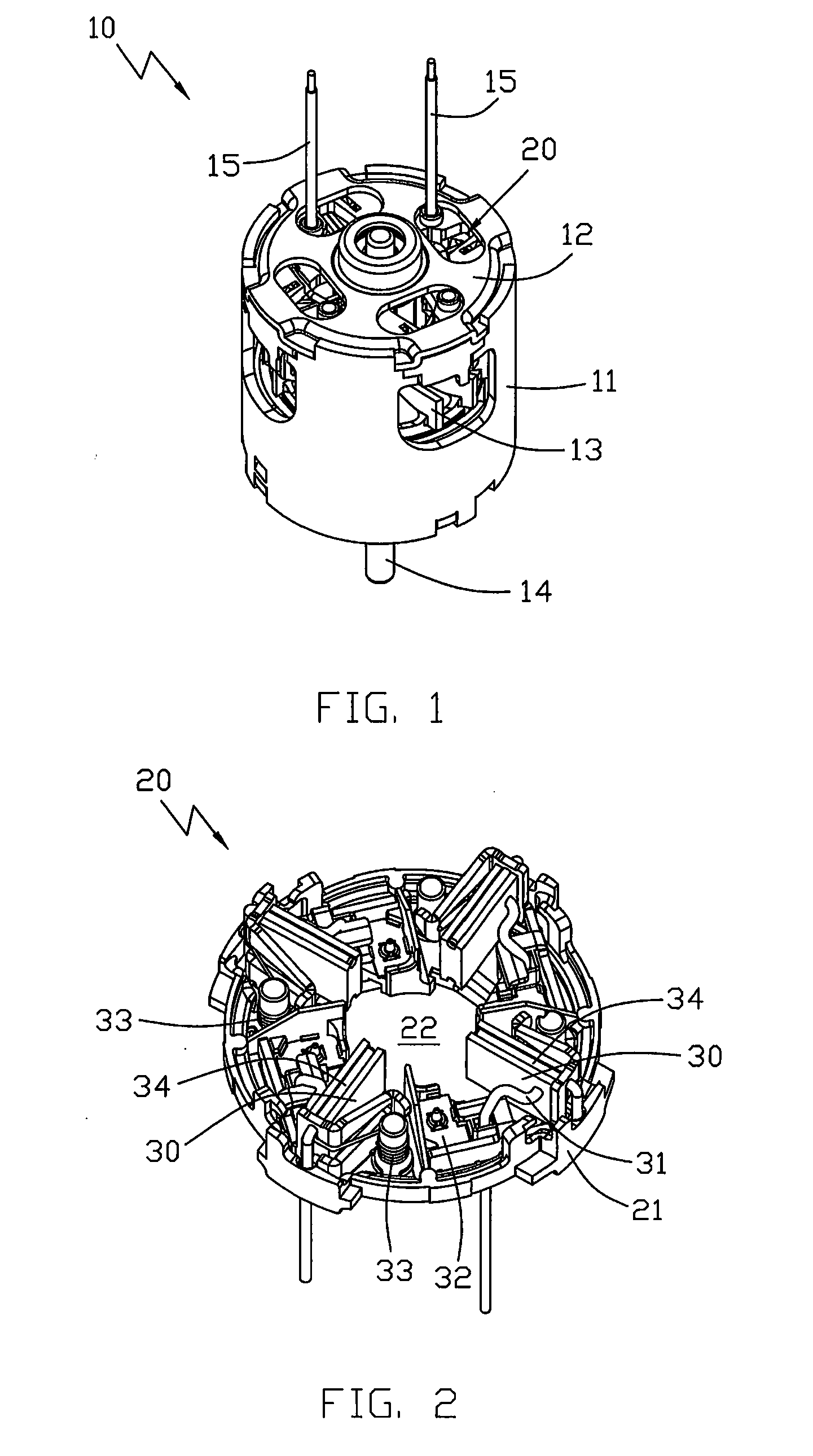

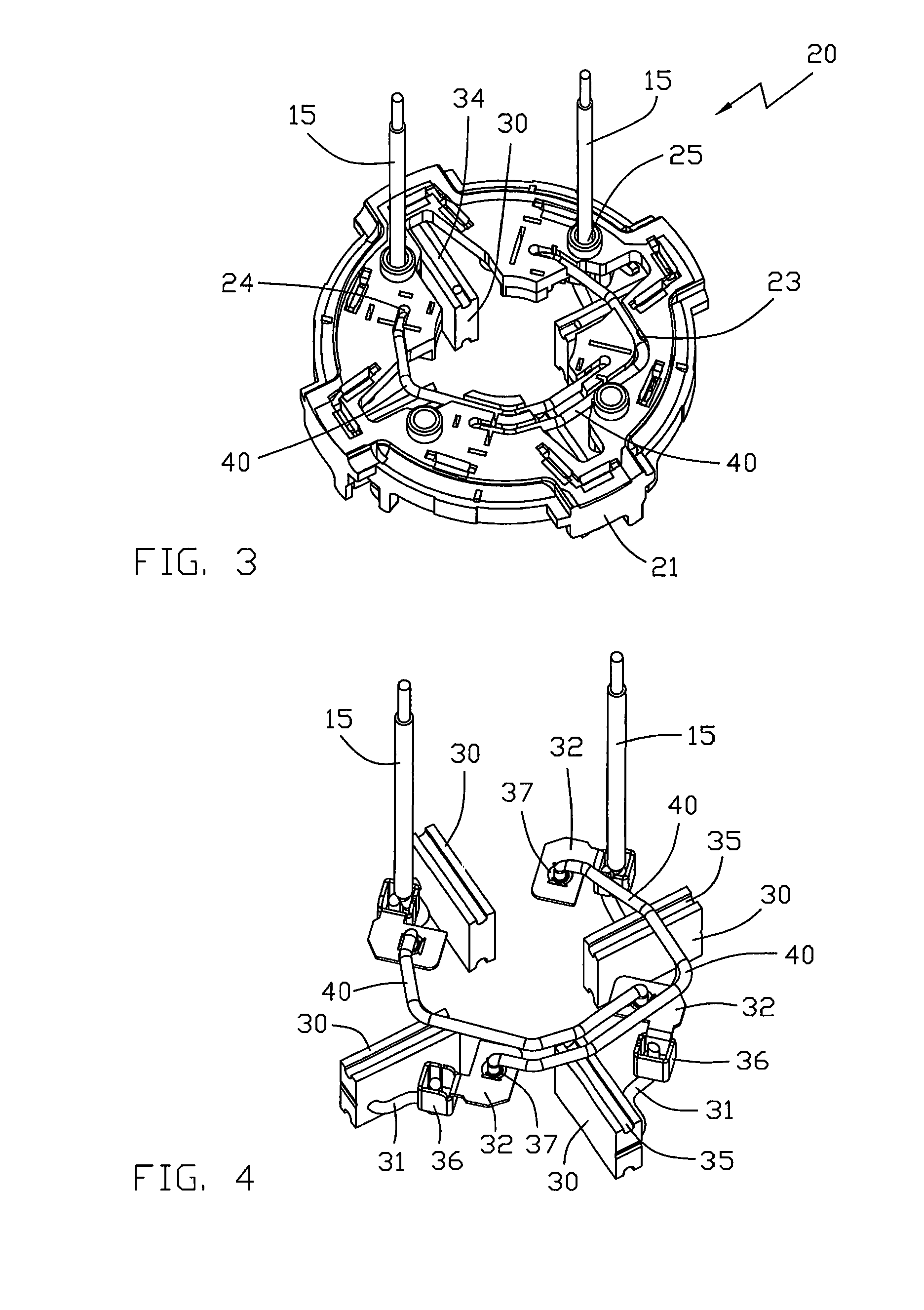

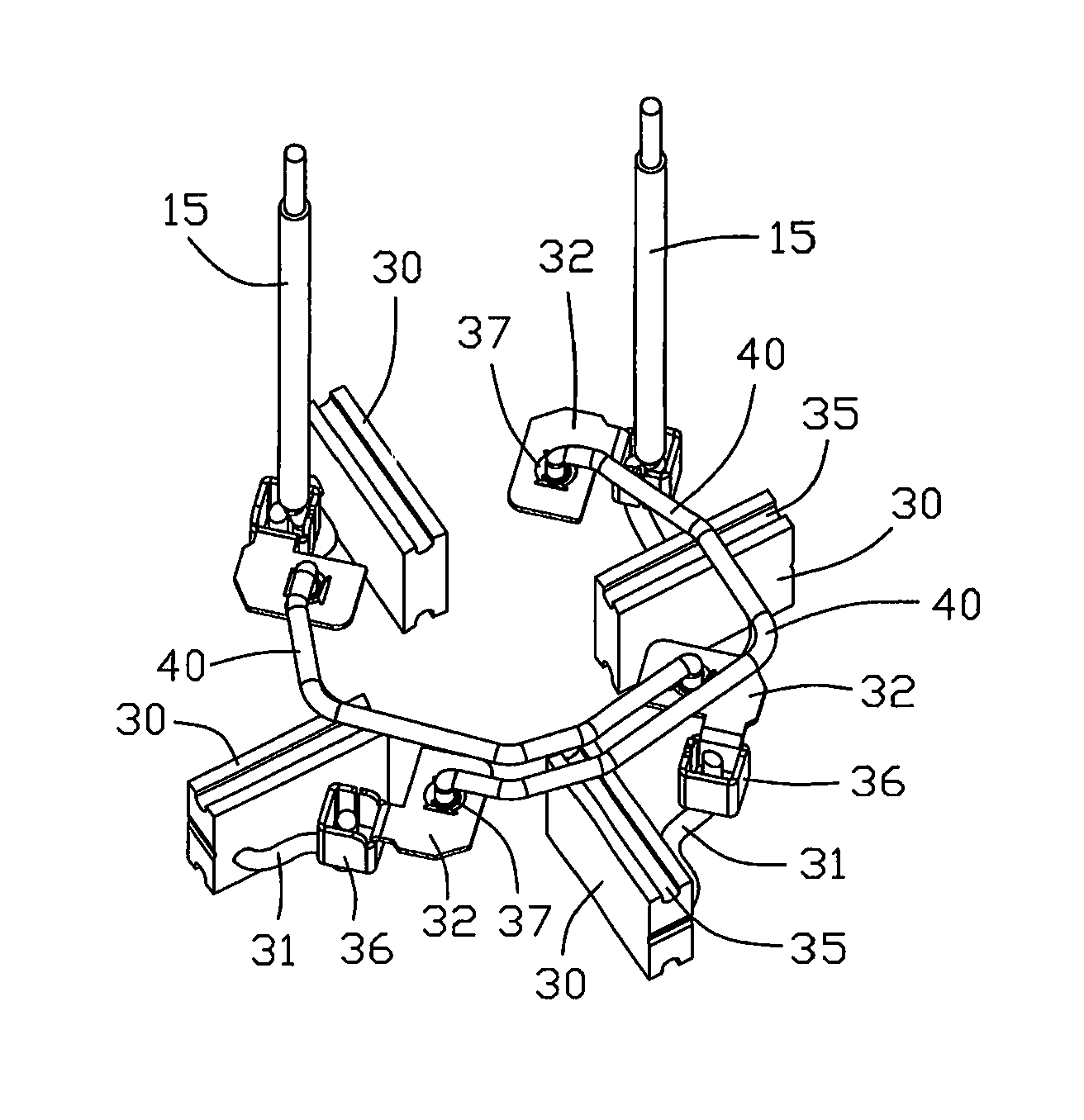

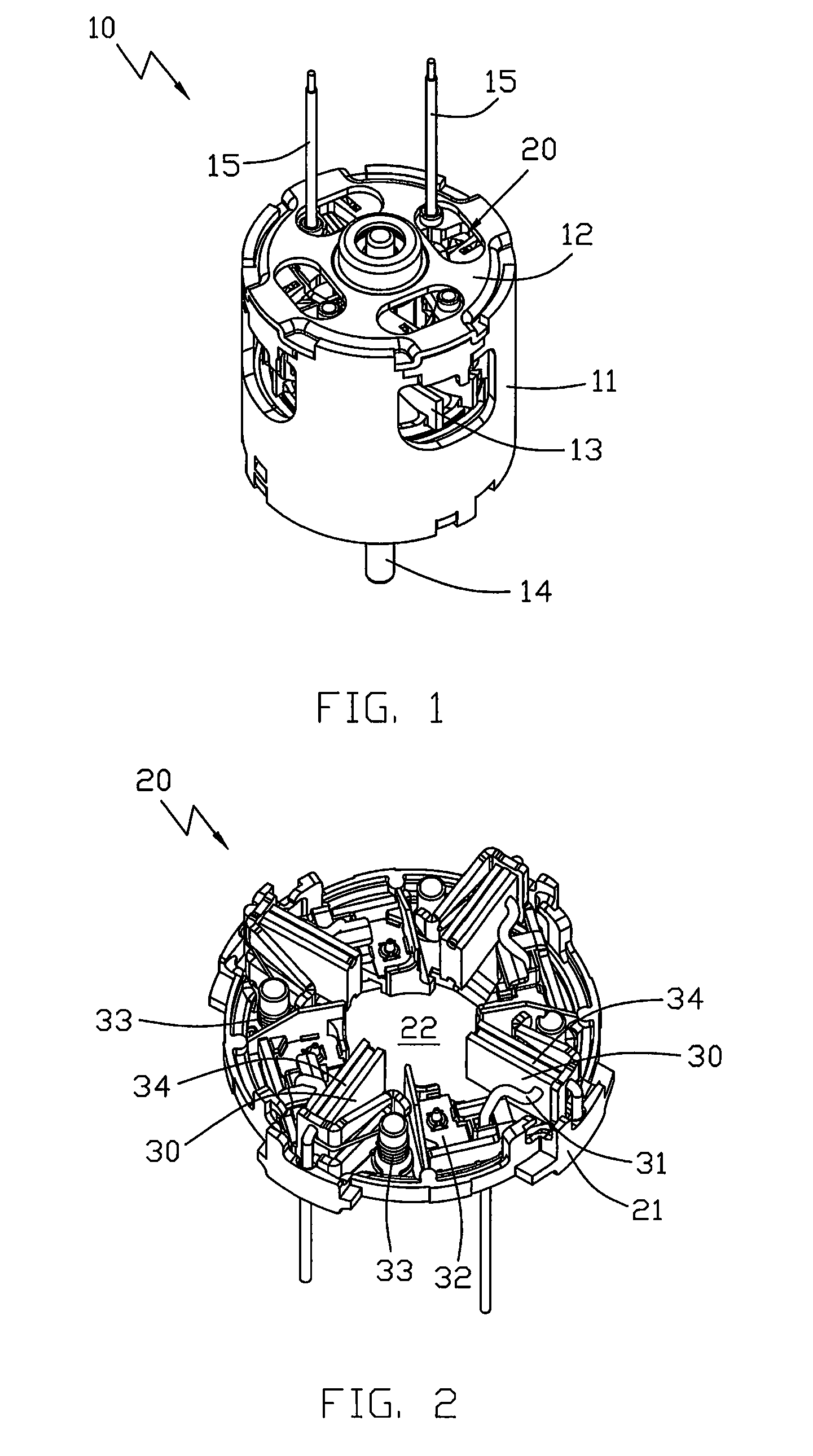

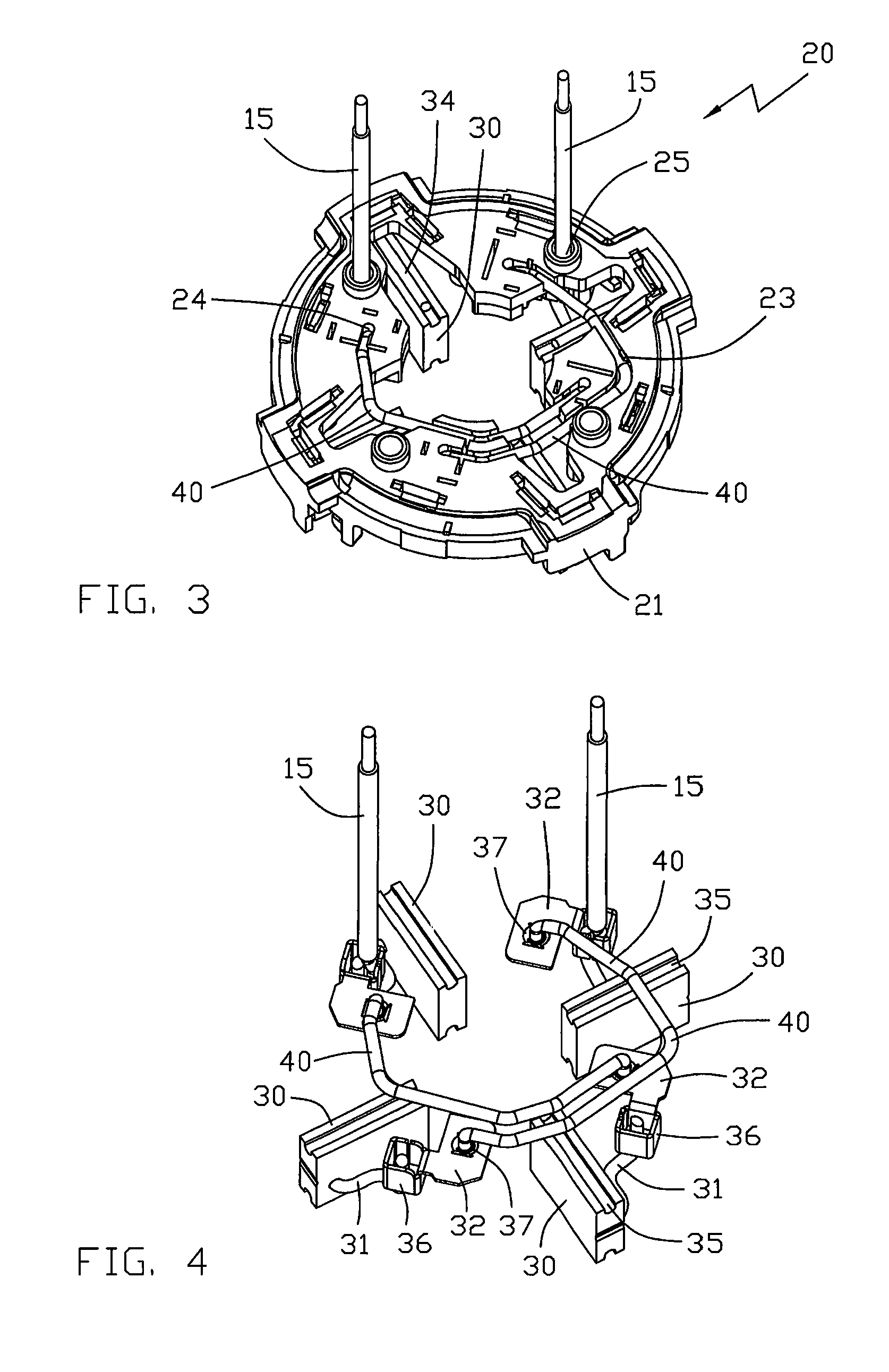

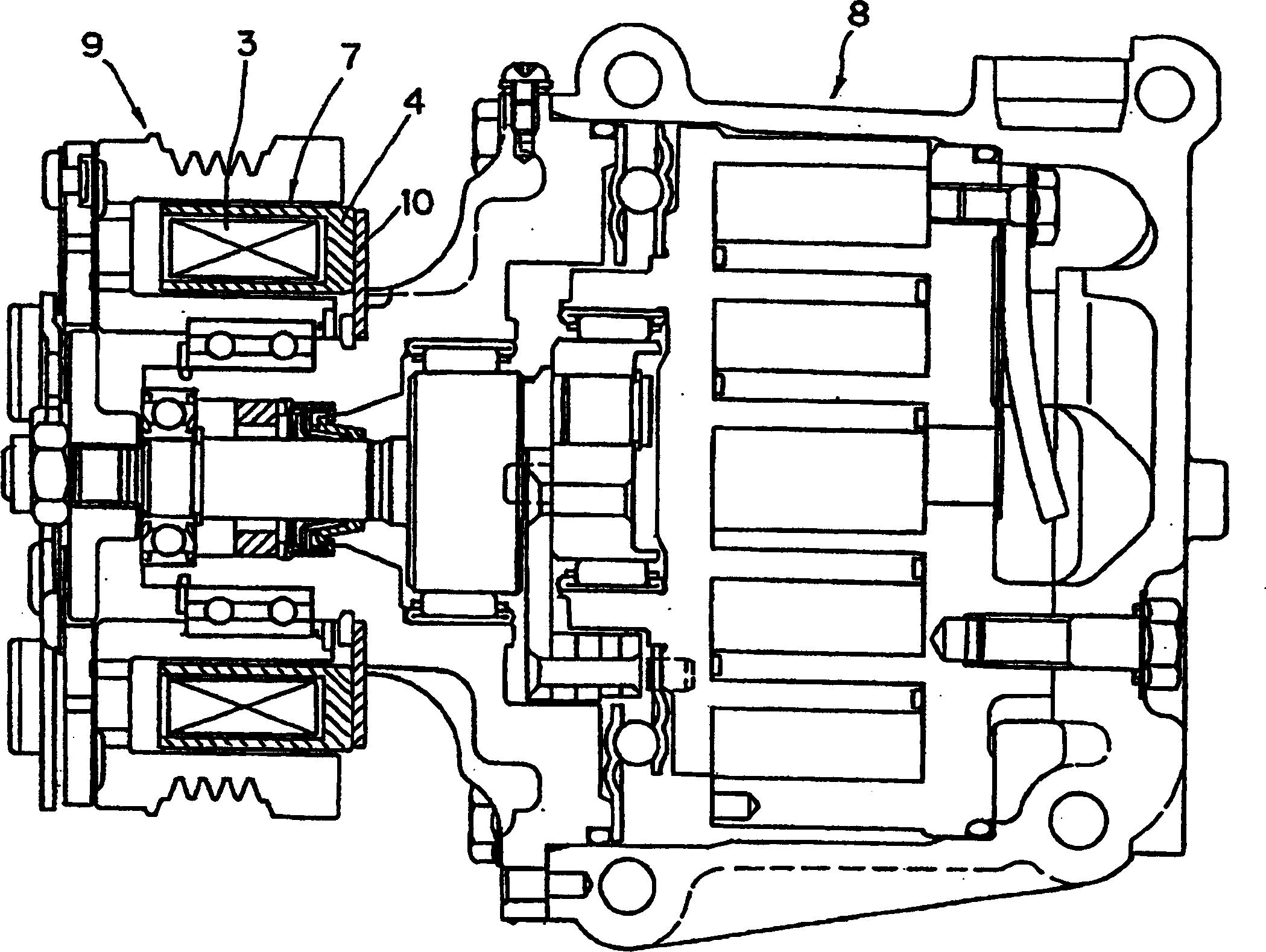

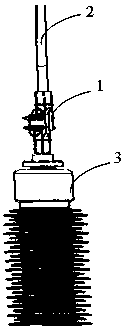

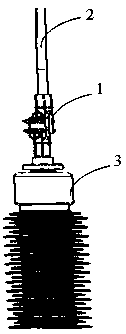

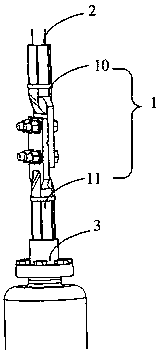

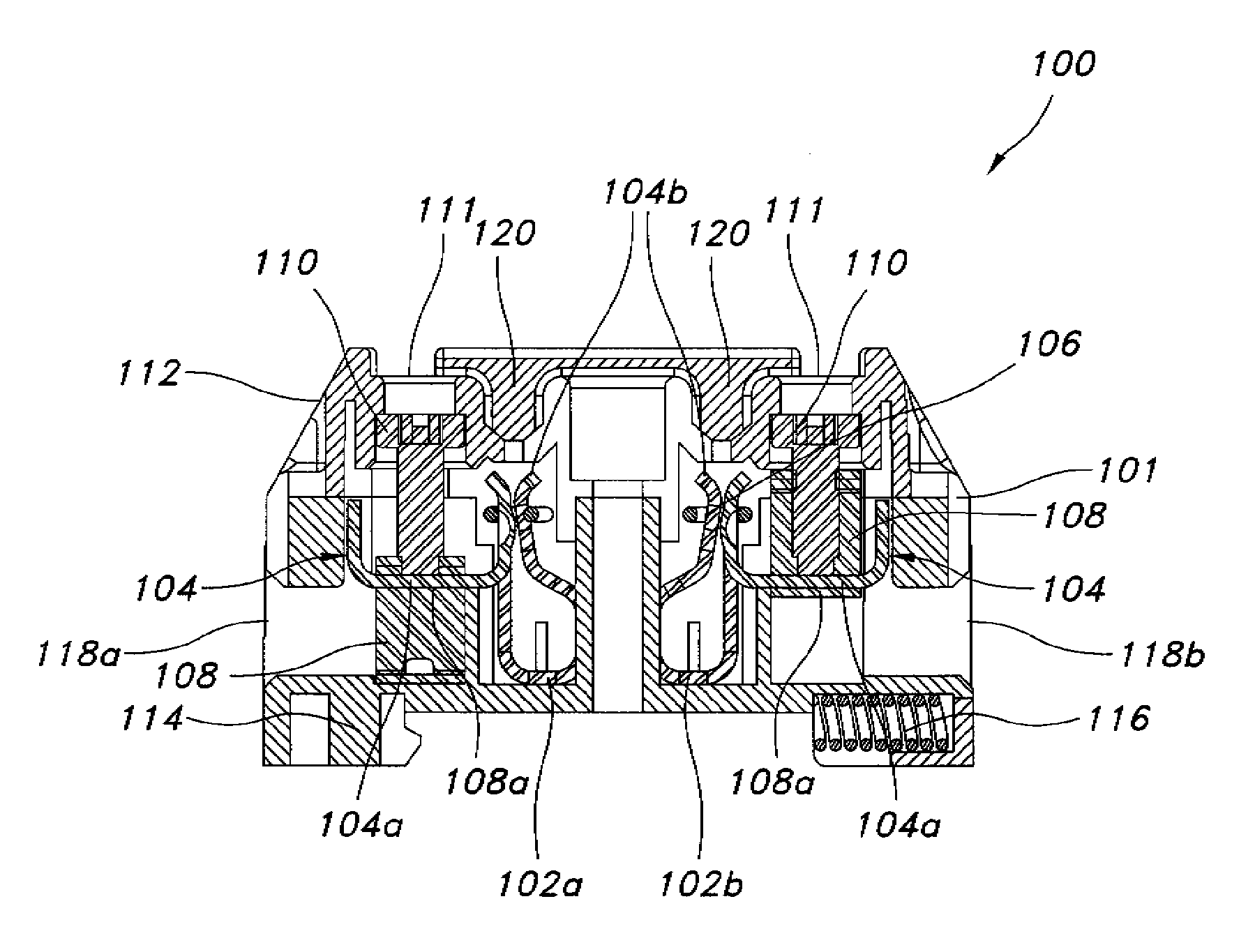

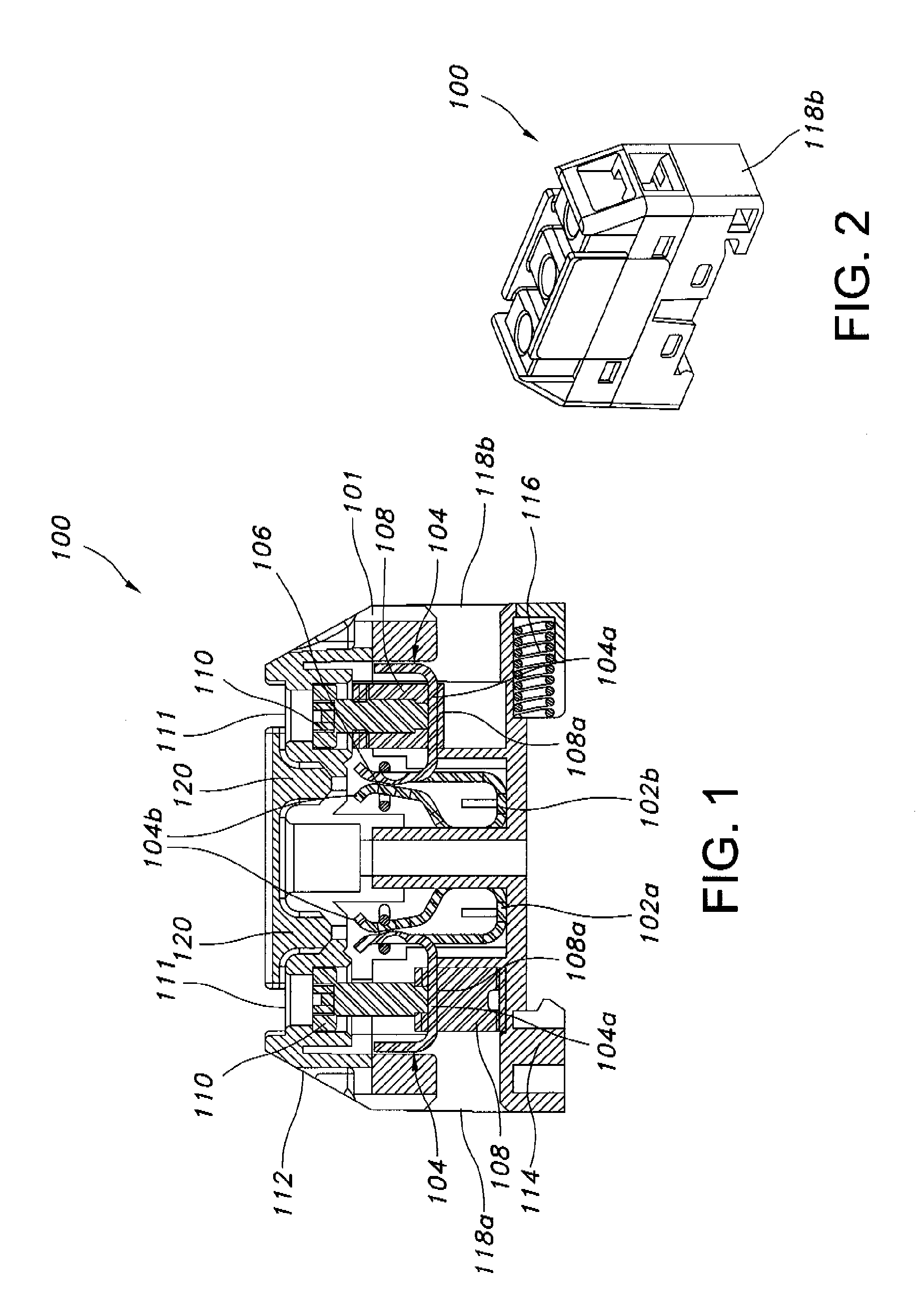

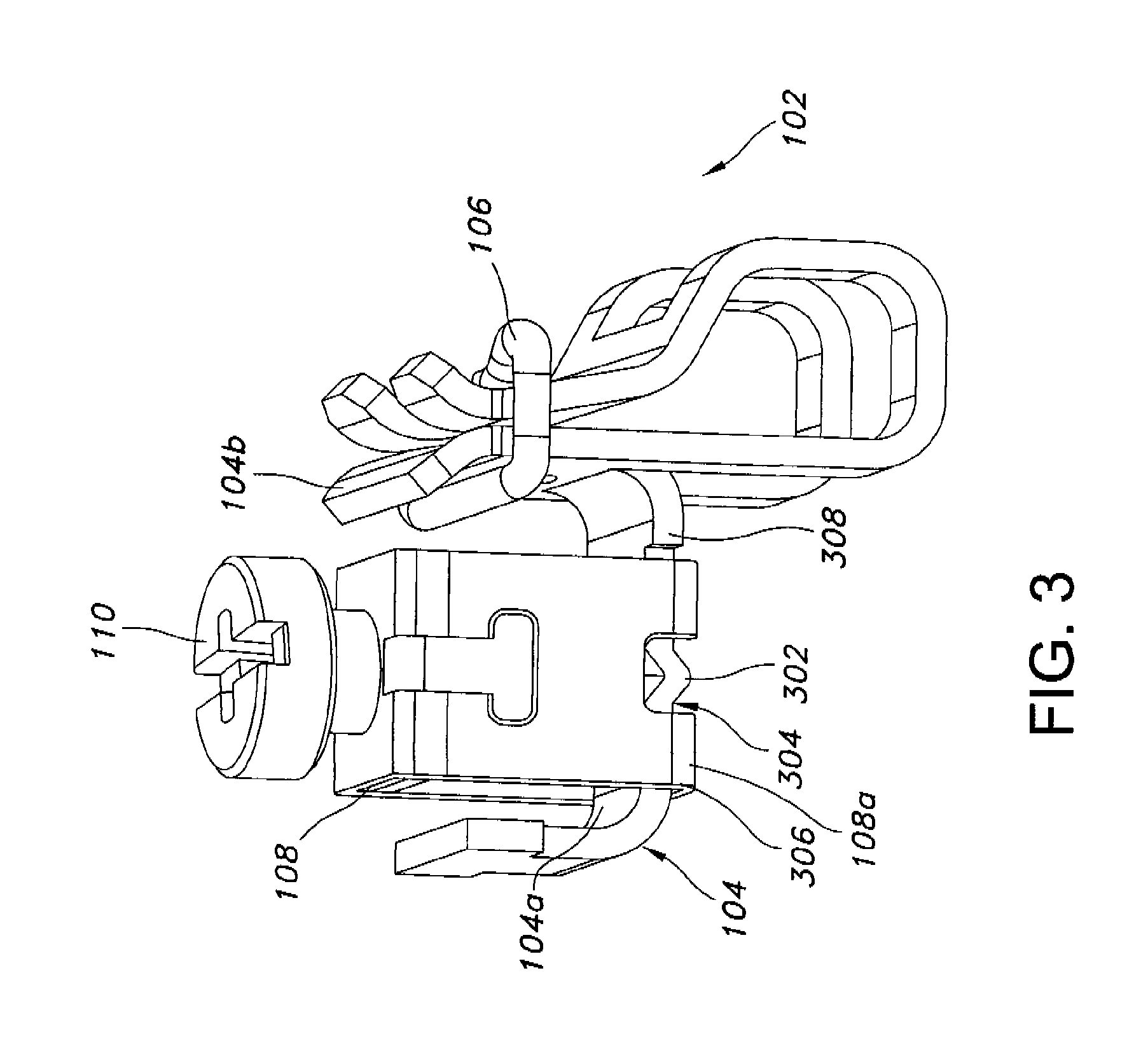

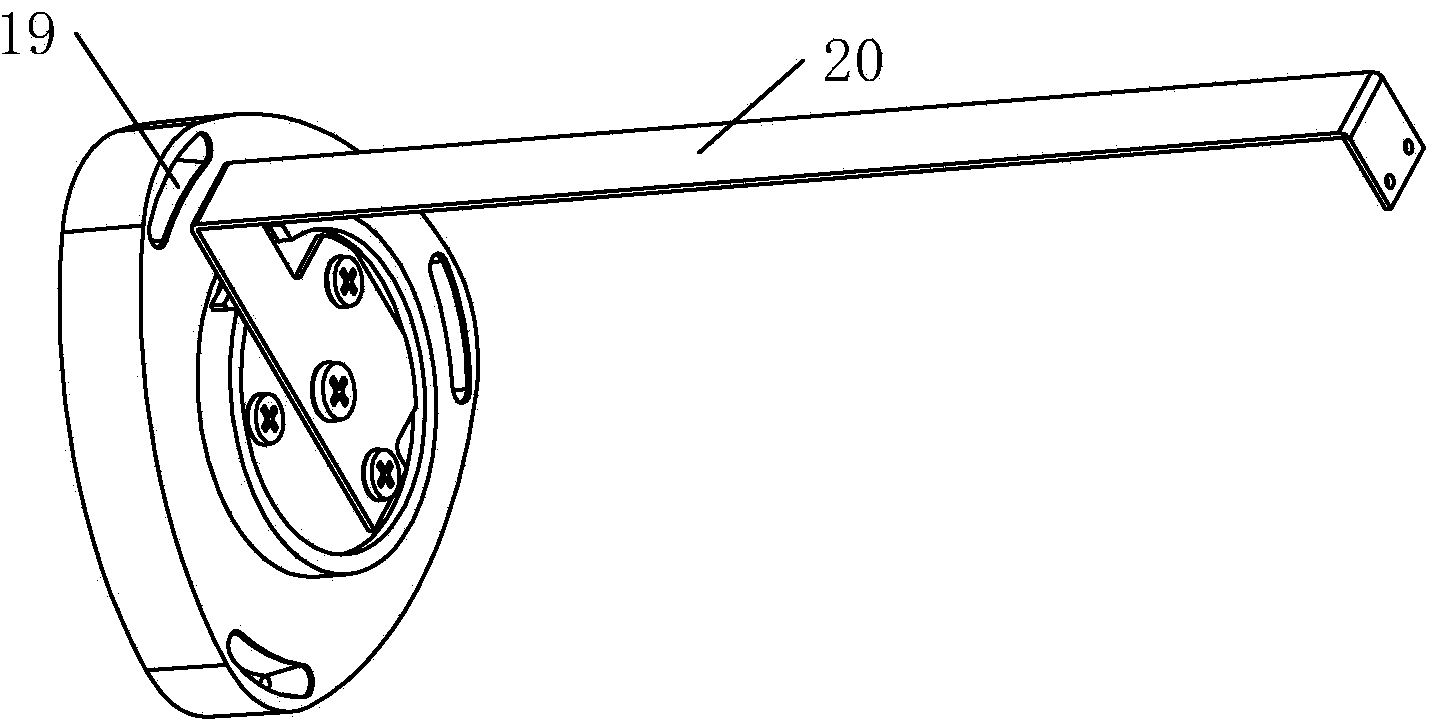

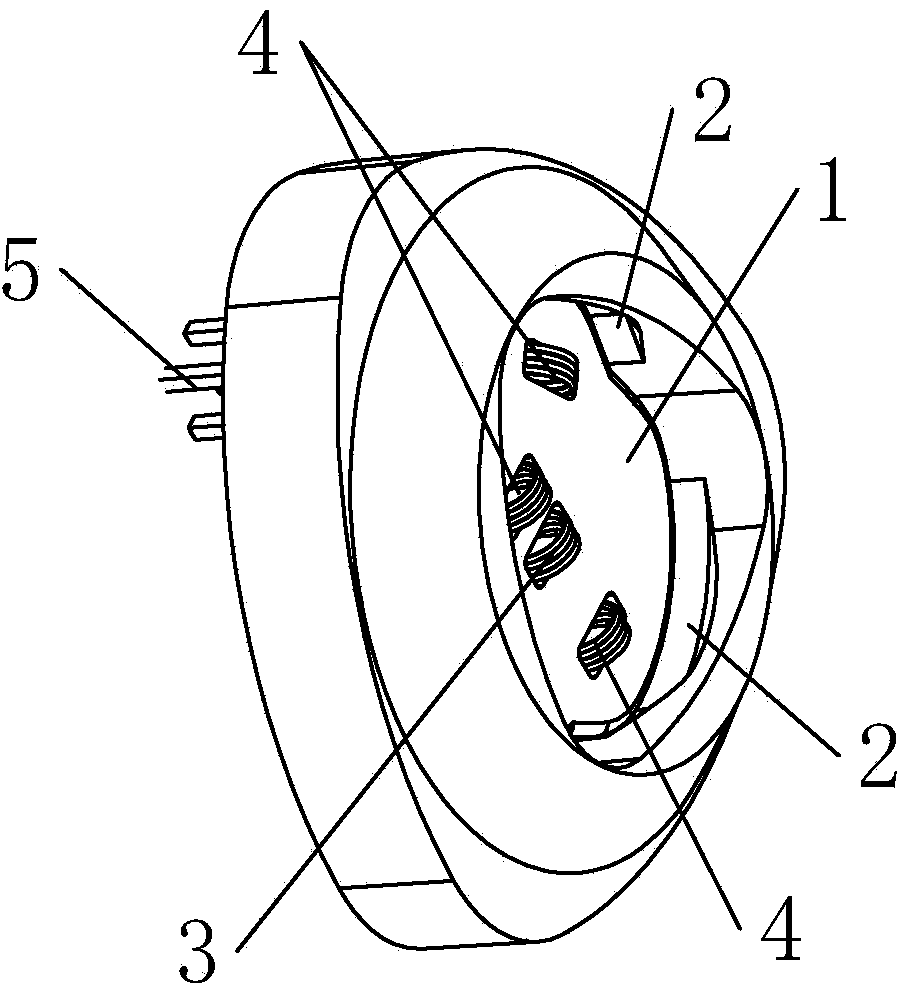

Brush gear of a motor

InactiveUS20100045136A1Prevent exitIncrease electrical contact areaRotary current collectorClamped/spring connectionsGear wheelEngineering

Brush gear of a motor has a brush card with a plurality of brushes installed at one side thereof. Each brush is electrically connected with a connector. Two motor terminations provide power to the brushes via the corresponding connectors and at least one wire connects two of the connectors. Each of said two of the connectors has a hole to receive one end of the wire and at least two fingers extends from an edge of the hole inclined toward the axis of the hole, such that when the end of the wire extends through the hole, the fingers are resiliently deformed and grip the wire to prevent withdrawal of the wire from the hole.

Owner:JOHNSON ELECTRIC SA

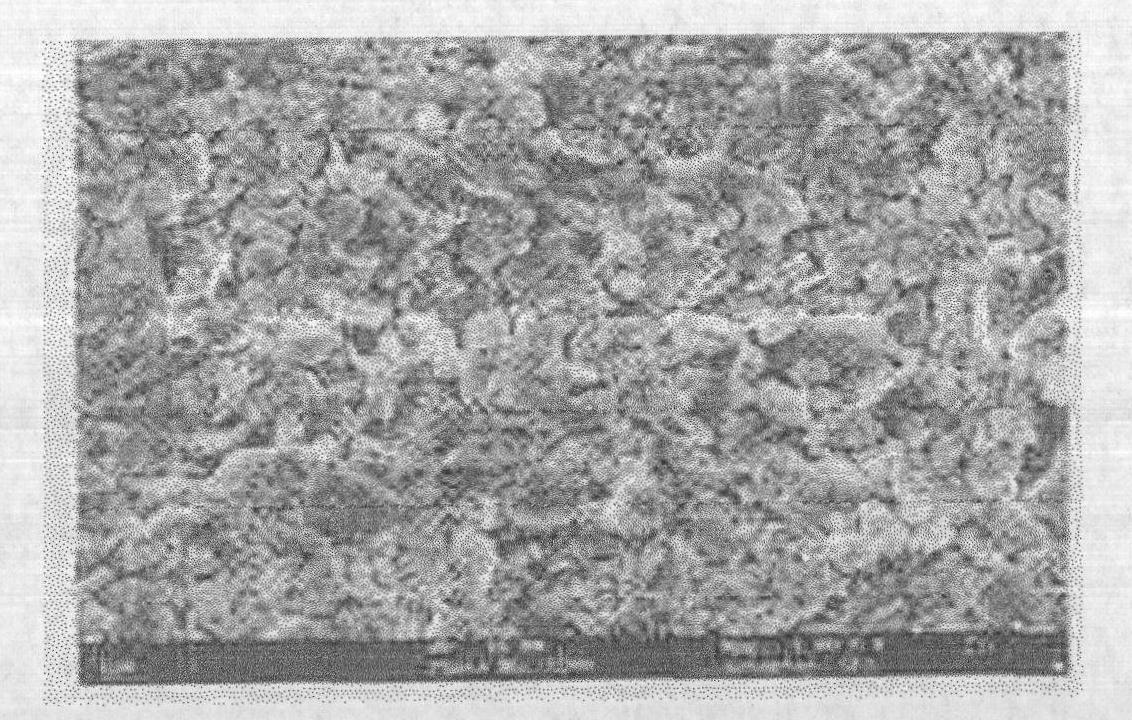

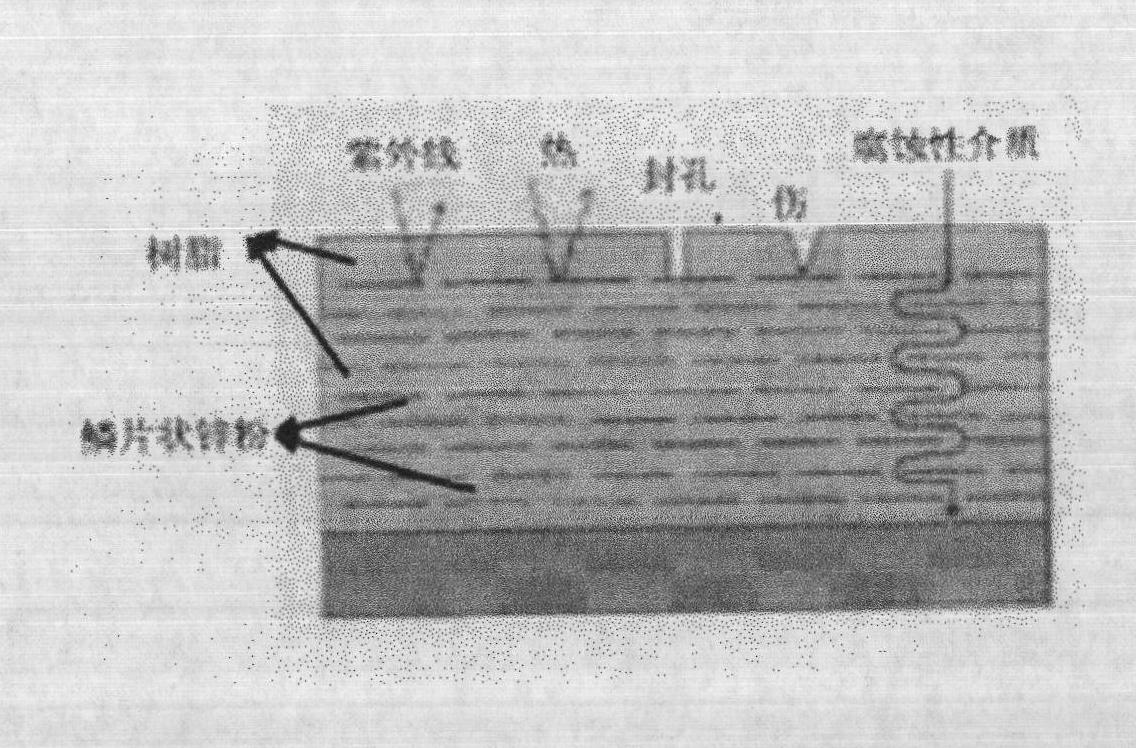

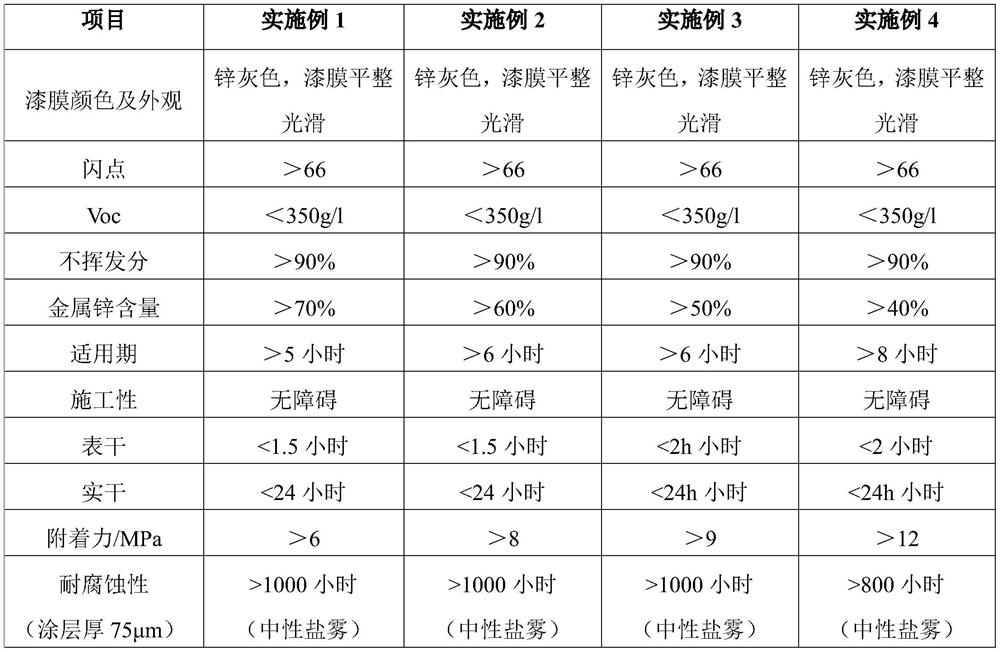

Scaly zinc-based inorganic zinc silicate heavy anti-corrosion coating and preparation method thereof

InactiveCN102002318AIncrease electrical contact areaImprove cohesionAnti-corrosive paintsEpoxy resin coatingsZincSilicon

The invention relates to scaly zinc-based inorganic zinc silicate heavy anti-corrosion coating and a preparation method thereof. The method comprises the following steps of: (1) mixing scaly zinc powder with initial film forming resin according to the weight ratio of components to obtain a component A; (2) mixing a hydrolyzing silicon solution with a modifier by stirring at intermediate speed according to the weight ratio of the components, adding a catalyst for hydrolyzing according to the weight ratio of the components and hydrolyzing to obtain a component B; and (3) mixing the component A and the component B which are prepared in the step (1) and the step (2) according to the component weight ratio of (1-1.5):1 to obtain the scaly zinc-based inorganic zinc silicate heavy anti-corrosion coating. The invention has the advantage of preparing the scaly zinc-based inorganic zinc silicate heavy anti-corrosion coating by mainly adopting domestic scaly zinc powder. Compared with traditional zinc rich primer, the invention can greatly reduce the zinc powder content and coating thickness; the traditional zinc rich primer generates large zinc fog in the coating welding process, and the scaly zinc powder primer generates less zinc fog, reduces damage to construction staffs and is a new generation product of the traditional inorganic and organic zinc rich primer.

Owner:湖北中科博策新材料研究院

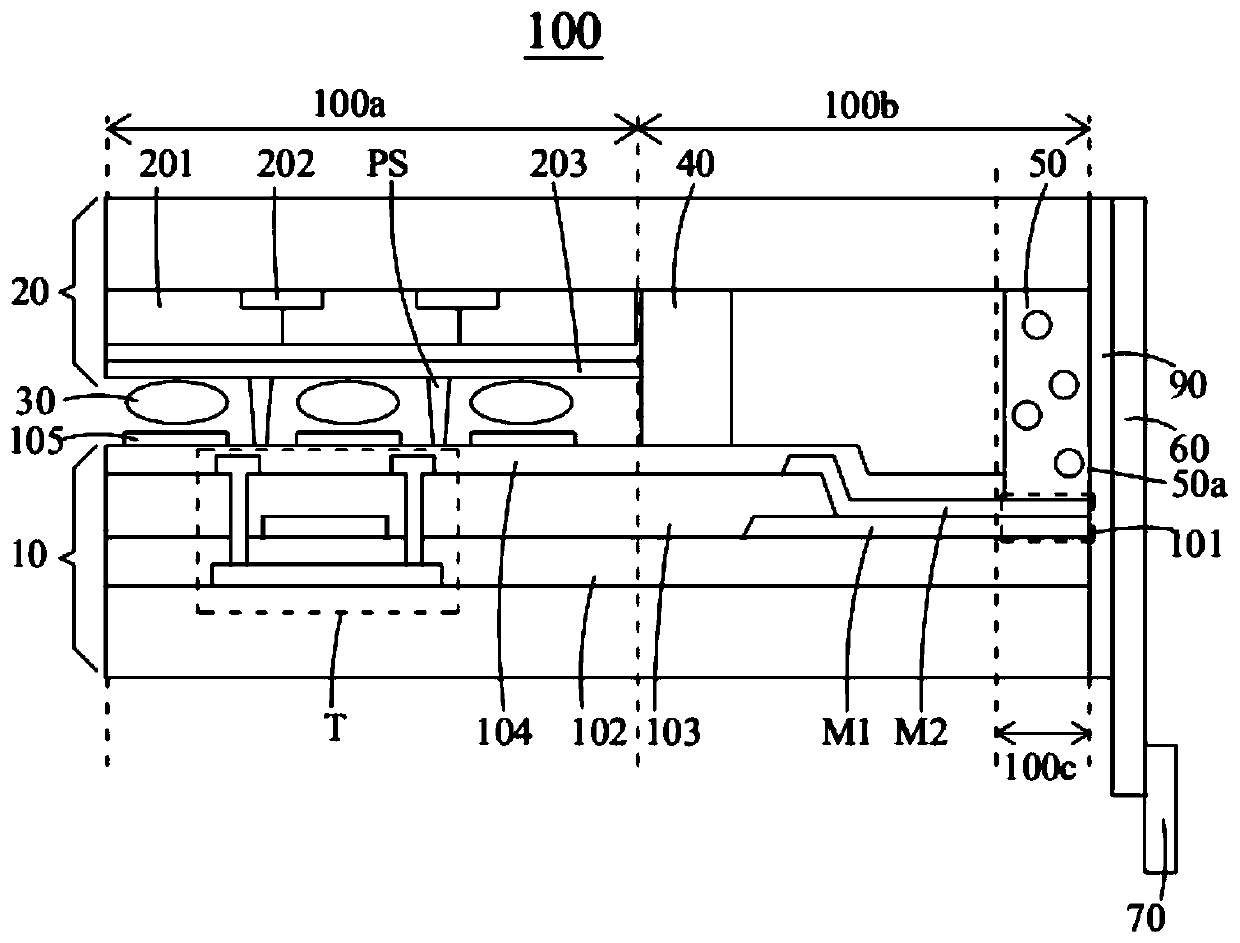

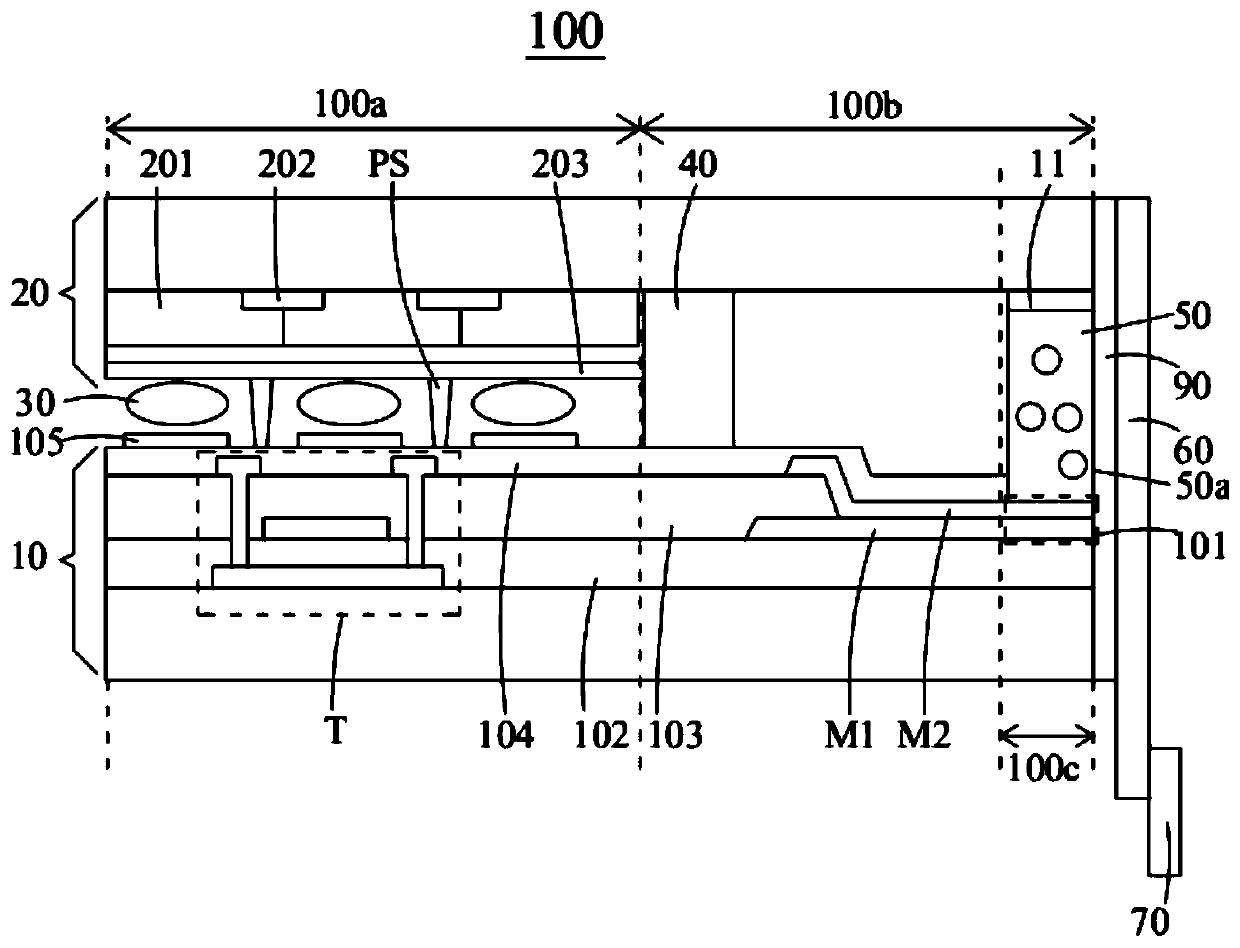

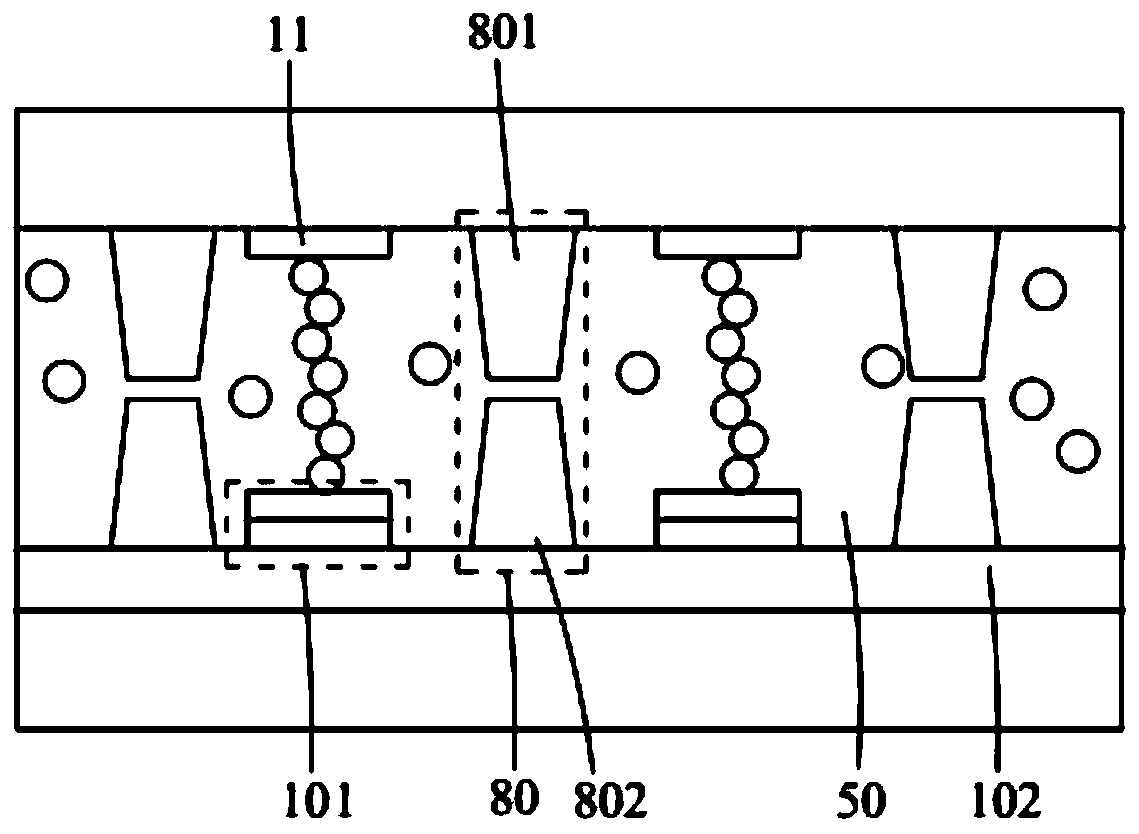

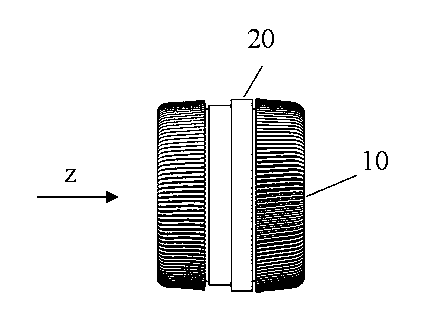

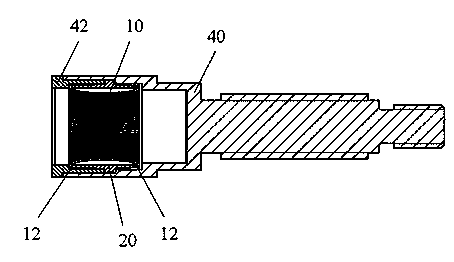

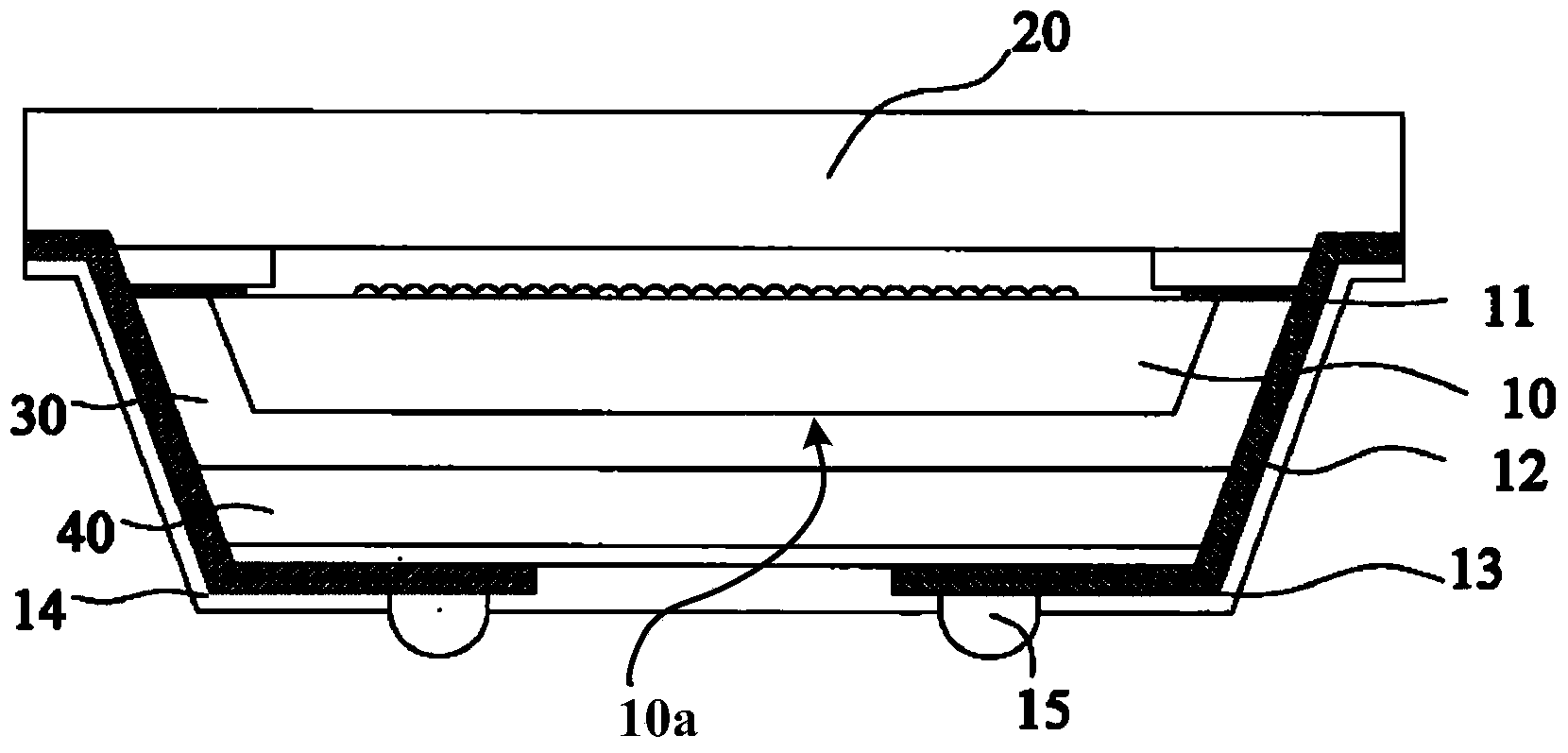

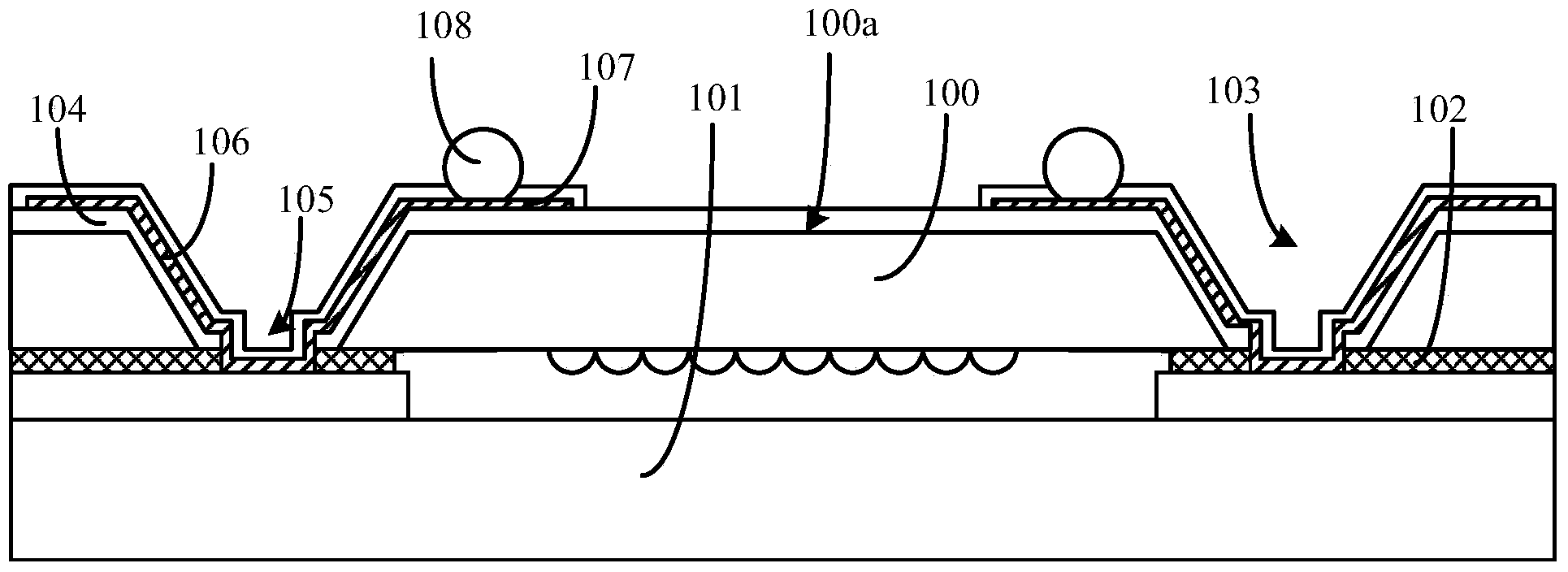

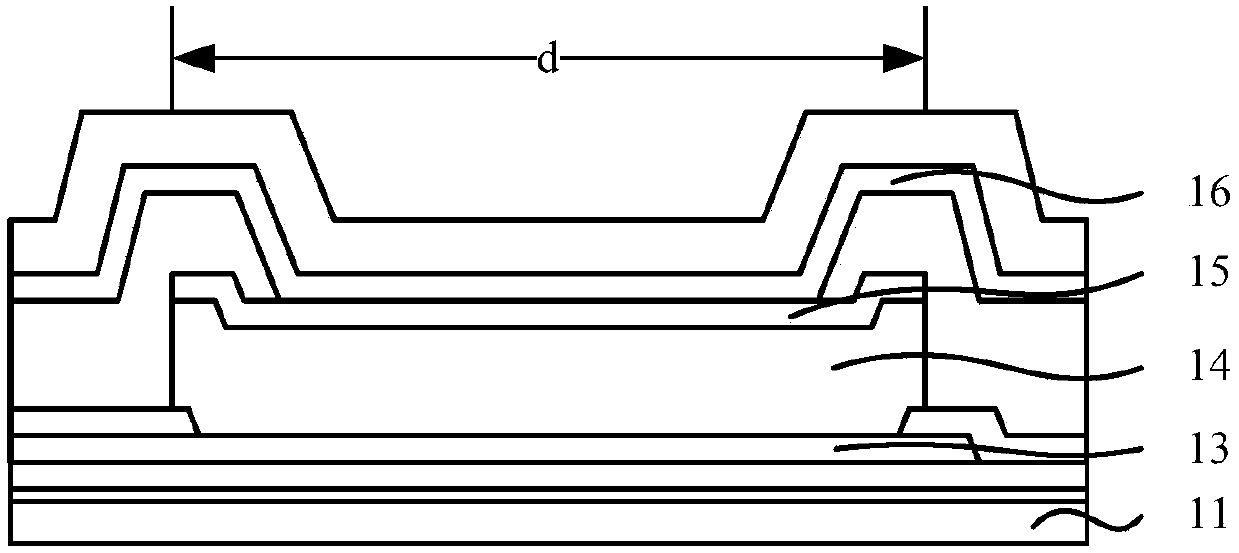

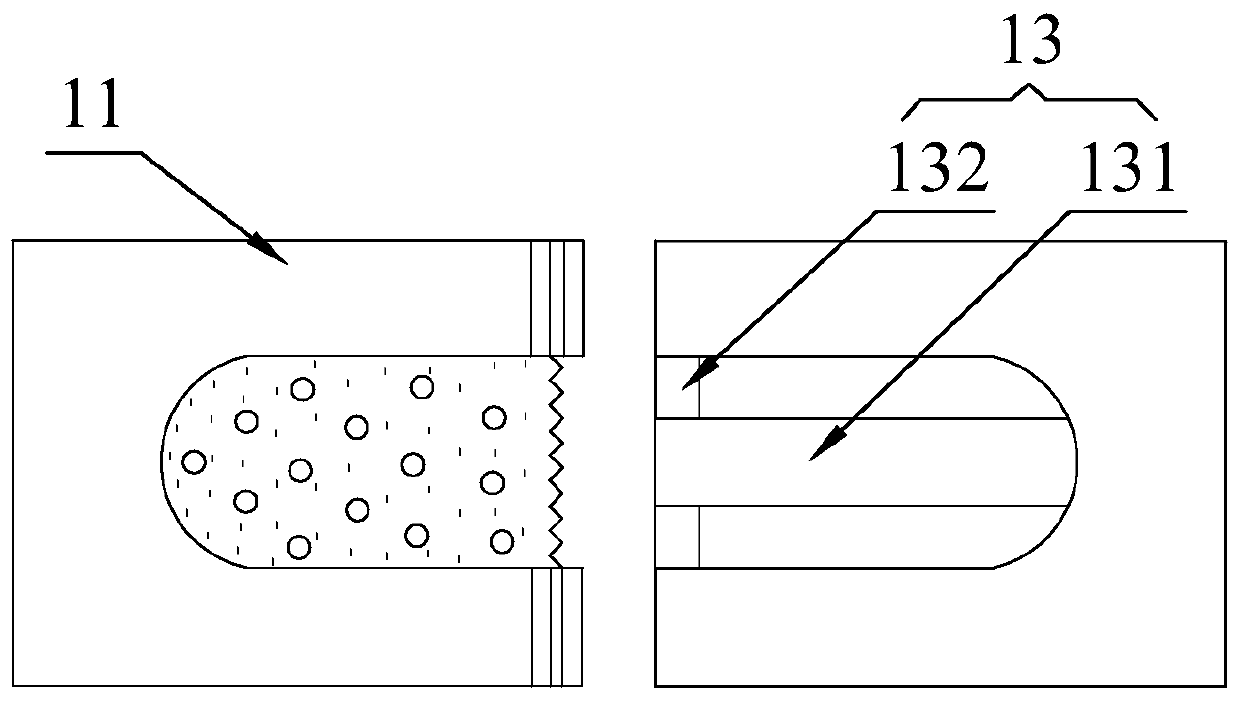

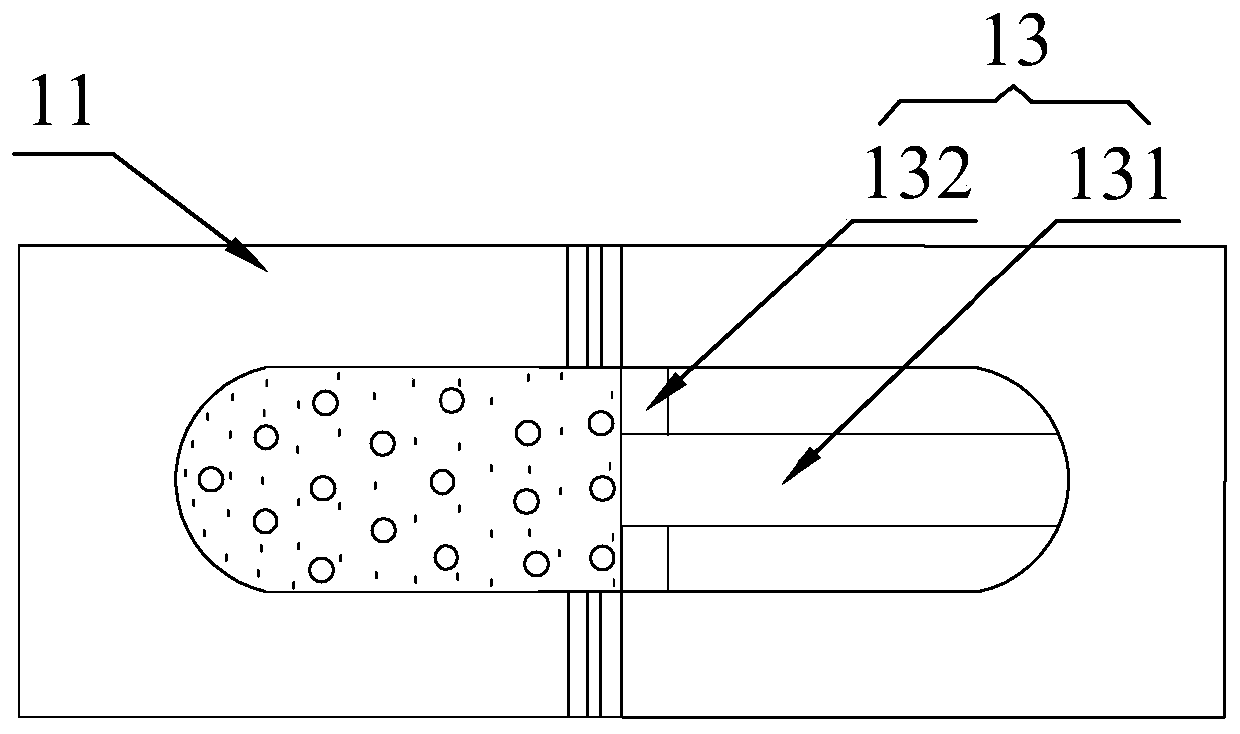

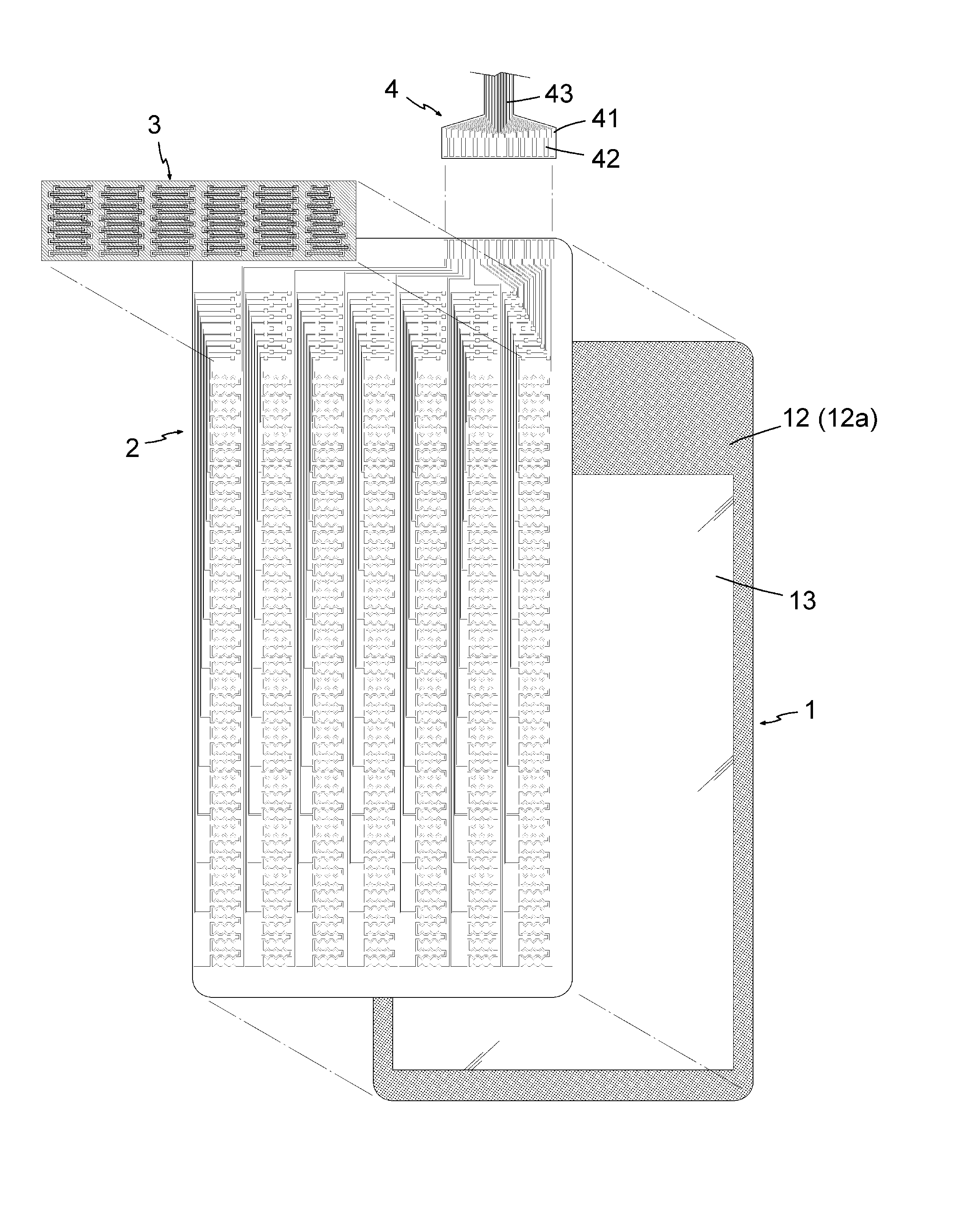

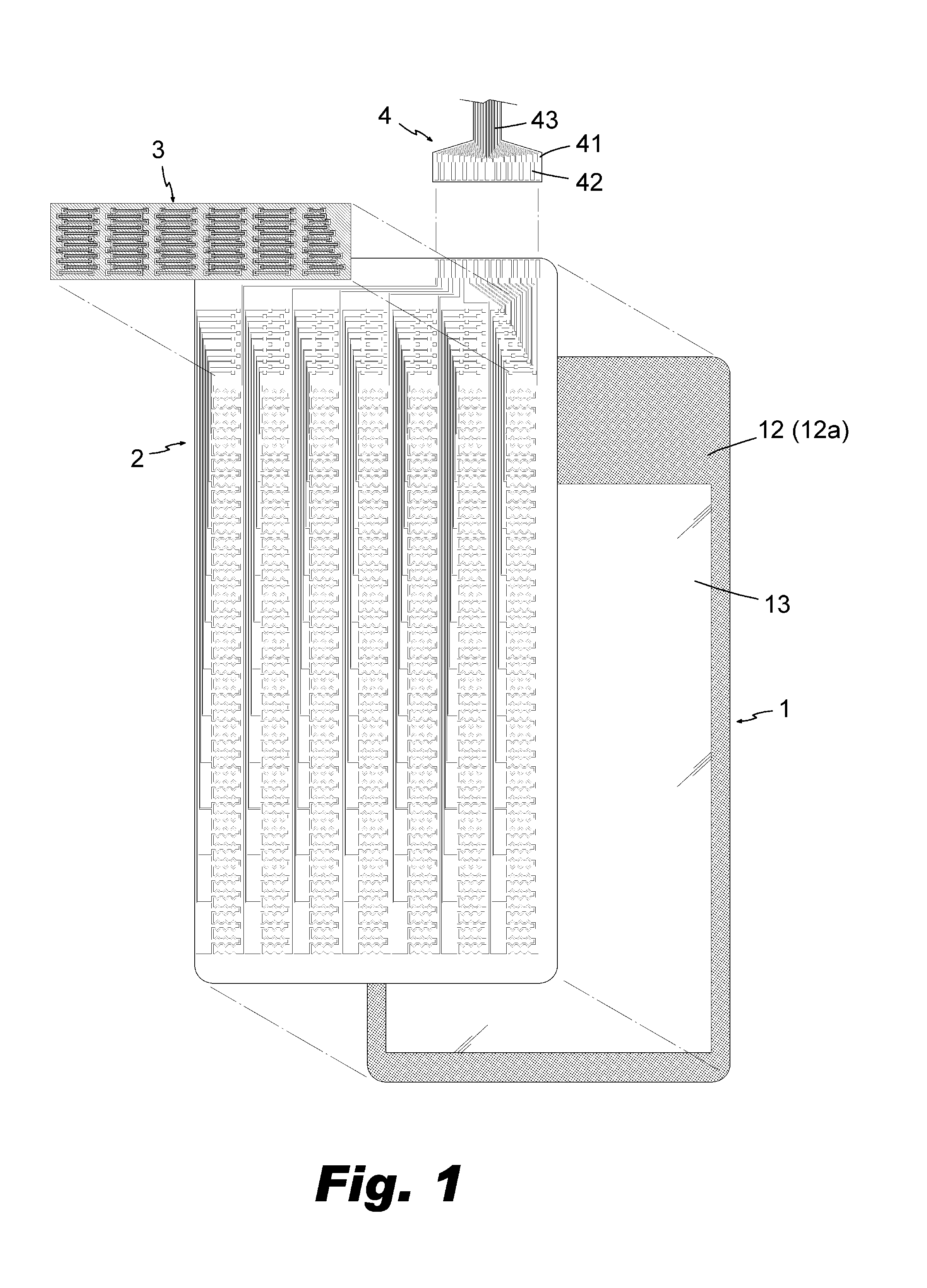

Liquid crystal display panel

ActiveCN110888276AIncrease electrical contact areaImprove bonding yieldNon-linear opticsLiquid-crystal displayColor film

The invention provides a liquid crystal display panel. The conductive frame adhesive is arranged between a plurality of terminals of an array substrate and a color film substrate, chip-on films are bound on side surfaces of the conductive frame adhesive and terminals in the thickness direction so as to increase the electrical contact area when the chip-on films are bound, and thereby the binding yield of the chip-on films is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

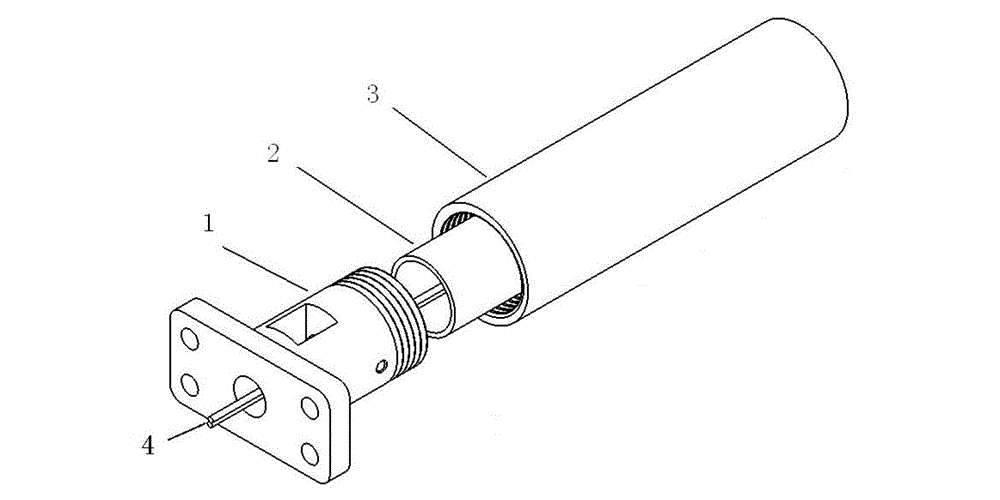

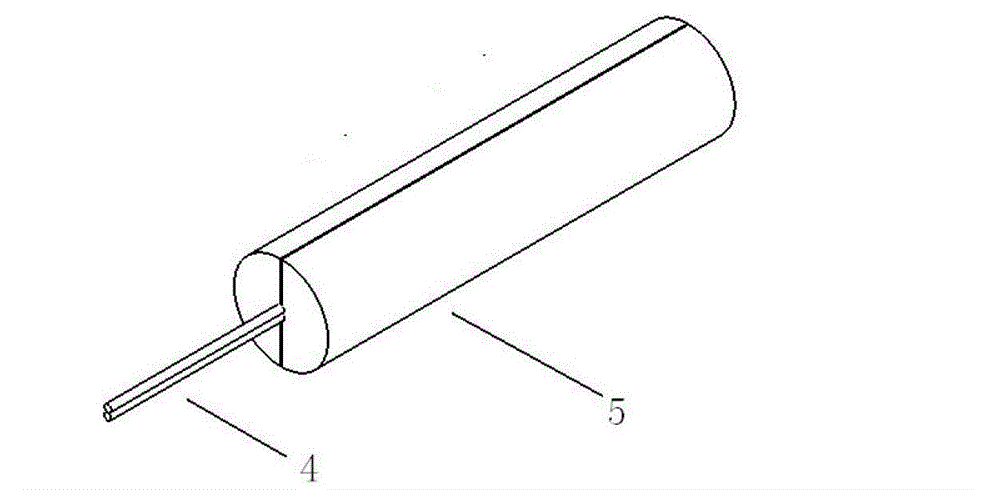

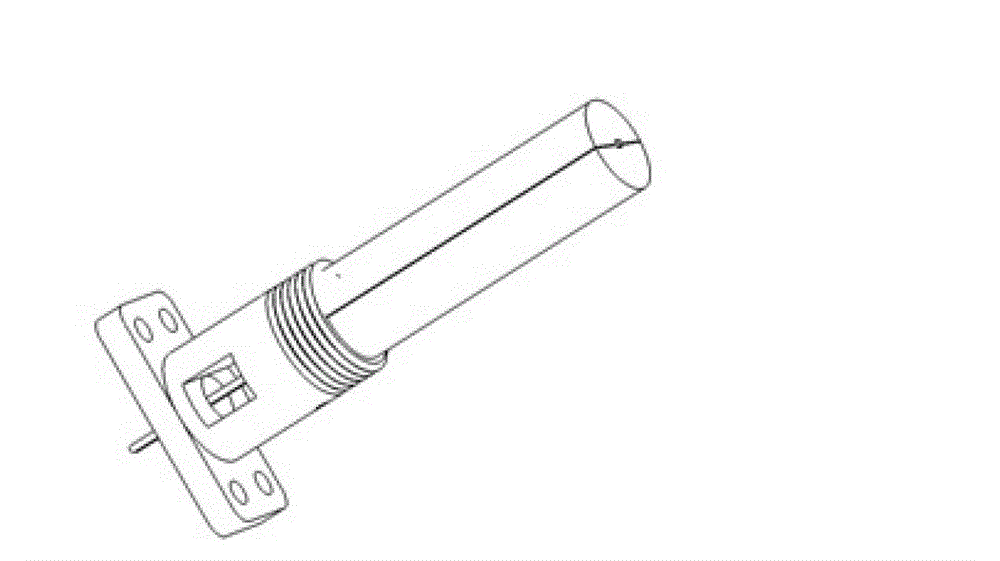

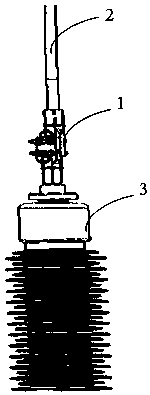

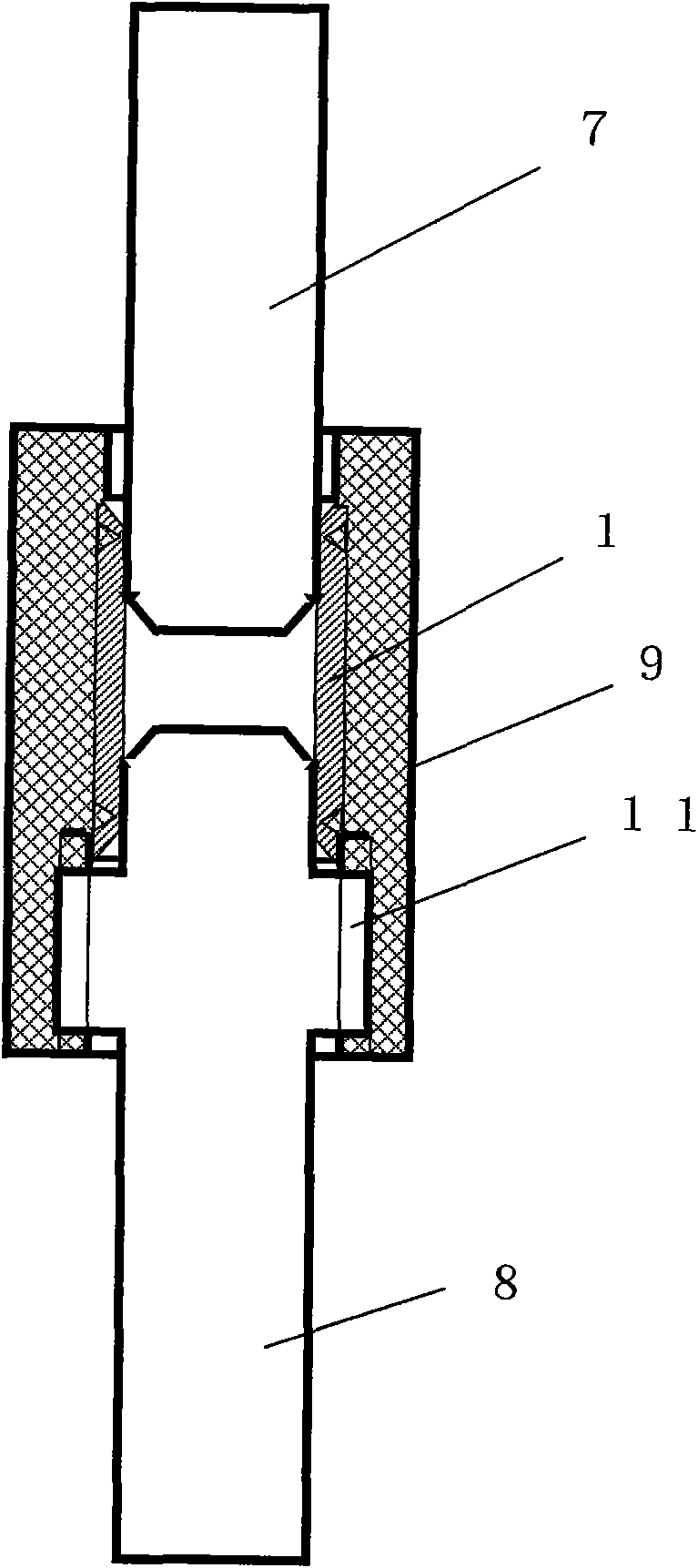

Superconducting magnet joint and manufacturing method thereof

ActiveCN102723160AHigh mechanical strengthReduce joint resistanceSuperconductor devicesSuperconducting magnets/coilsSuperconducting CoilsSoldering

The invention discloses a superconducting magnet joint which comprises a joint holder and a copper sleeve connected to the joint holder, wherein a superconducting line passes through the joint holder and the copper sleeve and is welded into a superconducting joint, and a soldering flux is embedded between the copper sleeve and the superconducting joint. According to the invention, the outer layer of the superconducting line is plated with a lead-bismuth conductor and formed into the superconducting joint, and the welding length of the superconducting joint is not less than 75 mm, thereby ensuring that two superconducting line terminals connected with the superconducting joint have electric contact areas large enough so that the resistance of the joint can be effectively reduced. A wood alloy achieves complementing and strengthening effects, and the superconducting joint is fixed by using a high-conductivity oxygen-free copper sleeve, so that the resistance is further reduced. The superconducting joint is completed after heat treatment, so that the insulation damages of the superconducting joint in the process of heat treatment can be effectively avoided, and a greater degree of freedom is provided for the production and maintenance of the superconducting joint; and the superconducting joint is simple in production method and easy to operate.

Owner:西安聚能医工科技有限公司

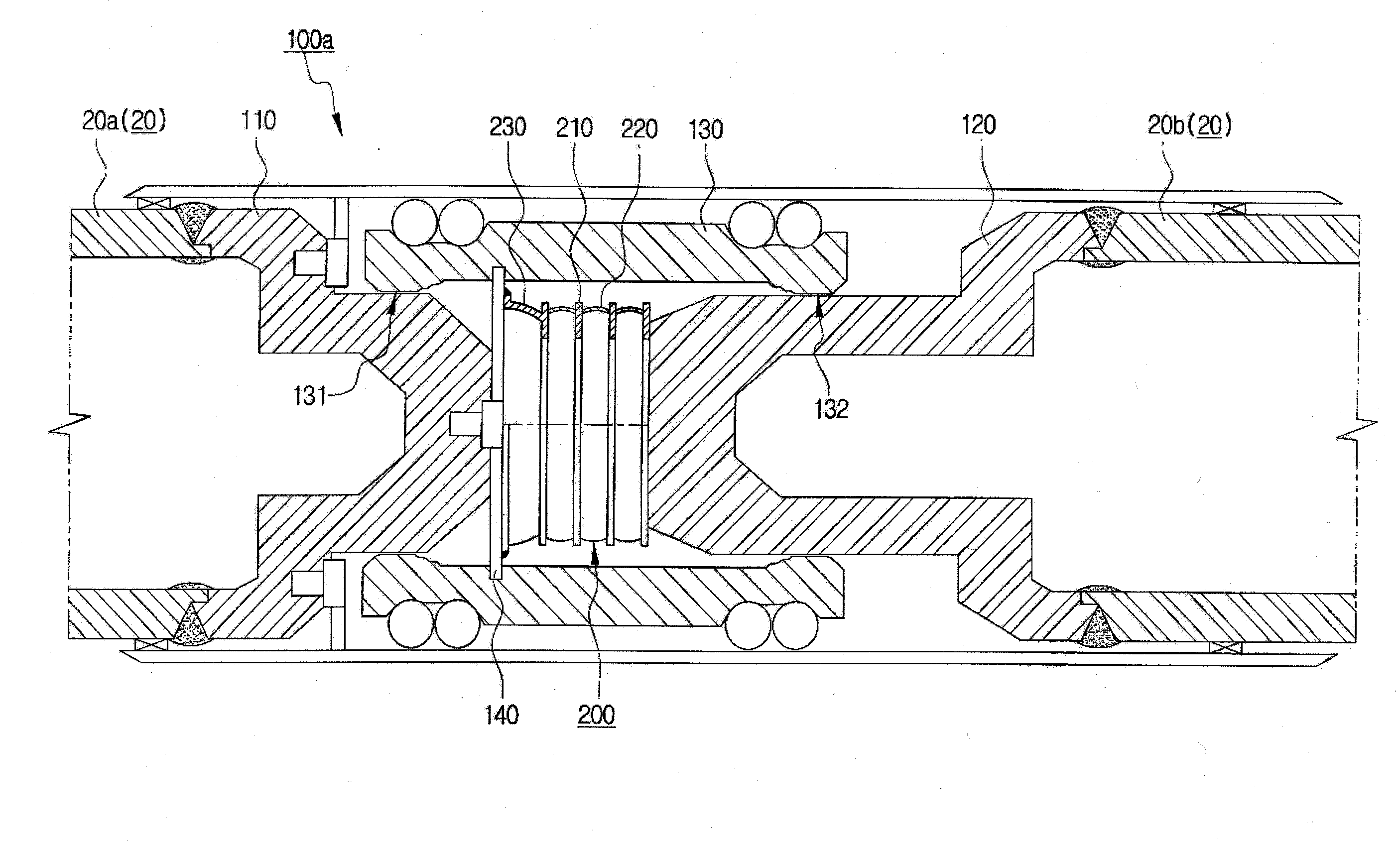

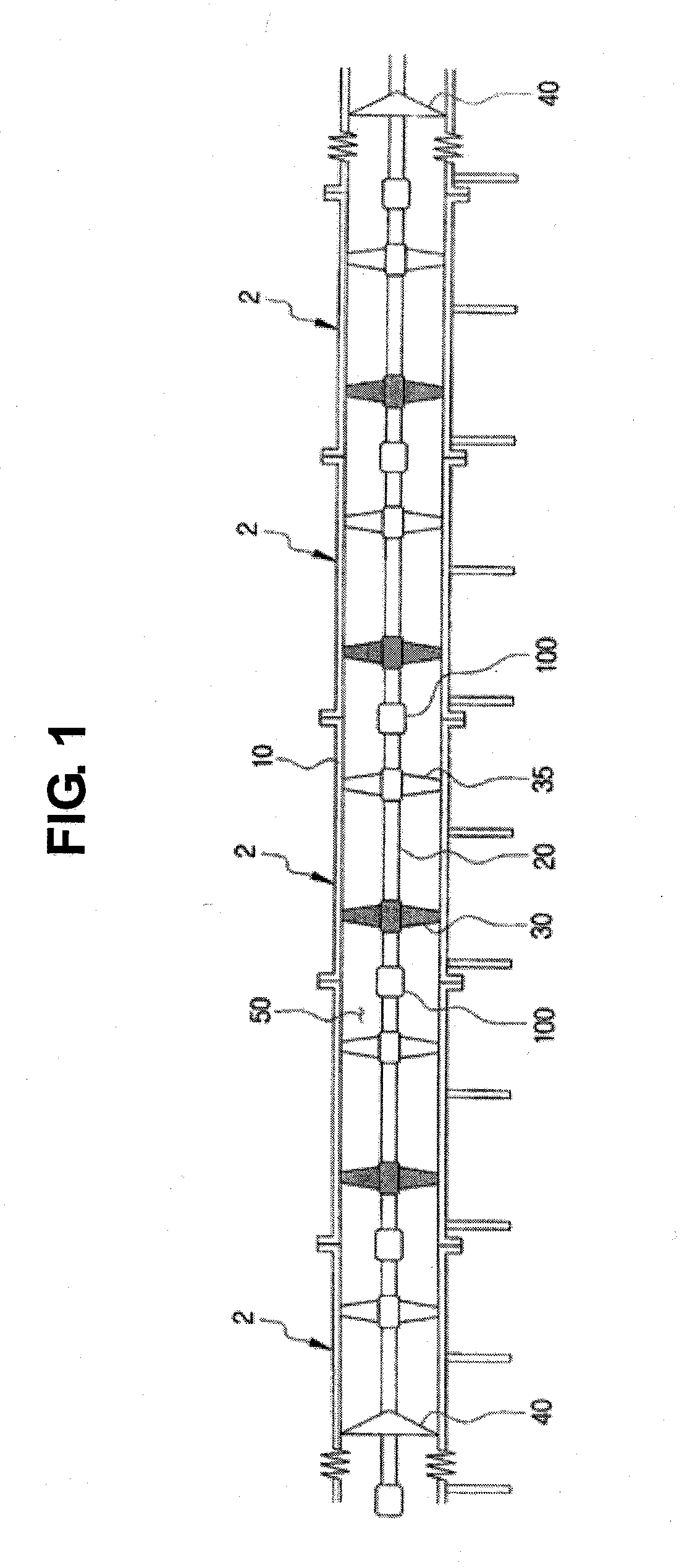

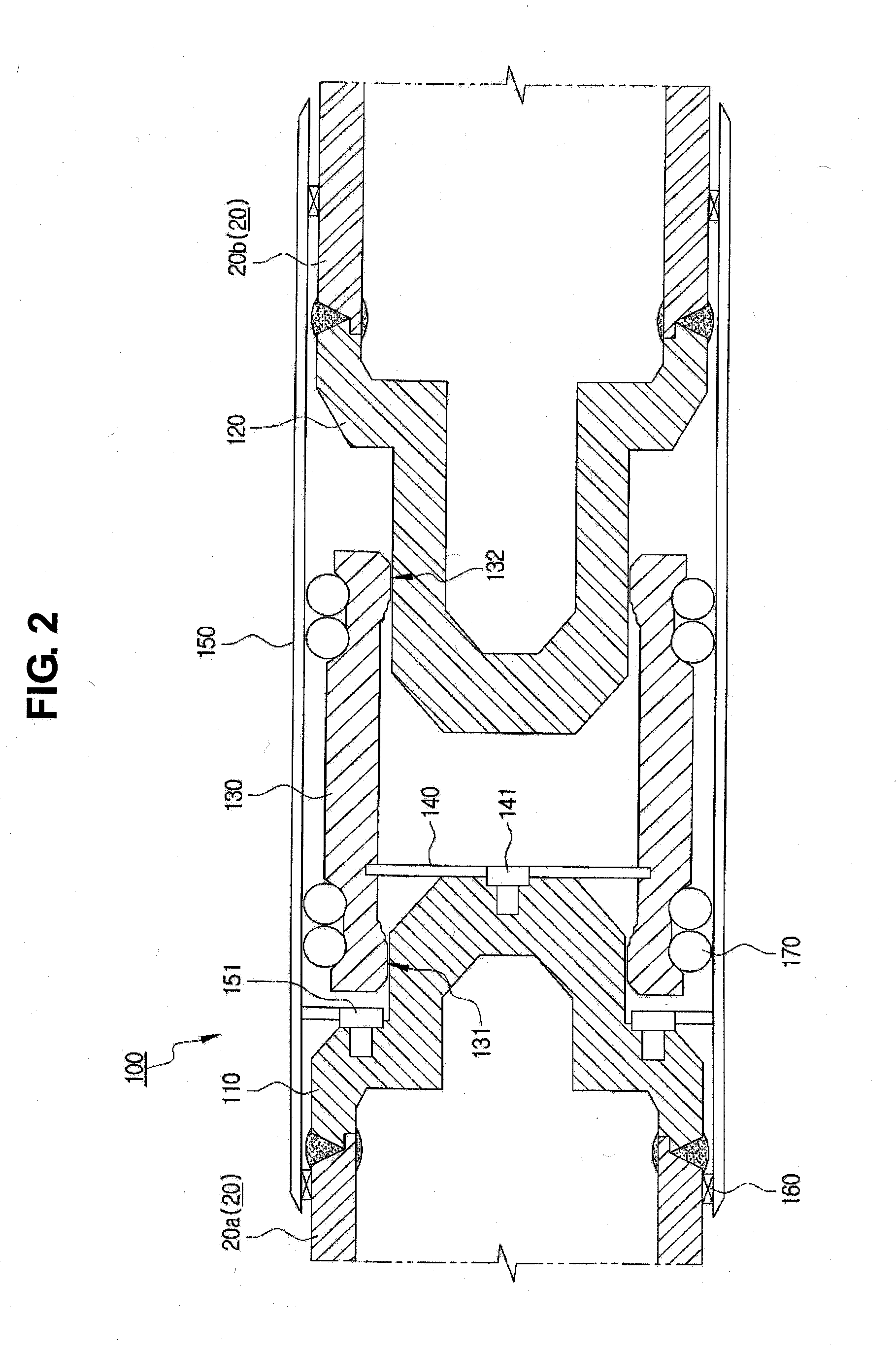

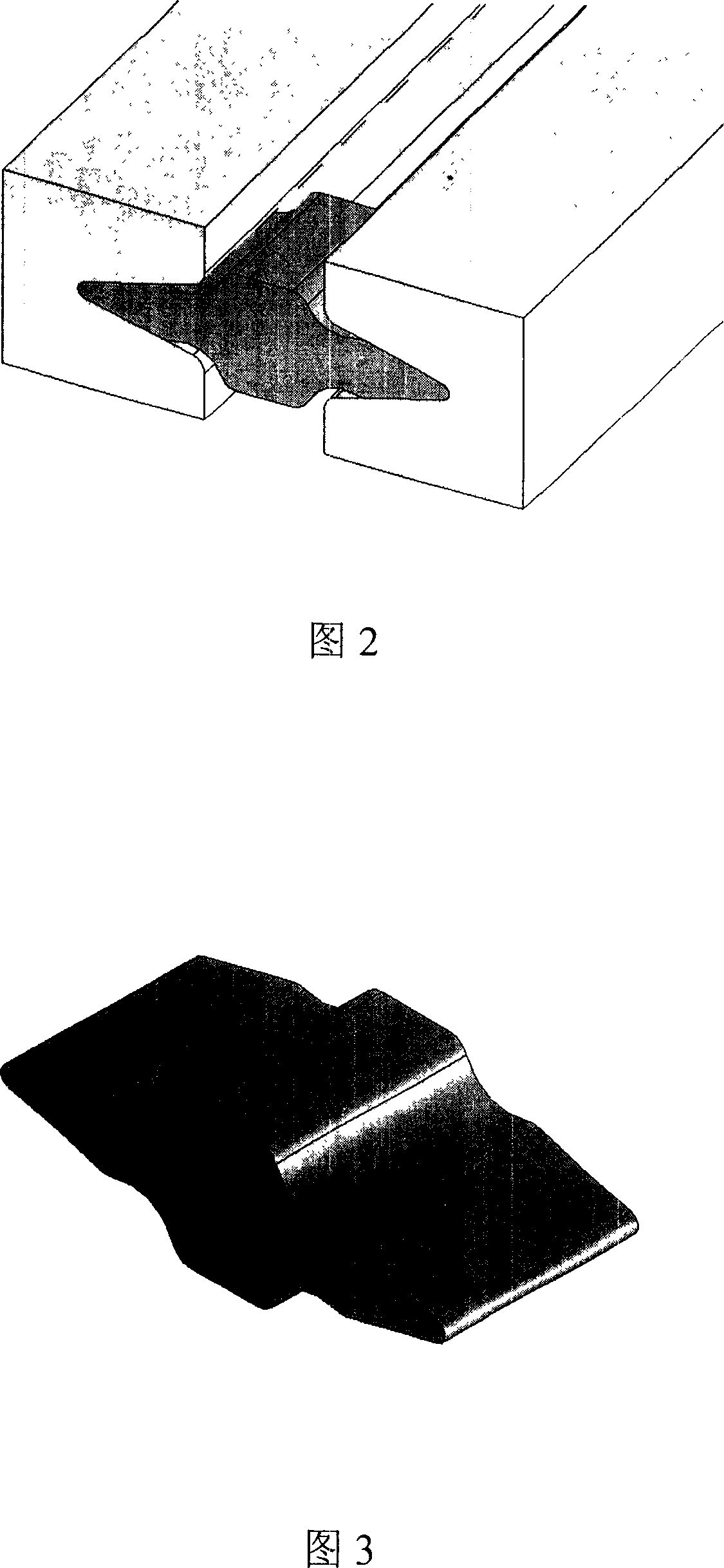

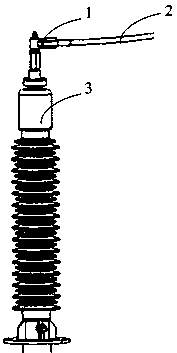

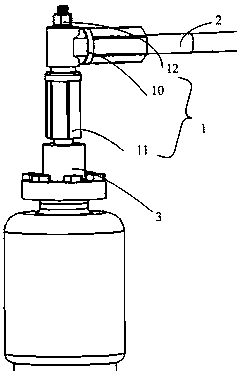

Gas insulated transmission line having improved performance of electric contact at connection parts of the conductors

InactiveUS20100200275A1Reduce the amount requiredIncrease the allowable currentLine/current collector detailsElectrically conductive connectionsElectrical conductorThermal expansion

The gas insulated transmission line includes: a pair of conductors disposed in a length direction; a fixed-side socket and a movable-side socket respectively coupled to one ends of the conductors; and a conductive flexible member interposed between facing end surfaces of the fixed-side socket and the movable-side socket, both ends of the conductive flexible member being closely adhered to the end surfaces of the fixed-side socket and the movable-side socket to keep electric contact therebetween, and the conductive flexible member being expanded or shrunken in an axial direction according to thermal expansion / shrinkage of the pair of conductors. The gas insulated transmission line provides a wide axial contact area while allowing thermal expansion / shrinkage of conductors.

Owner:DONGBU HITEK CO LTD +1

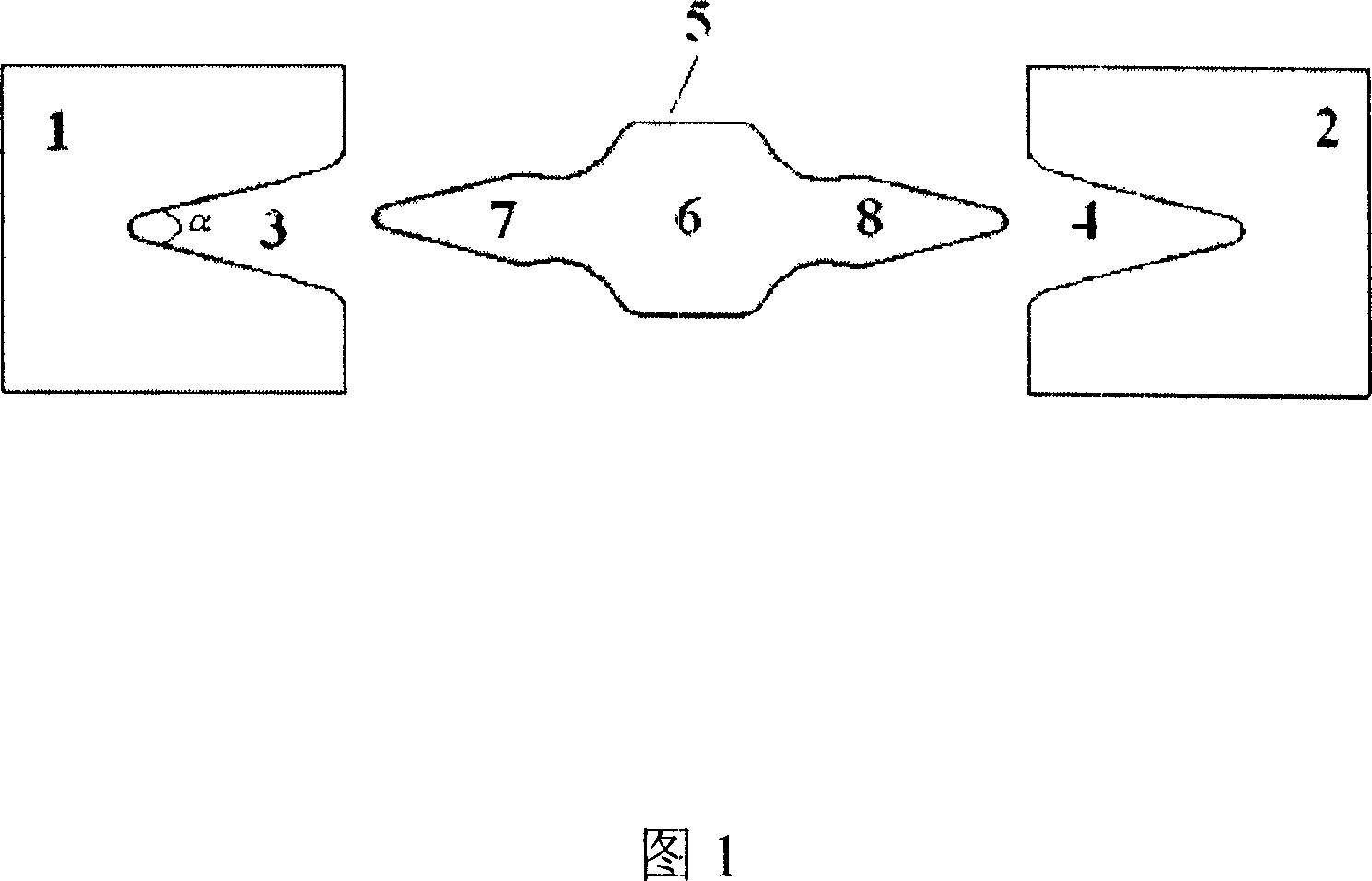

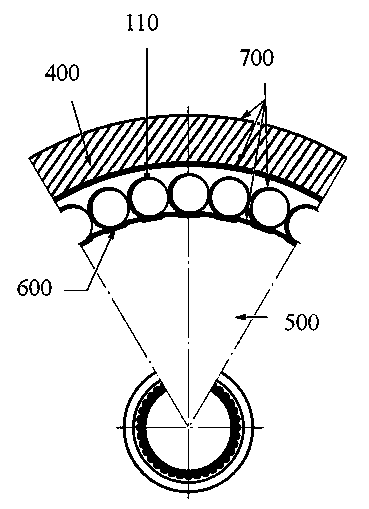

Electromagnetic railgun

InactiveCN101021396AExtended service lifeIncrease electrical contact areaElectromagnetic launchersElectricityEngineering

The invention discloses an electromagnetism rail gun which the structure is: the insulation material is between the first rail and second guide rail which are all opened with the symmetrical 'V' slot. The angle of the slot is 30-60degree. The solid armature is set between the first and second guide rail. The two symmetrical side wings extend to both sides from the body which the shape and size is matched to the 'V' slot. The upper and lower surface of the two side wing front contacts with the 'V' slot to form the electrical contact surface of the solid armature and the guide rail; the back end of the two side wings are separate with the two guide rail. The invention can control the damage of the transitional voltaic arc, so it can prolong the gun using life but getting the higher shooting speed (>3kms), so it has the widely future.

Owner:HUAZHONG UNIV OF SCI & TECH

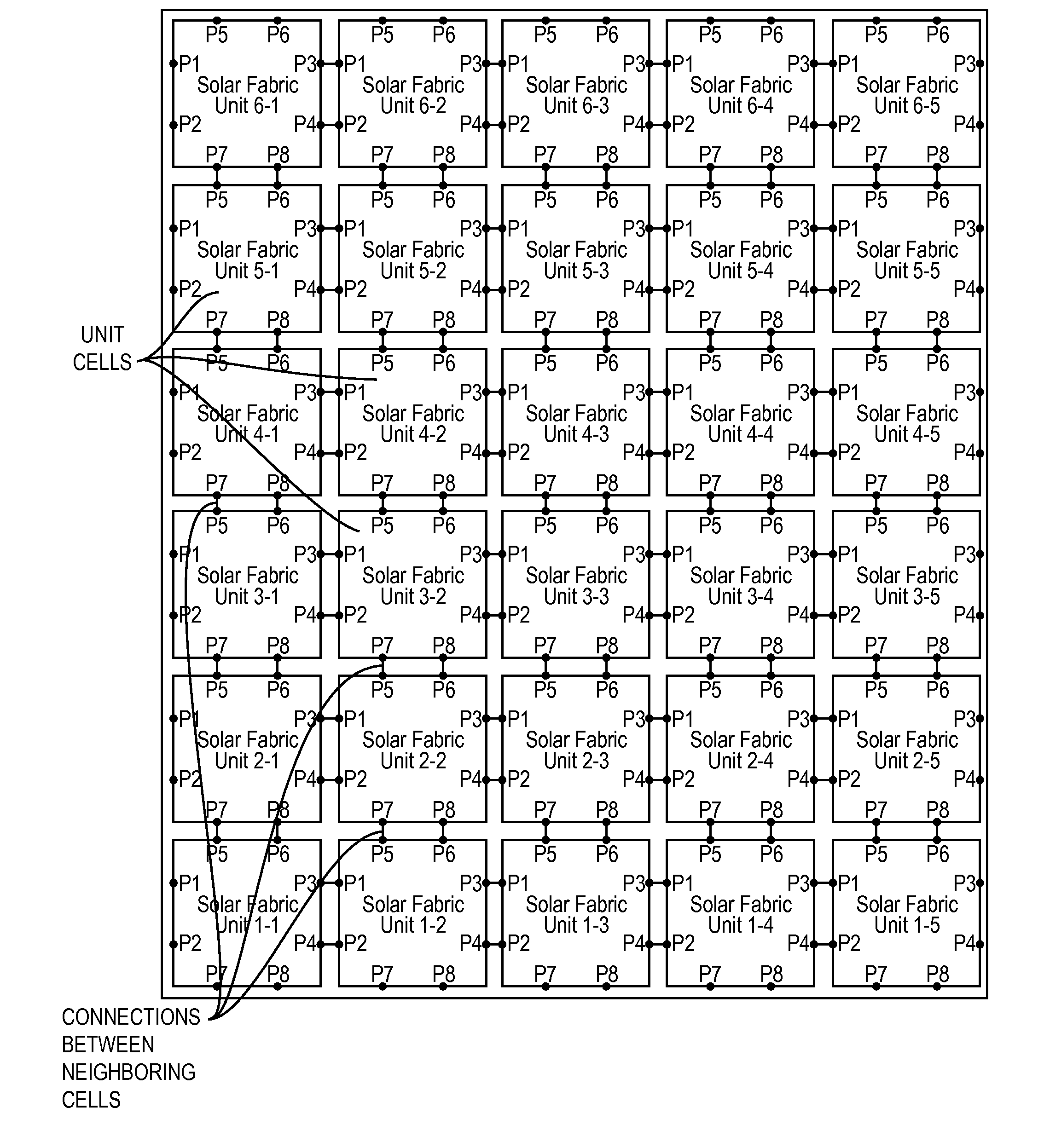

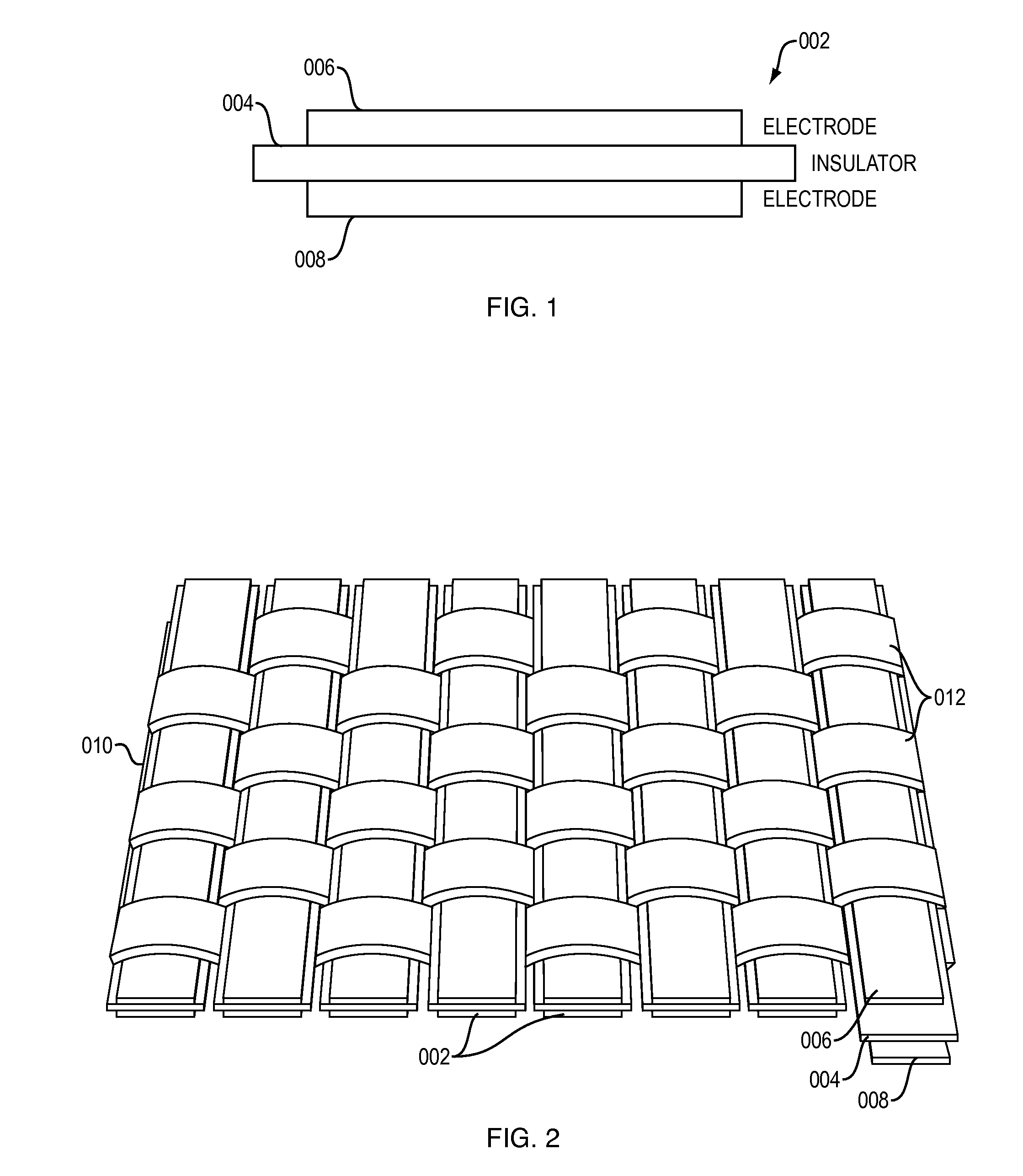

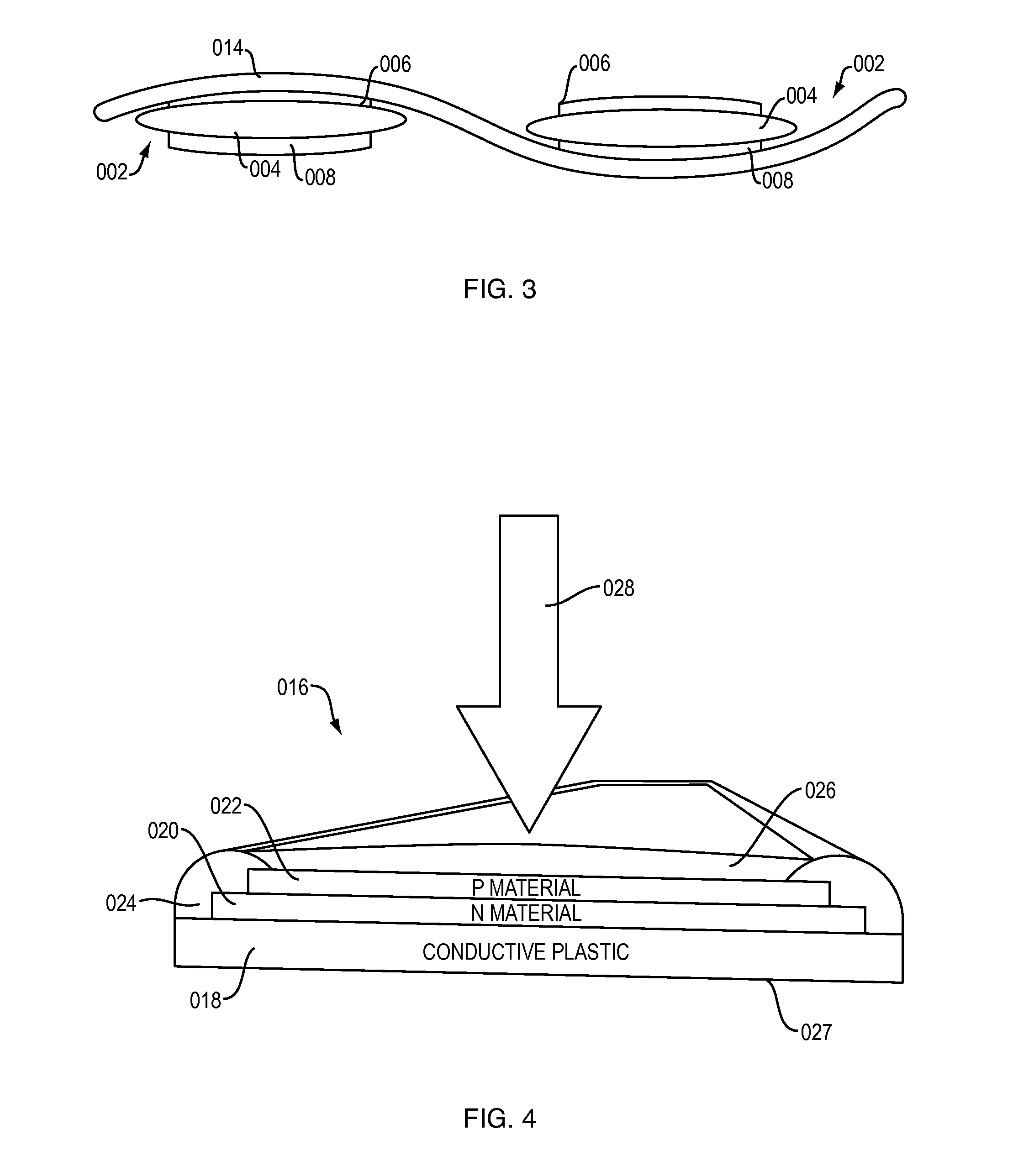

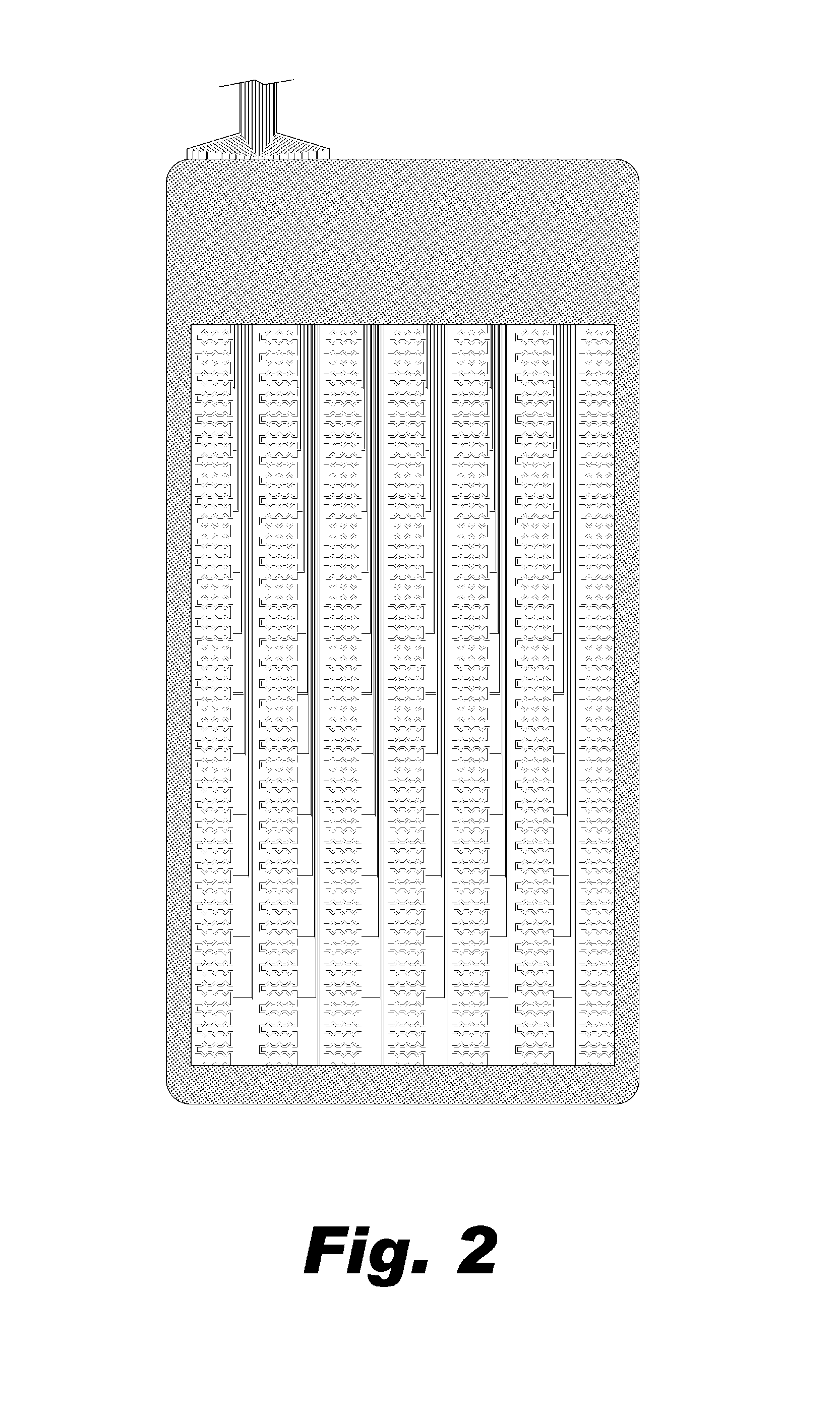

Photovoltaic textiles

InactiveUS20140338721A1Increase electrical contact areaReduce contact resistancePV power plantsPhotovoltaic energy generationElectrical and Electronics engineeringPhotovoltaics

Textile systems and components for establishing electrical characteristics of textiles. The textiles incorporate charge carrying components, such as photovoltaic components, in contact with highly conductive bus conduits to improve electrical properties without compromising physical characteristics of the textiles. Structure, geometries, and methods are provided for textile constructs, including photovoltaic textile constructs.

Owner:PARENT DONALD G +1

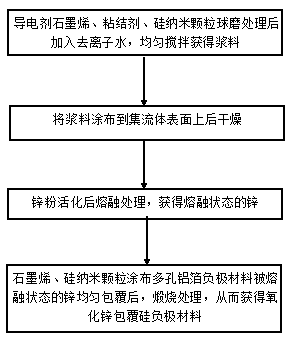

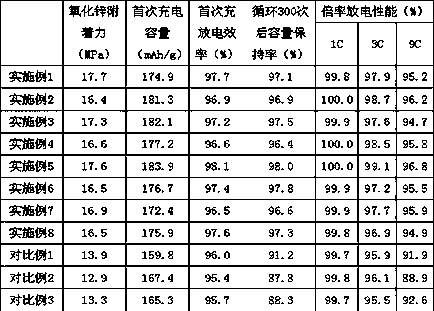

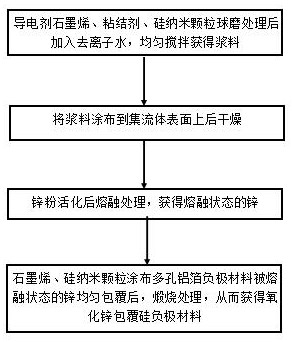

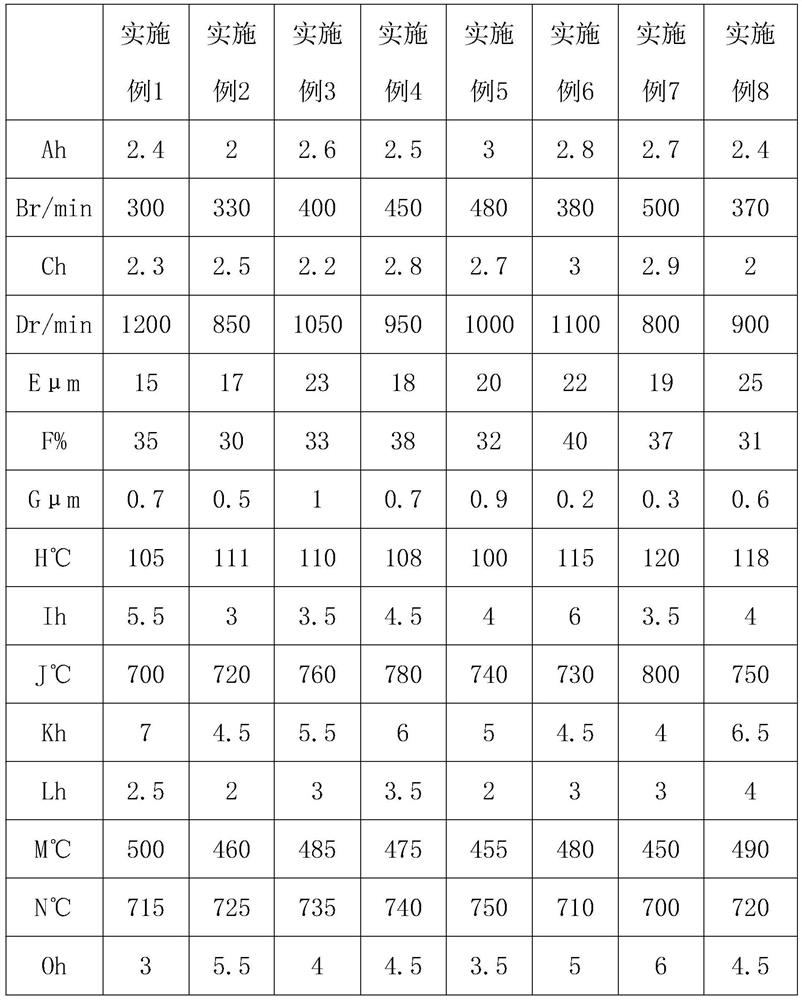

Preparation method of zinc oxide silicon-coated anode material

ActiveCN109560263AInhibition of volume expansionPhenomena that prevent damageSecondary cellsNegative electrodesMolten stateSlurry

The invention relates to the technical field of lithium ion battery anode materials, especially to a preparation method of a zinc oxide silicon-coated anode material. The method comprises the following steps of in order: 1) performing ball milling processing of conductive agent graphene, a binder and silicon nanoparticles, adding deionized water, and uniformly stirring the mixture to obtain slurry; 2) coating the slurry to the surface of a current collector and then performing drying; 3) performing zinc powder activation and then performing melting processing to obtain a zinc in a molten state; and 4) after the graphene and silicon nano-particle coating porous aluminum foil negative electrode materials are uniformly coated with the zinc in the molten state, performing calcination process to obtain the zinc oxide silicon-coated anode material. The preparation process is simple and practicable, simple to operate and low in required cost, and the prepared and obtained zinc oxide silicon-coated anode material can effectively avoid the problem that the expansion and contraction of silicon in the charge-discharge reaction process, can inhibit the secondary reaction of the anode materials, can improve the stability of electrode cycle and the cycle efficiency and can have a high electrical conductivity.

Owner:赵金保 +2

Brush gear of a motor

InactiveUS8294328B2Increase electrical contact areaRotary current collectorClamped/spring connectionsGear wheelEngineering

Owner:JOHNSON ELECTRIC SA

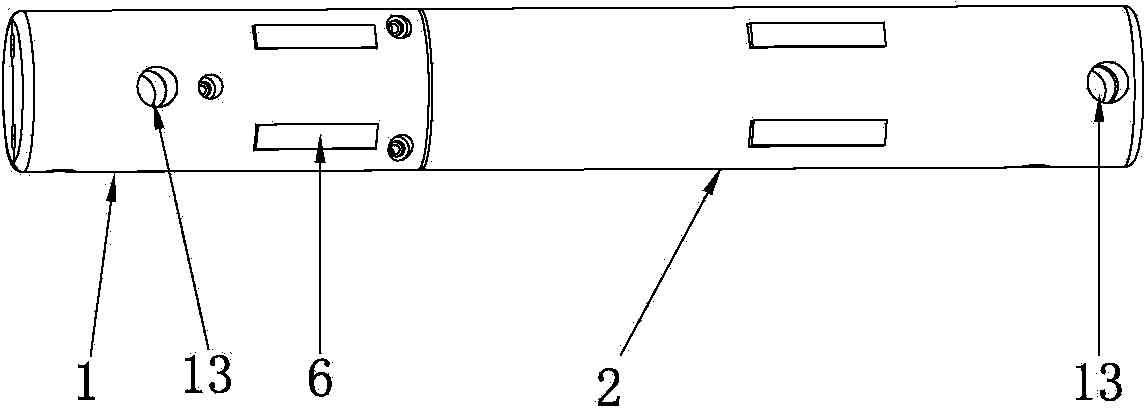

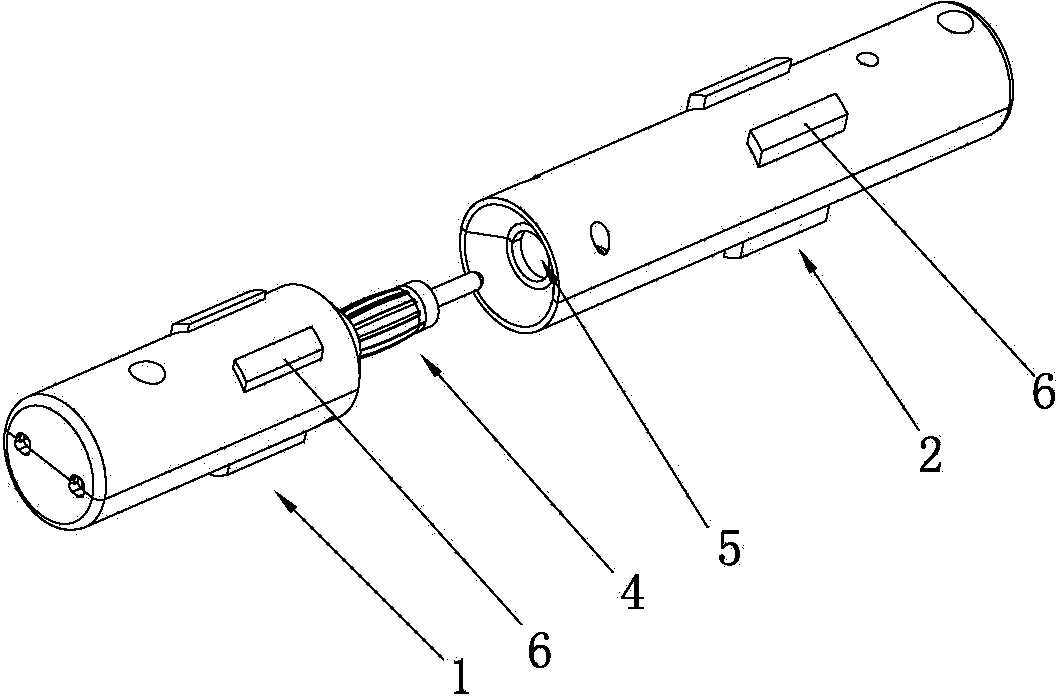

Novel rapid Christmas tree installation connector

ActiveCN104064899AQuick releaseQuick repairSecuring/insulating coupling contact membersCoupling contact membersInjection mouldingEmbedded system

The invention provides a novel rapid Christmas tree installation connector which comprises a connecting male head and a connecting female head connected with the connecting male head in a pluggable mode. The connecting male head and the connecting female head comprise a male head shell and a female head shell respectively, wherein the male head shell is detachably connected with the female head shell. The male head shell and the female head shell are respectively provided with a through hole. Clamping spring pins are arranged inside the through holes. The connecting male head and the connecting female head are fixed to an inner cavity of a Christmas tree rod through the clamping spring pins. According to the novel rapid Christmas tree installation connector, the detachable male head shell and female head shell replace a shell formed by solid core injection molding, and rapid disassembly and rapid maintenance can be carried out when quality problems appear. The pluggable end of the connecting male head extends outwards to be provided with an electric connecting plug rod, and an electric connecting plug hole corresponding to the electric connecting plug rod is formed in the connecting female head; when the connecting male head and the connecting female head are correspondingly combined and connected in the pluggable mode, the electric connecting plug rod is plugged into the electric connecting plug hole and electrically connected with the electric connecting plug hole, the electric contact area between the electric connecting plug rod and the electric connecting plug hole is larger, and the novel rapid Christmas tree installation connector is applicable to DC and AC at the same time and high in use universality.

Owner:DONGGUAN FEIYANG LIGHTING TECH CO LTD

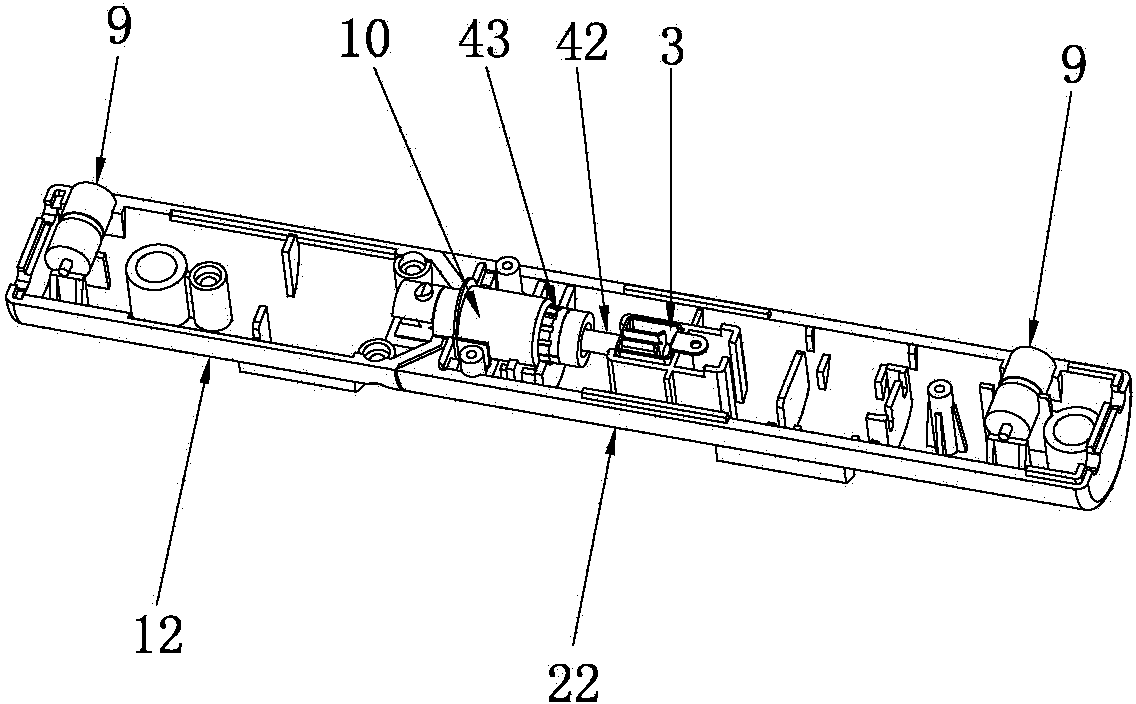

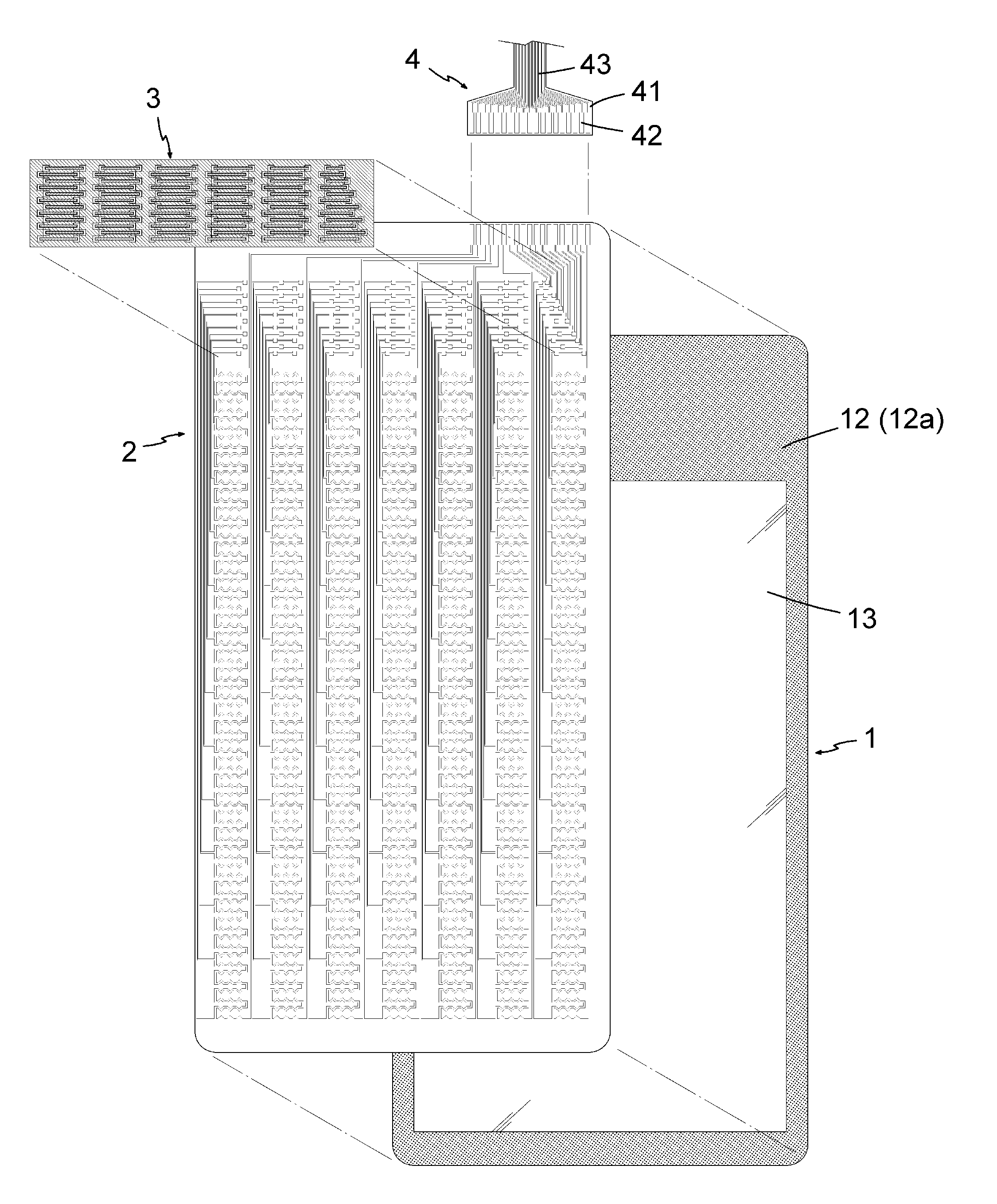

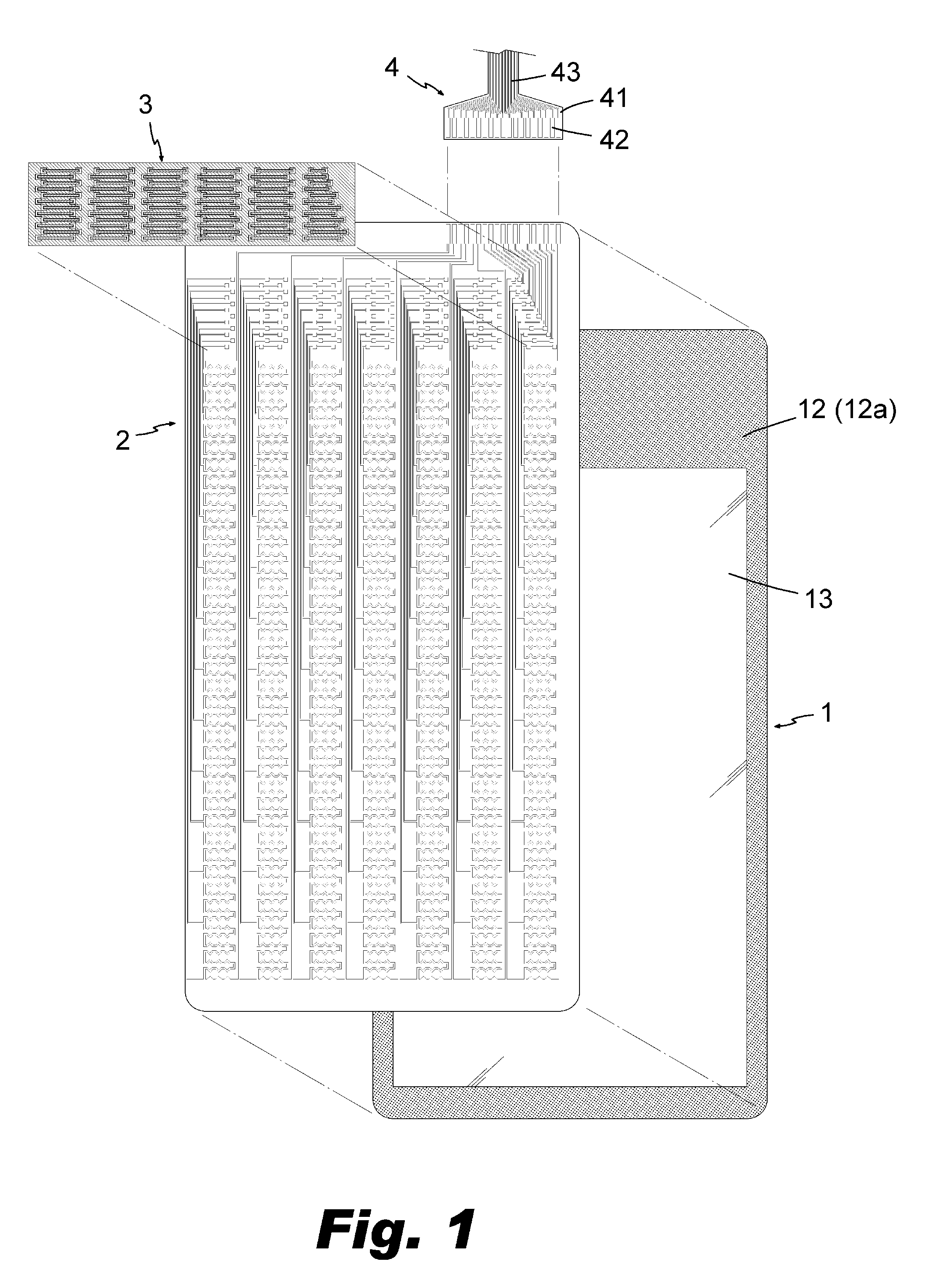

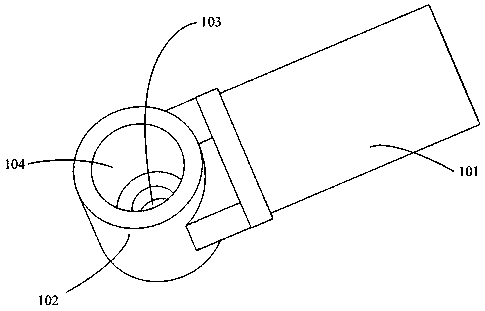

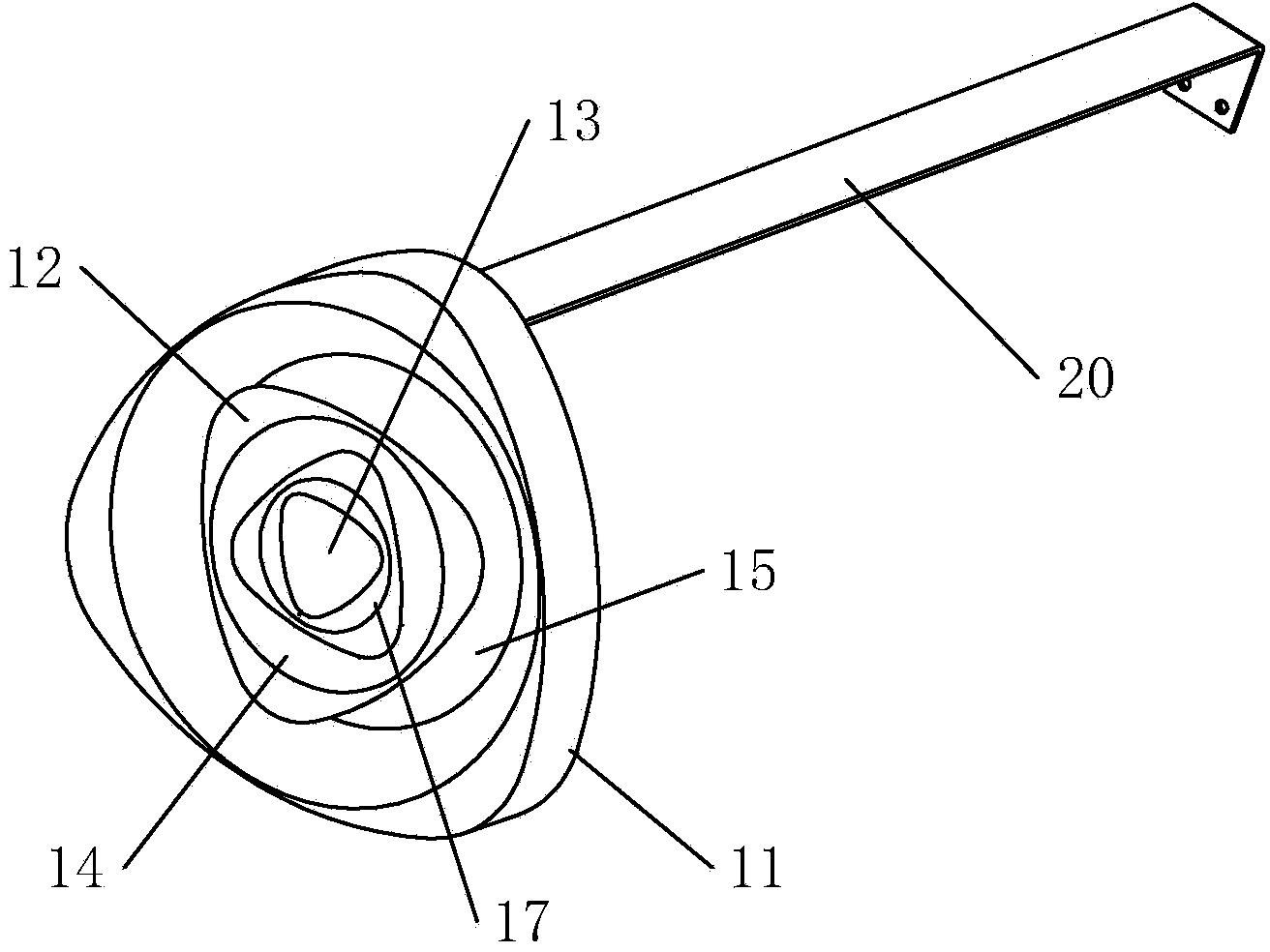

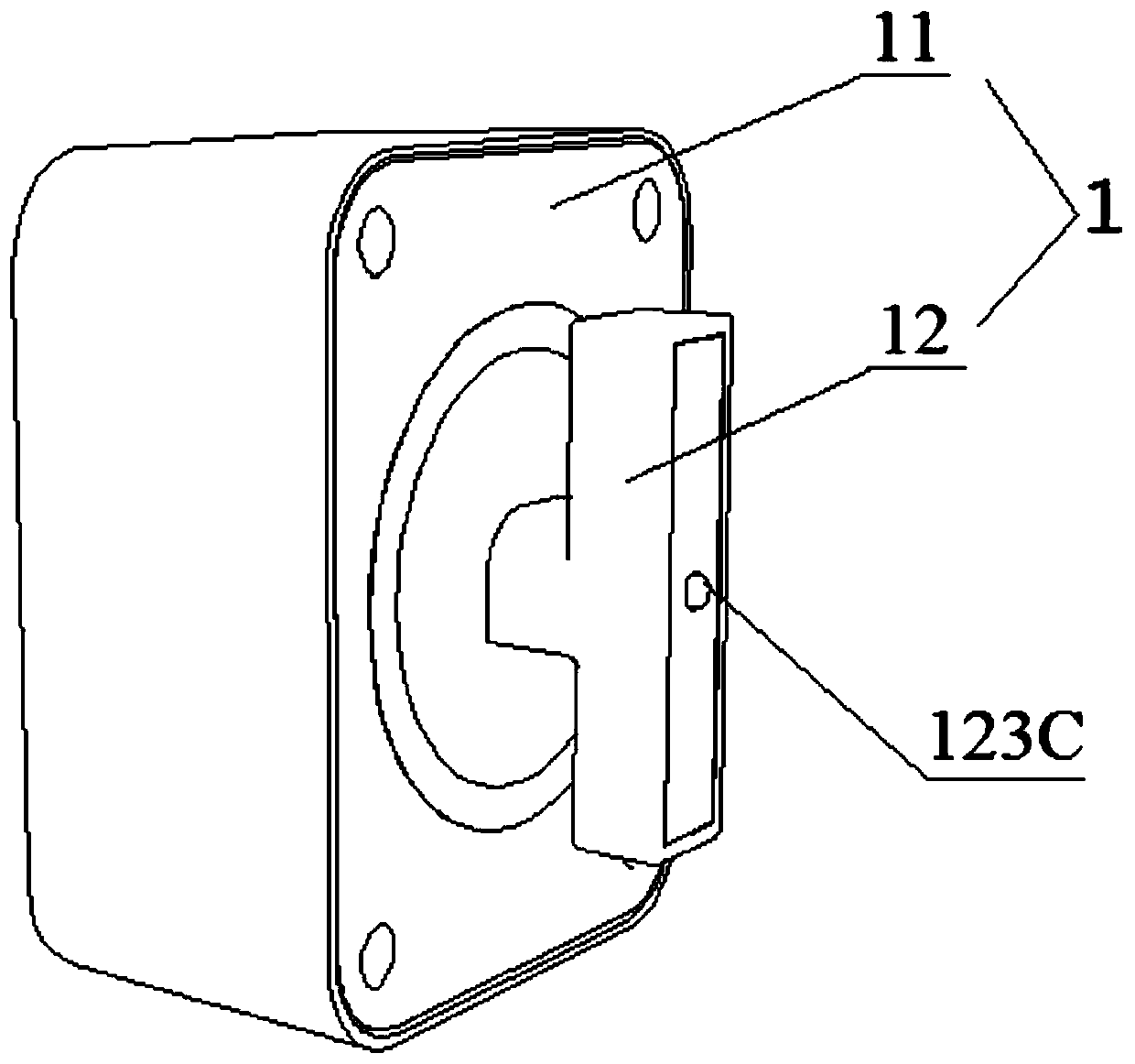

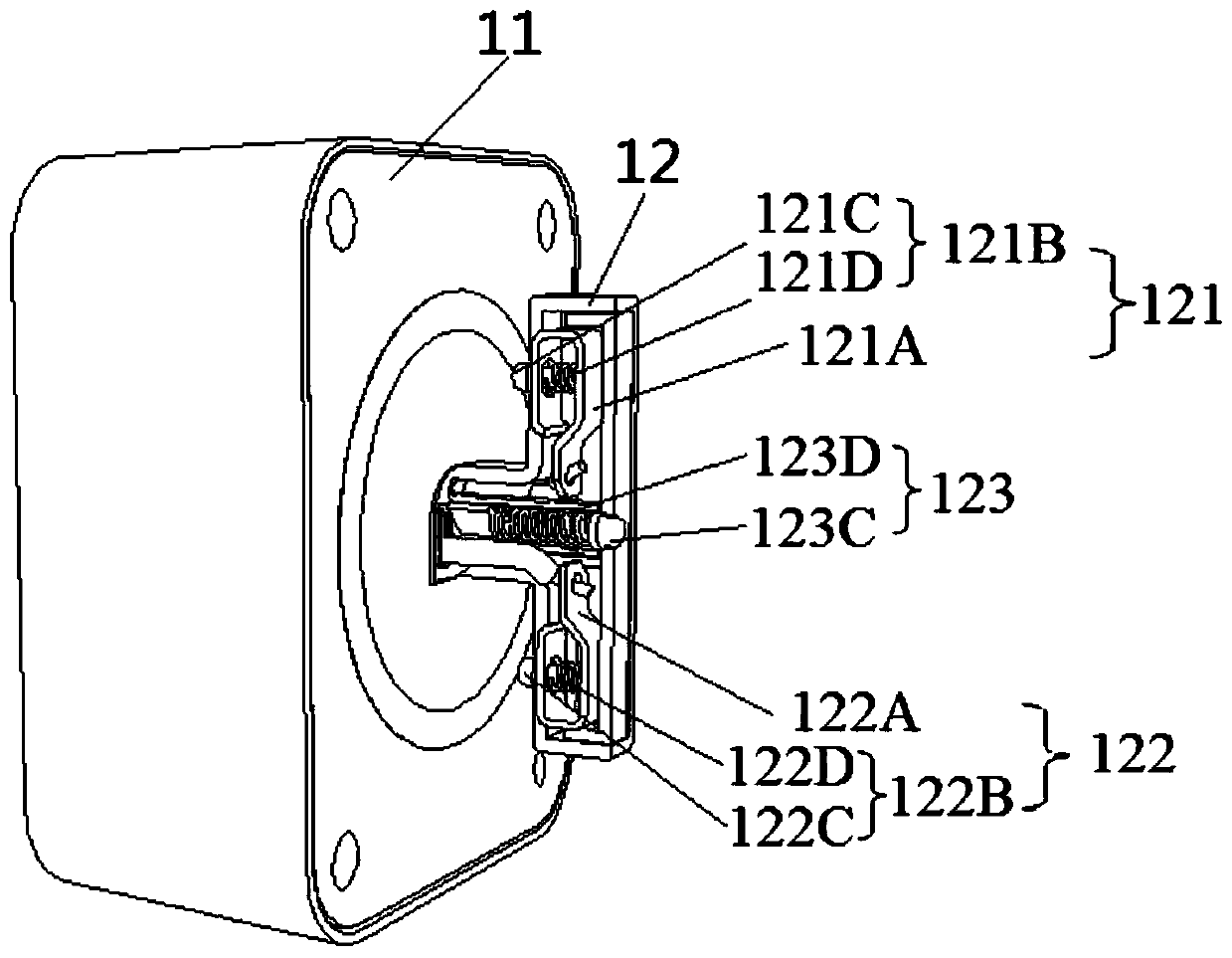

Electric connector and jack contact piece of rotating hyperboloid bus set densely-wound wire spring structure

ActiveCN104064898AIncrease electrical contact areaIncrease the break timeCoupling device detailsTwo-part coupling devicesElectric power transmissionElectricity

The invention relates to an electric connector and a jack contact piece of a rotating hyperboloid bus set densely-wound wire spring structure in the same. The jack contact piece comprises a wire spring ring, and a rotating hyperboloid densely-wound wire spring bus set, wherein a group of straight bus which is made of elastic metal wires rotates left or right in an equal inclination around the center axis of the spring ring to form the rotating hyperboloid densely-wound wire spring bus set. Both ends of each straight bus are respectively hanged in openings of two axial ends of the spring ring. When a pin is inserted into the jack contact piece, the inner side of the rotating hyperboloid densely-wound wire spring bus set coats the surface of the pin to form conductive contact. According to the invention, the electric contact area of the pin and the jack can be greatly increased; the transient fault probability and the transient fault time are greatly reduced; high current and high power transmission can be realized; a spiral angle is controlled to ensure reliable connection and smooth plugging of the electric connector; and stable and reliable electrical connection of a bumping and large current transmission carrier in high-speed operation and continuous vibration is ensured.

Owner:SHANGHAI SFUN ELECTRICAL TECH

Packaging structure and forming method thereof

ActiveCN103633038AUniform thicknessImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesInsulation layerElectrical performance

The invention discloses a packaging structure and a forming method thereof, wherein the forming method of the packaging structure is that the first surface of a chip layer is provided with a protective layer and a welding pad layer, and the second surface of the chip layer is provided with a plurality of grooves exposed out of the protective layer; a first insulation layer is formed at each of the second surface of the chip layer, and the surfaces of the side walls and the bottoms of the grooves; the thicknesses of the first insulation layers positioned at the bottoms of the grooves are thinner than the thickness of the first insulation layer positioned at the second surface of the chip layer; through holes penetrating through the first insulation layers, the protective layer and the welding pad layer are formed in the bottoms of the grooves; parts of the first insulation layers around the through holes are removed and are exposed out of the bottoms of the grooves; afterwards, conductive layers are formed at the surfaces of the first insulation layers, the surfaces of the bottoms of the grooves, and the surfaces of the side walls and the bottoms of the through holes. The electrical performance and the stability of the formed packaging structure are improved.

Owner:CHINA WAFER LEVEL CSP

Bridging structure for signal transmission of touch panel

ActiveUS20140190808A1Reduce in quantitySmall sizeElectronic switchingElectric switchesElectricityTouch panel

The invention includes a substrate with a visible area and a shielded area, a touch panel overlapped on the substrate and having touch sensor units overlapping with the visible area and a bridging layer with an insulating film. The touch sensor units are connected with signal wires to electric contacts corresponding to the shielded area. The insulating film cloaks the signal wires and electric contacts. The insulating film is formed with through holes corresponding to the electric contacts and is provided with bridging wires between every two adjacent through holes for connecting all of the electric contacts.

Owner:YOUNG FAST OPTOELECTRONICS

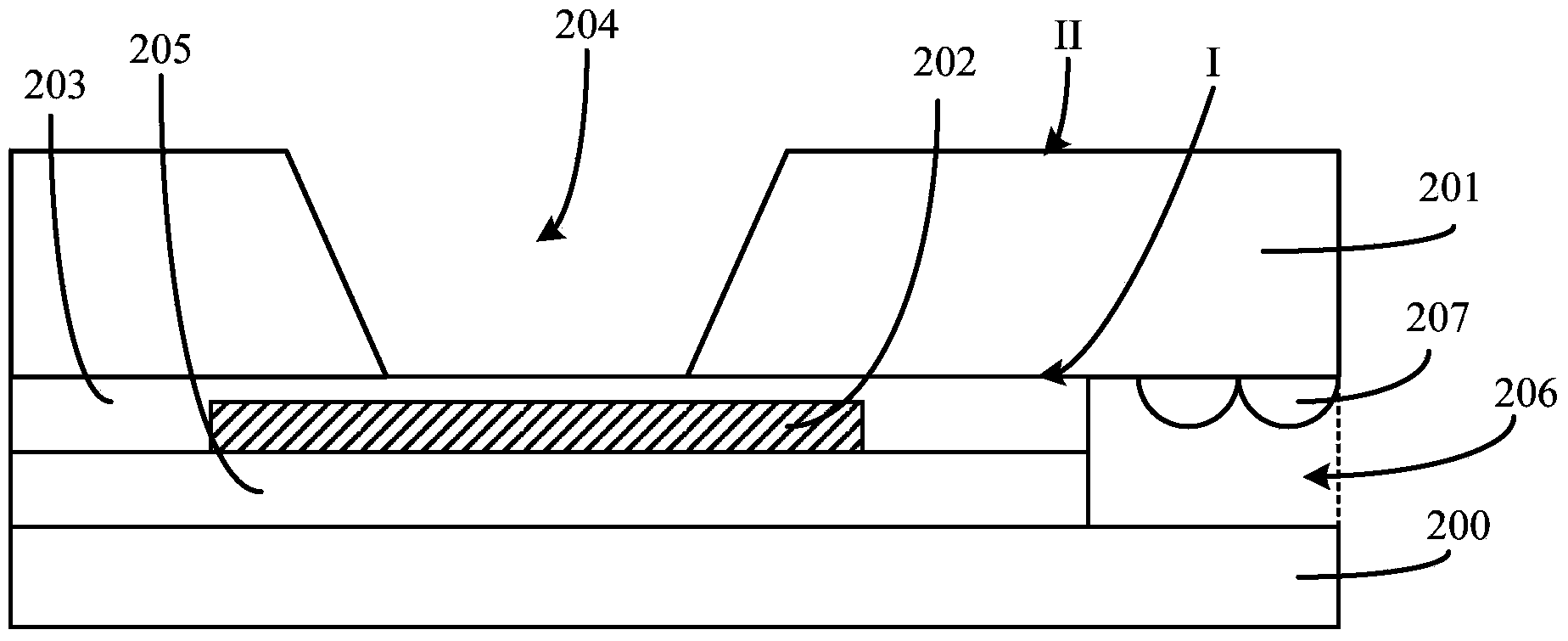

Photodiode and forming method thereof, image sensor and fingerprint imaging module

InactiveCN109728112AIncrease surface areaReduce reflection lossSemiconductor devicesImaging qualityPhotodiode

A photodiode and a forming method thereof, an image sensor and a fingerprint imaging module are provided. The forming method of the photodiode includes the following steps: providing a substrate; forming a bottom electrode on the substrate; forming a photosensitive layer on the bottom electrode; and processing the photosensitive layer by laser to form an uneven surface of the photosensitive layer.After the formation of the photosensitive layer, the photosensitive layer is processed by laser to form an uneven surface, so as to increase the surface area of the photosensitive layer, reduce the surface reflection loss of the photosensitive layer and achieve the purpose of improving the light collection ability of the formed photodiode and improving the image quality without increasing the size of the opening.

Owner:SHANGHAI OXI TECH

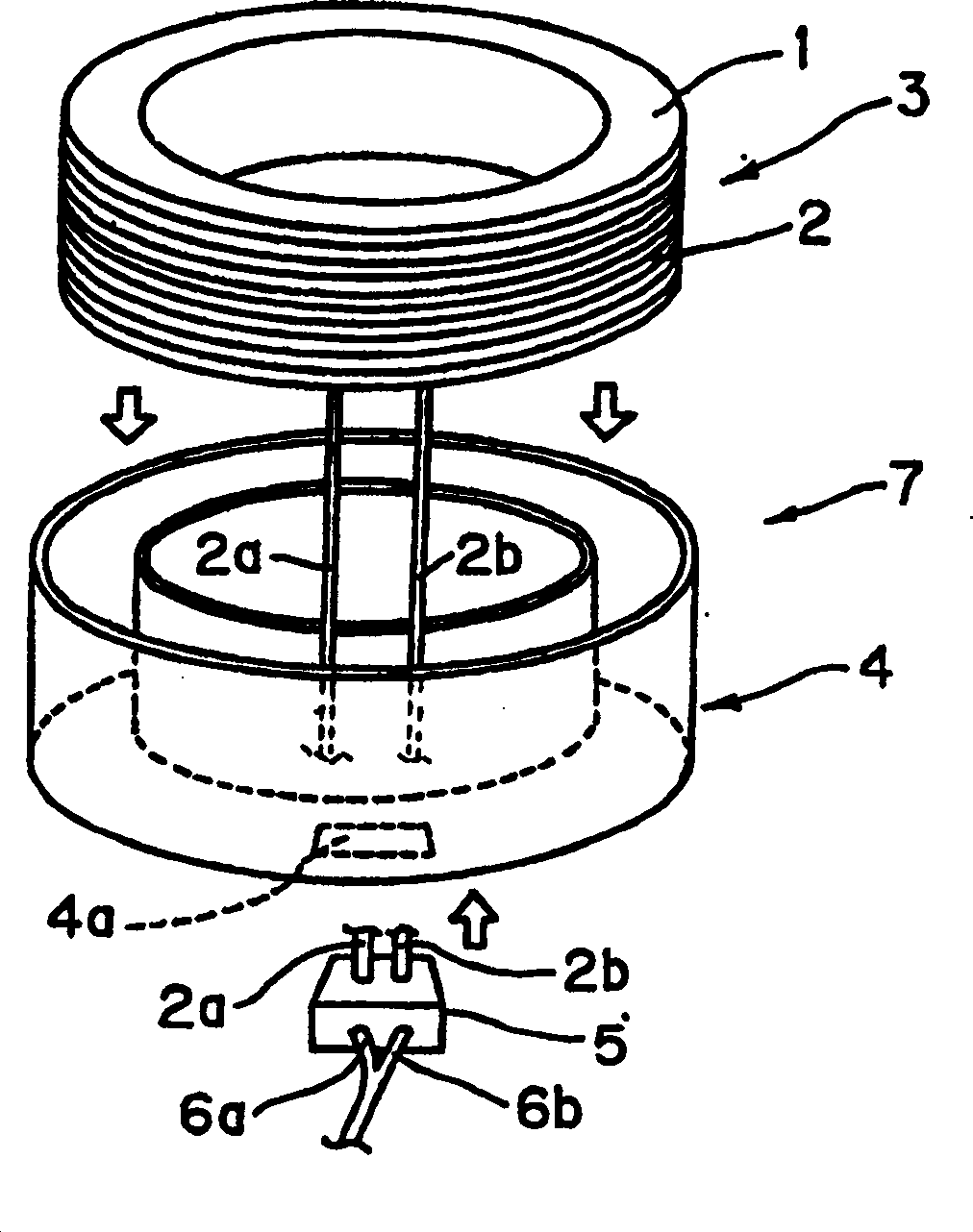

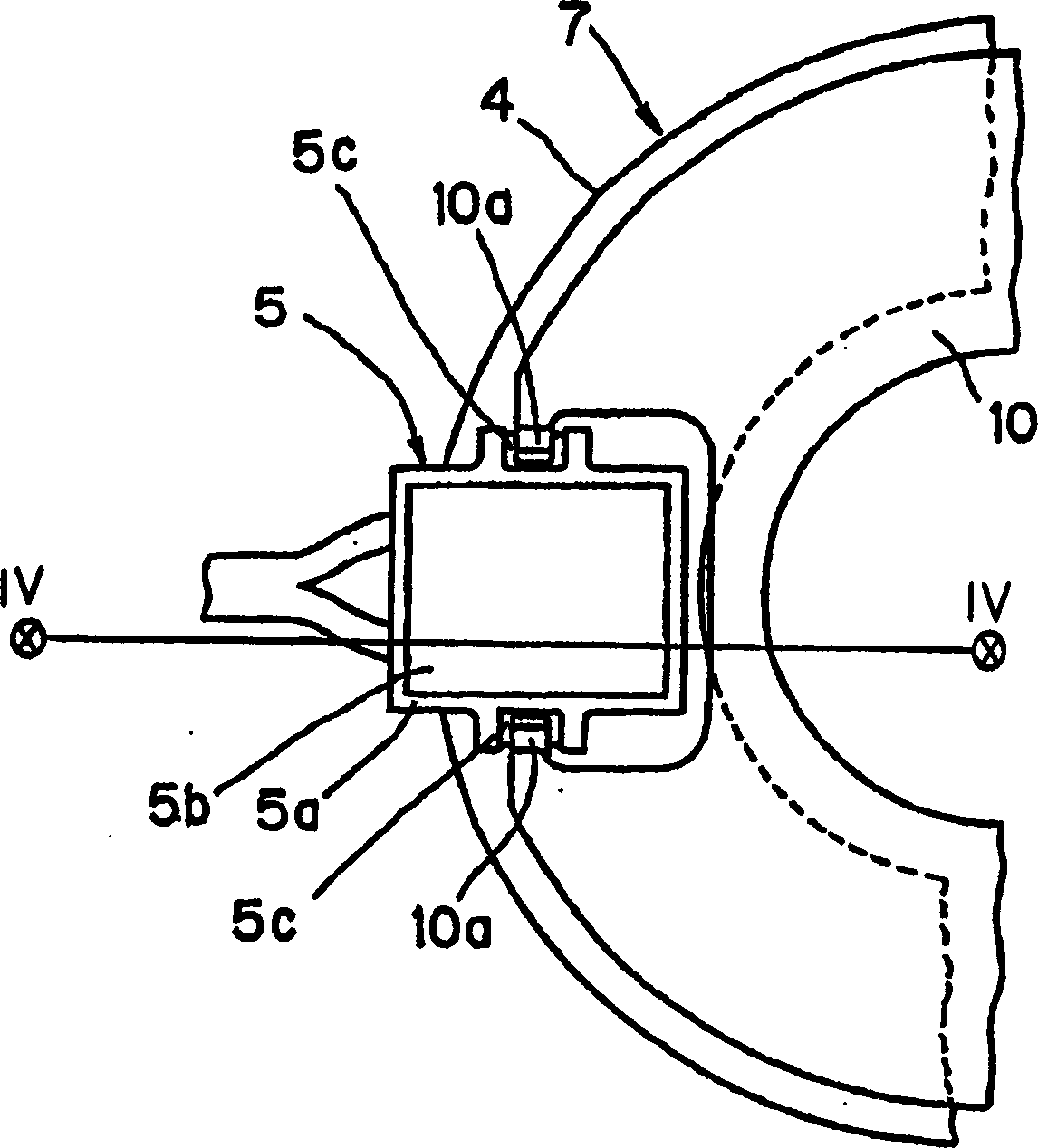

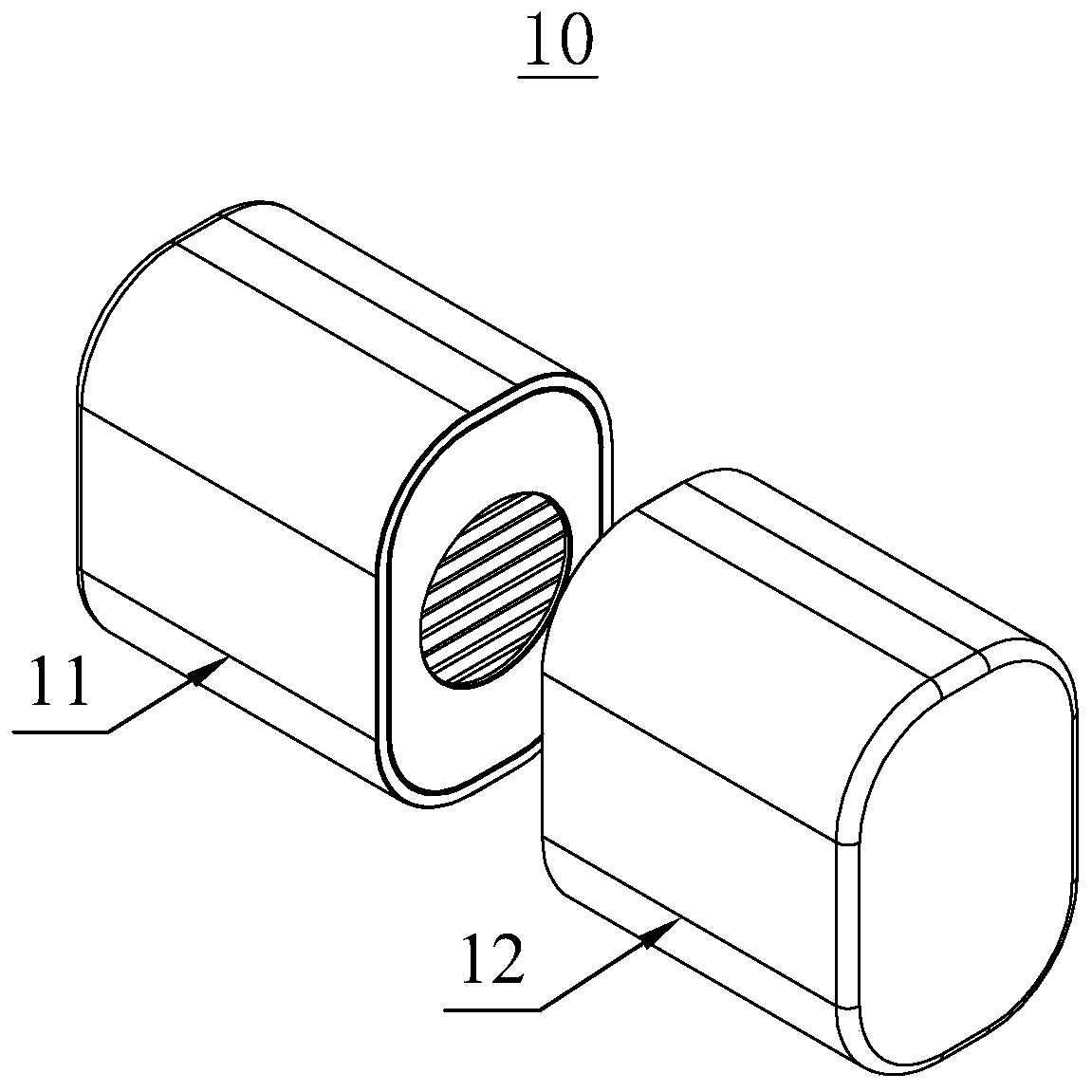

Magnetic yoke for electromagnetic clutch

InactiveCN1403724AAchieve electrical connectionEasy to manufactureTransformers/inductances coils/windings/connectionsMagnetically actuated clutchesElectromagnetic clutchElectrical connection

Owner:SANDEN CORP

Magnetic attraction joint, magnetic attraction connector and preparation method thereof

ActiveCN110165457AExtended service lifeIncrease contactEngagement/disengagement of coupling partsContact member manufacturingState of artMagnetic tension force

The invention relates to the technical field of connectors, and especially relates to a magnetic attraction joint, a magnetic attraction connector and a preparation method thereof. The magnetic attraction joint comprises a hollow column section with an opening at one end and a magnetic flexible conductive structure filled in the hollow column section, and the flexible conductive structure deformsunder the action of a magnetic force and protrudes out of the opening of the hollow column section. The magnetic attraction joint effectively avoids the problem of poor contact caused by metal contactwear in the prior art, and prolongs the service life of the magnetic attraction connector and electronic equipment. The magnetic attraction connector and the electronic equipment have the same effects as the magnetic attraction joint, thereby being not explained any more.

Owner:SHENZHEN BASEUS TECH CO LTD

Bridging structure for signal transmission of touch panel

ActiveUS8780067B1Reduce in quantitySmall sizeElectronic switchingElectrical apparatus contructional detailsTouchpadTouch panel

The invention includes a substrate with a visible area and a shielded area, a touch panel overlapped on the substrate and having touch sensor units overlapping with the visible area and a bridging layer with an insulating film. The touch sensor units are connected with signal wires to electric contacts corresponding to the shielded area. The insulating film cloaks the signal wires and electric contacts. The insulating film is formed with through holes corresponding to the electric contacts and is provided with bridging wires between every two adjacent through holes for connecting all of the electric contacts.

Owner:YOUNG FAST OPTOELECTRONICS

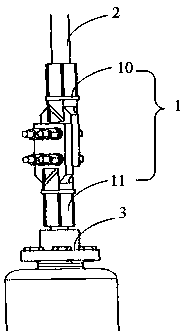

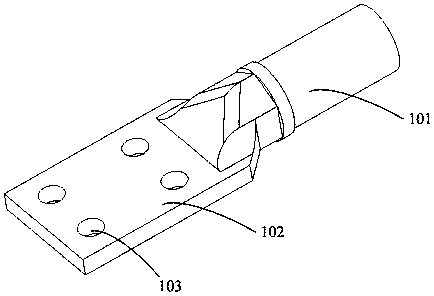

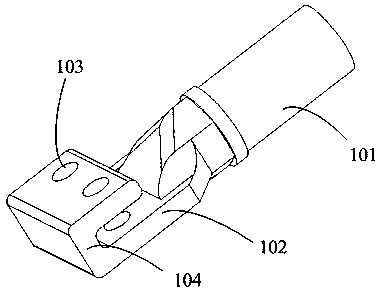

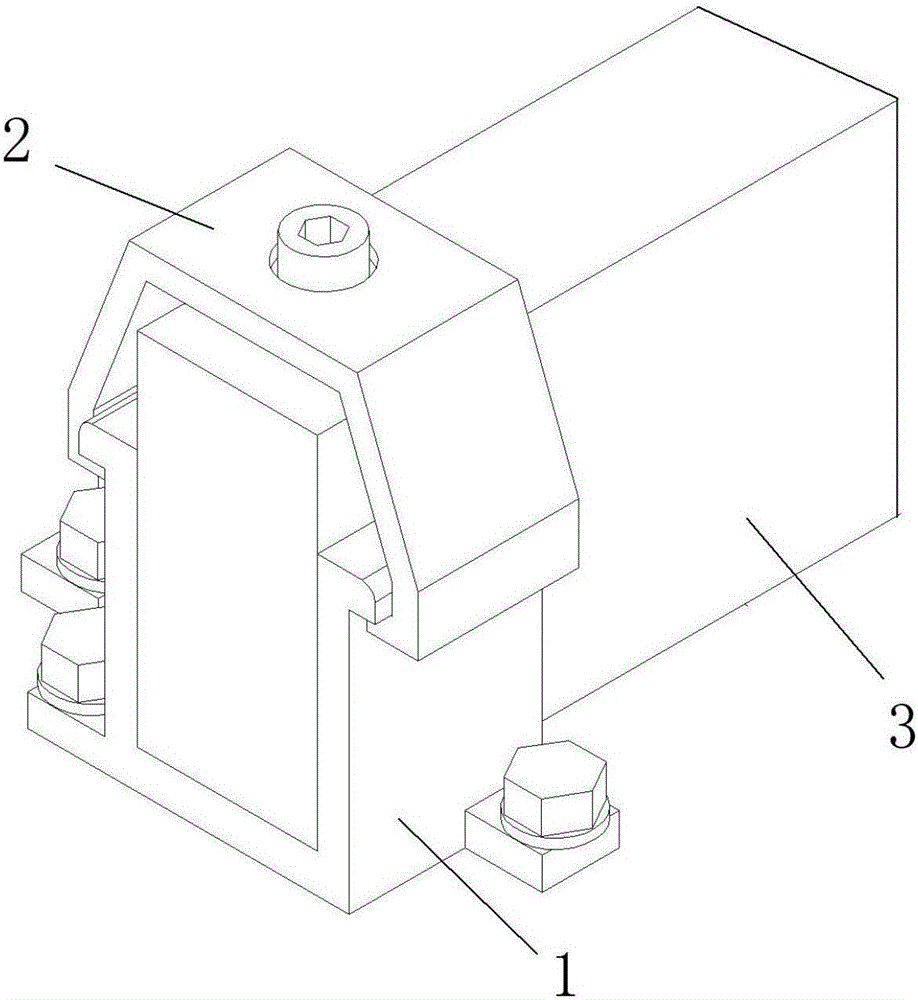

Comb-type high voltage and large current connecting terminal

InactiveCN107732500AIncrease electrical contact areaAvoid displacementCoupling contact membersTransformerEngineering

The embodiment of the invention discloses a comb-type high voltage and large current connecting terminal, wherein one end of the connecting terminal is connected with an aluminum twisted wire and theother end is connected with a lead-out bushing of a transformer; the connecting terminal comprises a first connecting terminal and a second connecting terminal; the first ends of the first connectingterminal and the second connecting terminal are hollow cylindrical sections and the second ends are panel sections with mounting holes; the panel section of the first connecting terminal is fixedly connected with the panel section of the second connecting terminal through a bolt; and the comb-type high voltage and large current connecting terminal is characterized in that at least one contact surface of the panel section of the first connecting terminal and the panel section of the second connecting terminal is provided with comb-type grooves and comb-type bulges coming in pairs. Through implementation of the comb-type high voltage and large current connecting terminal, displacement between the terminals can be avoided, and meanwhile, the contact area of the connecting terminals is improved.

Owner:SHENZHEN POWER SUPPLY BUREAU

Preparation process of zinc oxide coated silicon negative electrode material

InactiveCN112993228AInhibition of volume expansionPhenomena that prevent damageNegative electrodesSecondary cellsGraphiteAluminum foil

The invention relates to the technical field of lithium ion battery negative electrode materials, and in particular relates to a preparation process of a zinc oxide coated silicon negative electrode material. The preparation process sequentially comprises the steps of 1) performing ball milling treatment on conductive agent graphene, a binder and silicon nanoparticles, adding deionized water, and uniformly stirring to obtain slurry; 2) coating the slurry on the surface of a current collector and then drying; 3) activating and melting zinc powder to obtain zinc in a molten state; and 4) after the porous aluminum foil negative electrode material coated with the graphene and the silicon nanoparticles is uniformly coated with zinc in the molten state, performing calcination treatment to obtain the zinc oxide coated silicon negative electrode material. The preparation process provided by the invention is simple and easy to implement, simple and convenient to operate and low in required cost, and the prepared zinc oxide coated silicon negative electrode material can effectively prevent the problem of volume expansion and shrinkage of silicon in the charge-discharge reaction process, inhibit side reaction of the negative electrode material and improve the stability and the cycle efficiency of electrode circulation, and has relatively high conductive performance.

Owner:DONGGUAN UNIV OF TECH

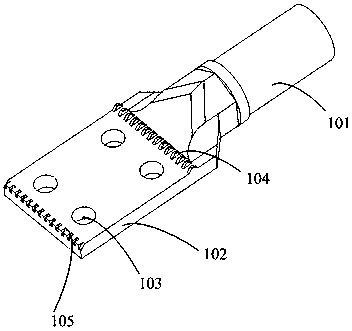

Dual-plane contact type high-voltage high-current terminal

InactiveCN107681298AIncrease electrical contact areaImprove conductivityTransformers/inductances coils/windings/connectionsElectric connection basesTransformerEngineering

An embodiment of the invention discloses a dual-plane contact type high-voltage high-current terminal. One end of the terminal is connected with an aluminum stranded wire while the other end is connected with a transformer wire outlet sleeve; the terminal comprises a first terminal and a second terminal; the first ends of the first terminal and the second terminal are both hollow cylindrical sections while the second ends are both flat plate sections with mounting holes; the flat plate section of the first terminal is fixedly connected with the flat plate section of the second terminal througha bolt; in the flat plate section of the first terminal and the flat plate section of the second terminal, a first contact sheet extends from one terminal while two parallel second contact sheets extend from the other terminal; and the first contact sheet is clamped and fixed between the two second contact sheets. By virtue of implementation of the embodiment, the contact area of the terminal canbe enlarged.

Owner:SHENZHEN POWER SUPPLY BUREAU

U-shaped high-voltage large-current wiring terminal

PendingCN107946798AIncrease electrical contact areaAvoid displacementElectric connection basesClamped/spring connectionsTransformerEngineering

The embodiment of the invention discloses a U-shaped high-voltage large-current wiring terminal. One end of the wiring terminal is connected with an aluminium twisted wire, and the other end of the wiring terminal is connected with a transformer outgoing wire casing pipe. The wiring terminal comprises a first wiring terminal and a second wiring terminal, wherein the first ends of the first and second wiring terminals are hollow cylindrical segments, and the second ends of the first and second wiring terminals are plate-shaped segments with installation holes. The plate-shaped segment of the first wiring terminal and the plate-shaped segment of the second wiring terminal are fixedly connected through a bolt. The wiring terminal is characterized in that the end part of the plate-shaped segment of the first wiring terminal and the end part of the plate-shaped segment of the second wiring terminal form a U-shaped bent plate. According to the embodiment of the invention, the wiring terminalcan avoid the displacement between the terminals, and increases the contact area of the wiring terminals.

Owner:SHENZHEN POWER SUPPLY BUREAU

Touch safe fuse module with improved wiring lugs

ActiveUS20110314671A1Minimal generation of wasteIncrease electrical contact areaContact member assembly/disassemblyClamped/spring connectionsMechanical engineeringEngineering

Owner:EATON INTELLIGENT POWER LIMITED

High-flash-point high-solid-content safe flaky zinc-based zinc-rich coating and preparation method thereof

InactiveCN112143335AReduce construction costsReduce material costsAnti-corrosive paintsEpoxy resin coatingsBenzyl alcoholFirming agent

The invention discloses a high-flash-point high-solid-content safe flaky zinc-based zinc-rich coating and a preparation method thereof. The flaky zinc-based zinc-rich coating is prepared from the following raw materials: 10-20wt% of low-molecular-weight epoxy resin; 2 to 5 wt% of nonylphenol; 2 to 5 wt% of dodecyl-tetradecyl glycidyl ether; 0.5 to 1 wt% of hydrogenated castor oil; 50 to 70 wt% offlaky zinc powder; 5-25 wt% of an antirust pigment JRM; 2-5 wt% of benzyl alcohol; and 5-10 wt% of a modified amine curing agent. The flaky zinc-based zinc-rich coating prepared according to the invention has the characteristics of high solid content and high flash point, solves the problem that the surface layer of the existing zinc-rich anticorrosive coating is easy to damage or crack, and improves the anticorrosive effect and performance.

Owner:HUAIAN PAINT MFG FACTORY

Single-nut grooved conical-surface fixed-type high-voltage large-current wiring terminal

PendingCN107946796AIncrease frictionAvoid displacementElectric connection basesMulticonductor cable end piecesStructural engineeringMechanical engineering

The embodiment of the invention discloses a single-nut grooved conical-surface fixed-type high-voltage large-current wiring terminal, and the wiring terminal comprises a first wiring terminal and a second wiring terminal. The first end of the first wiring terminal is a hollow cylindrical segment, and the second end of the first wiring terminal is a cylindrical segment perpendicular to the axial direction of the first end, wherein a conical hole segment and an installation hole segment which are communicated with each other are formed in the cylindrical segment. The first end of the second wiring terminal is a hollow cylindrical segment, and the second end of the second wiring terminal is a conical shaft segment and a stud segment which extend from the first end. The conical shaft segment is provided with a grooved structure, and the stud segment is provided with an external thread. The second end of the second wiring terminal is accommodated in the second end of the first wiring terminal, and the conical shaft segment of the second wiring terminal cooperates with the conical hole segment of the first wiring terminal. The stud segment of the second wiring terminal passes through theinstallation hole segment of the first wiring terminal, and is fixed through a nut. According to the embodiment of the invention, the wiring terminal can avoid the displacement between terminals, andincreases the contact area of the wiring terminals.

Owner:SHENZHEN POWER SUPPLY BUREAU

Inserted electric connection structure and charging power supply assembly

ActiveCN103515806AIncrease electrical contact areaSimple structureBatteries circuit arrangementsCoupling contact membersElectricityPower flow

The invention provides an inserted electric connection structure and a charging power supply assembly. The inserted electric connection structure comprises a first connecting part and a second connecting part, wherein the first connecting part comprises a first body, an electrode load bearing part, a first positive pole and a first negative pole; the second connecting part comprises a second body, a positive elastic electrode and a negative elastic electrode; under the locking condition, the positive elastic electrode is elastically propped against the first positive pole, and the negative elastic electrode is elastically propped against the first negative pole. The first positive pole and the first negative pole are in electric contact with the corresponding electrodes in an accommodating cavity in a surface contact manner, so that the electric contact area between the electrodes of the first connecting part and the second connecting part is enlarged, relatively large current can be transmitted, and the inserted electric connection structure and the charging power supply assembly have the characteristics that the structures are simple, the operation is convenient, and the cost is low.

Owner:尹隽晖

Integrated rotary power taking socket, wall-type extension socket wiring rail and light rail-type extension socket

PendingCN111193160ASimple structureEasy to operateCoupling contact membersCouplings bases/casesElectric power transmissionLight rail

The invention relates to the technical field of sockets, in particular to an integrated rotary power taking socket, a wall type extension socket wiring rail and a light rail type extension socket. According to the wall type extension socket wiring rail, an power taking arm based on an integrated rotary power taking socket., the distance between a first limiting frame and a second limiting frame isdesigned to be matched with the width of the power taking arm, the heights of the first limiting frame and the bottom plane are designed to be matched with the heights of the two sides of the power taking arm, and a strip-shaped groove in the middle of the designed bottom plane is matched with a ground wire connecting end of the integrated rotary power taking socket, so the socket is guided to becorrectly inserted at the first moment, rotation is performed then by taking the ground wire connecting end as a circle center, the two sides of the power taking arm are guided to reach the power taking position at the next moment, under the elastic action of the elastic live wire power taking assembly, the elastic zero wire power taking assembly and the elastic ground wire connecting assembly ofthe socket, the live wire power taking end and the zero wire power taking end are firmly connected with the first electric connecting piece and the second electric connecting piece in a face-to-facemode, and good power transmission between the wiring rail and the power taking socket is guaranteed.

Owner:惠州市加迈电器有限公司

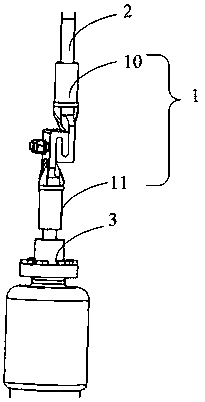

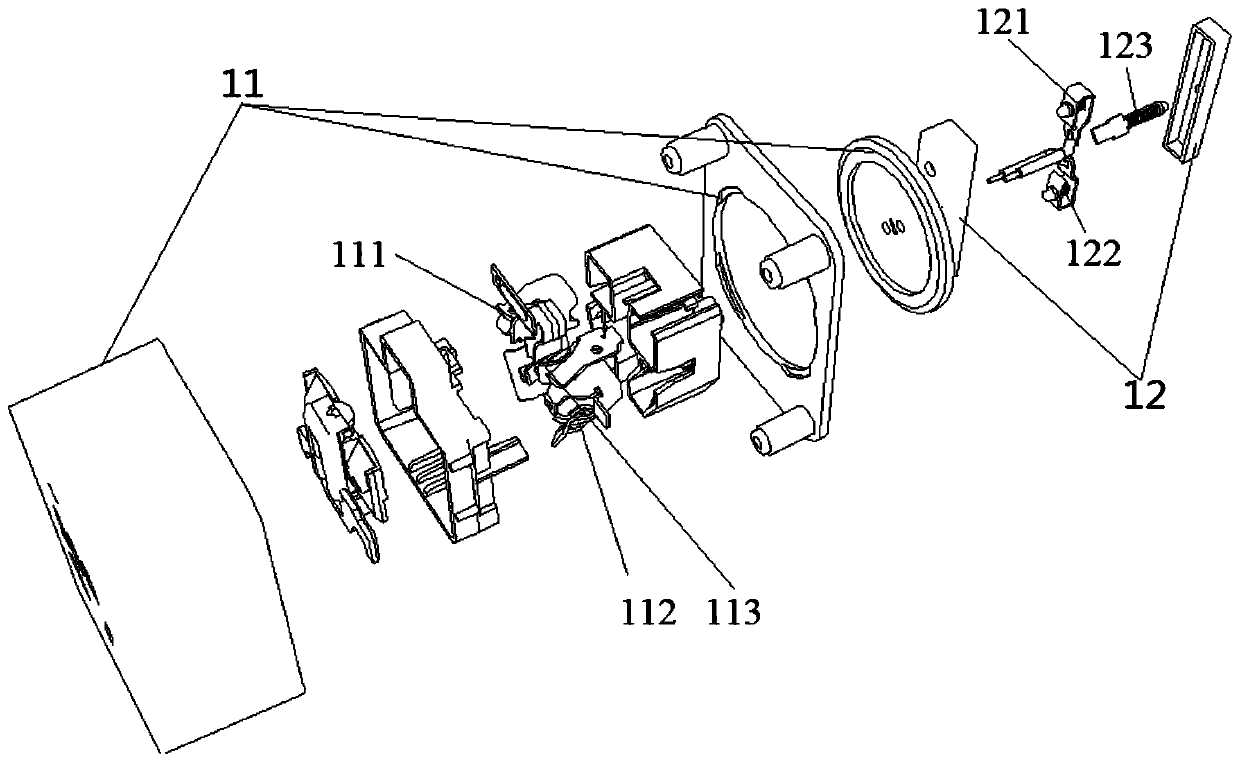

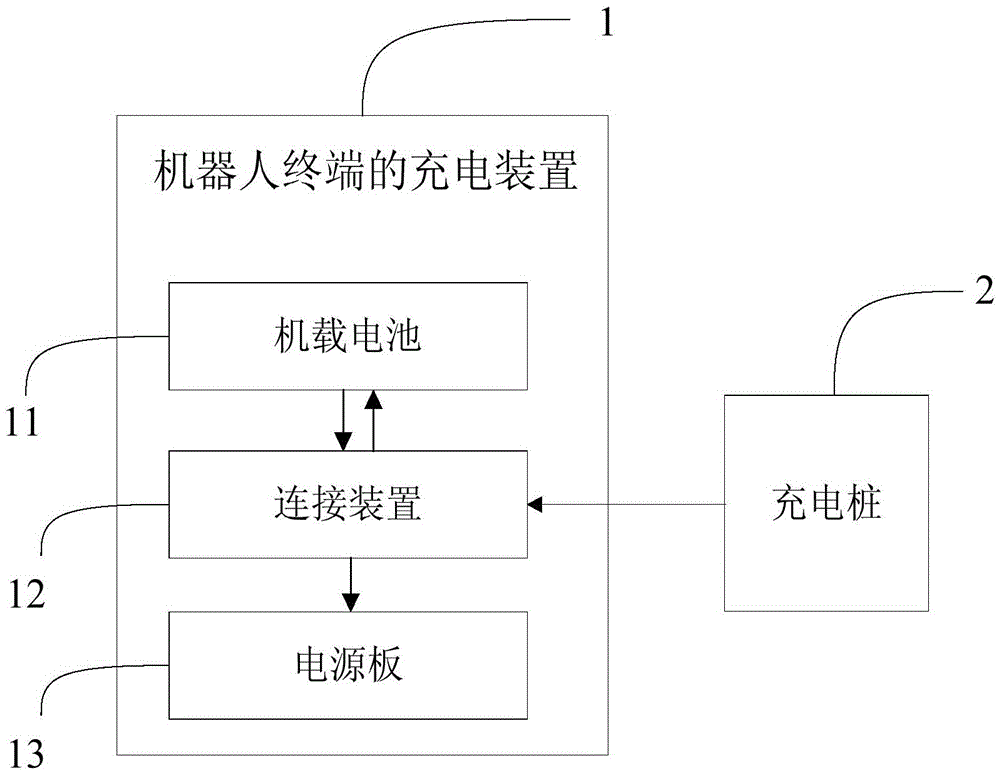

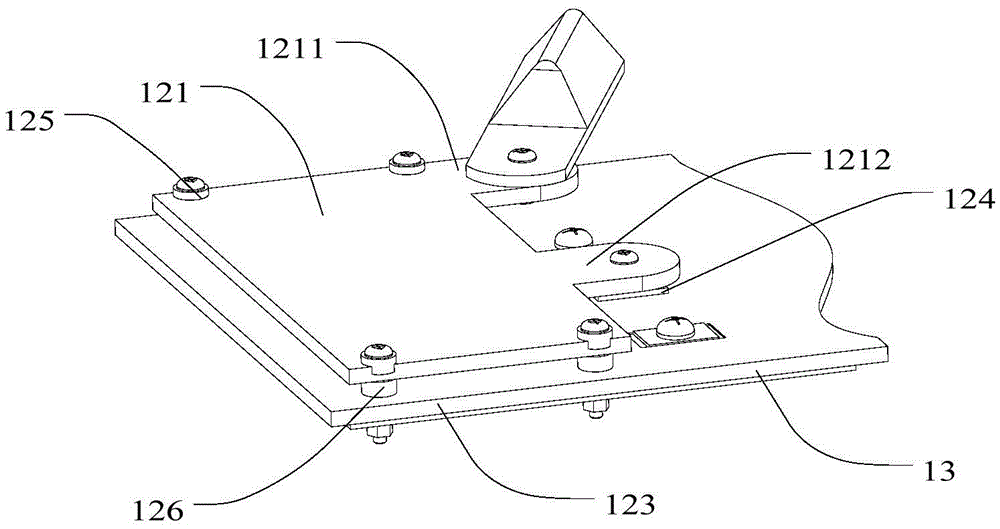

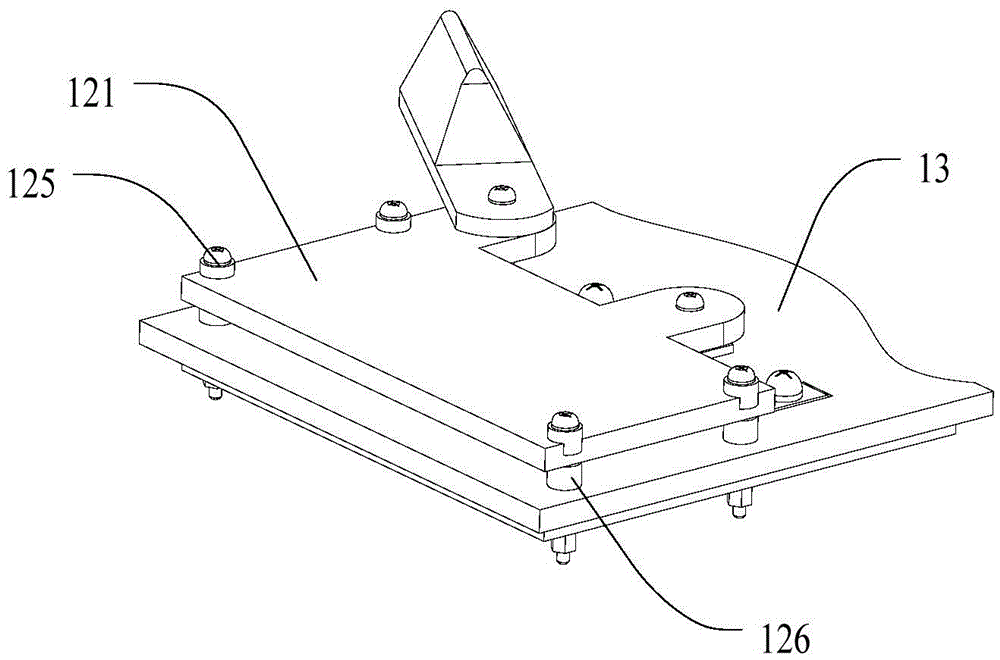

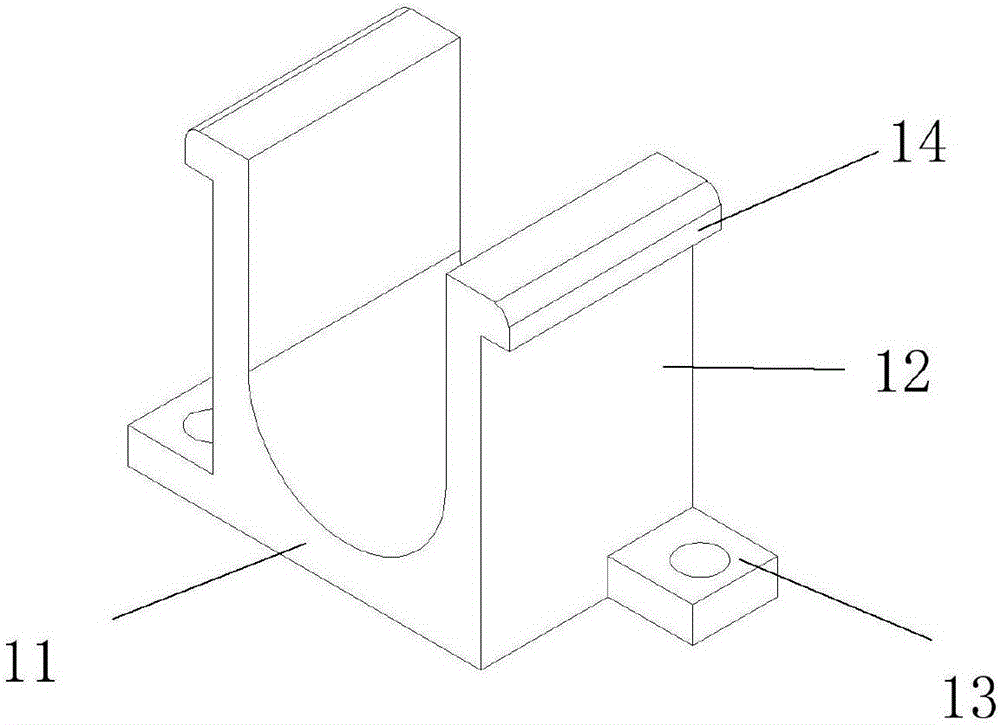

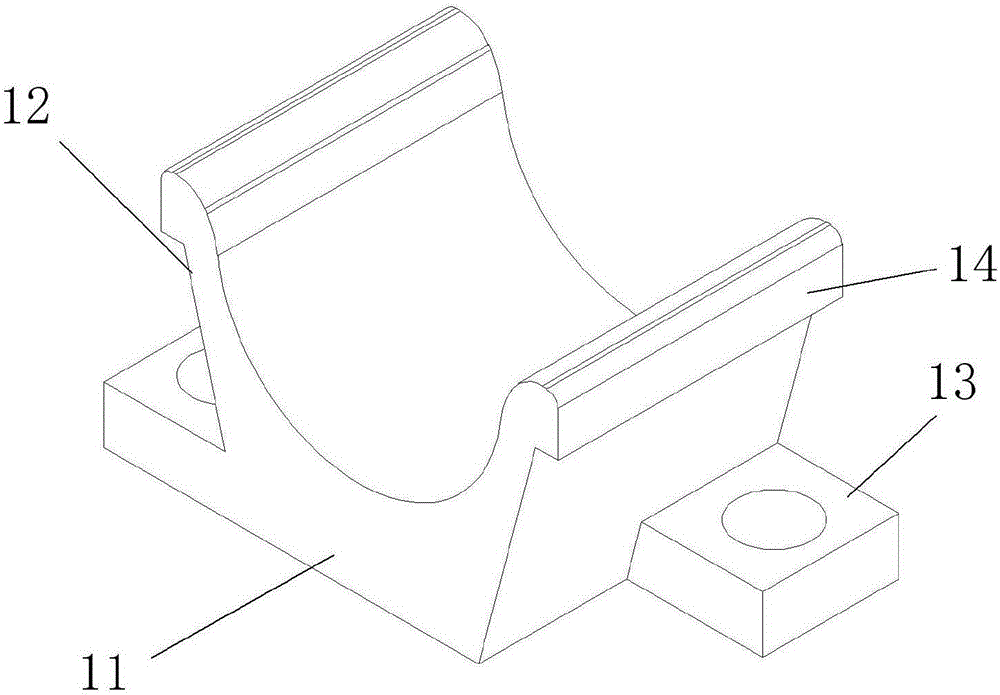

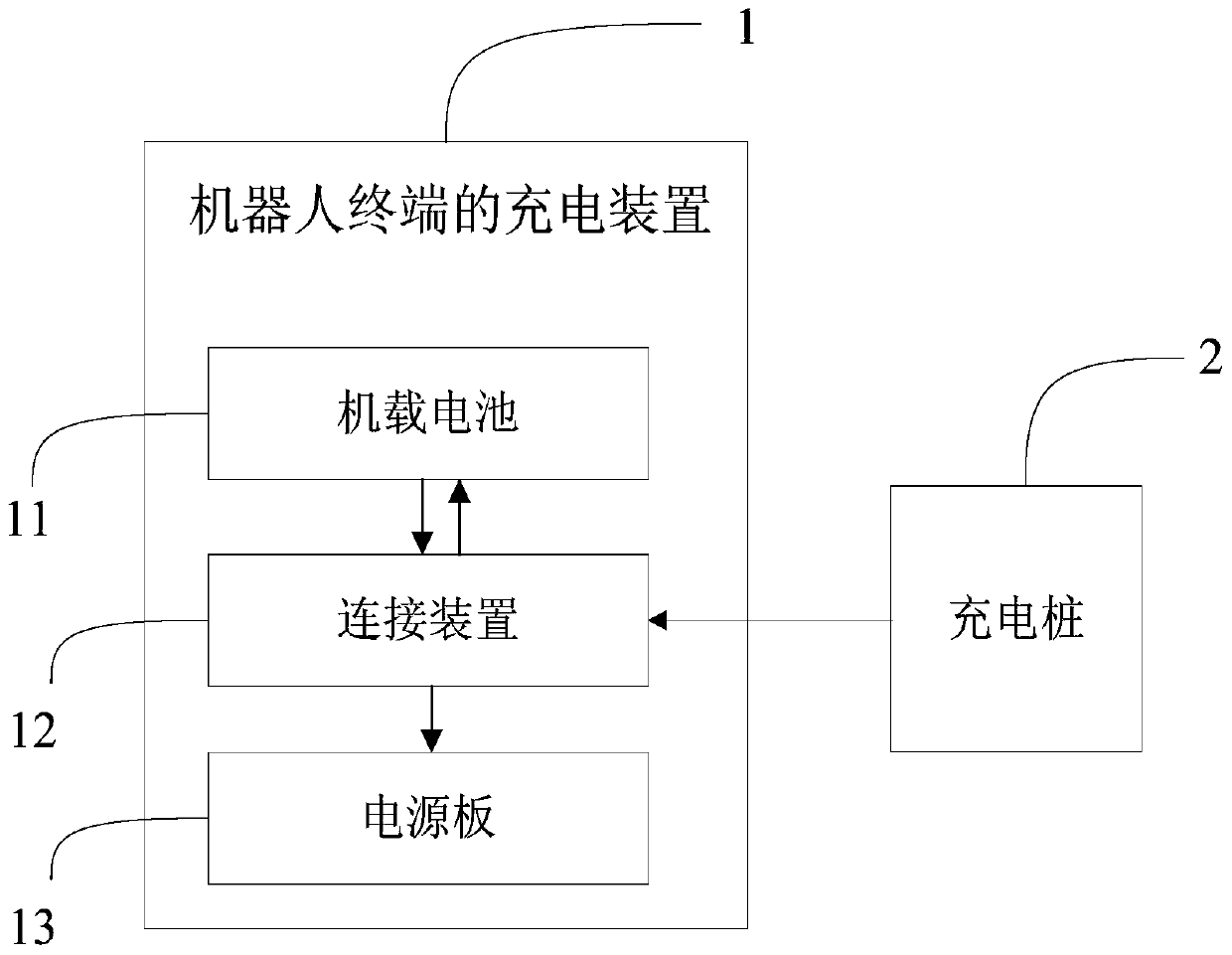

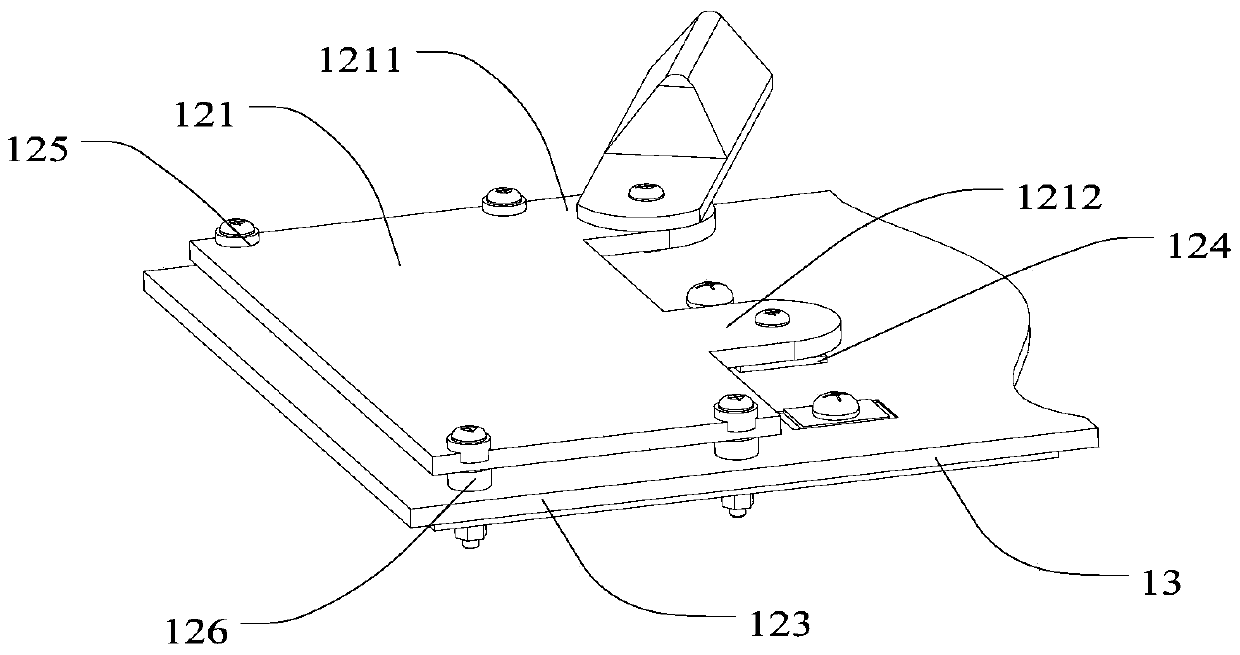

Charging system for robot terminal

ActiveCN105576754AImprove work efficiencyImprove charging efficiencyMobile unit charging stationsElectric powerElectricityElectrical battery

The invention provides a charging system for a robot terminal. The charging system comprises a charging apparatus and a charging pile for the robot terminal, wherein the charging apparatus for the robot terminal is arranged in the robot terminal; the charging apparatus for the robot terminal comprises a robot-mounted battery, a connecting apparatus and a power panel; the charging pile is electrically connected with the robot-mounted battery through the connecting apparatus and used for charging the robot-mounted battery through the connecting apparatus; the robot-mounted battery is electrically connected with the power panel through the connecting apparatus and used for transmitting the stored electric energy to the power panel through the connecting apparatus; and the power panel is used for supplying power supply to the robot terminal. According to the charging system, the novel connecting apparatus is adopted for charging and supplying power to the robot terminal; the stability of charging and power supply of the robot-mounted battery in the charging system is ensured, and meanwhile, a relatively large electric contact area between the connecting apparatus and the connection object of the connecting apparatus is realized, so that the charging and power supply efficiency of the robot-mounted battery are relatively high, and the working efficiency of the robot is further improved consequently.

Owner:ZHEJIANG LIBIAO ROBOT CO LTD

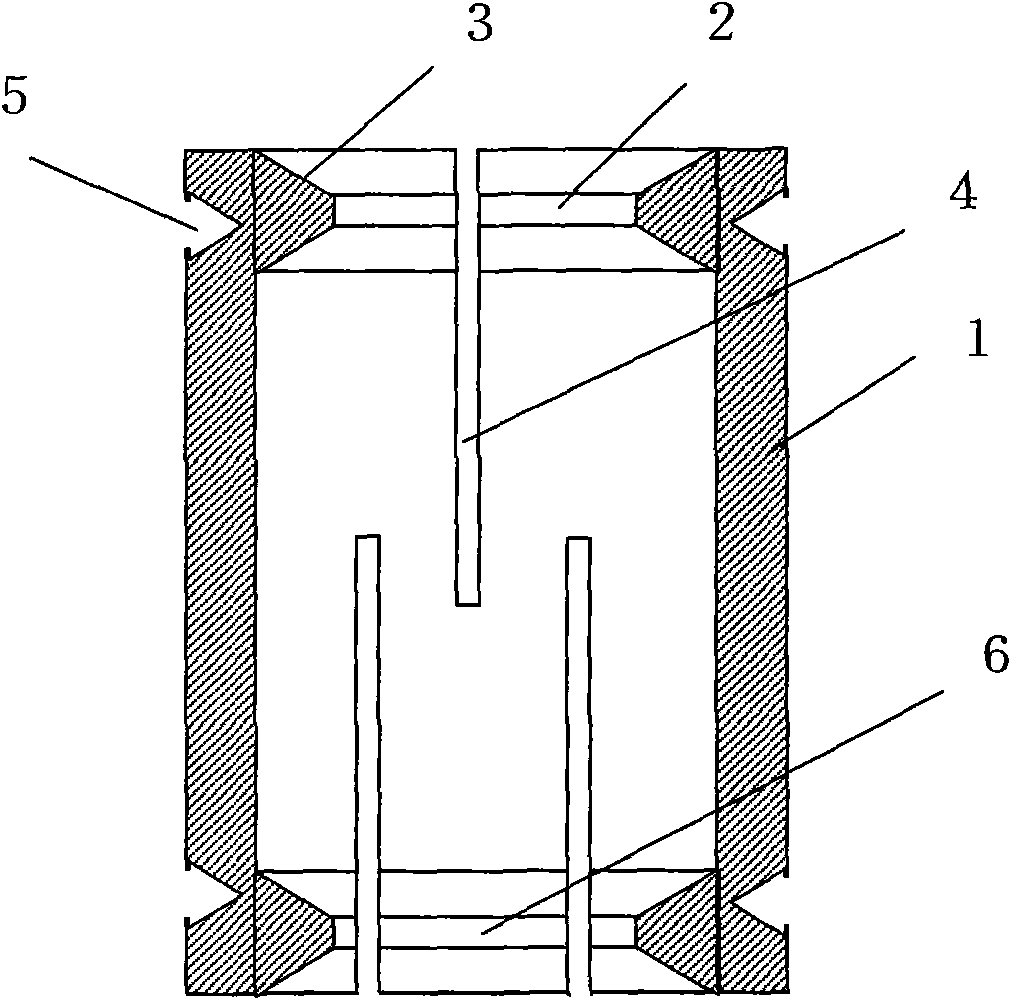

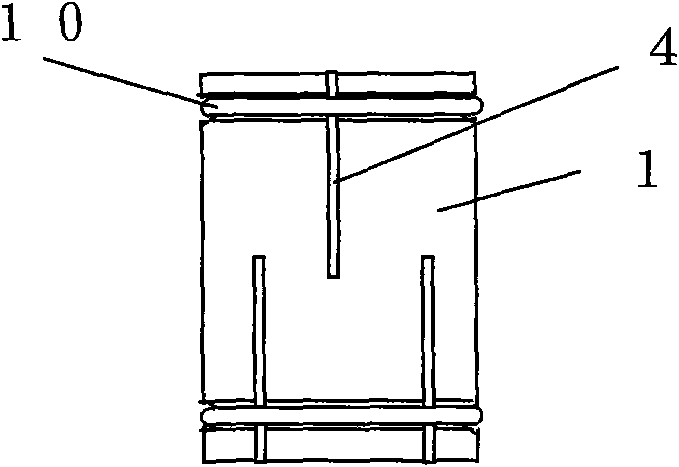

Contactor for realizing electric connection between moving and stationary contact poles in transformer

InactiveCN102110916AFit tightly and firmlyIncrease electrical contact areaTransformers/inductances coils/windings/connectionsClamped/spring connectionsElectricityTransformer

The invention discloses a contactor for realizing electric connection between moving and stationary contact poles in a transformer, which consists of a cylindrical metal tube, wherein an annular flange is arranged on an inner circumferential wall at one end of the cylindrical metal tube toward the direction of an axial centre; a connection surface between the annular flange and an end face of the cylindrical metal tube is a conical surface; more than two cracks are arranged in a tube wall of the cylindrical metal tube; the extending direction of any one of the cracks is parallel to the axial direction of the cylindrical metal tube; the cracks extend to the cylindrical metal tube from one end of the cylindrical metal tube where the annular flange is located; an annular groove is arranged on an outer circumferential wall of the end of the cylindrical metal tube where the annular flange is located; and a reinforcing clamping spring is sleeved in the annular groove. In the use of the contactor for realizing the electric connection between the moving and stationary contact poles in the transformer, the electric connection between an inner circumferential surface of the cylindrical metal tube and outer circumferential surfaces of the stationary and moving contact poles is realized, so that electric contact area is increased greatly and tight and firm connection between the annular flange and the conical surface thereof and between the stationary contact pole and an internal thread sleeve is realized.

Owner:SHANGHAI RITCHEY ELECTRICAL EQUIP

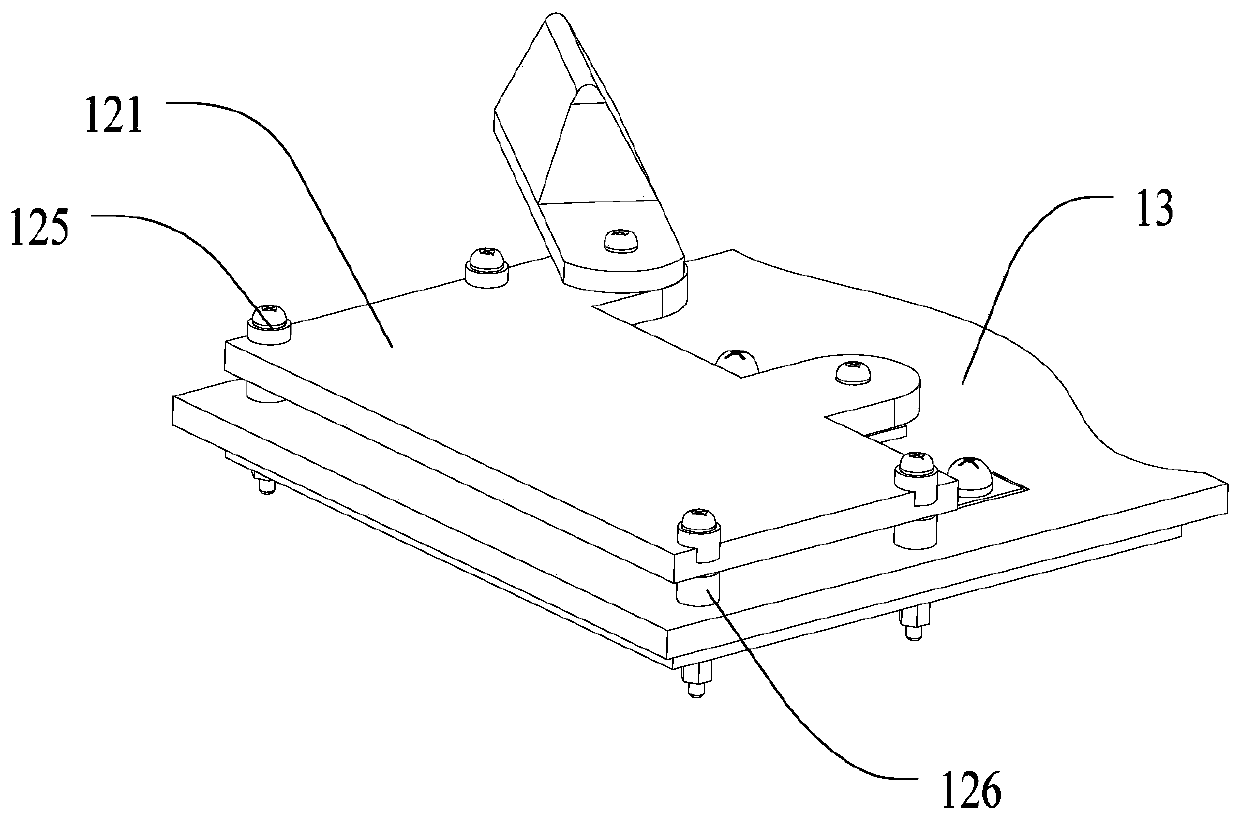

Split type polar plate lap joint structure and electrolytic bath with same

The invention discloses a split type polar plate lap joint structure which comprises a conductive bus bar, a conductive beam fixing seat and a limit seat, wherein the conductive beam fixing seat comprises a seat body and a cover body, the seat body is made from a conductive material and provided with a seat body bottom edge and two seat body side edges, and an opening is formed in the top; the cover body is made from an insulation material, the top of the seat body is covered with the cover body, and the cover body is provided with a cover body top surface and two cover body side edges; the limit seat is made from an insulation material and provided with a seat body bottom edge and two seat body side edges, and an opening is formed in the top. By the aid of the arrangement of the conductive beam fixing seat, the cover body applies pressure to a conductive beam from the top, and the conductive beam is accommodated in the seat body, so that the conductive beam is surrounded by the four surfaces of the conductive beam fixing seat, the electrical contact area of the conductive bus bar and the conductive beam is increased, the contact of the conductive beam and the conductive bus bar is good, the bath voltage is lower, the cathode and anode spaces are uniform and no error exists, the electric efficiency is higher, the conductive beam and a polar plate cannot be loosened along with human factors and electrolysis technology factors after the conductive beam is pressed by the cover body, and the false contact phenomenon cannot be caused.

Owner:HANGZHOU EMPEROR LOSSEN TECH

A charging system for a robot terminal

ActiveCN105576754BImprove work efficiencyImprove charging efficiencyMobile unit charging stationsElectric powerElectricityElectrical battery

The invention provides a charging system for a robot terminal. The charging system comprises a charging apparatus and a charging pile for the robot terminal, wherein the charging apparatus for the robot terminal is arranged in the robot terminal; the charging apparatus for the robot terminal comprises a robot-mounted battery, a connecting apparatus and a power panel; the charging pile is electrically connected with the robot-mounted battery through the connecting apparatus and used for charging the robot-mounted battery through the connecting apparatus; the robot-mounted battery is electrically connected with the power panel through the connecting apparatus and used for transmitting the stored electric energy to the power panel through the connecting apparatus; and the power panel is used for supplying power supply to the robot terminal. According to the charging system, the novel connecting apparatus is adopted for charging and supplying power to the robot terminal; the stability of charging and power supply of the robot-mounted battery in the charging system is ensured, and meanwhile, a relatively large electric contact area between the connecting apparatus and the connection object of the connecting apparatus is realized, so that the charging and power supply efficiency of the robot-mounted battery are relatively high, and the working efficiency of the robot is further improved consequently.

Owner:ZHEJIANG LIBIAO ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com