Split type polar plate lap joint structure and electrolytic bath with same

A connection structure, split technology, applied in the direction of electrolysis process, electrolysis components, electrodes, etc., can solve the problems of long electrolysis time, large contact resistance, virtual contact, etc., to improve the electrical contact area, the average distance between cathode and anode, and the cell voltage low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

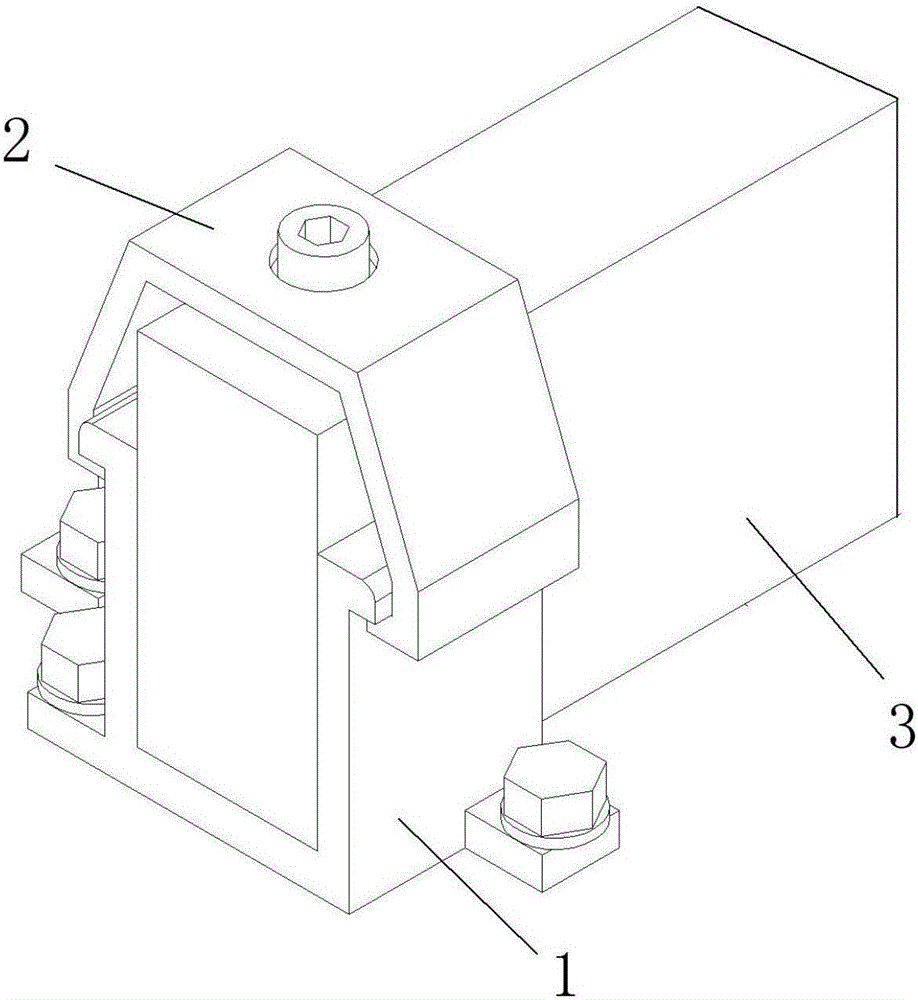

[0036] Figure 1-5 Schematically shows a split-type electrode plate overlapping structure according to an embodiment of the present invention. Such as Figure 5 shown, including:

[0037] At least two conductive busbars 7 arranged in parallel (the number is set according to needs);

[0038] The conductive beam fixing seat 4 and the limit seat 5 arranged on the conductive busbar 7 and located at both ends of the conductive beam 3 (each conductive beam 3 is located between two adjacent conductive busbars 7), the same The conductive beam fixing seat 4 and the limit seat 5 on the conductive busbar 7 are arranged at intervals;

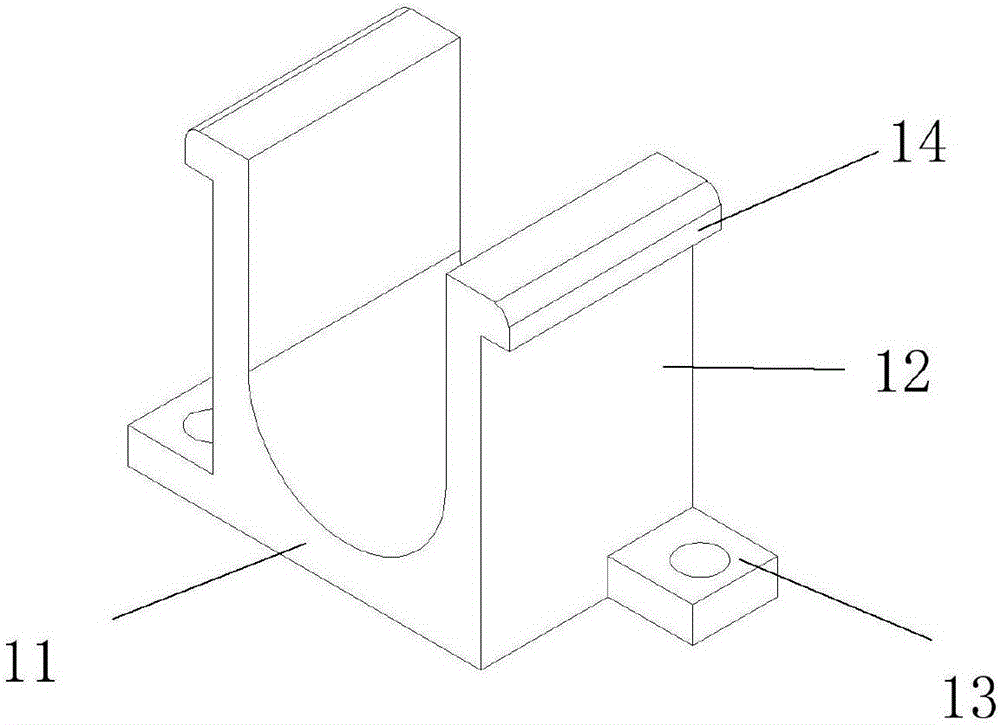

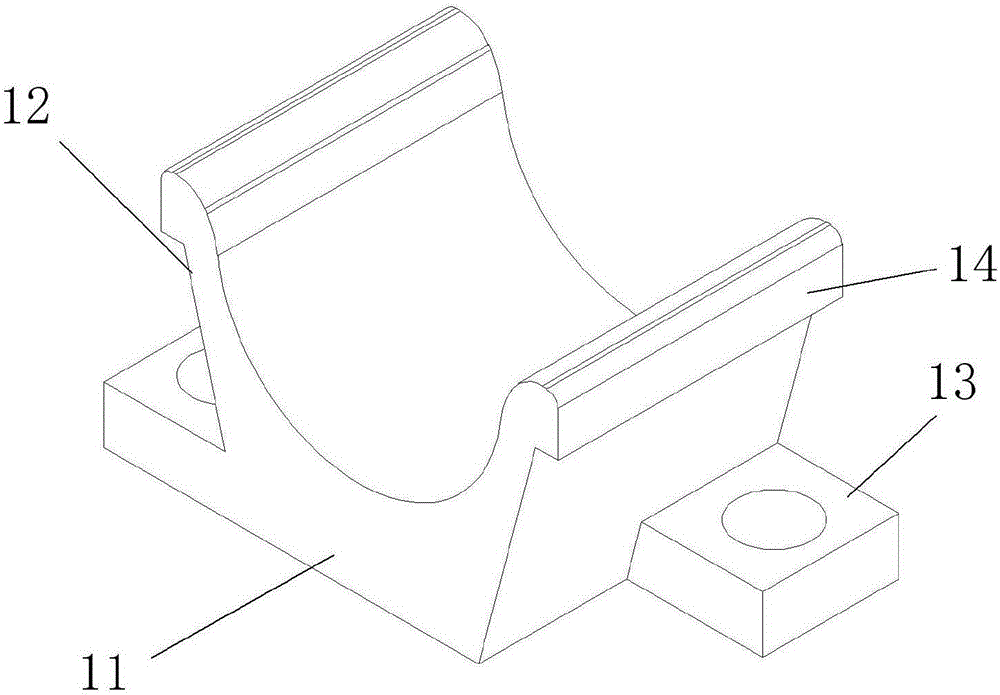

[0039] The conductive beam fixing seat 4 includes: a seat body 1, made of conductive material, having a bottom edge 11 of the seat body, two side edges 12 of the seat body and an opening at the top;

[0040] The position limiting seat 5 is made of insulating material, has a base body bottom 11 and two seat body side edges 12 and has an open top.

[004...

Embodiment 2

[0054] This embodiment provides an electrolytic cell, such as Figure 8 and 9 , including a rectangular tank 9 with an open top, two long sides of the tank 9 are provided with a split-type plate lap joint structure as described in Embodiment 1, and the split-type pole plate lap joint structure is fixed and arranged in the slot The conductive beam 3 on the body 9, and the electrode 8 (cathode or anode) protruding into the tank body 9 under the conductive beam 3 .

[0055] When multiple slot bodies 9 are arranged side by side, the adjacent sides of two adjacent slot bodies 9 can share one conductive bus bar 7 .

[0056] The electrolytic cell of this embodiment has the split-type electrode plate overlapping structure of Embodiment 1, and therefore also has the advantages described in Embodiment 1.

[0057] Such as Figure 9 The cathode and the anode of the electrodes 8 are arranged at intervals, and the conductive beam fixing seat 4 and the limit seat 5 in the same row are als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com